Method of preparing functional ceramic part of complex structure by powder injection molding

A technology for powder injection molding and functional ceramics, applied in ceramic molding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of increased powder cost, product performance impact, poor shape retention, etc., to improve product performance and reduce product performance. Quality, the effect of reducing the amount of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

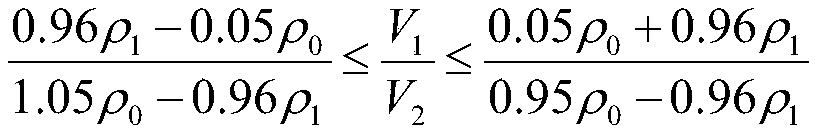

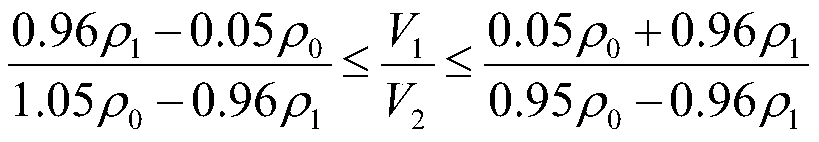

[0031] When the present invention prepares the alumina-based ceramic product with a product wall thickness of 2 mm by powder injection molding, it comprises the following steps:

[0032] S1. Feed preparation: uniformly mix alumina-based ceramic powder and binder to form a feed, the volume of alumina-based ceramic powder is V 1 and binder volume V 2 The ratio of Tap density ρ of alumina-based ceramic powder 1 1.82g / cm 3 , the theoretical density ρ of alumina-based ceramic powder 0 3.96g / cm 3 ; The particle size D of alumina-based ceramic powder 50 For: 2.3μm;

[0033] S2. Injection molding: place the feed material prepared in step S1 in a powder injection molding machine, and inject it into the mold cavity under the conditions of an injection pressure of 80-200 MPa and an injection temperature of 160-200°C to form an injection blank;

[0034] S3. Degreasing: Catalytic degreasing is performed on the injection billet prepared in step S2 to form a catalytic degreasing bill...

Embodiment 2

[0044] When the present invention prepares the alumina-based ceramic product with a product wall thickness of 4mm by powder injection molding, it comprises the following steps:

[0045] S1. Feed preparation: uniformly mix alumina-based ceramic powder and binder to form a feed, the volume of alumina-based ceramic powder is V 1 and binder volume V 2 The ratio of The tap density ρ1 of alumina-based ceramic powder is 1.62g / cm 3 , the theoretical density ρ0 of alumina-based ceramic powder is 3.96g / cm 3 ; The particle size D of alumina-based ceramic powder 50 For: 0.62μm;

[0046] S2. Injection molding: place the feed material prepared in step S1 in a powder injection molding machine, and inject it into the mold cavity under the conditions of an injection pressure of 80-200 MPa and an injection temperature of 160-200°C to form an injection blank;

[0047] S3. Degreasing: Catalytic degreasing is performed on the injection billet prepared in step S2 to form a catalytic degreasin...

Embodiment 3

[0057] When the present invention prepares the zirconia-based ceramic product with a product wall thickness of 3.5mm by powder injection molding, it comprises the following steps:

[0058] S1. Feed material preparation: uniformly mix zirconia-based ceramic powder and binder to form a feed material. The volume of zirconia-based ceramic powder is V 1 and binder volume V 2 The ratio of Tap density ρ of zirconia-based ceramic powder 1 2.89g / cm 3 , the theoretical density ρ of zirconia-based ceramic powder 0 6.01g / cm 3 ; Particle size D of zirconia ceramic powder 50 is: 1.85μm;

[0059] S2. Injection molding: place the feed material prepared in step S1 in a powder injection molding machine, and inject it into the mold cavity under the conditions of an injection pressure of 80-200 MPa and an injection temperature of 160-200°C to form an injection blank;

[0060] S3. Degreasing: Catalytic degreasing is performed on the injection billet prepared in step S2 to form a catalytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com