Process for synthesizing high pure electronic grade barium titanate by liquid phase method

An electronic grade, barium titanate technology, applied in the direction of titanium compounds, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of uneven particle size distribution and powder purity that cannot be used to make base metal electrode ceramic capacitors. Low-level problems, to achieve the effect of single powder particle shape, good dispersion and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

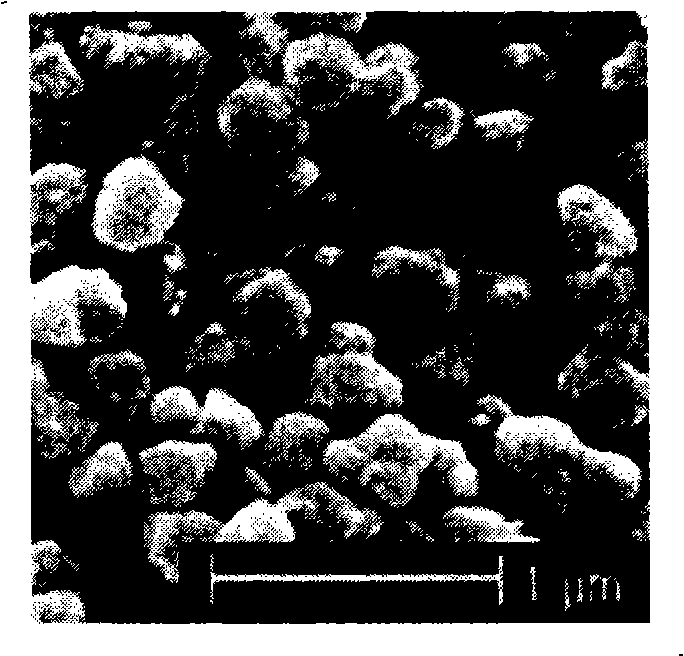

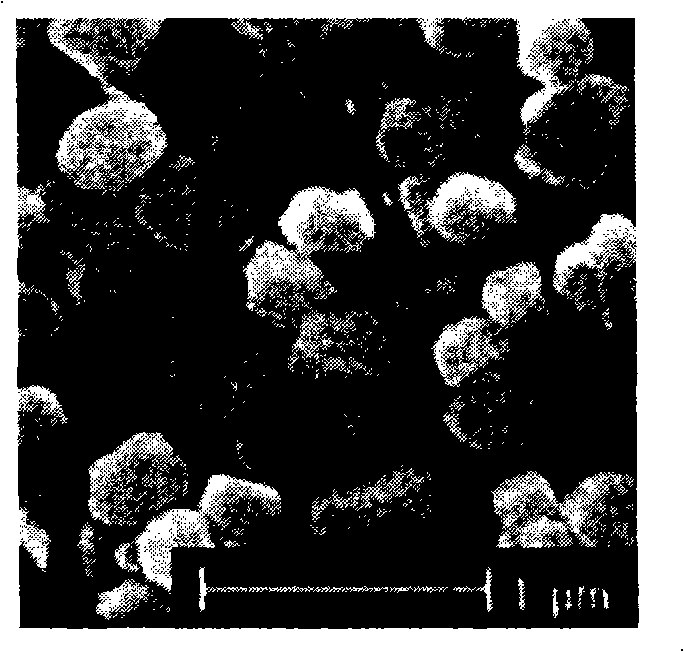

[0020] Example 1: Dissolve barium chloride in deionized water to prepare a 1.0mol / L barium chloride solution; dissolve titanium tetrachloride in deionized water at 35°C to prepare 2.0mol / L titanium tetrachloride Hydration solution; then measure 1.05 liters of the above-mentioned barium chloride solution and 0.5 liters of the titanium tetrachloride hydration solution with a graduated cylinder, place them in the same container, add 0.45 liters of deionized water and stir until they are evenly mixed to make a barium-titanium mixed solution Standby: Dissolve 2.2mol oxalic acid in 2L deionized water, add barium chloride with 2% oxalic acid molar weight and stir, then filter out the precipitate, prepare 1.1mol / L oxalic acid solution, and then heat the oxalic acid solution to 60°C , under the condition of vigorous stirring, add polyethylene glycol with a total weight of 2‰ of the oxalic acid solution, and at the same time mix the barium-titanium solution with 0.4m 3 The flow rate of ...

Embodiment 2

[0021] Example 2: Dissolving barium chloride in deionized water to prepare a 1.2mol / L barium chloride solution; dissolving titanium tetrachloride in deionized water at 35°C to prepare 1.5mol / L titanium tetrachloride Hydration solution; then measure 0.875 liters of the above-mentioned barium chloride solution and 0.583 liters of the titanium tetrachloride hydration solution with a measuring cylinder, place them in the same container, add 0.542 liters of deionized water and stir until they are evenly mixed to make a barium-titanium mixed solution Standby; dissolve 2.2mol oxalic acid in 2L deionized water, add barium chloride with 2% oxalic acid molar weight and stir, then filter out the precipitate, and prepare a 1.1mol / L oxalic acid solution; then heat the oxalic acid solution to 50°C , under the condition of vigorous stirring, add polyethylene glycol with a total weight of oxalic acid solution of 3‰, and at the same time mix the barium-titanium solution with 0.5m 3 The flow ra...

Embodiment 3

[0022] Example 3: Dissolving barium chloride in deionized water to prepare a 1.3mol / L barium chloride solution; dissolving titanium tetrachloride in deionized water at 35°C to prepare 2.5mol / L titanium tetrachloride Hydration solution; then measure 0.77 liters of the above-mentioned barium chloride solution and 0.83 liters of the titanium tetrachloride hydration solution with a graduated cylinder, and mix them to make a barium-titanium mixed solution for subsequent use; dissolve 2.2mol oxalic acid in 1.83L deionized water, add oxalic acid Stir barium chloride with a molar mass of 2%, then filter out the precipitate, and prepare a 1.2mol / L oxalic acid solution; then heat the oxalic acid solution to 70°C, and add 2‰ of the total weight of the oxalic acid solution under vigorous stirring Polyethylene glycol, while barium titanium mixed solution with 0.3m 3 The flow rate of / h is added to the oxalic acid solution for reaction. During the reaction, the reaction temperature is conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com