Fracturing process for removing breakdown fluid contamination

A fracturing fluid and fracturing technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of pollution and reduced fracture conductivity, improve conductivity, eliminate pollution blockage, Ease of use on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

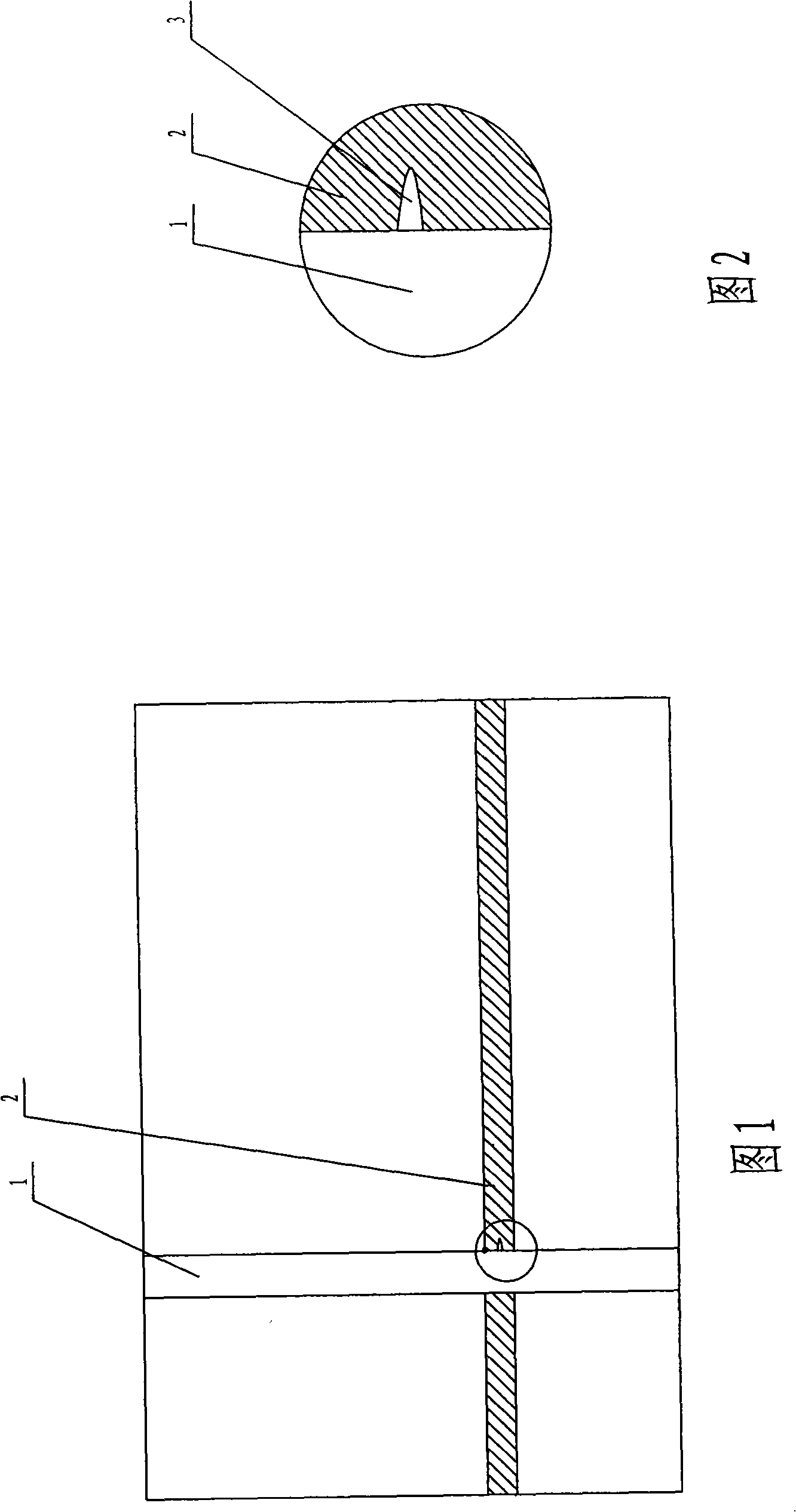

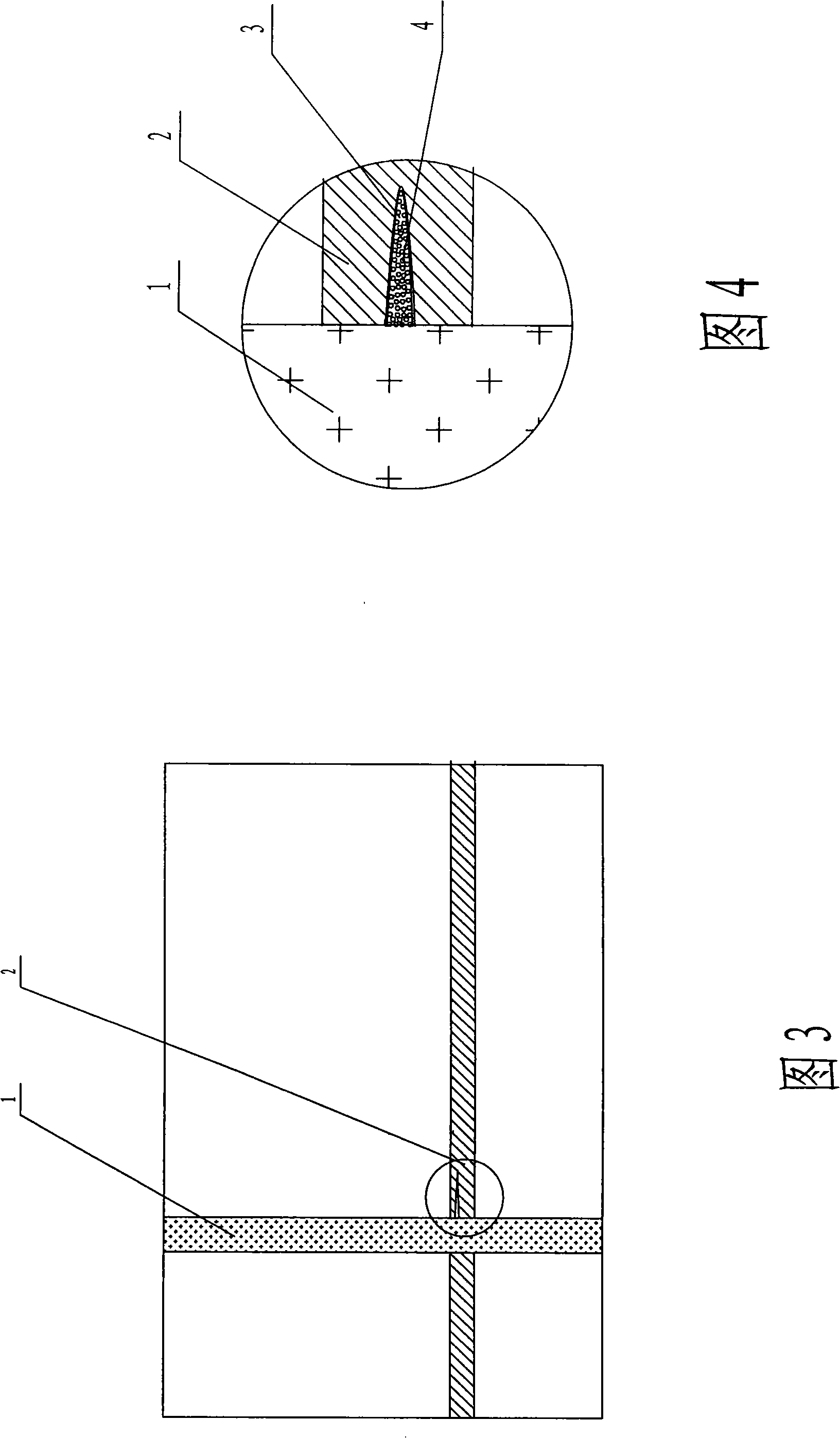

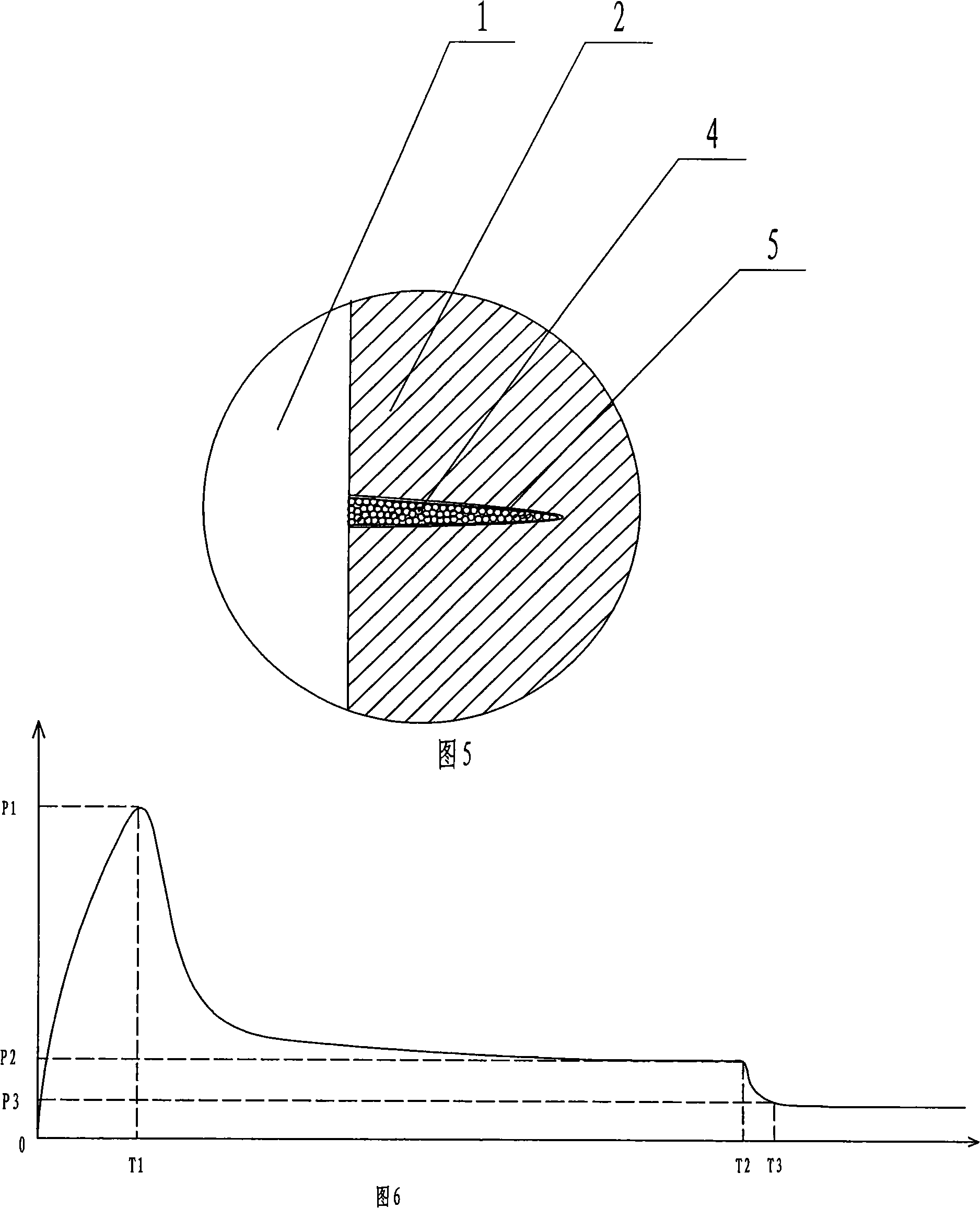

[0028] A fracturing process for decontaminating fracturing fluids, the main steps of which include: first injecting a pre-fluid into an oil and gas storage formation, causing fractures in the formation due to high pressure and displacement, and continuing to inject sand-carrying fluid to keep the fractures continuously extending and Fill and lay proppant in the fractures that have been generated, and then continue to inject displacement fluid until screenout occurs, then stop the pump on the ground, and as soon as possible (within 60 minutes) after the time T3 when the fractures gradually close by themselves, when the injection pressure is lower than that of the fractures Closing pressure (P shown in Figure 6 3 ), start to inject chlorine dioxide product solution or potassium permanganate or hydrogen peroxide or persulfate and other oxidant solutions capable of degrading polymers into the fracture as post-fracturing fluid, and finally inject displacement fluid to make the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com