Patents

Literature

1022results about How to "Good degreasing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High effective environmental protection multifunctional deoiling decontaminant

InactiveCN1919993AEfficient degreasing and decontamination abilityGood degreasing effectNon-ionic surface-active compoundsSurface-active agentsLotion

The invention relates decontaminant, comprising surface active agent and lotion and auxiliary agent. The decontaminant can be used for metal, cloth, ceramics, plastic, machinery, petroleum, transport, and other fields. The decontaminant is innocuous, nonirritant, and non-corrosiveness.

Owner:穆世民

Neutral oil removal rust remover and preparation method thereof

The invention discloses a neutral oil removal rust remover, which is mainly prepared from deionized water and the following components by mass fraction: 4-8% of physical dispersing agent, 8-10% of chemical chelating agent, 4-6% of oil-removing emulsifier and 1-4% of corrosion inhibitor. The preparation method disclosed by the invention comprises the following steps: firstly, preparing the components according to the proportioning requirements; weighting the ingredients in the chemical chelating agent to put into a container; adding the deionized water to evenly agitate, so as to obtain a solution A; adding the physical dispersing agent and the corrosion inhibitor to the solution A; agitating to obtain a solution B; additionally, adding the prepared components of the oil-removing emulsifier to the container; adding the deionized water to dissolve; adding a functional additive to obtain a solution C; and evenly mixing the solution B with the solution C under the agitation condition to obtain the neutral oil removal rust remover. By adopting the product disclosed by the invention, the oil and rust removal work can be quickly and efficiently finished, and the neutral oil removal rust remover is free of damage to a substrate.

Owner:HUNAN UNIV

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

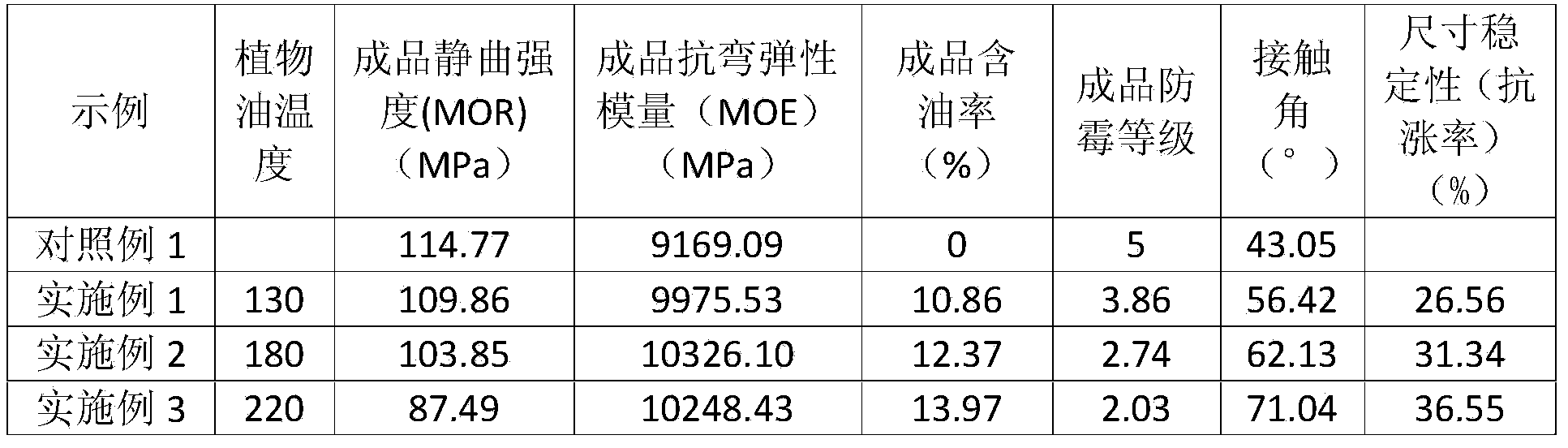

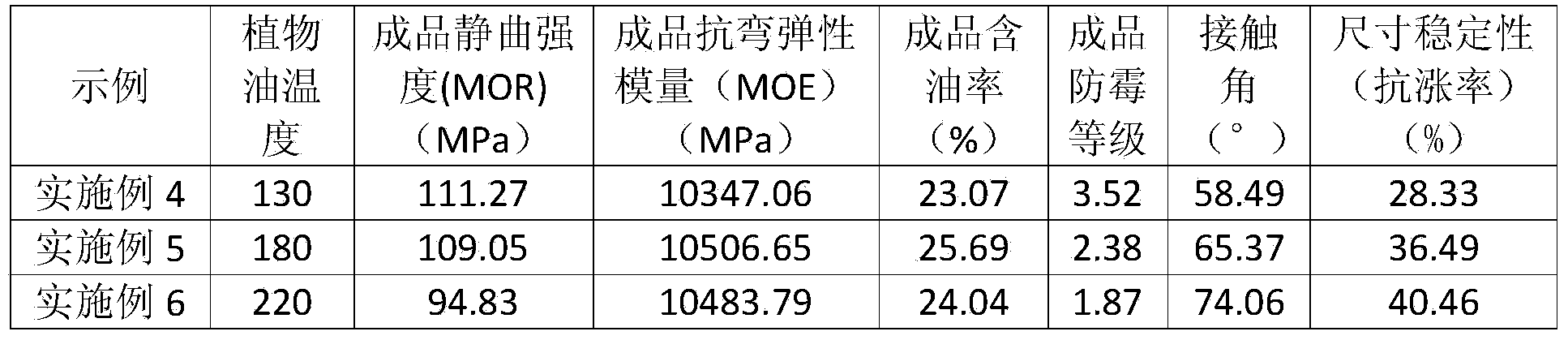

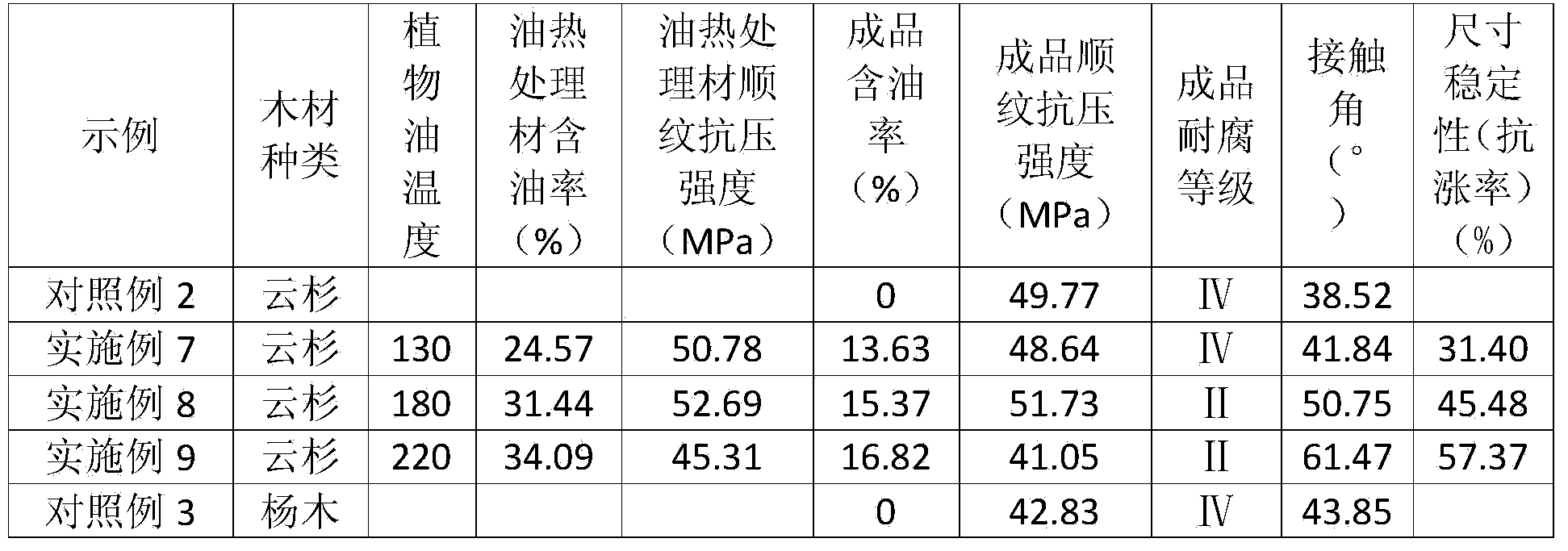

Modified treatment method of wood and bamboo, modified wood, modified bamboo and floor

InactiveCN103978532AGood dimensional stabilityImprove interfacial bonding propertiesWood treatment detailsWood impregnation detailsOrganic solventEngineering

The invention provides modified wood, modified bamboo and a modified treatment method of the wood and the bamboo. The wood and the bamboo processed by virtue of the method have the beneficial effects that mechanical properties are basically unchanged, anti-corrosive and anti-mold properties are good, the size stabilities are good, the machinability is good, and bonding strengths are high. The modified treatment method comprises the following steps: soaking a sheet below a liquid level of a thermal processing tank containing plant oil, heating the thermal processing tank until the temperature of the plant oil is 130-220 DEG C, and maintaining the temperature for 1-3 hours; draining the plant oil, and taking the sheet out; carrying out hot pressing on the sheet on a hot press for 10-20 minutes, wherein the pressure is 1-3MPa, and the temperature is 110-140 DEG C; soaking the pre-pressed sheet into a reaction kettle containing organic solvents at 60-80 DEG C for 1-3 hours, extracting the organic solvents in the reaction kettle, carrying out vacuumizing for 30-60 minutes, and leaching the plant oil on the surface of the sheet. The invention further provides a floor. The floor is good in corrosion resistance, mold resistance and size stability and has excellent mechanical properties and is made of the modified wood and the modified bamboo.

Owner:NANJING FORESTRY UNIV

Technique for reclaiming ethylene alkali-washing waste liquid

InactiveCN1789162AOvercome the disadvantage of dilutionReduce viscosityWater/sewage treatment by centrifugal separationWater/sewage treatment by ion-exchangeLiquid wasteEconomic benefits

The invention relates to a process of reactivating the ethane alkali washing liquid, comprising the following operating steps: deoiling, causticizing and desulfurizing the alkali waste liquid, adding loading flocculating agent and metallic oxide during the above steps. The invention is characterized by the simple process, sound deoiling effect and complete meeting the ethane alkali washing process demand of the regenerated alkali liquid. The side product got in the course of causticizing and desulfurizing, by transforming the S2- into sulfide of high added value by applying sulfide conversion method, can be sale as commercial articles, which simplifies the waste alkali liquid treating course and brings higher economic benefit for the waste alkali liquid treating.

Owner:HEBEI UNIV OF TECH

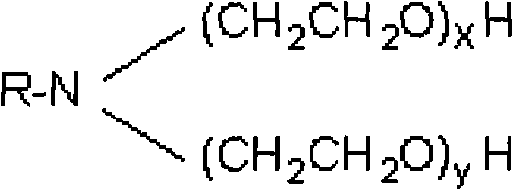

Fabric one-bath deoiling agent

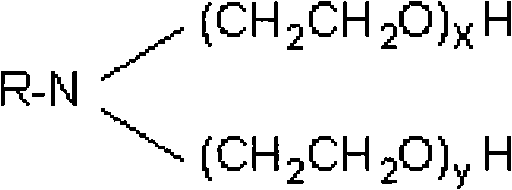

ActiveCN101629130AHigh affinityGood emulsificationNon-ionic surface-active compoundsDry-cleaning apparatus for textilesFiberPolymer science

The invention relates to a fabric deoiling agent, in particular to a fabric one-bath deoiling agent not only suitable for the single deoiling treatment of fabrics, such as terylene, chinlon, cotton, and the like, but also particularly suitable for treating chemical fiber fabrics, such as the terylene, the chinlon, and the like by a deoiling dyeing one-bath method. The invention provides the fabric one-bath deoiling agent with favorable deoiling effect under acidic conditions and an application thereof. The fabric one-bath deoiling agent comprises the following ingredients in percentage by weight: 10-60 polyoxyethylene alkyl amine, 5-40 alkyl sulfonate, 10-50 sulfate surface active agent or / and phosphate salt surface active agent and the balance of water. The fabric one-bath deoiling agent can be used for treating the fabrics of the terylene, the chinlon, the cotton, and the like by the deoiling dyeing one-bath method.

Owner:福建省晋江新德美化工有限公司

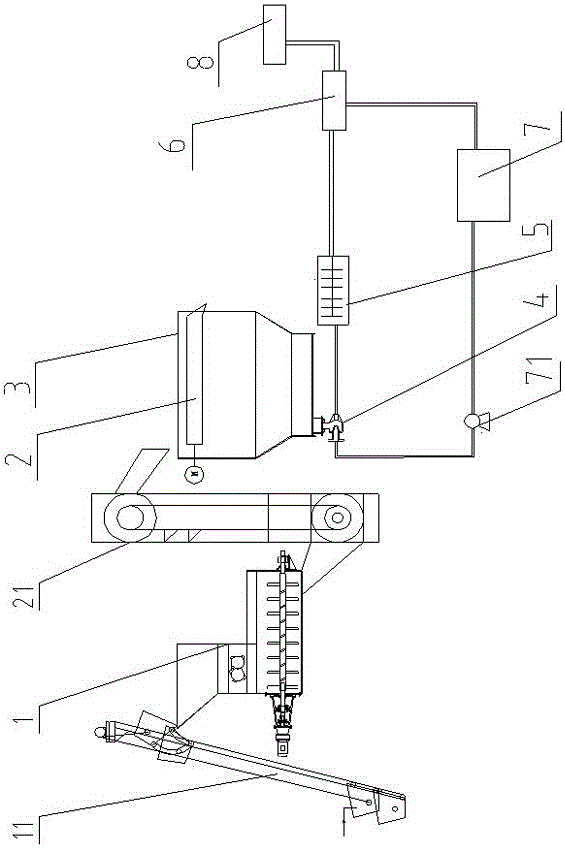

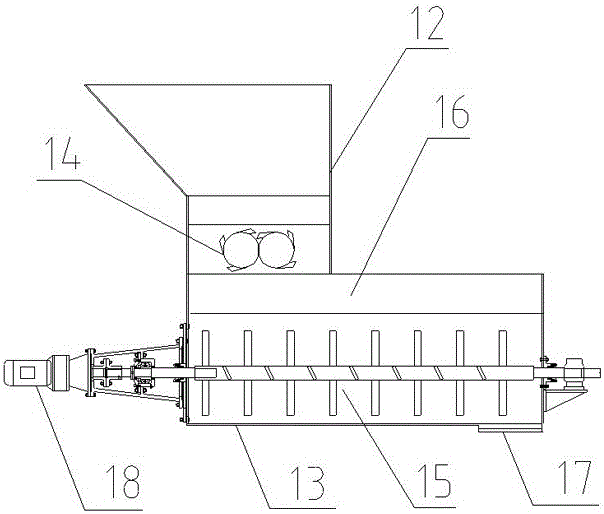

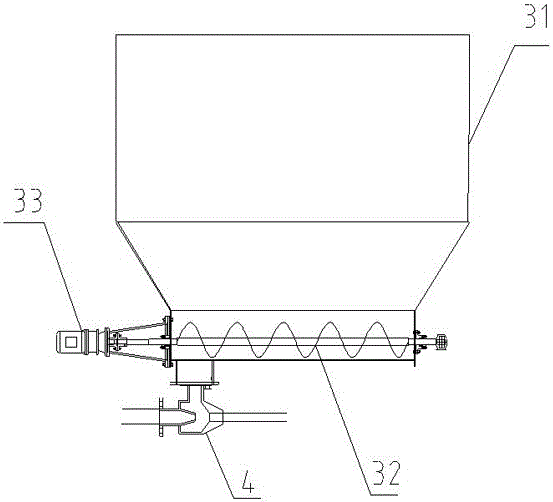

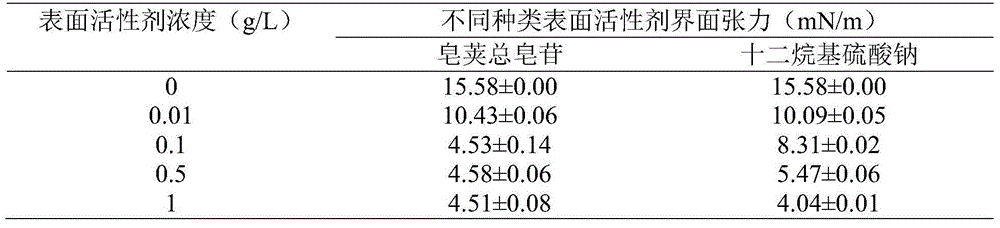

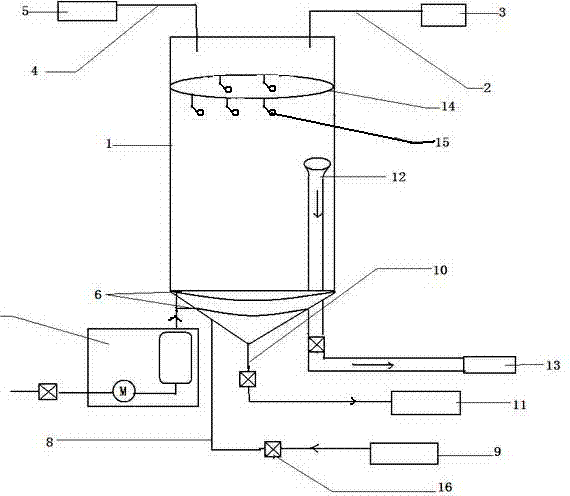

Oily sludge treatment system and treatment method thereof

PendingCN106746420AGood processing effectEasy to handleWaste water treatment from quariesSievingWater storageSludge

The invention discloses an oily sludge treatment system and a treatment method thereof. The treatment system comprises crushing equipment, a vibrating screen, a precipitation device, an ejector, a high-speed crushing device, a water storage device and separation device for separating oil, water and sludge, wherein the crushing equipment is used for primarily crushing oily sludge and is provided with an oil slick space and a first oil slick outlet which can be opened and closed; the vibration screen is located at the upper part of the precipitation device; the precipitation device is used for precipitating the screened oily sludge; the high-speed crushing device is used for crushing the oily sludge into fine particles; the precipitation device is sequentially connected with the ejector, the high-speed crushing device and the separation equipment; a water outlet of the water storage device is connected with a water inlet of the ejector. The treatment system can be applicable to dewatering of various oily sludges, meanwhile, the oil rate of the oily sludge can be reduced to below 3%, oil can be recovered to the maximal extent and secondary pollution of wastewater is not generated.

Owner:仇霞霞

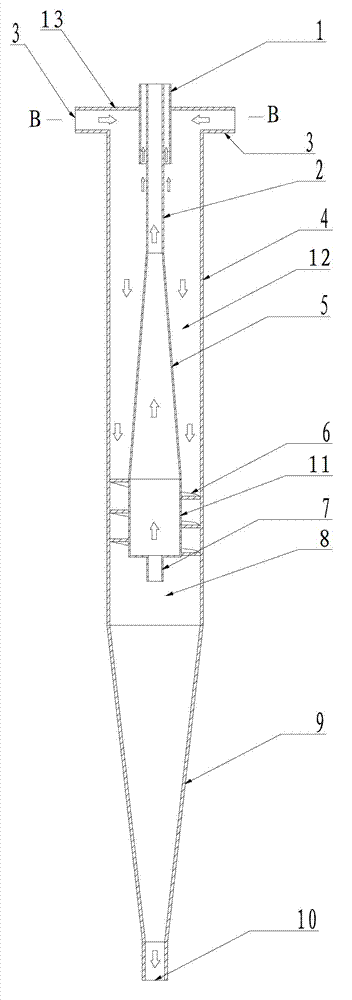

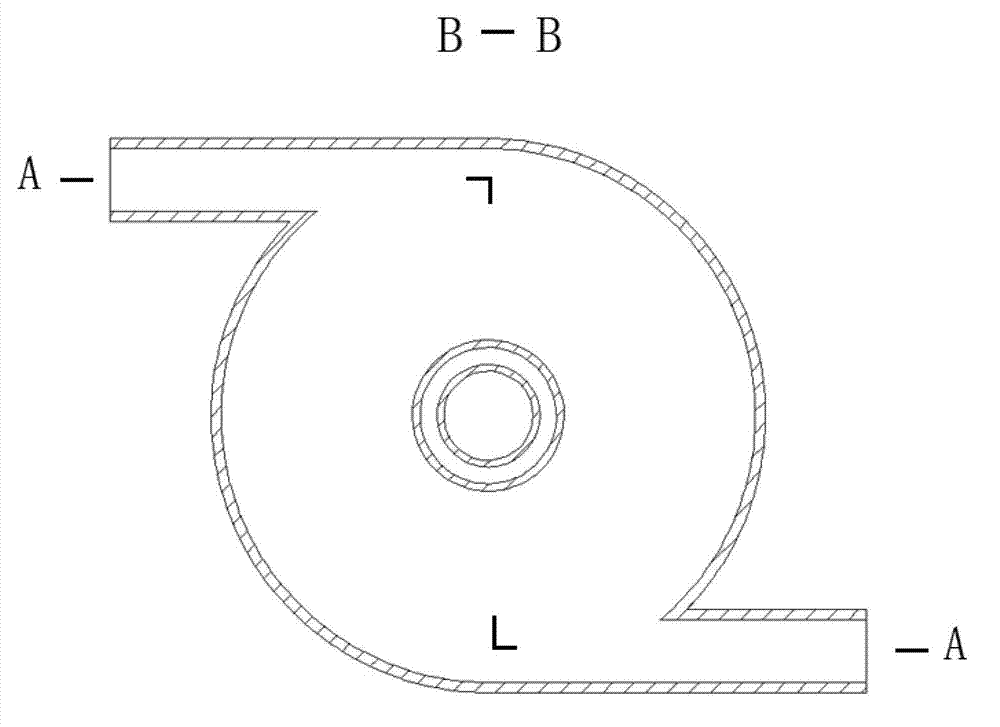

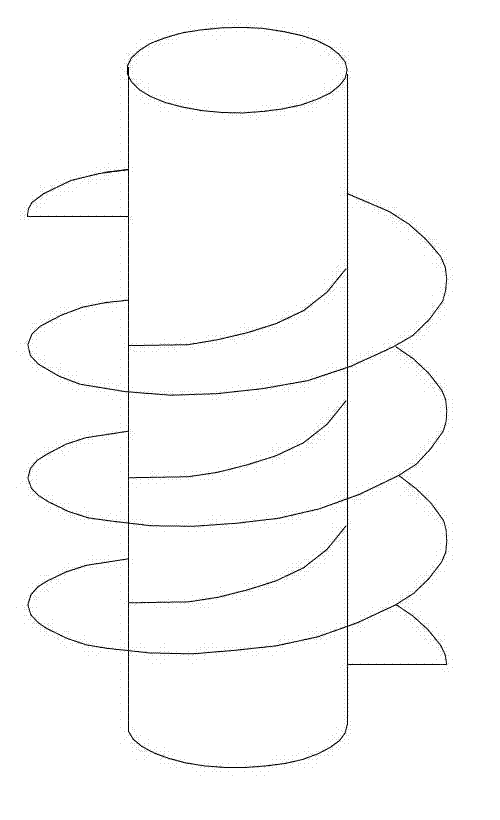

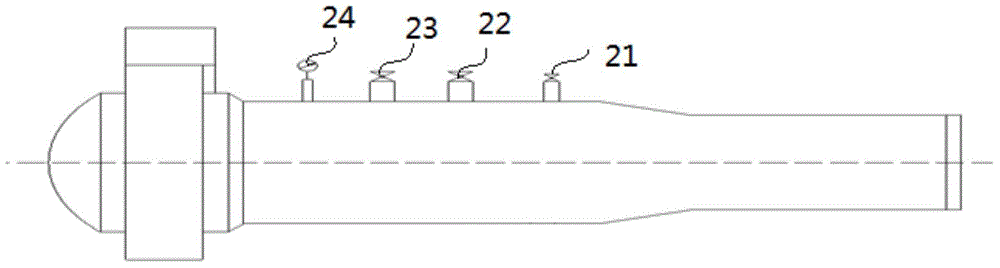

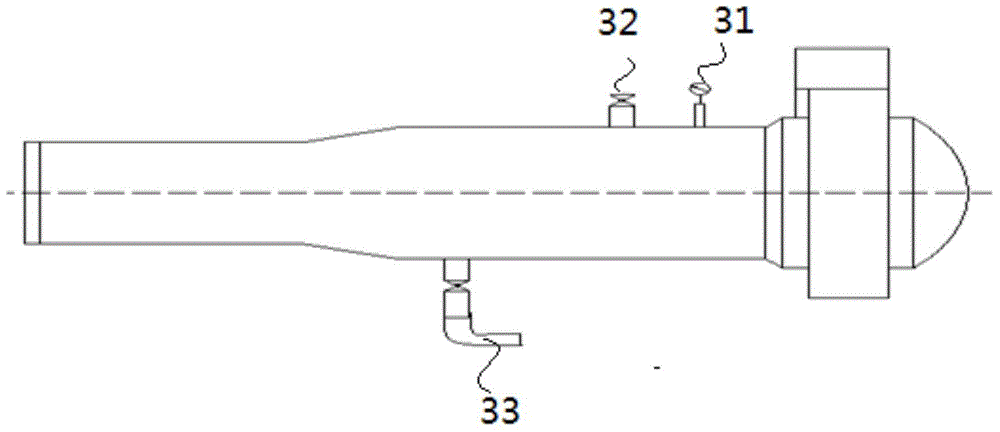

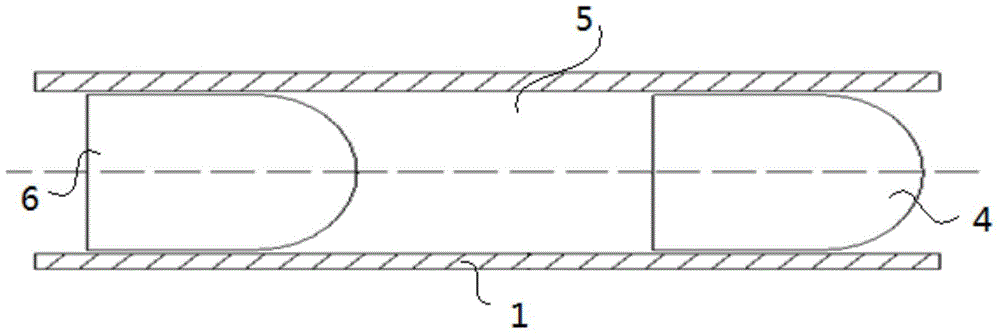

Secondary separation cyclone

ActiveCN102847618AImprove efficiencyGood degreasing effectReversed direction vortexCycloneStraight tube

The invention provides a secondary separation cyclone which is mainly used for solving the problem that the existing cyclone separator has a poor effect on separating small oil drops. The secondary separation cyclone is characterized in that: the lower end of a first-grade cyclone pipe is sequentially connected with a second-grade cone section and a second-grade underflow pipe; a cyclone separator is fixed in the cyclone pipe and is formed by connecting a second-grade overflow pipe, a second-grade overflow cone section, a spiral sheet fixing pipe and a second-grade liquid collecting port; a diversion spiral sheet is fixed outside the spiral sheet fixing pipe, and the contour of the diversion spiral sheet is in contact with the inner wall of the first-grade cyclone pipe; a first-grade overflow pipe is connected outside the second-grade overflow pipe, and an annular gap is formed between the two pipes so that a medium in a first-grade cyclone cavity overflows along the annular gap; and the straight pipe length of the first-grade overflow pipe is less than the straight pipe length of the second-grade overflow pipe, both the first-grade overflow pipe and the second-grade overflow pipepenetrate through an upper end cover, and the outer wall of the first-grade overflow pipe is in closed connection with a corresponding hole of the upper end cover. The separation cyclone can increasethe separation efficiency of small oil drops and can realize secondary separation.

Owner:NORTHEAST GASOLINEEUM UNIV

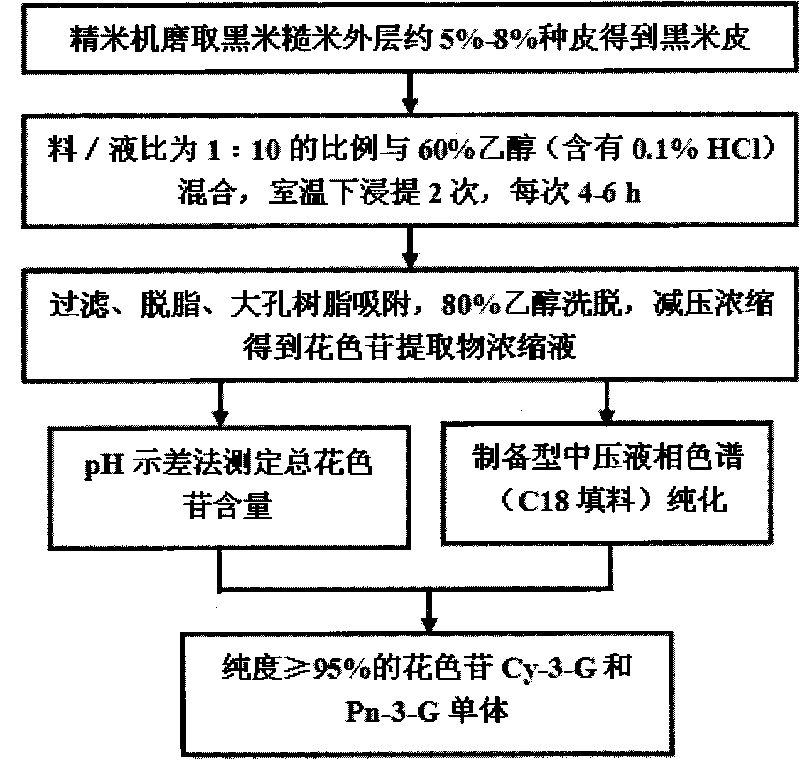

Method for separating high-purity anthocyanin monomers from black rice

ActiveCN101723996AGood choiceGood degreasing effectSugar derivativesSugar derivatives preparationFreeze-dryingEvaporation

The invention provides a method for separating high-purity anthocyanin monomers from black rice. The method comprises the following steps of: grinding 5 to 8 percent of episperm on the outer layer of black rice and brown rice to obtain black rice pericarp, leaching anthocyanin in the black rice pericarp by acidized ethanol, and extracting and defatting petroleum ether; performing primary purification of ethanol extracts of the black rice pericarp by using macroporous resin; separating the anthocyanin in coarse extracts of the anthocyanin of the black rice pericarp by the medium pressure preparation liquid phase chromatographic technique, collecting two leading anthocyanin components, which are cyanidin-3-glucoside and paeonidin-3-glucoside, in the black rice pericarp respectively according to the obtained chromatogram, and performing rotary evaporation of eluent at a temperature of below 45 DEG C until all methanol is gone, and performing freeze-drying to obtain powder of the anthocyanin monomers.

Owner:GUANGZHOU TRACE ELEMENTS BIOLOGICAL TECH CO LTD

Method of supersonic chemical plating nickel phosphorus of powder metallurgy material

InactiveCN1410592AUniform thicknessImprove corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingPowder metallurgy

In the invention, the sodium hypopphosphite is as the reducing agent of the bath, nickel sulfate as the main salt, with the complexing agent, accelerating agent and stabilizing agent being added. Theultrasonic chemical plating is adopted that utilizes the mechanical energy of the ultrasonic vibration, making the bath deposit nickel and phosphor under the catalysis of the metal surface and the chemical reduction method controlled. The plating procedure includes the steps of oil removal, rust removal, activation, chemical plating and post treatment. The multiple complexing, accelerating and stabilizing agents raises the stability of the bath. The plating speed is adjustable. The even, compact nickel and phosphor plating layer covers the surface of the base body of powder metallurgical material so as to increase the service life of the material and provide wide application area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

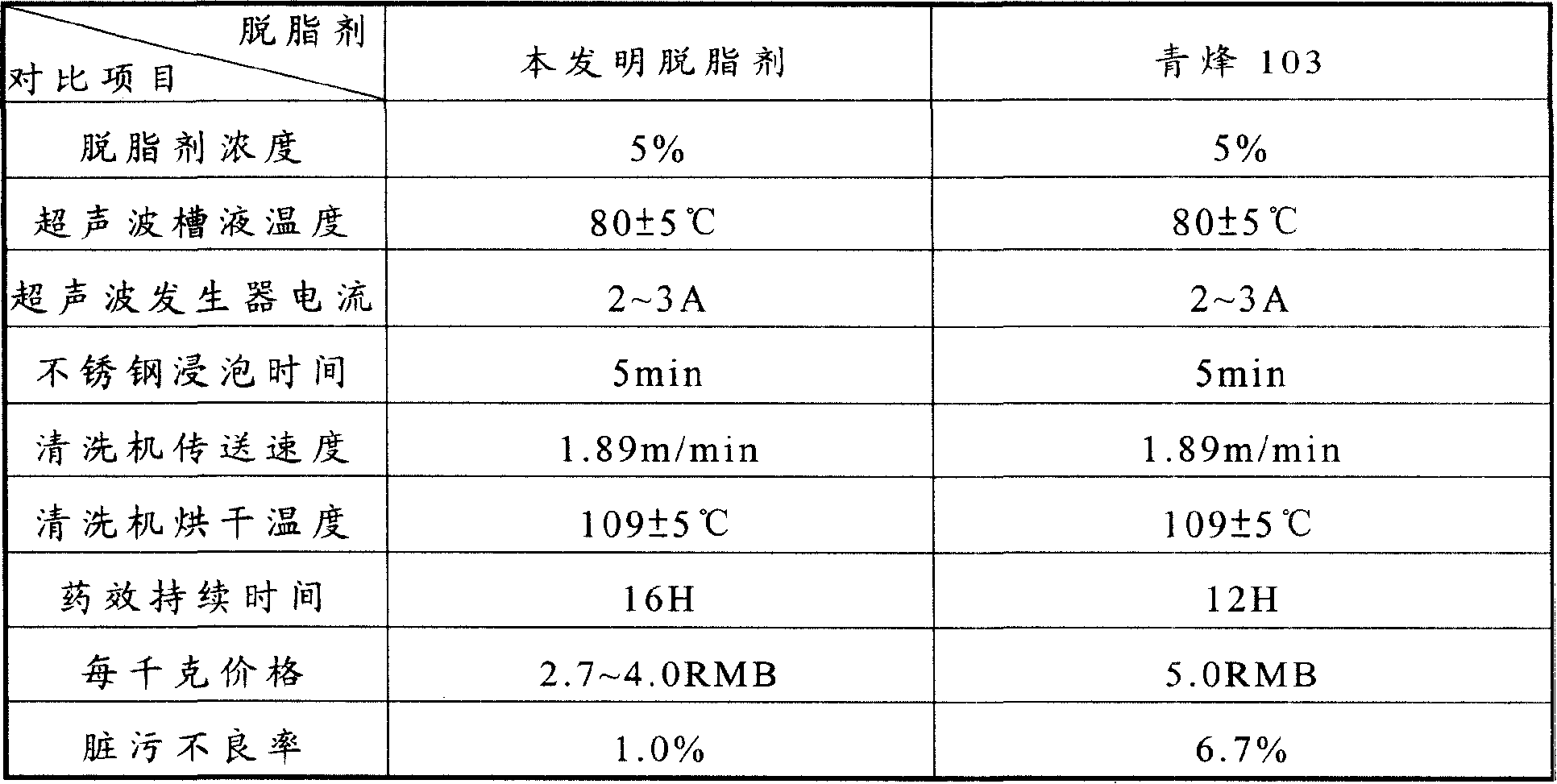

Degreasing agent and preparing method therefor

InactiveCN101200804ALong-lasting effectLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium silicateTrisodium phosphate

The invention relates to a degreaser, including trisodium phosphate, sodium silicate, sodium carbonate, sodium dodecyl benzene sulfonate, sodium hydroxide and octylphenol polyoxyethylene ether. Used for cleaning metal surface, the degreaser has the advantages of long efficacy duration, low cost and good degreasing effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Processing technology of aluminum veneer for curtain wall

InactiveCN108993838AGood degreasingReduce the amount of fatWallsPretreated surfacesSurface grindingLacquer

The invention relates to a processing technology of an aluminum veneer for a curtain wall, and relates to the field of curtain wall materials. The processing technology solves the problems that the existing aluminum veneer and coatings are insufficient in binding force and the coatings are easy to fall off are solved. The processing technology specifically comprises the following steps of cutting-punching-bending-weld joint grinding-surface grinding-surface pretreatment-spray coating-drying; the surface pretreatment comprises degreasing, pickling and passivation; and the spray coating comprises priming, finishing coating and finish-coat painting. According to processing technology, in the degreasing process, a degreasing agent selected has an excellent degreasing effect, and grease can beadsorbed in the degreasing process, so that quantity of the grease with which the aluminum veneer is coated is reduced in a flushing process; the degreasing process is matched with pickling operation,the grease can be removed as much as possible, the aluminum veneer is good in degreasing effect, so that viscosity fastness of a primer can be increased when the priming is conducted; and the primer,the finish coat and finish-coat paint are connected tightly, and therefore paint layers of the finally generated aluminum veneer do not easily fall off.

Owner:安信铝业集团有限公司

Method for surface treating calender copper foil of printing circuit board

InactiveCN101074484AFast degreasingGood degreasing effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilNickel alloy

A method for treating calendaring copper foil surface of printing circuit board is carried out by pre-treating by weak alkali mixed oil remover with Na2CO3, Na3PO4 and Na2SiO3, primary coarse treating, electroplating copper by electroplating liquid containing copper ion, H2SO4 and arsenic ion, clad treating by barrier, zinc-nickel alloy clad treating, passivating and electroplating chromium clad treating to obtain final product. It has better combination with printing base plate and corrosion resistance.

Owner:SHANGHAI UNIV

Fur fat removal agent

InactiveCN102660396AGood degreasing effectHigh glossOrganic detergent compounding agentsNon-ionic surface-active compoundsPreservativeSurface-active agents

The invention discloses a fur fat removal agent, and belongs to the field of detergent compositions. The fur fat removal agent comprises a non-ionic surface active agent, water-borne high polymer, silicone oil, alkali, solvent, chelant, preservatives and the balance water. The fur fat removal agent has an excellent fat removal effect to the surface and the deep layer of dermatome, removal ability to dirt on fur is high, and washed fur is high in whiteness and gloss. Due to the water-borne high polymer and the silicon oil, the content of fat of the dermatome after the oil of the dermatome is removed by the fur fat removal agent is low, and the fur is bright and smooth.

Owner:HEBEI YONGTAI LEATHER CHEM

Method for treating oil-containing waste water

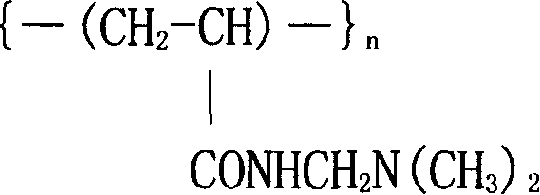

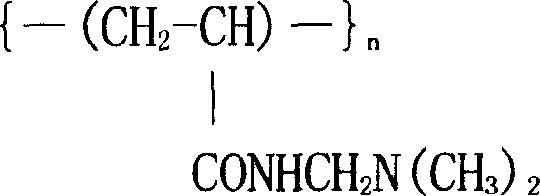

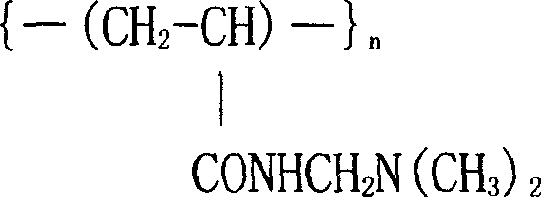

InactiveCN1955122AImprove water qualityHigh oil contentWater/sewage treatment by flocculation/precipitationChemistryPolyacrylamide

A process for treating the oil contained sewage in oil field includes such steps as adding demulsifier (linear low-molecular cationic ammine polymer with multiple hydroxy groups), demulsifying, and adding flocculant (cationic polymer whose principal component is aminomethyl polyacrylamide).

Owner:CHINA PETROLEUM & CHEM CORP +1

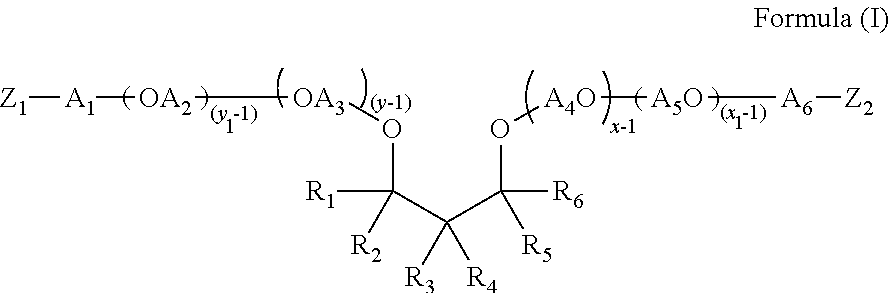

Cleaning composition containing a polyetheramine

ActiveUS20150315524A1Broaden grease clean profileGood degreasing effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSurfactant systemZwitterion

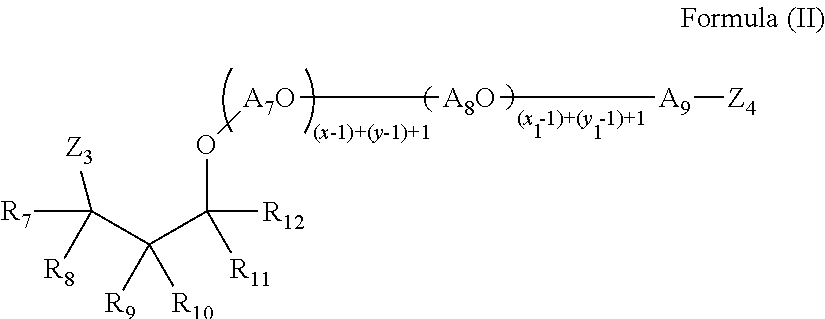

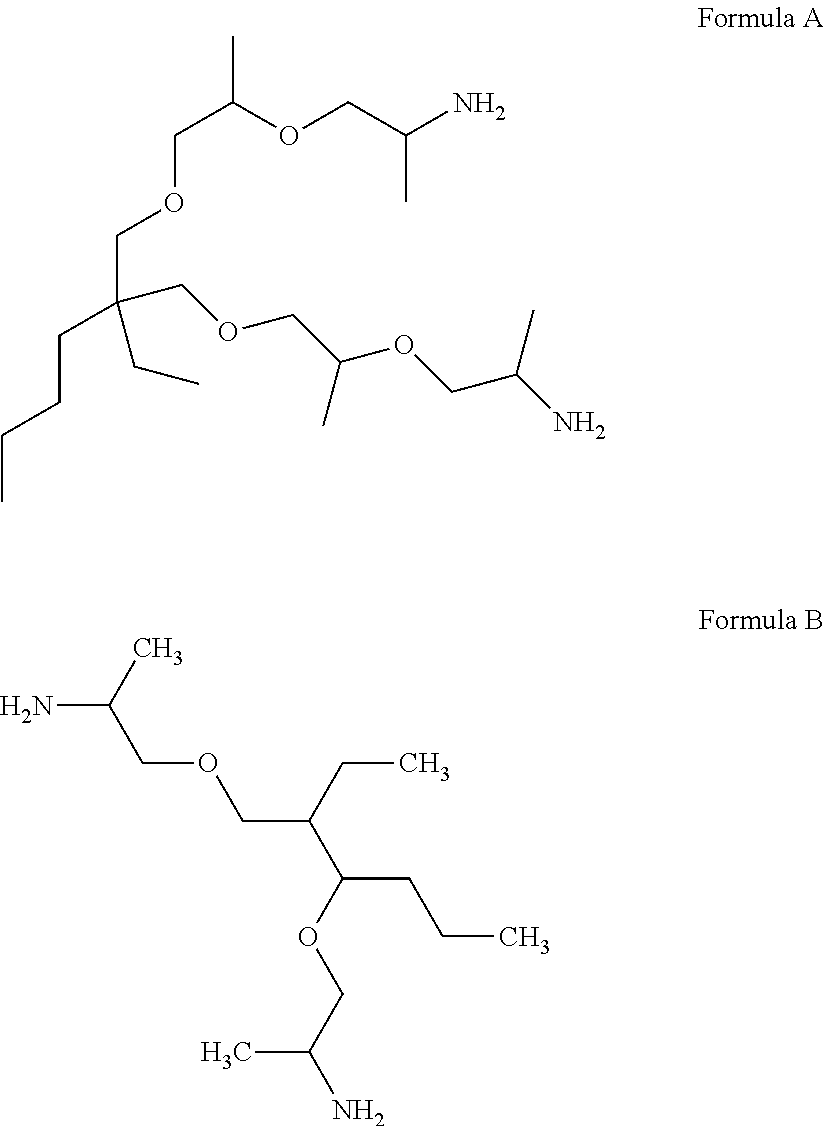

A hard surface cleaning composition comprising:a) from 1% to 60% by weight of the composition of a surfactant system comprising an anionic surfactant and a primary co-surfactant selected from the group consisting of amphoteric, zwitteronic and mixtures thereof; andb) from 0.1% to 10% by weight of the composition of a polyetheramine

Owner:THE PROCTER & GAMBNE CO

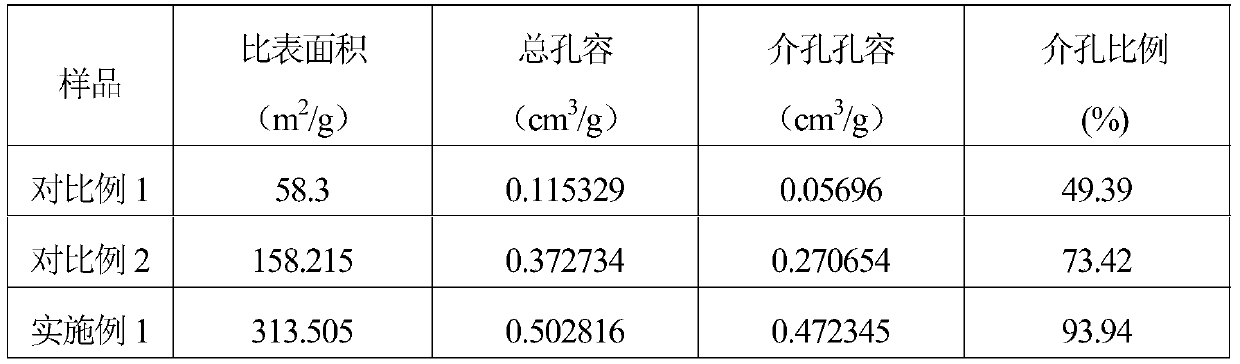

Preparation method of oily sludge based adsorption carbon material for oily sewage treatment

InactiveCN110078070AHigh carbon contentAchieve stabilizationCarbon compoundsOther chemical processesPorosityActivation method

The invention discloses a preparation method of an oily sludge based adsorption carbon material for oily sewage treatment. Oily sludge produced in the petroleum exploitation and refining process and subjected to reduction treatment is taken as a raw material and mixed with fruit shells and fruit seeds, the carbon content of the oily sludge and the porosity of a carbonization product are increased,ethanol amine is taken as a chemical pore-enlarging agent, industrial alkali waste is taken as an activator, and the oily sludge based adsorption carbon material is prepared in combination with chemical pore enlargement and activation methods. The reaction temperature is lower, the process is simple, the preparation cost is reduced, the obtained carbon material has a higher mesopore proportion, is applicable to adsorption of petroleum substances in the oily sewage, can effectively remove suspension oil and emulsification oil in the oily sewage, spot utilization of the oily sludge based adsorption carbon material is realized, and stable, harmless and recycling treatment of the oily sludge is realized.

Owner:XI'AN PETROLEUM UNIVERSITY +1

Foamless low temperature degreasing agent

The invention provides a non-foaming low-temperature degreasant which belongs to the chemical technique field. The non-foaming low-temperature degreasant is prepared from components by weight percentage as follows: water 77.4-96.35%, sodium hydroxide 3-20%, polyoxyethylene nonyl phenyl ether 0.1-0.5%, fatty alcohd-polyoxyethlene ether 0.1-0.5%, carmowax 0.05-0.1%, disodium EDTA 0.2-0.5%, silicone antifoam agent 0.1-0.5%, fatty alcohol polyethenoxy ether type osmotic agent 0.1-0.5%. The non-foaming low-temperature degreasant has advantages of better oil removing effect, low use temperature, and simple preparing method. The non-foaming low-temperature degreasant has better application prospect.

Owner:NORTHEASTERN UNIV

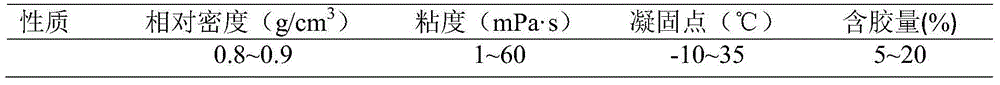

Application of plant source surface active agent

InactiveCN104874329AHas an activation effectIncrease gasification rateNon-ionic surface-active compoundsOther chemical processesEmulsionResource utilization

The invention relates to a total saponnis extraction technology of a honeylocust extract and an application field thereof. The total saponnis extraction technology is characterized in that the total saponnis is a plant source nonionic type surface active agent, and has the interfacial tension reduction property, emulsion activity, wetting property, temperature-resistant and salt-tolerant property, dispersant solubilizing and the like, so as to provide the applicability in the fields of recovery, storage and transportation of crude oil; the green surface active agent from the plant, namely the honeylocust, is applied to the bulk industrial purpose, so the resource utilization rate of the honeylocust is improved, the recovery rate of crude oil is improved, the storage and transportation cost of crude oil is reduced, and the pollution to the environment is reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

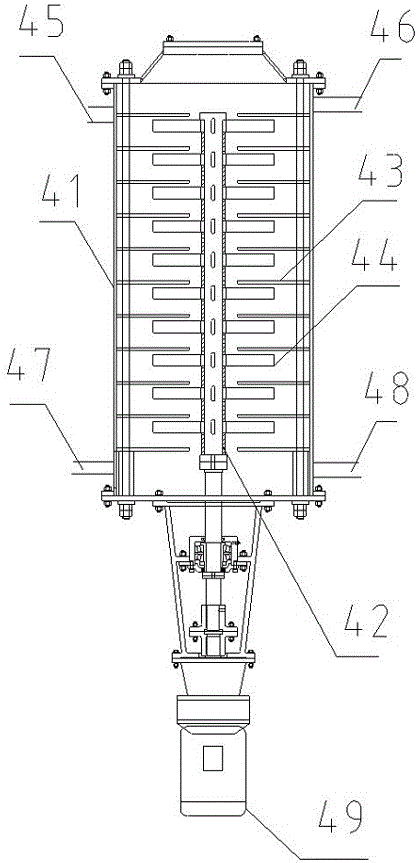

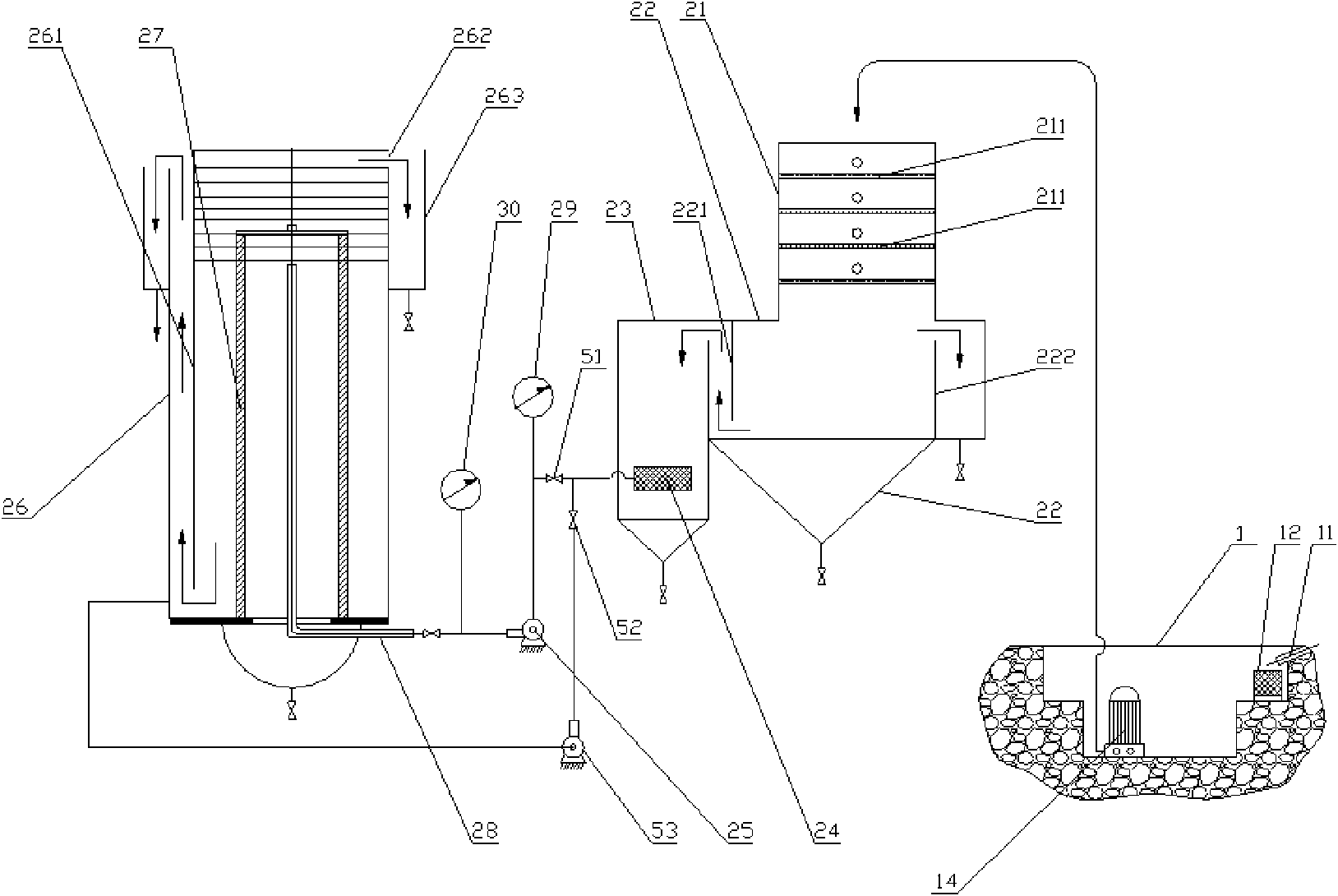

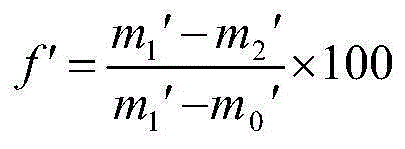

Treating system, separating apparatus and treating method for oily sludge

PendingCN106630514AExpand the scope of applicationLow oil contentWaste water treatment from quariesSievingOil contentHandling system

The invention discloses a treating system, separating apparatus and treating method for oily sludge. The separating apparatus comprises a stirring drum, a first drive unit, a stirring shaft, multiple layers of separator plates and stirring members, wherein the stirring shaft is arranged in the stirring drum; the multiple layers of separator plates divide the stirring drum into multiple layers of space; each of the multiple layers of space is provided with one stirring member which is connected with the stirring shaft; the upper part of the stirring drum is provided with a sludge inlet and first floating oil discharge outlet; the lower part of the stirring drum is provided with a sludge outlet; and the bottom or lower part of the stirring drum is provided with a feed inlet for one or more selected from a group consisting of an extractant, air-dissolved water and solid foam particles. The treating system is applicable to dehydration of a variety of oily sludge, enables the oil content of oily sludge to be decreased to 3% or below, can maximally recover oil and does not produce secondary pollution like waste water.

Owner:仇霞霞

Oily sludge recycling and treatment method

InactiveCN107253813AImprove extraction efficiencyAvoid separation and recycling inefficientWaste water treatment from quariesSludge treatmentChemistryUltrasonic oscillation

The invention discloses an oily sludge recycling and treatment method. The oily sludge recycling and treatment method comprises the following steps: mixing oily sludge, water and an extracting agent in a mass ratio of 1:2:(0.3-0.7), wherein the extracting agent is a mixture containing a low-boiling-point organic solvent, a dispersing agent and an anionic surfactant; carrying out ultrasonic oscillation on the mixture in the step S1, and forming an oily sludge extracting agent mixed solution; carrying out solid-liquid centrifugal separation on the oily sludge extracting agent mixed solution, so that deoiled sludge and oil-water extracting agent mixed solution are obtained; and carrying out water separation and oil purification and recycling on the oil-water extracting agent mixed solution. The oily sludge recycling and treatment method provided by the invention is low in separation cost and high in efficiency and can realize extraction and recycling of petroleum in oily sludge, so that resources are utilized again.

Owner:湖南云平环保科技有限公司

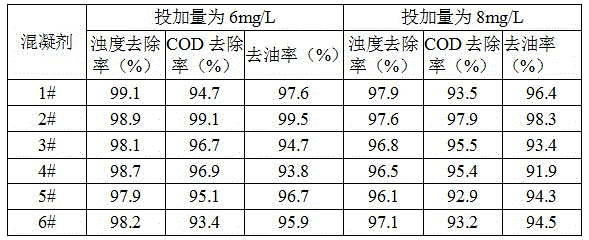

Preparation method and application of polyferric silicate coagulant

ActiveCN105645545AStabilize hydrophilic and hydrophobic propertiesStable suspension dispersionWater contaminantsWater/sewage treatment by flocculation/precipitationChemical oxygen demandSilicic acid

The invention relates to a preparation method and application of a polyferric silicate coagulant. According to the method, a ferrous salt and a specific functional metal salt are used as raw materials; the ferrous salt and the specific functional metal salt are dissolved in an inorganic acid solution, so as to prepare an acidic ferric salt solution; mixed liquor B is obtained by adding a stabilizer A of a weak acid, a weak alkali, a strong alkali-weak acid salt, a strong acid-weak alkali salt or a weak acid-weak alkali salt; the mixed liquor B is mixed and reacted with activated silicic acid into which a surfactant stabilizer C is added, so as to prepare and obtain the high-efficiency polyferric silicate coagulant. The coagulant can be used for the treatment of wastewater containing heavy oil. The preparation method is simple in process, low in cost and low in requirements on reaction equipment; the obtained coagulant can be widely used in the process of the treatment of the wastewater containing the heavy oil, and has the advantages of a good coagulation effect, a high oil removal rate, a quick reaction speed, a quick sedimentation rate and high COD (Chemical Oxygen Demand) removal rate and turbidity removal rate, high activity and the like; the treated wastewater containing oil completely meets requirements in the Integrated Wastewater Discharge Standard GB8978-96.

Owner:NANJING UNIV OF TECH

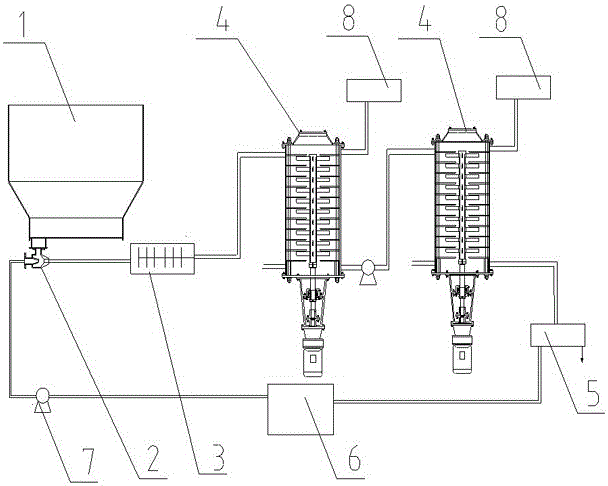

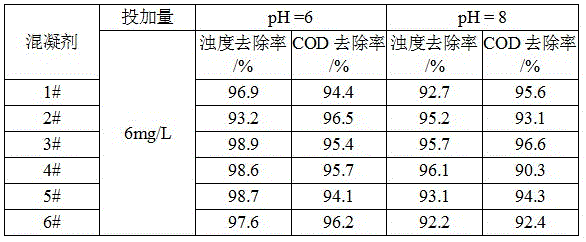

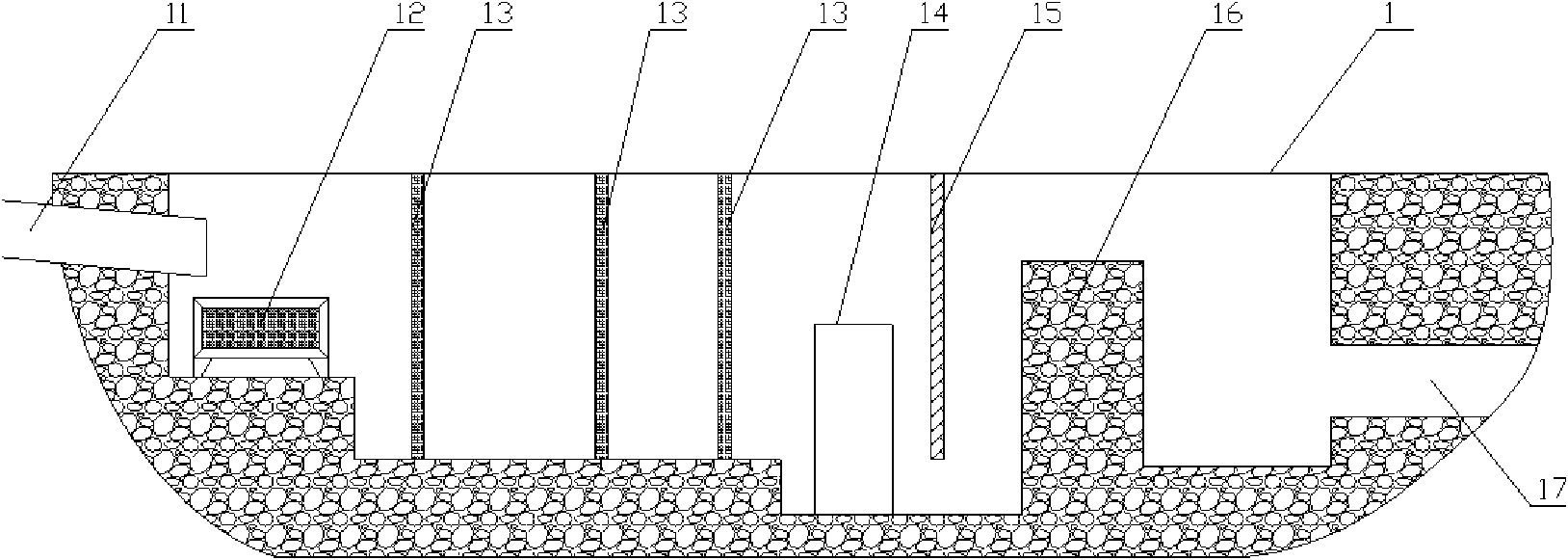

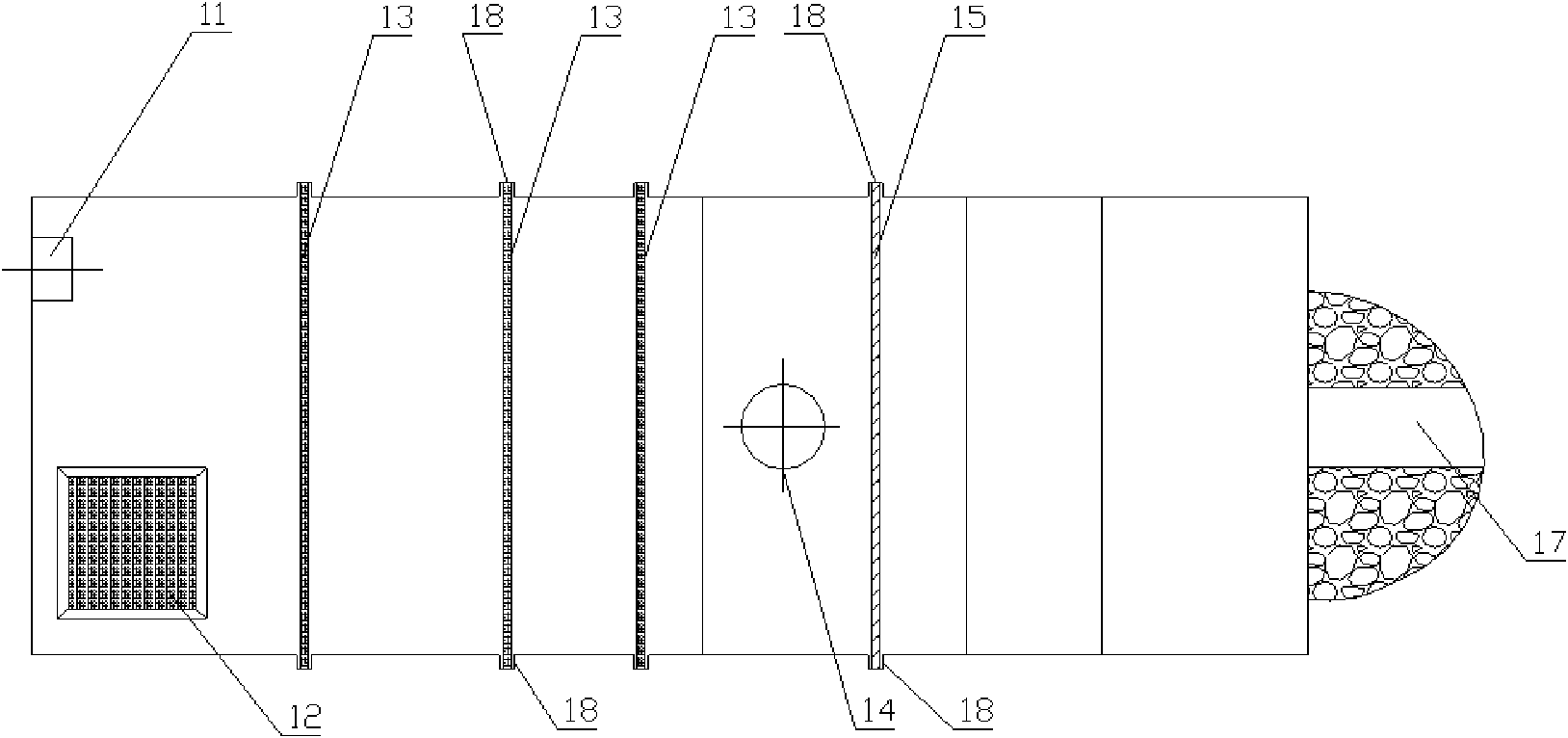

Oil-containing emulsion wastewater treatment method and apparatus thereof

ActiveCN103073119AImprove filtering effectGood degreasing effectMultistage water/sewage treatmentWater/sewage treatment by flotationFlocculationEmulsion

The present invention relates to the field of wastewater treatments, particularly to a treatment apparatus for oil-containing emulsion wastewater generated by cutting, burnishing and other steps during a mechanical processing process and a method thereof. According to the treatment method, a composite demulsification method is mainly adopted so as to carry out complete demulsification; and then air flotation, flocculation and filtration are performed, wherein a filler is added with filtration mediums such as rice hull and sawdust on the basis of traditional quartz sand active carbon so as to increase a filtration and oil removing effect, such that effluent water quality is excellent. In addition, with the integrated treatment apparatus designed according to the method, the whole processes such as pretreatment, demulsification, air flotation, flocculation and the like can be independently completed, and advantages of economy, energy saving, complete function, small occupation area and easy operation are provided.

Owner:大连格兰清水环境工程有限公司

Oil-water separation device for treating oil-containing wastewater

InactiveCN101602528AExtended service lifeEasy to separateFatty/oily/floating substances removal devicesLiquid separationFiltrationOil separation

The invention provides an oil-water separation device for treating oil-containing wastewater with the advantages of difficult blockage of filter element, long service life, low labor intensity and low treatment cost, which is characterized in that: the oil-water separation device has a multi-level oil-water separation structure which comprises a sewage filter tank and an oil-water separation mainframe, wherein the sewage filter tank is provided with a filter basket for primary filtration, a filter screen and a sewage pump; and the oil-water separation mainframe mainly comprises a I-level oil separation device and a II-level oil separation device. The oil-water separation device can be used for collecting and separating sump oil in the drainage of a kitchen, effectively solves the problem of secondary pollution caused by a dining table, and has the advantages of simple and reasonable structure, good oil-water separation effect, and suitability for oil-water separation of sewage in kitchens of big and small hotels in cities and towns and cruise ships.

Owner:ZHOUSHAN ZHONGBANG ENERGY SAVING TECH

Low-temperature deoiling scouring agent and preparation method thereof

InactiveCN105002022AGood degreasing effectGood emulsification and dispersionSurface-active non-soap compounds and soap mixture detergentsAlcoholSolvent

The invention discloses a low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent comprises, by weight friction, 10-20% of fatty alcohol-polyoxyethylene ether (EO9), 10-20% of fatty amine alcohol-polyoxyethylene ether (EO15), 5-10% of Isomeric ten alcohol-polyoxyethylene ether (EO5), 5-15% of secondary alcohol-polyoxyethylene ether (EO9), 3-6% of solubilizer, and the allowance is deionized water. The invention further discloses a preparation method for the low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent is applied to the pretreatment processes of refining, deoiling, detergent washing and the like, the deoiling problem of fabric (especially the fabric containing spandex) in the process of pretreatment is solved, and oil stain and impurities in the fabric are guaranteed to be removed effectively. The functions of dispersing, emulsifying and wetting are achieved, the permeability is good, the form is little, and detergency is strong.

Owner:BONUS FUJIAN TEXTILE IND CO LTD

Pollution-free, high-efficiency and long-distance pipe installing and cleaning method

ActiveCN104307822AGood degreasing effectShort construction periodNon-ionic surface-active compoundsOrganic detergent compounding agentsAlkylphenolEngineering

The invention discloses a pollution-free, high-efficiency and long-distance pipe installing and cleaning method, and belongs to the field of pipe cleaning. The pollution-free, high-efficiency and long-distance pipe installing and cleaning method comprises the following steps: installing a ball sending device and a ball receiving device, temporarily testing the leakage and the pressure of a system, sending a diameter-measuring ball, drying, derusting, passivating, chemically degreasing, drying, inspecting and accepting, performing nitrogen protection and transferring, wherein in the derusting, passivating and chemically degreasing steps, a pipe-cleaning train of a pipe cleaner-a chemical agent-a pipe cleaner is used, namely the chemical agent is integrally injected into a space between a first pipe cleaner and a second pipe cleaner; the chemical agent comprises a passivating agent or a degreasing agent; the degreasing agent adopts the formulation as follows: 2-3.5% of sodium tripolyphosphate, 1-2% of sodium carbonate, 0.5-1.5% of sodium hydroxide, 0.2-0.4% of sodium borate, 0.1-0.2% of disodium ethylenediamine tetraacetate, 0.05-0.1% of sodium oleate, 0.05-0.1% of sodium dodecyl sulfate, 0.05-0.1% of alkylphenol ethoxylate and 92.1-96.05% of water. By the pollution-free, high-efficiency and long-distance pipe installing and cleaning method, synchronous and high-efficiency operation of physical cleaning and chemical cleaning of a long-distance pipe can be achieved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Efficient low-foam normal-temperature phosphorous-free oil removing liquid

InactiveCN105483726AEasy to handleGood degreasing effectSodium metasilicateLinear alkylbenzene sulfonate

The invention discloses efficient low-foam normal-temperature phosphorous-free oil removing liquid. The oil removing liquid consists of the following components in percentage by weight: 3.0-7.0 wt% of alkylphenol polyoxyethylene ether, 1.0-5.0 wt% of fatty alcohol polyoxyethylene ether, 1.0-5.0 wt% of fatty acid methyl ester polyoxyethylene ether sulfonate, 0.5-4.0 wt% of linear alkylbenzene sulfonate, 10.0-30.0 wt% of carbonate, 4.0-15.0 wt% of sodium metasilicate pentahydrate, 5.0-15.0 wt% of sodium hydroxide, 4.0-12.0 wt% of sodium citrate, 0.5-1.0 wt% of redeposition resisting agent, 2.0-5.0 wt% of complexing agent, 0.1-0.3 wt% of defoaming agent, 1.0-3.0 wt% of corrosion inhibitor, 0.01-0.1 wt% of flocculating settling agent, and the balance of water. The oil removing liquid has the characteristics of cost saving, improvement of oil removing efficiency and economic benefit.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

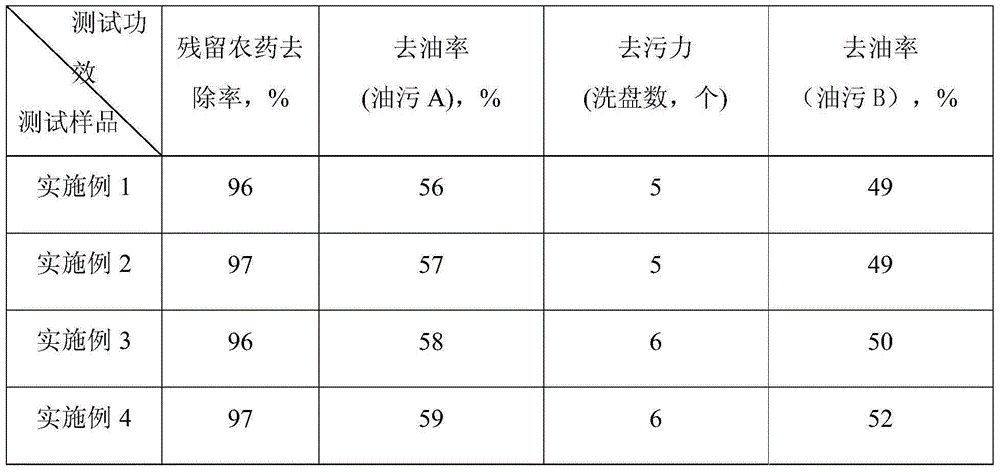

Foam type fruit-vegetable and tableware detergent composition

ActiveCN105062712AImprove cleaning methodsGood degreasing effectOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsDissolutionSolvent

The invention discloses a foam type fruit-vegetable and tableware detergent composition, which contains the following raw materials: 1%-15% of a special anionic surfactant magnesium alkylbenzene sulfonate; 5%-50% of other surfactant; 0.1%-5.0% of a cosolvent; 0.01%-2% of a bactericidal preservative; 0.04%-0.1% of other components; and the balance deionized water. The composition provided by the invention selects the special combination of magnesium alkylbenzene sulfonate, other surfactant and assistants, so that the detergent maintains the basically no viscosity and stable foam state. By means of a push type foam pump head or jet type foam nozzle, the detergent is extruded or jetted in the form of foam. Being different from traditional fruit-vegetable and tableware detergents, the detergent composition is used for cleaning by means of the foam directly pushed or jetted out of a container, dissolution of the detergent in water and stirring of it into foams before cleaning can be unnecessary. The detergent composition is mainly used for cleaning fruits and vegetables and tableware, and has the characteristics of convenience, rapidity, and strong decontamination, etc.

Owner:GUANGZHOU LIBY

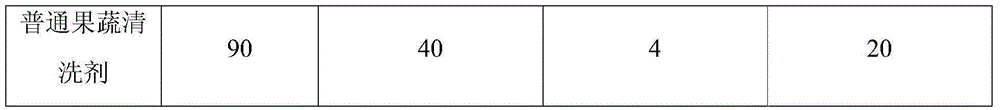

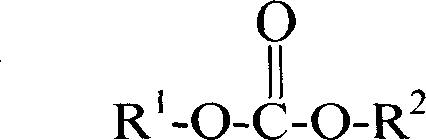

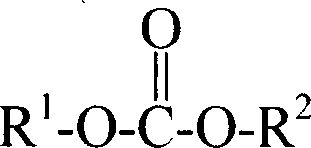

Application of alkyl carbonate as industrial solvent

InactiveCN101096339ASmall smellSmall and moderate evaporation rate Low odorOrganic chemistryStructural formulaSolvent

The invention discloses a using method of ester dialkyl carbonic acid as industrial solvent, which relates to the application of ester dialkyl carbonic acid and its composition, wherein the structural formula of ester dialkyl carbonic acid is as following; R1 is methyl, ethyl, propyl, butyl or its isomer; R2 is ethyl, propyl, butyl, amyl, hexyl, methoxylethyl, ethyoxylethyl, propoxyethyl, butoxyethyl, methoxypropyl, ethoxypropyl, propoxypropyl, butoxypropyl or its isomer; the sum of carbon atom of R1 and R2 is not more than 10.The invention is characterized by the following: (1)degradable, friendly for environment; (2)compatible with other organic phase solvent; (3)micro-toxicity and fitful evaporating speed; (4)higher degreasing ability; (5)low cost; (6)wide usage.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

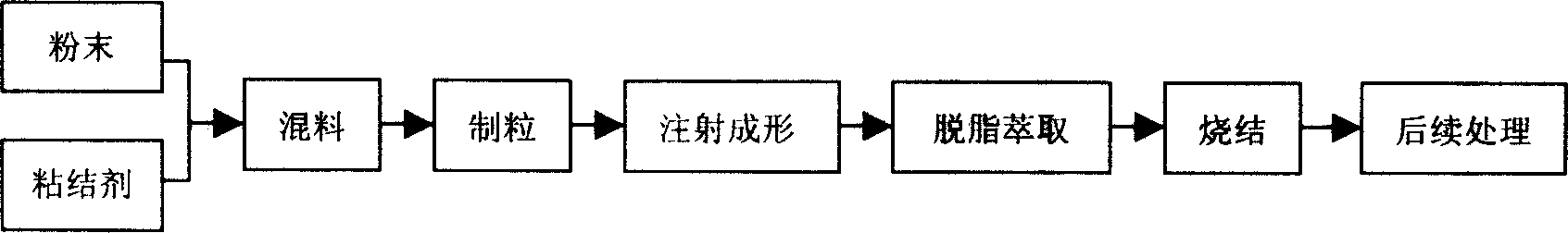

Electronic sealed metal casing powder injecting forming binder formula

An adhesive for the powder injection moulding of metal package used for electronic device is prepared from high-density polyethene, stearic acid, paraffin wax, MP-22 and polypropene proportionally. Its advantages are high strength and quality of said metal package, low dosage, no chemical reaction and poison and no pollution.

Owner:重庆工学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com