Method for preparing fluorine silicon rubber base glue

A technology of fluorosilicone rubber and base rubber, which is applied in the field of preparation of fluorosilicone rubber base rubber for the automotive industry and aerospace industry, and can solve the problems of fluorosilicone rubber tear strength, mechanical strength, high temperature aging, and oil resistance. , to achieve the effect of excellent mechanical properties and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

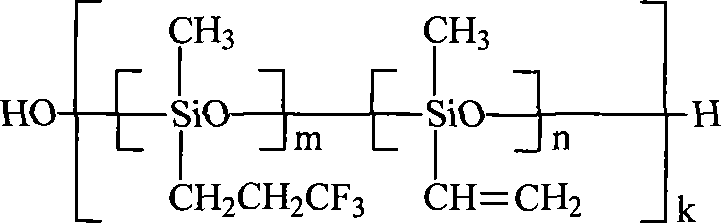

[0041]The preparation of fluorosilicone additives adopts the ring-opening polycondensation method. Mix and dehydrate hydroxyfluorosilicone oil, fluorosilicone monomer D3F, and vinyl monomer at 50-100°C for 1-3 hours, then add silanol sodium salt, and then mix and dehydrate for 0.2 ~1 hour. Raise the temperature to 115-150°C to react for 0.5-6 hours, then cool down to 60-90°C, add an equal volume of ethyl acetate and stir to dissolve, then wash with water until the pH value is close to 7, and finally evaporate the solvent to obtain the required fluorosilicone Agent, determination of viscosity, vinyl content, hydroxyl value.

[0042] The material needs to be mixed and dehydrated before reacting, and the dehydration condition is -0.01~-0.02MPa. The material can be dehydrated and added to the reactor, or dehydrated in the reactor.

[0043] It is required to control the hydroxyl value of the fluorosilicone additive to 1-6%, and the molar content of vinyl units to be 5-50%.

[00...

example 1

[0050] Add 100 grams of fluorosilicone monomer D3F monomer, 100 grams of hydroxyl fluorosilicone oil (hydroxyl value 6%), 50 grams of vinyl silicon monomer, and 0.8 grams of silanol sodium salt into a pre-dried 1000 ml reaction kettle. Turn on stirring, control the temperature at 70±3°C, -0.01~0.02MPa, pass in dry nitrogen, and dehydrate for 3 hours; then raise the temperature to 125°C±3°C, pass in dry nitrogen during the reaction process, and cool the system to 60°C after 25 minutes ℃, add 250 g of ethyl acetate and stir to dissolve. The material is washed with water until neutral, and the solvent is evaporated to obtain the desired fluorosilicone additive. The vinyl content and hydroxyl value in the fluorine-containing silicon additives were tested by chemical titration. The hydroxyl value of the fluorosilicone additive is 2.2%, and the molar content of vinyl units is 31%;

example 2

[0052] Change the quality of the vinyl silicon monomer to 10 grams, and other conditions are the same as in example 1. The hydroxyl value of the obtained fluorosilicone additive is 2.8%, and the molar content of vinyl units is 11% respectively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com