Patents

Literature

1047 results about "Cationic polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

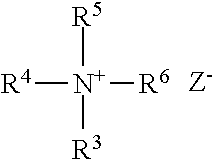

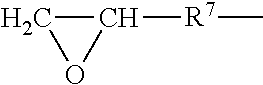

Cationic polymerization is a type of chain growth polymerization in which a cationic initiator transfers charge to a monomer which then becomes reactive. This reactive monomer goes on to react similarly with other monomers to form a polymer. The types of monomers necessary for cationic polymerization are limited to alkenes with electron-donating substituents and heterocycles. Similar to anionic polymerization reactions, cationic polymerization reactions are very sensitive to the type of solvent used. Specifically, the ability of a solvent to form free ions will dictate the reactivity of the propagating cationic chain. Cationic polymerization is used in the production of polyisobutylene (used in inner tubes) and poly(N-vinylcarbazole) (PVK).

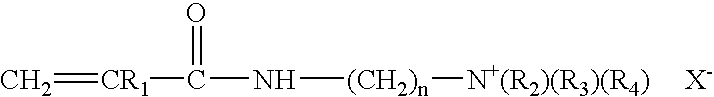

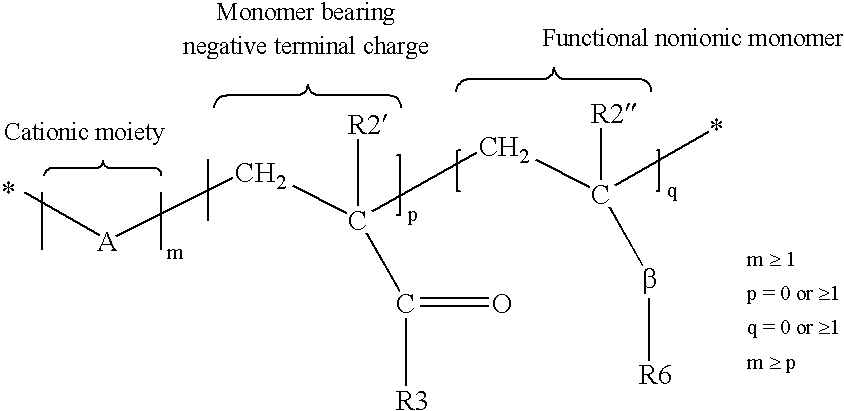

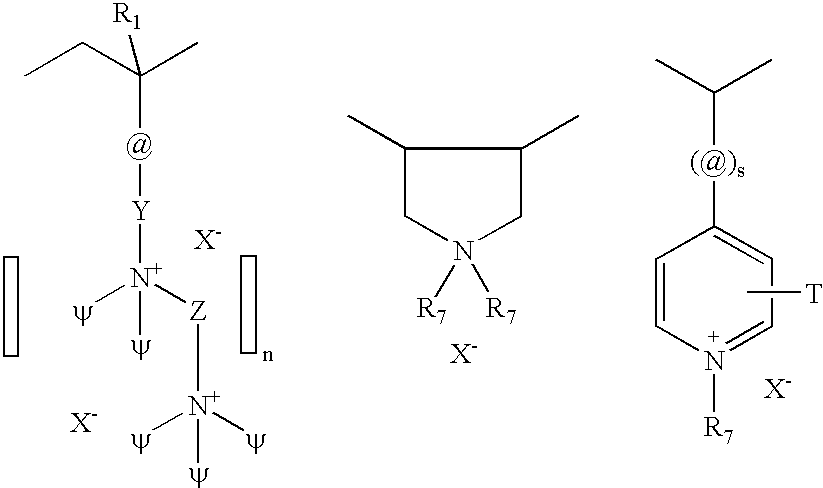

Personal Care Compositions Containing At Least Two Cationic Polymers and an Anionic Surfactant

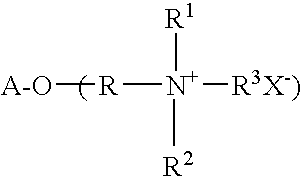

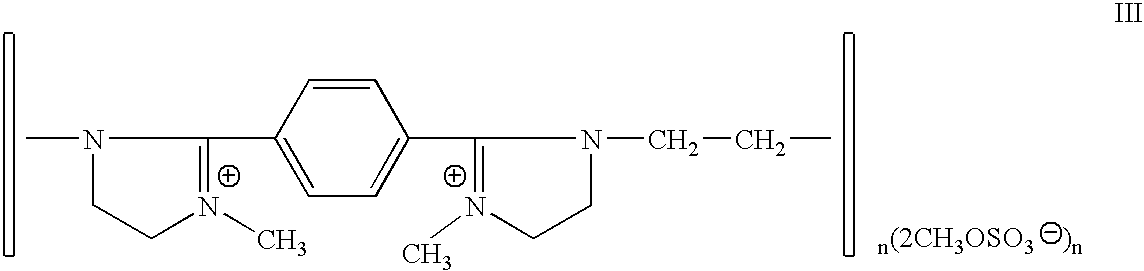

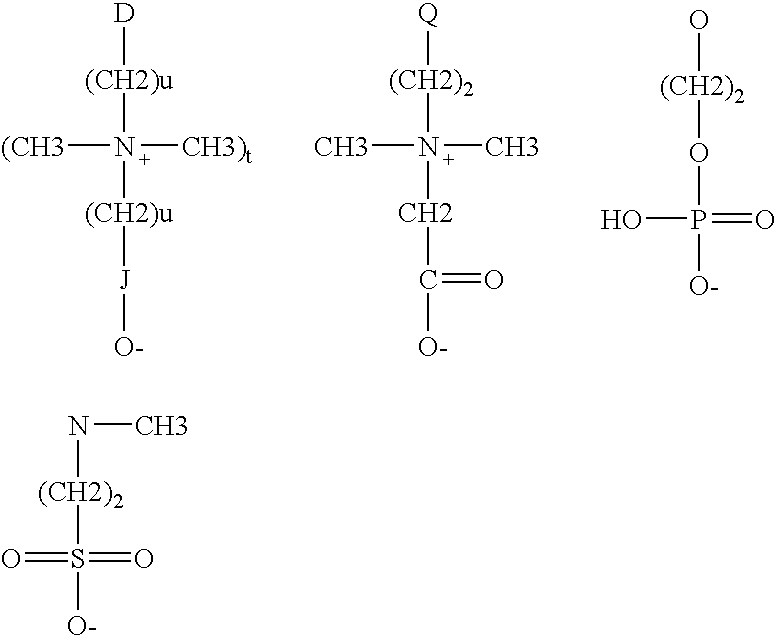

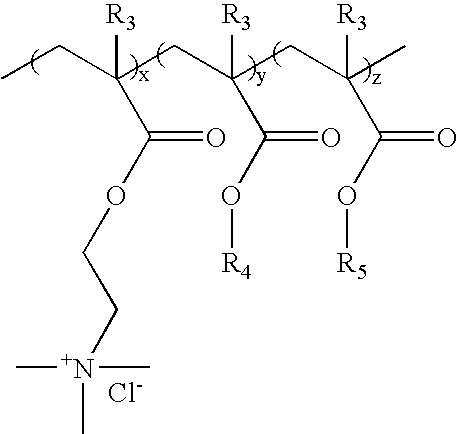

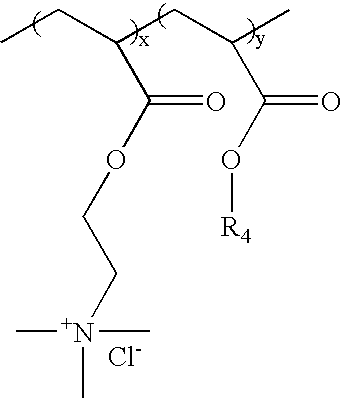

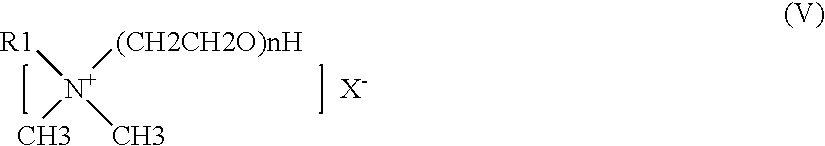

A personal cleansing composition comprising:a. from about 5% to about 50% by weight of an anionic detersive surfactant;b. from about 0.025% to about 5% by weight of a first cationic polymer having a cationic charge density of less than about 4 meq / gm, wherein said first cationic polymer forms an isotropic coacervate;c. from about 0.025% to about 5% by weight of a second cationic polymer having a cationic charge density of greater than or equal to about 4 meq / gm, wherein said second cationic polymer forms a lyotropic liquid crystal coacervate; andd. from about 20% to about 94% by weight of water.

Owner:THE PROCTER & GAMBLE COMPANY

Laundry cleansing and conditioning compositions

InactiveUS6949498B2Effective conditioningCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceCationic polymerization

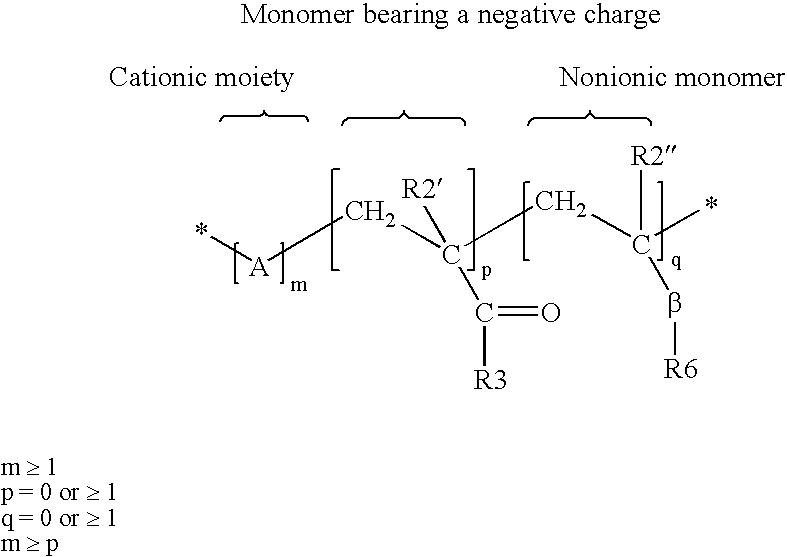

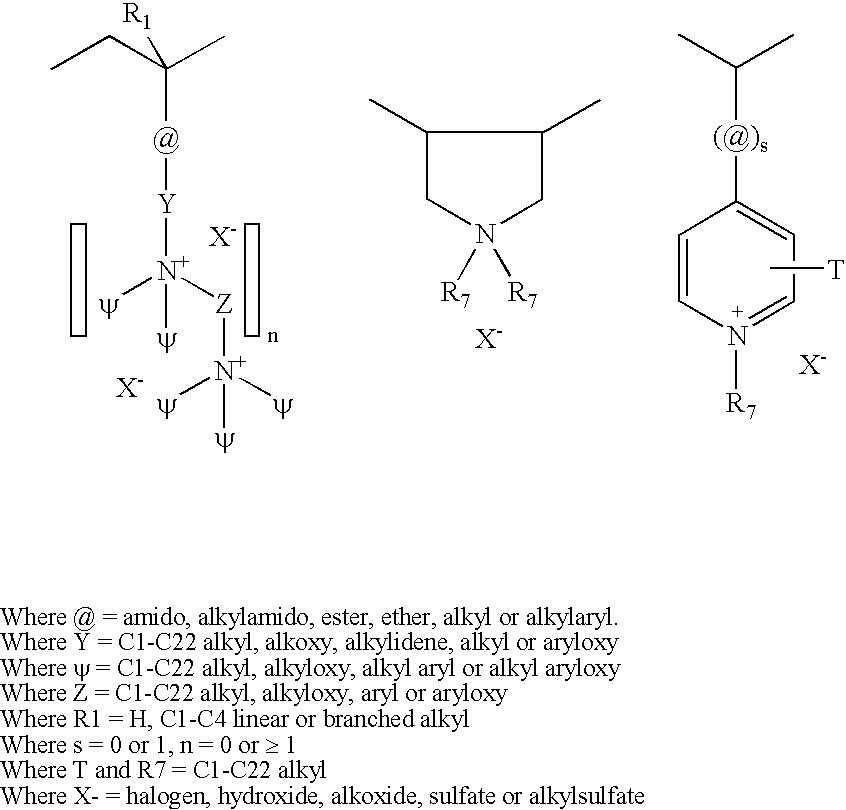

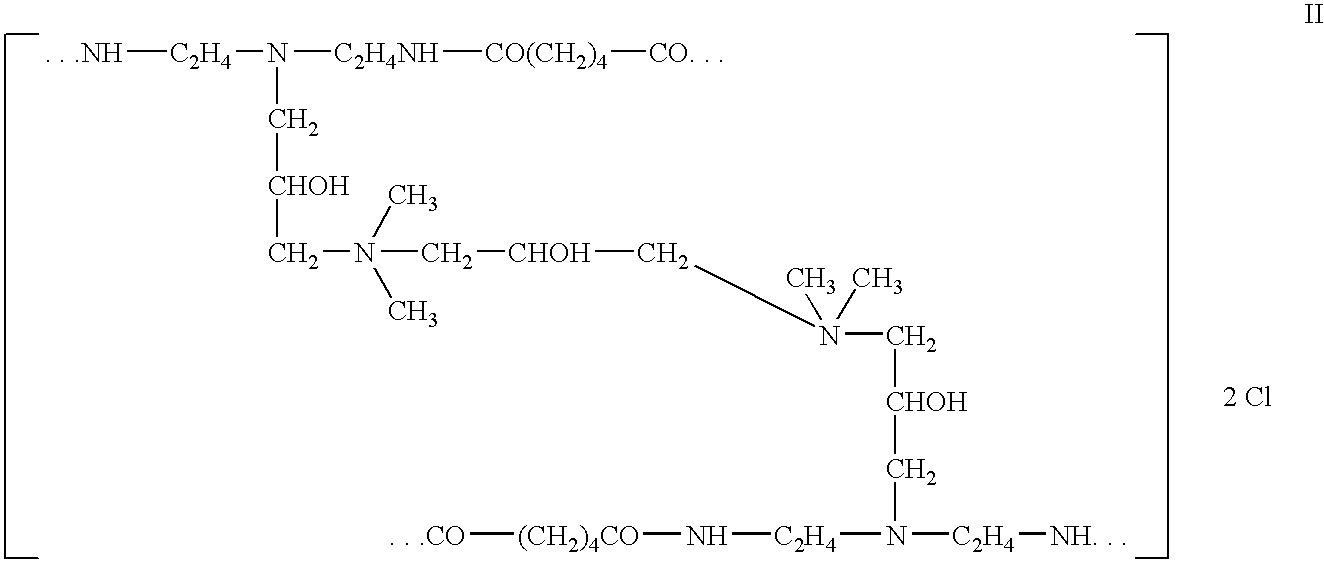

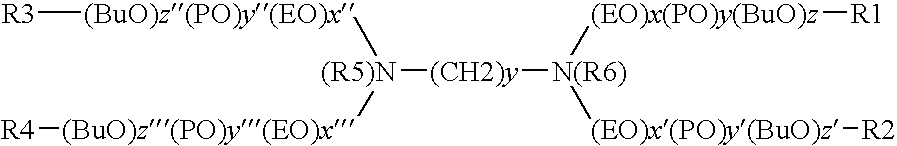

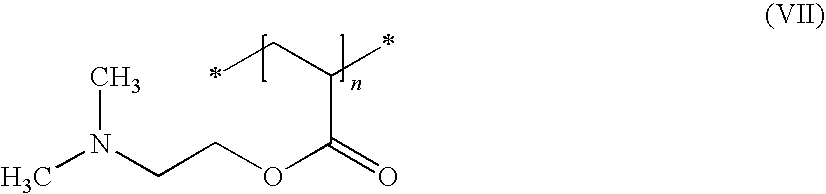

Fabric and textile conditioning compositions containing particular combinations of cationic polymers and anionic surfactants are disclosed. The polymers are soluble or dispersible to at least 0.01% by weight in distilled water at 25° C., are preferably below a particular molecular weight to afford optimal cleaning and conditioning, and must be present in an effective amount to yield a substantial conditioning benefit. A method of conditioning articles using the polymer / surfactant combinations is also disclosed.

Owner:HENKEL KGAA

Fabric care composition

A fabric enhancer composition comprising: (a) a cationic polymer; (b) less than about 20% silicone; and (c) a deposition aid; wherein the composition is essentially free of a coacervate.

Owner:THE PROCTER & GAMBLE COMPANY

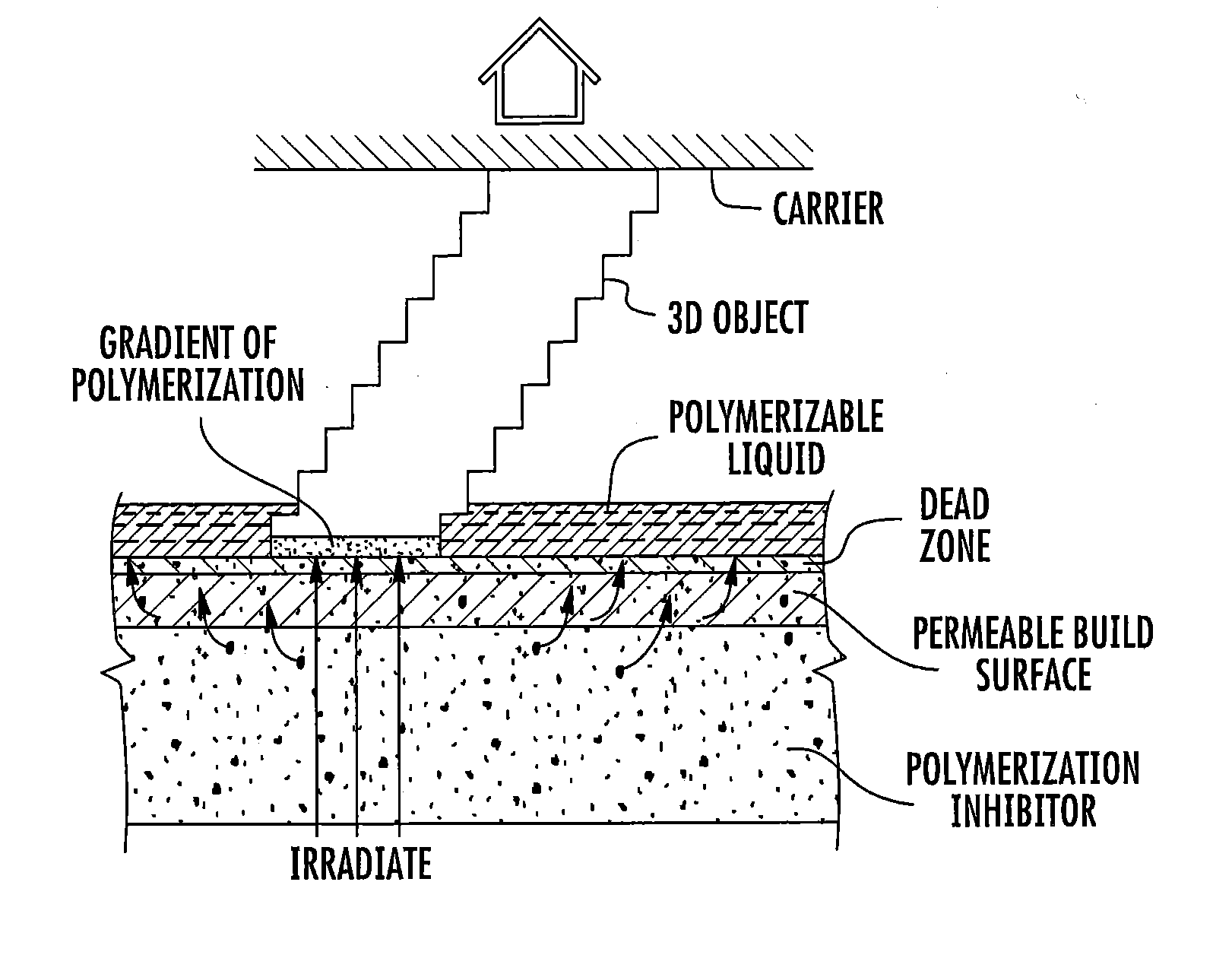

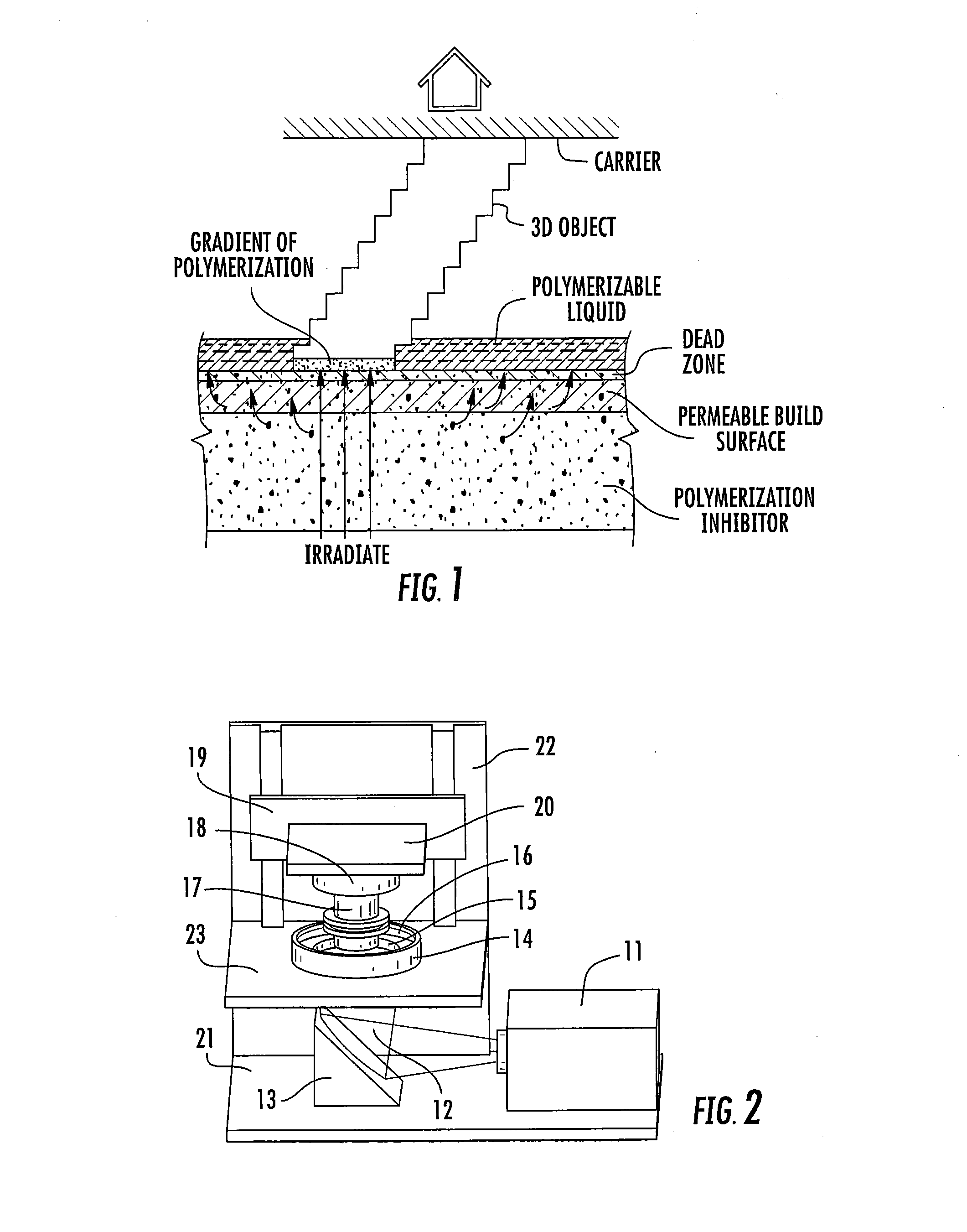

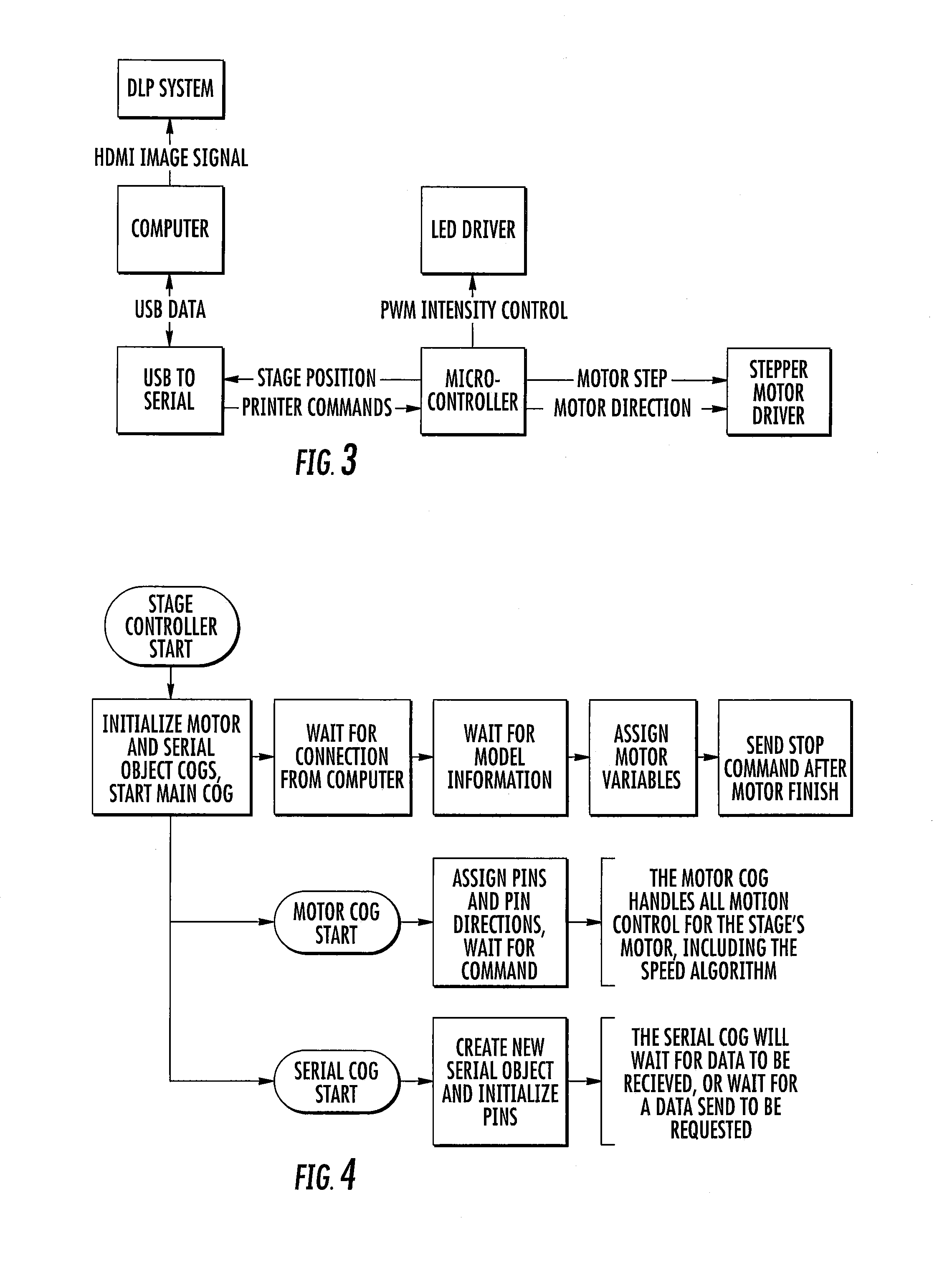

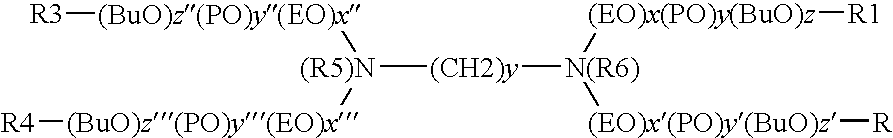

Three-dimensional objects produced from materials having multiple mechanisms of hardening

InactiveUS20160160077A1Enhance or speed the refilling of the build regionIncreased formationManufacturing enclosuresLayered productsPolymer scienceCationic polymerization

A three dimensional object includes (a) a light polymerized first component; and (b) a second solidified component different from the first component. The object is preferably of a polymer blend formed from the first component and the second component, with the polymer blend as an interpenetrating polymer network, a semi-interpenetrating polymer network, or a sequential interpenetrating polymer network. In some preferred embodiments, the second component does not contain a cationic polymerization photoinitiator. In some preferred embodiments, the three dimensional object is produced by the process of continuous liquid interface production.

Owner:CARBON INC

Encapsulated fragrance chemicals

InactiveUS7119057B2Increase depositionCosmetic preparationsOrganic detergent compounding agentsPersonal careFlavor

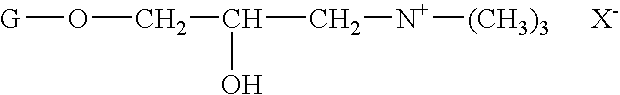

A polymeric encapsulated fragrance is disclosed which is suitable for use in personal care and cleaning products. In a preferred embodiment of the invention the fragrance is encapsulated by a first polymer material to form a fragrance encapsulated polymer, the polymer encapsulated shell is then coated with a cationic polymer, preferably a cationic starch and guar.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

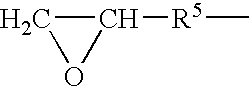

Encapsulated fragrance chemicals

InactiveUS7125835B2Increase depositionCosmetic preparationsOrganic detergent compounding agentsPersonal careFlavor

A polymeric encapsulated fragrance is disclosed which is suitable for use in personal care and cleaning products. In a preferred embodiment of the invention, the fragrance is encapsulated by a first polymer material to form a fragrance encapsulated polymer, the polymer encapsulated shell is then coated with a mixture of cationic polymers, in a preferred embodiment the coating polymers are a reaction product of polyamines and (chloromethyl) oxirane or (bromomethyl) oxirane.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Highly charged microcapsules

InactiveUS20080317795A1Cosmetic preparationsToilet preparationsCationic polymerizationCombinatorial chemistry

The invention encompasses compositions containing sol-gel microcapsules that are highly positively charged. The sol-gel capsules generally contain additives. The invention also encompasses methods for producing highly charged microcapsules using cationic additives which can include cationic polymers. The methods allow for the encapsulation of polar or non-polar active ingredients.

Owner:AQUEA SCI CORP

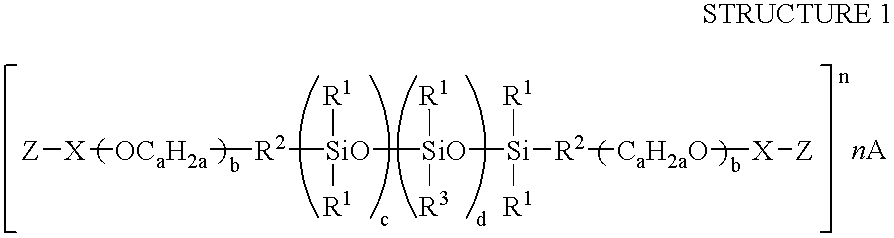

Liquid laundry detergent comprising cationic silicone block copolymers

InactiveUS7273837B2Increase deposition rateGood colorInorganic/elemental detergent compounding agentsCationic surface-active compoundsAminosilochromeCationic polymerization

The invention is directed to a liquid laundry detergent composition comprising at least one detergent ingredient selected from the group consisting of anionic surfactant, zwitterionic surfactant, amphoteric surfactant, and mixtures thereof; a coacervate phase forming cationic polymer; and one or more fabric care ingredients selected from the group consisting of one or more cationic silicone polymers comprising one or more polysiloxane units and one or more nitrogen moieties; one or more amino silicone polymers; one or more nitrogen-free silicone polymers; and mixtures thereof; and a liquid carrier for providing cleaning and fabric care benefits. A process for preparing such compositions, a method for treating substrates, a method for providing certain fabric care benefits and the use of such compositions are also described.

Owner:THE PROCTER & GAMBLE COMPANY +1

Composition containing a cationic polymer and water insoluble solid material

InactiveUS6849584B2Inorganic/elemental detergent compounding agentsCosmetic preparationsAmphiphileWater insoluble

The compositions of the present invention relate to personal cleansing compositions having from about 4% to about 50%, by weight, of a surfactant selected from the group consisting of an anionic, cationic, nonionic, amphoteric, and zwitterionic surfactants and mixtures thereof; from about 0.05% to about 10% by weight of a dispersed, water insoluble solid particles or solid, temperature stable particles; from about 0.025% to about 5% by weight of an organic, non crosslinked, cationic homopolymer or copolymer having a cationic charge density of from about 2 meq / gm to about 10 meq / gm and an average molecular weight of from about 1,000 to about 5,000,000; from about 0.1% to about 10%, by weight, of a phase separation initiator selected from the group consisting of electrolytes, amphiphiles and mixtures thereof; and from about 50% to about 95%, by weight, of water.

Owner:THE PROCTER & GAMBLE COMPANY

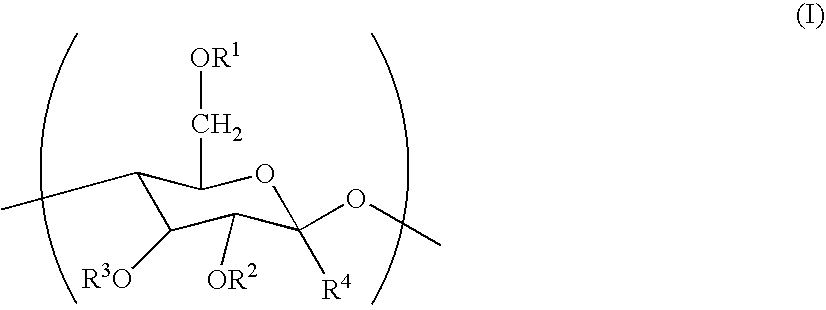

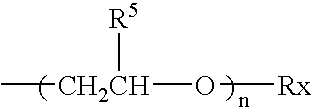

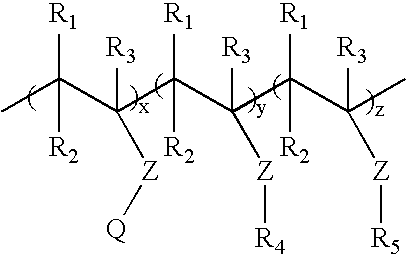

Ion triggerable, cationic polymers, a method of making same and items using same

InactiveUS7157389B2Maintain a desired level of strengthStrength drops below a critical levelCosmetic preparationsToilet preparationsFiberWater dispersible

The present invention is directed to ion triggerable, water-dispersible cationic polymers. The present invention is also directed to a method of making ion triggerable, water-dispersible cationic polymers and their applicability as binder compositions. The present invention is further directed to fiber-containing fabrics and webs comprising ion triggerable, water-dispersible binder compositions and their applicability in water-dispersible personal care products, such as wet wipes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Encapsulated fragrance chemicals

InactiveUS7196049B2Increase depositionCosmetic preparationsOrganic detergent compounding agentsPersonal careFlavor

A polymeric encapsulated fragrance is disclosed which is suitable for use in personal care and cleaning products. In a preferred embodiment of the invention, the fragrance is encapsulated by a first polymer material to form a fragrance encapsulated polymer, the polymer encapsulated shell is then coated with a mixture of cationic polymers, in a preferred embodiment the coating polymers are a reaction product of polyamines and (chloromethyl) oxirane or (bromomethyl) oxirane.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Water-dispersible, cationic polymers, a method of making same and items using same

InactiveUS6897168B2Improved wetting composition for wetFree of organic solventsSynthetic resin layered productsMedical applicatorsFiberWater dispersible

The present invention is directed to triggerable, water-dispersible cationic polymers. The present invention is also directed to a method of making triggerable, water-dispersible cationic polymers and their applicability as binder compositions. The present invention is further directed to fiber-containing fabrics and webs comprising triggerable, water-dispersible binder compositions and their applicability in water-dispersible personal care products, such as wet wipes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

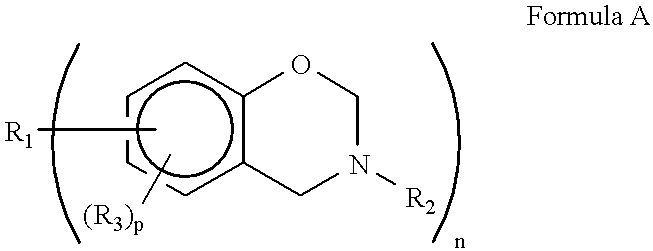

Cationic ring-opening polymerization of benzoxazines

Cationic polymerization of mono and polyfunctional benzoxazine monomers is described. The chemical structure of the polymers from cationic polymerization of benzoxazine monomers has been identified and distinguished from thermally polymerized products from the same monomers. The controllable microstructure of the polymers from benzoxazines prepared by cationic polymerization offers opportunities to prepare and optimize the polymer structure for specific applications.

Owner:EDISON POLYMER INNOVATION EPIC

Cationically polymerizable pigmented composition

InactiveUS6166100AGood dispersibilityMaintain good propertiesOrganic chemistryFilm/foil adhesivesEpoxyPolymer science

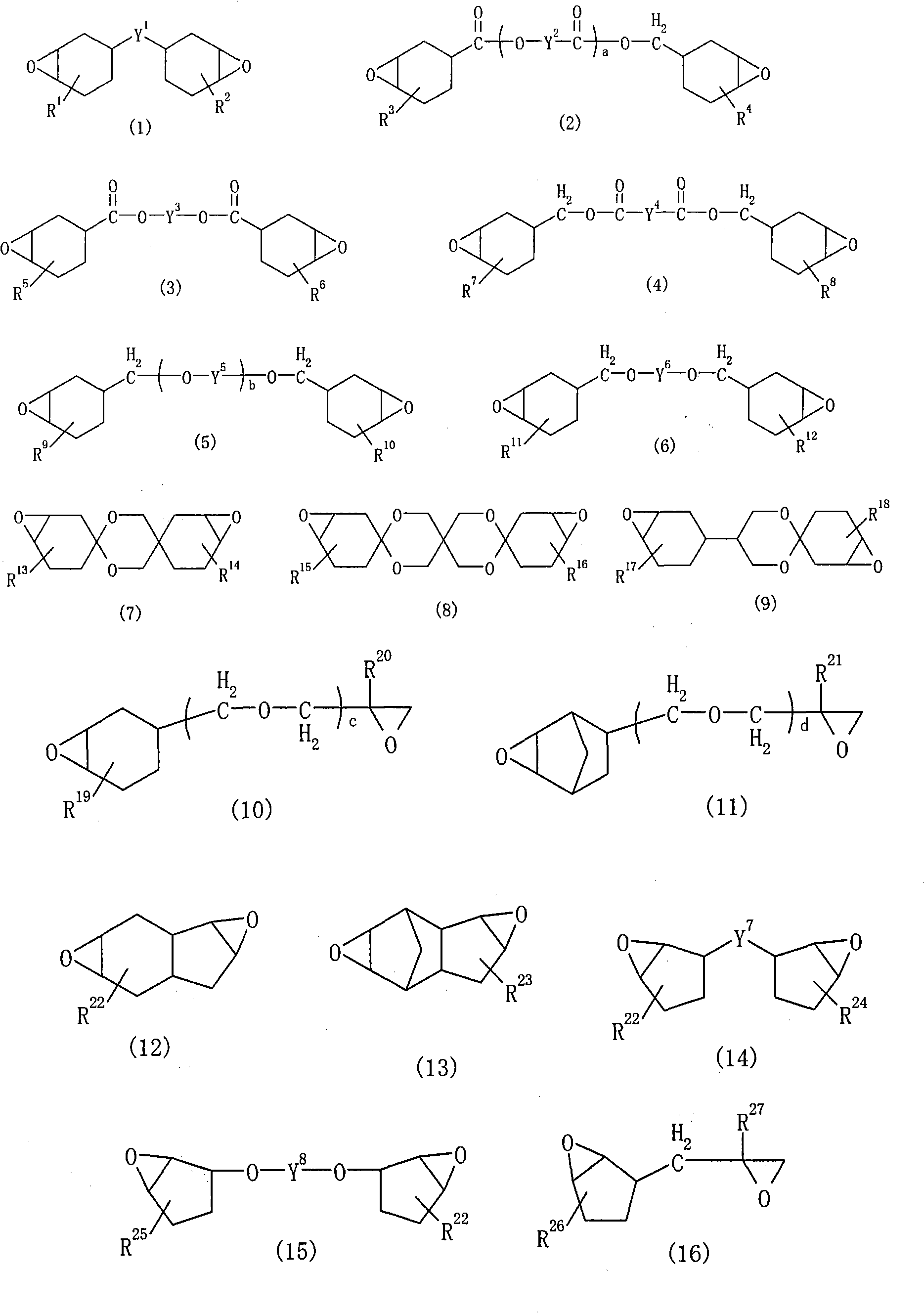

A cationically polymerizable pigmented composition comprising (A) a cationically polymerizable binder component containing at least one resin or compound selected from the group consisting of (A-1) a cationically polymerizable acrylic resin consisting of a copolymer of (a) a (meth) acrylic ester monomer having C6-31 aliphatic hydrocarbon group, (b) a polymerizable unsaturated monomer containing a polymerizable unsaturated group and at least one cationically polymerizable moiety selected from the group consisting of an epoxy group and an oxetane ring, and optionally (c) other polymerizable unsaturated monomer, and (A-2) a fatty acid-modified epoxy compound containing C6-32 aliphatic hydrocarbon group and epoxy group, (B) a cationic polymerization initiator initiating polymerization by irradiation or heating, and (C) a color pigment.

Owner:KANSAI PAINT CO LTD

Capping reactions in cationic polymerization; kinetic and synthetic utility

A method of synthesizing an endcapped polymer, comprising reacting in a solvent a cationic living polymer with an optionally substituted conjugated diene as an endcapping reagent, whereby the solvent causes termination by halogenation to be faster than the addition of additional molecules of the conjugated diene, thereby producing an endcapped polymer having a halogenated endcap group.

Owner:MASSACHUSETTS LOWELL UNIV OF

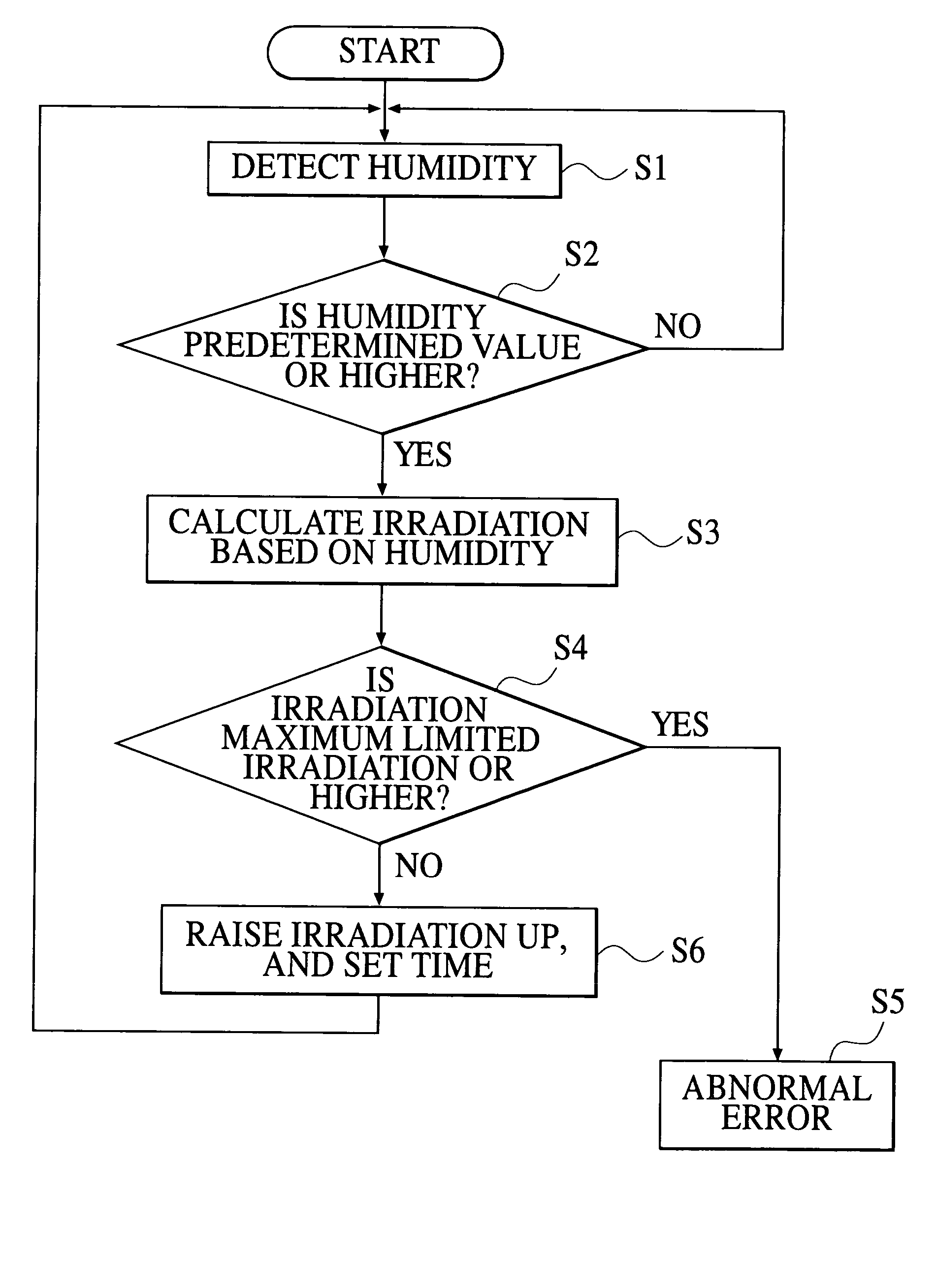

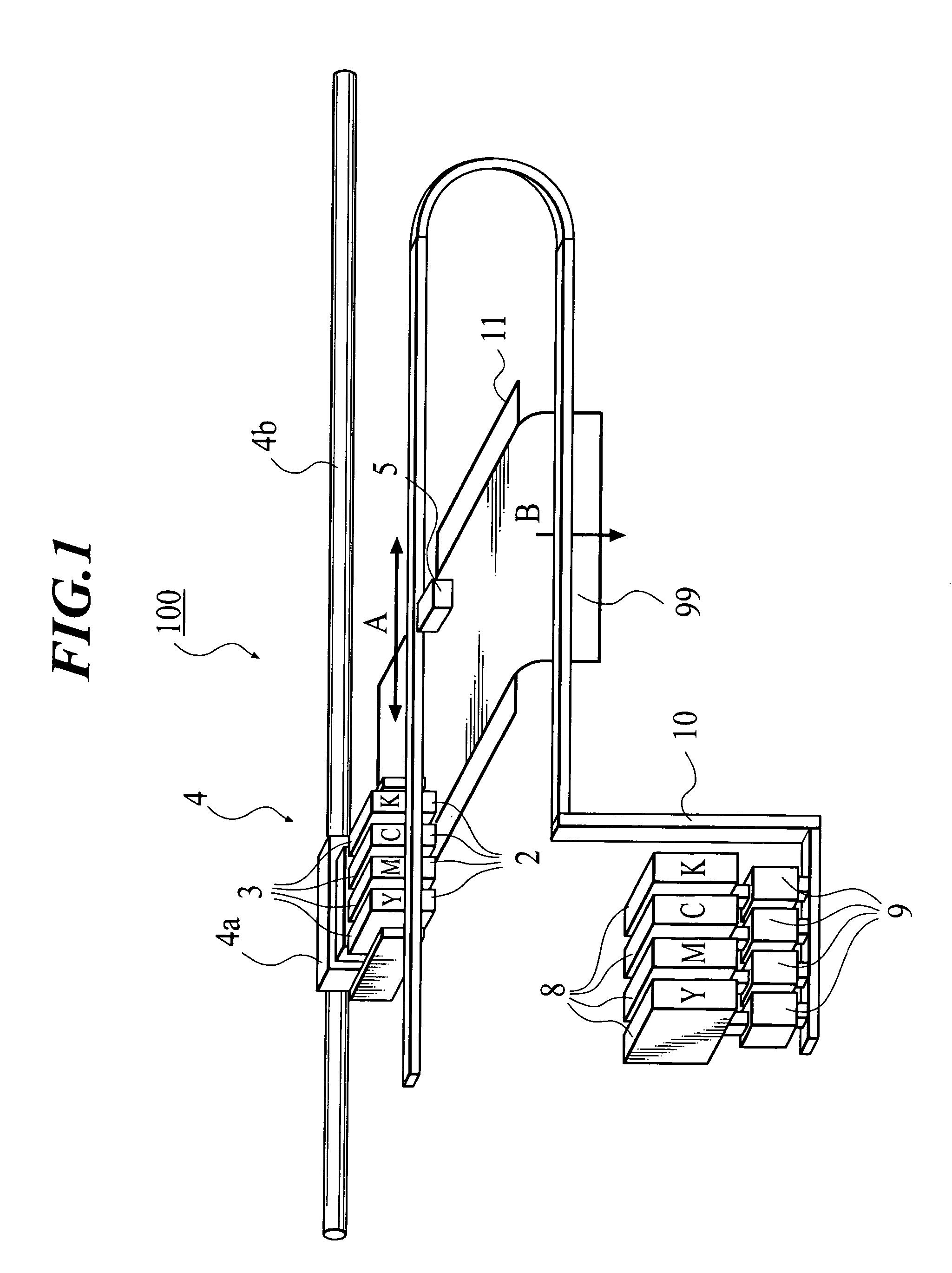

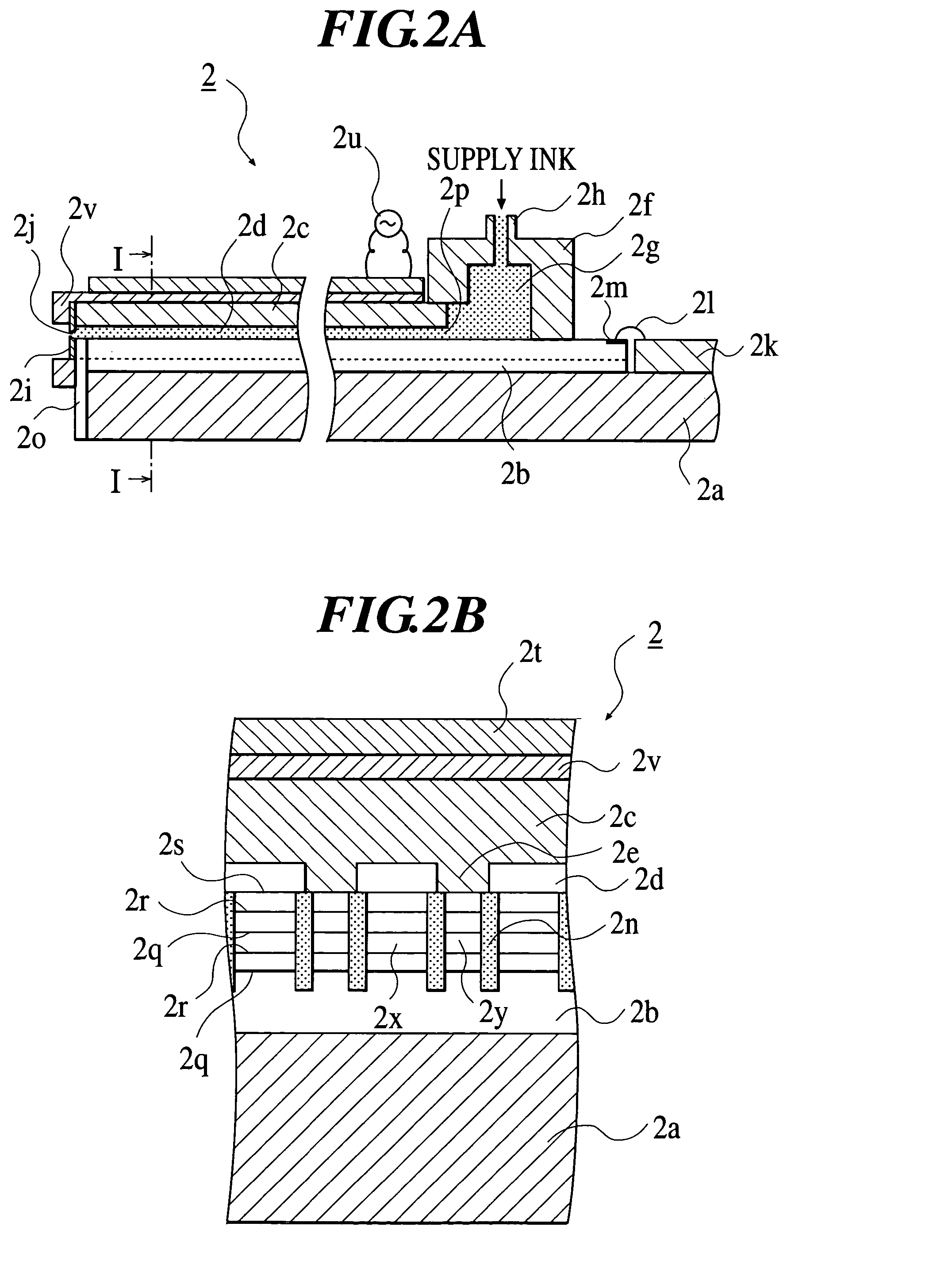

Ink jet printer and image recording method

InactiveUS20040041892A1Improve curing effectIncrease temperatureOther printing apparatusPrinting after-treatmentLight irradiationCationic polymerization

An ink jet printer capable of enhancing curability of cationic polymerization ink in a state that a raise in temperature of a recording medium is prevented as possible. The ink jet printer for recording a desired image on a recording medium by ejecting ink which includes a cationic polymerization component and which is curable when irradiated with light to the recording medium, has: a recording head for ejecting the ink to the recording medium; a light irradiation section for irradiating the light to the ink placed on the recording medium; a humidity detecting section for detecting humidity around the ink placed on the recording medium; and a controller for controlling irradiation of the light to be irradiated from the light irradiation section on the basis of detected humidity detected by the humidity detecting section.

Owner:KONICA CORP

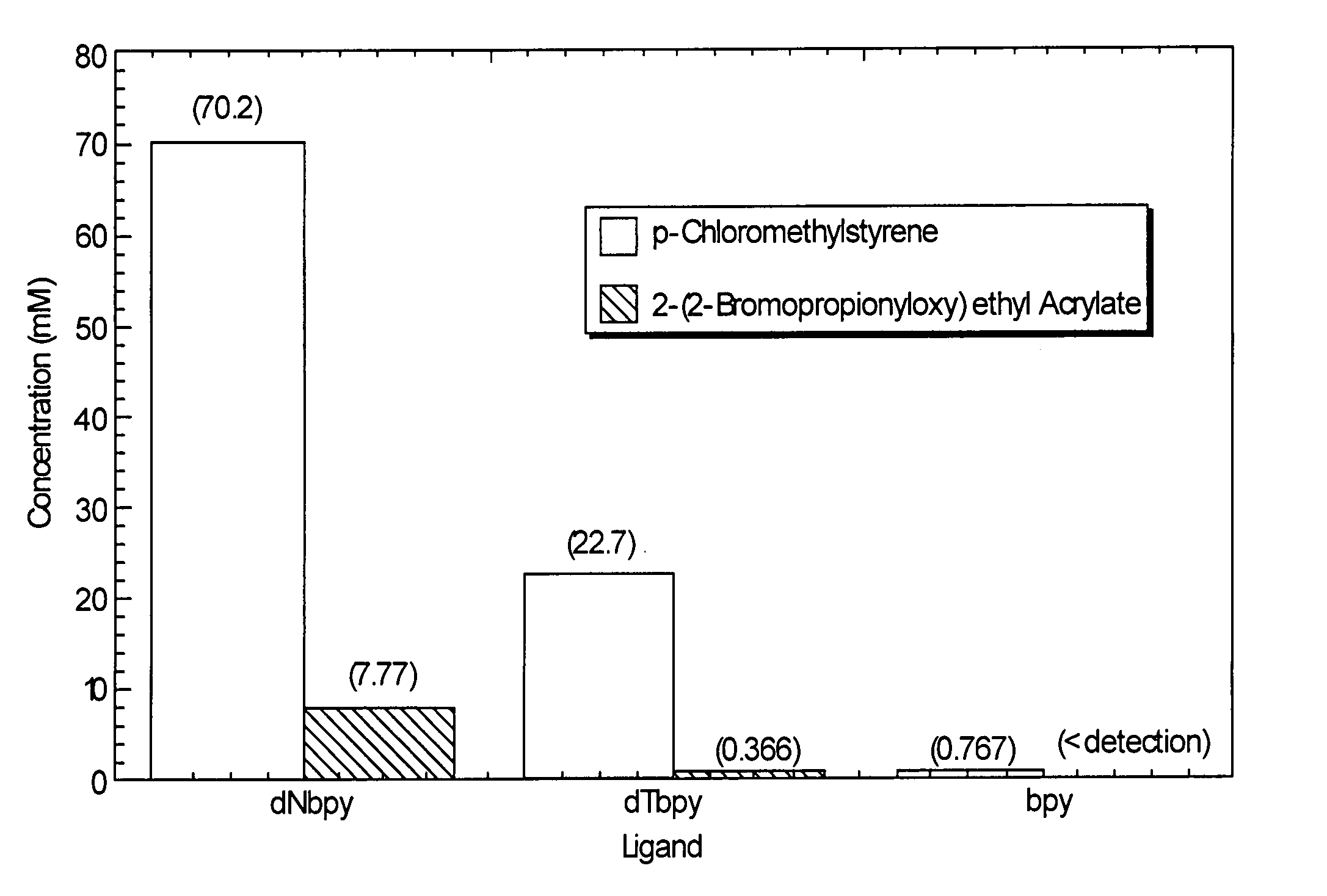

Atom or group transfer radical polymerization

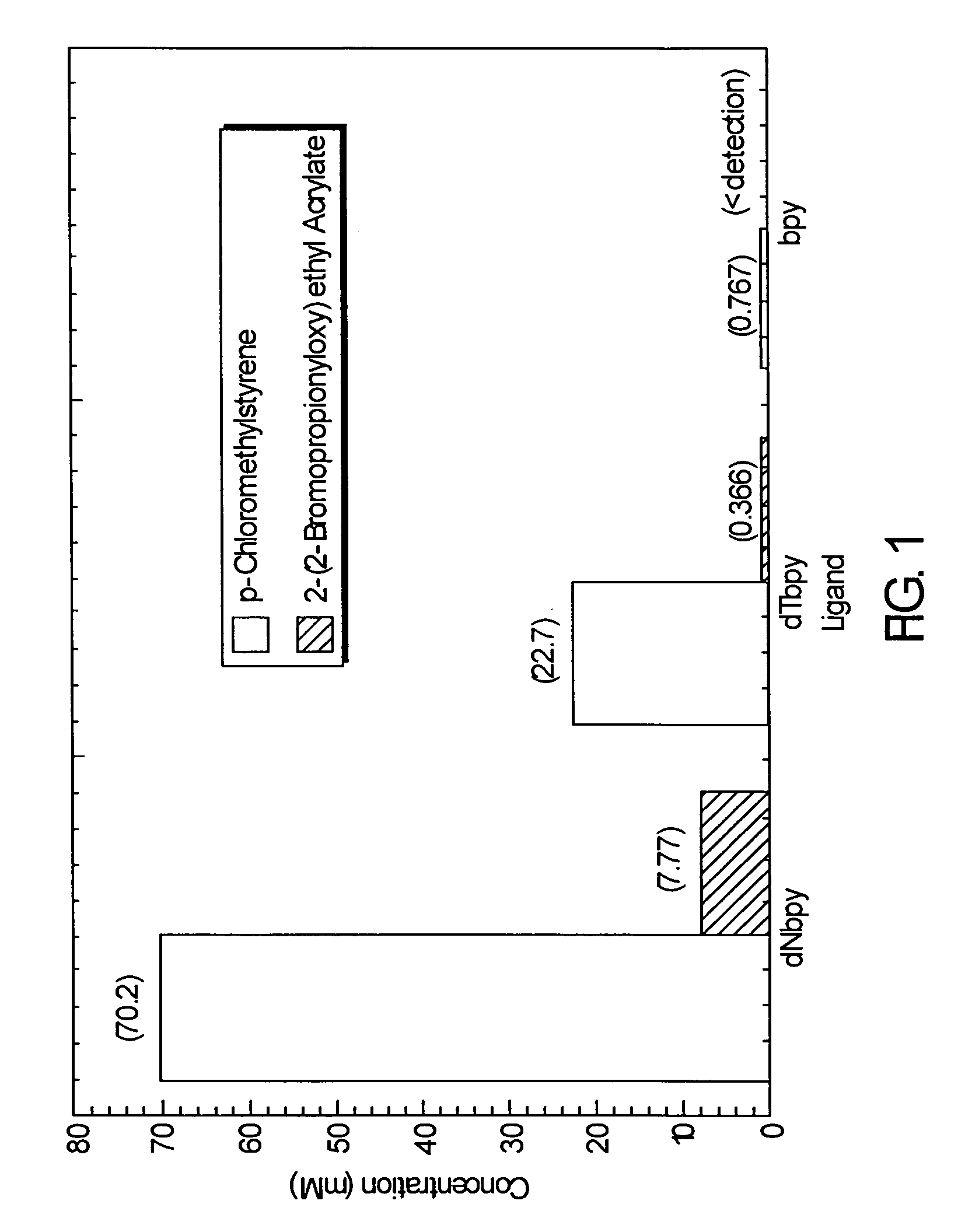

A polymerization process comprising initiating a first polymerization of monomers using an initiator functionalized with an ATRP initiating site, wherein the first polymerization is selected from the group of cationic polymerization, anionic polymerization, conventional free radical polymerization, metathesis, ring opening polymerization, cationic ring opening polymerization, and coordination polymerization to form a macroinitiator comprising an ATRP initiating site and further initiating an ATRP polymerization of radically polymerizable monomers using the macroinitiator comprising an ATRP initiating site. Novel block copolymers may be formed by the disclosed method.

Owner:CARNEGIE MELLON UNIV

Water-dispersible, cationic polymers, a method of making same and items using same

InactiveUS6908966B2Improved wetting composition for wetFree of organic solventsCosmetic preparationsToilet preparationsFiberWater dispersible

The present invention is directed to triggerable, water-dispersible cationic polymers. The present invention is also directed to a method of making triggerable, water-dispersible cationic polymers and their applicability as binder compositions. The present invention is further directed to fiber-containing fabrics and webs comprising triggerable, water-dispersible binder compositions and their applicability in water-dispersible personal care products, such as wet wipes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

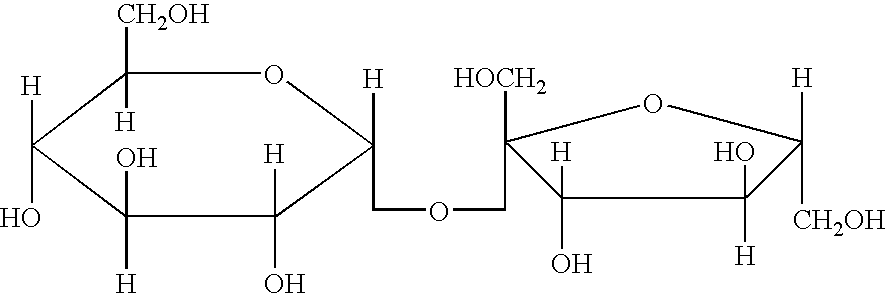

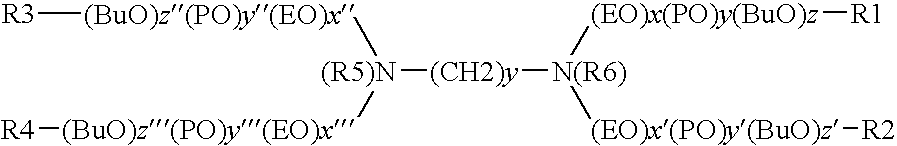

Hair conditioning composition containing a non-guar galactomannan polymer derivative

A hair conditioning composition comprising:a) from about 0.01 wt. % to about 10 wt. % of a non-guar galactomannan polymer derivative having a mannose to galactose ratio of greater than 2:1 on a monomer to monomer basis, said non-guar galactomannan polymer derivative selected from the group consisting of a cationic non-guar galactomannan polymer derivative and an amphoteric non-guar galactomannan polymer derivative having a net positive charge;i. wherein said non-guar galactomannan polymer derivative has a molecular weight from about 1,000 to about 10,000,000; andii. wherein said non-guar galactomannan polymer derivative has a cationic charge density from about 0.7 meq / g to about 7 meq / g;b) a conditioning agent selected from the group consisting of cationic surfactants, cationic polymers, nonvolatile silicones, nonvolatile hydrocarbons, saturated C14 to C22 straight chain fatty alcohols, nonvolatile hydrocarbon esters, and mixtures thereof; andc) wherein said hair conditioning composition is substantially free of an anionic surfactant.

Owner:THE PROCTER & GAMBLE COMPANY

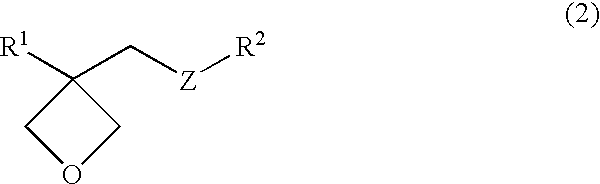

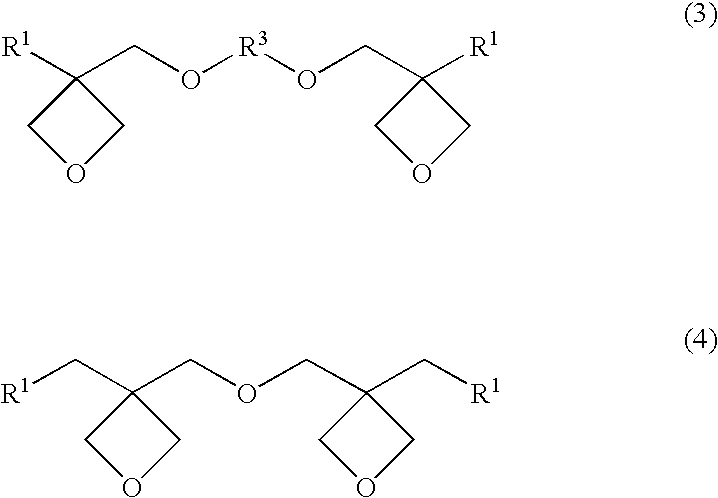

Photocurable resin composition for sealing material and method of sealing

InactiveUS6586496B1Liquid crystal compositionsNon-fibrous pulp additionCationic polymerizationHeat resistance

A photo-curable resin composition for sealing material, which is superior in the photo-curing performance and in the prompt curing property and is better in the adhesive property, in the resistance to moisture permeation and in the heat resistance, the photo-curable resin composition comprising(A) a compound having oxetane ring,(B) a photoinitiator for cationic polymerization and(C) a silane coupling agent,wherein the composition has a viscosity in the range from 0.01 to 300 Pa.s at 25° C.

Owner:MITSUI CHEM INC

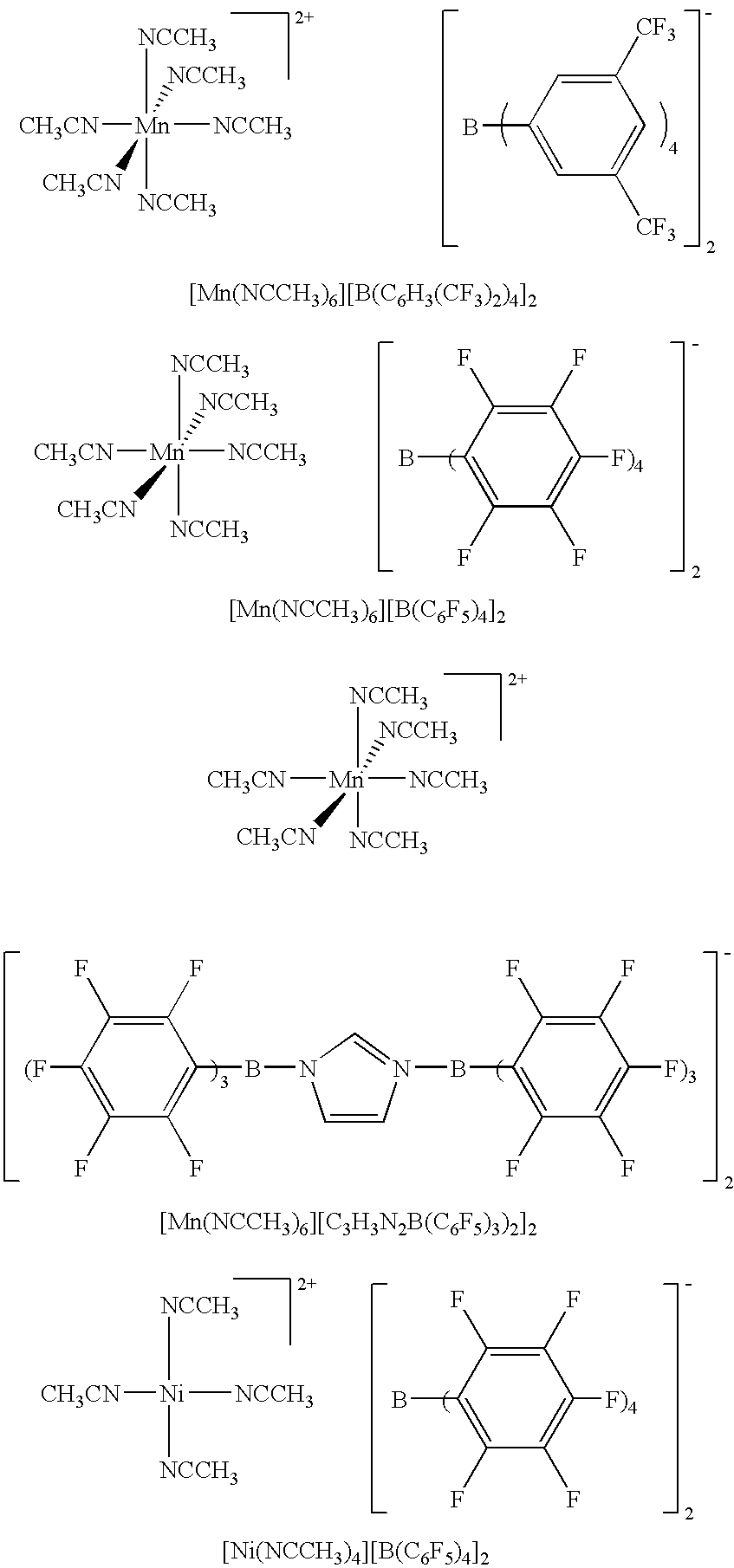

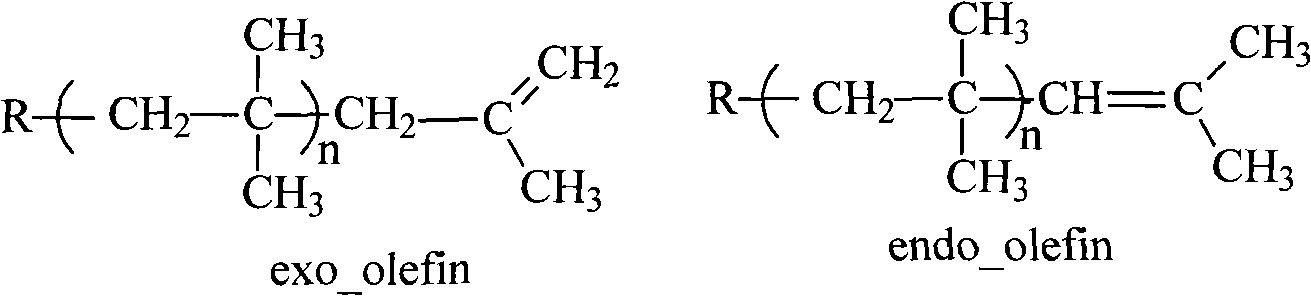

Process for the production of highly reactive polyisobutenes

InactiveUS7291758B2Hydrocarbons from unsaturated hydrocarbon additionHydrocarbonsCationic polymerizationSolvent

The present invention relates to a process for the production of highly reactive polyisobutenes with a content of terminal vinylidene groupings of greater than 80 mol % and an average molecular weight of 500 to 10,000 Dalton by cationic polymerization of isobutene or of isobutene and monomers copolymerizable with isobutene in the presence of solvent-stabilized transition metal complexes with weakly coordinated anions.

Owner:BASF SE

Liquid hand dishwashing detergent composition

InactiveUS20100197553A1Lower Level RequirementsGood grease cleaning performanceCationic surface-active compoundsDetergent mixture composition preparationCationic polymerizationPolymer

A liquid hand dishwashing detergent composition comprising a cationic polymer and a humectant, a method of cleaning dishes with a liquid hand dishwashing detergent composition comprising a cationic polymer and a humectant, and a method of providing skin hydration and / or moisturization the context of a manual dishwashing operation, using liquid hand dishwashing detergent composition comprising a cationic polymer and a humectant.

Owner:THE PROCTER & GAMBLE COMPANY

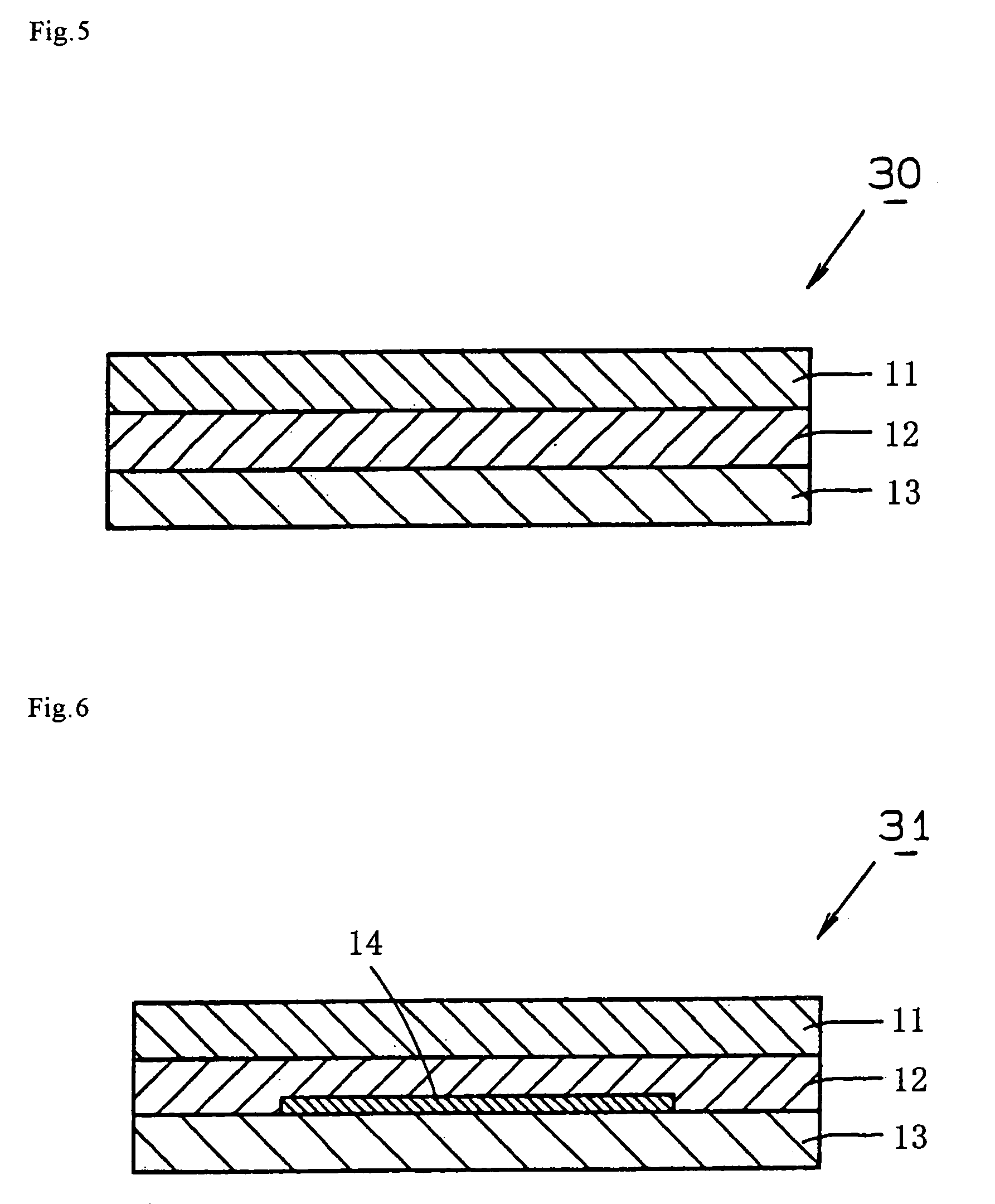

Cationic polymer composition and its use in conditioning applications

A composition of a cationic polygalactomannan or a derivative of cationic polygalactomannans is provided that has a mean average molecular weight (Mw) having a lower limit of 5,000 and an upper limit of 200,000 and has a light transmittance in a 10% aqueous solution of greater than 80% at a light wavelength of 600 nm and a protein content of less than 1.0% by weight of polysaccharide, and aldehyde functionality content of at least of 0.01 meq / gram. This composition is prepared in continuous or batch processes using either oxidizing reagents or combination of hydrolytic reagents and oxidizing reagents. This composition is used in personal care and household care products.

Owner:HERCULES LLC

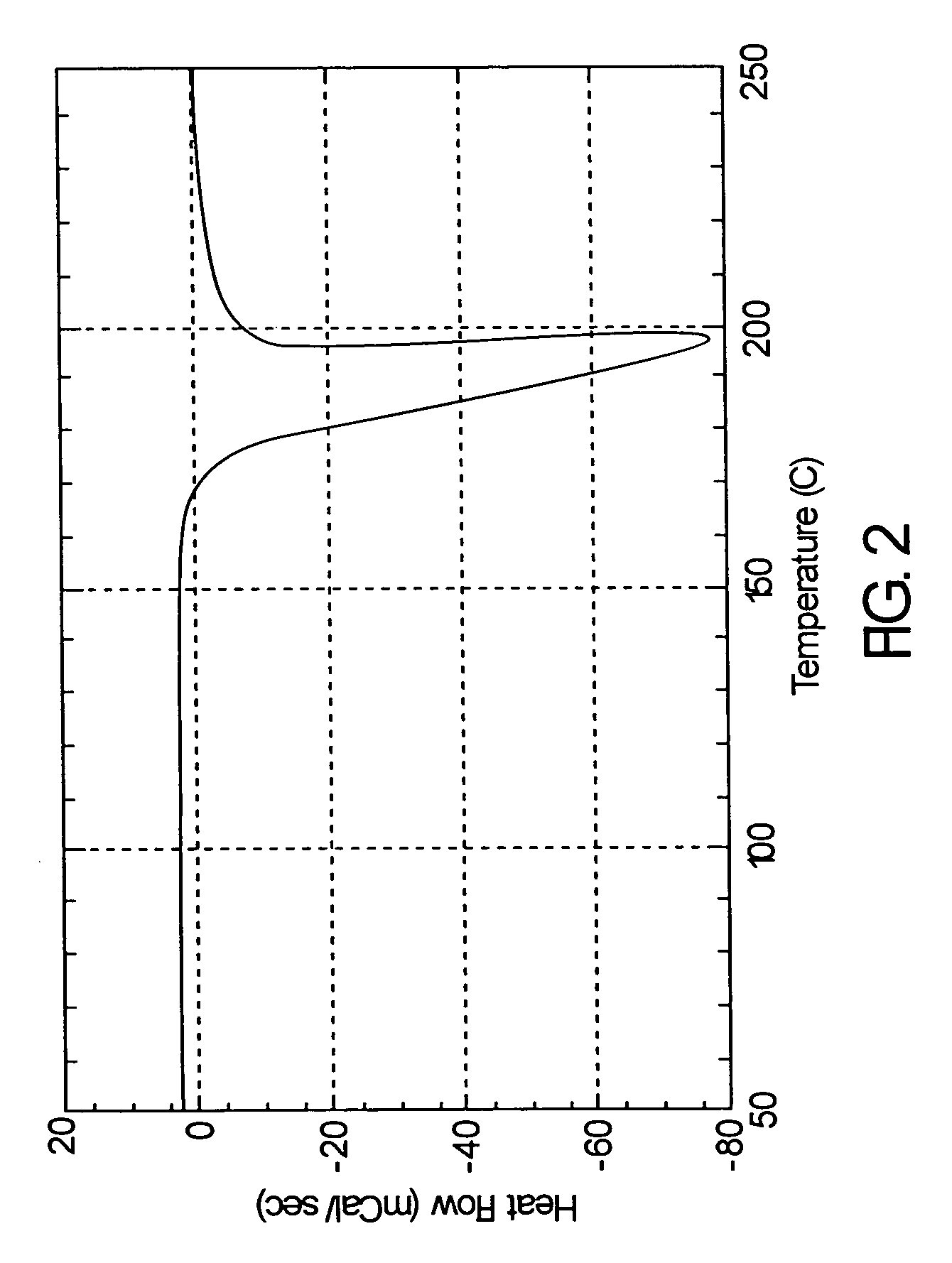

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

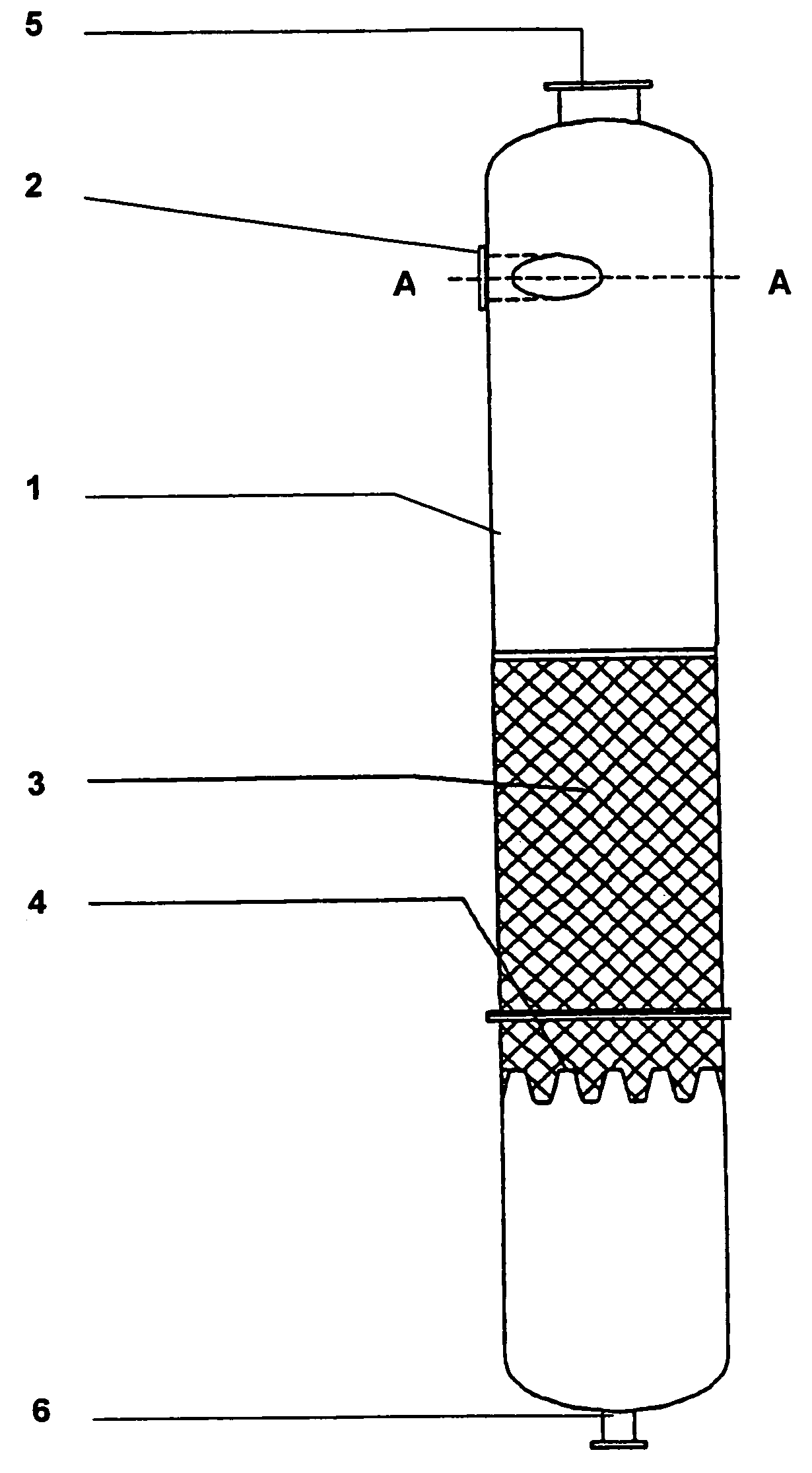

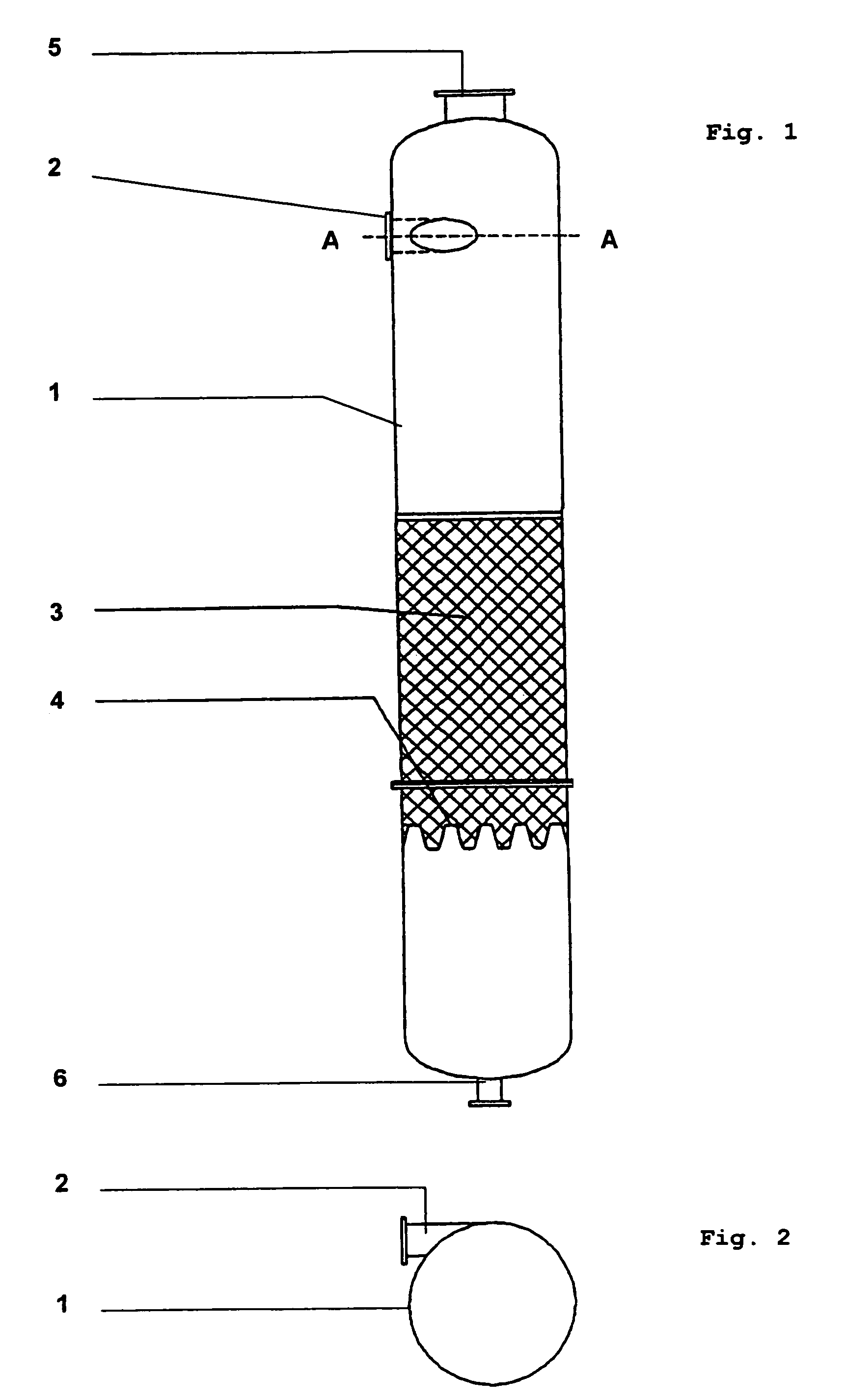

Method for the processing of a liquid reaction discharge of the cationic polymerization of isobutene

InactiveUS7038008B2Easy to useUndesired reactionWater/sewage treatment by centrifugal separationReversed direction vortexGas phaseCationic polymerization

A process for working up a liquid reaction discharge of the cationic polymerization of isobutene, which substantially comprises polyisobutene, unconverted isobutene and an inert diluent, in which the reaction discharge is heated and is let down into a flash container, is described, the reaction discharge separating, as a result of the flashing, into a polyisobutene-containing liquid phase and a gas phase containing the main amount of the isobutene contained in the reaction discharge and of the diluent.

Owner:BASF AG

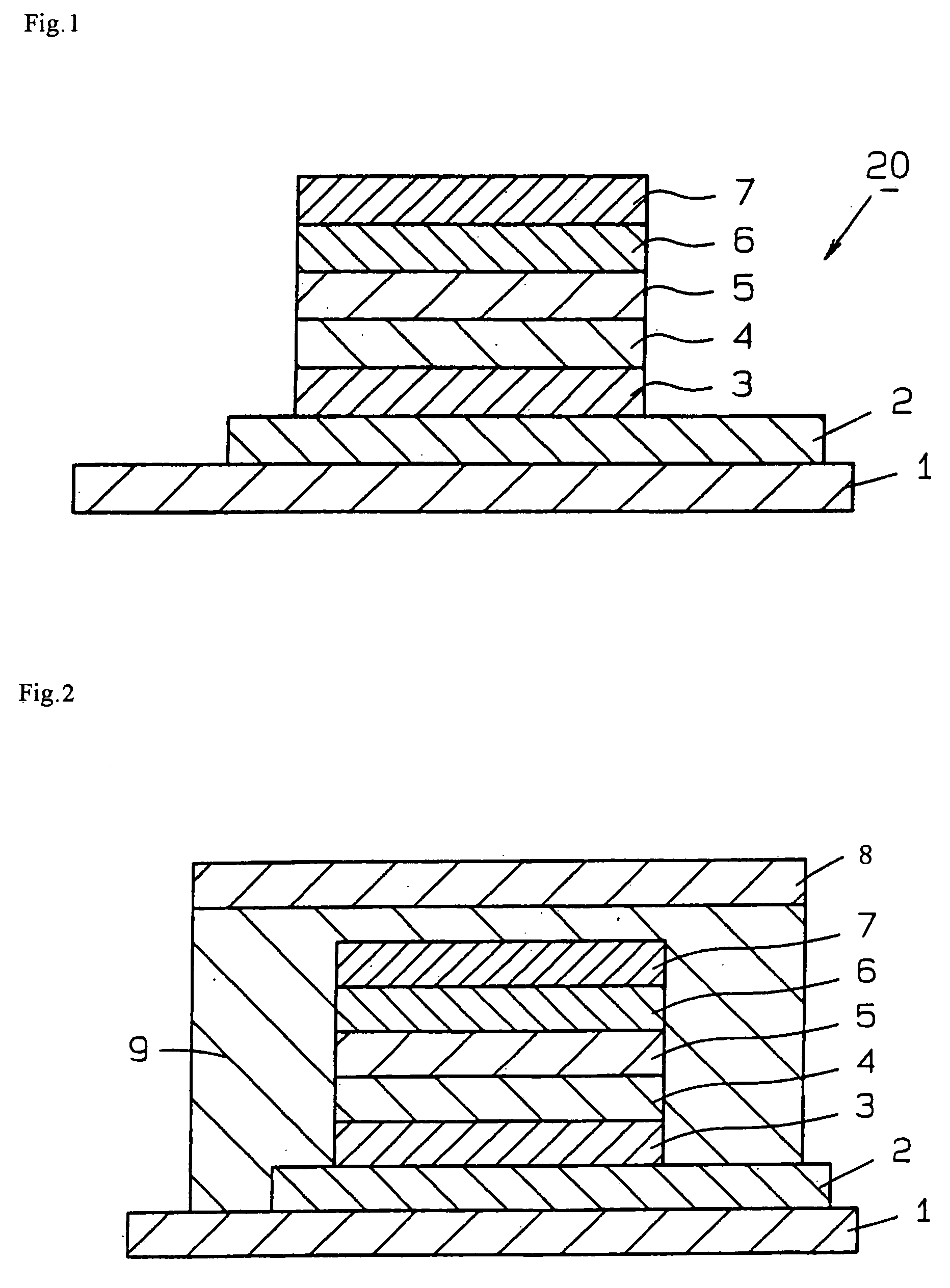

Adhesive for sealing organic electroluminescent element and use thereof

InactiveUS20050227082A1Synthetic resin layered productsSolid-state devicesLight irradiationCationic polymerization

It is an object of the present invention to provide an adhesive for sealing an organic electroluminescence device, an adhesive tape for sealing an organic electroluminescence device, a double-faced adhesive tape for sealing an organic electroluminescence device, a method of sealing an organic electroluminescence device and an organic electroluminescence device, which can seal an organic electroluminescence device without degrading it with light or heat. The present invention relates to an adhesive for sealing an organic electroluminescence device, which comprises a photo cationic polymerizable adhesive containing a photo cationic polymerizable compound and a photo cationic polymerization initiator and, initiating a curing reaction by light irradiation and proceeding the curing reaction by a dark reaction even after interrupting the light irradiation.

Owner:SEKISUI CHEM CO LTD

Low viscosity hair care composition

This invention relates to a foamable hair care composition comprising an anionic surfactant, a co-surfactant, a viscosity reducing agent, and a cationic polymer having a weight average molecular weight of less than about 1,000,000 g / mol. The hair care composition may further comprise a silicone, wherein the silicone particle size is less than about 10 microns. The hair care composition has a viscosity of from about 1 to about 3,000 cps.

Owner:THE PROCTER & GAMBLE COMPANY

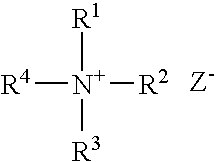

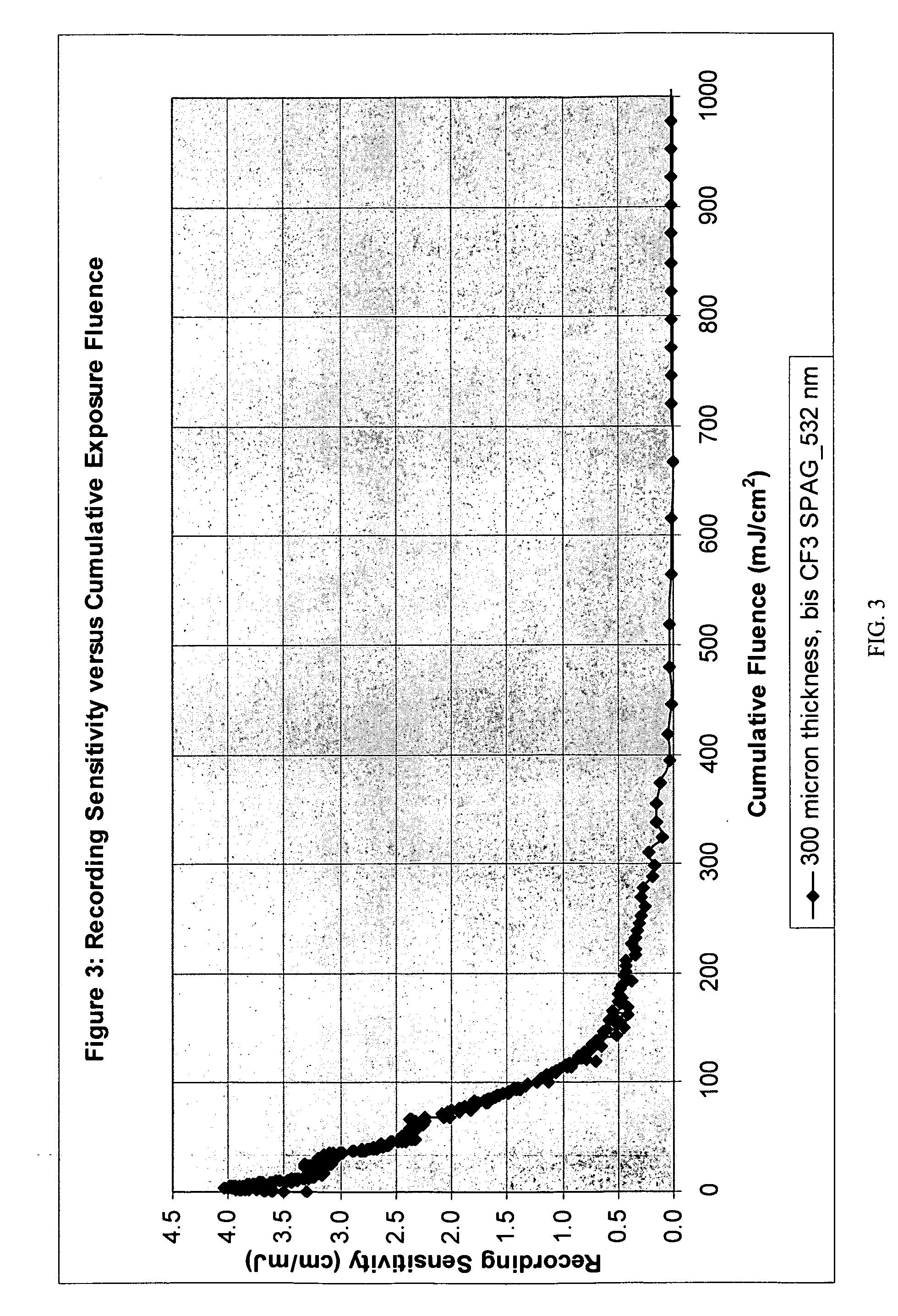

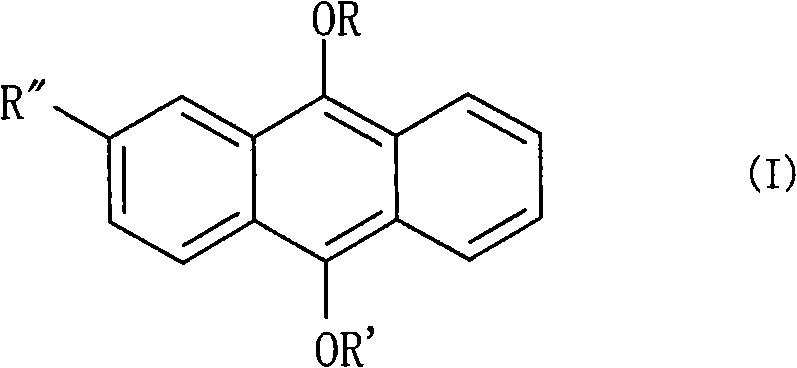

Fluoroarylsulfonium photoacid generators

InactiveUS20090182172A1Rapid sensitizationImprove efficiencyGroup 3/13 element organic compoundsPhosphorus organic compoundsCationic polymerizationPhotoacid

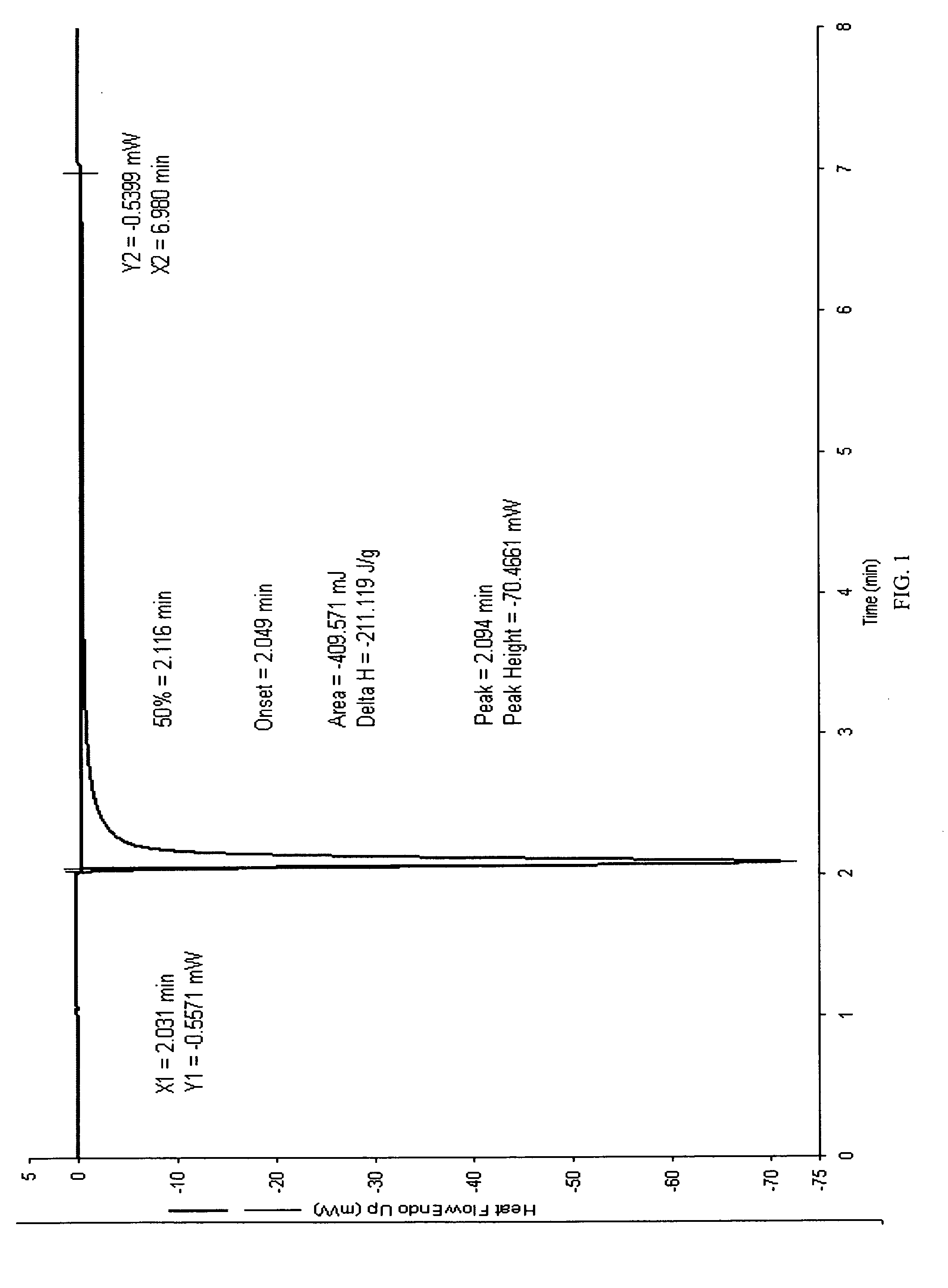

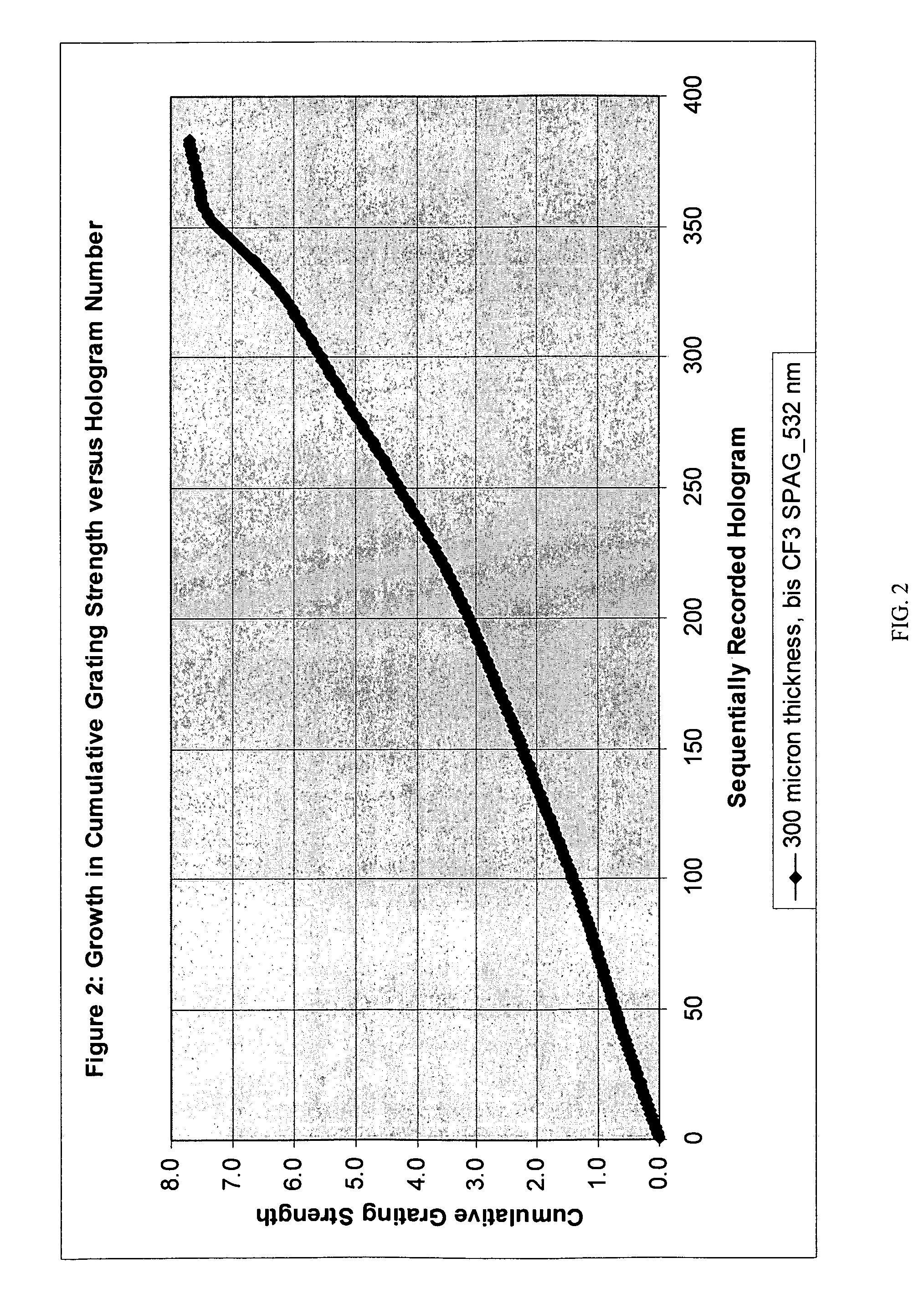

The present invention discloses a new class of triarylsulfonium salt photoacid generators (PAGs), which are thermally stable and can be activated by long wavelength UV or visible light. The sulfonium PAGs of the present invention are additionally soluble in monomers that can be polymerized by cationic polymerization chemistry, and mixtures of said sulfonium PAGs and monomers can be stored for long periods of time without undergoing polymerization. Furthermore, typical holographic recording media comprising one of these sulfonium PAGs, polymerizable monomer(s), a sensitizing dye, and a binder can be stored for long periods of time without exhibiting significant loss of recording sensitivity. Preferred sulfonium PAGs of the present invention are sulfonium PAGs substituted with one or more fluoro or fluoroalkyl groups.

Owner:APRILIS

Initiating system for preparing high-reaction activity polyisobutene and copolymer of polyisobutene

ActiveCN101955558ARegulate nucleophilicityReduce formationSimple Organic CompoundsCationic polymerization

The invention relates to an initiating system for preparing high-reaction activity polyisobutene and a copolymer of polyisobutene, which comprises an initiator for initiating the cationic polymerization of an isobutene-containing material, a coinitiator and a compounding ingredient, wherein the coinitiator is FeCl3; the compounding ingredient is an oxygen- or sulfur-containing organic compound; the molar mixing ratio of the FeCl3 and the isobutene raw material ranges from 0.01 to 3.0; the molar mixing ratio of the initiator to the FeCl3 ranges from 0.1 to 2.0; and the molar mixing ratio of the compounding ingredient to the FeCl3 ranges from 0.1 to 3.4. In the invention, the FeCl3 is used as the compounding ingredient to be compounded with the oxygen- or sulfur-containing compounding ingredient to promote a reaction for removing active central carbocations beta-H, thus the high-reaction activity polyisobutene and the copolymer of polyisobutene, which have terminal alpha-double bond content of more than 75mol percent (even over 90 percent) and narrow molecular weight distribution, can be obtained by a one-step method. The process steps are simplified. The production cost is low. Therepeatability is high. The environmental pollution is light. And the industrial application is easy.

Owner:BEIJING UNIV OF CHEM TECH

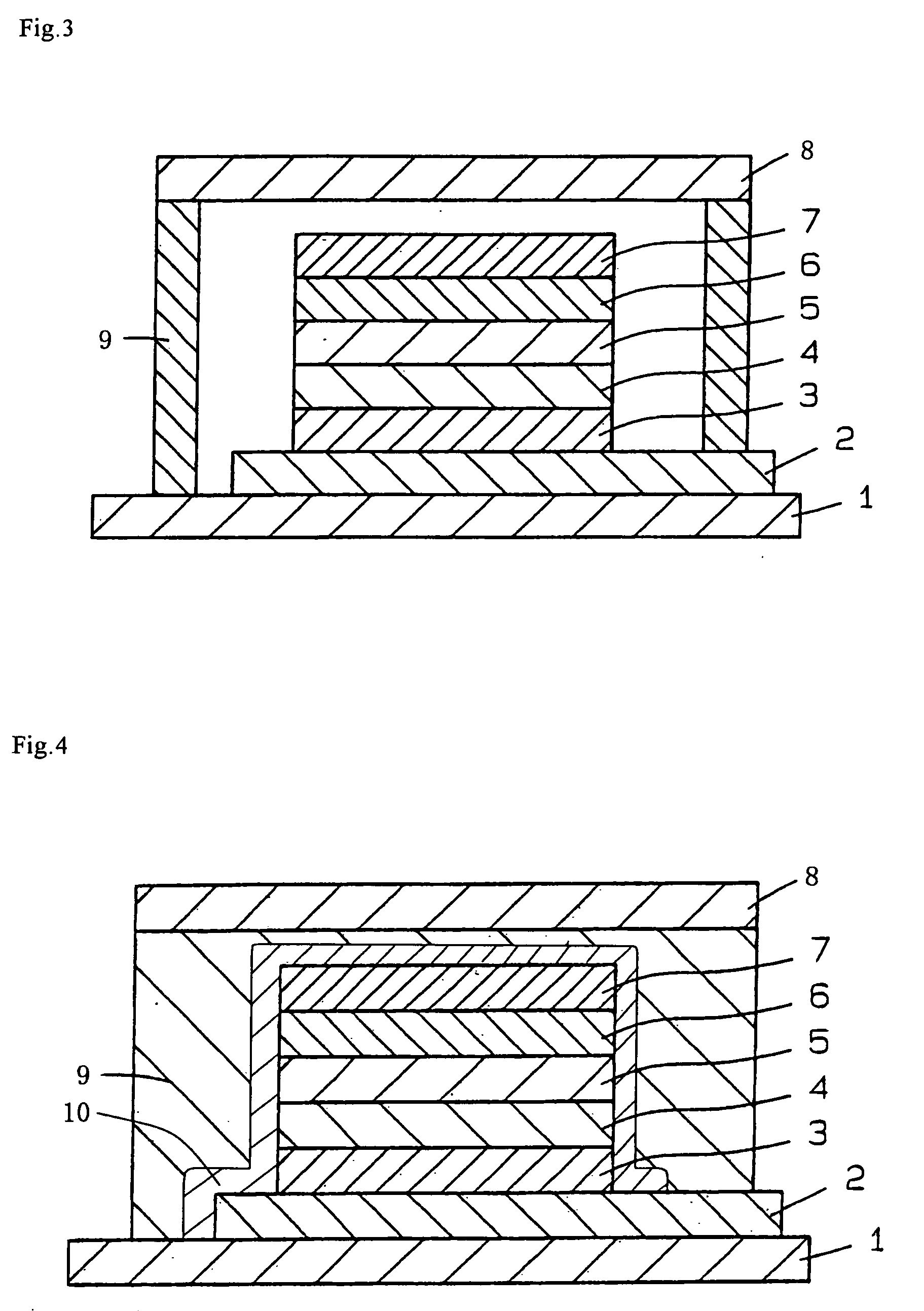

Photocurable adhesive agent, polarizing plate using the photocurable adhesive agent, method for production of the polarizing plate, optical member, and liquid crystal display device

ActiveCN101636672AImprove reliabilityPrevent discolorationNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyTectorial membrane

The invention provides a photocurable adhesive agent which has excellent storage stability, can prevent the discoloration of the adhesive agent itself or a material to be adhered during curing, has a high curing rate, and can provide good adhesion; a polarizing plate using the photocurable adhesive agent; a method for producing the polarizing plate; an optical member; and a liquid crystal displaydevice. Specifically, the invention discloses a photocurable adhesive agent for adhering a protective film to a polarizer comprising a polyvinyl alcohol resin film having iodine or a dichroic dye adsorbed and oriented thereon. The photocurable adhesive agent comprises: 100 parts by mass of an epoxy resin (A) having two or more epoxy groups in the molecule, wherein at least one of the epoxy groupsis an alicyclic epoxy group; 5 to 1000 parts by mass of an epoxy resin (B) having two or more epoxy groups in the molecule and containing substantially no alicyclic epoxy group; and 0.5 to 20 parts by mass of a photo-cationic polymerization initiator (C).

Owner:SUMITOMO CHEM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com