Method for preparing highly-damp-proof thin type medium density fiberboard

A medium-density, fiberboard technology, applied in the field of preparation of high moisture-proof thin medium-density fiberboard, can solve the problems of limited use, poor moisture-proof performance of medium-density fiberboard, etc., and achieve the effects of moderate cost, improved water resistance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

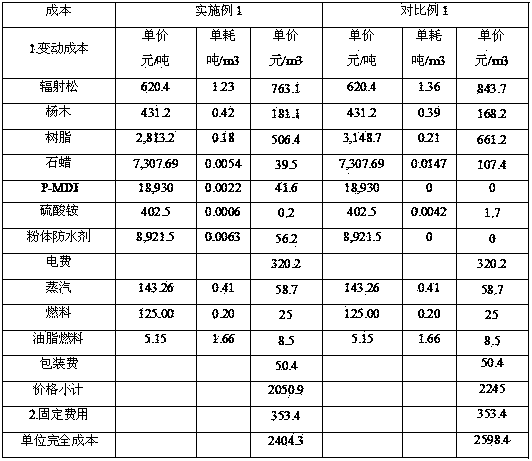

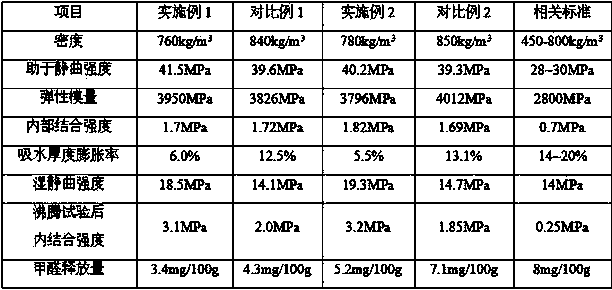

Embodiment 1

[0025] Example 1: Using radiata pine and fresh poplar as raw materials (radiata pine: poplar = 3:1), pressed with a thickness of 2.77mm and a density of 760kg / m 3 High moisture-proof thin medium density fiberboard. The process steps are as follows: first mix the two raw materials, wash the chipped chips with water to remove the sediment, and then pass through a shaking sieve to obtain mixed wood chips with a length of 30mm, a width of 20mm and a thickness of 3mm. The wood chips are preliminarily softened by pre-cooking, and then pressure-cooked at 0.8MPa for 3 minutes. Then, they enter the thermal grinder for thermal grinding at a pressure of 0.6MPa, and at the same time, add molten paraffin that accounts for 3% of the dry fiber. Apply PMUF resin accounting for 12% of the dry fiber, and add a composite liquid curing agent of 1.5% of the resin mass when adjusting the glue (the mass ratio of the curing agent is P-MDI:ammonium sulfate=8:2), and the two are mixed by a static mixer...

Embodiment 2

[0027] Example 2: Using radiata pine and fresh poplar as raw materials (radiata pine: poplar = 3:1), pressed with a thickness of 5.70mm and a density of 780kg / m 3 High moisture-proof thin medium density fiberboard. The process steps are as follows: first mix the two raw materials, wash the chipped chips with water to remove sediment, and then obtain mixed wood chips with a length of 30 mm, a width of 20 mm and a thickness of 3 mm through a shaker sieve. The wood chips are preliminarily softened by pre-cooking, and then pressure-cooked at 0.7MPa for 3 minutes, and then put into a thermal grinder for thermal grinding at a pressure of 0.6MPa, and at the same time, melted paraffin wax accounting for 2% of the dry fiber is added. Apply PMUF resin accounting for 11.5% of the dry fiber, and add a composite liquid curing agent of 1% of the resin mass when adjusting the glue (the mass ratio of the curing agent is P-MDI:ammonium sulfate=9:1), and the two are mixed by a static mixer Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com