Patents

Literature

826 results about "Barium dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium chloride is the inorganic compound with the formula BaCl2. It is one of the most common water-soluble salts of barium. Like most other barium salts, it is white, toxic, and imparts a yellow-green coloration to a flame.

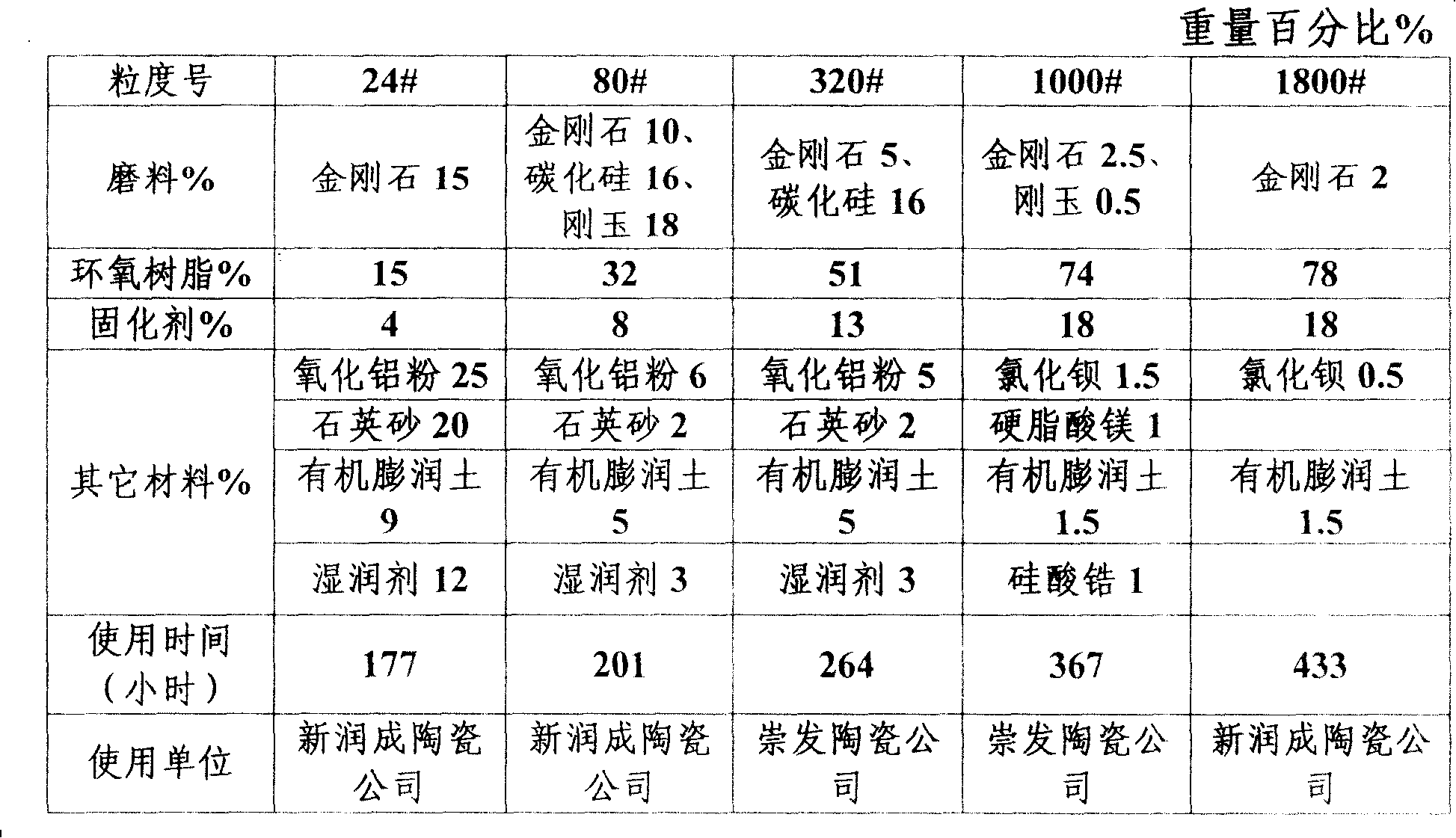

Abrasive tool of epoxy resin combined with compounded abrasive

Disclosed is an abrasive tool made of epoxy resin-bonded compound abrasive material, which comprises epoxy resin, abrasive material and curing agent. The weight percentages are as follow: the epoxy resin is 15 to 78 percent, the abrasive material is 2 to 44 percent and the curing agent is 4 to 18 percent. Wherein, the abrasive material comprises one of diamond, silicon carbide or corundum or the combination of more than one material. The curing agent comprises one of 4.4`-methylenedianil, solid diaminodiphenyl methane or liquid modified diaminodiphenyl methane or the combination of more than one material. The component of the abrasive tool also comprises the other auxiliary material, which comprises one of alumina, barium chloride, sodium chloride, quartz sand, organobentonite, wetting agent, zirconium silicate, calcium carbonate, graphite powder, garnet, magnesium sulfate, phenolic resin, zinc stearate and magnesium stearate, or the combination of more than one material. The product can be made into any shape the same with the present product, which can be applied in various grinding and polishing equipment with wide application scope.

Owner:广东奔朗新材料股份有限公司

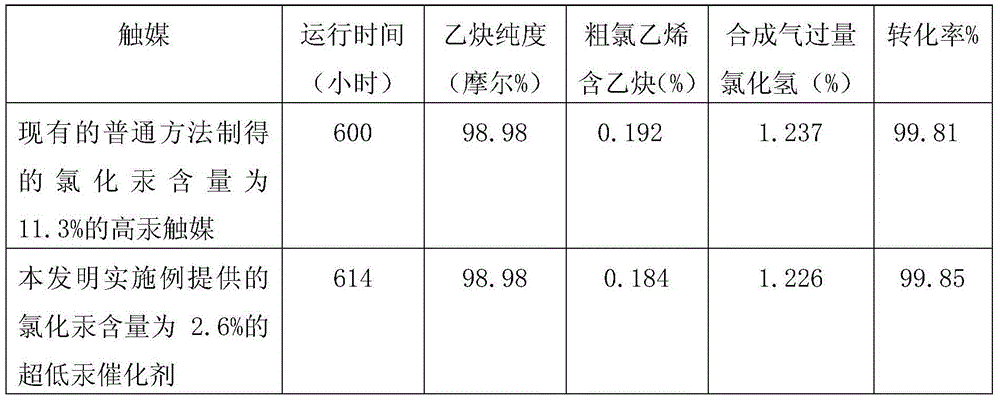

Low-mercury catalyst for acetylene hydrochlorination

InactiveCN102380407AEasy to makeLow costPhysical/chemical process catalystsPreparation by halogen halide additionO-Phosphoric AcidPtru catalyst

Disclosed is a low-mercury catalyst for acetylene hydrochlorination. Mercuric chloride is carried on activated carbon. Raw materials comprise, by weight, 100 parts of activated carbon, 4-5 parts of mercuric chloride, 8-10 parts of total essential assistant, 1-5 parts of total non-essential assistant, wherein the essential assistant comprises 2-5 parts of bismuth chloride, 1-5 parts of cerium chloride, 1-5 parts of barium chloride and 2-5 parts of copper chloride; and the non-essential assistant comprises at least one of potassium chloride, phosphoric acid, zinc chloride and cuprous chloride. After being subjected to surface subtraction and drying on acid and oxidizing conditions, activated carbon is in reflux treatment with urea solution; and the catalyst can be prepared by soaking the treated activated carbon with HgC12 dissolved in hydrochloric acid and assistant solution sufficiently after urea is removed by steps of heating, washing the activated carbon with hydrochloric acid and finally drying the same. The carrying capacity of mercuric chloride in the catalyst is lower so that cost for the catalyst is reduced and consumption of mercury resources is decreased. Furthermore, activity and stability of the low-mercury catalyst are much higher than those of the existing high-mercury catalyst, and reforming rate and selectivity of reaction of vinyl chloride can be 99.7% and be higher than 99.8%. Accordingly, the low-mercury catalyst for acetylene hydrochlorination is suitable for industry production and is environment-friendly.

Owner:CHENGDU HUIEN FINE CHEM

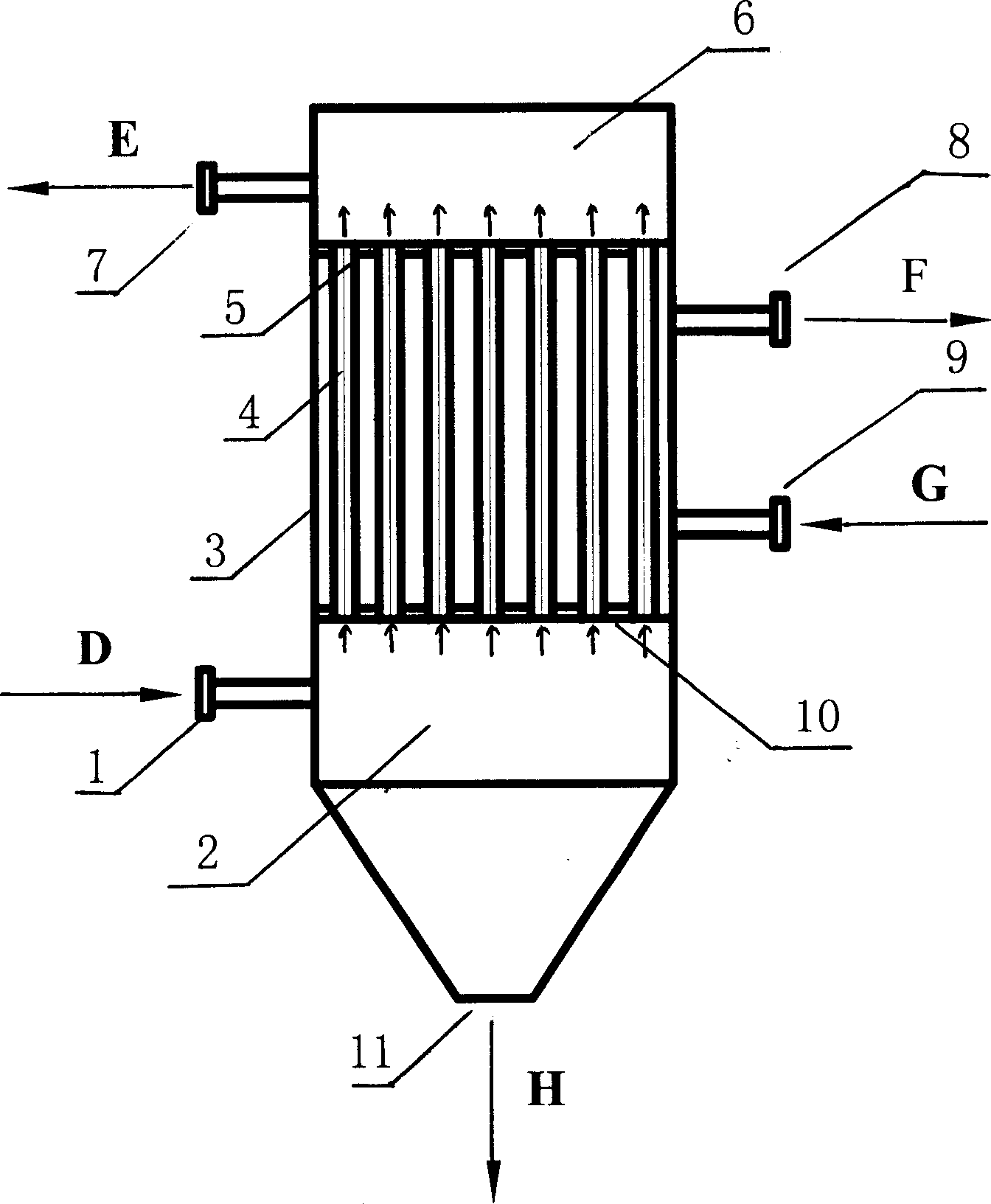

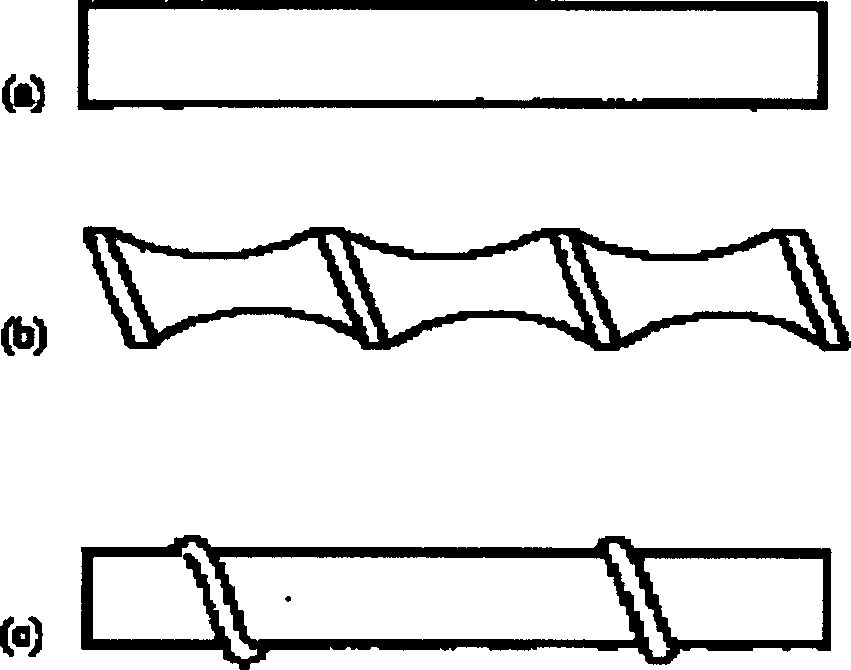

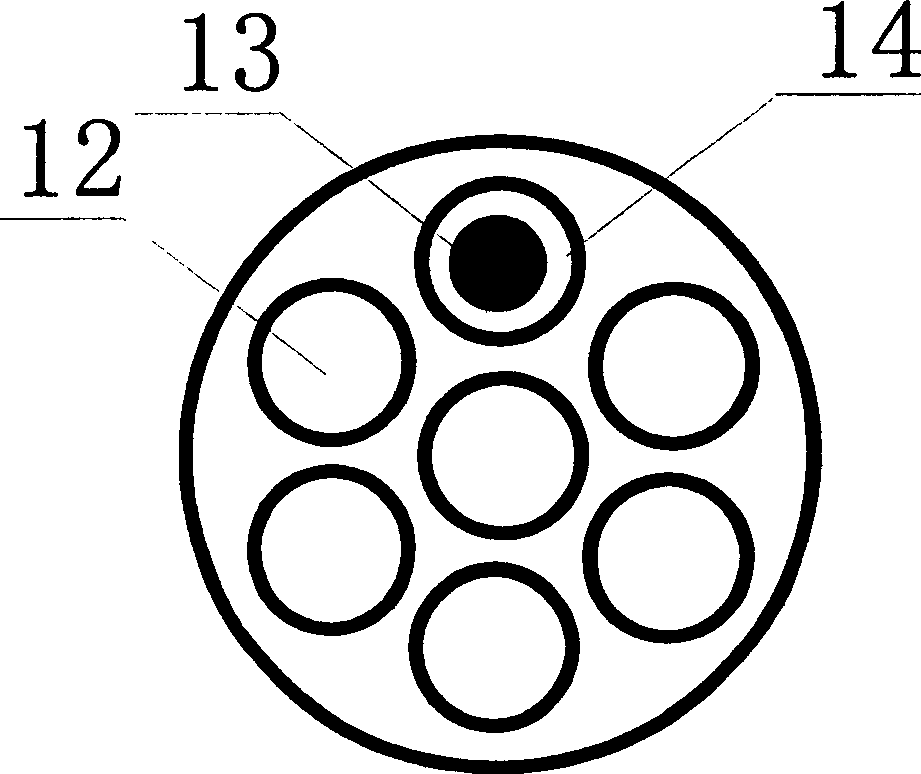

Method of refining salt by membrane filtration

ActiveCN1868878AReduce processing loadImprove permeabilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisIon exchangeCross-flow filtration

A membrane filter process for refining saline includes such steps as dissolving salt to obtain saturated solution, adding sodium hydroxide, sodium carbonate and barium chloride, reaction to generate magnesium hydroxide, calcium carbonate and barium sulfate, adding coagulating precipitant and oxidant for pre-treating, adsorbing and depositing to remove magnesium hydroxide colloid and part of particles, cross-flow filtering by inorganic membrane, and ion exchange.

Owner:JIANGSU JIUWU HITECH

Ultralow-mercury catalyst and production process thereof

InactiveCN103551139AReduce manufacturing costLow in Mercury ChlorideCatalyst carriersPreparation by halogen halide additionVoid ratioPotassium

Owner:SHIJIAZHUANG KECHUANG ADDITIVES CO LTD

Molybdenum phosphide catalyst for production of chloroethylene and preparation method thereof

ActiveCN102151581APhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonBarium dichloride

The invention provides a molybdenum phosphide catalyst for the production of chloroethylene by acetylene hydrochlorination, which is characterized in that: the catalyst uses activated carbon as carrier, MoP as active ingredient and barium chloride as auxiliary. The catalyst provided by the invention belongs to mercury-free catalyst, is green and environmentally-friendly, and has the advantages ofsimple production process, short production period, low cost and the like. The catalyst exhibits superior activity and selectivity in the reaction for preparing chloroethylene by acetylene hydrochlorination.

Owner:内蒙古海驰高科新材有限公司

Refining agent of Mg alloy and its preparing process

A refining agent of Mg-alloy contains magnesium chloride (40-60%), potassium chloride (10-25%), sodium chloride (10-25%), calcium chloride (1-10%), calcium fluoride (5-15%), barium chloride (1-10%), nano carbonate adsorbent (1-10%) and rare-earth compound as hidrogen-fixing agent (1-10%). Its advantages include high activity, high effect on fixating hydrogen, removing impurities, and improving mechanical and anticorrosion performance, and high chemical stability.

Owner:SHANGHAI JIAO TONG UNIV

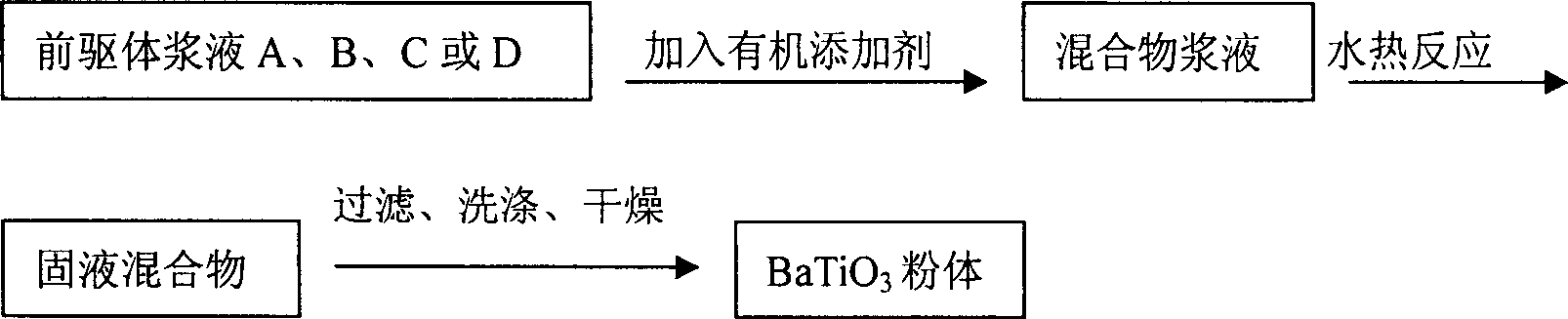

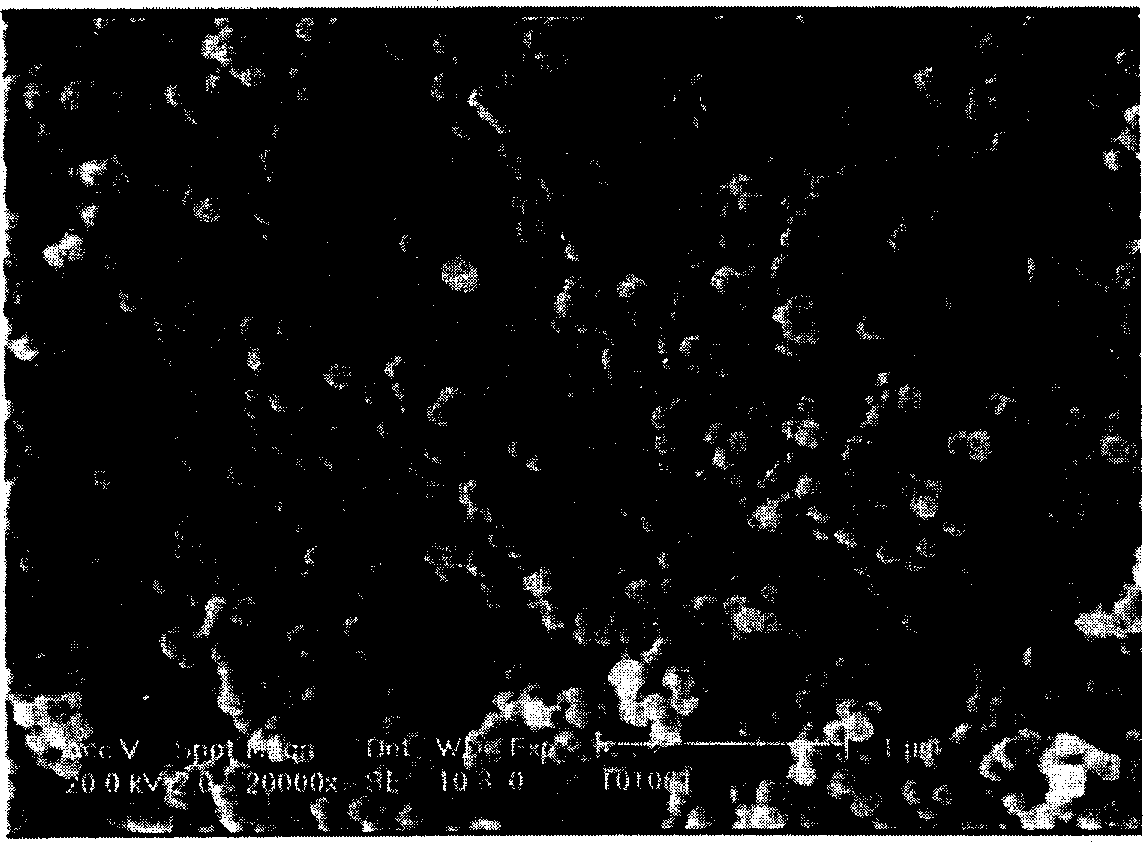

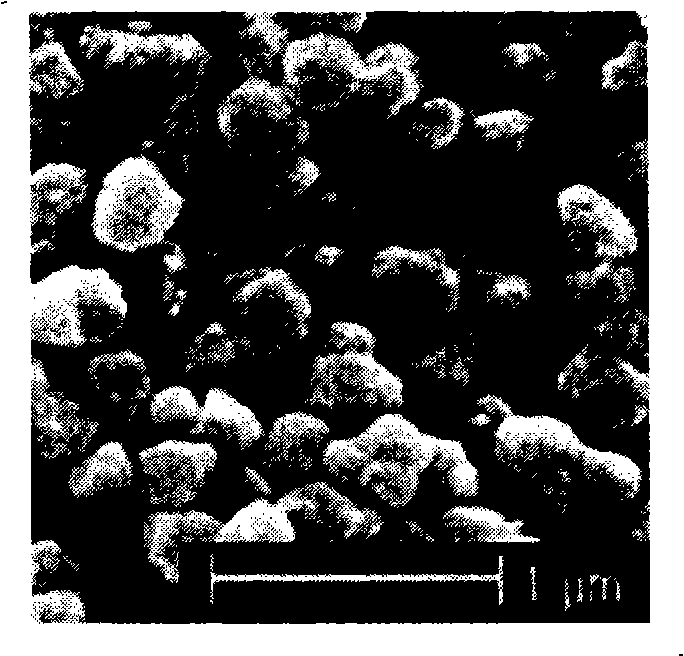

Preparation method of barium titanate powder body

InactiveCN1400168ANarrow particle distributionGood dispersionCalcium/strontium/barium carbonatesTitanium compoundsTitanium tetrafluorideBarium titanate

The preparation method of barium titanate (BaTiO3) includes the following steps: using titanium tetrafluoride and barium chloride or barium hydroxide as main raw material to prepare precursor body slurry liquor, then adding organic additive according to a certain ratio, placing them into reaction still to make hydrothermal reaction so as to obtain the invented product BaTiO3 powder body whose grain size is 20-200 nm. Said invented advantage lies in that it utilizes the regulation of class of organic additive and reaction condition to can regulate grain size distribution of product and make its product possess good grain uniformity, high sintering activity, high material property and chemical activity, and said method is easy to implement large-scale industrial production.

Owner:SHANDONG UNIV

Retardation method for alkali-activated-carbonate/slag gel material

InactiveCN1699251AEasy to useThe process steps are simpleSolid waste managementBarium dichlorideBarium nitrate

The invention provides a retardation method for alkali-activated-carbonate / slag gel material which comprises, at normal temperature, calculated by mass portions, dissolving 4-10 portions of barium chloride or barium nitrate into 100 portions of water, thus obtaining retarder solution, then charging 200-300 parts of slag powder, agitating homogeneously, charging in turn 220-3100 parts of exciting agent, 200-3800 parts of marginal carbonate powdered ore, agitating homogeneously, finally obtaining the end product.

Owner:SOUTH CHINA UNIV OF TECH

Salt bath nitrogenization heat treatment method for metal surface

InactiveCN101144148ASolve heat treatment problemsReduce distortionSolid state diffusion coatingPotassiumHeat treating

The present invention relates to a metal surface salt bath nitride nitriding heat treatment method which belongs to the metal part surface heat treatment technology field. The method is performed in the following technical process: first, loading and clamping: the metal part is hung and arranged in a charging basket; second, nitriding: the metal part hung and arranged in the charging basket is positioned in a nitriding furnace, heated and charged with nitriding salt for salt bath and nitriding, and heat is preserved for 30-80 minutes in the condition that the temperature is 540-570 DEG C; third, cleaning: the nitrided metal part is cleaned, and the water temperature is controlled at 60-80 DEG C; the nitriding salt in the nitriding working process comprises carbamide, potassium chloride or barium chloride, sodium carbonate, and K 2 S, etc., according to the weight percentage, the composition of each component is respectively: 30-40 percent of carbamide, 20-28 percent of potassium chloride or barium chloride, 38-44 percent of sodium carbonate, and 0.0001-0.1 percent of K 2 S, and the sum of the weight percentage of each component is 100 percent. The present invention has the advantages of smaller deformability, short time, high efficiency, and wide application range; and also can achieve the effect of reducing the cost obviously.

Owner:孙国飞

Non-mercury catalyst for production of vinyl chloride and preparation method thereof

InactiveCN102069000AAvoid pollutionEase of mass productionPhysical/chemical process catalystsPreparation by halogen halide additionBarium dichlorideCopper chloride

The invention discloses a non-mercury catalyst for the production of vinyl chloride and a preparation method thereof, belonging to the fields of chemical catalyst and the preparation thereof. The non-mercury catalyst of the invention uses cocoanut active charcoal as carrier and stannous chloride as main active substance, wherein the weight percentage of stannous chloride is 15%-30%; and at least one additive of barium chloride, zinc chloride and copper chloride is added and the total additive weight percentage is 0.5-2%. By using the non-mercury catalyst, the environmental pollution caused by the mercury-containing catalyst can be avoided; the large-scale production can be benefited, the conversion rate and selectivity of the catalyst can be increased, the yield of the product can be increased; by increasing the quality of the carrier, technical guarantee can be provided for the large-scale production device of vinyl chloride, the loss of the active matter can be slowed down, the service life of the catalyst can be prolonged; and the use efficiency of the catalyst can be increased by 500%.

Owner:YIBIN TIANYUAN GRP CO LTD

Production method for extracting chenodeoxycholic acid using chicken gall

InactiveCN1850846AEasy to separateSimple processUnknown materialsSteroidsCholic acidChenodeoxycholic acid

The feature of the invention includes: adopting frozen chicken gallbladder slicing, heating to 70 degree centigrade, adding 10% weight of the bile boiling for 24 hours, reflux cooling, adjusting the pH value by hydrochloric acid to gain cream, washing to neutrality; adding 95% alcohol and 10% diatomite, reflux cooling and adding active carbon, reflux, cooling and filtering, adding petrol to the filtrate to take degreasing, reflux, standing, separating alcohol liquid and washing to neutrality in reaction kettle, adding 95% alcohol, after resolving, adding barium chloride and active carbon, reflux, hot filtering, concentrating white crystal from the filtrate, washing, and adding water and sodium carbonate water solution, heating and reflux, filtering, adjusting the pH value, drying. The invention has simple technology, low cost, and could drastically separate cholesterol, lithocholic acid, and cholic acid from gall, and improves the purity.

Owner:辽宁百隆生物工程有限公司

Method of producing calcium chloride from industrial waste carbide slag

InactiveCN1923700ATake advantage ofReduce pollutionCalcium/strontium/barium chloridesSlagReaction temperature

The invention discloses a manufacturing method of calcium chloride through industrial waste carbide slag, which comprises the following steps: adding 20-40% industrial alcaine in the autoclave; adding carbide slag to react; controlling reacting temperature at 40-95 deg.c; terminating the reaction when the pH value is 5-8; filtering the product; adding activated carbon to discolor; adding barium chloride to remove sulfate ion; filtering; condensing the filtrate; crystallizing; drying to obtain calcium chloride.

Owner:游川北

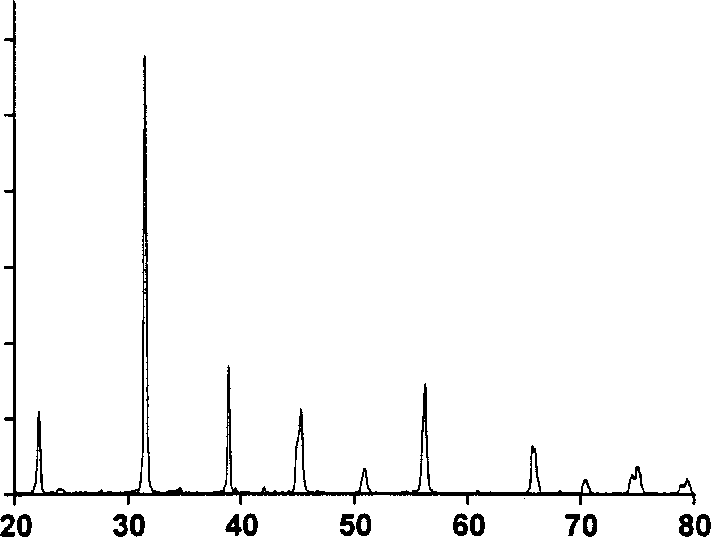

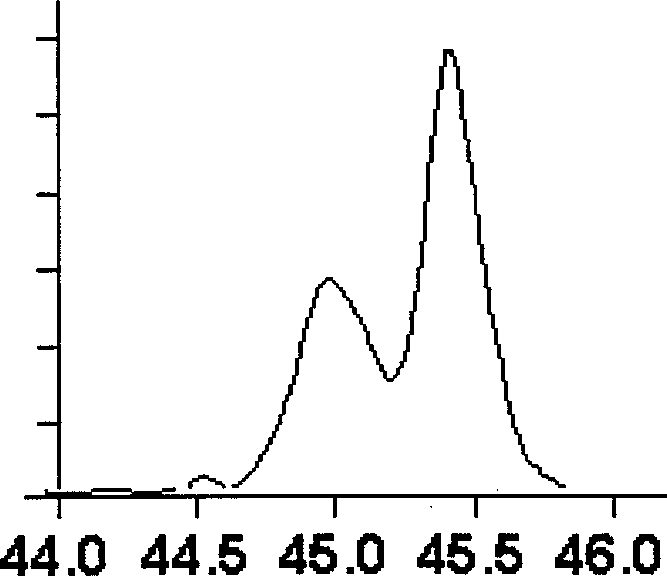

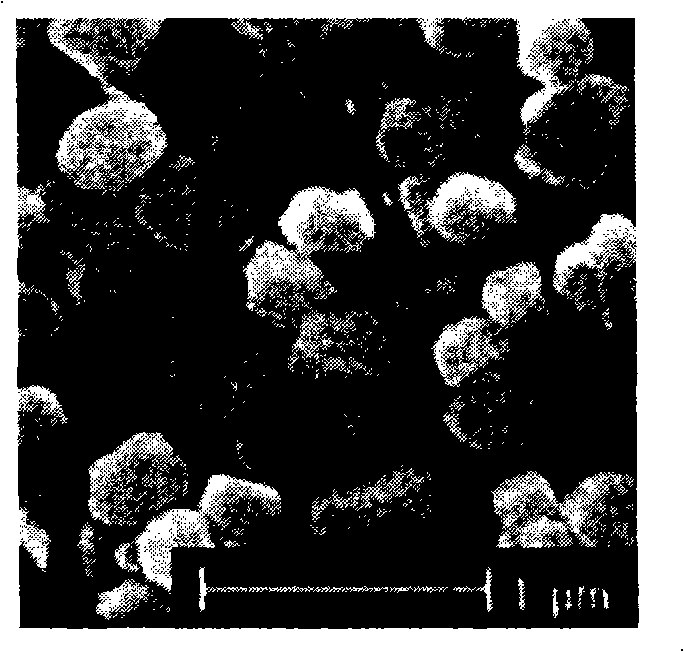

Nanometer grade tetragonal-phase barium titanate powder and its prepn.

InactiveCN1323759AHigh purityStable ratio of barium to titaniumTitanium compoundsHigh concentrationBarium dichloride

The present invention relates to method of preparing nanometer grade tetragonal phase barium titanate powder. Said method uses low price barium chloride, titanium tetrachloride as barium, titanium source for hydrothermal reaction and uses sodium hydroxide as mineralization agent. Prepare high concentration barium chloride solution and titanium tetrachloride solution respectively then mix together, add in sodium hydroxide to form colloidal sol with very good fluidity as hydrothermal reaction mixture which is put in high pressure anticorrosion reactor and raise temperature to 240 deg.C, maintain this temperature for 12hr., filter, wash with deionized water., dry to obtain monodispersional nanometer grade tetragonal phase barium titanate powder with average size smaller than 100 nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Copper phosphide catalyst for synthesizing chloroethylene and preparation method thereof

ActiveCN102151579ASimple production processShorten the production cyclePhysical/chemical process catalystsPreparation by halogen halide additionBarium dichlorideActive component

The invention discloses a copper phosphide catalyst for synthesizing chloroethylene, which is characterized in that the carrier of the catalyst is active carbon, the active component is Cu3P and the auxiliaries comprise one or more of copper chloride, nickel chloride and barium chloride. The catalyst disclosed by the invention is green, simple in production process and short in production period and shows excellent activity and selectivity in the reaction of synthesizing chloroethylene via the hydrochlorination of acetylene.

Owner:内蒙古海驰高科新材有限公司

Composite copper-based catalyst, preparation method and application thereof in the production of vinyl chloride

ActiveCN109821546AHigh activityImprove stabilityPreparation by halogen halide additionCatalyst activation/preparationCeriumPotassium

The invention provides a composite copper-based catalyst, a preparation method and an application thereof in the production of vinyl chloride. The preparation method of the composite copper-based catalyst includes the following steps: soaking acid-treated activated carbon in a solution containing copper salt and an auxiliary agent, and drying and roasting to obtain the composite copper-based catalyst, wherein the auxiliary agent is one or more of ferric chloride, cerium chloride, tin chloride, barium chloride, manganese chloride, zinc chloride, cobalt chloride, lanthanum chloride, nickel chloride, bismuth chloride and potassium chloride; and the mass ratio of the acid-treated activated carbon, the copper salt and the auxiliary agent is 100: 5: 1-100: 10: 5. The catalyst is environment-friendly, low in cost, simple in process and short in production period. The catalyst shows high activity, selectivity and good stability in the reaction of hydrochlorination of acetylene to produce the vinyl chloride, and is expected to be a good substitute for a mercury catalyst.

Owner:鄂尔多斯市瀚博科技有限公司

Quick detecting tube for micro-hydrogen sulfide gas

InactiveCN101672790AGood effectImprove adsorption capacityMaterial analysis by observing effect on chemical indicatorBarium dichlorideLead acetate

The invention relates to a detecting tube for low concentration hydrogen sulfide gas. Barium sulfate, silica gel or a mixture of the barium sulfate and the silica gel is used as a carrier; lead acetate solution and barium chloride solution are used as developing agents; glycerine is used as a wetting agent; and different detection indicators are obtained by controlling the dry condition. The hydrogen sulphide gas samples with different concentrations are introduced into the detecting tube, and the content of the hydrogen sulfide gas is determined according to the difference of the color changeof the developing agents. The detecting tube has simple structure, fast analysis, low cost and convenient carrying, and can detect weather the content of hydrogen sulfide in air of environment is over-proof at the field. The application experiment proves that the detecting tube has higher sensitivity and substantially meets the requirements of national standard.

Owner:BEIJING UNIV OF CHEM TECH

Magnesium alloy boride iron illiminating flux and its production method

A deironing boride flux for Mg-alloy contains magnesium chloride, potassium chloride, sodium chloride, calcium chloride, calcium fluoride, barium chloride, and boron oxide and / or sodium borate as deironing agent. Its advantages are high power removing impurities and Fe from molten Mg-alloy, easy separation, and low cost.

Owner:SHANGHAI HAOHUA MOLD

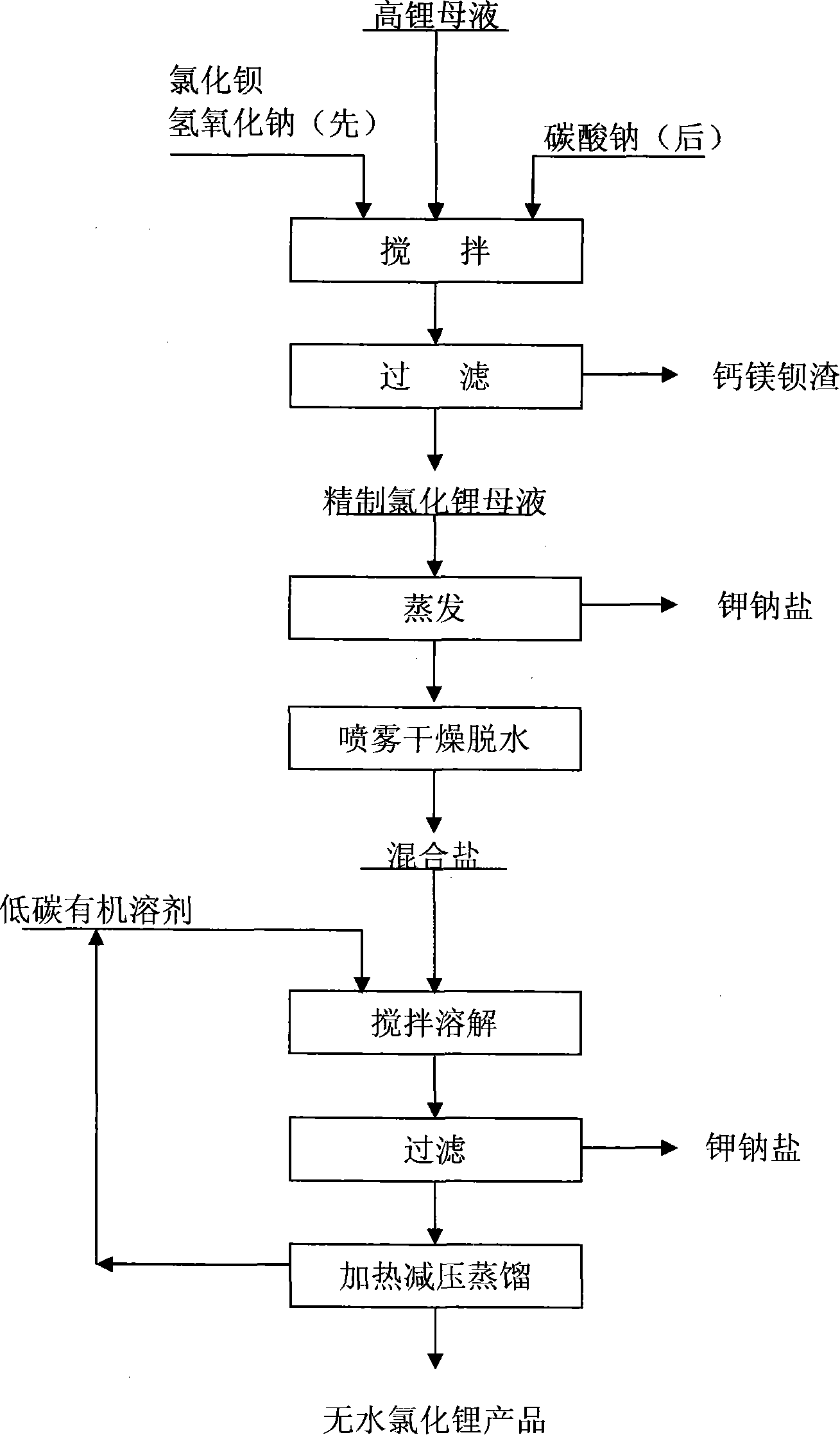

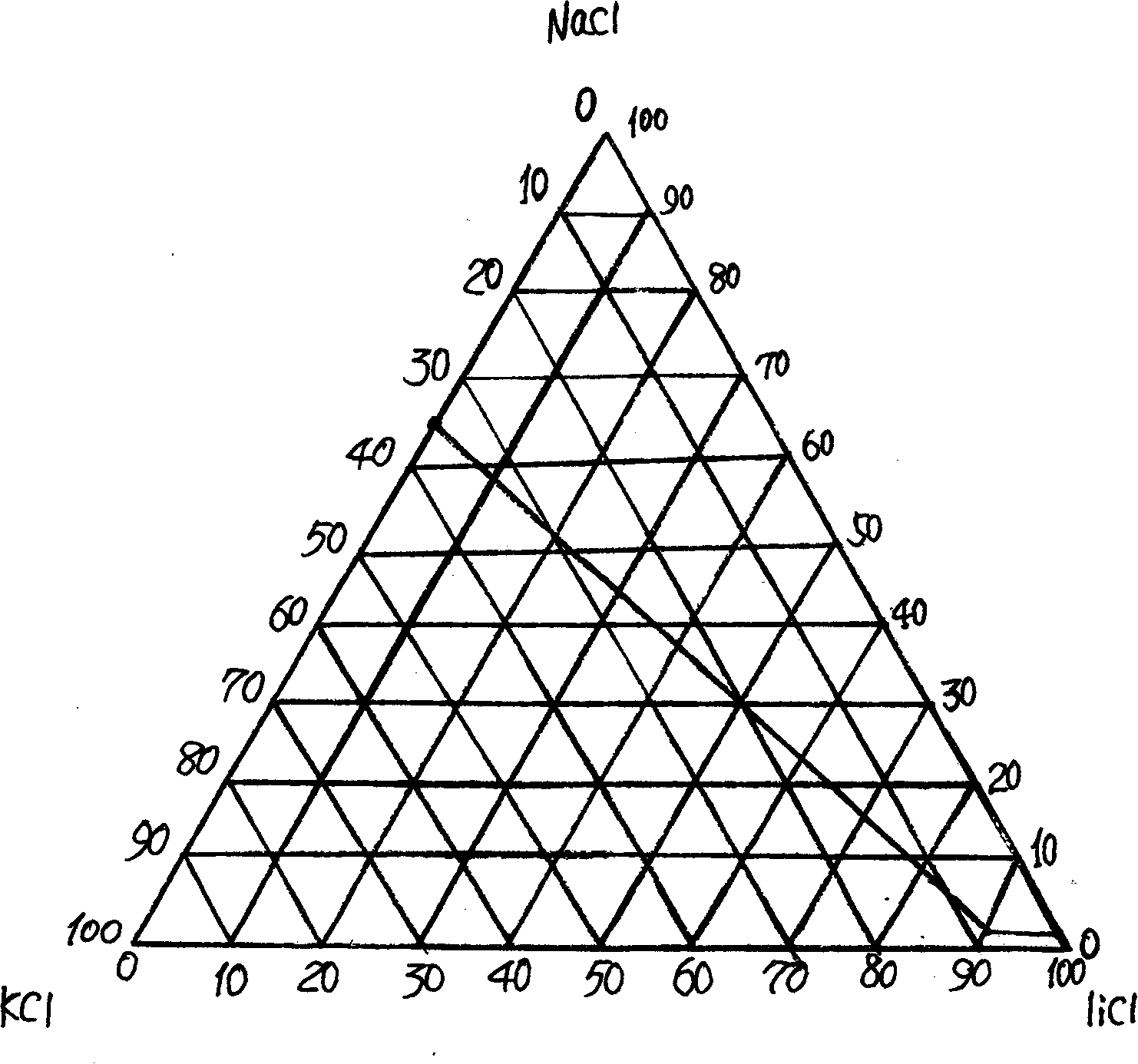

Method of producing high-purity anhydrous lithium chloride

InactiveCN101172624AEfficient separationEfficient purificationAlkali metal chloridesLithium chlorideSolvent

The invention belongs to the chemical field of inorganic salts, in particular to a preparation method of high-purity anhydrous lithium chloride; wherein, sodium hydroxide and barium chloride are added into the high-potassium sodium brine containing lithium chloride which is used as a raw material; the mixture is stirred and filtered to eliminate a great amount of Mg 2 <+> and SO 4 <2->; and the micro Mg 2 <+> and the SO 4 <2-> can be eliminated by adding sodium carbonate into the mixture, and then is filtered to get a refined mother liquid. The refined mother liquid can be evaporated and filtered to eliminate potassium chloride and sodium chloride; and high-potassium mixed salt containing 60 to 95 percent of lithium chloride can be achieved by spraying and drying the refined mother liquid. After adding low-carbon organic solvent, the high-potassium mixed salt is stirred to extract lithium chloride and filtered to eliminate potassium sodium salt. High-purity anhydrous lithium chloride with the purity of over 99.5 percent can be achieved by depressurizing and distilling the mother liquid. The invention is applicable to the extraction art of the lithium chloride used in all present low-magnesium salt lakes containing lithium, and the extraction process of the lithium chloride from the mother liquid achieved after pressing solid lithium ore. The invention not only has the advantages of simple process and low cost, but also is easy to be operated and used in industrialization and has no three-waste pollution.

Owner:青海中信国安科技发展有限公司

Method for treating chromium-containing wastewater by using barite adsorbent

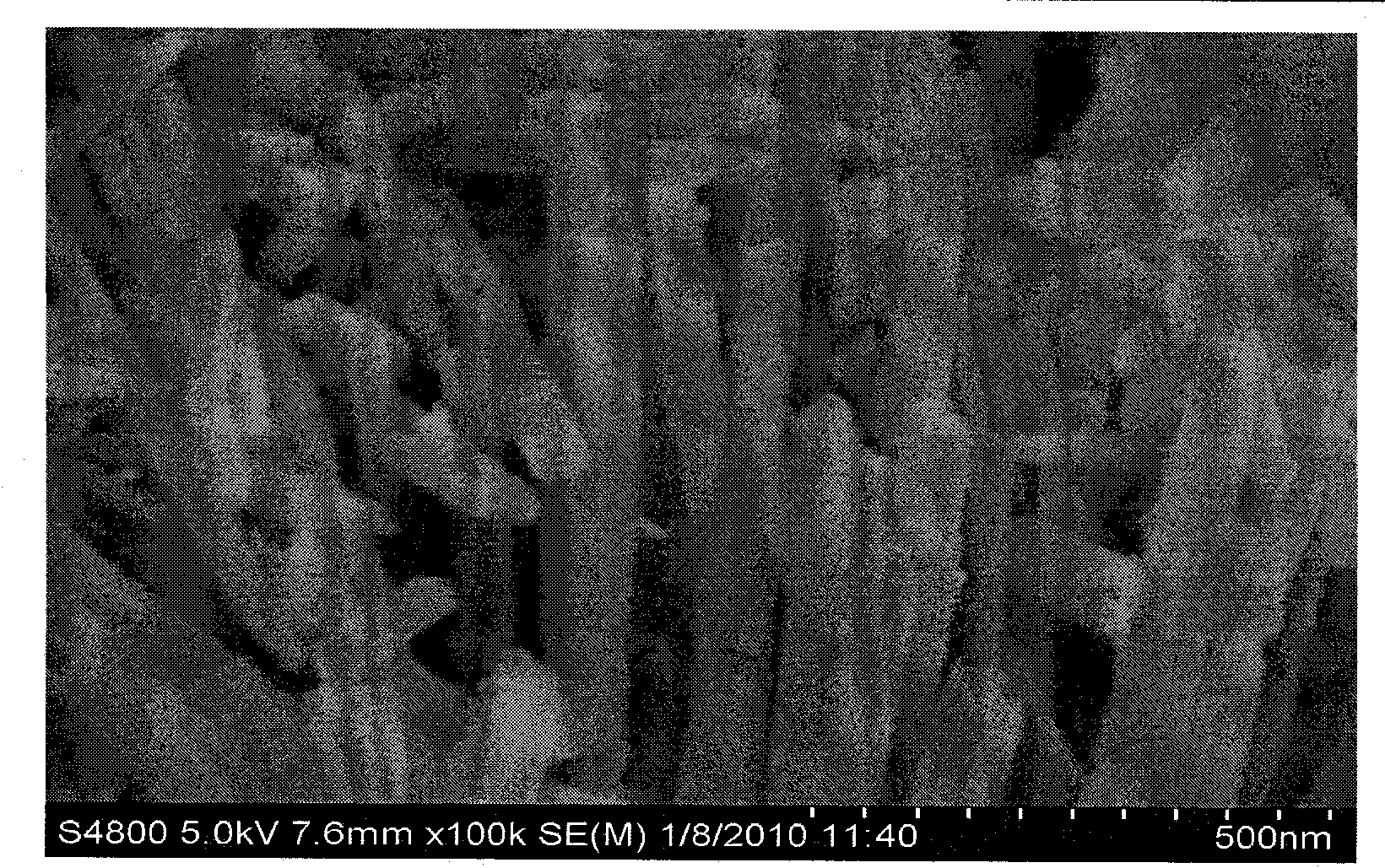

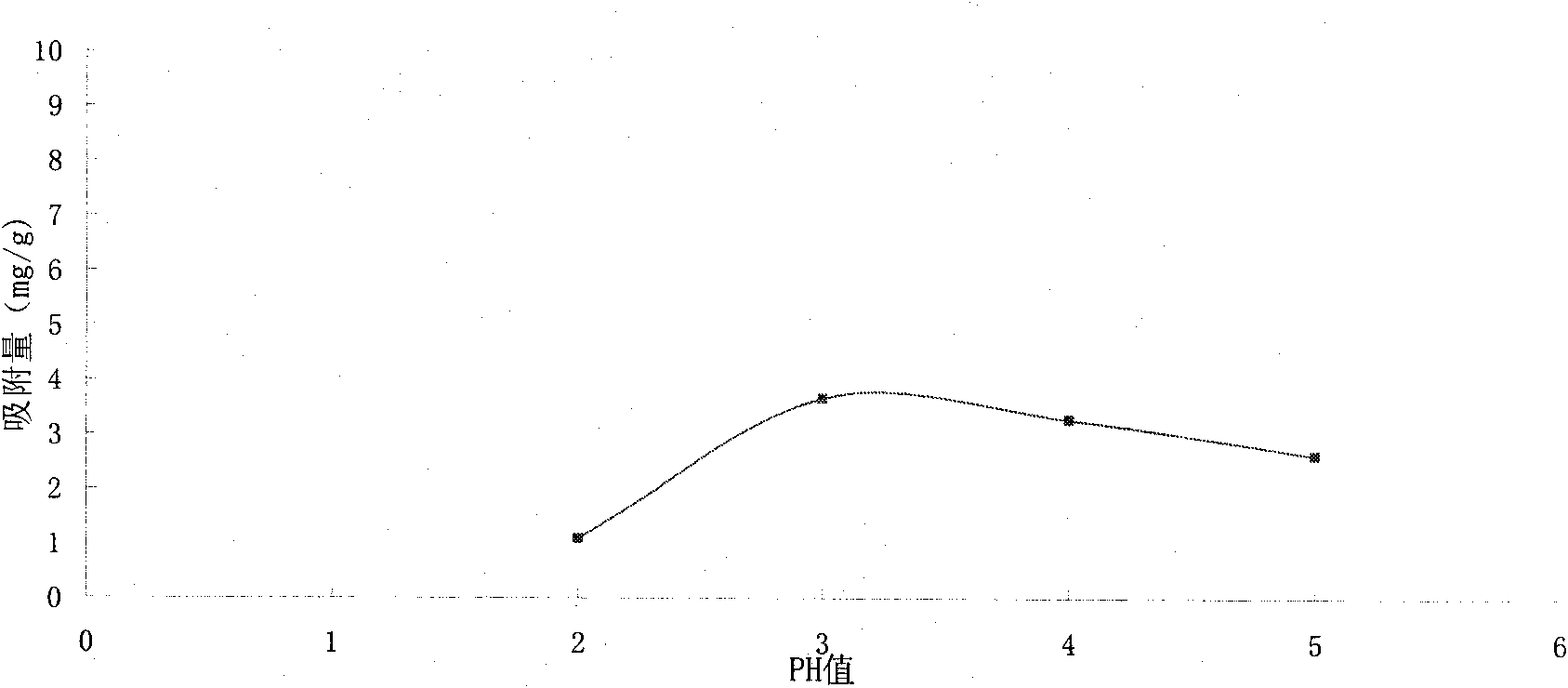

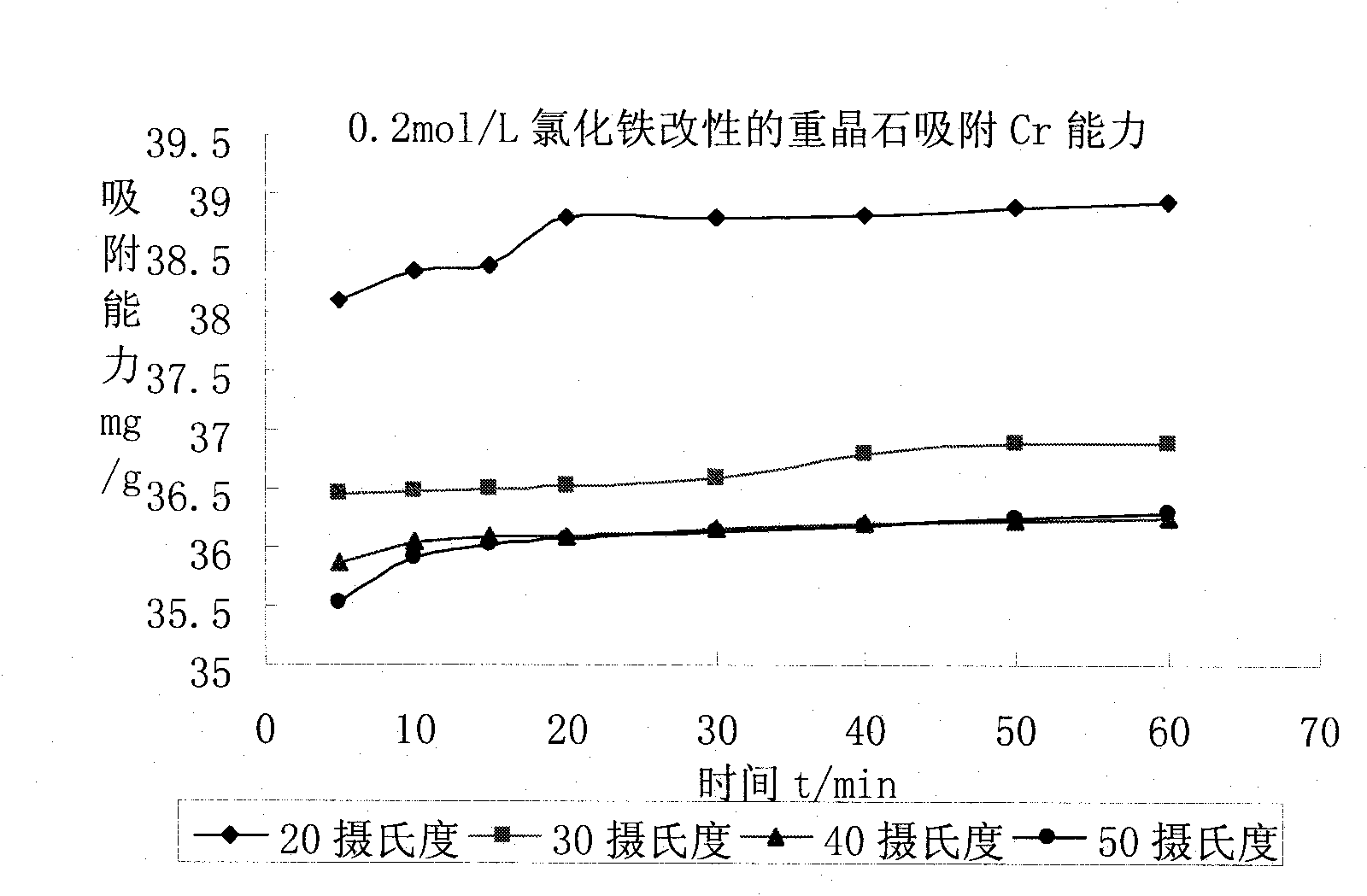

InactiveCN101898107AAbundant resourcesLow priceOther chemical processesWater contaminantsChromium CompoundsWater baths

The invention discloses a method for treating chromium-containing wastewater by using barite adsorbent. The method comprises the following steps of: fusing, crushing and screening a barite mineral material, reacting the barite mineral material by using ferric chloride solution to generate the barite adsorbent for removing chromium ions from sewage containing 50 to 150 mg / L of chromium compound, and shaking the barite adsorbent for 1 hour in a 20 DEG C water bath thermostatic oscillator when the pH is 3 to 4, wherein the removal rate of the chromium ions in the sewage is over 99 percent; and adding a proper amount of barium chloride powder into the barite adsorbent for treating the high chromium content sewage so as to improve the removal rate of the chromium ions. The method has the advantages that: the barite is a most common barium-rich sulfate mineral, the globe surface has rich resources and the cost is low, so the method is convenient for popularization and application; and the barite adsorbent has simple preparation process, convenient operation and high adsorption rate of the chromium ions in the wastewater, can be repeatedly regenerated and recycled, and meets the energy conservation and emission reduction requirements.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for preparing anhydrous lithium chloride by lithium-containing liquid waste

The invention discloses a method for preparing anhydrous lithium chloride by lithium-containing liquid waste. The lithium-containing liquid waste at least contains lithium ions, calcium ions, magnesium ions, sodium ions, potassium ions, sulfate ions and chloride ions. The method comprises the following steps of: (A) adding hydrogen peroxide to the lithium-containing liquid waste. To remove a residual organic phase; (B) adding a barium chloride solution and filtering the solution after reacting to obtain a mother liquid; (C) adding a sodium carbonate solution to the mother liquid and filtering the solution after reacting to obtain a refined mother liquid; (D) evaporating and concentrating the refined mother liquid until sodium chloride and potassium chloride solids are separated out, carrying out filtration to remove the sodium chloride and potassium chloride solids to obtain a lithium chloride clean liquid; (E) adding a sodium refining agent to the lithium chloride clean liquid, carrying out stirred reaction and then filtering the solution to obtain a high-concentrate lithium chloride solution; and (F) drying the high-concentrate lithium chloride solution and then obtaining anhydrous lithium chloride. The method is simple in technology, low in production cost, high in lithium recovery rate and friendly to environment.

Owner:天齐锂业(江苏)有限公司 +2

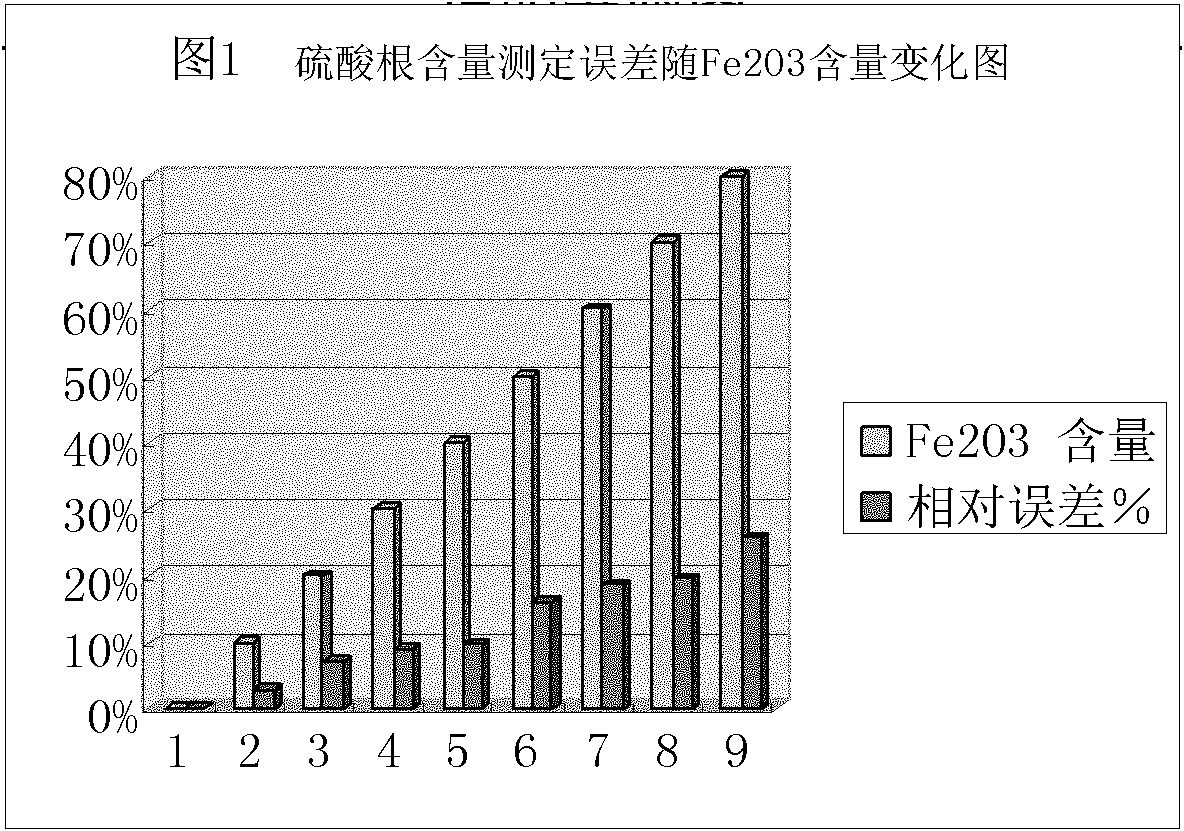

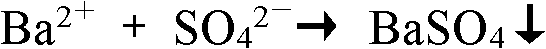

Method for measuring sulfate ions in scaled component of water vapor system in power station

ActiveCN102128790AEliminate interference effectsOvercoming bad linearityMaterial analysis by optical meansLinear correlationWater vapor

The invention discloses a method for measuring sulfate ions in a scaled component of a water vapor system in a power station, which overcomes the problems that the error of sulfate ion content is big because of the high content of iron ions, the linearity of test working curve is unsatisfactory, the data repeatability is poor, and the linear correlation coefficient r is difficult to reach 0.999. Besides, the invention perfects the test method to ensure that test data is accurate and reliable. The method comprises the following steps: taking a sulfate working solution; diluting the sulfate working solution; adding a condition agent into the solution, and then adding a barium chloride to enable the solution mixture to react and generate barium sulfate sediment; measuring the absorbance A, wherein blank absorbance A0 with the content of sulfate being 0 is deducted from the absorbance A to acquire absorbance (A-A0); drawing a curve according to the smooth curve relationship between the absorbance (A-A0) and the sulfate ion content m (within the range of 0-1.5mg); within the range, establishing a linear regression equation; taking a scaled sample to be measured, and preparing into a solution to be measured; measuring the A0 and A; substituting the A0 and A into the linear regression equation or checking the working curve, thereby acquiring the sulfate ion content; and finally, calculating the sulfuric anhydride content in the scaled sample to be measured.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

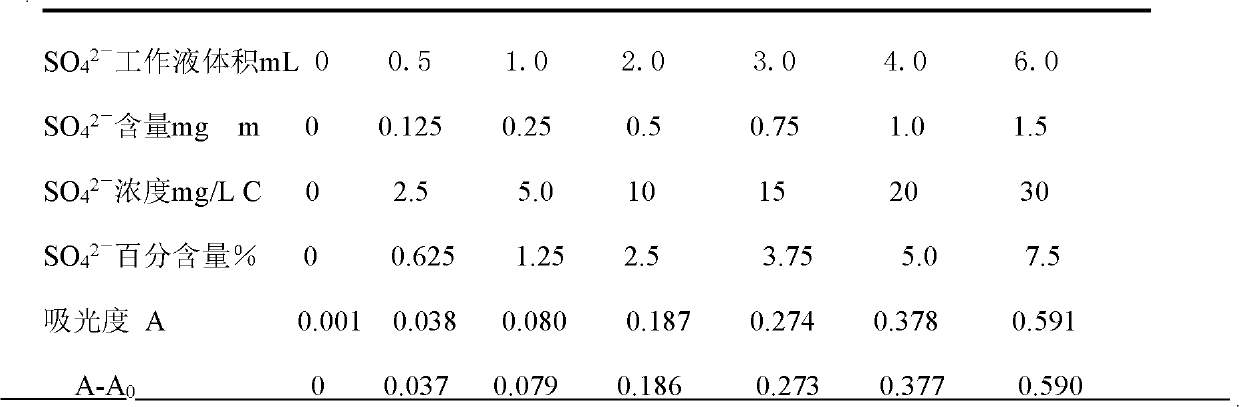

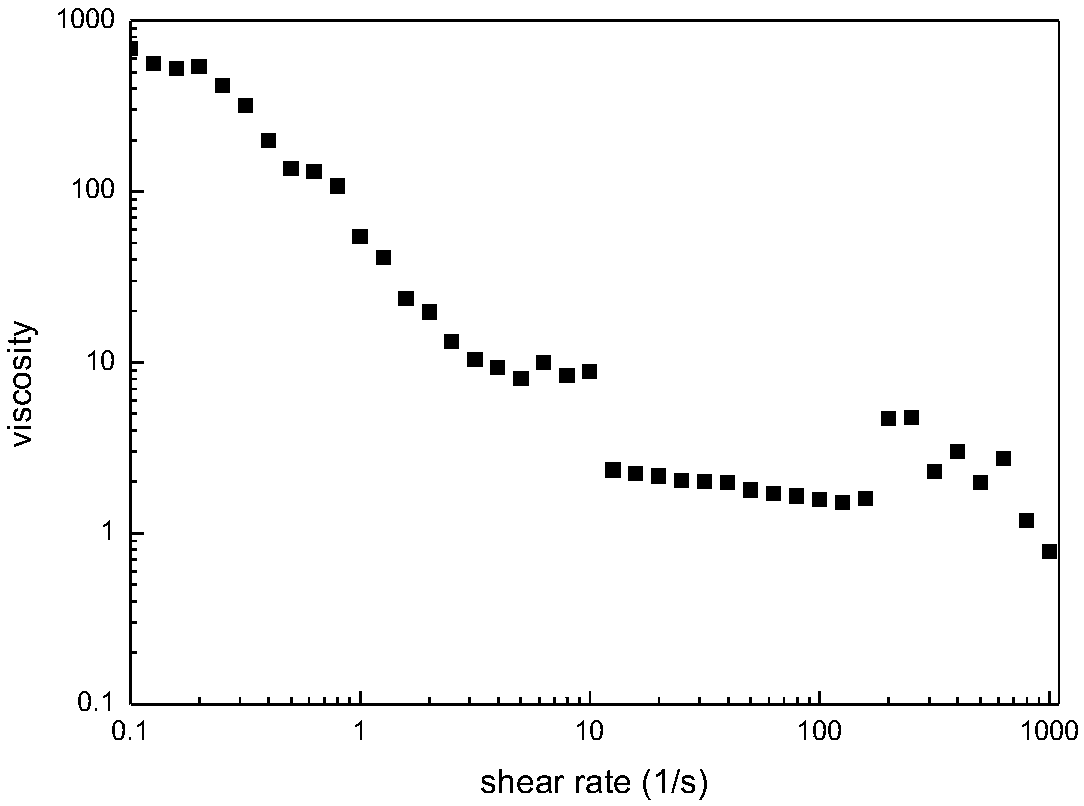

3D direct writing zirconium oxide ceramic ink

The invention relates to 3D direct writing zirconium oxide ceramic ink, which comprises zirconium oxide particles, a solvent, a binder, a dispersant and a salt, wherein the particle size of the zirconium oxide particles is 0.1-2 [mu]m, the solid content of the zirconium oxide particles in the ink is 40-58 vol%, the dispersant is one or a variety of materials selected from polyacrylic acid, polyvinyl acid, ammonium polyacrylate, polyvinyl acid salt, polyacrylate, polycarboxylate and polyacetyl imine, the dispersant accounts for 0.1-2% of the mass of the zirconium oxide particle dry powder, andthe salt is one or a variety of materials selected from ammonium chloride, zinc acetate, sodium chloride, magnesium chloride, potassium chloride, barium chloride, ammonium bicarbonate, anhydrous calcium chloride, potassium carbonate, sodium bicarbonate, sodium carbonate, anhydrous sodium carbonate, anhydrous sodium acetate, anhydrous calcium chloride, copper sulfate, basic copper carbonate, ammonium sulfate, ammonium bicarbonate, potassium aluminum sulfate and sodium citrate, and accounts for 0.001-0.1% of the mass of the ink. According to the present invention, the 3D direct writing zirconiumoxide ceramic ink can be printed at the room temperature, has high solid content while can flow out of the fine spraying nozzle and cannot cause the clogging, can be quickly cured into the fine wirewith a certain strength, and has good rheological property.

Owner:CENT SOUTH UNIV

Purification method of cobalt nickel hydroxide hydrochloric acid leaching solution

ActiveCN104073633AImprove qualityReduce usageProcess efficiency improvementPregnant leach solutionSulfate radicals

The invention discloses a purification method of a cobalt nickel hydroxide hydrochloric acid leaching solution. The purification method mainly comprises the following processing steps: I. dissolving and leaching a cobalt nickel hydroxide raw material produced by laterite-nickel ore transformation through industrial concentrated hydrochloric acid; II. adding barium chloride to a leaching solution and implementing sulfate radical removal operation; filter-pressing the solution and reserving the solution as an extracting pre-solution for later use; III. preparing an organic phase at ratio of 25% to 75% of P5O7 to sulfonated kerosene; saponifying the prepared organic phase in a soda soap kettle; reacting the saponified organic phase with a pure nickel chloride solution to obtain nickel soap; and IV. extracting the nickel chloride extracting pre-solution obtained from the step II through the P507 nickel soap, wherein the extracting solution obtained is a finished pure nickel chloride solution. The production process disclosed by the invention is safe and the extracting solution produced is better in component; and moreover, the purification method is short in technological process and more effective in process control.

Owner:JINCHUAN GROUP LIMITED

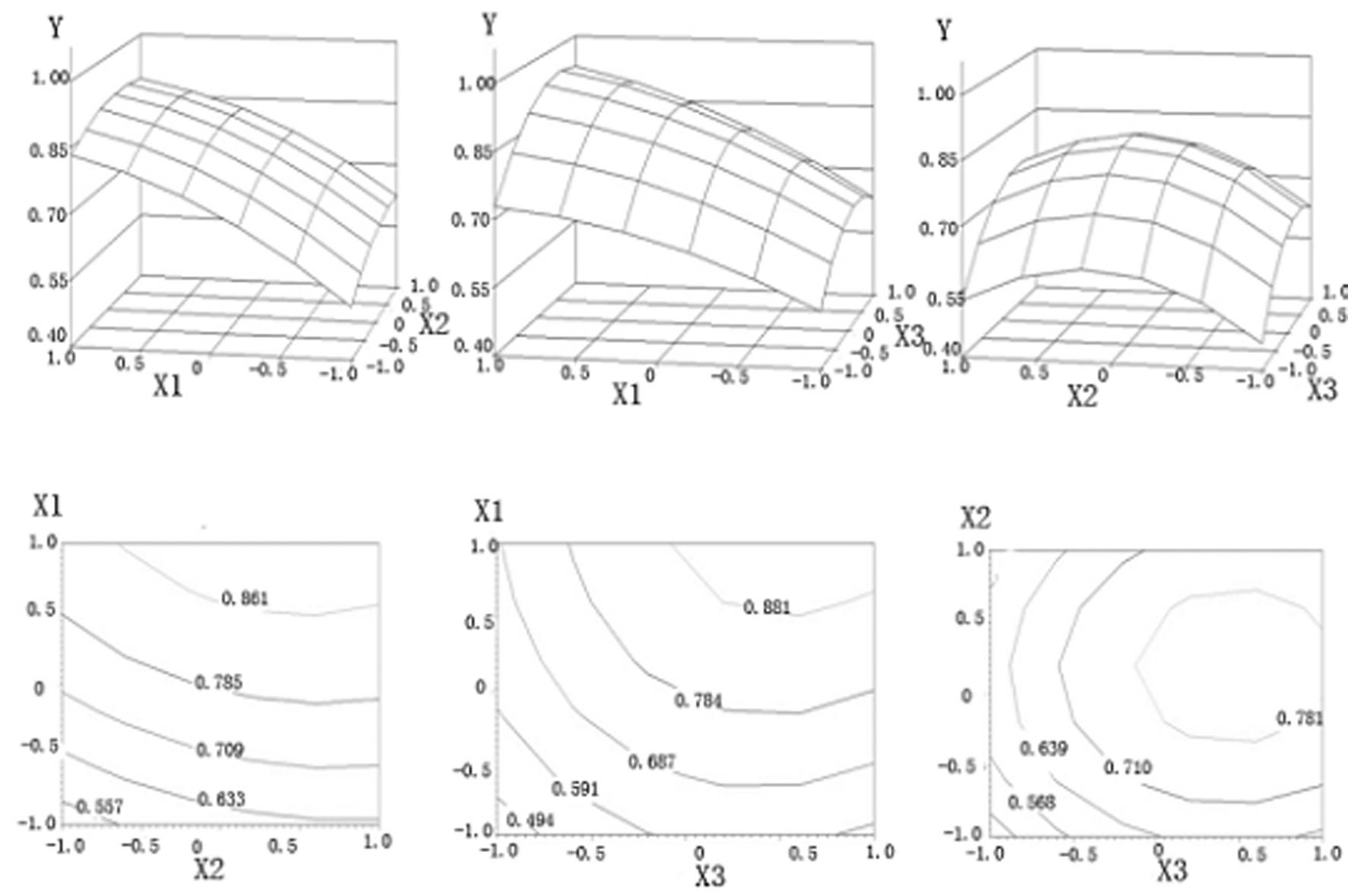

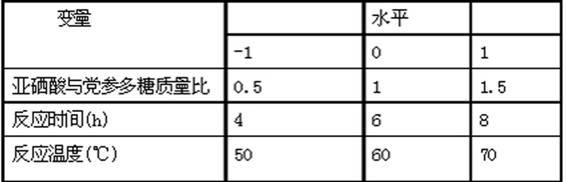

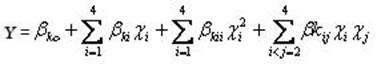

Method for selenizing pilose asiabell root polysaccharides and application of product

ActiveCN102532339AIncrease selenium contentImprove anti-tumor activityOrganic active ingredientsImmunological disordersBarium dichlorideCodonopsis pilosula

The invention provides a method for selenizing pilose asiabell root polysaccharides. The method comprises the following steps of: adding selenous acid into an aqueous solution of the pilose asiabell root polysaccharides with stirring, adding a catalyst, reacting at the temperature of between 50 and 70 DEG C for 4 to 8 hours, cooling, separating, and purifying to obtain a selenized pilose asiabell root polysaccharide product, wherein the catalyst is barium chloride. By the method, the content of selenium in the pilose asiabell root polysaccharides can be improved to 500-5,000mu g / g, the anti-tumor activity and immunity improving activity of the selenized pilose asiabell root polysaccharides are obviously improved compared with those of non-selenized pilose asiabell root polysaccharides, and the product can be used for preparing anti-tumor medicines or medicines or health care products for improving immunity.

Owner:LANZHOU UNIVERSITY

Gypsum mold formula for casting magnesium alloy and preparation method thereof

The invention discloses a gypsum mold formula for casting a magnesium alloy and a preparation method thereof, relating to preparation of a gypsum mold for casting a magnesium alloy. The gypsum mold formula comprises an additive component consisting of four basic components, including alpha-semihydrated gypsum, quartz powder, bauxite and magnesium sulfate as well as seven substances such as trisodium orthophosphate, barium chloride, a water reducing agent and the like. The invention further discloses a preparation method for the gypsum mold formula. Due to the adoption of scale graphite, oxidation of the magnesium alloy is effectively prevented; the water reducing agent is added into the formula, so that the fluidity of gypsum slurry is improved, the water consumption is lowered by 30 percent simultaneously, and the gypsum mold strength and drying efficiency are increased; the linear shrinkage of the gypsum mold can be remarkably lowered by using the gypsum mold formula together with barium chloride and urea; moreover, a solvent component consisting of tap water is adopted, so that the problems of high water consumption, poor fluidity, low strength, large size deformation, difficulty in breaking and the like existing in an ordinary gypsum mold are solved; and meanwhile, the problems of oxidization and combustion of the magnesium alloy are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Process for synthesizing high pure electronic grade barium titanate by liquid phase method

ActiveCN101333000AGuarantee product qualityNo chemical reactionCalcium/strontium/barium compoundsTitanium compoundsBarium titanateImpurity

The invention relates to a technique for synthesizing high-purity electronic grade barium titanate by a liquid phase method, which includes the following steps: oxalic acid is dissolved in deionized water, and barium chloride accounting for 2% of molar weight of oxalic acid is added in; the barium-titanium mixed solution is added into oxalic acid solution at the flow speed of 1.3-1.5m <3> / h for reaction; the obtained solid is put in a kiln for constant temperature calcination which lasts for 2-4 hours, then is taken out and processed by jet milling, placed in the kiln once more for secondary constant temperature calcination which lasts for 1-3 hours, and taken out for secondary jet milling and barium titanate powder is obtained finally. The barium titanate prepared by the invention has high purity, good dispersibility, uniform powder particle appearance and reasonable particle size. Therefore, the technique of the invention can solve the problem that the barium titanate powder prepared by the traditional method; more particularly, the existing coprecipitation method has sulphate impurities, severe glomeration, and the like, and can completely meet the requirements of the production of high-performance electronic components like base metal porcelain capacitors, etc.

Owner:仙桃市中星电子材料有限公司

Composition for building material, and gypsum board and construction method using them and wall and the like

InactiveUS20100043344A1Increase the proportionSeparation performanceSolid waste managementLayered productsOrganic synthesisTitanium oxide

Provided is a building material with a higher specific gravity and / or radioactive-ray-shielding function while maintaining a workability equivalent to that of a conventional gypsum board. It relates to a gypsum-based building material manufactured by adding water to a composition in which a base material is a combination of a hydraulic gypsum and one kind or two or more kinds of dry-hardening calcium carbonate or calcium hydroxide or synthetic resin emulsions and an inorganic filler with a high specific gravity is compounded to it so that reaction and setting or drying and setting are conducted, wherein the composition is characterized by comprising 100 parts by weight of at least one kind or two or more kinds of base materials selected from the group consisting of calcium sulfate, calcium carbonate, calcium hydroxide and organic synthetic resin emulsions, and 50-3,000 parts by weight of at least one kind or two or more kinds of inorganic fillers whose true specific gravity is 3.5-6.0 which are selected from the group consisting of barium chloride, zinc oxide, aluminum oxide, titanium oxide, barium oxide, strontium carbonate, barium carbonate, and barium sulfate.

Owner:YOSHINO GYPSUM CO LTD

Printing and dyeing auxiliary

The invention discloses a printing and dyeing auxiliary, and relates to the technical field of spinning dyeing. The printing and dyeing auxiliary comprises, by weight, 10-15 parts of guar gum, 7-9.5 parts of poly alkyl acrylate, 15-20 parts of sodium carboxymethylcellulose, 5-8 parts of octadecyl dimethyl benzyl ammonium chloride, 2-3 parts of tannin and 10-15 parts of barium chloride. A preparing method comprises the steps that the raw materials are weighed according to the weight part, the poly alkyl acrylate, the sodium carboxymethylcellulose and the octadecyl dimethyl benzyl ammonium chloride are added into a reaction kettle to be heated and stirred until reaction is thorough, and cooling is carried out; the tannin and the barium chloride are added, stirred and heated, the guar gum is added, and stirring is even. The printing and dyeing auxiliary has the advantages of being high color fastness, good in color protecting performance and fading proof.

Owner:江苏中诚印染股份有限公司

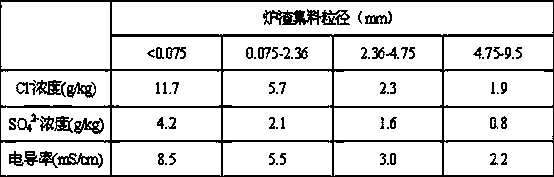

Method for detecting content of soluble salt in slag aggregate of waste incinerator

InactiveCN103411792AAccurately reflect the natureAccurately reflect engineering performance impactWeighing by removing componentMaterial analysis by observing effect on chemical indicatorSulfate radicalsSlag

The invention relates to the field of resource utilization of waste incinerator slag, in particular to a method for detecting the content of soluble salt in slag aggregate of a waste incinerator. The method comprises the following steps: (1) sampling: selecting a plurality of groups of uniformly distributed furnace slag with substantially the same mass at the top, in the middle and at the bottom of the furnace slag aggregate pile and uniformly mixing the selected furnace slag into a group of furnace slag aggregate; (2) preparing furnace slag leachate; drying, pulverizing in a mortar, mixing and oscillating furnace slag and distilled water at the mass ratio of 1:5 for 5-6 minutes to prepare slurry, and filtering; (3) titrating silver nitrate solution to determine the concentration of chloride(Cl<-1->) in the furnace slag leachate; (4) titrating barium chloride solution to determine the concentration of sulfate radical (SO4<2->); (5) utilizing the electric conductivity tested by a conductometer to determine the total amount of soluble salt in the furnace slag leachate. The method provided by the invention can accurately test the content of soluble salt in the slag aggregate of a waste incinerator, is simple, feasible, quick and accurate, is short in the test period, and can achieve batch detection of furnace slag aggregate to provide reference for resource utilization of furnace slag aggregate.

Owner:TONGJI UNIV

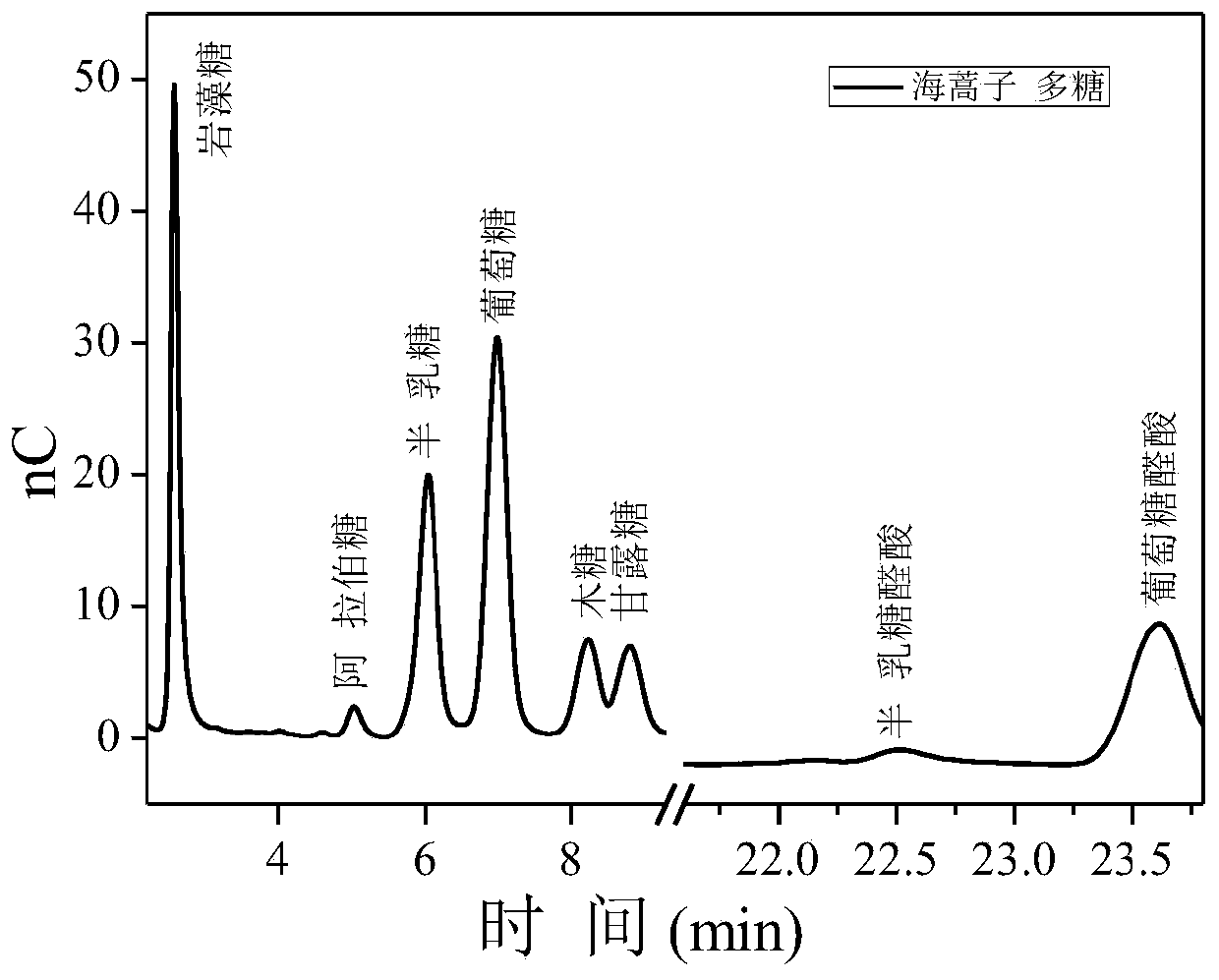

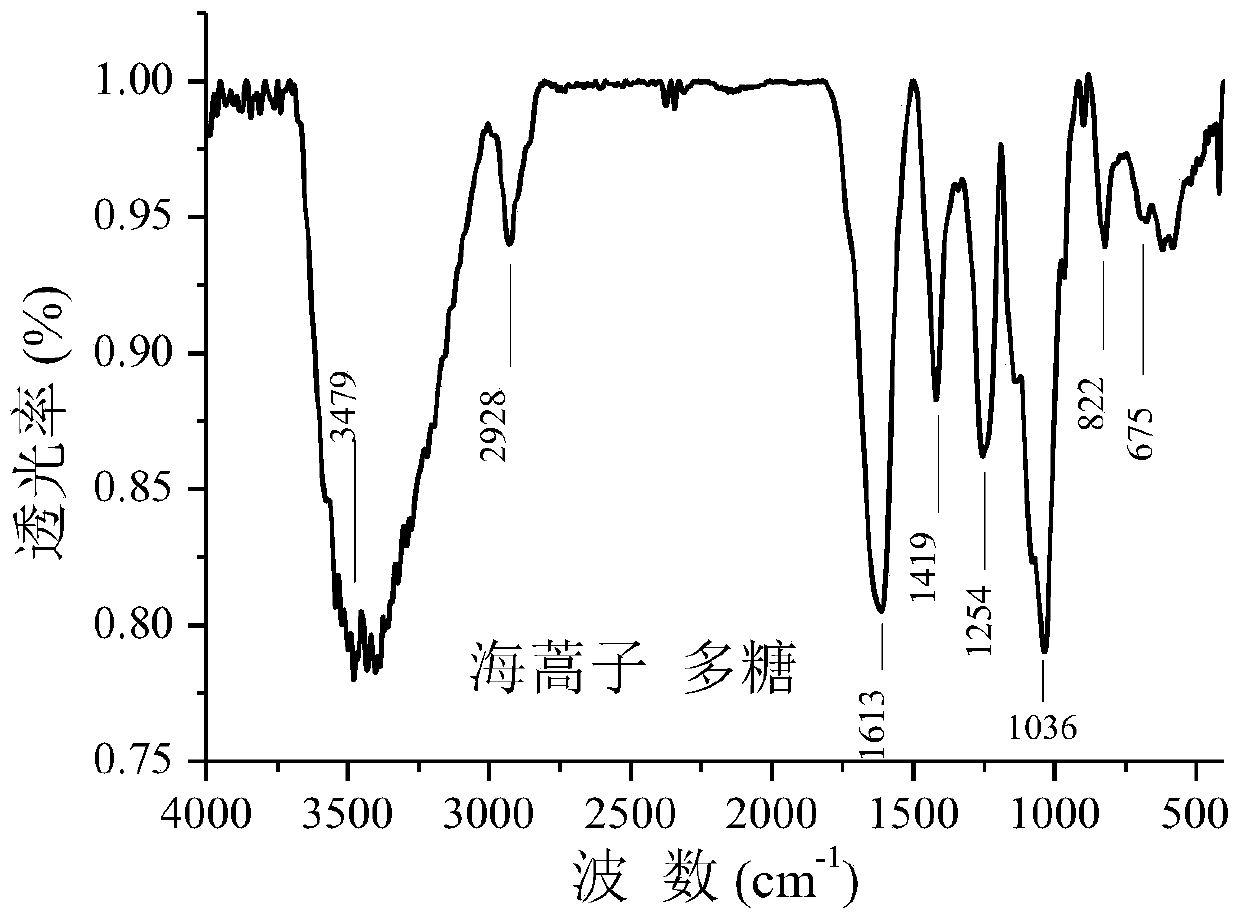

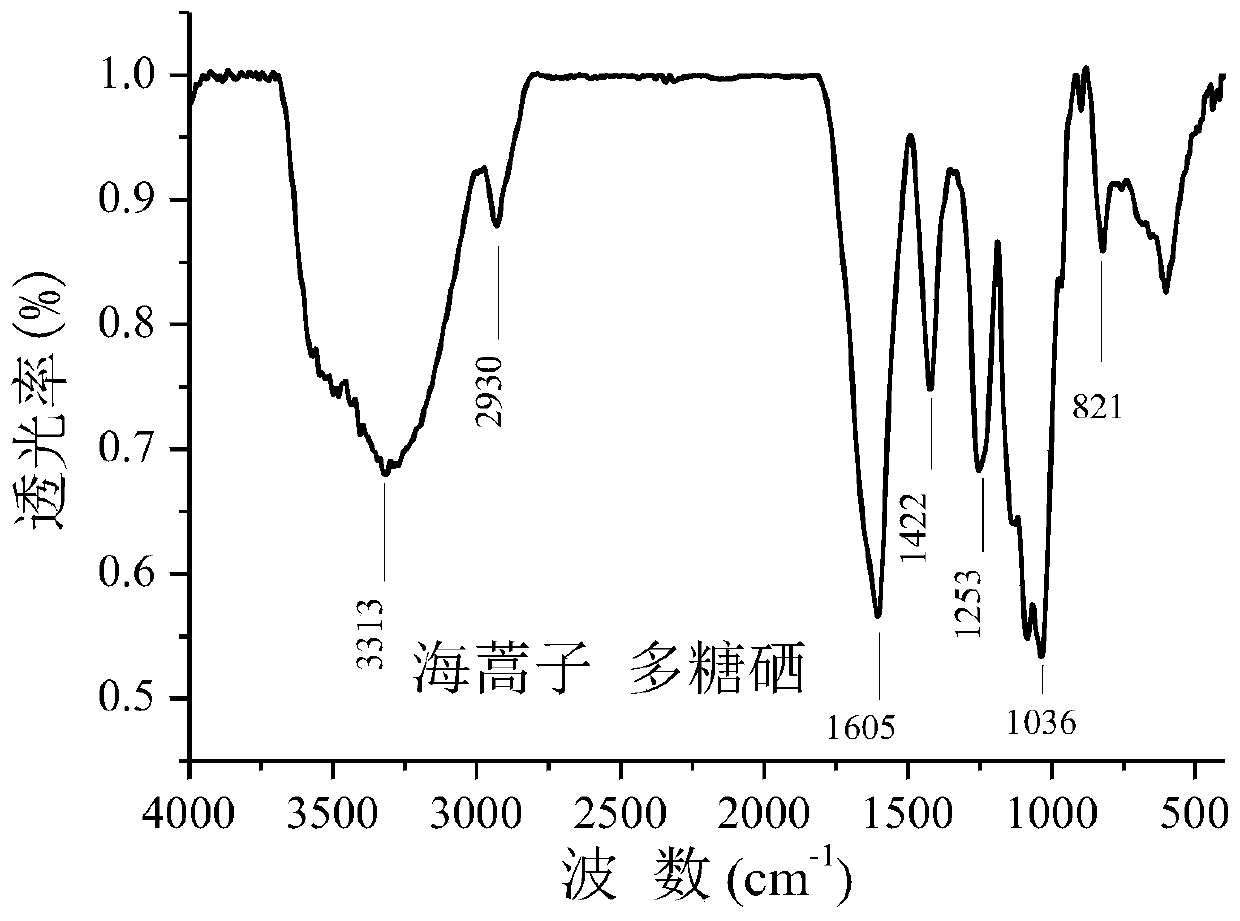

Sargassum pallidum polysaccharide selenium as well as preparation method and application thereof

InactiveCN110078840AIdeal α-glucosidase inhibitory activitySignificant cellular antioxidant enzyme activityOrganic active ingredientsMetabolism disorderDietary supplementFreeze-drying

The invention discloses sargassum pallidum polysaccharide selenium as well as a preparation method and an application thereof. The preparation method mainly comprises steps as follows: raw material pretreatment, hot water extraction, decoloration, deproteinization, freeze drying and selenylation reaction, wherein the selenylation reaction is implemented as follows: sargassum pallidum polysaccharide and dilute nitric acid are mixed and stirred at the room temperature, sodium selenite and barium chloride are added respectively, the mixture is heated to 60-80 DEG C, stirred and mixed uniformly toreact at the microwave power of 100-500 W for 3-5 min, a sargassum pallidum polysaccharide selenium solution is obtained, cooled to the room temperature, placed in a dialysis bag for dialysis and freeze-dried, and sargassum pallidum polysaccharide selenium is obtained. The preparation method is simple, the reaction condition is mild, the sargassum pallidum polysaccharide selenium is pollution-free and high in selenylation degree, has remarkable alpha-glucosidase inhibition activity, has the activity superior to that of acarbose and can remarkably improve the antioxidase activity of cells andreduce the content of malondialdehyde, a dietary supplement with antioxidant and blood sugar reducing efficacy can be developed, and the sargassum pallidum polysaccharide selenium can be applied to the field of food or medicines.

Owner:珠海中美普莱健康科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com