Patents

Literature

1640results about How to "Play a reinforcing role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

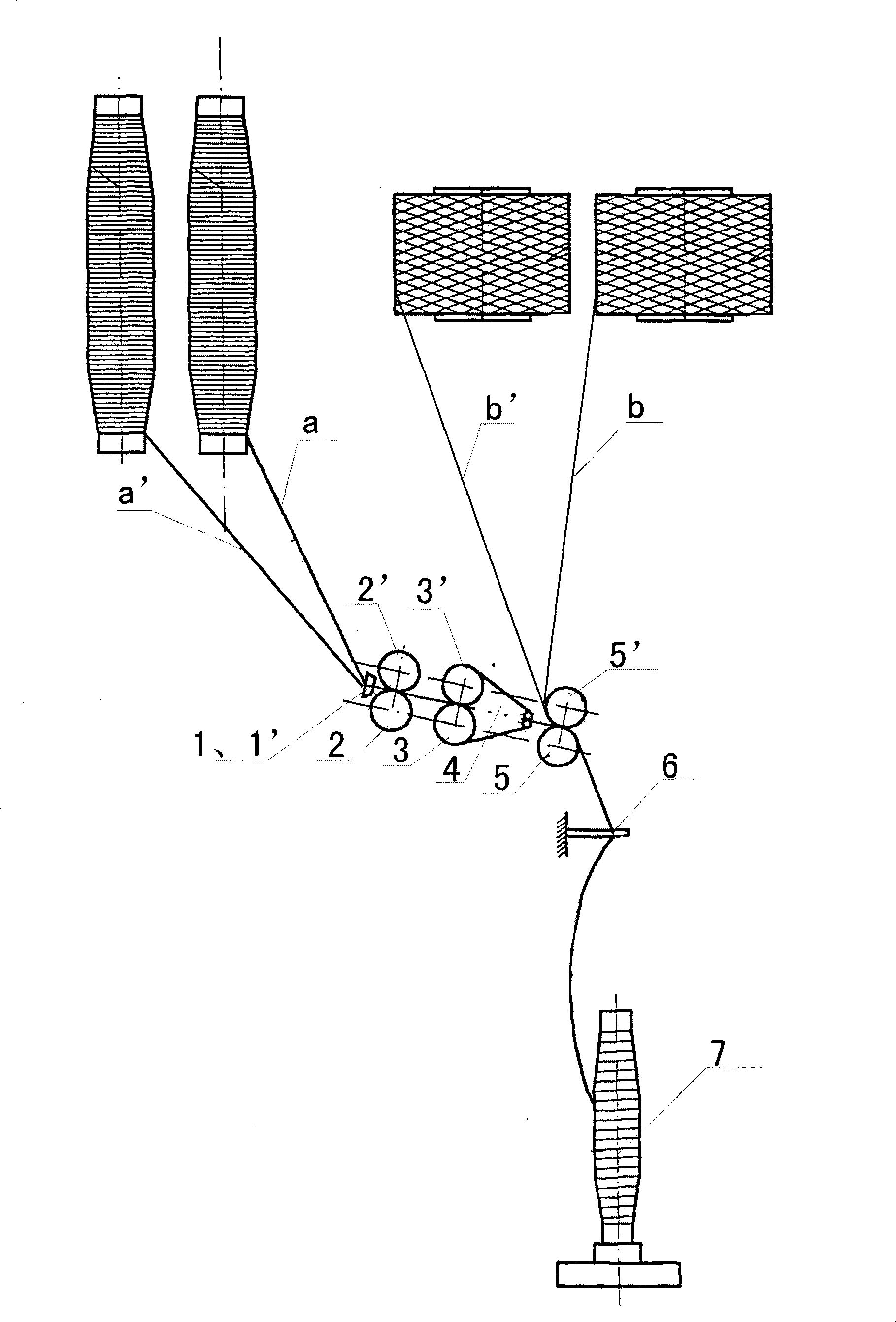

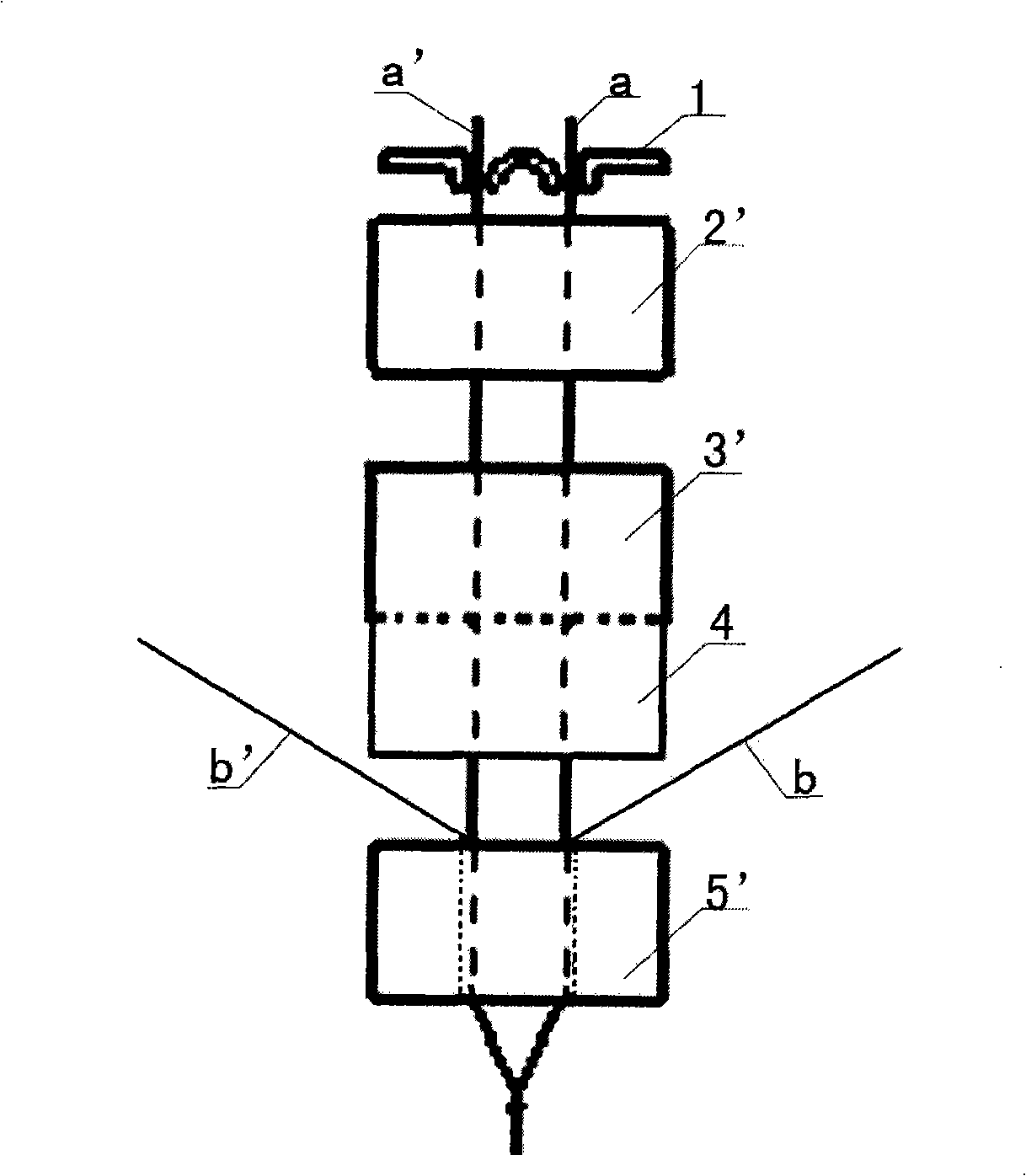

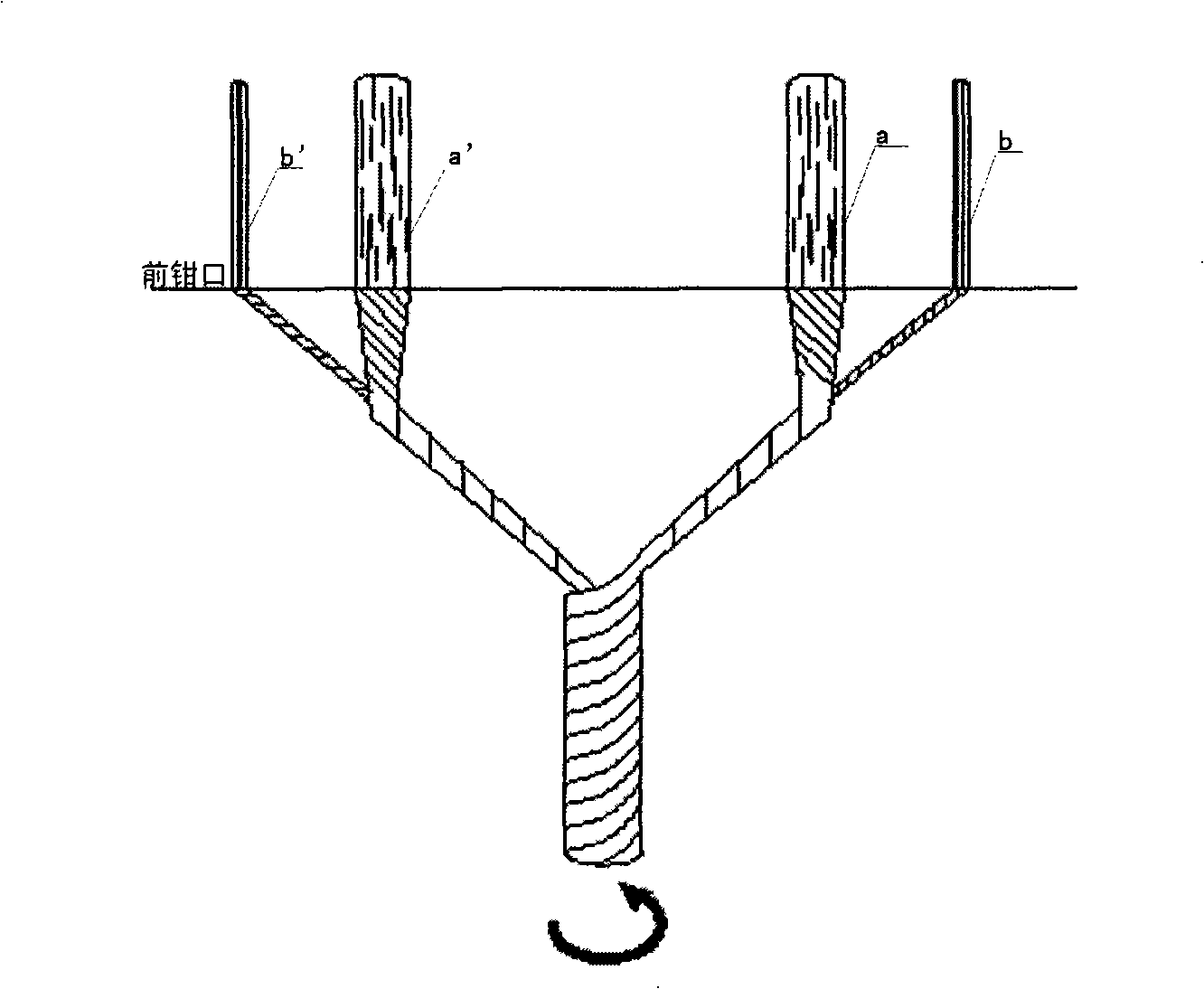

Positioning spinning method of embedded system

InactiveCN101492843ACompact structurePlay a reinforcing roleDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV +2

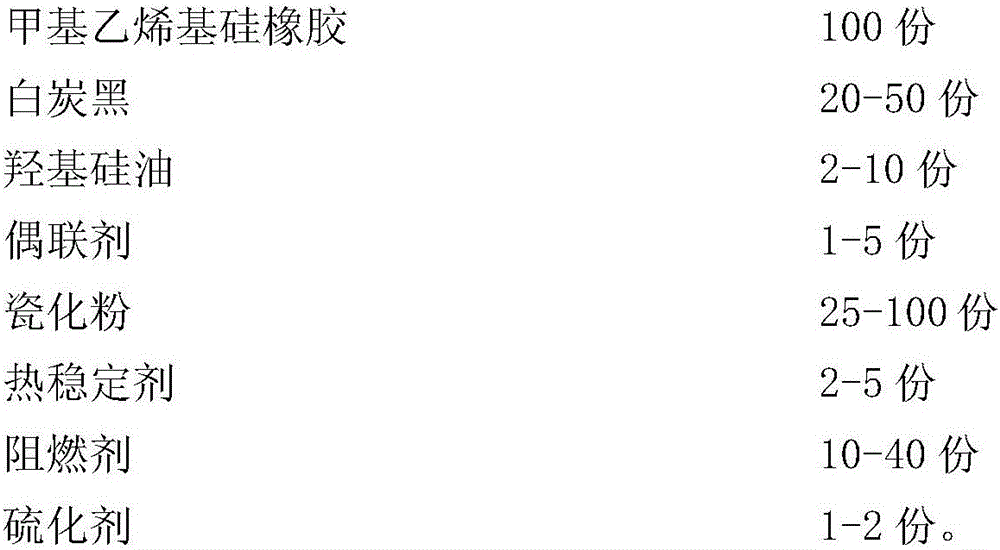

Preparation method of ceramizing fire-resistant silicon rubber

ActiveCN105694471AImprove flame retardant performanceWill not affect other performanceHalogenCombustion

The invention relates to a preparation method of ceramizing fire-resistant silicon rubber. The rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicon rubber, 20-50 parts of white carbon black, 2-10 parts of hydroxyl silicone oil, 1-5 parts of a coupling agent, 25-100 parts of ceramizing powder, 2-5 parts of a heat stabilizer, 10-40 parts of a fire retardant, and 1-2 parts of a vulcanizer. The preparation method includes the following steps: adding the methyl vinyl silicon rubber in a kneading machine; then adding the white carbon black and the hydroxyl silicone oil; mixing for 30 minutes at the temperature of 80 DEG C; then adding the coupling agent, the ceramizing powder, the heat stabilizer and the fire retardant; mixing for 1-1.5 hours; raising the temperature to be 100 DEG C and keeping high vacuum for 30 minutes; and after cooling to room temperature, adding the vulcanizer on an open mixing machine for mixing to obtain the ceramizing fire-resistant silicon rubber. The rubber has good mechanical property and electrical property at normal temperature, does not contain halogen, is smokeless and non-toxic during combustion, can be extinguished quickly and forms a ceramizing shell to guarantee integrity of the inside.

Owner:BEIJING UNIV OF CHEM TECH

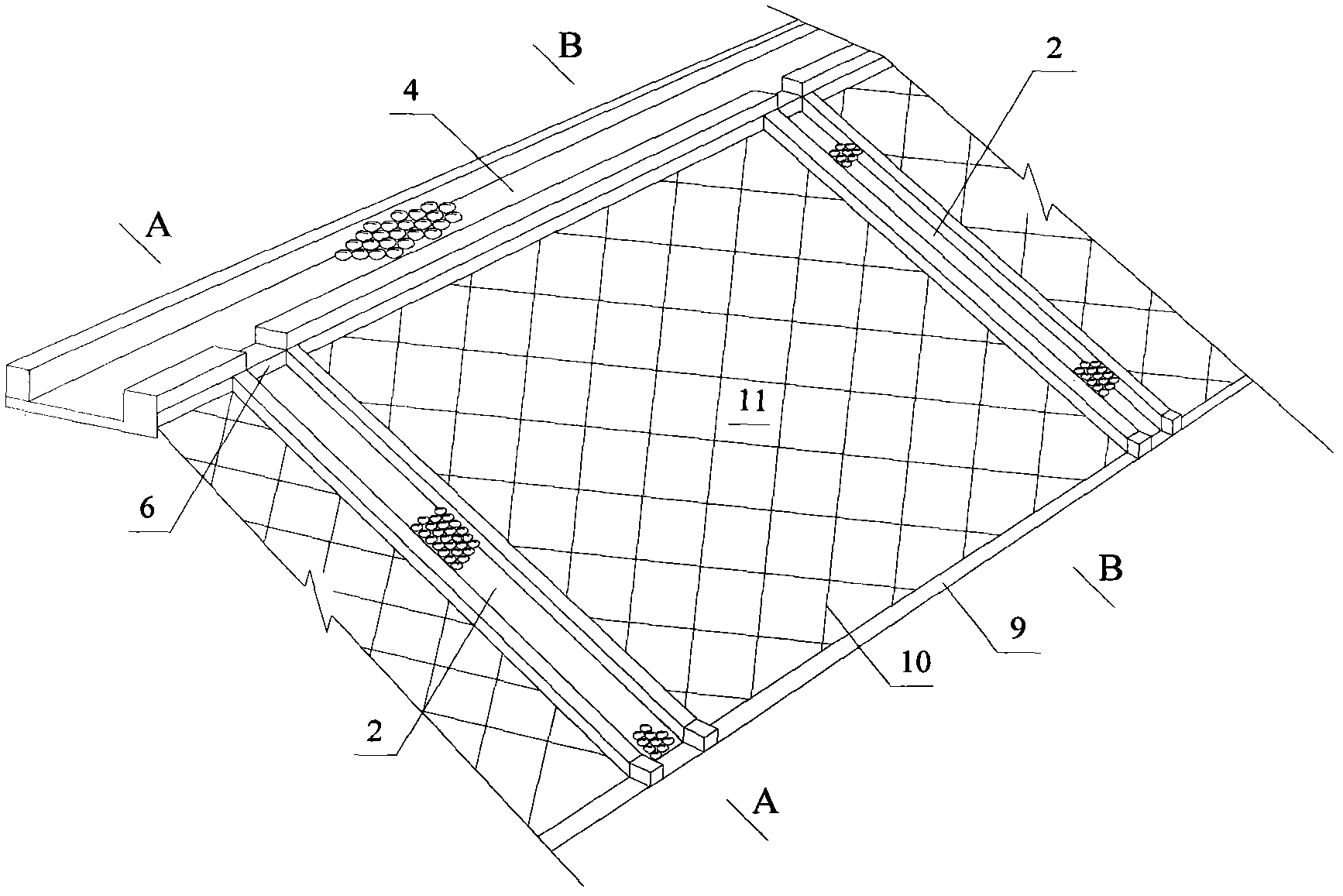

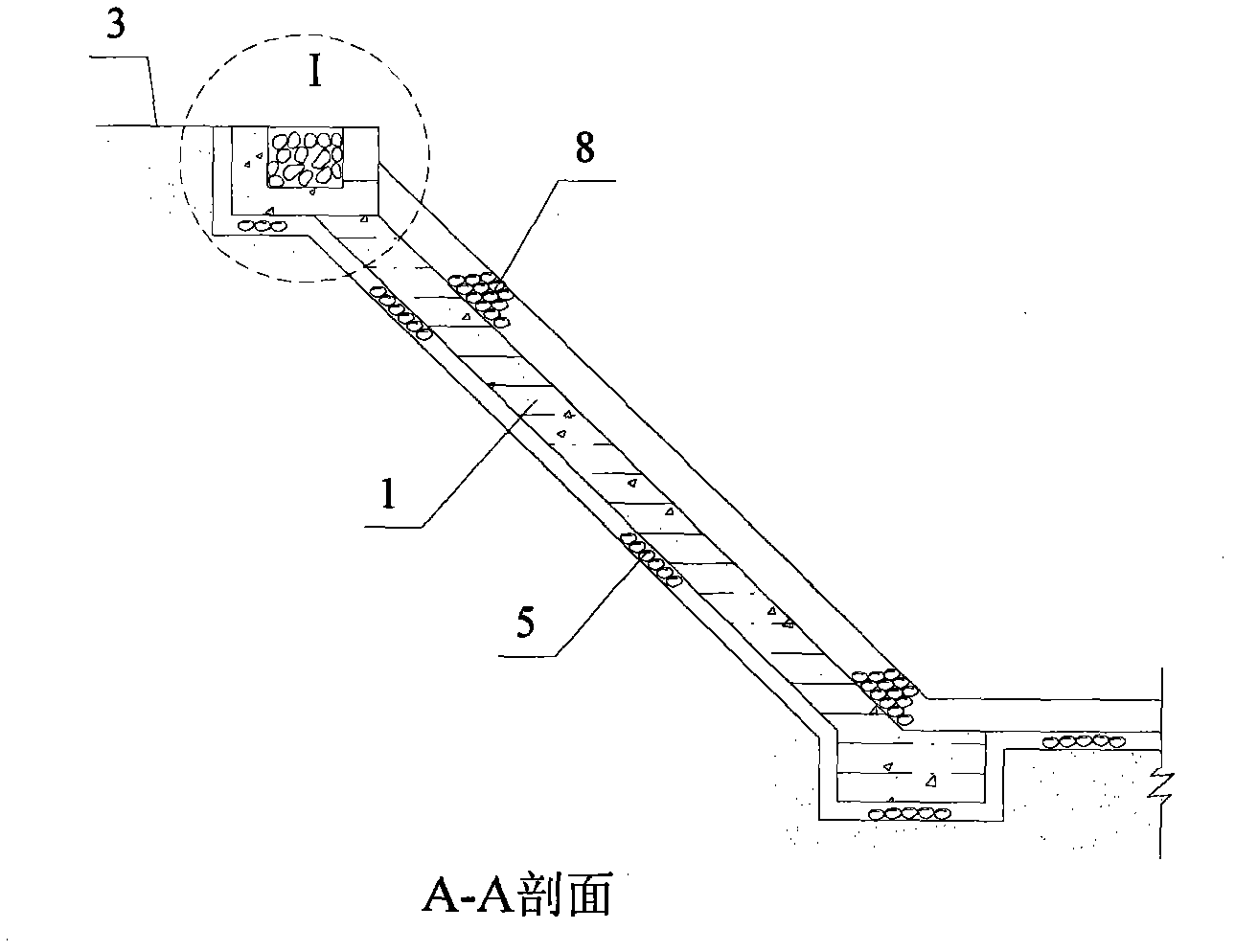

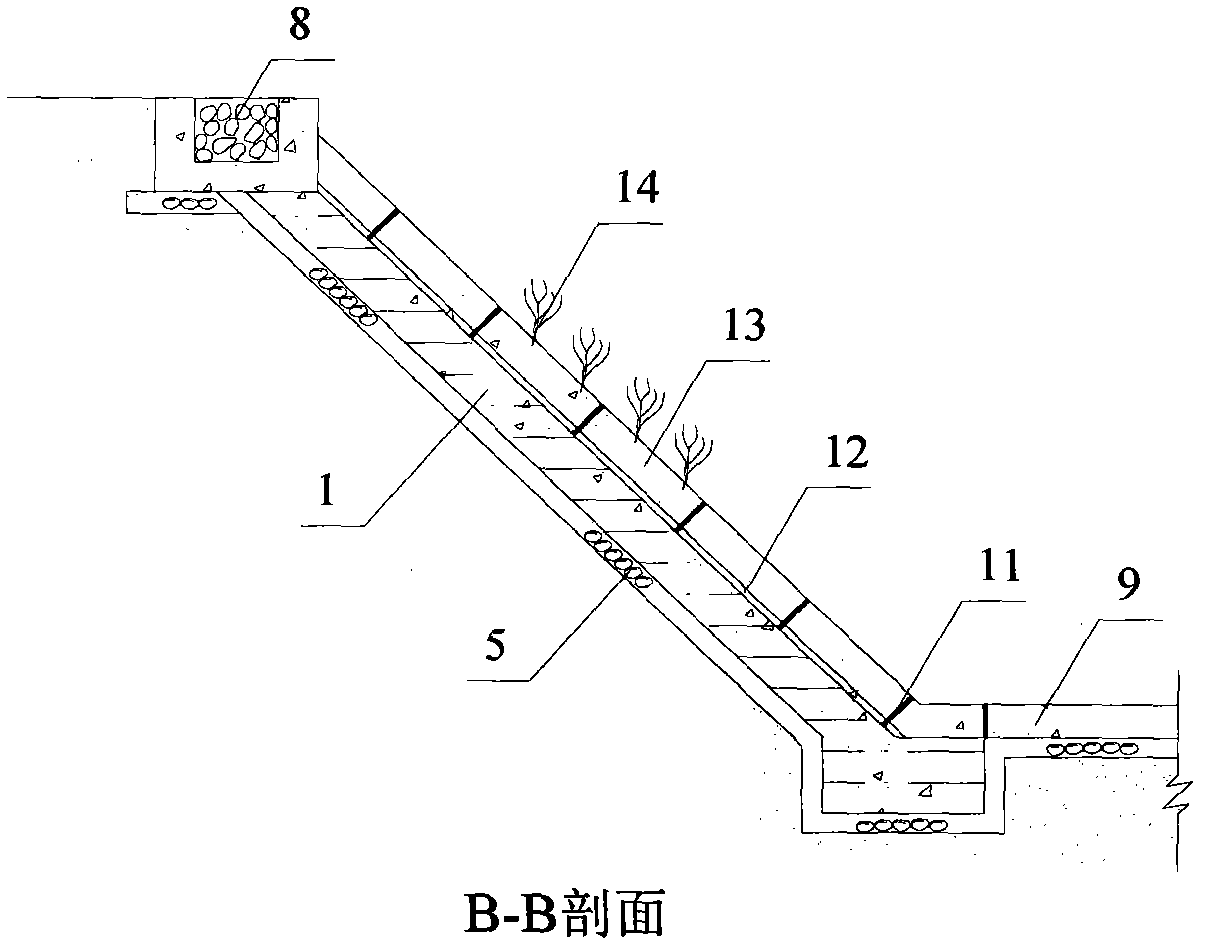

Hard reinforced concrete revetment slope biological repairing method

InactiveCN102071697AEffectively fixedPrevent landslidesSoil drainageCoastlines protectionPlant rootsRainfall runoff

The invention discloses a hard reinforced concrete revetment slope biological repairing method, which is characterized by comprising the steps of: roughing a concrete revetment and constructing drainage ditches at set intervals; digging a water collecting tank on one side of the cross of the revetment and a road, reserving an opening at the joint of the drainage ditch and the water collecting tank, and constructing a watertight concrete overflow bank; filling gravels in the water collecting tank and the drainage ditches; and welding earthwork grids by high-density polyethylene stripes on the protection slope, laying gravel cushion coats in the earthwork grids, and finally pouring biological slurry. The method has the advantages that: the whole project is stable and safe; rain flows into the water collecting tank and passes through grave areas, non-watertight sand-free concrete, a slope cushion coat, plant roots and the like to seep into rivers, so water quality is improved to a relatively large extent; when rainfall runoff is overlarge, the rain overflows from the overflow bank and passes through the graves of the drainage ditches, so the water quality is also purified to a certain extent, meanwhile the slope is protected; the biological slurry poured onto the slope is prepared from biological materials, and has certain anti-erosion strength and can be used as a substrate for plant growth, so the cost is low and the operation is simple.

Owner:HOHAI UNIV

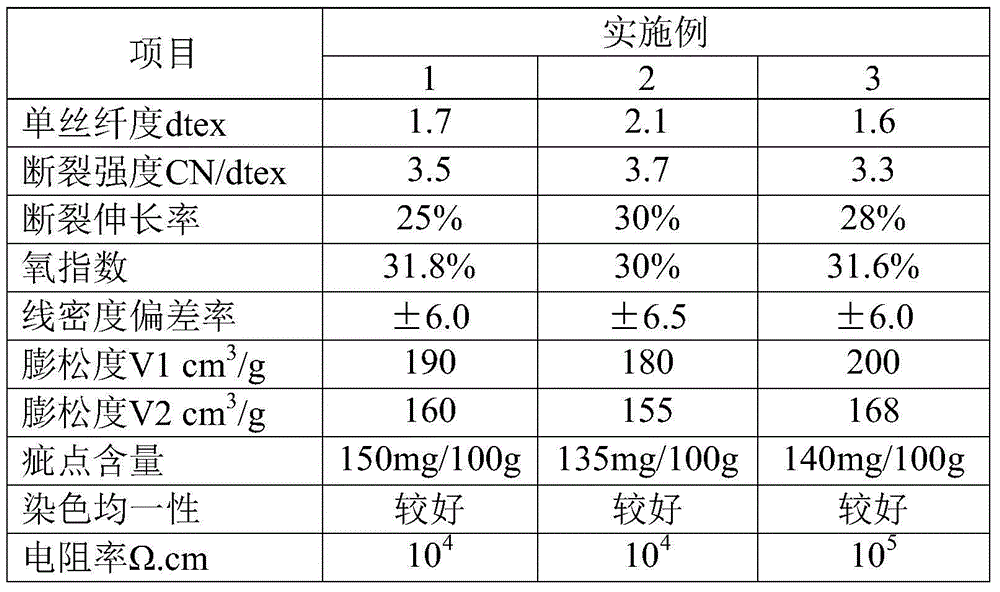

Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

ActiveCN104630928ASpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

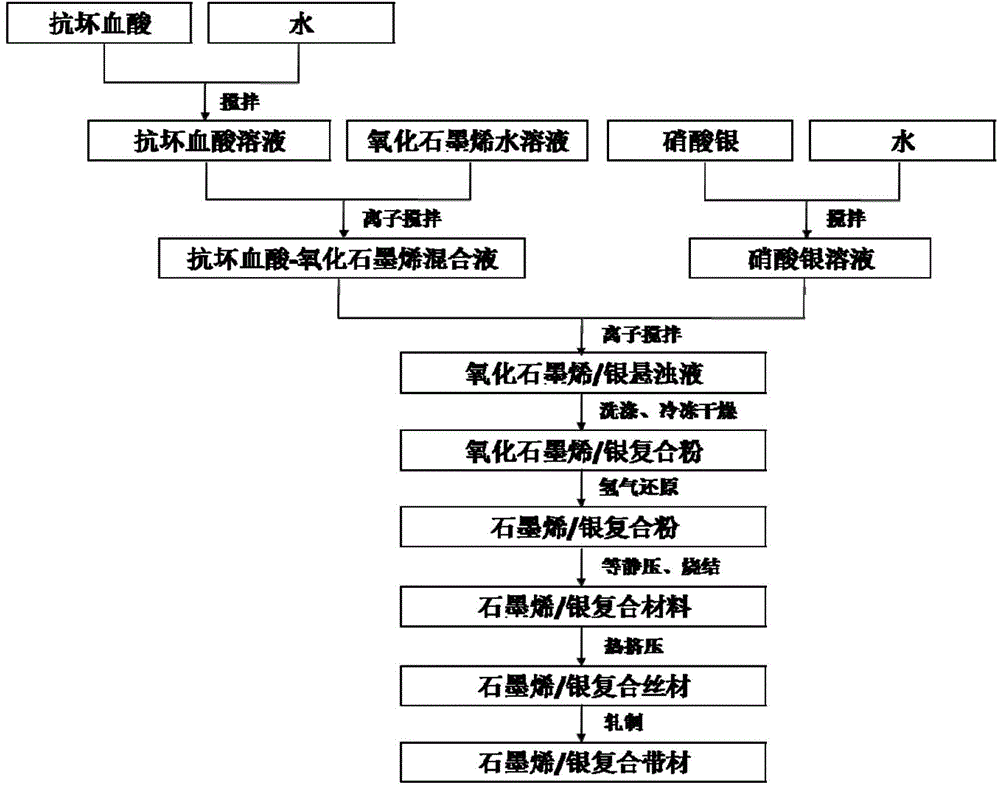

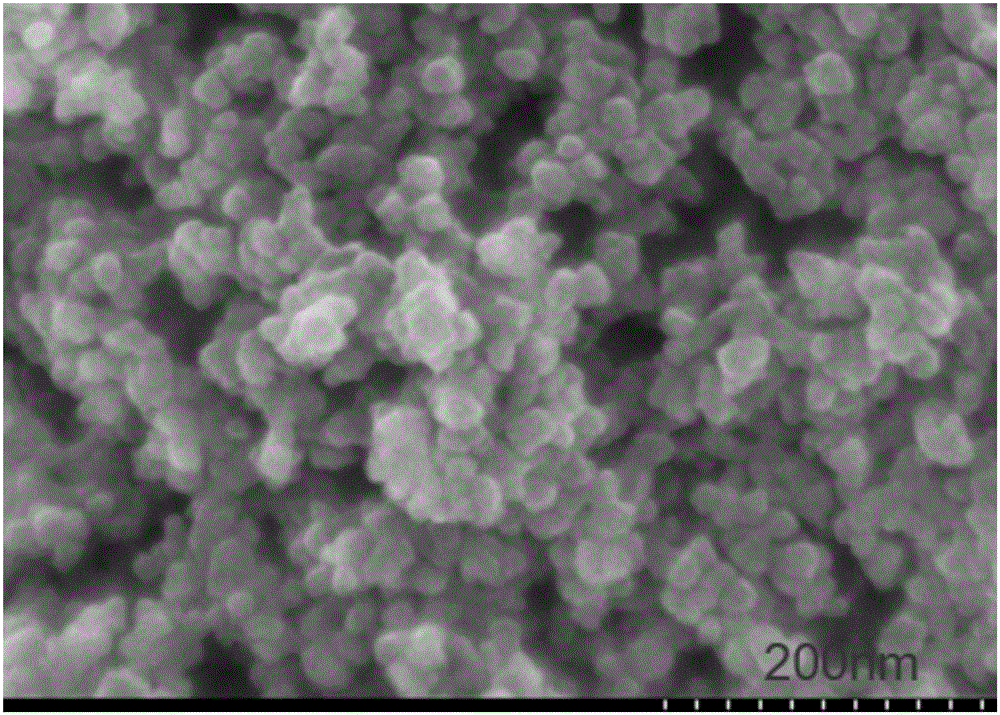

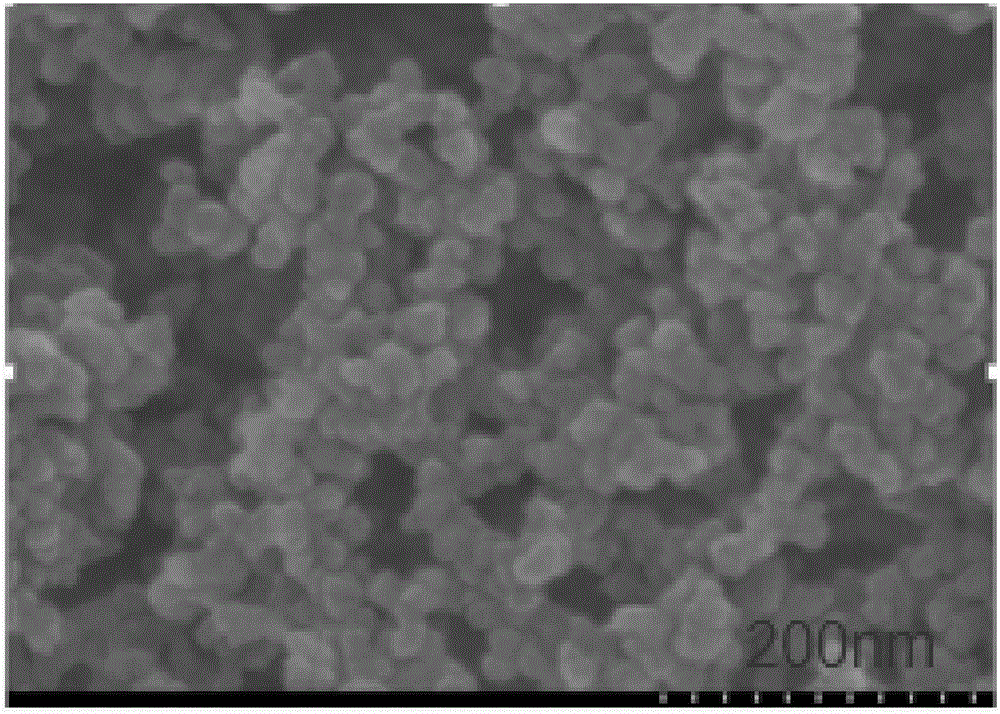

Graphene/silver composite material and preparation method thereof

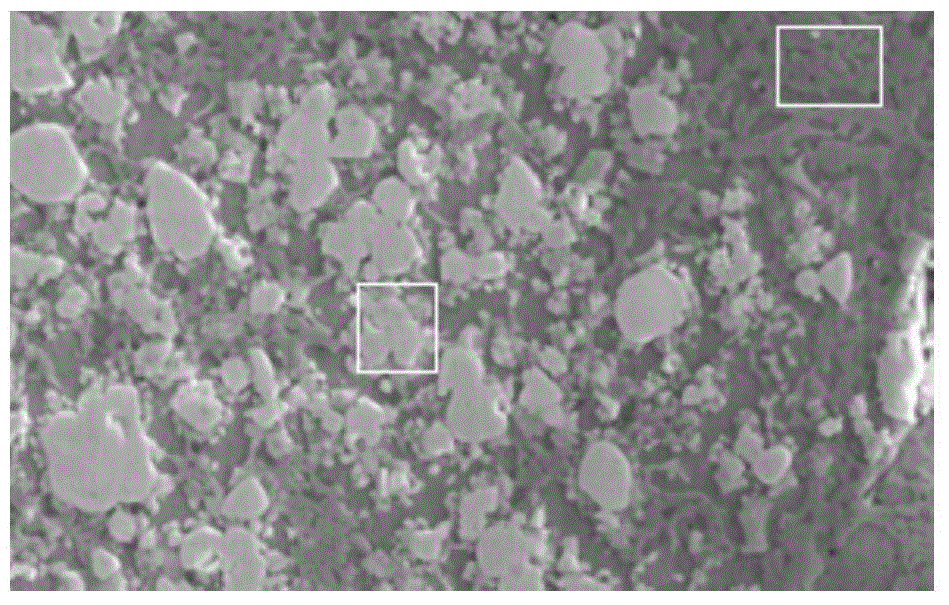

ActiveCN104700961AEvenly distributedTo achieve the effect of continuous productionMetal/alloy conductorsCarbon-silicon compound conductorsReducing agentGraphite oxide

The invention provides a graphene / silver composite material and a preparation method thereof. The preparation method comprises the steps of adding a reducing agent and silver nitrate successively into a graphene oxide solution, combining silver powder obtained by reduction and graphene oxide in the solution, so as to obtain graphene oxide / silver composite powder; drying the graphene oxide / silver composite powder to obtain graphene / silver composite powder; and obtaining graphene / silver composite blocks, composite wires and composite strips through powder metallurgy, hot extrusion and rolling techniques. According to the graphene / silver composite material and the preparation method provided by the invention, the graphene is dispersed uniformly in the composite material, the interface bonding between a substrate and an enhanced body is good, and the composite materials is excellent in physical performance; meanwhile, the preparation method is simple in process, is likely to control the process and likely to realize large-scale production and application.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

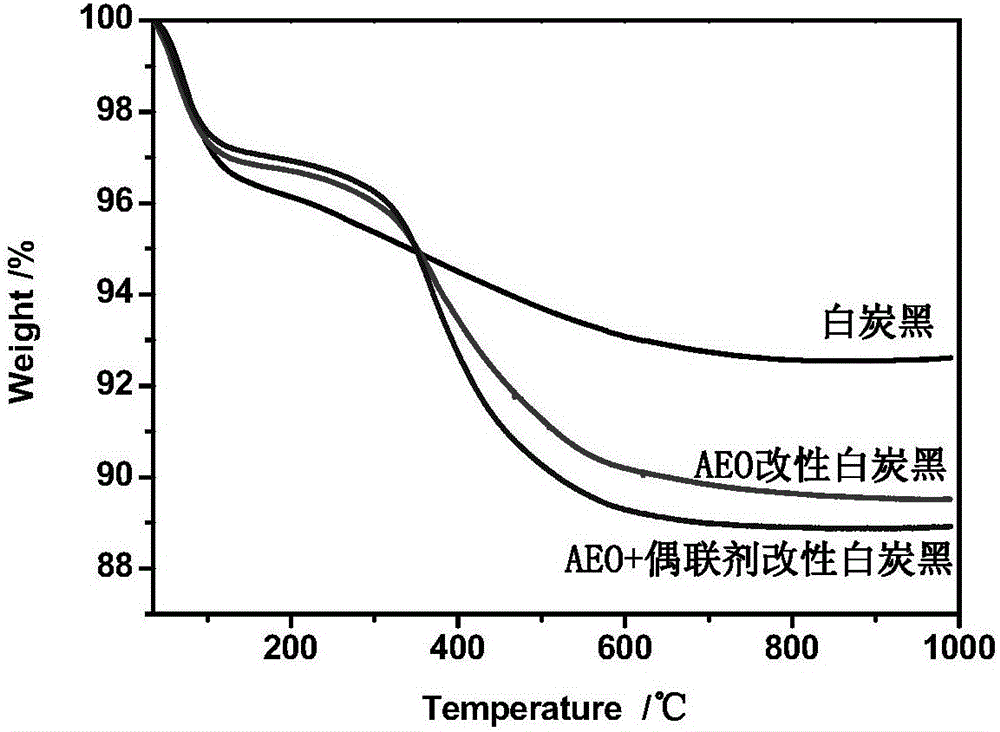

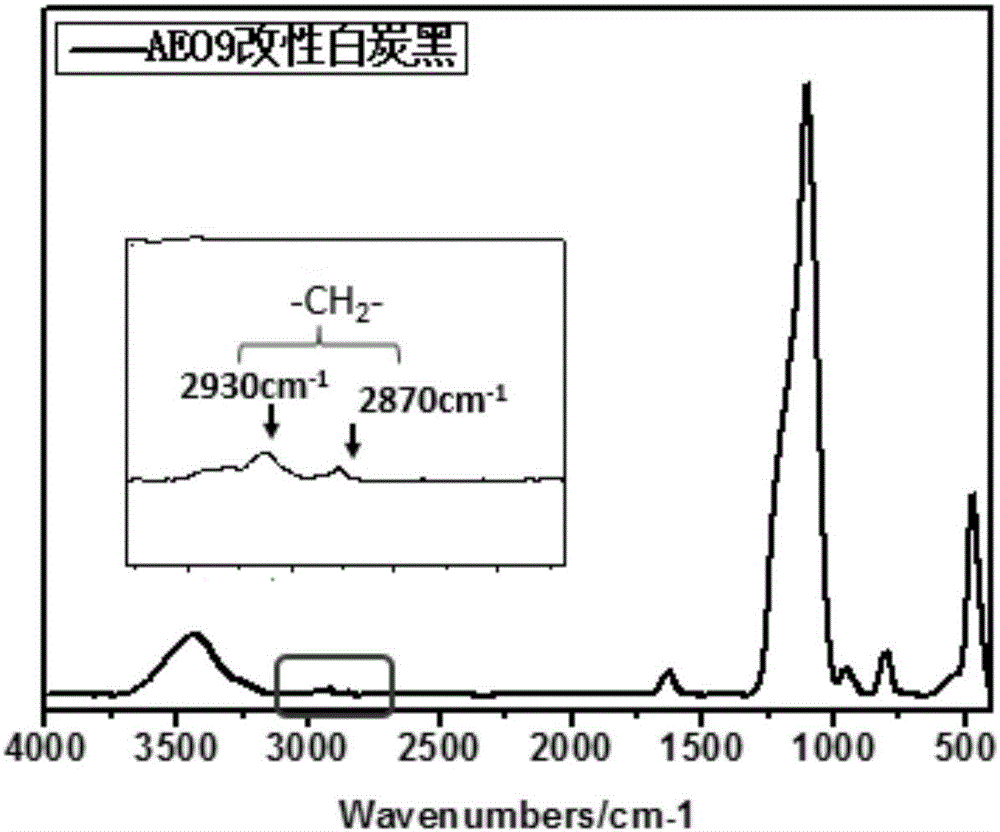

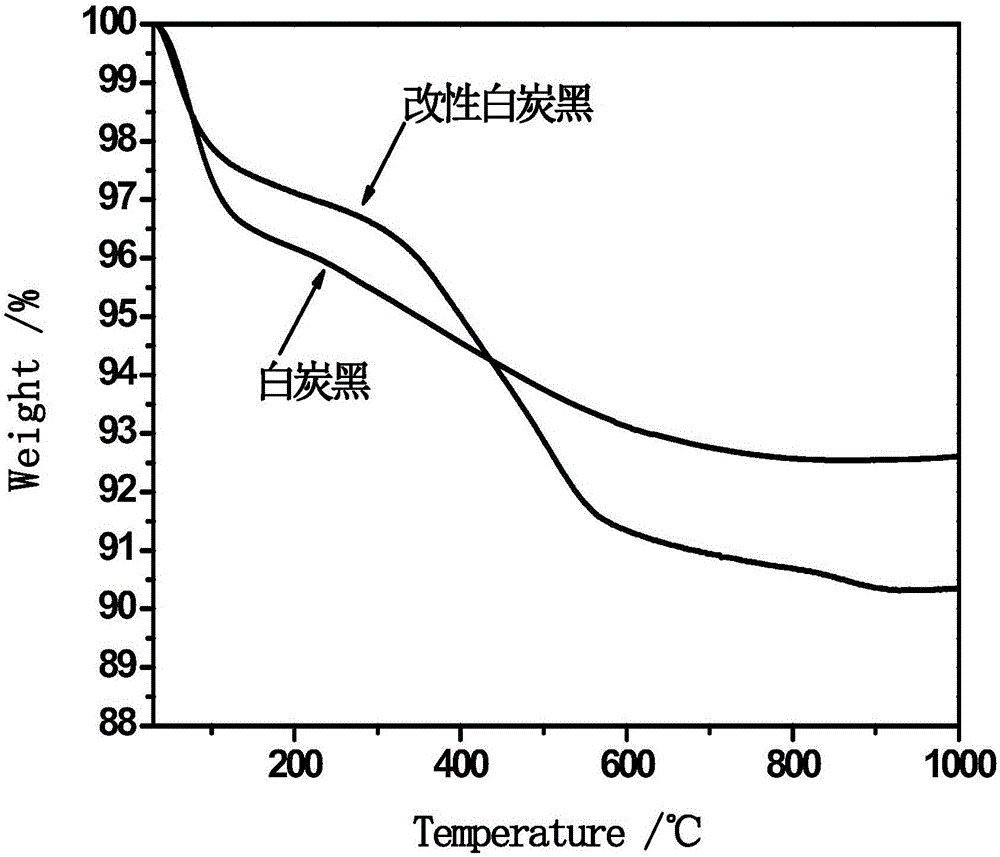

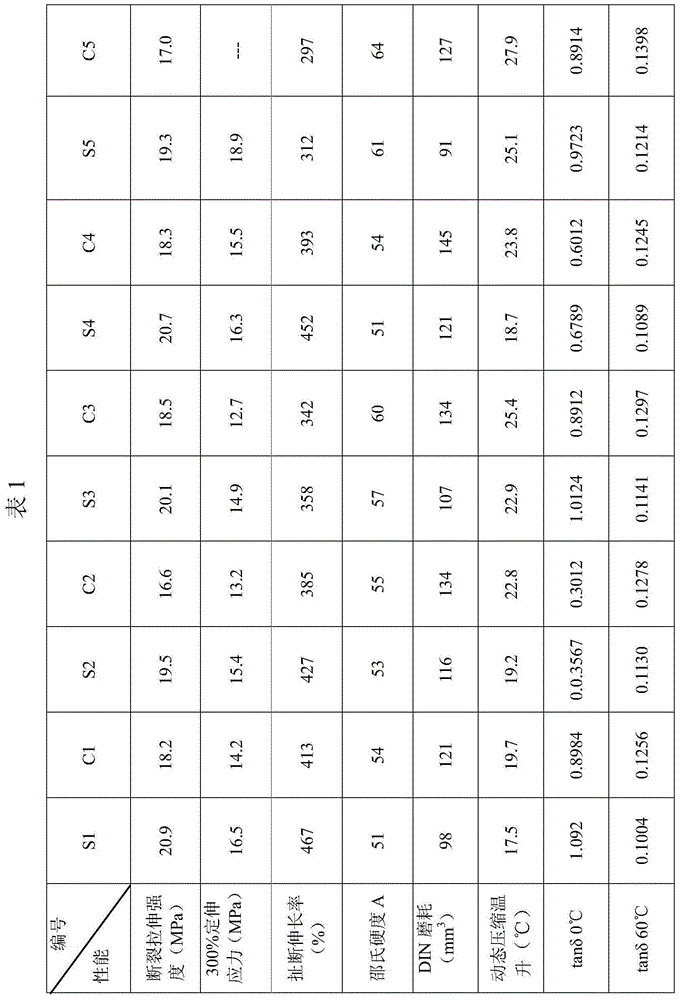

Modification of white carbon black by co-using AEO and silane coupling agent, and method for compounding modified white carbon black and rubber

The invention provides modification of white carbon black by co-using AEO and a silane coupling agent, and a method for compounding the modified white carbon black and a rubber, and relates to the field of applications of AEO (aliphatic polyoxyethylene ether) in wet modification of white carbon black by matching with a silane coupling agent. According to the present invention, the direct modification of white carbon black in a water phase by using an insoluble silane coupling agent can be achieved by using the amphiphilicity of AEO and the grafting property of AEO to white carbon black; compared to the traditional method for modifying the white carbon black in the water phase by using the silane coupling agent, the method of the present invention has the following characteristics that the use of a large amount of organic solvents is avoided, the white carbon black modification cost is saved, the VOC emission generated during the modification process is significantly reduced, and the environmental protection is easily achieved; the modification method is characterized in that AEO accounting for 1-100% of the mass of the white carbon black and the silane coupling agent accounting for 1-100% of the mass of the white carbon black are introduced to modify the white carbon black; and the modified white carbon black and the rubber can be compounded through a variety of methods, the white carbon black in the prepared composite material has the uniform distribution, and the dynamic mechanical property and the strength are significantly improved compared to the existing wet modified white carbon black / rubber composite material.

Owner:BEIJING UNIV OF CHEM TECH

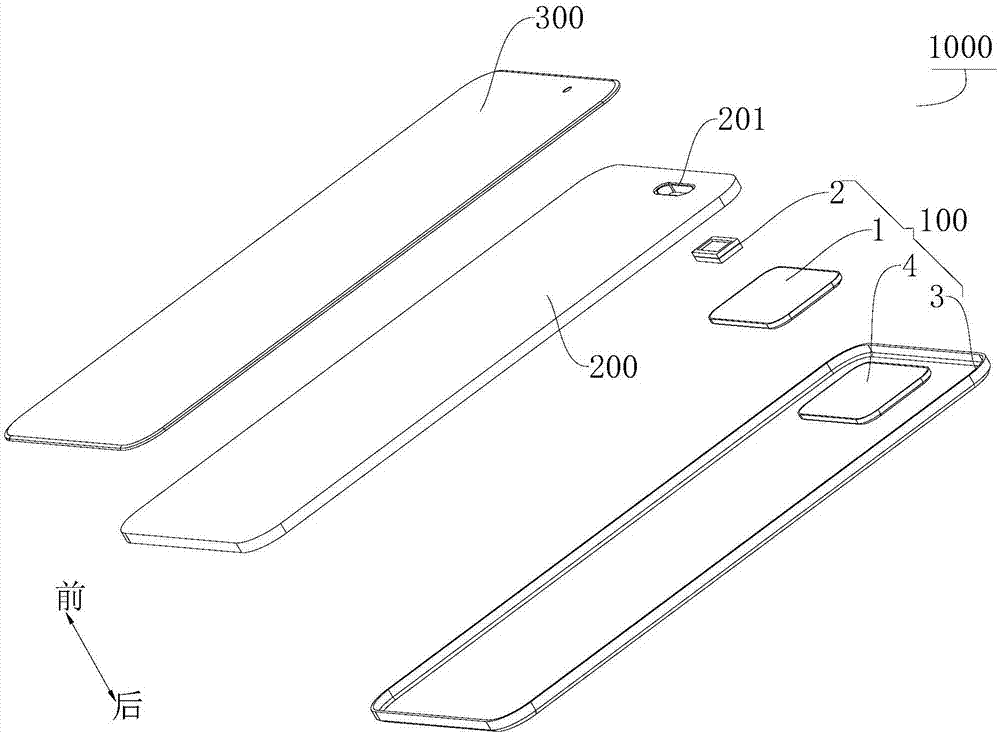

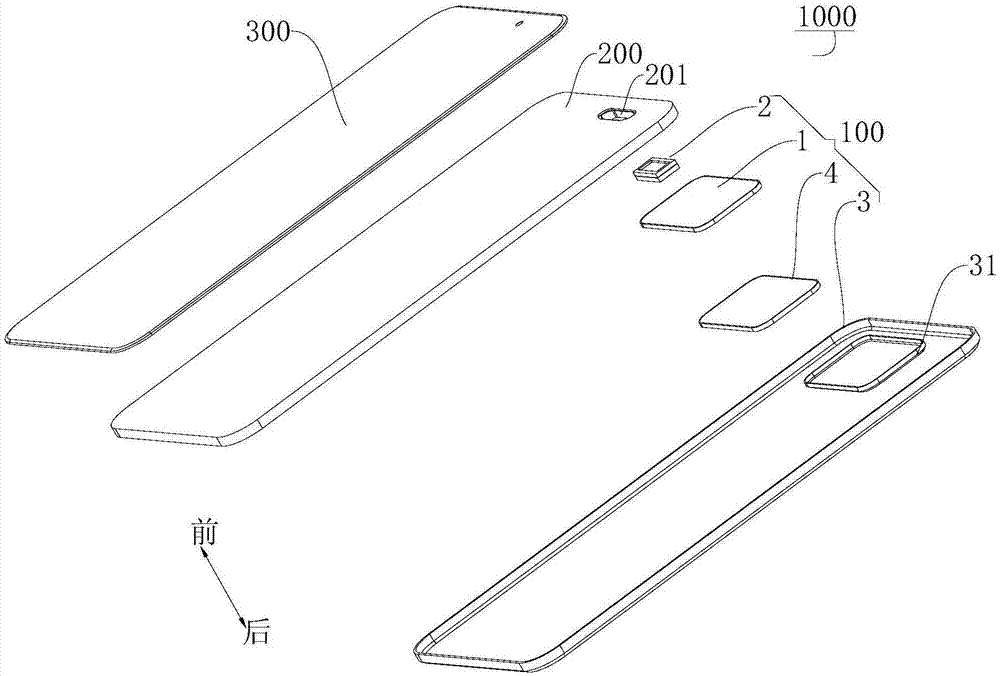

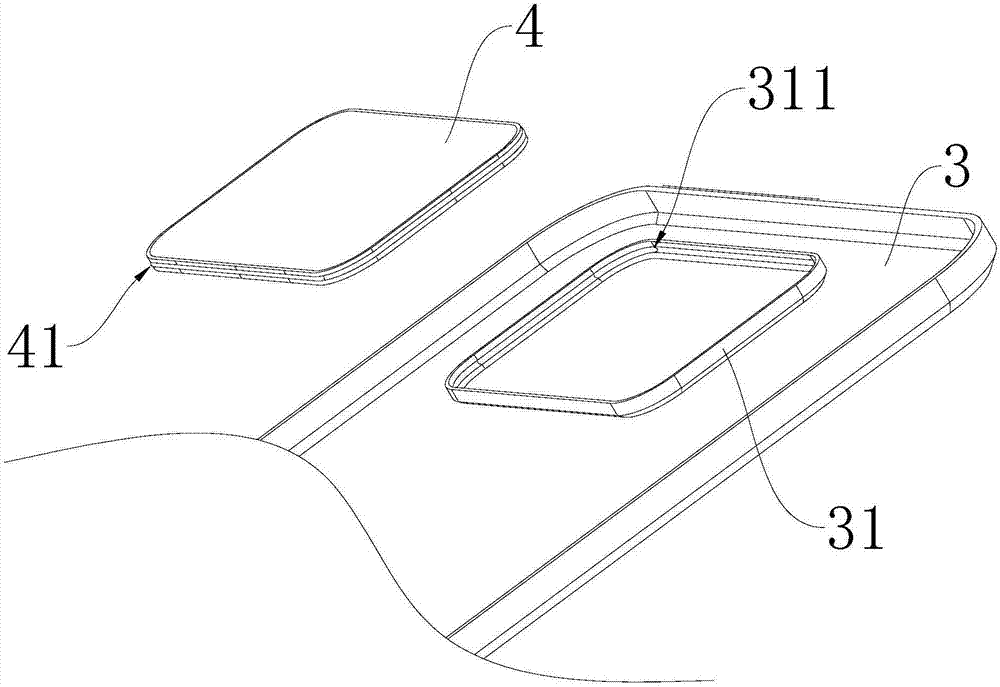

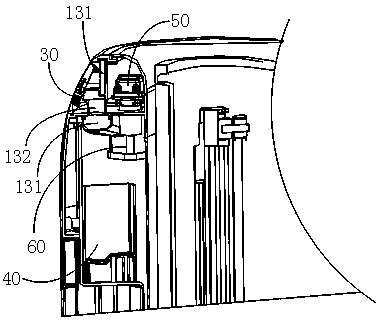

Cover assembly, shell assembly, shell assembly processing method and mobile terminal

InactiveCN107483692AReduce deformationAvoid impact deformationTelephone set constructionsComputer moduleComputer terminal

The invention discloses a cover assembly, a shell assembly, a shell assembly processing method and a mobile terminal. The cover assembly comprises a circuit board, a front camera module, a plastic cover and a reinforcing plate, wherein the front camera module comprises an image sensor, and the image sensor is arranged on the circuit board; the plastic cover is located at one side, away from the front camera module, of the circuit board; and the reinforcing plate is arranged on the surface of one side, facing the front camera module, of the plastic cover and is arranged correspondingly to the front camera module. According to the cover assembly of the invention, when the plastic cover is impacted, the reinforcing plate plays a role of reinforcement, the deformation generated by the plastic cover can be greatly reduced, the plastic cover can be prevented from being impacted and deformed to a certain degree, the impact force can be prevented from being transferred to the image sensor, reliable protection on the image sensor is further realized, and failure of the front camera module is prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for modifying white carbon black by adopting aliphatic polyoxyethylene ether and compounding white carbon black with rubber

The invention provides a method for modifying white carbon black by adopting aliphatic polyoxyethylene ether and compounding the white carbon black with rubber and relates to the field of application of the aliphatic polyoxyethylene ether to white carbon black modification, hoping to achieve the aims of modifying the white carbon black under the condition of no VOC emission by adopting a cheap and available modifying agent and enabling the modified white carbon black to be well dispersed as filler in a rubber matrix. The modification method is characterized in that chemical bonding and physical adsorption effect are utilized for bonding the white carbon black with 1-100% by mass of the aliphatic polyoxyethylene ether, so that the modified white carbon black is prepared. Preparation steps are as follows: white carbon black suspension is prepared, temperature of the suspension is adjusted, the white carbon black is modified, and the modified white carbon black is dried. The modified white carbon black has the advantages that particle size is reduced and hydrophobicity is obviously improved. Meanwhile, the modified white carbon black can be compounded with multiple rubbers in multiple ways, the white carbon black is uniformly distributed in the prepared rubber / modified white carbon black composite material, and all the performances of the composite material can be obviously improved compared with rubber / unmodified white carbon black.

Owner:BEIJING UNIV OF CHEM TECH

Room-temperature moisture-curable single-component flame-retardant polyurethane sealant

ActiveCN102504752AGood flame retardantNo reduction in physical propertiesNon-macromolecular adhesive additivesOther chemical processesPlasticizerRoom temperature

The invention discloses a room-temperature moisture-curable single-component flame-retardant polyurethane sealant and a preparation method thereof. The sealant is prepared from the following raw materials in parts by weight: 30-55 parts of liquid polyether type polyurethane pre-polymer base stock, 10-30 parts of flame-retardant plasticizer, 0.1-1 part of silane coupling agent, 15-30 parts of flame-retardant powder, 10-30 parts of filler, 0.01-0.05 part of catalyst and 0.2-3 parts of methyl benzenesulfonyl isocyanate, wherein the liquid polyether type polyurethane pre-polymer base stock is prepared from the following raw materials in parts by weight: 32.8-57.64 parts of common polyether glycol, 28.82-54.67 parts of flame-retardant polyether glycol, 12.51-13.53 parts of polyisocyanates, and 0.01 part of catalyst. The room-temperature moisture-curable single-component flame-retardant polyurethane sealant is excellent in physical performance, thixotropic property and flame-retardant performance, and convenient for construction.

Owner:SHANDONG NORTH MODERN CHEM IND

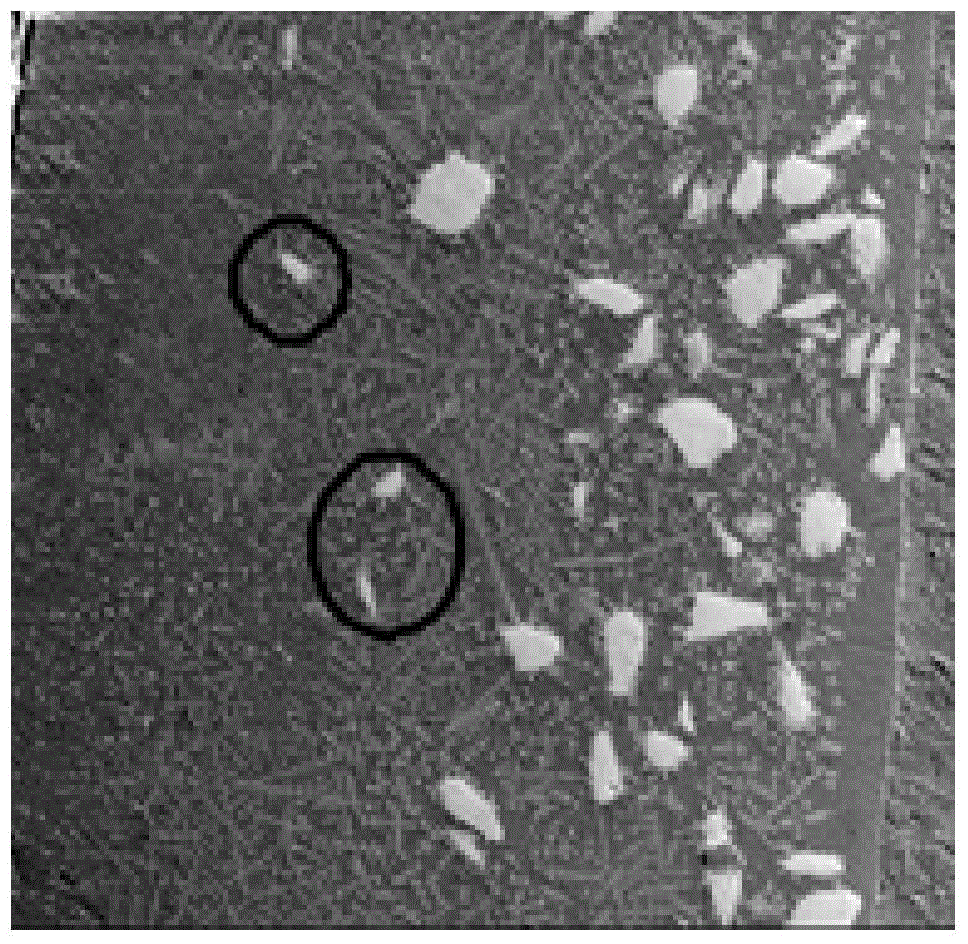

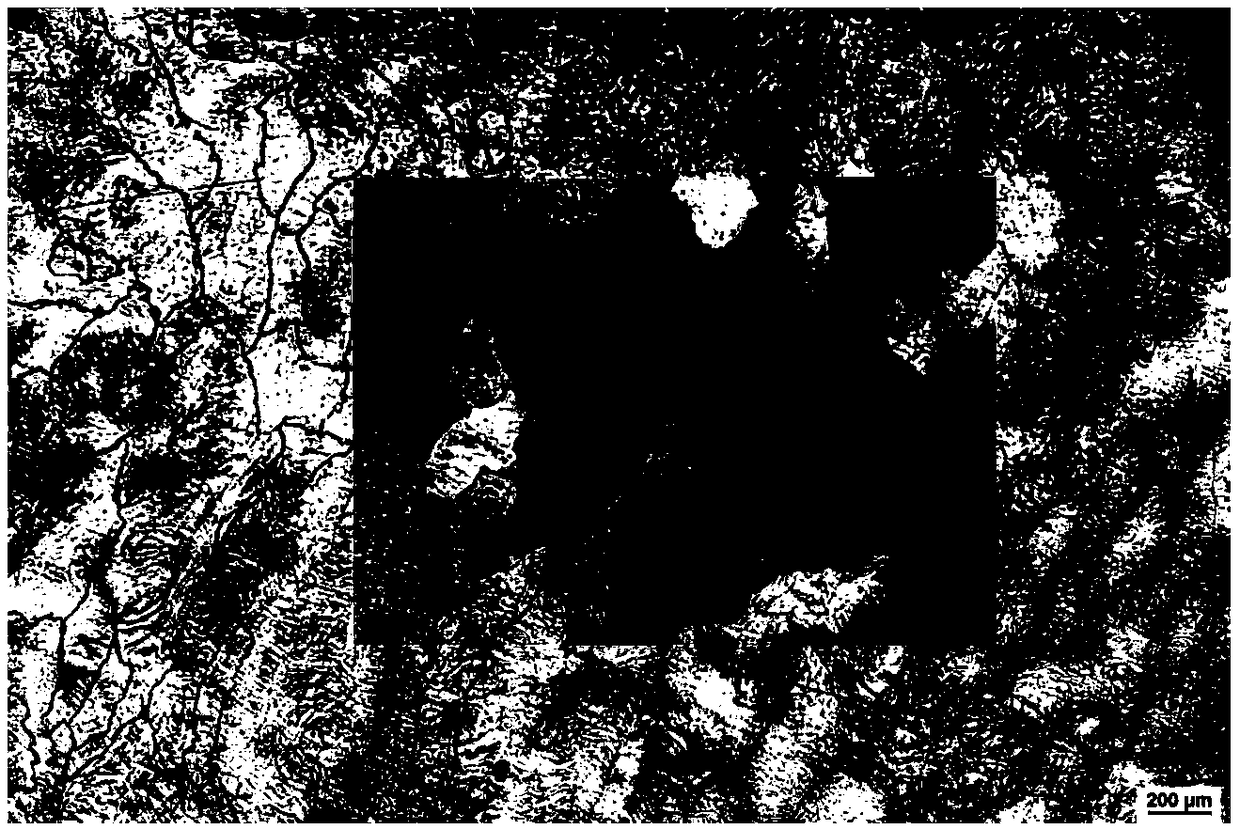

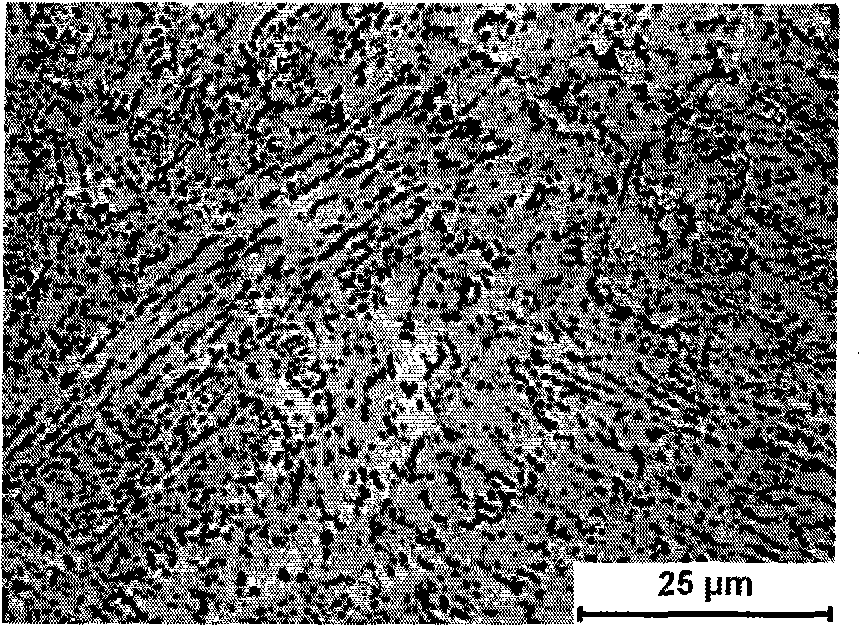

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

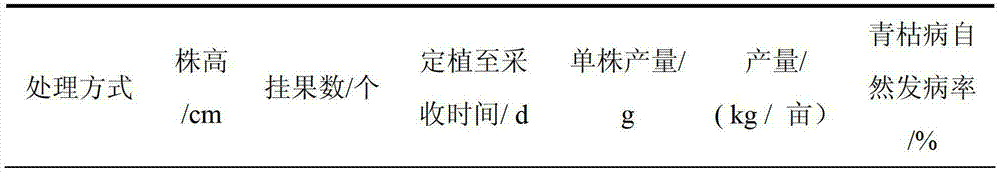

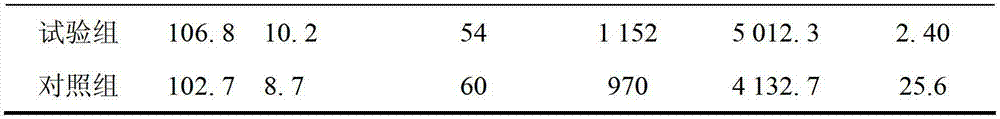

Compound microbial organic fertilizer and preparation method thereof

ActiveCN103113167AStrong stress resistancePromote growthFertilizer mixturesPotassiumOrganic fertilizer

The invention relates to a compound microbial organic fertilizer and a preparation method thereof. The compound microbial organic fertilizer is prepared from the following ingredients in parts by weight: 1-4 parts of trichoderma viride JUWEI002 fermentation liquor, 1-4 parts of bacillus subtilis JUWEI001 fermentation liquor, 20-30 parts of turfy soil, 33-38 parts of tobacco residue, 33-38 parts of silkworm faeces, 6-7 parts of calcium powder and 1-2 parts of potassium fulvate. The compound microbial organic fertilizer disclosed by the invention has the advantages that the quality of crops can be remarkably improved, the yield of the crops is increased, and the soil structure is improved.

Owner:JINAN ZEYUAN BIOTECH

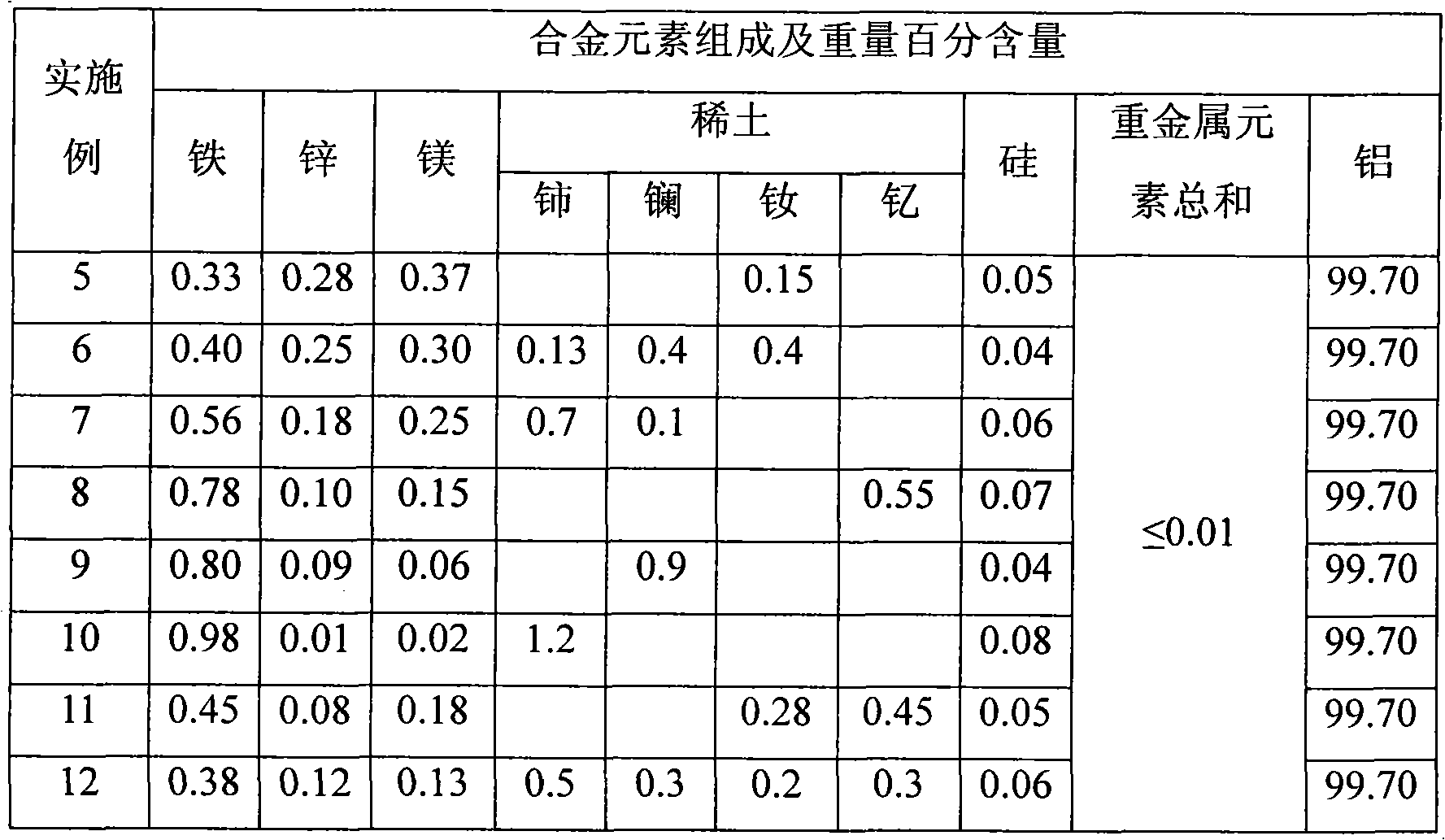

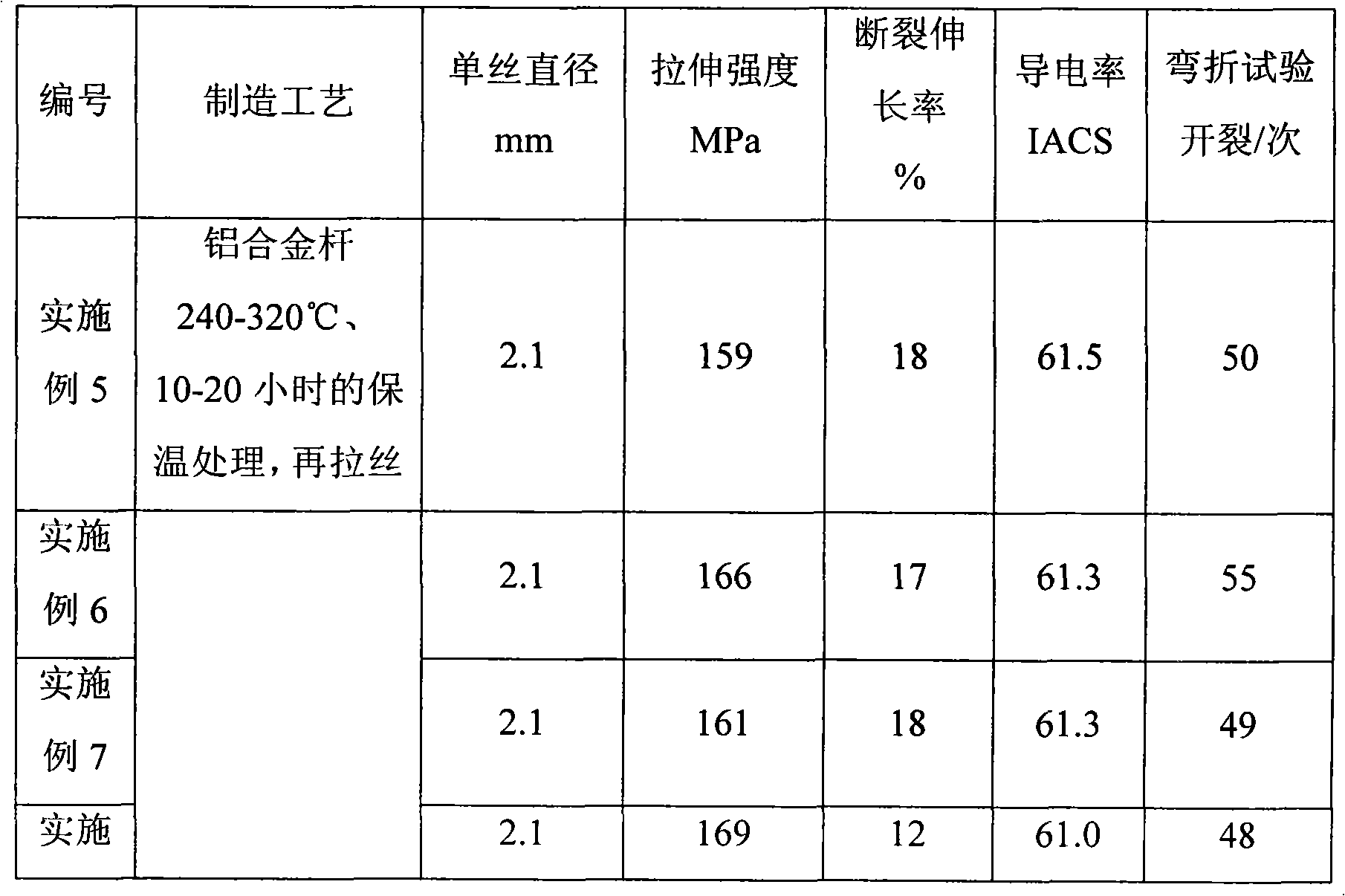

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

Polyester having thermal ageing resistant performance and production method thereof

The invention discloses polyester having thermal ageing resistant performance, which comprises a thermoplastic polyester, a flexibilizer, antioxygen, a heat stabilizer, a filler and other assistant. The product has high thermal ageing resistant performance and high flame-retarding performance.

Owner:东莞市东翔塑胶有限公司

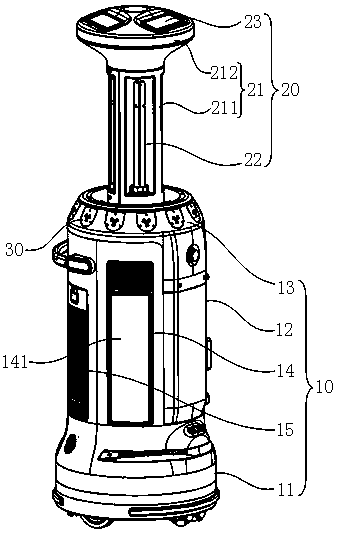

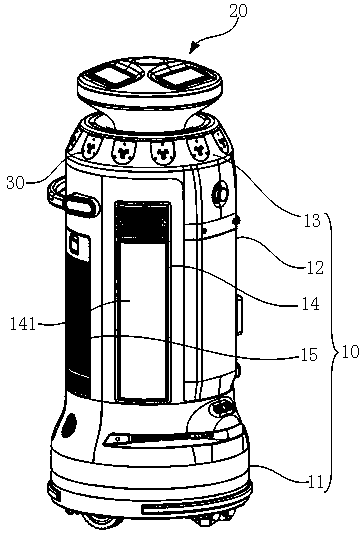

Disinfection robot and disinfection method of disinfection robot

ActiveCN111184888AImprove disinfection efficiencyImprove disinfection effectLavatory sanitoryChemicalsPhysicsProcess engineering

The invention discloses a disinfection robot and a disinfection method of the disinfection robot. The disinfection robot comprises a robot body, an ultraviolet lamp pole and an atomizing device, and acavity is formed in the robot body; the ultraviolet lamp pole is partially accommodated in the cavity, and the part, arranged outside the cavity, of the ultraviolet lamp pole is located above the robot body; and the atomizing device is arranged at the end, close to the ultraviolet lamp pole, of the robot body and can spray an atomized disinfectant. The disinfection robot can disperse the super dry mist disinfectant in a whole to-be-disinfected area more uniformly, so that the synergistic effect of ultraviolet and the super dry mist disinfectant is improved, and the disinfection efficiency canbe improved. Accordingly, the invention further provides the disinfection method of the disinfection robot.

Owner:SHANGHAI TMI ROBOTICS TECH CO LTD

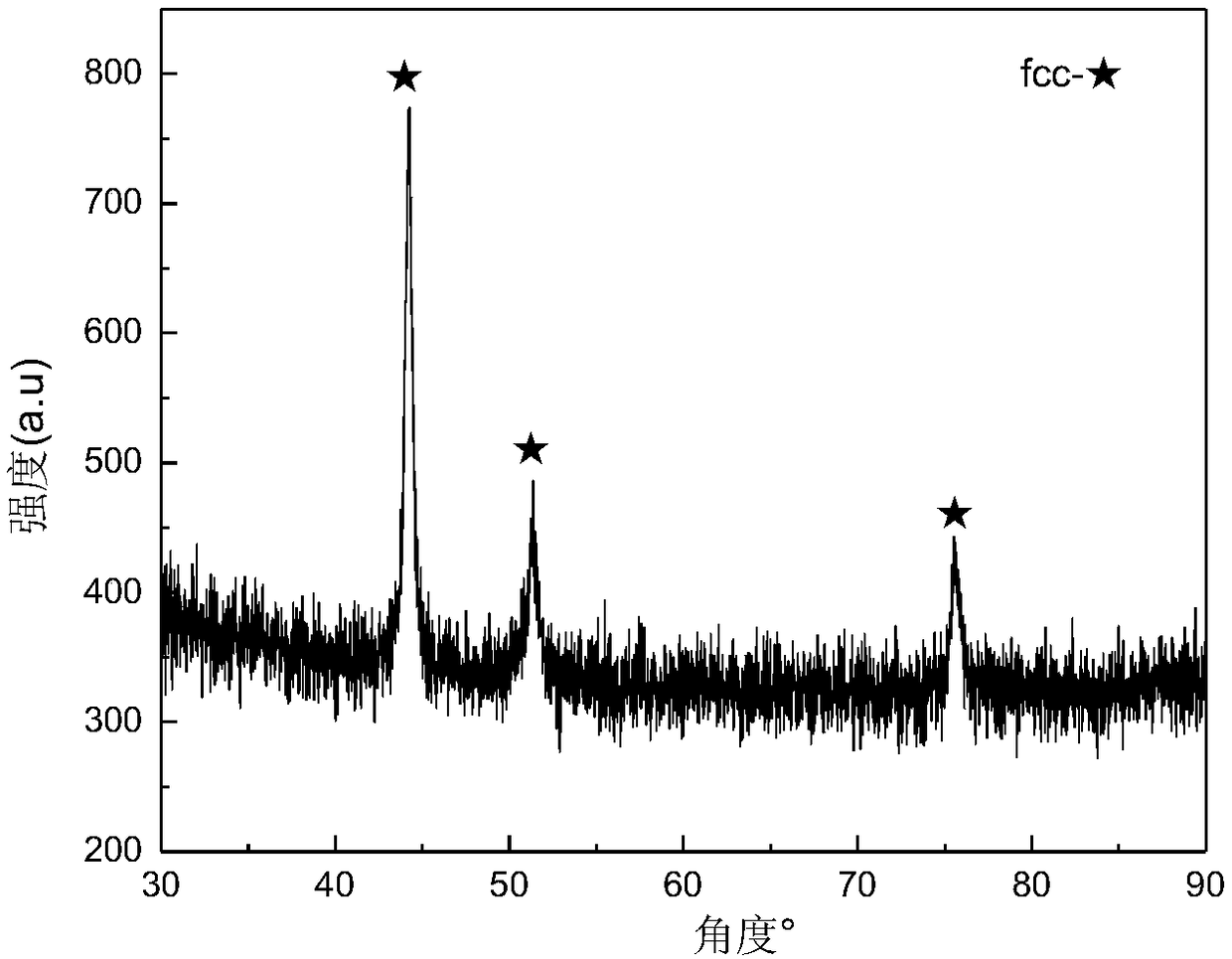

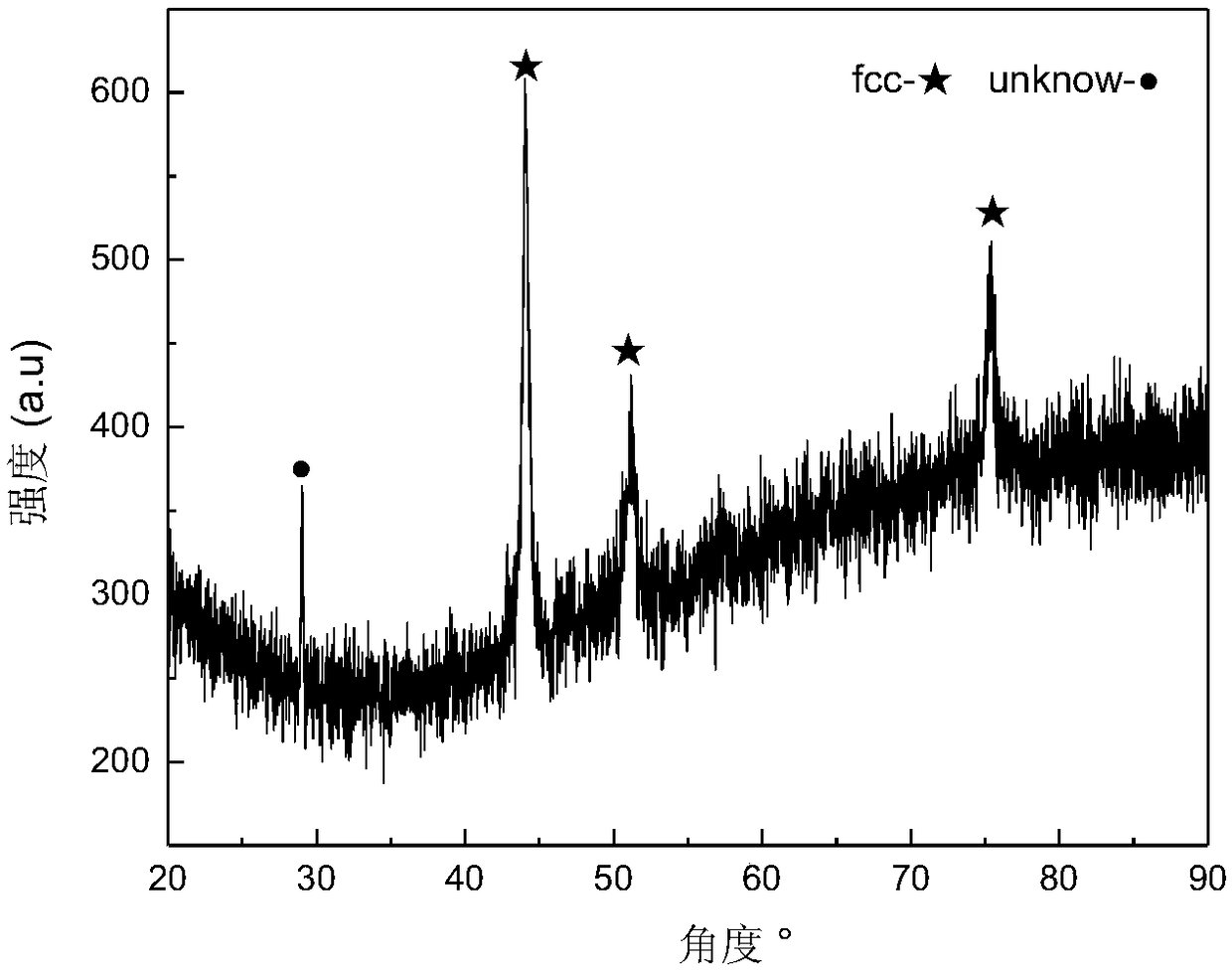

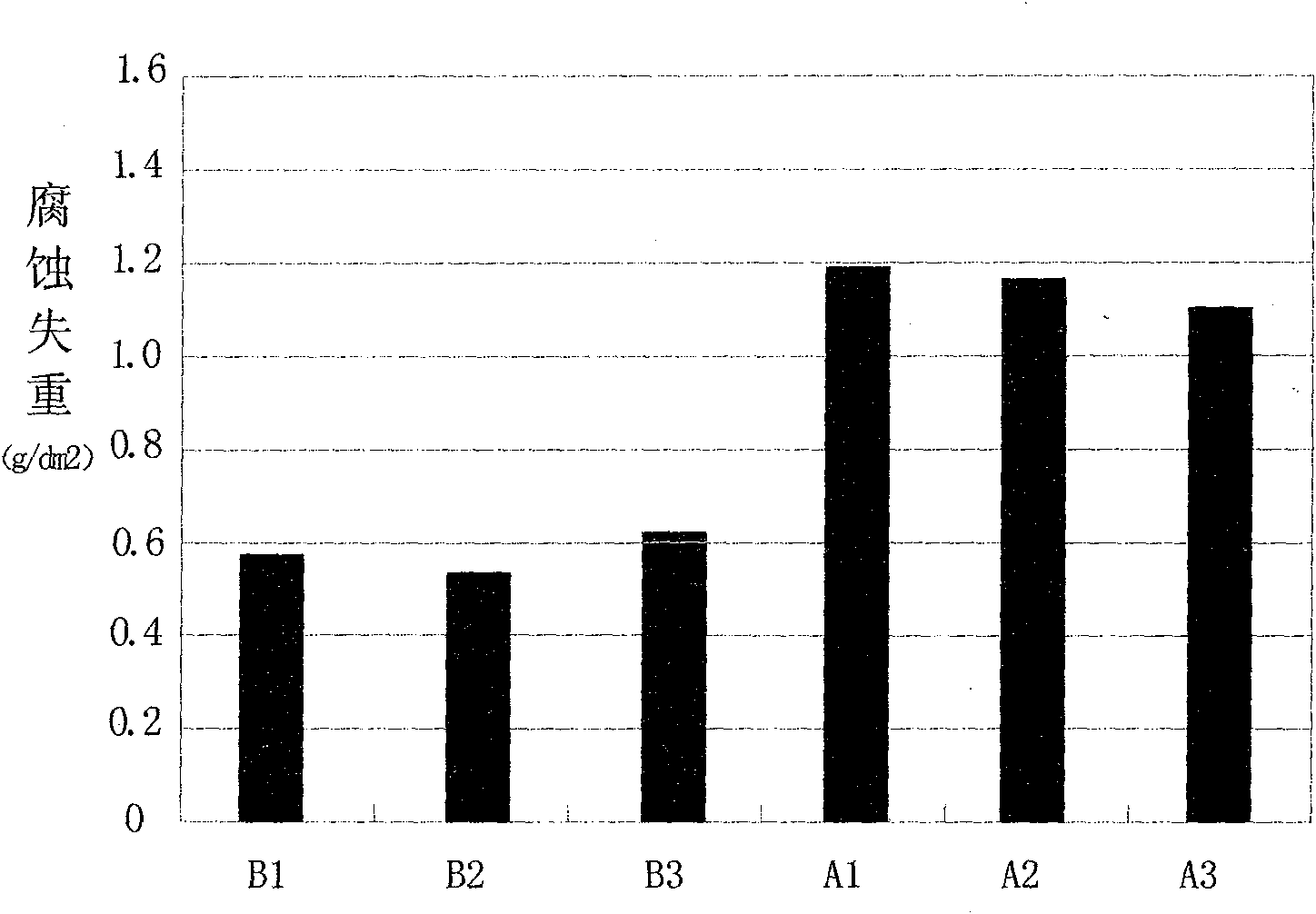

High-strength, corrosion-resistant and medium-entropy alloy and preparation method thereof

The invention discloses a high-strength, corrosion-resistant and medium-entropy alloy and a preparation method thereof. The component of the medium-entropy alloy is (CoCrNi)(100-x)Mnx, the atomic ratio of Co to Cr to Ni is (0.5-1):(0.5-1):(0.5-1), the value range of x is 1at%-10at%, , the alloy is formed through mixing, smelting, homogenizing treatment, rolling and heat treatment machining, the grain size of the alloy ranges from 30 mu m to 200 mu m, the manganese-rich phase is separated out of the grain boundary, the tensile strength of the alloy is higher than 1,200 MPa, the ductility is higher than 10%, the corrosion potential ranges from negative 0.43 V to negative 0.26 V, and the medium-entropy alloy is applicable to marine engineering equipment. The preparation process route of the alloy includes vacuum smelting, suction casting, homogenizing annealing, cold rolling and heat treatment. Co, Cr and Ni with the purity being 99% or higher are selected and weighed according to the proportion and are smelted repeatedly in a vacuum smelting furnace, suction casting forming is performed after the component is uniform, multi-pass cold rolling is adopted after annealing treatment, a plate which is 1-2 mm thick is obtained, the tensile strength of the plate is higher than 1,200 MPa, the ductility is higher than 10%, and the corrosion potential ranges from negative 0.43 V to negative0.26 V.

Owner:SOUTHEAST UNIV

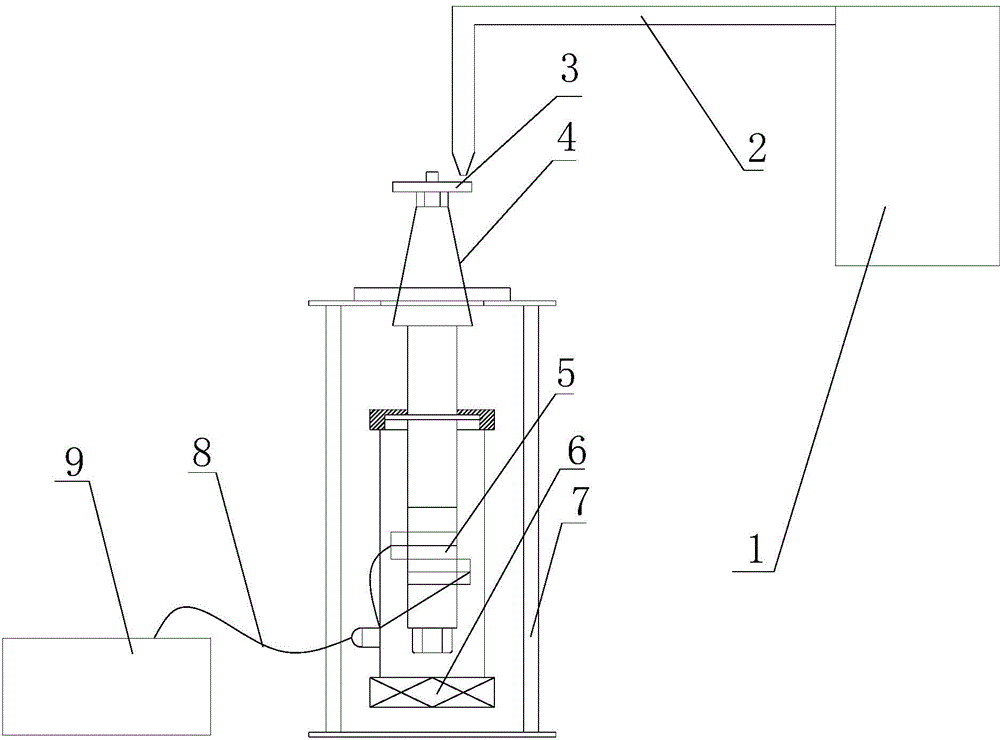

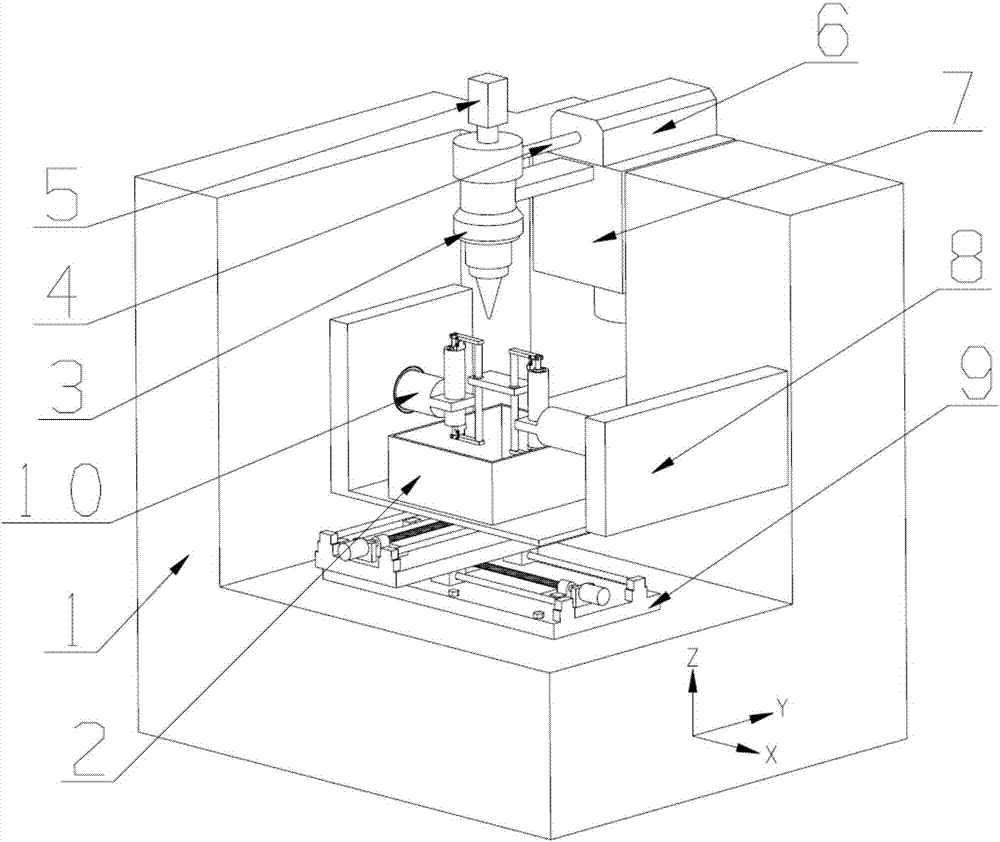

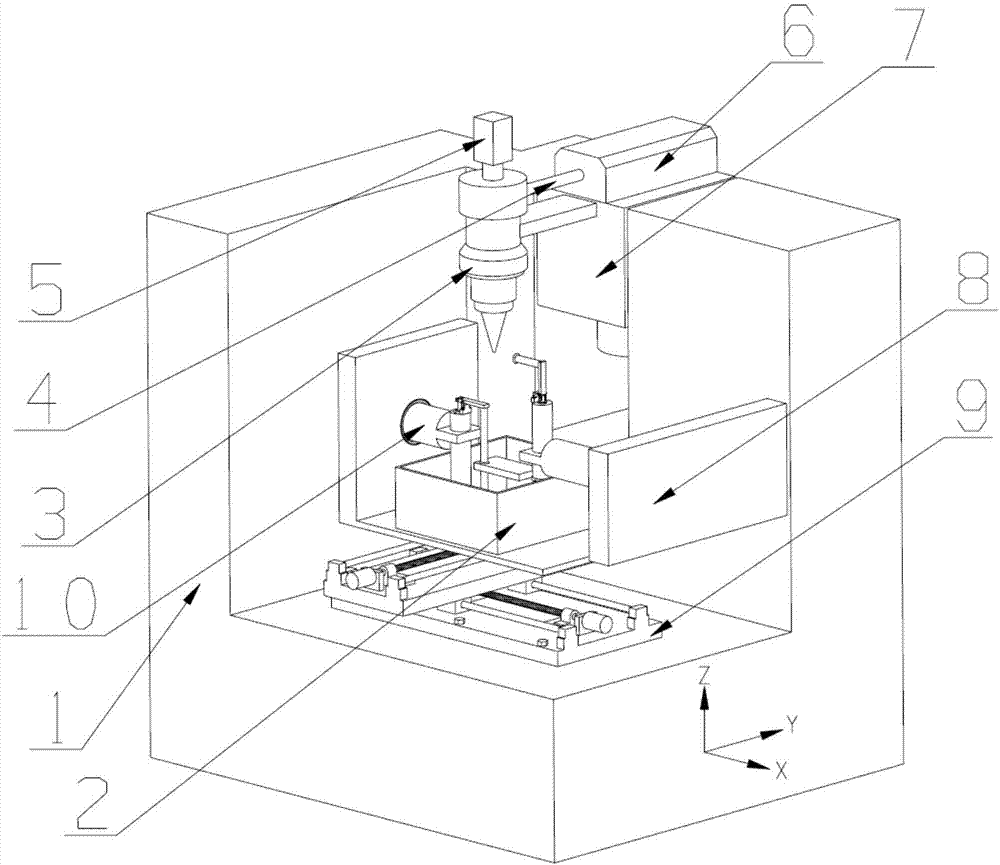

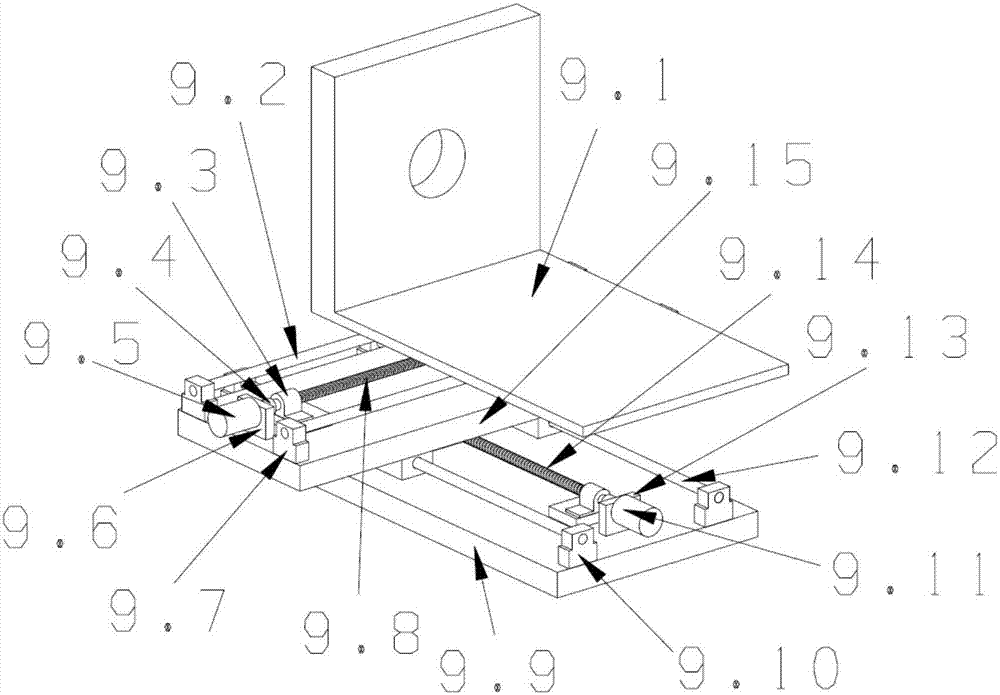

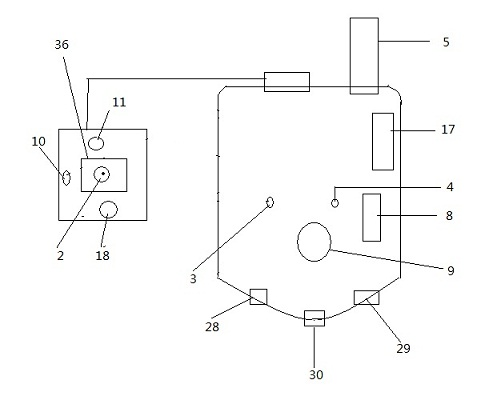

Laser perforating device capable of improving conical degree and inner wall quality of hole and method

ActiveCN107486640AImprove taperSuitable for group hole processingWelding/cutting auxillary devicesAuxillary welding devicesCavitationOptoelectronics

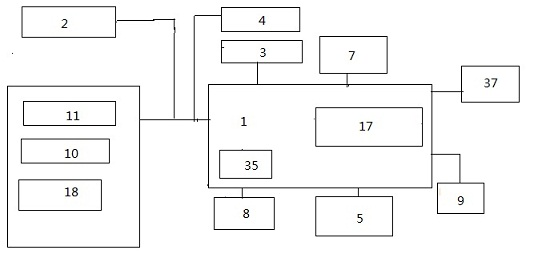

The invention discloses a laser perforating device capable of improving the conical degree and the inner wall quality of a hole, and a method. According to the method of the laser perforating device, a workpiece is subjected to primary laser perforating and then rotates 180 degrees in the x direction of the hole through a rotatable clamp, so that the workpiece is just soaked into water, x and y coordinates of the small hole are not changed, and then secondary laser perforating is conducted through a laser-induced cavitation technology; and in addition, the laser perforating device capable of improving the conical degree and the inner wall quality of the hole is designed and comprises a power box, an uncovered cuboid container, a laser head, a laser guide pipe, a CCD camera, a laser device, a z-direction moving mechanism, a fixing clamp device, an x-y moving platform and a rotatable clamp device. According to the laser perforating device and the method thereof, the mode of conducting laser perforating in air and the mode of conducting laser perforating in water are coupled, secondary perforating is completed by turning over the workpiece so that the conical degree of the hole can be improved, the laser perforating technology and the laser-induced cavitation technology are combined in the secondary perforating process, and the inner wall of the hole is strengthened by impact waves generated through cavitation.

Owner:JIANGSU UNIV

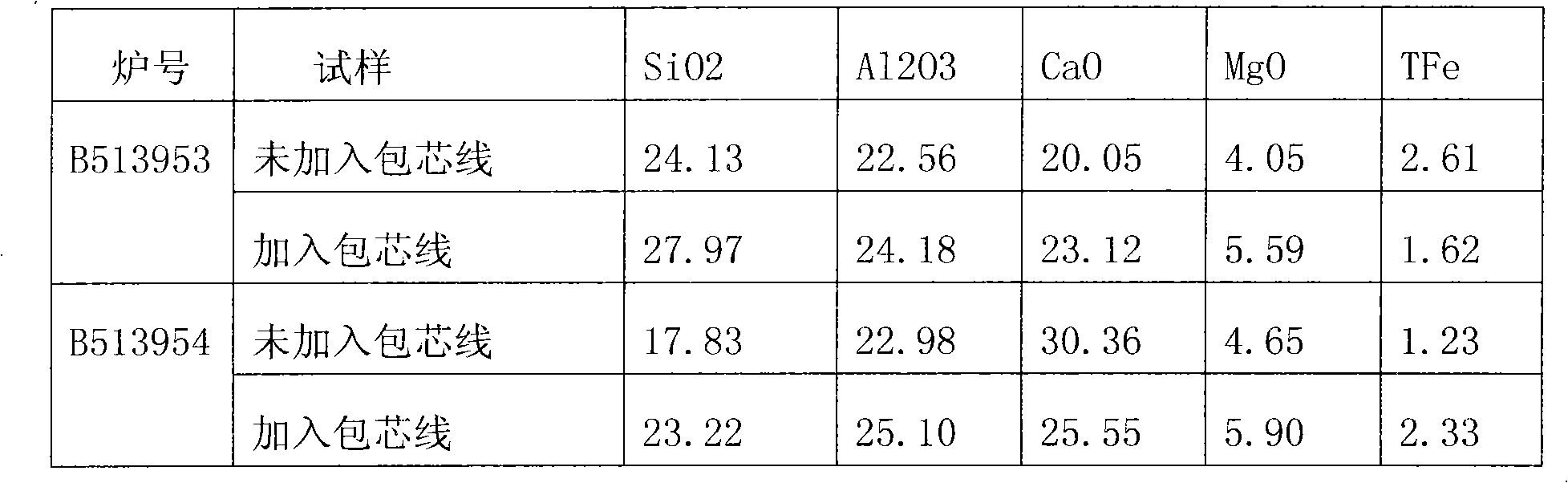

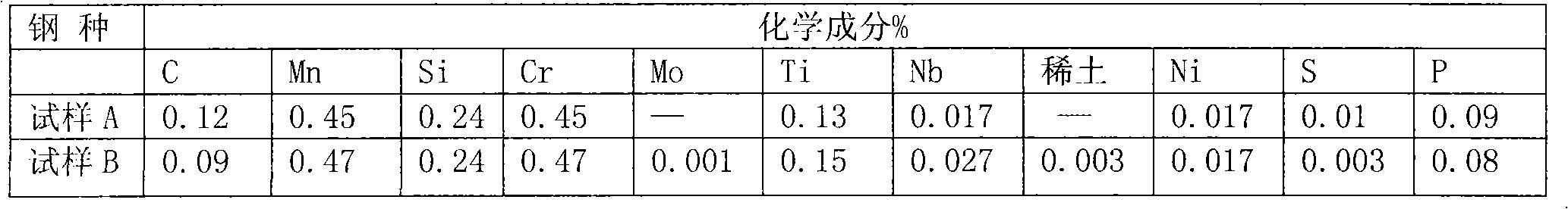

Novel weathering resistant steel microalloying compound core-spun yarn

The invention discloses a novel weathering resistant steel microalloying compound core-spun yarn comprising a steel sheath and a powdery inner core, wherein the powdery inner core is composed of the following chemical ingredients in percentage by weight: 20% of Ca, 0.5% of Mg, 38% of Si, 1.2% of Ba, 1.9% of rare-earth metal, 3.2% of Zr, 1.6% of Ti, 0.5% of B, 0.9% of Mo, 0.5% of Mn, 0.9% of Nb, 0.6% of V and the balance of Fe and inevitable impurity. The invention can obviously refine steel microstructure, improves the decay resistance of steel and lowers C, P and S content in steel by reasonably designing the chemical ingredients; and meanwhile the invention can reduce the amount of parts of alloy elements in steel so as to lower cost.

Owner:HUBEI KMK WELDING MATERIALS

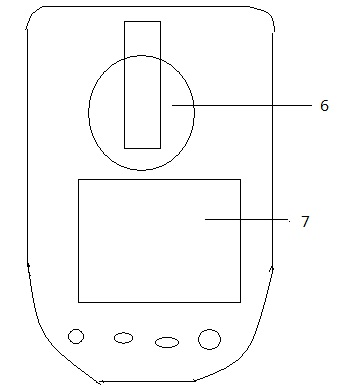

External high-definition on-site law enforcement recorder

InactiveCN101771850ASatisfy the protective effectPlay a protective effectClosed circuit television systemsCamera filtersCamera lensData interface

The invention relates to an external high-definition on-site law enforcement recorder. The recorder has the advantages of simple structure, convenient use, capability of imaging with high definition, convenient image playback, easy correction of camera shooting direction and the like. The structure of the recorder is that: a driving control circuit and a battery are arranged in a shell; the shell is externally connected with a high-definition camera through a connecting wire; the high-definition camera is connected with the driving control circuit and is provided with a corresponding movable filtering device and a lens direction aligning and imaging deflection correcting device; the driving control circuit is also connected with a wireless transmitting device; and the shell is provided with a data interface which is connected with the driving control circuit.

Owner:曹永军

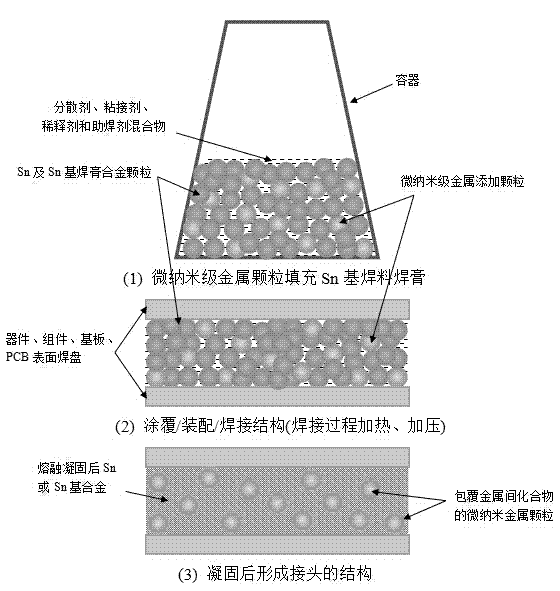

Method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles

ActiveCN104759725APlay a reinforcing roleImprove cooling effectWelding/cutting media/materialsMetal working apparatusMicro nanoBrick

The invention provides a method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles. The method comprises the steps that the micro-nano metallic particles are prepared and mixed with a dispersing agent, a caking agent, diluent and scaling powder; a micro-nano metallic particle mixture is evenly mixed with pure Sn or Sn-based soldering paste; the Sn-based soldering paste is filled with the micro-nano metallic particles and placed on a base plate, alignment process of a part to be welded is completed, and pressure is exerted on the Sn-based soldering paste; the Sn-based soldering paste is put back in a reflow oven and experiences a preheating stage, an insulation stage, a reflowing stage and a cooling stage. According to the method for achieving electronic building brick high-temperature packaging by filling the Sn-based solder with the micro-nano metallic particles, the Sn-based solder is filled with the micro-nano metallic particles, connection and assembly of high-power devices or components can be achieved under the process condition of being compatible with traditional reflow soldering, when the devices serve at high temperature, metallic particles are formed inside a connector, excellent conductivity property and heat-conducting property are achieved, and the heat dissipation index and the electrical performance index of the electronic building brick can be significantly improved.

Owner:HARBIN INST OF TECH

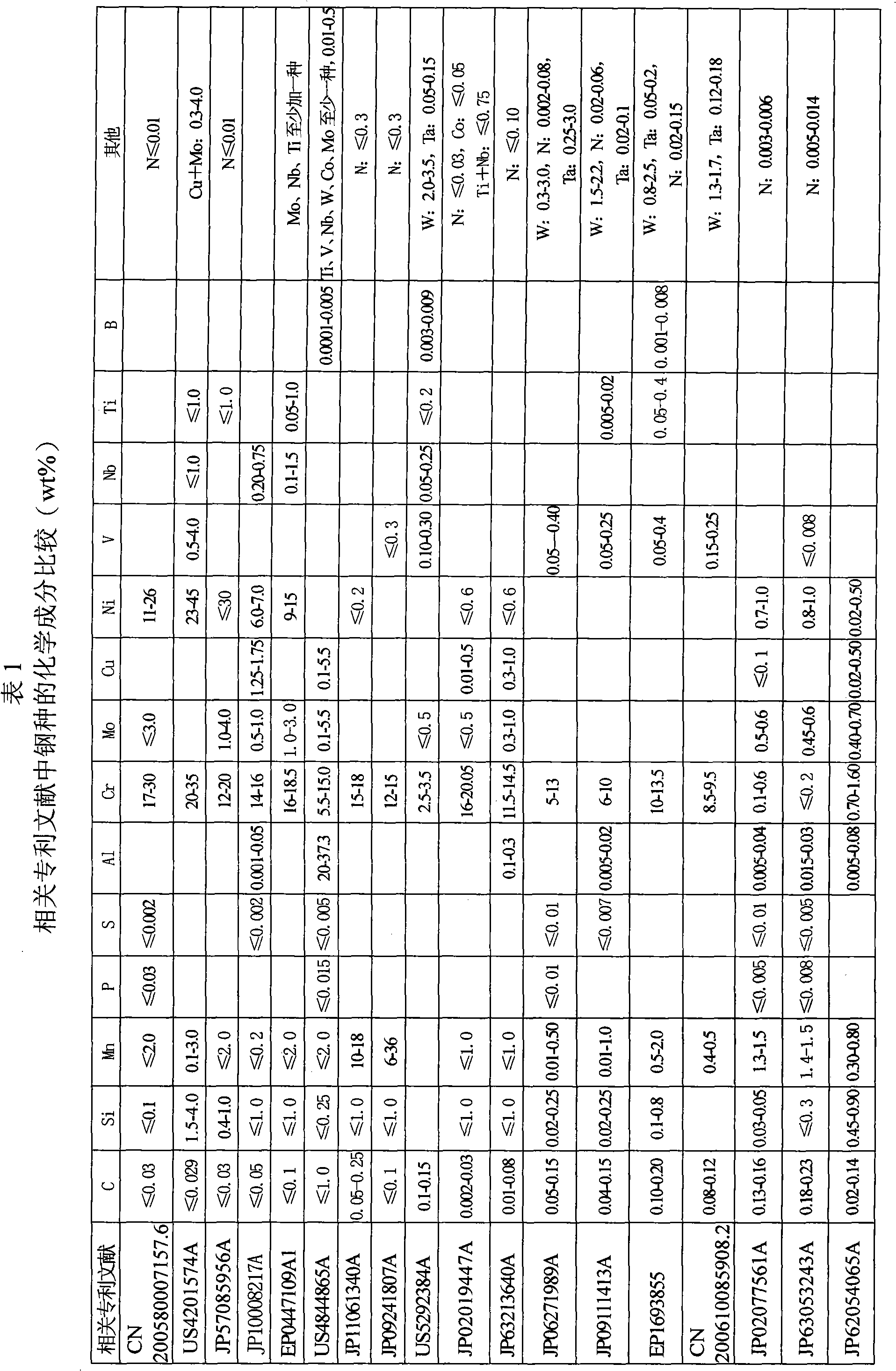

Thick steel plate for pressure vessel, method for manufacturing the same, use of the same

ActiveCN101514434AEasy to implementFacilitate the implementation of heat treatment processFurnace typesMetal rolling arrangementsSteel platesNuclear reactor

The invention provides a thick steel plate for a pressure vessel, a method for manufacturing the same and use of the same. The thick steel plate comprises the following chemical components: 0.08 to 0. 20 weight percent of C, 0.10 to 0.40 weight percent of Si, 1.0 to 1.6 weight percent of Mn, less than or equal to 0.01 weight percent of S, less than or equal to 0.012 weight percent of P, 0.015 to 0.05 weight percent of Al, 0.40 to 0.60 weight percent of Mo, less than or equal to 0.10 weight percent of Cu, 0. 40 to 0.80 weight percent of Ni, less than or equal to 0.05 weight percent of V, less than or equal to 0.008 weight percent of N, and the balance of Fe and inevitable impurities. Alloying and heat treatment ensure the high strength, excellent toughness and other characteristics of the thick steel plate. The product of the method can replace pressure vessel made of a forged piece, and is particularly suitable for manufacturing cylinders, sealing plug and the like for nuclear reactor pressure vessels, evaporators and stabilizers.

Owner:BAOSHAN IRON & STEEL CO LTD

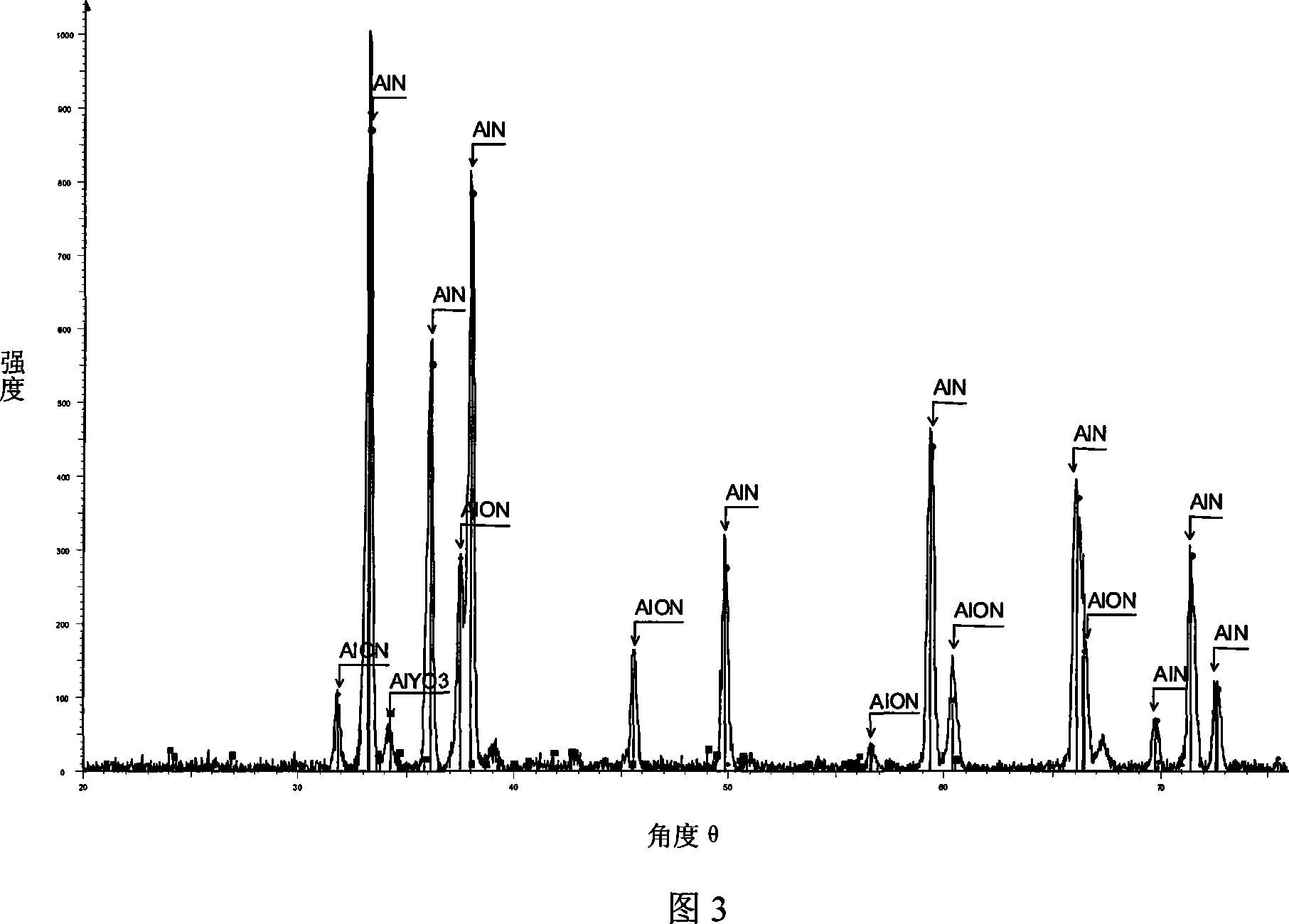

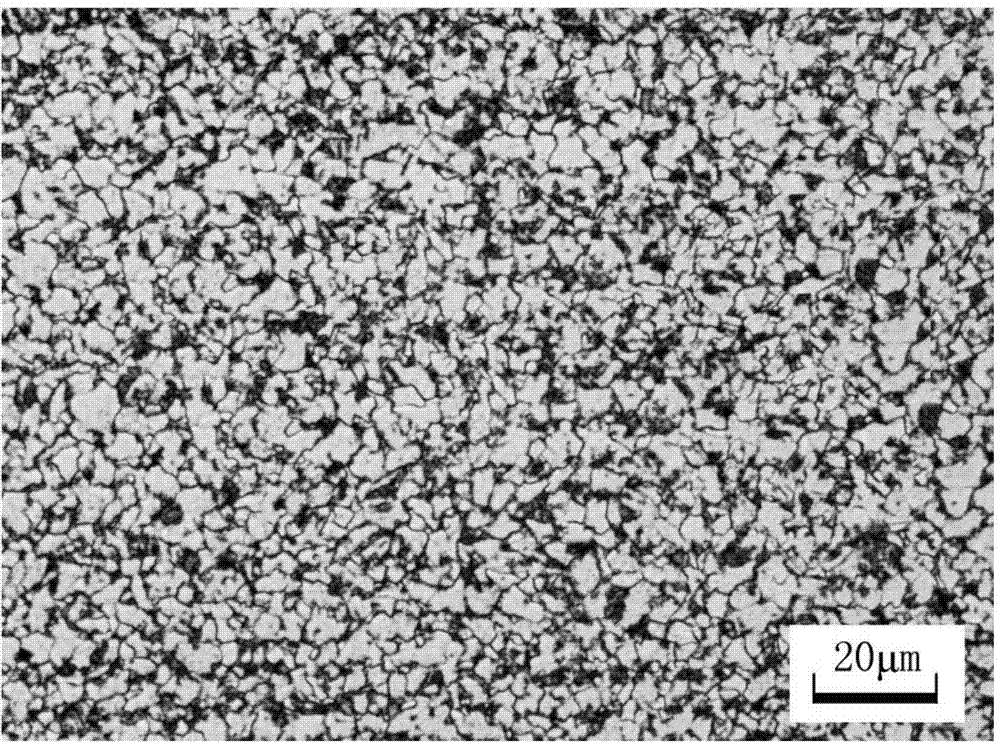

Carbon nano-tube enhanced aluminum nitride composite material and preparation method thereof

This invention relates to carbon nanometer tubes reinforced aluminium nitride composite material, and its preparation method. The preparation procedures are: the carbon nanometer tubes (1-3wt%) being chemically purified, ultrasonic dispersed, being mixed with aluminium nitride (89-95wt%) and agglutinants: yttrium oxide (2-4wt%) and calcium fluoride (2-4wt%); proceeding ball-milling dispersing to produce mixture slurry, drying, milling, sieving and finally pressure sintered to obtain this inventive product with excellent mechanical properties. This invention is of low temperature compacting agglutination with simple process and low cost.

Owner:NAT UNIV OF DEFENSE TECH

Wear-resistant steel with high resistance to tempering and manufacturing method thereof

ActiveCN101555574AEasy access to strengthGuaranteed StrengthTemperature control deviceMetal rolling arrangementsTemperingHardness

The invention relates to wear-resistant steel with high resistance to tempering and a method for manufacturing steel plates made of the same. The wear-resistant steel with high resistance to tempering comprises the following components according to the weight percent: 0. 10 to 0.24 of C, 0.15 to 1.40 of Si, 1.20 to 2.00 of Mn, 0.40 to 1.60 of Cr, 0.15 to 0.50 of Mo, not more than 0.30 of Ni, not more than 0.12 of V, not more than 0.03 of Ti, not more than 0.05 of Al, not more than 0.015 of P, not more than 0.010 of S and the balanced Fe and inescapable impurities. The wear-resistant steel with high resistance to tempering can keep the strength and the rigidity at higher temperature, remarkably improves the use temperature, has simple process and saves the cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of paper reinforcing agent

ActiveCN107141409AGood stabilityIncrease the copolymerization rateReinforcing agents additionRetention agents additionIonApparent viscosity

A paper reinforcing agent contains amphoteric polyacrylamide aqueous dispersion. A preparation method comprises the following preparation steps: adding part of main monomers into a water-phase medium dissolved with a chelating agent, a dispersion stabilizing agent and inorganic salt, and polymerizing by a previous initiator to obtain a seed polymer; and then adding deionized water, the remaining main monomers and a later initiator in the seed polymer, and carrying out polymerization reaction to obtain an amphoteric polyacrylamide water-in-water dispersion solution. The amphoteric polyacrylamide aqueous dispersion is water-in-water polymer emulsion which is small in apparent viscosity, good in mobility, large in molecular weight, uniform in particle size and excellent in storage stability; and the dispersion solution product is added in slurry or is sprayed and permeates in net wet paper, the strength, including tensile strength, bursting strength, ring crush compression resistance, surface strength and the like, of paper can be improved, and meanwhile, the retention and drainage effect in a papermaking process is improved.

Owner:GUANGDONG PAPER IND RES INST

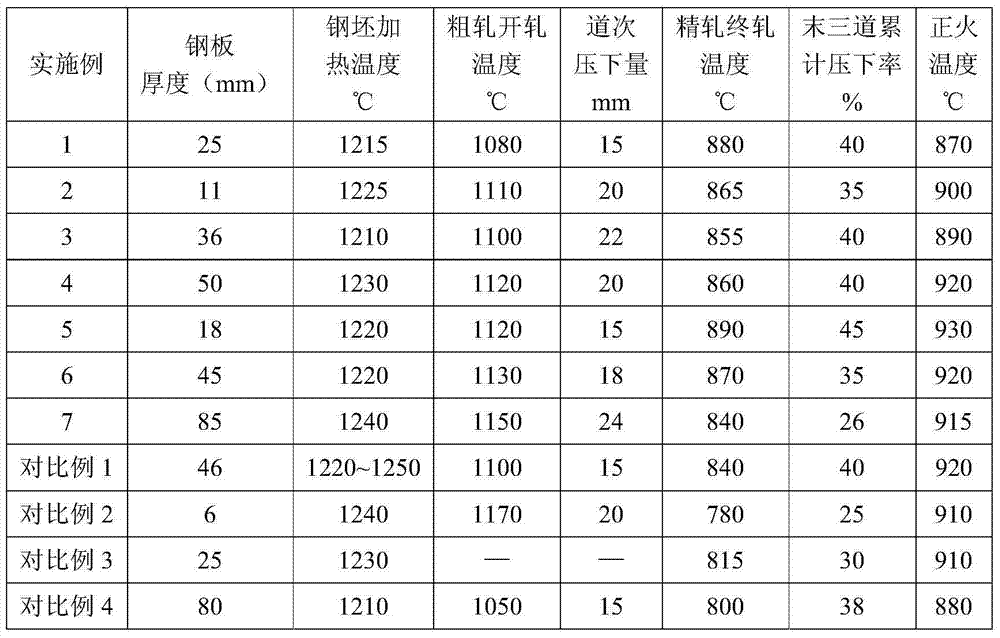

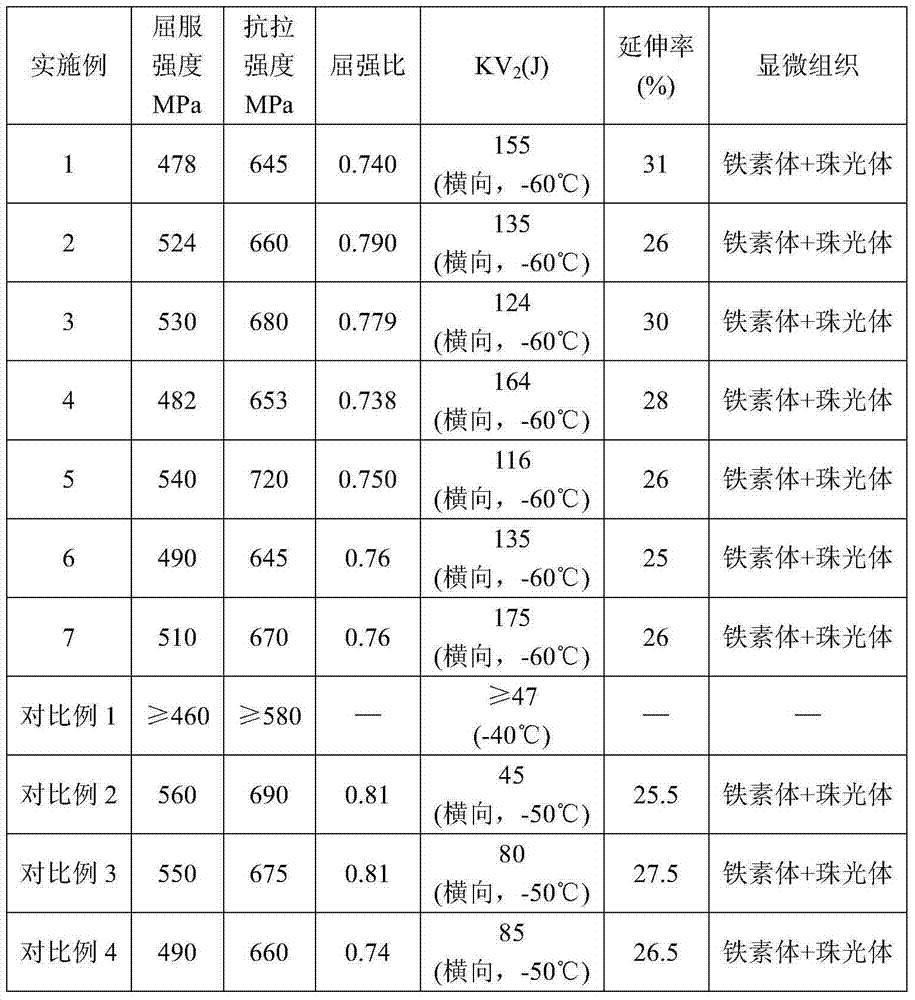

Normalizing-type high-strength pressure vessel steel plate with good low-temperature toughness at minus 50DEG C and manufacturing method of normalizing-type high-strength pressure vessel steel plate

The invention discloses a normalizing-type high-strength pressure vessel steel plate with good low-temperature toughness at minus 50DEG C. The normalizing-type high-strength pressure vessel steel plate is made of chemical compositions comprising, by weight, 0.10-0.22% of C, not more than 0.40% of Si, 1.10-1.74% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 0.40% of Ni, not more than 0.18% of V, 0.0070-0.0190% of N, 0-0.025% of Als, 0-0.018% of Ti, the balance of Fe and unavoidable impurities, wherein formulas: 3.5< / =(V+Ti) / N< / =15 and Ti / (3.5N)< / =C+V+2Ti< / =5V / (C+V) are satisfied simultaneously. The yield strength of the steel plate is > / =460MPa, the tensile strength ranges from 630MPa to 740MPa, the ductility is > / =25%, the yield ratio is < / =0.80, good welding property is achieved, and production cost is low.

Owner:武汉钢铁有限公司

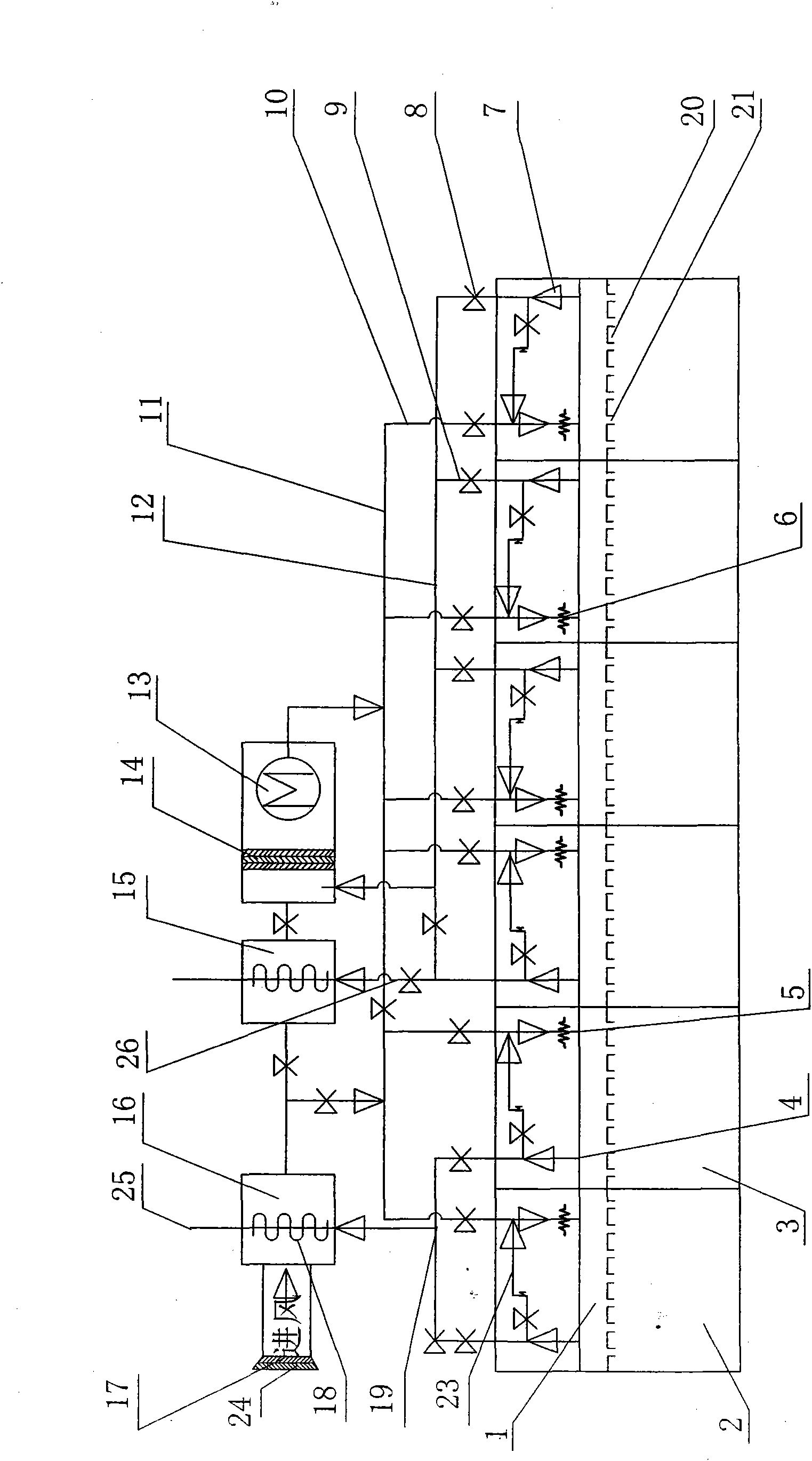

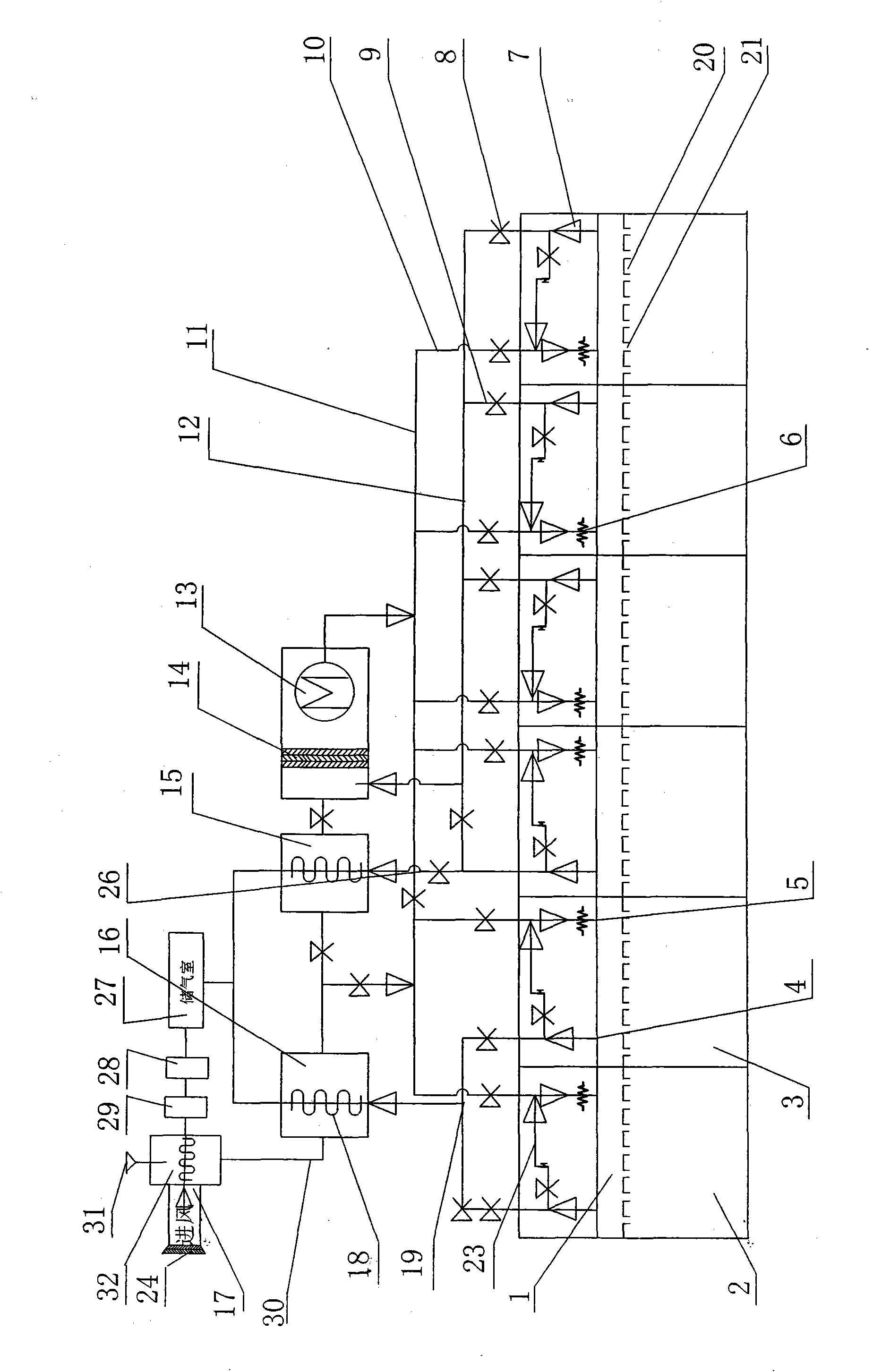

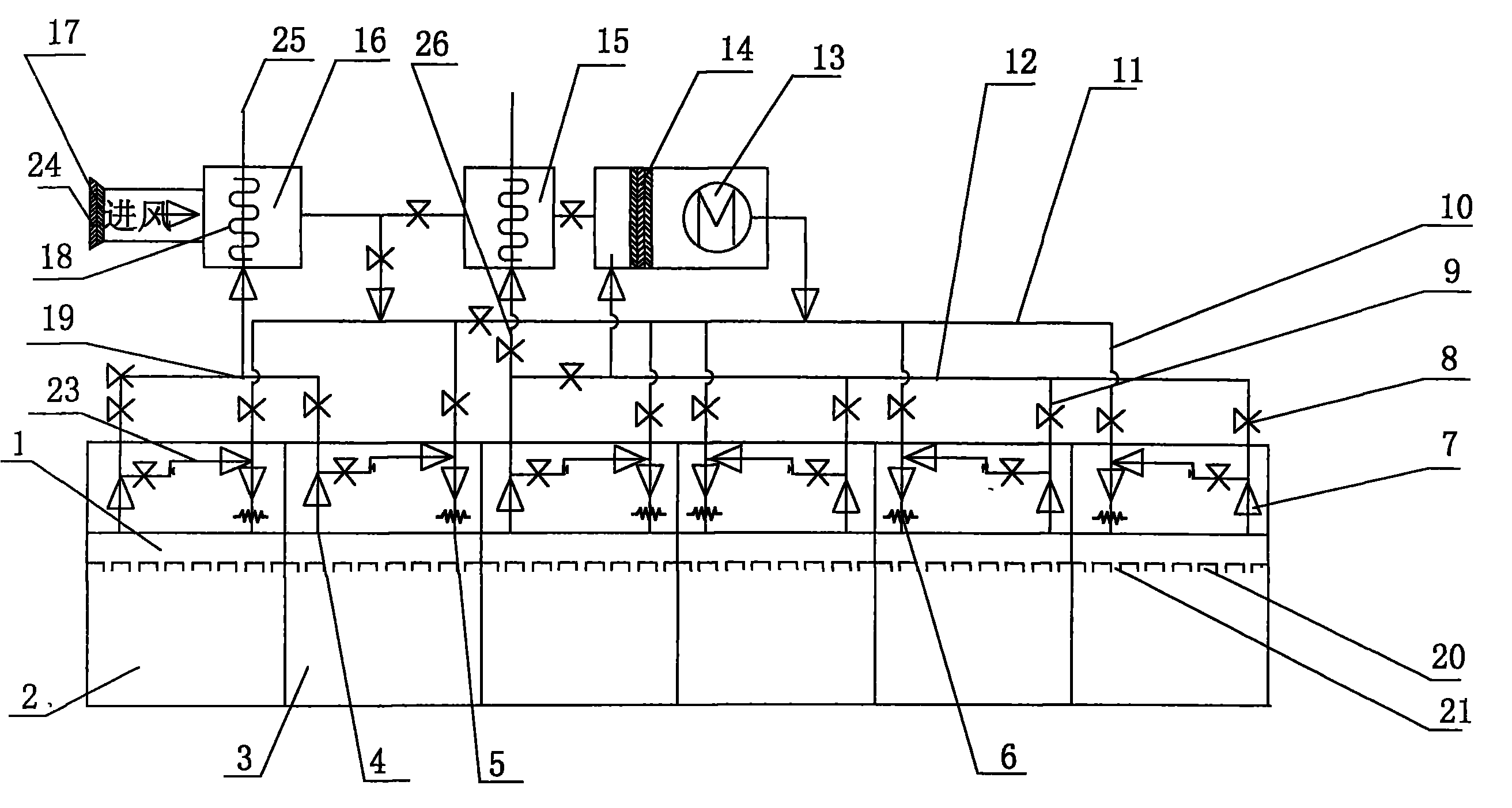

Energy-conserving drying device

InactiveCN101963439AReduce lossesEmission reductionDrying gas arrangementsPretreated surfacesTemperature controlAir volume

The patent refers to the field of 'drying solid materials or objects by removing liquid therefrom'. The invention relates to a drying device, particularly relating to an energy-conserving device, and providing a high-air-volume multistage circular energy-conserving drying device utilizing wastes to heat fresh air. A drying room is composed of multi-section drying ovens; each drying oven is provided with a diaphragm; an enclosed air room with multiple air flue slits is arranged on the diaphragm, and is communicated with a heat exchanger through an air inlet main pipe, an air inlet branch pipe, an air outlet main pipe and an air outlet branch pipe; a fresh-air taking opening is connected with the heat exchanger and a heat exchanging draught fan in sequence; the outlet of the heat exchanger, the air inlet main pipe and the air inlet branch pipe are connected with each air room; the air exhaust branch pipe of the previous two-section drying oven air room with high waste gas concentration is discharged through a primary heat exchanger; other air exhaust branch pipes are connected on the air outlet branch pipe, and are connected with a secondary heat exchanger and the front end part of the heat exchanging draught fan to form circulation; the inner air volume is increased; the hot air circulates in the drying oven; the waste gas temperature is utilized to save energy source; the drying oven temperature is flexibly set, and small circulation is flexibly regulated in the drying oven; and the temperature control is uniform.

Owner:武汉宇恩防伪技术有限公司

Method for preparing black polyurethane elastic fiber via in situ polymerization

ActiveCN102899739AGood spinnabilityLong lasting black effectMonocomponent synthetic polymer artificial filamentArtifical filament manufactureSolventPrepolymer

The invention relates to a method for preparing a black polyurethane elastic fiber via in situ polymerization, comprising the following steps: (1) evenly dispersing nanometer carbon black particles in low-polymer polyhydric alcohol by using a grinding or ultrasonic and powerful mechanical stirring method so as to form a stable mixture, (2) adding diisocyanate in the polyhydric alcohol containing the carbon black particles for full reaction and adding a solvent for full dissolution to obtain NCO end capped prepolymer polyurethane formic ether solution; (3) carrying out chain extension and chain termination on the prepolymer solution by using mixed amine solution to generate polyurethane urea solution, and (4) curing the polyurethane urea solution and spinning the polyurethane urea solution into the black polyurethane elastic fiber by means of a dry spinning system. The polyurethane elastic fiber prepared via an in situ polymerization method is lasting in black effect and high in color fastness, so that the subsequent processing is free of dyeing; and at the same time, the polyurethane elastic fiber has relatively good mechanical property.

Owner:ZHEJIANG HUAFENG SPANDEX

High-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and coating and preparing method of coating

ActiveCN105463359AImprove solid solution strengtheningPlay a reinforcing roleMolten spray coatingChromium carbideTurbine blade

The invention discloses high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and a high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide coating prepared through the composite powder. The composite powder comprises, by weight percentage, 65-85% of Cr3C2, 10-25% of NiCr, 1-5% of Nb and 1-5% of Ta. The coating is prepared in the manner that the composite powder is subjected to hypersonic flame spraying or high-enthalpy plasma spraying or is subjected to hypersonic flame spraying or high-enthalpy plasma spraying, and then the high-enthalpy plasma remelting technology is combined. The coating is greatly improved in the aspects of microhardness, combing strength, corrosion resistance and cavitation resistance. Meanwhile, the production cost is low, the preparing method is reliable in technology, performance is stable, and the coating is suitable for being applied to the fields such as hydraulic machine flow passage components, compressor screws and turbine blades on a large scale.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

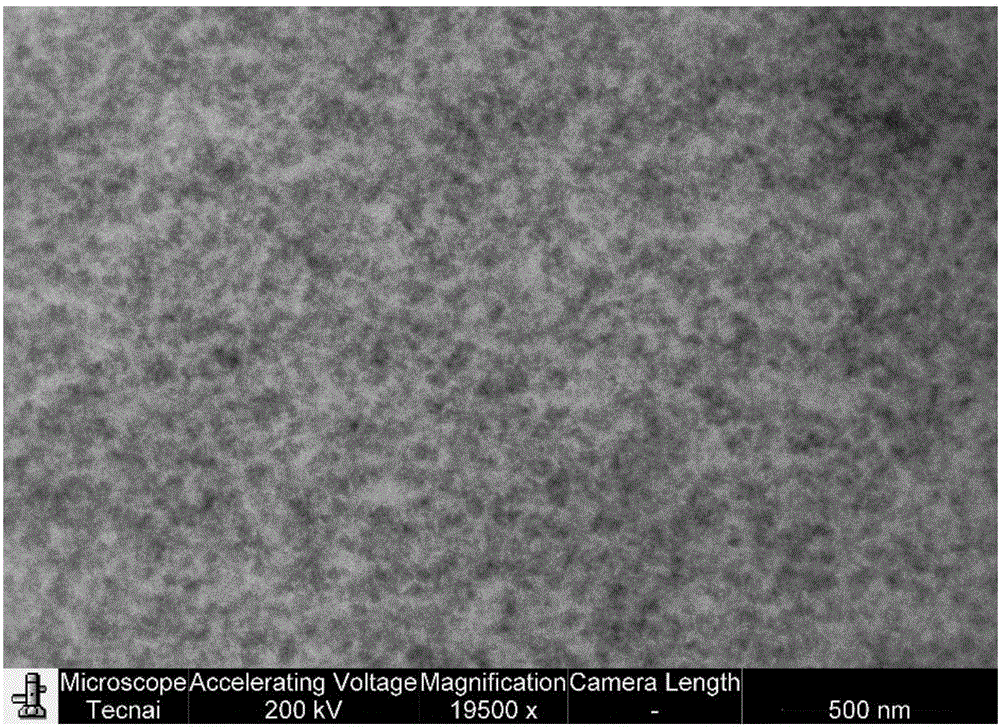

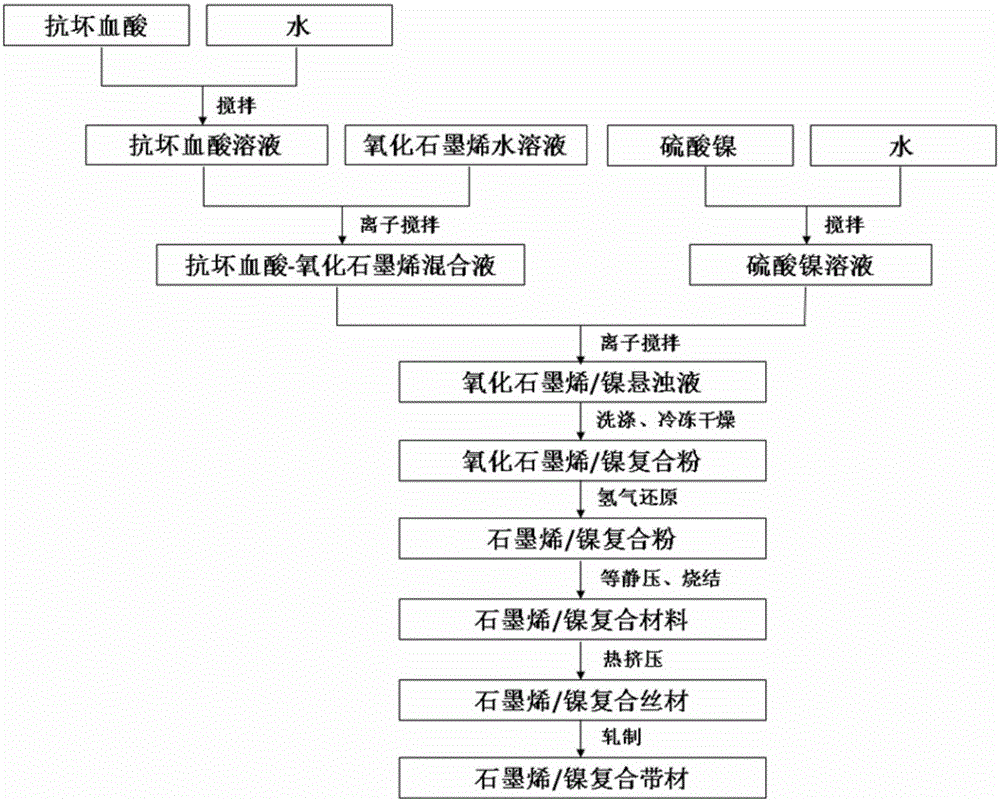

Graphene strengthening nickel base composite material and preparing method thereof

The invention discloses a graphene strengthening nickel base composite material and a preparing method thereof. The method includes the steps that a reducing agent and nickel sulfate are sequentially added into an oxidized graphene solution; nickel powder prepared through reduction is directly compounded with oxidized graphene in the solution, and oxidized graphene / nickel composite powder is initially obtained; the oxidized graphene / nickel composite powder is dried and restored to obtain graphene / nickel composite powder; and composite blocks, composite wires and composite strips of graphene / nickel are obtained through powder metallurgy, hot extrusion and rolling technologies. Graphene in the composite material is evenly scattered, base and strengthening body interface bonding is good, and the composite material has the excellent physical performance. Meanwhile, the process of the graphene strengthening nickel base composite material and the preparing method is simple, the procedure is easy to control, and large-scale application and production are easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

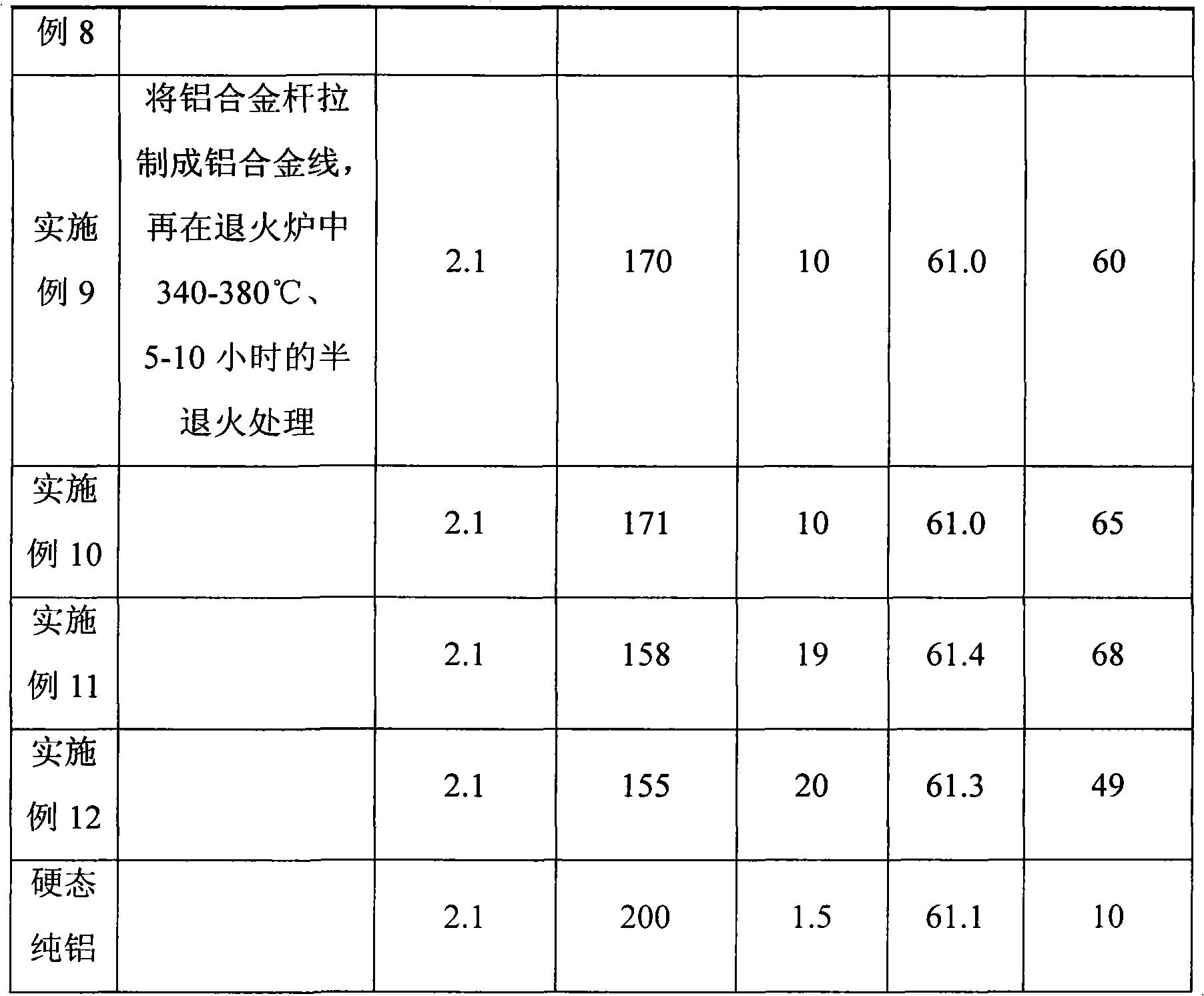

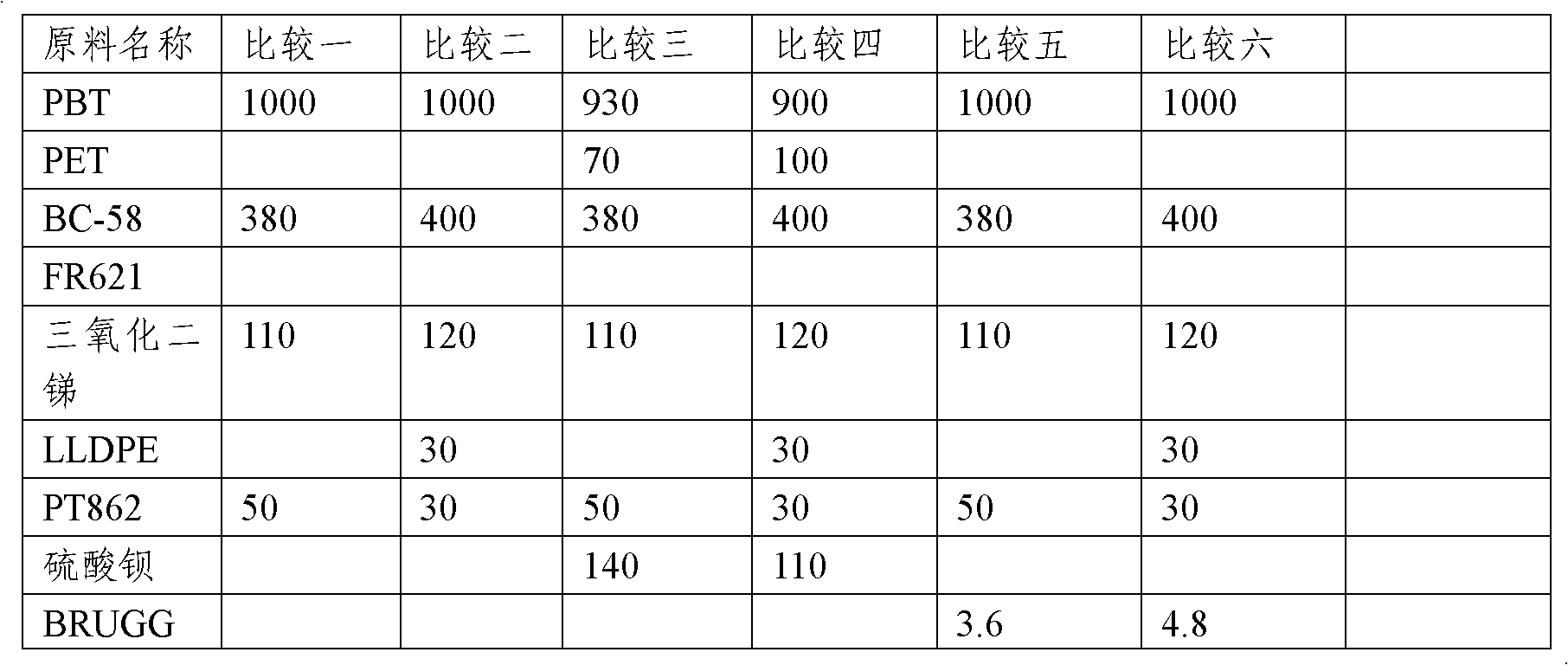

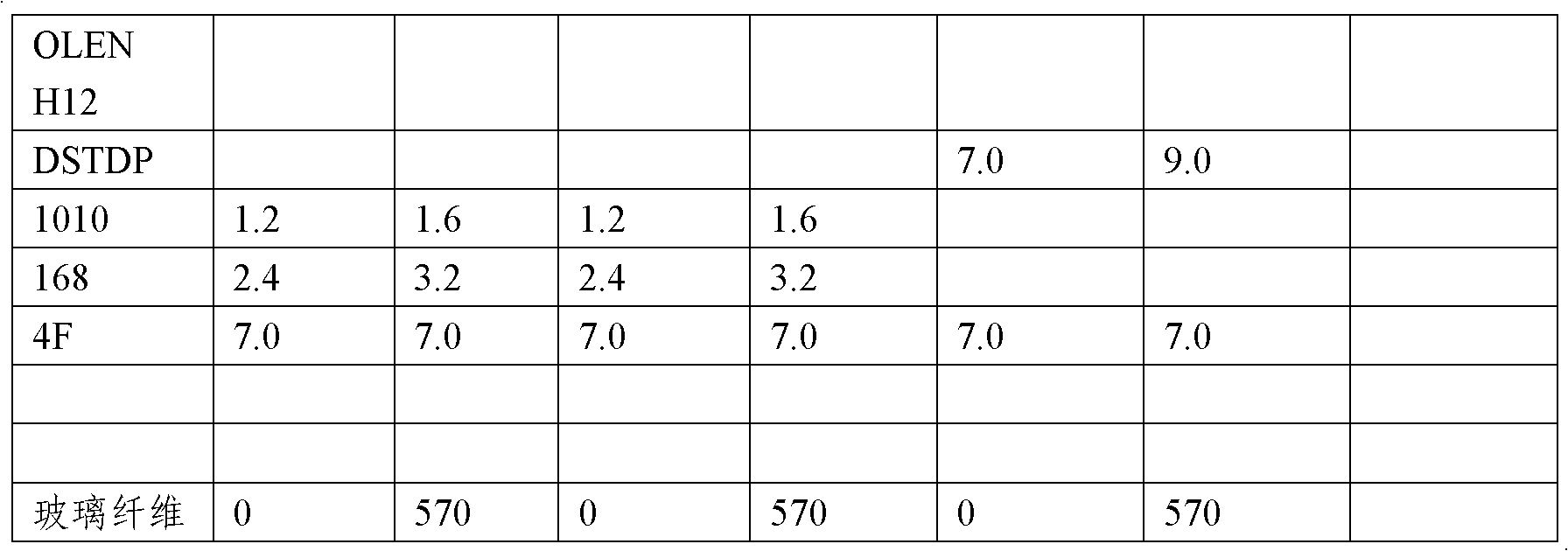

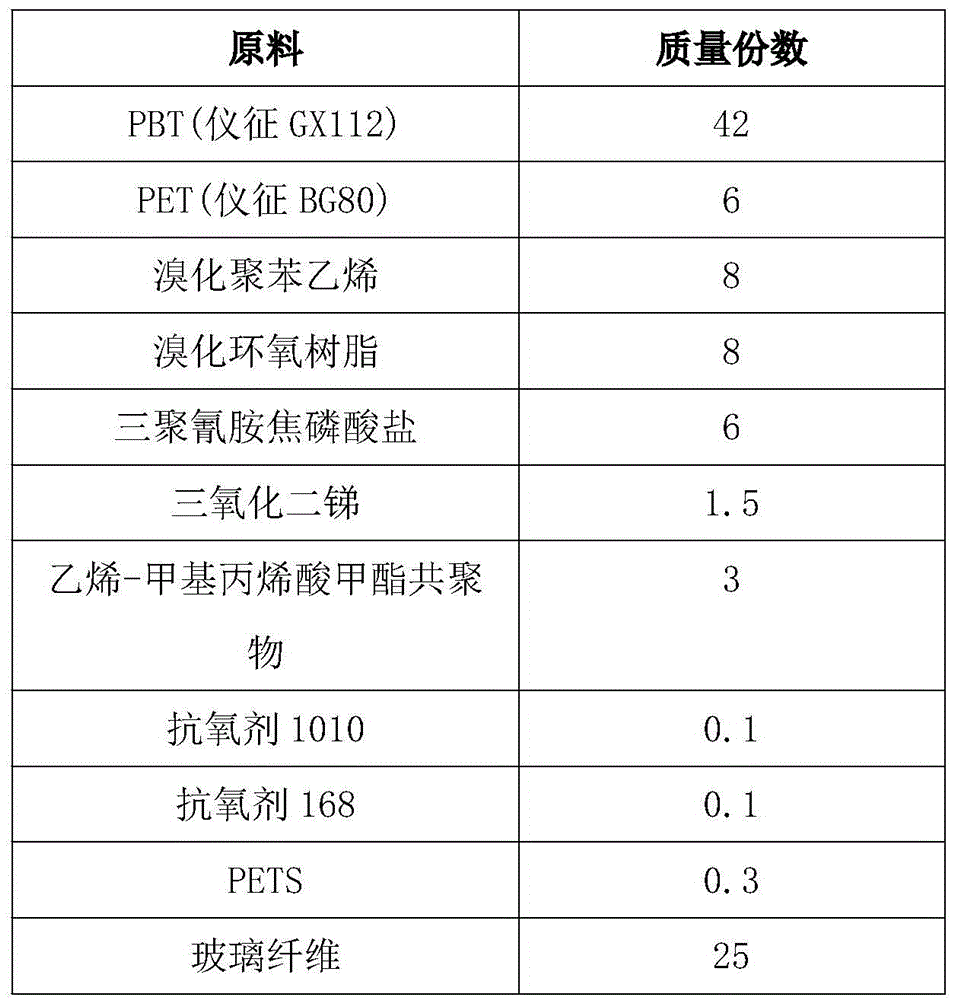

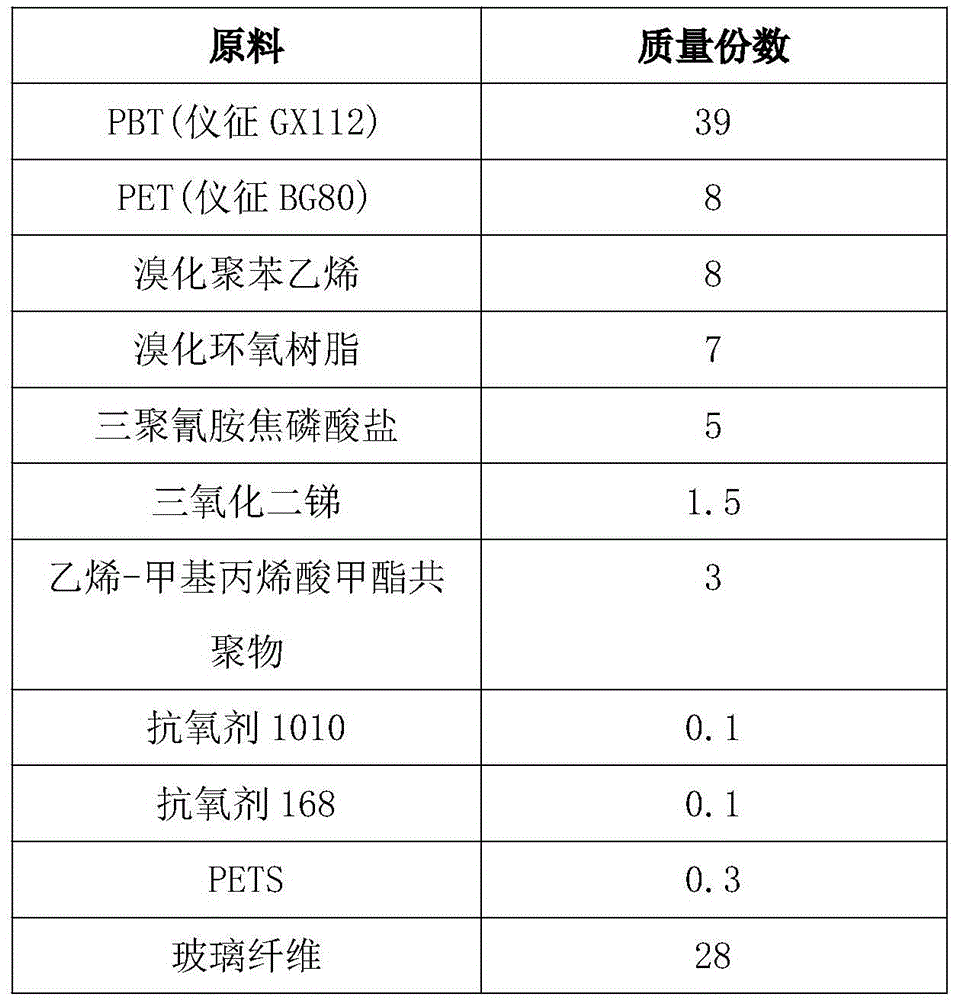

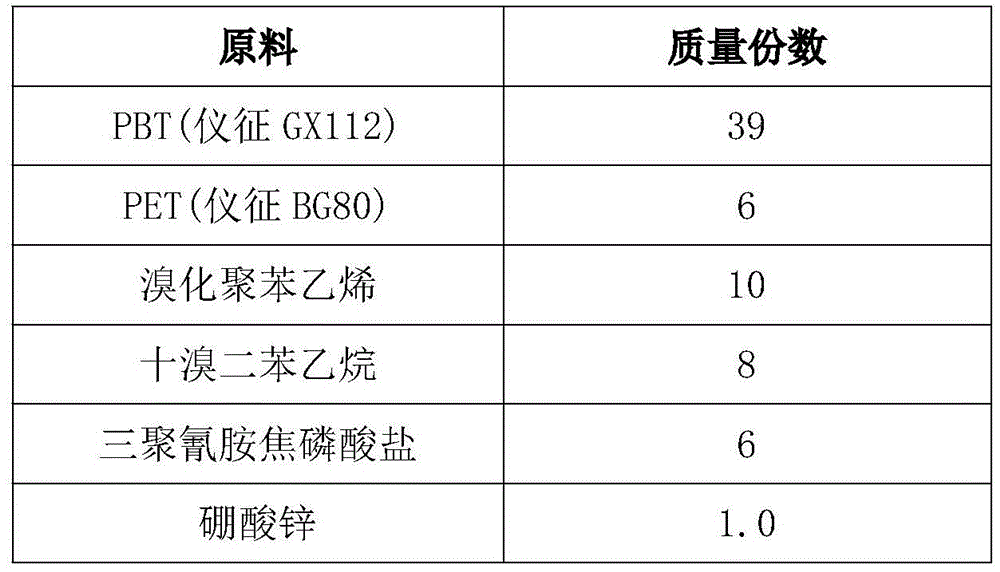

Flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and high CTI (comparative tracking index) value and method for preparing flame-retardant glass fiber reinforced PBT

InactiveCN105647134ARaise the ignition temperatureImprove mechanical propertiesAntioxidantPolyethylene terephthalate

The invention discloses a flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and a high CTI (comparative tracking index) value and a method for preparing the flame-retardant glass fiber reinforced PBT. The flame-retardant glass fiber reinforced PBT comprises, by weight, 38-45 parts of PBT, 5-8 parts of PET (polyethylene terephthalate), 15-18 parts of flame retardants A, 0.5-1.5 parts of flame retardants B, 5-8 parts of flame retardants C, 2-4 parts of toughening agents, 0.2-0.4 part of antioxidants, 0.3-0.6 part of lubricants and 25-30 parts of glass fibers. The flame-retardant glass fiber reinforced PBT and the method have the advantages that the glow wire ignition temperature (GWIT) of the flame-retardant glass fiber reinforced PBT can be increased and reaches 850 DEG C, and a comparative tracking index (CTI) of the flame-retardant glass fiber reinforced PBT can reach 400 V; the mechanical performance and the machining performance of the flame-retardant glass fiber reinforced PBT can be prevented from being damaged or only is damaged at low level.

Owner:贝克兰(厦门)新材料有限公司

Nanometer composite material and preparation method thereof, vulcanized rubber and applications thereof

InactiveCN105368097AGood dispersionGood compatibilitySpecial tyresPigment treatment with organosilicon compoundsMaterials preparationWear resistance

The present invention discloses a nanometer composite material and a preparation method thereof, the nanometer composite material prepared through the method, and a vulcanized rubber containing the nanometer composite material and applications thereof. According to the present invention, the nanometer composite material contains white carbon black, graphene oxide, and a surface modifier attached onto the surface of the white carbon black and / or graphene oxide; the nanometer composite material preparation method comprises uniformly mixing the white carbon black and the graphene oxide in water, carrying out spray drying to obtain a solid, mixing the obtained solid and the surface modifier, and drying; the present invention further provides the vulcanized rubber and applications of the vulcanized rubber in tire material preparation, wherein the mixture containing the nanometer composite material, a raw material rubber, a vulcanizing agent and an accelerator is subjected to mixing and vulcanizing to form the product, ie., the vulcanized rubber; the nanometer composite material has excellent dispersion property and excellent compatibility; and the vulcanized rubber has characteristics of good tensile property, good abrasion resistance and good dynamic mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com