Patents

Literature

33results about How to "Thorough heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

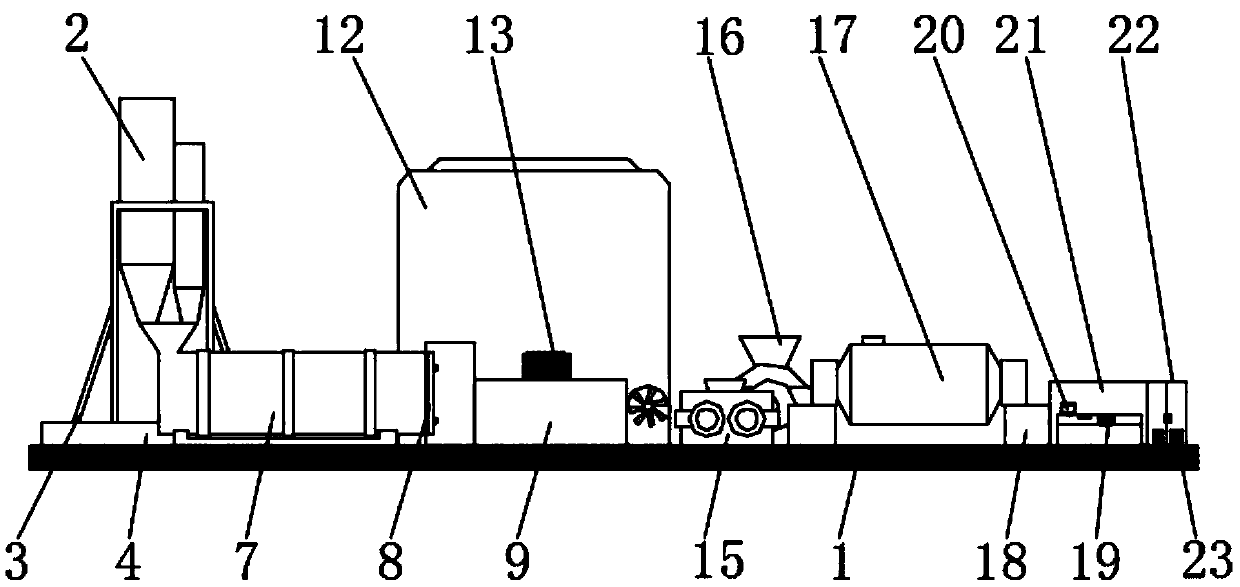

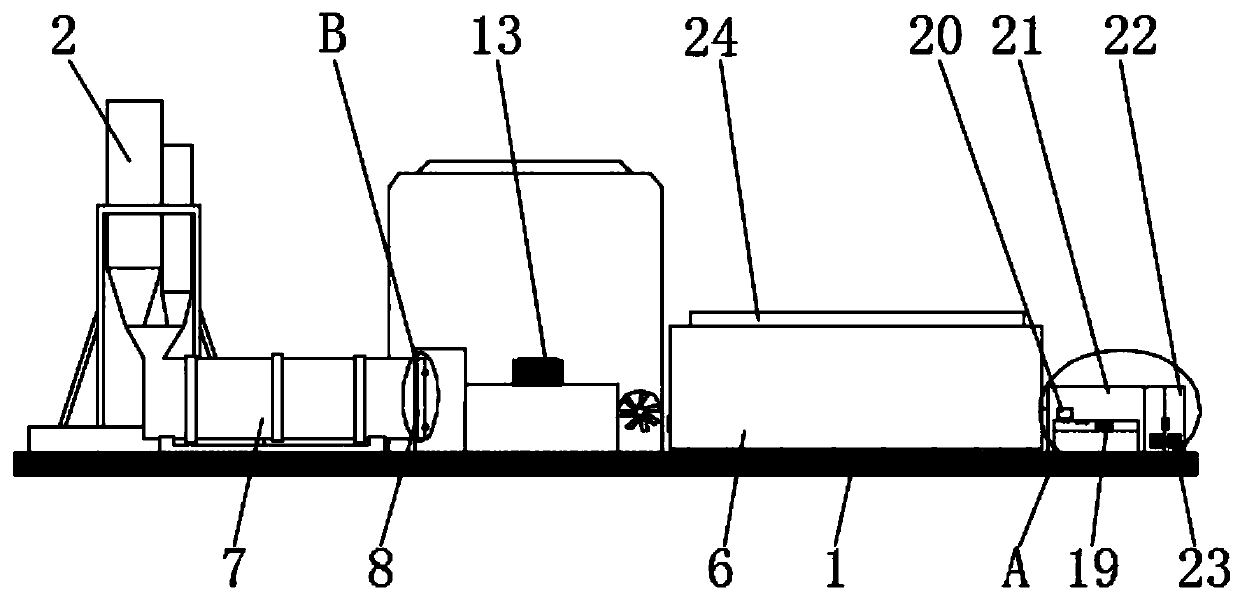

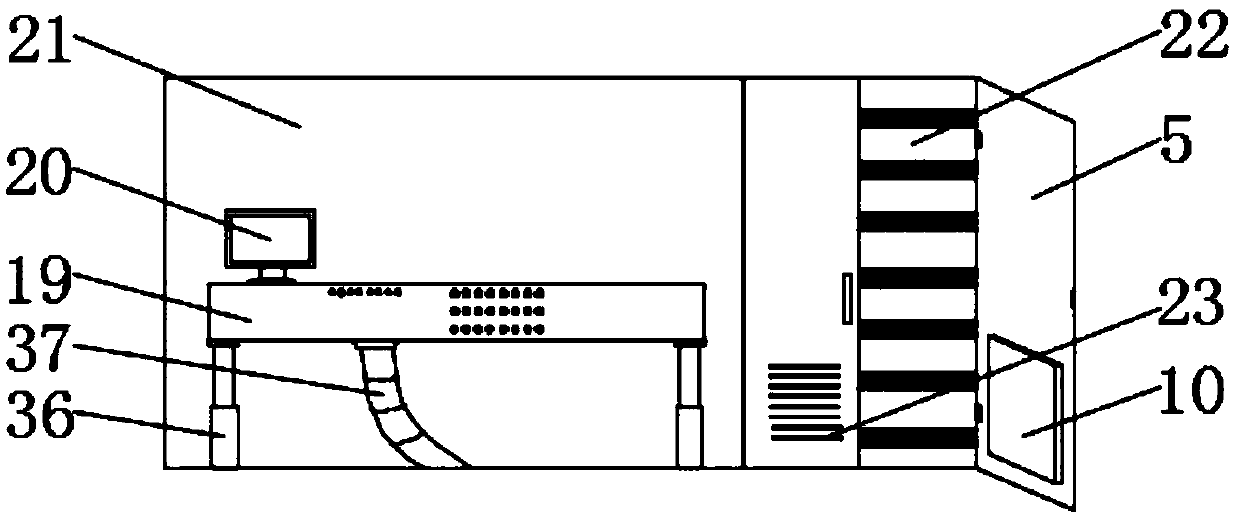

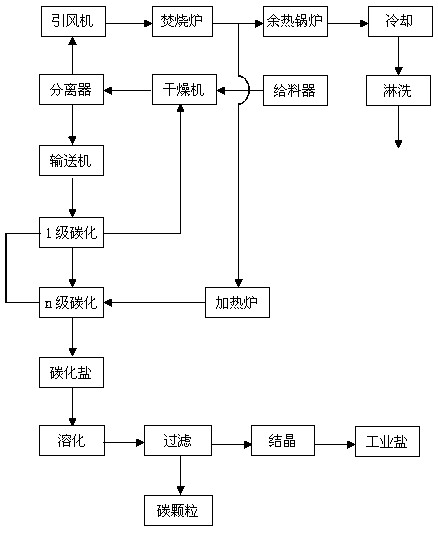

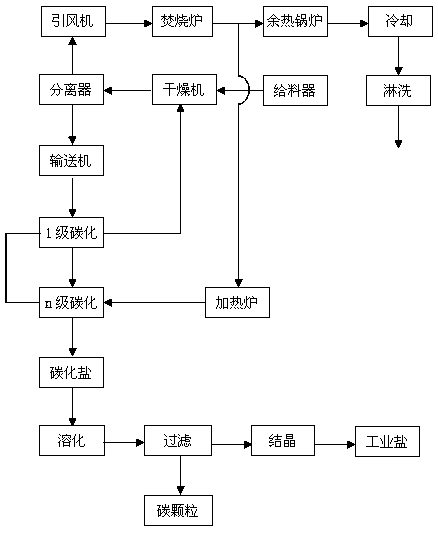

Process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt

ActiveCN106914474AGood dispersionLarge specific surface areaSolid waste disposalTransportation and packagingEnvironmental resistanceDecomposition

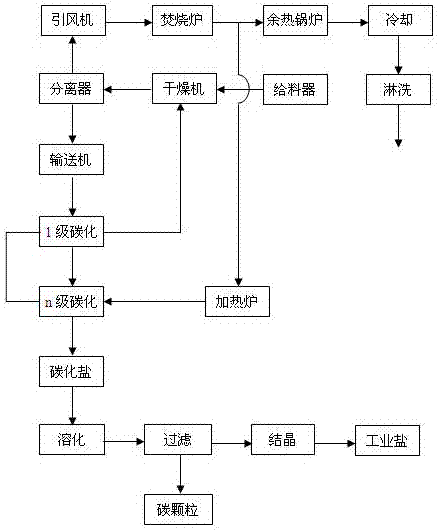

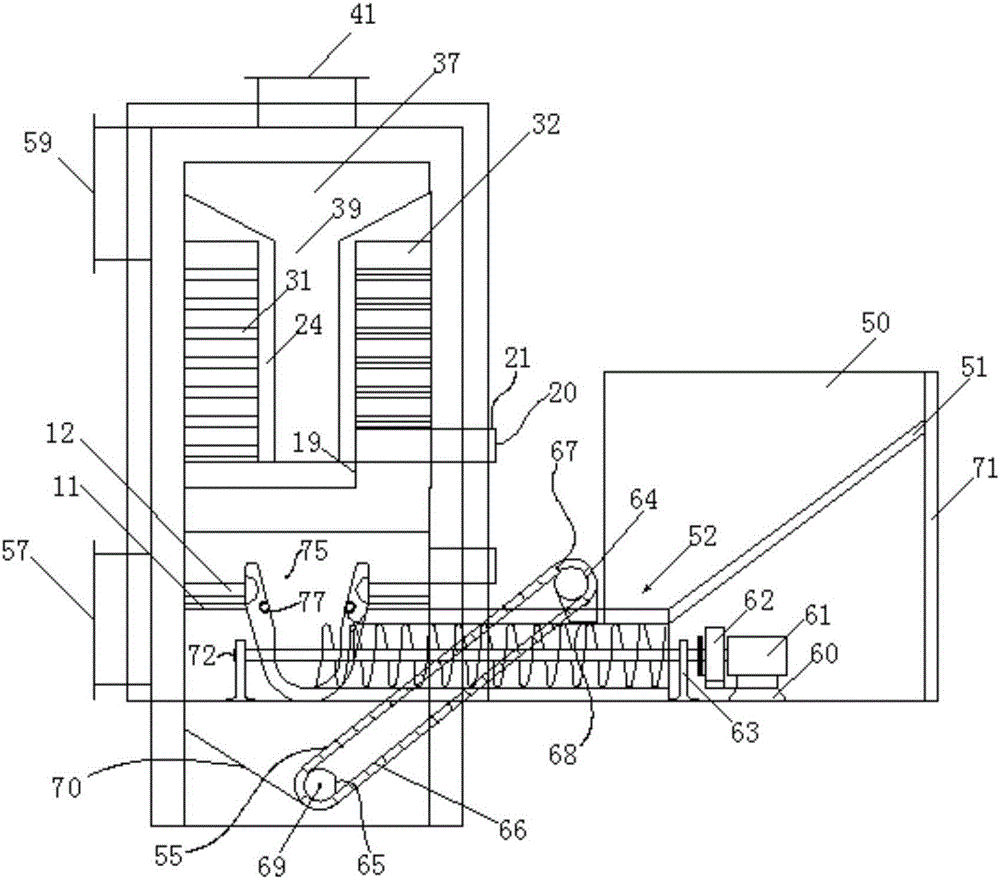

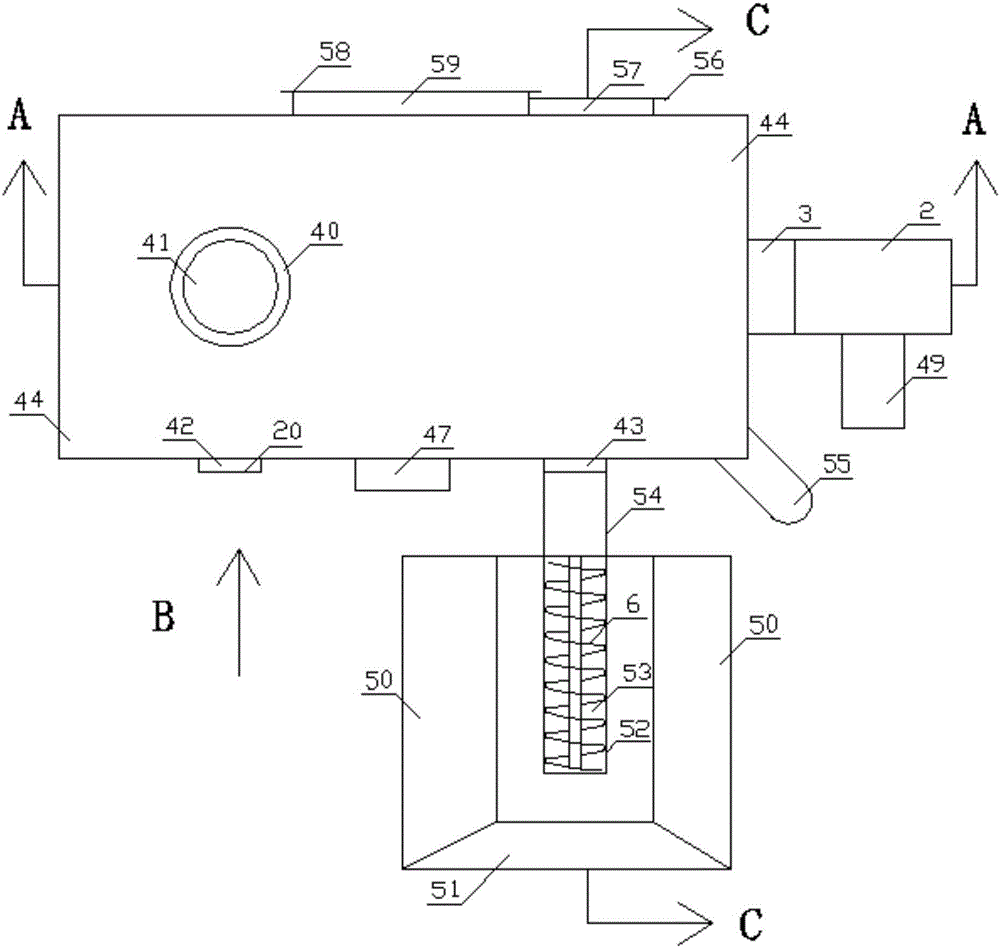

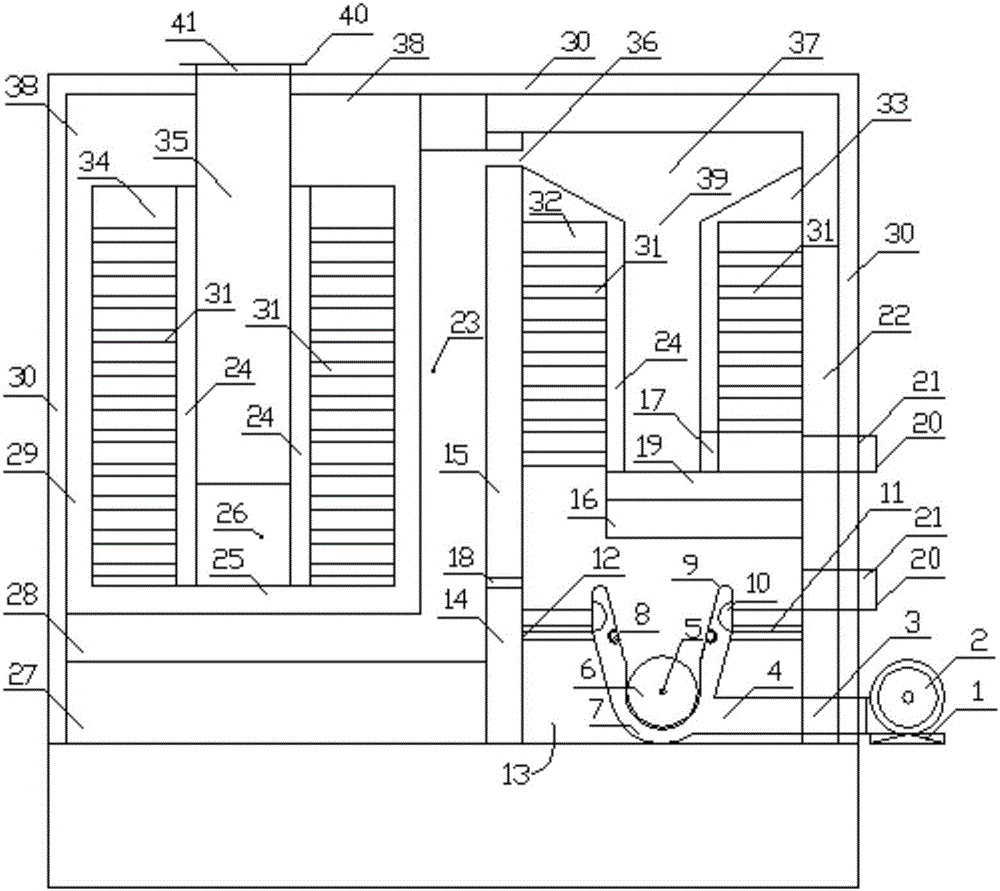

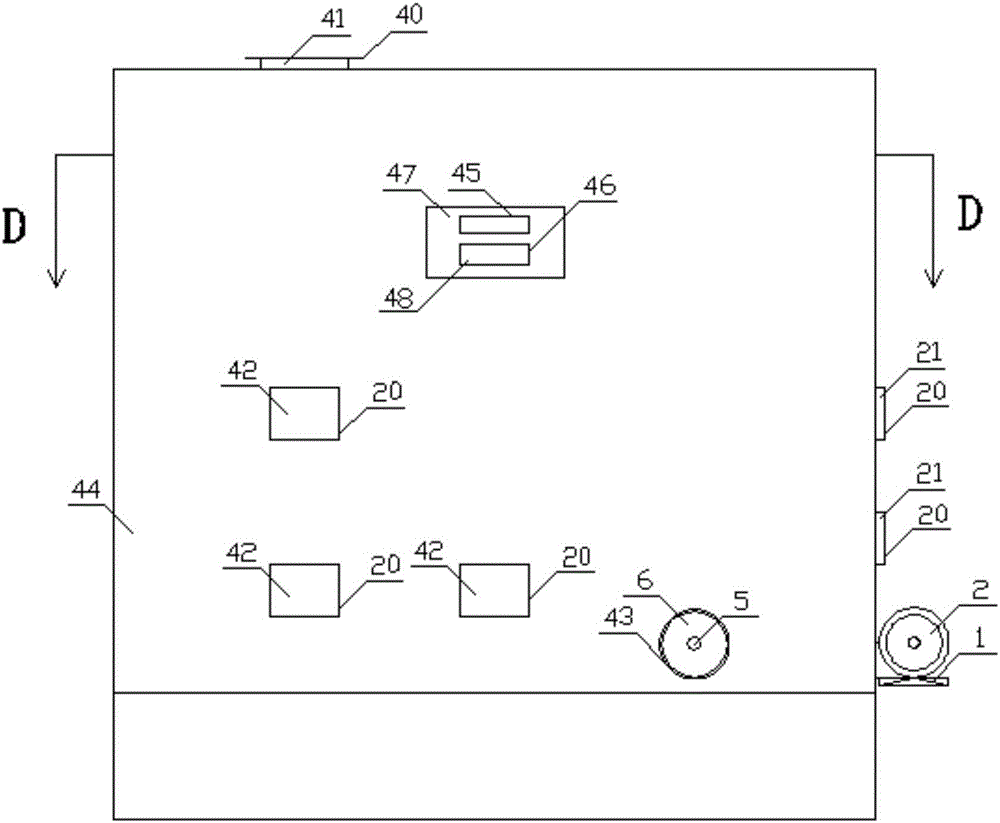

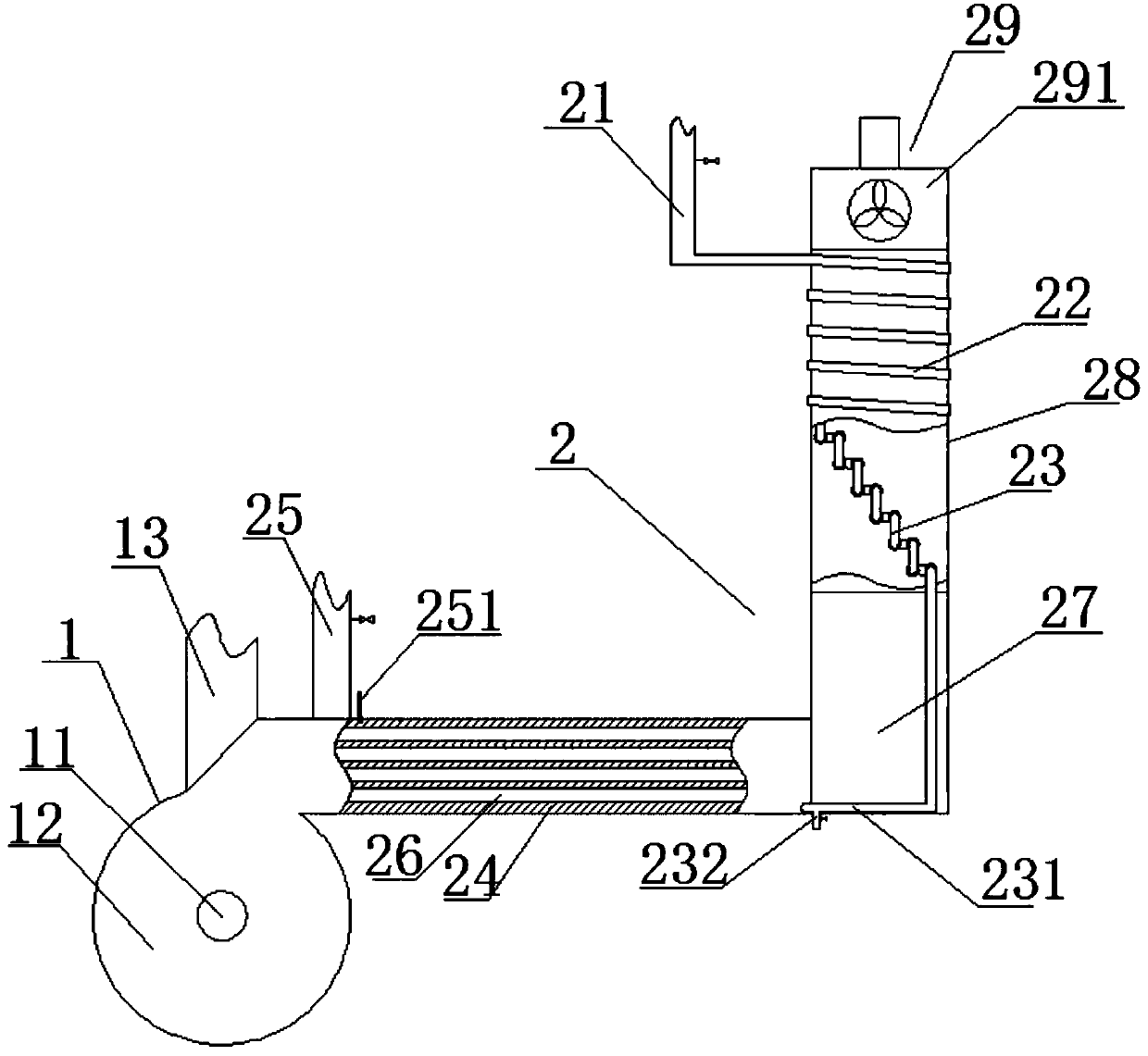

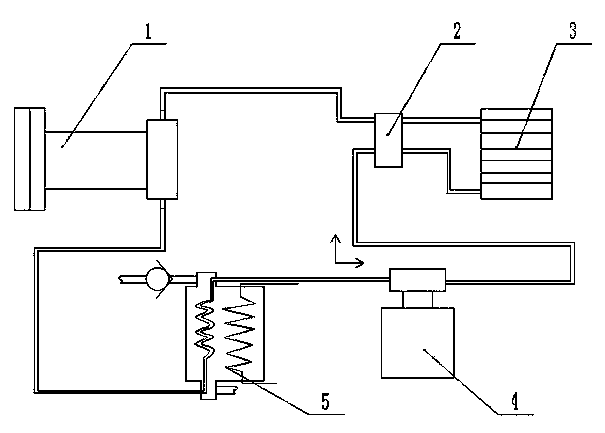

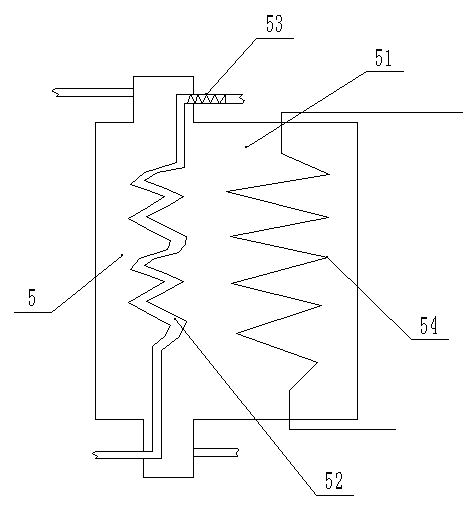

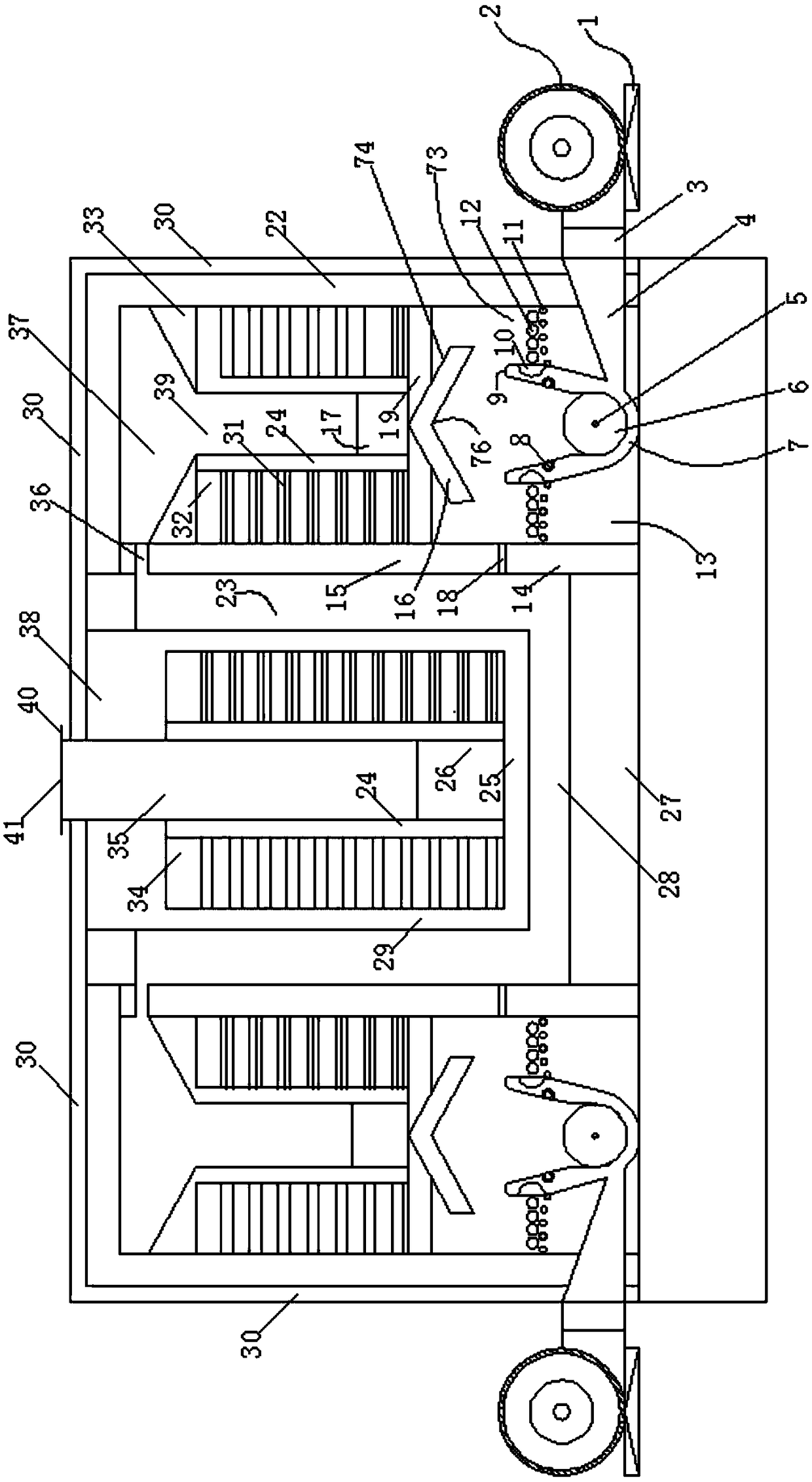

The invention belongs to the field of environmental protection, and particularly relates to a process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt. According to the process and the equipment disclosed by the invention, aiming at the characteristics that each kind of industrial waste salt contains various organic materials and has different physicochemical properties, a plurality of grades of decomposition and carbonization furnaces are arranged to perform graded heating on the industrial waste salt; the heating process is reasonable; the organic materials are decomposed and carbonized within the respective decomposition and carbonization temperature range; the heat-containing exhaust gas generated by decomposition and carbonization is used as a dry heat source; the exhaust gas generated by drying is introduced into an incinerator for incineration; and the hot gas generated by incineration is recycled. According to the process and equipment disclosed by the invention, continuous industrial production is realized, and during the operation of the system, no melting, agglomeration or bonding of the waste salt occurs, no secondary pollutants are generated, no toxic and harmful gas is exhausted, thermal efficiency is high, energy is saved, environmental protection is achieved, and the investment cost is lower than that of other methods; and the process and equipment have the advantages that the process and equipment are high in practicality, are suitable for the removal and harmless treatment of the organic materials of the industrial waste salt in various fields, and are suitable for popularization in industrial production.

Owner:辽宁东大粉体工程技术有限公司

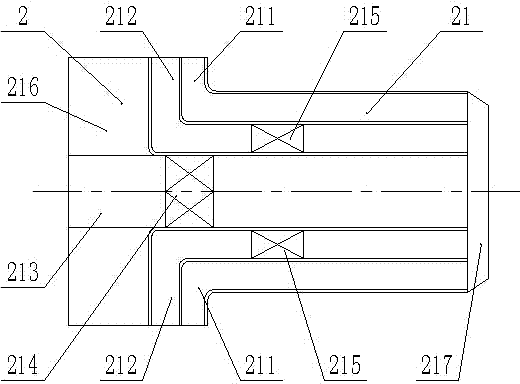

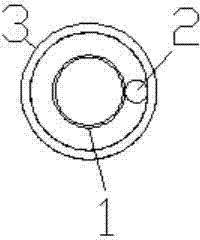

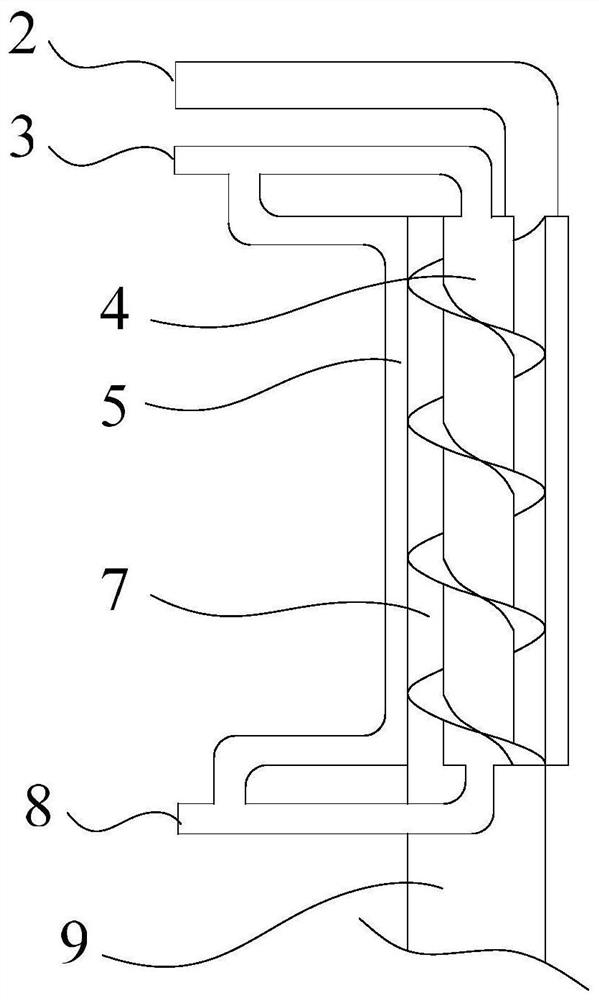

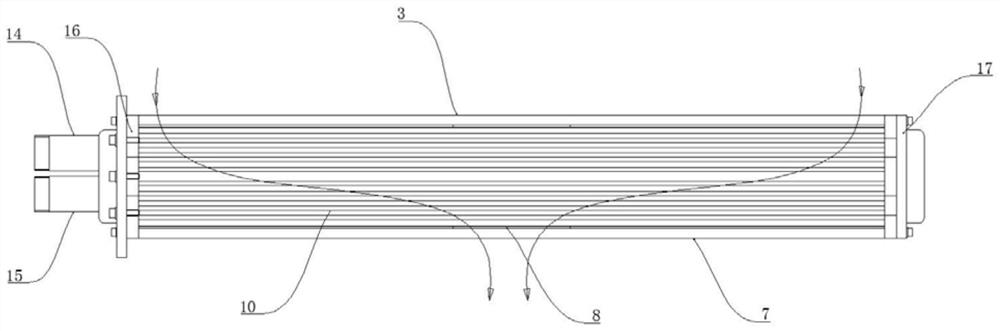

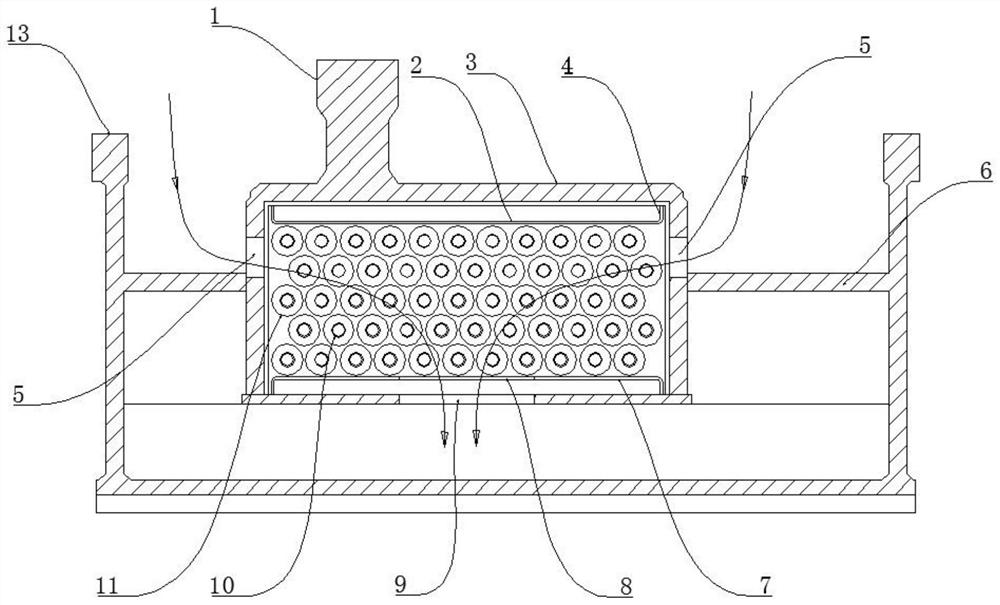

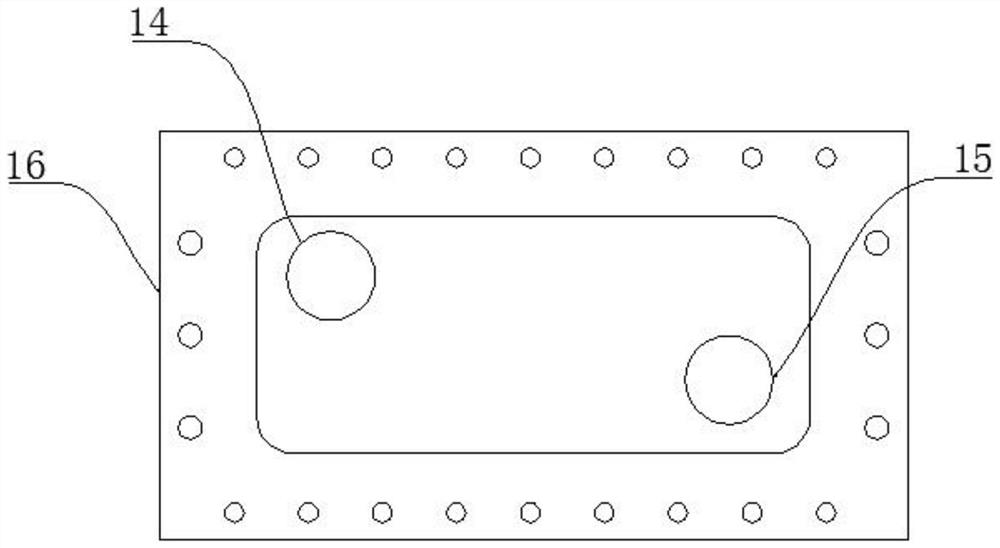

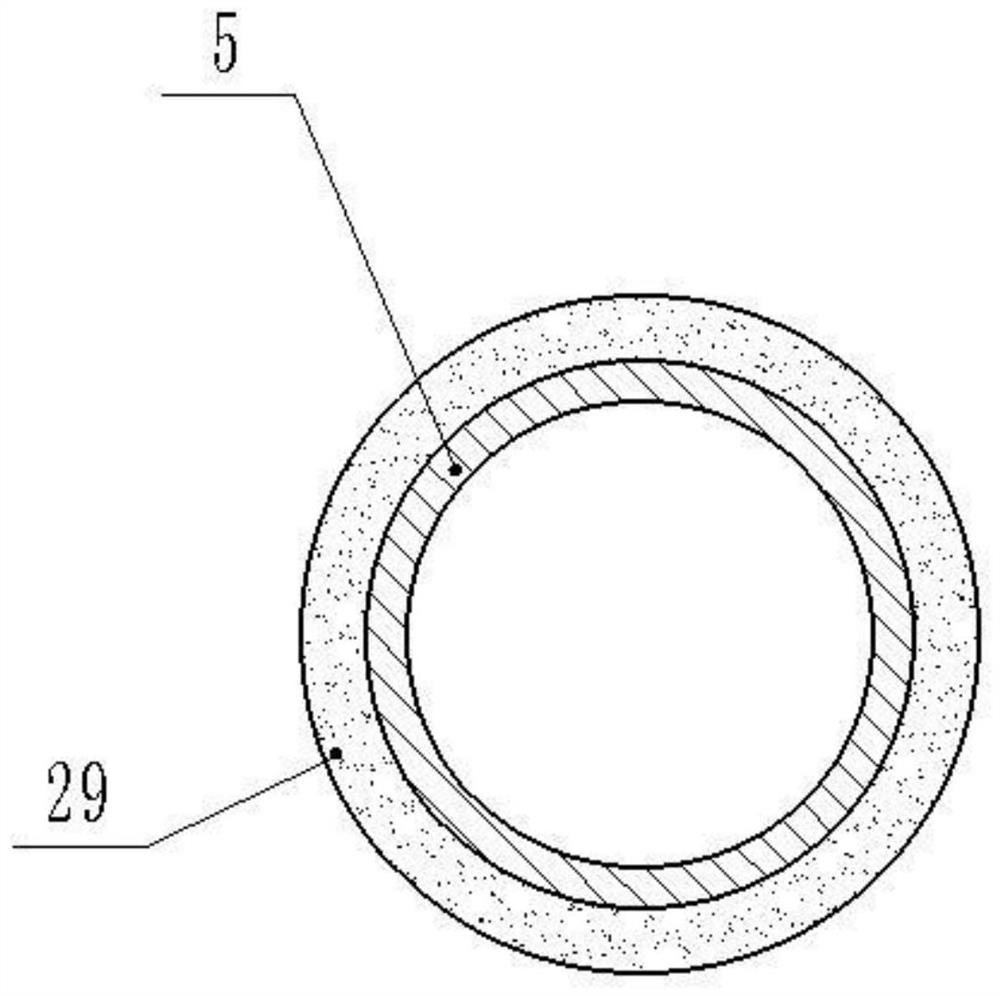

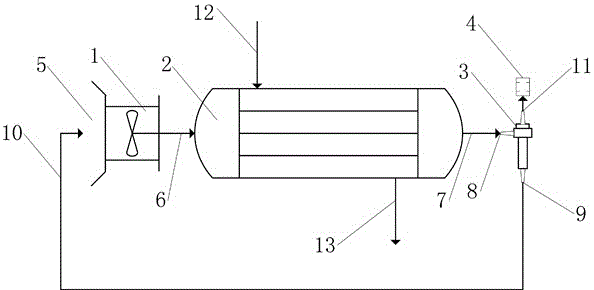

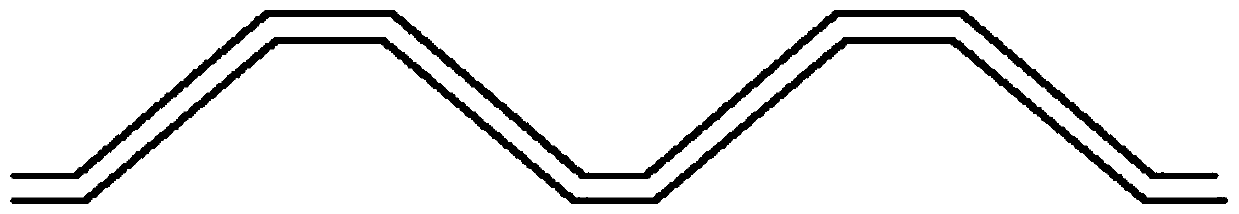

Double-layer threaded turbulent flow heat exchanger

ActiveCN102121799AFully heatedImprove heat utilization efficiencyStationary tubular conduit assembliesTubular elementsThreaded pipeEngineering

The invention discloses a double-layer threaded turbulent flow heat exchanger which comprises a big pipe, a medium pipe and a small pipe, wherein the big, medium and small pipes are coaxial and sleeved with one another; a first cold medium channel is formed between the big pipe and the medium pipe; a hot medium channel is formed between the medium pipe and the small pipe; a second cold medium channel is formed in the small pipe; the medium and small pipes are threaded turbulent flow pipes; and the big pipe is a smooth pipe or threaded turbulent flow pipe. The heat exchanger provided by the invention can resist chloride ion corrosion and ensure the service life of equipment; the structure of a stainless steel three-layer threaded pipe ensures entirely uniform heat exchange and can prevent the formation of cold bridge and dirt in the pipe to ensure the heat exchange efficiency; and moreover, as a strong turbulent flow can be produced, heat exchange between the medium close to the pipe wall and the medium at the pipe center can be accelerated, thereby ensuring thorough heat exchange, improving equipment efficiency and prolonging the service life; and the sleeve structure has strong pressure bearing capacity, prevents influence on the equipment caused by excessively high pressure, pressure leakage failure and other factors during the operation of the equipment, and prolongs the service life.

Owner:广东百思特管业科技有限公司

Inner finned tube condenser

InactiveCN102829646AIncrease flow rateSolve the problem of poor heat transferSteam/vapor condensersTubular elementsOrganic solventEngineering

The invention discloses an inner finned tube condenser which belongs to heat exchange equipment, and in particular relates to a condenser using an inner finned tube. The inner finned tube condenser comprises a vertical type shell, an upper tube box with a tail gas inlet, and a lower tube box with a condensation water outlet, wherein a cold water inlet and a hot water outlet are respectively located on two upper and lower sides of the shell, and the condenser is characterized in that an inner finned heat exchange tube is mounted between pipe sheets at both ends of the shell. An operation experiment of the heat exchanger shows that after the tail gas is subject to heat exchange, heat is very fully exchanged, the recovery effect, especially for organic solvent, is very good, and the recovery rate is increased by 10% compared with the heat exchanger currently in the market; at the same time the circulation interface of the heat exchanger is relatively large, and no resistance exists behind a vacuum pump; and the heat exchange is very thorough.

Owner:山东擎雷环境科技股份有限公司

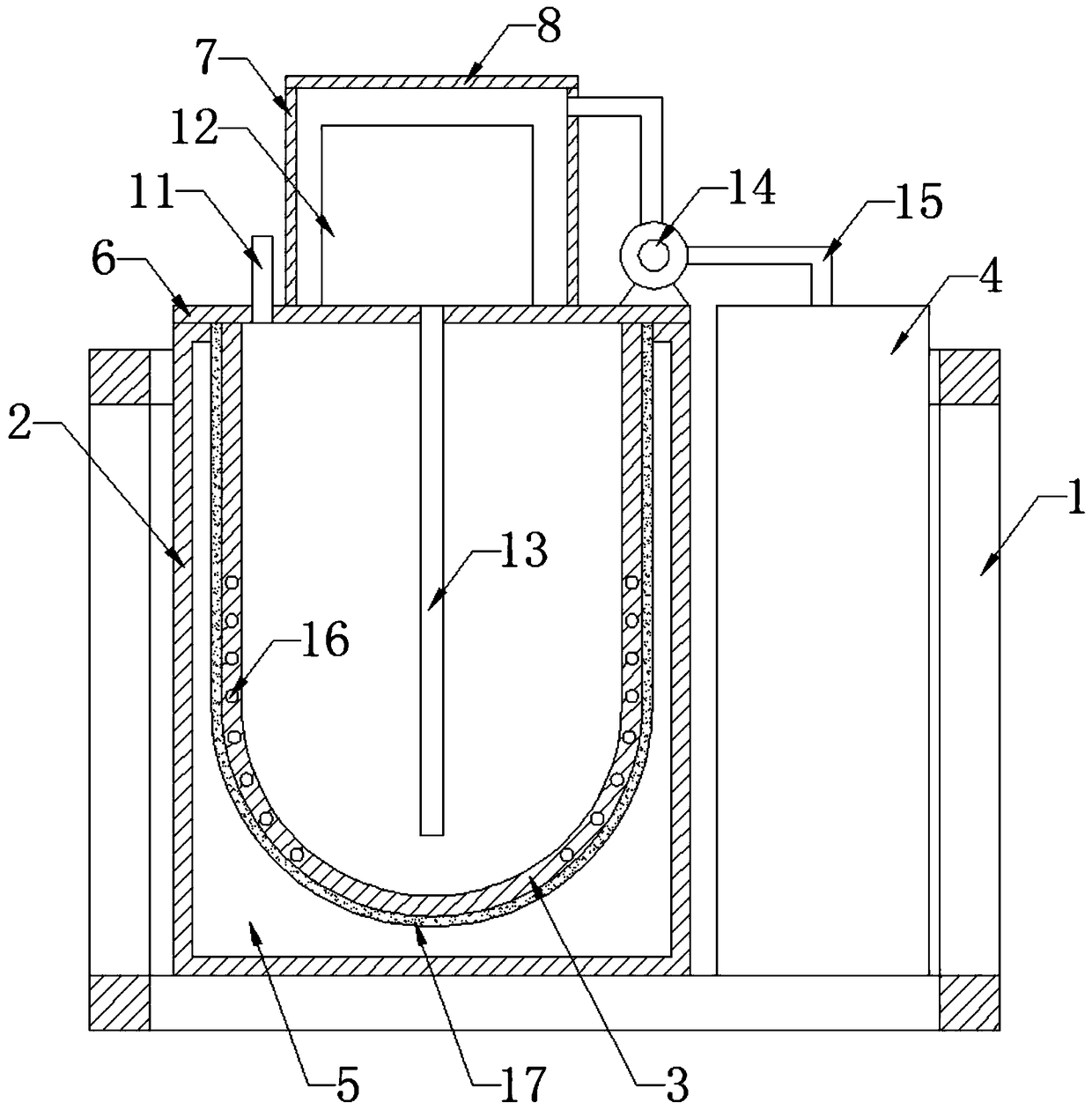

Boiler provided with dual-register pulverized coal burner on top

InactiveCN104121579AThorough heat exchangeReduce energy consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlueCoal

The invention discloses a boiler provided with a dual-register pulverized coal burner on the top, belonging to the technical field of boilers, and aiming at providing a U-shaped flame boiler which is provided with the dual-register pulverized coal burner on the top and is high in combustion efficiency. According to the technical scheme, the boiler provided with the dual-register pulverized coal burner on the top comprises a boiler body and an ash falling pit, wherein the ash falling pit is formed in the bottom of the boiler body, a membrane type water-cooling wall is arranged on the inner wall of the boiler body, a first partitioning wall is arranged on the top in the boiler body and is used for partitioning the boiler body into a combustion chamber and a waste gas chamber, the lower parts of the combustion chamber and the waste gas chamber are communicated with each other to form a first pair of flue channels, the dual-register pulverized coal burner is arranged at the top of the combustion chamber, a second partitioning wall is arranged at the bottom of the waste gas chamber and is used for partitioning the waste gas chamber into a left chamber and a right chamber, the upper parts of the left chamber and the right chamber are communicated with each other, and a flue discharging channel is arranged at the bottom of the side wall of the right chamber. The boiler is high in heat utilization rate and less in waste gas emission.

Owner:BEIJING DABANG SHICHUANG ENERGY SAVING TECHSERVICE

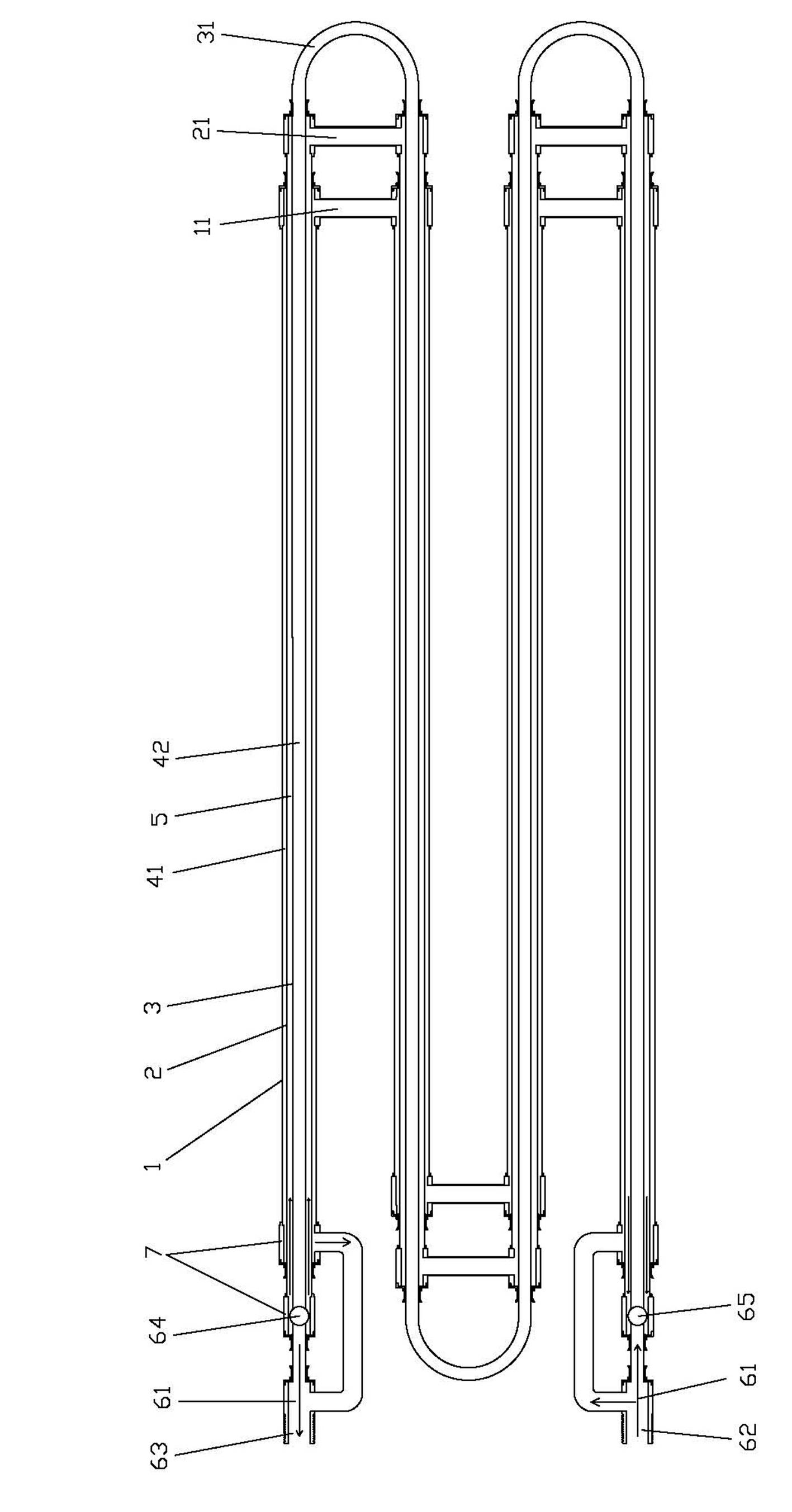

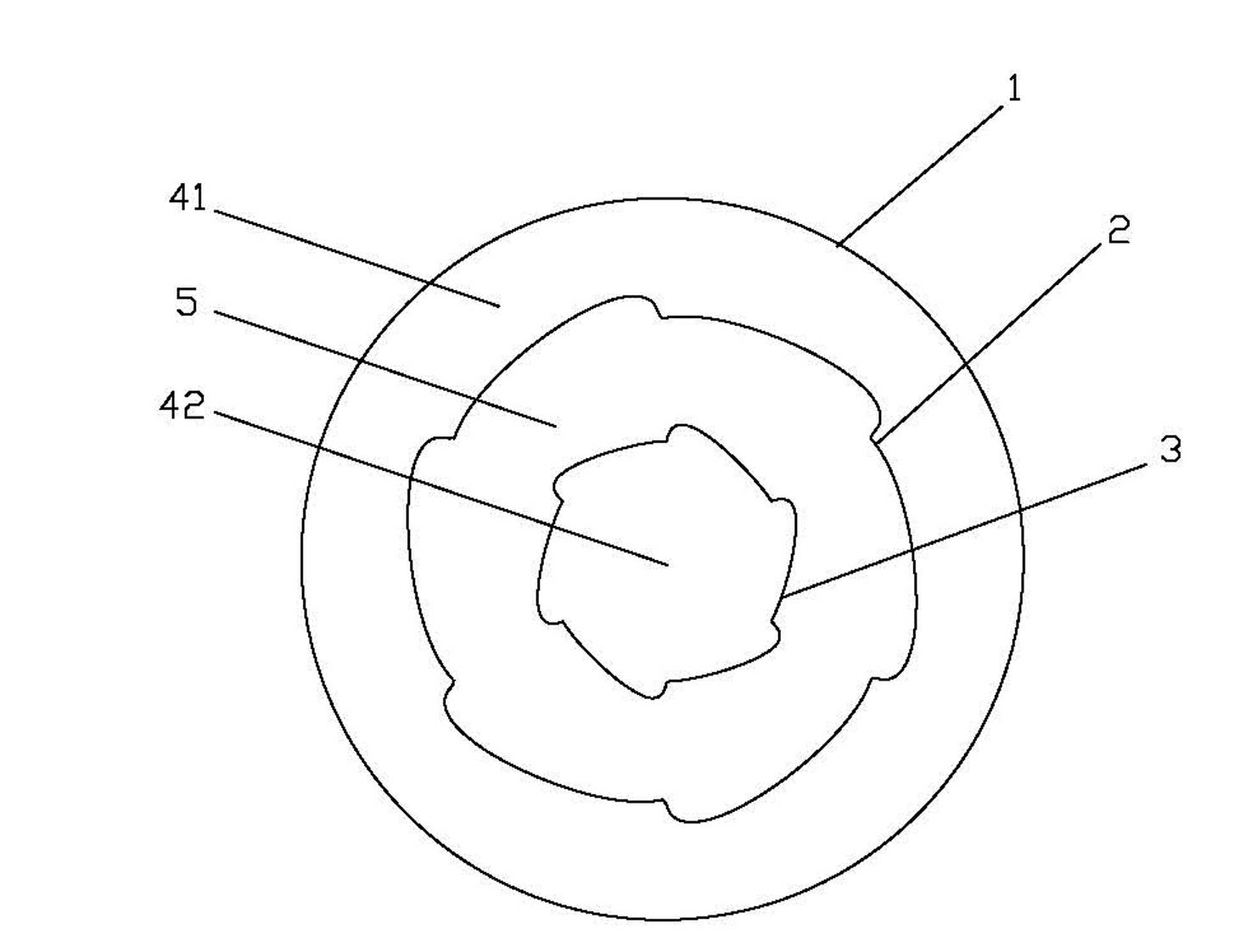

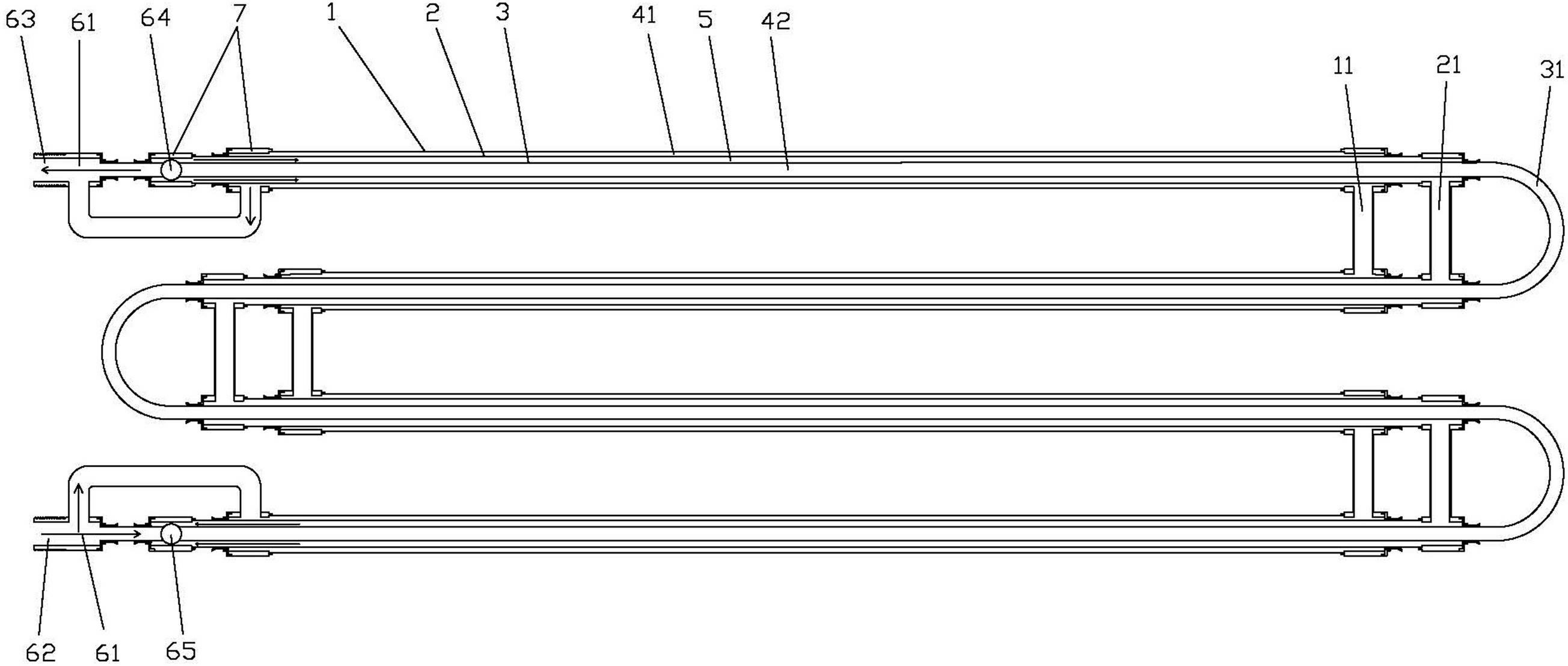

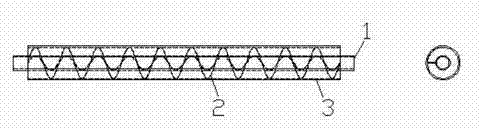

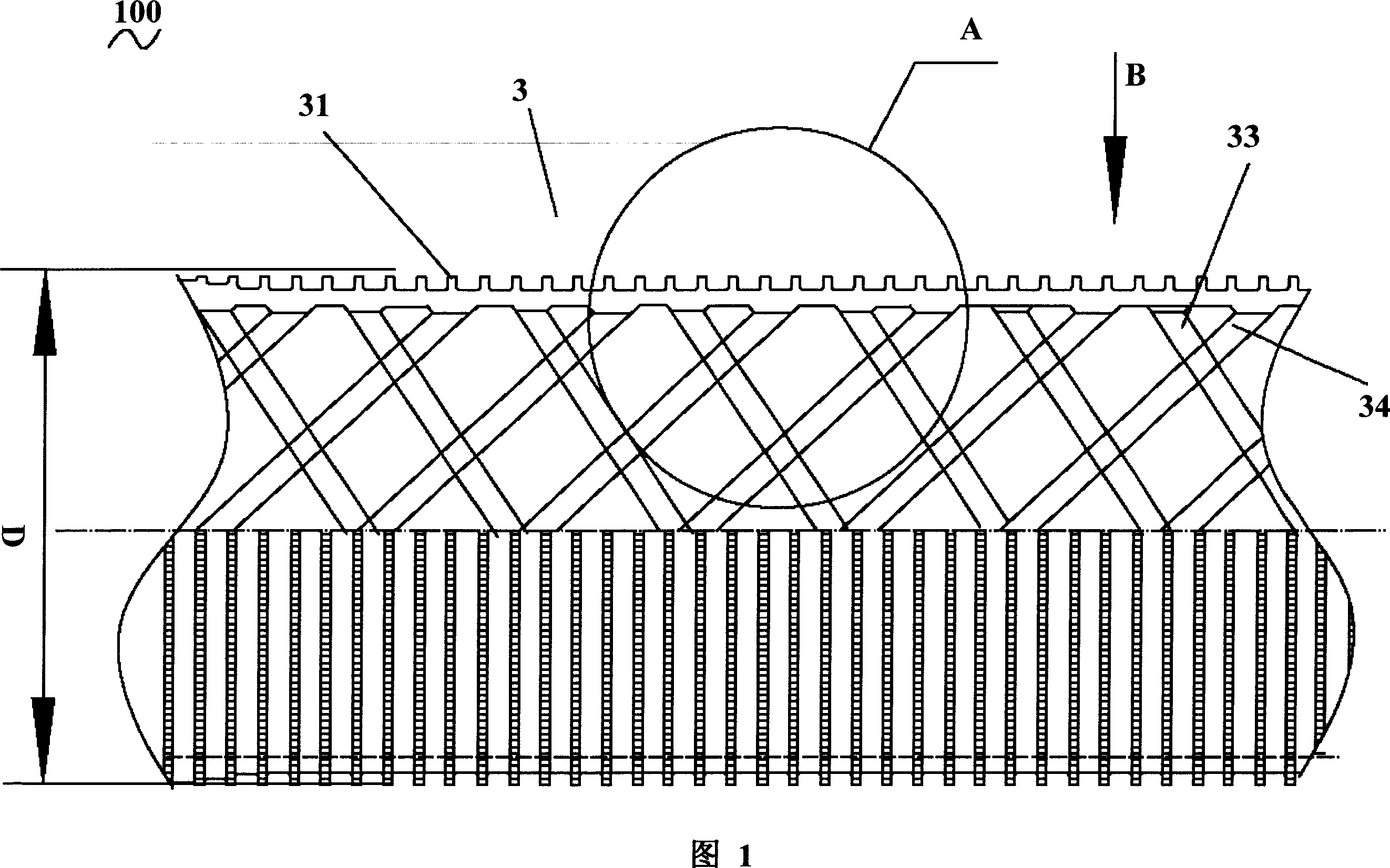

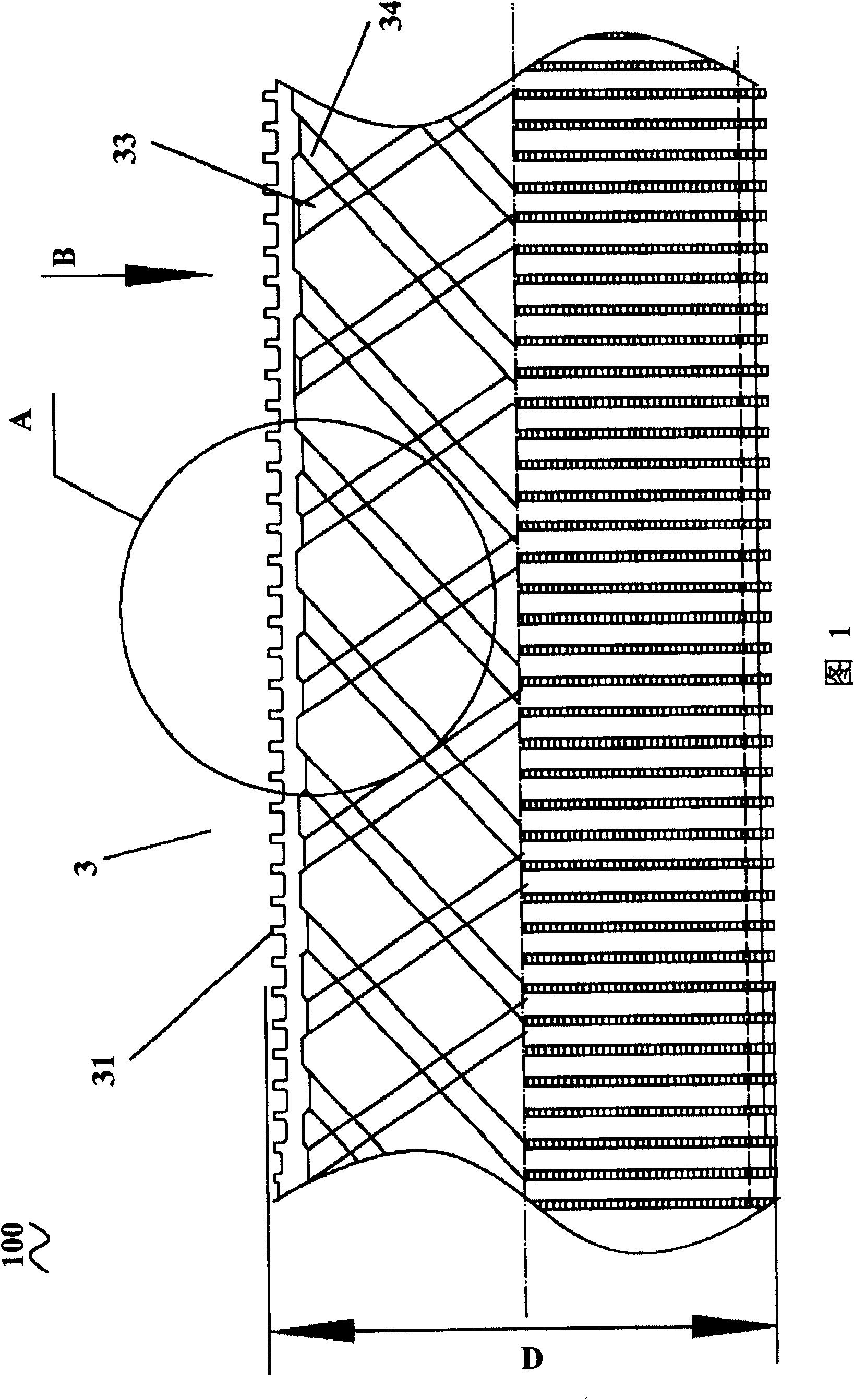

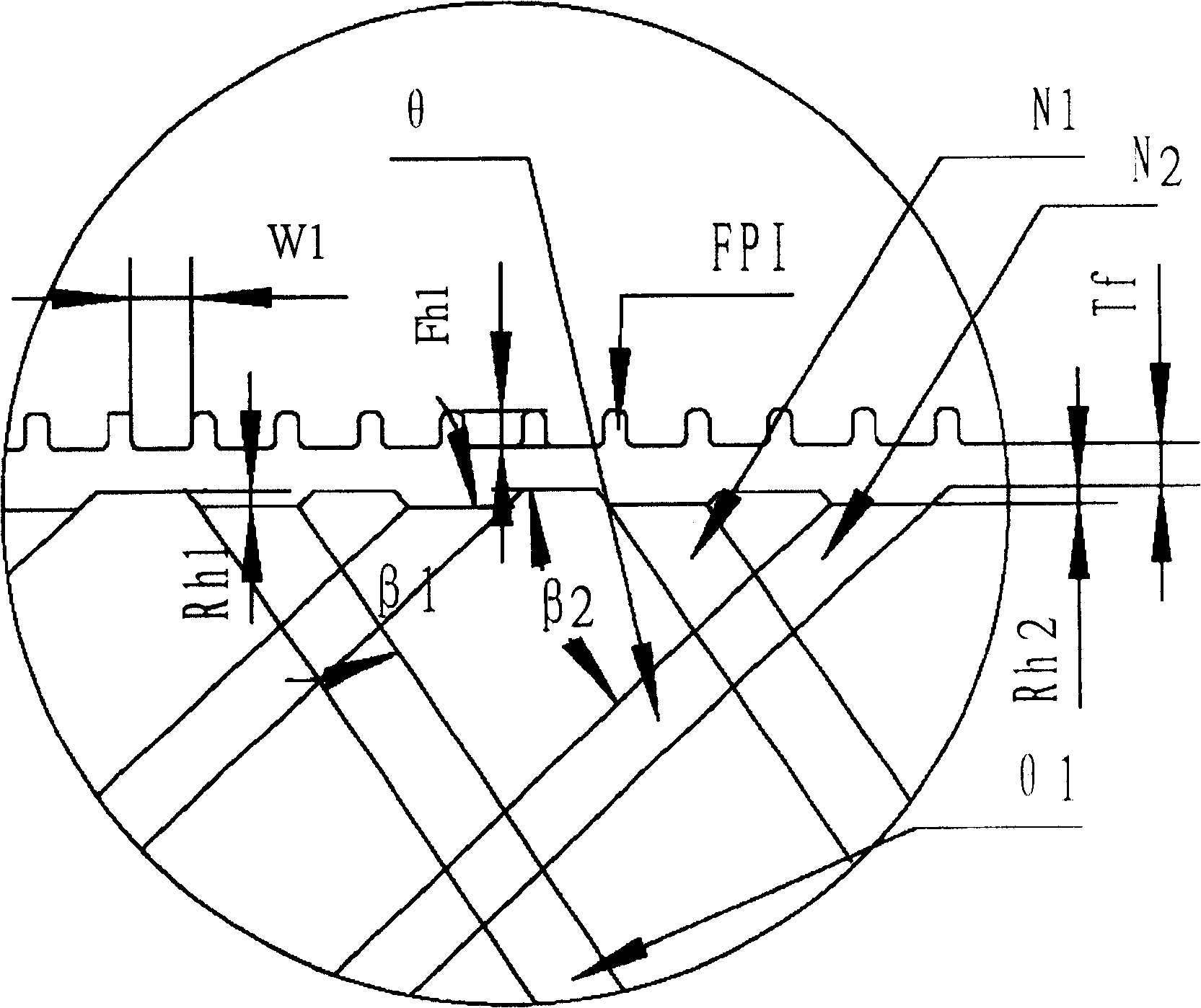

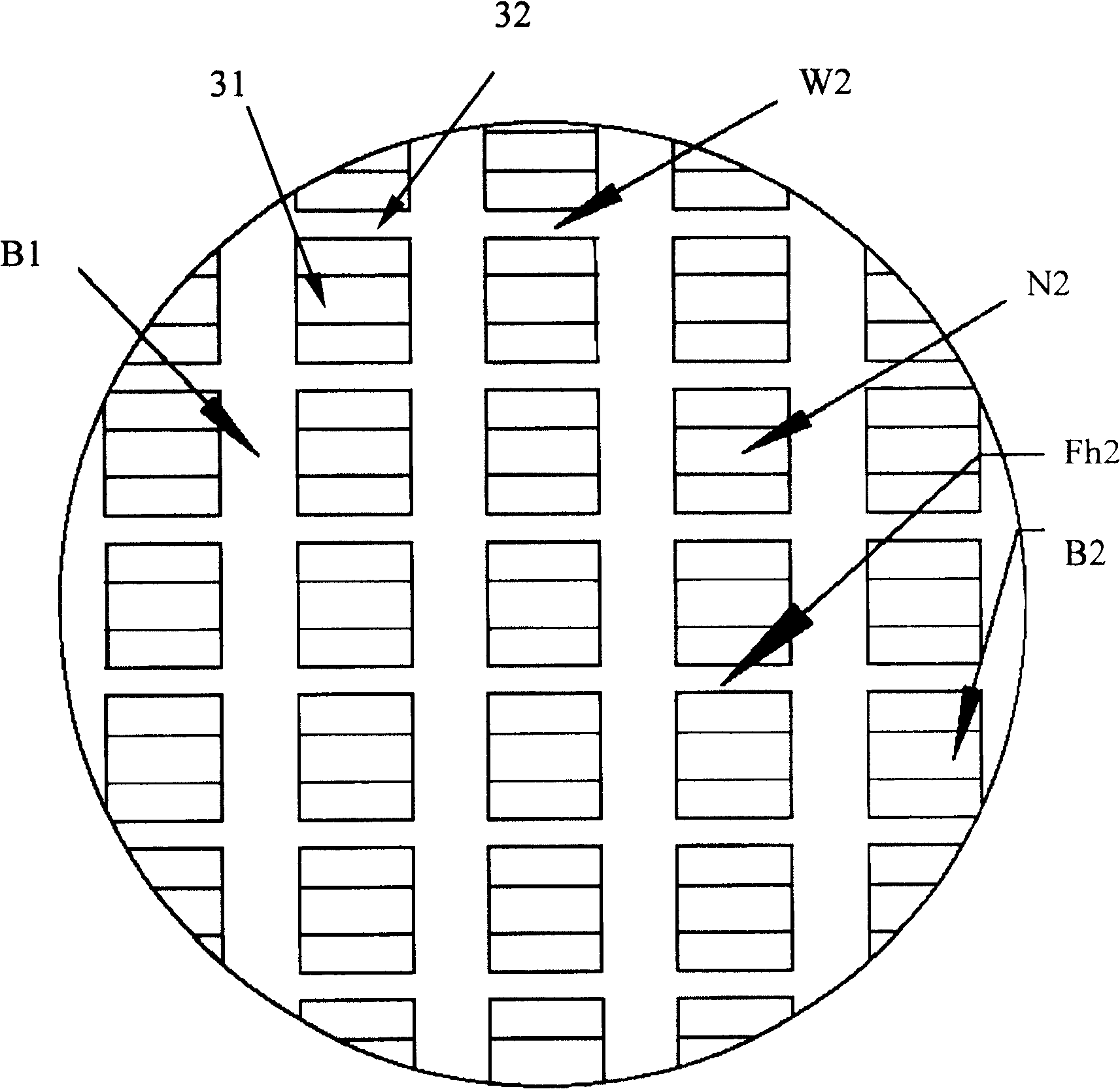

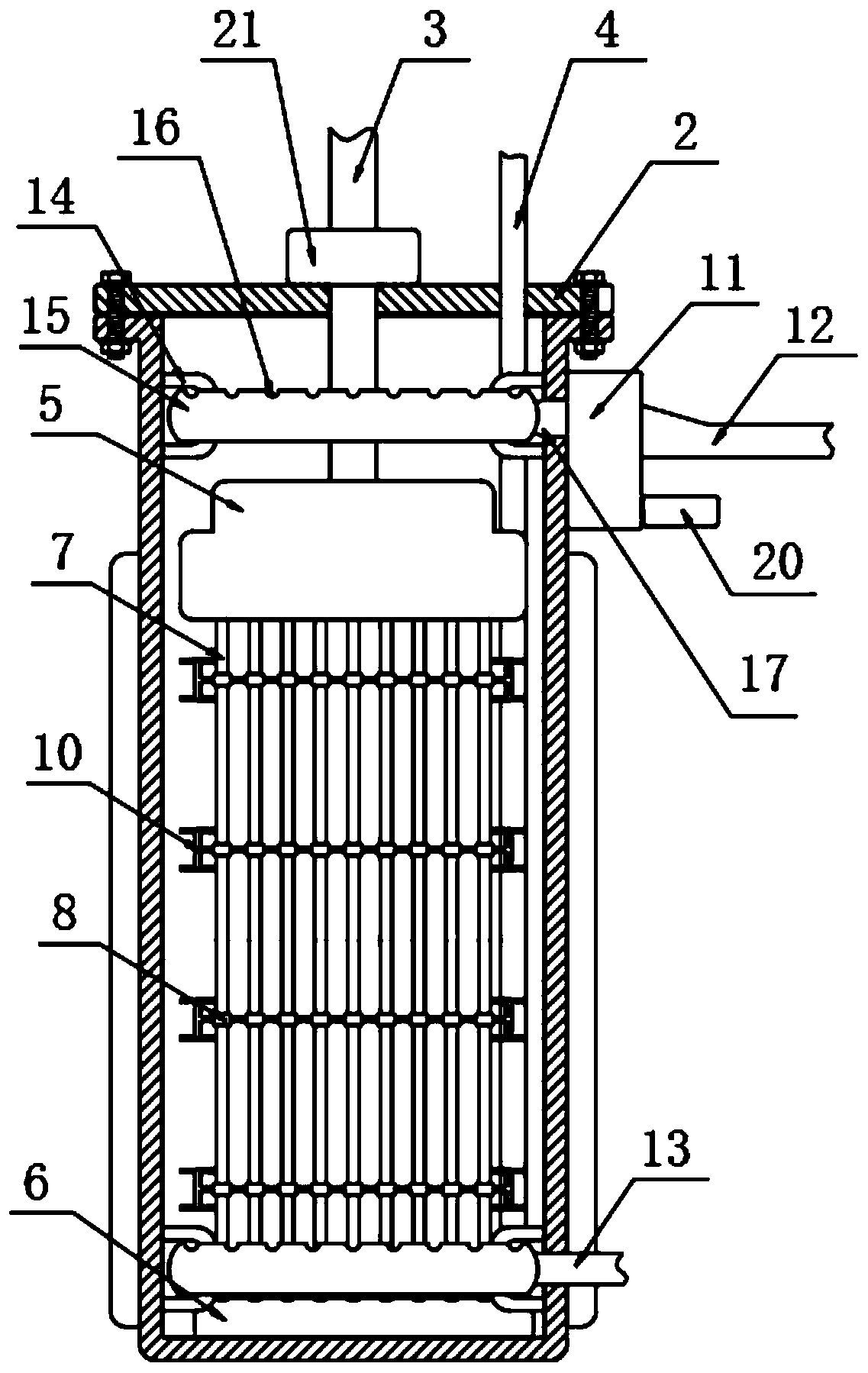

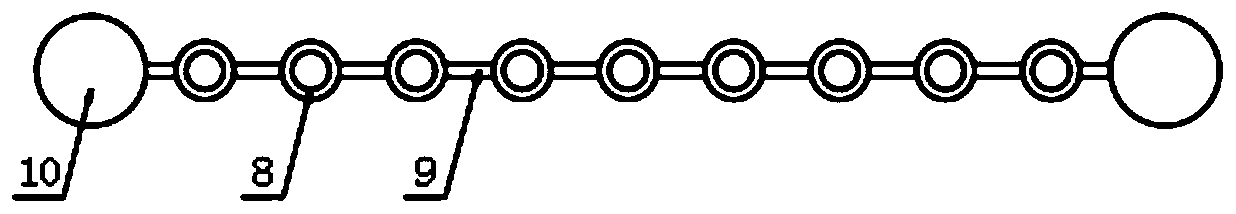

Line-up type full-contact heat exchange tube

InactiveCN104848712AIncrease flow lengthIncrease contact areaStationary tubular conduit assembliesHeat transfer modificationElectrical conductorContact time

The invention discloses a line-up type full-contact heat exchange tube and relates to the technical field of liquid and gas heat exchange, in particular to heat energy exchange and recovery. The line-up type full-contact heat exchange tube comprises an internal tube, a spiral guiding extend-range ferrule and an external tube; both the internal tube and the spiral guiding extend-range ferrule are arranged inside the external tube and are coaxial to the same; the spiral guiding extend-range ferrule sleeves the internal tube from the outer wall and is arranged inside the external tube, and a spiral guiding channel is formed between the internal tube and the external tube. The spiral guiding extend-range channel is formed between the spiral guiding extend-range ferrule and the internal and external tubes, flow length of materials in the channel is effectively increased, contact area and contact time of refined materials and a heat exchange conductor are increased, and uniformity in heat exchange is improved; the internal tube is arranged inside the spiral guiding extend-range channel, the materials inside and outside the material channel are subjected to heat exchange simultaneously, and utilization upon generation is achieved; the line-up type full-contact heat exchange tube is more complete in heat exchange, high in heat exchange efficiency, more compact in structure, good in shaping, flexible to use, wide in applicability and especially suitable for energy-saving recovery of instant heat exchange.

Owner:陈永秋

Efficient heat-exchanging pipe of evaporator for electric refrigerator set

ActiveCN1982831AIncrease the heat exchange areaHigh thermal efficiencyTubular elementsElectricityEngineering

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

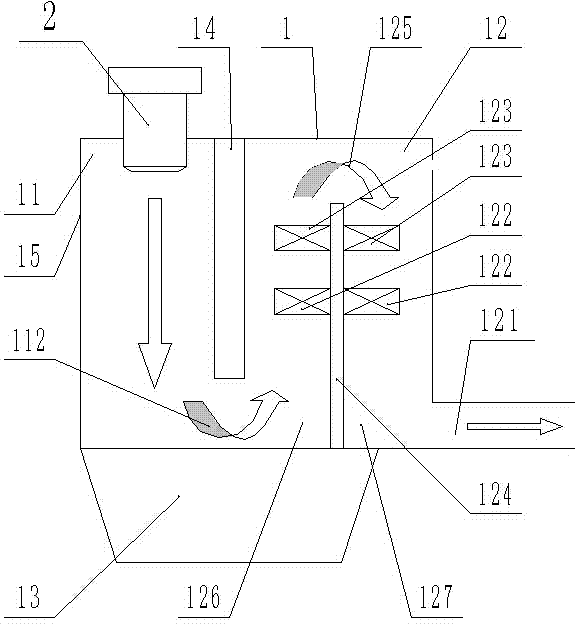

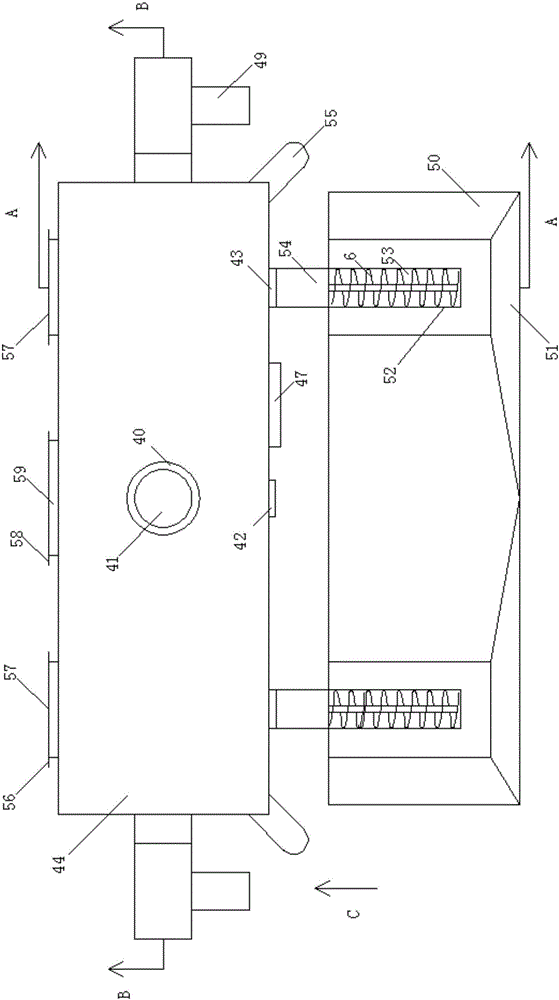

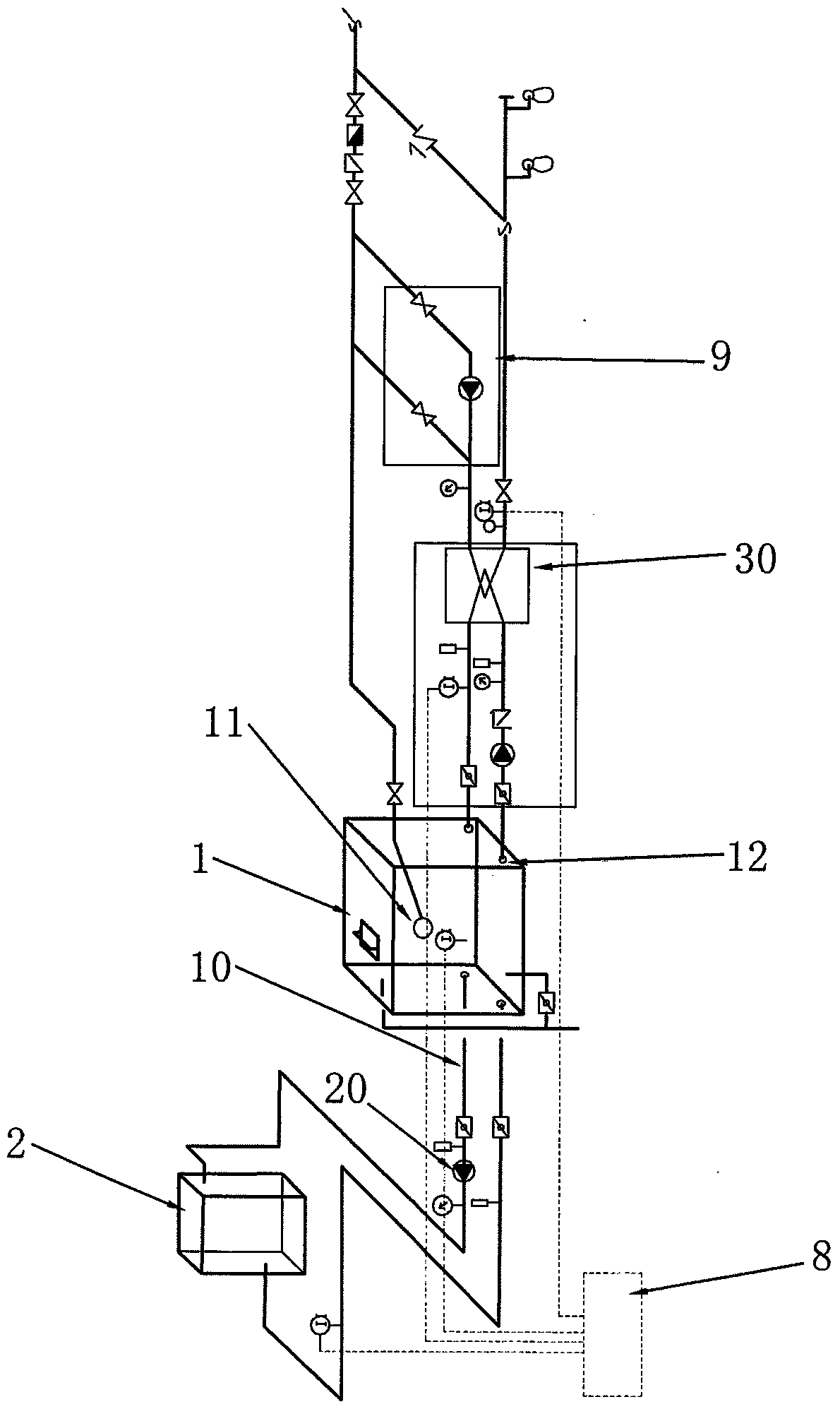

New-energy intelligent double-rotation boiler

ActiveCN106382623AIncrease profitImprove thermal efficiencyFuel feeding arrangementsSolid fuel combustionCombustion chamberSlag

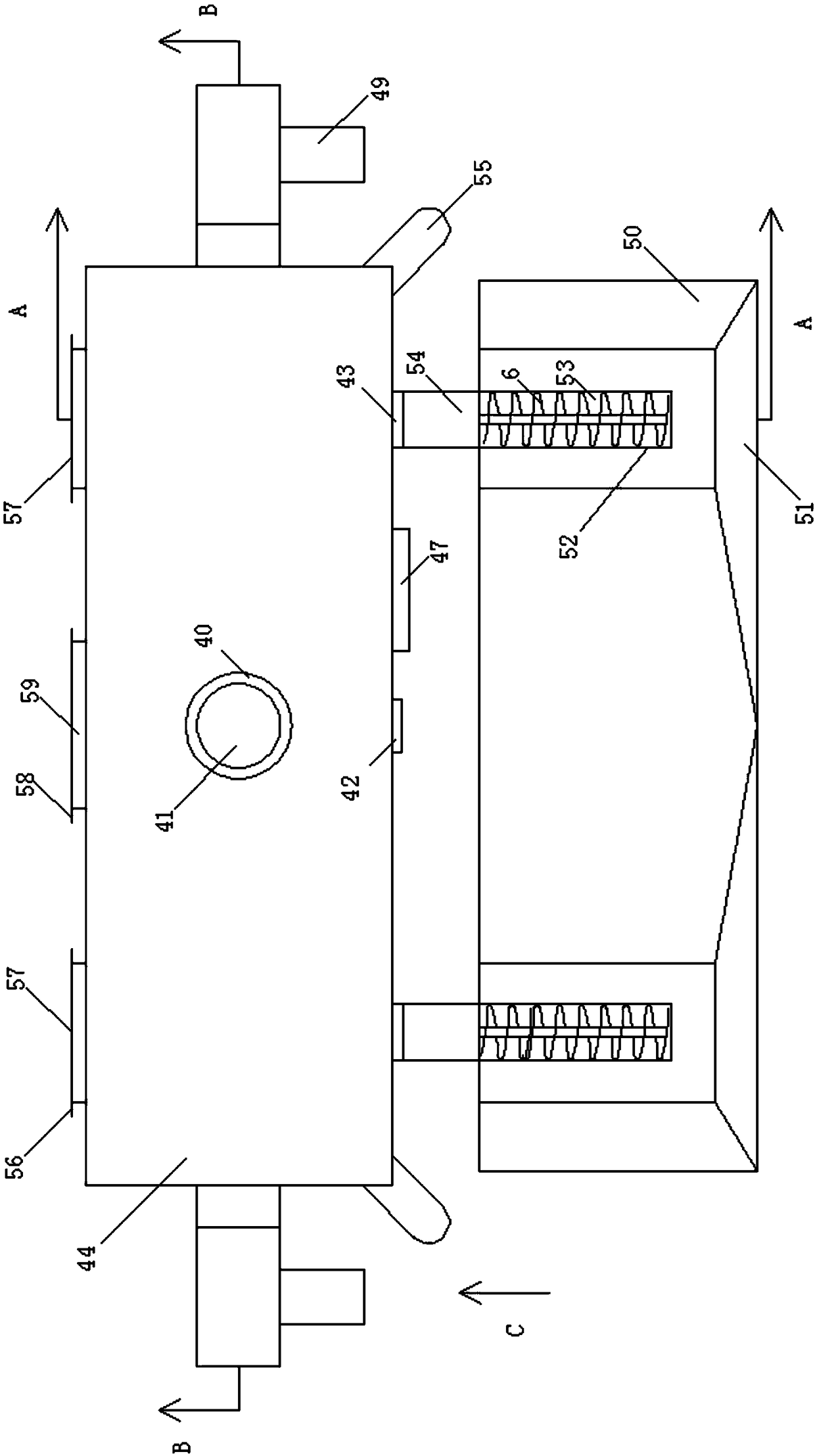

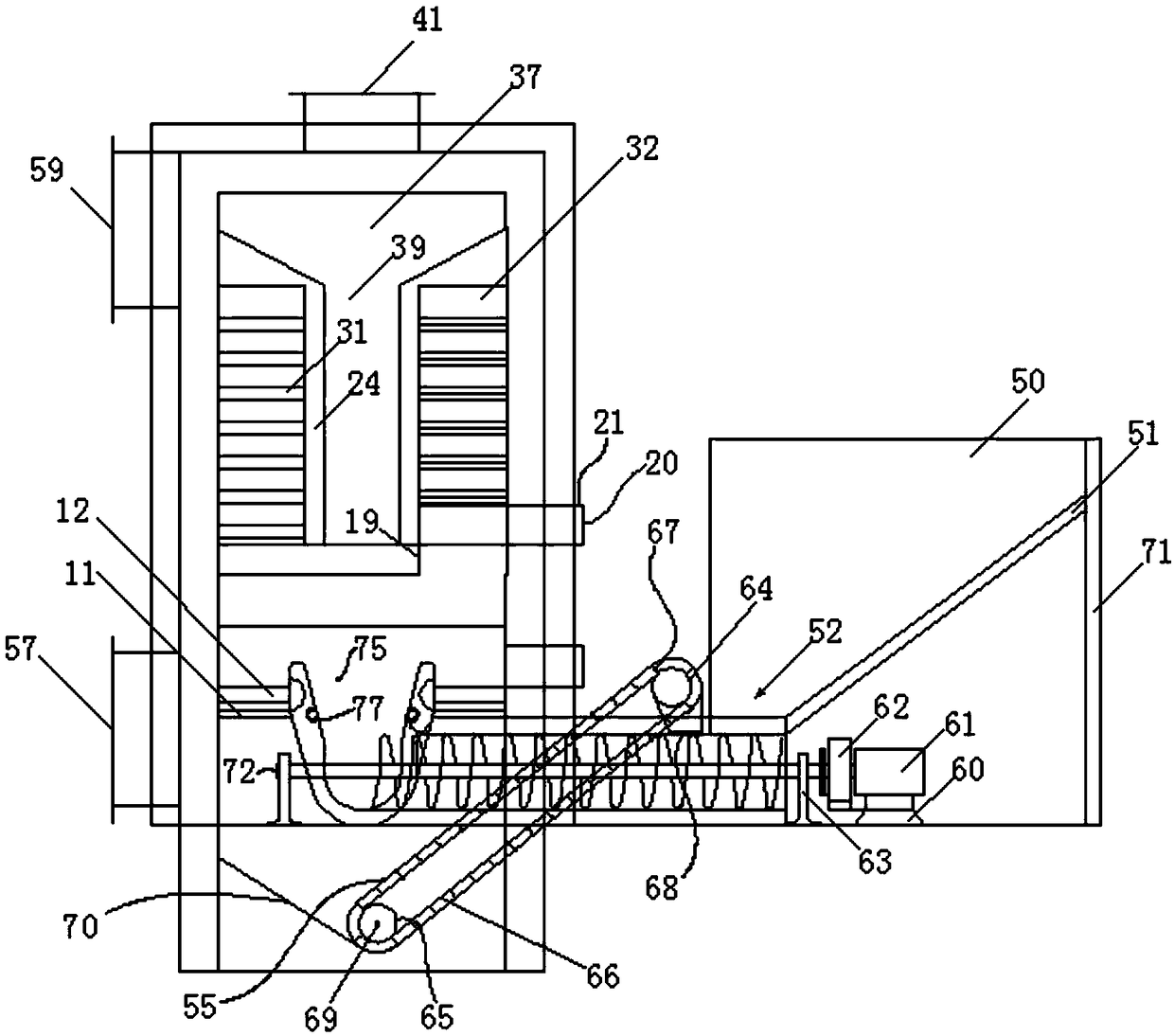

The invention relates to a new-energy intelligent double-rotation boiler. The boiler comprises a boiler body, a combustion chamber, a feeding system, a slag discharging and ash removing system, a combustion supporting oxygen conveying air inlet system, a smoke channel system and a hot air channel system. Fuel enters from the lower portion of an initial combustion volatile decomposition room and is subject to layered segmented combustion, the fuel utilization rate is improved, and energy waste is avoided; the multilevel multi-angle combustion supporting oxygen conveying air inlet system is adopted, the oxygen conveying amount in the fuel combustion process is ensured, the combustion speed and the combustion quality are improved, air is supplied through a porous air supply pipe and a material groove air supply container, and the effects of non-dead-corner combustion, balance oxygen supply and sufficient combustion are achieved. After initial combustion decomposition, fuel is turned over through ejecting force of a feeding machine and is re-combusted through a re-combustion chamber, combustible gas in smoke can be thoroughly burned out through a secondary ignition opening, natural air enters the boiler body and passes through a low-temperature air channel, a low-temperature air collection box, a medium-temperature air channel, a medium-temperature air collection box, a high-temperature air channel and a high-temperature air collection box to be subject to layer-by-layer warming, heat exchange is thorough, and energy is saved.

Owner:青岛智良环保科技有限公司

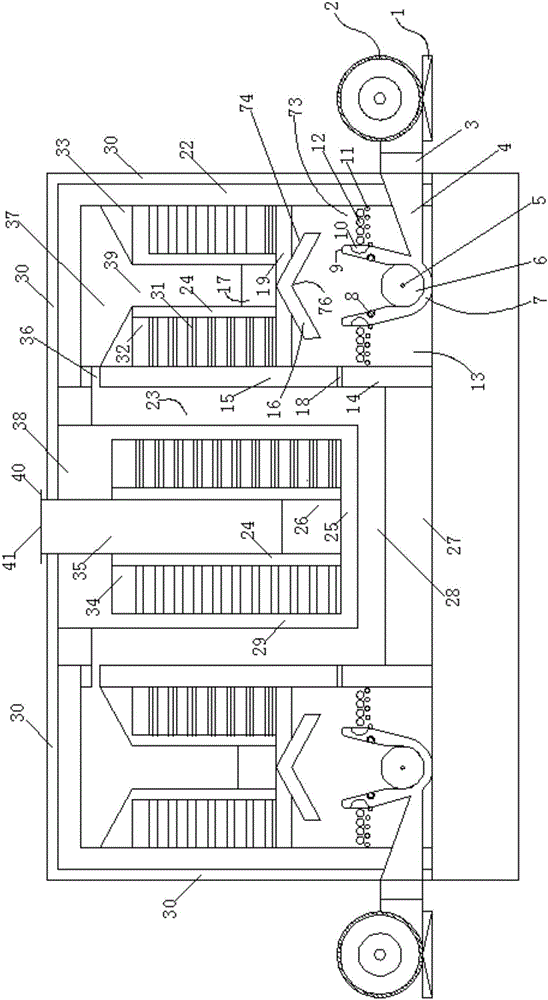

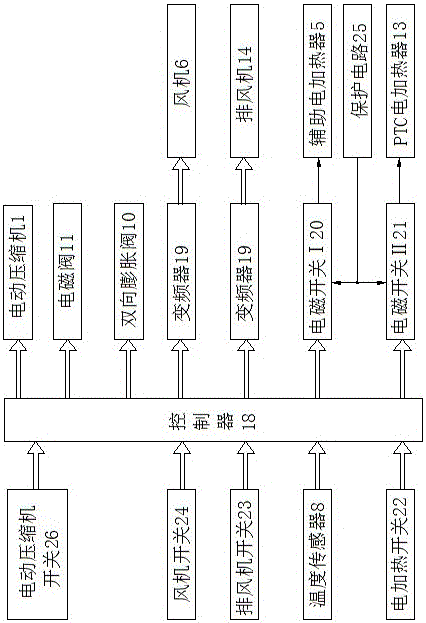

Electric automobile air conditioner system and control method thereof

InactiveCN106143056ALess power consumptionIncrease heating capacityAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningEngineering

The invention discloses an electric automobile air conditioner system and a control method thereof, belongs to the field of cooling and heating of electric automobiles and aims to solve the technical problem about how to improve the heating capacity and the cooling capacity of the electric automobile air conditioner system to reduce power consumption. The structure of the electric automobile air conditioner system comprises an electric compressor, a condenser assembly, an air conditioner host and a communication device, wherein the electric compressor, the condenser assembly and the air conditioner host are communicated through the communication device to form a cooling loop and a heating loop; a control panel comprises a controller, an electric compressor switch, a fan switch, an exhaust fan switch and an electric heating switch. The control method of the electric automobile air conditioner system comprises the following steps: controlling operation of the electric compressor, the fan, the exhaust fan and a PTC electric heater via the control panel; controlling electromagnetic valves on a pipeline I, a pipeline II and a pipeline III to enter the operation state via the control panel; and controlling electromagnetic valves on a pipeline IV, the pipeline II and a pipeline V to enter the operation state.

Owner:SHANDONG HAILI HUACHENG AUTOMOBILE AIR CONDITIONING CO LTD

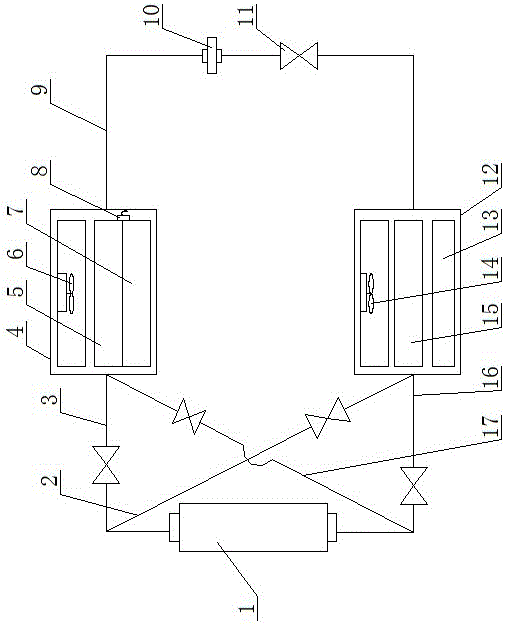

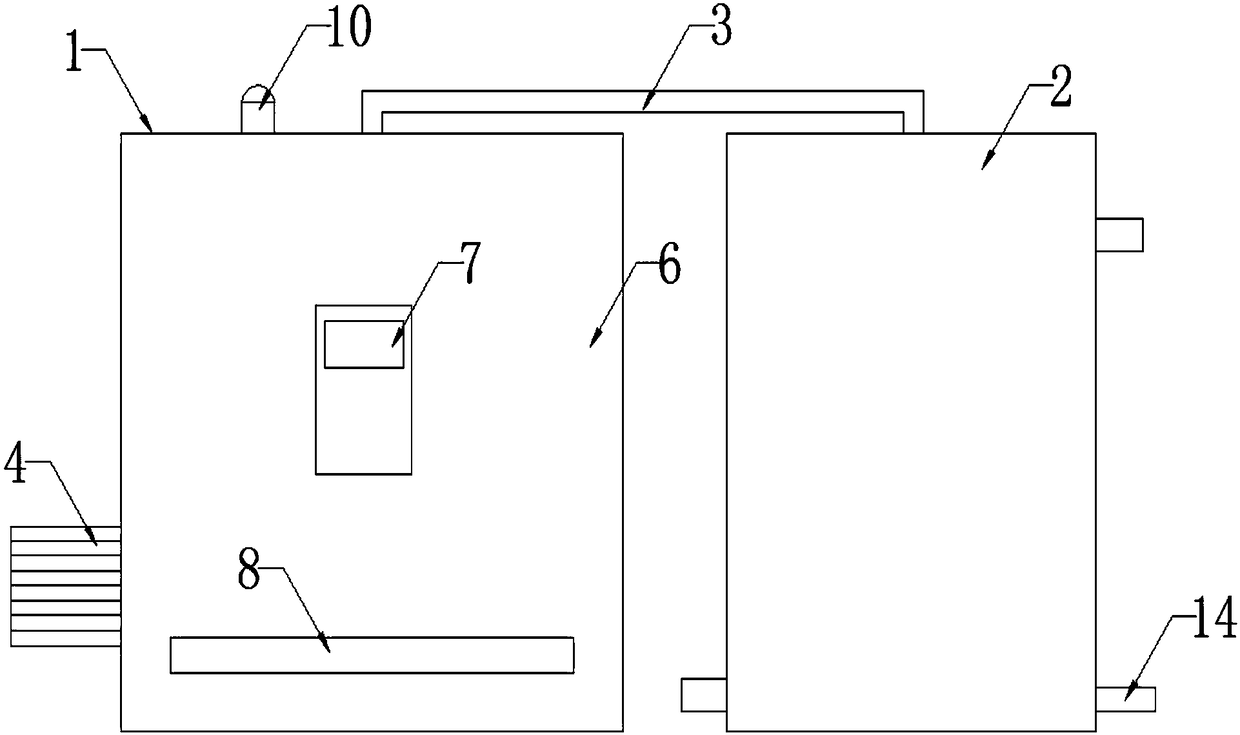

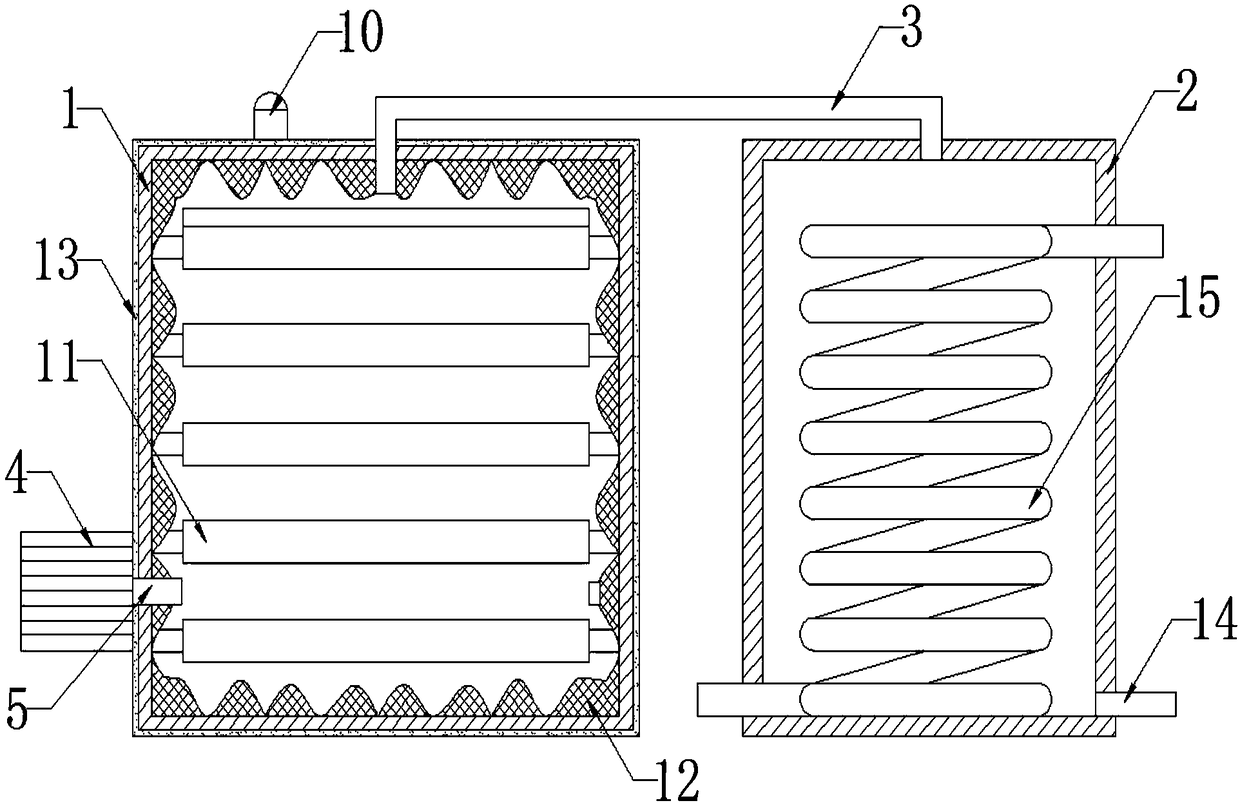

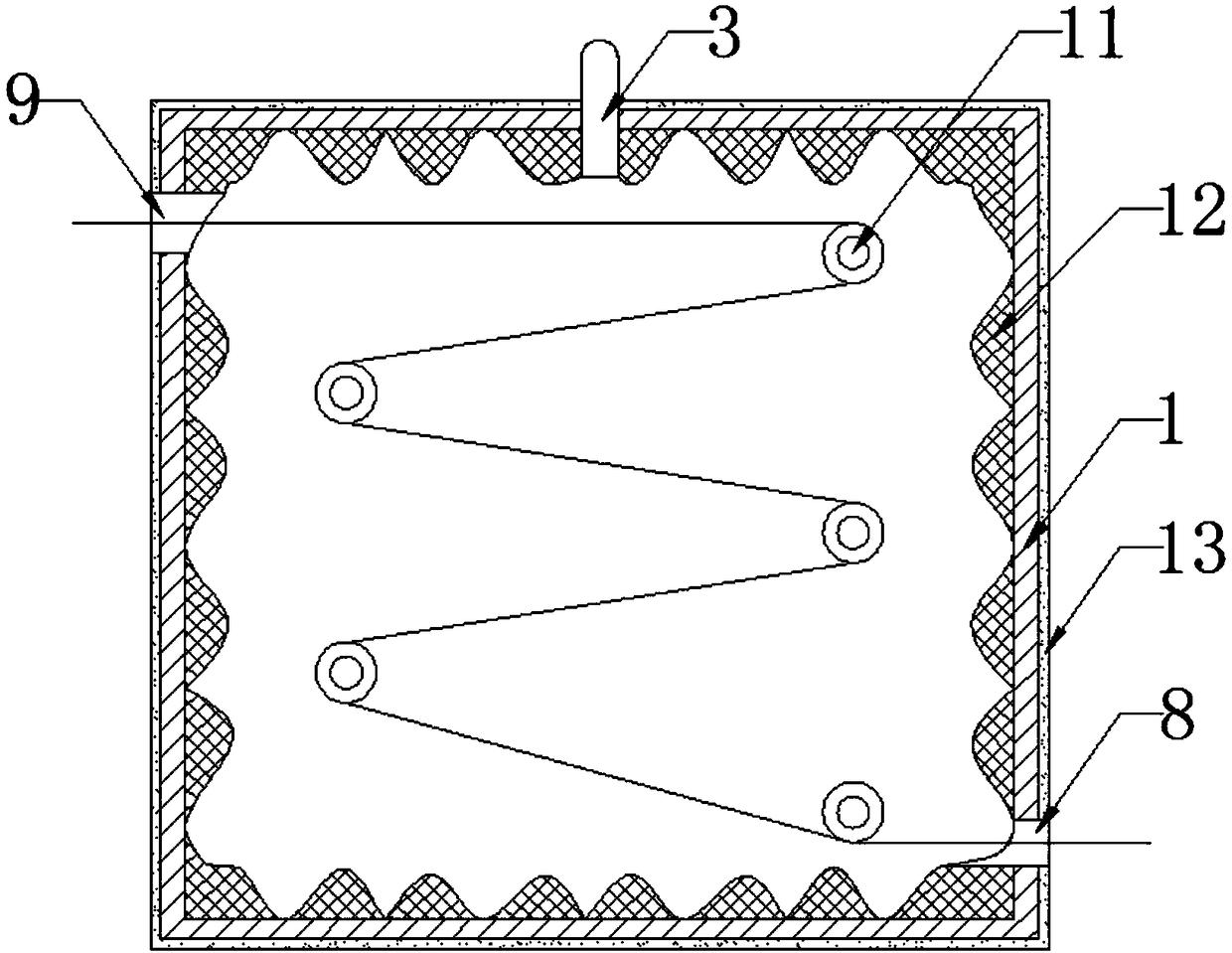

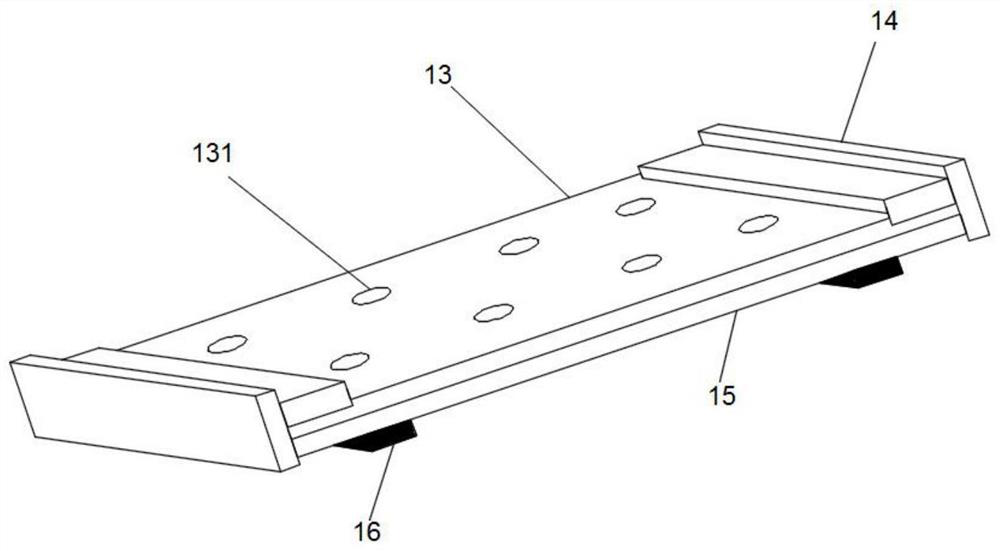

Wool spinning fabric drying device

InactiveCN108592583AEvenly heatedEasy maintenanceDrying gas arrangementsDrying machines with progressive movementsTemperature controlEngineering

The invention discloses a wool spinning fabric drying device. The wool spinning fabric drying device comprises a drying box and a heat exchange box, the heat exchange box is arranged on one side of the drying box, the middle of the top end of the drying box communicates with the middle of the top end of the heat exchange box through a connecting pipe, a circulating hot air blower is fixedly installed at the bottom of one side of the drying box, and an air outlet of the circulating hot air blower communicates with the interior of the drying box through an air conveying pipe; a box door is hinged to the edge side of the drying box, a temperature control switch is fixedly installed in the middle of the box door, a first opening is formed in the bottom of the box door, and a second opening isformed in the top of the edge side of the drying box; and an alarm is fixedly installed on one side of the top end of the drying box, a plurality of electromagnetic heating rollers are arranged insidethe drying box, and a water outlet pipe is arranged at the bottom of one side of the heat exchange box in a penetrating mode. According to the scheme, hot air generated by the circulating hot air blower can circularly flow inside the drying box through air guide layers, so that a wool spinning fabric is heated more uniformly; and the wool spinning fabric is dried through the plurality of electromagnetic heating rollers so that the drying effect can be further improved.

Owner:湖州吴兴永庆针纺织品有限公司

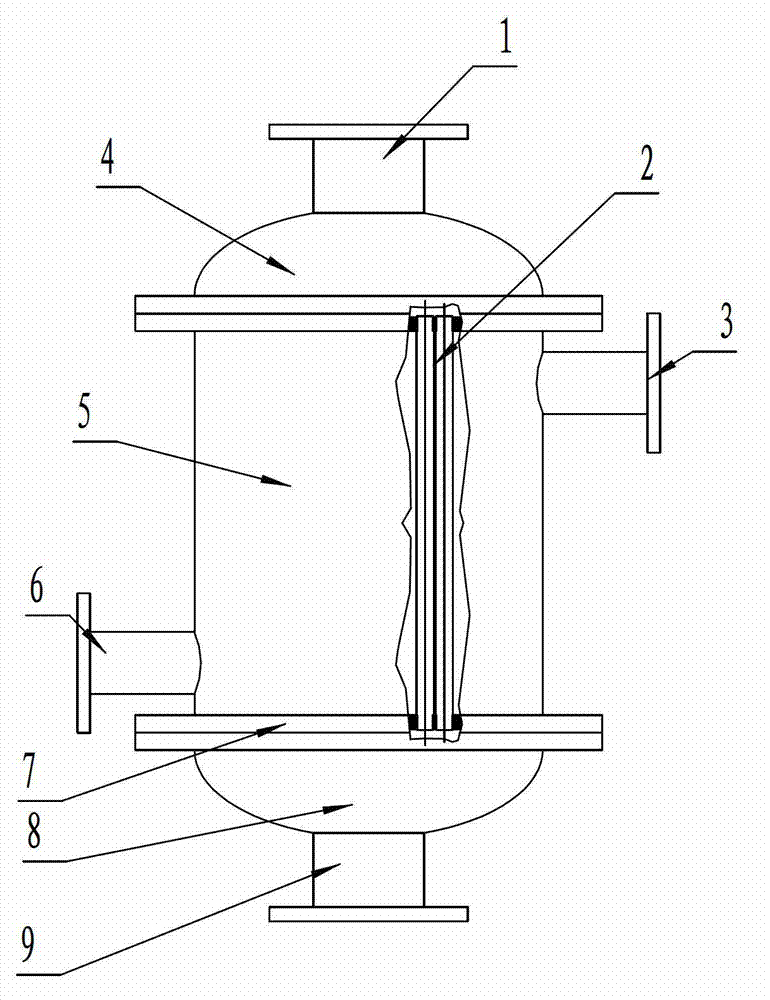

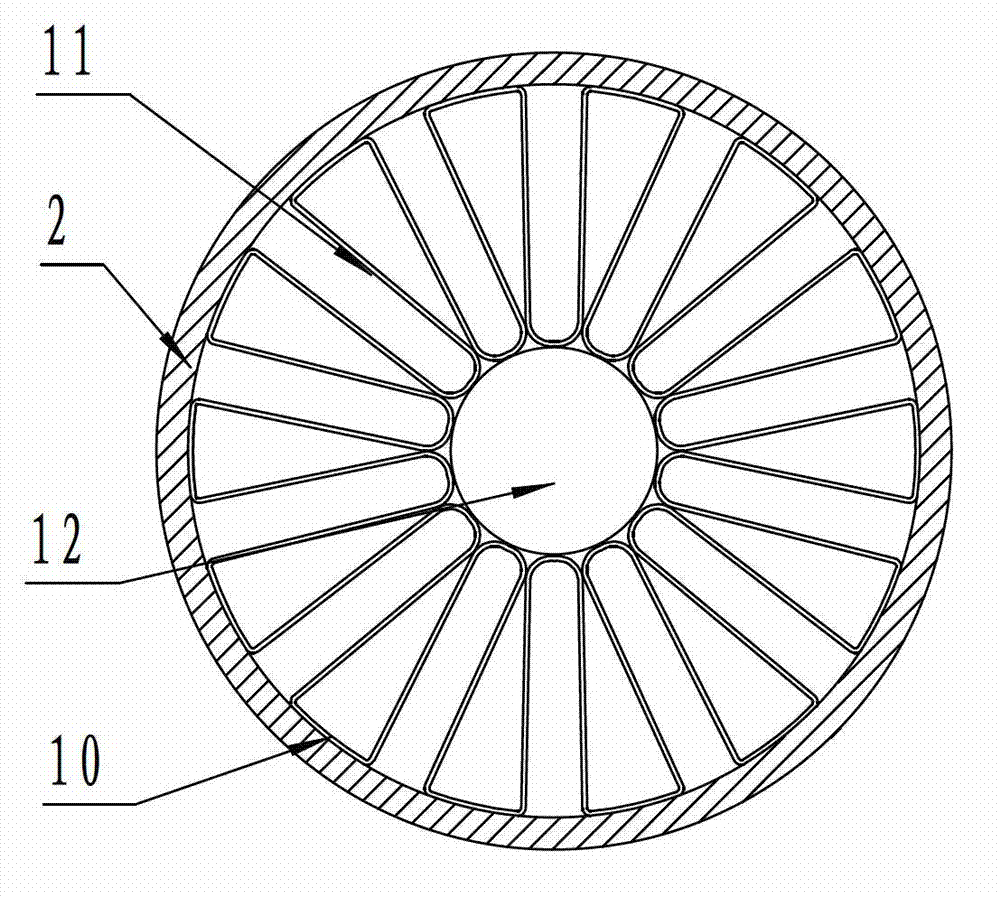

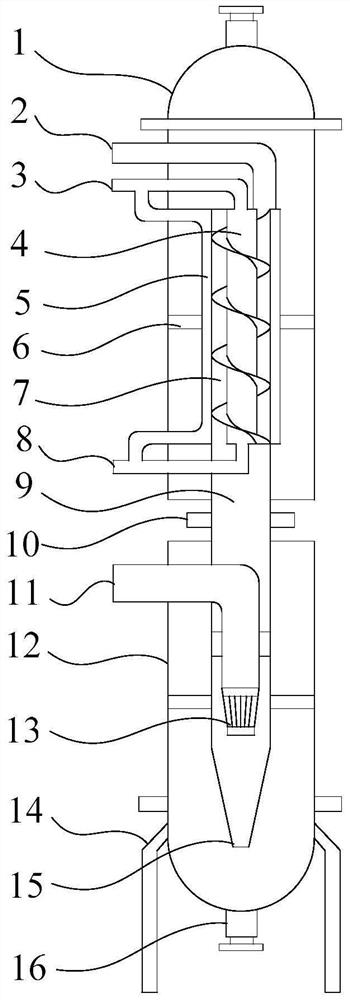

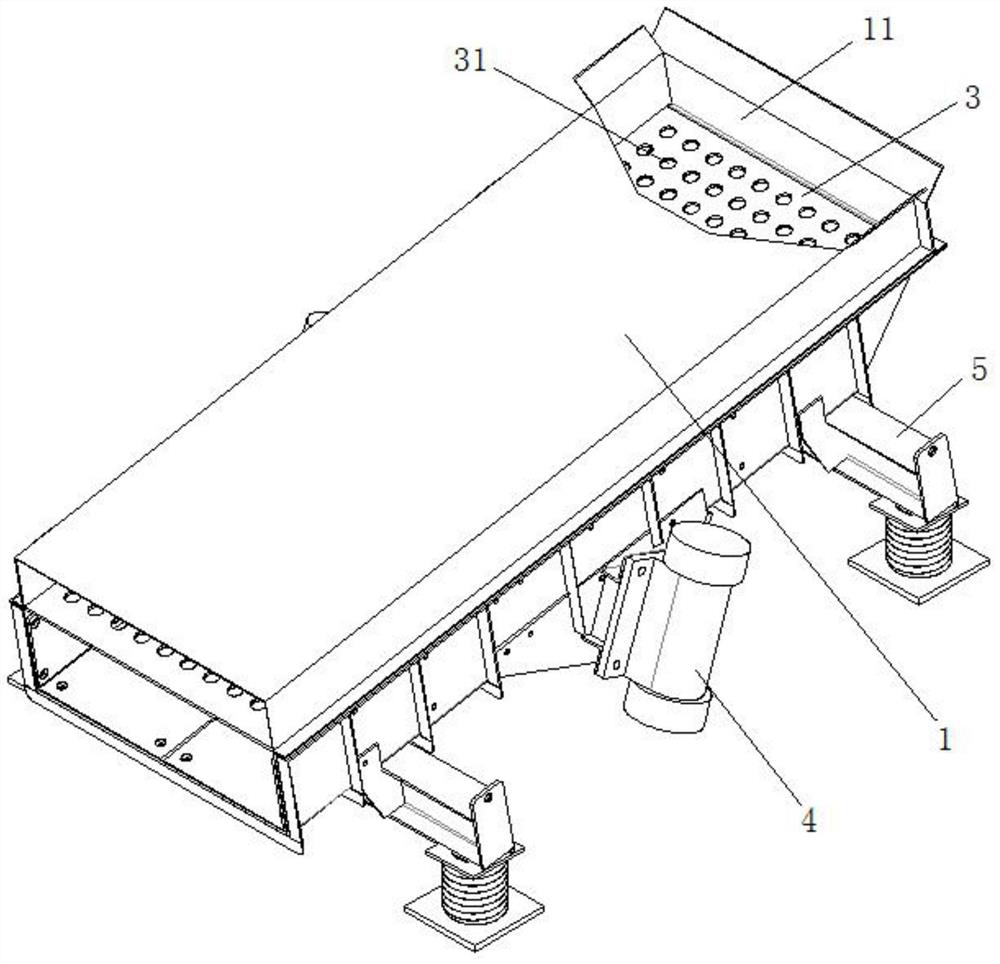

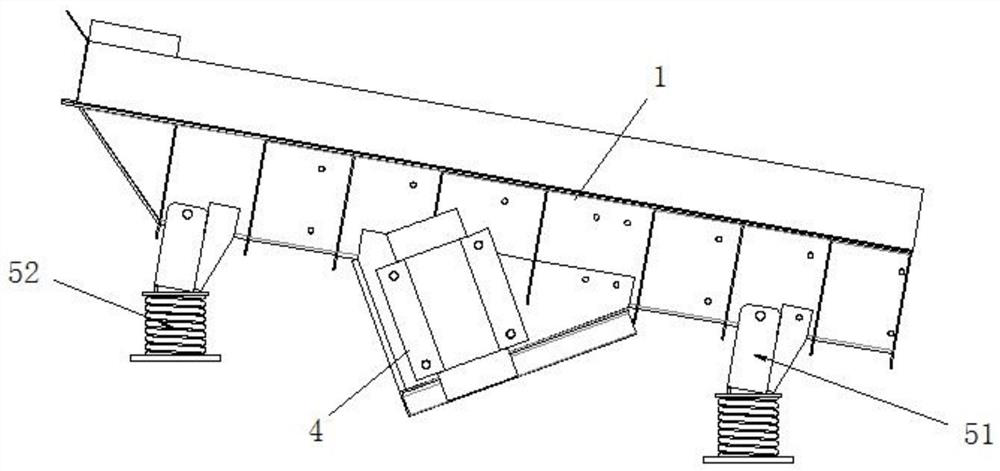

Heat exchange and separation integrated cyclone separation device

PendingCN113351385AImprove heat transfer effectImprove gas-liquid separation efficiencyReversed direction vortexCycloneThermodynamics

The invention provides a heat exchange and separation integrated cyclone separation device. The cyclone separation device comprises a shell, the shell is provided with an air inlet, an air outlet and an oil-gas mixture channel communicating with the air inlet and the air outlet; a heat exchange device for conducting heat exchange on an oil-gas mixture and an axial flow type cyclone separator are further arranged in the shell; the oil-gas mixture channel penetrates through the heat exchange device to lead to the cyclone separator, the oil-gas mixture channel is provided with a spiral flow channel in the heat exchange device, and the spiral flow channel is used for guiding the oil-gas mixture to spirally flow so as to be consistent with the airflow vortex direction of the cyclone separator. The heat exchange device and the separator are sequentially arranged in the cyclone separation device, high-temperature oil gas can be cooled and then separated, the spiral flow channel is formed in the inner cavity of the heat exchange device, the heat exchange area of the high-temperature oil-gas mixture is increased, and the heat exchange efficiency is improved; the spiral flow channel guides the airflow into a spiral shape to enter the axial flow type cyclone separator for multi-stage separation, and the high-temperature gas-liquid separation effect is effectively enhanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

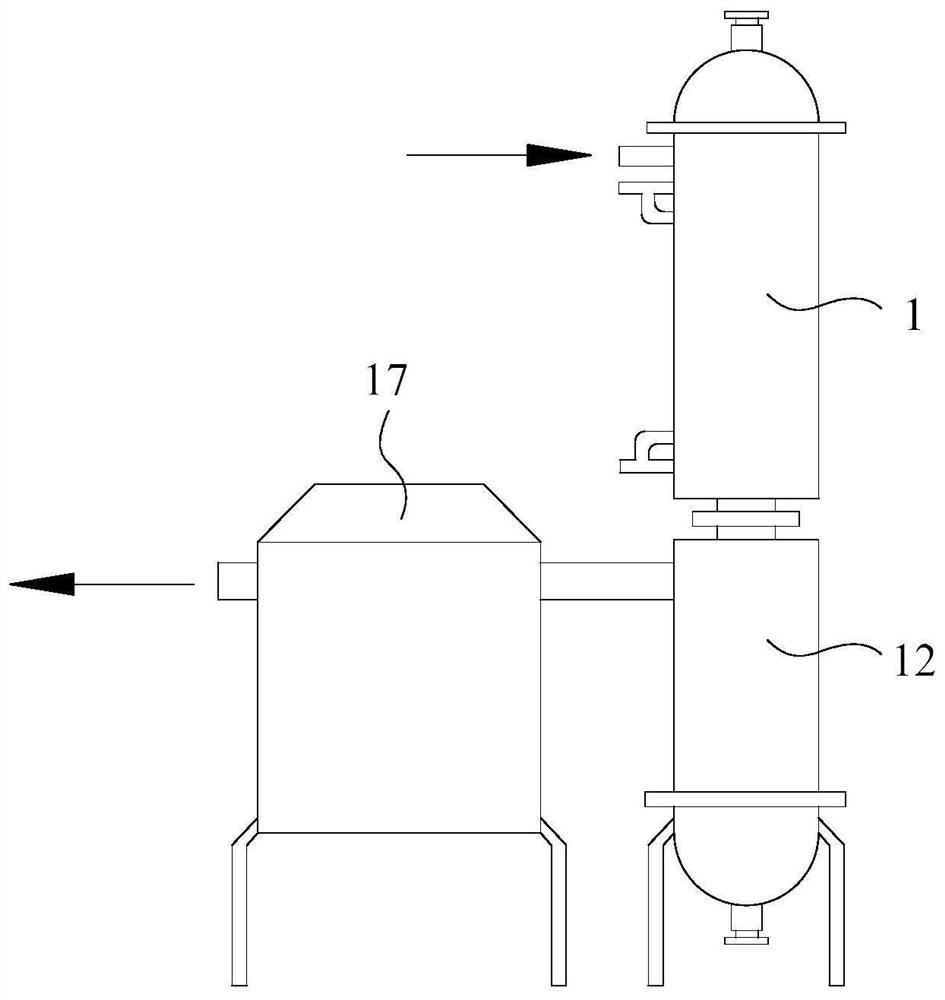

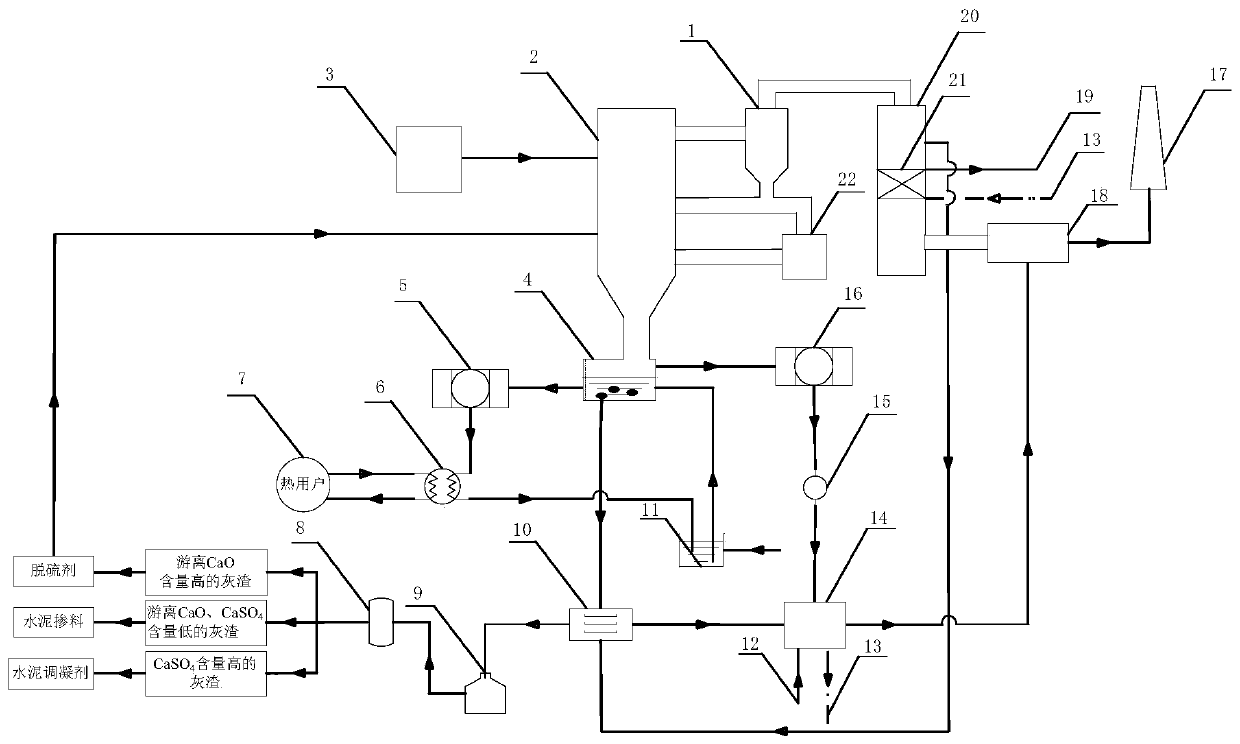

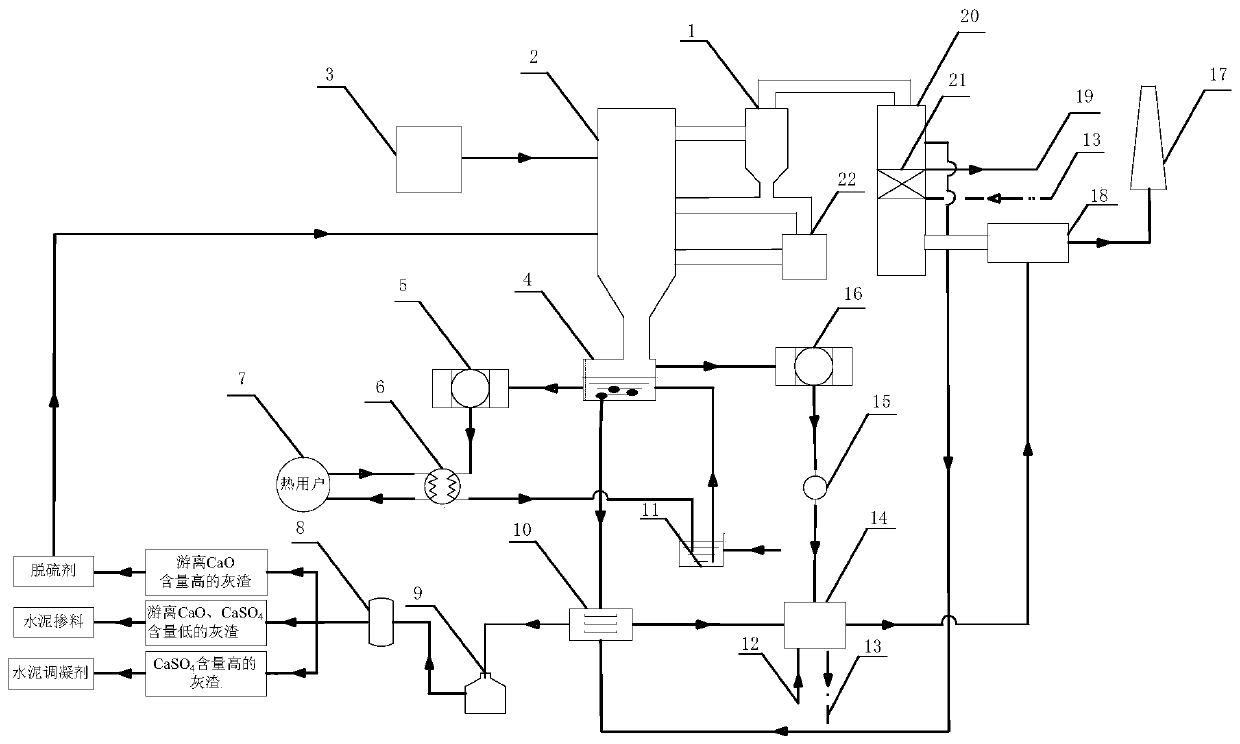

Comprehensive utilization method and system for bottom slag quenching treatment of circulating fluidized bed boiler

InactiveCN109990271AAchieve rapid coolingRealize waste heat utilizationFluidized bed combustionCombustion technology mitigationSlagQuenching

The invention discloses a comprehensive utilization method and system for bottom slag quenching treatment of a circulating fluidized bed boiler. The comprehensive utilization system is mainly composedof a quenching slag cooler, a heat exchanger, a bottom slag treatment device and a condensation heat exchanger. The comprehensive utilization method and system aim to solve the problems that a CFB boiler unit is large in slag discharge amount, low in sulfur slag utilization rate, large in limestone usage amount, too high in slag discharge temperature and the like. According to the comprehensive utilization method and system, furnace slag generated by a hearth is directly subjected to contact quenching treatment. The generated quenching bottom slag is firstly dried by tail fume and then is subjected to component analysis in a bottom slag component separation treatment device, and the bottom slag with high free CaO content is used as a desulfurizing agent and is sent back to the boiler again; the bottom slag with low content of free CaO and CaSO4 is used as cement admixture; and the bottom slag with high CaSO4 content is used as a cement adjusting retarder. The generated high-temperature steam and the dried fume are subjected to heat exchange with feed water and then enter a coal economizer as "economizer feed water". According to the comprehensive utilization method and system, residual heat of the slag is fully utilized, boiler fuel is saved, thermal pollution is reduced, and the thermal efficiency of the boiler is further improved.

Owner:XI AN JIAOTONG UNIV

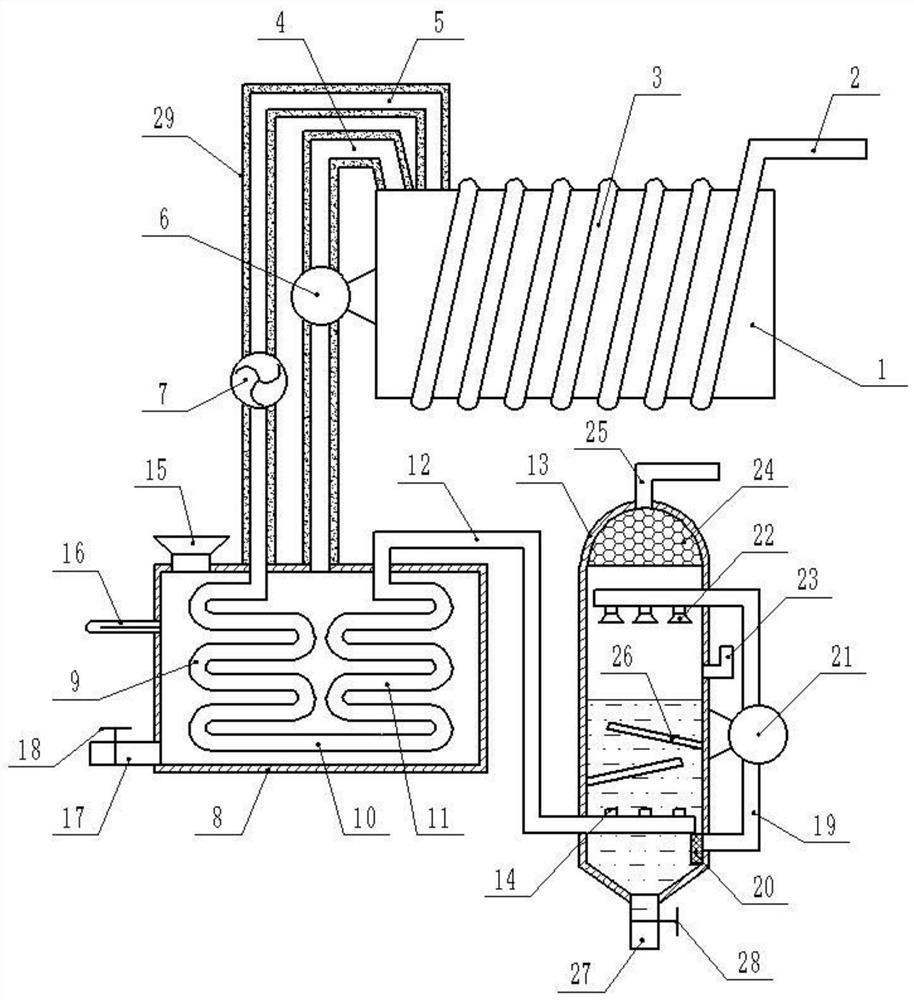

Biomass environment-friendly hot blast boiler

InactiveCN106403275AIncrease profitImprove thermal efficiencyAir heatersSolid fuel combustionCombustion chamberDecomposition

The invention relates to a biomass environment-friendly hot blast boiler. The biomass environment-friendly hot blast boiler comprises a boiler body, a combustion chamber, a feeding system, a slagging and ash removing system, a combustion-supporting oxygen conveying air inlet system, a flue gas channel system and a hot blast channel system. Fuel enters from the lower portion of a preliminary combustion volatilization decomposition chamber, the fuel utilization rate is increased through layered and segmented combustion, and energy source wasting is avoided; air is supplied through the multi-layer multi-angle combustion-supporting oxygen conveying air inlet system, the oxygen conveying amount in the fuel combustion process is ensured, the combustion speed is increased, and the combustion quality is improved; air is supplied through a porous air supply pipe and a material trough air supply liner, and the effects of being free of combustion dead angle, balanced in oxygen supply and sufficient in combustion are achieved; the fuel is pulled down through jacking force of a feeding machine after preliminary combustion decomposition and is combusted again through a re-combustion chamber, and combustible gas in fuel gas is thoroughly burned out through a secondary lighting-up tuyere; after entering the boiler body, natural air is heated up layer by layer through a low-temperature air channel, a low-temperature air collecting box, a medium-temperature air channel, a medium-temperature air collecting box, a high-temperature air channel and a high-temperature air collecting box; and heat exchange is thorough, and energy sources are saved.

Owner:青岛智良环保科技有限公司

Waste heat conversion integrated large stove

PendingCN107763680AControl flowControl flow rateFluid heatersWater heating stoves/rangesPlate heat exchangerEngineering

The invention discloses a waste heat conversion integrated large stove including a stove body and an exhaust gas treatment device. The stove body includes a burner and a furnace which are connected, anatural exhaust channel and the exhaust gas treatment device are connected with the furnace, and a conversion guide valve is arranged between the natural exhaust channel and the exhaust gas treatmentdevice. The exhaust gas treatment device includes an exhaust gas exhaust pipe and a tap water heating pipe. The tap water heating pipe includes a tap water inlet pipe, a low temperature heat exchanger, an intermediate temperature heat exchanger, a high temperature heat exchanger and a heat water outlet pipe. The exhaust gas exhaust pipe includes a high-temperature exhaust gas channel, an intermediate connection box, a middle-low temperature heat exchange box, and a forced-discharge suction fan. A high-temperature heat channel penetrates the high-temperature heat exchanger, and the intermediate temperature heat exchanger is arranged in the middle-low temperature heat exchange box, and the low-temperature heat exchanger is wound around the middle-low temperature heat exchange box. Through arrangement of the conversion guide valve, a large amount of generated waste heat is used, and through arrangement of the exhaust gas exhaust pipe and the tap water heating pipe, the utilization of waste heat is improved, and the thermal pollution is reduced.

Owner:南充烽英堂厨房电器设备科技有限公司

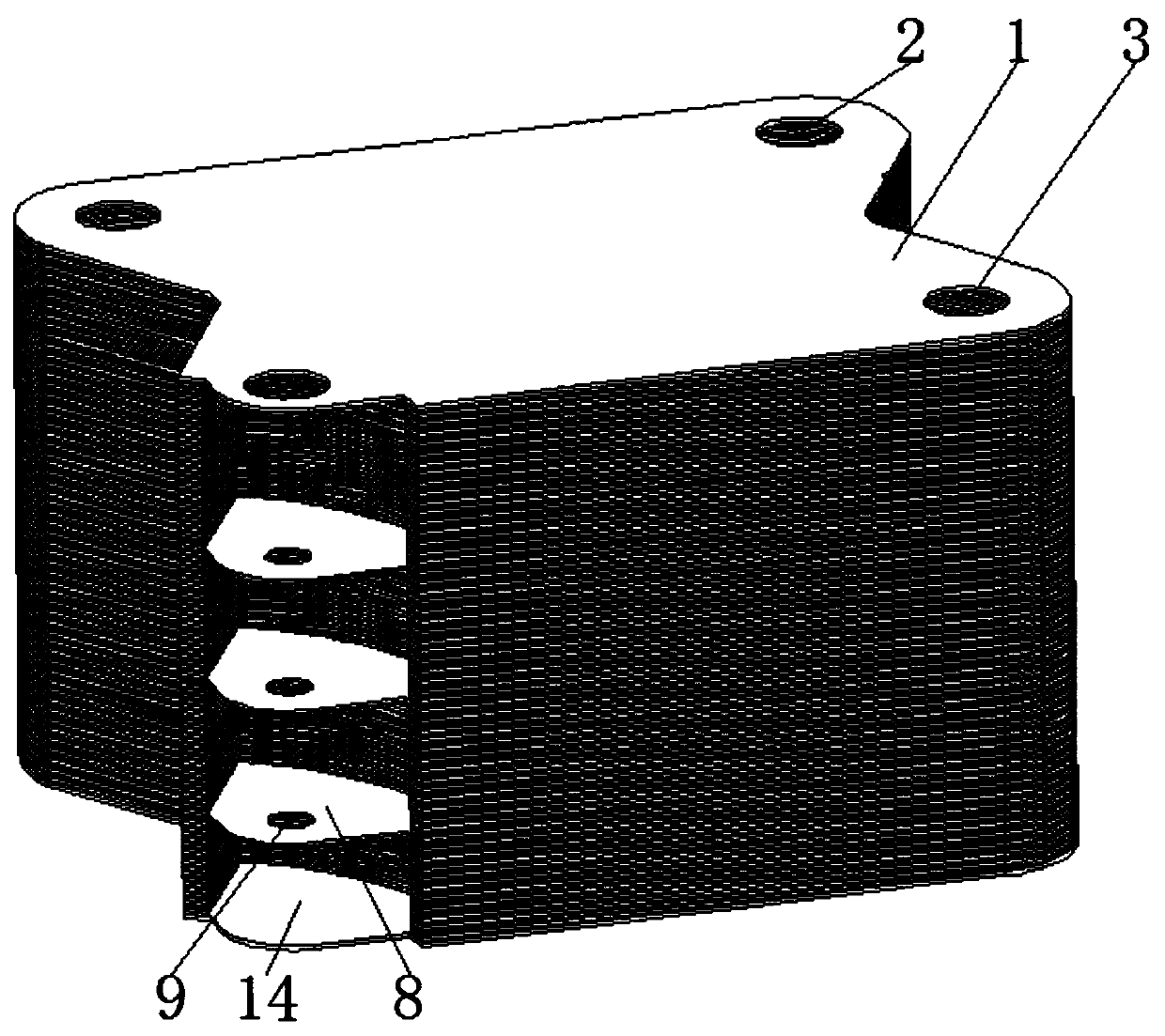

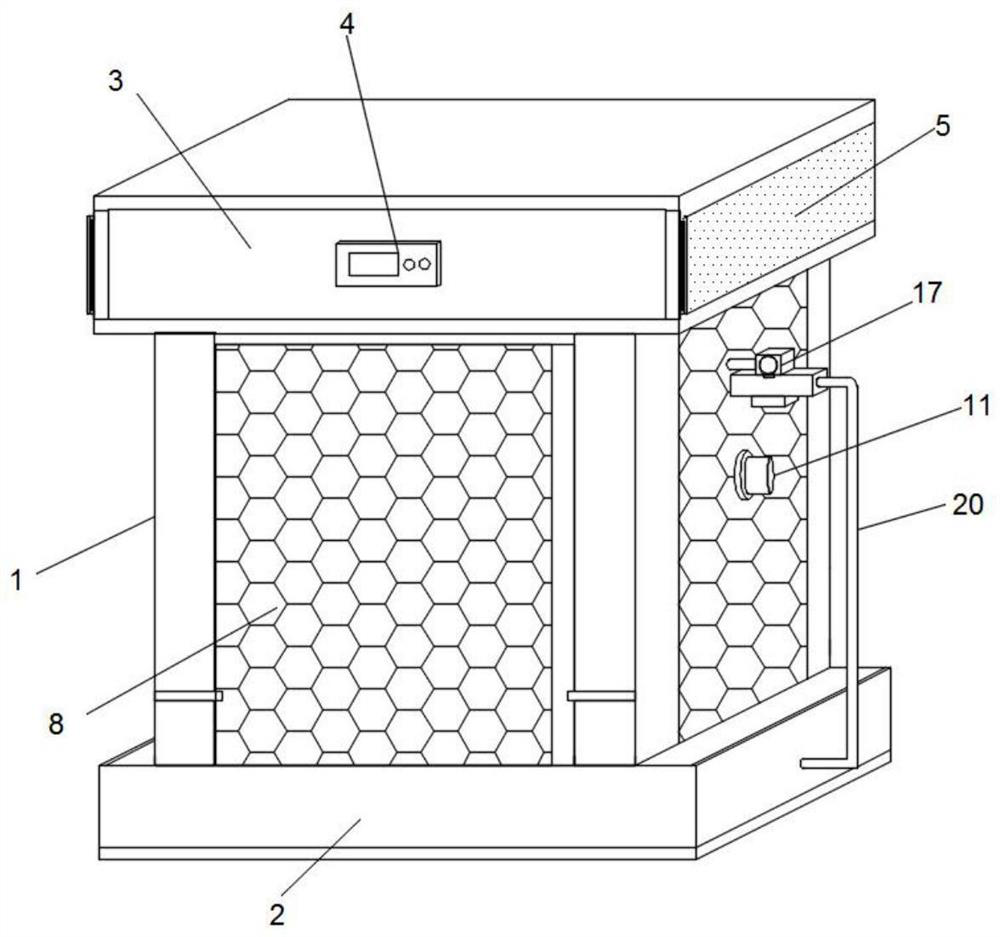

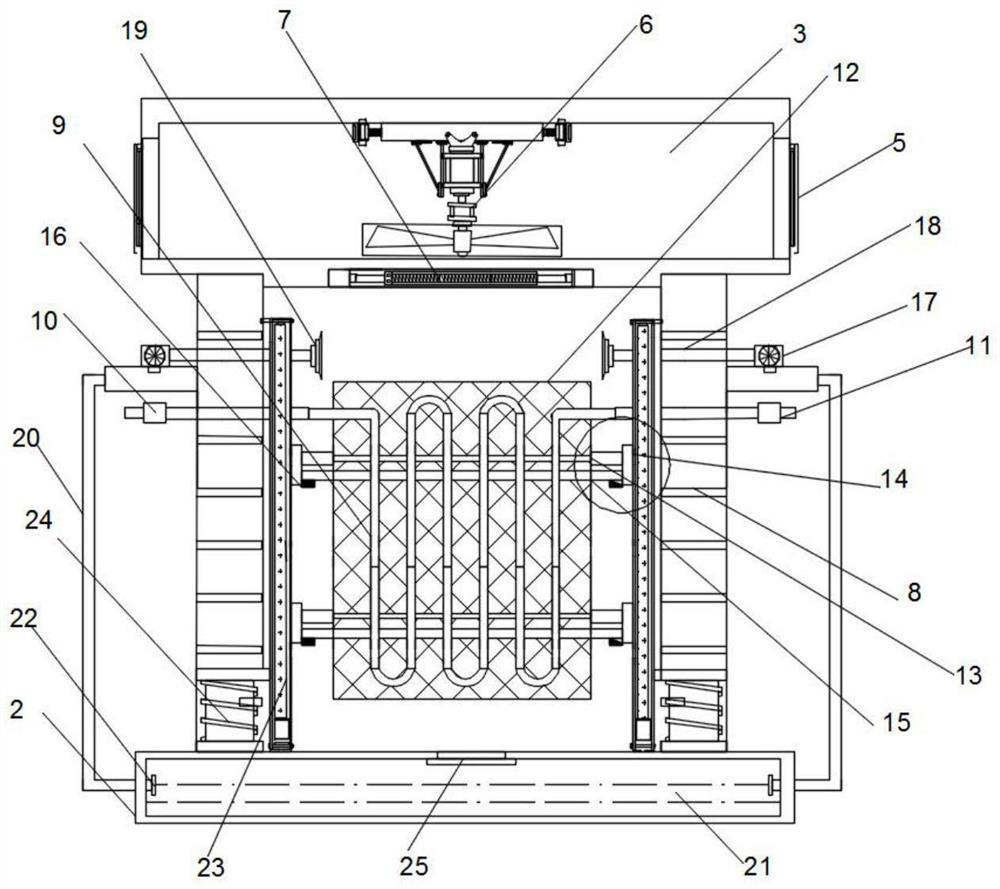

Seat type sliding bearing cooling mechanism

InactiveCN112160995AImprove flexural strengthAvoid warpingBearing coolingSlider bearingCooling effect

The invention discloses a seat type sliding bearing cooling mechanism in the field of seat type sliding bearing cooling. The seat type sliding bearing cooling mechanism comprises a bearing loading seat and a cooler, wherein the cooler is in a flat cuboid shape and comprises a left end plate, a right end plate, an upper panel and a lower panel; a rectangular loading box is arranged on the bearing loading seat; the cooler is inserted into the loading box; and a plurality of cooling copper pipes are arranged in the cooler. The seat type sliding bearing cooling mechanism can solve the problem thatan oil cooler in the prior art cannot provide a reliable oil cooling effect after the bearing load is increased.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

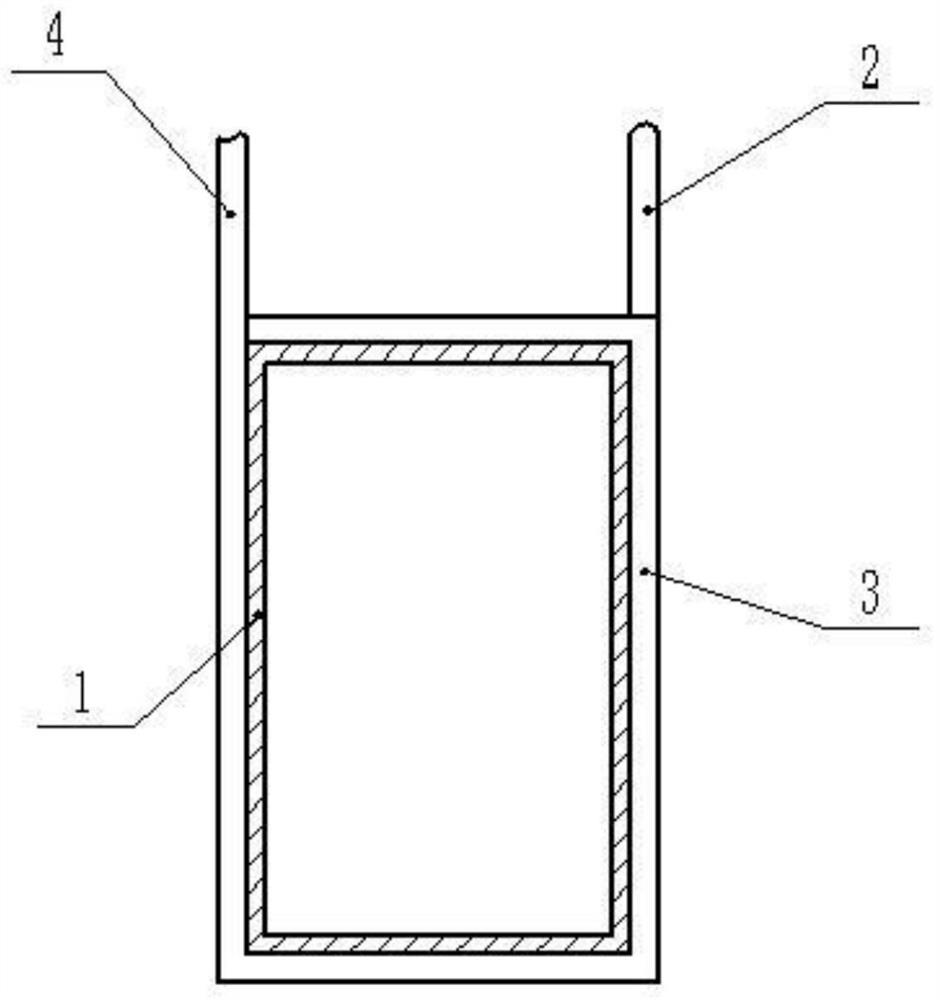

Novel low-pressure casting equipment

The invention discloses novel low-pressure casting equipment. The novel low-pressure casting equipment comprises a fixing bracket, a heat preservation furnace, a crucible and an air cooler; the heat preservation furnace and the air cooler are both fixedly arranged in the fixing bracket; the crucible is fixedly arranged in the heat preservation furnace; a vacuum cavity is formed between the crucible and the heat preservation furnace; a sealing cover is fixedly arranged at the top end of the heat preservation furnace, a fixing frame is fixedly arranged in the middle of the top end of the sealingcover, and a frame cover is hinged to the top end of the fixing frame; a mold is fixedly arranged in the fixing frame, the bottom end of the mold is fixedly connected with the top end of a liquid rising pipe, and the bottom end of the liquid rising pipe is arranged at the bottom of the inner wall of the crucible; and an air outlet pipe is arranged at the bottom of the side of the fixing frame ina penetrating mode. According to the novel low-pressure casting equipment, the air cooler and a circulating fan can cooperate with water cooling of the mold to cool the mold, the temperature loweringspeed is increased, the circulating fan can enable cold air to form convection in the fixing frame, heat exchange is more thorough, and then the cooling speed and the machining efficiency of the moldare increased.

Owner:甘肃欣福门窗工程有限公司

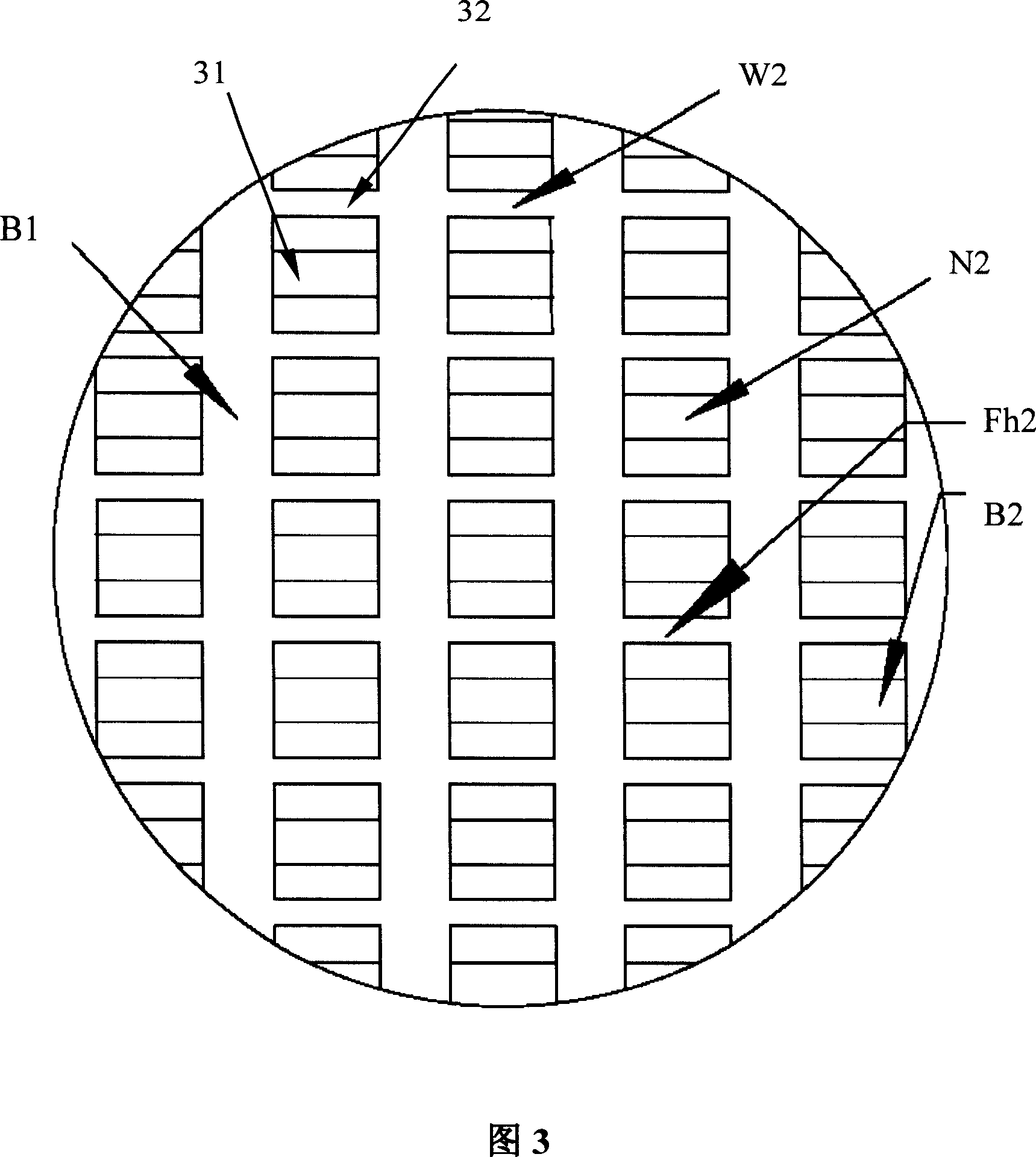

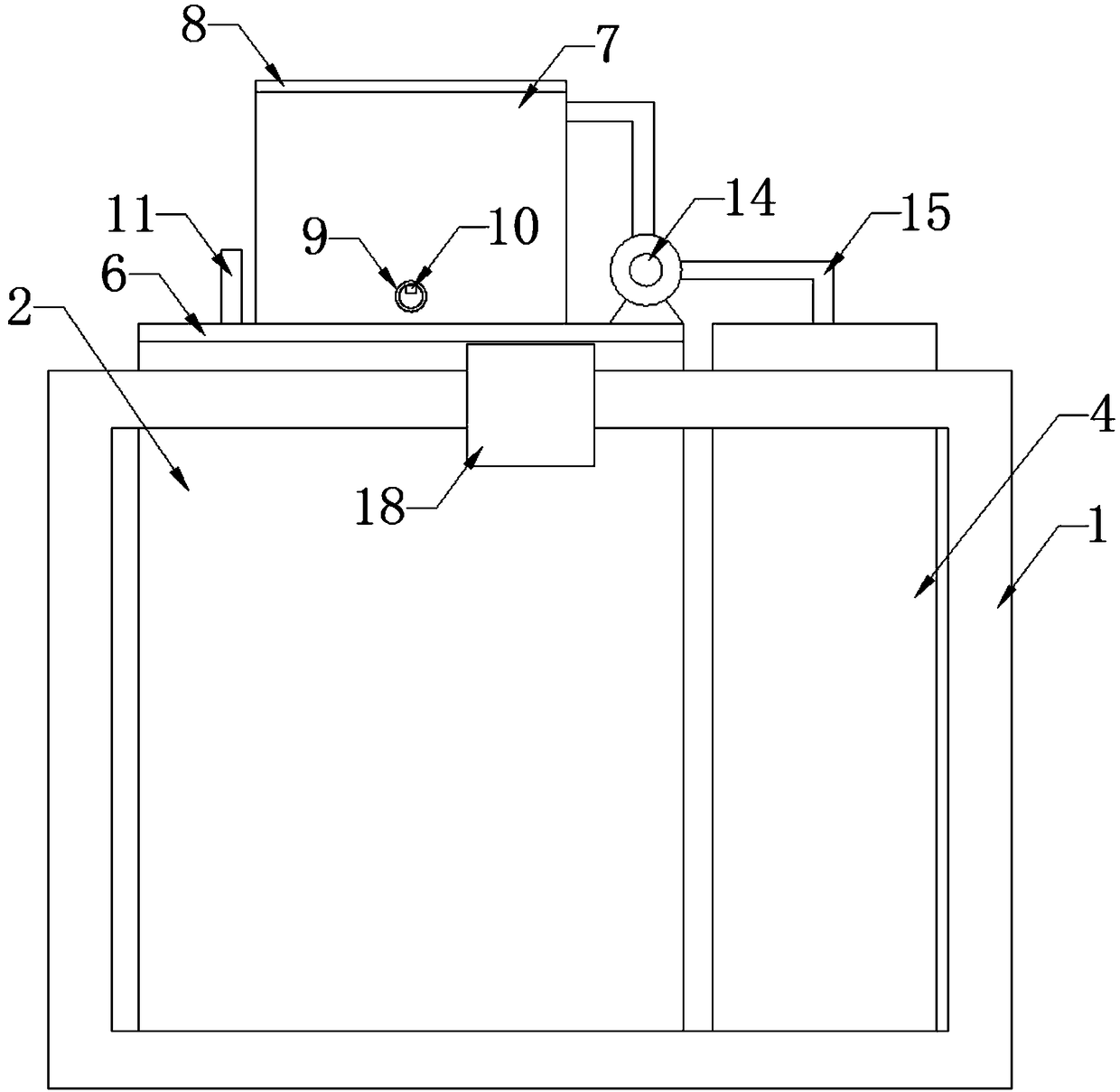

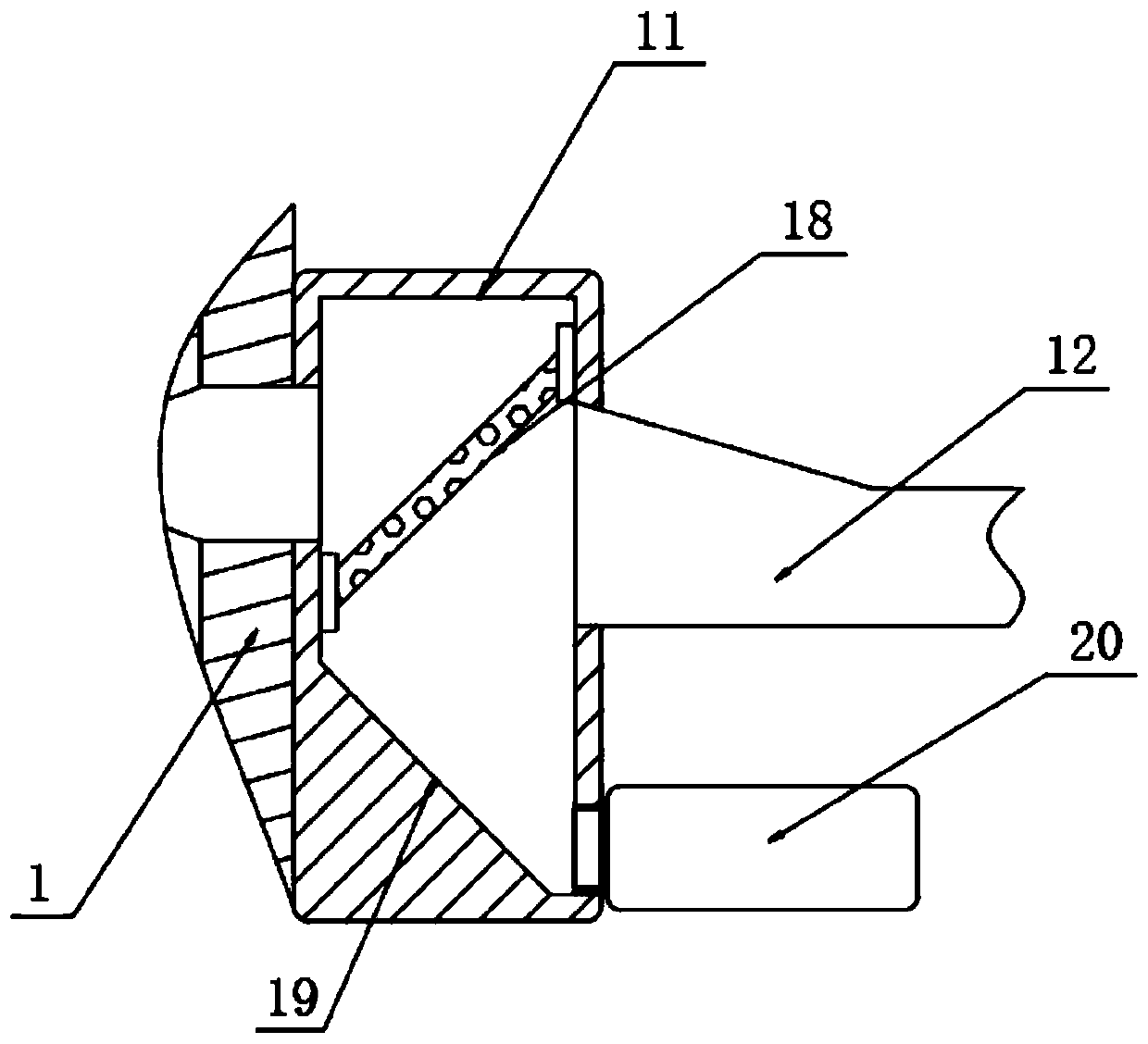

Integrated microchannel heat exchanger with liquid homogenizing device

InactiveCN109813157AImprove heat transfer effectThorough heat exchangeHeat exchanger casingsStationary plate conduit assembliesCold sidePlate heat exchanger

The invention relates to the technical field of heat exchangers, and discloses an integrated microchannel heat exchanger with a liquid homogenizing device. The integrated microchannel heat exchanger comprises a heat exchanger top plate, and a hot fluid connector is formed in the upper surface of the heat exchanger top plate. The interior of the hot fluid connector communicates with the lower surface of the heat exchanger top plate. A cold fluid connector is formed in the upper surface of the heat exchanger top plate. According to the integrated microchannel heat exchanger with the liquid homogenizing device, by arranging the heat exchanger top plate, a hot side heat exchange plate sheet, a cold side heat exchange plate sheet and a heat exchanger bottom plate, fluid can pass through the heat exchanger top plate to enter the hot side heat exchange plate sheet and the cold side heat exchange plate sheet for heat exchange; and by arranging a first fluid distributing groove, a second fluiddistributing groove, a damping plate and a damping hole, the fluid is distributed into the first fluid distributing groove and the second fluid distributing groove by the damping plate through the damping hole, and therefore the heat exchanger is better in heat exchange effect and thorough in heat exchange.

Owner:杭州微控节能科技有限公司

Boiler waste gas treatment device convenient for recycling heat

InactiveCN113117433AAffect the heat transfer effectHigh maintenance costGas treatmentDispersed particle filtrationThermodynamicsGlass cover

The invention relates to the technical field of boiler waste gas treatment, and discloses a boiler waste gas treatment device convenient for recycling heat, which comprises a filter chamber, a gas inlet pipe is fixedly communicated with one side in the filter chamber, the bottom end of the gas inlet pipe is hermetically inserted in a glass cover, and a filter element rod is plugged in the glass cover; the other side of the filter chamber is inserted with a gas transmission section connected with an air outlet pipe, the air outlet pipe further comprises a heat exchange section and an exhaust section, the heat exchange section is evenly wound on two heat exchange water bins, the two heat exchange water bins are directly connected through a connecting water pipe, an inner water flow channel of each heat exchange water bin is an interlayer of the bin wall, and flow blocking rings are evenly arranged on an interlayer support of the bin wall; and water holes are evenly formed in the flow blocking ring, the direction of water flow in the connecting water pipe is opposite to the direction of air flow in the air outlet pipe, waste gas exhausted by the boiler can be filtered, the filtered hot waste gas is subjected to heat exchange on the heat exchange water bin, and therefore heat of the waste gas is fully recycled.

Owner:珠海六和节能投资有限公司

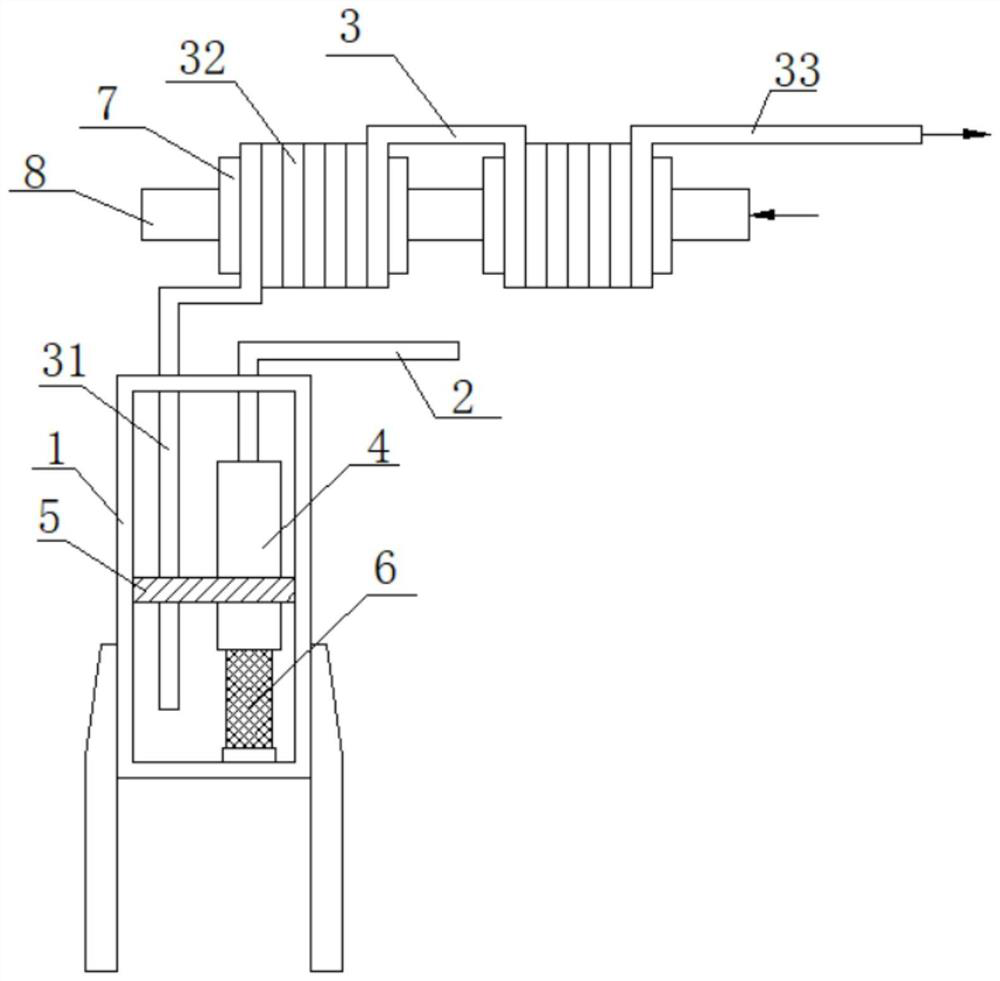

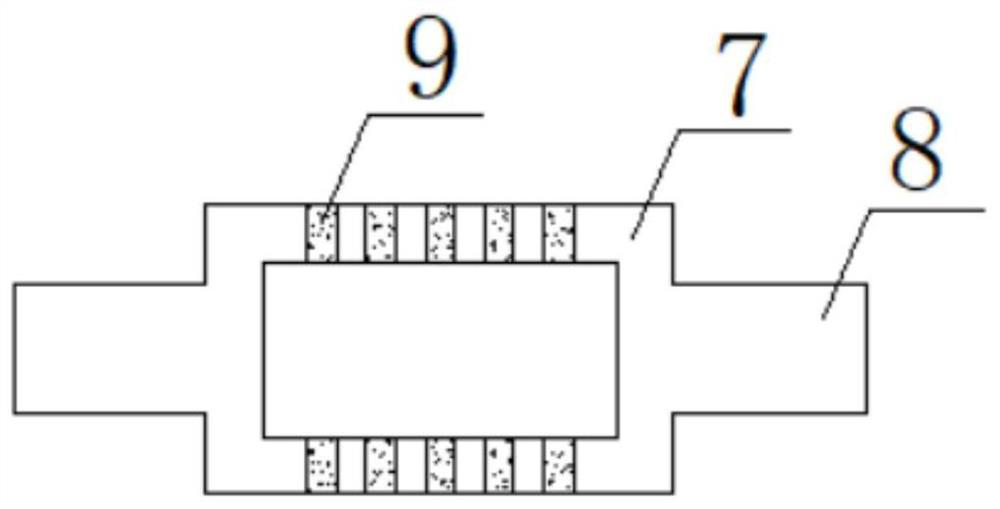

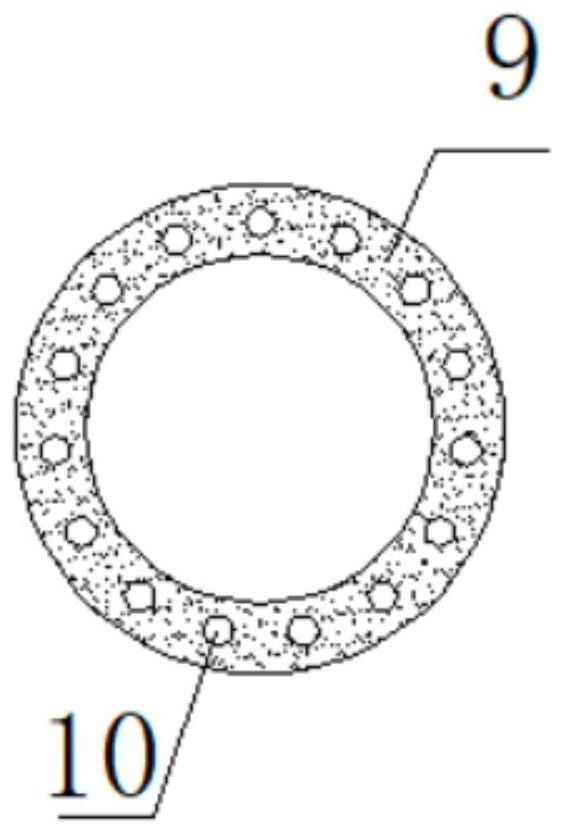

Heat energy recovery system of mute diesel generator

PendingCN113417759AThorough heat exchangeExtended stayInternal combustion piston enginesExhaust apparatusWater pipeElectric generator

The invention discloses a heat energy recovery system of a mute diesel generator. The heat energy recovery system comprises a mute diesel generator body, a smoke exhaust pipe, a water tank, a second spiral heat dissipation pipe, a purification tower, a second water pump and a flow guide plate. A disc shaped heat absorption pipe is mounted on the shell of the mute diesel generator body in a winding manner. The smoke exhaust pipe is installed on the left side of the upper portion of the mute diesel generator body. The lower portion of the left side of the smoke exhaust pipe is connected to a first spiral heat dissipation pipe. A second gas guide pipe is connected above the second spiral heat dissipation pipe; gas outlet holes are uniformly distributed above the part, positioned in the purification tower, of the second gas guide pipe. A second connecting water pipe is mounted above the right side of the purification tower, and the upper part of the second connecting water pipe is connected to the upper part in the purification tower. According to the heat energy recovery system, through cooperative use of the first spiral heat dissipation pipe and the second spiral heat dissipation pipe, heat exchange can be conducted on smoke generated by the mute diesel generator body twice, and heat exchange is more thorough.

Owner:厦门彼奥动力科技有限公司

Heat pump hot water unit

ActiveCN105466014BImprove heat storage capacityLow heat storage costFluid heatersEngineeringHeat transfer efficiency

Owner:ZHEJIANG LIDE ENERGY CONSERVATION TECH CO LTD

Intelligent production device used for cement on construction site

The invention relates to the technical field of cement production and discloses an intelligent production device used for cement on construction site. The intelligent production device includes a device body, wherein a preheater is arranged over the device body; a pedestal is disposed on the lower end of the preheater; a rotary kiln is disposed on one end of the pedestal; a cover board is arrangedon the outer surface of the front end of the rotary kiln; a cooling device is arranged at one side of the cover board; a clinker silo is disposed at one side of the cooling device; a roller press isarranged on one side, closed to one side of the cooling device, of the clinker silo; a crusher is arranged at one side of the roller press; a cement mill is arranged on one side, closed to one side ofthe roller press, of the crusher. In the intelligent production device, by means of an insulation cover, dust and noise are treated to achieve environment-friendly production. A filter screen is convenient to replace. A heat dissipater is used for accelerating heat dissipation of a power distribution box, thus enhancing power supply stability. The height of an operation table is convenient to adjust, so that a worker can conveniently use the intelligent production device.

Owner:刘道灵

Evaporator synergistic anti-frost device and method of use thereof

ActiveCN104359260BReduce the temperatureImprove heat transfer efficiencyMechanical apparatusEvaporators/condensersCold airFrost

Owner:苏州正美光电科技有限公司

A process and equipment for industrial waste salt grading decomposition carbonization and harmless treatment

ActiveCN106914474BGood dispersionLarge specific surface areaTransportation and packagingSolid waste disposalDecompositionCarbonization

The invention belongs to the field of environmental protection, and in particular relates to a process and equipment for graded decomposition, carbonization and harmless treatment of industrial waste salt. The process and equipment of the present invention are aimed at the diversification of organic matter contained in each industrial waste salt and its different physical and chemical properties. Several stages of decomposition and carbonization furnaces are set up to heat the industrial waste salt in stages. Decomposition and carbonization are completed in the carbonization temperature range, and the hot exhaust gas generated by decomposition and carbonization is used as a drying heat source. The exhaust gas generated by drying is introduced into the incinerator for incineration, and the hot gas generated by incineration is recycled. The invention realizes industrial continuous production, no waste salt melting, agglomeration or bonding during system operation, no secondary pollutants, no poisonous and harmful gas emissions, high thermal efficiency, energy saving and environmental protection, and investment cost lower than other methods , has strong practicability, is suitable for organic matter removal and harmless treatment of industrial waste salt in various fields, and is suitable for promotion in industrial production.

Owner:辽宁东大粉体工程技术有限公司

Durable condenser with high heat exchange efficiency

InactiveCN114413523AIncrease condensation strokeImprove heat exchange efficiencyDispersed particle filtrationEvaporators/condensersCold airWire gauze

The durable condenser comprises a shell, a base is arranged at the bottom of the shell, an electric control cabinet is arranged at the top of the shell, a controller is installed on the front face of the electric control cabinet, ventilation grooves are formed in the two sides of a shell body of the electric control cabinet, and an electric fan is installed in the electric control cabinet. A first dust filtering net is arranged between the electric control cabinet and the shell, heat dissipation holes are formed in the outer walls of the four faces of the shell respectively, a condensation pipe is arranged in the shell, one end of the condensation pipe is fixedly connected with an air inlet pipe, and the other end of the condensation pipe is fixedly connected with a water outlet pipe. According to the durable condenser with the high heat exchange efficiency, water is injected into the surface of a condensation pipe in a shell through a pump body, a water tank, a water inlet pipe and a nozzle, cold air is blown to the condensation pipe through heat dissipation holes in the upper portion of the condensation pipe, rapid heat exchange of the outer surface of the condensation pipe is achieved, and the surface temperature of the condensation pipe is directly reduced; and meanwhile, the metal wire mesh and the heat-conducting fins assist the condensation pipe in further heat dissipation, the condensation efficiency of the condensation pipe is improved, and efficient heat exchange is achieved.

Owner:YANCHENG SHENHAI MASCH CO LTD

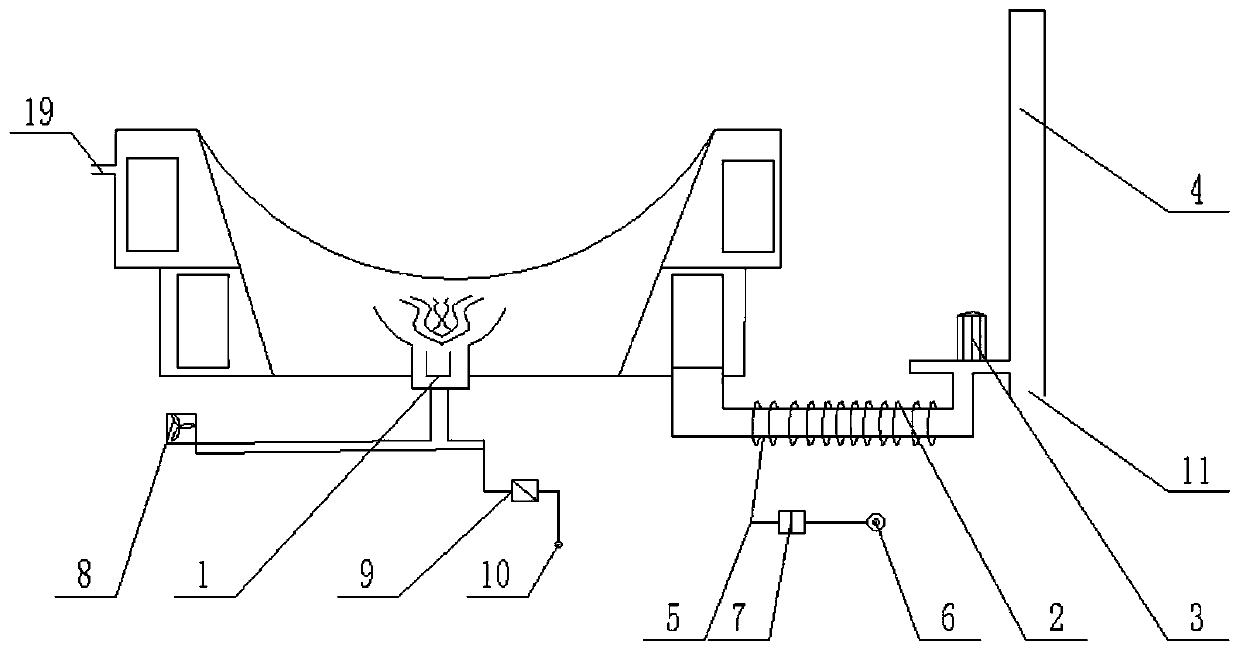

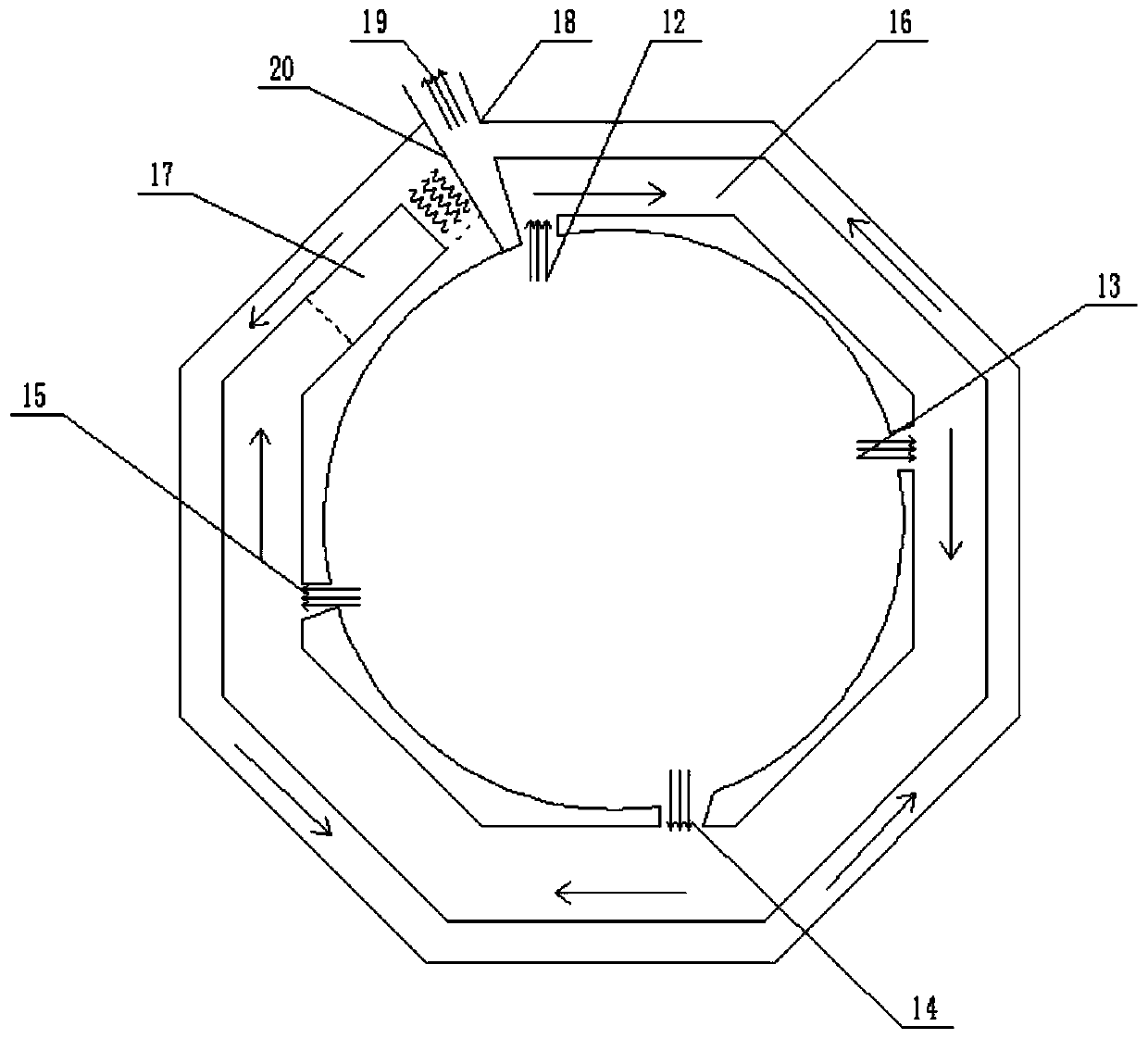

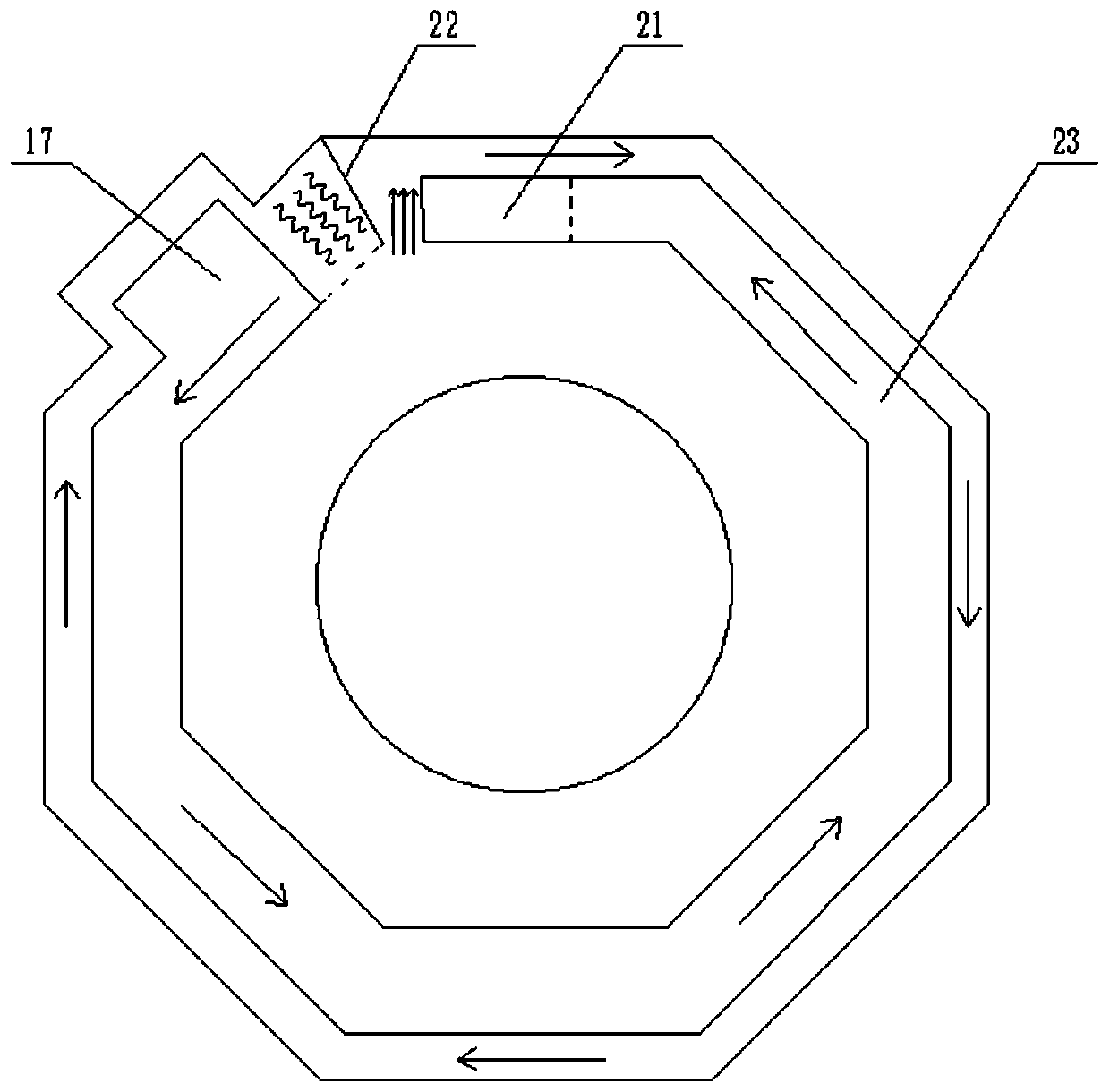

Condensing type afterheat recovering and water heating cooking oven

PendingCN110220225AIncrease profitReduce heat pollutionLighting and heating apparatusWater heating stoves/rangesHearthEngineering

The invention discloses a condensing type afterheat recovering and water heating cooking oven. The condensing type afterheat recovering and water heating cooking oven comprises an oven body, and a hearth which is arranged in the center of the oven body, wherein an oven head is mounted in the center of the inner middle part of the hearth; the oven body is an inverted hollow octagonal platform, andan empty chamber is formed in a circle around the outer wall of the hearth in the oven body; a horizontal separating plate is arranged in the empty chamber and divides an interlayer of the hearth intoan upper annular chamber and a lower annular chamber; a first-grade afterheat exchanging tube is arranged in the upper chamber, and a second-grade afterheat exchanging tube is arranged in the lower chamber; a plurality of high-temperature exhaust gas inlets which communicate with the inside of the hearth are formed at uniform intervals in the first-grade afterheat exchanging tube; the tail end ofthe first-grade afterheat exchanging tube is in communication connection with the head end of the second-grade afterheat exchanging tube through a first guide tube which is vertically arranged; and the tail end of the second-grade afterheat exchanging tube is connected to the head end of a smoke exhausting tube through a second guide tube. The condensing type afterheat recovering and water heating cooking oven further comprises a water tank which is connected to the smoke exhausting tube; fins are arranged around a door of a part where the water tank is connected to the smoke exhausting tube;and a water inlet of the water tank is connected to a tap water inlet through a water inlet tube.

Owner:南充烽英堂厨房电器设备科技有限公司

Efficient heat-exchanging pipe of evaporator for electric refrigerator set

ActiveCN100458348CIncrease the heat exchange areaHigh thermal efficiencyTubular elementsElectricityEngineering

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Improved capillary tube heat exchanger

InactiveCN110986642AReduce impactIncrease the itineraryChemical industryCorrosion preventionCapillary TubingEngineering

The invention discloses an improved capillary tube heat exchanger and relates to the technical field of heat exchangers. The improved capillary tube heat exchanger comprises a heat exchange box. The top of the heat exchange box is connected with a box cover through bolts in a sealing mode. According to the improved capillary tube heat exchanger, filtered heat exchange liquid is delivered into an annular pipeline along a connecting pipeline and flows down along hollow holes; impact force of heat exchange liquid on capillary heat exchange tubes can be reduced, and the travel distance of the heatexchange liquid in the heat exchange box can be increased, so that heat exchange is carried out more thoroughly. Meanwhile, the heat exchange liquid flows in the heat exchange box to continuously scour floating supports to drive scale removing sleeves to slide up and down along the capillary heat exchange tubes so as to clean water scale adhering to the surfaces of the capillary heat exchange tubes. The improved capillary tube heat exchanger can wash out the surfaces of the capillary heat exchange tubes all the time during heat exchange and effectively prevent the situation that much water scale coagulates to the surfaces of the capillary heat exchange tubes and reduces the heat exchange effect, the service life of the heat exchanger is prolonged, and the heat exchange efficiency of the heat exchanger is improved.

Owner:山东圣克莱尔新能源有限公司

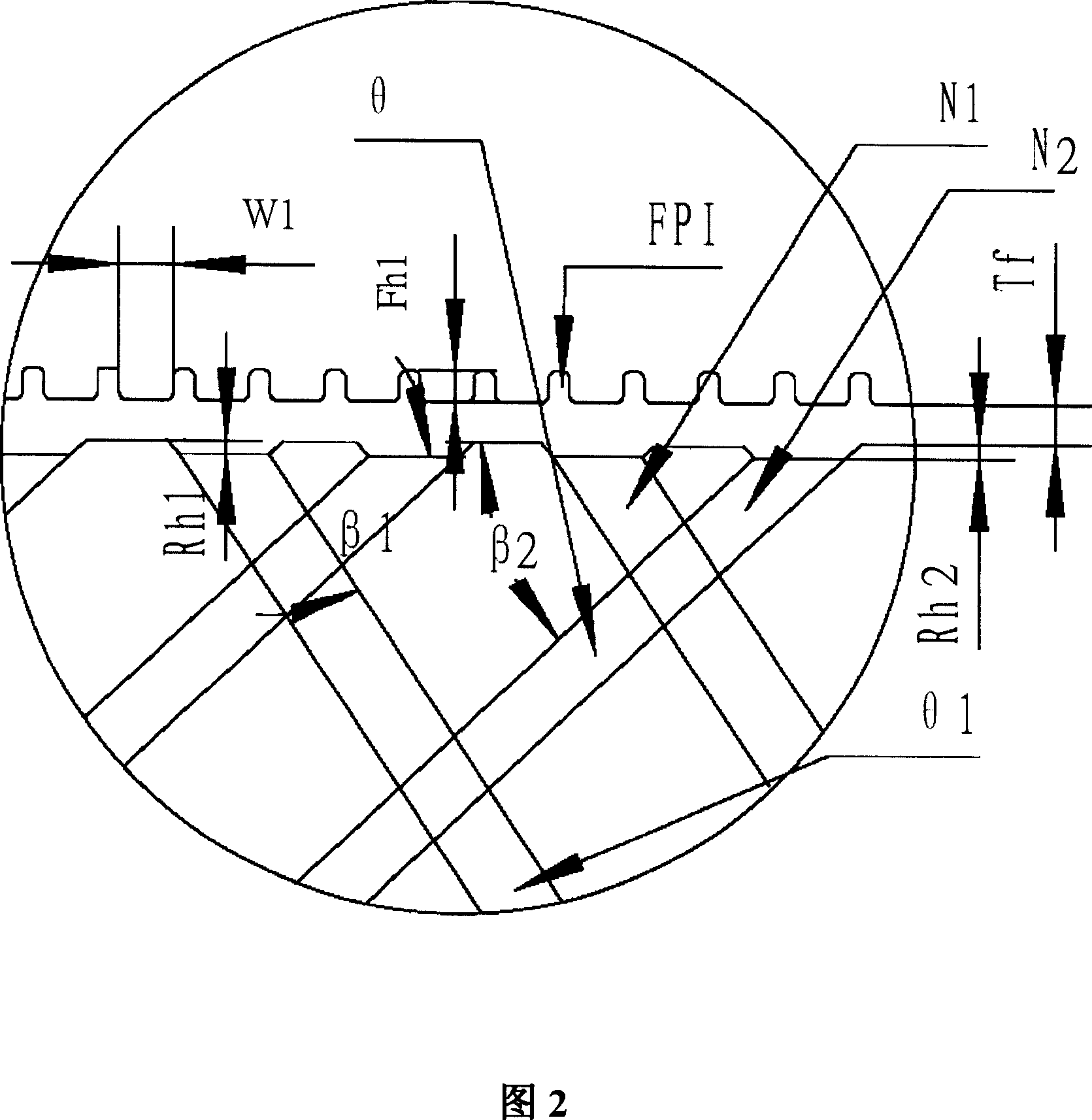

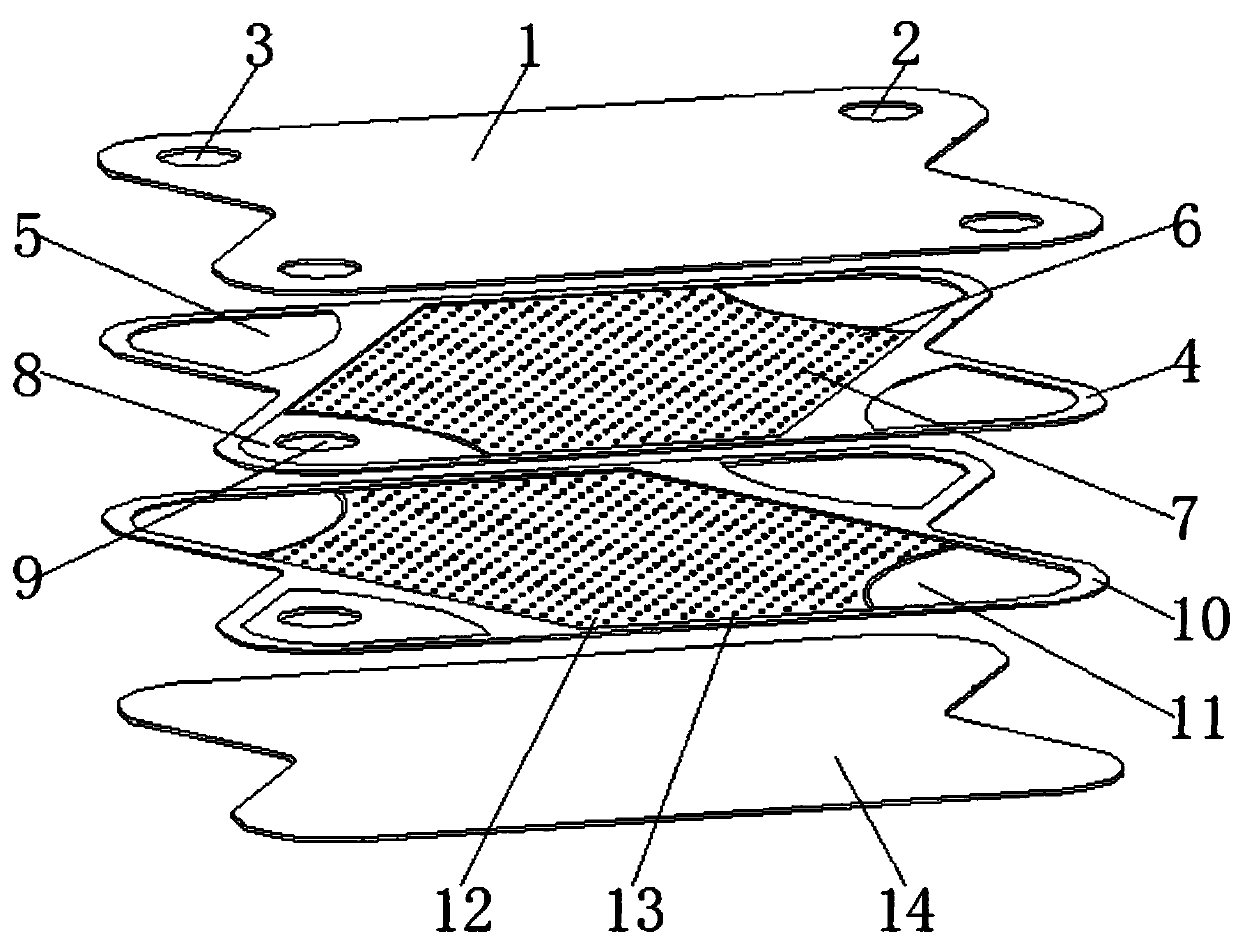

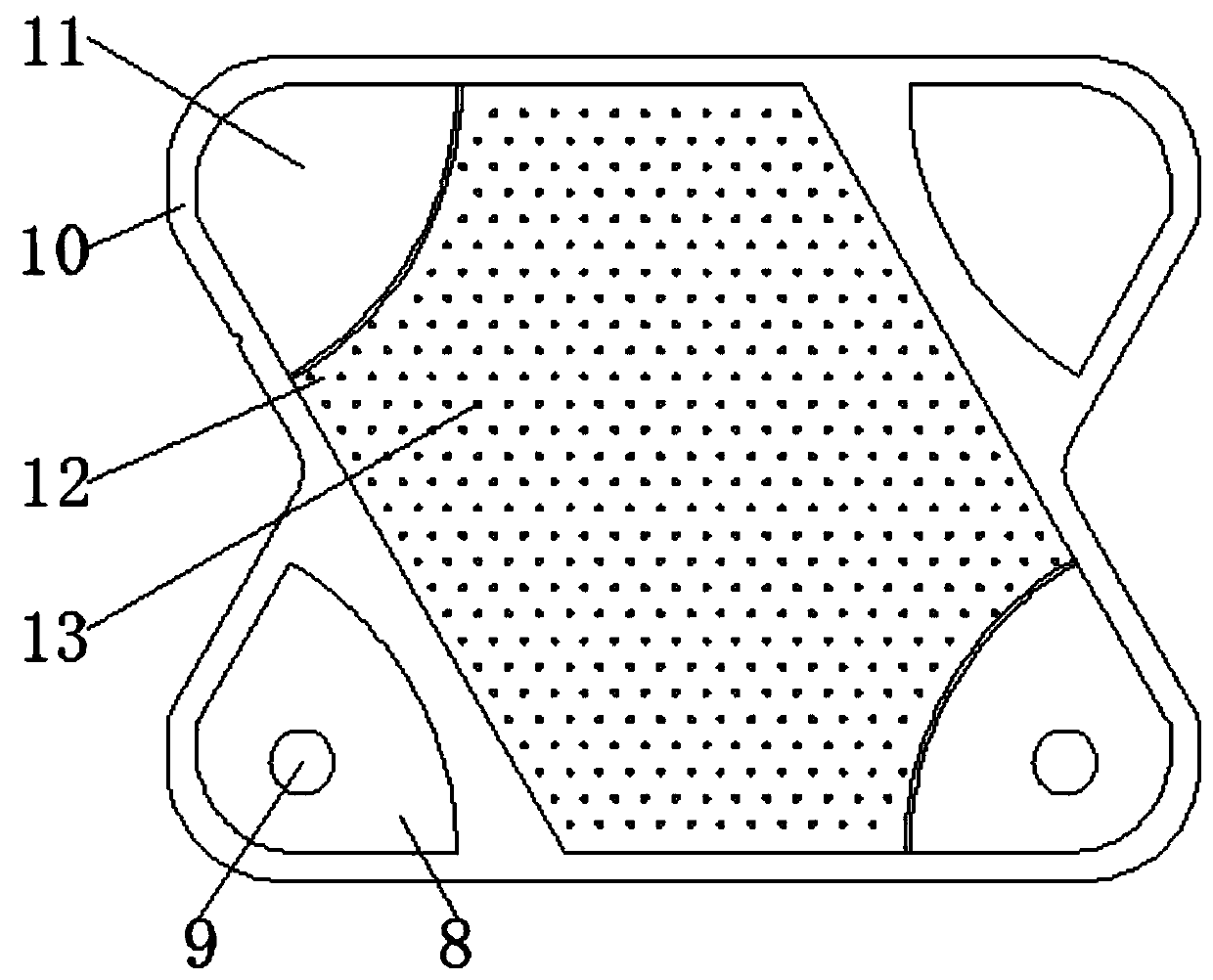

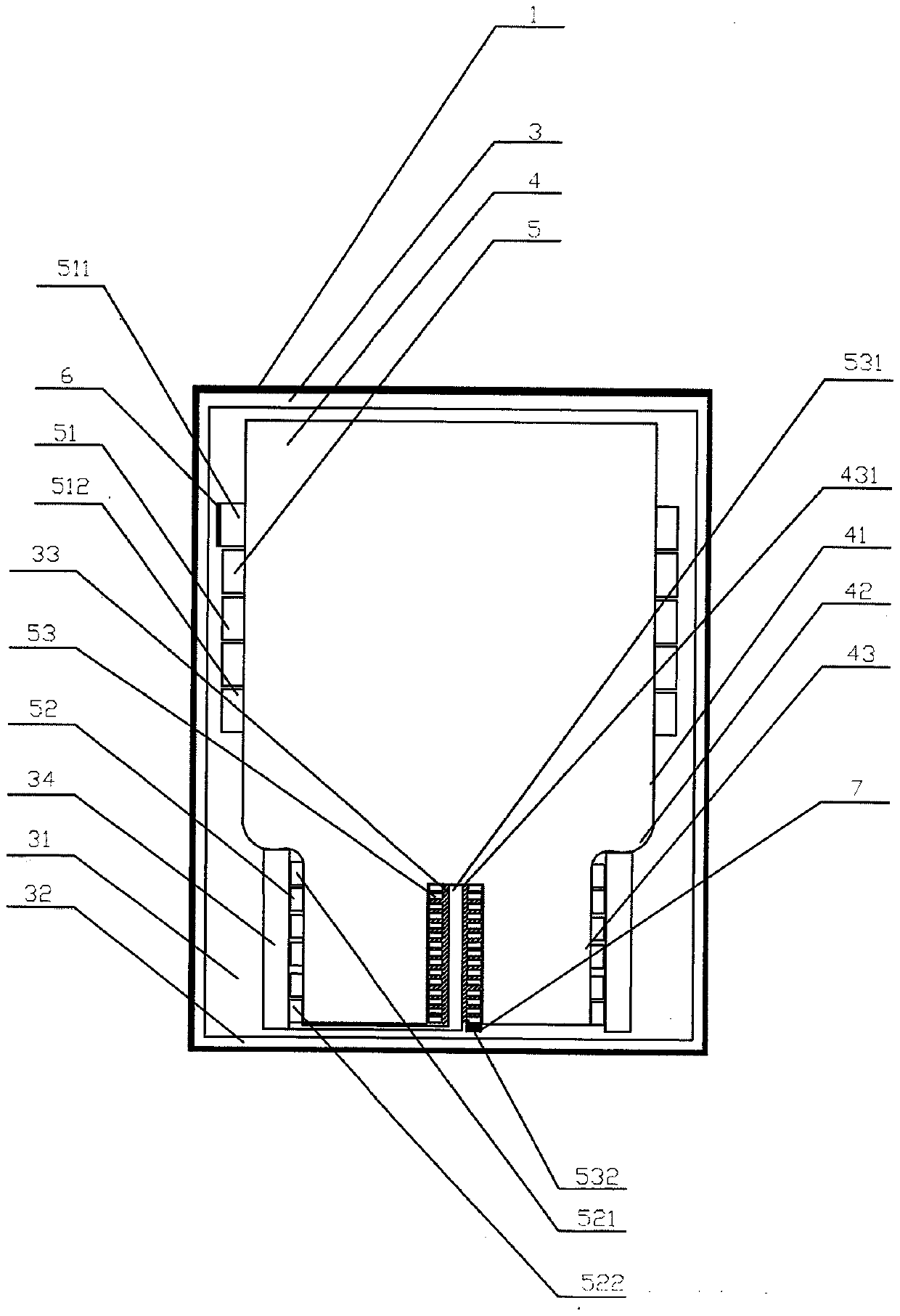

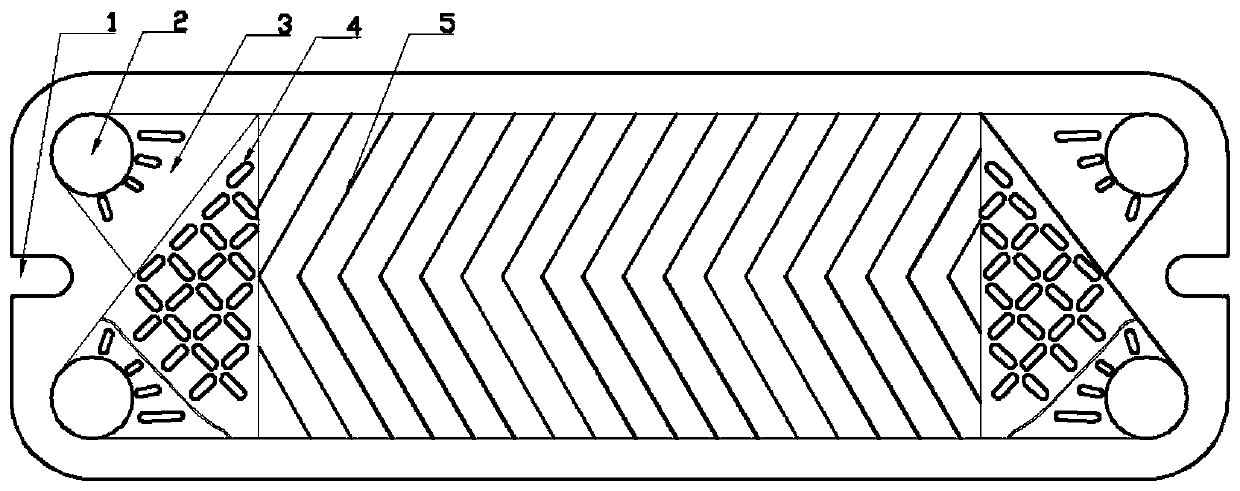

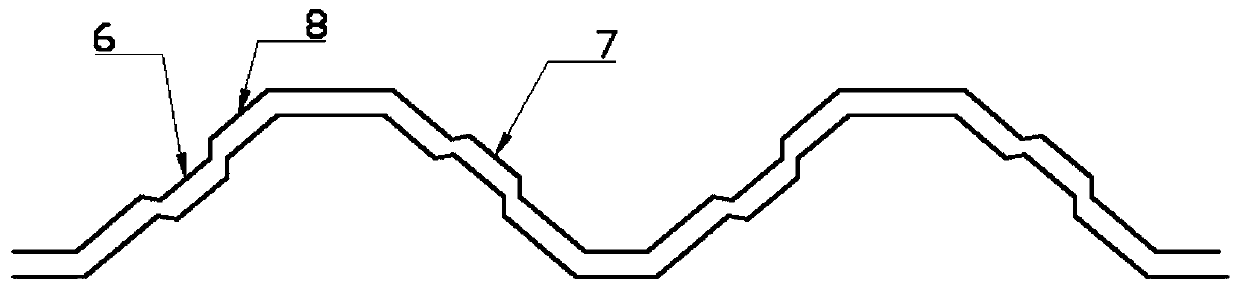

Plate heat exchanger herringbone plate

ActiveCN108592666BThorough heat exchangeImprove heat transfer effectHeat exchanger casingsLaminated elementsPlate heat exchangerEngineering

The invention provides a plate heat exchanger herringbone plate. The plate heat exchanger herringbone plate comprises a plate body; an angle hole, a guide area, a shunting area and a heat exchange area are arranged on the plate body; herringbone ripples are arranged in the flowing direction of a heat exchange medium in the heat exchange area; groove-shaped front small ripples are arranged on the surfaces, facing the flowing direction of the heat exchange medium, of the herringbone ripples; projected back small ripples are arranged on the other surfaces of the herringbone ripples; and the frontsmall ripples and the back small ripples are the same in shape.

Owner:NANJING UNIV OF SCI & TECH

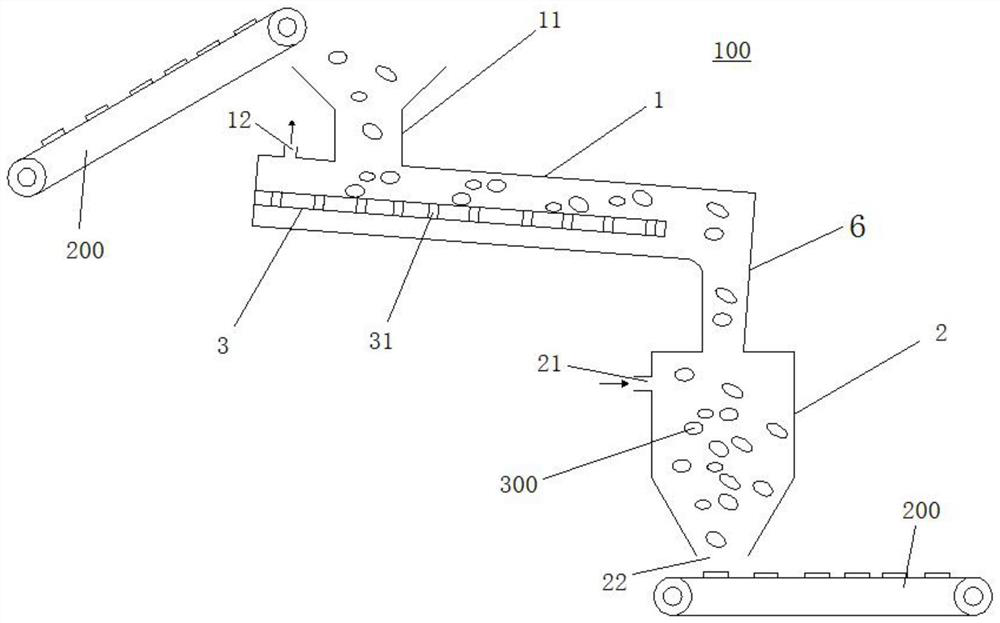

Pretreatment device for preparing colloidal particles by using waste tire rubber blocks

PendingCN111844543AImprove heat transfer effectThorough heat exchangePlastic recyclingMechanical material recoveryPhysical chemistryCooling chamber

The invention discloses a pretreatment device for preparing colloidal particles by using waste tire rubber blocks. The pretreatment device for preparing the colloidal particles by using the waste tirerubber blocks comprises a pre-cooling chamber, a freezing chamber, a vibration plate and a vibration mechanism; the pre-cooling chamber is obliquely arranged, and a feeding opening and an air outletare formed in the upper end of the pre-cooling chamber; the freezing chamber is in communication with the lower end of the pre-cooling chamber, and an air inlet and a discharging port are formed in the end, away from the pre-cooling chamber, of the freezing chamber; the vibration plate is arranged in the pre-cooling chamber and is opposite to the feeding hole; and the vibration mechanism is connected with the vibration plate and used for driving the vibration plate to vibrate. According to the technical scheme, rubber blocks are frozen, on one hand, friction heat generated during smashing canbe offset, and rubber particles are prevented from being in a desulfurized or semi-desulfurized state; and on the other hand, the elongation at break of the colloidal particles can be reduced, the colloidal particles are easy to crush, and the crushing heat can be greatly reduced, so that the yield and quality of rubber powder are improved.

Owner:QINGDAO UNIV +1

System for recycling waste heat of air conditioner

InactiveCN104110804AAchieve energy saving effectWill not affect operationEnergy recovery in ventilation and heatingHeat recovery systemsWaste heat recovery unitAir conditioning

The invention belongs to the air conditioning technical field, and particularly relates to a system for recycling waste heat of an air conditioner. The system for recycling the waste heat of the air conditioner can reasonably use the waste heat generated during the work process of the air conditioner. The technical scheme includes that the system for recycling the waste heat of the air conditioner absorbs the waste heat and achieves effectively recycle of the waste heat by adding a waste heat recovery device on a heat radiator of an air conditioning system and uses the waste heat to heat water, the water after being heated can be used for life, and refrigeration effects of the air conditioning system are good, and furthermore an idea of energy conservation and environment protection is achieved.

Owner:JINING LANCHUANG ENVIRONMENTAL PROTECTION TECH

New energy intelligent double-rotation boiler

ActiveCN106382623BIncrease profitImprove thermal efficiencyFuel feeding arrangementsSolid fuel combustionCombustion chamberDecomposition

The invention relates to a new-energy intelligent double-rotation boiler. The boiler comprises a boiler body, a combustion chamber, a feeding system, a slag discharging and ash removing system, a combustion supporting oxygen conveying air inlet system, a smoke channel system and a hot air channel system. Fuel enters from the lower portion of an initial combustion volatile decomposition room and is subject to layered segmented combustion, the fuel utilization rate is improved, and energy waste is avoided; the multilevel multi-angle combustion supporting oxygen conveying air inlet system is adopted, the oxygen conveying amount in the fuel combustion process is ensured, the combustion speed and the combustion quality are improved, air is supplied through a porous air supply pipe and a material groove air supply container, and the effects of non-dead-corner combustion, balance oxygen supply and sufficient combustion are achieved. After initial combustion decomposition, fuel is turned over through ejecting force of a feeding machine and is re-combusted through a re-combustion chamber, combustible gas in smoke can be thoroughly burned out through a secondary ignition opening, natural air enters the boiler body and passes through a low-temperature air channel, a low-temperature air collection box, a medium-temperature air channel, a medium-temperature air collection box, a high-temperature air channel and a high-temperature air collection box to be subject to layer-by-layer warming, heat exchange is thorough, and energy is saved.

Owner:青岛智良环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com