Patents

Literature

167results about How to "Improve molecular structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

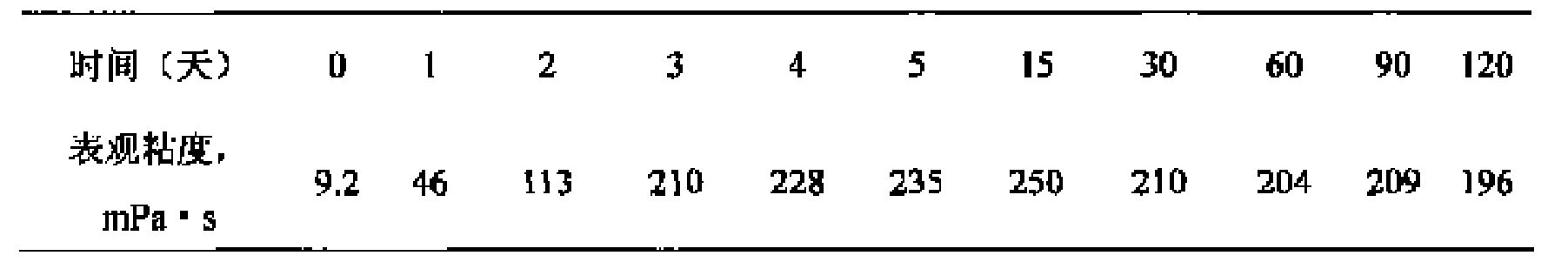

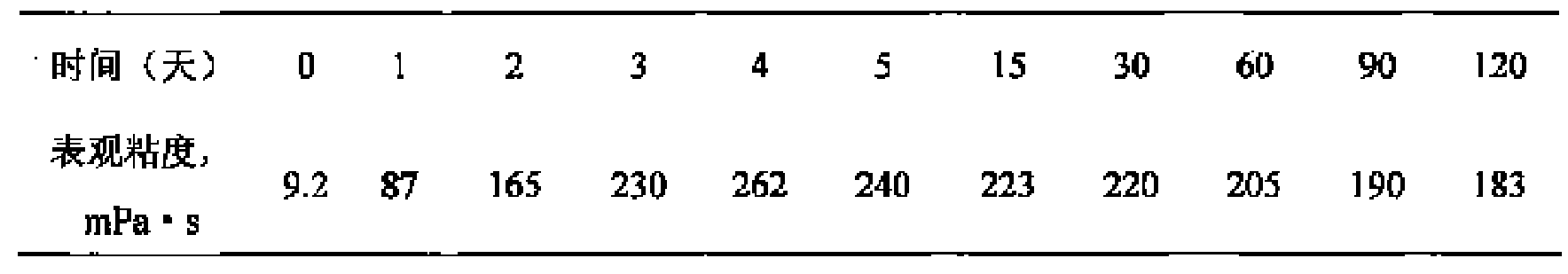

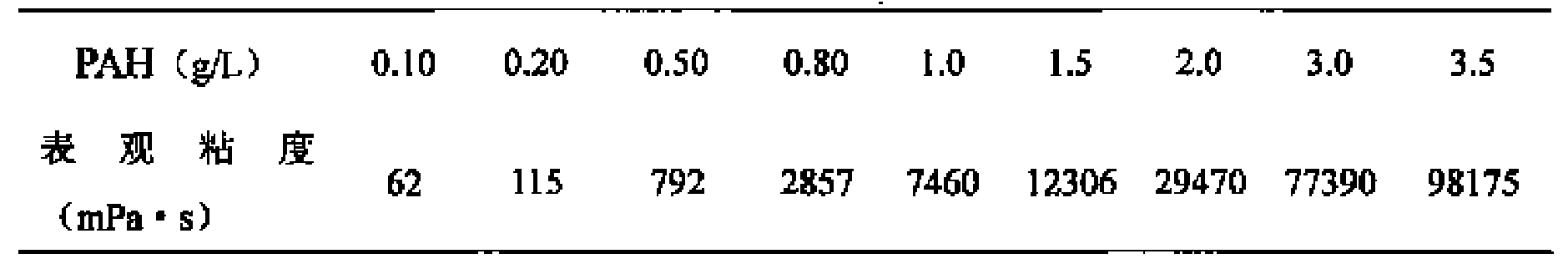

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

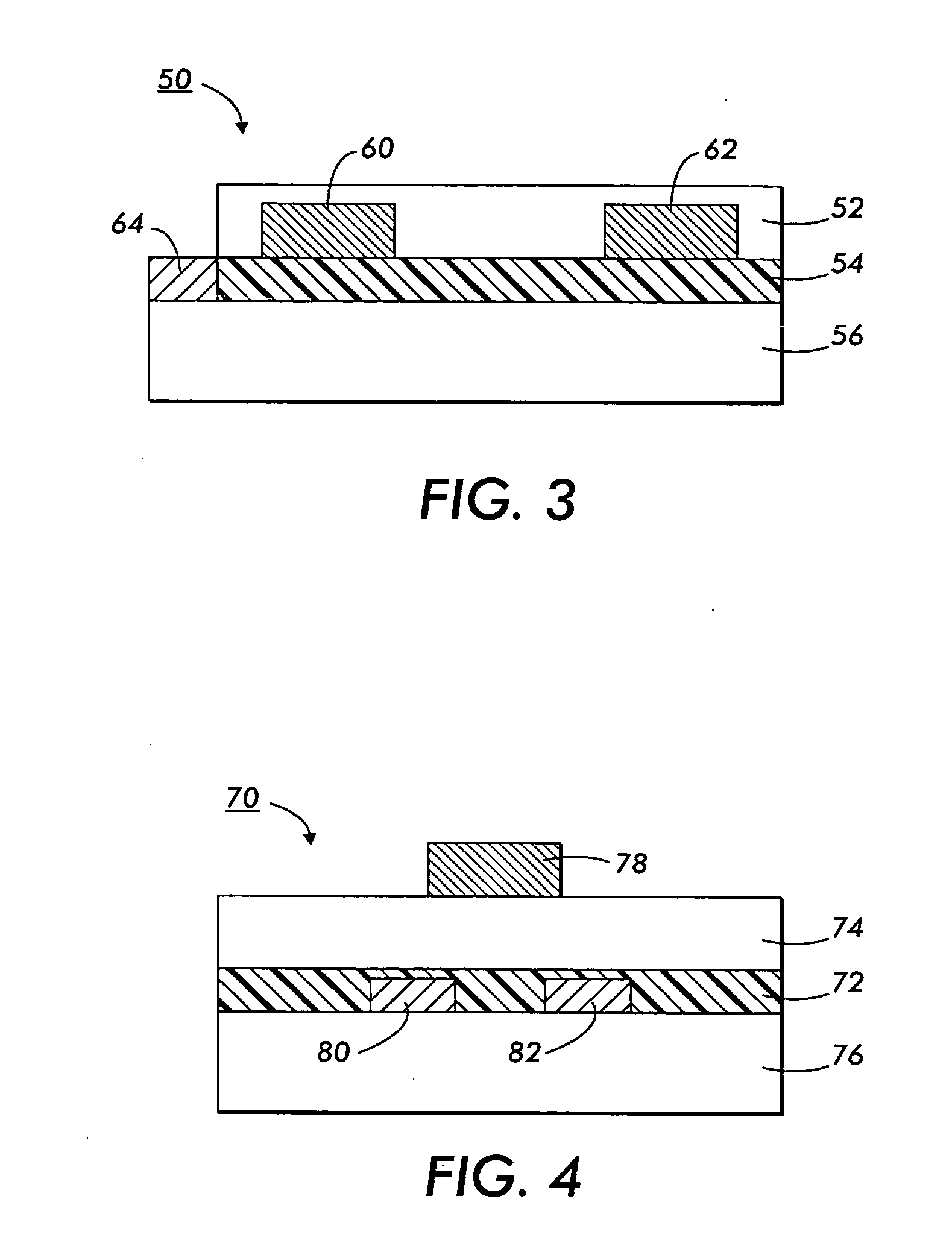

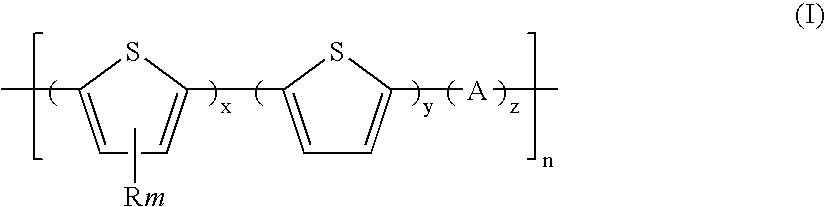

Polythiophenes and electronic devices generated therefrom

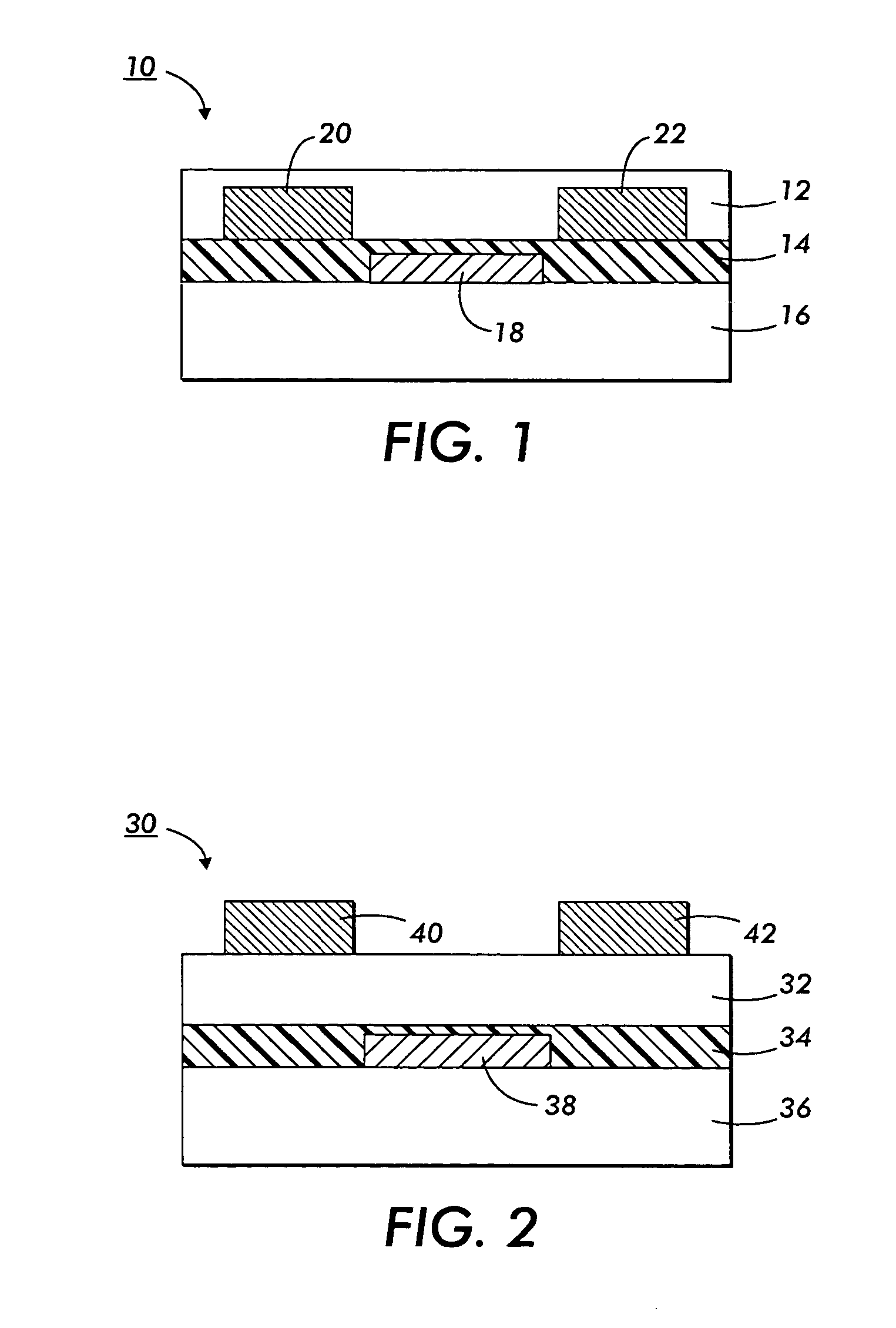

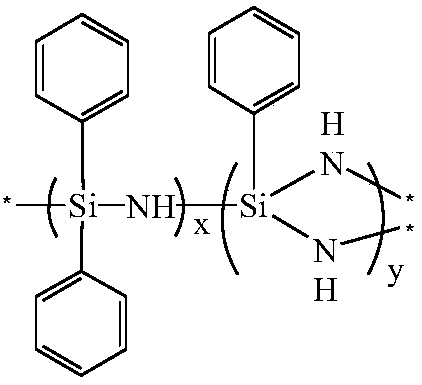

InactiveUS20050017311A1Improve stabilityImprove molecular structureTransistorSolid-state devicesPolymer scienceSide chain

An electronic device containing a polythiophene wherein R represents a side chain, m represents the number of R substituents; A is a divalent linkage; x, y and z represent, respectively, the number of Rm substituted thienylenes, unsubstituted thienylenes, and divalent linkages A, respectively, in the monomer segment subject to z being 0 or 1, and n represents the number of repeating monomer segments in the polymer or the degree of polymerization.

Owner:XEROX CORP

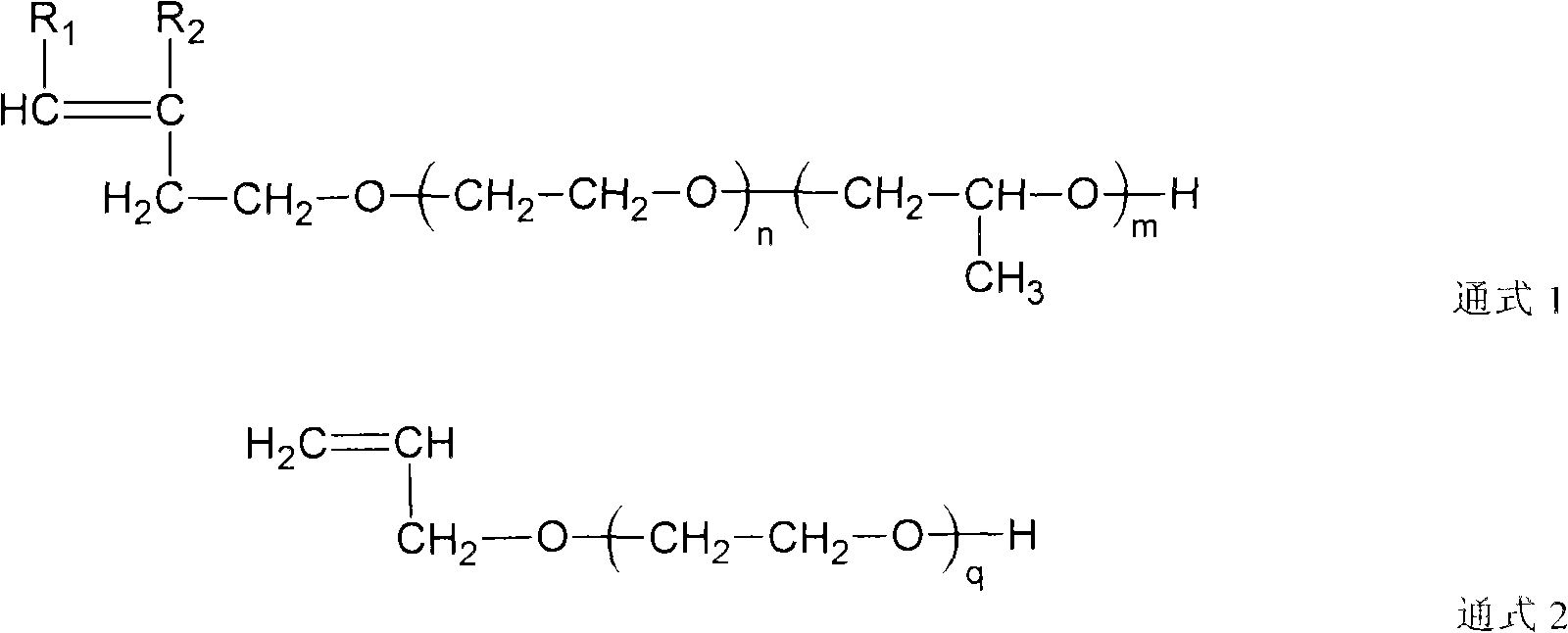

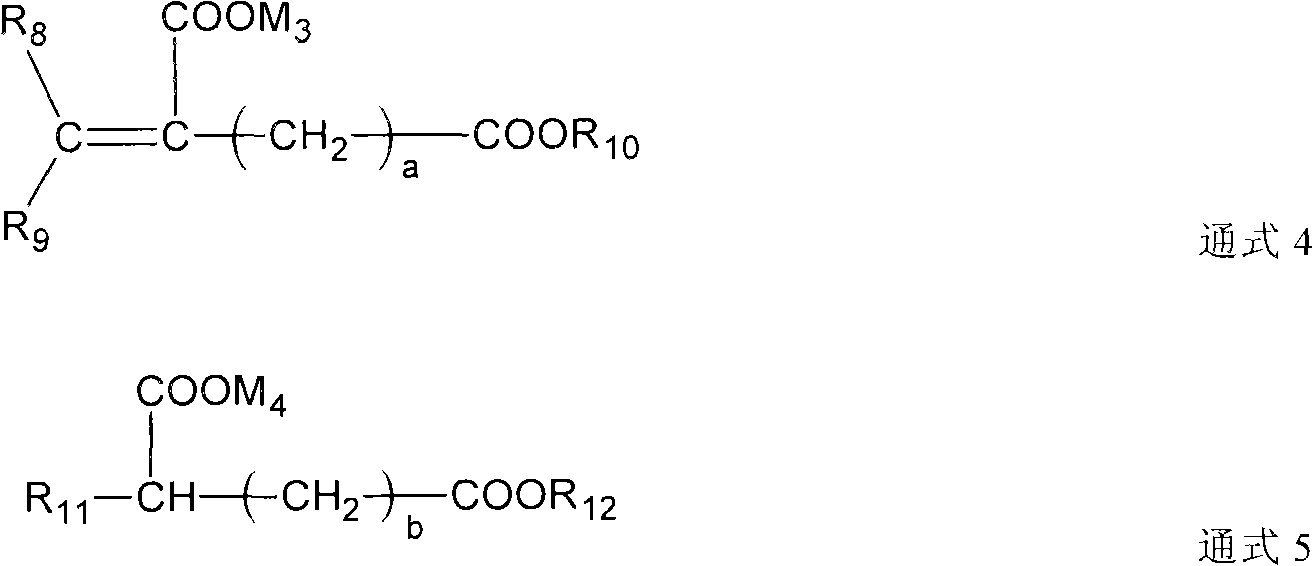

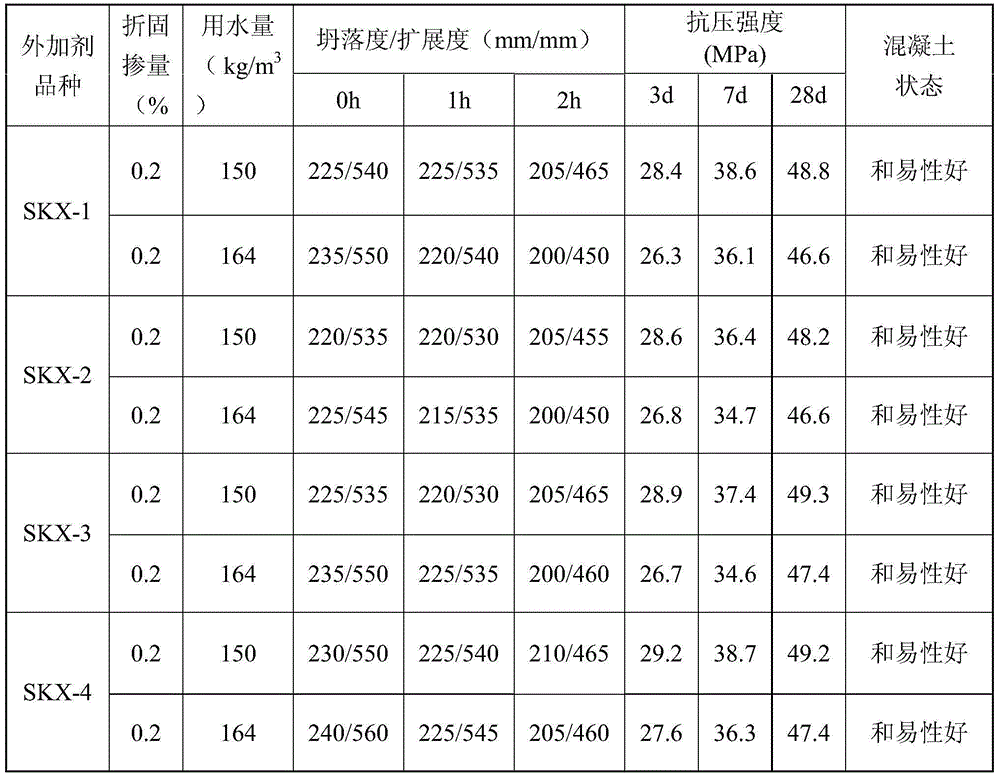

Plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and preparation method thereof

The invention discloses a plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and a preparation method thereof, mainly being applicable to the field of building materials. The water reducing agent is obtained in the following method: with the action of initiating agent, copolymerizing unsaturated polyalkyl ether monomer (A), unsaturated monocarboxylic acid and derivative monomer thereof (B), unsaturated dicarboxylic acid and derivative monomer thereof (C) and unsaturated sulfonic acid or salt monomer (D) in water solution for 2-8h at 50-80 DEG C and then reducing temperature to 35-45 DEG C, using alkaline solution to neutralize the mixture to a pH value of 5-7, thus obtaining the water reducing agent. The synthesized water reducing agent of the invention features changeable molecular structure, high water reducing ratio, high dispersion property under low dosage and fine slumps-retaining property, good adaptability to concrete raw material; in addition concrete with the water reducing agent added enjoys good peaceability; with the one-step method synthesis technology employed, the preparation method has the advantages of simple operation, low energy consumption in production and freedom from pollution.

Owner:CNBM ZHONGYAN TECH

Preparation method of high-reaction-activity hydroxyl acrylic resin

InactiveCN103130944AImprove molecular structureHigh glass transition temperaturePolyurea/polyurethane coatingsAcrylic resinSolvent

The invention relates to a preparation method of high-reaction-activity hydroxyl acrylic resin. According to the invention, a solvent in a reactor is heated to a preset temperature under the protection of an inert gas; a mixture of a monomer component A with hard monomer as a main component (and comprising a small amount of soft monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; a reaction is carried out for a certain period of time with maintained temperature; a mixture of a monomer component B with soft monomer as a main component (and comprising a small amount of hard monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; and reaction is carried out for a certain period of time with maintained temperature, such that acrylic resin comprising hydroxyl is obtained. The invention has the characteristic that common monomers are adopted, and only the synthesis process is changed wherein monomer dropping sequence is changed, such that resin molecular structure is substantially changed, and the synthesized hydroxyl acrylic resin shows high reaction activity during a curing reaction. The method provided by the invention also has the advantages of low cost, simple process, and suitability for industrialized productions.

Owner:XI AN JIAOTONG UNIV +1

Compositions And Methods For Enhancing The Structure Of Hair Fibers

InactiveUS20130319449A1Add additional massIncrease the diameterCosmetic preparationsHair removalFiber diameterMolecular geometry

Disclosed are compositions and methods that are able to increase the amount of molecular structure within the cortex of hair fibers. As result, hair fiber diameter, cross sectional area, elasticity and stiffness are all increased. The benefits are long term, surviving repeated rinsing and shampooing. These results are particularly beneficial in the treatment of fine hair.

Owner:ELC MANAGEMENT LLC

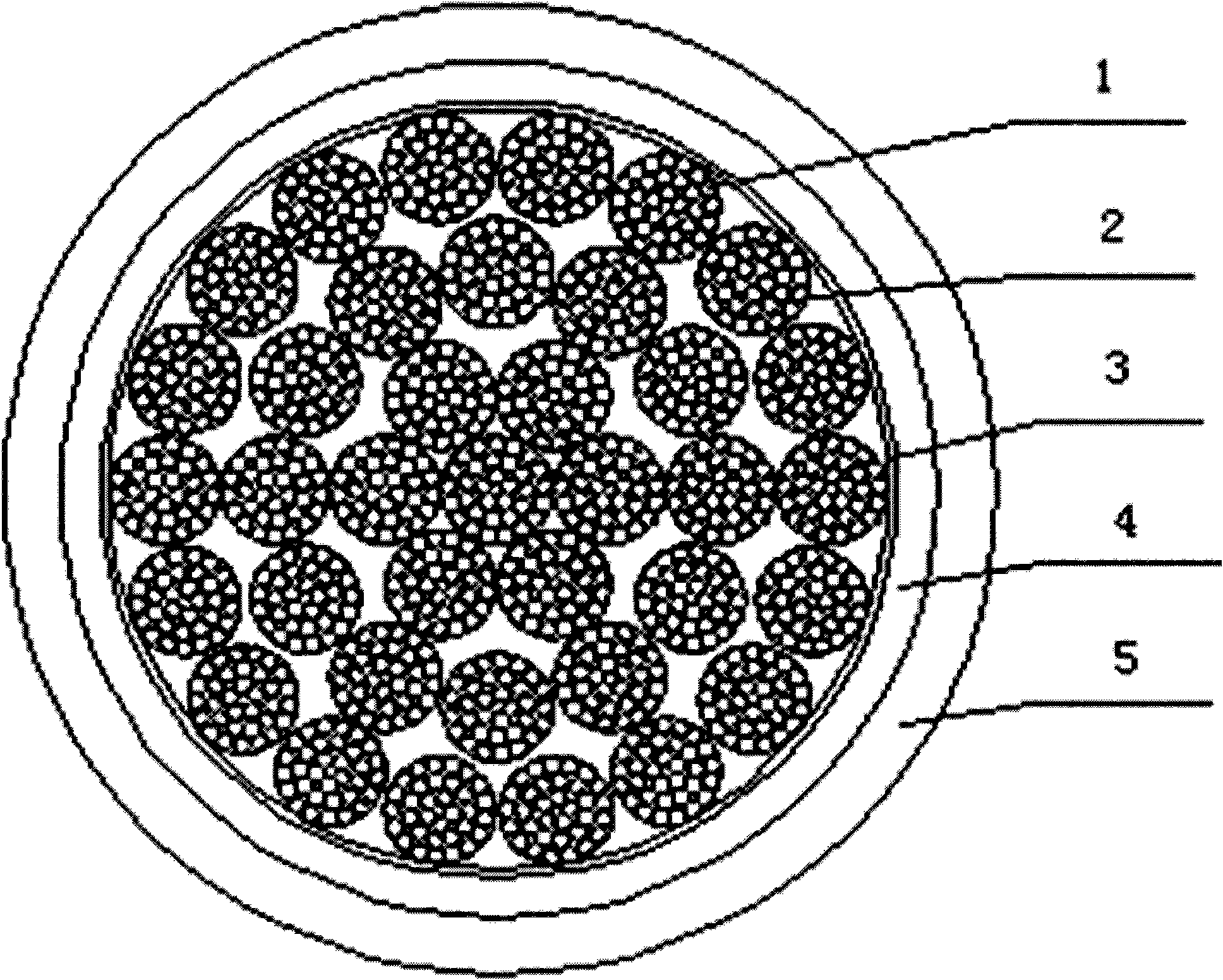

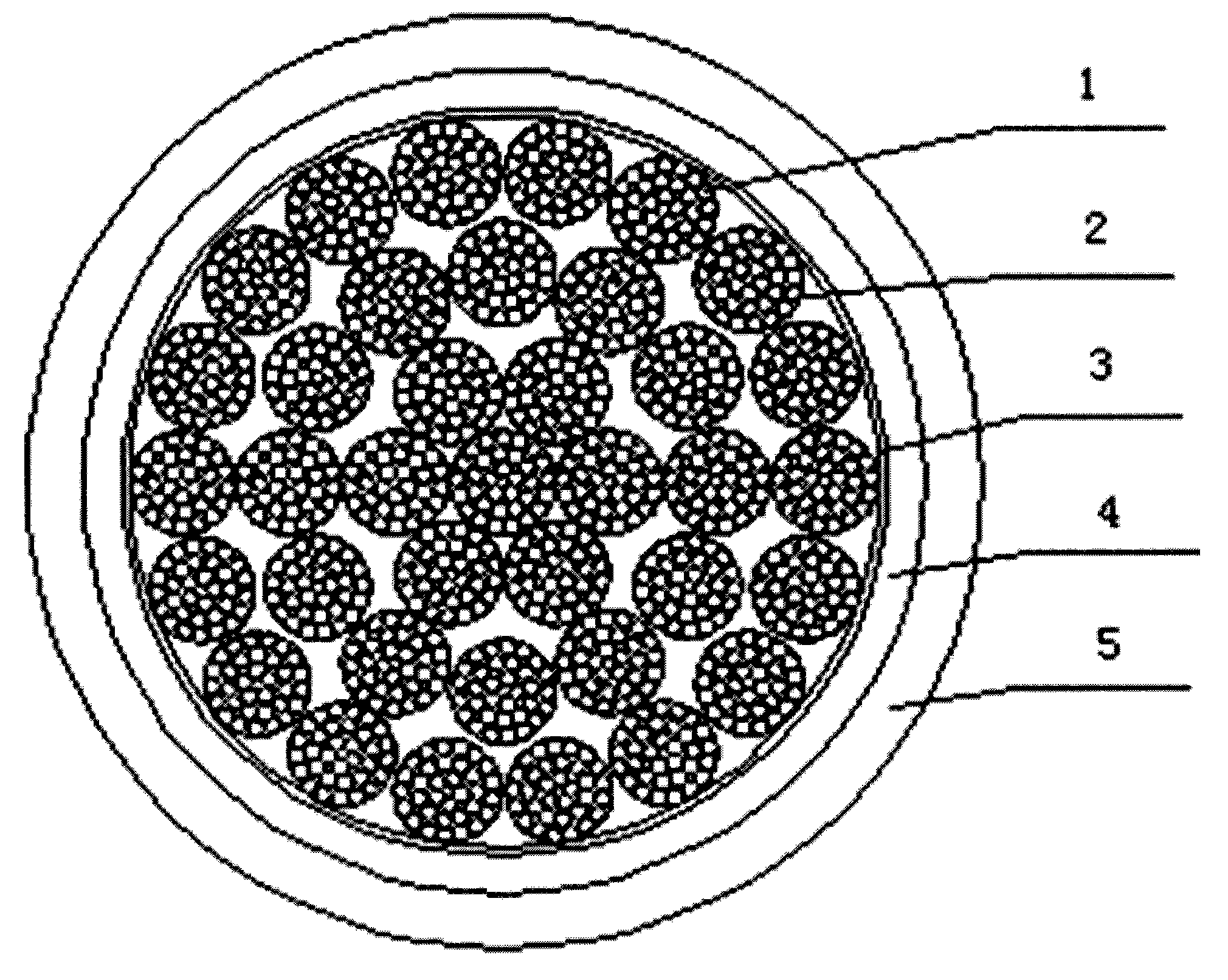

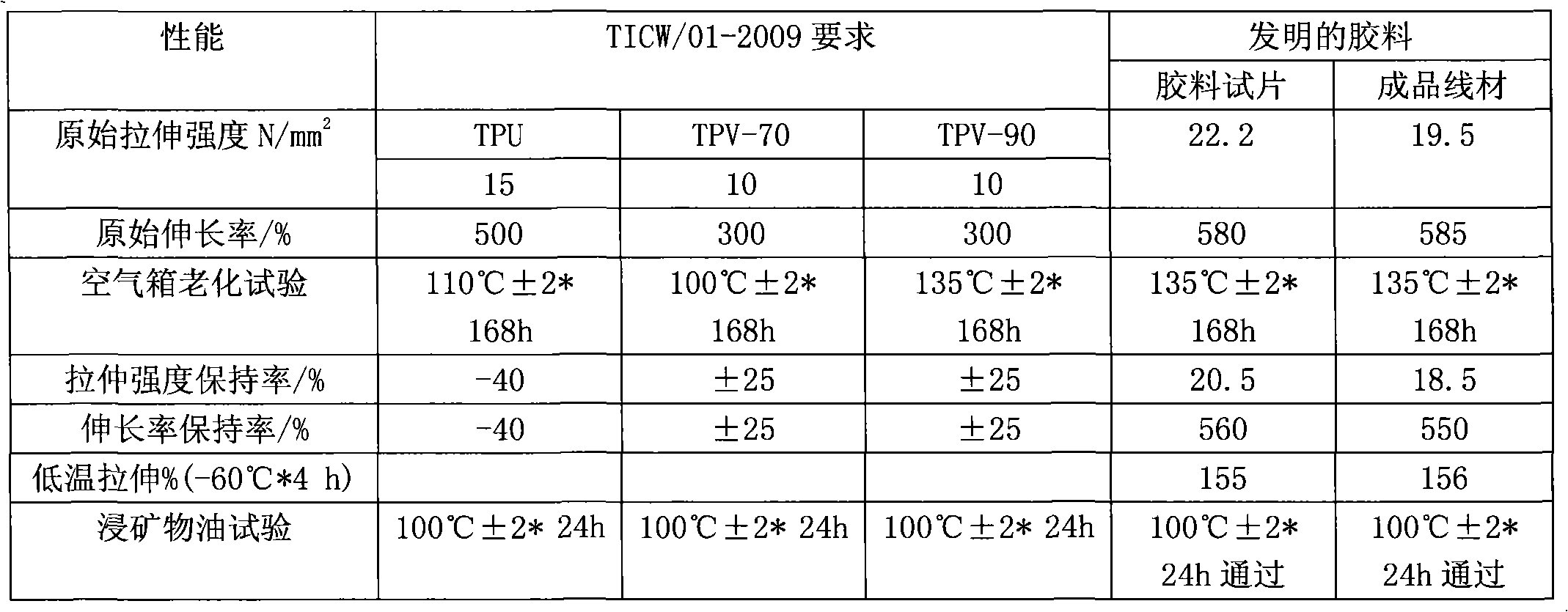

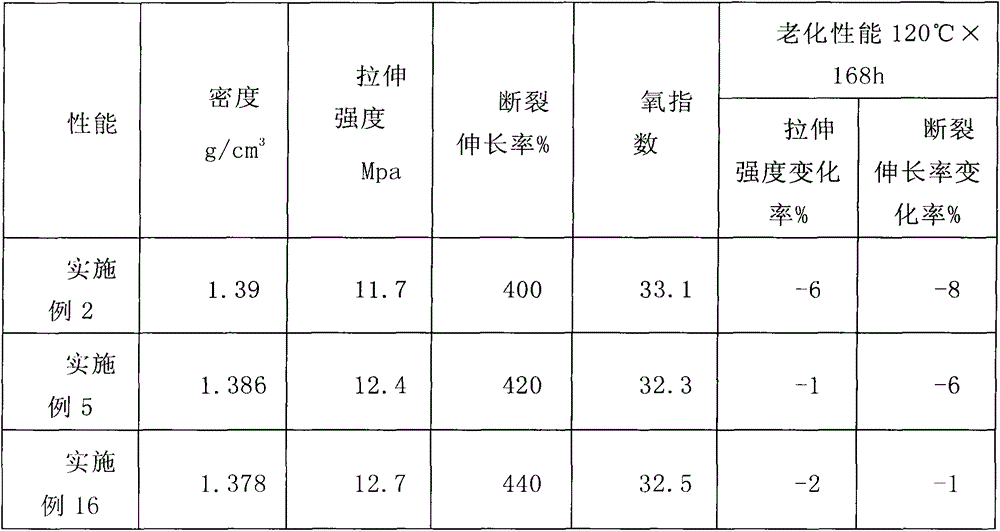

Distortion-resistance wind power generation cable sheath materials and cable

InactiveCN101838424AImproves UV resistanceFunction increasePlastic/resin/waxes insulatorsFlexible cablesElastomerCross-link

The invention discloses a distortion-resistance wind power generation cable sheath material and a cable. The cable material comprises the following components in weight parts: 100 parts of chlorinated polyethylene, 10-30 parts of amorphism copolymer, 10-20 parts of cold-resistant plasticizer, 40-80 parts of reinforcing filler, 5-15 parts of nanosacle inorganic active agent, 2.5-5 parts of cross-linking agent, 2-5 parts of cross-linking assistant agent, 1-2.5 parts of antioxidant antiager and 10-30 parts of inorganic fire retardant, wherein the amorphism copolymer is a mixture of amorphism polyolefin thermoplastic elastomer and chlorinated polyethylene elastic body; and the nanoscale inorganic active agent is nanoscale zinc oxide and magnesium oxide. The cable of the invention has low-temperature resistance (-60DEG C)and distortion resistance, excellent flexibility, improves the homogenisieren property of the other materials by adding the nanoscale inorganic active materials, improves the molecular structure, has better flexibility because of the uvio-resistance, and has the characteristics of distortion, cold, oil and corrosion resistance and the like.

Owner:江苏凯诺电缆集团有限公司

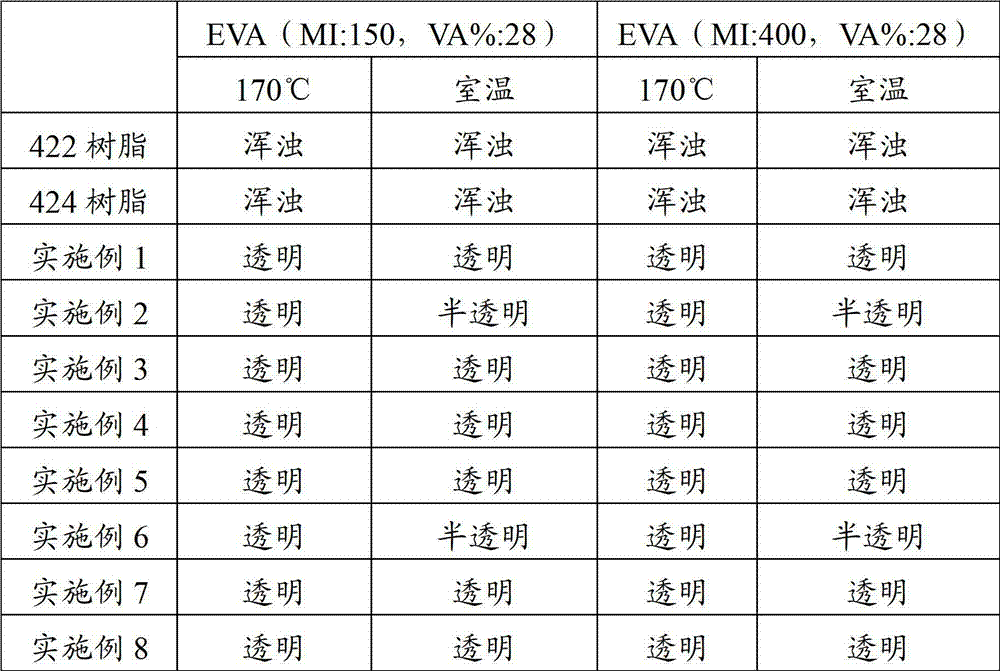

Rosin viscosified resin as well as preparation method and application thereof

ActiveCN102965024AImprove molecular structureHigh softening pointNatural resin chemical modificationRosin adhesivesElastomerDistillation

The invention discloses a preparation method of rosin viscosified resin, and the preparation method comprises the following steps of: (1) adding rosin into a distillation flask, vacuumizing, heating and distilling at the temperature of 240-280 DEG C, so that part of rosin is distilled; and (2) adding the rest rosin in the distillation flask into a reaction flask, adding a catalyst and polyalcohol into the reaction flask under the inert gas protection condition, and reacting for 4-24 hours at the temperature of 240-290 DEG C, so that the rosin viscosified resin is obtained, wherein the rosin contains pinus latteri acid. According to the preparation method disclosed by the invention, the pinus latteri acid contained in the rosin component is utilized, and the pinus latteri acid is rosin binary acid, so that the molecular structure of the resin is increased and the aim of increasing the softening point of the rosin viscosified resin is achieved. Meanwhile, the invention also provides rosin viscosified resin prepared by adopting the preparation method disclosed by the invention, and the rosin viscosified resin has higher softening point and good compatibility with EVA (ethylene vinyl acetate) elastomer and can be better used for preparing hot melt glue.

Owner:普洱科茂林化有限公司

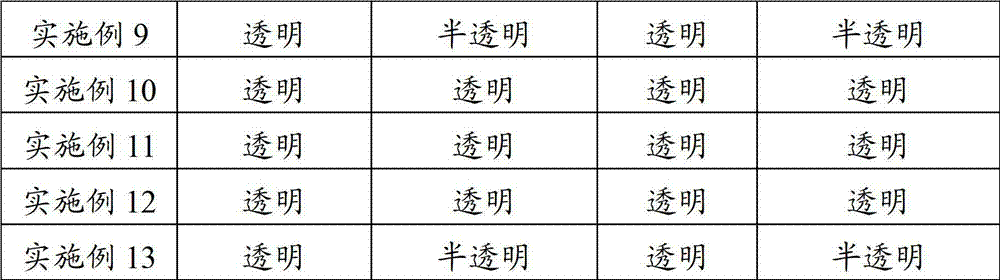

High-strength, high-modulus and high-melting point PVA (Polyvinyl Acetate) fiber and manufacturing method thereof

ActiveCN102337605AImprove molecular structureAvoid tanglesMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolymer science

The invention provides a high-strength, high-modulus and high-melting point PVA (Polyvinyl Acetate) fiber which is a PVA fiber manufactured by using a boron-containing gel wet spinning method, wherein the strength is larger than or equal to 13.5 CN / dtex, the modulus is larger than or equal to 320 CN / dtex, the initial melting point is larger than or equal to 108 DEG C, and the total stretching multiple is 13.0-14.5 times. The product has the advantages of excellent performance and wider application range so as to be especially suitable for being used in the field of high-end industry.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

Building thermal insulation dry powder mortar

A building thermal insulation dry powder mortar belongs to a building thermal insulation material. The weight ratio of a dry powder to water is 1: 1.5. The dry powder is prepared by mixing 450 parts by mass of ordinary portland cement, 70 parts by mass of a calcined gypsum powder, 37.5 parts by mass of a redispersible emulsion powder, 15 parts by mass of fine xylem fibers, 13 parts by mass of polypropylene staple fibers, 10 parts by mass of slaked lime, 10 parts by mass of sierozem, 10 parts by mass of heavy calcium carbonate, 3 parts by mass of hydroxypropyl methyl cellulose, 364 parts by mass of a calcined expanded perlite and 17.5 parts by mass of a premixed auxiliary agent. The thermal insulation building dry powder mortar has the advantages of strong thermal insulation, strong bond with walls, high compressive strength, strong drawing force, excellent weather resistance, and environmental protection, and also has the advantages of fire resistance, cracking resistance, leakage resistance, moisture resistance, sliding resistance, earthquake resistance and the like.

Owner:王荣

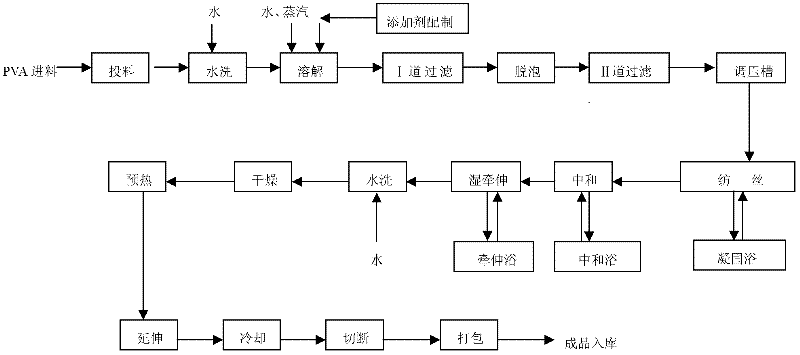

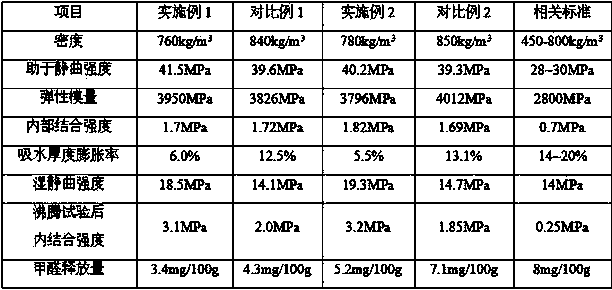

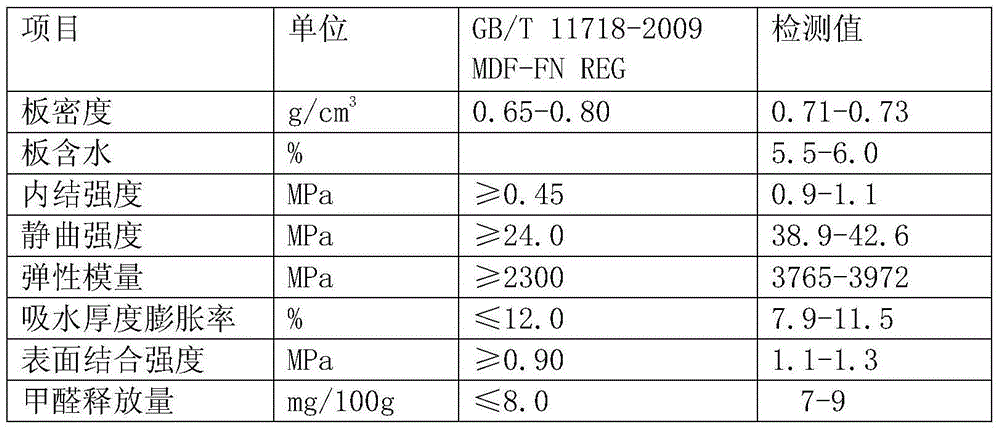

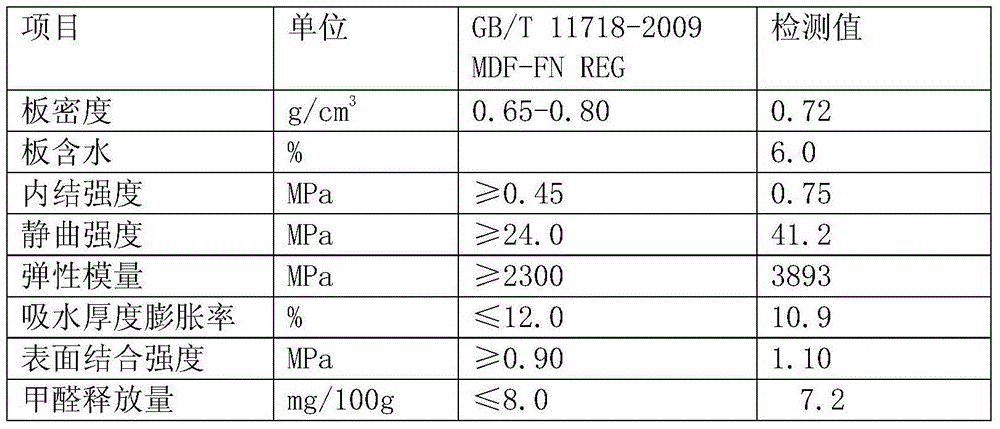

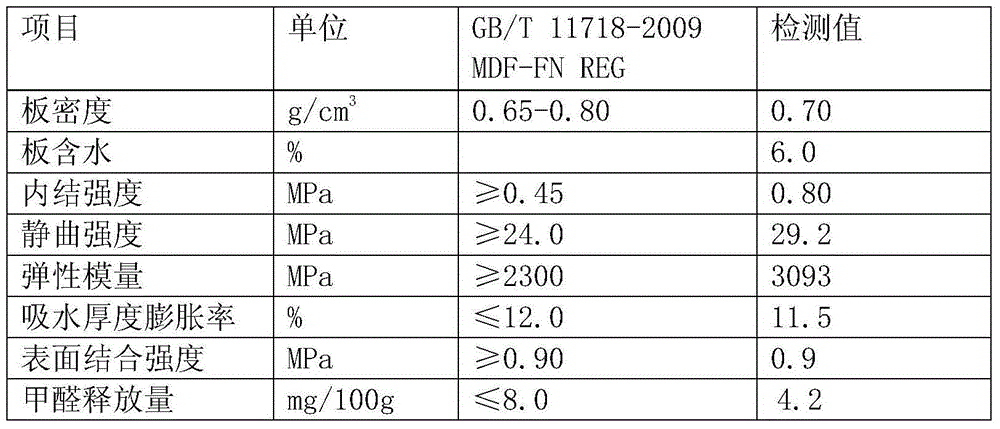

Method for preparing highly-damp-proof thin type medium density fiberboard

ActiveCN103878859AImprove molecular structureImprove water resistanceWood working apparatusDomestic articlesDecompositionUrea

A method for preparing a highly-damp-proof thin type medium density fiberboard includes the steps of firstly, mixing raw material Monterey pines with fresh poplars to obtain a mixed wood chip; secondly, conducting pre-cooking and cooking on the mixed wood chip, and adding paraffin in the molten state to conduct hot grinding and fiber decomposition; thirdly, adding phenol modified melamine urea resin and liquid composite curing agents to fiber where hot grinding is conducted; fourthly, drying the fiber where sizing is conducted, and adding powder waterproof agents in the drying process; fifthly, preparing the highly-damp-proof thin type medium density fiberboard by conducting continuous flat pressing on dried fiber after separation and mat formation are conduced. According to the method, the PMUF resin replaces traditional MUF resin for producing the highly-damp-proof thin type fiberboard, the resin cost is reduced by 10% to 15%, and the production cost for preparing the highly-damp-proof thin type medium density fiberboard through pressing is reduced by 180 yuan / m<3> to 220 yuan / m<3>. Isocyanate is introduced to serve as the curing agents of the PMUF resin, the molecular structure is improved after the resin is cured, and the waterproof performance of the fiberboard is improved.

Owner:DONGYING ZHENGHE WOOD IND

Low-smoke halogen-free coal mine electric cable material and preparation method thereof

InactiveCN104371199AGood flexibilityMeet the laying conditionsRubber insulatorsPlastic/resin/waxes insulatorsCrack resistanceEngineering

The present invention discloses a low-smoke halogen-free coal mine electric cable material and a preparation method thereof. The raw materials of the low-smoke halogen-free coal mine electric cable material comprise an ethylene propylene diene monomer, an ethylene-vinyl acetate rubber, a fire retardation agent, a reinforcing agent, an anti-hydrolysis agent and a peroxide cross-linking agent. The low-smoke halogen-free coal mine electric cable material of the present invention is a thermosetting electric cable material, has low smoke during burning, has advantages of high temperature-low temperature (-40-120 DEG C) resistance, cracking resistance, corrosion resistance, ozone resistance and the like, meets environmental protection requirements, and does not contain any halogen-containing components. According to the present invention, with the combination of the ethylene propylene diene monomer and the ethylene-vinyl acetate rubber, the dispersion uniformity of other materials in the electric cable material is increased, and the molecular structure is improved, such that the softness of the electric cable material is good, the conditions such as the laying under the -40 DEG C low temperature environment and the like can be met for a long time, and the oxygen index and the good fire retardation are provided; and the low-smoke halogen-free coal mine electric cable material is suitable for the underground mine or the occasion of the special work environment having high security.

Owner:TEBIAN ELECTRIC APP CO LTD

Concentrated feed for weaned pig and preparation method thereof

The invention relates to concentrated feed for a weaned pig and a preparation method thereof. The concentrated feed comprises puffed corn flour, high-protein soybean meal, puffed soybean, fish meal, high-protein milk replacer, calcium hydrogen phosphate, stone flour, first-grade bean oil, lysine, methionine, threonine, tryptophan, refined salt, piglet compound enzyme, zinc oxide, a sweetener, a flavoring agent, an anti-oxidant, probiotics, and a piglet premix. The concentrated feed for a weaned pig has comprehensive and balanced nutrition, strong pertinency, a low production cost, high efficiency, stable quality and storage convenience. In feeding, the concentrated feed has good attractability and stability, satisfies requirements of appetite improvement and fast growth of a weaned pig, greatly improves food consumption and a growth rate of a weaned pig, accelerates digestion and absorption of feed nutrients, has a high feed conversion rate, reduces a weaned pig diarrhea rate and a weaned pig death rate and has no adverse side effects.

Owner:NINGXIA DABEINONG TECH IND

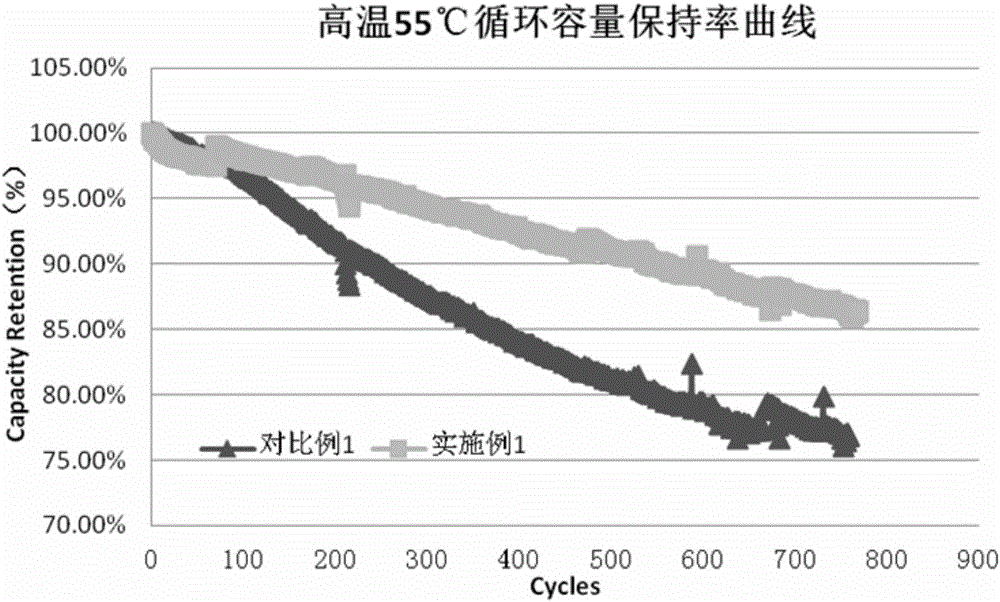

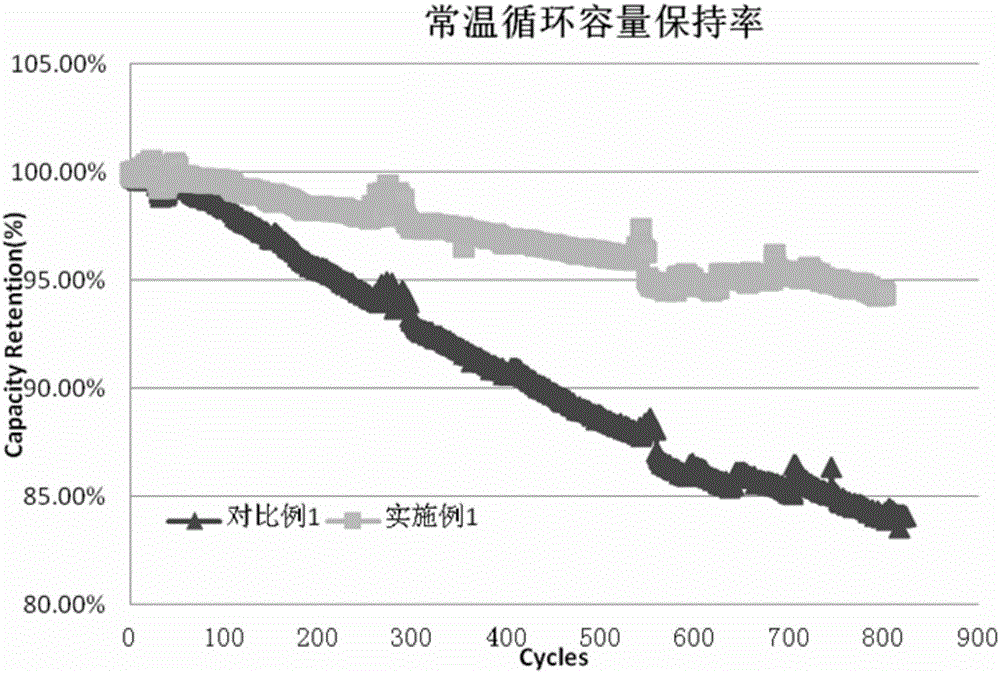

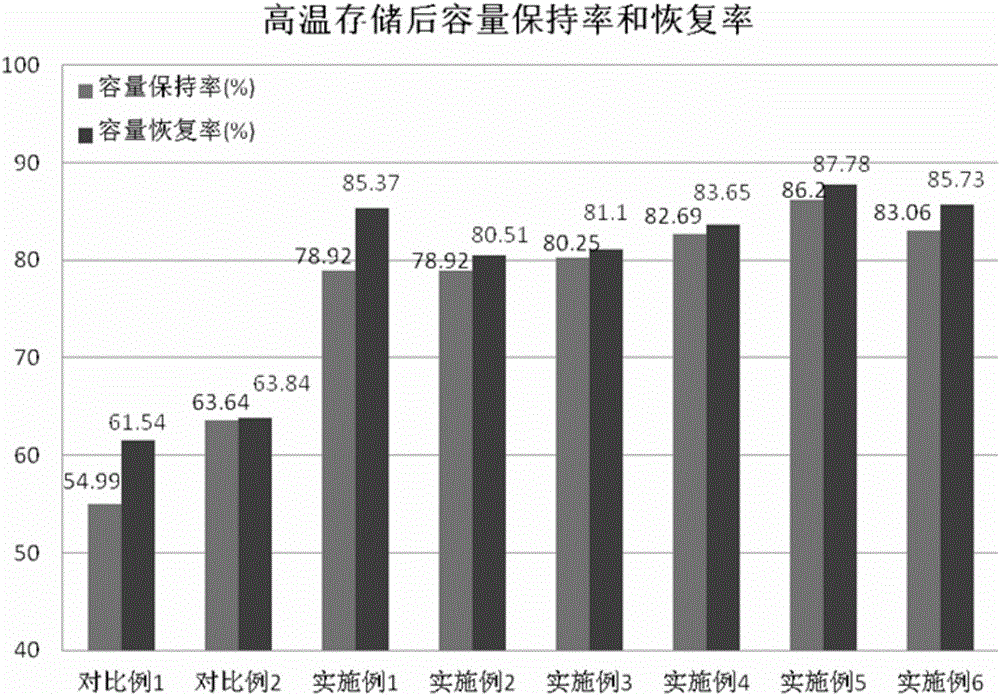

Electrolyte with polyanion functional group and preparation method and application thereof

ActiveCN106058319AAvoid corrosionLower lattice energySecondary cellsOrganic electrolytesMethyl carbonateOxalic acid

The invention discloses an electrolyte with a polyanion functional group and a preparation method and application thereof, and relates to a nonaqueous secondary battery electrolyte. For example, the preparation method of Li[PF2(PO2F2)2(C2O4)] comprises the following steps: (1) dissolving Li3PO4 into dimethyl carbonate, adding LiPF6, and recycling a settled solution for recrystallization after reaction so as to obtain LiPO2F2; (2) dissolving the LiPO2F2 obtained in the first step into dimethyl ether, then introducing PF5 gas, and recycling a settled solution for recrystallization so as to obtain LiPF4(PO2F2)2; and (3) under an inert atmosphere condition, dissolving the LiPF4(PO2F2)2 obtained in the second step into the dimethyl ether, then adding oxalic acid, and reacting to obtain the product LiPF2(PO2F2)2(C2O4). The electrolyte with the polyanion functional group can be used in the preparation of a nonaqueous electrolyte and a nonaqueous secondary battery.

Owner:XIAMEN UNIV

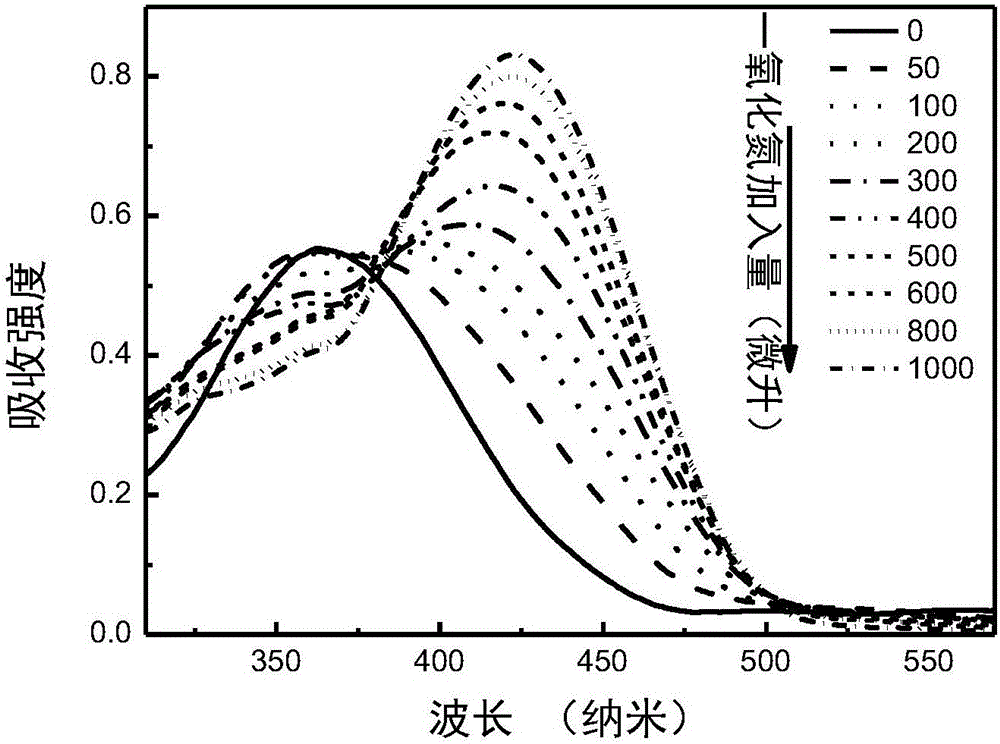

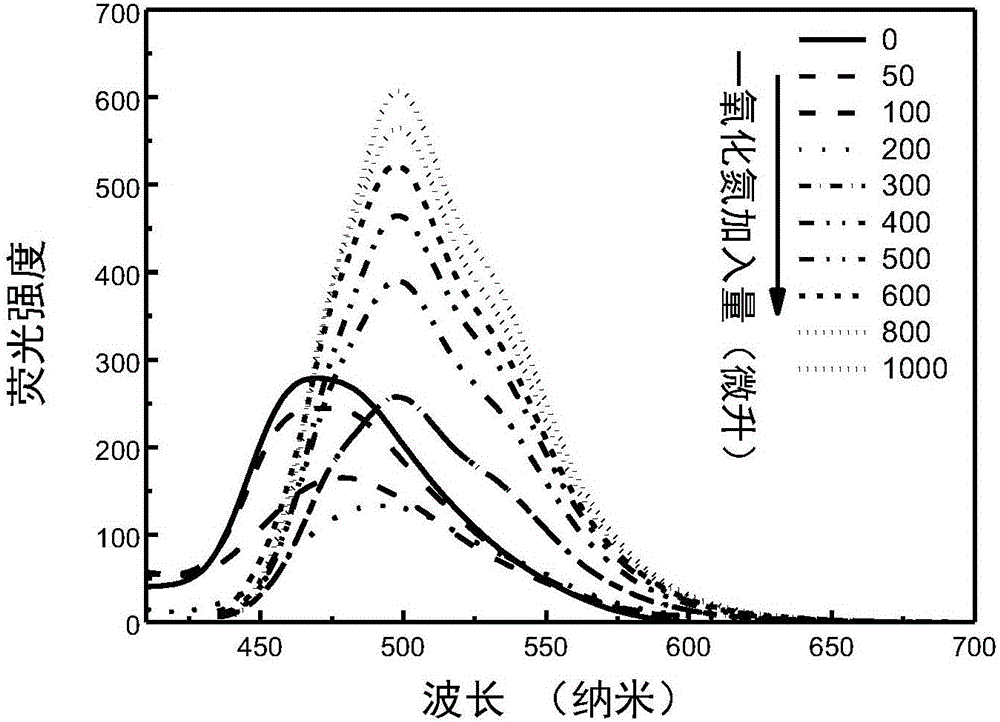

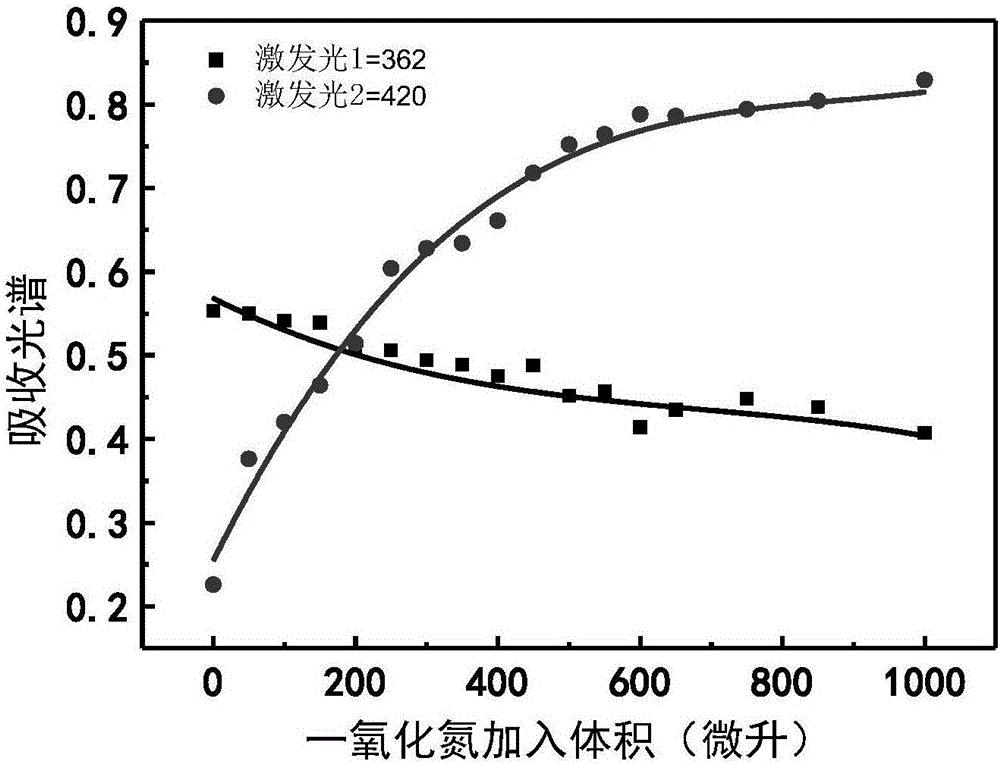

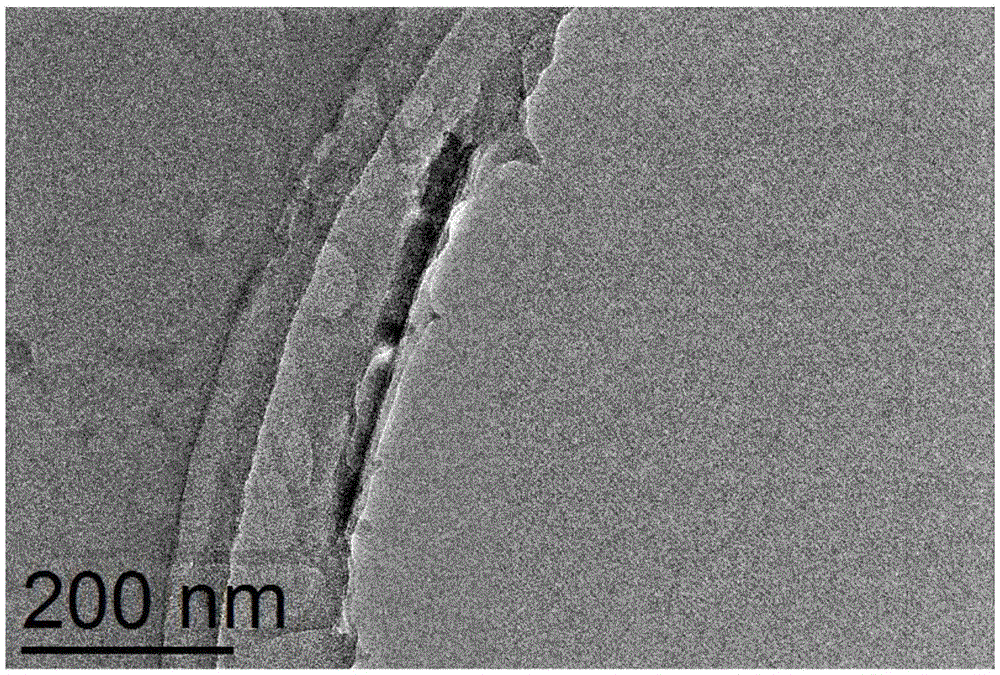

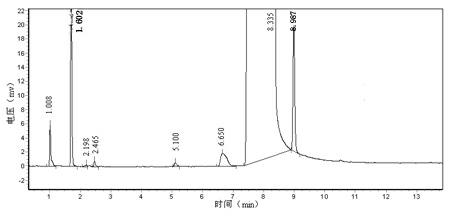

Nitric oxide probe based on fluorescent double-response mechanism and synthesis and application thereof

InactiveCN106432178AHigh sensitivityGood choiceOrganic chemistryFluorescence/phosphorescenceFluorescenceDirect observation

The invention discloses a molecular design and preparation method of a nitric oxide fluorescent probe based on a double-response mechanism. The structure of the nitric oxide fluorescent probe can be represented by a general formula (I) (please see the formula in the description), wherein Spacer represents a single bond or acetylene bond or thiophene or substituted aryl unit, Ar represents one of an aryl group, a substituted aryl group, a heterocyclic aryl group and substituted aryl amine, and the substituted group can be one of a hydrophilic ether chain, a sulfonic acid group, quaternary ammonium salt and the like. The key steps of synthesis of the probe molecule can be achieved through a Suzuki coupling reaction or a C-H activation coupling reaction and the like. The probe molecule has the advantages of being high in sensitivity, good in selectivity, short in response time, good in membrane permeability, low in background noise, capable of achieving direct observation and fluorescence-ultraviolet-visible spectrum dual-band response and the like, is a brand-new sensing detection platform and has a good application prospect.

Owner:NANJING UNIV OF TECH

Cellulose acetate/nano cellulose blended ultrafiltration film

ActiveCN105107390AImprove molecular structureAdd surface functional groupsSemi-permeable membranesN dimethylformamideFiltration

The invention discloses a cellulose acetate / nano cellulose blended ultrafiltration film, belonging to the technical field of films. The blended ultrafiltration film is characterized by being prepared through the steps of firstly, pretreating raw material filter paper by adopting a water solution of alkali system sodium hydroxide / urea, carrying out suction filtration to be neutral, baking, then carrying out acidolysis by using a sulfuric acid solution, and diluting, centrifuging and drying to obtain nano cellulose; and then by adopting cellulose acetate and nano cellulose as film materials, adding an additive, selecting acetone and N,N-dimethylformamide as a mixed solvent, stirring uniformly, then defoaming, and after film scraping, soaking the material into a gel tank with a certain temperature to obtain the blended ultrafiltration film. The blended ultrafiltration film has the effects and benefits that the obtained ultrafiltration film has the good performances of cellulose acetate / nano cellulose, the porosity of the cellulose acetate / nano cellulose ultrafiltration film is improved, the pore diameter is increased, the hydrophilicity is improved, the ultrafiltration film has the advantages of high flux, good pollution resistance, good mechanical performance and the like, the operation is simple, the pretreatment is not needed, and the cost is low.

Owner:DALIAN UNIV OF TECH

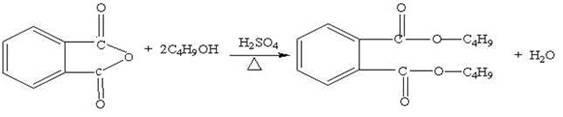

Method for improving thermal stability of dibutyl/diisobutyl phthalate

ActiveCN102219688AImproves intrinsic thermal stabilityImprove thermal stabilityOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisPolyvinyl chloride

The invention provides a method for r improving thermal stability of dibutyl / diisobutyl phthalate, and belongs to the technical fields of fine organic synthesis and application and machine shaping of macromolecular new materials. The method which improves the intrinsic thermal stability of plasticizers of dibutyl phthalate and diisobutyl phthalate by an inorganic carbonate heat treatment is characterized in that: protonic acid, such as sulfuric acid, is adopted to serve as an esterifying catalyst, coarse ester is thermally decomposed by anhydrous solid carbonates in a reaction system prepared through esterifying synthesis of benzoic anhydrides and n-butyl alcohol or isobutyl alcohol, the catalyst and byproducts generated in the reaction process are effectively removed, coloring byproducts in the esterifying reaction system can be effectively removed, the effect of improving the product stability is achieved, and the requirement on thermal treatment of polyvinyl chloride (PVC) products is met; compared with the conventional production methods, the method has the advantages that: process wastewater is reduced by two-thirds, the production period is shortened, and the aims of energy conservation and emission reduction are fulfilled.

Owner:JIANGNAN UNIV +1

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

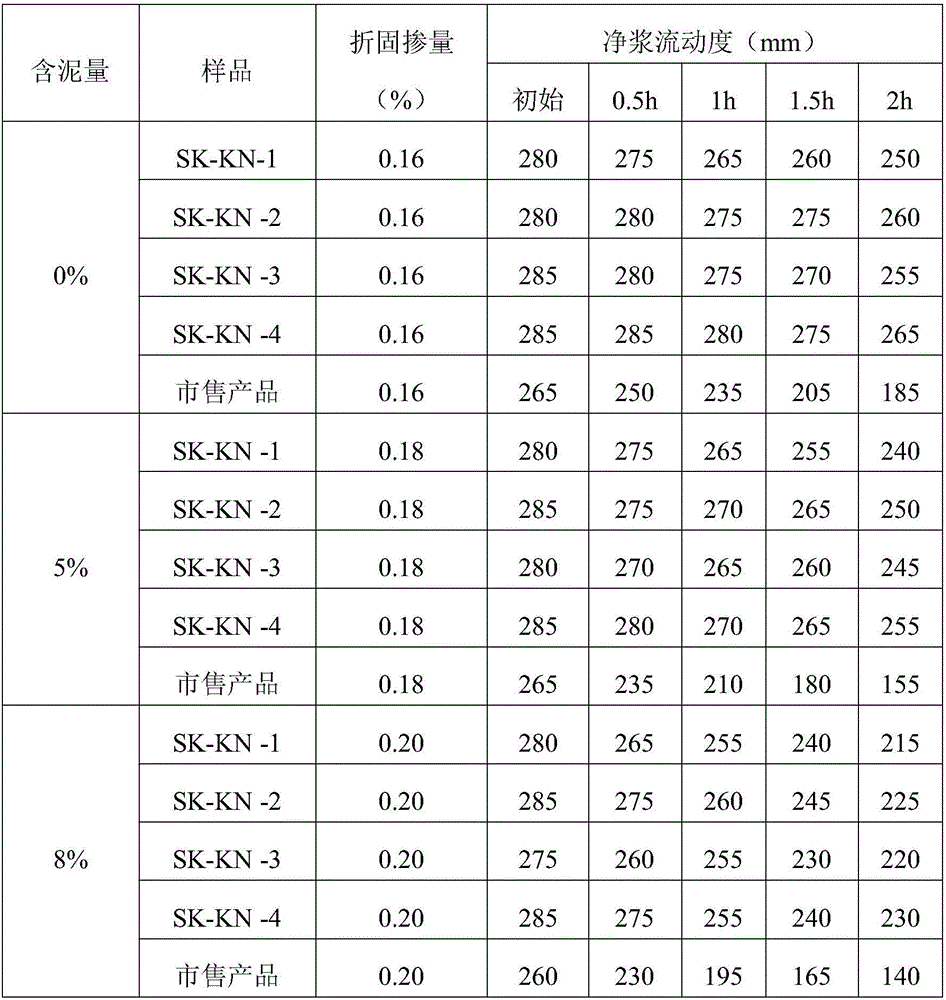

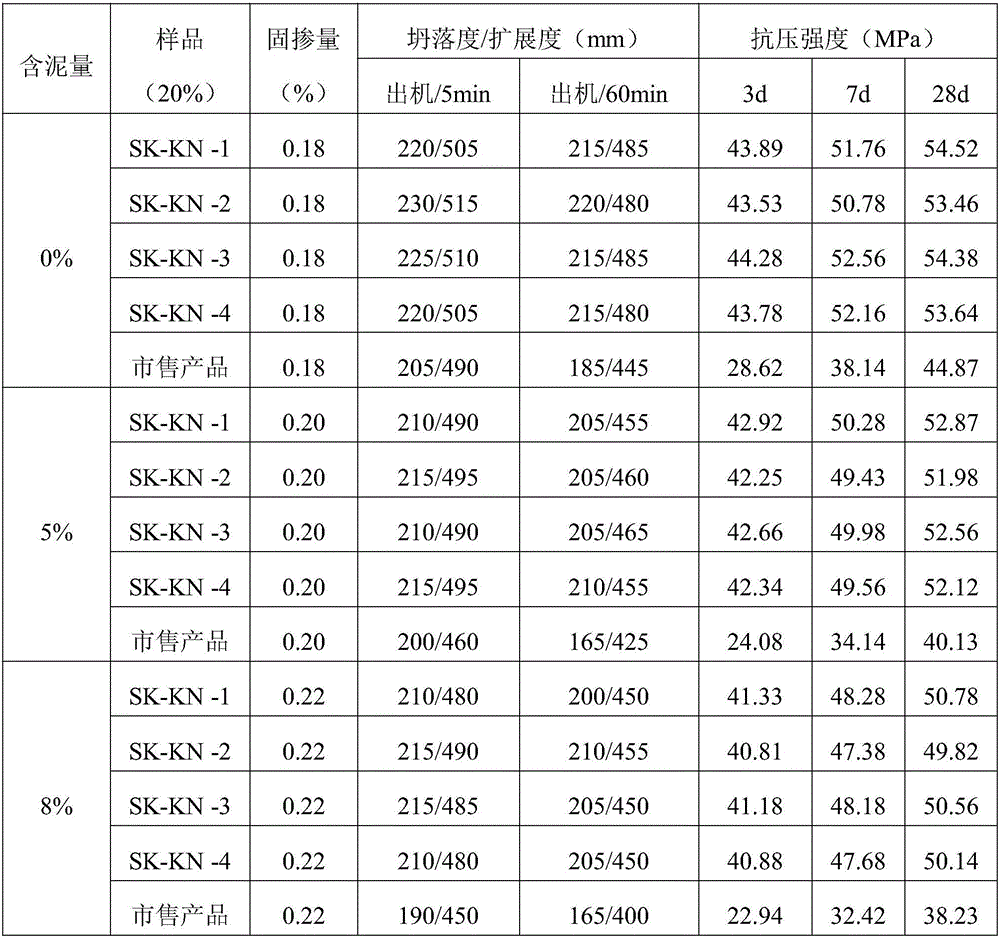

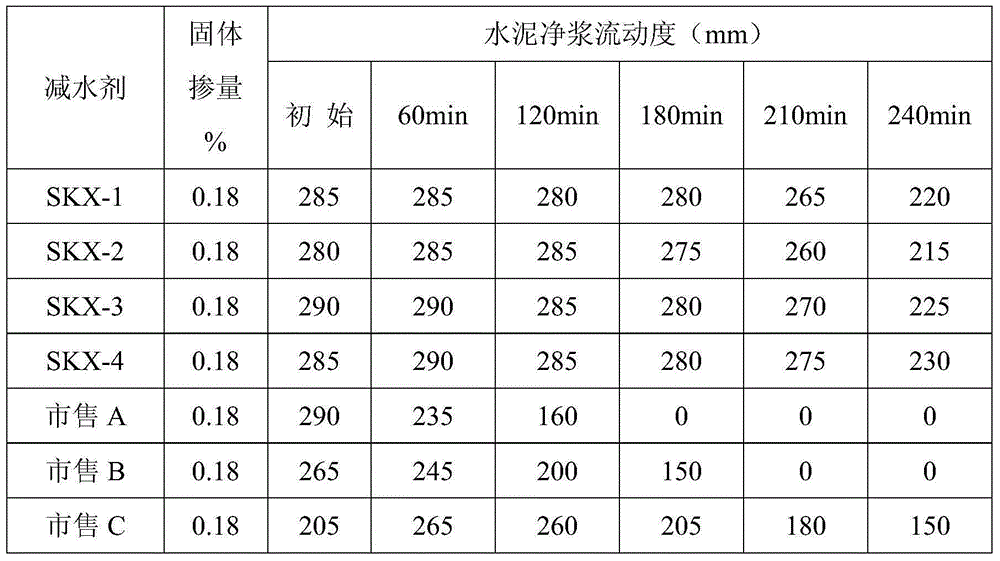

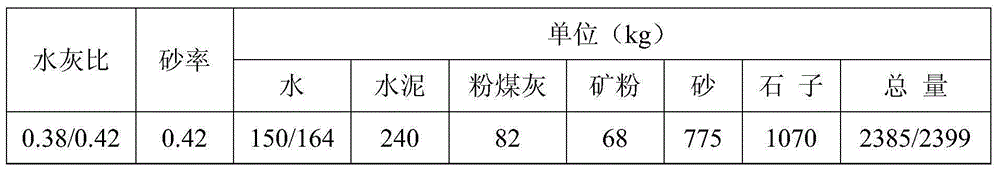

Anti-mud type low-slump-loss polycarboxylic acid water reducing agent and preparation method thereof

The invention discloses an anti-mud type low-slump-loss polycarboxylic acid water reducing agent and a preparation method thereof, and relates to the technical field of synthesis of concrete admixtures. Specifically, from the effect of a molecular structure and an initial pH value of a reaction system on the performance of a product, during a synthesis process, tartaric acid is selected as an adjusting catalyst of the initial pH value of the reaction system in a kettle, monomers succinic acid monoethyl propionyl oxyethyl ester and 2-allyloxy sodium ethanesulfonate having a special water reducing function, monomers cis-1-propylene phosphonic acid and 2-allyloxy sodium ethanesulfonate having a special anti-mud function, and monomers methoxyethyl acrylate, succinic acid monoethyl propionyl oxyethyl ester and isopentenol polyoxyethylene ether with the molecular weight M of 1400 having a special slump retaining function are introduced; after the reaction is finished, an organic alkali diethanolisopropanolamine is used for neutralizing, and the anti-mud type low-slump-loss polycarboxylic acid water reducing agent is synthesized. The reducing agent has the advantages of low alkali content, fast early strength achieving of concrete, and high strength, can significantly improve the workability and the slump retention of the concrete prepared by high-mud-content aggregates, has relatively good anti-mud ability, and also has the advantages of low gradual loss of newly blended concrete, high strength of hardened concrete, good durability and the like.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD

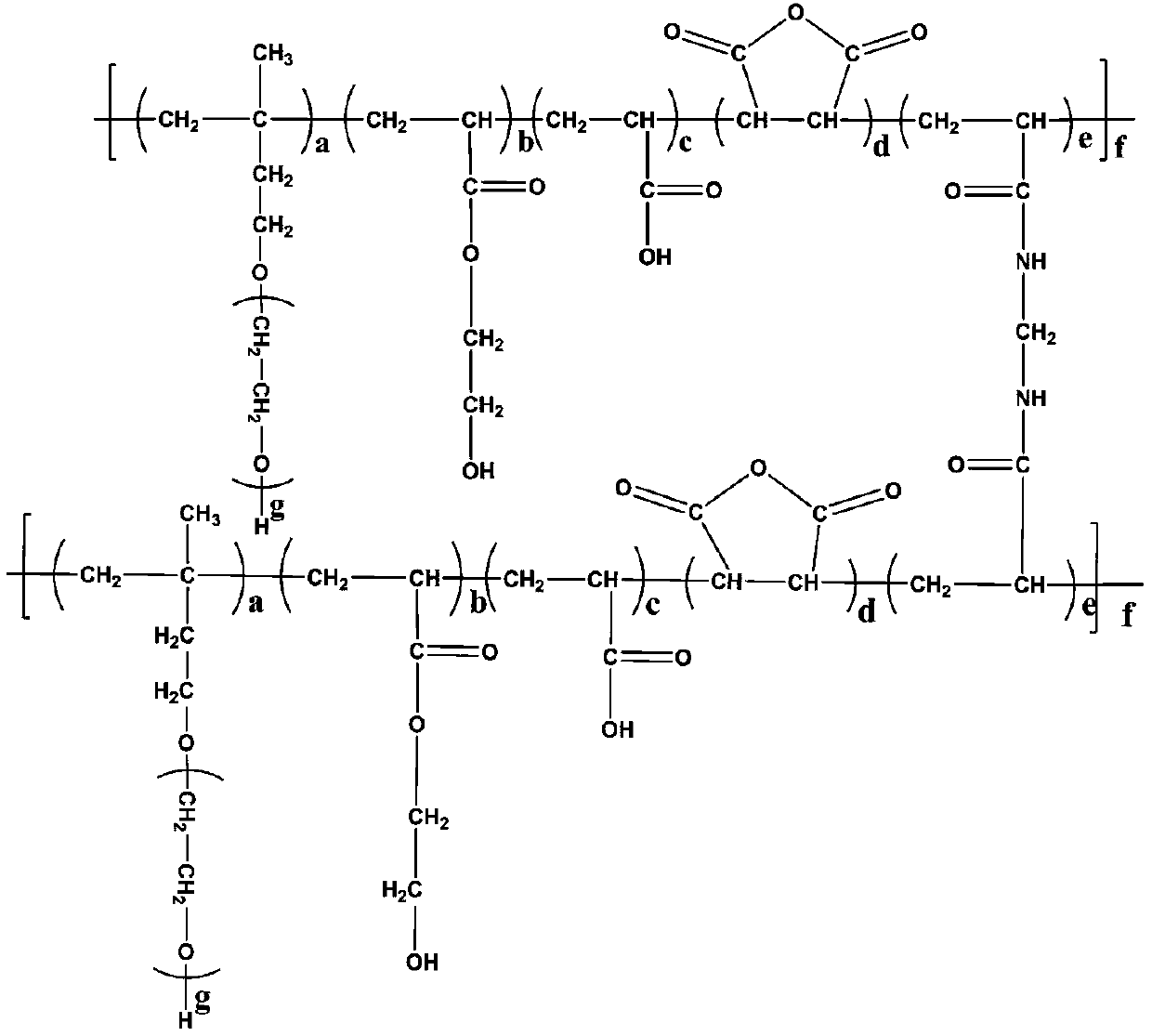

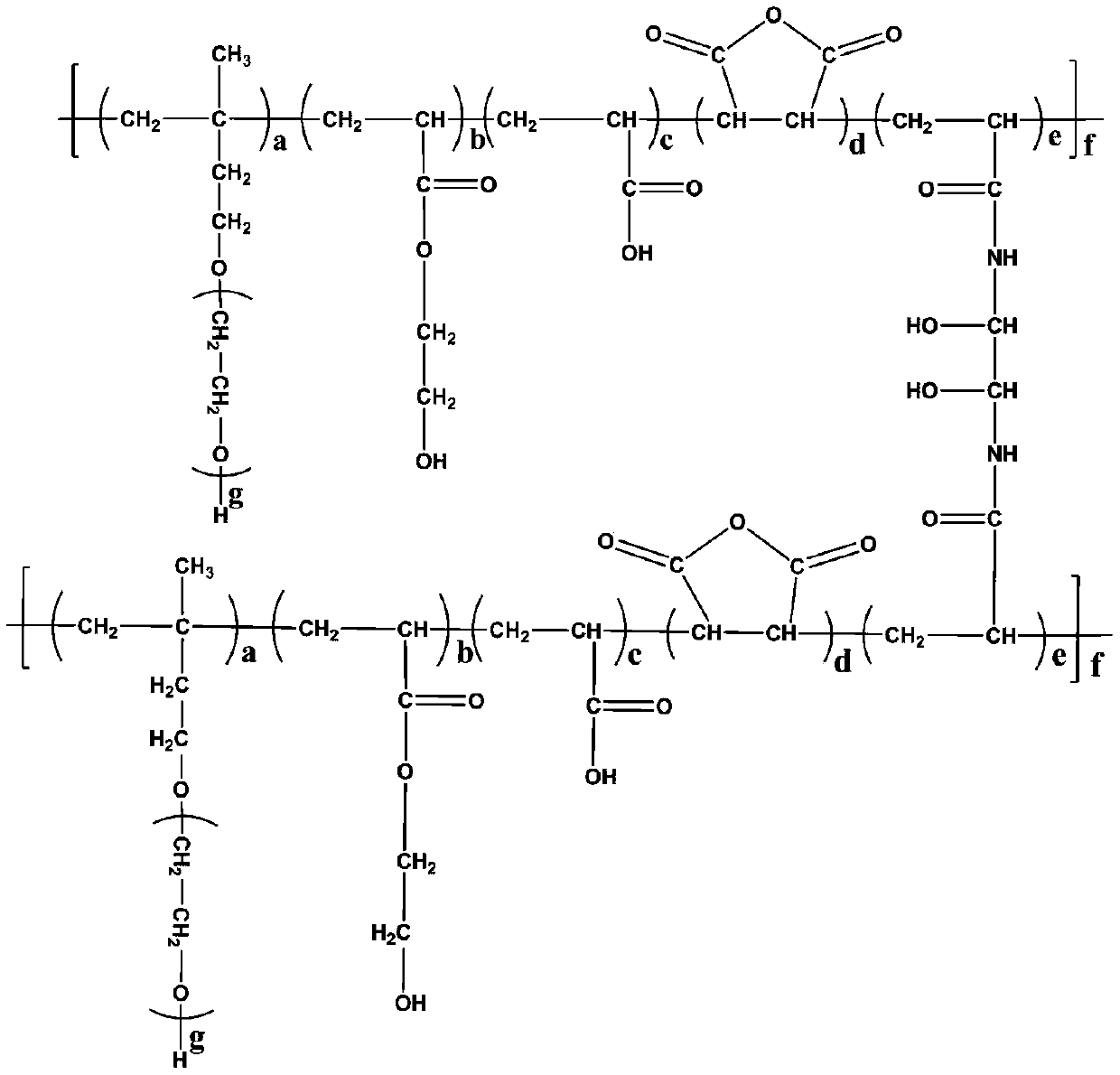

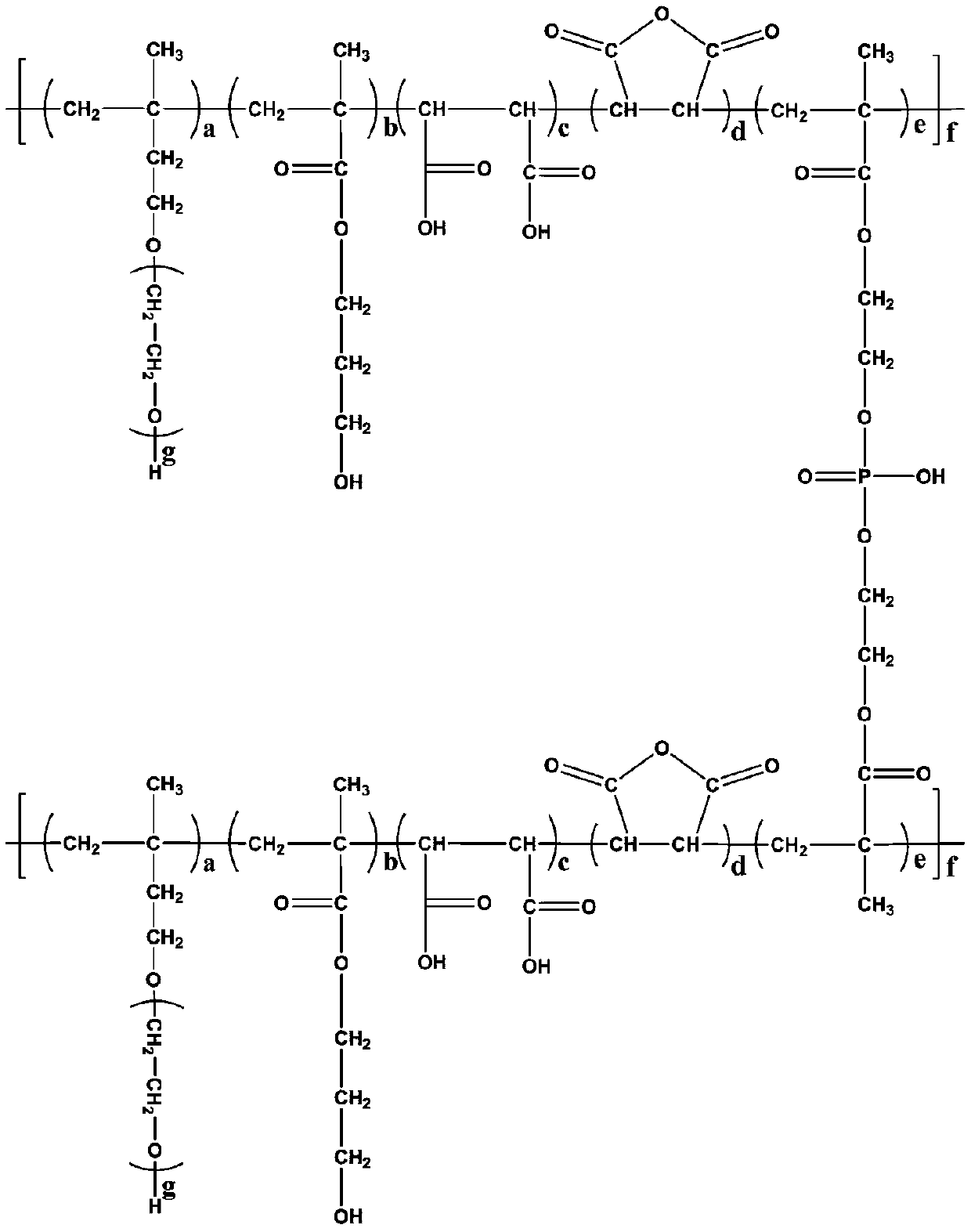

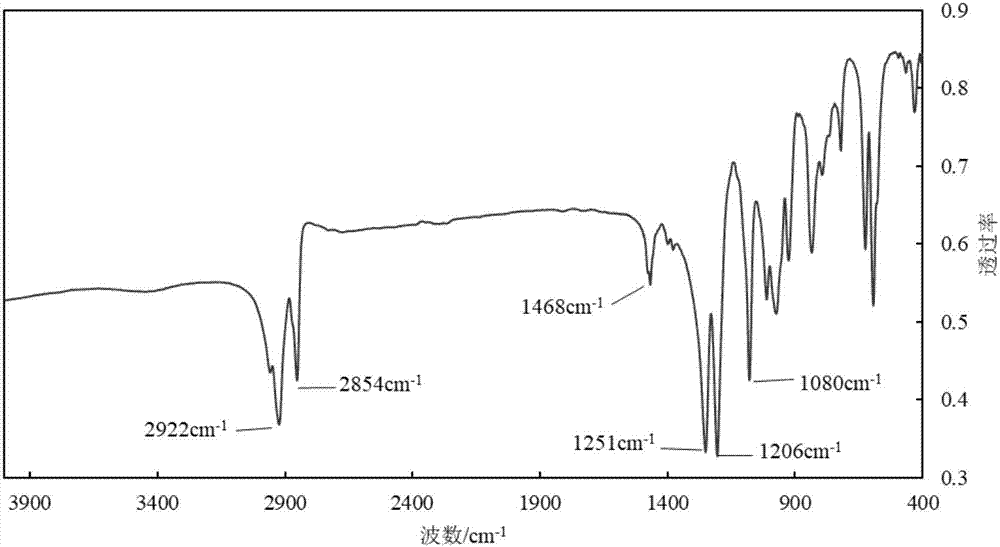

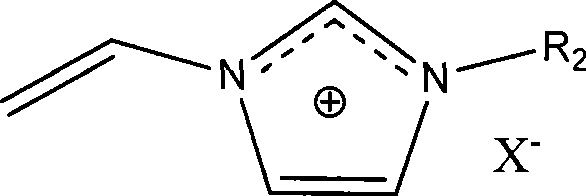

Viscosity reduction type polycarboxylate superplasticizer with microcrosslinking structure and preparation method of viscosity reduction type polycarboxylate superplasticizer

ActiveCN110790872AImprove molecular structureIncreasing the thicknessPolymer scienceSuperplasticizer

The invention discloses a viscosity reduction type polycarboxylate superplasticizer with a microcrosslinking structure. The viscosity reduction type polycarboxylate superplasticizer is prepared from unsaturated acids, unsaturated anhydride, isopentene polyoxyethylene ether, a crosslinking agent and a reactive cosolvent as polymerization raw materials through free radical pauperization under actions of an initiator and chain transfer, components and structures take mutual synergetic effects into play, and compared with a viscosity reduction type polycarboxylate superplasticizer synthesized in the prior art, the viscosity reduction type polycarboxylate superplasticizer has an excellent viscosity reduction effect and has collapse prevention and regulation and control on early strength functions as well; meanwhile, due to introduction of the structure, the thickness of an adsorption layer on the surface of cement granules can be increased, the cement granule surface covering rate can be increased, the concentration of the polycarboxylate superplasticizer retained in a cement pore liquid can be reduced, surface activation performance of the polycarboxylate superplasticizer can be enhanced, and a good viscosity reduction effect can be achieved. Due to adoption of the reactive cosolvent, the intermiscibility of monomers can be effectively improved, and the polymerization efficiency ofa polymer and structure arrangement of effective molecules can be improved. Due to adoption of a bifunctionality crosslinking agent in the polycarboxylate superplasticizer, the molecular structure ofthe polycarboxylate superplasticizer can be improved, and the viscosity reduction performance of the polycarboxylate superplasticizer can be improved.

Owner:CHINA WEST CONSTR GRP +2

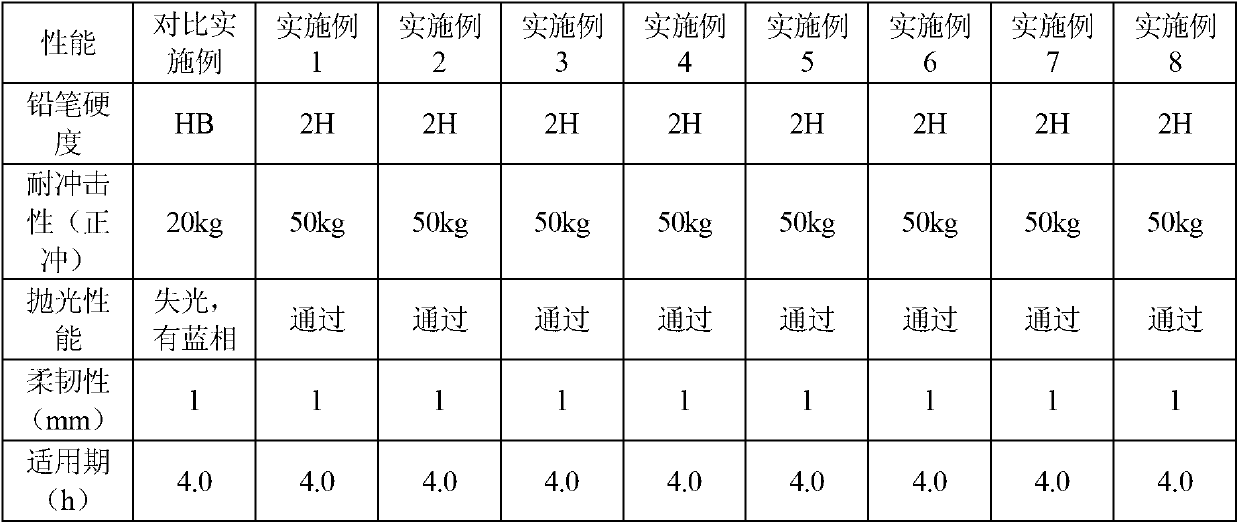

Synthetic method for organosilicone modified waterborne polyurethane resin

The invention discloses a synthetic method for organosilicone modified waterborne polyurethane resin. The synthetic method comprises the specific steps that firstly, polyester polyol Novomer is subjected to vacuum dehydration, diisocyanate is added dropwise, and a polyurethane prepolymer I is obtained after a reaction; secondly, polyhydroxy carboxylic acid is added to the polyurethane prepolymer I, a dihydric alcohol monomer is added dropwise, and a polyurethane prepolymer II is obtained after a reaction; thirdly, trimethylolpropane is added to the polyurethane prepolymer II, and a polyurethane prepolymer is obtained after a reaction; fourthly, organic amine is added to the polyurethane prepolymer for a salt forming reaction, a silane coupling agent, deionized water and diamine are sequentially added for chain extension and stirring, and the organosilicone modified waterborne polyurethane resin with high hardness is obtained after emulsification. The synthetic method has the advantages that the hardness of the organosilicone modified waterborne polyurethane resin reaches 3H, the adhesive force is good, and stability is good.

Owner:TONGGUANG JIANGSU INFORMATION TECH CO LTD

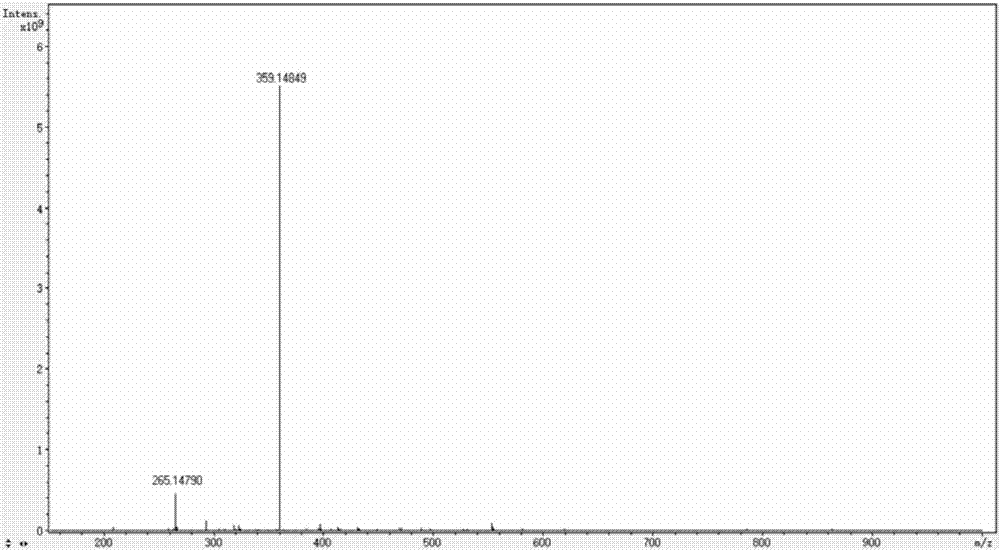

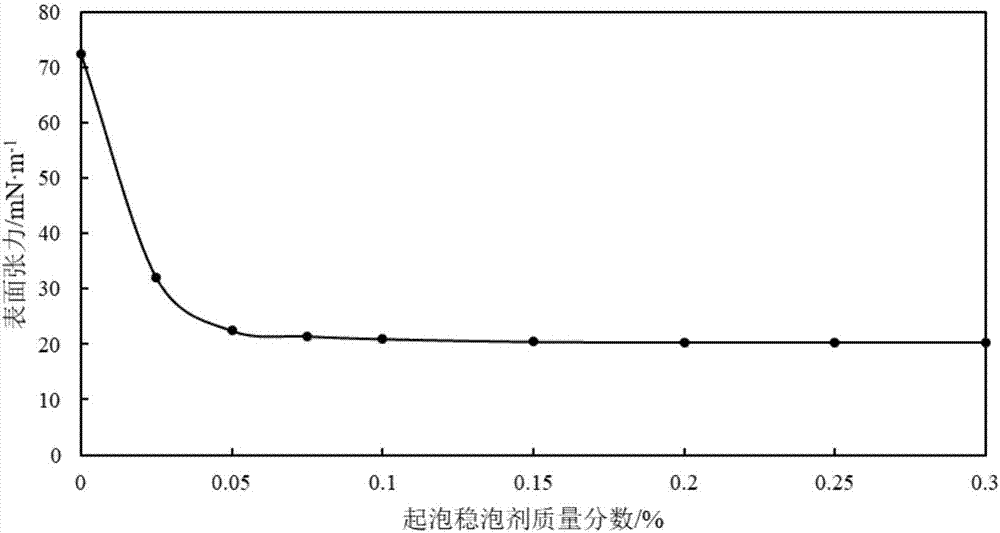

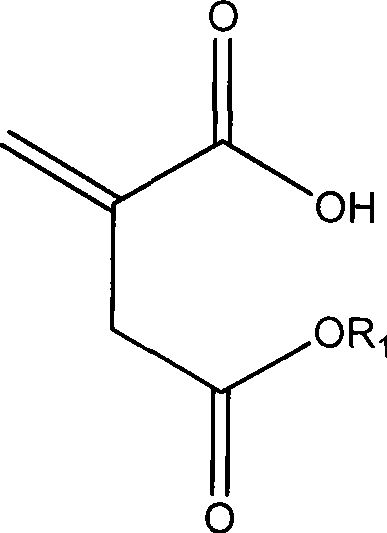

Novel foam drilling fluid system and preparation method thereof

InactiveCN107502321AFine foamImprove molecular structureDrilling compositionReduction rateFoaming agent

The invention relates to a novel foam drilling fluid system and a preparation method thereof. The novel foam drilling fluid system is developed on the basis of the development of a novel foaming foam stabilizer. The novel foaming foam stabilizer has the advantages of novel structure and excellent performance. A small amount of the foaming foam stabilizer can generate a large amount of foam, and the half-life of the foam can reach more than 3 times that of foam generated by a conventional foaming agent. A single foaming foam stabilizer can achieve the compounding effects of a plurality of foaming agents in the prior art, and the dosage is less. The novel foam drilling fluid system developed on the basis of the novel foaming foam stabilizer has a half-life up to 7.1 d when the foaming foam stabilizer is added in a small amount, the half-life of the novel foam drilling fluid system is obviously better than the half-life of a foam drilling fluid formulated by the conventional foaming agent The novel foam drilling fluid system has good performance, can resist temperature of 120 DEG C, can resist salt of 10%, and can resist rock debris pollution of 12%, shale recovery rate is 90% or more, the linear expansion reduction rate is 80% or more. The novel foam drilling fluid system is free of seepage loss in 80 / 120-mesh gravel, the seepage loss is 1.2 ml or less in 40 / 80-mesh gravel, and the novel foam drilling fluid system can effectively meet the requirements of on-site construction.

Owner:CHINA UNITED COALBED METHANE +1

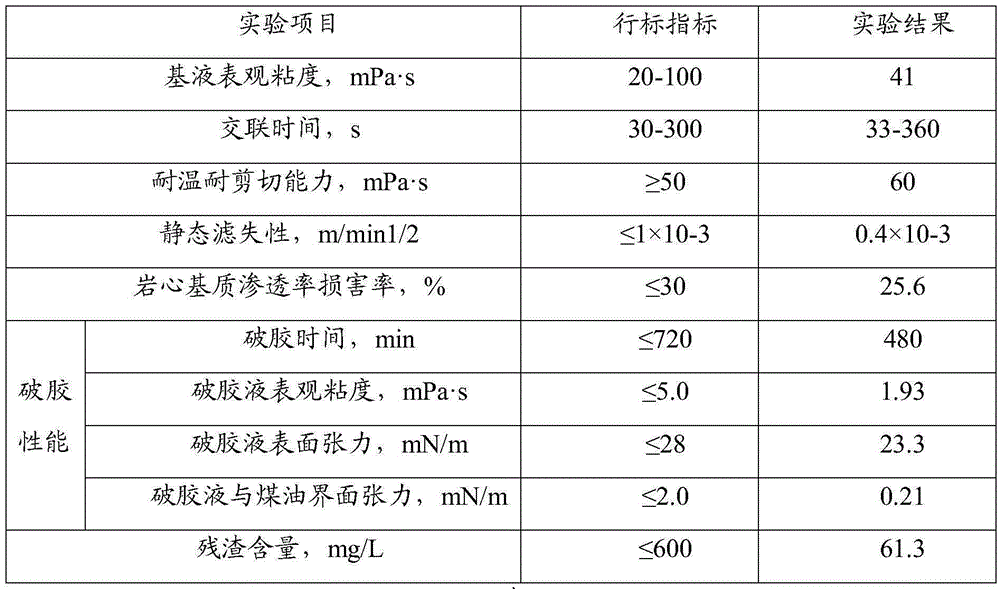

Seawater-based fracturing fluid and preparation method thereof

The present invention discloses a seawater-based fracturing fluid and a preparation method thereof. 100 parts of the fracturing fluid comprises, by weight, 0.3-0.8 part of a thickener, 0.1-0.6 part of a cross-linking agent, 0.05-0.1 part of an oxygen scavenger, 0.02-0.05 part of a tackifying auxiliary agent, 0.05-0.2 part of gel breaker, and the balance or part of seawater, wherein the thickener modified polyacrylamide is formed by carrying out copolymerization on acrylamide, a hydrophobically modified monomer and a sulfonate, the hydrophobically modified monomer is dodecyl alkyl halide, and the cross-linking agent is an organic zirconium cross-linking agent or an organic titanium-zirconium composite cross-linking agent. According to the present invention, with the seawater-based fracturing fluid and the preparation method thereof, the technical problems of being incapable of continuously mixing, insufficient tackifying performance, poor salt resistance and poor shearing resistance of the seawater-based fracturing fluid in the prior art are solved; and the seawater-based fracturing fluid with characteristics of good tackifying, strong salt resistance, strong shearing resistance and continuous mixing and suitable for offshore oil fields is provided.

Owner:PETROCHINA CO LTD

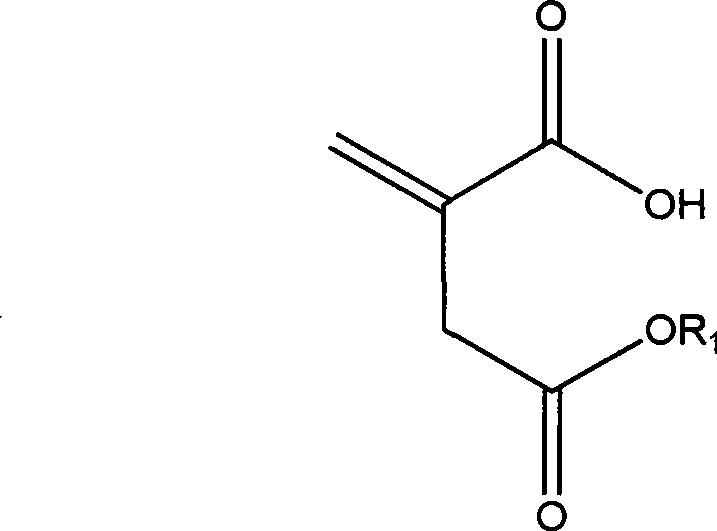

Acrylonitrile terpolymer spinning fluid containing hydrophilic group and preparation thereof

InactiveCN101413152AHigh molecular weightImprove spinnabilityMonocomponent synthetic polymer artificial filamentChain structureAcrylonitrile

The invention relates to an acrylonitrile terpolymer spinning solution containing hydrophilic groups and a preparation method. The preparation method comprises the following steps: in dimethyl sulfoxide solution, using azo-bis-iso-heptonitrile to initiate acrylonitrile, itaconate beta-monoester and vinyl imidazole salt to carry out copolymerization reaction, using small amount of chain transfer agent to adjust molecular weight of the copolymer, and synthesizing the acrylonitrile terpolymer at a temperature of between 25 and 45 DEG C, wherein the molecular weight of the acrylonitrile terpolymer is controllable to between 100, 000 and 500, 000, and distribution index of the molecular weight is lower than 2.3. The acrylonitrile terpolymer spinning solution has the characteristics of controllable molecular weight, even chain structure, narrower molecular weight distribution, and excellent hydrophilicity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Synthetic technology of slump-retaining polycarboxylic type water reducer

The invention discloses a synthetic technology of a slump-retaining polycarboxylic type water reducer. Specifically, beta-carboxyethyl acrylic ester with the high water-reducing function and slump-retaining function and 3-allyloxy-2-hydroxy sodium propanesulfonic acid with the high water-reducing function are introduced in the synthetic process, and diethylene glycol monoacrylate and other monomers with special functions are introduced into the slump-retaining component. According to the synthetic technology, an oxidation-reduction initiating system molecular weight regulator is adopted in the water phase, and therefore the monomers with the slump-retaining function and the water-reducing function are synthesized in a one-pot subsection relay dropwise addition synthetic mode. Concrete tests prove that the synthetic product has the water reducing performance and slump retaining performance, the workability of fresh concrete is greatly improved, and the sensitivity of the water reducer for the water amount is lowered.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD

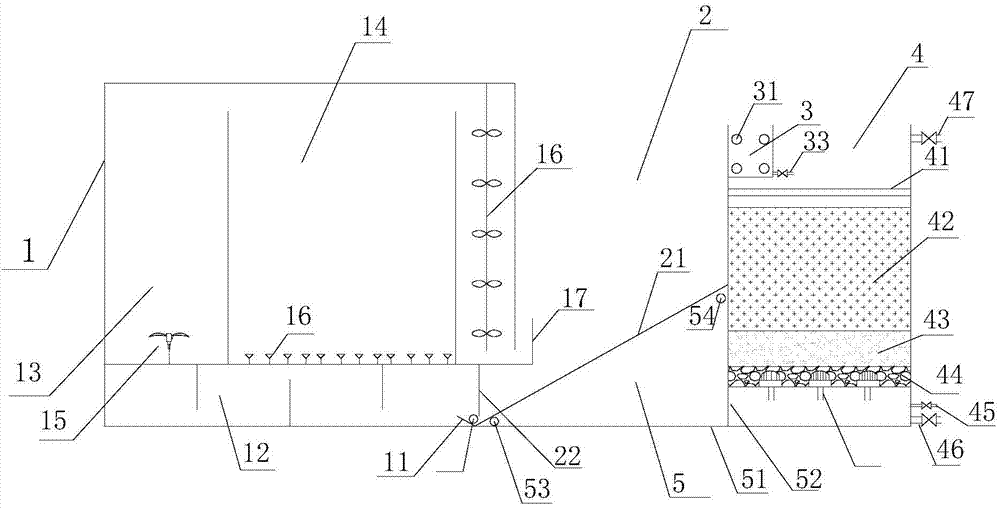

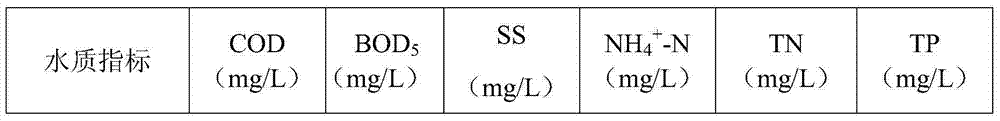

Medium- and small-sized sewage treatment integrated device

ActiveCN104773917ACompact structureSmall footprintMultistage water/sewage treatmentWater qualitySmall footprint

The invention provides a medium- and small-sized sewage treatment integrated device which comprises a biotreatment unit, a precipitate and sludge return unit, an optical catalytic oxidization unit, a deep treatment unit and a disinfection unit sequentially connected, wherein the precipitate and sludge return unit is respectively connected with the water inlet of the optical catalytic oxidization unit and the water inlet and water outlet of the deep treatment unit; the biotreatment unit comprises a water inlet region, an anaerobic treatment region, an anaerobic treatment region and an aerobic treatment region which are sequentially connected; the deep treatment region comprises a water distributing tank, a particle active carbon filter material layer, a quartz sand filter layer and a cobblestone supporting layer which are sequentially connected from top to bottom. The device has the characteristics of being compact in structure, small in occupied area, convenient to use, flexible to operate, low in treatment cost, high in effluent quality, strong in adaptability and the like and has relatively good popularization and application prospects.

Owner:HOHAI UNIV

Environment-friendly type modified coal asphalt and preparation method thereof

ActiveCN103834421AReduce dosageSimple processWorking-up pitch/asphalt/bitumen by chemical meansReaction temperatureProcess engineering

The invention relates to environment-friendly type modified coal asphalt and a preparation method thereof. The preparation method in the technical scheme comprises the following steps: placing 20-30 weight parts of coal asphalt into a reaction kettle with a reflux unit; then, under the conditions that temperature is 70 DEG C-90 DEG C and stirring speed is 80 r / minute-100r / minute, adding 67-77 weight parts of mixed solvent into the reaction kettle, stirring for 10 minutes, re-adding 2.6-3.2 weight parts of modifier and 0.20-0.32 weight parts of sulfuric acid under the condition that temperature and stirring speed are the same, and stirring for 1 hour-5 hours to obtain a coal asphalt mixture; and finally, under the condition with the temperature of 100 DEG C-110 DEG C, distilling the obtained coal asphalt mixture under reduced pressure to recycle solvent to prepare the environment-friendly type modified coal asphalt. According to the invention, process is simple, reaction temperature is low, dosage of the modifier is less, the solvent can be recycled, cost is low and content of polyaromatic hydrocarbon 3,4-benzopyrene in the coal asphalt can be effectively lowered.

Owner:盐城捷晶科技有限公司

Production method of fireproof and flame-retardant type medium-density fiber wood floor

InactiveCN109366680AAlleviate the contradiction between supply and demandImprove fire and flame retardant performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberMedium density

The invention discloses a production method of a fireproof and flame-retardant type medium-density fiber wood floor. The production method comprises the steps of (1) pretreatment of raw materials; (2)screening; (3) stewing softening operation; (4) grinding operation; (5) glue application and drying; (6) pre-pressing operation; (7) hot-pressing operation; (8) sawing and sanding; (9) glue coating and veneering hot-pressing operation; and (10) preservation and grooving, so that the finished product is obtained. According to the production method, the eucalyptus bark, branches and waste leftovermaterials which remain after board manufacturing is accomplished are used as main raw materials, then other miscellaneous trees are added, the waste is turned into the wealth, and therefore the sufficient and effective utilization of timber resources can be achieved; and due to the fact that modified paraffin and flame-retardant urea-formaldehyde resin adhesives are added, the fireproof and flame-retardant performance of the wood floor can be greatly improved, and the produced medium-density fiber wood floor is excellent in fireproof and flame-retardant performance, good in water resistance and low in formaldehyde content, and is a safe, environmentally friendly and durable wood floor.

Owner:广西横州丽冠环保材料有限公司

Two-step method for preparing modified urea-formaldehyde glue for environment-friendly artificial board

ActiveCN104086730AImprove molecular structureImprove cohesionAldehyde/ketone condensation polymer adhesivesAqueous solutionMelamine

The invention discloses a two-step method for preparing modified urea-formaldehyde glue for an environment-friendly artificial board. The modified urea-formaldehyde glue mainly comprises the following raw materials in parts by weight: 56-60 parts of formaldehyde aqueous solution with the mass concentration of 37%, 42-39 parts of agricultural urea, 0.2-2 parts of industrial-grade melamine, and is prepared by a weak acid step and a weak base step, wherein for the weak acid step, addition and condensation polymerization reactions of urea and formaldehyde are simultaneously conducted in a weak acid medium with pH value of 4-6.5. An inventor does improvement on the basis of the three-step weak base technology of the traditional modified urea-formaldehyde glue, the improvement mainly lies in all steps are integrated into weak acid-weak base two steps, the feeding mode that formaldehyde and melamine are fed at a time is adopted, and urea is fed in three to four batches. By applying the two-step method, the molecular structure of the glue can be improved, about a half of acid-base consumption can be reduced, the strength of the glue can also be improved, the release amount of formaldehyde can be reduced, and the modified urea-formaldehyde glue has the characteristics of low cost, high performances, environment friendliness and the like.

Owner:GUANGXI UNIV

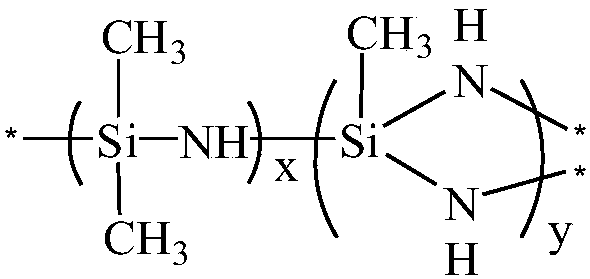

Room temperature curing agent for high-temperature-resistant organosilicon materials, preparation method and applications thereof

The invention provides a room temperature curing agent for high-temperature-resistant organosilicon materials, a preparation method and applications thereof. The room temperature curing agent comprises polysilazane and a catalyst, wherein the molecular structure of the polysilazane is optimized, and only contains difunctional Si-N chain segments and trifunctional Si-N chain segments, and the random branched structure is formed by a polymerization reaction; by adjusting the feeding ratio, pressurizing during the aminolysis and using ceramic ball-assisted mass transfer, the use amounts of the trifunctional silane and the ammonia gas for forming the trifunctional Si-N chain segment with the same content are substantially reduced, the molecular structure of the polysilazane is optimized, the generation of ammonium chloride is reduced, and the mass transfer and heat transfer control during the aminolysis is easily achieved; and the optimization does not affect the formation of the cross-linked network of the cured organosilicon material, and the structure optimizing meets the development trend of green chemistry.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com