A kind of mixed substrate for plant cultivation and preparation method thereof

A technology of mixing substrates and substrates, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of low fertilizer efficiency, environmental pollution, and low efficiency of finished products, and achieve the effects of accelerated decomposition, stable physical and chemical properties, and comprehensive utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

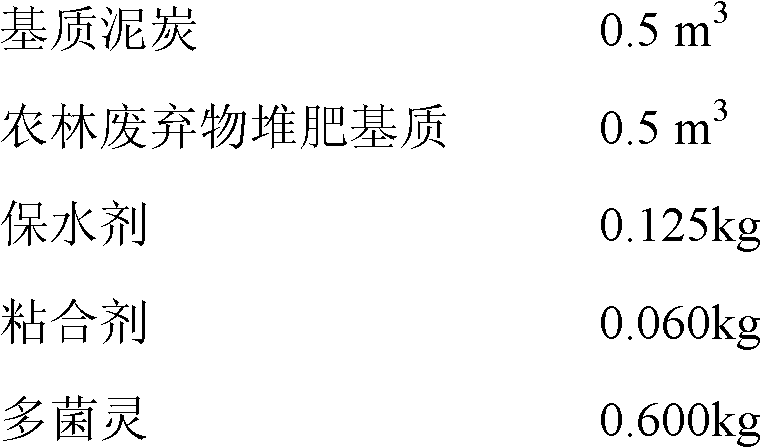

Embodiment 1

[0058] 1. Pretreatment of agricultural and forestry waste raw materials

[0059] 1) Use a pulverizer (Beijing Zhongyi Shenlong Machinery Co., Ltd.) to pulverize garden waste branches (twigs pruned from willows, pagoda trees, poplars, etc.) into particles with a particle size of ≤ 1 cm to obtain waste particles. At the same time, the organic carbon content and nitrogen content of the waste particles were measured, and the results are shown in Table 1.

[0060] Determination of the nitrogen content of waste particles by the Kjeldahl method;

[0061] Potassium dichromate volumetric method-external heating method is used to measure the organic carbon content in the cultivation mixed substrate. The specific measurement method is as follows: After adding the air-dried cultivation mixed substrate into the dry hard test tube, add K 2 Cr 2 o 7 Standard solution and concentrated H 2 SO 4 , then put the test tube at 170-180°C to boil the liquid in the test tube for 5 minutes, then p...

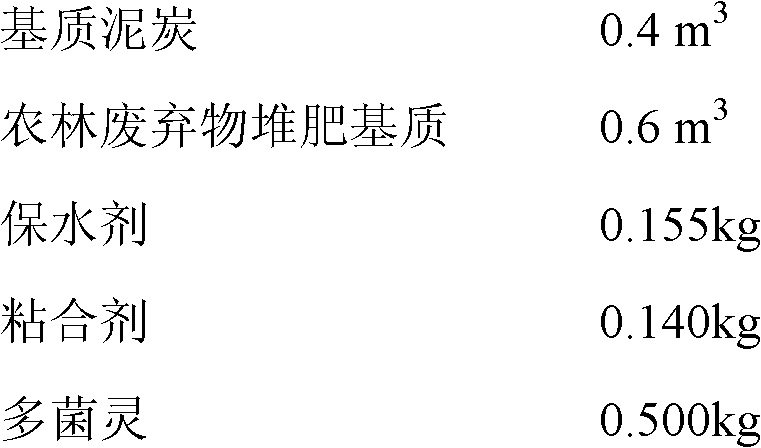

Embodiment 2

[0091] 1. Pretreatment of agricultural and forestry waste raw materials

[0092] 1) Using a pulverizer to crush corncobs into particles with a length of 0.5-1.5 cm to obtain waste particles, and simultaneously measure the organic carbon content and nitrogen content of the waste particles, and the results are shown in Table 1.

[0093] 2) Add urea to the corn cob granules, adjust the C / N ratio of the corn cob granules to 27, and make fermented compost corn cob granules, wherein 0.813 kg of urea is added to every 100 kg of waste granules (dry weight).

[0094] 2. Prepare fermentation additive dilution

[0095] Add bamboo vinegar liquid to water, mix uniformly, be mixed with bamboo vinegar liquid dilution (being fermentation additive dilution) for subsequent use, wherein the volume ratio of bamboo vinegar liquid and water is 1: 800, and the pH value of bamboo vinegar liquid is 2, The density is 1.5g / ml, the organic acid content is 11%, and the phenolic compound content is 8%.

...

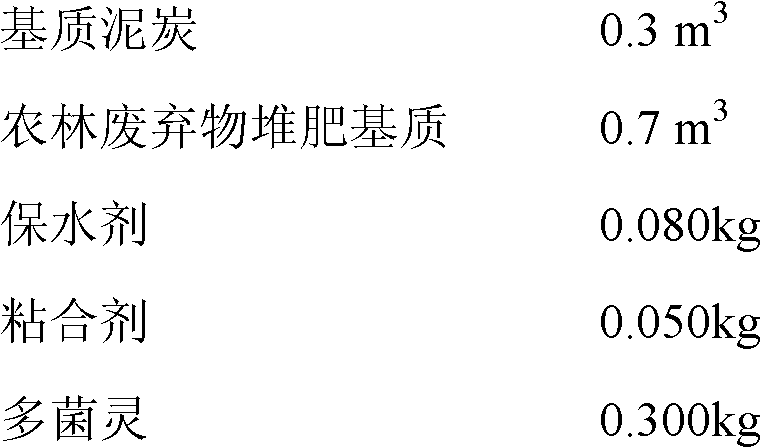

Embodiment 3

[0106] 1. Pretreatment of agricultural and forestry waste raw materials

[0107] 1) Using agricultural waste rice husk as raw material, the organic carbon content and nitrogen content of agricultural waste rice husk were measured, and the results are shown in Table 1.

[0108] 2) Add urea to the waste granules, adjust the C / N ratio of the waste granules to 30, and prepare fermented compost granules, wherein 1.473 kg of urea is added to every 100 kg of waste granules (dry weight).

[0109] 2. Prepare fermentation additive dilution

[0110] Add wood vinegar to water, mix well, be mixed with wood vinegar dilution (i.e. fermentation additive dilution) for subsequent use, wherein the volume ratio of wood vinegar and water is 1: 1500, and the pH value of wood vinegar is 3.2, The density is 1.0g / ml, the organic acid content is 7%, and the phenolic compound content is 7%. .

[0111] 3. Fermentation stacking treatment

[0112] 1) Add fermentation bacteria agent organic waste fermen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com