Patents

Literature

1699 results about "Raw rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low smoke halogen-free flame retardant ethylene-propylene-diene rubber and preparation method by extrusion molding thereof

ActiveCN101704976AGood mechanical propertiesEasy extrusionEngine sealsVehicle sealing arrangementsPolymer scienceMechanical property

The invention relates to a low smoke halogen-free flame retardant ethylene-propylene-diene rubber and a preparation method by extrusion molding thereof; the preparation method comprises the following steps: firstly, raw rubber matrix is evenly mixed at 80-100 DEG C by an open mill or a banbury mixer, and then cooled down to the room temperature; carbon black, modified nanometer / micrometer hydroxide, plasticizer, flame retardant synergist, vulcanization accelerator and vulcanizing agent are added in sequence according to the proportion and evenly mixed. Mixed rubber is added into a single screw extrusion machine; the temperature of a machine body, a screw and a machine head is controlled to be 50-90 DEG C; the rotating speed of the screw is within 15-40 r / min to cause that glue stock is continuously squeezed out; and hot air (175-200 DEG C) or microwave (915-2450 MHz) is adopted to cause that the glue stock is continuously vulcanized and molded. The flame retardant ethylene-propylene-diene rubber has excellent mechanical property, low smoke halogen-free flame retardant performance and good extrusion performance, and is applicable to manufacturing of flame retardant gland strips used in doors and windows for building and vehicles.

Owner:BEIJING UNIV OF CHEM TECH +1

Antimicrobial resin cured rubber articles and prevulcanized compositions

InactiveUS6846871B2Solve the lack of activitySufficient integrityAntifouling/underwater paintsConductive materialPolymer scienceSulfur

This invention relates to certain non-silicone resin cured rubber articles that are made from at least a majority by weight of non-silicone vulcanized rubber that include silver-based compounds to provide highly desirable long-term antimicrobial characteristics within the cured rubber articles. Such articles are in either solid or blown (foam or sponge) state (or combinations of both in multilayered forms) and can be utilized in a variety of different applications. This invention encompasses the presence of non-sulfur-based curing systems and agents, such as resin curing, that permit vulcanization and do not irreversibly bind silver ions thereto, thereby resulting in long-term antimicrobial performance of the ultimate rubber article itself. This invention also encompasses certain non-silicone pre-vulcanized raw rubber formulations made from at least a majority by weight of non-silicone rubber that include silver-based components to provide highly desirable long-term antimicrobial characteristics within the ultimate resin cured rubber articles made therefrom.

Owner:MILLIKEN & CO

High abrasion-resistant tread rubber for middle and long distance highway transportation type radial tire and producing method thereof

ActiveCN102030926AImprove wear resistanceLower Mooney ViscositySpecial tyresMicrocrystalline waxEngineering

The invention relates to a high abrasion-resistant tread rubber for a middle and long distance highway transportation type radial tire and a producing method of the tread rubber, wherein the producing method comprises the following processing steps:(1) first-stage mixing: adding nature rubber SMR20,butadiene rubber, butadiene styrene rubber and peptizer into a mixing chamber for raw rubber plastication, then adding N234 carbon black, white carbon black, a silane coupling agent, zinc oxide, stearic acid, a dispersing agent and a plasticizer for mixing, finally adding N234 carbon black for mixing, and obtaining the first-stage original rubber by discharging rubber; (2) standing for first time; (3) second-stage mixing: adding first-stage original rubber, the N234 carbon black, an anti-aging agent RD, an anti-aging agent 4020 and microcrystalline wax into an internal mixer for mixing, and obtaining second-stage original rubber by discharging rubber after the mixing; (4) standing for second time; and (5) final mixing: adding the second-stage original rubber, sulphur, an accelerator NS and a scorch retarder CTP (cytidine triphosphate) into the mixing chamber for mixing, and obtaining the tread rubber by discharging rubber. In the invention, the abrasion resistance of middle and long distance highway transportation type radial tires can be greatly enhanced, the producing and working efficiency is enhanced, and energy is greatly saved.

Owner:JIANGSU GENERAL SCI TECH

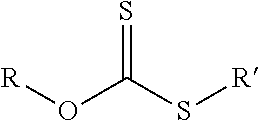

Chemically functionalized renewed rubber composition

ActiveUS20160152805A1Low hysteretic propertyImprove energy consumption efficiencySpecial tyresPneumatic tyre reinforcementsSolubilityElastomer

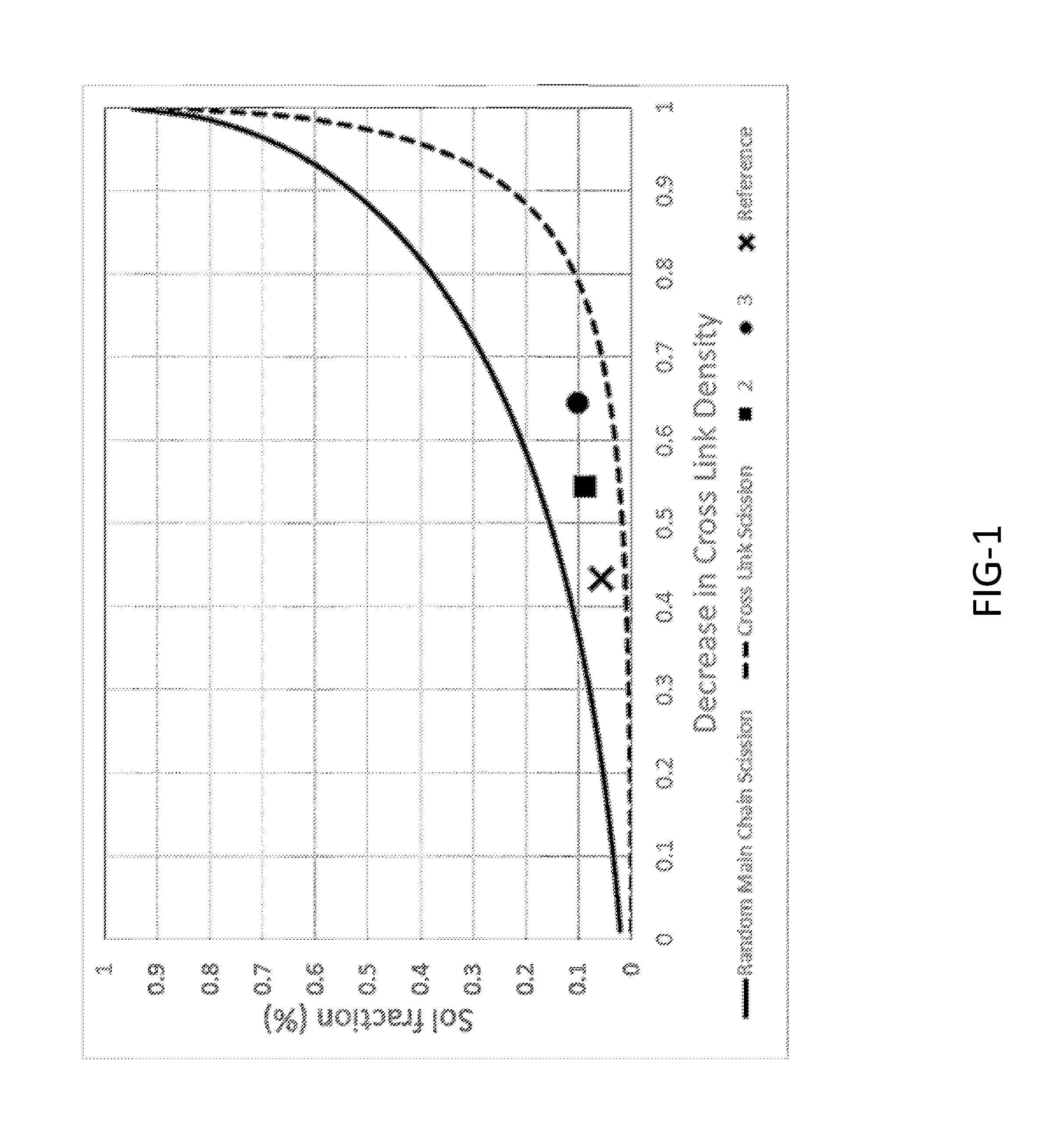

This invention relates to certain rubber formulations which exhibit a low level of hysteresis which are comprised of a chemically functionalized renewed rubber and virgin solution styrene-butadiene rubber. These rubber formulations are loaded with a reinforcing silica. The rubber formulations of this invention can be utilized in making rubber products such as, tires, tracks, and conveyor belts which will promote energy savings by virtue of their low hysteretic properties. The present invention more specifically discloses a rubber composition which is comprised of (1) a solution styrene-butadiene rubber; (2) a functionalized renewed rubber composition which is comprised of an elastomeric polymer and a stabilizer; wherein the rubber composition has a crosslink density which is within the range of 0.05 to 2.0×10−5 mole / g, and wherein the rubber composition has a solubility fraction of less than 90 percent; and (3) a reinforcing filler including reinforcing silica.

Owner:LEHIGH TECH INC

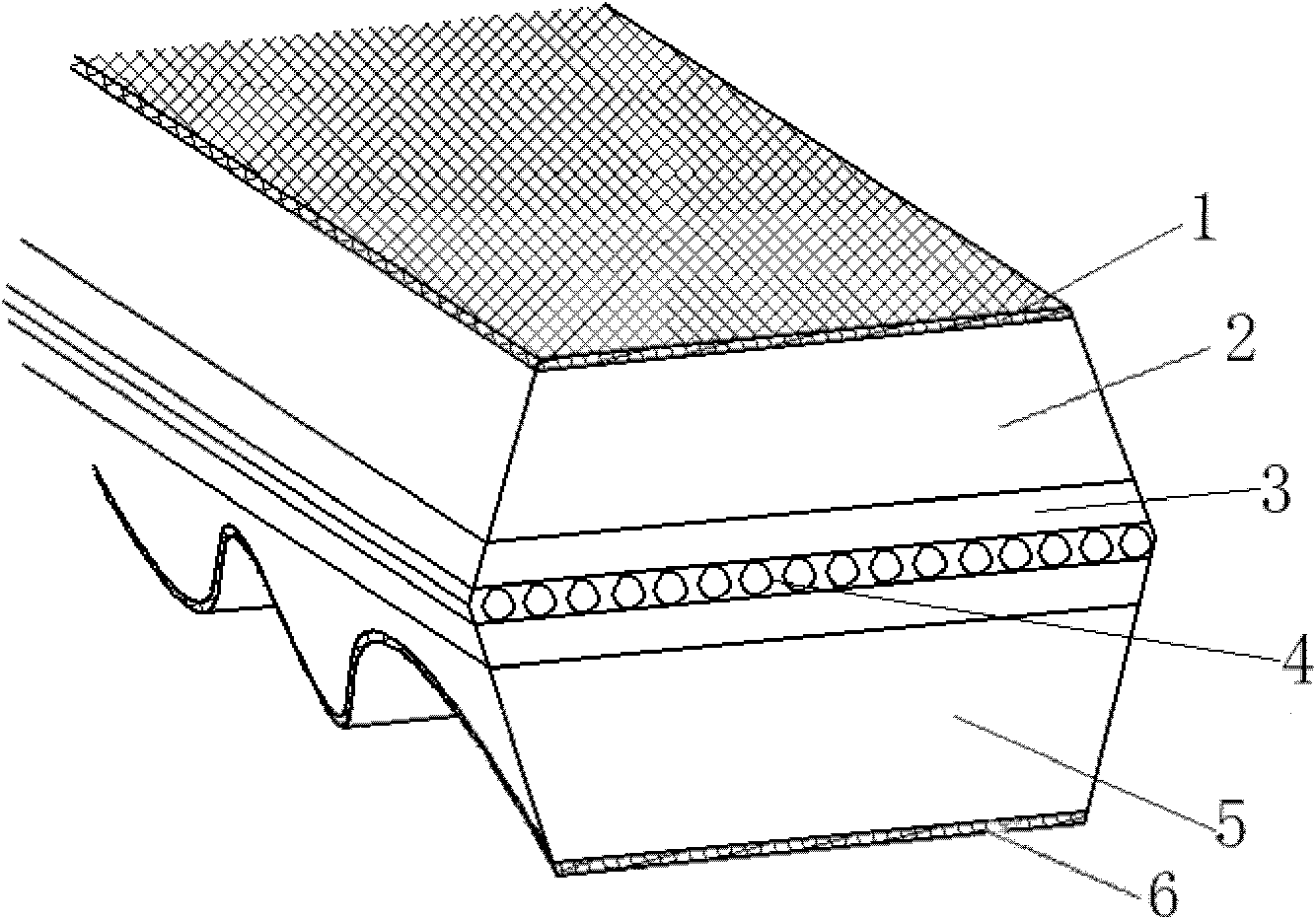

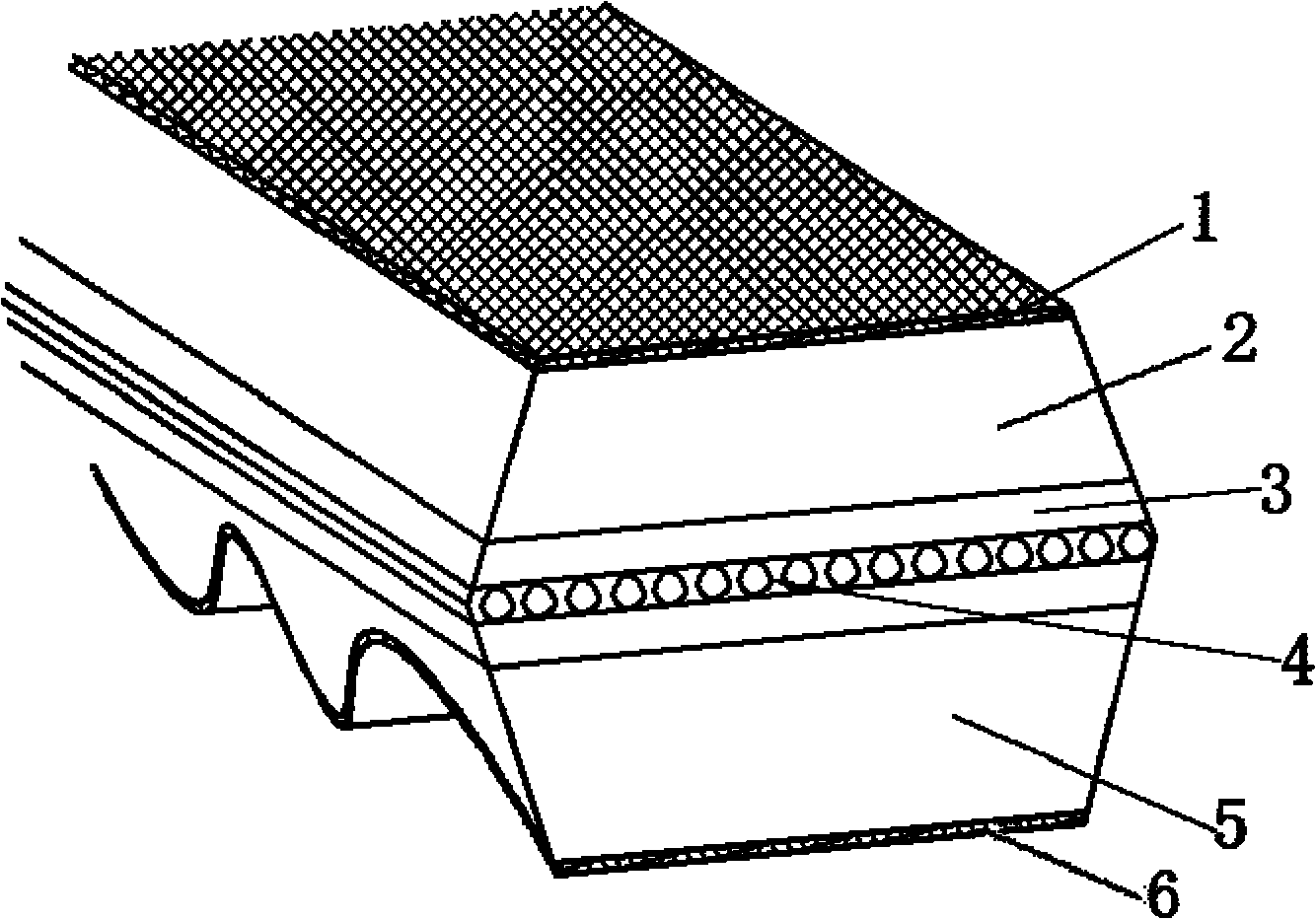

Production technology of double-surface clipping V-shaped band

The invention discloses a production technology of a double-surface clipping V-shaped band, comprising the following steps: 1) material preparing: taking raw rubber of a calendered adhesive, compounding agent of the calendered adhesive, raw rubber of a buffer glue, compounding agent of the buffer glue, raw rubber of a fiber primer, and compounding agent of the fiber primer and respectively weighing; 2) mixing; 3) calendaring; 4) reversing splicing: splicing the fiber primer reversingly; 5) shaping: successively coating a layer of base fabric, coating the fiber primer, coating the buffer glue, arraying wires, coating the buffer glue, coating the fiber primer, and coating a layer of top fabric; 6) vulcanizing: putting the shaped V-shaped band wholly in a mold, and putting the mold in a vulcanizing tank for vulcanizing; 7) clipping: controlling the clipping width and angle, and clipping the band into the required shape; and 8) grinding: controlling the grinding quantity, and grinding the band into the required dimension. According to the invention, the shaped V-shaped band is wholly put in the mold, and the mold with the V-shaped band is put in the vulcanizing tank for vulcanizing, thus the service life of the band is long, and the band is suitable for large power transmission.

Owner:杭州金瀚能源科技有限公司

Method for preparing multi-channel 3D nano texture mold

A method for preparing a multi-channel 3D nano texture mold comprises the steps of: coating photoresist on a PET photoetching material, and then entering a stainless steel dust-free furnace for dryingfor standby; arranging a mask pattern plate on the raw rubber surface of the PET photoetching material, vacuuming for photoetching, taking out the mask pattern plate after the photoetching is completed, putting the prepared developer into a cleaning box, putting the photoetching-finished PET photoetching material into the cleaning box for cleaning, displaying the pattern on the PET photoetching material, dehydrating and spinning to obtain a first texture layer; then, performing second texture layer photoetching process which is similar to the first layer, realizing second texture processing superposition to obtain the multi-channel 3D nano-texture mold. The method has the advantages of simple manufacturing process, low cost, reusability, multi-texture superposition, better texture rendering effect and improved working efficiency.

Owner:唐鸿微迅新材料科技有限公司

Large high-pressure seamless rubber airbag and production process thereof

ActiveCN102086637AHigh compressive strengthEasy to operateBarrages/weirsLifting devicesFiberPolymer science

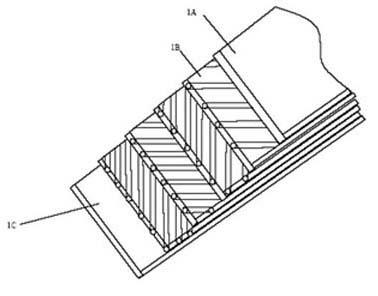

The invention discloses a large high-pressure seamless rubber airbag and a production process thereof, relating to a rubber product and a production process thereof. The large high-pressure seamless rubber airbag comprises the following compositions: EPDM (ethylene-propylene-diene monomer) externally-covered rubbers with excellent weather resistance, at least four (even number) skeleton layers, a middle adhesive layer and an inner adhesive layer, wherein each skeleton layer is composed of continuous high-strength tyre cords which are mutually crossed with an angle of 90 degrees and formed into an angle of 46-56 degrees, the middle adhesive layer is composed of chloroprene rubbers and natural synthetic rubbers, and the inner adhesive layer is made of butyl rubbers with excellent air tightness. The production process of the large high-pressure seamless rubber airbag comprises the following steps: (1) sequentially carrying out plastication, coordination, mixing and batching on raw rubbers; (2) carrying out impregnation and rubberizing on the high-strength tyre cords; (3) carrying out rotating preforming on the obtained object by using a roller; weaving open-end fibers, so that the joints of the fibers are arranged in a continuous shape, and sticking films on the fibers; (4) carrying out integral molding on the obtained object once; (5) carrying out integral vulcanization on the obtained object; and (6) carrying out reinforced heat vulcanization on edges and corners of the obtained product. The production process disclosed by the invention is simple and convenient in operation; the service time of the rubber airbag is more than 50 years, and the environmental sanitation index of the rubber airbag exceeds four orders of magnitude of the international standard requirement. The large high-pressure seamless rubber airbag and production process disclosed by the invention are used for the hoisting of pneumatic-shield gate dams and heavy objects.

Owner:TIELIN ERFAN RUBBER R & D CO LTD +1

Heat-conducting silicon rubber composite material and preparation method thereof

ActiveCN102757648ASmall coefficient of thermal expansionEfficient deliveryHeat conductingCarbon nanotube

The invention belongs to the technical field of silicon rubber materials and discloses a heat-conducting silicon rubber composite material and a preparation method thereof. The heat-conducting silicon rubber composite material comprises the following components by weight: 15 to 25 parts of high-temperature vulcanized silicon rubber raw rubber, 65 to 79 parts of heat-conducting filler, 2.5 to 4.5 parts of carbon nanotube, 0.05 to 0.1 part of hydroxyl silicon oil, 0.1 to 0.15 part of vulcanizing agent, 2 to 5 parts of white carbon black and 0.6 to 1 part of coupling agent. The invention further discloses the preparation method for the heat-conducting silicon rubber composite material. The heat-conducting silicon rubber composite material can effectively transfer heat, reduces the thermal expansion coefficient of the material and effectively prevents invasion of dust, water and the like on electronic devices. The method is simple and practical and the filler is easy to treat.

Owner:HEFEI GENIUS NEW MATERIALS

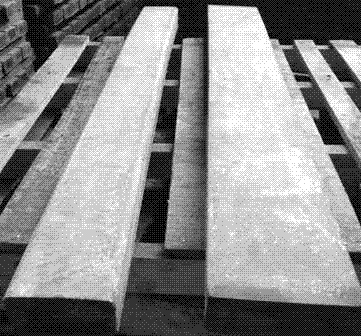

Pre-fabricated rubber running track and manufacturing process thereof

InactiveCN101805466AMprove weatheringExcellent ozone resistanceGround pavingsFlat articlesAluminum silicateUltraviolet

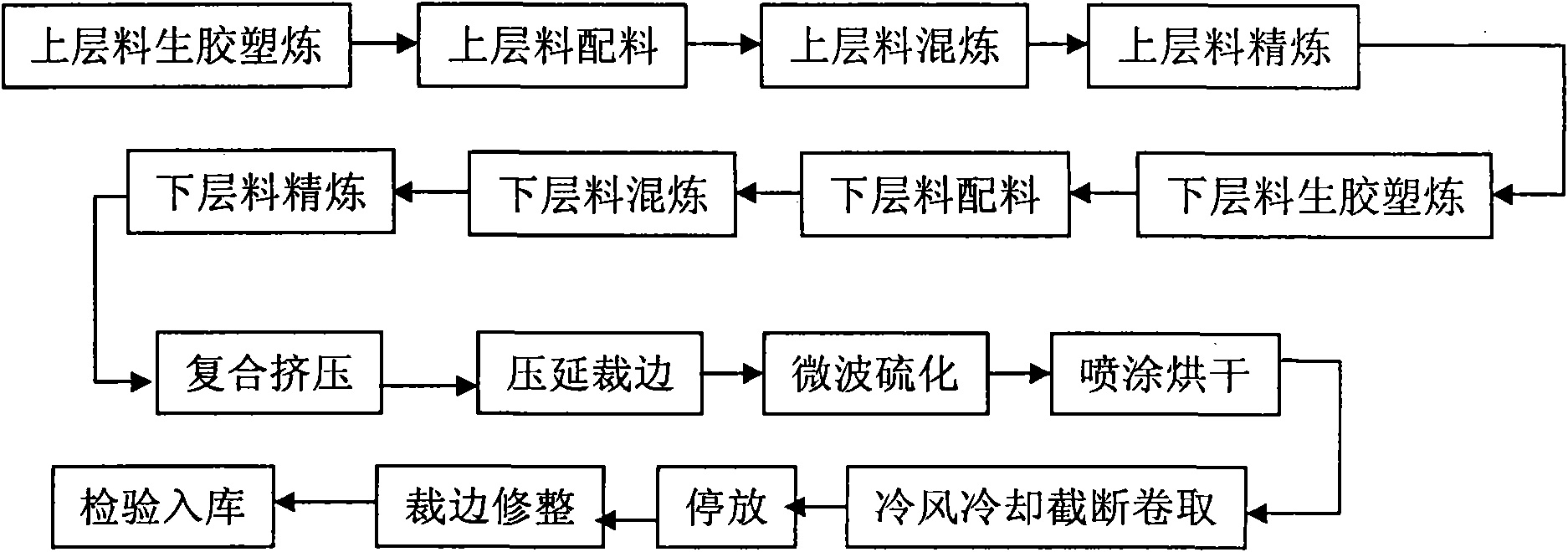

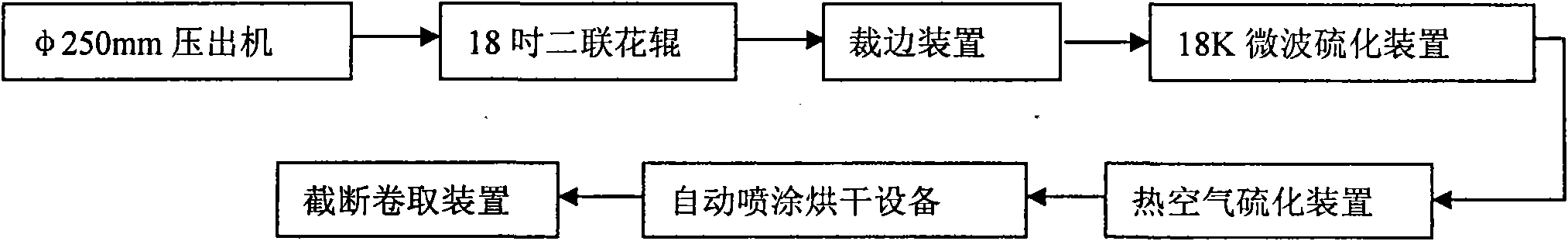

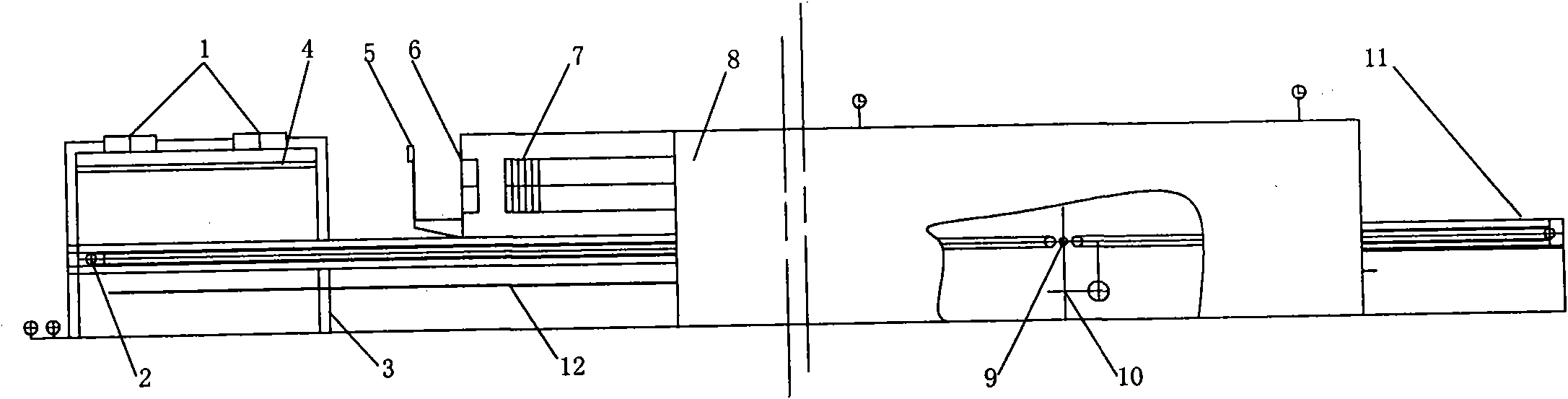

The invention relates to a pre-fabricated rubber running track and a manufacturing process thereof. The invention adjusts the proportion of selected rubber, a UV absorber, white carbon black, aluminum silicate and other components and researches and develops the novel process, and the process is as follows: upper layered material raw rubber plasticating->upper layered material preparation->upper layered material mixing->upper layered material refining->lower layered material raw rubber plasticating->lower layered material preparation->lower layered material mixing->lower layered material refining-> composite extrusion->rolling and edge cutting-> microwave vulcanization spray drying->cold air cooling, truncation and coiling. The invention adopts the novel process, reduces vulcanization process temperature difference, has uniform vulcanization temperature and consistent vulcanization degree, improves the product density, prevents surface cracks, delamination, bubbles and other quality problems, and reduces the labor intensity of a worker and the post manpower. As tested, under the condition of 40DEG C 50pphm, the surface of the running track does not crack for 200h, the rebound value is more than 30 percent, the tensile strength is more than 2MPa, and the tensile strength is more than 1.5MPa after 6h of hot air aging at 100DEG C. Therefore, the weather aging and ozone resistance performance of the running track are greatly improved, and the quality of the running track meets the IAAF standard.

Owner:天津纽威特橡胶制品股份有限公司

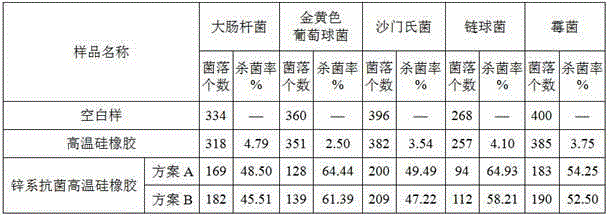

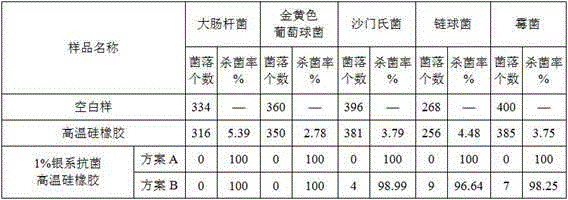

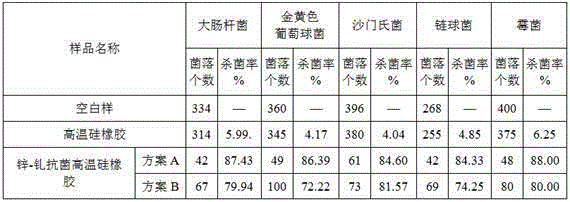

Preparation method of antibiosis high temperature silicone rubber

ActiveCN105238056AStrong antibacterial broad spectrumHigh antibacterial broad spectrumPolymer scienceTemperature resistance

The invention discloses a preparation method of antibiosis high temperature silicone rubber. The method comprises the following steps: adhering antibiosis ions to a white carbon black carrier through a sol-gel technology to obtain antibiosis gel; and adding corresponding high temperature silicone rubber raw rubber, fully mixing, and vulcanizing to prepare a high temperature silicone rubber material with antibiosis ability, or directly adding high temperature silicon sulfide rubber, fully fusing, and curing to obtain the silicone rubber material with antibiosis ability. The antibiosis high temperature silicone rubber prepared in the invention has the advantages of high temperature resistance, enhancement of the mechanical performances of silicone rubber, high antibiosis, strong antibiosis broad spectrum activity, high sterilization rate, no generation of drug resistance, safety to human bodies and environment, wide uses, and facilitation of the large-scale quantitative production of the future market.

Owner:KUNMING UNIV OF SCI & TECH

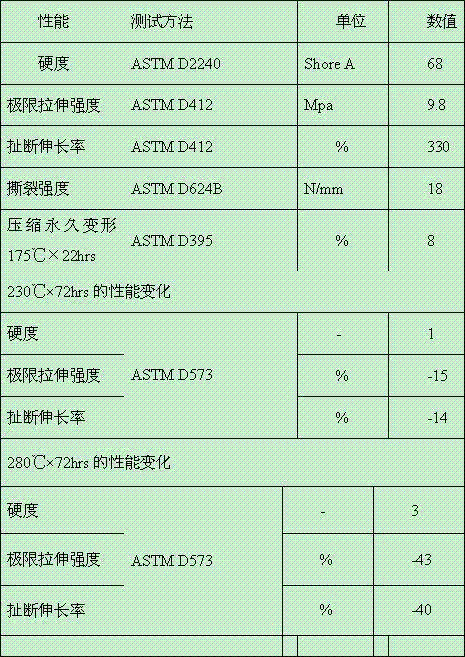

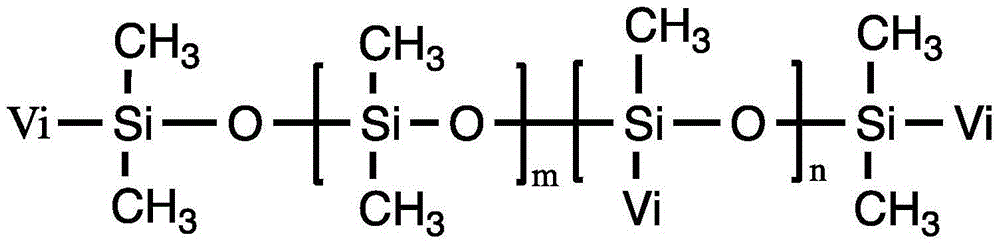

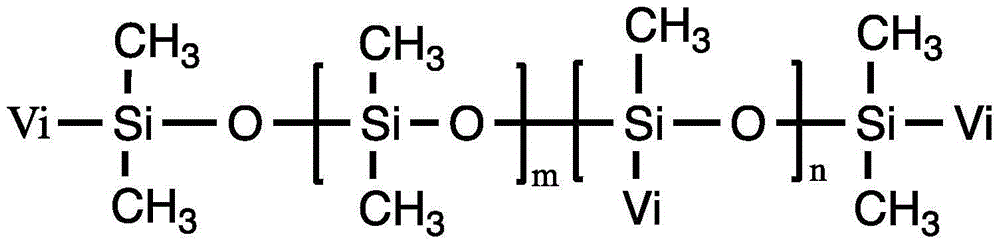

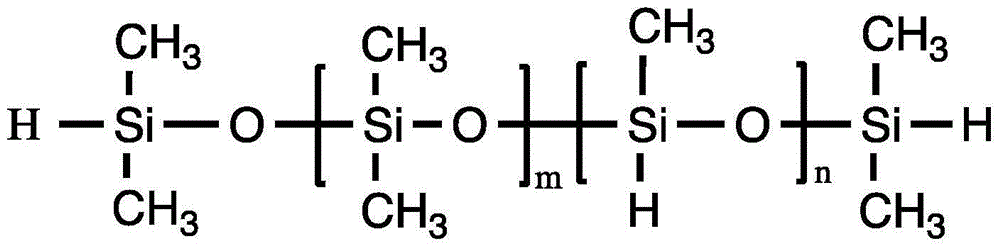

High temperature mixing silicone rubber as well as preparation method and application thereof

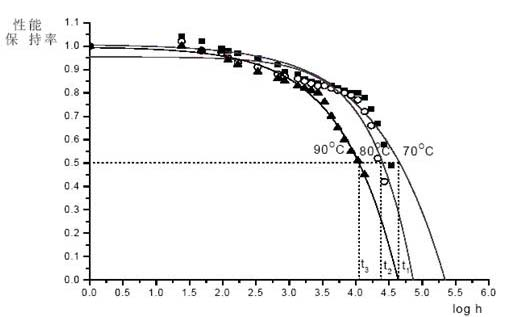

ActiveCN104761911AHelp with installationExtended service lifePolymer scienceLTV vinyl silicone rubber

The invention discloses high temperature mixing silicone rubber as well as a preparation method and an application thereof. According to the high temperature mixing silicone rubber disclosed by the invention, raw methyl phenyl vinyl silicone rubbers with different proportions are added in the raw methyl vinyl silicone rubber to serve as raw rubber, hydrophobic gas phase white carbon black is used as fillers, and ageing resistant additives are added, so that the obtained high temperature mixing silicone rubber has excellent high temperature ageing resistance. The high temperature mixing silicone rubber disclosed by the invention has the advantages of good high temperature ageing resistance, long service life, ultralow permanent compression deformation and is capable of automatically forming an oil film to isolate water vapor, and the like, and the high temperature mixing silicone rubber is particularly suitable for automobile sealing elements and has a good application prospect.

Owner:XINAN TIANYU SILICONE CO LTD +1

Vibrating diaphragm for electro-acoustic system and preparation method of vibrating diaphragm

The invention belongs to the technical field of acoustic materials and discloses a vibrating diaphragm for an electro-acoustic system. The vibrating diaphragm is prepared from a rubber mixed compound, wherein the rubber mixed compound is prepared by mixing raw rubber, a filling and an additive; the vibrating diaphragm is prepared from the rubber mixed compound through vulcanization; the rubber mixed compound is prepared by mixing raw rubber, the filling and the additive; the raw rubber contains nitrile groups and / or ester groups; the filling contains Si-O-Si groups; the additive contains a vulcanizing agent. The invention simultaneously provides a preparation method of the vibrating diaphragm. According to the preparation method, a rubber material is utilized for replacing a multi-layer resin composite film raw material to prepare the vibrating diaphragm, and distortion can be reduced by virtue of internal friction of the rubber, so that the nature of sound can be well restored by the prepared vibrating diaphragm; and besides, the material cost is low, the processing process is simple, the forming consistency is good, and the production efficiency can be substantially improved.

Owner:AAC TECH PTE LTD

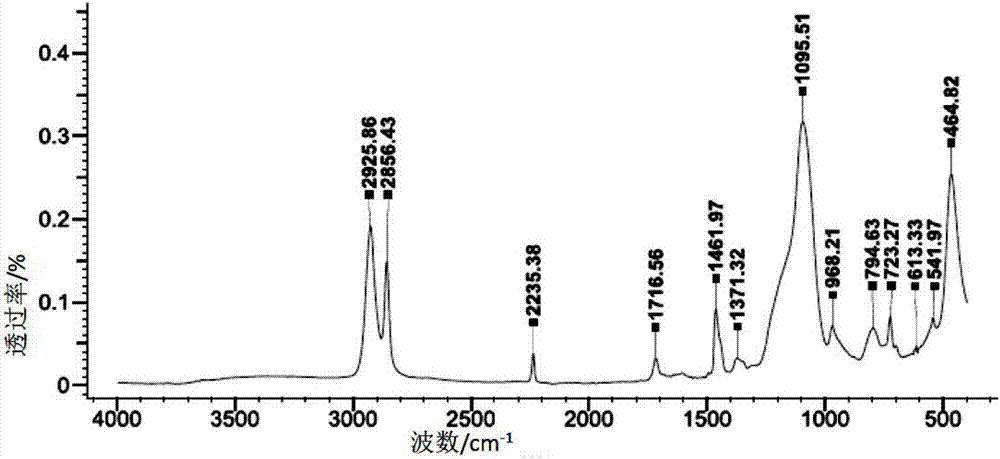

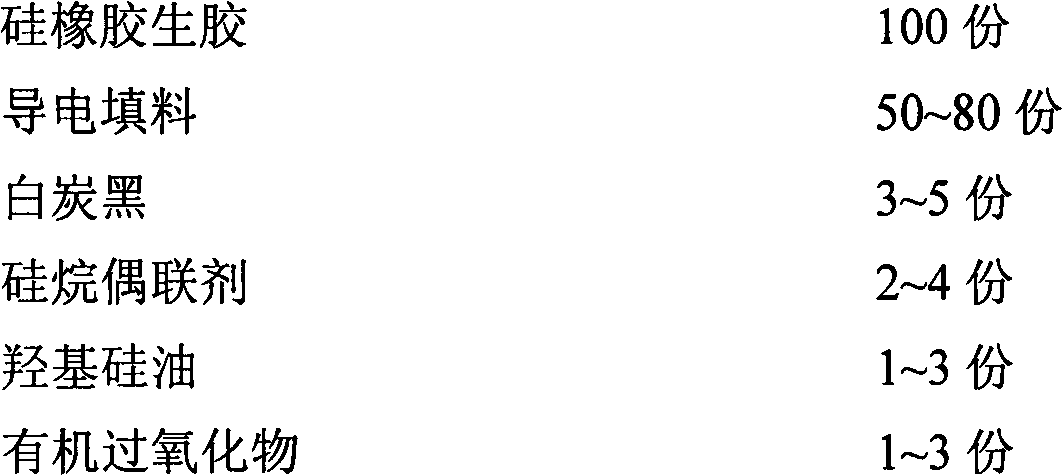

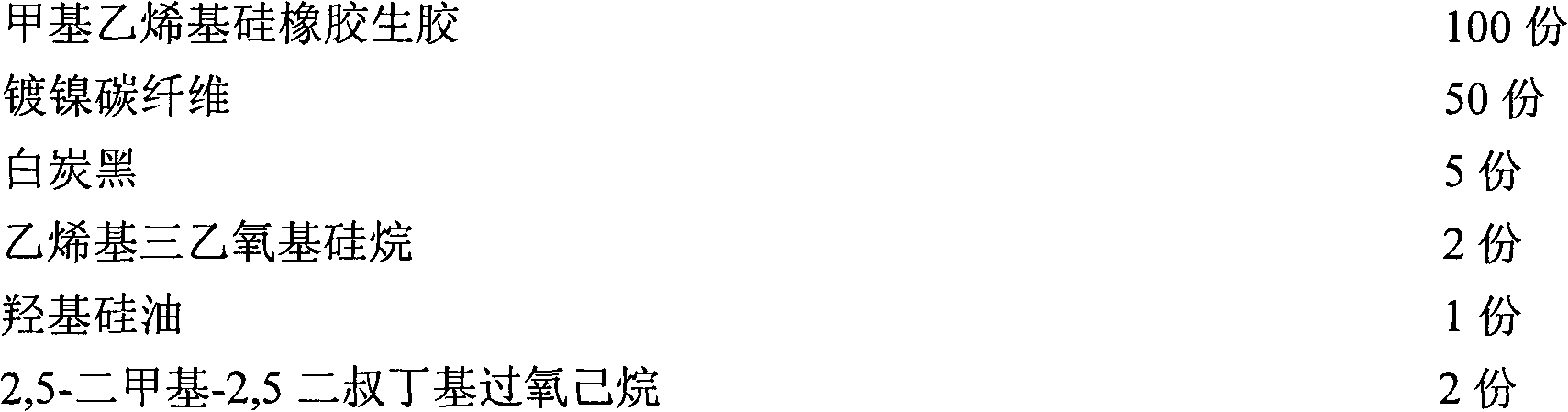

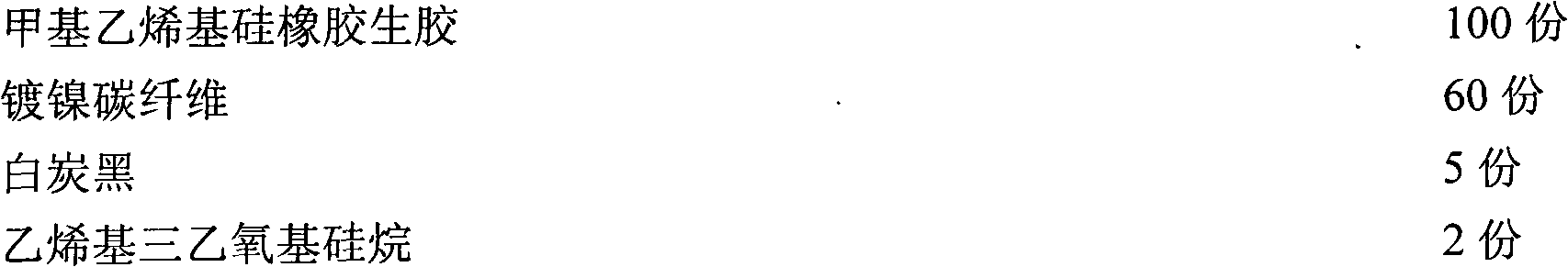

Low-density high-strength conductive rubber and preparation method thereof

The invention relates to a low-density high-strength conductive rubber and a preparation method thereof. According to mass, the raw materials comprise: 100 portions of raw silicon rubber, 50-80 portions of conductive filler, 3-6 portions of white carbon black, 2-5 portions of silane coupling agent, 1-3 portions of hydroxy silicone oil and 1-3 portions of organic peroxides. An open double-stick rubber mixing machine is used for processing. The method includes the following steps: after mill banding of raw rubber, adding the white carbon black, conductive fiber, silane coupling agent and hydroxy silicone oil for mixing; and after uniformly mixed sizing material goes through mill run, adding the organic peroxides, conducting mill run and rolling with output of sheets. A low-density high conductive rubber can be acquired with a relatively low additive amount of conductive filler that is served as by low-density high conductive fiber.

Owner:TIANJIN UNIV

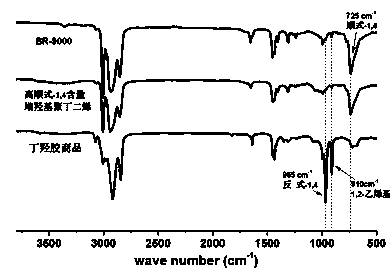

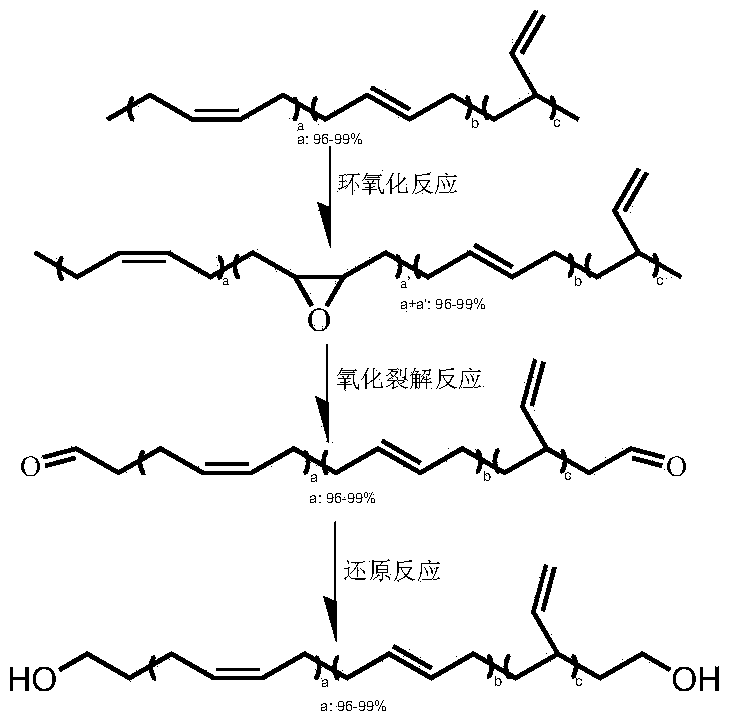

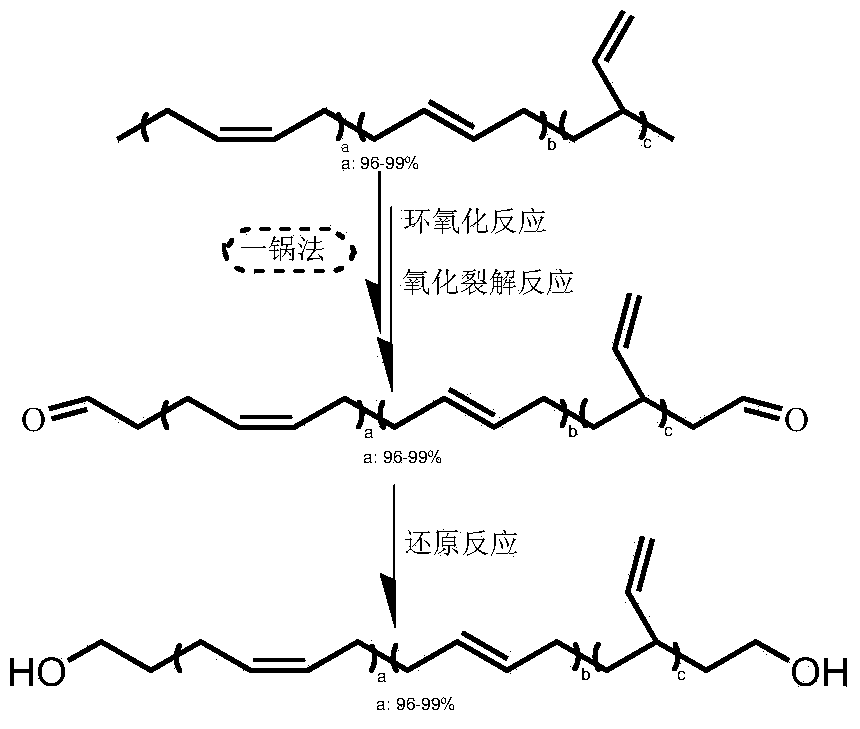

High-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and preparation method thereof

The invention discloses a high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and a preparation method thereof. The method includes following steps: (1) preparing epoxidized butadiene rubber from butadiene rubber; (2) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the epoxidized butadiene rubber; (3) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the butadiene rubber in a one-pot manner; (4) reducing the high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber to prepare the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber. In the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber is prepared from the butadiene rubber and the content of cis-1,4 can reach 95.0-99.0%. A number-average molecular weight of the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be regulated between 2000 g / mol and 10000 g / mol. A molecular weight distribution is 1.2-3.0 and a degree of functionality is 1.9-2.2. On the basis of excessive supply in raw rubber of butadiene rubber and increased tensing situation of petroleum sources, by means of the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be prepared through oxidative pyrolysis of the butadiene rubber, so that the method has a quite important practical significance.

Owner:ZHEJIANG UNIV

Blown rubber for thick product and variable temperature mould pressing preparation method thereof

The invention relates to a blown rubber for a thick product. The blown rubber comprises a raw rubber matrix, a filler, carbon black, a plasticizer, a vulcanizing agent, a vulcanization accelerator, a blowing agent and an antiager, wherein the blowing agent is compounded by an organic blowing agent, a blowing activator and an inorganic blowing agent, and the organic blowing agent is a blowing agent AC, blowing agent H or a blowing agent OBSH (p,p'-oxybis(benzenesulfonyl hydrazine)). In preparation, the raw materials are mixed and extruded to form mixed material films, the mixed films are placed in a die, the pressure of a plate vulcanizer is regulated to 13-15MPa, and the temperature is regulated according to following time ranges for sulfide forming: the first stage: 60-70 DEG C, 30-60 minutes; the second stage: 80-100 DEG C, 30-40 minutes; the third stage: 110-140 DEG C, 30-40 minutes, and then the blown rubber composite can be obtained. The product has good apparent density and strength and is uniform in foaming.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Silicon rubber/conductive ethylene propylene terpolymer and its preparing method

InactiveCN1470559AGood effectImprove mechanical propertiesNon-conductive material with dispersed conductive materialConductive polymer compositePolymer science

The present invention relates to a silicone rubber / EPT conductive rubber and its preparation method. Its raw material composition includes EPT rubber raw rubber, silicone rubber raw rubber, silane coupling agent, organic peroxide, carbon black and white carbon black, and its preparation method includes the following steps: adopting open double roller mixing machine, successively mixing them uniformly, sheeting, rolling and others. Said invention conductive rubber has good mechanical property, and its preparation method is simple, its cost is low and its product quality is good.

Owner:SHANDONG UNIV

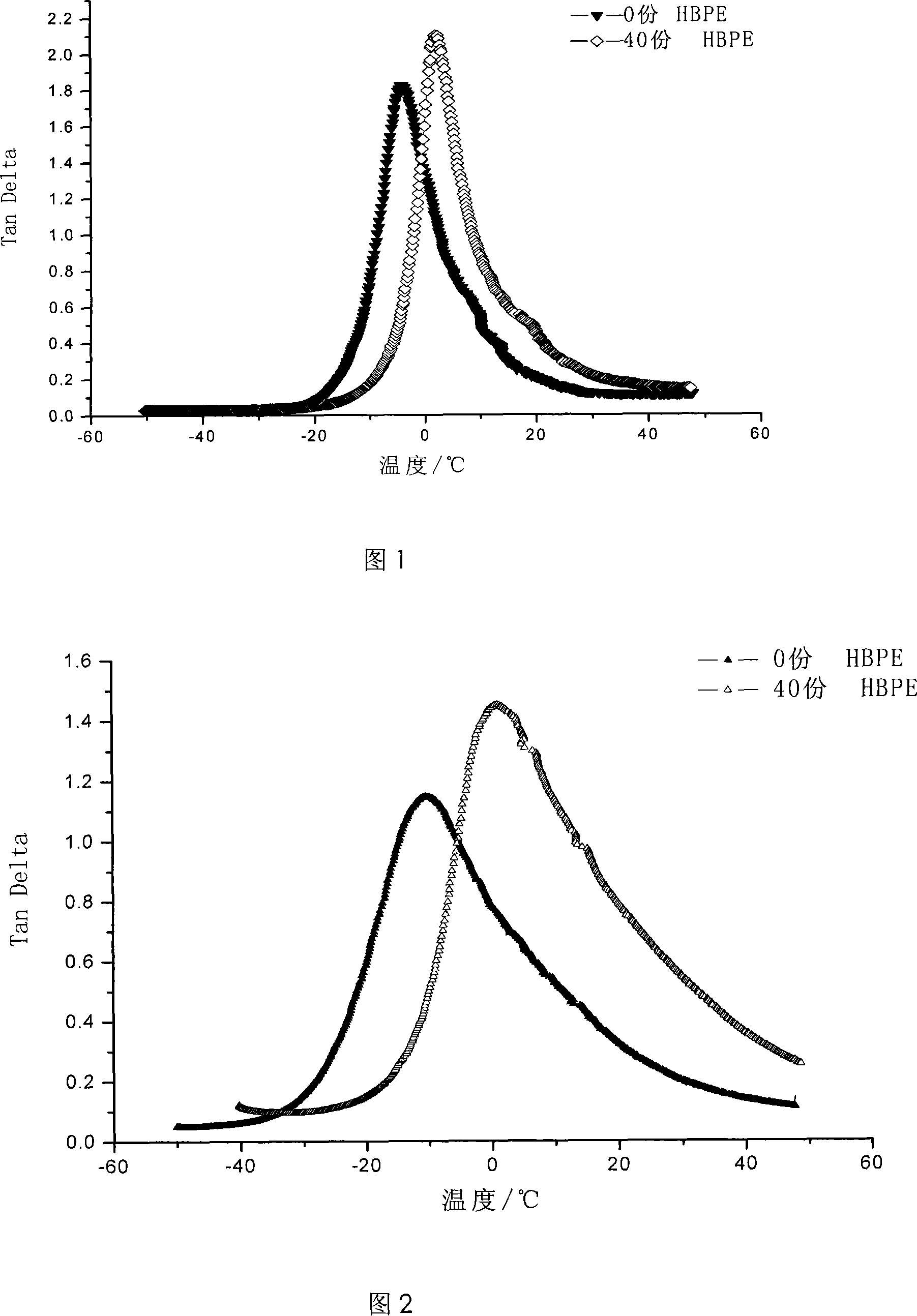

Preparation of high-damping rubber containing hindered phenol terminated hyper branched polymer

The invention belongs to the field of functional polymer materials. Aiming at the defect that the small organic molecules are easy to be moved and are easy to low the mechanical properties of a rubber, a hyperbranched polymer promoter capable of effectively enhancing the damping capacity of the rubber is designed. The invention is calcualted in mass percentage: 100 shares of raw rubbers, 10 to 40 shares of terminated hyperbranched polymers of hindered phenol, 0.5 to 1 share of potassium stearates, 3 to 5 shares of stearic acids, 5 to 8 shares of zinc oxides, 1 to 2 shares of sulfurs and 20 to 30 shares of carbon blacks are selected and the raw materials are mixed with each other uniformly on an open mill; the mixtures are subject to the packing mixing for 8 to 12 times; the mixtures are driven to rest for 10 to 16 hours with ventilation and the vulcanization time of the mixtures is tested on a rotor-free curometer at a temperature ranging from 150 DEG C to 170 DEG C; the curing time is recorded after the vulcanization curve flattens out; then the vulcanization is carried out utilizing a platten curometer, the temperature is set to range from 150 DEG C to 170 DEG C corresponding to the rotor-free curometer and the pressure is 15MPa and the strips are taken out. The invention can enhance the damping capacity of the rubber, overcome the defect of a small organic molecular promoter without lowering the mechanical properties of the rubber and maintain the stable performances for a long time.

Owner:BEIJING UNIV OF CHEM TECH

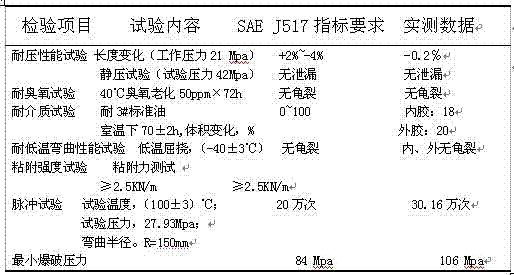

Compact steel wire braided rubber hose and preparation method thereof

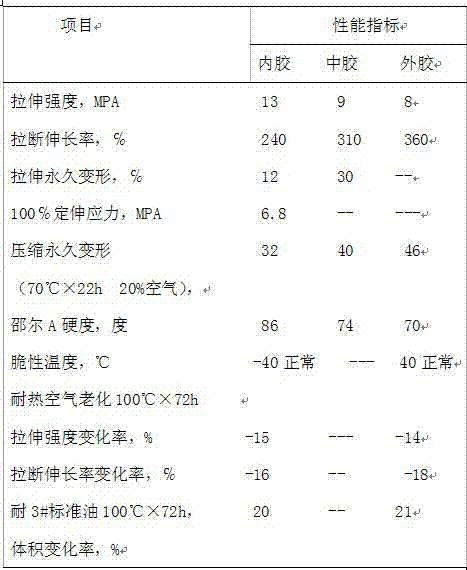

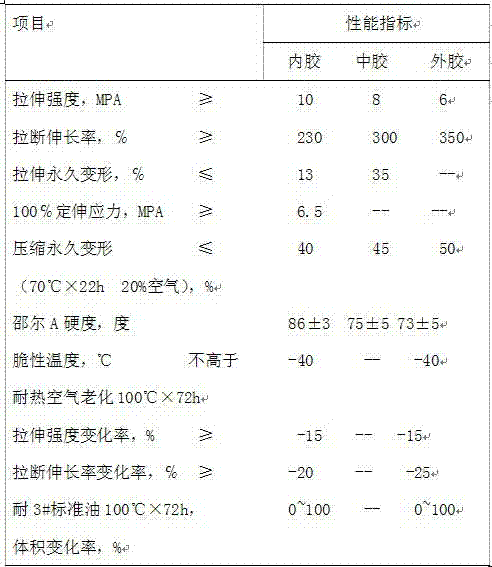

The invention discloses a compact steel wire braided rubber hose, which comprises an inner rubber layer, two steel wire layers which are braided outside the inner rubber layer, a middle rubber layer between the two steel wire layers and an outer rubber layer outside the steel wire layers. The inner rubber of the inner rubber layer, the middle rubber of the middle rubber layer and the outer rubber of the outer rubber layer are made of the following raw materials: raw rubber, reinforcing agents, softening agents, minor ingredients, adhesive and accelerating agents. The invention additionally discloses a preparation method of the compact steel wire braided rubber hose. The compact steel wire braided rubber hose has the advantages that the structure is reasonable, the pulse compression deformation is small, the weight of the rubber hose is light, the bending radius is small, all performances of the finished product satisfy requirements in notes of SAEJ517R17, the pulse performance is stable, the pulse times exceeds 300 thousand and the service life of the rubber hose is greatly prolonged.

Owner:LUOHE LETONE RUBBER

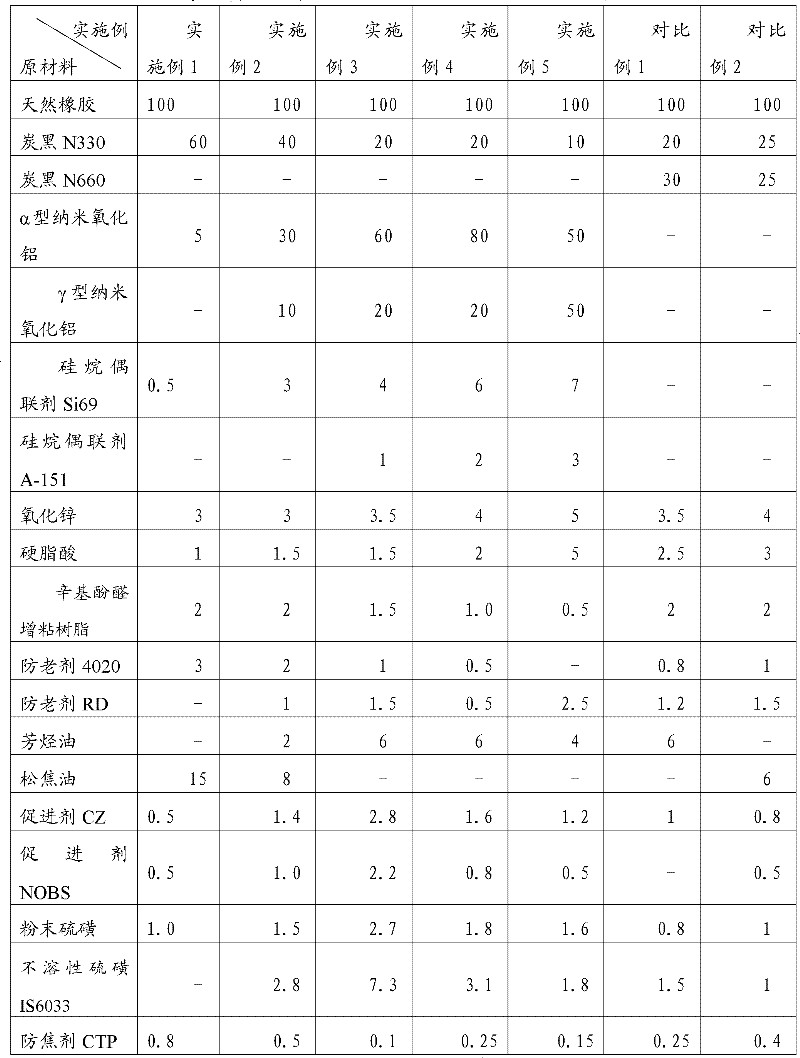

Strengthened and heat-conducting rubber for heavy truck tire shoulder

The invention provides a strengthened and heat-conducting rubber for a heavy truck tire shoulder, belonging to the technical field of rubber products. The existing pure-carbon-black-filled rubber for the tire shoulder has the problems that the heat generated under dynamic conditions is high, the heat conductivity is low and the rubber is easily destroyed at a high temperature. The strengthened and heat-conducting rubber for the heavy truck tire shoulder comprises the following components in parts by weight: 100 parts of raw rubber, 0.5-2 parts of 203 resin, 10-60 parts of carbon black, 5-100 parts of nano alumina, 0.5-10 parts of silane coupling agent, 1-3 parts of antioxidant, 1-5 parts of stearic acid, 3-5 parts of zinc oxide, 1-5 parts of accelerator, 1-10 parts of crosslinking agent, 2-15 parts of softener and 0.1-0.8 part of anti-scorching agent. The rubber composite material for the heavy truck tire shoulder has the excellent characteristics of high strength, low heat generationand high heat conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Antimicrobial articles and compositions made from styrene butadiene rubber

InactiveUS6943205B2Solve the lack of activitySufficient integrityAntifouling/underwater paintsConductive materialPolymer scienceSulfur

This invention relates to certain non-silicone vulcanized rubber articles that are made from at least a majority by weight of vulcanized styrene butadiene rubber that include silver-based compounds to provide highly desirable long-term antimicrobial characteristics within the cured rubber articles. Such articles are in either solid or blown (foam or sponge) state (or combinations of both in multilayered forms) and can be utilized in a variety of different applications. This invention encompasses the presence of non-sulfur-based curing systems and agents, such as peroxide curing, that permit vulcanization and do not irreversibly bind silver ions thereto, thereby resulting in long-term antimicrobial performance of the ultimate rubber article itself. This invention also encompasses certain non-silicone pre-vulcanized raw rubber formulations made from at least a majority by weight of styrene butadiene rubber that include silver-based components to provide highly desirable long-term antimicrobial characteristics within the ultimate cured rubber articles made therefrom.

Owner:MILLIKEN & CO

Flame retardant rubber and preparation method thereof

ActiveCN102040779ARegular chain structureFew branchesPolymer scienceEthylene-propylene-diene-monomer

The invention provides flame retardant rubber and a preparation method thereof. The flame retardant rubber is obtained by milling and vulcanizing a mixture containing ethylene-propylene-diene monomer raw rubber, modified polybutadiene, a vulcanizing agent and a hydroxide flame retardant. The modified polybutadiene is isocyanate terminated polybutadiene and / or maleated polybutadiene. The flame retardant rubber has good flame retardant property and excellent mechanical performance.

Owner:BYD CO LTD

High-temperature resistant self-adhesive polymer modified asphalt waterproofing membrane and preparation method thereof

InactiveCN102492368AWide variety of sourcesIncrease profitNon-macromolecular adhesive additivesRoof covering using flexible materialsPolymer sciencePolymer modified

The invention provides a high-temperature resistant self-adhesive polymer modified asphalt waterproofing membrane and a preparation method thereof. The high-temperature resistant self-adhesive polymer modified asphalt waterproofing membrane comprises the following raw materials by weight: 50 to 60 parts of No. 100 asphalt, 5 to 10 parts of softening oil, 20 to 30 parts of pulverization reclaimed rubber powder, 6 to 12 parts of rubber powder modifier, 20 to 30 parts of coarse whiting powder, and 2 to 3 parts of pure polypropylene. The preparation method comprises the following steps: taking the No. 100 asphalt and softening oil according to the parts by weight; stirring and mixing the No. 100 asphalt and the softening oil; adding the pure polypropylene when the temperature reaches 190 to 200 DEG C; adding the pulverization reclaimed rubber powder when the pure polypropylene is completely melted; keeping stirring for 120 min when the temperature reaches 200 minus or plus 5 DEG C; adding the rubber powder modifier when the temperature falls to 170 minus or plus 5 DEG C; mixing and stirring uniformly when the coarse whiting powder is added, so as to obtain a finished mixture; and making the finished mixture into modified asphalt waterproofing membranes according to the manufacture procedure. As asphalt is modified to bear temperature higher than 120 DEG C, the invention has the advantages that no sliding phenomenon is generated under a high temperature; the viscosity is higher; and the suitability to construction environments is high.

Owner:TANGSHAN DESHENG WATERPROOF

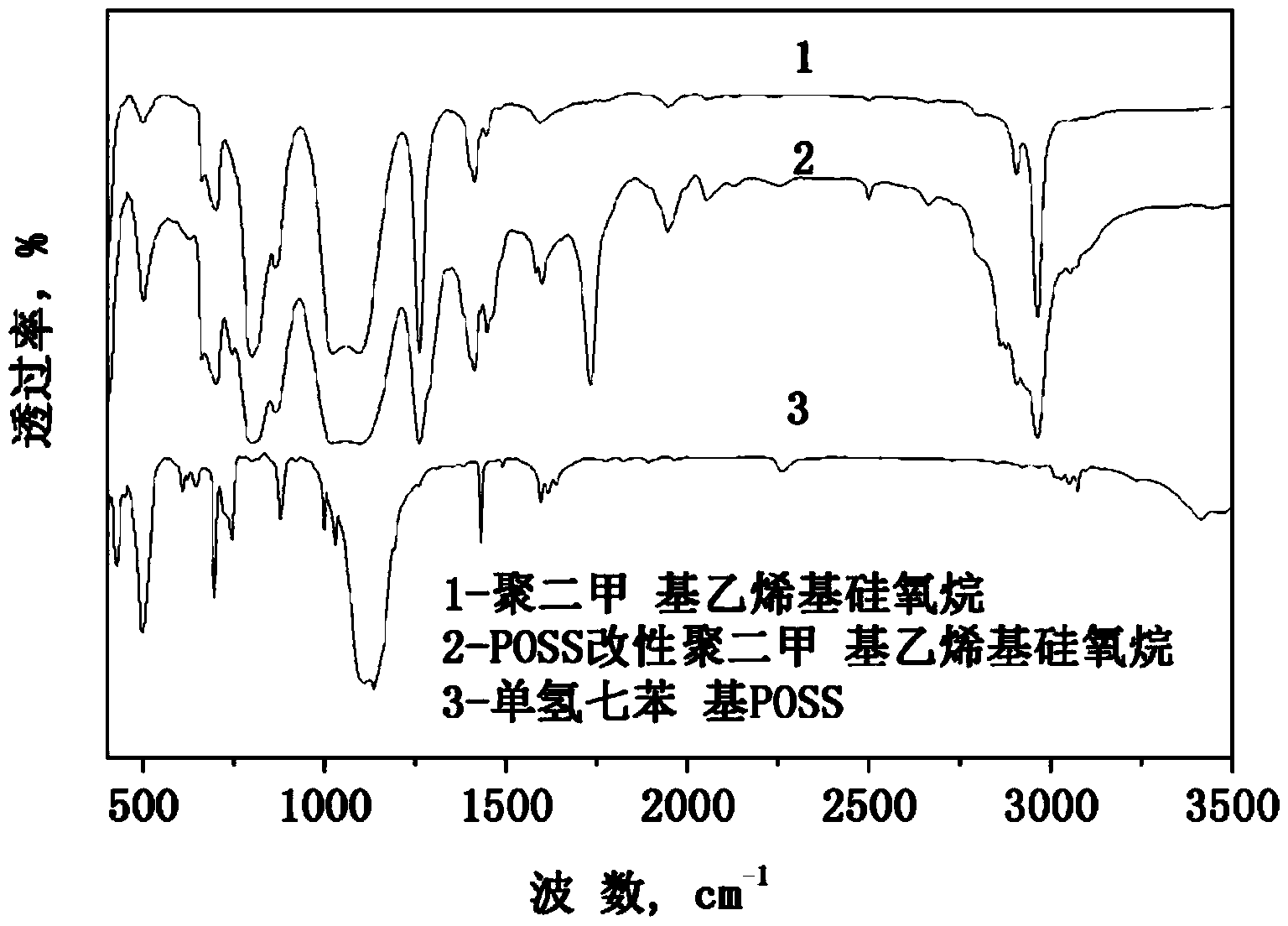

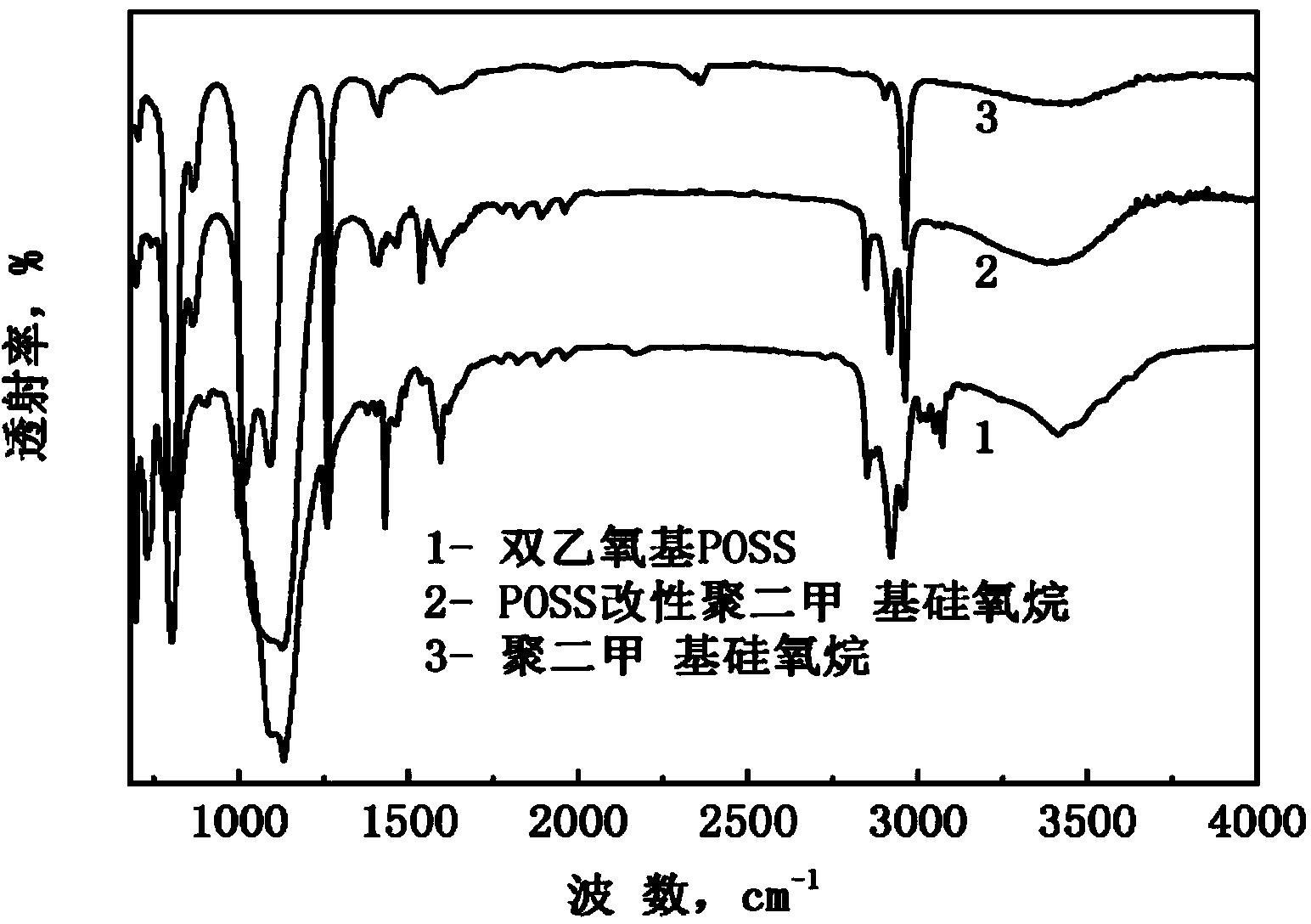

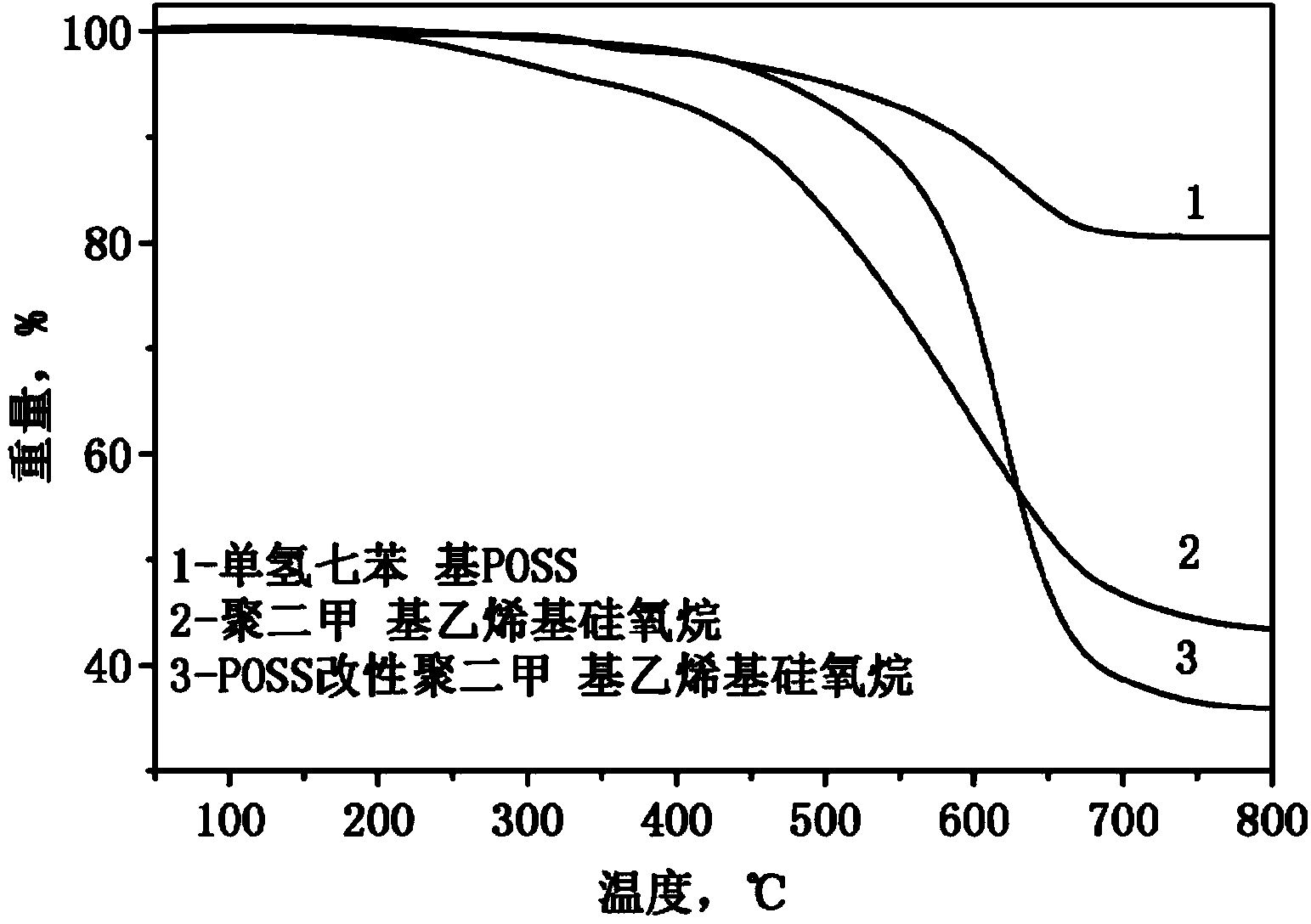

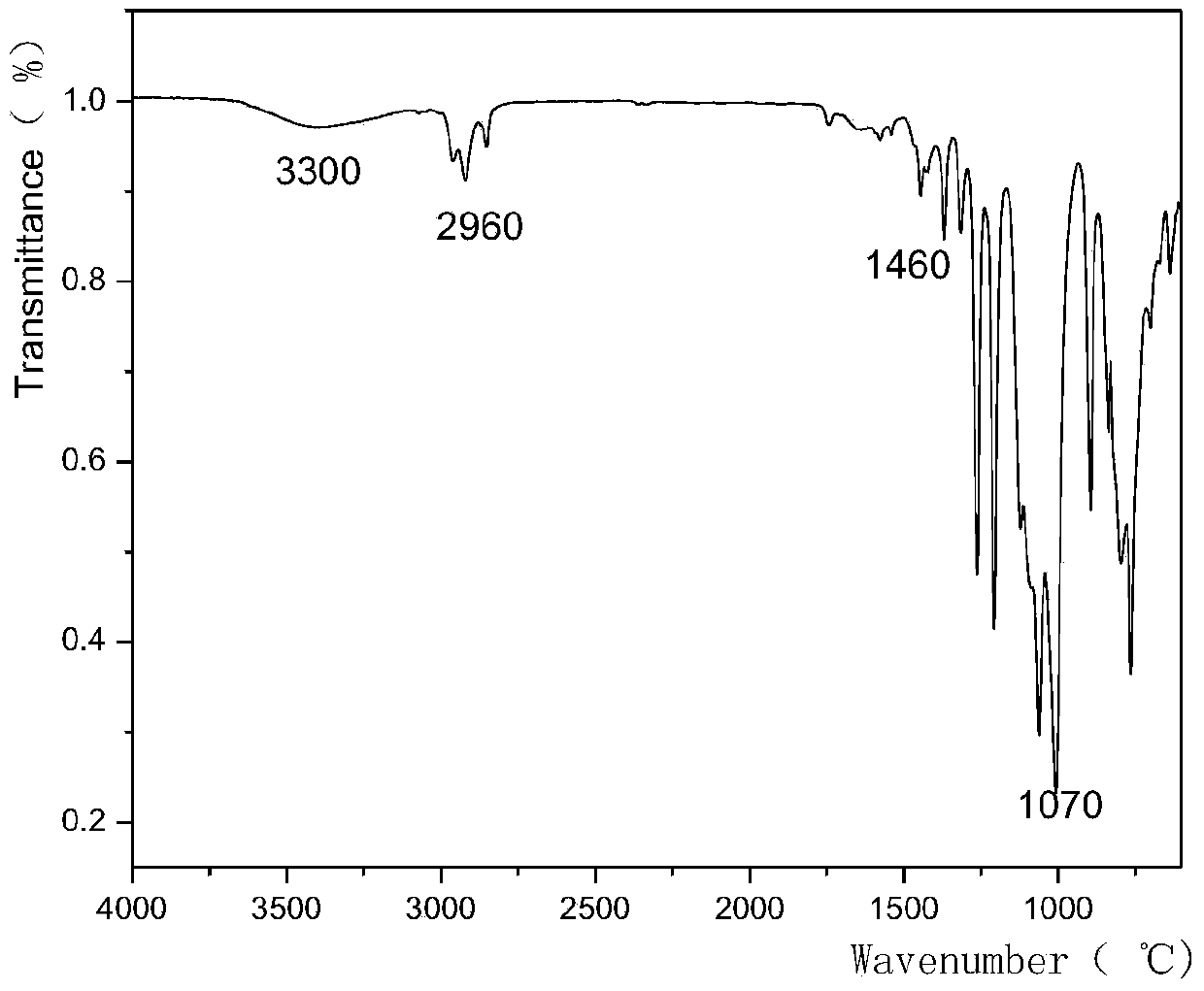

Preparation method of POSS modified polysiloxane rubber composite material

The invention discloses a preparation method of a POSS (Polyhedral Oligomeric Silsesquioxane) modified polysiloxane rubber composite material. The preparation method is characterized in that the POSS containing single / double reactive functional groups is introduced into a polysiloxane molecular chain containing a plurality of reactive functional groups by virtue of grafting or blocking in a chemical copolymerization manner, and then a POSS modified polysiloxane oligomer with the POSS as a polysiloxane hanging chain and the POSS as a polysiloxane block chain, next, 0.1-100 parts of POSS modified polysiloxane oligomer is evenly dispersed in 100 parts of polysiloxane raw rubber by virtue of physical blending, and finally, 0-50 parts of white carbon black and 0.2-10 parts of a curing agent are added to the mixture for cross-linking and solidification and then the POSS modified polysiloxane rubber composite material is obtained. The POSS modified polysiloxane rubber composite material has excellent high and low temperature resistance, mechanical properties and dielectric property, and can be applied to the technical fields of automobiles, electronics, building materials as well as national defense and aerospace.

Owner:SICHUAN UNIV

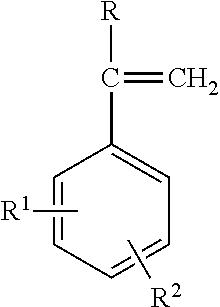

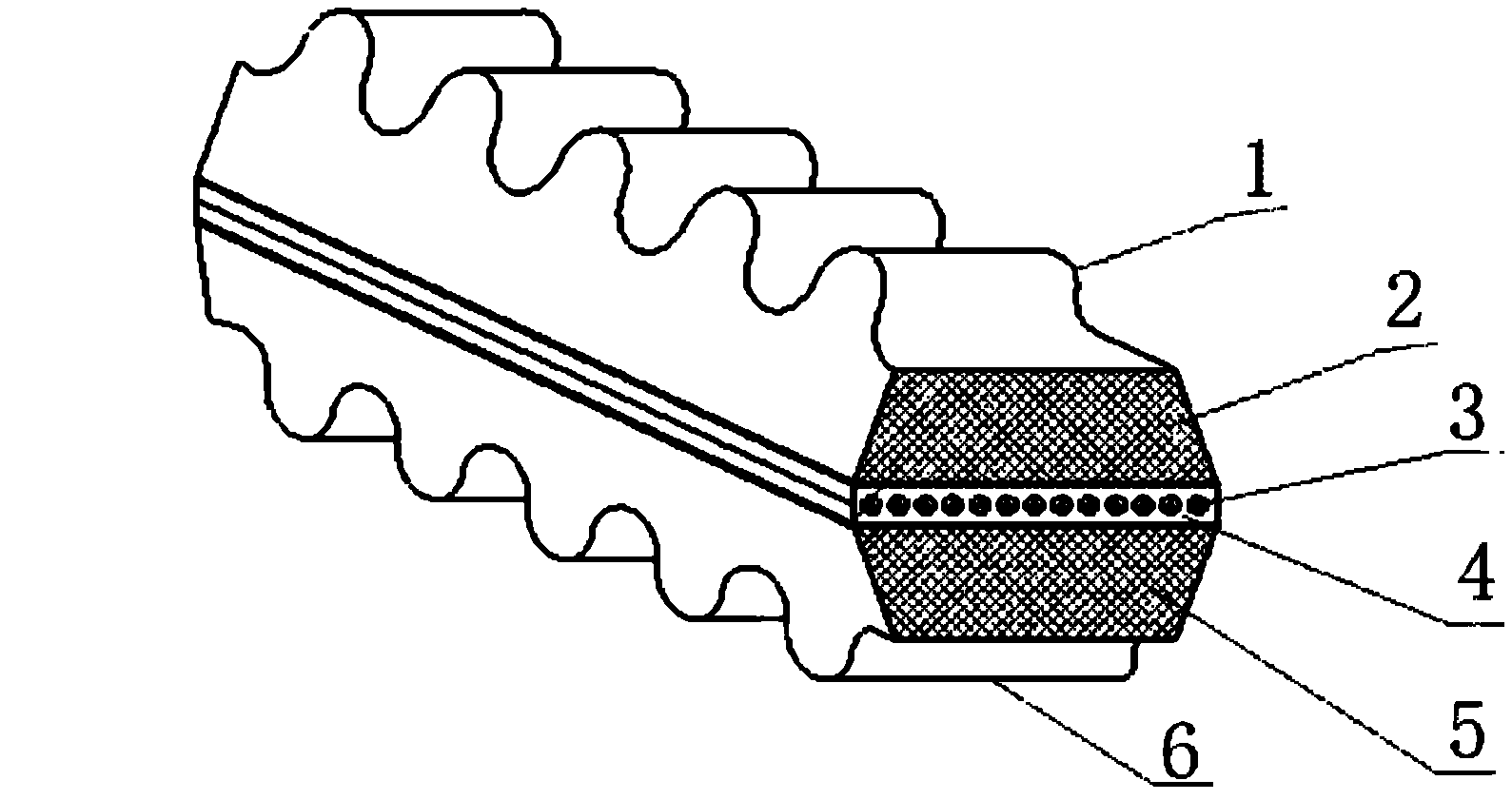

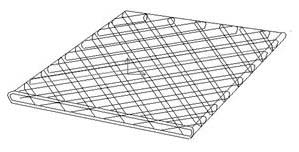

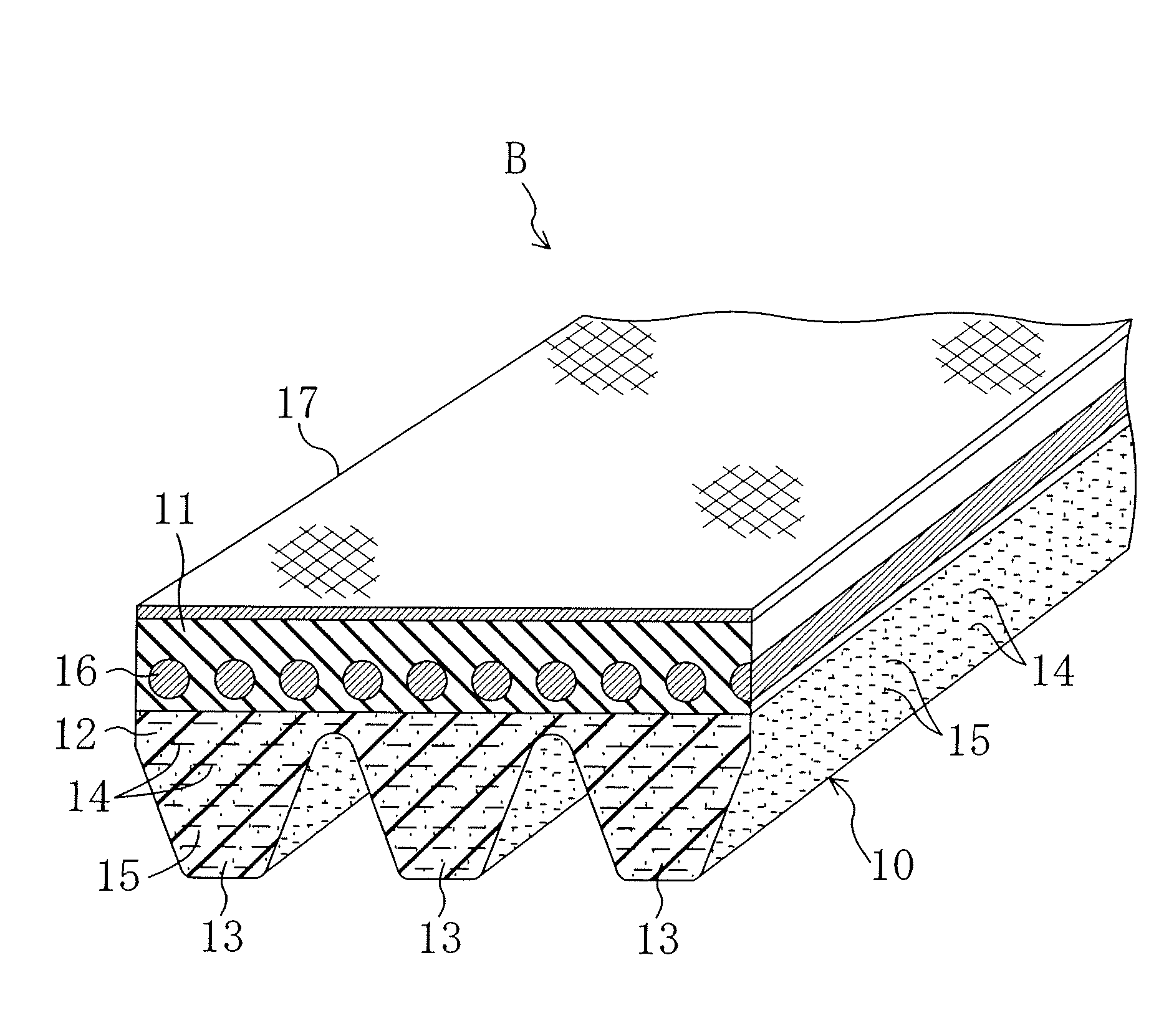

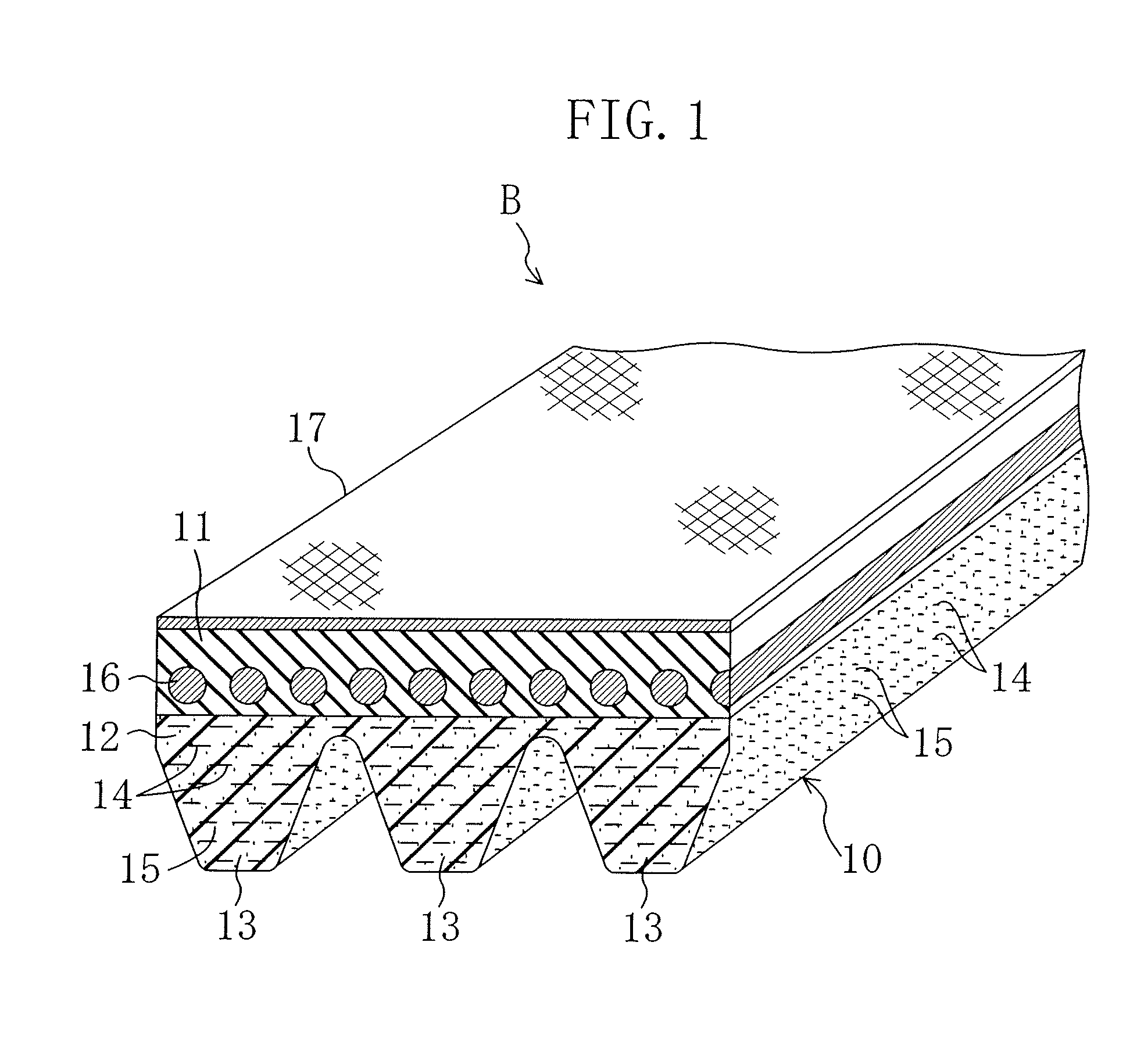

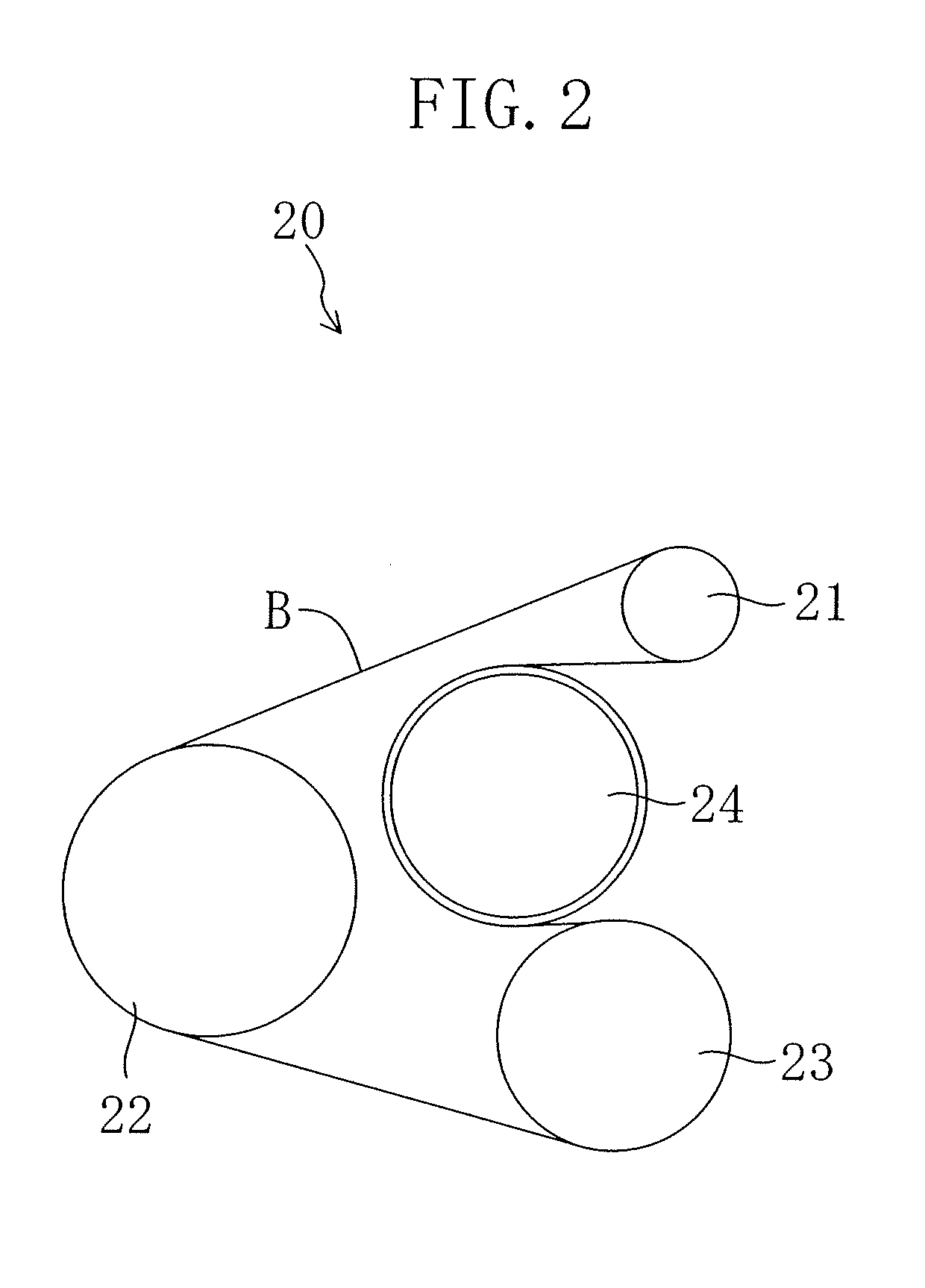

V-ribbed belt and automotive accessory drive belt drive system using the same

InactiveUS20090048048A1Production delayImprove heat resistanceV-beltsRopes and cables for vehicles/pulleyElastomerEngineering

A V-ribbed belt B includes a plurality of V-ribs 13 each formed to extend in a lengthwise direction of the belt, the plurality of V-ribs 13 are disposed in juxtaposition in a widthwise direction of the belt on the belt inner face, and the V-ribbed belt B is wrapped around a pulley to bring the plurality of V-ribs 13 into contact with the pulley for power transmission. The plurality of V-ribs 13 are made of a rubber composition in which 5 to 50 parts by mass of thermoplastic resin having a melting point of 110° C. or higher is mixed with 100 parts by mass of ethylene-α-olefin elastomer rubber which is raw rubber.

Owner:BANDO CHEM IND LTD

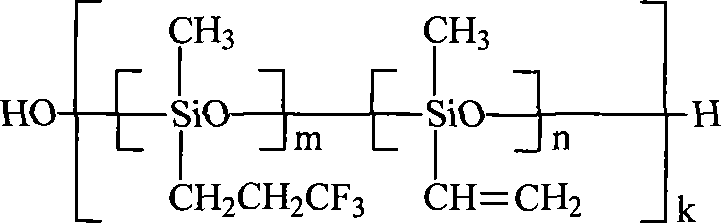

Method for preparing fluorine silicon rubber base glue

InactiveCN101177486AIncrease vinyl contentGood mechanical propertiesPolymer scienceMechanical property

The invention relates to a preparation method of fluorosilicone rubber base rubber, providing a preparation method of hydroxyl end capped fluorine silicon promoter with fluorine silicon structural unit and ethylene unit and certain polymerization degree, for preparing fluorosilicone rubber base rubber with excellent mechanical properties, high temperature properties and oil resistant properties. The invention prepares fluorine silicon promoter materials, materials of fluorine silicon promoter adopting open loop condensational procedure via general fluorine silicon monomer, vinyl silicone monomer, basic promoter and regulator, and obtains the needed fluorine silicon promoter; the fluorine silicon promoter and other promoters are added in the fluorine silicon raw rubber; the fluorine silicon raw rubber, the fluorine silicon promoter and the tetra butyl peroxy hexane are mixed uniformly for 5 to 60 minutes on a open mill or a internal mixer, thefluorosilicone rubber base rubber can be obtained after discharging. The invention prepares excellent fluorosilicone rubber base rubber with excellent mechanical properties, high temperature properties and oil resistant properties.

Owner:广东信力特种橡胶制品有限公司

Modified rubber prepared by oil shale waste slag and method for preparing modified rubber by oil shale waste slag

InactiveCN102504368AEliminate pollutionUniform carbonization on the surfaceResidual bodyThermal insulation

The invention relates to modified rubber prepared by oil shale waste slag and a method for preparing the modified rubber by oil shale waste slag. The method comprises the following steps that oil shale waste slag subject to oil extraction is smashed to be the particle size smaller than 300 mesh, the smashed oil shale waste slag is placed into a high temperature furnace for braking, isolated from the air to conduct the thermal insulation, cooled down with the high temperature furnace and made into carbonized oil shale waste slag, the carbonized oil shale waste slag, raw rubber, carbon black, zinc oxide, powdered sulfur and vulcanization accelerator are added into a mixing roll, are mixed at a certain temperature, and formed in a panel vulcanizing machine after being cooled down. The invention makes the best of the organic matter residual body of residual in oil shale waste slag to change the organic matter residual body into valuable, and eliminates the environmental pollution caused by that oil shale waste slag is stacked in the open air; and the surface of the carbonized oil shale waste slag powder is uniformly carbonized, covered firmly, and good in compatible with the organic matters; the performance is good, the process is simple, and the cost is low. The invention saves the afterbaked energy, and reduces the discharging of carbon dioxide generated in afterbaking. The various indexes of the mechanical property of a test sample reach the GB 3778-94 standard.

Owner:JILIN UNIV

Preparation method for novel ethylene propylene rubber sealing material product

InactiveCN103421249ALow priceEasy to processOther chemical processesPolymer sciencePolyvinyl alcohol

The invention discloses a preparation method for a novel ethylene propylene rubber sealing material product. The preparation method employs two different kinds of ethylene propylene diene monomer raw rubbers as basic materials with cooperation of certain amounts of carbon black, calcium carbonate, paraffin oil, zinc oxide, stearic acid, polyvinyl alcohol, high-molecular wax, compound antioxidants, dispersants, compound accelerants, vulcanizing agents, fire retardants and the like. The above materials are subjected to mixing, open milling and vulcanization technologies to obtain the novel ethylene propylene rubber sealing material product. The preparation method has advantages of simple formula, simple production technology, short vulcanizing time, high production efficiency, relatively low production cost, easy industrialization enforcement and the like. Through the preparation method, rubber sealing strip products which are advantaged by good sealing performance, uniform structure, resistance to corrosion, resistance to high and low temperature, flame resistance, environment protection and comfort can be produced.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

Method for preparing liquid silicone rubber for LCD screen protection film

ActiveCN104479622AWon't hurtImprove the performance of double 85 resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkPolymer science

Owner:浙江森日有机硅材料有限公司

Fluorosiloxane copolymer and preparing method thereof

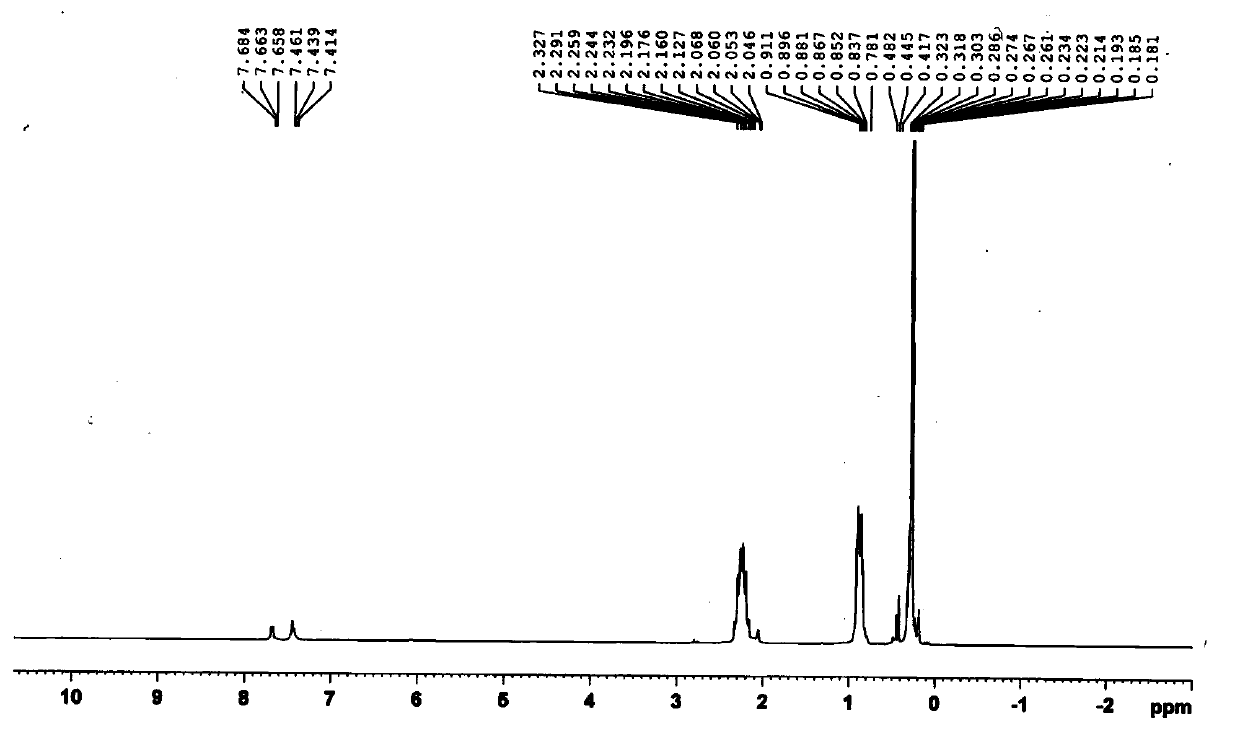

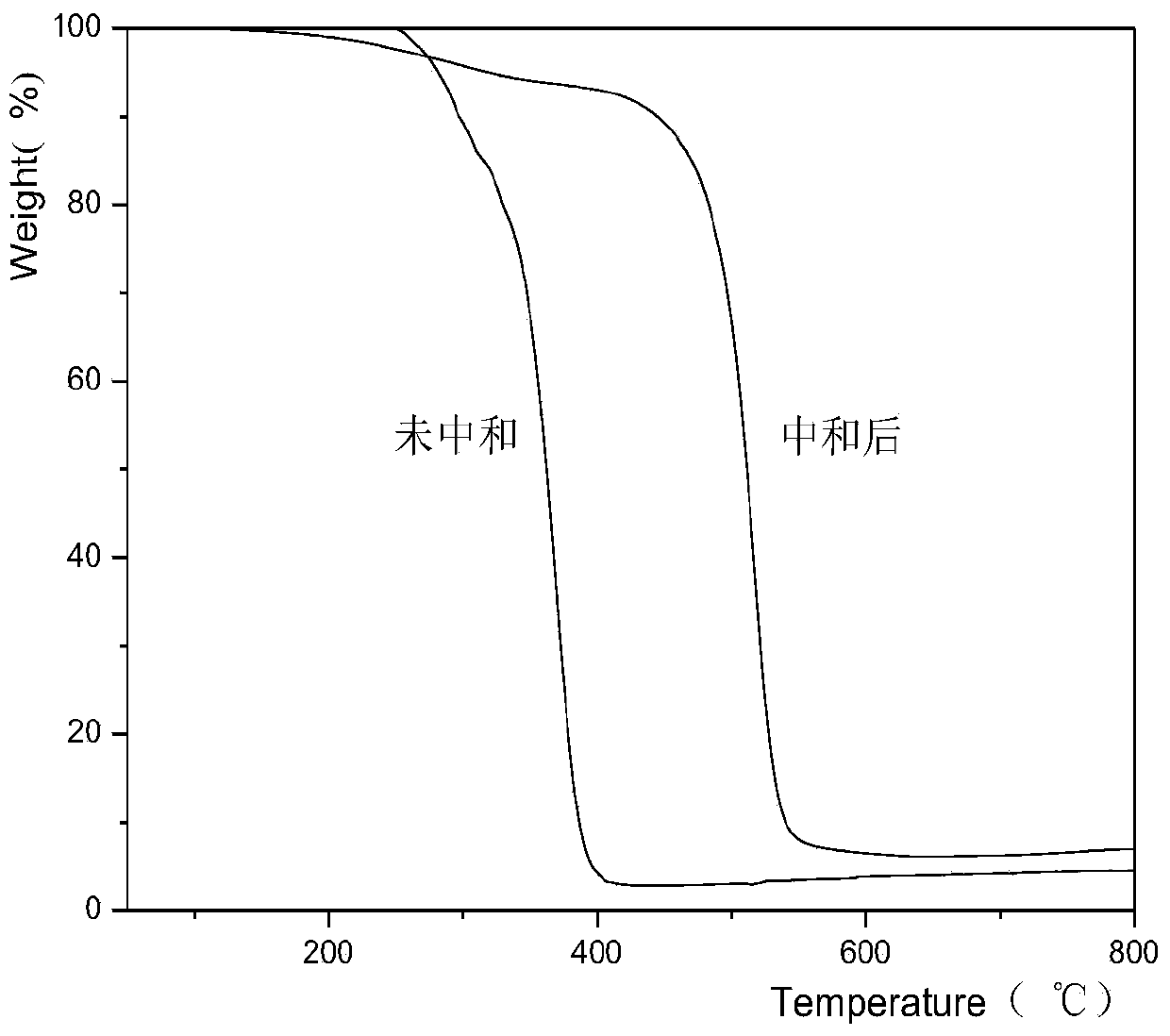

The invention discloses a fluorosiloxane copolymer and a preparing method thereof. The method includes the following steps that 0.1-50 parts of methylphenyldichlorosilane or diphenyl cyclosiloxane, 45-99.8 parts of 1,3,5-tris(3,3,3-trifluoropropyl)methylcyclotrisiloxane and 0.1-5 parts of polymethylphenylsiloxane are sequentially added into a reactor and dried under the heating condition of 60- 90 DEG C, and water and CO2 in a reactant are removed, wherein the total number of the methylphenyldichlorosilane or diphenyl cyclosiloxane, the 1,3,5-tris(3,3,3-trifluoropropyl)methylcyclotrisiloxane and the polymethylphenylsiloxane are 100 parts; an initiator and an accelerant are added, the use quantity of the initiator accounts for 0.001-1% the mass of the reactant, the use quantity of the accelerant accounts for 0.01-1% the mass of the reactant, at the temperature of 90-200 EDG C, preferentially 130-150 DEG C, stirring reaction is carried out until a shaft is wrapped in a N2 atmosphere under a normal-pressure condition, balanced reaction continues being carried out for 2-3 h, and raw rubber is manufactured; an acidoid neutralization initiator is added into the raw rubber manufactured in the step (2), extraction or high-vacuum processing is carried out on the neutralized raw rubber, and low-molecular matter is removed. Heat resistance of the fluorosiloxane copolymer is improved by about 80 DEG C compared with fluorosiloxane raw rubber with 100% of methyl trifluoropropyl.

Owner:SHANDONG UNIV

Antimicrobial articles and compositions made from non-silicone vulcanized rubber

InactiveUS6852782B2Losing levelLosing of strengthAntifouling/underwater paintsSpecial tyresPolymer scienceSulfur

This invention relates to certain non-silicone vulcanized rubber articles that are made from at least a majority by weight of epichlorohydrin, polybutadiene, or polychloroprene vulcanized rubber that include silver-based compounds to provide highly desirable long-term antimicrobial characteristics within the cured rubber articles. Such articles are in either solid or blown (foam or sponge) state (or combinations of both in multilayered forms) and can be utilized in a variety of different applications. This invention encompasses the presence of non-sulfur-based curing systems and agents, such as peroxide curing, that permit vulcanization and do not irreversibly bind silver ions thereto, thereby resulting in long-term antimicrobial performance of the ultimate rubber article itself. This invention also encompasses certain non-silicone pre-vulcanized raw rubber formulations made from at least a majority by weight of epichlorohydrin, polybutadiene, or polychloroprene rubber that include silver-based components to provide highly desirable long-term antimicrobial characteristics within the ultimate cured rubber articles made therefrom.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com