Method for preparing pyroligneous by utilizing apricot shells

A technology of wood vinegar and apricot shell, applied in chemical instruments and methods, manufacture of pyrolignoic acid, petroleum industry and other directions, can solve the problems of slow production efficiency, time-consuming process, delay and the like, achieve high production efficiency, increase additional The effect of high value and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

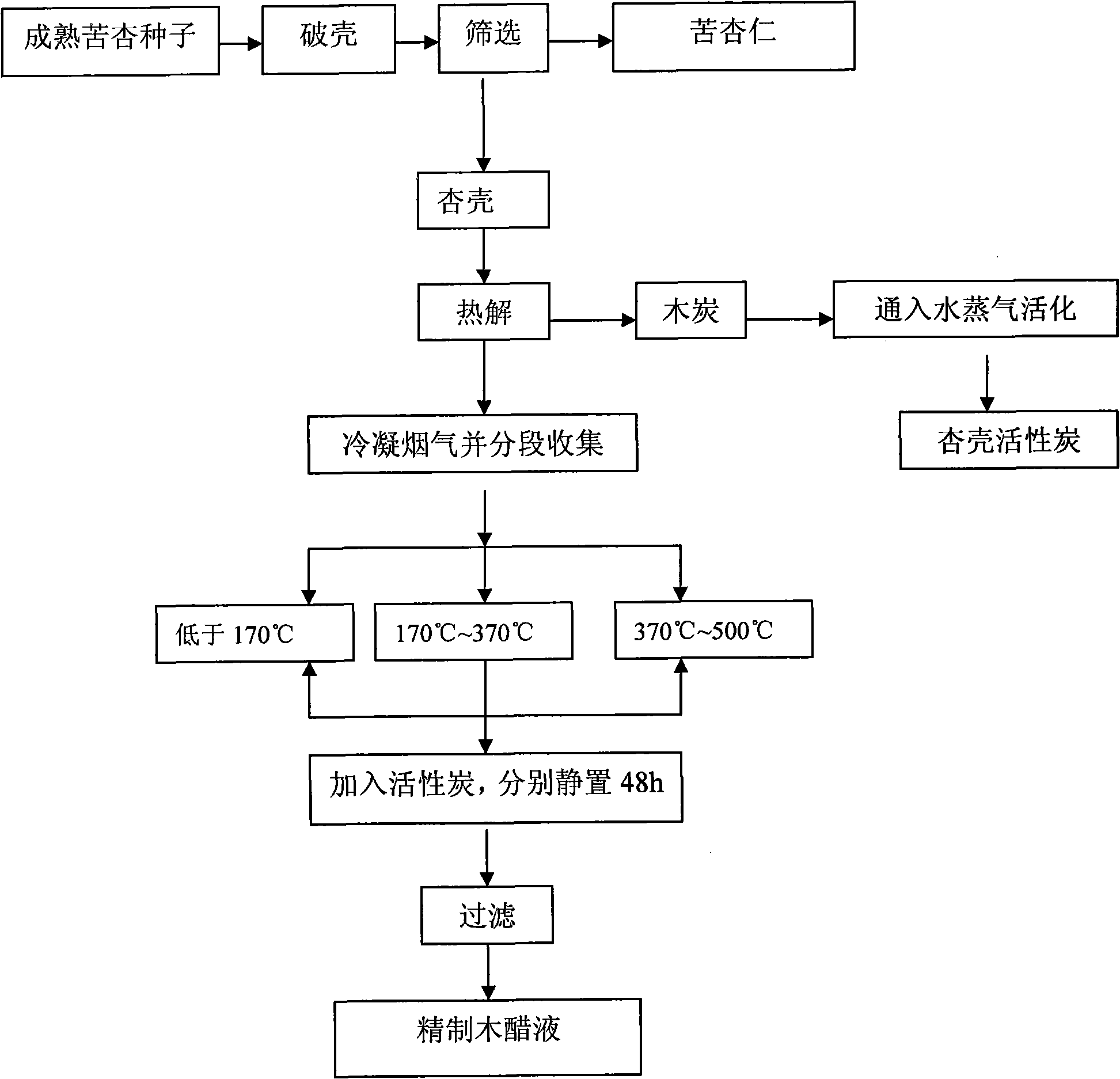

Method used

Image

Examples

Embodiment 1

[0034] Weigh 1000g of apricot shells into the dry distillation kettle and continue heating with 1KVA power. As the temperature rises, the apricot shells are heated and decomposed. When the temperature in the retort reaches 120°C, apricot shells will be pyrolyzed to produce flue gas. After the flue gas is condensed, crude wood vinegar can be obtained, and the charcoal remains in the retort.

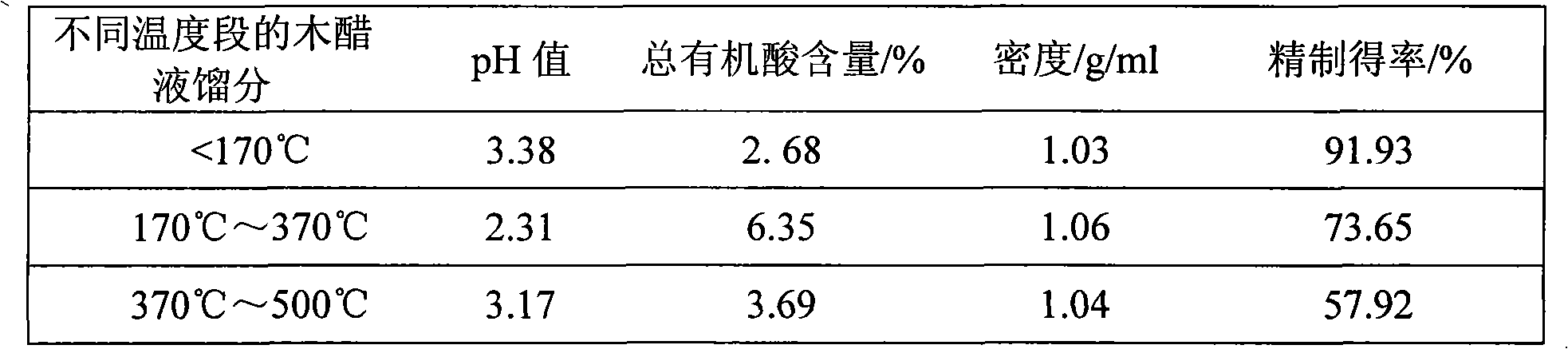

[0035] The present invention collects distillates at different temperatures separately. When the temperature in the retort is between 120°C and 170°C, this is the first collection temperature stage, and 40.80g of distillate is collected. The content of antibacterial active ingredients in this section is relatively low, and the main For water. When the temperature in the retort is 170°C to 370°C, this is the second collection temperature stage, and 338.64g of distillate is collected. There are many types of components in this temperature section, and the content of antibacterial active ingredie...

Embodiment 2

[0039] After the ripe mountain apricot seeds are air-dried, the shells are broken and sorted to obtain bitter almond and apricot shells.

[0040] Weigh 1500g of apricot shells into the dry distillation kettle and continue heating with a power of 1.2KVA. As the temperature rises, the apricot shells are heated and decomposed. When the temperature in the retort reaches 120°C, apricot shells will be pyrolyzed to produce flue gas. After the flue gas is condensed, crude wood vinegar can be obtained, and the charcoal remains in the retort.

[0041] The present invention collects fractions at different temperatures separately. When the temperature in the retort is between 120°C and 170°C, this is the first collection temperature stage. 54.80g of distillate is collected. The content of antibacterial active ingredients in this stage is relatively low. For water. When the temperature in the retort is 170℃~350℃, this is the second collection temperature stage, 306.54g of distillate is collect...

Embodiment 3

[0045] After the ripe apricot seeds are air-dried, the shells are broken and sorted to obtain almonds and apricot shells.

[0046] Weigh 800g of apricot shells into the dry distillation kettle and continue heating with 0.8KVA power. As the temperature rises, the apricot shells are heated and decomposed. When the temperature in the retort reaches 120°C, apricot shells will be pyrolyzed to produce flue gas. After the flue gas is condensed, crude wood vinegar can be obtained, and the charcoal remains in the retort.

[0047] The present invention collects fractions at different temperatures separately. When the temperature in the retort is between 120°C and 180°C, this is the first collection temperature stage, and 25.80g of distillate is collected. The content of antibacterial active ingredients in this stage is relatively low. For water. When the temperature in the retort is 240℃~300℃, this is the second collection temperature stage, and 280.50g of distillate is collected. There are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com