In-situ leaching method of electric field strengthened fine grain tailings

A fine-grain tailings and in-situ leaching technology, which is applied in the direction of improving process efficiency, can solve the problems of difficult solid-liquid separation, waste, high water consumption and energy consumption, and achieve the purpose of alleviating the contradiction between supply and demand, improving utilization rate, and improving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

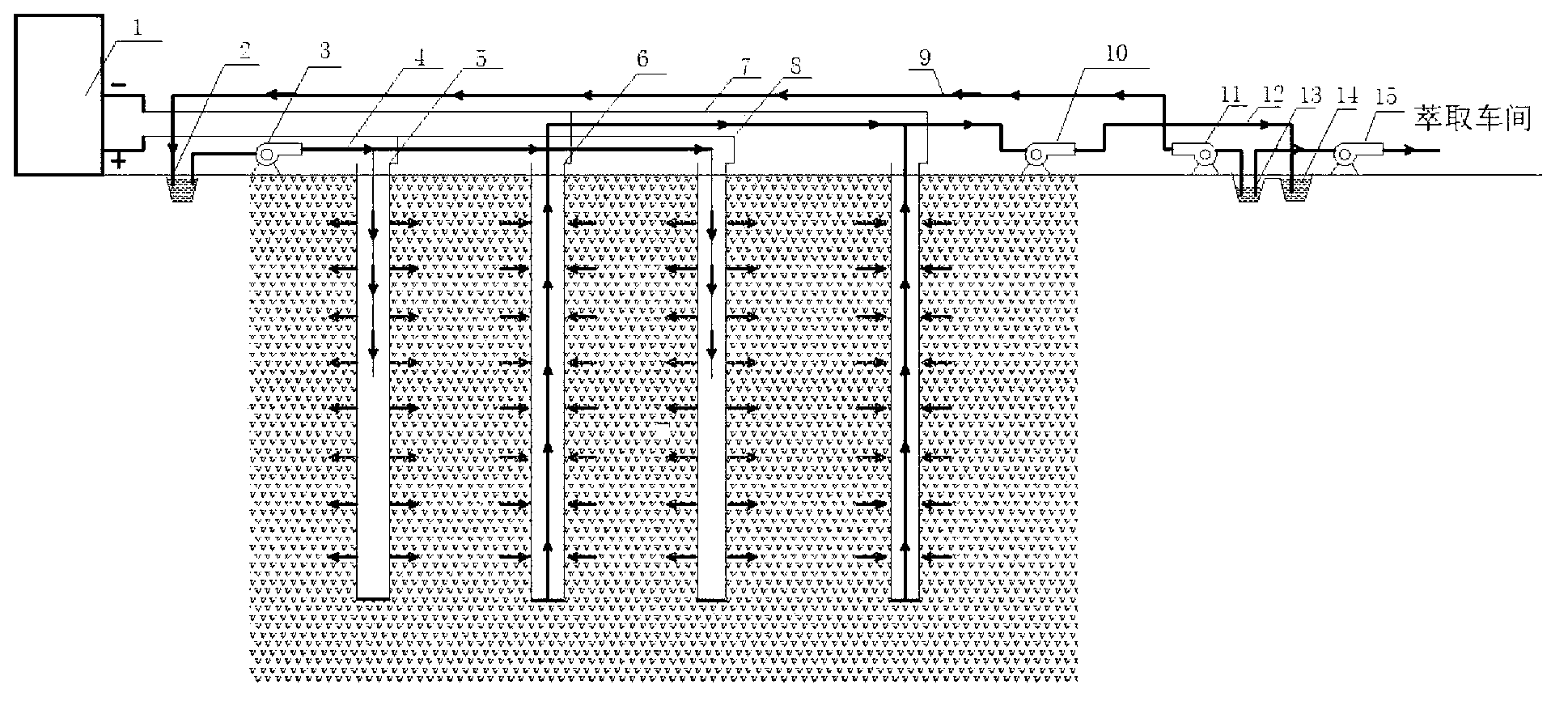

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0023] The mine copper tailings treated in this example contain an average of 0.56% soluble copper, -75um fine particles account for 55%, and the main component is malachite.

[0024] (1) Divide the mining area

[0025] The size of the mining area is 50m in length and 50m in width as a unit body, and 4 unit bodies form a mining area. Follow the direction of upstream damming to the inside of the tailings pond in turn.

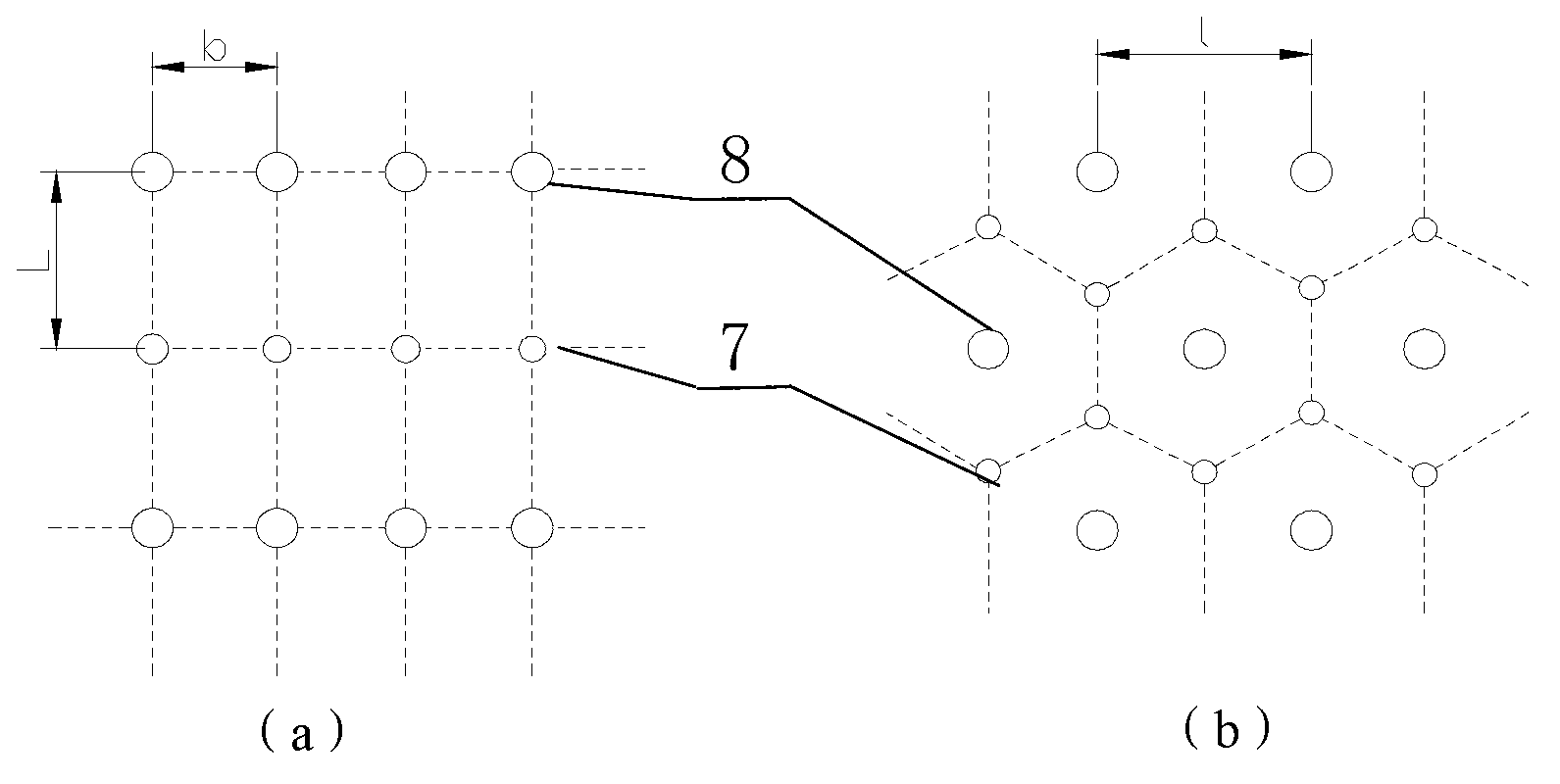

[0026] (2) Arranging electrode wells

[0027] The diameter of the injection well is 100cm, and the diameter of the pumping well is 50cm, arranged in a plum blossom shape. The distance between injection well and liquid injection well is 4m, and the distance between liquid injection well and pumping well is 2m. Six pumping wells are arranged around each injection well. The top of the electrode should be exposed to the ground by 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com