Patents

Literature

196results about How to "Alleviate the contradiction between supply and demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microgrid multi-energy joint optimal scheduling method

ActiveCN109327042AEasy to guideGood motivationSingle network parallel feeding arrangementsWind energy generationMicrogridDynamic planning

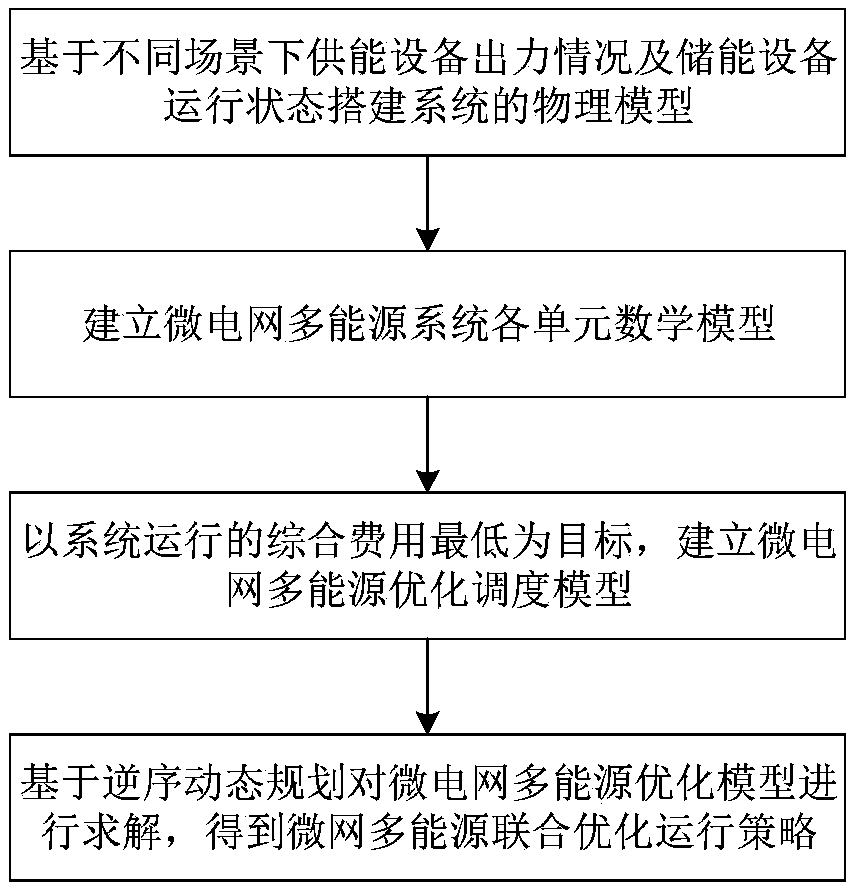

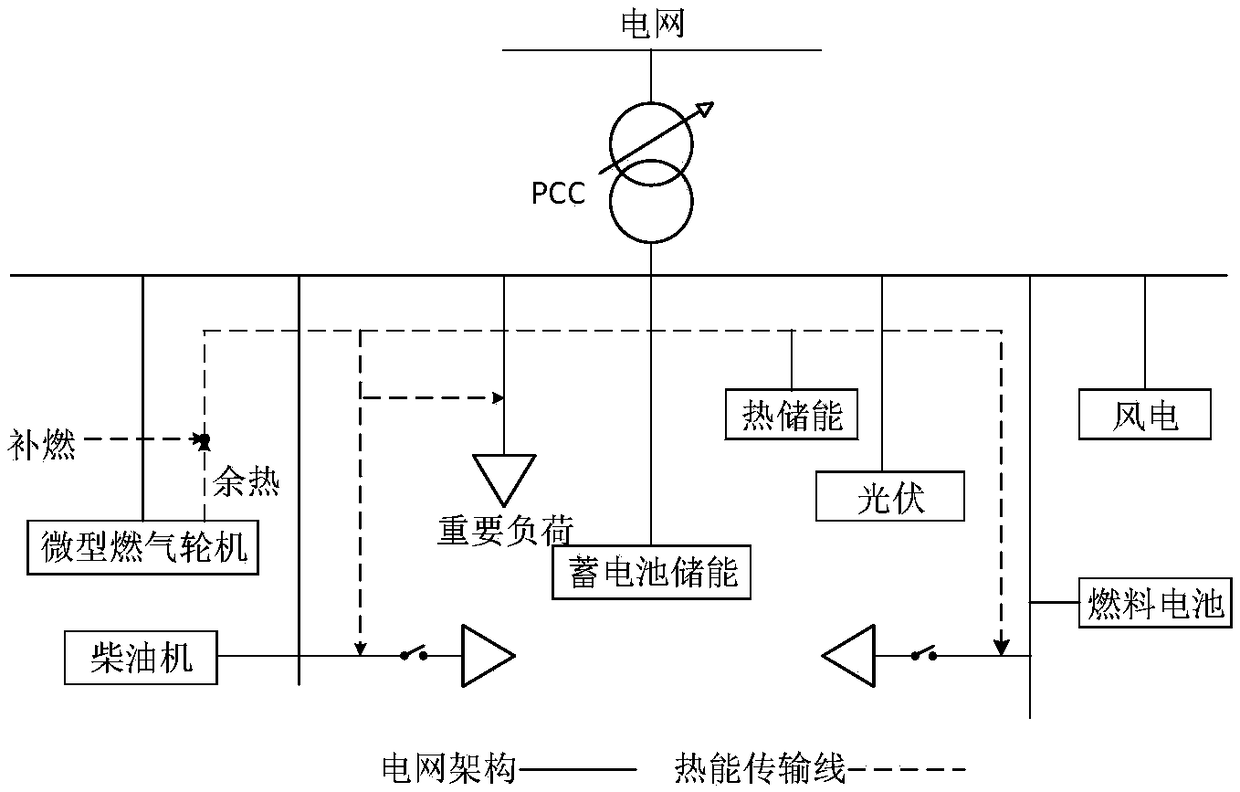

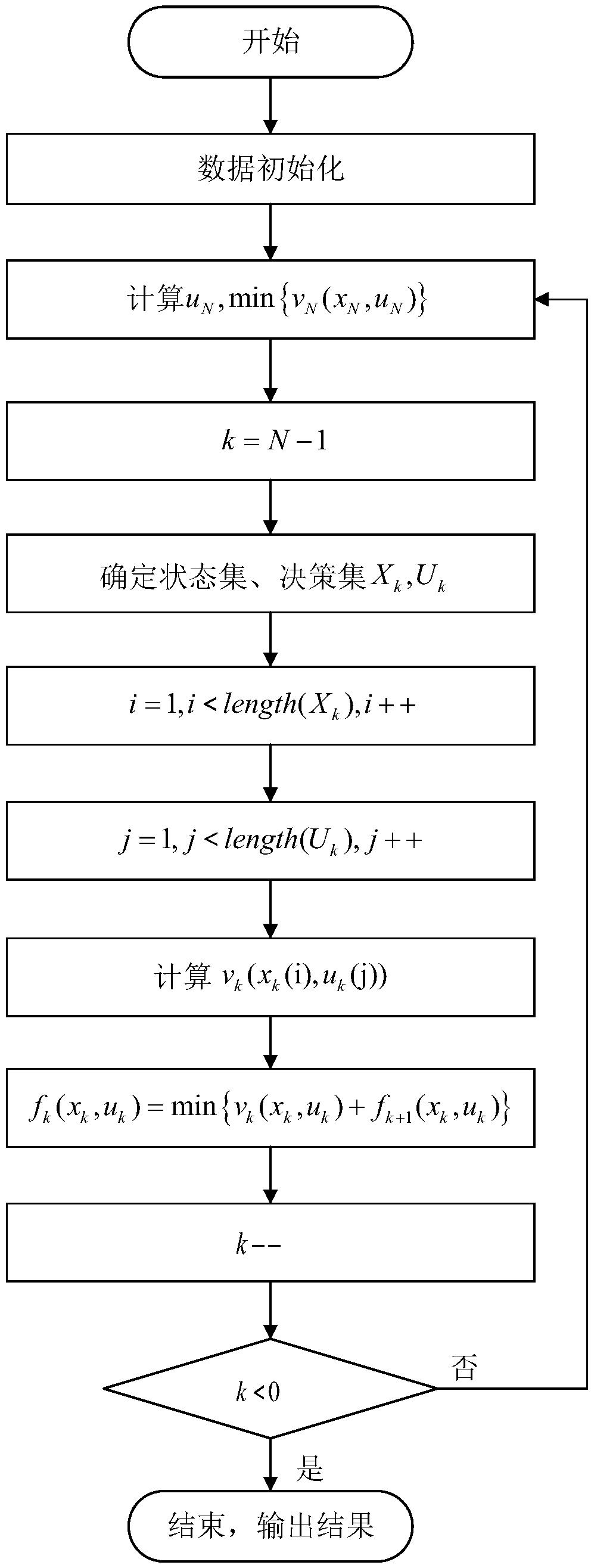

The invention relates to a microgrid multi-energy joint optimal scheduling method. The method includes: step 1, on the basis of force application conditions of energy supply equipment and operating states of energy storage equipment in different scenes, constructing a physical model of a multi-energy system; step 2, establishing unit mathematical models, including a wind power generator model, a photovoltaic power generation model, a micro-gas turbine model, a fuel cell model and an energy storage model, of the microgrid multi-energy system; step 3, in order to realize lowest comprehensive cost in system operation, constructing a microgrid multi-energy optimal scheduling model by taking DG operation constraints, system safety constraints and multi-energy coupling characteristics into comprehensive consideration; step 4, on the basis of reversed order dynamic planning, solving the microgrid multi-energy optimal scheduling model to obtain a microgrid multi-energy joint optimal operatingstrategy. By the microgrid multi-energy joint optimal scheduling method, operating demands in different scenes can be met, electricity-thermal coordinated optimal scheduling schemes are provided for operating of a comprehensive energy microgrid in different scenes, and high integral operating efficiency and high economic benefits are realized.

Owner:NANJING UNIV OF POSTS & TELECOMM

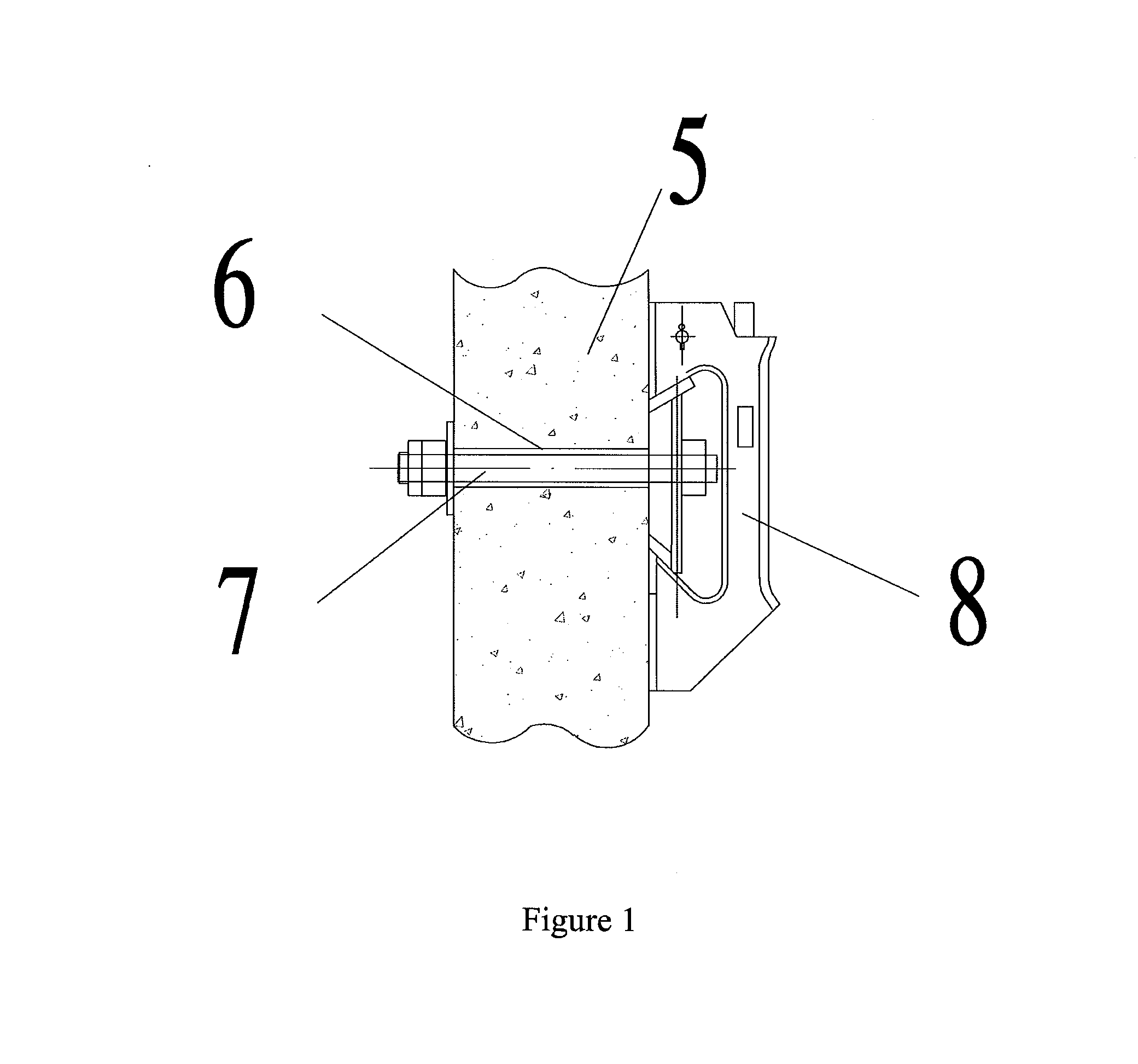

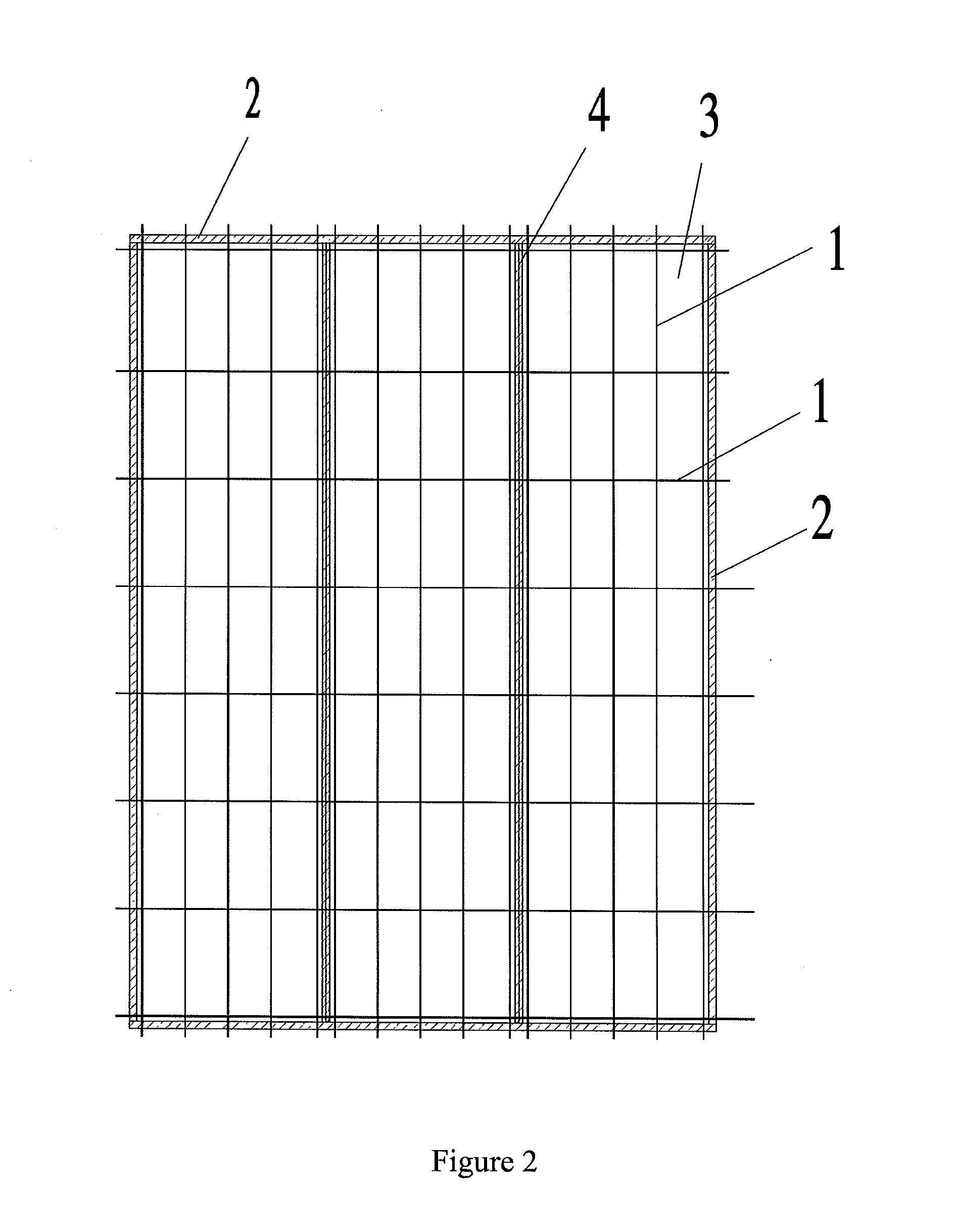

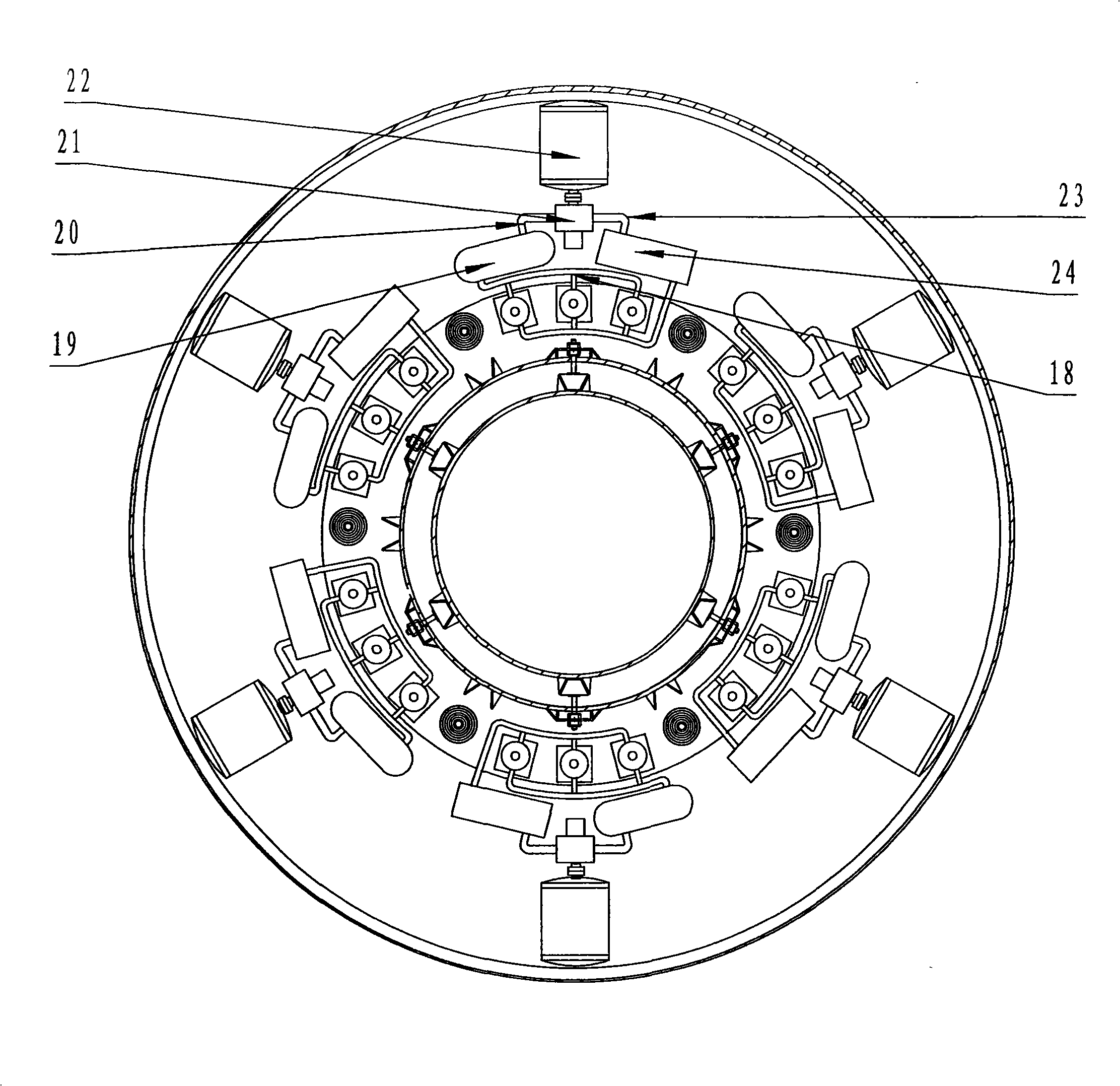

Constructing method for concrete cylinder of construction steel bar of high-rise steel structure

ActiveUS20140305070A1Construction safetyGood engineering qualityWallsBuilding repairsFalseworkReinforced concrete

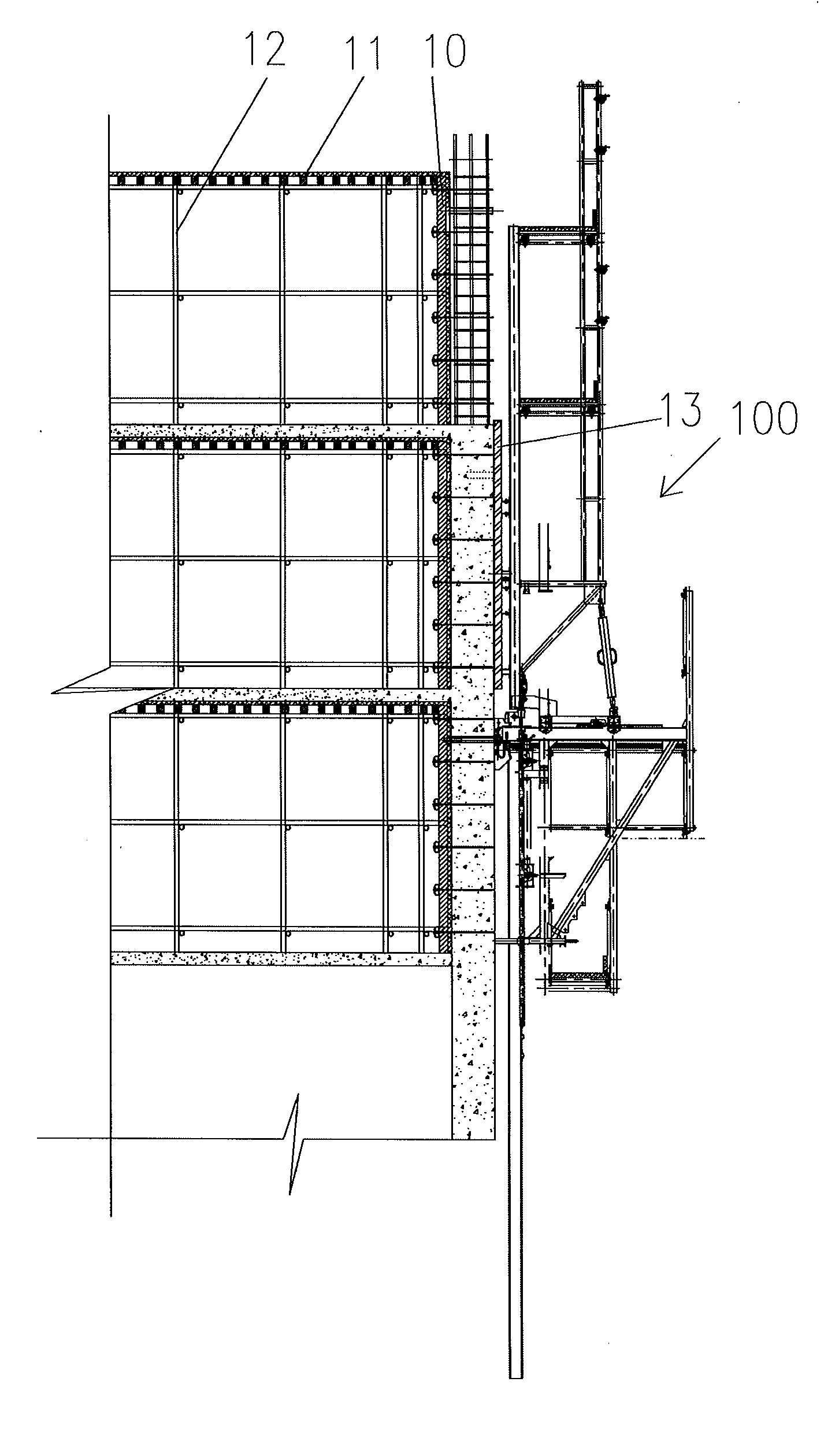

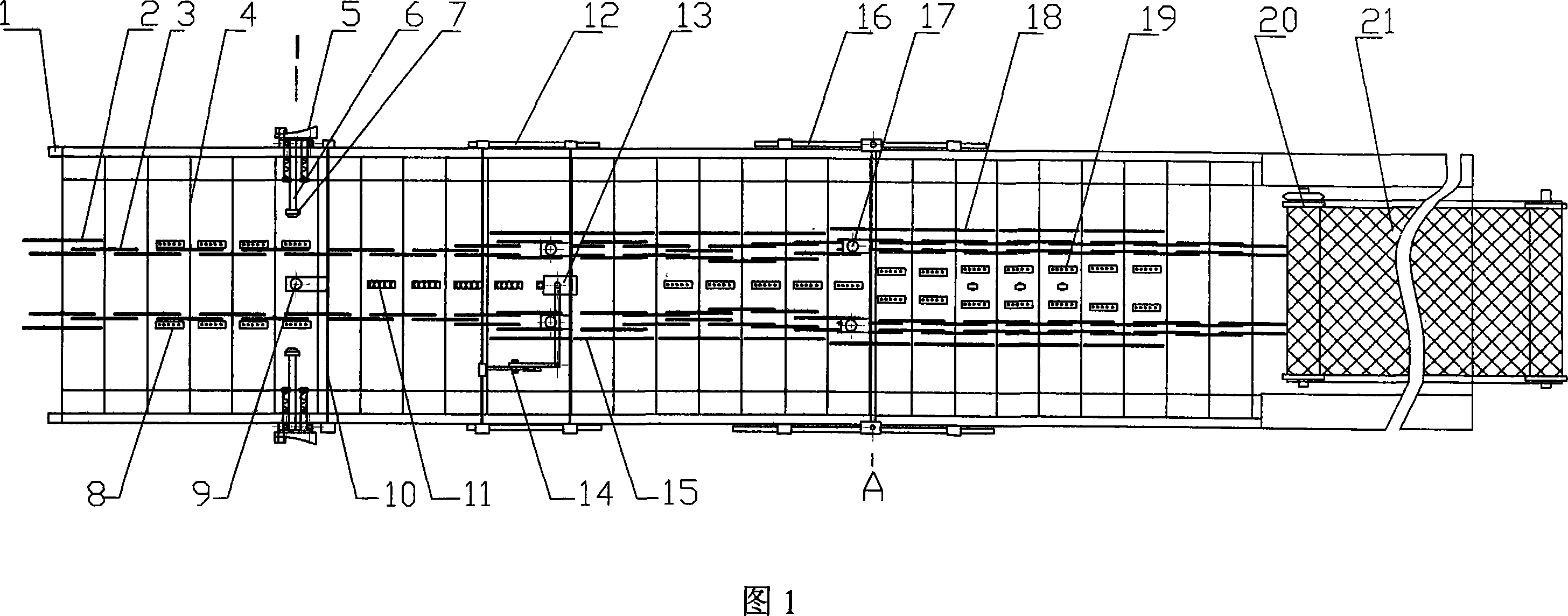

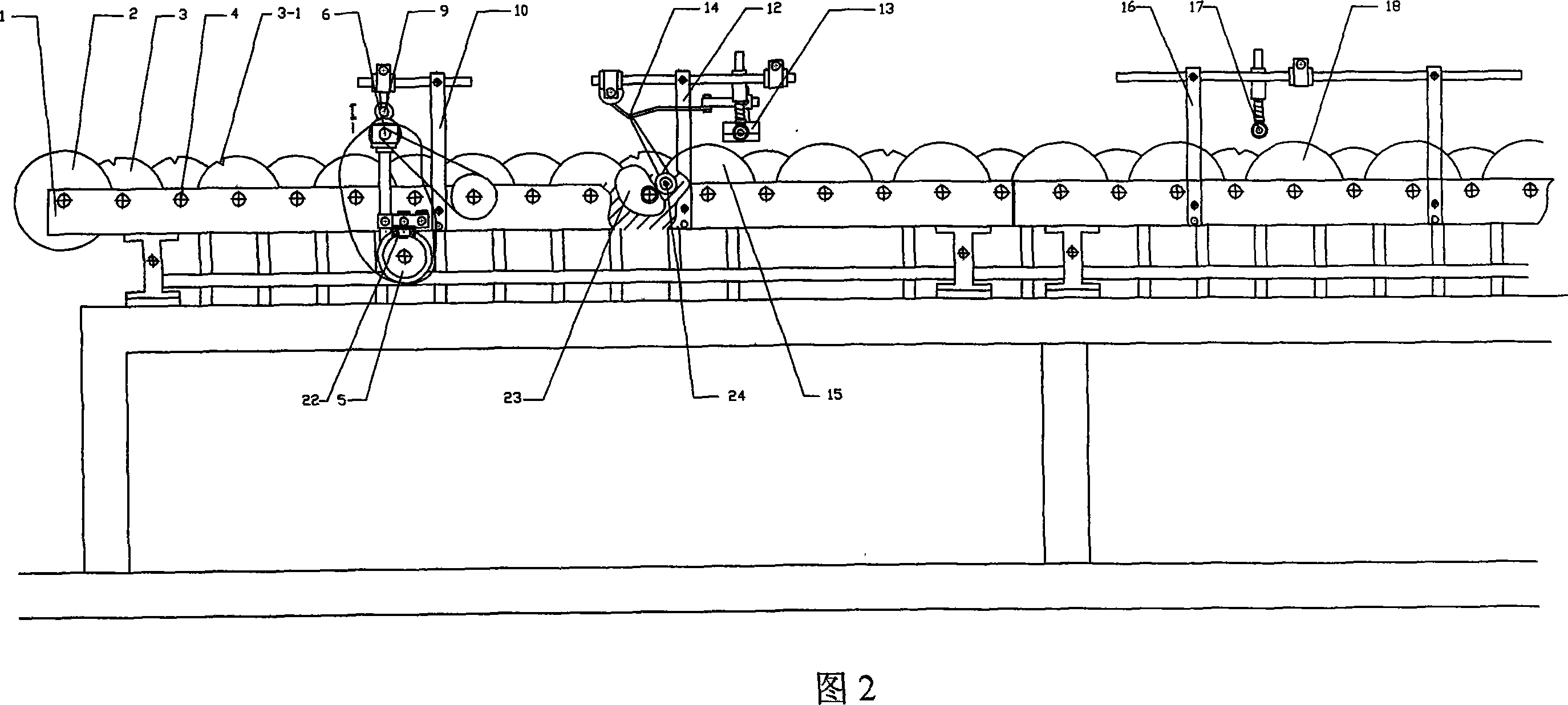

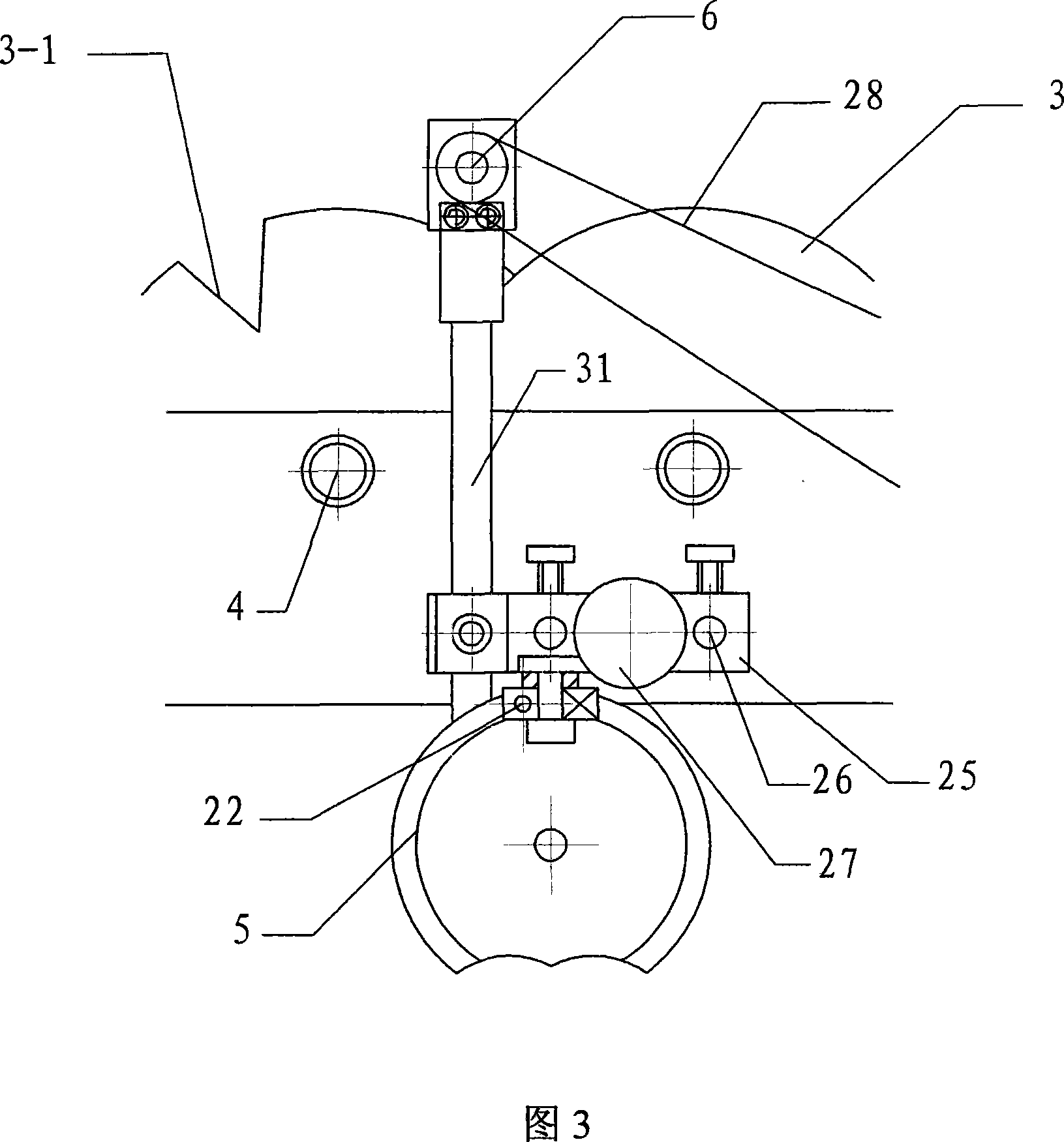

A constructing method for a concrete cylinder of a construction steel bar of a high-rise steel structure adopts a constructing method of supporting inside and climbing outside. The outside of the cylinder adopts hydraulic mutual-climbing adhesive lifting scaffold creeping formwork system (100), and also has an outside wallboard mechanical formwork erection function and an outer frame protection function. For the inside of the cylinder, except that an appropriate structure is left for later processing according to a schedule requirement, beam walls all adopt a steel cylinder support to perform formwork erection, so as to greatly reduce the workload of repeatedly mounting / dismantling the scaffold and the formwork at a high place. The scaffold itself carries the formwork erection system, so formwork erection and formwork removal can be mechanized, thereby reducing the risk of formwork erection and formwork removal at a high place

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

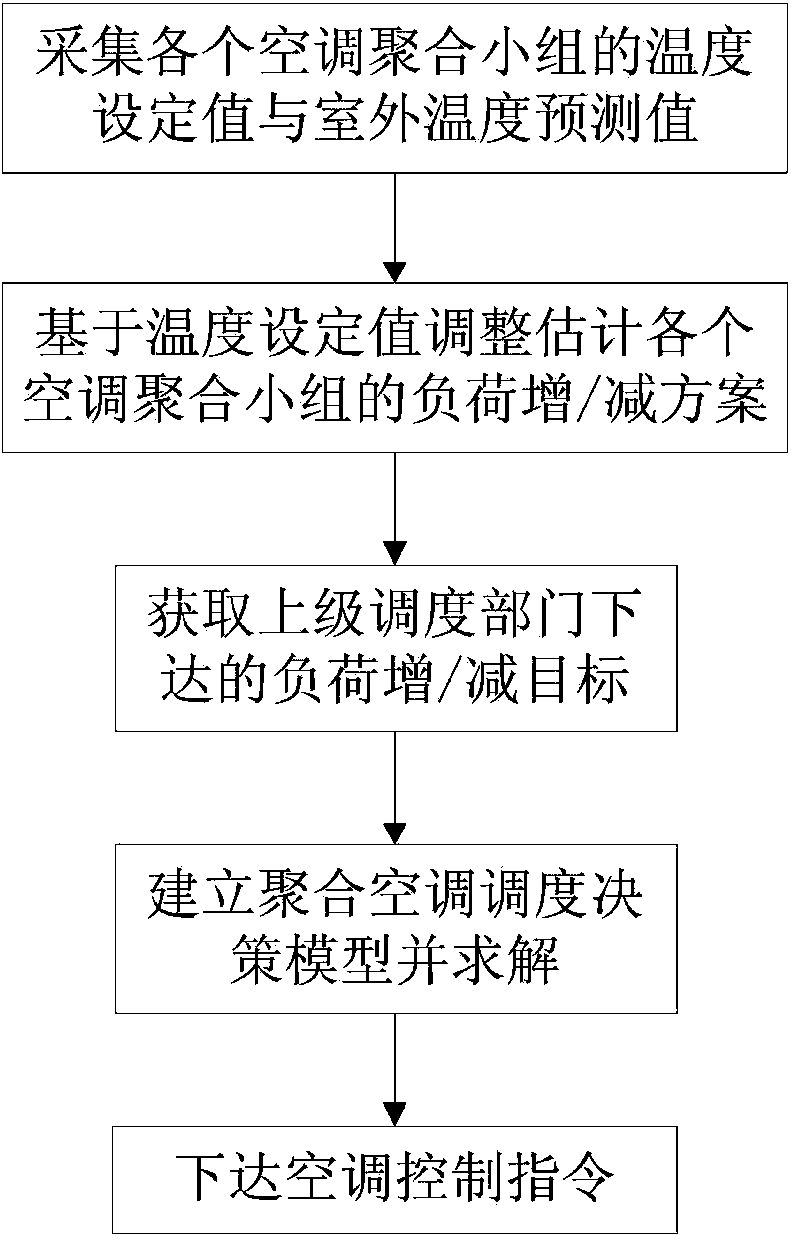

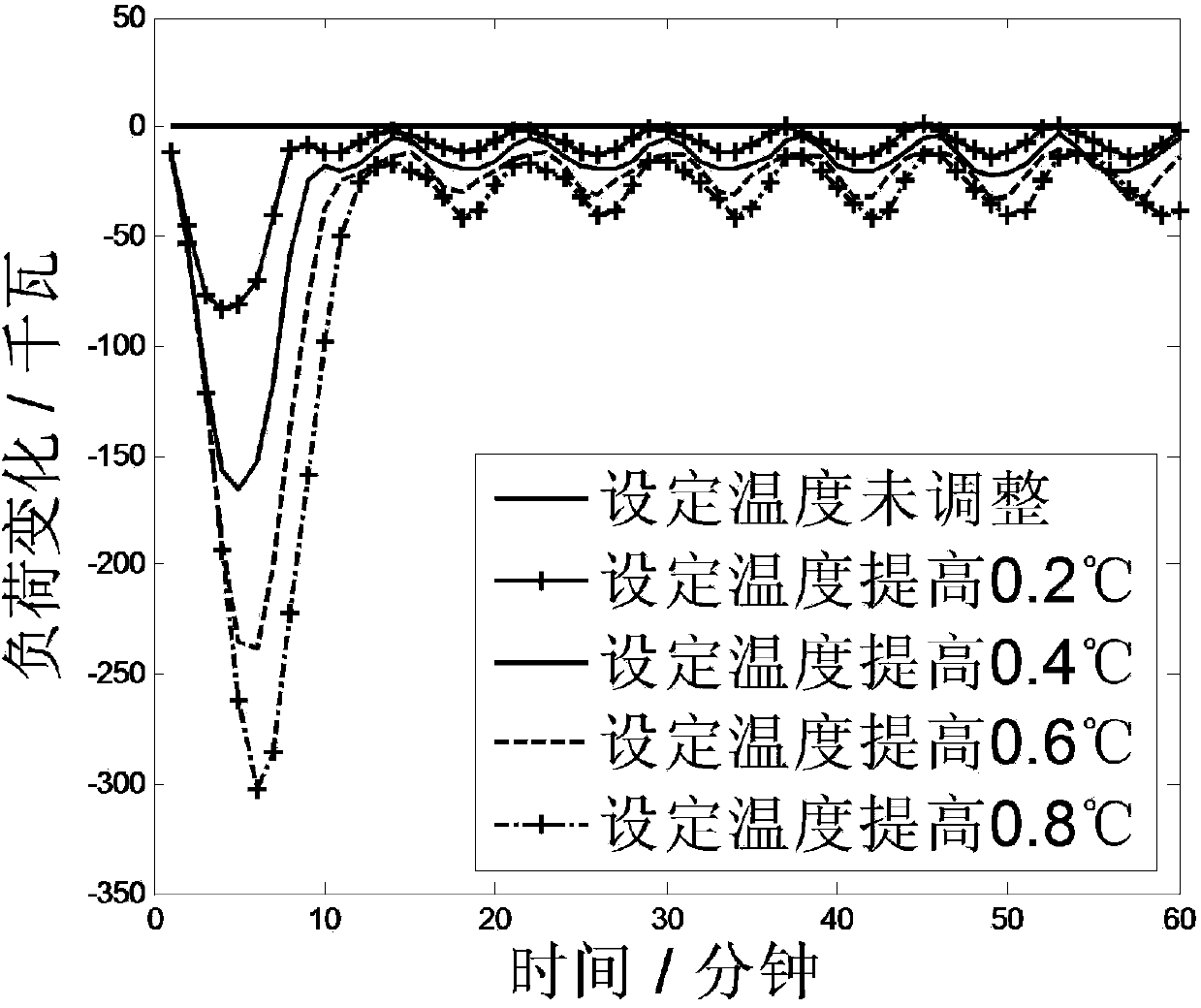

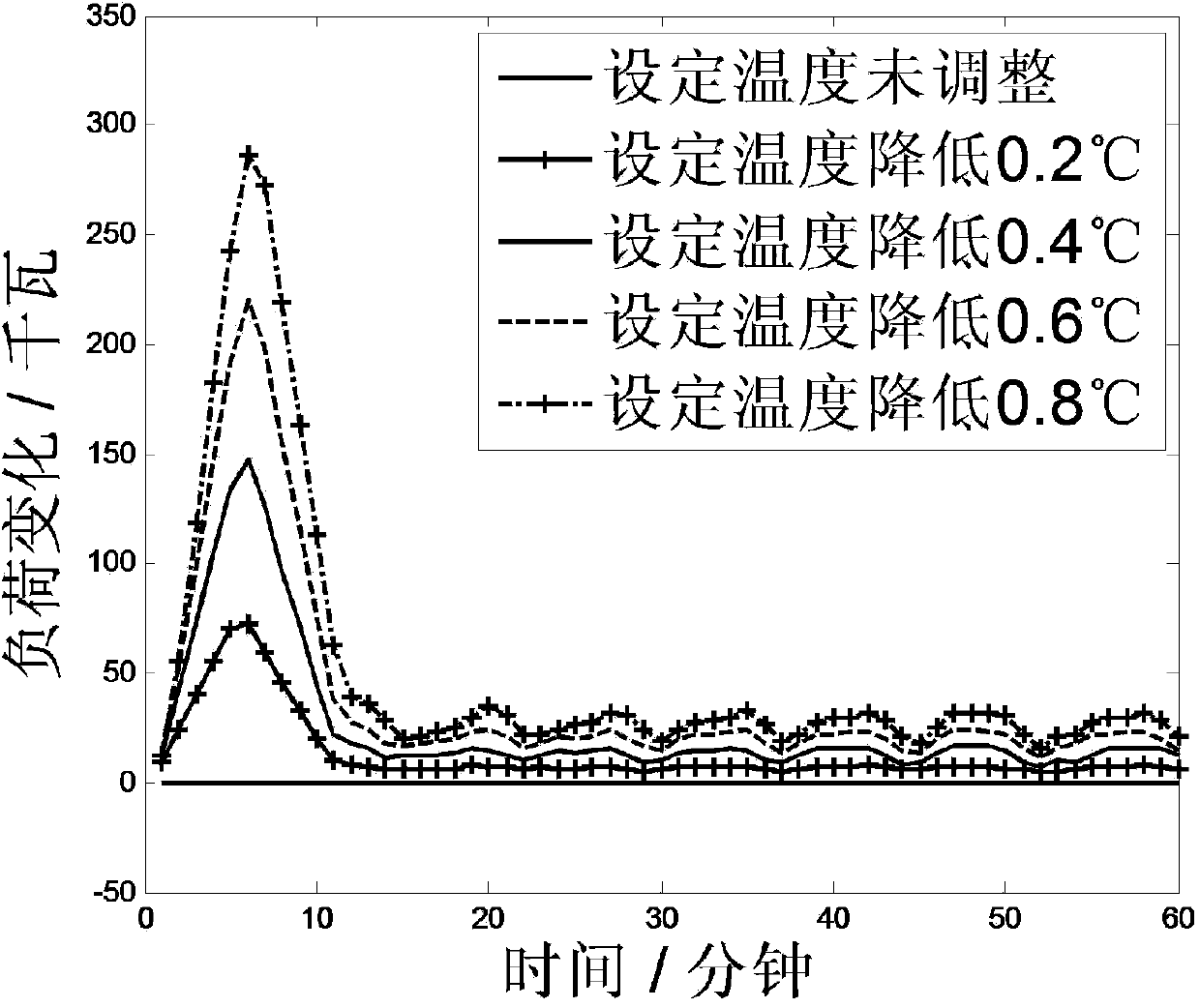

Aggregation air conditioning load scheduling method based on temperature set value adjustment

ActiveCN104214912ALittle or no impact on comfortReduce peak loadSpace heating and ventilation safety systemsLighting and heating apparatusDecision modelPower system scheduling

The invention discloses an aggregation air conditioning load scheduling method based on temperature set value adjustment. The method comprises the following steps: (1) acquiring the temperature set value and outdoor temperature prediction value of each air conditioner aggregation group through a bilateral information channel; (2) adjusting and estimating the load increase / decrease scheme of each air conditioner aggregation group based on the temperature set values; (3) acquiring a load increase / decrease target issued by a superior scheduling department; (4) establishing an aggregation air conditioner scheduling decision model, and solving; (5) issuing an air conditioner control command through the bilateral information channel. By adopting the aggregation air conditioning load scheduling method, load increase / decrease service can be provided for electric power system scheduling on the premise of not influencing the user comfort by using air conditioning equipment of a user, so that the user turns from an electric energy user to a participant of an electric power system and participates in running of the electric power system; meanwhile, by using the method, technical guidance can be provided for the innovation of the scheduling mode of a power grid scheduling department.

Owner:SOUTHEAST UNIV

New technology of culturing cordyceps sinensis using insect

InactiveCN1414091AAlleviate the contradiction between supply and demandSimple processFungiAnimal husbandryPhacusMicrobiology

A technique for culturing cordyceps by insect includes such steps as collecting fresh wild cordyceps, tissue separation to obtain its bacterial strain, reproduction, culturing slant strain and liquidbacteria, choosing host insect or host insect surrogate, spraying bacterial liquid for infecting the host insect, and culturing in the condition stimulating the wild environment. Its advantages are low cost and high effect.

Owner:李健

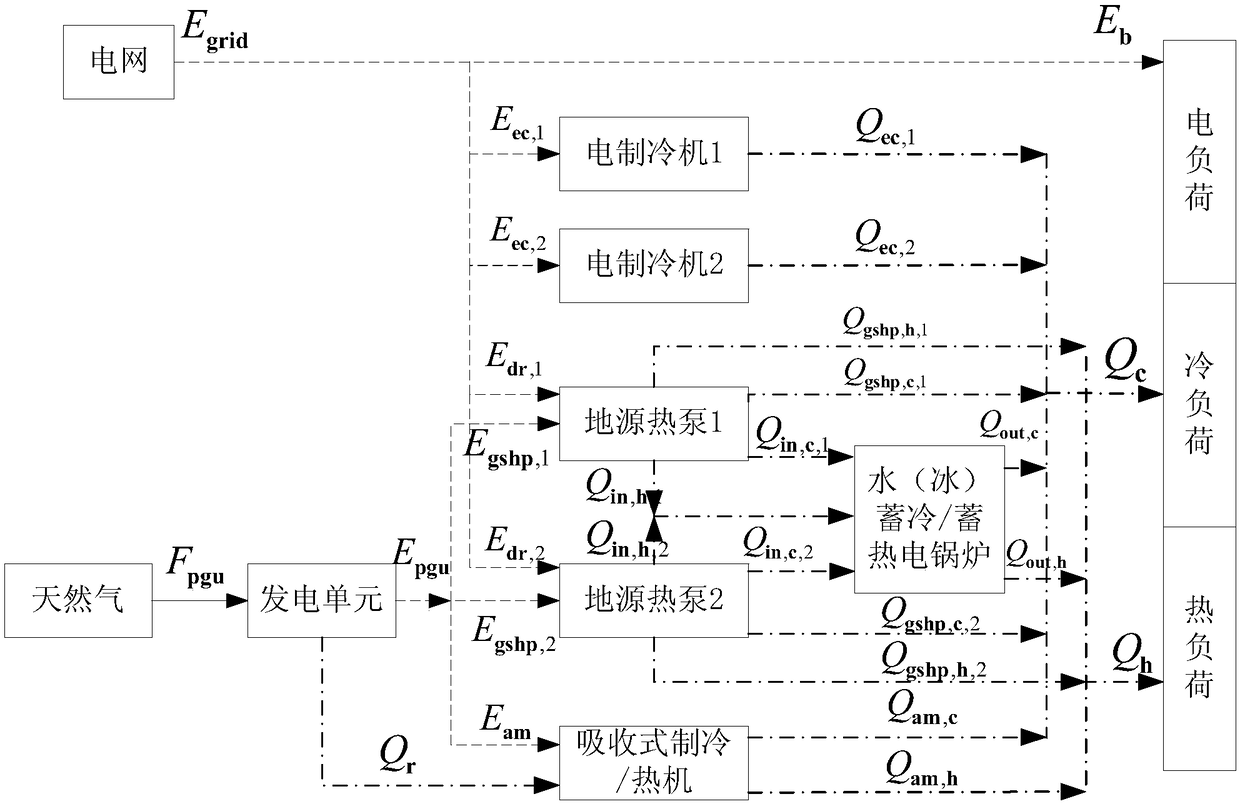

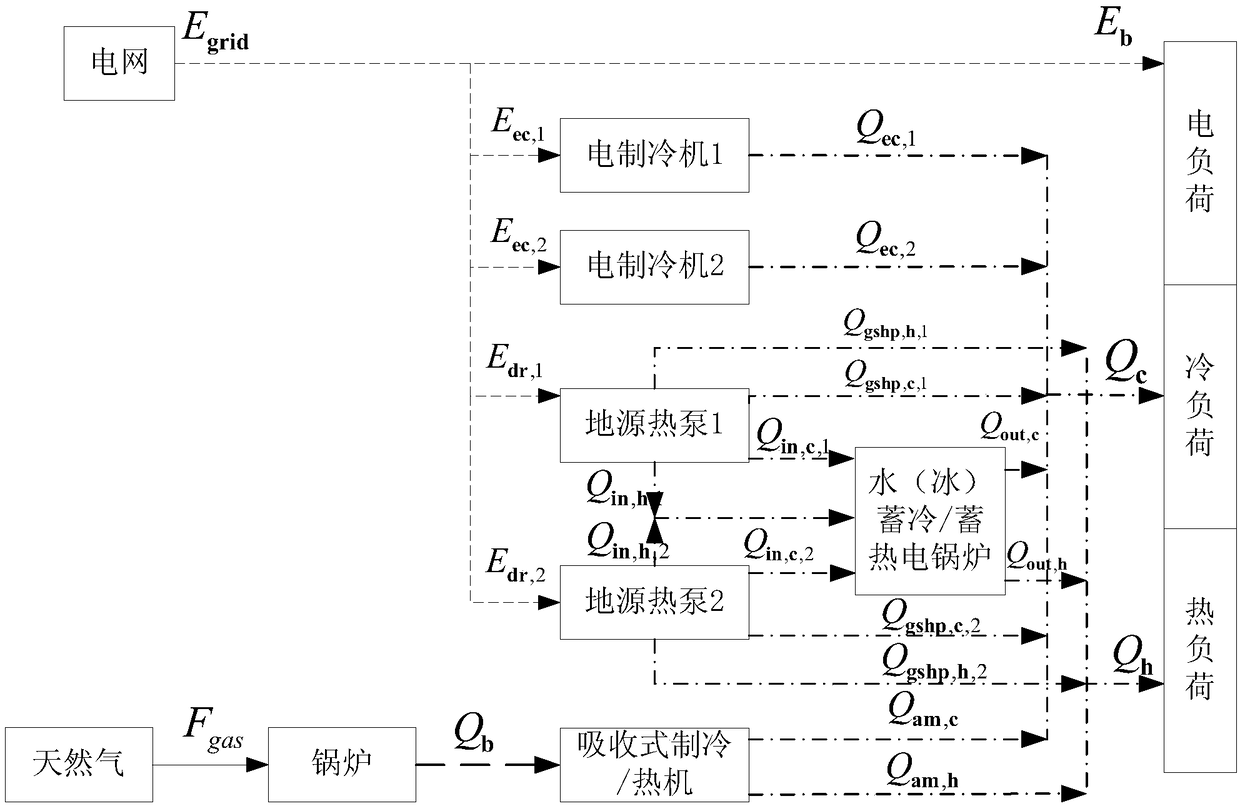

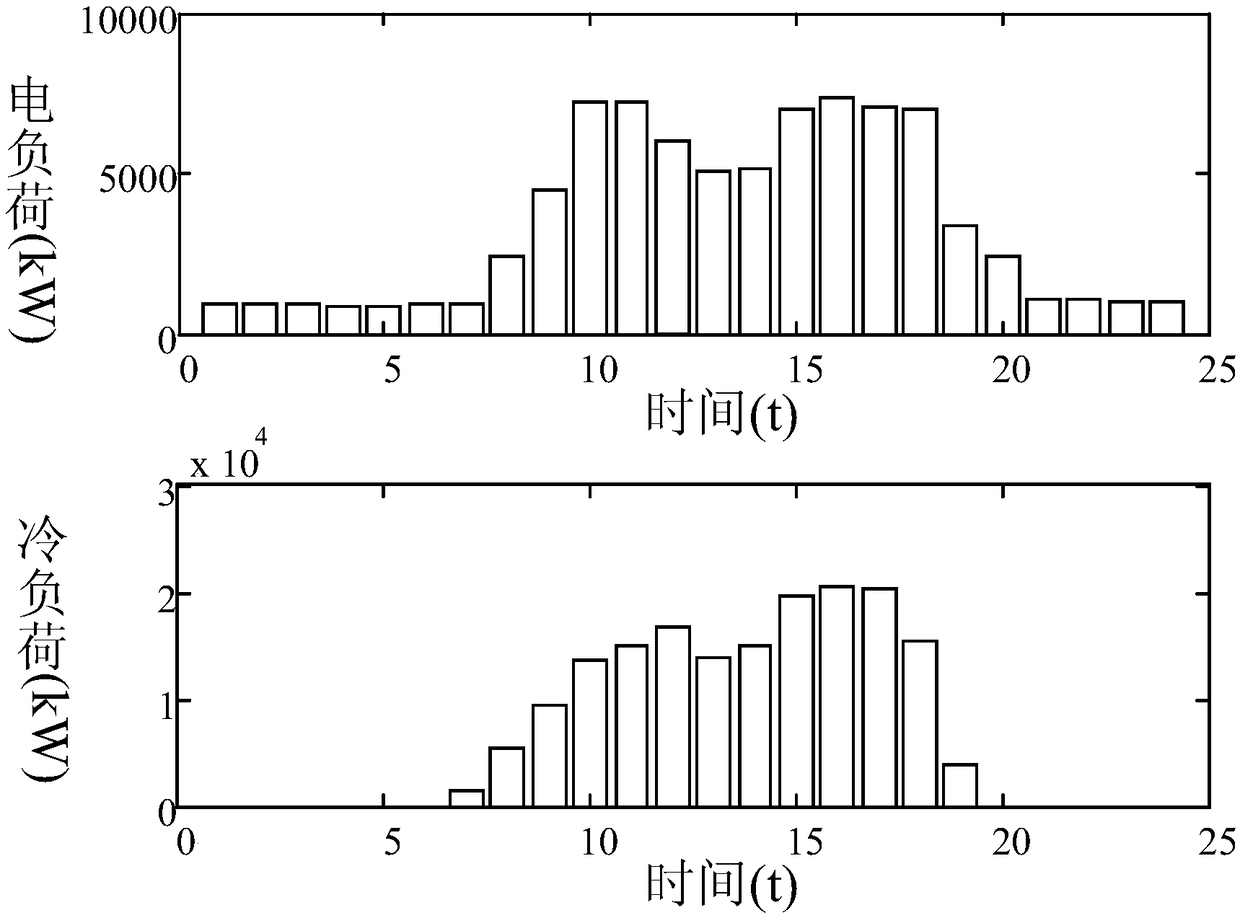

Multi-objective optimization operation method for combined cooling, heating and power supply system

InactiveCN108960556AImprove energy efficiencyAlleviate the contradiction between supply and demandForecastingTechnology managementMathematical modelPrimary energy consumption

The invention discloses a multi-objective optimization operation method for a combined cooling, heating and power supply system, which comprises the steps of firstly establishing mathematical models respectively for equipment of a combined supply system and a separated supply system; then respectively calculating the total operation cost, the total carbon emission and the total primary energy consumption of the combined supply system and the separated supply system in allusion to each set of the equipment; building a multi-objective optimization model by adopting a weighting method, then performing single-objective optimization solving on the separated power supply by adopting a mixed integer linear programming solver, finally obtaining an optimization operation strategy of the combined supply system, and being coupled to a ground source heat pump. The multi-objective optimization operation method can effectively improve the energy utilization efficiency of terminal users, alleviate the contraction between energy supply and demand in a regional power grid, promote the local absorption of distributed renewable energy and realize social benefits of the combined supply system to the greatest extent.

Owner:国网天津市电力公司滨海供电分公司 +4

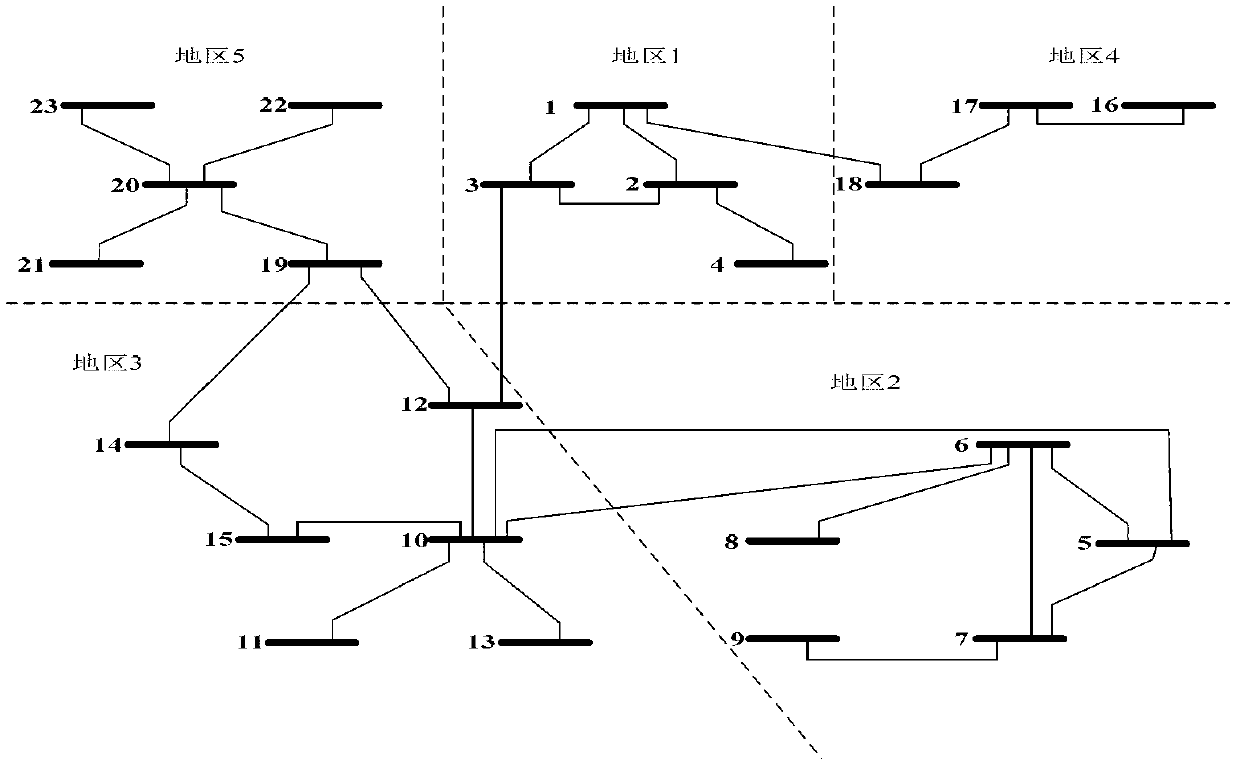

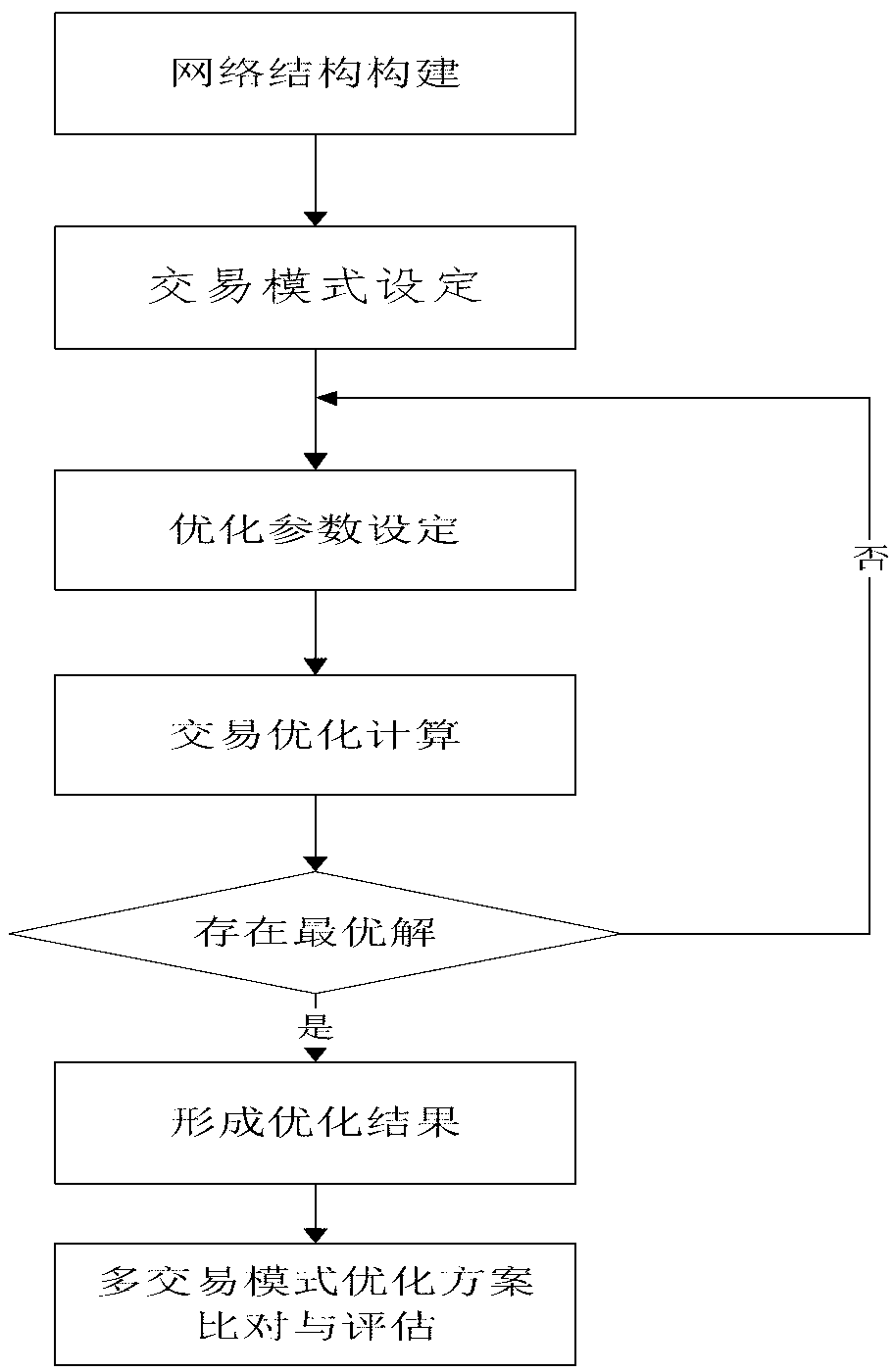

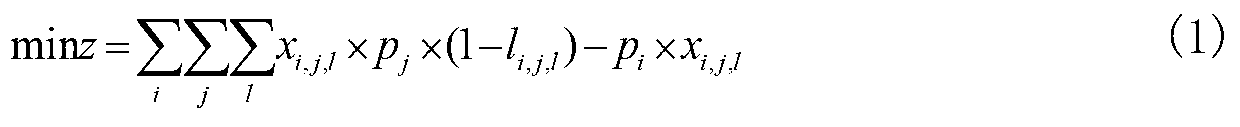

Method for optimizing medium and long term trans-regional trans-provincial deals and assessing modes of medium and long term trans-regional trans-provincial deals

InactiveCN103345712AAlleviate the contradiction between supply and demandOptimizationData processing applicationsElectricityPower grid

The invention relates to a method for optimizing medium and long term trans-regional trans-provincial deals and assessing the modes of the medium and long term trans-regional trans-provincial deals. The method for optimizing the medium and long term trans-regional trans-provincial deals and assessing the modes of the medium and long term trans-regional trans-provincial deals is characterized by comprising the steps of (1) building a network model, (2) setting an optimization scene according to the different modes, (3) setting optimization parameters, (4) building an optimization model, (5) carrying out optimization calculation, and (6) carrying out comparison, analysis and assessment. The method studies and tries the optimization and assessment of the medium and long term trans-regional trans-provincial deals under the actual power grid operation data, finds out a deal strategy with the priority of economical benefits or comprehensive benefits as a target based on simplification of a power grid model, and carries out optimization and assessment of the medium and long term trans-regional trans-provincial deals, thereby bringing certain guide significances on improving the economy, safety and standardability of a deal scheme. The method can relieve the power shortage situation through trans-regional trans-provincial deals when the power structures in electric energy areas are different, realizes optimized distribution of electricity in a larger range, compensates the shortage through the surplus among the areas, and effectively relieves the imbalance between supply and demand in the areas short of power supply.

Owner:STATE GRID CORP OF CHINA +1

Atractylis lancea tissue culturing and rapid propagating method

ActiveCN103960129AAlleviate the contradiction between supply and demandSolving Seedling ProblemsHorticulture methodsPlant tissue cultureTransplantingBacteria

The invention discloses an atractylis lancea tissue culturing and rapid propagating method which comprises the following steps: seed processing, disinfecting and sterilizing; building a bacteria-free culturing system; callus inducting, splitting callosity into seedlings; sterile seedling propagating and culturing; sterile seedling root taking and culturing; seedlings acclimatizing and transplanting. According to the method, a large number of the sterile seedlings can be acquired in a short period through the tissue culturing and rapid propagating technology, the problem of atractylis lancea seedlings is solved, the efficient path for large-scale cultivation and production as well as seedling propagation is provided. Through the tissue culturing, the atractylis lancea seedlings with high quality are provided, on this basis, new species with high yield and high quality are bred, novel officinal resources are developed, the imbalance between supply and demand is alleviated and significance for protecting wild atractylis lancea is achieved.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

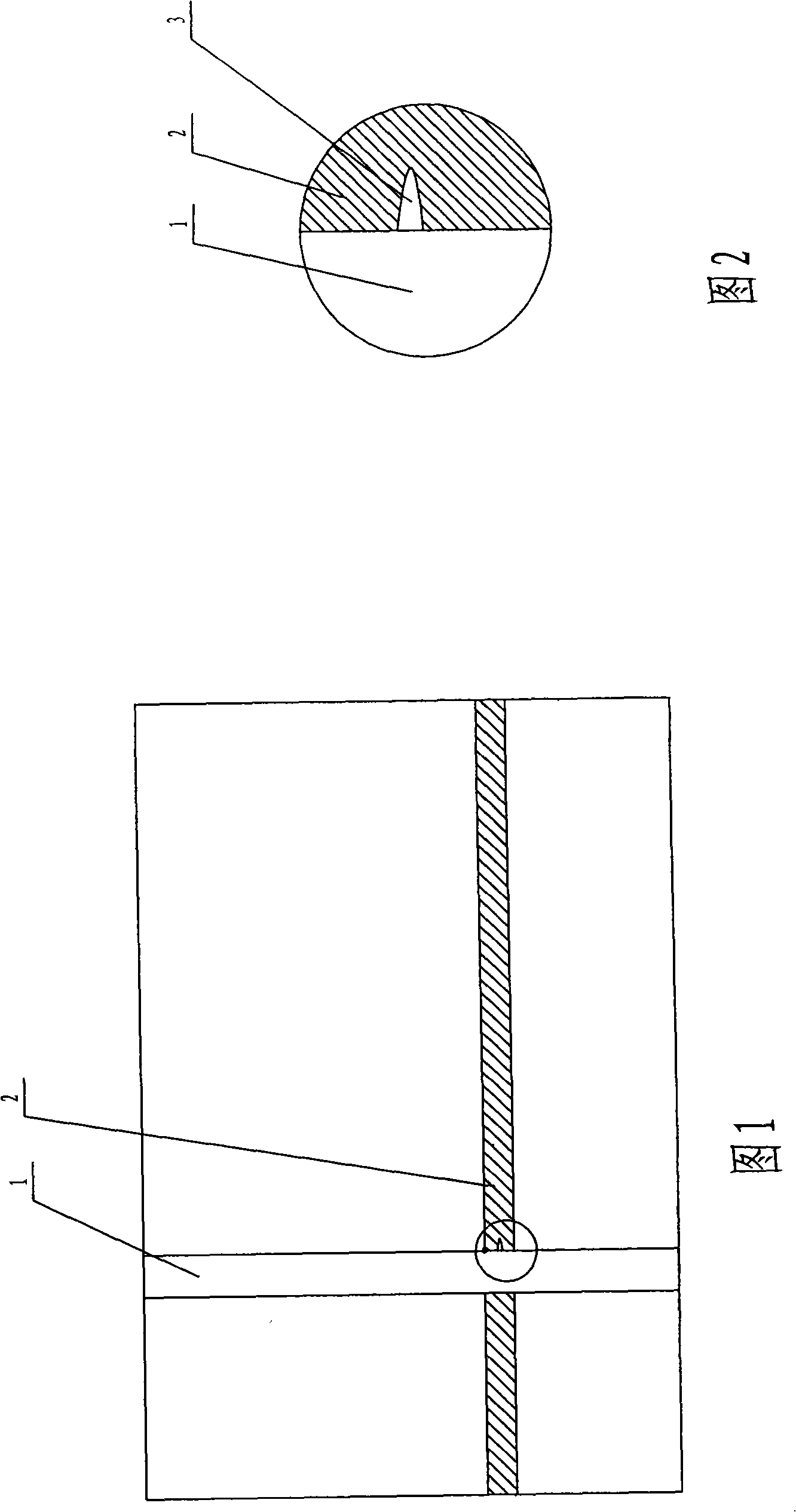

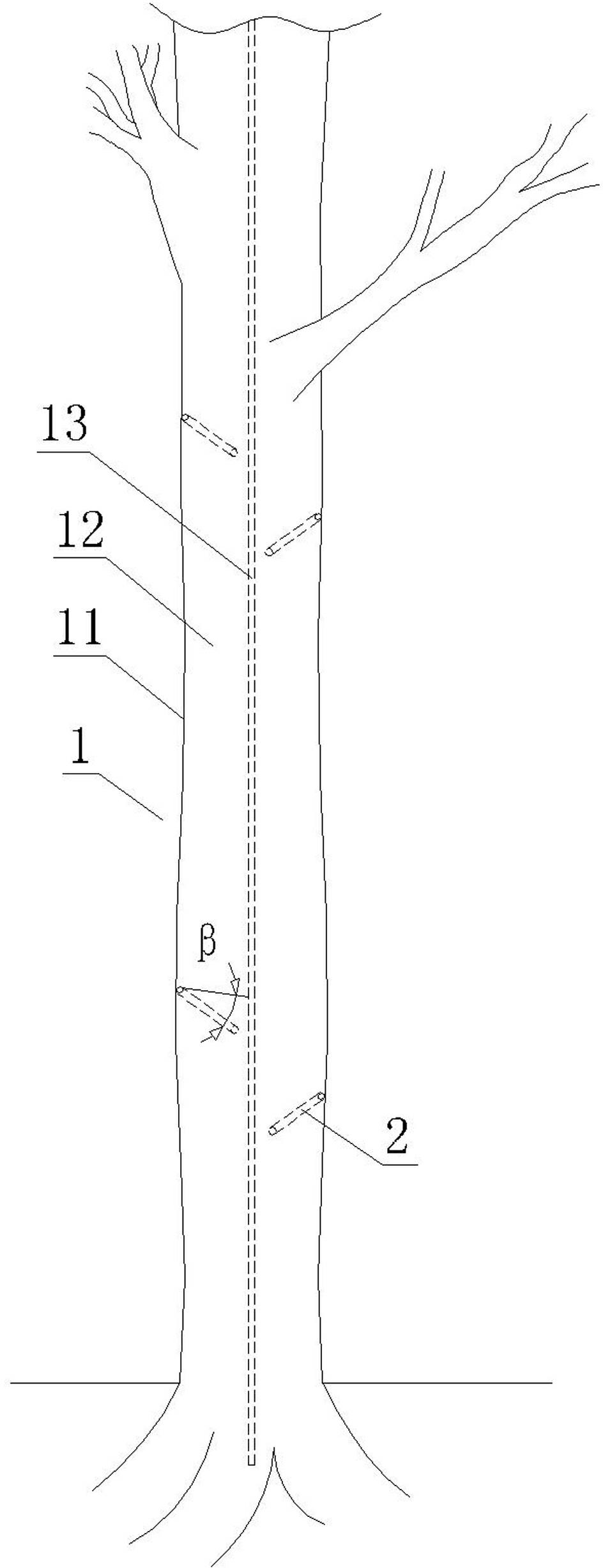

In vivo agilawood formation method for Aquilaria plants

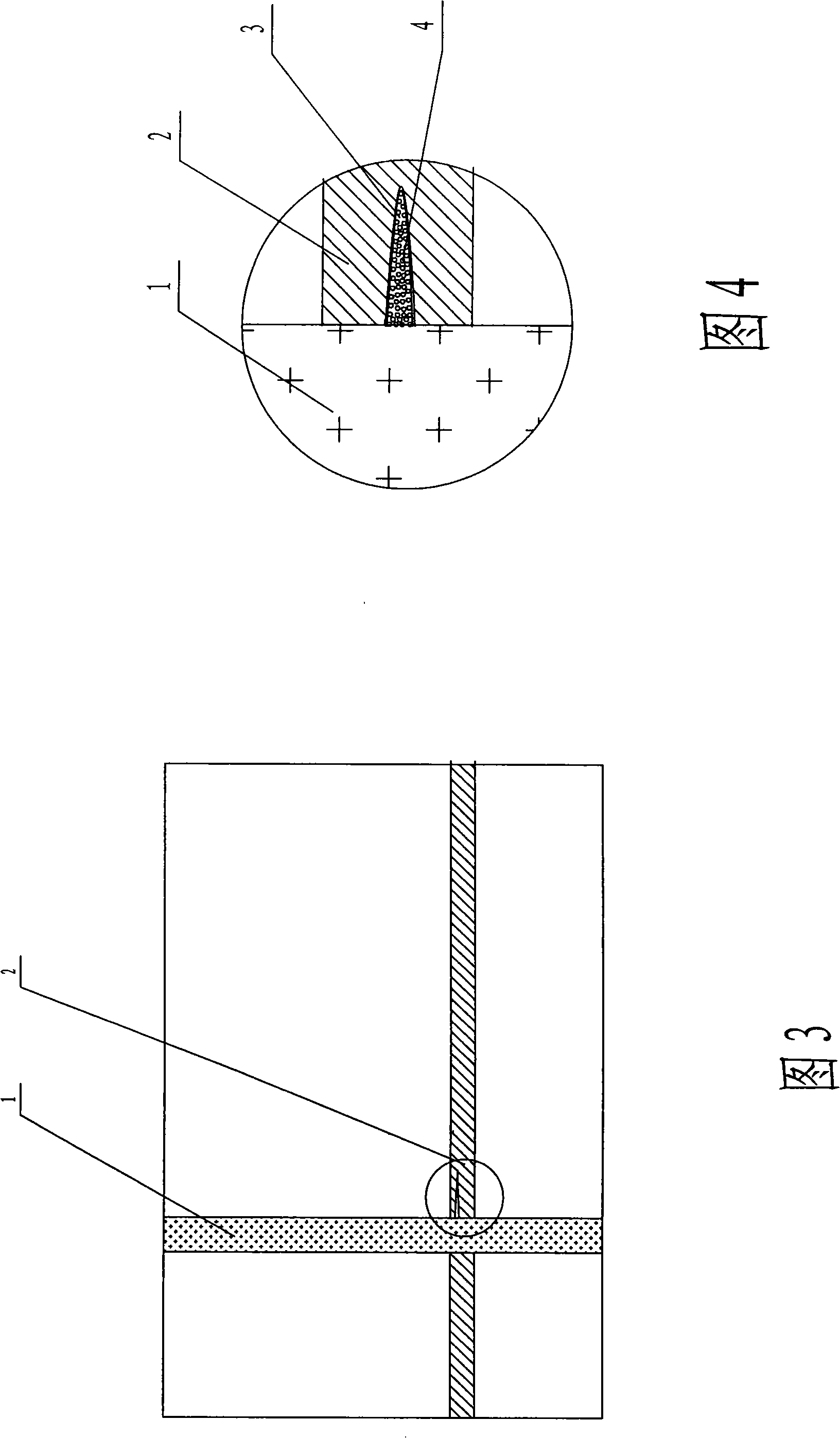

InactiveCN103181304AIncrease productionShorten the production cycleHorticulture methodsAquilariaIn vivo

The invention relates to an in vivo agilawood formation method for Aquilaria plants, and the method comprises the following steps: firstly, screening an aquilaria sinensis tree; secondly, cleaning the soil at the root part of the aquilaria sinensis tree to keep the root part of the aquilaria sinensis tree dry; thirdly, drilling the trunk of the aquilaria sinensis tree at a height of 0.35 m-1.5 m from the ground; fourth, feeding an agilawood prompting agent slowly into the aquilaria sinensis tree body with a transfusion method, and sealing the hole permanently; and after 12-18 months, cutting tan oily matters and yellowish-brown color changeable xylem formed in the trunk, and drying to obtain the agilawood. The invention aims to provide the in vivo agilawood formation method for the Aquilaria plants, which utilizes an artificial inductive manner to shorten the production period of the agilawood effectively and improve the agilawood output greatly, so that the method is suitable for the large-scale standard commercial production, provides an effective way for protection, development and comprehensive utilization of the aquilaria sinensis resource, and has great economic, social and ecological benefits.

Owner:INST OF GUOLIN AGARWOOD SCI ZHONGSHAN

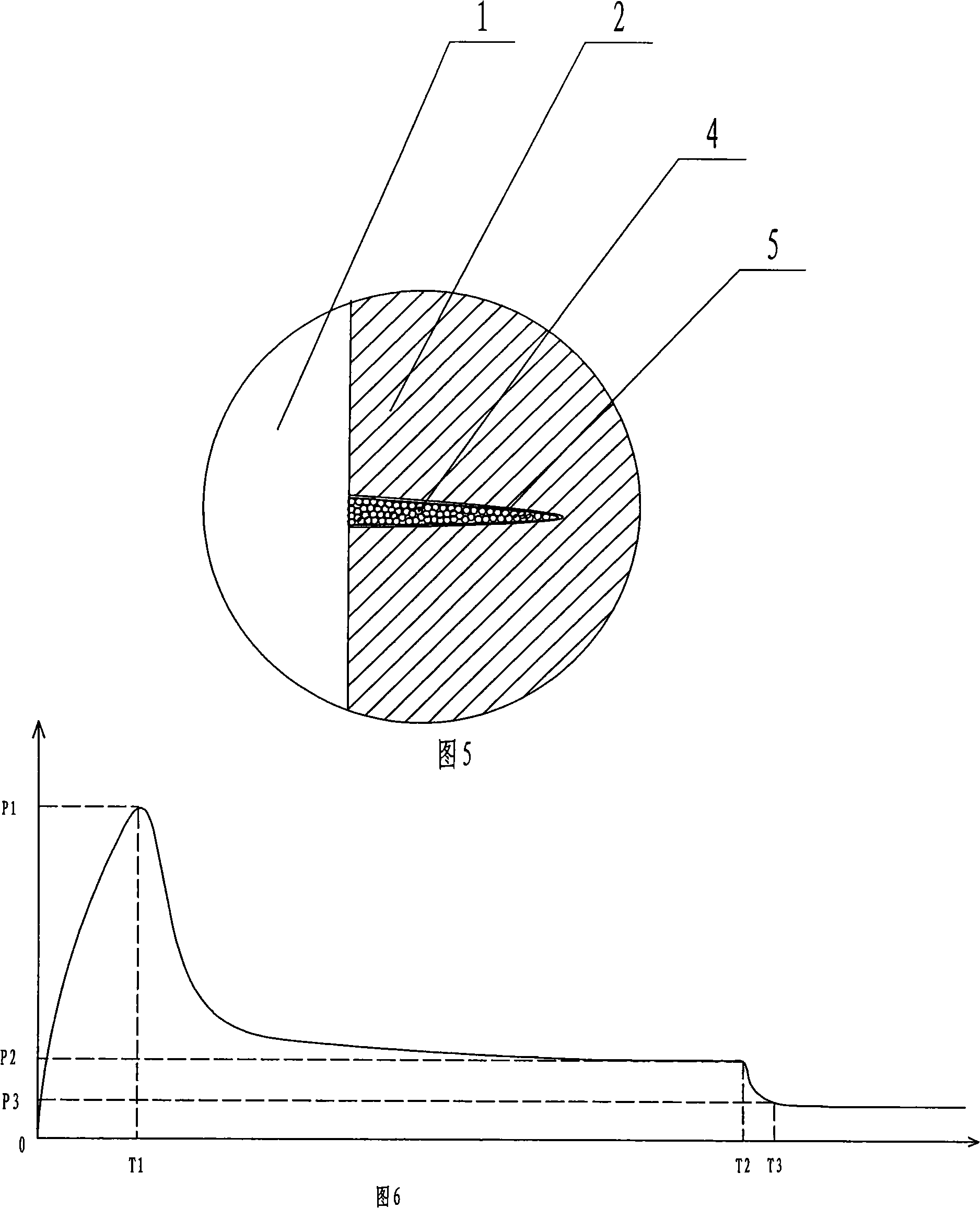

Fracturing process for removing breakdown fluid contamination

The invention relates to a mining technology for the petroleum, natural gas and the coal seam gas, in particular to a compression fracture process which avoids the fracturing fluid pollution and solves the problem that the fracture conductivity is reduced caused by the dense filter cake formed on the surface of the strata fracture by the thickener added in the fracturing fluid applied in all the compression fracture constructions found in the prior art. The construction steps include that the pad fluid is injected into the oil gas storage strata; the sand-laden fluid is injected continuously when the oil gas storage strata generates fractures; subsequently, the displacement fluid is injected; then the pump on the ground is stopped; 60 minutes later after the fracture closing time T3 and the pressure is lower than the fracture closing pressure P3, the oxidant solution such as the chlorine dioxide result solution, the potassium permanganate, the hydrogen peroxide solution or the persulphate which can degrade the polymers is injected into the fractures as the fracturing post pad fluid; finally, the displacement fluid is injected to extrude all the compression fracture post pad fluid to the strata fractures. The compression fracture process can radically avoid the pollution block of the fracturing fluid, exert the potential of the fracturing technology and increase the yield.

Owner:郝东 +1

Method for manufacturing soybean protein modified adhesive formaldehyde-free medium-density fiberboard

ActiveCN104059598AResolve dependenciesReduce dependenceNon-macromolecular adhesive additivesProtein adhesivesFiberPolymer science

The invention provides a method for manufacturing a soybean protein modified adhesive formaldehyde-free medium-density fiberboard, and belongs to the technical field of density fiberboard manufacture. The method comprises the following steps: heating, stirring and mixing raw materials (soybean pulp, a denaturing agent, a crosslinking agent, a defoaming agent, a preservative and water) to react; preparing the soybean protein formaldehyde-free adhesive by virtue of a colloid mill and a homogenizer; adding a water-proofing agent, a curing agent and a buffering agent into the soybean protein formaldehyde-free adhesive, stirring and mixing at room temperature, and uniformly mixing with wood fibers; performing drying, paving and hot-pressing to prepare the soybean protein modified adhesive formaldehyde-free medium-density fiberboard. The method is environment-friendly and non-pollution; the soybean protein modified adhesive formaldehyde-free medium-density fiberboard is high in adhesion strength, good in water proofing, low in price, low in viscosity and easy to treat and process, can be subjected to hot-pressing and cold-pressing in application, and is not easy to crack. The soybean protein modified adhesive formaldehyde-free medium-density fiberboard can be adhered to fibers and the like, and the processing process can be controlled, and an environment-friendly fiberboard can be manufactured.

Owner:DONGYING ARTIFICIAL BOARD FACTORY

Preparation method for multifunctional resin modifier for wood impregnation and application of multifunctional resin modifier

InactiveCN104070572AStrong loss resistancePromote environmental protectionWood treatment detailsPressure impregnationPhenolWeight gain

The invention belongs to a preparation method for a multifunctional resin modifier for wood impregnation and application of the multifunctional resin modifier. The low-alkali multi-element copolycondensation resin modifier which has functions of weight gaining enhancement, flame retardance and corrosion prevention is synthesized by taking phenol, formaldehyde, melamine and urea as main agents and taking boric acid and zinc borate as functional auxiliaries. By the adding of a certain amount of dipropylene glycol, the modifier can be stored stably for a long time, and repeated cyclic use is realized. The size stability, density, surface hardness, bending strength, bending-resistant elastic modulus, processing characteristic, the flame retardancy, the corrosion prevention and the abrasion resistance of plantation woods treated by the modifier are greatly improved; furthermore, the modifier is high in runoff resistance and high in environment al protection, does not have a loss effect on the toughness of the wood and cannot affect the painting decoration performance of the wood, and the application value of the plantation woods is increased.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

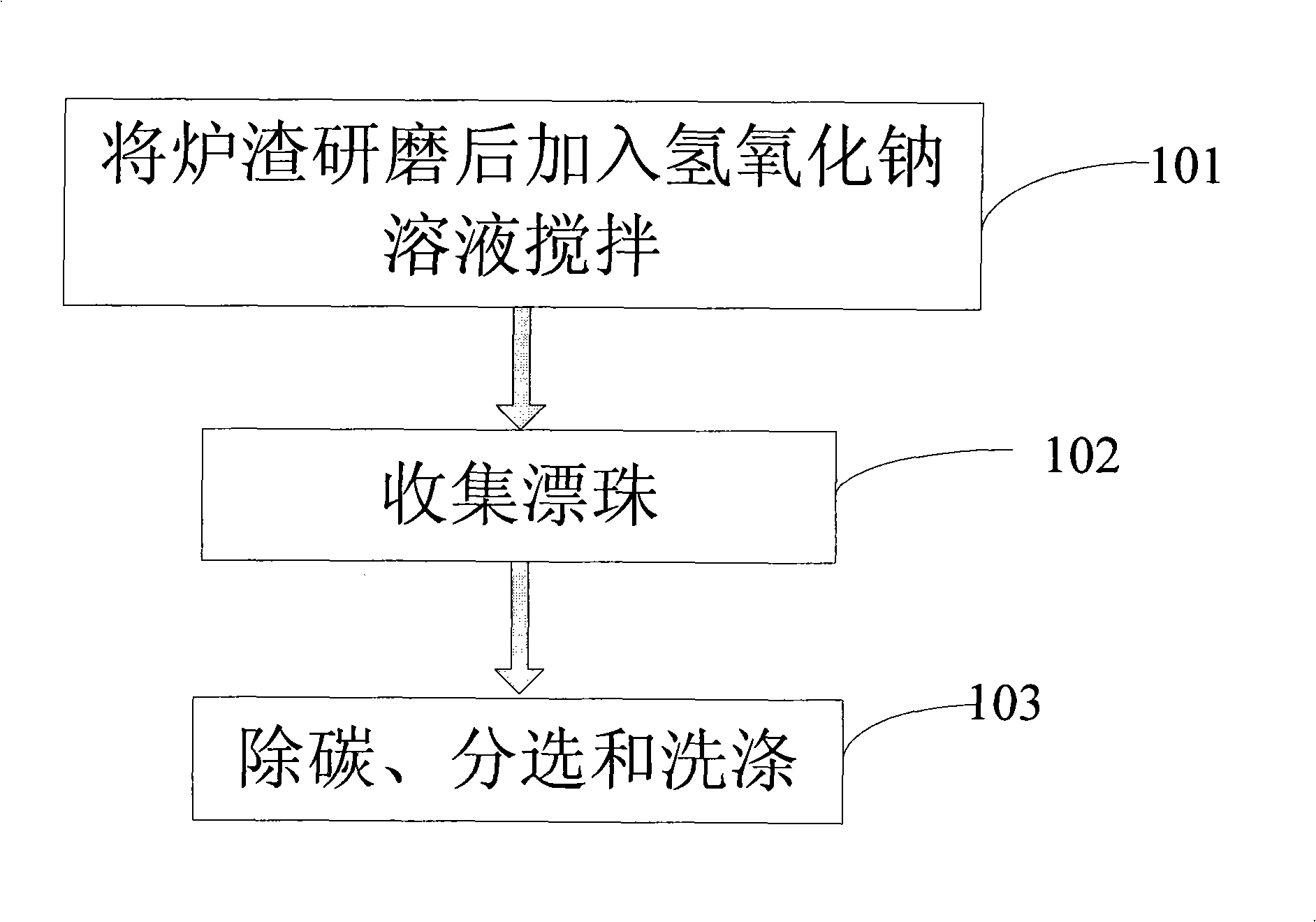

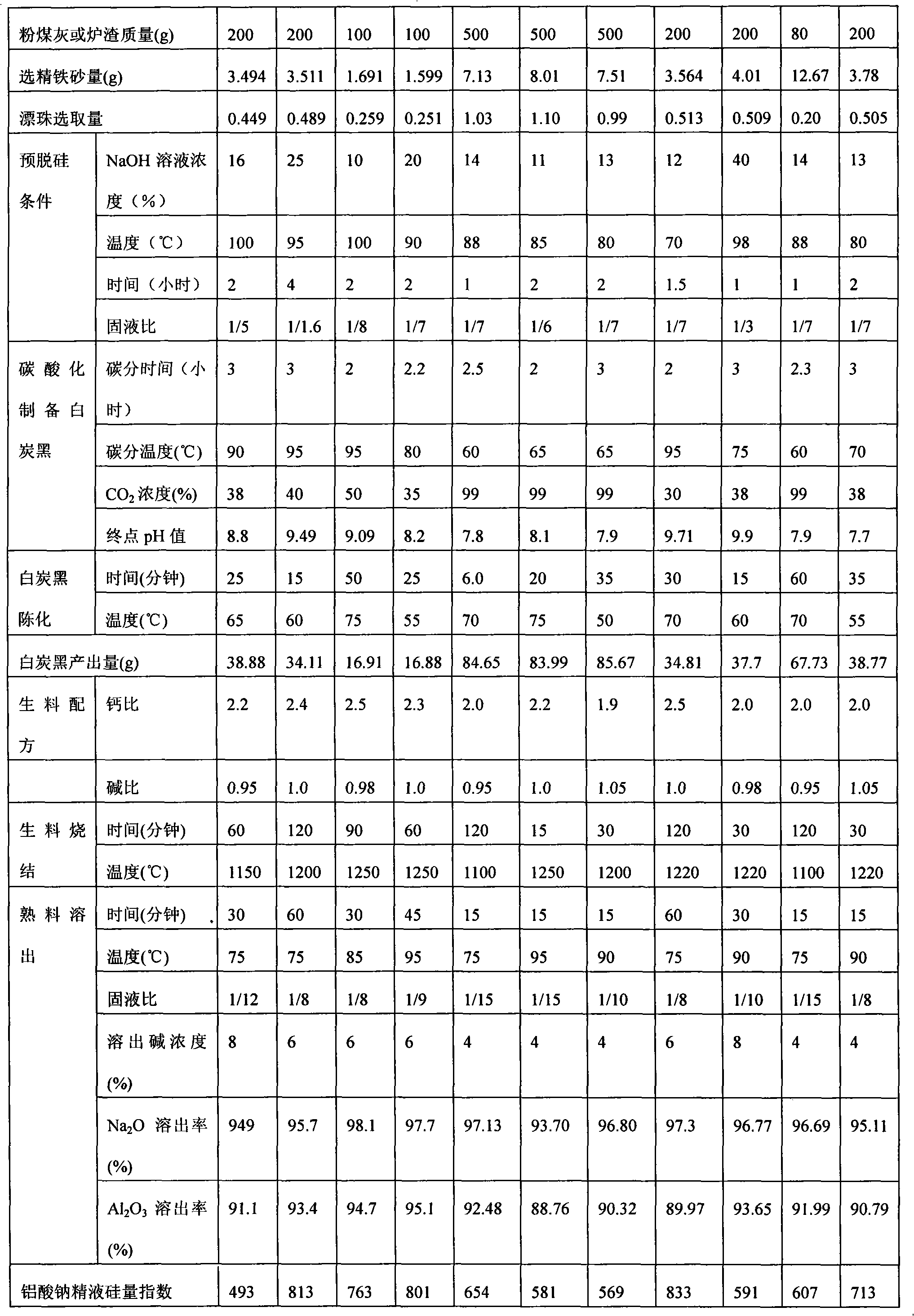

Process for abstracting floating air ball from fly ash or slag

The invention relates to a method for comprehensively utilizing fly ash and furnace cinder, in particularly to a method for extracting floating beads from the fly ash or the furnace cinder. The method comprises the following: a working procedure of screening refined iron sand from the fly ash or the furnace cinder; a working procedure of flotating floating beads; a working procedure of pre-desiliconization; a technological flow of producing white carbon black; a technological flow of producing aluminum oxide; and a technological flow of producing cement by utilization of waste residue. The method arranges a flotating device before pre-desiliconization technological reaction to extract the floating beads from the reacted mixture, and can obtain white floating bead products after decarbonization and secondary selection. Simultaneously, the white carbon black, the aluminum oxide and the joint cement can be organically, continuously and sequentially extracted from the fly ash or the furnace cinder after the floating beads are extracted, thereby the method realizes comprehensive utilization of the fly ash or the furnace cinder.

Owner:北京世纪地和控股有限公司

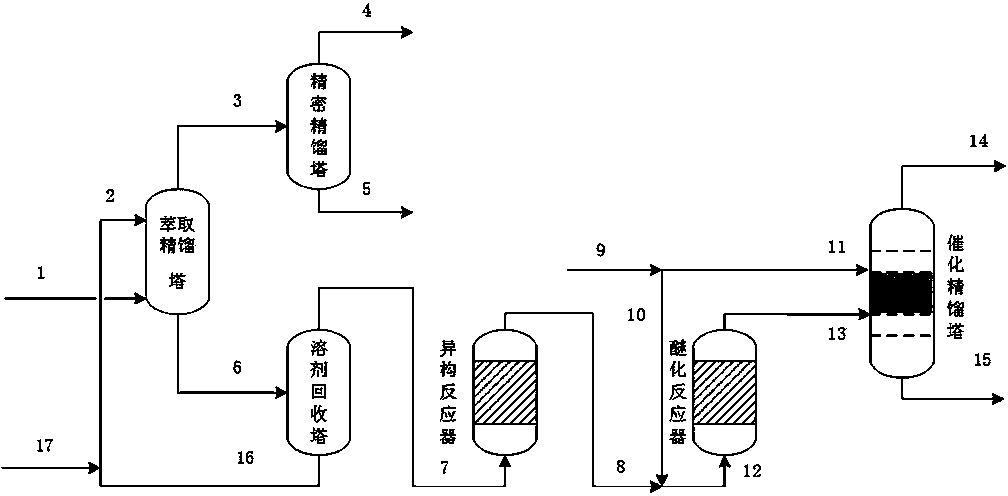

Comprehensive utilization method of olefin in Fischer-Tropsch-synthesized light distillate

ActiveCN104370678AAlleviate the contradiction between supply and demandReduce consumptionDistillation purification/separationEther preparation by compound additionProcess engineeringTert-Amyl methyl ether

The invention relates to a comprehensive processing method of olefin in Fischer-Tropsch-synthesized light distillate. The comprehensive processing method comprises the following steps: carrying out extractive distillation on raw material which is Fischer-Tropsch-synthesized C5 light distillate, further purifying an enriched 1-amylene material obtained at the top of an extractive distillation tower by virtue of precise distillation to obtain a 1-amylene product, introducing a mixed material of C5 components obtained at the bottom of the extractive distillation tower and an extraction agent into a solvent recycling tower, and recycling an extraction agent for circular use, wherein the extraction agent of the extractive distillation is N,N-dimethylformamide; carrying out olefin isomerism on C5 components obtained from the top of the solvent recycling tower by virtue of an isomerizing reactor; mixing heterogeneous-olefin-enriched C5 components obtained from an isomerism reactor with methanol, and adding the mixture into an etherification reactor for etherification; introducing materials at an exit of the etherification reactor into a catalysis rectifying column, separating a product (tert amyl methyl ether) when the etherification is carried out in the catalysis rectifying column, wherein a tert amyl methyl ether product reaching the industrial demands is obtained from the bottom of the catalysis rectifying column. According to the comprehensive processing method, high-value-added C5 olefin 1-amylene and a clean high-octane gasoline additive (tert amyl methyl ether) are obtained by virtue of deep processing of the Fischer-Tropsch-synthesized C5 distillate.

Owner:TAIYUAN UNIV OF TECH

Method for inducing and producing dalbergia substances on dalbergia odorifera tree

ActiveCN101663969AShorten the production cycleAlleviate the contradiction between supply and demandHorticulture methodsMedicinePlastic film

The invention discloses a method for inducing and producing dalbergia substances on a dalbergia odorifera tree. An artificial wound is formed in the xylem of the dalbergia odorifera tree, an inducer is applied around the wound, the wound is wrapped and treated by using a preservative film or a plastic film for 6 to 12 months, purple brown oily substances and purple brown discolored xylem formed around the wound are cut off and collected, and the dalbergia substances are obtained after drying and crushing such purple brown oily substances and purple brown discolored xylem. The invention has simple technique and convenient operation and greatly shortens the production cycle of the dalbergia substances by using the artificial induction manner, with outstanding induction effect, thus being applicable to mass production of standardized commodities, effectively relieving contradiction between supply and demand of dalbergia, providing effective approaches for protecting, developing and utilizing dalbergia odorifera tree resources and having significant economic, social and ecological effect.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI HAINAN BRANCH

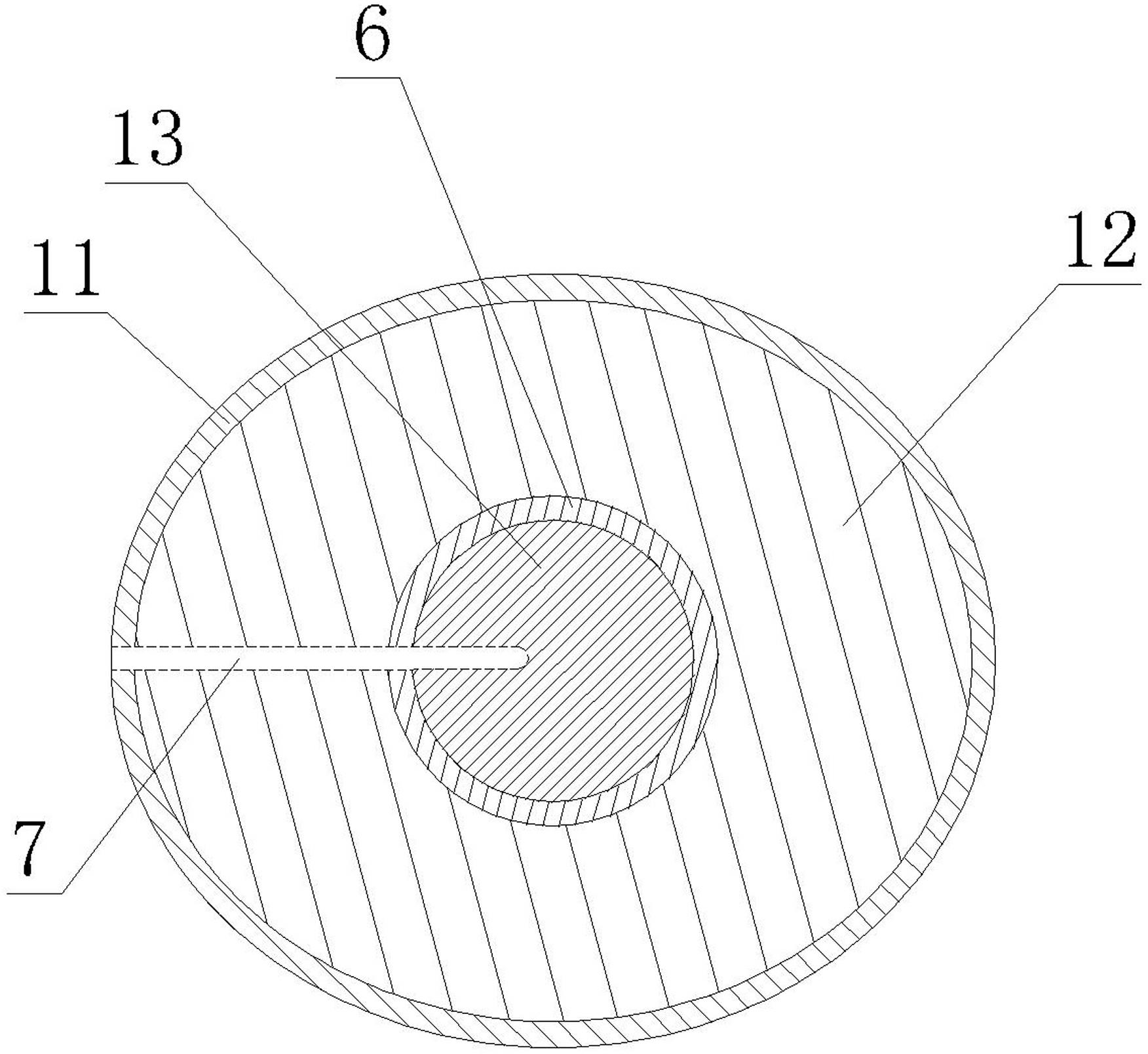

Method for producing agilawood on aquilaria plant by eccentric perfusion method and scent gland activator

ActiveCN102668908ADelayed time to necrosisGood qualityBiocidePlant growth regulatorsTrunkAquilaria subintegra

The invention discloses a method for producing agilawood on anaquilaria plant by an eccentric perfusion method. The method comprises the steps of: drilling at least one transversely eccentrical and downwards inclined hole in the trunk of the aquilaria plant; then, slowly pouring a scent gland activator into the trunk through the hole, after pouring, sealing the hole or punching the trunk; after the aquilaria plant grows for a period of time, harvesting two layers of sepia grease and allochroic yellowish-brown xylem formed on the inner and outer layers of the trunk xylem; and drying to obtainthe agilawood. By using the method provided by the invneiton, the scent gland activator is not only ensured not to flow out easily when the scent gland activator is poured into the aquilaria plant, but also the activation of the tree center (tree pith) is kept, and the agilawood yield is increased more than 30%, so the method effectively shortens the production period of the agilawood,greatly increases the yield of the agilawood, and has important ecological benefit, economic benefit and cultural benefit. The invention further relates to a formula of the scent gland activator.

Owner:蓝均炽 +1

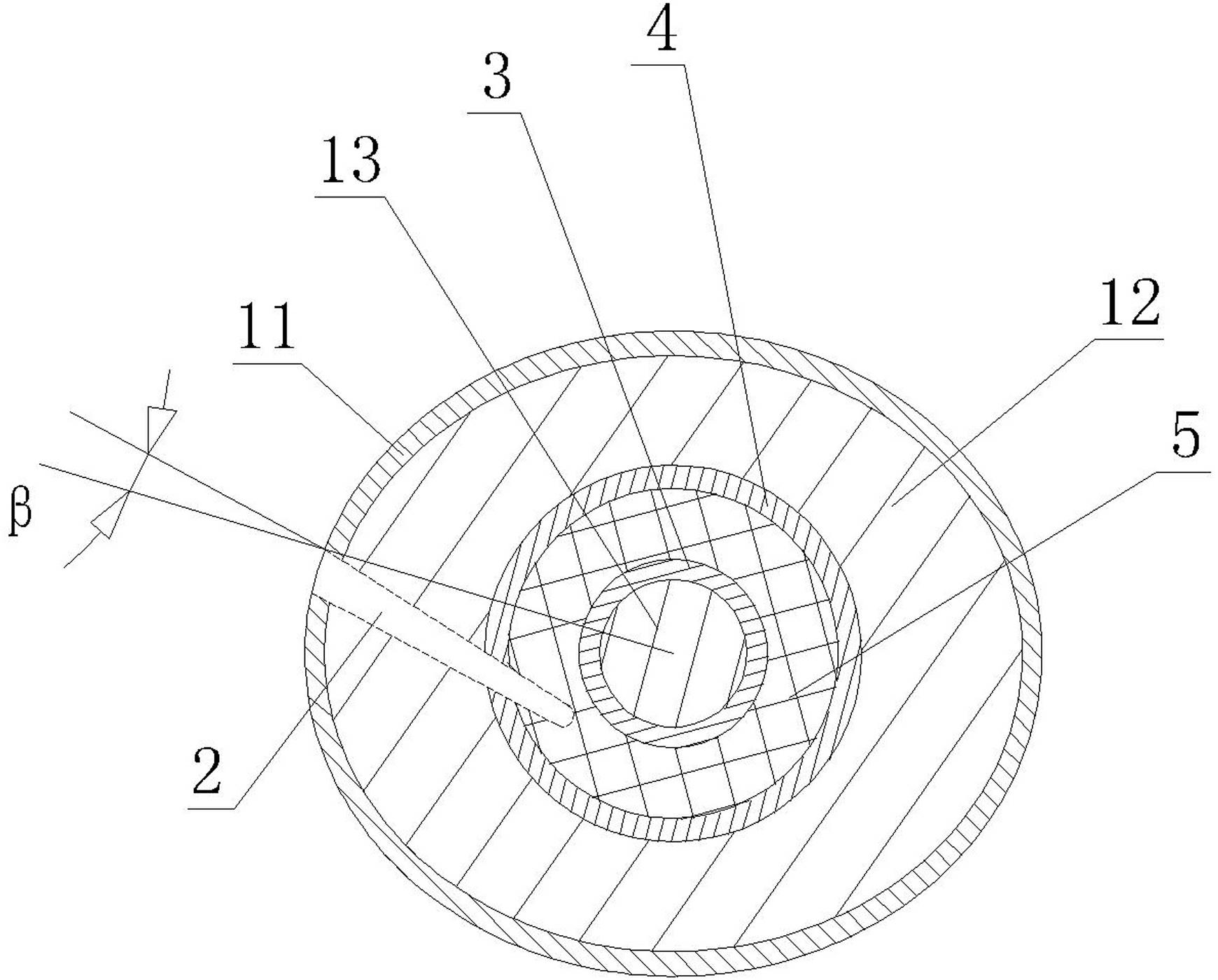

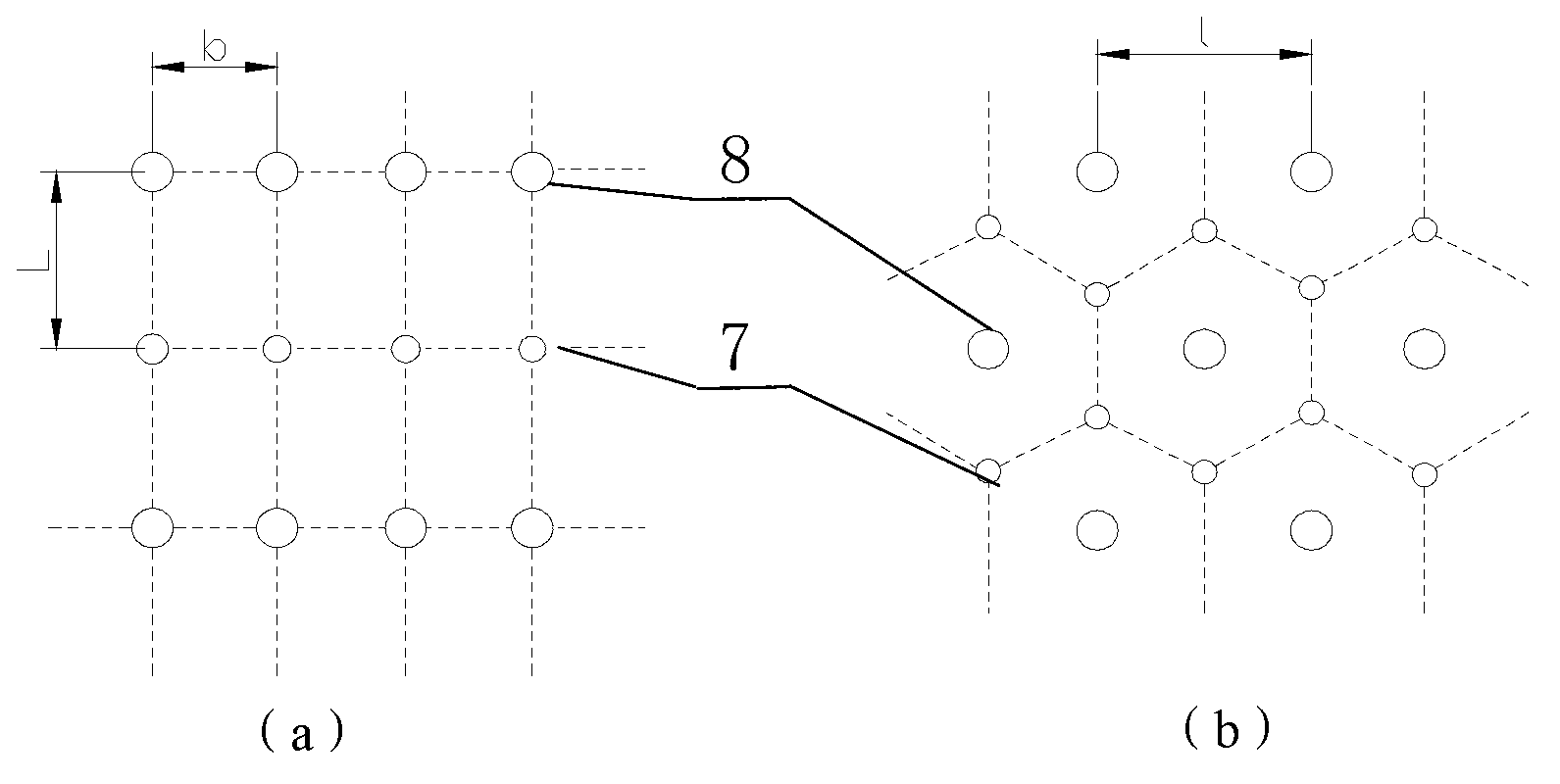

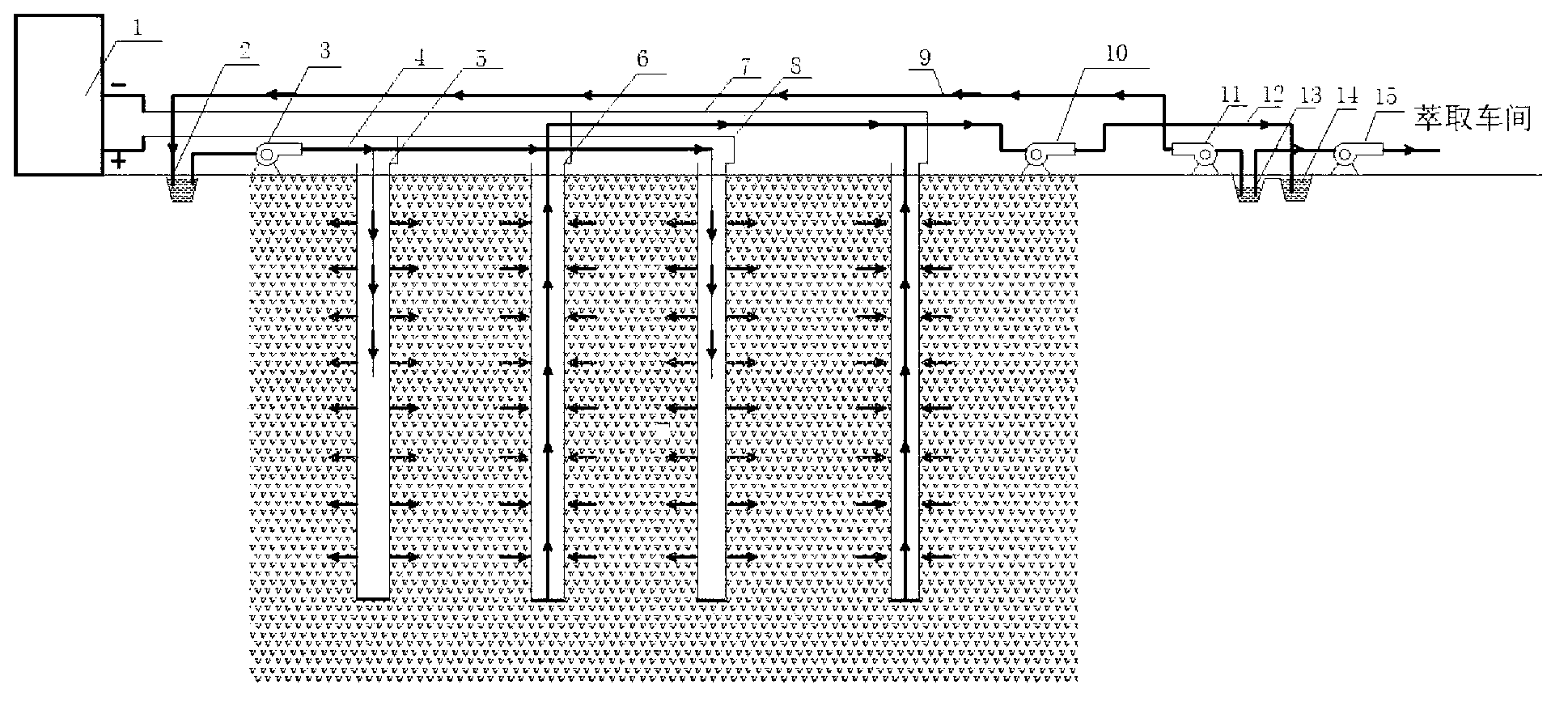

In-situ leaching method of electric field strengthened fine grain tailings

ActiveCN103194597AIncrease profitImprove securityProcess efficiency improvementPregnant leach solutionMineral Sources

The invention relates to an in-situ leaching method of electric field strengthened fine grain tailings. The method comprises the following steps of: changing a fine grain tailings pond into an in-situ leaching system by embedding electrodes, drilling filling ports and pumping filling ports without destroying the original tailings pond structure, controlling the flowing direction and flowing speed of infiltration liquid through the strengthening function of the electric field to meet a standard of infiltration liquid, and extracting valuable metal in an extraction and electrodeposition plant. Through the strengthening function of the electric field, the flowing speed of the infiltration liquid and the migration speed of solute are accelerated, the problem that the fine grain tailings pile body is poor in permeability and low in leaching efficiency is solved, the fine grain tailings pile body meets the requirement of environmental protection by regulating the pH value of the infiltration liquid, the use ratio of the tailings resources is improved, the environmental influence is avoided, and the safety of the tailings pond is improved by electrifying continuously after leaching for electroosmosis strengthening. The in-situ leaching method is a novel efficient and environment-friendly tailings disposal technique, and has a great significance in alleviating the imbalance between the supply and demand of mineral resources in China.

Owner:UNIV OF SCI & TECH BEIJING

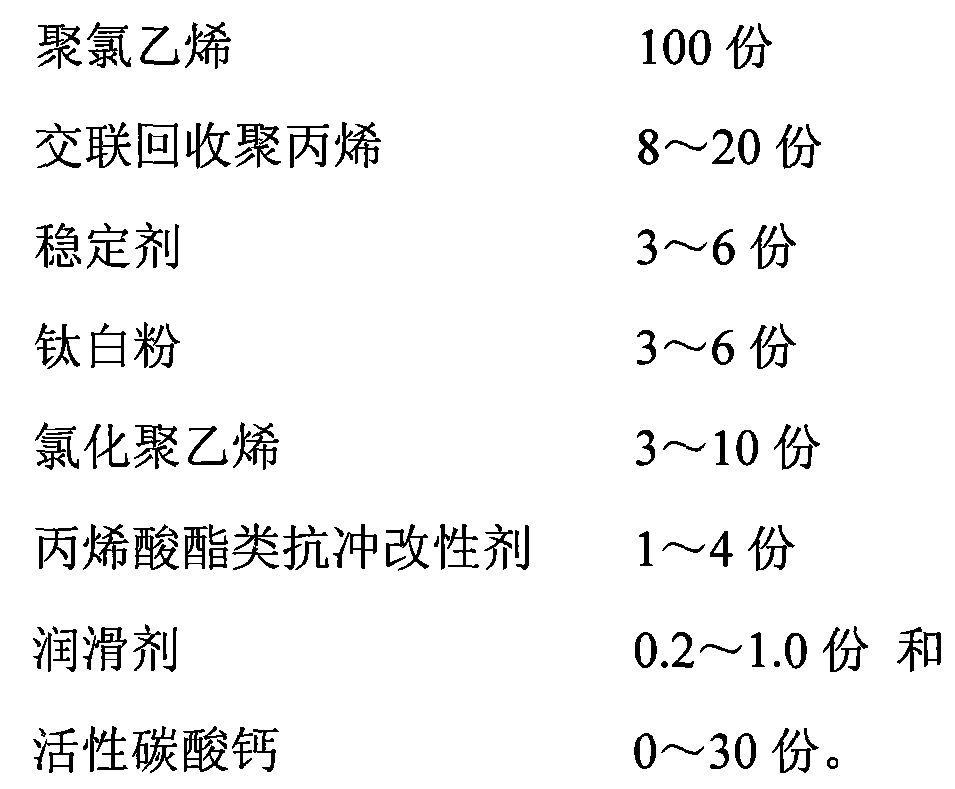

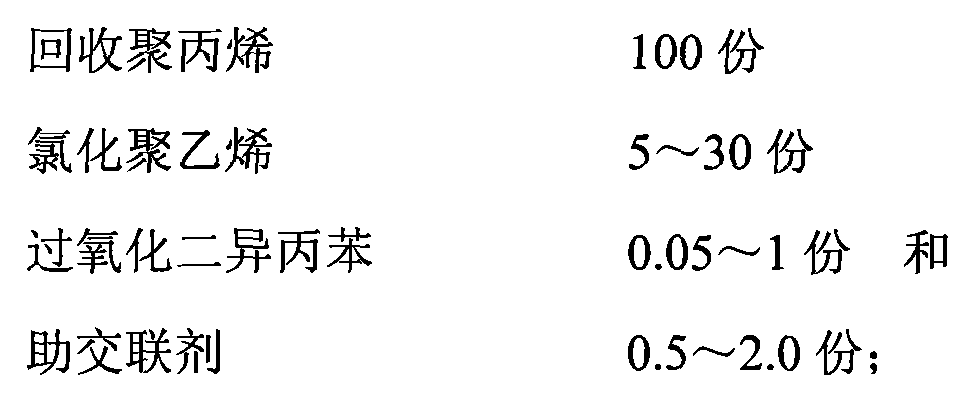

Recycled polypropylene modified polrvinyl chloride sectional material and preparation method thereof

The invention discloses a recycled polypropylene modified polrvinyl chloride sectional material and a preparation method thereof. The sectional material is mainly prepared by blending 100 parts of polrvinyl chloride, 8 to 20 parts of crosslinking recycled polypropylene, 3 to 6 parts of stabilizer, 3 to 6 parts of titanium white powder, 3 to 10 parts of chlorinated polyethylene, 1 to 4 parts of acrylic impact modifier, 0.2 to 1.0 part of lubricant and 0 to 30 parts of active calcium carbonate. The sectional material has excellent performance, can effectively improve recycling utilization rate,saves resources and cost and is environmentally-friendly and safe.

Owner:湖南五强产业集团股份有限公司

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

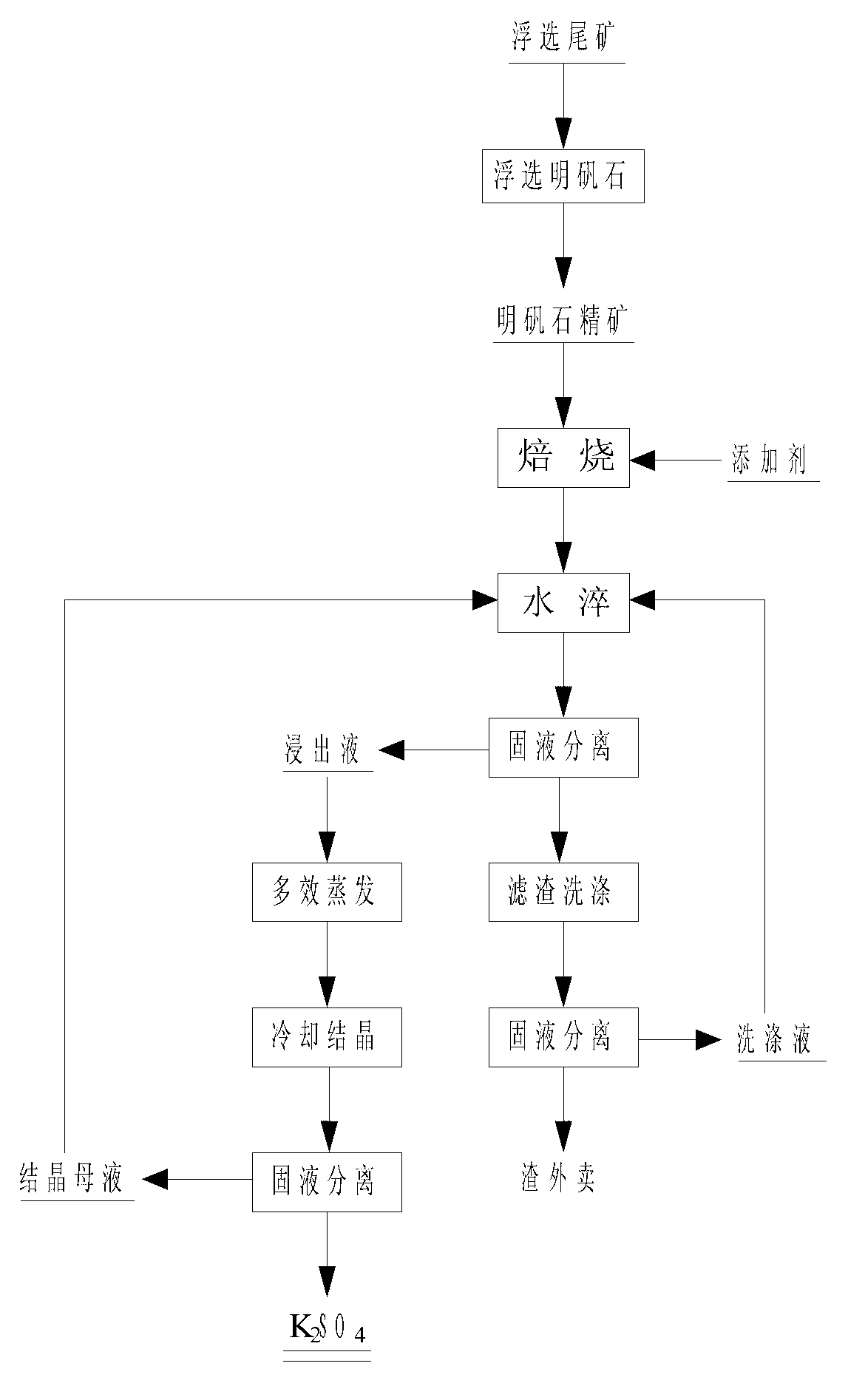

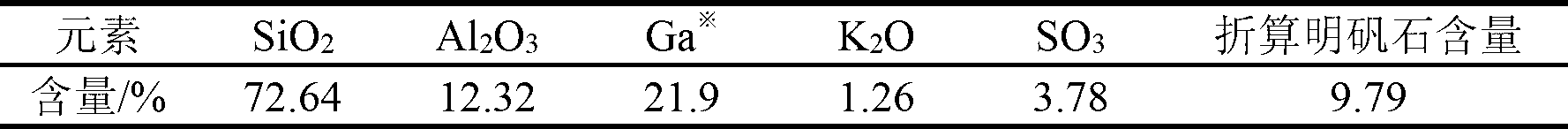

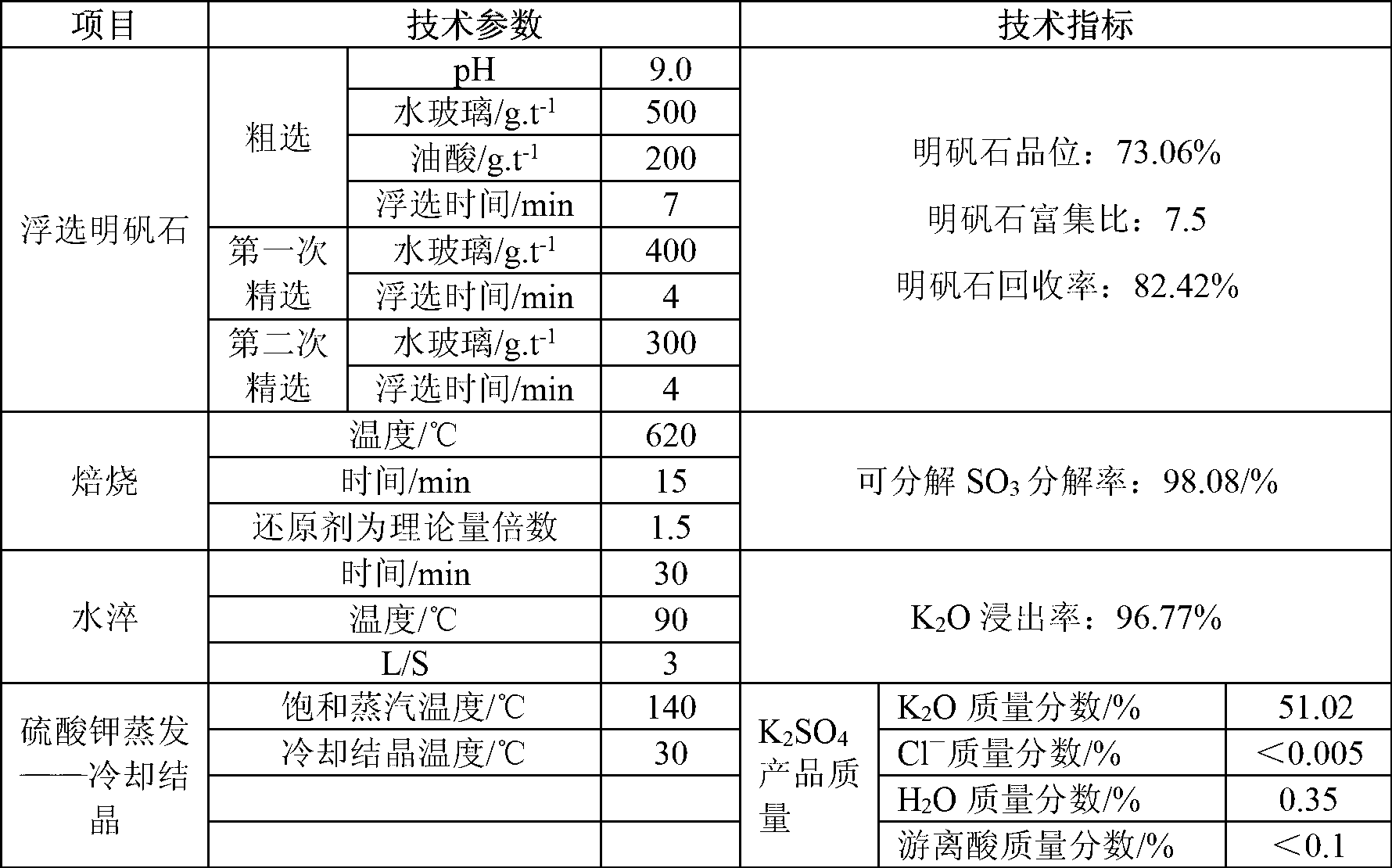

Method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof

ActiveCN103011206AImprove the level of comprehensive utilizationAlleviate the contradiction between supply and demandSulfate/bisulfate preparationEngineeringPotassium sulfate

The invention provides a method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof. The method fully utilizes secondary resources, changes waste into treasure, achieves minimizing, harmlessness and recycling of solid waste, improves comprehensive utilizing level of tailings in China, relieves an acute contradiction of supply and demand of potassium sulfate, reduces loss on foreign exchange caused by mass importation of the potassium sulfate, improves guarantee age limit of kalium and the international competitiveness of the kalium salt industry, completely solves the key scientific and technical problem of economic, clean efficient and comprehensive utilization of the alunite in flotation, the tailings are utilized as resources, establishes tailing comprehensive utilization technical demonstration project, and promotes the development of the comprehensive utilization technique of the tailing in China.

Owner:ZIJIN MINING GROUP

Method for preparing gasoline blending composition from Fischer-Tropsch synthesis oil-phase product

ActiveCN109762597AAlleviate the contradiction between supply and demandReduce external dependenceLiquid hydrocarbon mixture productionBio-feedstockMolecular sieveLow activity

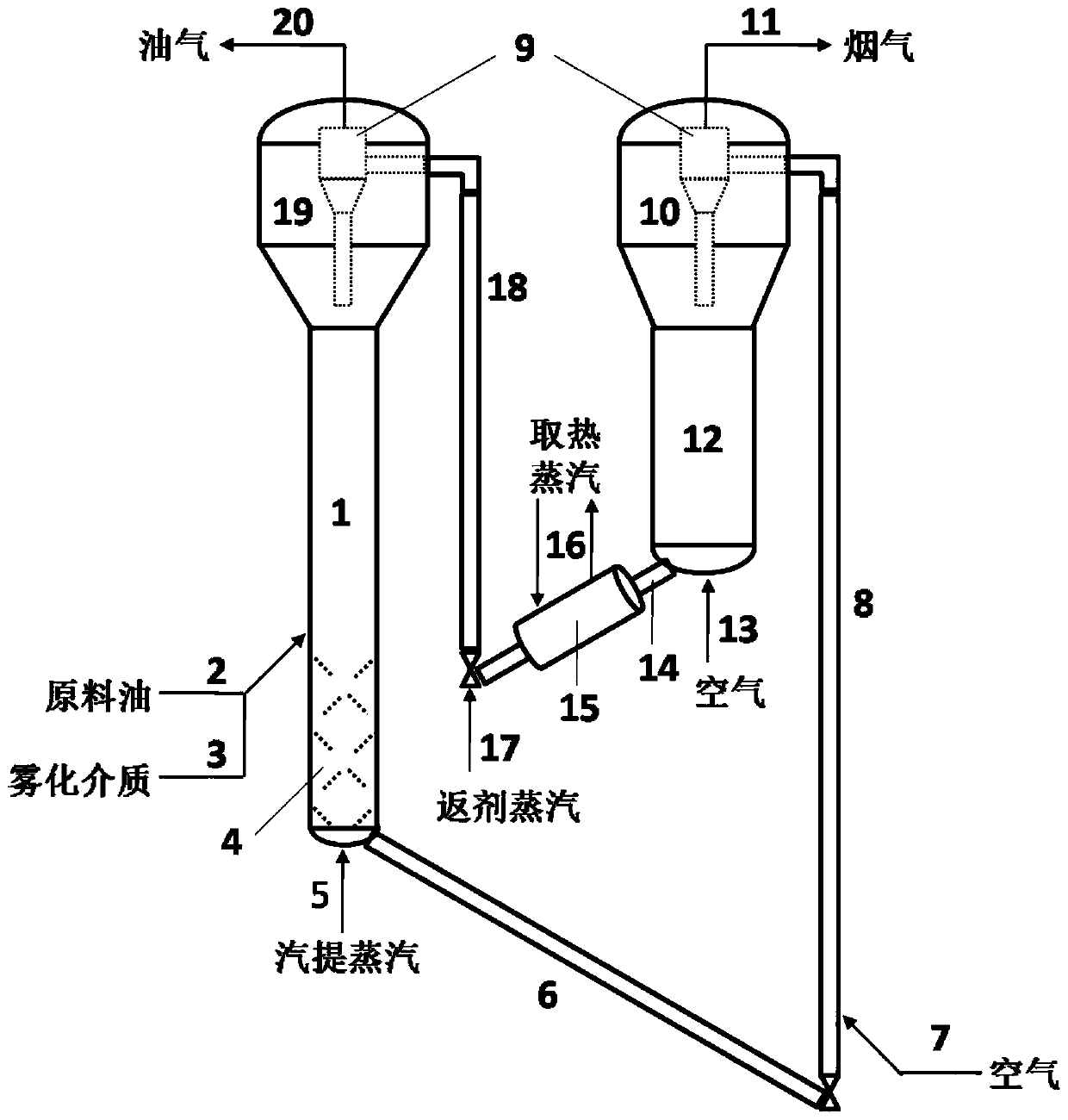

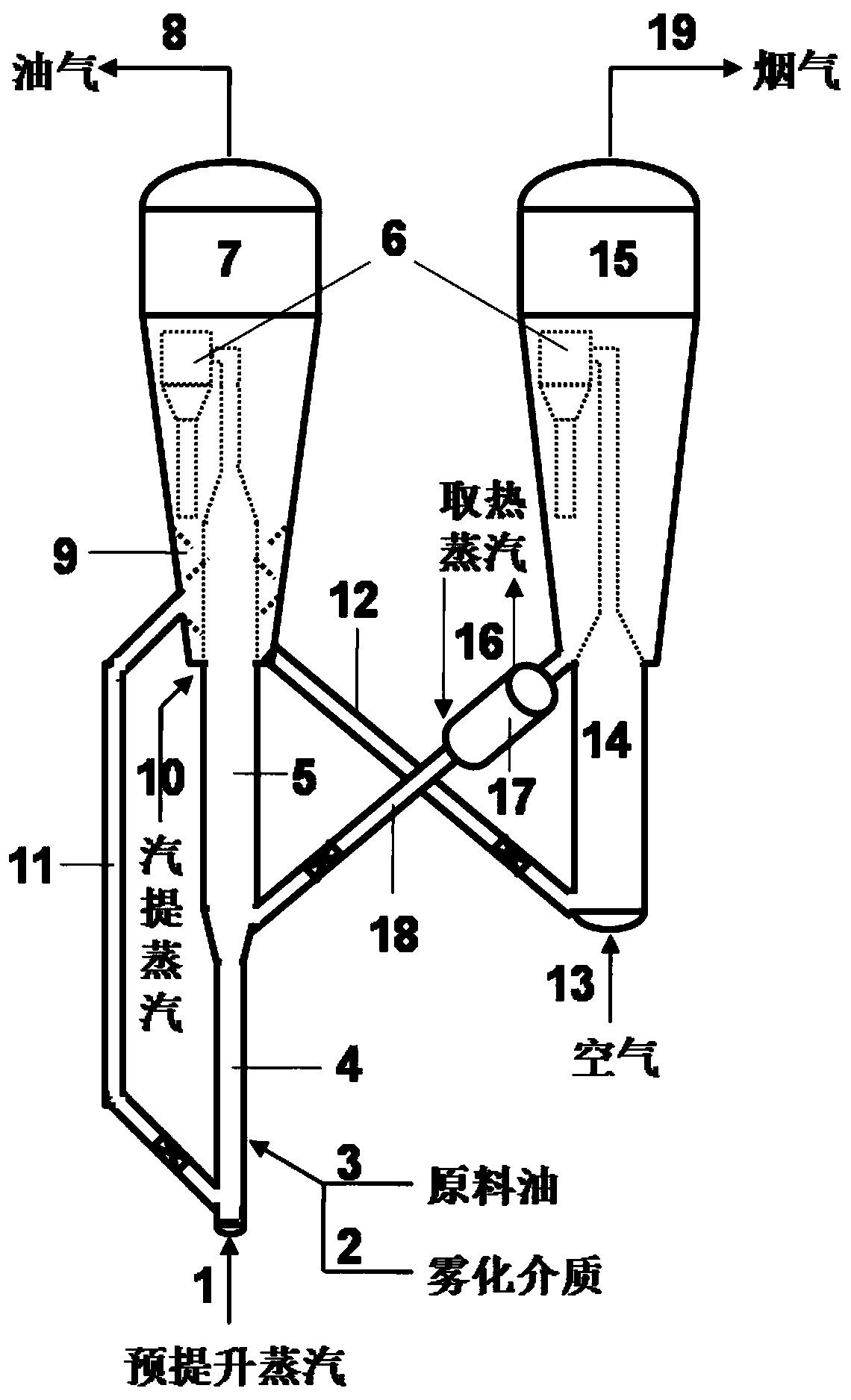

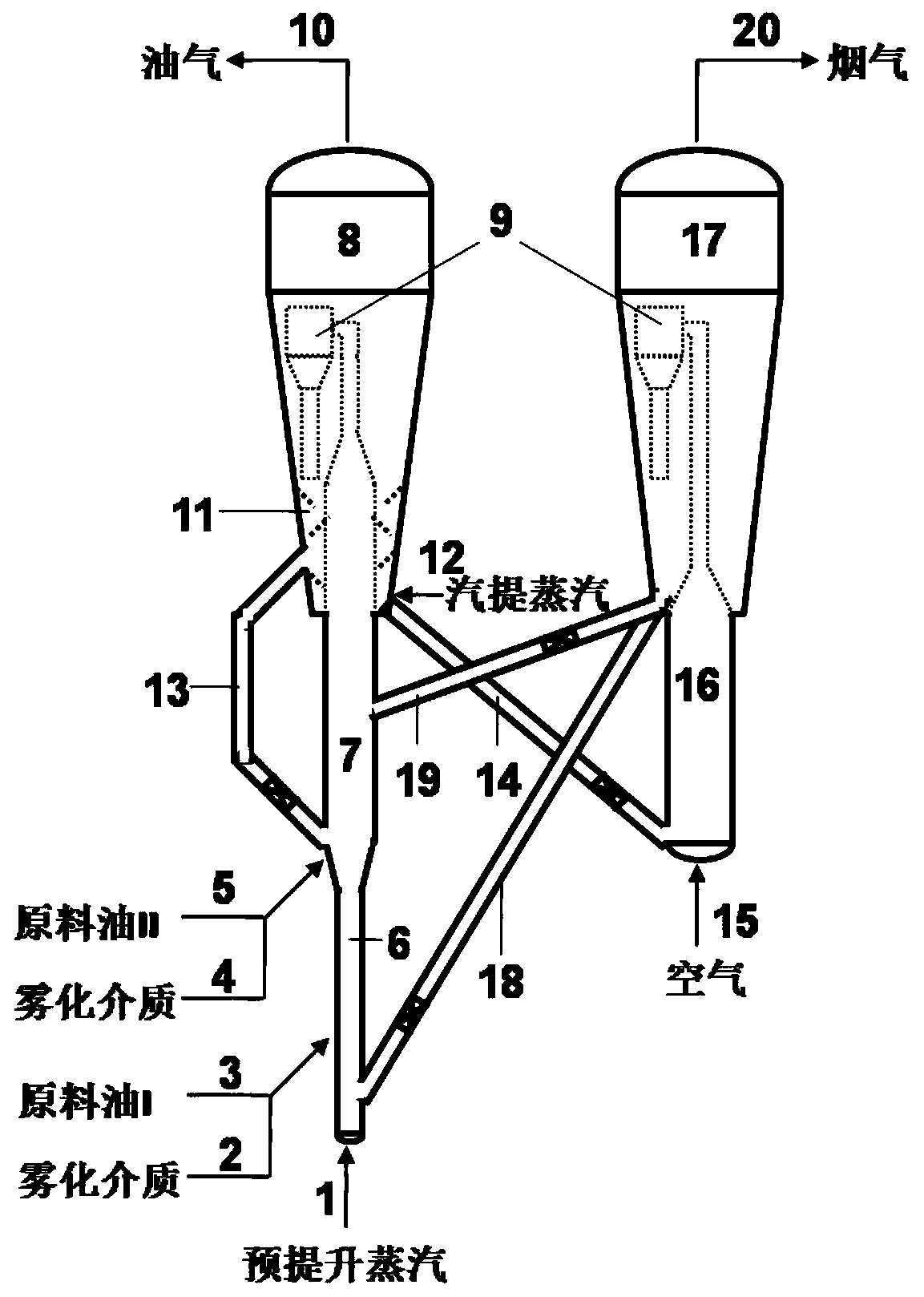

The invention discloses a method for preparing a gasoline blending composition from a Fischer-Tropsch synthesis oil-phase product. The method is characterized by taking the Fischer-Tropsch synthesis oil-phase product as a main raw material, injecting the Fischer-Tropsch synthesis oil-phase product into a fluidized bed reactor after preheating and atomizing the Fischer-Tropsch synthesis oil-phase product, enabling the preheated and atomized Fischer-Tropsch synthesis oil-phase product to be in contact with a low-activity catalyst to carry out cracking reaction, then carrying out aromatization reaction with a high-activity catalyst at a high temperature, and fractionating a generated oil-phase product, thus obtaining high-octane gasoline. The technology disclosed by the invention has the characteristics that a main active component of a catalyst is a molecular sieve with good aromatization performance, chain-like hydrocarbon molecules in the Fischer-Tropsch synthesis oil-phase product arefirstly subjected to the cracking reaction at a lower temperature so as to generate an olefin intermediate, the low temperature is beneficial for reducing the productivity of primary cracking gas, and the yield of gasoline is ensured; then the olefin intermediate is subjected to the aromatization reaction at the high temperature, so that the gasoline quality of a product can be improved; the technology ahs the advantages that the technology is simple, the gasoline yield of the product is high, the octane value is high, and the aromatic hydrocarbon content is high.

Owner:SYNFUELS CHINA TECH CO LTD

Method for producing low cost oriented silicon steel using continuous casting and rolling technique of sheet bar

InactiveCN101433911AReduce precipitationHigh continuous casting slab surface temperatureTemperature control deviceMetal rolling arrangementsThin slabAcid washing

The invention relates to a method for producing low-cost oriented silicon steel by the thin slab continuous casting and tandem rolling technique, which belongs to a manufacturing technique for steel materials with high added value. The method is as follows: continuous casting billets with a thickness of between 50 and 120 millimeters are formed by a thin slab continuous casting and tandem rolling device, and enter a soaking furnace for heat preservation at casting speed of between 3.1 and 6 meters per minute when the surface temperature of the casting billets is guaranteed to be not less than 800 DEG C; the continuous casting billets are heated by the soaking furnace and subjected to hot-rolling to form hot-rolling plates with a thickness between 1.5 and 3.5 millimeters; and after the hot-rolling plates are subjected to acid washing, cold rolling, intermediate annealing, cold rolling and secondary recrystallization and annealing, and the structure and the texture required by the oriented silicon steel are obtained, and the magnetism of the products can reach the performance index of the trademark of the oriented silicon steel of the national standard requirement. The method has the characteristic of production of the low-cost oriented silicon steel with the national standard trademark by the thin slab continuous casting and tandem rolling technique used in actual industrial production, has the advantages of short flow, low cost and high production efficiency, and can save the process of normalized annealing by controlling the finishing temperature, so as to further save the cost and improve the production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

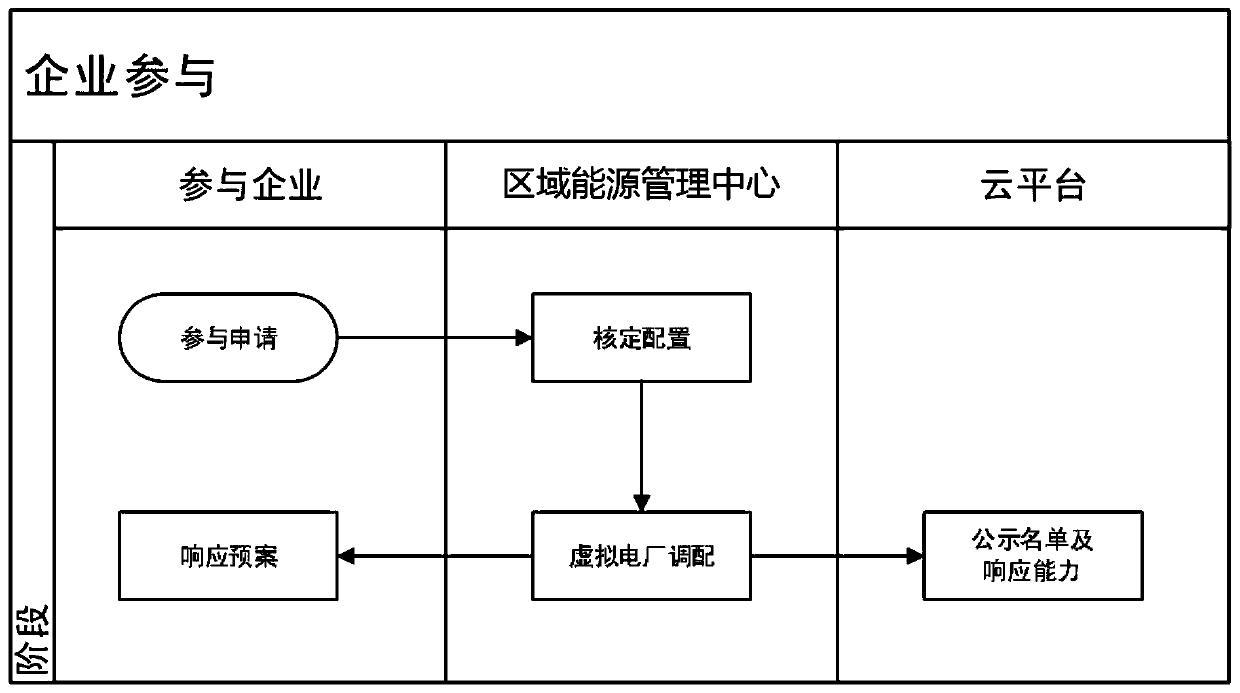

Regional load accurate adjustment method based on virtual power plant technology

InactiveCN110245790AImprove securityGuaranteed uptimeEnergy industryForecastingPower gridVirtual power plant

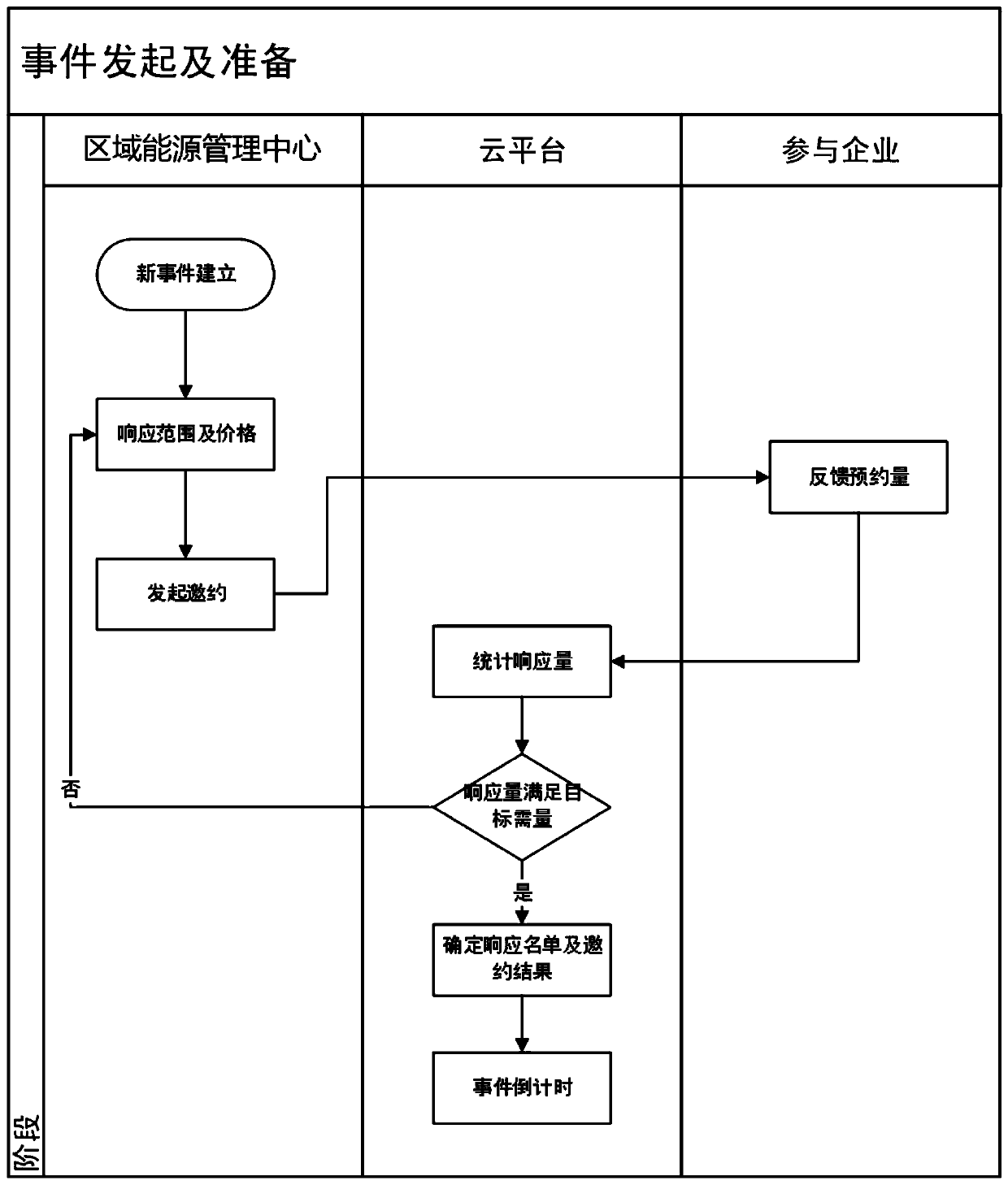

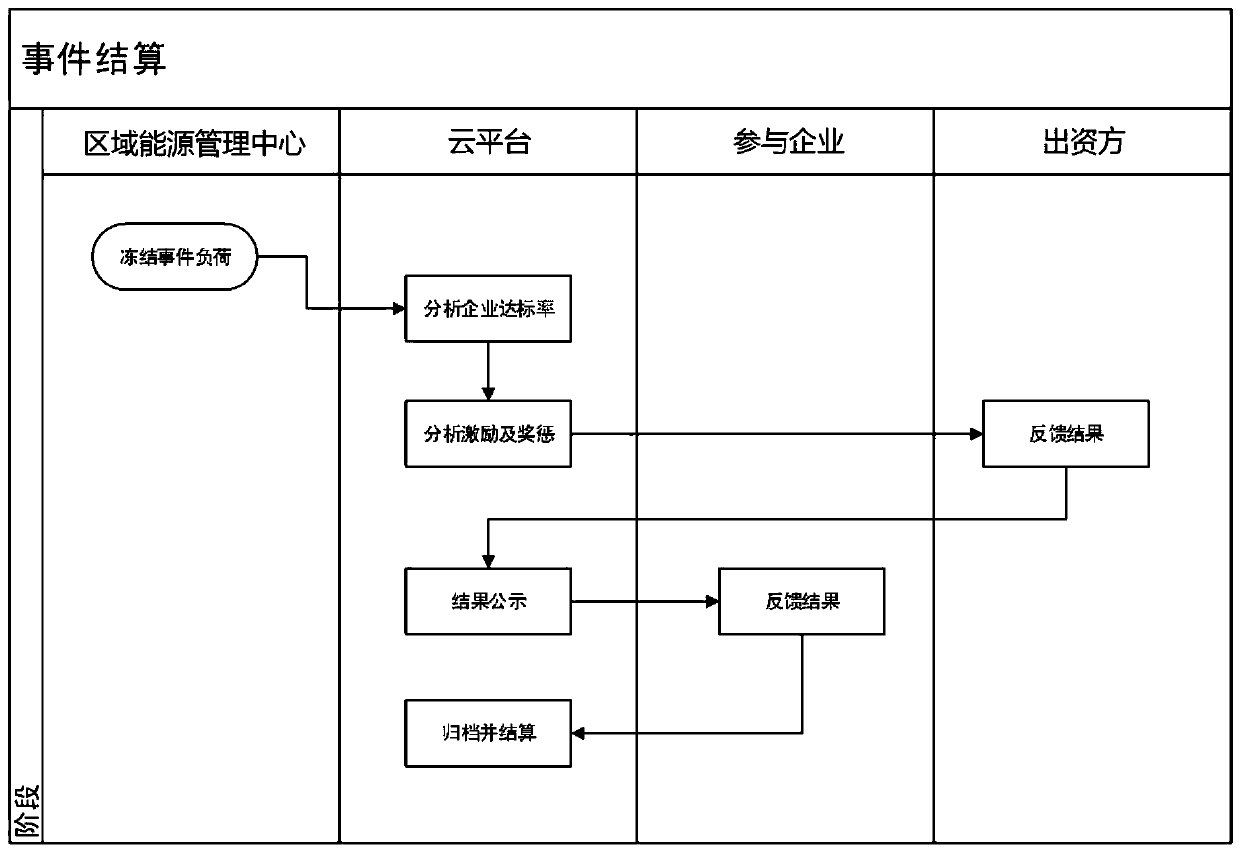

The invention relates to a regional load accurate adjustment method based on a virtual power plant technology. The method comprises the stages of enterprise participation, event initiation and preparation and post-event settlement; the server of the regional energy management center establishing an event corresponding to the target demand of power utilization, and determining a response range and a response price of the event; selecting one part from member enterprises forming the virtual power plant, initiating an invitation participating in the event demand response to the client, and tracking a feedback result of the enterprise; and the cloud platform carrying out response quantity statistics according to the invitation response quantity fed back by the enterprise, determining the enterprise invited to participate in demand response when judging that the statistical response quantity meets a target demand quantity, carrying out event countdown, waiting for an appointed time so as to start event execution, and carrying out demand response by the participating enterprise. A virtual power plant system is constructed, users are invited and guided to adjust the energy consumption time, the power resource scheduling is optimized, the power grid supply and demand contradiction is relieved, and the method has the advantages of being practical, marketized and online.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Method and equipment for producing cup of beaker

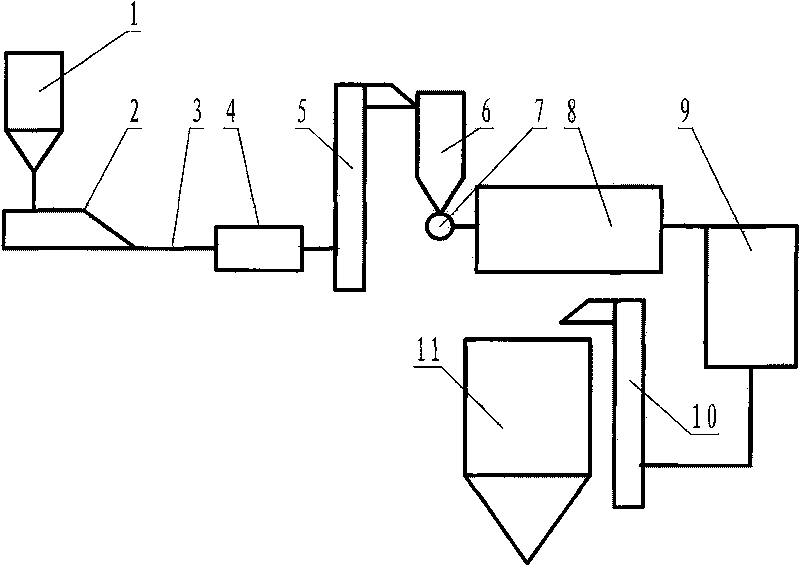

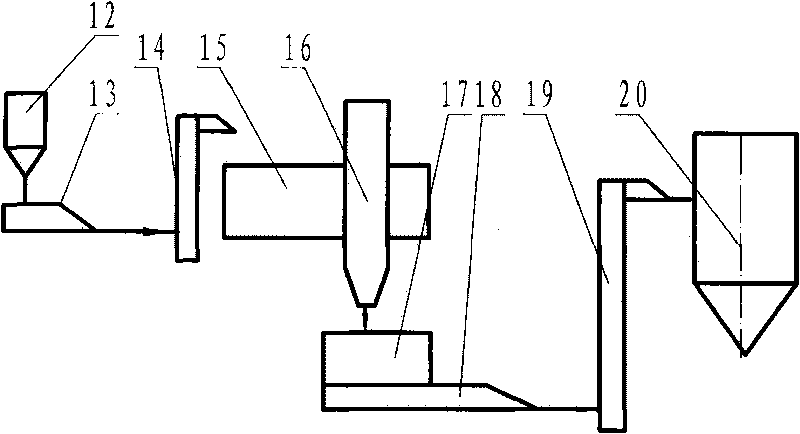

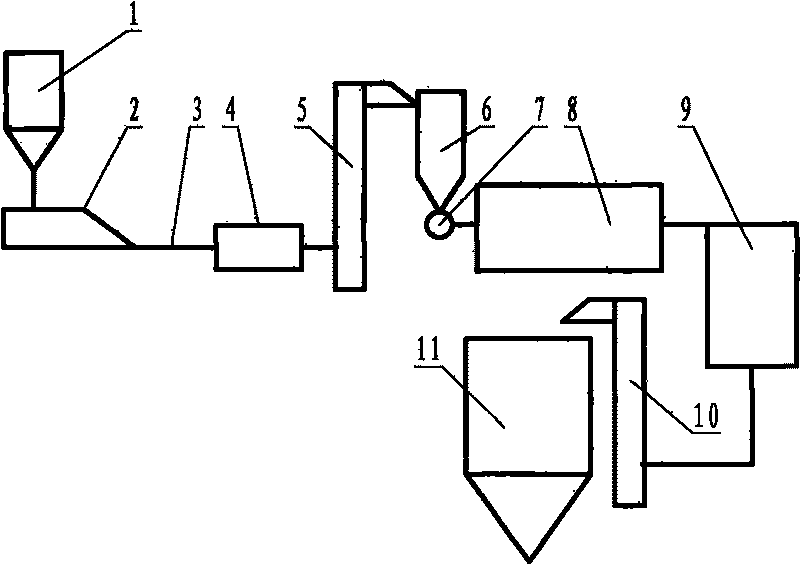

ActiveCN101050055AIncrease productivityGood lookingGlass reforming apparatusGlass productionCutting glassNeck parts

This invention provides method and apparatus for producing beaker. The method comprises: (1) cutting glass tube into 2.1-2.3 times of the height of beaker body, placing the cut glass tube on the transmission tray at the front end of the frame, moving by the channel on the transmission tray to the nozzle of the flaring device, heating both ends of the glass tube and flaring; (2) heating the middle part of the flared glass tube, pressing the middle part into bottle neck shape by a neck-pressing mold, cooling, heating the middle part again, and separating at the middle neck part by the force toward the two ends from the bottom pressure foot to obtain the bodies of two beakers; (3) pre-sealing the bottoms by the nozzle, sealing the bottoms, finishing, polishing, annealing, and outputting by a conveyer belt. The method has such advantages as high production efficiency, high product quality, and low raw material consumption.

Owner:YANCHENG HUAOU IND

Building polymer powder based on composite silicate

InactiveCN101712537ALarge specific surface areaRich functionalitySolid waste managementPolymer scienceSlag

Owner:高庆越 +1

Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

ActiveCN103073210AFix bugsSolve hidden dangersSolid waste managementPolyethylene vinyl acetatePolyvinyl alcohol

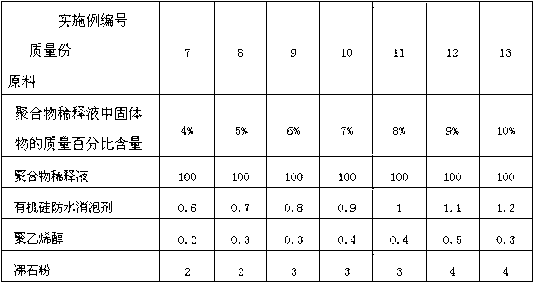

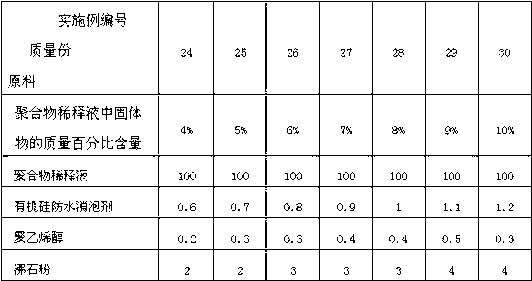

The invention discloses a modified high carbon ferro-chrome slag aggregate for road concrete and a preparation method of the modified high carbon ferro-chrome slag aggregate. The modified high carbon ferro-chrome slag aggregate is characterized by being prepared from a high carbon ferro-chrome alloy slag aggregate and a chemical modifying agent accounting for 2-6 percent of the mass of the high carbon ferro-chrome alloy slag aggregate through mixing, wherein the chemical modifying agent is prepared from 100 parts by mass of polymer diluting solution, 0.5-1.2 parts by mass of organic silicon waterproof defoaming agent, 0.2-0.5 part by mass of polyvinyl alcohol and 2-4 parts by mass of zeolite powder through uniform mixing; the polymer diluting solution is prepared by diluting a polymer emulsion stock solution through adding water; and the polymer emulsion stock solution is any one of a butylbenzene emulsion, a polyacrylate emulsion, a polyethylene-vinyl acetate emulsion and a styrene-acrylic emulsion. By adopting the invention, waste alloy waste is used as a raw material, and thus building materials of carbon chromic slag can be recycled and efficiently utilized, and the defects and the hidden dangers of the carbon chromic slag as the concrete aggregate are solved; and the preparation method is simple and easy to realize and is strong in practicability.

Owner:李素娥

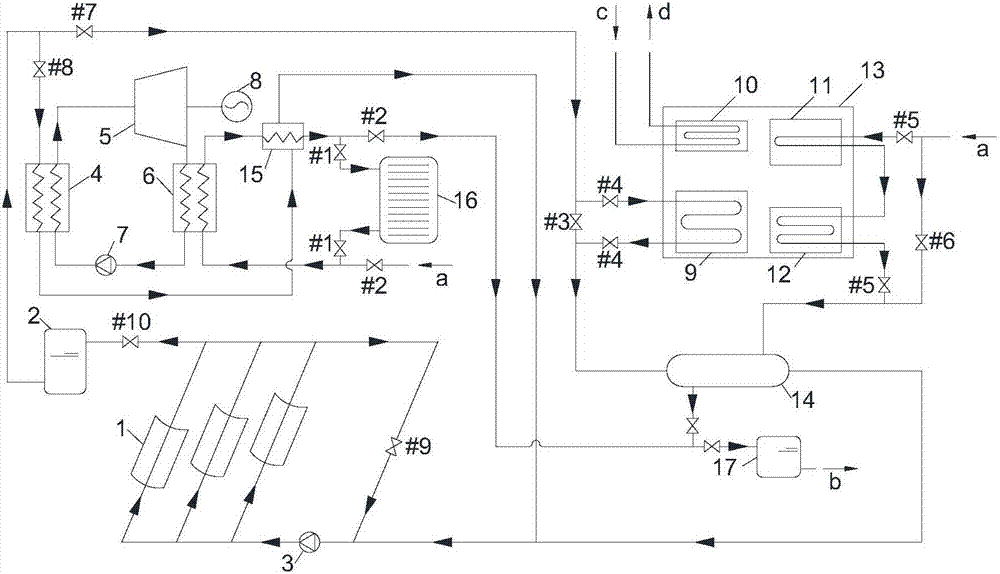

Solar combined cooling heating and power generation system based on organic rankine cycle and lithium bromide refrigerating

PendingCN106958963AAlleviate the contradiction between supply and demandSmall sizeFrom solar energyMachines/enginesOrganic Rankine cycleCogeneration

The invention relates to a solar cogeneration system based on organic rankine cycle and lithium bromide refrigeration, including a solar heat collection system, an organic rankine cycle power generation system, a lithium bromide absorption refrigerator, terminal heating, and a domestic heat system. The organic Rankine cycle power generation system includes an evaporator A, a steam turbine, a generator, a condenser A and a working medium pump, the evaporator A is respectively connected with a heat accumulator and a reheater, and the evaporator A is respectively connected with a The connection of the working medium pump and the steam turbine constitutes an organic Rankine cycle power generation system using solar heat collection heat source; and it is connected with the lithium bromide absorption refrigerator and the terminal heating and domestic heating system to form an overall cogeneration system of cooling, heating and power. Beneficial effects: the present invention combines organic Rankine cycle and lithium bromide refrigeration by using solar medium and low temperature energy, which not only achieves the purpose of temperature matching, cascade utilization, and heat refrigeration, but also realizes the functions of power supply, winter heating, and summer cooling. Cogeneration of cooling, heating and power.

Owner:TIANJIN CHENGJIAN UNIV

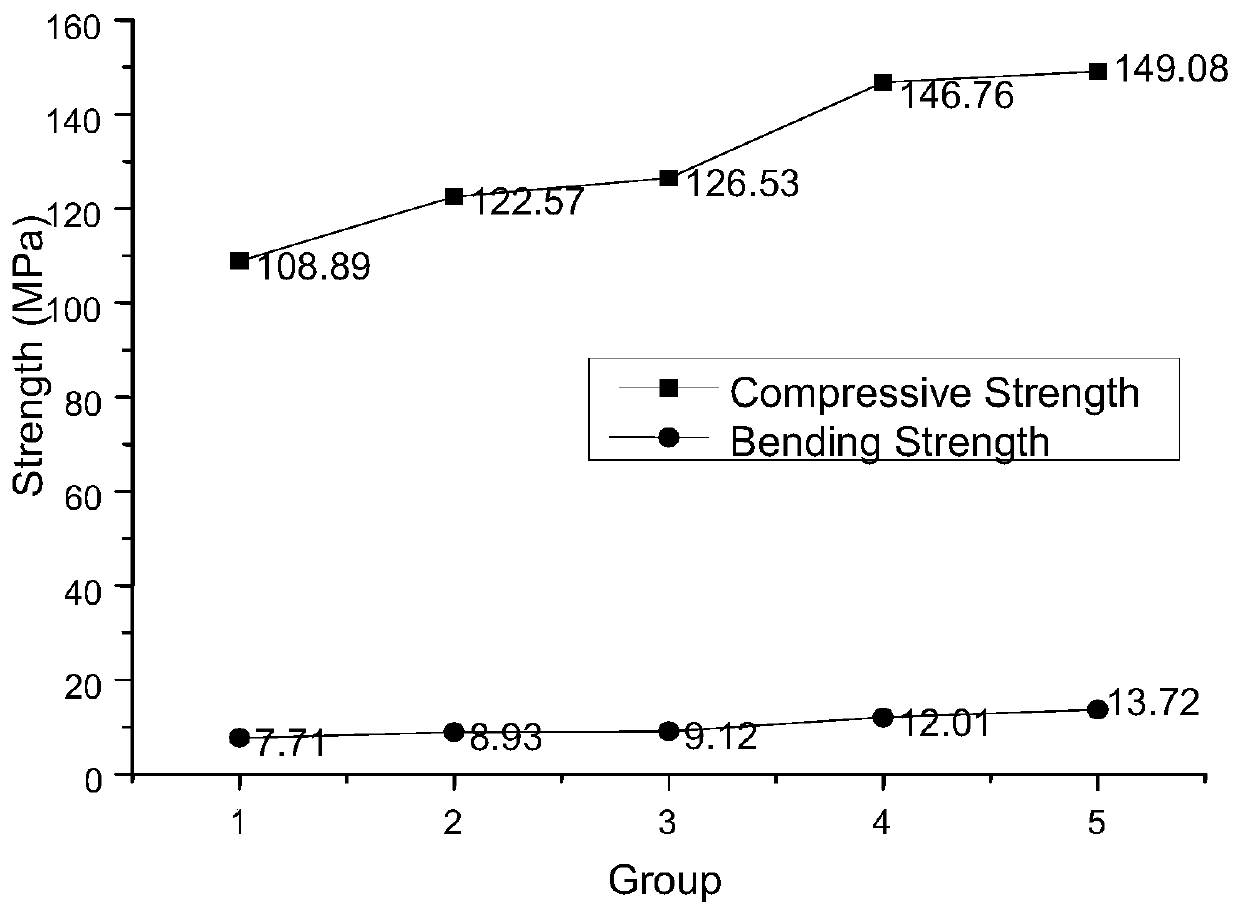

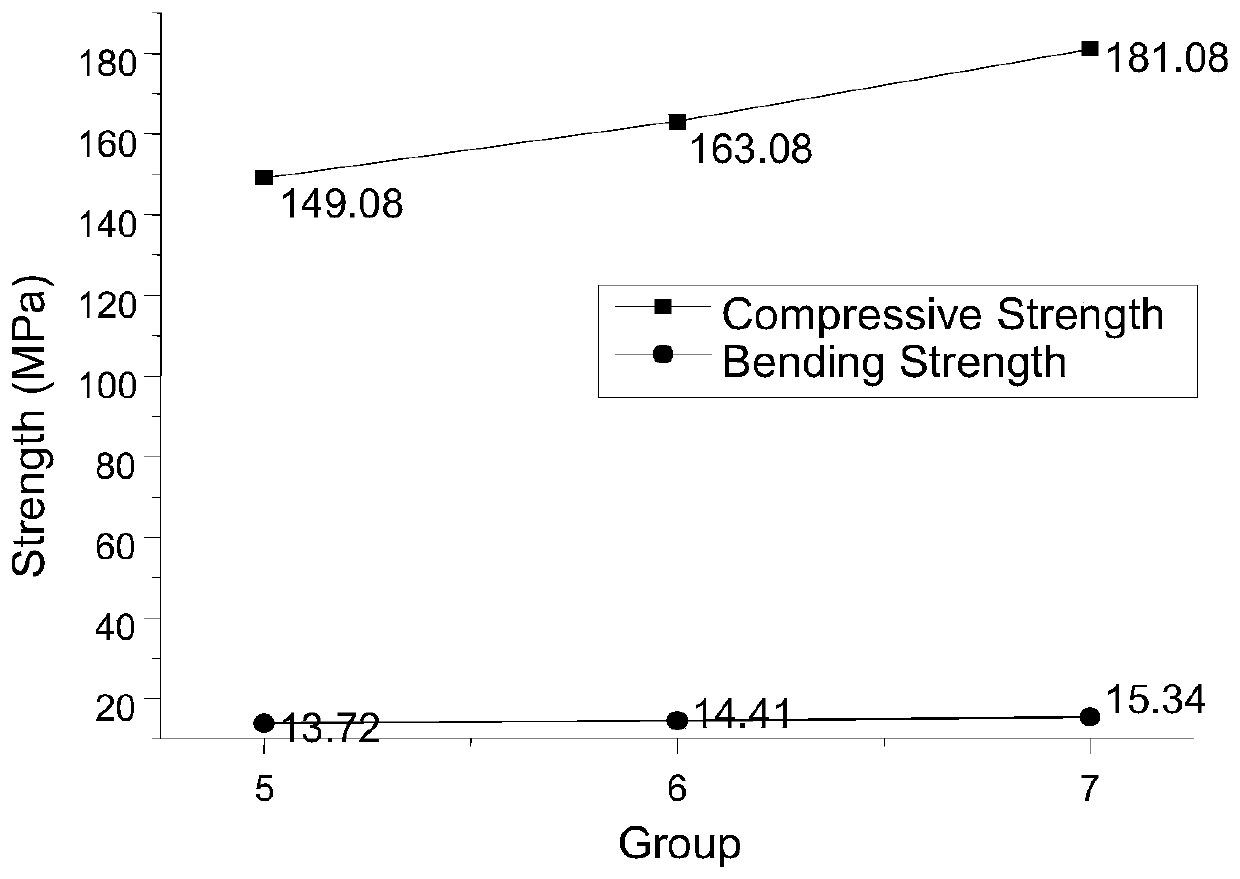

Concrete and preparation method thereof

ActiveCN110655369AImprove mechanical propertiesAlleviate the contradiction between supply and demandSlagBuilding energy

The invention discloses concrete and a preparation method thereof. The concrete comprises the following components in parts by weight: 50 parts of cement, 20 parts of silica fume, 20 parts of fly ash,10 parts of superfine slag powder, 15-45 parts of antirust steel fibers, 15 parts of water, 3 parts of a polycarboxylate superplasticizer and 140 parts of desert sand and / or river sand. The preparation method comprises the following steps: mixing the components, adding the mixture into a stirrer, and stirring to a specified collapse degree to obtain a mixture; moulding, removing a mold after themixture is solidified and formed, performing box girder steam curing and watering curing in sequence to obtain the concrete with the compressive strength exceeding 100 MPa, the performance requirementof a high-performance building is met, and the concrete is suitable for application and popularization. Building energy consumption can be reduced, the mechanical property of concrete is improved, and the problem of shortage of the river sand is relieved.

Owner:HOHAI UNIV

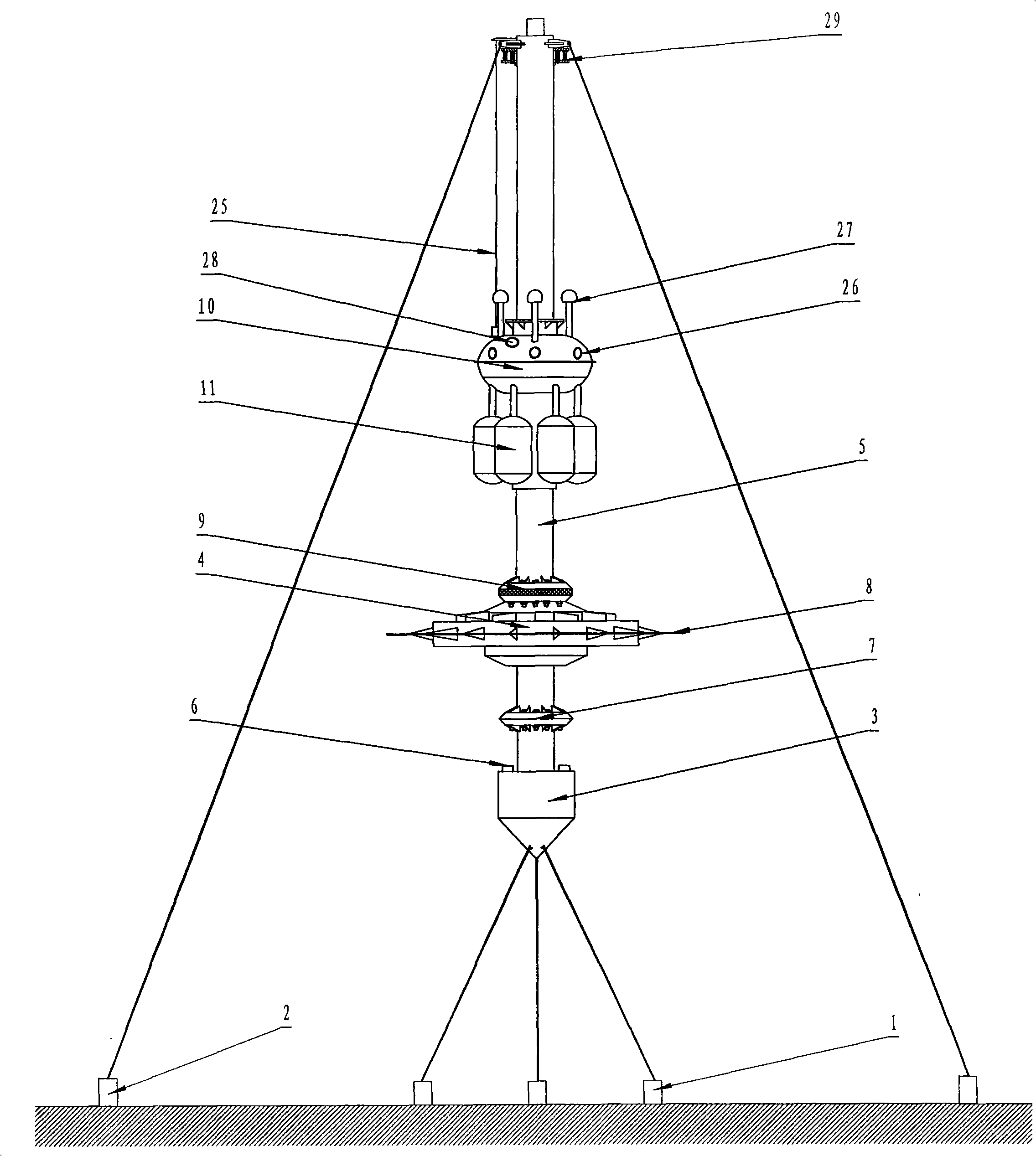

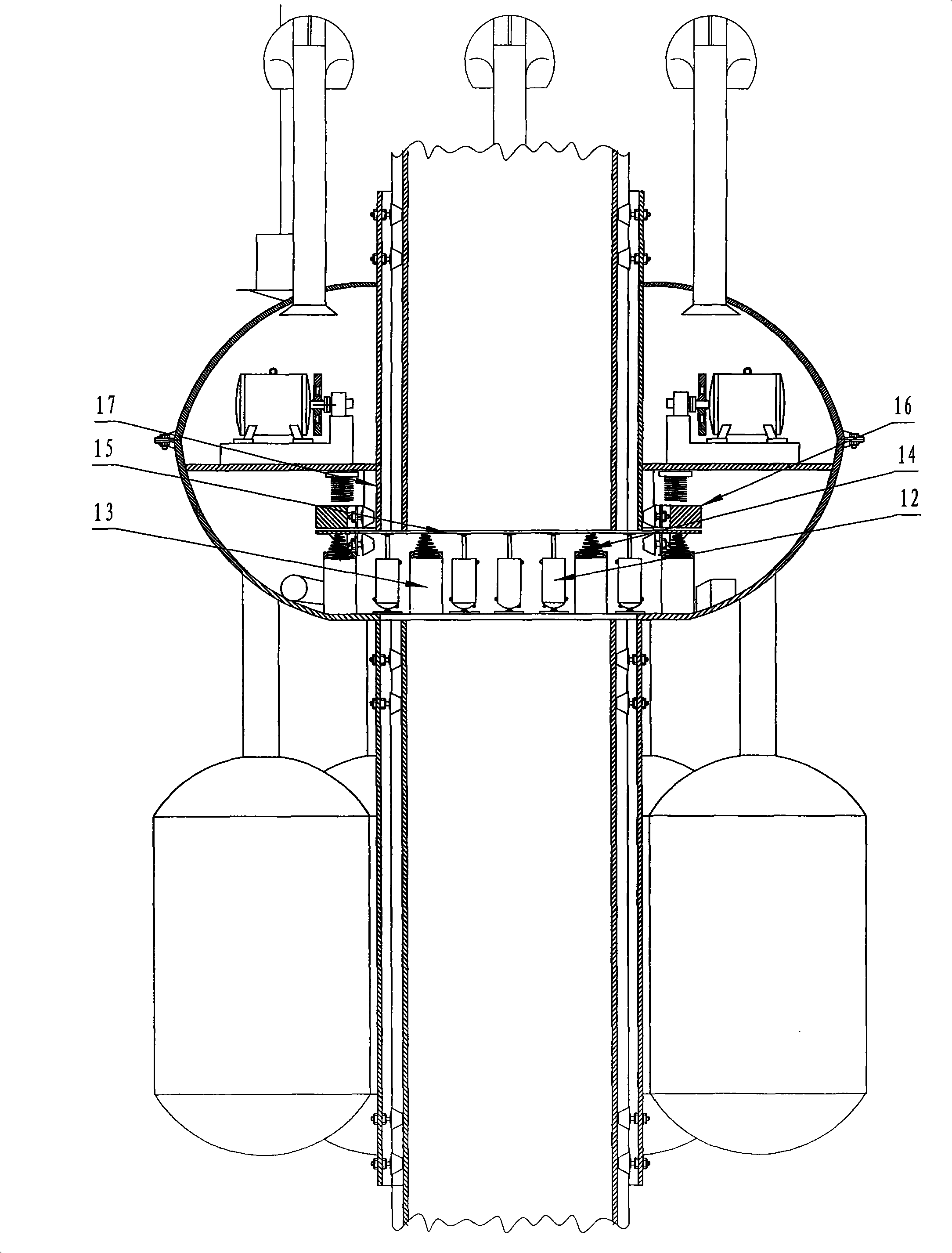

Floating type sea wave power station

InactiveCN101852166AHigh technical contentWide adaptabilityMachines/enginesEngine componentsSurface oceanGravitational force

The invention provides a floating type sea wave power generation facility, which belongs to the filed of renewable energy sources, is different from the prior sea wave power generation technology in the world, comprises a hard cabin, a soft cabin, a guidepost, a mooring gear, a power plant compartment and the like and is a brand new technology of utilizing wave forces and power of gravity to generate electricity. A piled anchor and mooring ropes in the mooring gear vertically fix the hard cabin, the soft cabin and the guidepost at the proper positions in the sea; the watertight power plant compartment is sleeved on the guidepost and is pushed by sea wave to do up-and-down motion; and a counter weight slide block in the power plant compartment moves up and down along the sea wave to drive a heavy-duty hydraulic cylinder to do work so as to enable high pressure oil to be pushed by a high-pressure oil tube in order to push the hydraulic motor to rotate to drive a generator to generate electricity. The technology of the invention has high promotion and application values under the conditions of undeveloped wide sea area of our country, serious coal-fired power pollution and shortness of energy sources.

Owner:路广耀

Process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation

ActiveCN103992200AExpand the range of industrial applicationsRich production methodsHydrocarbon by hydrogenationCalcium carbidePtru catalystHydrogenation reaction

The invention relates to a process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation. A process for producing methanol or dimethyl ether from coal-based or natural gas-based synthetic gas and further producing low-carbon olefins mainly comprising ethylene and propylene has the disadvantages of long process flow, complex process and large investment. The process method provided by the invention comprises the steps of drying and screening semi-coke, then mixing with lime powder, producing calcium carbide in a closed calcium carbide furnace and obtaining hydrogen from tail gas of the calcium carbide furnace through PSA; enabling obtained calcium carbide to react with water to produce acetylene gas; mixing acetylene gas with hydrogen according to a proportion, then compressing, entering an acetylene gas hydrogenation reactor, performing acetylene gas hydrogenation reaction under the action of a palladium-series silver-added additive catalyst, cooling the gas after reaction and then purifying through a rectification device to obtain ethylene gas. According to the ethylene production process provided by the invention, the supply-demand contradiction of semi-coke and calcium carbide can be relieved, the range of industrial applications of semi-coke and calcium carbide is expanded, the ethylene production method is enriched and the shortcomings of long process flow, high investment and large water demand of the existing ethylene production method are overcome.

Owner:榆林科大高新能源研究院有限公司

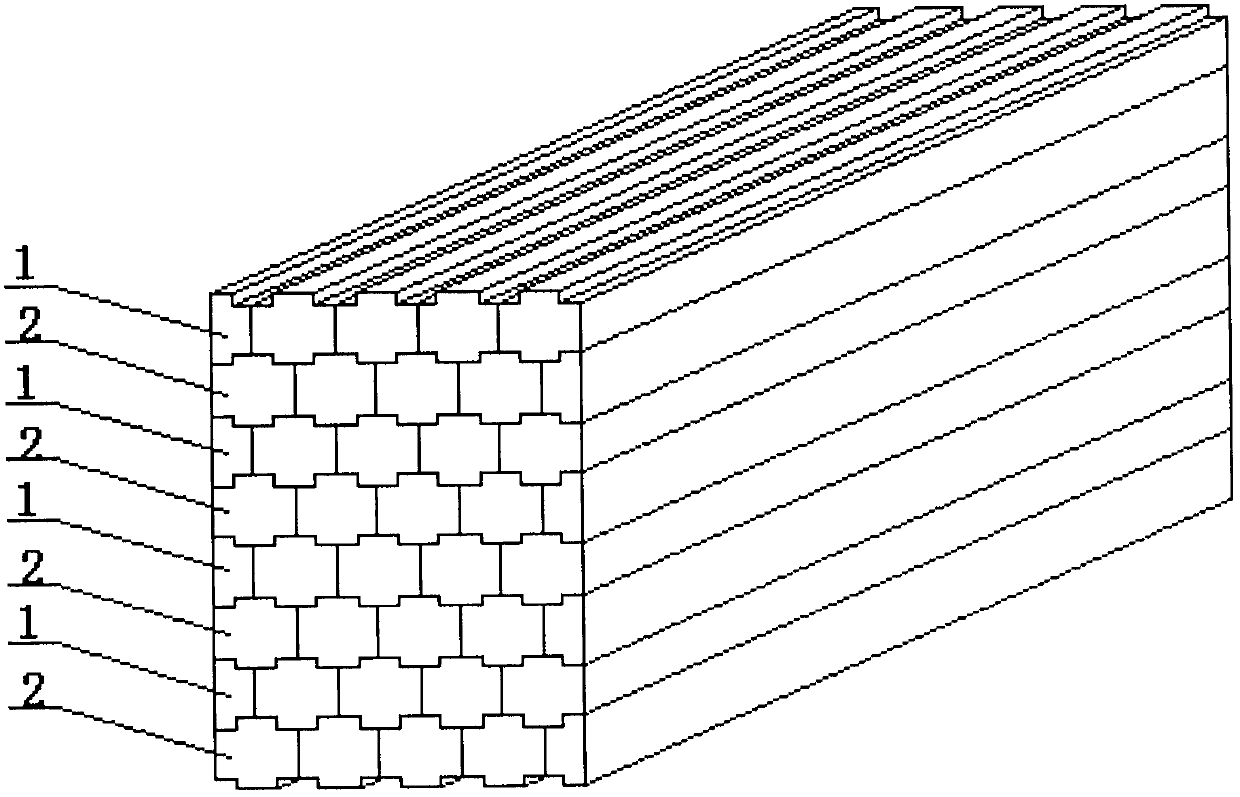

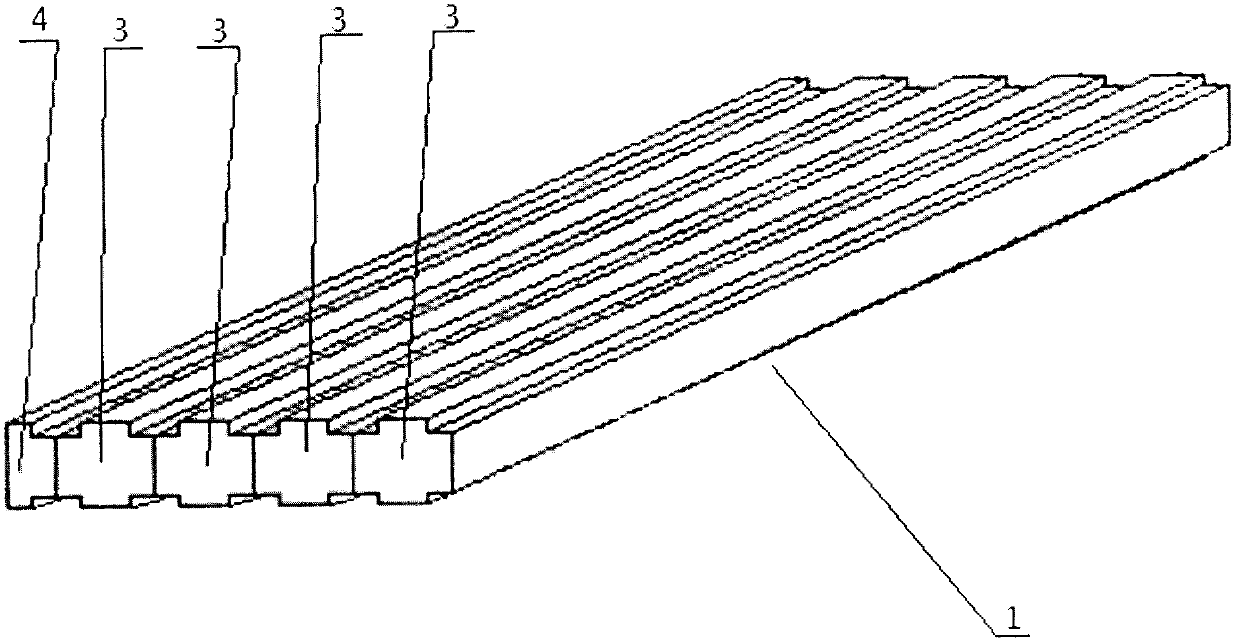

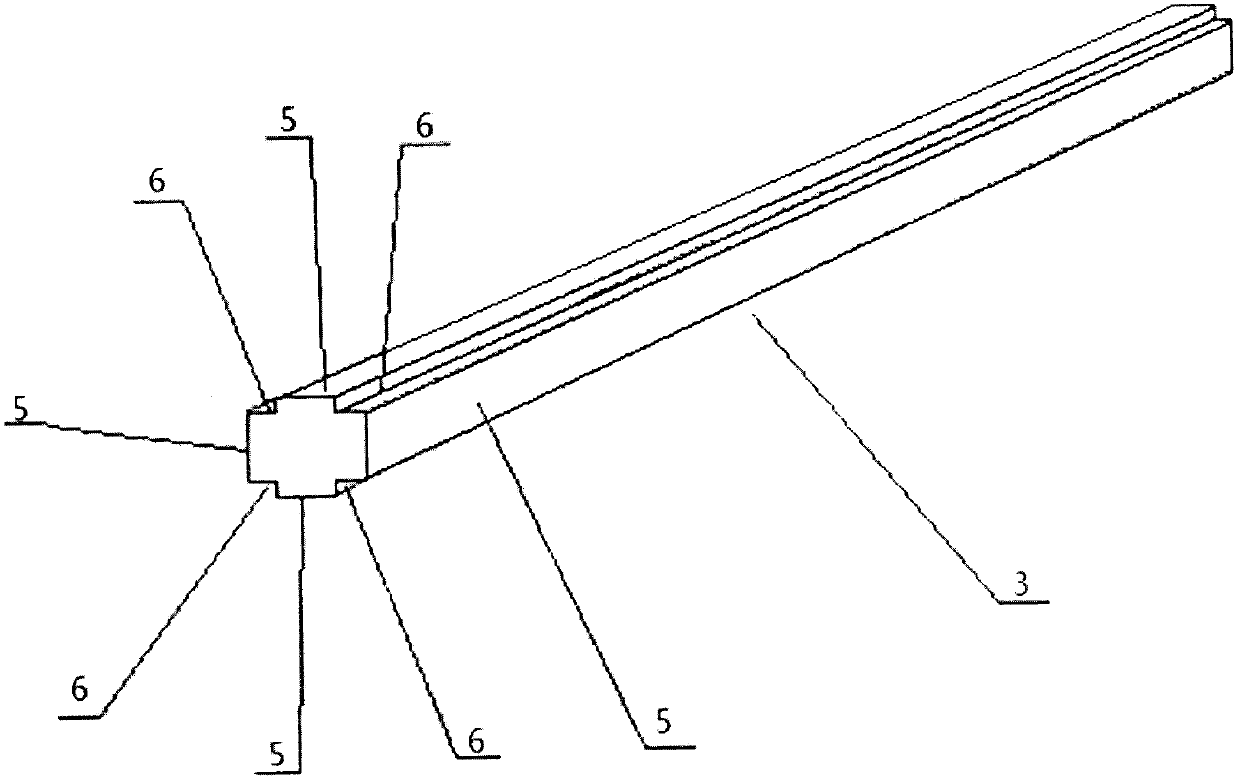

Strip-shaped solid wood mortise and tenon combined mosaic structure laminated wood

Strip-shaped solid wood mortise and tenon combined mosaic structure laminated wood is composed of a first spliced plate and a second spliced plate. Crossed battens and T-shaped battens by which the first spliced plate and the second spliced plate are formed through assembly are all of the structures with tenons and mortises, the defects of arc falling edges of strip cylindrical wood mandrels are reasonably overcome, the percentage of outturn is high, and machining is easy. The first spliced plate and the second spliced plate are of a mortise and tenon correspondence structure, the tenons and the mortises are mosaic correspondingly when the two plate timbers are subjected to combined mosaic adhesion, and the combined laminated wood is higher in adhesion area and firmer in adhesion after combined mosaic adhesion. In addition, after combined mosaic adhesion of the first spliced plate and the second spliced plate, original combined splicing points of small square bars adhere in inverted T-shaped and staggered modes, so that the strength of the laminated wood is improved.

Owner:GUANGXI NANNING QIAOSHENG WOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com