Patents

Literature

82 results about "Lyotropic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

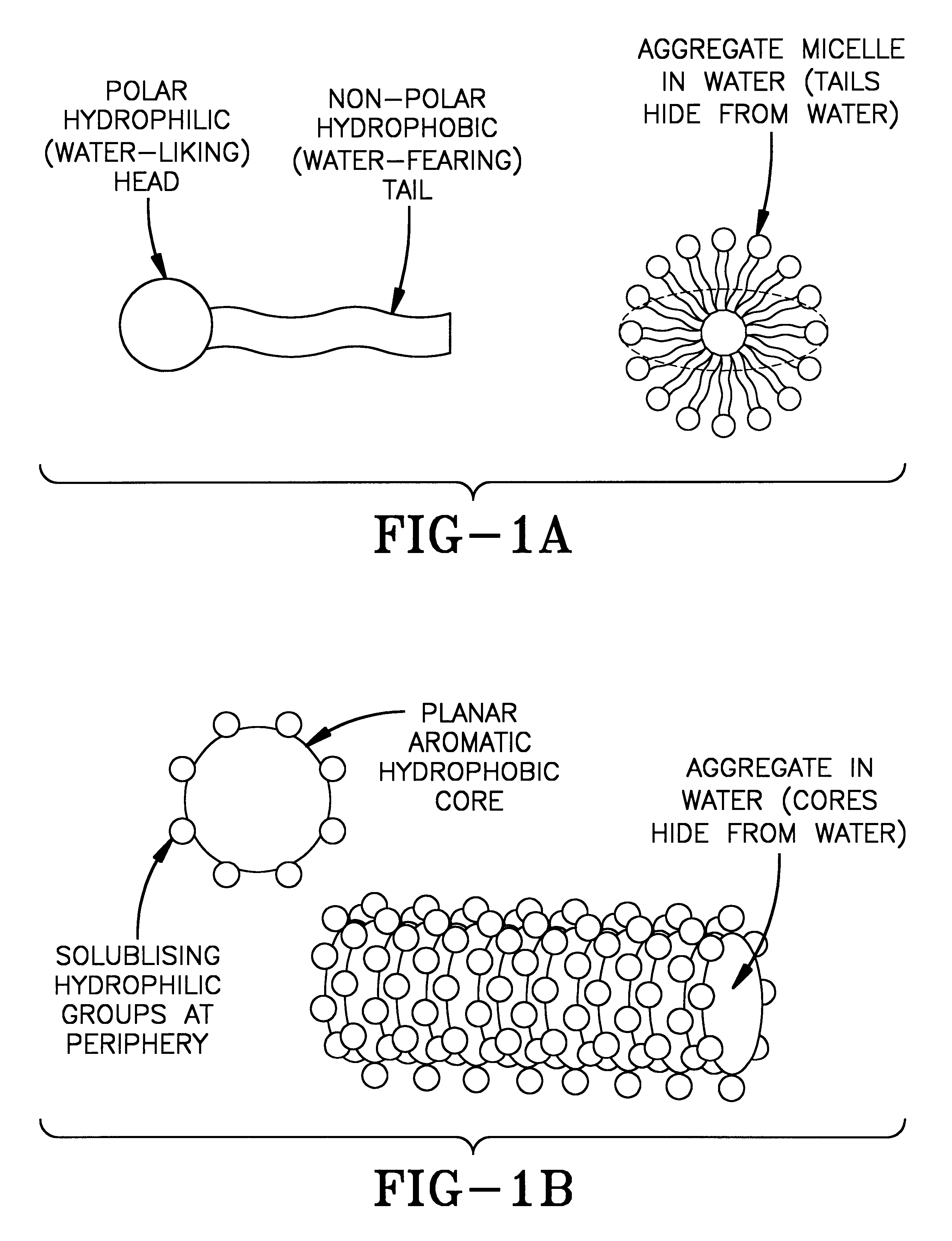

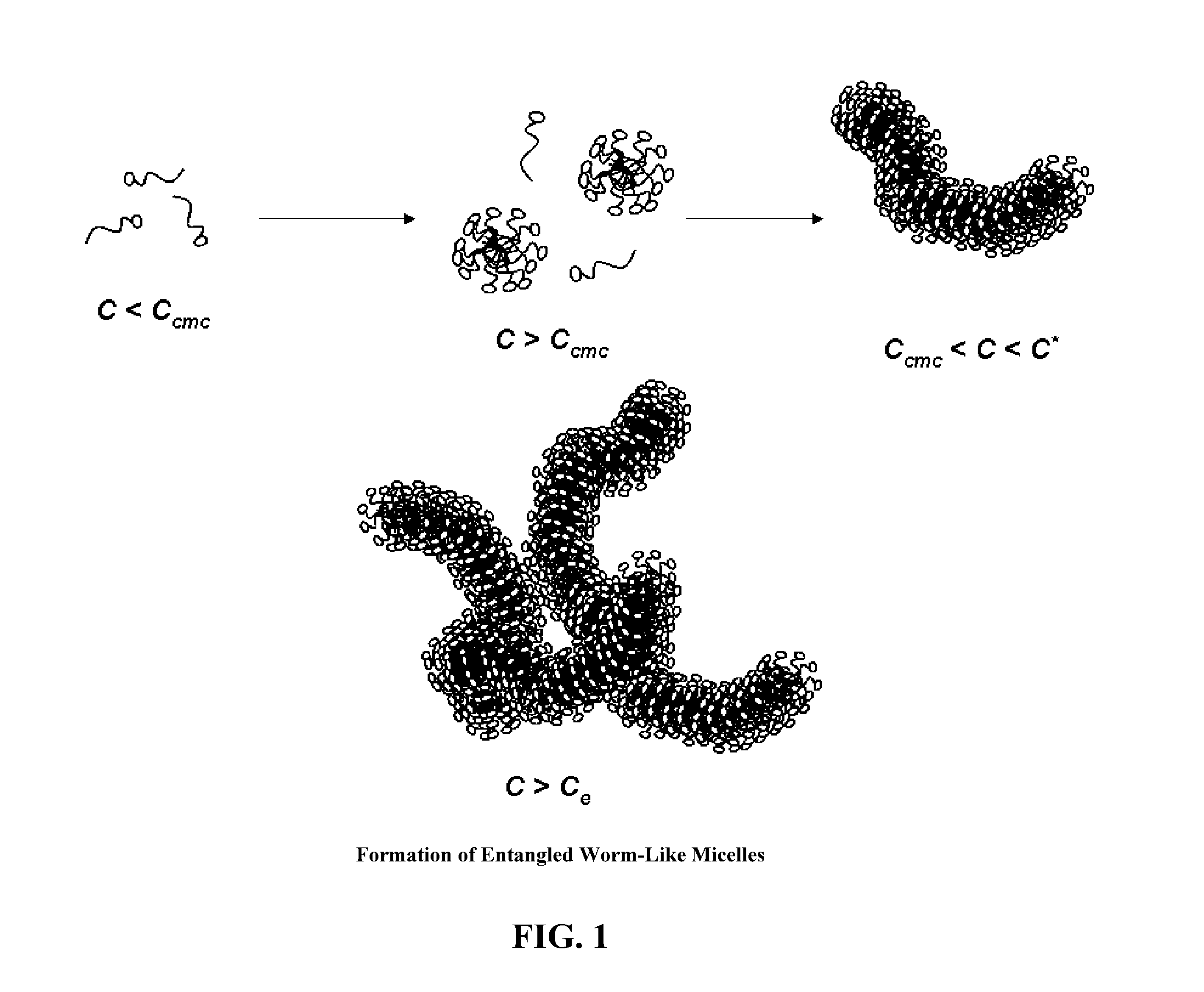

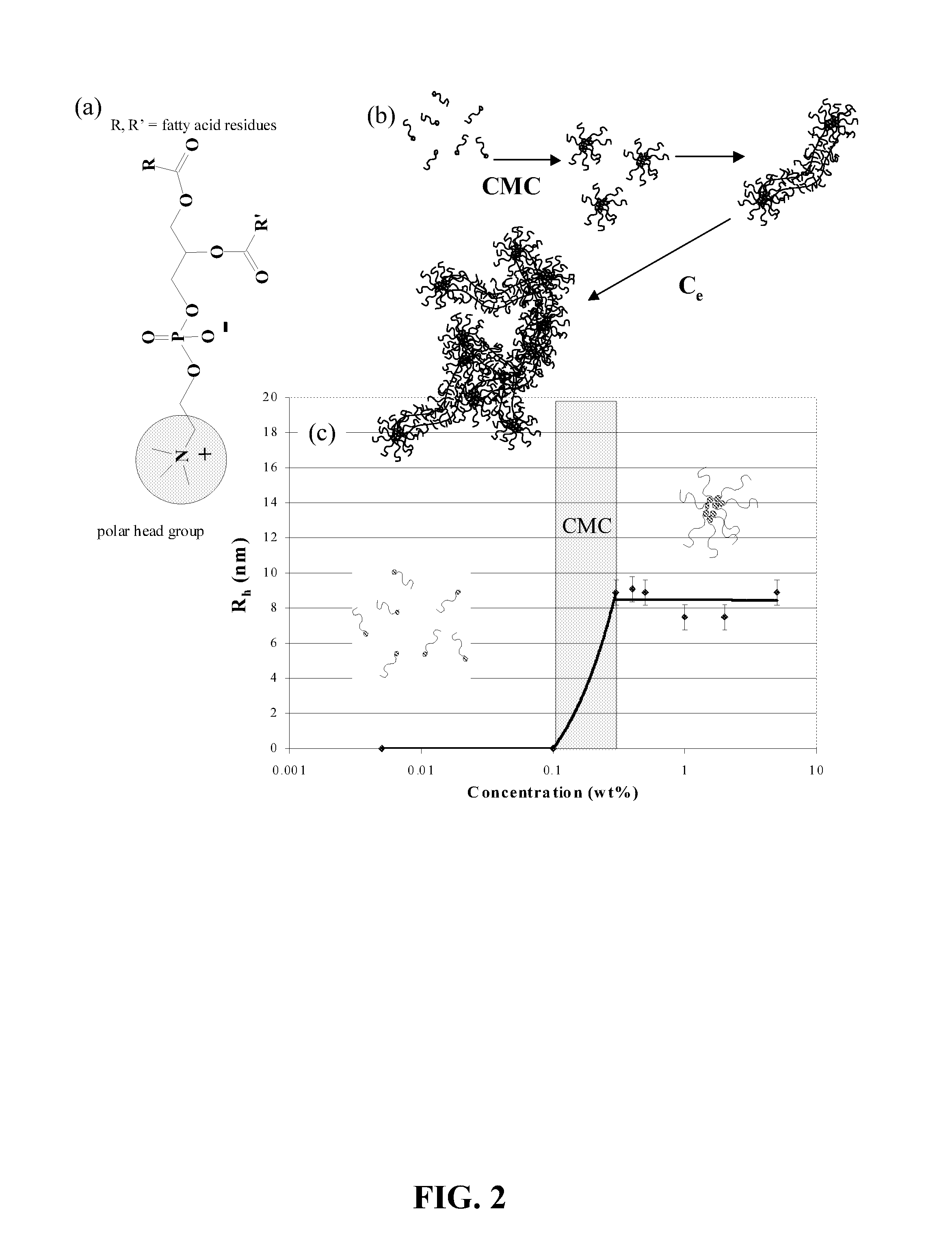

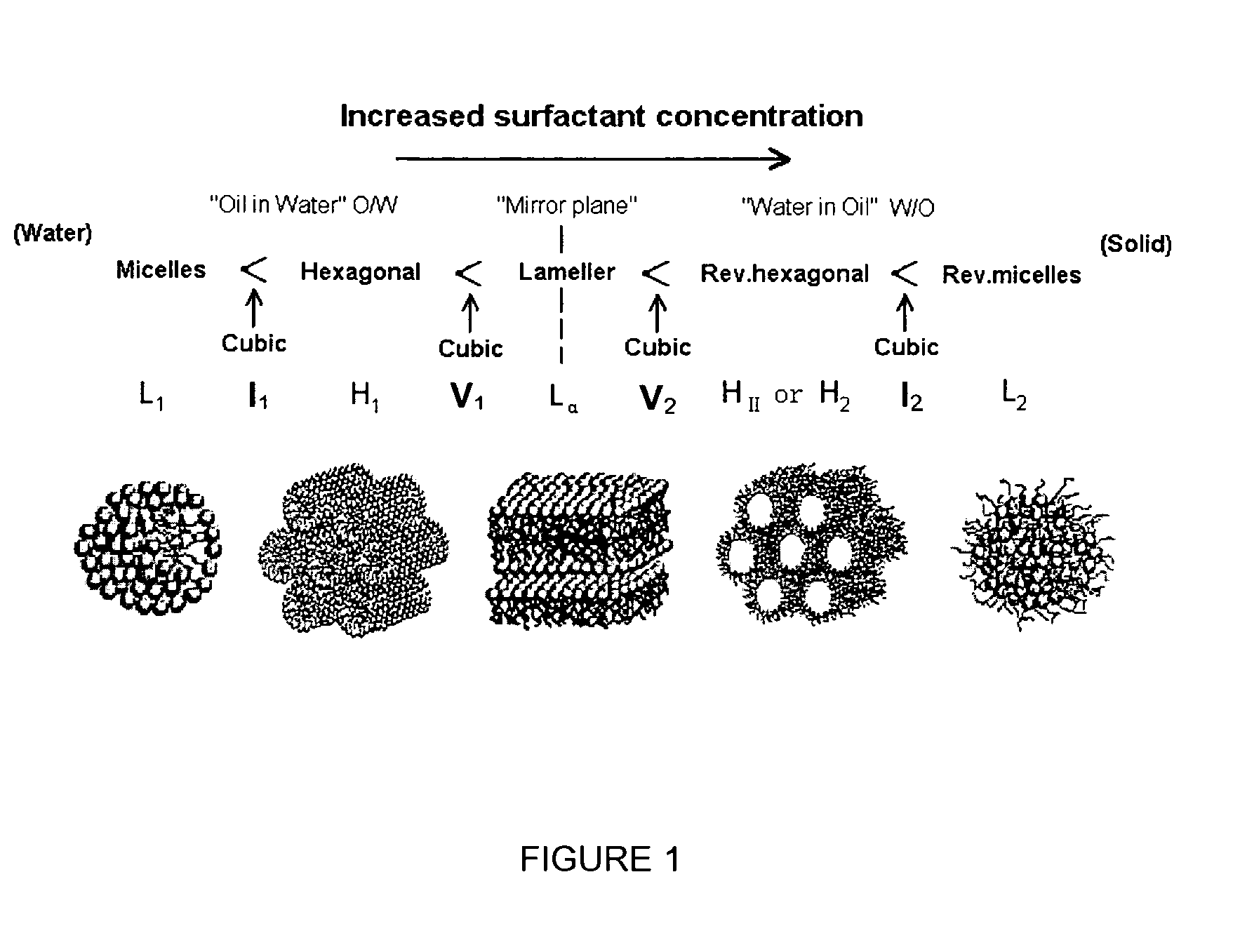

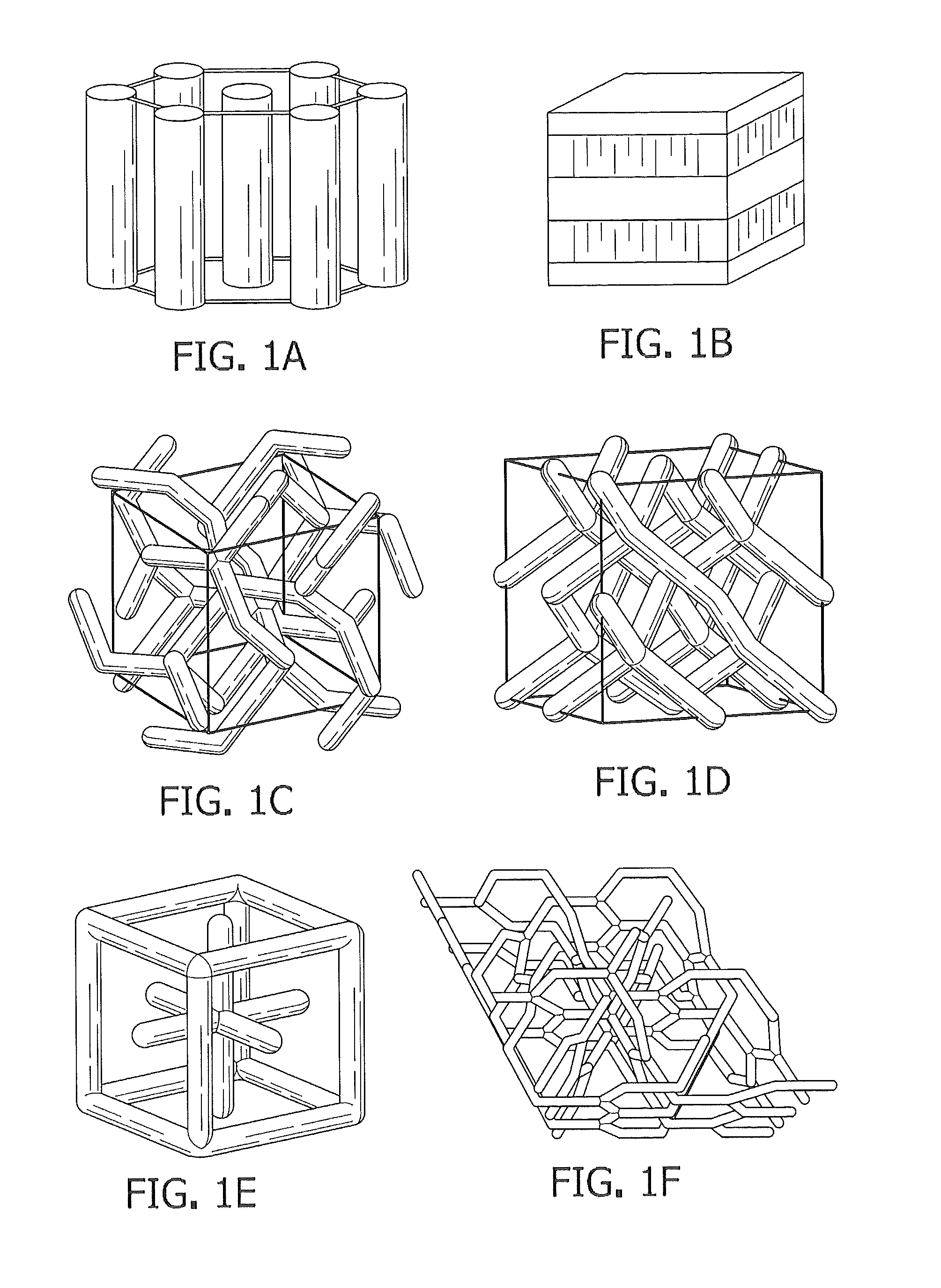

A material is called lyotropic if it forms liquid crystal phases upon the addition of a solvent. Historically the term was used to describe materials composed of amphiphilic molecules. Such molecules consist of an ionic or non-ionic hydrophilic head-group which is attracted to water, and attached to a hydrophobic group which is repelled by water. Typical hydrophobic groups are saturated or unsaturated hydrocarbon chains. Examples of amphiphilic compounds are the salts of fatty acids; phospholipids. Many simple amphiphiles are used as detergents. Lyotropic liquid crystal phases in these materials are formed by a process of self-assembly that is driven by the hydrophobic effect. Lyotropic liquid crystal phases are formed on the dissolution of amphiphilic molecules of a material in a solvent. There are several different type of lyotropic liquid crystal structures. Each of these different types has a different extent of molecular ordering within the solvent matrix.

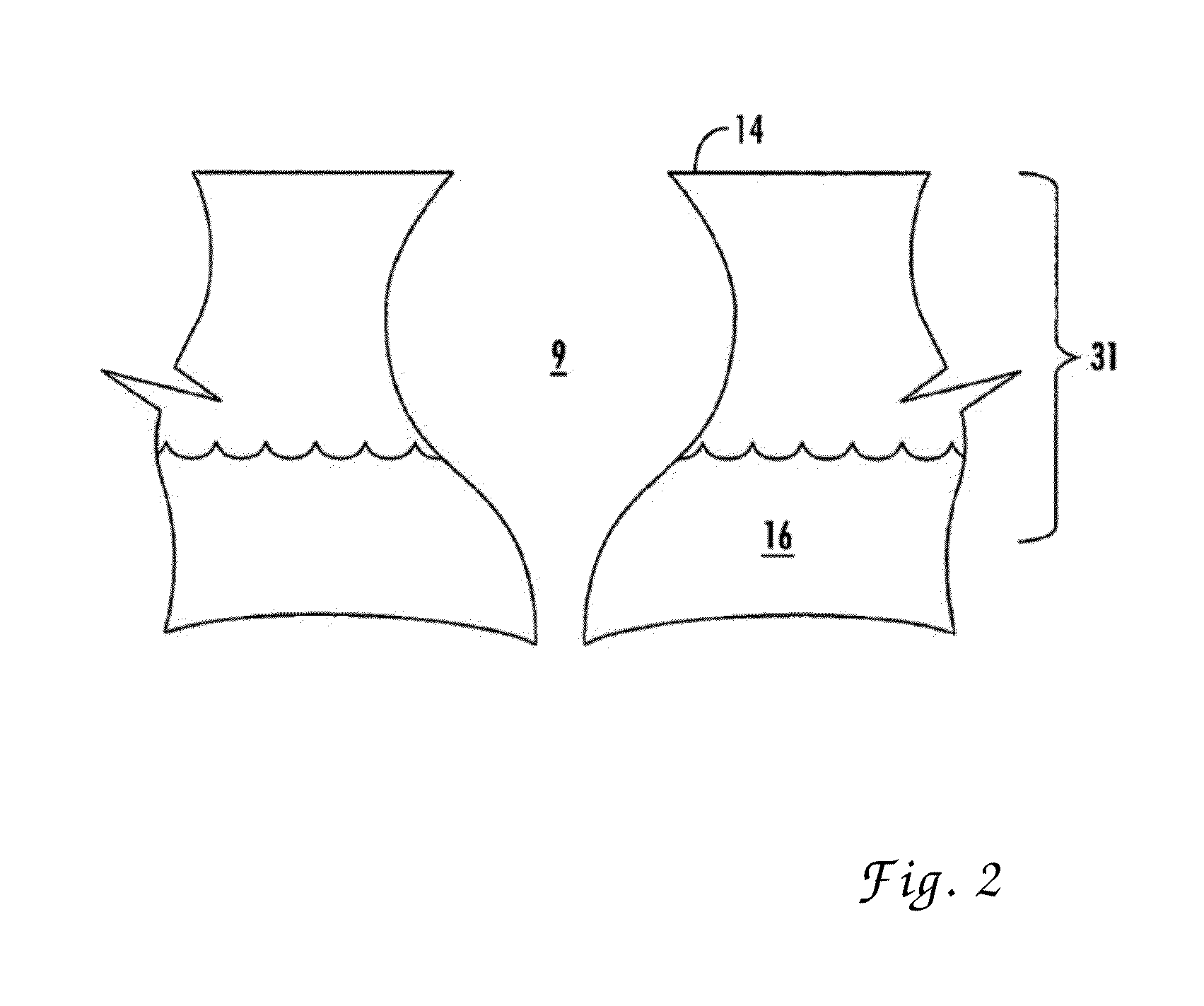

Liquid crystalline peroxide compositions and methods for coloring and/or bleaching hair

InactiveUS6238653B1Shorten the timeCosmetic preparationsHair removalLiquid crystallineAdditive ingredient

An aqueous peroxide composition for coloring or lightening hair comprising (a) 1-99% of an aqueous phase containing (ii) 1-55% by weight of the total composition of water, (ii) 1-45% hydrogen peroxide, and (iii) a water soluble cosolvent; and (b) 0.1-60% of an oil phase; and (c) 1-65% of an organic, amphiphilic, surface active ingredient capable of interacting with the water phase and the oil phase to form lyotropic liquid crystals containing said water phase ingredients; a method for coloring or lightening hair using the peroxide composition, and a method for reducing the amount of time necessary to permanently color hair using the peroxide composition.

Owner:REVLON CONSUMER PROD CORP

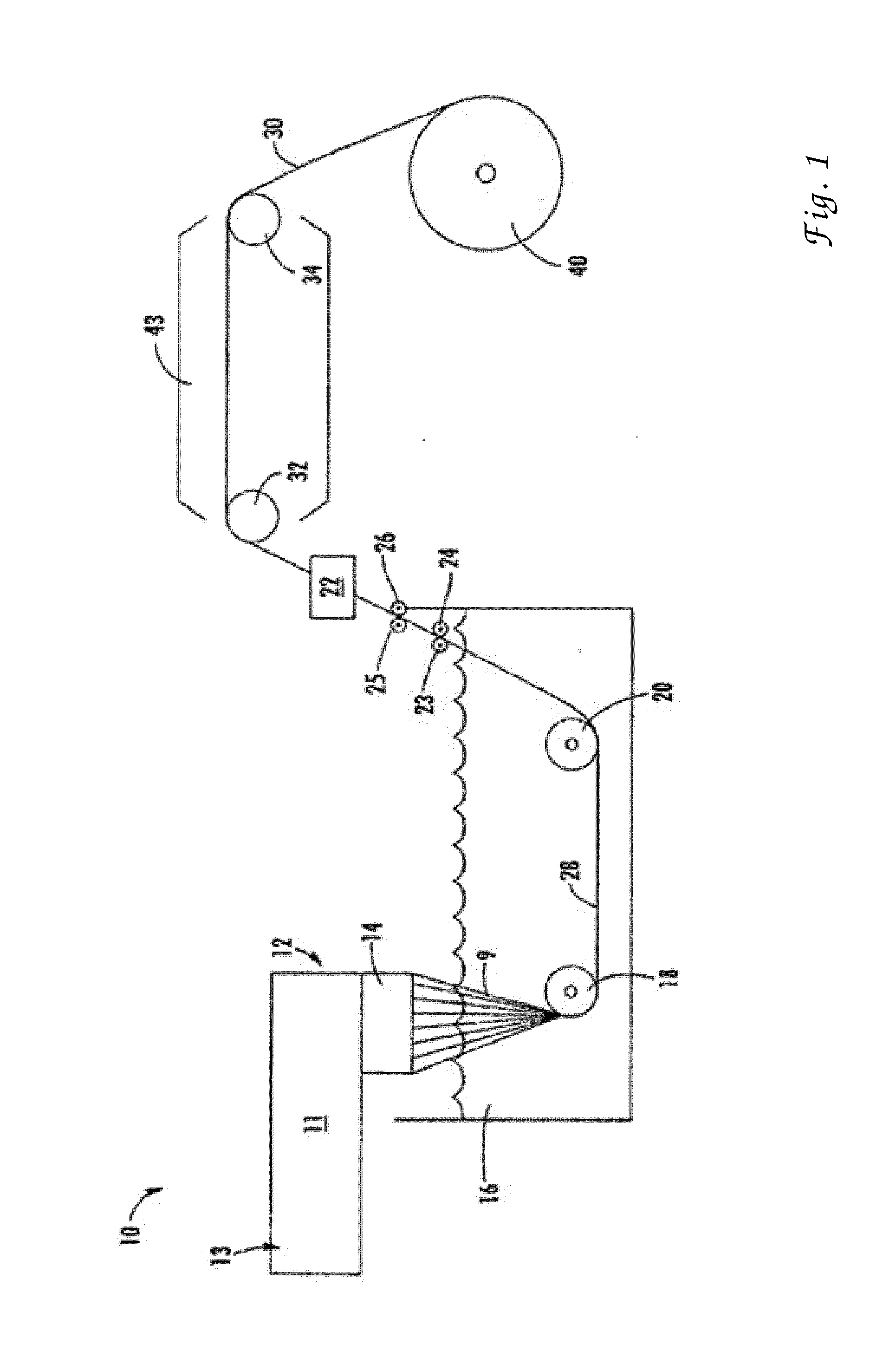

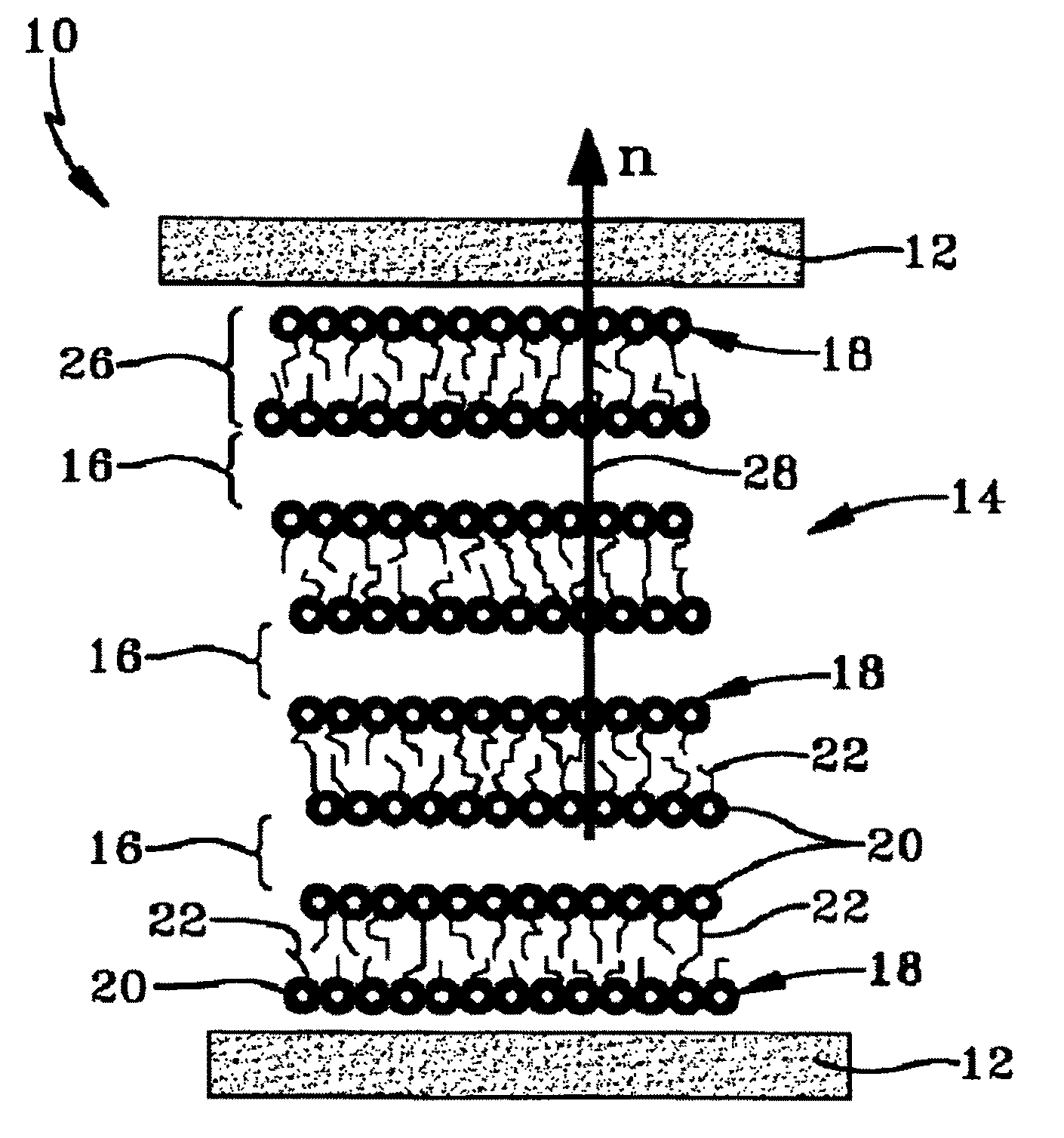

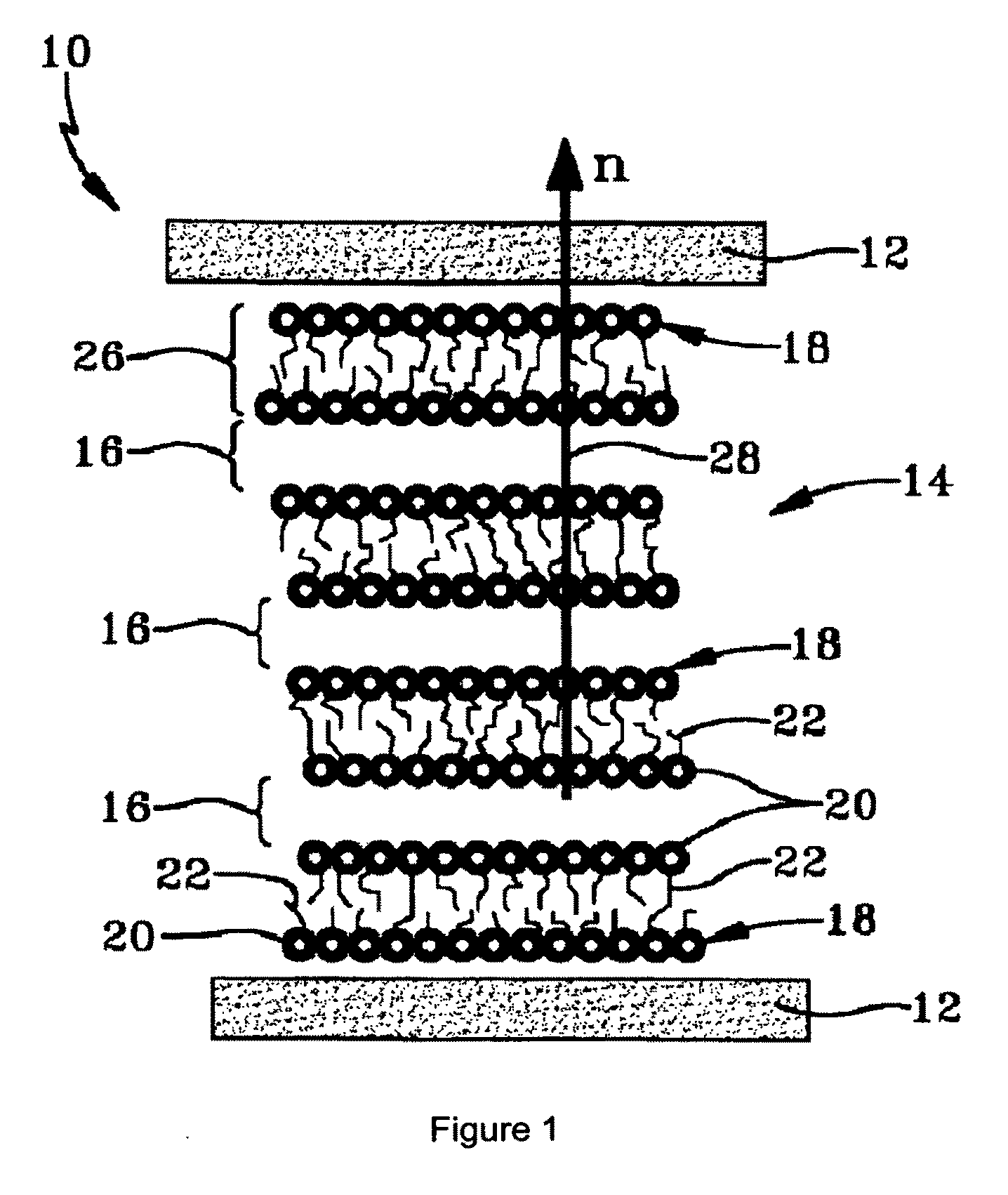

Alignment of lyotropic chromonic liquid crystals at surfaces as monolayers and multilayered stacks

InactiveUS6673398B2Eliminate needEasy to controlLiquid crystal compositionsMaterial nanotechnologyLiquid crystallineChemical physics

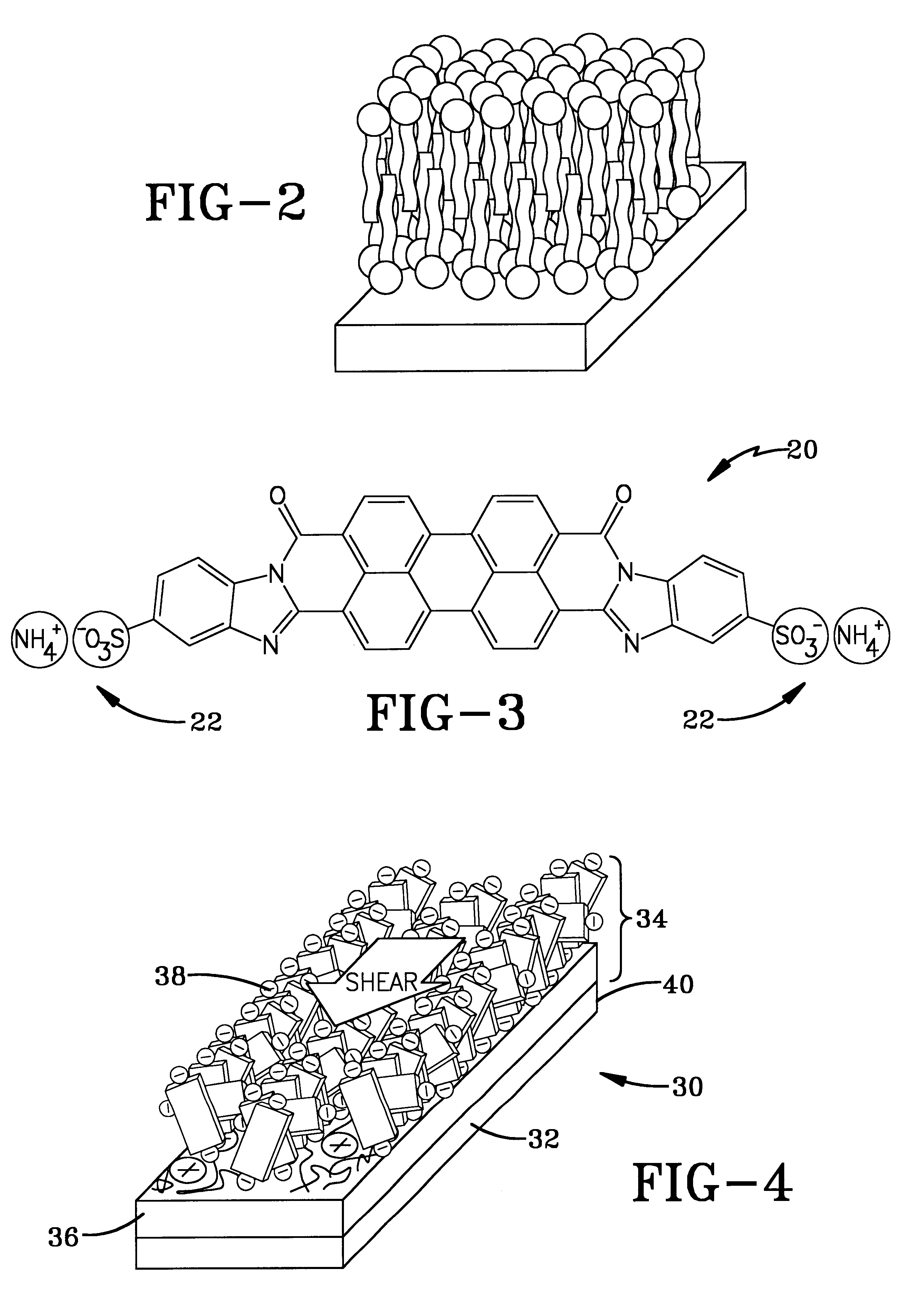

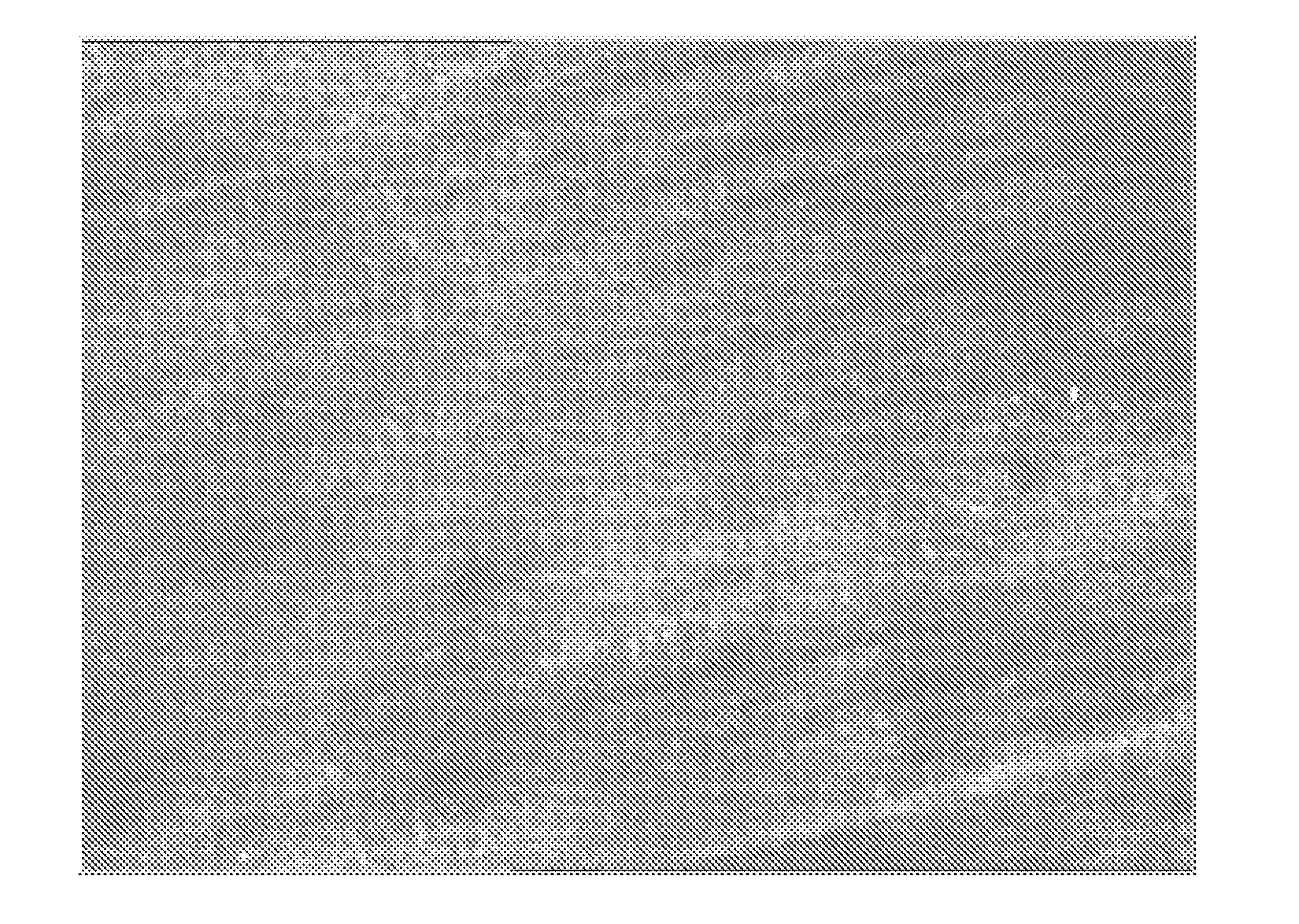

A broad class of lyotropic liquid crystals of a non-surfactant nature, the so-called lyotropic chromonic liquid crystals (LCLCs), are alignable with the techniques, in particular, LCLCs can be aligned at a surface as one monomolecular layer as a stack of monomolecular layers. The method for monolayer alignment is based on alternate layer-by-layer adsorption of polyions and dyes from aqueous solutions that have liquid crystalline structure. Using this method, one is able to stack alternate monolayers of dye and polyion while controlling the long-range in-plane orientation of the dye molecules within the plane of each layer. The feature of controlling the alignment of LCLCs enables one to create practical devices from them. For example, alignment of multilayered stacks allows one to use the resulting dried LCLC films in optical devices, for example, as internal polarizers, color filters, optical compensators, band-gap filters, and the like.

Owner:KENT STATE UNIV

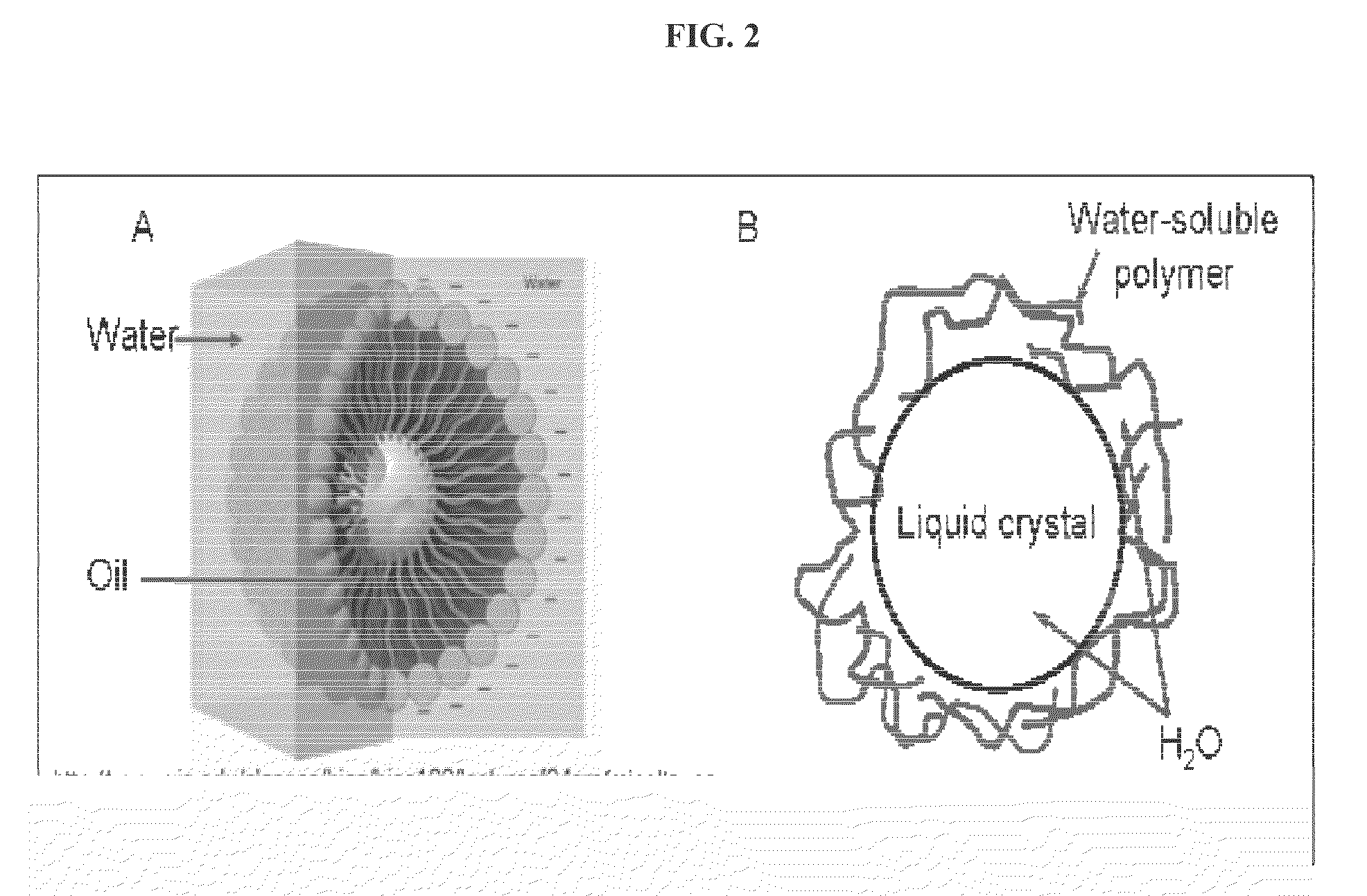

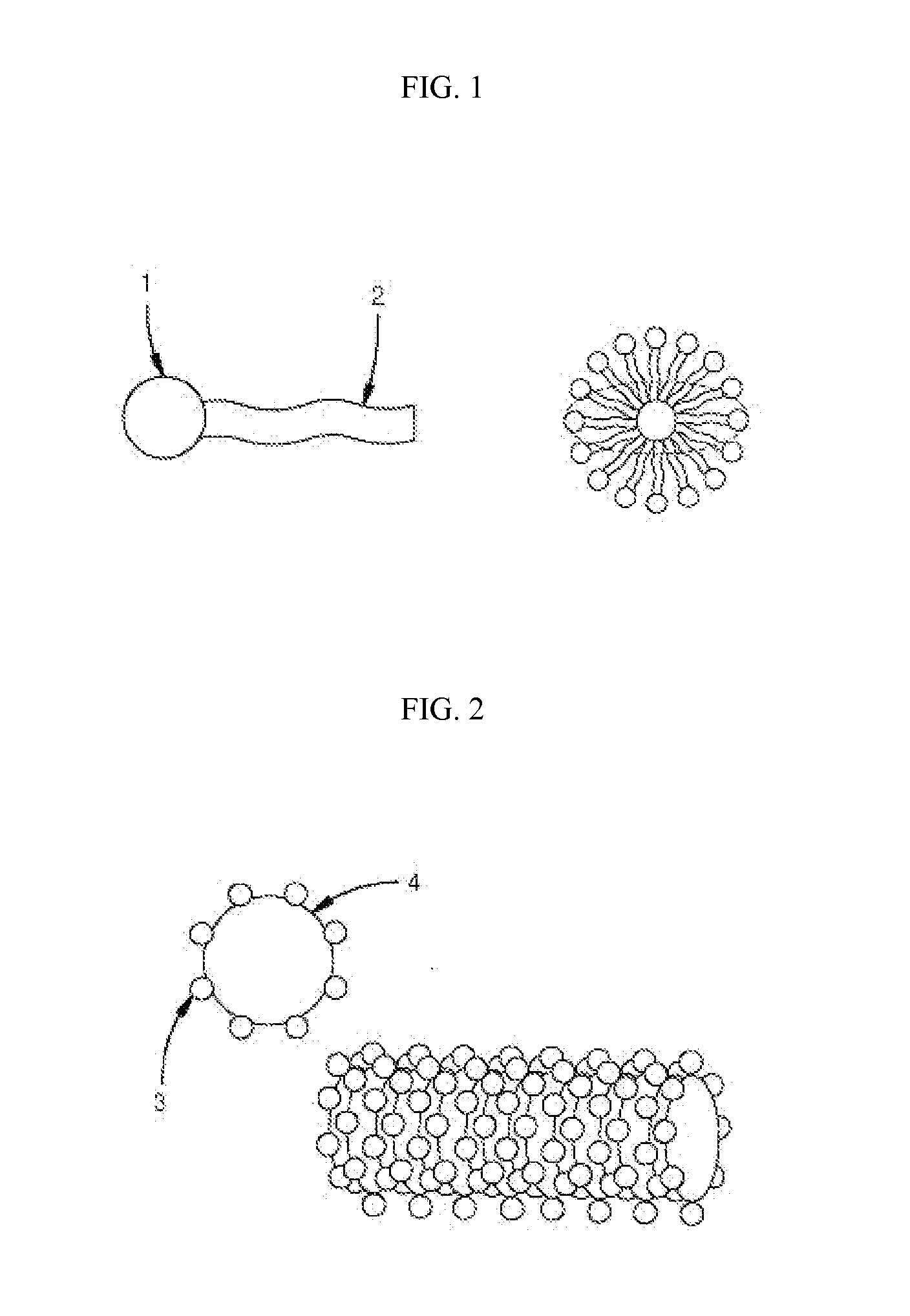

Non-amphiphile-based water-in-water emulsion and uses thereof

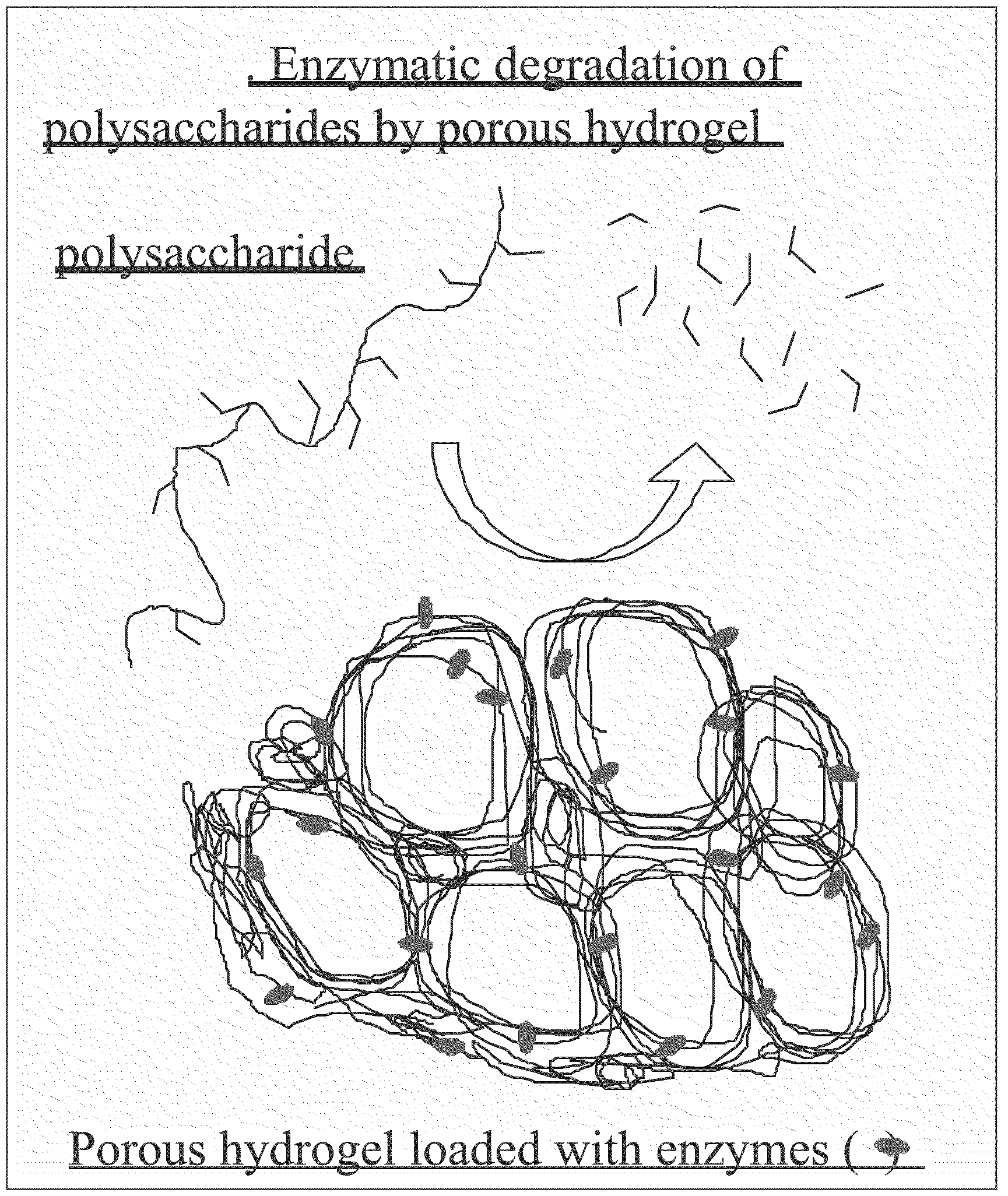

ActiveUS20090269323A1Satisfies needMeet actual needsLiquid crystal compositionsBiocideDisodium cromoglycateMesogen

The present invention relates to a non-amphiphile-based water-in-water emulsion composition. The non-amphiphile-based water-in-water emulsion composition includes a water-soluble polymer, a non-amphiphilic lyotropic mesogen encapsulated by the water-soluble polymer; and water. In one embodiment, the non-amphiphilic lyotropic mesogen includes, without limitation, a lyotropic chromonic liquid crystal, and more specifically disodium cromoglycate (DSCG). In another embodiment, the water-soluble polymer can include, without limitation, a polyacrylamide, a polyol, a polyvinylpyrrolidone, a polysaccharide, or a water-soluble fluoride-bearing polymer. The present invention also relates to a porous hydrogel made with the use of the non-amphiphile-based water-in-water emulsion. The present invention further relates to using the emulsion and hydrogel for various applications.

Owner:SYRACUSE UNIVERSITY

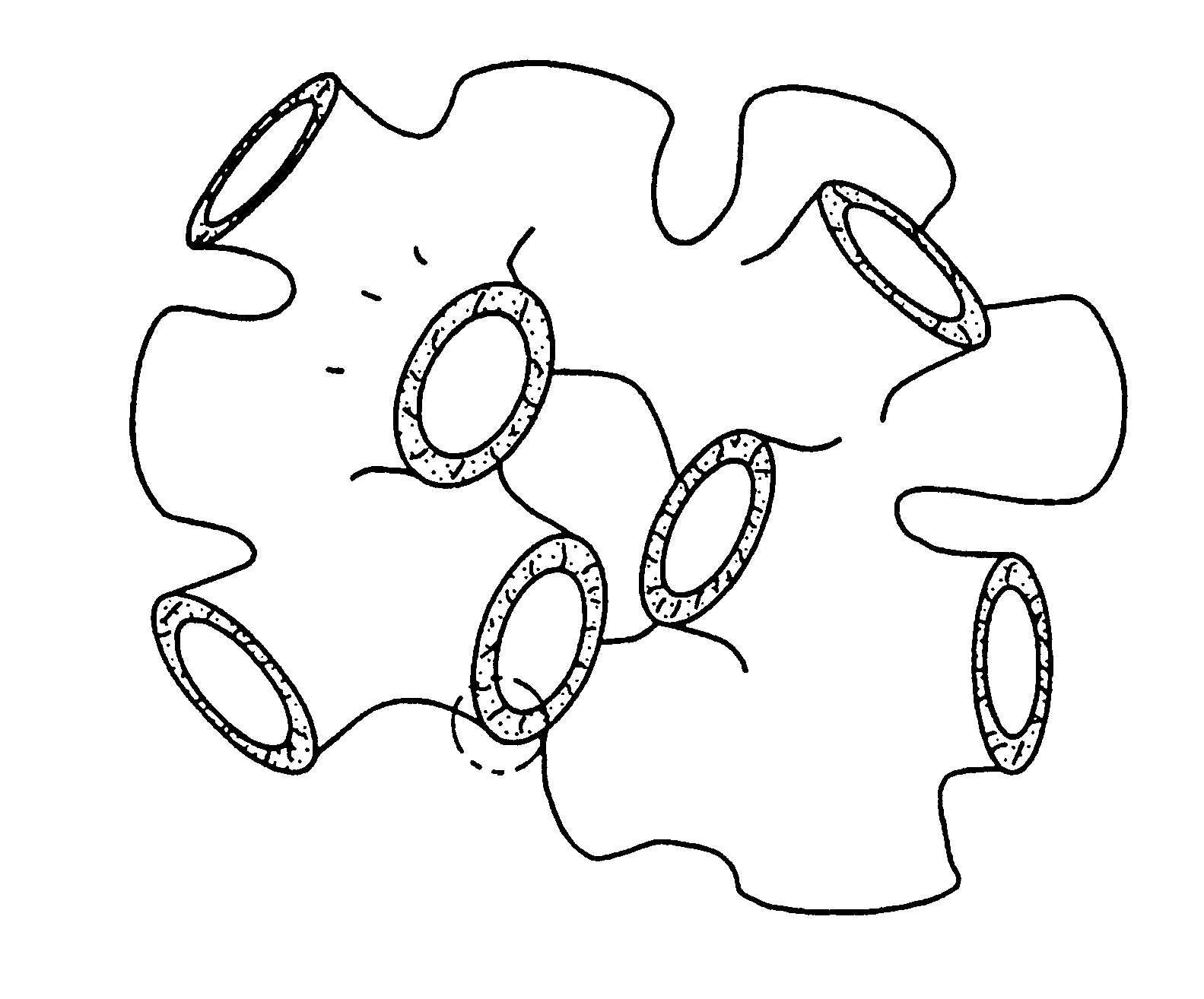

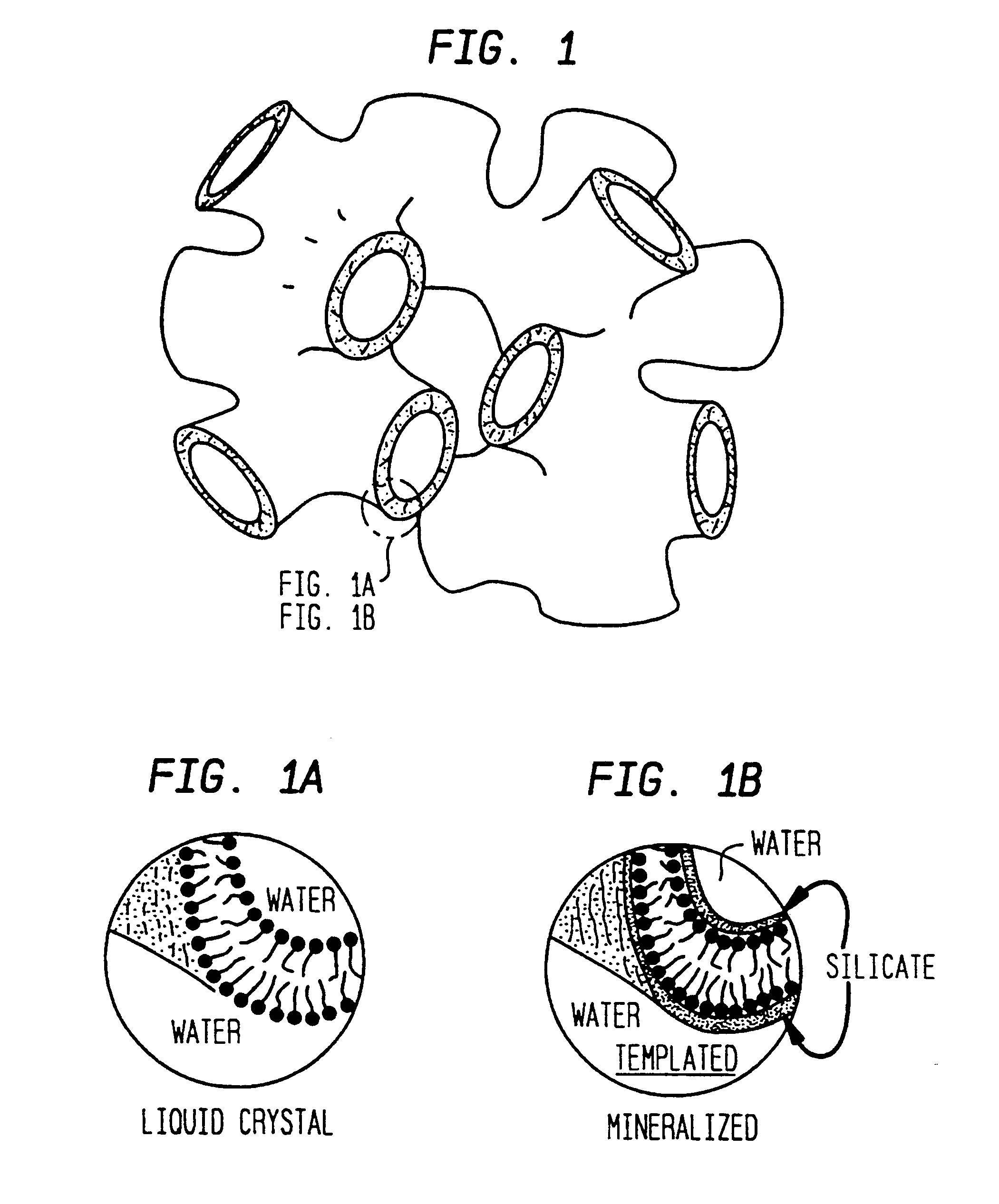

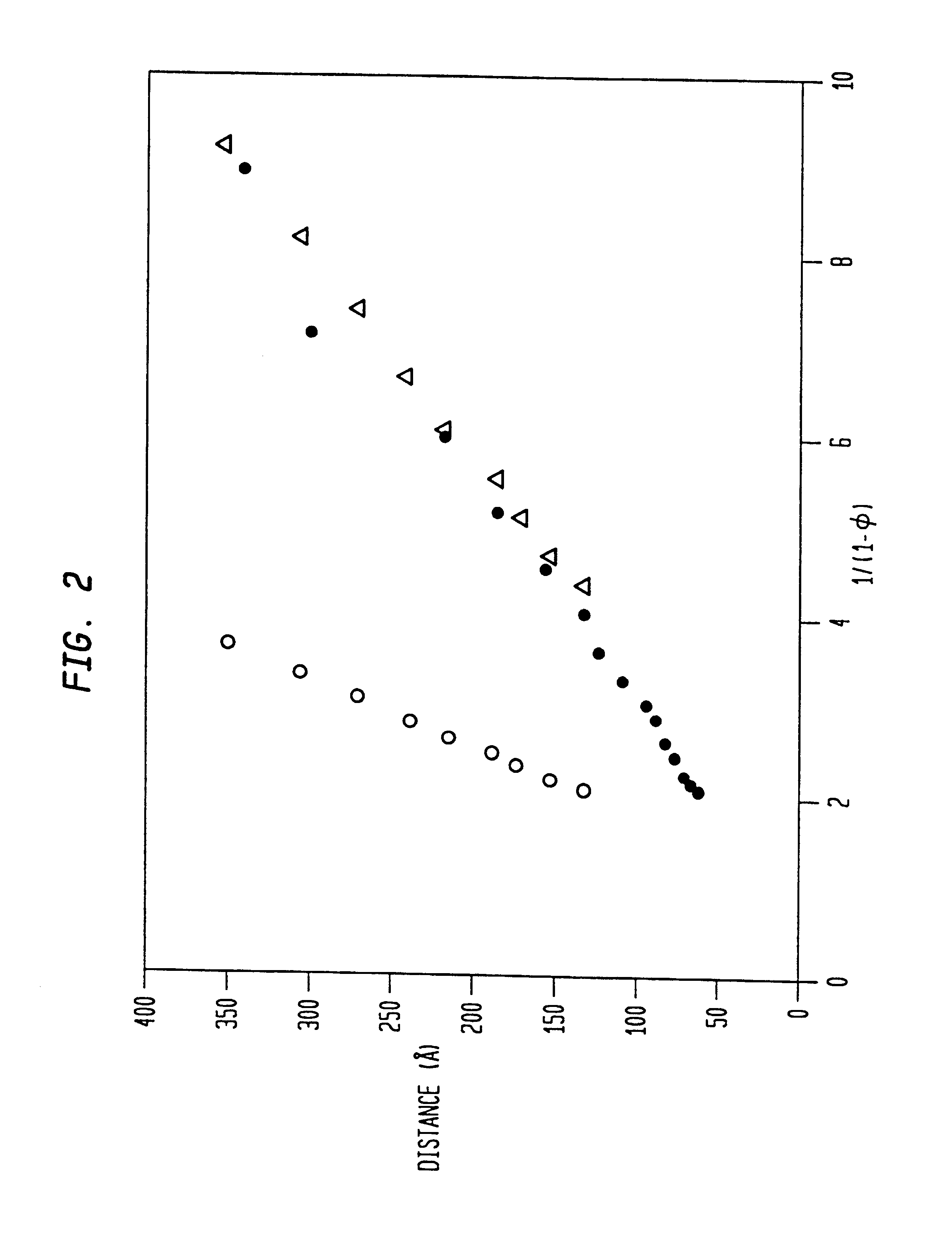

Lyotropic liquid crystalline L3 phase silicated nanoporous monolithic composites and their production

InactiveUS6638885B1Easy to changeEasy to disassembleMaterial nanotechnologyIon-exchanger regenerationLiquid crystallineNanometre

A mesoporous ceramic material is provided having a pore size diameter in the range of about 10-100 nanometers produced by templating with a ceramic precursor a lyotropic liquid crystalline L3 phase consisting of a three-dimensional, random, nonperiodic network packing of a multiple connected continuous membrane. A preferred process for producing the inesoporous ceramic material includes producing a template of a lyotropic liquid crystalline L3 phase by mixing a surfactant, a co-surfactant and hydrochloric acid, coating the template with an inorganic ceramic precursor by adding to the L3 phase tetramethoxysilane (TMOS) or tetraethoxysilane (TEOS) and then converting the coated template to a ceramic by removing any remaining liquids.

Owner:THE TRUSTEES FOR PRINCETON UNIV

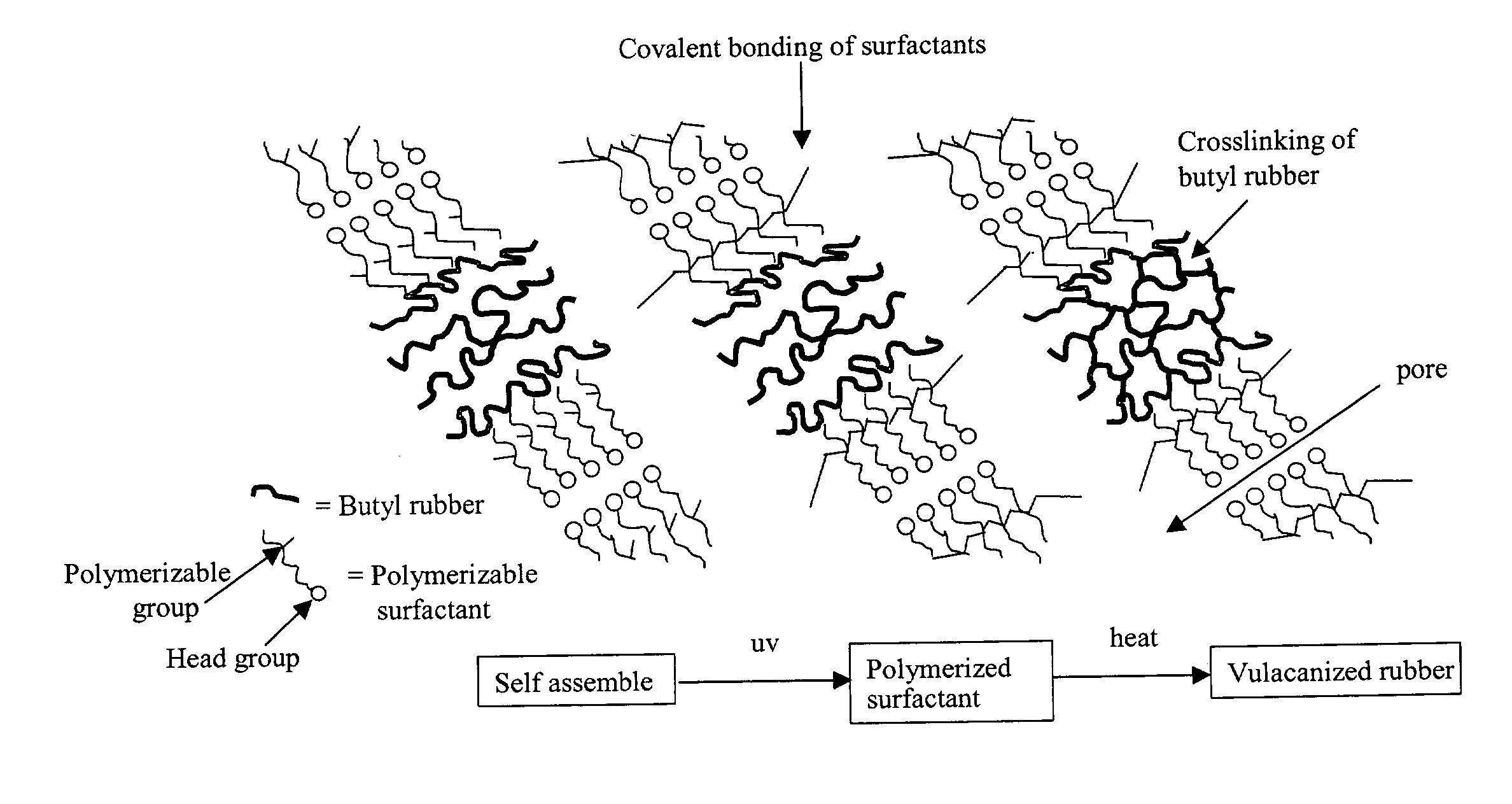

Nanoporous composites of polymerized lyotropic liquid-crystalline monomers, and hydrophobic polymers

This invention provides composite materials that combine the material properties of hydrophobic polymers with internal structure and order provided by polymerization of lyotropic liquid crystals (LLCs). Composites, particularly nanocomposites, are made by forming a LLC assembly that has hydrophobic regions and hydrophilic regions, combining hydrophobic polymer in the assembly and polymerizing the polymerizable LLC monomers in the assembly. The hydrophobic polymer, polymerized LLC assembly or both can be crosslinked in the composite. Nanoporous composites, particularly those with uniform-sized pores and / or with uniform pores distribution can be prepared in this way. In addition, complex polymers in which a second polymeric material, which may be organic or inorganic, can be introduced into the pores or other structural features of the composite can be prepared. Adding flexible hydrophobic polymers to the LLC assembly increases the flexibility and toughness of the resultant polymerized composite material to provide improved composite materials for use as membranes and in other applications. Hydrophobic polymer addition can also increase the diffusion resistance in the organic phase of the composite. Of particular interest are composites in which the hydrophobic polymer is butyl rubber or related synthetic rubber.

Owner:TDA RES

Method for improving hydrophilicity of polymer porous membrane by dentritic branching molecule

InactiveCN1799682AImprove hydrophilicityImprove hydrophilic abilitySemi-permeable membranesTemperature controlPolymer science

The invention discloses a method for using tree branching molecule to improve the hydrophilicity of polymer porous membrane. The method comprises following steps: (1) adding the tree branching molecule and polymer into solvent to be heated, mixed and dissolved; (2) laying casting liquid on the carrier of stainless steel plate or glass plate and using erasing knife to make it into a liquid film with a certain thickness; (3) dipping the carrier with casting liquid into coagulating bath via the lyotropic conversion process to make the liquid film into tree branching molecule to improve the property of polymer porous membrane. The invention can adjust the molecular weight, terminal group and added amount of tree branching molecule to control the surface property of polymer porous membrane; and adjust the components of casting liquid and coagulating bath and temperature to control the structure of porous membrane. The inventive method can effectively control the balance between hydrophilicity and dewatering of dewatering polymer; improve the dirt resistance and biocompatibility, which can improve the preparation and application of ultra and micro filtration film.

Owner:ZHEJIANG UNIV

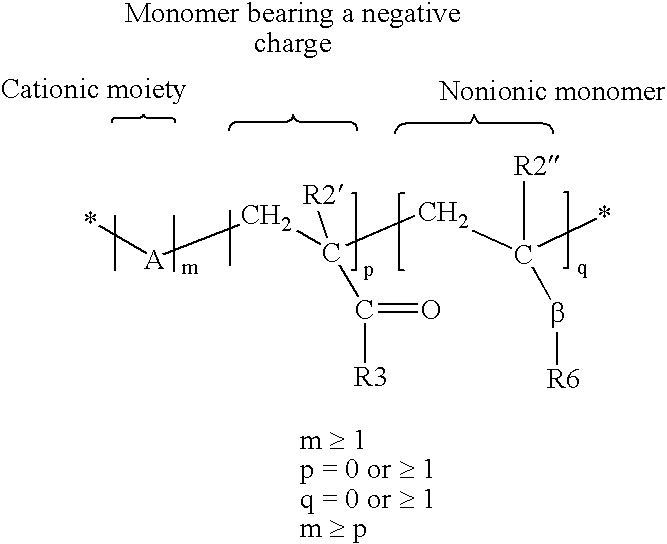

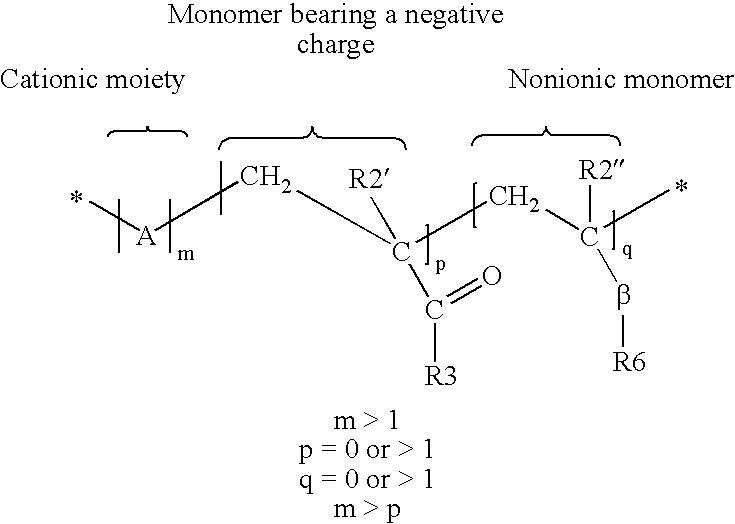

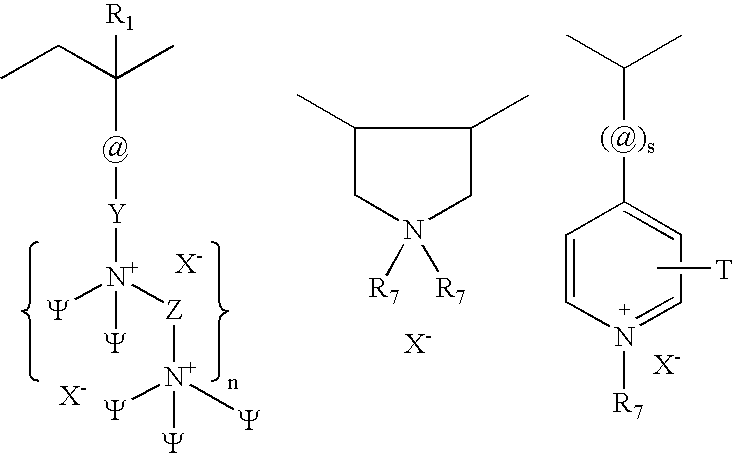

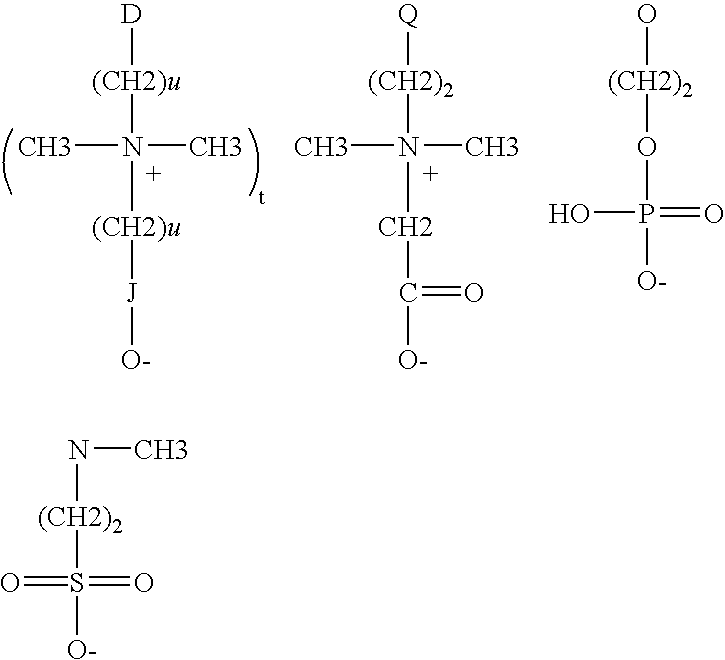

Method for Treating Damaged Hair

The present invention relates to a method for treating damaged hair comprising the steps of: a) contacting the hair with a shampoo composition, the shampoo comprising: from about 5% to about 50% of an anionic surfactant; from about 0.025% to about 5% by weight of a synthetic cationic polymer having a cationic charge density from about 2 meq / gm to about 7 meq / gm, wherein the synthetic cationic polymer forms lyotropic liquid crystals upon combination with the anionic surfactant; and water; and b) rinsing the composition from the hair, where, following the treatment, silicone deposition efficiency (DE) on the hair is greater than 1.

Owner:THE PROCTER & GAMBLE COMPANY

Organic Polymer Compound, Optical Film and Method of Production Thereof

InactiveUS20100190015A1Liquid crystal compositionsSynthetic resin layered productsLiquid-crystal displayVisible spectral range

The present invention relates generally to the field of organic chemistry and particularly to the organic polymer compound, optical films for liquid crystal displays and method of production of the films. An isotropic solution or birefringent lyotropic solution of the organic polymer compound is capable of forming a solid optical retardation layer of a negative C-type or Ac-type plate substantially transparent to electromagnetic radiation in the visible spectral range.

Owner:CRYSOPTIX

Amphiphilic Fibers and Membranes and Processes for Preparing Them

The present invention relates to the fields of chemistry and biology and more particularly to the field of biomaterials. The present invention includes amphiphilic fibers and membranes, which can be used for biomembranes and biocompatible devices. The present invention also relates to processes for preparing amphiphilic fibers and membranes from solutions comprising amphiphilic molecules. More particularly, the present invention relates to processes for preparing fibers and membranes from electrospinning solutions comprising amphiphilic molecules. The present invention further provides fibers and nonwoven membranes comprising amphiphilic fibers chosen from anionic surfactants, cationic surfactants, nonionic surfactants, phospholipids, sulfobetaines, lyotropic liquid crystalline molecules, and / or block copolymers. Electrospun fibers offer the potential for direct fabrication of biologically based, high-surface-area membranes without the use of multiple synthetic steps, complicated electrospinning designs, or post-processing surface treatments. Polymeric phospholipids, for example, have been shown to be attractive candidates for blood purification membranes, artificial heart valves and organs, and other prosthetics, including other biocompatible devices.

Owner:VIRGINIA TECH INTPROP INC

Treatment methods with low-dose, longer-acting formulations of local anesthetics and other agents

InactiveUS20050119340A1Prolong the action timeProlonged durationBiocidePowder deliveryAnesthetic AgentDose reduction

Drug formulations that provide sustained action and / or reduced dosage requirements are provided. In the formulations the drugs (particularly local anesthetics) are associated with reversed cubic phase and reversed hexagonal phase lyotropic liquid crystalline material.

Owner:LYOTROPICS THERAPEUTICS INC

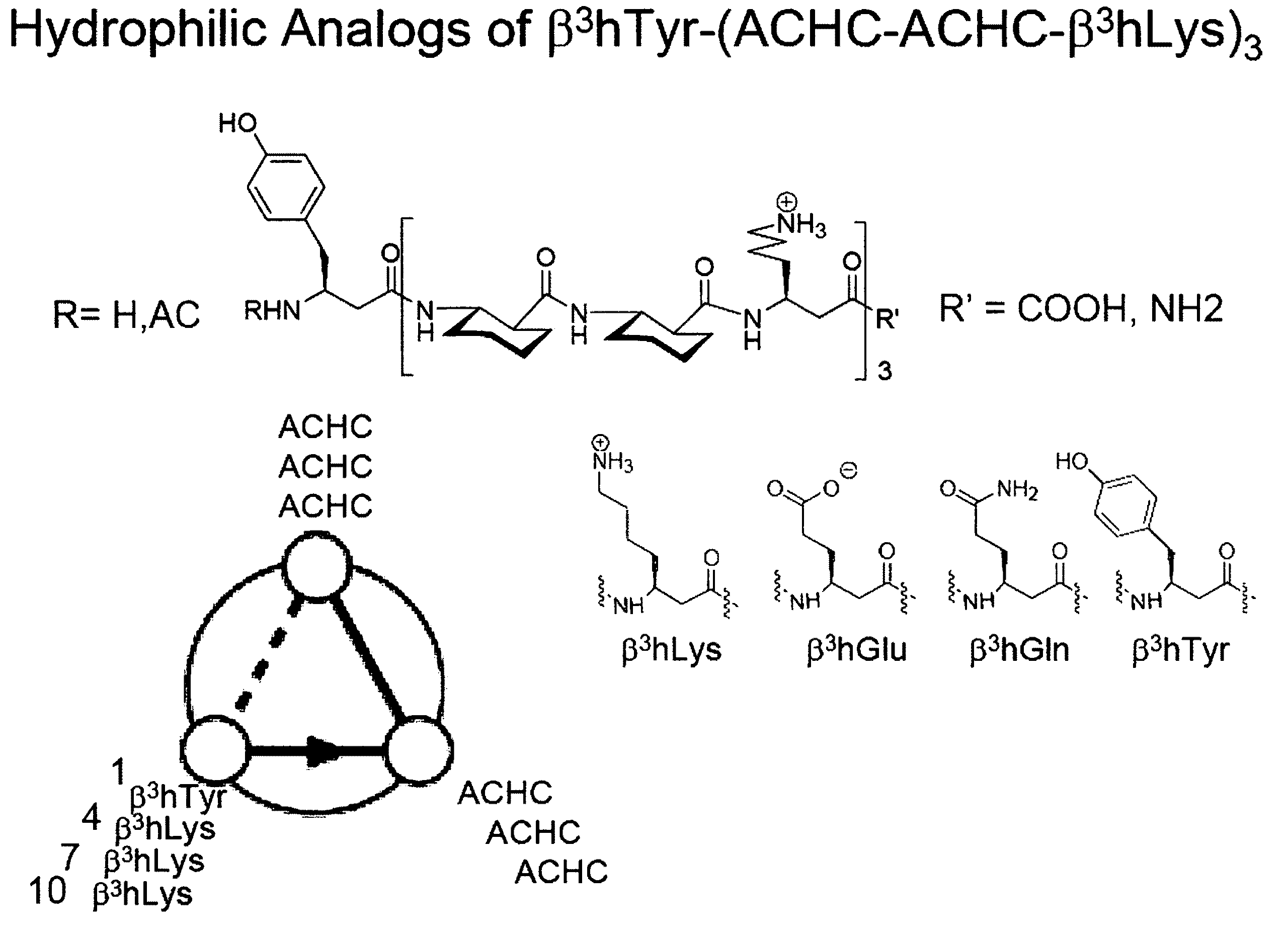

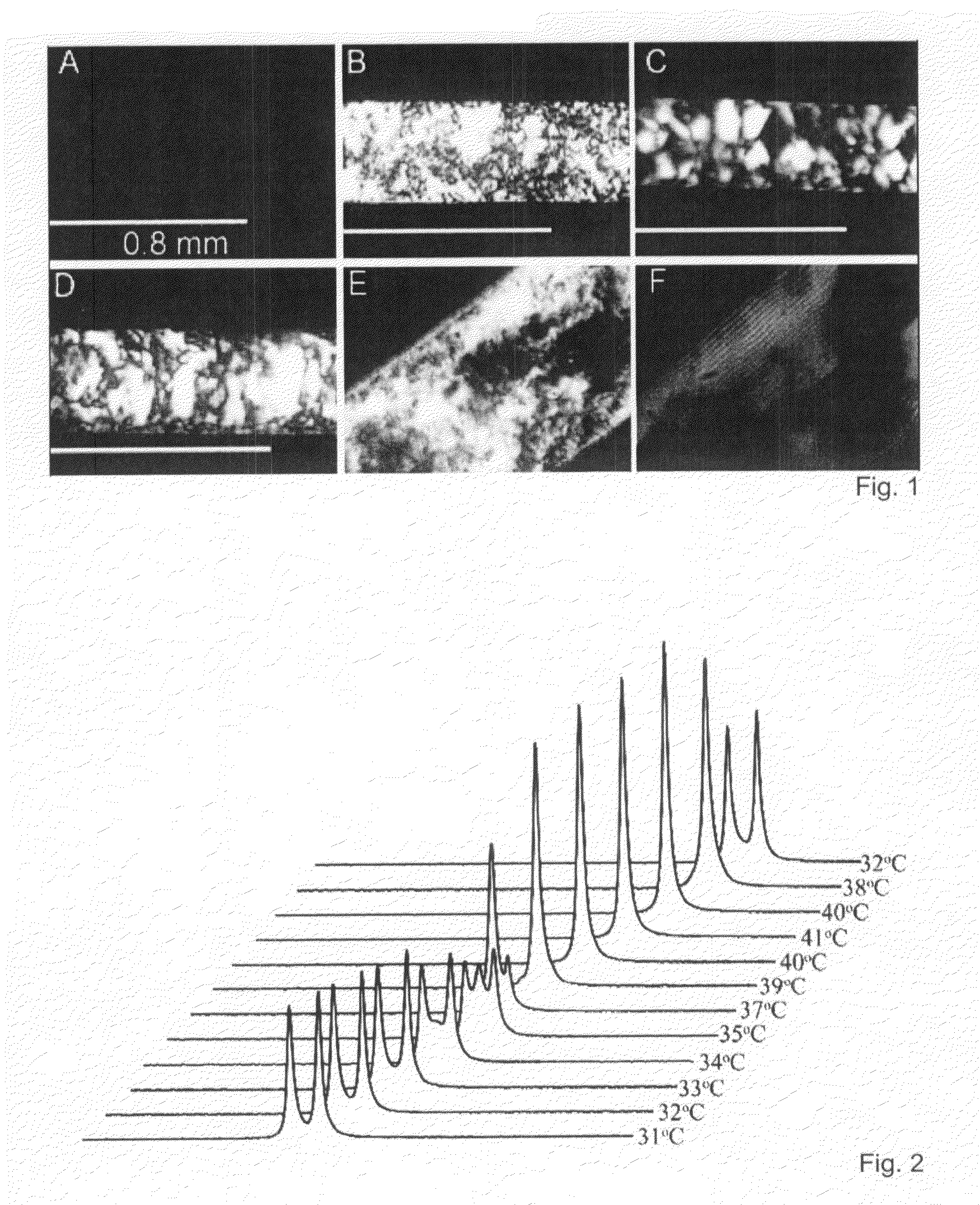

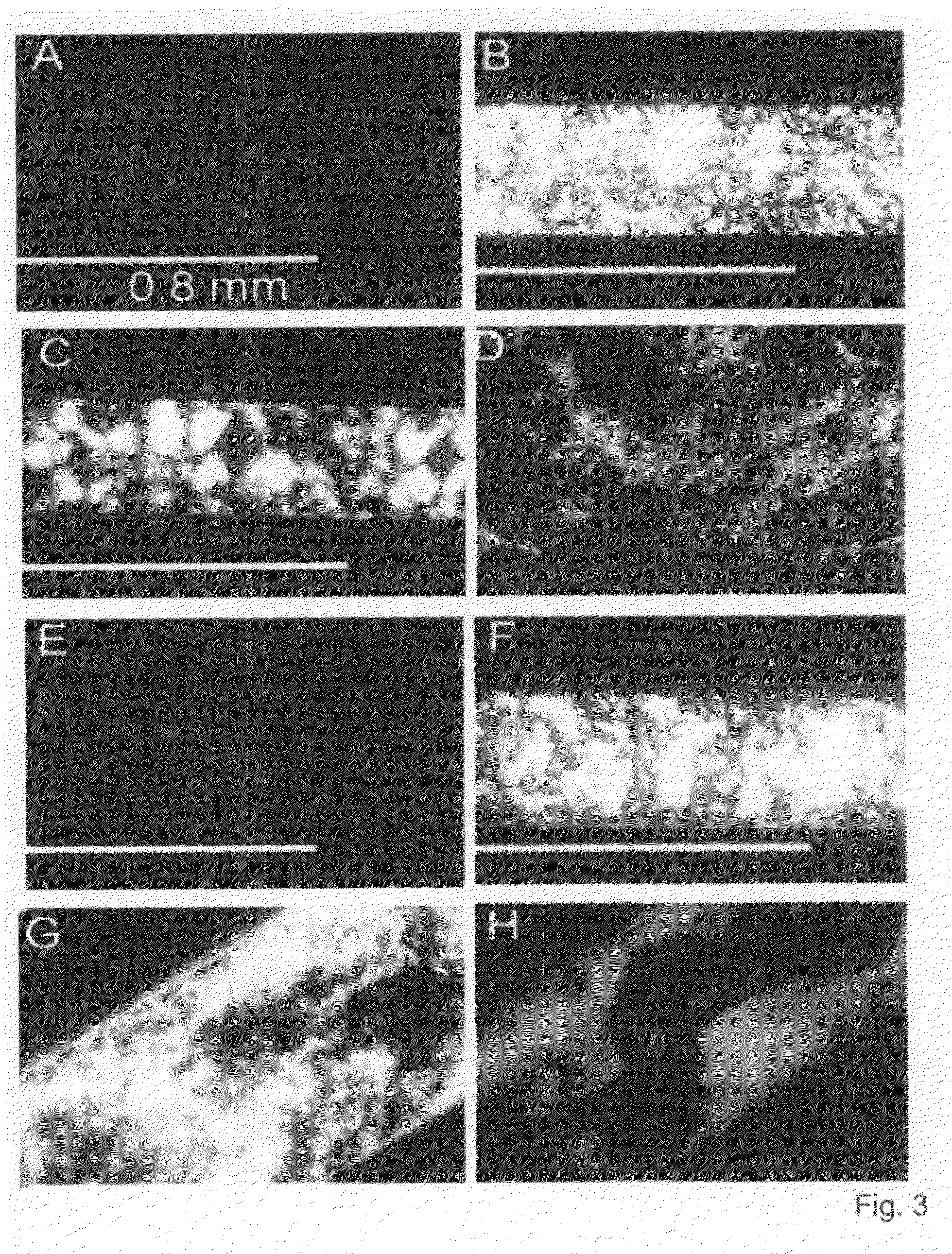

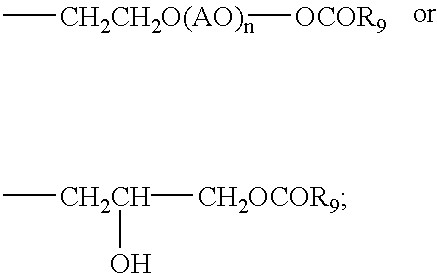

Β-peptide lyotropic liquid crystals and methods of manufacture and use thereof

ActiveUS8021570B2Liquid crystal compositionsPeptide/protein ingredientsCrystallographyOrganic chemistry

The present invention provides materials and methods that make liquid crystal phases accessible with relatively short β-peptides in aqueous solvents.

Owner:ALCATEL LUCENT SAS +1

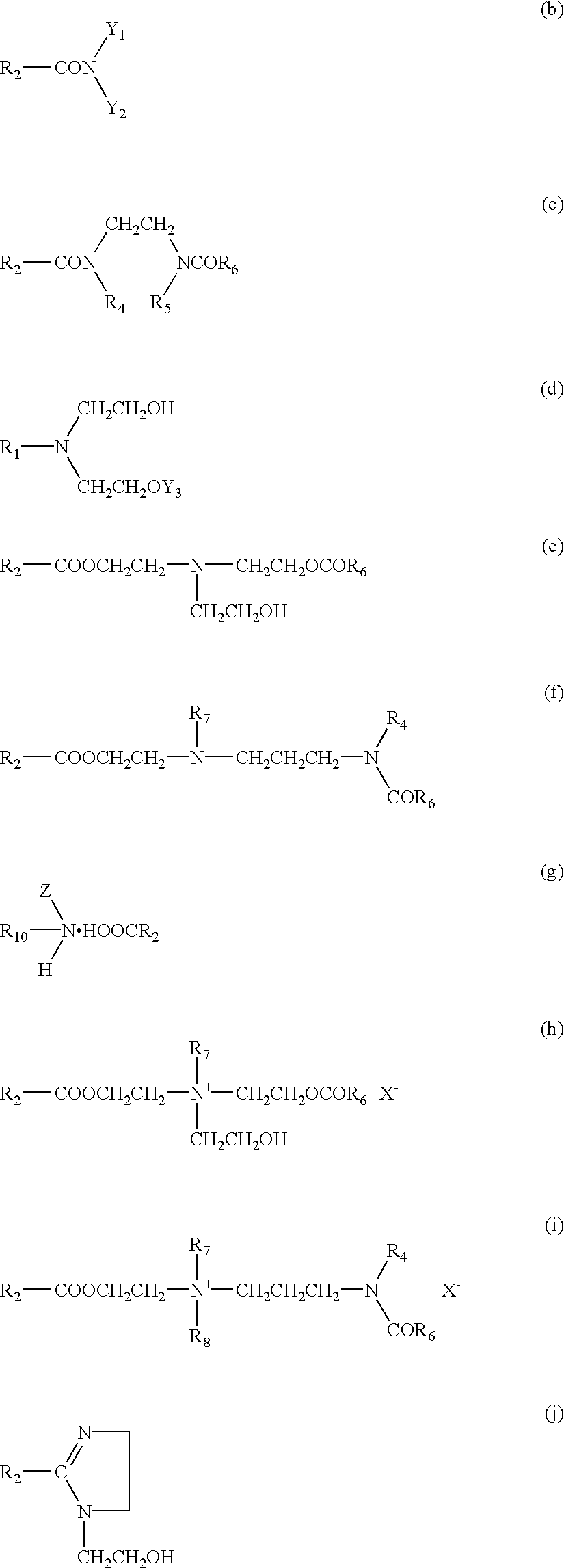

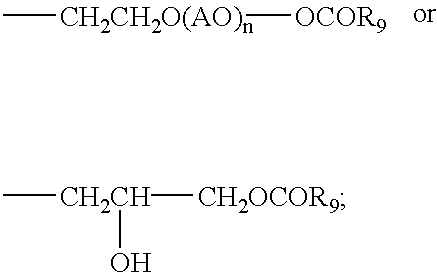

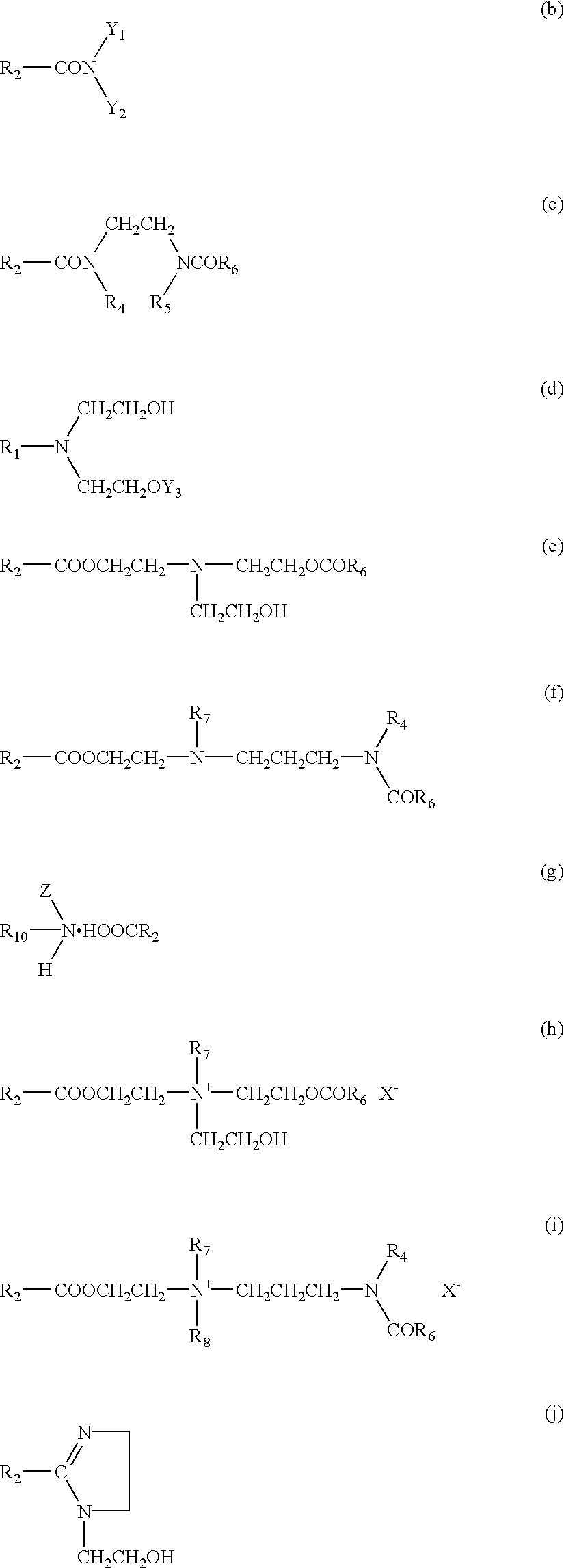

Amphiphile prodrugs

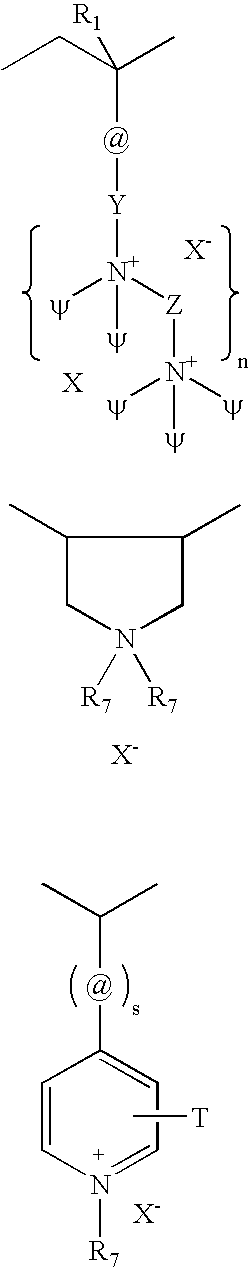

Amphiphilic prodrugs of general formula A-X are disclosed, wherein A is a biologically active agent or may be metabolised to a biologically active agent; and X is selected from the group consisting of R, or up to three R moieties attached to a linker, Y1, Y2 or Y3, wherein R is selected from a group consisting of alkyl, alkenyl, alkynyl, branched alkyl, branched alkenyl, branched alkynyl, substituted alkyl, substituted alkenyl and substituted alkynyl groups and their analogues; Y1 is a linker group which covalently attached to an R group at one site and is attached to A at a further independent site; Y2 is a linker group which is covalently attached to two R groups at two independent sites and is attached to A at a further independent site; and Y3 is a linker group which is covalently attached to three R groups at three independent sites and is attached to A at a further independent site. Self-assembly of the amphiphilic prodrugs into reverse lyotropic phases, particularly hexagonal, cubic and sponge, is disclosed. In preferred embodiments A is dopamine or a 5-fluorouracil prodrug.

Owner:NANOMED HLDG PTY LTD

Preparation method of Pt-Ru alloy catalyst with high catalytic activity

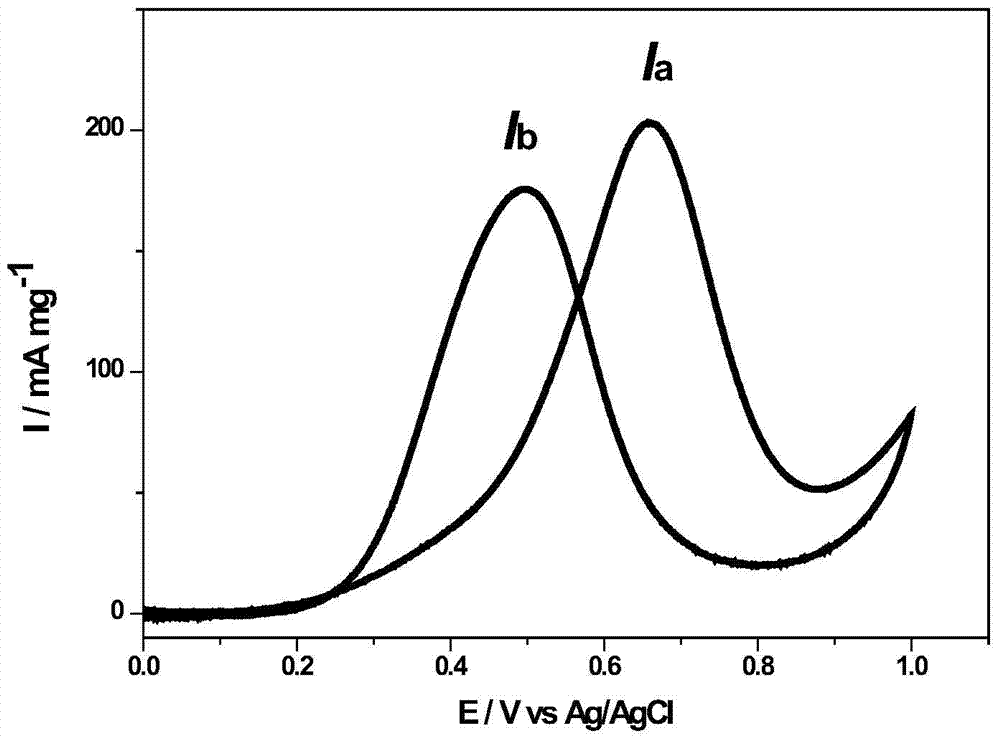

InactiveCN103933975AEnhanced anti-toxicityHigh electrocatalytic activityMetal/metal-oxides/metal-hydroxide catalystsWater bathsAlloy

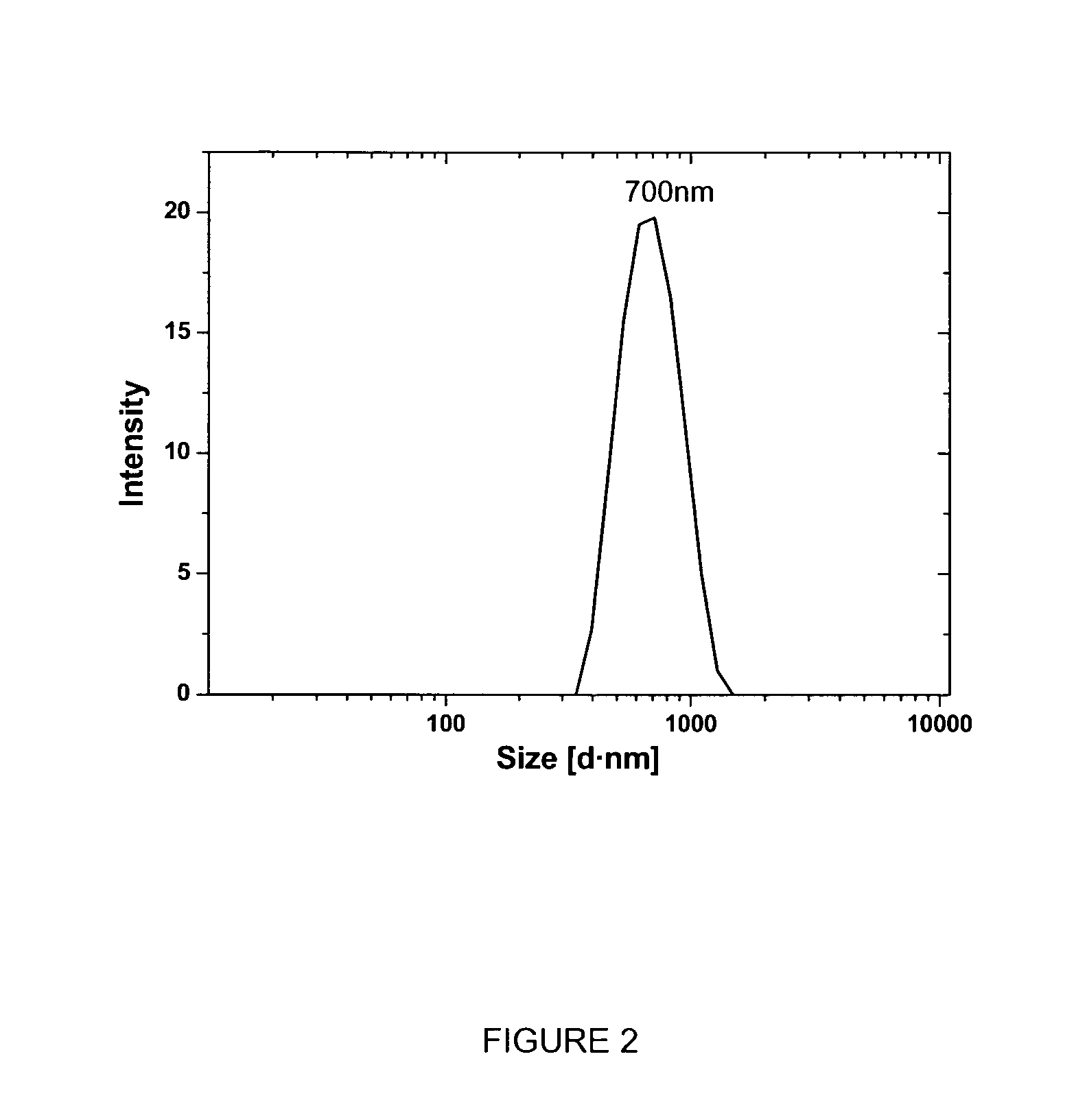

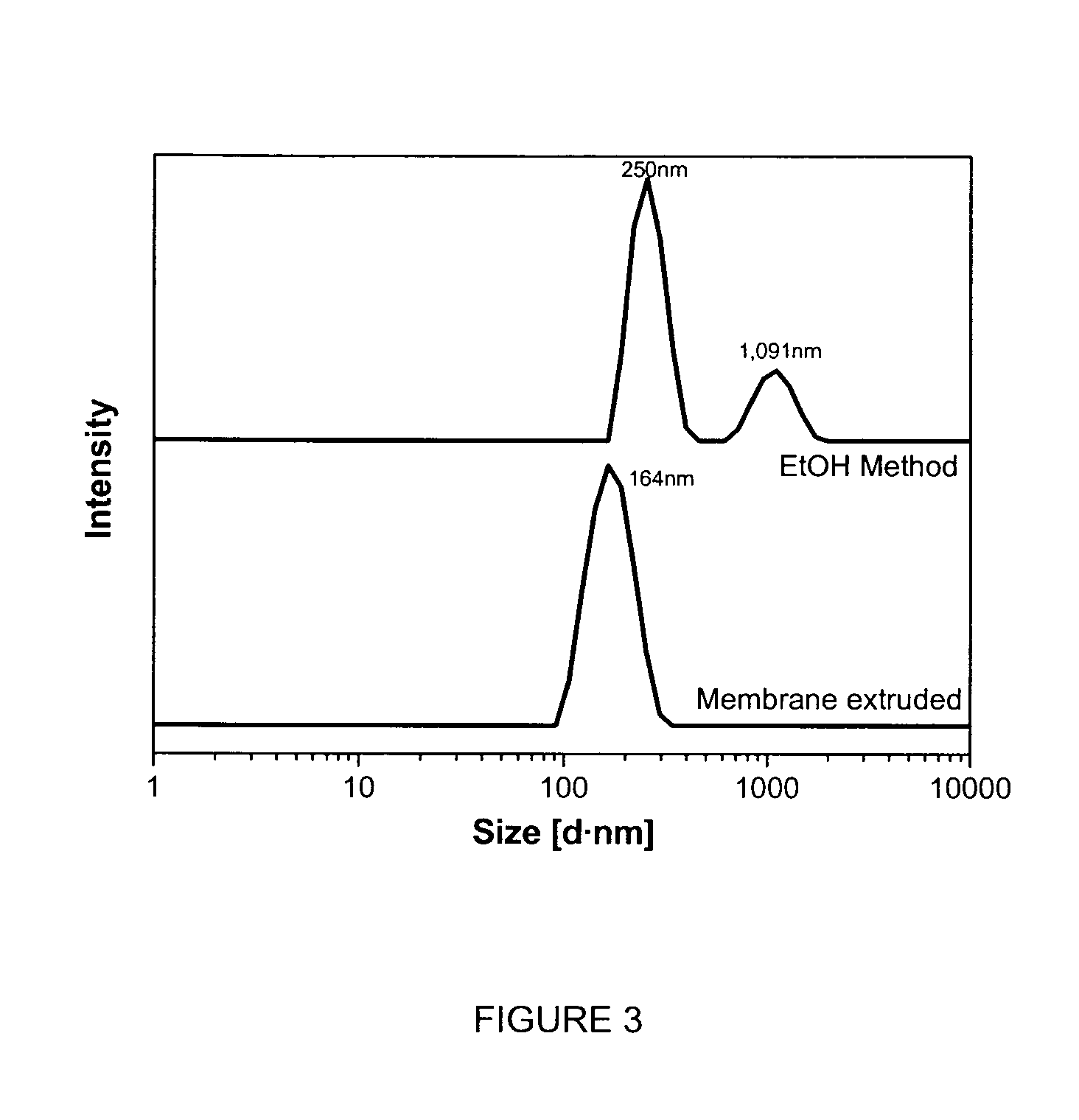

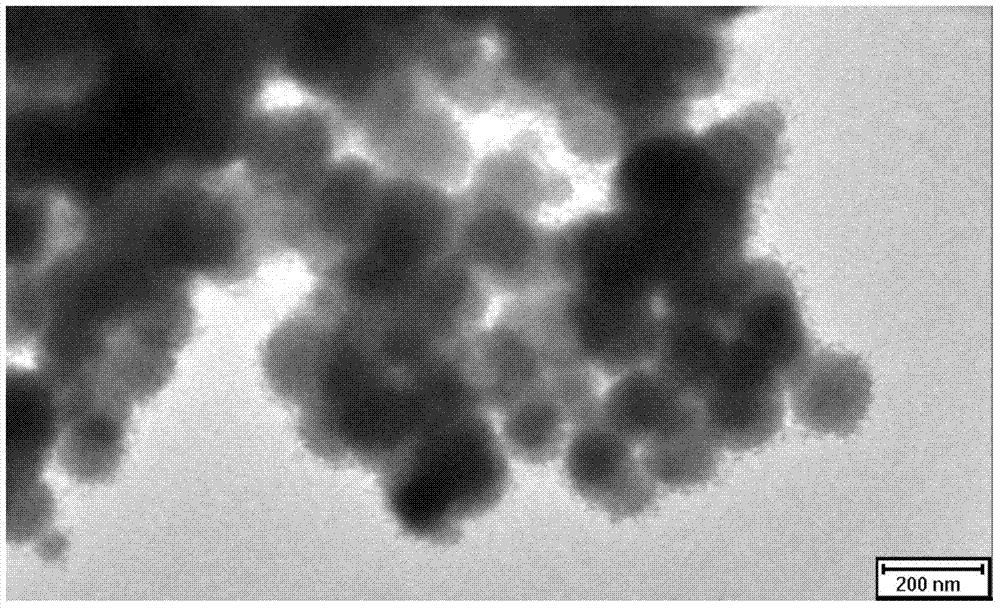

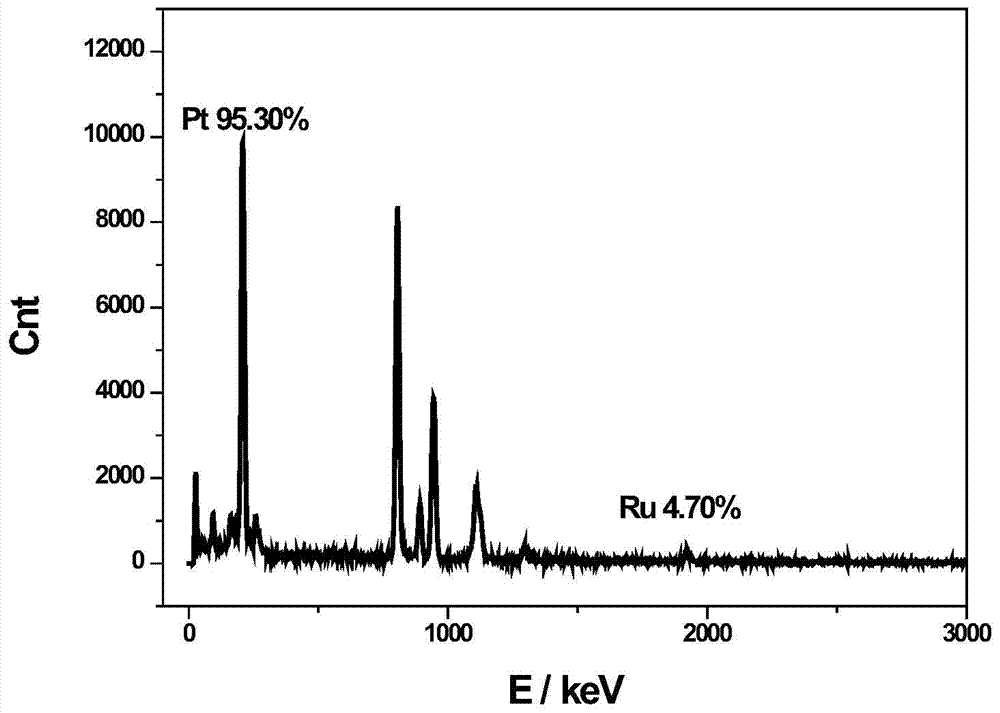

The invention provides a preparation method of a Pt-Ru alloy catalyst with high catalytic activity. According to the preparation method, Pt and Ru of the alloy catalyst come from chloroplatinic acid and rutheniumchloride hydrate respectively; lyotropic liquid crystals are formed from Pt and Ru with amphipathic segmented copolymer P123, water, and ethanol; ascorbic acid is taken as a reducing agent for reduction via ultrasonic water bath; and the Pt-Ru alloy catalyst with high catalytic activity is obtained via washing, centrifugation, and roasting. Catalytic activity and poison resistance of the Pt-Ru alloy catalyst with high catalytic activity obtained via the preparation method are higher than that of commercial Pt black catalyst.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting microcrystalline cellulose from sea squirts and preparing lyotropic cholesteric crystal

The invention relates to a method for extracting microcrystalline cellulose from sea squirts and preparing lyotropic cholesteric crystal, which comprises the steps of: soaking the sea squirts with distilled water, cleaning and only reserving tunics with thin skin scraped out; soaking the tunics with strong base for 6-24h to remove protein and lipid; subjecting the tunics in a buffering solution at 40-90 DEG C to reaction for 1-5h, and repeating the step 2-8 times; placing obtained cellulose on watch glass for drying; crushing to a micrometer or millimeter level; pouring into a beaker containing a proper amount of concentrated acid for hydrolysis, stirring to react for 30min-6h, and adding a large amount of distilled water again for terminating the reaction; and repeatedly centrifuging and dialyzing to remove acid in suspension so as to ensure that the solution outside a dialysis bag to be neutral or subacid finally, and then evaporating for concentration to obtain the lyotropic cholesteric crystal. The method has simple reaction processes, easier control of technological method, rich raw material resources, low cost, good repeatability, environmental protection, no toxicity and lower cost, is easier for mass production, and can be applied to industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

Method for Treating Damaged Hair

InactiveUS20090087398A1Damage of in useIncrease salesCosmetic preparationsHair cosmeticsChemical treatmentSURFACTANT BLEND

The present invention relates to a method for treating damaged hair, where the hair is chemically treated, comprising the steps of: a) contacting the hair with a shampoo composition, the shampoo comprising: from about 5% to about 50% of an anionic surfactant; from about 0.025% to about 5% by weight of a synthetic cationic polymer having a cationic charge density from about 2 meq / gm to about 7 meq / gm, wherein the synthetic cationic polymer forms lyotropic liquid crystals upon combination with the anionic surfactant; and water; and b) rinsing the composition from the hair, wherein following the treatment, the surface energy of the hair is reduced, as compared to that measured prior to the treatment.

Owner:THE PROCTER & GAMBLE COMPANY

Nitrogen oxide removal process based on hydrogen peroxide catalytic oxidation

InactiveCN106861392AGood dispersionEfficient activationHeterogenous catalyst chemical elementsDispersed particle separationCerium(IV) oxideCatalytic oxidation

The invention relates to the fields of industrial catalysis and environmental management, and particularly relates to a nitrogen oxide removal process based on hydrogen peroxide catalytic oxidation. A hydrogen peroxide solution is directly sprayed into a flue after passing through an atomizer; after the hydrogen peroxide solution is mixed with flue gas, a mixture enters a catalyst layer; the mixture is activated under the contact action of a catalyst; NO in the flue gas is oxidized into high valence lyotropic nitrogen oxides such as NO2, N2O4, N2O5 and the like; absorption processing is carried out by using alkali slurry to remove the nitrogen oxides in the flue gas. The process is simple, easy to operate, compact in device structure, good in economy and flexible to regulate, has various mode configurations, and can implement efficient denitration. Meanwhile, the catalyst used in the technical process uses nano titanium dioxide as a carrier and uses one or more of ceric oxide, cobaltosic oxide, nickel oxide, chromium sesquioxide and manganese dioxide as active ingredients; the catalyst is low in price and simple in preparation process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

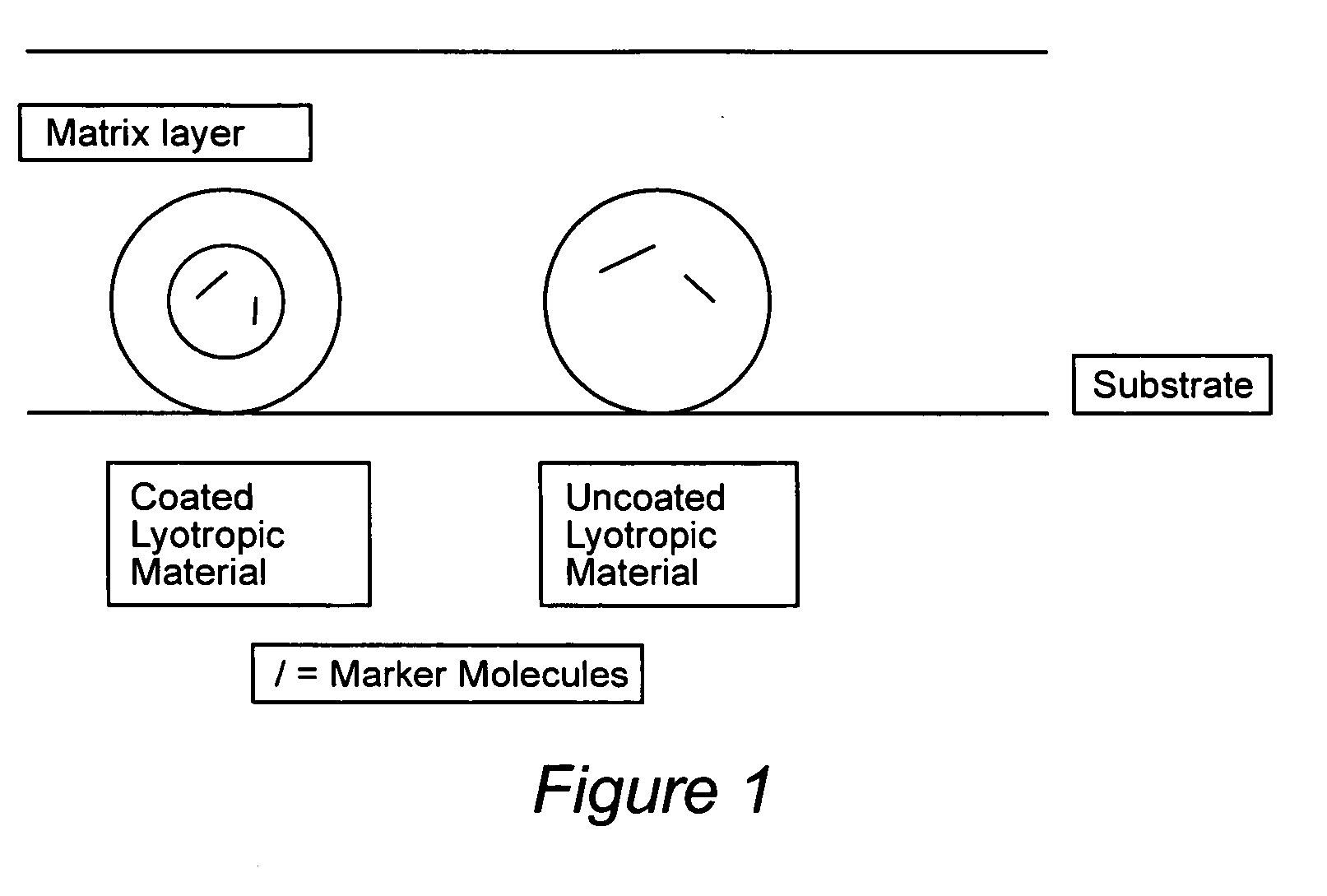

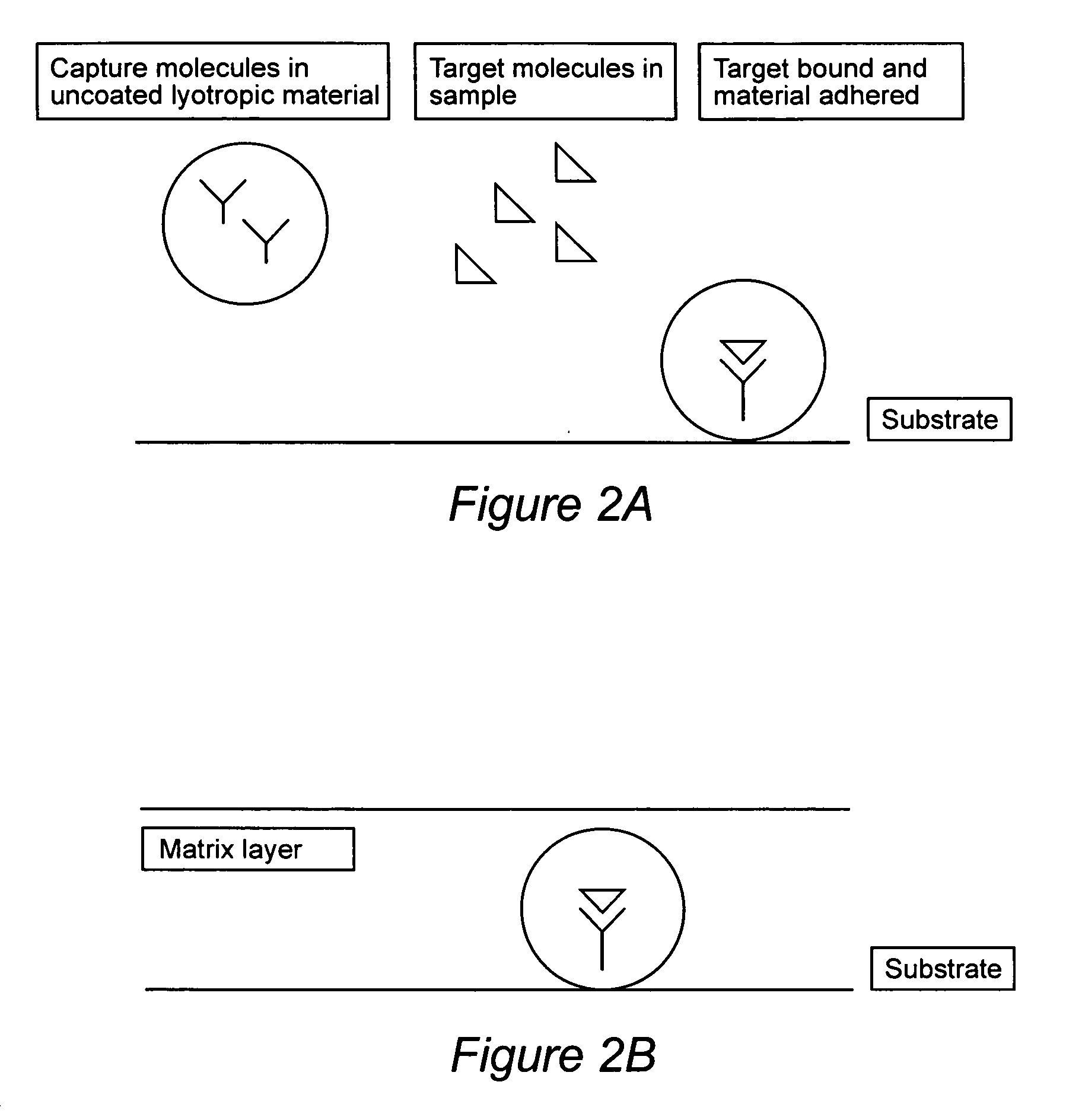

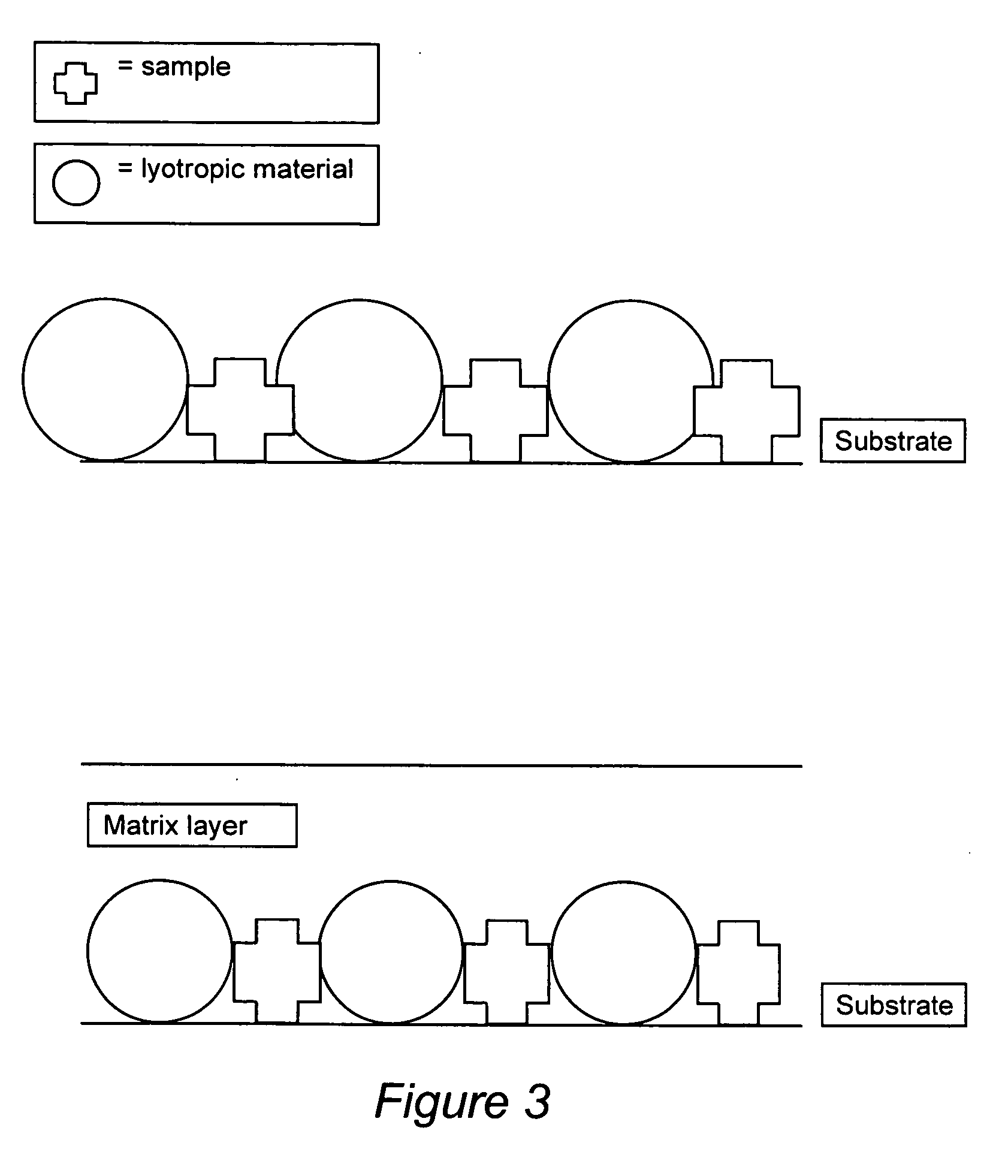

Compositions for binding to assay substrata and methods of using

ActiveUS20060141544A1Reduce run-to-run variabilityHigh measurement accuracyAnalysis by subjecting material to chemical reactionBiological testingSpectroscopyMass spectrometry

Compositions and methods for binding to assay substrata in a stable and protective manner, thereby enhancing assay performance, are provided. The compositions comprise lyotropic materials (for example, lyotropic liquid and / or liquid crystalline materials) and may contain macromolecular standards, markers or capture compounds. The compositions are capable of binding to assay substrata such as that of chips that are employed for MALDI and SELDI mass spectroscopy analyses and plates that are used for ELISA type assays.

Owner:LYOTROPICS THERAPEUTICS INC

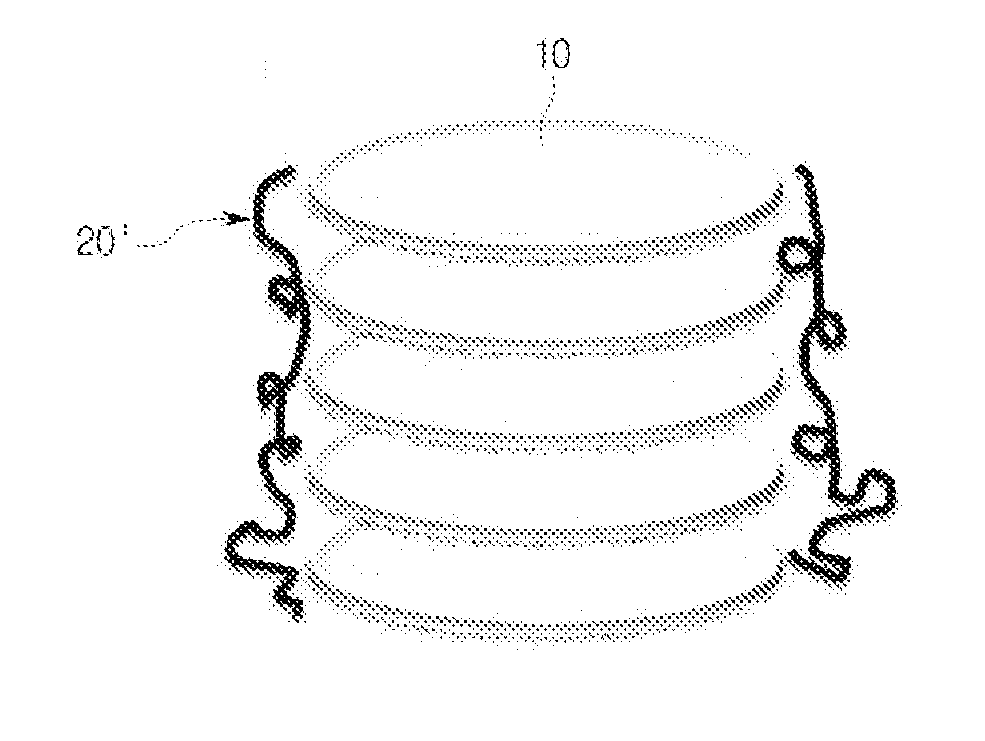

Hybrid Composite Yarn

This invention is a hybrid composite yarn comprising: a first polyolefin yarn having >about 80% crystallinity according to WAXS measuring techniques; a second yarn taken from the group consisting of: glass; quartz; carbon; poly(p-phenylene terephthalamide), poly(m-phenylene terephthalamide); poly(vinyl alcohol); poly(1,4-phenylene-2,14-benzibisoxazole) (PBO); poly(1,4-phenylene-2,14-benzobisthiazole) (PBT); poly(benzimidizole) (PBI); poly(ethylene-2,14-naphthalate) (PEN); lyotropic liquid crystalline polymers formed by polycondensation of aromatic organic monomers to form aromatic polyesters, polyamides, aluminia-silicates, basalt, regenerated cellulosic materials and ultra-high molecular weight polyethylene (UHMWPE); and, wherein the first polyolefin yarn and the second yarn are physically combined to form a composite yarn having at least one of the following properties: tenacity greater than about 100% of the expected tenacity based on the volume fraction of the second; an initial modulus >about 100% of the expected modulus based on the volume fraction of the second; elongation at break <about 320% of the elongation at break of the second.

Owner:INNEGRITY C +1

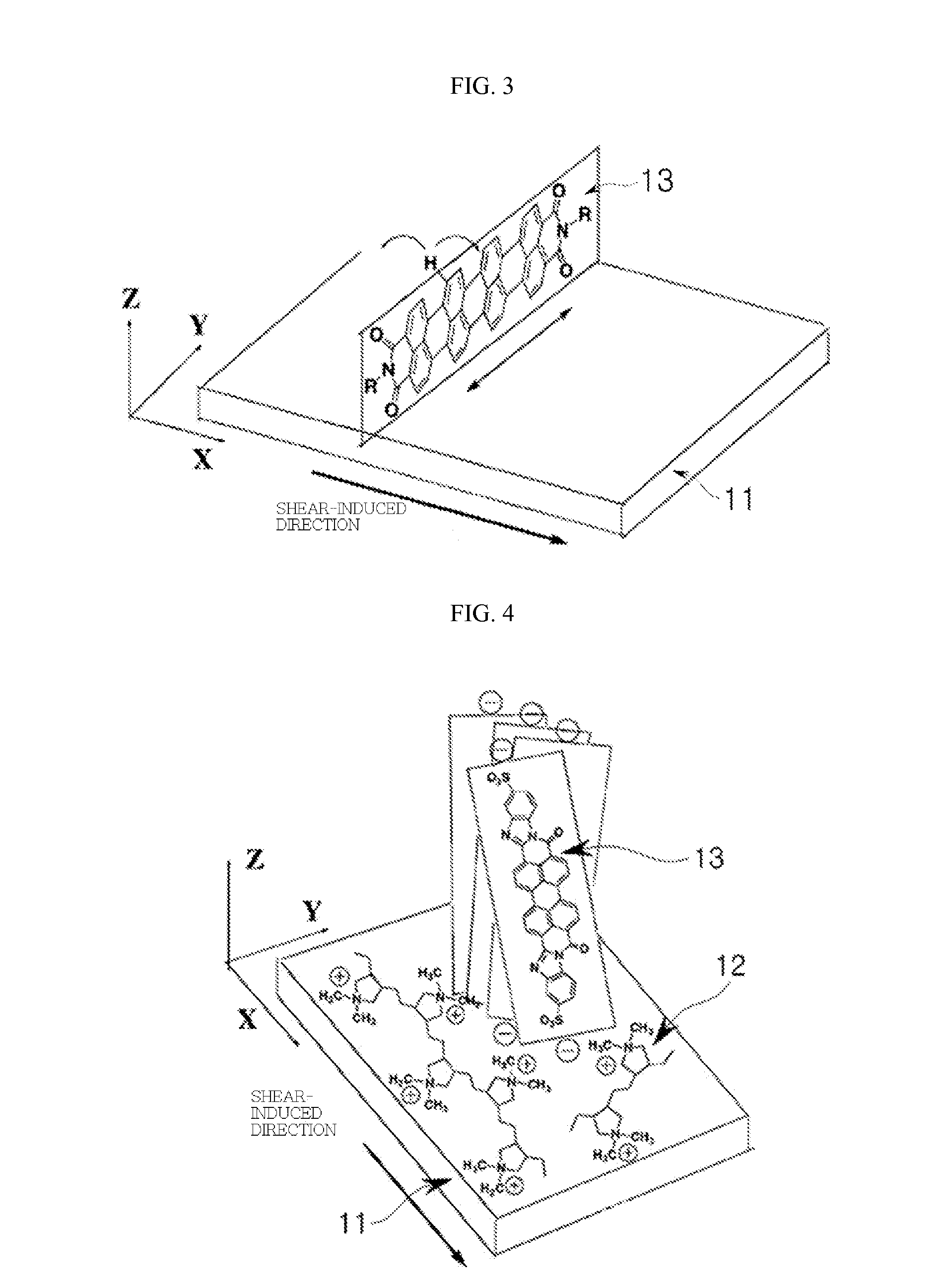

Lyotropic chromonic liquid crystal composition, method for manufacture of lyotropic chromonic liquid crystal coating film, and lyotropic chromonic liquid crystal coating film manufactured thereby

ActiveUS20110272629A1Excellent electrical and optical propertyMechanical strengthLiquid crystal compositionsMixing methodsCrystallographyOptical property

The present invention relates to a lyotropic chromonic liquid crystal composition, a method for manufacturing a lyotropic chromonic liquid crystal coating film and a lyotropic chromonic liquid crystal coating film manufactured thereby. The lyotropic chromonic liquid crystal composition of the present invention includes chromonic liquid crystal compounds and monomers each having opposing acid-base properties. Use of the lyotropic chromonic liquid crystal composition in the formation of optical films leads to improvements in electrical and optical properties such as mechanical strength, an insulating characteristic and a refractive index.

Owner:KOREA INST OF IND TECH +1

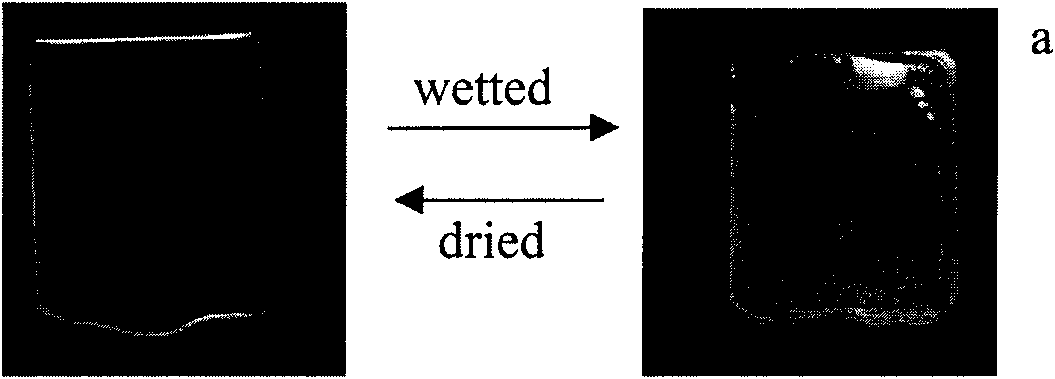

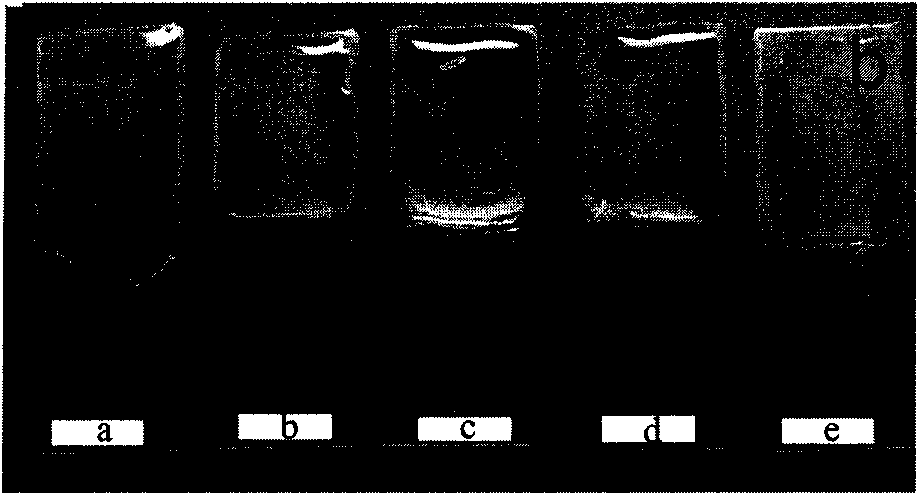

Lyotropic color response transparent film material and preparation method thereof

The invention belongs to the technical field of chemical materials, and in particular relates to a lyotropic color response transparent film material and a preparation method thereof. Methods of emulsion polymerization, dispersion polymerization, suspension polymerization, mini-emulsion polymerization and the like are adopted to prepare polymer latex which has hydrophilic groups, average particle size of between 100 and 500 nanometers, narrow particle size distribution, and glass-transition temperature of between 0 and 100 DEG C, the polymer latex is coated on a substrate material and is dried; and when the moisture is volatized, the polymer latex can be automatically assembled into a three-dimensional order colorless transparent film arranged periodically. The transparent film material has the advantages of quick lyotropic color responsibility and wide-range reversible regulation; and when the film contacts with a solvent, the colorless transparent film material can be changed into a colorized film material with beautiful colors which disappear along with the volatilization of the solvent. The material has excellent mechanical properties and lyotropic color response reversibility, simple, environment-friendly and nontoxic production process, and can be prepared in large areas directly. The lyotropic color response transparent film material can be widely applied to film or coating materials for color response, an optical and detection sensor, simulation, decoration, printing, anti-counterfeiting and the like.

Owner:FUDAN UNIV

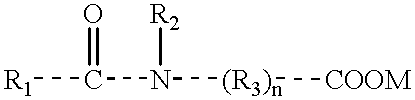

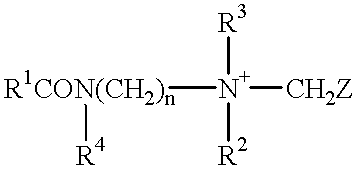

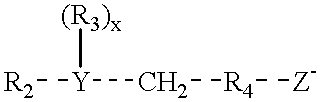

Paper quality improver composition for papermaking

InactiveUS6565708B2Bulky brightnessBulky opacityNatural cellulose pulp/paperSpecial paperCLARITYPapermaking

The present invention provides a paper quality improver composition for papermaking, which is excellent in improved efficiencies of bulky value, brightness, opacity and the like of pulp sheet, demanded at lightening paper and increasing a blending amount of deinked pulp, even by adding a small amount thereof as well as which is further excellent in an improved efficiency of paper-strength. That is, the present invention provides a paper quality improver composition for papermaking; which comprises (A) a compound having lyotropic degree measured by a specific method of not less than 4% and satisfying at least two of (i) standard improved bulky value of not less than 0.02 g / cm3, (ii) standard improved brightness of not less than 0.5 point, and (iii) standard improved opacity of not less than 0.5 point and (B) a water-soluble polymer satisfying an average molecular weight and / or a viscosity thereof of specific value.

Owner:KAO CORP

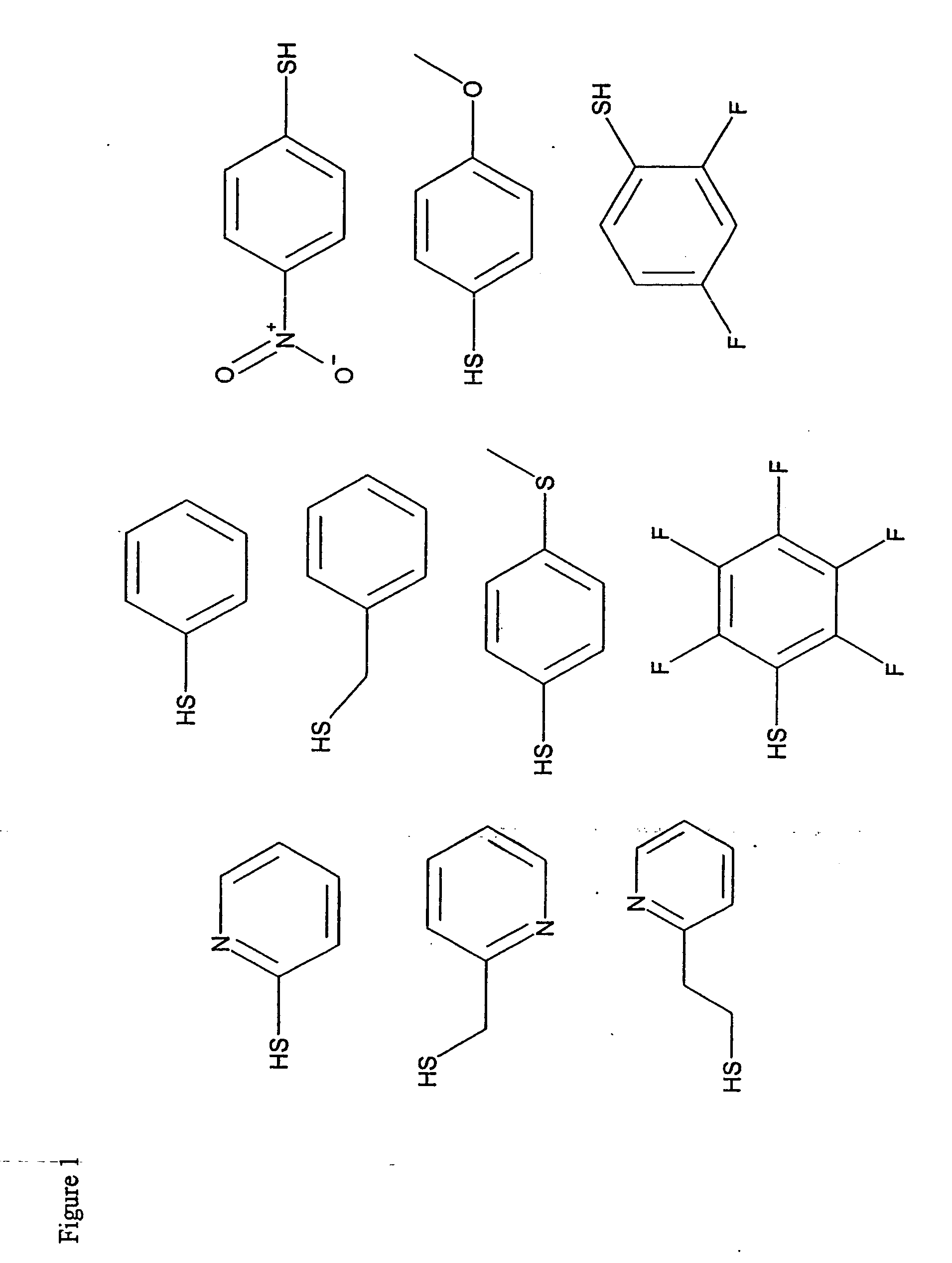

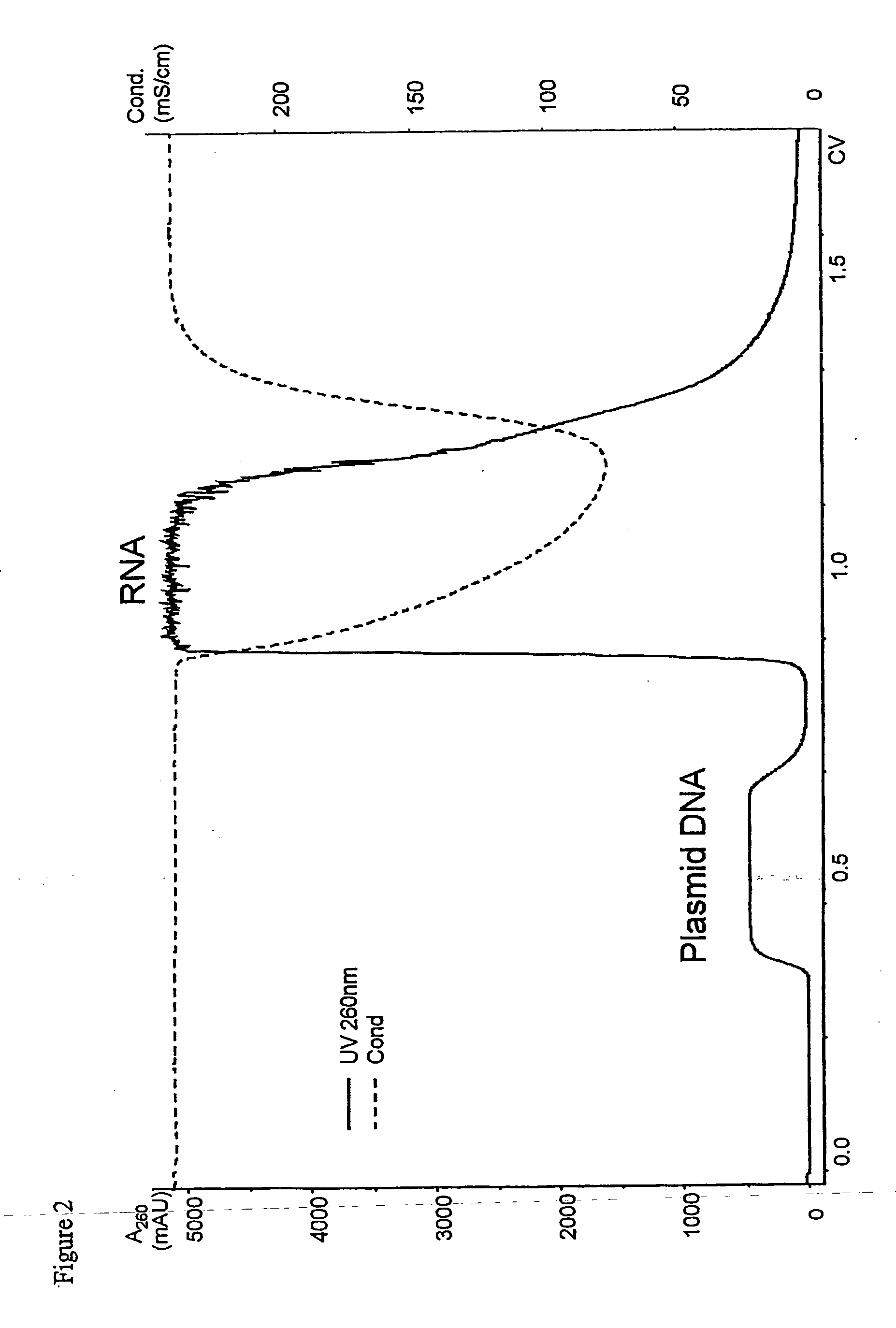

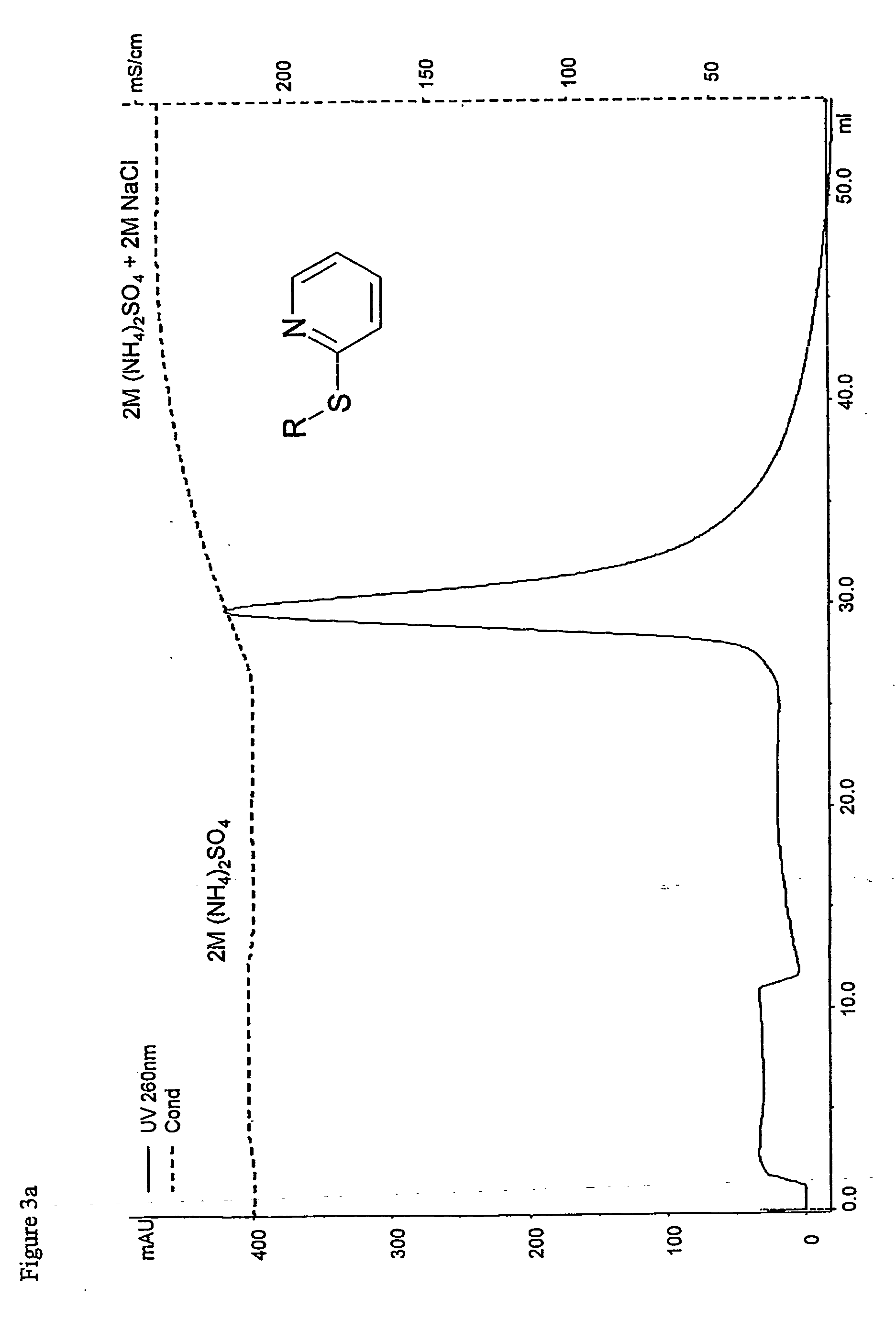

Method of separation using aromatic thioether ligands

InactiveUS20050080251A1Efficient separationSugar derivativesMicrobiological testing/measurementIonic strengthThioether

The present invention is a method of separating nucleic acid molecules from contaminants, such as proteins, in a solution and isolating one or more desired nucleic acid molecules, which method comprises the following steps (a) providing an aqueous adsorption solution, which includes nucleic acids and a salt that forms lyotropic ions when dissolved; (b) passing said solution over a matrix to adsorb the nucleic acids onto the matrix, said matrix including an aromatic ring moiety and at least one thioether moiety; (c) passing an aqueous eluent over said matrix to desorb the nucleic acid molecules therefrom, which eluent includes a salt that forms lyotropic ions and a gradient of increasing ionic strength originating from an increasing concentration of a salt that forms less lyotropic ions when dissolved than the ones present in said aqueous adsorption solution; and (d) isolating a fraction comprising the desired nucleic acid molecules.

Owner:GE HEALTHCARE BIO SCI CORP

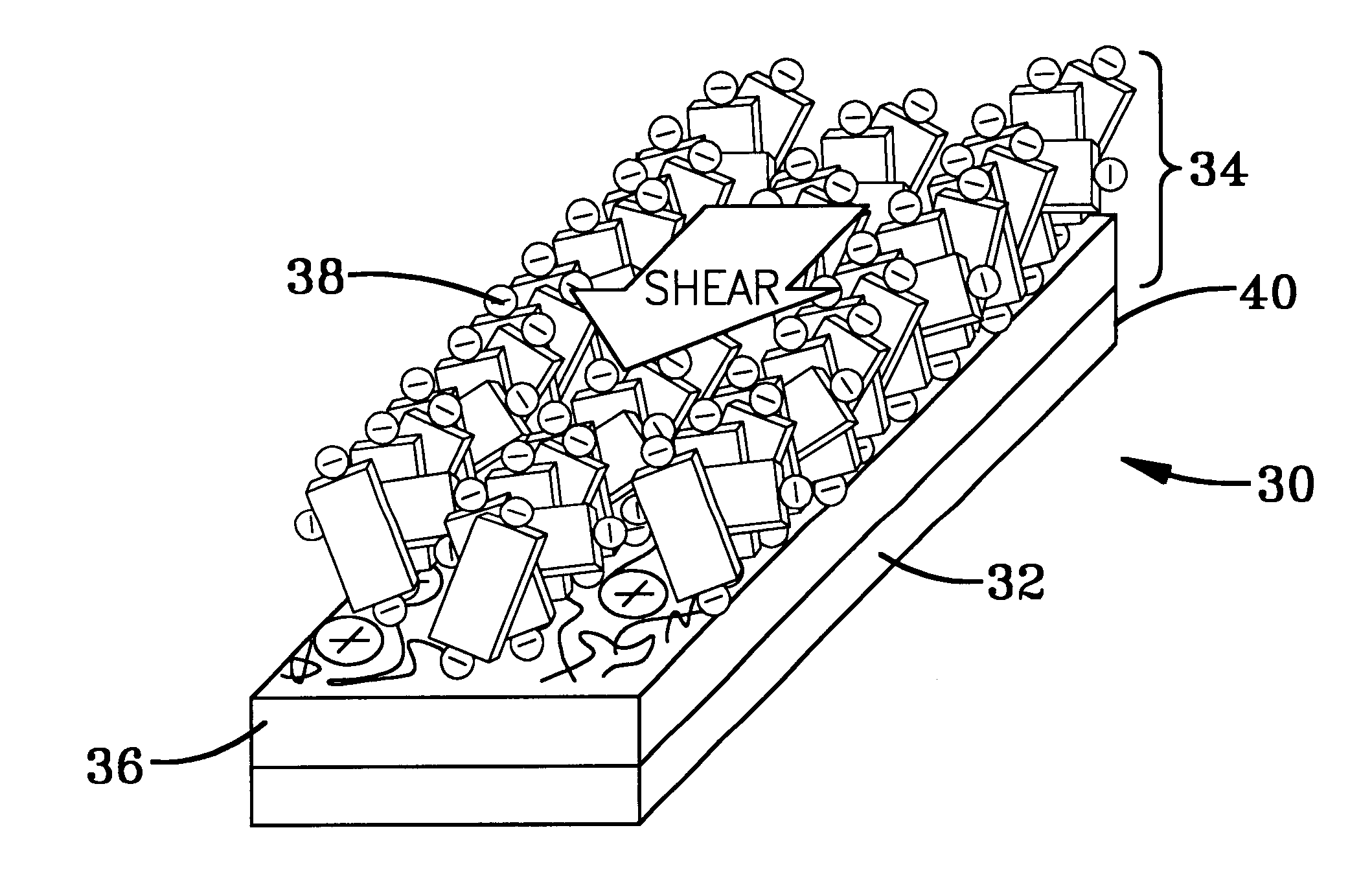

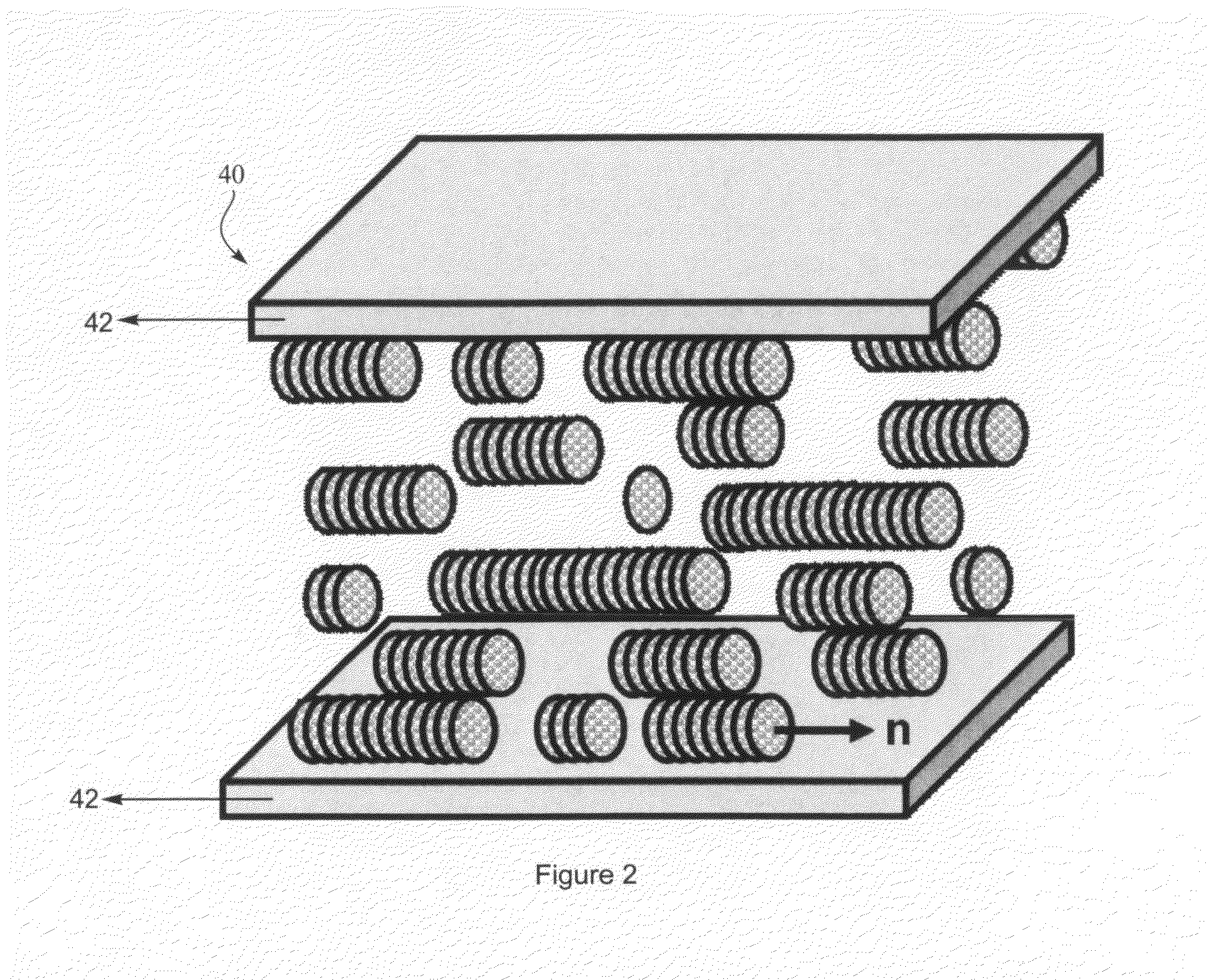

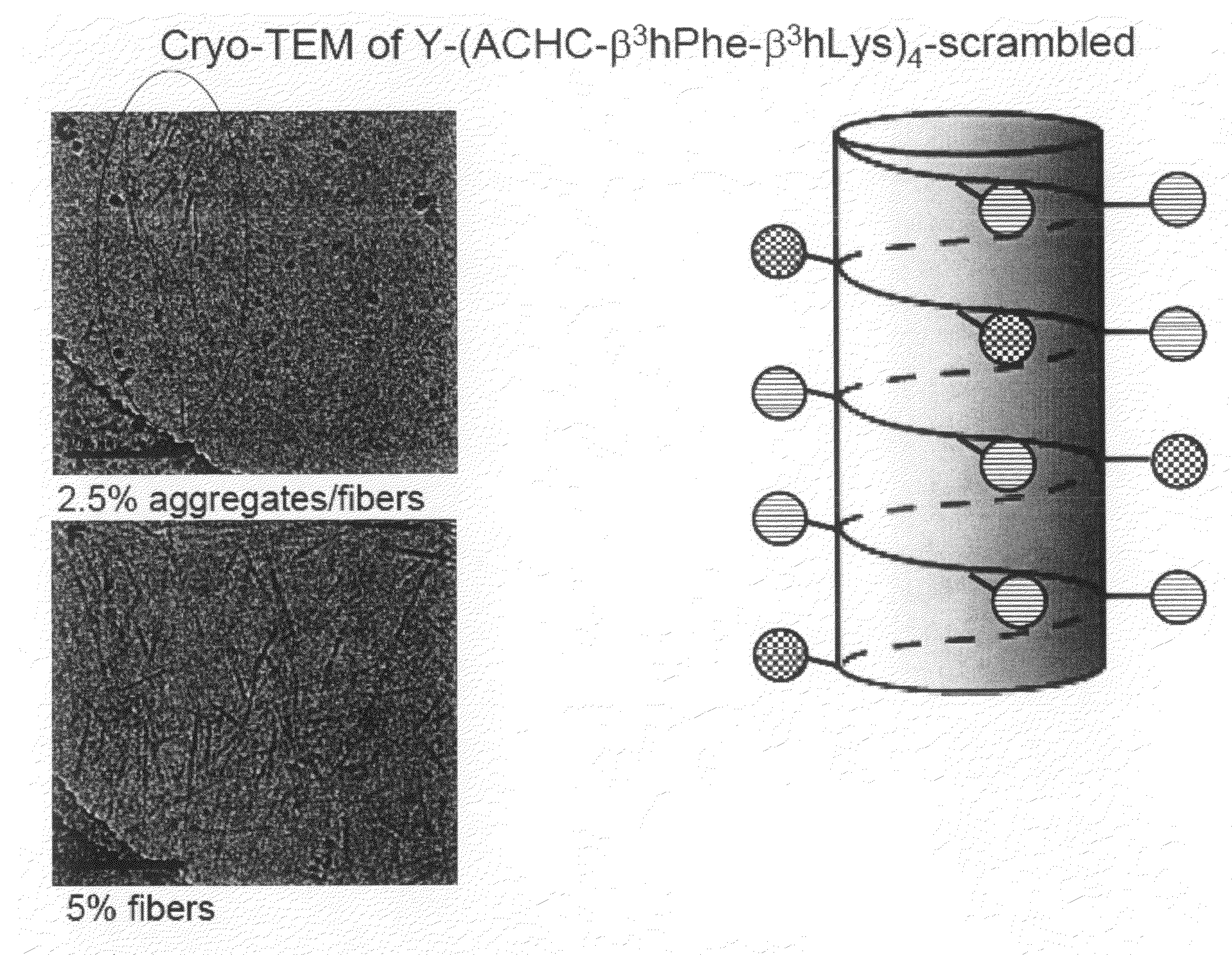

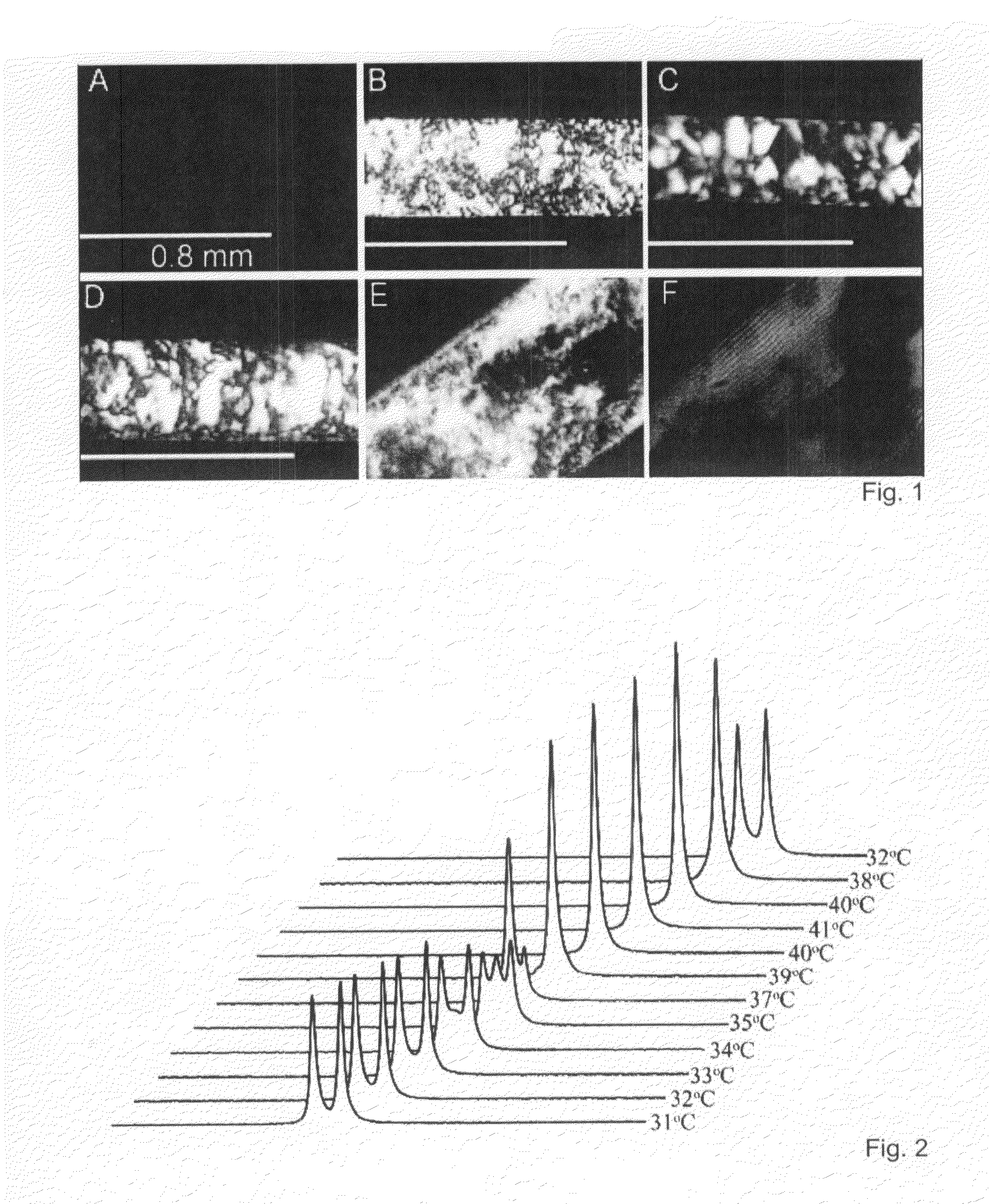

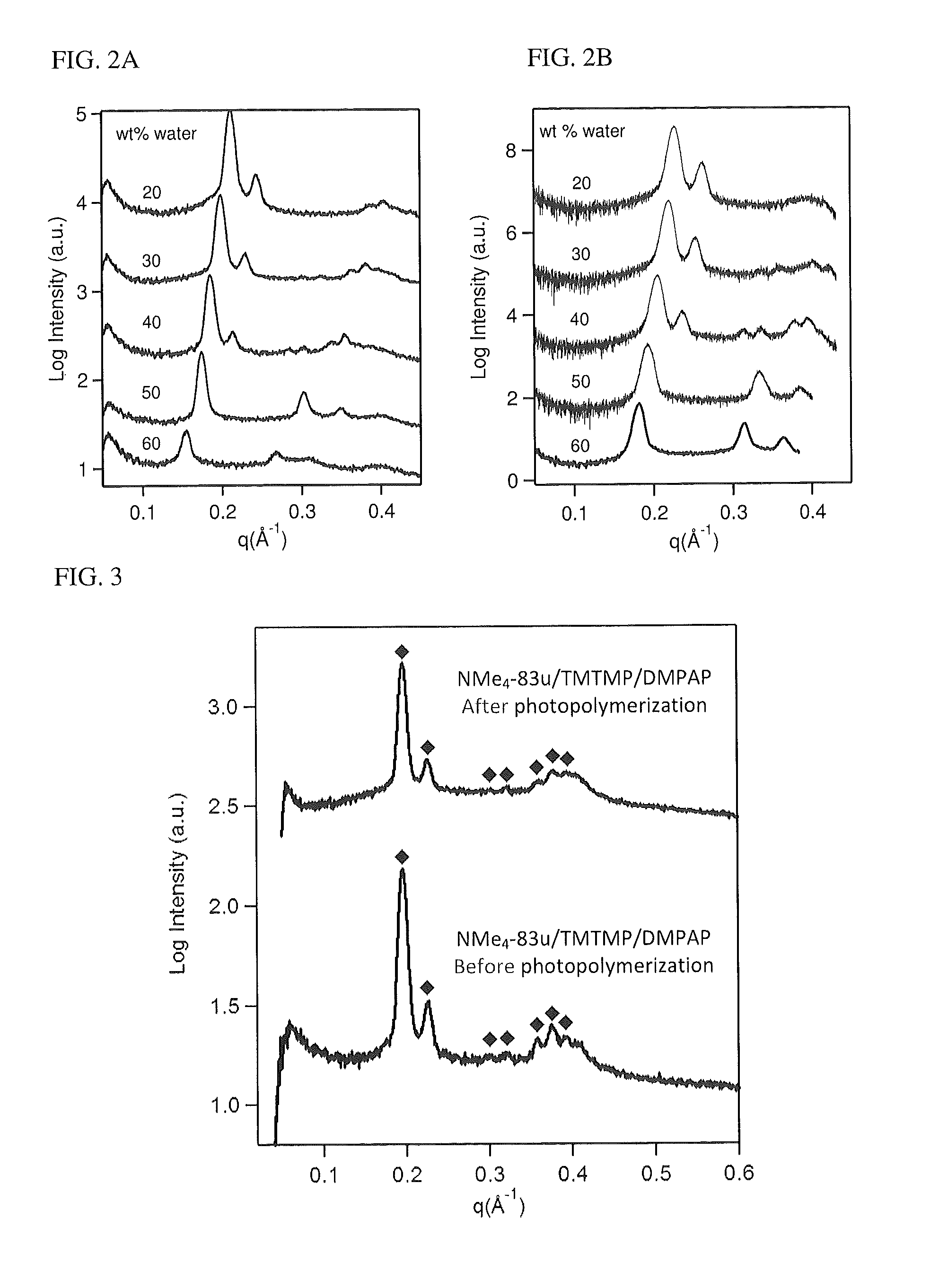

Homeotropic and hybrid bulk alignment of lyotropic chromonic liquid crystals

The invention provides a liquid crystal cell and method thereof. The cell comprises two opposed substrates and a surfactant-free lyotropic chromonic liquid crystals (LCLC) material disposed therebetween. By using an ammonium compound with LCLC or surface treatment on the substrates, the alignment of the LCLC material can be manipulated as a homeotropic bulk alignment; or a hybrid bulk alignment in which the LCLC alignment is changed from homeotropic bulk alignment in the vicinity of one substrate to planar alignment in the vicinity of another substrate. The cell can be used in biosensing, detection and amplification of ligands, optical devices, and photovoltaics etc.

Owner:KENT STATE UNIV

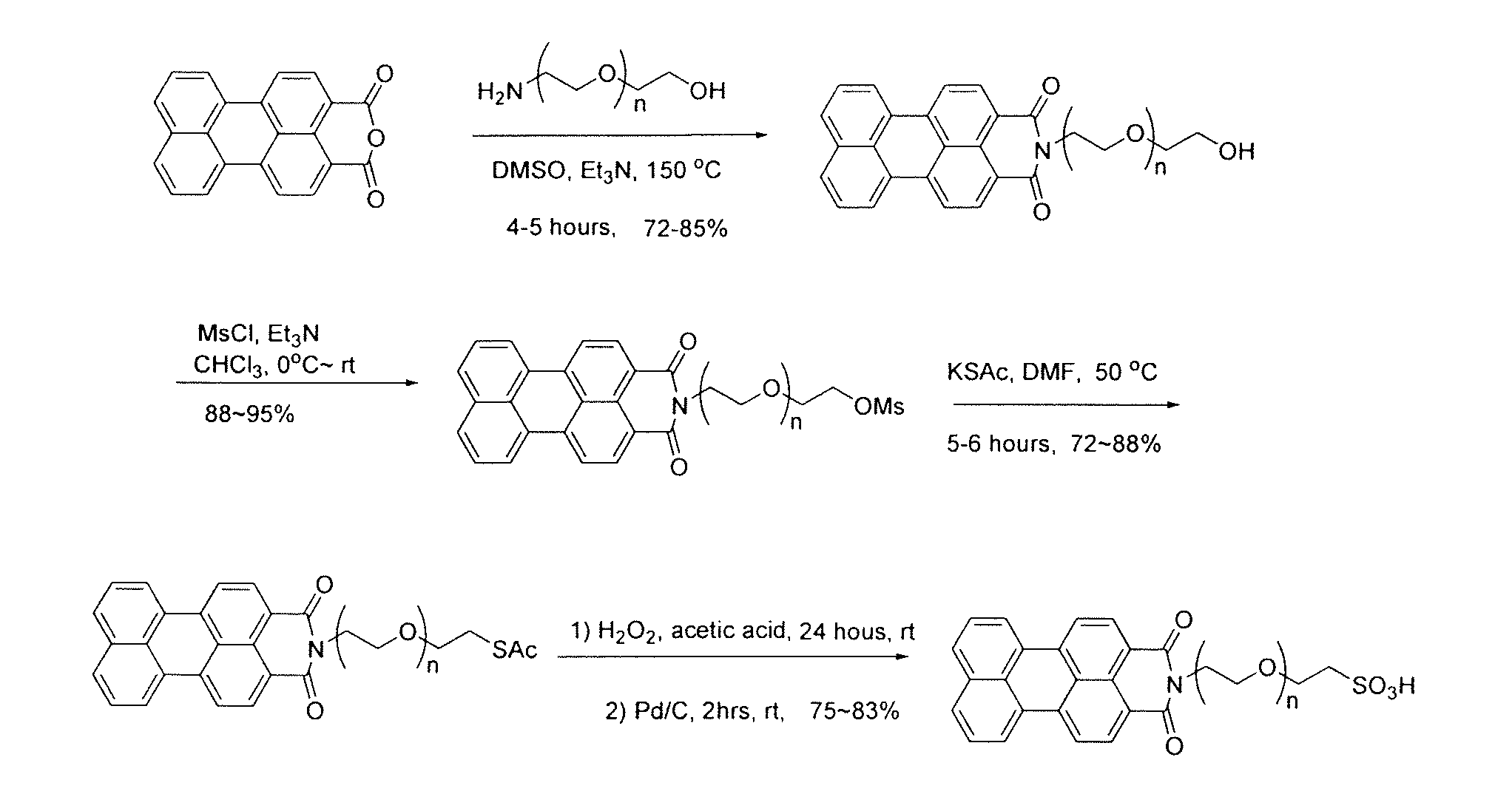

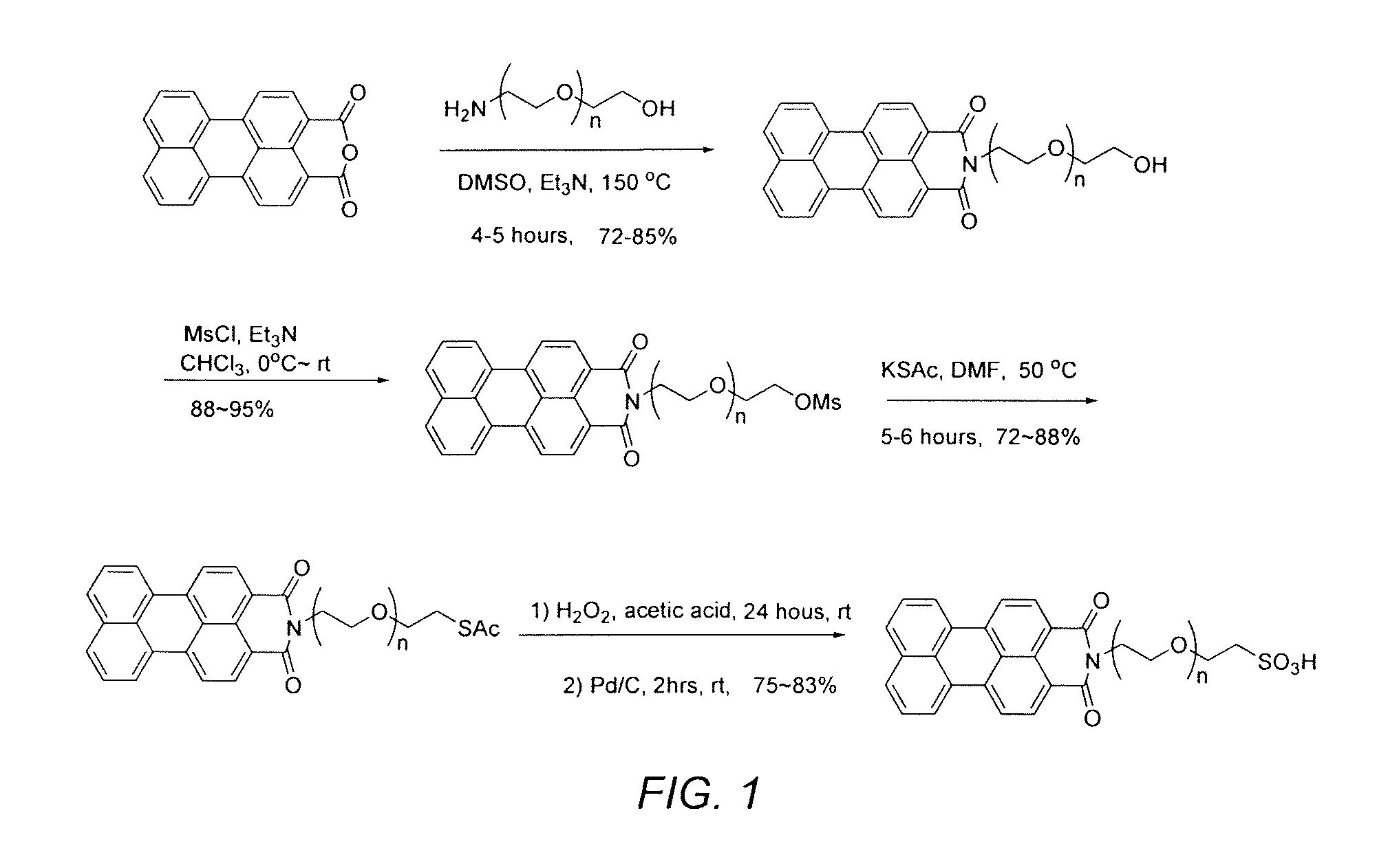

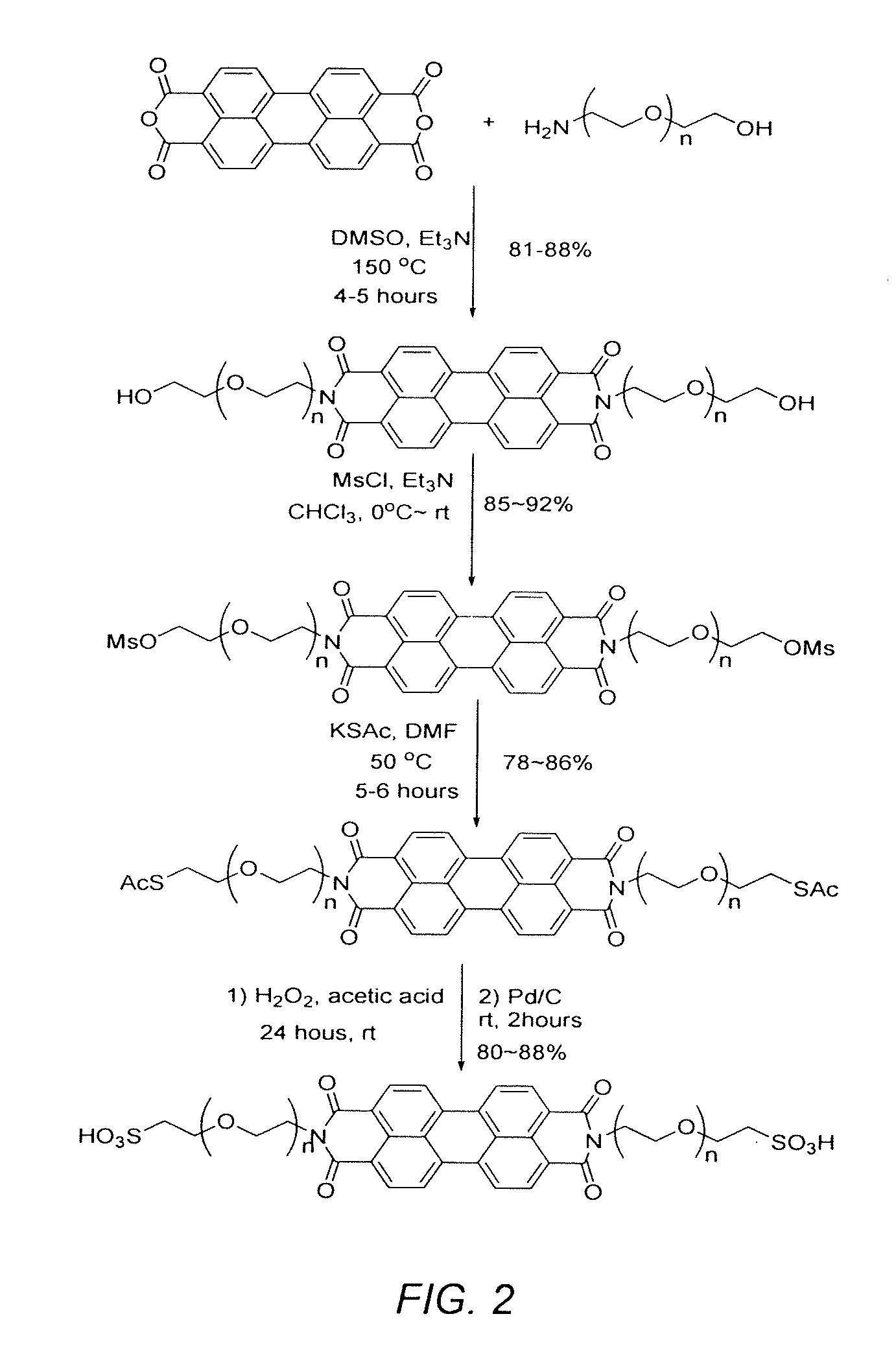

Lyotropic chromophoric compounds, liquid crystal systems and optically anisotropic films

Lyotropic chromophoric compounds comprised of a naphthalimide derivative, a perylene-3,4-dicarboxylic imide derivative, or a perylenetetracarboxylic diimide derivative are described. The compounds can be used to form liquid crystal systems possessing high quality optical properties. The resulting liquid crystal systems are readily applied onto a substrate to obtain optically isotropic or anisotropic, at least partially crystalline films applicable in various fields.

Owner:NITTO DENKO CORP

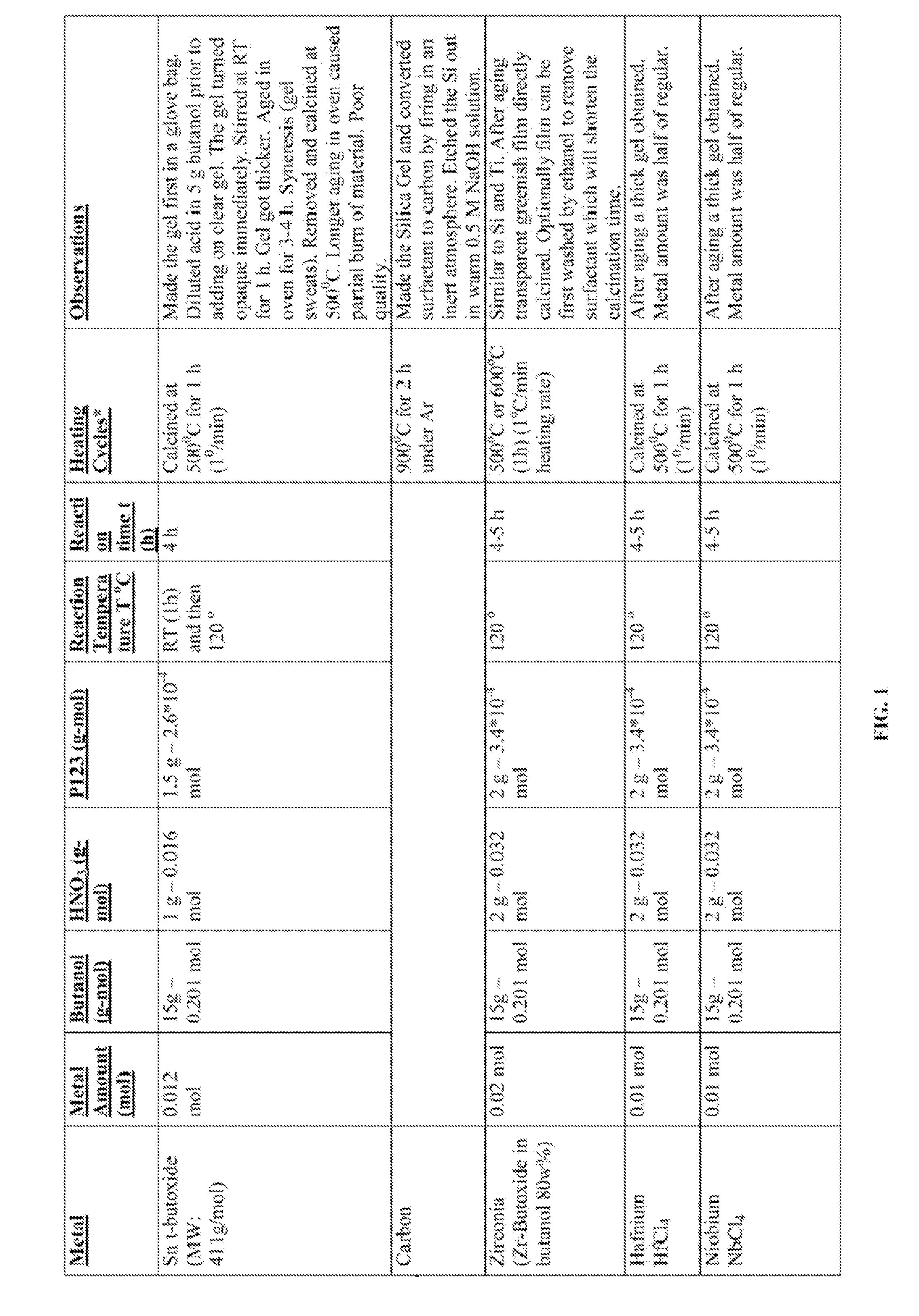

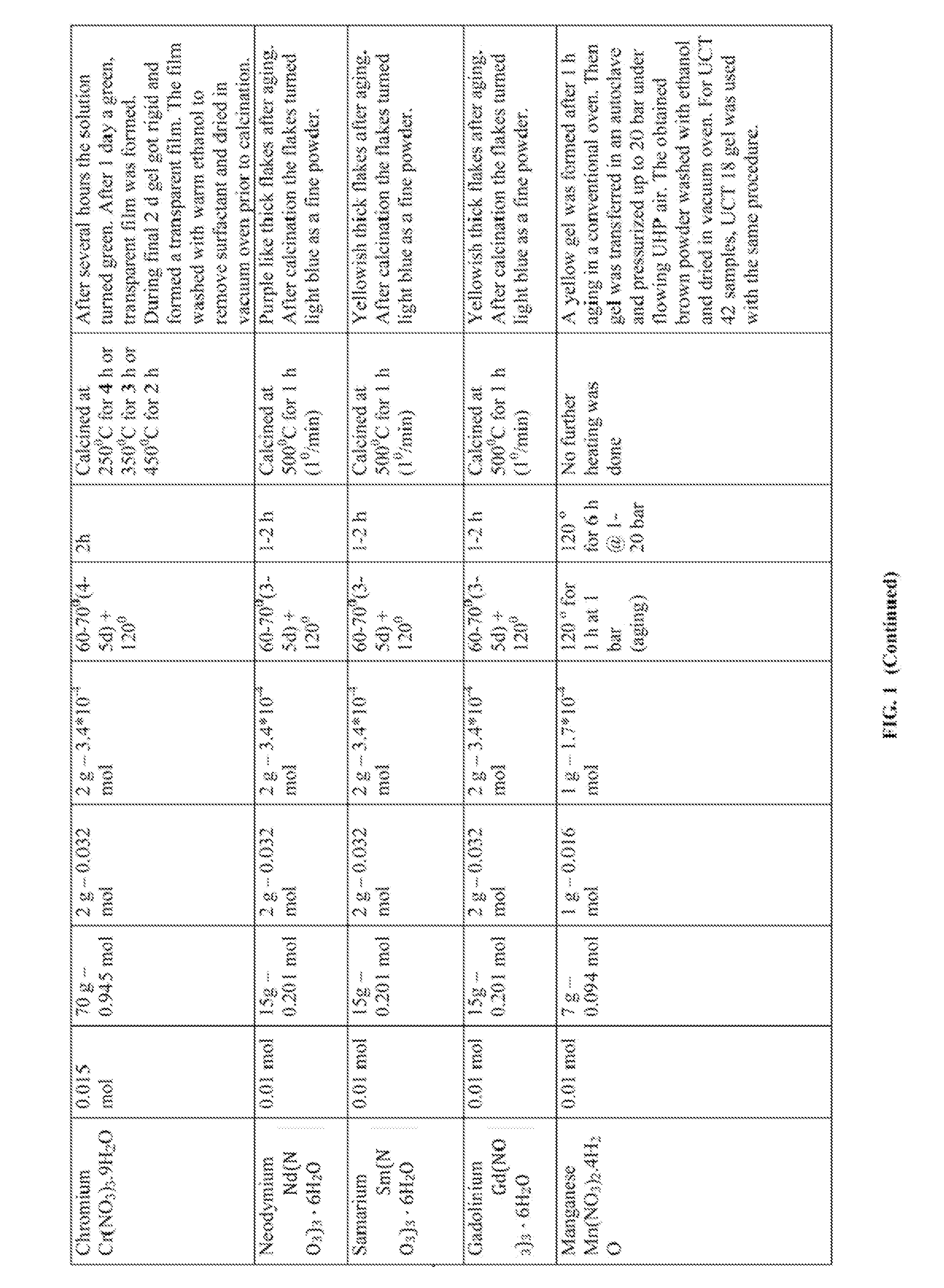

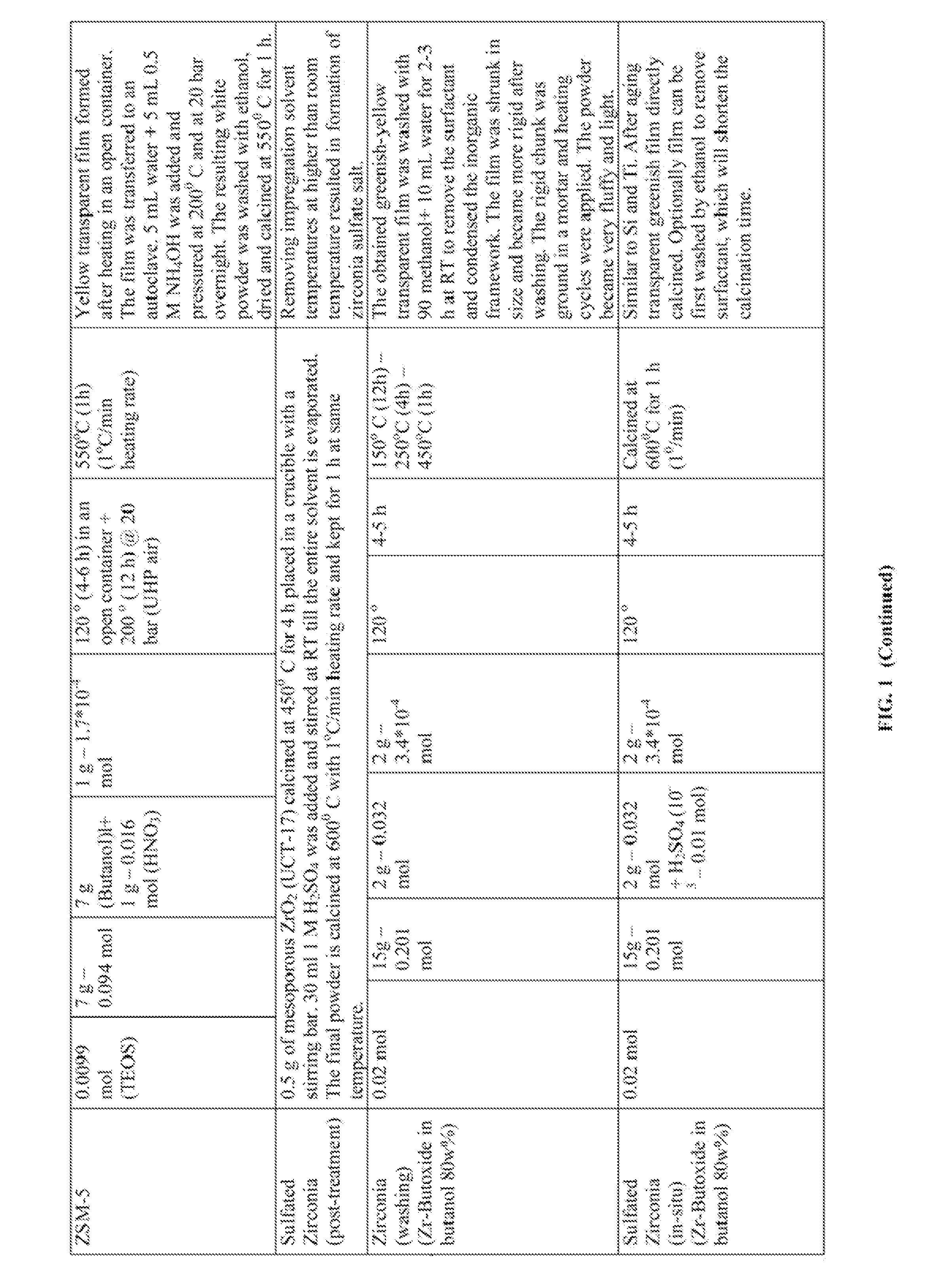

Mesoporous materials and processes for preparation thereof

ActiveUS20160151768A1Stable for calcinationPreserving mesostructureRare earth metal oxides/hydroxidesCarbon compoundsHydrotropeMesoporous material

A process for preparing a mesoporous material, e.g., transition metal oxide, sulfide, selenide or telluride, Lanthanide metal oxide, sulfide, selenide or telluride, a post-transition metal oxide, sulfide, selenide or telluride, and metalloid oxide, sulfide, selenide or telluride. The process comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic or lyotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to form the mesoporous material. A mesoporous material prepared by the above process. A method of controlling nano-sized wall crystallinity and mesoporosity in mesoporous materials. The method comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic or lyotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to control nano-sized wall crystallinity and mesoporosity in the mesoporous materials. Mesoporous materials and a method of tuning structural properties of mesoporous materials.

Owner:UNIV OF CONNECTICUT

Paper quality improver composition for papermaking

InactiveUS20020117278A1Bulky brightnessBulky opacityNatural cellulose pulp/paperSpecial paperCLARITYPapermaking

The present invention provides a paper quality improver composition for papermaking, which is excellent in improved efficiencies of bulky value, brightness, opacity and the like of pulp sheet, demanded at lightening paper and increasing a blending amount of deinked pulp, even by adding a small amount thereof as well as which is further excellent in an improved efficiency of paper-strength. That is, the present invention provides a paper quality improver composition for papermaking; which comprises (A) a compound having lyotropic degree measured by a specific method of not less than 4% and satisfying at least two of (i) standard improved bulky value of not less than 0.02 g / cm3, (ii) standard improved brightness of not less than 0.5 point, and (iii) standard improved opacity of not less than 0.5 point and (B) a water-soluble polymer satisfying an average molecular weight and / or a viscosity thereof of specific value.

Owner:KAO CORP

Beta-peptide lyotropic liquid crystals and methods of manufacture and use thereof

ActiveUS20100021344A1Increased birefringenceLiquid crystal compositionsPeptide/protein ingredientsCrystallographyProviding material

The present invention provides materials and methods that make liquid crystal phases accessible with relatively short β-peptides in aqueous solvents.

Owner:ALCATEL LUCENT SAS +1

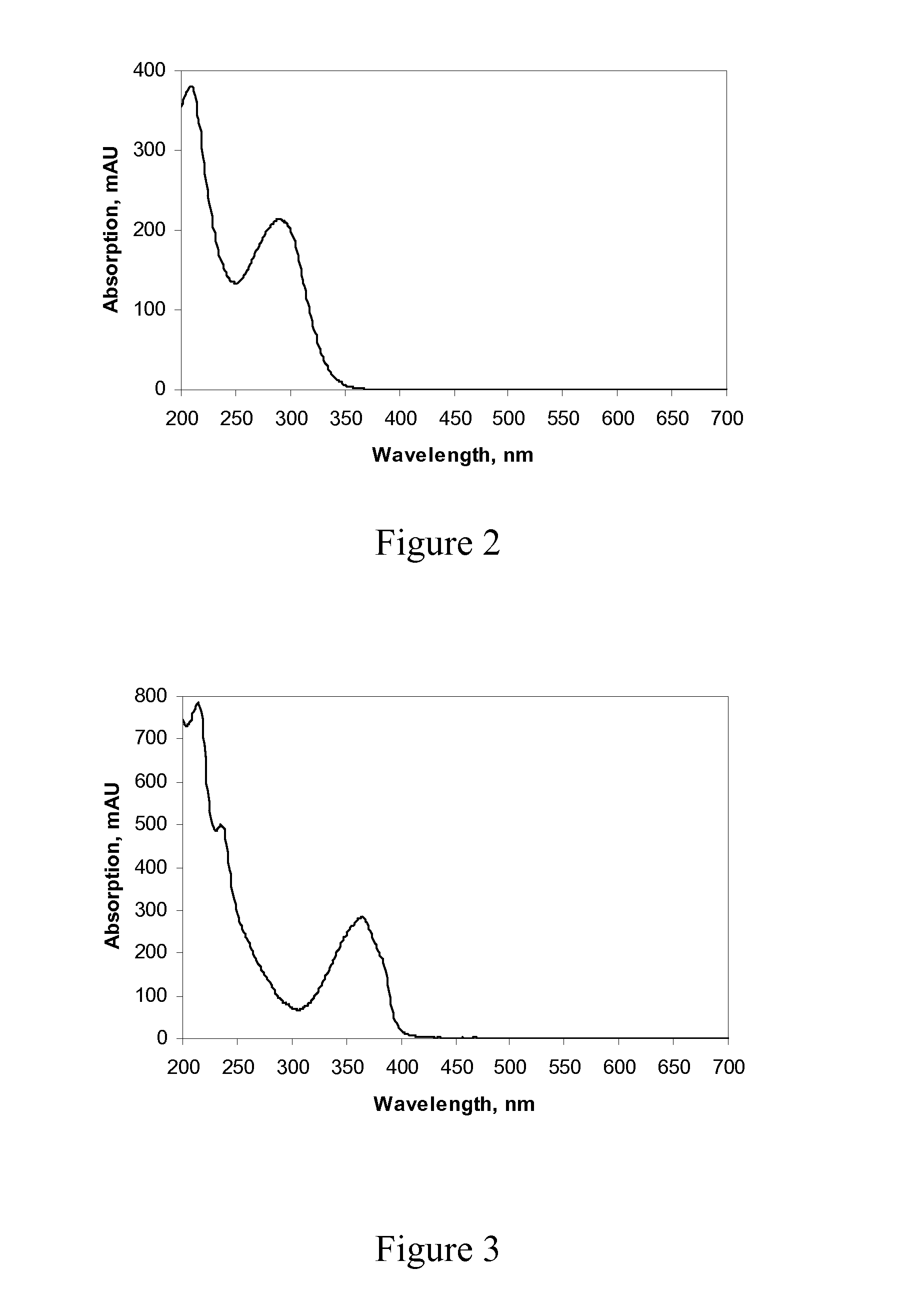

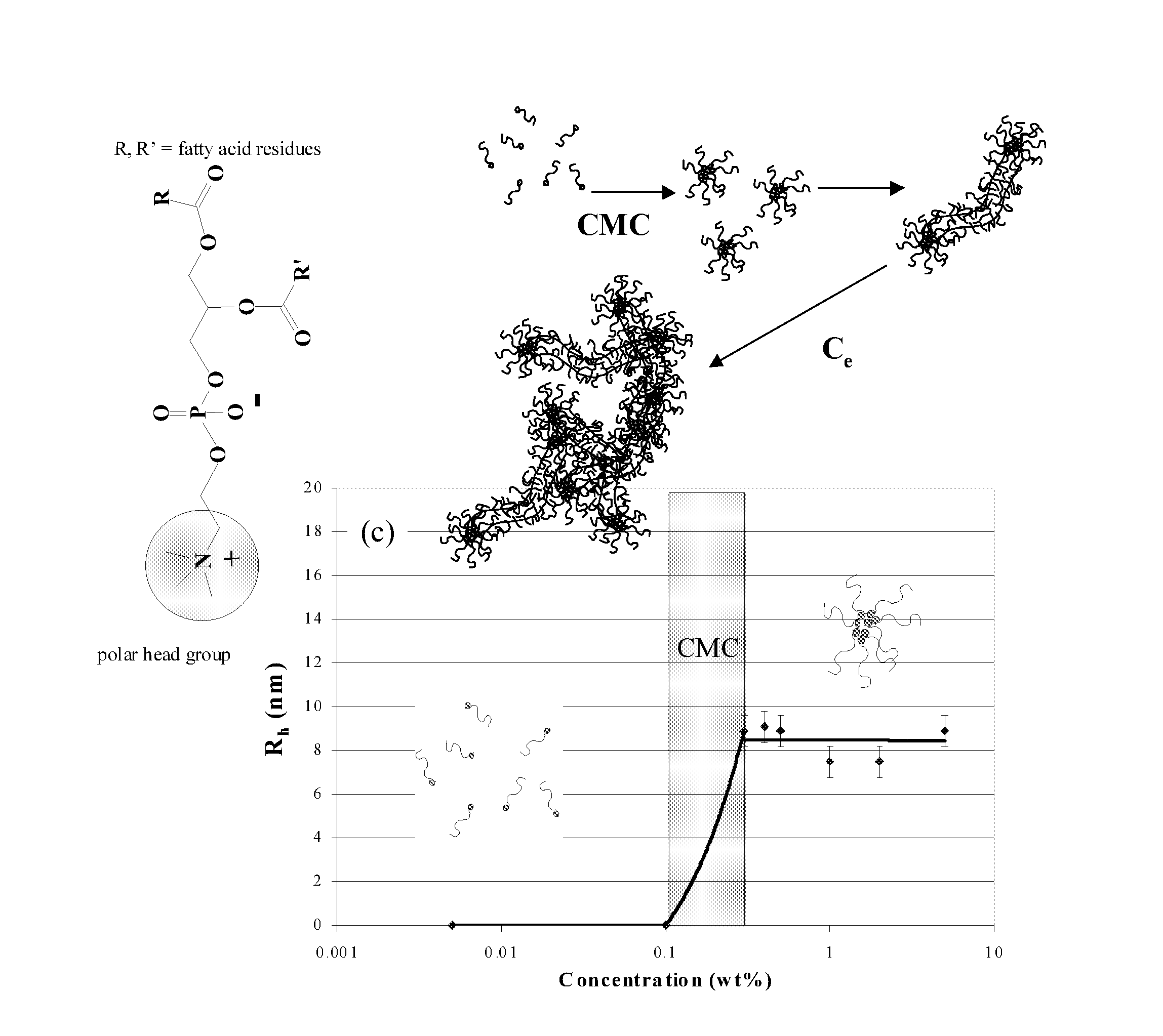

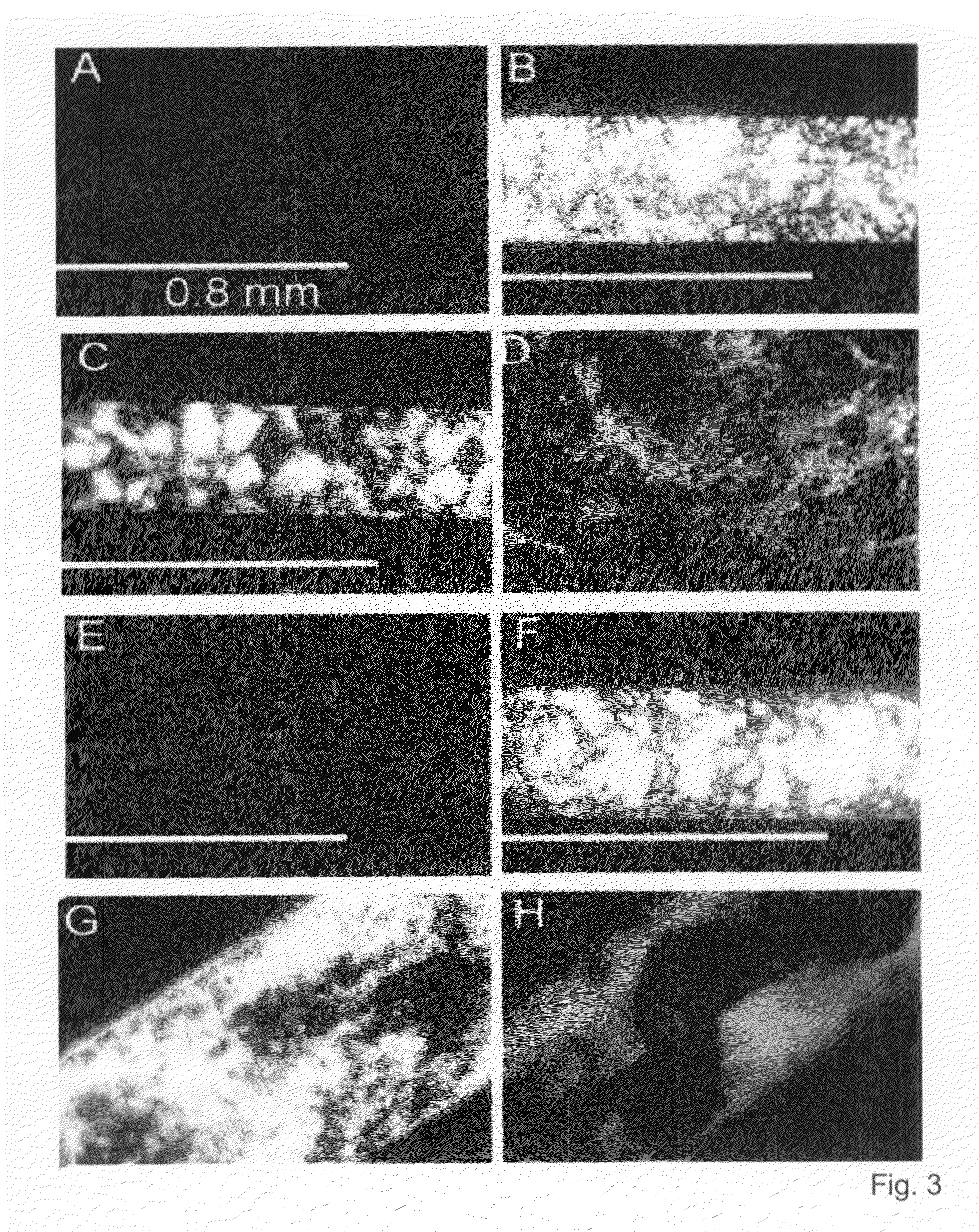

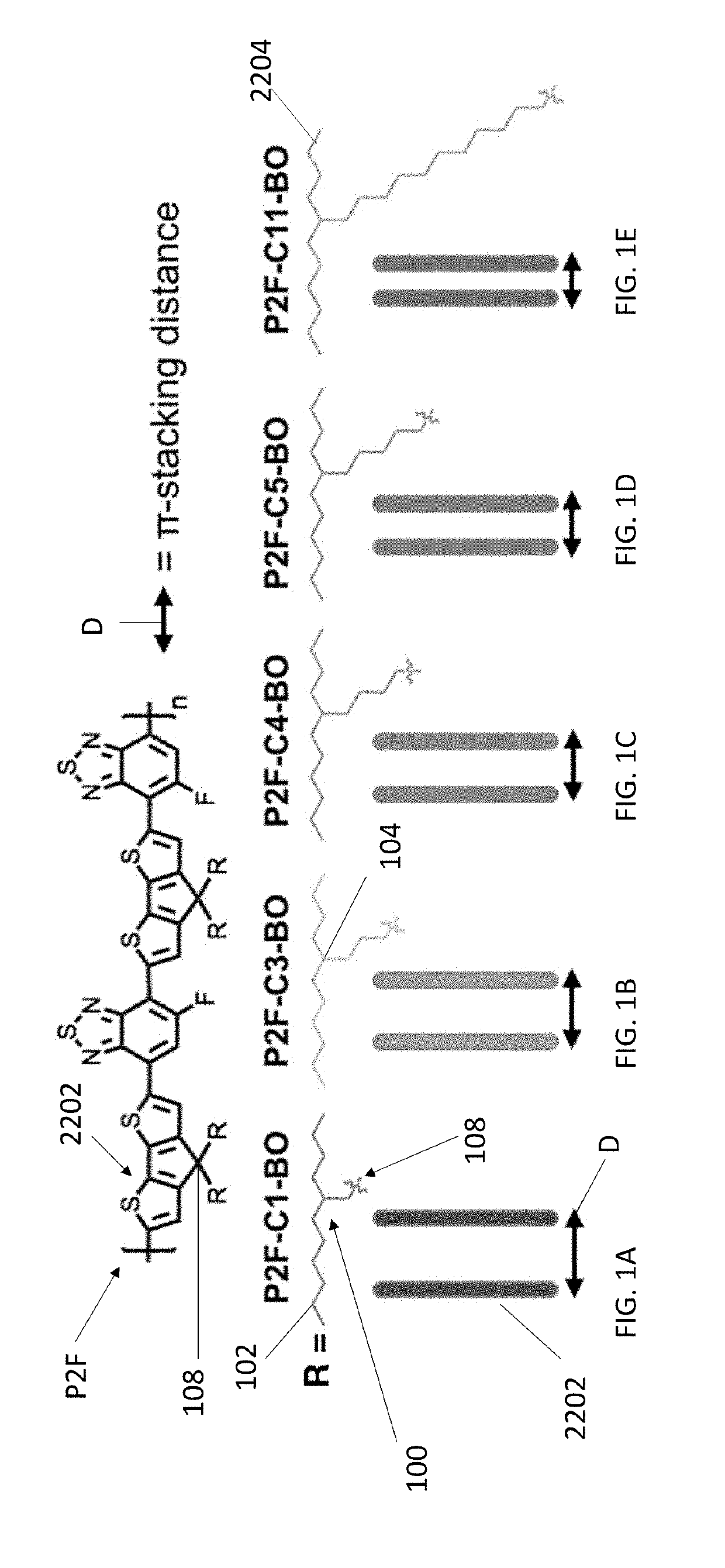

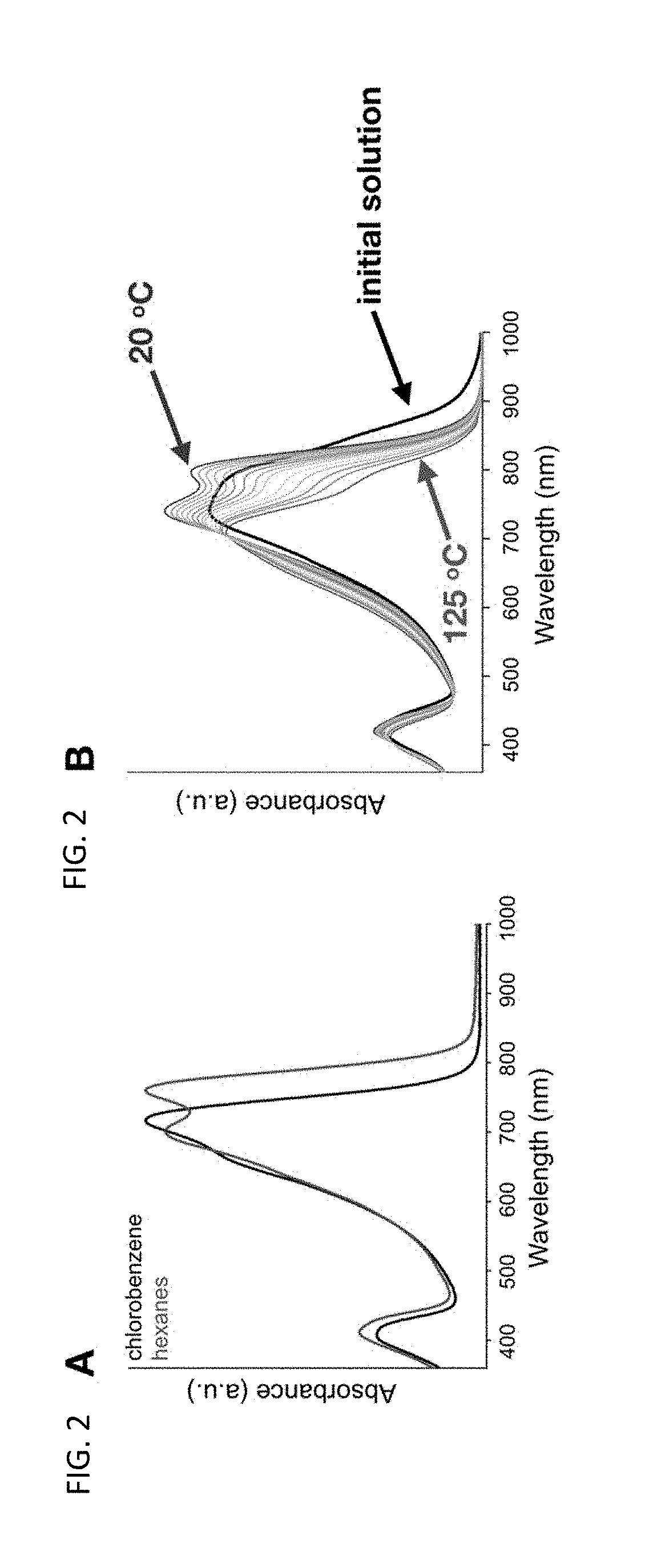

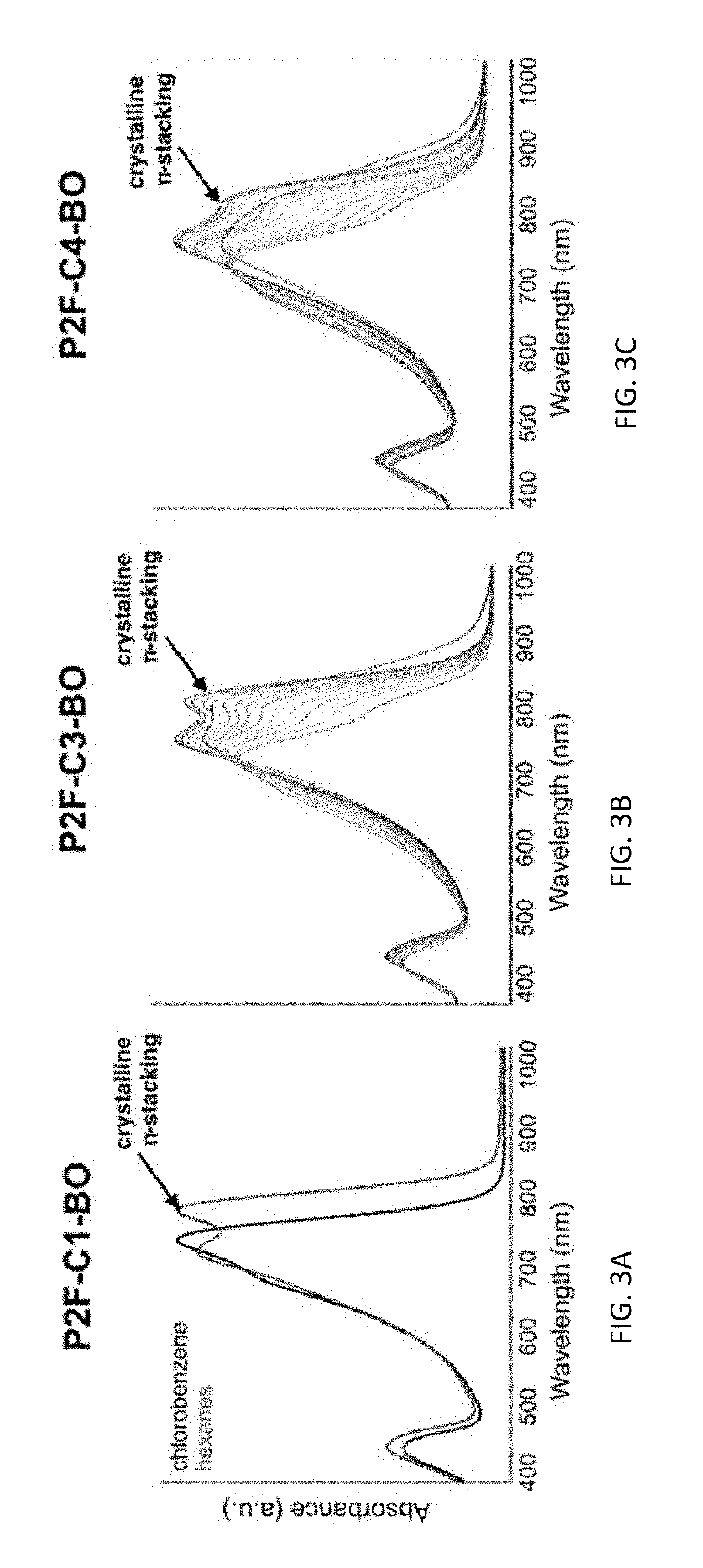

Branch point effect on structure and electronic properties of conjugated polymers

InactiveUS20190181348A1Poor charge carrier mobilityEffective alignmentSolid-state devicesSemiconductor/solid-state device manufacturingLiquid crystallineSide chain

Synthesis of lyotropic semiconducting polymers having novel side chains enabling control over crystalline fraction, crystalline orientation, and the unit cell (specifically the π-stacking distance). Moving the branch point in the side chain further from the conjugated backbone not only retains the lyotropic liquid crystalline behavior as observed by UV-vis and POM, but also achieves reduced π-stacking distance. This results in higher charge carrier mobility, reaching (in one or more examples) a mobility of at least 0.41 cm2V−1s−1 when the polymers were non-aligned.

Owner:RGT UNIV OF CALIFORNIA

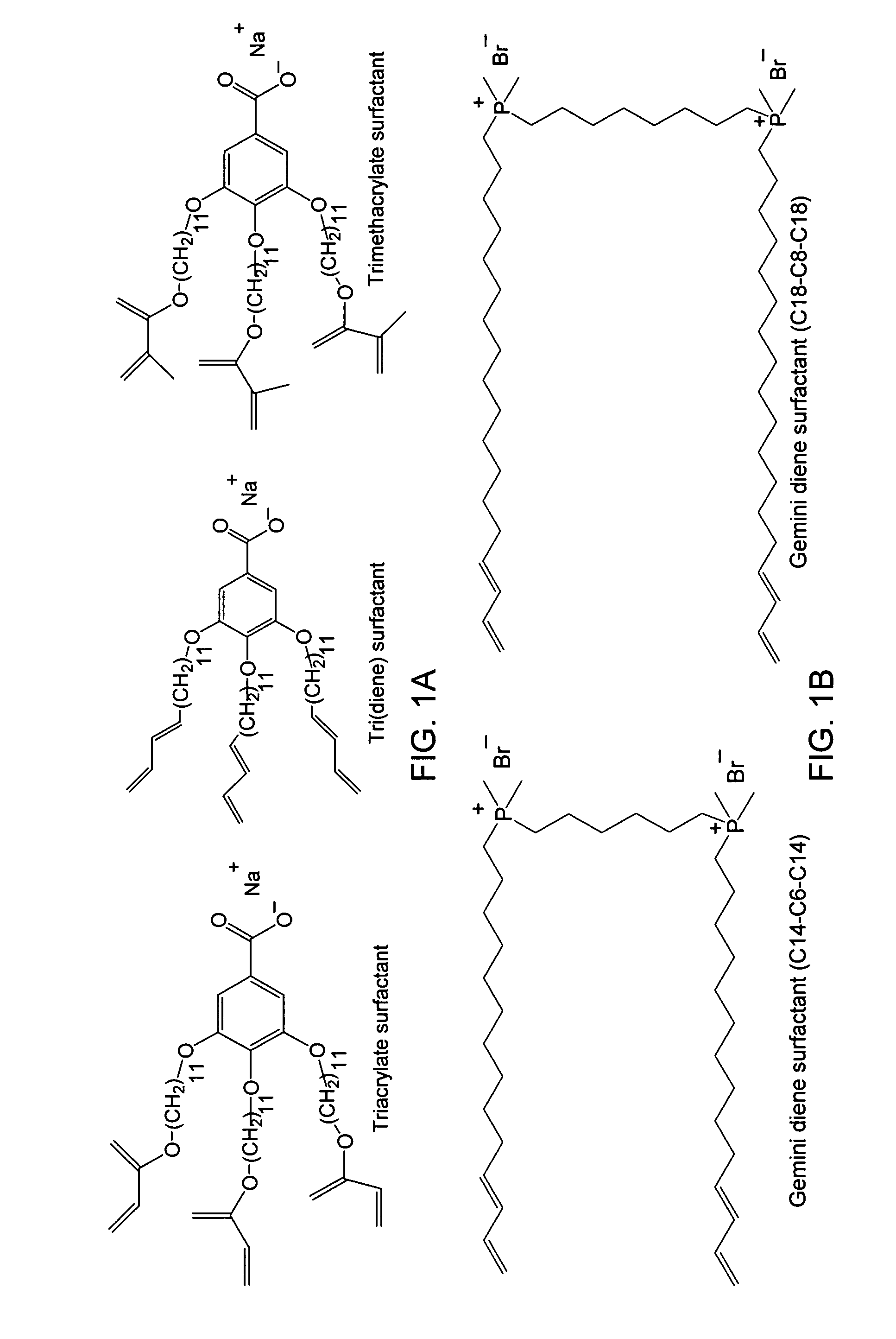

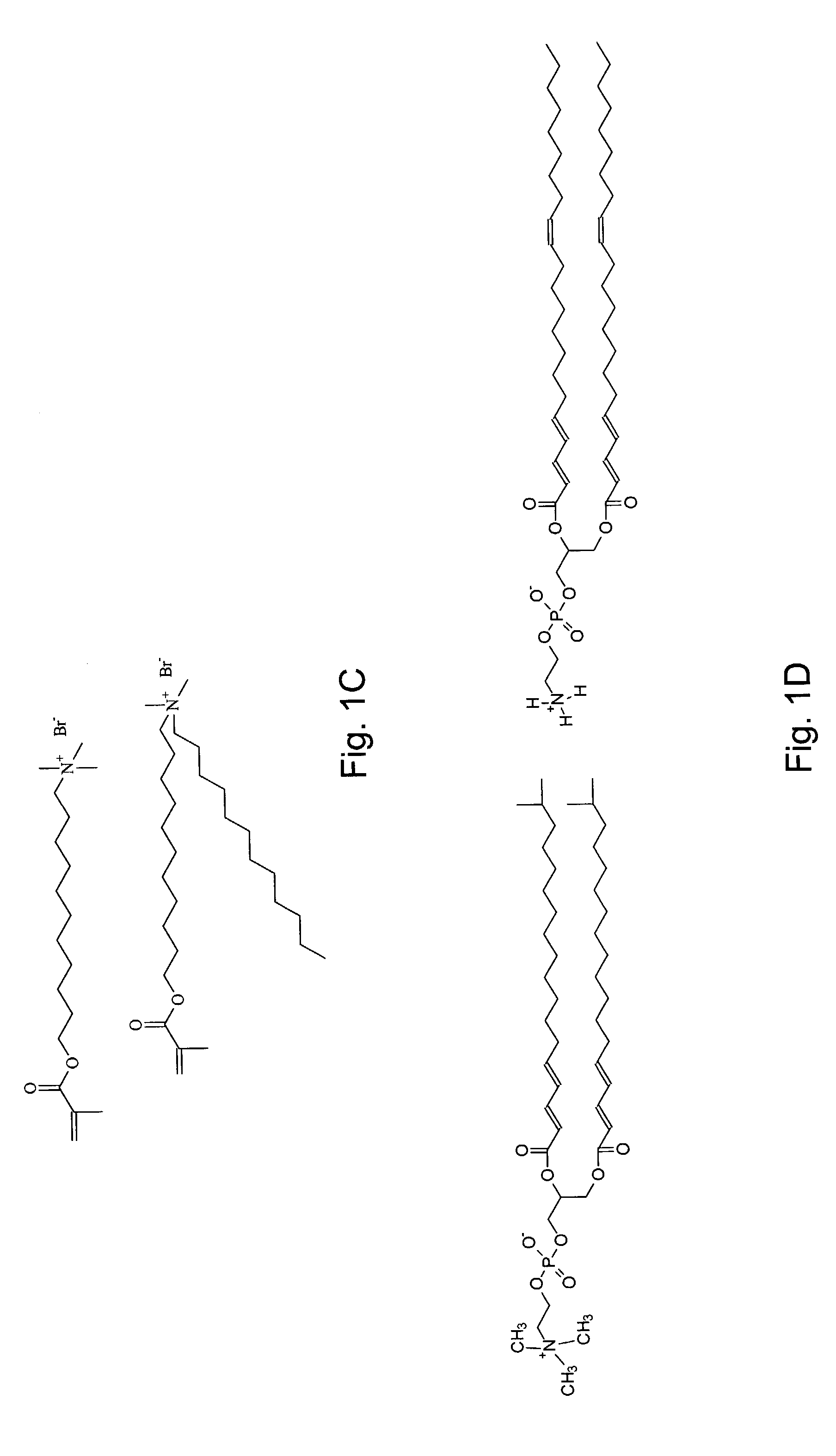

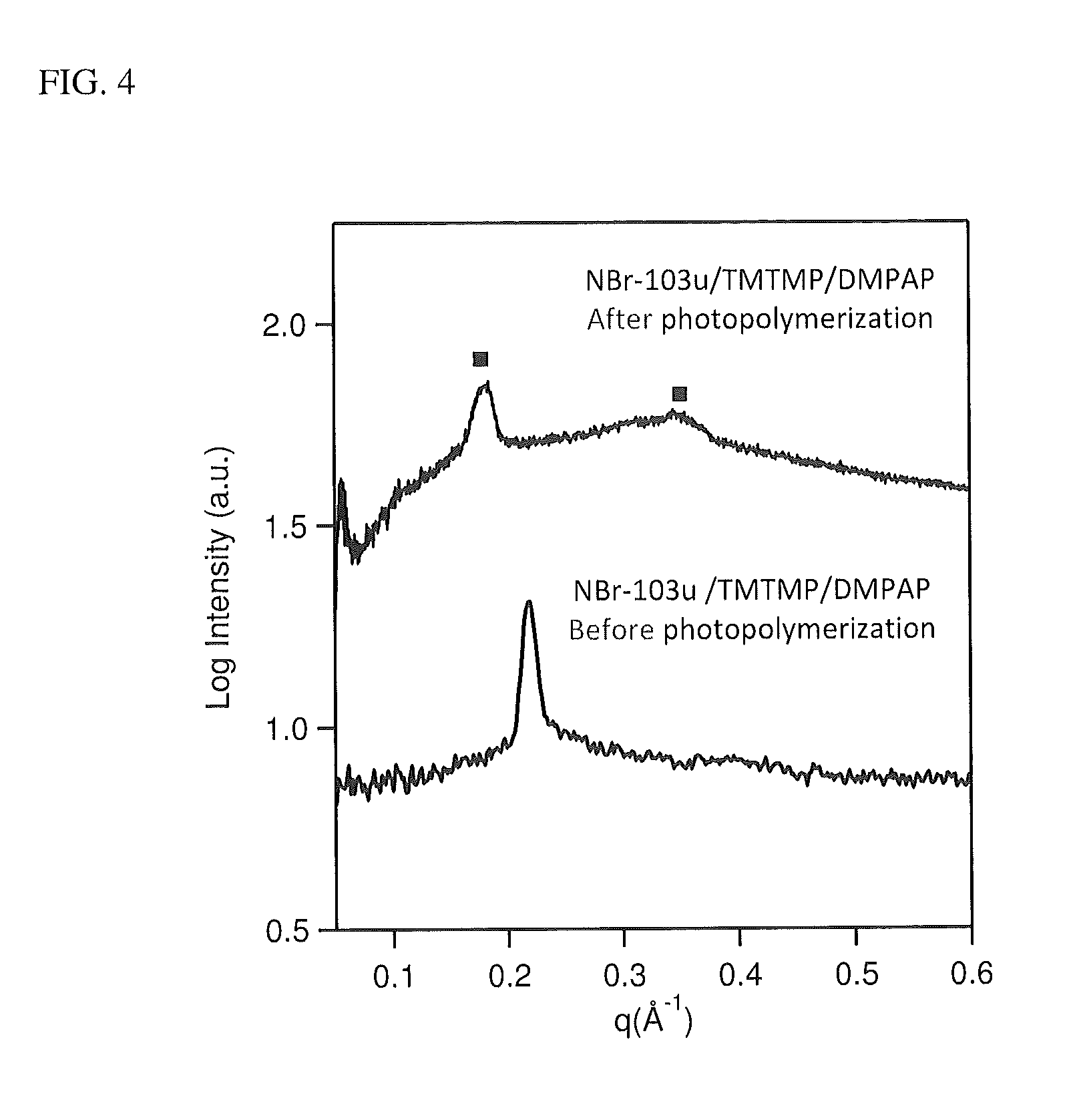

Polymerizable mixtures containing ionic gemini surfactants; and lyotropic liquid crystals, polymers, and membranes made therefrom

Disclosed are polymerizable mixtures comprising a functionalized ionic gemini surfactant and a thiol-ene crosslinking agent. The polymerizable mixtures that further comprise a polar solvent may be used to form the surfactant into a triply periodic multiply continuous lyotropic phase in the presence of the crosslinking agent. Upon crosslinking, the lyotropic phase morphology is substantially retained.

Owner:WISCONSIN ALUMNI RES FOUND

Linear pixel confining layer structure and preparation method thereof

ActiveCN106129090ALiquid repellency hasSimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingOxygen ionsSolvent

A preparation method of a linear pixel confining layer structure comprises the following steps of A, depositing a lyotropic insulating layer on the surface of a substrate; B, printing a solvent which can dissolve the insulating layer on the surface of the insulating layer, thereby forming a pixel wall and a pixel confining area; C, performing oxygen ion bombardment processing, and eliminating the insulating layer which residues in the pixel confining area, wherein an integral structure is in a lyophilic state; and D, performing thermal processing so that lyophobicity of the insulating material is partially restored, and the pixel confining area is kept in the lyophilic state. According to the linear pixel confining structure, the pixel confining layer is obtained through printing the solvent on the surface of the insulating layer; the pixel confining area has lyophilicity, thereby facilitating solution expansion; the pixel wall has lyophobicity and can prevent overflowing of the solution; and furthermore because the insulating material can be only dissolved in specific solvents, pixel confining layer corrosion by the solution of a light emitting layer can be prevented. The linear pixel confining layer structure and the preparation method thereof have advantages of simple preparation process and high material utilization rate.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com