Preparation method of high-nickel, low-cobalt and low-manganese ternary positive electrode material precursor for lithium battery

A cathode material and precursor technology, which is applied in the field of precursor preparation, can solve the problems of inaccurate control of the process, harsh operating environment, and increased cost of ammonia nitrogen-containing wastewater treatment, so as to save the process and operation of ammonia nitrogen-containing wastewater Good environment and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

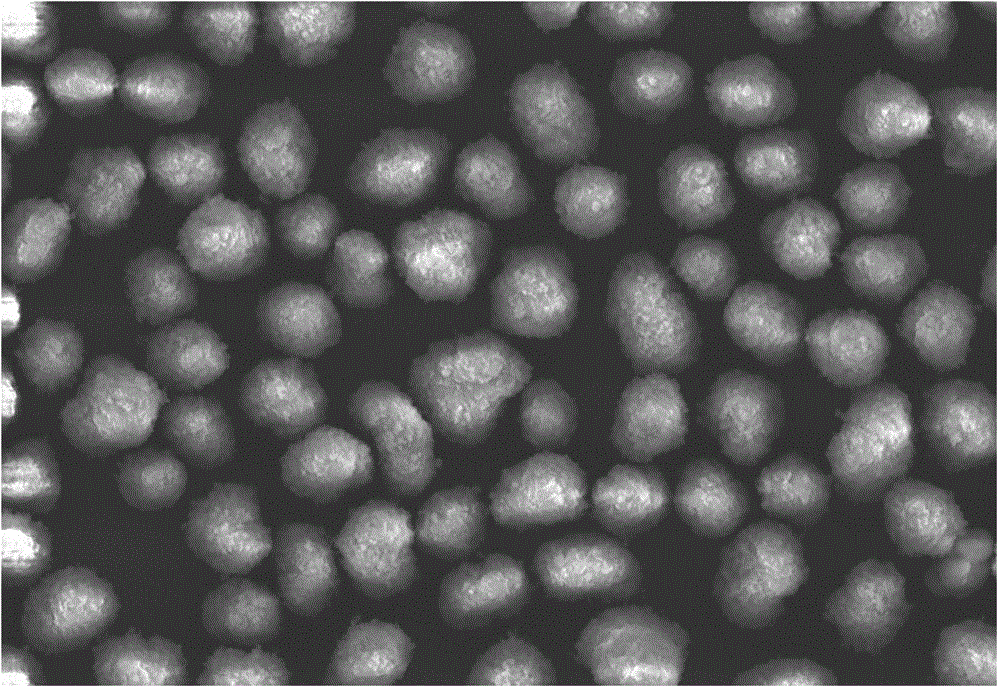

Image

Examples

Embodiment approach

[0029] The implementation mode includes the following steps:

[0030] Preparation raw material solution, the nickel salt solution that solution A contains nickel 80 grams / liter, solution B contains nickel 60-90 grams / liter, contains cobalt 10-30 grams / liter, contains the mixed solution of manganese 10-30 grams / liter (according to Nickel Hydroxide Cobalt Manganese Ni 1-x-y co x mn y (OH) 2 , 0.1≤x≤0.25, 0.1≤y≤0.25, 0.2≤x+y≤0.5 in which x and y ratios are different configurations), solution C contains sodium hydroxide 8mol / L solution, solution D contains surface active dispersant solution.

[0031]In a heated reactor with stirring, inject a certain volume of deionized water, add the calculated and metered solution C (keep the pH 10 at the end of the reaction) and solution D containing a certain amount of dispersant (volume ratio 0.01-0.05%) ) for stirring and mixing, after fully mixing, quickly add the calculated and metered solution A (the amount of Ni in the seed crystal / (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com