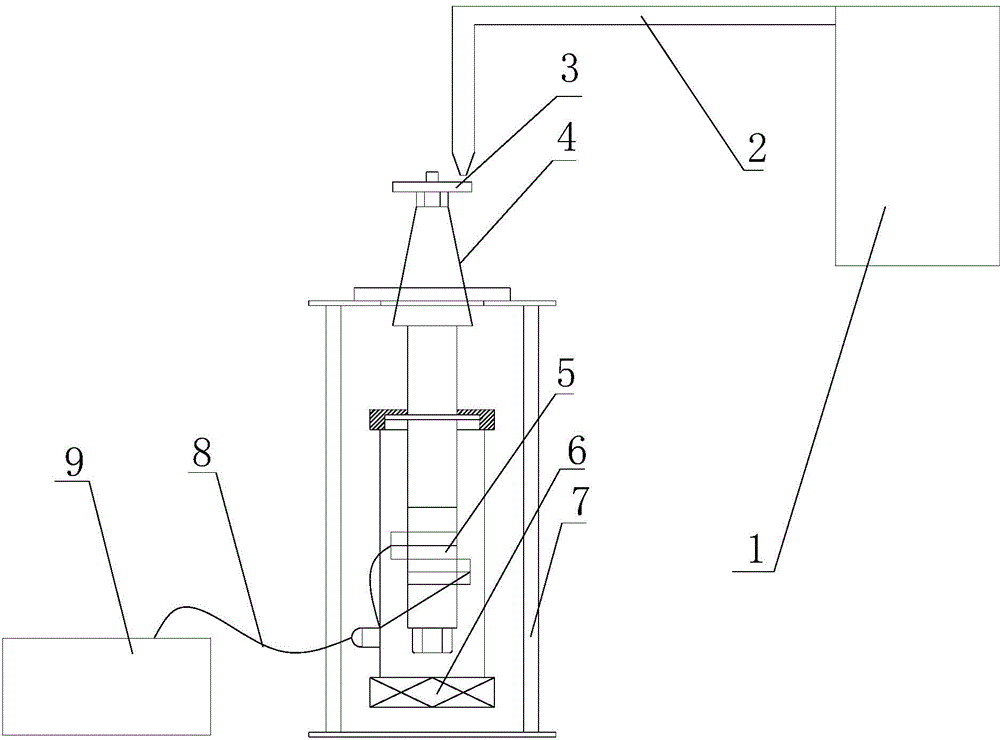

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

A technology of ultrasonic vibration and auxiliary laser, applied in the direction of coating, metal material coating process, etc., can solve problems such as complex process, achieve the effect of good working environment, good wear resistance, and save process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing an ultra-high hardness cladding layer by synchronous ultrasonic vibration-assisted laser technology, the specific process steps are as follows:

[0040] (1) Taking 45# steel as the treatment object, first use sandpaper to remove rust on the surface of 45# steel, and then wipe the surface of high chromium cast steel with acetone to remove oil stains;

[0041] (2) Will contain 50wt% WC and 5wt% CaF 2 The Ni-based powder of the powder is kept at 200°C for 1h, and then the cladding powder is pre-placed on the surface of 45# steel with a thickness of 1mm;

[0042] (3) Fix 45# steel to the end of the ultrasonic vibration device with bolts;

[0043] (4) Laser cladding treatment is carried out by continuous lapping, and the specific process parameters are: 5kW cross-flow CO 2 Laser processing system, the spot size is 10mm×1mm, the power is 3500W, and the scanning speed is 200mm / min, and the overlap is 2.0mm, and the 45# steel surface is continuously sca...

Embodiment 2

[0050] A method for preparing an ultra-high hardness cladding layer by synchronous ultrasonic vibration-assisted laser technology, the specific process steps are as follows:

[0051] (1) Taking 45# steel as the treatment object, first use sandpaper to remove rust on the surface of 45# steel, and then wipe the surface of high chromium cast steel with acetone to remove oil stains;

[0052] (2) Will contain 60wt% WC and 5wt% CaF 2 The Ni-based powder of the powder is kept at 300°C for 1h, and then the cladding powder is pre-placed on the surface of 45# steel with a thickness of 1mm;

[0053] (3) Fix 45# steel to the end of the ultrasonic vibration device with bolts;

[0054] (4) Laser cladding treatment is carried out by continuous lapping, and the specific process parameters are: 5kW cross-flow CO 2 Laser processing system, the spot size is 10mm×1mm, the power is 3600W, and the scanning speed is 250mm / min, and the overlap is 2.0mm, and the 45# steel surface is continuously sca...

Embodiment 3

[0062] A method for preparing an ultra-high hardness cladding layer by synchronous ultrasonic vibration-assisted laser technology, the specific process steps are as follows:

[0063] (1) Taking 45# steel as the treatment object, first use sandpaper to remove rust on the surface of 45# steel, and then wipe the surface of high chromium cast steel with acetone to remove oil stains;

[0064] (2) Will contain 60wt% WC and 5wt% CaF 2 The Ni-based powder was kept at 250°C for 1 hour, and then the cladding powder was pre-placed on the surface of 45# steel with a thickness of 1mm;

[0065] (3) Fix 45# steel to the end of the ultrasonic vibration device with bolts;

[0066] (4) Laser cladding treatment is carried out by continuous lapping, and the specific process parameters are: 5kW cross-flow CO 2 Laser processing system, the spot size is 10mm×1mm, the power is 3550W, and the scanning speed is 200mm / min, and the overlap is 1.8mm, and the 45# steel surface is continuously scanned; be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com