Cylindrical tube type heating furnace capable of being assembled

A tubular heating furnace and circular technology, which is applied in the field of flue gas heat exchange equipment and circular tubular heating furnaces, can solve the problems of rising investment costs, inconvenient installation and construction, loosening, etc., and achieve lower construction costs and lower construction costs. Low, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

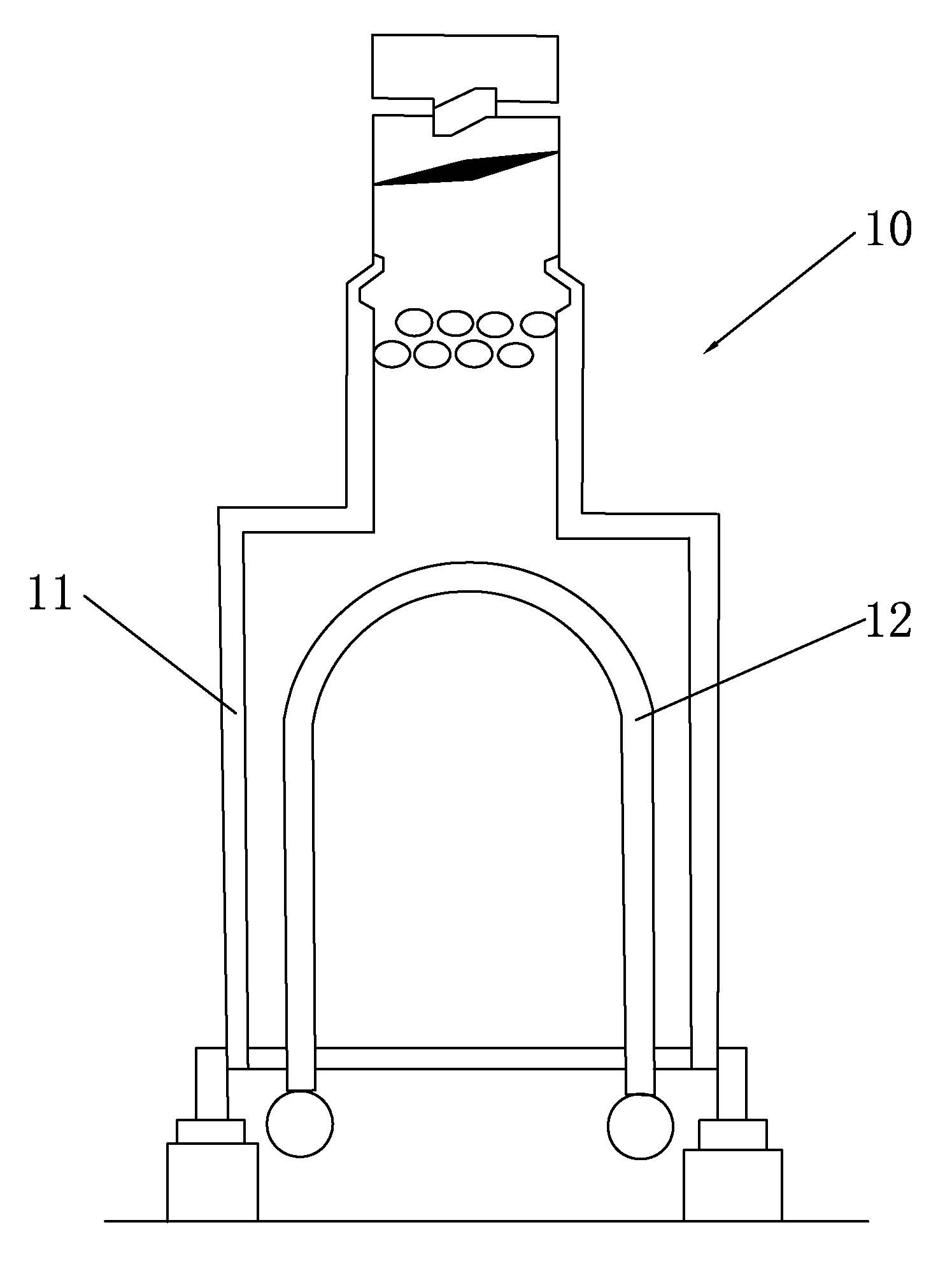

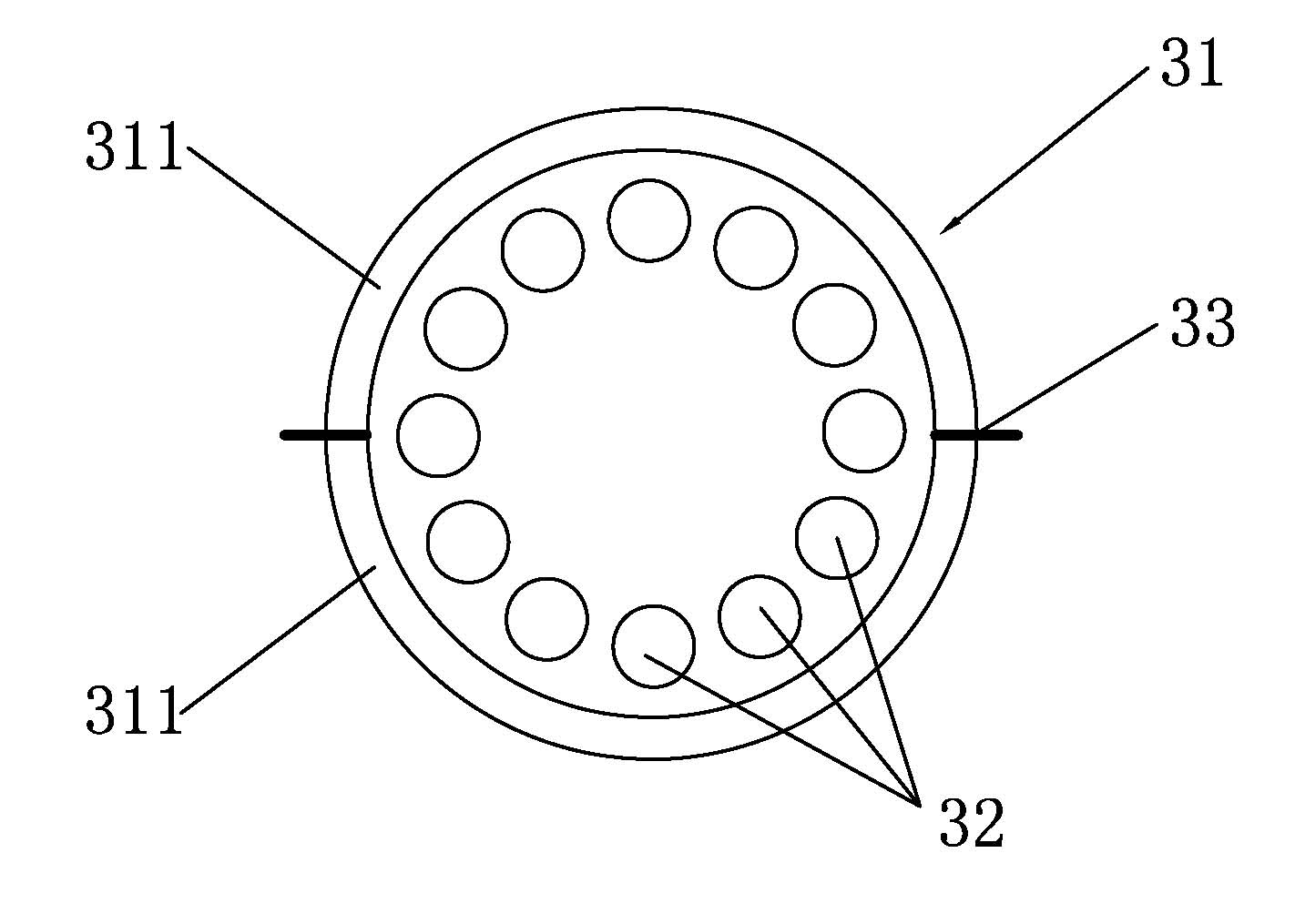

[0042] One of the specific implementations of a kind of assembleable circular tubular heating furnace of the present invention, such as image 3 As shown, a furnace shell 31, a furnace tube 32 and a burner are included. The furnace tube 32 is arranged in the furnace shell 31, and the burner is arranged in the furnace shell 31. Specifically, the burner can be arranged at the bottom of the furnace shell 31 for bottom firing , It can also be set on the top of the furnace shell 31 for top firing. Wherein, the furnace shell 31 is a furnace shell 31 assembled and connected by at least two furnace shell modules 311 .

[0043] Specifically, the furnace shell module 311 can be an arc-shaped furnace shell module 311, and there are two arc-shaped furnace shell modules 311, and the furnace shell 31 is formed by the arc-shaped furnace shell modules 311 interacting with each other along the radial direction. The assembled and connected furnace shell 31 has a circular cross-sectional shape....

Embodiment 2

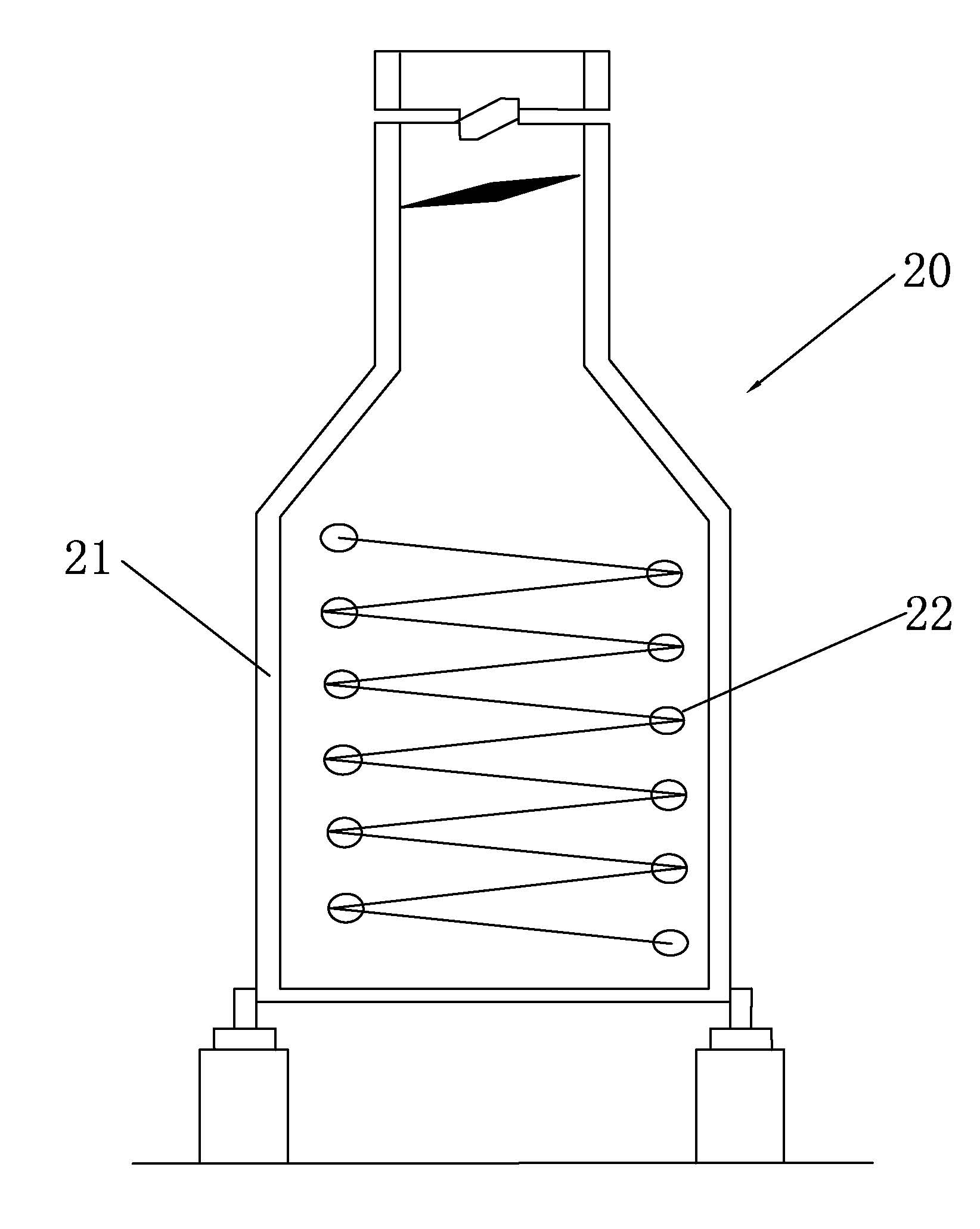

[0047] The second embodiment of a kind of assembleable circular tubular heating furnace of the present invention, as Figure 4 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, and will not be repeated here, and are described in Figure 4 neutralize image 3 The same parts bear the same reference numerals. The difference between this embodiment and Embodiment 1 is that the furnace shell module 311 is an elliptical arc-shaped furnace shell module 311, and there are four elliptical arc-shaped furnace shell modules 311, and the furnace shell 31 is an elliptical arc-shaped furnace shell The modules 311 are assembled and connected to each other along the radial direction, and have a furnace shell 31 with an elliptical cross-sectional shape. Wherein, the elliptical arc-shaped furnace shell module 311 constituting the furnace shell 31 having an ellipt...

Embodiment 3

[0049] The third specific embodiment of a kind of assembleable circular tubular heating furnace of the present invention, as Figure 5 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, and will not be repeated here, and are described in Figure 5 neutralize image 3 The same parts bear the same reference numerals. The difference between this embodiment and Embodiment 1 is that the furnace shell module 311 is an arc-shaped furnace shell module 311 and a linear furnace shell module 311, wherein the arc-shaped furnace shell module 311 is provided with two, and the linear furnace shell module 311 There are two shell modules 311, and the furnace shell 31 is a furnace shell 31 with a cross-sectional shape of an oblong ring (the The long circular ring approximates the track shape of the sports field). Wherein, the arc-shaped furnace shell module 311 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com