Static var compensator (SVC) and DC ice melting device and realization method thereof

A technology of static var compensation and DC ice melting, which is applied in the directions of reactive power compensation, reactive power adjustment/elimination/compensation, overhead installation, etc., to achieve the effects of prolonging service life, improving operating environment, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a preferred embodiment of the present invention, and the technical solutions realized by the present invention will be further described below in conjunction with the accompanying drawings.

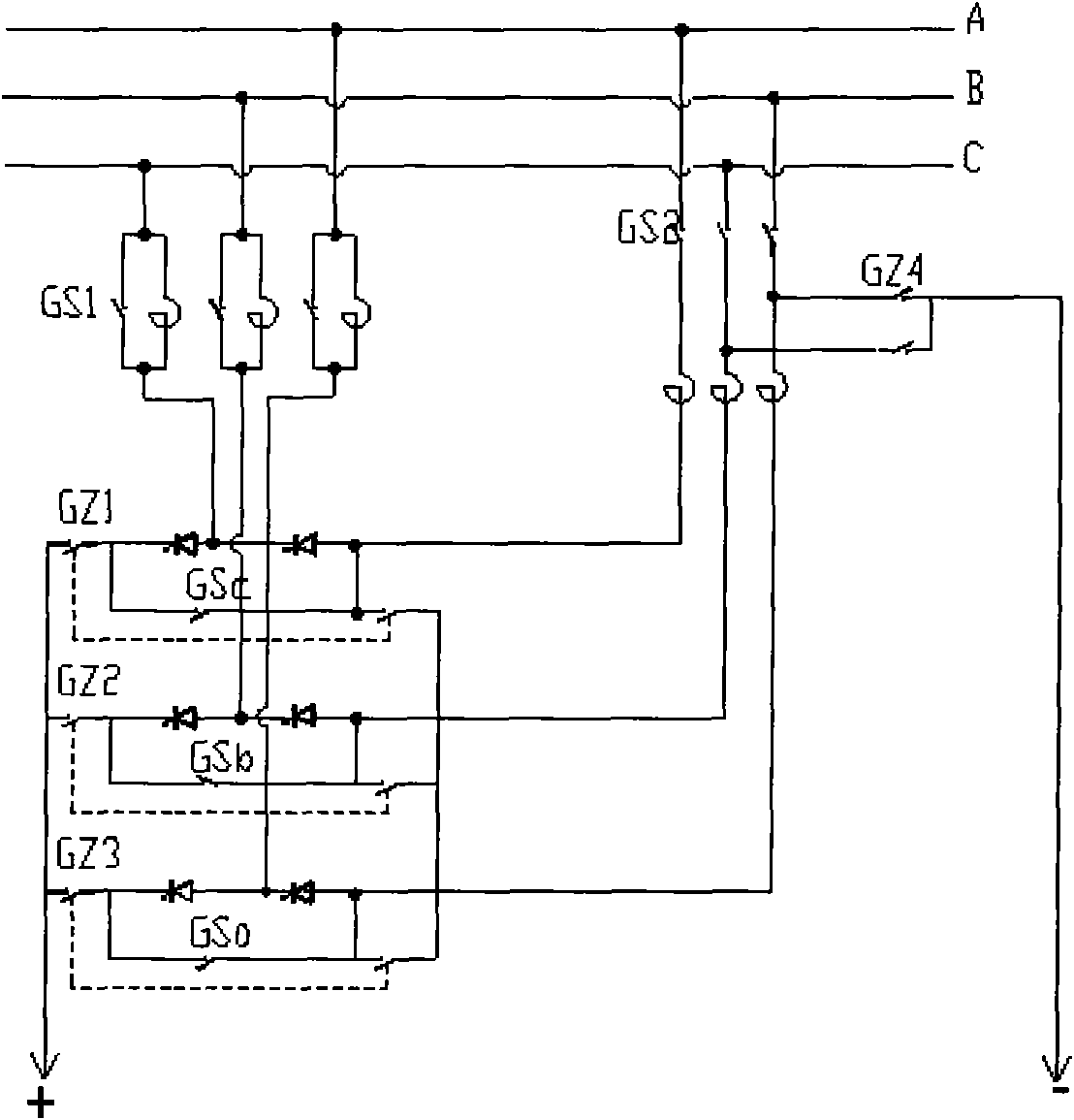

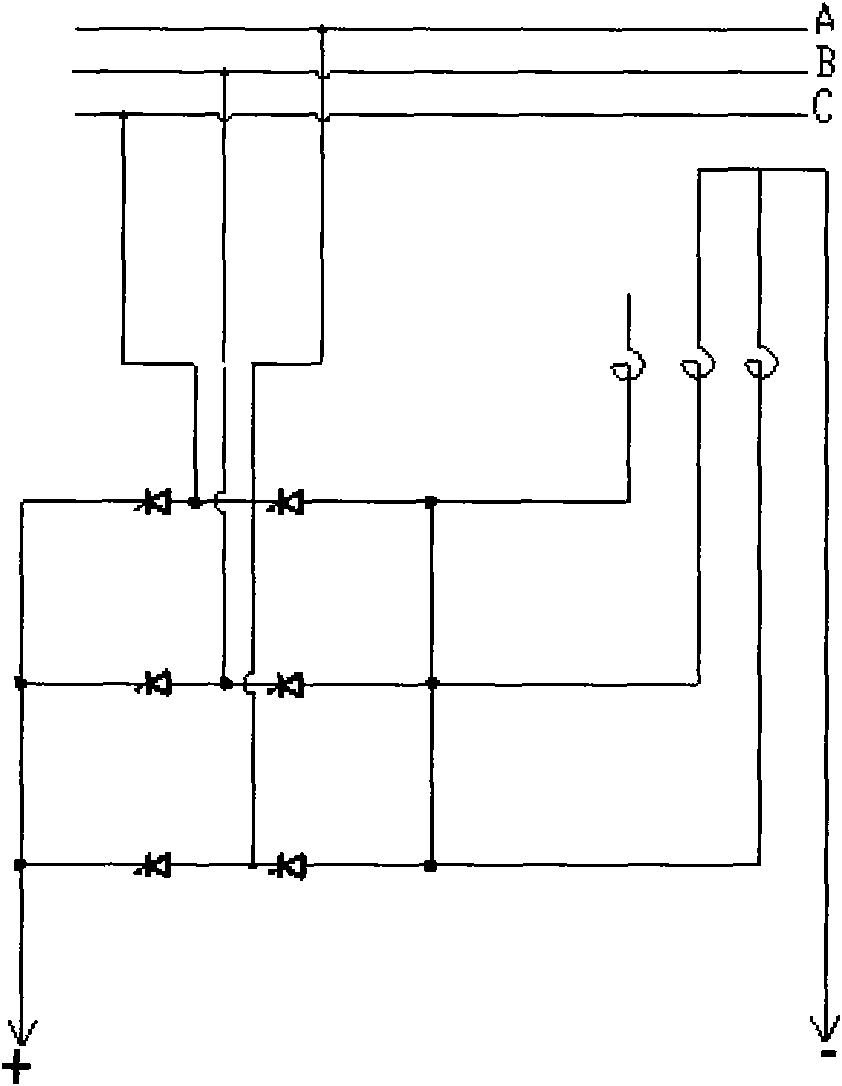

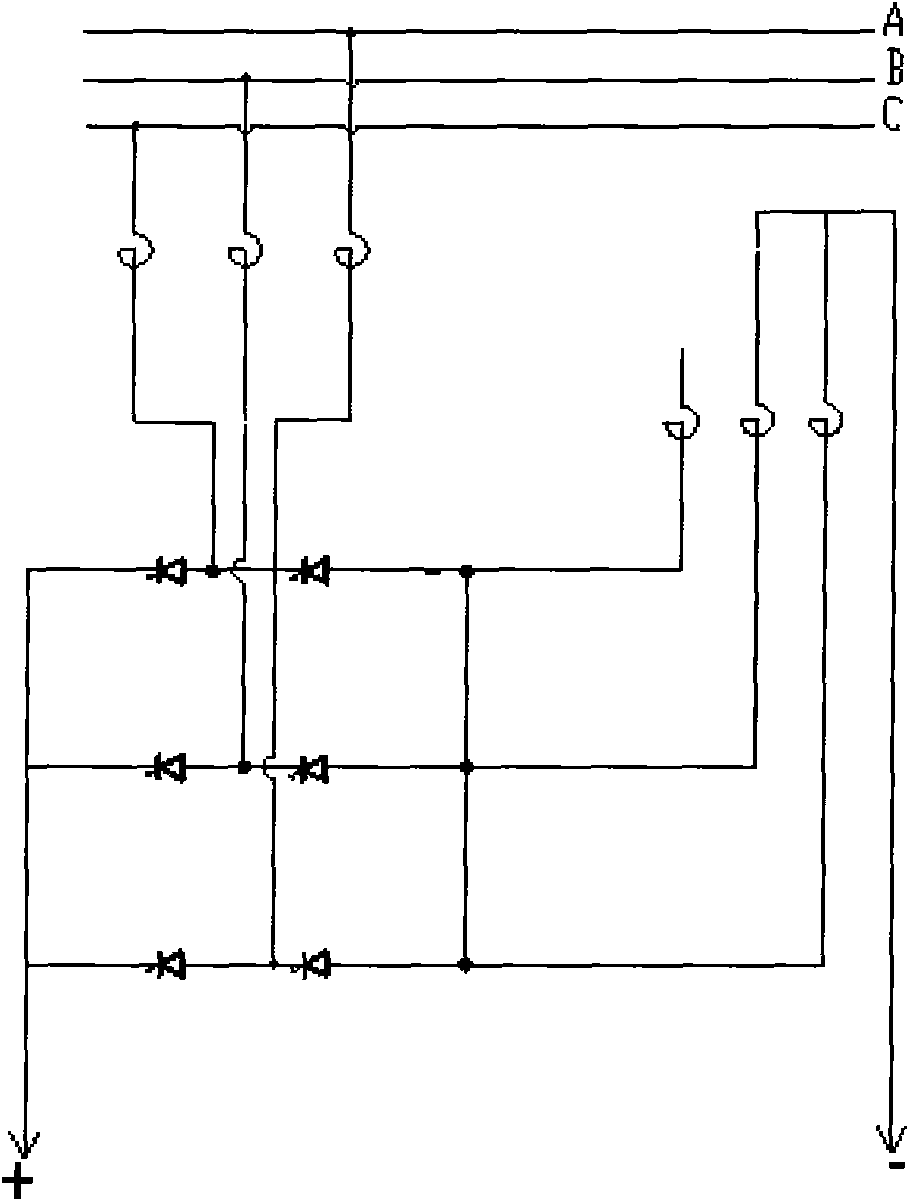

[0019] The invention proposes a static var compensation (SVC) and direct current ice-melting device and a realization method thereof. The primary equipment of the device mainly includes thyristor rectifiers, reactors, AC and DC filters, isolating switches, and zinc oxide arresters. The reconfigurable main circuit is as follows: figure 1 As shown, the thyristor rectifier is also used as a thyristor-controlled reactor type TCR valve group, and the reactor can be used as a commutation reactor and a smoothing reactor in the DC ice-melting mode, and as a thyristor-controlled reactor in the SVC mode. (TCR) phase-controlled reactor, and the thyristor rectifier and the reactor are detachable structures, by setting isolating switches between each detachable structure, seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com