Patents

Literature

130 results about "Burning head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air thermalization gas burner

InactiveCN101196308AReduce dosageHarm reductionDomestic stoves or rangesStoves/ranges topsCombustion chamberProduct gas

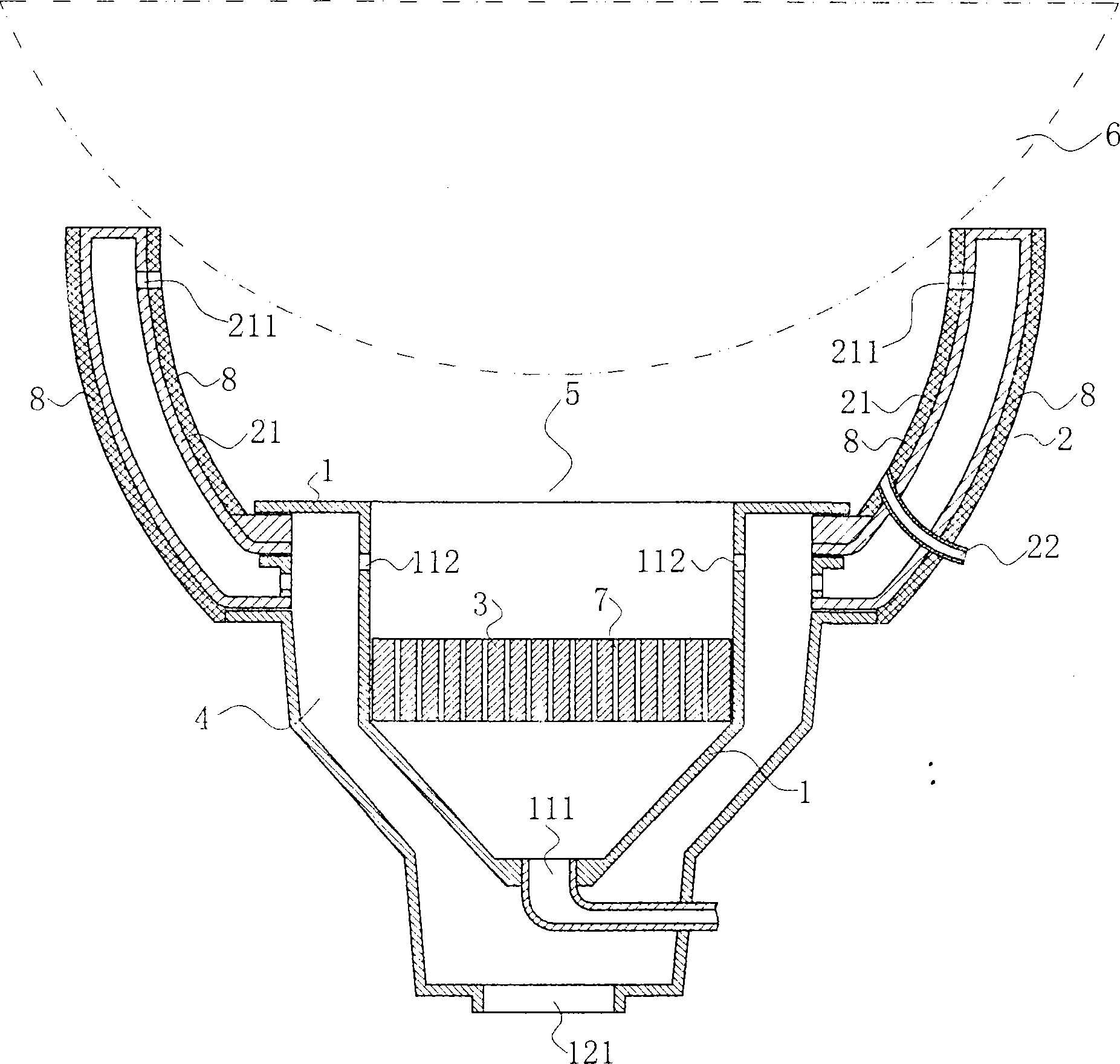

The invention discloses an air thermalization gas burner, which comprises a burner base, a furnace ring and a burning head. The burner base is provided with an air supply port and a plurality of air nozzles as well as an air supply channel communicated with the air nozzles at external side; the air supply channel is positioned with a blower air inlet; the furnace ring, a popper and a burner base form a firebox; wherein, the furnace ring is a hollow interlayer, which is provided with a plurality of back-wind ports on the internal layer interning wall near to the port; an internal cavum of the furnace ring is communicated with the air supply channel; the blower preaches the air form the air inlet, the air supply channel and the air nozzles into the firebox and the air can burn with the gas entered from the air supply port in the firebox to heat the popper; the high temperature air can pass through the back-wind ports and then return to the firebox for burning after passing through the internal cavum of the furnace ring, the air supply channel and the air nozzles; the heat of the high temperature air can be recovered and utilized as well as sufficiently burned, thereby reducing the usage of gas and restraining the generation of gas harmful to human's health as well as deducing the pollution for environment.

Owner:姜亦迎

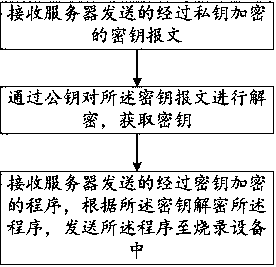

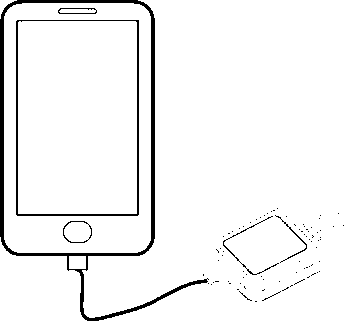

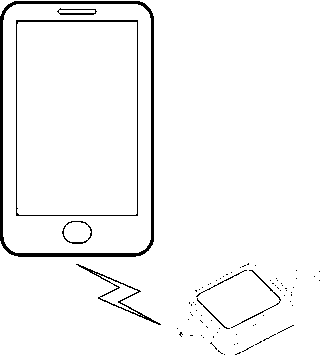

Integrated circuit program burning method, storage medium and system

PendingCN109274488AImprove securitySolve the problem of damage to interests, which is not conducive to the protection of intellectual property rightsKey distribution for secure communicationProgram/content distribution protectionThird partyIntellectual property

The invention discloses an integrated circuit program burning recording method, a readable storage medium and a burning recording system. The key information is encrypted by a public key and a privatekey, and the program is encrypted by the key again. After two encryption processes, the safety of the program in transmission can be improved, and the program is not conducive to being intercepted and cracked by a third party. The invention solves the problem that the program is easy to be cracked after the third party user obtains the key, or the source program of the program developer is stolenby decompilation, thereby causing the benefit damage of the program developer and disadvantageous to the protection of the intellectual property right, and improves the security of the burning program. Moreover, the mobile terminal is used as the host of the burning system, which solves the problem of inconvenience of carrying the burning equipment, and the user can finish the chip burning work through the mobile terminal and the smaller burning head.

Owner:GUANGZHOU ZHONO ELECTRONICS TECH CO LTD

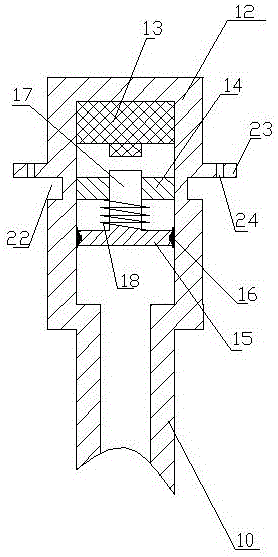

Medical temperature-adjustment pressure-adjustment instrument for small-area burn

InactiveCN101401744AObjective pressure displayAdjustable pressureDiagnosticsSurgeryElectricityTemperature control

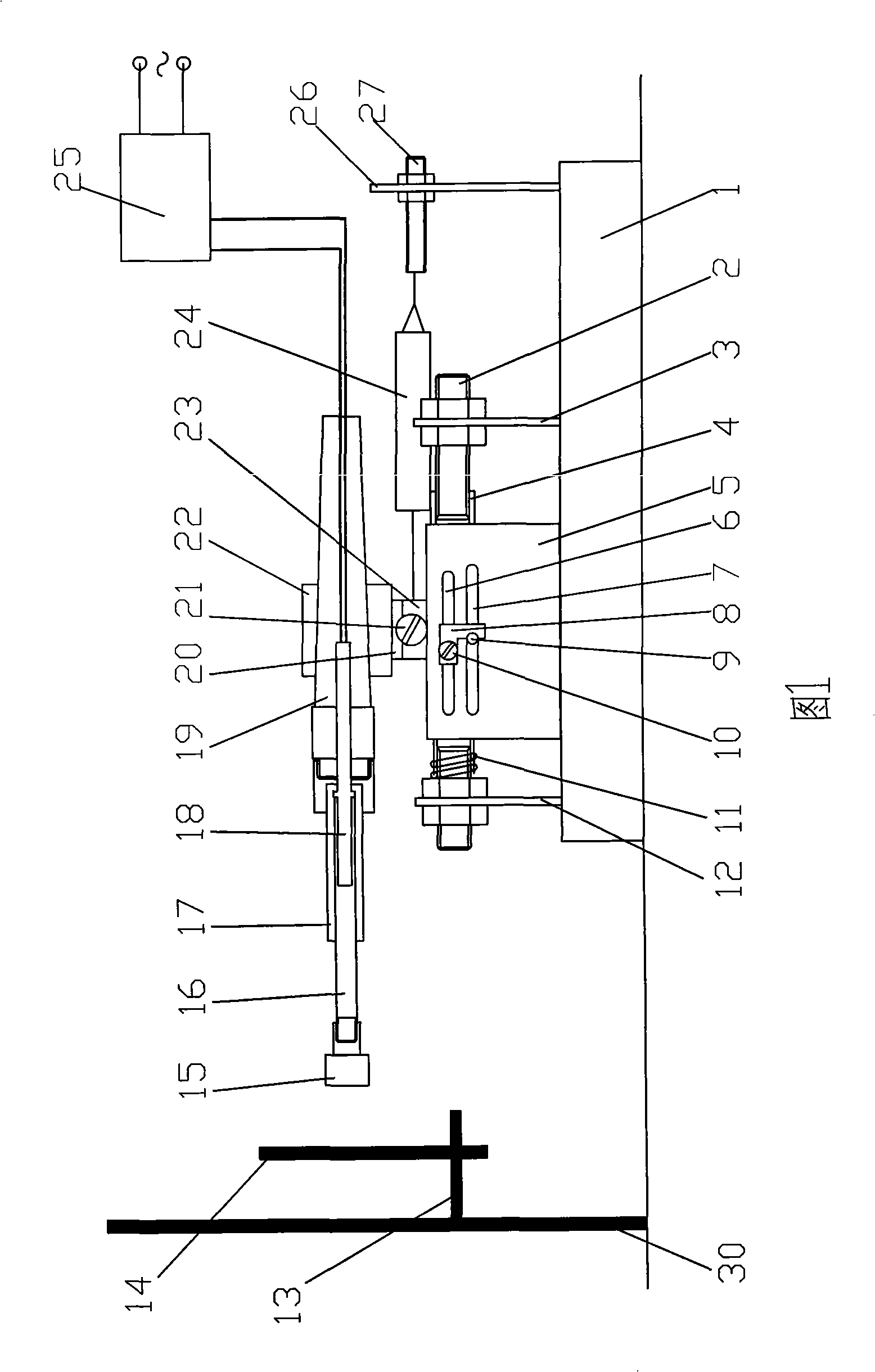

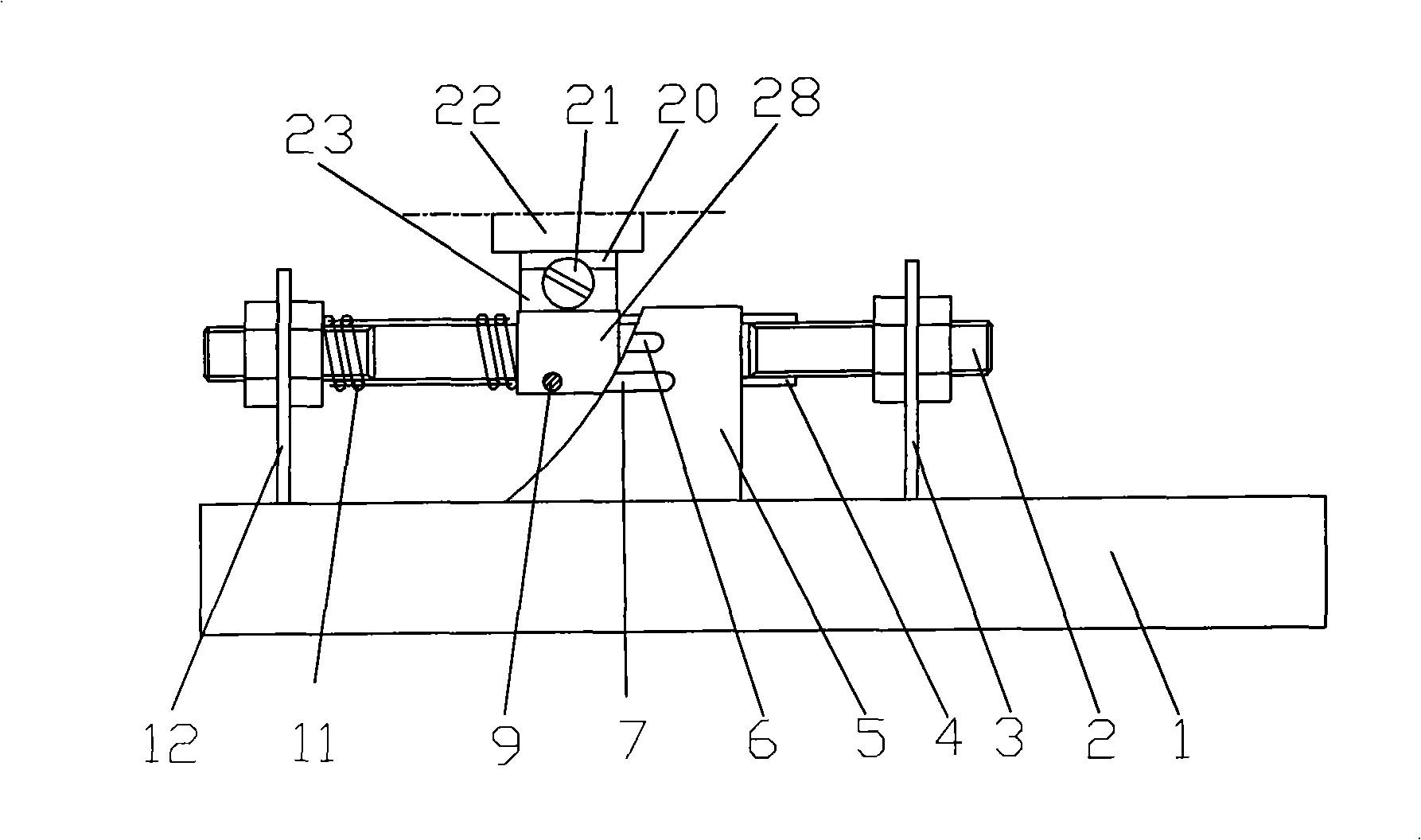

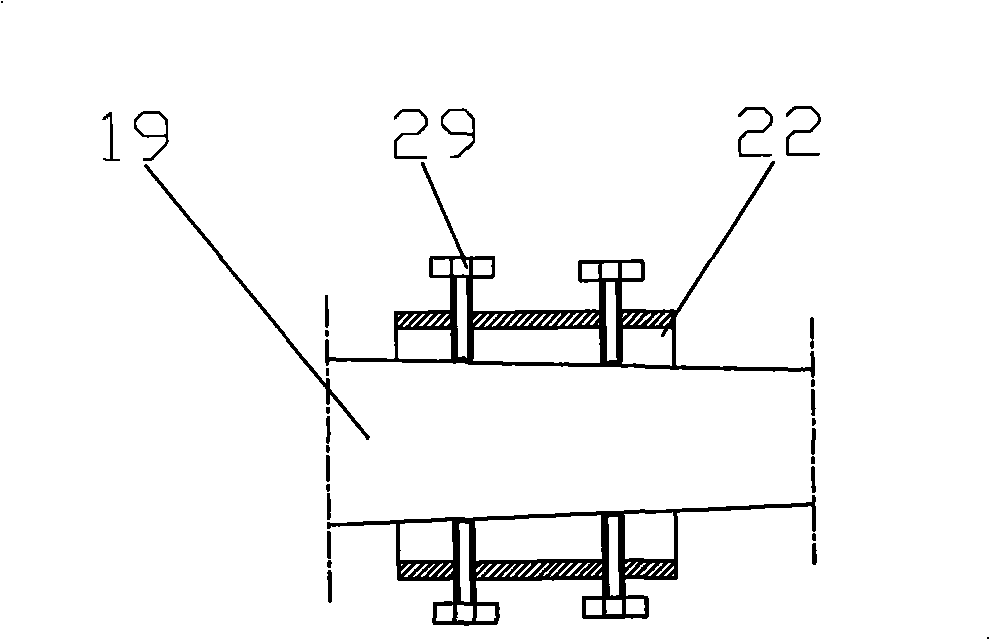

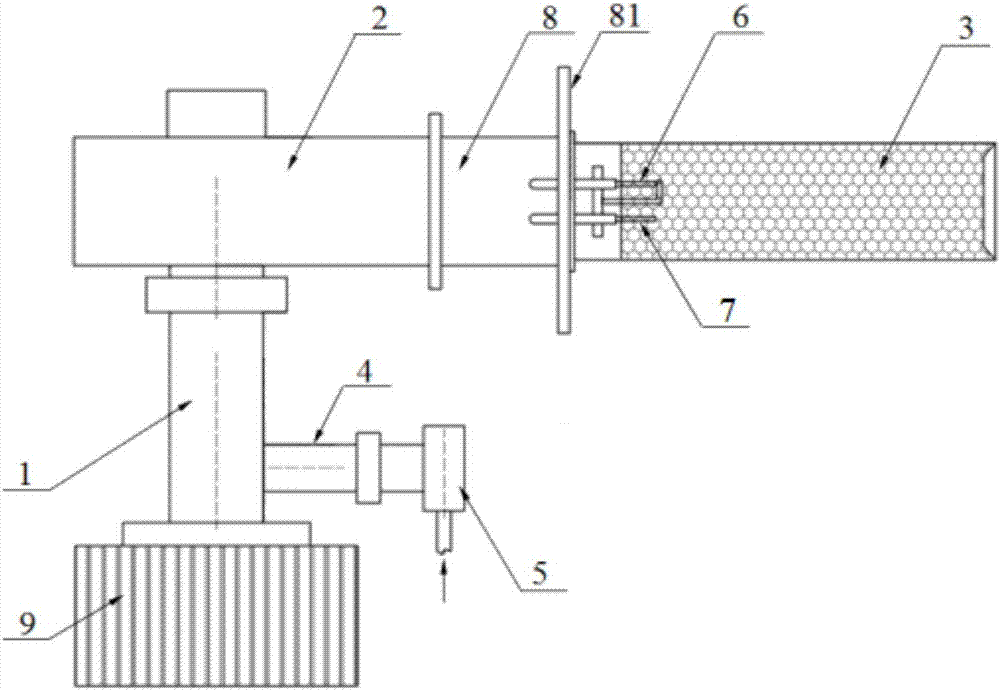

The invention discloses a medical small-area burn instrument for adjusting temperature and pressure, which comprises an animal fixing device, a burn device, a pedestal, a clamper and an elastometer. The burn device is fixed on the clamper, the pedestal is fixedly provided with a pull rod, the clamp is arranged on the pull rod in an axial sliding mode, one end of the elastometer is fixed oppositely to the pedestal and the other end of the elastometer is axially and fixedly connected with the back end of the clamper, the burn device is an electric heating burn device and comprises a burn head and an electric heater, and the electric heater is connected with an electric source through a temperature control device. The medical small-area burn instrument has the advantages that the medical small-area burn instrument has objective pressure display by adopting a pressure indicating device and a temperature adjusting device, can adjust pressure, temperature and burn area, and can adjust burn temperature, burn pressure and area according to the test requirements to make a standardized burn wound surface.

Owner:ARMY MEDICAL UNIV

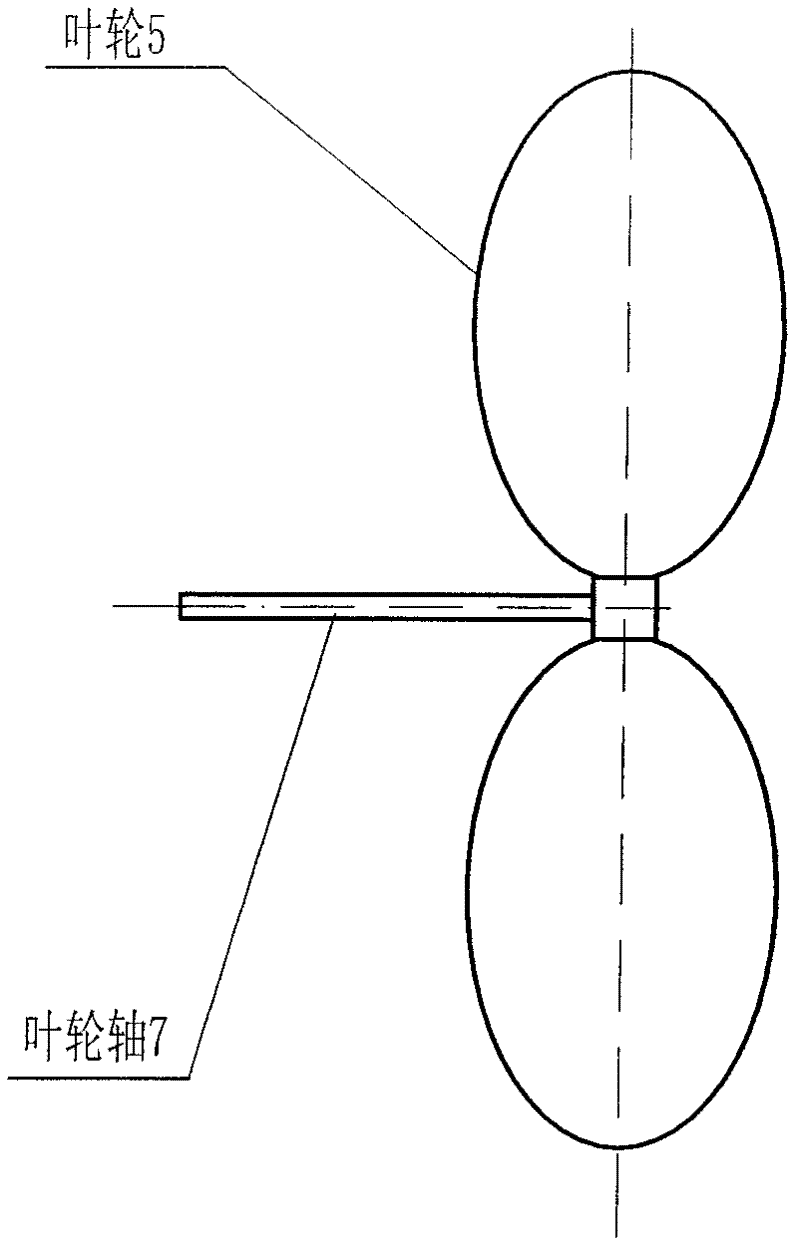

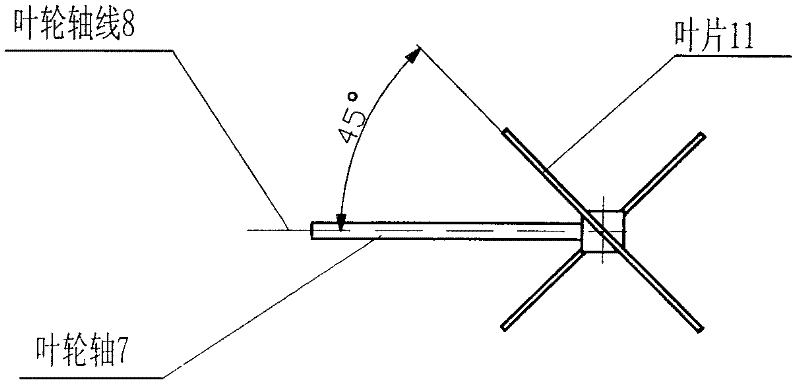

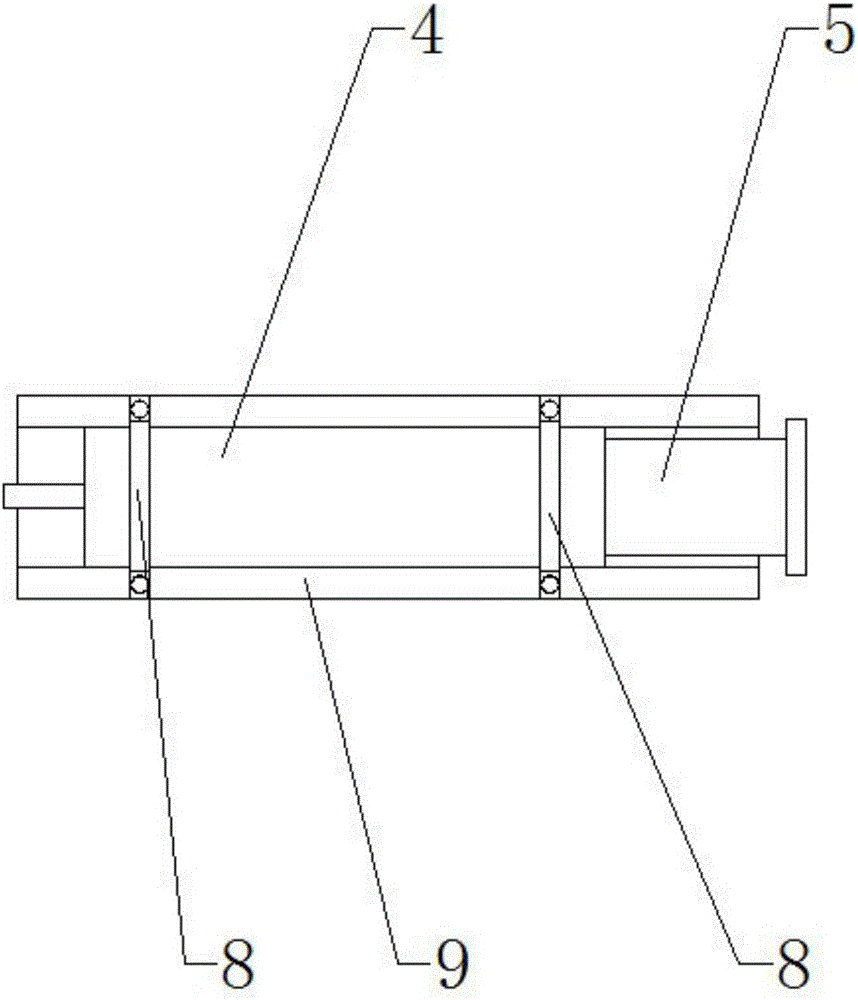

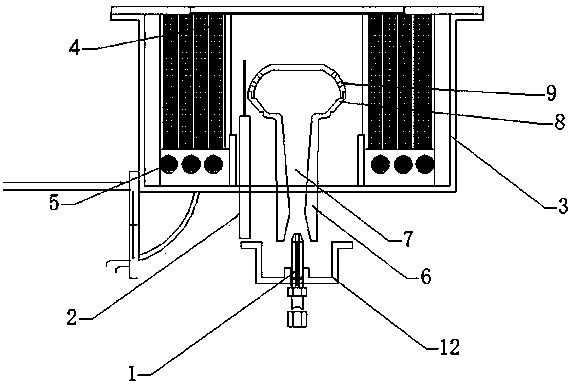

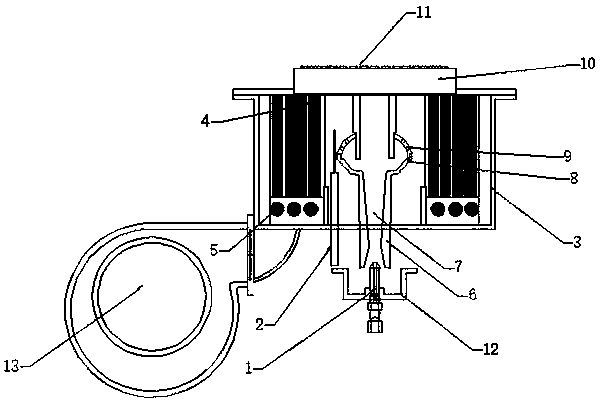

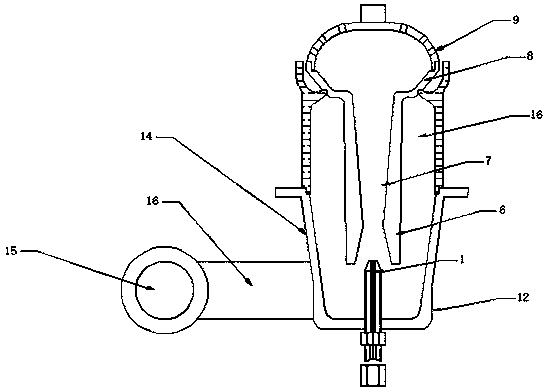

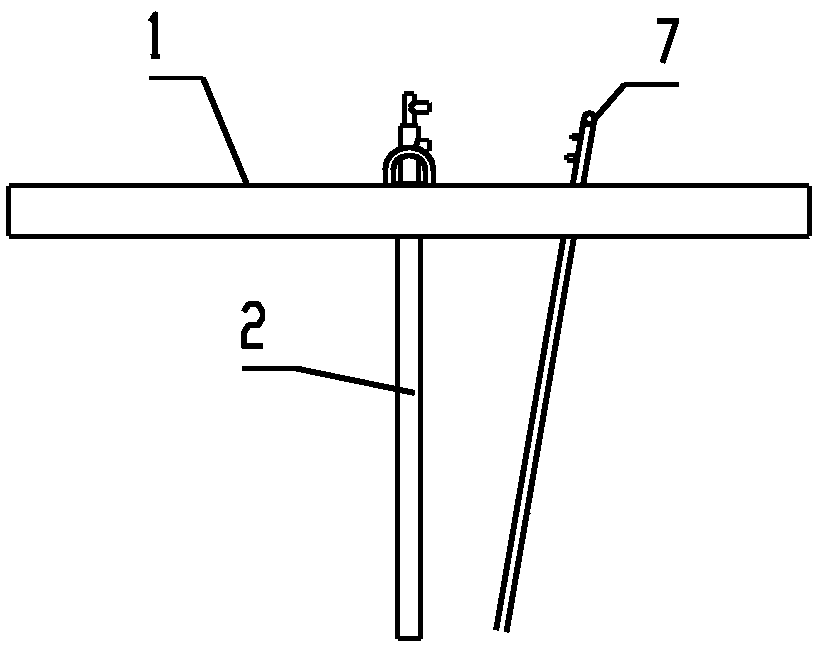

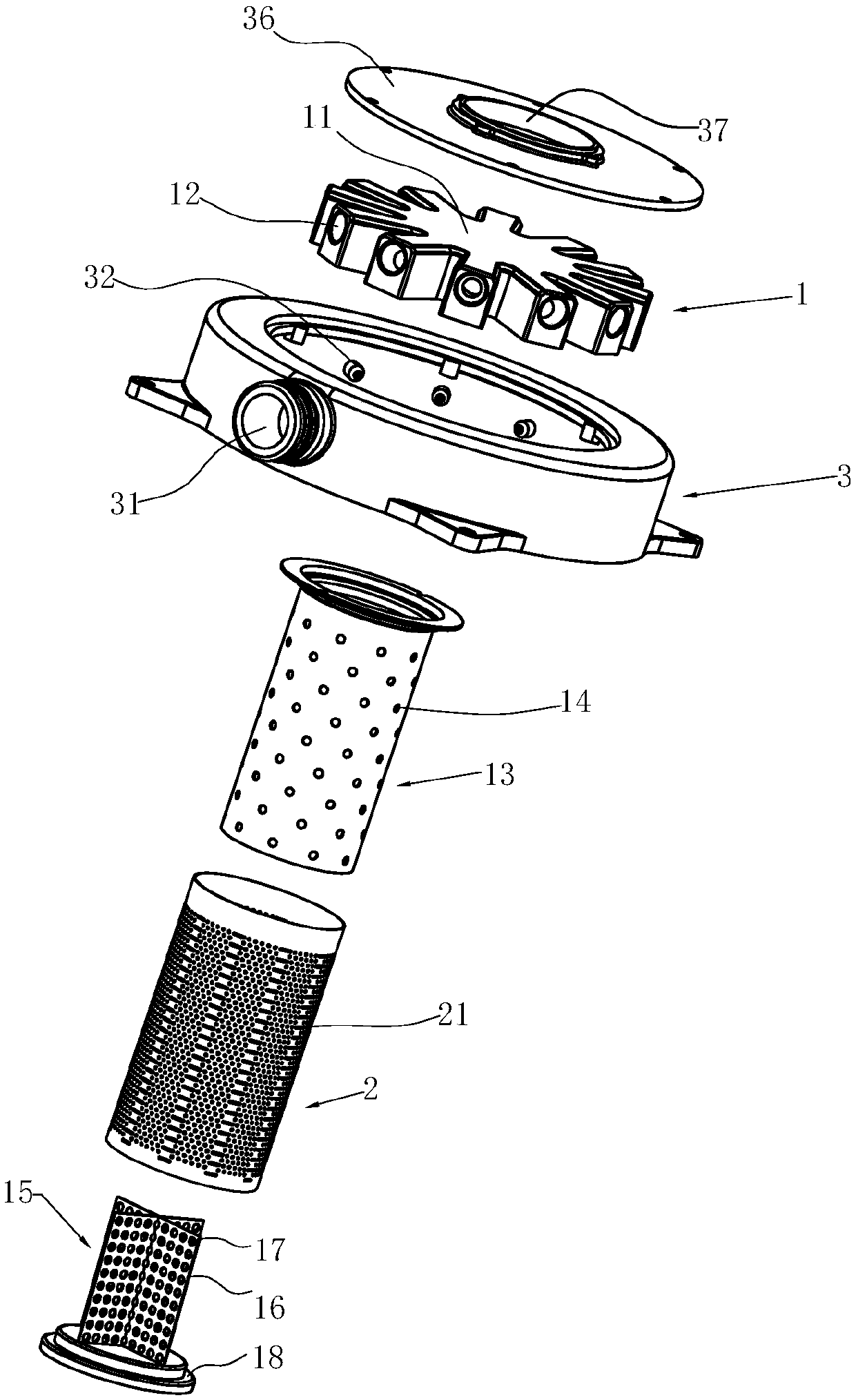

Injection impeller burner

InactiveCN102359727ALight in massThe effect of small air intakeGaseous fuel burnerImpellerEngineering

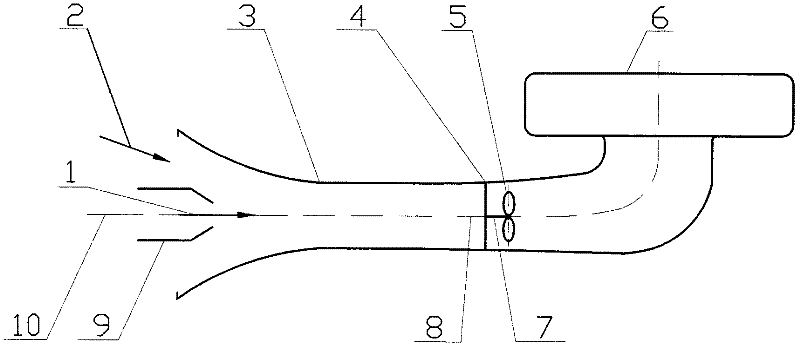

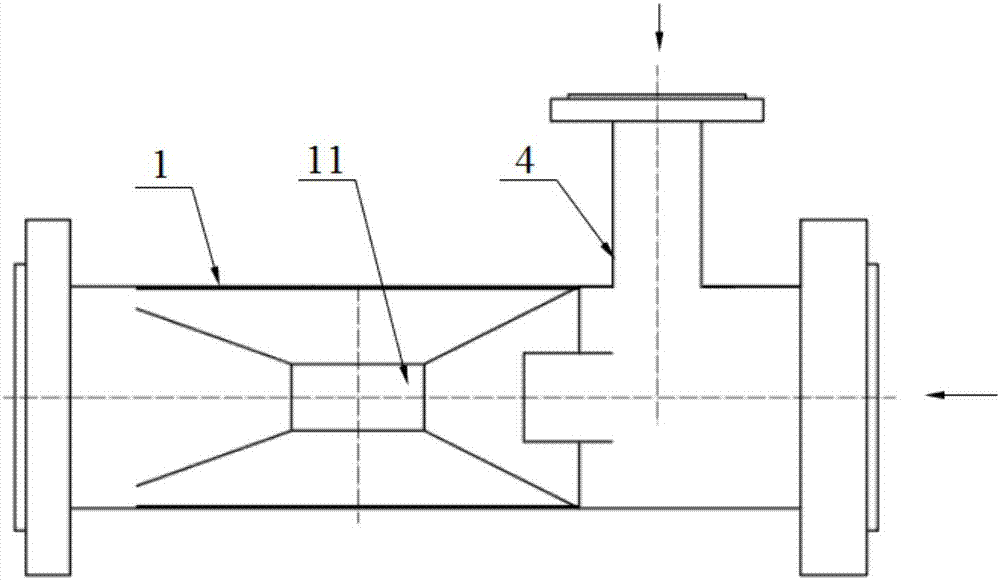

The invention discloses an injection impeller burner, and in particular relates to a civil gas cooker. The burner comprises a spray pipe (9), an injection pipe (3), an impeller (5) and a burning head (6), wherein a shaft bracket (4) is arranged in the injection pipe (3) and provided with an impeller shaft (7); the impeller (5) is arranged on the impeller shaft (7) and can freely rotate relative to the shaft bracket (4); the injection pipe (3) is fixedly connected with the shaft bracket (4); and an impeller axis (8) is overlapped with an injection pipe central line (10). When gas (1) at a certain flow velocity is injected from the spray pipe (9) and enters the injection pipe together with injected air (2) simultaneously to push the impeller (5) jointly to quickly stir in a rotary mode, so that the gas (1) and the air (2) are fully and uniformly mixed at the moment of passing through the impeller (5), and the gas and the injected required theoretical air are distributed in each burning hole of the burning head in the same ratio and enter the burning head (6) to be burnt; therefore, the burning heat efficiency of the injection burner is obviously improved.

Owner:王萍 +1

Process for preparing ceramic cartridge for super long type high voltage fuse

ActiveCN101456741AMeet the use requirementsAchieve mass productionEmergency protective devicesSpray GranulationMaterial distribution

The invention discloses preparation technology for a ceramic envelope of a super-long high-voltage fuse. After a ceramic raw material is subjected to isostatic compaction to be prepared into a hollow tube through material distribution and spray granulation, a blank of a tube to be burned with a suspension burning head is turned first, and then a special calcination slab and suspension firing kiln tool are used to perform high-temperature calcinations in a high-temperature kiln by adopting a suspension burning and sleeving mode. The preparation technology is suitable for preparing the ceramic envelope of the super-long high-voltage fuse (the length is more than 400mm). The envelope is processed and produced by adopting a special ceramic process, is calcined by adopting a special calcination method, and solves the problems of the ceramic envelope such as deformation and bending. The preparation technology meets the operating requirement of the fuse. The preparation technology ensures that the qualification rate of products reaches more than 90 percent through practical production application, and realizes mass production.

Owner:陕西宝光陶瓷科技有限公司

Energy-efficient ceramic kiln burner

The invention discloses an energy-efficient ceramic kiln burner. A base consists of an air intake chamber and an air outlet chamber, a cylindrical shell is connected with the air outlet chamber in a sealing manner, a cup-shaped burning head is fixed at the front end of the cylindrical shell in a sealing manner, a gas pipeline is arranged in the cylindrical shell, and a gas nozzle at the front end of the gas pipeline is aligned to the bottom of the cup-shaped burning head. The gas nozzle is arranged at the rear end of the burner and keeps a certain distance from the burning head, so that gas and air are premixed at the rear end of the burning head and form mixing concentration gradient, thereby effectively eradicating the backfire detonation phenomenon due to uniform mixing of the air and the gas in the cylindrical shell. The energy-efficient ceramic kiln burner automatically controls an air volume through a circuit to reach the best ratio of the gas to the air, can save above 20% of the gas than the existing burner, and has huge social and economical benefits of energy conservation, emission reduction, low carbon and environment friendliness.

Owner:北京中宇先创能源科技有限公司

Fuel gas cooking utensils of having new type set for adjusting firepower

ActiveCN1661277AProper cooking powerAccurately adjust the size of the firepowerDomestic stoves or rangesGaseous fuel burnerEnergy conservationFuel gas

A flame regulation device of gas stove consists of burner, burning head, ejecting tube, valve body, valve core and gas nozzle. It is featured as setting hollow tube through to valve body on radial of the valve body, setting elastic positioning mechanism with different rotary position in hollow tube for positioning valve core, having positions corresponding to elastic positioning mechanism on peripheral surface of valve core for realizing accurate regulation of flame.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

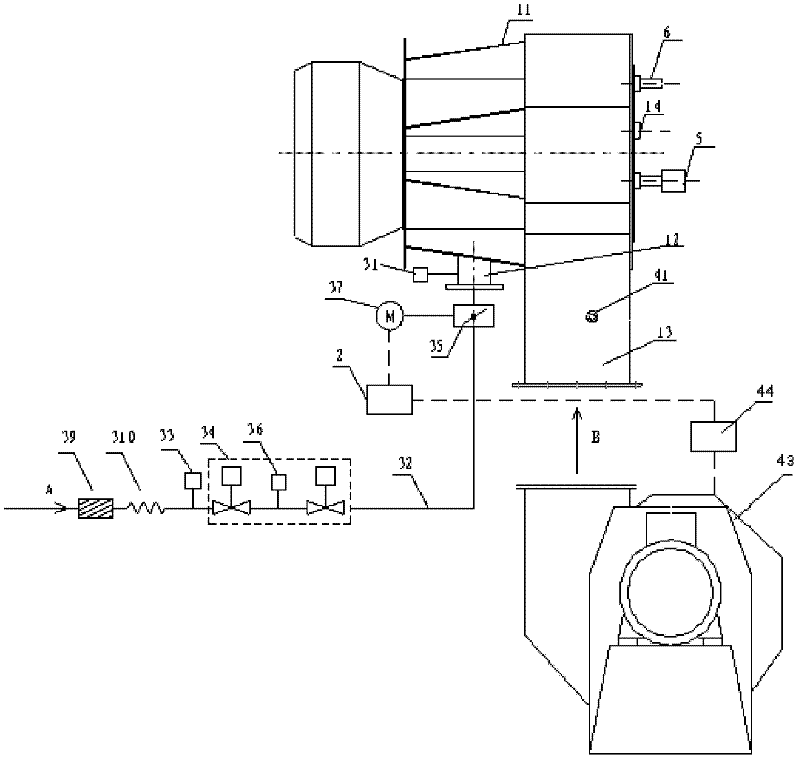

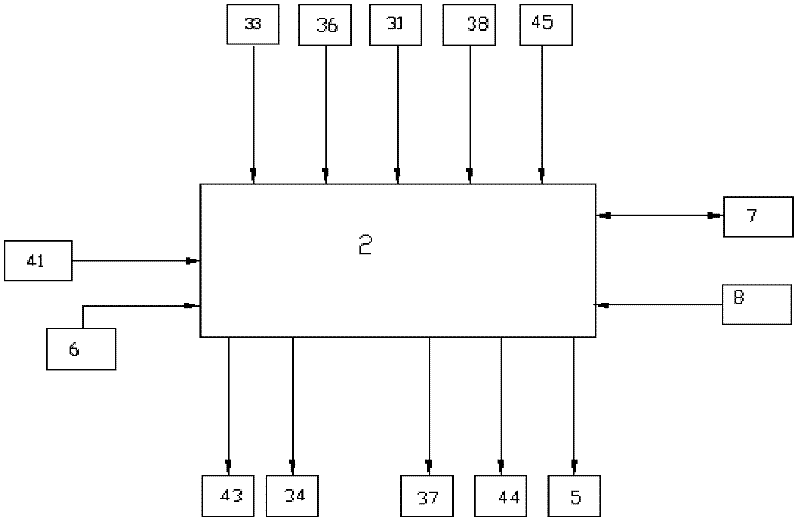

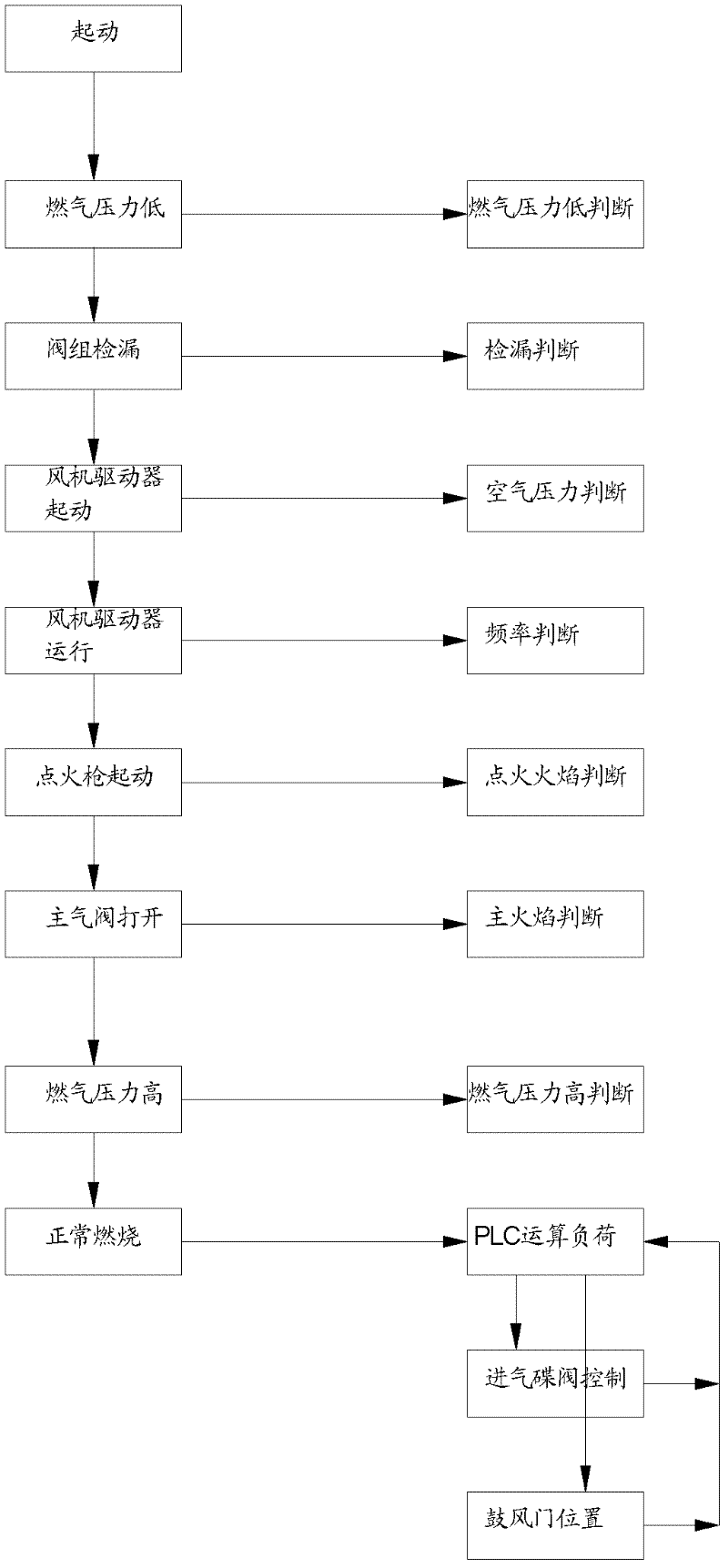

Gas burner

InactiveCN102563645AEmission reductionAvoid emissionsGaseous fuel burnerTemperature controlAir volume

The invention discloses a gas burner, which comprises a burning head, a controller, a man-machine interaction device, an ignition device, a flame monitoring device, a fuel device and an air supply device, wherein the ignition device and the flame monitoring device are mounted on the burning head, and the fuel device and the air supply device are respectively connected with the controller. The air supply device comprises a blower device, an air pressure detecting device and a fan driver, the blower device corresponds to an air inlet pipe of the burning head, the air pressure detecting device and the fan driver are mounted on the air inlet pipe of the burning head, the fan driver is used for changing the air outlet volume of the blower device by changing the frequency of the blower device, a fan driver feedback device is arranged on the fan driver, and the air pressure detecting device, the fan driver feedback device, the fan driver and the blower device are respectively connected with the controller. The gas volume and the air volume are individually and automatically adjusted, an air-gas ratio is preset by the aid of the man-machine interaction device, and energy consumption is low, so that emission of waste gas is reduced. By the aid of the man-machine interaction device, the problem of complicated operation is solved, and the gas burner is high in automation degree, accurate in temperature control and high in gas adjusting ratio.

Owner:JIANGSU OUBIAO

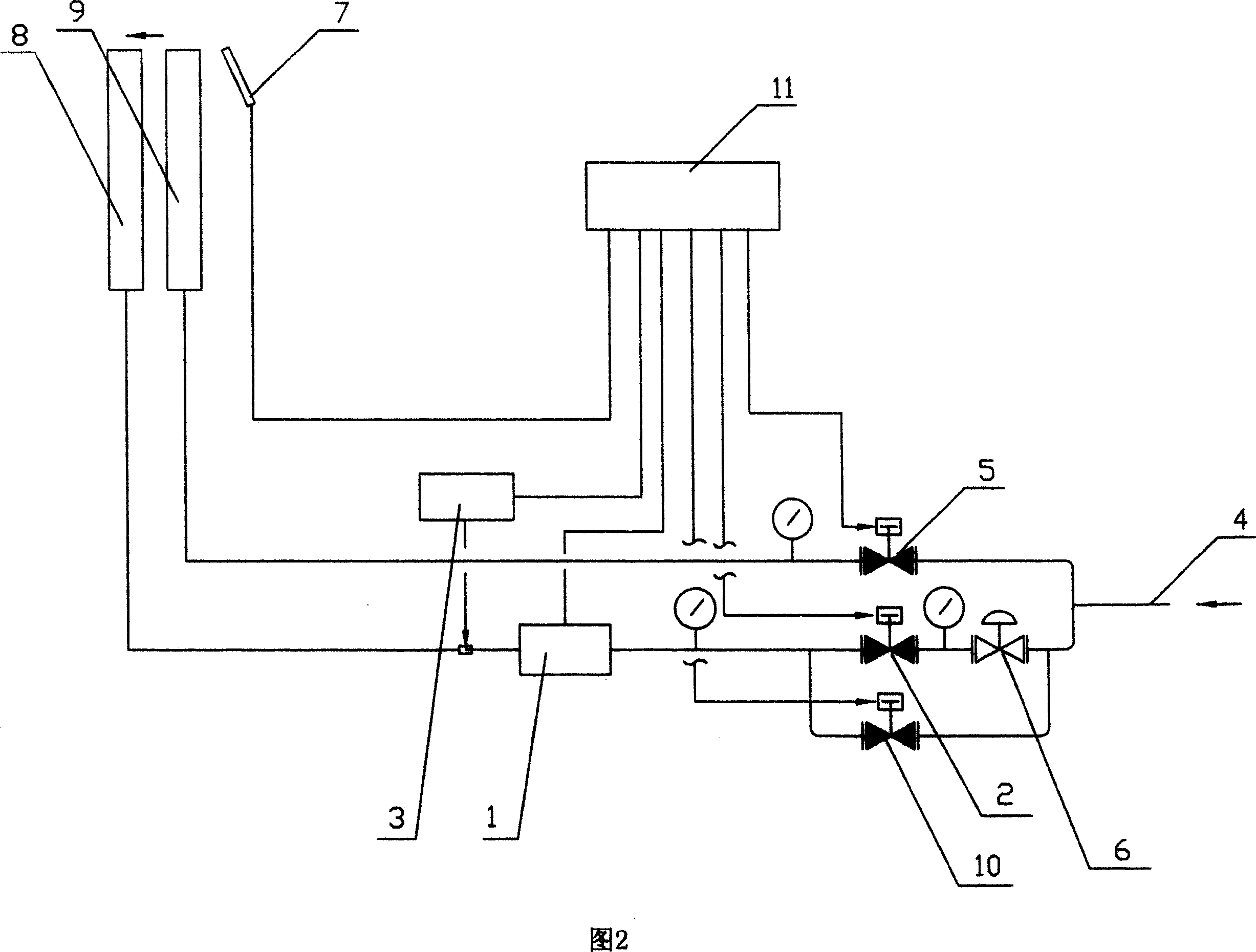

Gas headwind injection gas mixing combustor

InactiveCN105402726AImprove blending effectImprove combustion efficiencyGaseous fuel burnerEngineeringBurning head

The invention discloses a gas headwind injection gas mixing combustor. The combustor comprises a burning head, a gas pipe, an air cylinder, a fan and a nozzle, and is characterized in that the lower end of the air cylinder is connected with the fan; the upper end of the air cylinder is connected with the burning head; the gas pipe penetrates through the wall of the air cylinder to enter the air cylinder; the nozzle is connected to an outlet end of the gas pipe; an outlet of the gas pipe is downwards; and gas injected by the nozzle is opposite to the wind direction. The gas headwind injection gas mixing combustor has the following beneficial effects: the fuel and air mixing effect is intensified to improve the combustion efficiency; and the length of a mixed gas pipeline is shortened to improve the safety of the gas combustor.

Owner:YUNNAN AEROSPACE IND

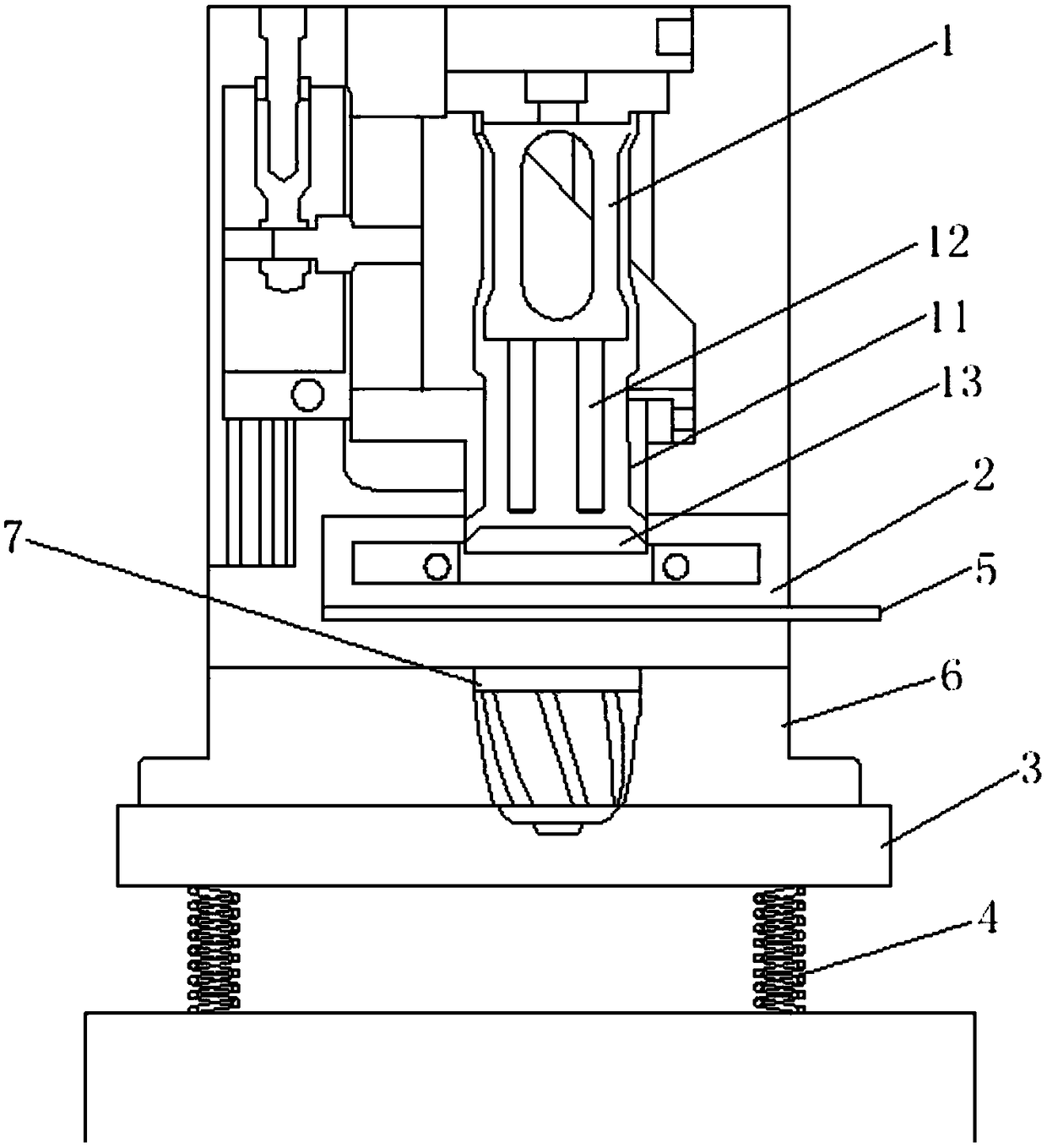

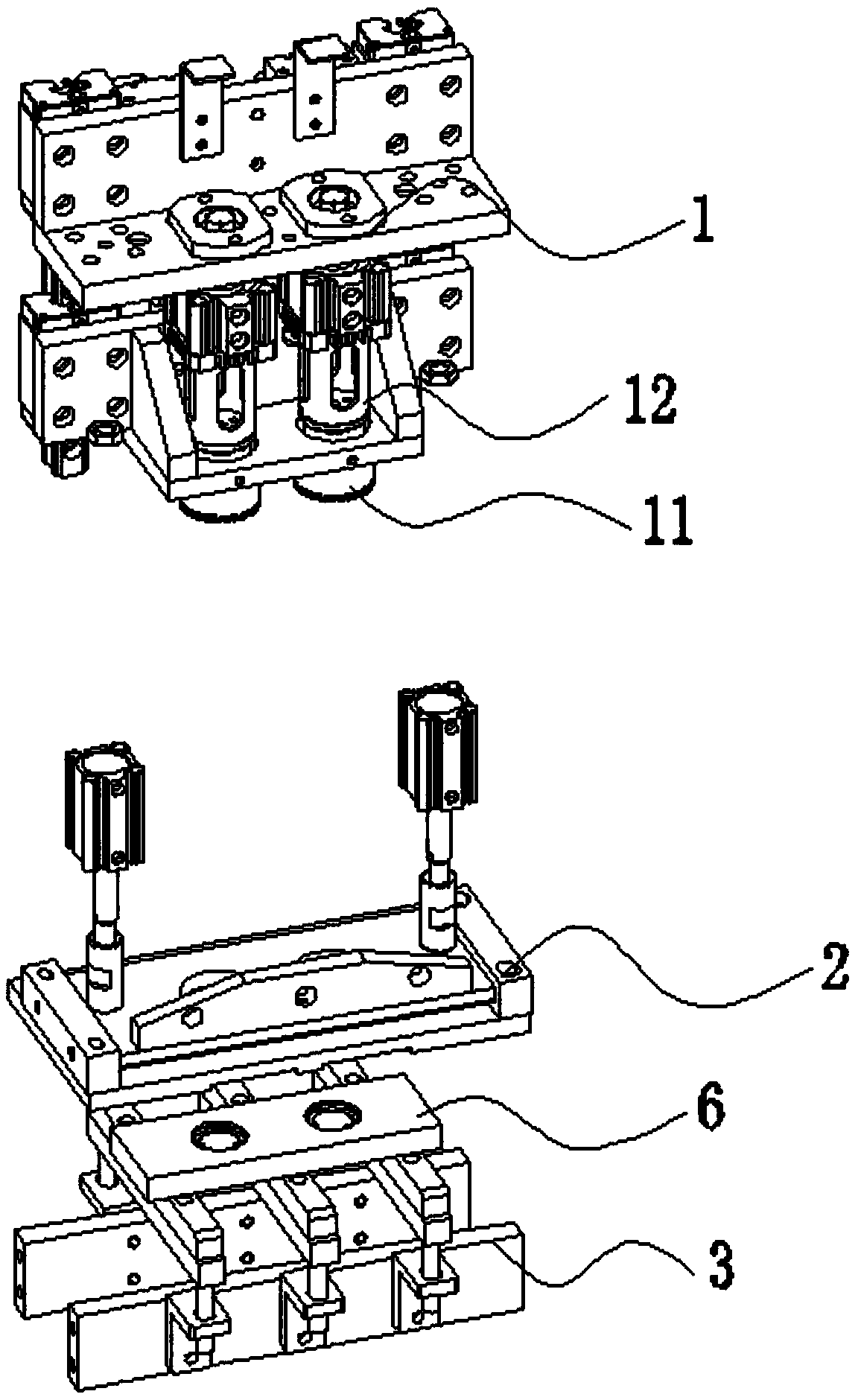

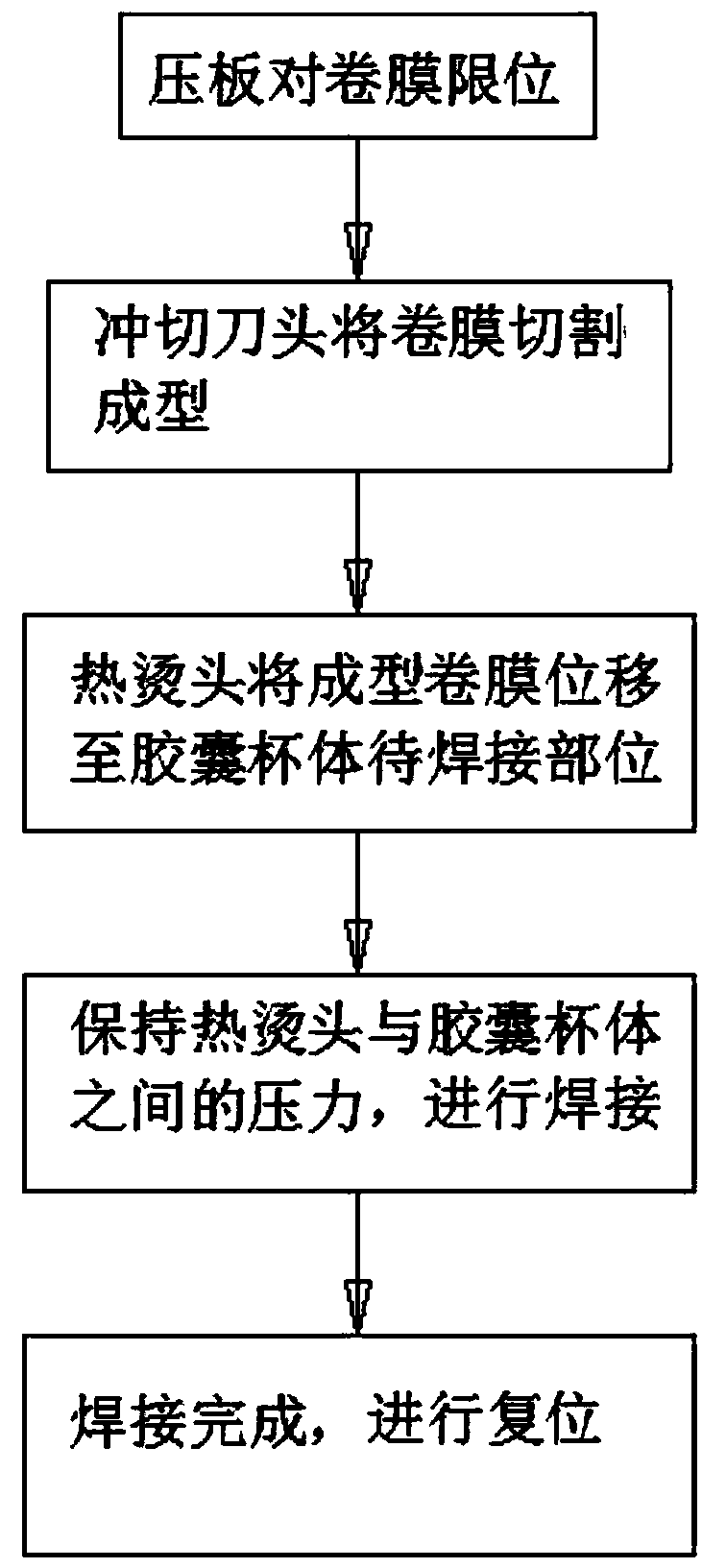

Film pressing, cutting and welding integral machining technological method

InactiveCN108454973AGuaranteed uptimeAffect the service lifeWrapper twisting/gatheringPunchingUltimate tensile strength

The invention discloses a film pressing, cutting and welding integral machining technological method. A punching welding mechanism, a pressing plate and a jig are included. The punching welding mechanism comprises a punching tool bit and a hot burning head. The hot burning head is movably installed in the punching tool bit. The film pressing, cutting and welding integral machining technological method comprises the following machining steps that S1, the punching welding mechanism drives the pressing plate to move downwards, and the pressing plate stops moving after limiting a rolled film; S2,the punching welding mechanism continues moving downwards, the rolled film is cut off by the punching tool bit, and movement is stopped after a formed film is formed; S3, the hot burning head pushes the formed film and continues moving downwards to a welded workpiece, and the temperature of the hot burning head is 203 DEG C-245 DEG C; S4, the formed film is hot-welded to the workpiece through thehot burning head according to preset time, meanwhile a buffer device is further arranged in the linear direction of the hot burning head and the formed film, and welding pressure is adjusted through the buffer device; and S5, after welding, the punching welding mechanism drives the pressing plate to move upwards to return. According to the film pressing, cutting and welding integral machining technological method, time of film material hot burning technology is shortened greatly, hot burning work efficiency is improved, labor intensity is lowered, and product quality is improved.

Owner:无锡鼎加弘思饮品科技有限公司

Device for fixing moxa stick

The invention relates to a device for fixing moxa stick, comprising a seat frame in prismatic table shape capable of being placed on the surface of human skin; the upper surface of the seat frame is provided with a through hole for extending the moxa stick in the inner cavity of the seat frame for clamping and fixing the moxa stick; when the device for fixing moxa stick is used, the moxa stick is burnt; one burnt head of the moxa stick is extended in the inner cavity of the seat frame and then fixed; the seat frame is positioned on the surface of human skin for hot moxibustion; thus, patients can operate without helps of others conveniently.

Owner:徐智常

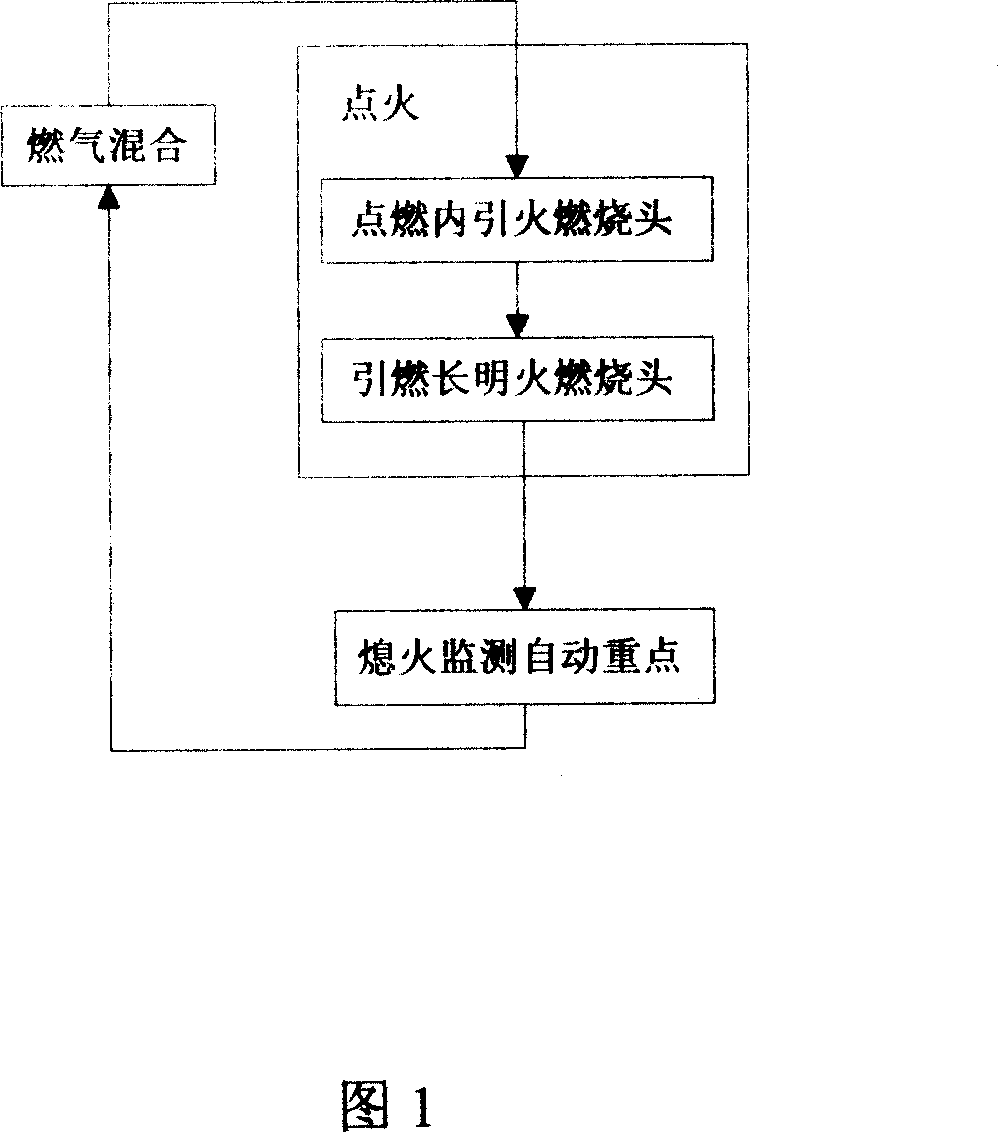

Ignition control method

InactiveCN101055092ANot affectedRealize fully enclosed ground operationPilot flame ignitersChemical industryIgnition coil

The invention disclose an ignition control method, specially relates to an ignition control method for igniting another combustible gas by employing inner ignition mode, and is used for solving the weakness existing in current ignition method such as unsafe aloft ignition work, low ignition success rate, inconvenient maintain and so on. The method includes steps as following: mixing ignition gas with air, igniting inner ignition burning head, adjusting flame of the inner ignition burning head, igniting all-time fire burning head, shutting off the inner ignition system, automatically monitoring flameout and so on. For employing the inner ignition mode, the method can realize ground ignition, and ignition will not be affected by climate, environment, and the ignition success rate can be enhanced, and the method has better safety, is widely applicable for ignition control in petroleum chemical industry or other.

Owner:逯兆林

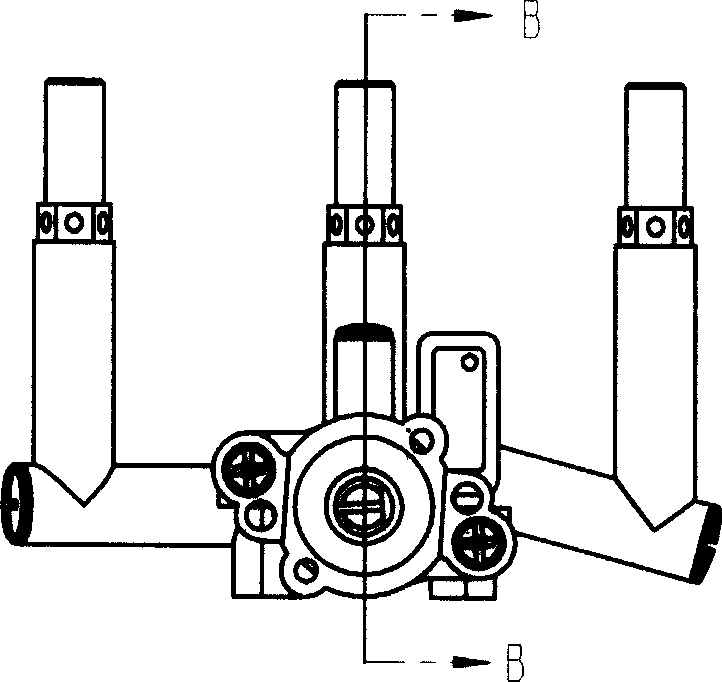

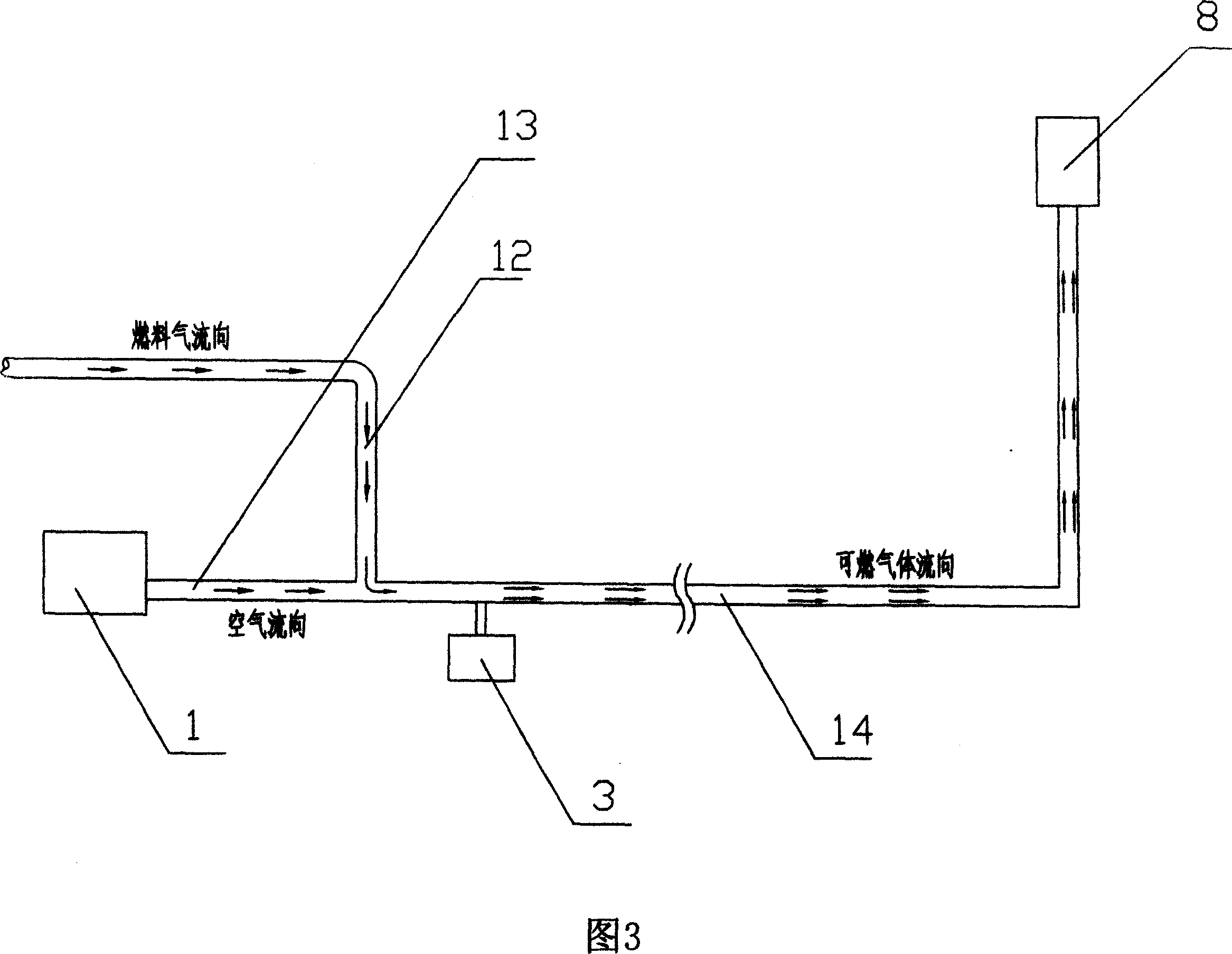

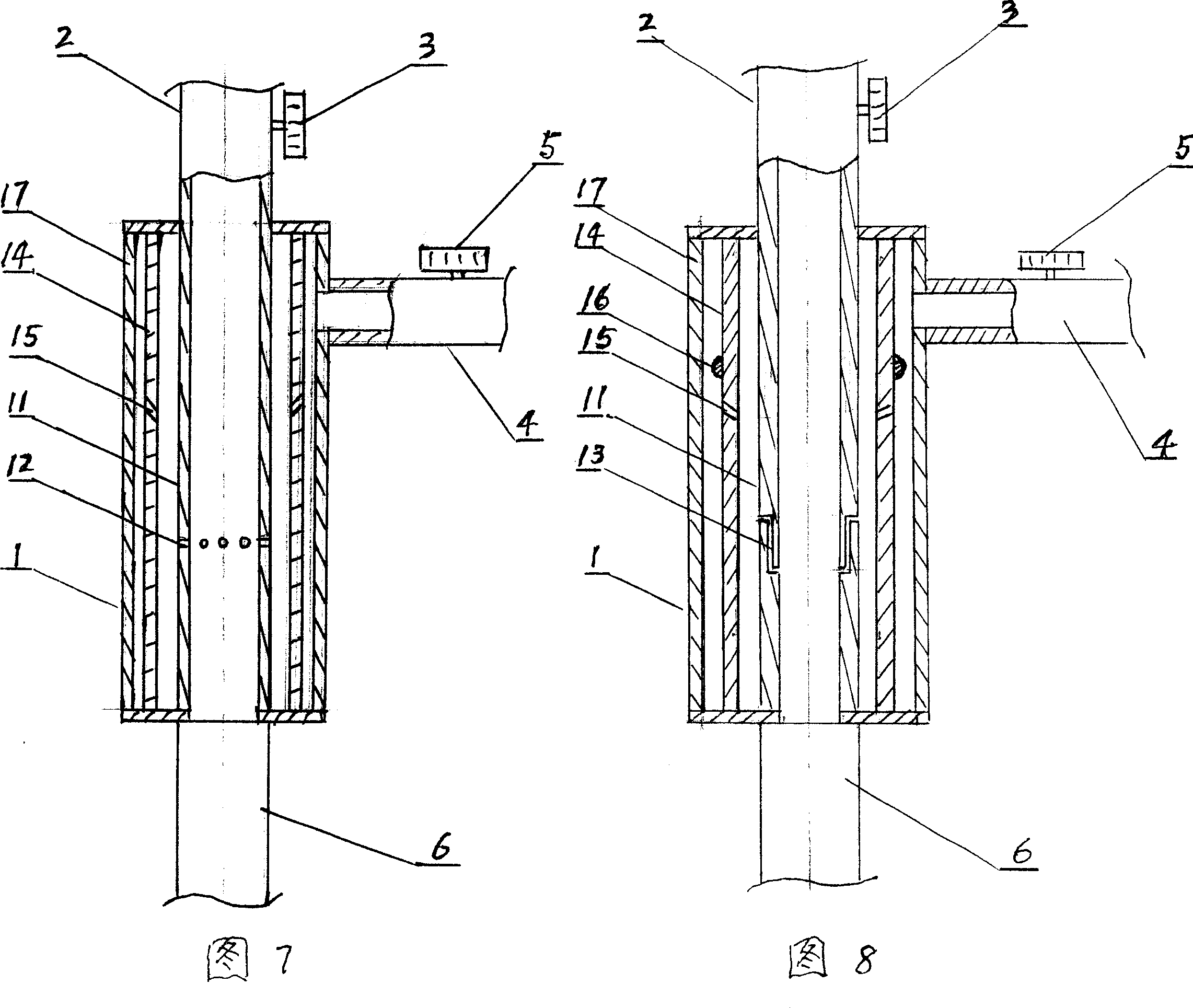

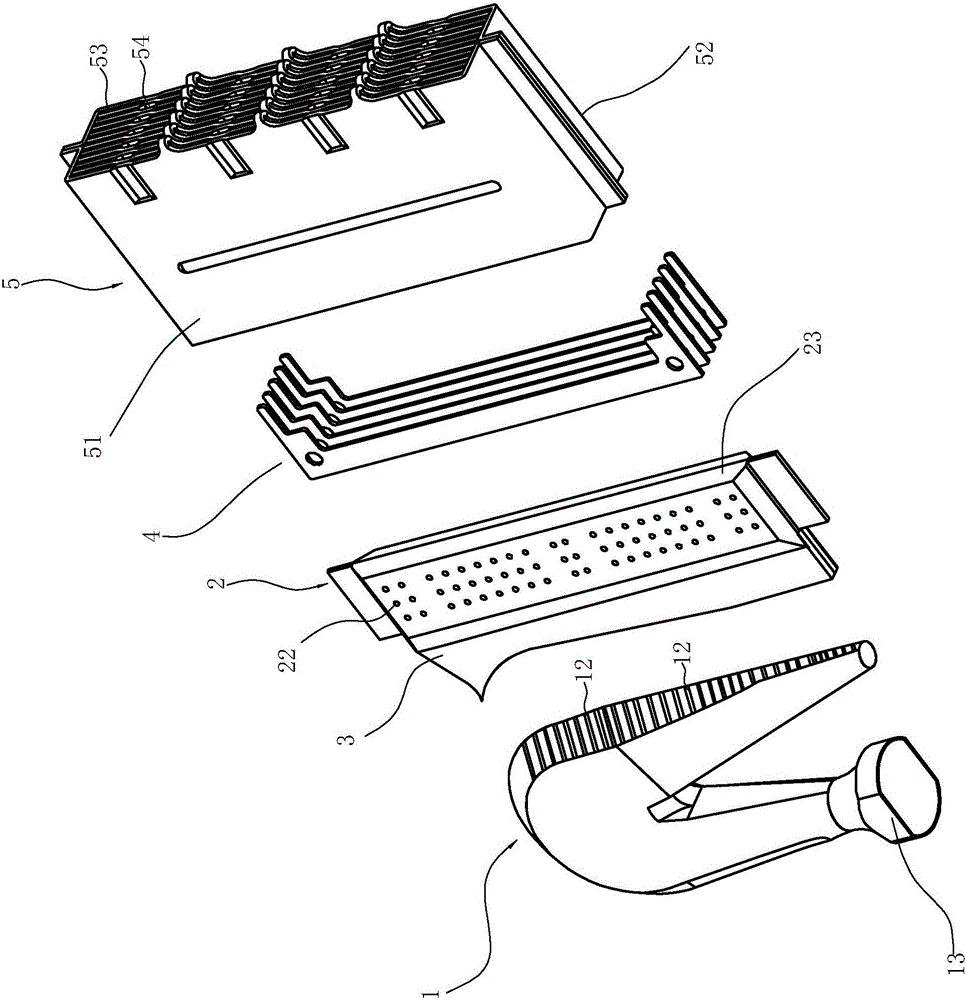

Flame spraying gun mainly used for laying water-proof coiled material

A flame spray gun essentially for paving water-proof coils is provided, which relates to the spraying, baking and heating equipment for paving waterproof coils. The spray gun comprises a mixture air distribution valve 1, a mixed-air delivery pipe 6, a burning head 7, and a fixing support 10. The mixture air distribution valve comprises an inner pipe 11, an intermediate casing pipe 14 and an outer pipe 17. The burning head comprises a sandwich air disc for burning head 8 or a hollow air pipe for burning head 8', the air disc 8 or the air pipe 8' is provided with a plurality of flame nozzles 9. The invention connects a hose with LPG and compressed air, the dead weight is light, the invention is easy and flexible for handheld construction, the labor intensity is reduced; by using LPG as energy, especially compressed air for supporting combustion, the temperature is high, fire is strong, the surfaces of waterproof coils can melt rapidly, but the temperature rise in the inner layer is low, the structure and the waterproof property of the whole material are not damaged, the construction efficiency is high, the quality is good, and the construction cost is much lower than using a gasoline blowtorch.

Owner:王新格

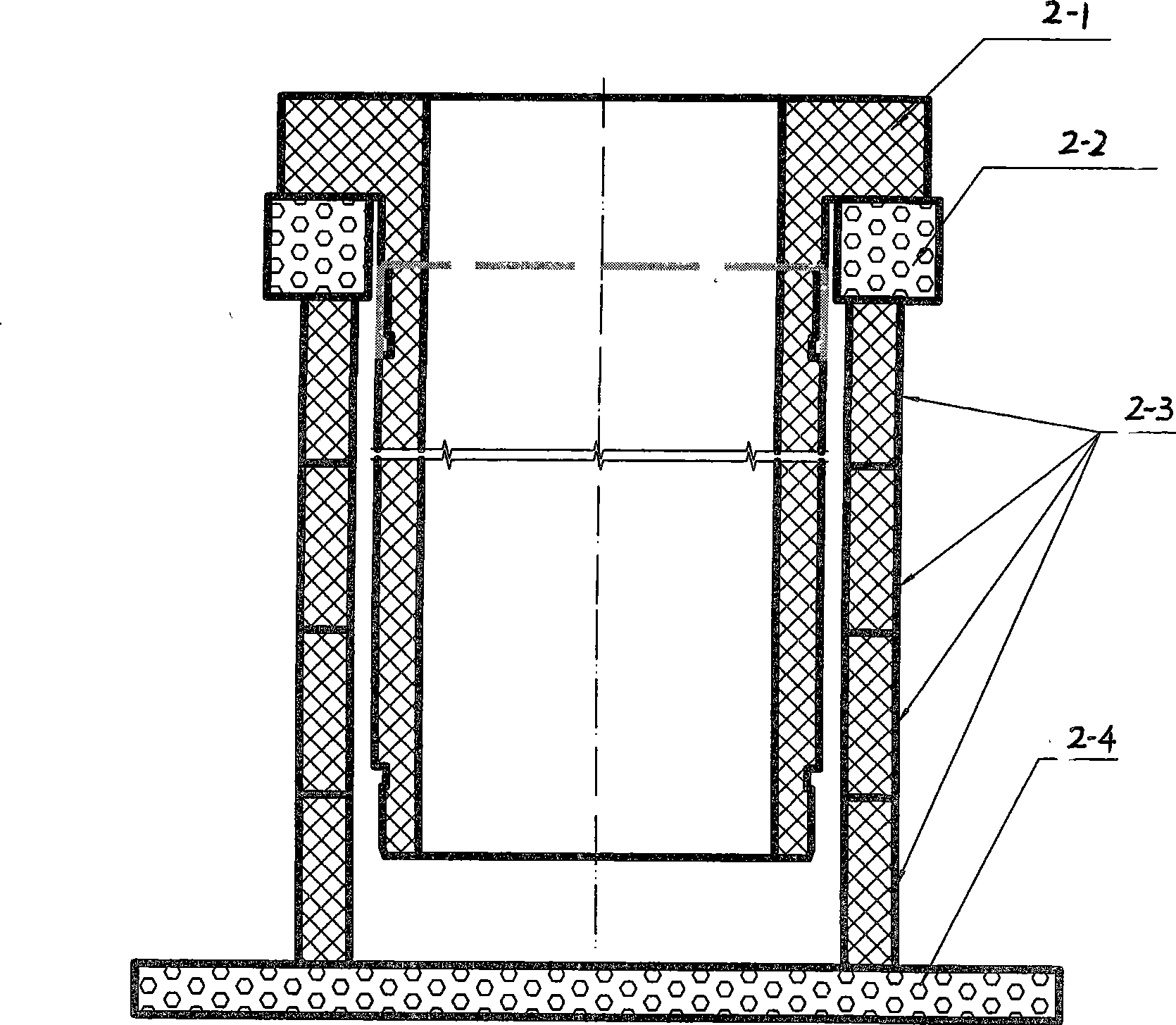

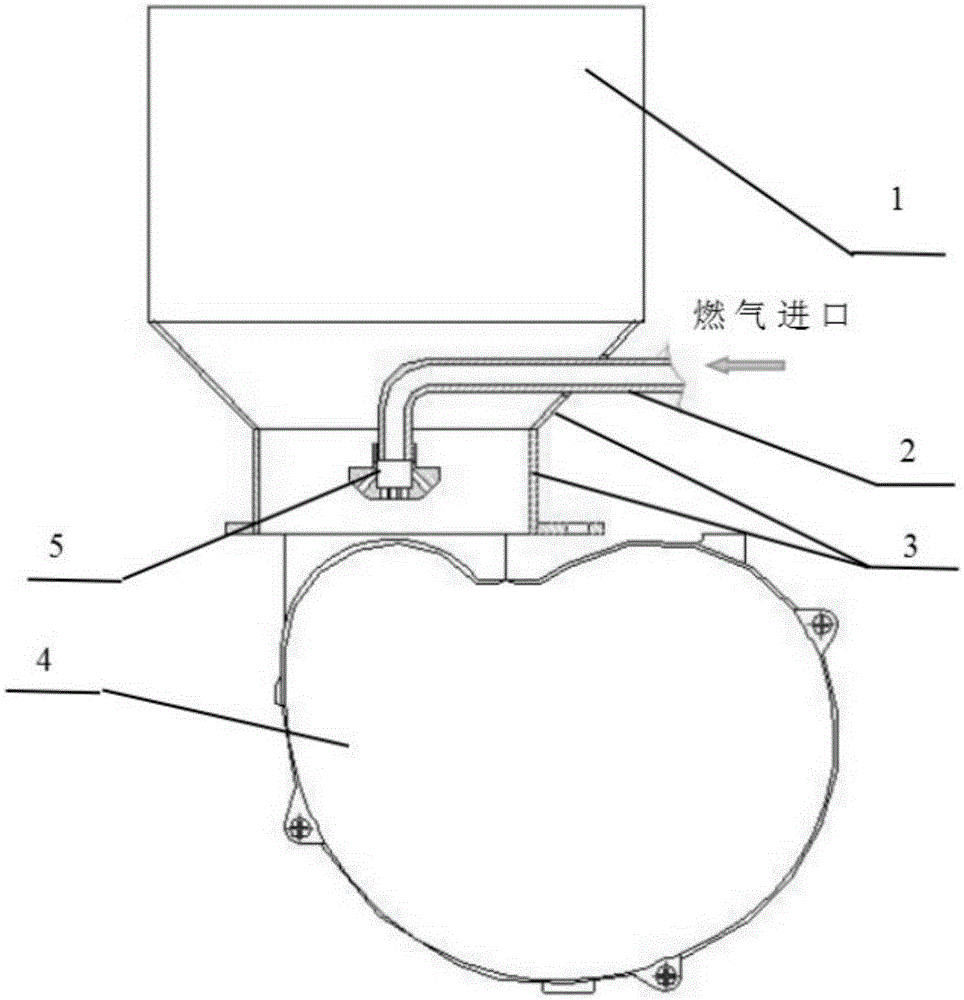

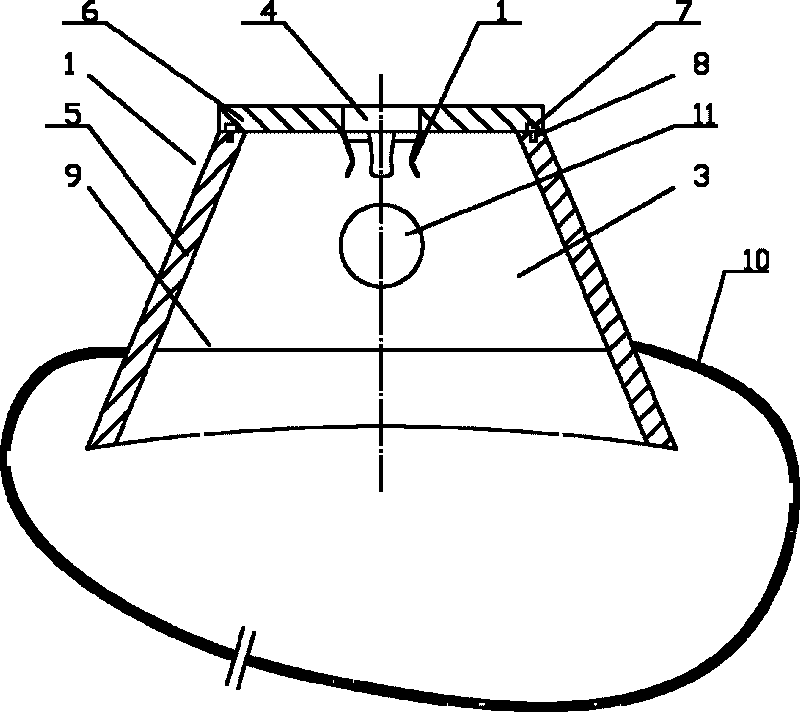

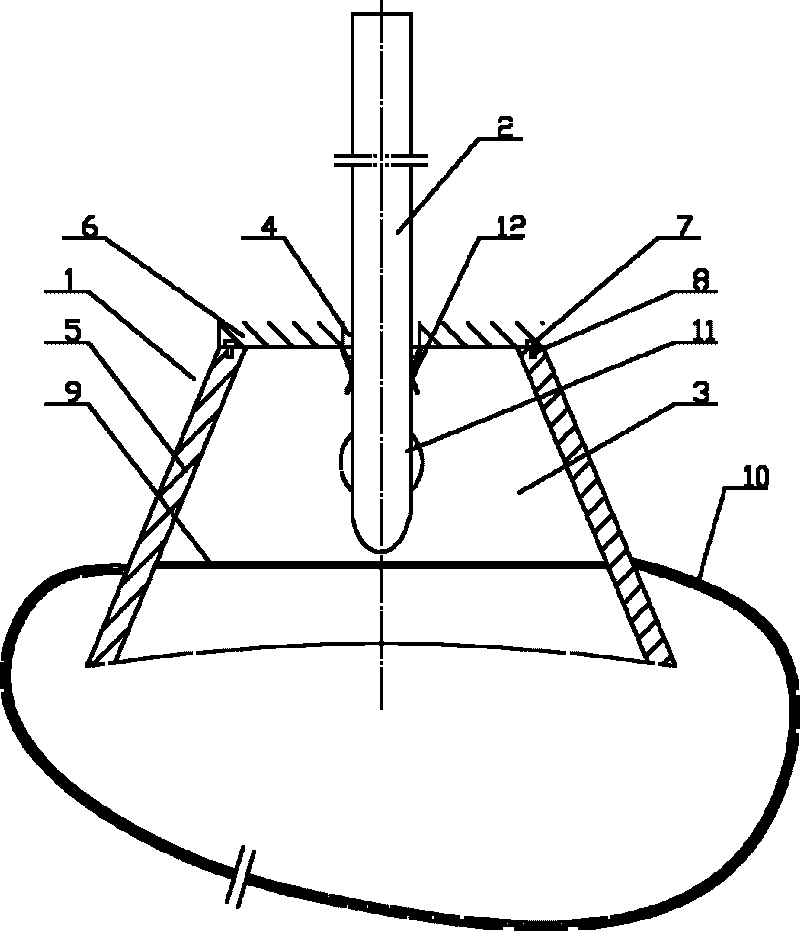

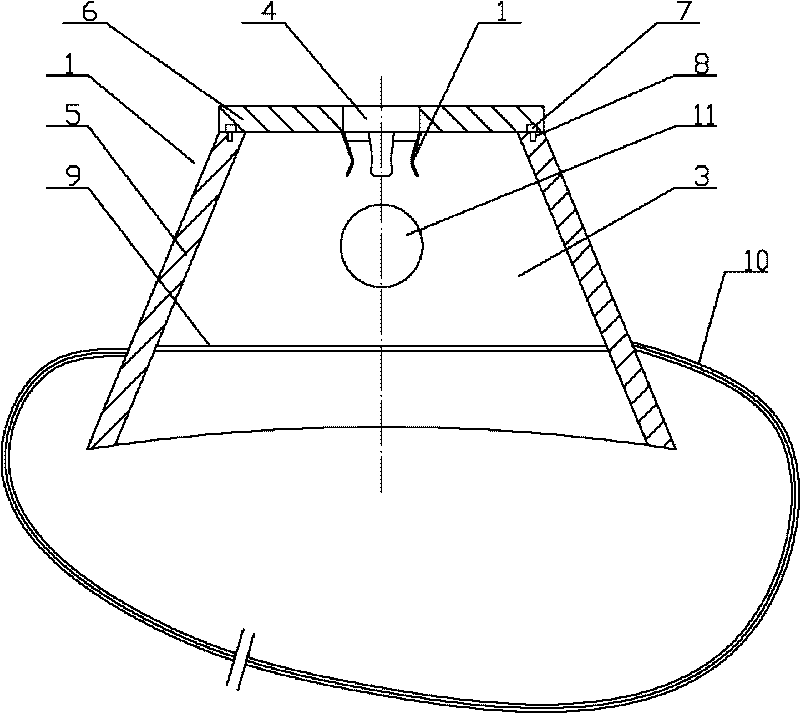

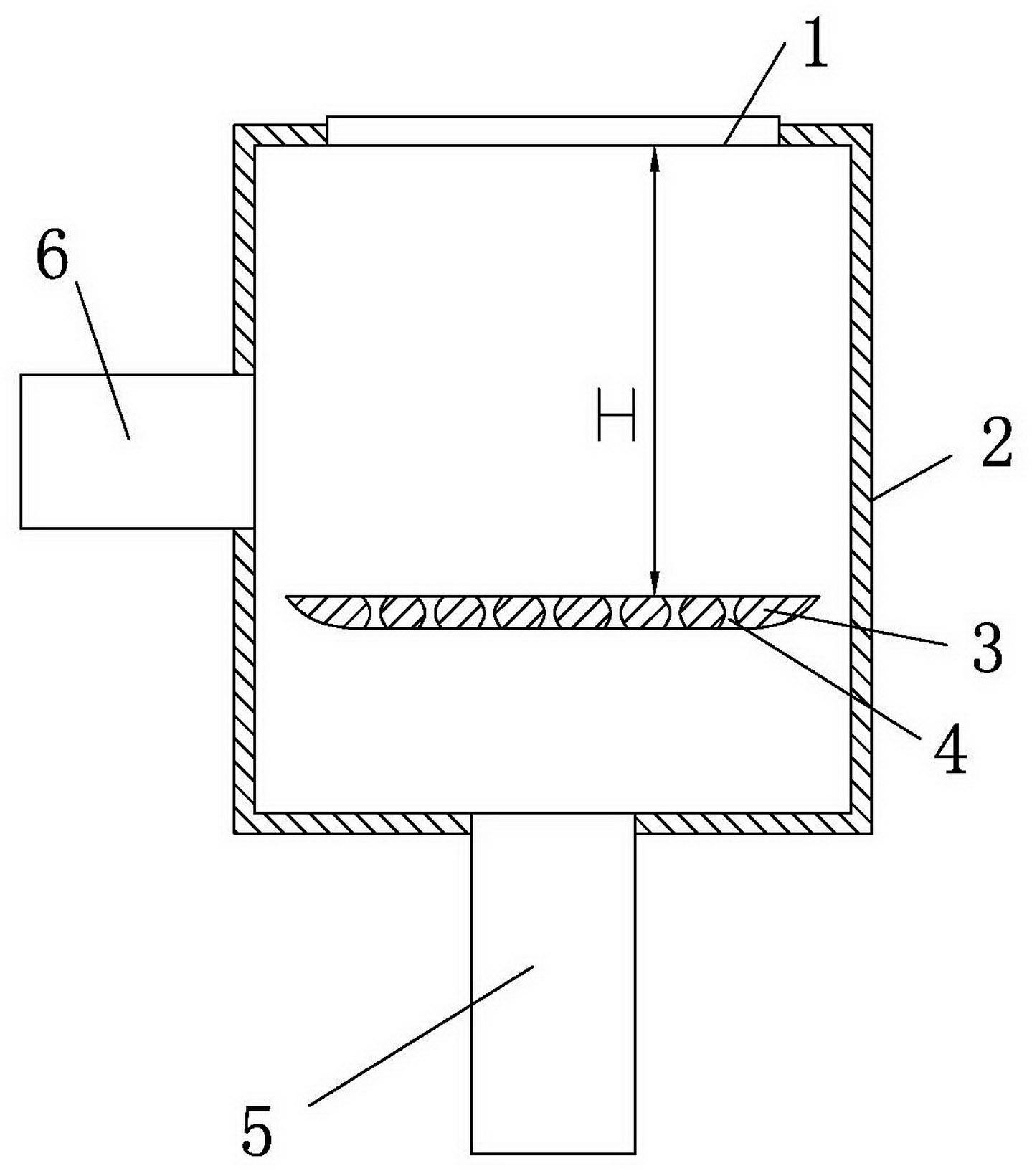

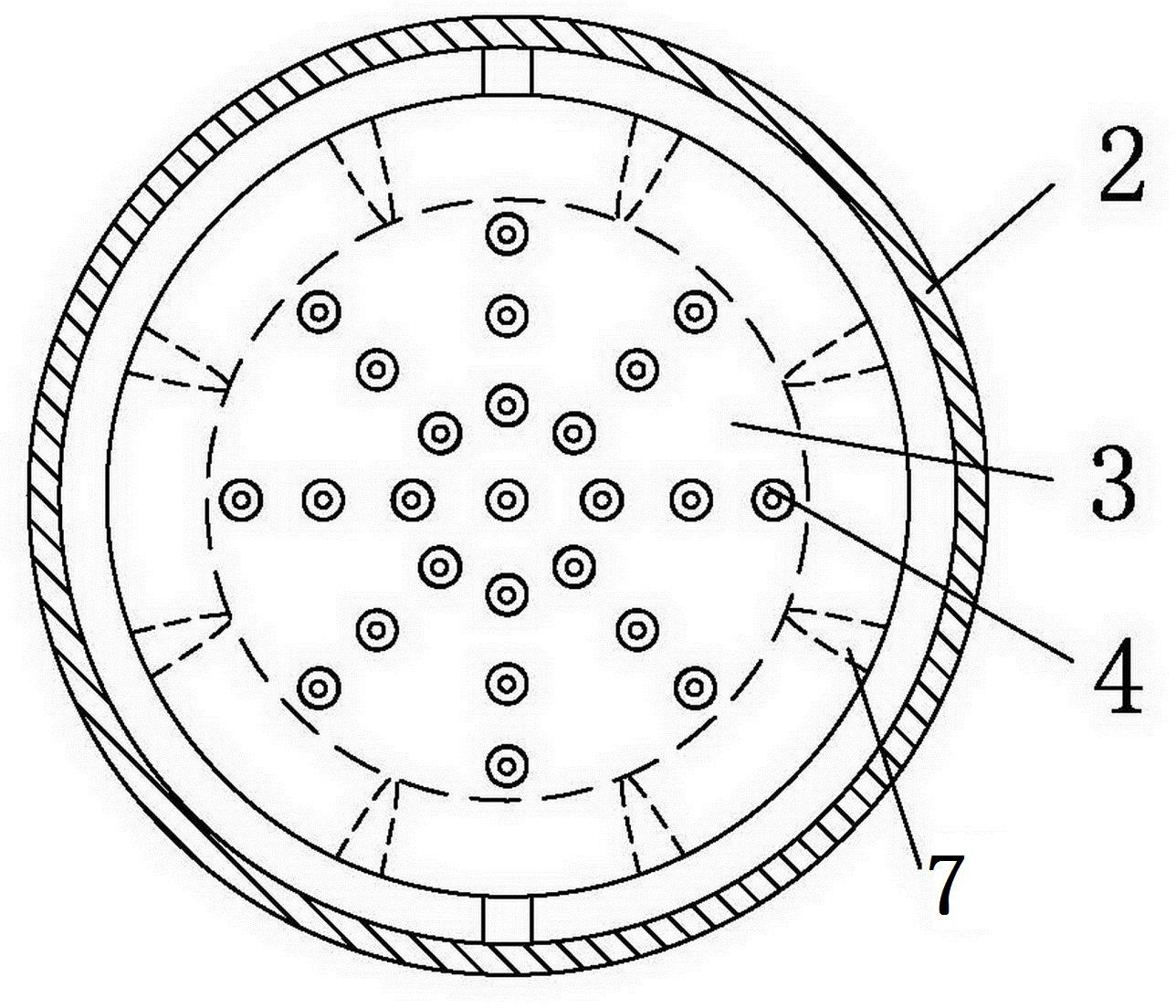

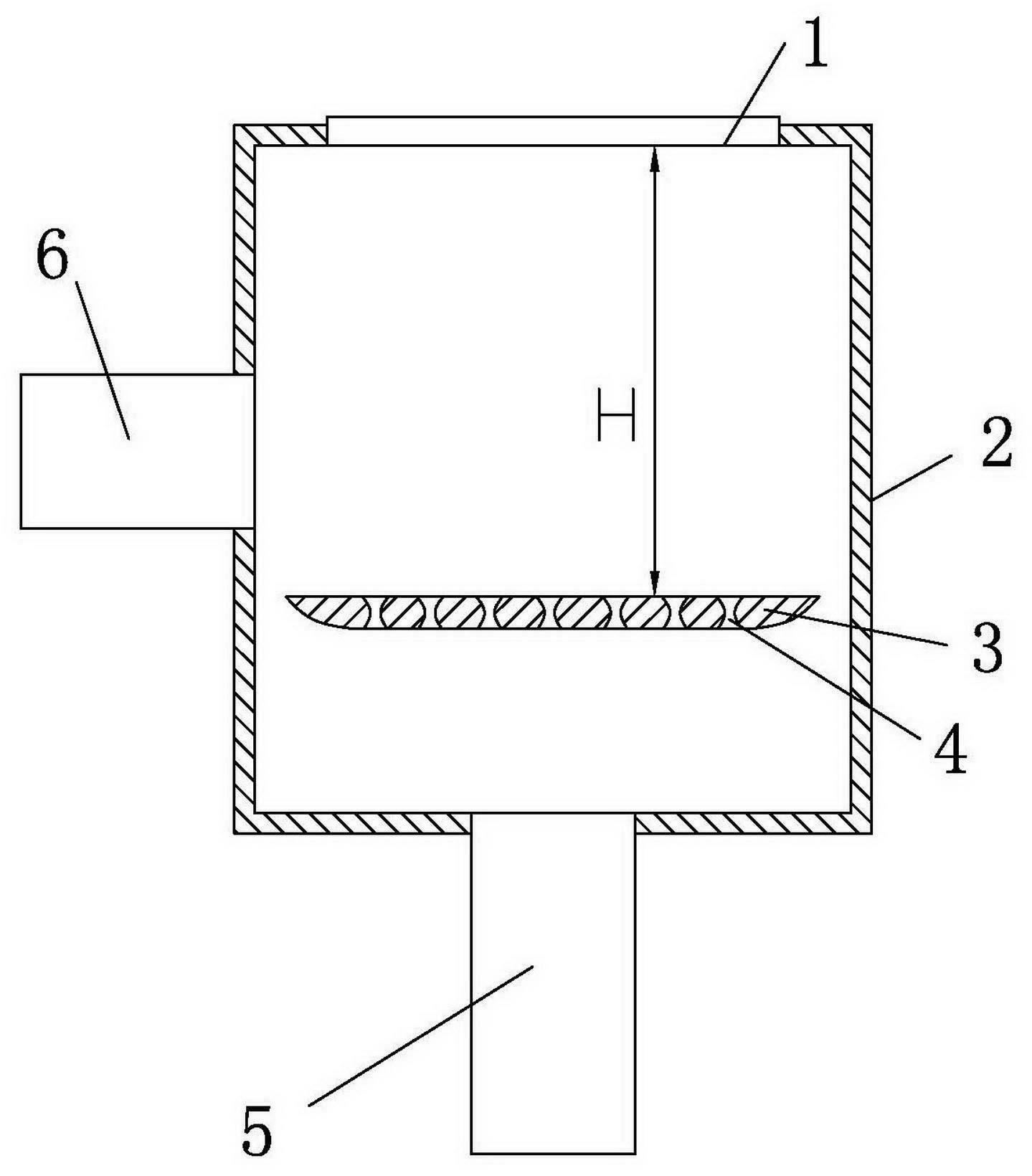

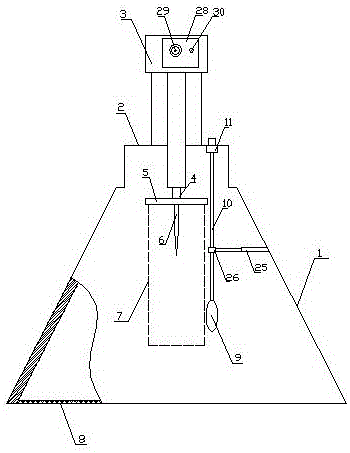

Burning head device of straw gasifier

The invention discloses a burning head device of a straw gasifier, which comprises a cylindrical burning cylinder. A top surface of the cylindrical burning cylinder is provided with a fire outlet; the bottom end of the burning cylinder is connected with a gas inlet pipe; an air inlet pipe is connected to a side wall of the burning cylinder; a fire stop plate is horizontally arranged in the burning cylinder below an air inlet pipe port; a burning chamber is formed in the burning cylinder arranged between the fire stop plate and the air inlet pipe port; an annular fire-out gap is reserved between the outer peripheral edge of the fire stop plate and an inner peripheral wall of the burning cylinder; the height from the top surface of the fire stop plate to the fire outlet is 5-10cm; burning holes are centrally and symmetrically arranged on a plate surface of the fire stop plate; hole walls of the burning holes are rotary double-curved surfaces; the hole aperture of the central throat part of the burning hole is 5mm; flame guiding grooves are uniformly arranged at intervals on the outer peripheral edge of the bottom surface of the fire stop plate in the radial direction; the upper ends of the flame guiding grooves stretch to the position of the outer periphery of the top surface of the fire stop plate; the outer periphery of the fire stop plate is in an arc shape from bottom to top; and the annular fire-out gap is 2cm and the diameter of the fire stop plate is 10-18cm.

Owner:吐鲁番市库吾迪亚红外线采暖设备有限公司

Manufacturing process of tin-phosphor bronze stretching rod

ActiveCN103320596AGood cold and hot processing performanceGood casting performanceElectrical resistance and conductancePhosphor bronze

The invention relates to a manufacturing process of a tin-phosphor bronze stretching rod. The manufacturing process flow with the product specification of phi 15-phi 38 mm comprises the following steps of: carrying fusion casting; sawing a cast ingot; carrying out diplopore extrusion by using a 4000-ton oil press; sawing; pickling; stretching; carrying out intermediate annealing; finishing; annealing a finished product; and packaging. The manufacturing process disclosed by the invention can carry out the fusion casting on an ingot blank by using a cored or coreless line-frequency furnace, carry out the diplopore extrusion by using the 4000-ton oil press, carry out gate stretching on a rod blank subjected to the diplopore extrusion by adopting a chain stretcher and carry out stress-relief annealing on the rod by adopting a resistor annealing furnace, thereby greatly improving the production efficiency, meeting the requirement of a customer, simplifying the technical treatment process, cancelling the heading mode of a burning head furnace, reducing the energy consumption, further reducing the production cost, realizing the short-flow operation, shortening the production period, improving the integrated finished product ratio, improving the production efficiency, enlarging the product range, reducing the energy consumption and realizing the industrialized production.

Owner:中铝洛阳铜加工有限公司

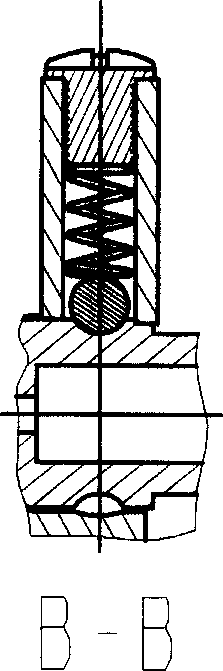

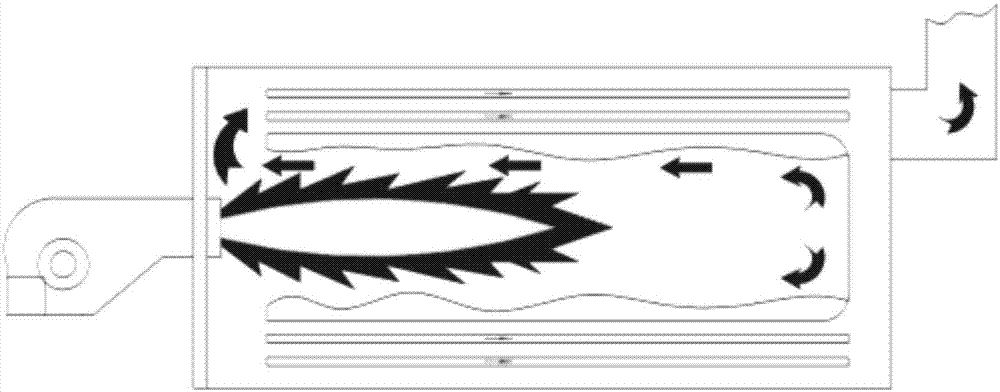

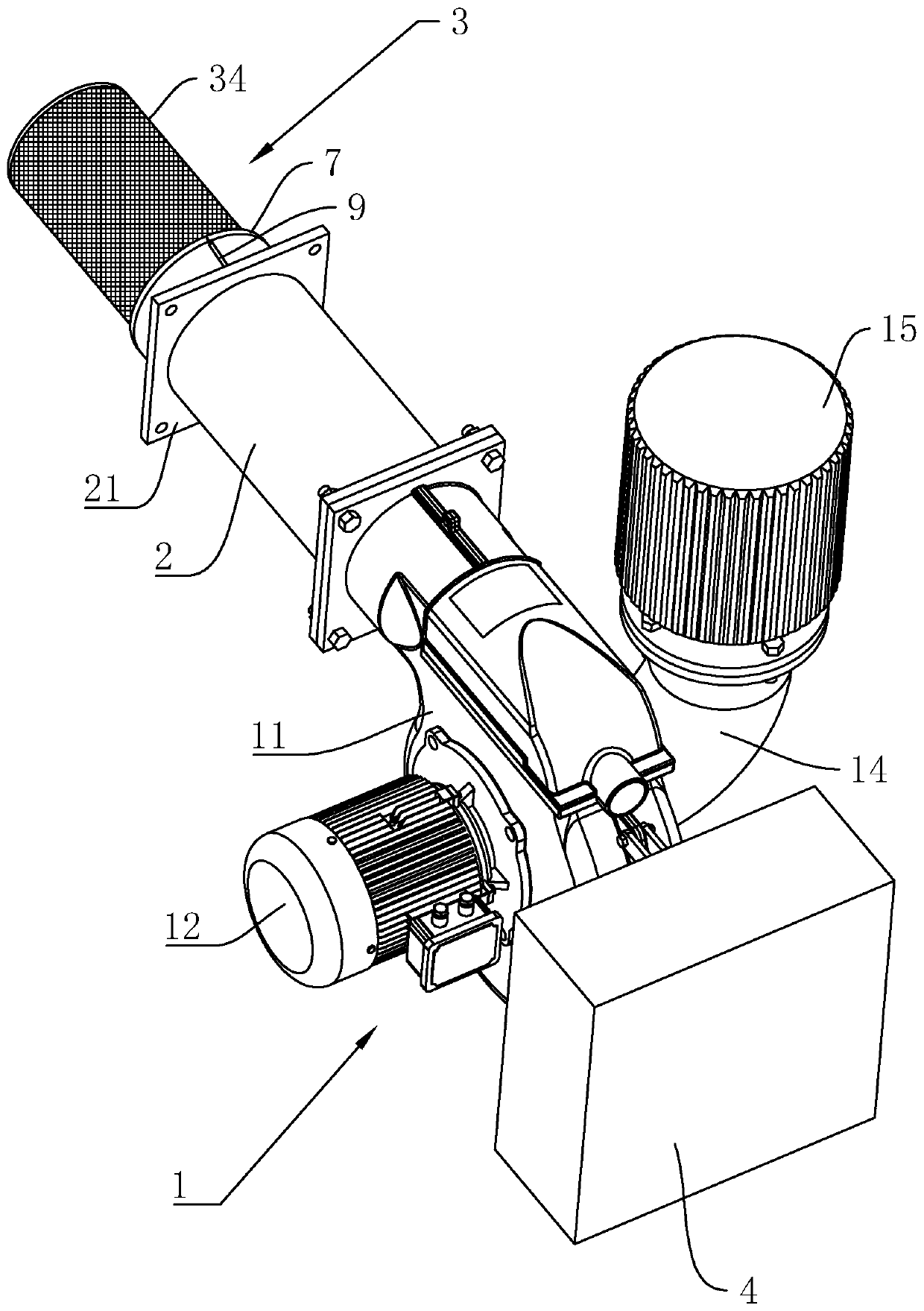

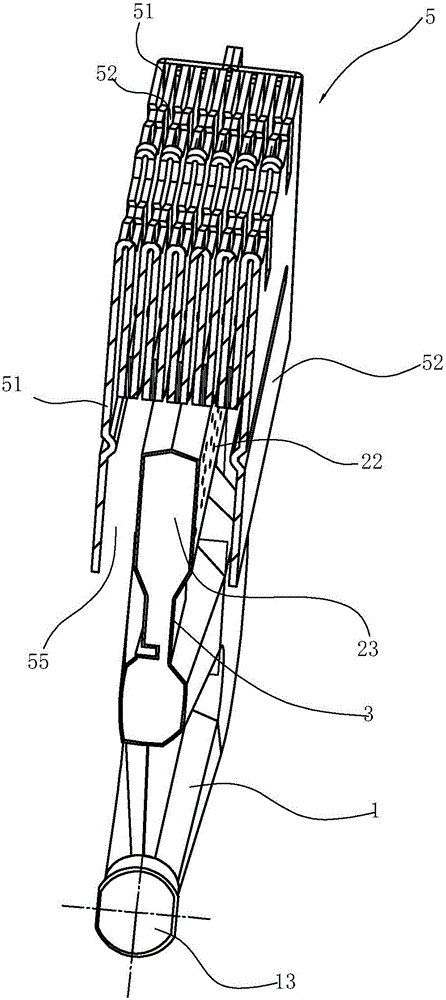

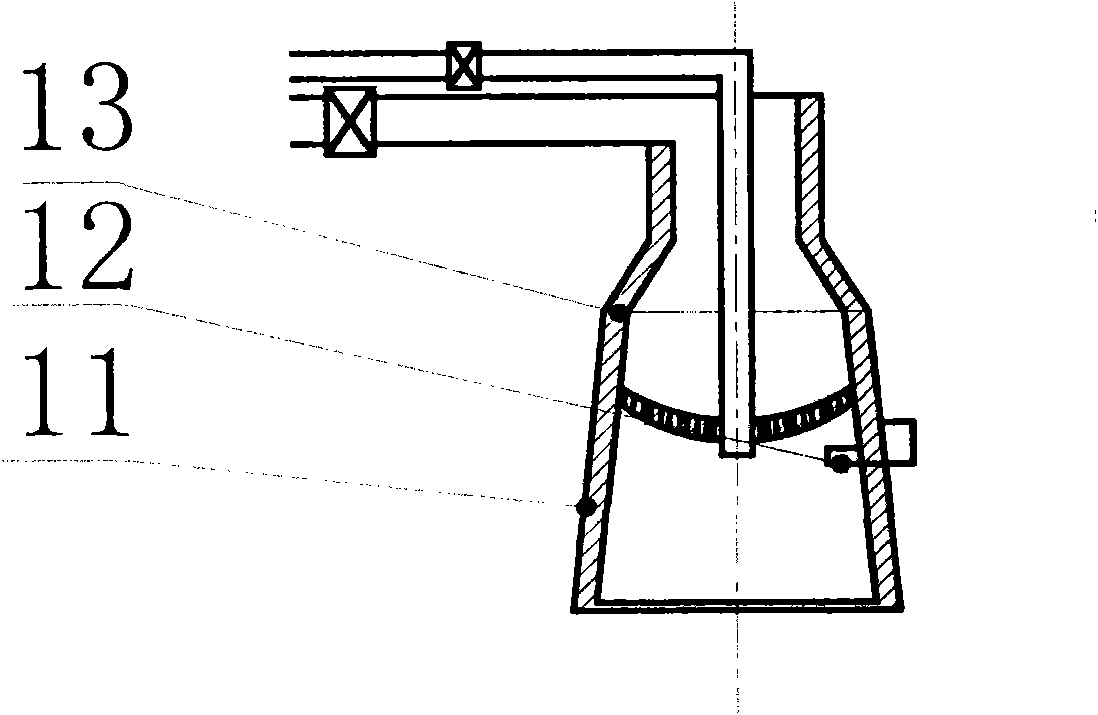

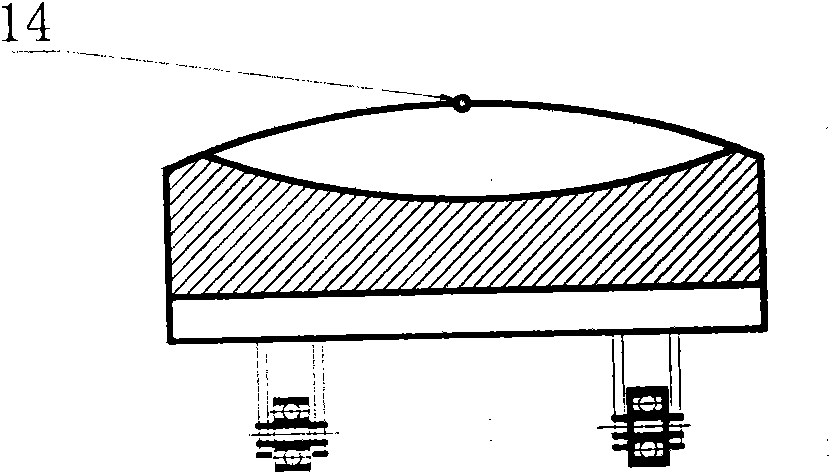

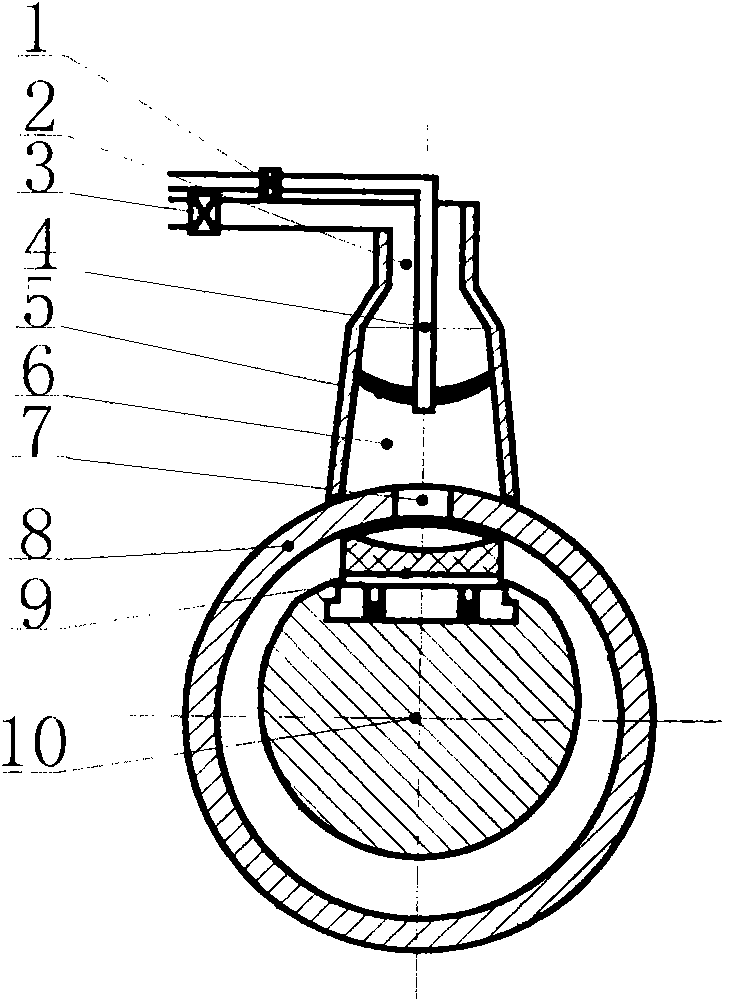

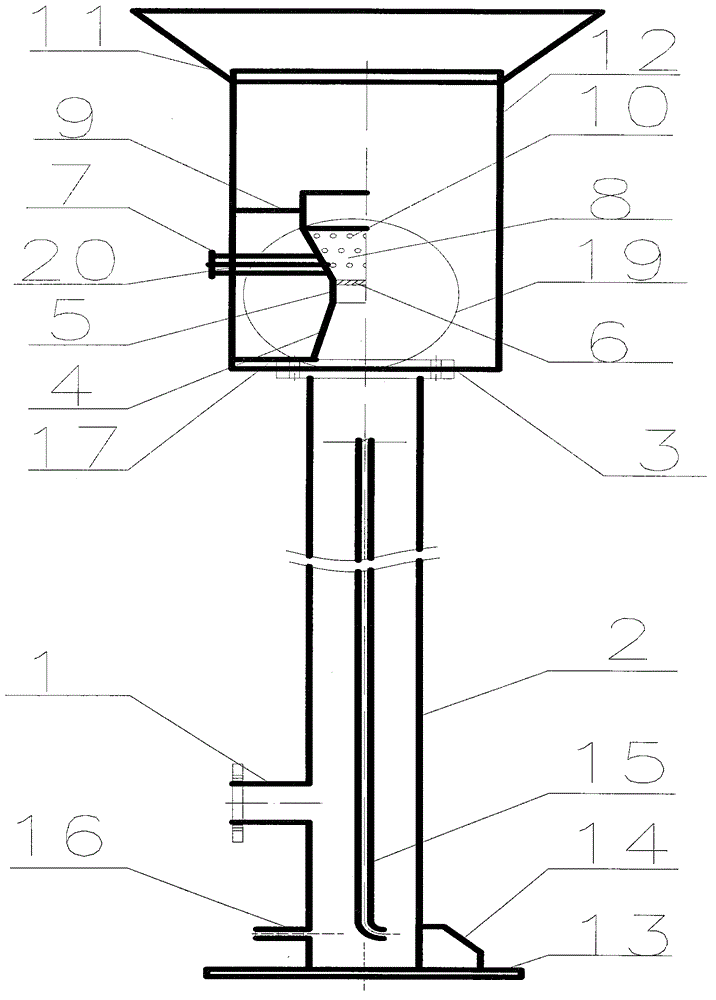

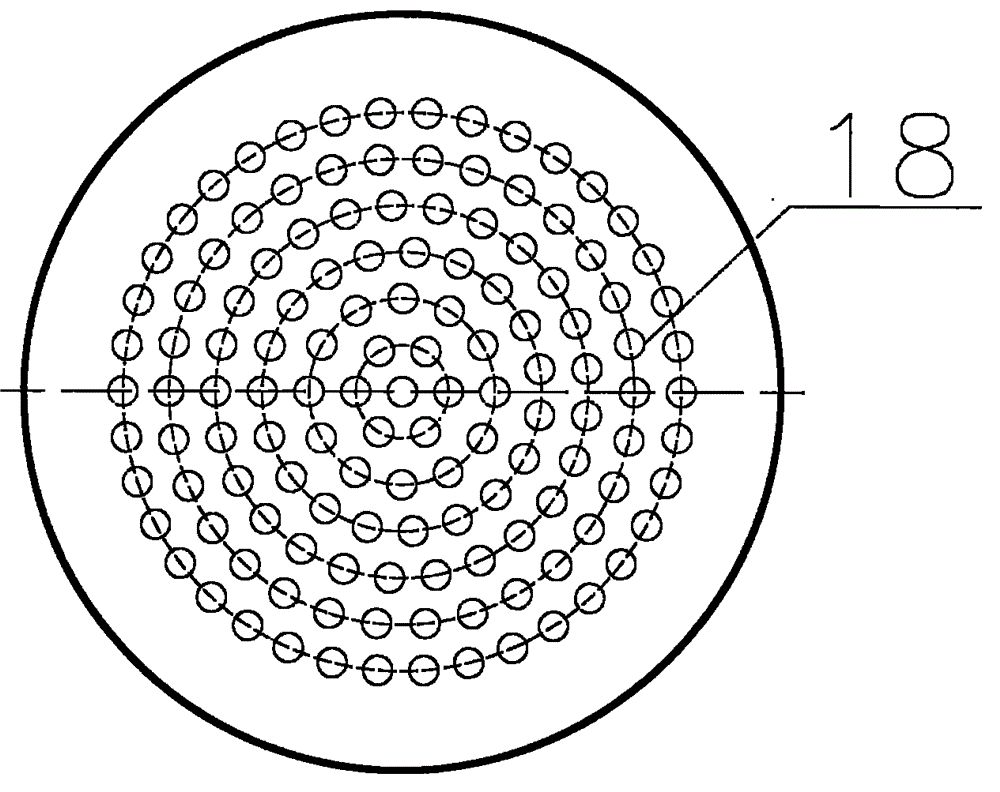

Metal-fiber front mixing burner based on central reverse burning head

The invention relates to a metal-fiber front mixing burner based on a central reverse burning head. The metal-fiber front mixing burner comprises a premixing chamber, a fan and the central reverse burning head. The premixing chamber comprises a Venturi structure, fuel gas and air sequentially pass through the premixing chamber and the fan, and are mixed two times in the premixing chamber and an inner cavity of the fan to enter the central reverse burning head, and the mixture is burned on the surface of a metal fiber. According to the metal-fiber front mixing burner based on the central reverse burning head, the central reverse burning head has the smoke flow direction similar to the smoke flow direction of a diffusion-type burner, and also can overcome the defect of high nitrogen oxide of the diffusion-type burner, and the efficiency and outputting force of a boiler are not influenced. The premixing chamber is arranged on an air feeding opening of the fan, an air mixing structure of an air discharging opening of the fan is reduced, and air and fuel gas are directly mixed under stirring of impellers of the fan; meanwhile, a zero pressure valve is adopted, the air-fuel ratio is automatically controlled, a control system is simplified, and the stability and the safety of the burner are improved.

Owner:北京节能技术监测中心

Gas sample collector

InactiveCN105758681ARealize sampling testMeet the design requirementsWithdrawing sample devicesEngineeringPiston rod

The invention provides a gas sample collector.The gas sample collector is characterized by comprising a sleeve and a piston rod matched with the sleeve, a first branch gas pipe is arranged at the front end of the sleeve and communicated with a gas guiding pipe, a rubber head is arranged at the end, far away from the sleeve, of the gas guiding pipe, the gas guiding pipe is communicated with a second branch gas pipe, a burning head is arranged at the end, far away from the gas guiding pipe, of the second branch gas pipe, a first valve is arranged on the first branch gas pipe, and a second valve is arranged on the second branch gas pipe.By site testing, all technical indexes of the gas sample collector conform to design requirements, sampling tests of gas are achieved, using is convenient, and sampling results are accurate.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO QINGZHOU POWER SUPPLY CO +2

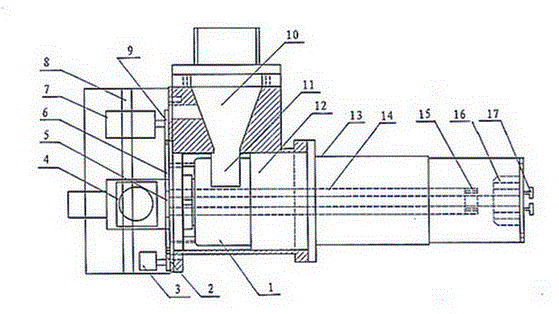

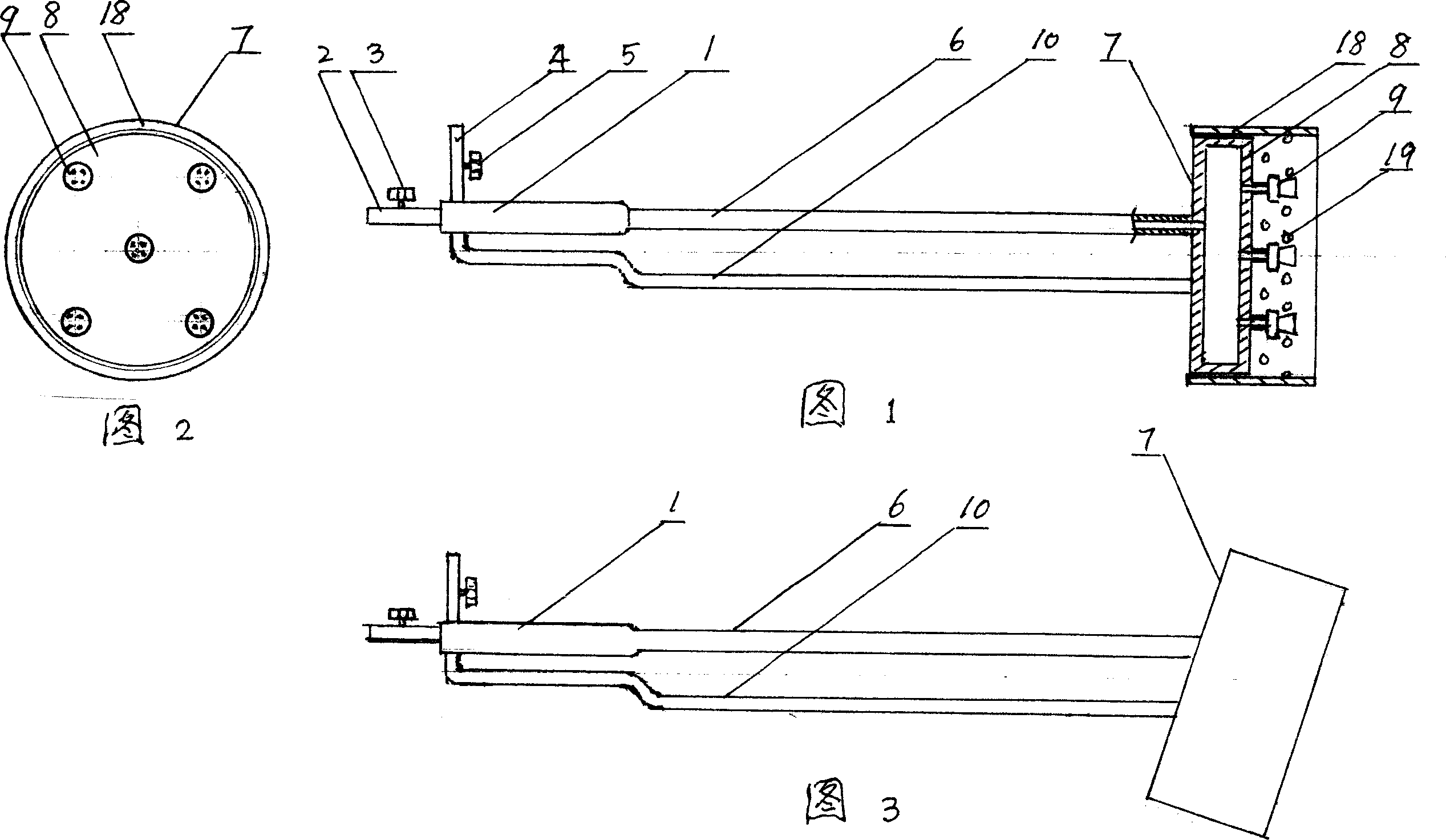

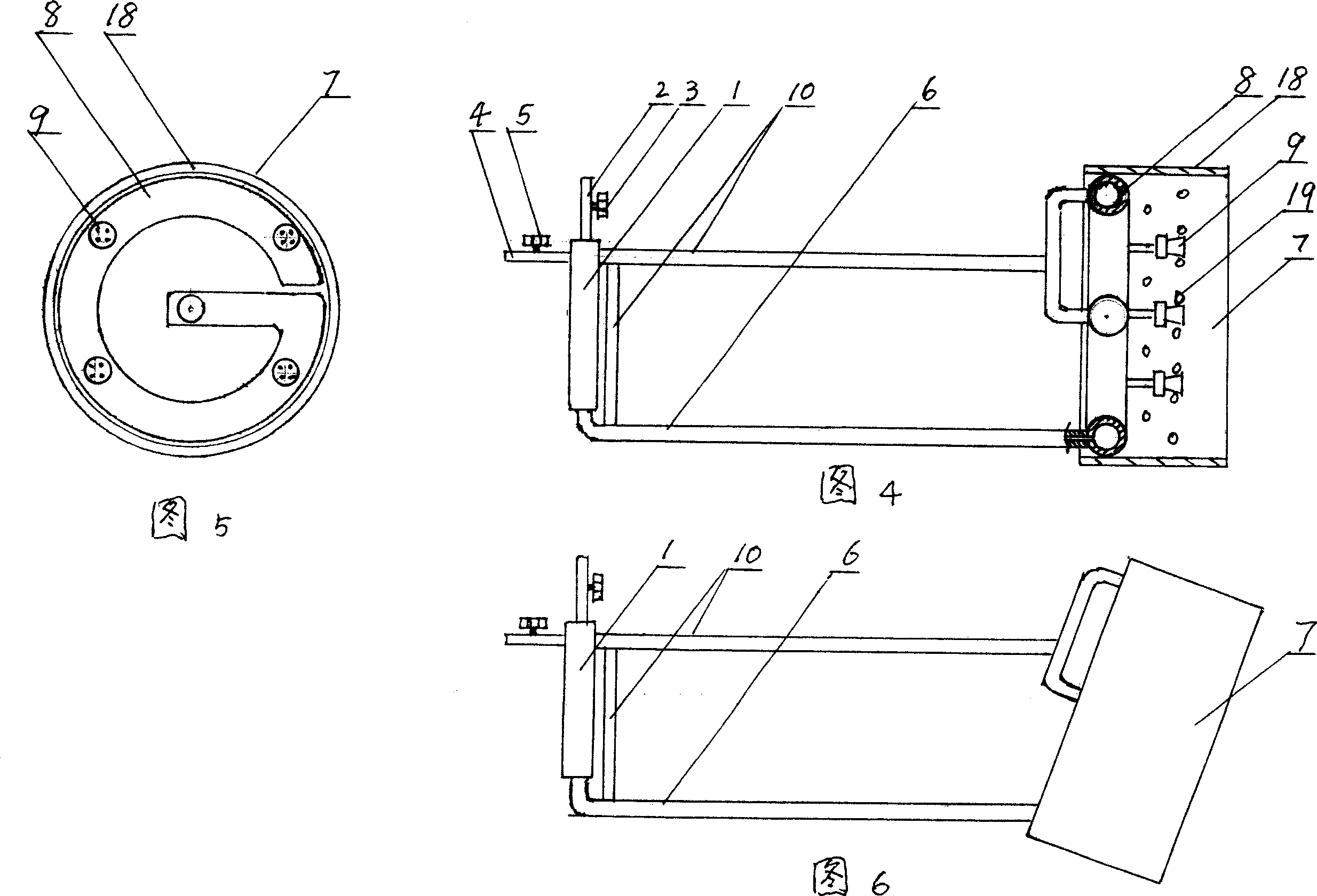

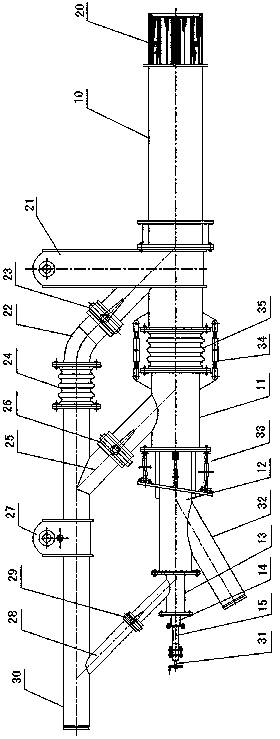

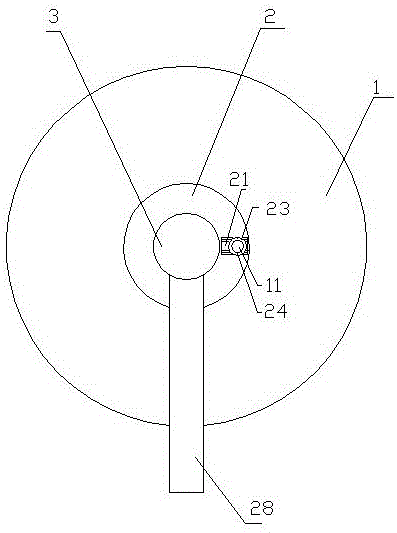

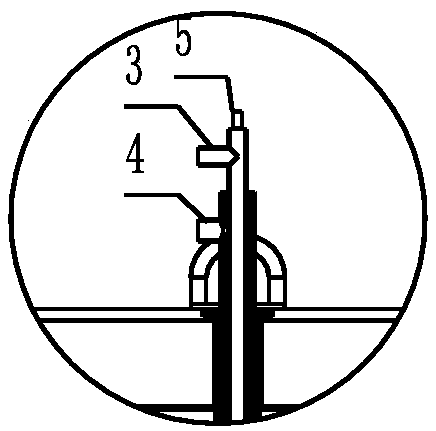

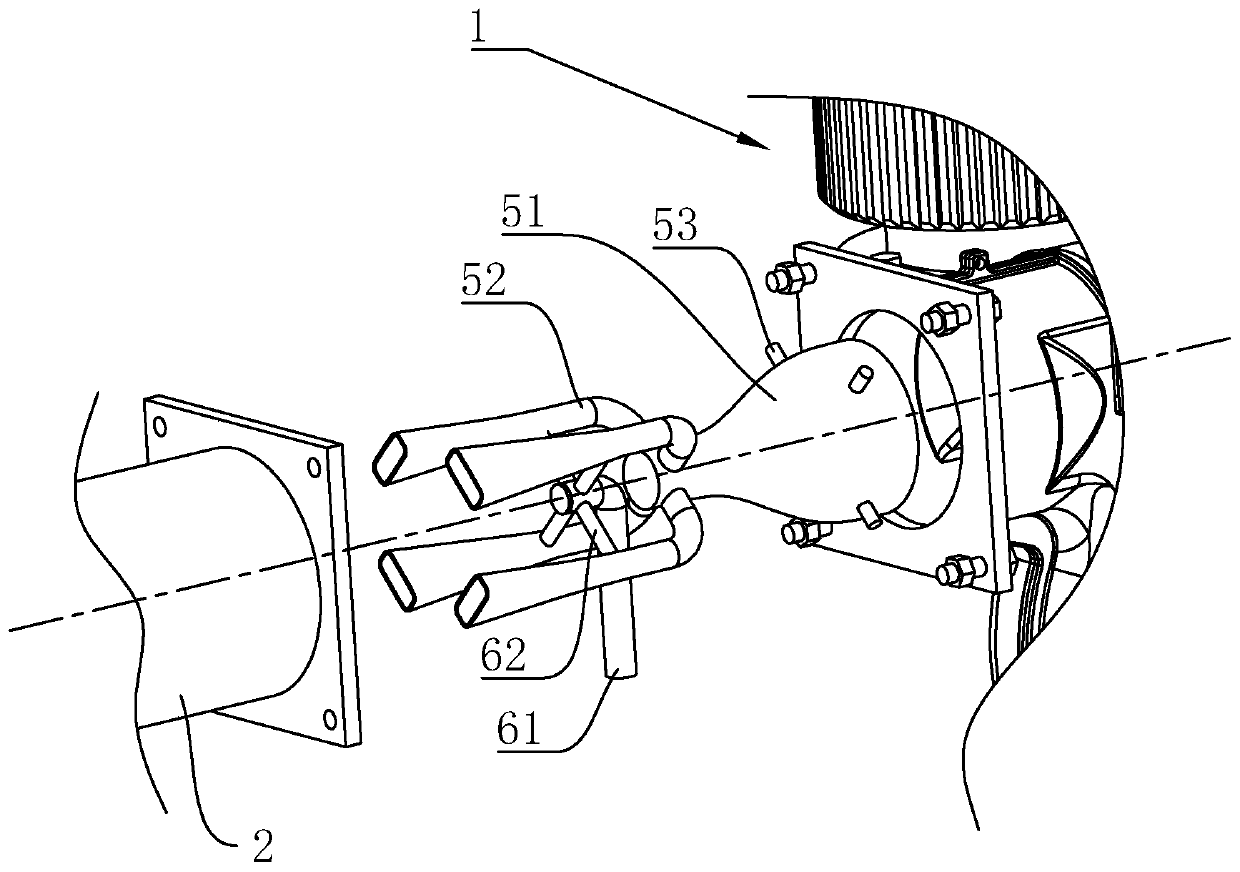

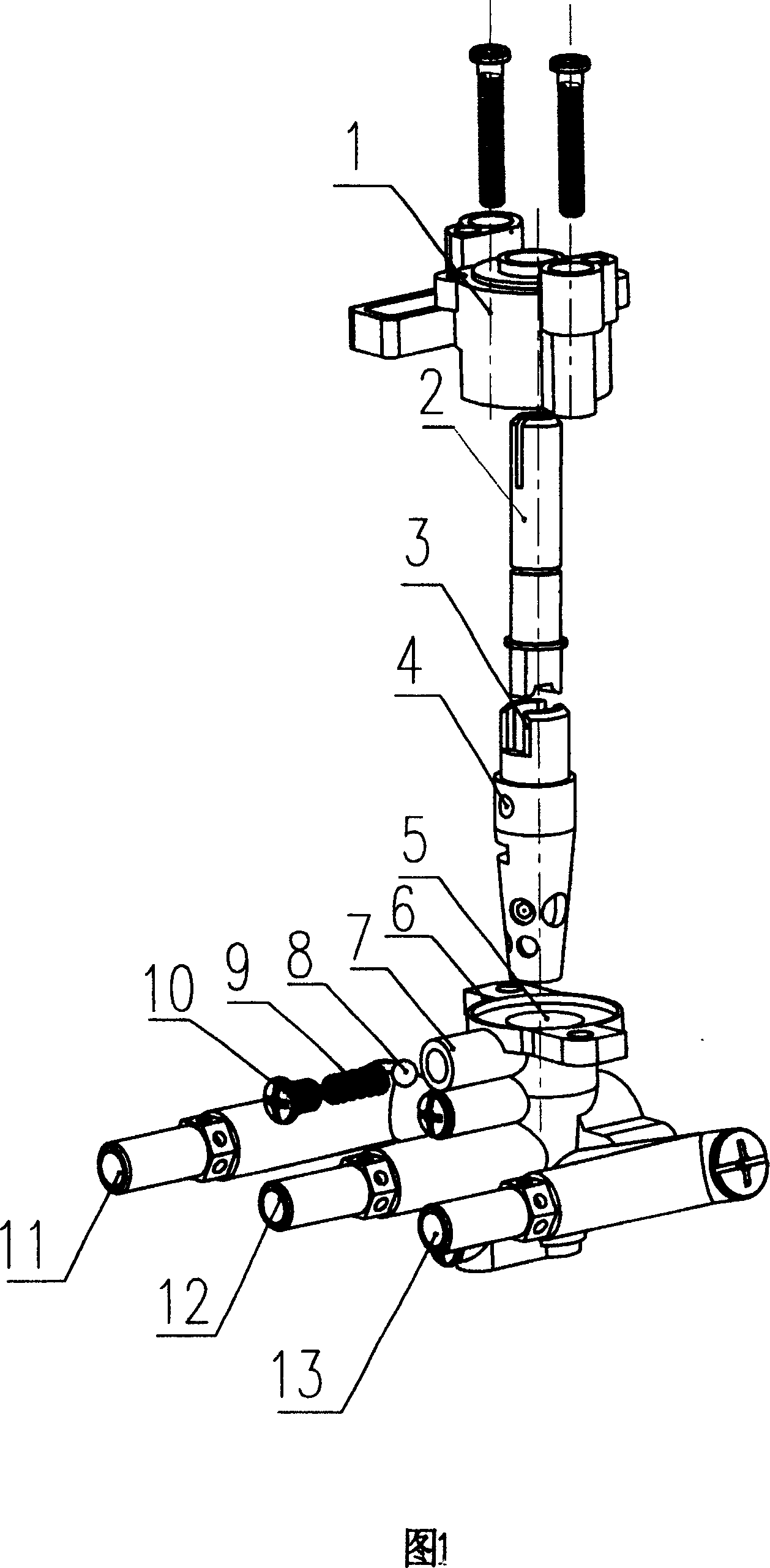

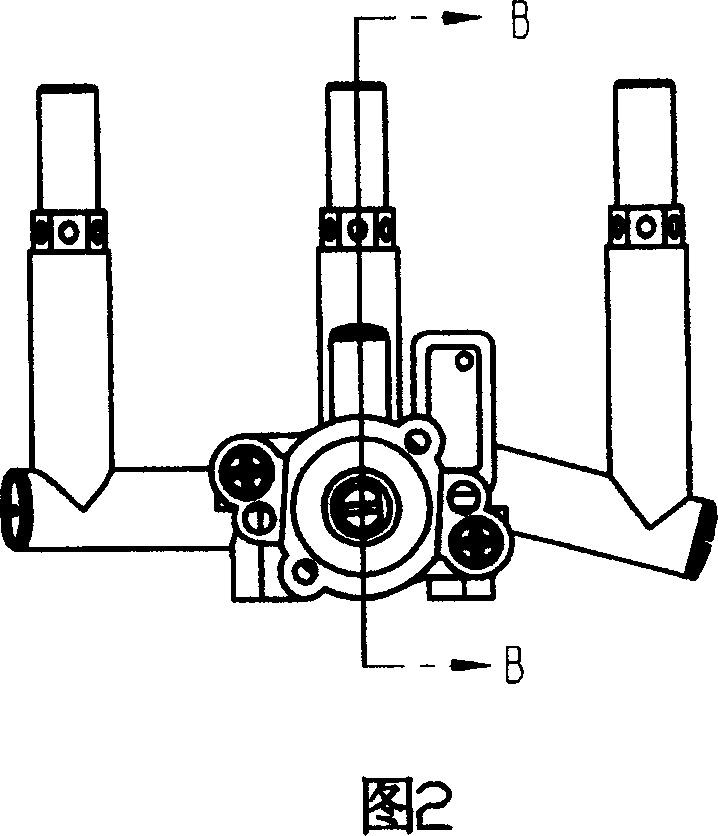

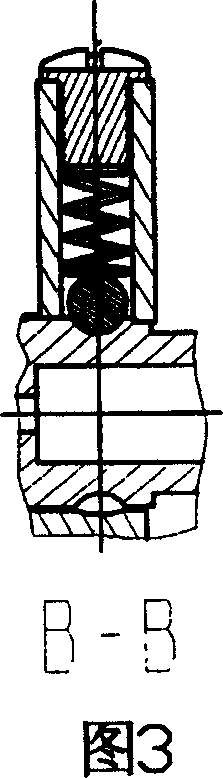

Blade angle adjustable four-channel whirl pulverized coal burner

InactiveCN104696953AQuality improvementReasonable structurePulverulent fuel combustion burnersEngineeringCoal

The invention discloses a blade angle adjustable whirl pulverized coal burner, and solves the difficult problem that a universal four-channel whirl pulverized coal burner cannot adjust the swirling intensity of a swirler by changing the angle of a blade. The blade angle adjustable four-channel whirl pulverized coal burner is characterized in that (shown in figure 1) a blade angle adjustable swirler is arranged on the outer surface of a swirling air pipe (12) of a burning head (20), the swirling air pipe (12) forms a swirling air channel, and a swirling air pull rod adjusting device (33) is arranged at the tail end of the swirling air pipe (12) of an air supply device. The structure is reasonable, the operation is convenient, the swirler is arranged in the swirling air channel, the blade angle of the swirler is changed online through the adjusting device, so that the ideal burning state is achieved, and equipment support is provided for the production of high-quality calcined cement clinker.

Owner:黄冈圣嘉高新机电设备有限公司

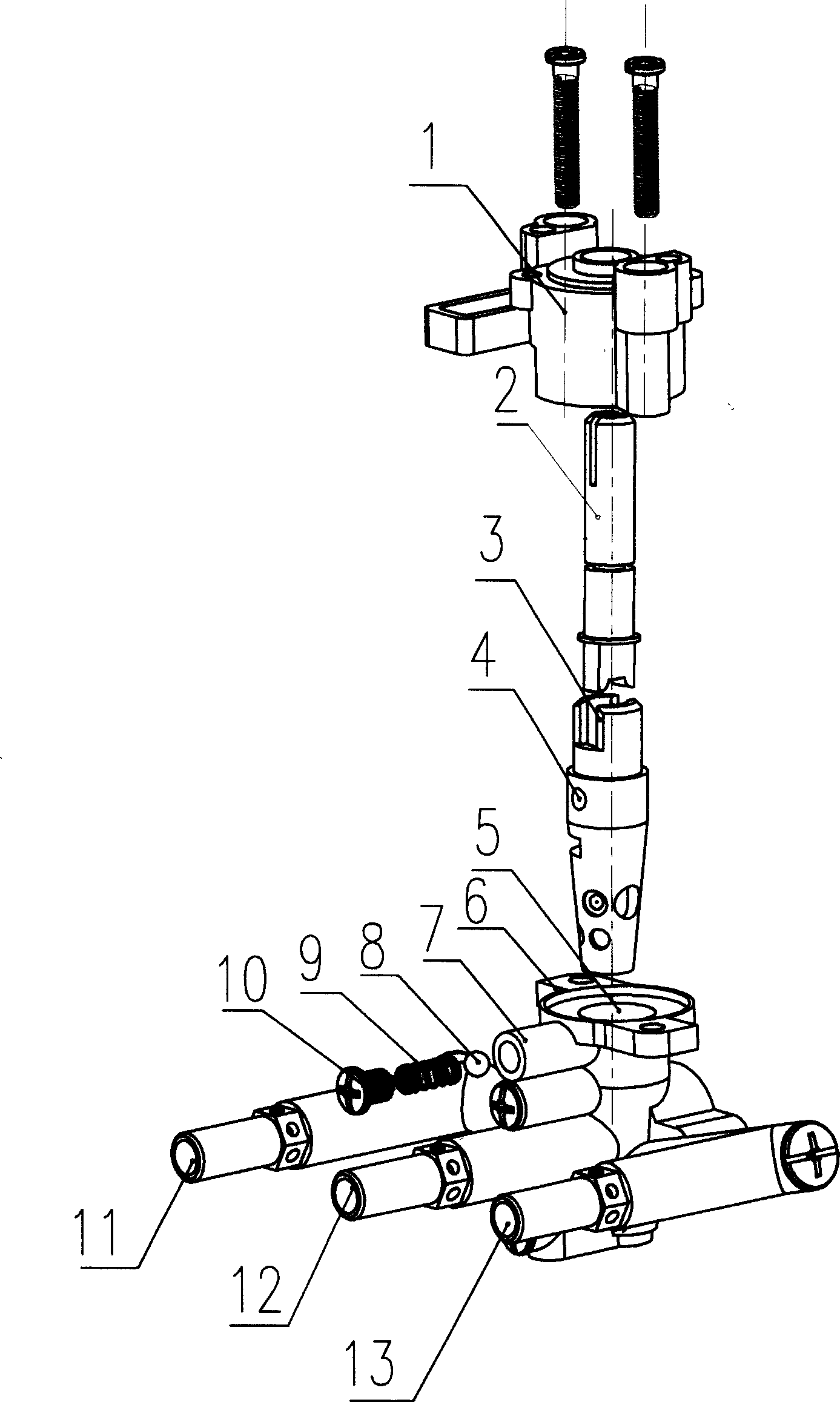

Stable moxibustion device

InactiveCN106137738AEffective stimulationImprove the effect of moxibustion therapyDevices for heating/cooling reflex pointsEngineeringBurning head

The invention belongs to the technical field of physical therapy. To solve current technical problem in the moxibustion process, a stable moxibustion device comprises a flared seat cylinder and a supporting device fixed on an end plate, wherein an electric push rod is arranged at the top of the seat cylinder, a seat plate is fixed at the bottom of the telescopic rod of the electric push rod, and a pin is arranged at the center of the seat plate; a liquid storage bubble is arranged inside the seat cylinder, and is provided with an upward extending liquid pipe; expanding liquid in the liquid storage bubble is expanded after being heated, the supporting device is driven to act, and the electric push rod is controlled to start. According to the moxibustion device, a burning head can be accurately aligned to an acupoint, and the distance between the burning head and skin can be adjusted in real time along with burning of a moxa stick, so that a relatively fixed interval between the burning head and skin can be guaranteed, effective stimulation on the acupoint can be sufficiently ensured, and the moxibustion physical therapy effect can be effectively improved.

Owner:张誉凡

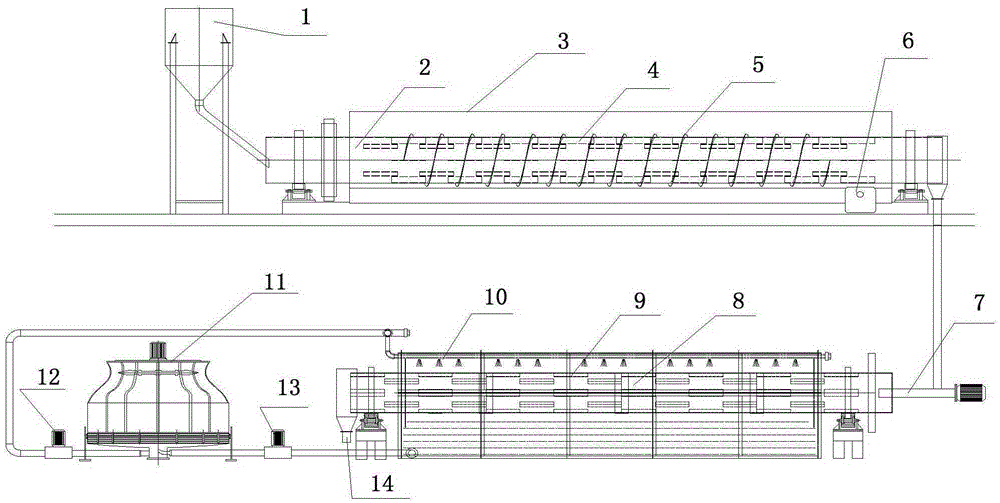

Novel rotary furnace system

InactiveCN105258496AFast heatingIncrease temperatureRotary drum furnacesGas emission reductionEngineeringRotary furnace

The invention relates to the technical field of magnesium oxide drying equipment, and provides a novel rotary furnace system. The system comprises a material storage tank, a rotary furnace and a cooling device. A feeding opening of the rotary furnace is communicated with the material storage tank, and a discharging opening of the rotary furnace is communicated with the cooling device. At least one natural gas burner for heating the rotary furnace is arranged in the circumferential direction of the rotary furnace, and the natural gas burner is close to the discharging opening of the rotary furnace. The rotary furnace comprises a rotary cylinder and a heat preservation cylinder arranged on the outer portion of the rotary cylinder in a sleeving manner. The rotary cylinder is electrically connected with a motor. An opening is formed in the side wall of the heat preservation cylinder. A burning head of the natural gas burner penetrates through the opening of the heat preservation cylinder and faces the rotary cylinder. A spiral heat conduction plate is arranged on the outer wall of the rotary cylinder. The natural gas burner can be adopted for heating the rotary furnace, the production cost is greatly reduced, the temperature rising speed of the rotary furnace is high, and the temperature is high.

Owner:DASHIQIAO MEIR MAGNESIUM PROD

Electronic vaporizing combustion equipment based on alcohol-based liquid fuel

InactiveCN108592021AUniform gasificationFaster preheating and vaporizationBurnersDomestic stoves or rangesAlcoholSpray nozzle

The invention provides electronic vaporizing combustion equipment based on alcohol-based liquid fuel. The electronic vaporizing combustion equipment based on alcohol-based liquid fuel comprises a spray nozzle, a spark electrode arranged nearby the spray nozzle, a cover arranged on the peripheries of the spray nozzle and the spark electrode in a sleeving manner, a vaporizing channel arranged in a cover body, an electric heating device, a circuit control device and a burner body connected to the spray nozzle, wherein the burner body may comprise a first fire spraying hole formed in a spherical burning head, and may further comprise a second fire spraying hole formed in a T-shaped burning disc; gases and air are mixed very well through the two fire spraying holes and the combination of the spherical burning head and an air mixing cavity, so that the full burning of the alcohol-based liquid fuel is facilitated, and the burning efficiency is relatively high; and as the diameters of the firespraying holes are relatively large, the power of a burner is relatively high. Meanwhile, the power of the burner can be further improved by additionally arranging the T-shaped burning disc above thespherical burning head and the air mixing cavity or by additionally arranging an air channel matched with a draught fan.

Owner:万专知识产权运营有限公司

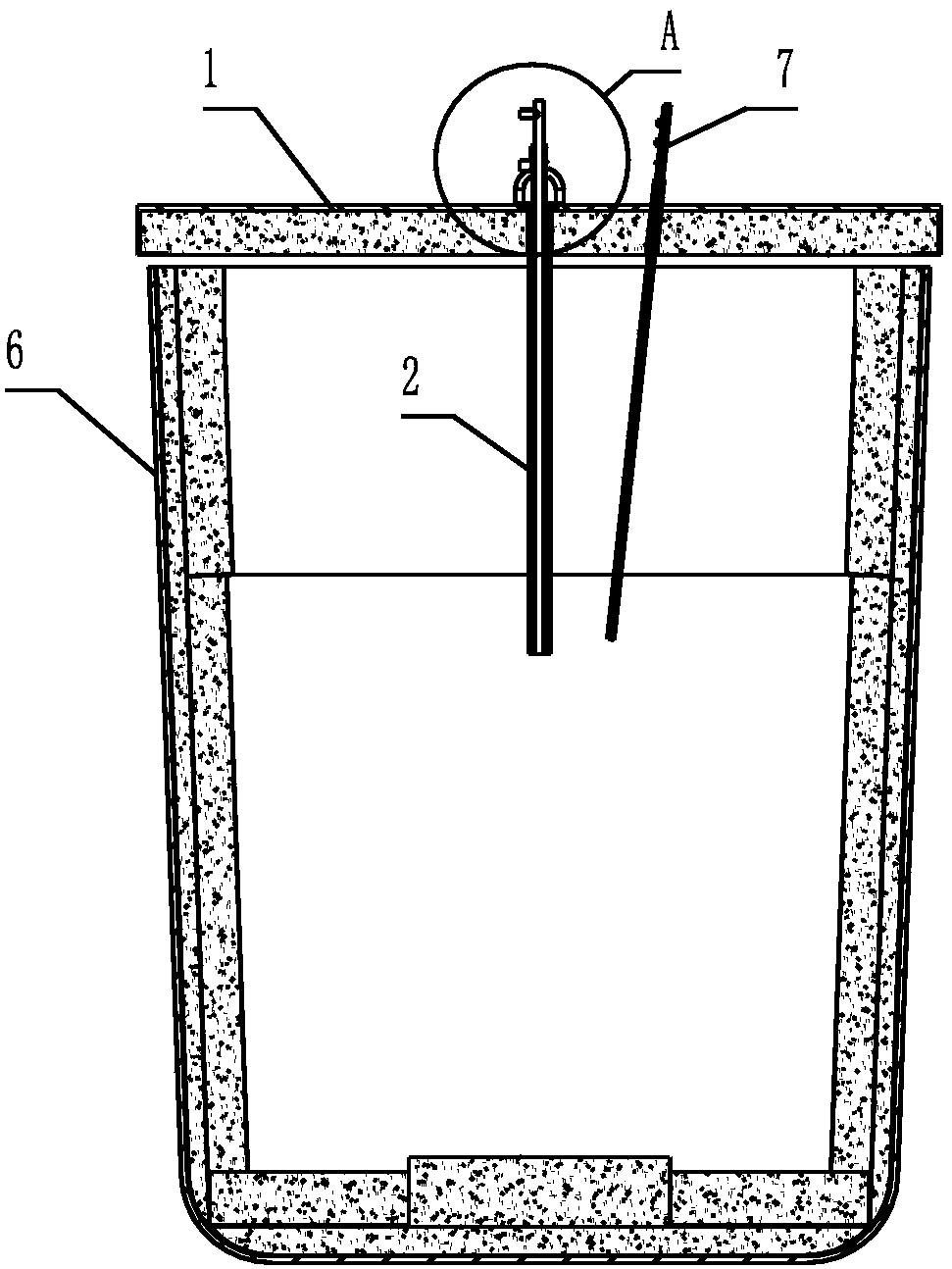

High-efficiency intelligent steel ladle baking device and application method thereof

The invention relates to a high-efficiency intelligent steel ladle baking device. The device is provided with a ladle cover and a burner, and the high-efficiency intelligent steel ladle baking deviceis characterized in that the ladle cover is provided with a plurality of specifications, the ladle cover is matched with the steel ladle with various specifications, a refractory material is arrangedon the lower layer of the steel ladle, and the refractory material covers a steel ladle opening during ladle baking operation, and a gap is reserved between the periphery and the edge of steel ladle opening; the burner is arranged in the middle of the ladle cover, the burner is of a tubular column made of a high-temperature-resistant material, an ignition gun, a flame detector, a fuel gas channeland a auxiliary fuel gas channel are further arranged, and a burning head is arranged at the lower end of the burner; a fuel gas inlet, a auxiliary fuel gas inlet and an ignition gun port are arrangedat the upper end, outside the steel ladle, of the burner; and the burning head of the burner extends to the lower part of the steel ladle during the ladle baking operation, the fuel gas inlet communicates with a fuel gas source through a fuel gas valve, and the auxiliary fuel gas inlet communicates with an auxiliary fuel gas source through an auxiliary fuel gas valve. The high-efficiency intelligent steel ladle baking device and the application method thereof has the advantages of being reasonable in structural design, safe and reliable in operation, high in automation degree and operation and use are conveniently carried out, the baking of steel ladle is uniform, the baking time is effectively reduced, the baking efficiency is improved, the environmental pollution is low, and the like.

Owner:王研

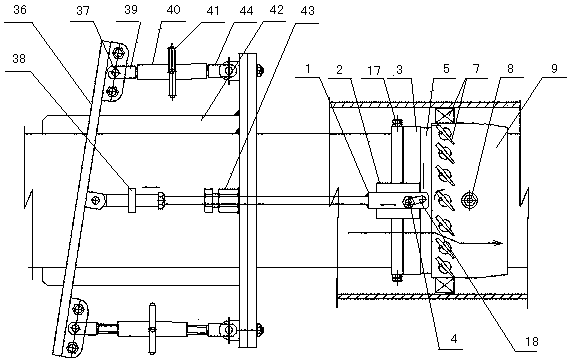

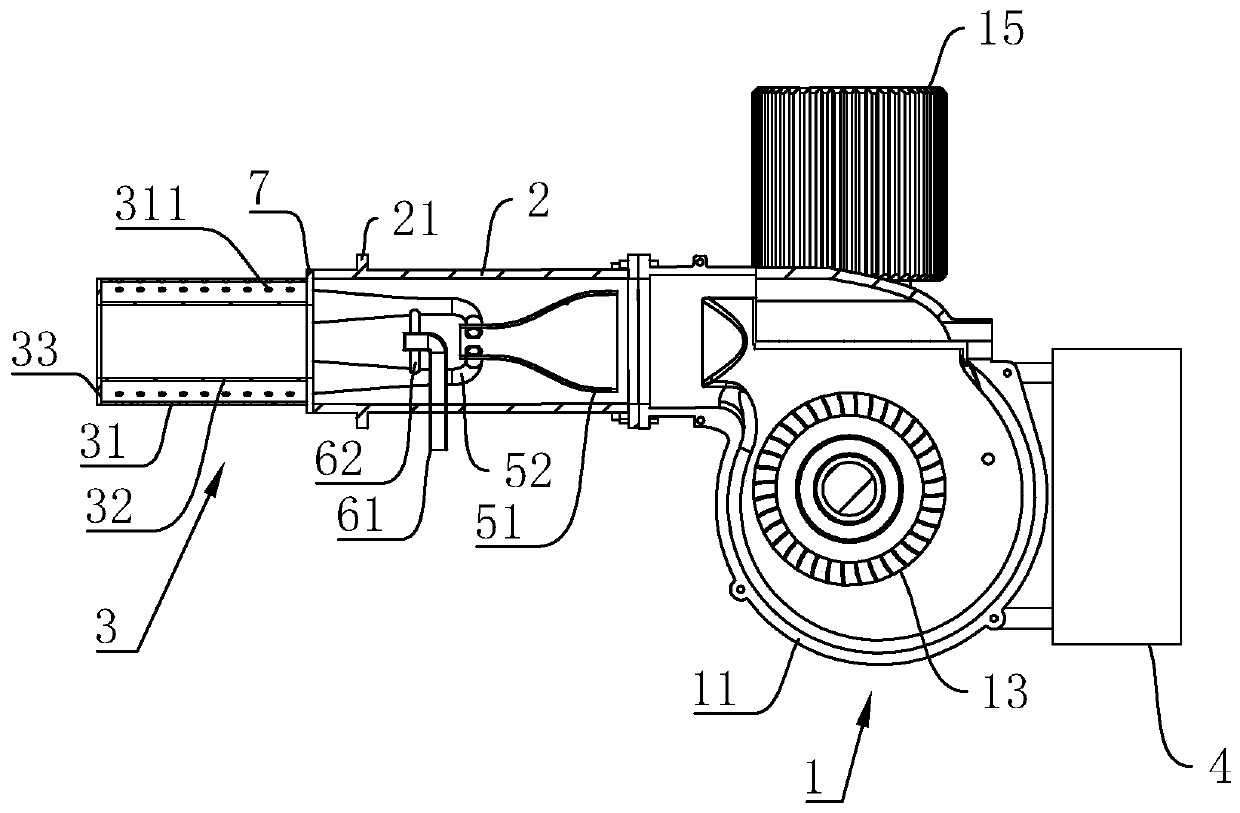

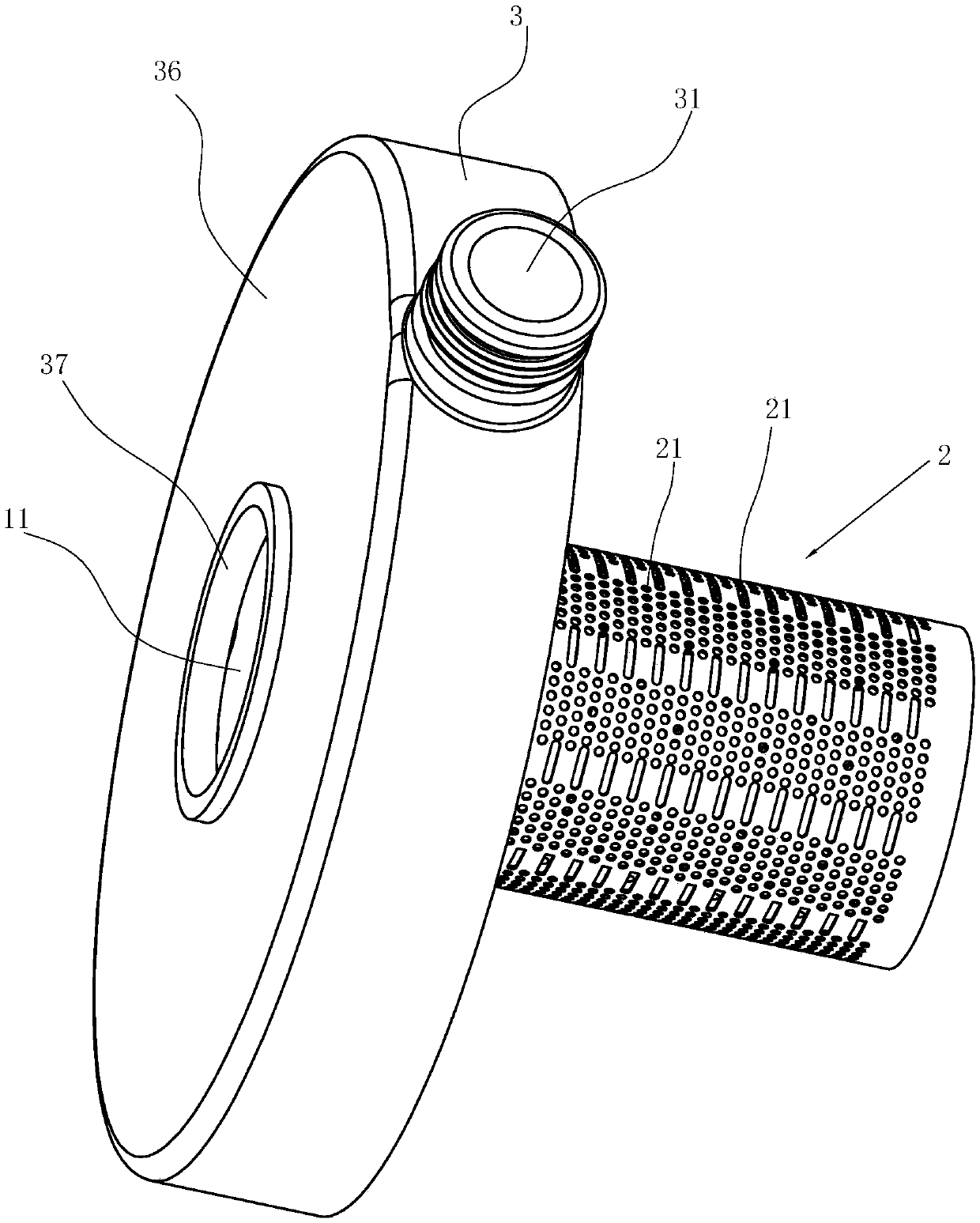

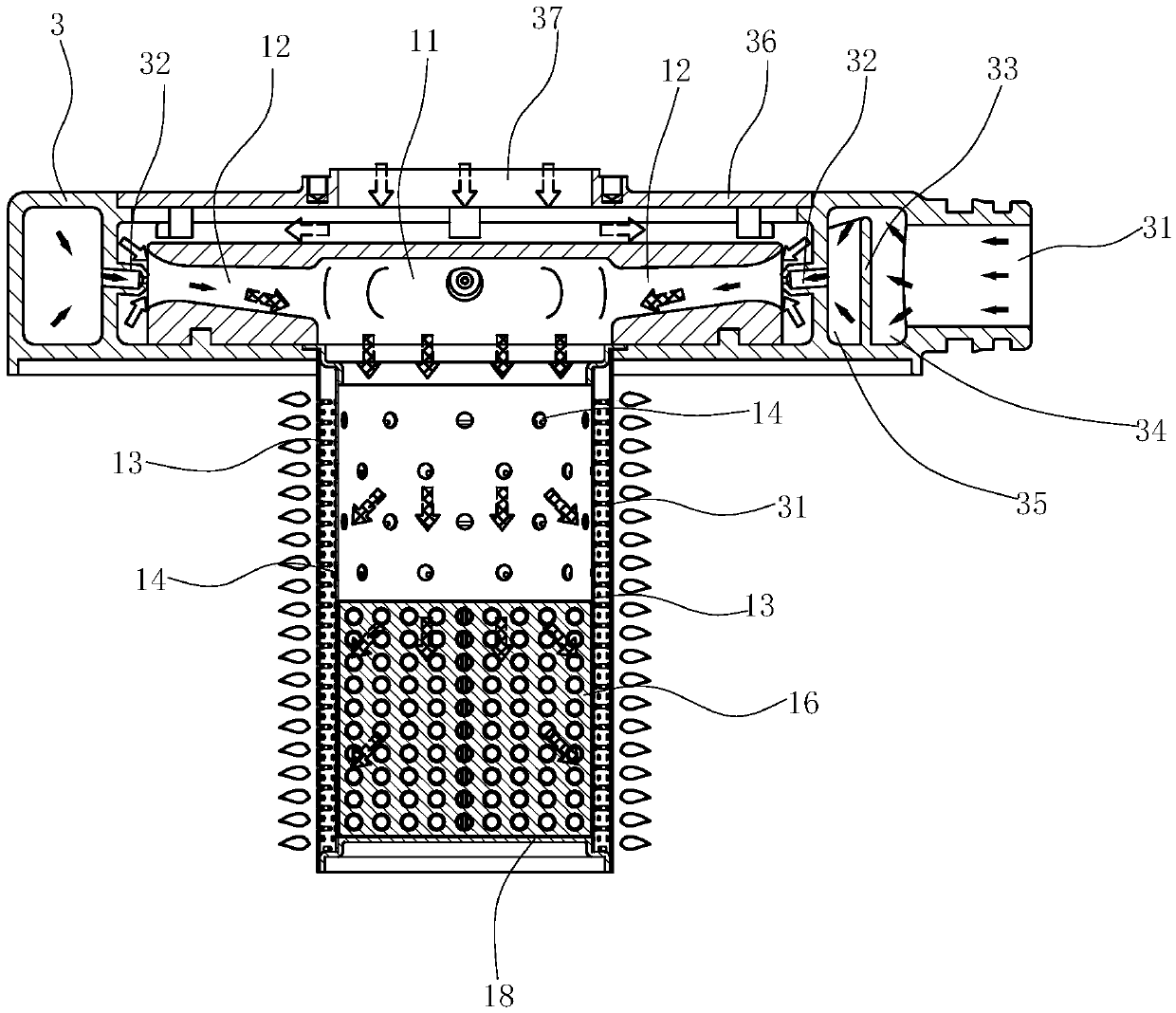

Full-premix burner

ActiveCN110260310AReduce lossesDiffusion is no longer requiredGaseous fuel burnerEngineeringMixing effect

The invention discloses a full-premix burner, and relates to the technical field of burners. The full-premix burner comprises a fan, a mixing chamber shell, a burning head and an igniter, wherein the mixing chamber shell is connected between the fan and the burning head; an air main pipe and a gas main pipe are arranged in the mixing chamber shell; multiple air branch pipes communicate to the air main pipe; multiple gas branch pipes communicate to the gas main pipe; the outlet ends of the air branch pipes are deviated from the fan; the multiple gas branch pipes communicate to the air branch pipes in a one-to-one corresponding way; a connecting plate is arranged between the air branch pipes and the burning head; two ends of the connecting plate are in sealed connection with the multiple air branch pipes and the burning head; and air guiding holes corresponding to the multiple air branch pipes are formed in the connecting plate. The full-premix burner provided by the invention has the effects of simple structure, low processing cost, a good mixing effect of gas and air, and a stable mixing result.

Owner:江苏卡瓦诺热能科技有限公司

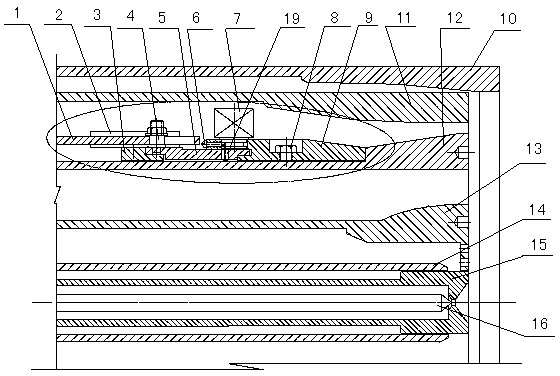

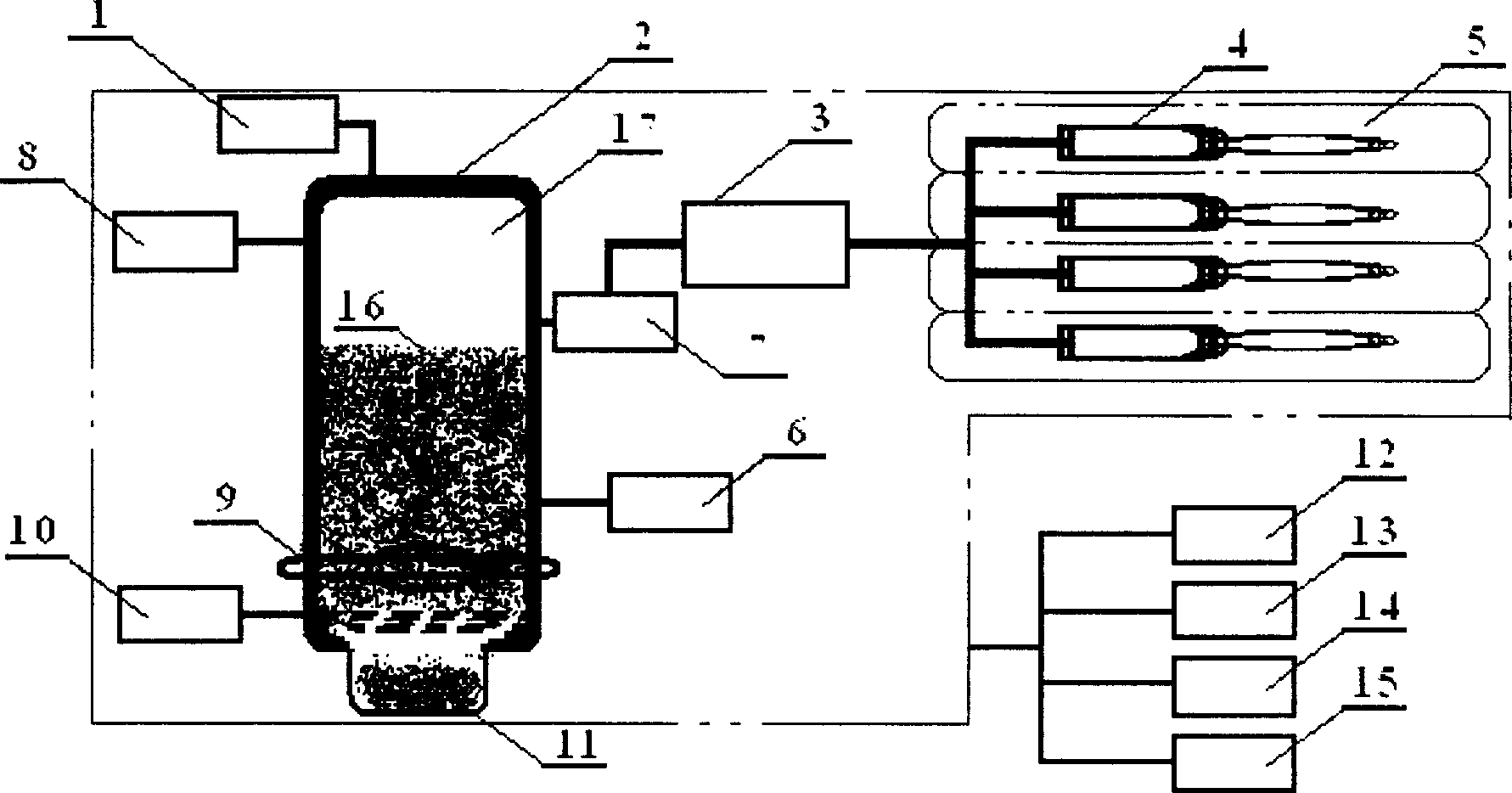

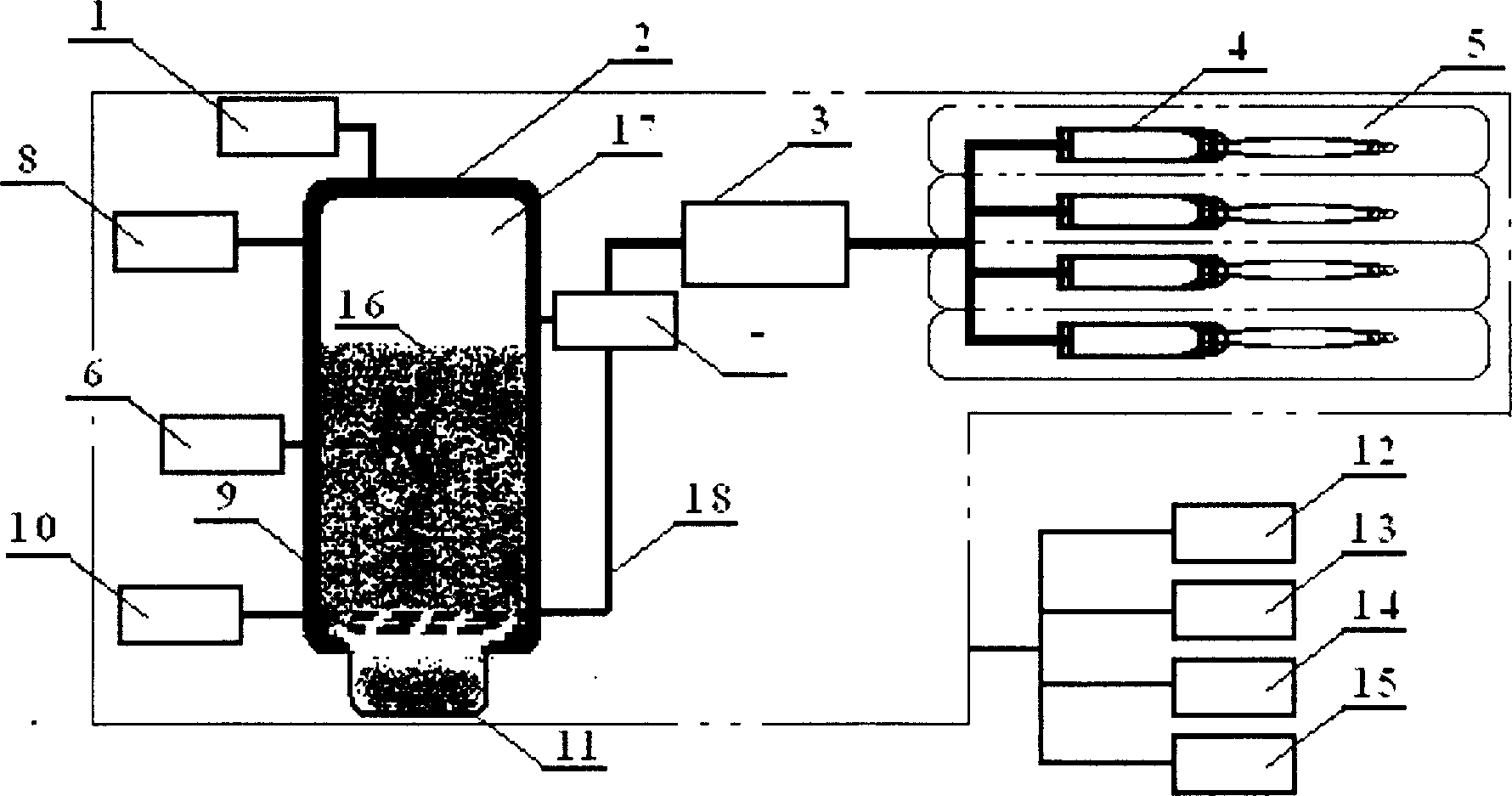

Cracking ignition device for pulverized coal fired boiler

InactiveCN1804467ARapid realization of thermochemical conversionIncrease burnoutIncandescent ignitionSlagCombustible gas

The invention relates to a power plant ignition device, especially providing a crack ignition device used in firepower coal boiler. It comprises a crack furnace (2), a feeding system (8) inside the crack furnace (2), a crack medium feeding system (10) and a slag discharge system (11). Wherein, the furnace chamber contains a heating device (9); the crack furnace (2) has a gas output tube; or it can mount a fuel gas feedback heating system (18) on the gas output tube to replace the heating device (9); the another end of fuel gas feedback heating system (18) is through to the furnace chamber of crack furnace (2); the end of output tube has a ignition burning head (4) which is connected to the burner (5) of boiler or directly burn the coal powder inside the furnace chamber. The invention has the advantages that: it has stable property, the cold and hot resistance and long service life; when the boiler is started, it can be used as ignition burner and when in normal burning, it can be used as main burner; and it is compatible with the boiler.

Owner:赵龙章

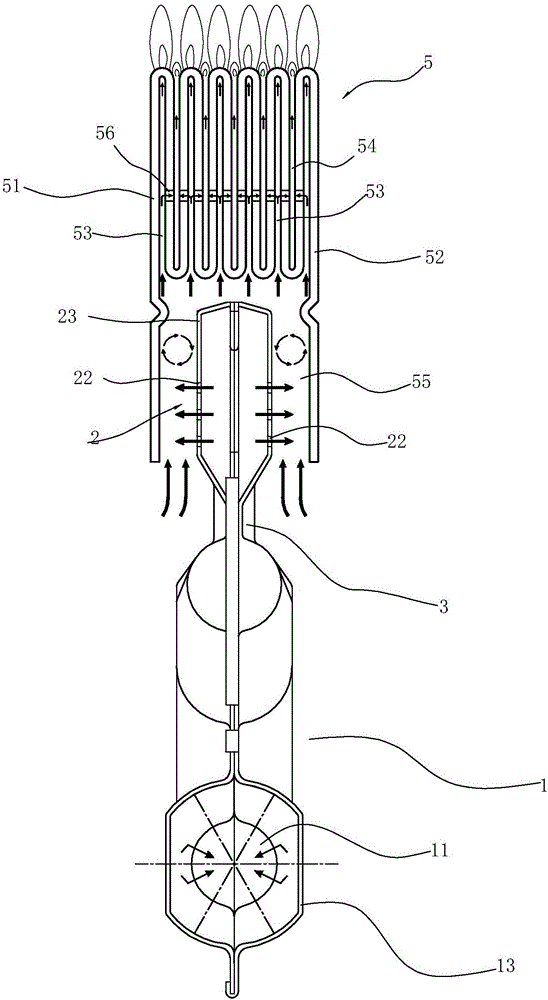

Burner

The invention relates to a burner. The burner comprises an ejector (1) and a burning head (2) and is characterized in that the ejector (1) is sleeved with an annular fuel gas distribution pipe (3), the fuel gas distribution pipe (3) is provided with a fuel gas inlet (31) communicating with an inner cavity of the fuel gas distribution pipe, and the side wall of the fuel gas distribution pipe is further provided with multiple spray nozzles (32) communicating with the inner cavity of the fuel gas distribution pipe at intervals. The ejector (1) comprises a gas mixing chamber (11) and multiple mutually-independent ejection channels (12), inlets of all the ejection channels are opposite to the corresponding spray nozzles (32) respectively and communicate with the surrounding environment, outletsof all the ejection channels communicate with the gas mixing chamber (11), and an outlet of the gas mixing chamber (11) is connected with an inlet of the burning head (2).

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Burner for gas water heater

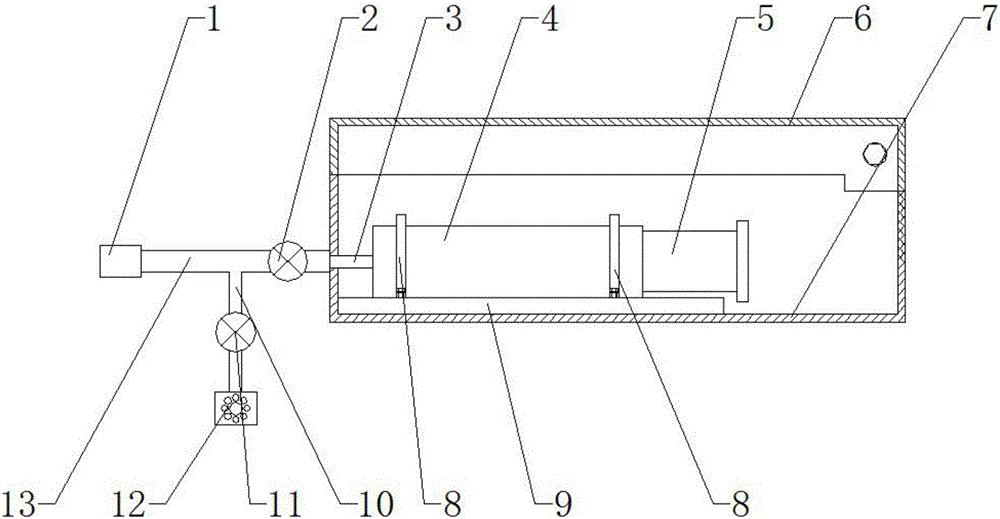

ActiveCN105003915AGuaranteed mixing amountEnsure mixing uniformityGaseous fuel burnerEngineeringBurning head

The invention relates to a burner for a gas water heater. The burner comprises an injecting pipe and a burning head. The burner is characterized in that an outlet of the injecting pipe is connected with the inner cavity of a gas box in a sealing manner, and a plurality of gas outlets are formed in the lateral wall of the gas box; the burning head comprises a first baffle and a second baffle, and a plurality of gas flow passages and a plurality of overflow passages, which are sequentially and alternately arranged in parallel, are arranged between the first baffle and the second baffle; a cavity with an openmouthed lower end for accommodating the gas box is formed between the first baffle and the second baffle under the gas flow passages and the overflow passages, the upper end and the lower end of each of the gas flow passages are opened, the lower opening of each of the gas flow passages is communicated with the cavity, an overflow hole communicated with the adjacent overflow passage is formed in the lateral wall of each of the gas flow passages, the lower ends of the overflow passages are closed, and the upper ends of the overflow passages are opened; the gas box is accommodated in the cavity, and gaps are formed between the gas box and the first baffle and between the gas box and the second baffle.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Fuel gas cooking utensils of having new type set for adjusting firepower

ActiveCN100335842CProper cooking powerAccurately adjust the size of the firepowerDomestic stoves or rangesGaseous fuel burnerEngineeringEnergy conservation

A flame regulation device of gas stove consists of burner, burning head, ejecting tube, valve body, valve core and gas nozzle. It is featured as setting hollow tube through to valve body on radial of the valve body, setting elastic positioning mechanism with different rotary position in hollow tube for positioning valve core, having positions corresponding to elastic positioning mechanism on peripheral surface of valve core for realizing accurate regulation of flame.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

Local heater used in molding of pipe orifice of main steam super pipe and method for heating master pipe blank by using same

The invention relates to a local heater used in molding of a pipe orifice of a main steam super pipe and a method for heating a master pipe blank by using the same. The local heater comprises a combustion head and a fire damper disk, wherein the combustion head consists of an air inlet pipe, a combustible gas inlet pipe, a combustion chamber and the like; the contact surface of the combustion chamber and the master pipe blank of the main steam super pipe is a curved surface; the fire damper disk is provided with a contact type thermocouple, an automatic ignition device and a fire-resistant, heat-insulating and heat-preservation layer; and the contact type thermocouple is in contact with the master pipe blank of the main steam super pipe. During heating, air and combustible gas enter the combustion chamber, the movable fire damper disk is arranged on a supporting rod in the master pipe blank of the main steam super pipe and is in fit with the inner wall of the master pipe through a circular arc surface, and a fire is lighted for heating. By using the local heater, the master pipe blank of the main steam super pipe can be heated uniformly and rapidly to the target temperature required by plastic deformation of the material within 40 minutes; and due to the local heating, the fuel consumption is reduced and large deformation of the master pipe is prevented when the master pipe is reversely penetrated by a molding punch head.

Owner:武汉重工铸锻有限责任公司

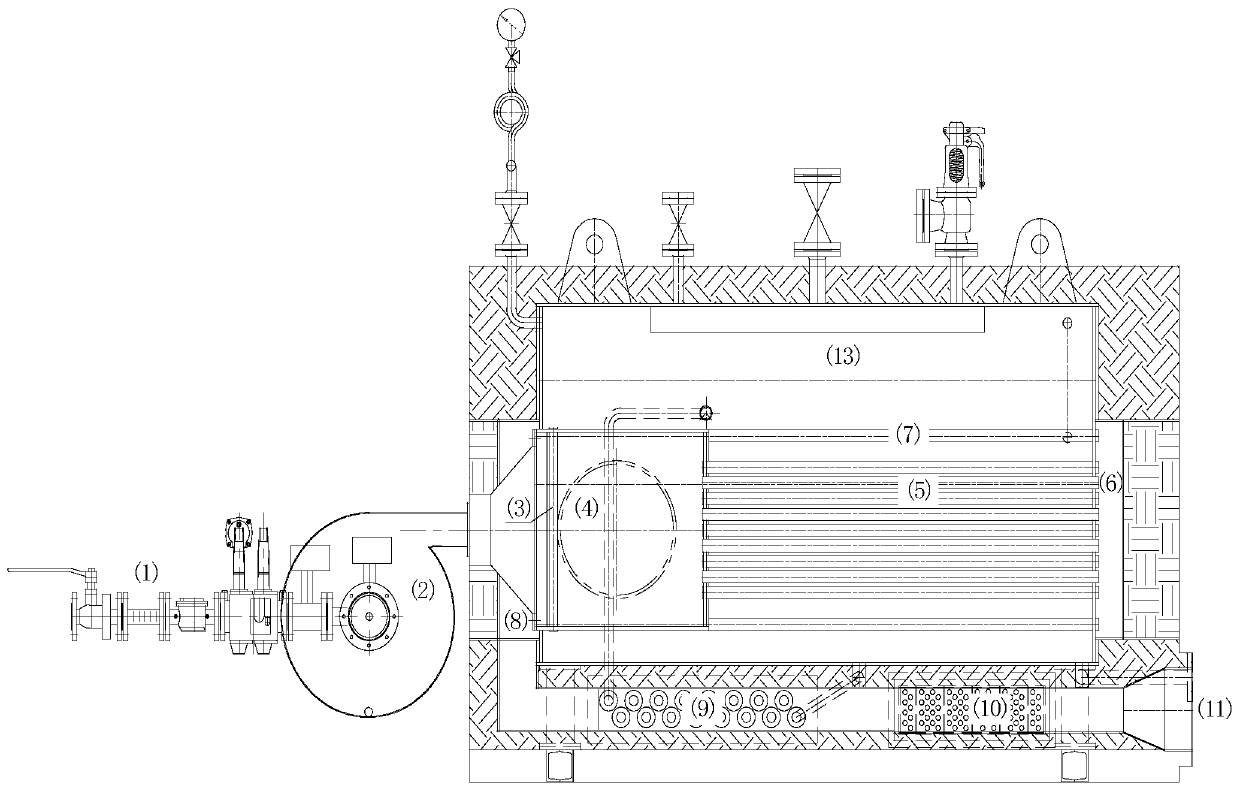

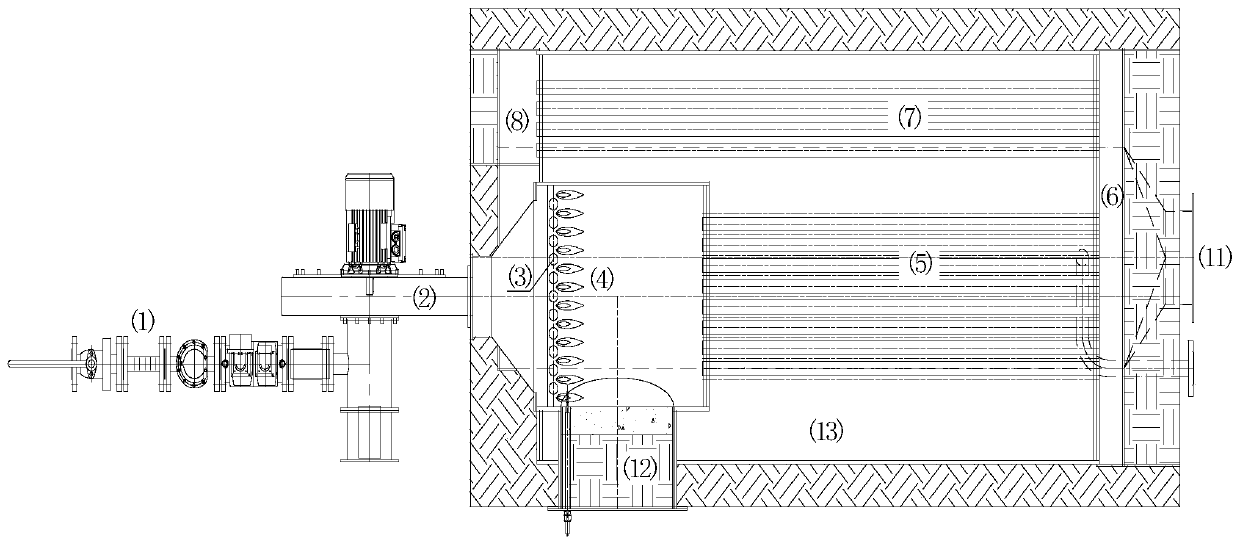

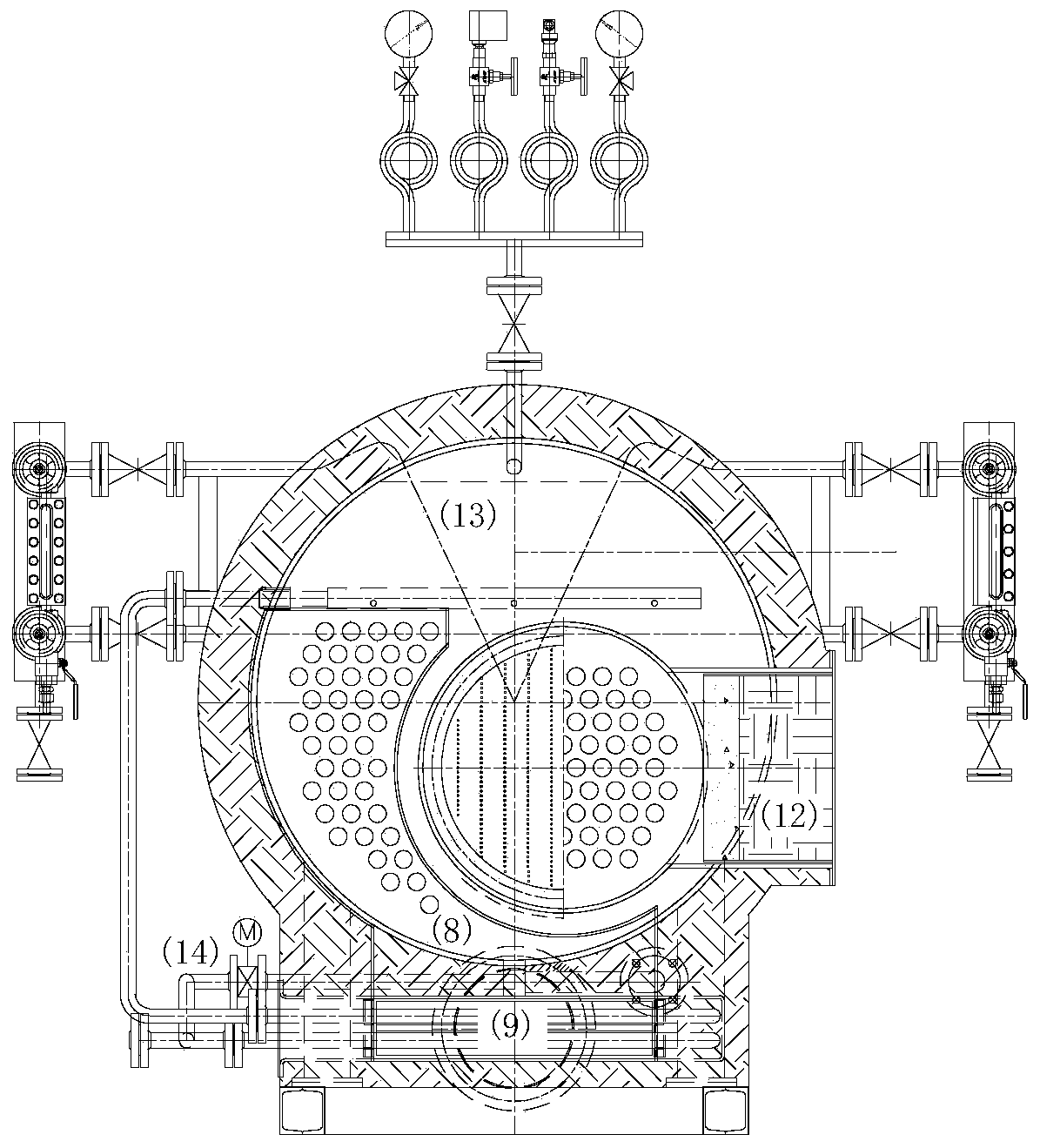

Natural gas cold flame horizontal type fire tube steam boiler

InactiveCN110887032AReduce length dimensionLower exhaust gas temperatureBoiler controlWater-tube boilersThermodynamicsEngineering

The invention discloses a natural gas cold flame horizontal type fire tube steam boiler which comprises a fuel gas valve group (1), an anti-explosion fan (2), a burning head, a hearth (4), a first return stroke thread smoke tube (5), a rear smokebox (6), a second return stroke thread smoke tube (7), a turning smoke chamber (8), an energy saver (9), a condenser (10), a smoke outlet (11), a hearth access door (12), a shell cylinder (13) and a recycling pipeline (14); the burning head is a cold flame burning head; the outlet of the anti-explosion fan is connected with the cold flame burning head;mixed gas is sprayed into the hearth via the cold flame burning head for combustion; the hearth, the first return stroke thread smoke tube and the second return stroke thread smoke tube are arrangedin the shell cylinder; the first return stroke thread smoke tube is directly connected with the back of the hearth; the first return stroke thread smoke tube and the second return stroke thread smoketube are connected in series through the rear smokebox; a single row of water tube bundles is vertically arranged at the front end of the hearth; a mixed gas spray hole (a steel plate is a spray holecarrier) is formed between every two adjacent tube bundles; the energy saver is arranged at the lower part of the shell cylinder and is connected with the second return stroke thread smoke tube through the turning smoke chamber; the condenser is connected with the back of the energy saver; and a smoke outlet is formed in the back of the condenser.

Owner:JIANGSU SHUANGLIANG BOILER

Open-type methane burning torch

The invention discloses an open-type methane burning torch, relating to an open-type methane burning device. The open-type methane burning torch comprises an air inlet, a main air inlet pipe, a torch burning head assembly, an air-proof cover and an ignition wire inlet pipe. The bottom of the main air inlet pipe is provided with a water drainage pipe, a base and a reinforcing rib and directly connected with a foundation. The air inlet is arranged above the water drainage pipe and communicated with the main air inlet pipe. The ignition wire inlet pipe comprises an ignition electrode guide pipe. An ignition electrode is located into the ignition electrode guide pipe installed near a torch burning head. The air-proof cover and the torch burning head assembly are fixed by means of a connecting support and a support pipe. The torch burning head assembly, the connecting support and the support pipe are located in the interior of the air-proof cover. The main air inlet pipe and the torch burning head assembly are connected by means of a flange. The open-type methane burning torch is capable of preventing flames from entering a pipeline due to insufficient output of methane gas in order to ensure full and complete combustion of methane gas. No secondary pollutant due to incomplete combustion is produced. The open-type methane burning torch has a simple structure and is installed conveniently and flexibly.

Owner:BEIJING JIANYAN ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com