Novel circuit forming method

A circuit and circuit pattern technology, which is applied in the removal of conductive materials by chemical/electrolytic methods, printed circuits, and printed circuit manufacturing, etc., can solve the problems of high overall cost, affecting circuit etching, and chemical residue, and simplify the production process. steps, the effect of reducing the cost of labor and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

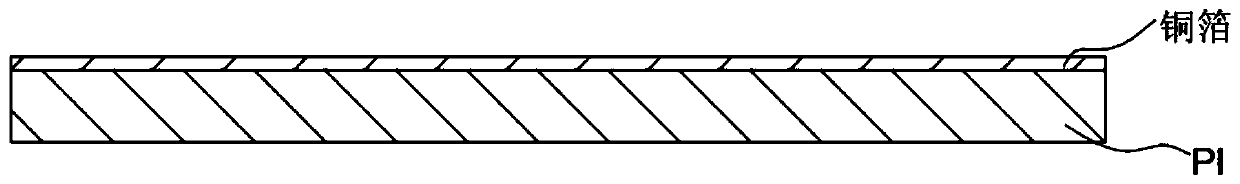

[0026] Such as Figure 1-4 As shown, the embodiment of the present invention provides a new method for forming a line, including the following steps:

[0027] S1. Pretreat the product base material;

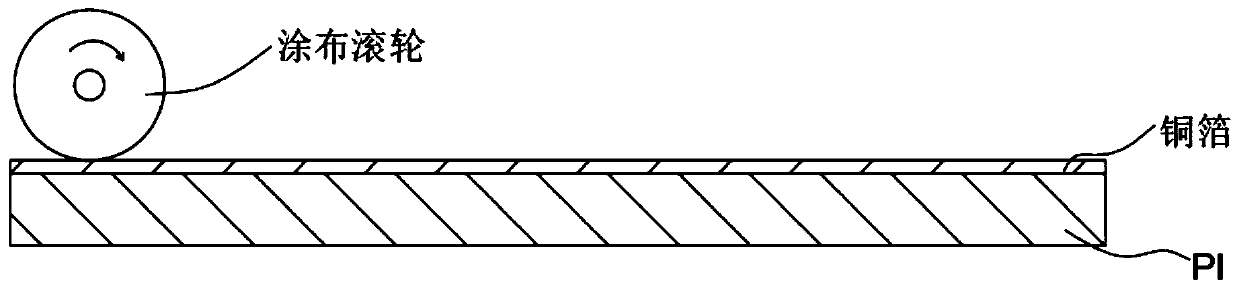

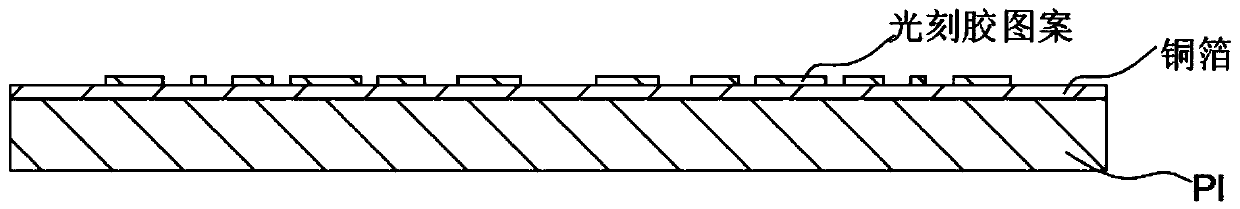

[0028] S2, using a coating roller to coat the photoresist on the pretreated substrate to obtain a product with a photoresist pattern;

[0029] S3, baking the product coated with the photoresist pattern to cure the photoresist;

[0030] S4. Etching the product with the photoresist pattern cured after baking, etching away the copper foil that is not covered by the photoresist, and then developing to remove the photoresist on the surface of the product to obtain the desired circuit pattern .

[0031] The coating roller used in step 2 is provided with a mask pattern corresponding to the circuit, and the pattern on the roller can be the pattern on the final product, or the pattern opposite to the pattern on the final product.

[0032] By using the method of roller coating pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com