Preparation method of TC4ELI titanium alloy bar

A titanium alloy and bar technology, applied in the field of preparation of TC4ELI titanium alloy bars, can solve the problems of coarse equiaxed grains, low overall level, poor batch stability, etc., to reduce the generation of cracks and unevenness. improve the effectiveness of internal organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

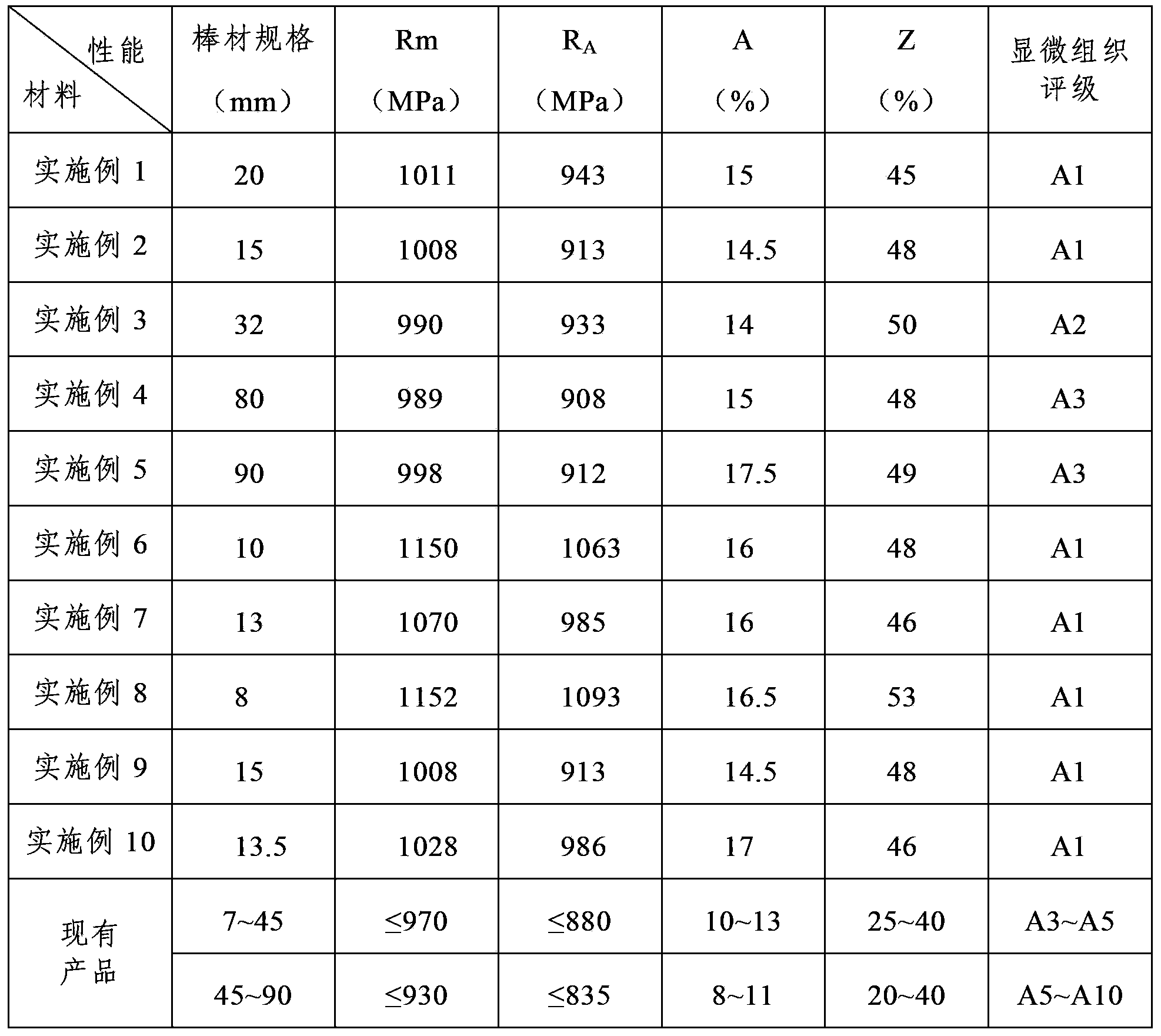

Examples

Embodiment 1

[0036] The preparation method of present embodiment TC4ELI titanium alloy bar comprises the following steps:

[0037] Step 1: Utilize the fast forging machine to carry out blank forging to the TC4ELI titanium alloy ingot, and obtain the primary forging blank after air cooling; the TC4ELI titanium alloy ingot is a cylindrical ingot with a cross-sectional diameter of 640mm, and the primary forging blank is The cross-sectional shape is a square, and the side length of the square is 300mm; the blank forging is divided into 2 fires, and the initial forging temperature of each fire is 150°C above the β transformation point. The final forging temperature is not lower than 700°C;

[0038] Step 2. Use free forging equipment to carry out upsetting and drawing forging of the primary forging billet described in step 1, and obtain an intermediate forging billet after water cooling; the upsetting and drawing forging is completed in 6 fires, of which the first fire and the second fire The i...

Embodiment 2

[0043] The preparation method of present embodiment TC4ELI titanium alloy bar comprises the following steps:

[0044] Step 1: Utilize the fast forging machine to carry out billet forging to the TC4ELI titanium alloy ingot, and obtain a primary forging billet after air cooling; the TC4ELI titanium alloy ingot is a cylindrical ingot with a cross-sectional diameter of 410 mm, and the primary forging billet is The cross-sectional shape is square, and the side length of the square is 260mm; the blank forging is divided into 3 fires, and the initial forging temperature of each fire is 180°C above the β transformation point. The final forging temperature is not lower than 700°C;

[0045] Step 2. Use free forging equipment to carry out upsetting and drawing forging of the primary forging billet described in step 1, and obtain an intermediate forging billet after water cooling; the upsetting and drawing forging is completed in 6 fires, of which the first fire and the second fire The i...

Embodiment 3

[0050] The preparation method of present embodiment TC4ELI titanium alloy bar comprises the following steps:

[0051] Step 1: Utilize the fast forging machine to carry out blank forging to the TC4ELI titanium alloy ingot, and obtain a primary forging billet after air cooling; the TC4ELI titanium alloy ingot is a cylindrical ingot with a cross-sectional diameter of 950 mm, and the primary forging billet is The cross-sectional shape is square, and the side length of the square is 480mm; the blank forging is divided into 2 fires to complete, and the initial forging temperature of each fire is 200°C above the β transformation point, and each fire The final forging temperature is not lower than 700°C;

[0052] Step 2. Use free forging equipment to carry out upsetting and drawing forging of the primary forging billet described in step 1, and obtain an intermediate forging billet after water cooling; the upsetting and drawing forging is completed in 6 fires, of which the first fire a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com