Patents

Literature

466results about How to "Control granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

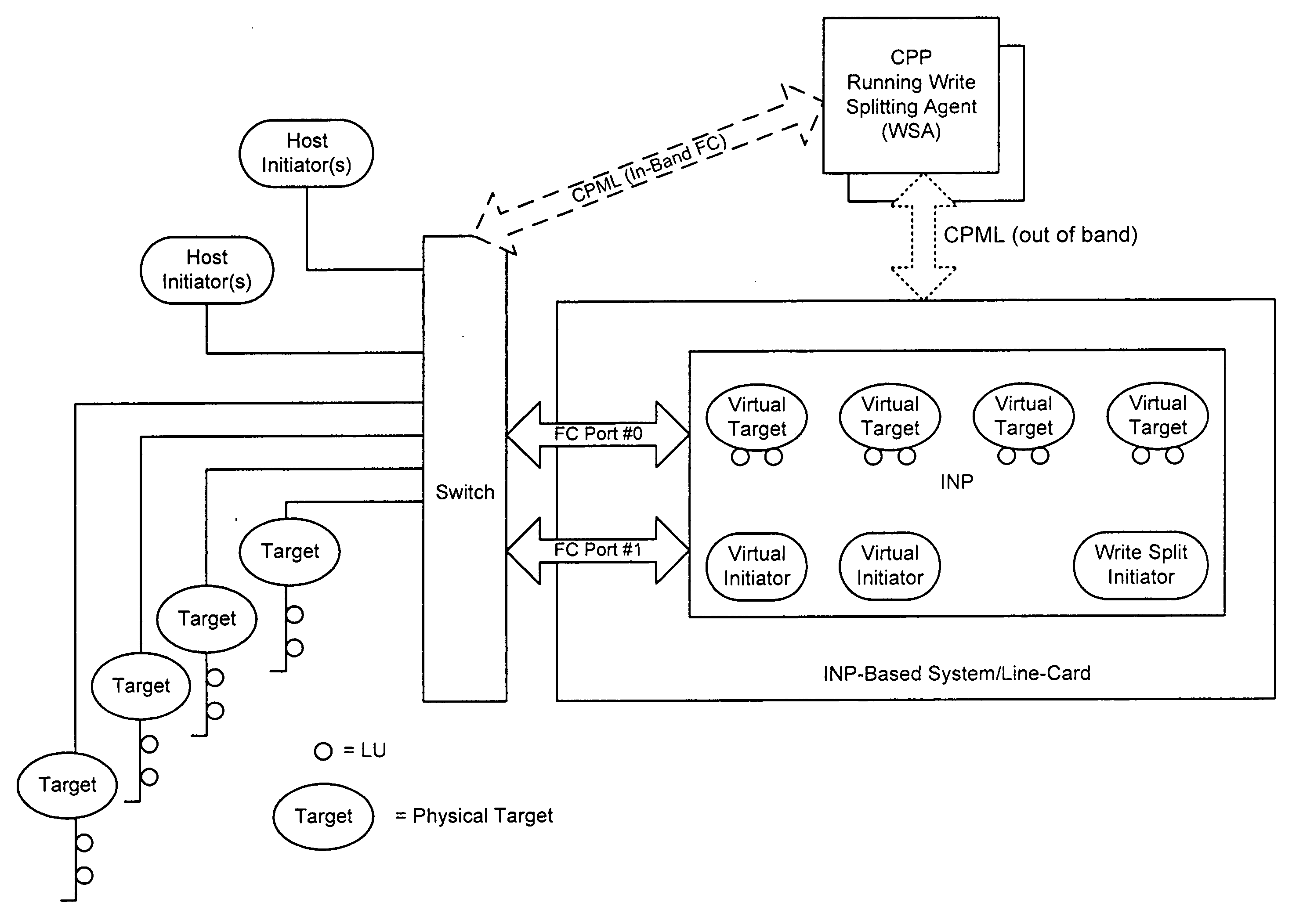

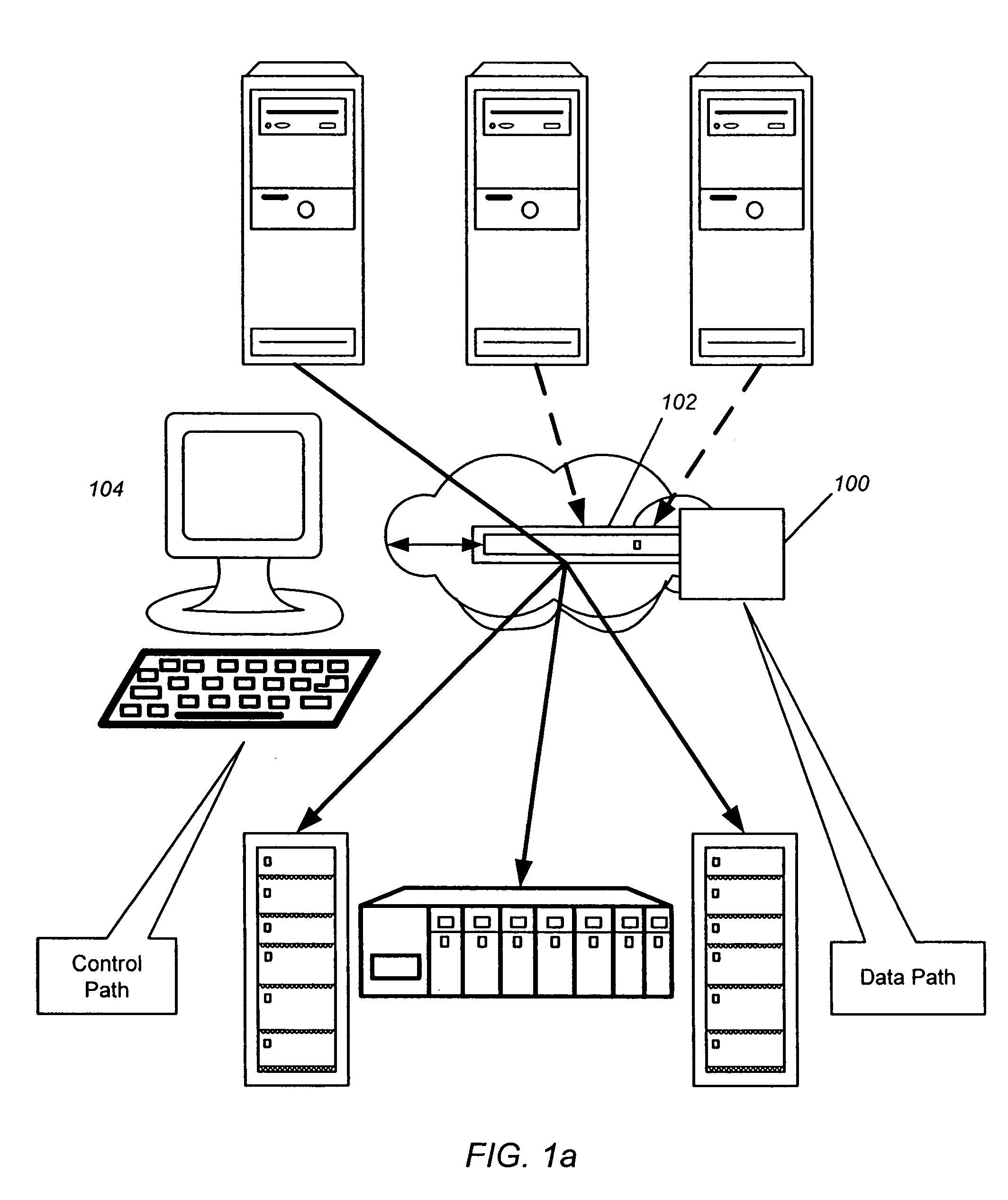

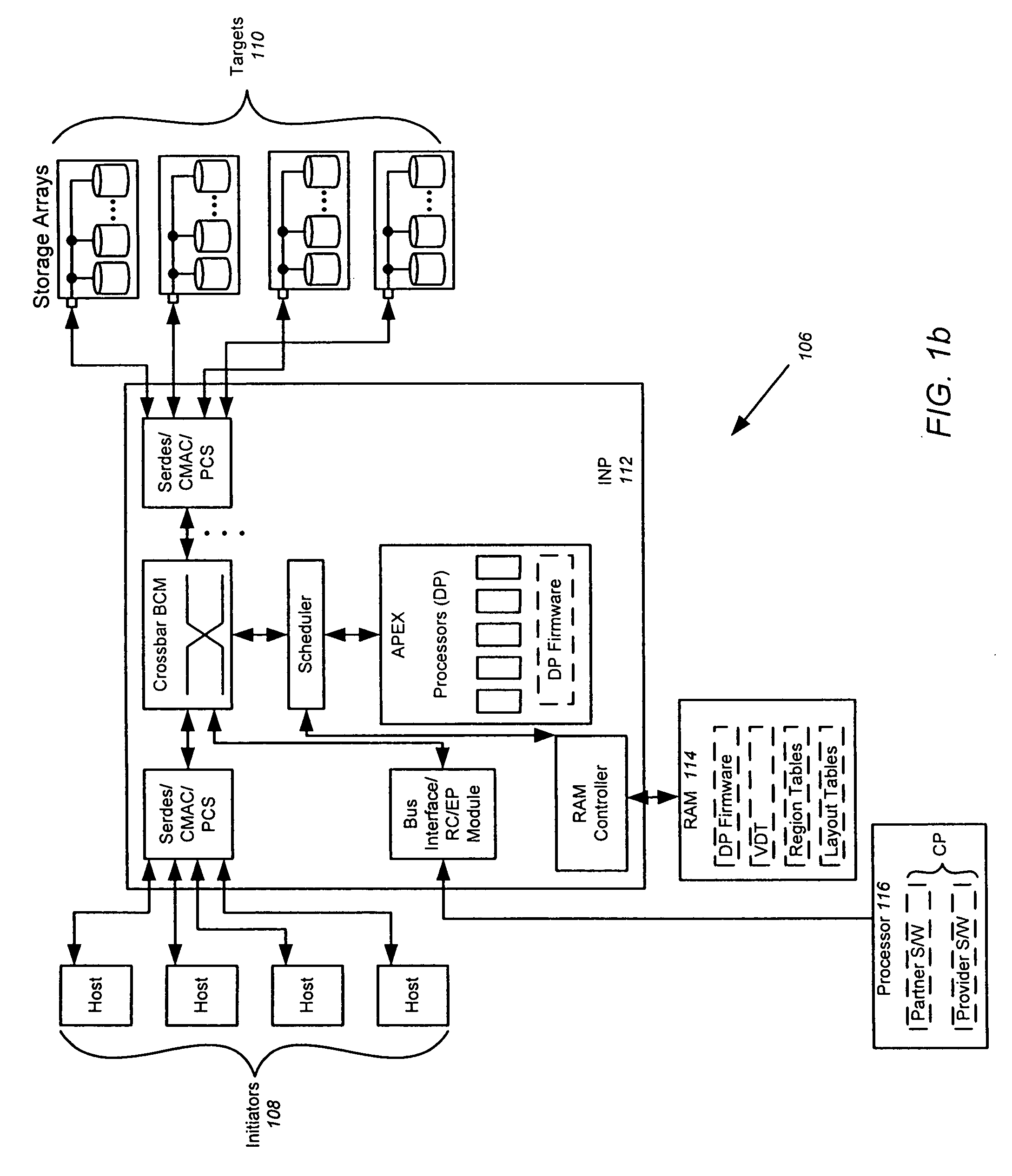

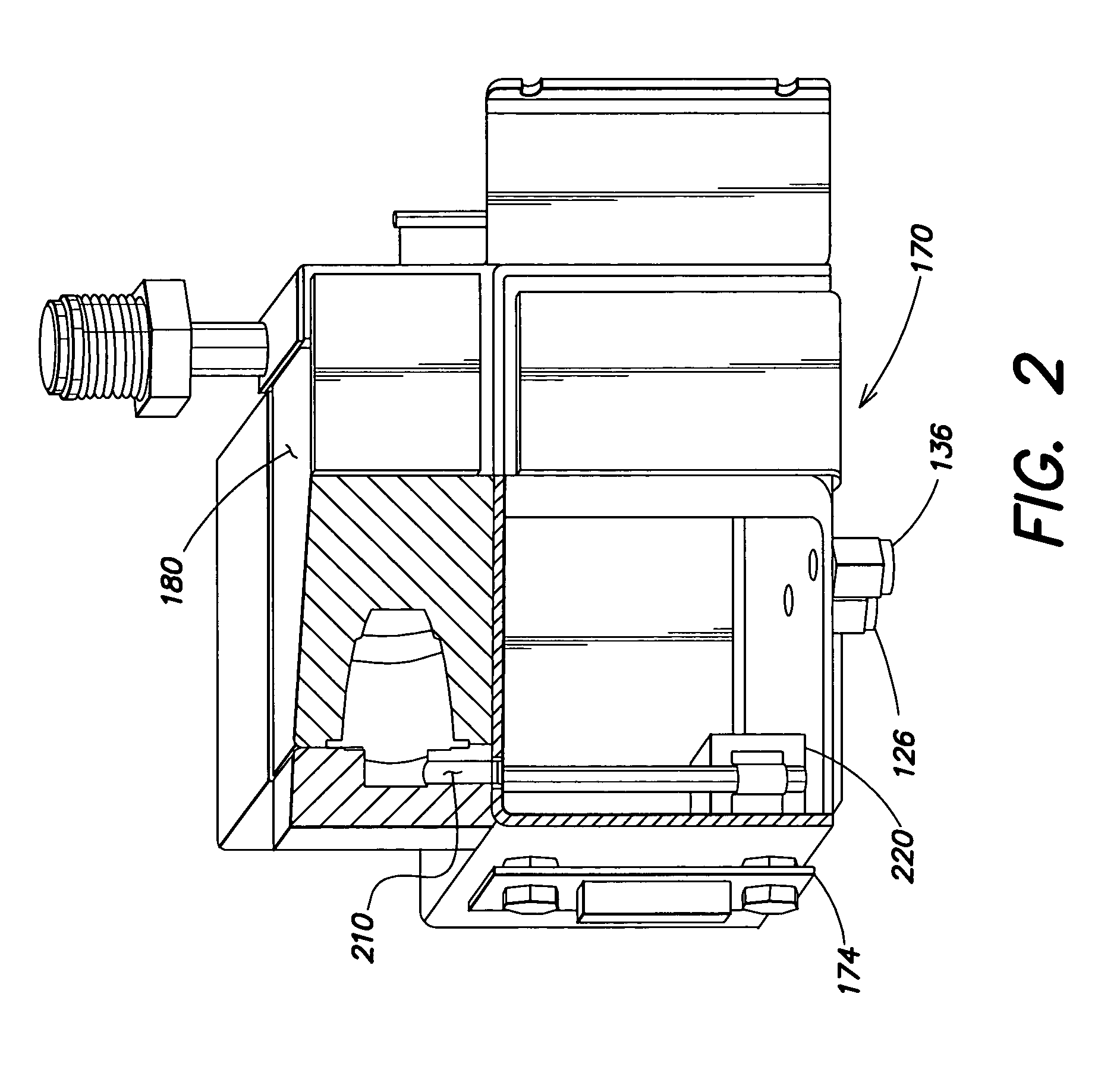

Apparatus for performing storage virtualization

ActiveUS20070239944A1Simplify writingIncrease overheadError detection/correctionMemory adressing/allocation/relocationVirtual targetData management

The splitting of storage applications and functions into a control path (CP) component and a data path (DP) component is disclosed. Reads and writes may be handled primarily in the DP. The CP may be responsible for discovery, configuration, and exception handling. The CP can also be enabled for orchestrating complex data management operations such as snapshots and migration. Storage virtualization maps a virtual I / O to one or more physical I / O. A virtual target (vTarget) in the virtual domain is associated with one physical port in the physical domain. Each vTarget may be associated with one or more virtual LUNs (vLUNs). Each vLUN includes one or more vExtents. Each vExtent may point to a region table, and each entry in the region table may contain a pointer to a region representing a portion of a pExtent, and attributes (e.g. read / write, read only, no access) for that region.

Owner:AVAGO TECH INT SALES PTE LTD

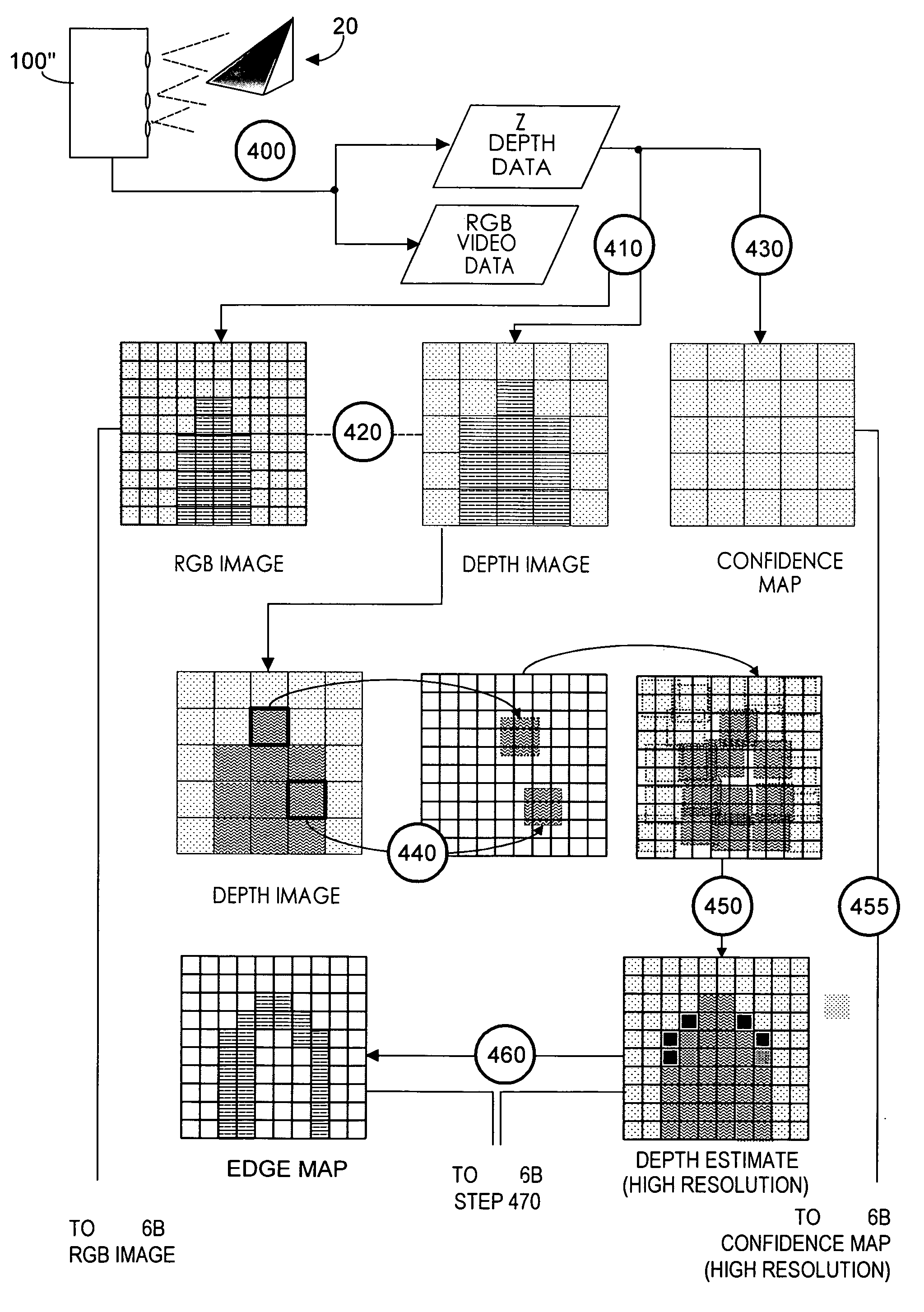

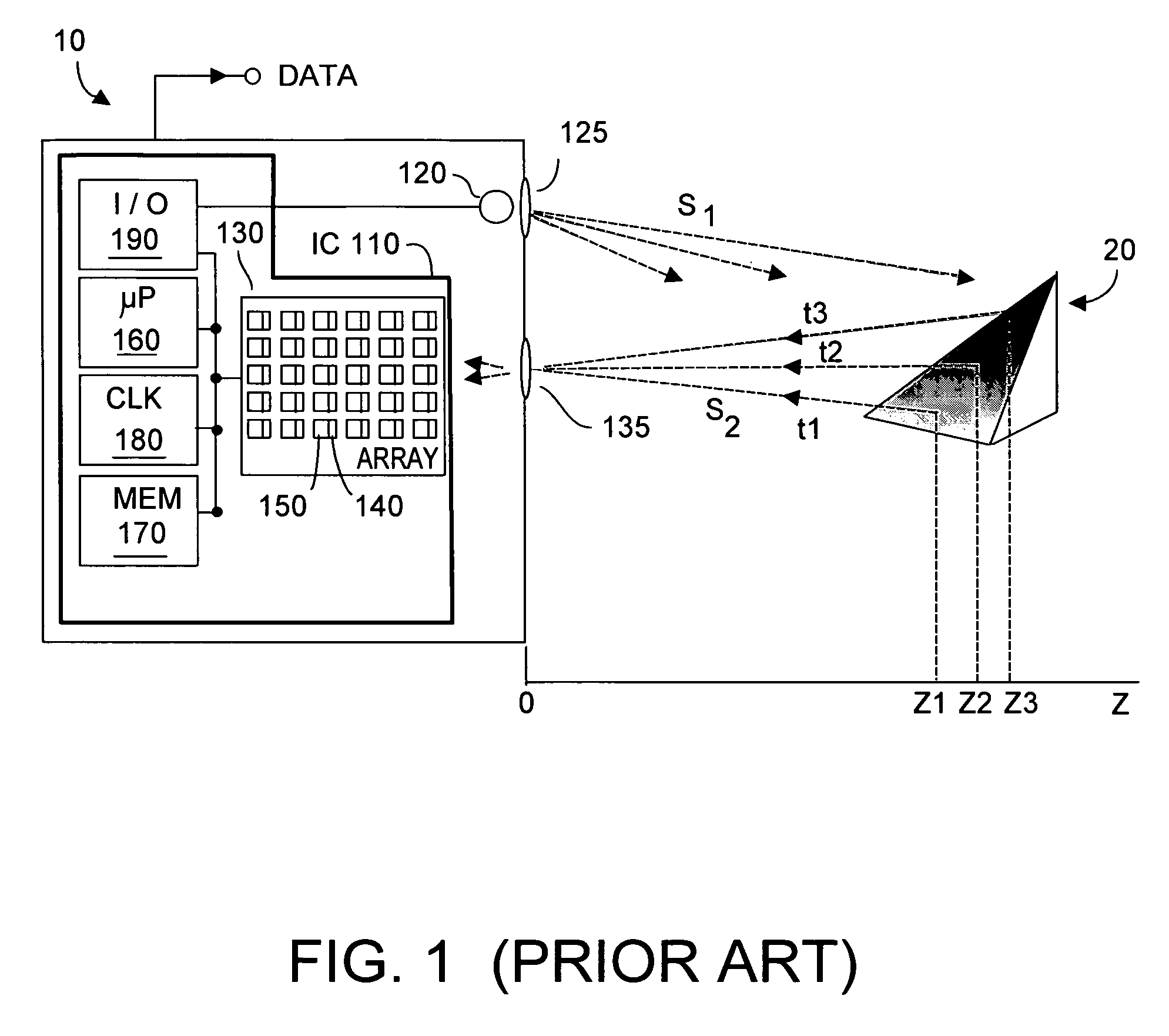

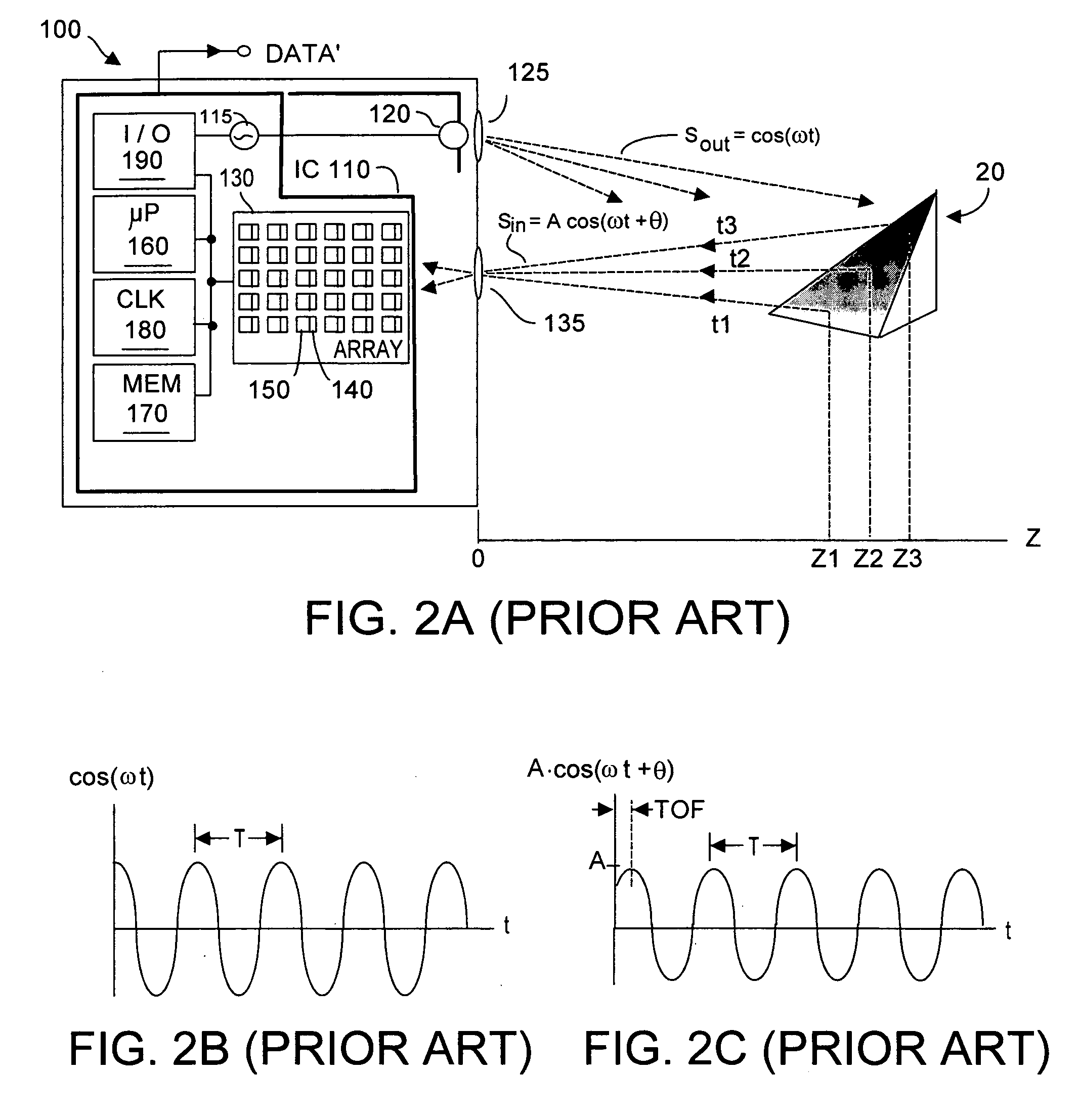

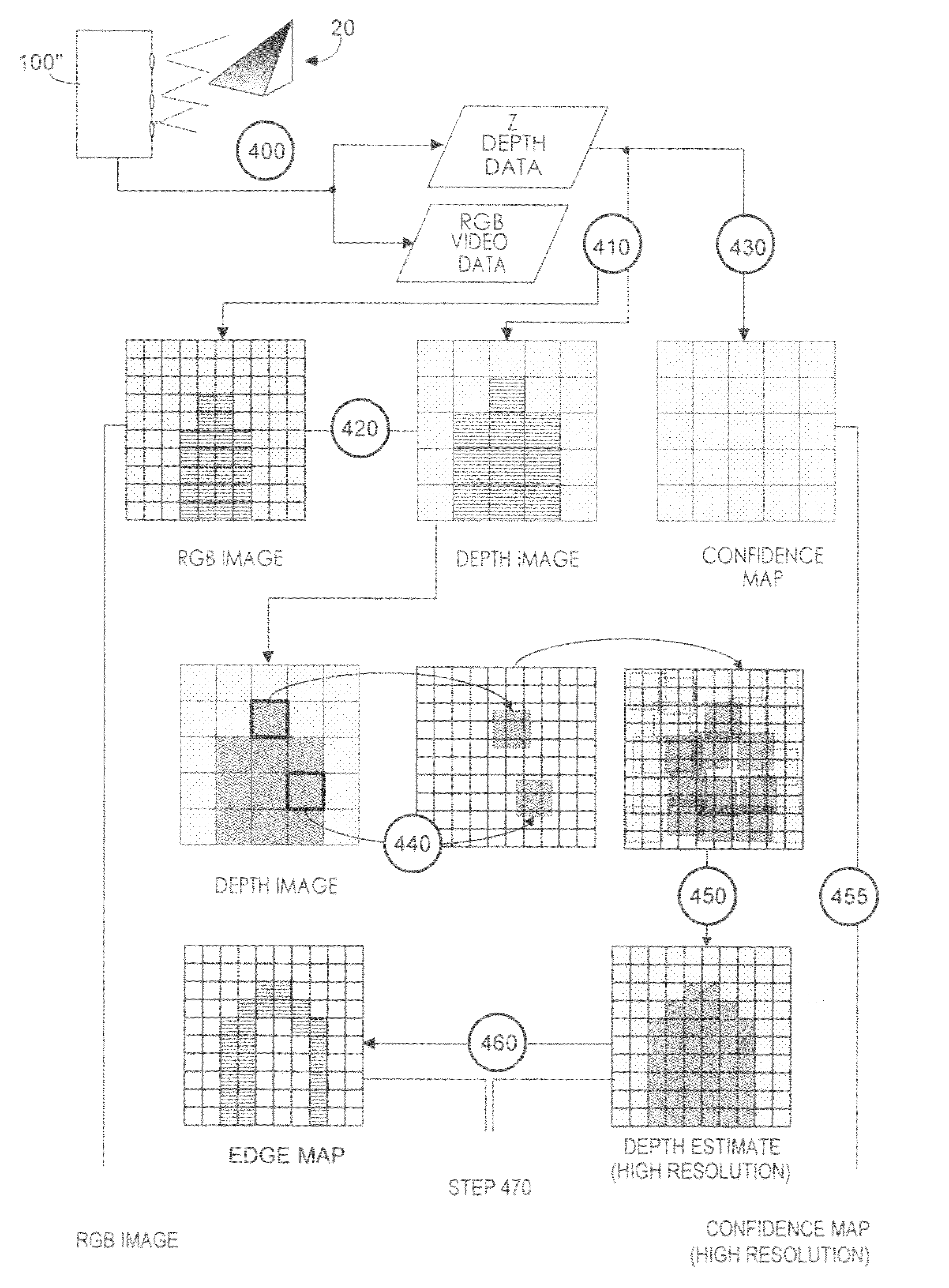

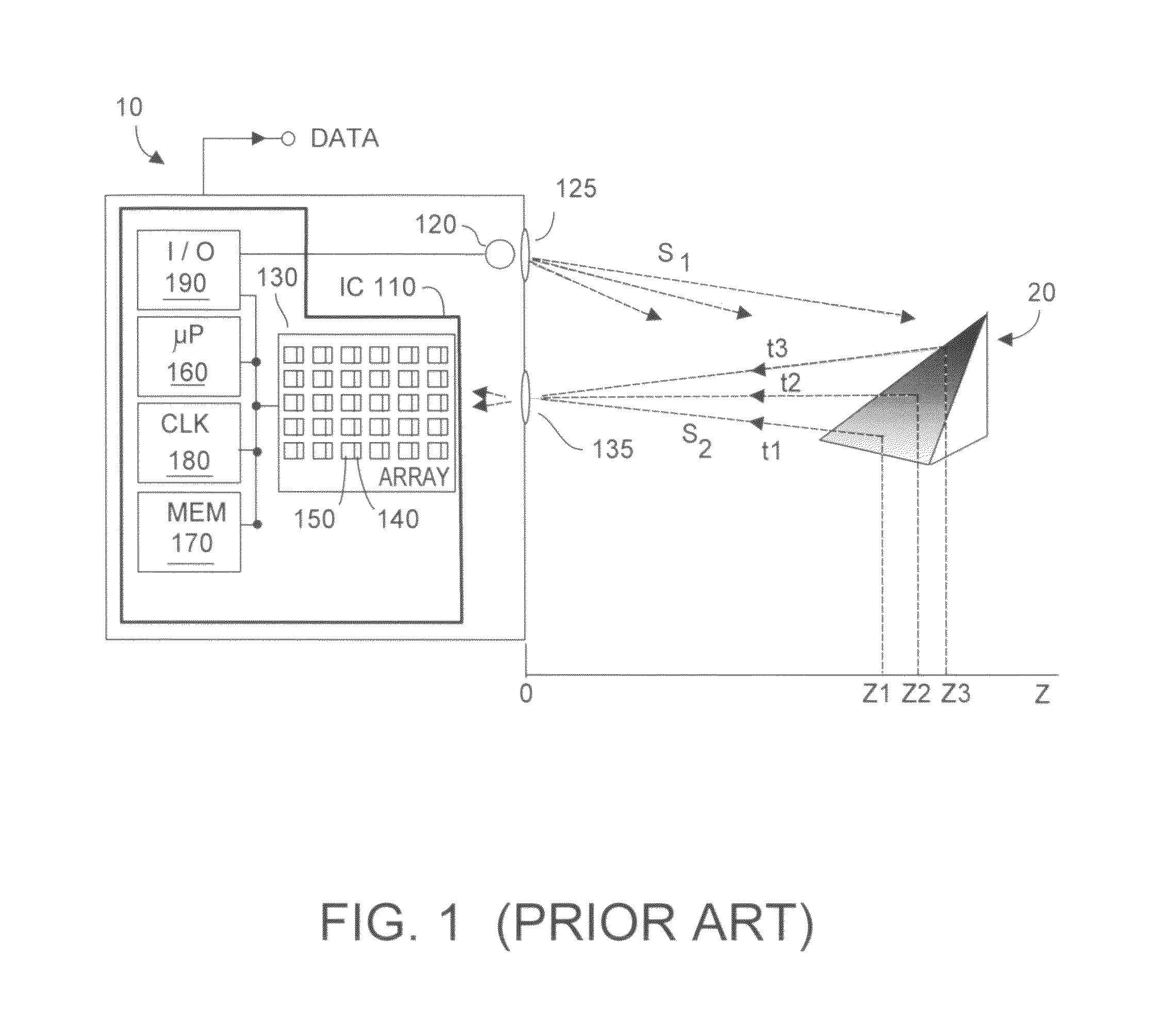

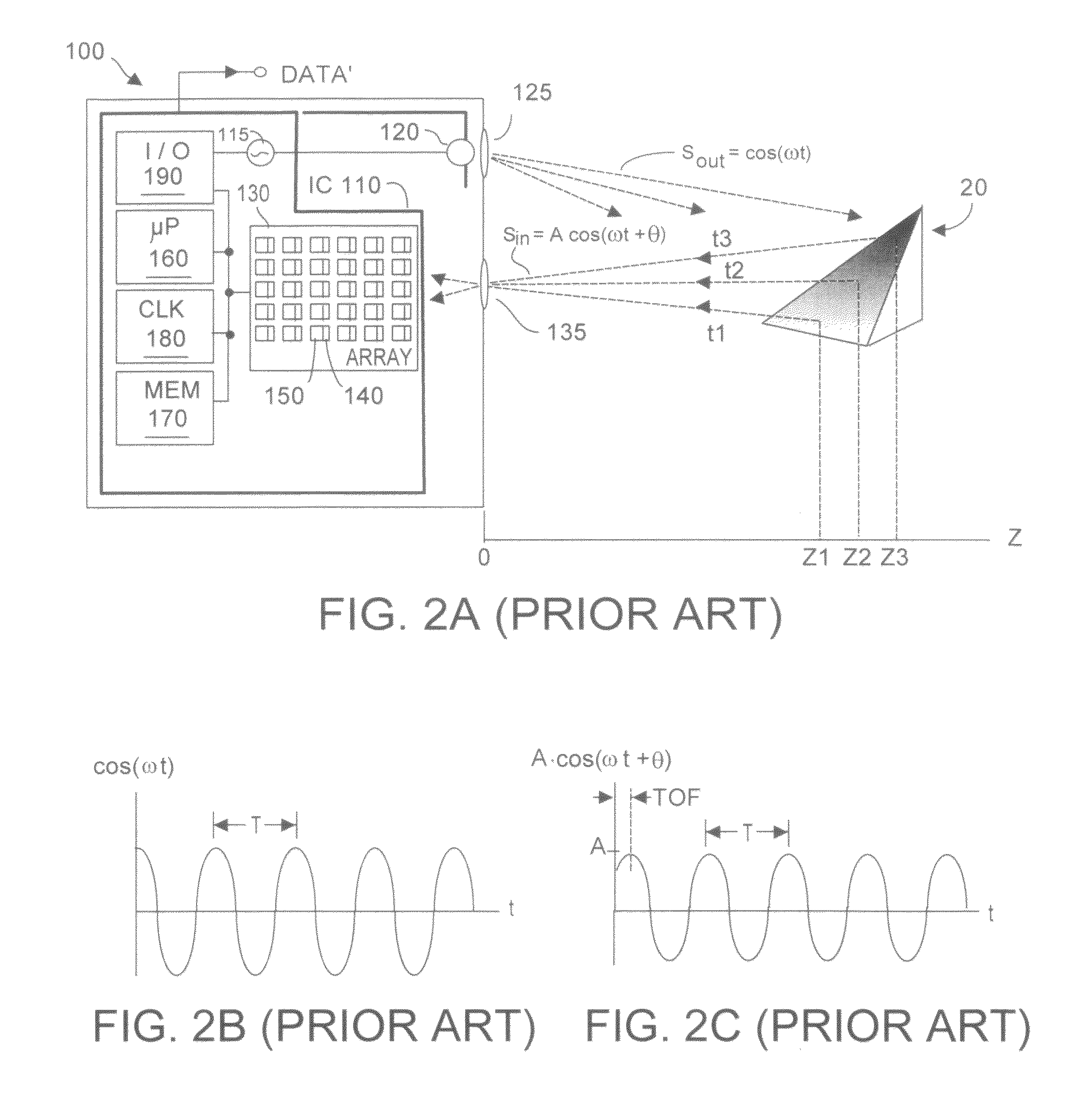

Video manipulation of red, green, blue, distance (RGB-Z) data including segmentation, up-sampling, and background substitution techniques

ActiveUS20110285910A1Improve resolutionEasy to processTelevision system detailsOptical rangefindersImage resolutionSignal characteristic

RGB-Z imaging systems acquire RGB data typically with a high X-Y resolution RGB pixel array, and acquire Z-depth data with an array of physically larger Z pixels having additive signal properties. In each acquired frame, RGB pixels are mapped to a corresponding Z pixel. Z image resolution is enhanced by identifying Z discontinuities and identifying corresponding RGB pixels where the Z discontinuities occur. Thus segmented data enables RGB background substitution, which preferably blends foreground pixel color and substitute background color. The segmented data also enables up-sampling in which a higher XY resolution Z image with accurate Z values is obtained. Up-sampling uses an equation set enabling assignment of accurate Z values to RGB pixels. Fixed acquisition frame rates are enabled by carefully culling bad Z data. Segmenting and up-sampling enhanced video effects and enable low cost, low Z resolution arrays to function comparably to higher quality, higher resolution Z arrays.

Owner:MICROSOFT TECH LICENSING LLC

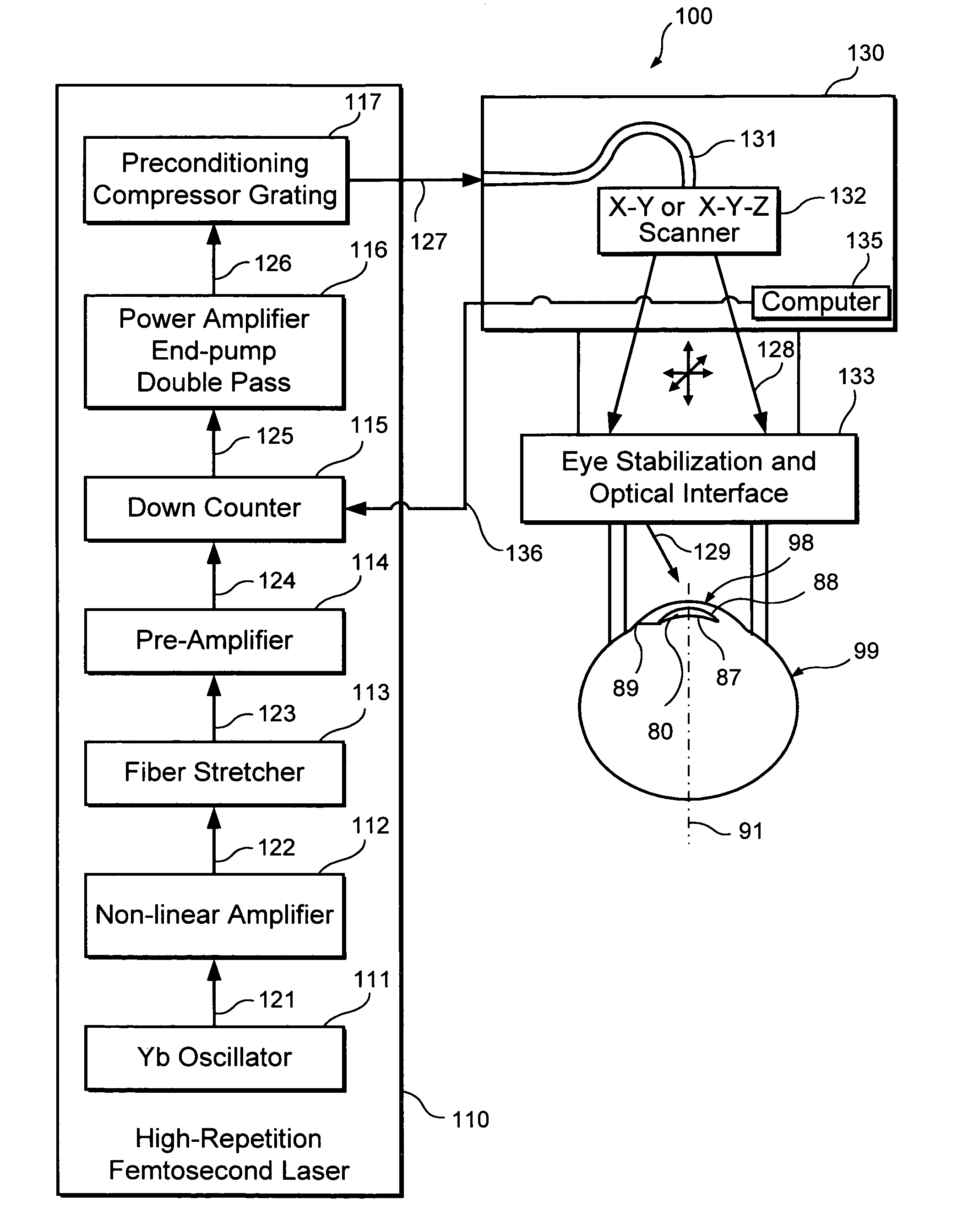

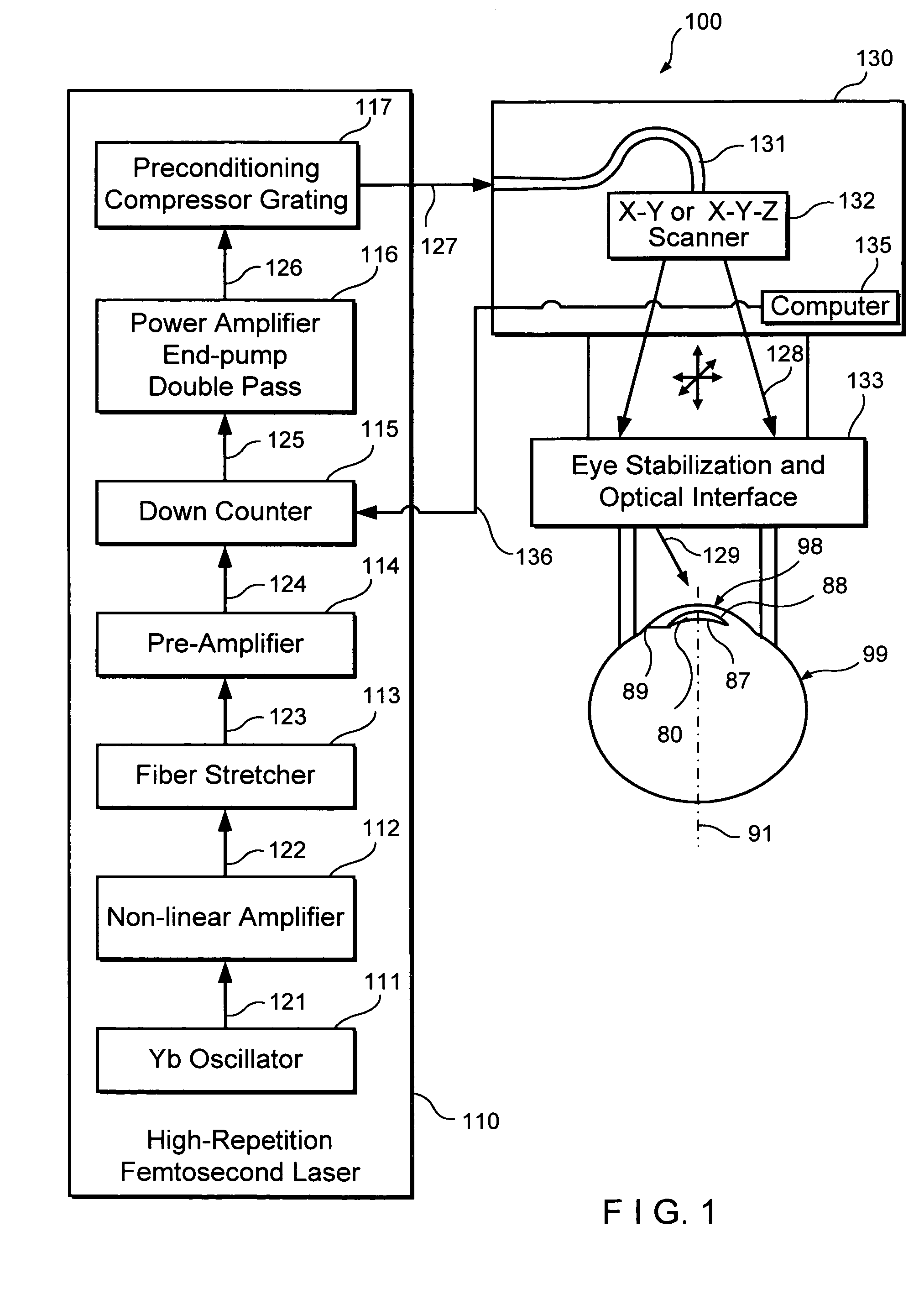

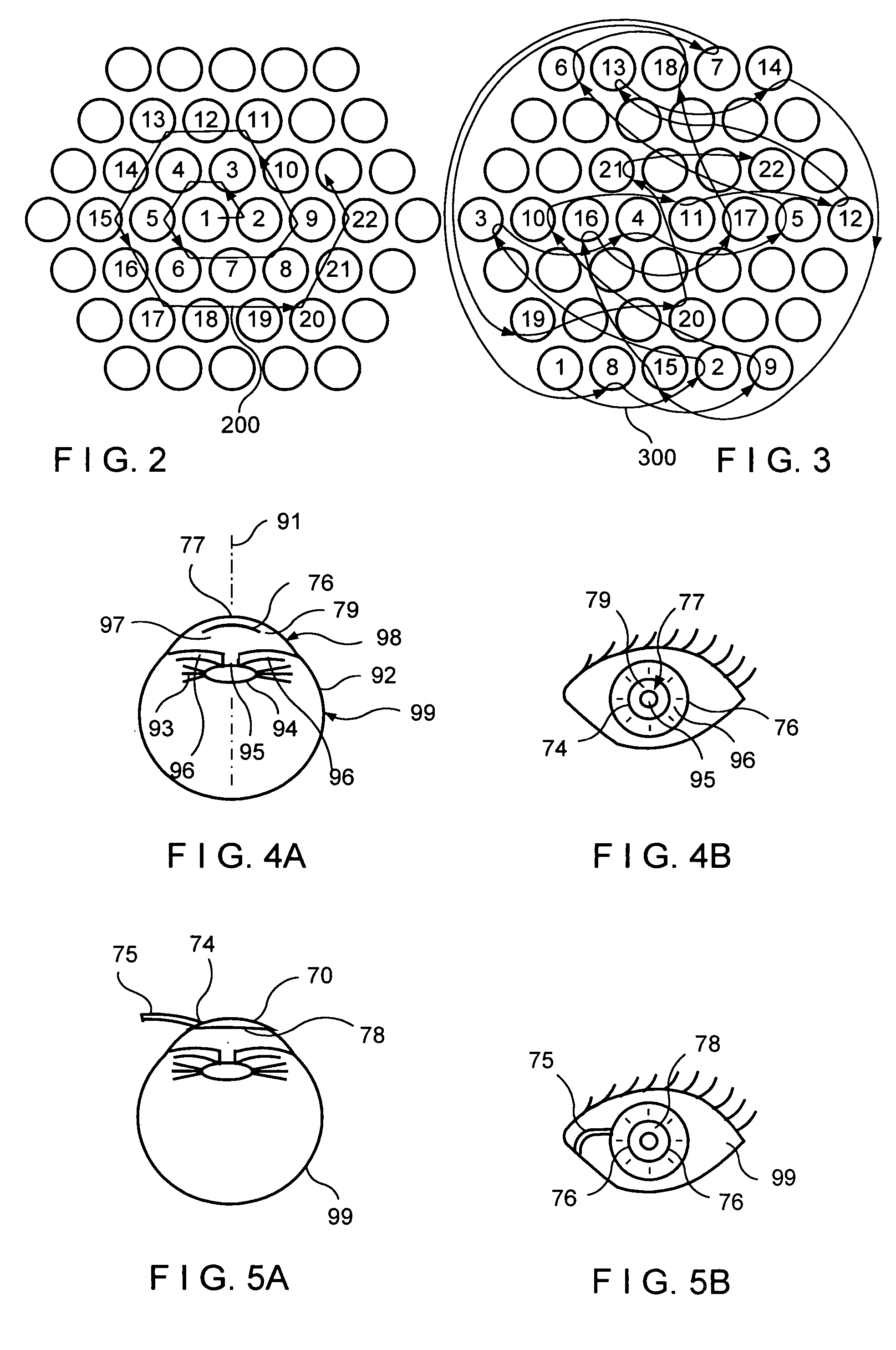

Apparatus and method for opthalmologic surgical procedures using a femtosecond fiber laser

ActiveUS7131968B2Reduce chanceFiner granularity in cutLaser surgeryLaser detailsPre treatmentCornea surface

Apparatus and method to generate a stream of pulses having a pulse repetition rate of at least about 50000 pulses per second and a per-pulse length of less than one picosecond, and to scan and focus the stream to an output light pattern suitable to sculpt tissue for a surgical procedure (e.g., ophthalmologic) using at least a high number of pulses to complete the operation in a matter of a few second, e.g., 100000 pulses in less than ten seconds. A laser having a optical fiber gain medium generates a stream of femtosecond pulses. Some embodiments create a preconditioning negative dispersion that compensates for positive dispersion in the scanning system. In some embodiments, a lenticule is cut using the laser and scanning system and is mechanically removed through a side slit formed through the cornea surface.

Owner:CARL ZEISS MEDITEC AG +1

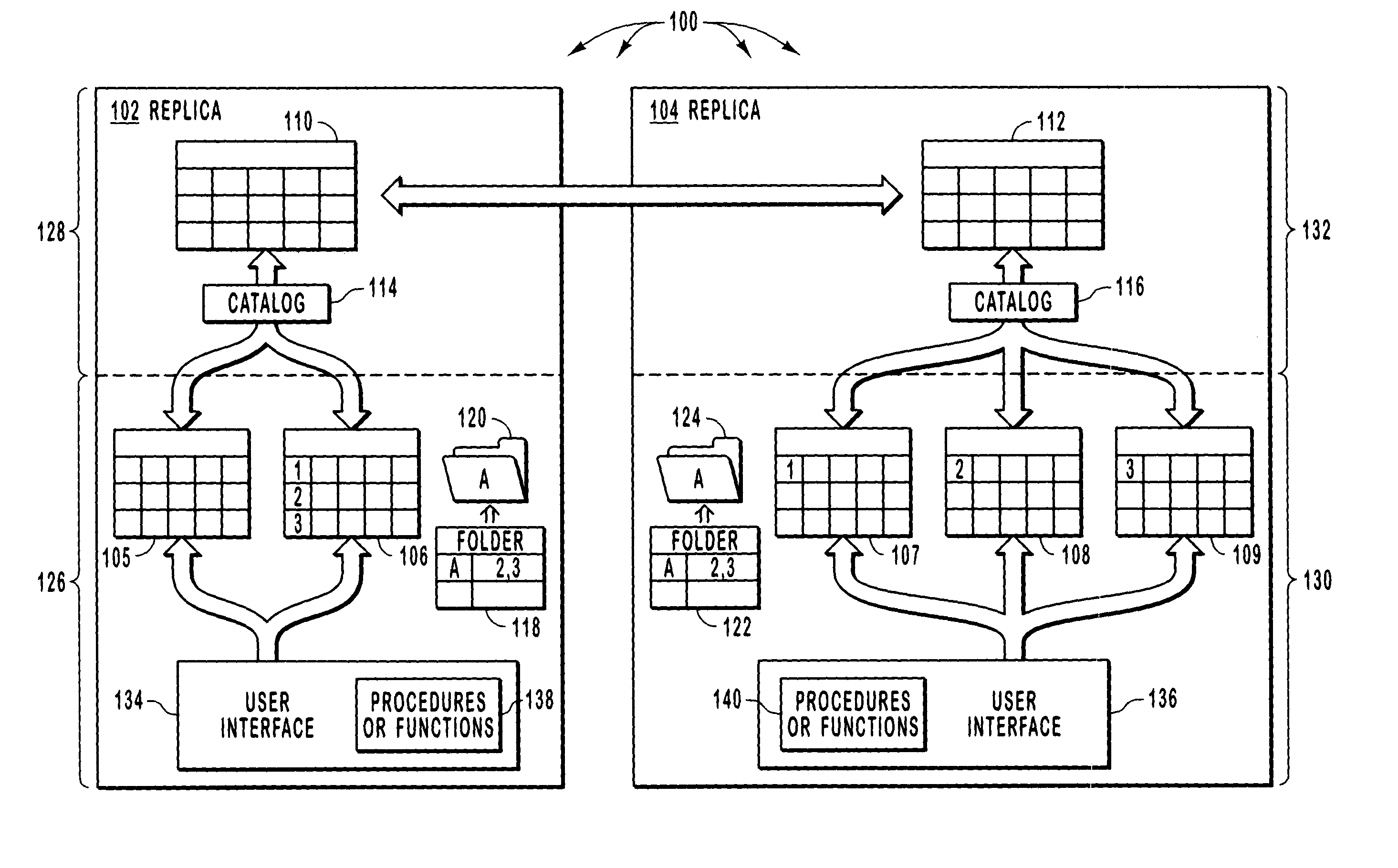

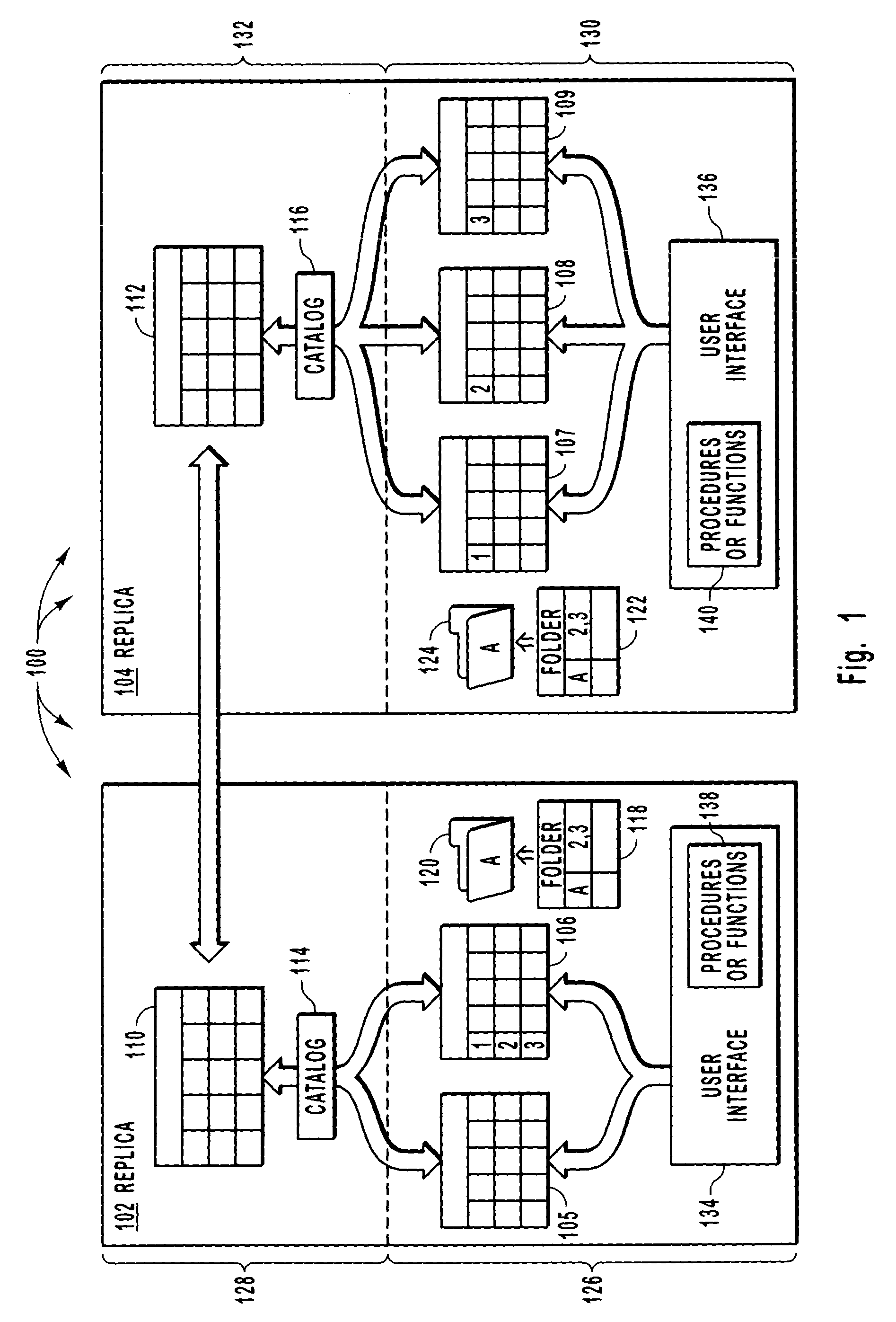

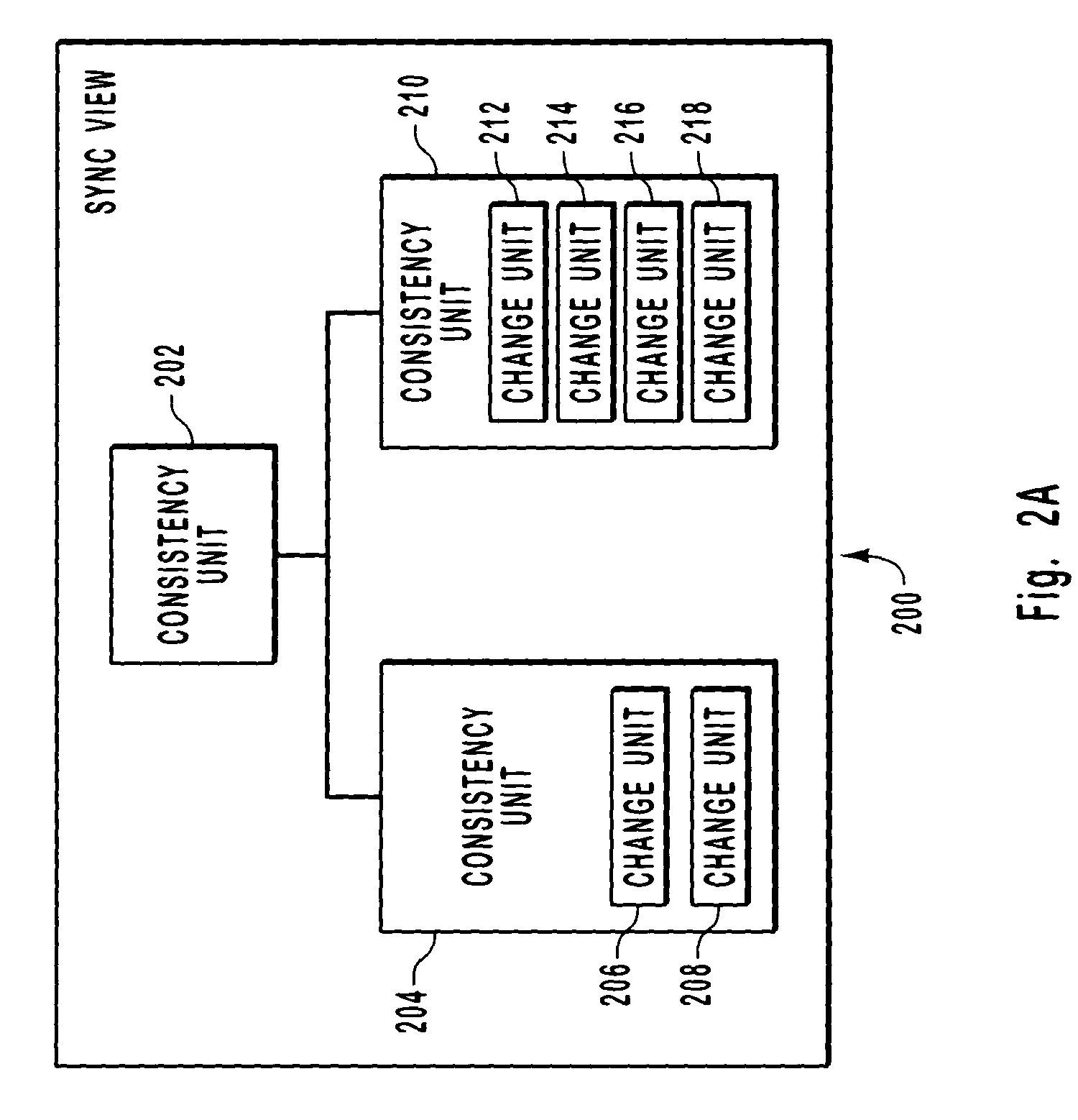

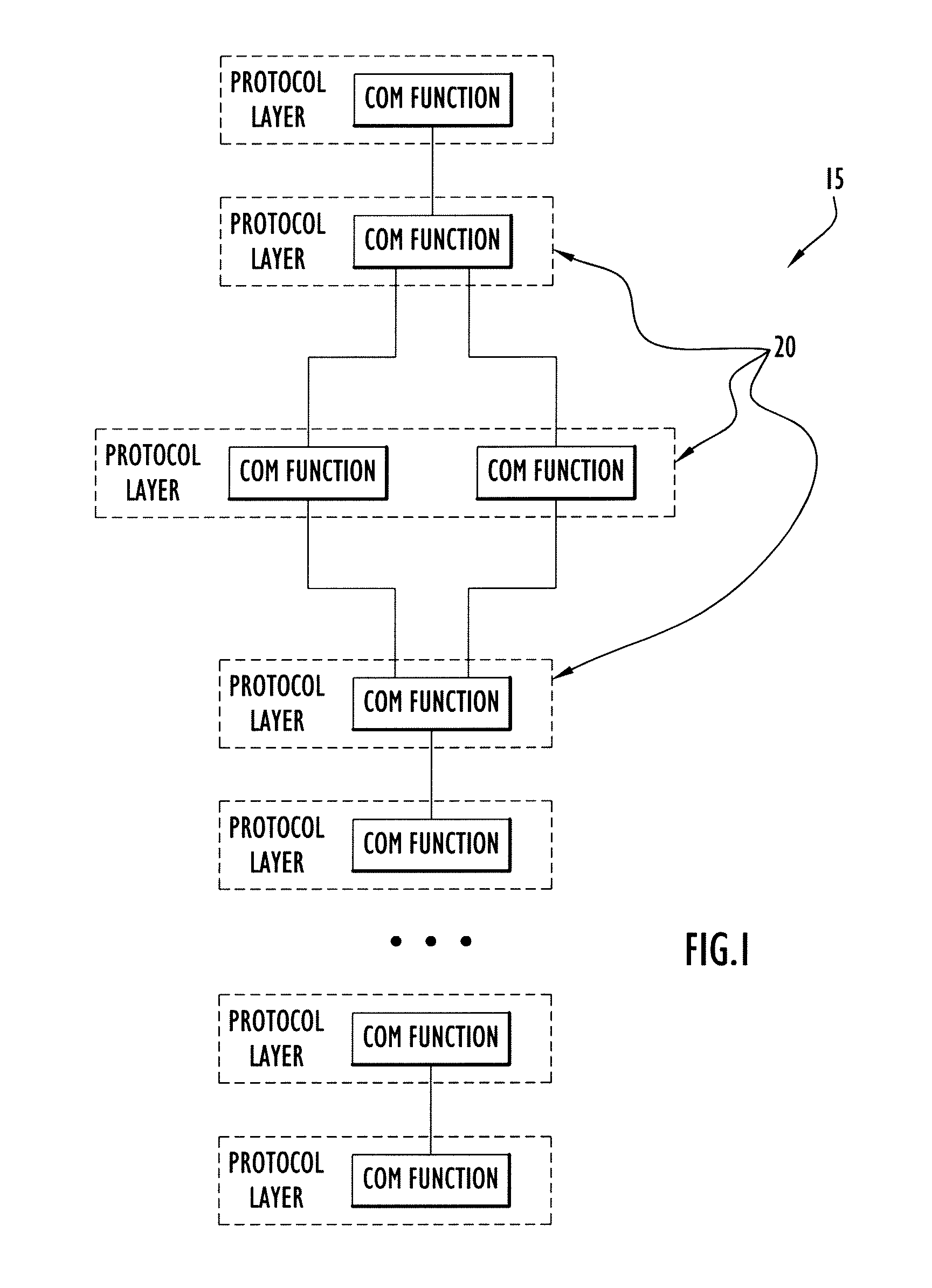

Synchronizing logical views independent of physical storage representations

ActiveUS7216133B2Easy to compileLess on networkDigital data processing detailsDatabase distribution/replicationLogical viewDistributed computing

Systems, methods, and computer program products for synchronizing items at replicas within a topology is disclosed. Items are stored in physical tables at the replicas. The physical table layouts at each replica can differ but are mapped to a common logical view. When a replica receives an indication that synchronization should be performed, the replica determines if changes have been made at the replica that should be mapped to the logical views. Replicas can facilitate this by comparing local change enumerations for changes made in physical tables to synchronization local change enumerations for changes in the logical views. Any changes that need to be synchronized are sent through the logical views to other replicas in the topology.

Owner:SERVICENOW INC

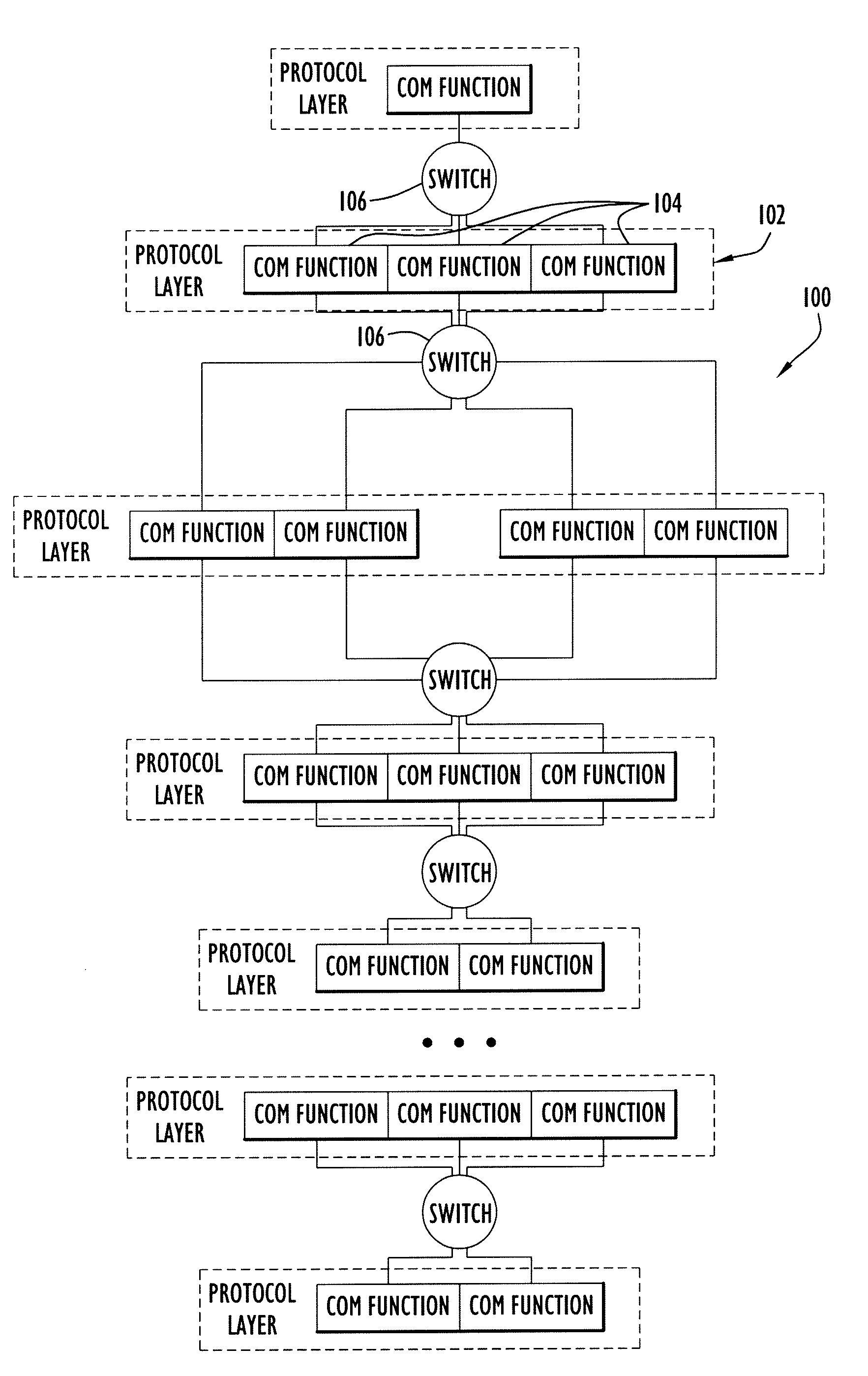

Network modeling system and method of simulating network operation with configurable node models

ActiveUS7765093B2Shorten speedFast executionAnalogue computers for electric apparatusDigital computer detailsGranularityModeling and simulation

Owner:HARRIS GLOBAL COMM INC

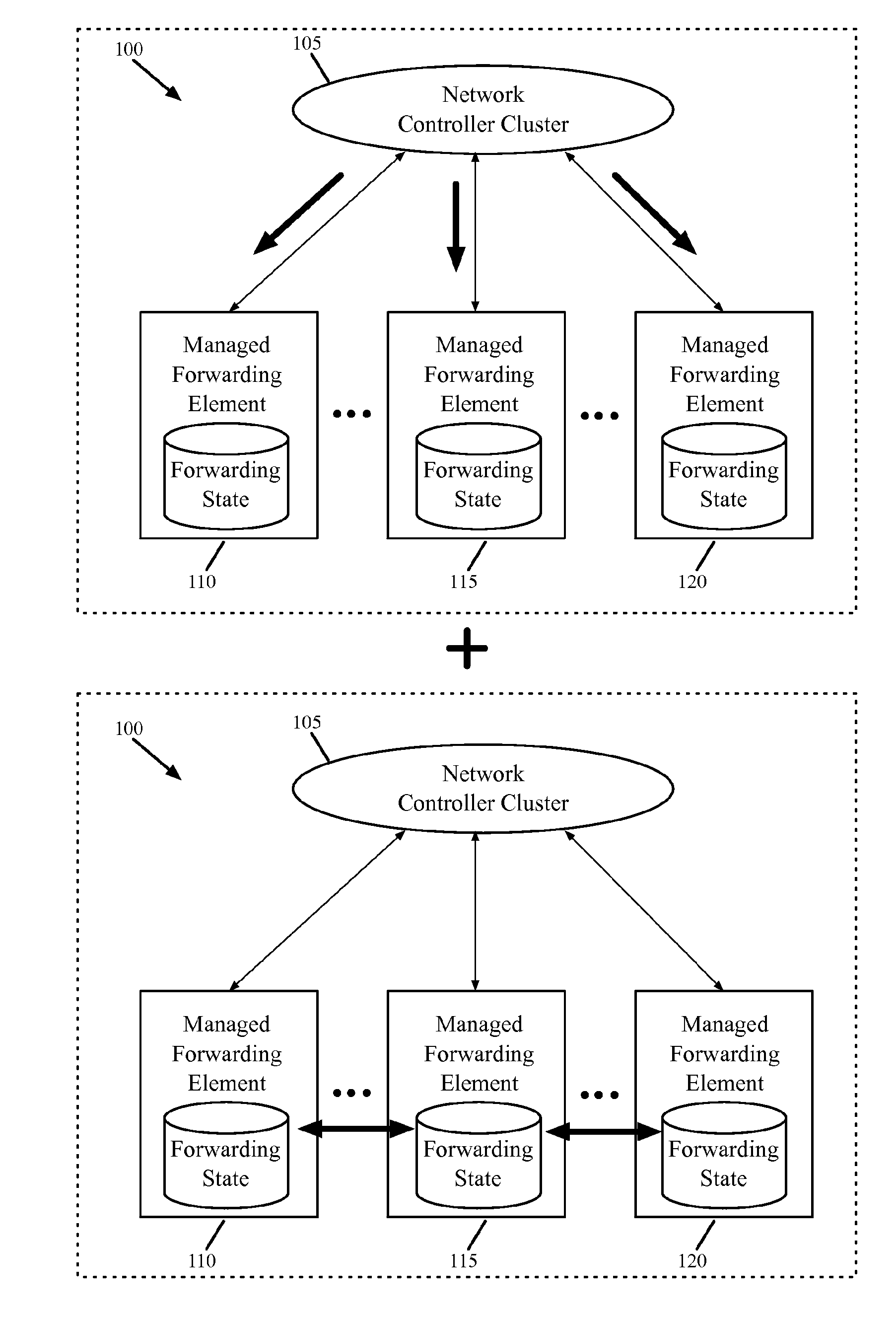

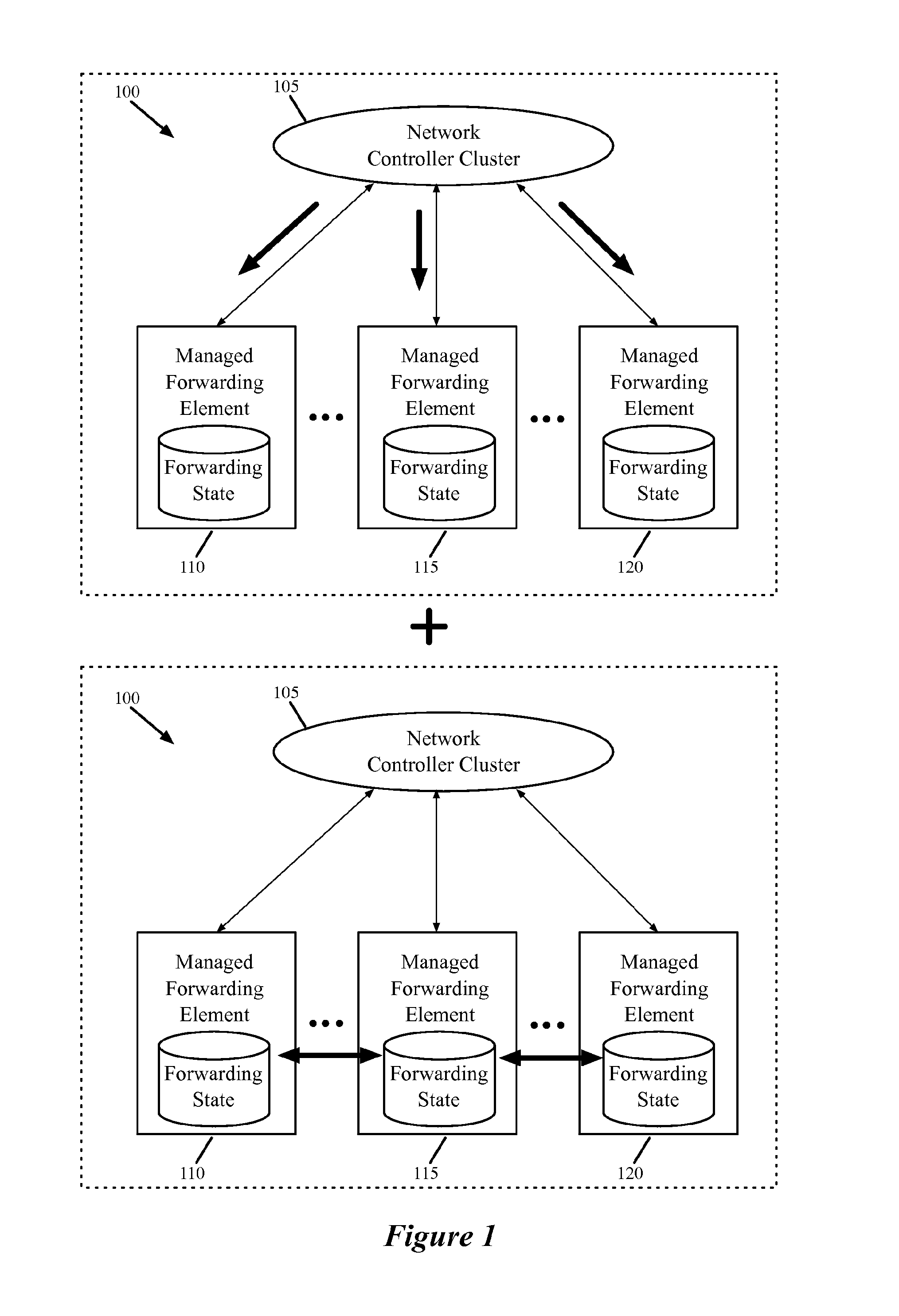

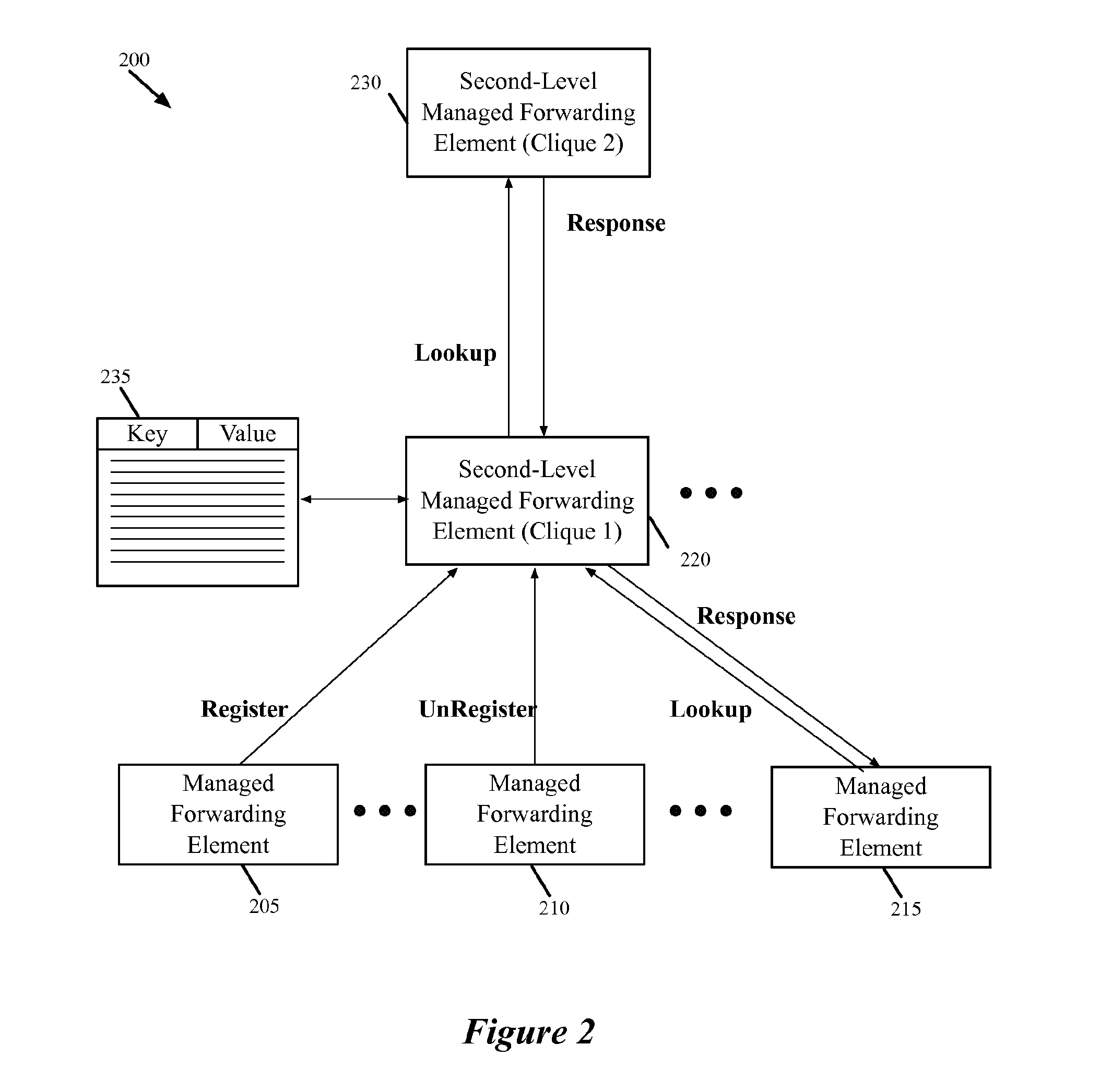

Exchange of network state information between forwarding elements

ActiveUS20140348161A1Distribute quicklyControl granularityData switching by path configurationProgram controlNetwork controlTrunking

Owner:NICIRA

Video manipulation of red, green, blue, distance (RGB-Z) data including segmentation, up-sampling, and background substitution techniques

ActiveUS8139142B2Easy to processRobust substitutionTelevision system detailsOptical rangefindersImage resolutionVideo processing

RGB-Z imaging systems acquire RGB data typically with a high X-Y resolution RGB pixel array, and acquire Z-depth data with an array of physically larger Z pixels having additive signal properties. In each acquired frame, RGB pixels are mapped to a corresponding Z pixel. Z image resolution is enhanced by identifying Z discontinuities and identifying corresponding RGB pixels where the Z discontinuities occur. Thus segmented data enables RGB background substitution, which preferably blends foreground pixel color and substitute background color. The segmented data also enables up-sampling in which a higher XY resolution Z image with accurate Z values is obtained. Up-sampling uses an equation set enabling assignment of accurate Z values to RGB pixels. Fixed acquisition frame rates are enabled by carefully culling bad Z data. Segmenting and up-sampling enhanced video effects and enable low cost, low Z resolution arrays to function comparably to higher quality, higher resolution Z arrays.

Owner:MICROSOFT TECH LICENSING LLC

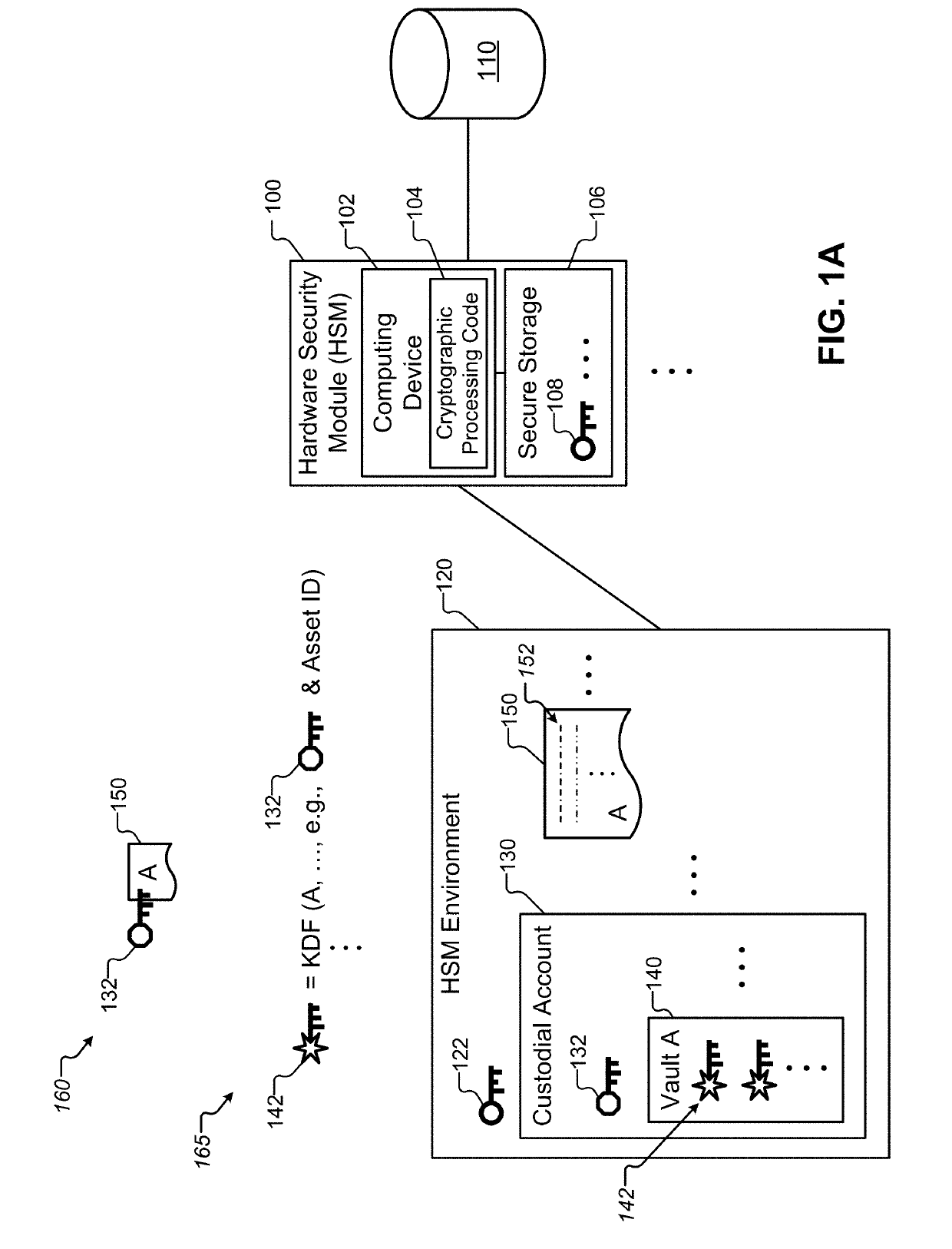

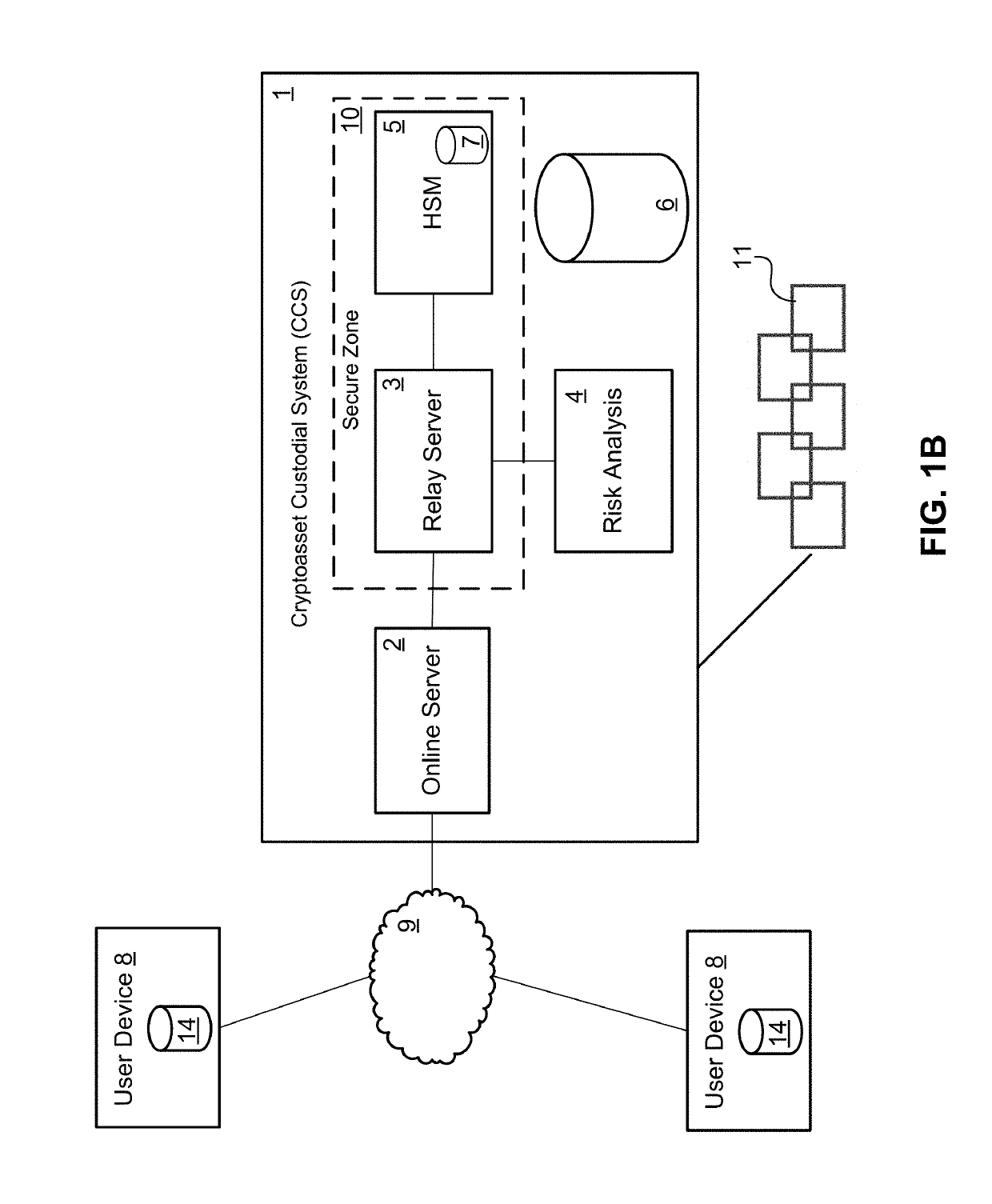

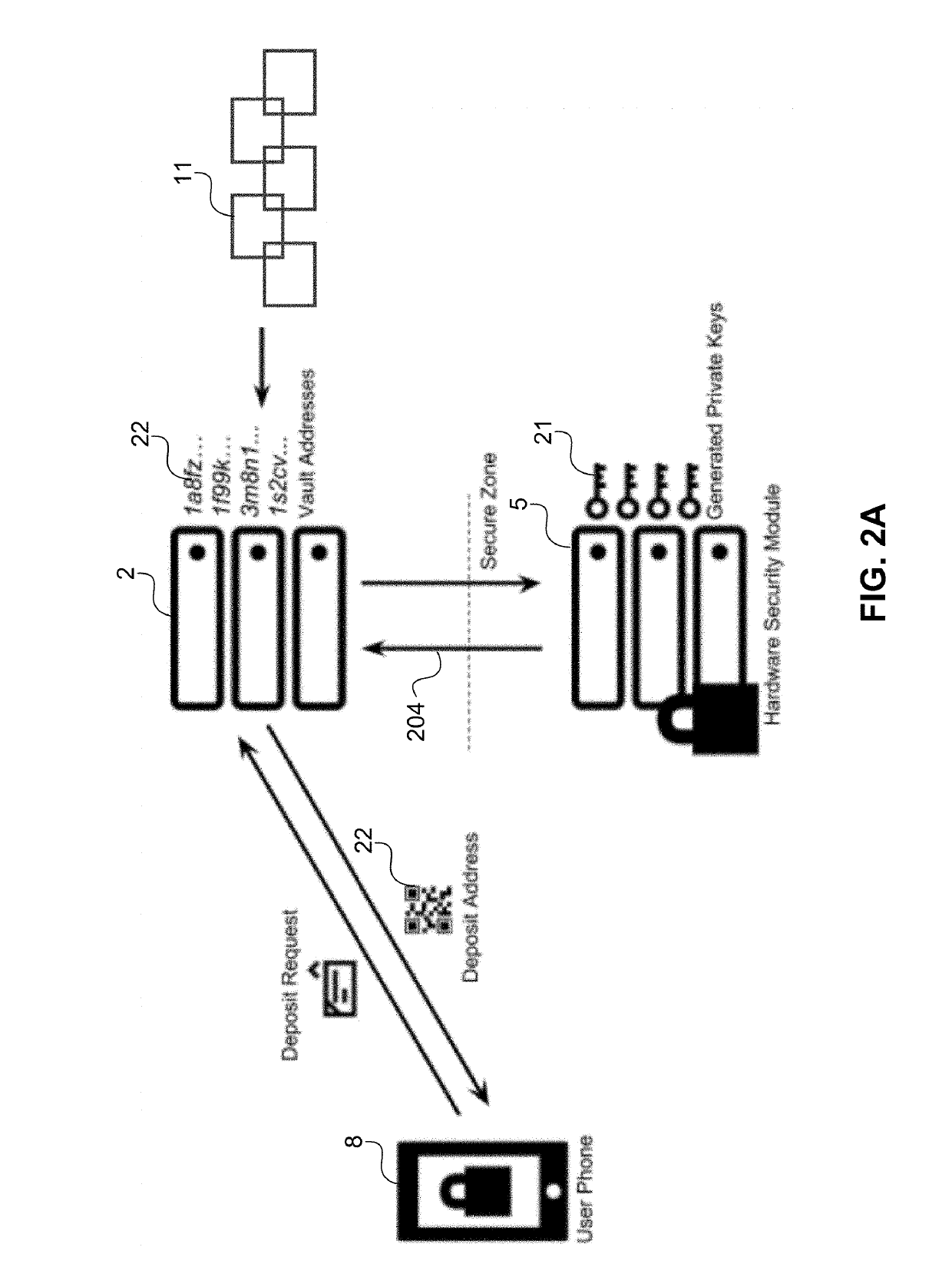

Cryptoasset custodial system with different rules governing access to logically separated cryptoassets

PendingUS20190268165A1Reduce harmImprove securityKey distribution for secure communicationEncryption apparatus with shift registers/memoriesBlockchainComputer program

Methods, systems, and apparatus, including medium-encoded computer program products, for secure storage and retrieval of information, such as private keys, useable to control access to a blockchain, include, in at least one aspect, a method including: receiving a request to take an action with respect to a vault of multiple different vaults in a cryptoasset custodial system; authenticating, by an HSM, the policy map for the vault based on a cryptographic key controlled by the HSM; checking, by the HSM, the action against the policy map for the vault when the policy map for the vault is authenticated based on the cryptographic key controlled by the HSM; and effecting, by the HSM, the action when the action is confirmed to be in accordance with the policy map for the vault.

Owner:ANCHOR LABS INC

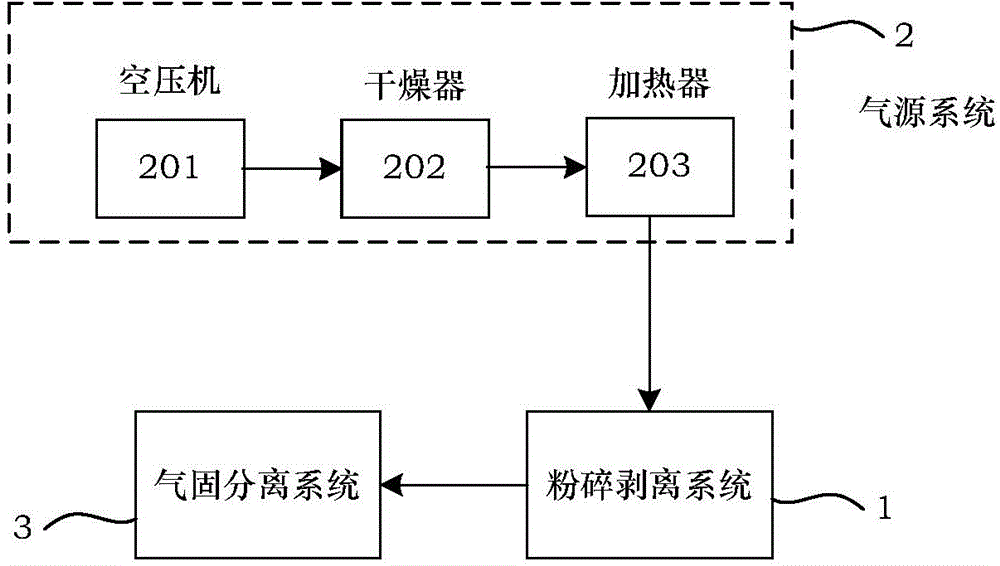

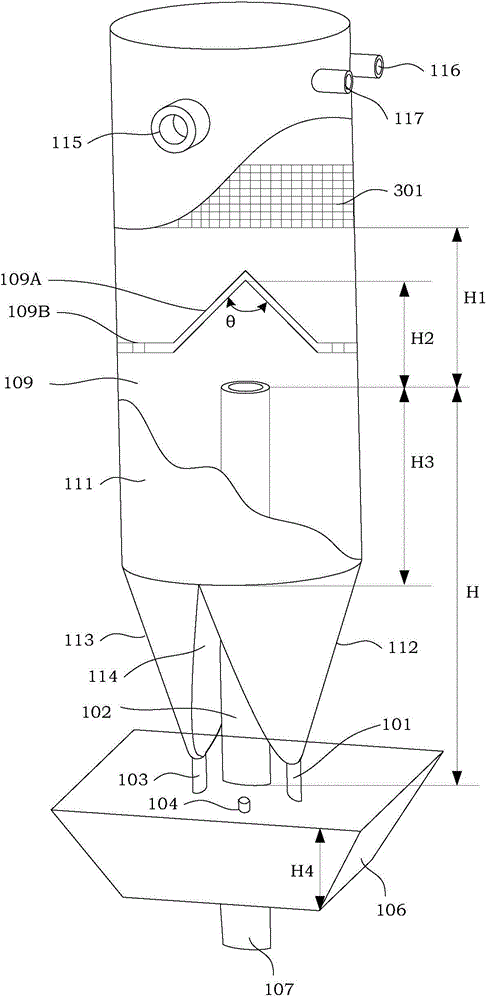

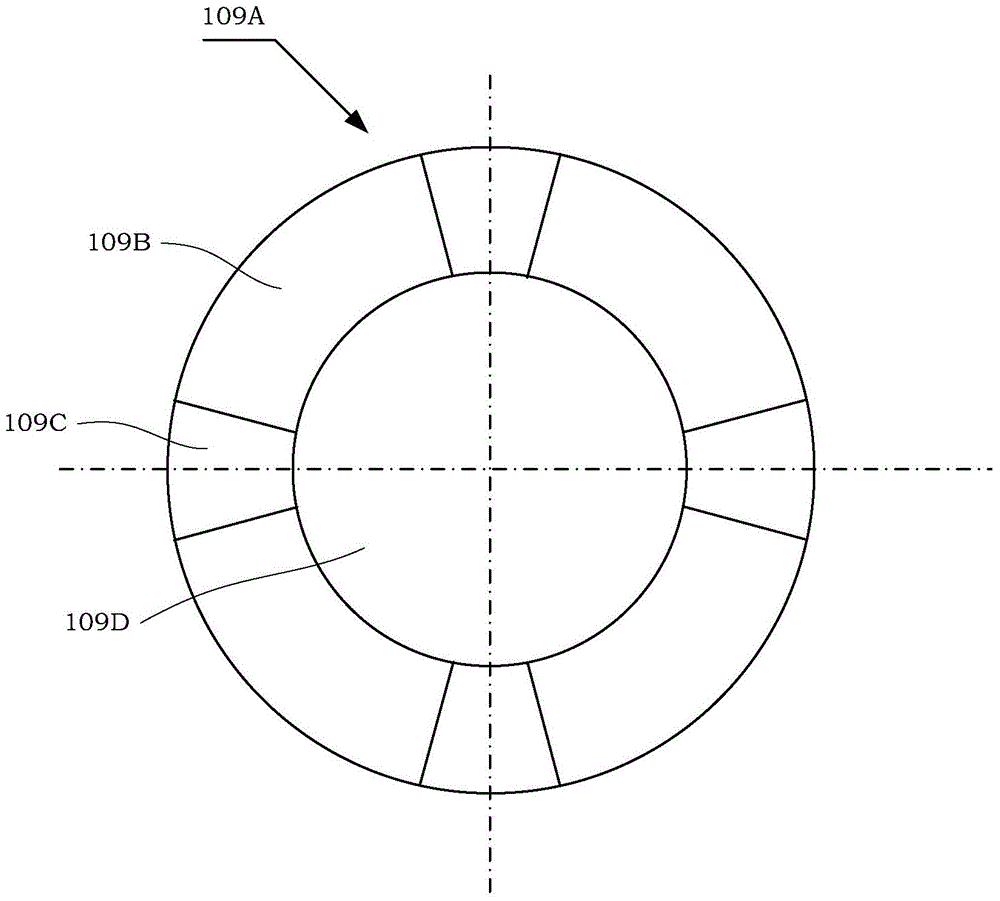

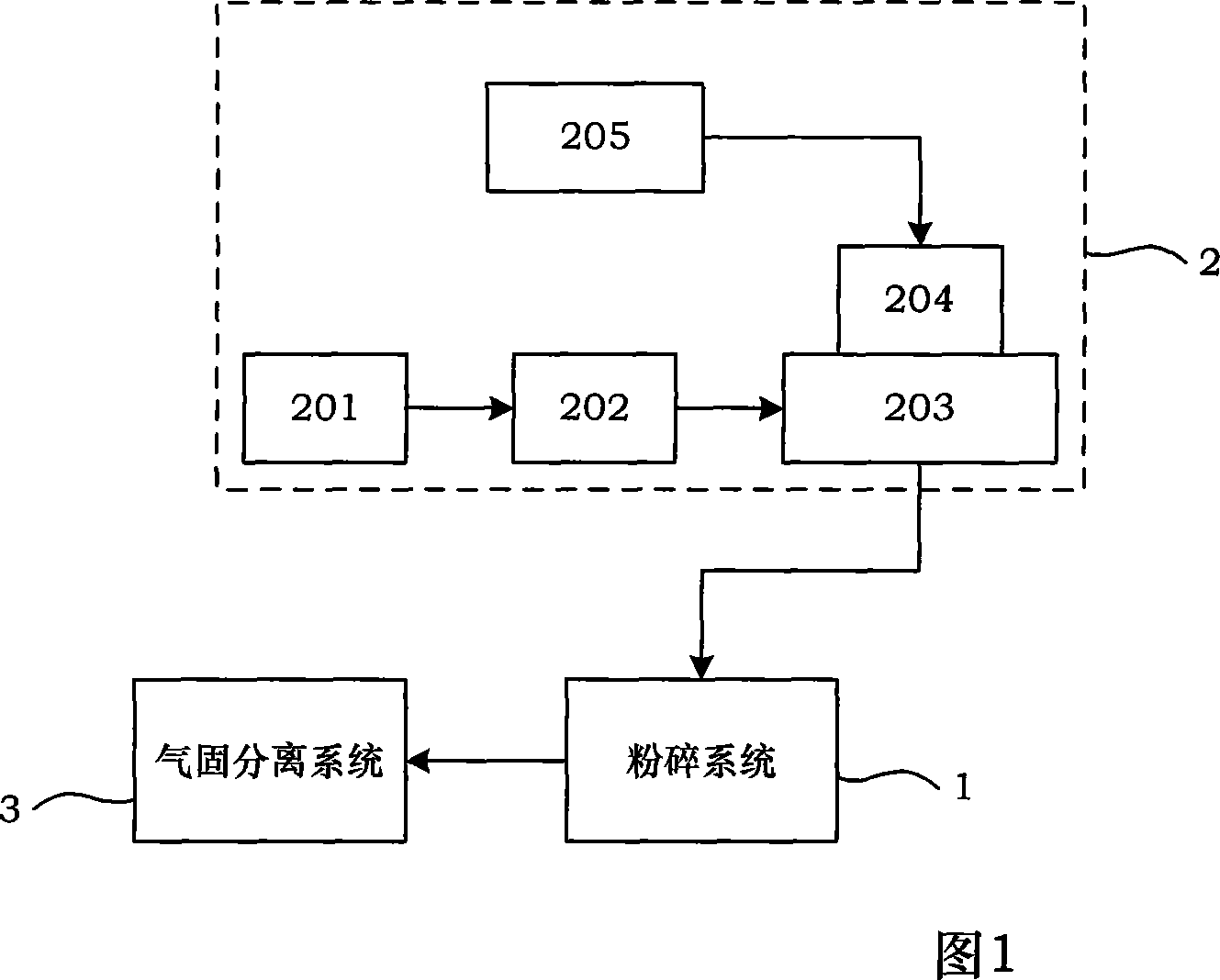

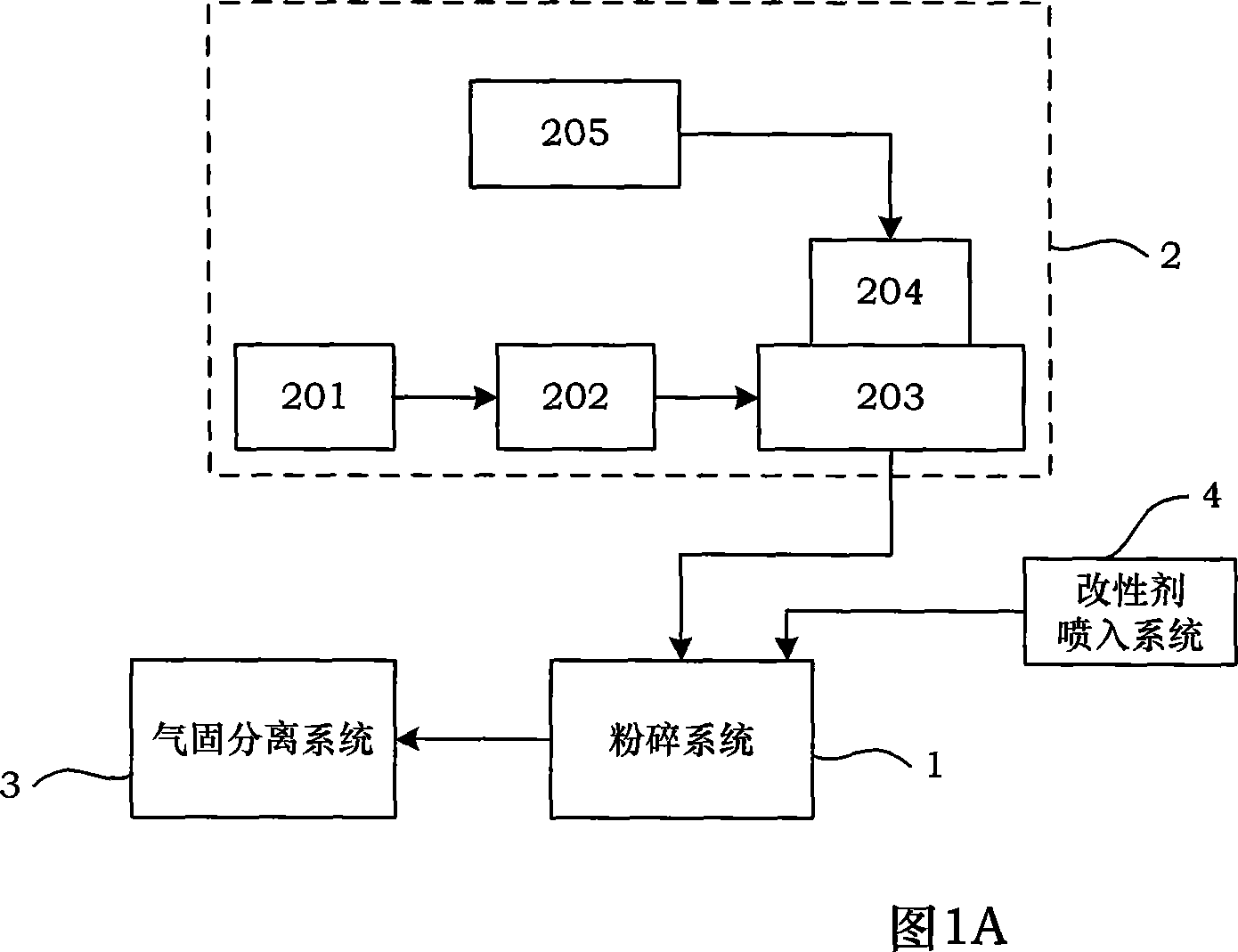

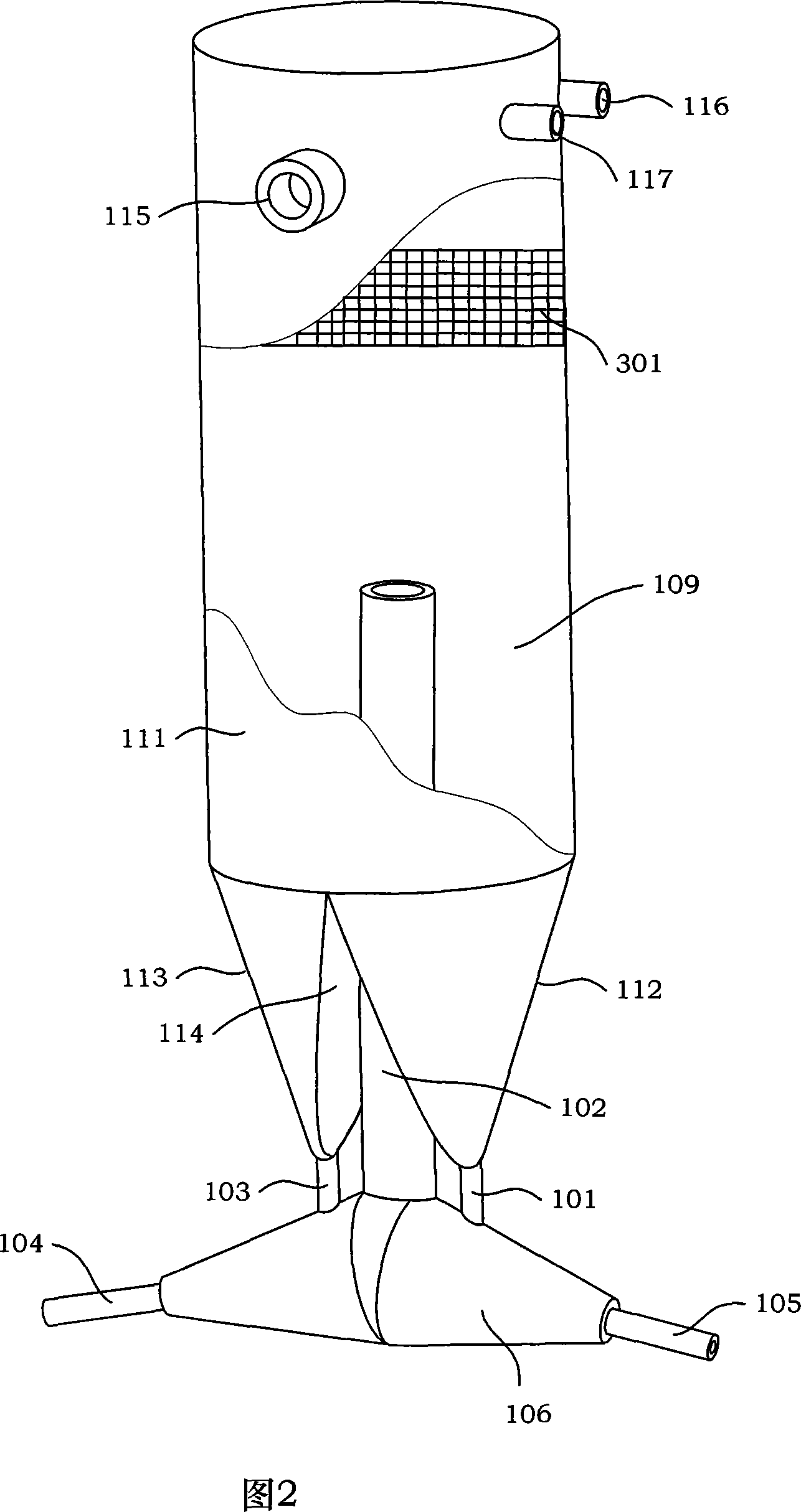

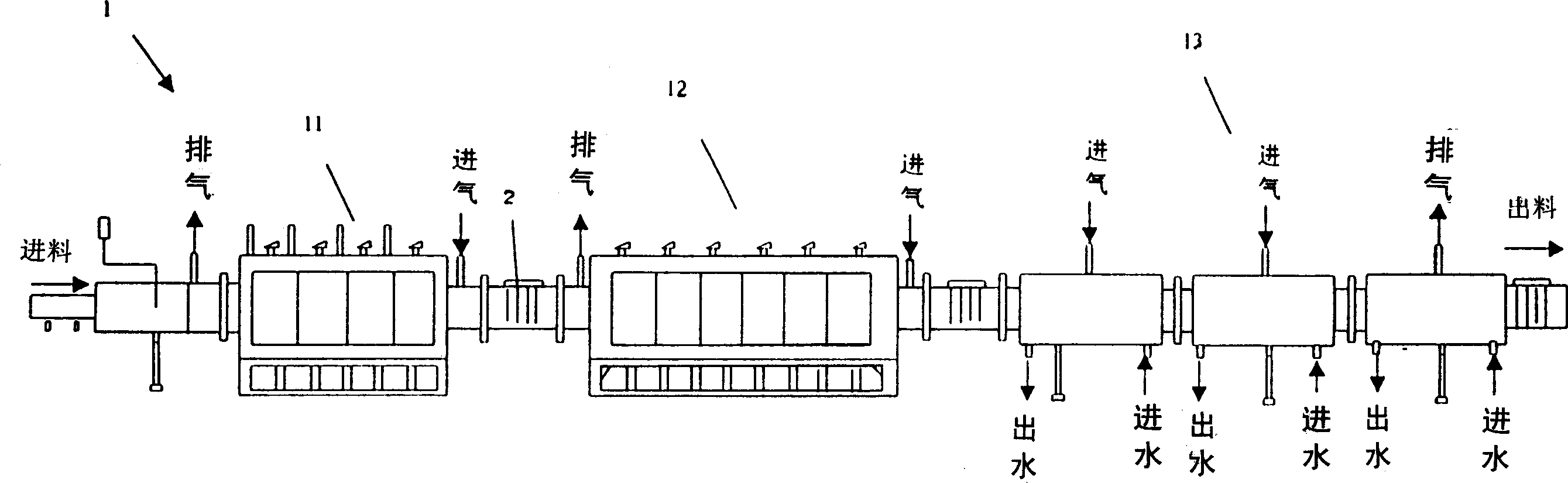

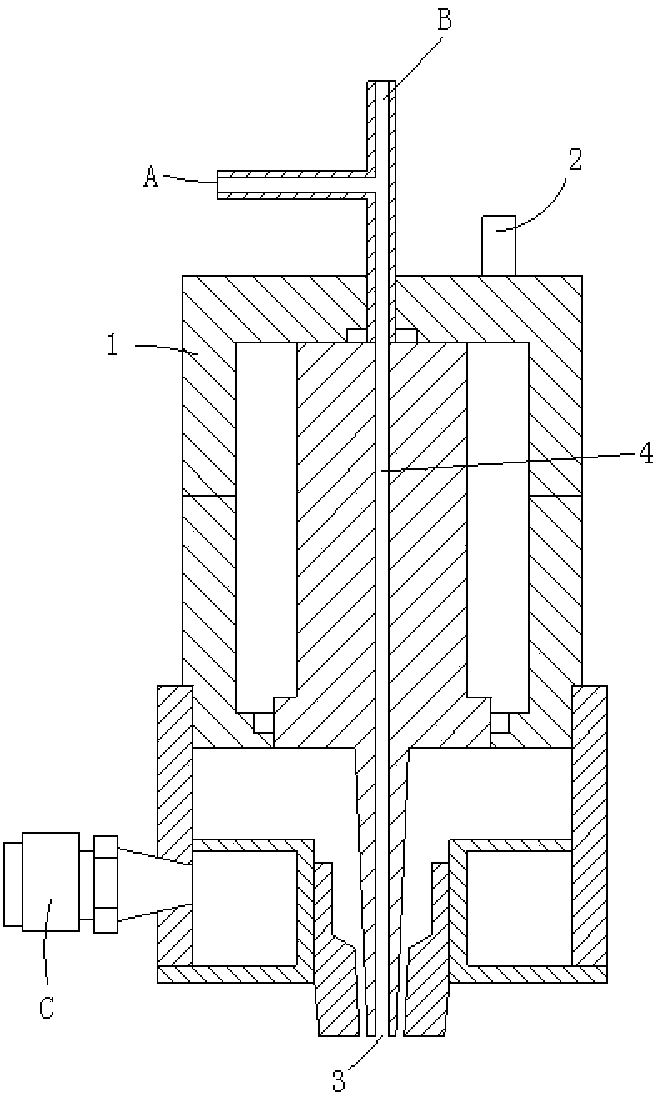

Process and device for preparing graphene precursor two-dimension nanoscale graphite powder by adopting airflow crushing and peeling method

The invention discloses a method and a device for preparing graphene precursor two-dimension nanoscale graphite powder by adopting an airflow crushing and peeling method. The device comprises an air source system, a crushing and peeling system and a gas-solid separation system; in the crushing and peeling system, an A return pipe, a B return pipe and a riser pipe form a material circulation loop of an airflow crushing and peeling process; an A gas guide pipe, a B gas guide pipe and a C gas guide pipe form an airflow crushing passage of the airflow crushing and peeling process. The graphene precursor two-dimension nanoscale graphite powder is prepared by adopting three supersonic speed jet flows to carry graphite particles together; through collision and friction of strip jet flows, high-purity crushing and peeling of the graphite particles are realized; through circulated and continuous crushing and peeling of the graphite particles, the two-dimension nanoscale graphite powder is obtained. The process is adopted for crushing and peeling the graphite powder, the crushing and peeling of the graphite powder are realized by utilizing mutual collision and friction among the graphite powder, friction of other media does not exist, and thus the two-dimension nanoscale graphite powder with high purity can be obtained.

Owner:BEIHANG UNIV

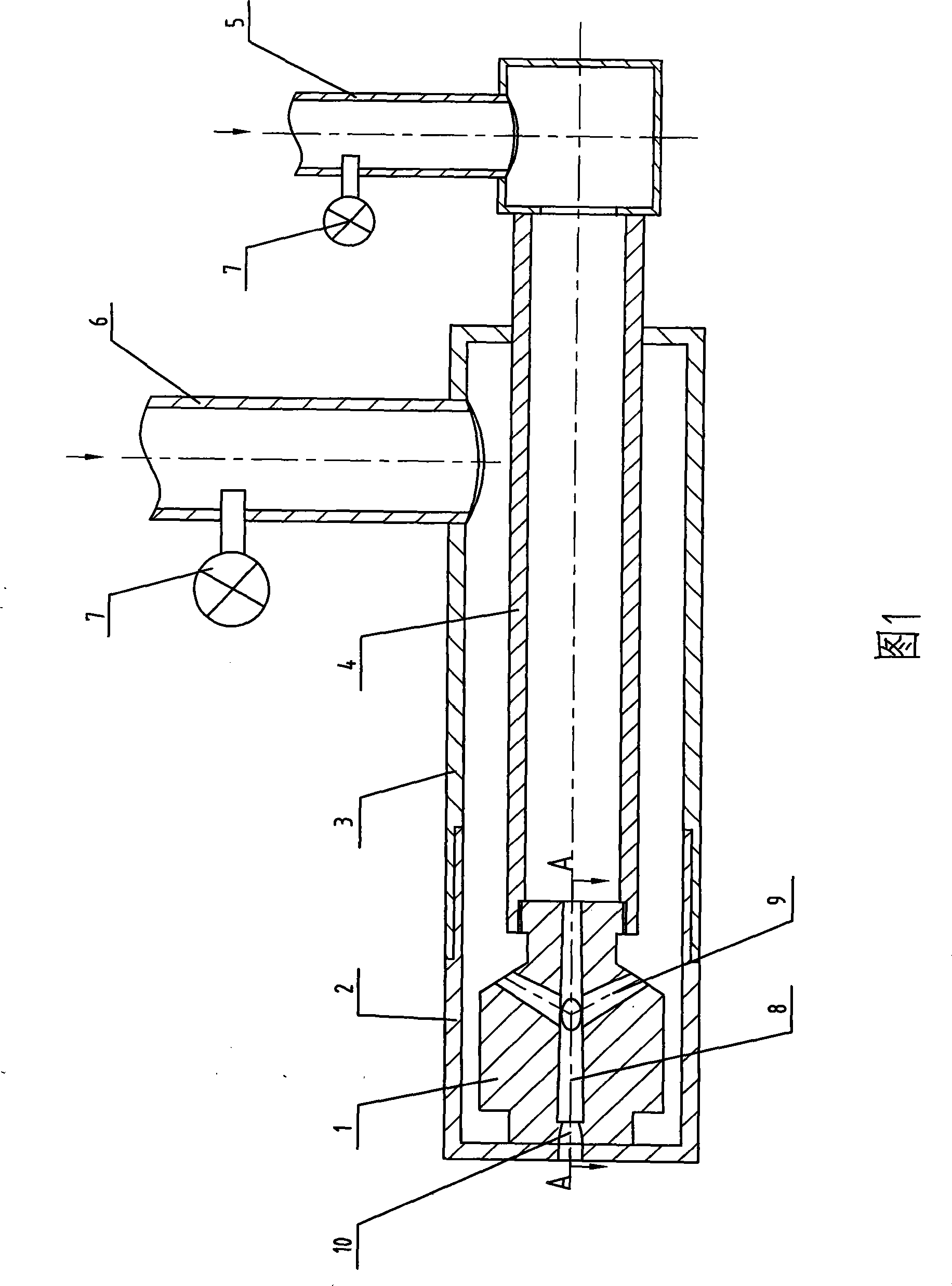

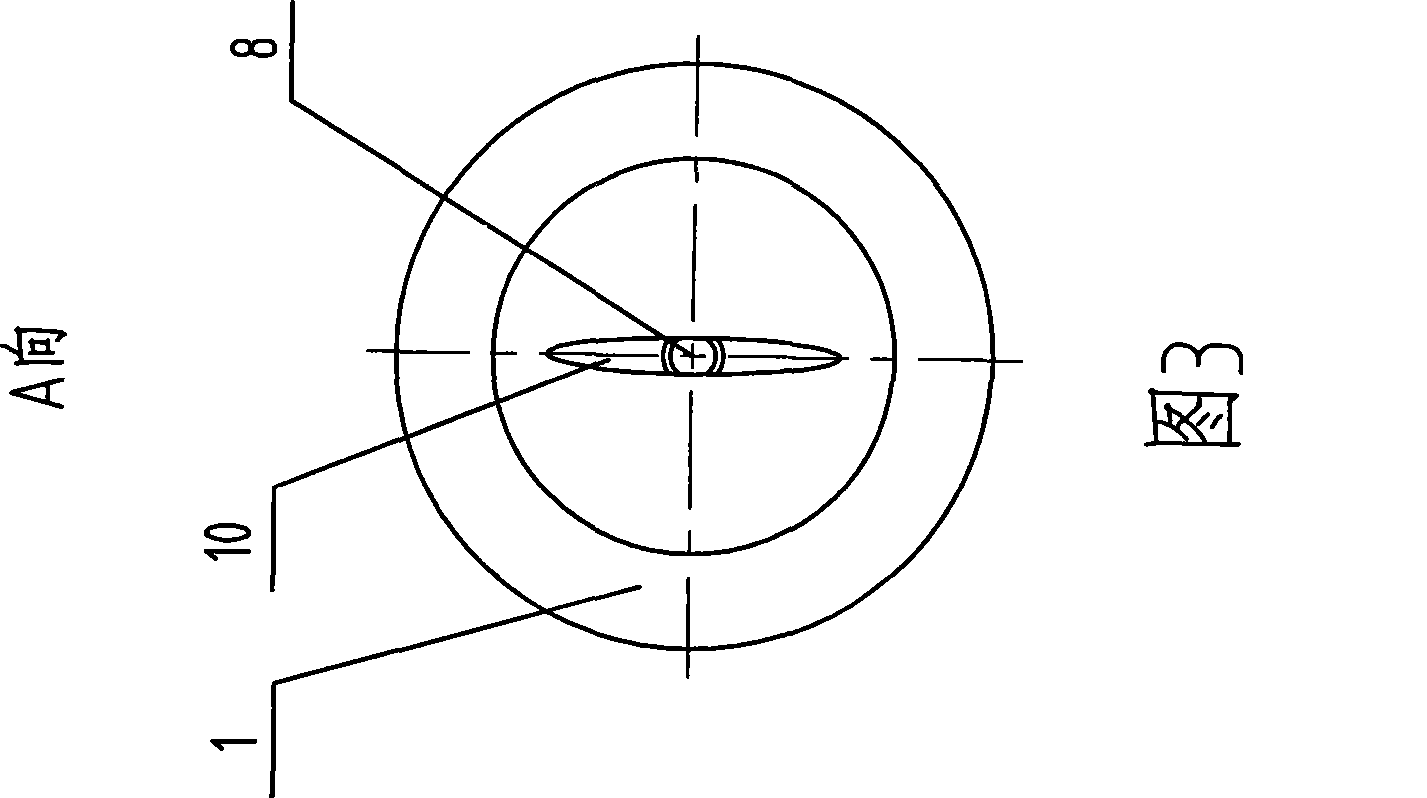

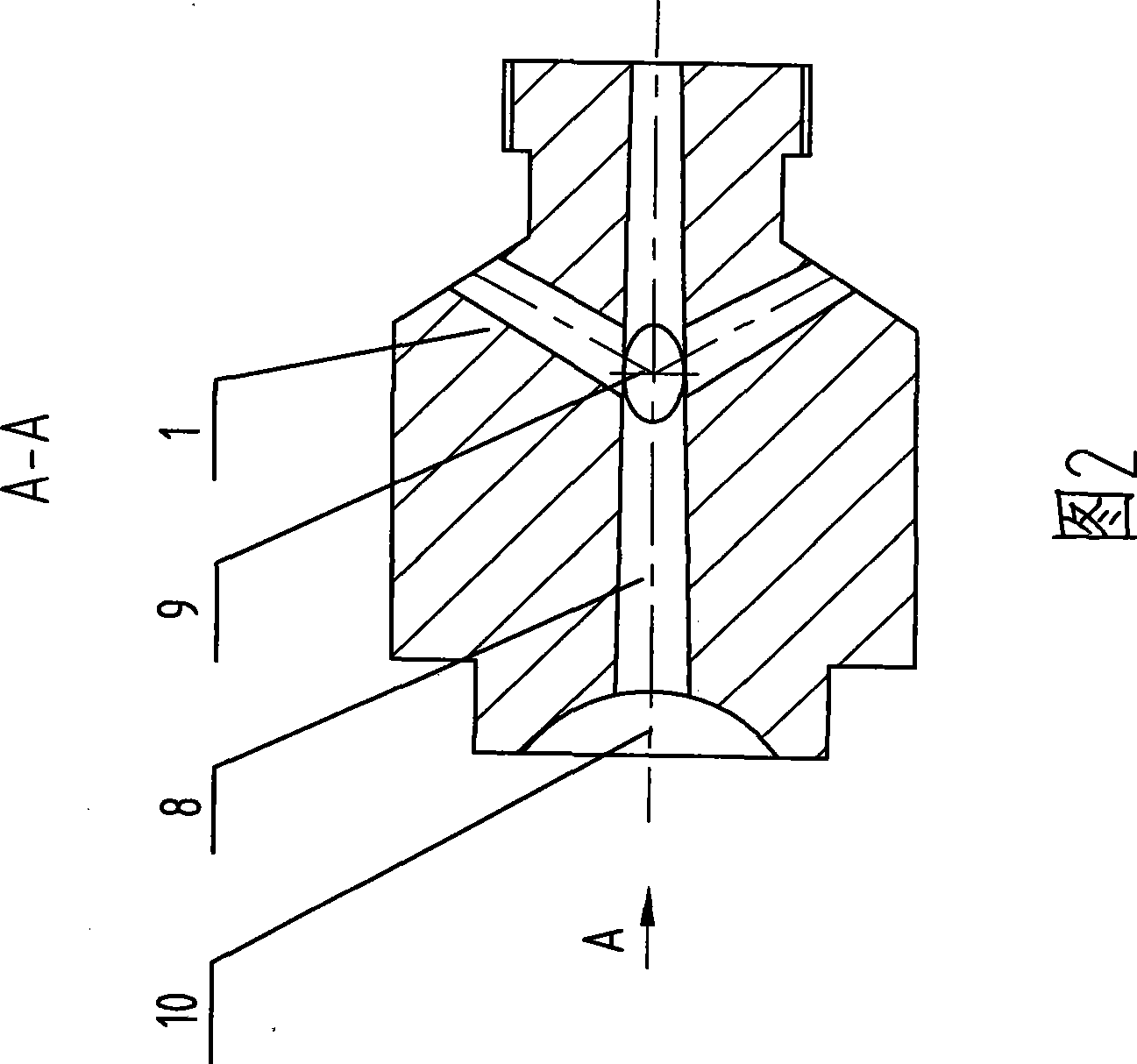

Technique and equipment for preparing Nano granules in high purity by using method of comminution by gas stream

InactiveCN101049580AEasy accessGood for collision smashingDispersed particle filtrationGrain treatmentsNanoparticleEngineering

An apparatus for preparing high-purity nanoparticles by airflow pulverizing method is composed of an air source system, a pulverizing system consisting of left and right reflux pipes and flow-up pipe to form a circulating loop of material, and air-solid separating system. Its process features that the raw material is carried by two supersonic jets for mutual and cyclic collision to obtain nanoparticles.

Owner:BEIHANG UNIV

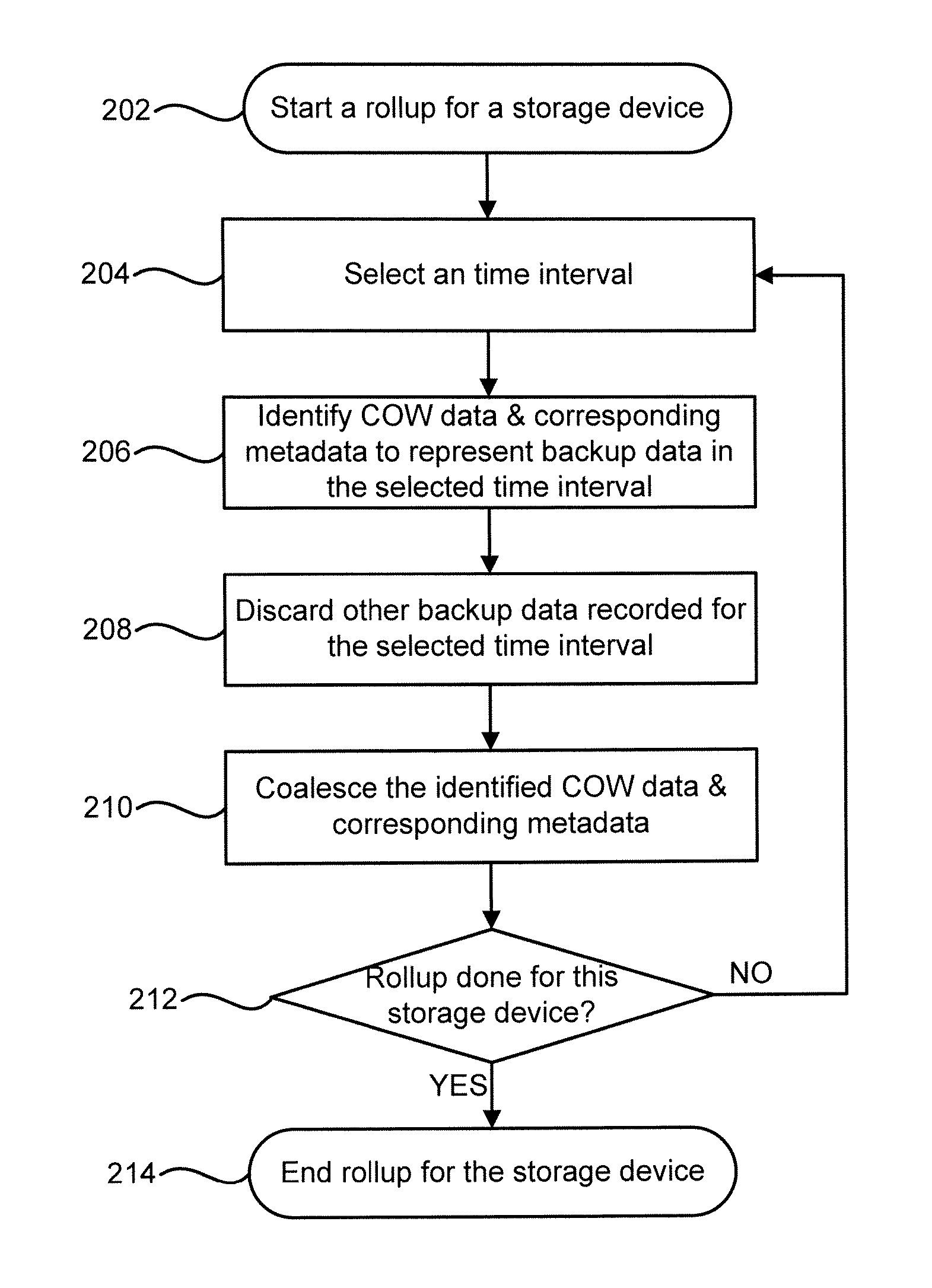

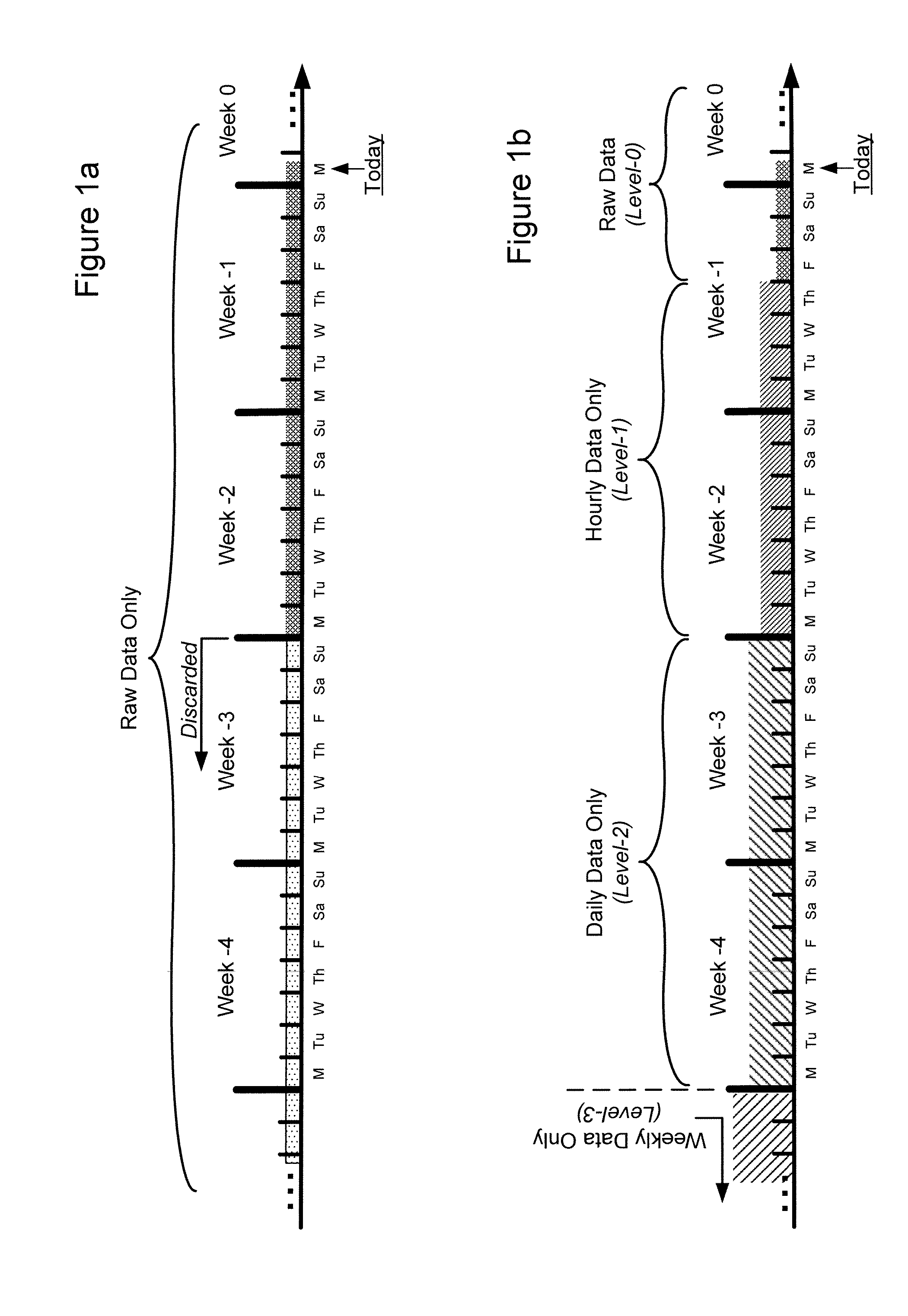

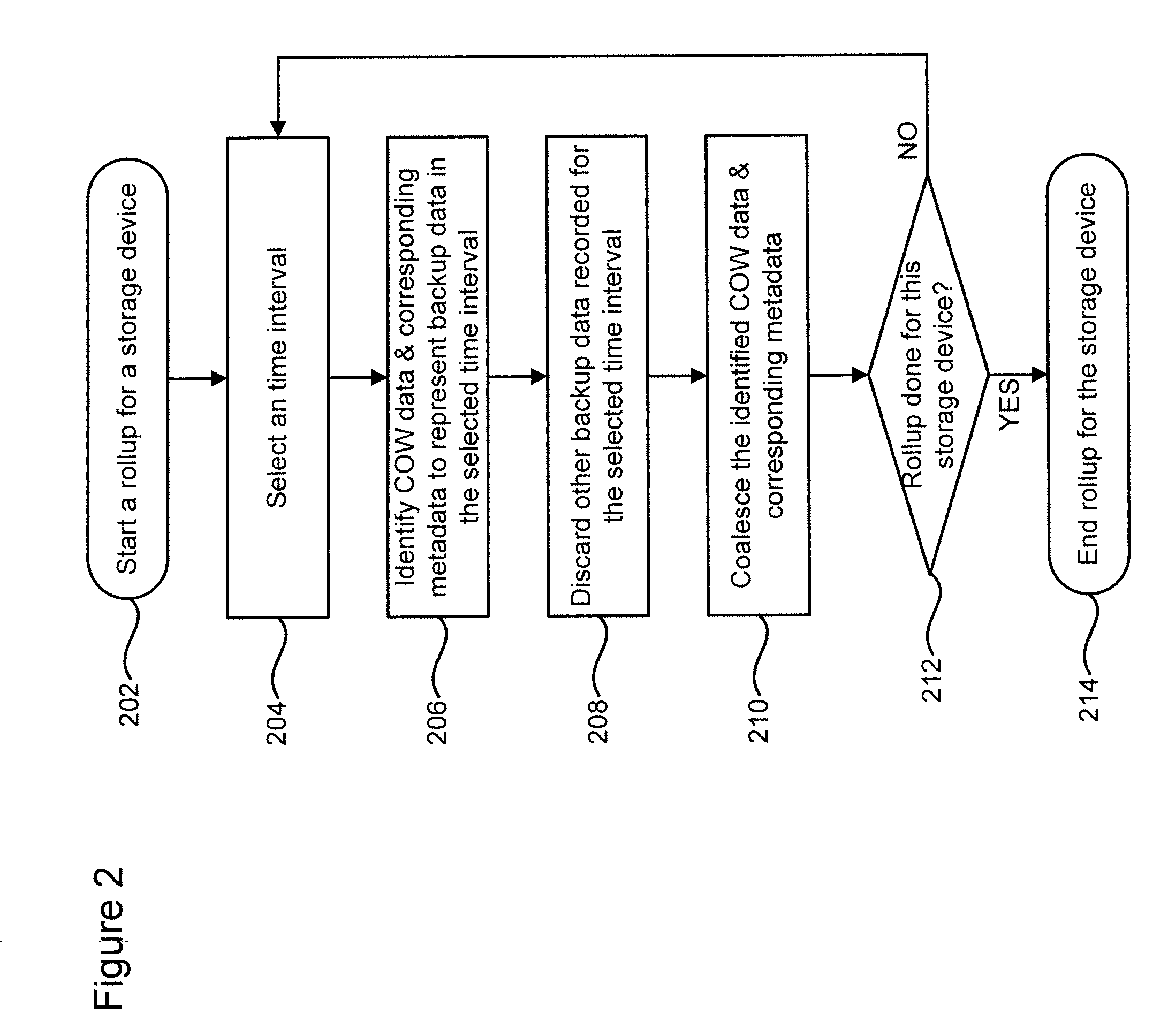

Technique for timeline compression in a data store

ActiveUS20070088973A1Reducing granularity levelControl granularityRecording carrier detailsMemory loss protectionGranularityDigital content

A technique for timeline compression in a data store is disclosed. In one particular exemplary embodiment, the technique may be realized as a method for timeline compression in a storage system, wherein digital content of the storage system is backed up to enable restoration of the digital content to one or more points in a timeline. The method may comprise selecting a time interval in the timeline. The method may also comprise identifying one or more sets of backup data recorded for the selected time interval, wherein the identified one or more sets of backup data represent at least a portion of old data overwritten during the selected time interval. The method may further comprise discarding other backup data recorded for the selected time interval, thereby reducing a granularity level of the timeline in the selected time interval.

Owner:SYMANTEC OPERATING CORP

Color-magnetic separation combined sorting method for high-purity quartz sand produced through quartzite

ActiveCN106000622AGood working environmentNo tailings dischargeWet separationMagnetic separatorChemical substance

The invention discloses a color-magnetic separation combined sorting method for high-purity quartz sand produced through quartzite. The method comprises the steps of adopting a crushing-ore washing technology to crush quartzite ore into 1.5-to-2.5 cm blocks, and carrying out ore washing through adopting a cylindrical rotating screen or a linear vibration screen; carrying out roughing and purification on the washed ore through utilizing a color sorter; after parts of a high-quality raw material are selected, carrying out ore grinding, desliming and classification; controlling the particle size of the material at 20 to 140 meshes, and carrying out secondary deironing purification on the part of material through utilizing a vertical ring pulsating high gradient magnetic separator; and after concentrating an obtained product, stacking the product, and carrying out natural dehydration to obtain the high-purity quartz sand. According to the method, adopted technologies belong to physical beneficiation, any chemical substance does not need to be added, and the method is safe and efficient to operate, good in working environment and free of tailing discharge; environmental pollution is avoided; and the method has wide application prospect in high-purity quartz sand manufacturing under the situation that high-quality ore resources are exhausted day by day.

Owner:赣州金环磁选科技装备股份有限公司

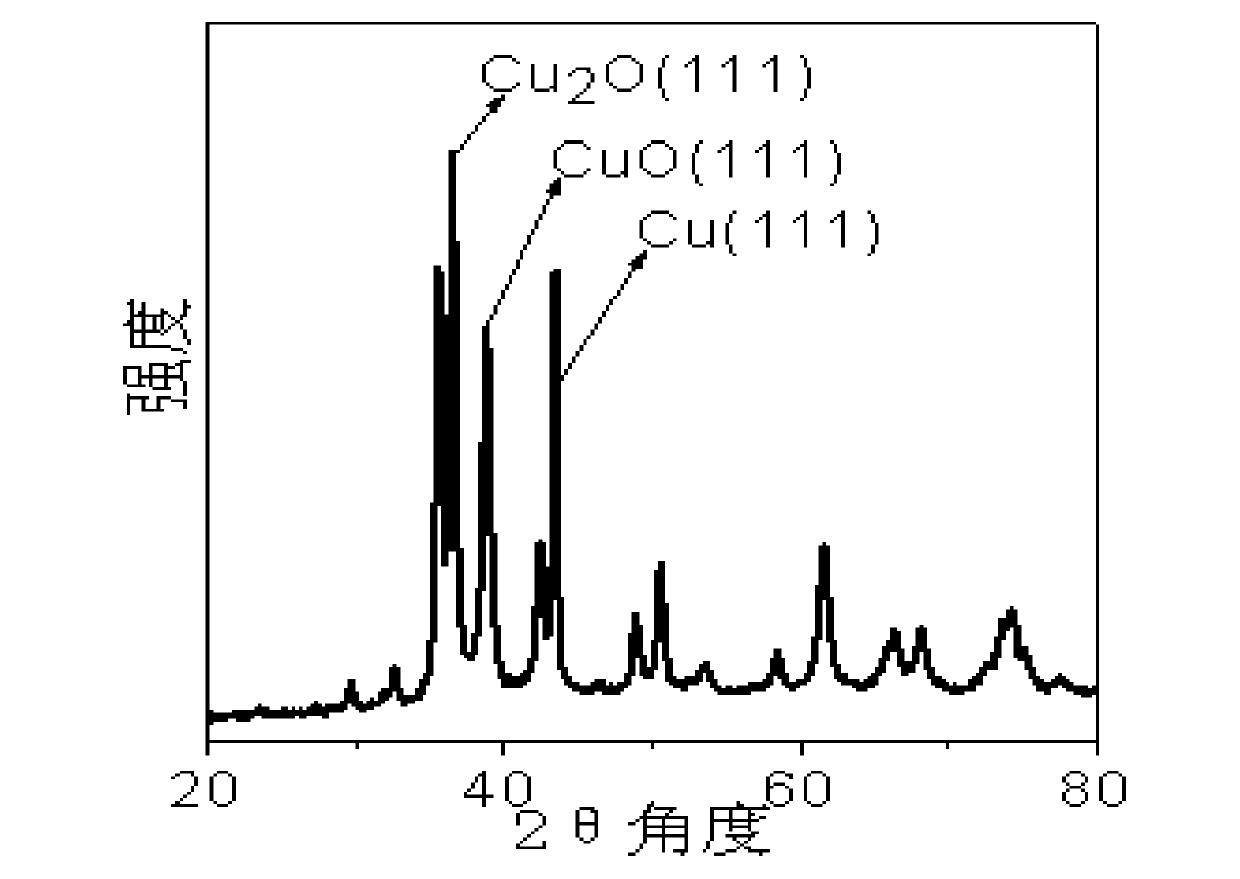

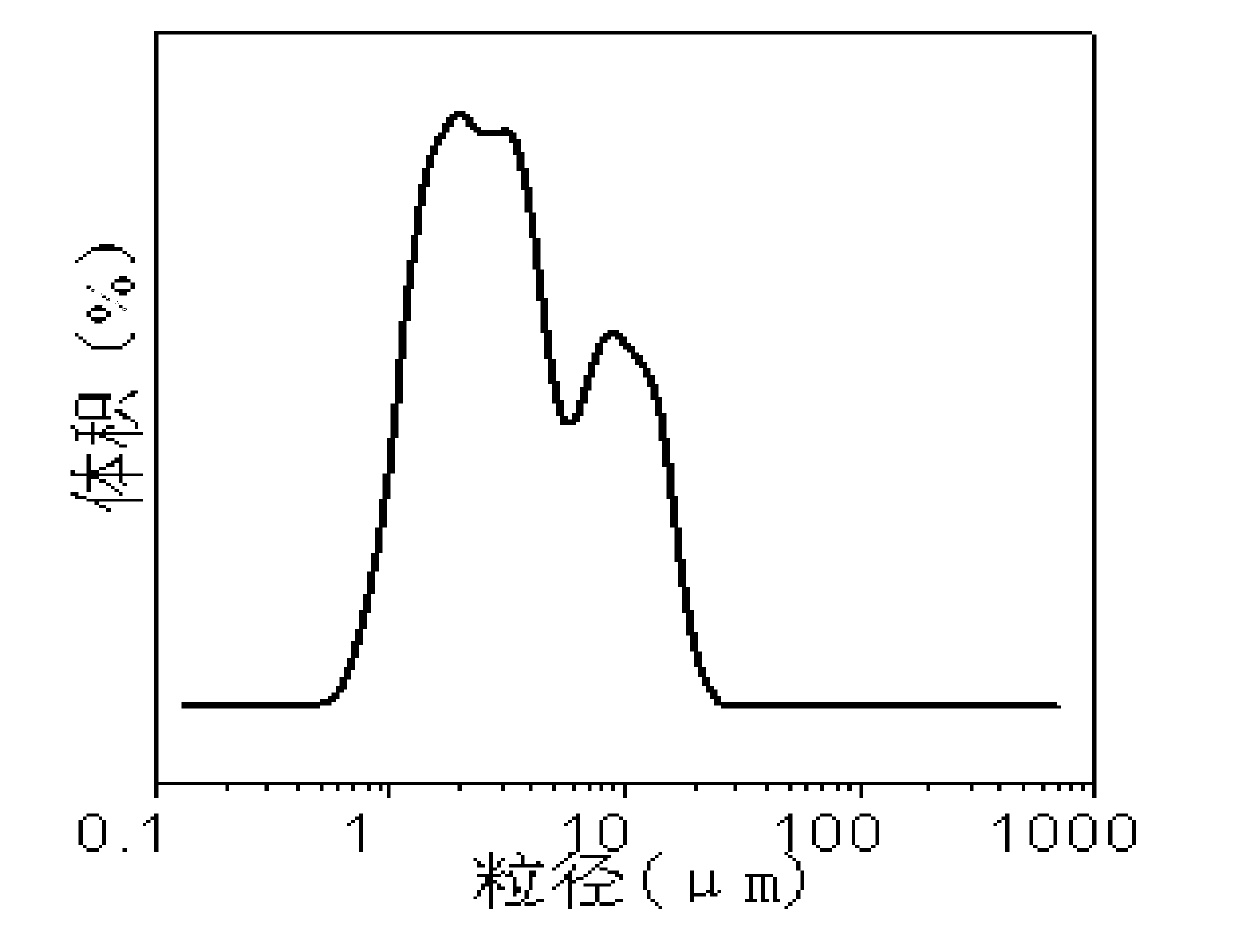

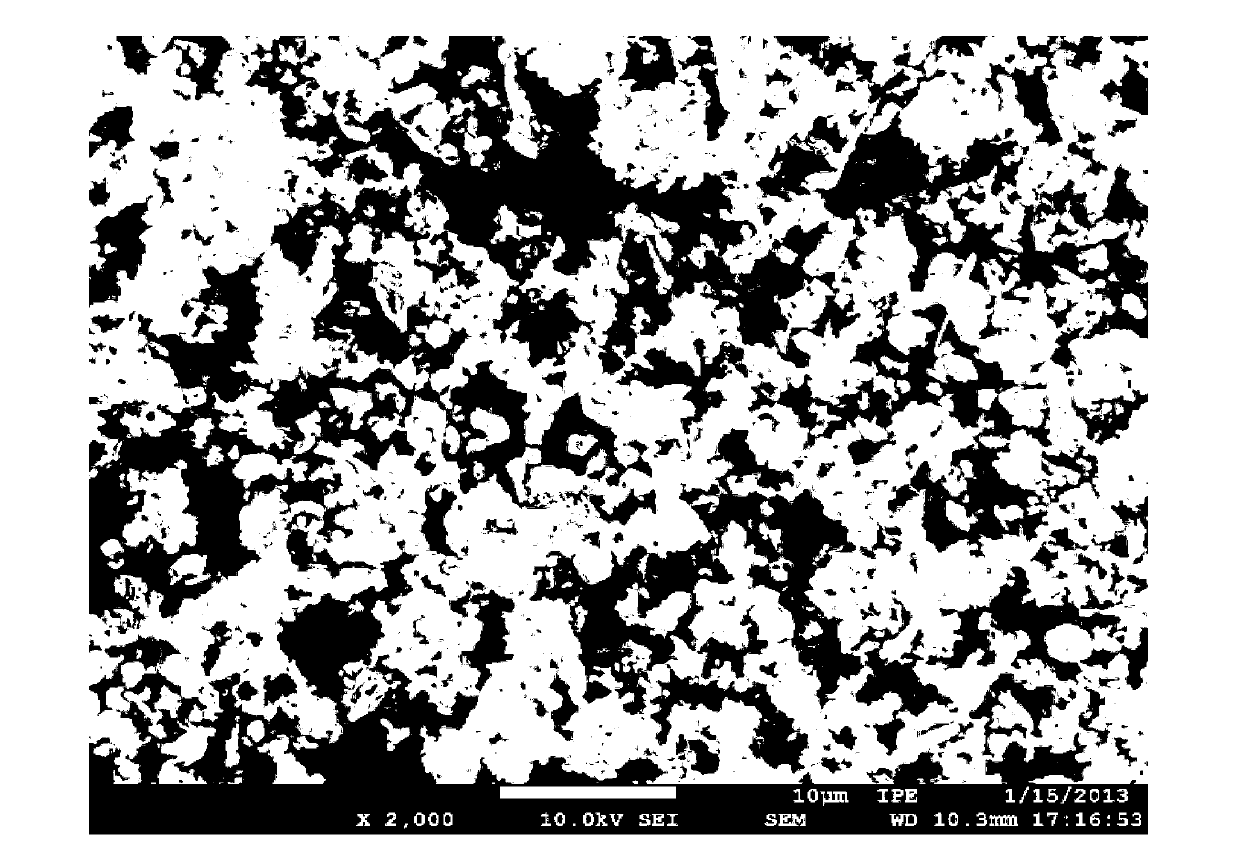

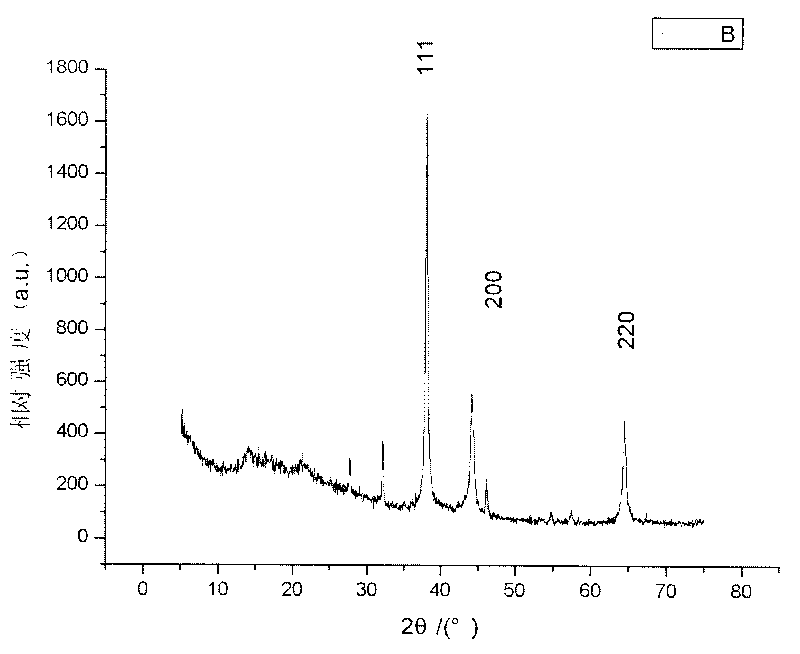

Method preparing catalyzer through liquid phase ball-milling partial reduction method and ternary copper catalyzer

ActiveCN103127936AEnhanced ability to participate in reduction reactionsEnhanced interactionGroup 4/14 element organic compoundsCatalyst activation/preparationFiltrationCopper oxide

The invention relates to a method preparing a copper catalyzer used for dimethyldichlorosilance synthetic reaction through a liquid phase ball-milling partial reduction method. The method includes the steps of taking copper oxide as raw material, adding solvent media containing reducing substances, enabling copper oxide particles to become small and achieve partial reduction through mechanical ball-milling, obtaining the copper-based catalyzer containing the ternary components of copper, cuprous oxide, copper oxide after suction filtration, drying and smashing, and obtaining the ternary copper catalyzer with adjustable components and controllable particles through adjusting the parameters of reducing agent types, concentration and ball-milling conditions. In catalytic reaction of organosilicone monomer synthesis, the catalyzer is high in catalytic activity and selectivity and helpful for improving the processing ability of an existing organosilicone monomer device, reduces production cost, and improves the yield of target products. The method preparing the catalyzer through the liquid phase ball-milling partial reduction method is simple in process, mild in condition and convenient to operate, and brings convenience to achieve large scale production.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

Preparation method of high-nickel, low-cobalt and low-manganese ternary positive electrode material precursor for lithium battery

The invention relates to a lithium battery preparation material, and provides a preparation method of a high-nickel, low-cobalt and low-manganese ternary positive electrode material precursor for a lithium battery. The shape and the appearance of nickel, cobalt and manganese hydroxide co-precipitated product can be precisely and conveniently controlled. A raw material solution is prepared from A, namely a nickel salt solution containing 80g / L of nickel, B, namely a mixed solution containing 60-90g / L of nickel, 10-30g / L of cobalt and 10-30g / L of manganese (prepared according to different proportions of x and y in nickel, cobalt and manganese hydroxide Ni(1-x-y)CoxMny(OH)2, wherein x is greater than or equal to 0.1 and smaller than or equal to 0.25, y is greater than or equal to 0.1 and smaller than or equal to 0.25, x+y is greater than or equal to 0.2 and smaller than or equal to 0.5), C, namely a solution containing 8mol / L of sodium hydroxide, and D, namely a solution containing a surface active dispersing agent. A preparation method comprises the steps of nickel hydroxide seed crystal cultivation, crystal particle maturing, slurry aging, precipitate filtering, washing and drying. Compared with the prior art, the preparation method has the advantages that ammonia water does not need to be added in the whole process including cultivation and confirmation of Ni(OH)2 crystals, so that high ammonia-nitrogen wastewater cannot be produced; the working procedure of treating the ammonia-nitrogen wastewater is omitted, so that the production cost is further lowered.

Owner:GANZHOU TENGYUAN COBALT INDAL

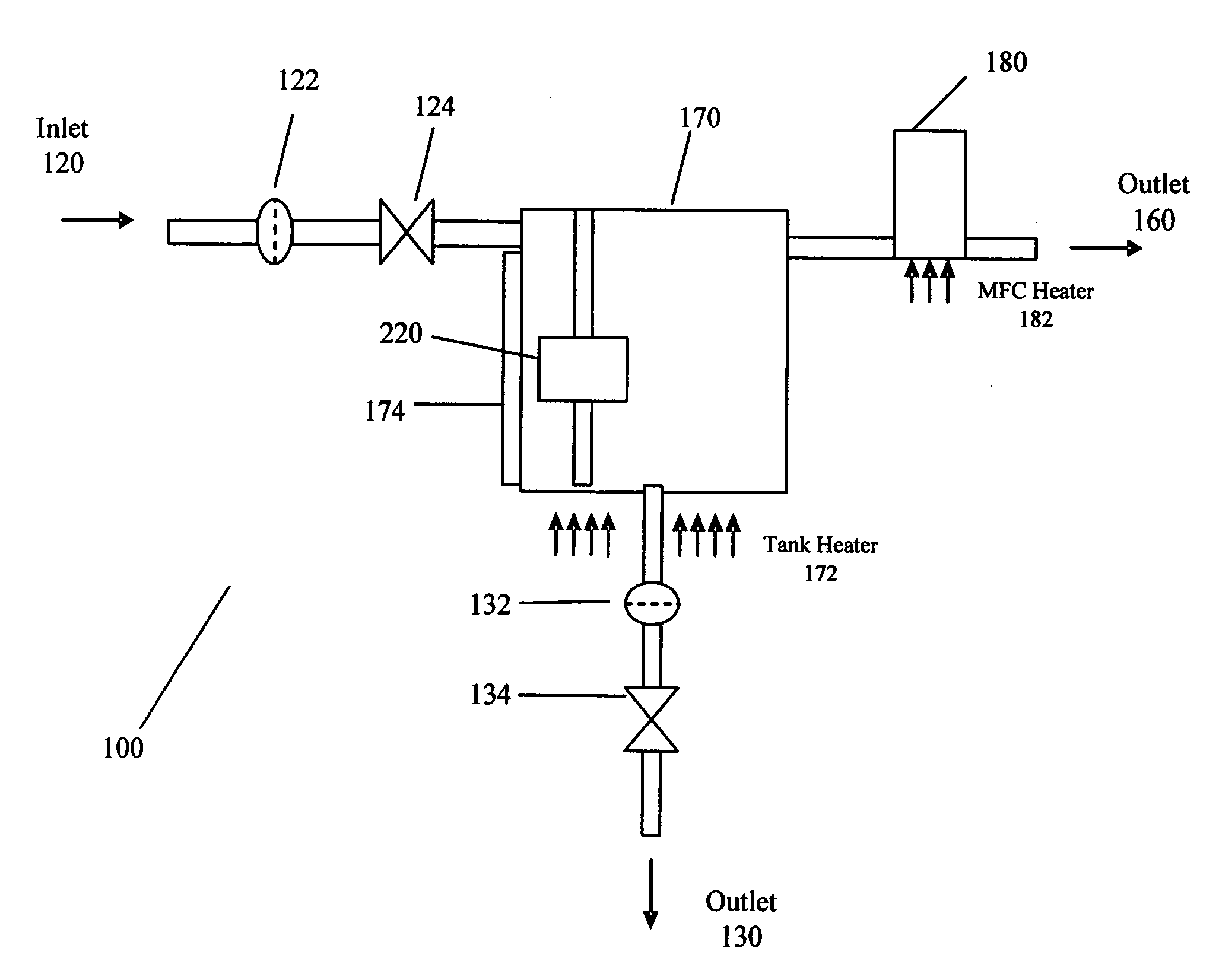

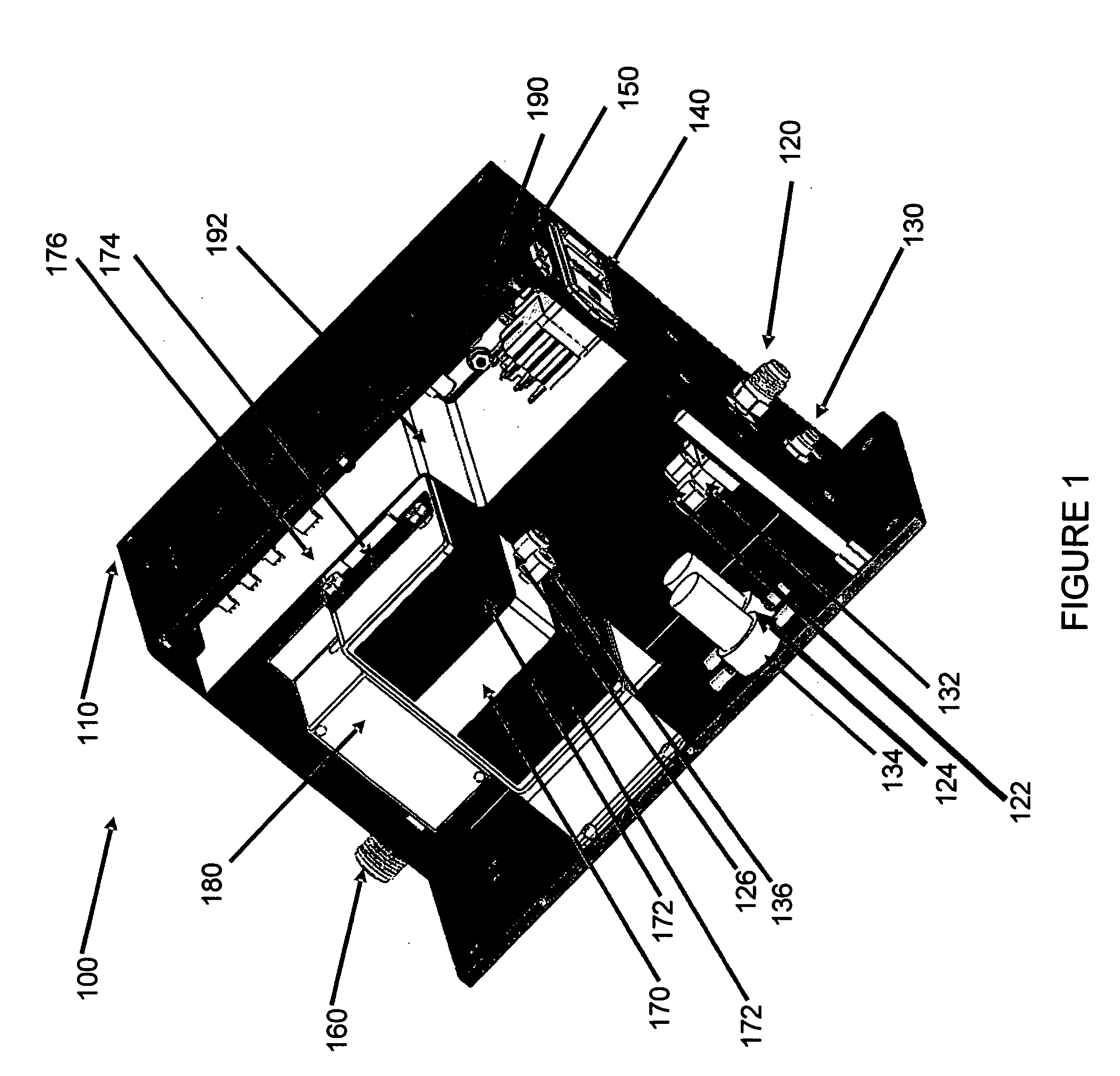

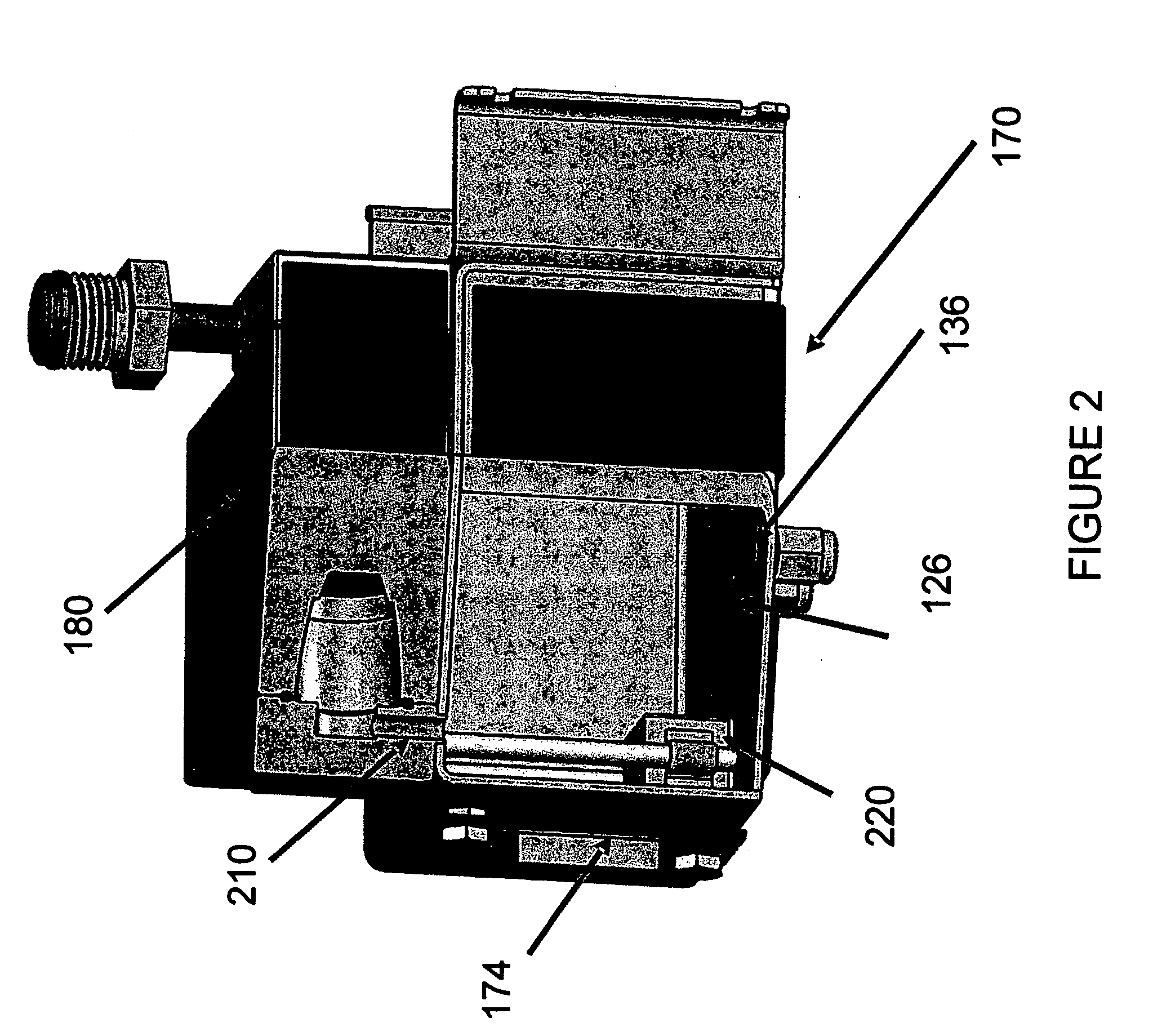

System and method for producing and delivering vapor

ActiveUS20070181703A1Quickly and more efficientlyImprove securitySteam generation using steam absorptionBoiler controlProcess engineering

Systems and methods for producing and delivering vapor are disclosed. A vaporizer tank containing a liquid may be heated such that liquid within the tank is heated and vapor generated. The flow of this vapor to a destination may then be regulated. Embodiments of the present invention may control the temperature of this liquid such that a saturated vapor condition is substantially maintained in the vaporizer tank. The vaporizer tank is coupled to a mass flow controller which regulates the delivery of the vapor to downstream components. By substantially maintaining the saturated vapor condition within the vaporizer tank the pressure of vapor at the mass flow controller can be substantially maintained and a stable and consistent flow rate of vapor achieved.

Owner:ENTEGRIS INC +1

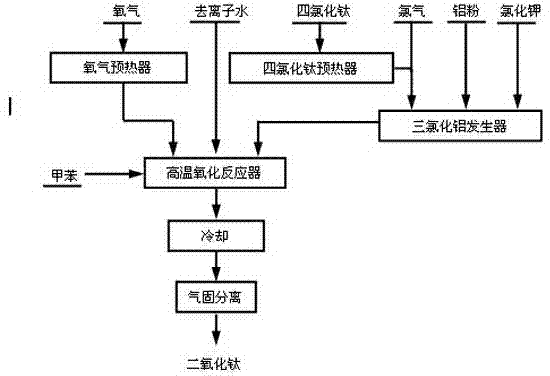

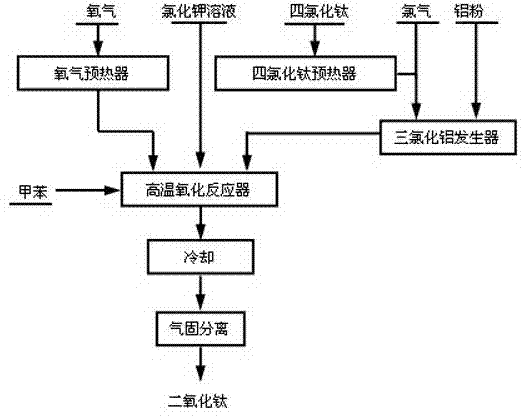

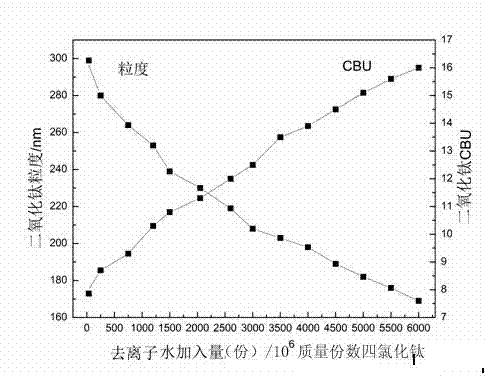

Production method of granularity-controllable titanium dioxide

ActiveCN102583531AIncrease the conversion rate of crystal formGood dispersionNanotechnologyTitanium dioxideFiberGas phase

The invention provides a production method of granularity-controllable titanium dioxide. Titanium tetrachloride and oxygen gas are preheated under pressure of 200kPa to 800kPa and respectively led into a high temperature oxidation reactor; hot oxygen is secondarily preheated in the high temperature oxidation reactor by using heat produced during toluene combustion to enable the titanium tetrachloride and the oxygen gas to produce a gas-phase oxidation reaction, and meanwhile, aluminum chloride, potassium chloride and deionized water are added to the high temperature oxidation reactor; and a gas-solid mixture generated through the reaction is cooled and subject to gas-solid separation, and then the titanium dioxide with the granularity of 160nm to 310nm is obtained. The method has the advantages that the cost is low, the operation is simple, the granularity of the titanium dioxide can be controlled within a large range through regulating the addition amount of the deionized water in the reaction process, and the application field of pigment is widened; and the method can be widely applied to the industries of coatings, plastics, building materials, papermaking, printing, ink, chemical fiber, rubber, ceramics, and the like.

Owner:中信钛业股份有限公司

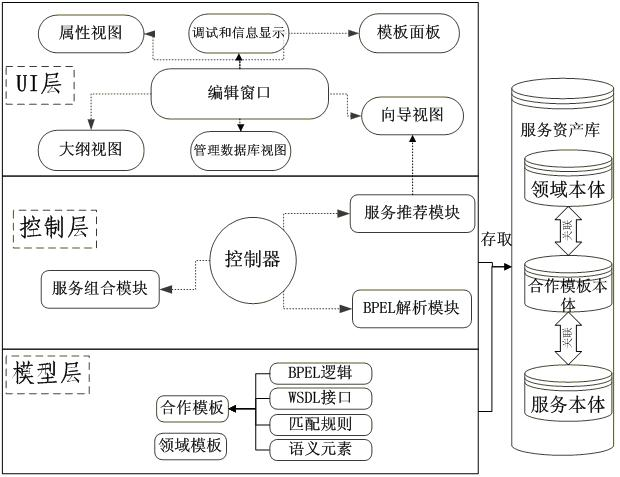

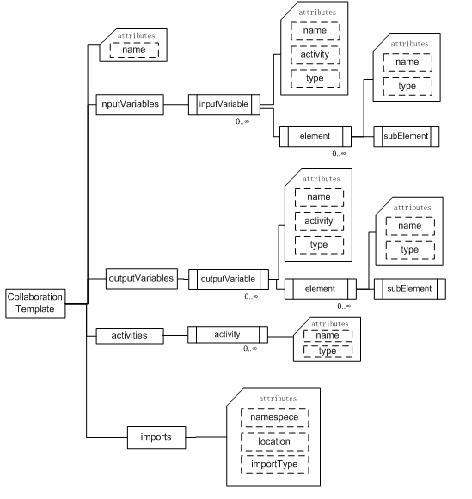

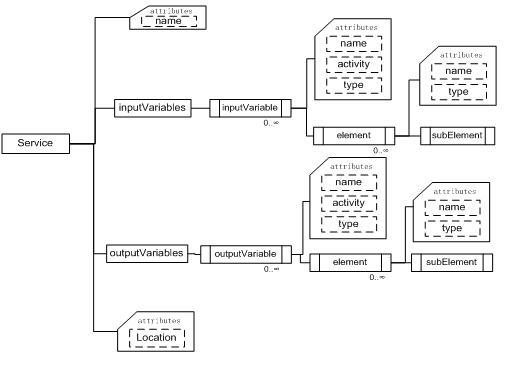

Linked data-based multiplexing method of business process execution language (BPEL) templates and services and system thereof

InactiveCN102426519AReduce the work of secondary developmentImprove development efficiencySpecific program execution arrangementsService compositionMultiplexing

The invention discloses a linked data-based multiplexing method of business process execution language (BPEL) templates and services and a system thereof. The system comprises a model layer, a control layer, a user interface (UI) layer and a service asset library, wherein the model layer is used for providing models required by graphing and various functions of the whole system; the control layer is used for carrying out a control operation on a visualization process in the whole system, and further, realizing functions of script parsing of BPEL, template extracting and packaging, service combining and business exporting; the UI layer is mainly used for the functions of a palette, an editing window, an attribute view, an outline view and a guide view; and the service asset library specifically consists of field bodies, template bodies and service bodies. With the adoption of the linked data-based multiplexing method of the BPEL templates and services and the system thereof, the multi-granularity service asset multiplexing which includes the multiplexing by taking a BPEL subprocess as a template and the atomic Web service multiplexing can be realized; and the development efficiency for service combinations can be increased so as to shorten a development cycle through a pre-designed process template or a user-defined multiplexing template.

Owner:BEIJING UNIV OF POSTS & TELECOMM

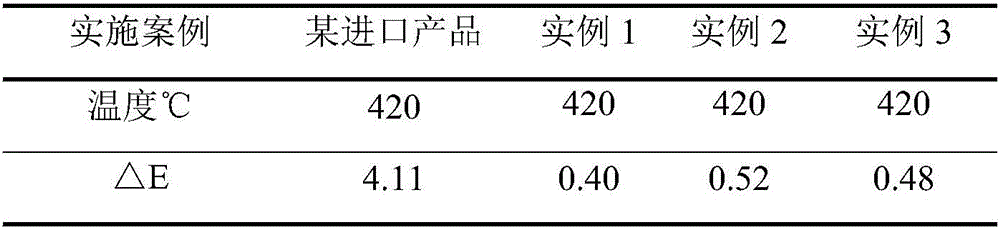

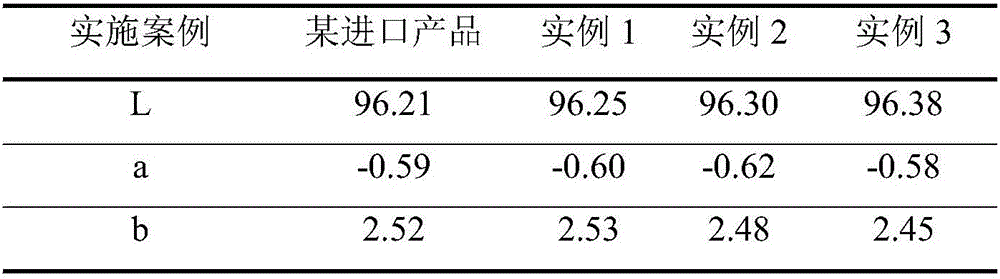

Preparation method of high-whiteness high-temperature-resistance color masterbatch level titanium dioxide

ActiveCN106118140AControl granularityHigh whitenessPigment treatment with organosilicon compoundsPigment physical treatmentTitaniumMoisture absorption

The invention discloses a preparation method of high-whiteness high-temperature-resistance color masterbatch level titanium dioxide. Based on a sulfuric acid process production technology, rutile type color masterbatch special titanium dioxide is prepared through the following steps of performing sufficient rinsing, performing washing with water, performing salting, and then performing calcining so as to prepare a rutile base material free from surface treatment, wherein the rutile base material has favorable whiteness and favorable particle fineness; and performing sufficient crushing through wet grinding and sand grinding, then performing inorganic enveloping, and performing flash evaporation and drying, wherein during crushing by gas streams, organic enveloping treatment is performed, so that the high-whiteness high-temperature-resistance color masterbatch level titanium dioxide with low moisture absorption and fine particle size is prepared. The color masterbatch level titanium dioxide prepared by the preparation method disclosed by the invention can notably improve the temperature resistance situations in down-stream enterprises and the application properties of resin, and has a wide market prospect that the color masterbatch level titanium dioxide can be used for different industrial uses and can be used for manufacturing different colorful plastic articles.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Reducing reagent nozzle for denitration by SNCR method

InactiveCN101371969ANarrow temperature rangeStrong penetrating powerDispersed particle separationSpray nozzlesGranularityReducer

The present invention provides a reducer nozzle used for denitration by an SNCR method. The reducer nozzle comprises a main pipe, an accessory pipe, a cutting ferrule, liquid pipes and a nozzle. The cutting ferrule is connected with the accessory pipe by screw threads to form a relative closed space. The front end of the main pipe is equipped with the nozzle and is arranged in the accessory pipe. The front end of the nozzle is contacted with the cutting ferrule. The back end of the main pipe is communicated with the liquid pipe I which is provided with a manometer. The accessory pipe is communicated with the liquid pipe II which is provided with the manometer. The nozzle is provided with a mixing hole which runs through the main pipe axially and is provided with a plurality of branch holes of the accessory which are communicated with the mixing hole and the accessory pipe. Olivary spray ports are arranged at the nozzle at a liquid outlet of the mixing hole and the cutting ferrule. The reducer nozzle has reasonable structure; when reducer penetrates an oven, the temperature range is narrow, the penetrable performance is good, and the spray distance is long; the reducer nozzle can also effectively control the granularity of atomized particles of the reducer and the vaporizing time of atomized liquid drops; and the reducer is mixed with NOx in smoke uniformly to improve the efficiency of denitrating the smoke.

Owner:JIANGSU ZHONGKE ENERGY SAVING ENVIRONMENTAL PORTECTION TECH

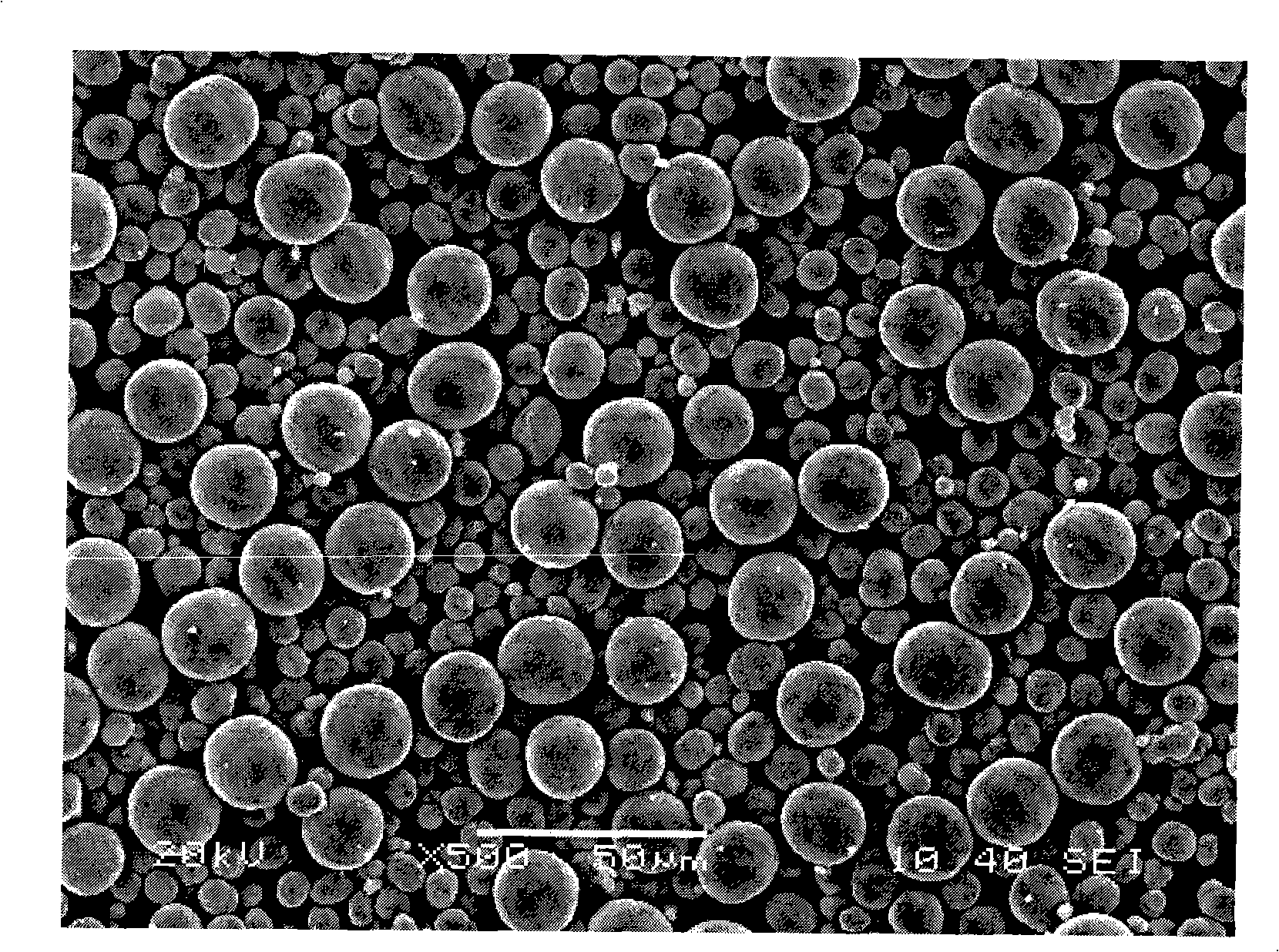

High-density spherical cobaltic-cobaltous oxide and method for preparing the same

InactiveCN101269848AImprove liquidityImprove performanceCobalt oxides/hydroxidesHigh densityCobalt(II,III) oxide

The invention provides a high density spherical shape Co3O4 and a preparation method thereof, and relates to a Co3O4, in particular to the preparation of the high density spherical shape Co3O4, which is mainly used for preparing lithium cobaltoxide of anode material of a lithium ion battery, and also is used as Co3O4 of electronic grade, and belongs to the products of chemical industry. The invention provides a preparation method of the high density spherical shape Co3O4 with good fluidity, the prepared Co3O4 is enabled to be a spherical shape particle which has best stacking density and can effectively improve the tap density of the particle, thereby improving the electrochemistry property of the lithium ion battery and the quality of the lithium ion battery. The Co3O4 prepared by the method is a spherical shape crystal, the mean grain size is 5-25 micrometers, the loose packed density is more than or equal to 1.0g / cm<3>, the tap density is more than or equal to 2.0g / cm<3>, and the cobalt content is more than or equal to 73 percent. The process of the method is simple, and the lithium cobaltoxide synthesized by the Co3O4 presents better property, compared with the past Co3O4, the electrochemistry property of the lithium ion battery can be improved.

Owner:GUANGZHOU RONGJIE MATERIAL TECH

Method for preparing spherical cobalt hydroxide in the absence of complexing agent

The invention relates to a method for preparing a spherical cobalt hydroxide in the absence of a complexing agent. Though the shape of the cobalt hydroxide can be improved to a certain degree by complexing to control crystallization, the cobalt hydroxide is mostly particles in sheet shape or irregular block shape, and the addition of a complexing agent can cause negative effects. The technical scheme adopted by the invention comprises the following steps of: taking pure water as a base solution; adding a cobalt solution and a sodium hydroxide solution into the base solution with stirring at the same time to cause a precipitation reaction, wherein the pH value of the solution is kept between 5 and 7 in the process of adding the cobalt solution and the sodium hydroxide and is kept between 10.5 and 13.5 in the end of the process; adding an antioxidant into the solution to prevent the solution from being oxidized; and obtaining the cobalt hydroxide product after washing and drying the cobalt hydroxide slurry. The method adopts a forward feeding mode in the absence of complexing agent to form pink spherical cobalt hydroxide powder with very good crystallinity. The spherical cobalt hydroxide powder is easily filtered and washed, and the reaction condition is simple and easy to control. Therefore, the method is suitable for industrial mass production.

Owner:ZHEJIANG HUAYOU COBALT

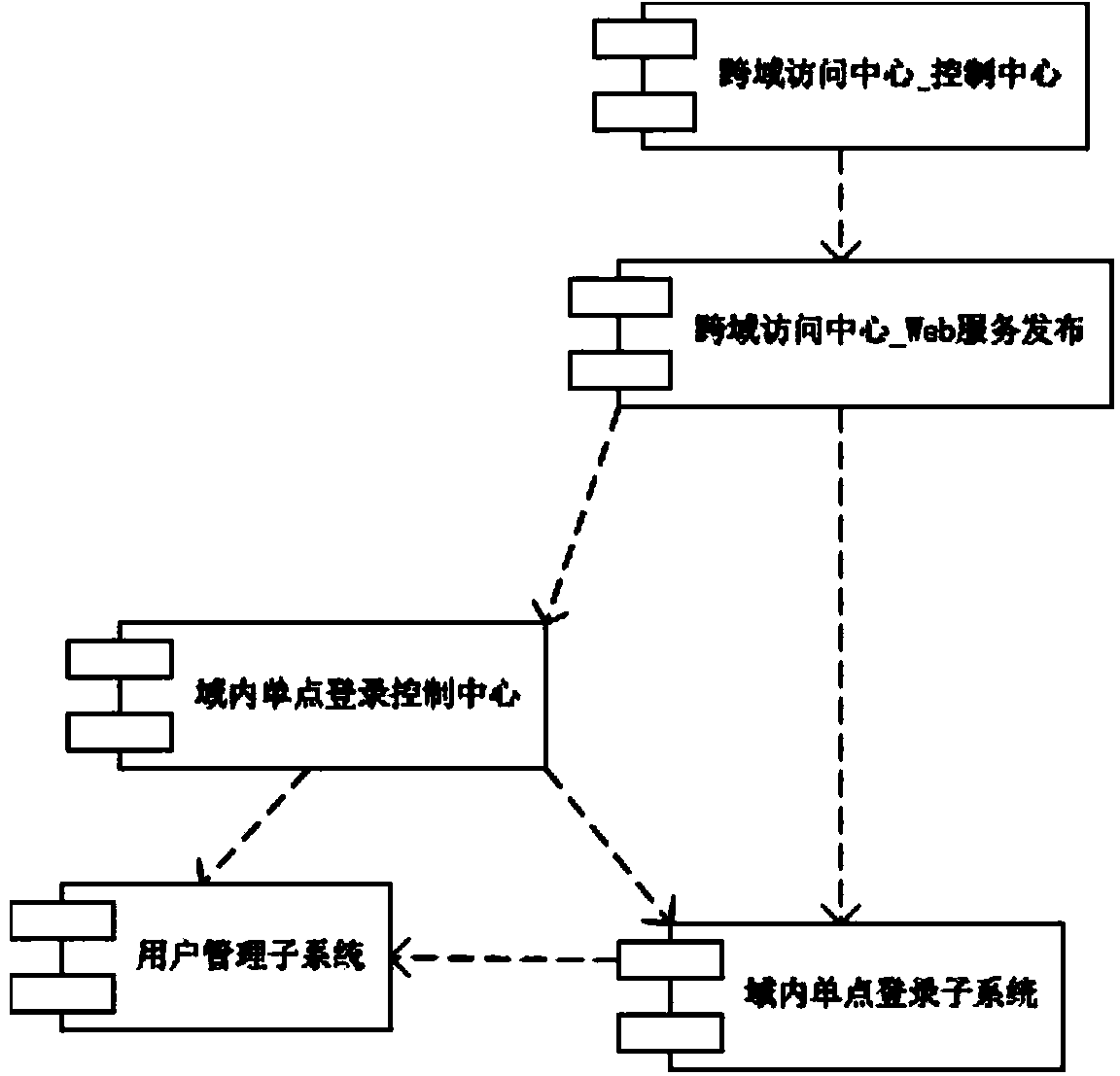

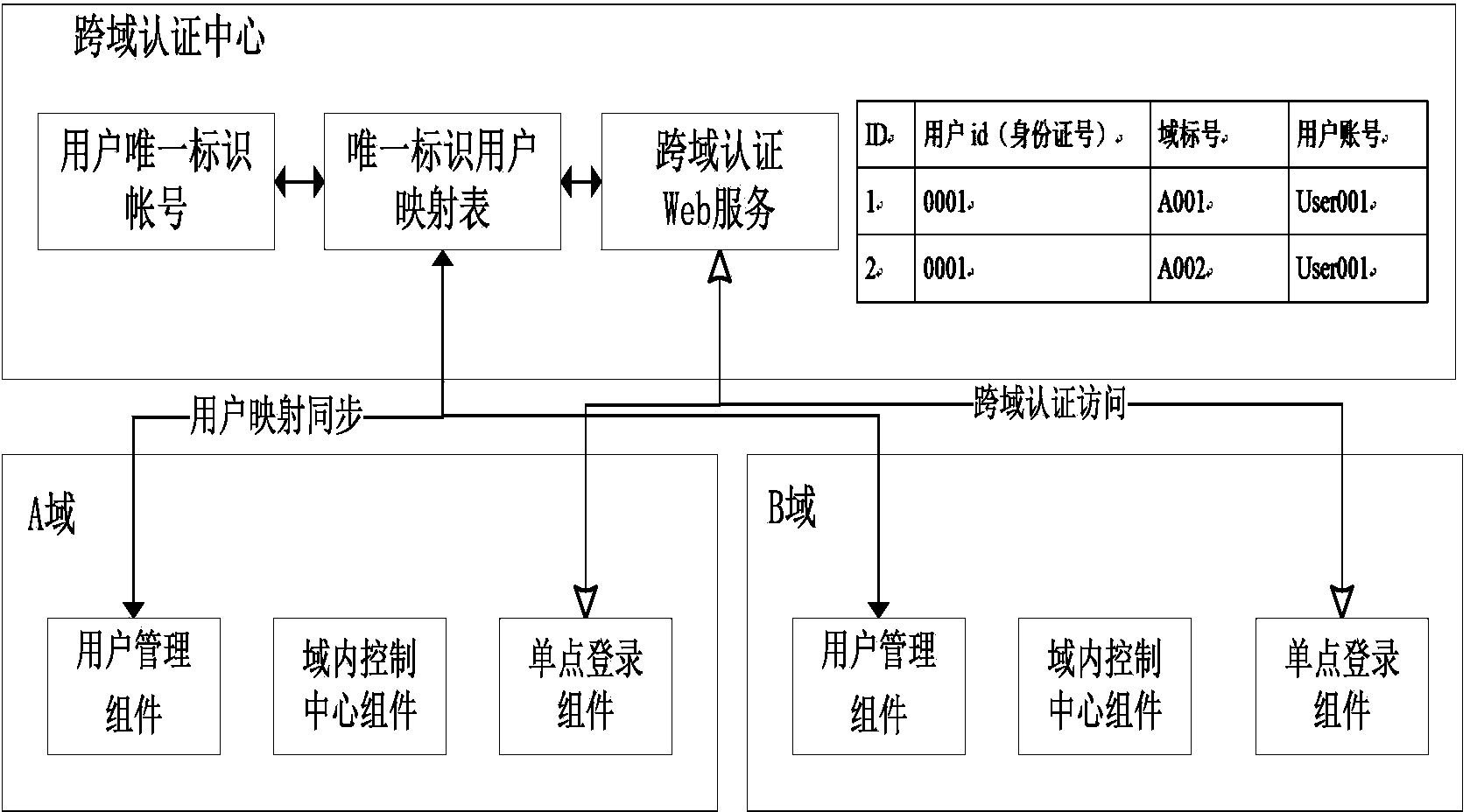

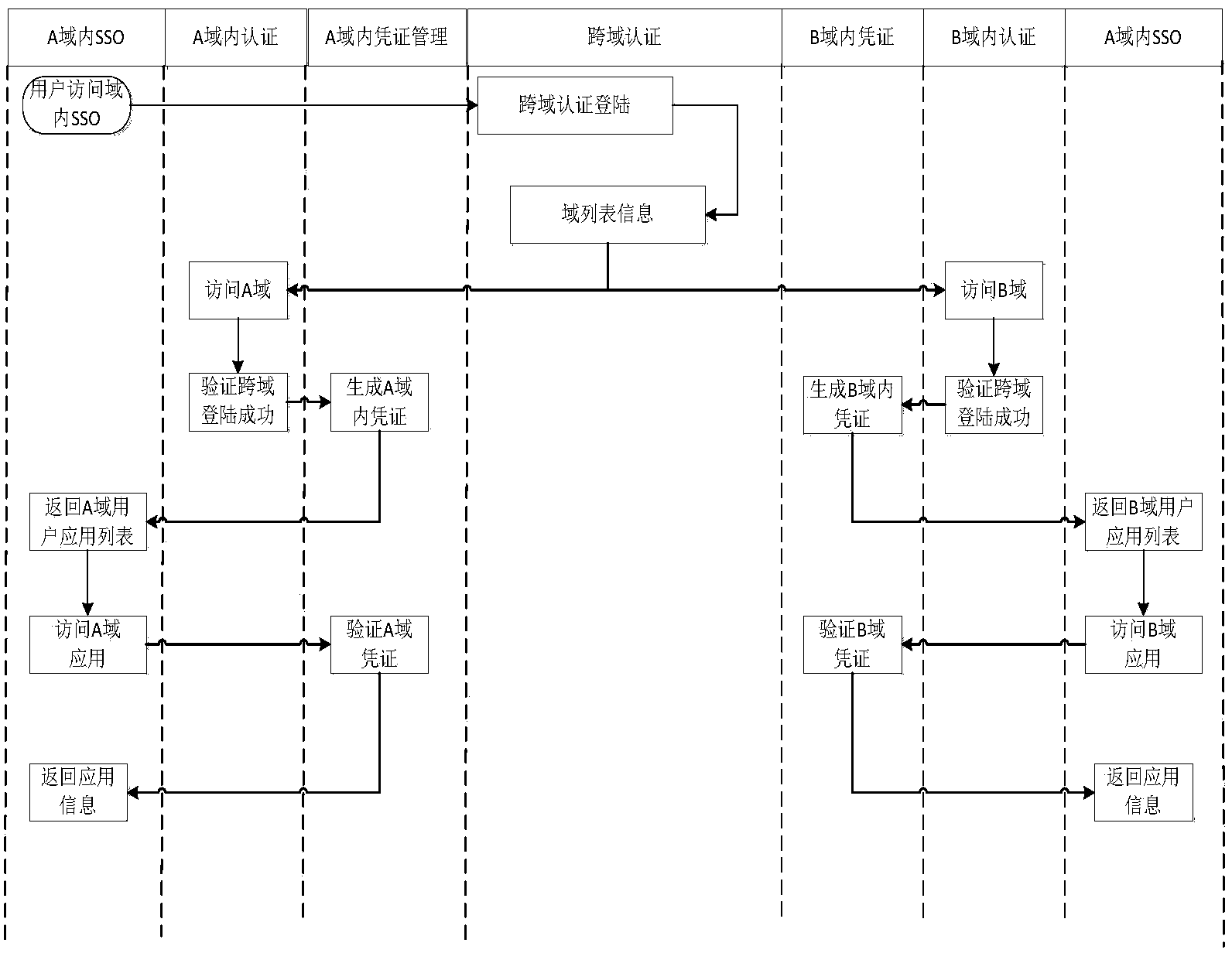

Cross-domain single point login system and method based on SAML

The invention discloses a cross-domain single point login system and method based on the SAML. The cross-domain single point login system comprises a cross-domain access center module, an inside-domain single point login sub-system module, a user management sub-system module and an inside-domain single point login control center module, wherein the cross-domain access center module comprises a cross-domain user data mapping synchronizing module, a multi-stage domain ID generating module and a multi-stage domain access authentication interface module. According to the cross-domain single point login system, the inside-domain authentication of multi-stage domains is improved to the unified cross-domain authentication among the multi-stage domains by establishing a cross-domain access center, inlets of the multi-stage domains are integrated by integrating unified authentication sources, the cross-domain single point login system becomes more efficient, the time for having access to the multi-stage domains is saved for users, and the authentication efficiency is improved.

Owner:XIAN FUTURE INT INFORMATION CO LTD +1

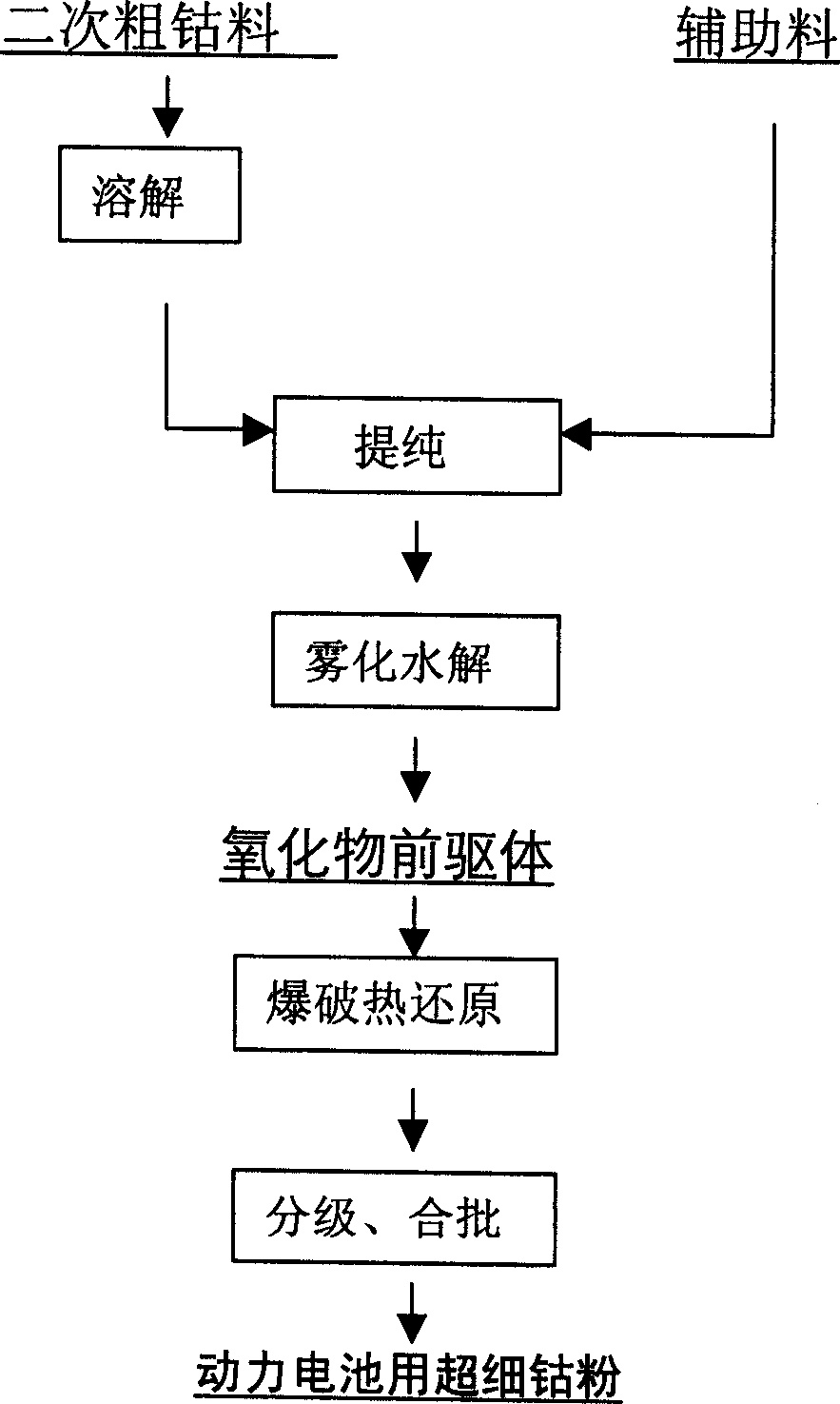

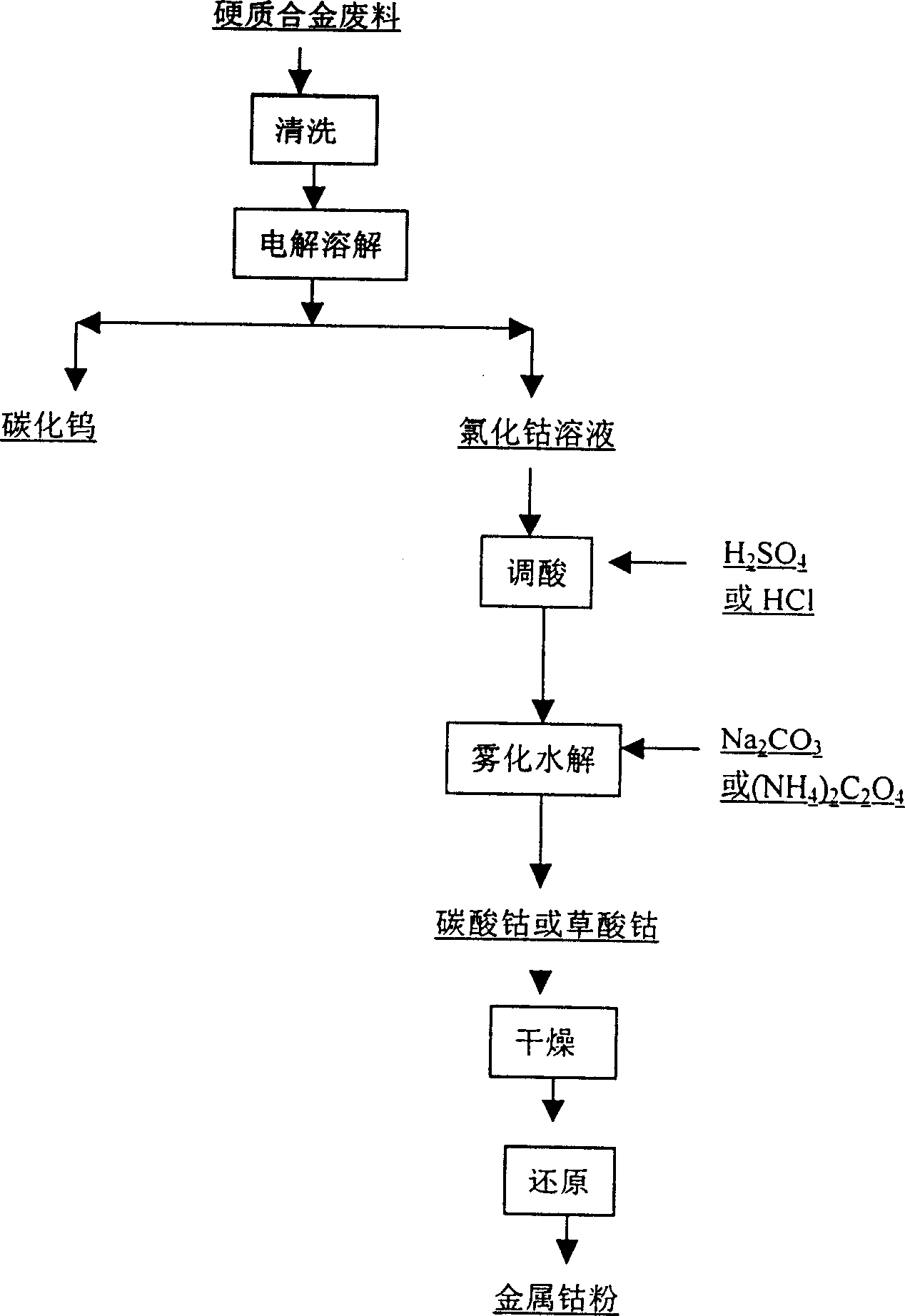

Production and producing apparatus for super fine cobalt powder by circulating technology

A process for preparing superfine spherical or fibrous Co particles from used battery by the circulation technique includes such steps as extracting twice for purifying, atomizing, hydrolyzing, depositing to obtain the Co compound precursor, and exploding for thermal reduction at multiple temp segments to obtain the superfine Co particles (0.1-0.2 microns) used for power battery and powder metallurgy. Its apparatus is also disclosed.

Owner:JINGMEN GEM NEW MATERIAL

Preparation method of coal tar-based mesocarbon microbead

InactiveCN102653397AHigh content of phase carbon microspheresControl granularityCarbon preparation/purificationMicrosphereQuinoline

The invention discloses a preparation method of a coal tar-based mesocarbon microbead, comprising a process flow of pretreatment of raw materials, pyrocondensation polymerization reaction, separation and drying. The preparation method specifically comprises the following steps of: extracting, separating and removing primary quinoline insolubles of coal tar, as the raw materials, by using a mixed solvent to obtain coal tar refined soft pitch; then polymerizing the coal tar refined soft pitch for 1-8 hours at 350-450 DEG C under the rotating speed of 100-500 r / min and under the protection of inert gases by using anthracene oil or silicone oil as a reaction system viscosity regulator to obtain carbon microbead-containing mesophase pitches; and extracting by using a solvent, and drying to obtain the mesocarbon microbead. The particle diameter of the coal tar-based mesocarbon microbead prepared by using the method is 1-150 mu m, and the mass percent can reach 20-50%. The preparation method of the coal tar-based mesocarbon microbead has the characteristics of high product yield, controllable particle diameter, good sphericity, simple and convenient process, rich raw material sources, low cost and the like.

Owner:UNIV OF SCI & TECH LIAONING

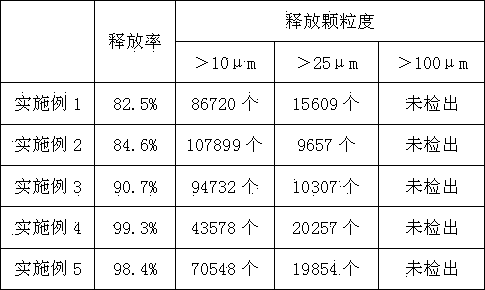

Method for preparing balloon dilatation catheter medicinal coating for treatment

The invention relates to a method for preparing a balloon dilatation catheter medicinal coating for treatment. The method comprises the following steps: adding a diluted solvent into a glass bottle filled with a medicine for treating vascular endothelial re-proliferation, oscillating to completely dissolve the medicine to prepare a medicine solution; mixing the medicine solution and an interference solvent which is incompatible with the medicine, and feeding into a dual-channel ultrasonic nozzle to coat a balloon dilatation catheter; drying, sterilizing and packaging the coated balloon dilatation catheter. According to the method, the medicine solution is mixed with another incompatible interference solvent before ultrasonic coating, so that the shape of the medicine in the solution is changed, and the mixture is fed into the ultrasonic nozzle to perform ultrasonic coating to achieve the aims of controlling the coating granularity, increasing the coating binding force and controlling the releasing rate of the medicine. The medicine coating formed by the method has the characteristics of uniformity, strong binding force with balloon, controllable crystal granularity, durable drug effect and the like.

Owner:ZHEJIANG BELONGS TO A MEDICAL INSTR

Spherical manganese carbonate and preparing method thereof

The invention relates to a spherical manganese carbonate and the preparation method thereof, and mainly relates to the spherical manganese carbonate for preparing a manganese compound (manganese dioxide, etc.) of a dry battery, lithium manganese oxide of cathode materials for lithium ion batteries and derivatives, and the spherical manganese carbonate belongs to a chemical product. On the premise of easy industrial production realization, a method for simply preparing the spherical manganese carbonate with good fluidity is provided, and the spherical manganese carbonate is synthetized through controlling a synthesis technology. Particles of the manganese carbonate powder are spherical crystallization, the average particle size ranges from 2 to 30microns, the apparent density ranges from 1.3 to 1.8g per cm <3>, the tap density can reach over 2.0g per cm<3>, and the manganese content is equal to and larger than 47 percent. Experimental results indicate that the lithium manganese oxide synthetized by the manganese carbonate used as a precursor has better performance, and can improve electrochemical properties of lithium ion batteries. The lithium manganese oxide has good fluidity and highest bulk density, and can effectively improve the tap density of powder to cause materials to obtain higher specific capacity, thereby improving the electrochemical properties of the lithium ion batteries.

Owner:GUANGZHOU RONGJIE MATERIAL TECH

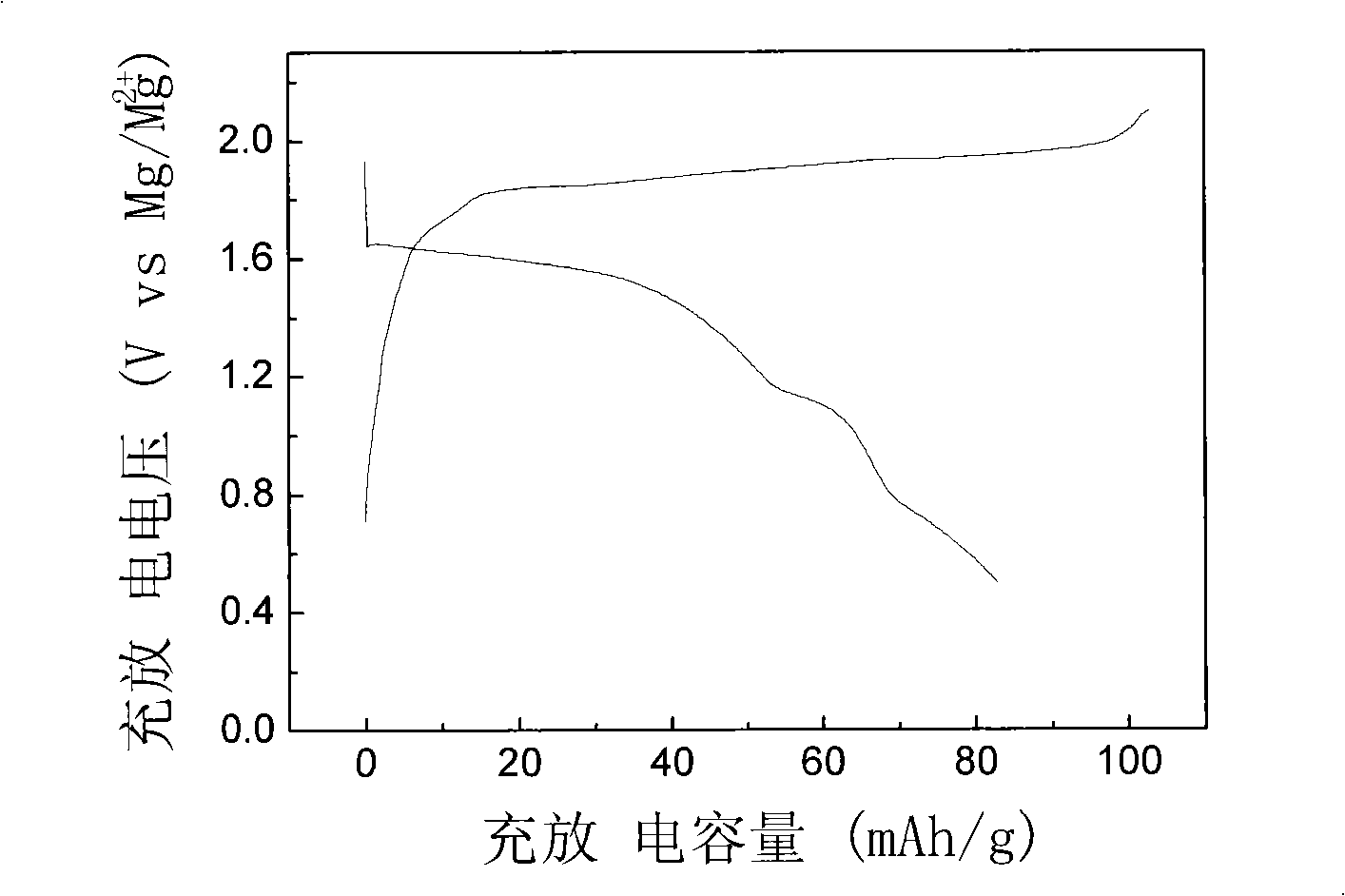

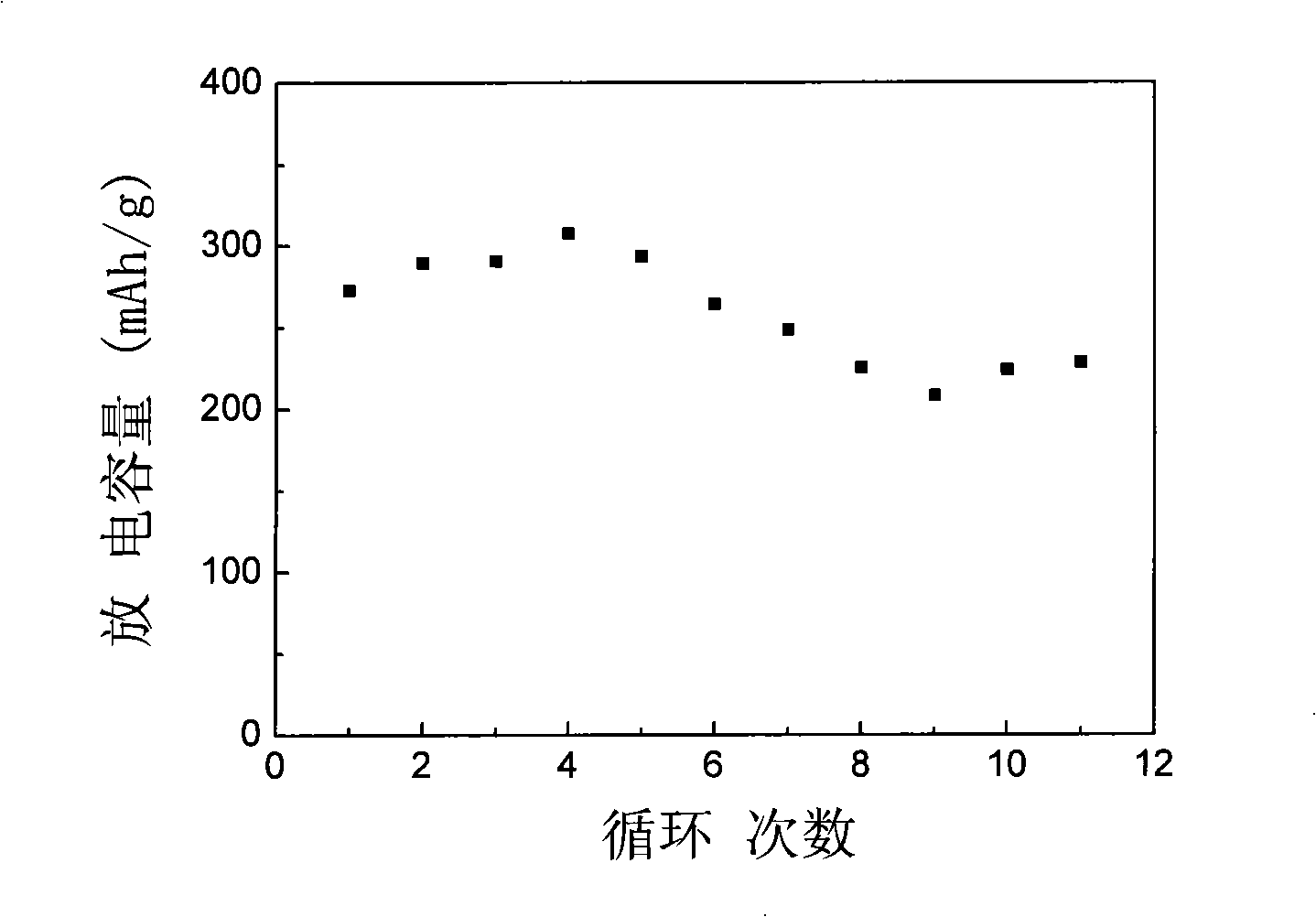

Preparation method for anode material manganese magnesium silicate of rechargeable magnesium cell

InactiveCN101320806AImprove crystal structureImprove electrochemical activityElectrode manufacturing processesChemical/physical/physico-chemical processesCapacitanceManganese

The invention discloses a production method for manganous / magnesium silicate of chargeable magnesium battery positive pole material, which is the manganous / magnesium silicate of chargeable magnesium battery positive pole material using molten salts as reaction medium and having the characteristics of quickening up reaction speed, shortening reaction cycle, simplifying synthesis course, reducing synthesis cost, small synthesis particle size and symmetrical distribution of the particles. The material exhibits remarkable electrochemical charge and discharge effects, the steady discharge platform works up to 1.6V and 1.1V(vs.Mg / Mg<2+>); on the charge and discharge conditions of C / 20 current density, the discharge capacitance can reach 289.3mAh*g<-1>(theoretical capacitance is 92%). In contrast to the relatively ideal positive pole material Mo3S4 of the current chargeable magnesium battery, the manganous / magnesium silicate positive pole material produced by the molten salt process has the advantages of simple production, large capacitance, high discharge voltage platform and the like.

Owner:SHANGHAI JIAO TONG UNIV

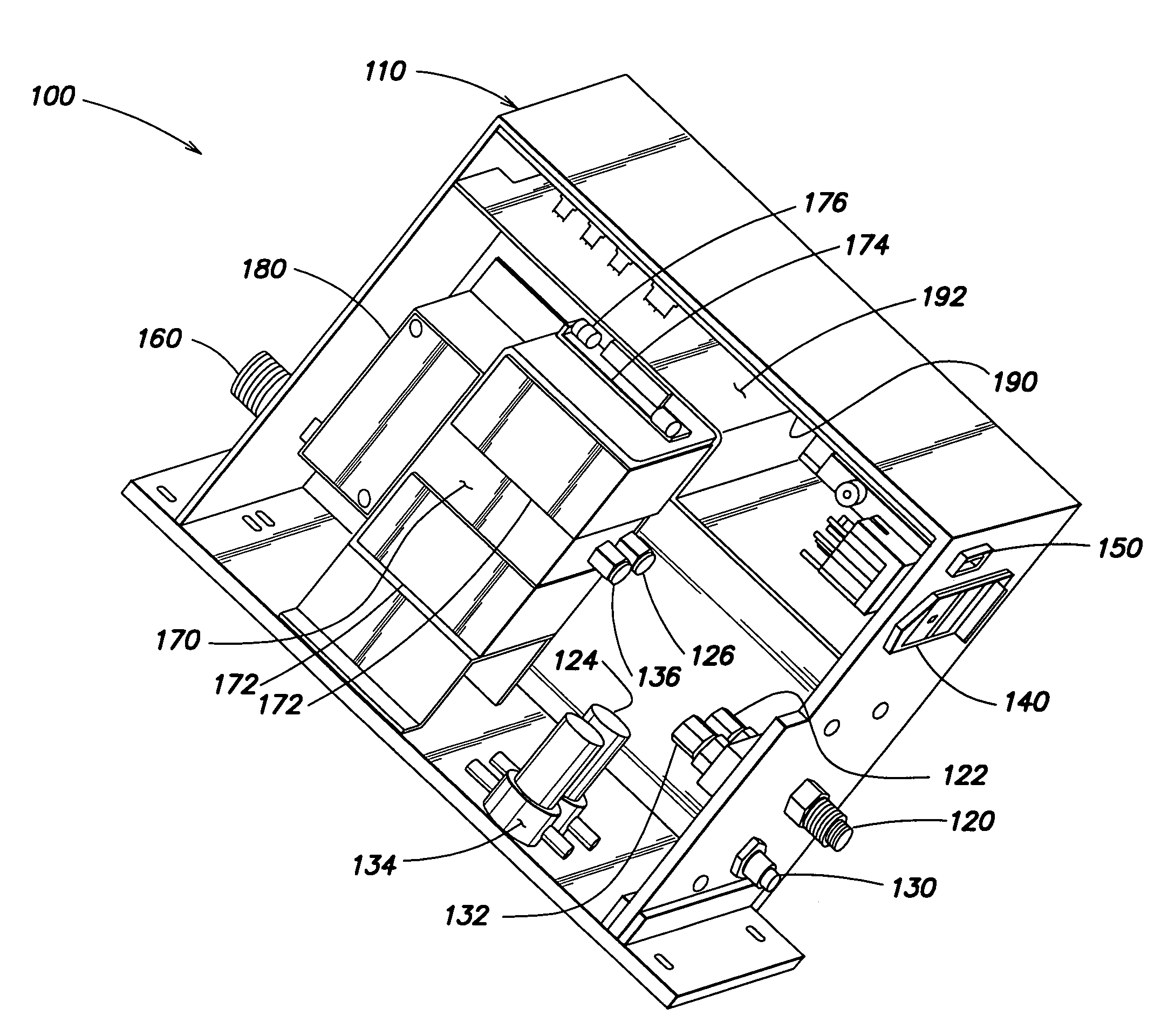

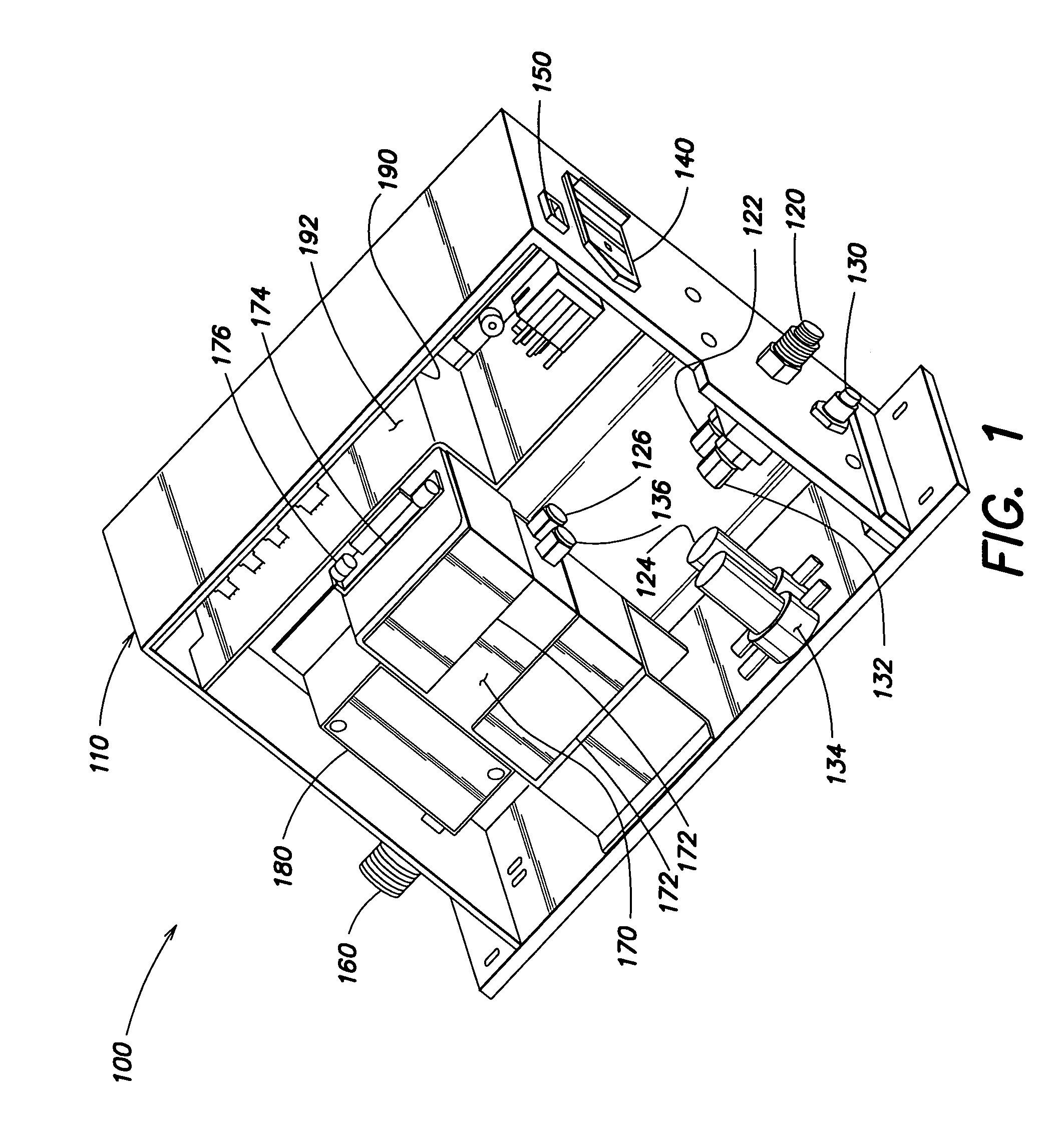

System and method for producing and delivering vapor

ActiveUS7680399B2Small sizeControl granularitySteam generation using steam absorptionBoiler controlProcess engineeringEvaporator

Systems and methods for producing and delivering vapor are disclosed. A vaporizer tank containing a liquid may be heated such that liquid within the tank is heated and vapor generated. The flow of this vapor to a destination may then be regulated. Embodiments of the present invention may control the temperature of this liquid such that a saturated vapor condition is substantially maintained in the vaporizer tank. The vaporizer tank is coupled to a mass flow controller which regulates the delivery of the vapor to downstream components. By substantially maintaining the saturated vapor condition within the vaporizer tank the pressure of vapor at the mass flow controller can be substantially maintained and a stable and consistent flow rate of vapor achieved.

Owner:ENTEGRIS INC +1

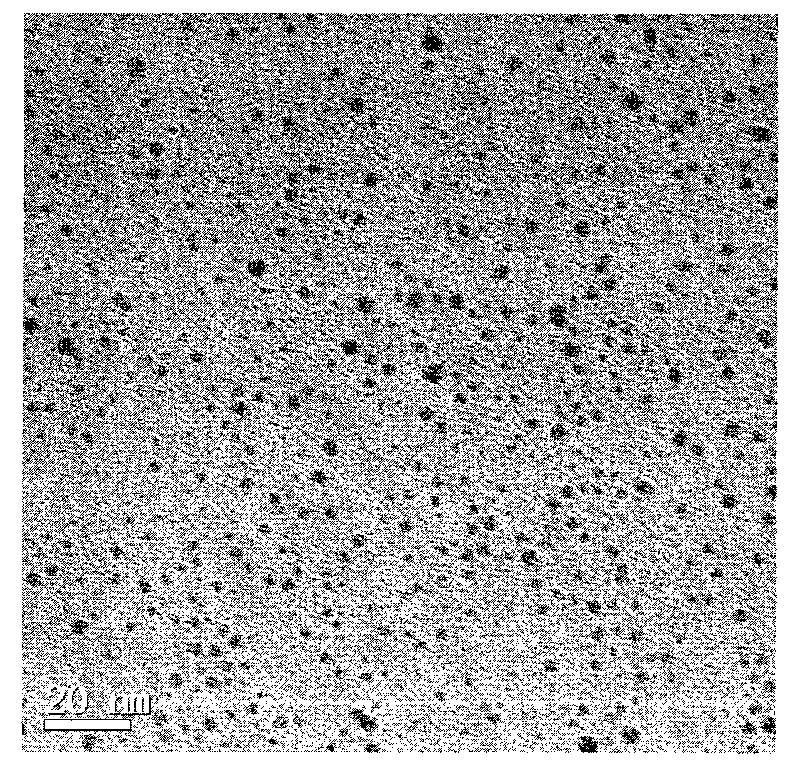

Highly dispersible spherical nano-silver powder and preparation method thereof

The invention discloses highly dispersible spherical nano-silver powder and a preparation method thereof. The method comprises the following steps of: mixing PEG and deionized water in a molar ratio of 1 to (0.005-5), and uniformly stirring the obtained solution; then mixing AgNO3 and a glucose solid in the molar ratio of 1 to (0.005-2), then adding the mixture into solution of the PEG, dissolving the mixture, uniformly stirring the obtained solution, and reacting for 3 to 10 hours at the temperature of between 20 and 70 DEG C, wherein the molar ratio of the PEG to the AgNO3 is (400-10) to 1; and then centrifugating and filtering a reaction product, and washing the obtained product with distilled water to obtain the nano-silver particles. The preparation method is simple and easy to operate; the spherical nano-silver powder has the particle size of between 3 and 20nm, and belongs to a nanometer level; silver nano-particles have the advantages of small size, uniform distribution, good stability and strong antibacterial ability; all used solvents are non-toxic; and the spherical nano-silver powder is easy to add into other products.

Owner:ZHEJIANG KUNZHILIN BIOMEDICINE TECH

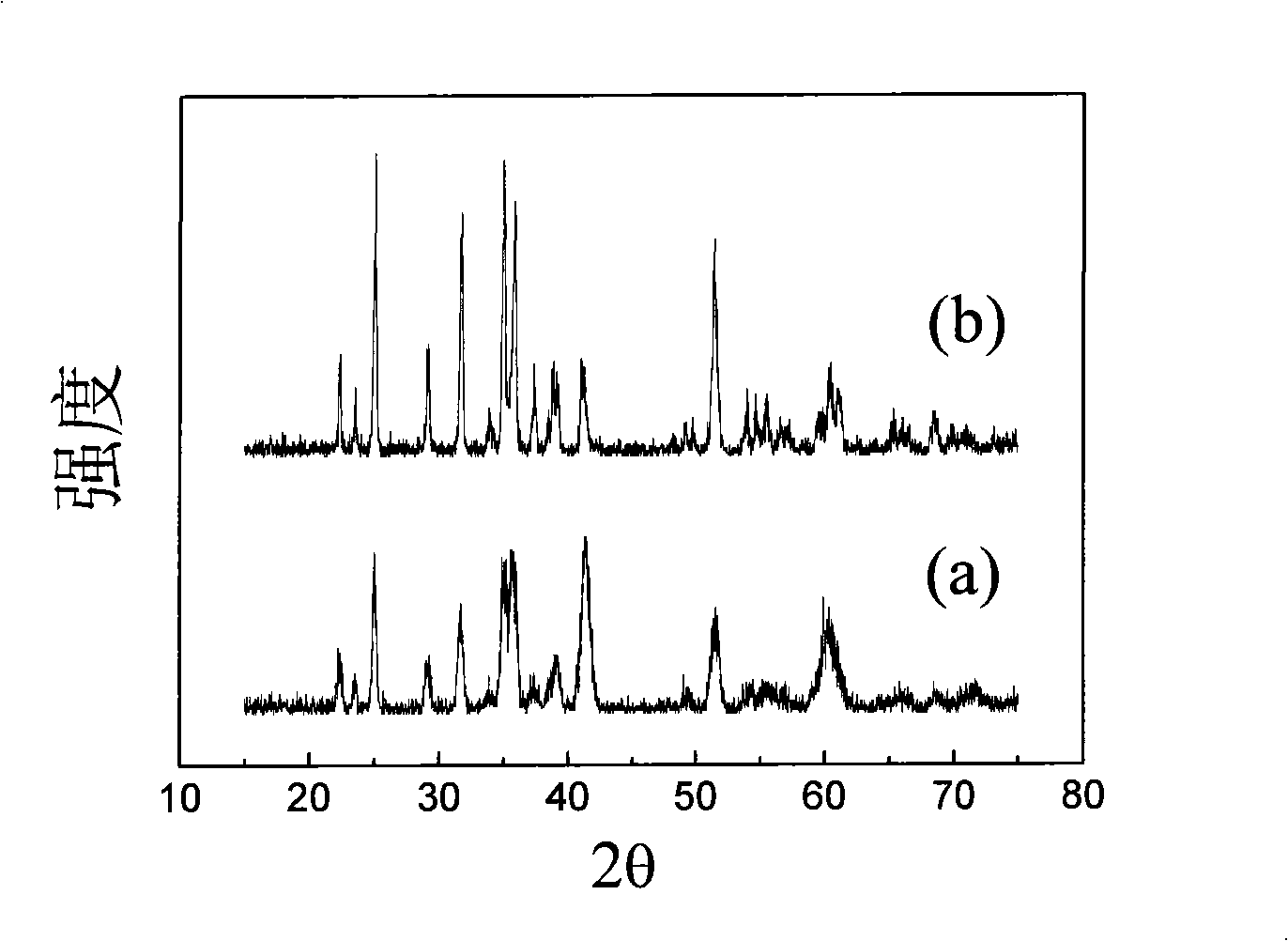

Preparation method of vanadium nitride nano powder body

InactiveCN1380247AHigh yieldControl granularityNitrogen-metal/silicon/boron binary compoundsMicrometerVanadium nitride

The preparation method of vanadium nitride nano powder body includes the following steps: using industrial-grade V2O5 to make reduction reaction to prepare VOCl2 solution, making said solution react with (NH4)2CO3 or NH4HCO3 to synthesize vanadyl (IV) basic ammonium carbonate precursor, in the atmosphere of NH3 and under the moderate condition making the above-mentioned precursor undergo the processes of ammonization and nitrogenation so as to obtain the invented vanadium nitride nano powder body whose grain size is 20nm-1 micrometer, distribution of particle size is uniform and vanadium nitride content is greater than 98%.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com