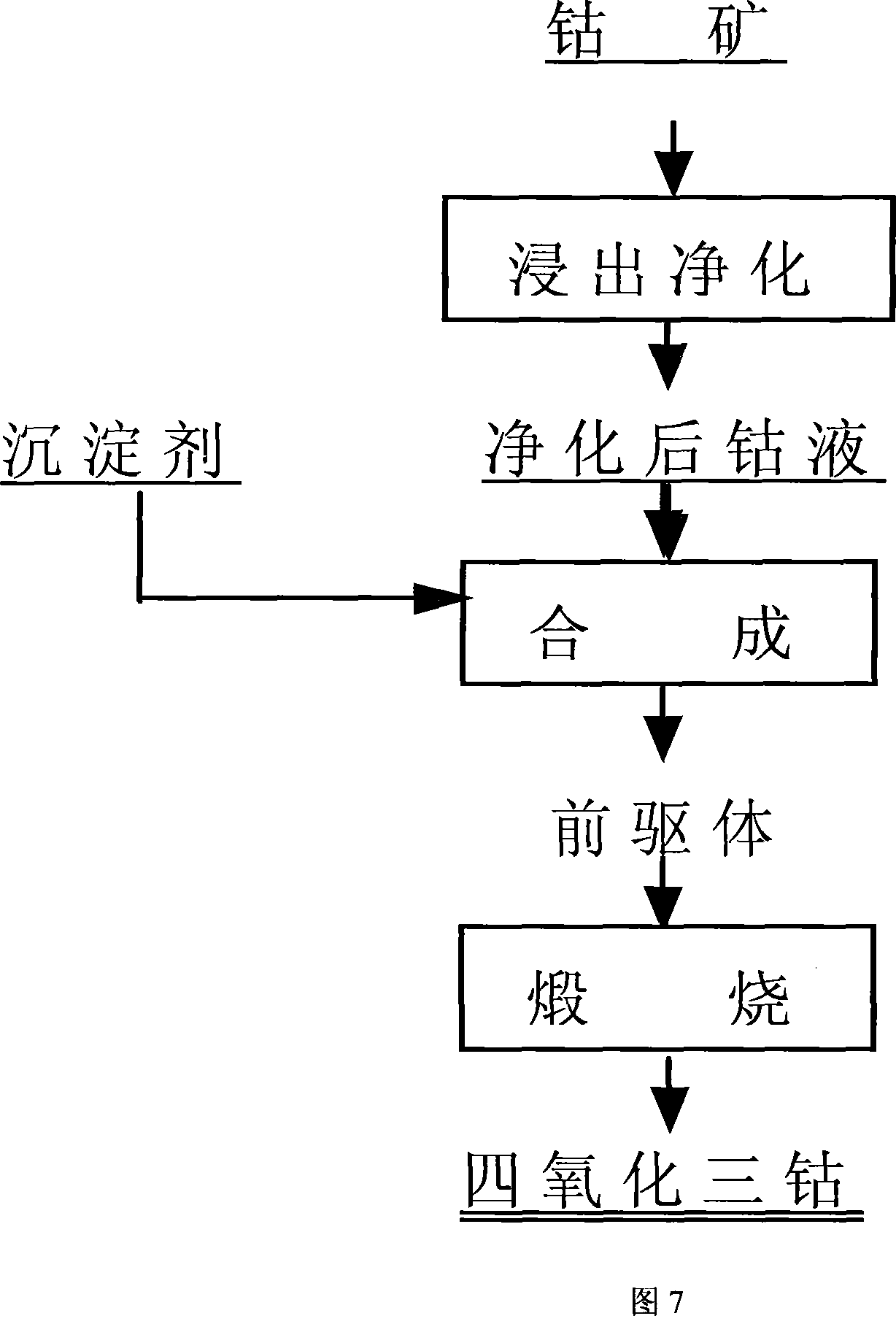

Preparation method of cobaltosic oxide for electric battery

A technology of tricobalt tetroxide and batteries, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., which can solve the problems of uneven distribution of particle size composition, increase of battery internal resistance, short discharge time, etc., and achieve the effects of good fluidity, reduced dosage, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

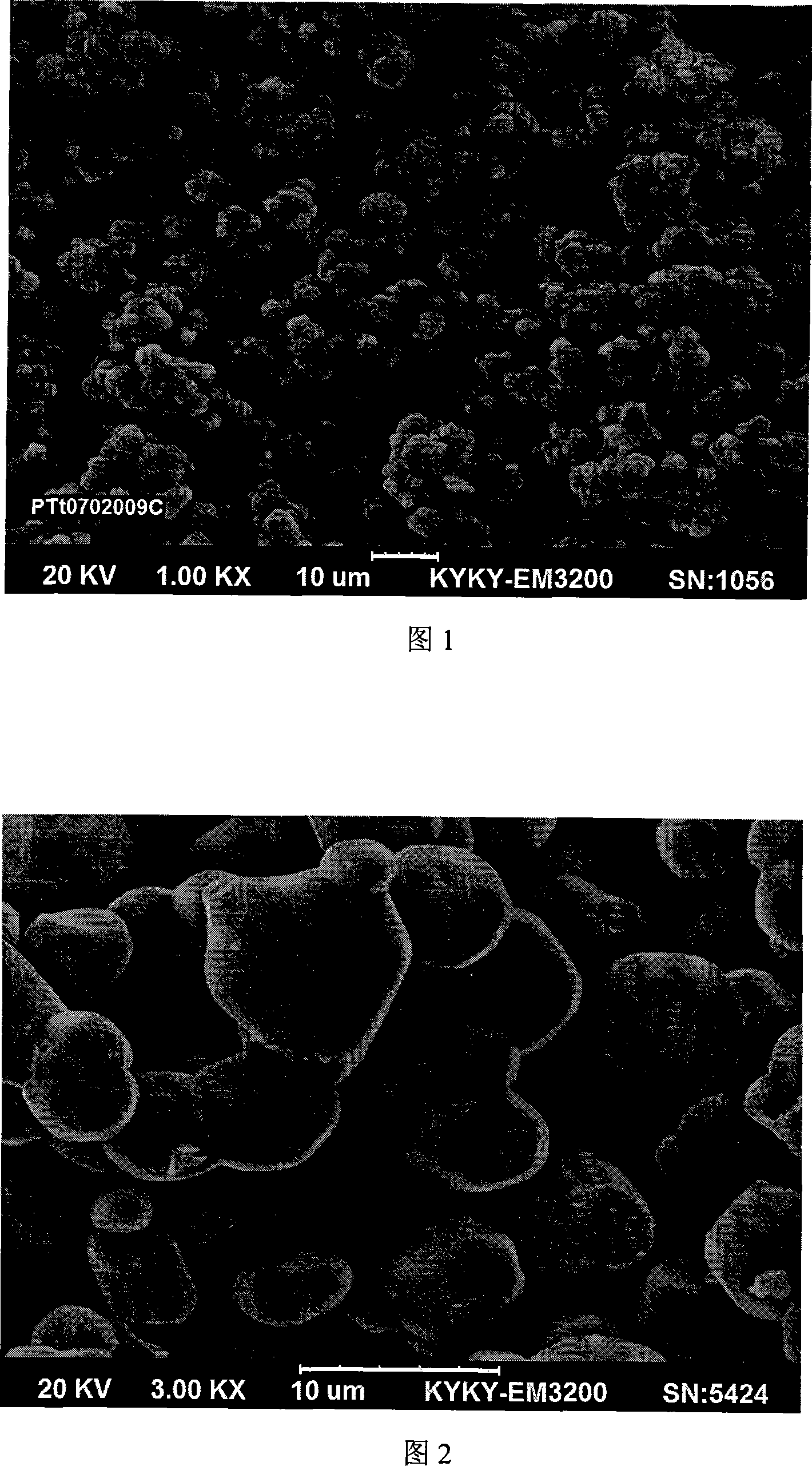

[0032] Using cobalt-containing ore as raw material, after leaching and purification, high-purity 50g / L-150g / L cobalt liquid is obtained, and ammonia water and polyvinylpyrrolidone (PVP) are added to the above-mentioned cobalt liquid according to 0.05%-10% of the cobalt mass. ), polyvinyl alcohol (PVA), cetyltrimethylammonium bromide (CTAB), polyethylene glycol PEG (1000), one or more of water-soluble starch (such as adding ammonia and polyethylene Glycol PEG1000), as complexed cobalt salt solution, selects a kind of in ammonium bicarbonate, ammonium carbonate as precipitant, after dissolving, filtering, be made into 80g / L-200g / L precipitant solution; Excessive 10%- 30% precipitant solution and complex cobalt salt solution are added to the reactor by co-current feeding method, the DCS distributed control system is used to control the reaction temperature at 30°C-90°C, the reaction pH value is 5.0-9.0, and the stirring speed is 400rpm-2000rpm , the precipitate of cobalt salt is ...

Embodiment 2

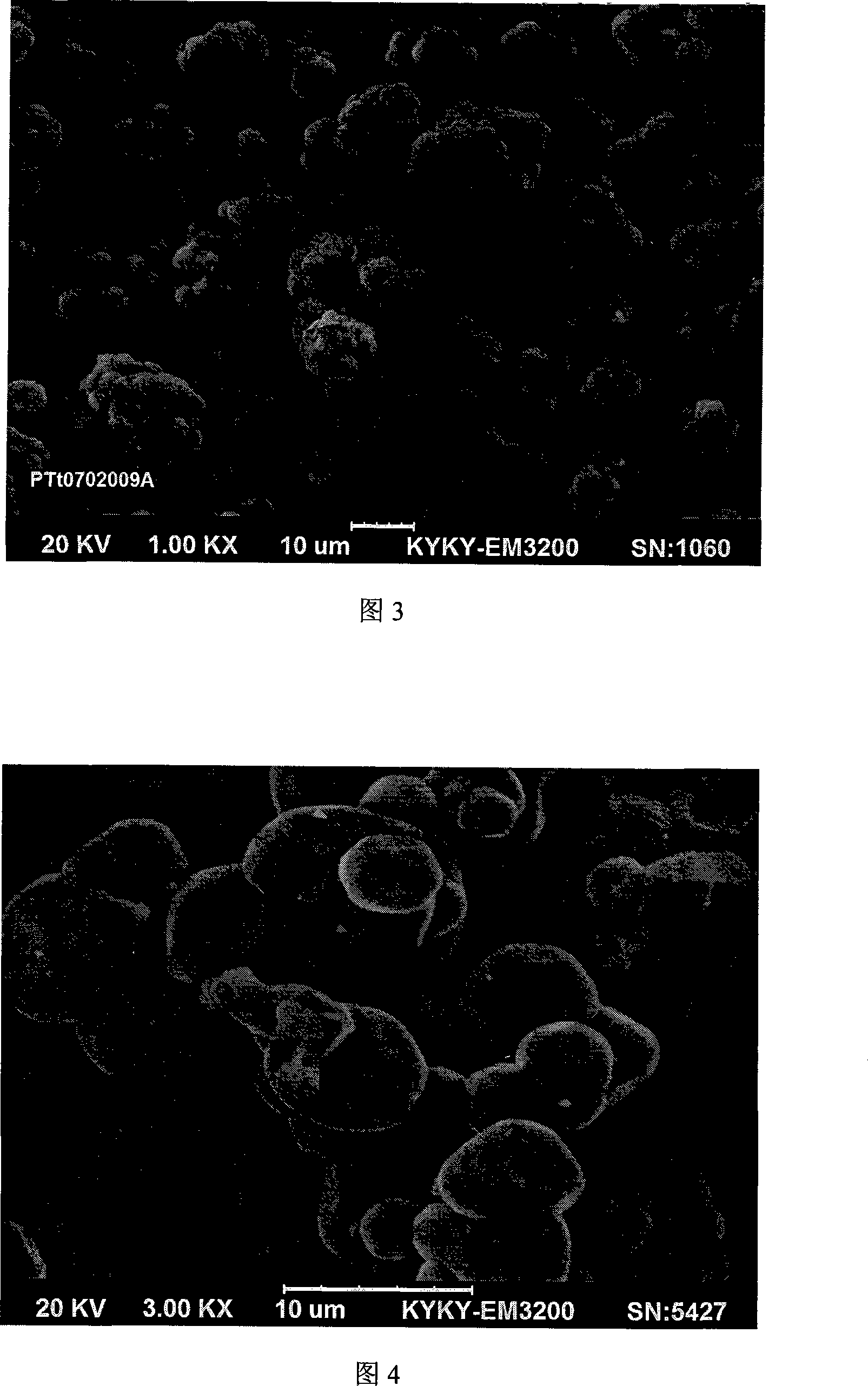

[0034] Using cobalt-containing ore as raw material, after leaching and purification, high-purity 50g / L-150g / L cobalt liquid is obtained, and ammonia water and polyvinylpyrrolidone (PVP) are added to the above-mentioned cobalt liquid according to 0.05%-10% of the cobalt mass. ), polyvinyl alcohol (PVA), cetyltrimethylammonium bromide (CTAB), polyethylene glycol PEG (1000), one or more of water-soluble starch (ammonia, polyvinylpyrrolidone PVP Add another kind of water-soluble starch), as complex cobalt salt solution, select a kind of in ammonium bicarbonate, ammonium carbonate as precipitation agent, after dissolving, filtering, be made into 80g / L-200g / L precipitation agent solution; Excessive 10%-30% precipitant solution and complex cobalt salt solution are added to the reactor by co-current feeding method, and the DCS distributed control system is used to control the reaction temperature at 30°C-90°C, the reaction pH value is 3.0-9.0, and the stirring speed For 400rpm-2000rpm...

Embodiment 3

[0036]Using cobalt-containing ore as raw material, after leaching and purification, high-purity 50g / L-150g / L cobalt liquid is obtained, and polyvinylpyrrolidone (PVP), One or more of polyvinyl alcohol (PVA), cetyltrimethylammonium bromide (CTAB), polyethylene glycol PEG (1000), water-soluble starch (ammonia, polyvinyl alcohol PVA or cetyl Alkyltrimethylammonium bromide (CTAB), as a complex cobalt salt solution, select one of ammonium bicarbonate and ammonium carbonate as a precipitant, and dissolve and filter to form an 80g / L-200g / L precipitant solution Add excess 10%-30% precipitant solution and complexed cobalt salt solution to the reactor by co-current feeding method, adopt DCS distributed control system to control the reaction temperature to 30°C-90°C, and the reaction pH value to 3.0-9.0, The stirring speed is 400rpm-2000rpm, and the precipitate of cobalt salt is continuously obtained as the precursor (its appearance is shown in Figure 5) by the complexation-homogeneous p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com