Patents

Literature

64results about How to "To achieve the purpose of harmless treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

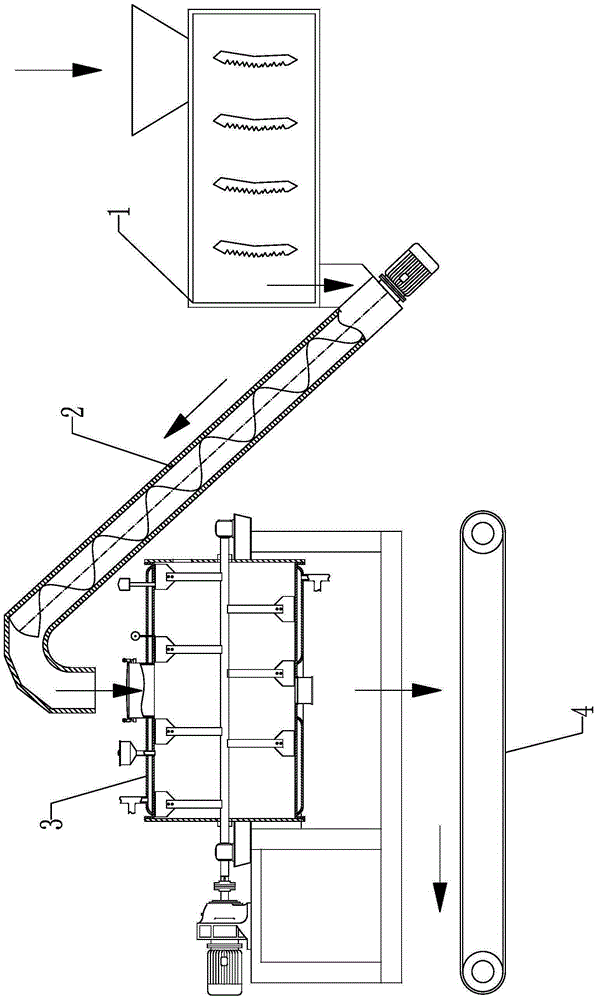

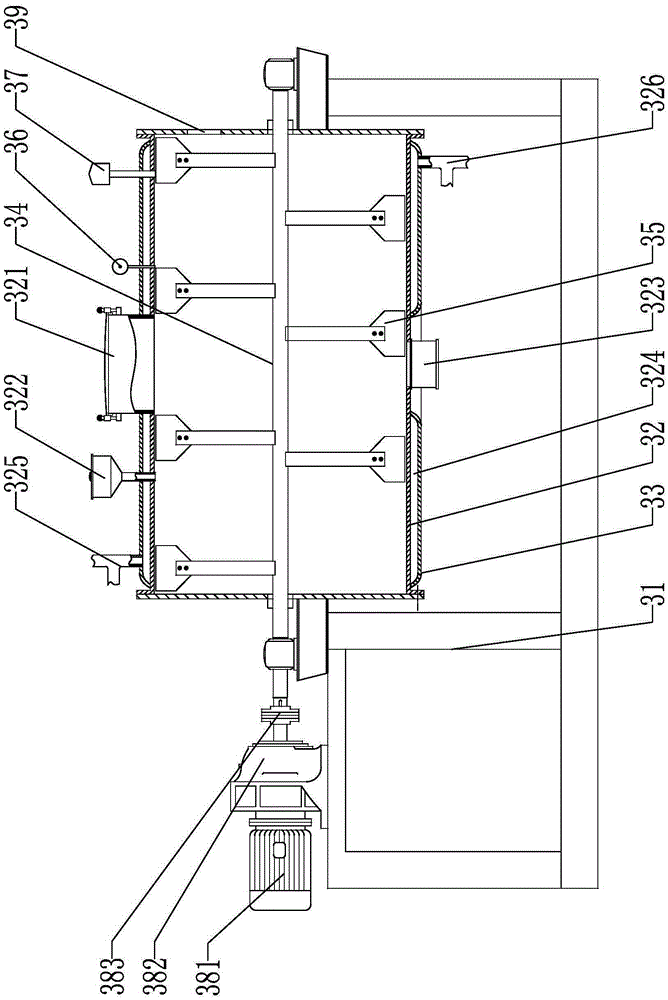

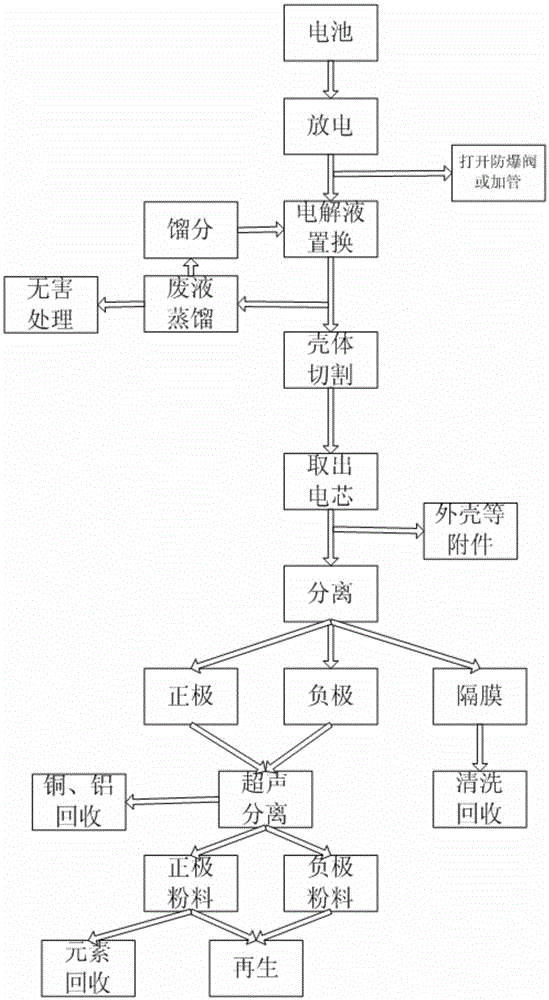

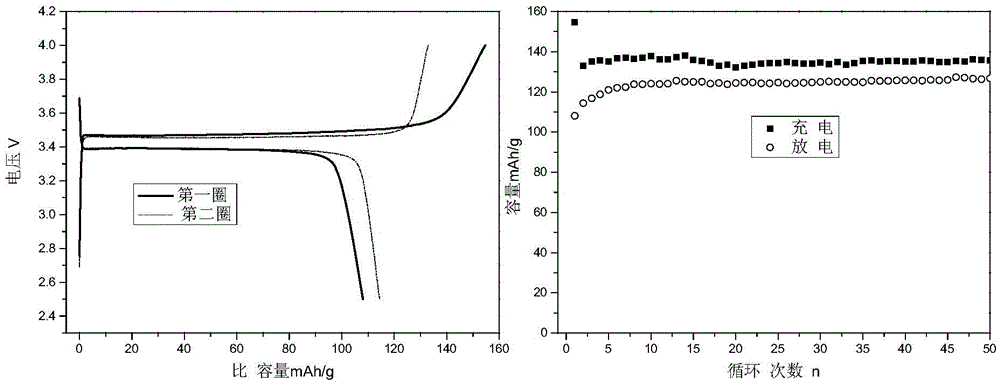

Demonstration process for recovering waste and old dynamic lithium iron phosphate cell in environmental protection mode

InactiveCN103825064AHarm reductionAvoid it happening againWaste accumulators reclaimingCell component detailsLithium iron phosphateSolvent

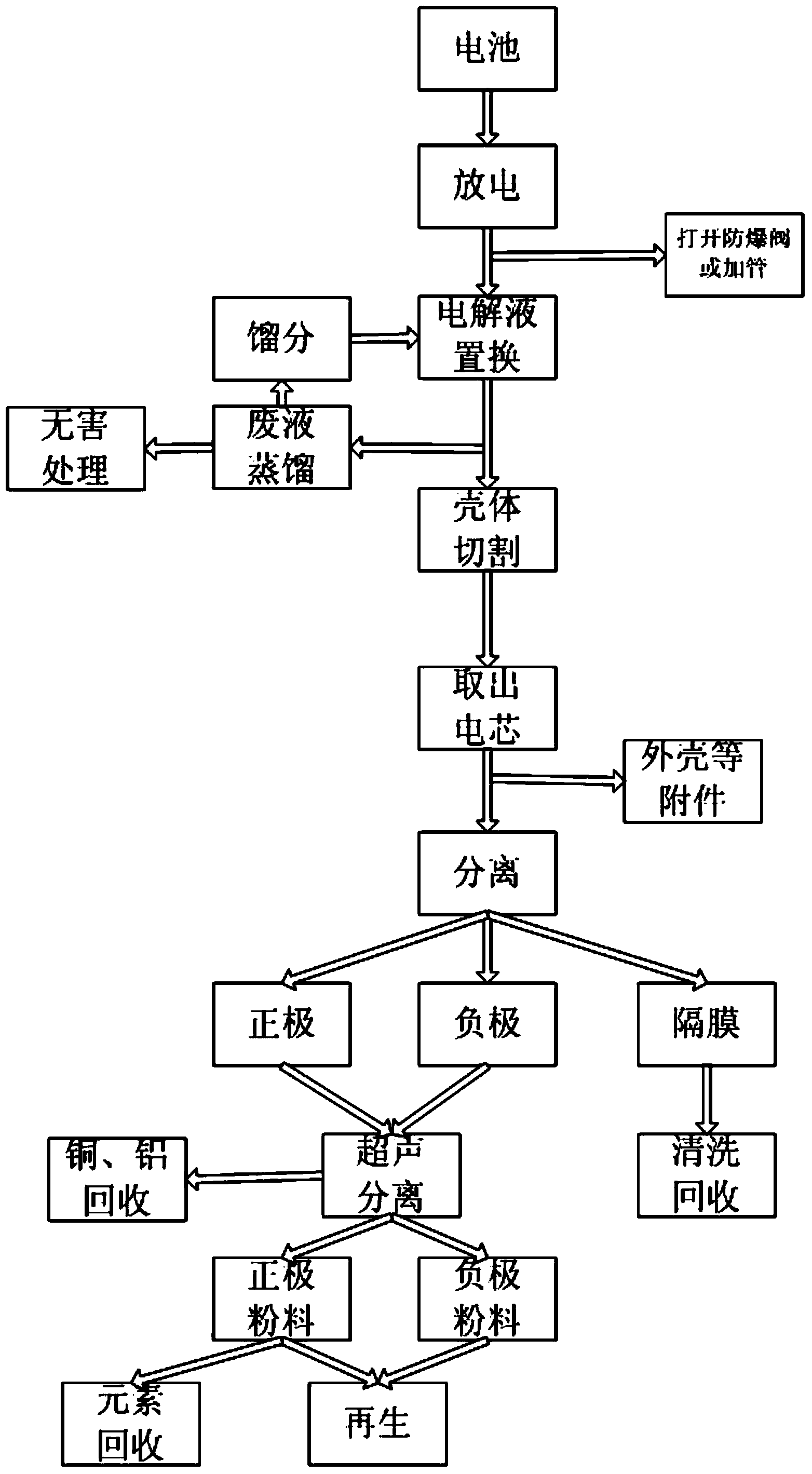

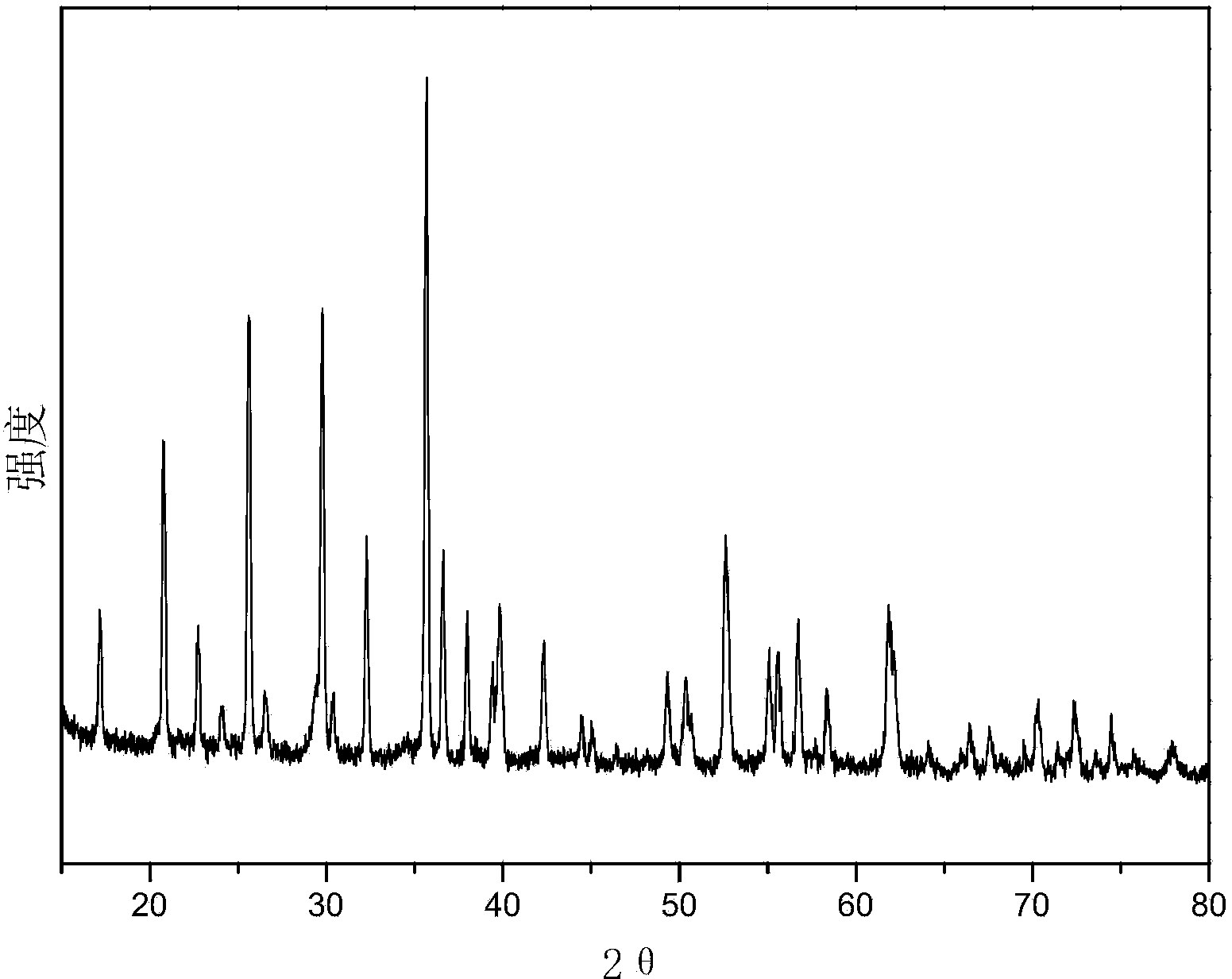

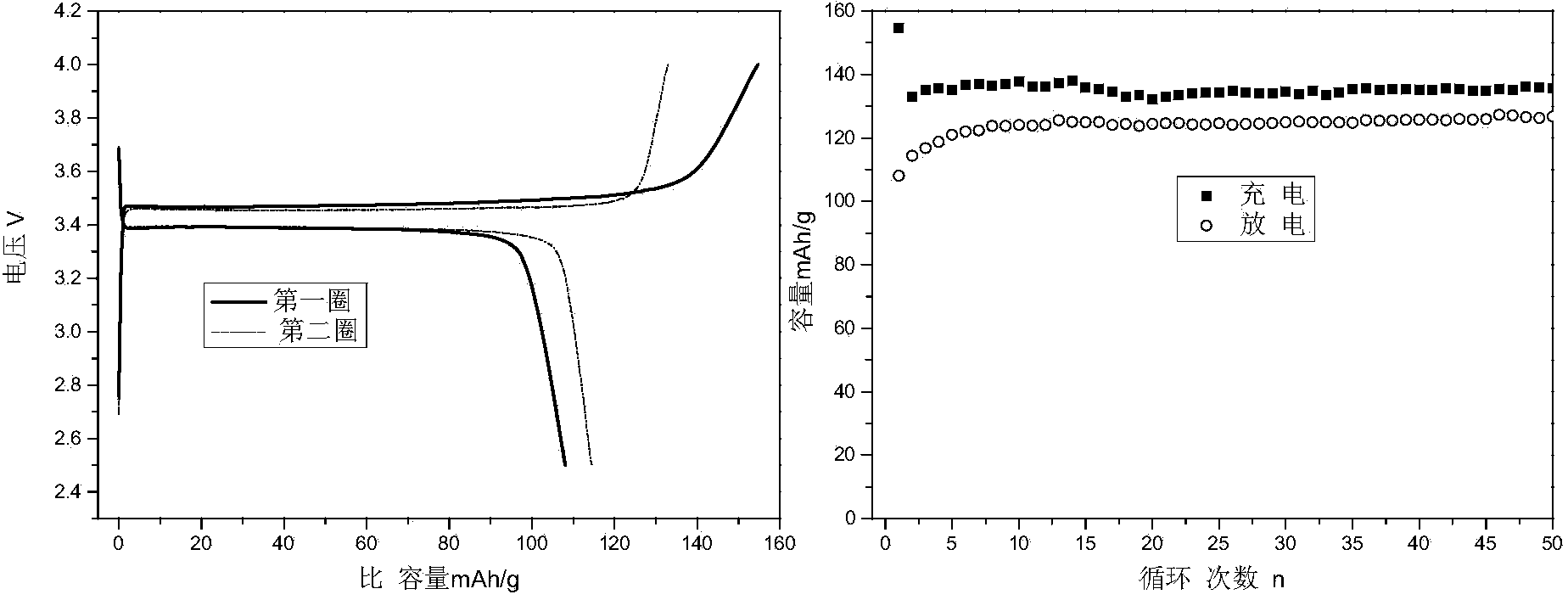

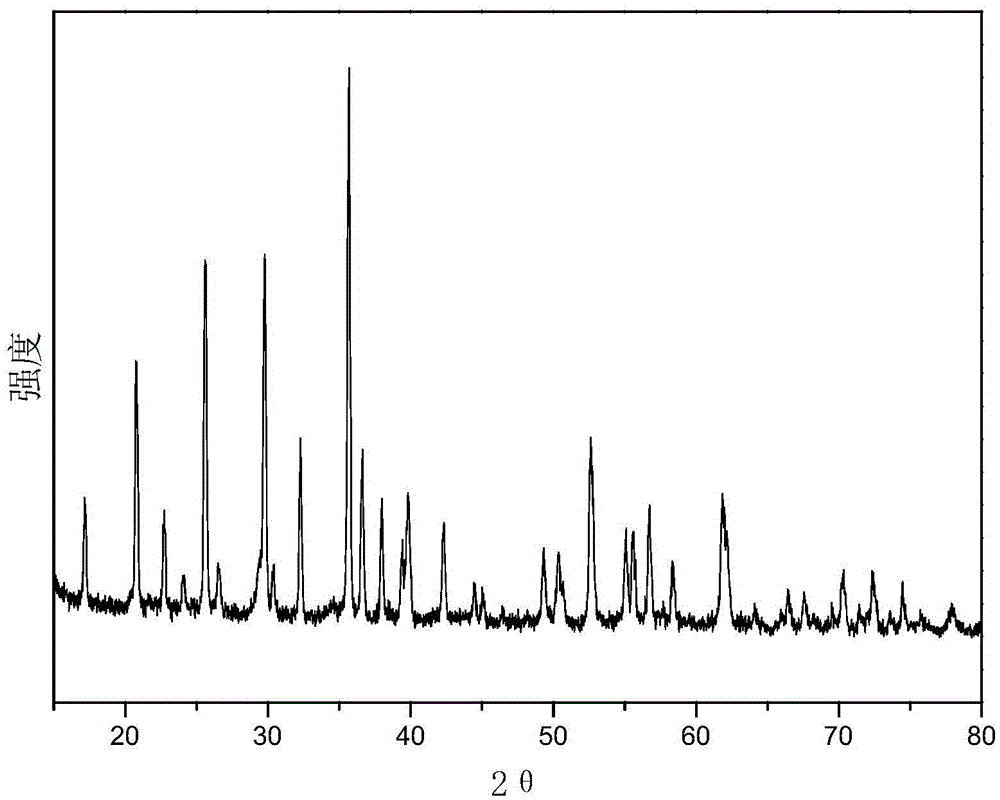

The invention relates to a demonstration process for recovering a waste and old dynamic lithium iron phosphate cell in an environmental protection mode, which belongs to the technical field of recovery of the power lithium iron phosphate cell. The method comprises the following steps: completely discharging the cell, extracting an electrolyte in the cell, adding a certain amount of solvent or displacement liquid, standing for 30 minutes and extracting the inner liquid of the cell, and distilling the extracted electrolyte to obtain the liquid for cycle usage when the electrolyte is displaced. According to the invention, the cell is cut by 1cm at the position along the cell top through a water jet, an electrical core is taken, wherein the steel casing, or aluminium casing or a PP plate can be directly recovered for usage. The anode, the cathode and a diaphragm are separated, and the diaphragm can be directly recovered through cleaning by ethanol. After the anode and the cathode are separated through physical methods such as ultrasound, a copper foil and an aluminium foil can be directly recovered, anode and cathode powder can be reused to be a cell material through high temperature treatment, and the purposes of no waste and no pollution can be reached by recovering the elements through a chemical method.

Owner:BEIJING UNIV OF TECH +1

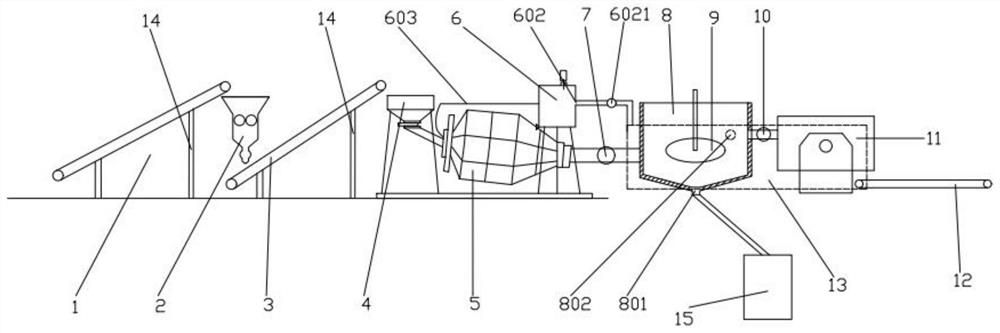

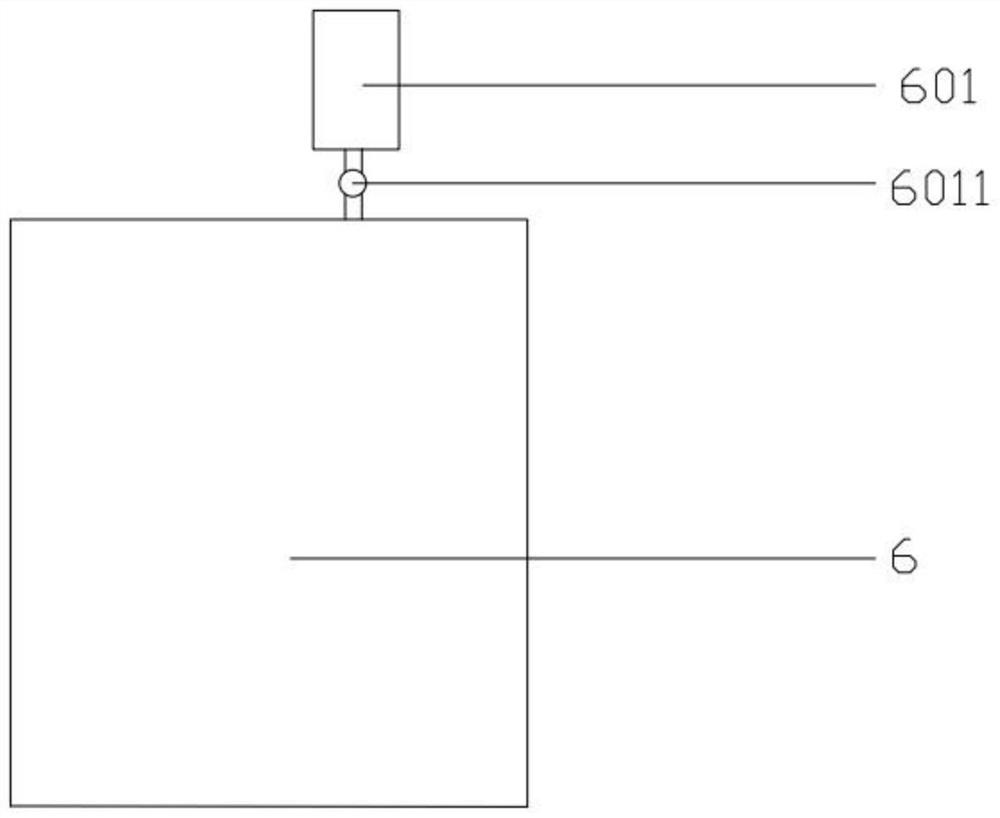

Process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt

ActiveCN106914474AGood dispersionLarge specific surface areaSolid waste disposalTransportation and packagingEnvironmental resistanceDecomposition

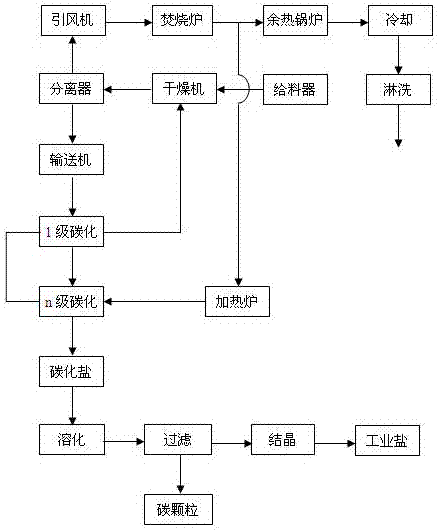

The invention belongs to the field of environmental protection, and particularly relates to a process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt. According to the process and the equipment disclosed by the invention, aiming at the characteristics that each kind of industrial waste salt contains various organic materials and has different physicochemical properties, a plurality of grades of decomposition and carbonization furnaces are arranged to perform graded heating on the industrial waste salt; the heating process is reasonable; the organic materials are decomposed and carbonized within the respective decomposition and carbonization temperature range; the heat-containing exhaust gas generated by decomposition and carbonization is used as a dry heat source; the exhaust gas generated by drying is introduced into an incinerator for incineration; and the hot gas generated by incineration is recycled. According to the process and equipment disclosed by the invention, continuous industrial production is realized, and during the operation of the system, no melting, agglomeration or bonding of the waste salt occurs, no secondary pollutants are generated, no toxic and harmful gas is exhausted, thermal efficiency is high, energy is saved, environmental protection is achieved, and the investment cost is lower than that of other methods; and the process and equipment have the advantages that the process and equipment are high in practicality, are suitable for the removal and harmless treatment of the organic materials of the industrial waste salt in various fields, and are suitable for popularization in industrial production.

Owner:辽宁东大粉体工程技术有限公司

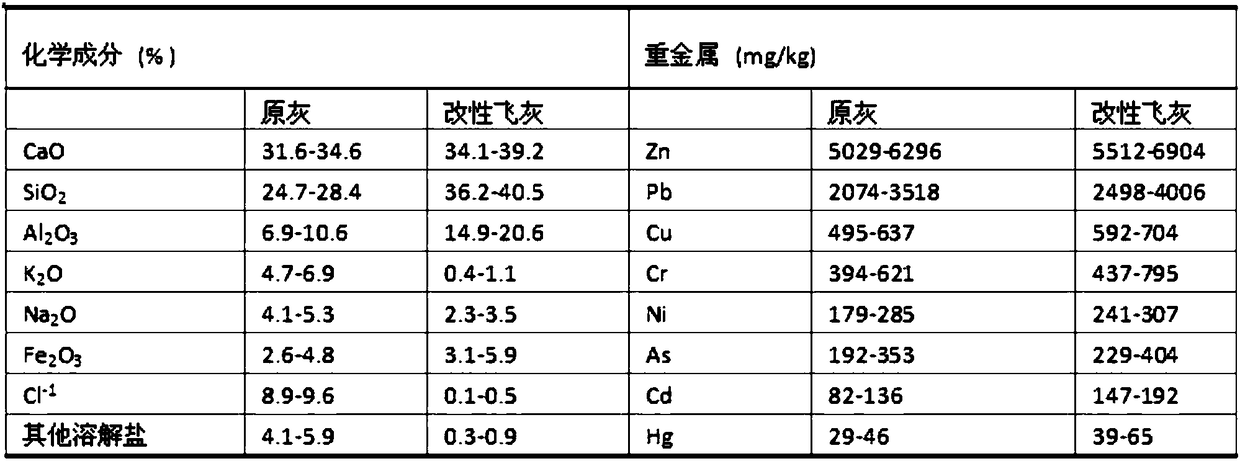

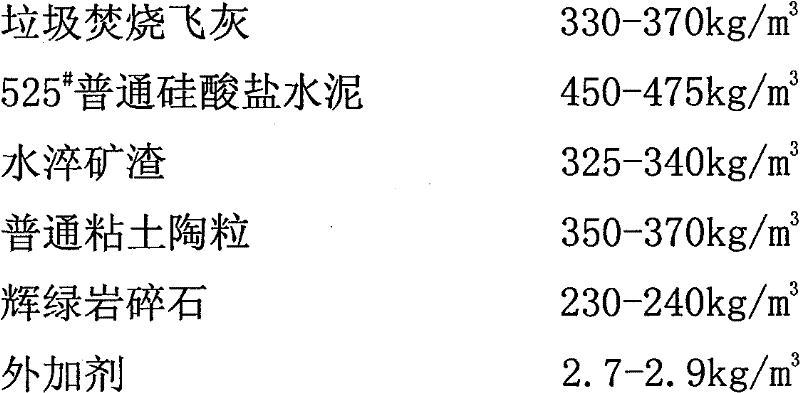

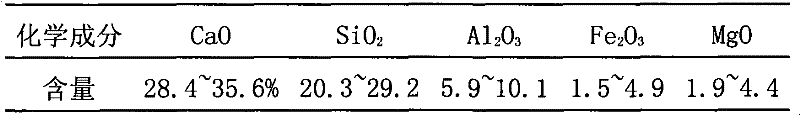

Method for preparing light concrete by municipal solid waste incineration fly ash

InactiveCN101531492ATo achieve the purpose of harmless treatmentSimple processSolid waste managementApparent densityPortland cement

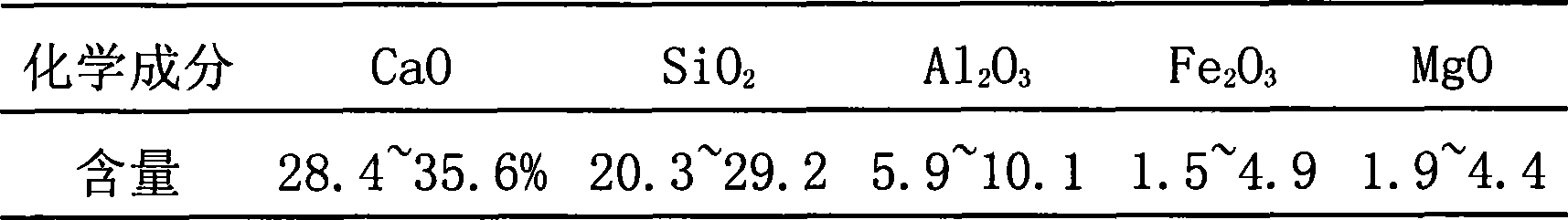

The invention discloses a method for preparing light concrete by municipal solid waste incineration fly ash. The light concrete comprises the following compositions according to material ratio: 330 to 370kg / m<3> of the municipal solid waste incineration fly ash, 450 to 475kg / m<3> of 525# common Portland cement, 325 to 340kg / m<3> of water-granulated slag, 350 to 370kg / m<3> of ordinary clay porcelain granules, 230 to 240kg / m<3> of diabase slag, and 2.7 to 2.9kg / m<3> of admixture. The method uses the municipal solid waste incineration fly ash to prepare the light concrete, can solidify heavy metal in fly ash, thereby achieving the aim of innocent treatment of the municipal solid waste incineration fly ash. The method has a simple process, and the obtained finished product has strength grade of CL40 and apparent density of 1800, and has good macroscopic performance.

Owner:SHANGHAI INST OF TECH

Complete-set device for recycling metal in waste lithium battery

InactiveCN103515668AThe method is simple and clearAdaptableWaste accumulators reclaimingProcess efficiency improvementEnvironmental resistanceRare earth

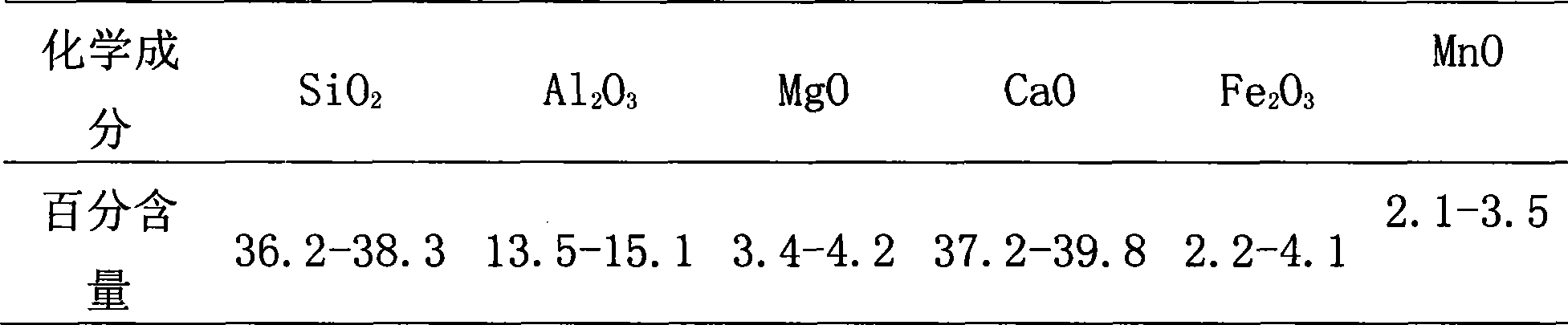

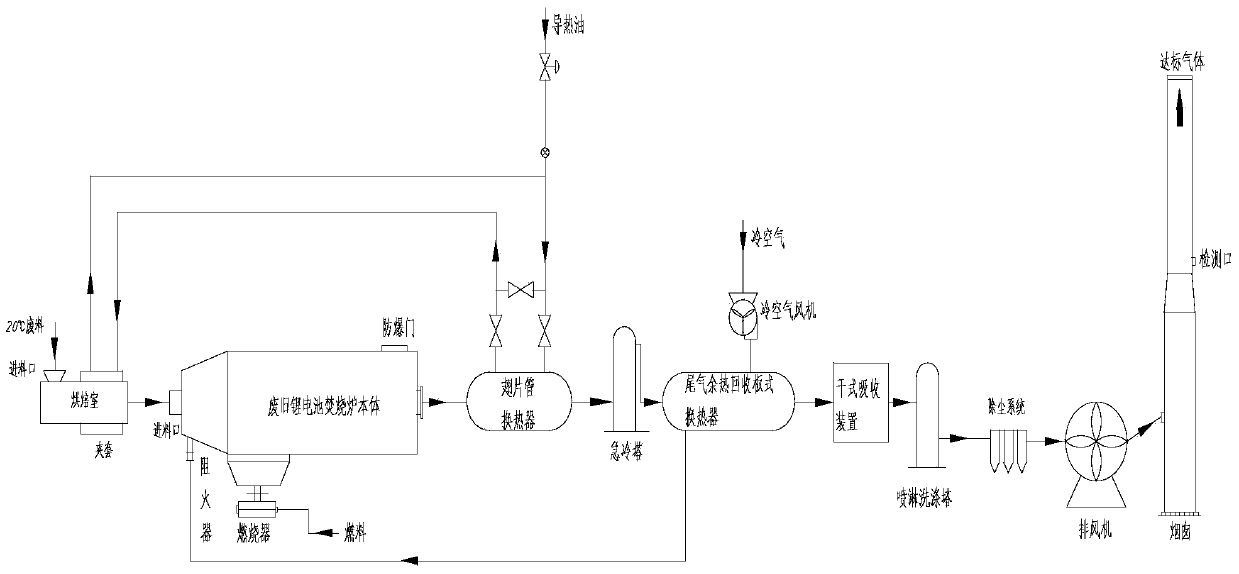

The invention provides a complete-set device for recycling metal in a waste lithium battery and belongs to the technical field of environmental protection. Materials such as lithium, cobalt, copper, nickel and light rare earth can be extracted from the waste lithium battery; the lithium battery recycling has huge potential commercial value and a broad prospect. According to the design, crushing pre-treatment is performed on the waste lithium battery firstly, feeding is performed, the waste lithium battery enters into a baking room for first baking, and then enters into a rotary incinerator for secondary combustion, three-time cooling is performed continuously and tail gas purification is performed, and smoke is discharged into air after reaching standards finally. During the process of smoke discharging, a rapid cooling device is used to enable the tail gas to be cooled so as to prevent dioxin from being produced. The heat quantity of a plate-type heat exchanger is adopted for recycling, and the purpose of recycling can be achieved.

Owner:CHANGZHOU UNIV

Enhanced montmorillonite adsorbent and preparation method thereof

InactiveCN102247798AImprove processing efficiencyImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionInorganic arsenicIron salts

The invention discloses an enhanced montmorillonite adsorbent and a preparation method thereof. The enhanced montmorillonite adsorbent is made by modifying montmorillonite with sodium salts, iron salts and microwave. The preparation method comprises the following steps of: firstly treating montmorillonite used as a raw material with a sodium carbonate solution with mass concentration of 8-10 g / L, then treating the montmorillonite with 0.1 mol / L FeCl3 solution, treating with microwave, and drying and calcining to obtain the enhanced iron-based montmorillonite. After being treated with the adsorbent disclosed by the invention, the waste water containing arsenic and inorganic arsenic has the arsenic content lower than 50 mcg / L. The purpose of environment-friendly treatment is achieved, the raw material can be obtained easily, the adsorbent can be prepared easily with low cost and has bright application prospect.

Owner:HEFEI UNIV OF TECH

Method for producing microorganism luminous energy organic fertilizer by utilizing table/kitchen wastes

InactiveCN102746034ATo achieve the purpose of harmless treatmentObvious beneficial effectClimate change adaptationOrganic fertilisersSolid componentFiltration

The invention relates to a method for producing a microorganism luminous energy organic fertilizer by utilizing table / kitchen wastes. The method comprises the steps of: (1) carrying out solid-liquid separation on the table / kitchen wastes, deoiling the separated liquid, and inputting the separated solid ingredients into a grinder for grinding and then carrying out oxidative degradation; (2) inputting the deoiled liquid into a fermentation tank and inputting lactobacillus into the fermentation tank to carry out amino acid fermentation; (3) inputting the fermented mixture into a membrane filtration concentrator for concentration and then carrying out storage so as to generate a concentrated lactobacillus prepared fertilizer; (4) taking the concentrated lactobacillus and the oxidative degraded product as base materials, then mixing the base materials with an organic matter carrier and carrying out hydrolysis; (5) adding a photocatalyst to carry out nitrogen fixation and granulation; and (6) carrying out low-temperature drying to obtain the microorganism luminous energy organic fertilizer. According to the method provided by the invention, high-energy oxygen and microorganism lactobacillus are used for realizing the rapid hydrolysis, oxidation and degradation of organic biomasses in the table / kitchen wastes so as to generate the lactobacillus prepared fertilizer, so that the aims of harmlessly treating and recycling the organic biomass table / kitchen wastes are achieved.

Owner:深圳市创宇百川环境科技有限公司

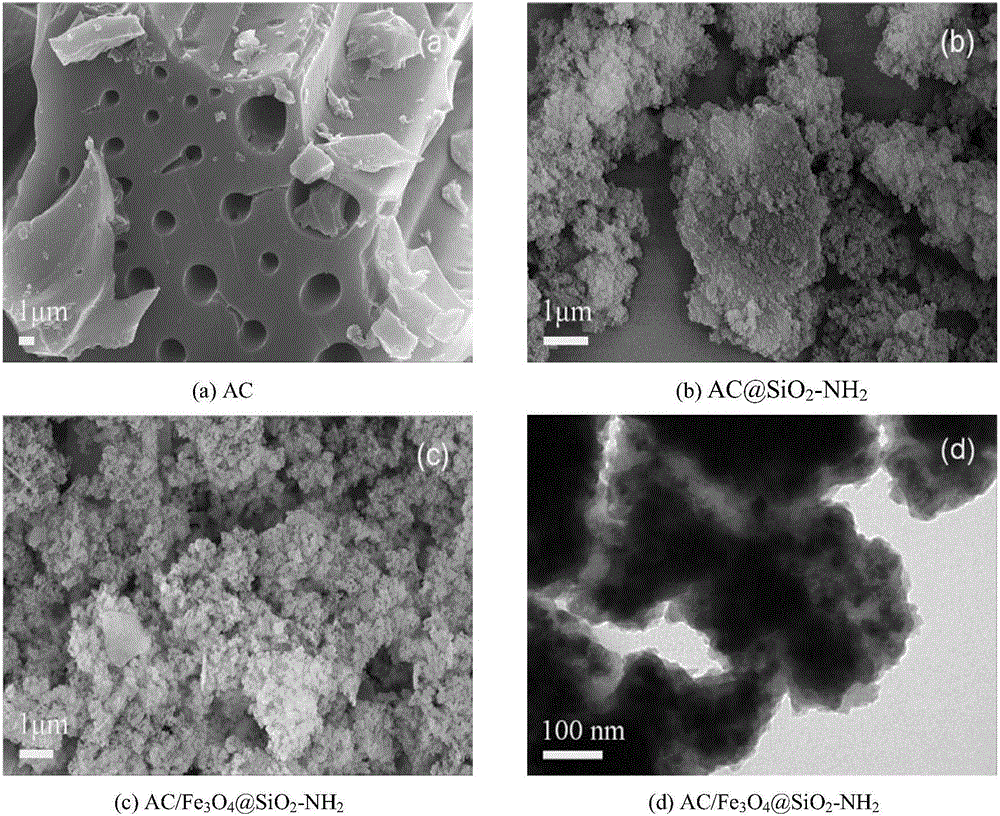

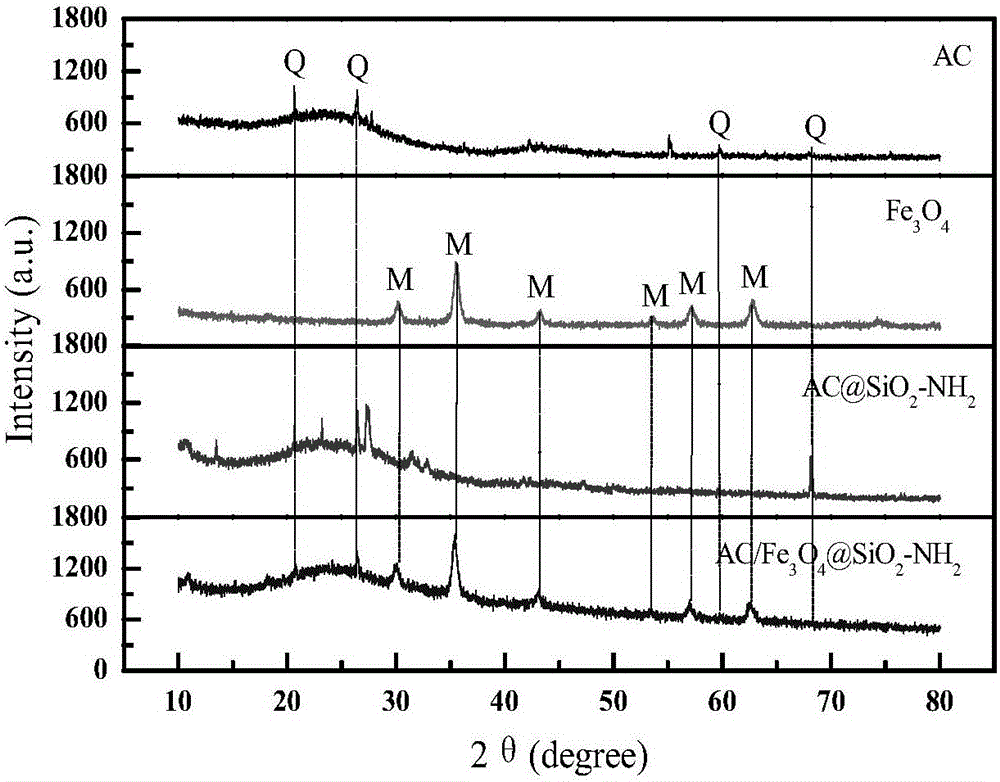

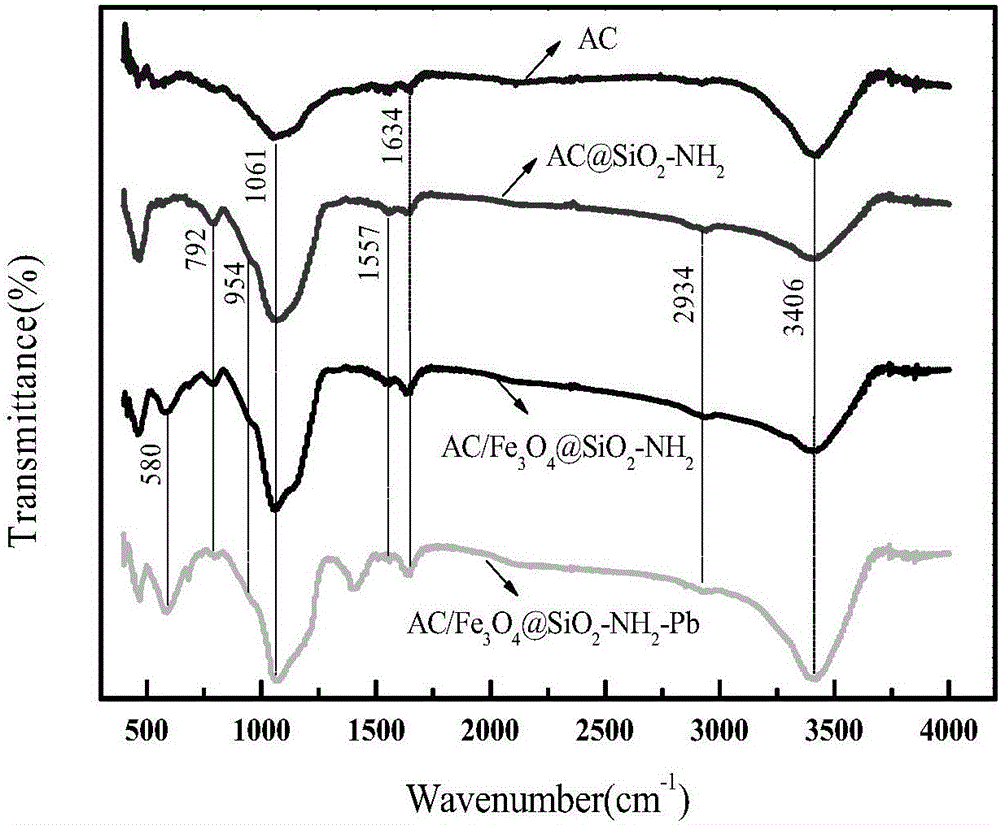

Functional magnetic carbon material and preparation method and application thereof

InactiveCN105727913AThe synthesis process is simple and low consumptionModified content is highOther chemical processesWater contaminantsMagnetite NanoparticlesSilicon dioxide

The invention belongs to the technical field of functional materials and magnetic materials, and in particular relates to a functionalized magnetic carbonaceous material and its preparation method and application. One-step synthesis of the process; (2) The surface of activated carbon is doped with magnetic nanoparticles, which improves the easy aggregation of magnetic particles and enables the products to be magnetically separated without causing secondary pollution of water bodies; (3) Controlling the reaction conditions during the preparation process can achieve magnetic Controllable nanoparticle content, silica layer and amino layer; (4) Enhance the dispersion performance of the material by adjusting the mass ratio of activated carbon and magnetic particles in the magnetic activated carbon carrier, and selectively adsorb and remove Pb(II) in wastewater , to achieve the purpose of harmless treatment, and provide the possibility to realize its application and promotion in engineering.

Owner:ZHEJIANG UNIV

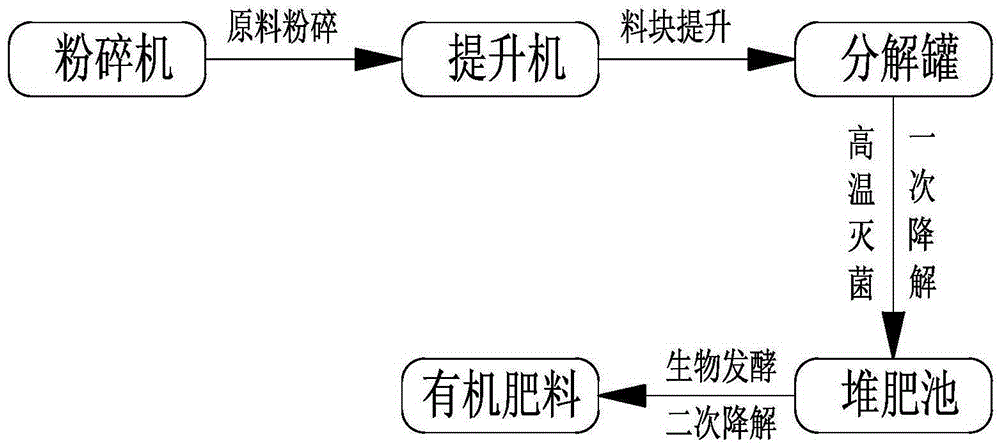

Biological degradation method and degradation device for animal carcasses

InactiveCN105418183AAchieve inactivationCause some damagesAnimal corpse fertilisersClimate change adaptationDecompositionOrganic manure

The invention discloses a biological degradation method and degradation device for animal carcasses. The degradation method comprises the following steps of 1 raw material smashing, wherein animal carcass raw materials needing to be treated are smashed into blocks through a smashing machine; 2 high-temperature sterilizing and one-time degrading, wherein the smashed animal carcass raw materials are conveyed into a decomposition tank, high-temperature sterilizing bacteria and auxiliary materials for adsorbing oil and fat are added into the tank, then the decomposition tank is sealed and heated to 120 DEG C or above, stirring is performed in a timing mode in the heating process, standing is performed for 10-14 hours, and then the materials are discharged; 3 secondary degrading, wherein composting fermentation is performed on the animal carcass raw materials processed through high-temperature sterilizing and one-time degrading to complete secondary degrading. According to the method, sterilizing is safe and thorough, sterilizing, decomposing and waste gas condensing and recycling of the animal carcasses are achieved at a time in the decomposition tank, the application range is wide, produced organic fertilizer cannot damage crops, the technology is reasonable, operation is easy and convenient, and energy conversation and environmental protection are achieved.

Owner:裴德修

A Demonstration Process Method for Environmentally Friendly Recycling of Waste Power Lithium Iron Phosphate Batteries

InactiveCN103825064BHarm reductionAvoid it happening againWaste accumulators reclaimingCell component detailsCopper foilSolvent

The invention relates to a demonstration process for recovering a waste and old dynamic lithium iron phosphate cell in an environmental protection mode, which belongs to the technical field of recovery of the power lithium iron phosphate cell. The method comprises the following steps: completely discharging the cell, extracting an electrolyte in the cell, adding a certain amount of solvent or displacement liquid, standing for 30 minutes and extracting the inner liquid of the cell, and distilling the extracted electrolyte to obtain the liquid for cycle usage when the electrolyte is displaced. According to the invention, the cell is cut by 1cm at the position along the cell top through a water jet, an electrical core is taken, wherein the steel casing, or aluminium casing or a PP plate can be directly recovered for usage. The anode, the cathode and a diaphragm are separated, and the diaphragm can be directly recovered through cleaning by ethanol. After the anode and the cathode are separated through physical methods such as ultrasound, a copper foil and an aluminium foil can be directly recovered, anode and cathode powder can be reused to be a cell material through high temperature treatment, and the purposes of no waste and no pollution can be reached by recovering the elements through a chemical method.

Owner:BEIJING UNIV OF TECH +1

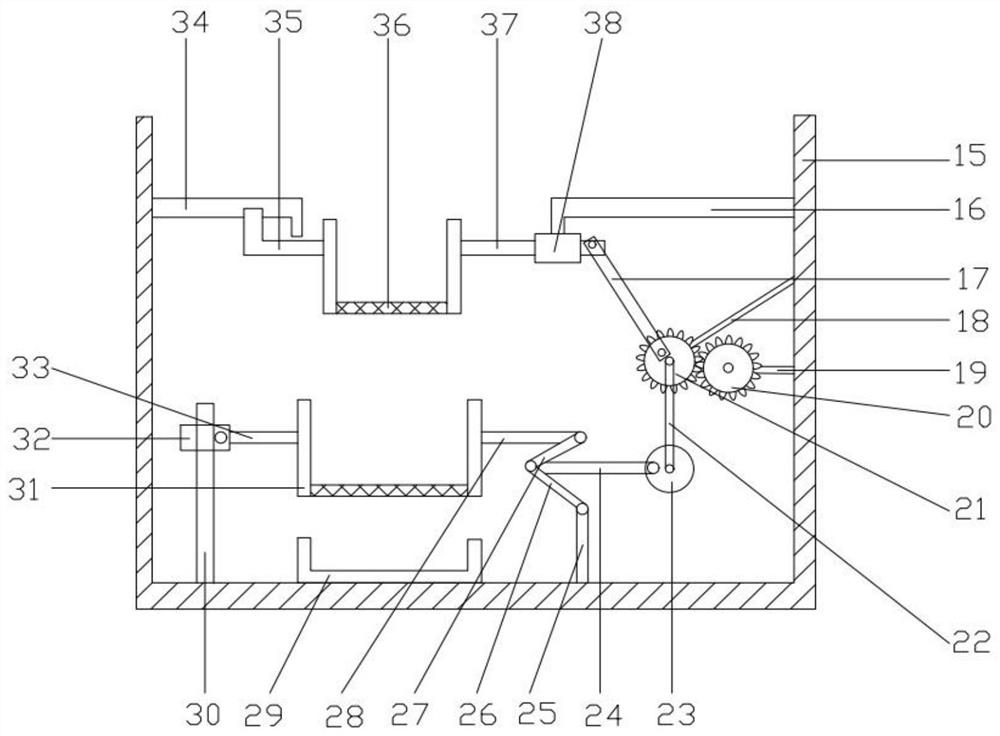

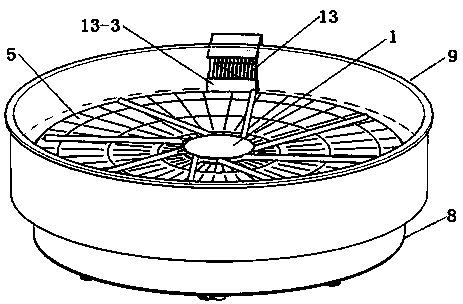

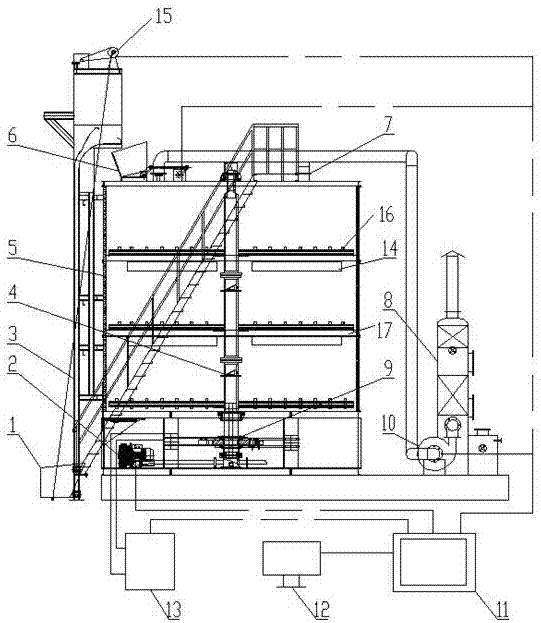

Harmless muck treatment system

ActiveCN112718794AEasy to operateEasy to handleTransportation and packagingSolid waste disposalFilter pressCrusher

The invention provides a harmless muck treatment system. The harmless muck treatment system comprises a crusher, a stirring device, a repairing box, a separation pool and a filter press, wherein a feeding opening of the crusher is connected with a raw material conveying device, a discharging opening of the crusher is connected with a second conveying device, and the second conveying device is connected with a hopper; a feeding opening of the stirring device is connected with the hopper, the stirring device can be a rotary tank stirrer, the repairing box is also connected to the feeding opening of the stirring device, the discharging opening of the stirring device is connected with a feeding opening of the separation pool, a feeding opening of the filter press is connected with the discharging opening of the separation pool through a filter pressing pump, and a discharging opening of the filter press is connected with a discharging opening of the separation pool; and a discharging opening of the filter press is connected with the second conveying device. According to the harmless muck treatment system, by arranging the repairing box and the stirring device, waste soil and repairing liquid are mixed more evenly, the repairing effect is more obvious, the treated waste soil can be free of pollution residues, and the purpose of innocent treatment is achieved.

Owner:深圳市卓域环保科技有限公司

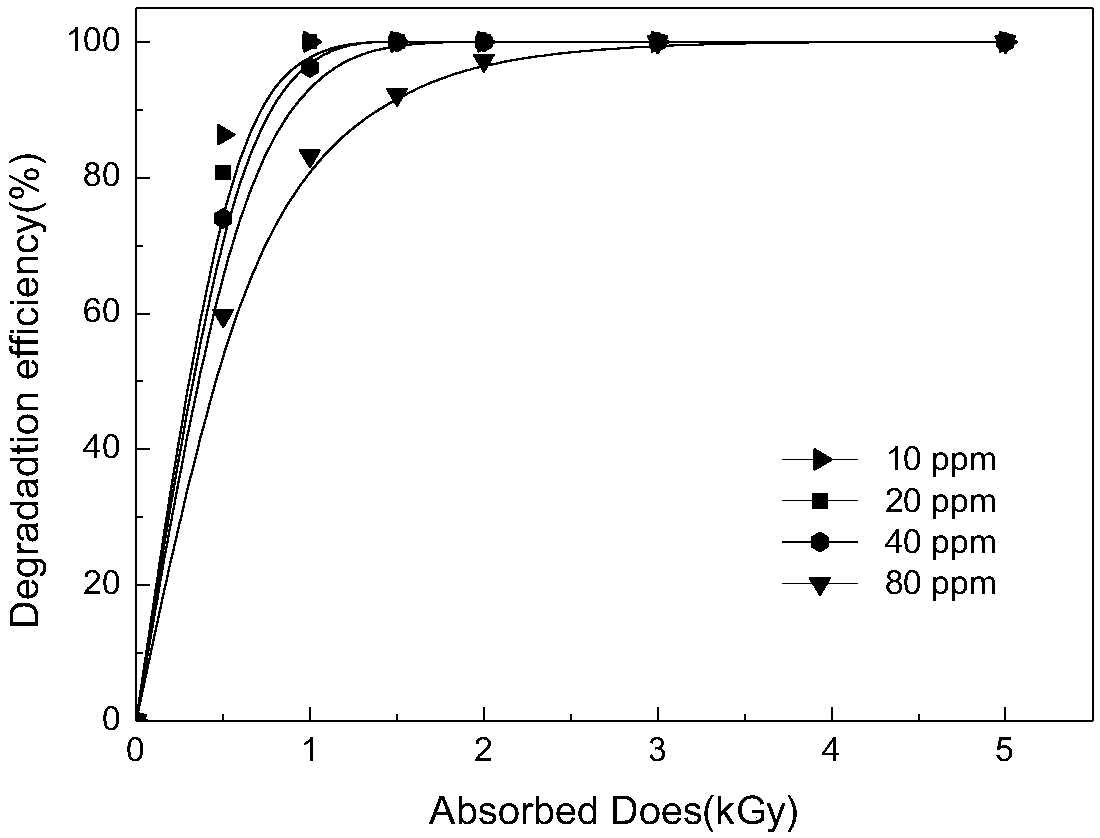

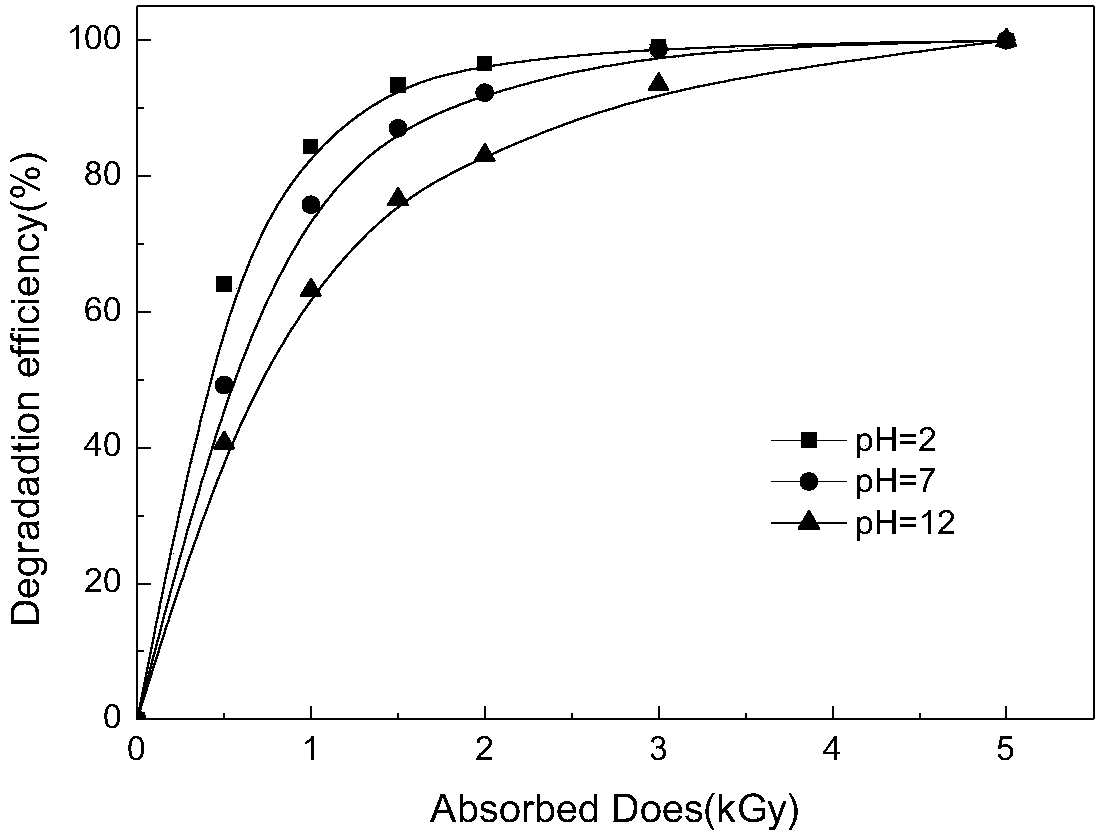

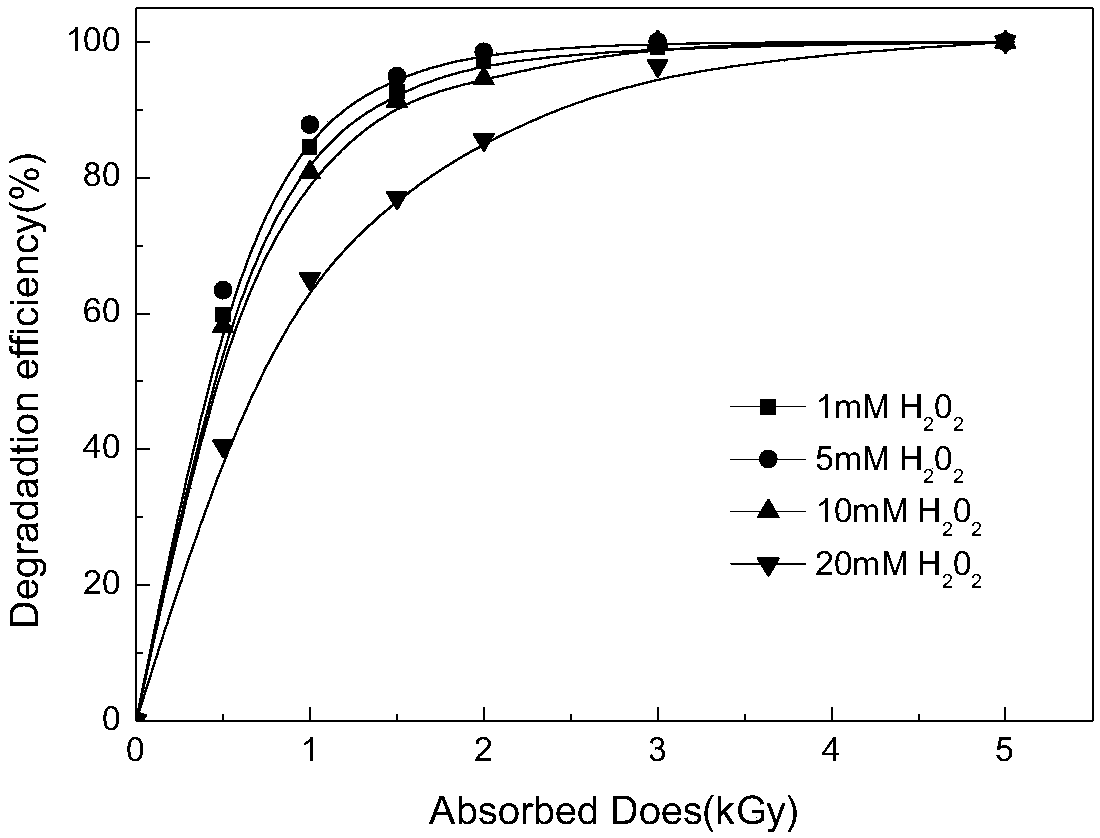

Method for degrading venlafaxine in water by utilizing electron beam irradiation

InactiveCN108585319AStrong handling toxicityRefractory ToxicityWater treatment parameter controlWater treatment compoundsNuclear technologyHigh energy

The invention discloses a method for treating an antidepressant venlafaxine in water by utilizing electron beam irradiation, particularly electron irradiation, and belongs to the technical fields of nuclear technology application, water treatment and environmental protection. According to the method disclosed by the invention, a water body containing the venlafaxine is treated by utilizing high energy electrons generated under electron accelerator radiation conditions to degrade the venlafaxine. An electron accelerator adopted in the method disclosed by the invention has an electron irradiation dose of 0.5-5 KGy. Concentrated sulfuric acid is added in a used sample pretreatment solution of the venlafaxine to regulate the pH value of the solution to reach 2-7, and 1-5 mM of hydrogen peroxide is added into the solution, so that a radiation degradation effect is promoted; moreover, the irradiation dose can be properly reduced. The method disclosed by the invention can remove the venlafaxine drug pollution in the water body, is high in reaction speed and high in degradation efficiency, has better applicability when being compared with other traditional methods and is an efficient and energy-saving water treatment technology.

Owner:SHANGHAI UNIV

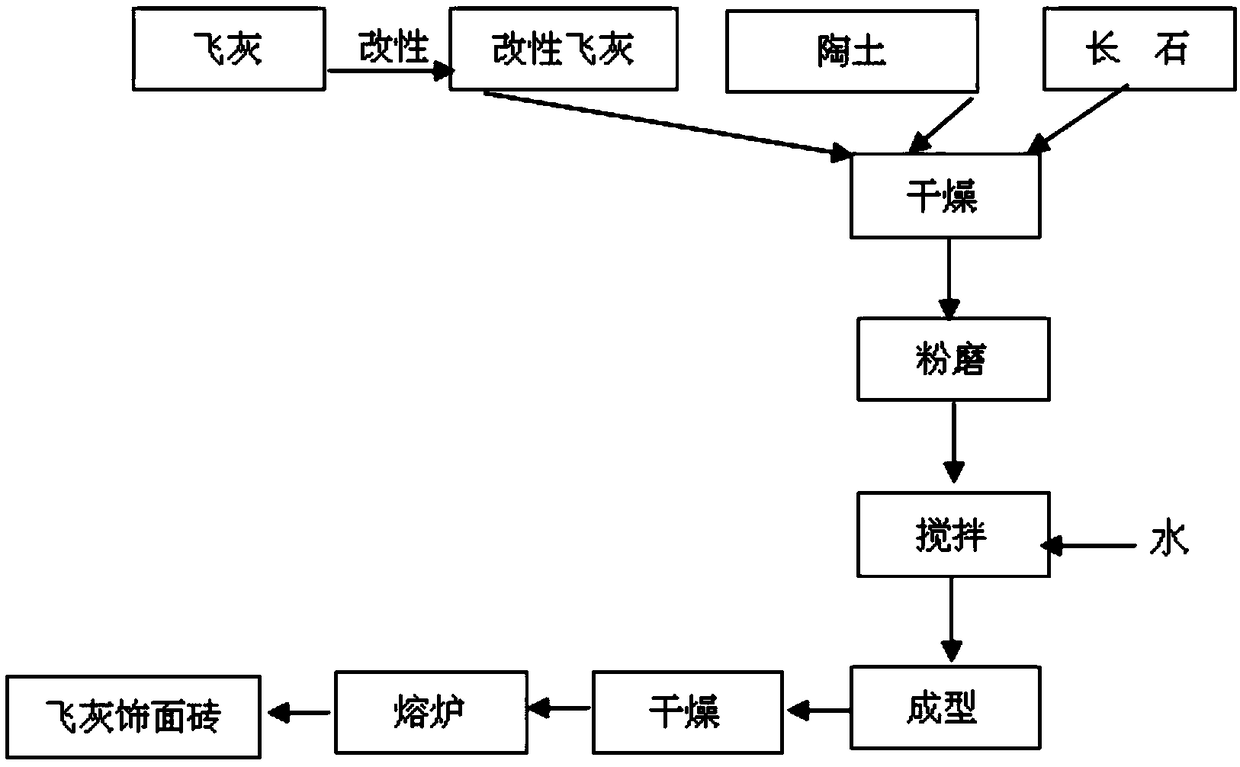

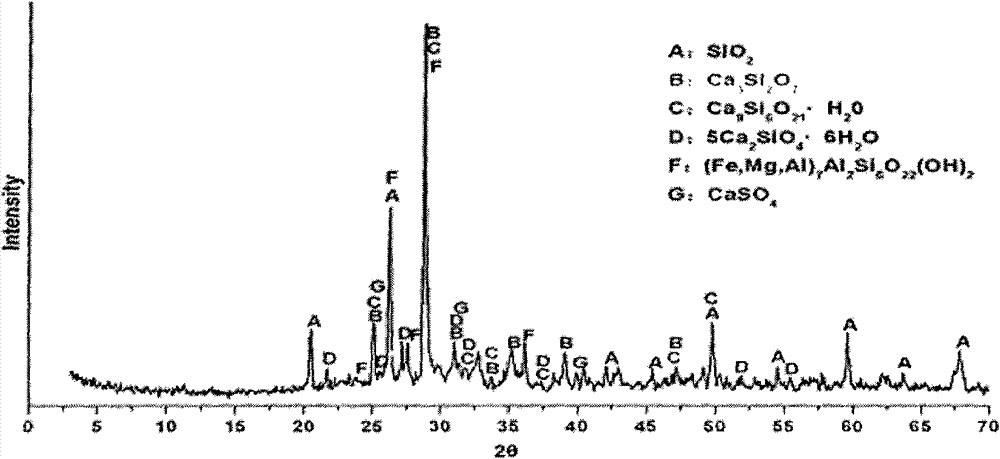

Preparation method for preparing facing bricks by modifying household waste incinerated fly ash

InactiveCN109437849ACost savingsSave land resourcesAuxillary shaping apparatusCeramic materials productionBrickLand resources

The invention relates to a preparation method for preparing facing bricks by modifying household waste incinerated fly ash. The preparation method comprises the following steps: taking a NaOH solutionas a modifier, mixing and stirring with fly ash, and washing with water, performing suction filtration and drying to obtain modified fly ash; mixing the modified fly ash, china clay and feldspar, performing aeration-drying in a drying chamber for 36-48 hours, grinding, adding the material obtained by grinding into a stirrer, adding water to stir, standing at a room temperature for 12-24 hours soas to age, and screening the aged material by a screen of 50-100 meshes; and performing compression molding on the aged and screened material on a brick making machine, drying the molded green body ina dry kiln for 12+ / -2 hours, and calcining the dried green body in a smelting furnace, thereby obtaining the product. According to the method disclosed by the invention, potential secondary pollutionof the fly ash in the landfill process can be avoided, potential hazards to the society are reduced, and lots of fly ash safety landfill disposal cost and land resources can be saved.

Owner:SHANGHAI INST OF TECH

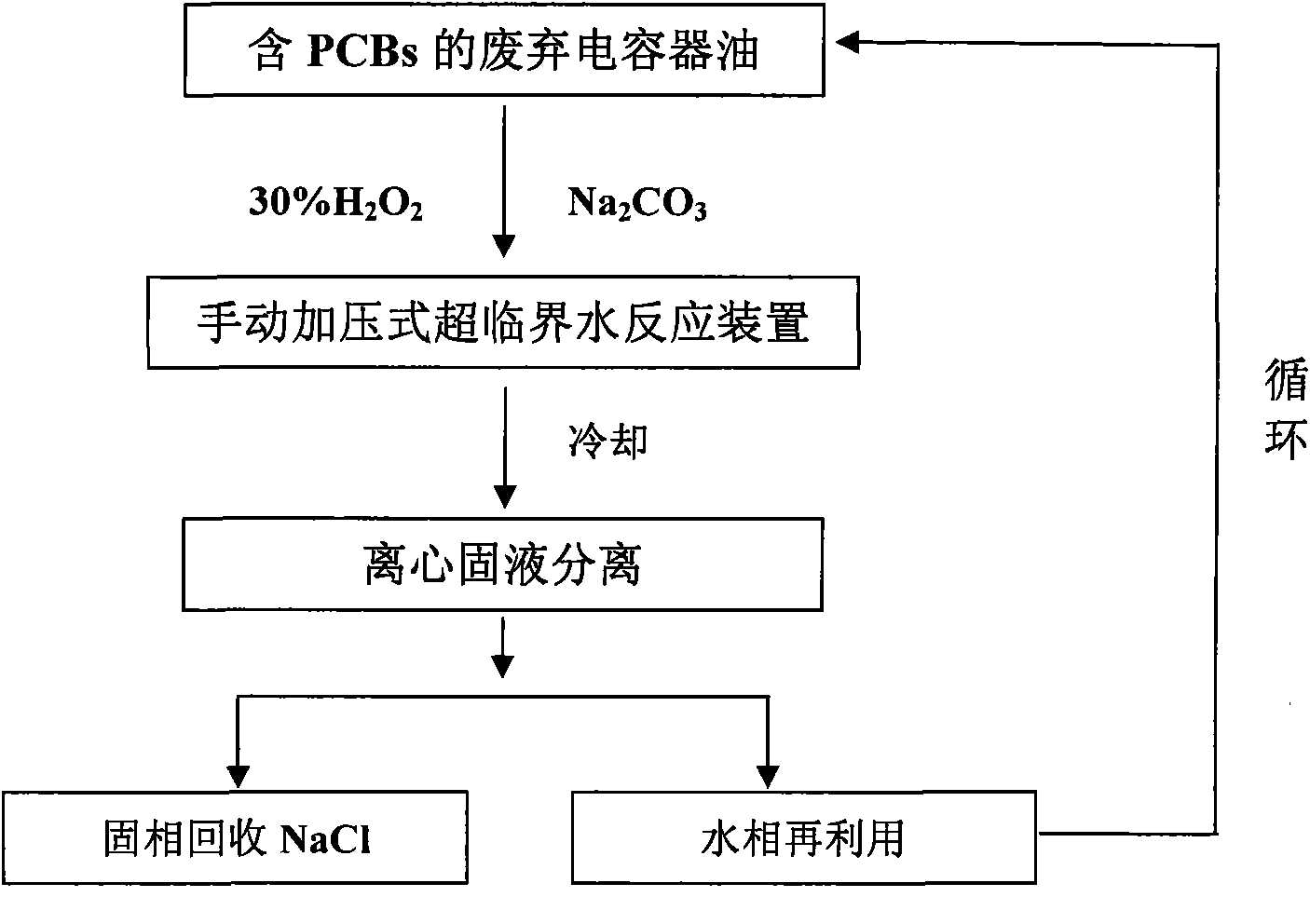

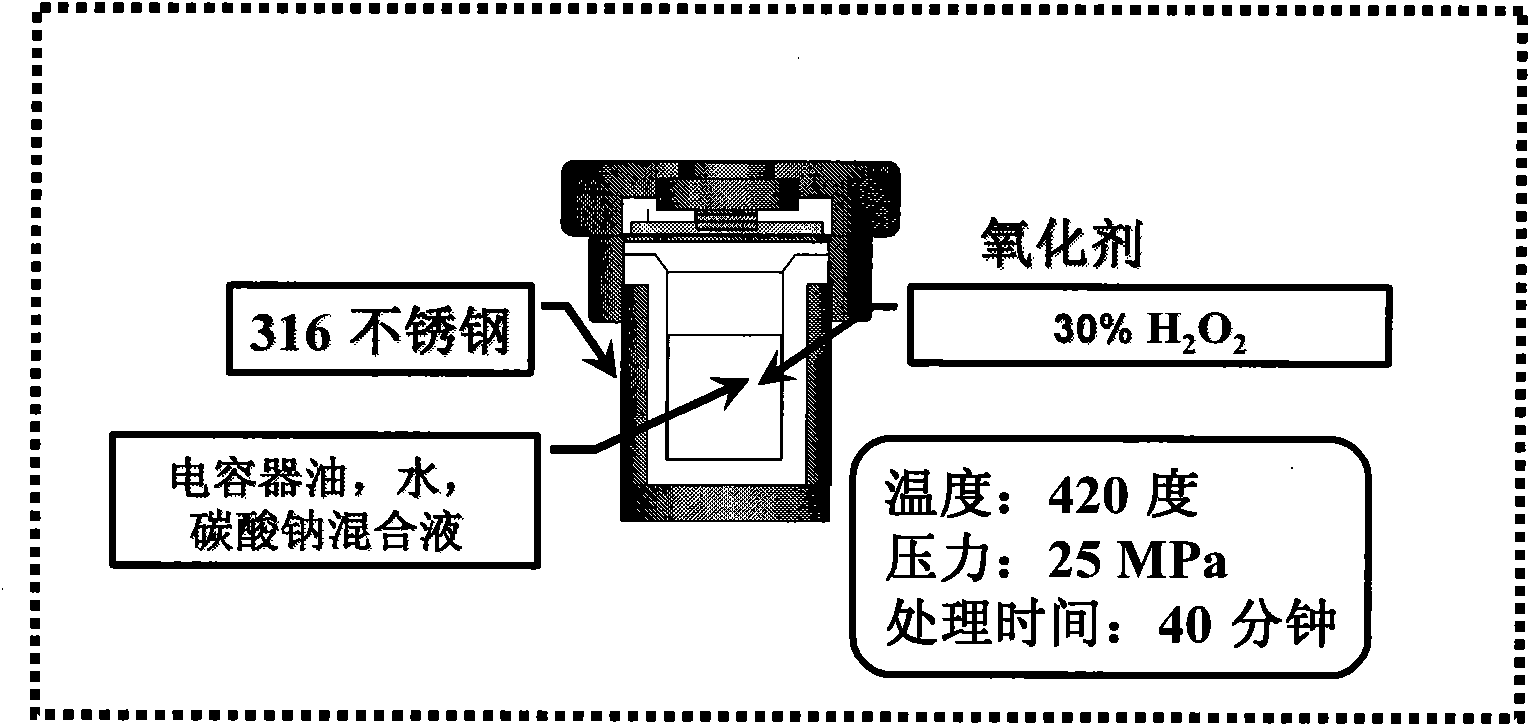

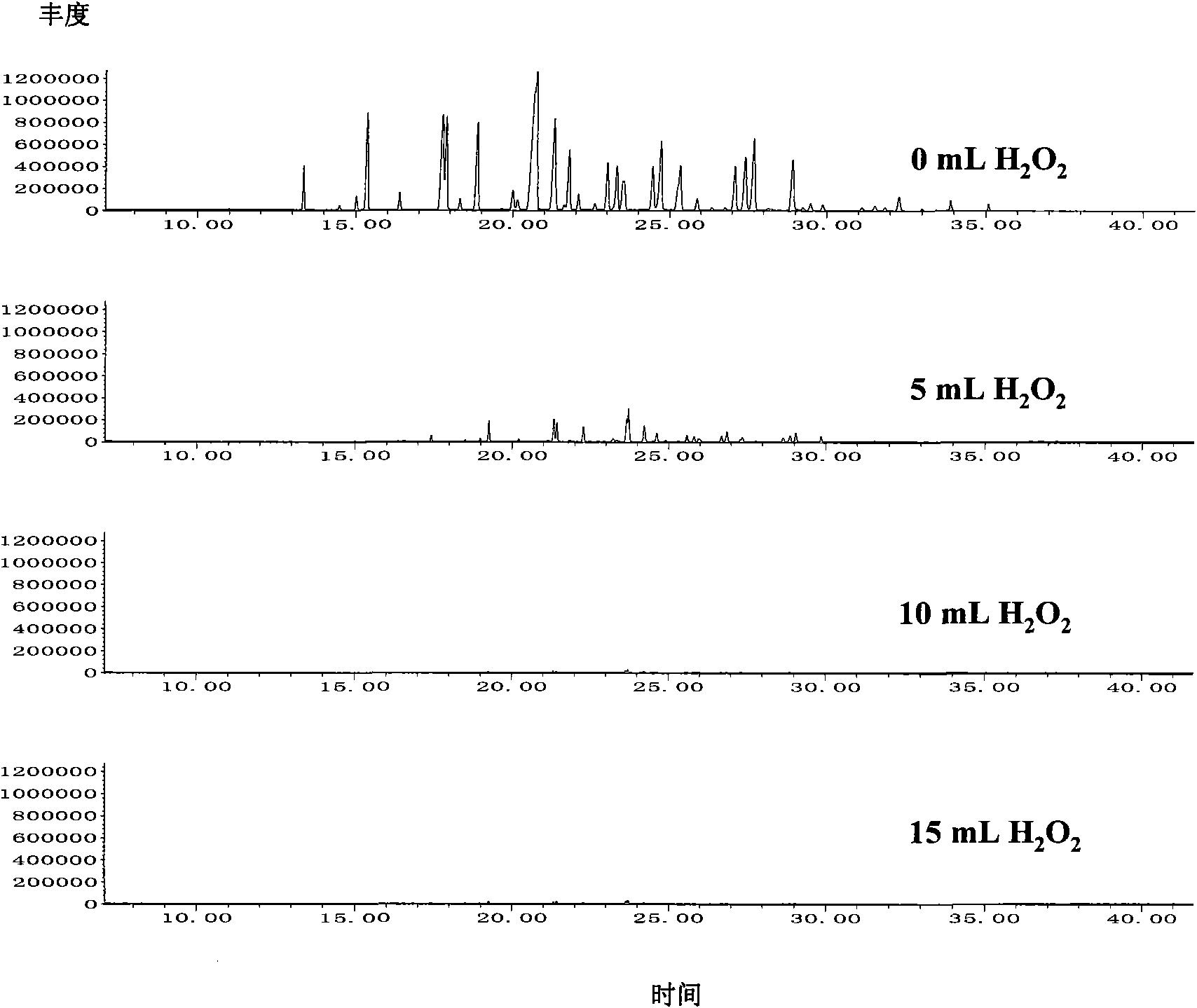

Technical process for supercritical water treatment of polychlorinated biphenyls (PCBs) waste and complete plant thereof

InactiveCN101850168ATo achieve the purpose of harmless treatmentChemical protectionLiquid mediumBurn treatment

Aiming at the difficulties for harmlessly treating polychlorinated biphenyl (PCBs) waste and heavy pollution caused by burning treatment, the invention develops a suit of environment-friendly technical process for treating PCBs waste and establishes related complete plant thereof. The invention combines morphological characteristics of PCBs, especially the morphological characteristic of PCBs in waste capacitor oil and transformer oil and then adopts the technique of supercritical water oxidation to oxidize the PCBs contained in liquid medium into environment-friendly CO2 and H2O completely by introducing catalysts and reaction active agent. Therefore, the PCBs waste can be treated harmlessly.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

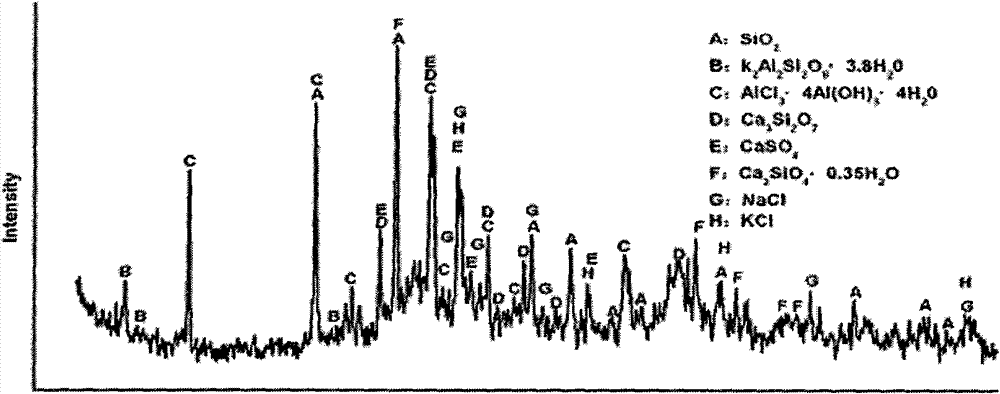

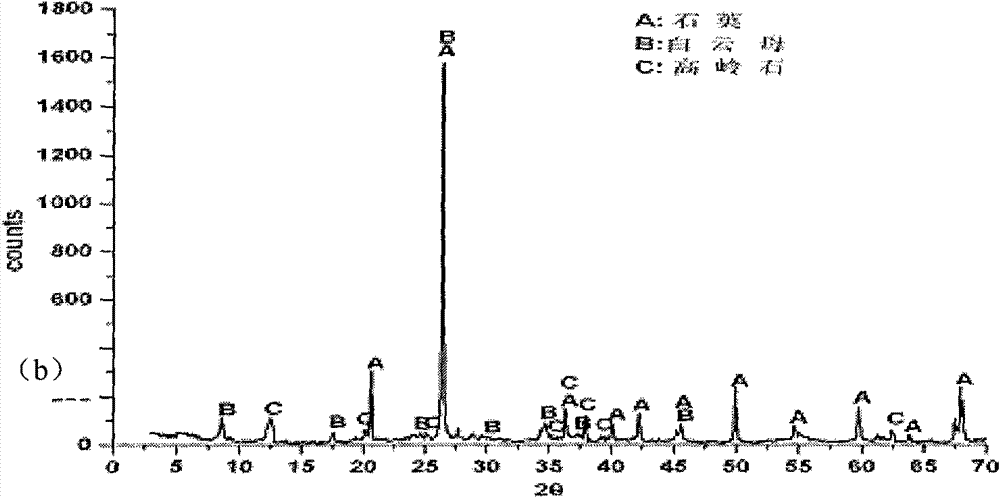

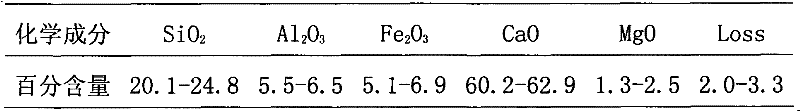

Fly ash baked brick prepared by washed incineration fly ash of house refuse and preparation method thereof

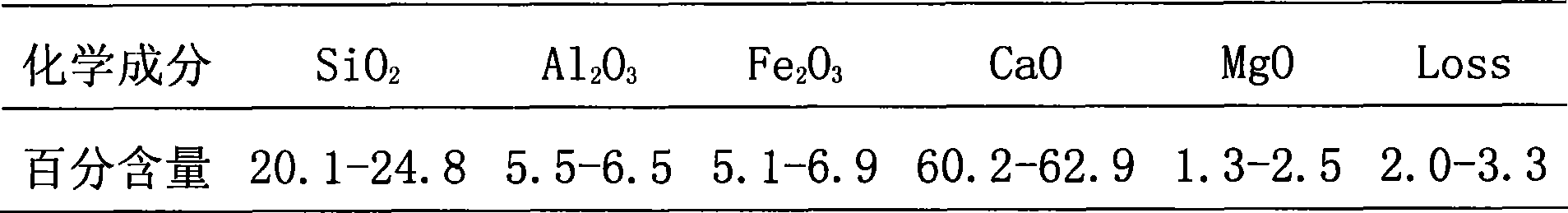

InactiveCN101905967BImprove macro performanceTo achieve the purpose of harmless treatmentSolid waste disposalCeramic materials productionBrickFly ash

The invention discloses a fly ash baked brick prepared by washed incineration fly ash of house refuse and a preparation method thereof. The fly ash baked brick consists of 25-35% of washed incineration fly ash of house refuse, 45-70% of clay and 5-20% of feldspar in percentage by weigh. The preparation method comprises seven steps of washing treatment of incineration fly ash of house refuse, pretreatment before crushing materials, material crushing, aging of raw materials, forming of raw materials, green body drying and sintering to form brick. Finally, the fly ash baked brick prepared by washed incineration fly ash of house refuse is obtained. In the invention, the washed incineration fly ash of house refuse is used to prepare the baked brick; by calcining, dioxin in the incineration flyash can be destroyed thoroughly and heavy metals in the fly ash can be cured, thereby achieving the purpose of innocent treatment of incineration fly ash of house refuse and turning the waste into valuable. The manufacturing process of the fly ash baked brick is simple and the fly ash baked brick has good macroscopic properties and can be used for paving roads.

Owner:SHANGHAI INST OF TECH

Foundation hardening and soil property improving agent thereof

InactiveCN1560192ANot easy to peel offEasy to operateOrganic fertilisersSoil conditioning compositionsSoil propertiesFragility

The invention relates to a groundwork curing and soil property improving agent, developed for curing the soil and simultaneously achieving long-term stability. Its components are inorganic metal elements, thus having no problem of environmental pollution. Whether in soil property or sea water, it has the properties of curing in water, freeze resistance and high-temperature resistance. It also absorbs the advantages of previous method of maming cement-earth mixture, overcomes the disadvantages, like curing contractility, freeze-thaw resistance and fragility. It cures year by year, therefore it is uneasy to age and be eroded by acids or alkalis. It can directly use the earth on the spot without sand and other raw materials and has characters of short construction cycle and environmental protection.

Owner:王怀东 +1

Environment-friendly organic fertilizer for improved saline alkali soil and preparation method of fertilizer

InactiveCN108046860AHigh in nutrientsImprove featuresBio-organic fraction processingAnimal corpse fertilisersAlkalinityAlkali soil

The invention discloses an environment-friendly organic fertilizer for improved saline alkali soil and a preparation method of the fertilizer. The environment-friendly organic fertilizer is prepared by composting and fermenting, by weight, 10-20 parts of animal carcasses obtained after high temperature sterilization, 5-10 parts of plant straw, 15-30 parts of livestock excrement and 1-5 parts of composite decomposing microbial inoculums. The soil alkalinity can be effectively lowered, the nutrient content of saline alkali soil is increased, characteristics of the saline alkali soil are improved, and the saline alkali soil is improved conveniently; the handling method is mature, the technology is stable, and it is ensured that carcasses obtained after animals are dead are effectively handled, and environmental protection is achieved.

Owner:WEIFANG YOURONG IND

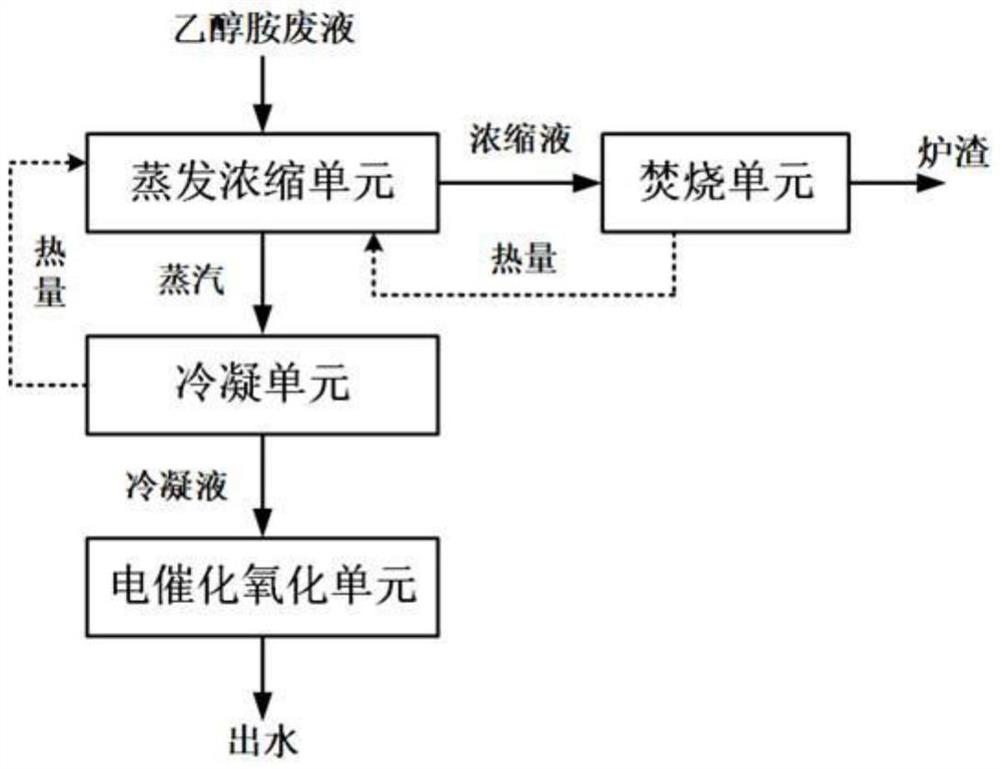

Treatment method of ethanolamine waste liquid

InactiveCN113233674AReduce energy consumptionMeet the water quality requirementsWater contaminantsMultistage water/sewage treatmentChemical oxygen demandCatalytic oxidation

The invention discloses a treatment method of ethanolamine waste liquid, which comprises the following steps: directly feeding ethanolamine waste liquid into an evaporation and concentration unit, feeding steam obtained by evaporation and concentration into a condensation unit, introducing heat exchanged by condensation into the evaporation and concentration unit to preheat the waste liquid, and feeding condensate obtained by condensation into an electrocatalytic oxidation unit; feeding effluent subjected to electrocatalytic oxidation degradation treatment into a refinery sewage treatment plant; and feeding an evaporated and concentrated organic residue concentrated solution into an incineration unit for incineration, and introducing heat generated by incineration into the evaporation and concentration unit to evaporate the waste liquid, so as to complete the treatment process of the ethanolamine waste liquid. The treatment method provided by the invention is clean and economical, heat generated by condensation heat exchange and incineration is fully utilized to evaporate the waste liquid, the energy consumption of waste liquid treatment is greatly reduced, water quality indexes such as ammonia nitrogen, total nitrogen and COD (Chemical Oxygen Demand) of discharged sewage after treatment are remarkably reduced, and the biodegradability is greatly improved; and finally, the inlet water quality requirement of a refinery sewage treatment plant can be met.

Owner:SHENYANG UNIV

Method for preparing light concrete by municipal solid waste incineration fly ash

InactiveCN101531492BTo achieve the purpose of harmless treatmentSimple processSolid waste managementApparent densitySlag

The invention discloses a method for preparing light concrete by municipal solid waste incineration fly ash. The light concrete comprises the following compositions according to material ratio: 330 to 370kg / m<3> of the municipal solid waste incineration fly ash, 450 to 475kg / m<3> of 525# common Portland cement, 325 to 340kg / m<3> of water-granulated slag, 350 to 370kg / m<3> of ordinary clay porcelain granules, 230 to 240kg / m<3> of diabase slag, and 2.7 to 2.9kg / m<3> of admixture. The method uses the municipal solid waste incineration fly ash to prepare the light concrete, can solidify heavy metal in fly ash, thereby achieving the aim of innocent treatment of the municipal solid waste incineration fly ash. The method has a simple process, and the obtained finished product has strength grade of CL40 and apparent density of 1800, and has good macroscopic performance.

Owner:SHANGHAI INST OF TECH

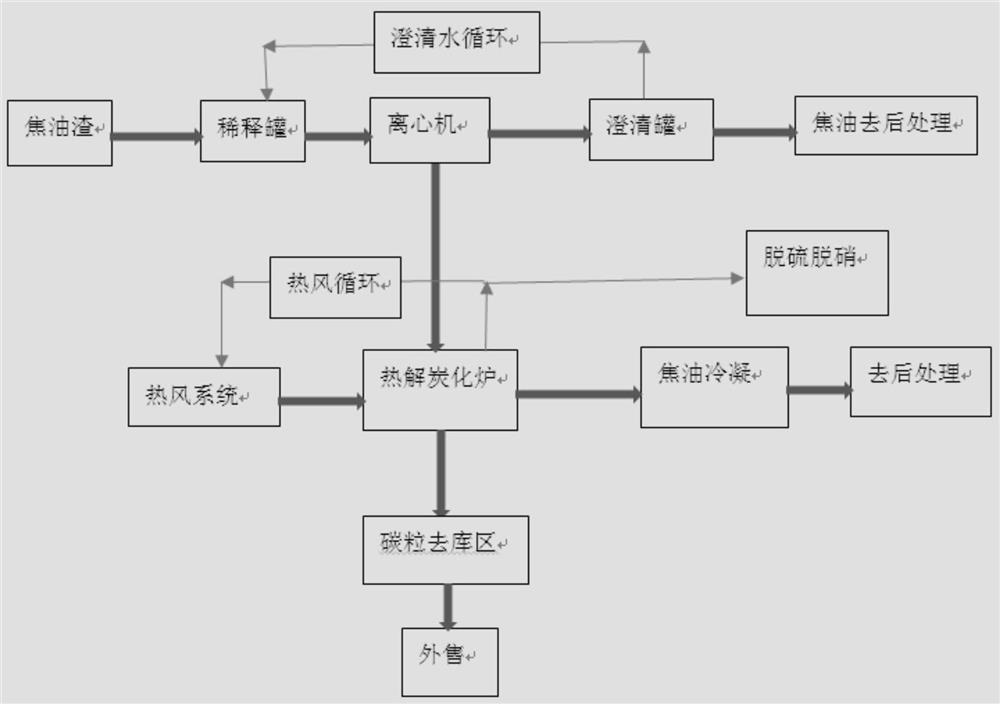

Tar residue treatment method

InactiveCN111732971ASimple processing methodEasy to operateTreatment with plural serial stages onlyCoking carbonaceous materialsCokeFuel treatment

The invention belongs to the field of chemical engineering, and discloses a tar residue treatment method which comprises the following steps: 1, heating tar residues by adopting a preheater to obtainheated tar residues; 2, adding water into the heated tar residues through a dilution tank for dilution to prepare diluted tar residues; 3, centrifuging the diluted tar residue by adopting a centrifugal machine to obtain liquid and solid; 4, feeding the liquid into a clarification tank for clarification to obtain water and tar; 5, feeding the solid into a carbonization pyrolyzing furnace for pyrolyzing to obtain tar and coke particles; and cooling the tar by adopting a condenser to obtain cooled tar. The tar residue treatment method is simple, easy to operate and implement and low in cost, therecovery rate of the tar component in the tar residue reaches 90% or above, and the purposes of resource utilization, reduction and harmless treatment of the tar residue are truly achieved; meanwhile,coke particles separated from the tar residues are fed into a powder warehouse to be treated as fuel, so that the resource utilization rate is further increased.

Owner:陕西臻厚能源科技有限公司

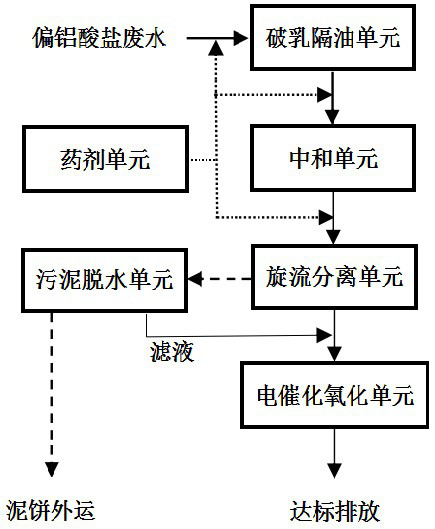

Treatment method for metaaluminate-containing C5 resin wastewater

PendingCN112960820AProcessing method is safeEfficient treatment methodWater treatment parameter controlFatty/oily/floating substances removal devicesAluminateAmmoniacal nitrogen

The invention discloses a treatment method for metaaluminate-containing C5 resin wastewater. The treatment method comprises the following steps: directly feeding the metaaluminate-containing C5 resin wastewater into a demulsification and oil separation unit, feeding the oil-removed wastewater into a neutralization unit, feeding the wastewater into a cyclone separation unit after pH regulation, feeding a supernatant into an electrocatalytic oxidation unit after solid-liquid sedimentation of a cyclone separation device, and discharging effluent obtained after the electrocatalytic oxidation degradation treatment when the effluent reaches the standard; and allowing sludge at the bottom of the cyclone separation unit to enter a sludge dewatering unit, and after solid-liquid separation of the sludge dewatering unit, enabling a filtrate to enter the electrocatalytic oxidation unit, collecting mud cakes, and transporting the mud cakes outwards for disposal, thereby finishing the treatment process of the C5 resin wastewater containing meta-aluminate. The treatment method provided by the invention is economical and efficient, the water quality indexes of SS, ammonia nitrogen, COD and the like of discharged sewage after treatment are remarkably reduced, biodegradability is greatly improved, and finally, the water quality requirements of inlet water of a sewage treatment plant can be met.

Owner:SHENYANG UNIV

Method for preparing chemical leakage accident adsorbents from excess activated sludge

InactiveCN105170089ALow priceHigh carbon contentSludge treatmentOther chemical processesPhosphoric acidChemistry

The invention relates to a method for preparing chemical leakage accident adsorbents from excess activated sludge, and mainly solves the problems of higher cost and environment pollution in the prior art. According to the method for preparing the chemical leakage accident adsorbents from the excess activated sludge, crushed excess activated sludge with the moisture content being lower than 60 percent and alkali liquor are subjected to sealing steeping after being mixed and are then put into an electric heating box for constant temperature heating; the mixture is taken out and is then washed until the pH is 6 to 8; then, drying is carried out; the dried excess activated sludge is ground; the ground excess activated sludge and a phosphoric acid solution are mixed; the mixed solution is put into a drying box to be subjected to air pre-oxidation; the excess activated sludge subjected to pre-oxidation is subjected to temperature rise under the nitrogen gas atmosphere for carbonization and activation; the excess activated sludge subjected to carbonization and activation is taken out after the temperature is lowered; after washing, the chemical leakage accident adsorbents are obtained. Through the technical scheme, the problems are better solved, and the method can be used for preparing the chemical leakage accident adsorbents.

Owner:CHINA PETROLEUM & CHEM CORP +1

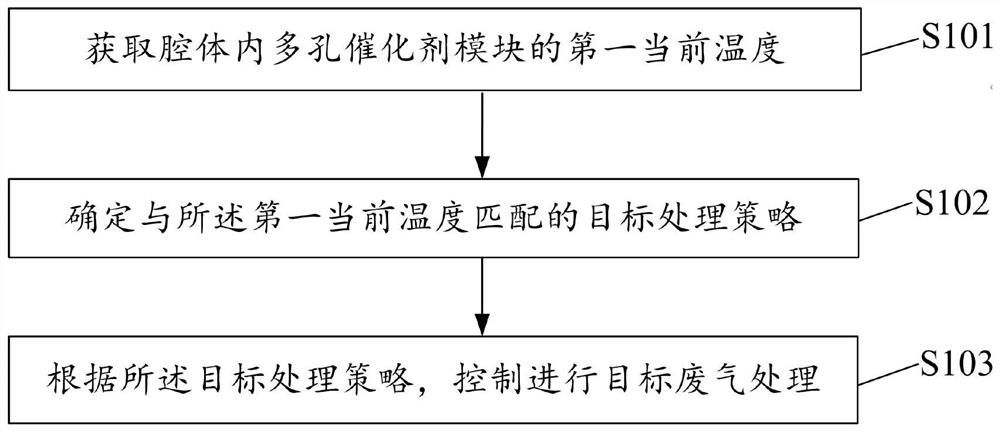

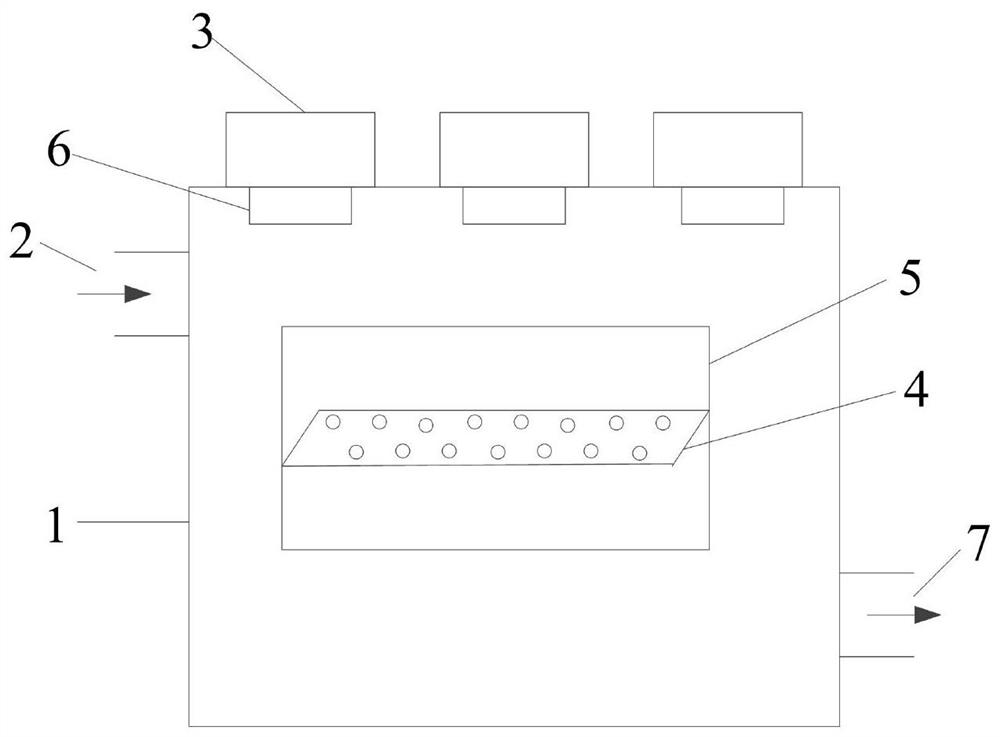

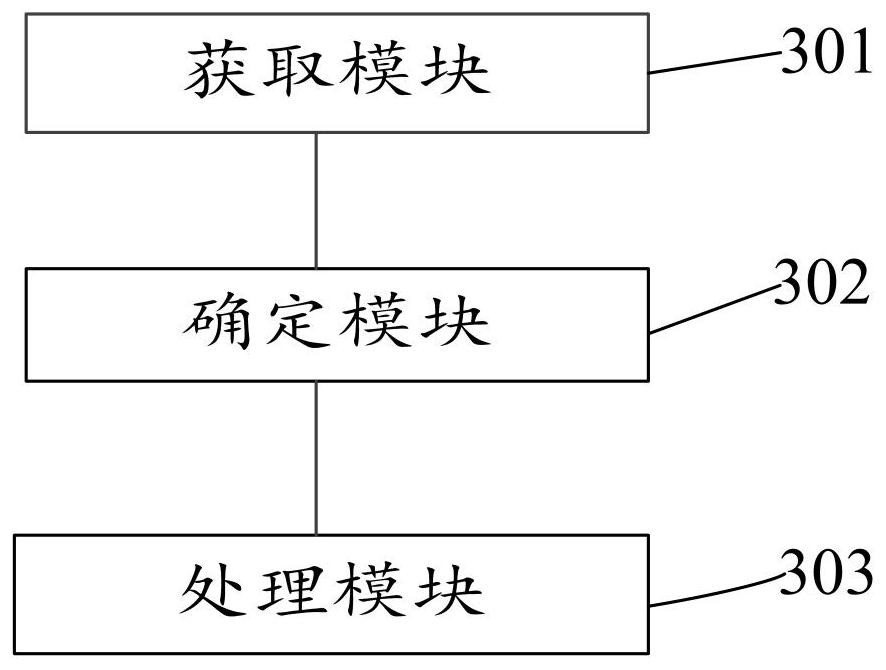

Microwave catalysis waste gas treatment method and control system thereof

PendingCN114588733AFlexible and High Processing EfficiencyImprove processing efficiencyGas treatmentInternal combustion piston enginesExhaust fumesProcess engineering

The invention provides a microwave catalysis waste gas treatment method and a control system thereof, and belongs to the technical field of waste gas treatment.The microwave catalysis waste gas treatment method comprises the steps that the first current temperature of a porous catalyst module in a cavity is obtained; determining a target processing strategy matched with the first current temperature; and target waste gas treatment is controlled according to the target treatment strategy. That is to say, according to the first current temperature of the porous catalyst module, the purpose of harmless treatment of the waste gas can be achieved; the problems that in the prior art, the waste gas treatment efficiency is not high and the application range is limited due to the fact that waste gas treatment can be carried out after a catalyst is heated only when a microwave scattering device rotates to generate reflection in all directions on microwaves are solved, the waste gas treatment efficiency is flexibly and efficiently improved, and energy consumption is reduced; therefore, the service life of the microwave catalytic waste gas treatment equipment is prolonged.

Owner:陕西青朗万城环保科技有限公司

Organic fertilizer for improving soil fertility and preparation method thereof

InactiveCN111807910ARich in nutrientsImprove fertilityBio-organic fraction processingExcrement fertilisersSoil scienceFurfural

The invention provides an organic fertilizer for improving soil fertility. The organic fertilizer mainly comprises the following raw materials in parts by weight: pig manure, furfural residues, plantash and zymophyte. The preparation method comprises the following steps: (1) weighing the raw materials; pig manure and furfural residues are crushed and sieved respectively; (2) adding plant ash andcrushed furfural residues into a batching machine, uniformly stirring, and standing for 1 hour to obtain a mixture a; (3) uniformly mixing the crushed pig manure with the mixture a, adding zymophyte,and uniformly stirring to obtain a mixture b; (4) composting: piling the mixture b for 2-3 days; standing for 1-2 days after the temperature in the pile reaches about 60 DEG C; (5) turning: turning the pile for the first time, turning the pile for the second time after standing for 3-5 days, and turning the pile for the third time after standing for 3-5 days; and (6) slowly reducing the temperature in the pile, and packaging after the temperature is reduced to normal temperature. The organic fertilizer has the beneficial effects of improving soil fertility and soil air permeability and breaking soil hardening, and is suitable for the field of organic fertilizers.

Owner:山西绿丰肥业有限公司

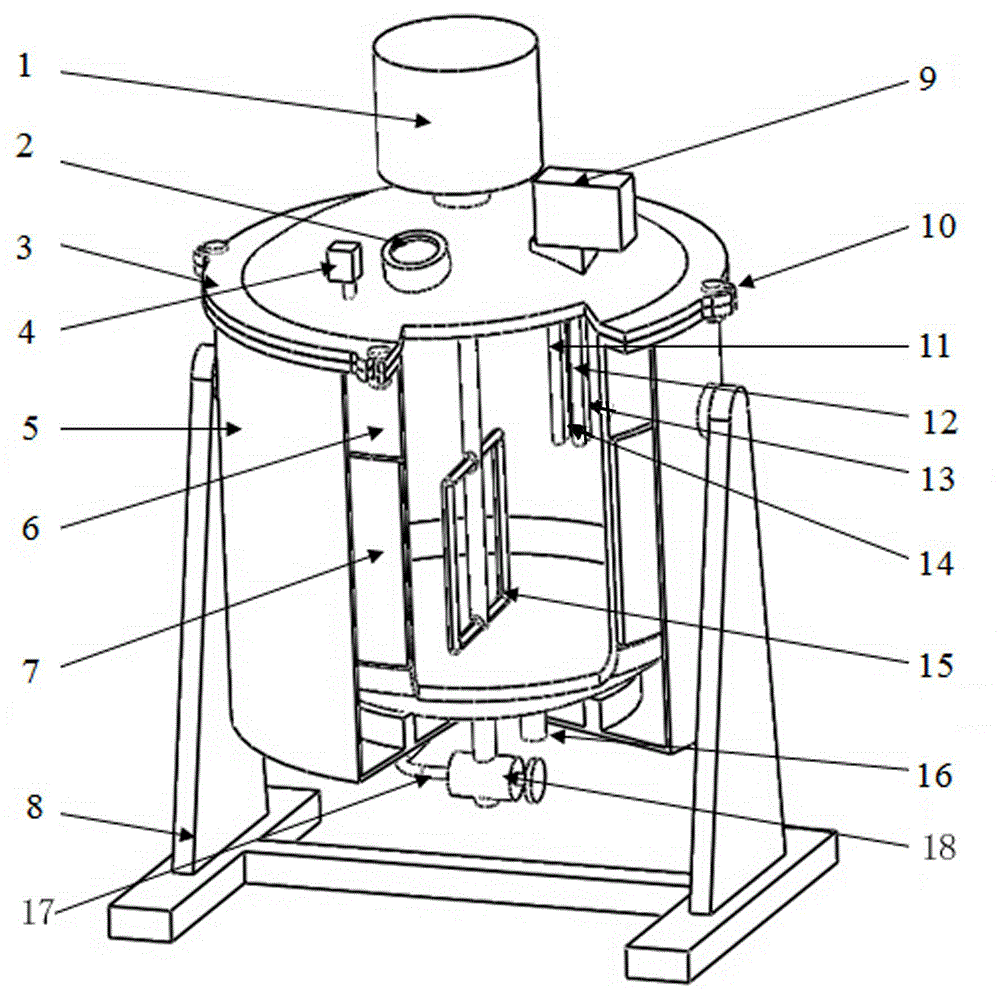

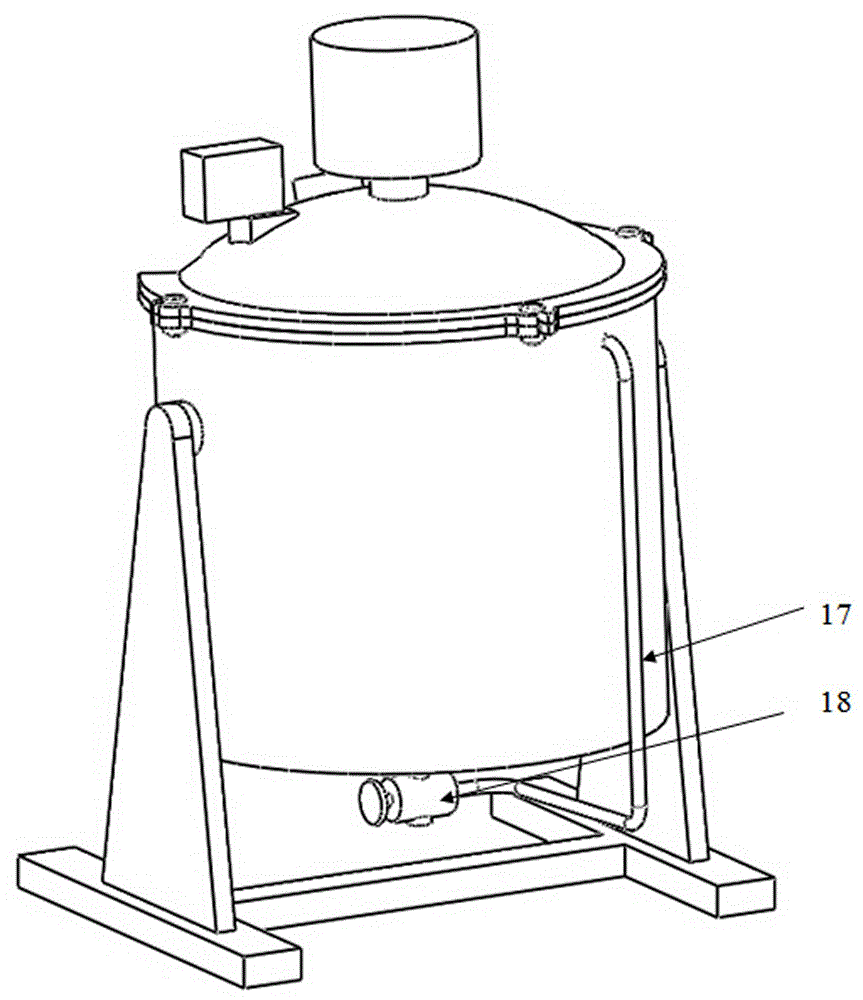

Small anaerobic/aerobatic integrated fermentation tank for research education

InactiveCN105414144ATo achieve the purpose of harmless treatmentIncrease credibilitySolid waste disposalRefluxResearch education

The invention discloses a small anaerobic / aerobatic integrated fermentation tank for research education. A tank body and a tank cover fixedly connected in a sealed mode through fastening screws; a stirring motor and a controller are arranged on the tank cover; the tank cover is further provided with an exhaust port and an inner observation opening; the tank body is of an inner-and-outer layer cylinder structure; a heating layer is arranged on the outer wall of the inner layer of tank body; the interior of the inner layer of tank body is provided with a stirring rod connected with the stirring motor. The small anaerobic / aerobatic integrated fermentation tank for research education is further provided with a thermoelectric couple, an acidimeter, a methane concentration sensor and a pressure sensor which are connected with the controller through wires; the lower end of the tank body is provided with an air supply port and a reflux pump / liquid outlet; a reflux pipe is arranged outside the tank body and is connected with the reflux pump / liquid outlet; the reflux pipe is communicated into the inner layer of tank body; the reflux pump / liquid outlet presses percolate generated by fermentation back into the fermentation tank through the reflux pump or discharges the percolate generated by fermentation; bearings are arranged on the two sides outside the tank body and connected with a support; the tank body can rotate in a reciprocating mode by 0-180 degrees. The small anaerobic / aerobatic integrated fermentation tank for research education is compact in structure and convenient to use.

Owner:GUILIN UNIV OF ELECTRONIC TECH

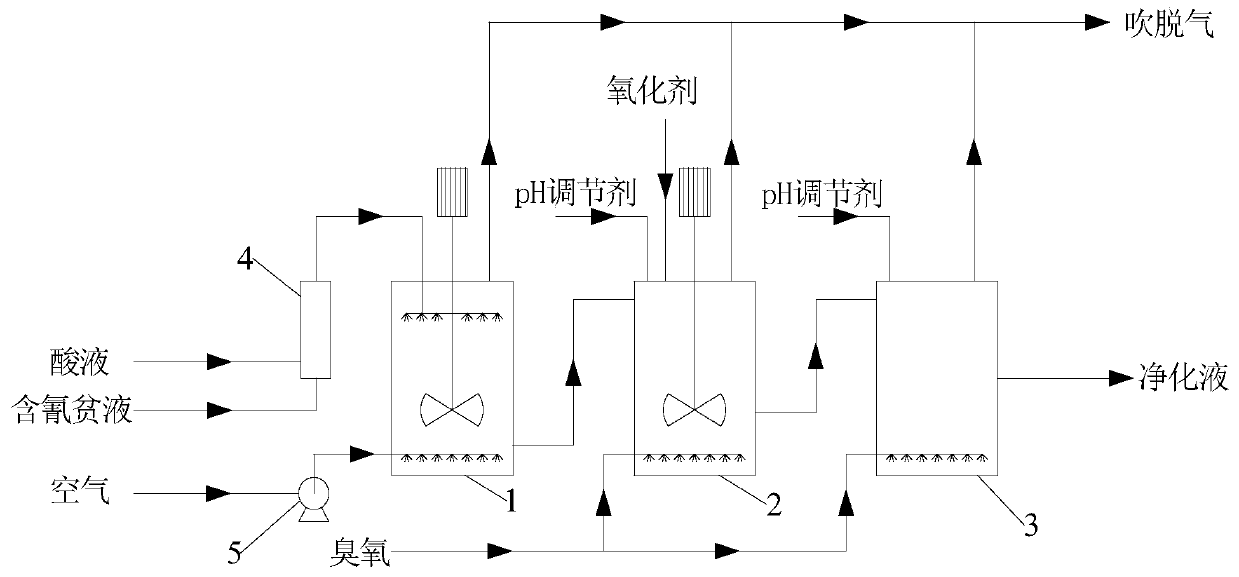

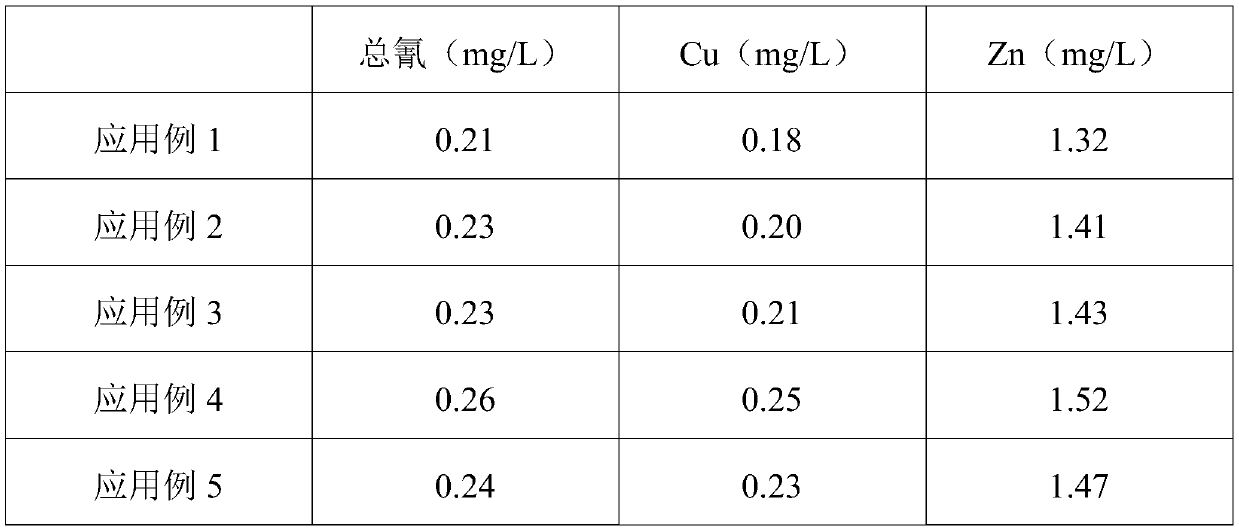

Cyanide-containing wastewater treatment system and method

InactiveCN110902894ATo achieve the purpose of harmless treatmentReduce total cyanide contentWater contaminantsWaste water treatment from metallurgical processCyanideWastewater

The invention provides a cyanide-containing wastewater treatment system and method. The cyanide-containing wastewater treatment system comprises an ozone supply unit, an acid regulation unit, a firstprecipitation device and a second precipitation device, the acid regulation unit, the first precipitation device and the second precipitation device are connected in sequence, the acid adjusting unitcomprises a mixing device, a gas conveying device and an acid adjusting device; a discharge hole of the mixing device is connected with a top liquid inlet of the acid adjusting device; a gas outlet ofthe gas conveying device is connected with a bottom gas inlet of the acid adjusting device; an oxidant adding port, a precipitant adding port and a pH regulator adding port are independently formed in the top of the first precipitation device respectively; a pH regulator adding opening is formed in the top of the second precipitation device; and the ozone supply unit is independently connected with bottom air inlets of the first precipitation device and the second precipitation device respectively. According to the method, Cu < 2 + > and Zn < 2 + > in the cyanide-containing wastewater can beeffectively recycled, CN <-> in the cyanide-containing wastewater is reduced to meet the requirements of Integrated Wastewater Discharge Standard, and good economic benefits are brought to enterprises.

Owner:广州市真爱环保科技股份有限公司

Biomass burner and use method

PendingCN108488781AImprove abilitiesIncrease output powerSolid fuel combustionAir/fuel supply for combustionProcess engineeringEngineering

The invention relates to a biomass burner and a use method. The biomass burner is arranged inside a boiler cavity, biomass fuel is scattered at the center of a stirring disc, a motor I drives the stirring disc to rotate, a plurality of stirring rods of the stirring disc lay the biomass fuel on the surface of a burning disc, meanwhile, an air supplying motor conveys high-pressure air to an air cavity tray, the concentrated bunch high-pressure air is turned into high-pressure spiral air by air uniforming protective blocks to be conveyed to a burning space inside a boiler, oxygen filling aid-combustion is performed on the biomass fuel, the burned biomass fuel is circled and blocked by an ash block when entering the burning disc step by step to perform tail burning namely the carbon burning stage, the multiple stirring rods of the stirring disc stir residue after tail burning into an ash discharging box again, and the biomass fuel residue is smashed and discharged by two residue breaking devices. The biomass burner and the use method have the beneficial effects that the problem perplexing straw fuel burning for a long time of coking, slagging and being unable to be popularized and applied is solved, the purpose of innocuous treatment is realized, and discharged flue gas reaches the standard of clean energy.

Owner:天津市星拓科技发展有限公司

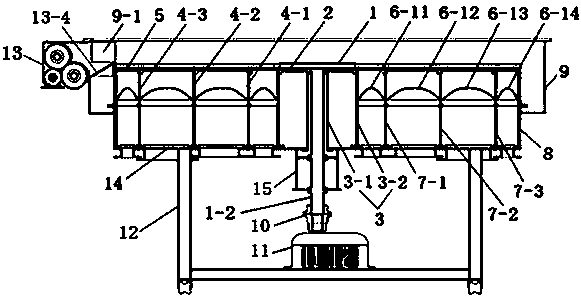

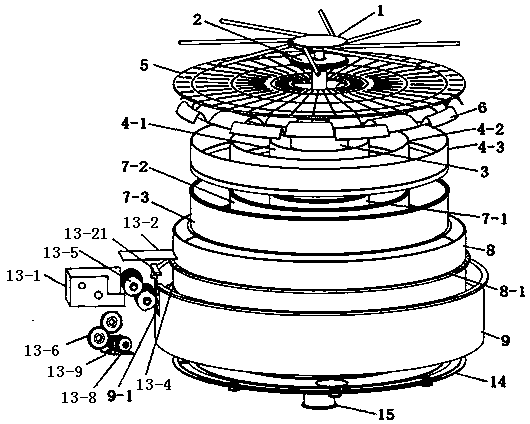

Waste fermentation device using overclocking technology

InactiveCN106915980ATo achieve the purpose of harmless treatmentRealize resource utilizationBio-organic fraction processingFertiliser treatment heating/coolingHydraulic cylinderResource utilization

The invention discloses a waste fermentation device using an overclocking technology. The device comprises a base, a fermenting silo is fixed to the top end of the base, a lifting frame body is fixed to one side wall of the fermenting silo, the top end of the lifting frame body is provided with a lifting machine by screws, a steel wire rope winds the lifting machine, the bottom end of the steel wire rope passes through the lifting frame body and is connected to a loading stock bin, the loading stock bin is located at the bottom end of the side wall of the lifting frame body, the loading stock bin is slidingly connected to the side wall of the lifting frame body, the top end of the fermenting silo is provided with a feeding inlet, the feeding inlet is located at the bottom of one side of the lifting frame body, the side wall of the bottom of the fermenting silo is provided with a cavity, a vortex gas pump, a transmission device and a hydraulic cylinder are arranged in the cavity, the transmission device is located between the vortex gas pump and the hydraulic cylinder, and an output end of the vortex gas pump extends into the fermenting silo through a conduit. The device realizes harmless treatment and resource utilization of wastes and reduces fermentation exhaust damage.

Owner:NANJING BEITE AC EQUIP CO LTD

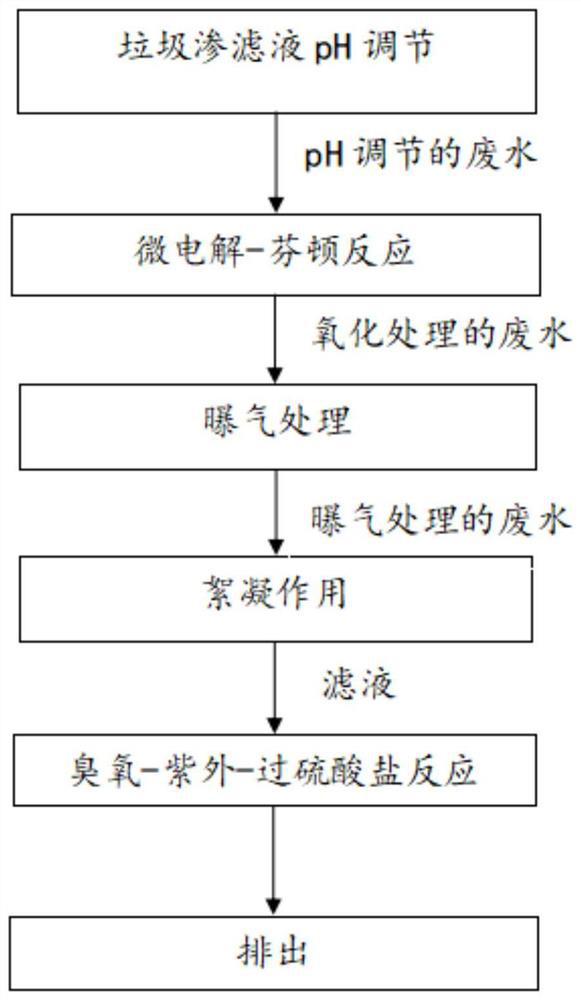

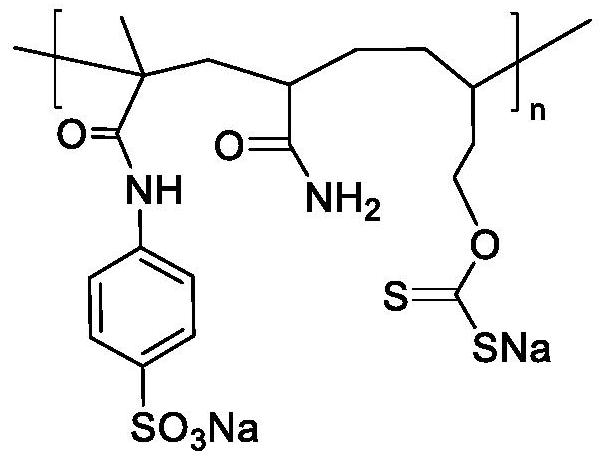

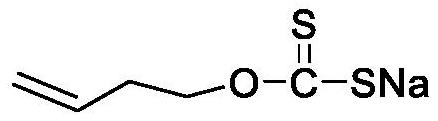

Treatment method of landfill leachate

ActiveCN114212921AHigh removal rateControls are responsiveWater/sewage treatment by irradiationWater treatment compoundsHydration reactionPersulfate

The invention relates to a landfill leachate treatment method, which belongs to the technical field of wastewater treatment, and comprises the following steps: 1, adjusting the pH value of landfill leachate to obtain pH-adjusted wastewater; step 2, adding an iron-carbon filler into the wastewater subjected to pH regulation, and then adding ferrous sulfate heptahydrate and hydrogen peroxide to obtain wastewater subjected to oxidation treatment; 3, aerating the wastewater subjected to oxidation treatment to obtain wastewater subjected to aeration treatment; step 4, adding a flocculating agent and a coagulant aid into the wastewater subjected to aeration treatment for flocculating settling, and filtering to obtain filtrate; and 5, adjusting the pH value of the filtrate, adding persulfate into the wastewater under the conditions of ultraviolet light irradiation activation and ozone aeration, carrying out an oxidation reaction, and discharging. According to the method, the removal rate of organic matters is increased through an iron-carbon micro-electrolysis-Fenton and ozone-ultraviolet-persulfate two-round composite oxidation process; and the modified anionic polyacrylamide coagulant aid is introduced, so that the flocculation effect is improved.

Owner:中新联科环境科技(安徽)有限公司

Method for preparing surplus activated sludge-based activated carbon water treatment agent

ActiveCN105170090BLow priceHigh carbon contentOther chemical processesWater/sewage treatment by sorptionActivated sludgeAluminium chlorohydrate

Owner:CHINA PETROLEUM & CHEM CORP +1

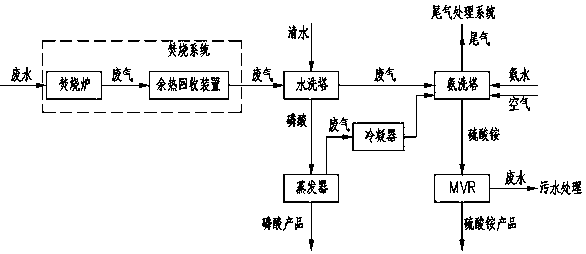

Resourceful treatment process for high-concentration organic wastewater containing phosphorus and sulfur

InactiveCN111573695AGood processing effectAdaptableAmmonium salt fertilisersPhosphoric acidAmmonium sulfateEnvironmental chemistry

The invention discloses a resourceful treatment process for high-concentration organic wastewater containing phosphorus and sulfur. The process comprises the following steps: (1) spraying wastewater into an incineration system for high-temperature combustion; (2) cooling incineration tail gas, enabling the cooled incineration tail gas to enter a water washing tower for absorption, absorbing a phosphorus pentoxide component in the incineration tail gas via clean water, dissolving phosphorus pentoxide in the clean water, and conducting reacting to generate a phosphoric acid component; (3) enabling the washed tail gas to enter an ammonia washing tower for absorption, and conducting oxidizing to generate an ammonium sulfate component; (4) carrying out vacuum evaporation and concentration on clear water absorption liquid at the bottom of the water washing tower to obtain a phosphoric acid product; and (5) feeding ammonia water absorption liquid at the bottom of the ammonia washing tower into an MVR evaporative crystallizer, and carrying out evaporative crystallization to obtain an ammonium sulfate product. By adopting the process, the high-concentration organic wastewater containing phosphorus and sulfur can be effectively treated, recycling of phosphorus and sulfur in the wastewater is achieved, and economic benefits are increased.

Owner:浙江省天正设计工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com