Patents

Literature

396results about How to "Evenly broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

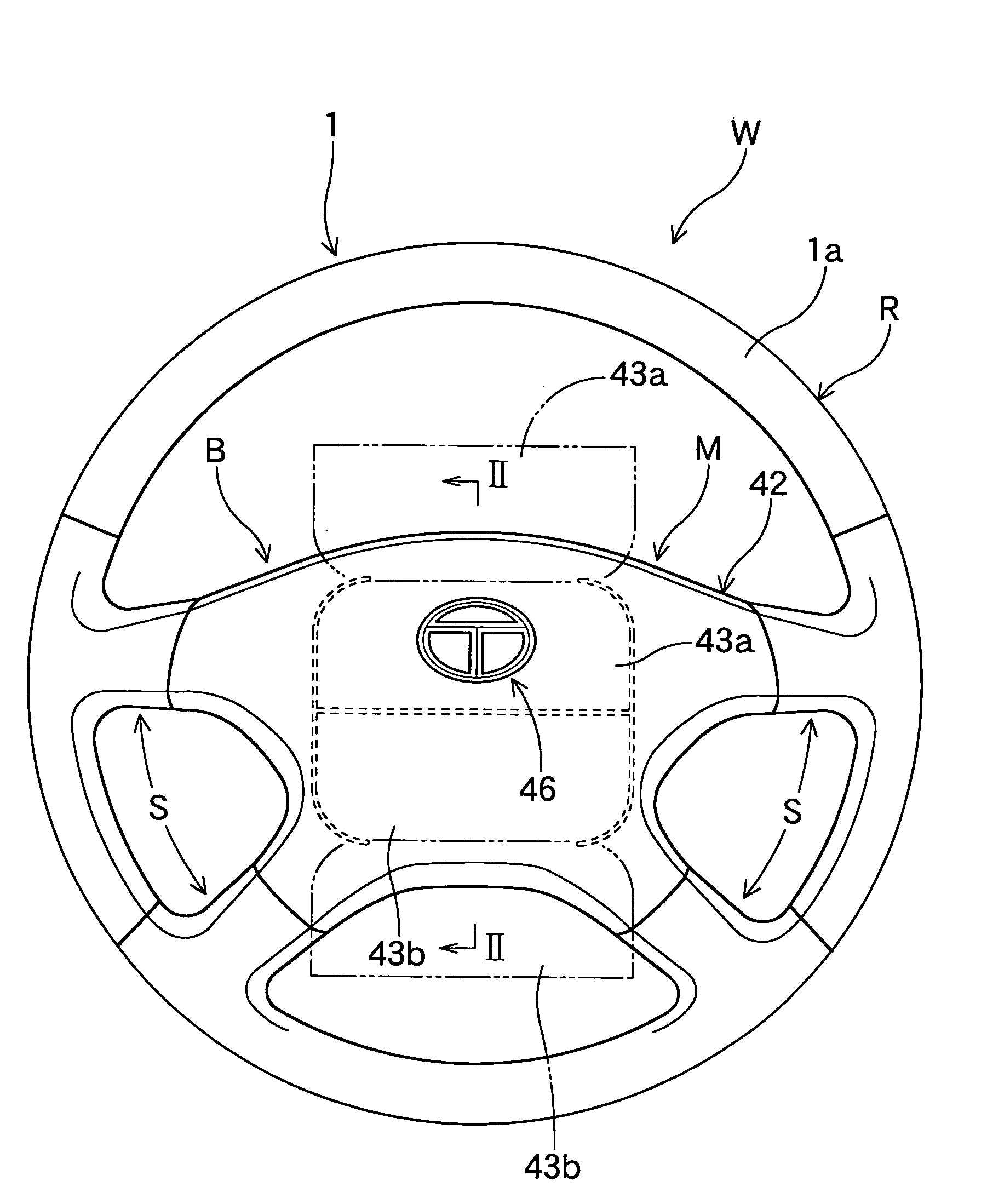

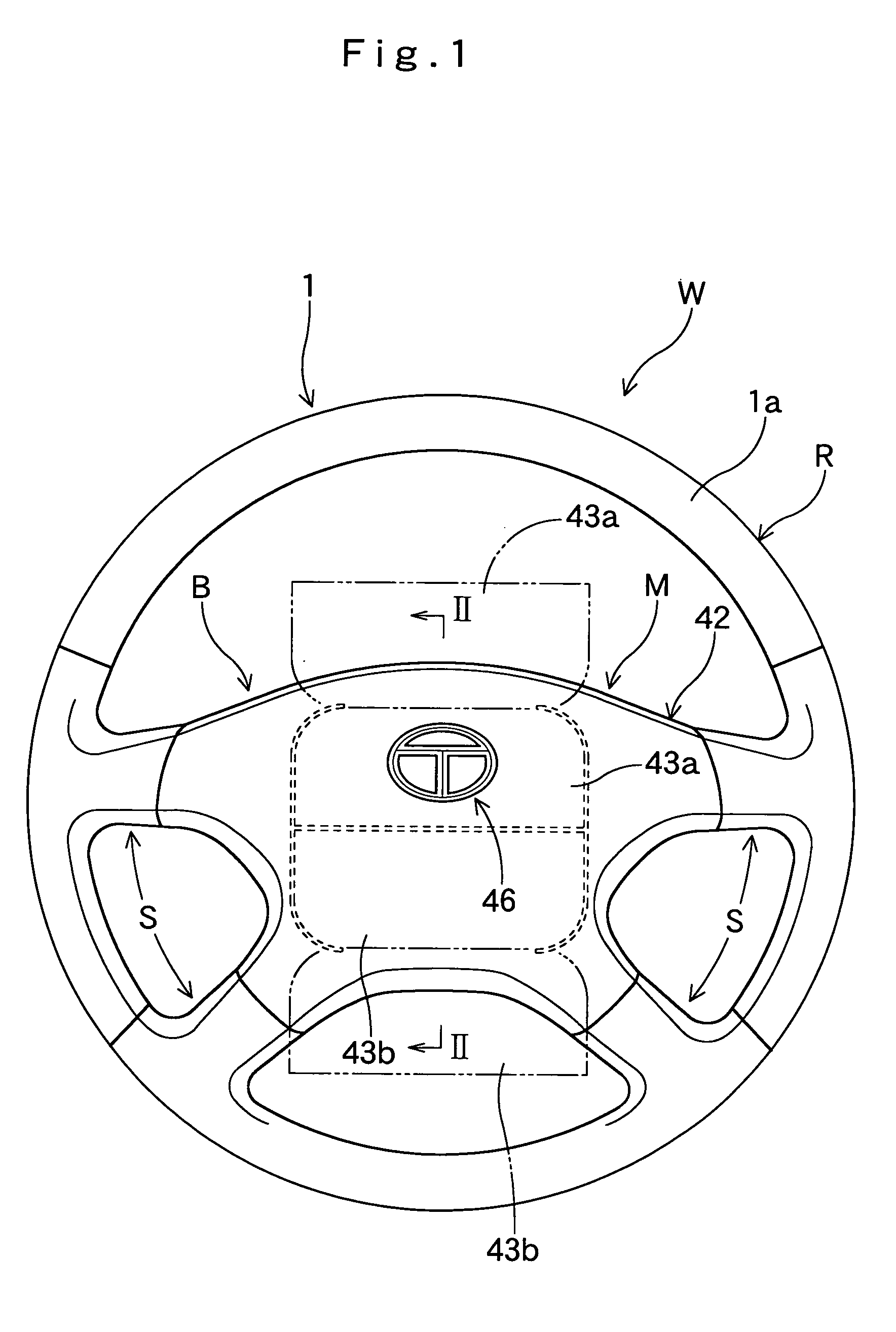

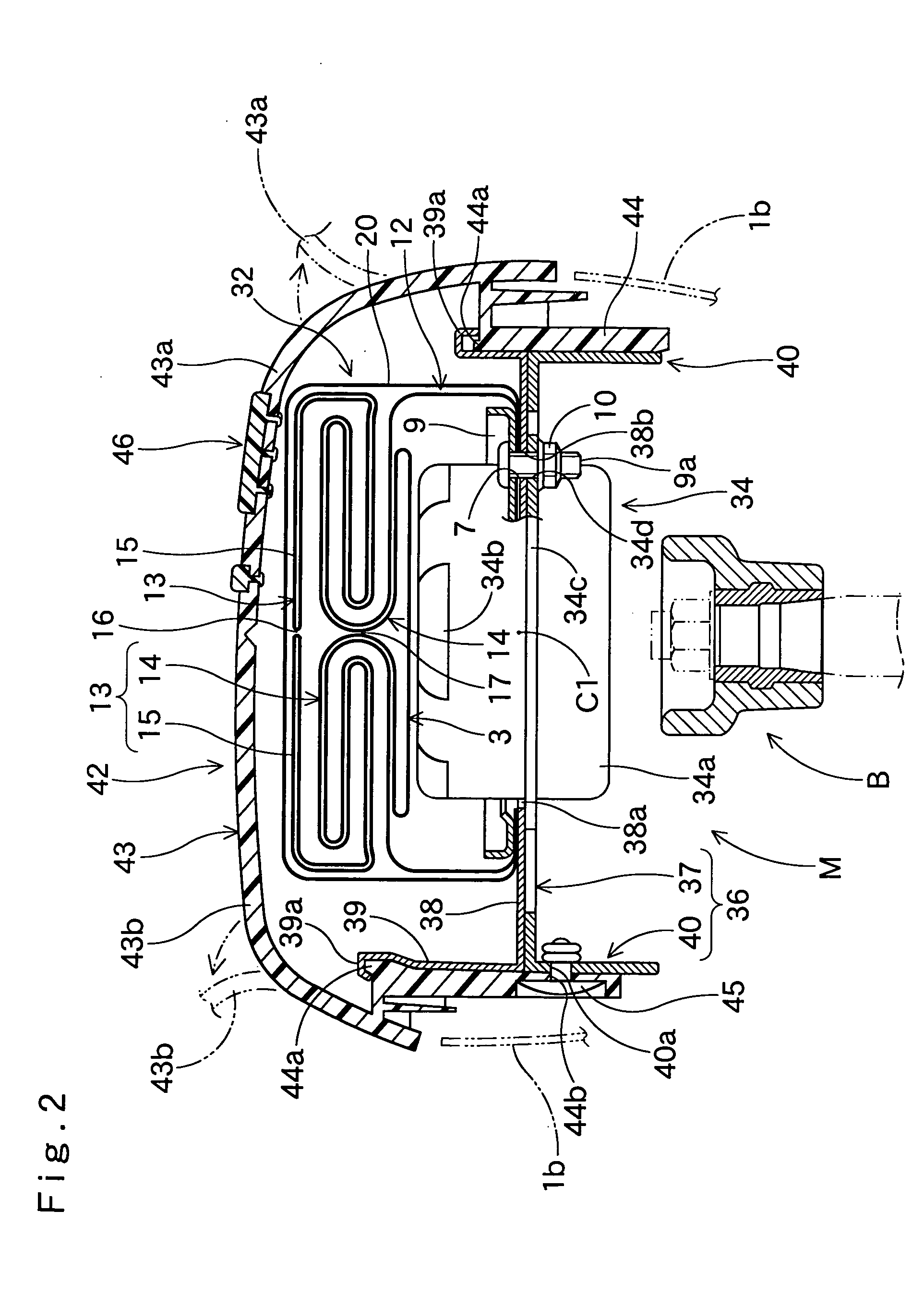

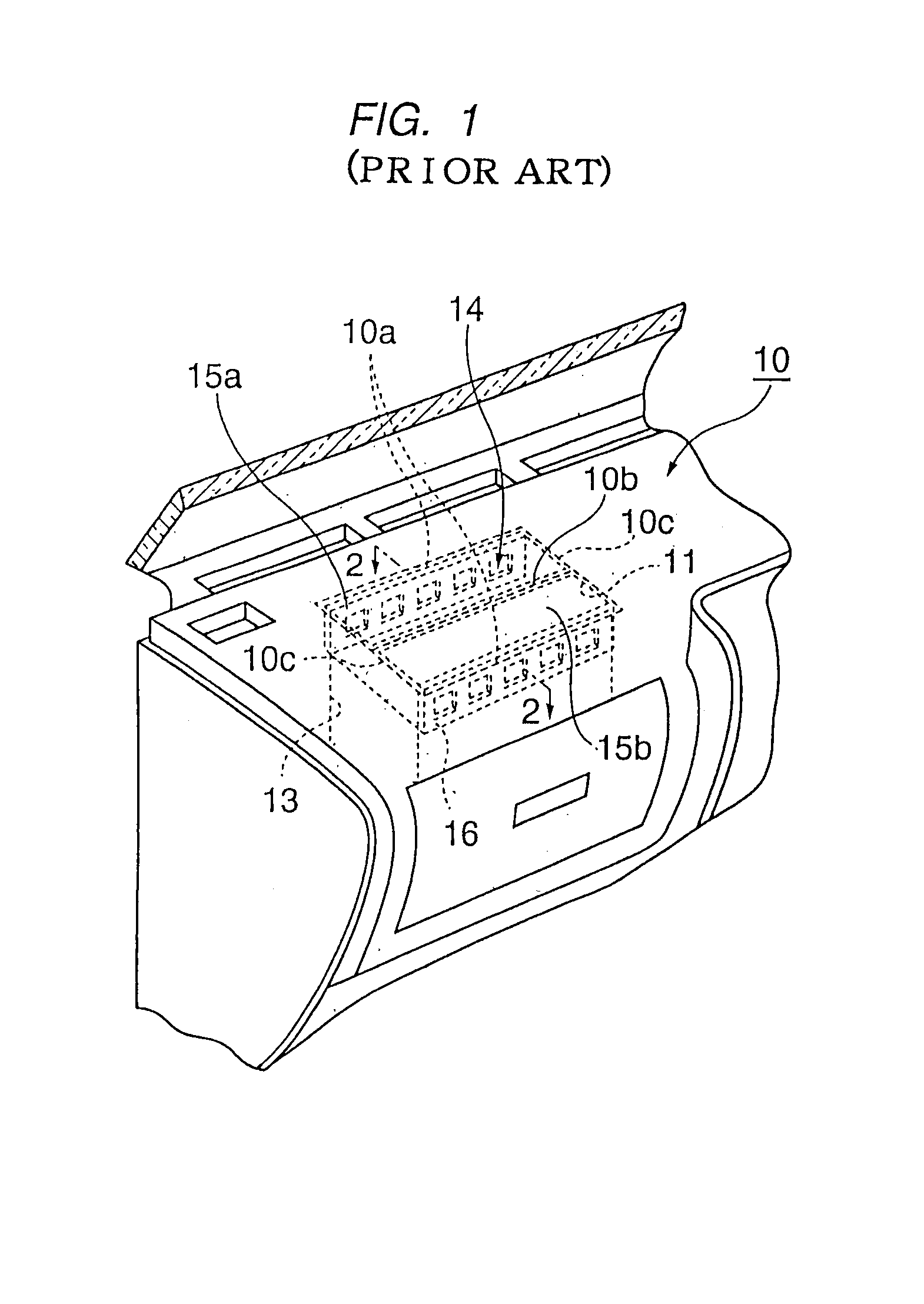

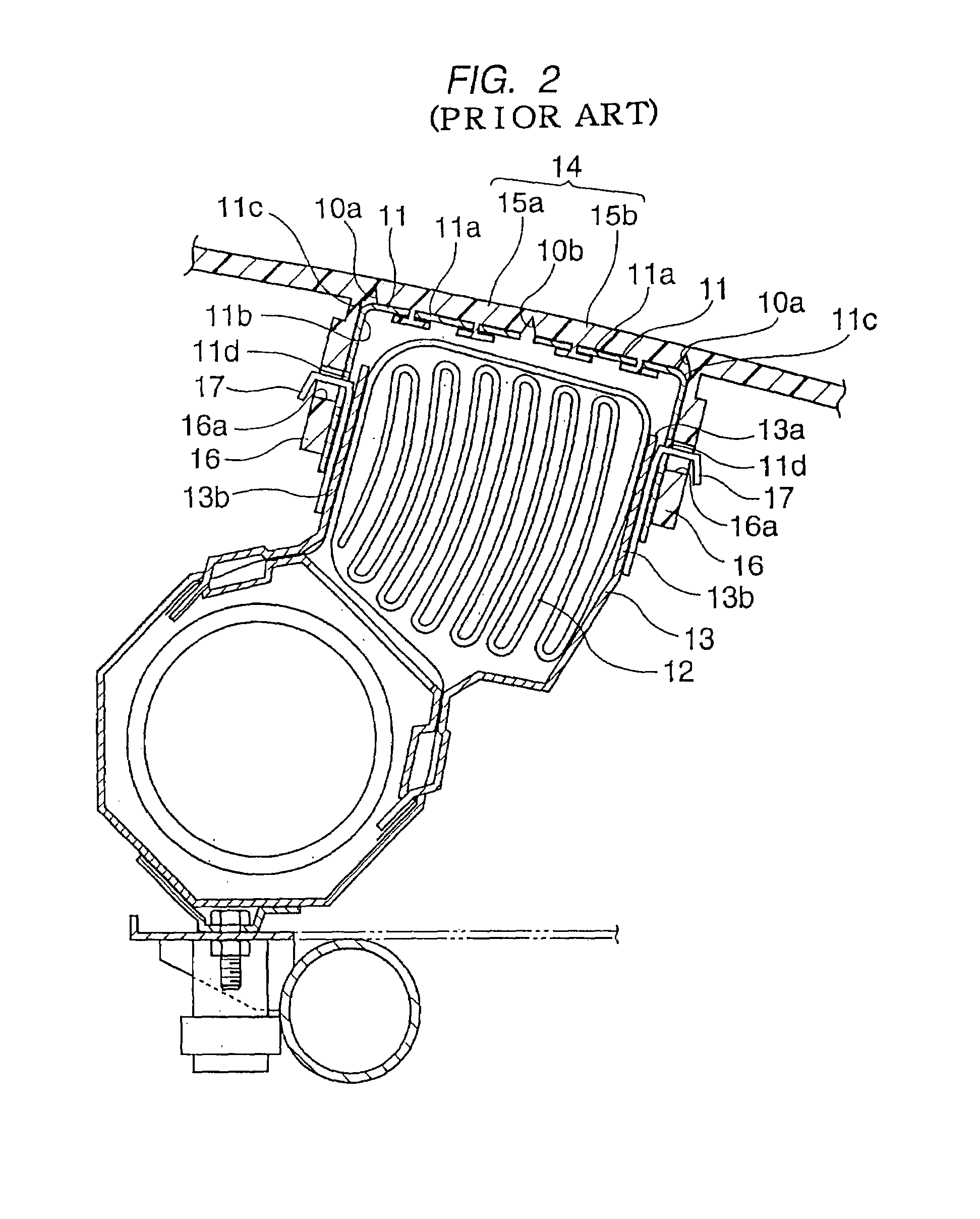

Airbag device

ActiveUS7314228B2Stay in shapeMounting is preventedPedestrian/occupant safety arrangementEngineeringAirbag

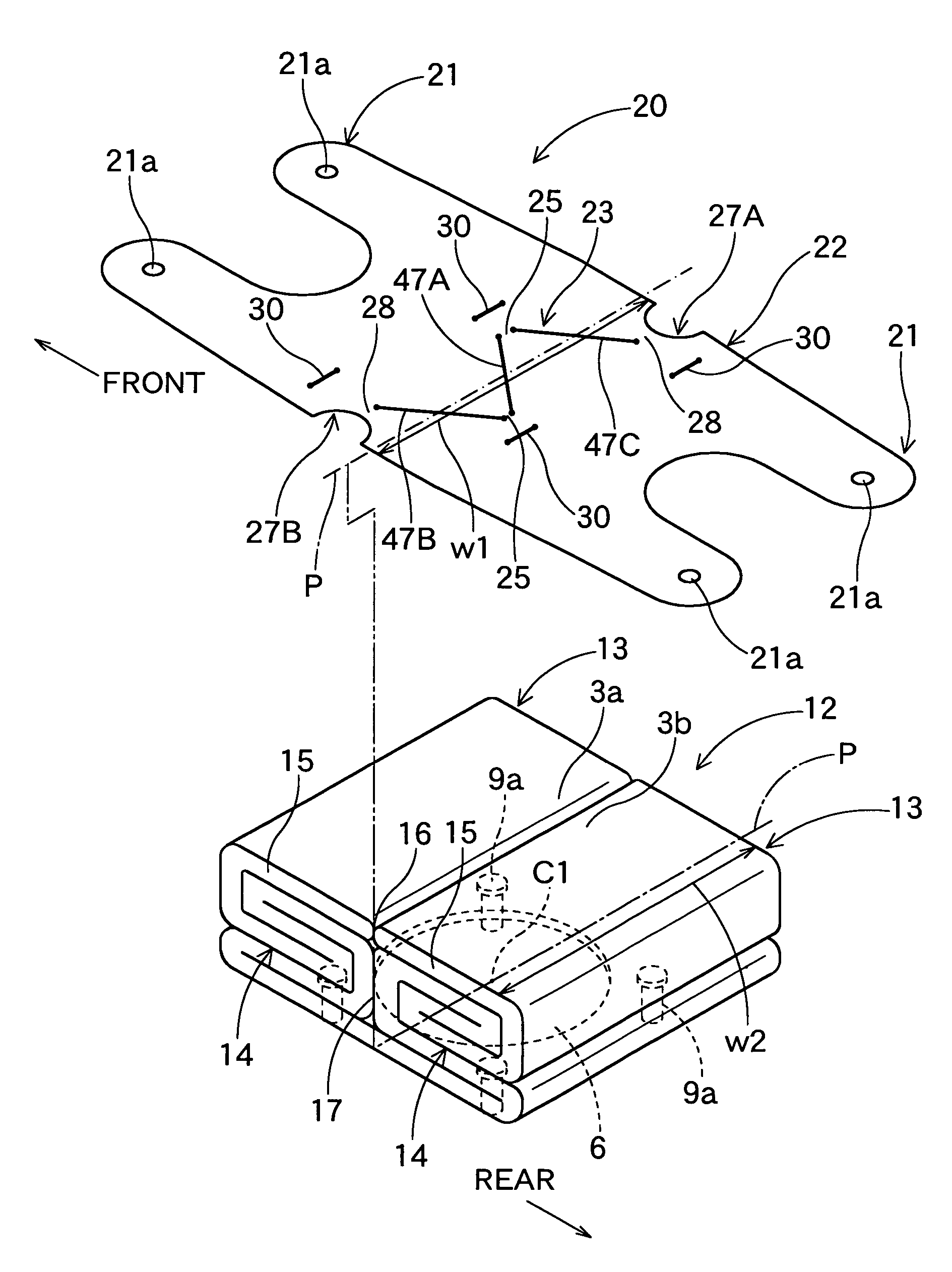

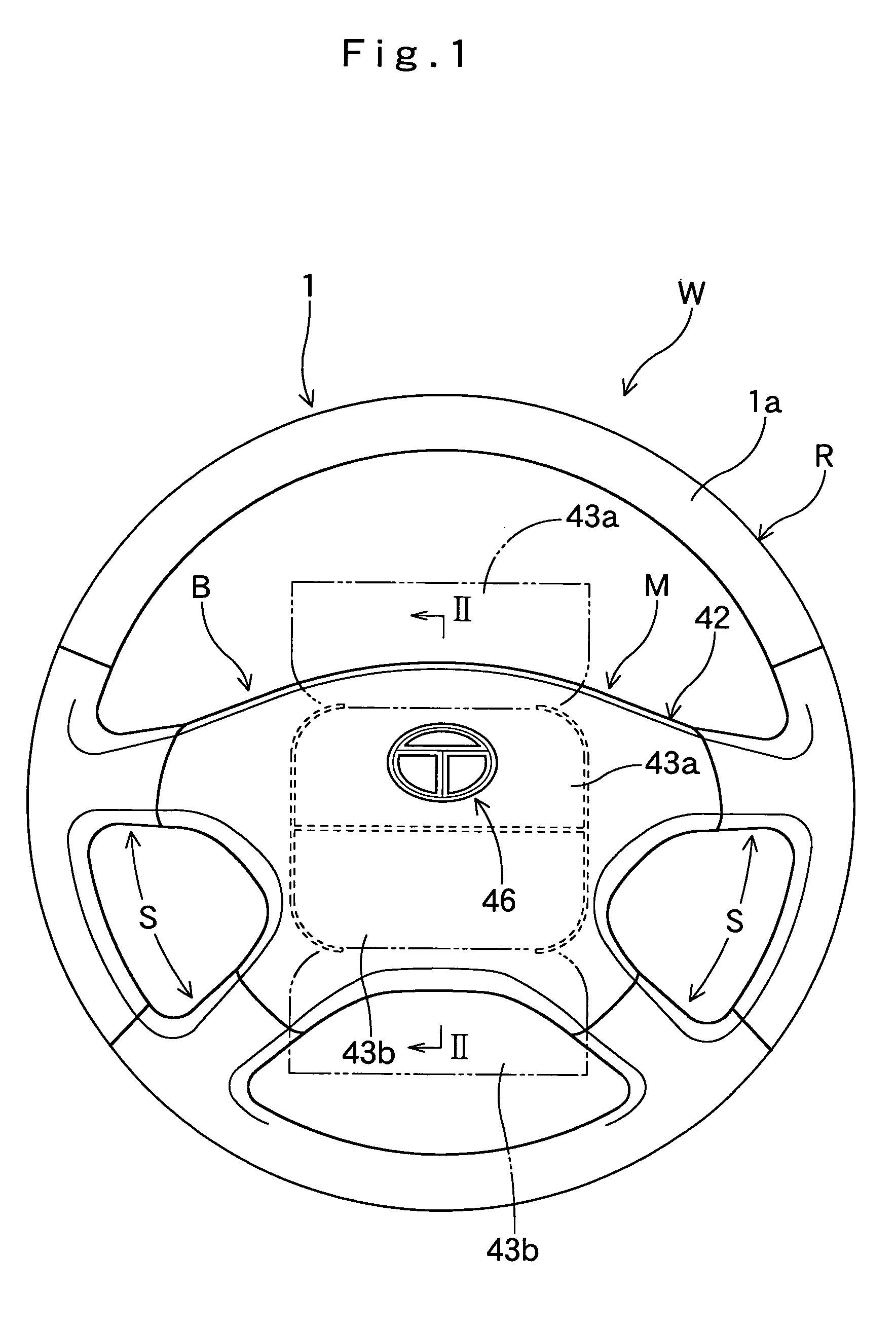

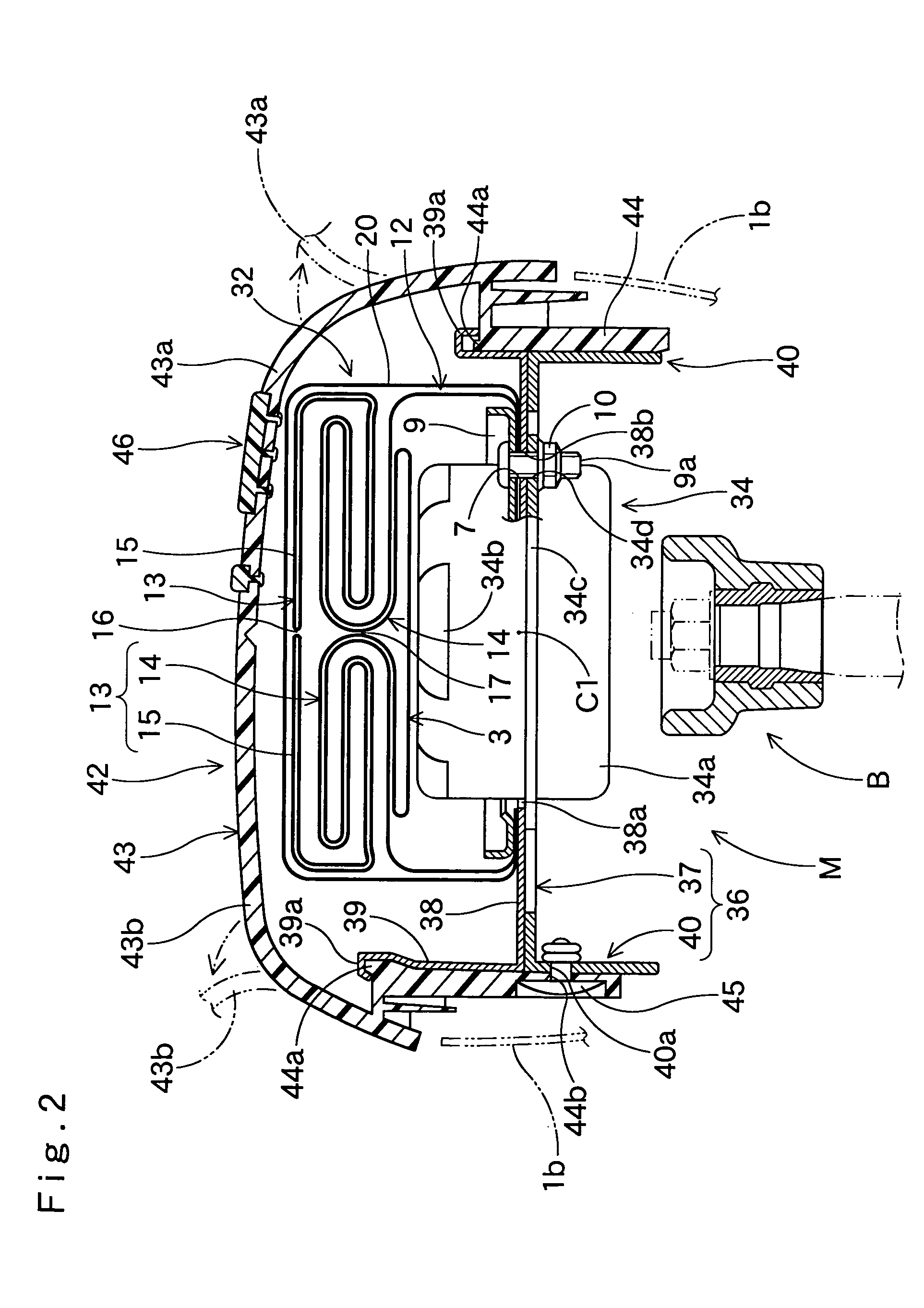

An airbag device according to the present invention includes an airbag folded and housed in the shape of folded-up body, and an airbag wrapping member for keeping the folded-up configuration of the airbag. The folded-up body is formed by bringing both ends of the airbag close to a base line, such that the folded-up body is symmetric with respect to the base line. The wrapping member includes a breakable portion in a region above the base line. The breakable portion includes a plurality of apertures each of which is located across the base line as to extend toward both sides from the base line, and connecting portions for connecting adjacent apertures into a larger opening upon breakage. The connecting portions disposed by the side of both ends of each of the apertures are located in opposite sides of the base line. The wrapping member further includes two cut-out portions in edges of a cover portion in a direction along the base line.

Owner:TOYODA GOSEI CO LTD

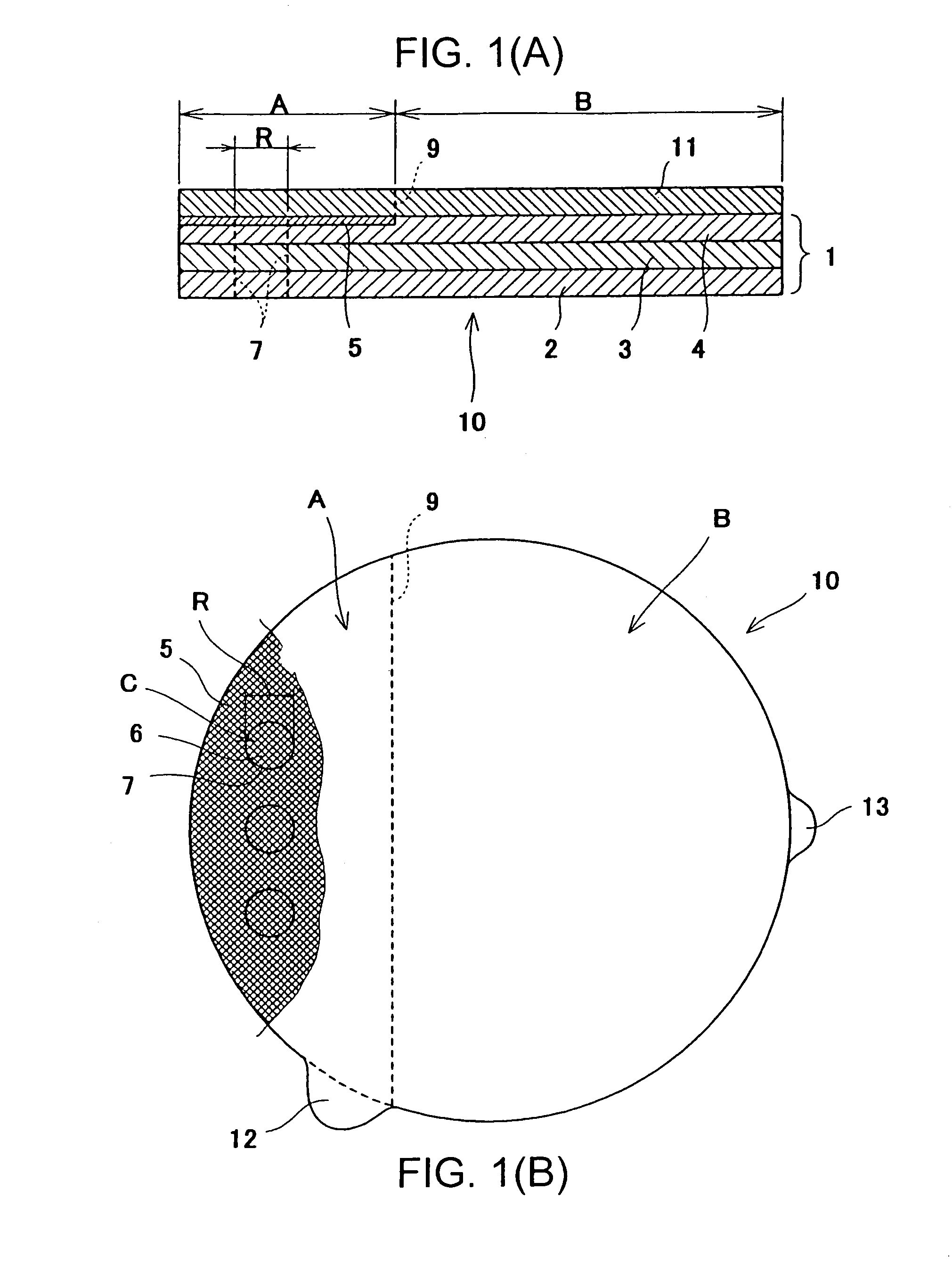

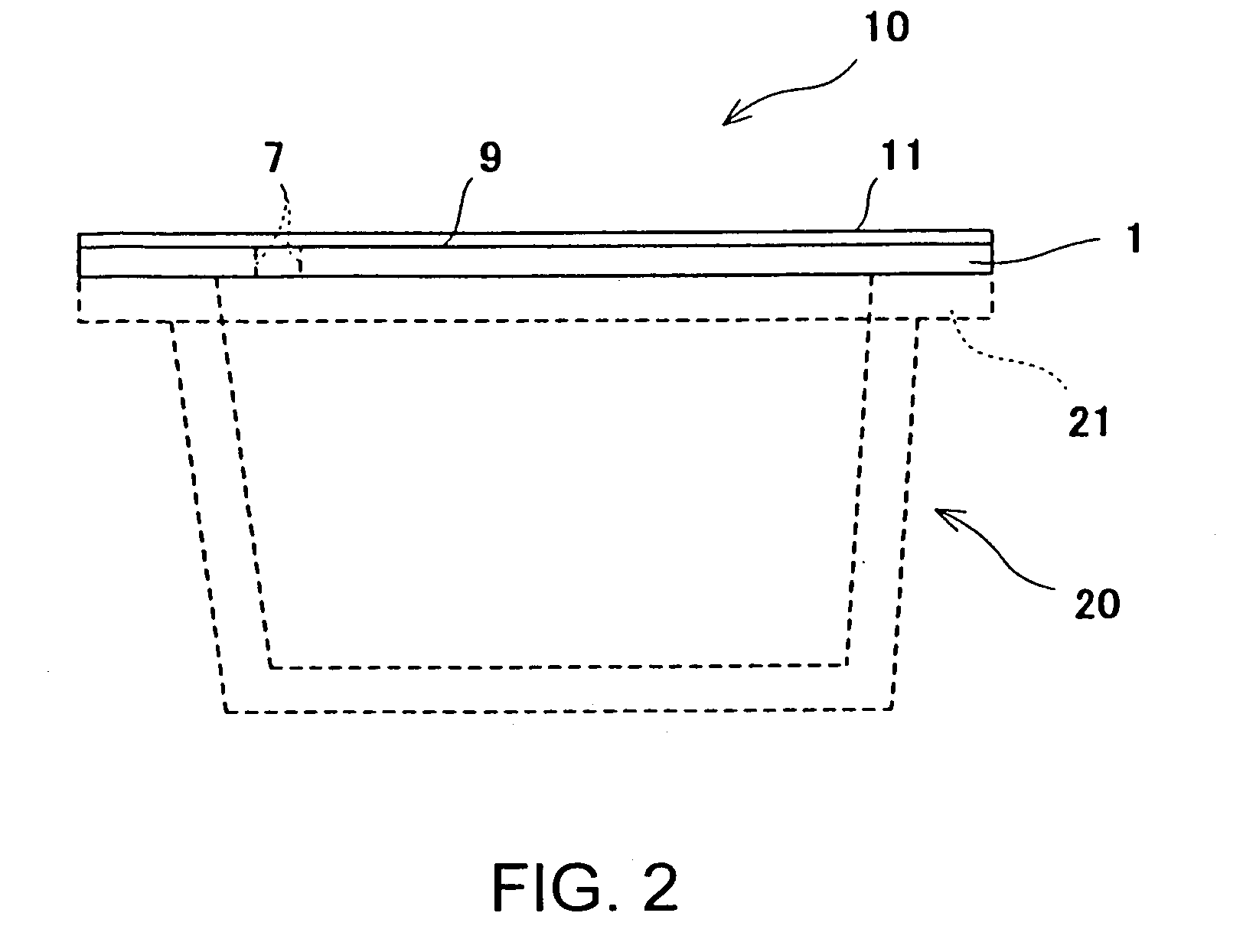

Lid member for food container

A lid member for a food container having a layered structure in which a surface sheet is laid on a composite sheet, said surface sheet including an easily-peelable area that is easily separated from the composite sheet, formed by applying a lubricant between the surface sheet and the composite sheet, said surface sheet including a non-peelable area adjacent to said easily-peelable area; a first slit cut vertical-sectionally through the composite sheet, said first slit defining one or more apertures in said lid to form an opening area in said composite sheet; a second slit in said surface sheet defining a boundary between the easily-peelable area and said non-peelable area of said surface sheet; and said surface sheet being adhered to said composite sheet at said composite sheet opening area over an area that is smaller than said composite sheet opening area.

Owner:NISSIN YORK

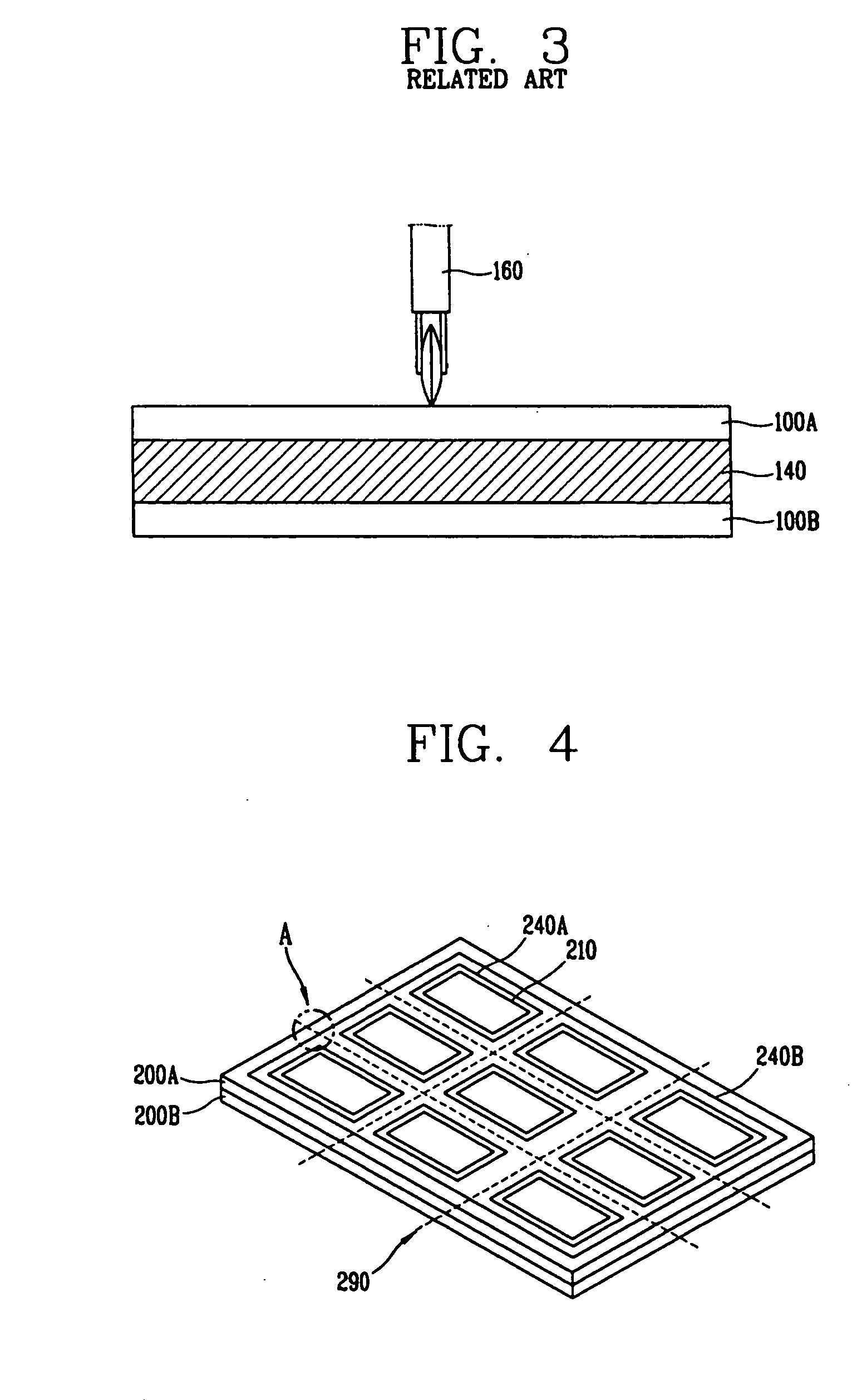

Airbag device

ActiveUS20060012157A1Stay in shapeMounting is preventedPedestrian/occupant safety arrangementEngineeringAirbag

An airbag device according to the present invention includes an airbag folded and housed in the shape of folded-up body, and an airbag wrapping member for keeping the folded-up configuration of the airbag. The folded-up body is formed by bringing both ends of the airbag close to a base line, such that the folded-up body is symmetric with respect to the base line. The wrapping member includes a breakable portion in a region above the base line. The breakable portion includes a plurality of apertures each of which is located across the base line as to extend toward both sides from the base line, and connecting portions for connecting adjacent apertures into a larger opening upon breakage. The connecting portions disposed by the side of both ends of each of the apertures are located in opposite sides of the base line. The wrapping member further includes two cut-out portions in edges of a cover portion in a direction along the base line.

Owner:TOYODA GOSEI CO LTD

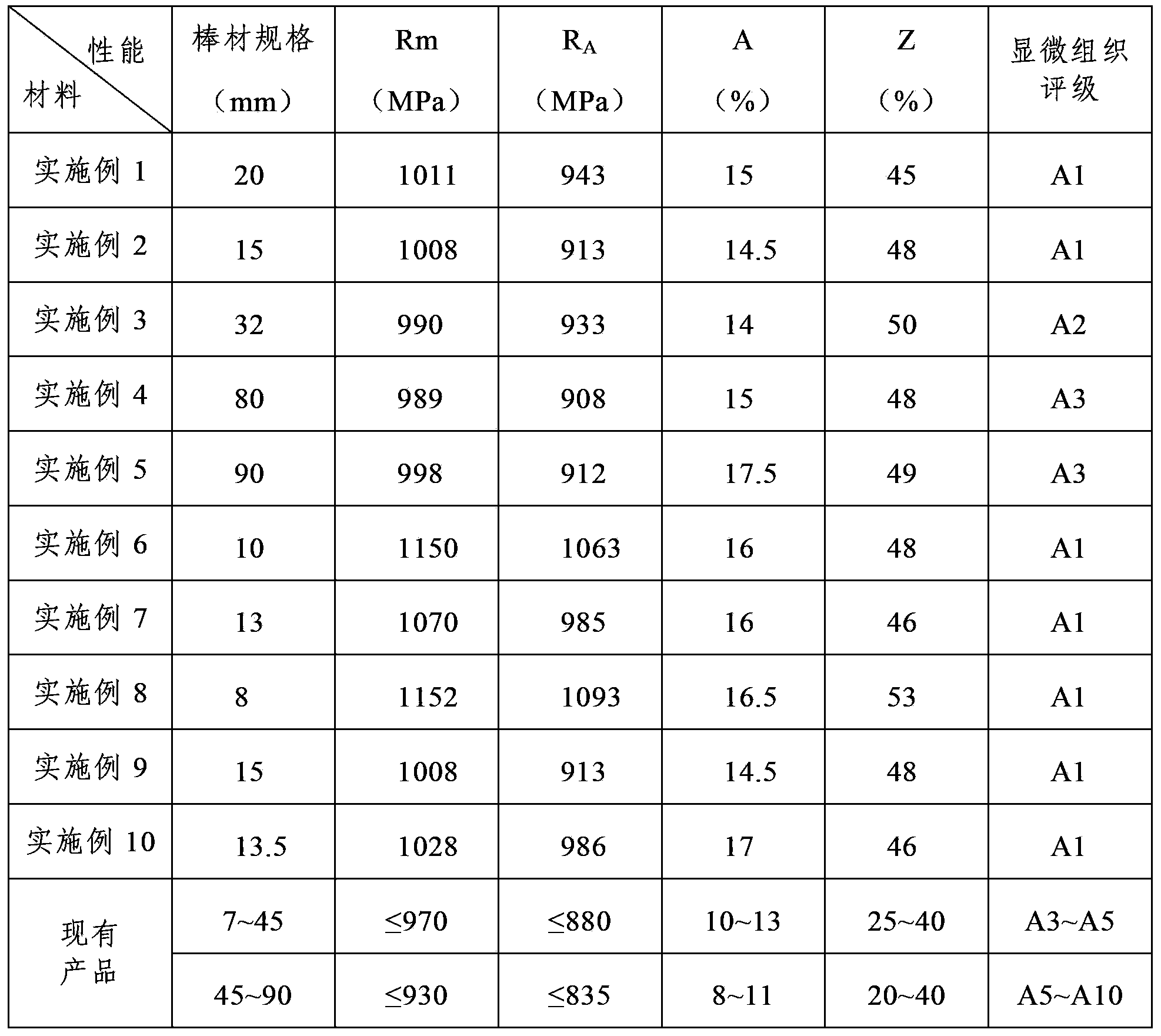

Preparation method of TC4ELI titanium alloy bar

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

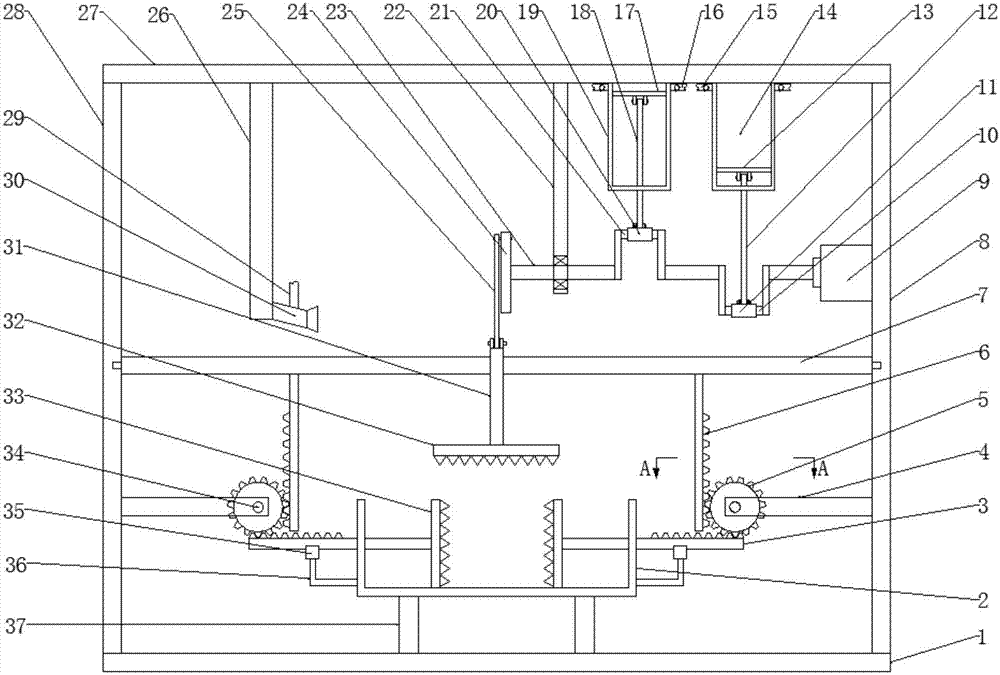

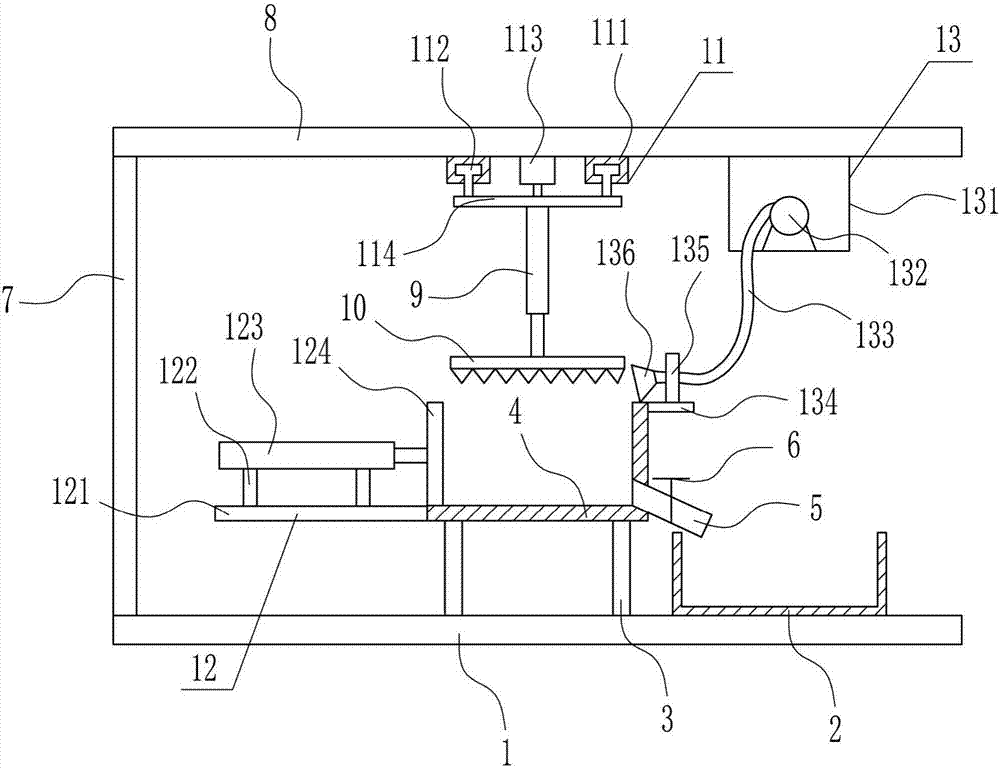

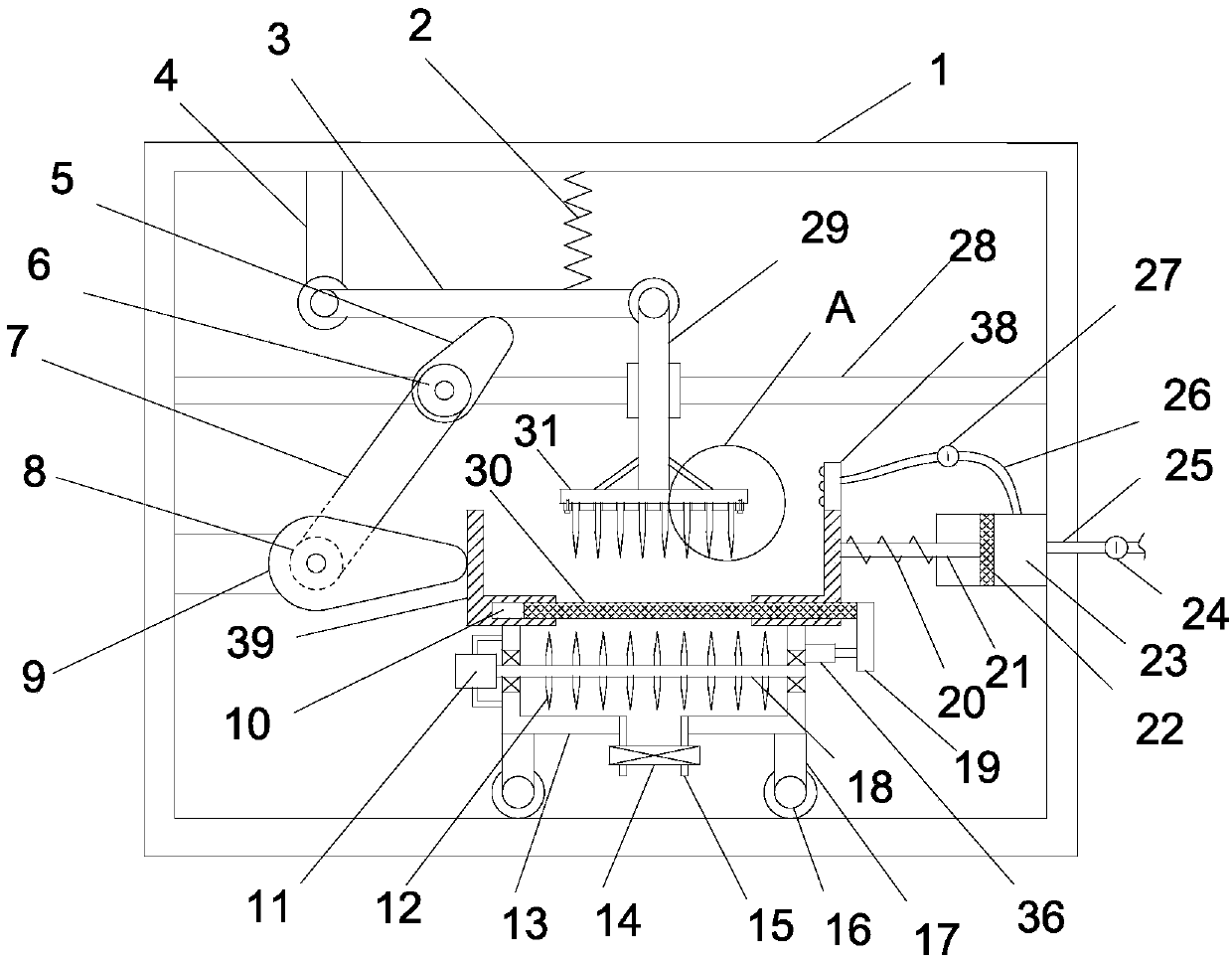

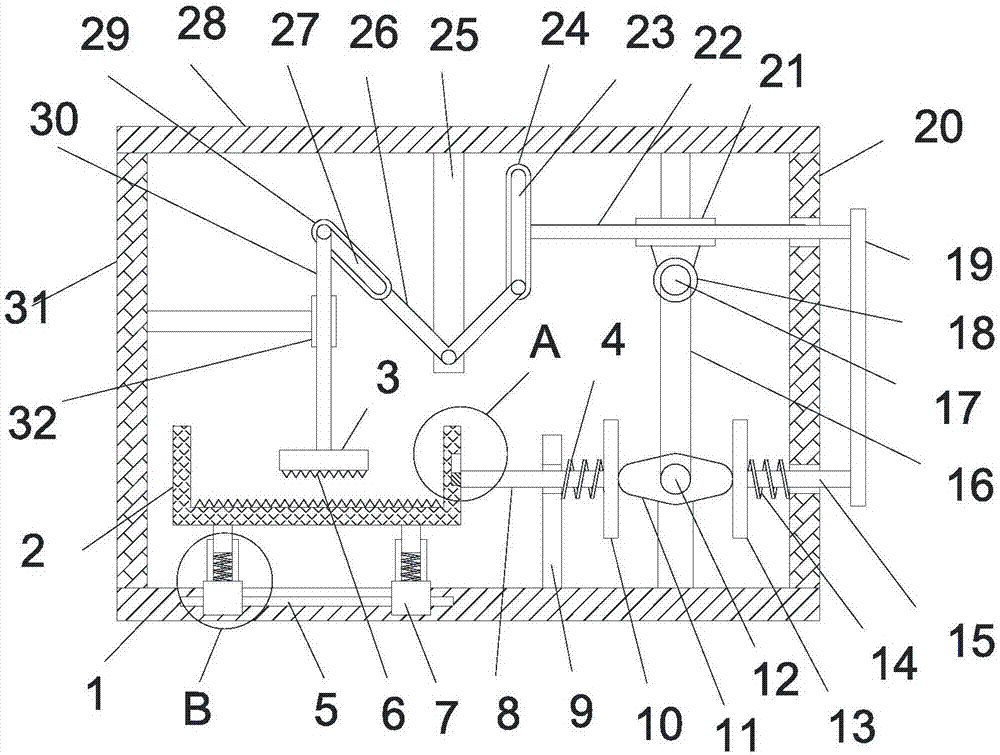

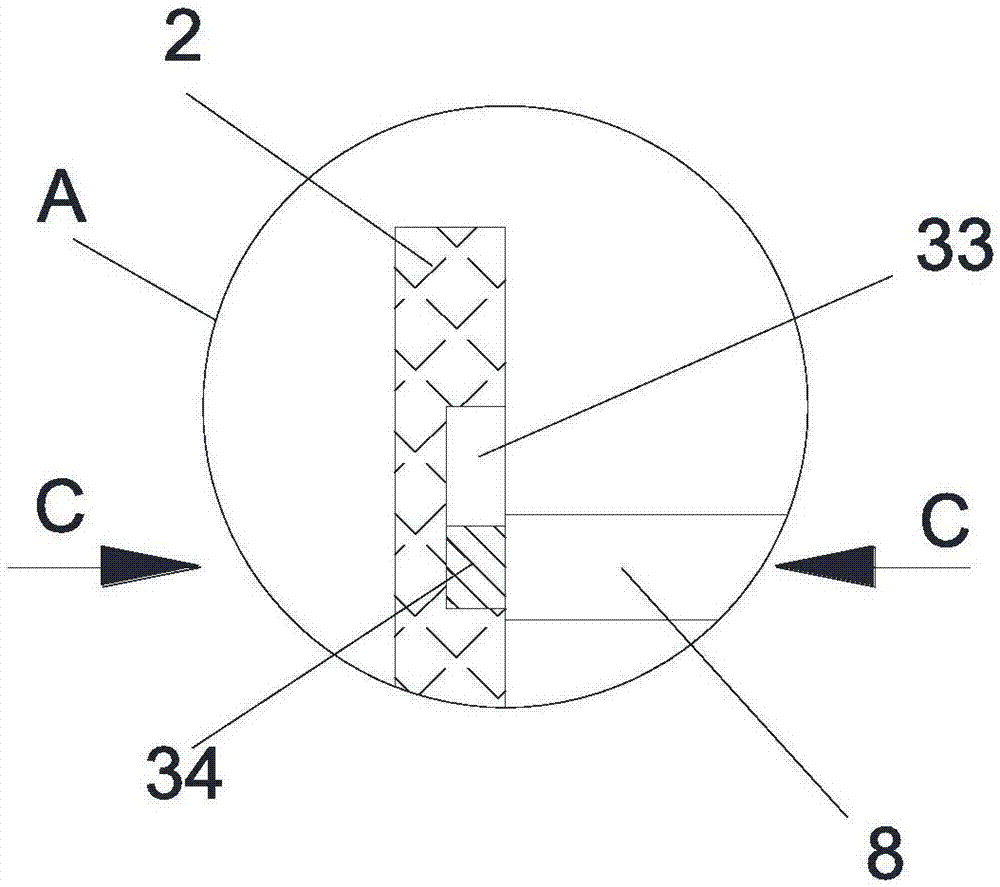

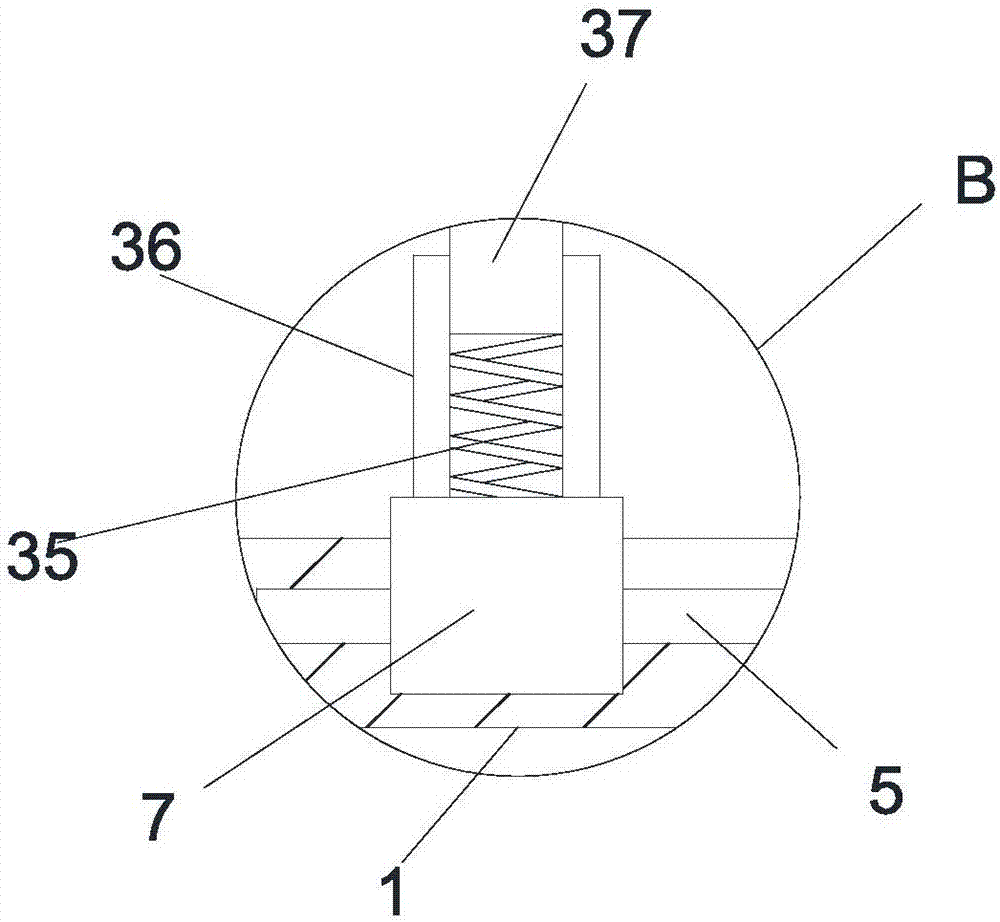

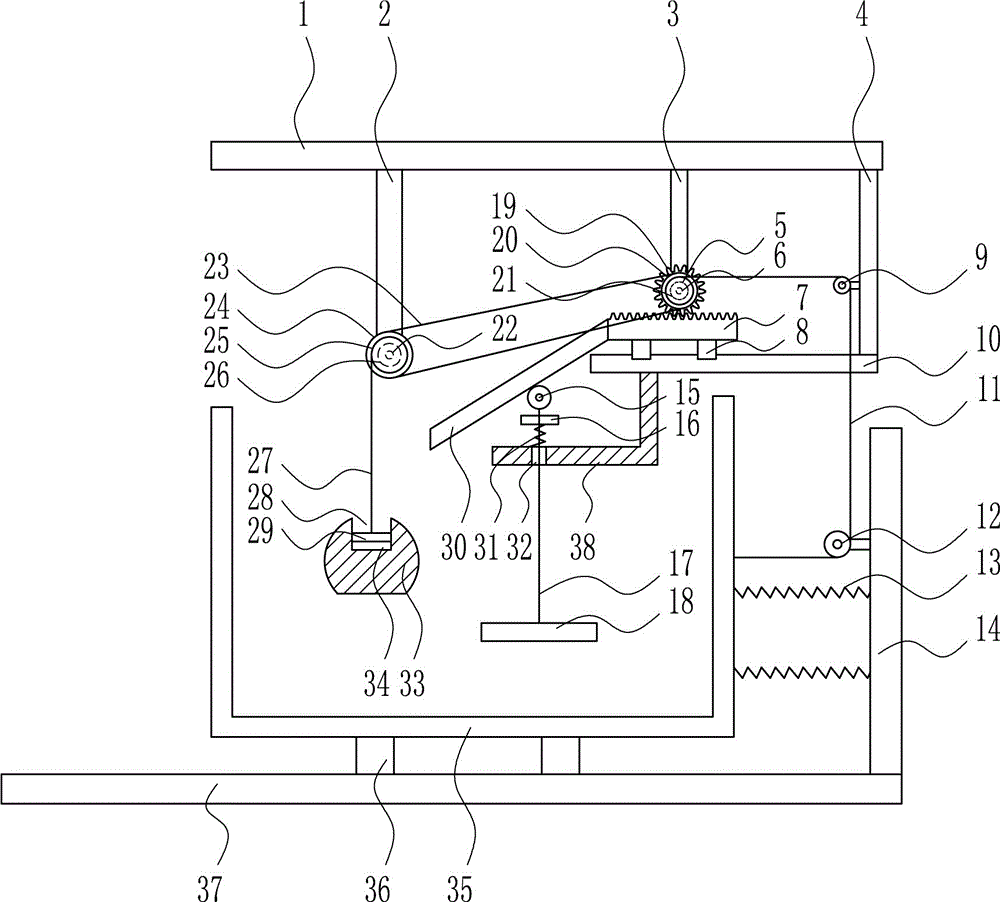

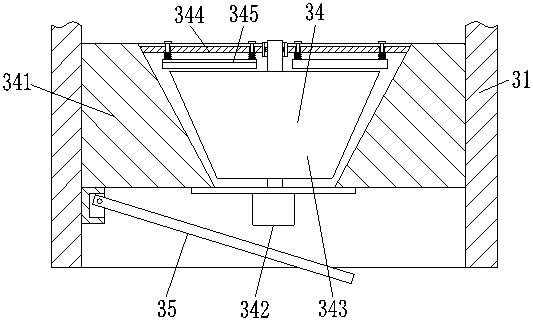

Efficient breaking device of waste bricks serving as wall material for building

InactiveCN107377064AReduce labor intensityBroken fastUsing liquid separation agentGrain treatmentsCircular discBrick

The invention discloses a high-efficiency crushing device for waste bricks of building wall materials, which comprises a bottom plate, a crushing frame, a first crushing plate, a first rack, a gear, a second crushing plate, a first connecting rod, a guide rod, a second rack, second connecting rod, disk, crankshaft, motor, first connecting rod journal, second connecting rod journal, first piston rod, second piston rod and nozzle, the present invention is provided with motor, crankshaft, circle The plate, the first connecting rod and the second connecting rod are used to crush waste bricks from top to bottom through the cooperation of the above parts, and the crushing speed is fast. There are guide rods, second racks, gears and first racks. Cooperate with the first crushing plate to crush the waste bricks from the left and right sides, making the crushing more thorough and even, improving the crushing efficiency and reducing the labor intensity of the staff. There are first connecting rod journal and second connecting rod journal , the first piston rod, the second piston rod and the nozzle, through cooperation to achieve continuous water spraying and dust reduction, to avoid affecting the health of the staff.

Owner:伍超群

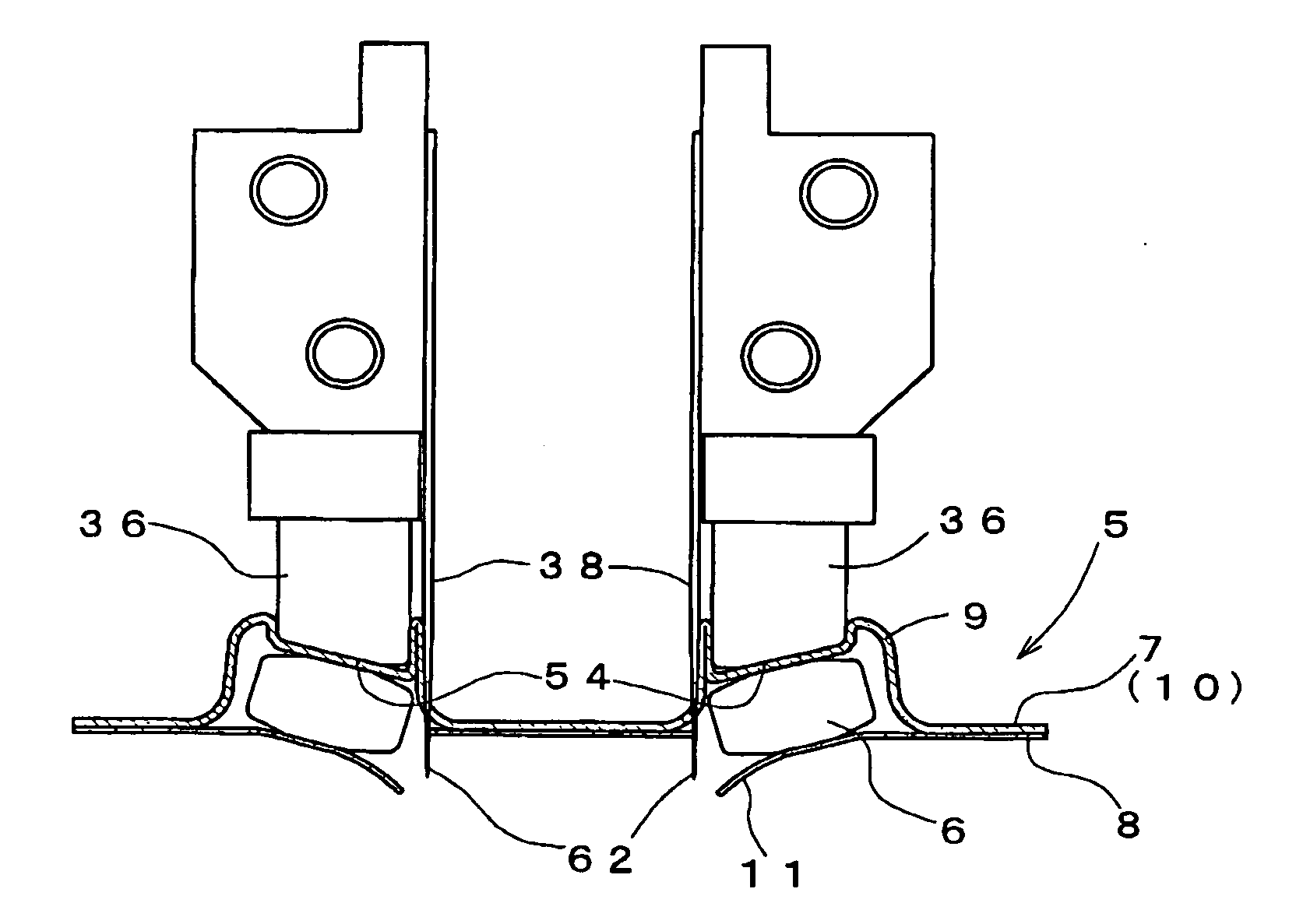

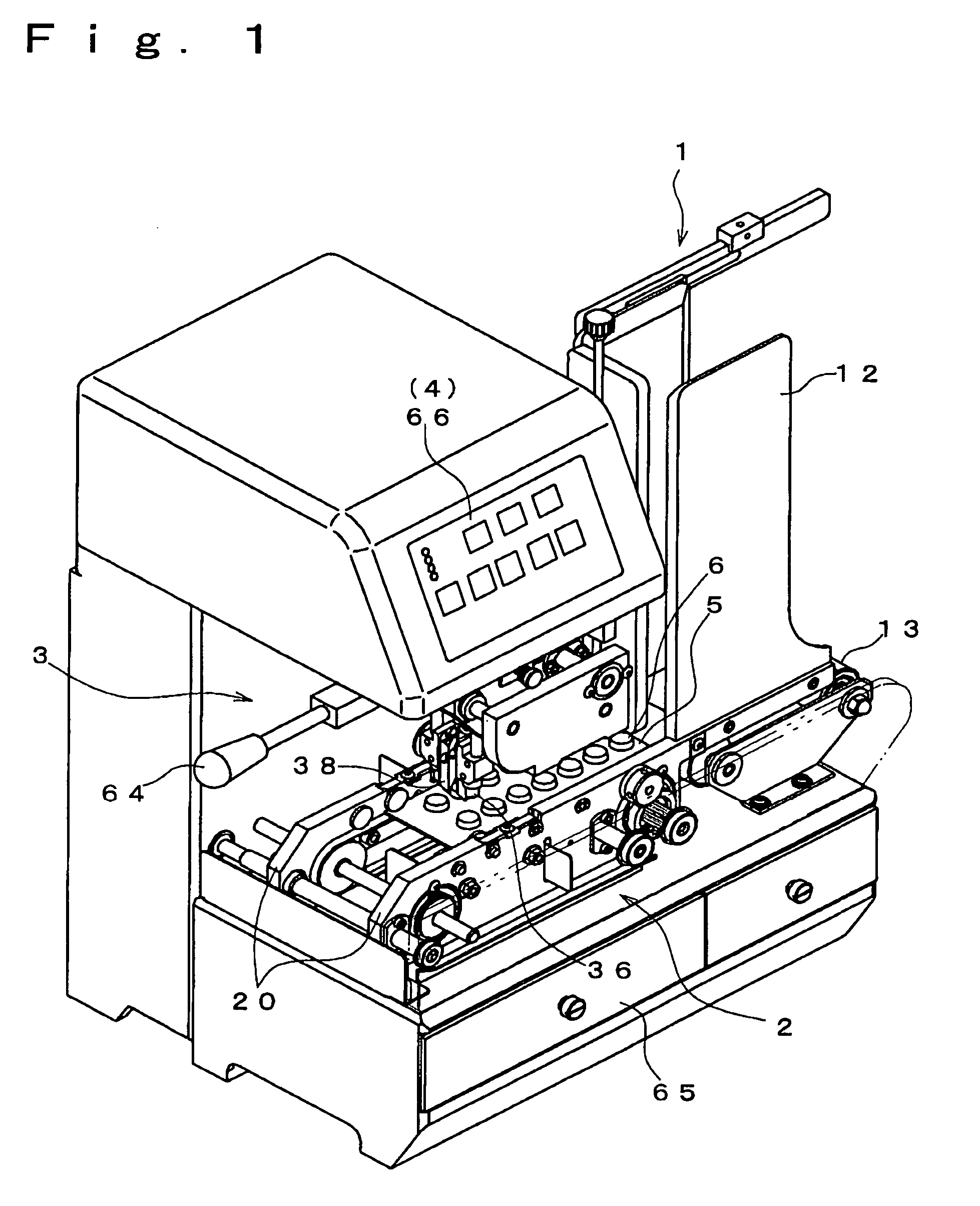

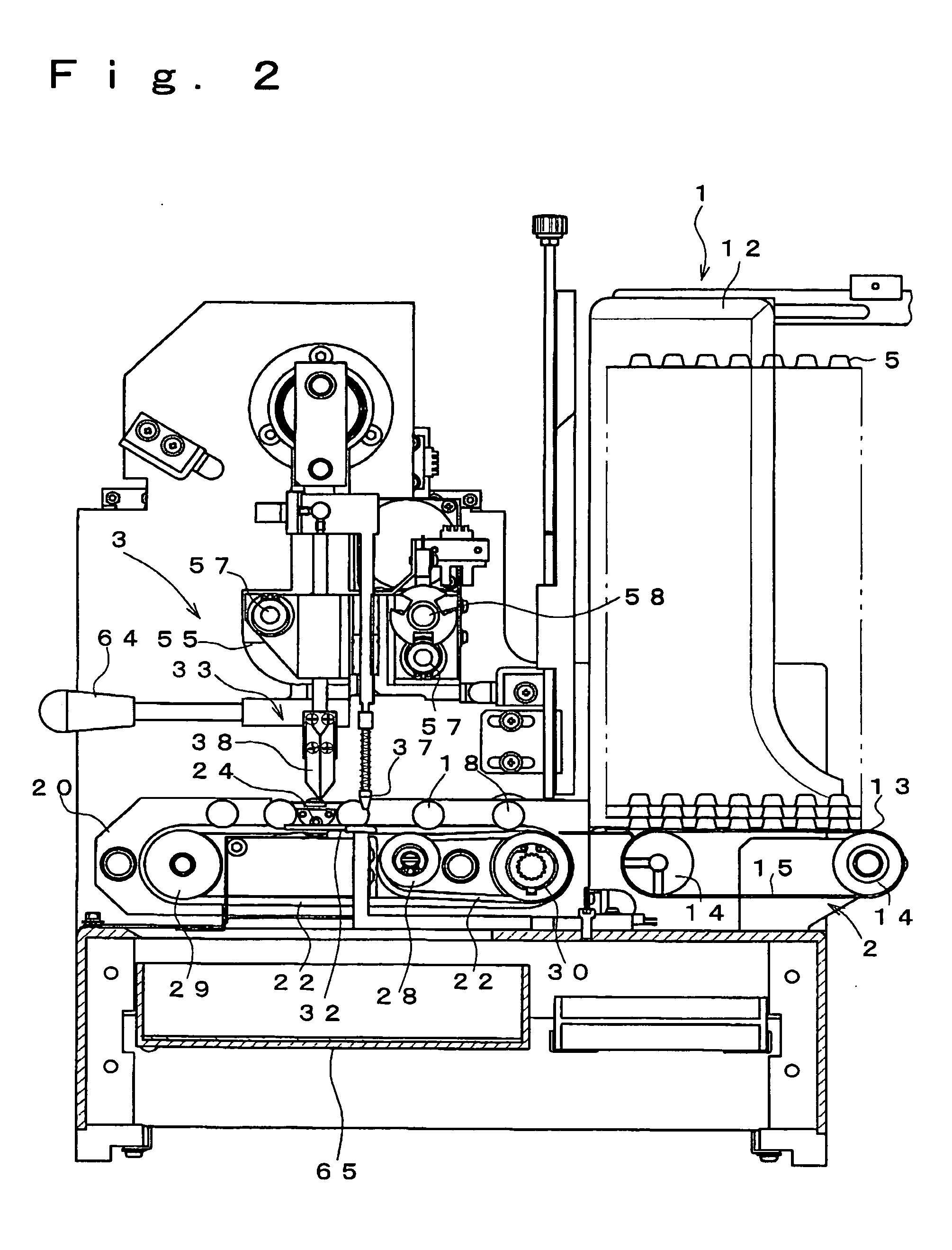

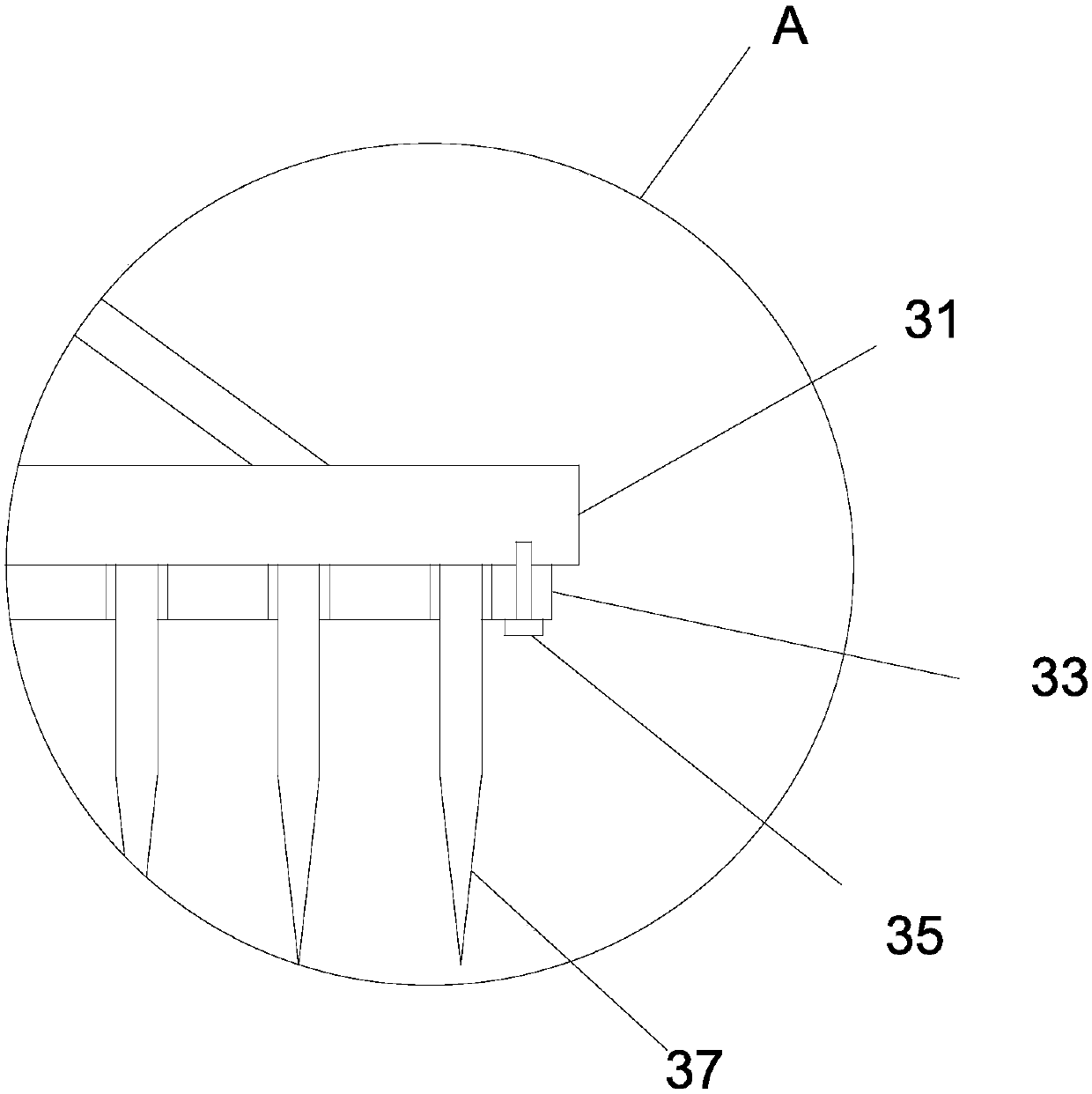

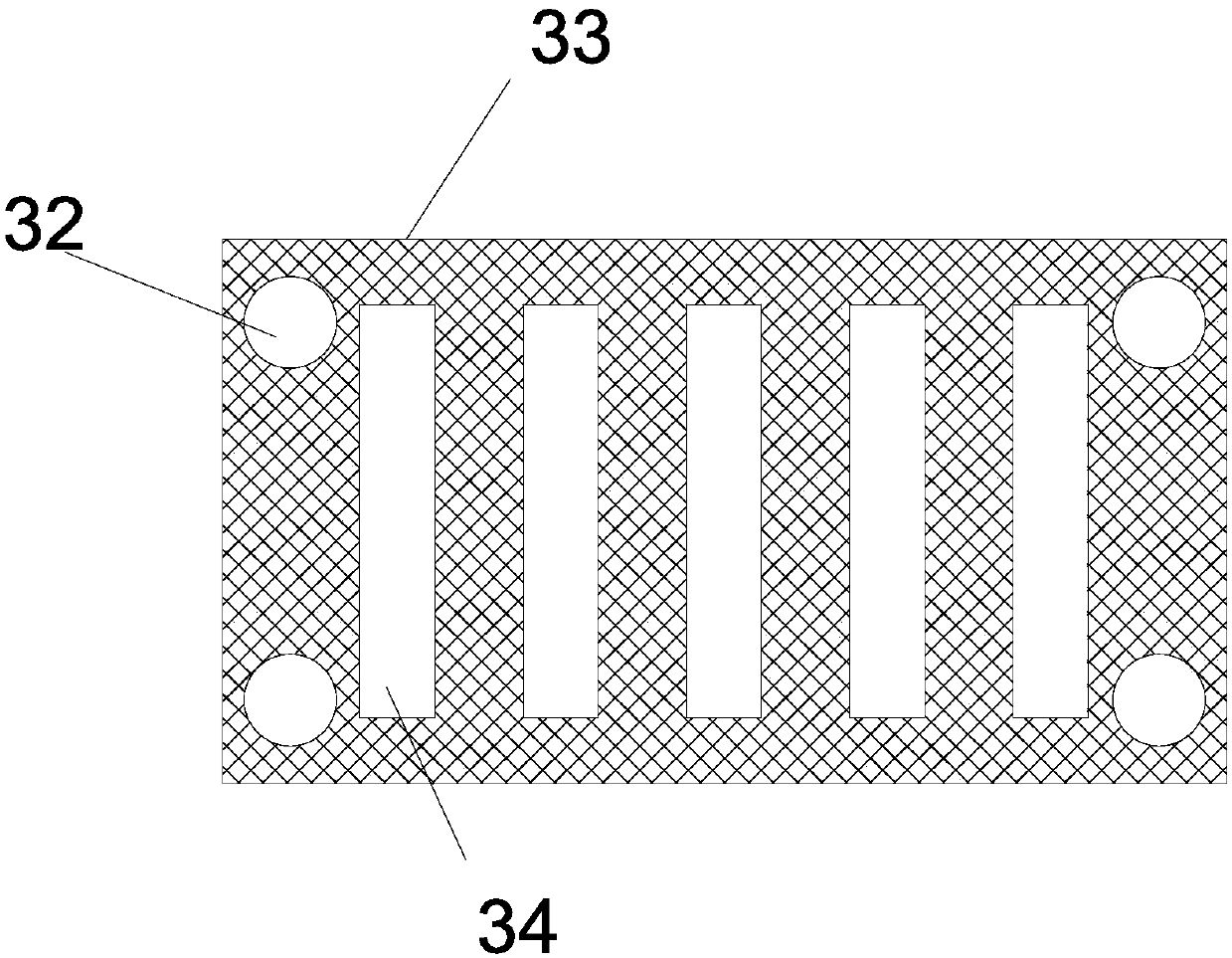

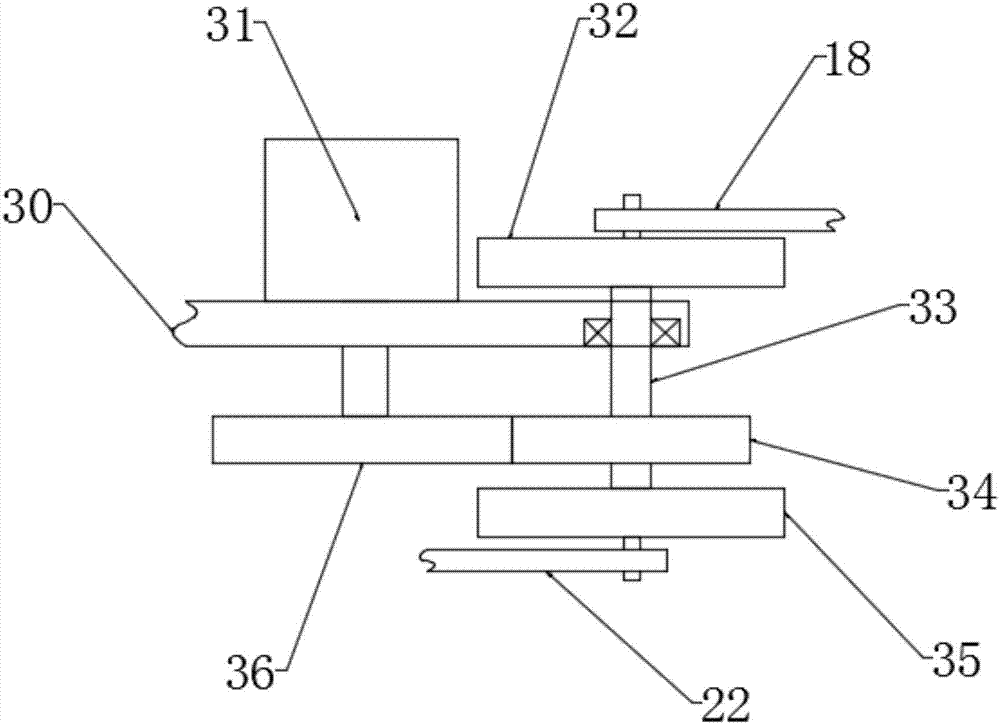

Medicine feeding device

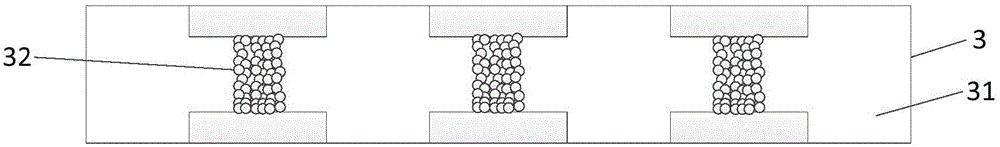

InactiveUS20060104765A1Evenly brokenSheet can be broken promptly and smoothlyArticle unpackingLoading/unloadingMechanical engineeringEngineering

The medicine feeding device includes a support portion 32 for supporting a seal surface side of a press through pack 5, a press section 33 for pressing the housing recess portions 9 from one side other than the seal surface of the press through pack 5, and a cutter 38 for making a cut slit in the sheet 11 at a boundary portion between the housing recess portions 9 and the seal surface 8 at least before the sheet 11 is broken or the medicine 6 is damaged by the press exerted by the press section 33.

Owner:YUYAMA MFG CO LTD

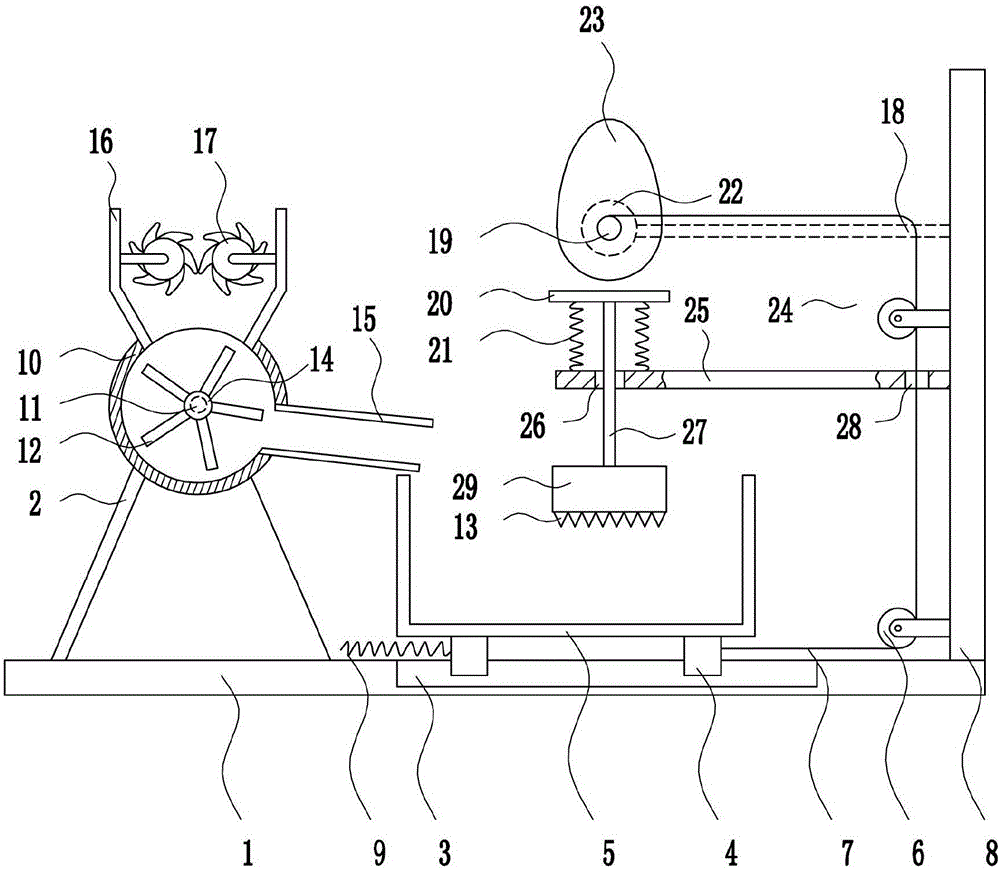

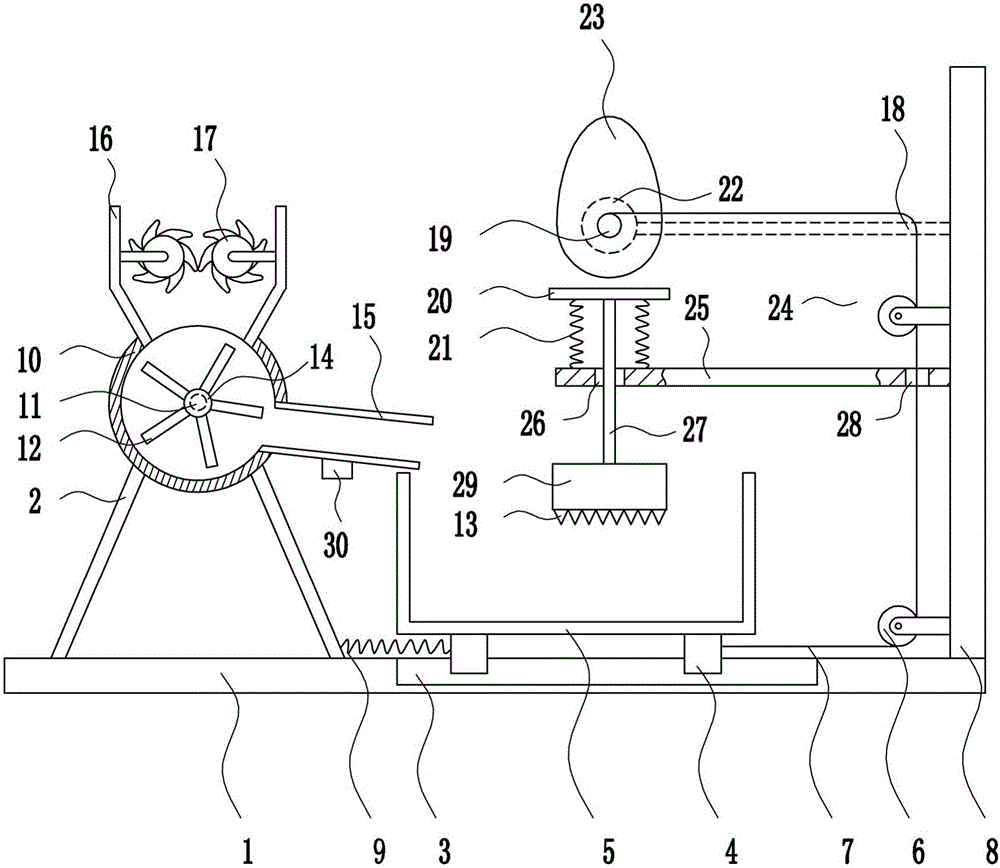

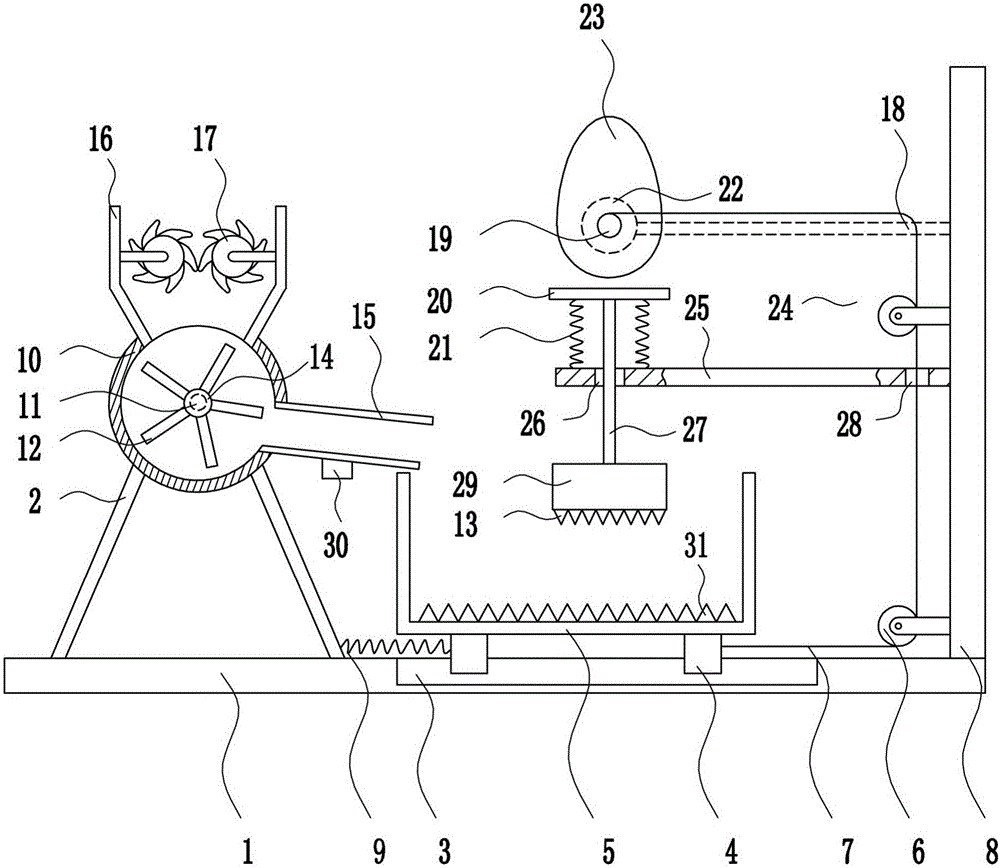

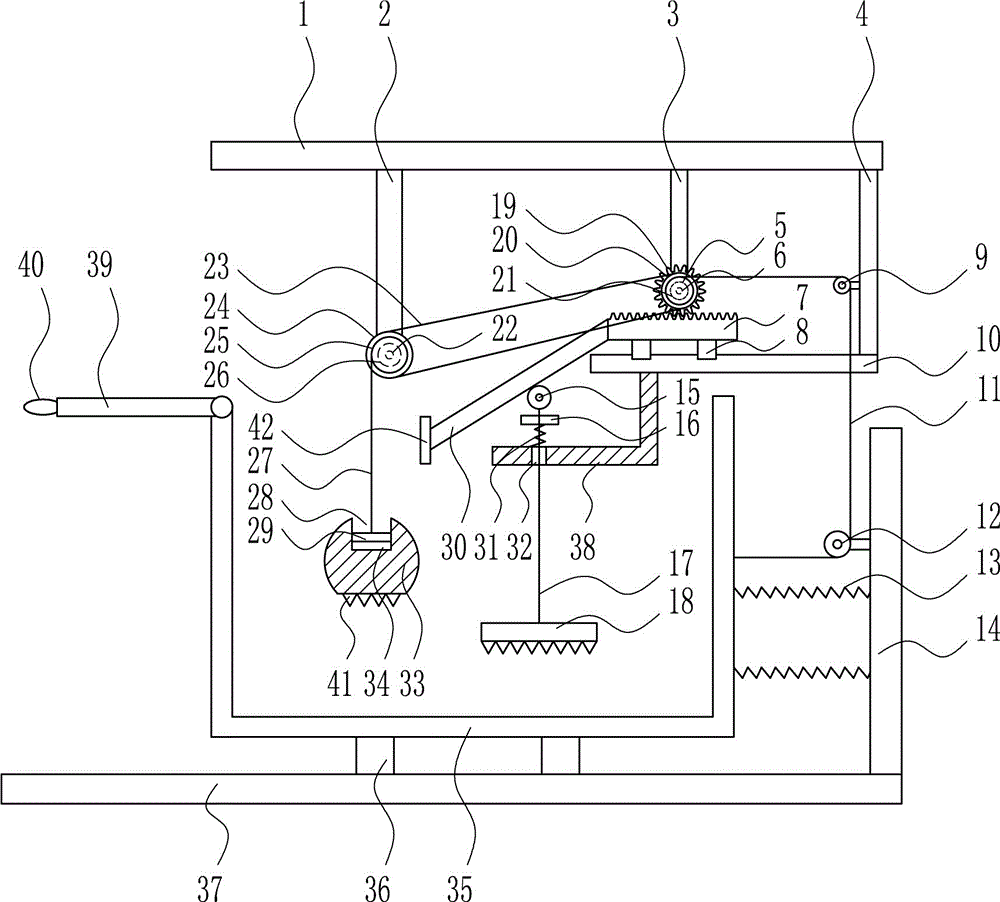

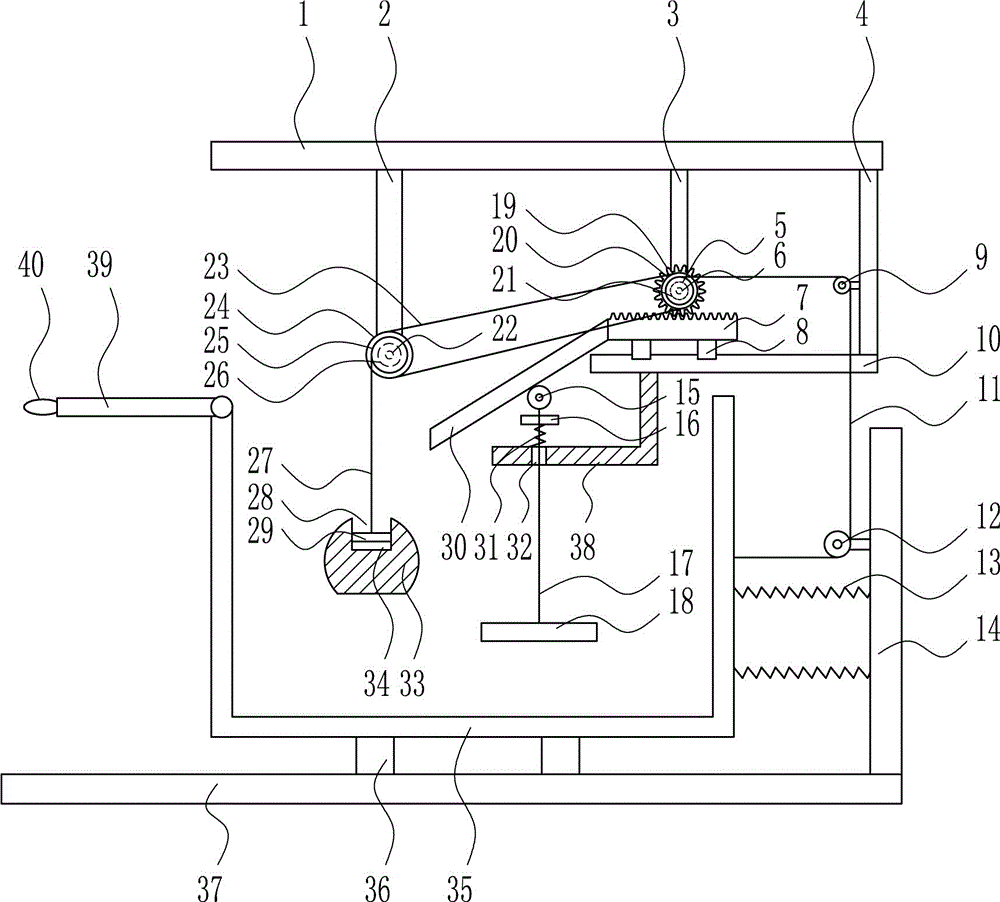

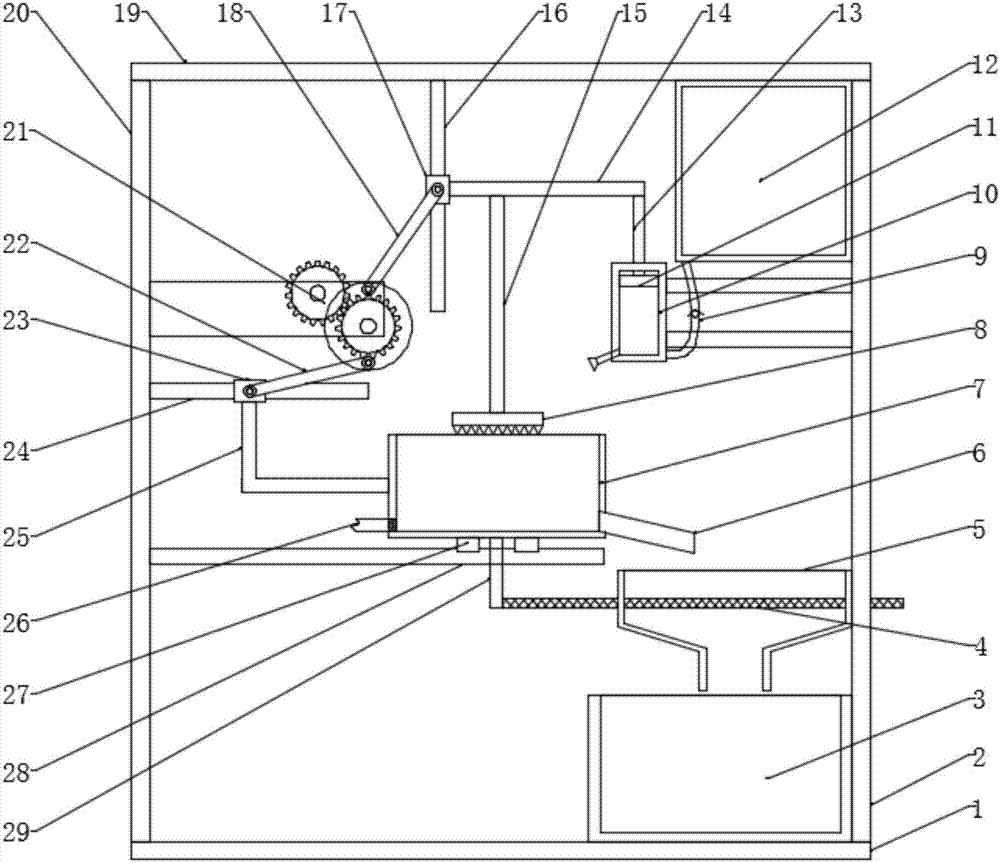

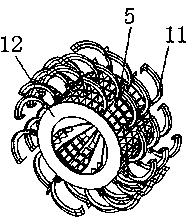

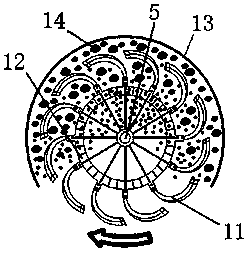

Efficient treatment device for waste vamps for shoe factory

The invention relates to a waste vamp treatment device for a shoe factory and particularly relates to an efficient treatment device for waste vamps for the shoe factory. The invention aims to solve the technical problem of providing the efficient treatment device for waste vamps for the shoe factory, wherein the device crushes thoroughly and uniformly and is simple in structure. In order to solve the technical problem, the invention provides the efficient treatment device for waste vamps for the shoe factory. The device comprises a bottom plate, a mounting base, a slide rail, a slide block, a first fixed pulley, a guy wire, a right rack, a first spring, a spherical housing, a first motor, blades, a first cone-shaped gear, a rotating disc, a discharge pipe, a feeding hopper, electric crushing wheels, a supporting rod, a reel, a pressure plate, second springs, a second motor, a camp, a second fixed pulley, a guide plate, a lifting rod and a pressure block. The device provided by the invention achieves the effects of crushing thoroughly and uniformly and being simple in structure, so that the waste vamps are quickly and efficiently treated, and the production benefit of an enterprise is increased.

Owner:临沂临港投资管理有限公司

Ore breaking device for smelting

InactiveCN107138211ABroken comprehensiveGood crushing effectDirt cleaningGrain treatmentsEngineeringSmelting

The invention relates to an ore breaking device for smelting, in particular to an ore breaking device for the smelting, so as to achieves the effects that the ore breaking device for the smelting is easy and simple to operate and uniform in breaking, and thus the smelting effect during ore smelting is improved without affecting the quality after the smelting. The ore breaking device for the smelting comprises a bottom plate, a collection frame, support rods, a breaking frame, a discharge pipe, a valve, a support plate, a top plate, a first air cylinder and the like; the support rods are symmetrically arranged in the top middle of the bottom plate in a bolted connection manner; the top ends of the support rods are in bolted connection with the breaking frame; the lower part of the right side of the breaking frame is connected with the discharge pipe; and the discharge pipe communicates with the interior of the breaking frame, and is arranged obliquely. The ore breaking device achieves the effects that the ore breaking device is easy and simple to operate and uniform in breaking, and thus the smelting effect during ore smelting is improved without affecting the quality after the smelting.

Owner:雷海涛

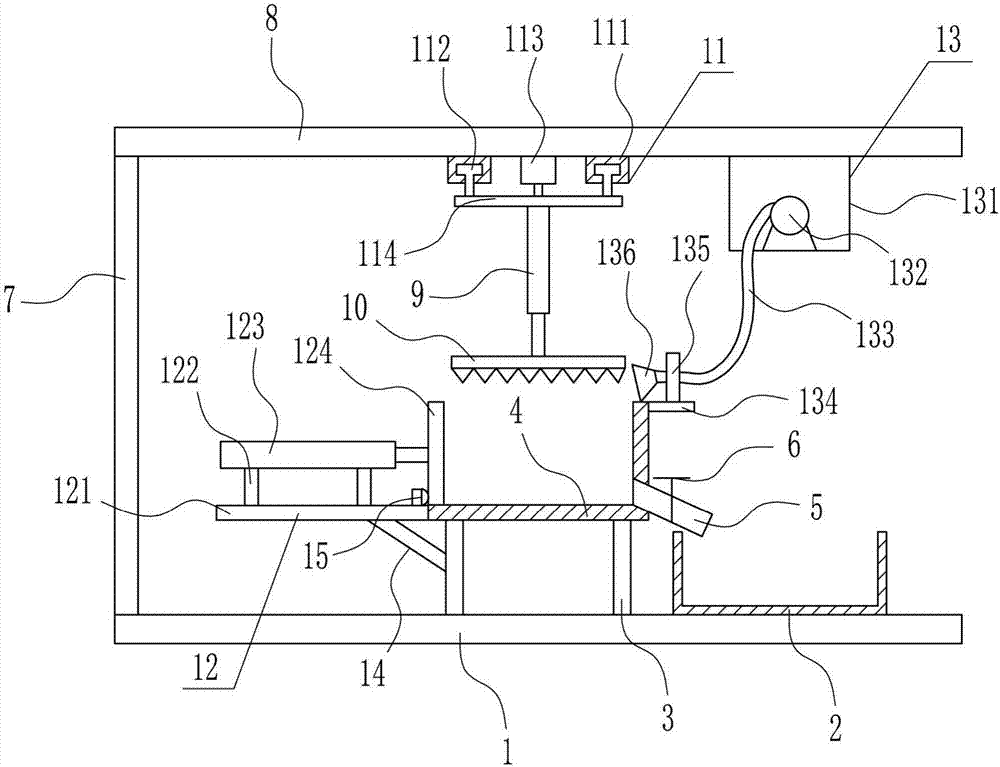

Agglomerated cement recycling and crushing device for building

InactiveCN107321424ABroken comprehensiveCompletely brokenUsing liquid separation agentCement productionCircular discEngineering

The invention discloses an agglomerated cement recycling and crushing device for a building. The device comprises a bottom plate, a crushing frame, a motor, a disc-shaped cam, a first belt pulley, a second belt pulley, a roller, a first connecting rod, a crushing plate, a spring, a third belt pulley, a first rotating shaft, a disc, a second connecting rod, a second sliding block, a second sliding rail, a third connecting rod and a dust falling mechanism. The device is provided with the disc-shaped cam, the roller, the first connecting rod, the spring and the crushing plate, through cooperation of the parts, agglomerated cement in the crushing frame is crushed through the crushing plate, the crushing speed is high, and the labor intensity of workers is relieved. The first belt pulley, a first belt, the third belt pulley, the disc, the second connecting rod and the third connecting rod are arranged, through cooperation of the parts, the crushing frame moves leftwards and rightwards, thus the cement in the crushing frame can be comprehensively crushed through the crushing plate, crushing is more through and uniform, and the crushing efficiency is improved. The dust falling mechanism is arranged, continuous water spraying is realized, dust falling is carried out, and influence on the health of the workers is avoided.

Owner:陈仲义

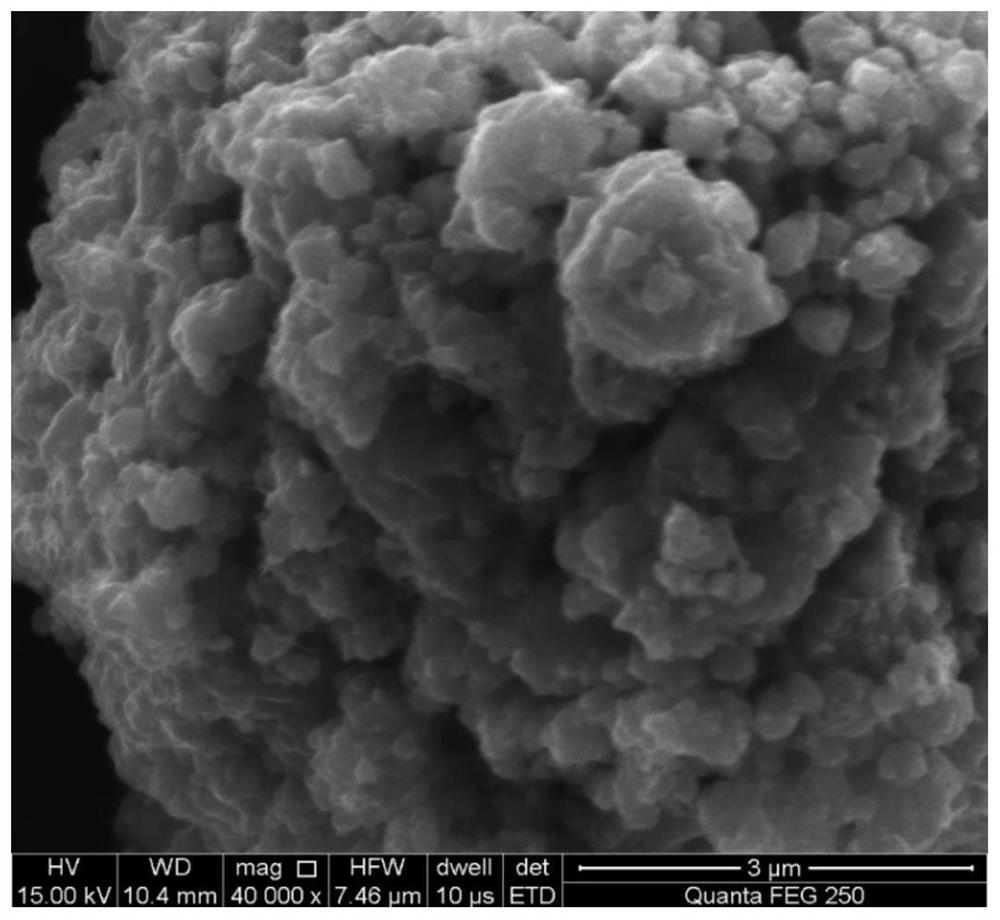

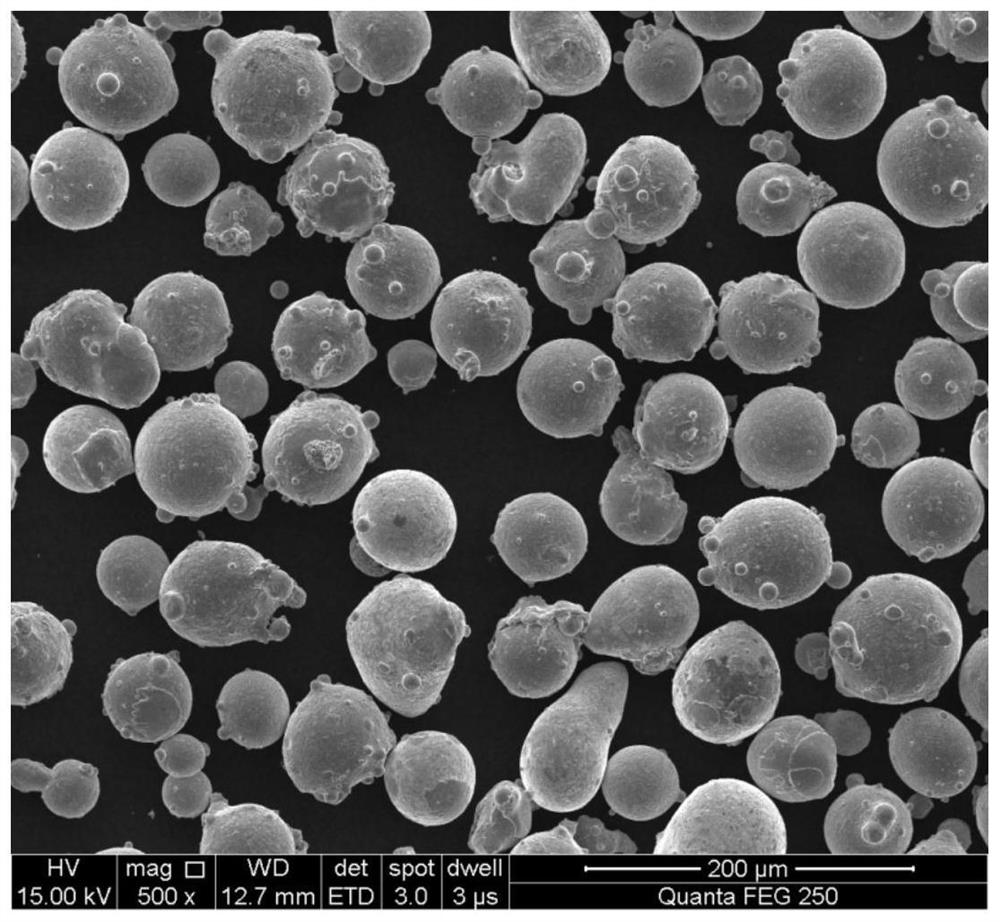

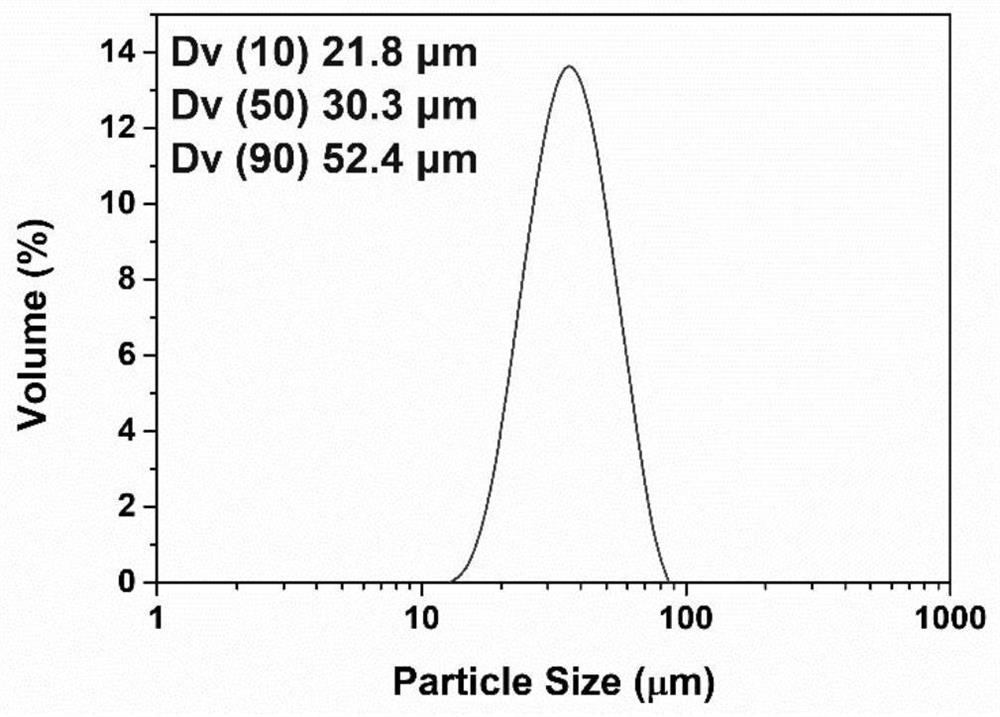

Nano ceramic metal composite powder for 3D printing and application

ActiveCN111940723AHigh sphericityGood liquidityAdditive manufacturing apparatusTransportation and packagingCeramic particleCeramic metal

The invention provides nano ceramic metal composite powder for 3D printing and application. A metal material is used as a matrix, and ceramic particles are used as a reinforcing phase. One or more ceramic particles of micron-sized TiC, TiB2, WC, SiC, CrC, Al2O3, Y2O3 and TiO2 are used as raw materials, the mass percent of the added ceramic particles is 0.5-10.0%, through a specific ball milling process, plasma spheroidization, airflow classification and screening, the metal composite powder with high sphericity, good fluidity, narrow particle size range and uniformly distributed nano-ceramicsis obtained, and the high requirement of a 3D printing technology for powder is met; and a nano-ceramic reinforced metal composite material is prepared through the 3D printing technology. According tothe prepared metal composite material, nano ceramic phases are uniformly distributed, and the metal composite material has excellent mechanical properties. Micron-sized ceramic particles are adopted,uniform dispersion is achieved through nanocrystallization, and the cost is low; and parts in any complex shape can be integrally formed and prepared, and the material utilization rate is increased.

Owner:CENT SOUTH UNIV

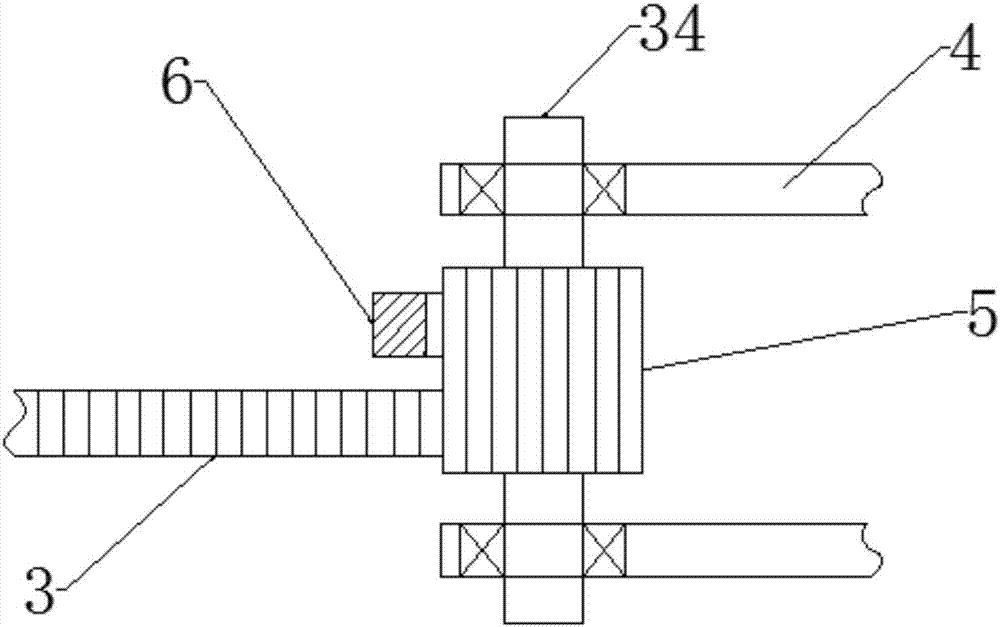

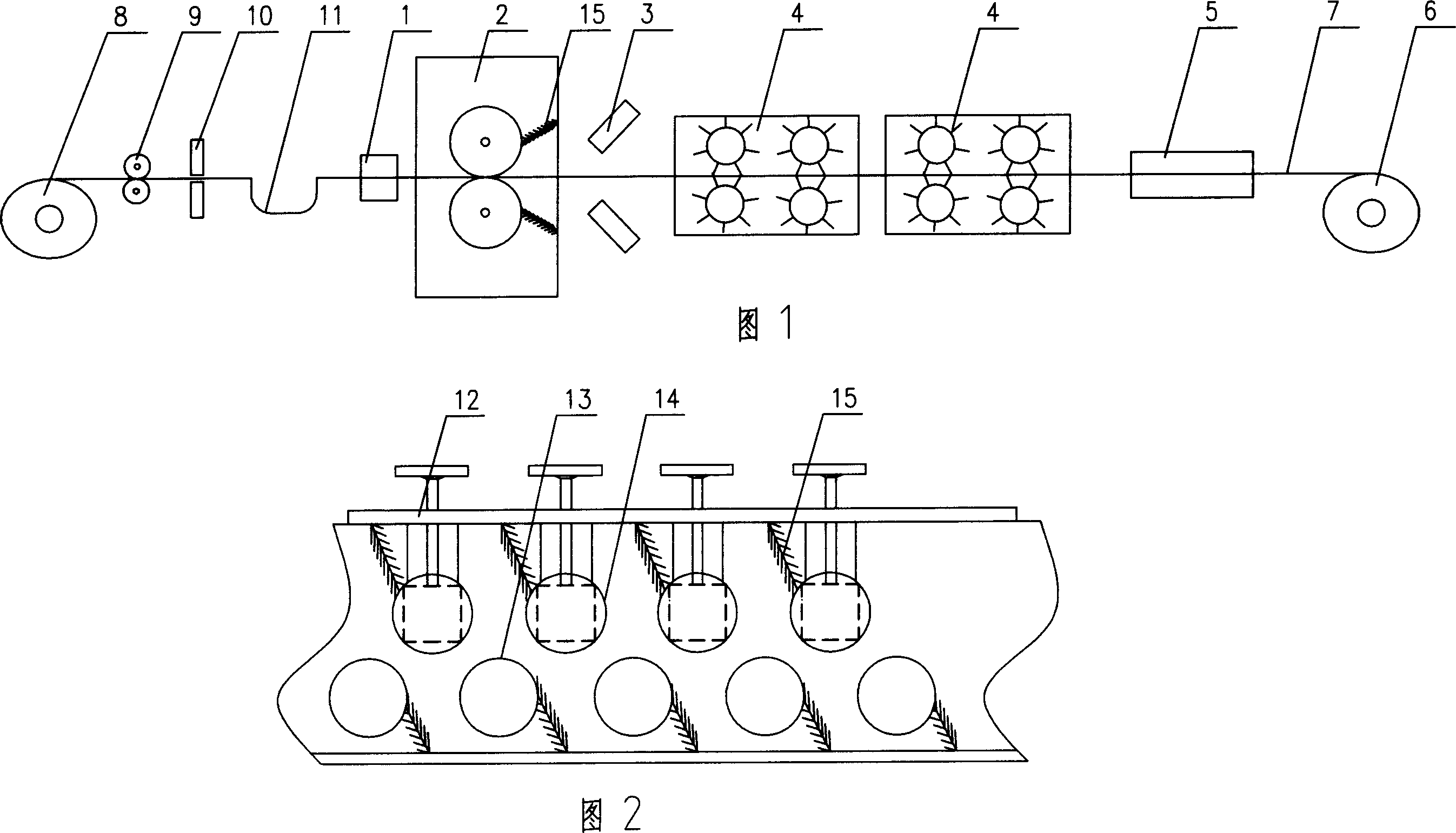

Leveling machine, black strip acid-free derusting device using the same and method thereof

InactiveCN1962105ARust removal achievedEliminate corrosionRoll mill control devicesWork treatment devicesEmulsionEngineering

The invention relates to a flattener, relative thermal rolling band steel non-acid scaling device and method, wherein said flattener comprises a roller cleaner (15) whose end contacts the lower roller and compression lower roller (14); the cleaner (15) can clean the ferric oxide in each rotation of roller, to improve work efficiency. And the scaling device comprises emulsion feeder (1), flattener (2), high-pressure water injector (3), iron brush (4), washing drier (5), and coiling machine (6). The invention can improve the service life and effect of iron brush. And the method comprises that adjusting the injected amount of emulsion to adjust the scaling quality and save cost.

Owner:武钢集团有限公司

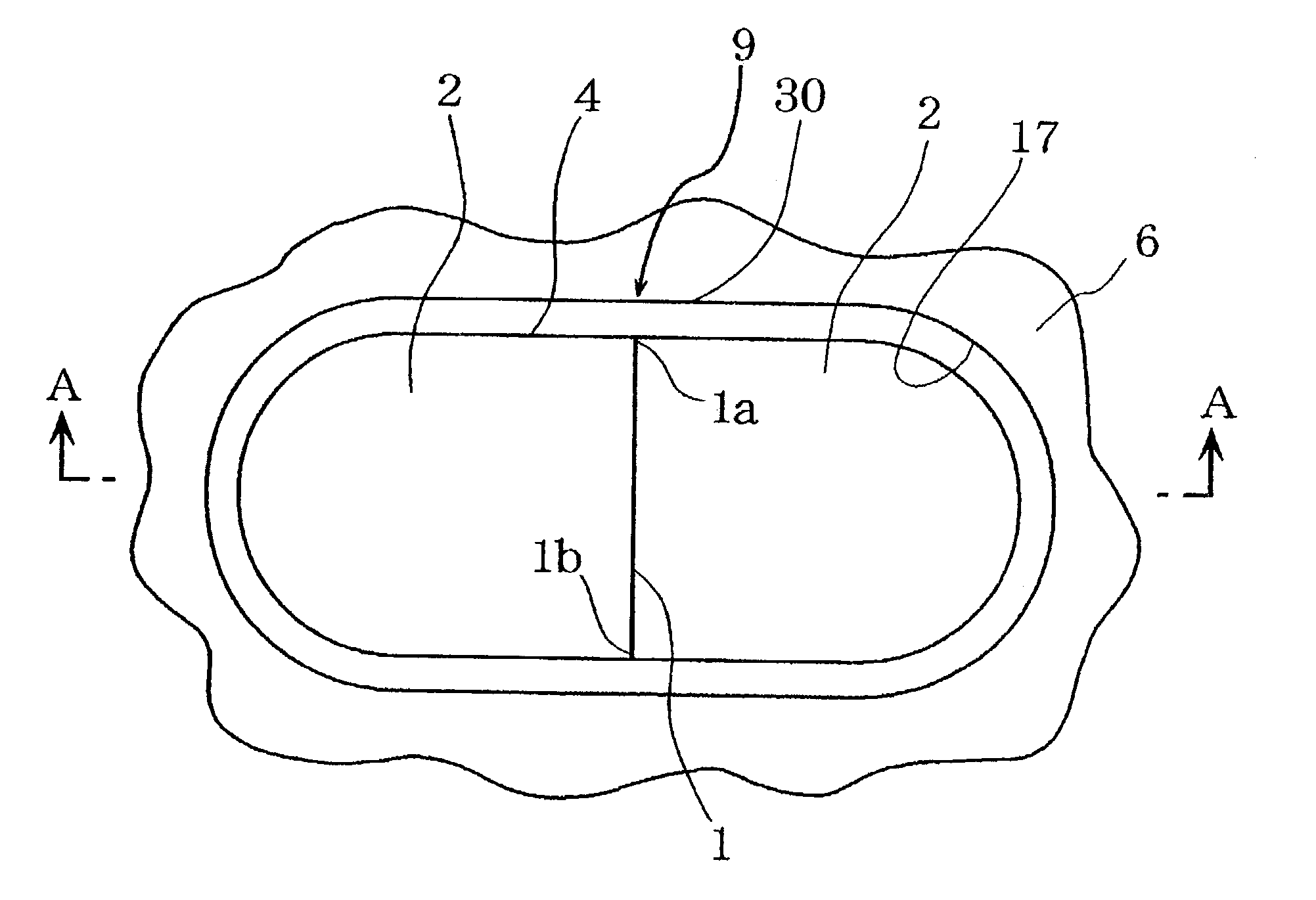

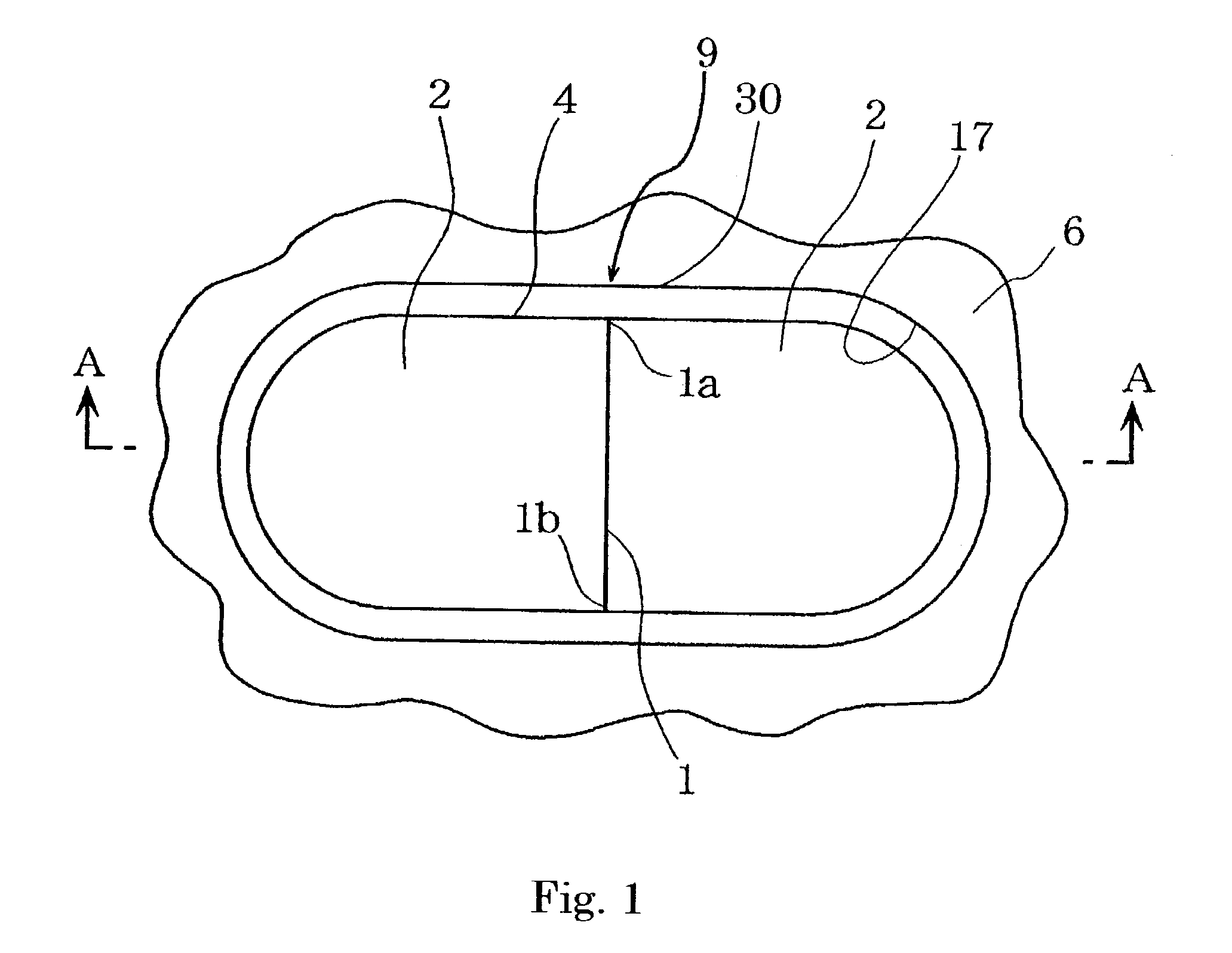

Cell safety valve and cell having same

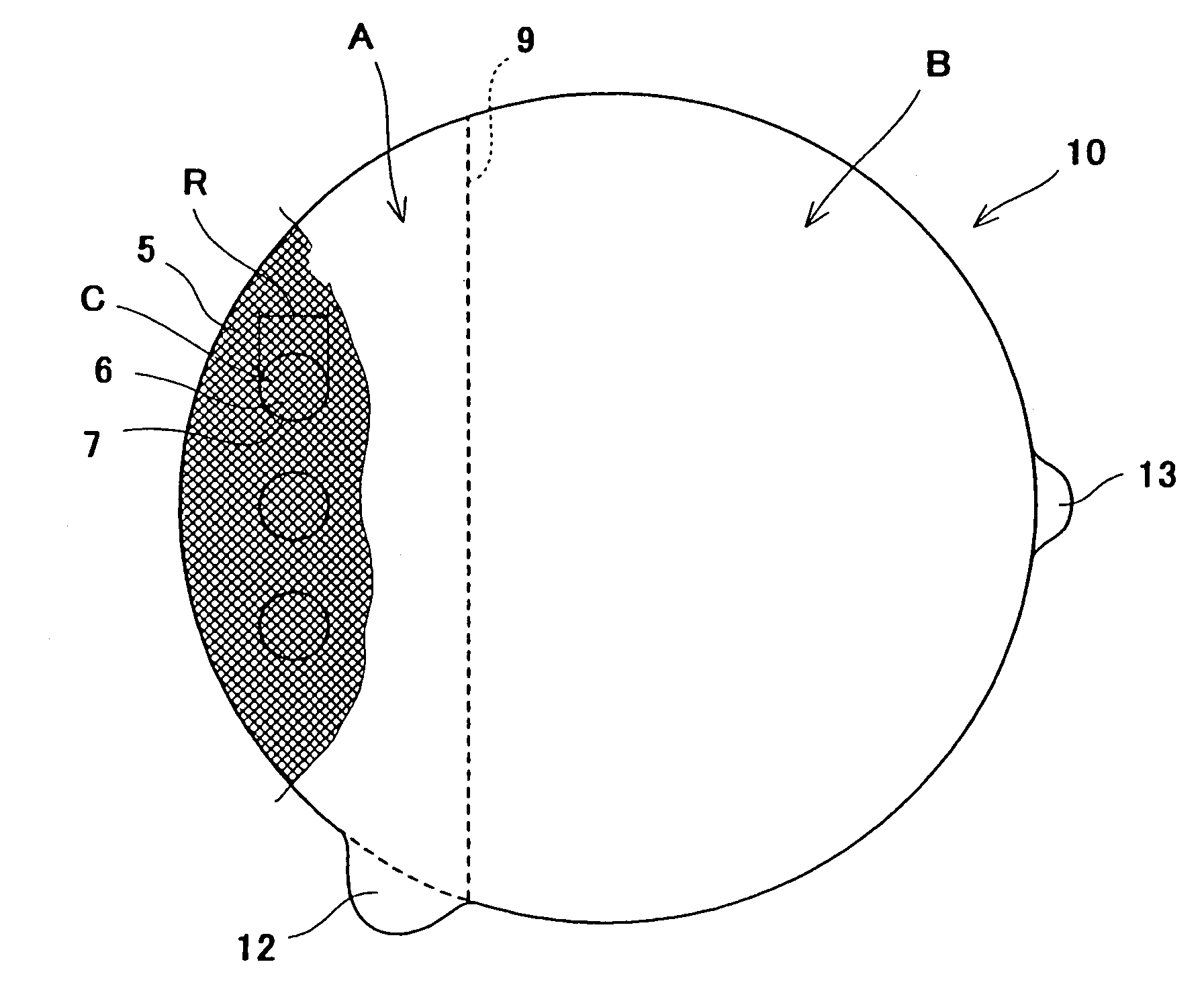

InactiveUS7140380B2Quickly release generatedAvoid breakingEqualizing valvesSafety valvesDrop impactEngineering

A cell according to the present invention comprises a positive electrode, a negative electrode, an electrolyte solution, and an outer casing, wherein the outer casing comprises a valve plate 30 having a thickness, an annular-shaped break groove 4 formed on the valve plate, and one or more of break aiding grooves 1 in the inner area of the break groove, and wherein the break aiding groove comprises such configurations that remaining thickness of the valve plate at the break aiding groove is thicker than remaining thickness of the valve plate at the break groove, and at least one end of the break aiding groove is connected with the break groove. In a cell provided with a valve plate which is a safety valve 9 comprising the break groove and the break aiding groove, the safety valve operates smoothly and releases a gas inside the cell quickly, and resistance to dropping impact is improved.

Owner:SANYO ELECTRIC CO LTD

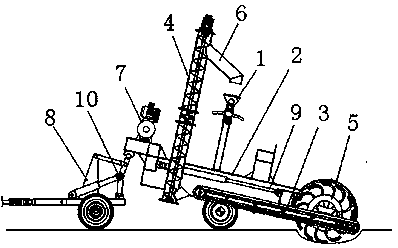

Straw crushing device for livestock breeding

InactiveCN107624387AFully crushed and refinedGuaranteed normal cuttingShaking/oscillating/vibrating mixersUsing liquid separation agentSlagScrew thread

The invention discloses a straw crushing device for livestock breeding. The straw crushing device includes an operating room, a horizontal rod is fixedly arranged inside the operating room in a horizontal mode, a sliding rod is arranged penetratingly on the horizontal rod in a vertical sliding mode, the upper end of the sliding rod is connected with the end, away from a hanging rod, of a rotatingplate in a hinged mode, a number of cutting blades are arranged at equal spacing on the bottom of a connecting plate, locking screws are arranged on screw holes in a penetrating mode, and the lockingscrews are connected with the connecting plate in threaded fit; a number of crushing blades are arranged on the surface of a rotating shaft uniformly, and a water inlet pipe connected with an externalwater source is arranged on a water drawing sleeve. The straw crushing device for livestock breeding is ingenious in structure and convenient to operate, and a first crushing effect is achieved through straws receiving the cutting handling of the cutting blade and then receiving the rotary cutting and crushing of the crushing blades, the situation that longer straws clamp crushing blades is avoided, meanwhile the straws receive full crushing refinement, the straws sandwiched between the cutting blades or stuck on the cutting blades can be removed through the removal of a slag filter plate, and the normal cutting of the straws by the cutting blades is ensured.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

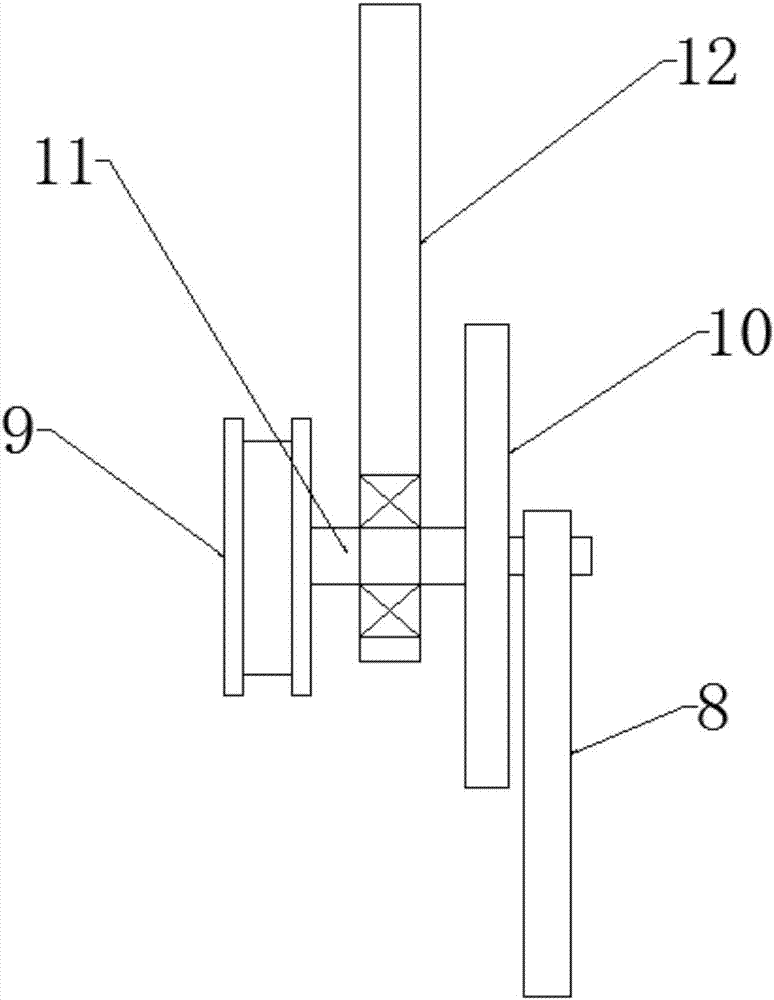

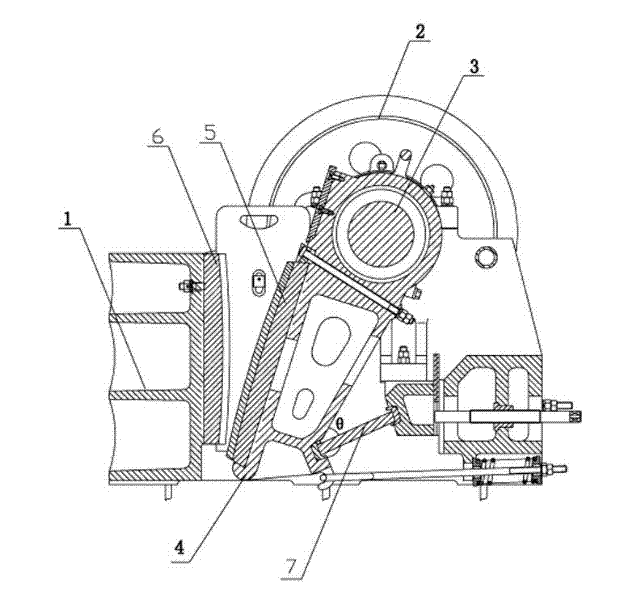

Jaw crusher with single-shaft double-crank-rocker mechanism

ActiveCN102198409AChange the mechanical structureEasily brokenGrain treatmentsDrive wheelDrive shaft

The invention discloses a jaw crusher with a single-shaft double-crank-rocker mechanism. The jaw crusher comprises a frame, a fixed jaw plate, a movable jaw plate, a front crank-rocker mechanism, a rear crank-rocker mechanism and a driving wheel, wherein, the front crank-rocker mechanism comprises a front movable jaw, a front toggle plate and an eccentric drive shaft; the rear crank-rocker mechanism comprises a rear movable jaw, a rear toggle plate and an eccentric drive shaft; the front movable jaw and the rear movable jaw are jointly pivoted with the eccentric drive shaft; one end of the front toggle plate is pivoted below the rear side of the front movable jaw, the other end of the front toggle plate is pivoted below the front side of the rear movable jaw, one end of the rear toggle plate is pivoted below the rear side of the rear movable jaw, and the other end of the rear toggle plate is pivoted with the frame; and the movable jaw plate is fixedly connected with the front movable jaw and is opposite to the fixed jaw plate to form a crushing cavity together with the fixed jaw plate. The jaw crusher has the obvious effect that horizontal movement stroke of the lower parts of the movable jaws with the main function of discharging materials is improved to a stroke with a main function of crushing so that one crusher has two-stage crushing efficacy.

Owner:ZHEJIANG SHENGDA MACHINERY

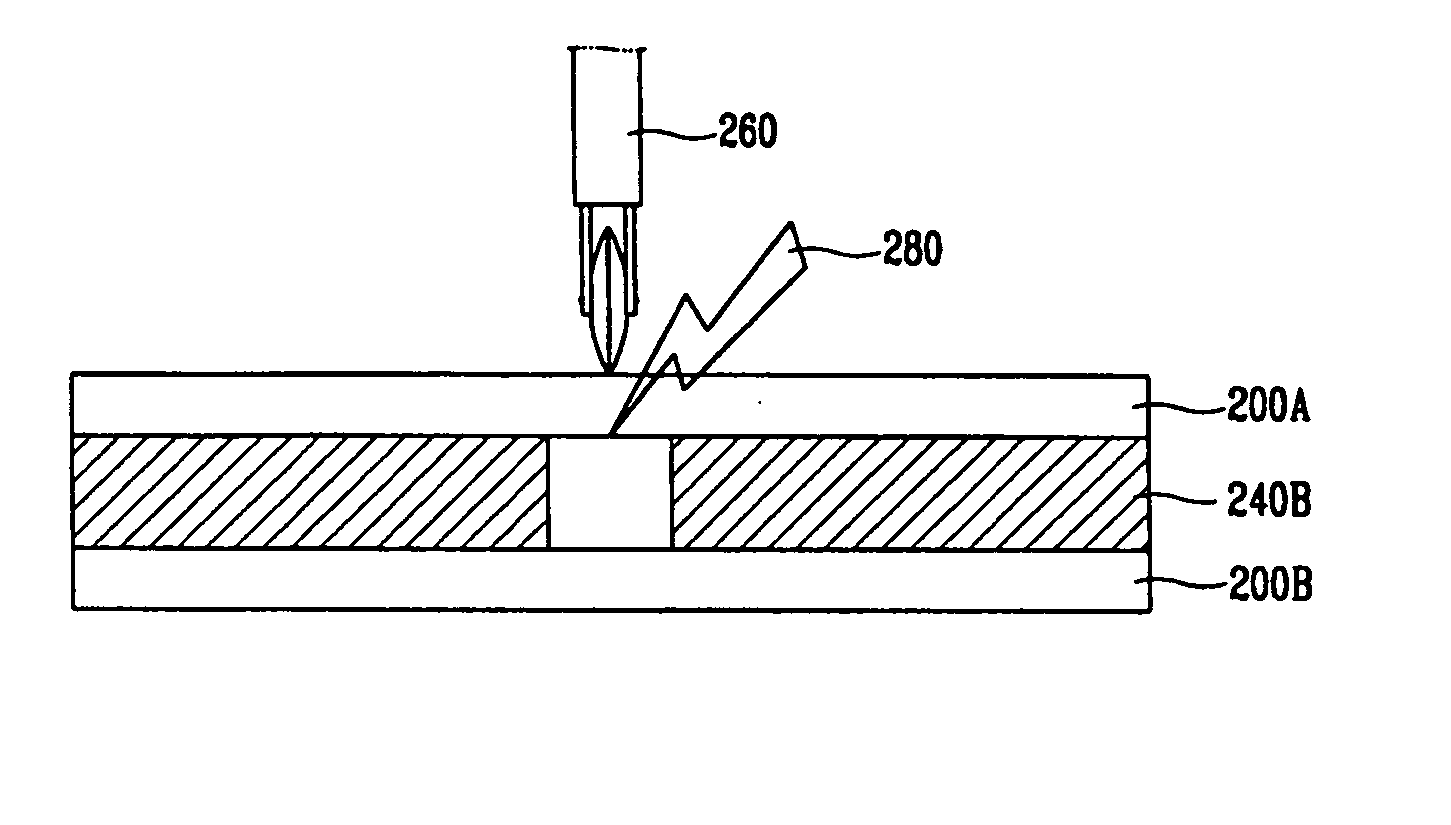

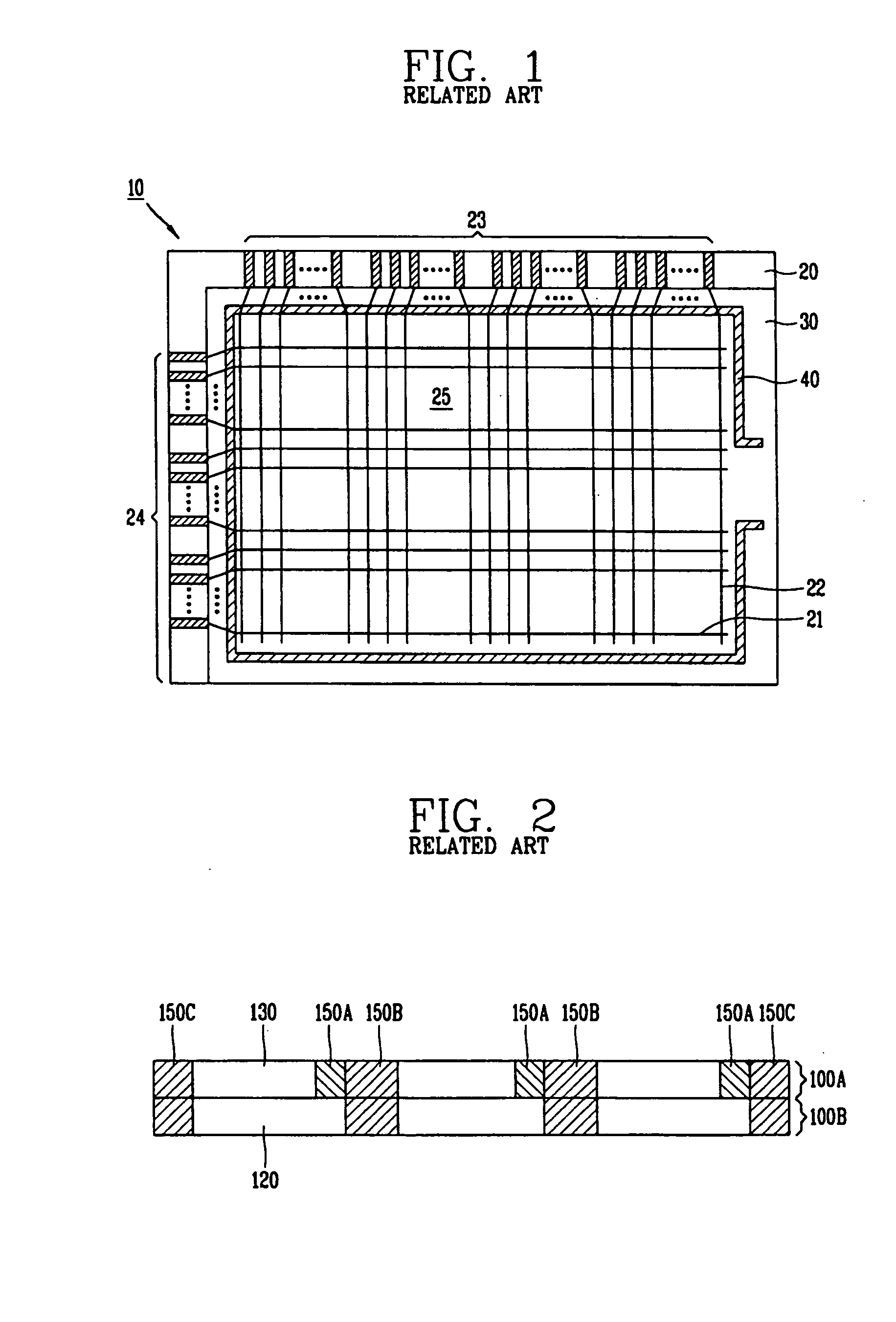

Method for cutting liquid crystal display panel

ActiveUS20050118921A1Evenly brokenFabrication yield can be improvedVessels or leading-in conductors manufactureFine working devicesLiquid-crystal displayEngineering

A method for cutting a liquid crystal display panel includes providing first and second mother substrates, forming a scribing line on the first and second mother substrates, removing a portion of a seal line being overlapped with the scribing line, the seal line formed on one of the first and second mother substrates, and dividing the first and second mother substrates into a plurality of unit liquid crystal display panels along the scribing line.

Owner:LG DISPLAY CO LTD

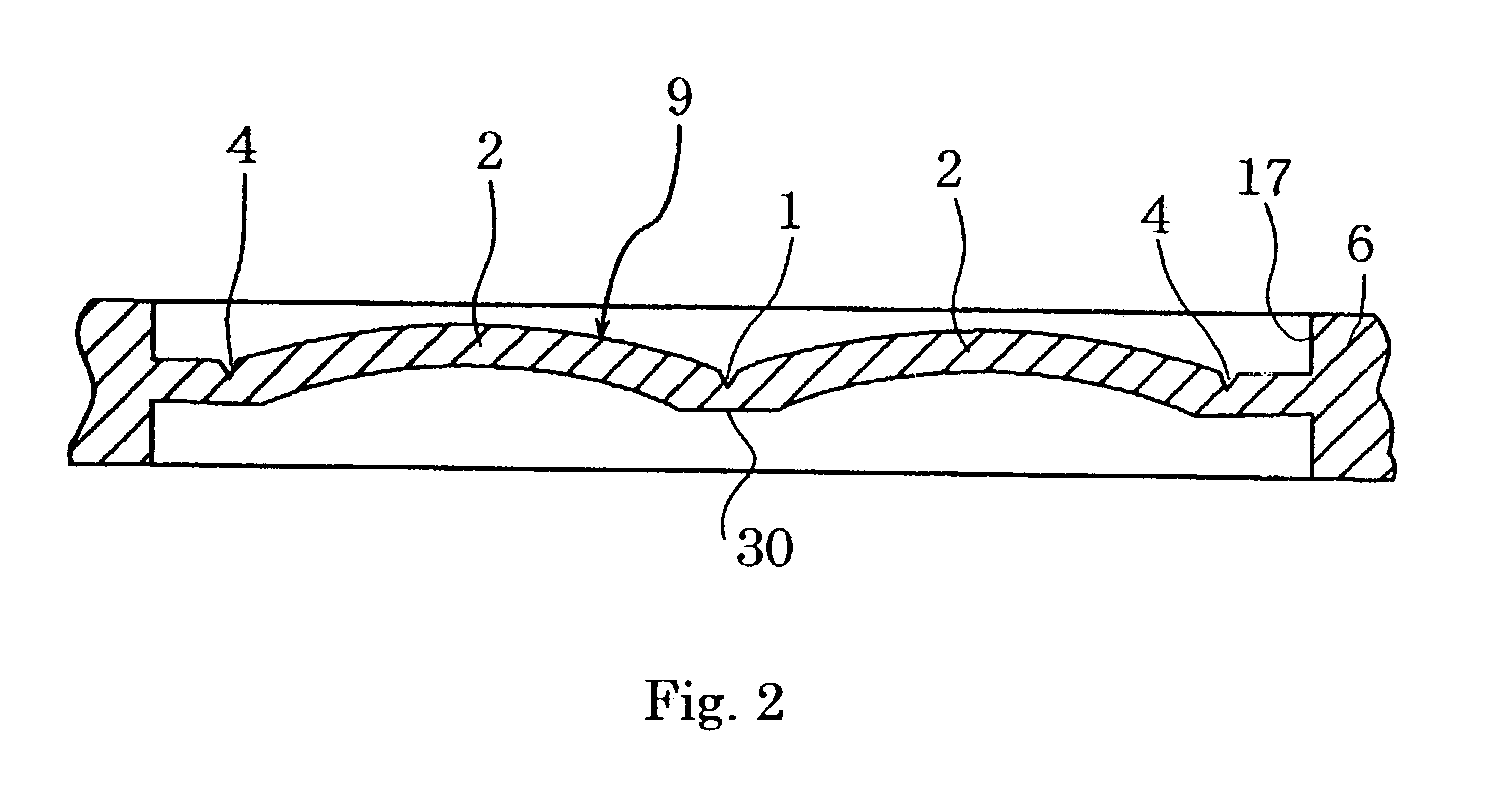

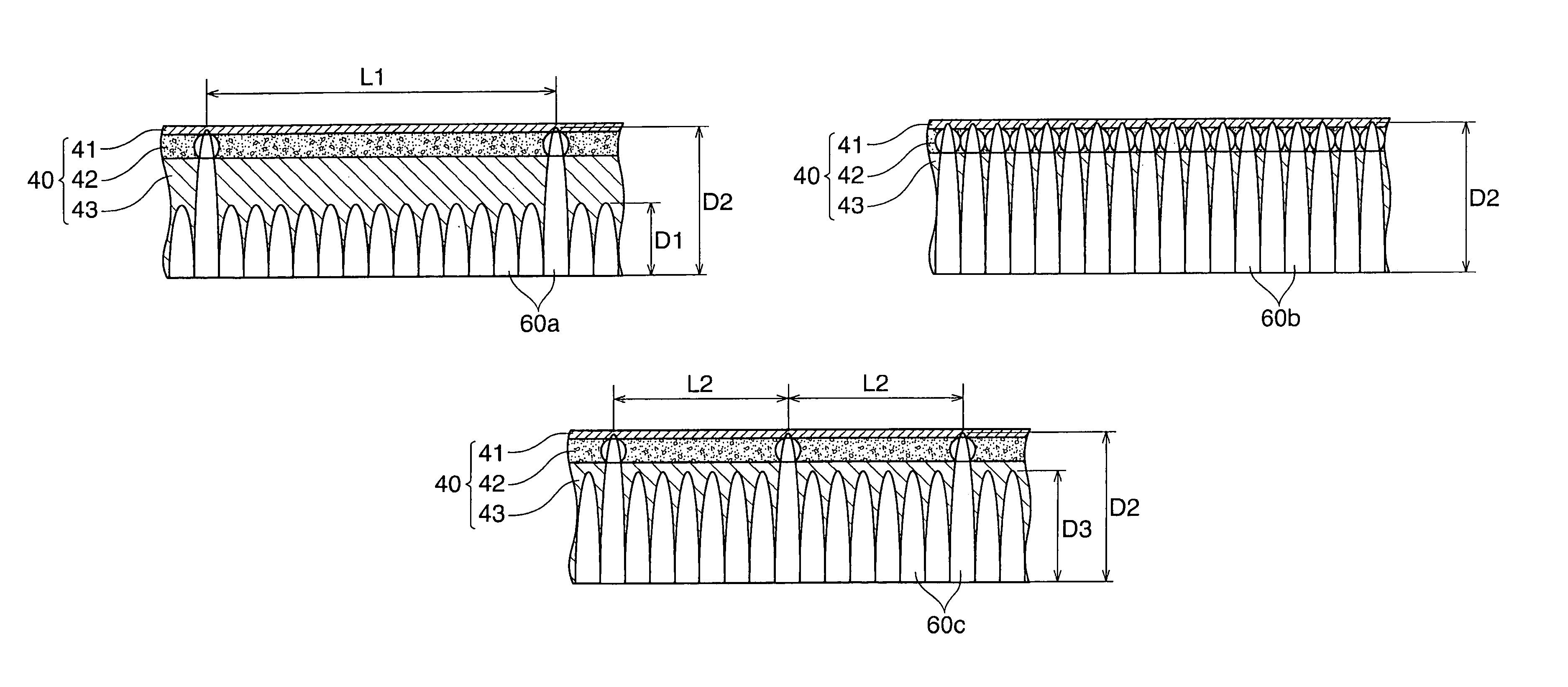

Airbag apparatus for automobile

ActiveUS7168731B2Smooth brakingGood lookingPedestrian/occupant safety arrangementSurface layerEngineering

An airbag apparatus uses an interior panel of an automobile. The interior panel is formed of a multi-layer sheet including a surface layer, an intermediate foam layer, and a base layer. The interior panel has front and rear hinge grooves and left and right fracture grooves for defining a fracture-opening section, and a center fracture groove for dividing the fracture-opening section into front and rear fracture-opening subsections to be split apart from each other in a casement condition. The hinge grooves, the center fracture groove, and the left and right fracture grooves are formed of laser-machined holes which have different depths and do not pass through the surface layer of the interior panel.

Owner:SANGO GOSEI

Manufacturing process of high-strength aluminum alloy ring forge

ActiveCN106363352AImprove the problem of low mechanical propertiesAchieve productionNumerical controlHigh intensity

The invention relates to a manufacturing process of a high-strength aluminum alloy ring forge. The manufacturing process comprises the following operation steps of blank purchasing, blank cut-off, heating of the forge, blank forming, machining of an inner hole, heating, broaching of a mandrel supporter, return heating, ring milling, cooling, curing, cold deformation, aging and machining to the required dimension. Through combination of the multiway improving forging technology, the mandrel supporter broaching technology, the lubricating technology, the numerical control ring-milling technology, the high-intensity thermal treatment technology and the cold deformation technology, the problems that an existing aluminum alloy ring forge is low in overall performance, nonuniform in mechanical property, obvious in anisotropism and the like.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

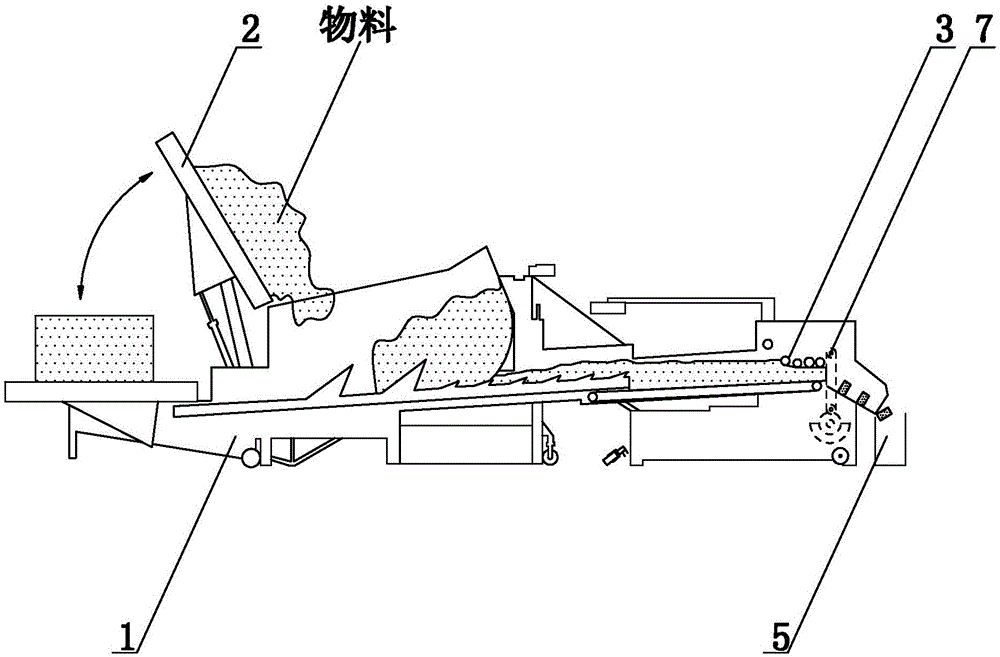

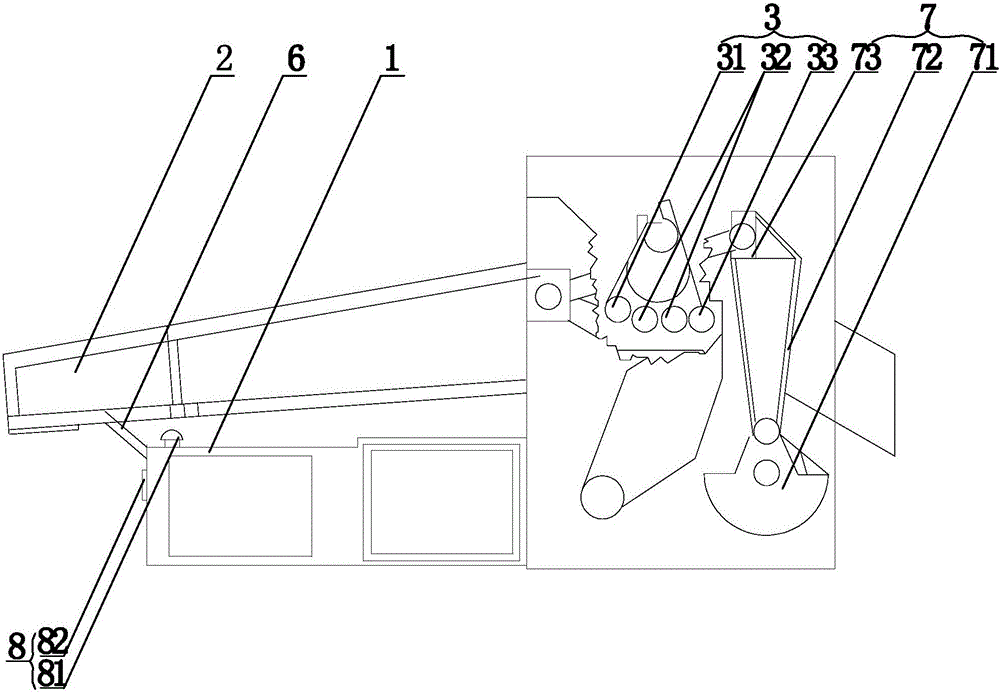

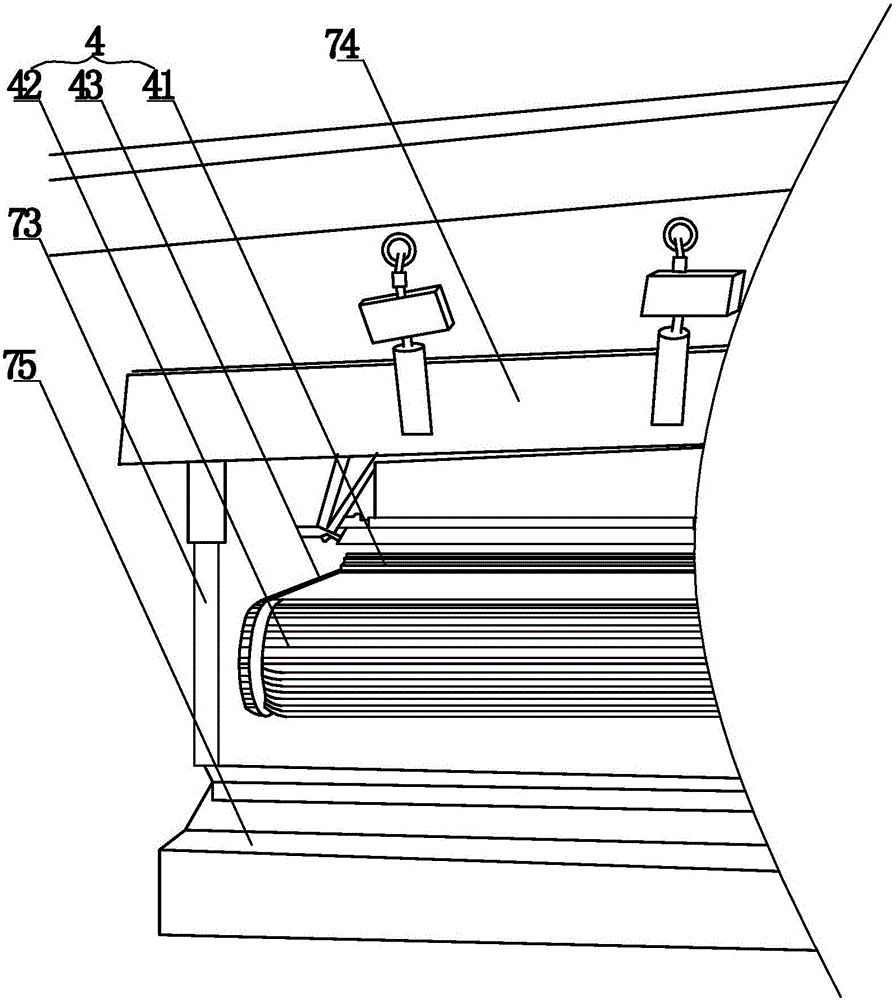

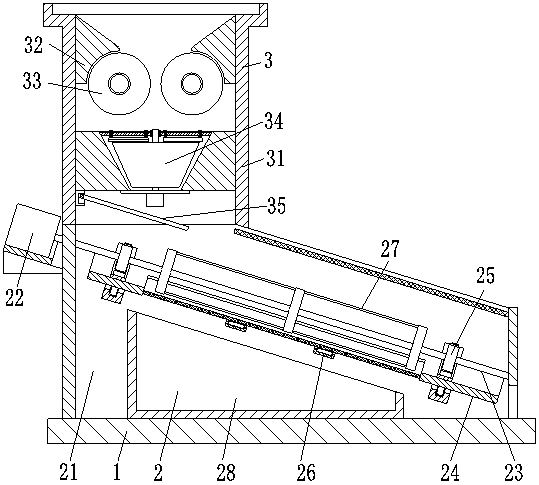

Waste fiber and product pre-treatment system

ActiveCN105690600ADoes not affect the compaction processAvoid damagePlastic recyclingGrain treatmentsFiberWire rod

The invention relates to a waste fiber and product pre-treatment system, and belongs to the technical field of wire rod machining. The waste fiber and product pre-treatment system comprises a rack, a hopper, a material pressing roller, wire feeding wheels, a power driving mechanism and a compression compaction machine; the hopper is located on the rack, one end of the hopper is provided with a lifting arm, and the other end of the hopper is located in front of the material pressing roller, and the hopper supplies materials to the material pressing roller; the wire feeding wheels comprise an upper wire feeding wheel and a lower wire feeding wheel, and the upper wire feeding wheel and the lower wire feeding wheel are both located behind the material pressing roller and connected though a conveying belt; the power driving mechanism comprises a motor, an eccentric gear, a transmission belt, a knife rest, a fixed cutter and a movable cutter; and the compression compaction machine is located behind the movable cutter. The waste fiber and product pre-treatment system is applied to cutting pre-treatment of waste like waste silks, and has the beneficial effects of being less in energy dissipation, high in efficiency and the like.

Owner:湖北绿宇环保有限公司

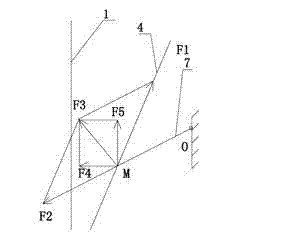

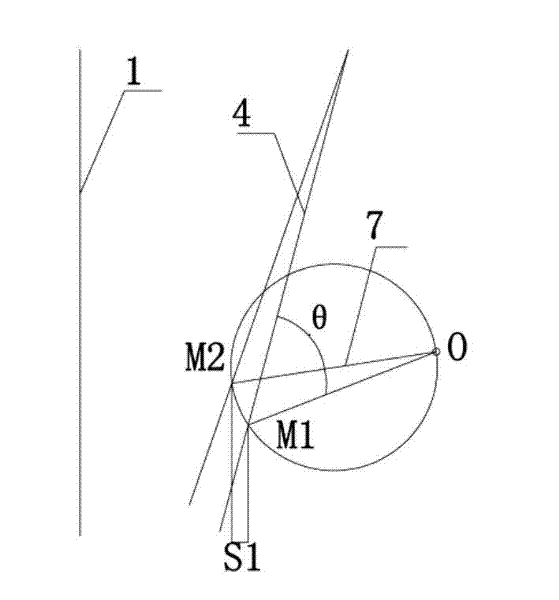

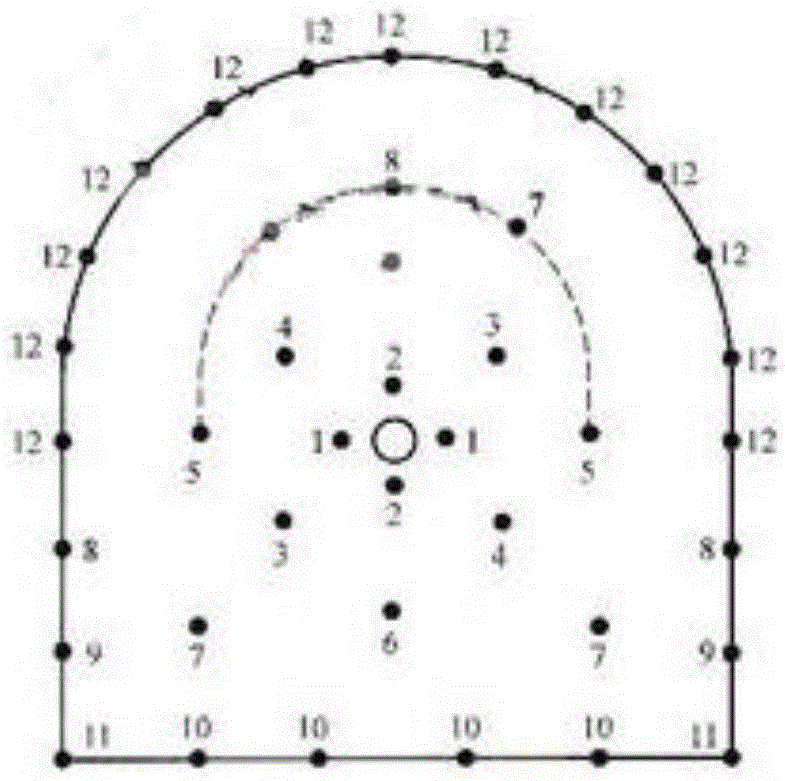

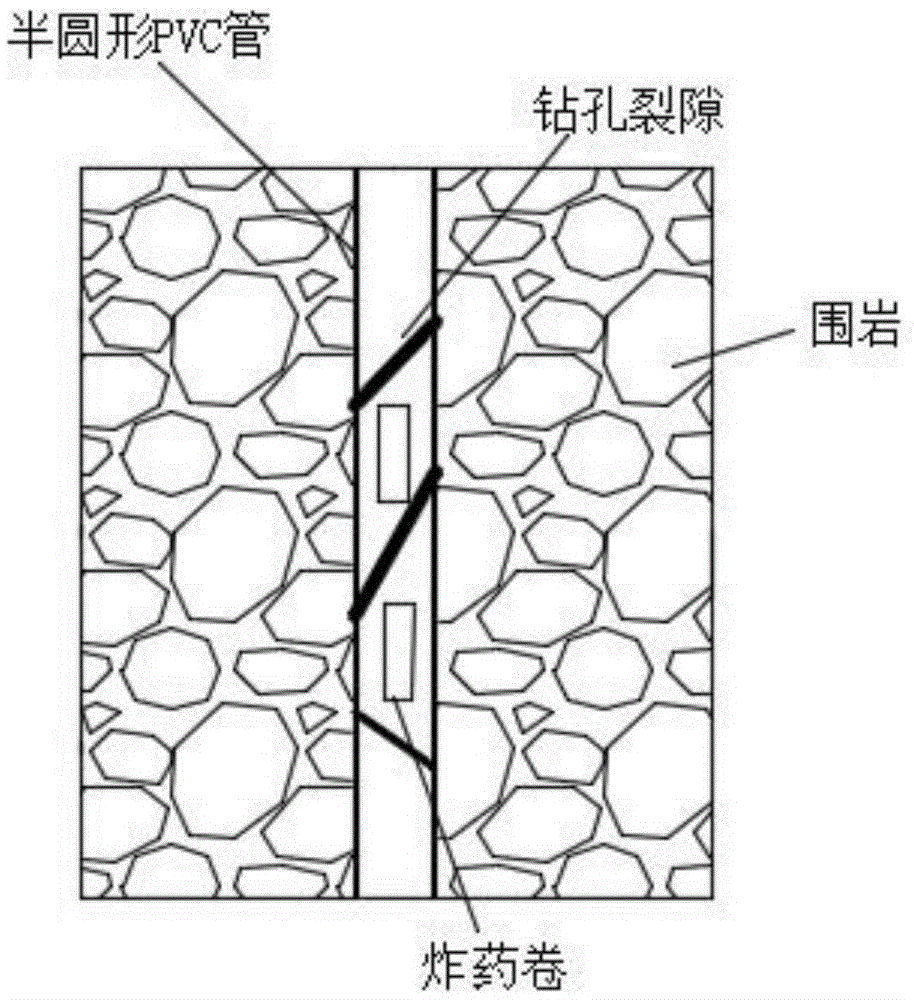

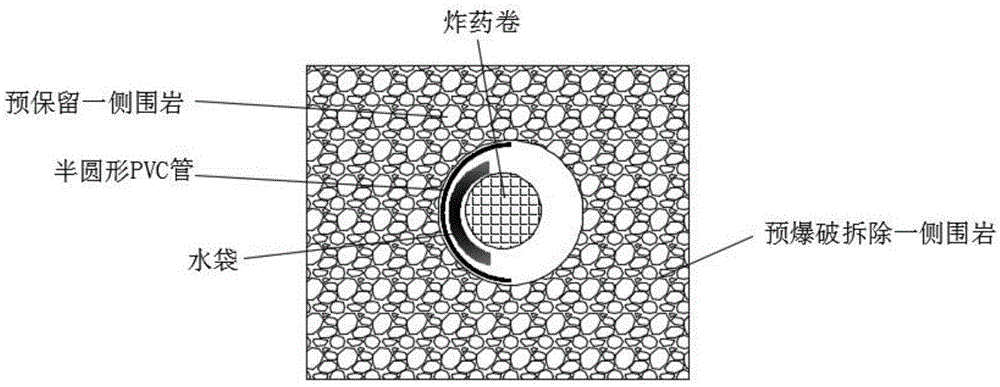

Precise control method for smooth surface blasting of fractured rock mass of highway tunnel

The invention relates to a precise control method for smooth surface blasting of fractured rock mass of a highway tunnel. The method comprises the following steps: step S1, acquiring the parameters required by precise control on smooth surface blasting; step S2, performing precise control on smooth surface blasting, namely arranging explosives according to a rule that no explosive cartridges are arranged at fractured positions inside a drilling hole; calculating the single-hole explosive load; determining the amount of water in a water bag; respectively controlling according to the drilling holes which are different in completeness; step S3, after blasting is ended, regulating the single-hole explosive load and water amount according to the overbreak and underbreak amount and the value of the half-hole ratio; step S4, drilling again and blasting again according to the updated single-hole explosive load and water amount, sequentially circulating until the tunnel is accomplished. According to the method, dynamic regulation is continuously performed and the explosion effect is precisely controlled as far as possible, so that the aim of controlling the overbeak and underbreak of blasting is realized, the utilization of the explosives is increased, loss of the explosives is reduced, and the engineering cost is lowered.

Owner:CHONGQING UNIV

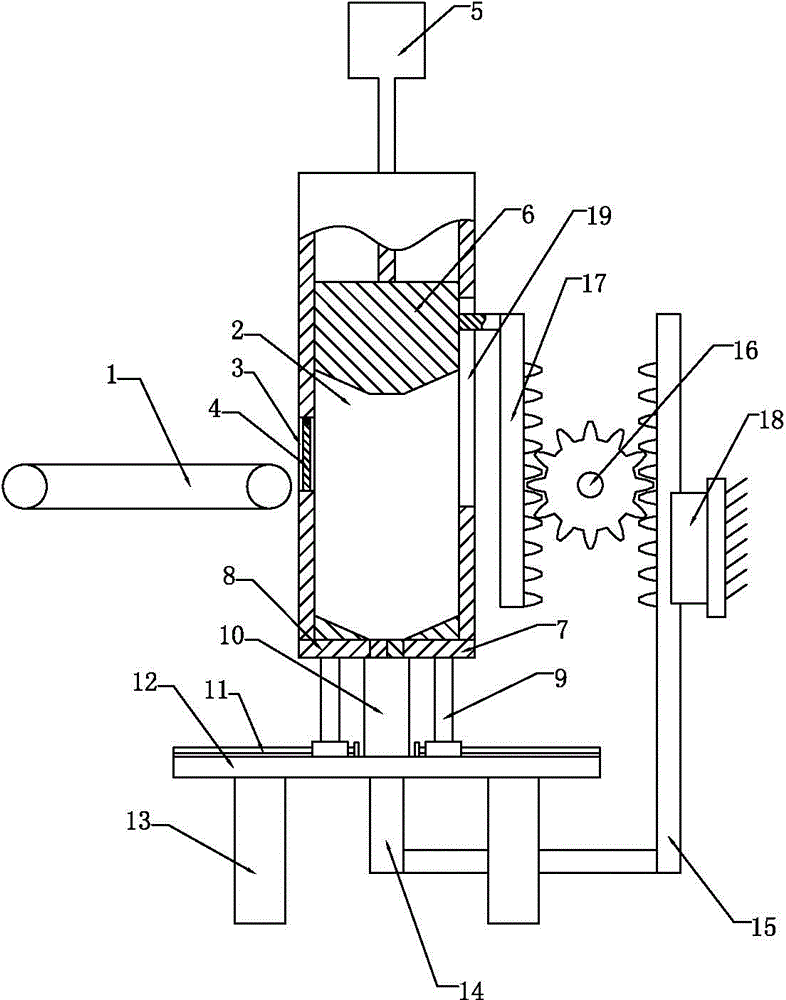

Hammer crusher for ceramic manufacturing

The invention relates to a crushing device, and discloses a hammer crusher for ceramic manufacturing. The hammer crusher comprises a crushing cylinder, and a crushing weight is connected to the upper portion of the crushing cylinder in a sliding manner and is driven by a hydraulic cylinder; a discharging opening is formed in the bottom end of the crushing cylinder, and a cover plate is in sliding connection to the wall of the discharging opening; the cover plate comprises a first plate and a second plate which are symmetric with the discharging opening as the center, and supporting rods are connected on the lower portions of the first plate and the second plate respectively; sliding rails are arranged below the two supporting rods, and the supporting rods are connected to the sliding rails in a sliding manner; a through groove is formed in one side of the crushing cylinder, and the crushing weight penetrates the through groove to be connected with a first rack arranged outside the crushing cylinder; the first rack is meshed with a gear, and the gear is meshed with a second rack; and the second rack is connected with a rubber ejector rod for ejecting the cover plate in a pressing manner. The problem that a cover plate of an existing ceramic crusher is prone to deformation is solved, and the hammer crusher for ceramic manufacturing can prolong the deformation generating time of the cover plate.

Owner:CHONGQING XINSHENG CERAMICS

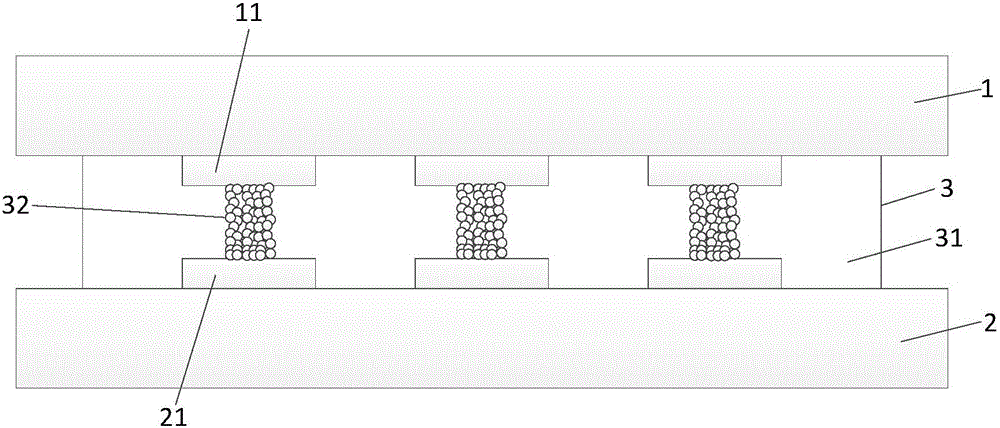

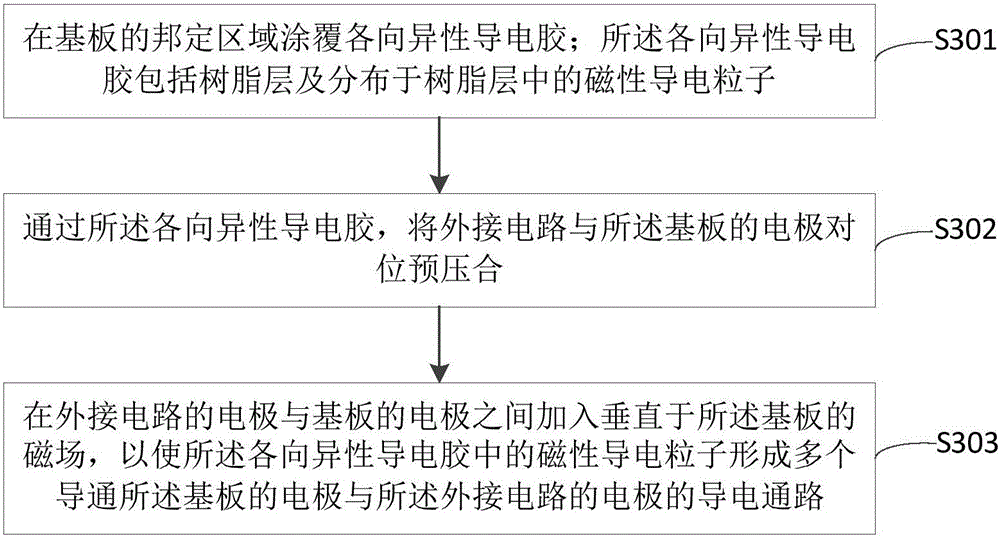

Method using anisotropic conductive adhesives to bond display, substrate and external circuit

InactiveCN105845204AAvoid short circuitAvoid misalignmentNon-insulated conductorsSemiconductor/solid-state device detailsAnisotropic conductive adhesiveElectrode pair

The invention provides a method using anisotropic conductive adhesives to bond a display, a substrate and an external circuit. Each anisotropic conductive adhesive comprises a resin layer and magnetic conductive particles that are distributed on the resin layer. The magnetic conductive particles, under the force of a magnetic field, form a plurality of conductive paths in orientation arrangement so that the electrodes at two sides of the anisotropic conductive adhesives are communicated. According to the invention, when anisotropic conductive adhesives are used to bond a substrate and an external circuit, it does not require heating. Therefore, position deviation of electrode pairs driven by the expansion of the external circuit from heated pressure does not occur. At the same time, as the magnetic field induced magnetic conductive particles, short circuits of magnetic conductive particles do not occur as what is seen in the arrangement of other directions. The low conductivity caused by the uneven distribution of traditional conductive particles when they break can also be overcome. With the method, even at a low temperature, a bonding effect can be achieved with high efficiency.

Owner:BOE TECH GRP CO LTD

Ore coarse crushing device for mining

InactiveCN107321420ALarge rigid impactThe coarse crushing process is stableGrain treatmentsDrive shaftDrive motor

The invention discloses an ore coarse crushing device for mining. The device comprises a lower baseplate; a left stand column and a right stand column are vertically and fixedly mounted on the lower baseplate; the lower end of a lifting rod is hinged with a V-shaped rod; the right end of the V-shaped rod is in sliding fit connection with a first kidney-shaped hole through a pin; a transverse transmission shaft penetrates through the right stand column in a manner of sliding rightwards; a connecting rod is vertically and fixedly mounted at the right end of the transverse transmission shaft; a slide cavity is formed in the right side wall of a crushing basket; a movable block is embedded in the slide cavity in an up-down sliding manner; a limiting column is vertically and fixedly mounted on the lower baseplate; an elliptic cam is rotationally arranged on the lower baseplate through a bracket; an output shaft of a driving motor is connected with a driving belt wheel; a crushing pressure block is fixedly mounted at the lower end of a longitudinal transmission rod; and the crushing pressure block is positioned above the crushing basket. The device is skillful in structure; and ores in the crushing basket can be uniformly spread and distributed on the bottom surface in the crushing basket, so that the ores can be uniformly crushed by the crushing pressure block, the crushing efficiency is higher, and the coarse crushing process of the ores is more stable.

Owner:王少平

Method and device for breaking polysilicon

ActiveCN102836765ARealize large-scale crushing productionSimple processGrain treatmentsElectrical field strengthEngineering physics

The invention discloses a method for breaking polysilicon, which comprises the following steps of: 1) putting the polysilicon into a pool by taking the case that the polysilicon is just sunk in the water as the reference; and 2) applying instant high-voltage electricity to the pool, wherein the electric field intensity generated by the high-voltage electricity is more than or equal to the critical electric field intensity of the pool. With the method for breaking the polysilicon, which is provided by the invention, the traditional polysilicon breaking thought is broken through, the polysilicon is broken by the hydroelectric effect, the large-scale breaking production can be realized, and the technology is simple. The device for breaking the polysilicon, which is provided by the invention, has the advantages of simple and safe structure and easiness in operation. According to the invention, the metal pollution problem in the prior art is avoided, breaking is even, the formation of polysilicon powder is effectively reduced, and the method and the device for breaking polysilicon provided by the invention have a very important meaning for improving the enterprise benefit.

Owner:XINTE ENERGY CO LTD

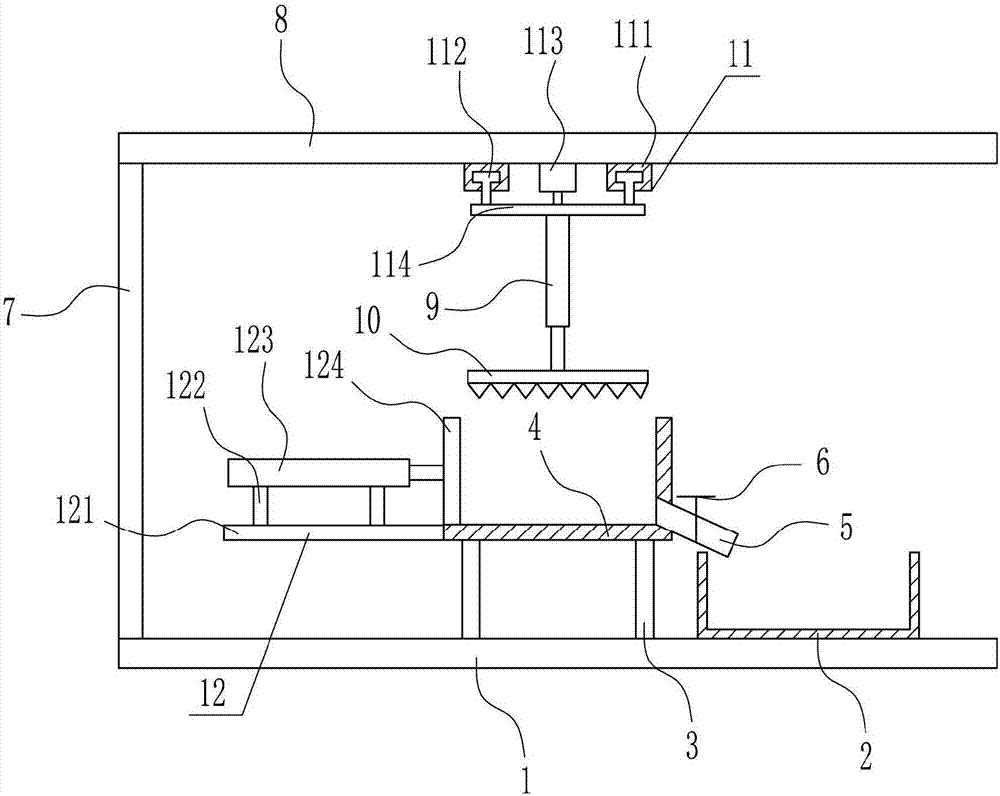

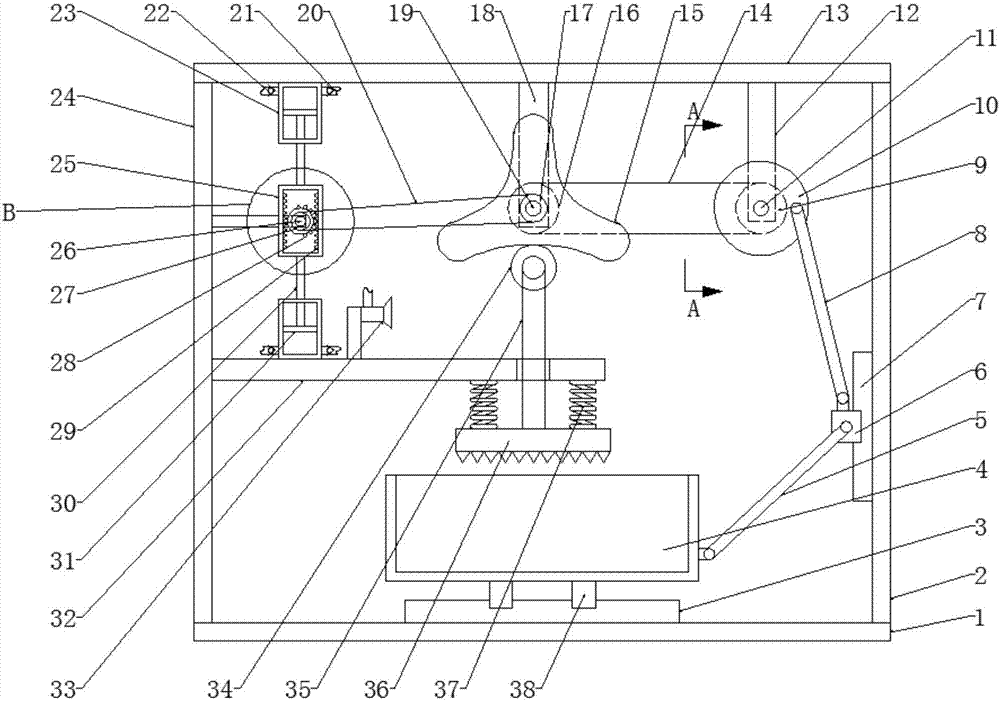

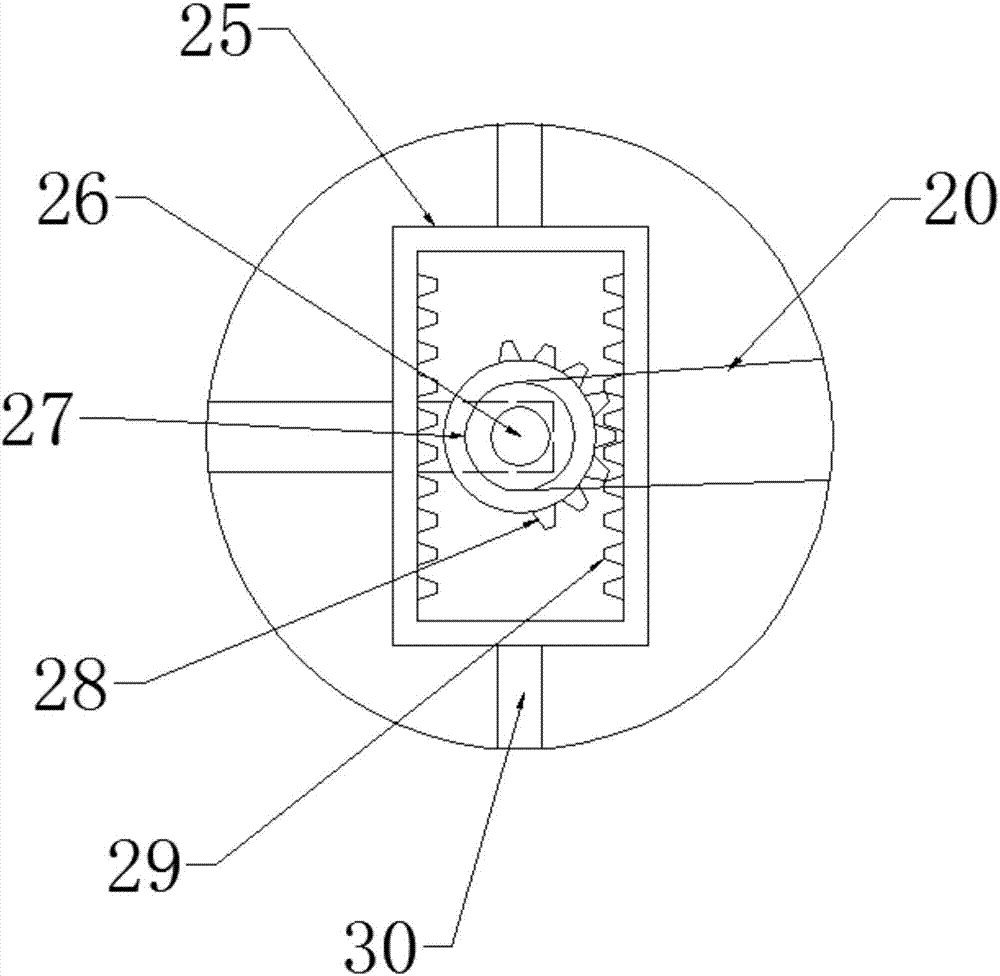

High-reliability glass crushing device

The invention relates to a crushing device and particularly relates to a high-reliability glass crushing device. The technical problem to be solved by the invention is to provide a high-reliability glass crushing device which is uniform in crushing. In order to solve the technical problem, the invention provides the high-reliability glass crushing device comprising a top plate, a first supporting rod, a second supporting rod, a third supporting rod, a rotating motor, a first rotating shaft, a rack, a first sliding block, a first fixed pulley, a first sliding rail and the like; the right side of the top of a second sliding rail is provided with a fourth supporting rod located at the right of a second sliding block; the top of the second sliding block is provided with a crushing tank; a first elastic element is arranged between the right side of the crushing tank and the left side of the fourth supporting rod; and a second fixed pulley is arranged above the left side of the fourth supporting rod. By using the high-reliability glass crushing device, the effects that glass can be uniformly crushed, the crushing treatment efficiency is high, and the device is simple in operation are achieved.

Owner:青岛穗禾集成房屋有限公司

Construction waste crushing and screening device

InactiveCN107335498AAvoid cloggingAffect healthSievingUsing liquid separation agentCircular discGear wheel

The invention discloses a crushing and screening device for construction waste, which comprises a bottom plate, a left side plate, a right side plate, a top plate, a transmission mechanism, a first connecting rod, a second connecting rod, a first sliding sleeve, a vertical sliding rod, a horizontal Rod, third connecting rod, crushing plate, second sliding sleeve, L-shaped rod, crushing frame, slide block, slide rail, discharge pipe, fourth connecting rod, screen mesh, screen box and collection frame, the present invention provides There is a transmission mechanism. The transmission mechanism includes a mounting plate, a motor, a first disc, a mounting shaft, a first gear, a second disc and a second gear. Through the cooperation of the above components, the crushing plate can crush the construction waste in the crushing frame. The structure is simple and the working efficiency is high. At the same time, the crushing frame moves left and right, and the garbage in the crushing frame is constantly turned, so that the crushing is more uniform and thorough, and the crushing efficiency is further improved. There is a fourth connecting rod, a screen and a screen box. The above components work together to drive the screen to move left and right to prevent the screen from being blocked and improve the screening efficiency.

Owner:陈婷

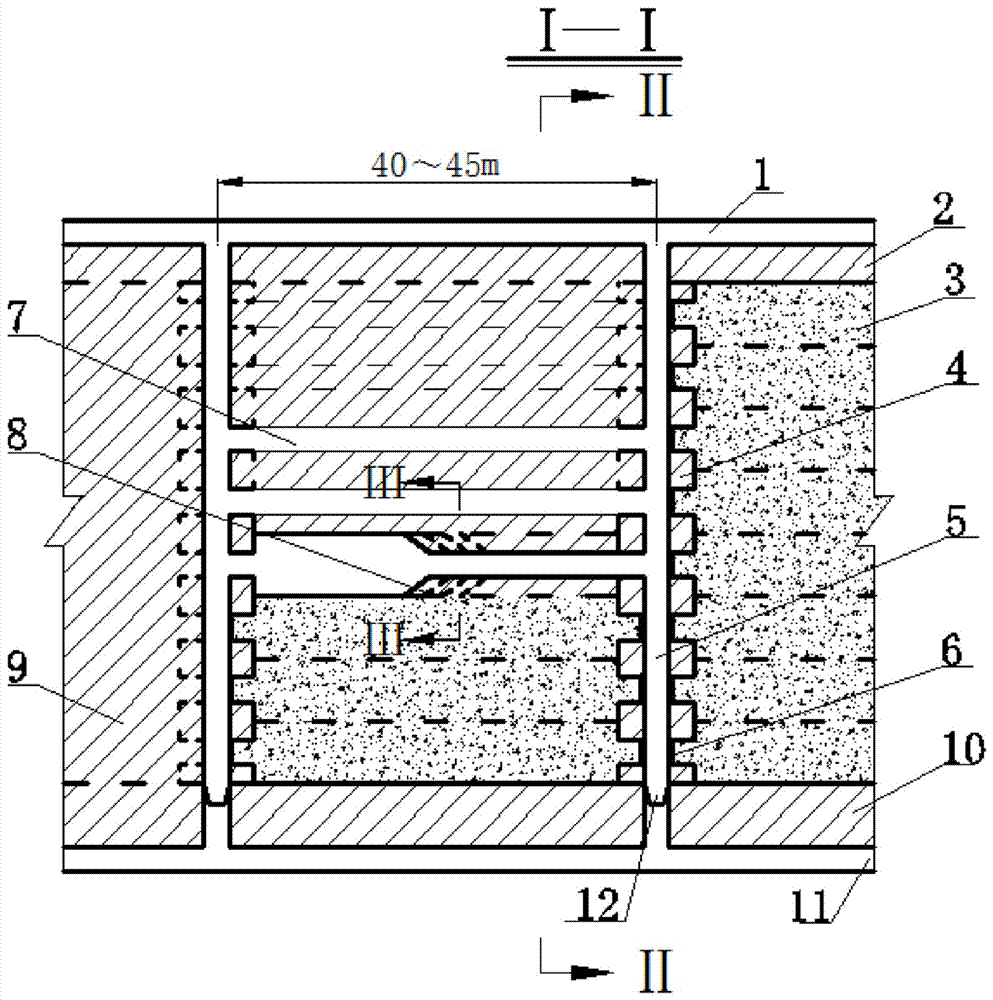

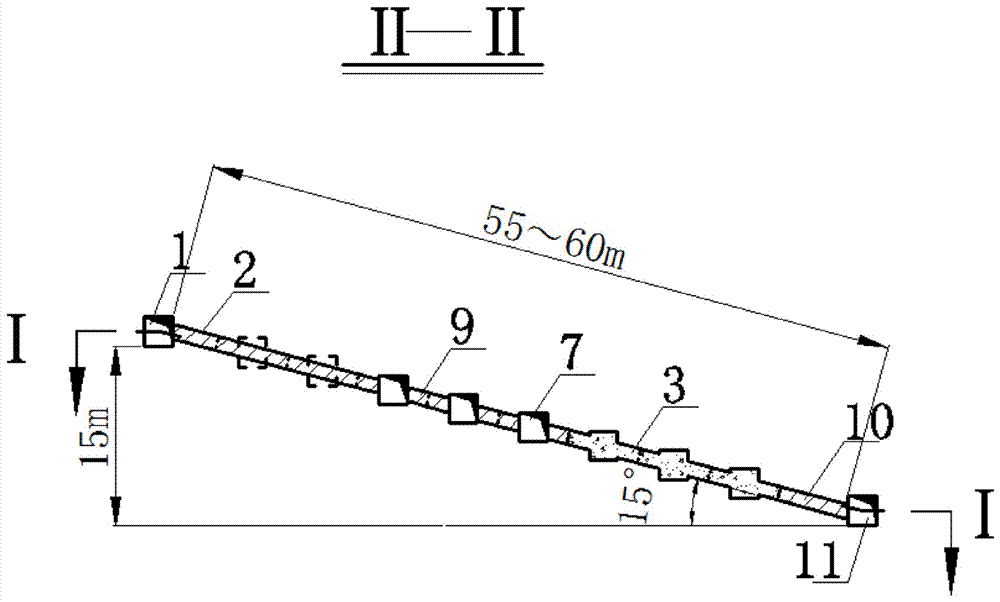

Oblique throwing blasting mining method for gently-inclined thin ore body

InactiveCN107165635AReduce depletion rateReduce mining costsUnderground miningBlastingUnit structureMineralogy

The invention provides an oblique throwing blasting mining method for a gently-inclined thin ore body. The oblique throwing blasting mining method for the gently-inclined thin ore body comprises the following steps that structure parameters of an ore block stoping unit are determined, a stope is arranged in the direction of the ore body, two mining preparation upward-inclining roadways communicating the upper, middle and lower sections are arranged in the stope, and the upward-inclining roadways are arranged in spacer pillars; cutting roadways are sequentially constructed between the two upward-inclining roadways from a bottom pillar to a top pillar of the stope; the oblique distance between the center line of the first cutting roadway and the bottom pillar is 2.5 m, and the oblique distances between the center lines of the subsequent cutting roadways and the bottom pillar are 5 m; stoping starts from the first cutting roadway, backward stoping is adopted, and two controlled blasting methods including oblique pre-splitting blasting and throwing blasting are adopted in order to reduce dilution and loss; after stoping of the first cutting roadway is completed, wooden walls are erected on two sides of the spacer pillars and cementing filling is conducted; after a filling curing period is finished, the second cutting roadway is stoped upwards, and the same stoping process is adopted; and stoping is sequentially recycled until stoping of a mining room is finished. The oblique throwing blasting mining method for the gently-inclined thin ore body is safe, efficient and low in loss, and the loss of mineral resources is reduced.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

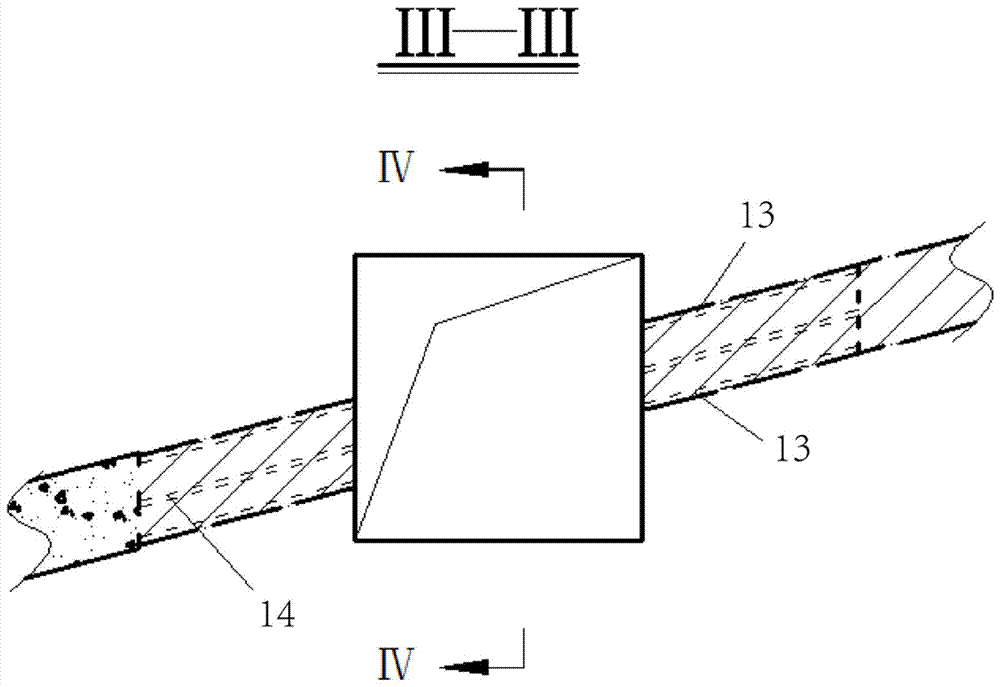

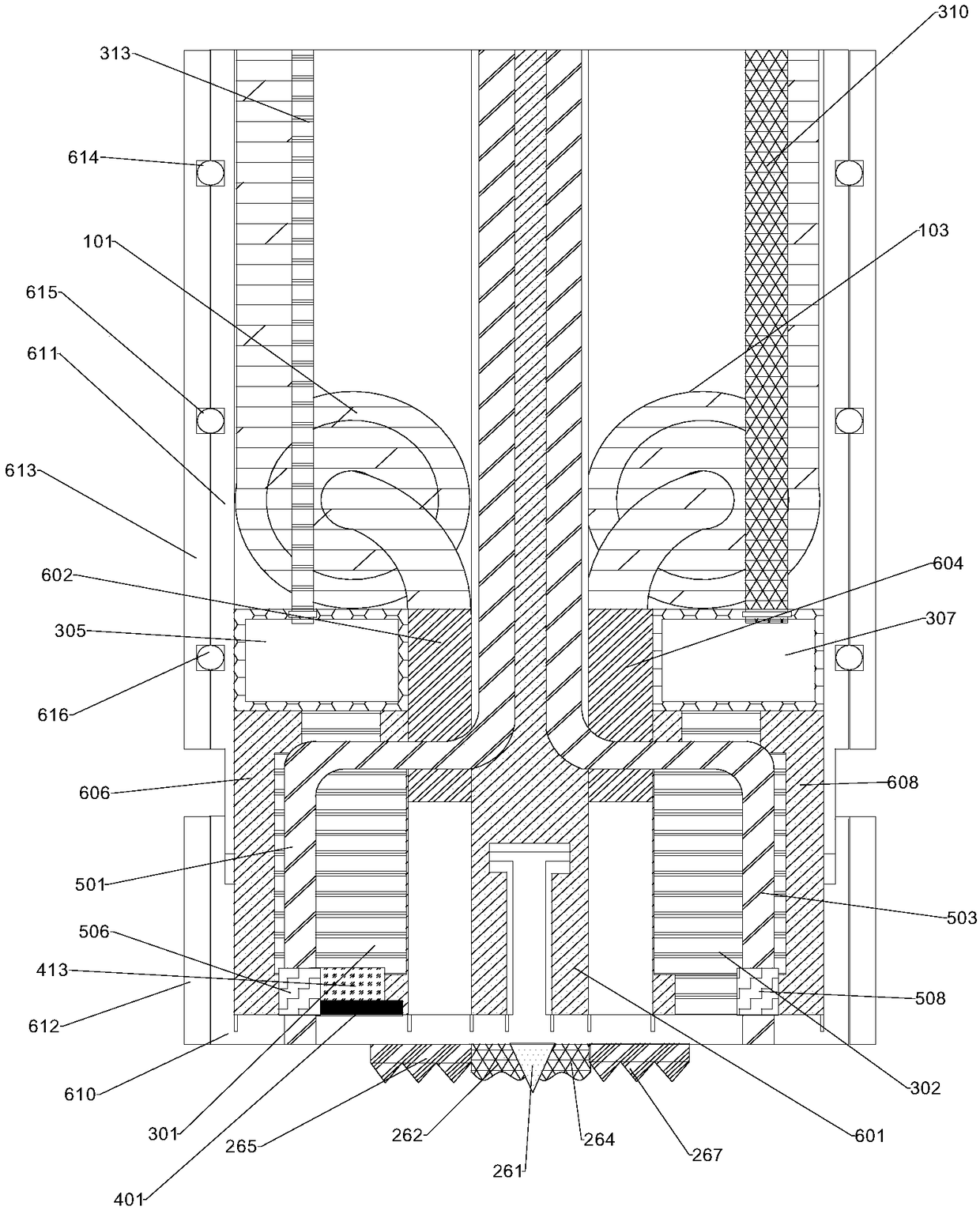

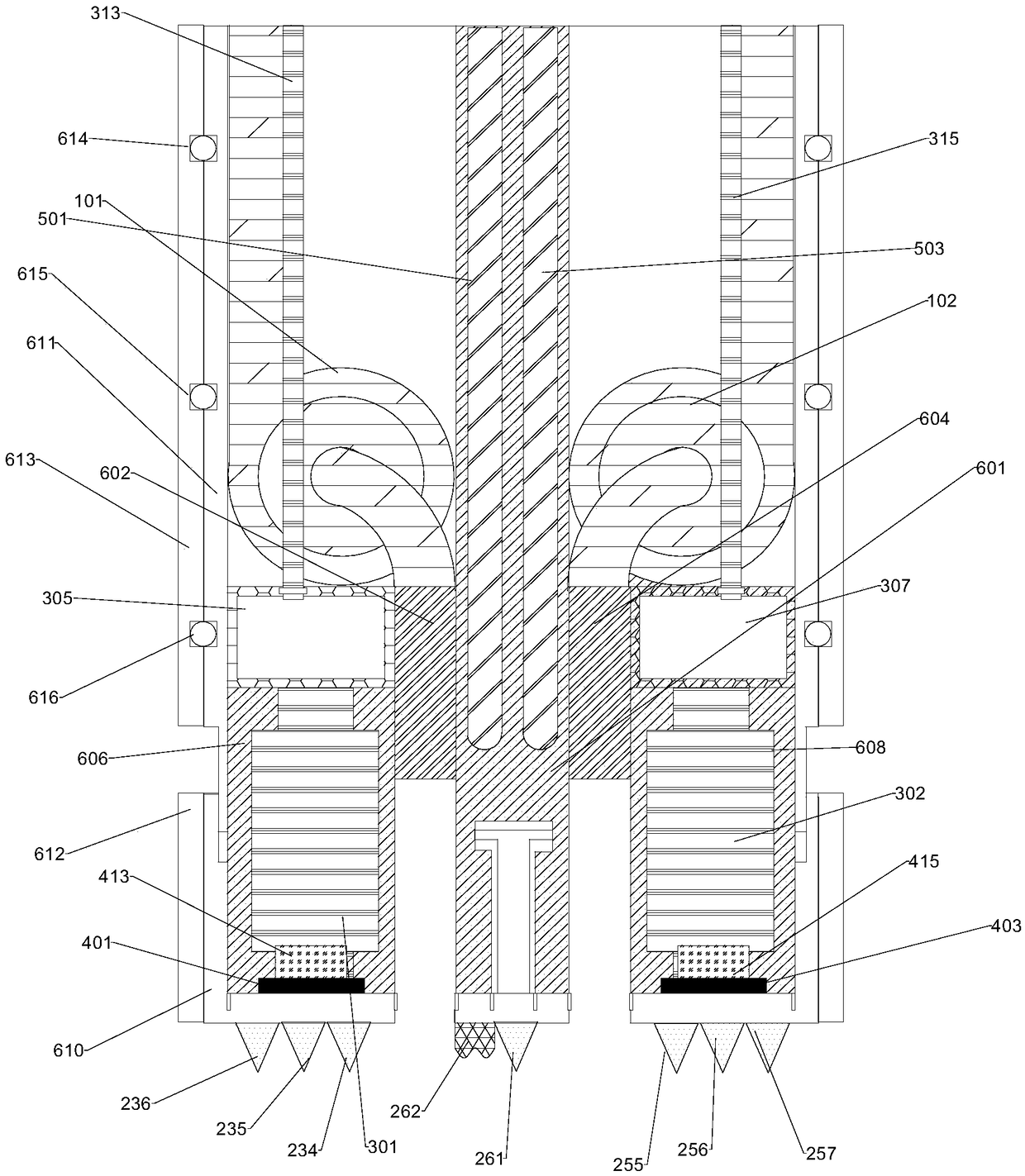

Centrifugal mud discharging type air pressure pressurized drilling and cutting device for soft and hard strata

ActiveCN108643820AEfficient air supplyEfficient decompressionConstructionsBorehole drivesSupporting systemEngineering

The invention provides a centrifugal mud discharging type air pressure pressurized drilling and cutting device for soft and hard strata, and belongs to the technical field of underground engineering rock and soil drilling and cutting and underground engineering disaster prevention and mitigation. The centrifugal mud discharging type air pressure pressurized drilling and cutting device for soft andhard strata comprises a spiral-type centrifugal mud discharging system, a composite drilling and cutting system, a pressurized system, a sensing system, a pump water scouring system and a skeleton supporting system. Operating can be flexibly and quickly conducted during drilling and cutting construction; the composite drilling and cutting system is adopted to conduct drilling and cutting work, thus the uniformity of soil is guaranteed, smooth discharging of the soil is guaranteed, rapid drilling and cutting construction of the soft and hard strata is guaranteed, and the construction speed isincreased; the spiral-type centrifugal mud discharging system is adopted, and a plurality of spiral-type centrifugal mud discharging devices and a plurality of mud discharging pipes are connected, sothat high-speed discharging of rock debris during drilling and cutting construction of the soft and hard strata is guaranteed; and a high-pressure pipe and a wire pipe are embedded in a linear connecting arm, thus the member stiffness and safety are not affected, and materials are saved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

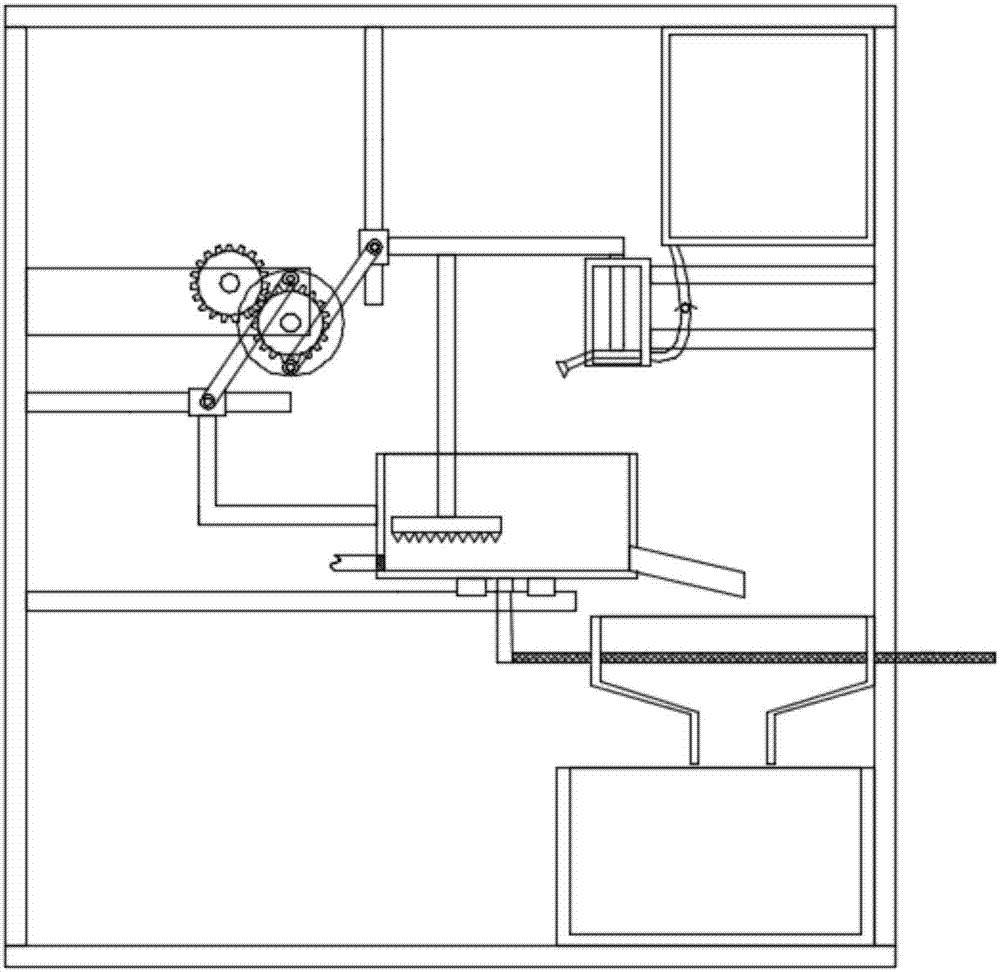

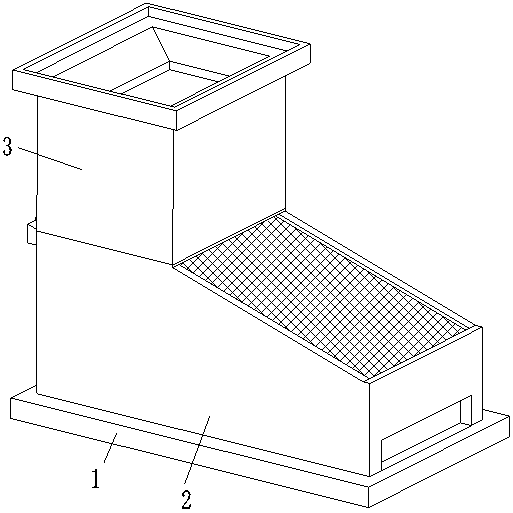

Waterproof coating preparing and processing system

ActiveCN111569995AGood crushing effectEvenly brokenSievingScreeningProcess engineeringManufacturing engineering

The invention relates to a waterproof coating preparing and processing system. A bottom plate, a screening device and a grinding device are included. The screening device is arranged at the upper endof the bottom plate. The left side of the upper end of the screening device is provided with an opening groove provided with the grinding device. The waterproof coating preparing and processing systemcan solve the problems that when existing equipment conducts crushing processing on coating raw materials, the crushing effect is poor, crushing is incomplete, the crushed raw materials cannot be subjected to even grinding processing, the coating preparing effect is influenced, in addition, when the existing equipment screens the coating raw materials, the section area of the raw materials and afilter net is small, consequently, the raw material filter effect is poor, filtering is incomplete, meanwhile, meshes of the filter net are prone to blockage through large-particle impurities, and theraw material screening efficiency is influenced.

Owner:ZHEJIANG YUTONG NEW MATERIAL

Soil raising fire extinguisher and fire extinguishing method

The invention discloses a soil raising fire extinguisher and a fire extinguishing method. The soil raising fire extinguisher comprises a soil raising device, a soil sampling device and a conveying device, which are arranged on a vehicle frame, wherein the soil sampling device is a rotary tillage type operating machine, and is at least provided with a soil sampling cutting head; the soil sampling cutting head rotates at low speed to crush soil on the ground, and the sampled crushed soil is conveyed to a fire extinguishing soil inlet of a screw conveyor arranged on the vehicle frame through a chain conveyor of the conveying device by the soil sampling cutting head; the screw conveyor is vertically arranged on the vehicle frame; the fire extinguishing soil is conveyed to an inlet of the soil raising device after being further crushed through the screw conveyor; the soil raising device is also arranged on the vehicle frame; the fire extinguishing soil is ejected for fire extinguishing operation through the soil raising device. According to the soil raising fire extinguisher and the fire extinguishing method, the fire extinguishing soil can be uniformly crushed by twice pulverization and twice conveyance, is spirally conveyed to a part above a soil ejection gun, and is ejected by utilizing high-pressure airflow, so that soil ejection fire extinguishing effects can be effectively improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

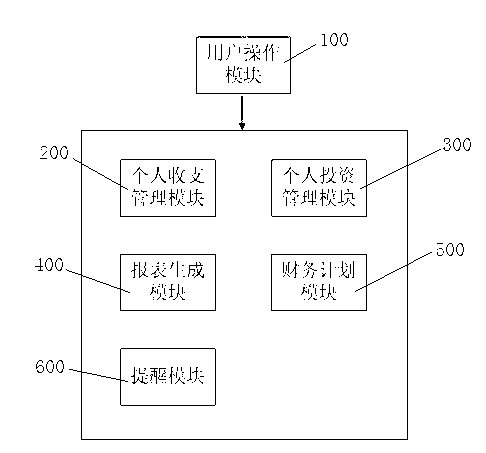

Personal financial management system

InactiveCN102708467AEvenly brokenReasonable financial planningResourcesFinancial well beingProgram planning

The invention discloses a personal financial management system which comprises a user operation module, a personal income and expenditure management module, a personal investment management module, a report generation module, a financial planning module and a reminding module, wherein the user operation module is used for a user to input user a name and password login system to input relevant financial data; the personal income and expenditure management module is used for managing daily income and expenditure information of the user; the personal investment management module is used for managing information of income from investment of financial products of the user; the report generation module is used for generating various financial reports to know about the current financial status of the user; the financial planning module is used for generating a future financing plan and calculating a simulated result; the reminding module is used for reminding the user of various financial deadlines and financial operations going beyond the financing plan. With the adoption of the personal financial management system, the user can master the current financial status to achieve the balance of income and expenditure and can draw up a reasonable financing planning on the basis of the current property status and the financial goal.

Owner:苏州奇可思信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com