Boiler provided with dual-register pulverized coal burner on top

A pulverized coal burner and air conditioning technology, which is applied in the boiler field, can solve the problems that restrict the large-scale development of tangential combustion boilers, and achieve the effects of full utilization, low emissions, and thorough heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

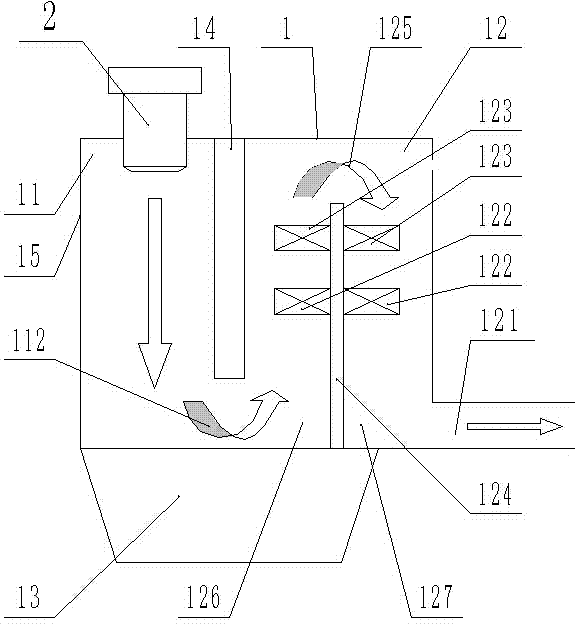

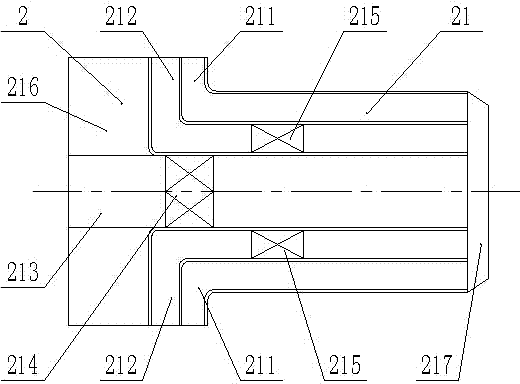

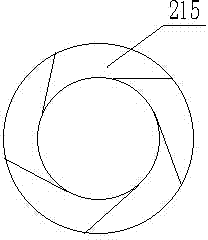

[0029] The present invention will now be further described in detail in conjunction with the accompanying drawings. The accompanying drawings are simplified schematic diagrams, which only schematically illustrate the basic structure of the present invention, and therefore only show the configurations related to the present invention.

[0030] The boiler with the double air-regulating pulverized coal burner on the top includes a furnace body 1 and an ash pit 13. The ash pit 13 is installed at the bottom of the furnace body 1, and the inner wall of the furnace body 1 is provided with a membrane-type water-cooled wall 15. The top in the furnace body 1 is provided with a first partition wall 14, the first partition wall 14 divides the furnace body 1 into a combustion chamber 11 and an exhaust gas chamber 12, and the lower part of the combustion chamber 11 and the exhaust gas chamber 12 communicates, Form the first pair of smoke passages 112, the top of the combustion chamber 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com