Method for treating oil-containing waste water

A treatment method and technology for oil extraction wastewater, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, high moisture content of scum, accelerated equipment corrosion, etc. The effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a four-necked flask with a stirring system, a thermometer, and a condenser with a volume of 1 L, add 146.26 grams of triethylenetetramine, install the four-necked flask in a constant temperature water bath, start stirring, and control the reaction temperature at 40 ° C. 176 grams of ethylene oxide was added. After reacting for 5 hours, add 80 grams of bifunctional dichloroethylene, control the reaction temperature at 150° C., continue the reaction for 8 hours, and finally add 134 grams of hydrochloric acid (chemically pure) to stop the reaction, and let it cool to room temperature to obtain the demulsifier A-1. The kinematic viscosity is 2890mm 2 / s, the cationic degree is 3.1mmol / g.

Embodiment 2

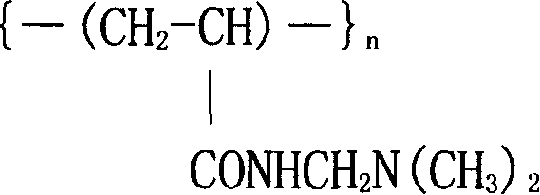

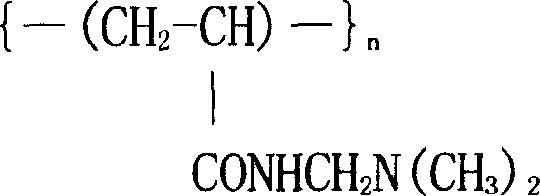

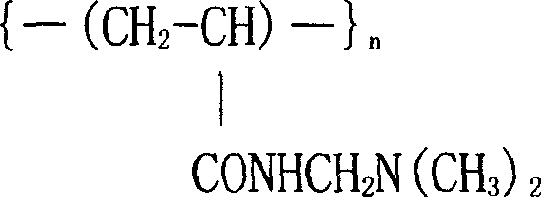

[0035] In a four-neck flask with a volume of 1 L, add 765 grams of fresh water, start stirring, and add 1.8 grams of nonionic polyacrylamide. After it was completely dissolved, 0.31 g of sodium hydroxide (chemically pure) was added to adjust the pH value of the solution to 11-12. Then add 2.8×10 -4 Gram EDTA disodium (chemically pure), add 3.5×10 -4 gram of ammonium persulfate (chemically pure), add 4.2×10 -4 Gram N, N-dihydroxyethyl azobisisobutylamidine hydrochloride (chemically pure), control the reaction temperature at 50 ° C, after mixing 2.1 gram of formaldehyde (chemically pure), 3.8 gram of dimethylamine (chemically pure) , into the four-necked flask, the reaction time is 6h. Finally, 4.3 g of hydrochloric acid (chemically pure) was added to stop the reaction to obtain flocculant B-1. The kinematic viscosity is 406.5mm 2 / s, the cationic degree is 16.7mmol / g.

Embodiment 3

[0037] In a four-necked flask with a volume of 1 L, add 116 grams of hexamethylenediamine, install the four-necked flask in a constant temperature water bath, control the reaction temperature at 40° C., start stirring, and add 116 grams of propylene oxide. After 2 hours of reaction, the reaction temperature was raised to 80°C, and the reaction was continued for 5 hours to obtain a substituted amine, and then 73.9 grams of difunctional epichlorohydrin was added to control the reaction temperature at 110°C, and the reaction was continued for 10 hours, and finally 120 grams of Hydrochloric acid (chemically pure) stopped the reaction, and allowed to cool to room temperature to obtain demulsifier A-2. The kinematic viscosity is 3460mm 2 / s, cationic degree is 3.6mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com