Patents

Literature

105results about How to "Increase burnout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

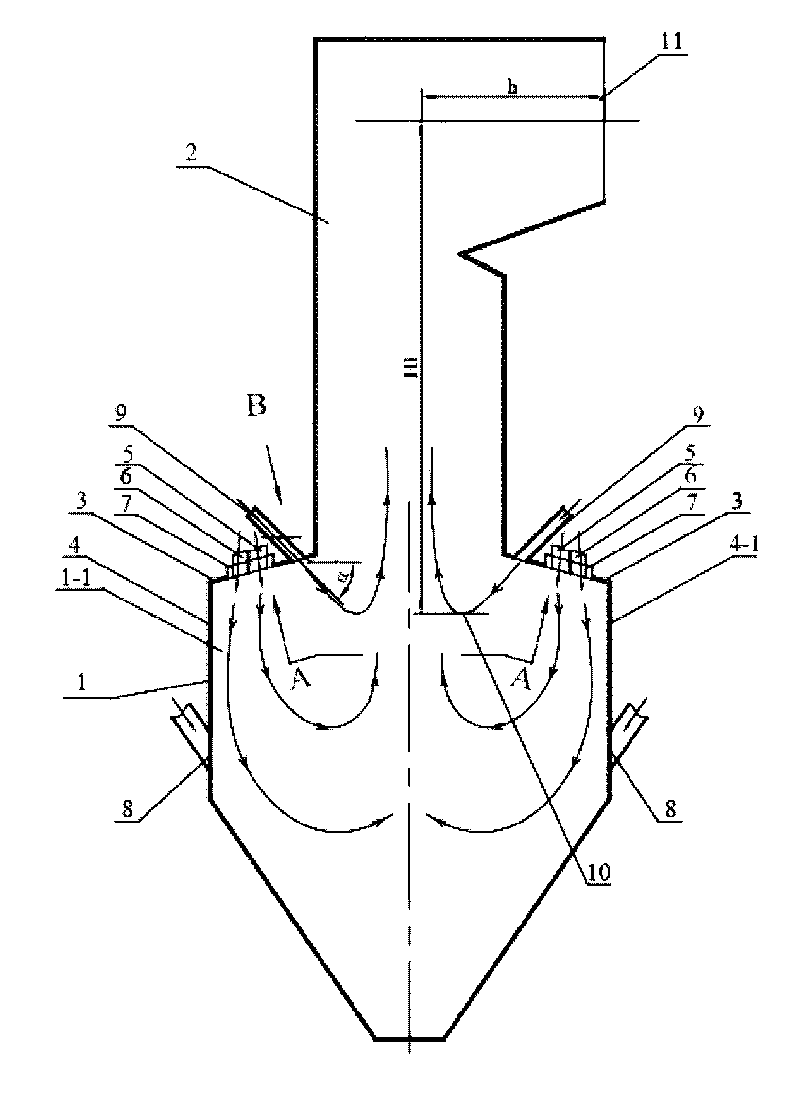

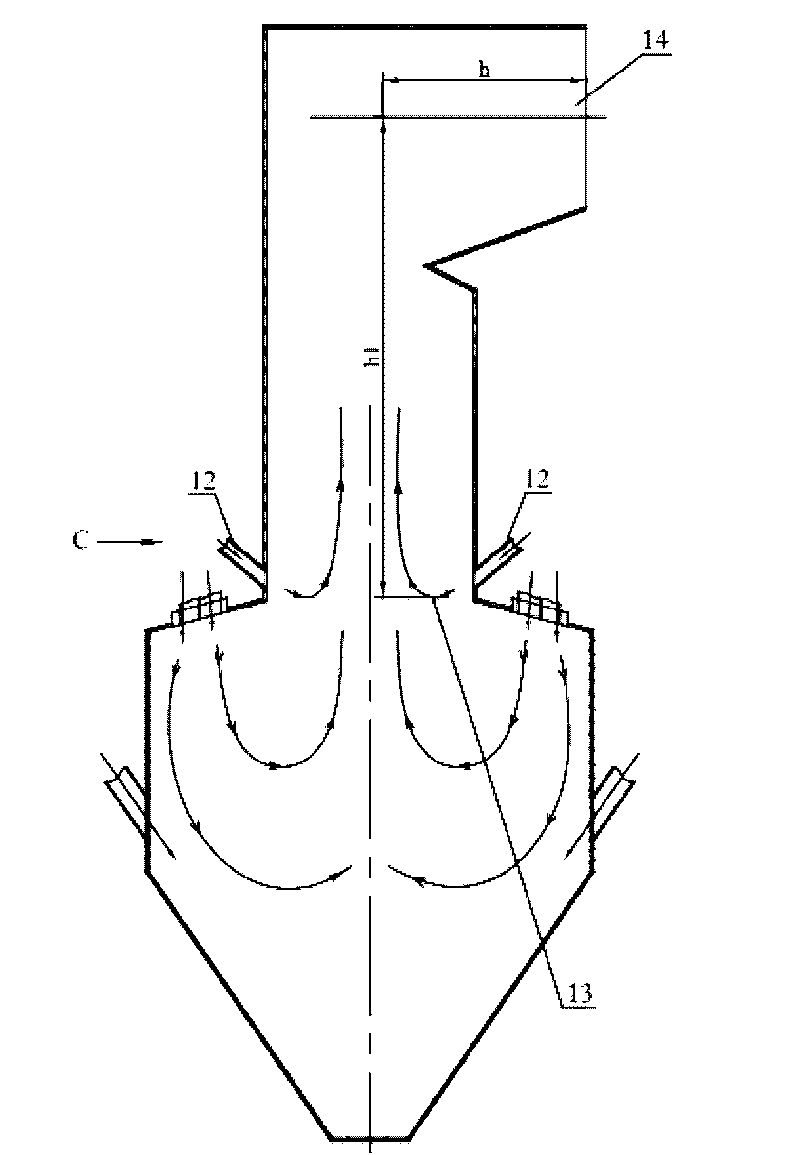

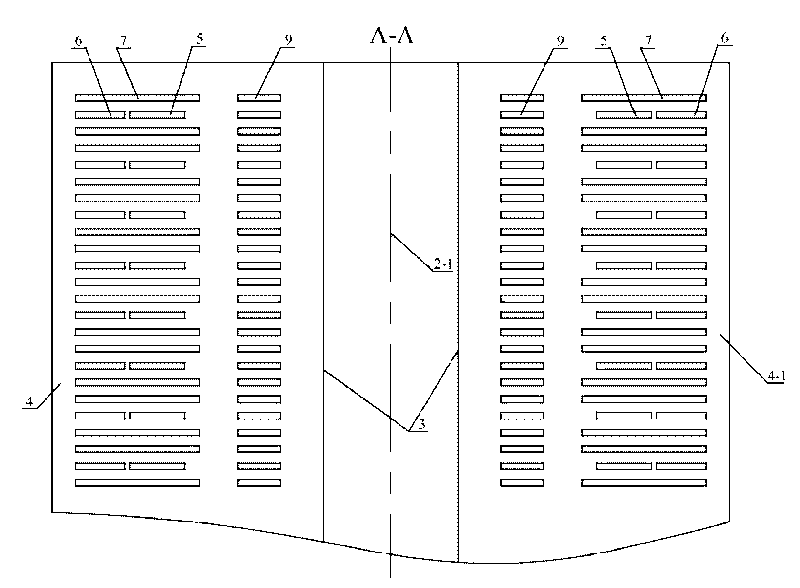

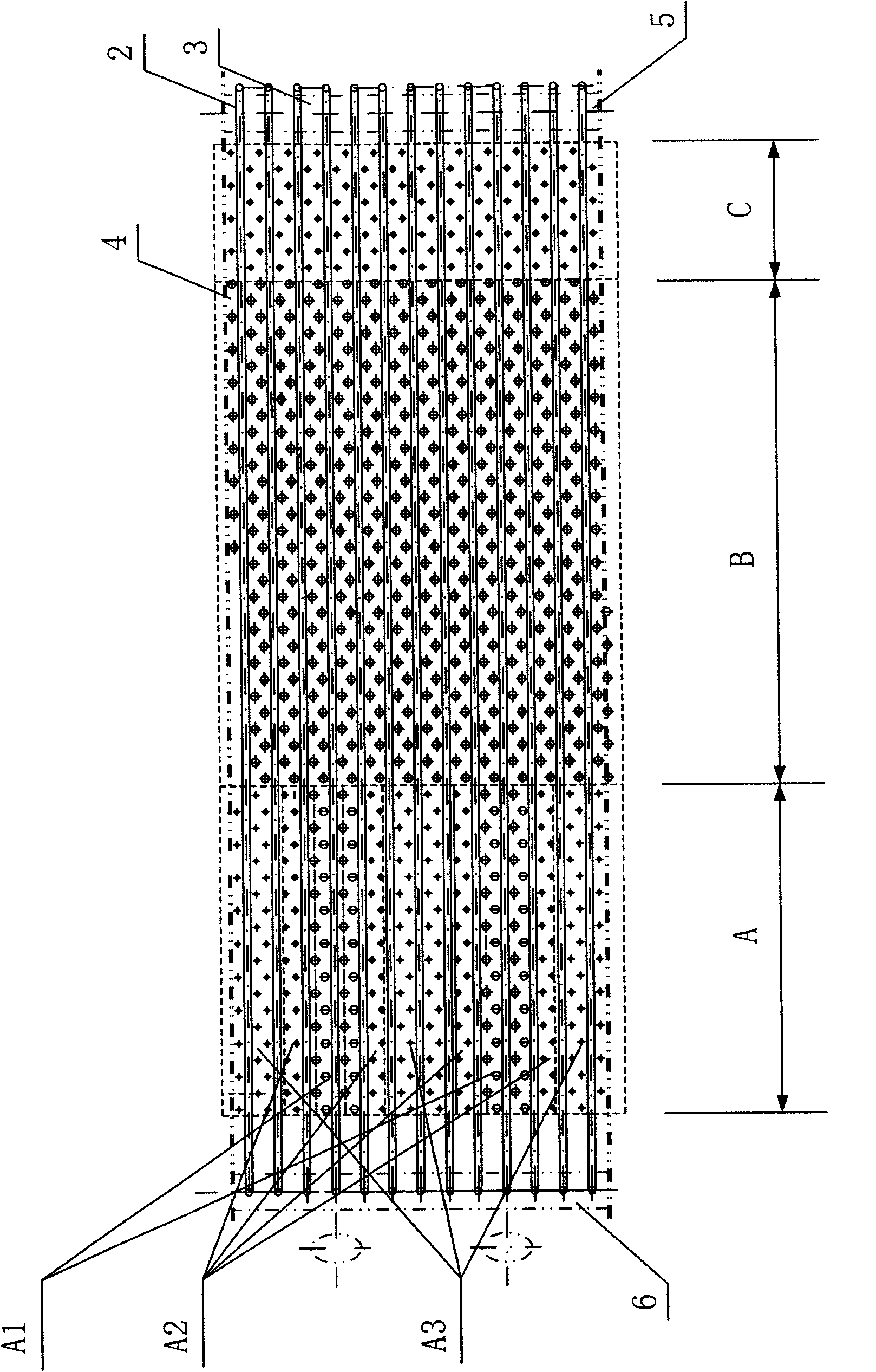

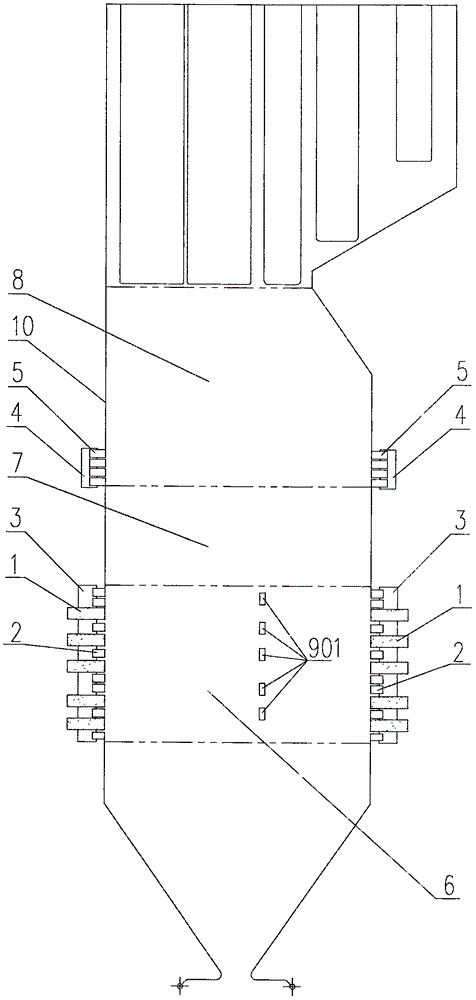

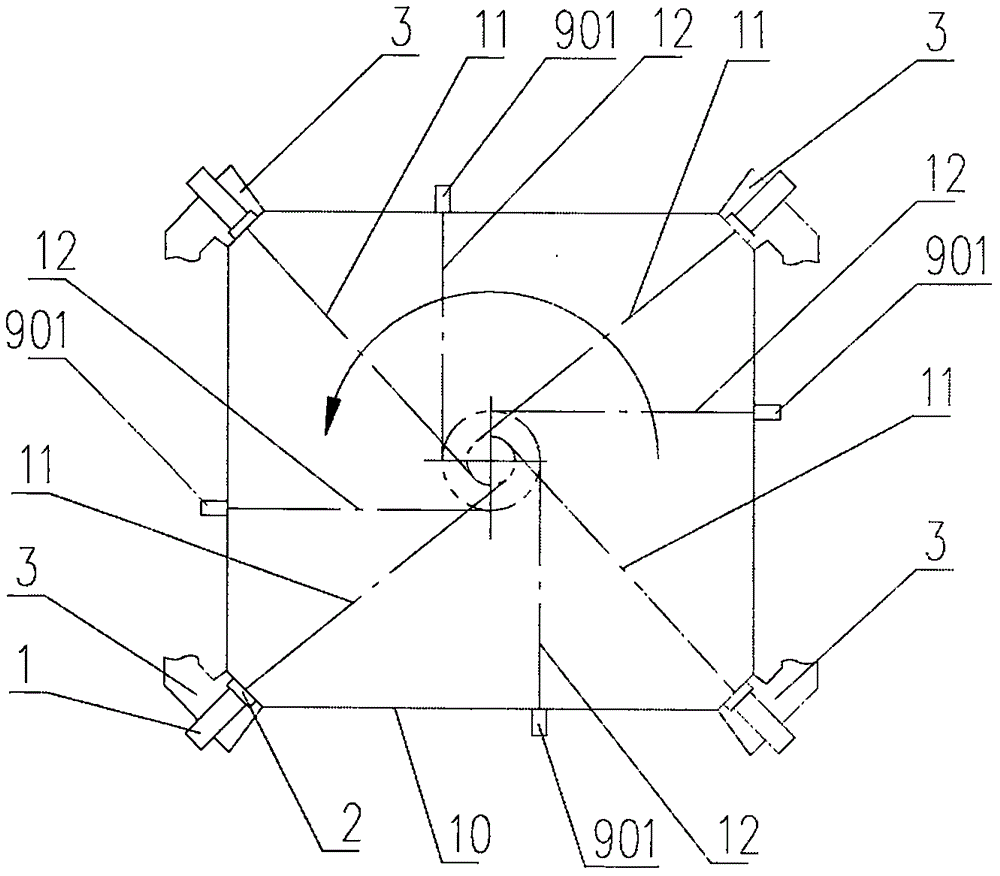

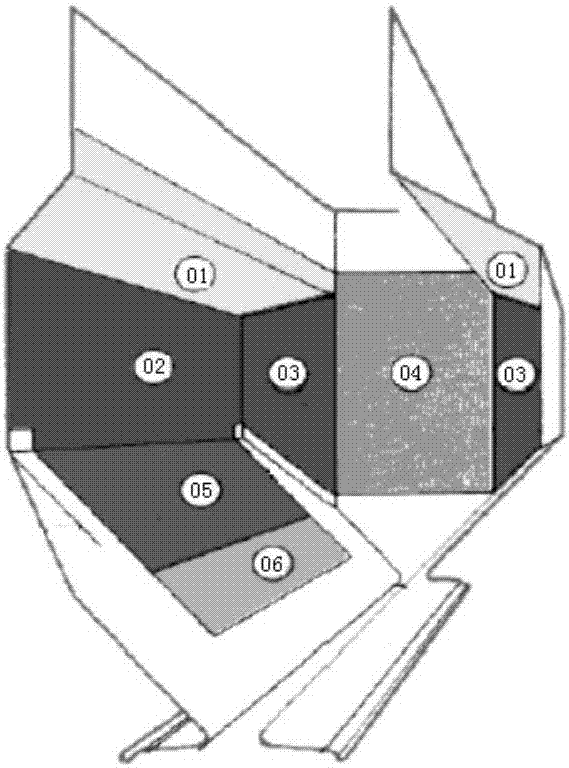

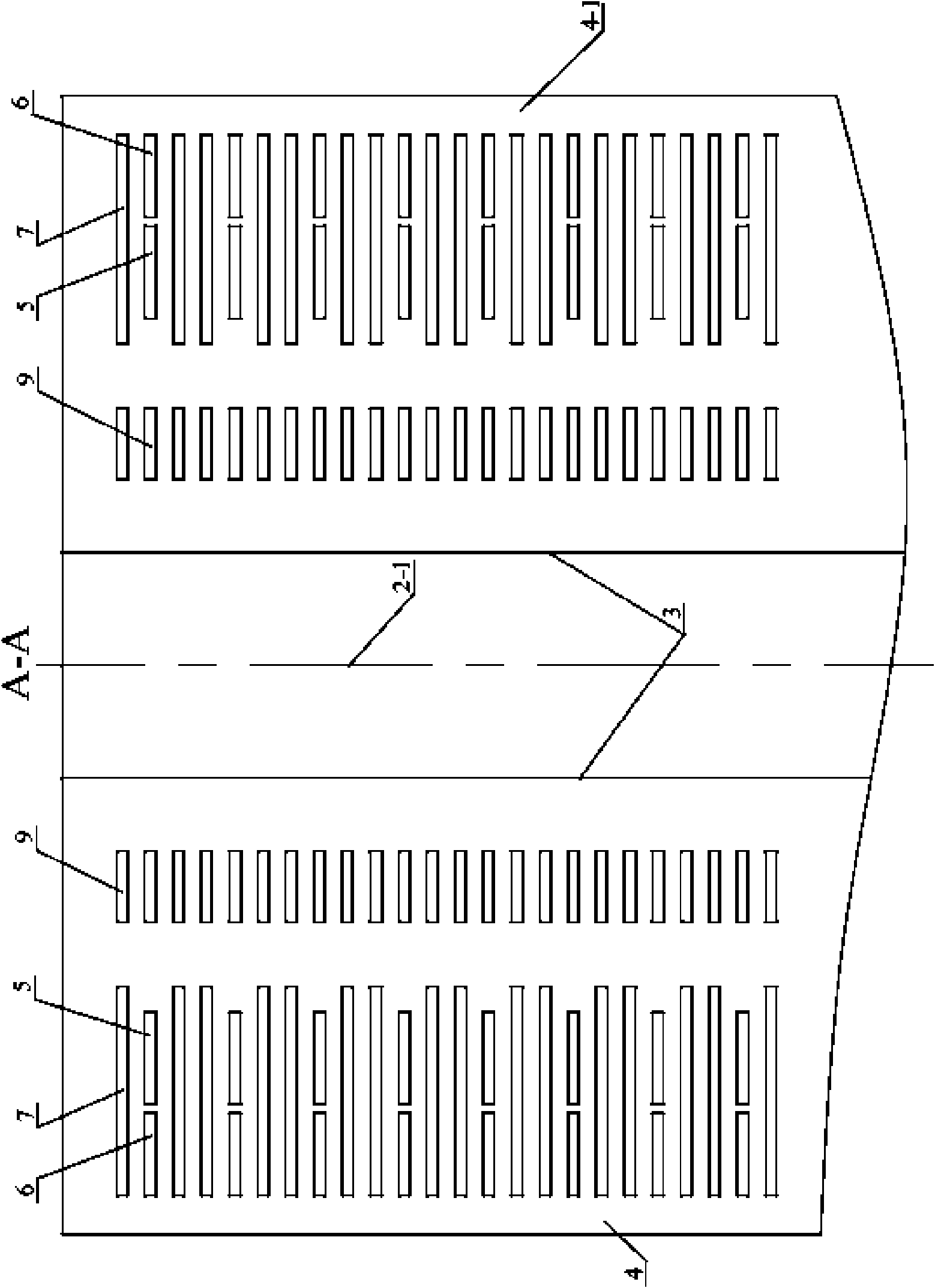

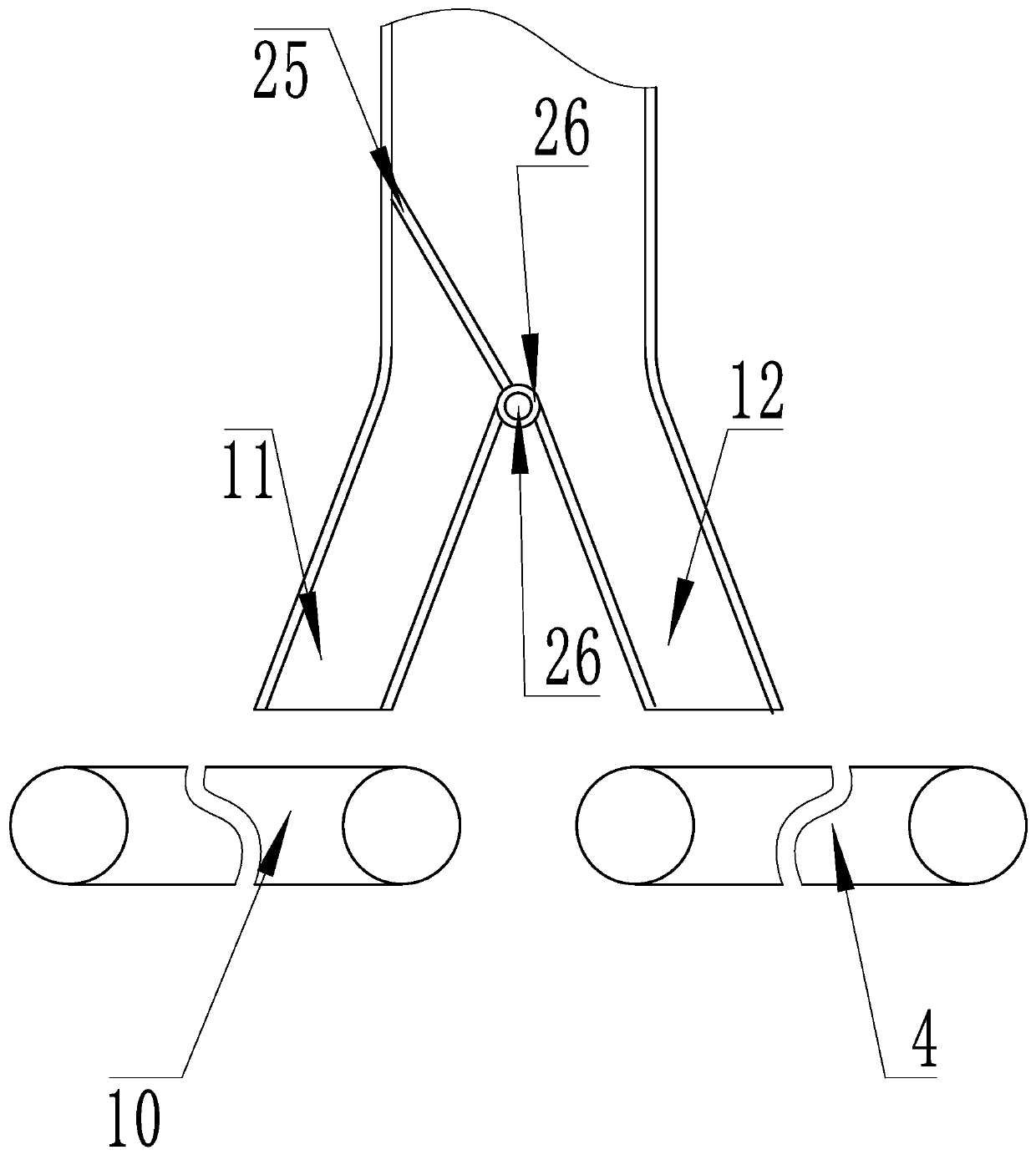

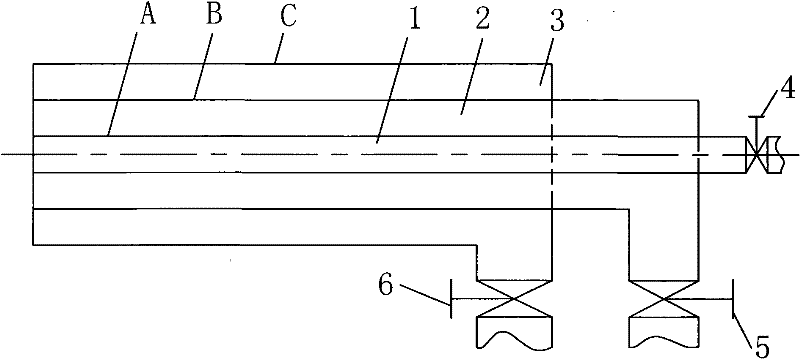

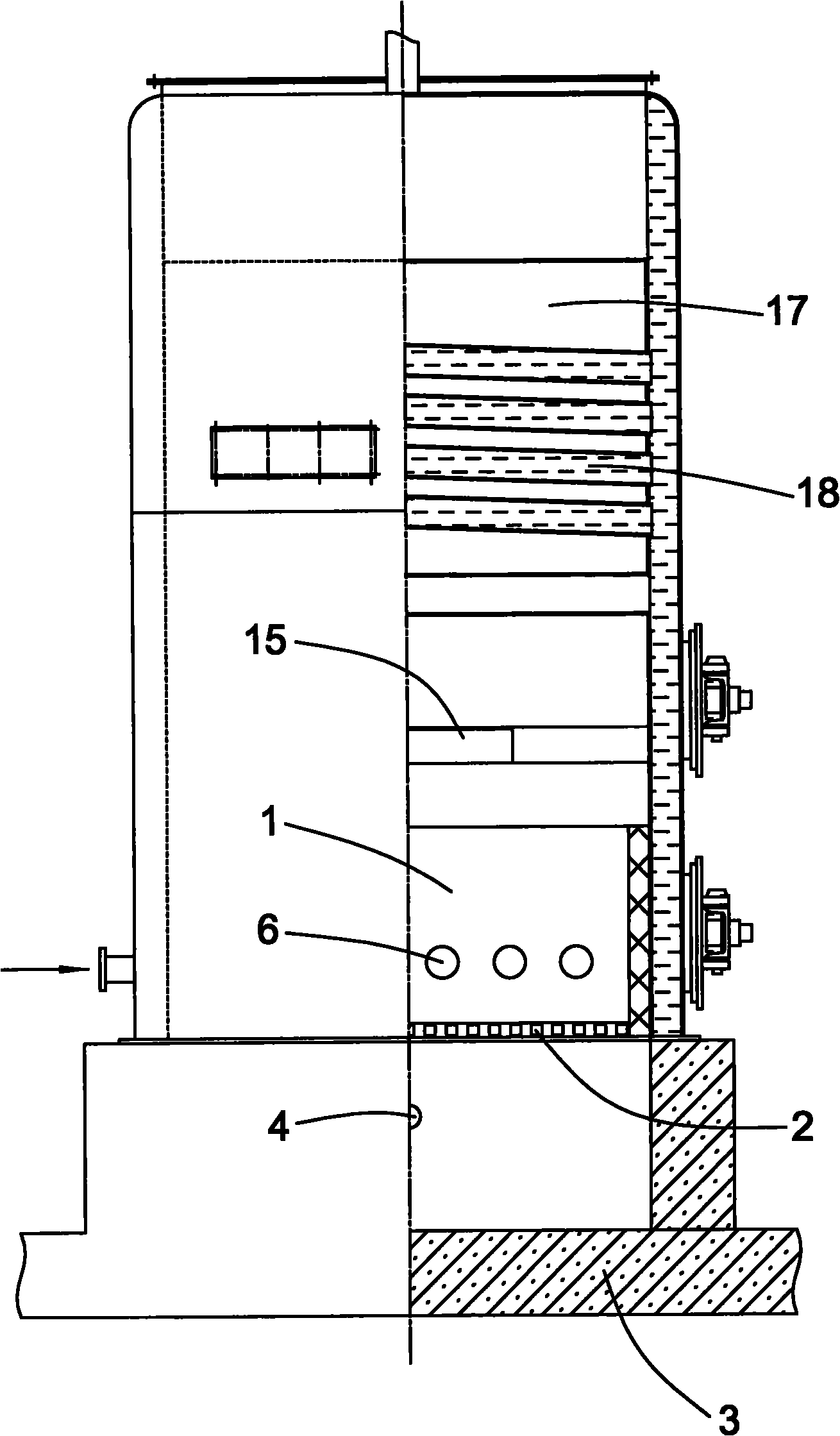

W-shaped flame boiler disposing aperture type over-fire air spouts on stove arch

ActiveCN101694295AExtended reaction timeImprove combustion efficiencyAir/fuel supply for combustionNon-combustible gases/liquids supplyHearthControl theory

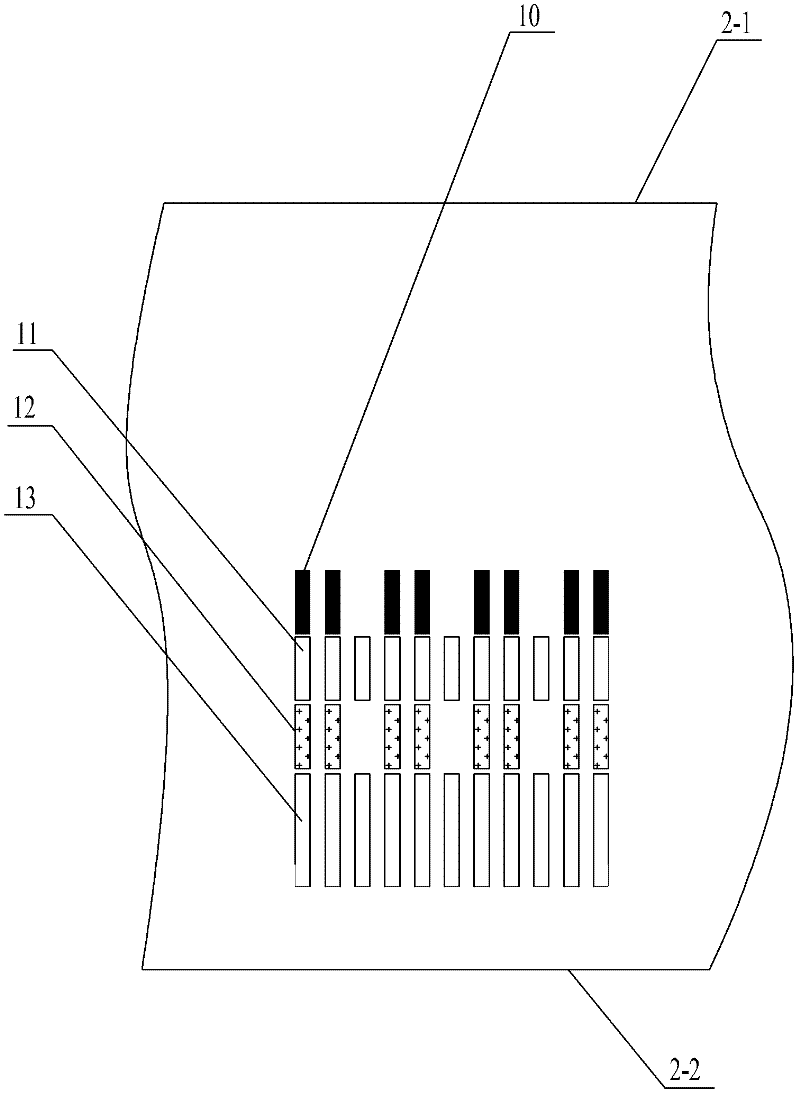

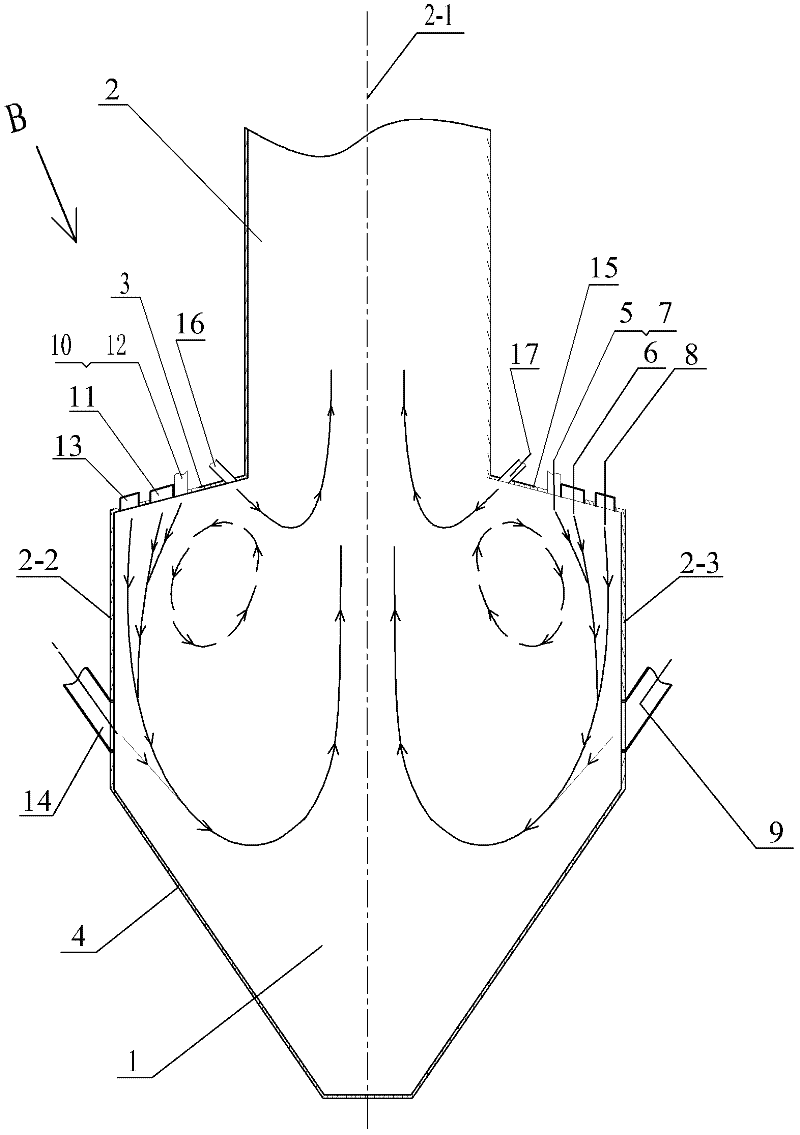

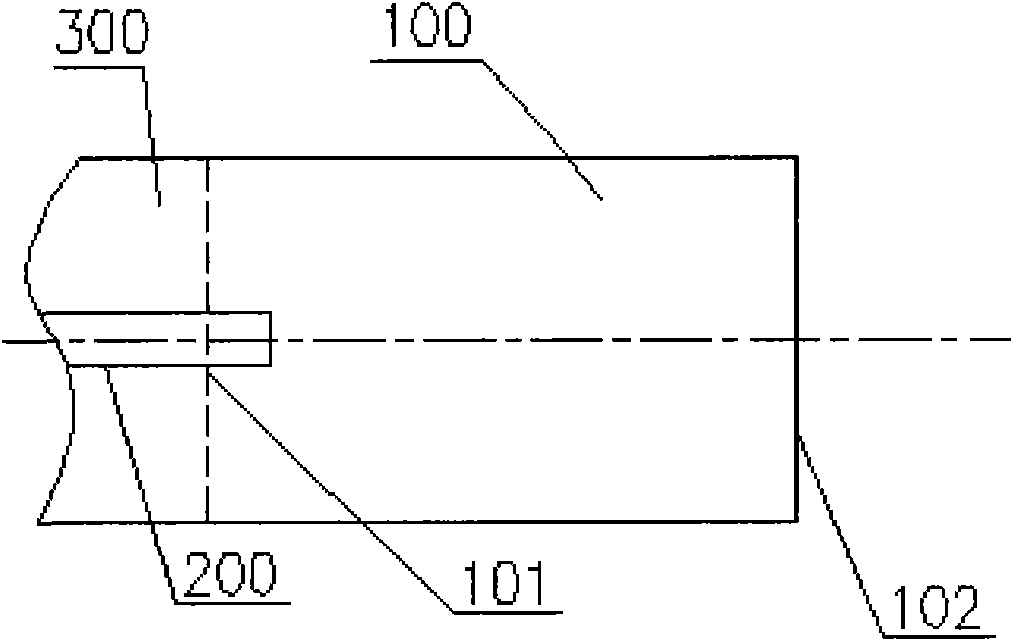

A W-shaped flame boiler disposing aperture type over-fire air spouts on a stove arch relates to a W-shaped flame boiler. The invention aims at solving the problems of existing W-shaped flame boilers that the burnout degree of coal powder is low, and the efficiency of the boiler is reduced when simultaneously increasing over-fire air and reducing the discharge of NOx. A plurality of the aperture type over-fire air spouts are divided into two groups, the two groups of the aperture type over-fire air spouts are symmetrically arranged along the central line of a boiler body, a group of aperture type over-fire air spouts are correspondingly arranged on each stove arch near the neck aperture of a hearth, one group of the aperture type over-fire air spouts are arranged in parallel along the length direction and are all communicated with a lower hearth of the lower boiler body, the sections of the aperture type over-fire air spouts are rectangles with the ratio of length to width is (5-7):1, and the central line of each aperture type over-fire air spout and the horizontal line form an included angle of 20-35 degrees. The distance between adjacent aperture type over-fire air spouts is 100 mm. The setting of the aperture type over-fire air spouts prolongs the reacting time between uncombusted coal powder granules and the over-fire air, and enables the combustion to be more compete.

Owner:HARBIN INST OF TECH

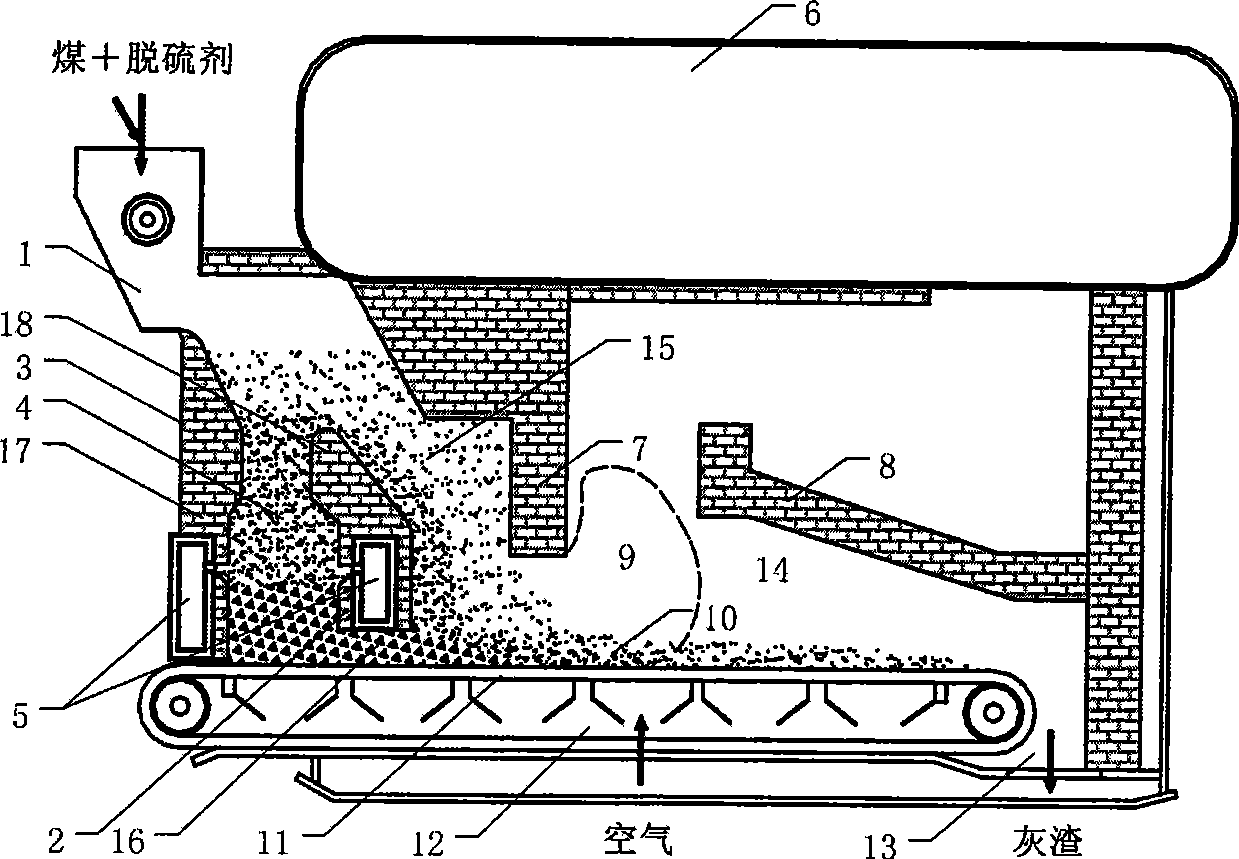

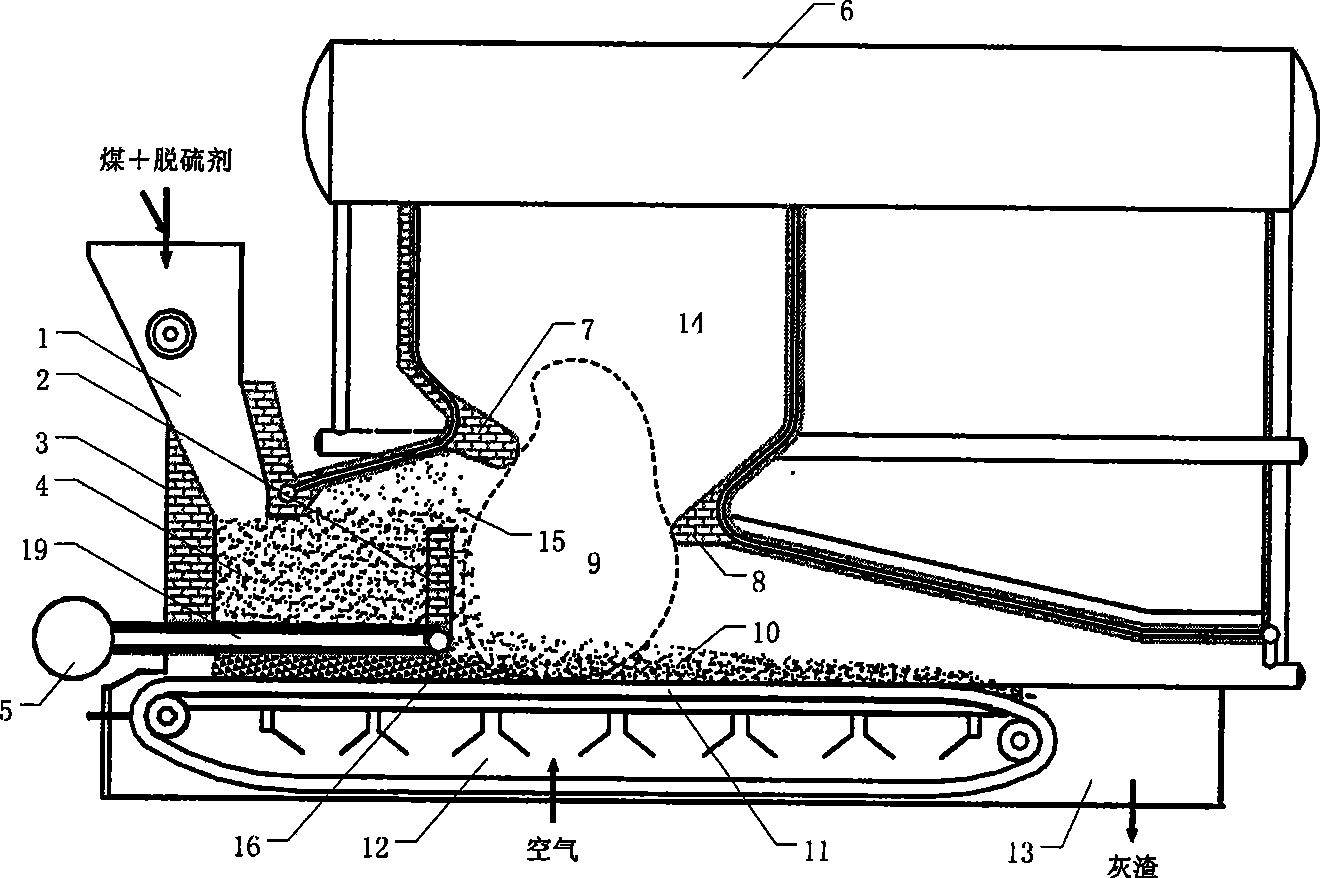

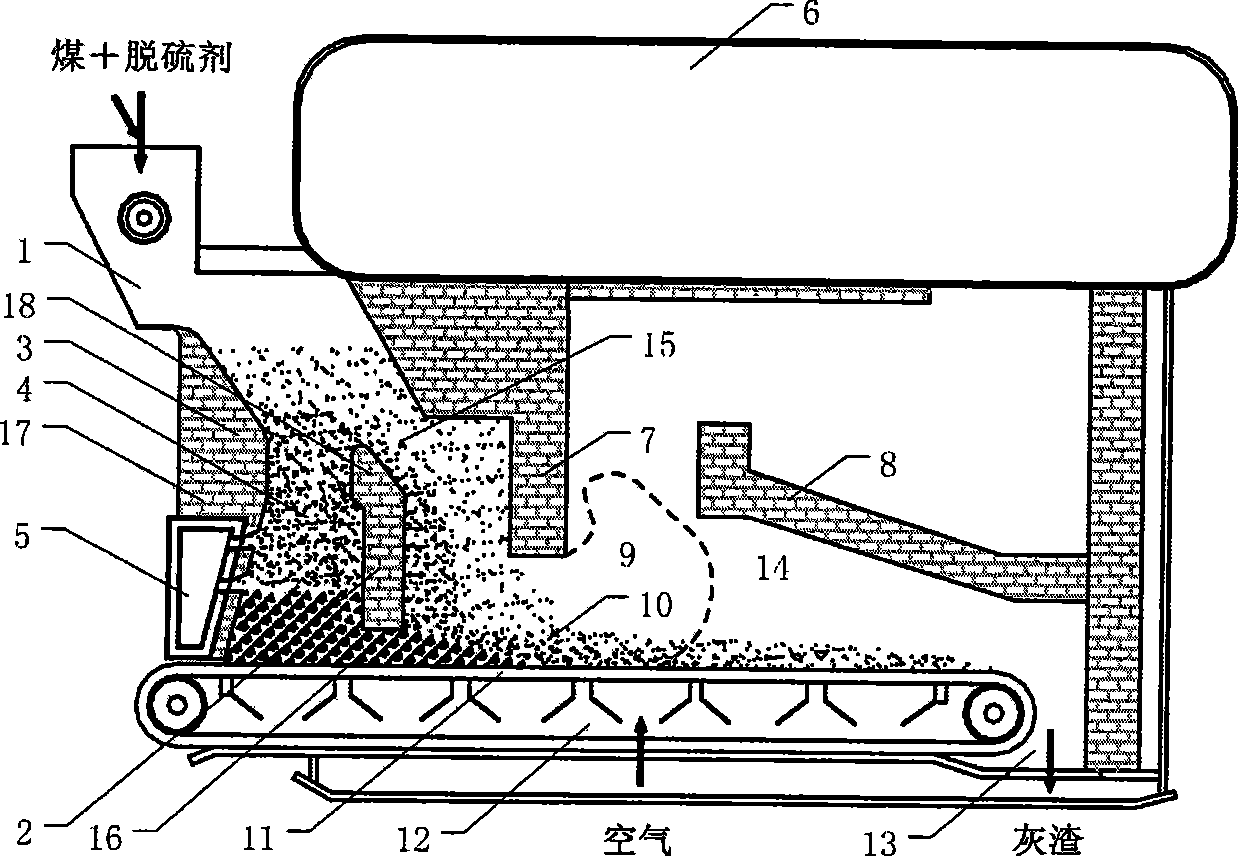

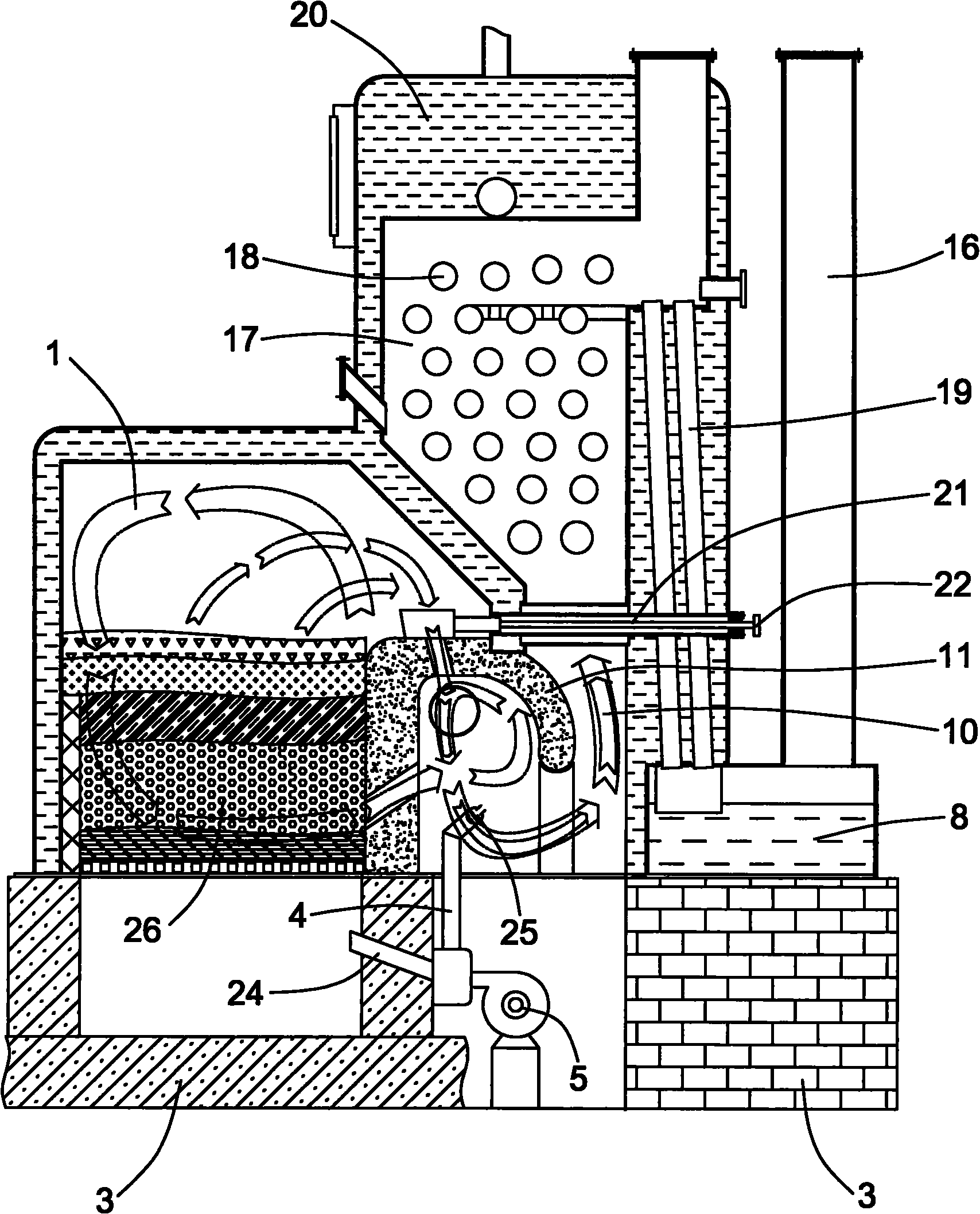

Coal thermal decomposition grate firing apparatus and its combustion method

InactiveCN101368724ASimple structureNo increase in sizeSolid fuel combustionCombustion apparatusCombustion chamberCombustible gas

The invention relates to a coal pyrolysis layer combustion device and the combustion method thereof, including that the furnace body interior of the first layer combustion furnace is divided into an upper oxidation pyrolysis chamber and a lower fire grate layer combustion chamber which is communicated with each other; the coal and desulfurizer are mixed to be fed into the middle part of the oxidation pyrolysis for oxidation pyrolysis through a hopper; the generated combustible gas and the smaller semi-coke particles are overflowed through the upper-connected through port or are carried in the airflow to be fed into the mechanical fire grate layer combustion chamber; the bigger semi-coke particles fall on the mechanical fire grate and are fed into the layer combustion layer for combustion; the mechanical fire grate layer combustion chamber is provided with a front arch and a back arch for organizing the airflow field inside the furnace; the coal pyrolysis layer combustion device and the combustion method thereof adopt the fluidization characteristics of the coal particles with different particle diameters and the high thermal capacity characteristic inside the oxidation pyrolysis chamber to realize the natural separation of the coal particles with different particle diameters and the rapid oxidation pyrolysis of coal, reduce the fire grate coal leakage loss and the incomplete combustion loss caused by the front segment low temperature of the fire grate and reduce the emission of the SOx and NOx pollutant through the combination of the pyrolysis desulfurization and the combustion desulfurization, and the reburning denitration formed by the coal pyrolysis product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

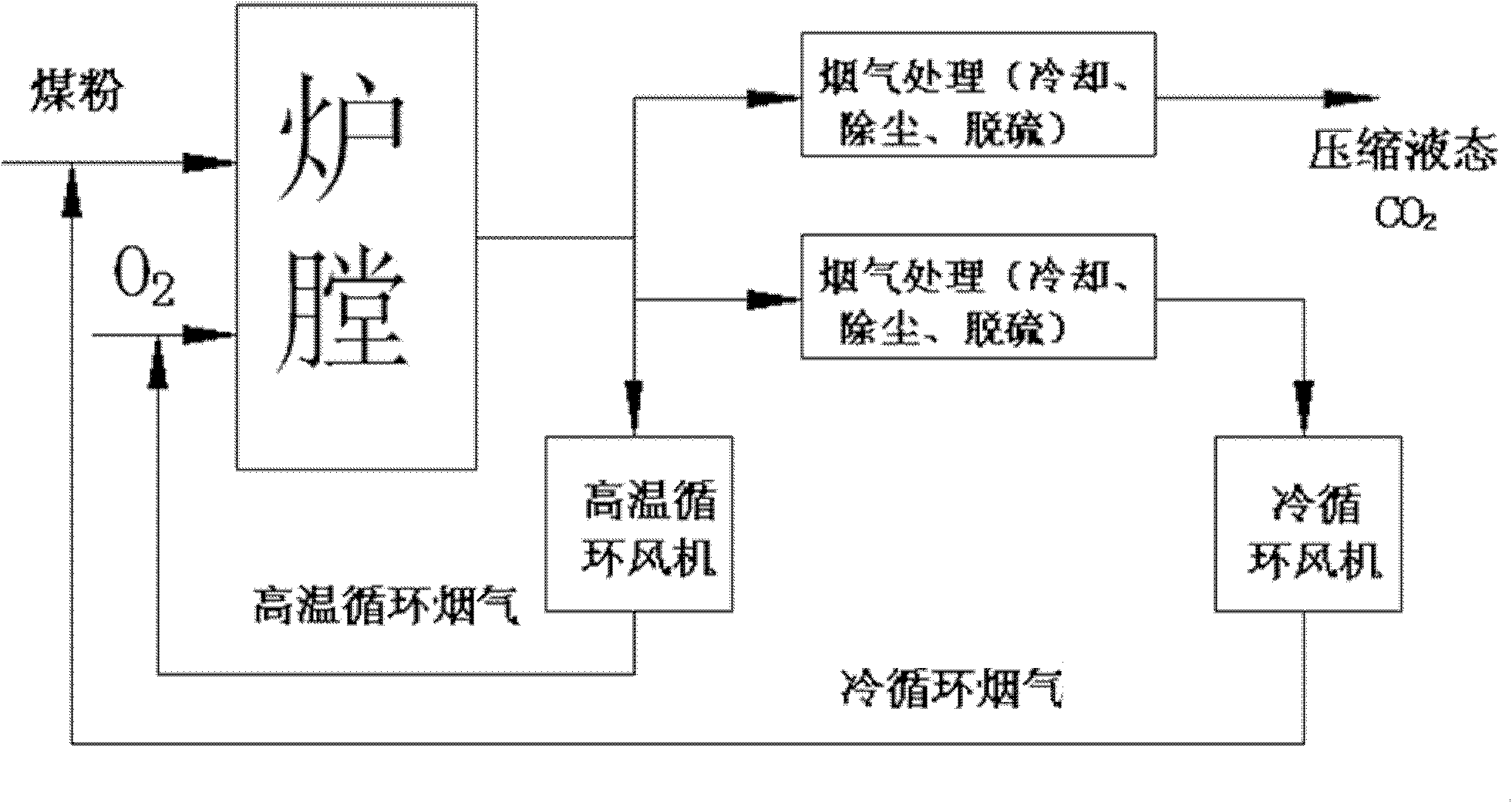

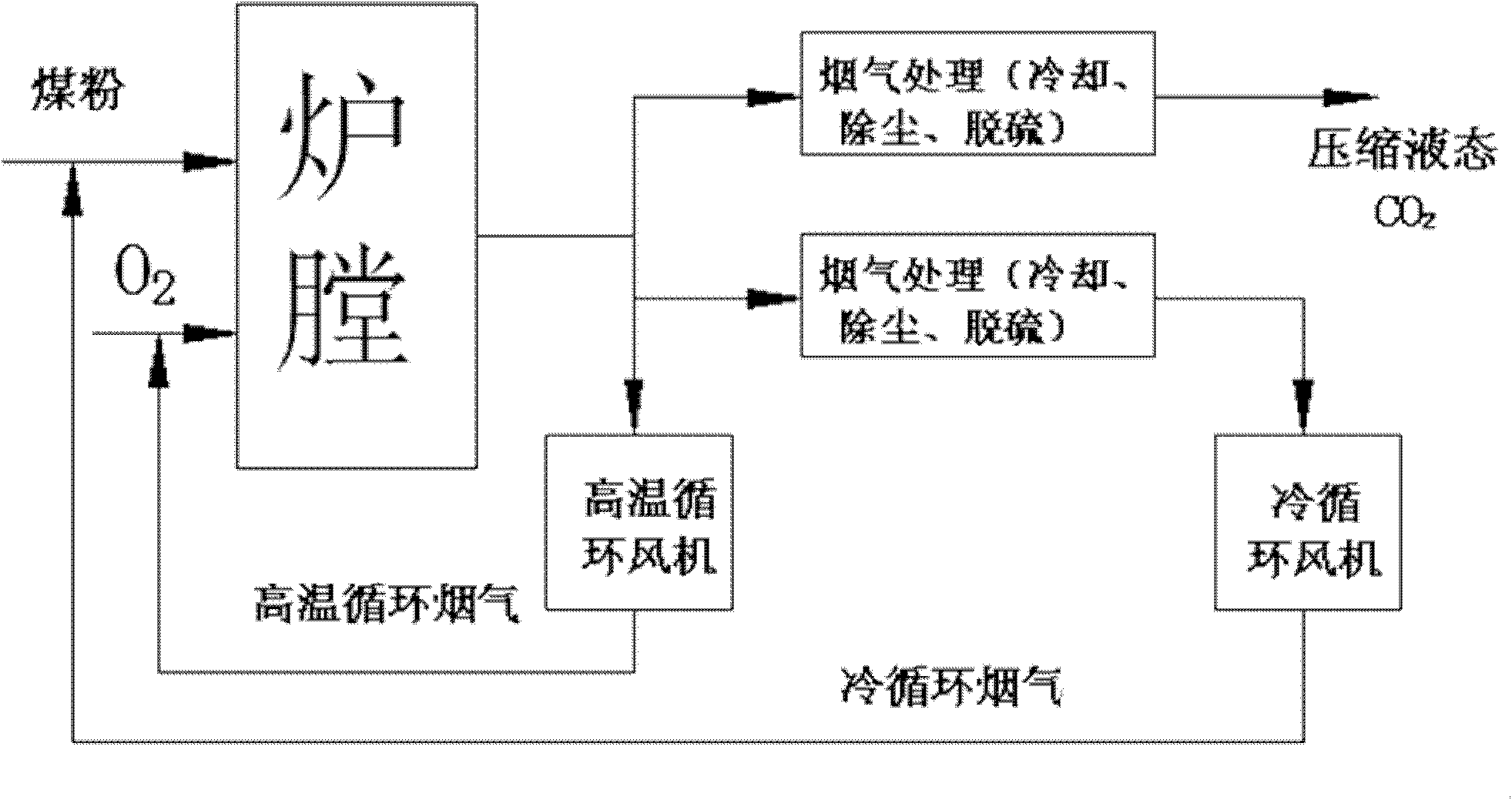

Method for micro positive pressure oxygen-enriched combustion of pulverized coal

InactiveCN101839476AIncrease pressureIncrease burnoutIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyProcess engineeringCoal

The invention provides a method for micro positive pressure oxygen-enriched combustion of pulverized coal, belongs to a method for circulating combustion of oxygen gas (O2) and carbon dioxide (CO2) of the pulverized coal, and aims to solve the problems of serious air leak and difficult ignition and stable combustion existing in the conventional combustion method. The method comprises the steps of: 1,igniting and combusting: conveying the pulverized coal to a furnace hearth by using the circulation flue gas, and simultaneously conveying O2 to the furnace hearth for ignition; 2, circulating the flue gas: dividing the high-temperature flue gas generated by combustion into two parts, and performing cooling, dust removal and desulfurization compression on the first part of the flue gas to obtain liquid CO2; dividing the second part into two paths, conveying the first path to an entrance of the furnace hearth by using a high-temperature circulation fan and mixing the first path of the flue gas and O2; and performing cooling, dust removal and desulfurization on the second path of the flue gas, and conveying the second path carrying the pulverized coal to the furnace hearth by using a cold circulation fan, wherein the micro positive pressure in the furnace hearth is maintained in the combustion process. The method has the advantages of adjusting the steam temperature of the boiler by using the circulation flue gas, maintaining the pressure, avoiding air leak, increasing the steam temperature of the boiler, improving the heat efficiency of the boiler and the denitration rate, increasing the CO2 content after the high-temperature flue gas is cooled, reducing emission load of NOx, lowering CO2 capturing and collecting cost, and meeting the national energy conservation and environmental protection standard.

Owner:HUAZHONG UNIV OF SCI & TECH

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

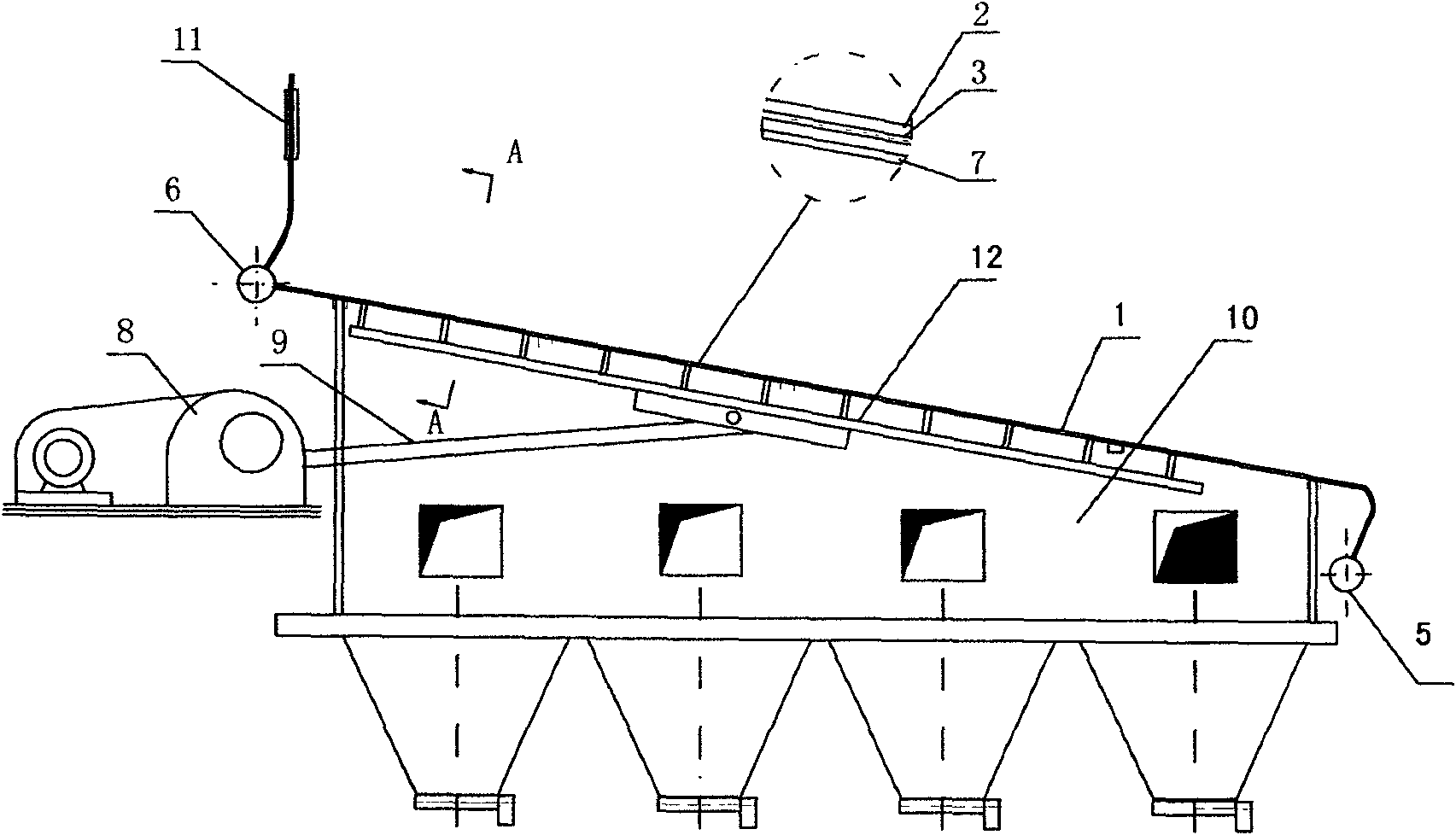

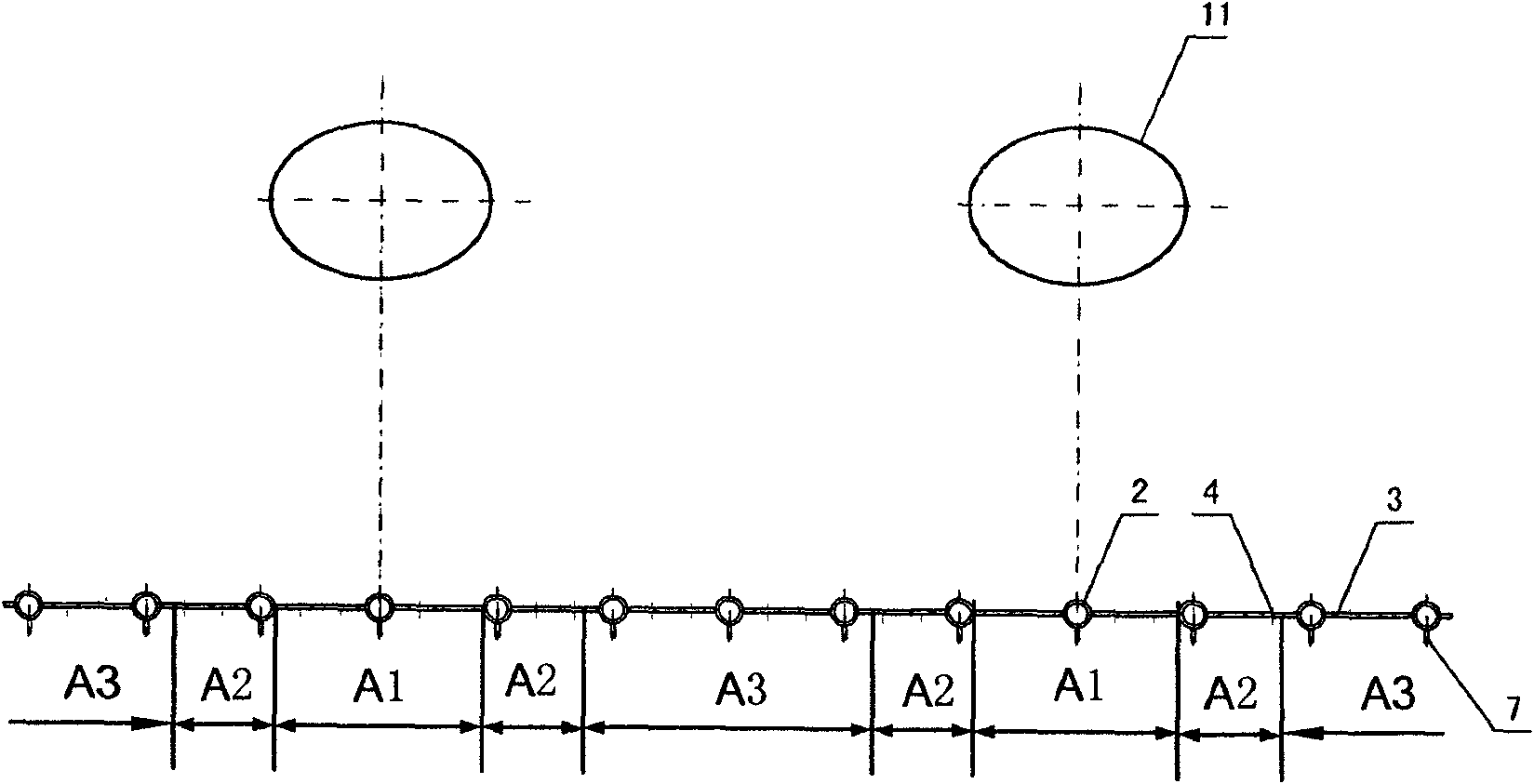

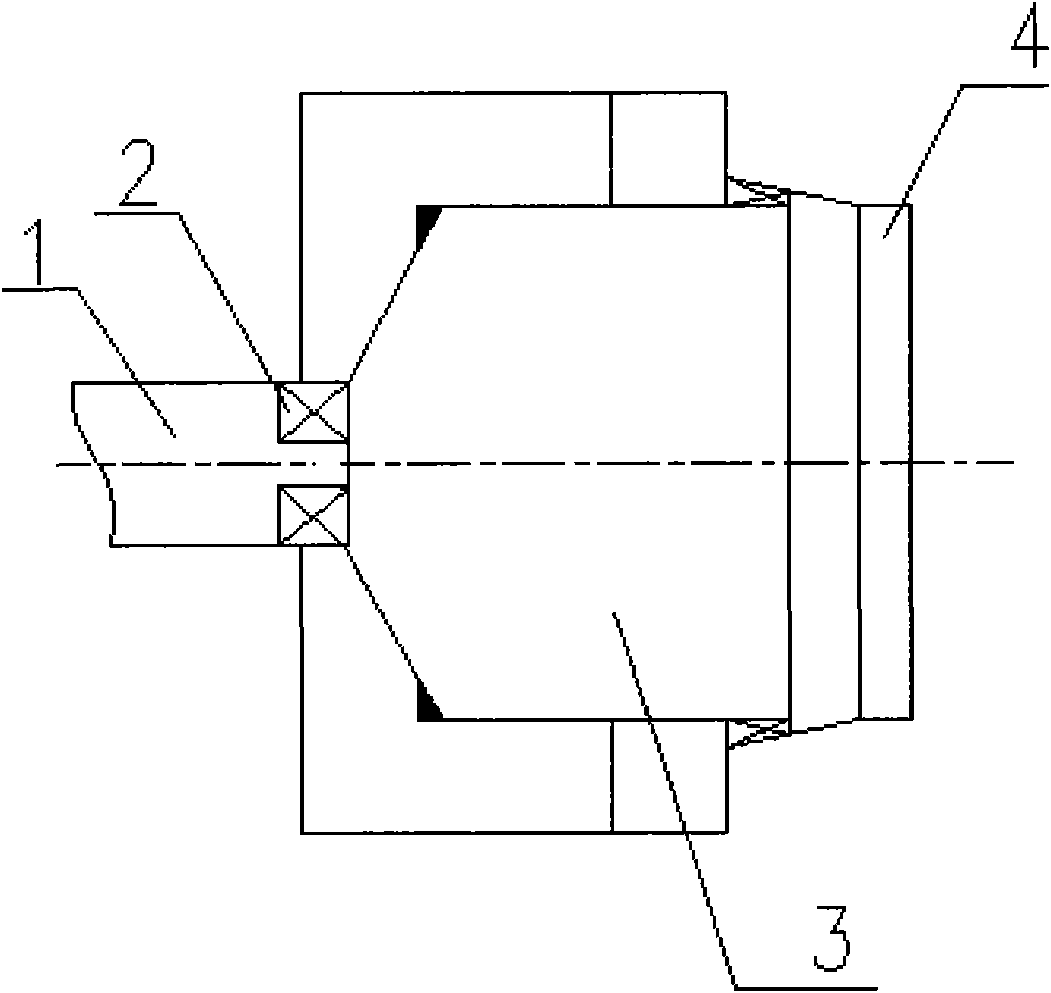

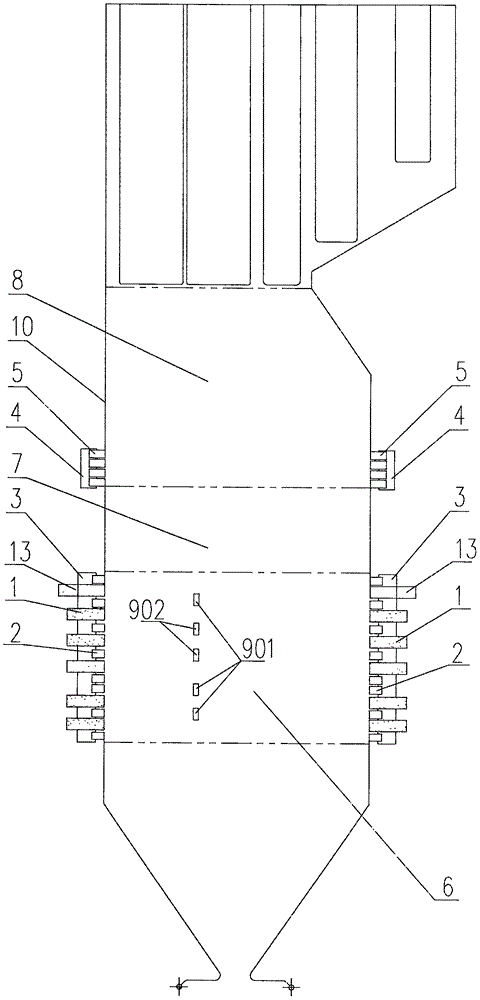

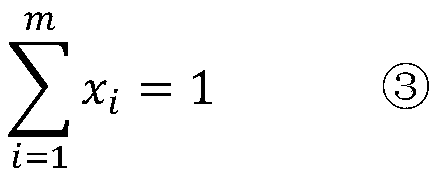

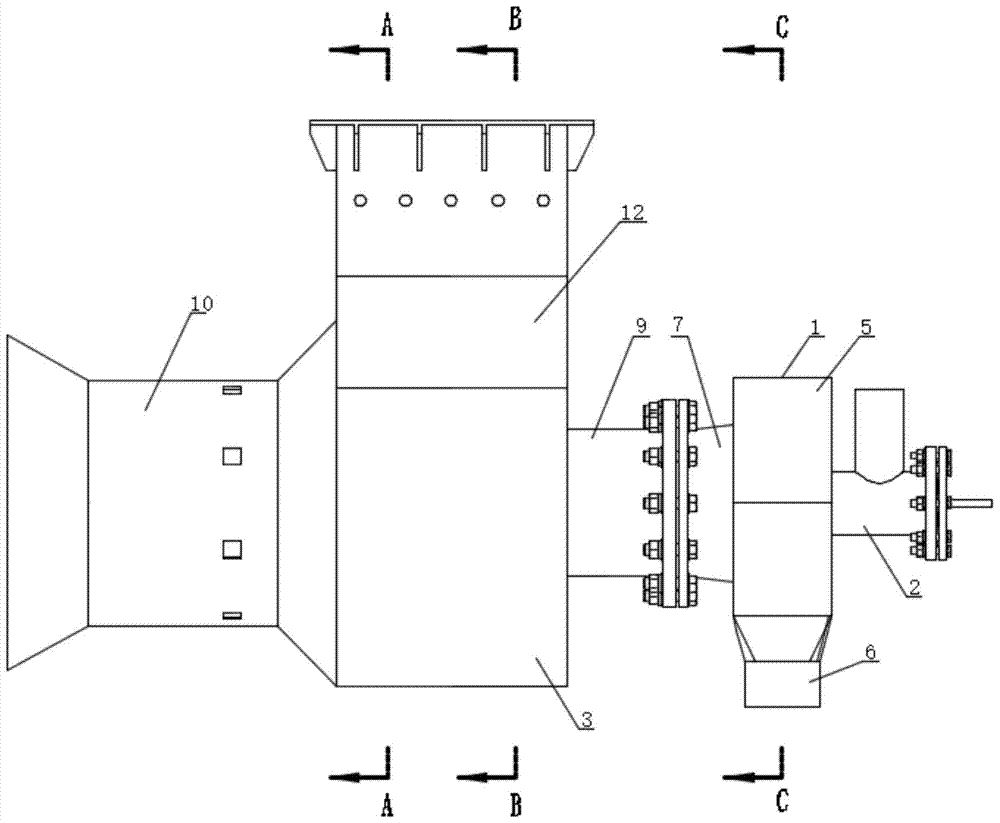

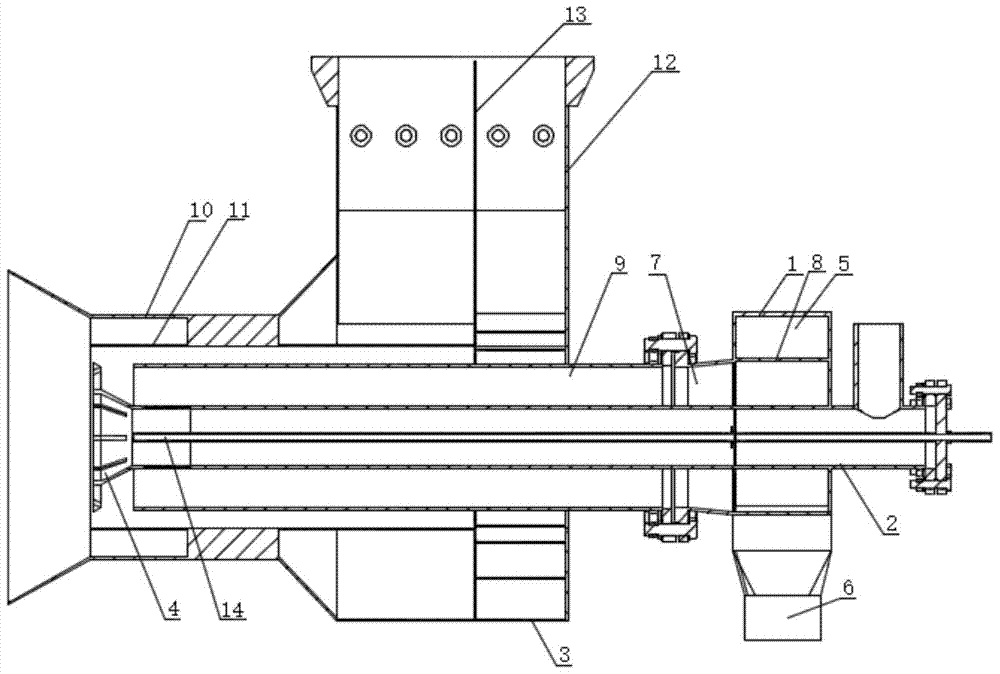

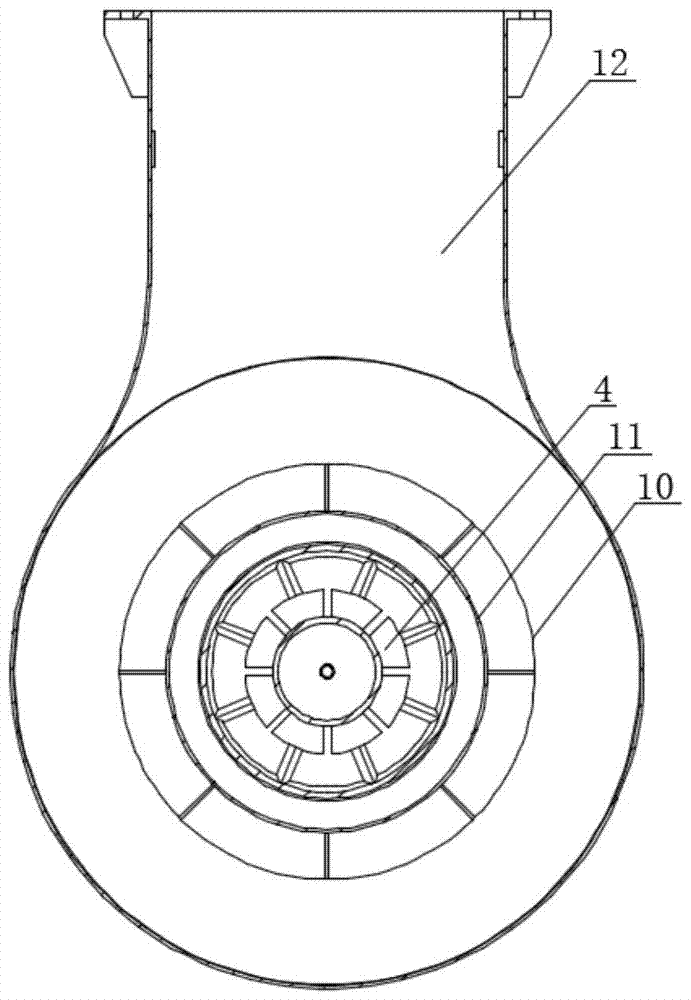

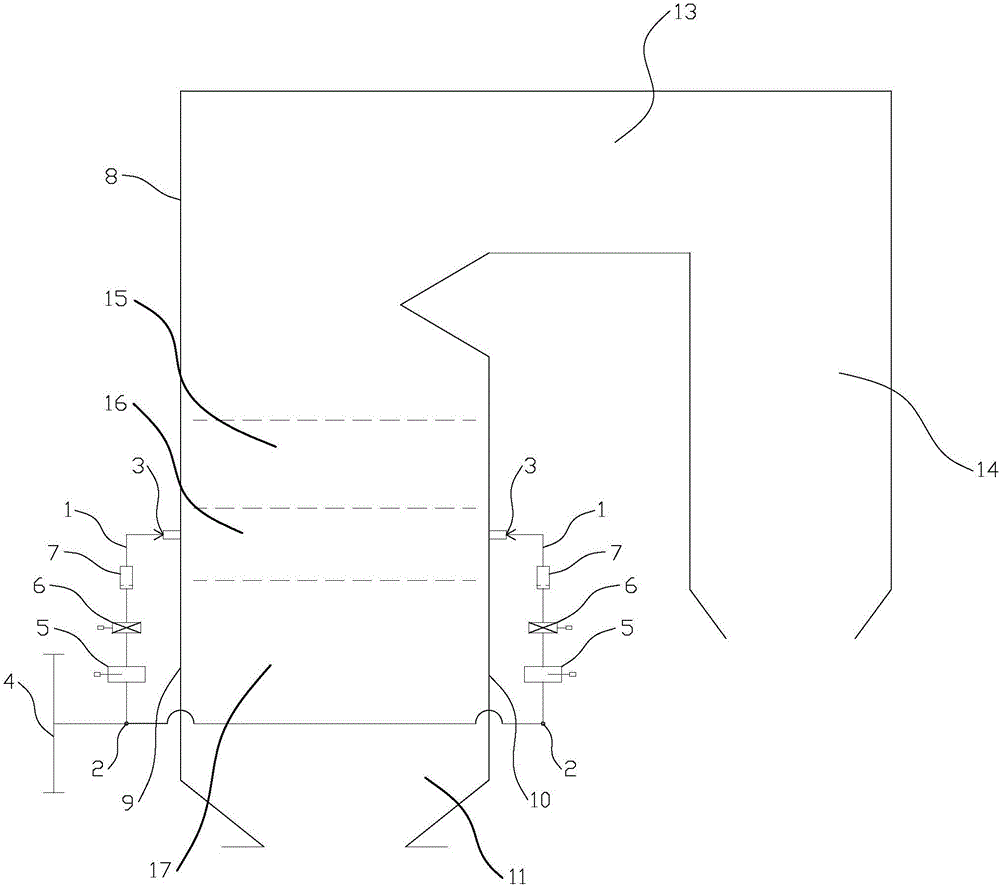

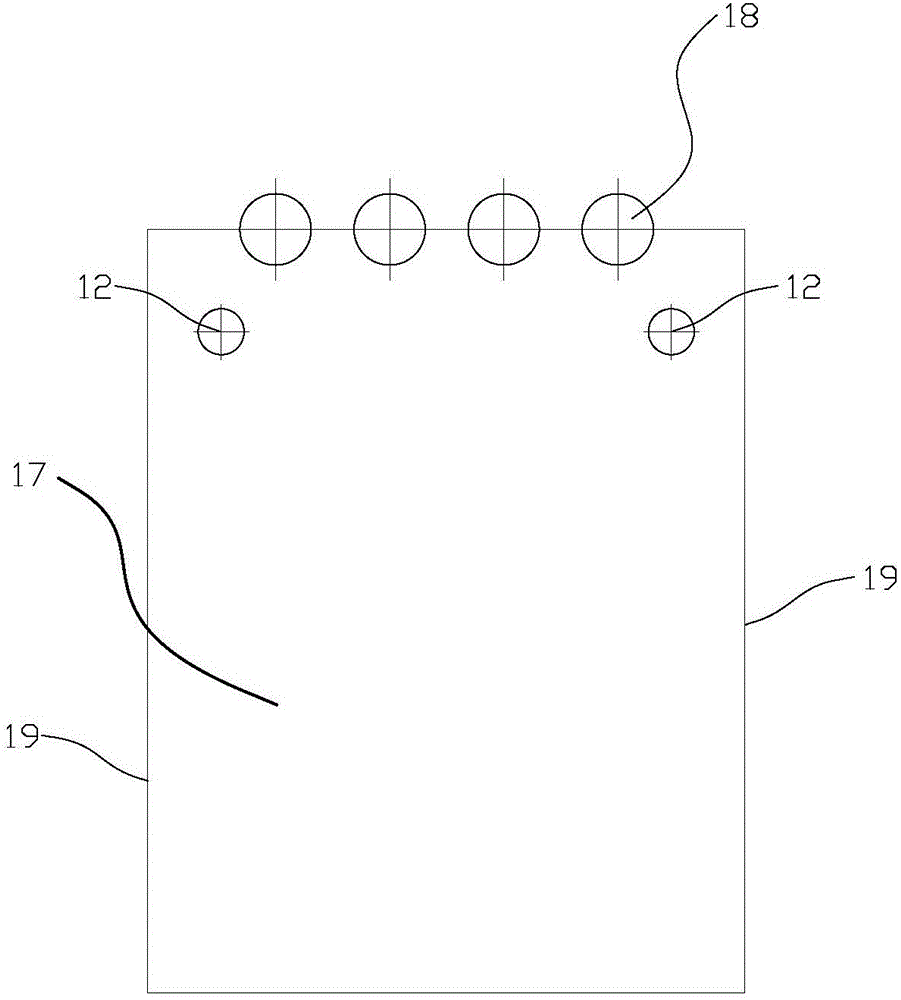

Bidirectional non-uniform matching air distributing water-cooled vibration grate of biomass direct-combustion boiler

InactiveCN101625126ASimple structureWide adaptabilityHollow bar grateRevolving grateDirect combustionEngineering

The invention relates to a bidirectional non-uniform matching air distributing water-cooled vibration grate of a biomass direct-combustion boiler, comprising a grate (1) formed by arranging a plurality of inclined water-cooled pipes (2) in parallel at predetermined intervals, wherein the grate (1) is fixed on a support frame (12); an air chamber (10) is arranged below the support frame (12); a discharge hole (13) is arranged below the air chamber (10); the water-cooled pipes (2) are connected with each other by a membrane (3) which is provided with an air inlet hole (4); an inlet end of the water-cooled pipe (2) is connected with an inlet collection tank (5); an outlet end of the water-cooled pipe (2) is connected with an inlet collection tank (6); and a driving device (8) is connected with the support frame (12) at the lower part of the grate (1) through a connecting rod (9) to provide vibration for the grate (1). A drying initial combustion zone, a primary combustion zone and an after-combustion zone are divided in the moving direction of biomass with different aperture ratios for each zone. In addition, the drying initial combustion zone is divided into three sub-zones according to the feeding amount of biomass with larger aperture ratio closer to the sub-zone of a feeding inlet.

Owner:SOUTHEAST UNIV

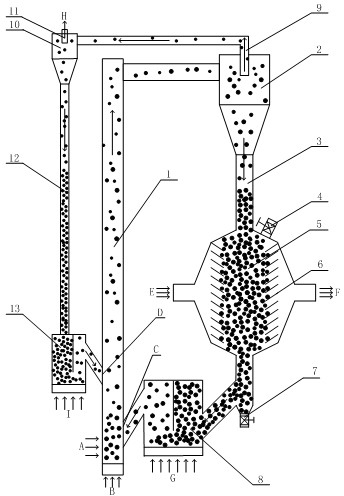

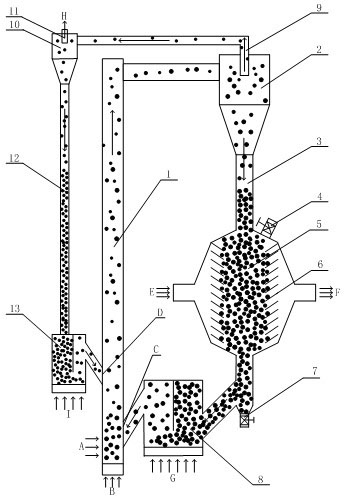

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

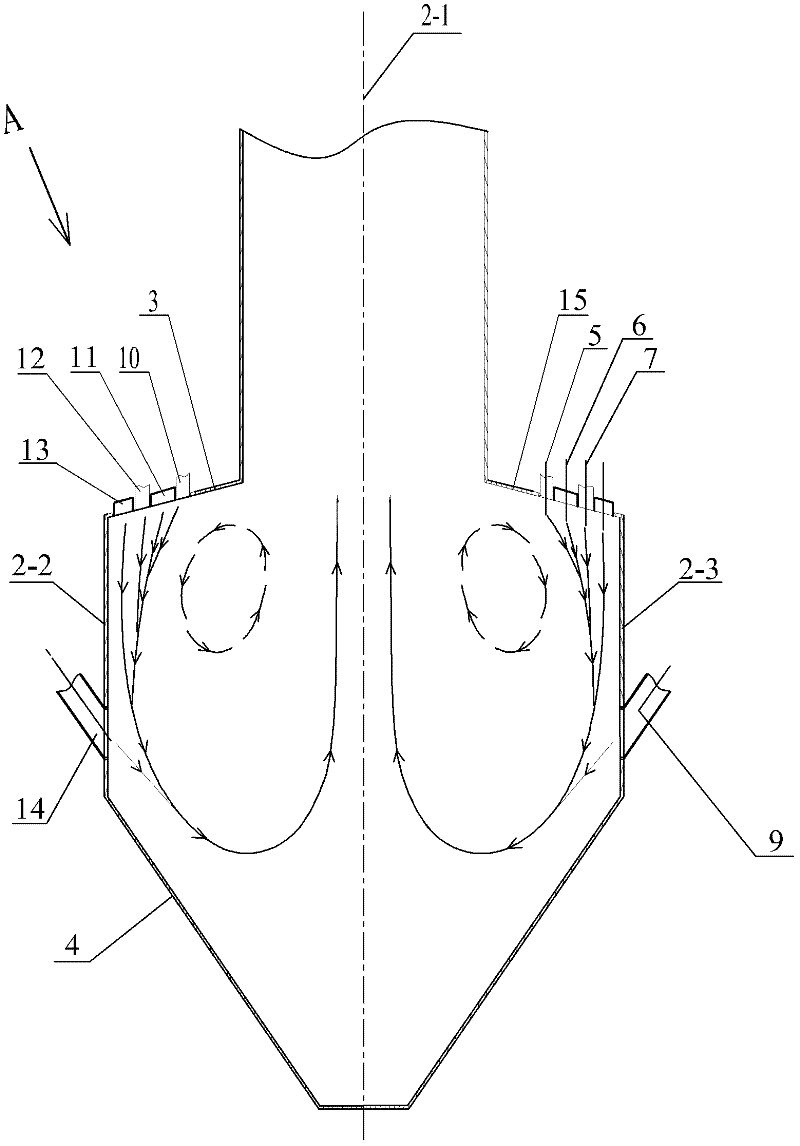

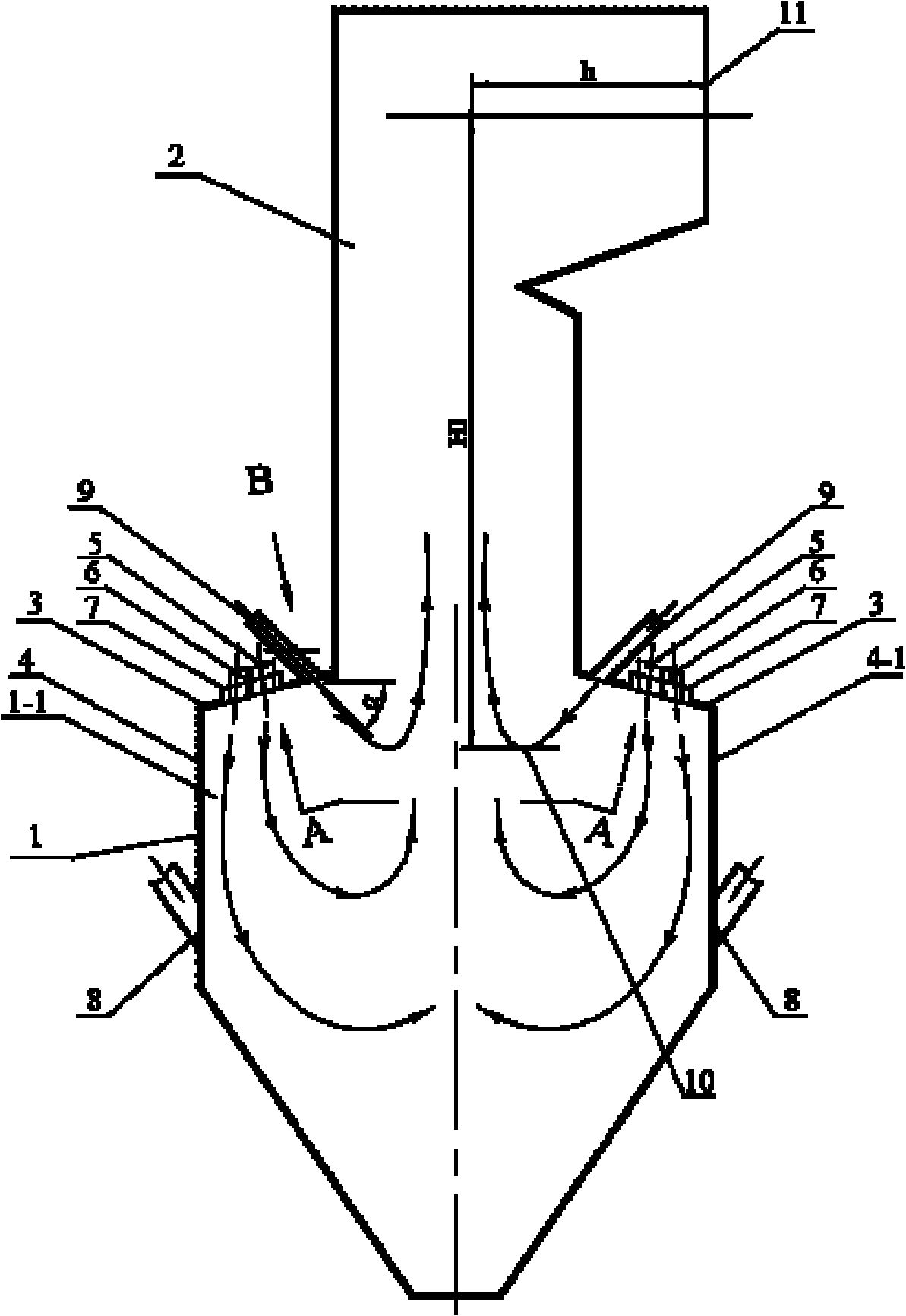

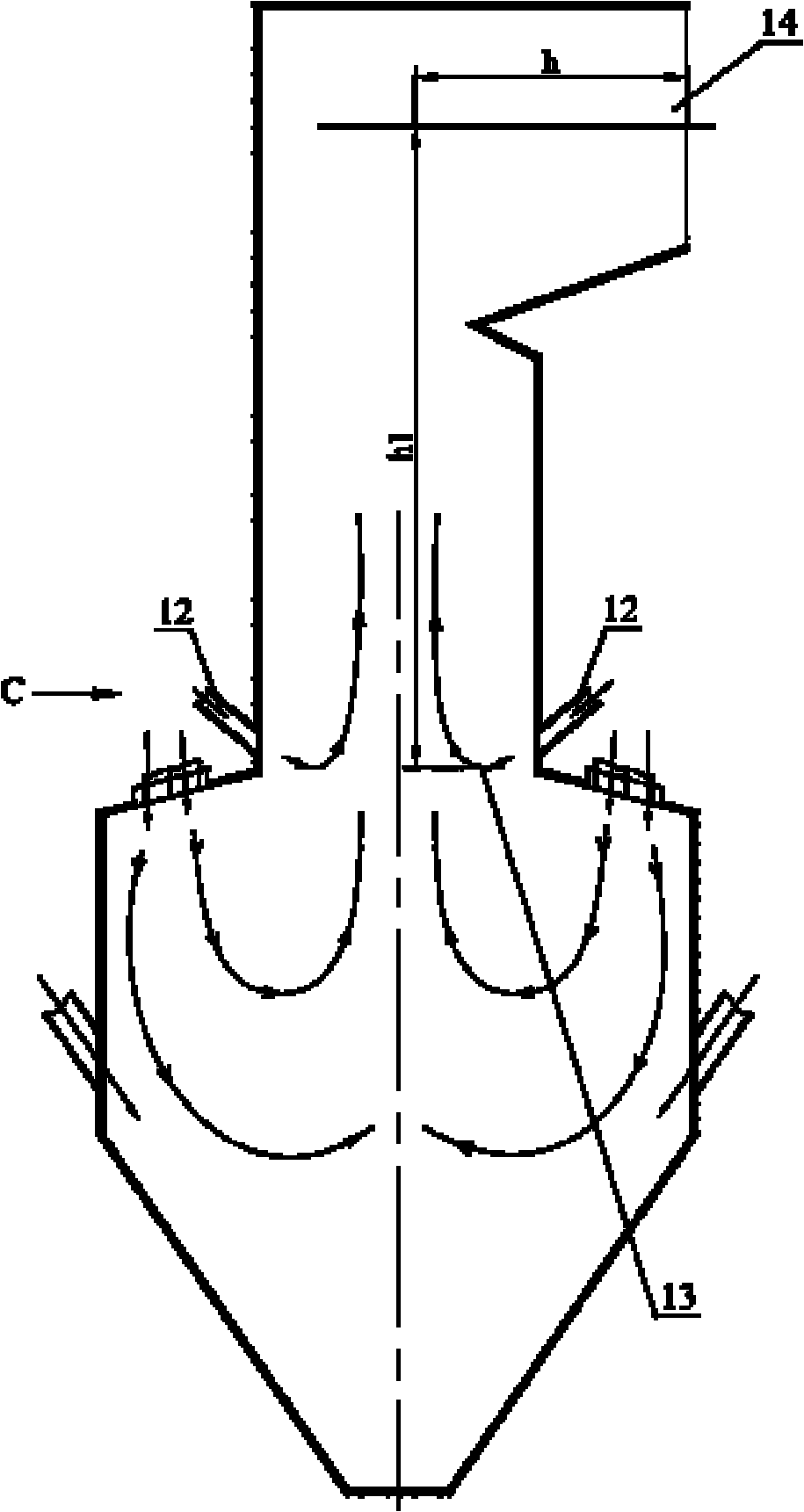

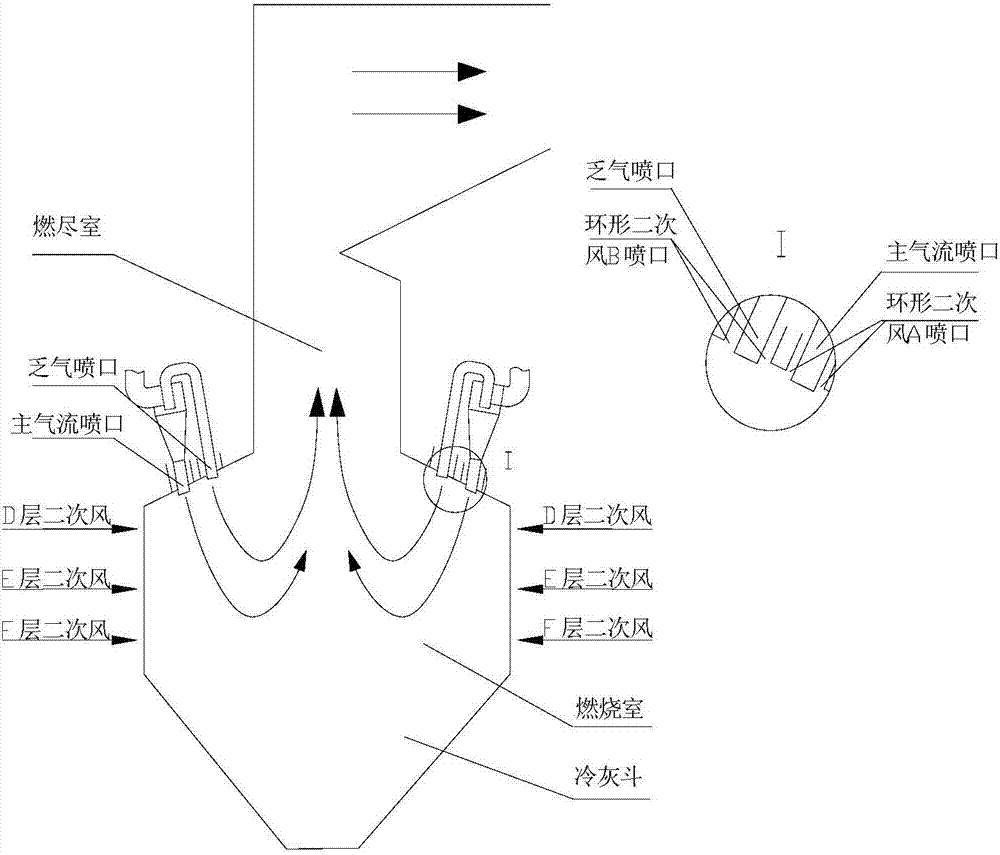

Multi-injection staged combustion w-flame boiler with thick and light coal powder nozzles arranged alternately

ActiveCN102297418AEmission reductionEnhanced ejector carryCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionEngineering

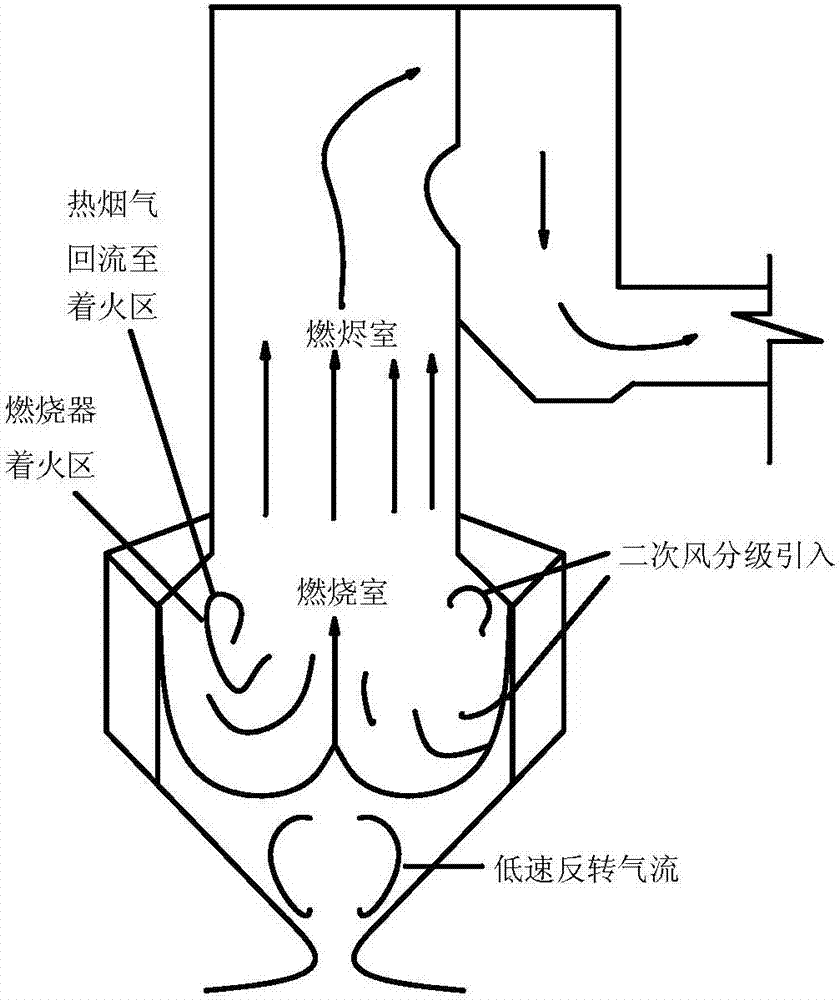

The invention relates to a W-flame boiler with multiple ejections and staged combustion, which is used to solve problems of NOx discharge and high content of combustible matters in fly ash existing in W-flame boilers with present technologies of multiple ejections and staged combustion. The W-flame boiler of the invention is characterized in that: a plurality of thick pulverized coal nozzles comprise a plurality of thick pulverized coal nozzle clusters, and each thick pulverized coal nozzle cluster is formed by two thick pulverized coal nozzles which are close together; a plurality of thin pulverized coal nozzles comprise a plurality of thin pulverized coal nozzle clusters, and each thin pulverized coal nozzle cluster is formed by two thin pulverized coal nozzles which are close together; and the thick pulverized coal nozzle clusters and the thin pulverized coal nozzle clusters are arranged in an in-line and equal interval way along the hearth width direction, and the thick pulverized coal nozzle clusters and the thin pulverized coal nozzle clusters are arranged in a side by side and interlaced way. The W-flame boiler of the invention allows the NOx discharge to be greatly reduced, and the combustible matters content in the fly ash to be reduced.

Owner:HARBIN INST OF TECH

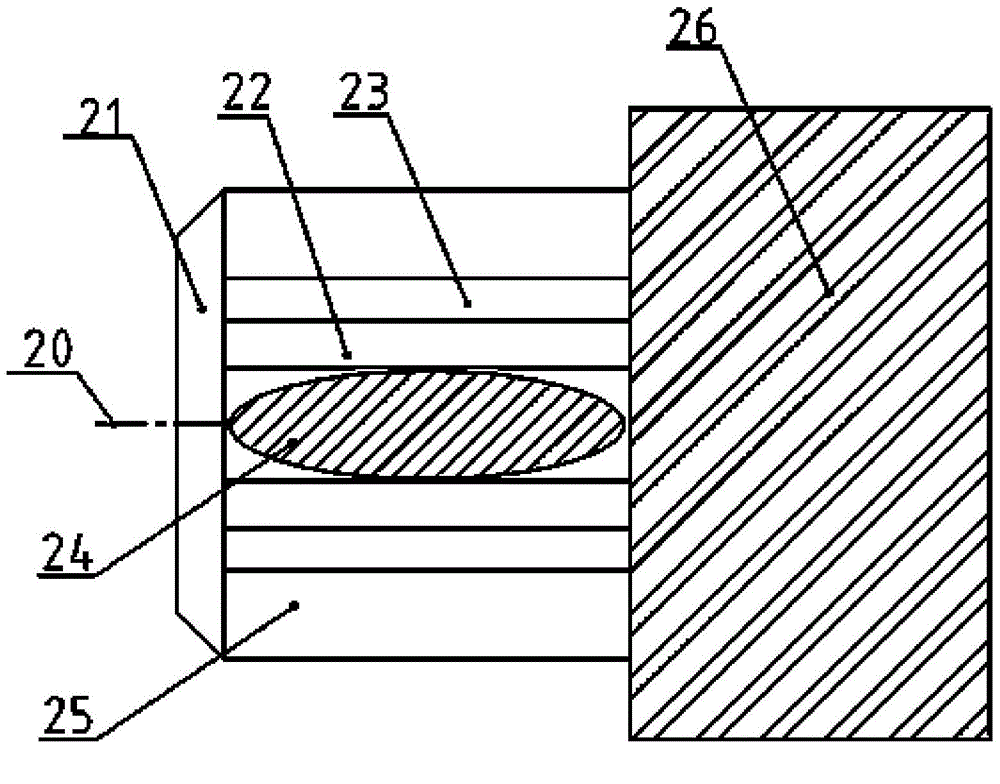

Pulverized coal burner and boiler with same

ActiveCN102032563AAchieve combustionOptimizationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberNitrogen

The invention discloses a pulverized coal burner and a boiler with the same. The disclosed pulverized coal burner comprises a heat source and an internal burning chamber, wherein the internal burning chamber ensures that an internal pulverized coal flow has a predetermined excess air coefficient; the heat source is positioned in the internal burning chamber; the internal burning chamber is provided with an inlet, a long cylindrical main burning chamber and an outlet; the heat source can ignite pulverized coal which passes through the internal burning chamber and ensures that the pulverized coal reducibly burns in the internal burning chamber; preferably, the internal burning chamber comprises the main burning chamber and a decelerating inlet section; and the sectional area of the decelerating inlet section is less than that of the main burning chamber. The internal burning chamber of the pulverized coal burner can maintain a smaller air coefficient, so reducing atmosphere is formed in the internal burning chamber; the pulverized coal reducibly burns in the internal burning chamber, so the pulverized coal flow enters a hearth in the form of high-temperature pulverized coal burning flame to improve the burning stability of the pulverized coal; meanwhile, the reducing burning can also convert a nitrogen element into a reducing intermediate product, so that fuel type nitrogen oxides are prevented from being produced.

Owner:YANTAI LONGYUAN POWER TECH

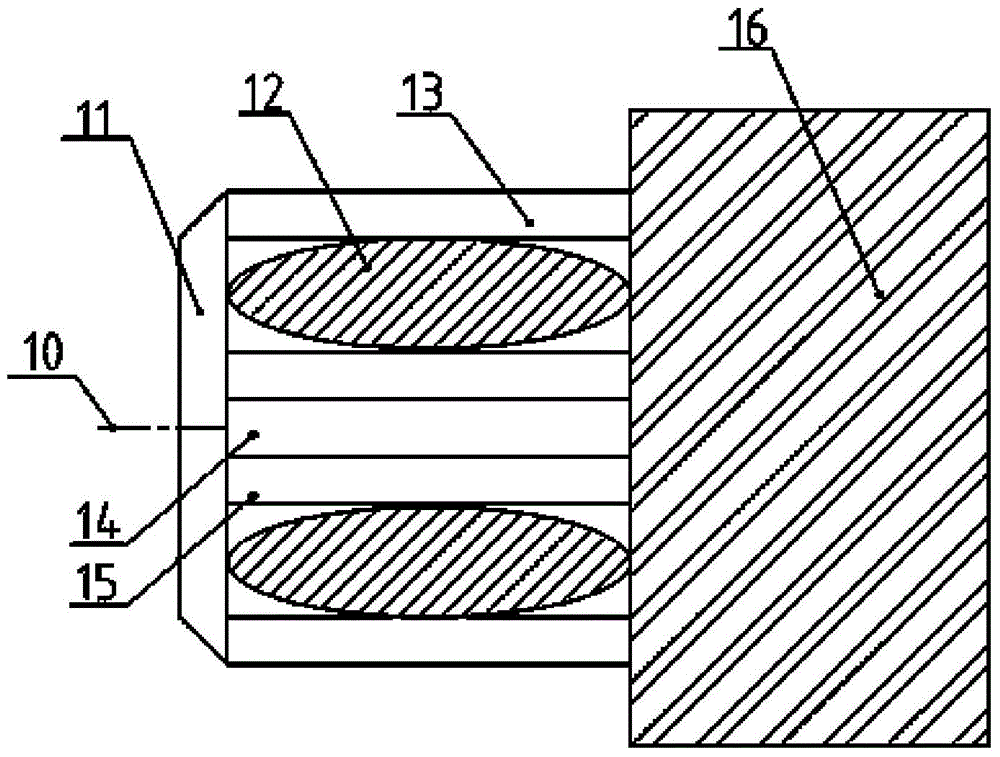

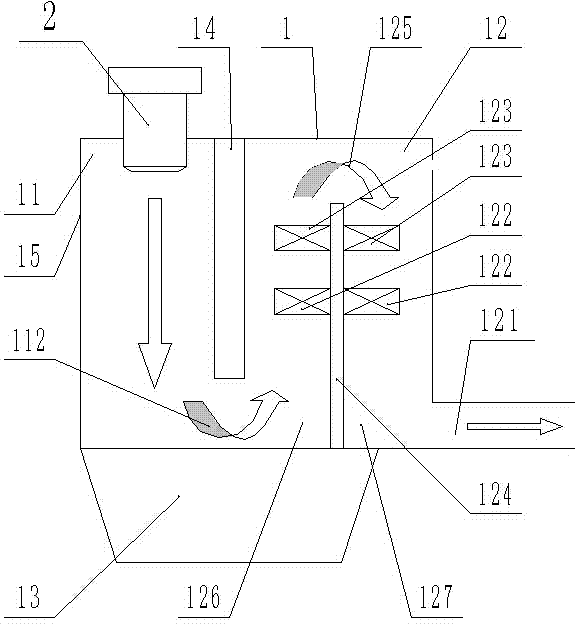

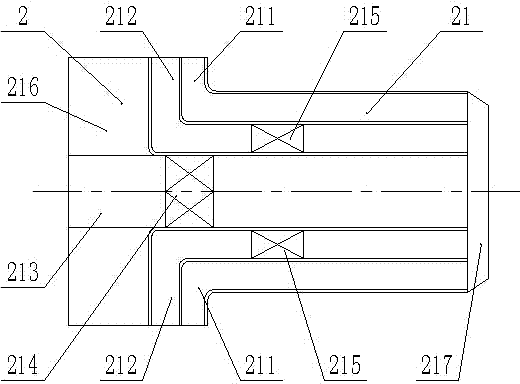

Pulverized coal burner and boiler

ActiveCN104566358AReduce concentrationIncrease burnoutPulverulent fuel combustion burnersEngineeringCoal

Disclosed are a pulverised coal burner and a boiler using the pulverised coal burner, wherein the pulverised coal burner comprises a central air cylinder (46, 56), a primary air cylinder (42, 52) and a twin flow field generating structure provided in the primary air cylinder (42, 52). The primary air cylinder (42, 52) is sheathed outside the central air cylinder (46, 56); the twin flow field generating structure can make the concentration of pulverised coal as an air flow containing powders that passes through the twin flow field generating structure and is injected by the primary air cylinder (42, 52) distributed as sparse on the outside and dense on the inside, and can form an annular recirculation area (12, 32, 63) between a sparsely concentrated air flow containing powders (65) and a highly concentrated air flow containing powders (64), and form a central recirculation area (24, 62, 71) in the highly concentrated air flow containing powders (64). The burner can more effectively inhibit production of NOx.

Owner:YANTAI LONGYUAN POWER TECH

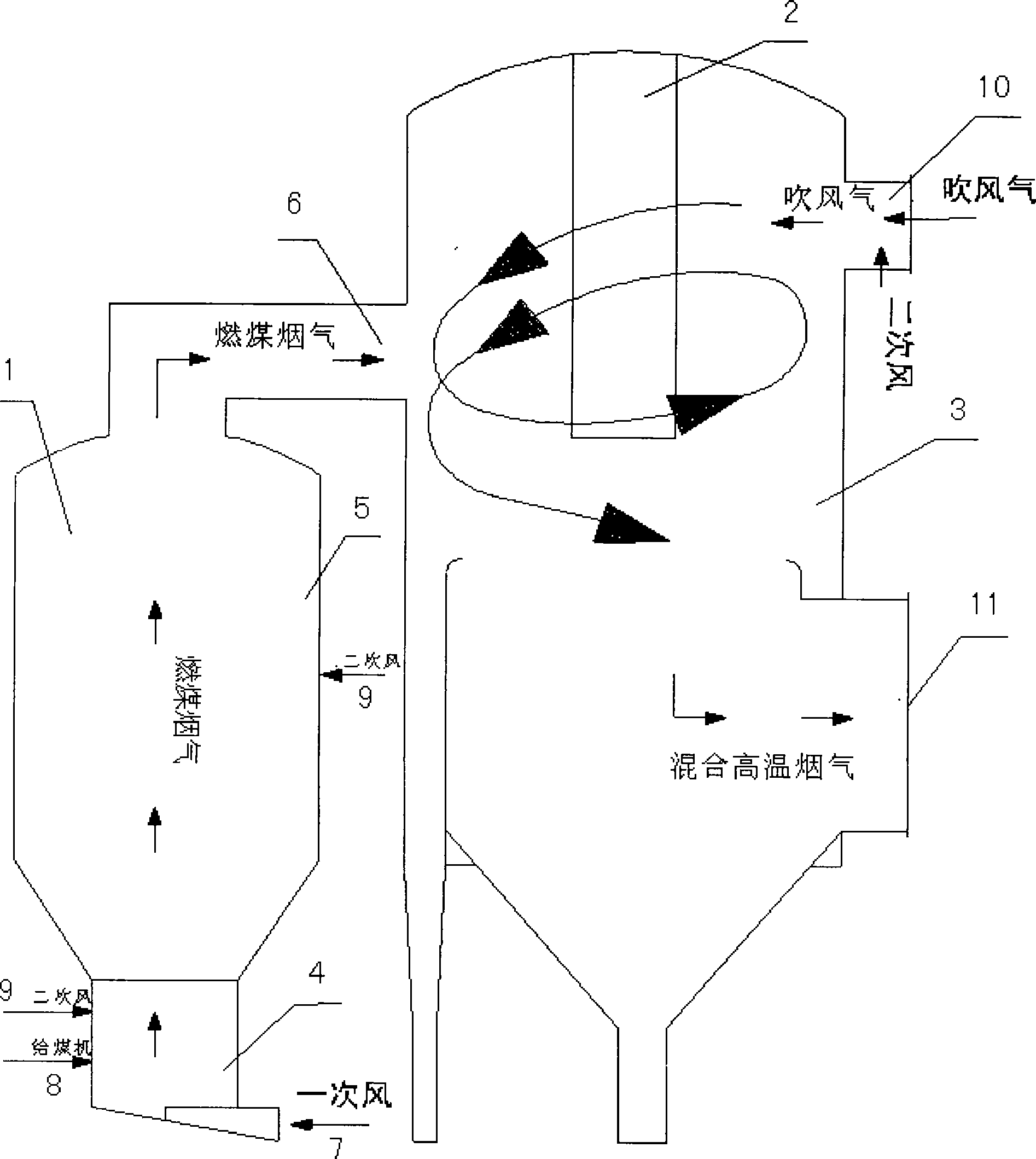

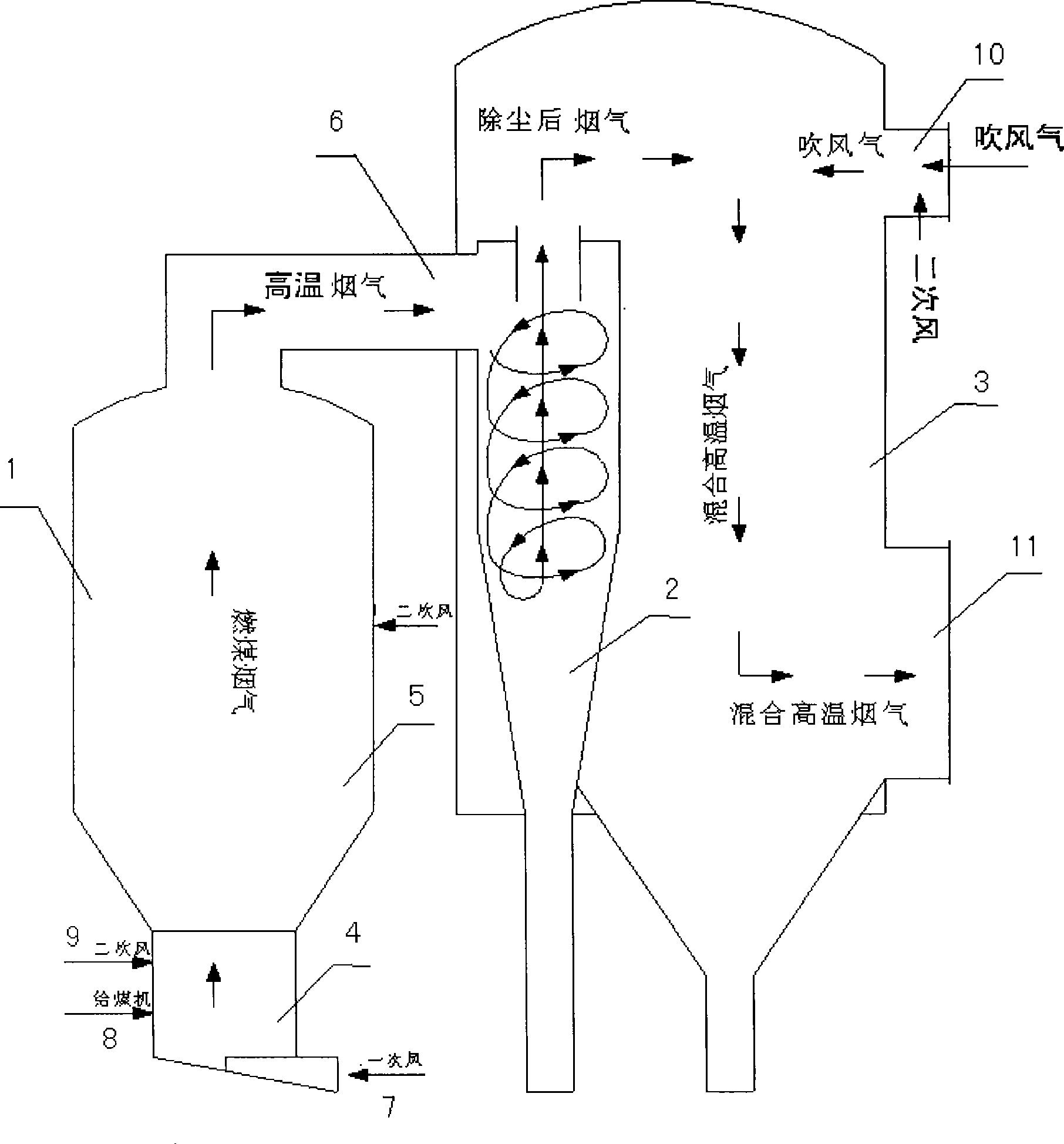

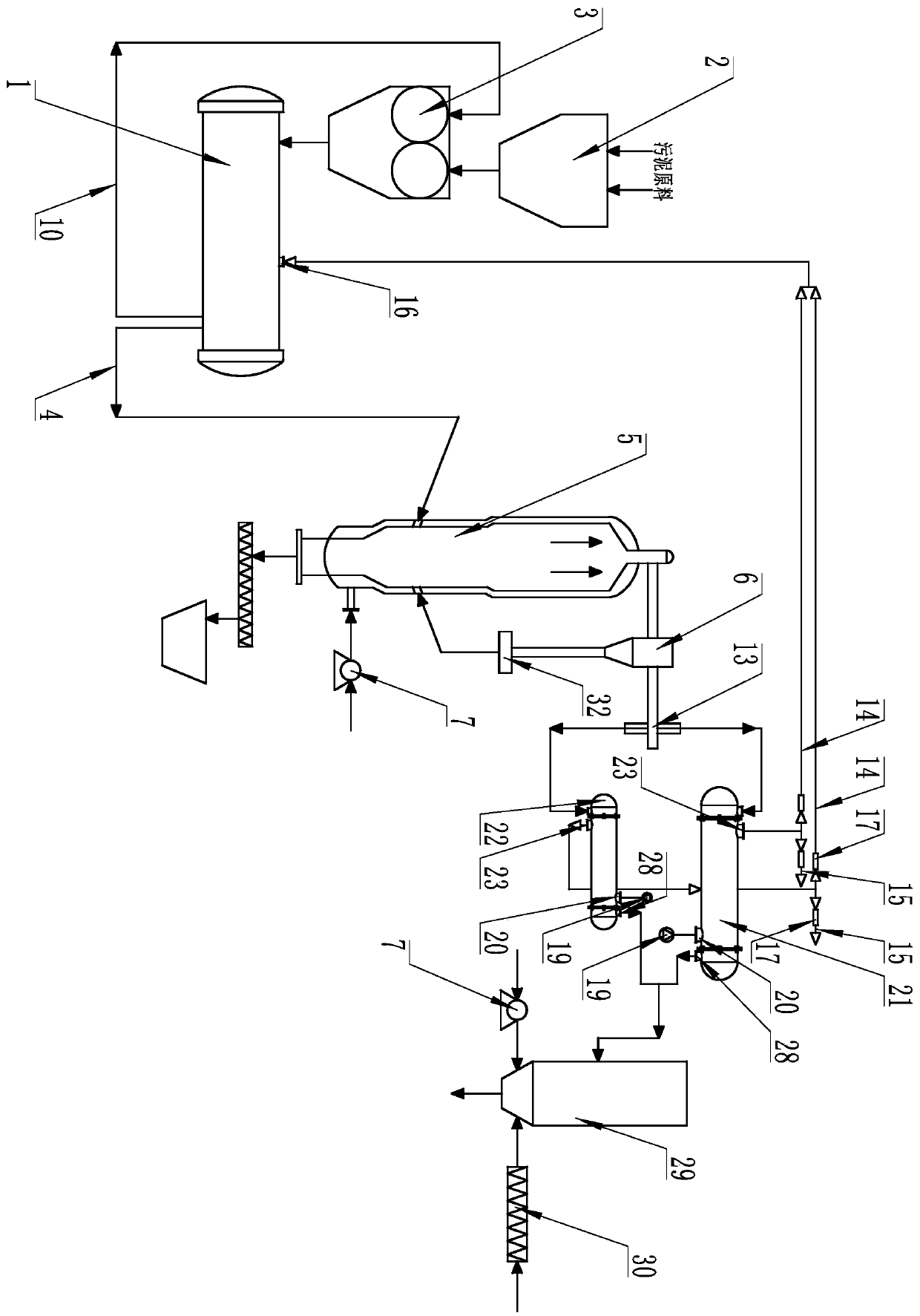

Process and device for reclaiming blown gas made from coal and by oxygen-enriched combustion

InactiveCN101545636ALower ignition pointRaise conditions for fireIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterFlue gas

The invention relates to a process and a device for reclaiming blown gas made from coal and by oxygen-enriched combustion. The flow of the reclaiming process comprises that: gas making furnace residue and coal ash are sent to the lower part of a fluidized bed furnace through a screw-type coal feeder and subjected to heat exchange through an air preheater, primary air fluidization at the temperature of approximately 120 DEG C and partial combustion reaction; uncombusted portions are continuously combusted in secondary air and generate high-temperature flue gas at the temperature of between 950 and 1,000 DEG C which enters a cyclone dust collector in a blown gas combustion furnace; flue gas subjected to dust collection by the cyclone dust collector is drained into the blown gas combustion furnace from the top of the cyclone dust collector; the blown gas is completely combusted under the action of the secondary air; flue gas reaches the temperature of between 950 and 1,050 DEG C, is drained out from the blown gas combustion furnace and enters a boiler system; and finally flue gas at the temperature of between 130 and 150 DEG C is emptied by chimneys. The device of the reclaiming process comprises the fluidized bed furnace, the blown gas combustion furnace and the cyclone dust collector, wherein a furnace chamber of the fluidized bed furnace is communicated with the cyclone dust collector in the blown gas combustion furnace through a flue; the lower part of the fluidized bed furnace is provided with a primary air and fuel inlet, and the lower part and the middle part of the fluidized bed furnace are provided with a secondary air inlet respectively; the inside of the blown air combustion furnace is provided with the cyclone dust collector; and the upper part of the blown air combustion furnace is provided with a blown gas inlet and the lower part of the blown air combustion furnace is provided with a flue gas outlet pipe.

Owner:杭州东安科技有限公司

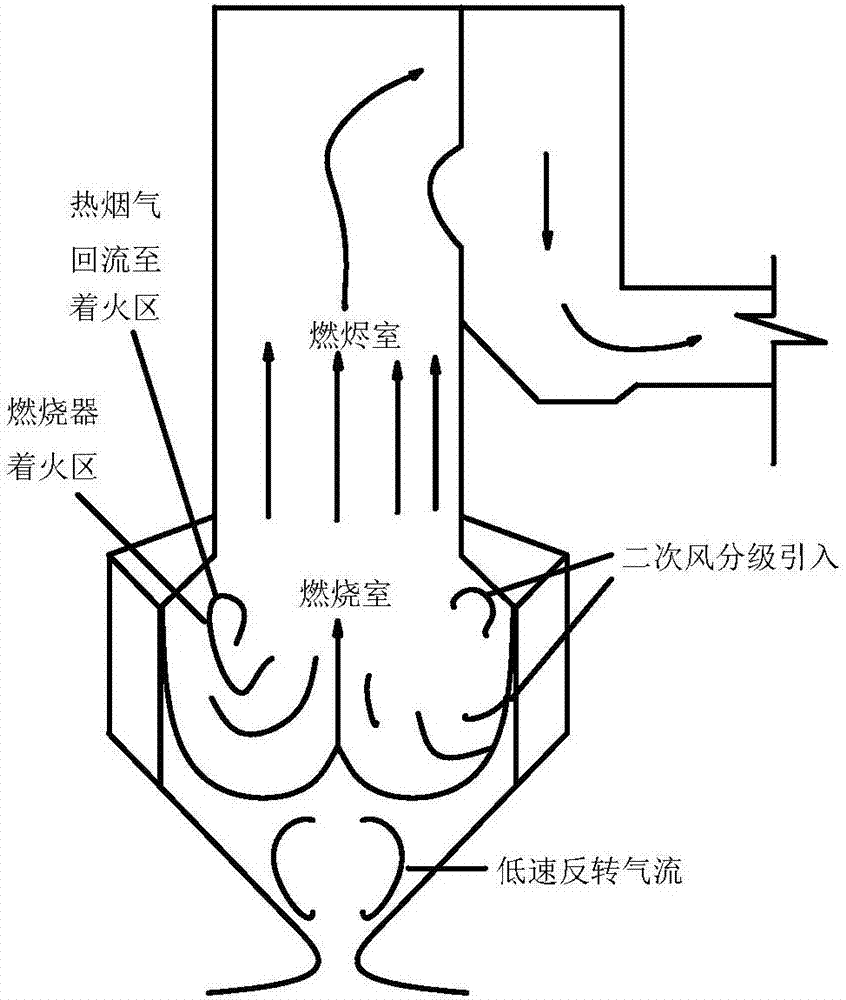

Boiler provided with dual-register pulverized coal burner on top

InactiveCN104121579AThorough heat exchangeReduce energy consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlueCoal

The invention discloses a boiler provided with a dual-register pulverized coal burner on the top, belonging to the technical field of boilers, and aiming at providing a U-shaped flame boiler which is provided with the dual-register pulverized coal burner on the top and is high in combustion efficiency. According to the technical scheme, the boiler provided with the dual-register pulverized coal burner on the top comprises a boiler body and an ash falling pit, wherein the ash falling pit is formed in the bottom of the boiler body, a membrane type water-cooling wall is arranged on the inner wall of the boiler body, a first partitioning wall is arranged on the top in the boiler body and is used for partitioning the boiler body into a combustion chamber and a waste gas chamber, the lower parts of the combustion chamber and the waste gas chamber are communicated with each other to form a first pair of flue channels, the dual-register pulverized coal burner is arranged at the top of the combustion chamber, a second partitioning wall is arranged at the bottom of the waste gas chamber and is used for partitioning the waste gas chamber into a left chamber and a right chamber, the upper parts of the left chamber and the right chamber are communicated with each other, and a flue discharging channel is arranged at the bottom of the side wall of the right chamber. The boiler is high in heat utilization rate and less in waste gas emission.

Owner:BEIJING DABANG SHICHUANG ENERGY SAVING TECHSERVICE

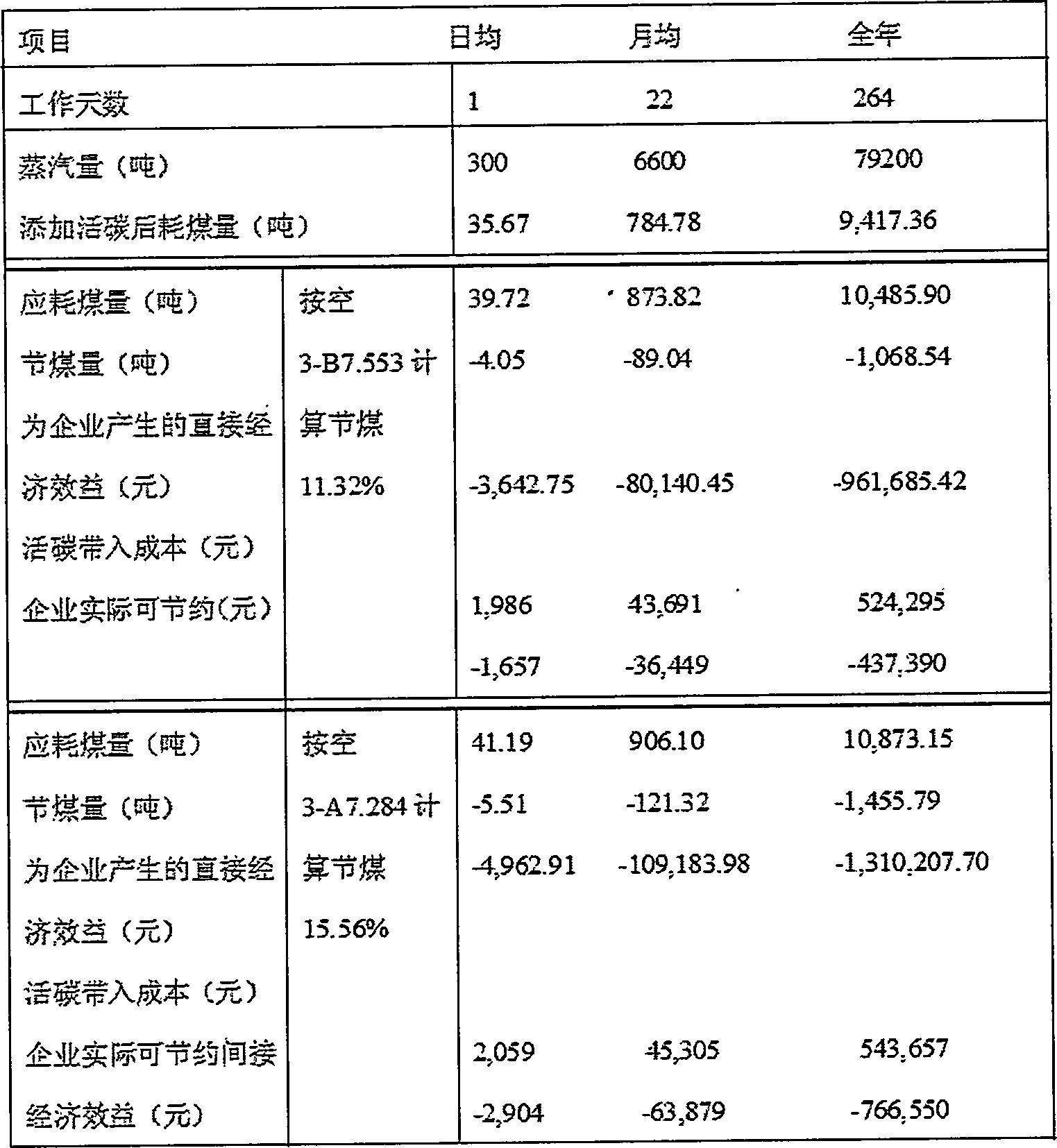

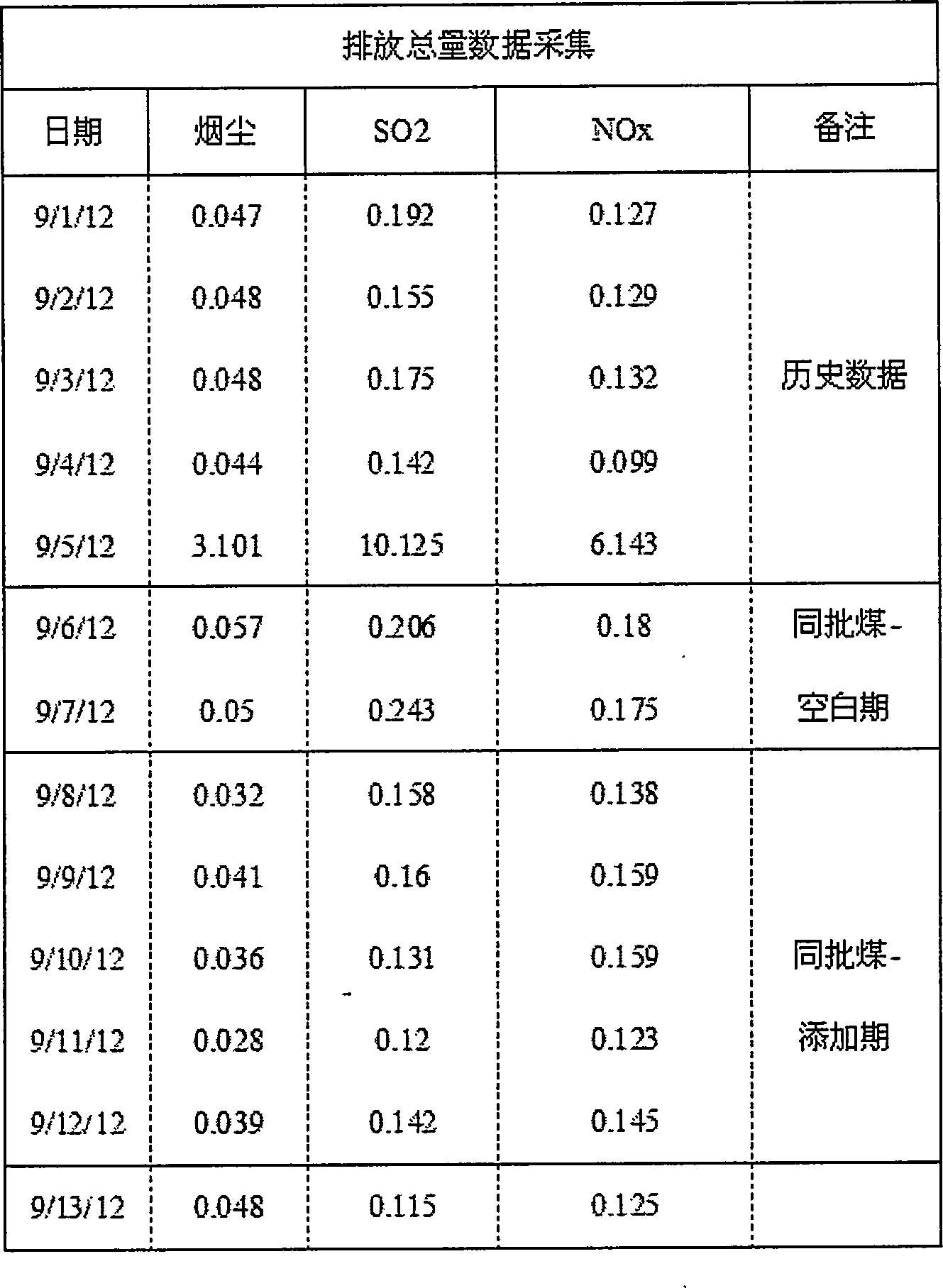

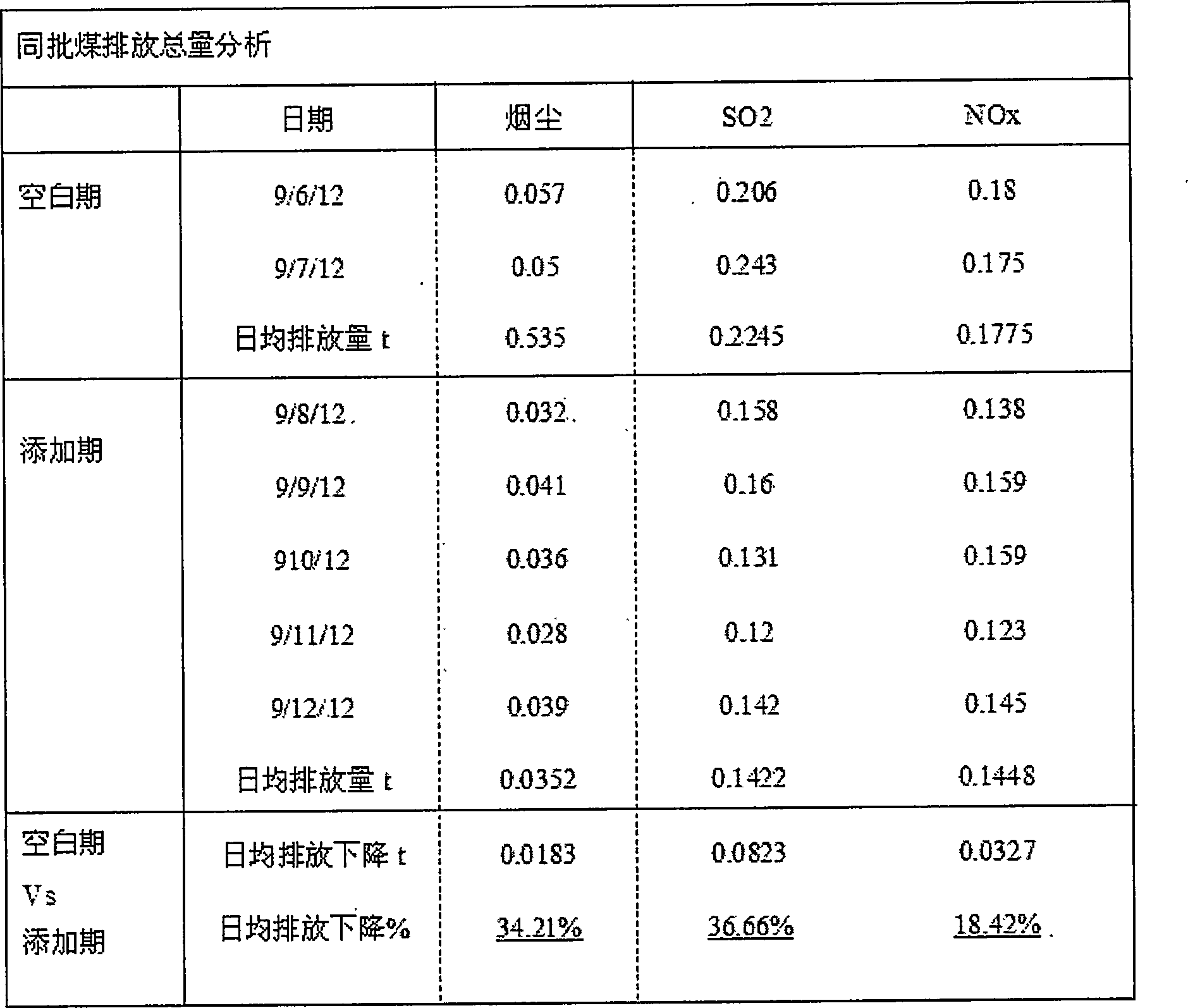

Coal additive

ActiveCN103320195APlay a catalytic roleLower the ignition temperatureSolid fuelsRare-earth elementCombustion

The invention provides a coal additive. The coal additive comprises an emulsifier, a dispersant, a corrosion inhibitor and a penetrant. The coal additive contains O, Mg, Al, Si, S, Ca, Ba and Mn. The coal additive has the advantages that the emulsifier, the dispersant, the corrosion inhibitor and the penetrant are used and the rare earth elements improve catalyst activity so that a traditional exterior-to-interior combustion mode is changed into an interior-exterior synchronous combustion mode and thus a coal complete-combustion degree is improved and a heat loss caused by chemical incomplete combustion and mechanical incomplete combustion of coal in a furnace is reduced; and through composite carriers having mesoporous structures, catalyst activity is improved, a hydrodesulfurization process is finished and discharge amounts of flue dust and harmful gas in exhaust gas are reduced so that coal saving and sulfur fixation are realized.

Owner:甘肃泰聚环保科技有限公司

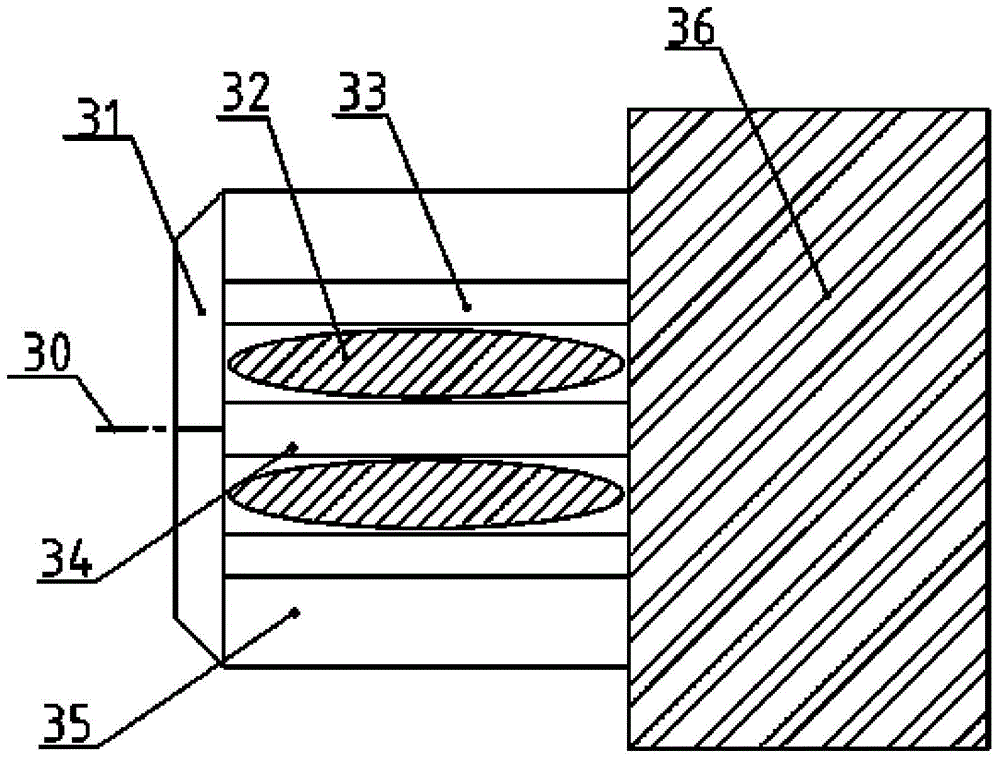

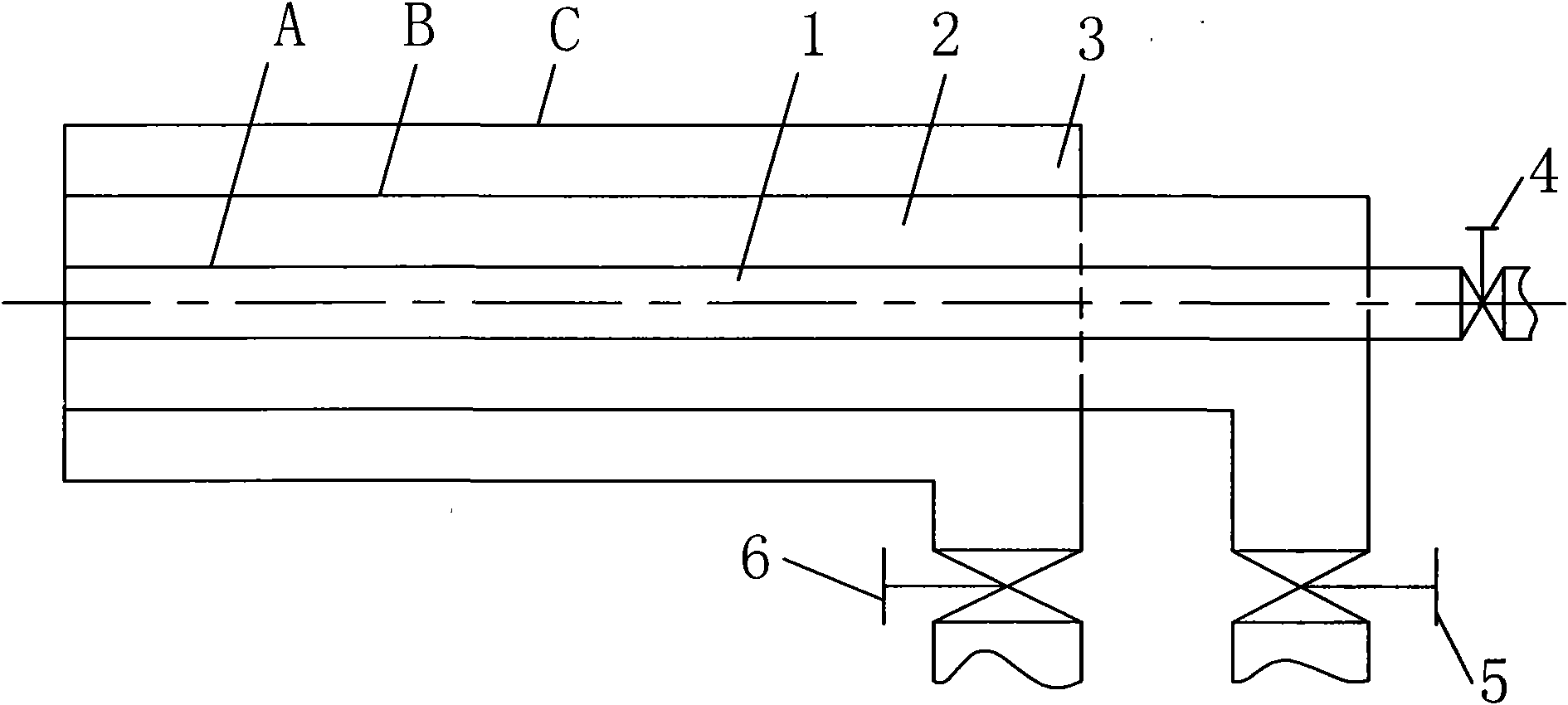

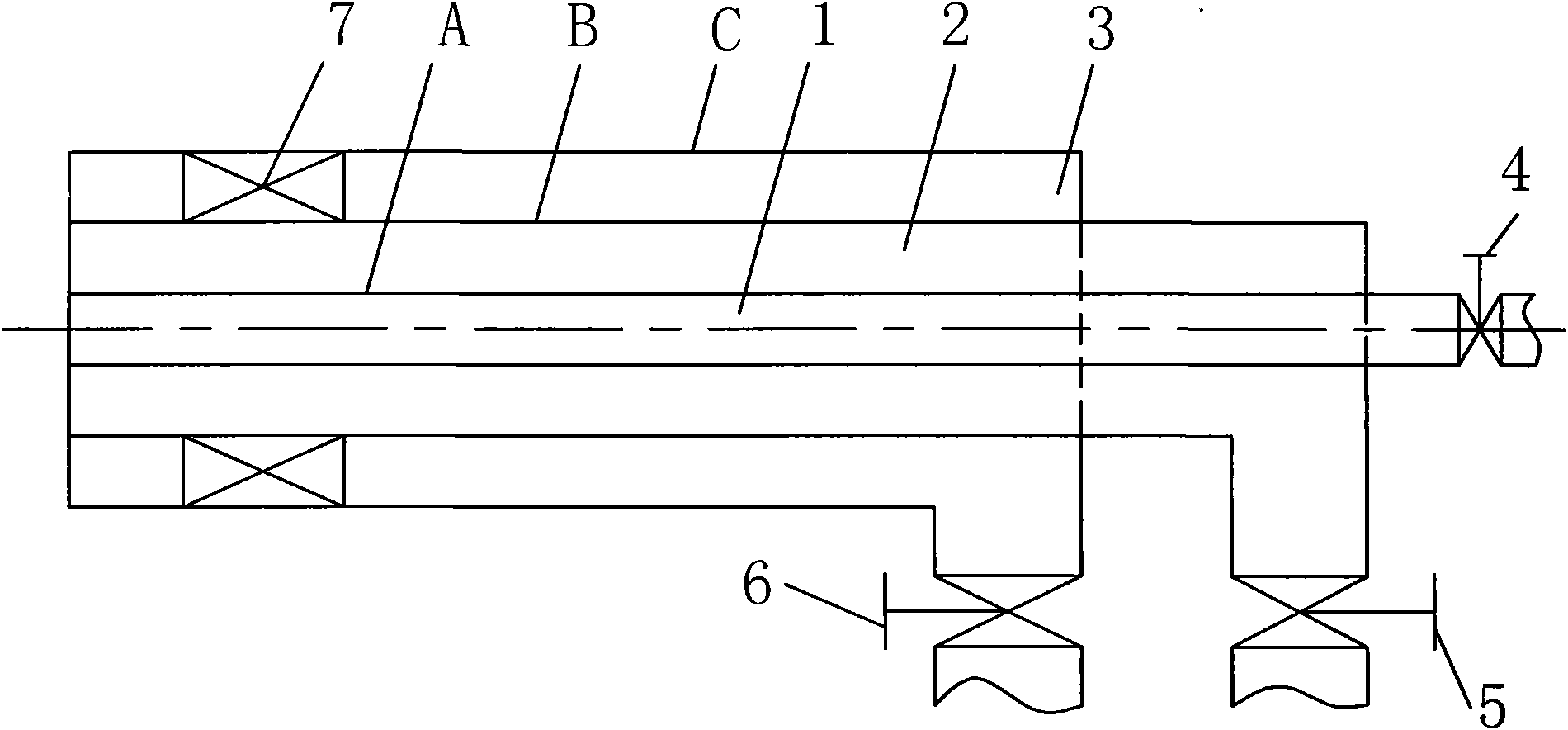

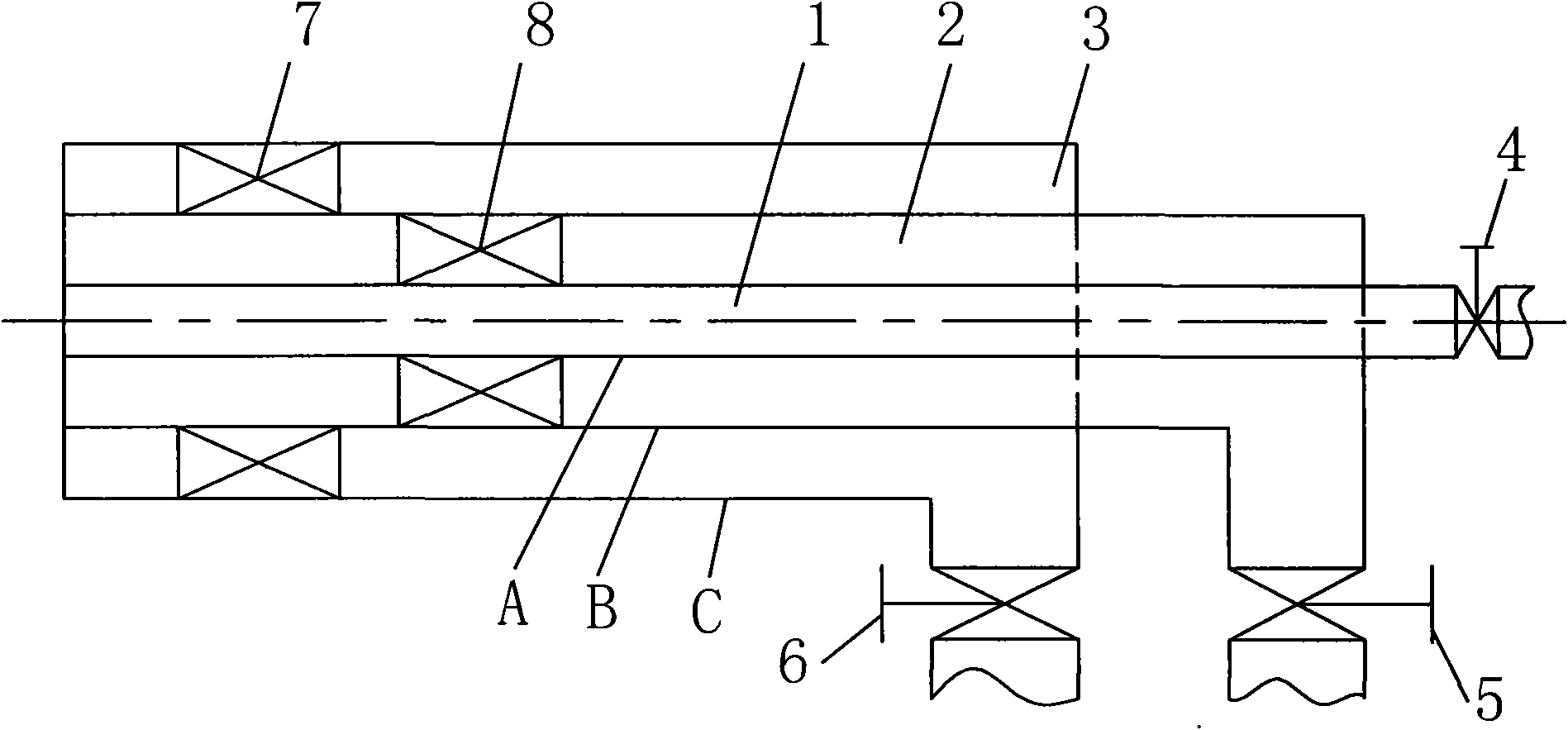

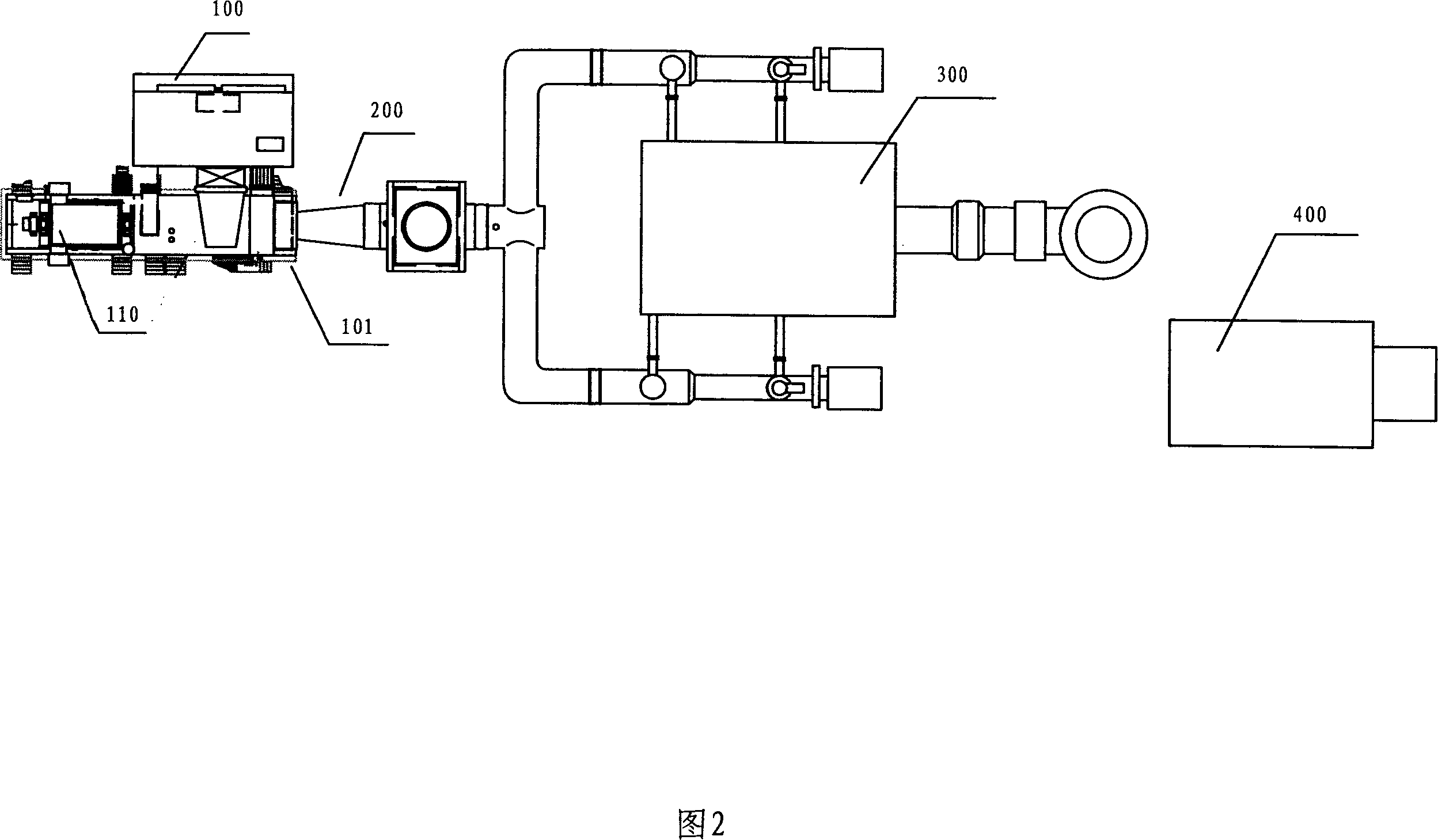

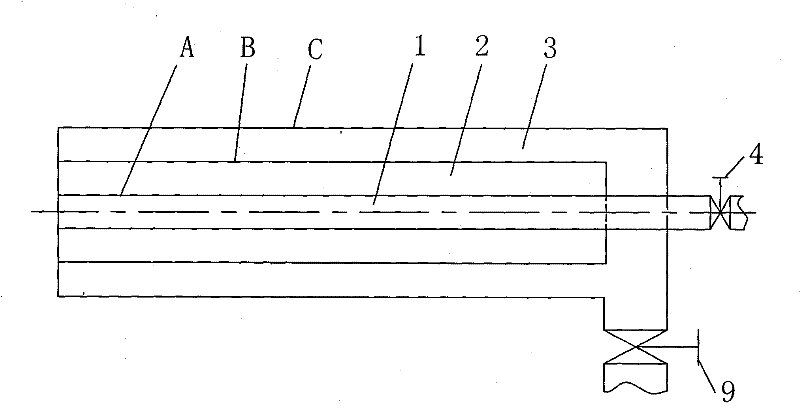

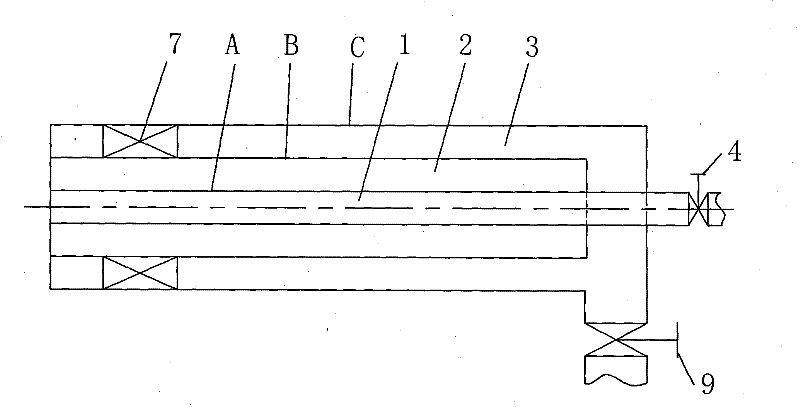

Over-fire-air device for different load pulverized-coal fired boilers

The invention relates to an over-fire-air device for different load pulverized-coal fired boilers, and to an over-fire-air device, which solves the problems of the pulverized-coal fired boiler by utilizing the present over-fire-air device that when the load is different and particularly when the device runs at a low load, the over-fire-air momentum is reduced, the penetrating power is weakened, the mixing of the over-fire-air is non-uniform in the flow field, the ash combustible substance content in the smoke is high, the content of NOx is high, and the like. An inner air-course valve is arranged at an entrance of an inner over-fire-air air course, an intermediate air-course valve is arranged at an entrance of an intermediate over-fire-air air course, and an outer air-course valve is arranged at an entrance of an outer over-fire-air air course. A share air-course valve is arranged at the communication place of the intermediate and the outer over-fire-air air courses. An intermediate air-course valve is arranged at the entrance of the intermediate over-fire-air air course, and an outer air-course valve is arranged at the entrance of the outer over-fire-air air course. By adjusting the openness of the valves, and under the high load and the low load, good combustion effect can be realized, while the NOx content is reduced.

Owner:HARBIN INST OF TECH

Combustion machine and steam turbine combined circulation system for gas boiler

InactiveCN1987058ASmall boost power consumptionValid conversionGas turbine plantsSteam engine plantsCombustionSteam drum

A gas turbine and steam turbine combined circulation system using gas boiler is composed of a gas turbine unit, a steam turbine unit, and a gas boiler using blast furnace gas as main fuel and with a combustion promoting air inlet connected to the exhaust outlet of gas turbine unit and an over-heat steam outlet connected with the steam inlet of steam turbine. Said gas boiler consists of negative-pressure combustion box, water cooled wall, over-heat grate, burner and steam drum.

Owner:中航世新燃气轮机有限责任公司

Pulverized coal jet flow midstream and downstream combustion organization method in tangent circle pulverized coal combustion boiler

InactiveCN106287678AIncrease oxygen concentrationIncrease burn rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBurning tissueCombustor

The invention discloses a pulverized coal jet flow midstream and downstream combustion organization method in a tangent circle pulverized coal combustion boiler. Corresponding wall air nozzles are distributed in a hearth main combustion area of the pulverized coal combustion boiler in a manner of corresponding to primary air pulverized coal combustors, and are formed in the positions, close to the pulverized coal jet flow midstream and downstream positions of outlets, of a hearth water cooling wall, part of hot air is introduced into the wall air nozzles, and is directly sprayed into the corresponding primary air pulverized coal jet flow midstream and downstream interval in a jet flow manner, pulverized coal jet flow midstream and downstream combustion organization is carried out, the oxygen concentration and the pulverized coal combustion rate of the pulverized coal jet flow midstream and downstream interval are improved, and wall attaching happening of the pulverized coal jet flow midstream and downstream interval is directly obstructed. According to the method, pulverized coal jet flow midstream and downstream interval combustion organization and control can be achieved, happening of water cooling wall coking and high-temperature corrosion is prevented, the pulverized coal combustion efficiency is further improved, NOx generation and emissions are reduced, the proper combustion capacity of the pulverized coal combustion boiler for combustion low-volatile lower-ash-melting-point coal is expanded, and the fuel procurement cost is reduced.

Owner:张泽

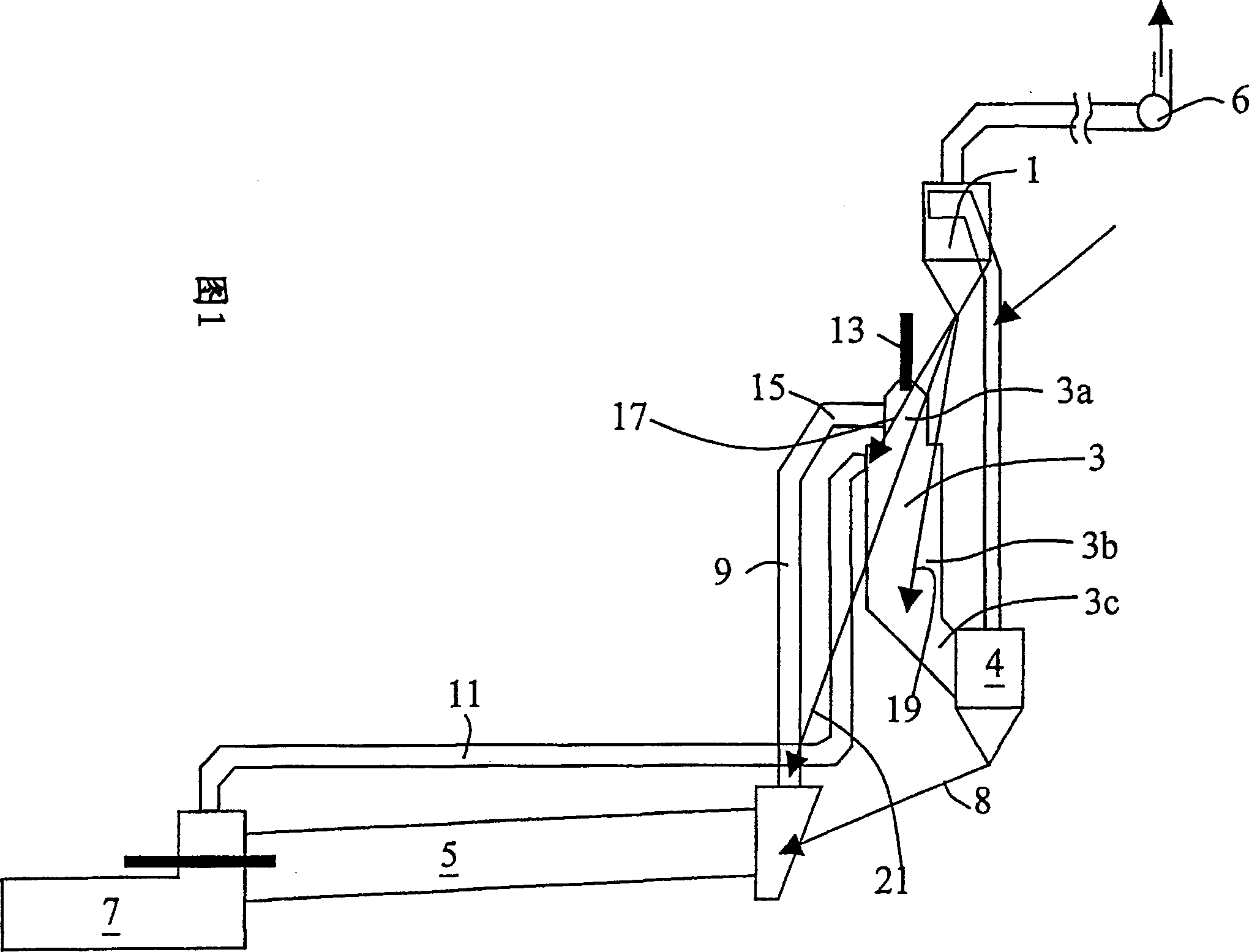

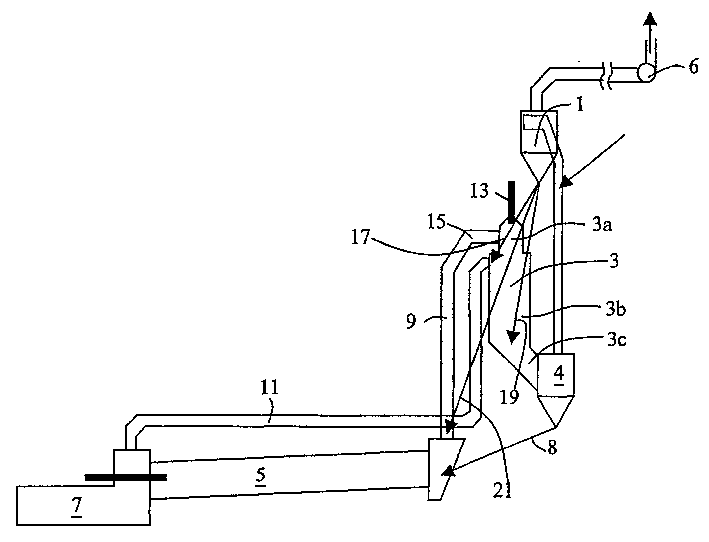

Method and plant for mfg. cement clinker

A description is given of a method as well as a plant for manufacturing cement clinker by which method cement raw meal is preheated in a preheater (1), calcined in a calciner (3) comprising an upper end (3a) and a lower end (3b), burned into clinker in a kiln (5) and cooled in a subsequent clinker cooler (7). The invention is peculiar in that exhaust gases from the kiln (5) are introduced into the upper end (3a) of the calciner, in that fuel is likewise introduced into the upper end (3a) of the calciner, in that the exhaust gas / fuel suspension is directed down through the calciner (3), in that preheated air from the clinker cooler (7) and preheated raw meal from the preheater (1) in combination or separately are fed into the calciner (3) at a location under the zone where exhaust gases from the kiln and fuel are introduced, in that the preheated air is directed down through the caliciner (3), being gradually mixed with the exhaust gas / fuel suspension, in that the raw meal under the action of gravity is directed down through the calciner (3) along its wall, being suspended in the exhaust gases at the lower end (3b) of the calciner, and in that the exhaust gas / raw meal suspension is extracted from the lower end (3b) of the calciner and conveyed to a separating means (4) for separating the raw meal which is subsequently directed to the kiln (5). Hereby is obtained a significant reduction of the NOx which is led to the calciner together with the kiln exhaust gases, a high degree of fuel burn out even when using fuels with a low content of volatile constituents, and a low degree of conversion into NOx of the nitrogen which is led to the calciner together with the fuel.

Owner:F・L・施米思公司

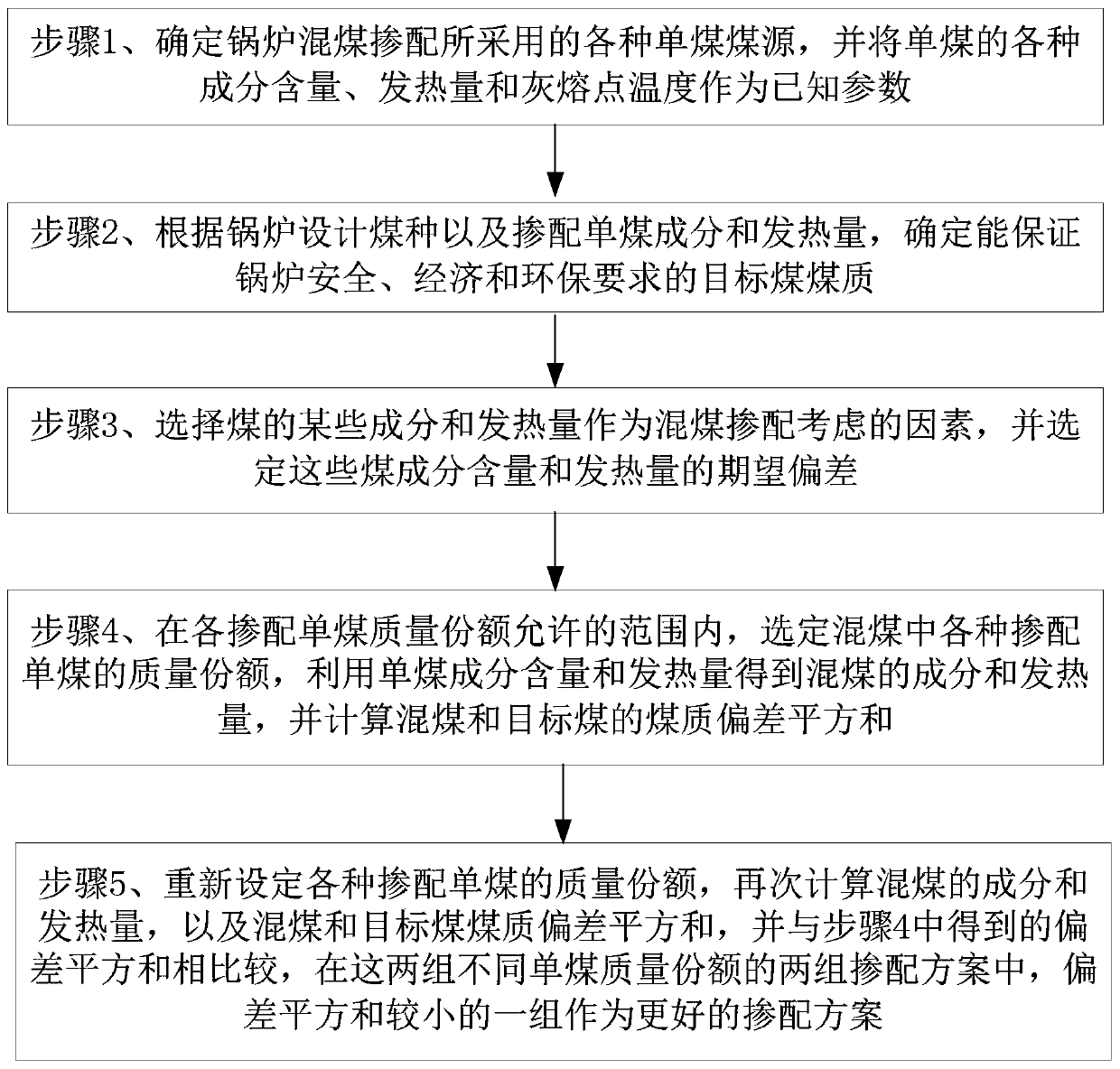

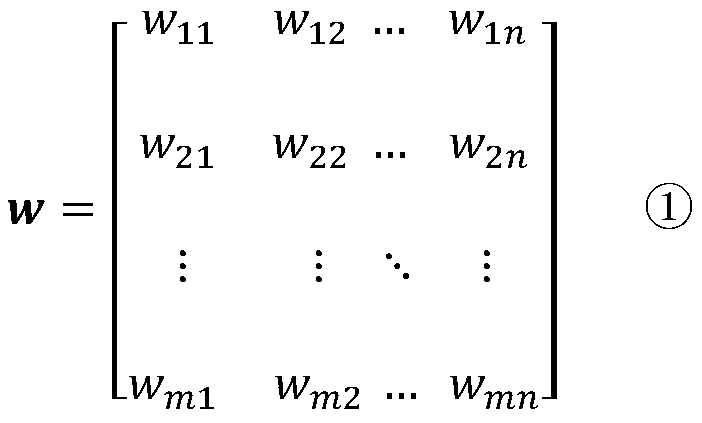

Blending method for mixed coal of boiler

ActiveCN110319455AGuaranteed maximum output requirementsIncrease burnoutFuel supply regulationNitrogen oxidesPollutant emissions

The invention discloses a blending method for mixed coal of a boiler. The method is characterized in that the coal quality is used as an optimization target, the blending method can be used for finding a scheme closest to a target coal quality from a complex single coal source; due to the fact that the components in the coal are more, the mixed coal quality obtained by blending cannot be completely the same as the target coal quality; the blending scheme is not completely the same as the target coal, but is closest to the target coal; and the proximity degree of the component in the mixed coaland the target coal can be independently adjusted by setting an expected error of a certain component. According to the scheme of taking the target coal as a blending optimization objective, the maximum output requirement of a generator set can be met in the market environment of which the coal quality is generally reduced and no stable coal sources exist, the situations that the boiler heating surface is overheated and a hearth is coked in large area are avoided, the burning rate of pulverized coal at an outlet of a hearth is relatively high, and emission of pollutants such as the nitrogen oxide content and the sulfur dioxide content meets the environmental protection requirements.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

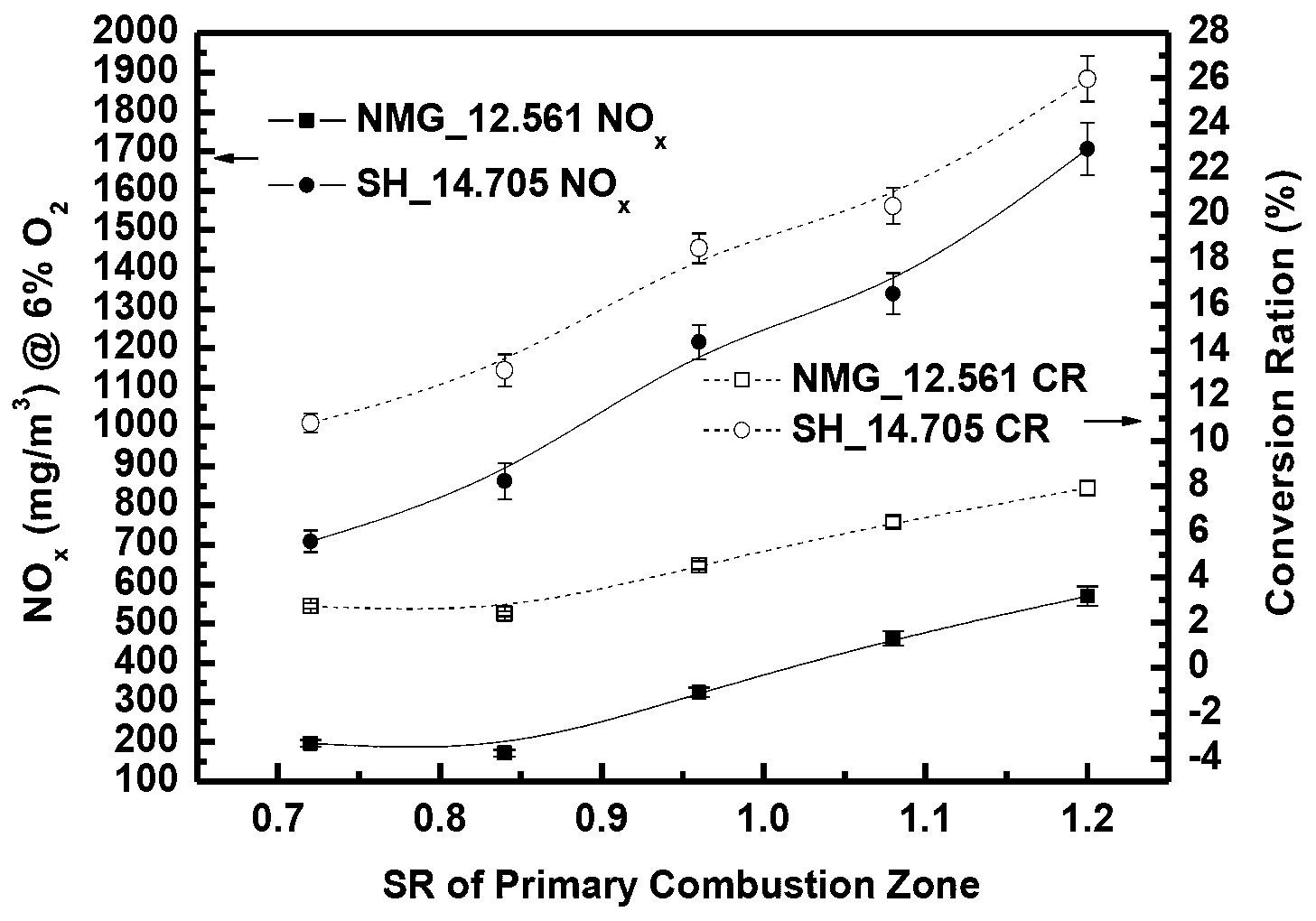

W-shaped flame boiler grading combustion method

InactiveCN107355802AIncrease burnoutReduce generationSolid fuel pretreatmentStaged combustionFlue gasSlag

The invention relates to a W-shaped flame boiler grading combustion method. Free-burning coal reacts with oxygen to form first grade combustion; the free-burning coal is formed by bituminous coal or a mixture between the bituminous coal and meager coal; and high-temperature flue gas atmosphere formed in the first stage ignites anthracite wrapped up with the high-temperature flue gas and second grade combustion is formed. A method for determining an optimal mixture ratio of a mixture ratio of the bituminous coal and the anthracite and a mixture ratio of the bituminous coal, the meager coal and the anthracite comprises steps of pre-deciding a boiler combustion strategy according to coal quality elements and an industrial analysis result, and comparing and analyzing boiler work conditions when different combustion strategies are employed to achieve an optimal boiler grading combustion coal type ratio, and an coal mill coal powder injection way. A combustion coal and the anthracite mixture ratio is determined during the boiler grading combustion process, so second combustion burn-off rate can be effectively improved; and secondary flying ash and large slag carbon content can be reduced.

Owner:中国大唐集团科学技术研究总院有限公司

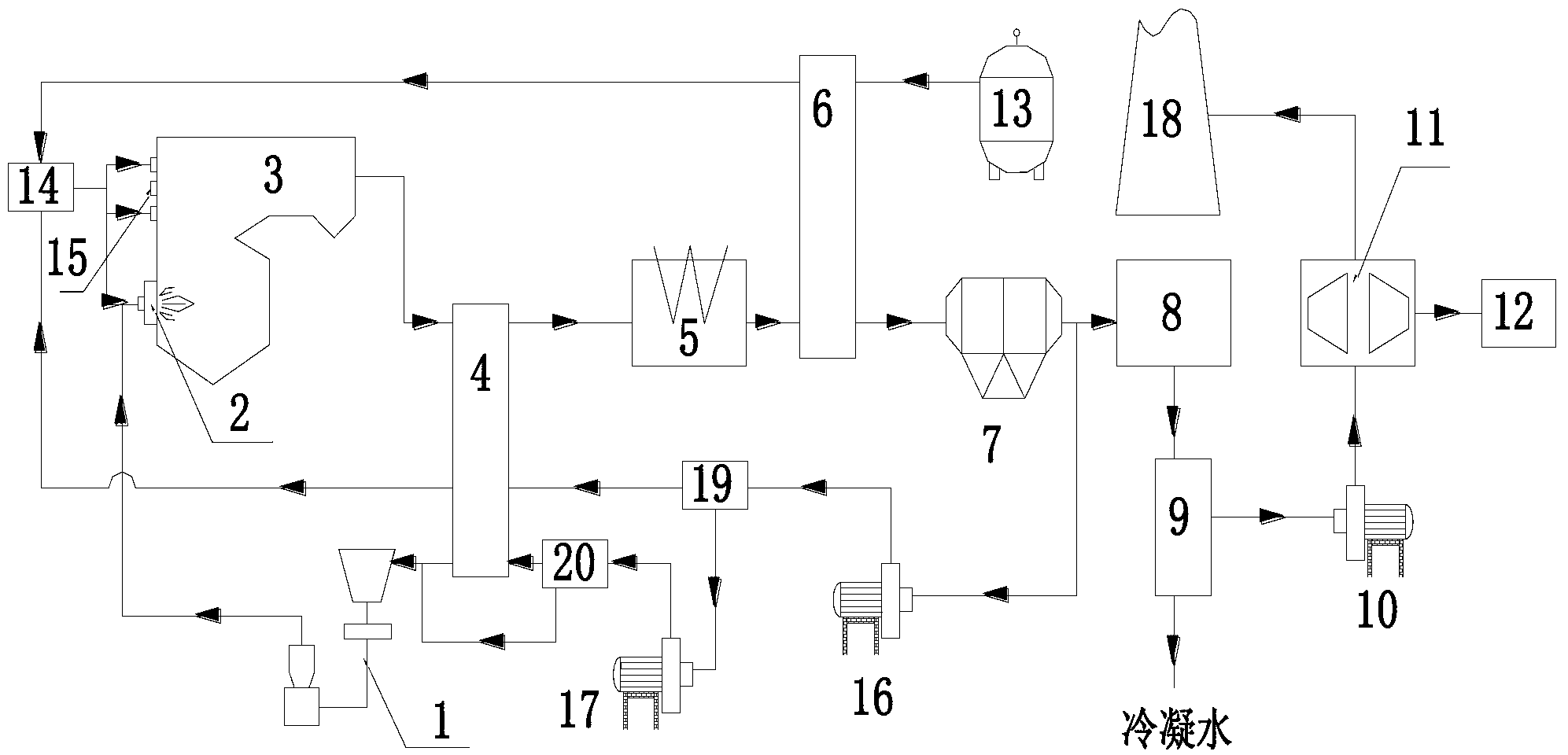

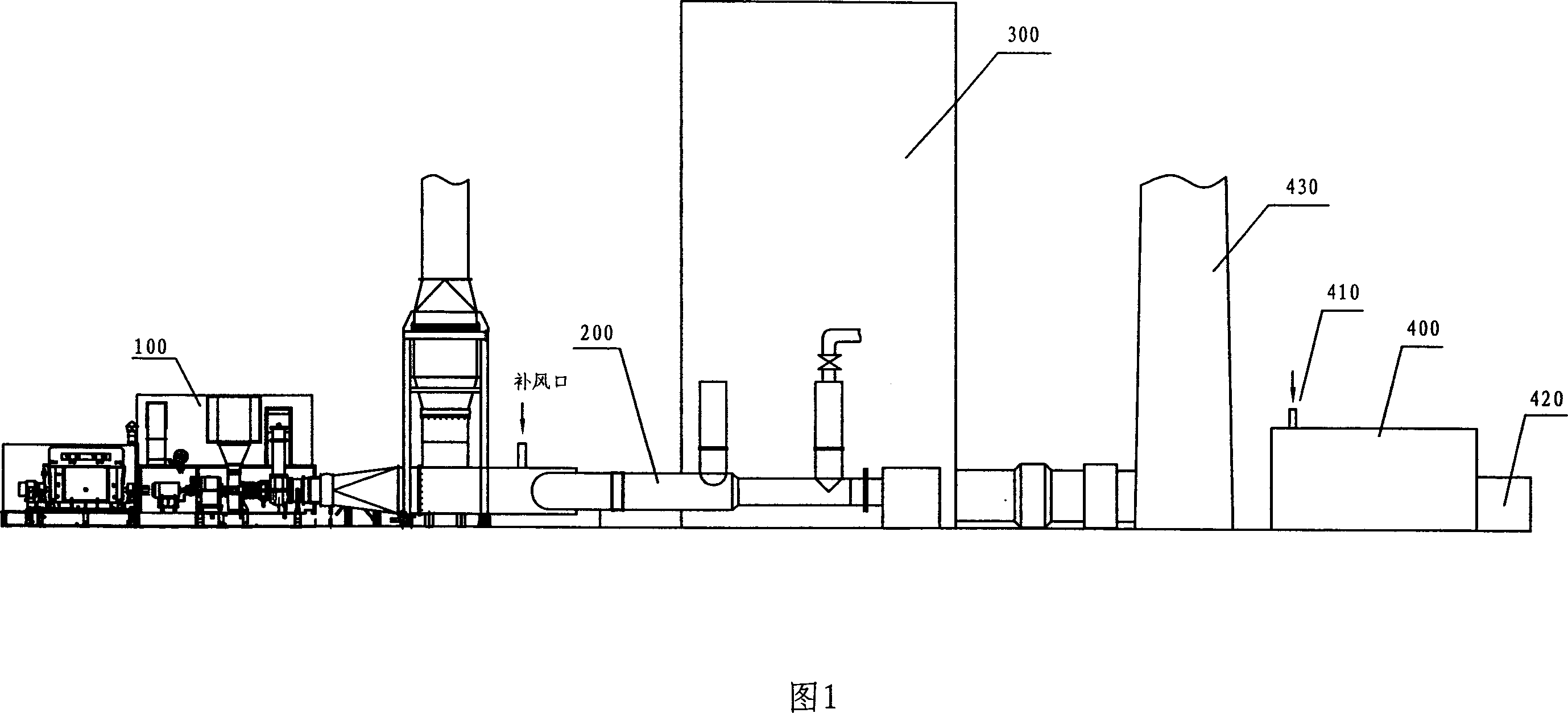

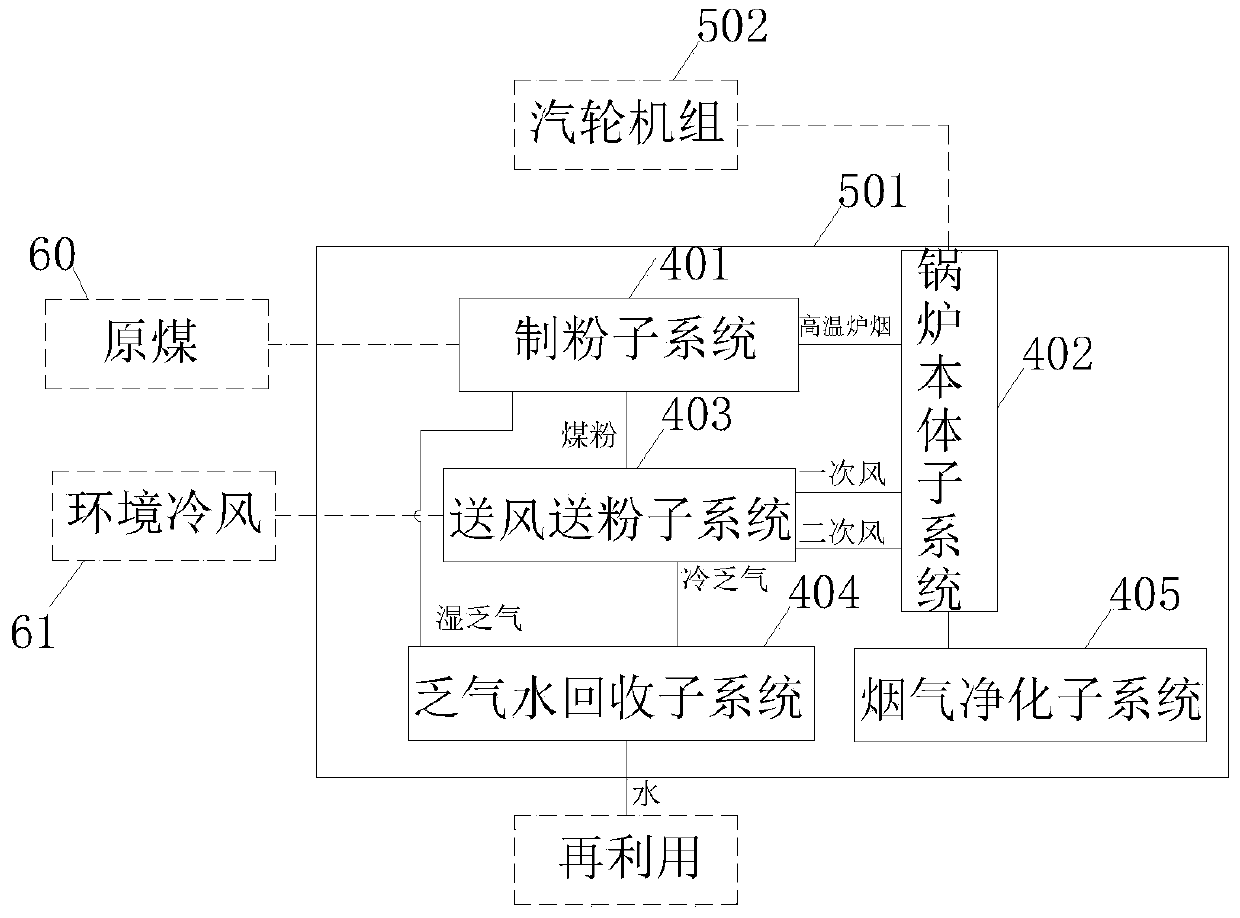

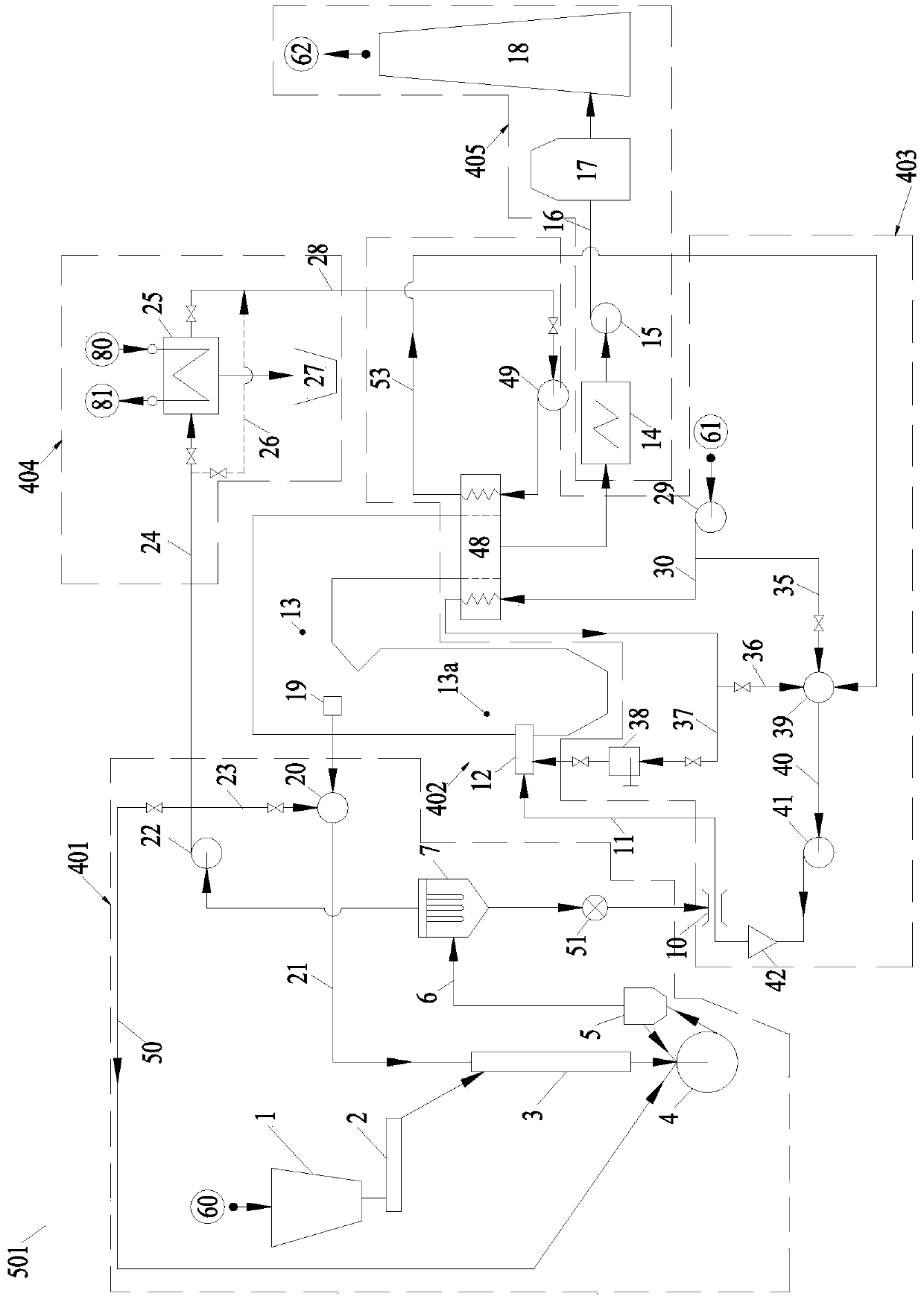

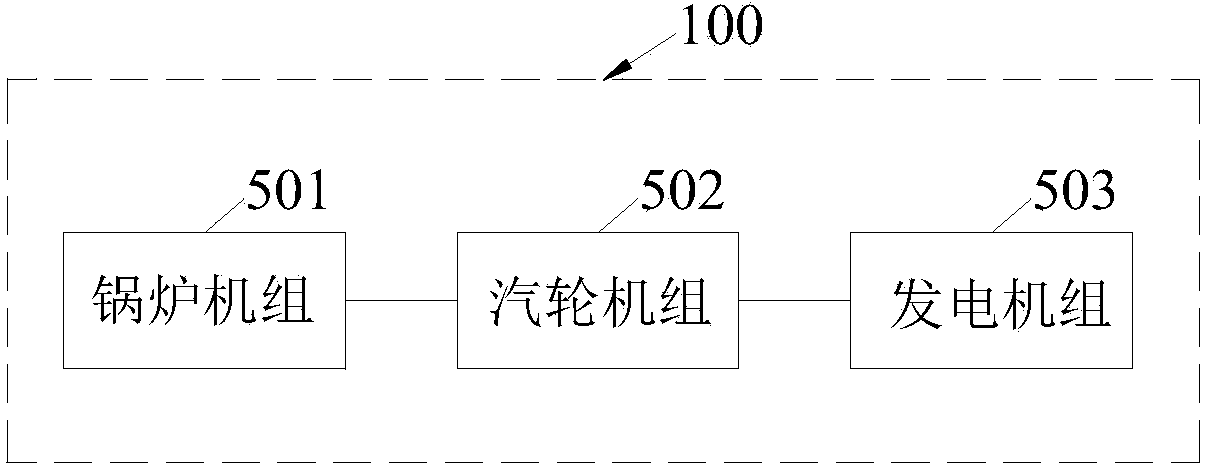

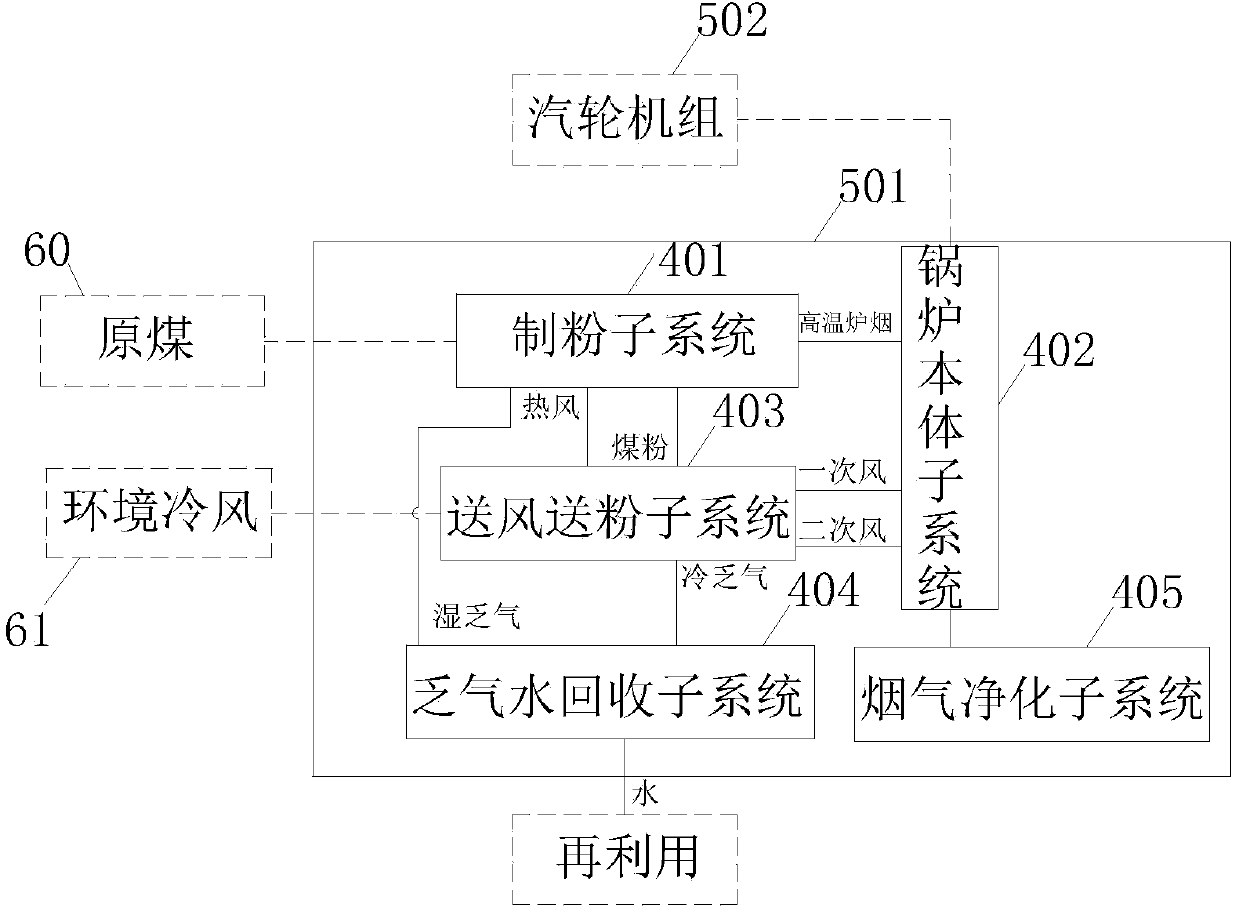

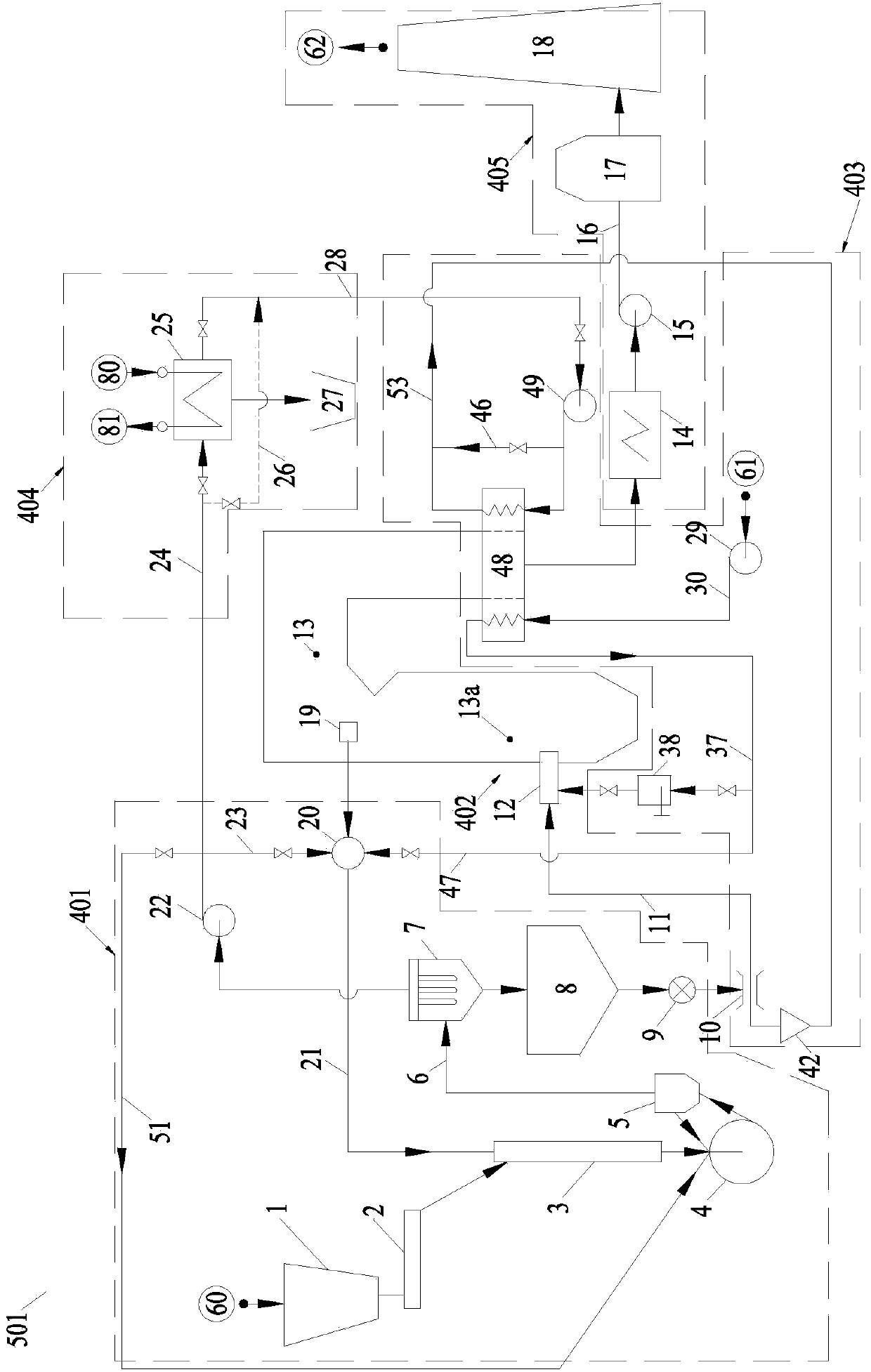

Fume-dried closed pulverization coal-fired boiler unit with function of exhaust water recovery

InactiveCN104197362AHigh implementabilityCost-effective recyclingIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionCold airThermodynamics

The invention provides a fume-dried closed pulverization coal-fired boiler unit with a function of exhaust water recovery. The fume-dried closed pulverization coal-fired boiler unit is characterized in that a weighing coal feeder weighs coal fed into a boiler and performs adjustment control, an air-locking powder feeder is provided, a drier mixing chamber is connected with a fume suction opening and a gas outlet of a pulverized coal collector and allows a first part extracted from exhaust and a part of fume extracted from the fume suction opening to be mixed into drier which is fed to a raw coal pre-drying device, an exhaust water recovery device cools high-humidity exhaust discharged by a pulverization subsystem so as to obtain a great deal of condensate and discharge cold exhaust, an air exhaust preheater heats a part of ambient cold air into hot air and heats the cold exhaust into hot exhaust, a part of the hot air, the other part of the ambient cold air and the hot exhaust are mixed into primary air, an air-powder mixer mixes the primary air and pulverized coal into air-powder mixture, and the other part of the hot air is used as secondary air directly supplied to a pulverized coal burner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

W-shaped flame boiler disposing aperture type over-fire air spouts on stove arch

ActiveCN101694295BExtended reaction timeFull reaction timeAir/fuel supply for combustionNon-combustible gases/liquids supplyEngineeringControl theory

Owner:HARBIN INST OF TECH

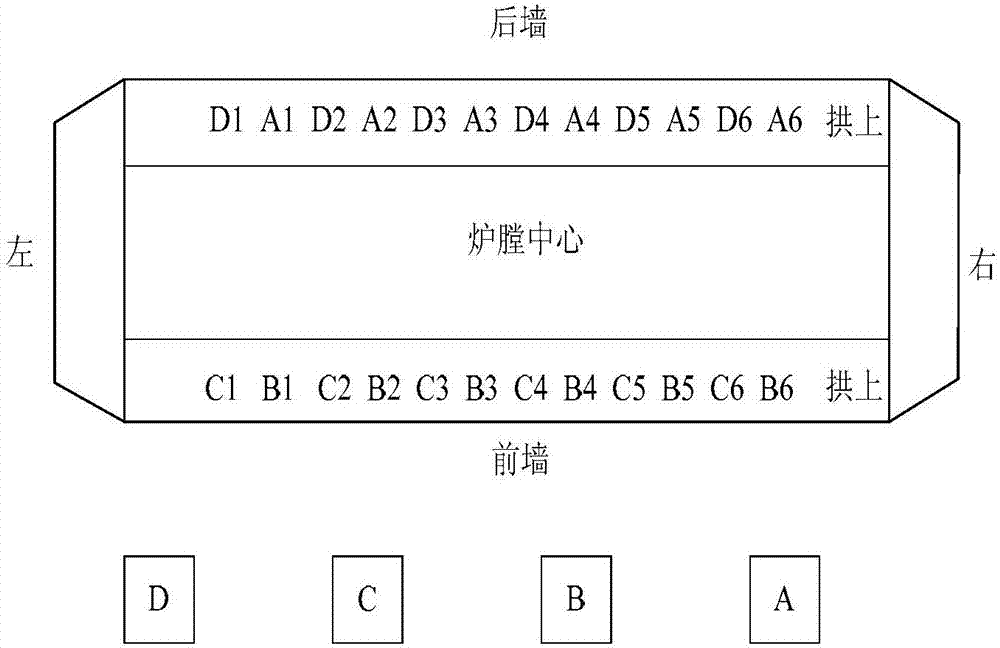

W-shaped flame boiler air distribution way optimization method

ActiveCN107355807AImprove adaptabilityImprove stabilitySolid fuel pretreatmentStaged combustionCombustionEngineering

The invention relates to a W-shaped flame boiler air distribution way optimization method. The method comprises steps of analyzing an acquired boiler operation condition, determining an F wind downward inclination angle and D,E wind opening degree, in which for a back wall, the F wind downward inclination angle is 25,25,5,5,30,30,30,30,5,5,25,25, the E wind opening degree is 25,25,5,20,20,20,20,20,5,5,10,10, the D wind opening degree is 5,5,5,5,5,5,5,5,5,5,5,5 and for a front wall, the F wind downward inclination angle is 25,25,5,5,30,30,30,30,5,5,25,25, the E wind opening degree is 25,25,5,20,20,20,20,20,5,5,10,10 and the D wind opening degree is 5,5,5,5,5,5,5,5,5,5,5,5. An in-furnace combustion work condition can be improved; and CO can be reduced and flying ash carbon content can be also reduced at the same time.

Owner:中国大唐集团科学技术研究总院有限公司

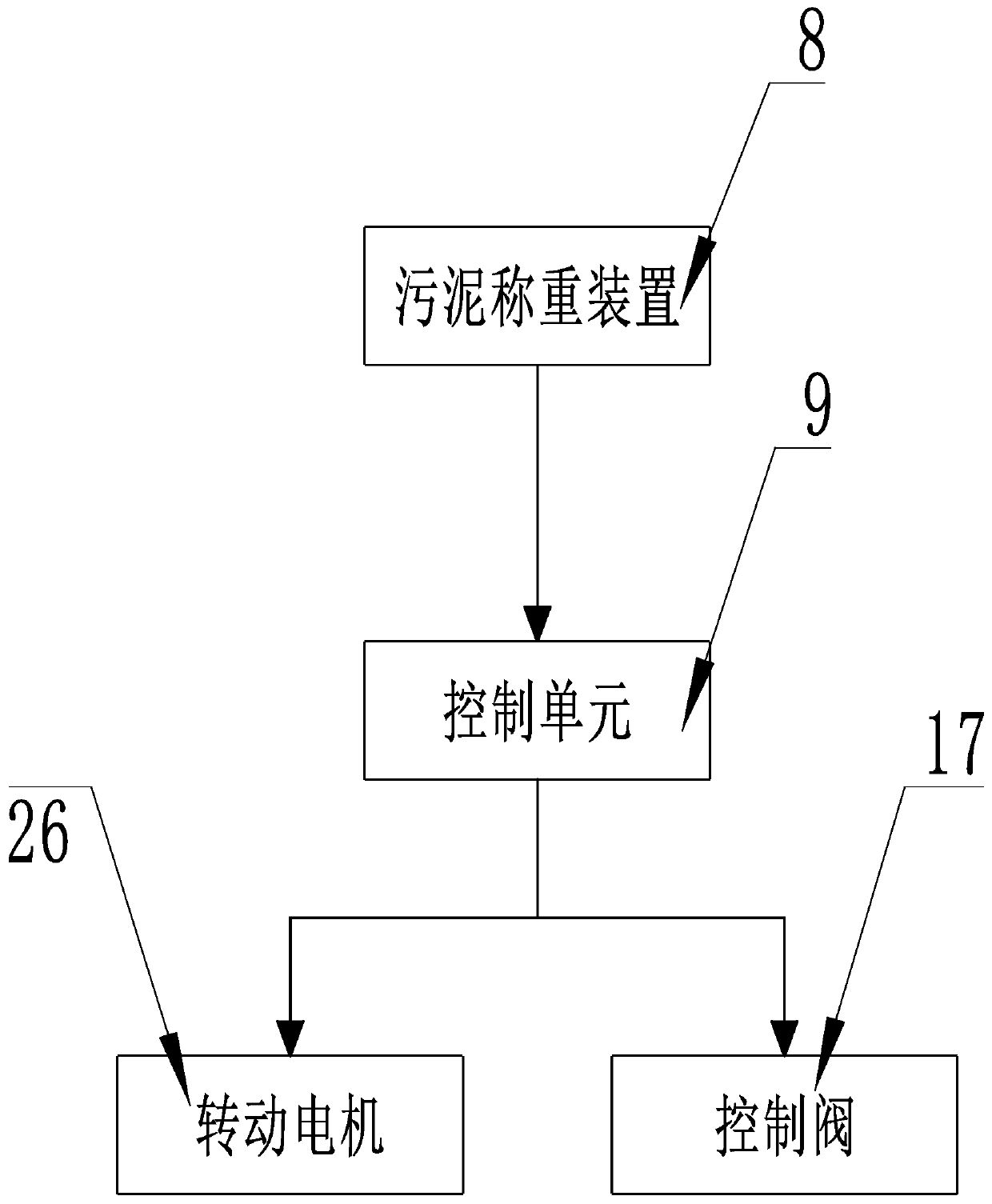

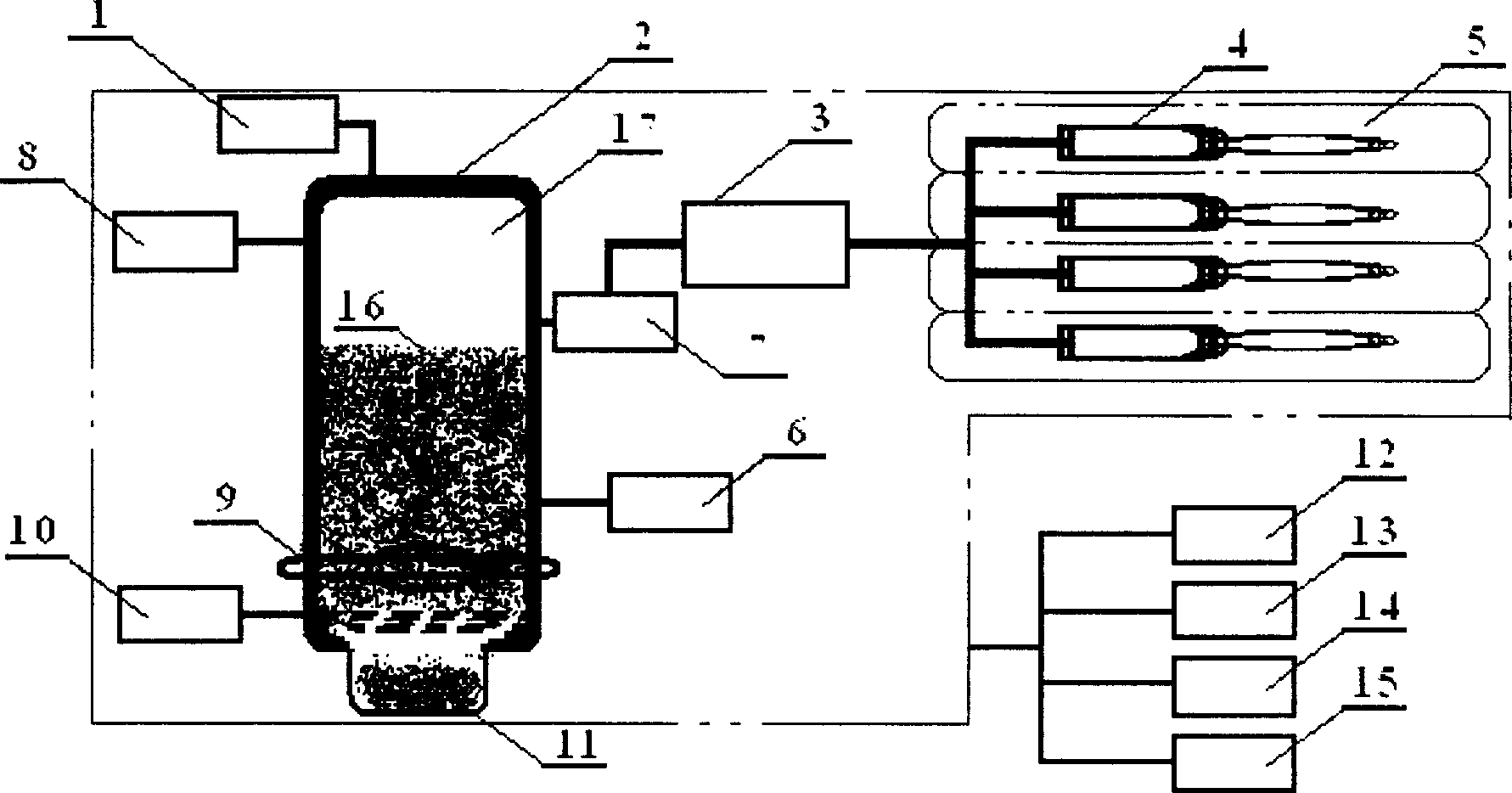

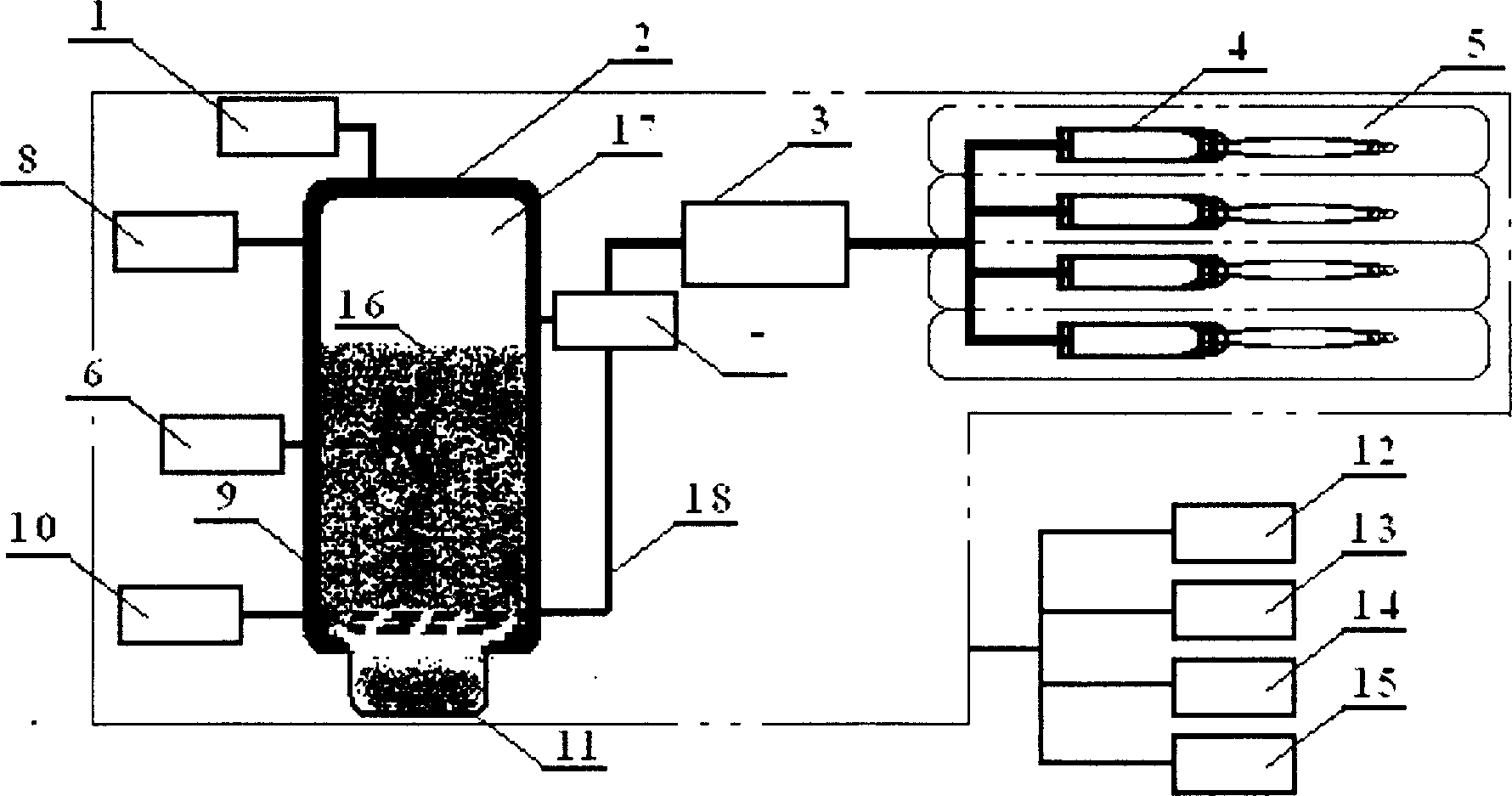

Sludge grading drying gasification coupled coal-fired power generation system and process method thereof

PendingCN110436740AIncrease burnoutIncrease profitSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeWater content

The invention relates to a sludge grading drying gasification coupled coal-fired power generation system, which is characterized in that a sludge weighing device is arranged in a drum type sludge drying box, and is connected to a control unit set with a sludge water content threshold, a dry sludge conveying device comprises a gasification conveying branch line connected to a circulation fluidizedbed sludge gasification furnace and a sludge circulation drying branch line connected to a sludge conveyor, the material outlet of the drum type sludge drying box comprises a gasification material outlet and a circulation sludge outlet closed or opened by the control unit, the gasification material outlet is connected to the gasification conveying branch line, and the circulation sludge outlet isconnected to the sludge circulation drying branch line. According to the present invention, the sludge grading drying gasification coupled coal-fired power generation system for reducing the sludge water content through circulation grading drying, and the process method thereof are provided.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Low-heating-value coal gangue combustion method

InactiveCN111023107ABurn fullyImprove combustion conditionsIncinerator apparatusGrain treatmentsCombustionProcess engineering

The invention provides a low-heating-value coal gangue combustion method, belongs to a coal combustion method, and aims to provide the low-heating-value coal gangue combustion method capable of improving the coal gangue combustion efficiency and reducing polluted gas emission. A biomass, a combustion improver and a sulphur-fixing agent are added according to a certain mass ratio, and are aged fora certain time after being uniformly mixed to obtain fuel for a coal-fired boiler, and three-times air supply is performed forcedly at the bottom of a fire grate of the coal-fired boiler when the fuelis fed at constant speed according to the fire coal amount required in combustion of the boiler by a mechanical coal feeding device, so that the sufficient combustion of the fuel of the coal-fired boiler is ensured. By improving the concentrations of oxygen and carbon dioxide, the rate of dissociation of carbon dioxide in fume is reduced, the content of carbon monoxide is reduced, the chemical incomplete combustion loss is reduced, the combustion burnout degree is beneficially improved, the heating value requirements of thermal power generation fuel are met, and finally the heating efficiencyof low-heating-value coal gangue can be improved by 30%-50%.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

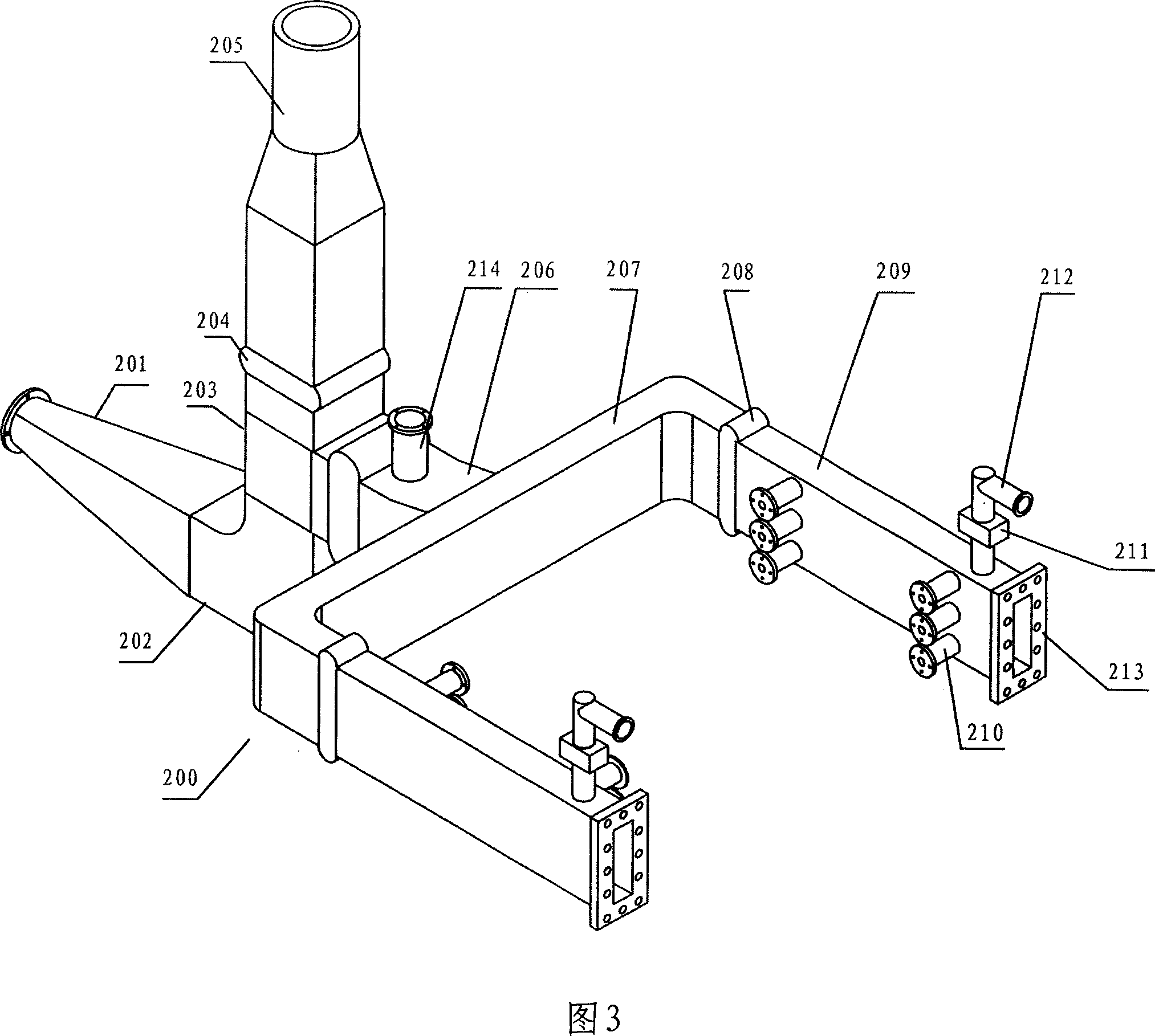

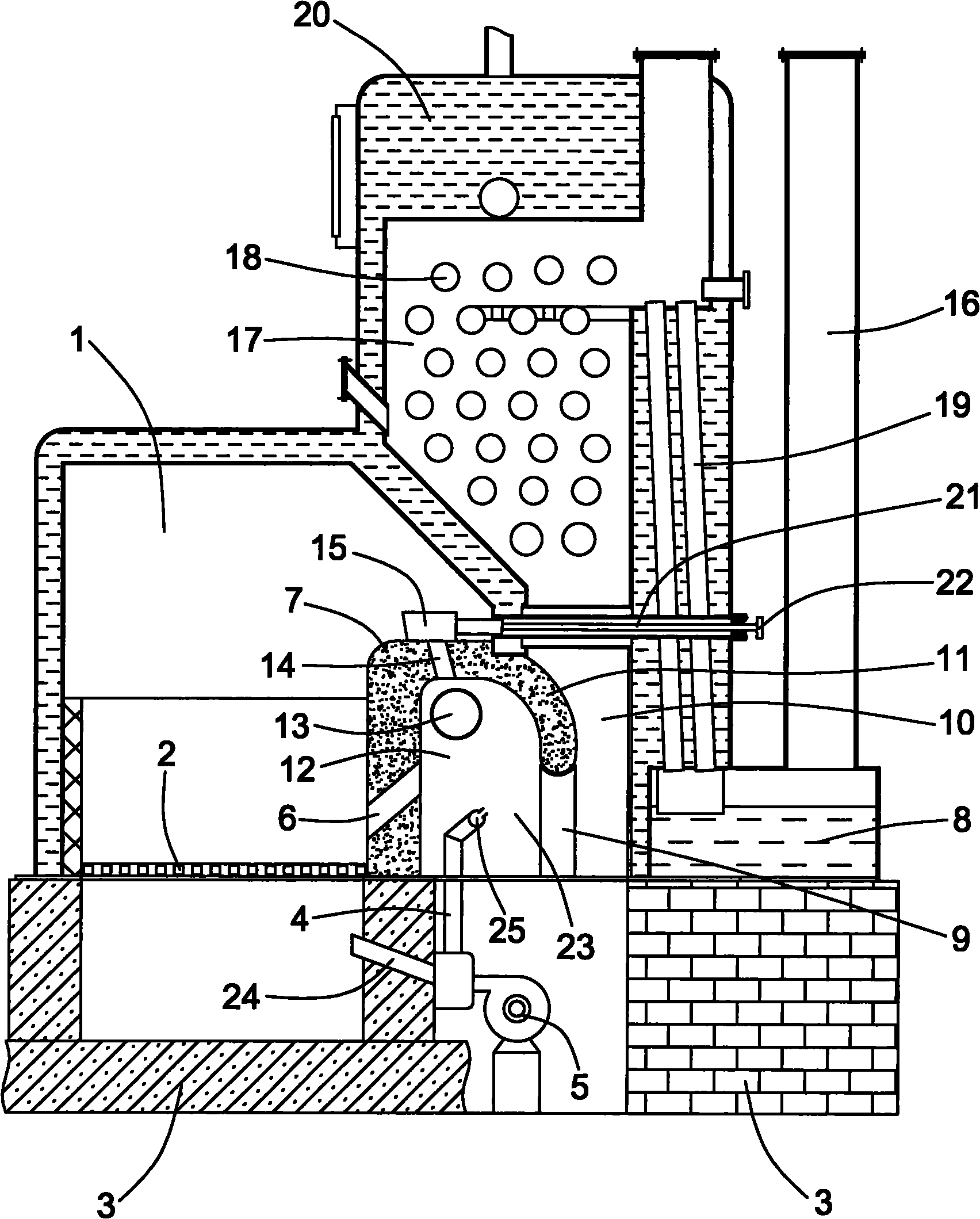

Cracking ignition device for pulverized coal fired boiler

InactiveCN1804467ARapid realization of thermochemical conversionIncrease burnoutIncandescent ignitionSlagCombustible gas

The invention relates to a power plant ignition device, especially providing a crack ignition device used in firepower coal boiler. It comprises a crack furnace (2), a feeding system (8) inside the crack furnace (2), a crack medium feeding system (10) and a slag discharge system (11). Wherein, the furnace chamber contains a heating device (9); the crack furnace (2) has a gas output tube; or it can mount a fuel gas feedback heating system (18) on the gas output tube to replace the heating device (9); the another end of fuel gas feedback heating system (18) is through to the furnace chamber of crack furnace (2); the end of output tube has a ignition burning head (4) which is connected to the burner (5) of boiler or directly burn the coal powder inside the furnace chamber. The invention has the advantages that: it has stable property, the cold and hot resistance and long service life; when the boiler is started, it can be used as ignition burner and when in normal burning, it can be used as main burner; and it is compatible with the boiler.

Owner:赵龙章

pulverized coal burner

InactiveCN105042585BStable and more complete combustionIncrease burnoutPulverulent fuel combustion burnersEngineeringHot blast

The invention discloses a pulverized coal burner. The pulverized coal burner comprises a feed mixer, a center wind pipe, a wind inlet shell, a burning stabilizer and an igniter, wherein a guide plate perpendicular to an axial end surface is arranged in the connected part between a feed pipe of the feed mixer and a cylindrical side wall; the wind inlet shell comprises a pulverized coal conveying pipe, a secondary wind pipe and a primary wind pipe arranged in sequence from inside to outside; the center wind pipe penetrates in from one axial end surface of the feed mixer, and extends to the front end of the pulverized coal conveying pipe after penetrating out of a discharge pipe of the feed mixer; the burning stabilizer is fixedly mounted at the front end of the center wind pipe; and the igniter penetrates in from the back end of the center wind pipe, and extends into the burning stabilizer. The pulverized coal burner has the following beneficial effects: the burning of pulverized coal approaches or reaches an ideal state; the pulverized coal and air are fully mixed; the burning of the pulverized coal is more stable and more complete; and the pulverized coal burner is environment-friendly, energy-saved, high in efficiency and simple in structure, can realize in-furnace desulfurization and denitrification, and is suitable for such boiler equipment as industrial boilers, industrial kilns and hot-blast stoves.

Owner:山东富海泰来新能源科技有限公司

Over-fire-air device for different load pulverized-coal fired boilers

The invention relates to an over-fire-air device for different load pulverized-coal fired boilers, and to an over-fire-air device, which solves the problems of the pulverized-coal fired boiler by utilizing the present over-fire-air device that when the load is different and particularly when the device runs at a low load, the over-fire-air momentum is reduced, the penetrating power is weakened, the mixing of the over-fire-air is non-uniform in the flow field, the ash combustible substance content in the smoke is high, the content of NOx is high, and the like. An inner air-course valve is arranged at an entrance of an inner over-fire-air air course, an intermediate air-course valve is arranged at an entrance of an intermediate over-fire-air air course, and an outer air-course valve is arranged at an entrance of an outer over-fire-air air course. A share air-course valve is arranged at the communication place of the intermediate and the outer over-fire-air air courses. An intermediate air-course valve is arranged at the entrance of the intermediate over-fire-air air course, and an outer air-course valve is arranged at the entrance of the outer over-fire-air air course. By adjusting the openness of the valves, and under the high load and the low load, good combustion effect can be realized, while the NOx content is reduced.

Owner:HARBIN INST OF TECH

Side over fire air distribution method and coal-fired boiler

InactiveCN106642083AReduce incomplete combustion heat lossImprove combustion efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionCombustorUnit operation

The invention relates to the technical field of pulverized coal combustion of a large-scale coal-fired power plant boiler, and concretely relates to a side over fire air distribution method and a coal-fired boiler. Aiming at the defects such as large combustion heat loss, poor unit operation economy and high temperature corrosion of a water cooled wall caused by poor side over fire air supplying of an existing domestic coal-fired power plant boiler, the invention provides the side over fire air distribution method and the coal-fired boiler. The air distribution method is characterized in that hot primary air in a hot primary air bus pipe is used as an air source, air is fed to a side over fire air area of the coal-fired boiler, the fed hot primary air can deeply penetrate through flue gas, and incompletely combusted pulverized coal and generated combustible gases such as carbon monoxide are continuously combusted sufficiently, so that incomplete combustion heat loss of the boiler is reduced, the combustion efficiency of the boiler is improved, meanwhile, an after-combustion effect of the over fire air is improved, a trend of the high temperature corrosion occurred on the water cooled wall between a main combustor and the over fire air is alleviated, and the operating economy and the safety of the coal-fired boiler adopting the air distribution method are greatly improved.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Coal-fired gasification swirl combustion furnace

InactiveCN101650024BIncrease burnoutExtended burn timeSolid fuel combustionWater heatersCombustion chamberHearth

Owner:王守信

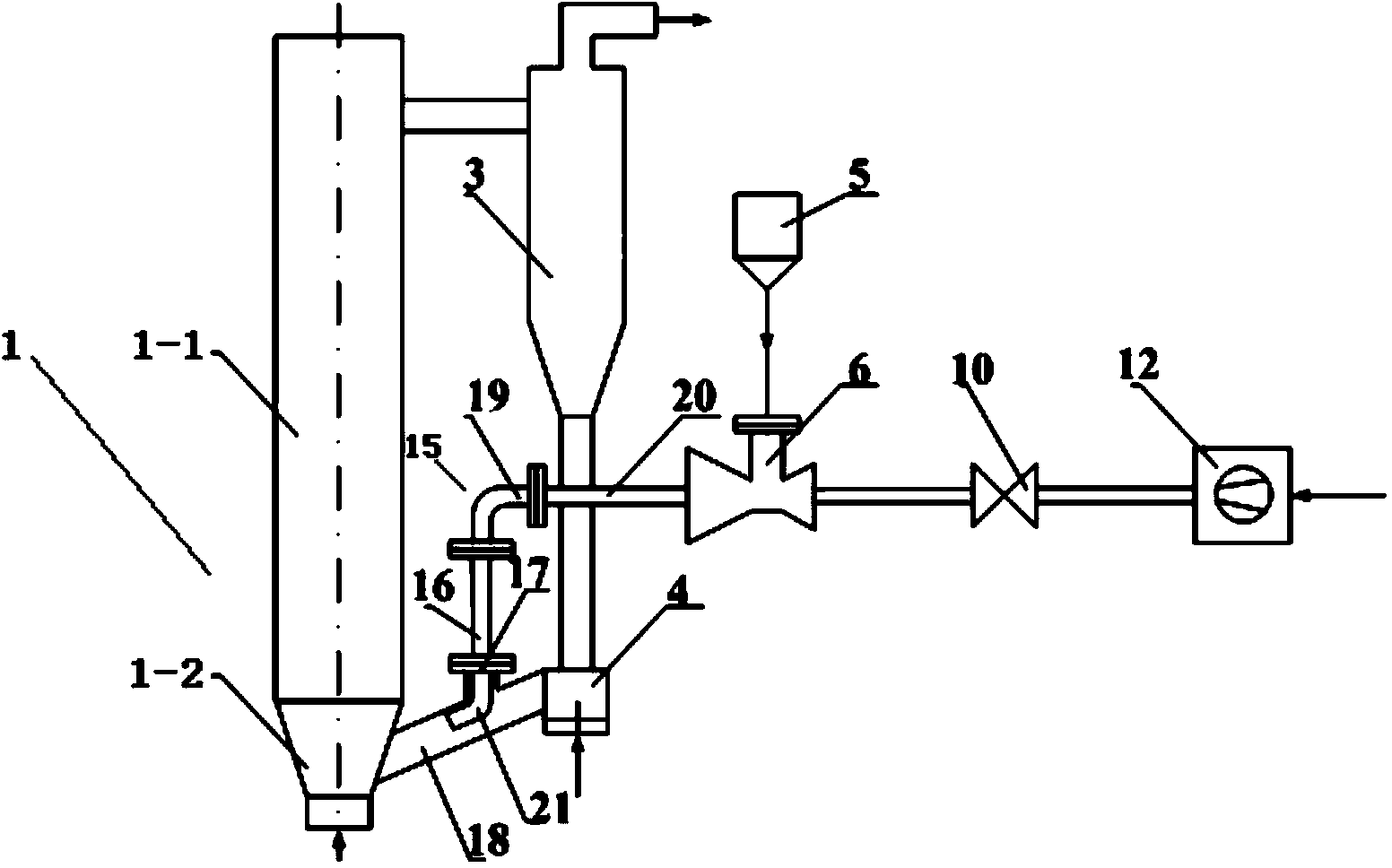

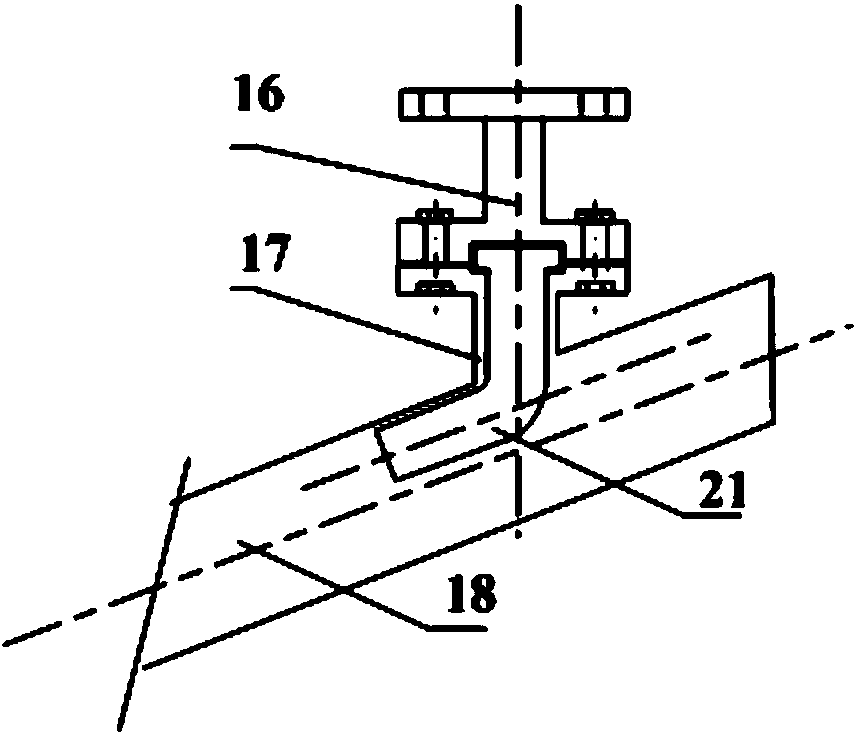

Combustion device of gasified carbocoal type nonflammable fine-grained fuel and combustion method with same

ActiveCN103982894AIncrease flexibilityOvercoming Hard-to-Troubleshoot ProblemsFluidized bed combustionApparatus for fluidised bed combustionFluidized bedHearth

The invention discloses a combustion device of gasified carbocoal type nonflammable fine-grained fuel and a combustion method with the same, which relate to a combustion device and a combustion method with the same and aim to solve the problem of low combustion efficiency of gasified carbocoal type nonflammable fine-grained fuel in a circulating fluidized bed in the prior art. The device comprises a raw material bin, a pneumatic ejector, a Roots blower, a regulating valve, an ejector pipe, a return inclined pipe, a cyclone separator, a return valve and a hearth, wherein the raw material bin is positioned above the pneumatic ejector, the ejector pipe is connected to one end of the pneumatic ejector, the Roots blower is connected to the other end of the pneumatic ejector, the return valve is connected to one end of the return inclined pipe, a dense-phase zone of the hearth is connected to the other end of the return inclined pipe, and the cyclone separator is connected to the return valve below. The combustion method comprises the following steps: (1) turning on a boiler of a circulating fluidized bed and starting the Roots blower, and (2) putting the fuel into the raw material bin, opening the regulating valve and starting the pneumatic ejector, so that the fuel enters the return inclined pipe and then is sent to the dense-phase zone of the hearth to be burnt. The combustion device and the method are used for combustion of the vaporized carbocoal type nonflammable fine-grained fuel.

Owner:HARBIN INST OF TECH

Flue gas hot air drying closed type pulverization coal-fired boiler unit with exhaust water recycling function

InactiveCN104197358AHigh implementabilityAvoid burnsIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionCold airFlue gas

The invention provides a flue gas hot air drying closed type pulverization coal-fired boiler unit with an exhaust water recycling function. The boiler unit used for combusting raw coal is characterized in that an air exhaust preheater heats environment cold air to obtain hot air, the first part of the hot air which serves as secondary air is directly fed into a pulverized coal burner, the second part of the hot air is directly fed into a drying agent mixing chamber to be mixed with flue gas pumped from a flue gas pumping opening, the mixture is used as drying agent and fed into a raw coal pre-drying device, the drying agent mixing chamber is respectively connected with the flue gas pumping opening and the air exhaust preheater, an exhaust water recycling device cools exhaust, high in humidity, discharged by a pulverization sub-system to obtain a large amount of condensate and discharges cold exhaust, one part of the cold exhaust is heated by the air exhaust preheater to form hot exhaust, the hot exhaust is mixed with the other part of the cold exhaust to form primary air, and the primary air enters an air-pulverized coal mixer to be mixed with pulverized coal to obtain air-pulverized coal mixture.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com