High shear stress induced desulfurization and modification method for waste and old tyre rubber

A waste tire rubber and high-shear technology, which is applied in the field of polymer material modification, can solve the problems of difficult large-scale industrialization, environmental pollution, reclaimed rubber product quality, and high labor intensity of operators, so as to achieve easy automation, Low energy consumption, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 (desulfurization reaction of radial tire rubber powder blended with EPDM thermoplastic elastomer and properties of blended SBR rubber): radial tire rubber powder (GTR) 20 mesh, provided by Jiangsu Tongjiang Plastic Co., Ltd., obtained through thermogravimetric analysis: rubber content The carbon black content is 57.3%, the carbon black content is 30.1%, the ash content is 6.2%, and the volatile matter content is 6.4%.

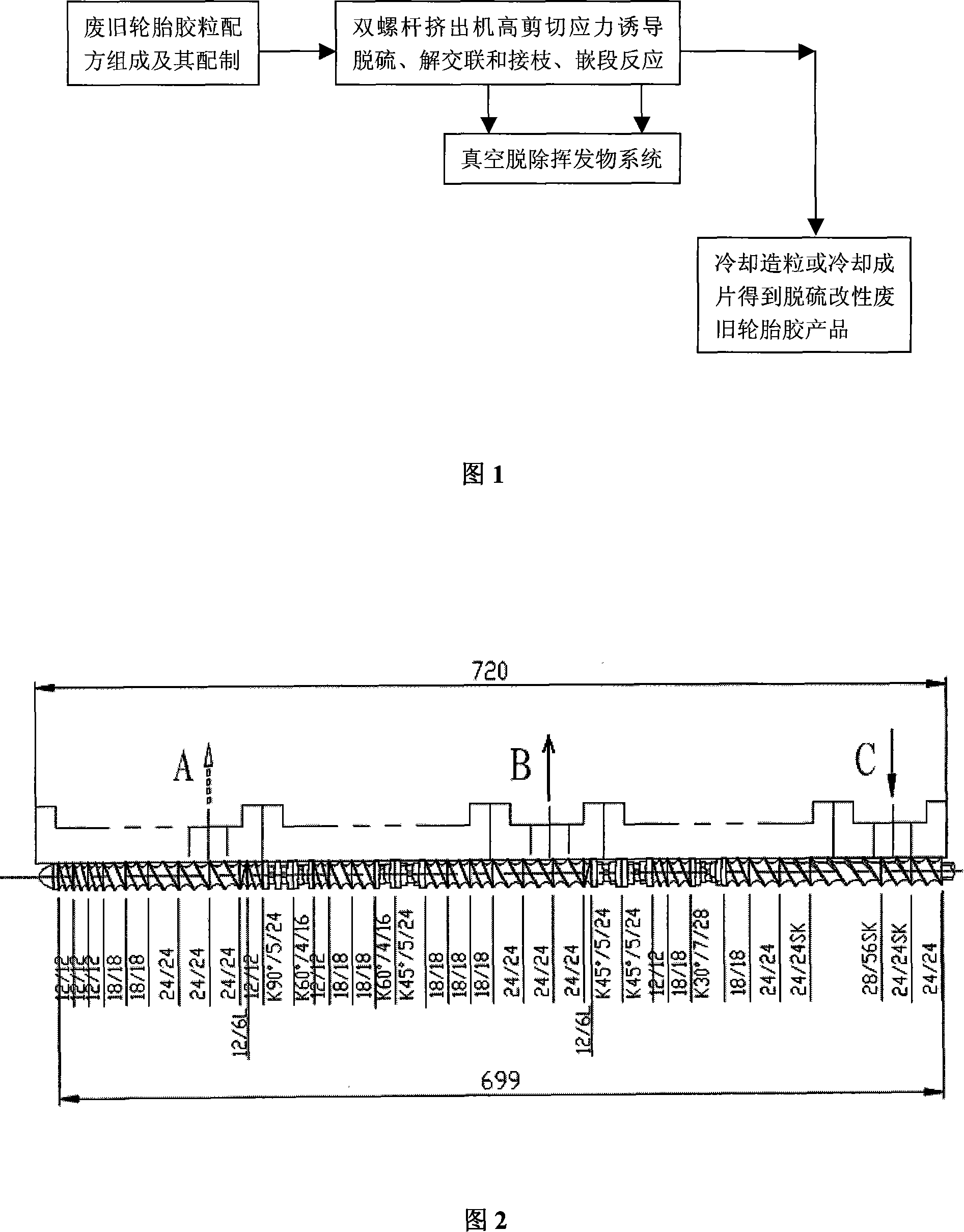

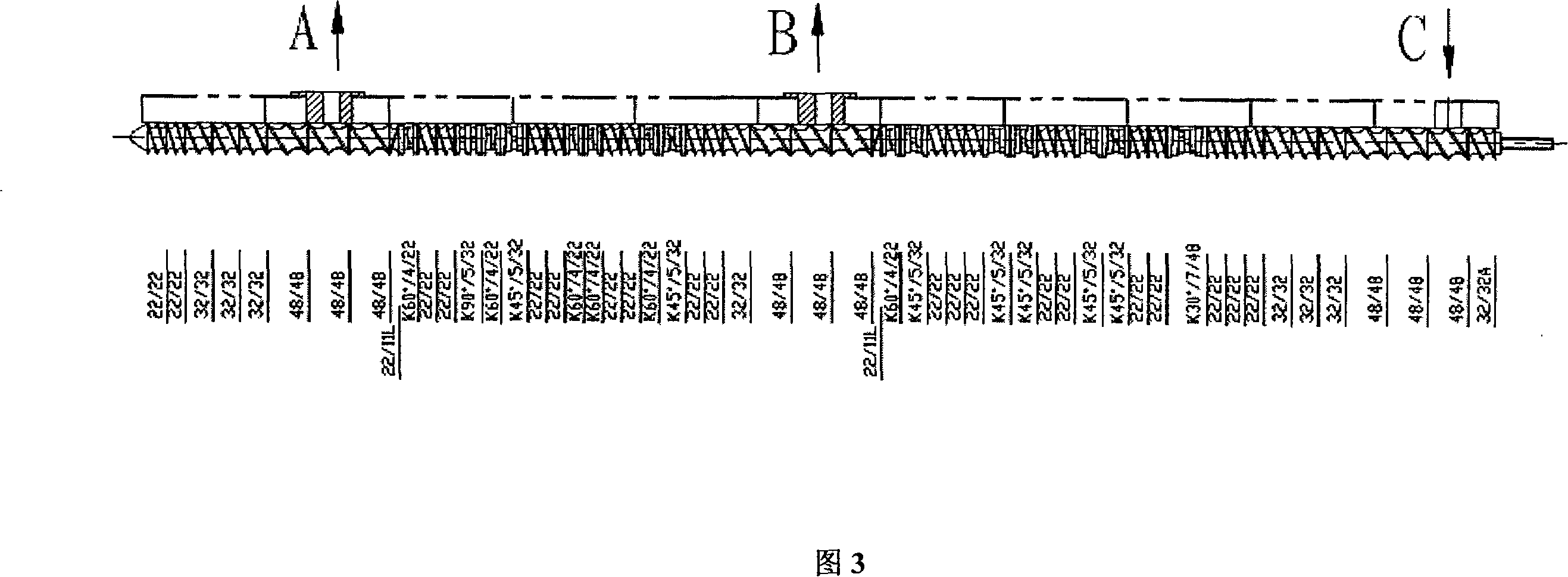

[0027]800 grams of above-mentioned tire rubber powder are mixed with 200 grams of EPDM (NDR3745 U.S. DuPont-Amoy Company product), 0.15 grams of antioxidant 1010 and 0.3 grams of calcium stearate; In the three-stage co-rotating twin-screw extruder of 45 (produced by Nanjing Keya Machinery Equipment Co., Ltd., see the attached drawings 1 and 3 for the extrusion process and the screw combination diagram of the extrusion device); the extrusion reaction temperature is controlled to 250°C, control the screw speed to 1000r / min; start the water ring v...

Embodiment 2

[0043] Embodiment 2 (radial tire rubber powder blended natural rubber NR desulfurization reaction and blended SBR rubber performance): change the EPDM in embodiment 1 into NR compound rubber containing 33.3% carbon black (N330), and the extrusion reaction temperature Change it to 180°C, change the screw speed to 800r / min, and others are the same as in Example 1. The gel content of the desulfurized product was 65.4%, the tensile strength of the vulcanized rubber sheet was 17.1MPa, the elongation at break was 330%, the tear strength was 33.7kN / m, and the Shore A hardness was 73.

Embodiment 3

[0044] Embodiment 3 (radial tire rubber powder blended butadiene rubber BR desulfurization reaction and blended SBR rubber performance): change the EPDM in embodiment 1 into BR compound rubber containing 33.3% carbon black (N330), and the extrusion reaction The temperature was changed to 180°C, the screw speed was changed to 800r / min, and the others were the same as in Example 1. The gel content of the desulfurized product was 70.9%, the tensile strength of the vulcanized rubber sheet was 17.0 MPa, the elongation at break was 312%, the tear strength was 31.8 kN / m, and the Shore A hardness was 72.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com