Patents

Literature

313 results about "Manufacturing Factories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

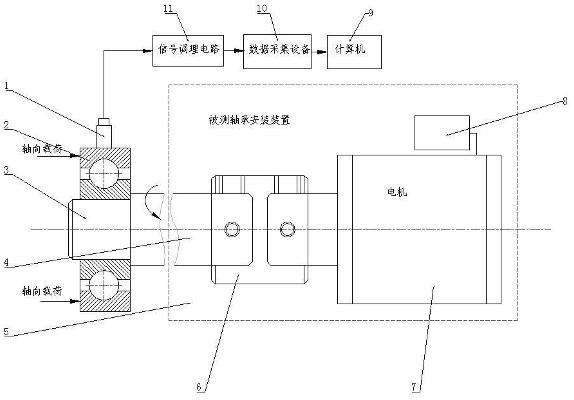

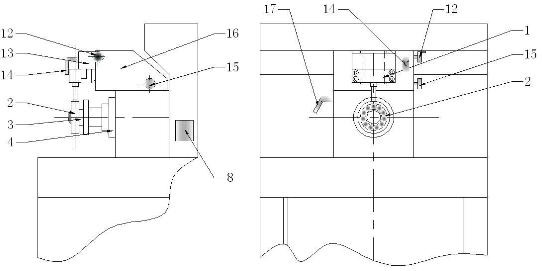

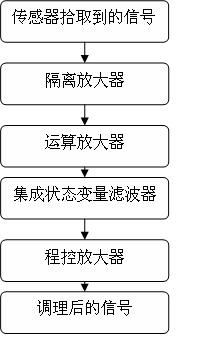

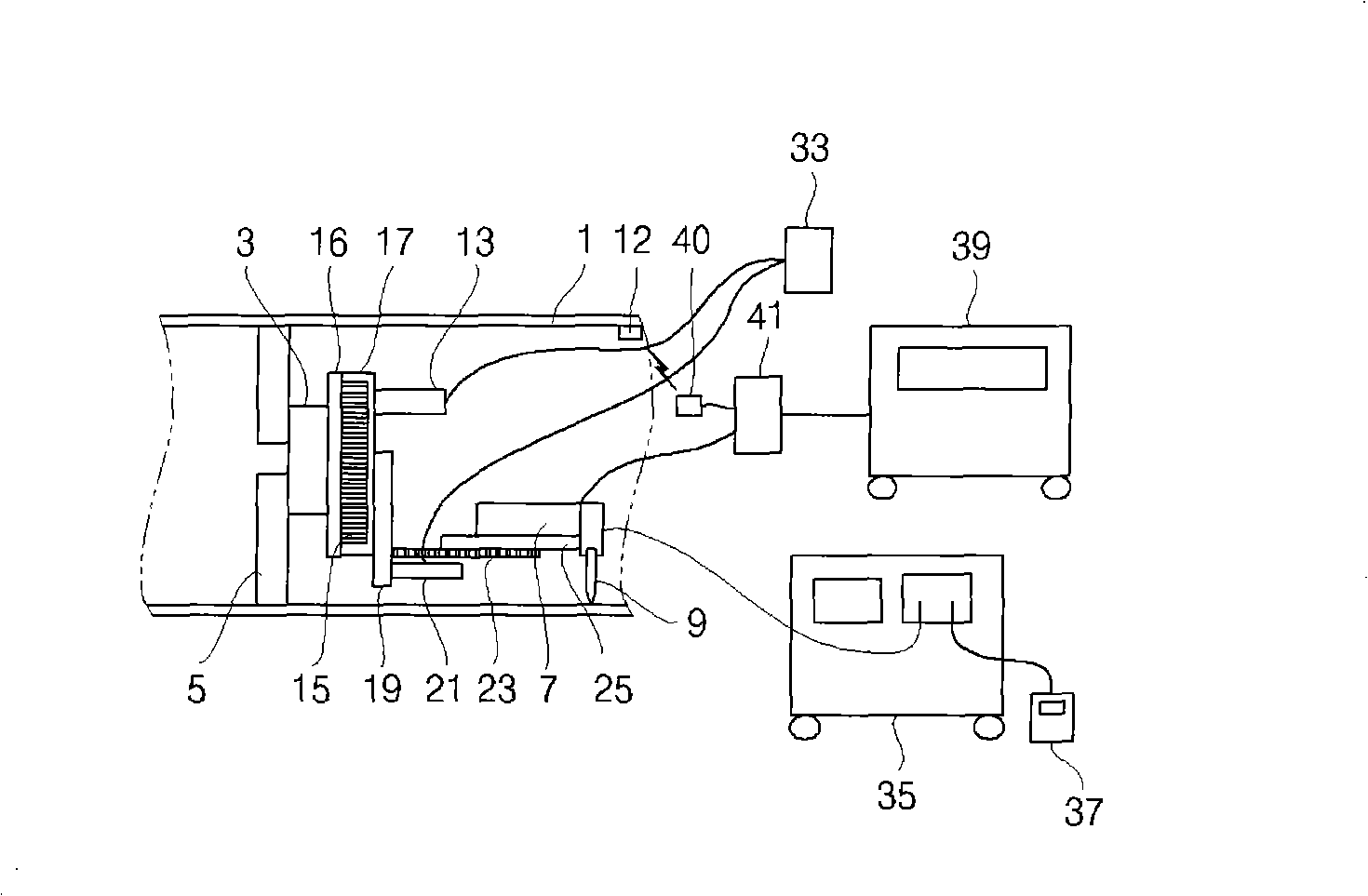

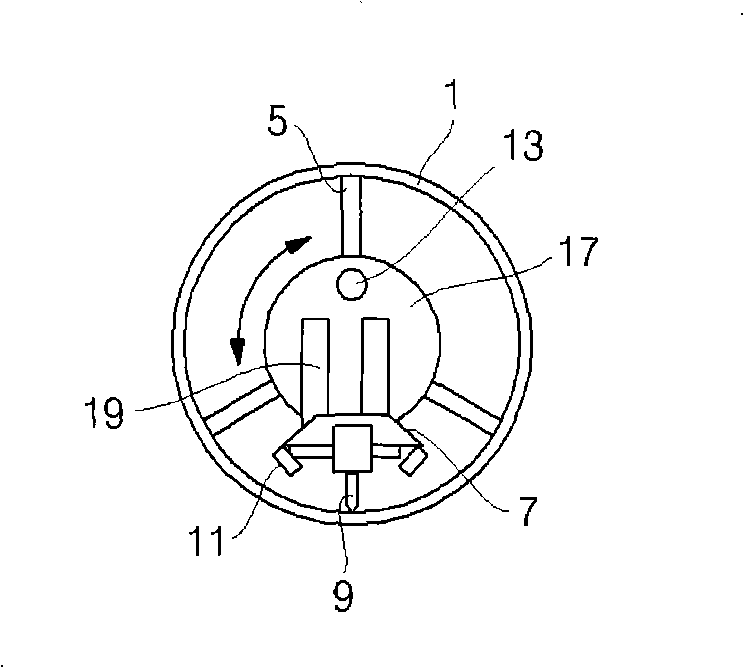

Device and method for vibration measurement and failure analysis of rolling bearing

InactiveCN102183366AAccurate measurementImprove anti-interference abilityVibration measurement in solidsMachine bearings testingVibration measurementSignal conditioning circuits

The invention relates to a device and method for vibration measurement and failure analysis of a rolling bearing. The device comprises a detected bearing mounting device, a speed sensor, a signal conditioning circuit, a data collection device and a computer, wherein a detected bearing is mounted on a mandrel of the detected bearing mounting device; a vibration rod of the speed sensor is arranged on a middle plane of an outer cylindrical surface of an outer ring of the detected bearing with prescribed pressure, the measurement direction is along the radial direction of the bearing and vertical to the axis of the bearing, and the signal conditioning circuit and the data collection device are connected to the computer; the speed sensor measures radial vibration speed signals of the outer ring of the bearing, the picked bearing radial vibration speed signals are converted into corresponding electric signals which are processed by the signal conditioning circuit and then transferred to the data collection device which carries out A / D conversion of the conditioned signals to convert the conditioned signals into digital signals capable of being processed by the computer, and finally the computer carries out analysis and processing of the digital signal. The device and the method are applicable to production test and user acceptance of finished bearings by laboratories and bearing manufacture factories.

Owner:SHANGHAI UNIV

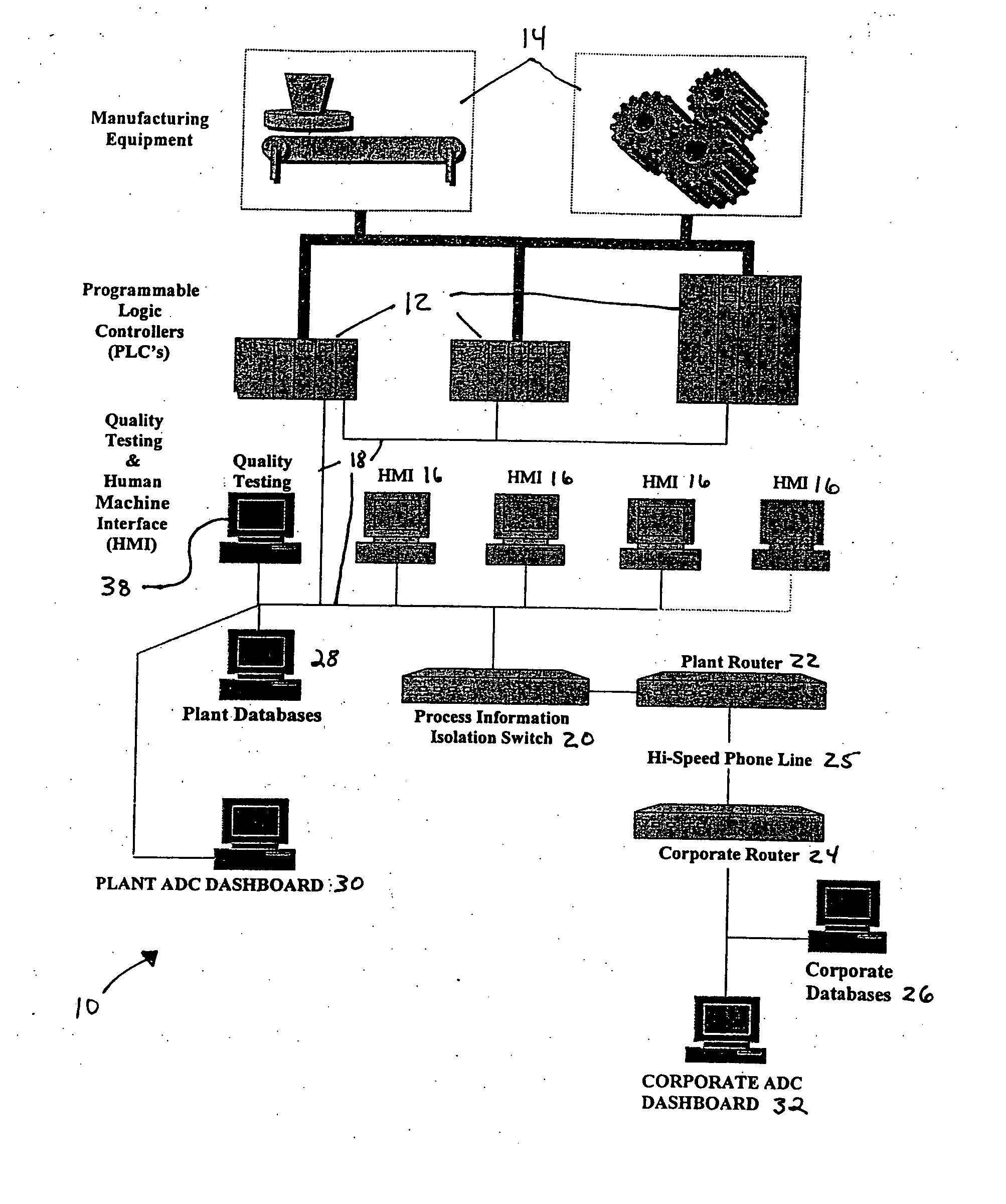

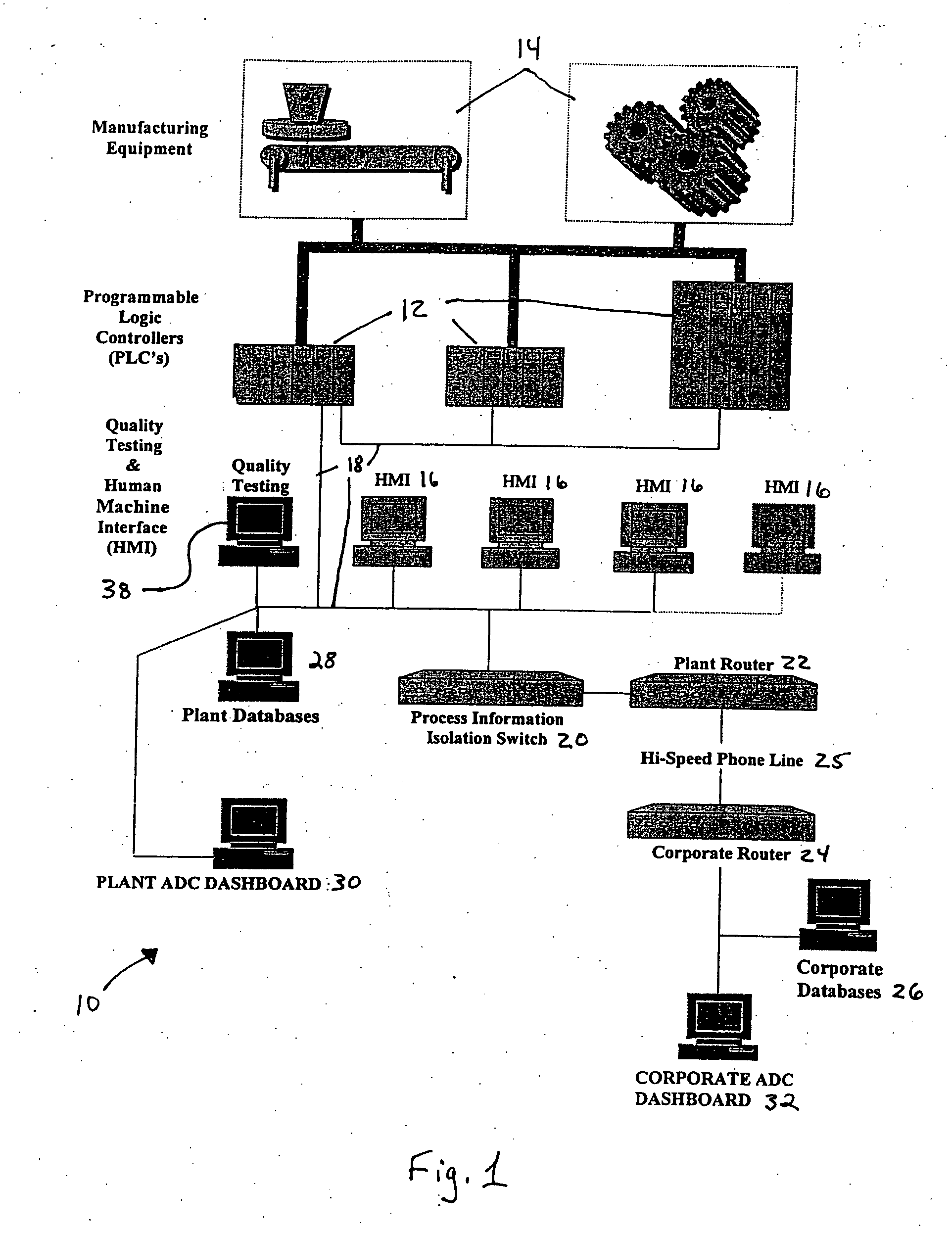

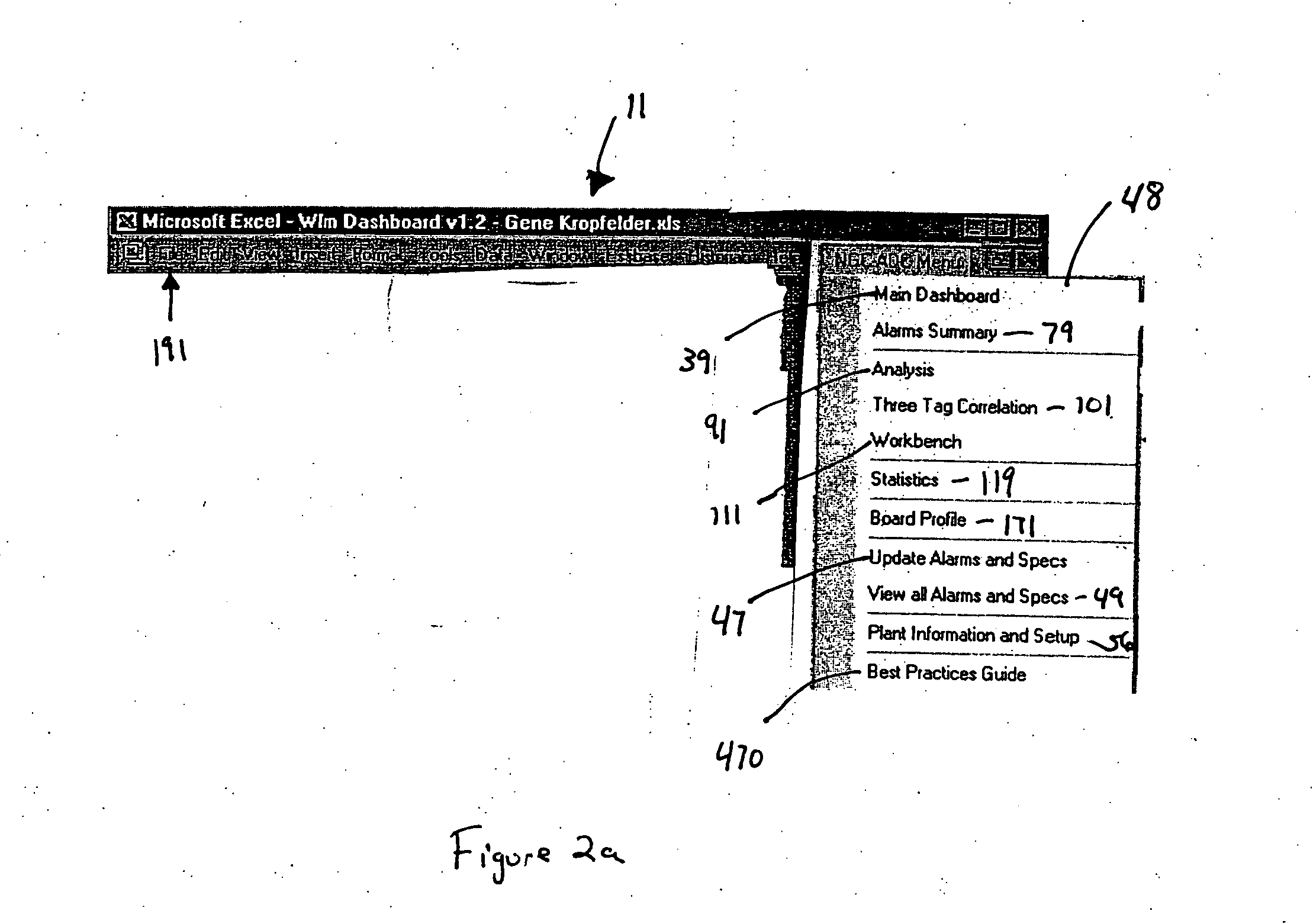

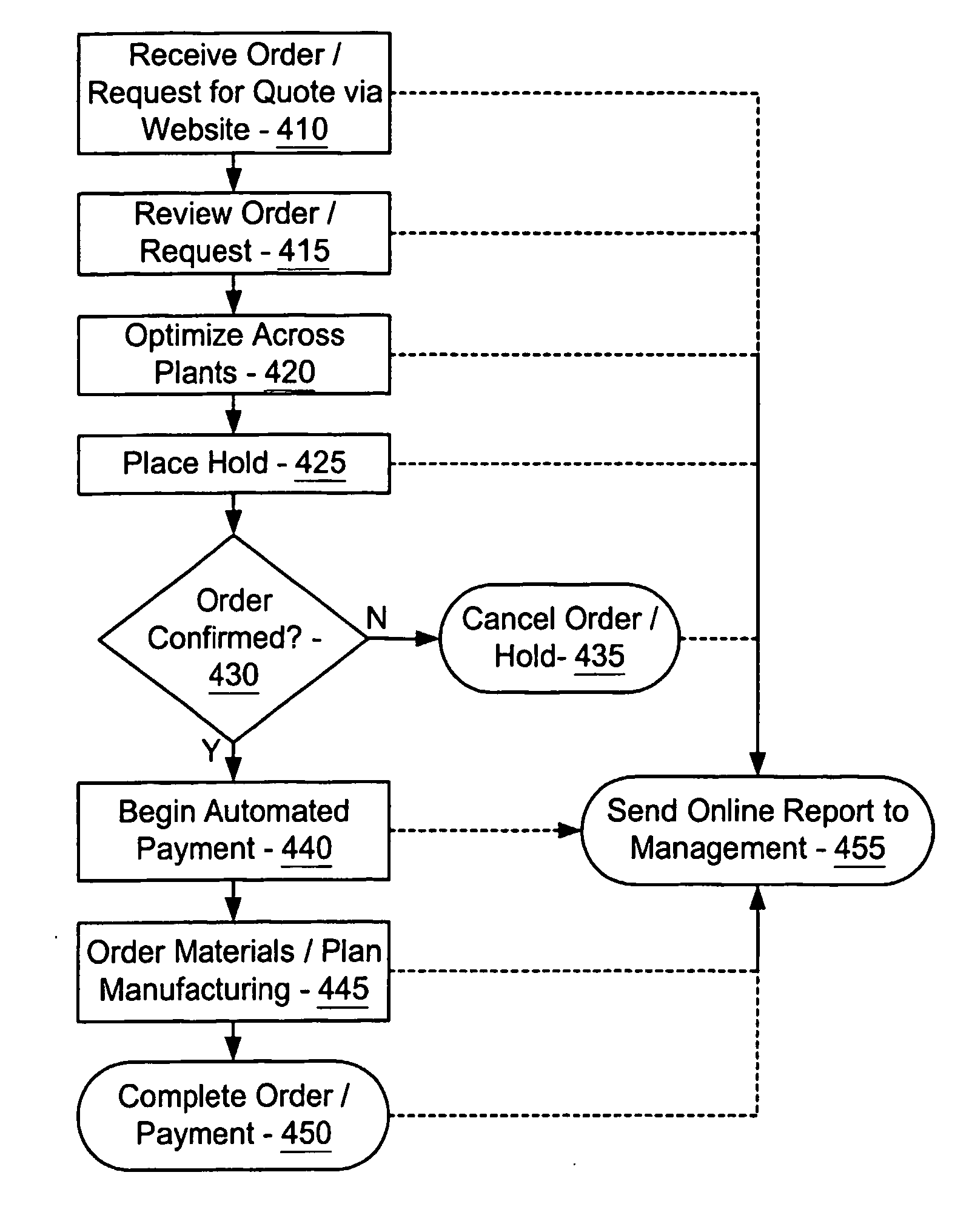

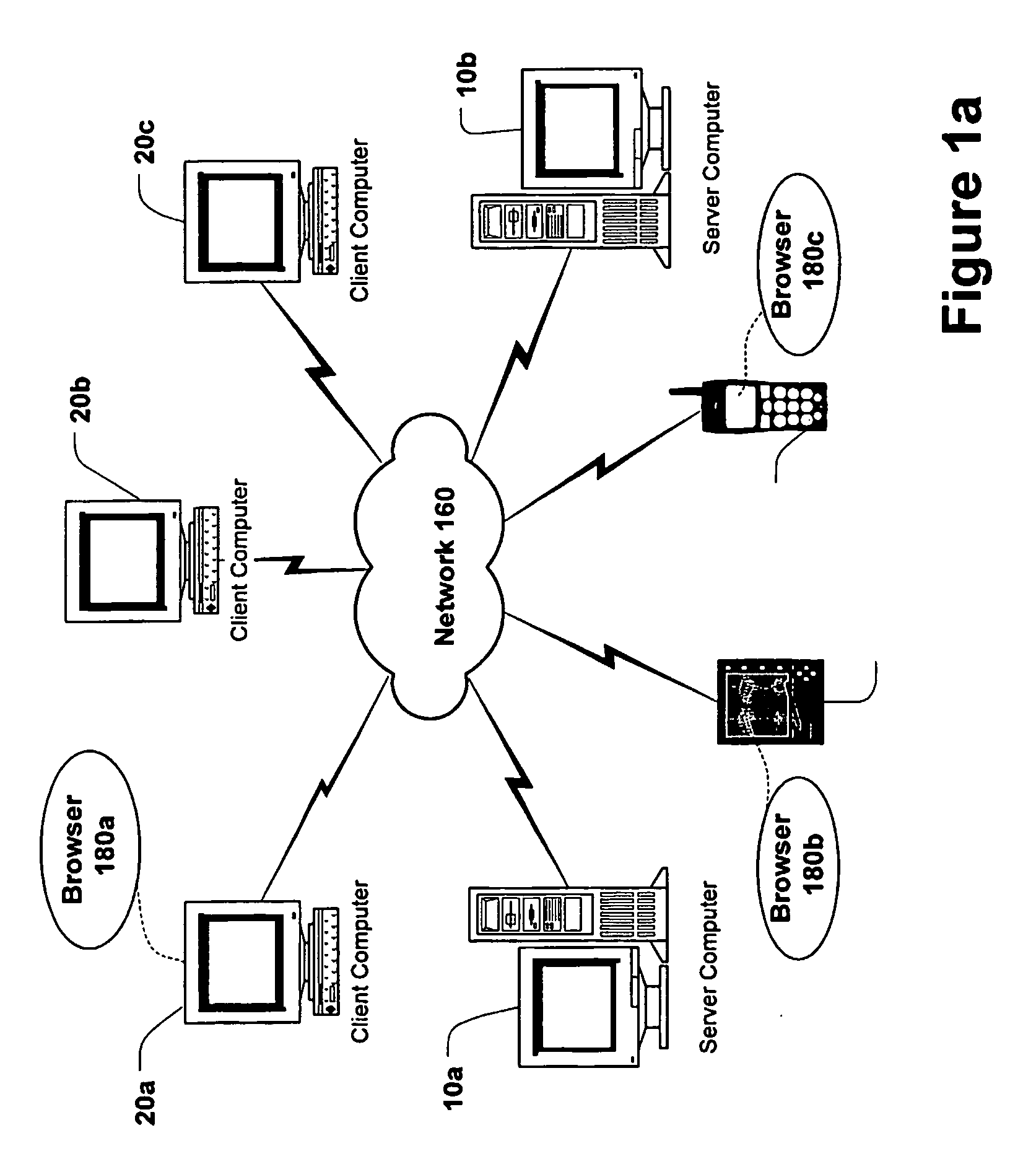

System and method for plant management

InactiveUS20050004781A1Easy to customizeProgramme controlComputer controlManagement systemPlant management

A system and method for plant management that generates real time reports and eliminates the heavy reliance on IT personnel to analyze data. A system and method that eliminates the multiple data entry points and the use of multiple databases for the storing of manufacturing process data. A system and method that can easily and quickly be customized to any manufacturing plant and that enables plant personnel to configure customized views of the collected data. A system and method that that can be tailored to focus on certain specifications to ensure that plant personnel are alerted in real time if the manufacturing process is producing products that do not meet those specifications.

Owner:NAT GYPSUM PROPERTIES

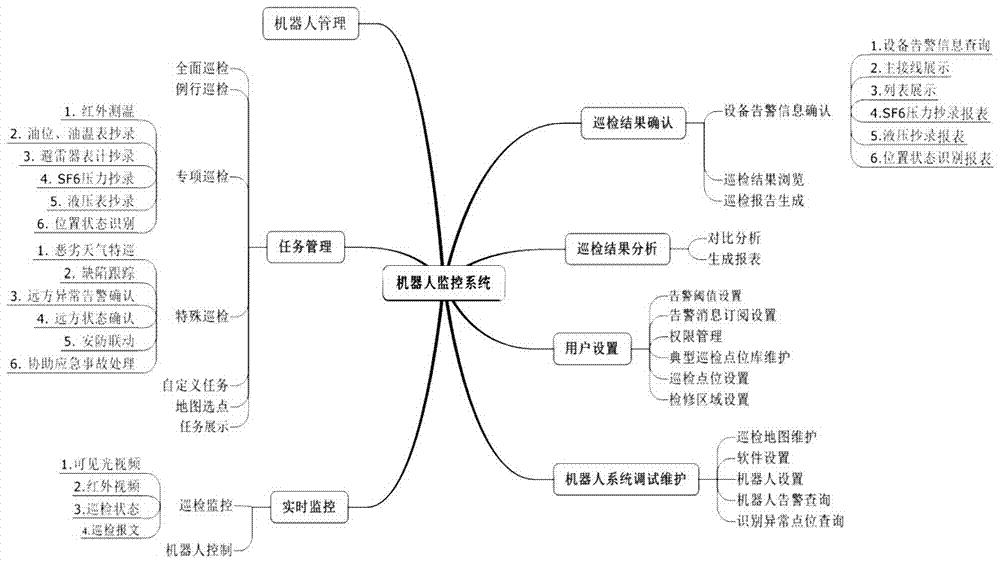

Substation intelligent inspection robot monitoring system

ActiveCN107160388ASolve the problem of inconsistent monitoring background functionsRich design and development functionsProgramme-controlled manipulatorRobotic systemsSimulation

The invention discloses a substation intelligent inspection robot monitoring system and relates to a substation monitoring system. An existing substation intelligent inspection robot monitoring system has the following problems that the monitoring system is not powerful and perfect in function and does not conform to habits of operation and maintenance staff, and robot background system functional interfaces are not unified and are diverse in mode. The substation intelligent inspection robot monitoring system comprises a robot management module, a task management module, a real-time monitoring module, an inspection result confirmation module, an inspection result analysis module, a user setting module, a robot system debugging and maintenance module and a display module. The problem of non-unified robot monitoring background functions is solved. Through the technical scheme, the substation intelligent inspection robot standardized background monitoring system which is abundant in function and friendly in interface and has a state identification function is designed and developed according to the actual requirements of substation operation and maintenance, the robot monitoring background functions and the interfaces are unified, and thus the problem of multiple systems of substation intelligent inspection robots due to different manufacturing factories and different models is solved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

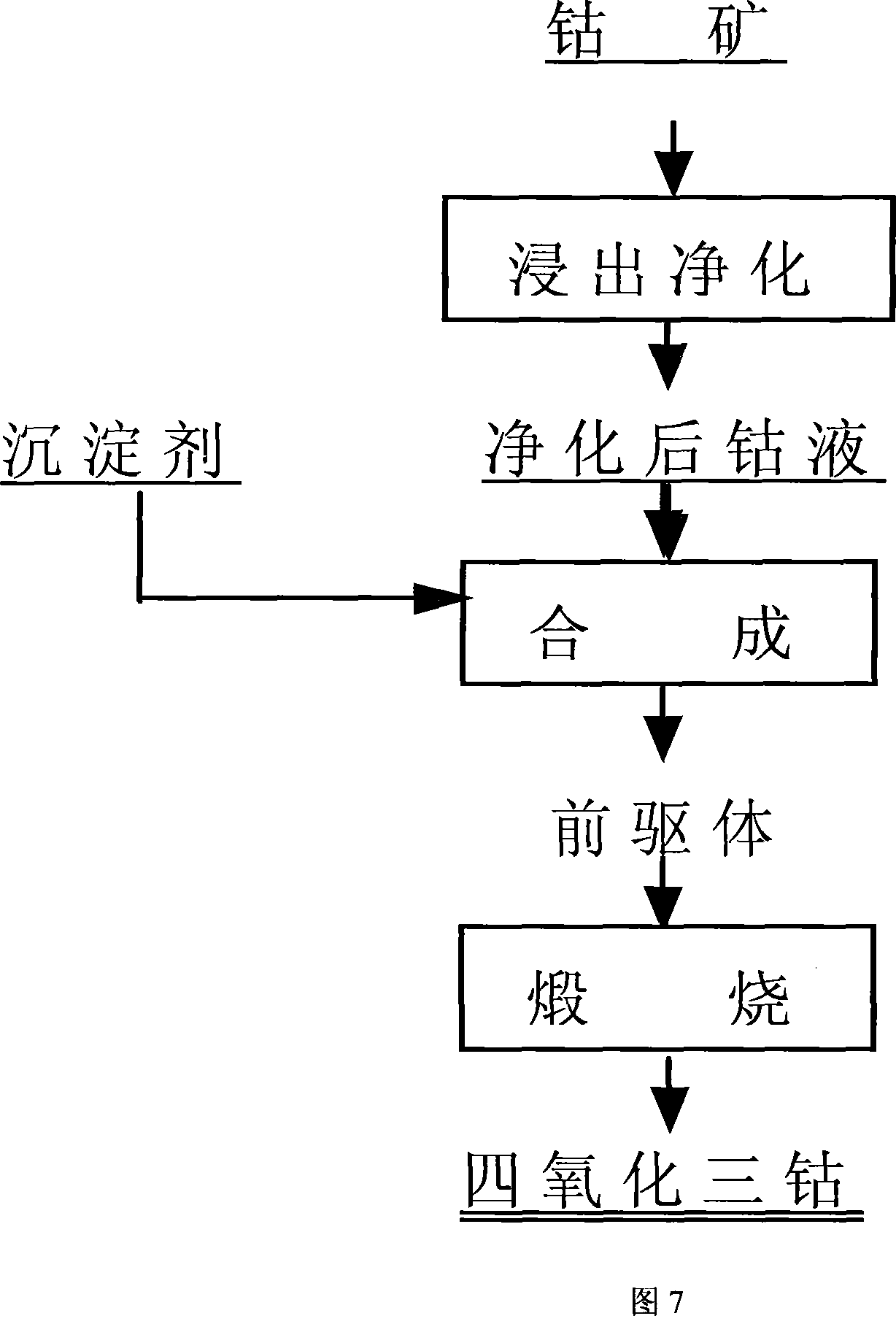

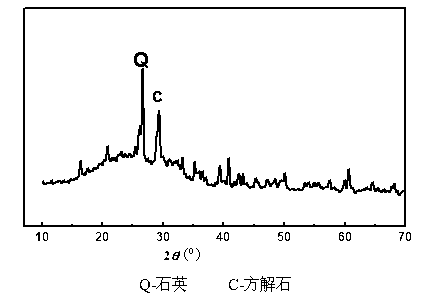

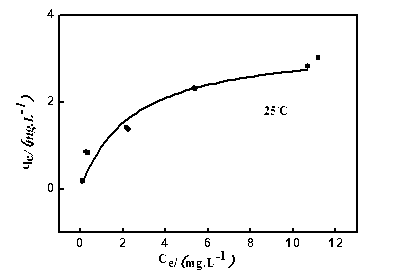

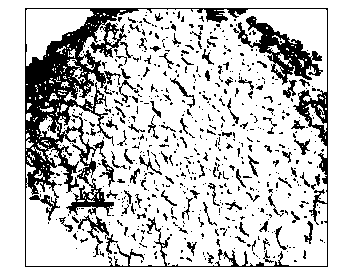

Preparation method of cobaltosic oxide for electric battery

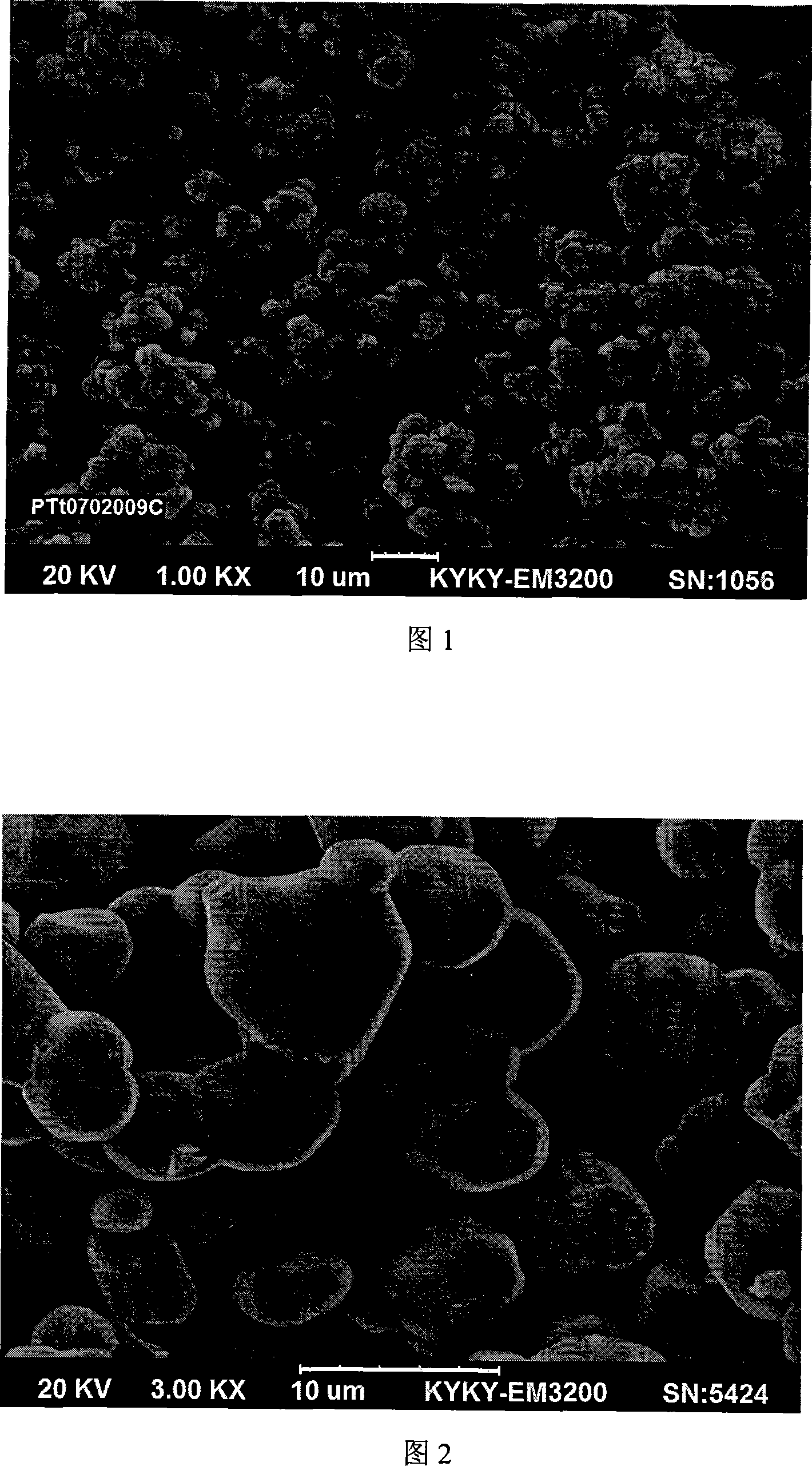

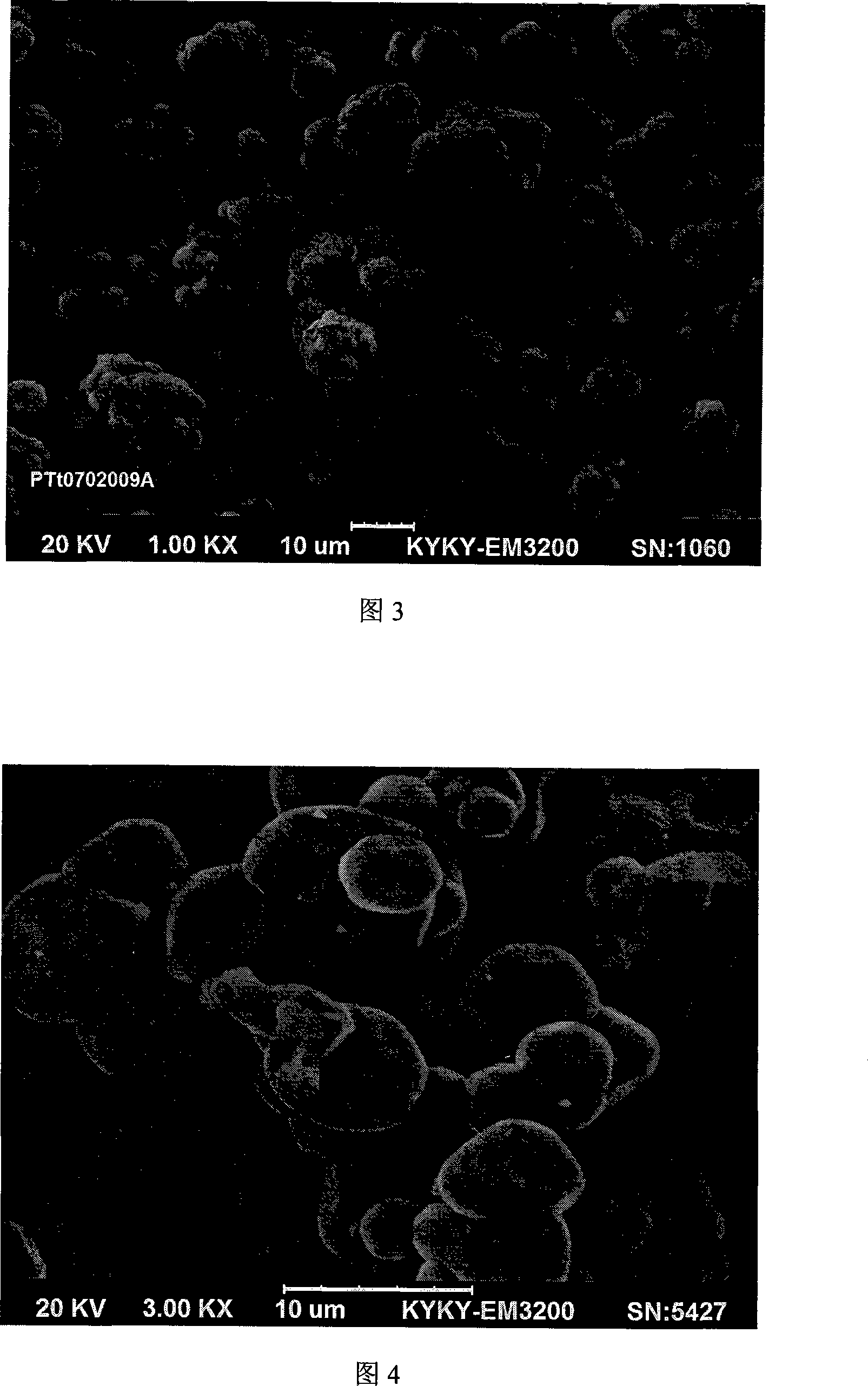

ActiveCN101200308AImprove liquidityUniform particle sizeCobalt oxides/hydroxidesGranularityCobalt(II,III) oxide

The invention discloses a preparation method of Co3O4 for batteries, Co mineral is used as Co raw material, after purified the Co liquid is obtained, complexing-homogeneous sedimentation method is adopted to prepare precursor, i.e the Co liquid is prepared into the complexing Co salt solution, and then added with precipitator solution, the synthesis of the precursor is controlled to obtain single-dispersion sedimentation precursor so as to make the production and growth of the nucleation be separated, and then sintered under high temperature, the precursor is thermally decomposed to obtain the Co3O4 for batteries finally. The prepared Co3O4 powder has good flow property, even granularity and can utilize DCS system to adjust process parameters accurately to realize the control (D50=3um-6um,6um-9um,9um-12um), the tap density can reach 2.5g per cubic centimeter to 3.5g per cubic centimeter, microcosmic shape is single-crystal or like spherical, moreover the invention has the advantages of high chemical purity, good electrochemical performance, and no environmental pollution. The invention has simple process, stable product quality, low cost, and can adapt for the requirements of material performance and cost of various lithium cobalt oxide manufacturing factory.

Owner:ZHEJIANG HUAYOU COBALT

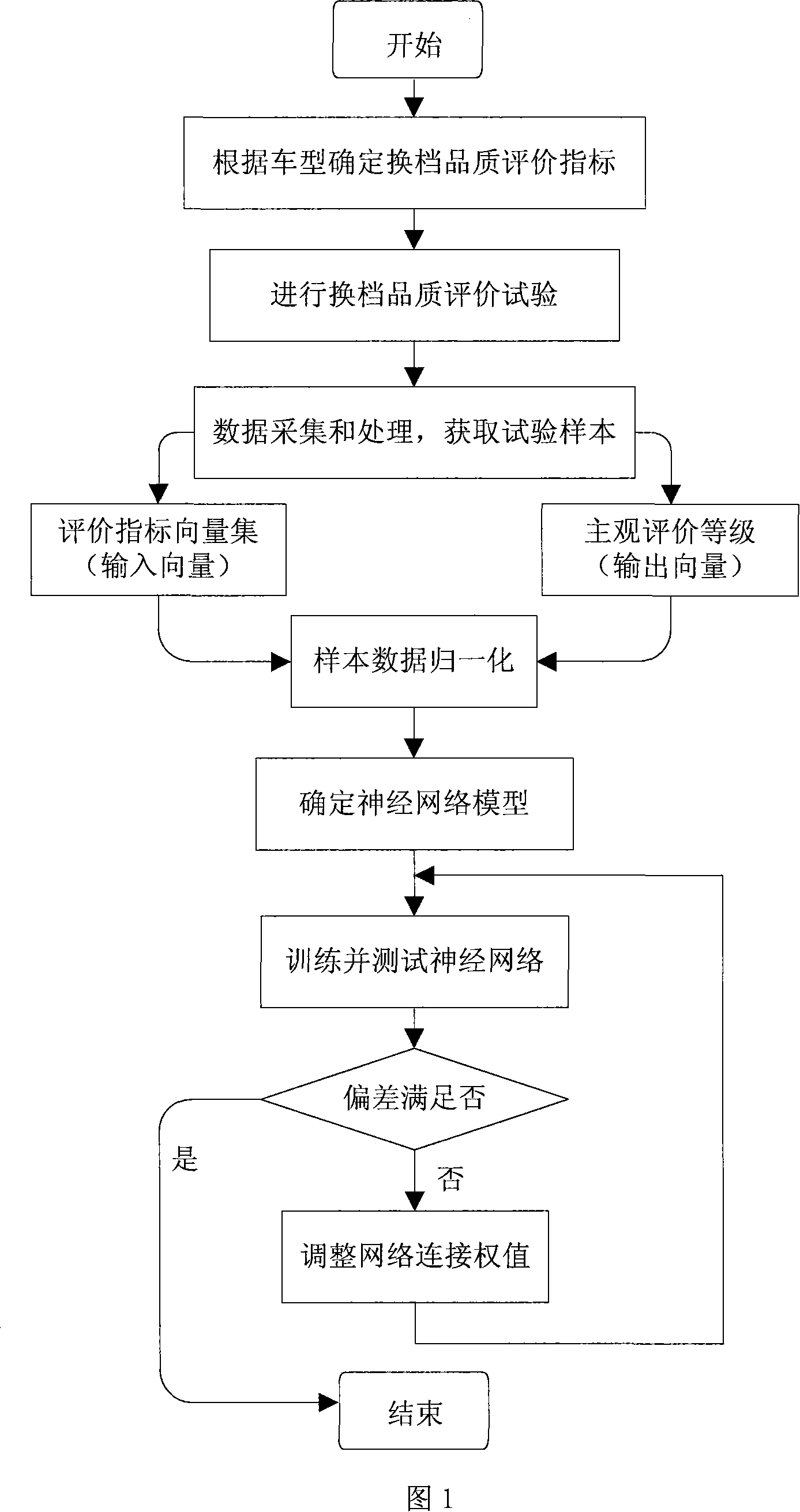

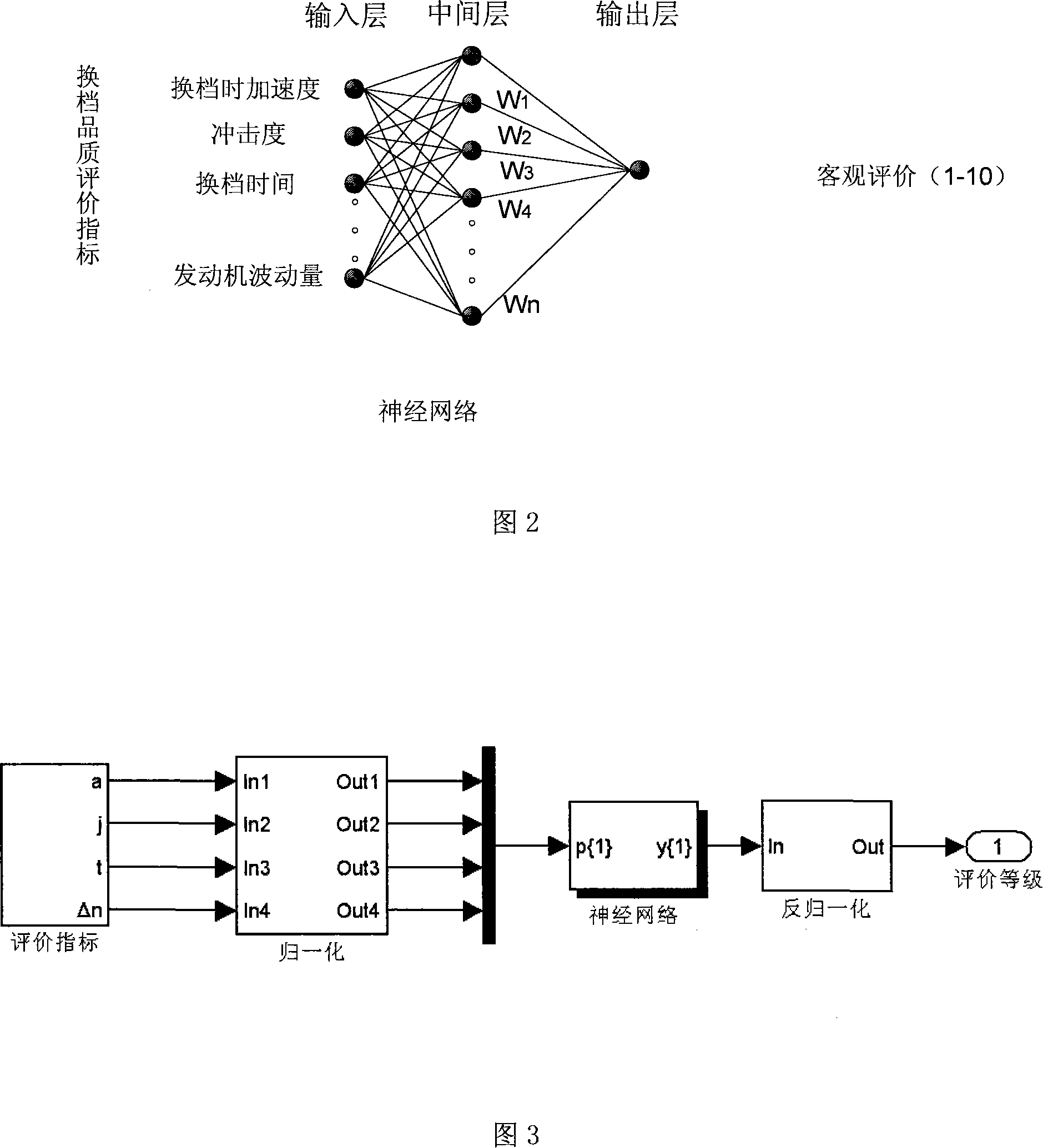

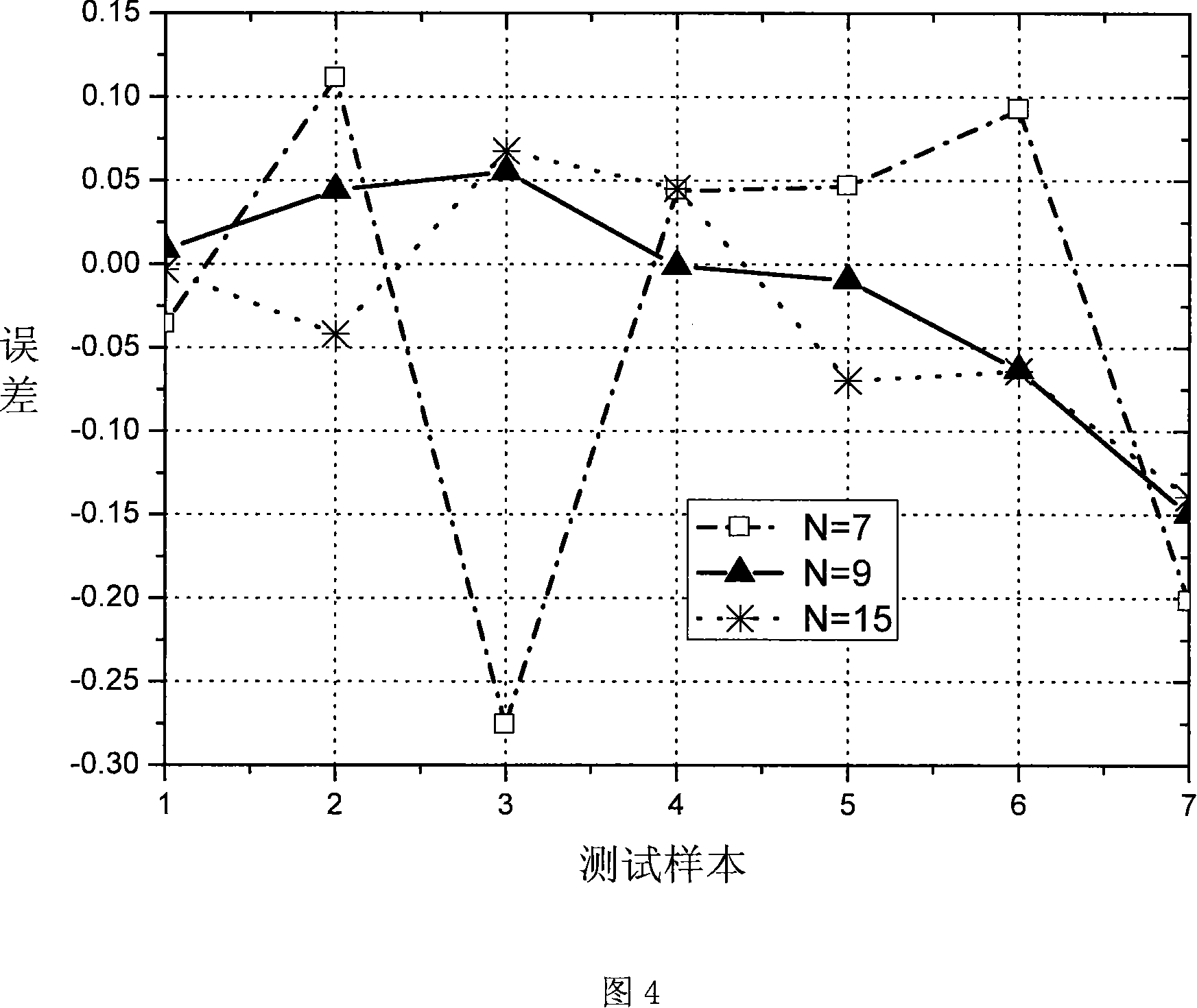

Vehicle gear shifting quality evaluation method based on nerval net

InactiveCN101118620AEvaluation is scientific and reasonableIncrease credibilityData processing applicationsBiological neural network modelsHigh effectivenessEvaluation system

The present invention relates to a method for evaluating the property of vehicle gearshift based on the Neural Network, and includes four basic procedures as follows: First, the index for the evaluation of the property of a gearshift is determined. Second, the sample data of evaluation index and subjective evaluation ratings are withdrawn. Third, the Neural Network is trained. Fourth, a model for the property of the gearshift is built, and an objective evaluation is achieved. The objective evaluation method is accomplished by adopting the mode identification and the prediction capability of the Neural Network. The present invention can evaluate the property of the gearshift effectively and objectively, possess good intelligence and stability and have good consistency with the outcome of the subjective evaluation. The present invention can provide guidance and aid for increasing the property of a vehicle gearshift and establishing a dynamic comprehensive evaluation system for the property of the vehicle gearshift. Manufacturing factories and research institutes in the industry can use the system to accomplish an evaluation task of the property of the gearshift efficiently.

Owner:JILIN UNIV

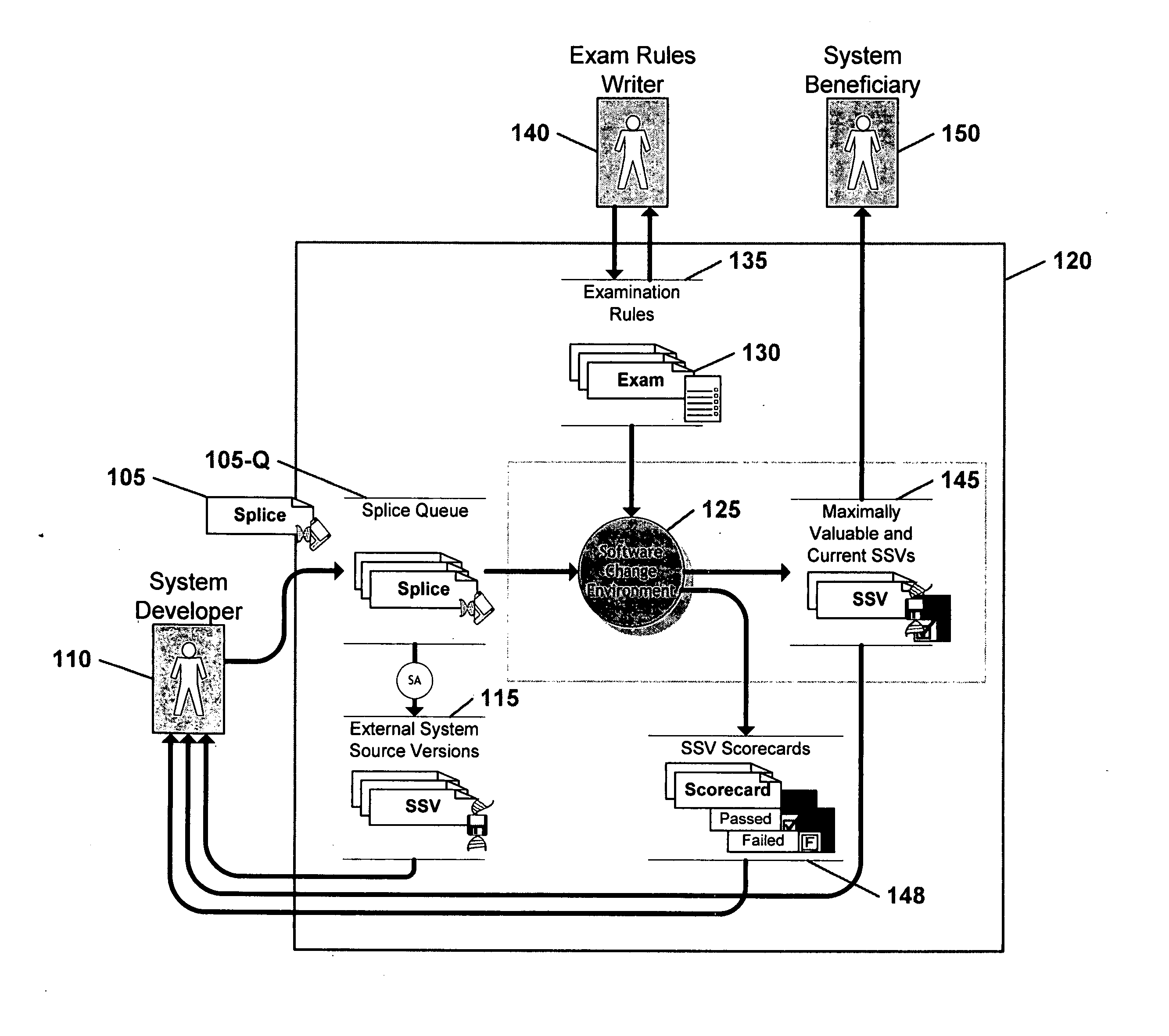

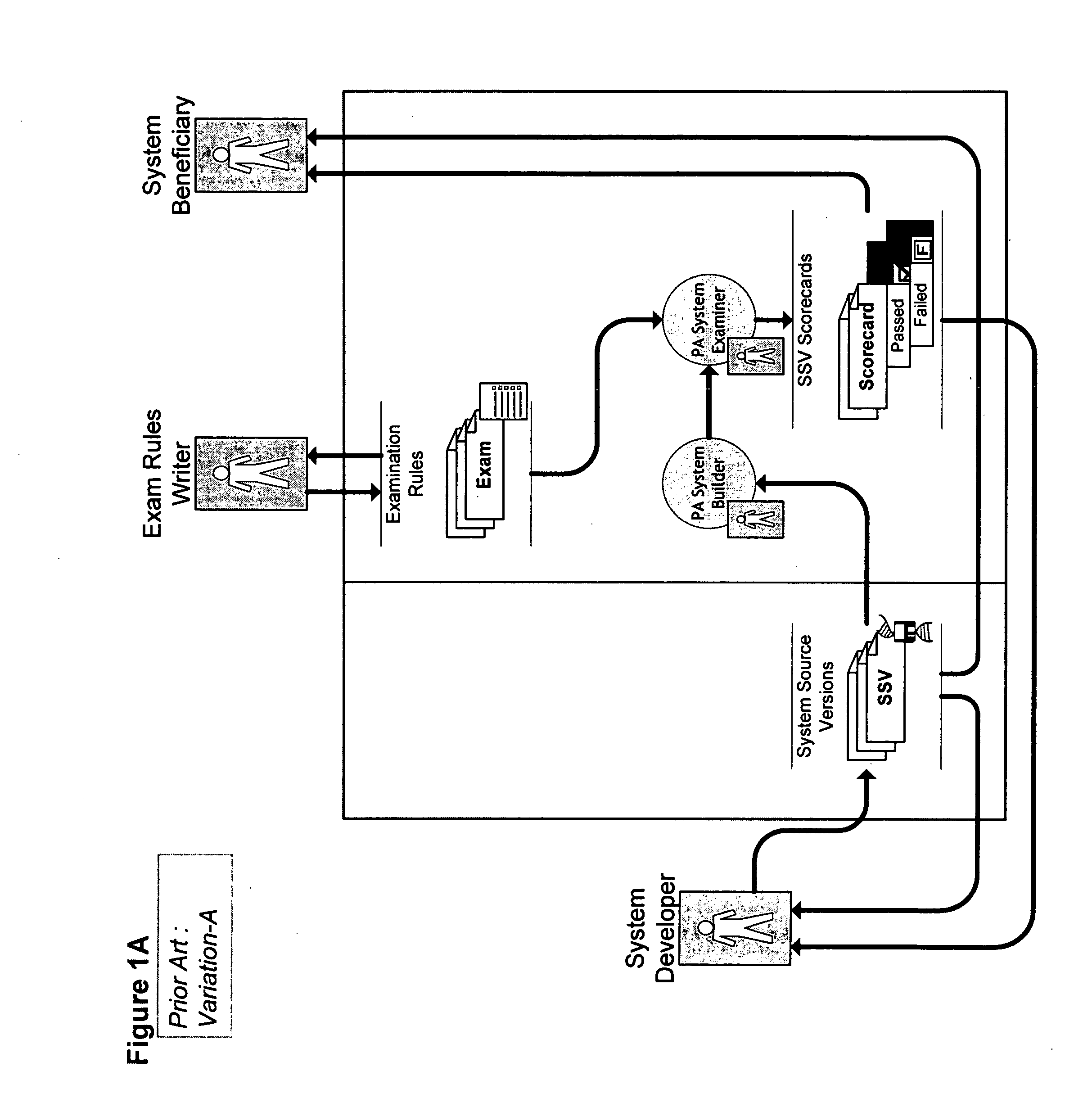

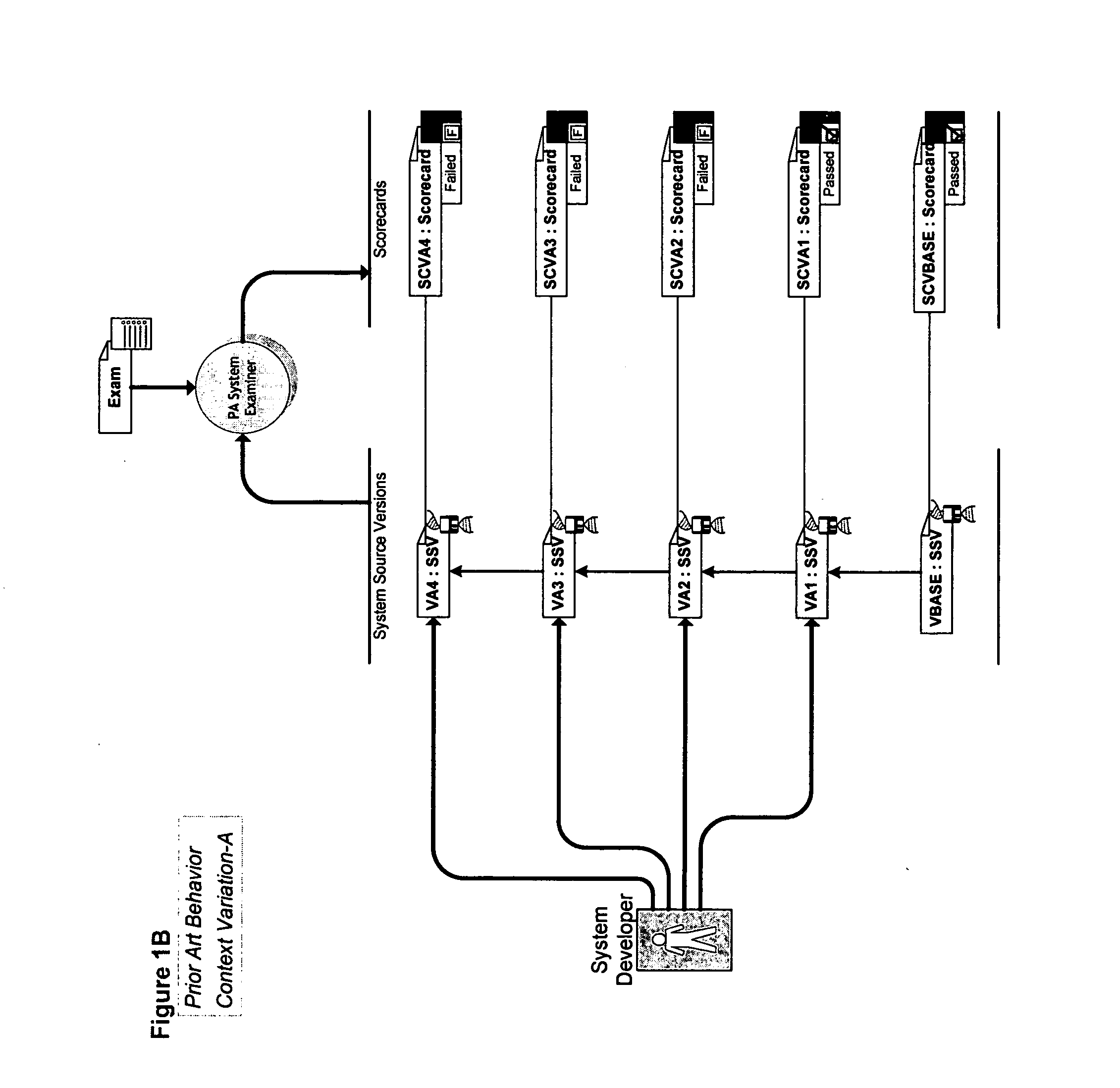

Software manufacturing factory

InactiveUS20070083859A1Simple processImproved system configurationVersion controlSpecific program execution arrangementsAutomatic controlSoftware system

This invention discloses an automated software development system that includes an automated version control and evaluation processing platform for automatically evaluating a quality and value of a plurality of software changes and corresponding versions of a software system for automatically controlling an automated software development and change process of the software system. The automated version control and evaluation processing platform further includes a database for storing statistic and relevant data including the quality and value of the plurality of software changes and versions of the software system. The automated version control and evaluation-processing platform further applies the statistic and relevant data for automatically controlling an automated software development and change process of the software system.

Owner:VELIDOM

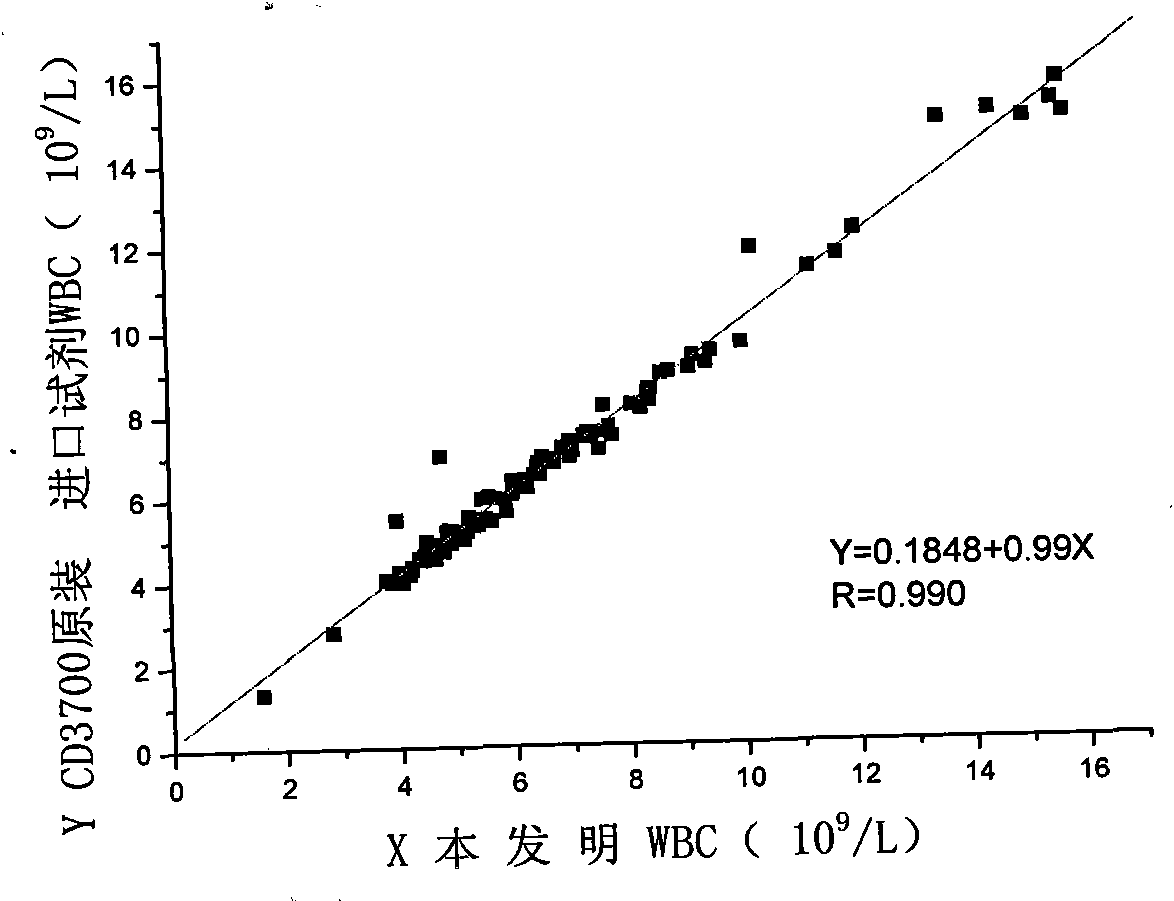

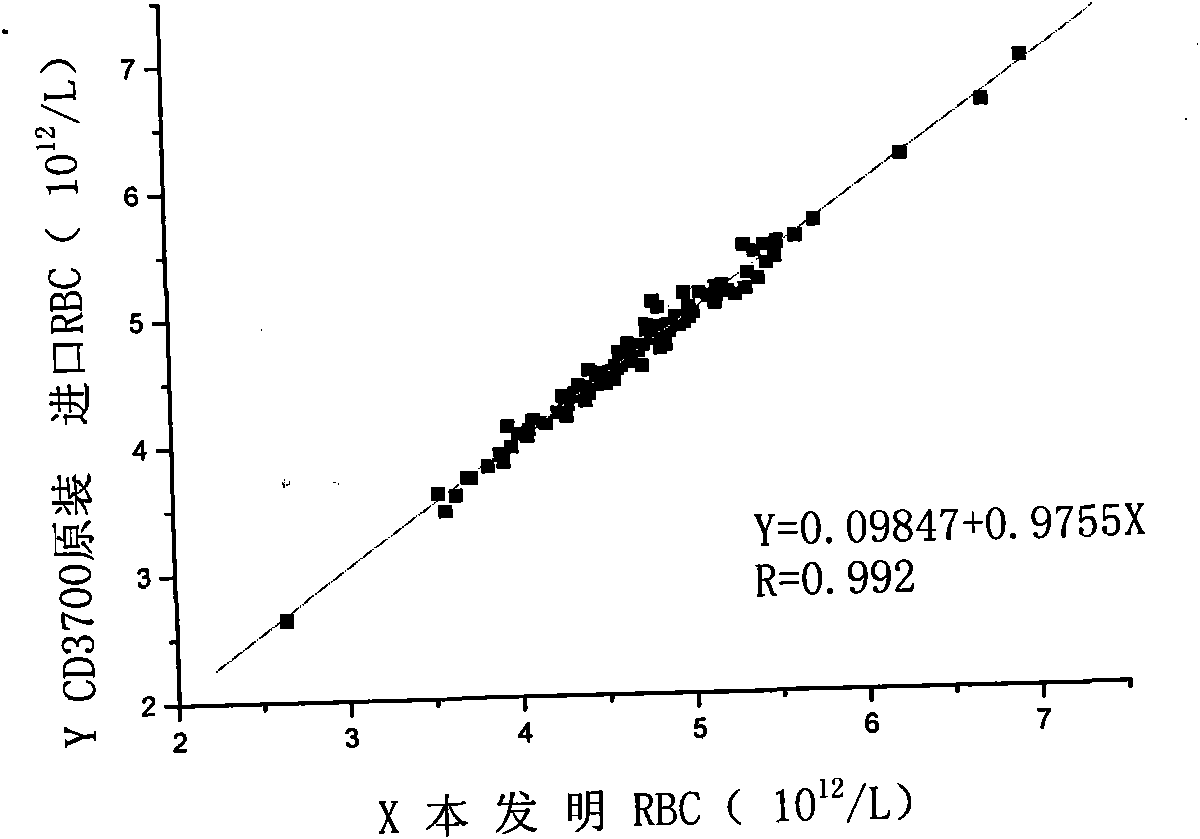

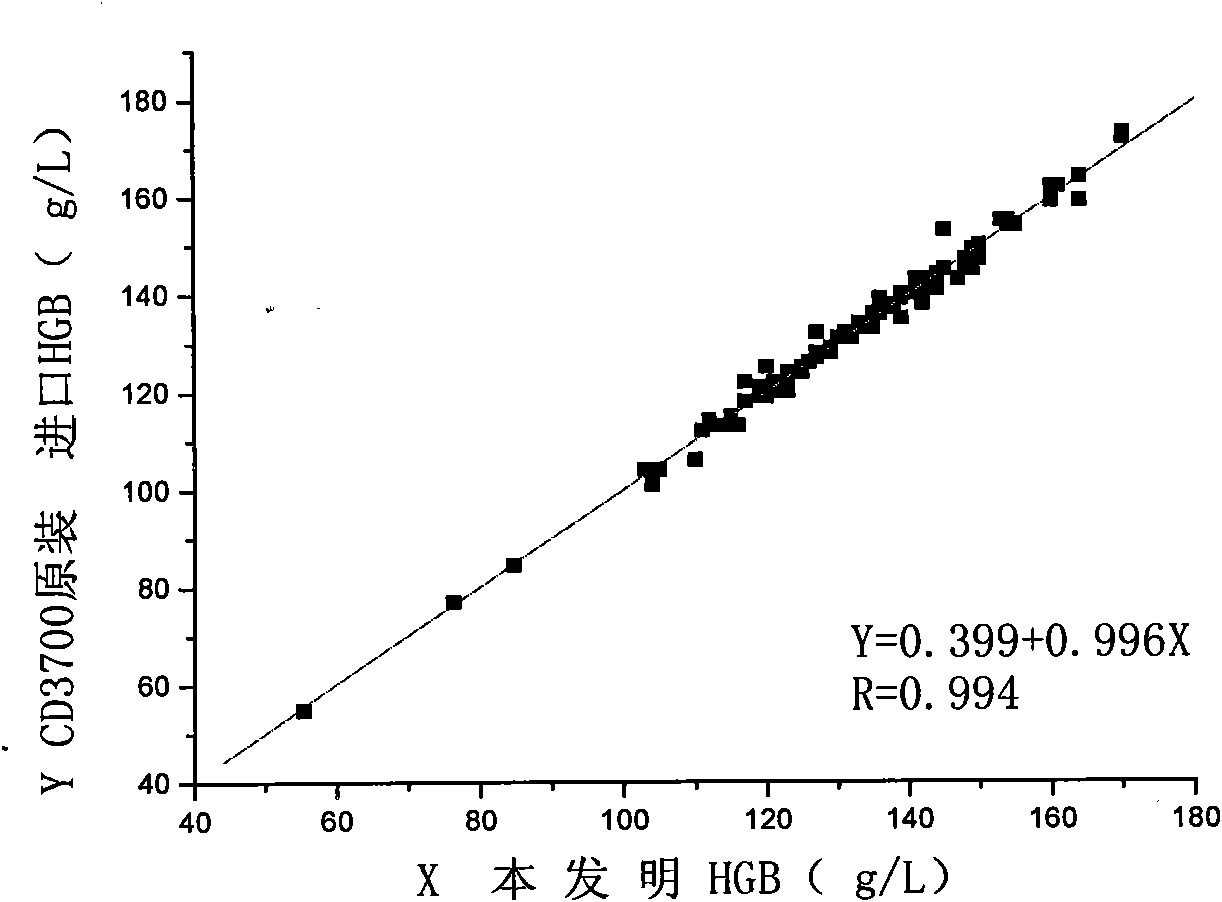

Reagent for hemocyte analyzers

The invention discloses a reagent for hemocyte analyzers, which is prepared from diluent, hemolytic agent, sheath flow liquid and cleaning fluid. Compared with the prior art, the invention changes the actual state of long-term dependence on import of the reagent for hemocyte analyzers in China, and is produced and sold in China, thereby greatly reducing the production cost; the hemolytic agent in the reagent does not contain cyanogen, thereby greatly reducing the injury to health of the personnel and experiment operators in manufacturing factories, and avoiding the environment pollution of prussiates; the reagent is especially suitable for the CD3700 / 3500, CD3000 and CD3200 differential count full-automatic hemocyte analyzers of Abbott Laboratories in America, and the hemolytic agent A750test indicates the reagent achieves the ICSH standard; and the correlation coefficients of leucocyte, erythrocyte, hemoglobin, thrombocyte and the like relative to the imported ABBOTT CELL-DYN3700 / 3500 reagent are respectively greater than 0.95.

Owner:URIT MEDICAL ELECTRONICS CO LTD

Electric reactor turn-insulating detection device based on pulse oscillation principle

InactiveCN104515941AImprove product qualityGuaranteed safe operationTesting dielectric strengthLow voltageCapacitive voltage divider

The invention relates to an electric reactor turn-insulating detection device based on pulse oscillation principle. Two output ends of a transformer are connected with a high voltage silicon rectifier stack, a protective resistor and a resistance voltage divider high / low voltage arm resistor which are connected sequentially and serially; controllable discharge spark gaps and two ends of a damping oscillating circuit are all connected with two ends of the resistance voltage divider high / low voltage arm resistor in parallel; the damping oscillation circuit consists of a damping resistor, a main capacitor and an electric reactor test object; a controller unit is adopted to control the discharge spark gaps to discharge electricity and the transformer to output voltage according to voltage at two ends of the resistance voltage divider high / low voltage arm resistor; pulse oscillation is formed on a pulse oscillation test product in the spark gap discharge process, pulse oscillation signals formed on the electric reactor are transmitted to an oscilloscope through capacitive voltage dividers which are serially connected at two ends of the electric reactor test product, and thus diagnosis on the turn-insulating of the electric reactor is achieved. The electric reactor turn-insulating detection device aims to solve the passive situation that the turn-insulating of the electric reactor cannot be monitored for a long time at present, and has benefits of improving the product quality of an electric reactor manufacturing factory and ensuring the safe operation of a whole power grid.

Owner:STATE GRID CORP OF CHINA +2

Biological aerated filter filler preparation method capable of simultaneously removing phosphorus and nitrogen, and application thereof

InactiveCN103172168ASustainable biological treatmentBiological water/sewage treatmentVoid ratioNitrogen

The invention discloses a biological aerated filter filler preparation method capable of simultaneously removing phosphorus and nitrogen, and application thereof. The preparation method comprises the following steps of: crushing powder ash air-entrained concrete or defective products of a building block manufacturing factory into particles by using a crusher; sieving to obtain particle materials within different grain size ranges to be used as the biological aerated filter filler. The powder ash air-entrained concrete has the characteristics of small density, high void ratio, large specific surface area and the like, has the characteristics of large phosphate adsorption capacity in water and high loaded microorganism quantity when being used for the biological aerated filter filler, and has the function of simultaneously removing phosphorus and nitrogen.

Owner:HEFEI UNIV OF TECH

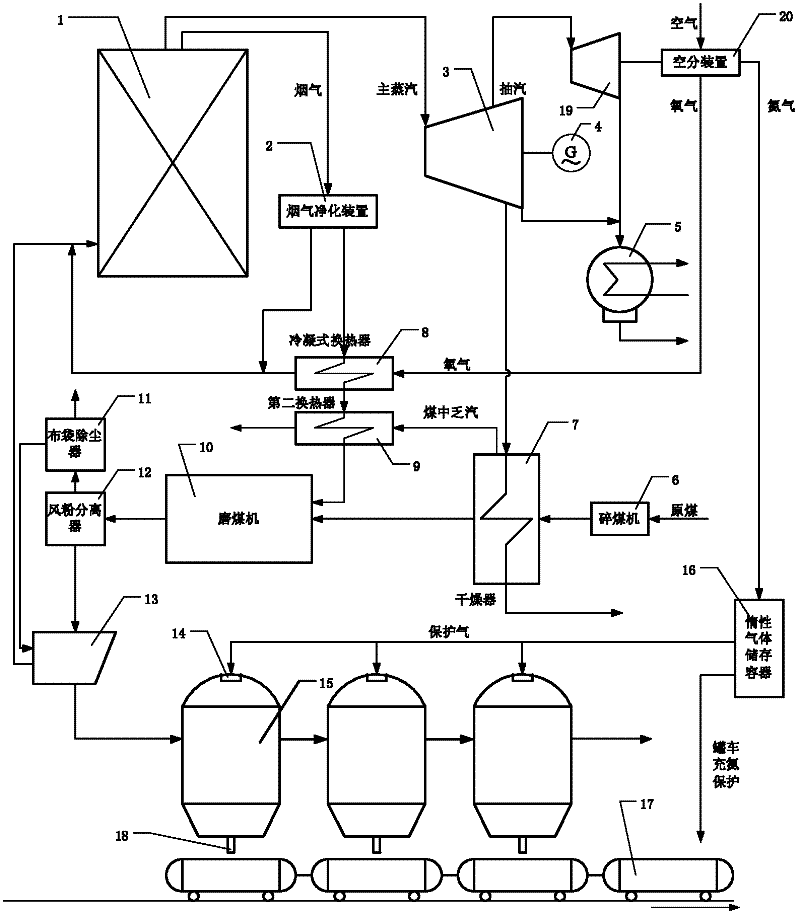

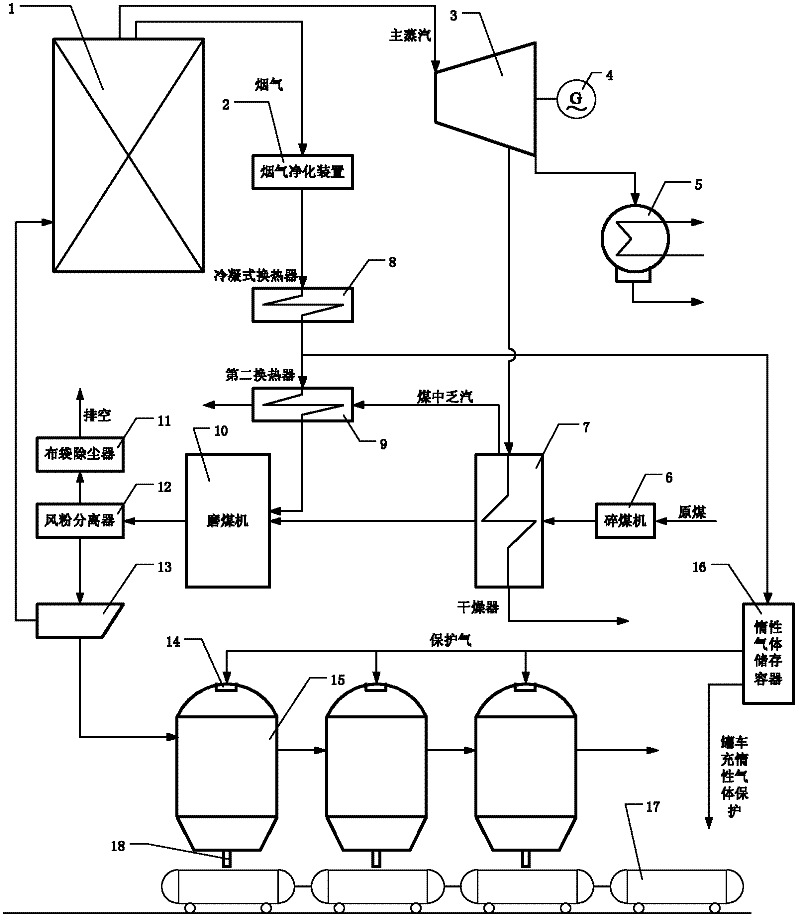

Large-scale centralized preparation system for pulverized coal and distribution method

InactiveCN102410552AGuaranteed feasibilityEnsure safetyLump/pulverulent fuel preparationCoal briquetteDistribution method

The invention discloses a large-scale centralized preparation system for pulverized coal and a distribution method. In the invention, raw coal is dried in a drying system by virtue of heat energy from a power generation enterprise in a raw coal producing area; dried coal briquettes are input into a grinding system so as to be processed into qualified pulverized coal; then the qualified pulverized coal is conveyed to coal-based power enterprises and other pulverized coal users for use by means of conveying equipment; and the whole pulverized coal processing and transportation process is in an inert environment so as to ensure the safe operation of the whole system. The large-scale centralized preparation system and the distribution method are mainly applied to large-scale centralized pulverized coal manufacturing factories in mining areas, wherein the factories provide the pulverized coal for the coal-based power enterprises and other pulverized coal users by a mode of conveying the qualified pulverized coal.

Owner:XI AN JIAOTONG UNIV

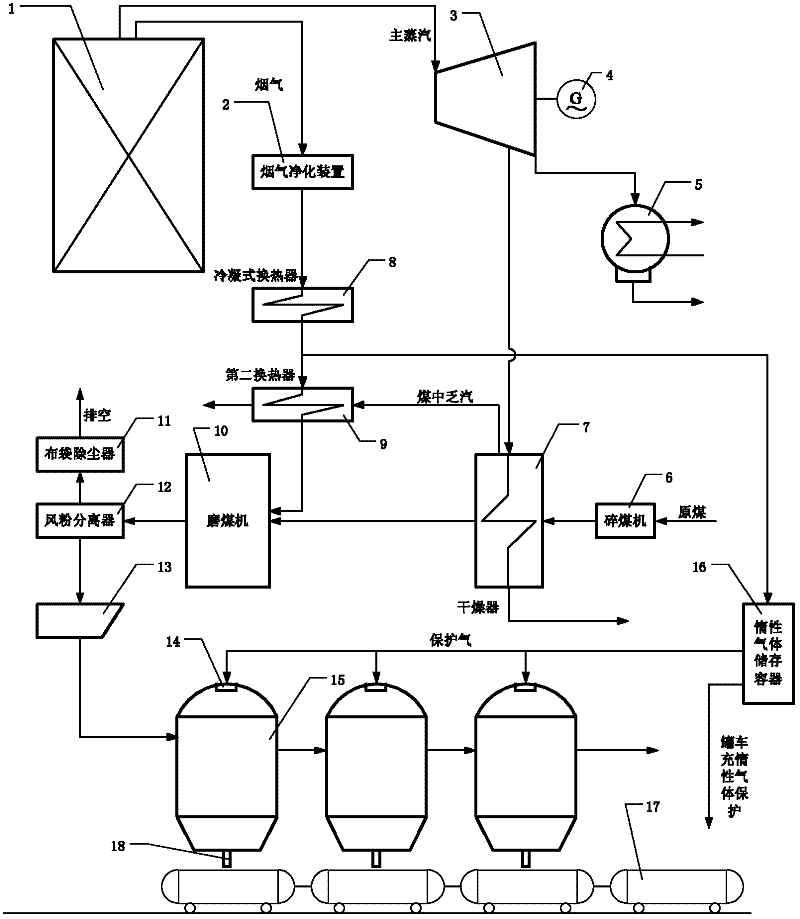

Industrial it system for production of distribution power transformers

InactiveUS20050256776A1Buying/selling/leasing transactionsSpecial data processing applicationsPaymentDistribution transformer

An order for a product from a customer by way of a website viewed on a display device of a customer computer is received and reviewed. An optimization across a plurality of manufacturing plants is requested, where each plant has a product manufacturing capacity, and the optimization takes place according to the capacity. The optimization is then received and a determination whether to confirm the order is made. If the order is confirmed, materials are ordered and a hold is placed on all or part of the capacity. Finally, an automated payment process is initiated with the customer.

Owner:ABB RES LTD

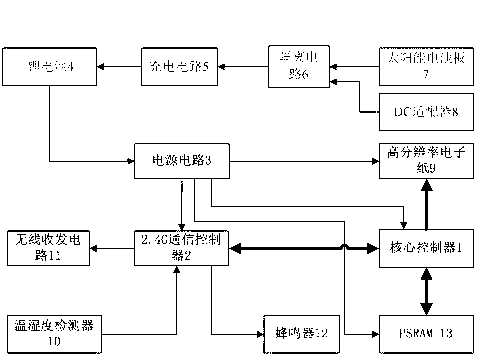

Electronic goods shelf label based on FPGA

InactiveCN103324965AReduce labor and other costsLow update delayStampsCo-operative working arrangementsElectronic shelf labelImage resolution

The invention discloses an electronic goods shelf label based on an FPGA. A 2.4G wireless communication module, a high-resolution electrophoresis type electronic paper display screen, a core controller based on a low-power-consumption FPGA chip, a lithium cell, a power supply circuit, a solar cell panel, an external DC charging module, a temperature-humidity detecting module, an alarming module and a PSRAM display buffer are integrated. Commodity information such as prices, sales promotion and manufacturing factories, one-dimensional bar codes and two-dimensional bar codes of various commodities can be displayed in extremely-high resolution, corresponding commodity inventory information can be displayed, zero power consumption can be nearly achieved, relevant content renewal can be achieved, a brand new and advanced price renewing method is provided for retailing merchants of similar supermarkets, and meanwhile an interface of a commercial POS system is reserved, seamless joint can be achieved conveniently, and an on-line checking function is achieved. The auxiliary temperature-humidity detecting module can monitor environment temperature and humidity in real time, and the alarming module can give an alarm under abnormal situations timely.

Owner:佛山市广华合志科技有限公司 +1

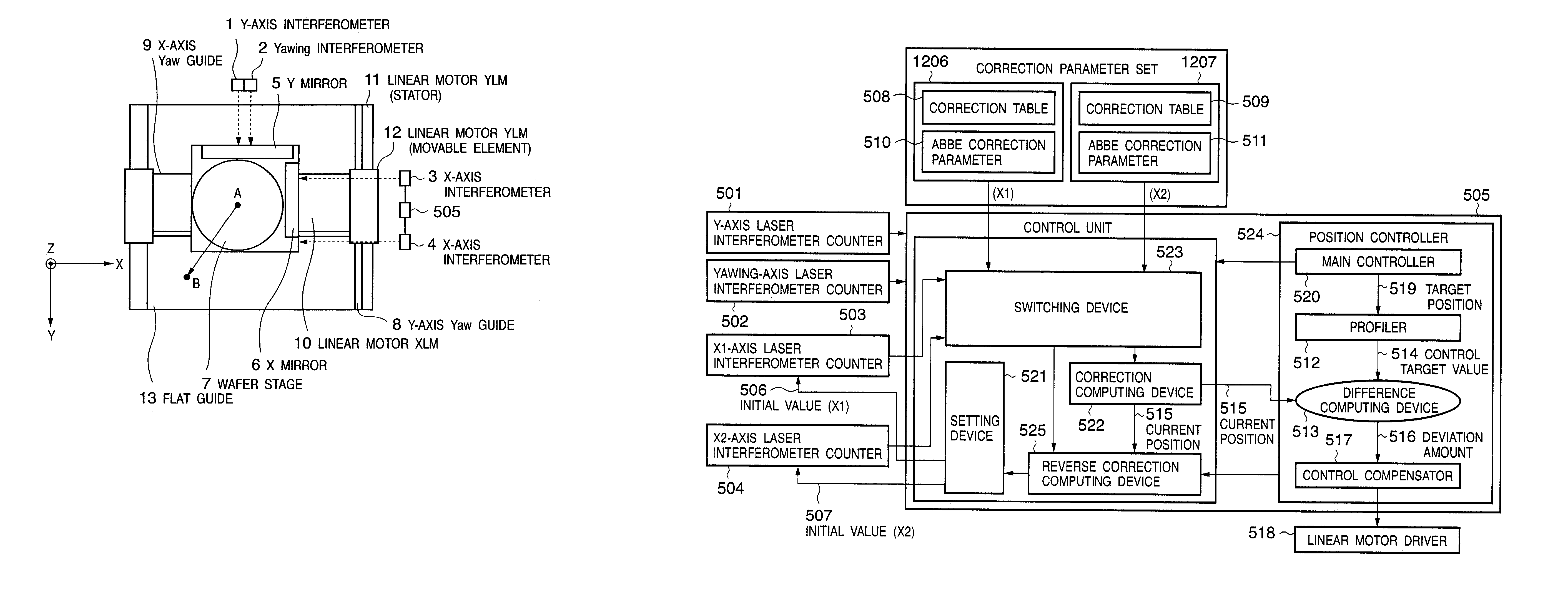

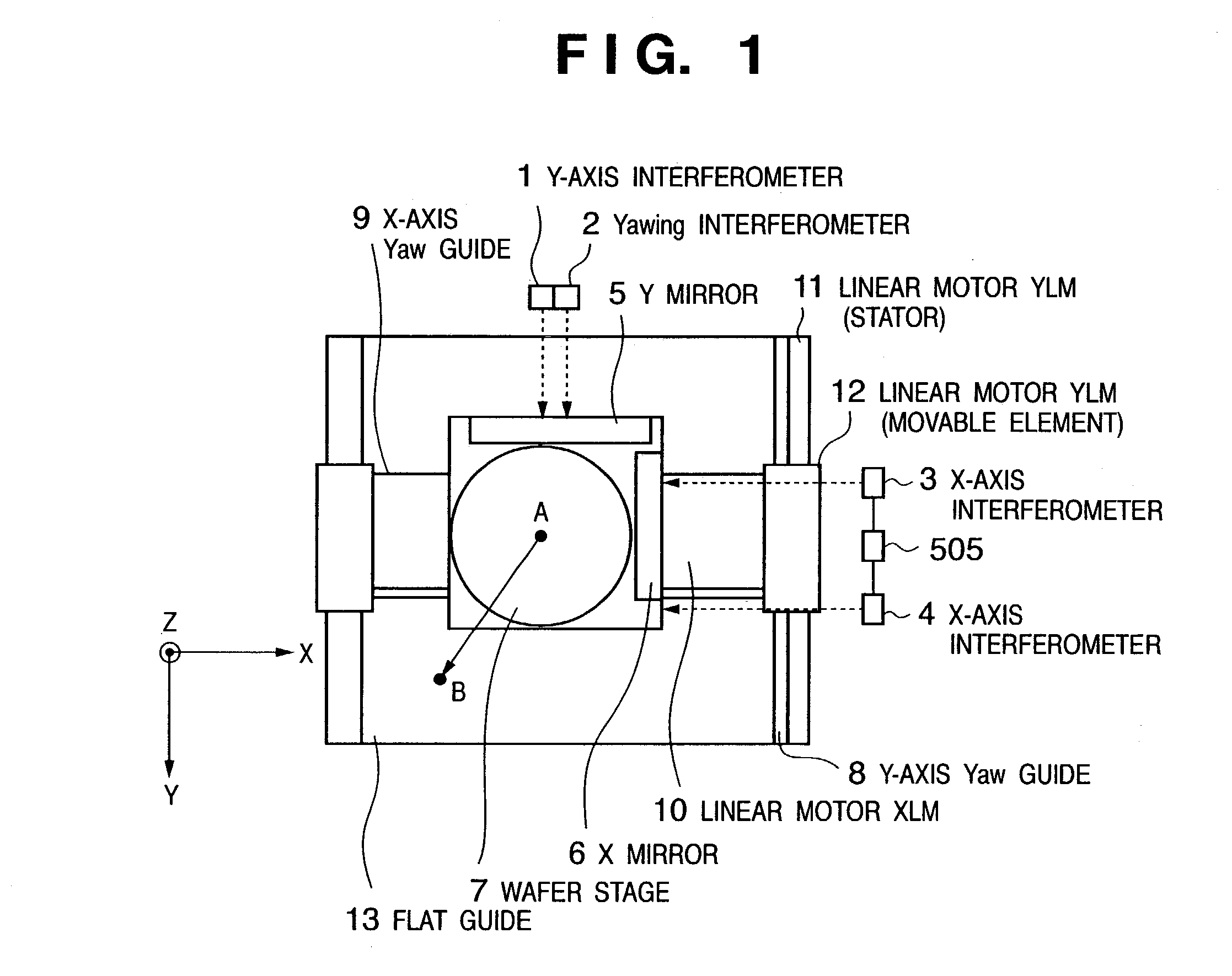

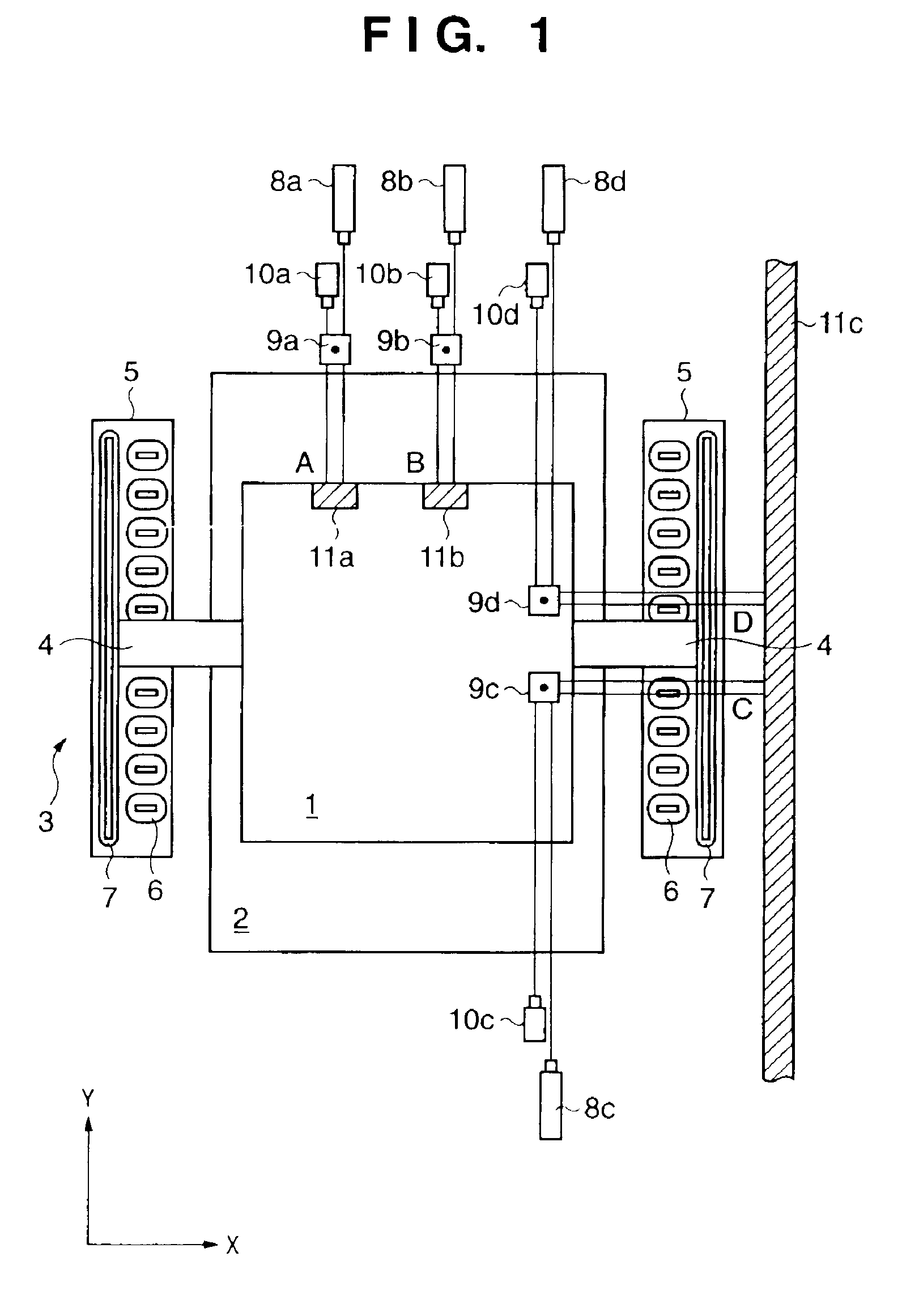

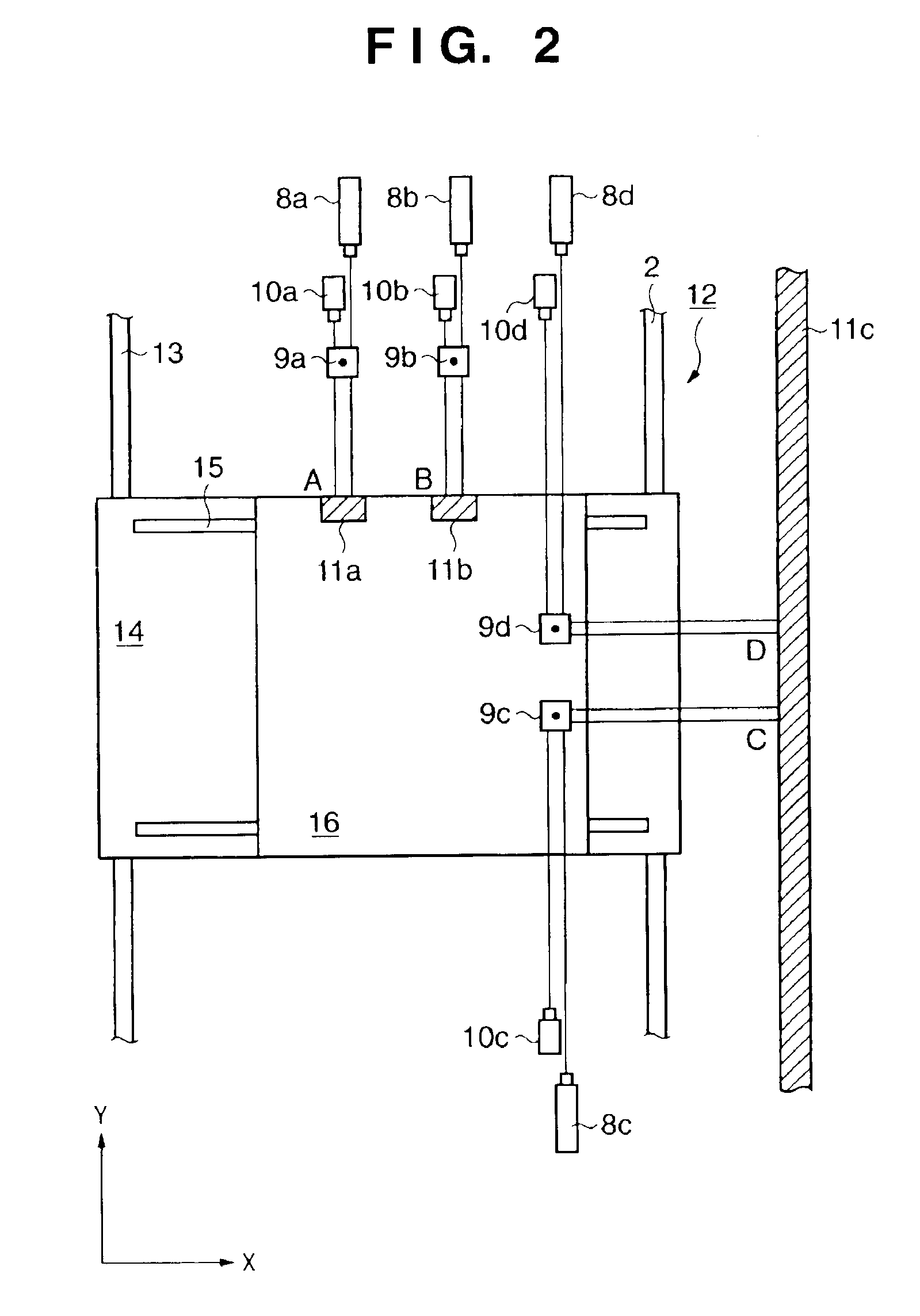

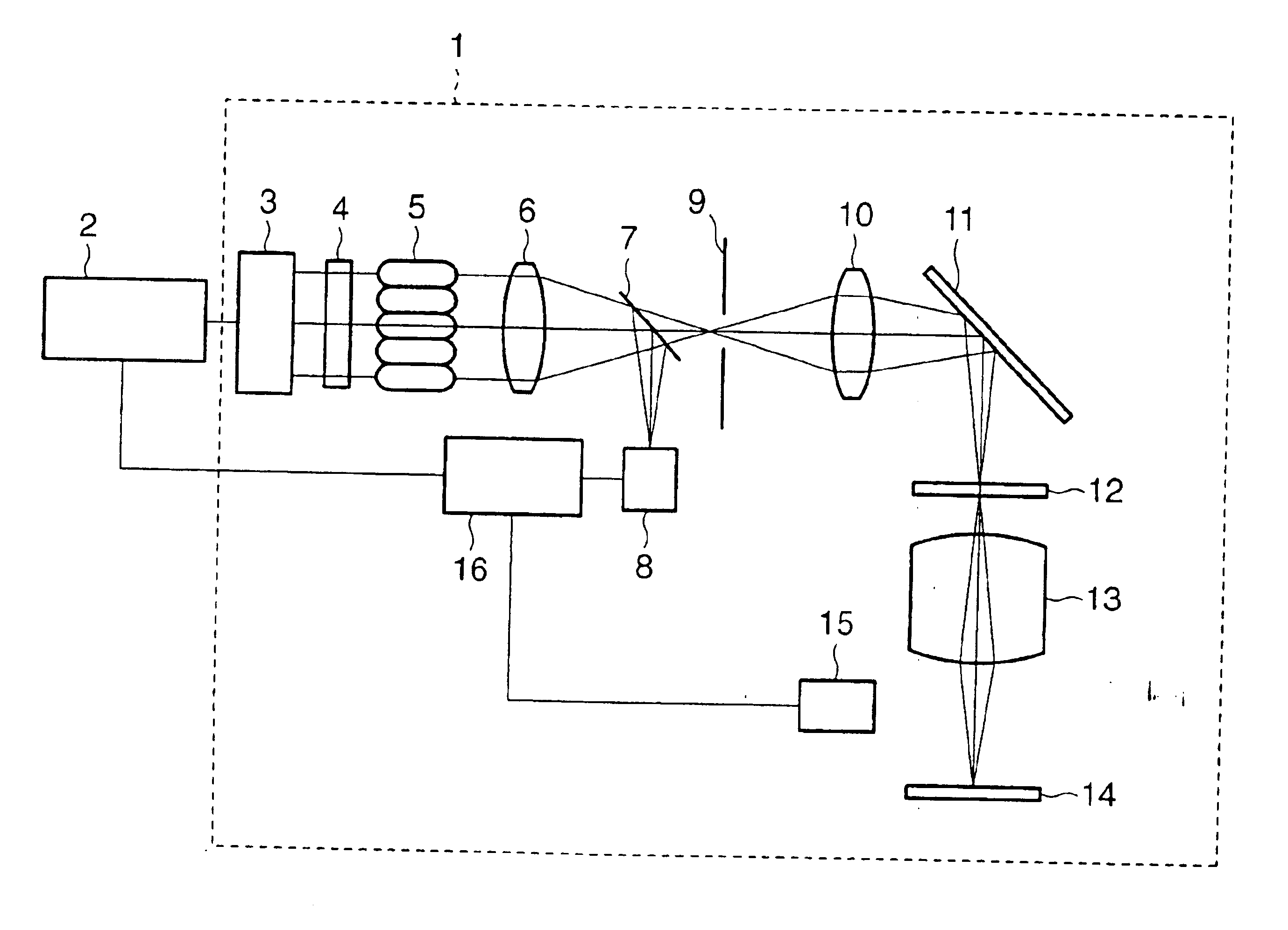

Alignment apparatus, control method therefor, exposure apparatus, device manufacturing method, semiconductor manufacturing factory, and exposure apparatus maintenance method

InactiveUS7016049B2High precision measurementSemiconductor/solid-state device manufacturingUsing optical meansSemiconductorManufacturing Factories

An alignment apparatus including a first position measuring device and a second position measuring device which measure position information of an object to be controlled, a switching device which switches a position measuring system from the first position measuring device to the second position measuring device, depending on a moving area of the object to be controlled, a correction computing device which performs a correction calculation for a measurement result from the first position measuring device using a first correction parameter set to obtain a current position of the object to be controlled, a predicted coordinate computing unit which predicts coordinates of the object to be controlled on the basis of progress of a correction calculation result from the correction computing device, and a reverse correction computing device which performs a calculation for the coordinates predicted by the predicted coordinate computing unit using a second correction parameter set to obtain a command value for the second position measuring device.

Owner:CANON KK

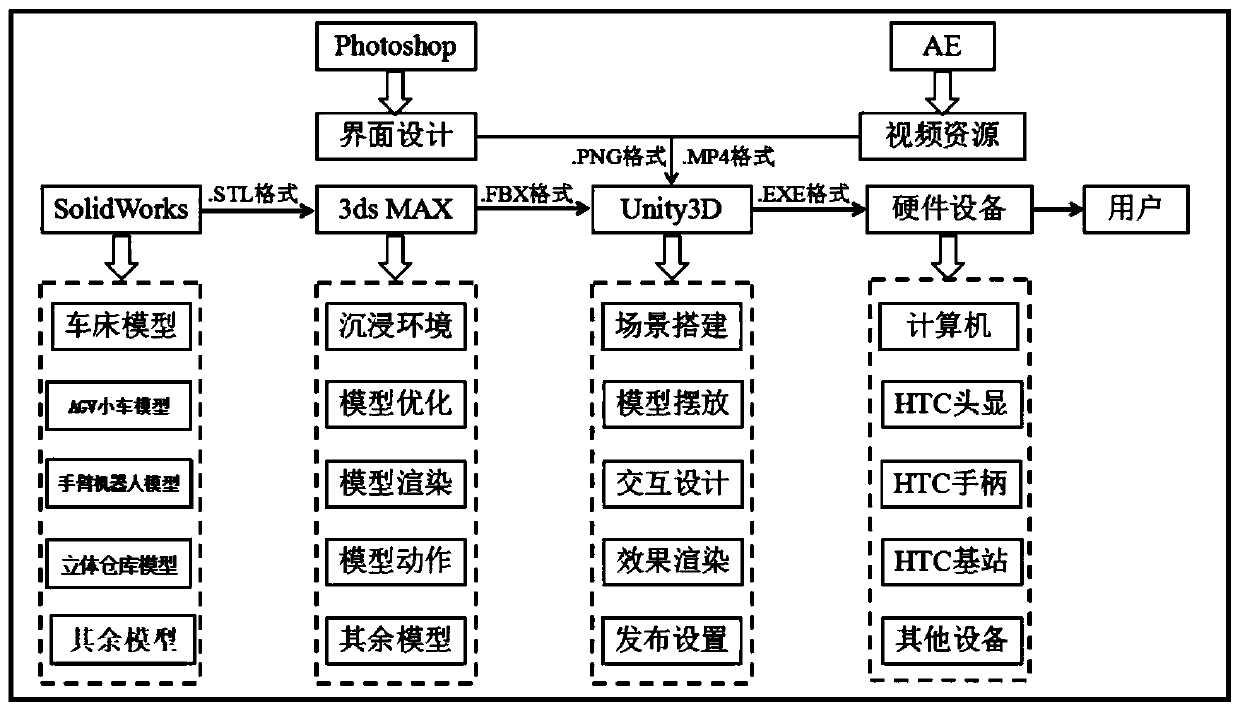

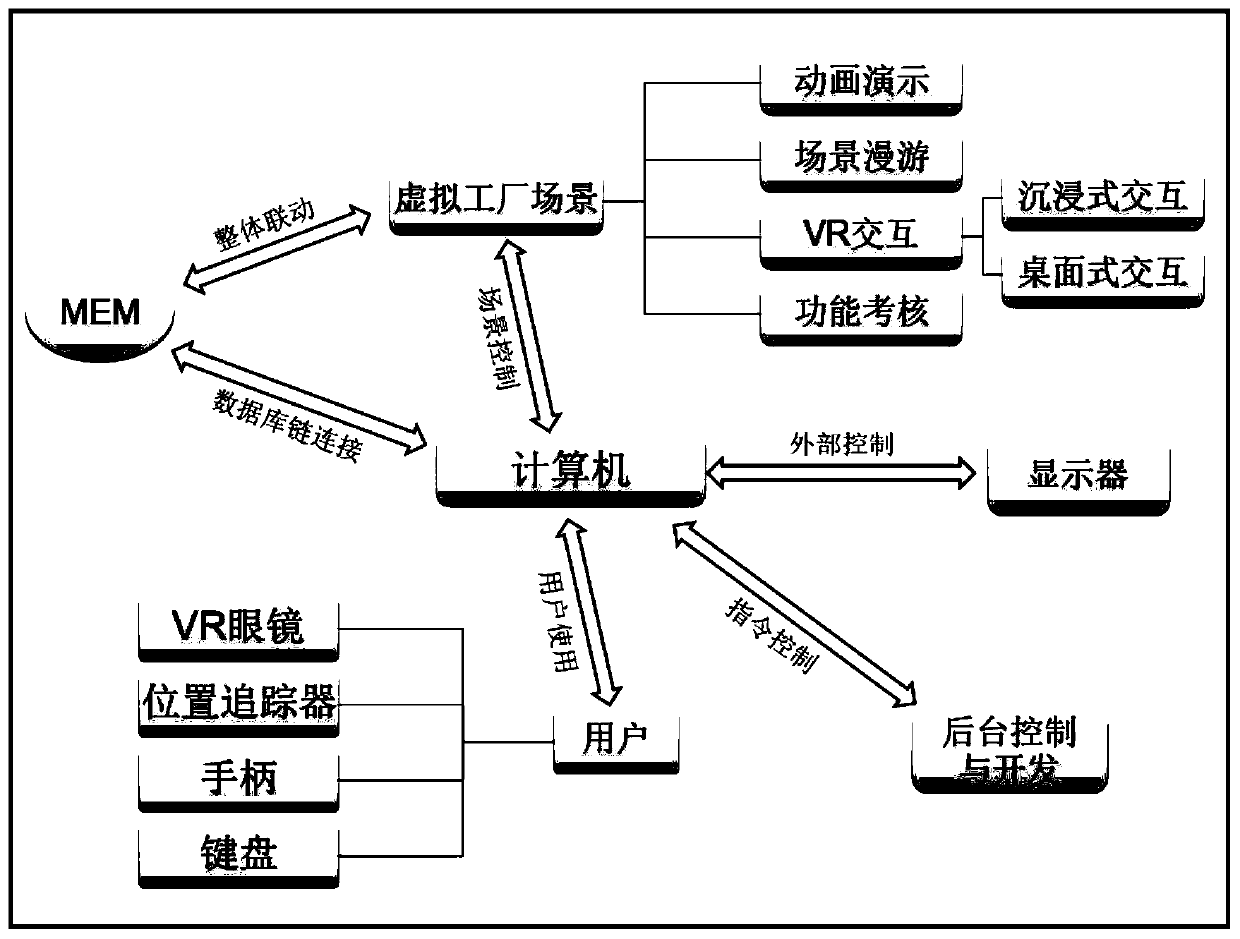

Intelligent manufacturing factory simulation teaching system and method based on 3D virtual technology

InactiveCN110264816AEasy to understandEasy to masterCosmonautic condition simulationsSimulatorsThree dimensional simulationThe Internet

The invention provides an intelligent manufacturing factory simulation teaching system based on a 3D virtual technology. The intelligent manufacturing factory simulation teaching system includes an intelligent manufacturing virtual simulation scene terminal, a student operating terminal, a control platform and a teacher evaluation terminal which are all connected by the Internet of Things, wherein the intelligent manufacturing virtual simulation scene terminal is used for establish a three-dimensional simulation system of an intelligent manufacturing factory to display a three-dimensional scene of the intelligent manufacturing factory; the student operating terminal includes VR glasses, operating tools and storage devices, and the VR glasses displays the three-dimensional scene, the operation tools input data, and the storage devices take the three-dimensional scene experienced by students and data input as practice tasks of the students for saving; the control platform selectively displays part of the three-dimensional scene to corresponding student operating terminal according to an authority of the student operating terminal and a teaching purpose; and the teacher evaluation terminal calls the practice tasks stored by the student operating terminal, scores and evaluates according to the data input by the students. According to the intelligent manufacturing factory simulation teaching system, teaching efficiency is improved by intelligent manufacturing virtual reality simulation training without being limited by time and space, and teaching quality is improved by adding data input and teacher evaluation.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

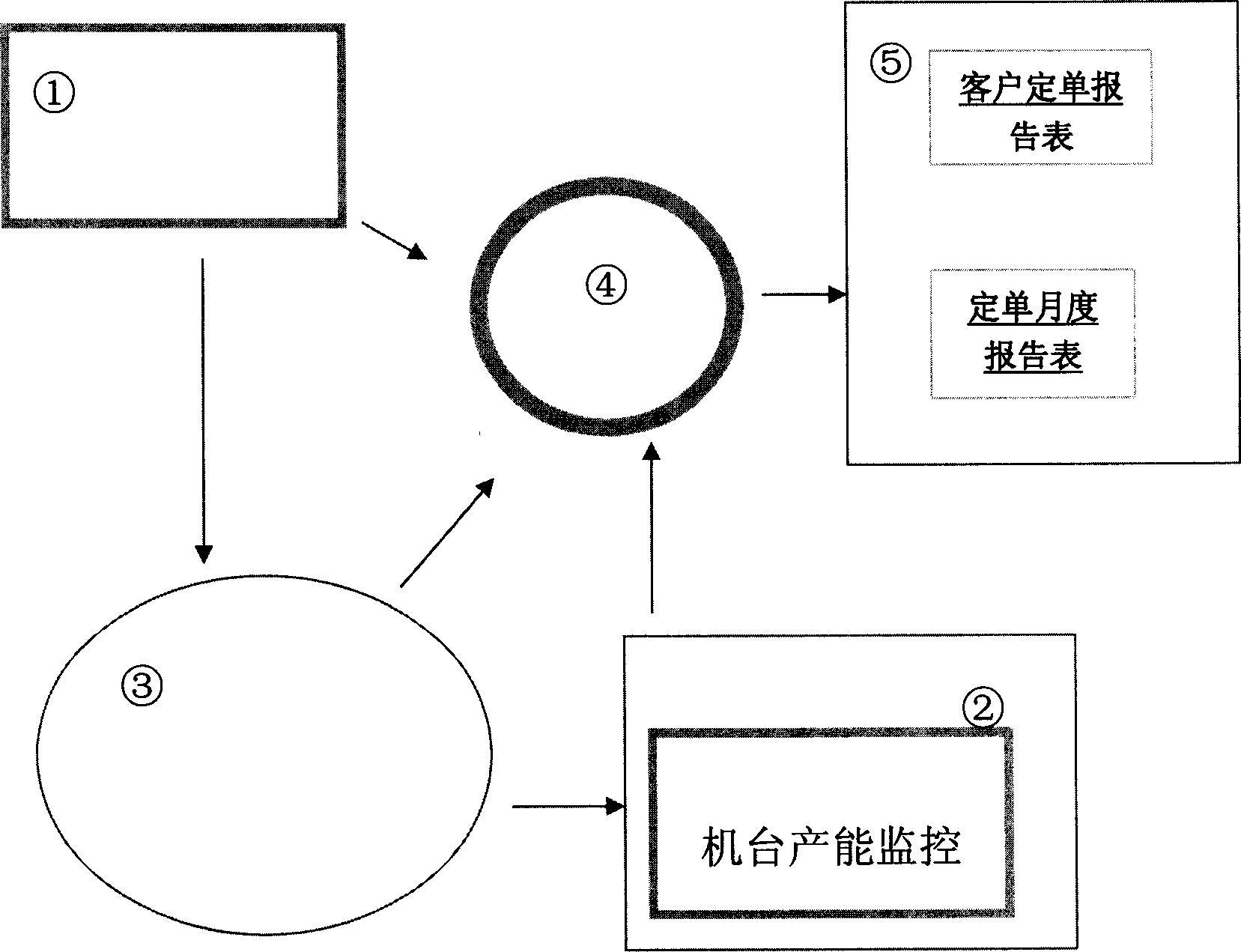

Real-time work allocation prediction system for key machine in semiconductor manufacturing factory

Disclosed is a real-time dispatch estimation system which comprises: 1. dispatch rules storage display; 2. manufacture performing system database which includes information of position order of each box of chips, processing time, sequentially processing time of every kind of components; 3. database forms, data processing program and instruction generating device; 4. real-time dispatch device; 5. estimation device for products generating time.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Welding joint conveying device on inner surface of piping

ActiveCN101537553ALow costEasy to installWelding/cutting auxillary devicesAuxillary welding devicesDrive motorMotor controller

The invention provides a welding joint conveying device on the inner surface of a piping. The length of a fixing part can be adjusted according to the size of the piping, and the device does not need to be remanufactured according to the size of the piping, so the cost can be lowered; and the device is not related with a manufacturing factory of welding joints, so the installation becomes easy, and the using range can be greatly enlarged. The device comprises a linkage chuck used as a main body, a fixing part for fixing the main body inside the piping, a rotary drive motor for generating power required by welding the piping along the circumferential direction, a rotary drive part for transferring the power of the rotary drive motor to a rotary cover, the rotary cover rotating along the circumferential direction of the piping, a rotary part mounting rod connected with the rotary cover, a back-and-forth conveying motor for generating power required by welding the piping along the lengthdirection, a drive part for transferring the power of the back-and-forth conveying motor to the length direction of a welding joint part, the welding joint part moving along the length direction of the piping, a motor controller, a wireless camera, a wireless receiving part, a camera controller, and a display part.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

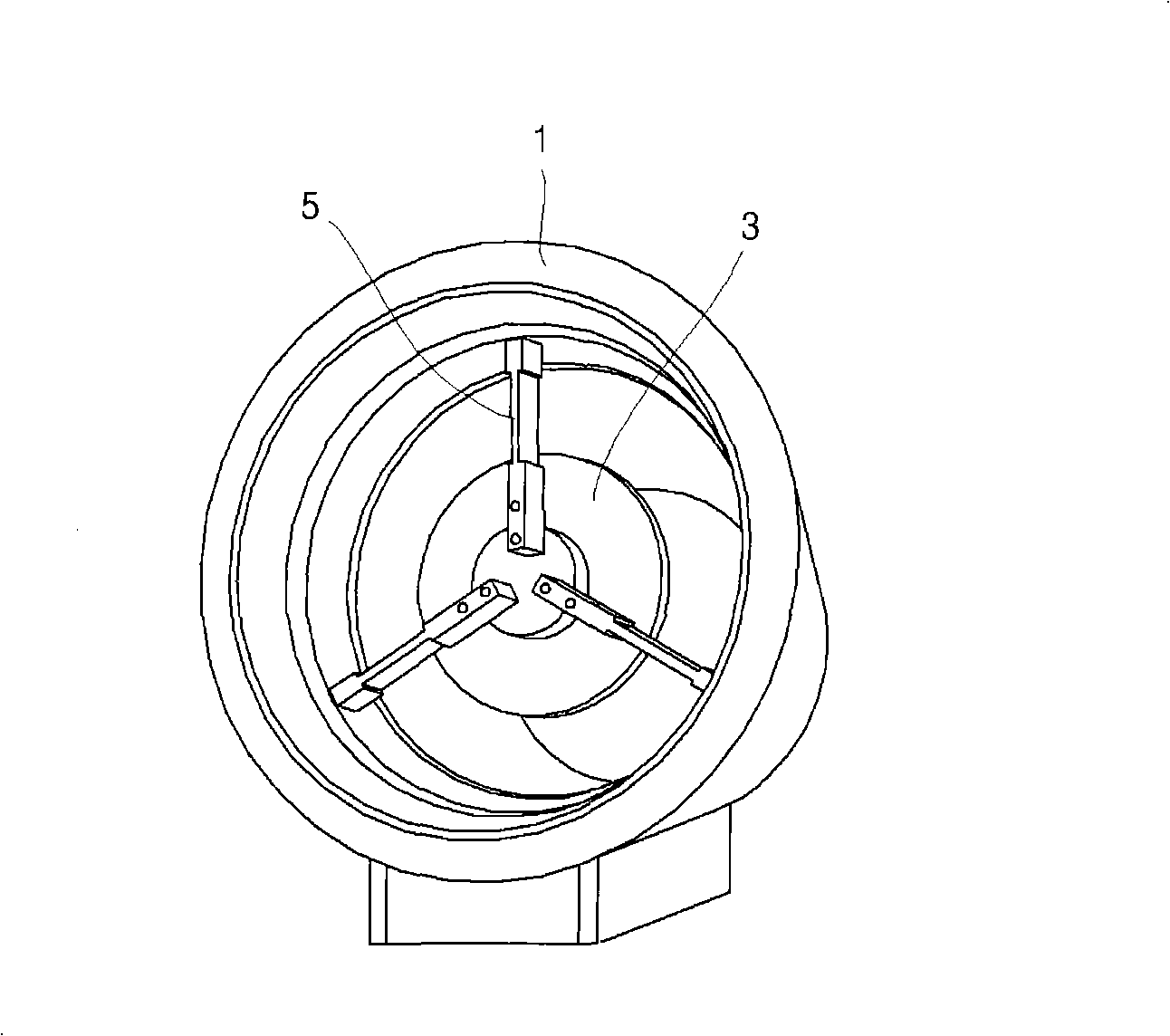

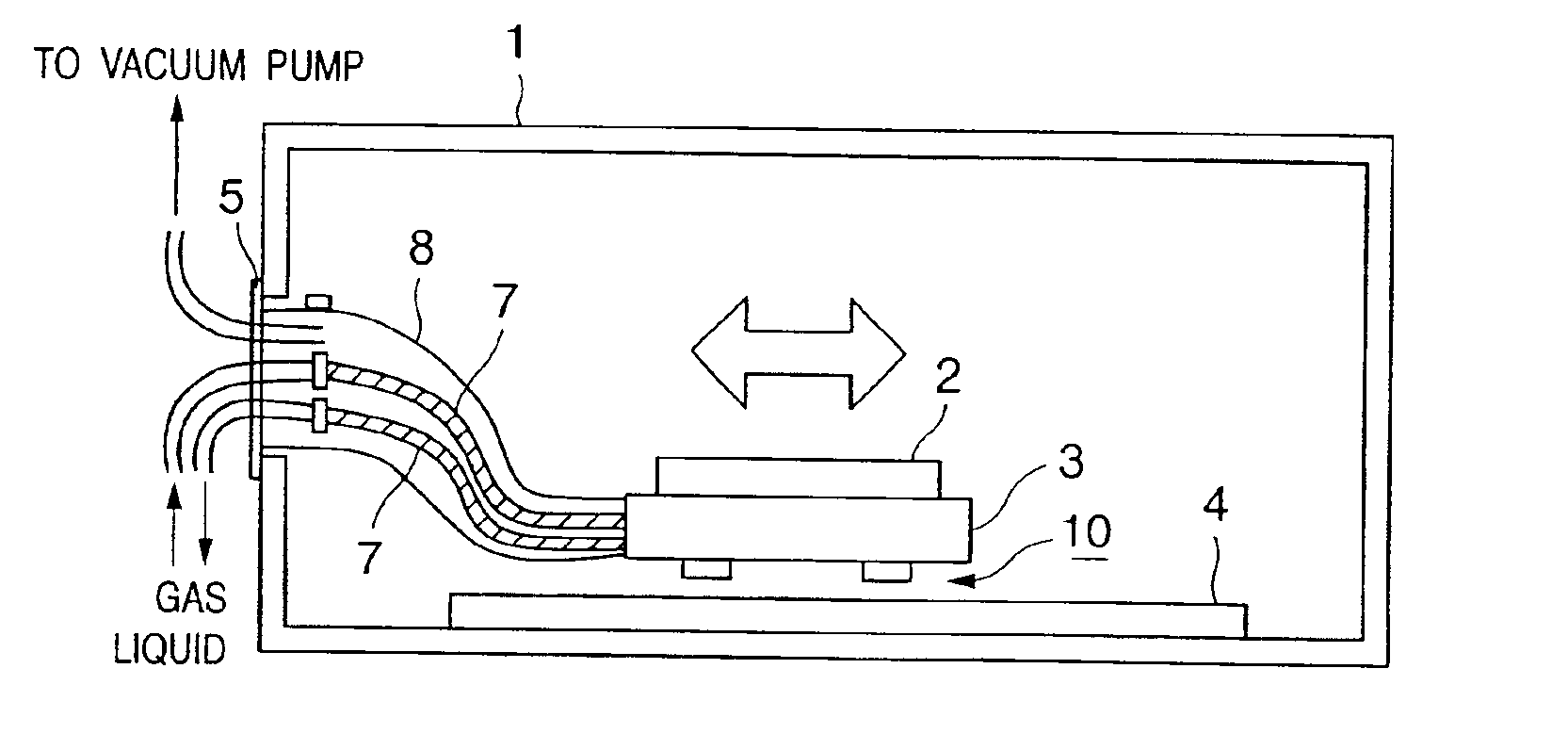

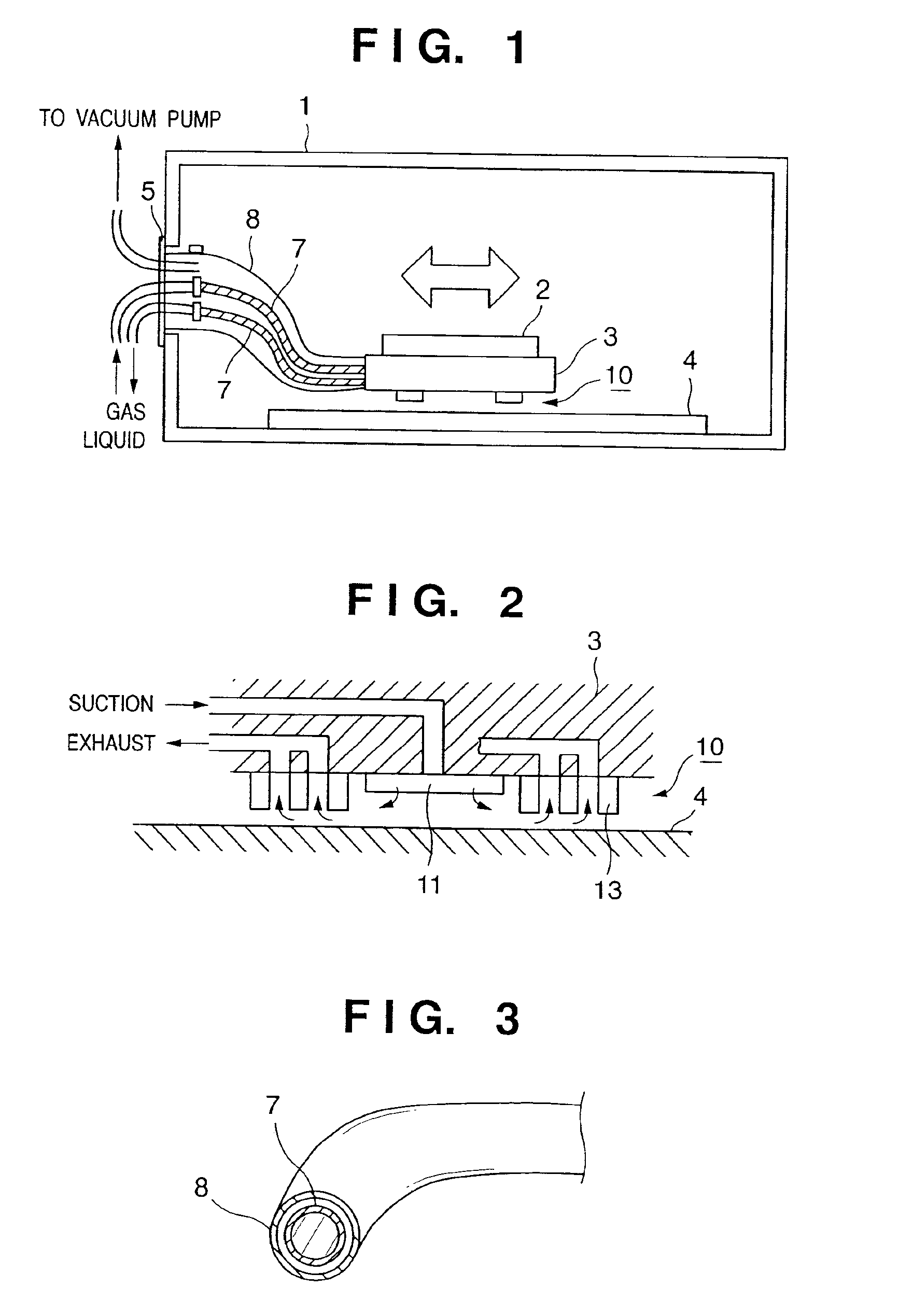

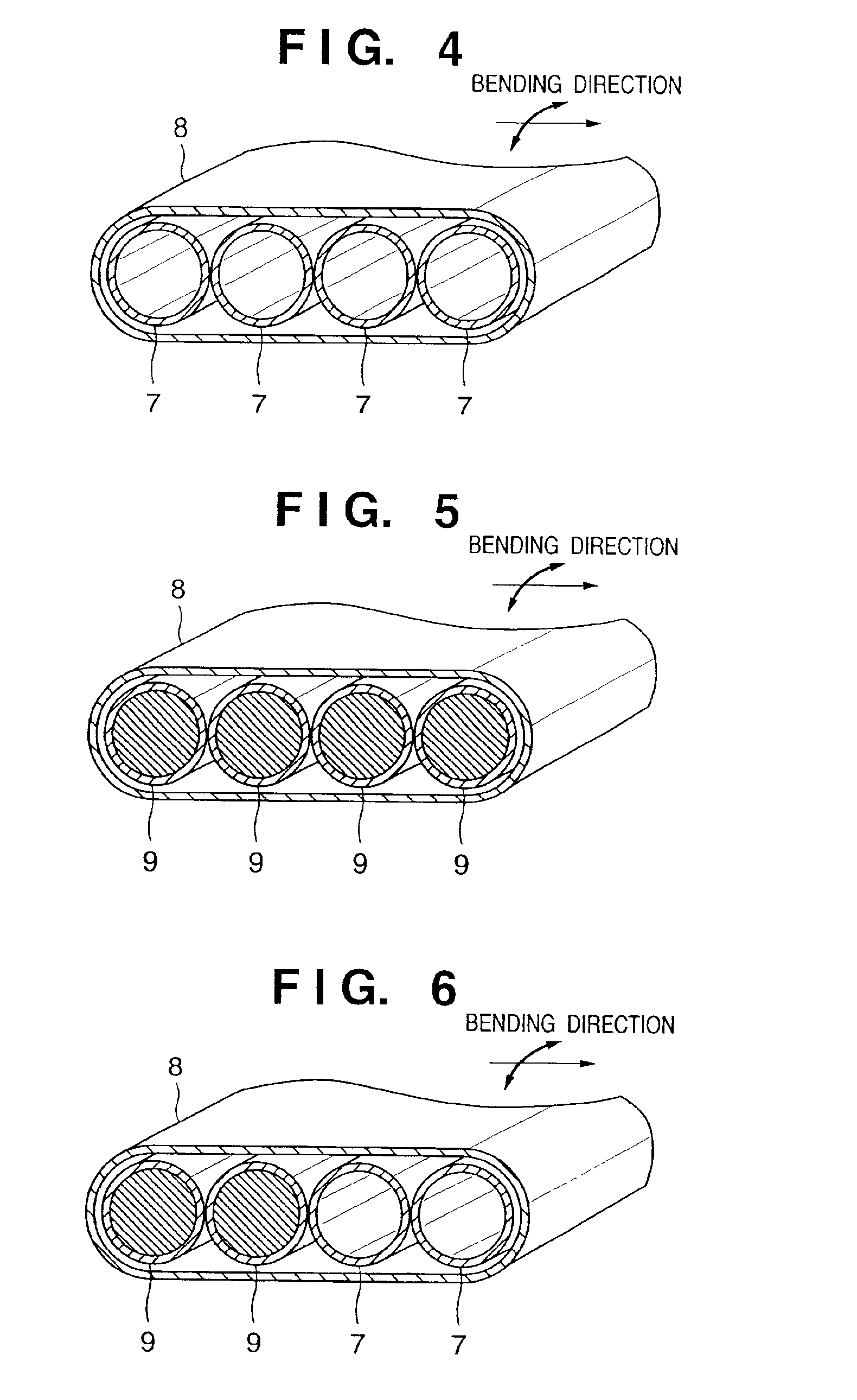

Pipe structure, alignment apparatus, electron beam lithography apparatus, exposure apparatus, exposure apparatus maintenance method, semiconductor device manufacturing method, and semiconductor manufacturing factory

InactiveUS6915179B2High in flexibility and durabilityNanoinformaticsSemiconductor/solid-state device manufacturingDouble tubeEngineering

A pipe structure includes a double pipe having a resin inner pipe and a resin outer pipe covering an outside of the inner pipe, and a discharge mechanism for discharging fluid in a space between the inner pipe and the outer pipe. The double pipe is used in a vacuum chamber having a vacuum atmosphere.

Owner:CANON KK

Granulated feed of velvet-deer

The invention discloses a full-fare particle fodder and fodder manufacturing method to improve the quantity and quality of pilose deer horn of horse deer and sika deer, which comprises the following parts: maize, soya bean waste or soya bean cake, cotton seed waste or cotton-seed cake, maize germ waste or maize germ cake, fermented maize spirit glutinour rice (DDGS), fermented beer glutinour rice, wheat bran, maize albumen powder as concentrate, bulking aquacare, mineral and vitamin additive, stone powder, magnesium oxide, calcium hydrophosphate, calcium carbonate, table salt, zeolite powder, molasses as additive fodder, wherein the content of dried material is 85%-90%; the crude protein content is 16%-20%, which contains plenty of amino acid, calcium, phosphor, vitamin and trace element to satisfy the need of horse deer and sika deer during pilose deer horn growing period. The invention improves the utility of fodder by 15-20% and productivity over 30%, which is fit for using in the deer culturing place and fodder manufacturing factory.

Owner:钟立成

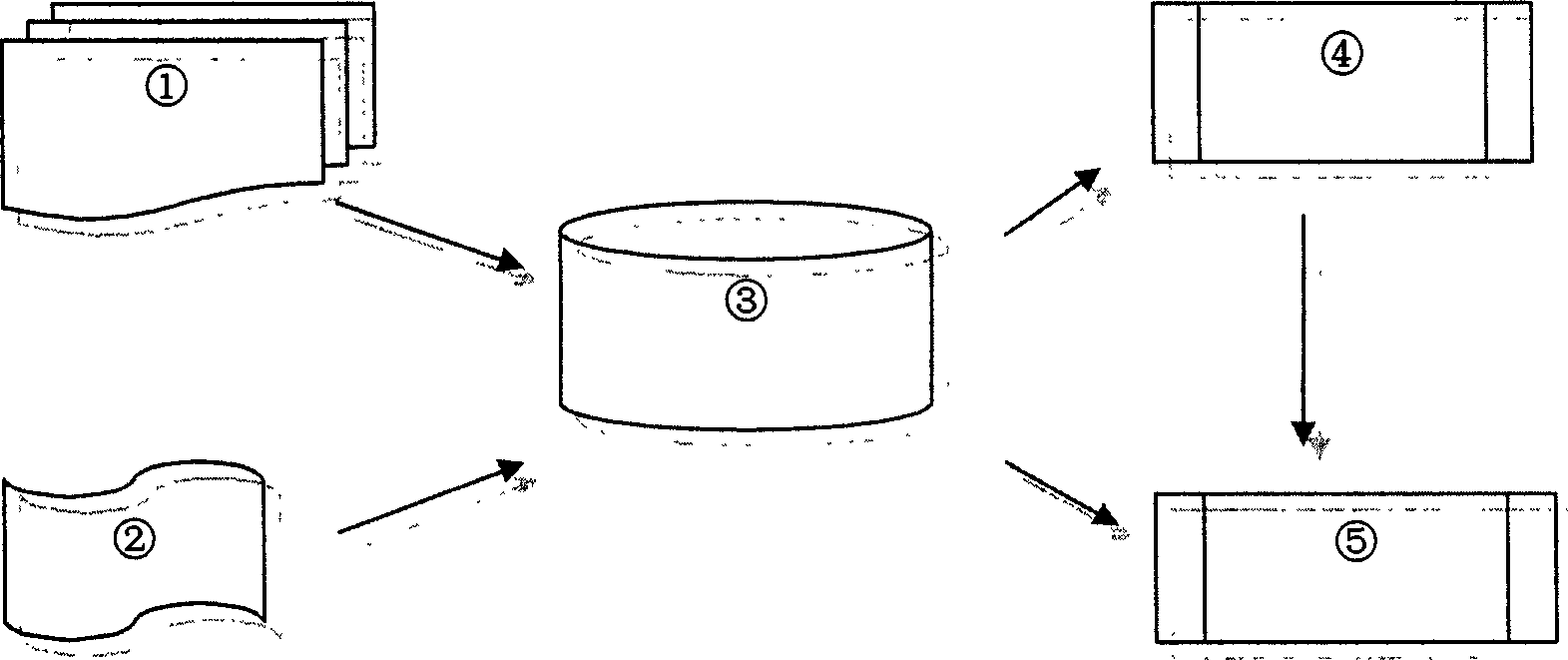

Automatic tracking monitoring system for products processing catalog of semiconductor manufacturing factory

InactiveCN1773667AData processing applicationsSemiconductor/solid-state device manufacturingProduction lineMonitoring system

An automatic tracking and monitoring system of client product processing catalog in semiconductor manufacturer comprises storage unit of product processing information by using client as unit, device for monitoring capacity of each machine set on production line, tracking and monitoring unit of client product processing catalog, producing and dispatching centre of client product, predicting and issuing unit of client product delivery information.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

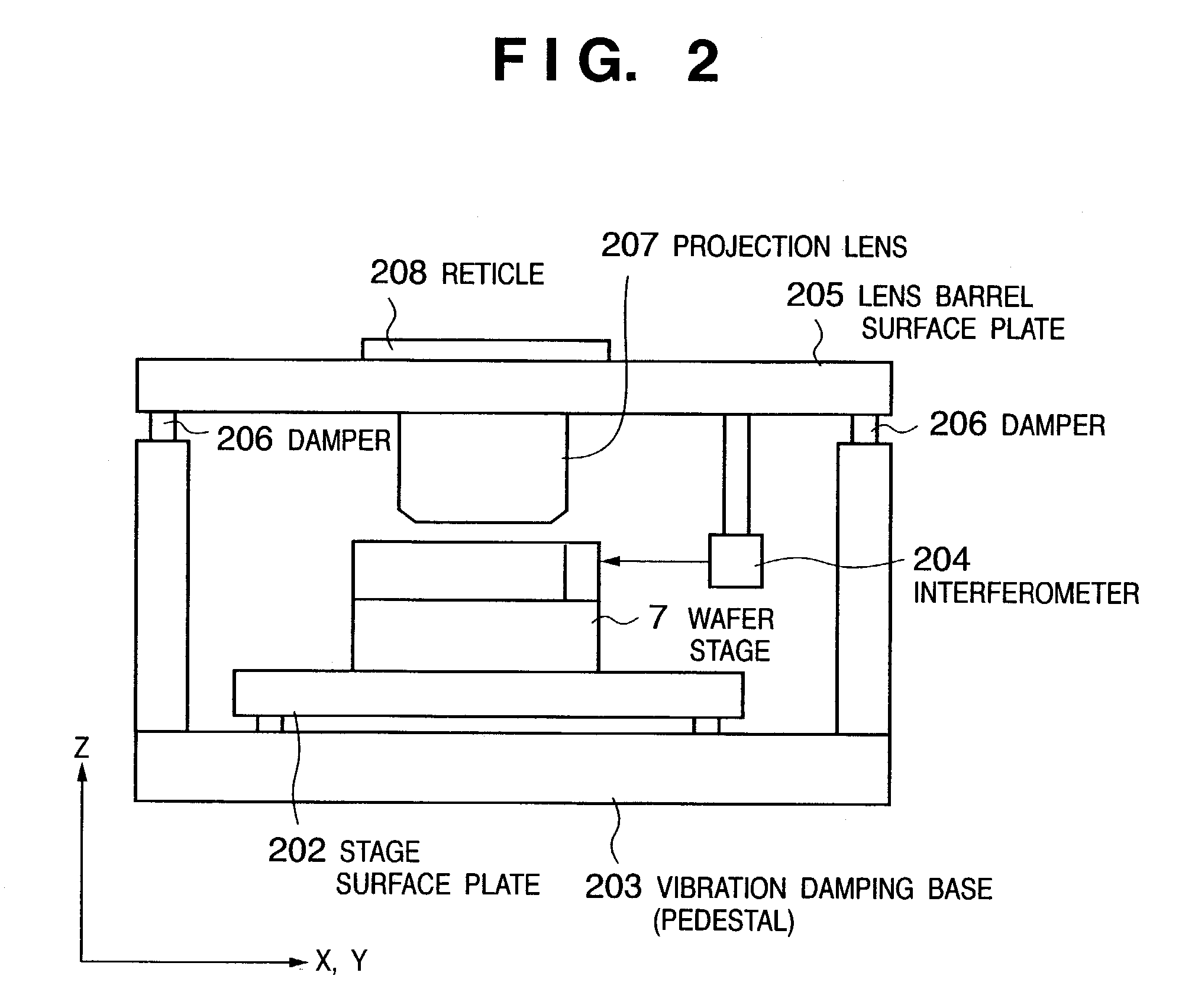

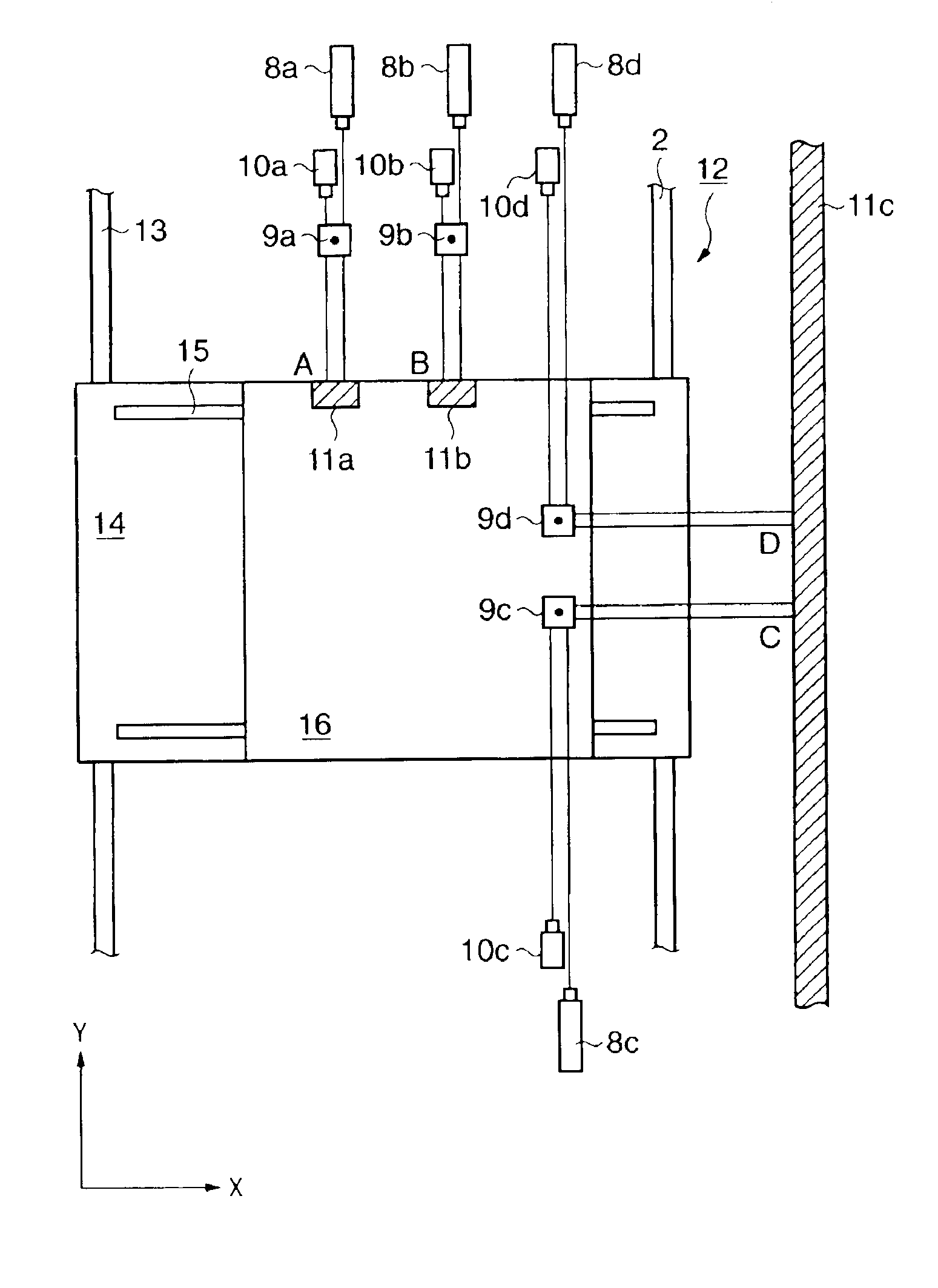

Stage apparatus which supports interferometer, stage position measurement method, projection exposure apparatus, projection exposure apparatus maintenance method, semiconductor device manufacturing method, and semiconductor manufacturing factory

InactiveUS6867849B2High precision measurementSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansManufacturing FactoriesLaser beams

A stage apparatus includes a stage movable along at least one axis, a laser head for generating a laser beam, an optical unit which is mounted on the stage and splits the laser beam into reference and measurement beams, a mirror which is arranged outside the stage and reflects the measurement beam, and a detector which is arranged outside the stage and detects an interference beam of the reference and measurement beams.

Owner:CANON KK

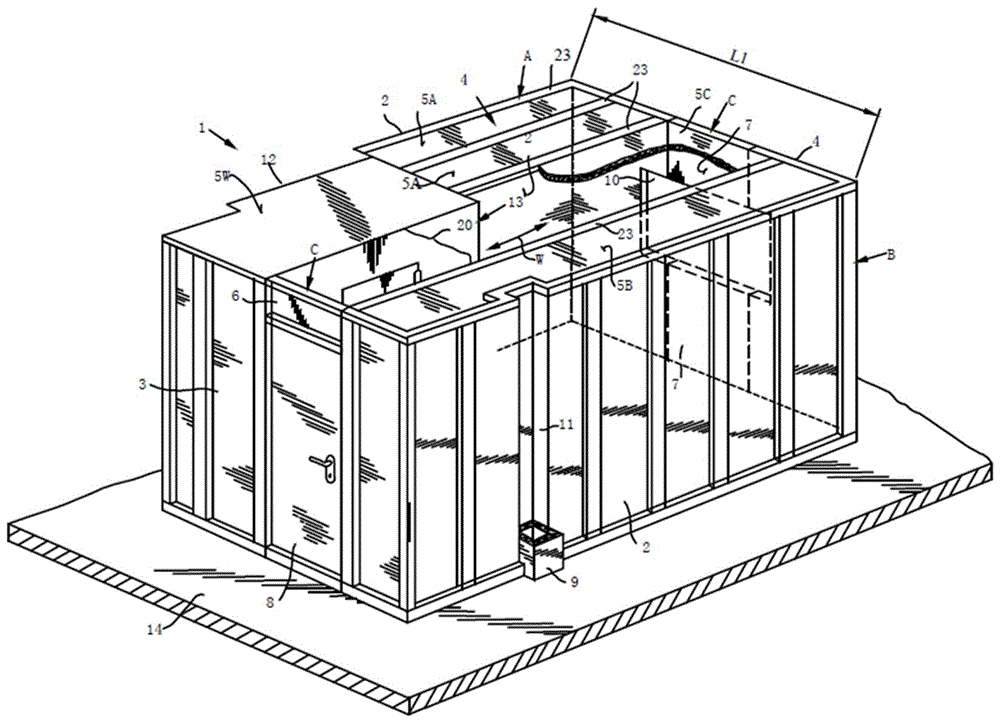

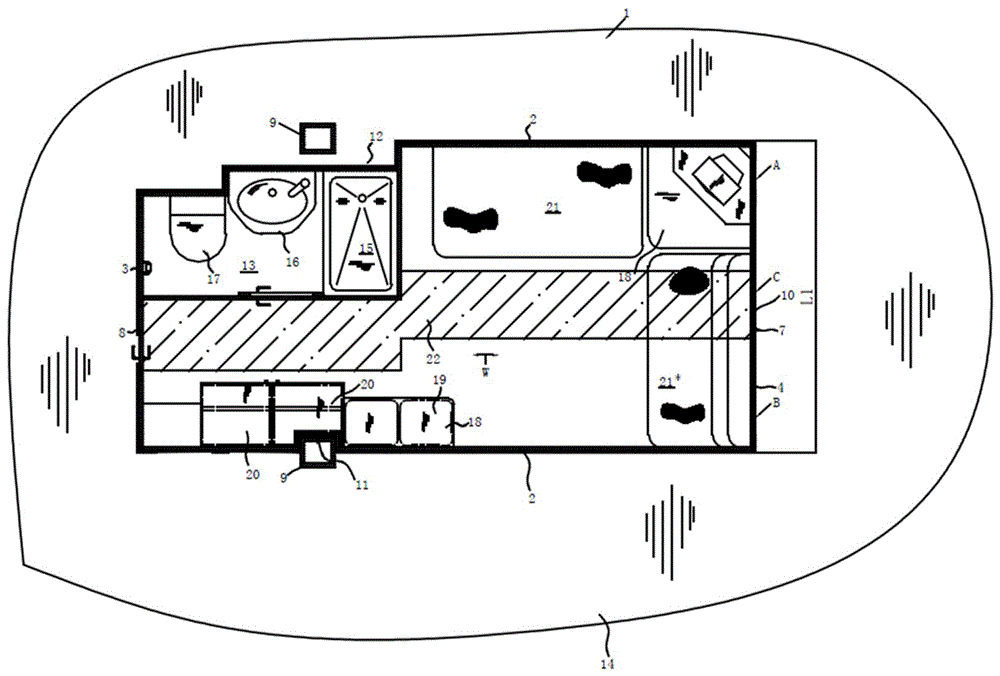

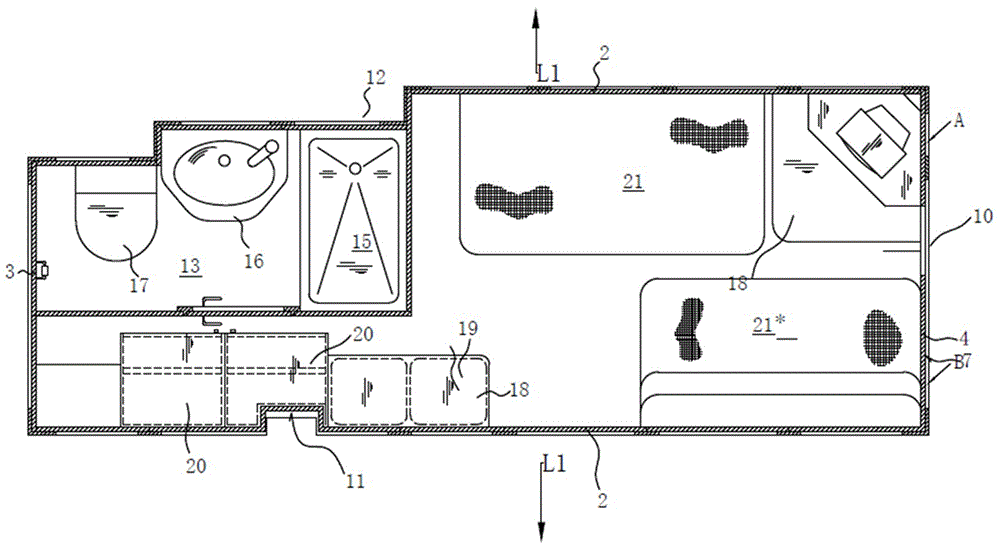

Modularized ship cabin and manufacturing and installing method thereof

InactiveCN106628012ASatisfy the width limit requirementAdd supportVessel designingPrefabricated cabinsMarine engineeringOn board

The invention relates to a modularized ship cabin. The modularized ship cabin is formed by connecting of side wall plates, a front wall plate and a rear wall plate; two independent area modules are installed in the modularized ship cabin and connected through a connection assembly; and the two independent area modules are symmetrically installed in the in the ship cabin and each provided with a cabin roof and a sanitary unit module correspondingly. According to the modularized ship cabin and a manufacturing and installing method thereof, a matching mode that the ship cabin is modularly manufactured in a professional site, then transferred to a ship outfitting quay as a whole and then integrally hoisted and installed on board can shorten the construction period and improve outfitting efficiency; and meanwhile, the width-limit requirement of highway transportation can be met, transportation efficiency is improved, transportation from a manufacturing factory to an installing site is facilitated, and professional matching is facilitated; and because of the unitization characteristic of the ship cabin, all the modules are standard, and interchangeability of a product is improved.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

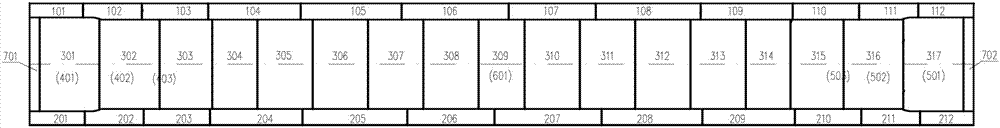

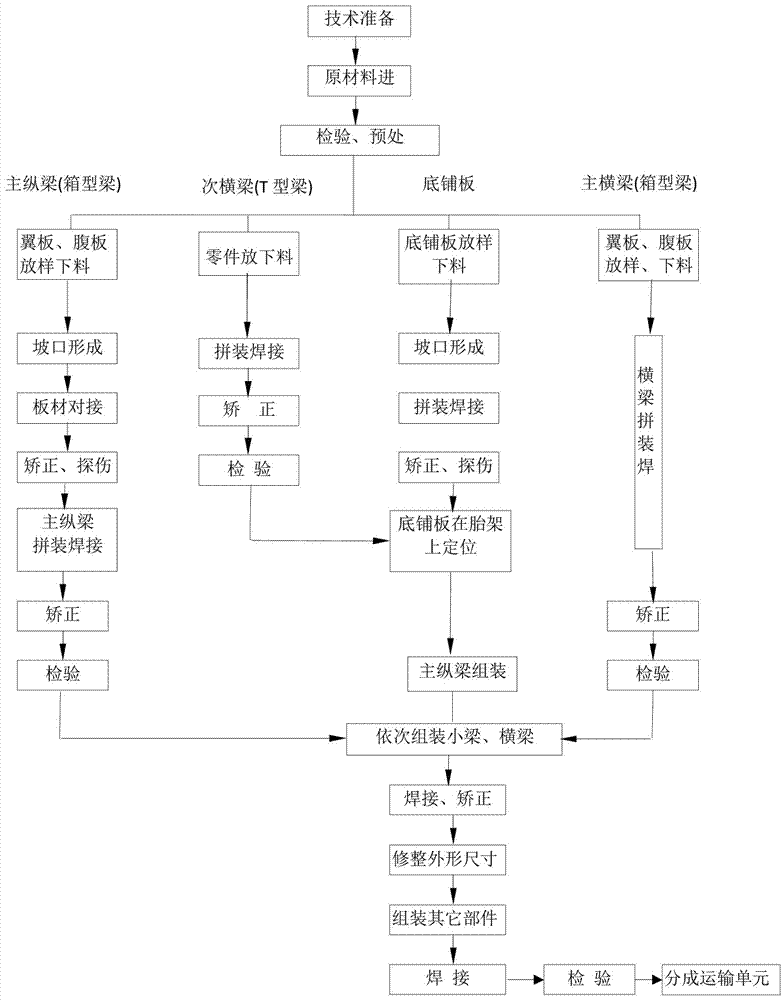

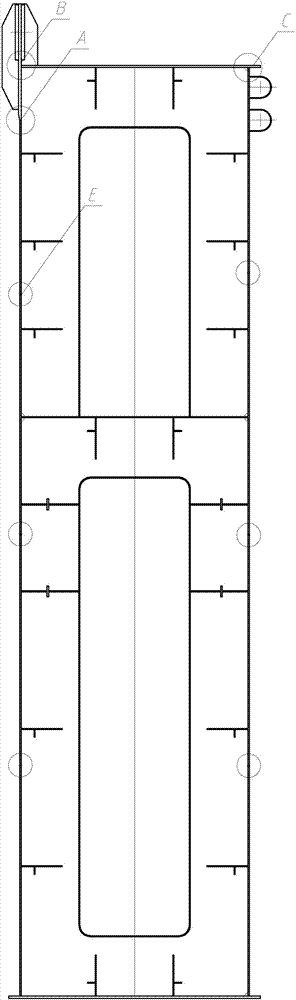

Manufacturing method of large ship reception chamber suitable for dry type ship compartment

ActiveCN107498269AReduce the amount of deposited metalReduce the degree to which concentrated weld interactionsVertical ship-liftingSocial benefitsMarine engineering

The invention discloses a manufacturing method of a large ship reception chamber suitable for a dry type ship compartment and solves the problem that under this circumstance of being limited by lifting conditions and space of the ship compartment in mounting the ship reception chamber, a method of segmental and sectional modular manufacturing and integral pre-splicing in a manufacturing factory is adopted to ensure that the ship reception chamber is quickly assembled and welded in the ship compartment to accelerate the ship reception chamber mounting speed, reduce civil engineering coordination and improve the integral construction progress on the premise of meeting safety and controllable quality. According to the method disclosed by the invention, a non-standard metal structure product is produced on a large scale, production automation is easily implemented, the quality is reliable, and convenience is brought to mounting. The manufacturing method has huge economical benefit and social benefit.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

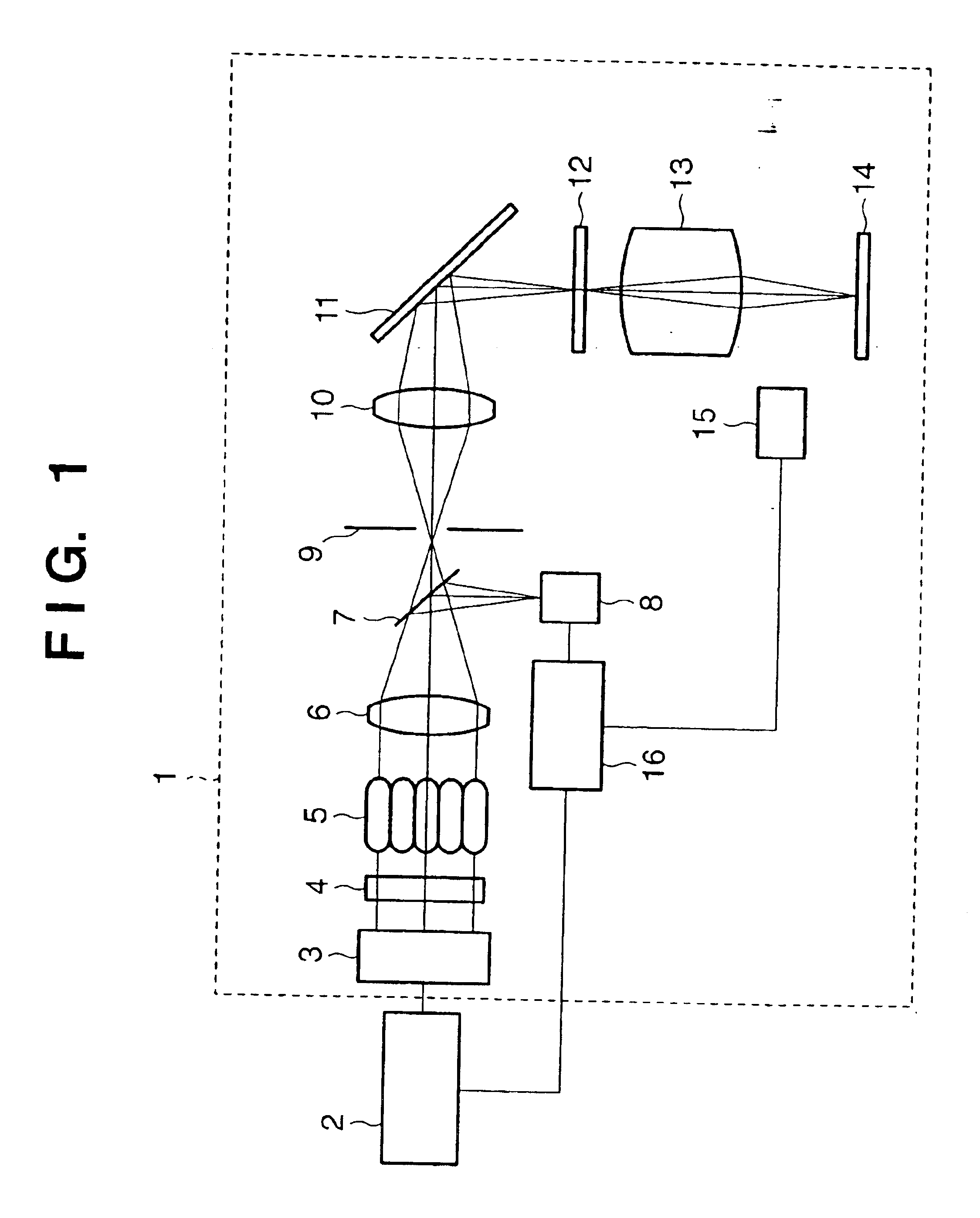

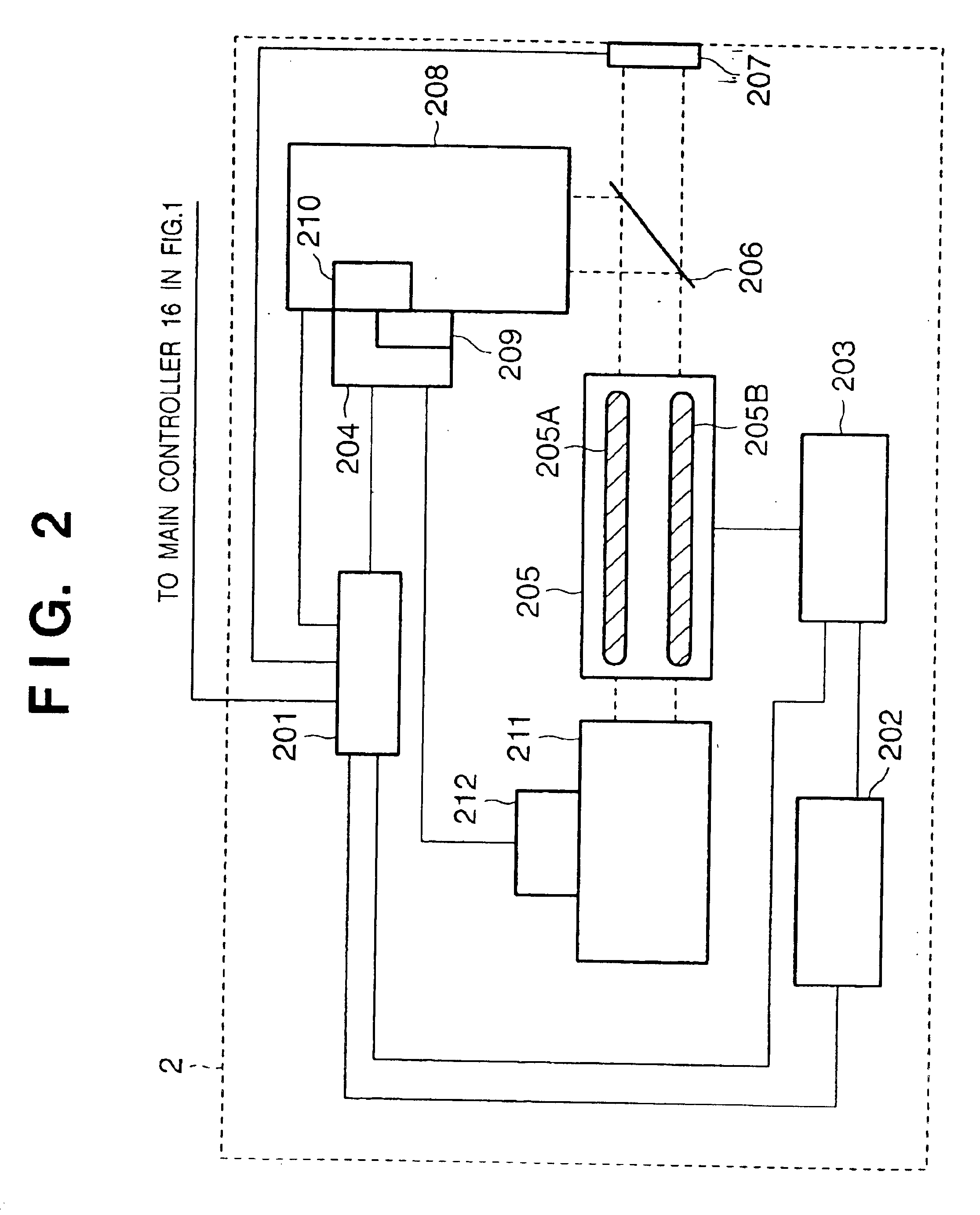

Laser oscillation apparatus, exposure apparatus, semiconductor device manufacturing method, semiconductor manufacturing factory, and exposure apparatus maintenance method

InactiveUS6870865B2Increase productivitySemiconductor laser arrangementsSemiconductor/solid-state device manufacturingComputer moduleLength wave

A laser oscillation apparatus includes a wavelength change unit for driving a wavelength selection element in a band-narrowing module and changing the oscillation wavelength of a laser beam to a target value, and an oscillation history memory for storing the oscillation state of the laser beam as an oscillation history. The wavelength change unit drives the wavelength selection element on the basis of the oscillation history and changes the oscillation wavelength of the laser beam to the target value.

Owner:CANON KK

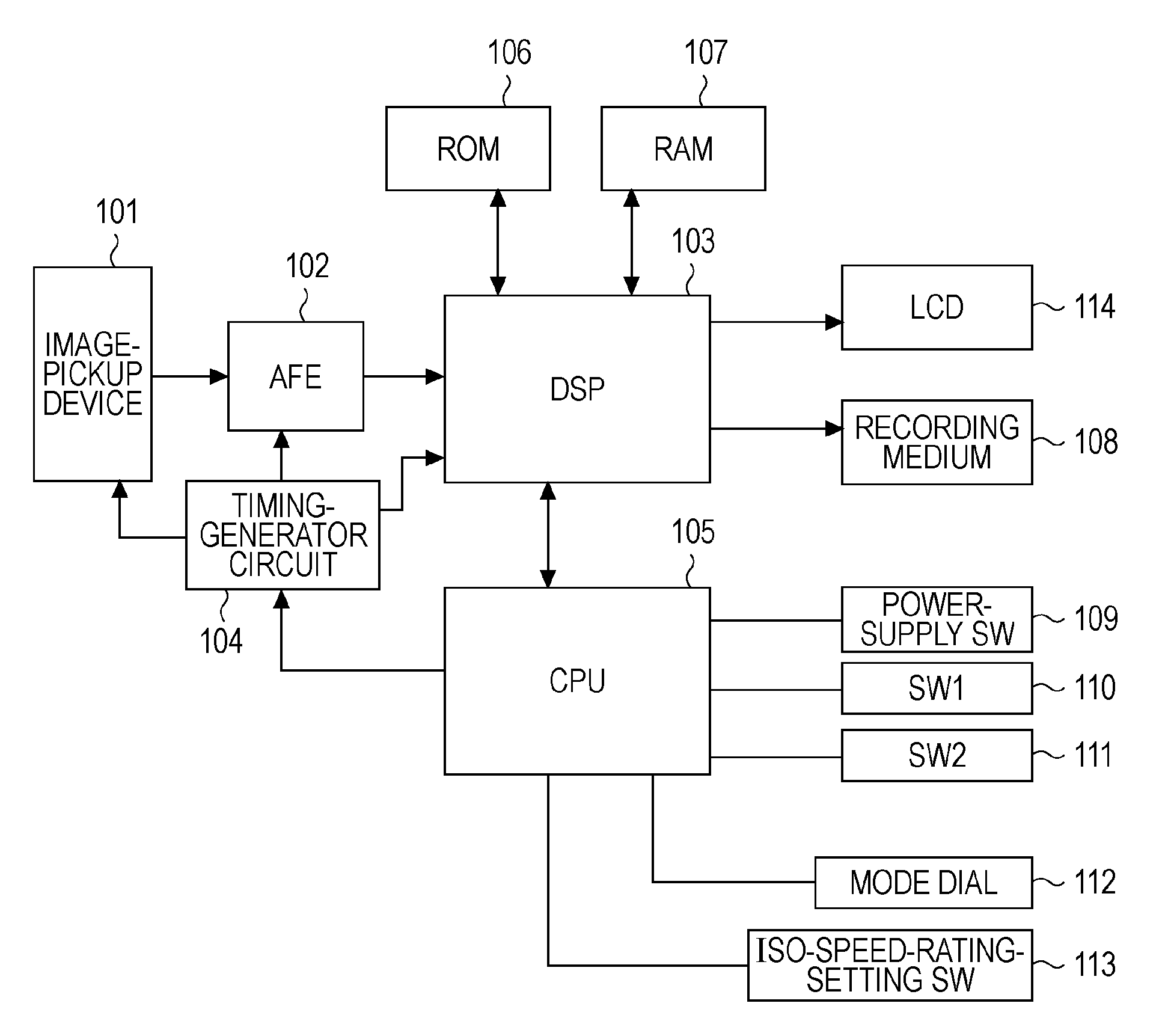

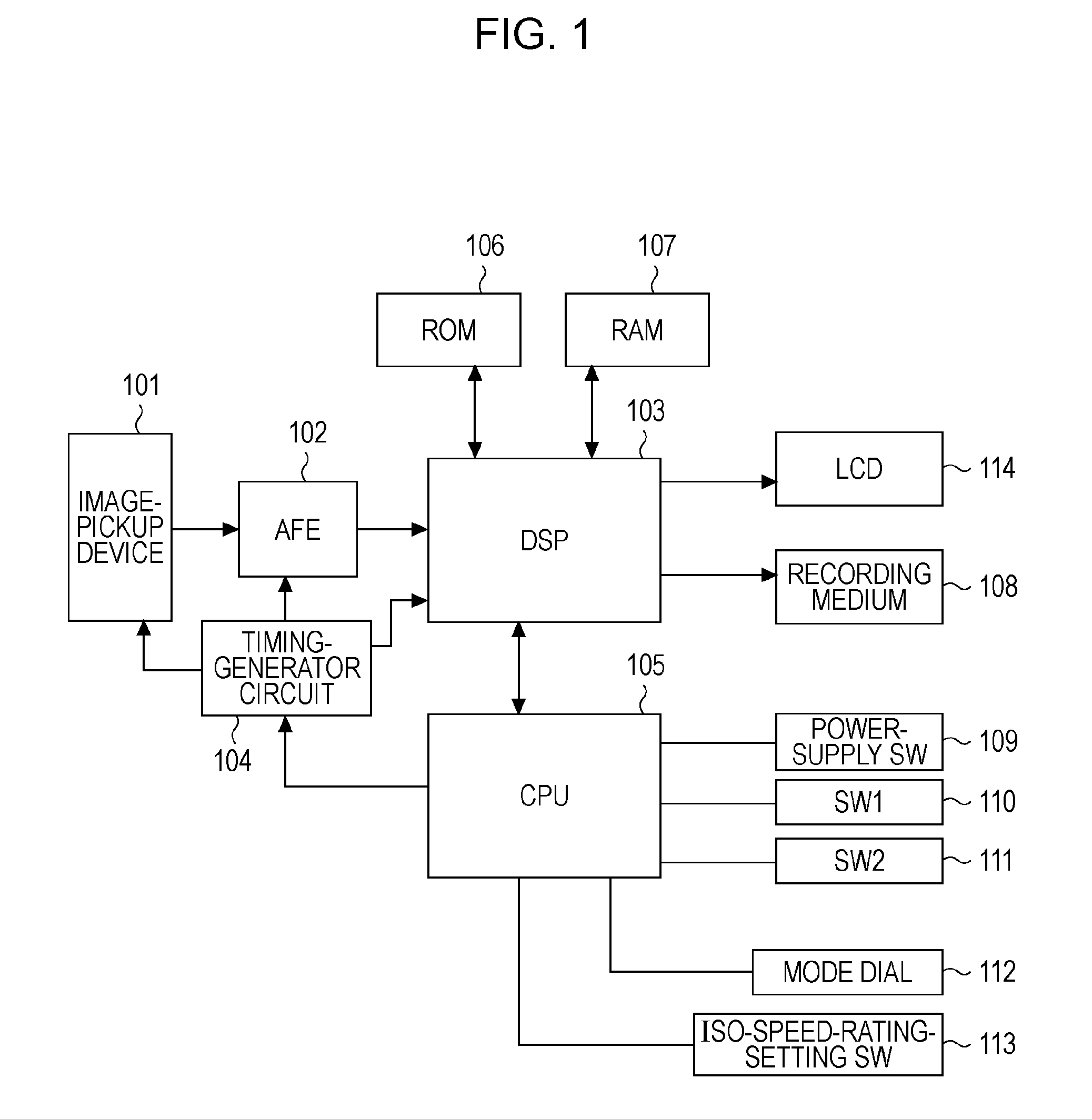

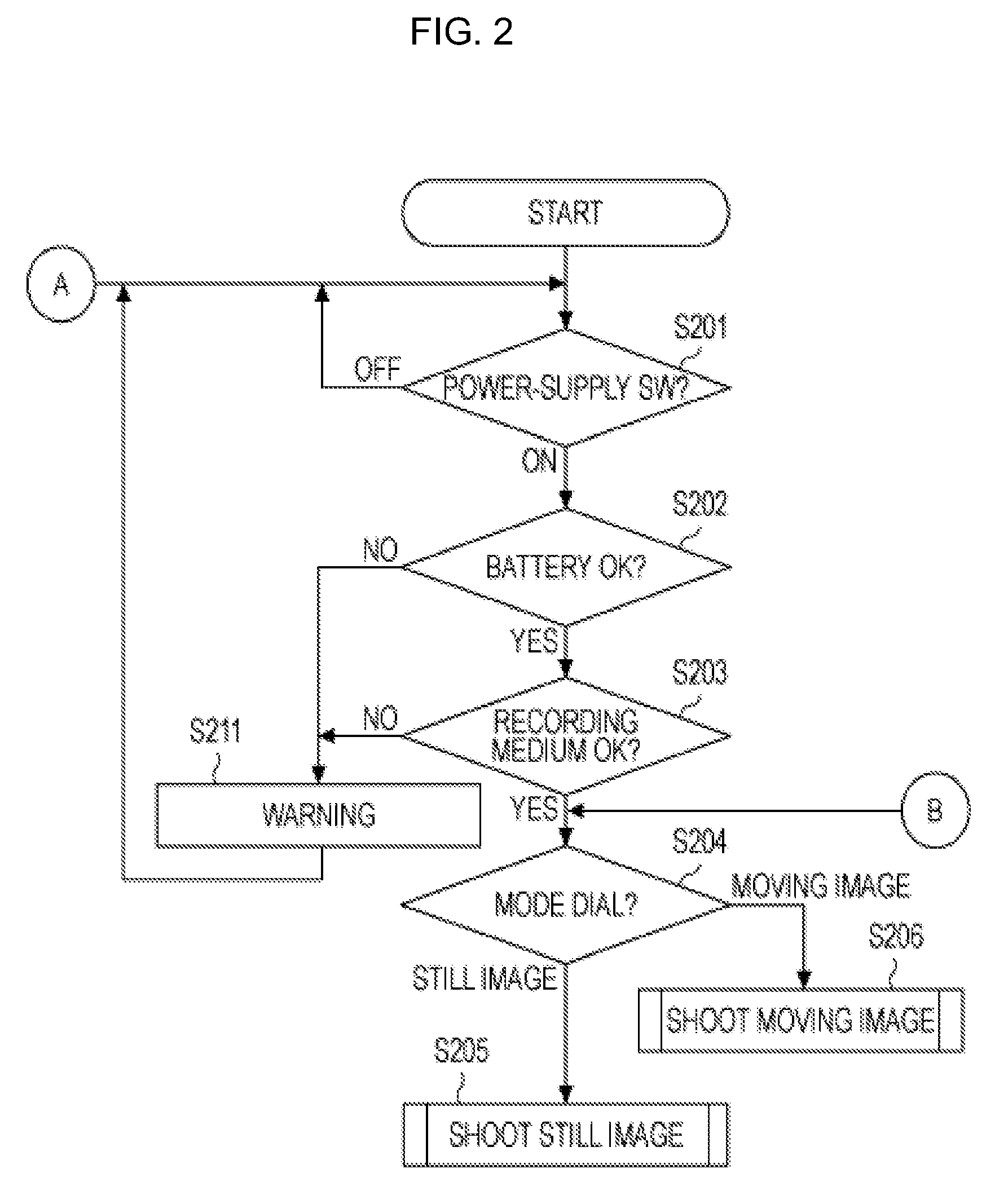

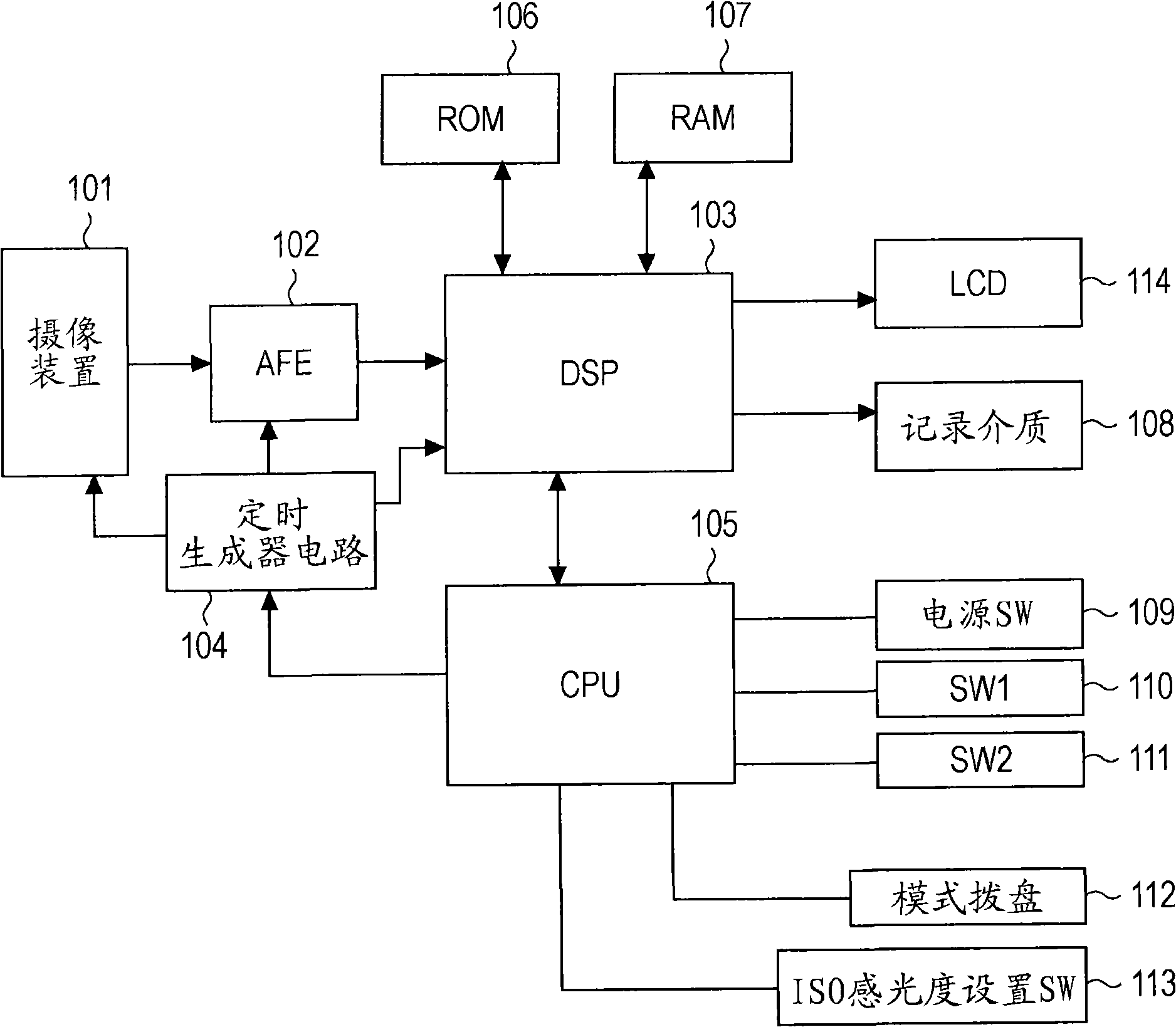

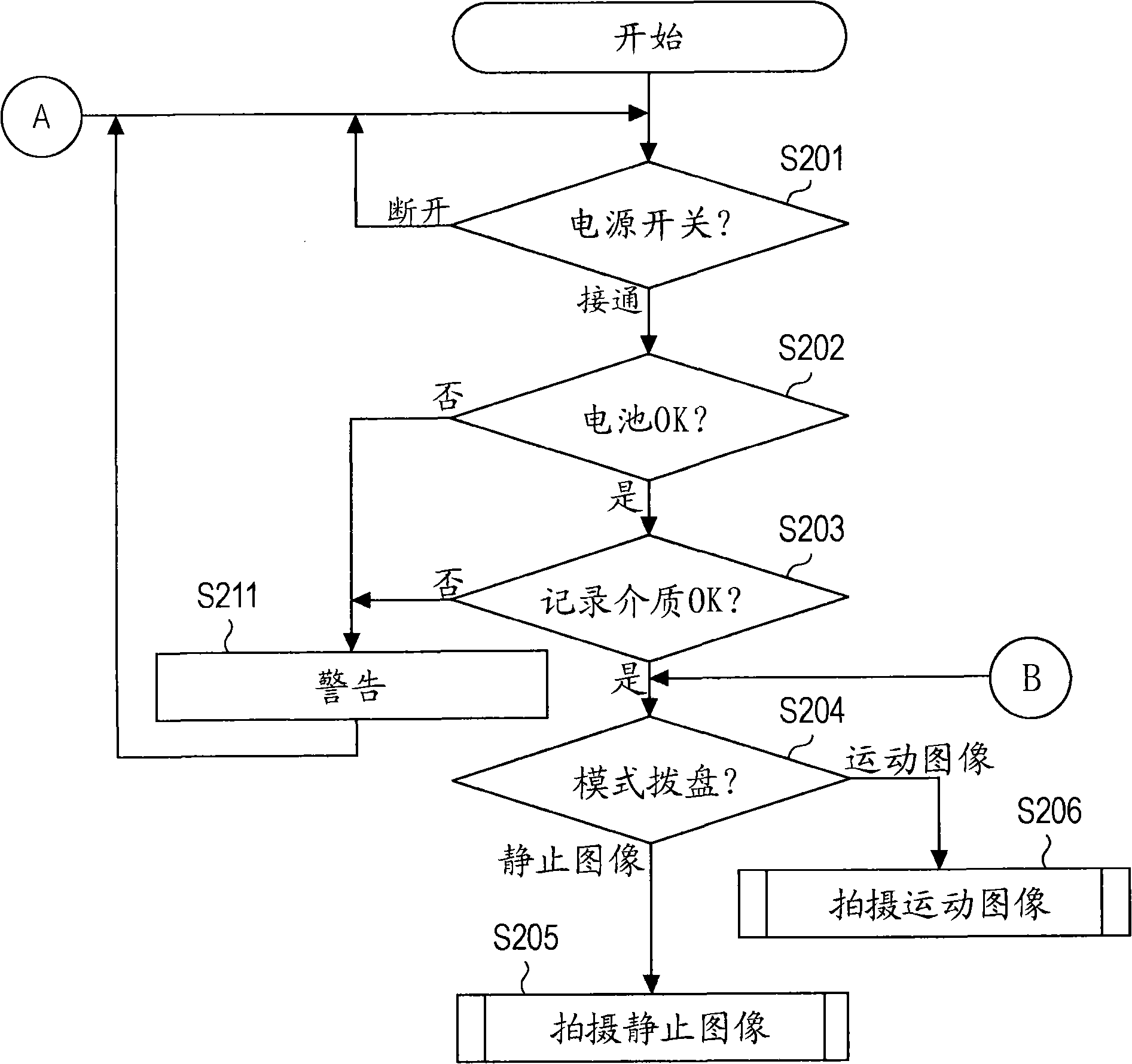

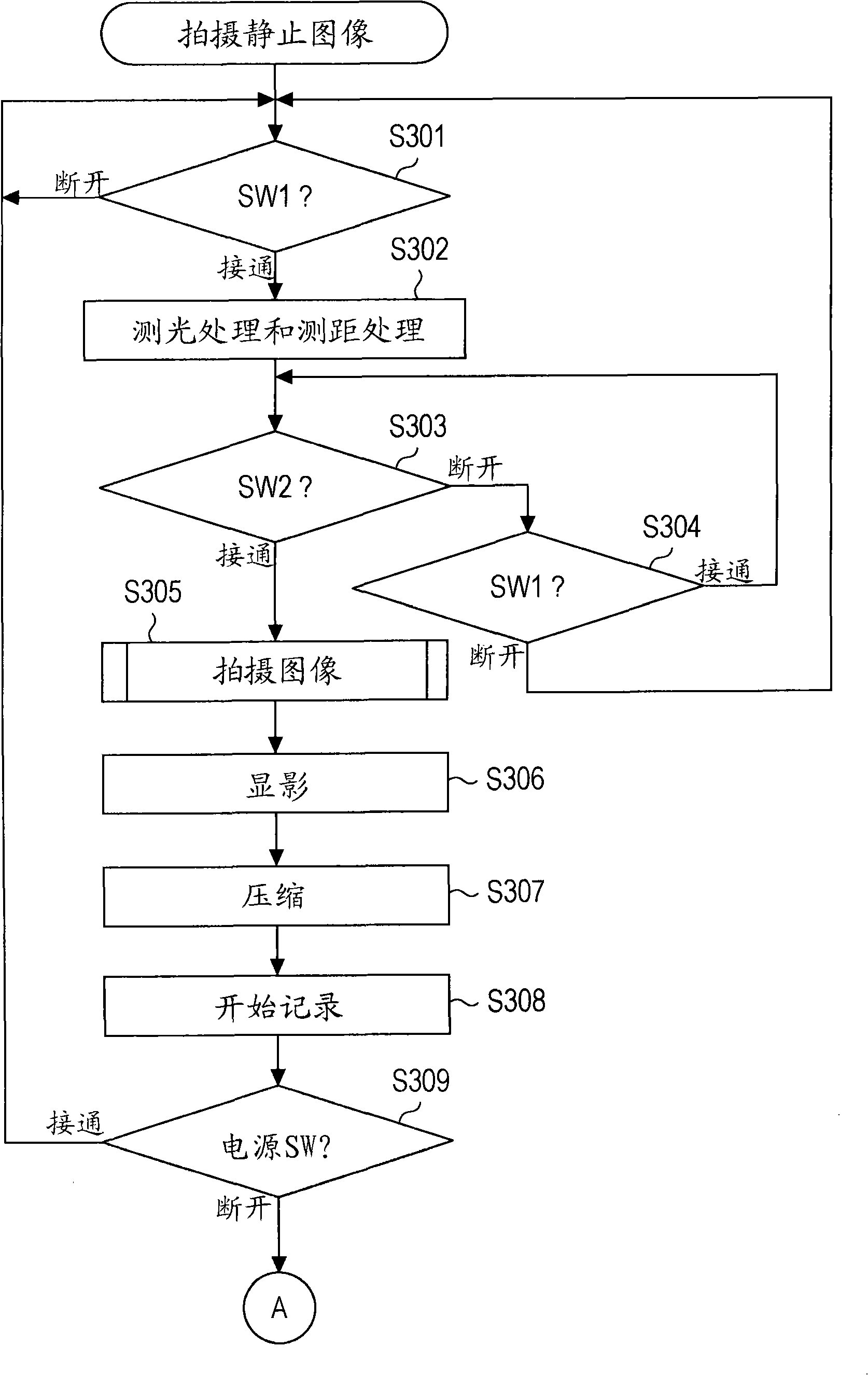

Image processing apparatus and image processing method

InactiveUS20080297629A1Television system detailsColor signal processing circuitsImaging processingImaging data

When pixel data of a solid-state image-pickup device is read in various types of methods to pick up images, a correction process for defective pixels is easily performed at a low cost. As defect-correction data in a case in which a still image is shot, data is used, which is acquired when an image-pickup device is shipped from a manufacturing factory. In a case of an operation in a reading mode for a moving image, immediately before a reading operation is performed, charge is accumulated in a state in which the image-pickup device is shielded from light, and image data is read. Addresses of defective pixels to be corrected are detected from the image data, and stored in a RAM as the defect-correction data. When a moving image is shot, a defect-correction process is performed using the data.

Owner:CANON KK

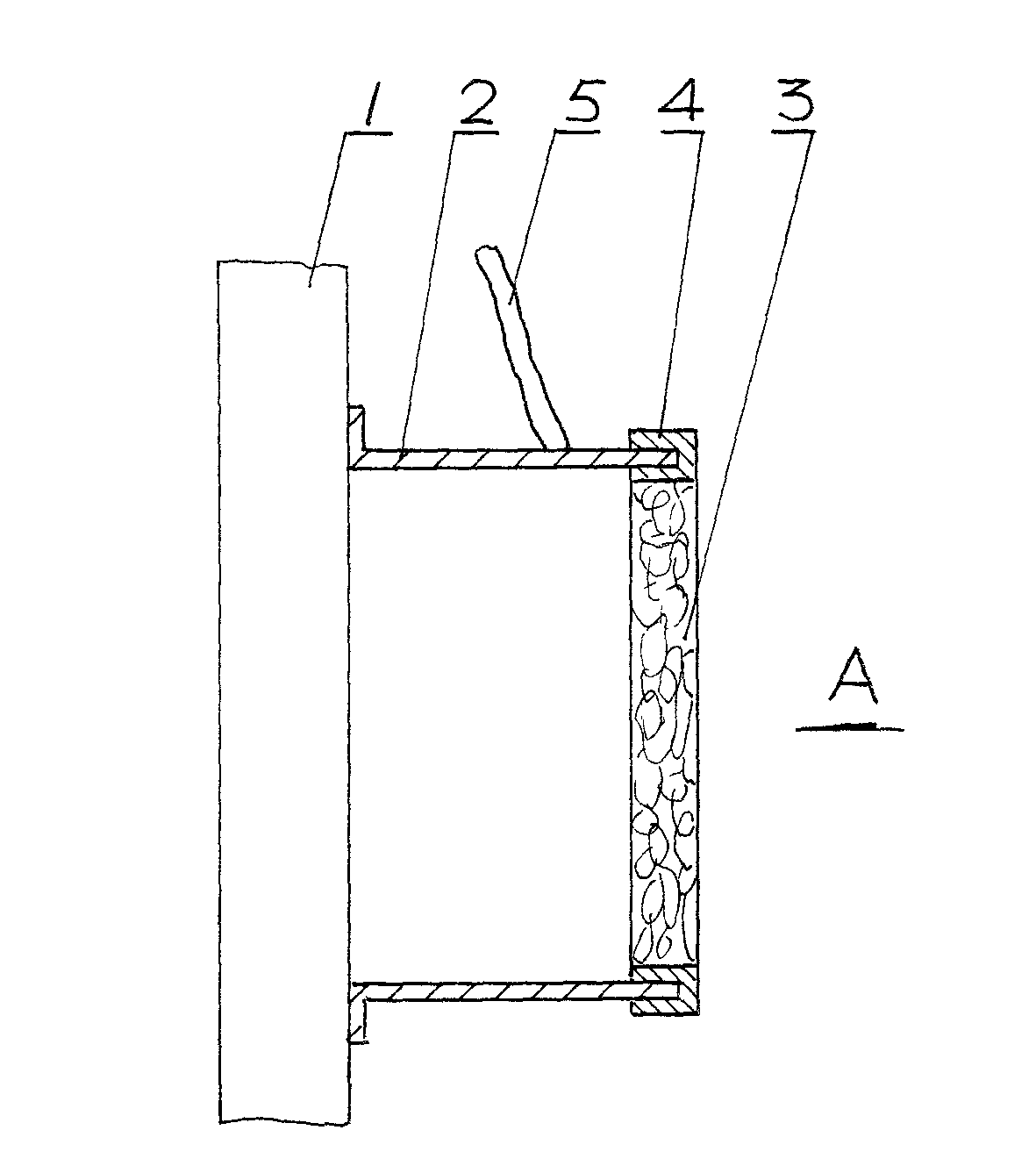

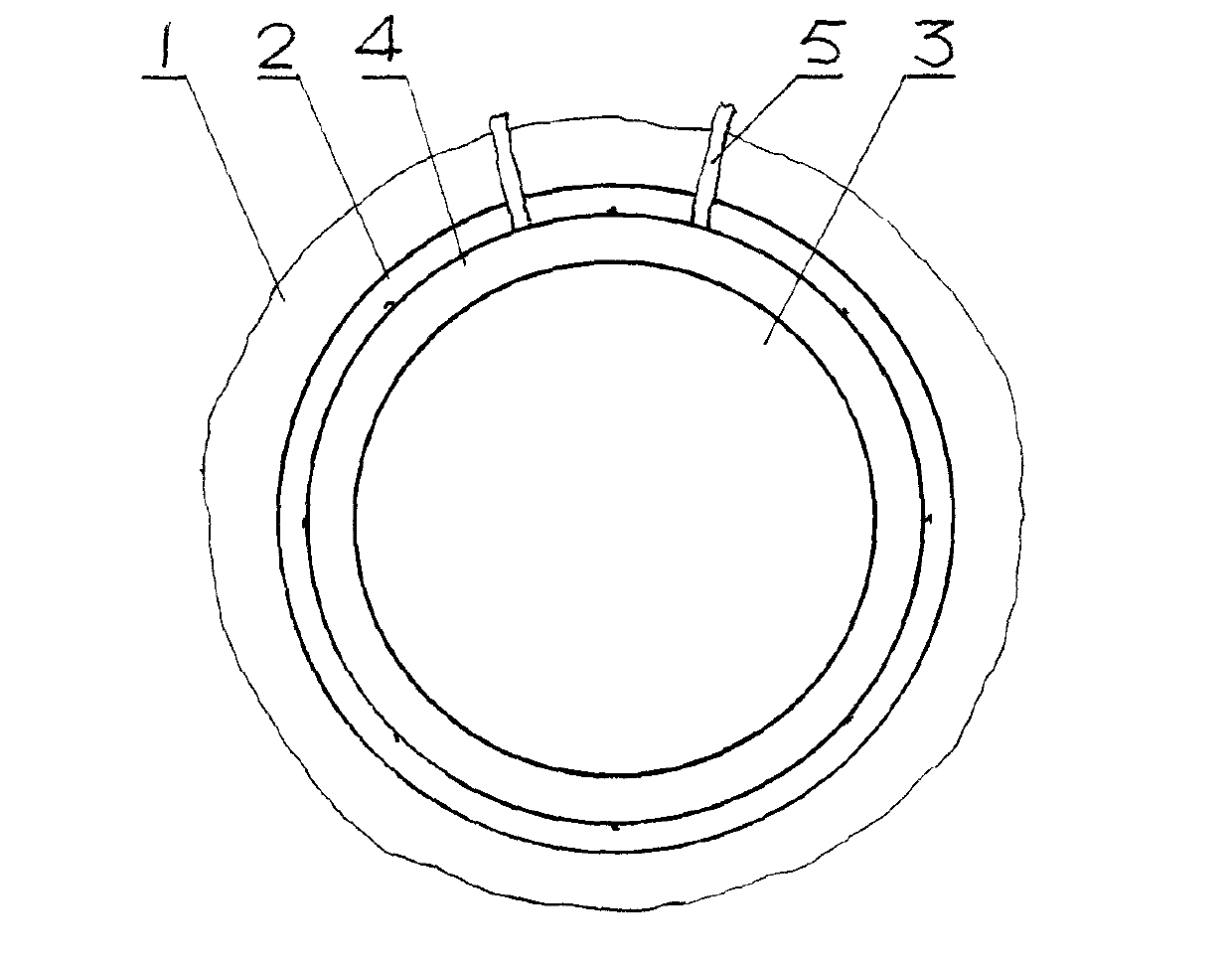

Mouth-muffle provided with humidifying filter layer

InactiveCN103099348AImprove cleanlinessImprove the efficiency of filtering fine dust particles such as "PM2.5" in the airProtective garmentMicrometerRespirator

The invention discloses a mouth-muffle provided with a humidifying filter layer, belongs to the technical field of personal hygienic products in daily life, and aims at overcoming the defects that an existing mouth-muffle is very poor in filtering function on fine dust particles such as the fine particulate matter with grain diameter smaller than 2.5 micrometers (PM2.5), and if the mouth-muffle is thickened, people breathe hardly, the dust particles obtain large motion energy and the like. The mouth-muffle provided with the humidifying filter layer comprises a mouth-muffle body and a cylindrical hollow support ring. The inner end of the support ring is connected with the exterior of the mouth-muffle body, and the humidifying filter layer is placed at the outer end of the support ring. The mouth-muffle provided with the humidifying filter layer is suitable for being adopted by mouth-muffle manufacture factories to improve products.

Owner:宣伯民

Lens having protection film that prevents moving of axis and damage of surface from the lens cutting and method and coating solution thereof

InactiveUS20060244910A1Great coefficient of frictionEasy to peelOptical partsOptical elementsTectorial membraneOptical axis

The present invention relates to an eyeglass, and more particularly to an eyeglass having a protective film exhibiting a greater coefficient of friction than the lens and easy peeling and removal, formed on the surface of the eyeglass lens, so as to prevent a shift of an optical axis and damage of lens surface occurring when processing the eyeglass lens, in particular a high-slip lens, and further to prevent surface damage and aging occurring during transportation or storage of lenses shipped from the a manufacturing factory and preparation thereof, and a protective film coating solution for the same.

Owner:NAM SANG WOOD

Image processing apparatus and image processing method

InactiveCN101316322ATelevision system detailsTelevision system scanning detailsImaging processingImaging data

The present invention provides an image processing apparatus and image processing method. When pixel data of a solid-state image-pickup device is read in various types of methods to pick up images, a correction process for defective pixels is easily performed at a low cost. As defect-correction data in a case in which a still image is shot, data is used, which is acquired when an image-pickup device is shipped from a manufacturing factory. In a case of an operation in a reading mode for a moving image, immediately before a reading operation is performed, charge is accumulated in a state in which the image-pickup device is shielded from light, and image data is read. Addresses of defective pixels to be corrected are detected from the image data, and stored in a RAM as the defect-correction data. When a moving image is shot, a defect-correction process is performed using the data.

Owner:CANON KK

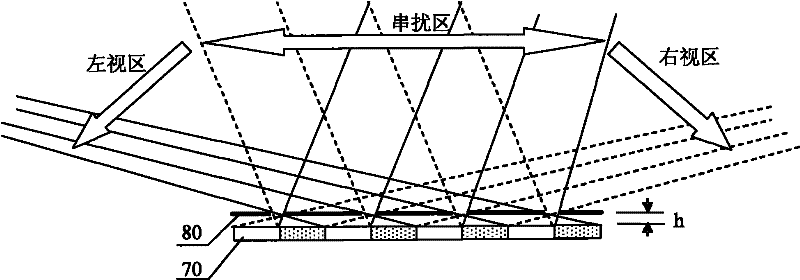

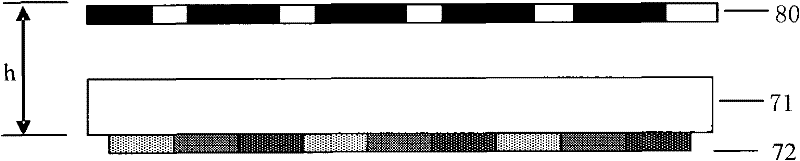

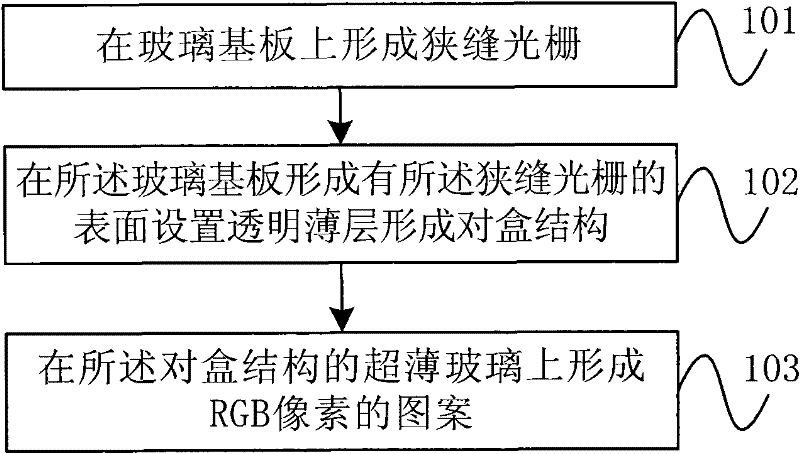

Double vision display, double vision colour membrane structure and manufacturing method of double vision colour membrane structure

ActiveCN102236201ASuitable for automated mass productionCathode-ray tube indicatorsNon-linear opticsGratingLiquid-crystal display

The invention provides a double vision display, a double vision colour membrane structure and a manufacturing method of the double vision colour membrane structure. The manufacturing method comprises the following steps of: forming a slit grating on a glass substrate; placing a transparent thin layer on the surface of the glass substrate where the slit grating is formed so as to form a double-box structure; and forming an RGB (Red, Green and Blue) pixel pattern on the transparent thin layer in the double-box structure. According to the invention, the double vision colour membrane structure is manufactured by adopting the traditional material and the traditional equipment of the traditional LCD (Liquid Crystal Display) manufacturing factory, thus automatic large scale production is facilitated.

Owner:BOE TECH GRP CO LTD

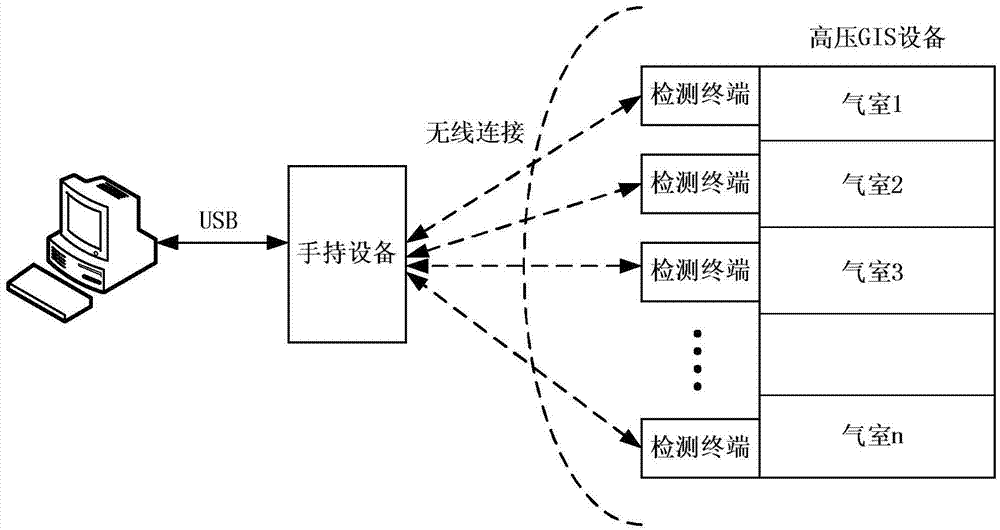

High voltage GIS device breakdown discharge positioning system based on vibration signals

ActiveCN104749489AEasy to judgeDoes not involve isolationTesting dielectric strengthSubsonic/sonic/ultrasonic wave measurementManufacturing FactoriesPeak value

Disclosed is a high voltage GIS device breakdown discharge positioning system based on vibration signals. The system comprises a wireless vibration detection device, a controlling and receiving device and an upper computer. The vibration detection device captures vibration signals of a GIS shell during the discharging instant through a piezoelectric acceleration sensor and transmits data to the controlling and receiving device through a beige wireless module; the controlling and receiving device controls the operation, data acquisition and transmitting functions of the wireless vibration detection device through keys and displays the vibration signal peak values and accumulation values of terminals through a liquid crystal screen; the upper computer has the functions of acquired waveform displaying, analysis and historical data calling. By the aid of the system, the breakdown discharge fault position can be judged rapidly and accurately during GIS voltage resistance tests, and the testing efficiency of products can be improved greatly for GIS manufacture factories.

Owner:XI AN JIAOTONG UNIV

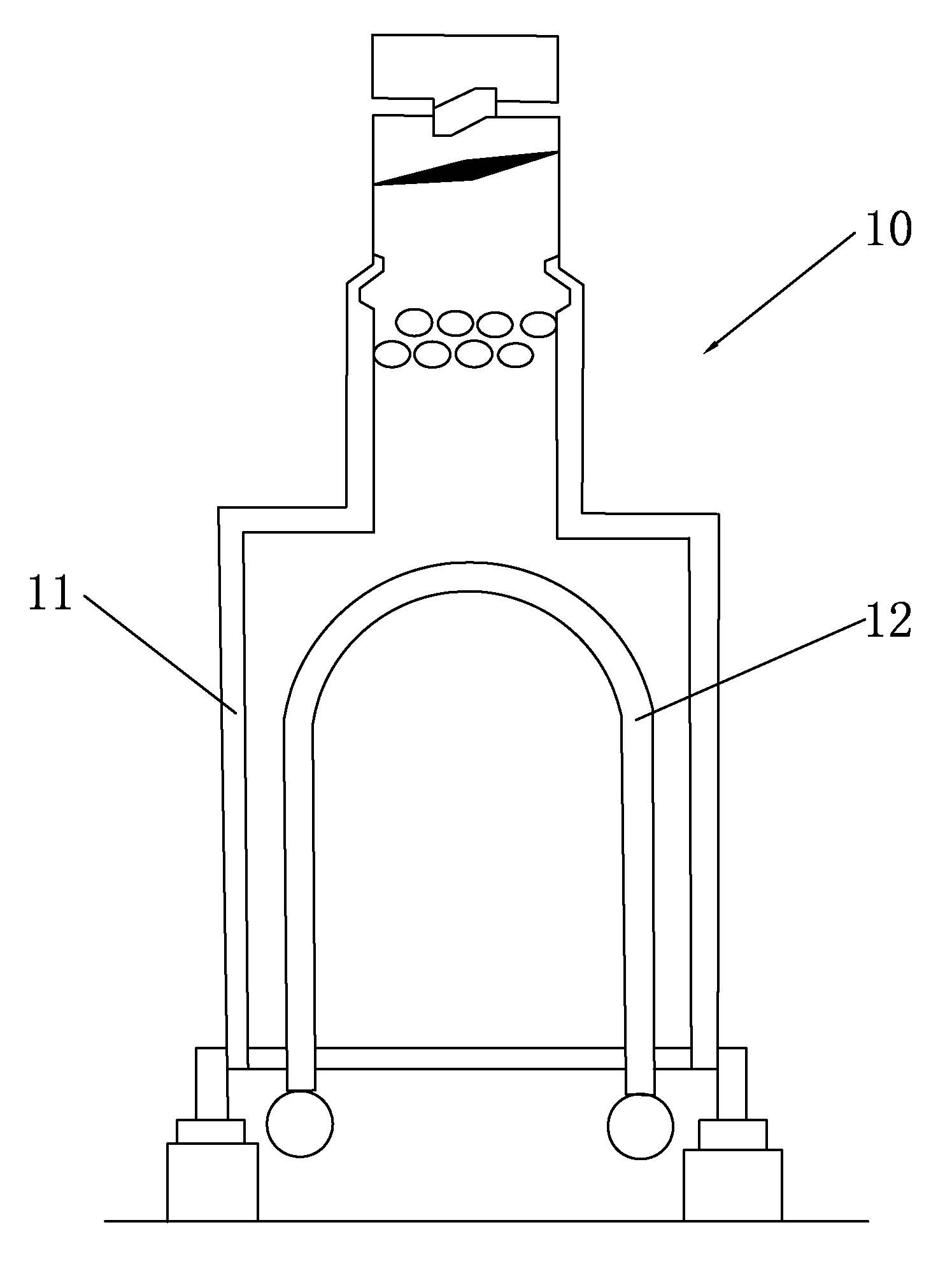

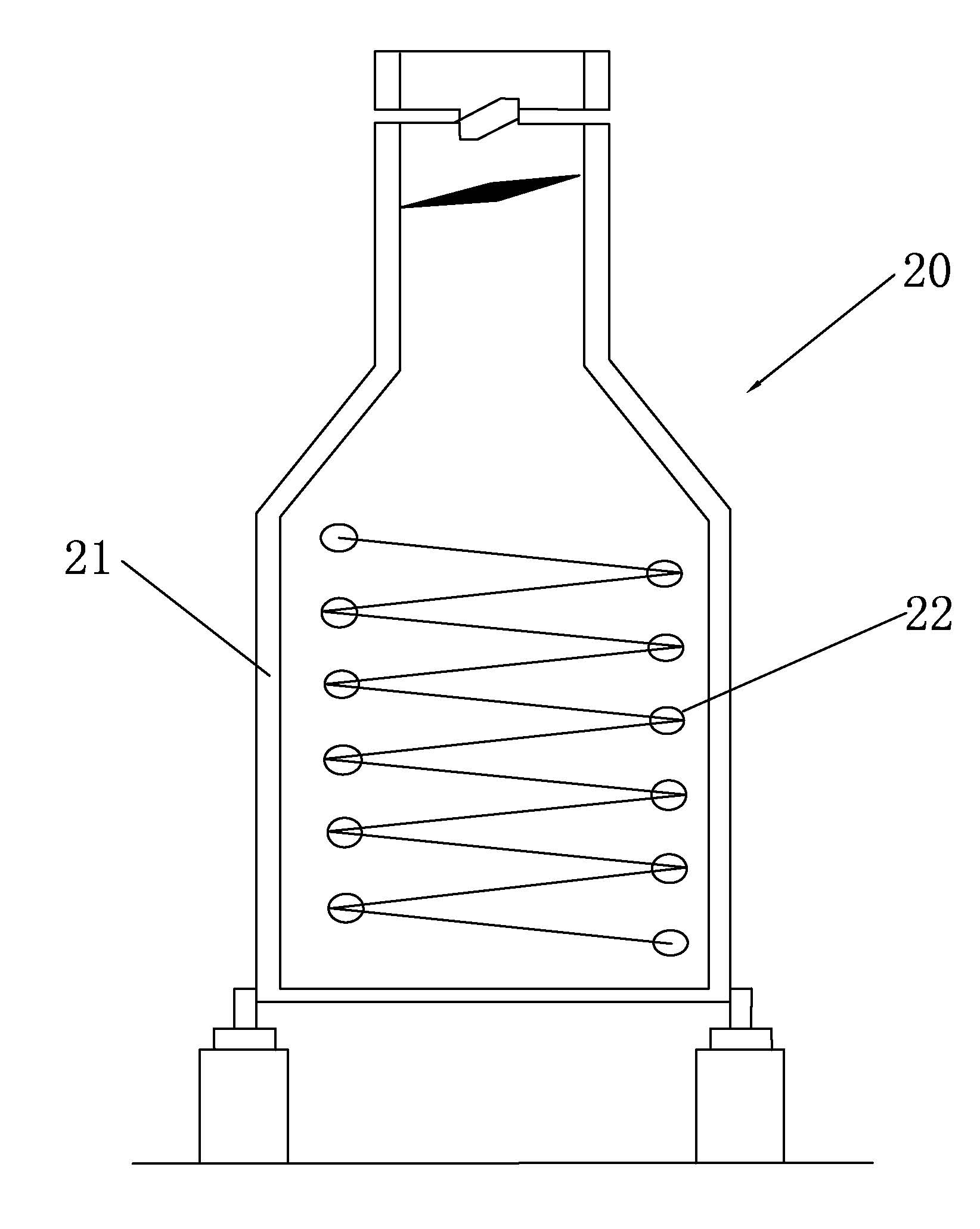

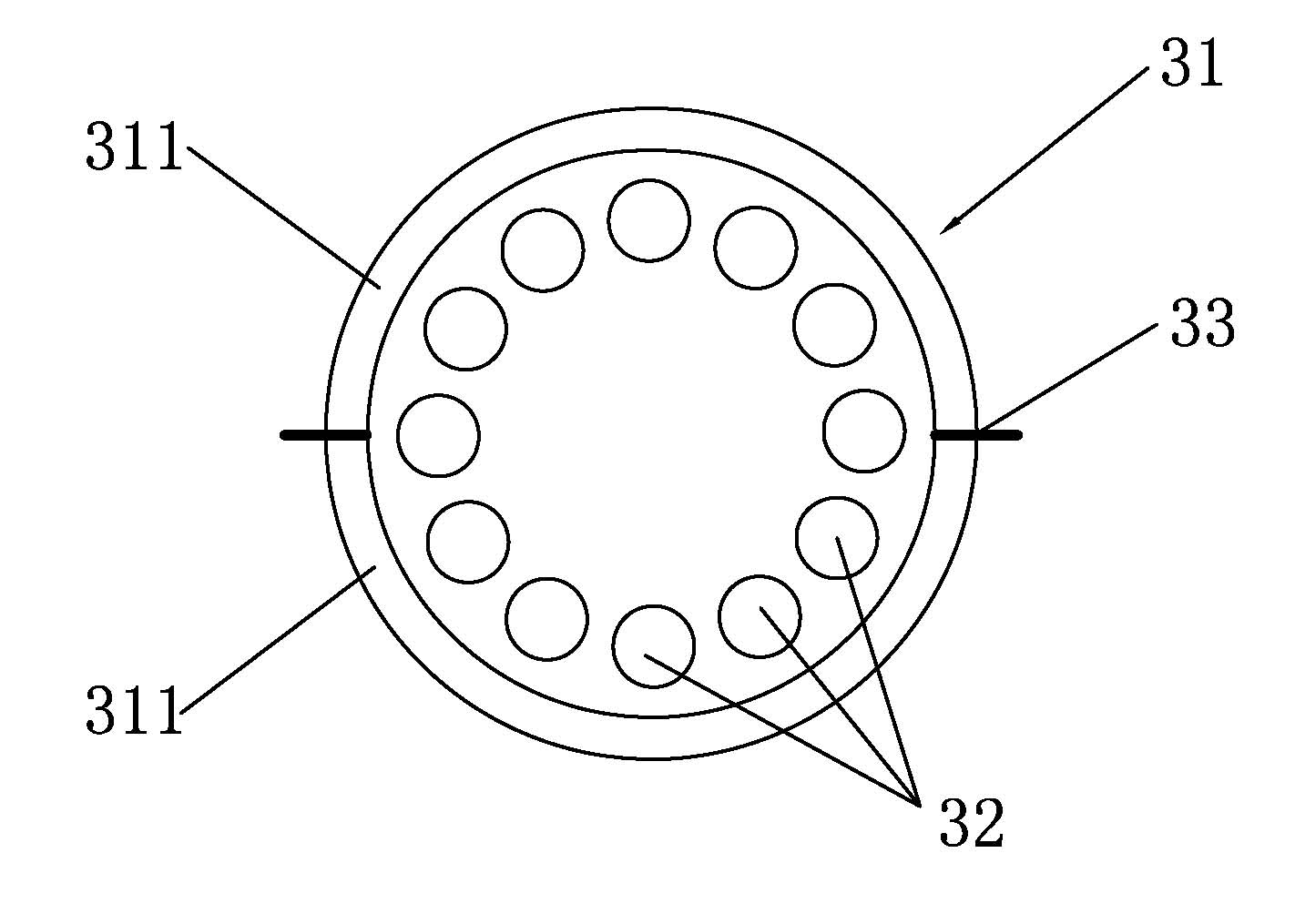

Cylindrical tube type heating furnace capable of being assembled

ActiveCN101968313AEasy to buildAvoid chaosFurnace componentsFurnace typesCombustorProcess engineering

The invention relates to a cylindrical tube type heating furnace capable of being assembled, comprising a furnace shell, a furnace tube and a burner. The furnace tube is arranged in the furnace shell, the burner is also arranged in the furnace shell, wherein the furnace shell is composed of at least two furnace shell modules which are assembled and connected. As the heating furnace of the invention is provided with the furnace shell modules which can be assembled and connected and are applied to furnace shell, so that assembly and welding of the parts of the furnace shells can be carried out in a workshop of a manufacturing factory and then the furnace shells can be transported to the construction site to perform modularized 'block building' type construction. The mode in which the furnace shell modules are assembled to form the furnace shell changes the traditional construction mode in which a tubular heater is assembled and welded on site at the construction site, avoids the mess that various parts are scattered at the construction site, facilitates construction of large tubular heaters, leads to industrial application of the gradual implementation of modularized construction of industrial furnaces and has the characteristics of simple assemblage, low construction cost, short construction period and convenient overhauling.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com