Patents

Literature

65results about How to "The method is simple and clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

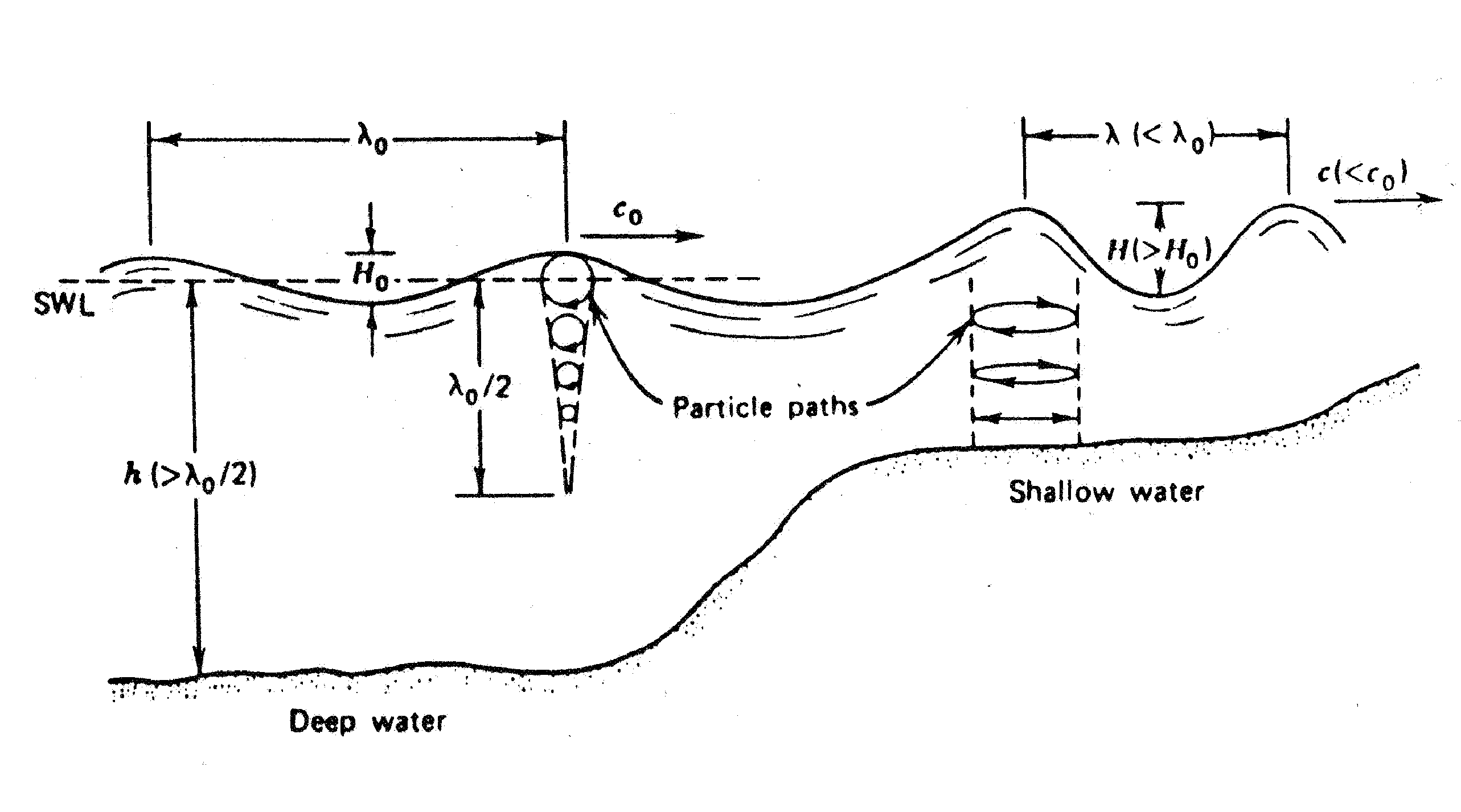

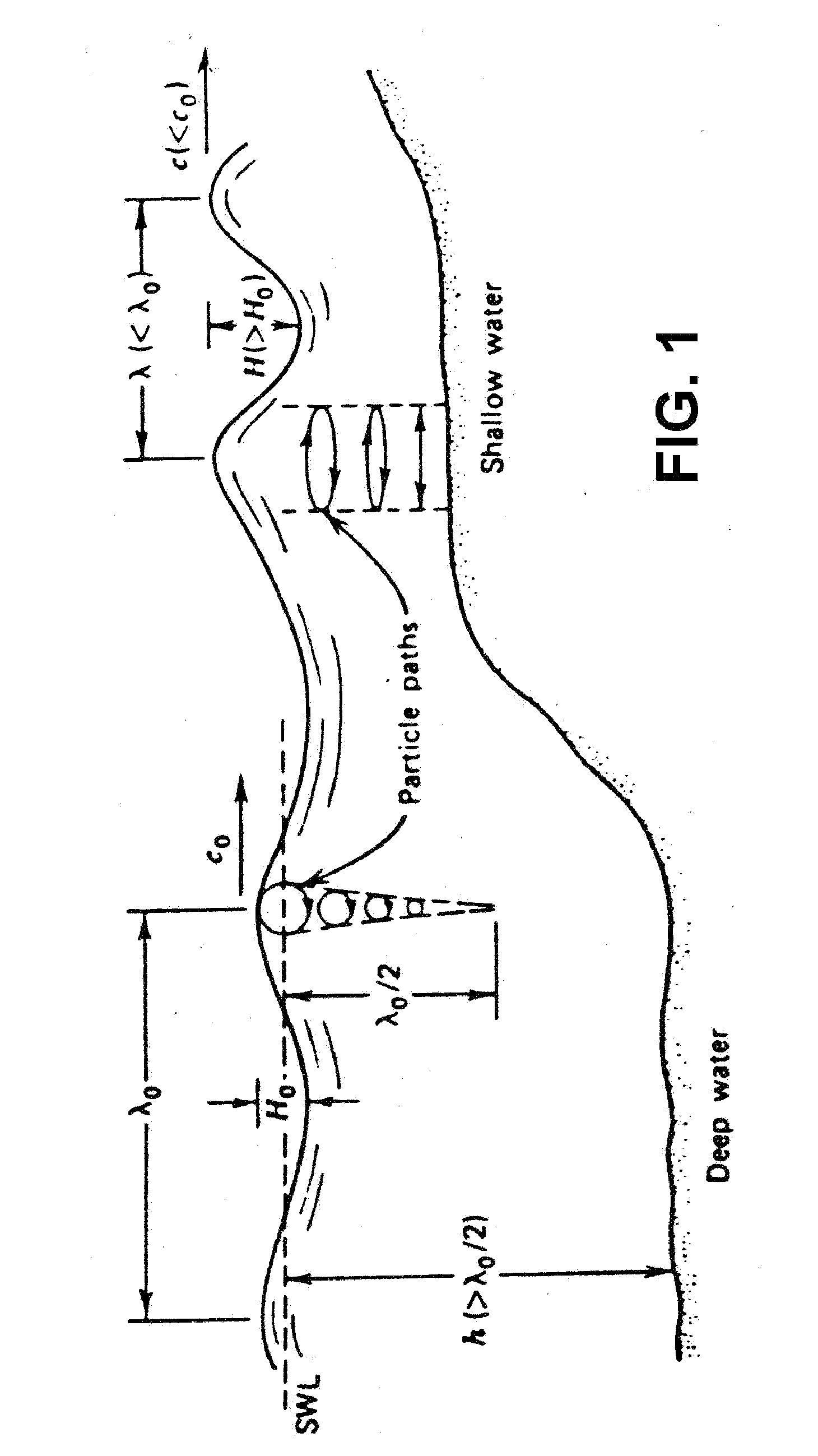

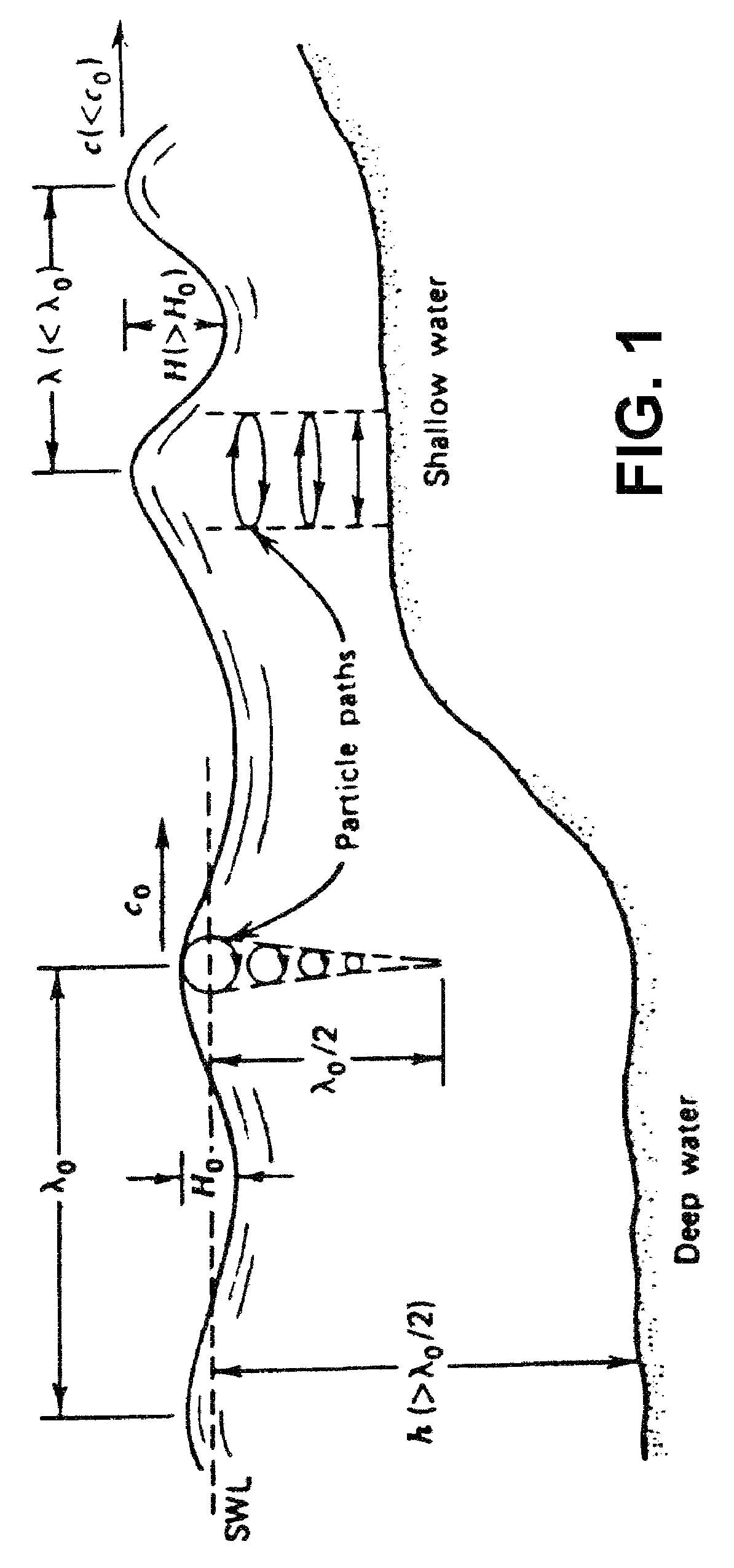

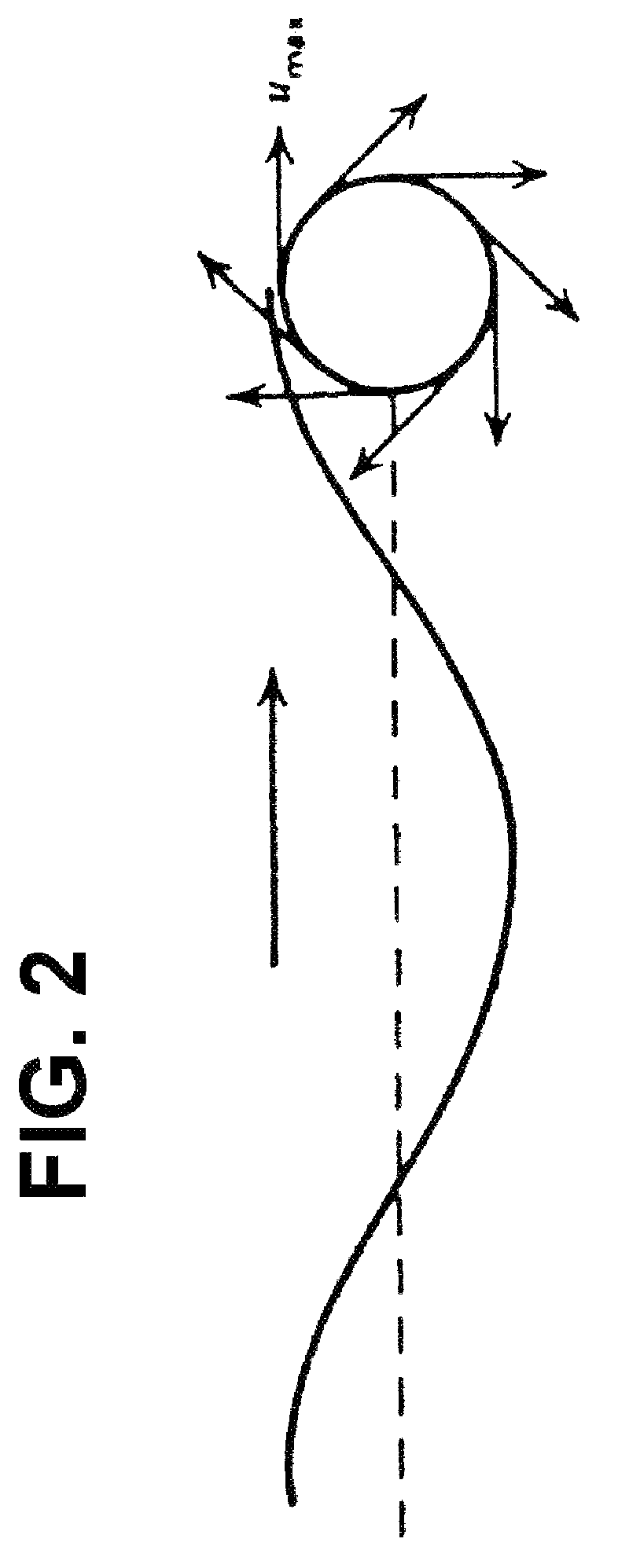

Hydroelectric Wave-Energy Conversion System

ActiveUS20070158950A1The method is simple and clearLess expensiveMachines/enginesEngine componentsHydraulic motorSea waves

A method and system to capture kinetic energy of the sea waves and convert it to electrical power is presented. The hydrodynamic power of the waves is converted to mechanical power after impacting and moving a special panel. The mechanical power is converted into a controlled-cycle hydraulic power to activate a hydraulic motor, which in turn activates an electrical generator. Electrical power is then measured, controlled and distributed to a power grid or end users.

Owner:STRATEGIC DESIGN FEDERATION W LLC

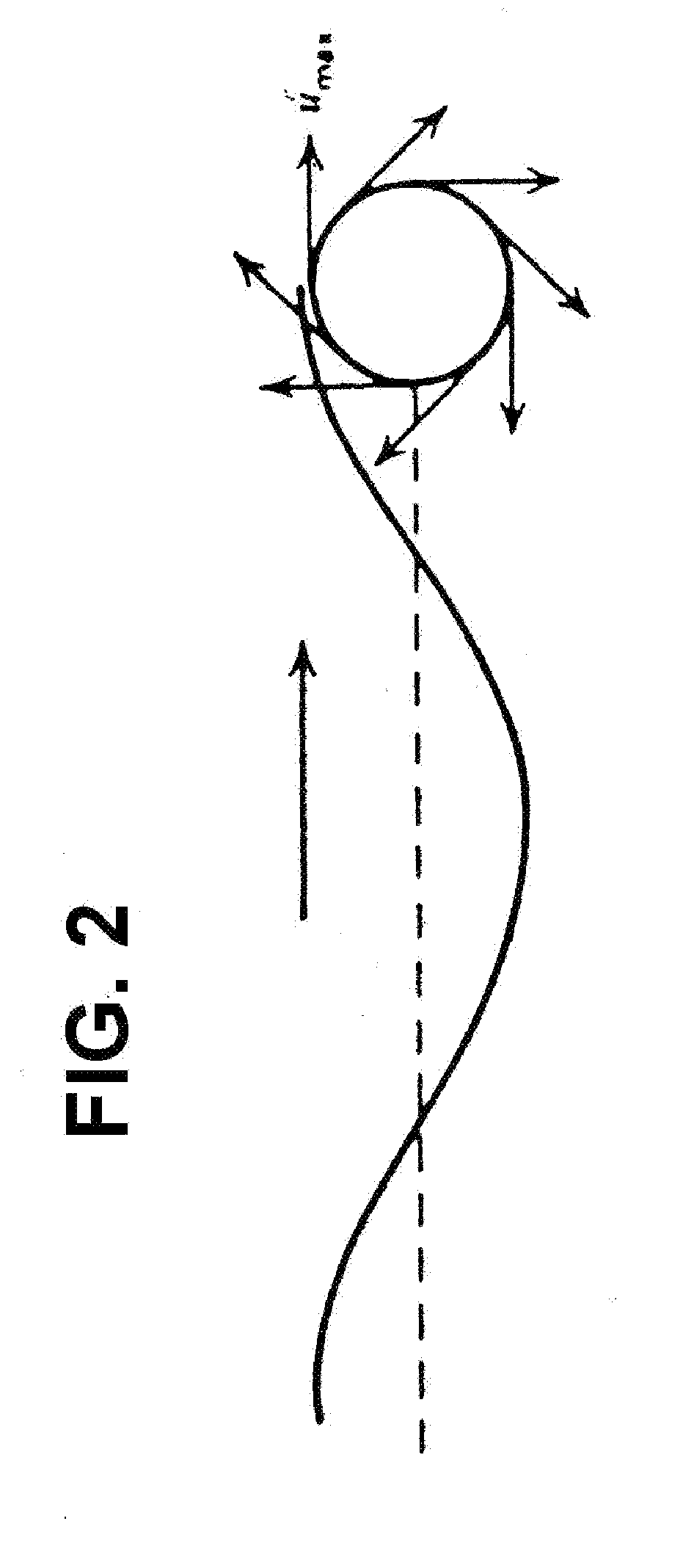

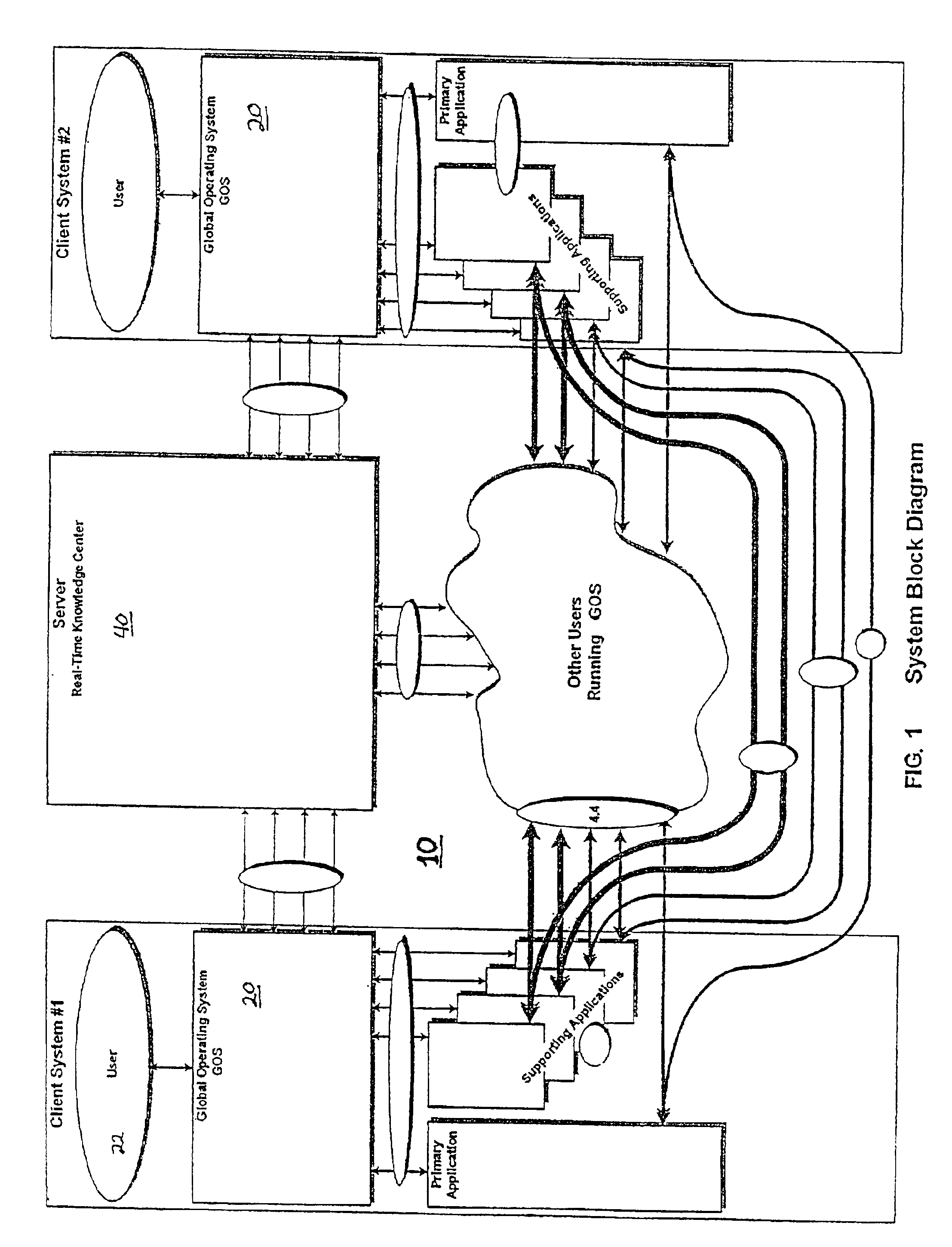

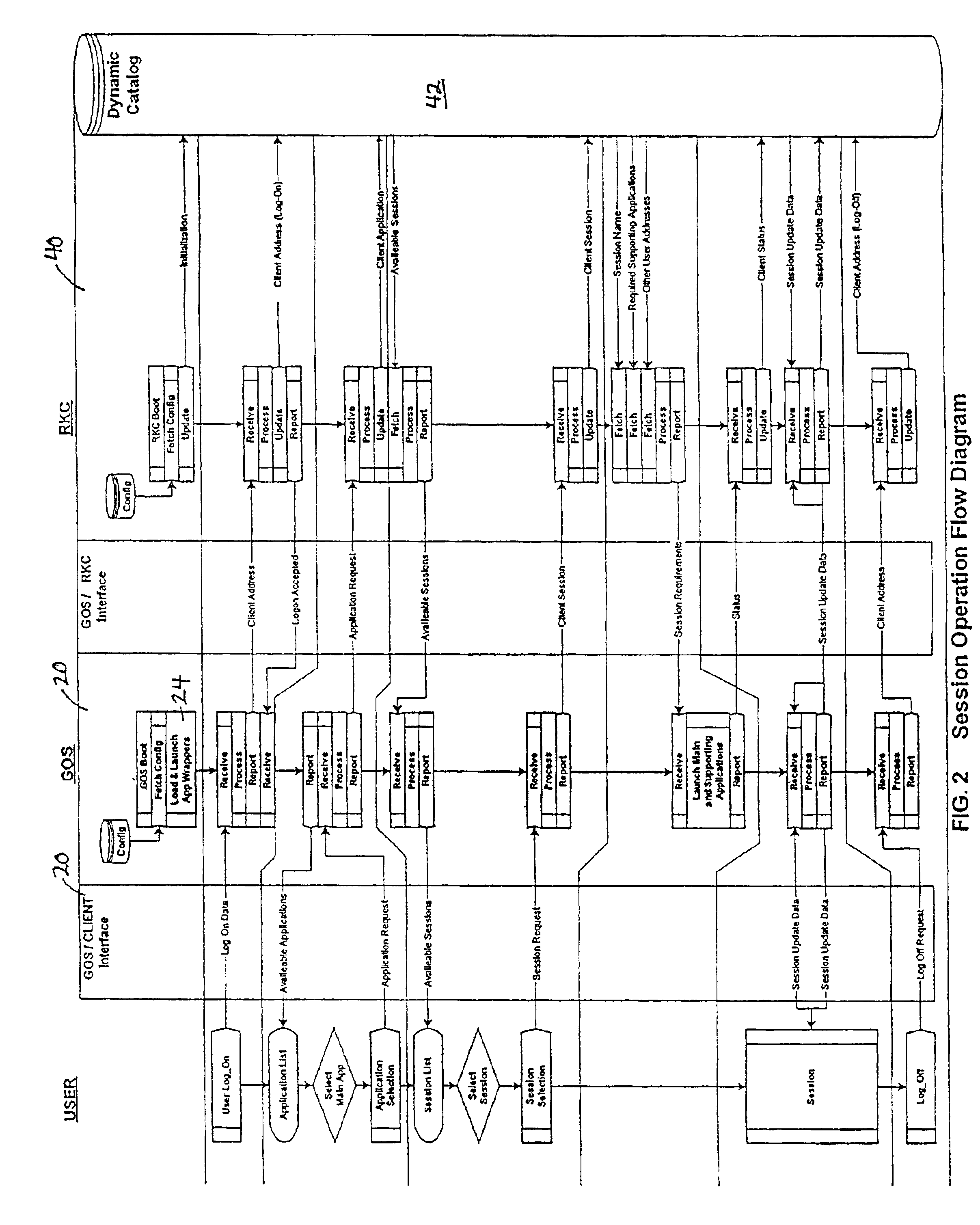

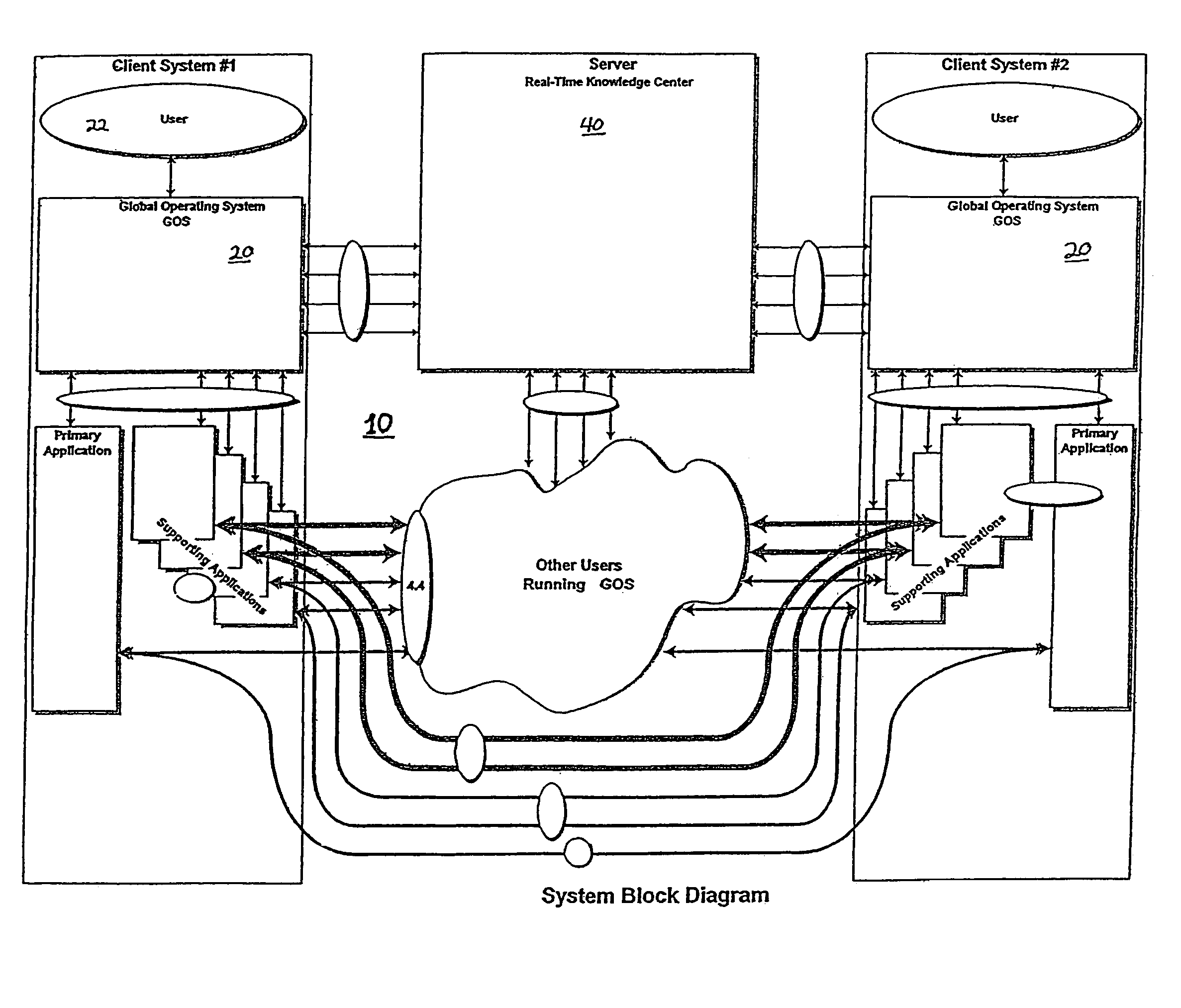

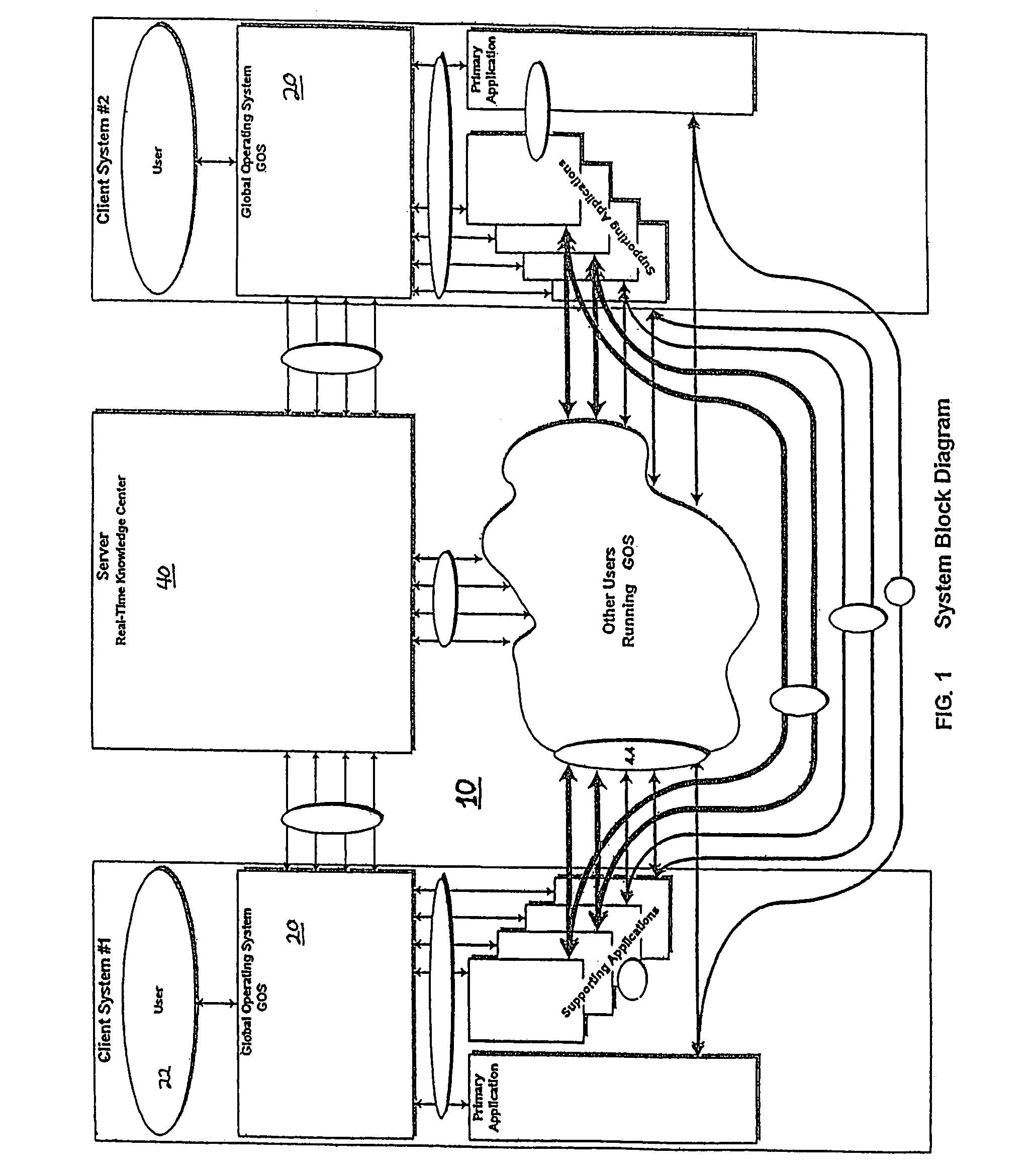

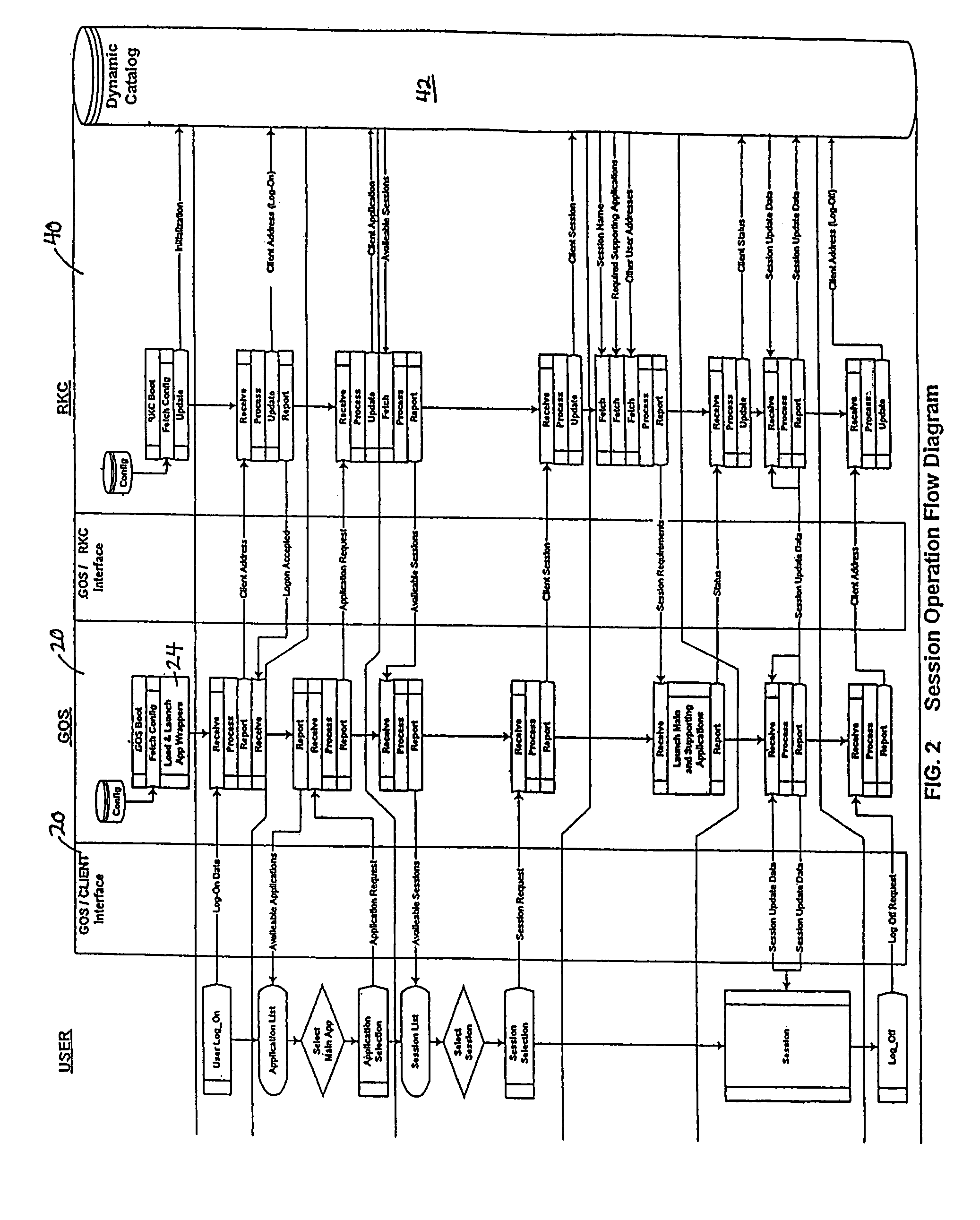

Method for managing the simultaneous utilization of diverse real-time collaborative software applications

ActiveUS6941344B2Easy to useThe method is simple and clearMultiplex system selection arrangementsSpecial service provision for substationCollaborative softwareApplication software

The present invention describes a system 10 and method for managing the simultaneous utilization of diverse real-time collaborative software applications. This method allows linking of multiple computer operators or users in a single collaborative session, involving multiple collaborative applications transparent to the operator or user.

Owner:PRELL ANDREW J

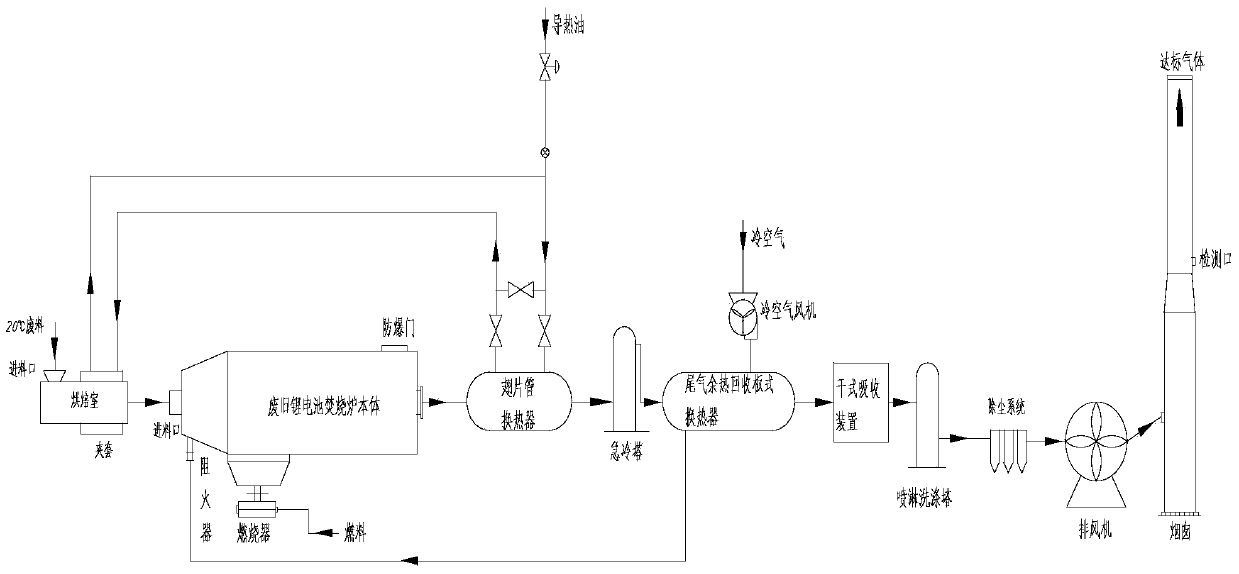

Complete-set device for recycling metal in waste lithium battery

InactiveCN103515668AThe method is simple and clearAdaptableWaste accumulators reclaimingProcess efficiency improvementEnvironmental resistanceRare earth

The invention provides a complete-set device for recycling metal in a waste lithium battery and belongs to the technical field of environmental protection. Materials such as lithium, cobalt, copper, nickel and light rare earth can be extracted from the waste lithium battery; the lithium battery recycling has huge potential commercial value and a broad prospect. According to the design, crushing pre-treatment is performed on the waste lithium battery firstly, feeding is performed, the waste lithium battery enters into a baking room for first baking, and then enters into a rotary incinerator for secondary combustion, three-time cooling is performed continuously and tail gas purification is performed, and smoke is discharged into air after reaching standards finally. During the process of smoke discharging, a rapid cooling device is used to enable the tail gas to be cooled so as to prevent dioxin from being produced. The heat quantity of a plate-type heat exchanger is adopted for recycling, and the purpose of recycling can be achieved.

Owner:CHANGZHOU UNIV

Hydroelectric wave-energy conversion system

ActiveUS7339285B2The method is simple and clearLess expensiveMachines/enginesEngine componentsHydraulic motorSea waves

A method and system to capture kinetic energy of the sea waves and convert it to electrical power is presented. The hydrodynamic power of the waves is converted to mechanical power after impacting and moving a special panel. The mechanical power is converted into a controlled-cycle hydraulic power to activate a hydraulic motor, which in turn activates an electrical generator. Electrical power is then measured, controlled and distributed to a power grid or end users.

Owner:STRATEGIC DESIGN FEDERATION W LLC

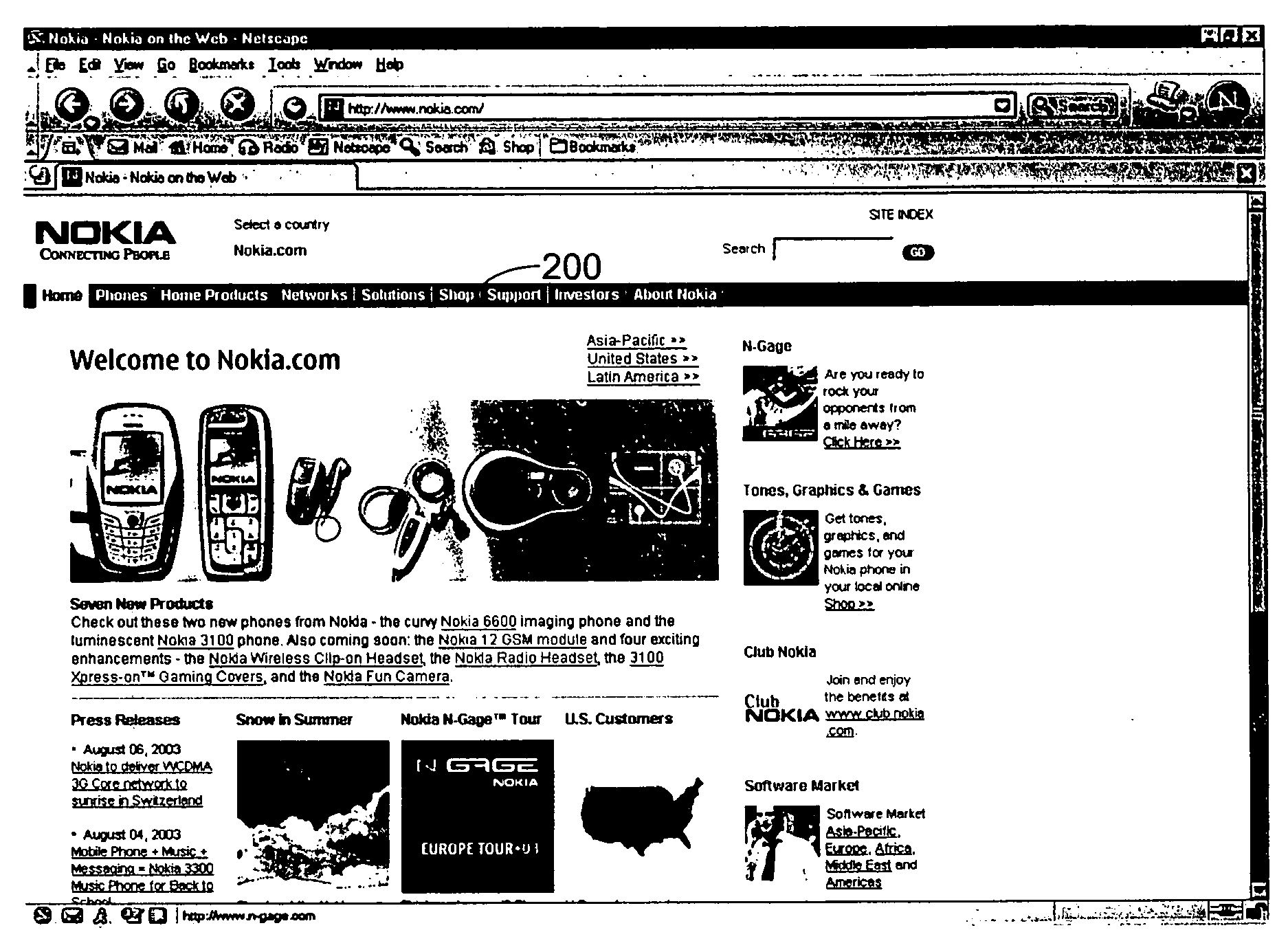

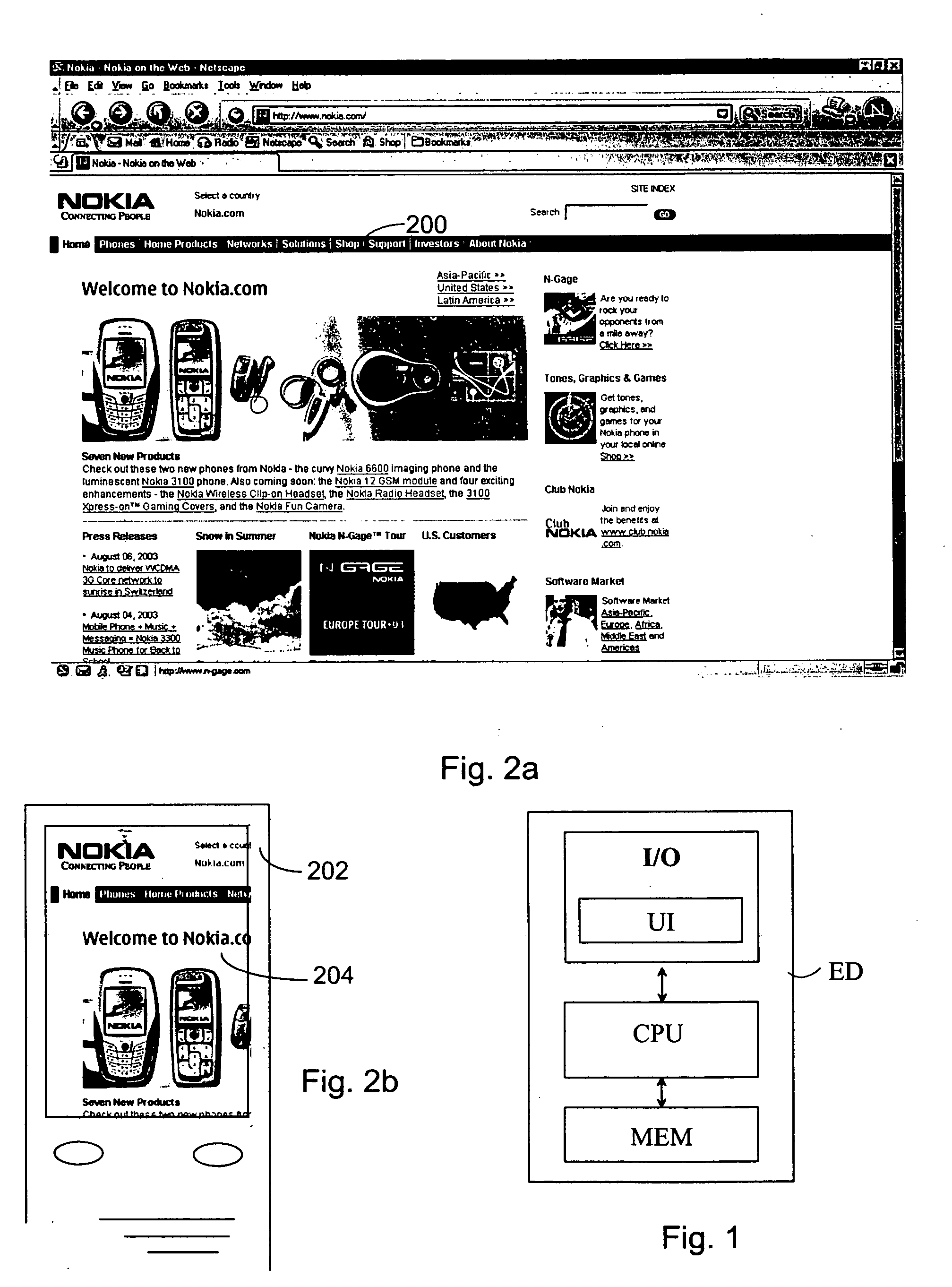

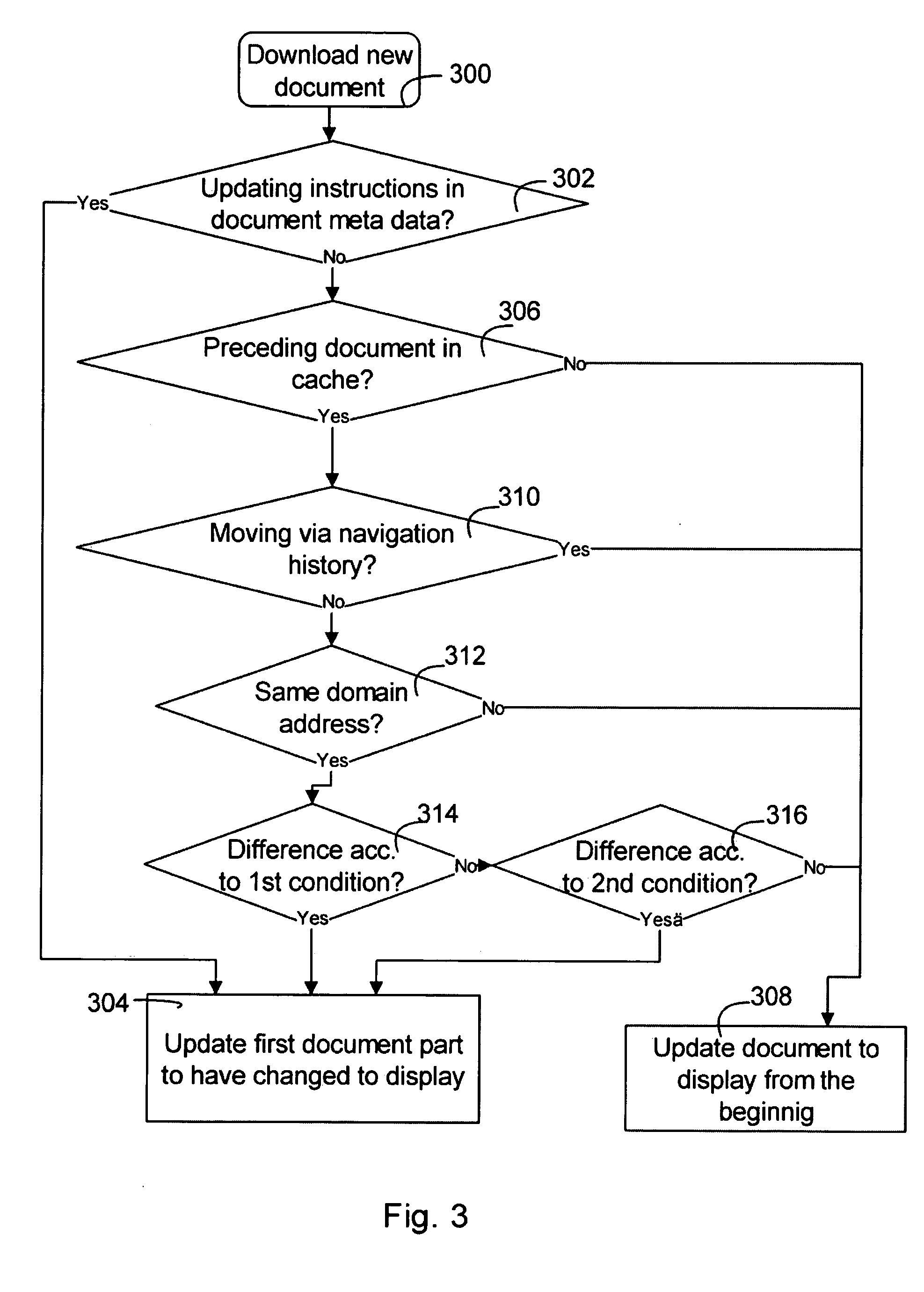

Updating information content on a small display

InactiveUS20050044506A1Improve clarityThe method is simple and clearDigital data information retrievalCharacter and pattern recognitionElectronic documentDisplay device

A method for fitting information content comprised by an electronic document onto the display of an electronic device, formatting of the information content of the electronic document being originally adapted to be shown on a display larger than that of the electronic device. The electronic document is loaded to the memory of the electronic device, and the information content of the document is compared with the information content of another electronic document defined as a reference document. If the information content of the loaded electronic document differs from the information content of the reference document more than a predetermined limit value, the loaded electronic document is shown on the display of the electronic device in such a way that the first part to have information content that differs from the reference document more than the limit value is updated on the display.

Owner:NOKIA CORP

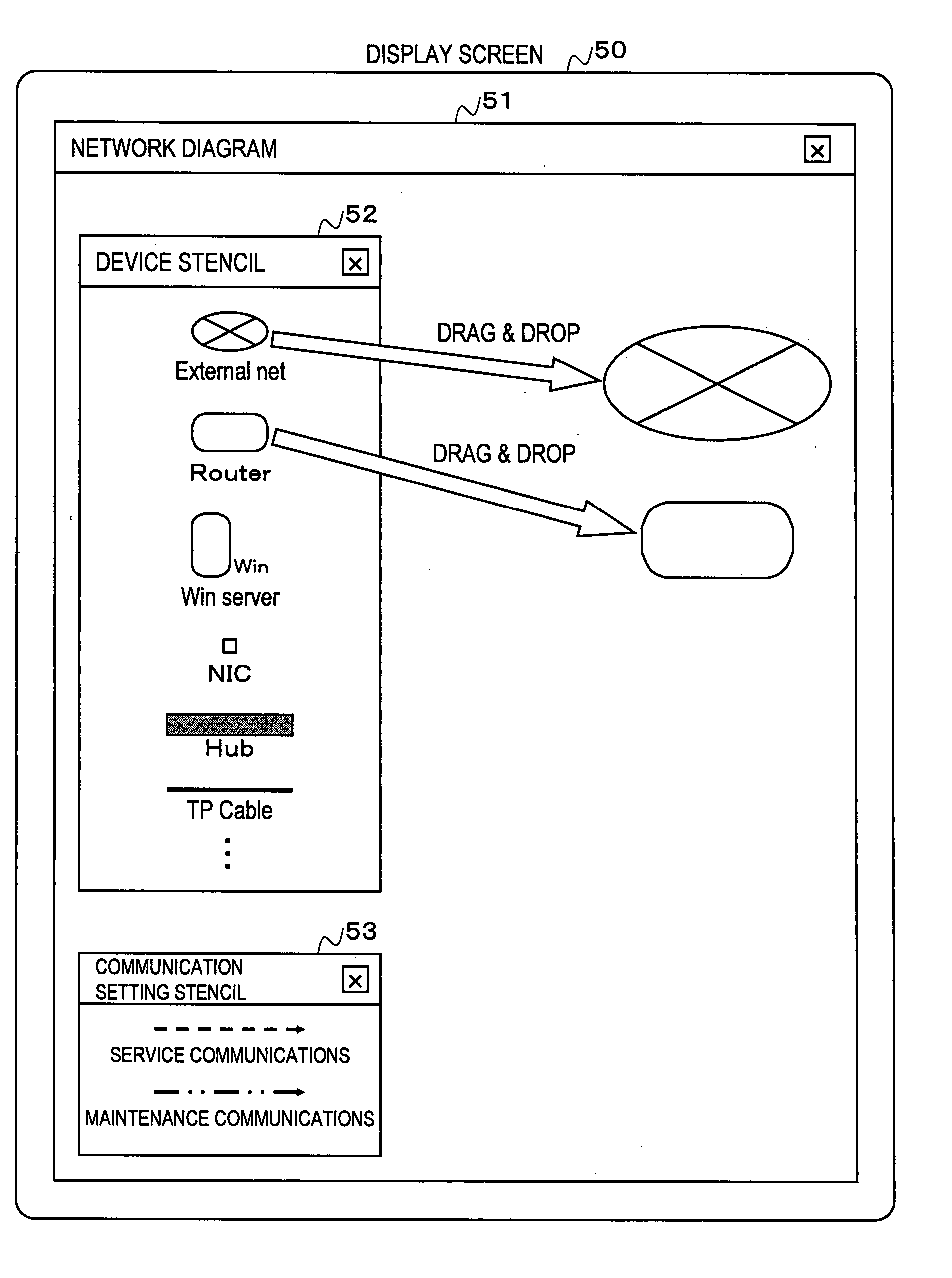

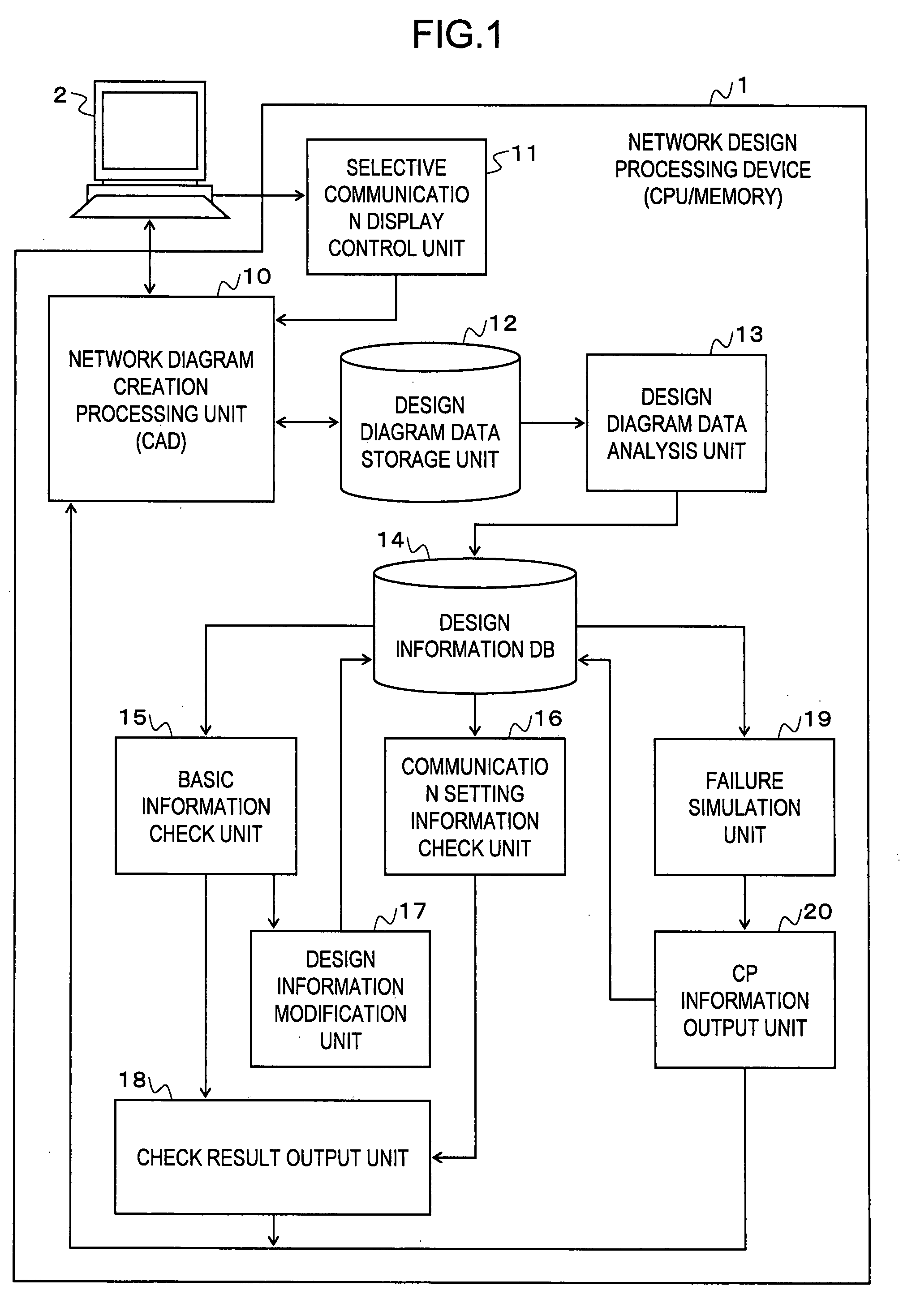

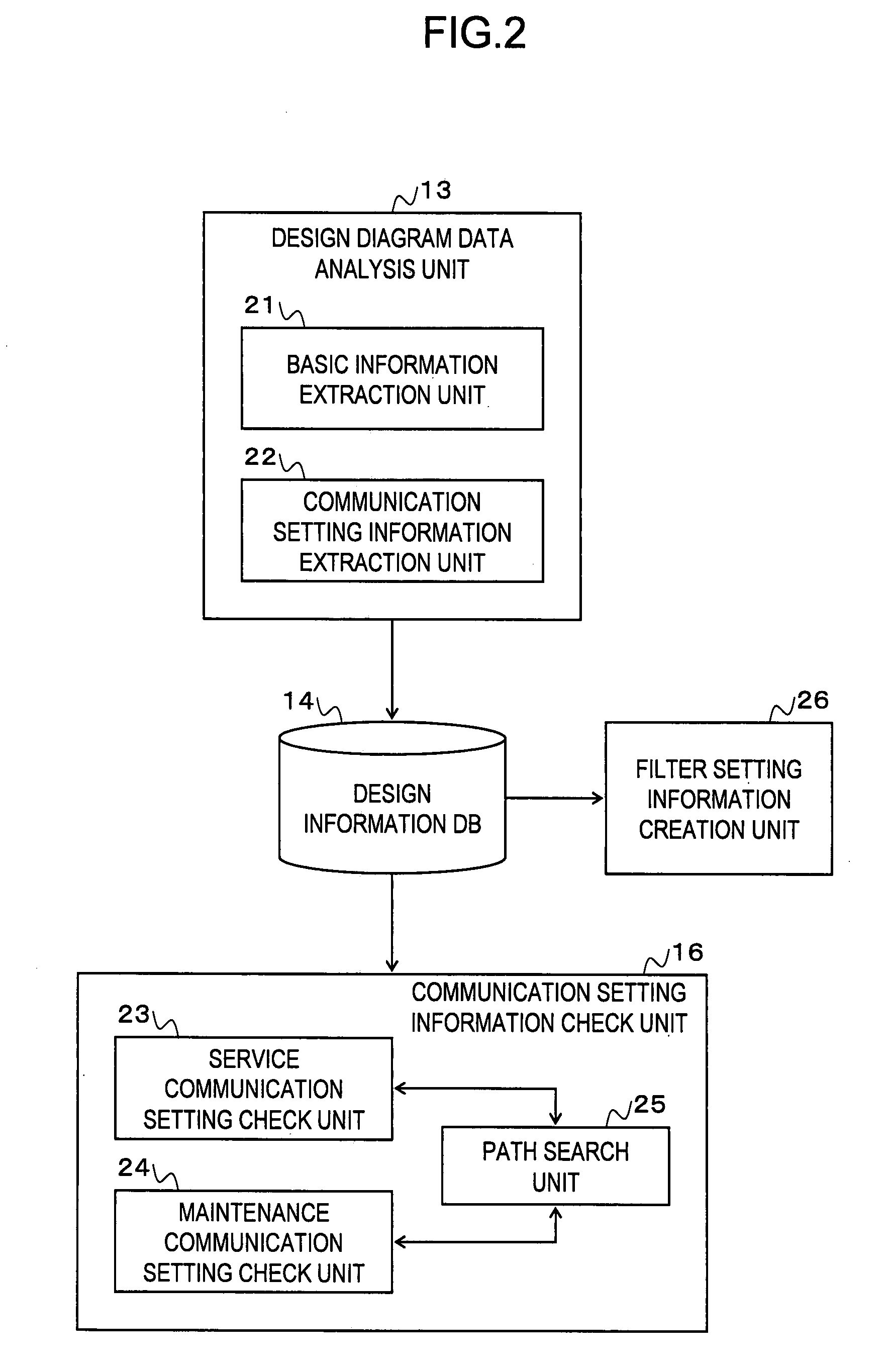

Network design processing device and method, and program therefor

InactiveUS20080091387A1Improve reliabilityTake setGeometric CADAnalogue computers for electric apparatusMaintenance managementProcessing element

In a network design processing device, a network drawing creation processing unit inputs the service communication setting information for business execution in a network system to be designed and the maintenance communication setting information for maintenance management of the network system, while differentiating two types of information on a network diagram, and displays the line joining the starting point and the ending point of communications in the network diagram in display modes different for the service communications and for the maintenance communications. The design diagram data expressing the network diagram inputted by the network diagram creation processing unit is stored in a design diagram data storage unit. Based on this, a design diagram analysis unit creates a design information DB. With reference to this design information DB, a communication setting information check unit detects a setting error concerning the communication.

Owner:FUJITSU LTD

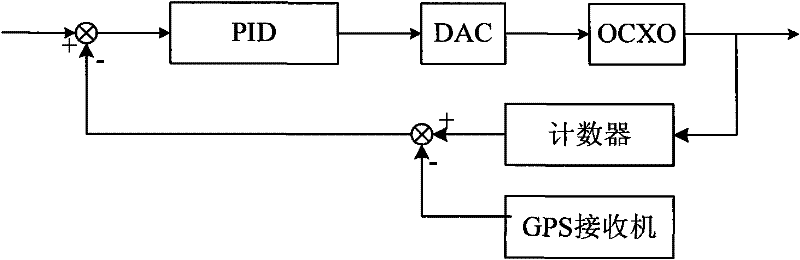

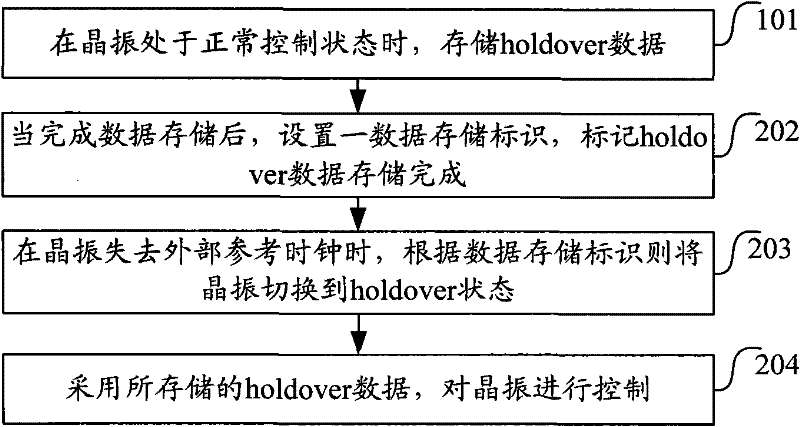

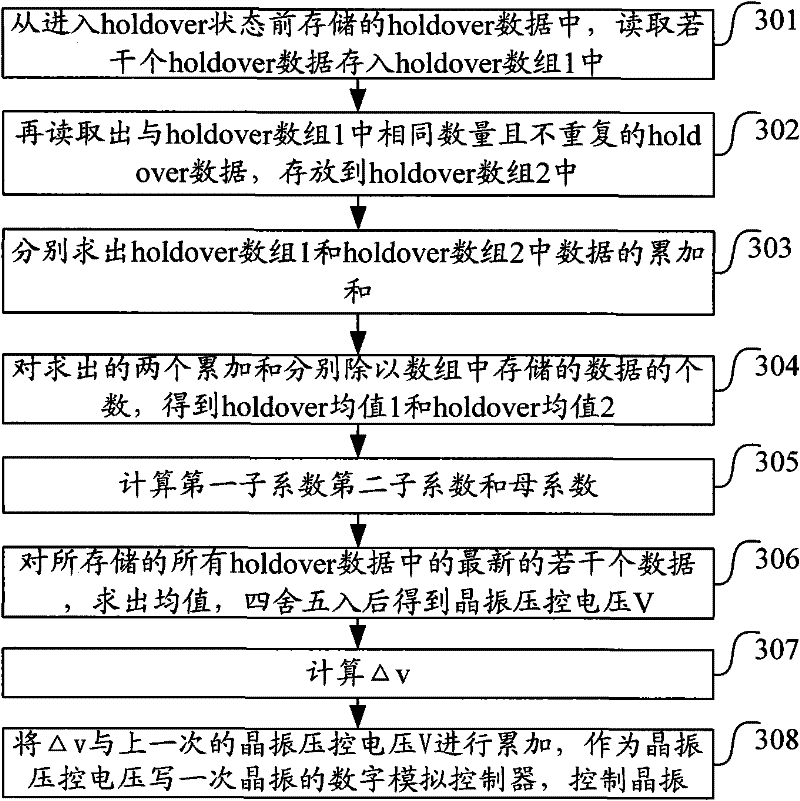

Method and device for controlling crystal oscillator output clock

InactiveCN102291122AStable output clockImprove reliabilityPulse automatic controlMicrowaveExternal reference

A method and a device for controlling a crystal oscillator output clock are provided, and the method includes: when the crystal oscillator is in a normal control state, the crystal oscillator voltage-controlled voltage for controlling the crystal oscillator is stored; when the external reference clock is lost, the stored crystal oscillator voltage-controlled voltage is used to control the crystal oscillator. Using the present solution, in the case of losing the reference clock of one second output by a Global Positioning System (GPS) receiver, the crystal oscillator can still control the crystal oscillator voltage-controlled voltage, so as to achieve the effect that the clock is output as stably as possible, and the reliability of the system is improved. The method of the present solution is simple and clear, it is easy to be implemented and without additional hardware and software resource requirements, it can be as a general method, which is used by the Oven Controlled Crystal Oscillator (OCXO) and the Temperature Compensate crystal Oscillator (TCXO) having the GPS reference to continue to output the clock stably when the reference is lost, and the method of the present solution is important for a system which is very strict to the clock, such as Worldwide Interoperability for Microwave Access (WIMAX), etc.

Owner:ZTE CORP

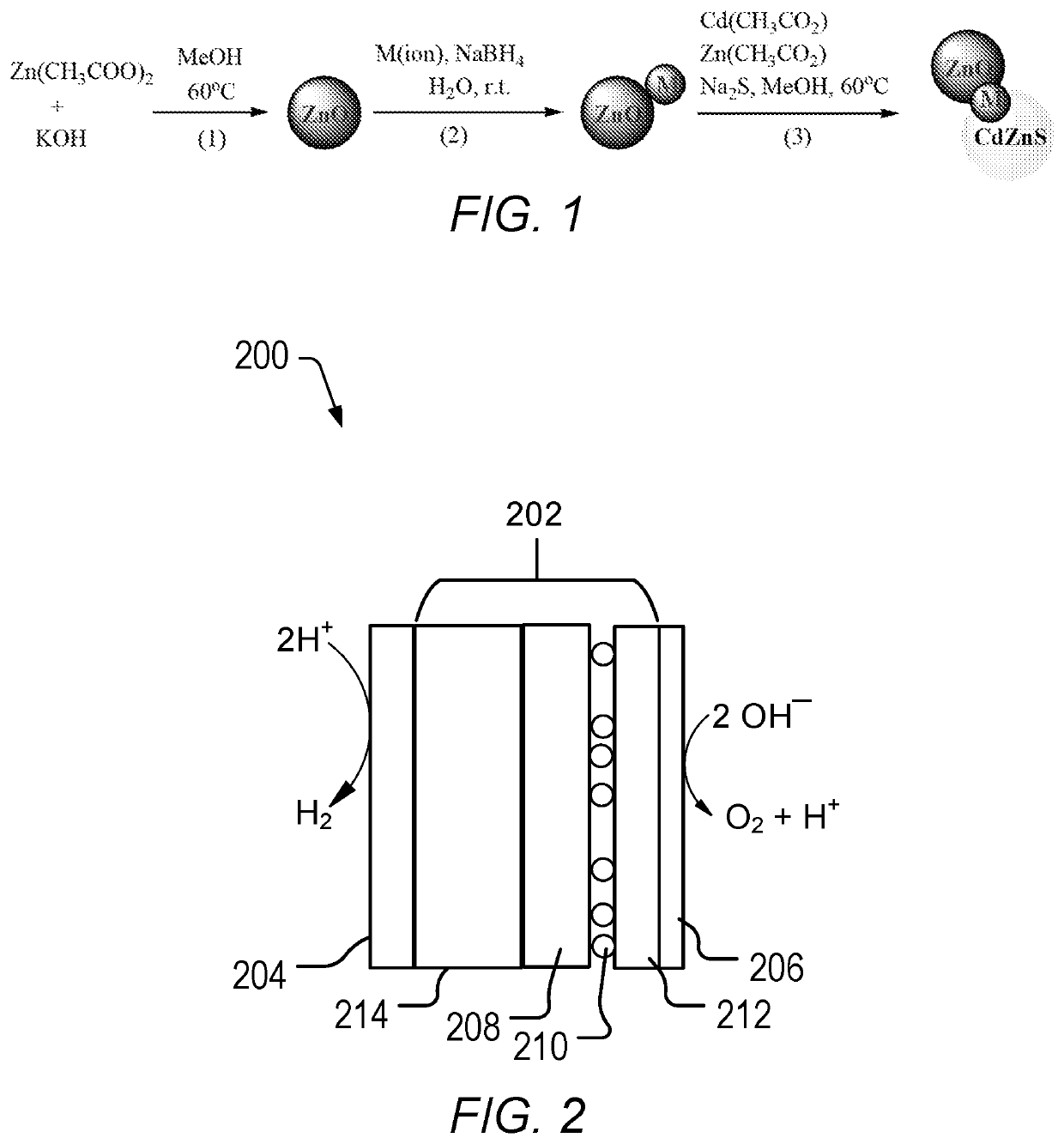

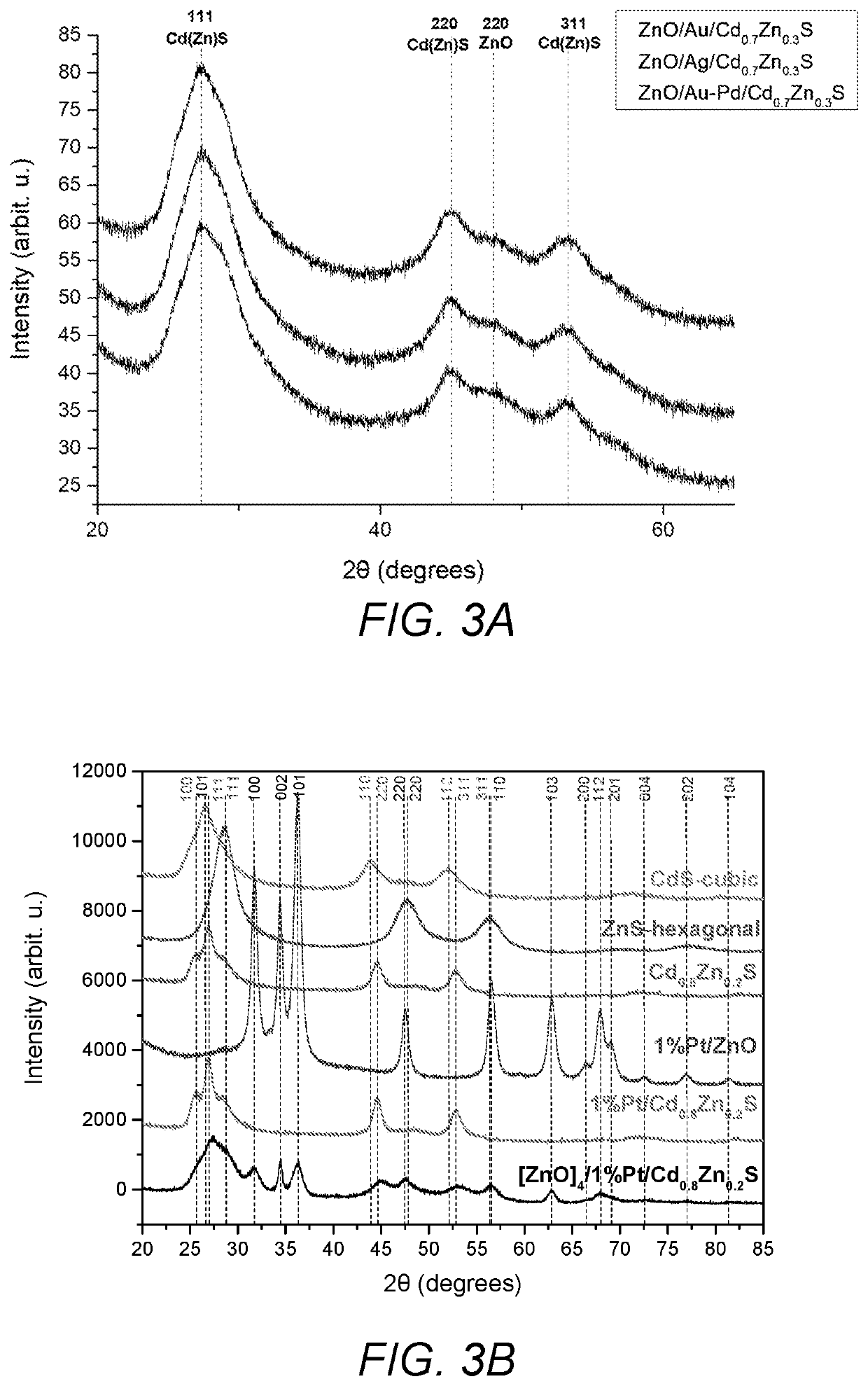

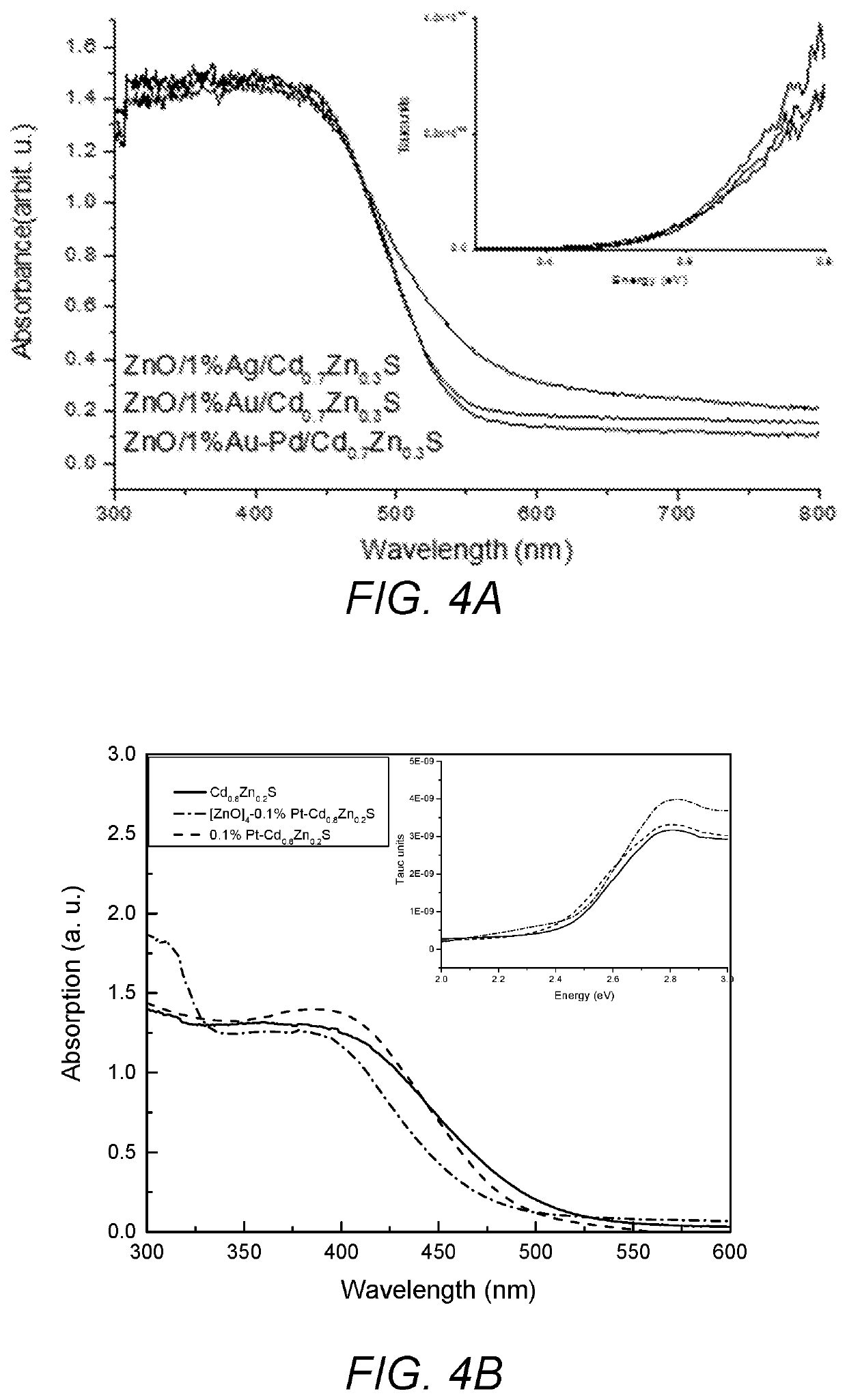

Photocatalyst for efficient hydrogen generation

InactiveUS20200002826A1Efficient removalLong-term stabilityMultiple component coatingsEnergy inputEngineeringPhotoelectrochemistry

Certain embodiments of the invention are directed to a water splitting photo electrochemical (PEC) thin film comprising metal nanostructures positioned between a CdxZn1−xS semiconductor and a ZnO semiconductor to form a Z-scheme for total water splitting.

Owner:SABIC GLOBAL TECH BV

Method for managing the simultaneous utilization of diverse real-time collaborative software applications

InactiveUS7237006B1Easy to useThe method is simple and clearResource allocationInterprogram communicationApplication softwareCollaborative software

The present invention describes a system 10 and method for managing the simultaneous utilization of diverse real-time collaborative software applications. This method allows linking of multiple computer operators or users in a single collaborative session, involving multiple collaborative applications transparent to the operator or user.

Owner:PRELL ANDREW

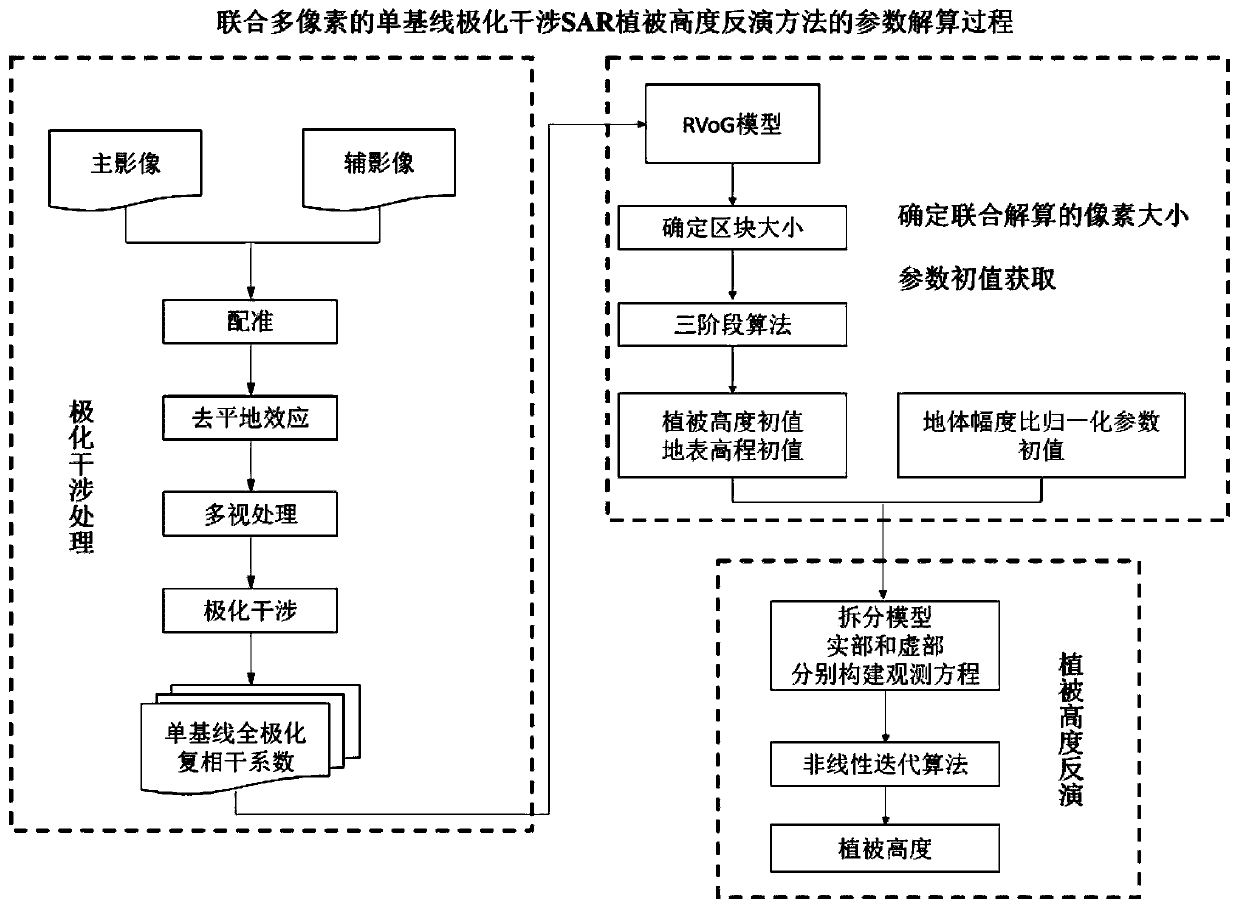

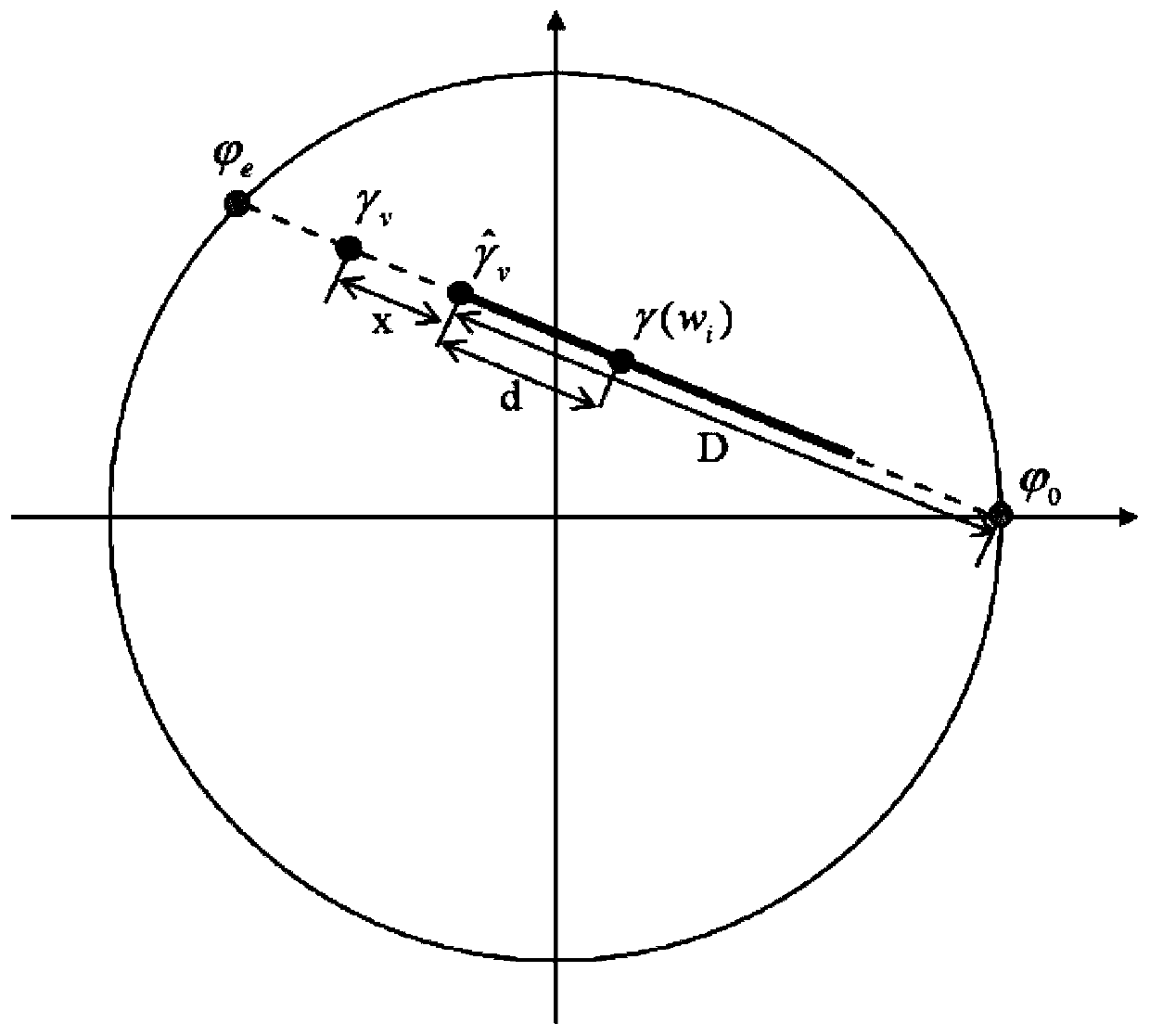

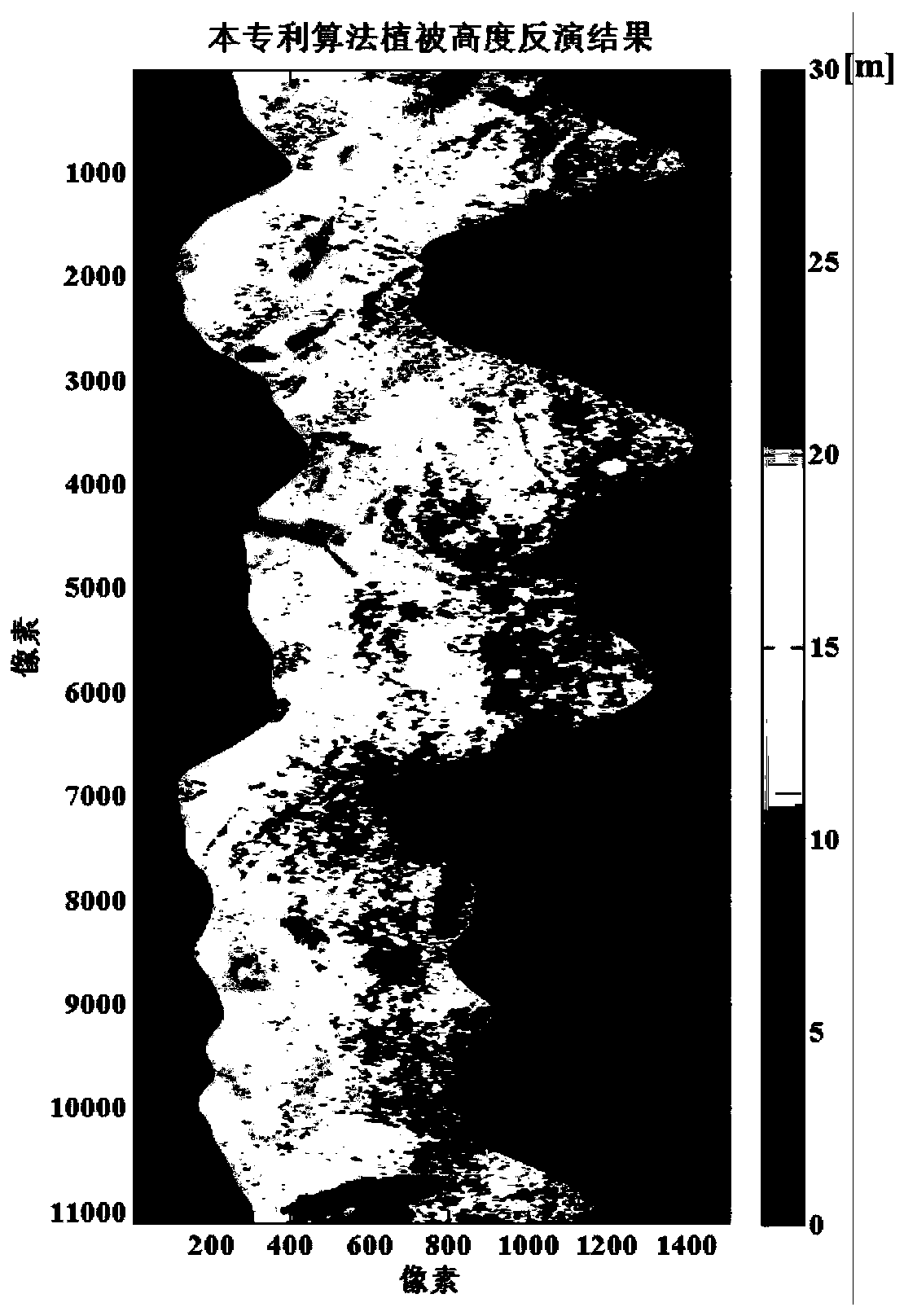

Vegetation parameter inversion method, terminal equipment and storage medium

ActiveCN110988879AImprove solution stabilityThe method is simple and clearRadio wave reradiation/reflectionSoil scienceAlgorithm

The invention discloses a vegetation parameter inversion method, terminal equipment and a storage medium. The method comprises the following steps of: 1, carrying out preprocessing and polarization interference processing on two SAR images so as to obtain a single-baseline complete polarization multi-correlation coefficient observation value; 2, determining the size of a block participating in joint calculation, namely the number of pixel points participating in joint calculation, and setting an initial value of unknown parameter inversion; 3, constructing an observation equation based on thecomplete polarization multi-correlation coefficient of a RVoG model and all pixels; and 4, according to the obtained parameter initial values, carrying out vegetation height inversion by a nonlinear iterative algorithm. According to the invention, the rank deficient problem in application of the RVoG model to invert the vegetation height is solved, and the resolving stability during parameter inversion solving is improved.

Owner:CENT SOUTH UNIV

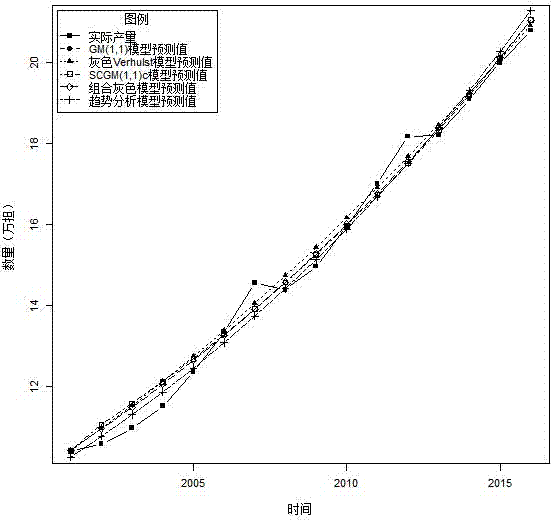

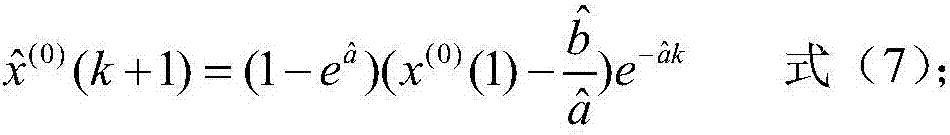

Combined grey model-based prediction management method for raw material requirements of curl tobacco leaves

InactiveCN106897803AGuiding and adjusting the proportion of procurementGuarantee the dynamic balance of supply and demandForecastingResourcesEngineeringInventory management

The invention relates specifically to a method for predicting and managing demand for recured tobacco leaf raw materials based on a combined gray model, and belongs to the technical field of tobacco inventory management. The method includes four steps: the establishment of the basic model, the calculation of preliminary forecast and error, model combination and weight calculation, and the forecast of output and necessary stock of raw materials. The method of the invention is simple and clear, easy to operate, does not need to increase equipment, does not change the existing production and management mode, can effectively guide and adjust the proportion of raw material procurement, and ensure the dynamic balance of supply and demand of raw materials in stock. The invention adopts a combination model to reduce the systematic error caused by a single model and improve the prediction accuracy; and not only can predict a single brand, but also can be used for total quantity prediction, so as to provide scientific and effective production and management decisions for producers.

Owner:CHINA TOBACCO YUNNAN IND

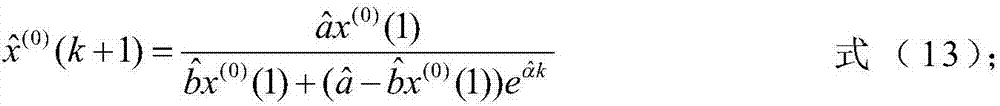

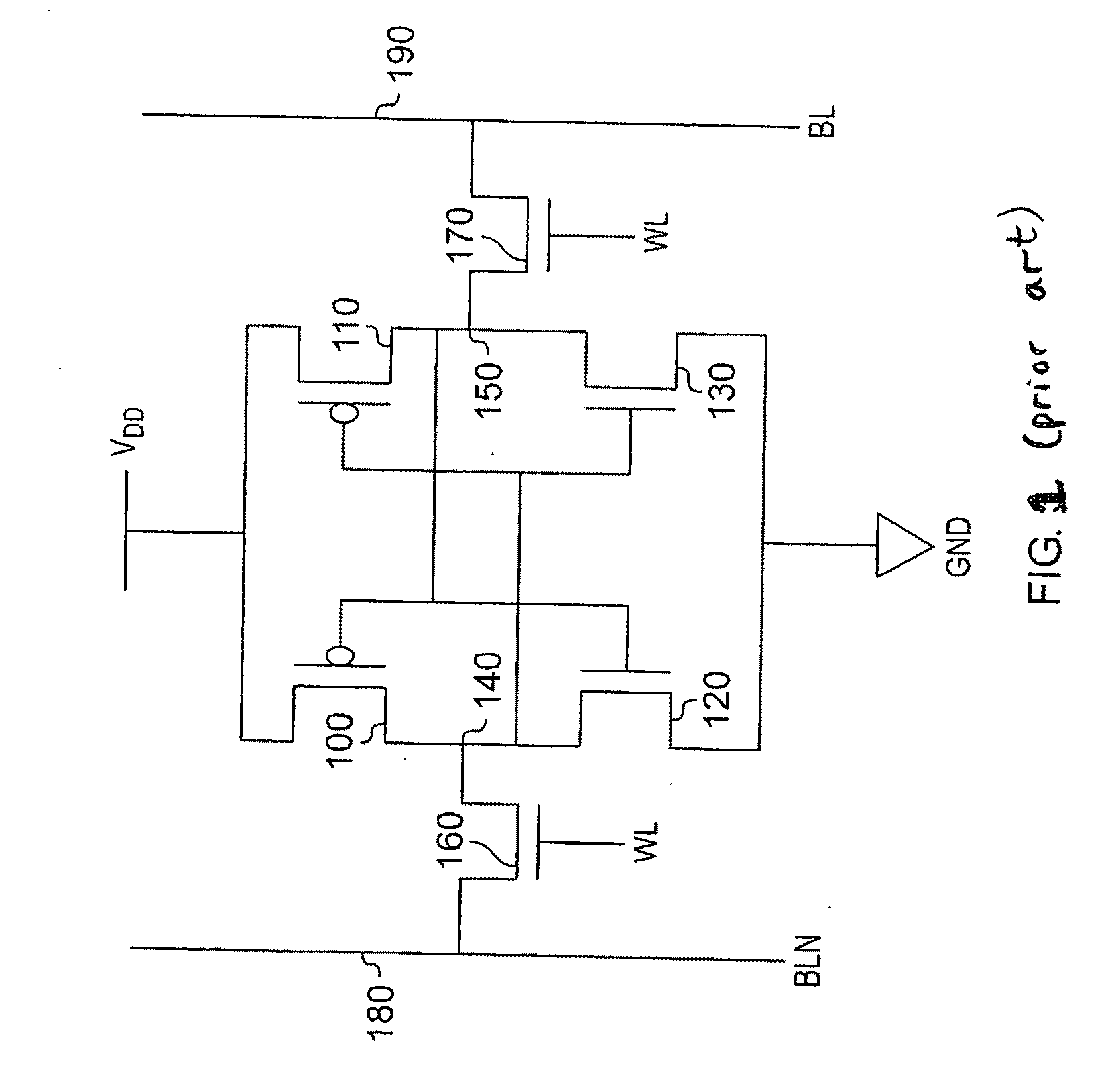

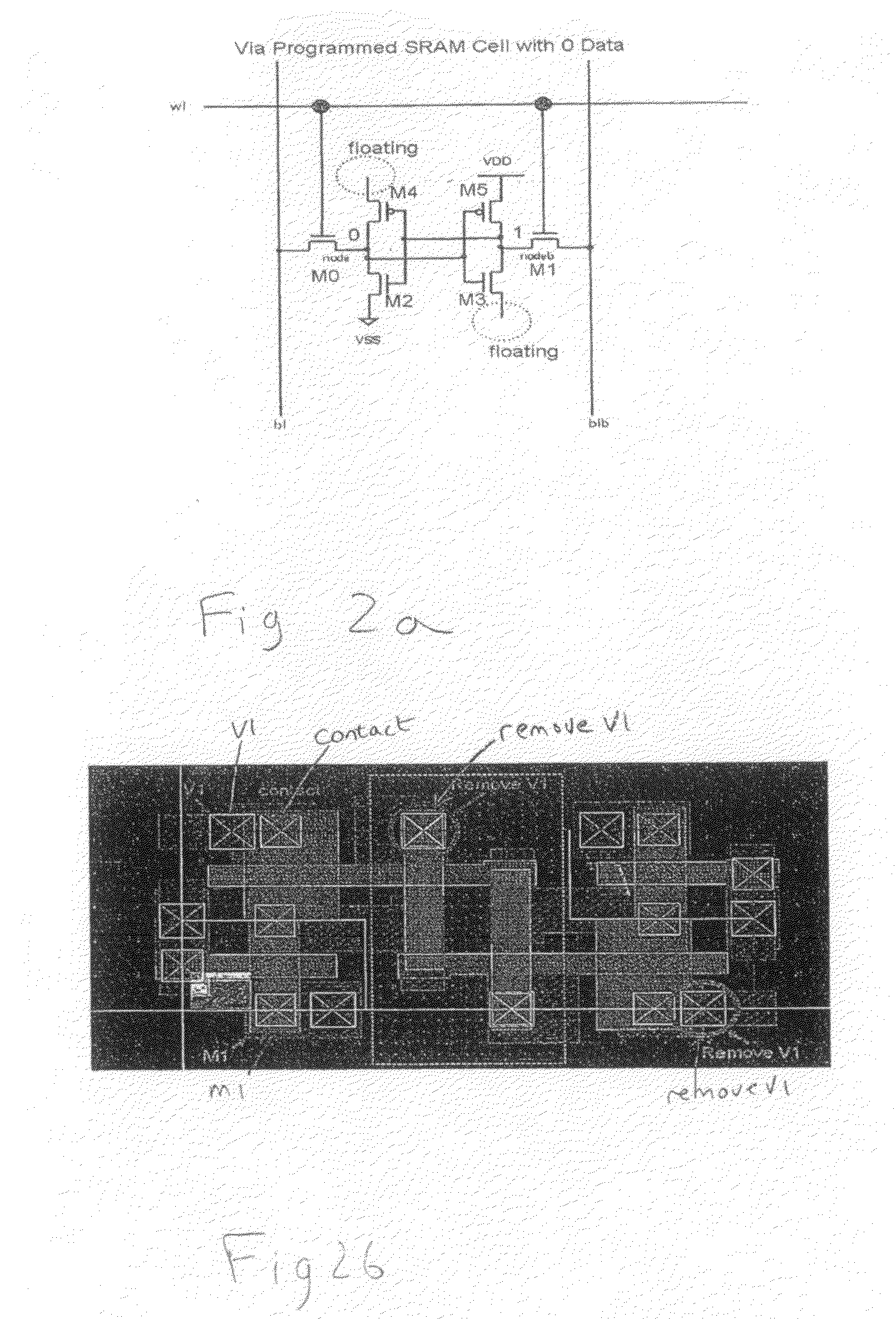

Converting SRAM cells to ROM Cells

InactiveUS20100214824A1Easy to convertThe method is simple and clearRead-only memoriesDigital storagePower inverterStatic random-access memory

A method of converting a static random access memory cell to a read only memory cell and the cell thus converted is disclosed. The cell to be converted comprises a data retention portion powered by a higher and lower voltage supply line and four transistors arranged as two cross coupled inverters. It is converted to a read only memory cell by severing a connection between at least one of said transistors within a first of said two inverters and one of said voltage supply lines such that when powered said first inverter outputs a predetermined value.

Owner:ARM LTD

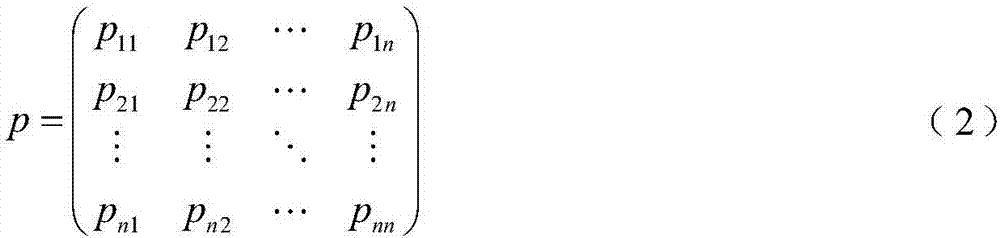

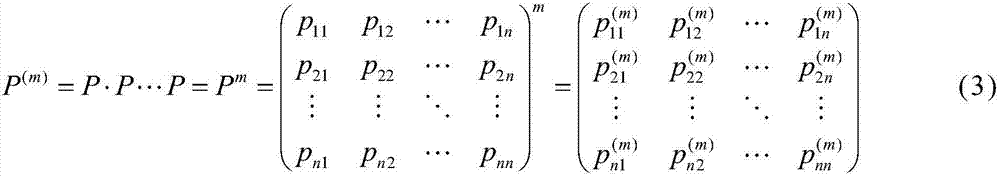

Markov-process-based curl tobacco leaf inventory dynamic balance method

ActiveCN106901394AThe method is simple and clearEasy to operateTobacco preparationDynamic balanceTransfer matrix

The invention relates to a Markov-process-based curl tobacco leaf inventory dynamic balance method and belongs to the technical field of tobacco inventory management. The method comprises steps of cigarette output prediction, curl tobacco demand calculation, curl tobacco reserve calculation, Markov transfer matrix calculation, and curl tobacco practical reserve demand calculation. Total amount of raw material required for a production plan is considered and raw material demand is refined; changes of the curl tobacco aging process is explicated from a point of view of random process and an inventory administrative decision is adjusted; daily production can be guaranteed to be smoothly conducted from the aspect of raw material supply; meanwhile, the method has strong adaptability; when single mark cigarette raw material demand is measured, total demand and constitute condition of the raw material can be achieved with collection of all mark cigarette raw material demand; and also, during the production, monitoring work to the production and raw material consumption processes is strengthened.

Owner:CHINA TOBACCO YUNNAN IND

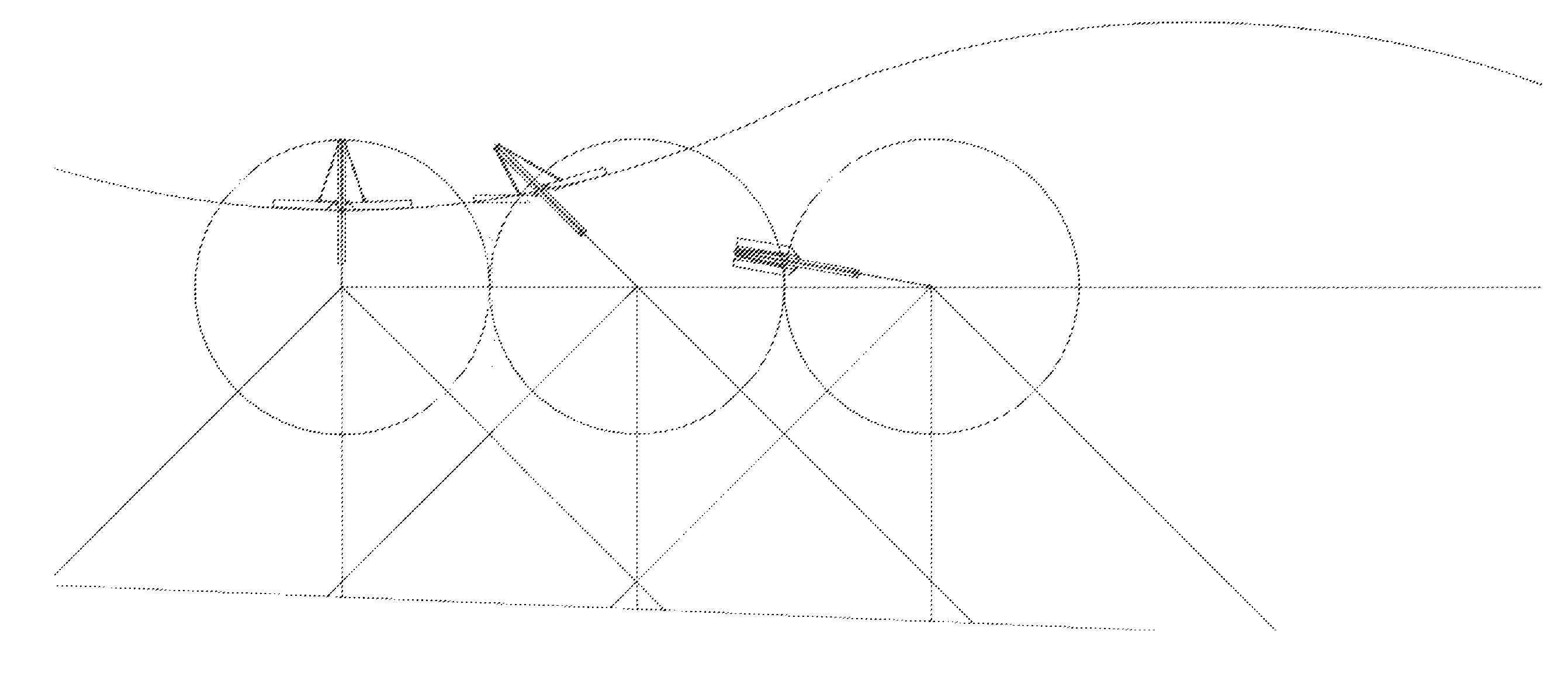

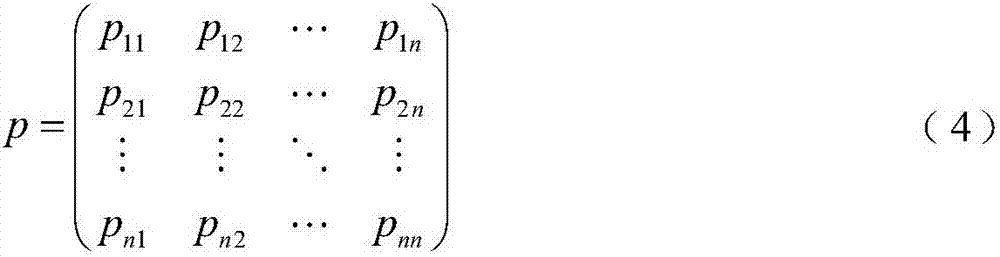

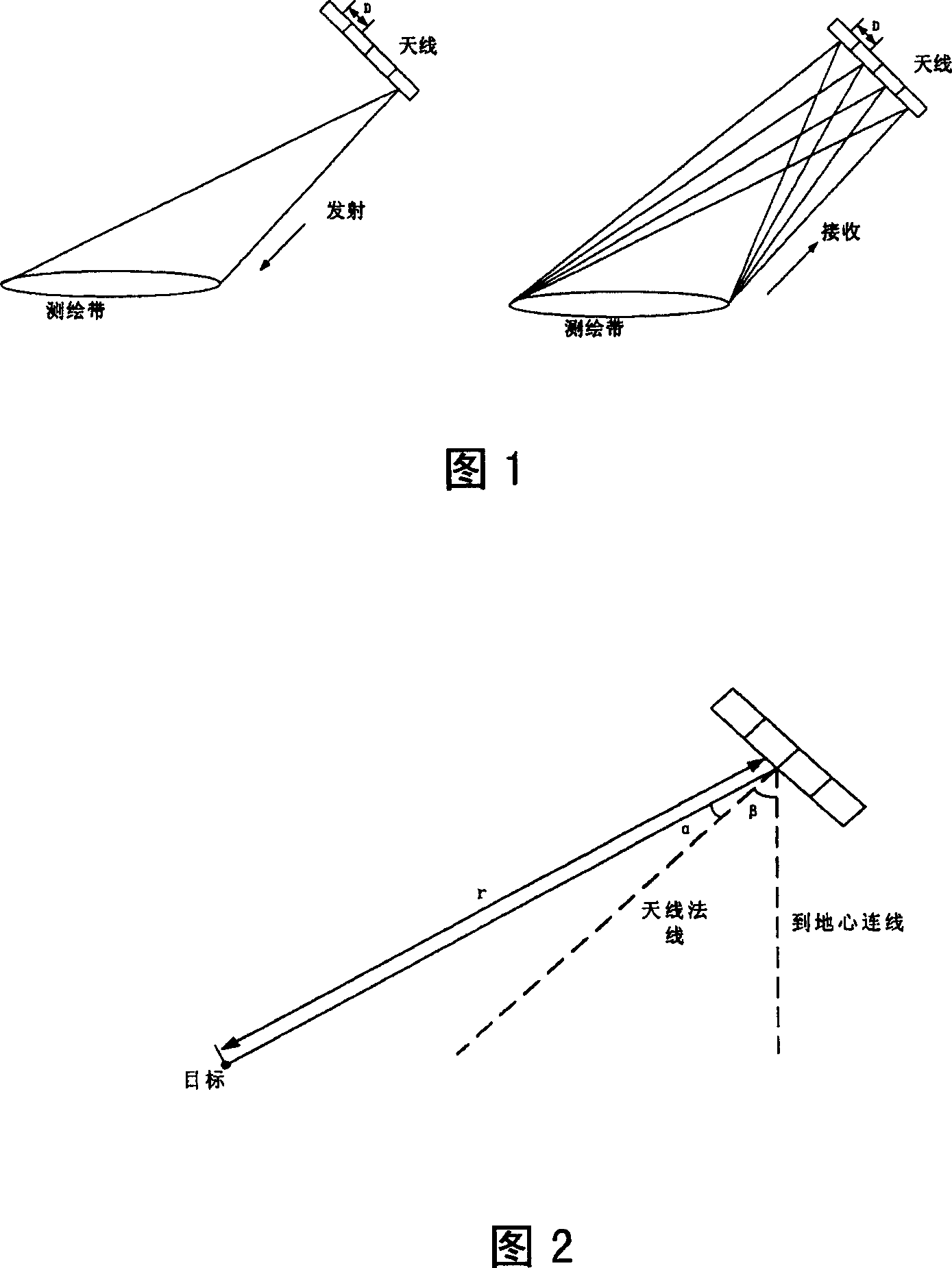

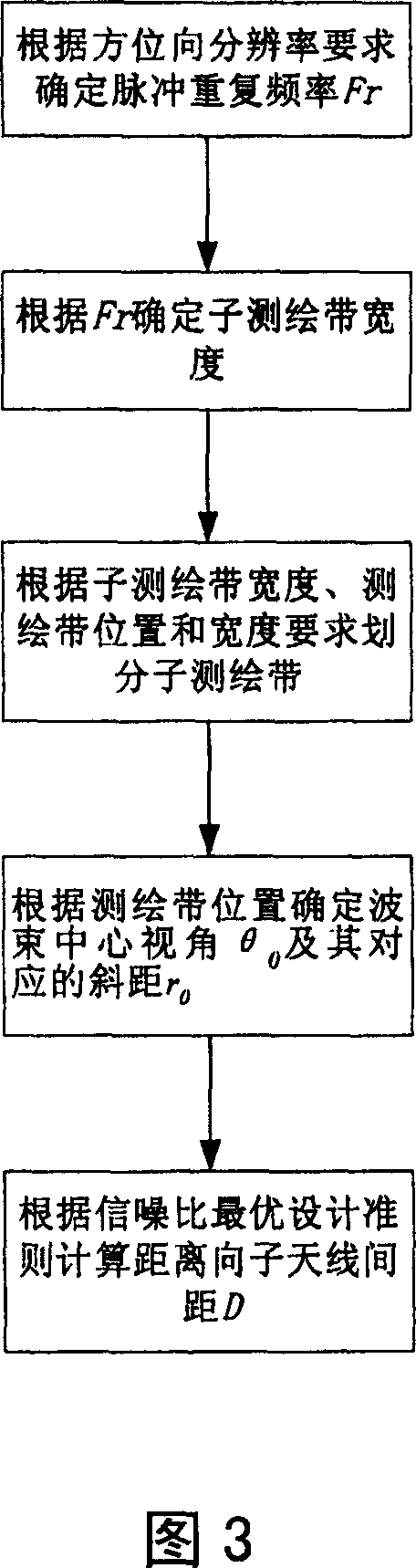

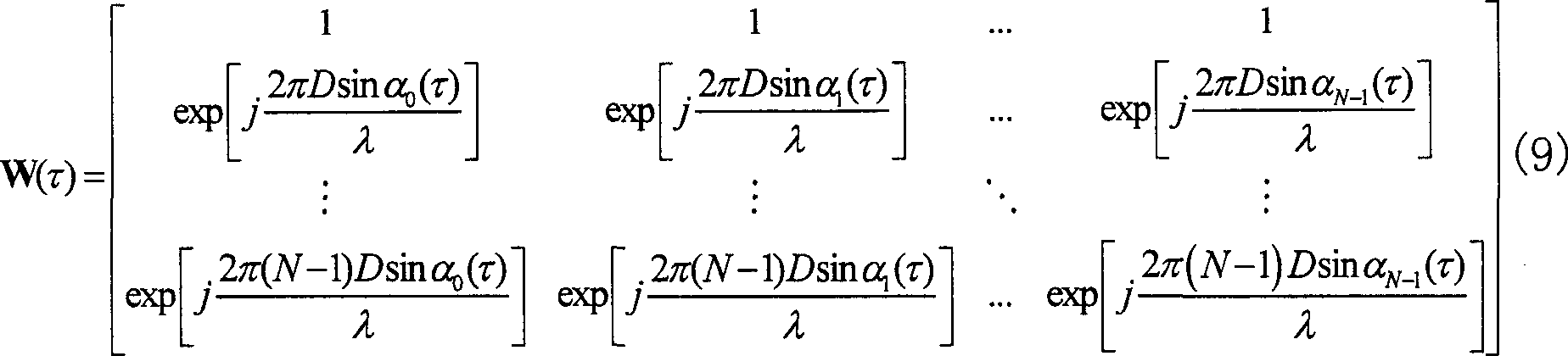

Range multi-aperture wide-swath synthetic aperture radar design method

InactiveCN1996046AThe method is simple and clearRadio wave reradiation/reflectionPhysicsImage resolution

The design for distance to multi aperture receiving width measuring band synthetic aperture radar provides its optimal signal to noise ratio design principle, with theta0 being the center angle of the measuring band inner wave beam, r0 the corresponding slant distance of the wave beam center line, C being the optical speed, RE being the radius of the local earth, H synthetic aperture radar platform height, Fr pulse repeated frequency, D sub antenna distance oriented space, lambada wavelength, N measuring band number. It solves the conflict of the directional resolution and measuring bandwidth.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

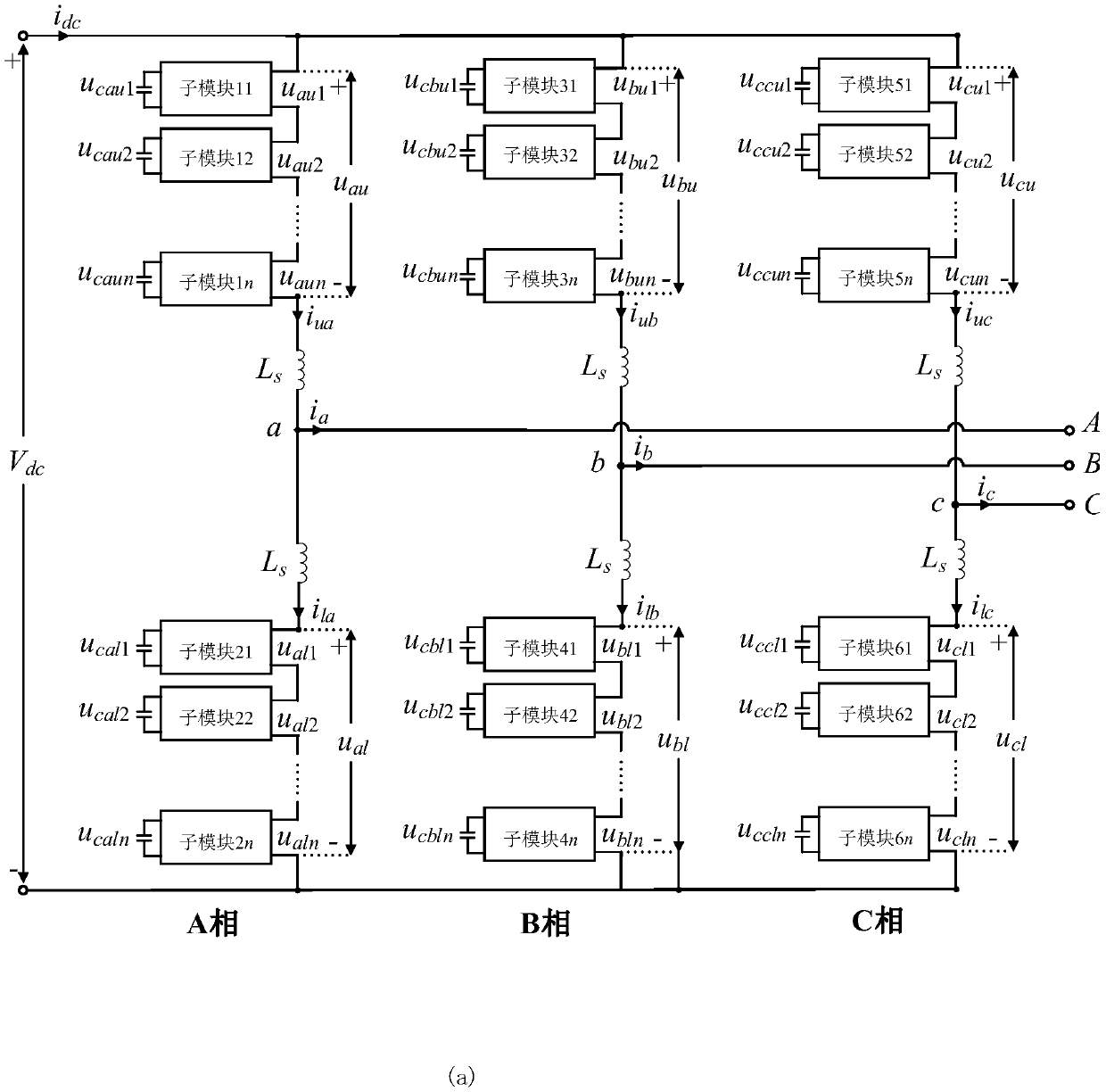

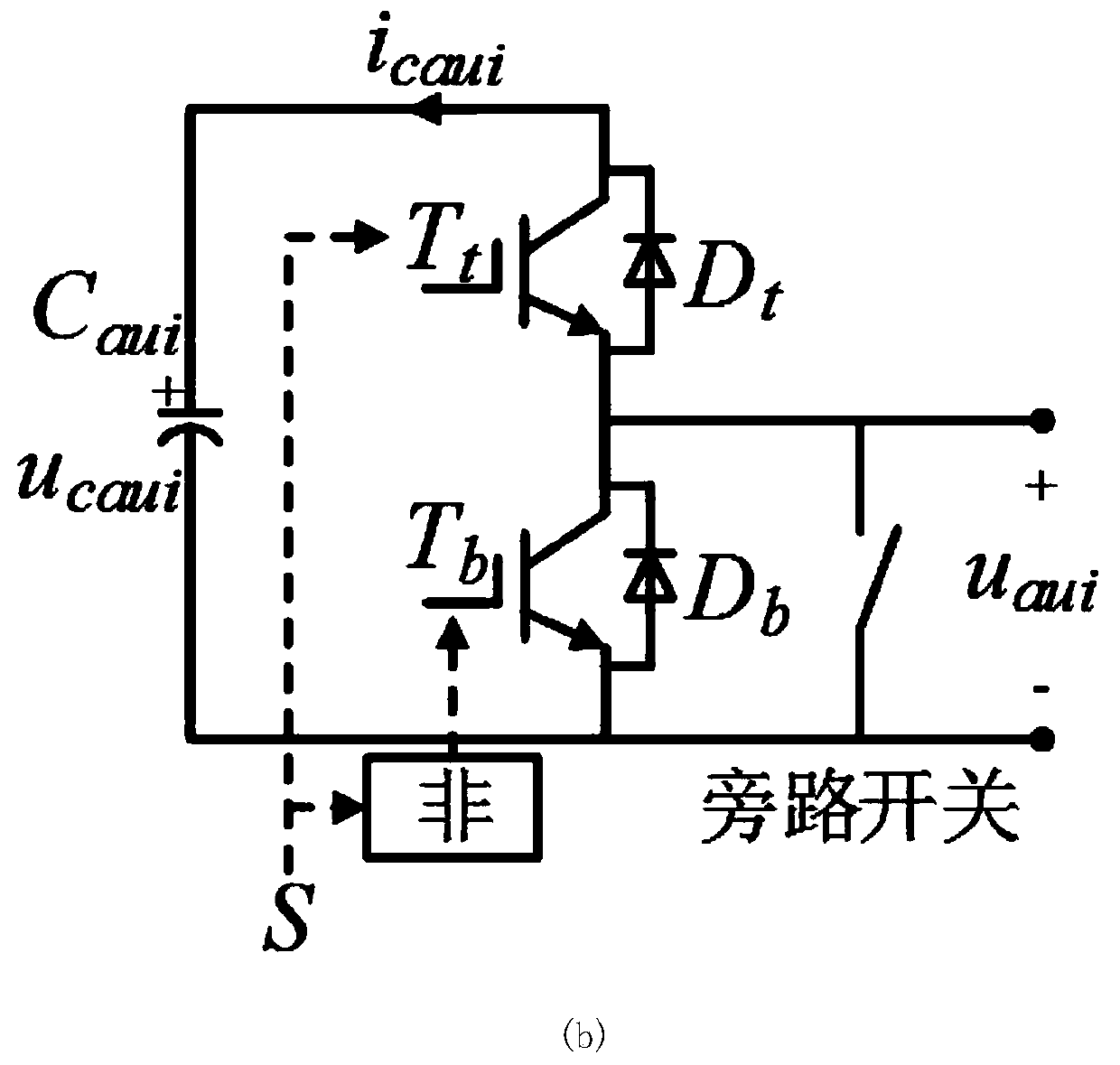

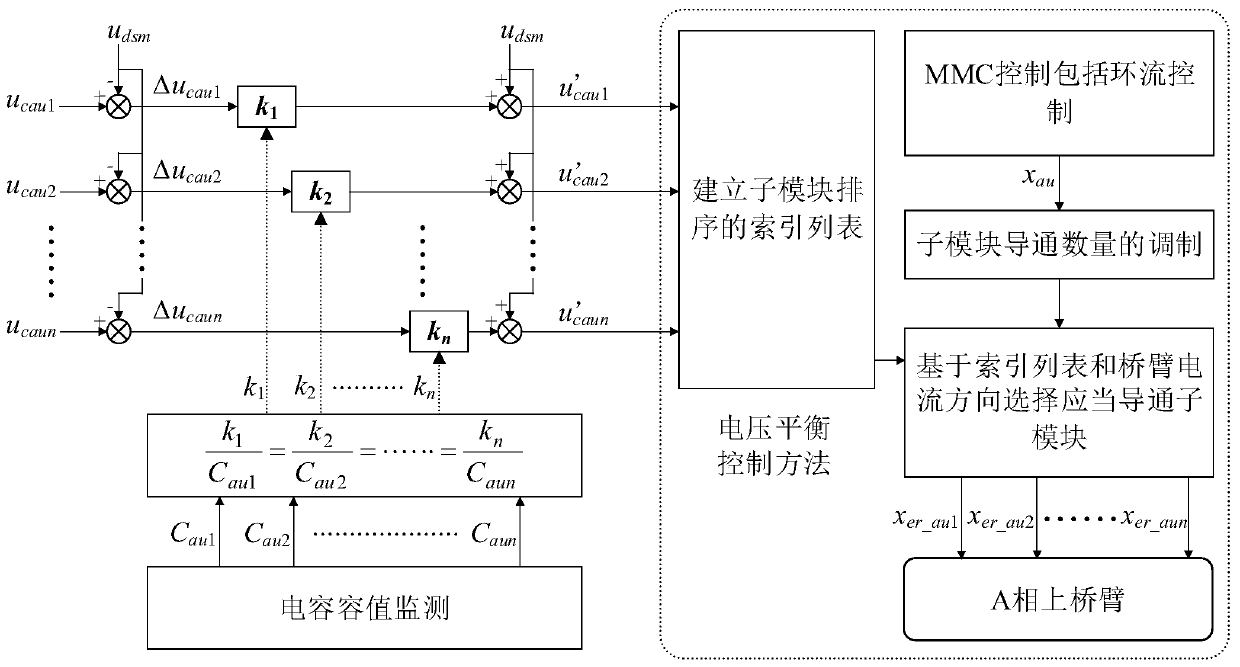

Modular multilevel converter loss balance control method under capacitor soft fault

InactiveCN110289779AThe method is simple and clearSimple calculationEfficient power electronics conversionAc-dc conversionLoss balanceComputer module

The invention relates to a modular multilevel converter loss balance control method under capacitor soft fault. The method comprises the following steps: a capacitance value Caui is calculated by using the external characteristics of a submodule capacitor; the fluctuation coefficient ki of a required capacitance voltage AC component is then calculated according to the capacitance value; according to the fluctuation coefficient ki and a capacitance voltage AC / DC component, virtual capacitance voltage u'caui is obtained; and through controlling balance of the virtual capacitance voltage, the equivalent modulation wave xer_aui of each submodule is similar, and the loss of each submodule is further balanced. In the method, through introducing the AC component fluctuation coefficient ki, the influences on the submodule equivalent modulation wave xer_aui by the capacitance value are cancelled, the loss of each submodule is balanced, and the loss of a power switching device at the same position in each submodule is balanced.

Owner:SOUTHEAST UNIV

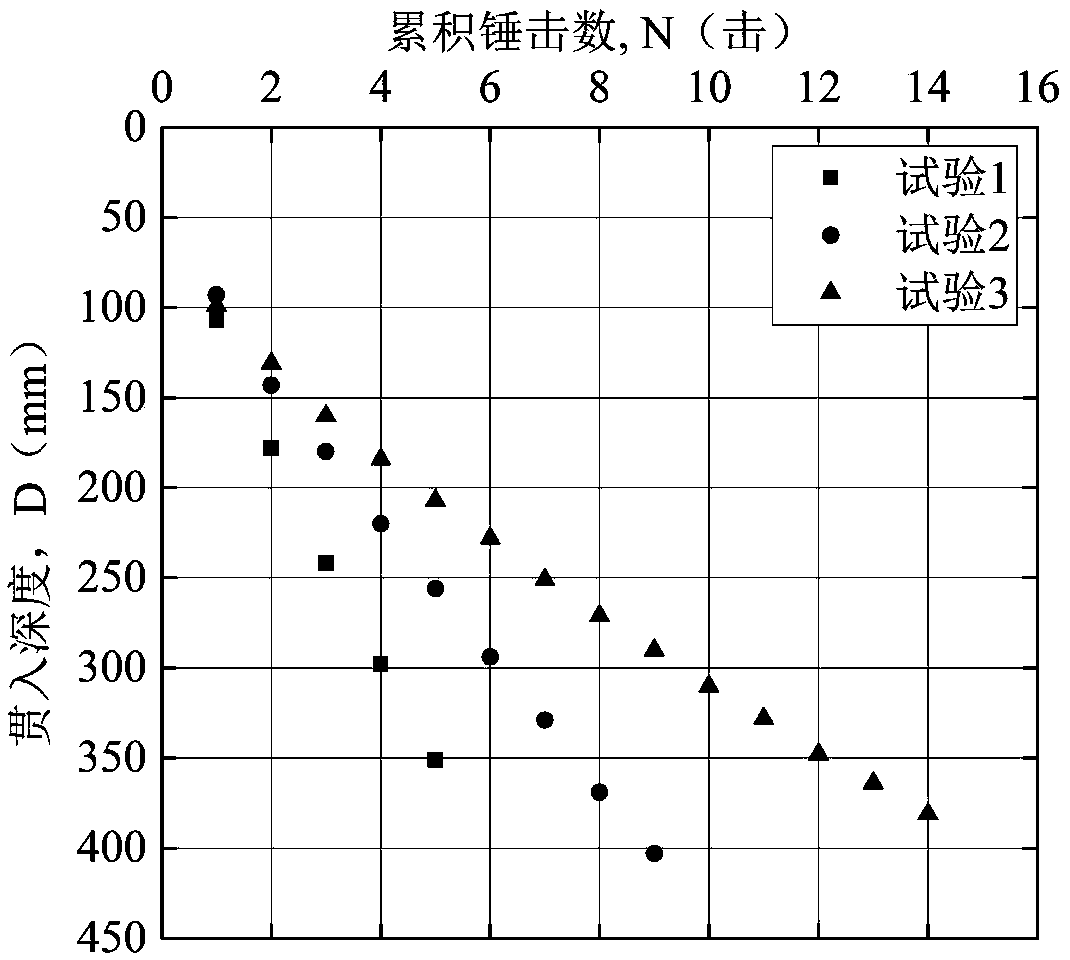

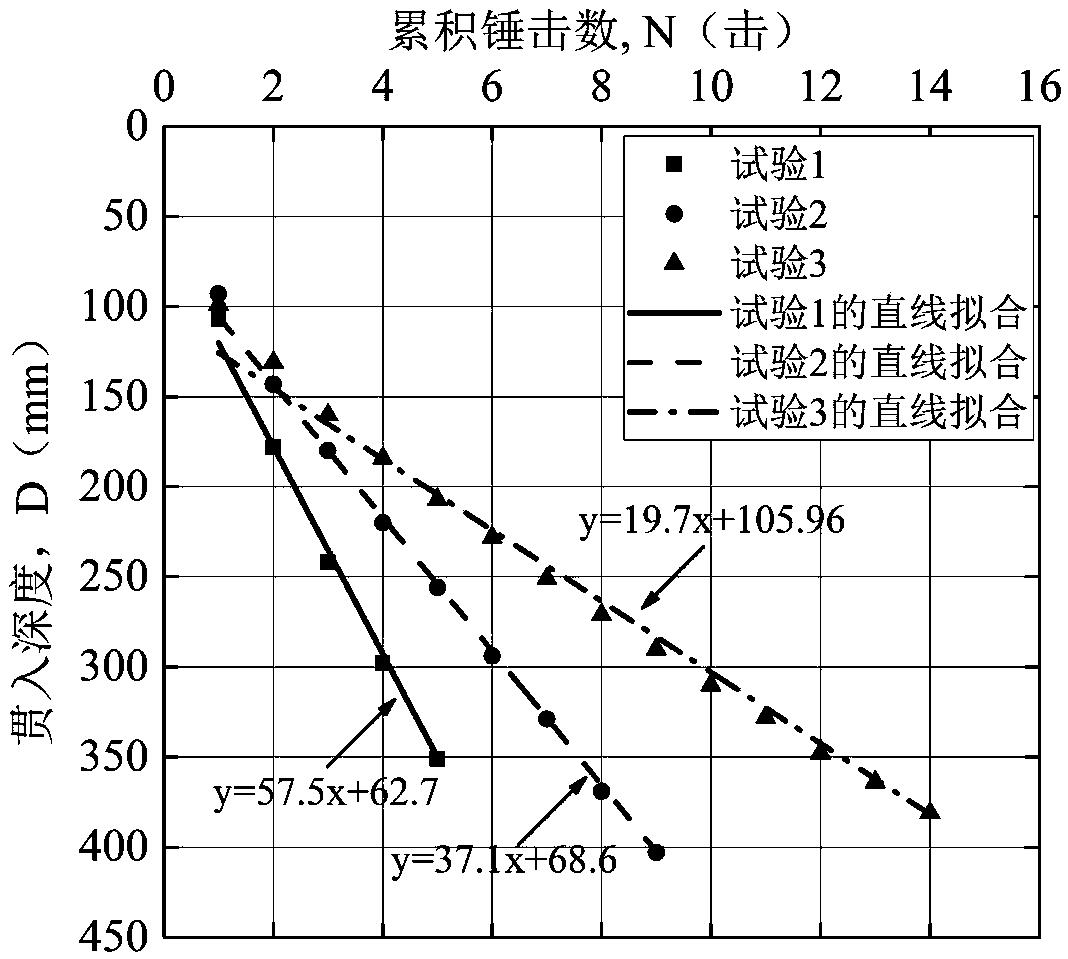

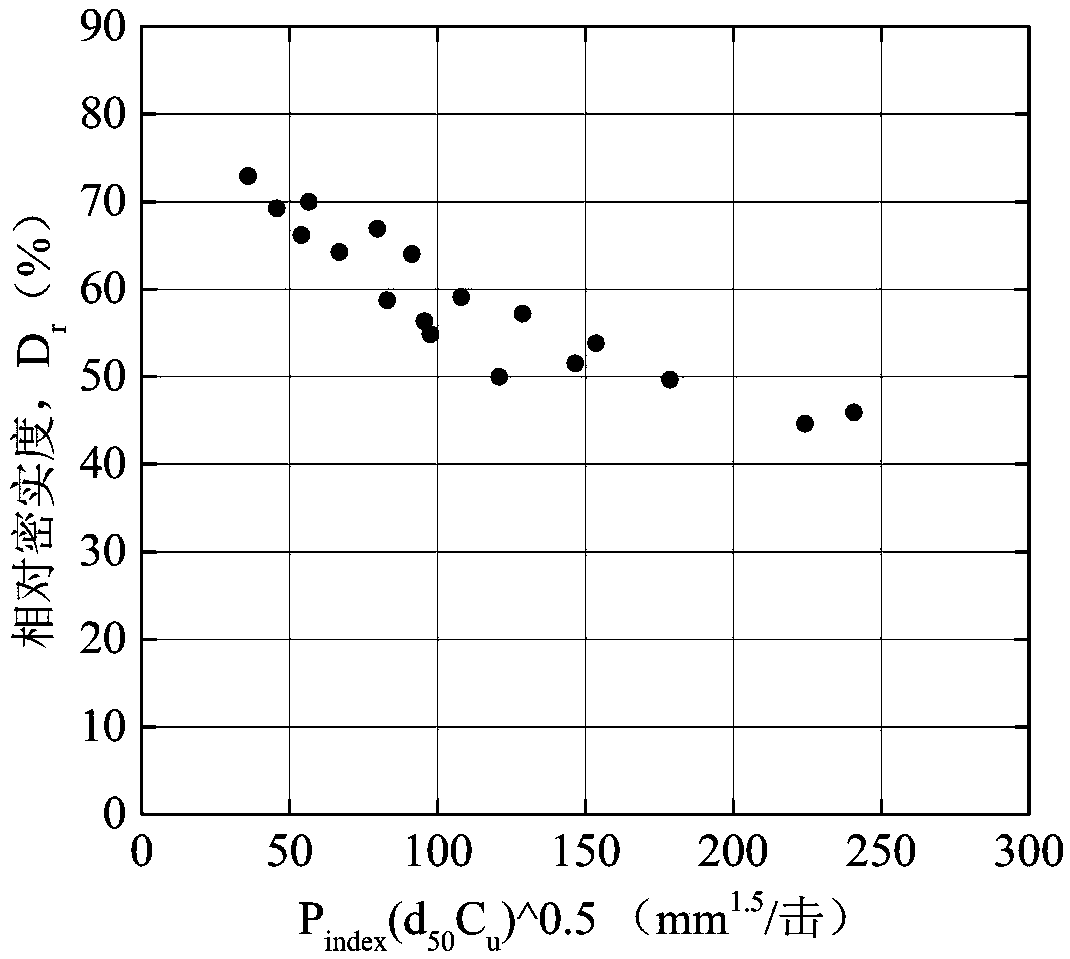

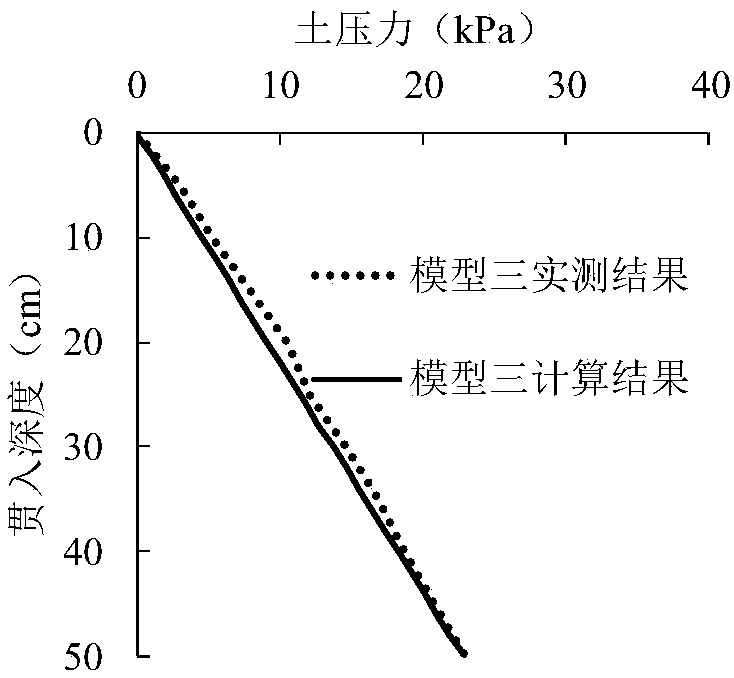

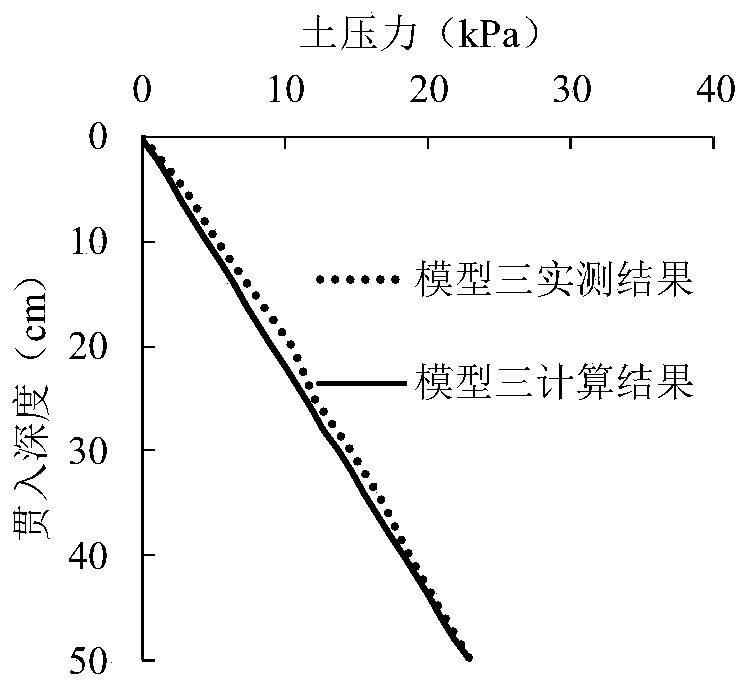

Method for evaluating relative compactness of quartz soil based on light dynamic penetration test index

ActiveCN109142108AAccurate predictionHigh densityMaterial strength using repeated/pulsating forcesLand basedQuartz

The invention discloses a method for evaluating the relative compactness of quartz soil based on a light dynamic penetration test index. The quartz soil sample taken back at the site is dried, and theRhod, max, Rhod, min of each type of quartz soil sample is determined by a geotechnical test. D50, Cu, Dri is set to calculate the Rhodi of each type of quartz soil sample under various Dri; the penetration hammering numbers of each type of quartz soil sample under different Rhodi and the cumulative penetration depth of the probe after each hammering were measured respectively, the hammering number of each type of quartz soil sample-accumulated penetration depth scatter plot was plotted respectively, each set of test data points in each figure is fitted into a straight line, and the slope ofeach straight line is the pindex, i of such quartz soil sample under Dri; the formula is shown in the description. A scatter plot is drawn; the expressions of the formula and Dri are shown in the description. The relative compactness of the predicted quartz land based on the method is more consistent with the actual situation.

Owner:TIANJIN UNIV

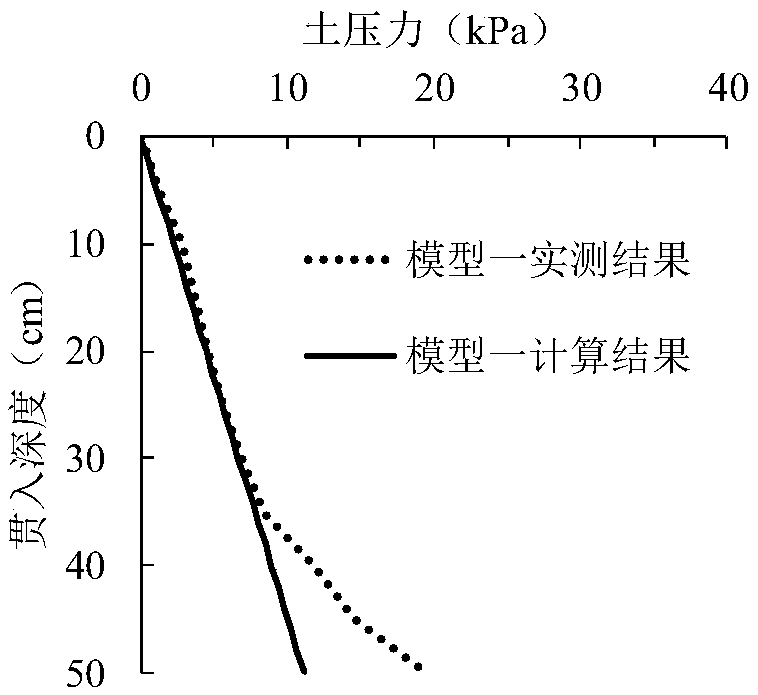

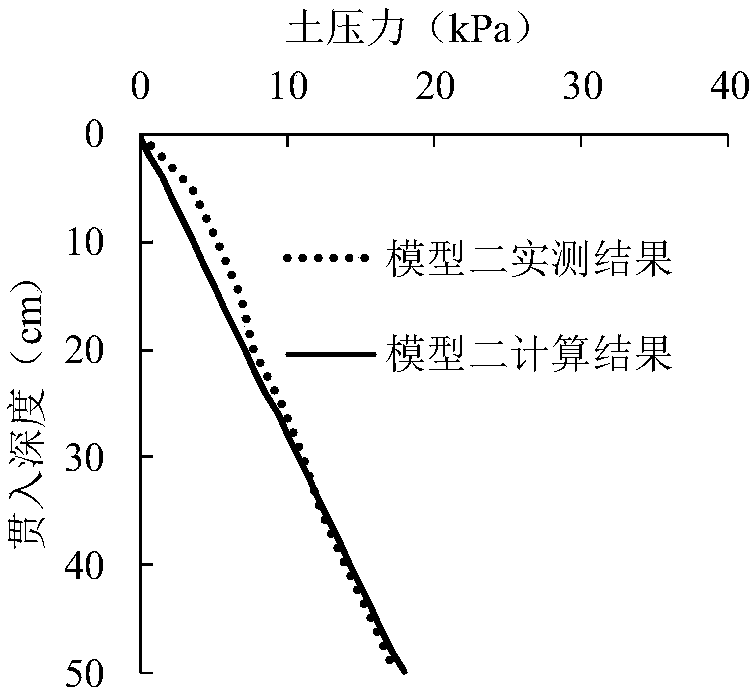

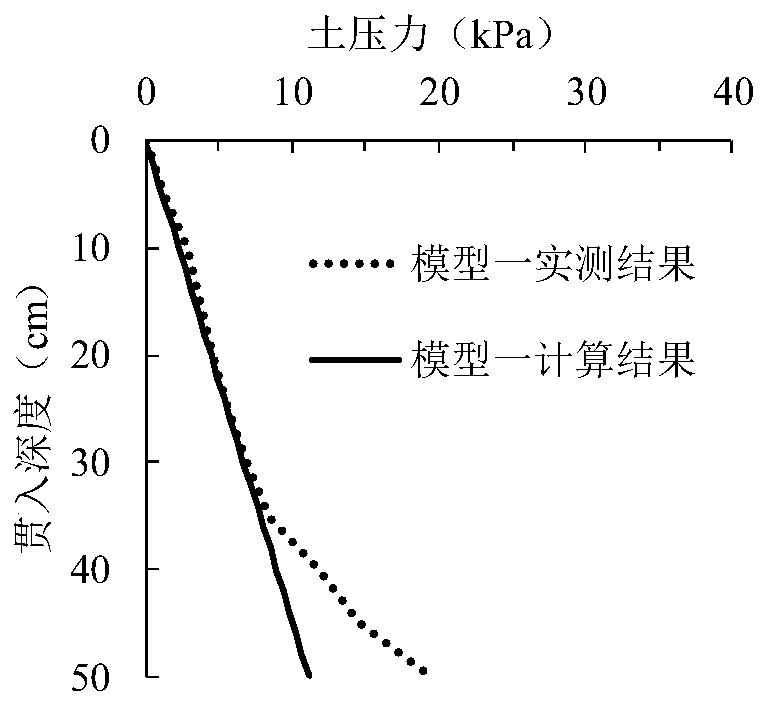

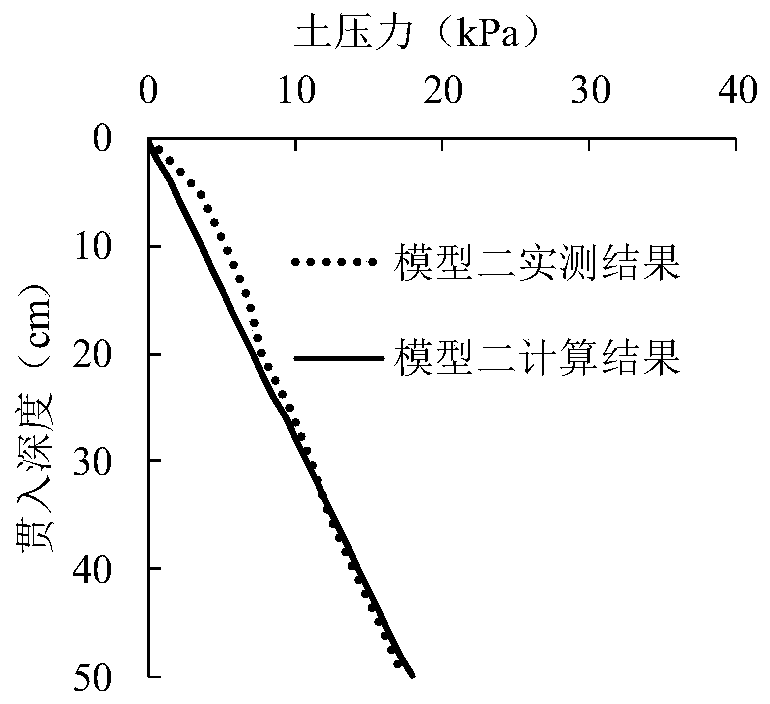

Positive pressure sinking resistance calculation method suitable for barrel foundation in sandy soil

ActiveCN107871026AIncrease lateral pressureSimple methodDesign optimisation/simulationSpecial data processing applicationsPositive pressureEngineering

The invention discloses a positive pressure sinking resistance calculation method suitable for a barrel foundation in sandy soil. The situation that a soil squeezing effect in a positive pressure sinking process increases a lateral pressure on an outer side barrel wall is considered; a lateral soil pressure coefficient derived based on a cavity expansion theory is compared with a lateral soil pressure coefficient given in a DNV specification; and a calculation result is closer to an actual condition. The situation that a constraint effect of an inner side wall on a soil body enables a soil plug effect to be formed in a barrel is considered; the generated soil squeezing effect is far greater than that outside the barrel; and compared with a specification method, a method for calculating a soil pressure located in the barrel and derived based on the soil plug effect has the advantage that the calculation result is closer to the actual condition. The situation that soil bodies inside andoutside a barrel body in the positive pressure sinking process present different densities is considered; the barrel wall end resistance inside and outside the barrel is calculated; especially the inner side resistance of the barrel is calculated by adopting a reversely derived frictional angle phi; the method is simple and convenient; and the calculation result is closer to the actual condition.

Owner:TIANJIN UNIV

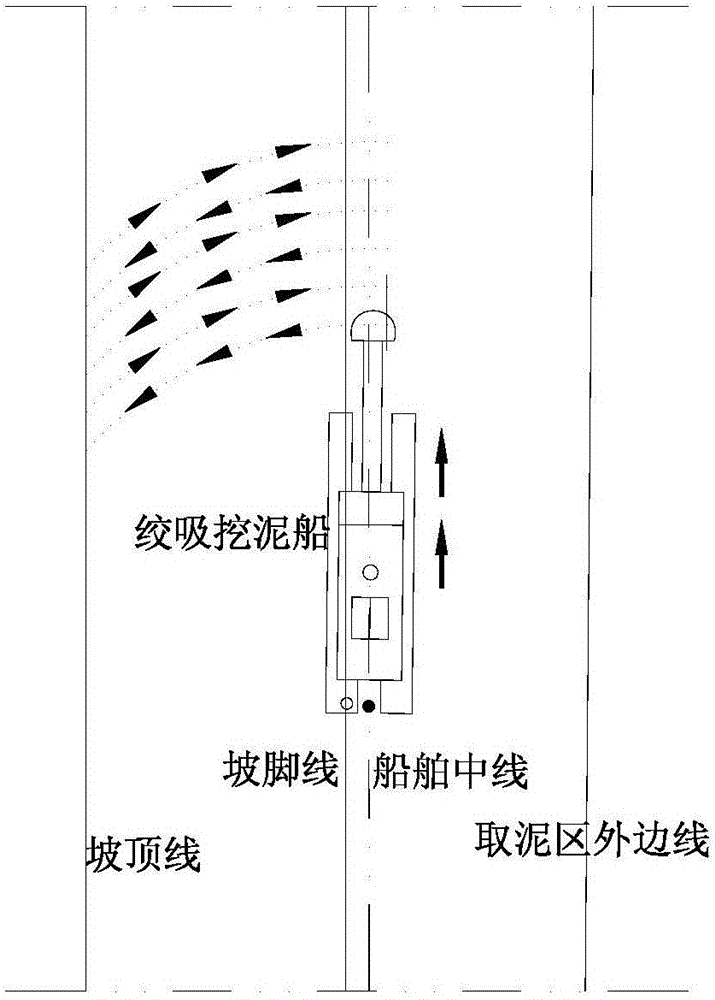

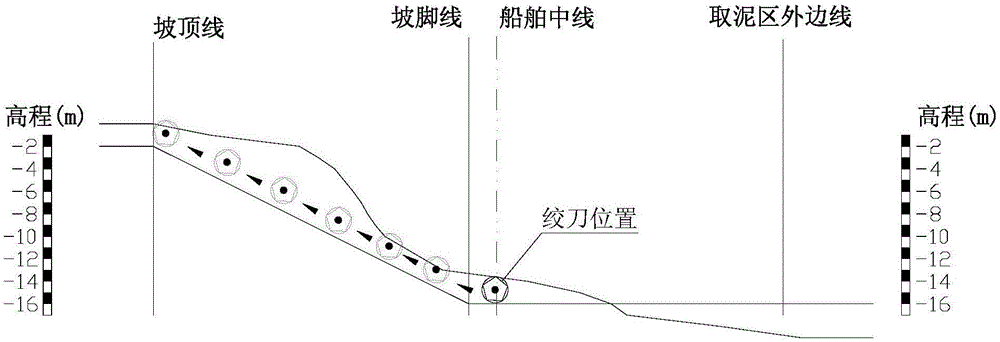

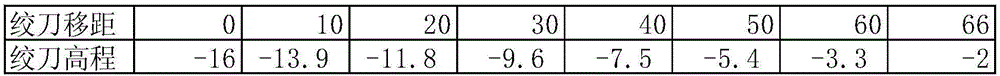

Ultra-long harbor basin slope excavation construction method

ActiveCN106320261AImprove productivityAvoid wasteSoil-shifting machines/dredgersMarine site engineeringProduction rateGeomorphology

The invention relates to an ultra-long harbor basin slope excavation construction method. The method comprises the following steps that 1, sweeping measurement is carried out on an existing mud taking-out area, particularly a slope area before formal construction, and an accurate slope excavation area bathymetric chart is sorted out; 2, the water depths of all slope excavation areas are analyzed, and a slope excavation process is made; according to the practical situation of the slope, two slope construction processes are made for regularity or irregularity of the slope for on-site construction, and the two slope construction processes comprise a slope hob excavation method and a layered excavation method; 3, the slope to which the two processes are applicable is scientifically and approximately divided into a plurality of areas to which different processes are applicable; 4, the subsection construction situation of each process is reasonably divided according to the width of each section of slope; and 5, different slope excavation construction processes are adopted in different areas through on-site organization for organizing on-site construction. According to the slope excavation scheme with on-site operability, on the basis of the original production rate, the production rate is improved by 20% or above on the premise that the time-benefit rate is not changed.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

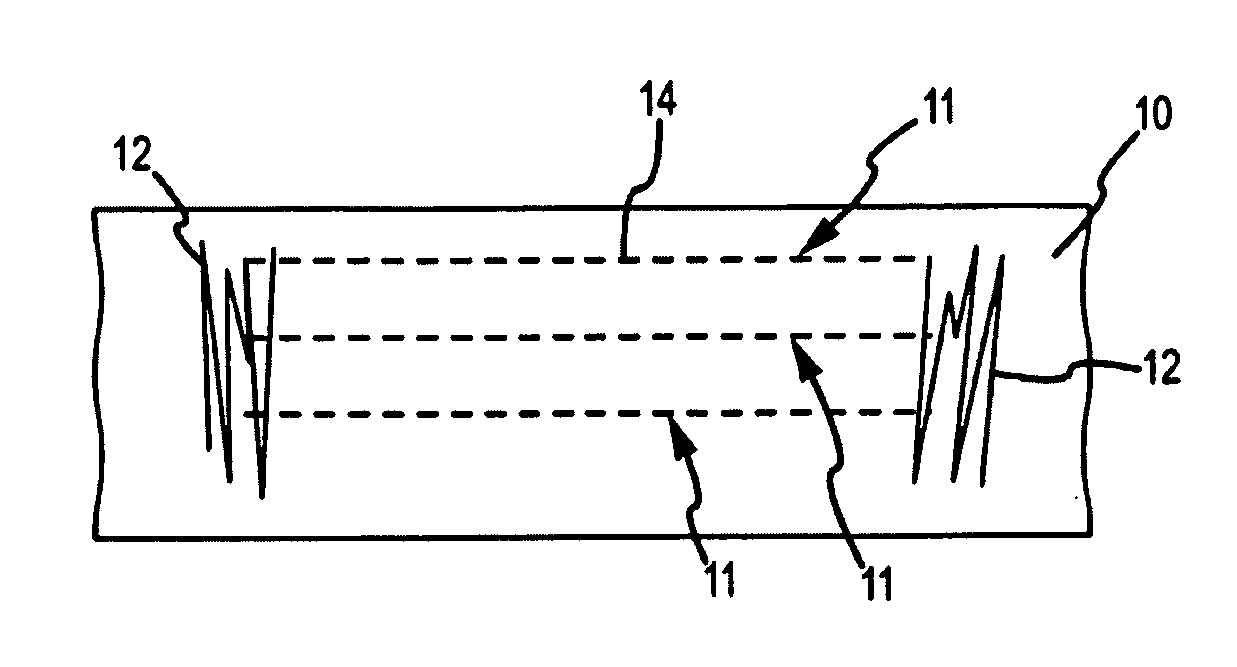

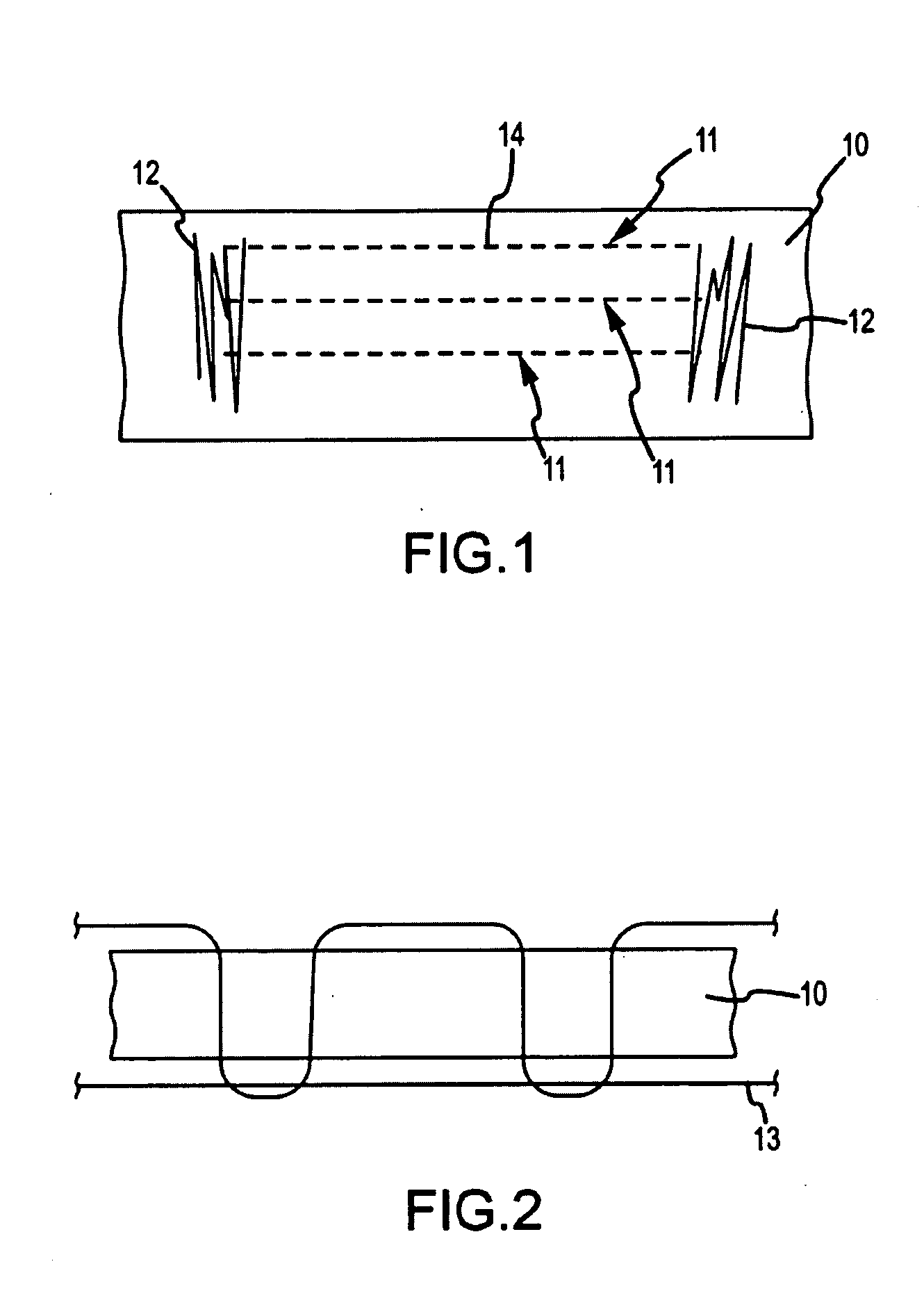

Textile Belt Strap Having Load Recognition

InactiveUS20080290643A1The method is simple and clearImprove securitySafety beltsBelt control systemsStructural engineeringWatercraft

A textile belt strap, especially for use in personnel safety devices in land vehicles, aircraft and watercraft. At least one seam is provided on the belt strap for representation of loading of the belt strap that occurs. The seam extends in a longitudinal direction of the belt strap over a portion thereof, and is comprised of an upper thread disposed on one side of the belt strap and a lower thread disposed on the other side of the belt strap. Respective transverse seams are fixedly connected with the belt strap for delimiting opposite ends of the seam. An interlocking of the upper thread and the louver thread is provided externally of the belt strap such that either the upper thread or the lower thread has a linear length or extension between the transverse seams that delimit the seam.

Owner:AUTOFLUG GMBH & CO

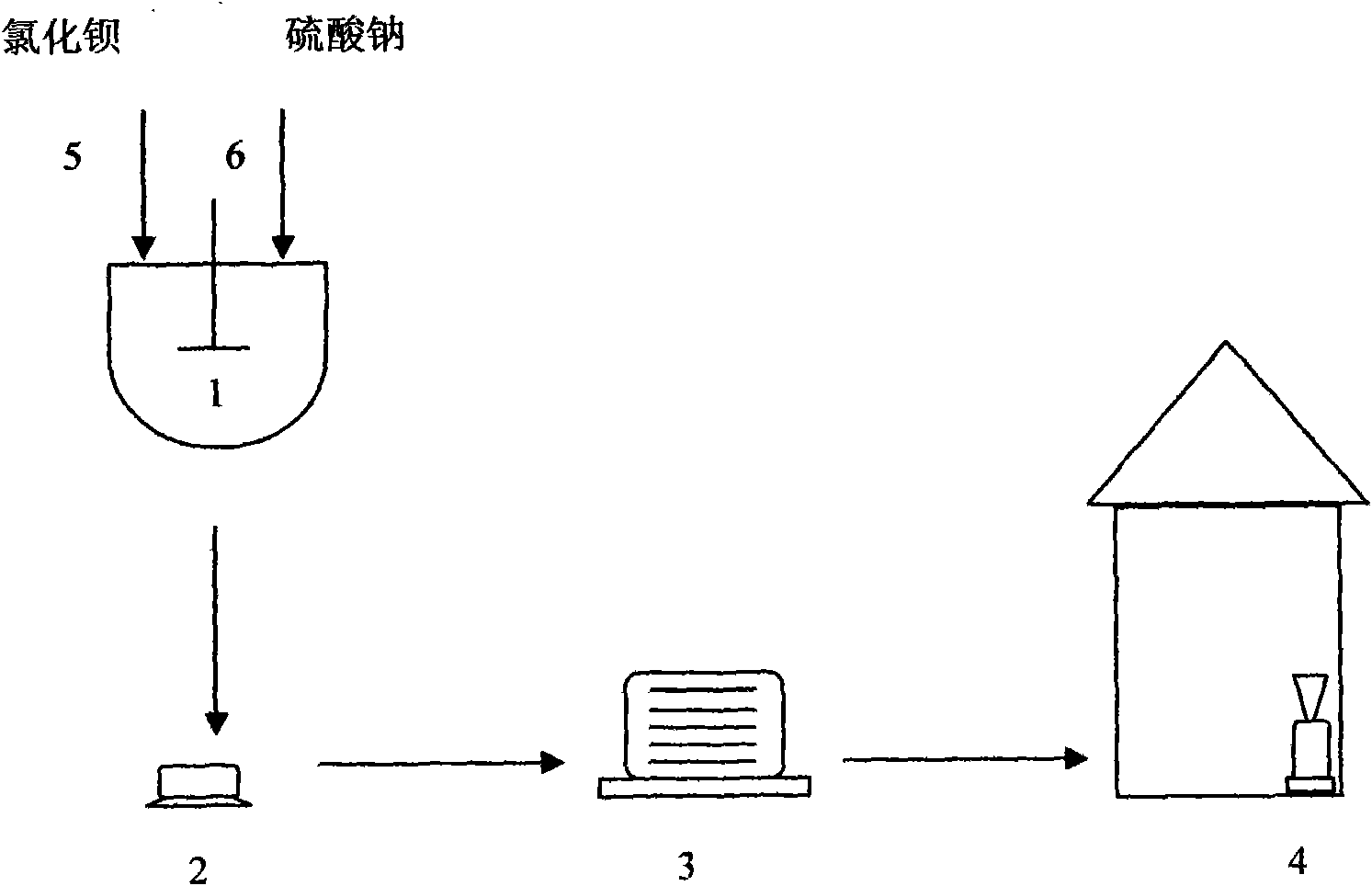

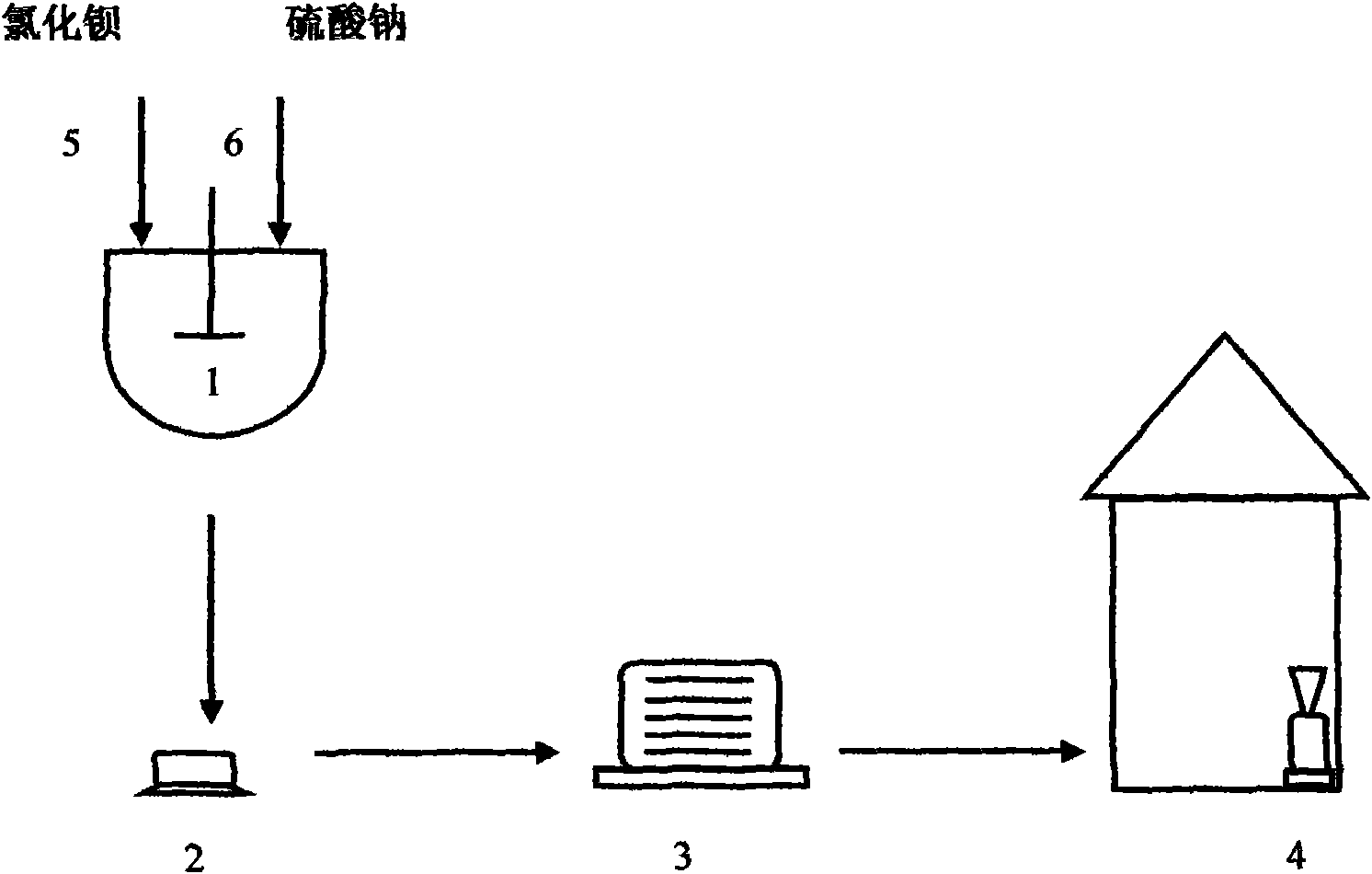

Method for preparing co-production sodium chloride of precipitated barium sulfate

InactiveCN101643233AThe method is simple and clearIncrease profitCalcium/strontium/barium sulfatesAlkali metal chloridesProduction rateBarium dichloride

The invention discloses a method for preparing co-production sodium chloride of precipitated barium sulfate, which is characterized in that barium chloride and sodium sulfate react according to a certain proportion and are filtered; precipitated barium sulfate and sodium chloride are obtained; a filtering cake obtained by filtration is washed, dried, pulverized and packed into a precipitated barium sulfate product; filtering liquor is decompressed and distilled, and an industrial salt sodium chloride product is obtained. The method is convenient and quick; especially, low-grade barium chlorideand sodium sulfate are used for producing high-grade precipitated barium sulfate, and thereby the method has the advantages of simple production technology and equipment as well as high production rate and profit.

Owner:王嘉兴

Method for coproducing sodium chloride by using micro barium sulphate prepared by barium chloride

InactiveCN101580264AThe method is simple and clearIncrease profitCalcium/strontium/barium sulfatesAlkali metal chloridesBarium dichlorideSalt sodium

The invention discloses a method for coproducing sodium chloride by using micro barium sulphate prepared by barium chloride, which is technically characterized in that: reacting the barium chloride and sodium sulphate according to certain proportion to obtain micro barium sulphate and sodium chloride after filtration; filtering the micro barium sulphate and sodium chloride to obtain filter cake, washing, drying, grinding, and packaging into micro barium sulphate products; and distilling the filtrate under reduced pressure to obtain industrial salt sodium chloride products. The method is simple and concise, and particularly uses low-grade barium chloride and sodium sulphate to produce high-grade precipitated barium sulphate, the production technology and equipment are simple, the productivity is extremely high, and the profit is high.

Owner:王嘉兴

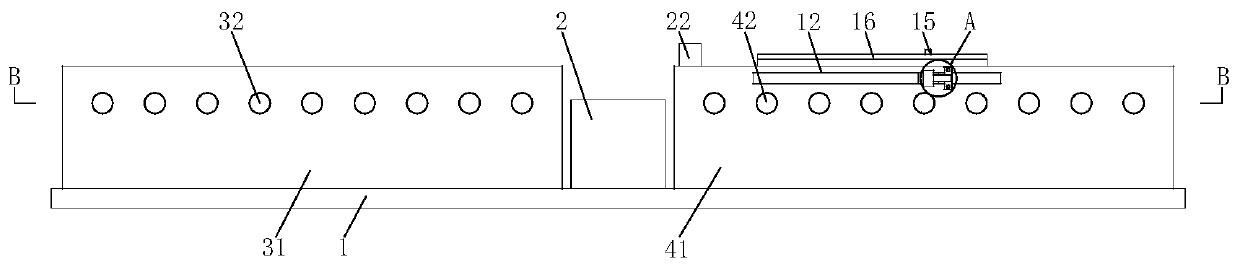

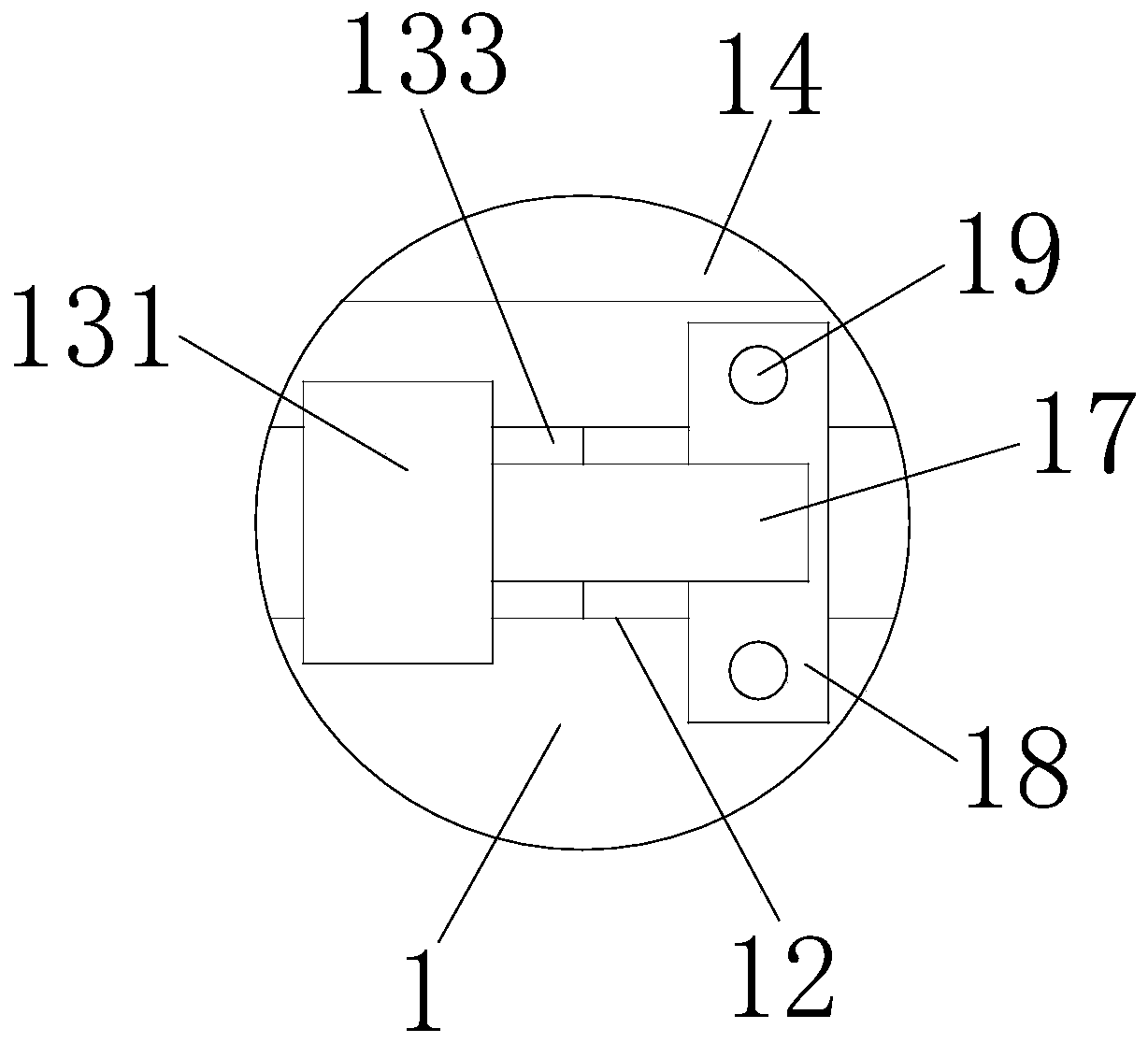

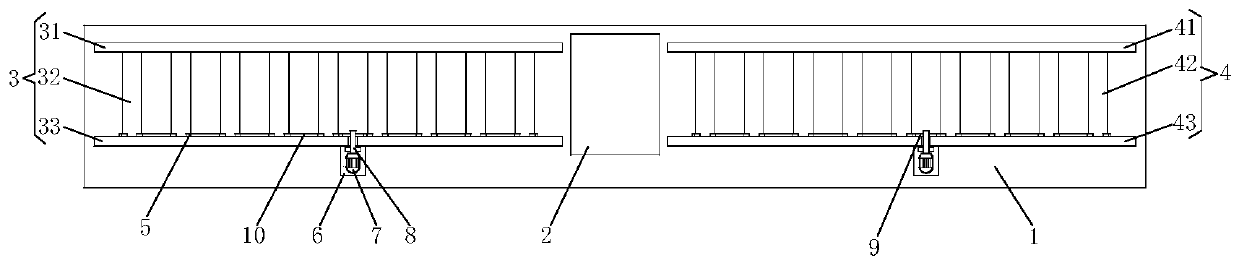

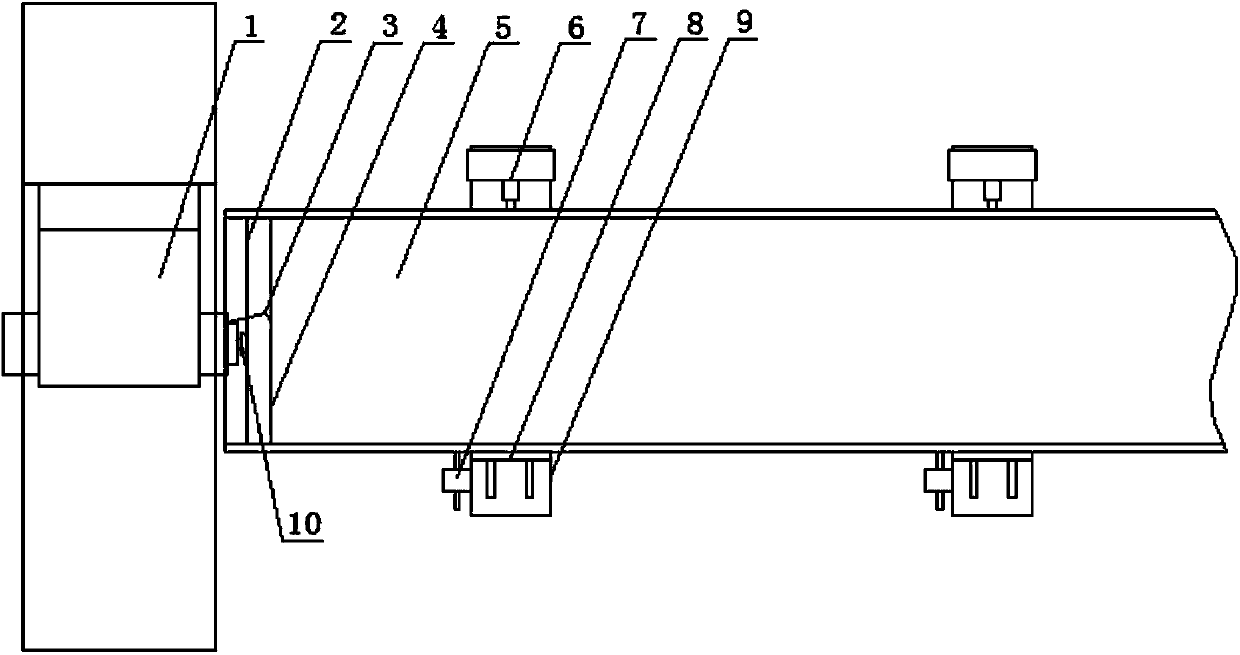

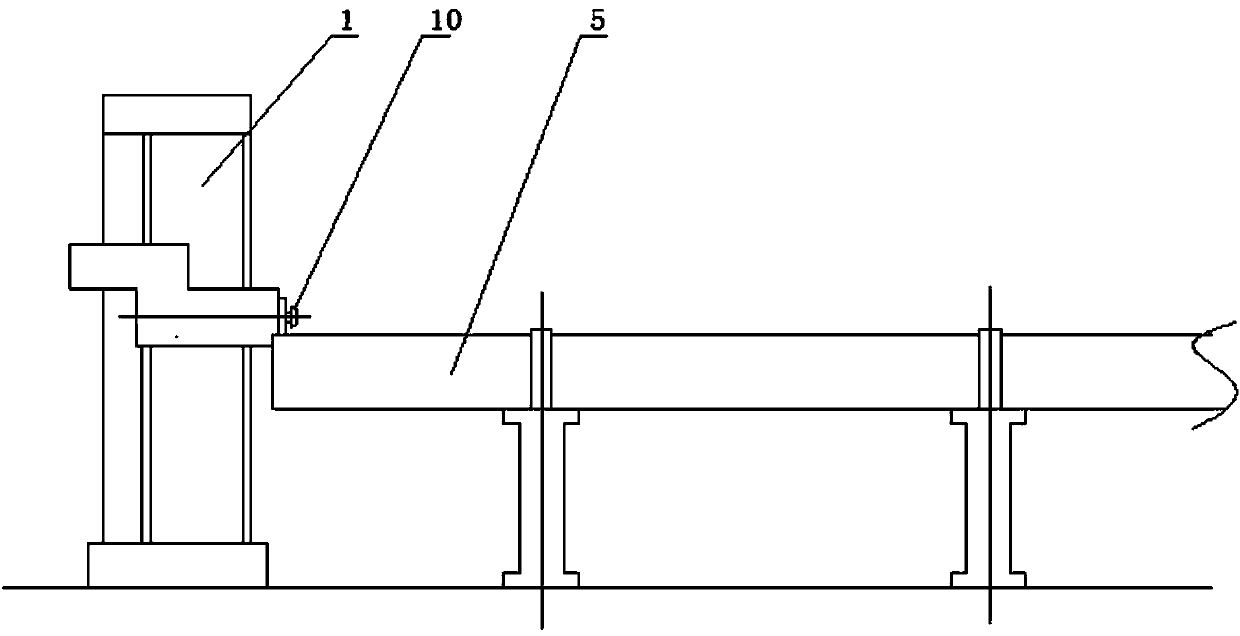

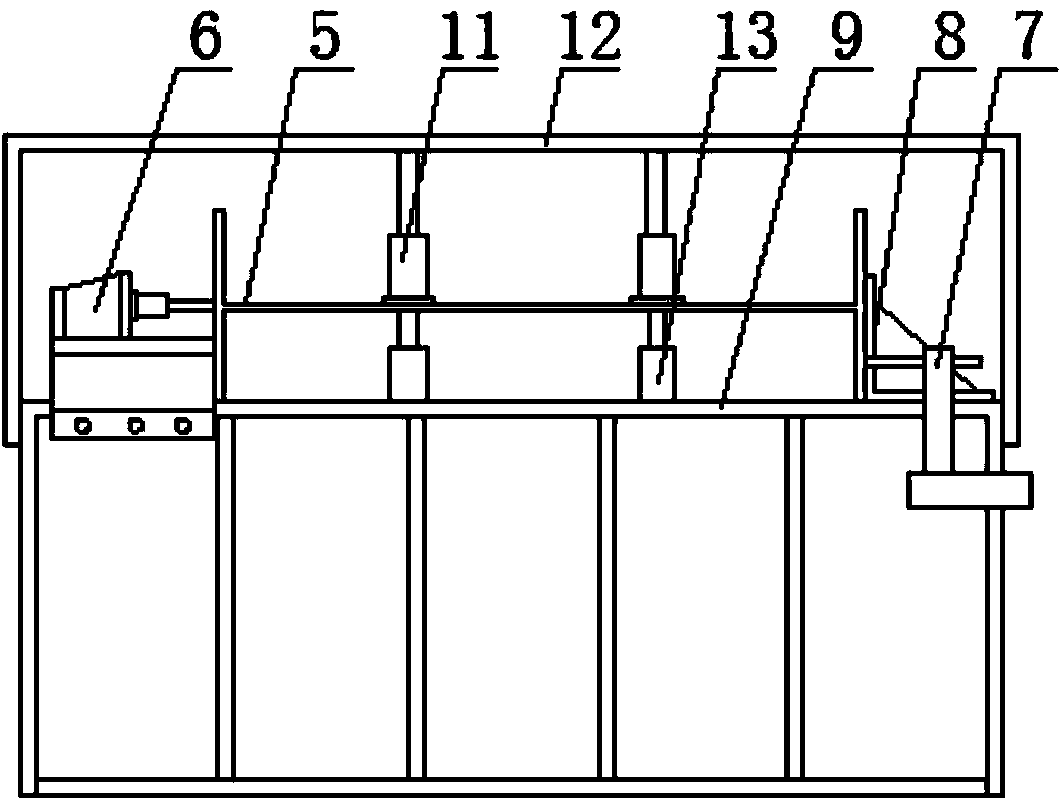

Section steel cutting device and use method thereof

ActiveCN111112809APrecise positioningFacilitate scale ruler, in cuttingWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention relates to the technical field of section steel machining, and discloses a section steel cutting device and a use method thereof. The section steel cutting device comprises a bottom plate. The upper surface of the bottom plate is fixedly connected with a plasma cutting device, the upper surface of the bottom plate is fixedly connected with a feeding mechanism, the feeding mechanism is located on the left side of the plasma cutting device, the upper surface of the bottom plate is fixedly connected with a discharging mechanism, the discharging mechanism is located on the right sideof the plasma cutting device, and the surface of the feeding mechanism and the surface of the discharging mechanism are fixedly connected with first gears. Before cutting, the position of a positioning mechanism is adjusted according to the cutting length firstly, then section steel is put on the feeding mechanism, the section steel tightly makes contact with a positioning column through the feeding mechanism and the discharging mechanism, then the section steel is fixed through a jacking mechanism, at the moment, the positioning column achieves a positioning effect on the section steel, theplasma cutting device and cutting positions are aligned, and then the section steel with the designated length can be conveniently cut by workers.

Owner:MCC TIANGONG GROUP +1

Method for milling end surface of large-cross-section steel component

The invention relates to a method for milling an end surface of a large-cross-section steel component. The method comprises the following steps: (1) calibrating a manufactured large-cross-section steel component to ensure that each size of the component is within an allowable deviation range; (2) scribing an end milling line and an end milling observation line; (3) primarily adjusting the longitudinal direction and the transverse direction of the placement position of the large-cross-section steel component; (4) performing fine adjustment on the consistency of an end milling cutter running track and the end milling line of the large-cross-section steel component; (5) fixing the large-cross-section steel component; (6) performing end milling. The method for milling the end surface of the large-cross-section steel component disclosed by the invention is easy to operate; the error of the end milling line is effectively reduced by precise calibration; the end surface milling precision and the end surface milling efficiency are greatly improved by the methods of precisely scribing the end milling line and the end milling observation line, performing fine adjustment on a clamping tool fixing component of the component, performing component end milling track tracking by a machine scribing needle frame and the like, and the cost is reduced greatly.

Owner:MCC TIANGONG GROUP

Vehicle door electric control anti-pinch system and anti-pinch method

ActiveCN112854942AImprove experienceEnsure safetyPower-operated mechanismDoorsForeign matterData information

The invention relates to the technical field of automobile control methods, in particular to a vehicle door electric control anti-pinch system and an anti-pinch method. The vehicle door electric control anti-pinch system comprises a sensing module, an anti-pinch control module, a vehicle door driving module and a vehicle body control system; the sensing module is used for acquiring data information of foreign matters appearing at a door opening of a vehicle door; the anti-pinch control module is used for analyzing and judging the data information transmitted by the sensing module to identify the type of the foreign matters and selecting a corresponding control measure according to the type; the vehicle door driving module is used for receiving a control measure instruction of the anti-pinch control module to correspondingly control the vehicle door; the vehicle body control system is used for receiving the control measures of the anti-pinch control module and sending an instruction to in-vehicle audio and video equipment to enable the in-vehicle audio and video equipment to send prompts to passengers; the anti-pinch control module is in signal connection with the sensing module, the vehicle door driving module and the vehicle body control system. According to the vehicle door electric control anti-pinch system and the anti-pinch method, corresponding control measures can be taken for the foreign matters appearing at the door opening of the vehicle door, the safety performance is extremely high, a recognition and judgment method and a control method are extremely simple and clear, and the popularization value is extremely high.

Owner:DONGFENG MOTOR GRP

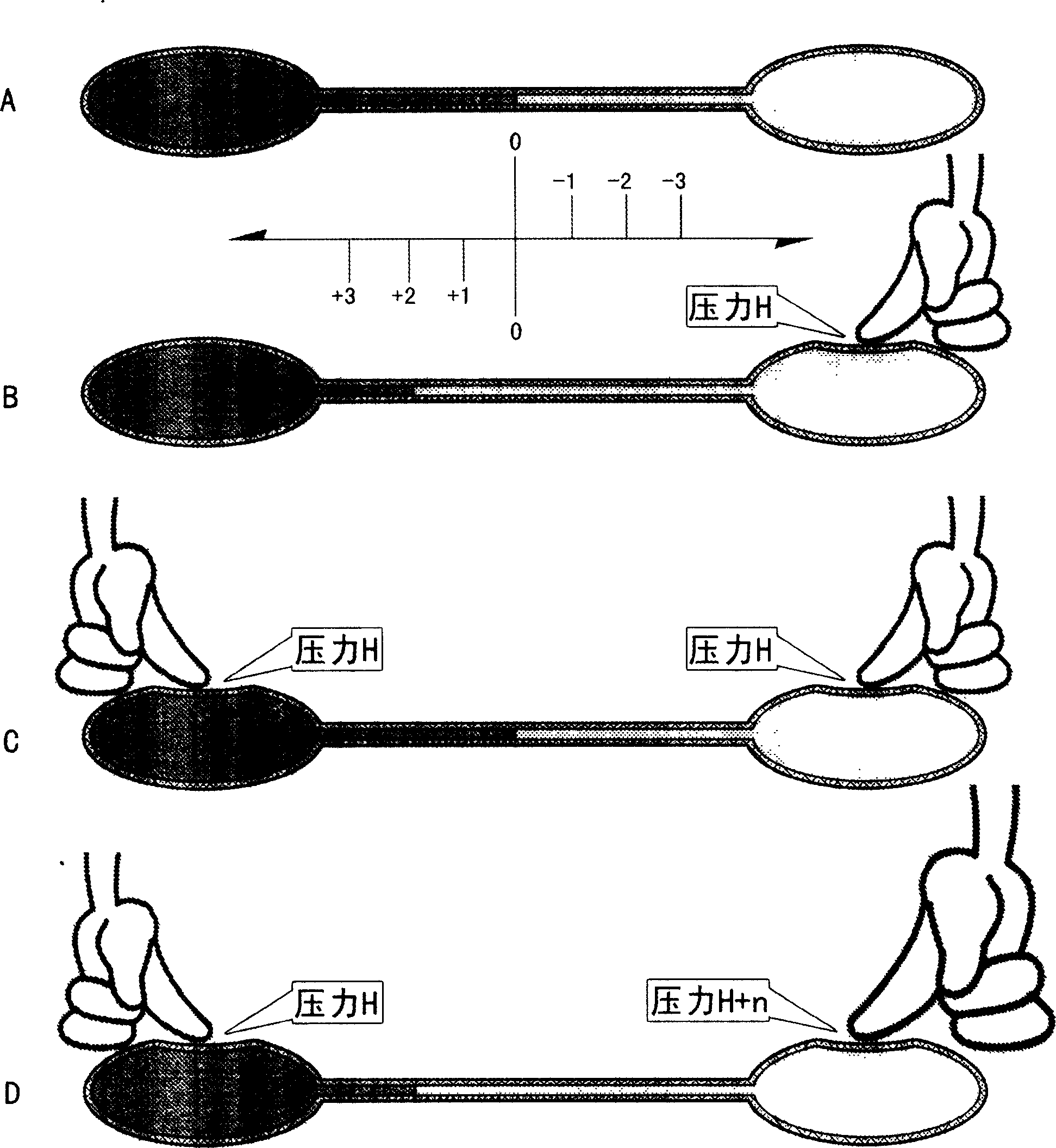

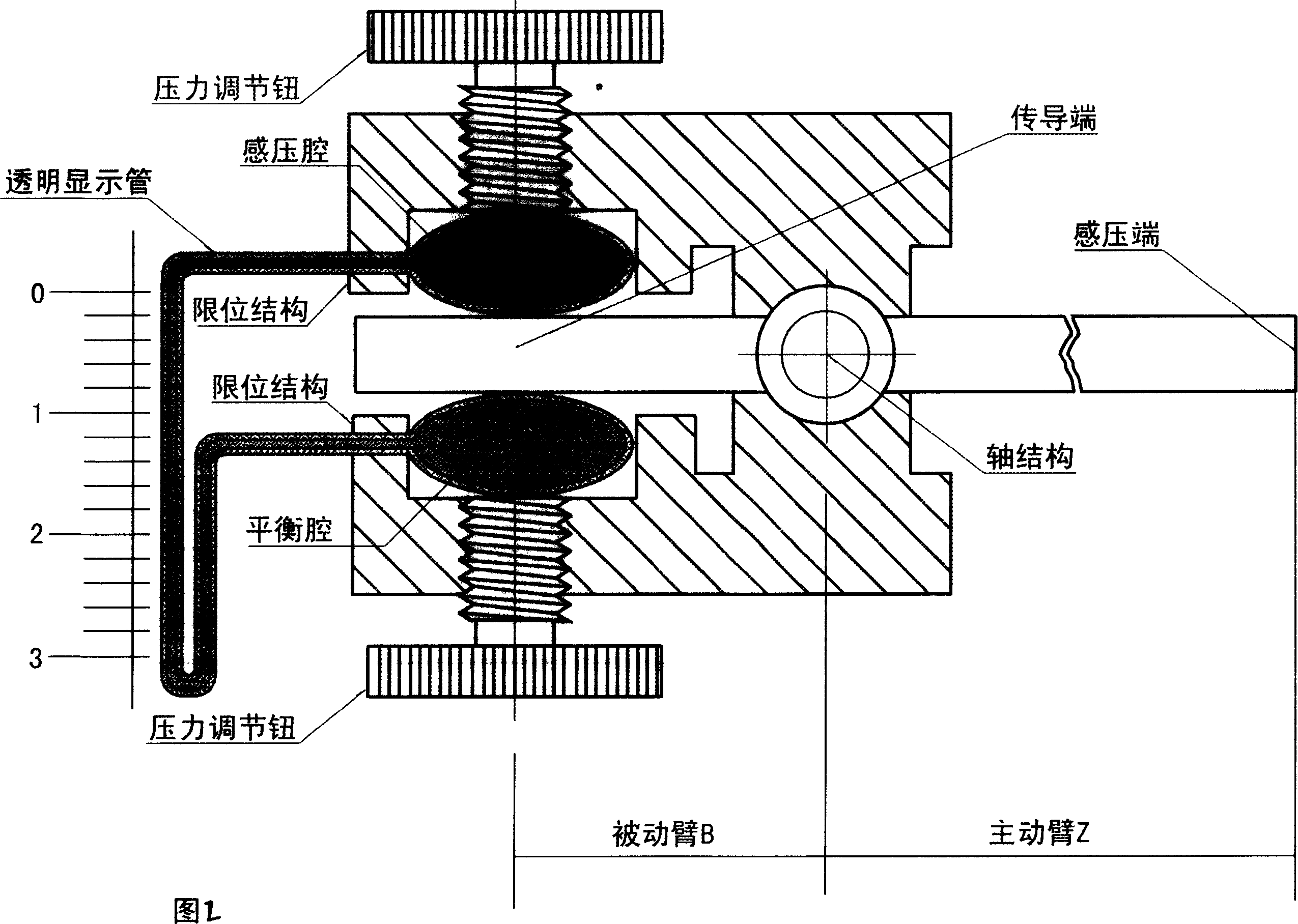

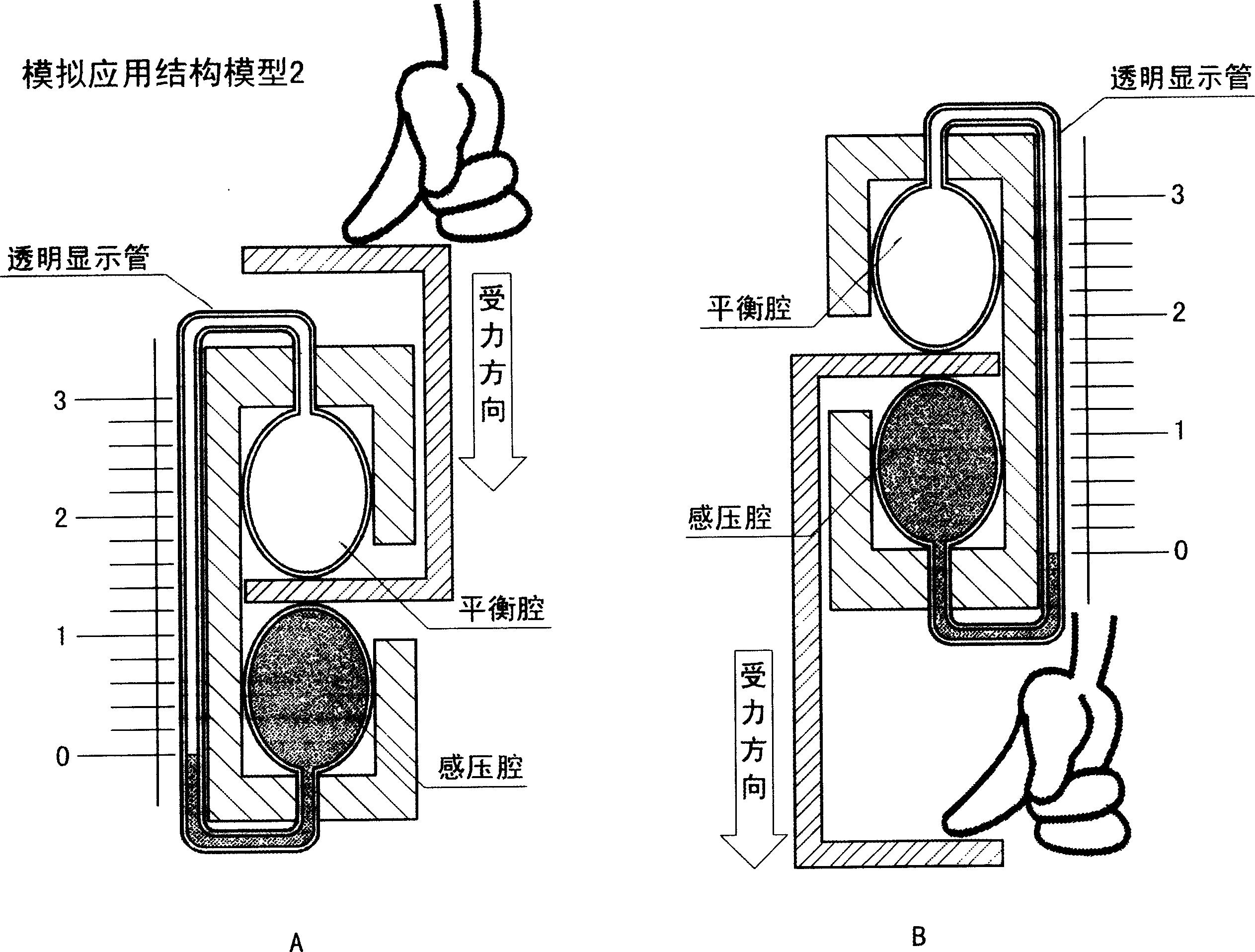

Duplex cavity bimedium pressure sensing and dynamic display integrated application technology

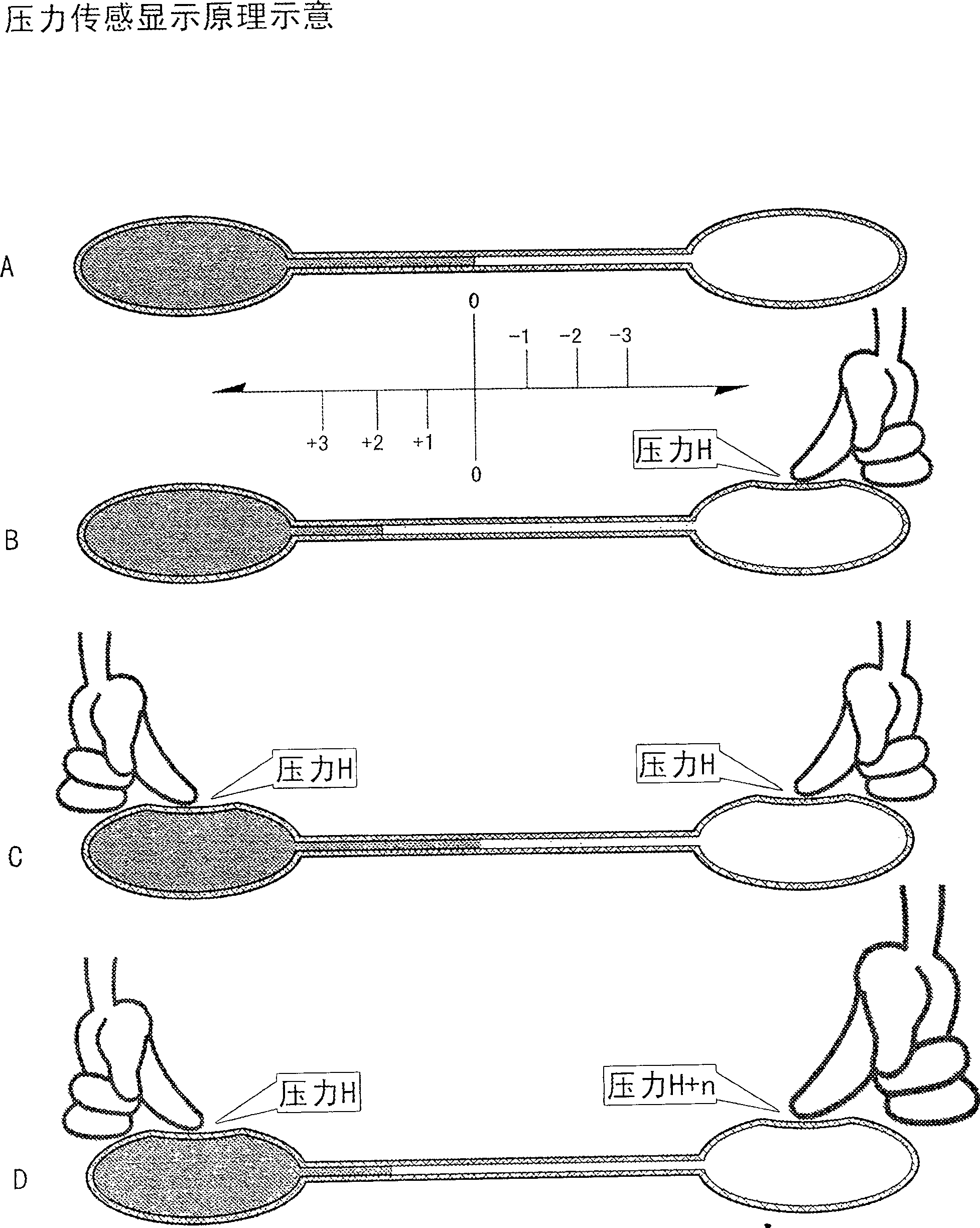

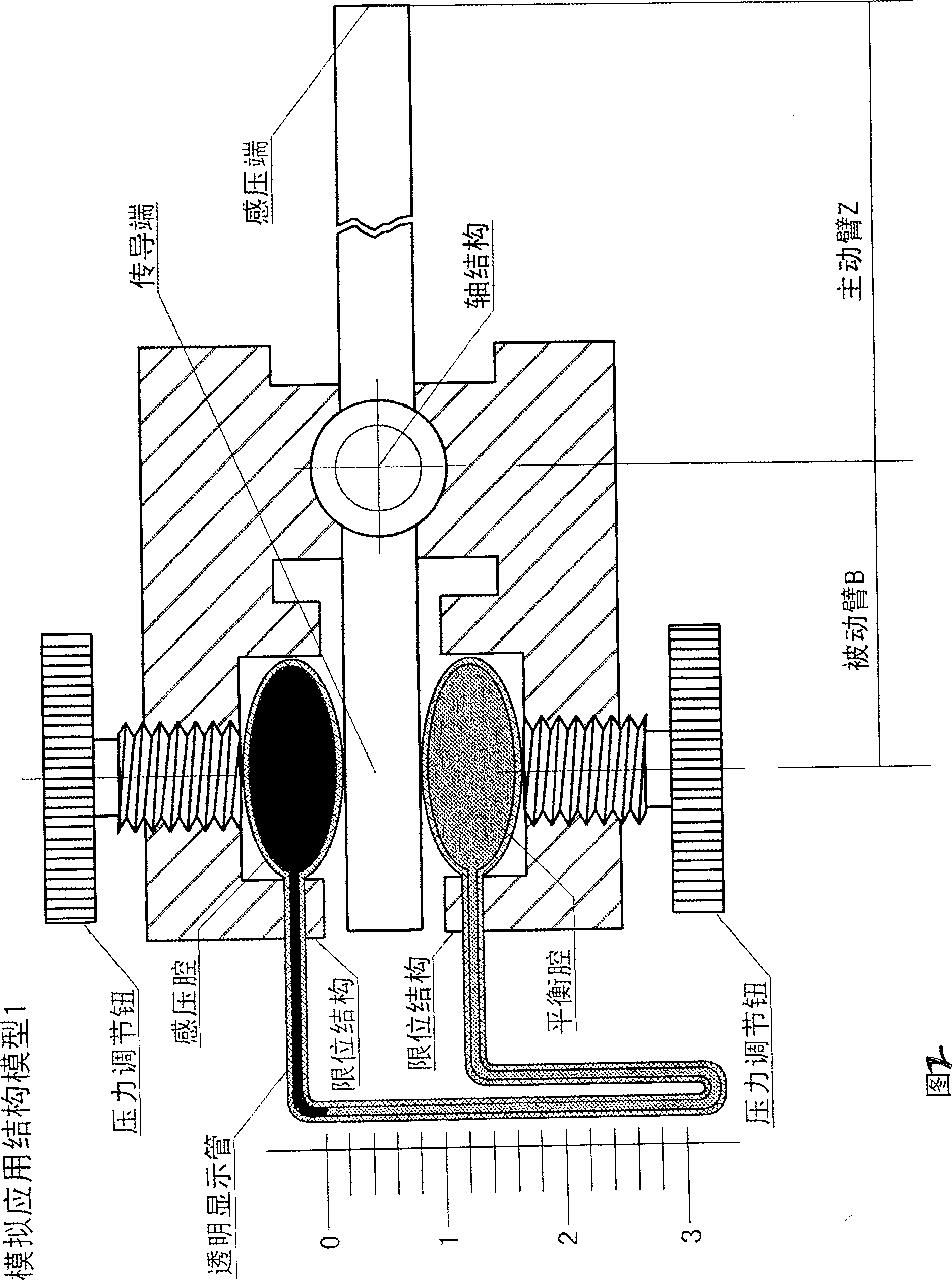

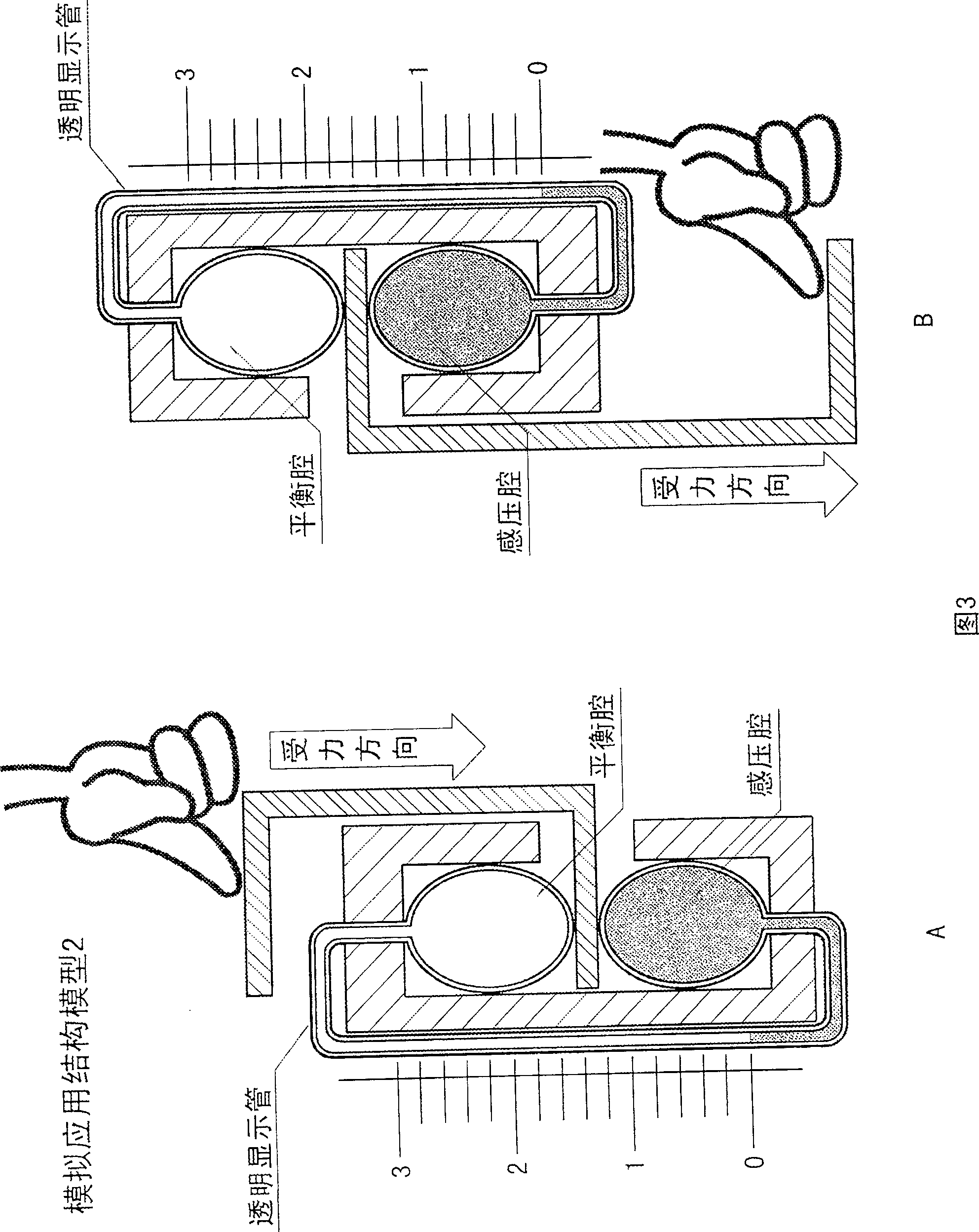

InactiveCN1493860ASimple structureSave materialFluid pressure measurement using pressure-sensitive liquidFluid pressure measurement using elastically-deformable gaugesRelative pressureExternal pressure

An integrated dual-cavity dual-medium pressure sensing-dynamic indication technology for developing relative pressure measuring tools features that two media with different colors are respectively contained in two elastic cavities which are communicated to each other via a transparent indicating tube in sealed mode. The interface between two media with different colors is used as a dynamic cursor. When an external pressure is applied to one of two elastic cavities, the dynamic cursor will move in the transparent tube to indicate the value of said pressure.

Owner:和近建

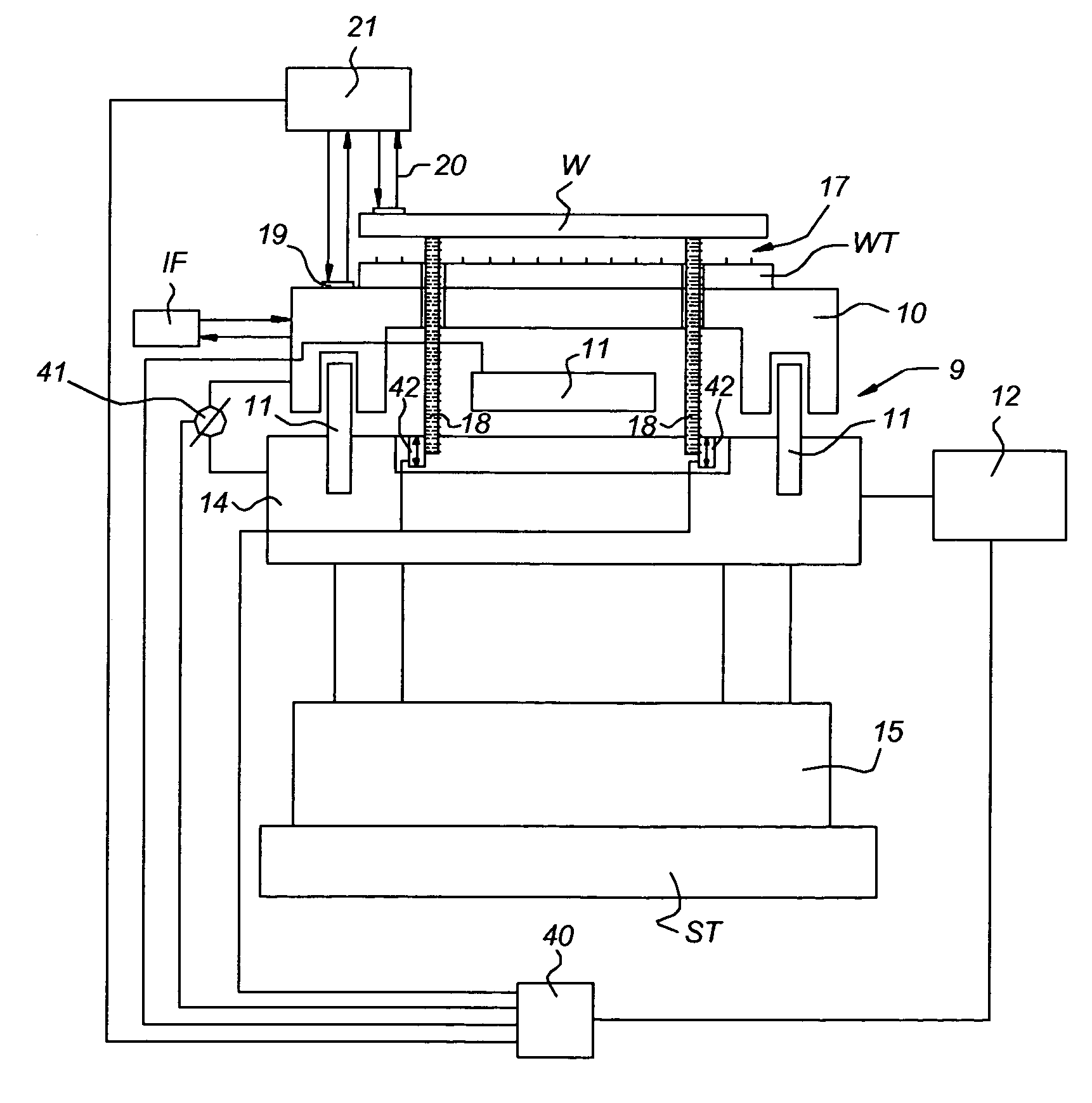

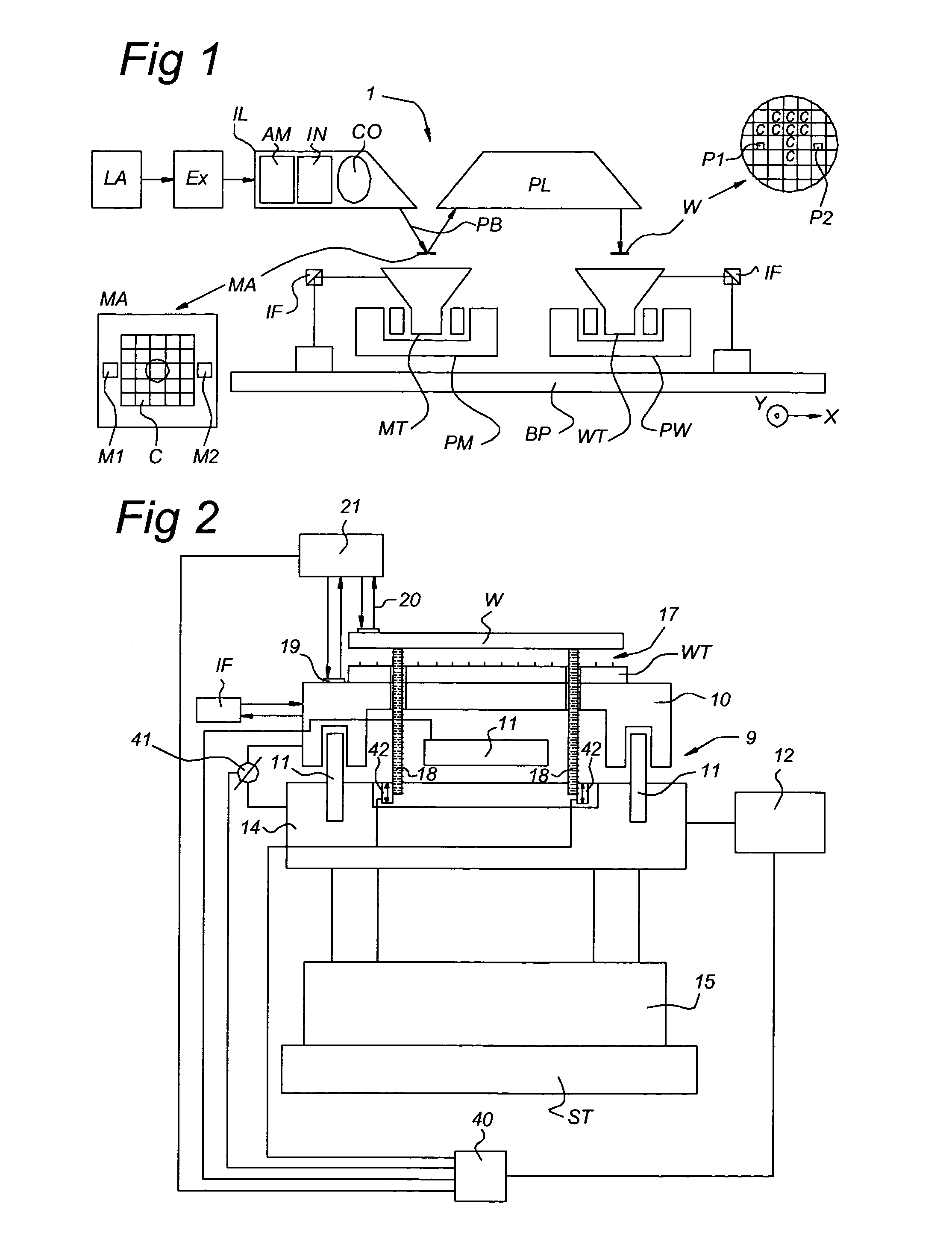

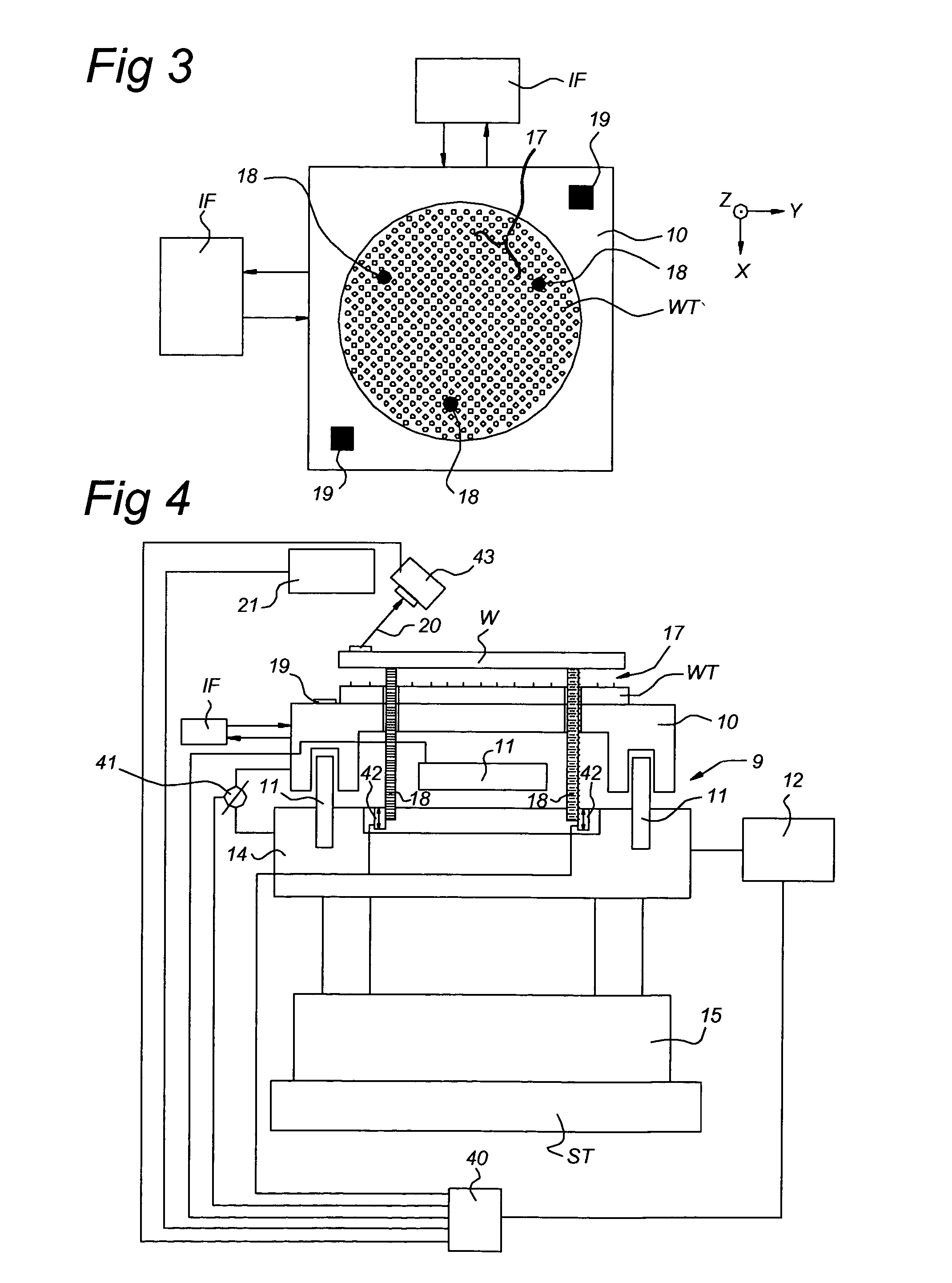

Method and apparatus for positioning a substrate on a substrate table

InactiveUS7405810B2Errors can be reduced and avoidedThe method is simple and clearSemiconductor/solid-state device manufacturingUsing optical meansOptoelectronics

Owner:ASML NETHERLANDS BV

Duplex cavity bimedium pressure sensing and dynamic display integrated application technology

InactiveCN100491944CSimple structureSave materialFluid pressure measurement using pressure-sensitive liquidFluid pressure measurement using elastically-deformable gaugesRelative pressureEngineering

An integrated dual-cavity dual-medium pressure sensing-dynamic indication technology for developing relative pressure measuring tools features that two media with different colors are respectively contained in two elastic cavities which are communicated to each other via a transparent indicating tube in sealed mode. The interface between two media with different colors is used as a dynamic cursor. When an external pressure is applied to one of two elastic cavities, the dynamic cursor will move in the transparent tube to indicate the value of said pressure.

Owner:和近建

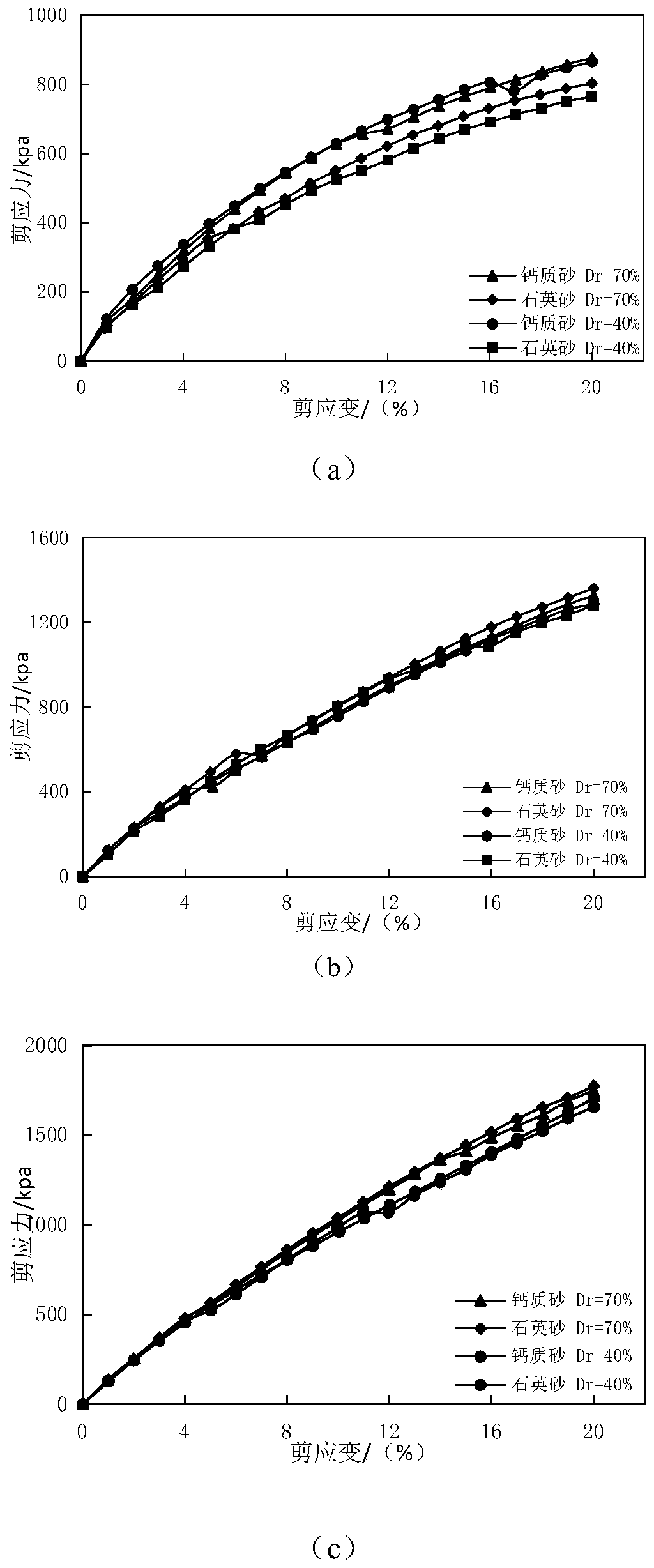

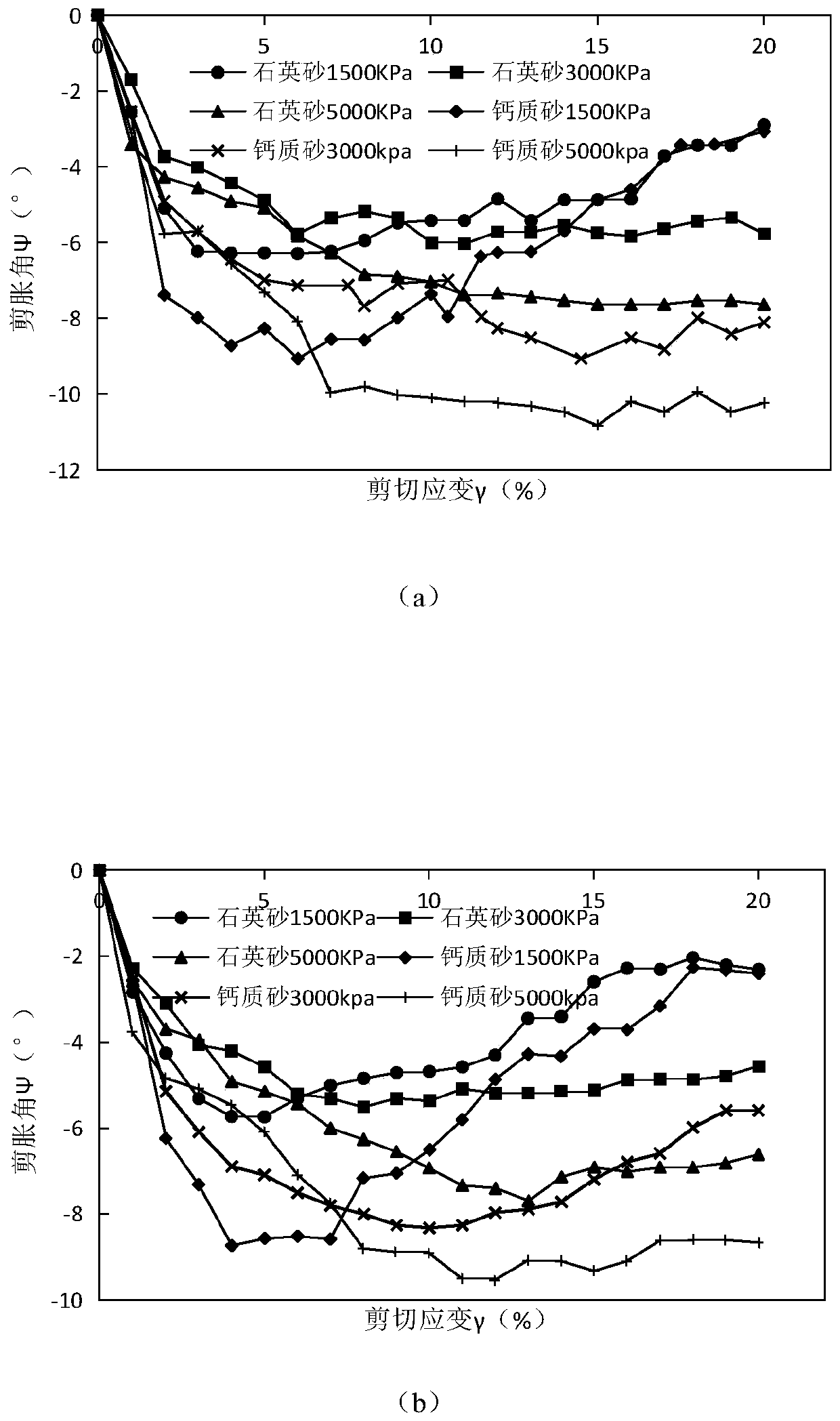

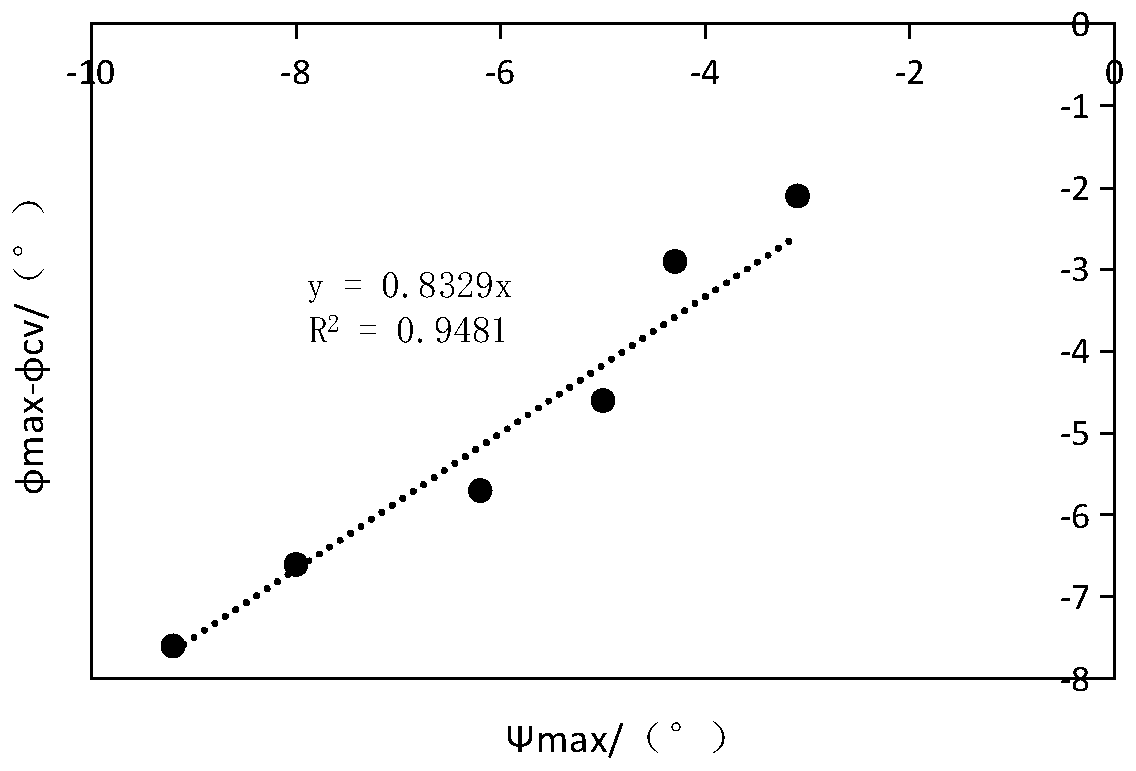

Method for determining shear strength of calcareous sands under high stress

ActiveCN111077027AEasy to determineImprove reliabilityMaterial strength using steady shearing forcesSoil sciencePhysical chemistry

The invention discloses a method for determining the shear strength of calcareous sands under high stress. The method comprises the following steps: taking calcareous sands and quartz sands with the same grain composition, and preparing samples with different relative densities; respectively carrying out 1500KPa, 3000KPa and 000KPa constant-stress single shear tests by adopting layered filling; under the condition that the shearing force tends to a stable value, determining the soil sample to be sheared, otherwise, stopping the test when the shearing displacement reaches 20%; drawing a stress-strain relation curve, and calculating a maximum internal friction angle of the sandy soil through a coulomb formula; calculating a shear expansion angle to obtain maximum shear expansion angles of different sandy soil with different densities; calculating a critical internal friction angle; acquiring a breakage rate BrH or BrM of the sample by using a Hardin method or a Marsal method; fitting unbroken quartz sands to obtain a shear strength formula; and introducing a crushing component into a calcareous sand strength formula, calculating a crushing component according to a coefficient determined by the quartz sand, and fitting the crushing component with the crushing rate to obtain a calcareous sand shear strength formula.

Owner:TIANJIN UNIV

A calculation method for positive pressure subsidence resistance of cylindrical foundation in sandy soil

ActiveCN107871026BIncrease lateral pressureSimple methodDesign optimisation/simulationSpecial data processing applicationsPositive pressureEngineering

The invention discloses a positive pressure sinking resistance calculation method suitable for a barrel foundation in sandy soil. The situation that a soil squeezing effect in a positive pressure sinking process increases a lateral pressure on an outer side barrel wall is considered; a lateral soil pressure coefficient derived based on a cavity expansion theory is compared with a lateral soil pressure coefficient given in a DNV specification; and a calculation result is closer to an actual condition. The situation that a constraint effect of an inner side wall on a soil body enables a soil plug effect to be formed in a barrel is considered; the generated soil squeezing effect is far greater than that outside the barrel; and compared with a specification method, a method for calculating a soil pressure located in the barrel and derived based on the soil plug effect has the advantage that the calculation result is closer to the actual condition. The situation that soil bodies inside andoutside a barrel body in the positive pressure sinking process present different densities is considered; the barrel wall end resistance inside and outside the barrel is calculated; especially the inner side resistance of the barrel is calculated by adopting a reversely derived frictional angle phi; the method is simple and convenient; and the calculation result is closer to the actual condition.

Owner:TIANJIN UNIV

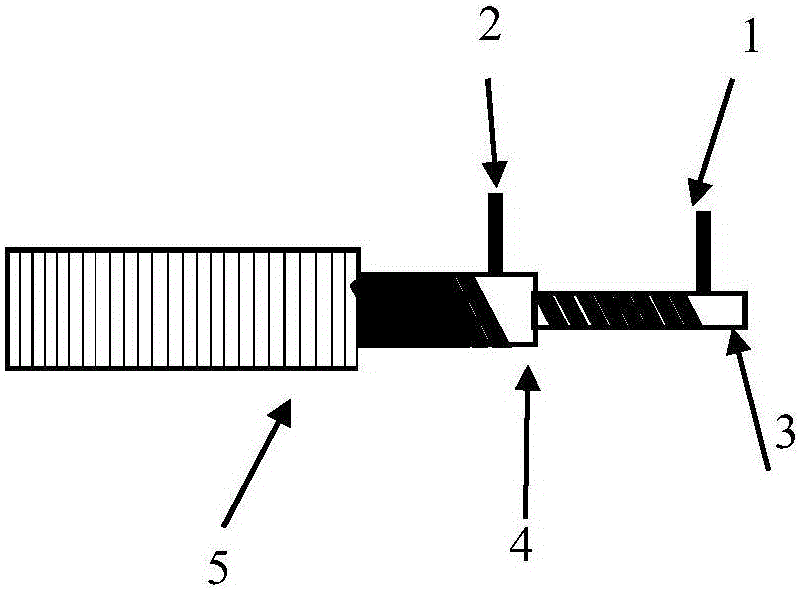

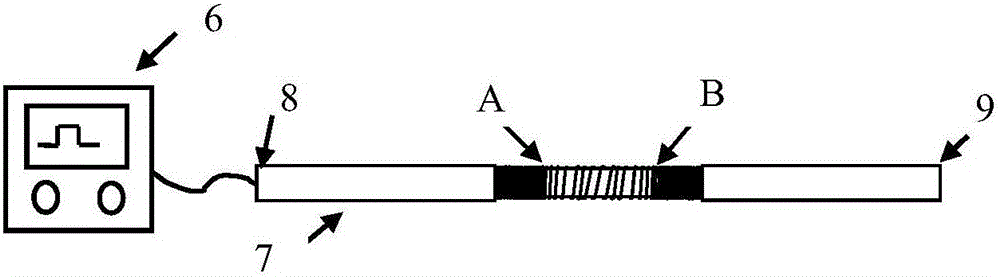

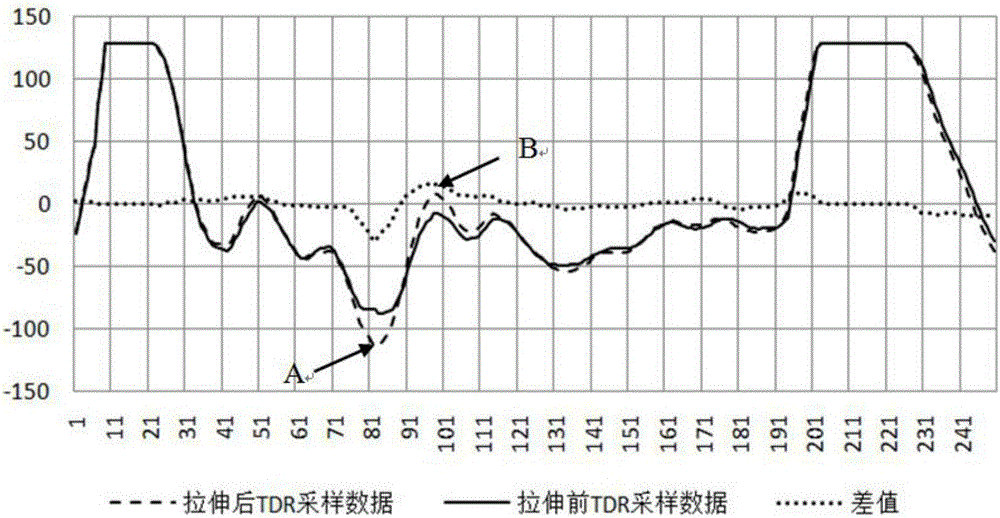

Method for identifying local collapse edge of rock and soil body via distributed spiral parallel line sensor

ActiveCN106017299AThe method is simple and clearImprove accuracyElectrical/magnetic solid deformation measurementPhysicsLine sensor

The invention discloses a method for identifying a local collapse edge of the rock and soil body via a distributed spiral parallel line sensor. A TDR measuring instrument samples reflection voltages before and after local collapse of the rock and soil body, sampling curves is obtained, and the sampling curve after deformation is subtracted from the sampling curve before deformation to obtain a difference curve; a first valley point from the starting end point of the distributed spiral parallel line sensor except a blind area is searched from the difference curve and is positioned in an inflection point where the gradient is changed from negative to positive, and the first valley point serves as the left edge of local collapse of the rock and soil body; and a first inflection point where the gradient is changed from positive to negative from the left edge to the tail end point is searched, and serves as the right edge of local collapse of the rock and soil body. The method can be used to find two edges of local collapse of the rock and soil body simply and clearly, the accuracy is high, and local deformation is located.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com