Hybrid Composite Yarn

a composite yarn and hybrid technology, applied in the field of hybrid composite yarns, can solve the problems that high-tenacity and high-modulus polyolefin multifilament yarns have seen little application in the field of fiber-reinforced composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

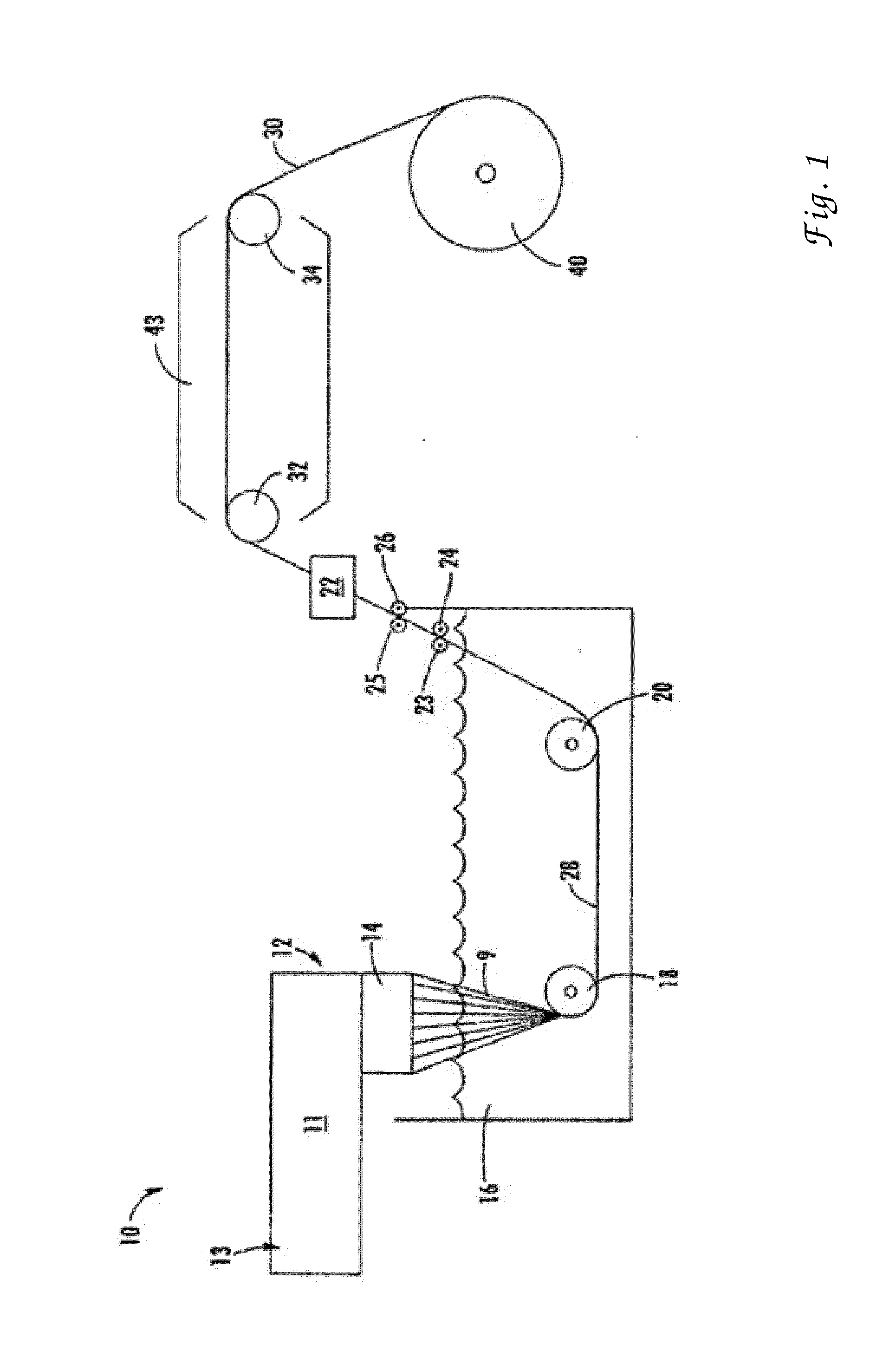

[0066]Yarn samples were formed on system similar to that illustrated in FIG. 1. In particular, the system included a ¾ inch, 24:1 single screw extruder with three temperature zones, a head with a melt pump and spinneret, a liquid quench tank (40 inch length), with two rollers in the tank, a vacuum water removal system, a spin finish applicator, three heated godet rolls, a forced air oven (120 inch length) and a Leesona® winder.

[0067]Materials utilized in forming the yarns included Atofina® 3462, a polypropylene homopolymer with a melt flow index of 3.7 and Atofina® 3281, a polypropylene homopolymer with a melt flow index of 1.3 (both available from ATOFINA Petrochemicals, Inc. of Houston, Tex.), a 10% concentrate of a nucleating agent composition, specifically Millad® 3988 (3,4-dimethyl dibenzylidiene sorbitol) in a 12 MFI polypropylene homopolymer (available from Standridge Color Corporation, Social Circle, Ga., USA), and a polyethylene homopolymer with a melt flow index of 12 (ava...

examples

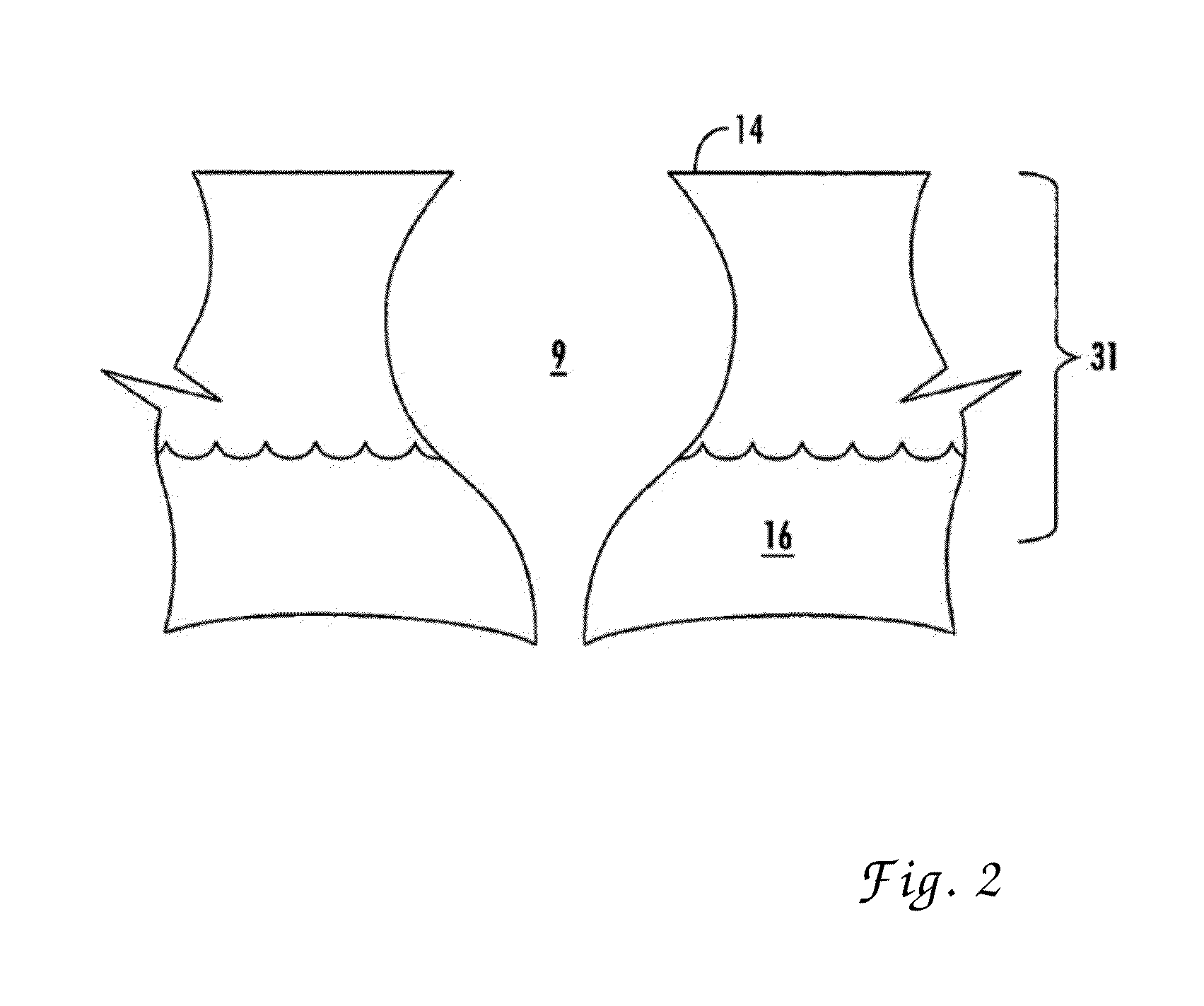

[0100]“Hybrid” Composite yarn samples were formed by combination of a first yarn component and a second yarn component in a substantially parallel orientation using a controlled aerodynamic turbulence applied in a chamber to intermingle the first and second yarn components, using equipment such as the DS60 machinery made by Dietze & Schell for air-texturing of glass fibers.

[0101]A high-modulus polypropylene yarn, as described in Tables 1-3 above, was used as the First Yarn Component. First Yarn Components used were Innegra™ S yarns in 625 denier and 940 denier yarn sizes. Second Yarn Components used were E-glass, carbon, and basalt yarns. The E-glass yarn used was a resin-compatible yarn (RCY), size G75, with 0.7Z twist from AGY. In one embodiment, the E-glass is alumino-borosilicate glass with less than 1% w / w alkali oxides. The carbon yarn used was an AS4-GP-3k type from Hexcel. The carbon yarn can have one or more of the following physical properties: tensile strength of about 67...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com