Polymer flooding oil reservoir microbial plugging removal method

A technology of microorganisms and polymers, which is applied in the direction of drilling compositions, chemical instruments and methods, earthwork drilling and mining, etc., to achieve good experimental results, long validity period, and the effect of unblocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

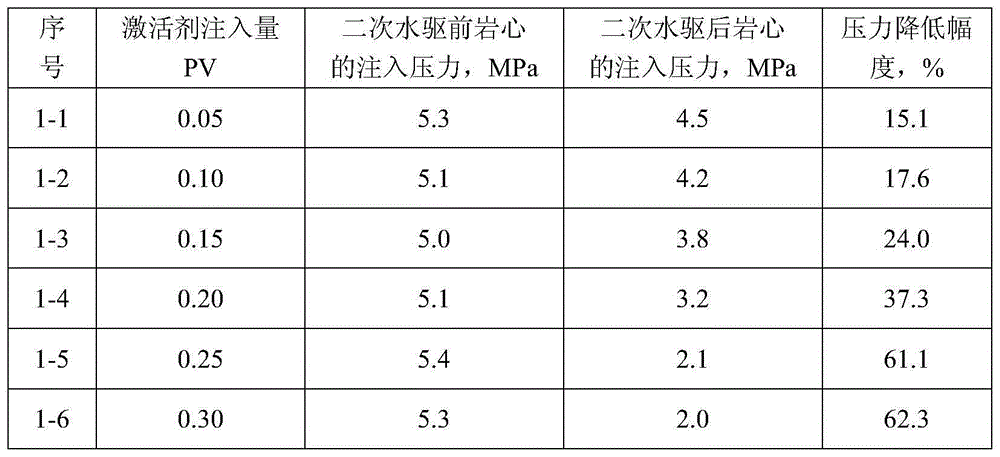

Embodiment 1

[0029] Implementation 1, taking Block F of Shengli Oilfield as an example

[0030] Block F of Shengli Oilfield is an unconsolidated sandstone reservoir with high permeability, medium-high viscosity, and high salinity. The reservoir temperature is 65°C, the porosity is 34.0%, and the pore volume is 3.6×10 4 m 3 , recoverable reserves 3.6×10 4 t, this block began to implement polymer flooding since August 2009, and the injection pressure before the implementation of polymer flooding was 6.2MPa. As of December 2011, the injection pressure rose to 11.3MPa. In March 2012, the method of the present invention began to be used. The specific implementation steps for oil reservoir plugging removal are as follows:

[0031] (1) Screening of polymer flooding reservoirs

[0032] The reservoir temperature in Block F is 65°C, and the water injection pressure increases by 82.2% before and after polymer injection, which meets the screening conditions for polymer flooding reservoirs.

[0033...

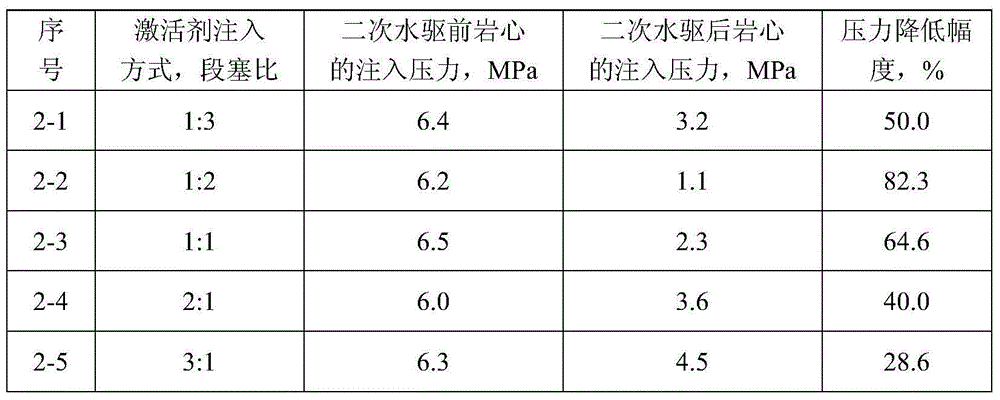

Embodiment 2

[0048] Implementation 2, taking Shengli Oilfield block L as an example

[0049] Block L of Shengli Oilfield is an unconsolidated sandstone reservoir with high permeability, medium-low viscosity, and medium-high salinity. The reservoir temperature is 72°C, the porosity is 33.5%, and the pore volume is 3.1×10 4 m 3 , recoverable reserves 2.1×10 4 t, this block began to implement polymer flooding since December 2004, and the injection pressure before the implementation of polymer flooding was 3.1MPa. As of December 2007, the injection pressure rose to 7.2MPa, and the method of the present invention began to be used in June 2008. The specific implementation steps for oil reservoir plugging removal are as follows:

[0050] (1) Screening of polymer flooding reservoirs

[0051] The reservoir temperature in Block L is 72°C, and the water injection pressure increases by 132.3% before and after polymer injection, which meets the screening conditions for polymer flooding reservoirs. ...

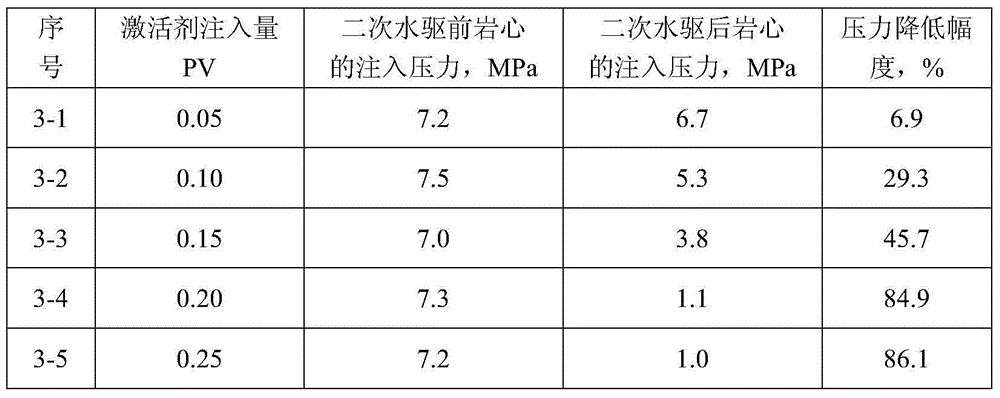

Embodiment 3

[0067] Implementation 3, taking block G of Shengli Oilfield as an example

[0068] Block G of Shengli Oilfield is an unconsolidated sandstone reservoir with high permeability, medium-high viscosity, and high salinity. The reservoir temperature is 75°C, the porosity is 33.0%, and the pore volume is 3.2×10 5 m 3 , recoverable reserves 3.2×10 5 t, this block began to implement polymer flooding since May 2006, and the injection pressure before the implementation of polymer flooding was 3.5MPa. As of December 2009, the injection pressure rose to 8.2MPa. In February 2010, the method of the present invention began to be used. The specific implementation steps for oil reservoir plugging removal are as follows:

[0069] (1) Screening of polymer flooding reservoirs

[0070] The reservoir temperature in Block G is 75°C, and the water injection pressure increases by 134.3% before and after polymer injection, which meets the screening conditions for polymer flooding reservoirs.

[0071...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com