Patents

Literature

82results about How to "Resolve aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

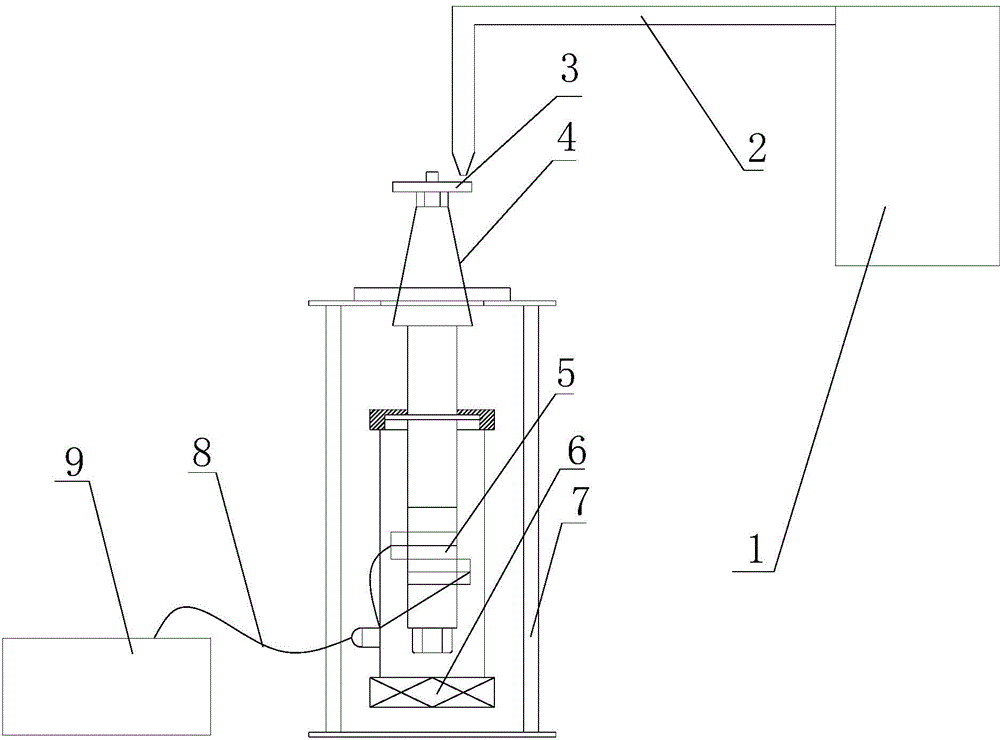

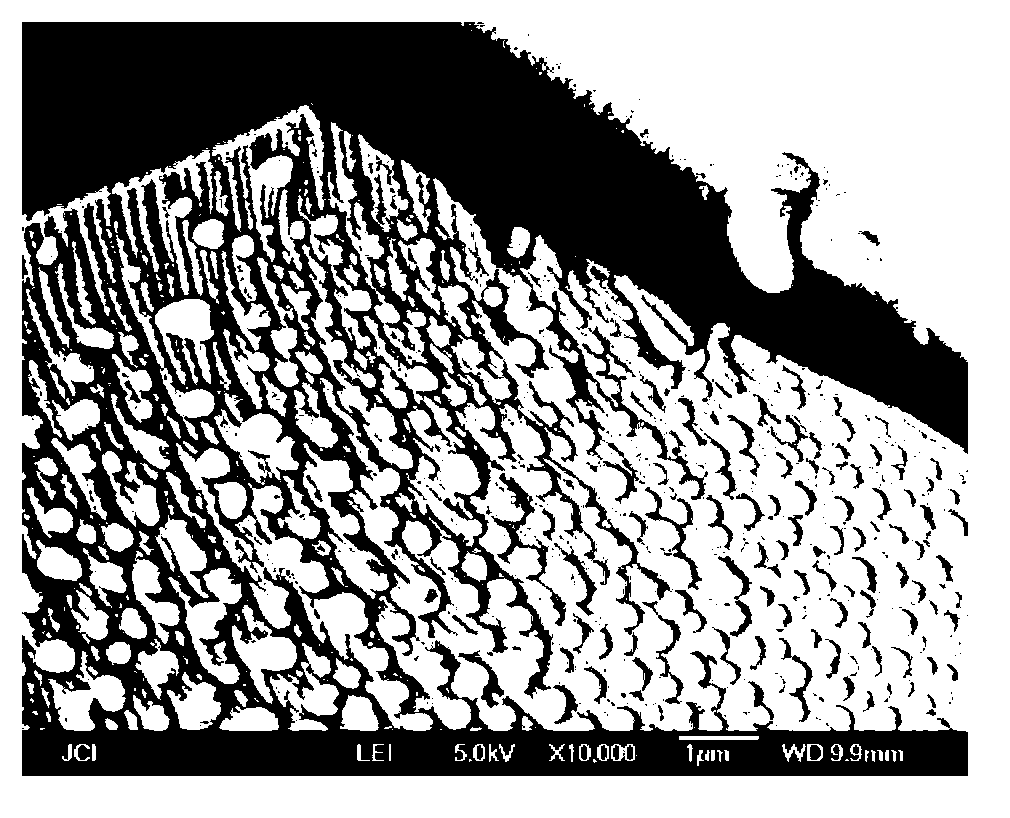

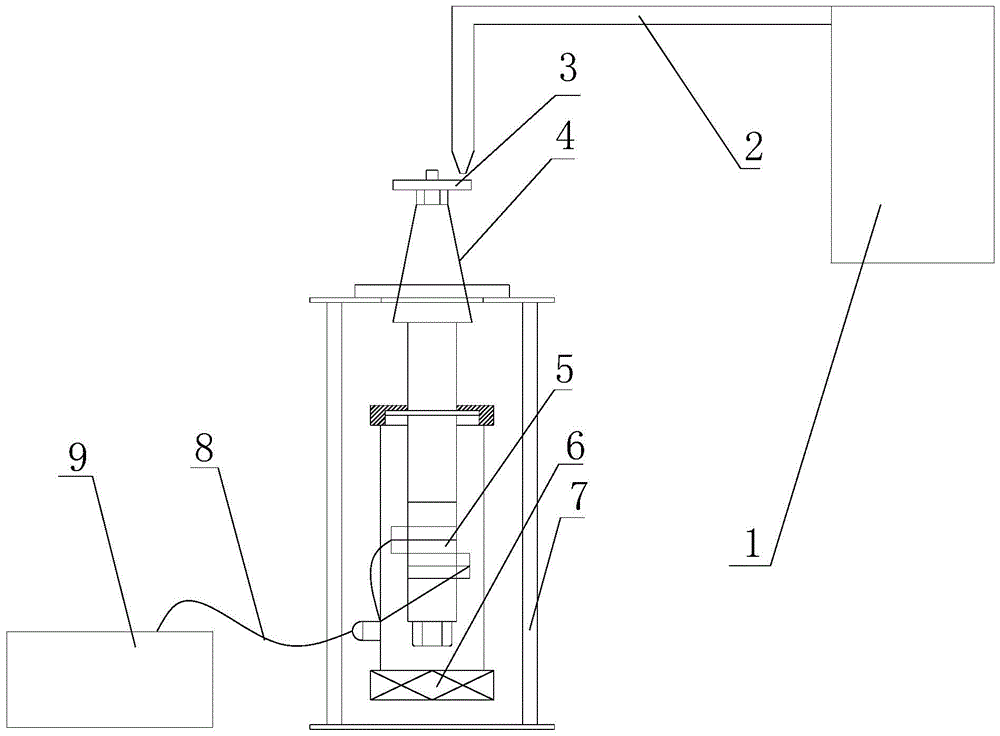

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

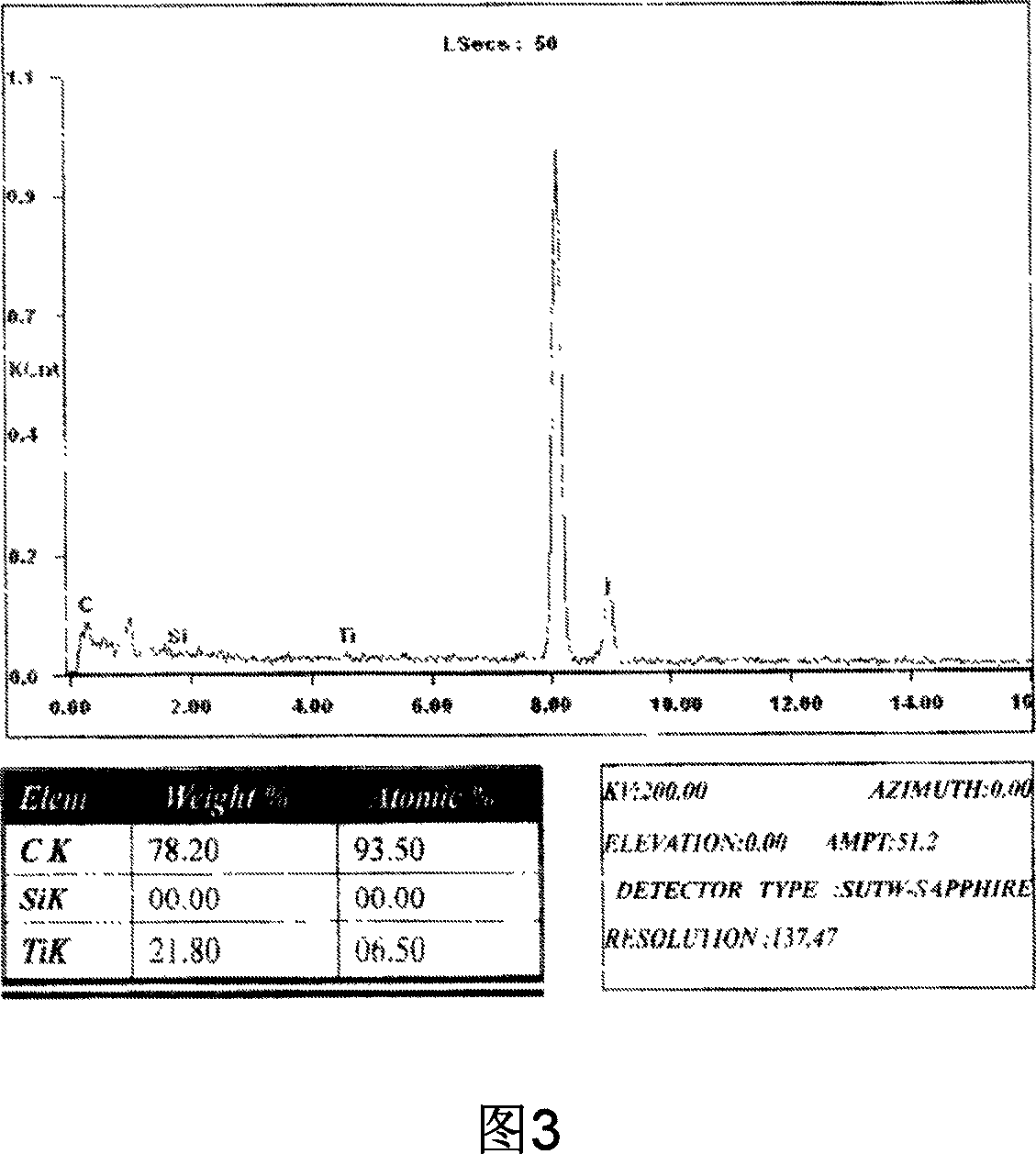

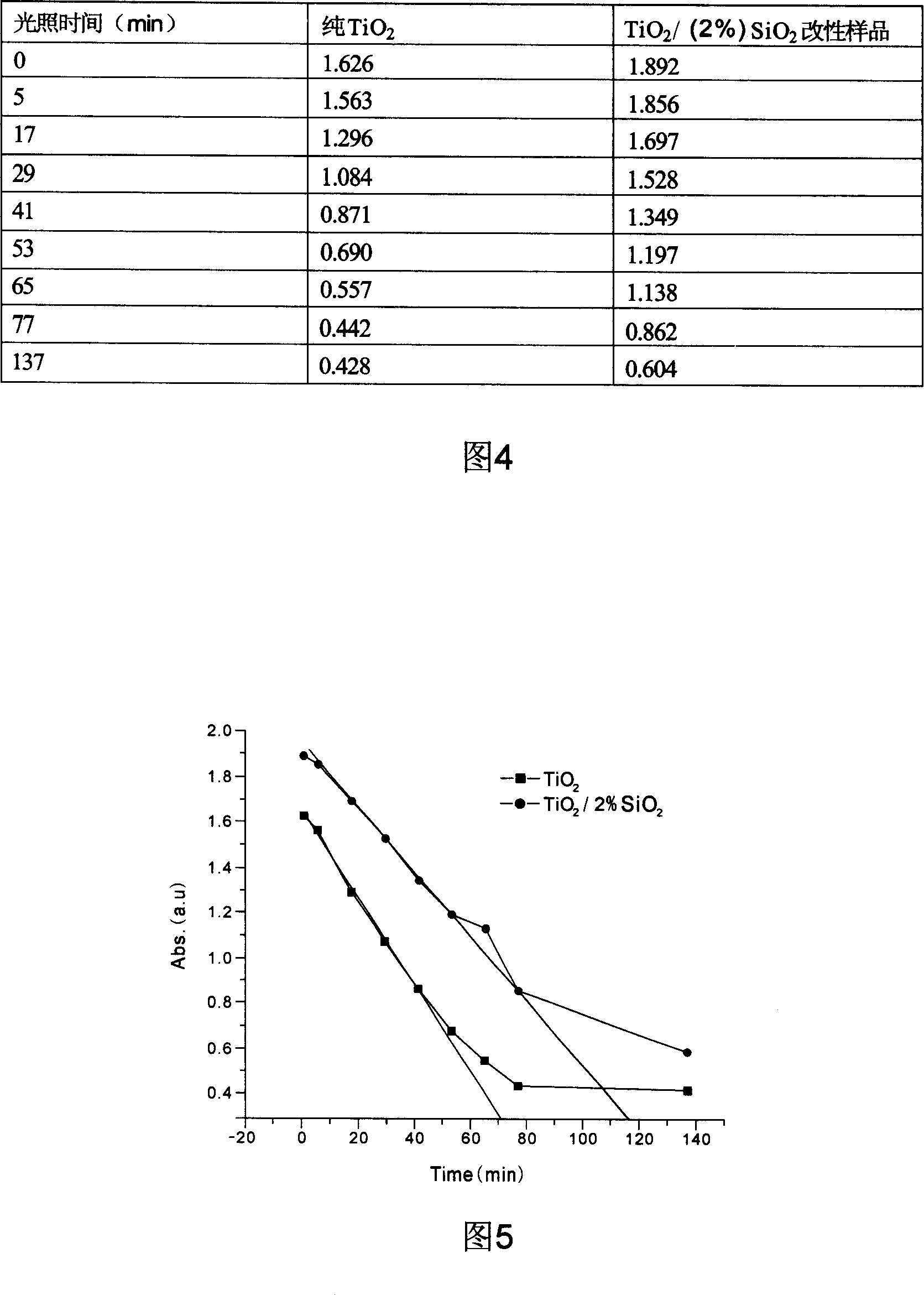

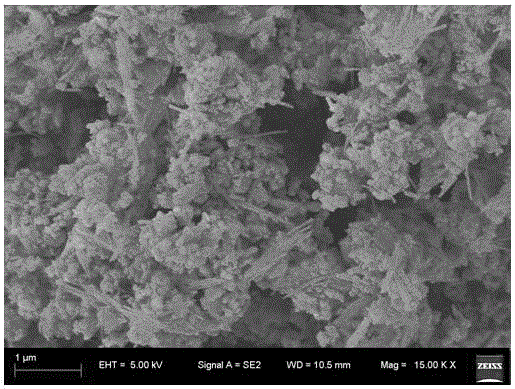

Photo-catalyst micro-particles and its preparing method, photocatalyst and preparing method and use

This invention relates to a copper-coated nm titanium dioxide light accelerant particle and preparation method, while relates to a light accelerant and preparation method and its applications. This invention by adding TiO2 Solution metal copper, surfactant, reductant and under the UV irradiation, Use nm titanium dioxide as a photochemical reaction induced, copper metal particles were produced by light reduction reaction in the surface of nm titanium dioxide, and obtain copper nm TiO2 composite materials. This invention not only solves the TiO2 nm particles aggregation problem, and copper coated with TiO2 because of long-term metal ions release effects, in dark conditions with a good antibacterial antifungal function, it overcomes the shortcomings of traditional light accelerant must acting under the illumination conditions, has a broader application.

Owner:GUANGZHOU MENTE NANOMETER SCI & TECH

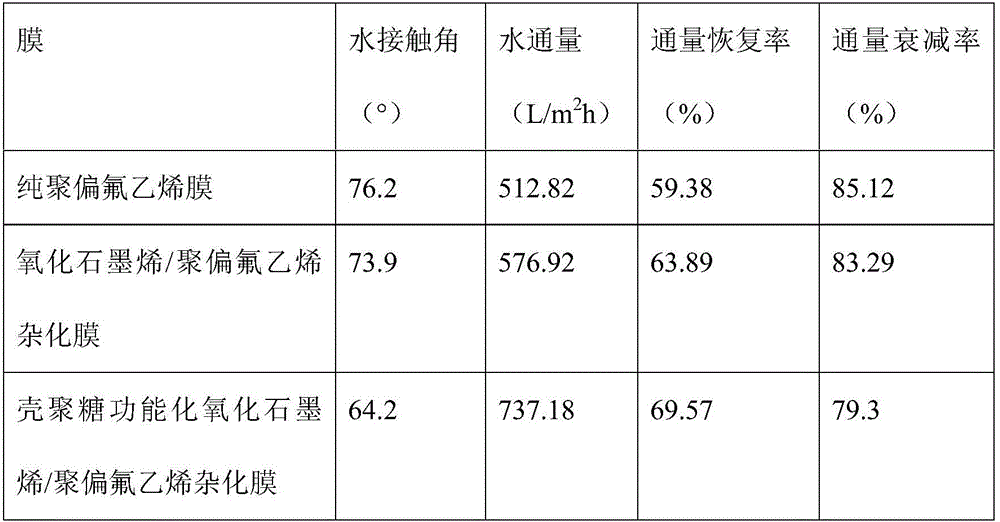

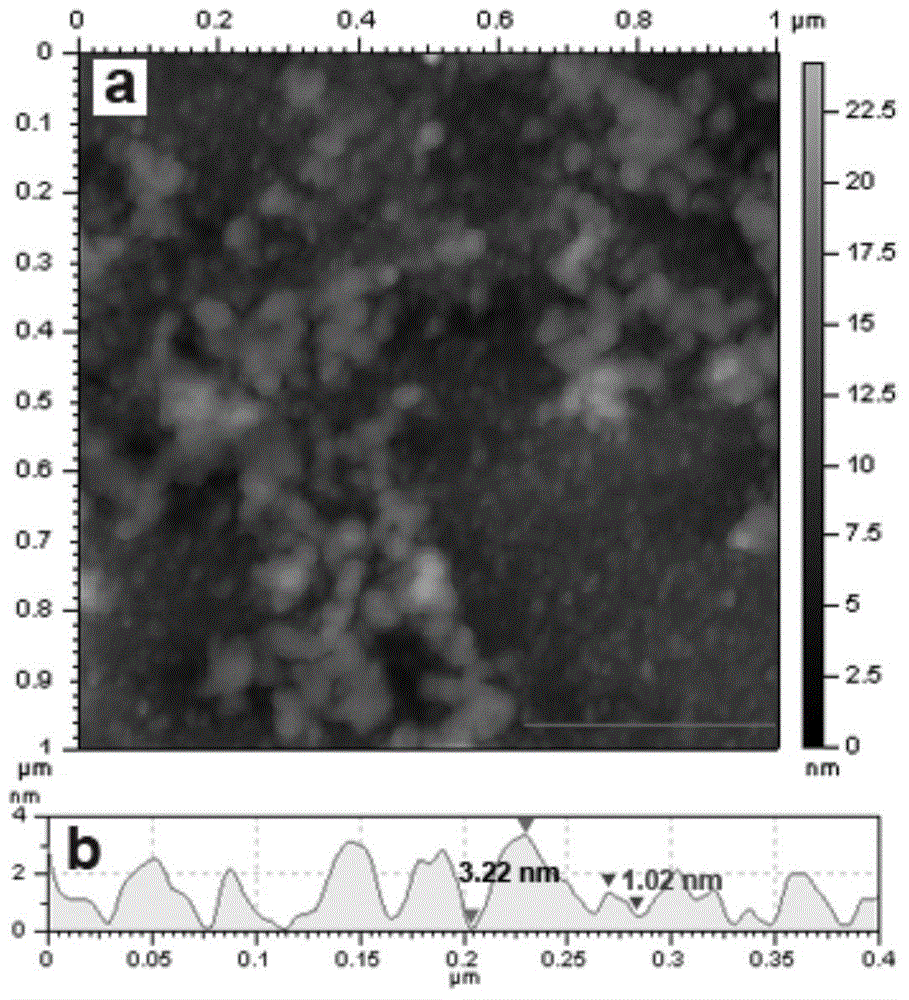

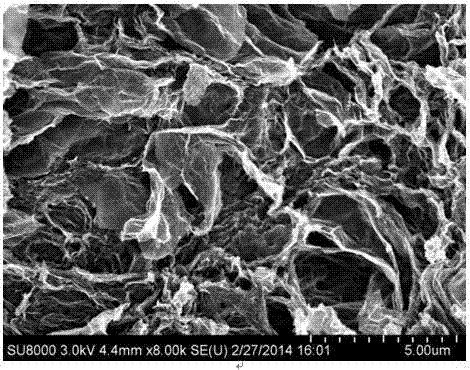

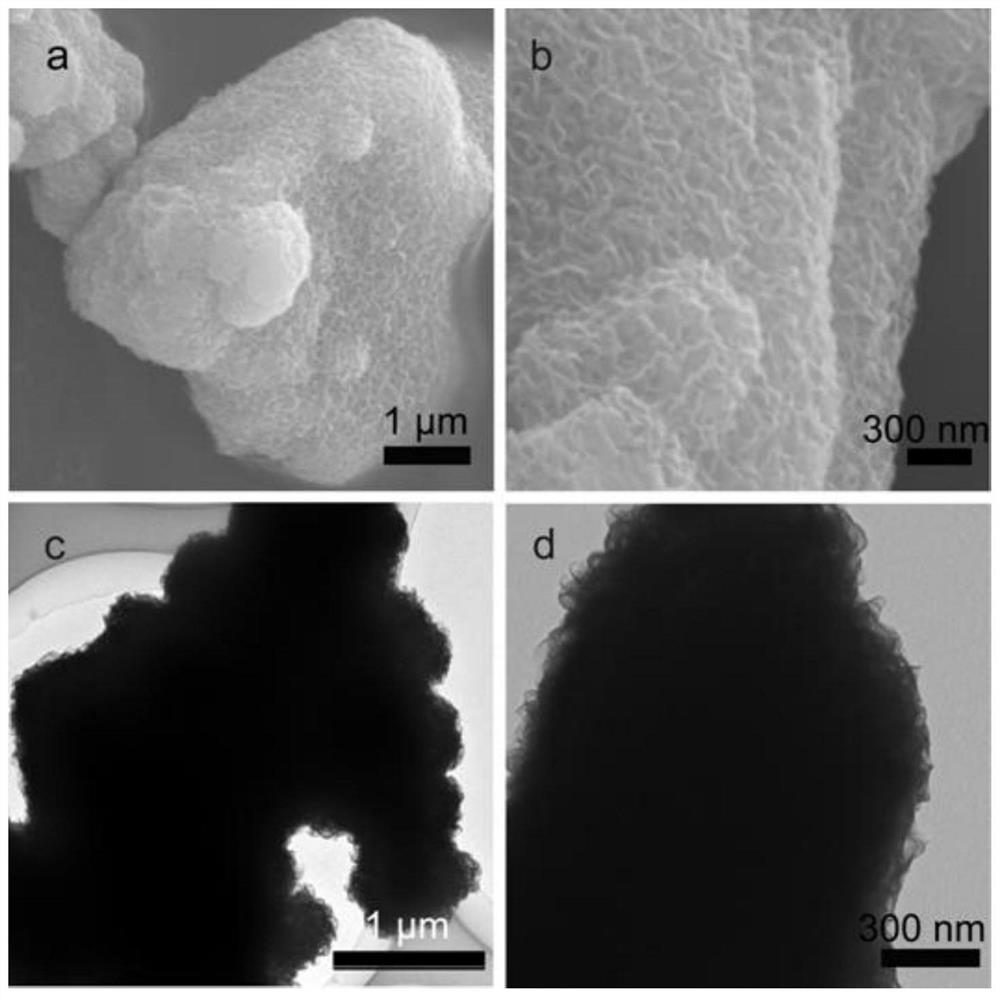

Chitosan functionalized graphene oxide/polyvinylidene fluoride hybrid ultrafiltration membrane and preparation method thereof

InactiveCN105903359AGood dispersionImprove performanceMembranesUltrafiltrationUltrafiltrationFunctionalized graphene

The invention provides a chitosan functionalized graphene oxide / polyvinylidene fluoride hybrid ultrafiltration membrane and a preparation method thereof. Firstly, chitosan is used for covalent functionalization of graphene oxide to prepare chitosan-graphene oxide; the chitosan-graphene oxide is dispersed in an organic solvent in an ultrasonic mode, then polyvinylidene fluoride and a pore-foaming agent are added and stirred at certain temperature to be evenly dissolved to obtain a membrane casting solution, water serves as a coagulating bath, and the chitosan-graphene oxide / polyvinylidene fluoride hybrid ultrafiltration membrane is prepared through the immerged phase-inversion process. The chitosan-graphene oxide / polyvinylidene fluoride hybrid ultrafiltration membrane prepared through the method improves dispersibility of graphene oxide in a membrane matrix, and compared with a graphene oxide / polyvinylidene fluoride ultrafiltration membrane, hydrophilicity, water flux, antifouling property and other aspects are greatly improved.

Owner:NORTHWEST UNIV(CN)

High-surface-quality 1200 MPa-grade hot-dip galvanized dual-phase steel and production method thereof

ActiveCN110499457AControlling the Scale StructureImprove roll stabilityHot-dipping/immersion processesHigh surfaceZinc

The invention relates to a high-surface-quality 1200 MPa-grade hot-dip galvanized dual-phase steel. The hot-dip galvanized dual-phase steel comprises the following chemical components of, in percentage by mass, 0.07%-0.10% of C, 0.25%-0.55% of Si, 1%-4% of Mn, less than or equal to 0.016% of P, less than or equal to 0.008% of S, 0.01%-0.05% of Als, less than or equal to 0.006% of N, 0.04%-0.08% ofTi, 0.015%-0.055% of Nb, 0.15%-0.45% of Mo, 0.008%-0.010% of B, and the balance Fe. The production method comprises the steps of continuous casting, hot rolling, cold rolling and galvanization, wherein in the hot rolling process, the coiling temperature is controlled by adopting a U-shaped coiling process, the coiling temperature of a head part and a tail part of a steel coil is 600 + / -20 DEG C,the coiling temperature of the middle section is 550 + / -20 DEG C, and the stability of the uncoiling performance is improved. According to the method, the production cost is remarkably reduced, the steel coil with stable mechanical property in the head part, middle part and tail part is obtained by combining the U-shaped coiling process and a pre-oxidation technology in a zinc plating furnace, thesurface quality of a steel strip is good and can reach the FB1 grade, and the production reliability is high.

Owner:HANDAN IRON & STEEL GROUP +1

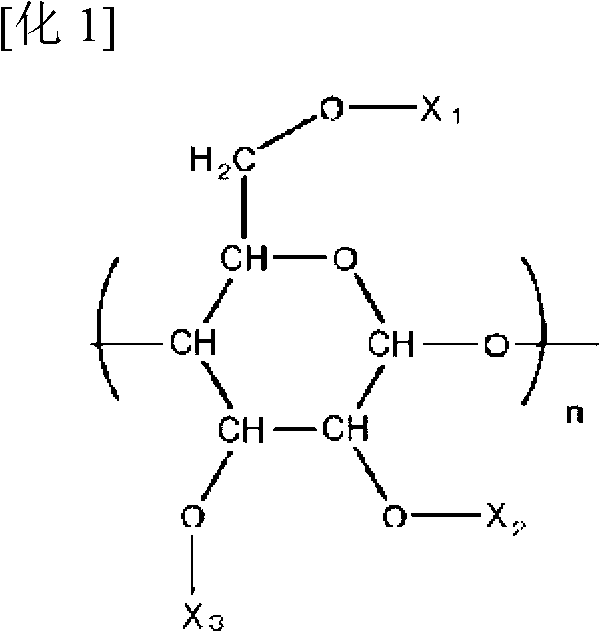

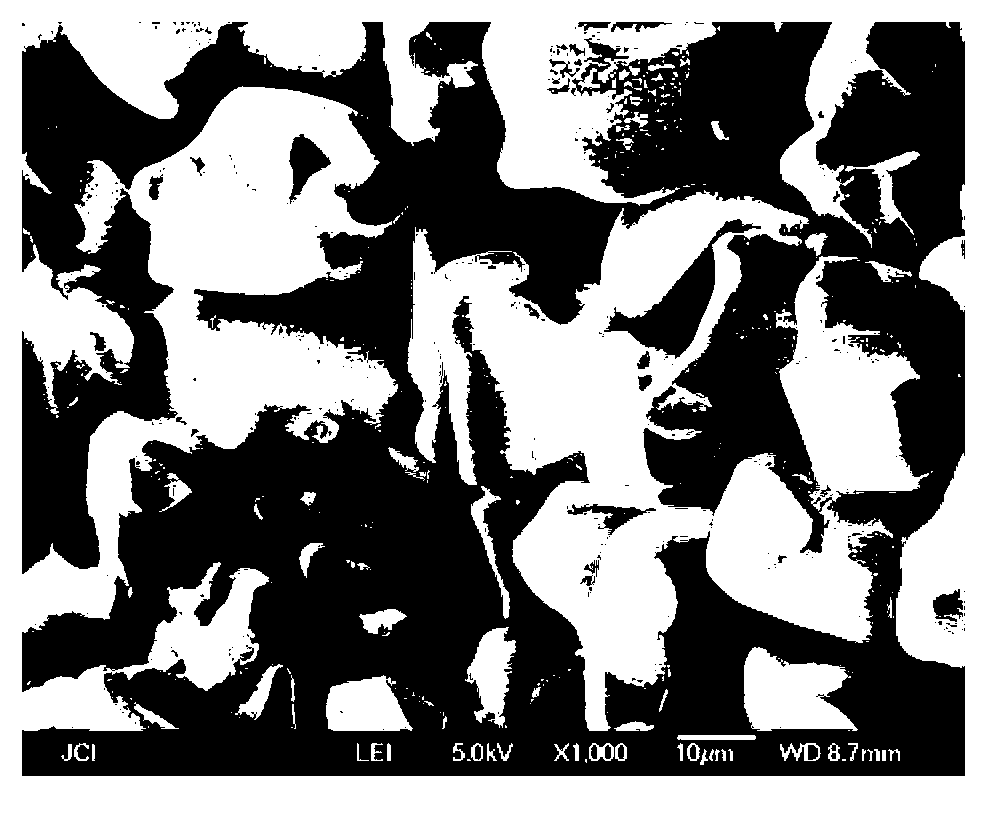

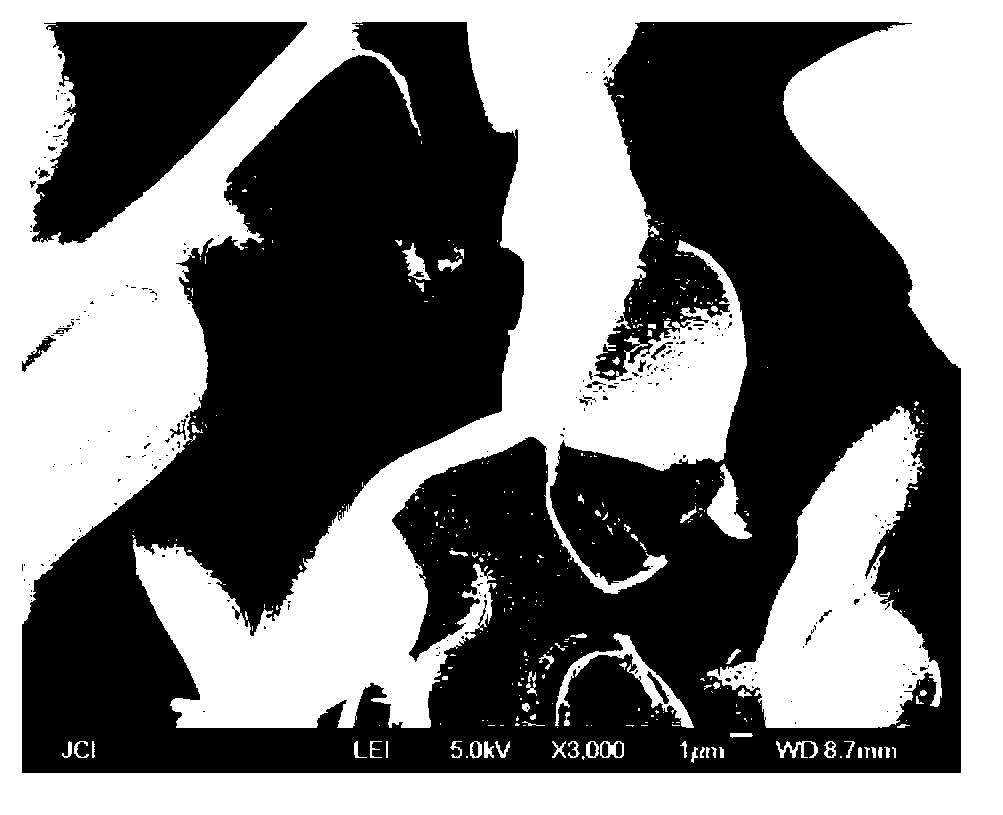

Process for production of fine cellulose fiber dispersion

ActiveCN102834448AExcellent film forming and formabilityExcellent liquid stabilityThin material handlingResin compositeDispersion stability

Provided is a process for the production of a fine cellulose fiber dispersion which comprises an organic solvent, fine cellulose fibers uniformly dispersed therein, and a resin or a resin precursor and which exhibits excellent dispersion stability and film-formation properties and enables the production of a fine cellulose fiber / resin composite with high productivity. A process for the production of a fine cellulose fiber dispersion that comprises fine cellulose fibers, a resin and / or a resin precursor, and an organic solvent, which includes a fibrillation step of fibrillating cellulose fibers in a raw material dispersion to form fine cellulose fibers, said raw material dispersion comprising cellulose fibers, a resin and / or a resin precursor, and an organic solvent.

Owner:MITSUBISHI RAYON CO LTD

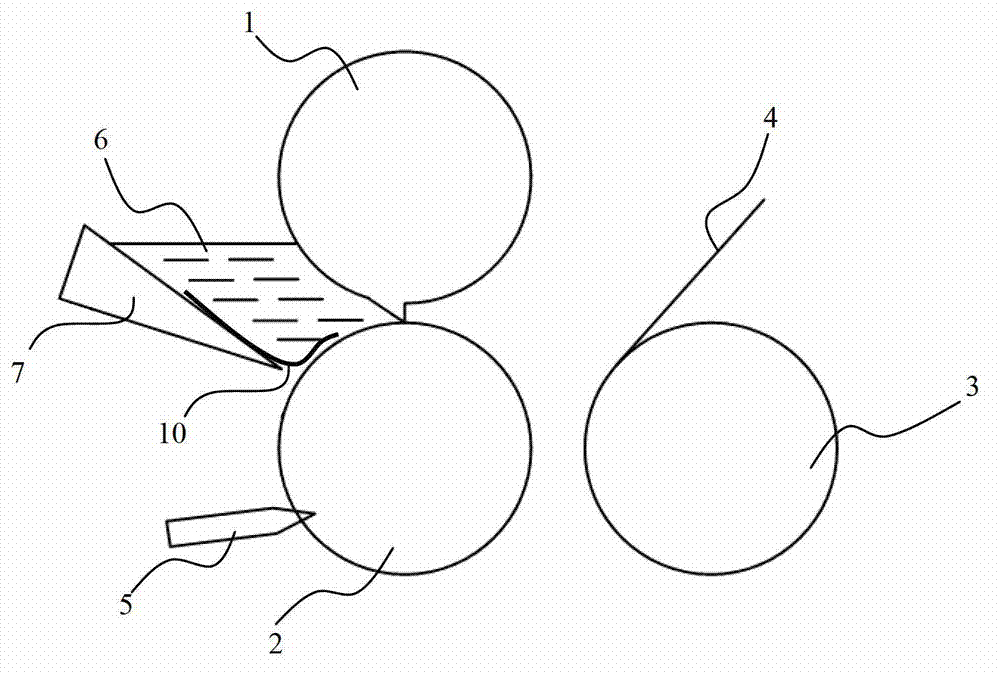

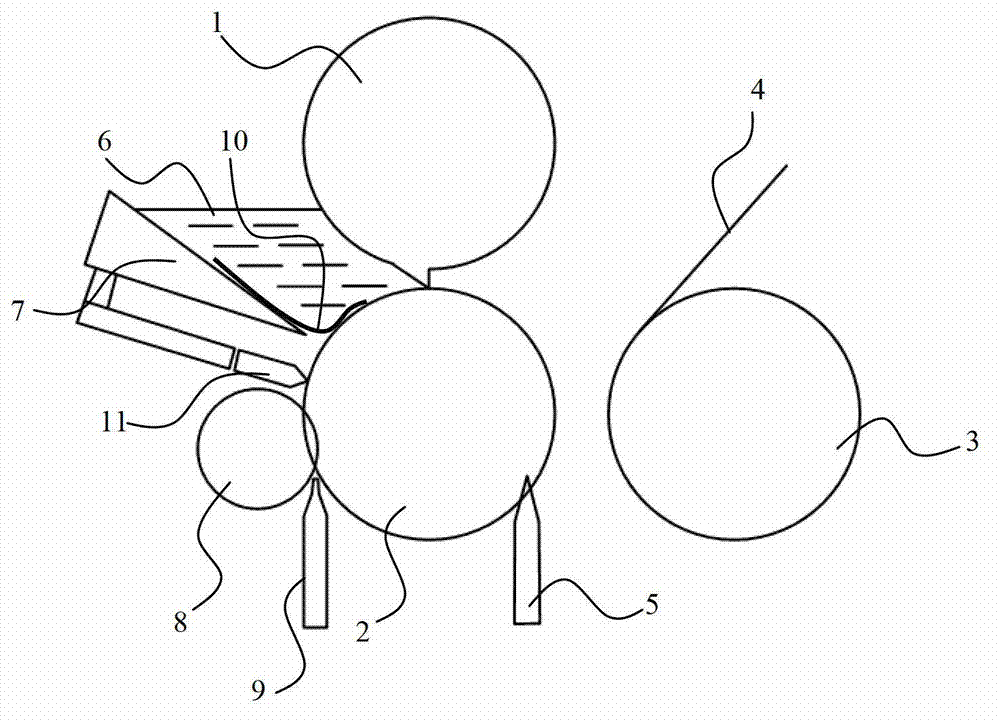

Roller C cleaning device and method for coating machine

InactiveCN102806218AImprove uniformityAvoid gatheringLiquid surface applicatorsCleaning using toolsSpray nozzlePulp and paper industry

The invention discloses a roller C cleaning device for a coating machine. The roller C cleaning device comprises a first scraping knife fixedly arranged below the right side of a material discharging roller and further comprises a brush roller, which is positioned between the first scraping knife and a baffle and arranged parallel to an axial direction of the material discharging roller, wherein a washing liquid spray nozzle is arranged below the brush roller; and a second scraping knife in contact with the external surface of the material discharging roller is arranged between the brush roller and the baffle. A material discharging roller cleaning method of the coating machine comprises the following steps: 1) scraping a paste on the surface of the material discharging roller by the first scraping knife; 2) spraying a washing liquid to the material discharging roller by the washing liquid spray nozzle; and rotating the brush roller so as to wash the surface of the material discharging roller; and 3) wiping the surface of the material discharging roller by the second scraping knife so as to remove the paste and the washing liquid remaining on the surface of the material discharging roller. According to the invention, a problem that the paste is gathered at the bottom of a diaphragm can be solved, so that particle scratch problems generated due to material accumulation at the bottom of the diaphragm is completely solved and the quality of a pole piece is improved.

Owner:TIANJIN LISHEN BATTERY

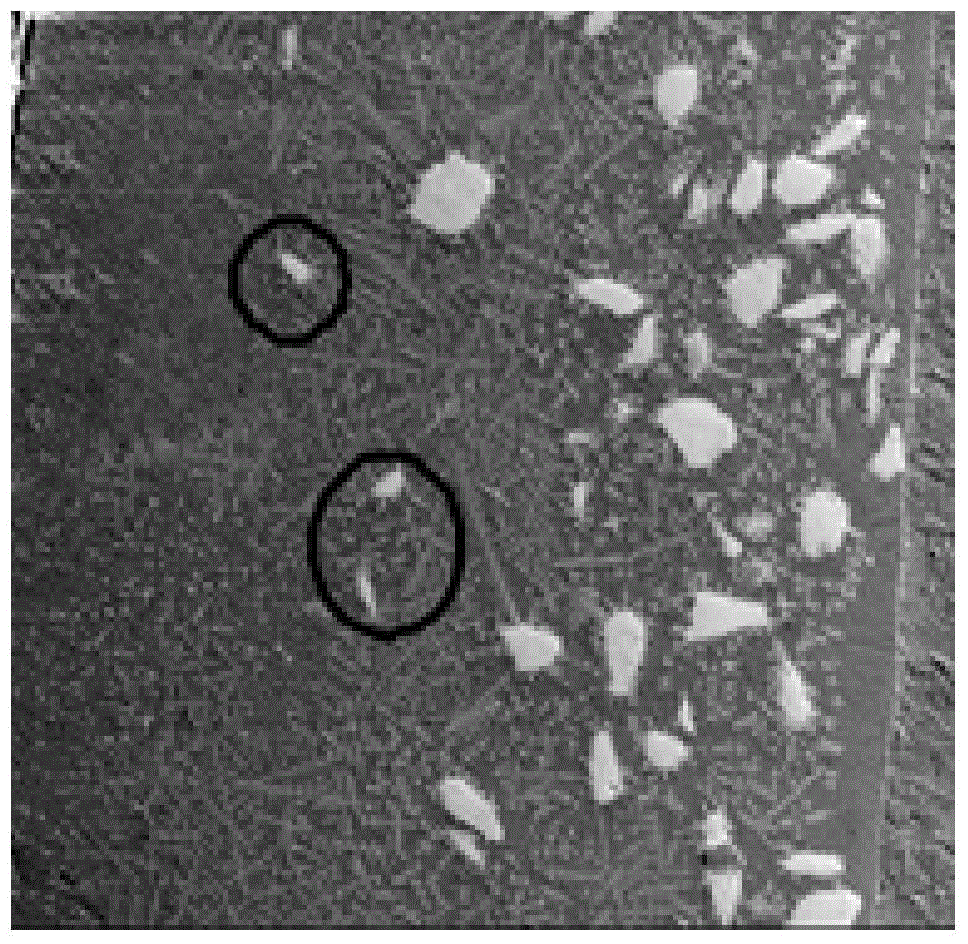

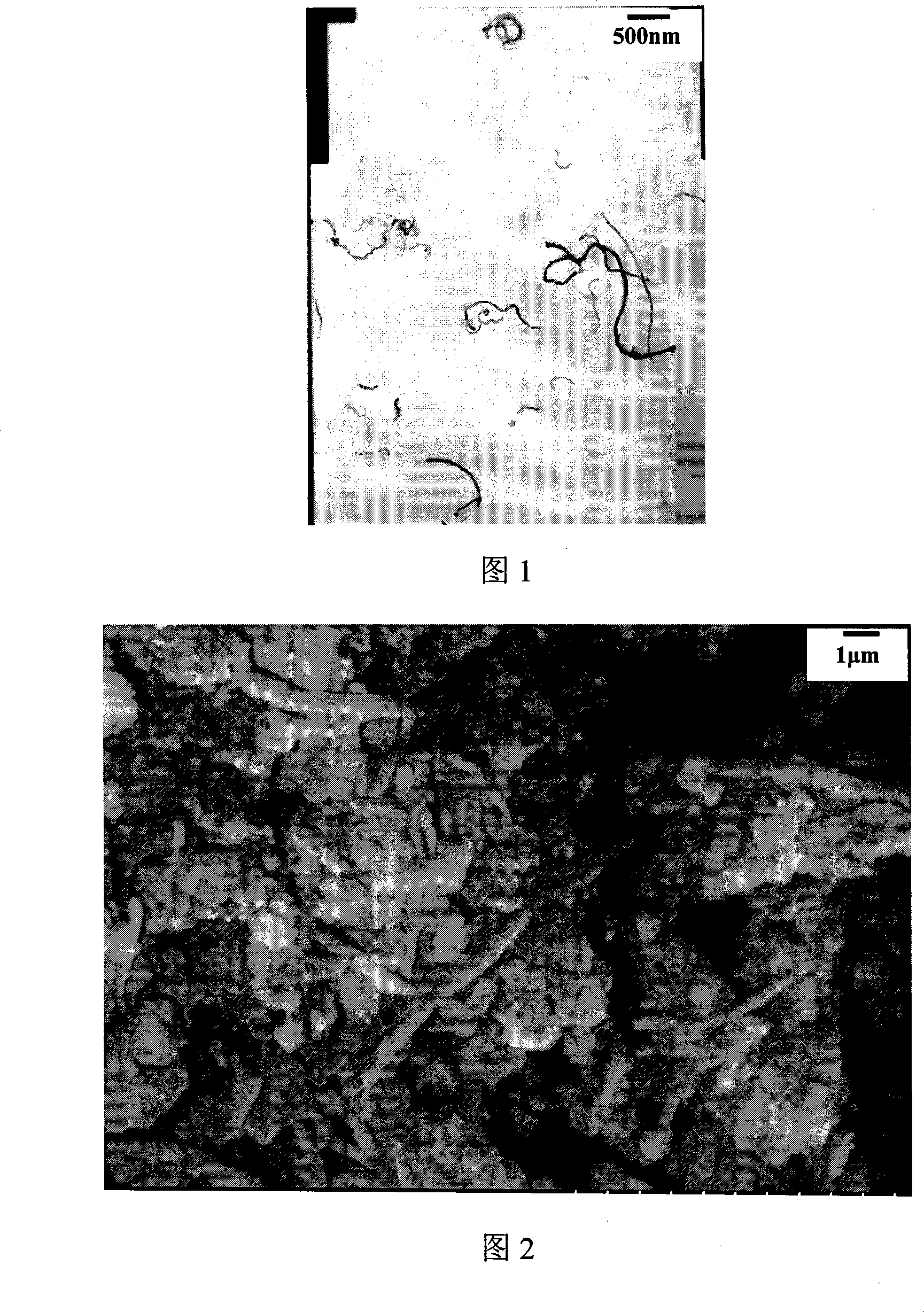

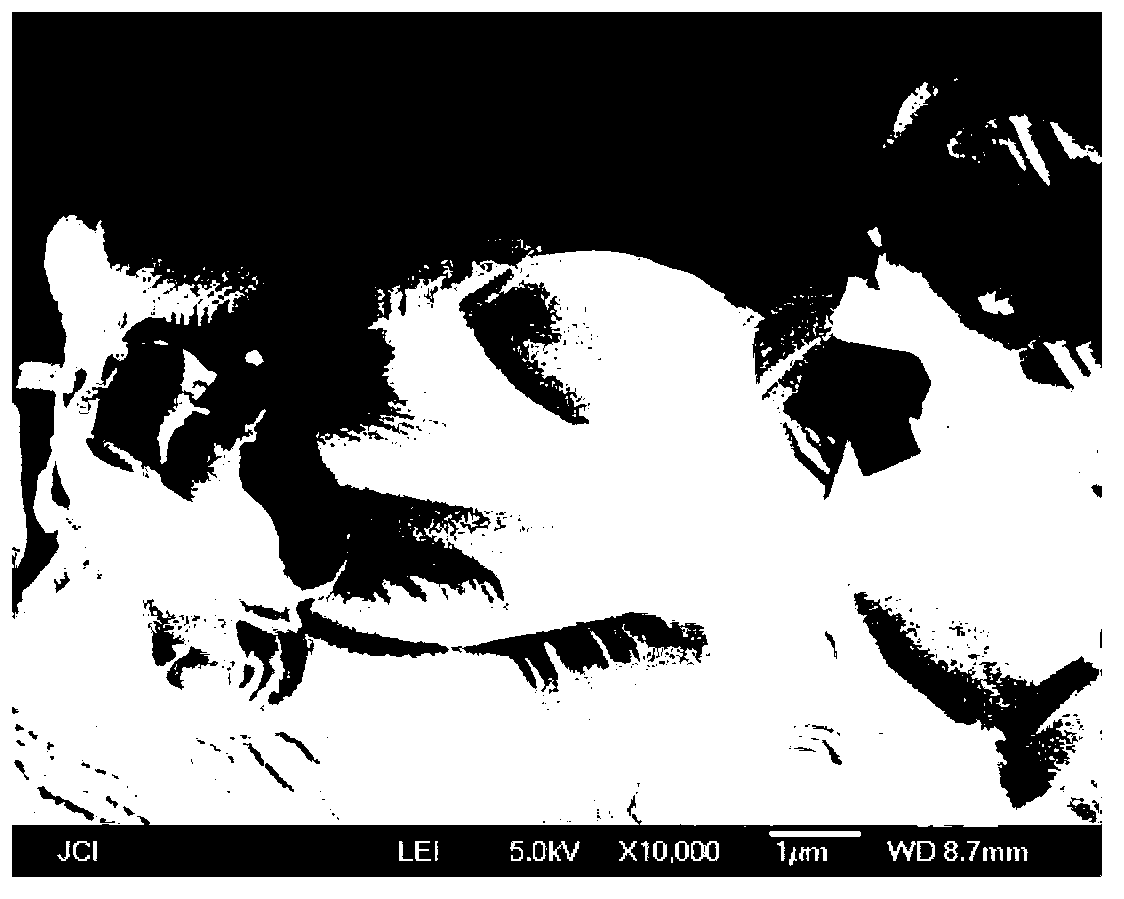

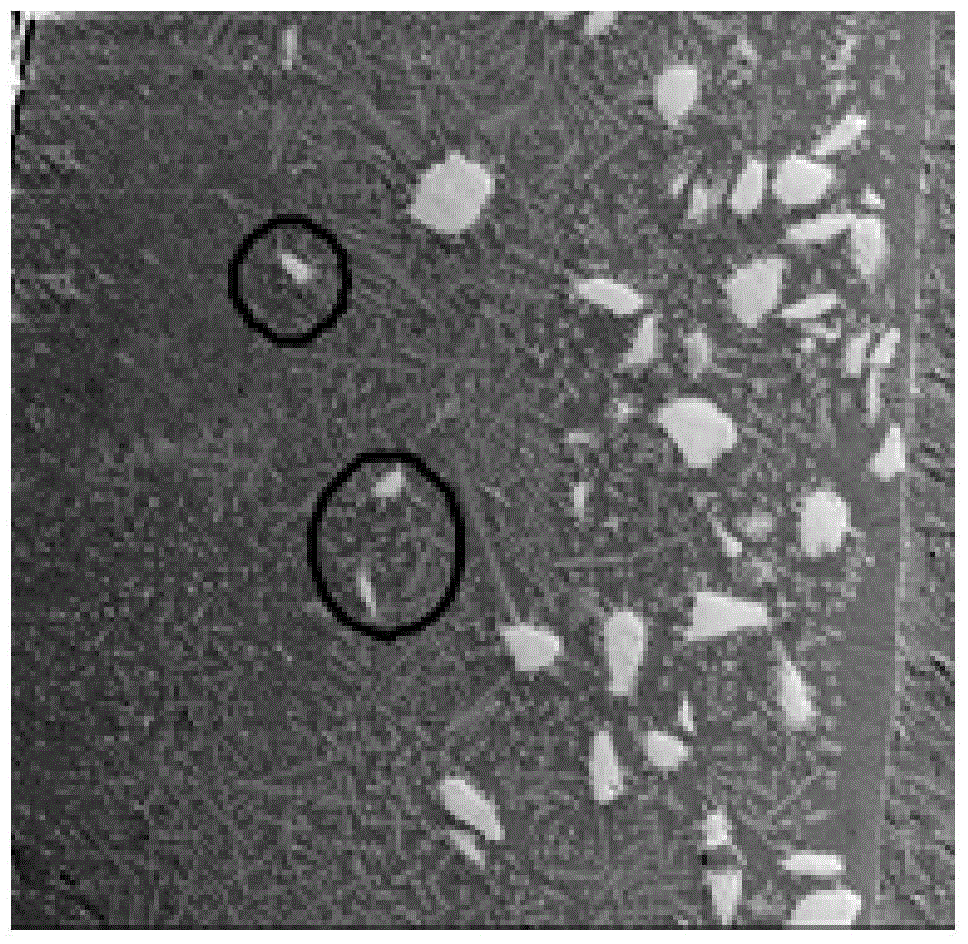

Carbon nano-tube enhanced cement-base composite material and preparation method thereof

InactiveCN101239800BResolve aggregationImprove adhesionSolid waste managementMetal fiberCarbon fibers

The present invention provides a carbon nano-tube reinforcing cement-based composite material and the preparing method thereof, which relates to an inorganic non-metal fiber-reinforced cement-based composite material and the preparing method thereof. The invention settles the problem that the carbon nano-tube is hard to uniformly dispersed in the cement substrate, and the carbon nano-tube reinforcing cement-based composite material of the invention is mainly composed of carbon nano-tube, dispersing agent, thickening stabilizing agent, cement blending material, superplasticiser, antifoaming agent and cement; the method of the invention comprises the following steps: slowly injecting the continuous phase mixed liquid of the thickening stabilizing agent into the carbon nano-tube disperse phase mixed liquid; adding the cement mixing material, mixing to uniform, heating and ultrasonic agitating, then vacuum discharging the bubble; then adding into the mixed liquid of the superplasticiser and the water for mixing to uniform, further eliminating the bubble with the antifoam agent; at last adding cement for mixing to uniform, adding the slurry into the oil mould and jolt ramming for molding; mode removing and standard maintaining to the prescribed lifetime. The carbon nano-tube in the product prepared by the method of the invention is uniformly dispersed in the cement substrate. The mechanical property and conductivity of the product is increased for several times.

Owner:HARBIN INST OF TECH

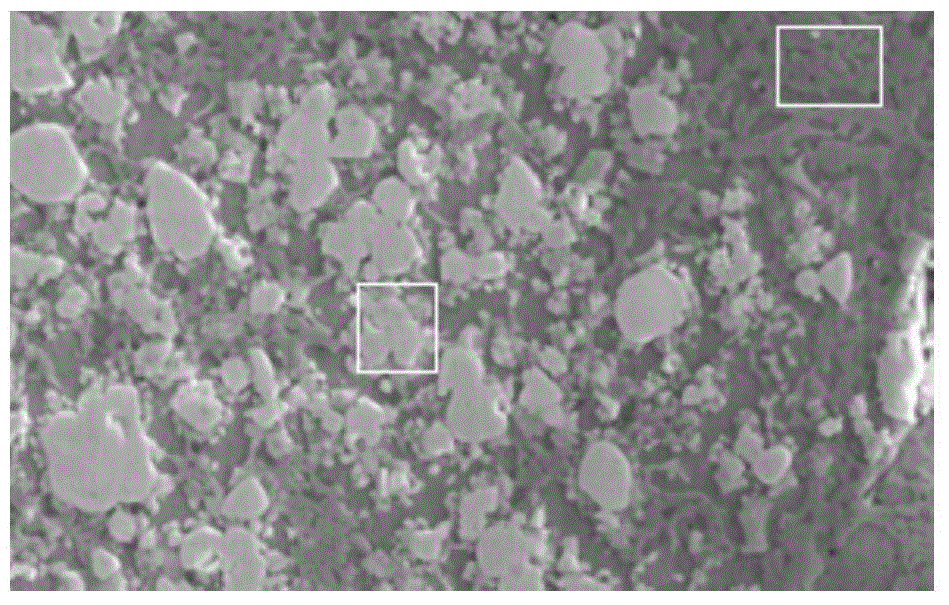

Preparation method of high-purity aluminum oxide ceramic

The invention discloses a preparation method of a high-purity aluminum oxide ceramic. According to the preparation method, a nano Al2O3 coating formed on the surfaces of aluminum oxide particles is used as a sintering aid to ensure that a small amount of the sintering aid can be uniformly dispersed in a main phase, so that uniform adding of a small dose of the sintering aid is realized. The preparation method not only ensures the purity and performance of the high-purity aluminum oxide ceramic and meets process requirements for preparation of the aluminum oxide ceramic, but also effectively solves the problem that when the particle size difference of main phase powder and the sintering aid is large, particles of a nano auxiliary agent are gathered in a main phase powder particle gap; and moreover, partial over-firing is avoided, so that the uniformity of sintering of the main phase powder particles and the sintering assisting effect of the sintering aid are effectively improved.

Owner:重庆兀盾纳米科技有限公司

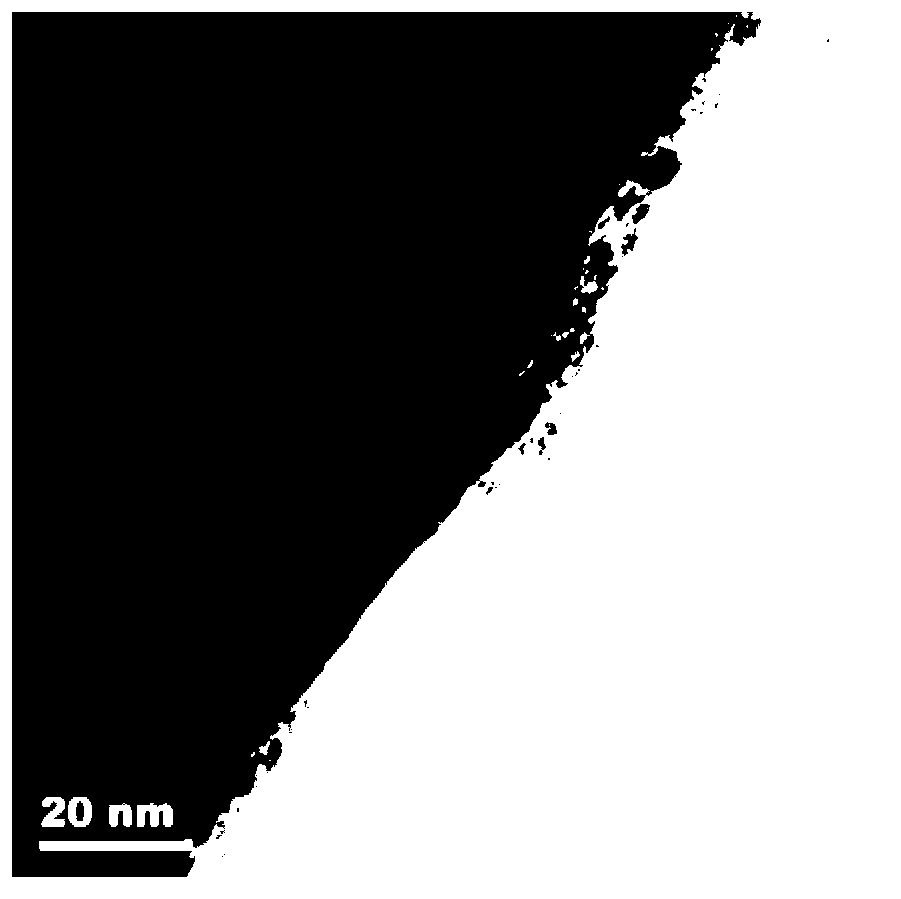

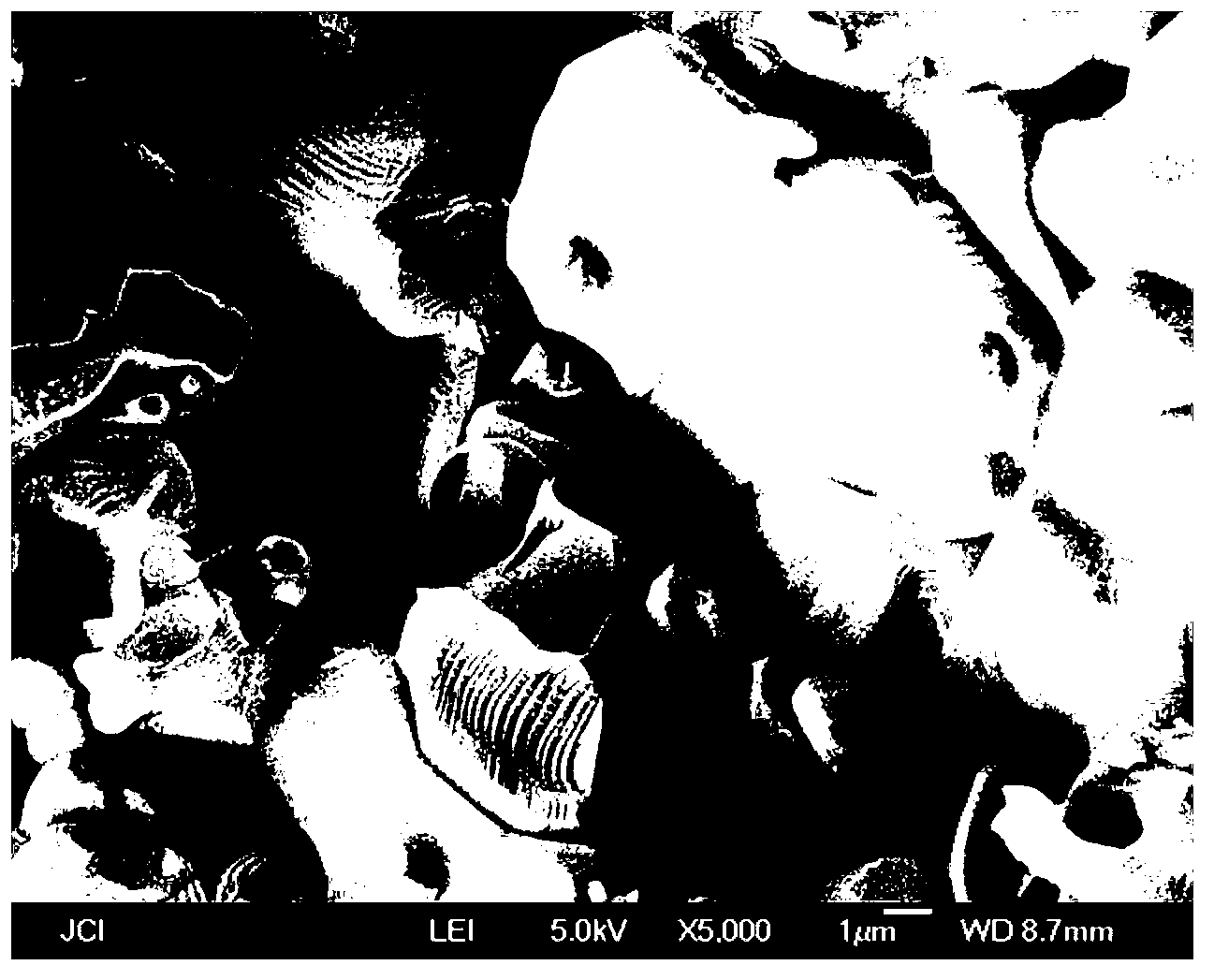

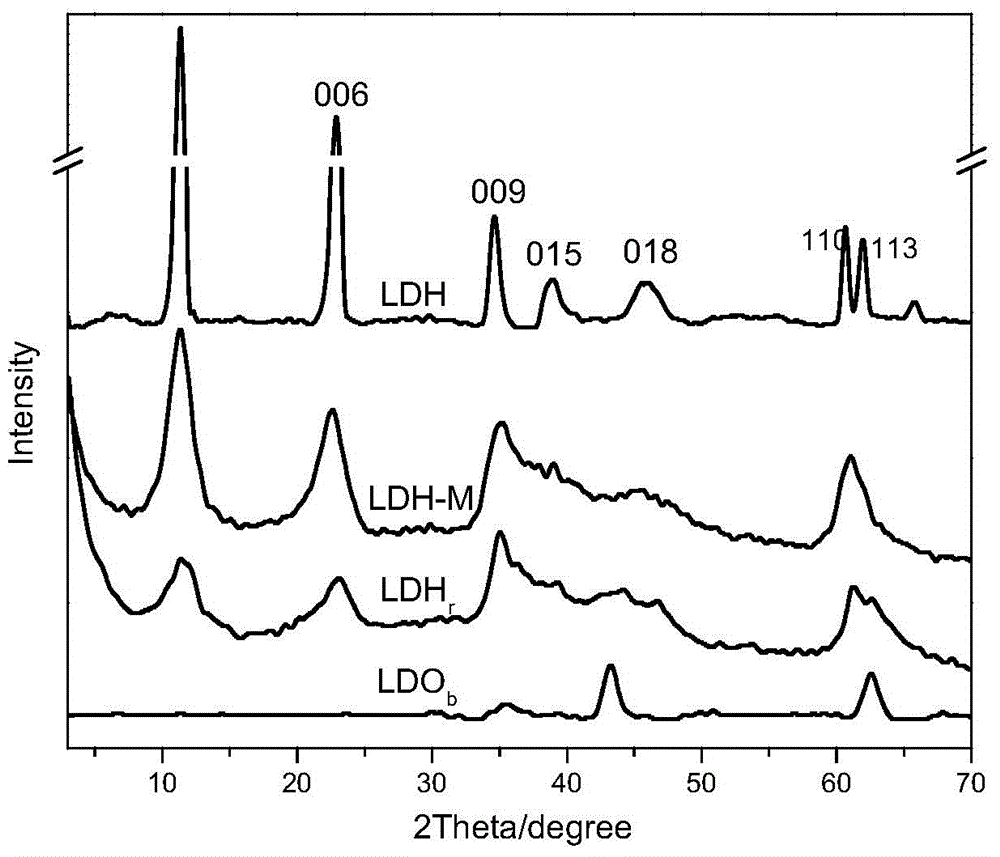

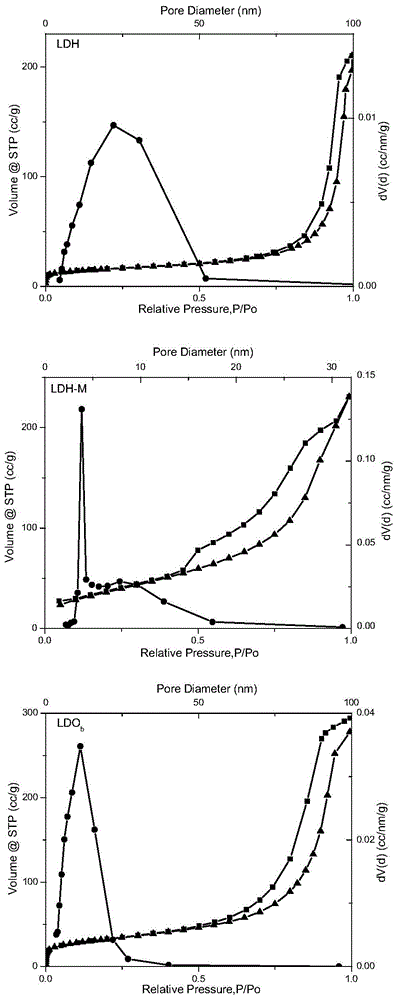

Preparation method of stratiform bimetallic oxide sorbent capable of effectively removing low-concentrated phosphate radical

ActiveCN105032342AImprove adsorption capacityResolve aggregationOther chemical processesWater/sewage treatment by sorptionPhosphateSorbent

The invention discloses a preparation method and application of a stratiform bimetallic oxide sorbent capable of effectively removing low-concentrated phosphate radical. According to the invention, a hydrophobic ionic liquid BmimPF6 is taken as oil phase, and N,N-dimethyl formamide (DMF) is taken as a cosolvent in a Bmim PF6 / DMF / H2O ionic liquid-in-water inverse surfactant-free microemulsion system, a small particle diameter ultrathin stratiform bimetallic hydroxide nanosheets precursor is prepared according to a double microemulsion coprecipitation method, calcination of the precursor is carried out at high temperature of 500 DEG C so as to prepare stratiform bimetallic oxides adsorbent. The obtained stratiform bimetallic oxides are 107.36-158.46 cm<2> / g in specific surface area, 8.56-11.17 nm in pore diameter, and 0.358-0.468 cm<3> / g in pore volume. The stratiform bimetallic oxides can restore and form stratiform bimetallic hydroxide nanosheets in an aqueous medium, wherein the particle diameter of nanosheets is 150-200 nm, the thickness is about 5 nm, and the distribution of particle diameters is uniform. The adsorption rate of the stratiform bimetallic oxides is far higher than that of large-grained hydrotalcite prepared from the precursor stratiform bimetallic oxides of the sorbent according to the traditional coprecipitation method.

Owner:肇庆市高要区永恒之辉金属制品有限公司

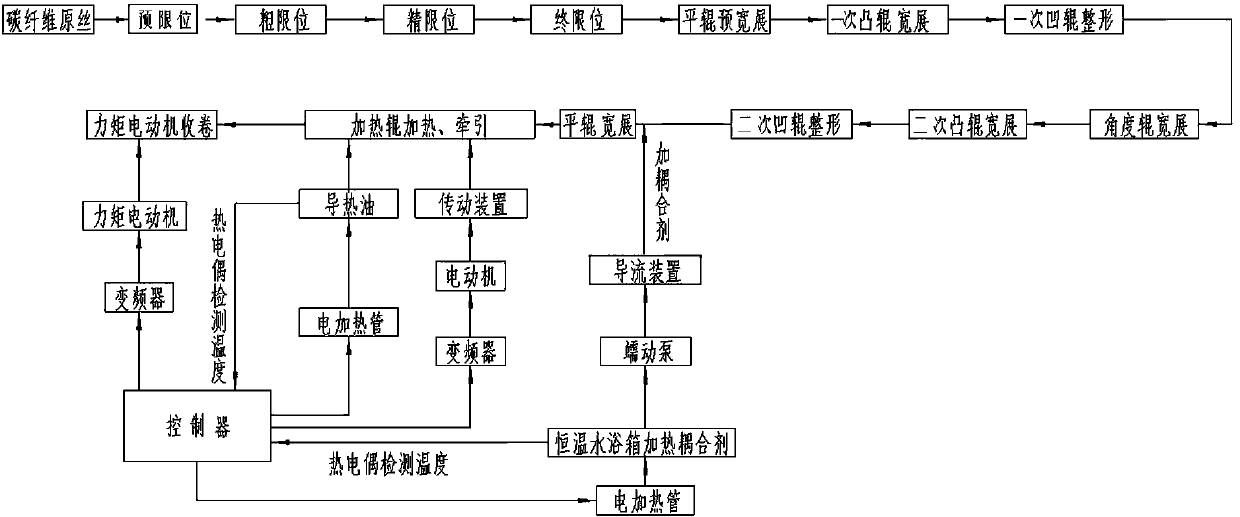

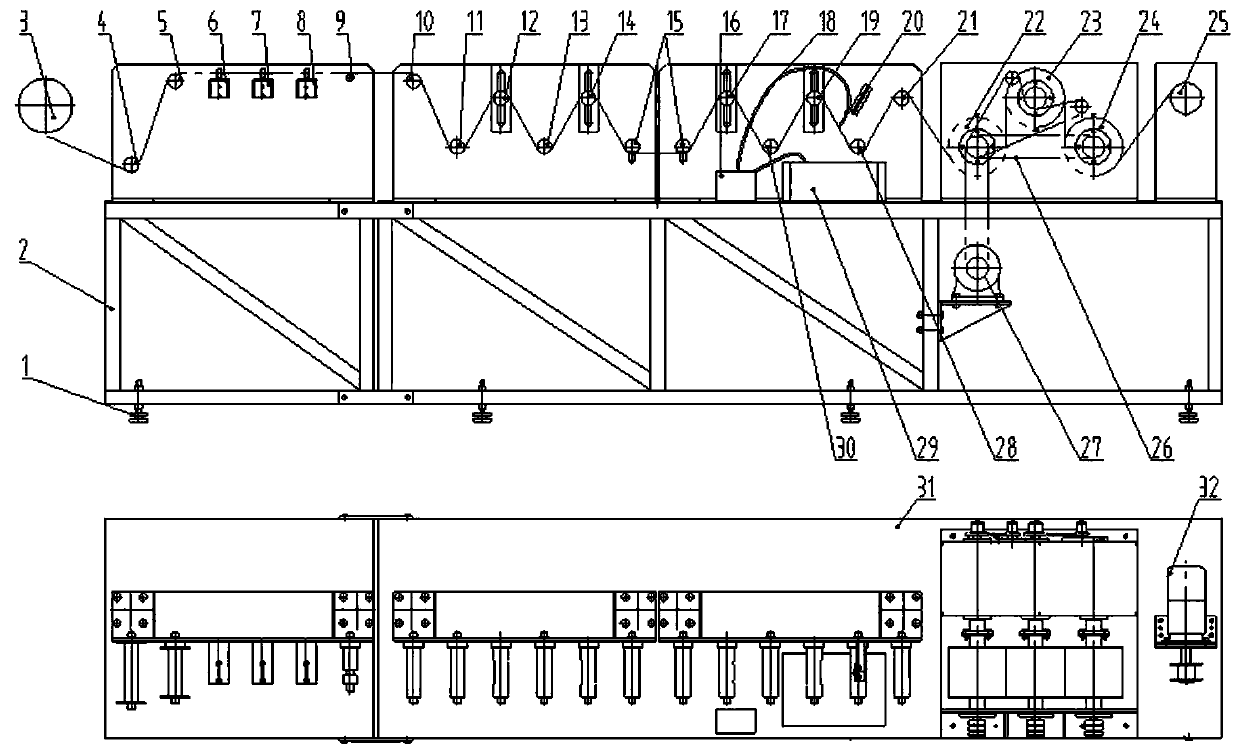

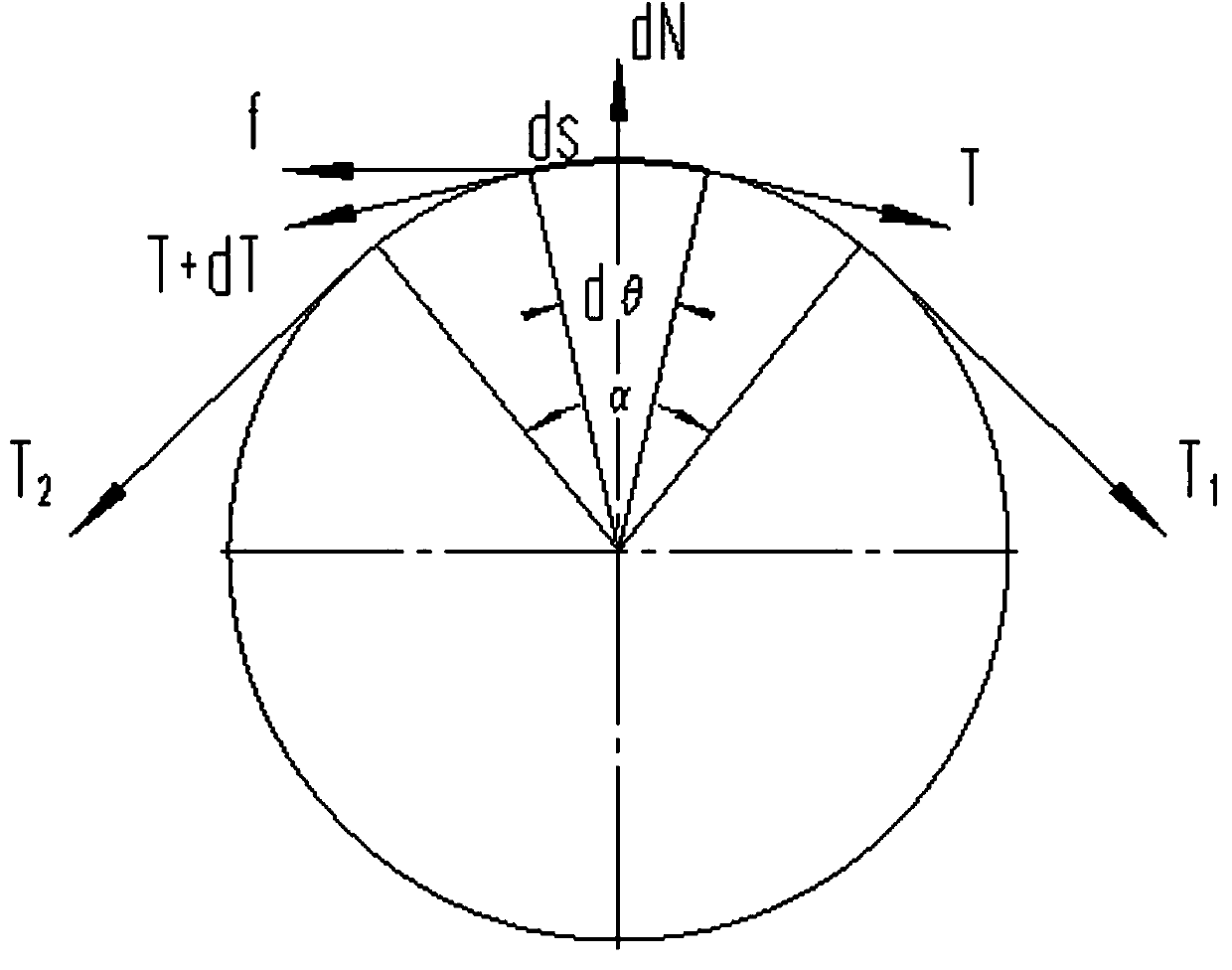

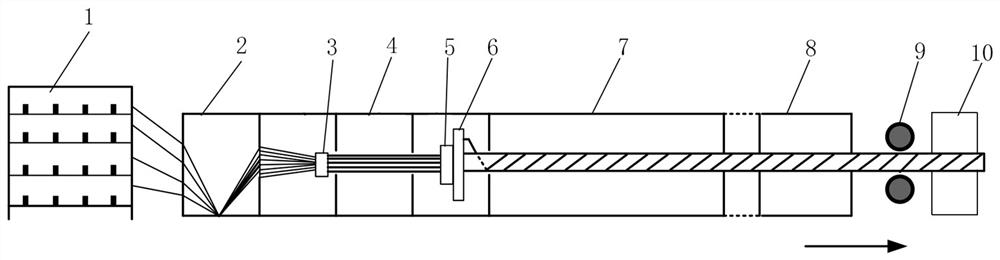

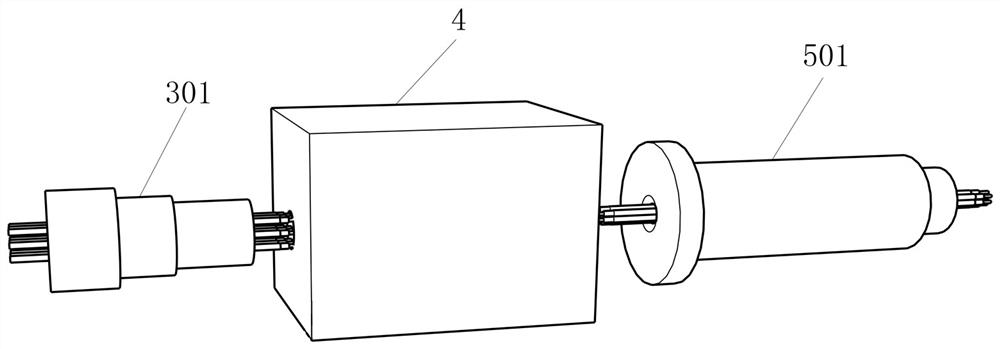

Integrated preparation process of big-tow carbon fiber spreading and curing

ActiveCN107904738ASolve hard-to-extend problemsSolve the problem of poor permeabilityLiquid/gas/vapor removalFibre chemical featuresFiberYarn

The invention provides an integrated preparation process of big-tow carbon fiber spreading and curing, which comprises the following steps: a carbon fiber precursor is precisely limited to ensure theneutrality of the carbon fiber precursor when the fiber is spread; the carbon fiber precursor is spread after the precise limiting position, and then a coupling agent is added to permeate the carbon fiber precursor before the spreading process of the carbon fiber precursor is completed; a heat curing process is carried out by traction through a heating roller on the carbon fiber precursor after being permeated; a winding process is carried out; preparation devices are provided. The invention adopts an integrated preparation process of spreading--permeating--heat curing of combination of a special-shaped multiple-roller and an angle roller. The carbon fiber becomes obviously wider and thinner and more evenly arranged after the spreading process, which effectively solves the problem of poorpermeability of the big-tow carbon fiber precursor caused by the bad spreading effect. Furthermore, the phenomena of precursor adhesion, yarn breaking, buckling and lamination angle dislocation afterspreading can be overcome during the spreading process of the big-tow carbon fiber precursor.

Owner:北京方硕复合材料技术有限公司

Production method for low-fat yogurt ice cream

The invention provides a production method for a low-fat yogurt ice cream, wherein the method includes the steps: raw materials are mixed and fermented to obtain a material liquid after fermentation; the material liquid after fermentation is demulsified and aged, and a material liquid after aging is obtained; then the material liquid after aging is homogenized, and a material liquid after homogenization is obtained; and the material liquid after homogenization is agitated, wherein the total fat content of the raw materials is lower than 3%, and the homogenization pressure is 10-15 bar. The produced yogurt ice cream is strong in yogurt flavor and delicate in mouthfeel.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

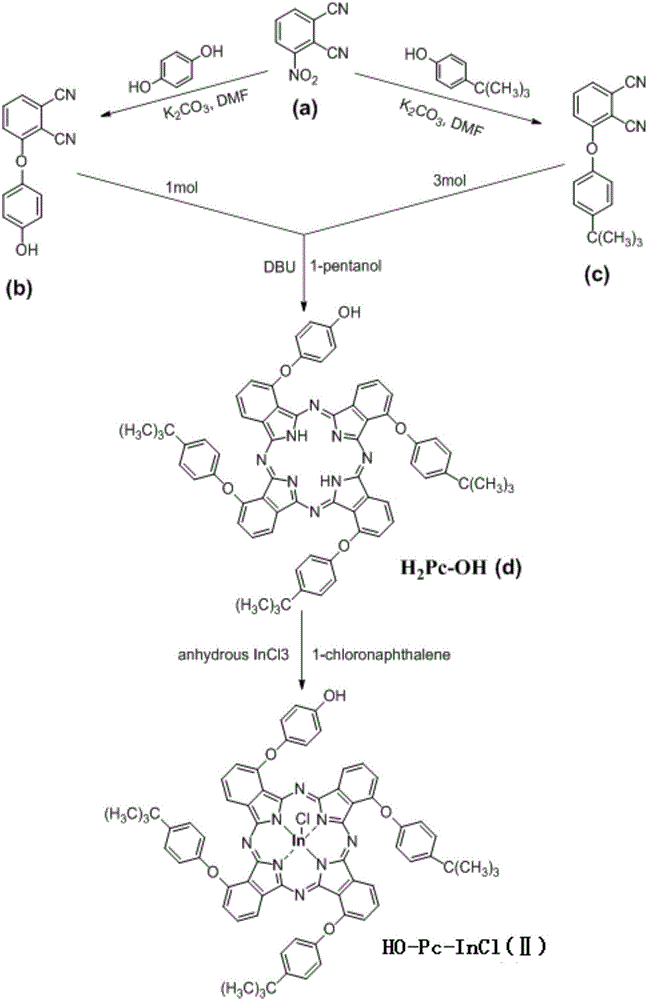

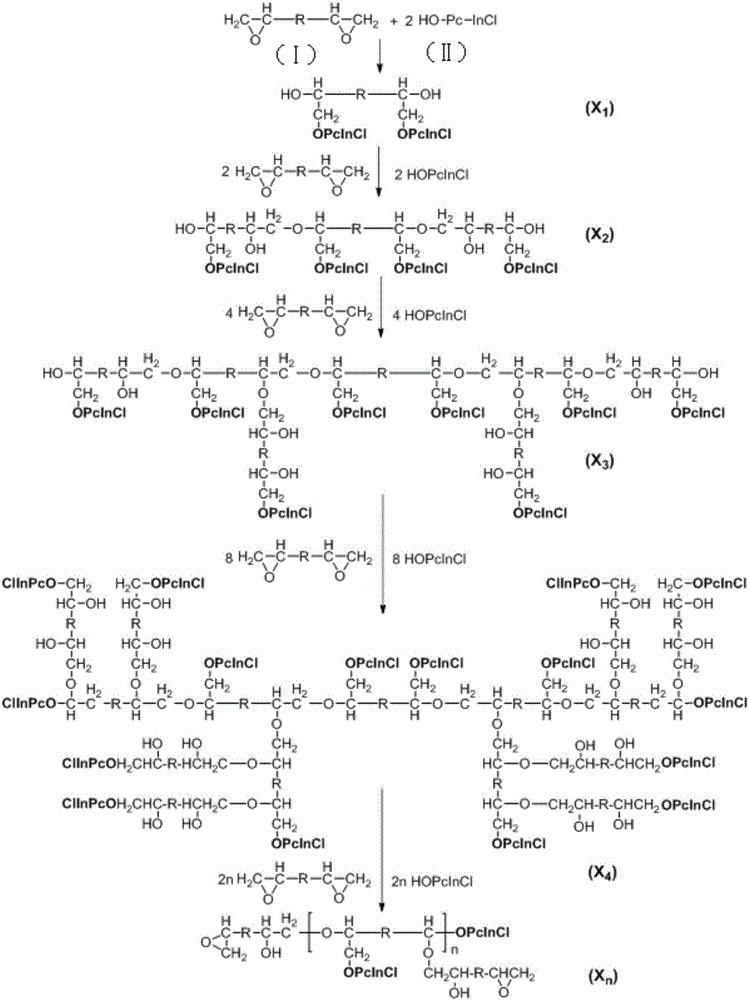

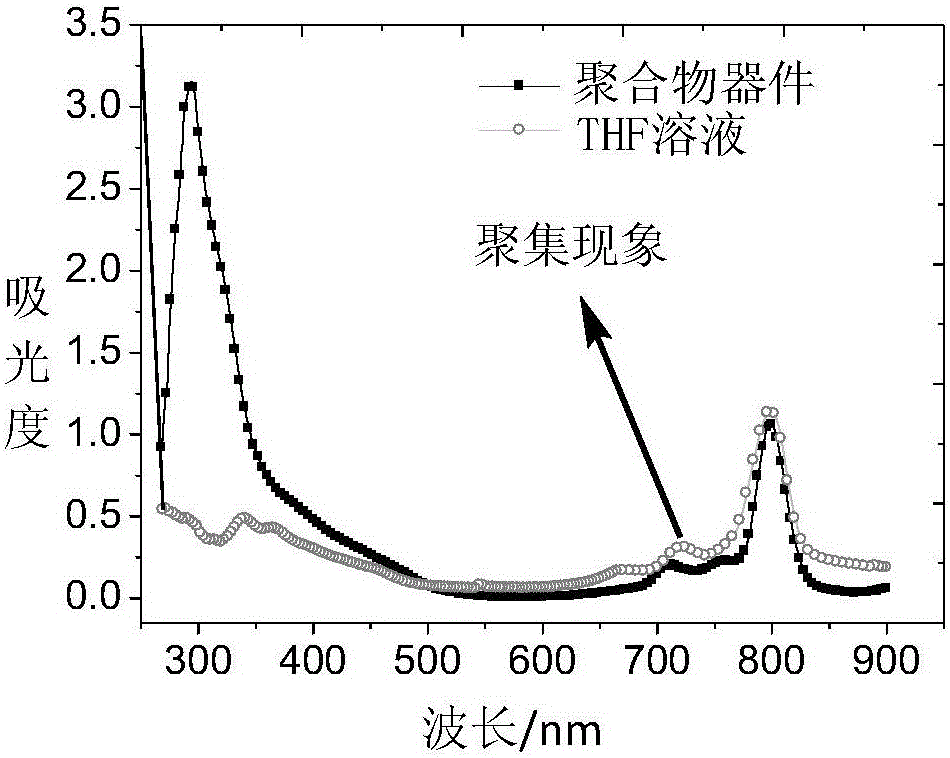

Phthalocyanine polymer, optical limiting device and preparation method therefor

ActiveCN105017504AResolve aggregationHigh mechanical strengthOrganic chemistryNon-linear opticsEpoxyPolymer science

The invention relates to a phthalocyanine polymer, an optical limiting device and a preparation method therefor. A special synthetic technique is adopted for synthesizing an asymmetric phthalocyanine compound containing monohydric radicals, and then epoxy resin adhesive monomers with excellent performance after curing are selected, so that the hydroxide radicals of the asymmetric phthalocyanine perform a polymerization reaction with an epoxy group of the adhesive, the phthalocyanine is grafted onto the epoxy resin monomers, and then a curing polymerization reaction is carried out continuously under a modified flexibilizer and a curing agent so as to obtain a low molecular polymer system containing a phthalocyanine unit. The phthalocyanine in the polymer system is uniformly distributed in the whole polymer structure in a single-molecule monomer structure; compared with a traditional doped hybrid and LB film low molecular sol-gel composite method, the phthalocyanine polymer has higher uniformity, transparency, strength, chemical stability and processing stability performance; and the prepared optical limiting device has good optical limiting performance and mechanical performance.

Owner:JIANGXI UNIV OF SCI & TECH

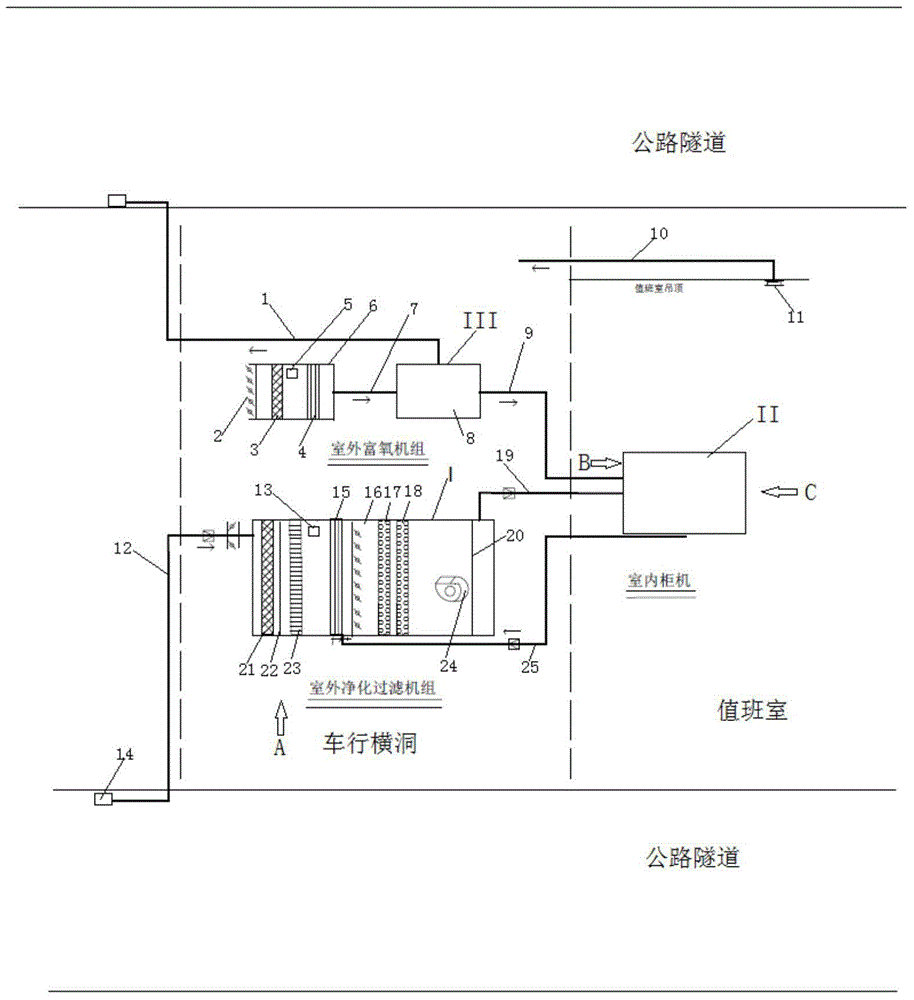

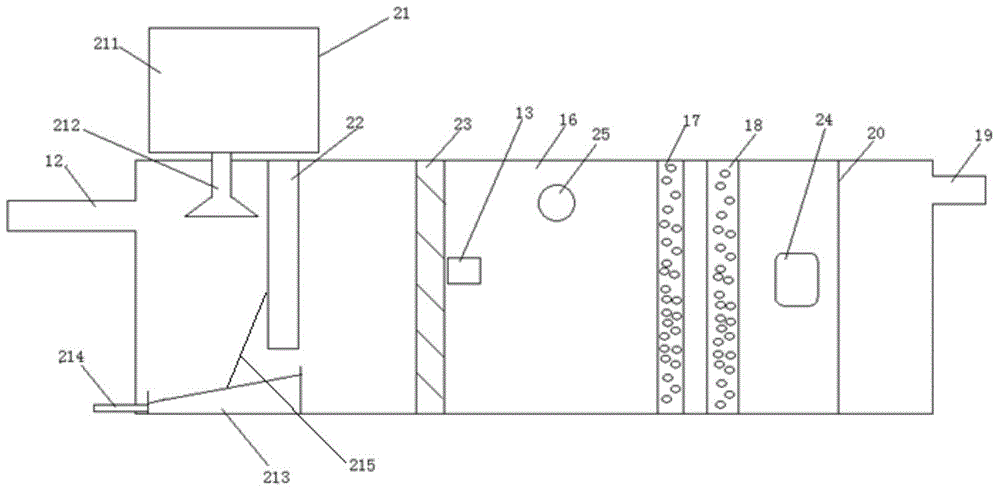

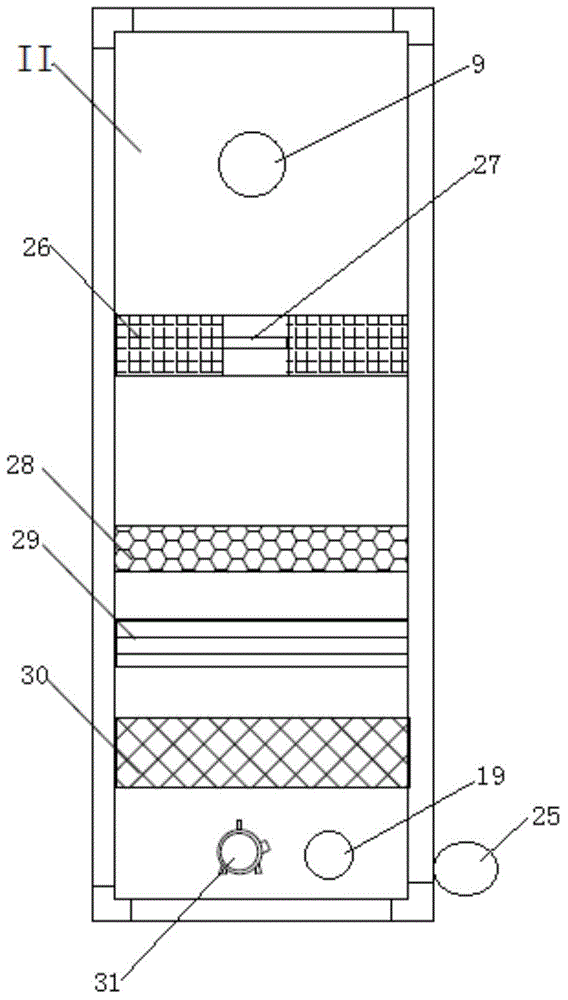

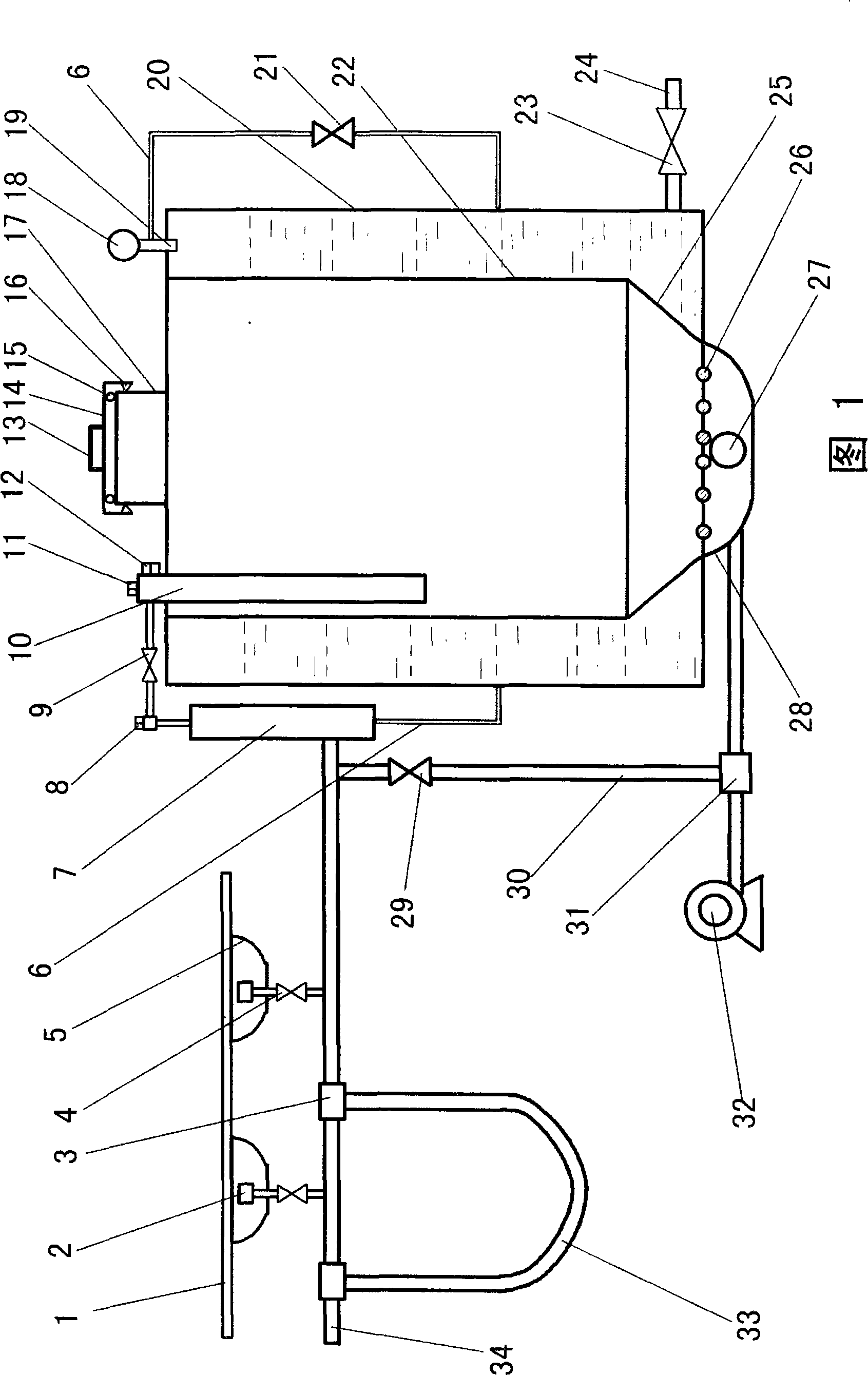

Combined air purifying system and method for duty room in ultralong highway tunnel

InactiveCN104879839ACan relieve stressExtend your lifeMechanical apparatusLighting and heating apparatusActivated carbonOxygen

The invention discloses a combined air purifying system and method for a duty room in an ultralong highway tunnel. The combined air purifying system comprises an outdoor purifying and filtering unit arranged in a tunnel lane horizontal adit, filtering devices, a flow mixing cavity and an air supply device are arranged in the outdoor purifying and filtering unit, the filtering devices are arranged on two sides of the flow mixing cavity, and air collected from the tunnel enters the flow mixing cavity after passing the filtering device on one side of the flow mixing cavity, passes the filtering device on the other side of the flow mixing cavity after being mixed with air guided out from the duty room in the flow mixing cavity, and is fed into the duty room through the air supply device. Air purifying technology and oxygen generating technology are combined and applied to improving air quality of the duty room of the ultralong highway tunnel, an air purifying, circulating and controlling method capable of meeting needs of working staff for 24h's work is provided, purifying efficiency can be improved to greatest extent, maintenance frequency is reduced, activated carbon regeneration times are reduced especially, and operation cost is lowered.

Owner:CHANGAN UNIV

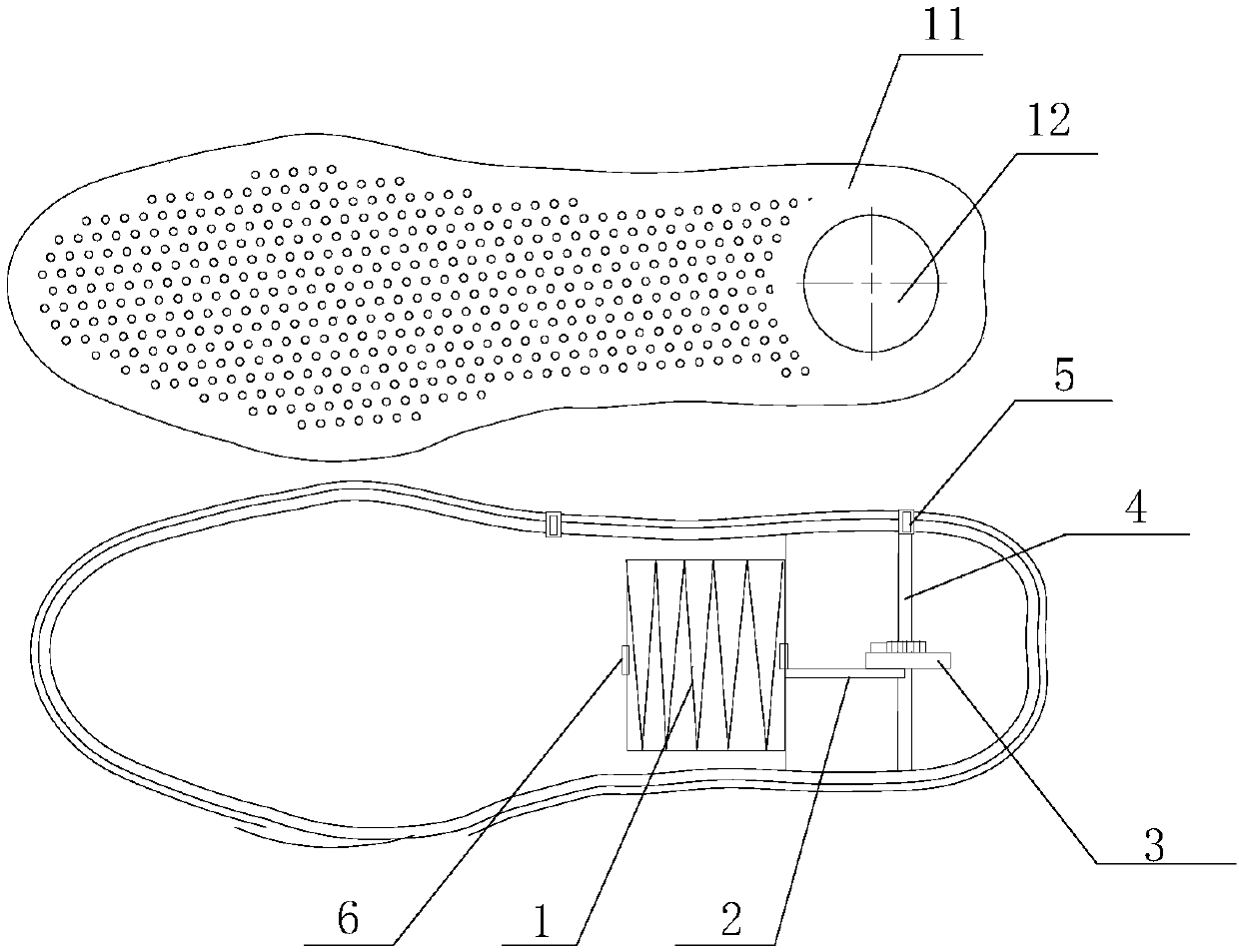

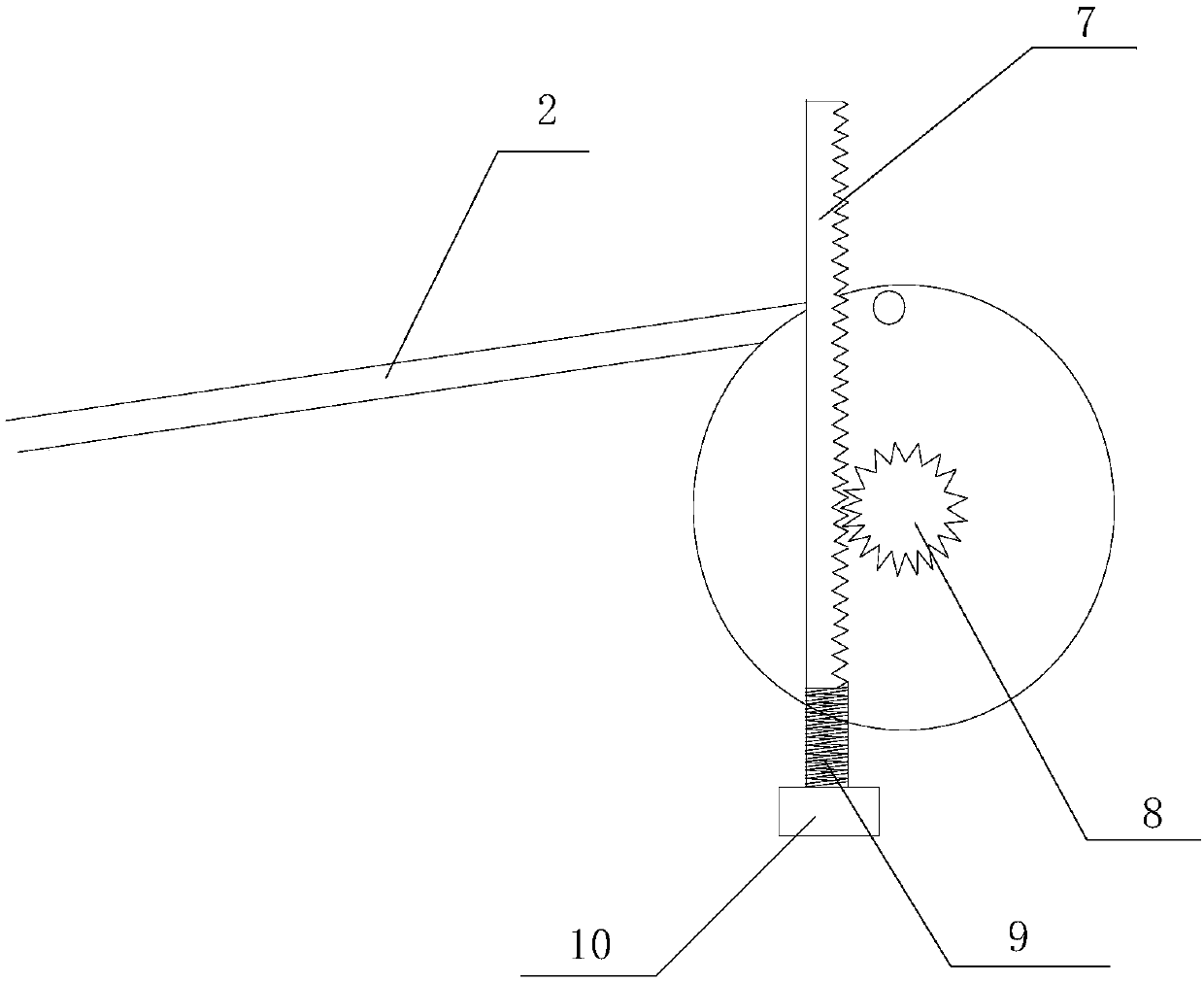

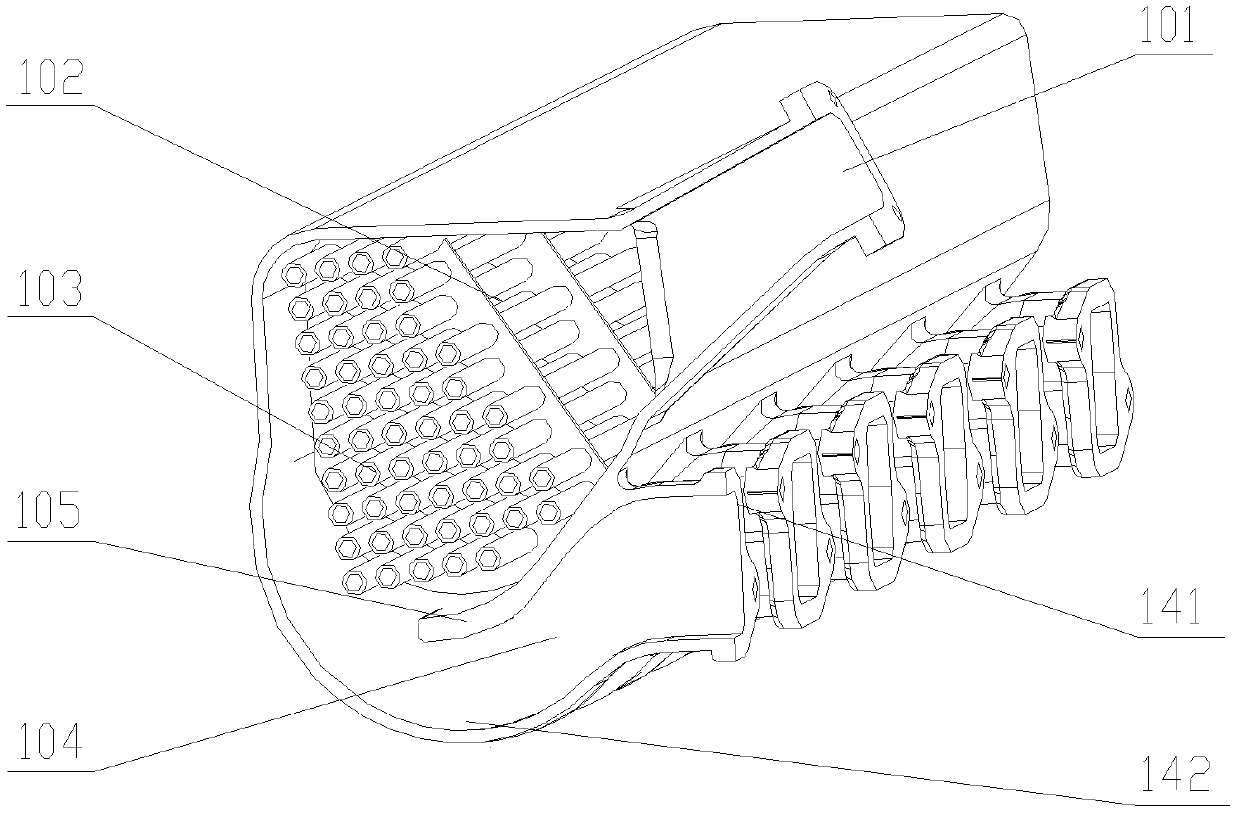

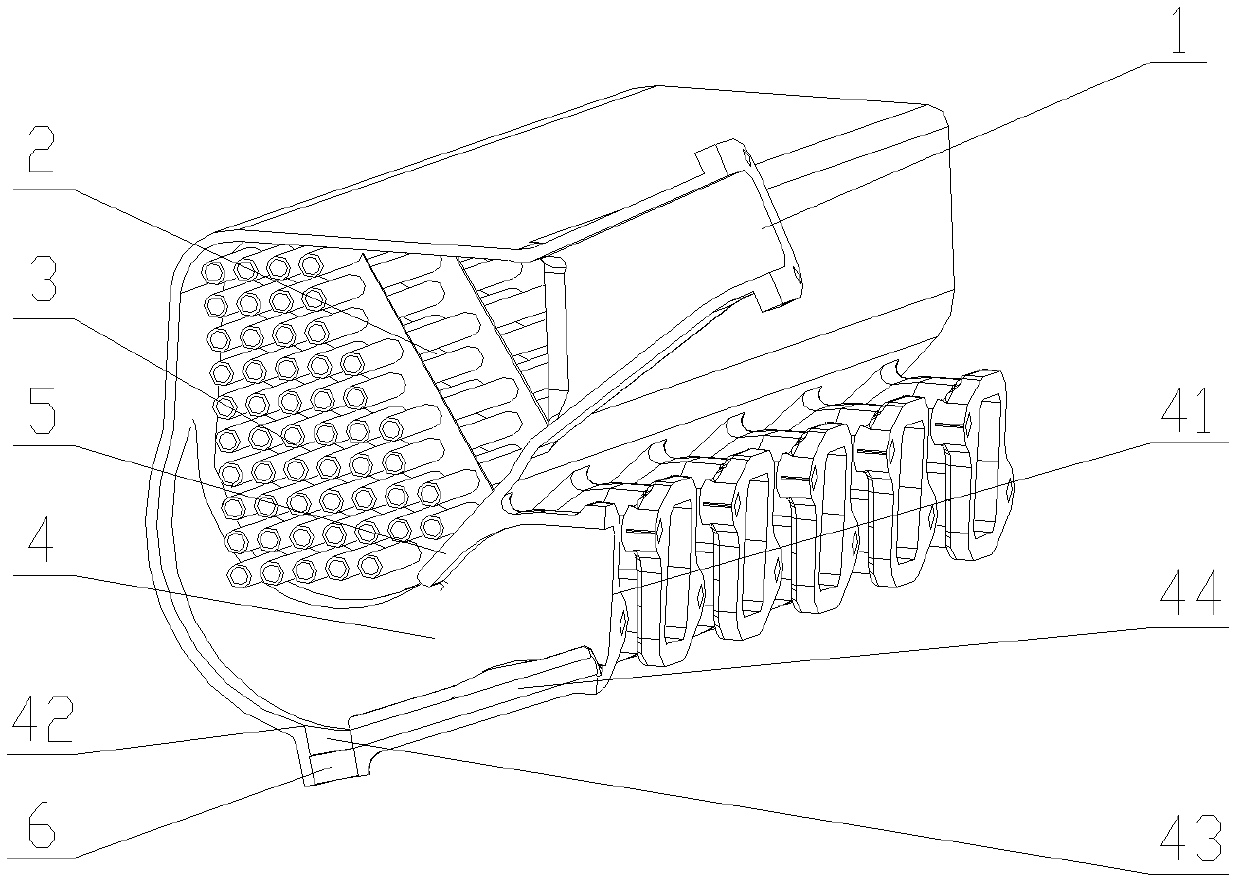

Gear air compression sole

The invention discloses a gear air compression sole. An insole is provided with a plurality of small holes, the sole is hollow, and moisture in a shoe is diffused to the hollow position of the insole.When a user wears the shoe and walks, a root heel compresses a soft arc-shaped projection arranged at the root of the insole, a saw tooth strip in a shoe heel presses downwards and drives a gear, sothat a turntable rotates a certain distance and drives a transmission rod, and an air bag is compressed through the transmission rod. When a foot of the user lifts up, the saw tooth strip moves upwards under the action of the elastic force of a spring to drive the gear to rotate, so that the transmission rod restores, and the air bag is stretched. When the air bag is compressed and stretched, theair enters from one end of air bag through a one-way valve arranged at the corresponding end of the air bag, the air exits from the other end of the air bag through a one-way valve arranged at the corresponding end of the air bag, so that air flow is formed, the air is repeatedly exchanged through two air exchange holes formed in the side surface of the sole, the air exchange holes in the sole only discharges air and cannot inhale through the one-way valves, on one hand, water cannot enter the cavity of the sole, the air bag is provided with horizontal wrinkles, so that air bag more easily changed, and the effect of the air bag is better.

Owner:重庆慧高科技有限公司

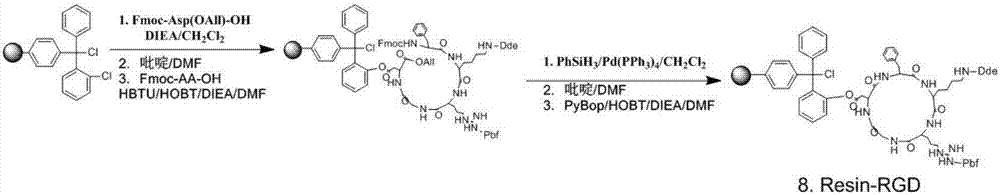

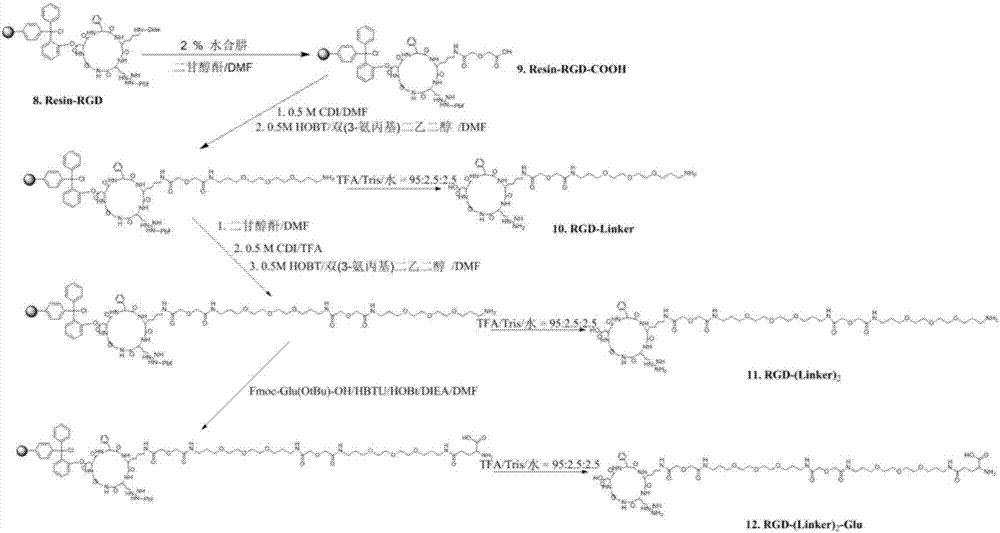

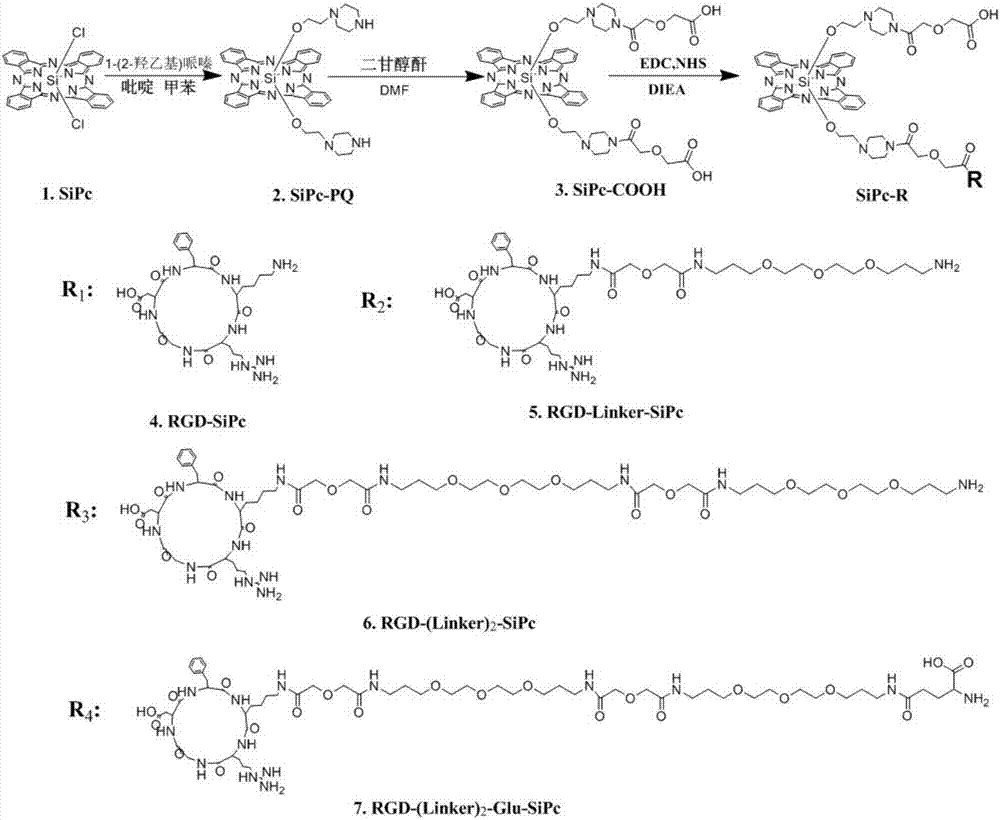

Synthesis and application of RGD polypeptide coupled SiPc (silicon phthalocyanine) photosensitizer

ActiveCN107226839AGood water solubilityResolve aggregationEnergy modified materialsPeptide preparation methodsTumor targetTumor targeting

The invention relates to a SiPc (silicon phthalocyanine) photosensitizer using RGD polypeptide as a targeted group, a preparation method of the SiPc photosensitizer and application of the SiPc photosensitizer to an aspect of tumor photodynamics therapy. The SiPc is used as a photosensitive part to be connected with an RGD polypeptide ligand; PEG (polyethylene glycol) and fragments containing carboxy groups are introduced into the structure; a series of novel photosensitizers with the tumor targeting performance can be prepared. One coupling compound RGD-(Linker)2-Glue-SiPc has good optical physic and photodynamic performance; the EC50 value on the receptor positive tumor cells is 10 to 20nm; under the condition of once medication, the spongioblastoma on the mouse body can be cured; after the continuous observation for 35 days, recurrence does not occur; good application prospects are shown in the field of tumor photodynamics therapy.

Owner:KANGHONG YAOYUAN TECH CO LTD TIANJIN

Preparation method for stably suspended and dispersed nano-zinc oxide slurry

ActiveCN106543795AResolve aggregationPrevent subsidenceCosmetic preparationsNon-macromolecular adhesive additivesNano zinc oxideCalcium carbonate

The invention discloses a preparation method for stably suspended and dispersed nano-zinc oxide slurry, and relates to the technical field of semiconductor material production. The method comprises the steps of firstly, adding nano-zinc oxide in a process of preparing calcium carbonate by adopting a gas-solid reaction, and obtaining monodisperse nano-zinc oxide loaded to the surface of calcium carbonate of a submicrometer structure after calcium carbonate is completely generated; and secondly, taking attapulgite clay as anti-settling, thixotropic and thickening agents, and performing sanding to obtain a target product. According to the method, a nano-zinc oxide dispersion modification technology is successfully formed, and the stably suspended and dispersed nano-zinc oxide slurry is further prepared, so that the difficult problem of aggregation of nano-zinc oxide in use is radically solved.

Owner:扬州市维纳复合材料科技有限公司

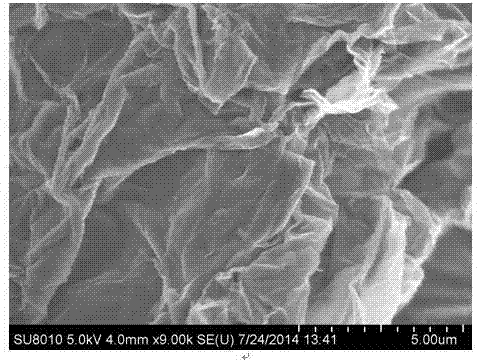

Method for preparation of graphene/carbon aerogel composite material

InactiveCN107256803AImprove conductivitySolve the homogeneous compounding problemHybrid capacitor electrodesComposite processGraphene foam

The invention discloses a method for preparation of a graphene / carbon aerogel composite material. The method comprises: oxidized grapheme is used as a raw material and reduction and assembling are carried out by a liquid phase to obtain a reduced graphene foam; vacuum impregnation is carried out and composite processing is carried out on a carbon aerogel precursor and the reduced graphene foam; and then polymerization, drying, pyrogenic decomposition, and activation are carried out to obtain a graphene / carbon aerogel composite material. The method has the following advantages: on the basis of the vacuum impregnation composite process, grapheme and carbon aerogel are composited uniformly. During the process, the simple equipment is needed; and the process is stable. The method has the broad large-scale preparation prospects.

Owner:TIANJIN NORMAL UNIVERSITY

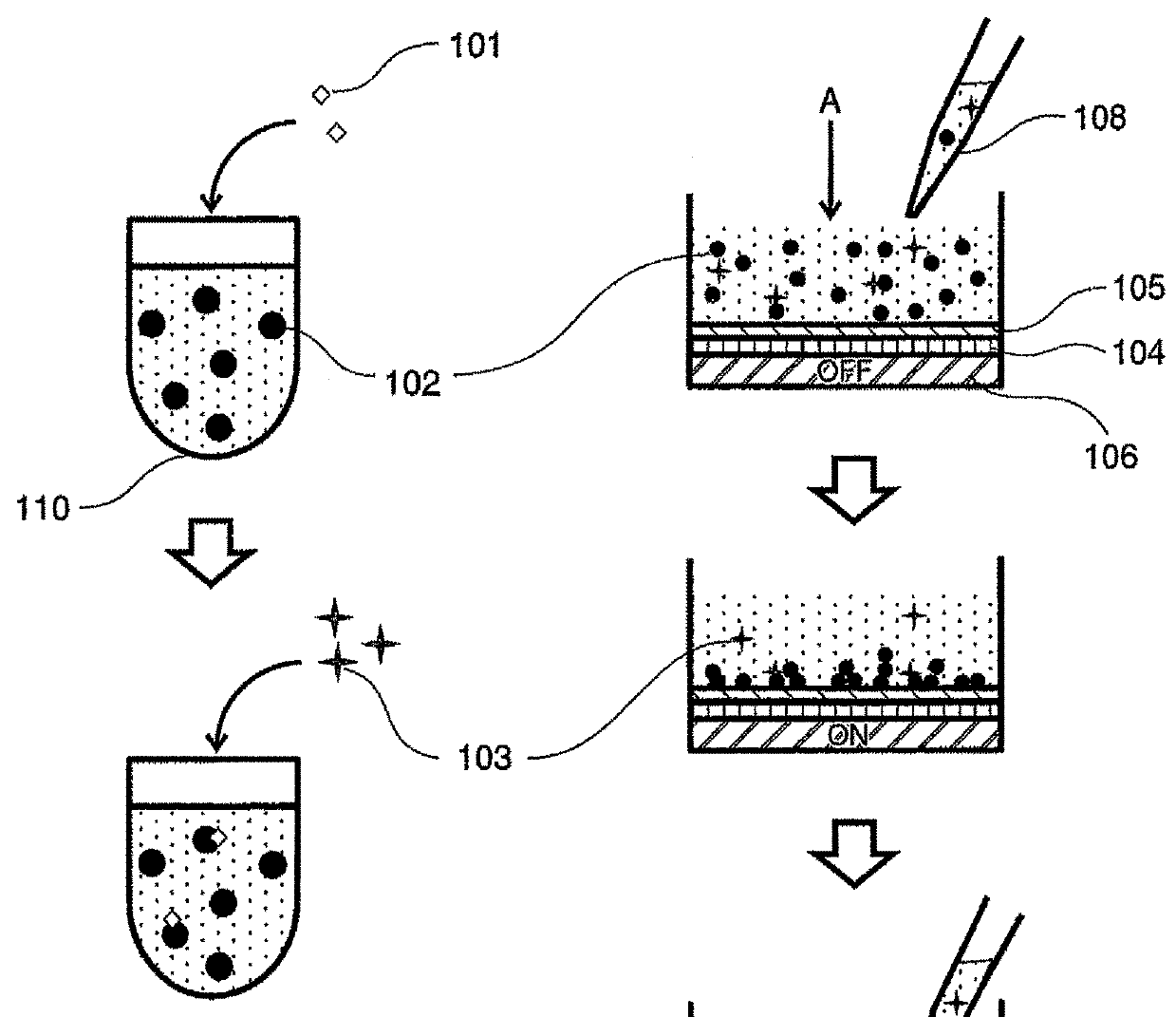

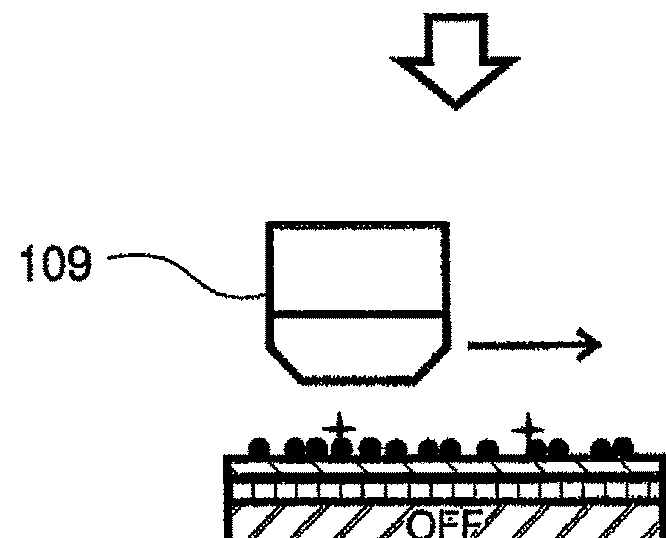

Analysis device and analysis method

ActiveUS9964539B2Easy to implementPreventing the engulfment of fluorescent dyesMicrobiological testing/measurementFluorescence/phosphorescenceFluorescenceAnalysis method

Biomolecules are specifically captured with magnetic particles and the biomolecules are labeled with fluorescence. A magnetic field generator, for attracting the magnetic particles to the support substrate, is provided on the reverse face of the support substrate, and an adhesion layer is provided on the surface of the support substrate to hold the magnetic particles. First, a dispersing solution for the magnetic particles is placed on the surface of the support substrate with the magnetic field in an off state. Next, the magnetic field is turned on, and the magnetic particles in solution are attracted to the support substrate surface. The magnetic particles colliding with the support substrate adhere to the adhesion layer of the support substrate surface, and then the magnetic field is turned off. Thus, aggregations can be broken up while the magnetic particles are held, and a magnetic particle layer on the support substrate can be a single layer.

Owner:HITACHI HIGH-TECH CORP

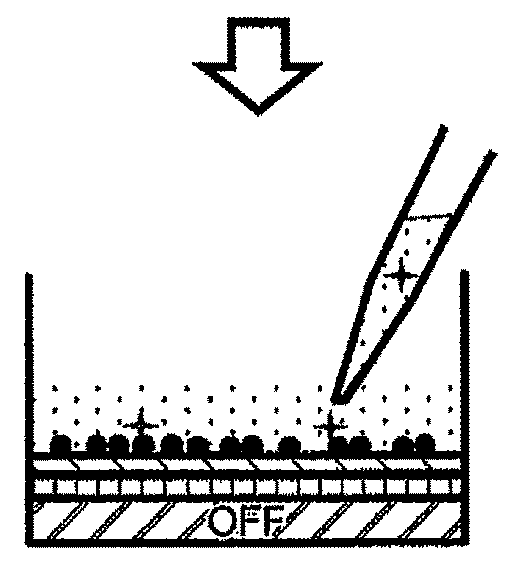

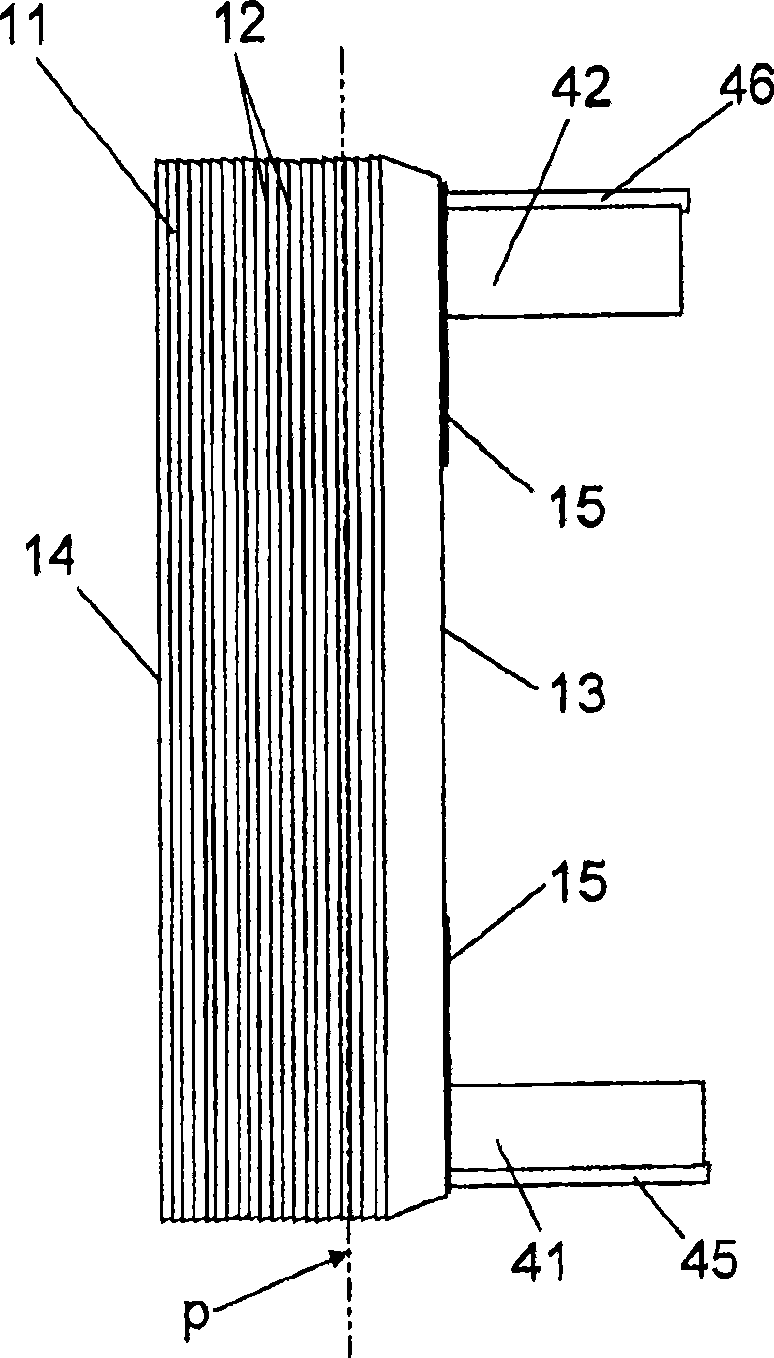

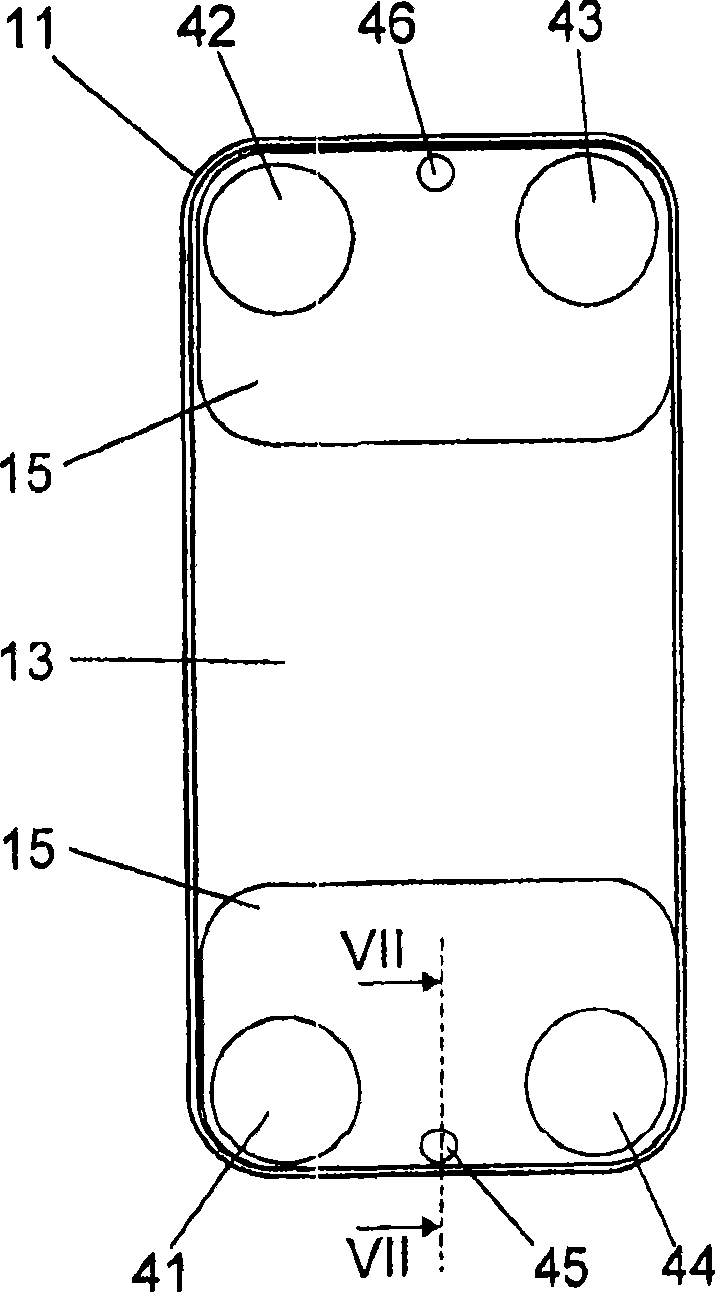

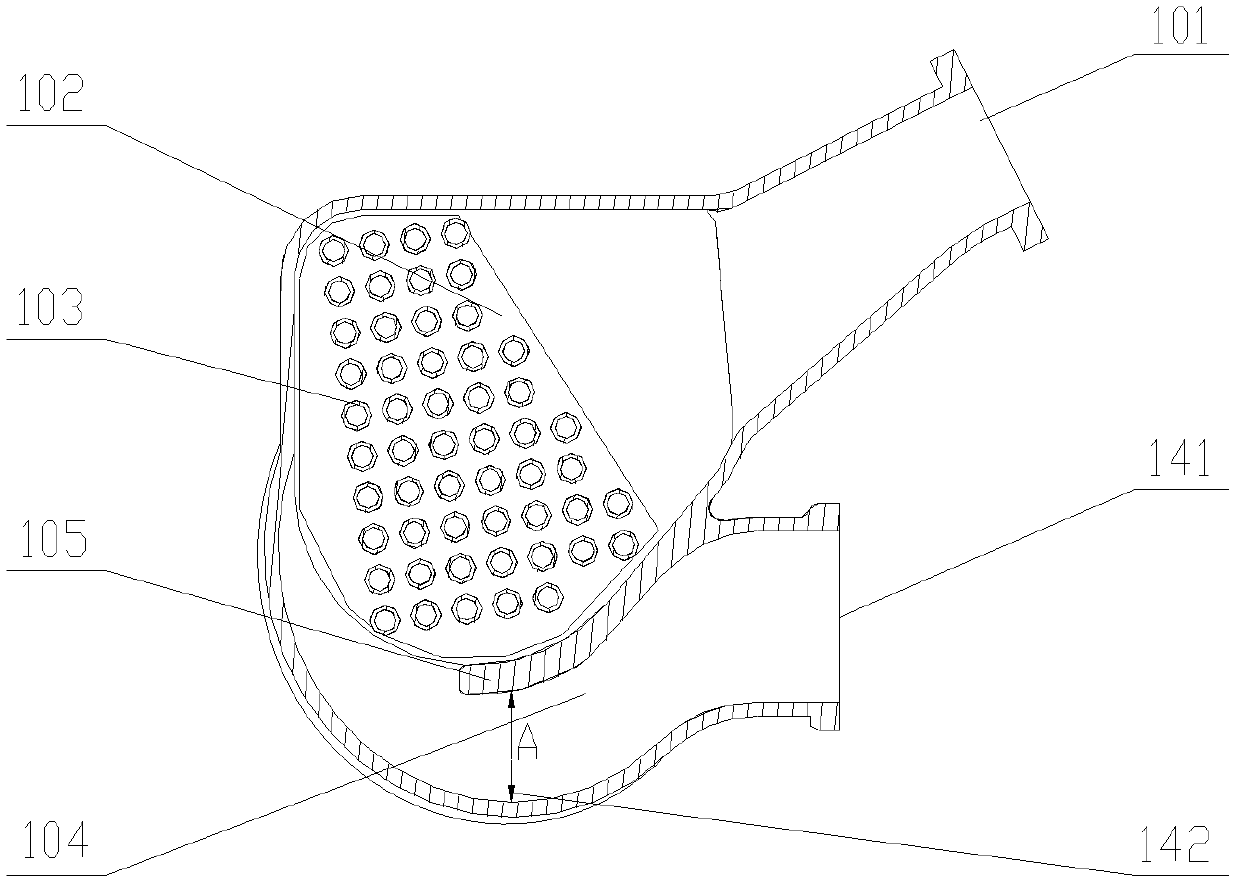

Plate heat exchanger and heat exchanger plant

InactiveCN101512252AResolve aggregationCompressorReinforcing meansEngineeringPlate fin heat exchanger

The invention refers to a heat exchanger plant and a plate heat exchanger. The plate heat exchanger comprises a plate package (11) having heat exchanger plates provided beside each other for forming first plate interspaces for a first medium to be evaporated and second plate interspaces for a second medium in an alternating order in the plate package. Each heat exchanger plate comprises four portholes forming a first inlet port, which communicates with the first plate interspaces for supply of the first medium, a first outlet port, which communicates with the first plate interspaces for discharge of the first medium, a second inlet port, which communicates with the second plate interspaces for supply of the second medium, and a second outlet port, which communicates with the second plate interspaces for discharge of the second medium. The plate package comprises a drainage port (45), which communicates with the first plate interspaces and is closed in relation to the second plate interspaces. The drainage port permits discharge of a fluid collected in the first plate interspaces.

Owner:ALFA LAVAL CORP AB

Method for adding ceramic sintering auxiliary

The invention discloses a method for adding a ceramic sintering auxiliary. The ceramic sintering auxiliary is added in the form of forming a nano TiO2 or nano ZrO2 coating on the surface of a main phase powder; in such a way, even dispersion of a small quantity of sintering agent in the main phase powder is realized; the sintering assisting effect is effectively improved through addition of a small dosage of sintering auxiliary. The method is advantageous for sintering preparation of high-purity phase ceramics, and also effectively capable of solving the aggregation problem of the sintering auxiliary when the difference between the grain sizes of the main phase powder and the sintering auxiliary is overhigh, and avoiding local overburning; as a result, the sintering homogeneity of the main phase powder particles and the sintering assisting effect of the sintering auxiliary are effectively improved.

Owner:重庆兀盾纳米科技有限公司

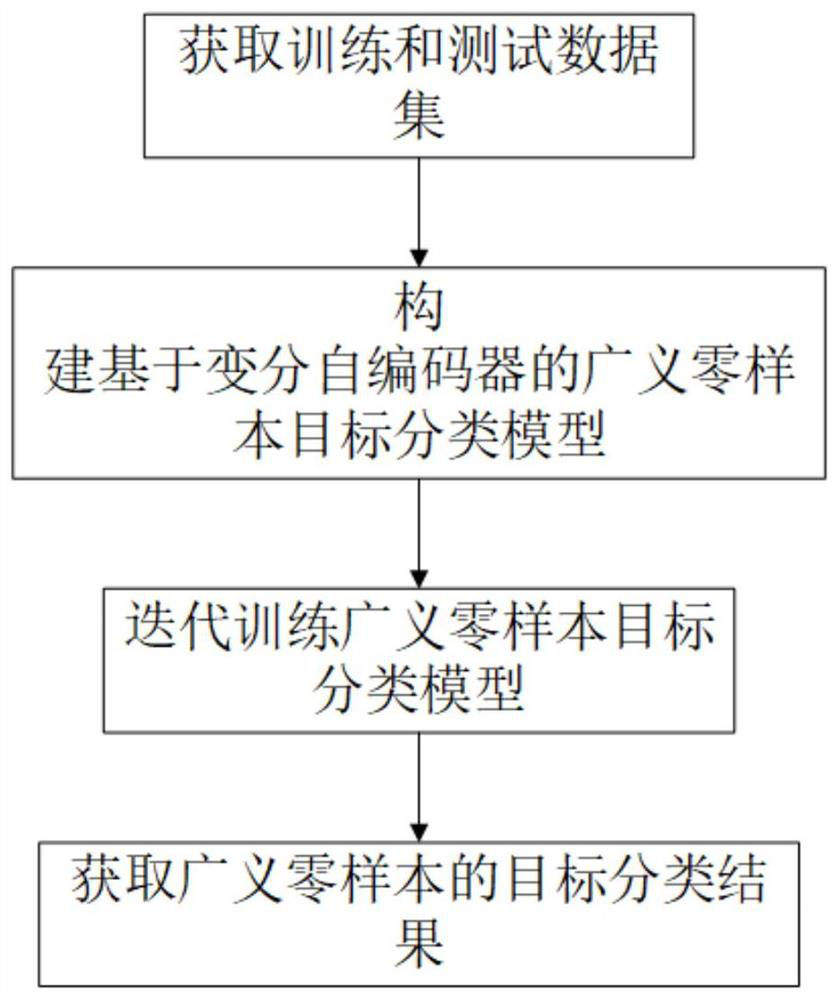

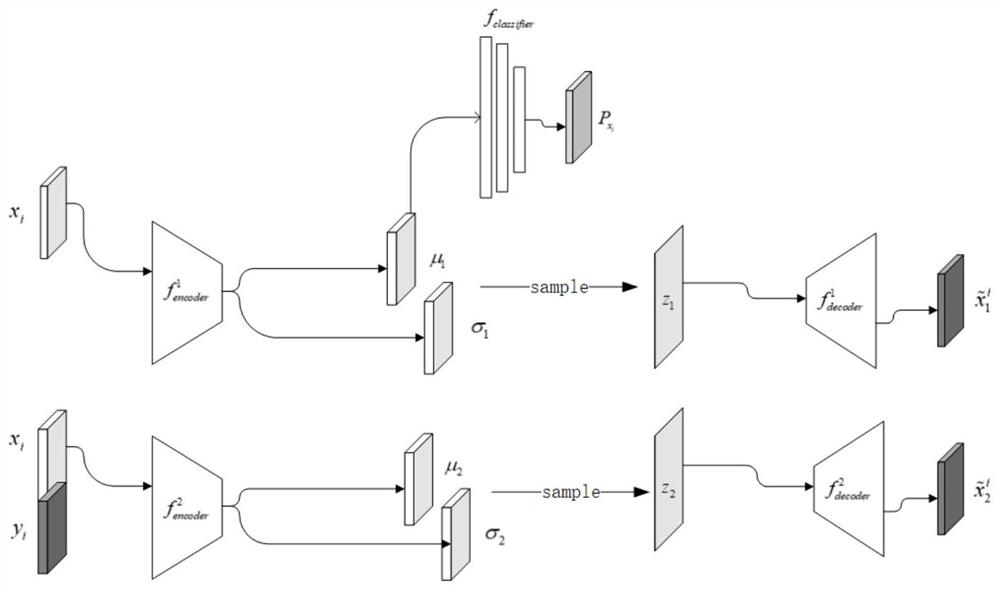

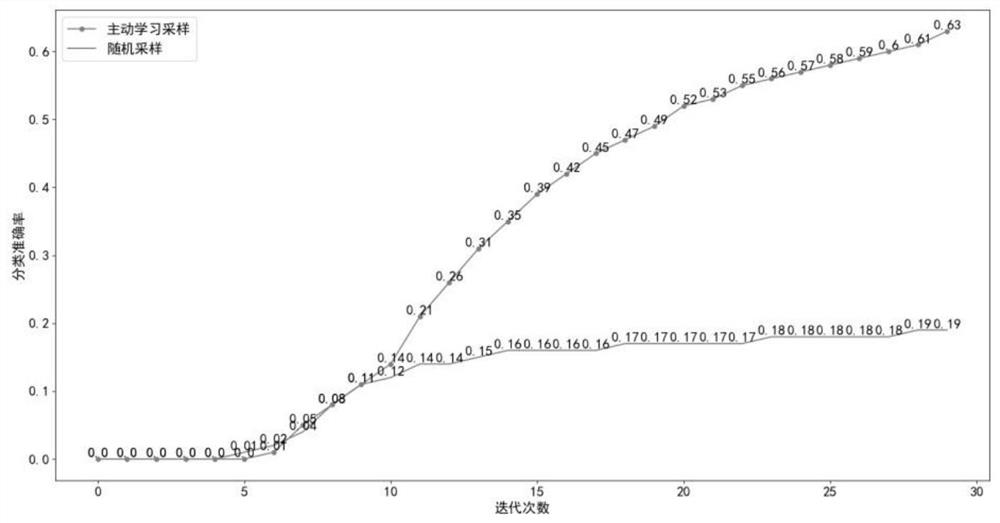

Generalized zero sample target classification method based on active learning and variational auto-encoder

ActiveCN113177587AEnable active learningEliminate biasCharacter and pattern recognitionClassification methodsProactive learning

The invention provides a generalized zero sample target classification method based on active learning and a variational auto-encoder. The method is used for solving the problem of bias caused by loss of unknown class supervision information and the problem of low-dimensional feature aggregation caused by projection from high-dimensional features to low-dimensional space in the prior art, and effectively improving the classification accuracy. The method comprises the following implementation steps: acquiring a training sample set Ptrain and a test sample set Ptest; constructing a generalized zero sample classification model H based on the variational auto-encoder; carrying out iterative training on the variational auto-encoder f and a nonlinear classifier fclassifier in the generalized zero sample classification model H based on the variational auto-encoder; and obtaining a target classification result of a generalized zero sample. The method can be applied to the fields of classification of rare species lacking training data, biomedical image recognition and the like.

Owner:XIDIAN UNIV

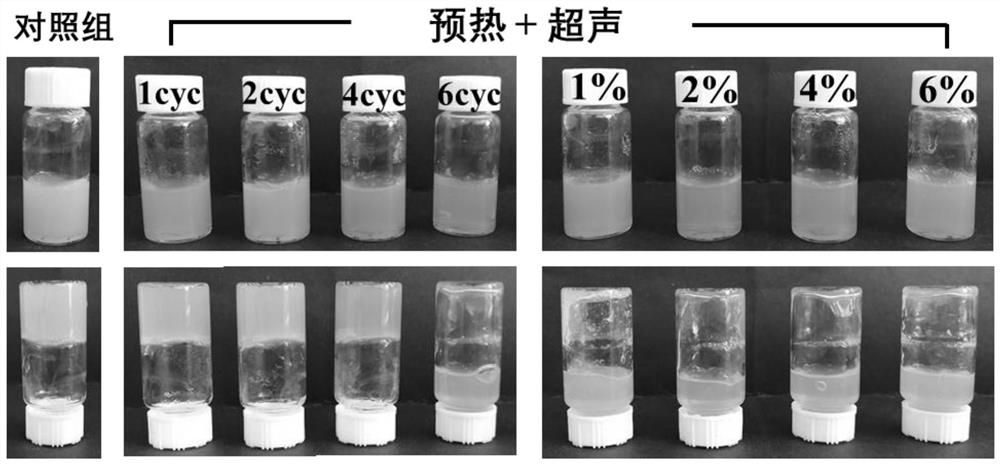

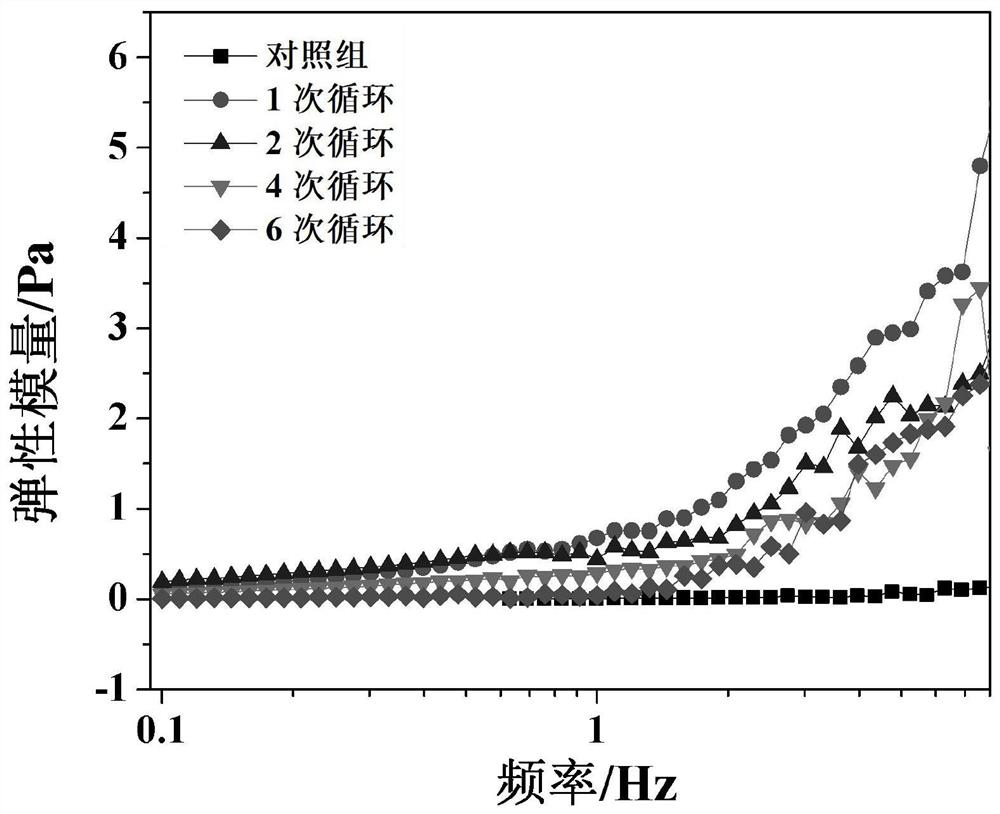

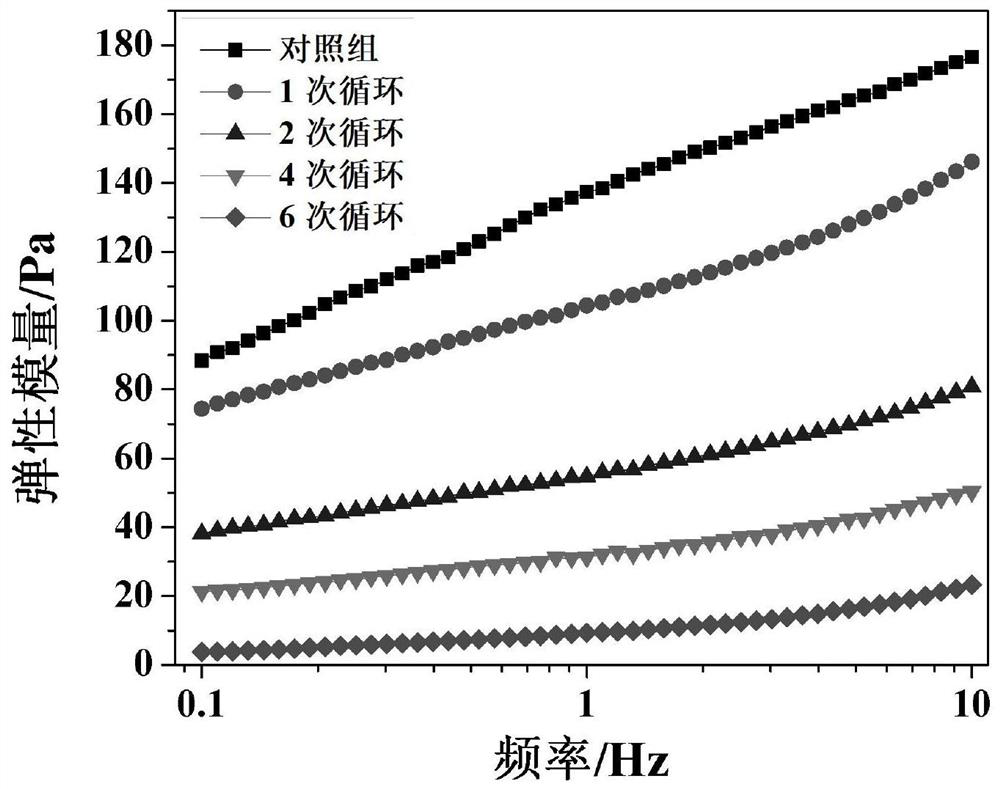

Method for improving thermal stability of soybean protein by combining preheating and ultrasonic treatment

PendingCN112913963AResolve aggregationSimple methodVegetable proteins working-upPhysical chemistrySoybean Proteins

The invention discloses a method for improving thermal stability of soybean protein by combining preheating and ultrasonic treatment. The method comprises the following specific steps of: taking soybean protein powder, dispersing the soybean protein powder in deionized water, and stirring at room temperature to ensure that the soybean protein powder is completely hydrated to obtain a first soybean protein dispersion liquid, wherein the mass concentration range of the first soybean protein dispersion liquid is 1-6%; preheating the first soybean protein dispersion liquid, and then immediately cooling to obtain a second soybean protein dispersion liquid; treating the second soybean protein dispersion liquid under ultrasonic waves to obtain a third soybean protein dispersion liquid; and repeatedly preheating, cooling and ultrasonically treating the third soybean protein dispersion liquid, repeating once as one cycle, and drying after at least six cycles to obtain a modified soybean protein dispersion liquid to obtain modified soybean protein powder. The thermal-stability soybean protein prepared by the method disclosed by the invention can be widely applied to protein-containing beverages, and the stability of related products in a hot processing process is improved while the protein content is increased.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Supercharged engine and intercooling inlet pipe thereof

ActiveCN102606281AIncrease gas flow rateSolve condensation accumulationInternal combustion piston enginesCondensed waterEngineering

The invention discloses an intercooling inlet pipe of a supercharged engine, which comprises an inlet main pipe and an inlet branch pipe communicated with the inlet main pipe. The bottom of the inlet branch pipe is provided with a bypass hole, and the bypass hole is communicated with the inlet branch pipe and an air cylinder of the supercharged engine. Compared with the prior art, the intercooling inlet pipe modifies a structure of the inlet branch pipe, the bypass hole communicated with the inlet branch pipe and the air cylinder are arranged at the bottom of the inlet branch pipe so that when gas flows into the air cylinder through the bypass hole, the differential pressure caused by the Venturi effect enables condensed water located at the bottommost end of the inlet branch pipe to be sucked into the air cylinder to be combusted, and the problem of accumulation of the condensed water is effectively solved. The invention further discloses the supercharged engine comprising the intercooling inlet pipe.

Owner:WEICHAI POWER CO LTD

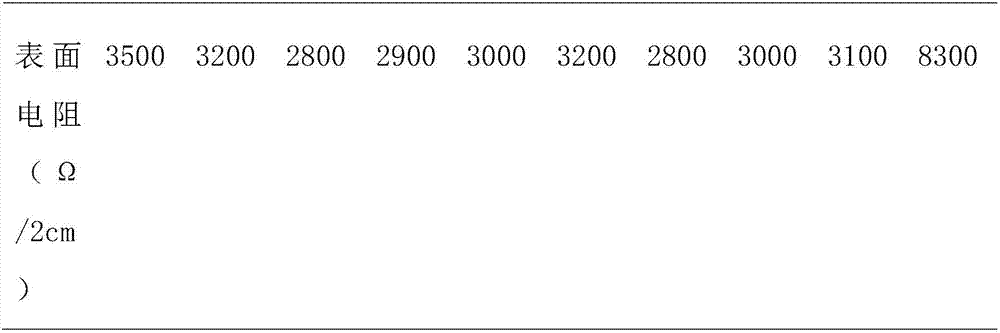

Antistatic treating agent and preparation method thereof

The invention provides an antistatic treating agent and a preparation method thereof, and relates to the technical field of material preparation. Raw materials of the antistatic treating agent comprise the following components in parts by weight: 20-30 parts of polymer polyol, 5-22 parts of polyisocyanate and 0.1-1 part of a conductive agent, wherein various commonly used diols are mainly adopted as the polymer polyol, the polyisocyanate includes one or both of diisocyanate and triisocyanate, and the conductive agent comprises graphite oxide and / or graphene oxide. Isocyanate groups on the polyisocyanate can react with hydroxyl groups on the graphite oxide or graphene oxide, and the isocyanate groups can also react with hydroxyl groups of the polymer polyol simultaneously. Therefore, the graphite oxide is linked into a molecular chain of polyurethane by taking the polyisocyanate as a bridge, thereby fundamentally solving the problems of aggregation and sedimentation of the graphite oxide in polyurethane resin, and enhancing the antistatic capability of a surface of polyurethane synthetic leather.

Owner:江苏多森新材料科技有限公司

A method for preparing ultra-high hardness cladding layer by synchronous ultrasonic vibration assisted laser technology

InactiveCN104451673BGuaranteed hardnessGuaranteed wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing ultra-high hardness cladding layer by synchronous ultrasonic vibration assisted laser technology. The specific scheme is to introduce ultrasonic vibration synchronously in the process of cladding Ni-based cermet coating, and this method can improve the flow of liquid metal In the process of solidification, the growing dendrite network can be broken and dispersed to various parts of the melt to form evenly distributed small crystal nuclei to prevent segregation of cermets, thereby It ensures that the cladding layer does not crack while obtaining ultra-high hardness; the equipment is simple, it is convenient for calibration and installation, the energy consumption is small, and the working environment is good. The obtained coating cermet has uniform particle distribution, high hardness and good wear resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

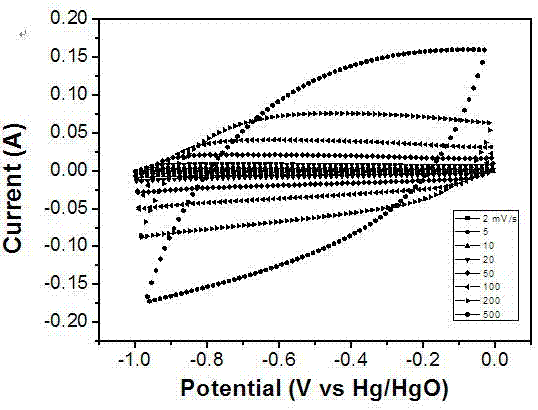

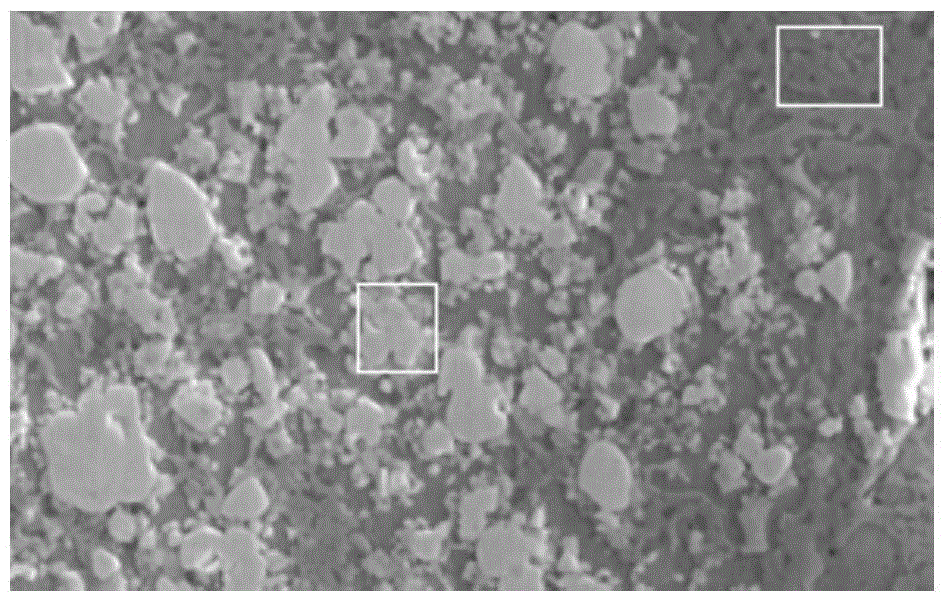

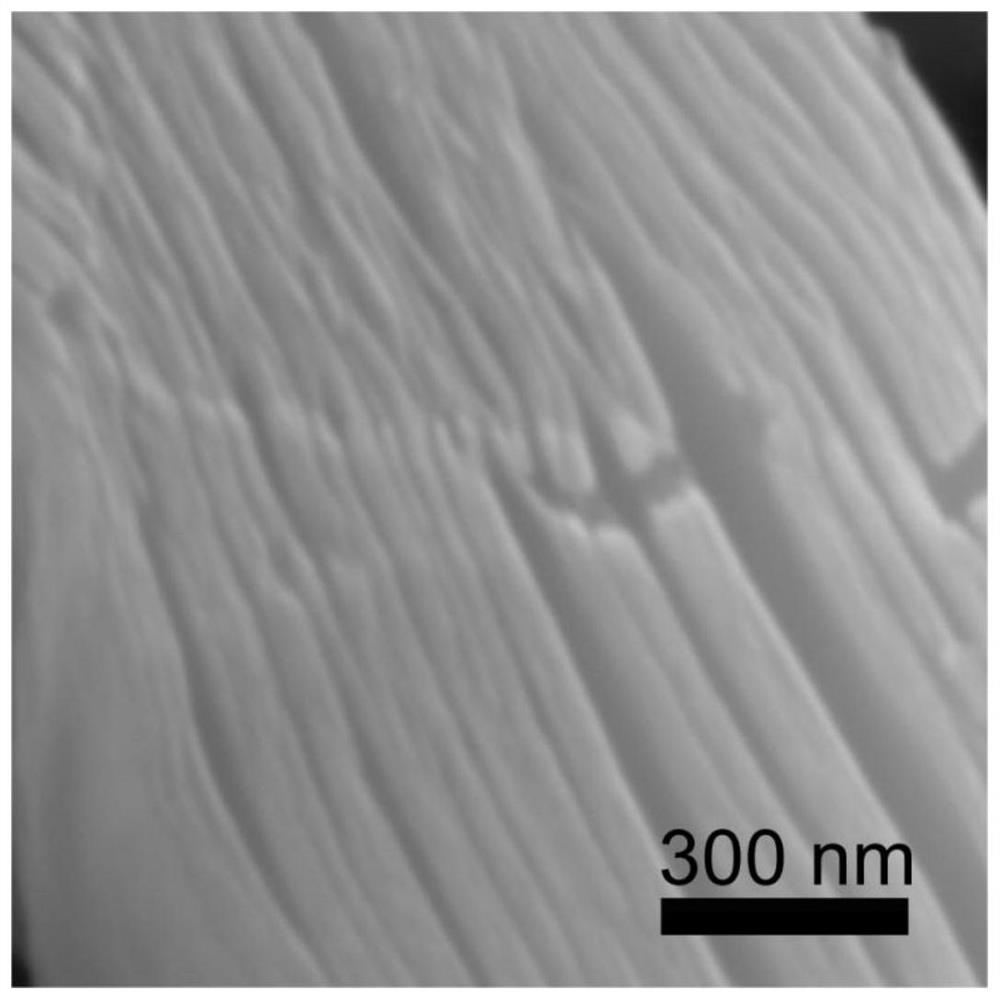

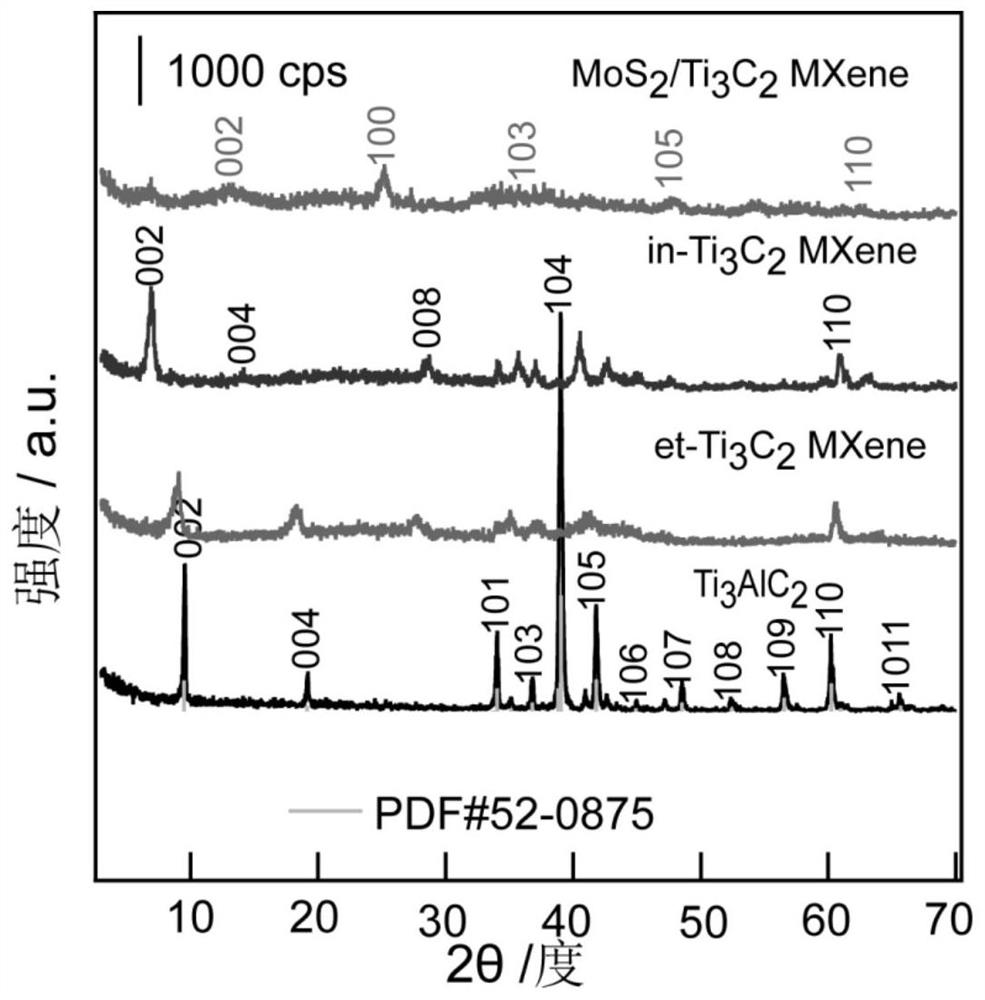

Preparation method of MoS2/Ti3C2 MXene composite material for high-performance potassium ion battery

ActiveCN113675408AFully contactedImprove transfer efficiencyMaterial nanotechnologySecondary cellsPhysical chemistryBattery cell

The invention provides a preparation method of a MoS2 / Ti3C2 MXene composite material for a high-performance potassium ion battery. The preparation method comprises the following steps of: dispersing a plurality of layers of et-Ti3C2 MXene nanosheets in an intercalator solution, reacting at room temperature, centrifuging, washing and drying to obtain in-Ti3C2 MXene nanosheets; under ultrasonic and stirring conditions, adding a mixed solution of a molybdenum precursor and a sulfur precursor into an in-Ti3C2 MXene nanosheet dispersion liquid, and subjecting the obtained mixed solution to a high-temperature reaction; and after the reaction is completed, centrifuging, washing and drying the solution to obtain the product. The composite material disclosed by the invention overcomes the defects of a single material, and solves the problems of rapid reversible capacity attenuation and poor cycling stability caused by huge volume expansion and crushing of an electrode in a K<+> repeated intercalation / deintercalation process, so that the cycling stability and the specific capacity of the potassium ion battery are remarkably improved.

Owner:SHANDONG UNIV

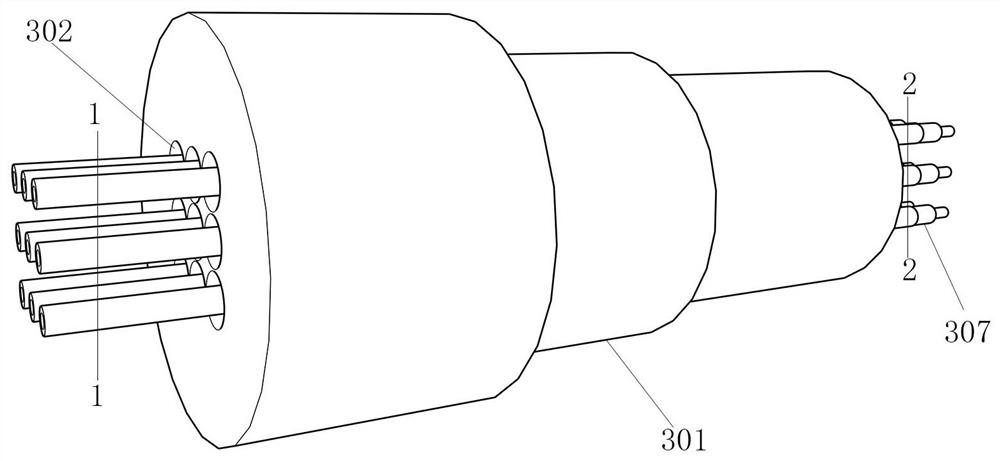

Pultrusion die for producing hybrid fiber reinforced polymer rod and preparation process

The invention belongs to the technical field of composite material processing, and particularly relates to a pultrusion die for producing a hybrid fiber reinforced polymer rod and a preparation process. The pultrusion die comprises a yarn roll containing frame, a glue dipping device, a pre-forming device, a preheating device, a secondary forming device, a winding device, a high-temperature curingforming device, a cooling device, a traction device and a cutting device which are connected in sequence; the pre-forming device is used for extruding fiber bundles which are impregnated with the resin and are distributed in an array to form an array of hybrid fiber secondary rods; the preheating device is used for heating the hybrid fiber secondary rods output by the pre-forming device, an inletof the preheating device is connected with the pre-forming device through a glue scraping device, and an outlet of the preheating device is connected with the secondary forming device through the gluescraping device; and the secondary forming device is used for extruding the plurality of preheated hybrid fiber secondary rods to form a main rod. According to the pultrusion die, the problem that low-strain fibers cannot be uniformly dispersed on the cross section of the HFRP rod according to a preset mode when the HFRP rod is produced can be solved.

Owner:ZHENGZHOU UNIV

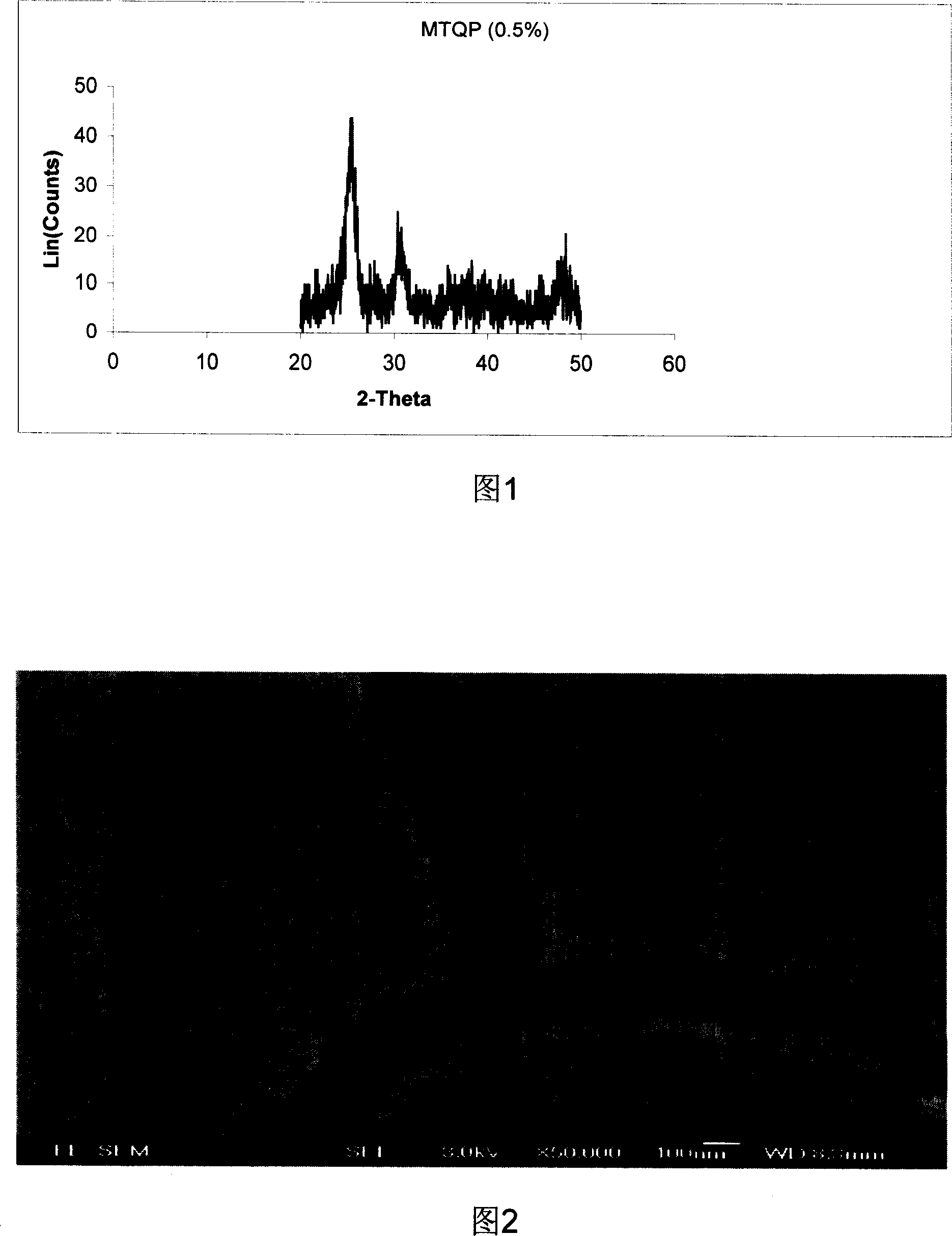

Production of fatty acid silver salt for photosensitive heat display imaging material

ActiveCN1746767AResolve aggregationImprove clarityPhotothermographic systemsCarboxylic acid salt preparationFatty acidCrystal growth

A method for preparing fatty acid silver salt used to produce photosensitive heat development imaging material includes crystal growing process of fatty acid silver salt, superflitering process, concentrating process, redispersing process of fatty acid silver salt. . The abovesaid preparing processes are carried out in closed container under vacuum condition with internal negative pressure value of 0.01 - 0.09 Mpa in closed container.

Owner:BAODING LUCKY FILM

Multi-fuel energy-saving environment-friendly range

InactiveCN101240905AHigh flame temperatureReduced burn-outLighting and heating apparatusBiofuelsCombustible gasEngineering

The present invention provides a multi-fuel energy saving environmentally-friendly cooker. The invention belongs to burner, especially a cooker generating combustible gas using solid combustible as fuel material. The pattern is an imporved pattern to the traditional fuel cooker, the lower of the furnace is a conical surface which upper is big and lower is small, the dust storage chamber wall is a bowl shaped curve and smoothly connected with the conical surface of the furnace, the inlet of the gas-guide tube extends to the center of the furnace, outlet tube of the blower is connected with the appendix previous to the dust storage chamber and the burning head. The invention has a reasonably designing structure, generating combustible gas by combustible such as straw, Eupatorium adenophorum, hyacinth, garbage etc, burning completely, generating less clinker, having no waste gas drainage, and having a simple feeding operation.

Owner:姚邵昆

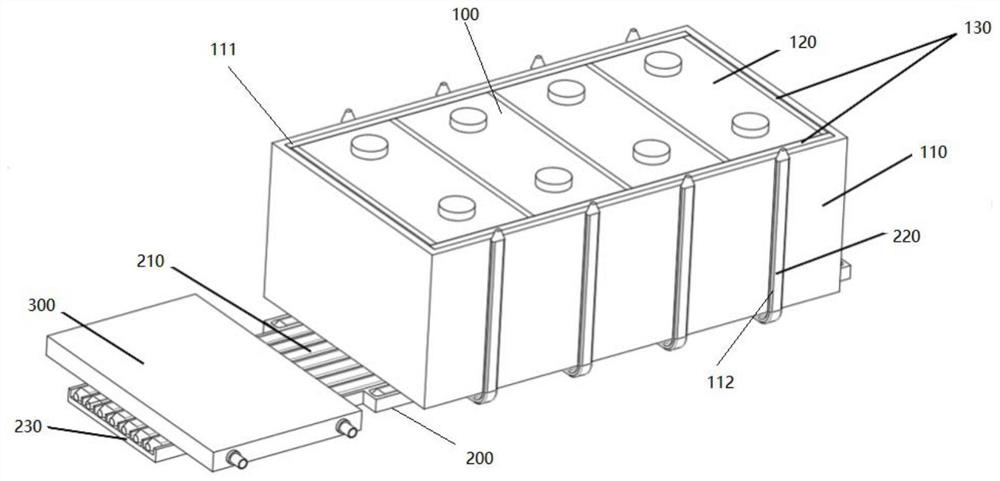

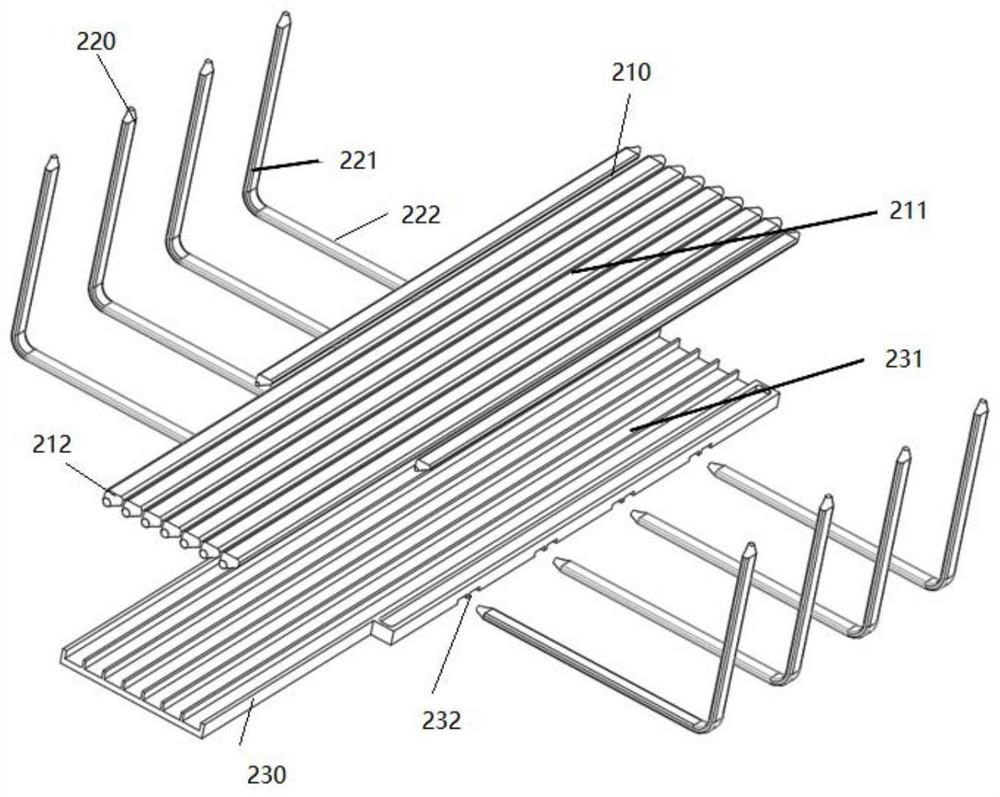

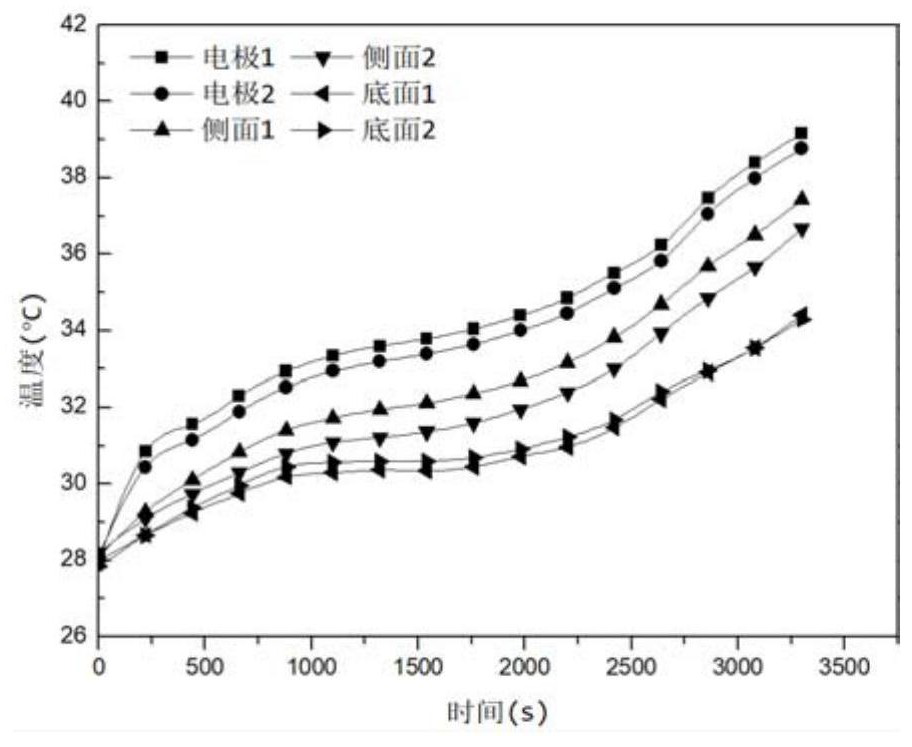

Power battery module cooling system

ActiveCN113410540AImprove temperature uniformityImprove cooling efficiencySecondary cellsPower batteryThermodynamics

The invention discloses a power battery module heat dissipation system, and the system comprises a battery module, a heat dissipation assembly and a water-cooling heat dissipation module; the battery module comprises a shell and a plurality of battery cell units, the battery cell units are placed in a containing cavity, and the battery cell units are connected in series or in parallel to form a group and are packaged and formed through the shell; the heat dissipation assembly comprises a plurality of transverse heat pipes arranged in an array and a plurality of longitudinal heat pipes arranged in an array; the transverse heat pipes and the longitudinal heat pipes are combined to form an installation area, the battery module is installed in the installation area, heat dissipation working media are arranged in the transverse heat pipes and the longitudinal heat pipes, and the transverse heat pipes are connected with the water-cooling heat dissipation module; in the charging and discharging process of the battery module, the heat inside the battery module and near an electrode is quickly transferred to the bottom of the battery module through the longitudinal heat pipes and then transferred to the water-cooling heat dissipation module through the transverse heat pipes for heat dissipation, so the problem of heat accumulation inside the battery module is effectively solved, the temperature of the side wall of the battery module and near the electrode is reduced, and the temperature uniformity and the heat dissipation efficiency of the battery module are improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com