Chitosan functionalized graphene oxide/polyvinylidene fluoride hybrid ultrafiltration membrane and preparation method thereof

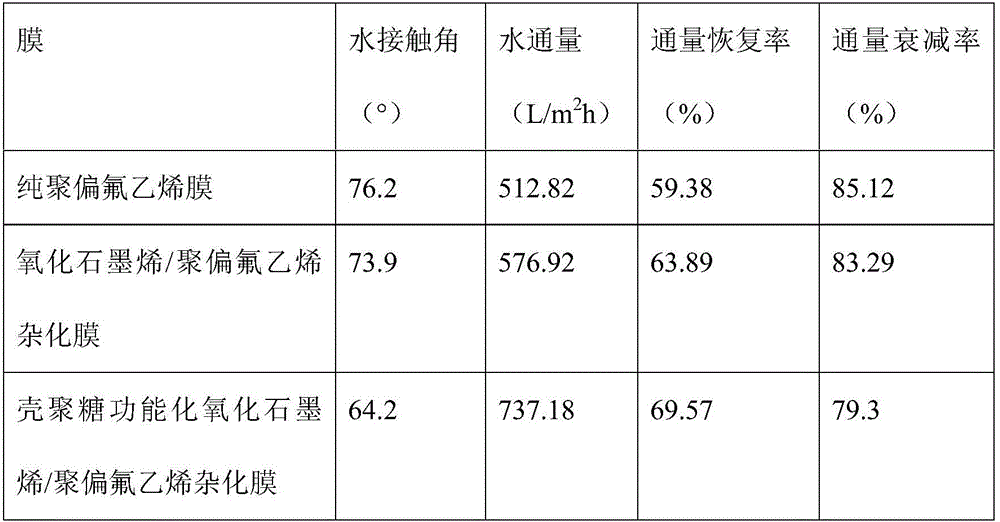

A technology of polyvinylidene fluoride and chitosan, applied in chemical instruments and methods, ultrafiltration, membranes, etc., can solve problems such as uneven dispersion of graphene oxide and hydrophilic constraints of polyvinylidene fluoride ultrafiltration membranes, etc. Achieve the effects of performance improvement, simple preparation method, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) take 3g chitosan and be dissolved in 147g volume fraction and be made into the chitosan glacial acetic acid solution that mass fraction is 2% in the glacial acetic acid solution of 2%, then add 0.3g graphene oxide to deionized water, under room temperature Ultrasound for 1h to obtain a uniform graphene oxide dispersion;

[0027] Slowly add the graphene oxide dispersion into the chitosan glacial acetic acid solution dropwise while stirring, stir at room temperature for 24 hours, and wash several times with glacial acetic acid after the reaction to remove unreacted chitosan sugar, and then centrifuged and washed several times with deionized water, and vacuum-dried at 60° C. for 24 hours to prepare chitosan-graphene oxide, which is a nanocomposite.

[0028] 2) Prepare 30 g of casting solution: weigh 0.036 g of chitosan-graphene oxide, add 23.064 g of dimethylacetamide, and ultrasonicate for 1 hour at room temperature to obtain a uniform chitosan-graphene oxide dispersio...

Embodiment 2

[0039] 1) The preparation of the chitosan-graphene oxide nanocomposite is exactly the same as in Example 1.

[0040] 2) The difference with embodiment 1 is that the amount of chitosan-graphene oxide added in the casting solution is different. The specific operation is as follows: prepare 30 g of casting solution, weigh 0.018 g of chitosan-graphene oxide, add 23.082 g of dimethylacetamide, and ultrasonicate for 1 hour at room temperature to obtain a uniform chitosan-graphene oxide dispersion;

[0041] Sequentially weigh 6g of polyvinylidene fluoride (110°C vacuum drying for 12h), add 0.9g of polyvinylpyrrolidone (molecular weight 58000g / mol) into the above chitosan-graphene oxide dispersion, stir at 60°C for 24h, and then Stand at a constant temperature at 60°C for 12 hours for defoaming, scrape evenly on the polyester non-woven fabric with a scraper to form a casting layer, the thickness of the casting layer is 150±10μm, and then immediately put it into deionized water at 25°C...

Embodiment 3

[0044] 1) Preparation of chitosan-graphene oxide:

[0045] Dissolving chitosan in a 1% glacial acetic acid solution by volume fraction is prepared into a 3% chitosan glacial acetic acid solution by mass fraction;

[0046] Add graphene oxide into deionized water, and ultrasonicate at room temperature for 1 hour to obtain a graphene oxide dispersion; add the graphene oxide dispersion to chitosan glacial acetic acid solution under stirring, stir at room temperature for 24 hours, and then centrifugally wash with glacial acetic acid Several times, remove unreacted chitosan, then centrifuge and wash several times with deionized water, and vacuum dry to obtain chitosan-graphene oxide; wherein, the mass ratio of graphene oxide to chitosan is 1 : 10; Gained chitosan-graphene oxide is a lamellar structure with a thickness of 2-3nm.

[0047] 2) chitosan-graphene oxide is added in the organic solvent, after ultrasonic 1h at room temperature, obtain chitosan-graphene oxide dispersion liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com