Ultrahigh-hardness silicon resin film as well as preparation method and application thereof

The technology of silicone resin and vinyl silicone resin is applied in the field of ultra-high hardness silicone resin film and its preparation. Good repeatability and controllability, simple preparation process, and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

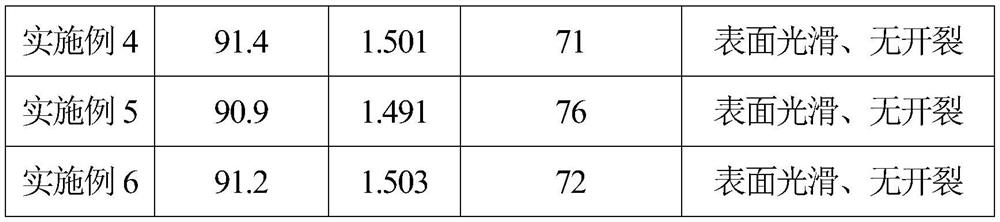

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing an ultra-high hardness silicone resin film.

[0029] (1) Preparation of vinyl silicone resin: Get 0.61g of anion resin catalyst and 10.2g of methyltrimethoxysilane and join successively in a 150ml three-necked flask with condensate receiver, stirrer and thermometer, and heat up to 85°C. Take 50g of hydroxyvinyl silicone resin, add it to the constant pressure dropping funnel, and drop it into the system within 2 hours. The system was then allowed to react at 85°C for 6 hours. The product was filtered under reduced pressure. Move the product to a distillation flask, and carry out vacuum distillation under the conditions of 100°C and -0.096MPa to remove the by-product methanol in the reaction system to obtain vinyl silicone resin, which is a clear transparent viscous liquid. After testing, n D 25 =1.502, the vinyl content was 14.10%, and the vinyl content loss was 14.8%.

[0030] (2) Preparation of hydrogen-containing s...

Embodiment 2

[0033] This embodiment provides a method for preparing an ultra-high hardness silicone resin film.

[0034](1) Preparation of vinyl silicone resin: Get 0.61g of anion resin catalyst and 10.2g of methyltrimethoxysilane and join successively in a 150ml three-necked flask with condensate receiver, stirrer and thermometer, and heat up to 85°C. Take 50g of hydroxyvinyl silicone resin, add it to the constant pressure dropping funnel, and drop it into the system within 2 hours. The system was then allowed to react at 85°C for 6 hours. The product was filtered under reduced pressure. Move the product to a distillation flask, and carry out vacuum distillation under the conditions of 100°C and -0.096MPa to remove the by-product methanol in the reaction system to obtain vinyl silicone resin, which is a clear transparent viscous liquid. After testing, n D 25 =1.502, the vinyl content was 14.10%, and the vinyl content loss was 14.8%.

[0035] (2) Preparation of hydrogen-containing si...

Embodiment 3

[0038] This embodiment provides the preparation method of the silicone resin film of ultrahigh hardness

[0039] (1) Preparation of vinyl silicone resin: Get 0.61g of anion resin catalyst and 10.2g of methyltrimethoxysilane and join successively in a 150ml three-necked flask with condensate receiver, stirrer and thermometer, and heat up to 85°C. Take 50g of hydroxyvinyl silicone resin, add it to the constant pressure dropping funnel, and drop it into the system within 2 hours. The system was then allowed to react at 85°C for 6 hours. The product was filtered under reduced pressure. Move the product to a distillation flask, and carry out vacuum distillation under the conditions of 100°C and -0.096MPa to remove the by-product methanol in the reaction system to obtain vinyl silicone resin, which is a clear transparent viscous liquid. After testing, n D 25 =1.502, the vinyl content was 14.10%, and the vinyl content loss was 14.8%.

[0040] (2) Preparation of hydrogen-contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com