Patents

Literature

261results about How to "Low peel strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Touch panel

ActiveUS20140134433A1Enhancing performance of inhibiting changeImprove cohesive strengthFilm/foil adhesivesMacromolecular adhesive additivesElectrical conductorMeth-

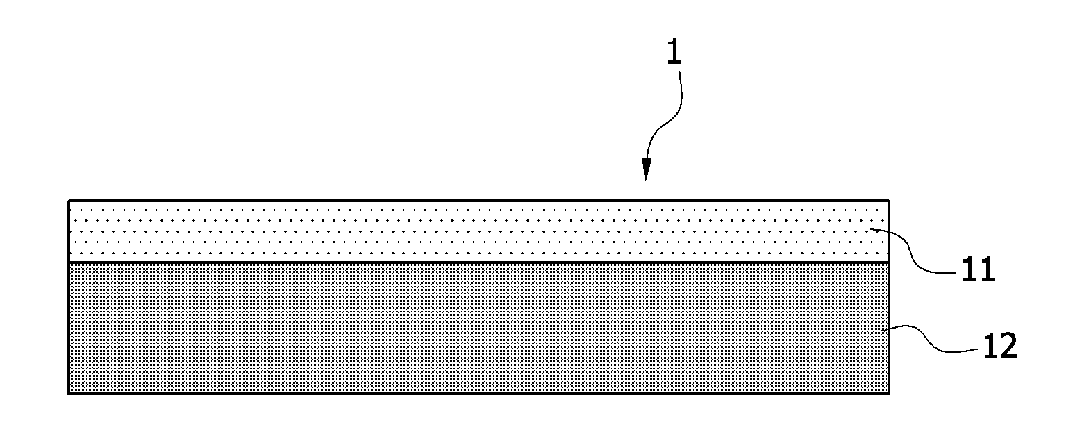

Provided is a touch panel. The touch panel includes a base and a pressure-sensitive adhesive layer attached to the base and including an acryl-based polymer containing an acryl polymer containing 5 to 30 parts by weight of isobornyl (meth)acrylate, and 5 to 40 parts by weight of methyl (meth)acrylate in a polymerized form. Accordingly, it can effectively inhibit penetration of oxygen, moisture or other impurities at an interface between the base and the pressure-sensitive adhesive layer, or at an interface between a conductor thin film and the pressure-sensitive adhesive layer, and prevent degradation in optical properties such as visibility, etc. due to bubbles generated at the pressure-sensitive adhesive interface. In addition, when the pressure-sensitive adhesive layer is directly attached to the conductor thin film and even exposed to severe conditions such as high temperature or high temperature and high humidity, a change in the resistance of the conductor thin film may be effectively inhibited, and thus the touch panel can be stably driven for a long time.

Owner:LG CHEM LTD

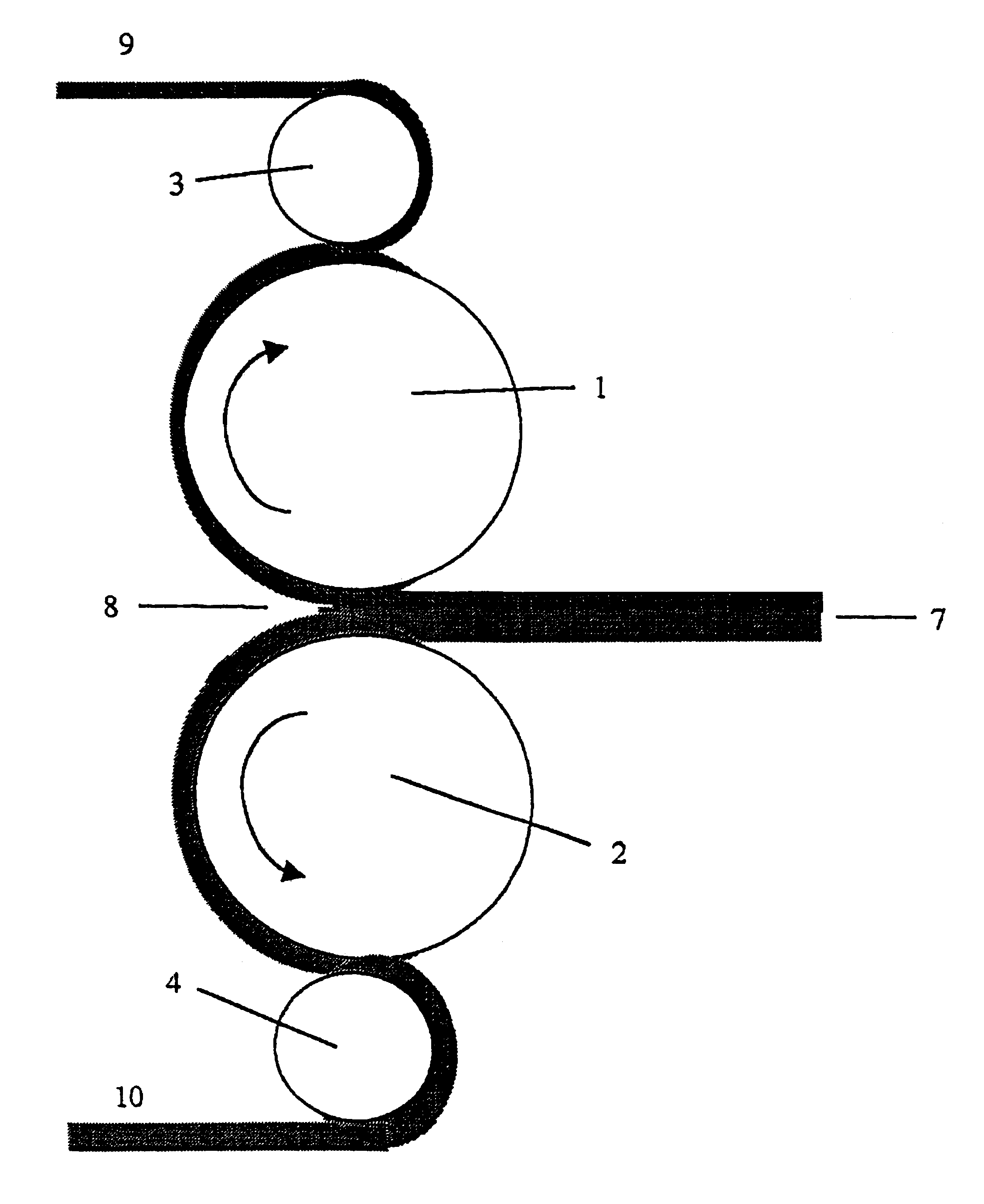

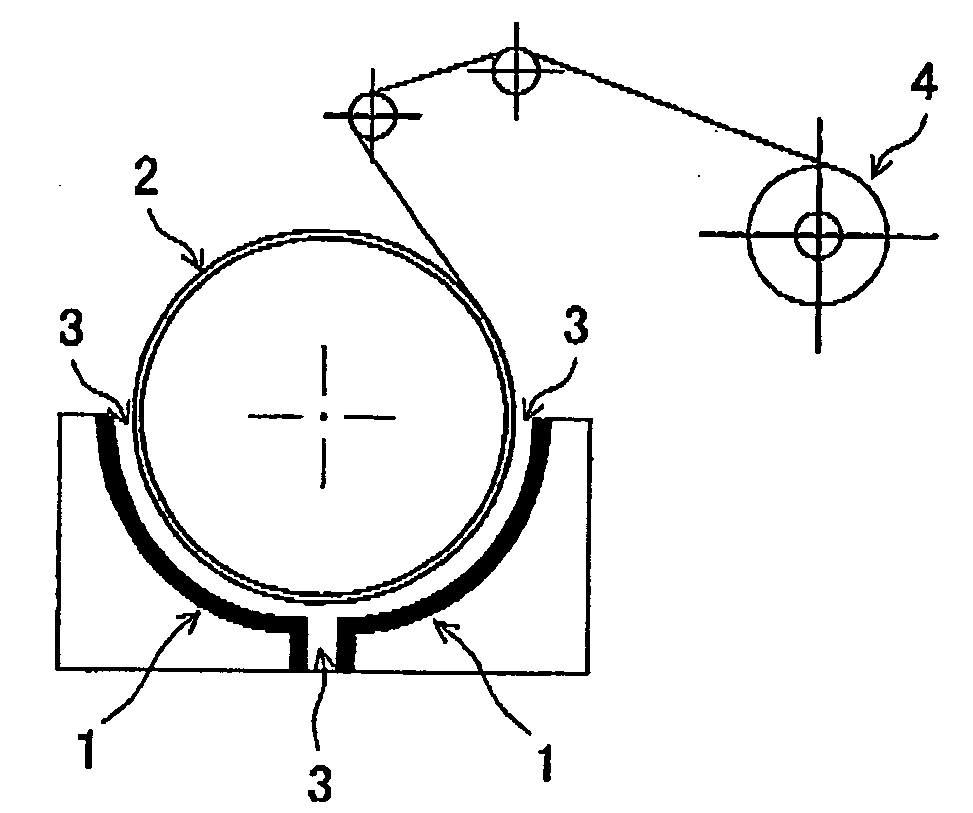

Multi-layer paper peelable into at least two thin sheets

InactiveUS6977111B2Low densityLose weightNon-fibrous pulp additionSpecial paperWood veneerStencil printing

Disclosed is a multi-layer paper suitable as a material for preparing heat-sensitive stencil printing masters. The multi-layer paper is produced by combining a plurality of thin paper layers by paper making. The multi-layer paper has a peel strength of 10 N / m or less and may be delaminated into at least two tissue sheets.

Owner:RICOH KK +1

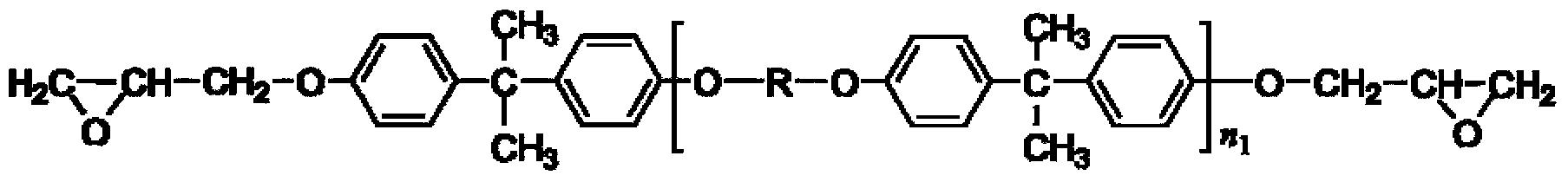

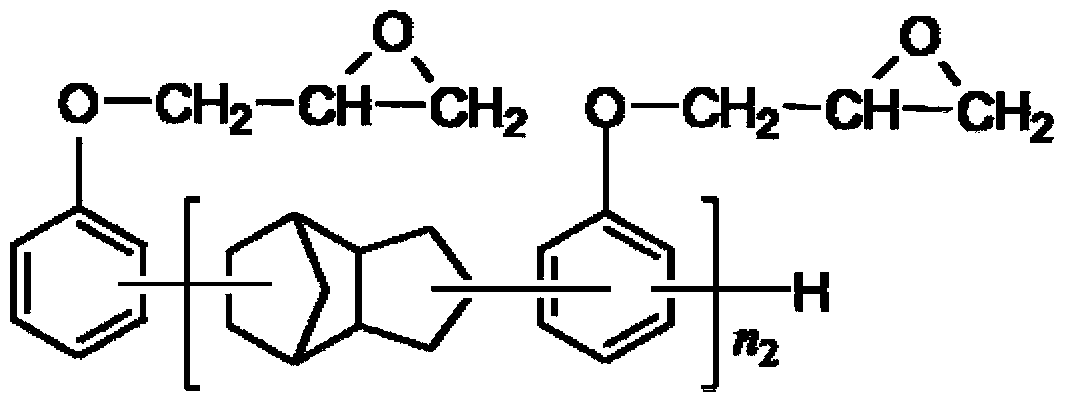

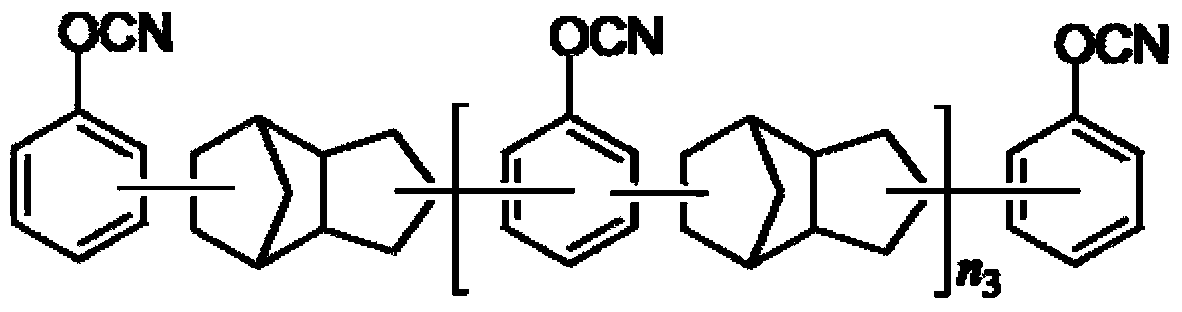

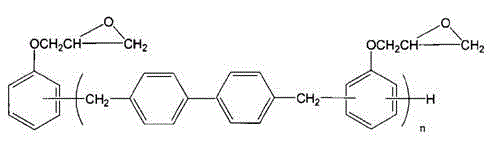

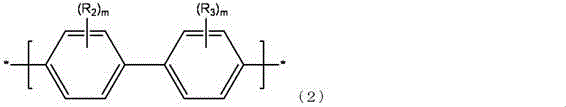

High-dielectric-constant resin composition and application thereof

InactiveCN103351581ALow dielectric lossExcellent dielectric propertiesSynthetic resin layered productsMetal layered productsGlass fiberDielectric loss

The invention relates to a high-dielectric-constant resin composition, as well as a prepreg and a copper-clad laminate (CCL) which are manufactured thereby. The prepreg manufactured by the high-dielectric-constant resin composition comprises high-dielectric-constant glass fiber fabric and a high-dielectric-constant resin composition subjected to impregnation drying and then attached to the high-dielectric-constant glass fiber fabric. The CCL manufactured by the high-dielectric-constant resin composition comprises at least one overlapped prepreg and copper foils pressed and coated on both sides of the overlapped prepregs. The CCL manufactured by the high-dielectric-constant resin composition has the performances of high dielectric constant, low dielectric loss, high glass transition temperature, high peel strength and the like and can meet the performance requirement of the high-dielectric-constant antenna substrate.

Owner:GUANGDONG SHENGYI SCI TECH

Card intermediates

InactiveUS20050147781A1Different peeling strengthTightly boundThin material handlingMetal layered productsSoftware engineeringMechanical engineering

Owner:POLYMERIC CONVERTING

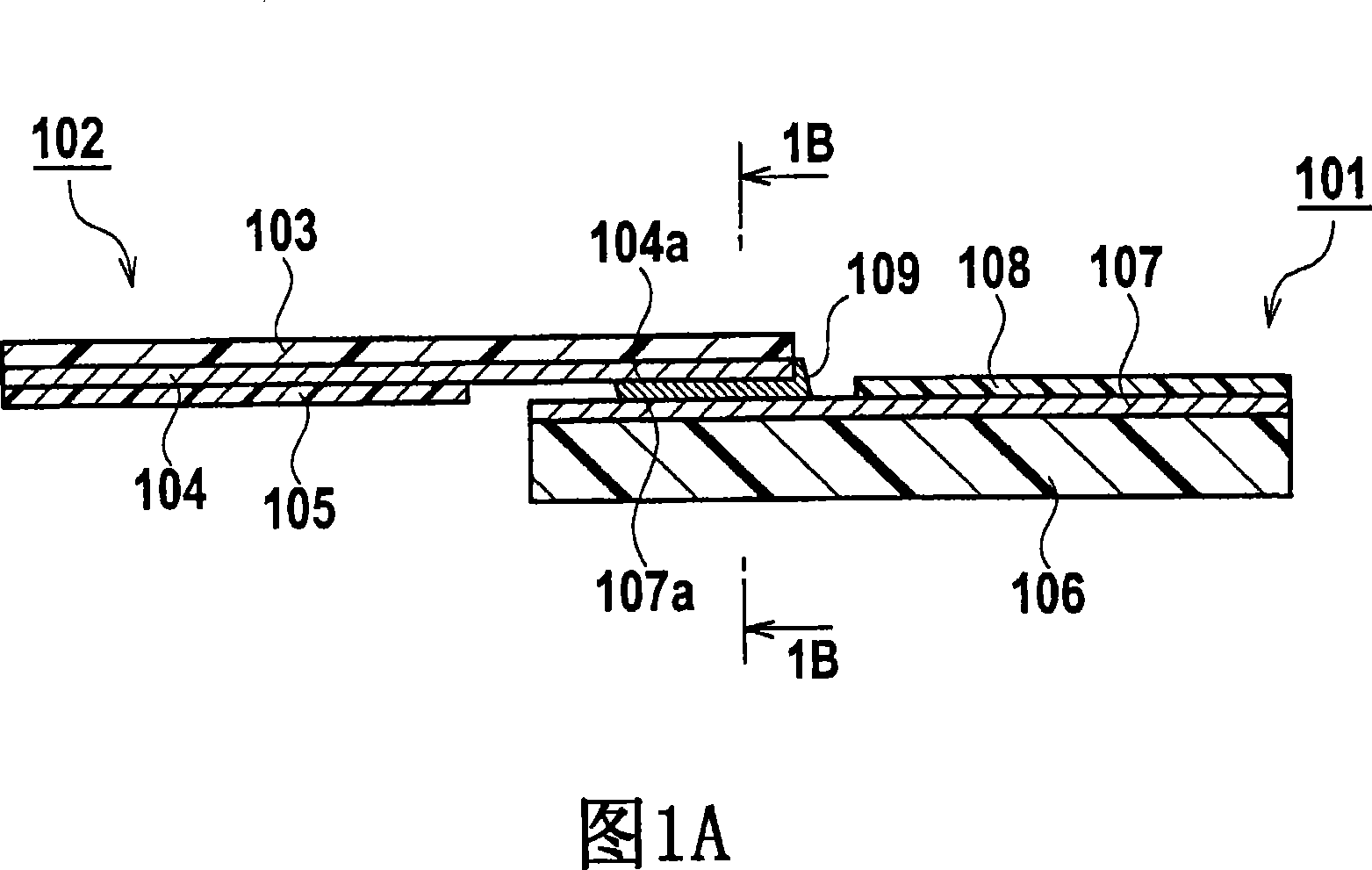

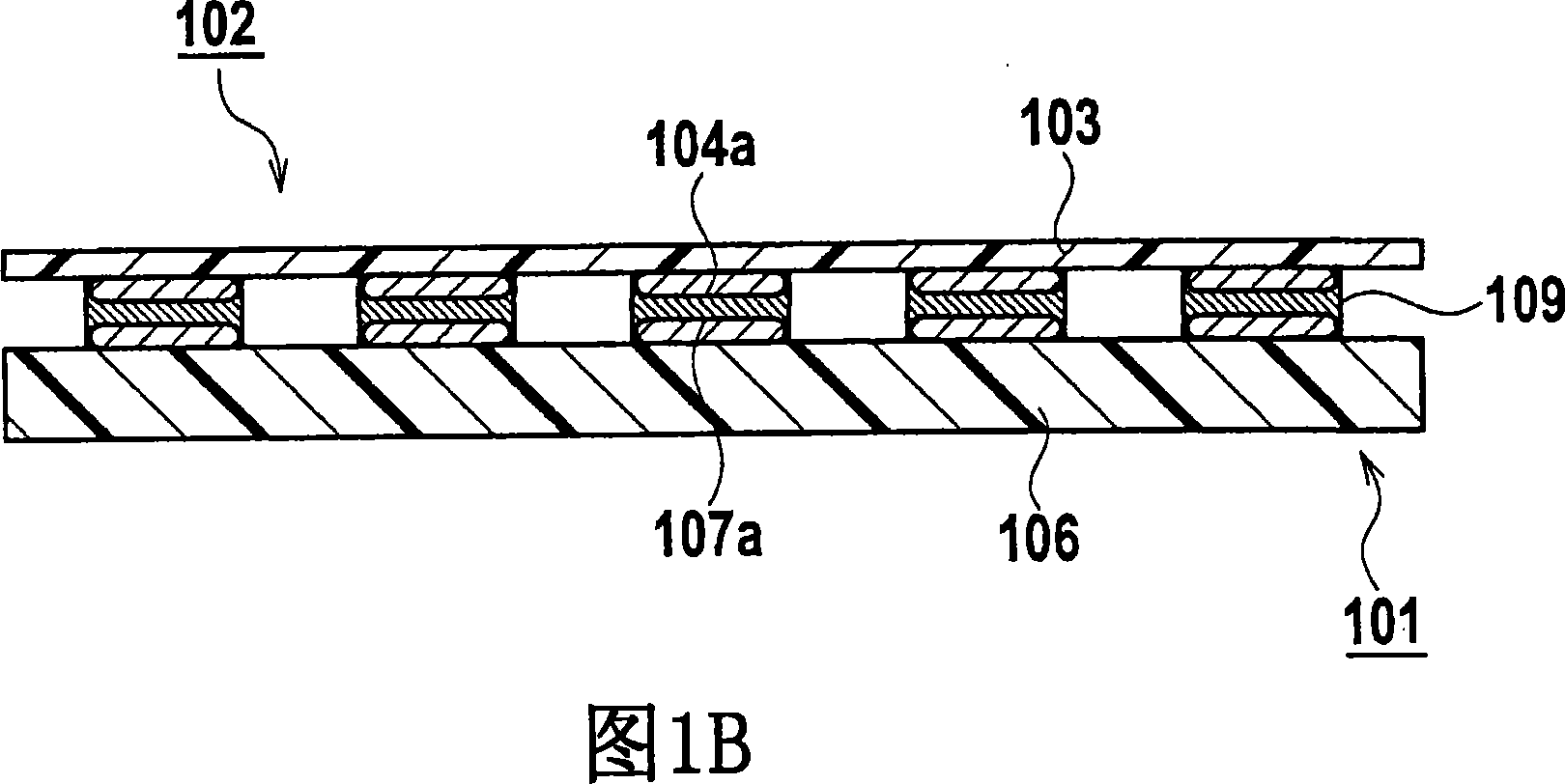

Printed wiring board, method for forming the printed wiring board, and board interconnection structure

InactiveCN101080138ALow peel strengthReduce spacingSolid-state devicesPrinted circuit manufactureEngineeringInterconnection

A board interconnection structure having a first printed wiring board in which a first conductive circuit is arranged on a first insulating layer, the first conductive circuit having, on an end portion thereof, a first connection terminal in which an upper surface width is narrower than a bottom surface width; a second printed wiring board in which a second conductive layer having a second connection terminal is arranged on a second insulating layer; and a connection layer that forms fillets along longitudinal side surfaces of the first connection terminal, and interconnects the first connection terminal and the second connection terminal. The first connection terminal may have a projection portion.

Owner:THE FUJIKURA CABLE WORKS LTD

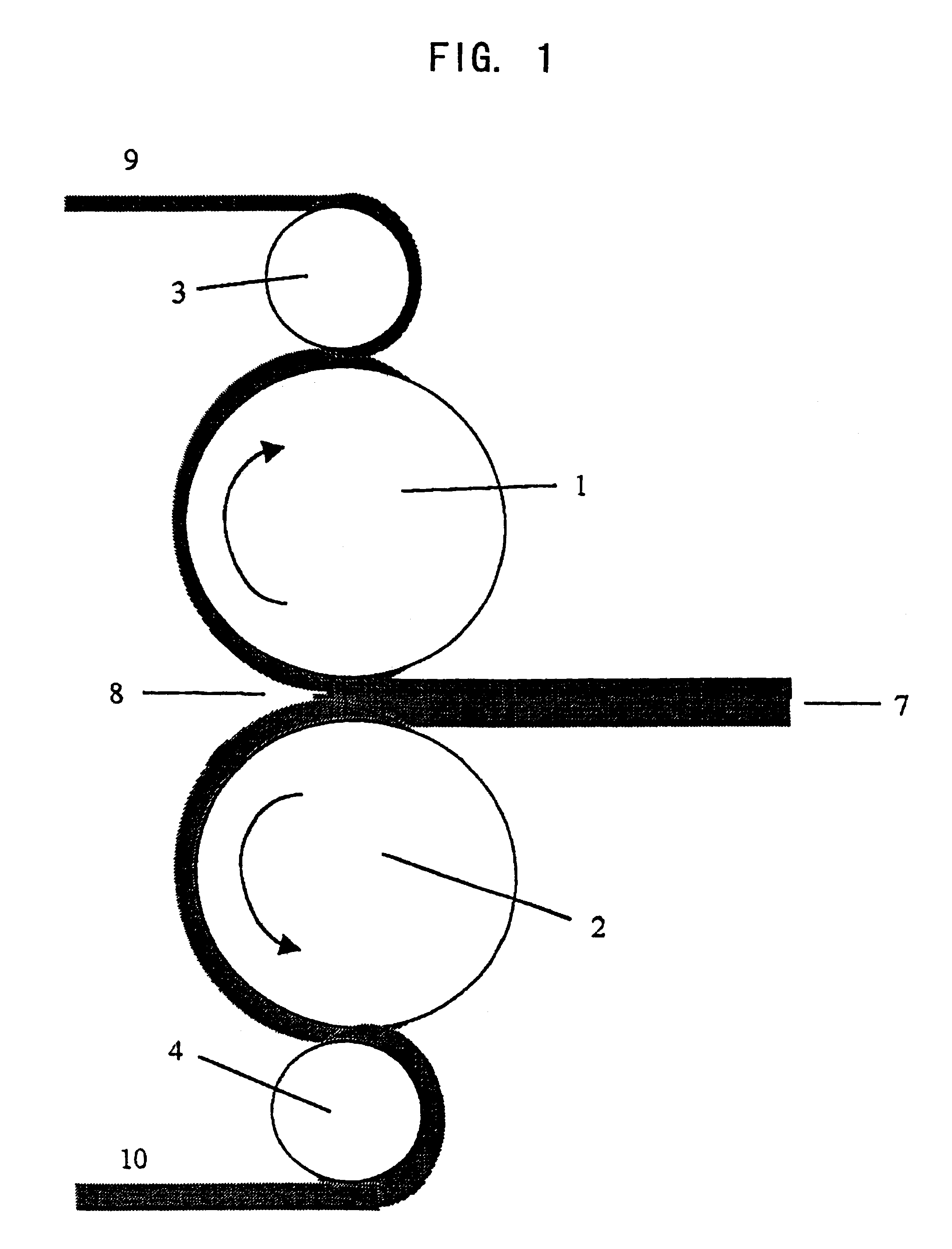

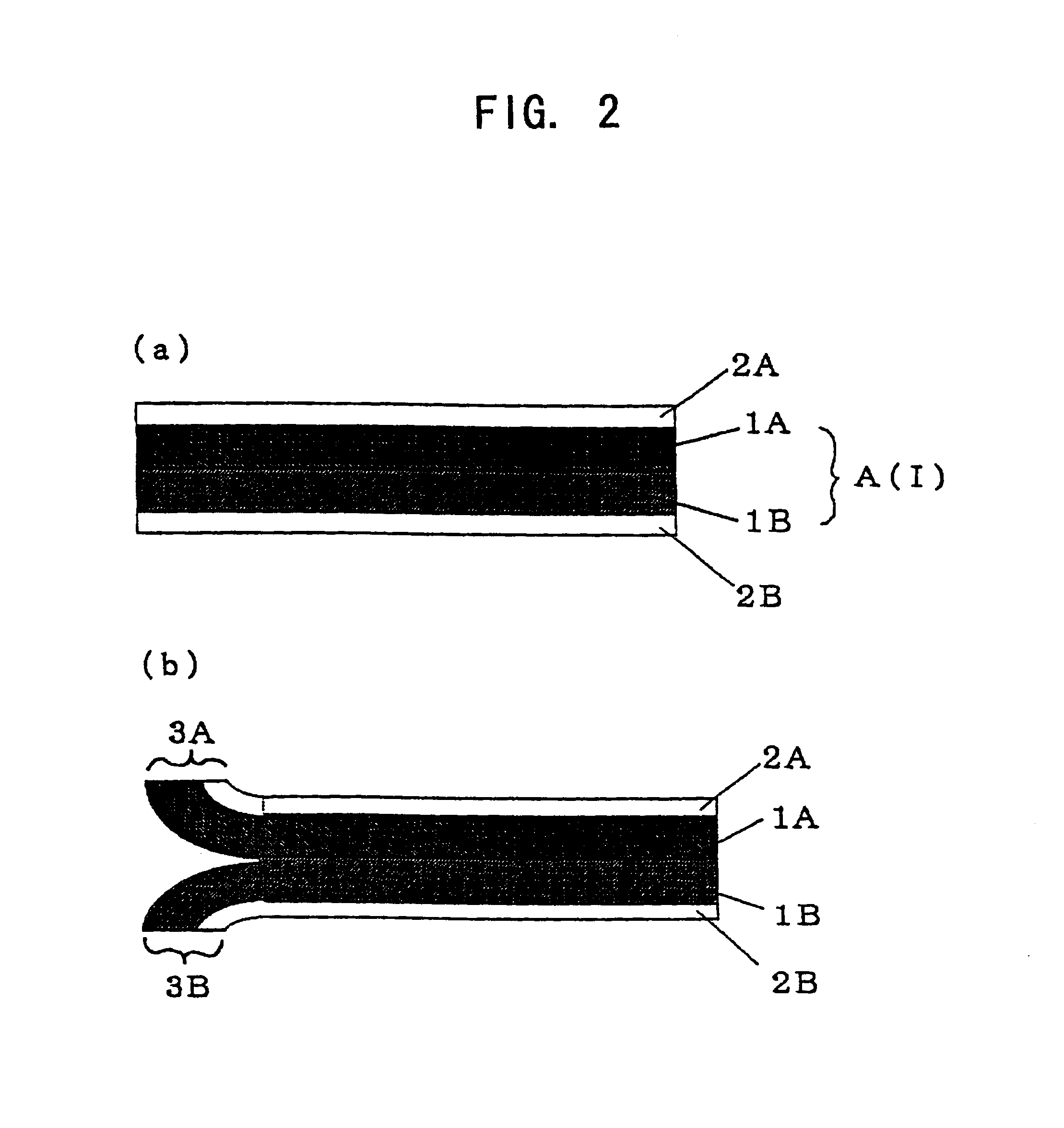

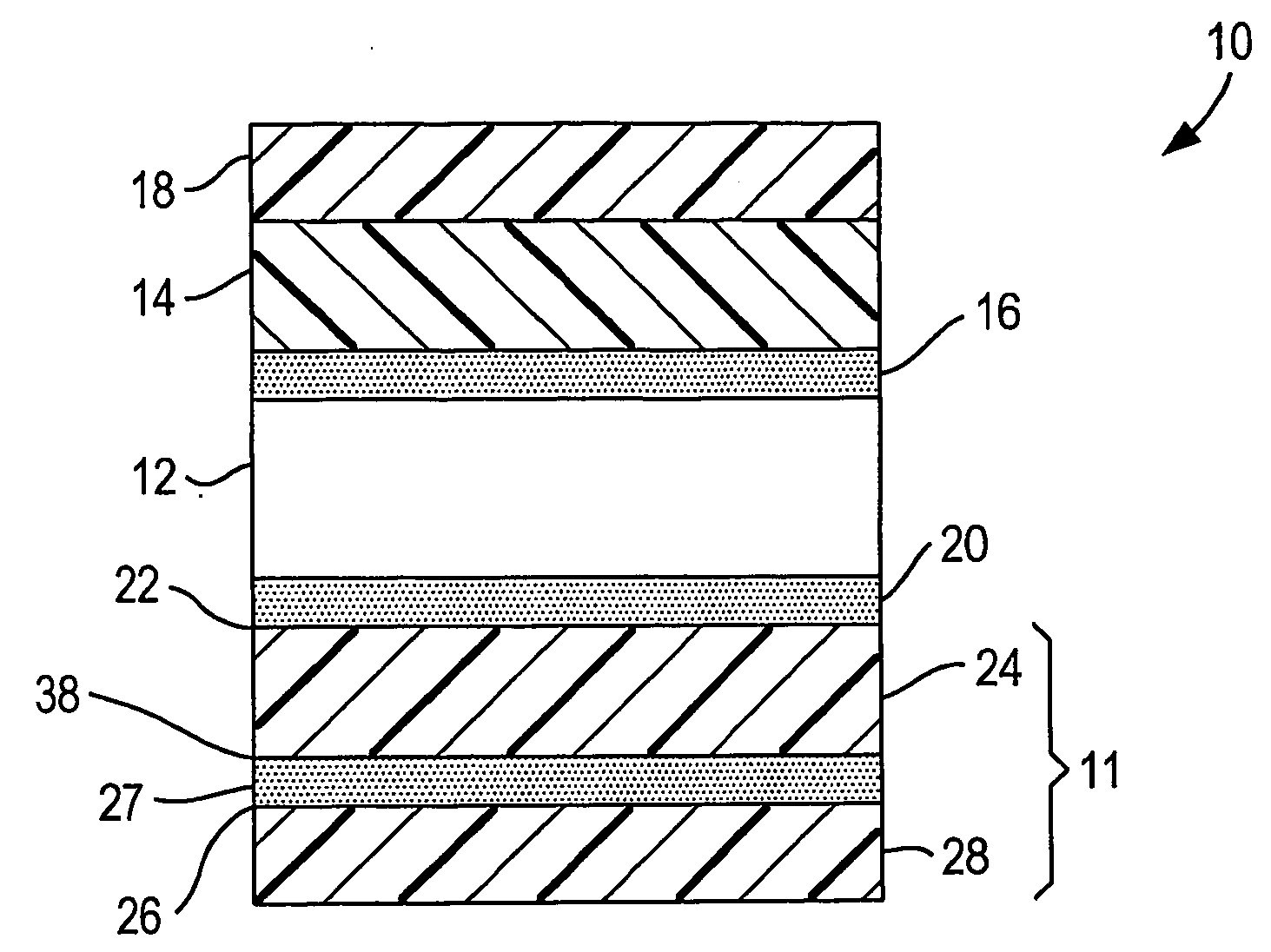

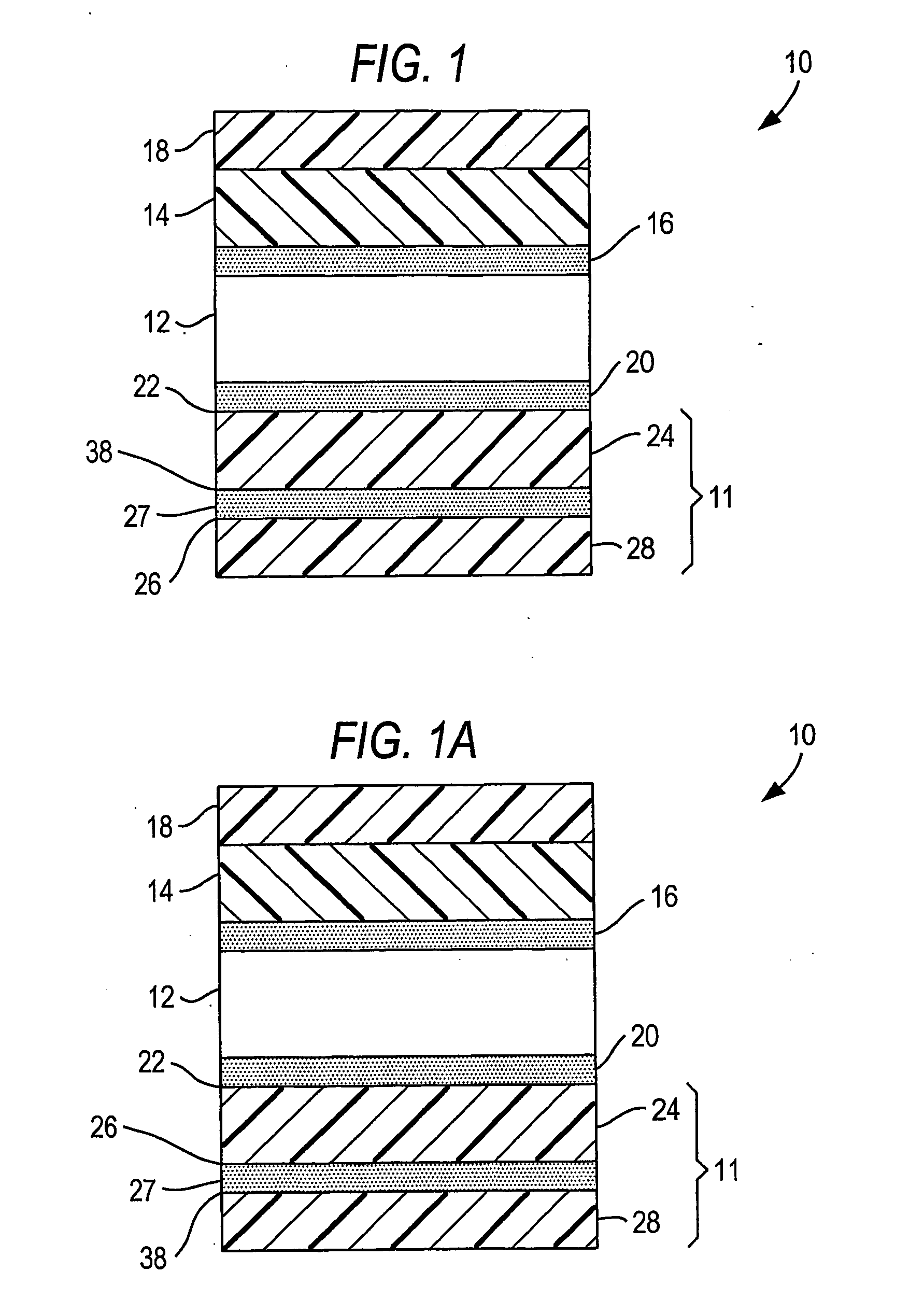

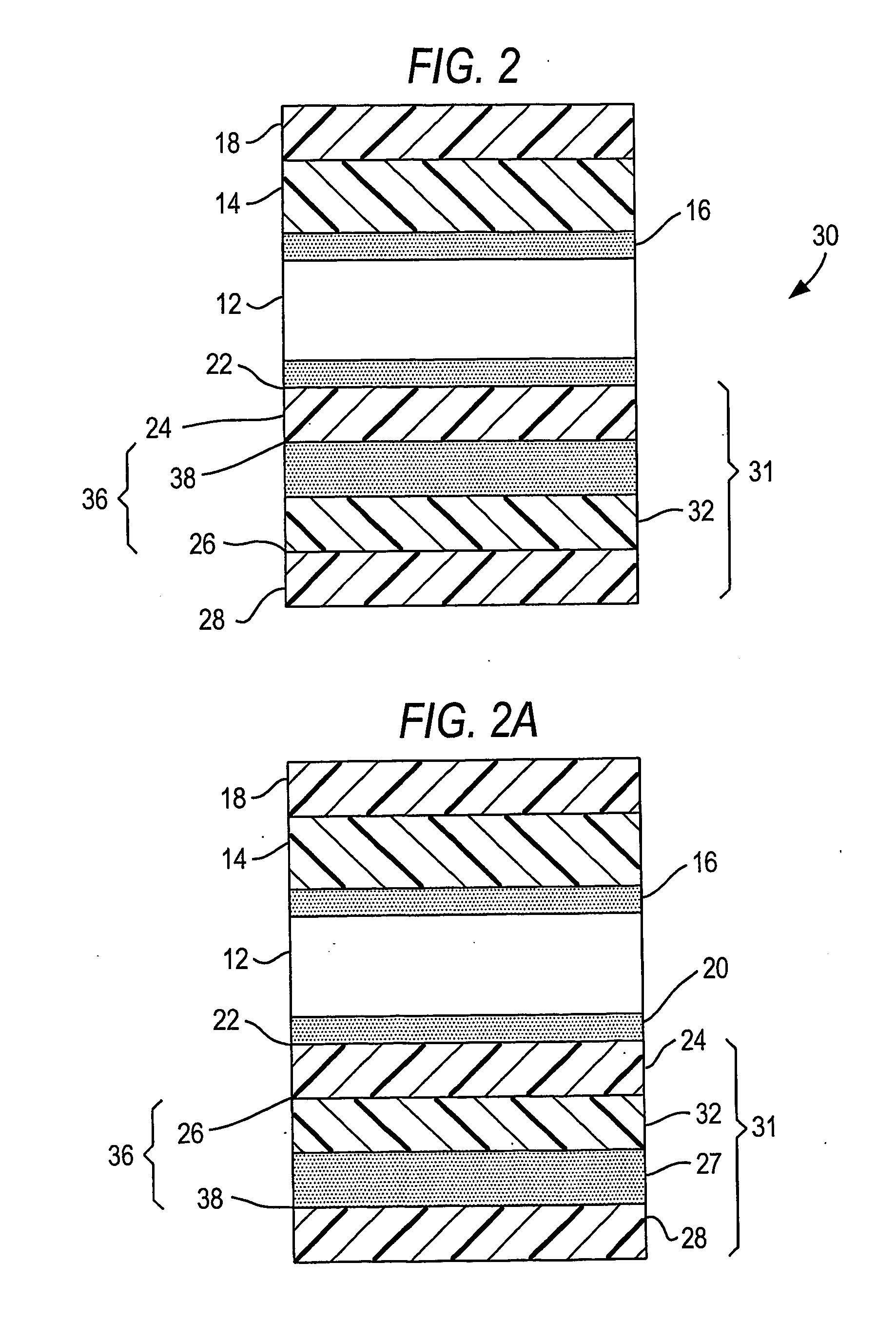

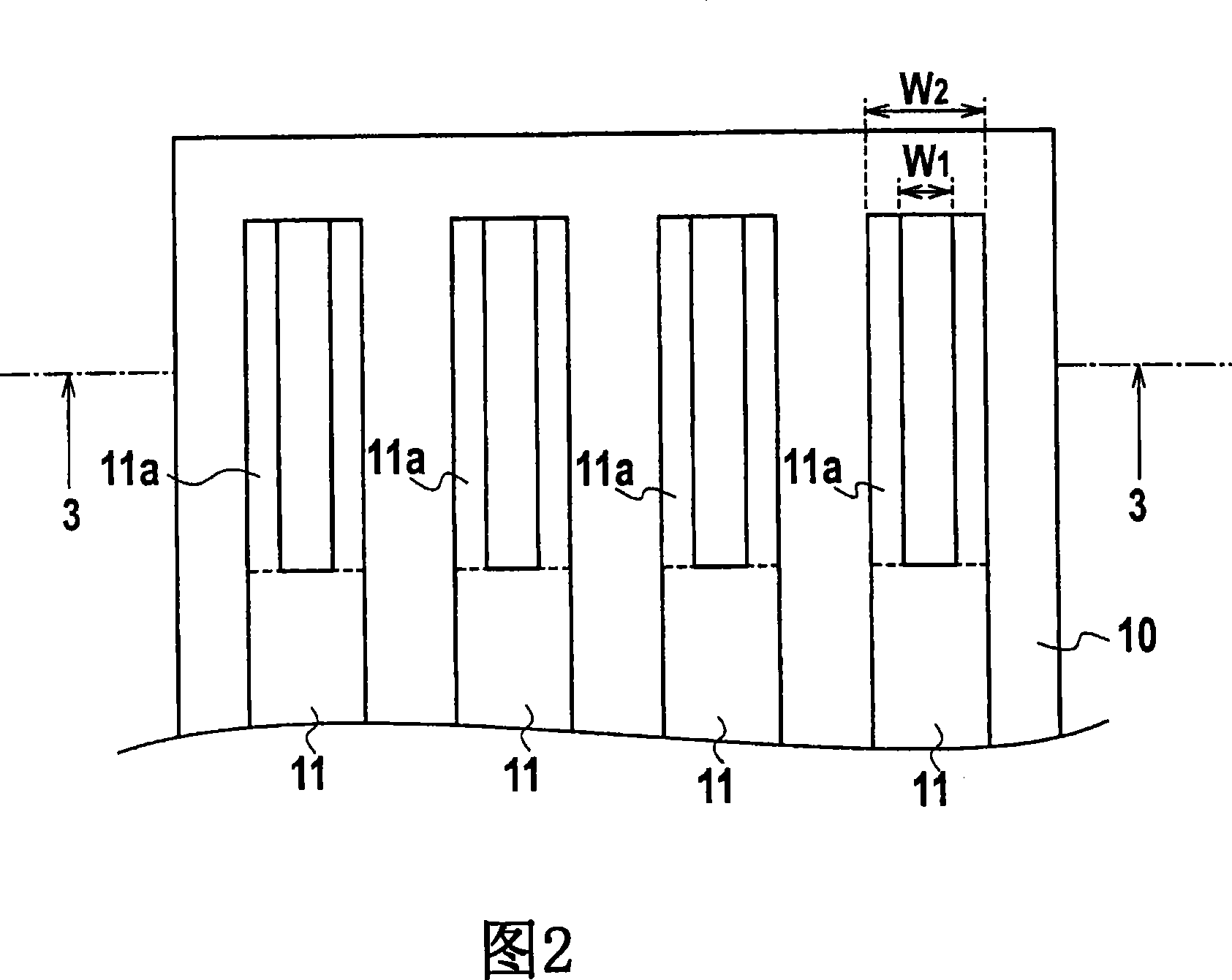

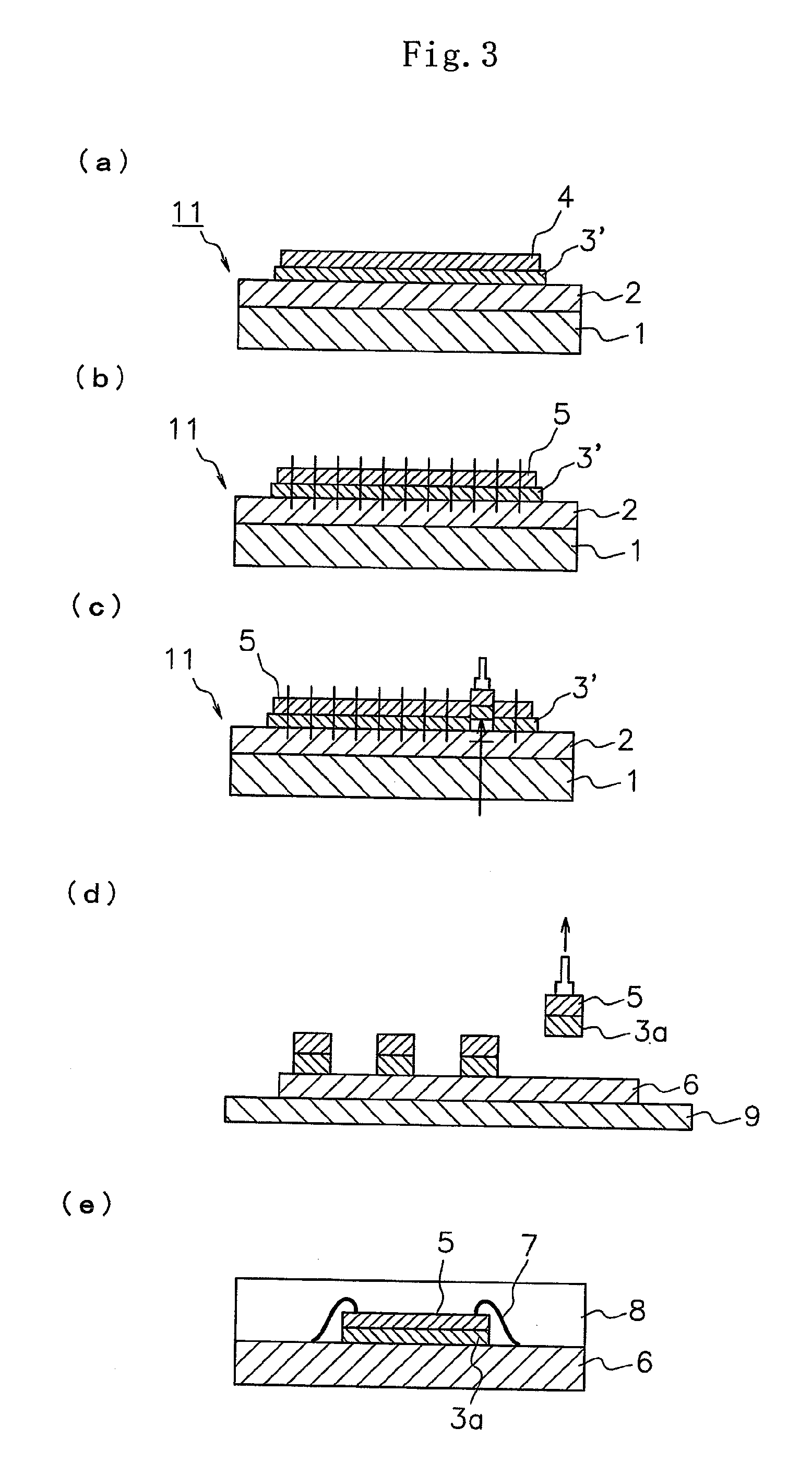

Dicing die-bonding film

InactiveUS20100233409A1Inhibit deteriorationLow peel strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxySemiconductor chip

A dicing die-bonding film having a pressure-sensitive adhesive layer on a base material, and a die-bonding film on the pressure-sensitive adhesive layer, which, even if the semiconductor wafer is thin, is excellent in balance between holding strength of the semiconductor wafer during dicing and peeling property of its semiconductor chip obtained by dicing upon being peeled together with the die-bonding film. A dicing die-bonding film having a dicing film having a pressure-sensitive adhesive layer on a base material, and a die-bonding film formed on the pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer contains a polymer comprising an acrylic acid ester as a main monomer, 10 to 30 mol % of a hydroxyl group-containing monomer based on the acrylic acid ester, and 70 to 90 mol % of an isocyanate compound having a radical reactive carbon-carbon double bond based on the hydroxyl group-containing monomer, and the die-bonding film comprises an epoxy resin.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

InactiveUS20090104450A1Easy to processExcellent reworkabilityFilm/foil adhesivesSynthetic resin layered productsMeth-Display device

A pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent. The pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout.

Owner:NITTO DENKO CORP

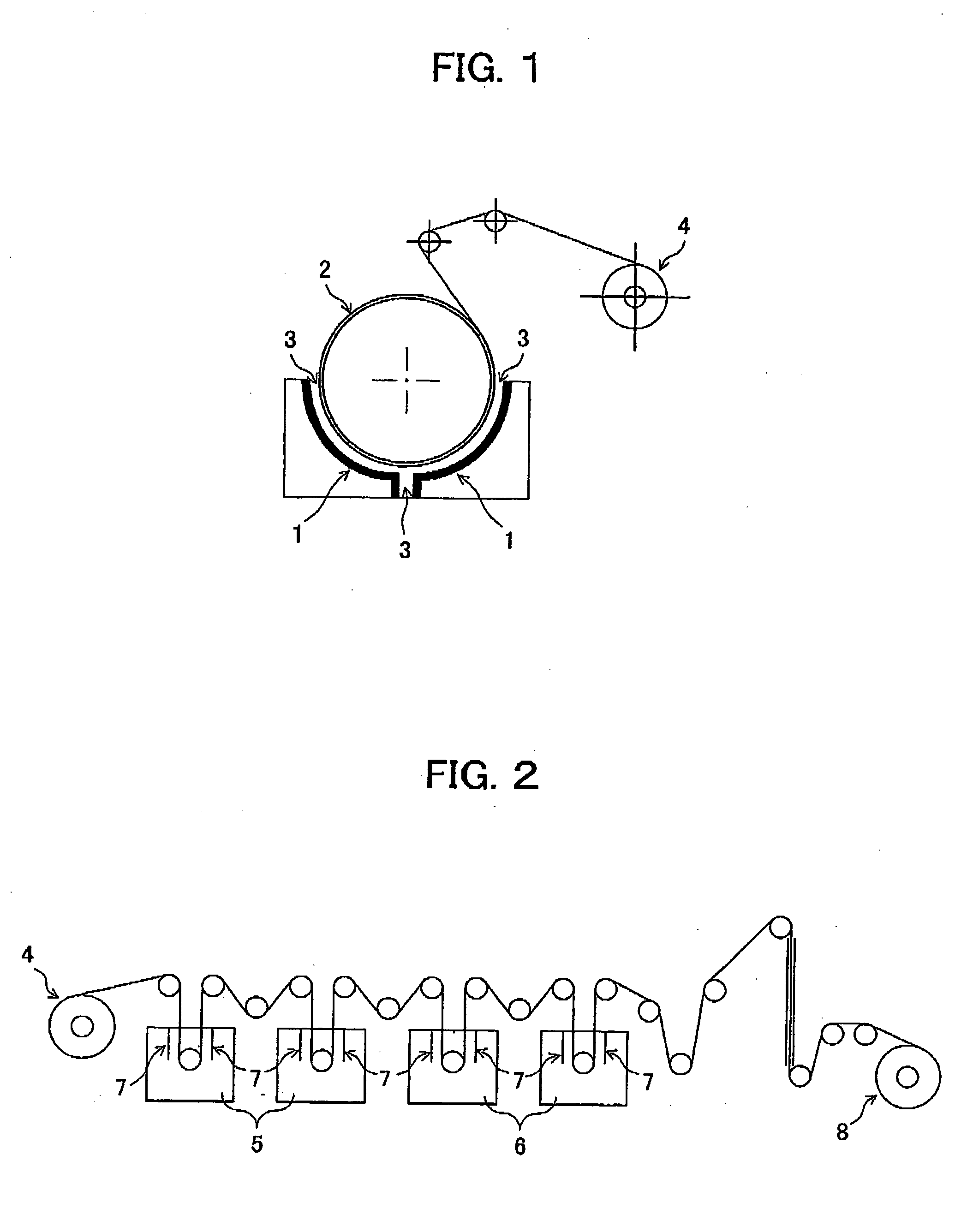

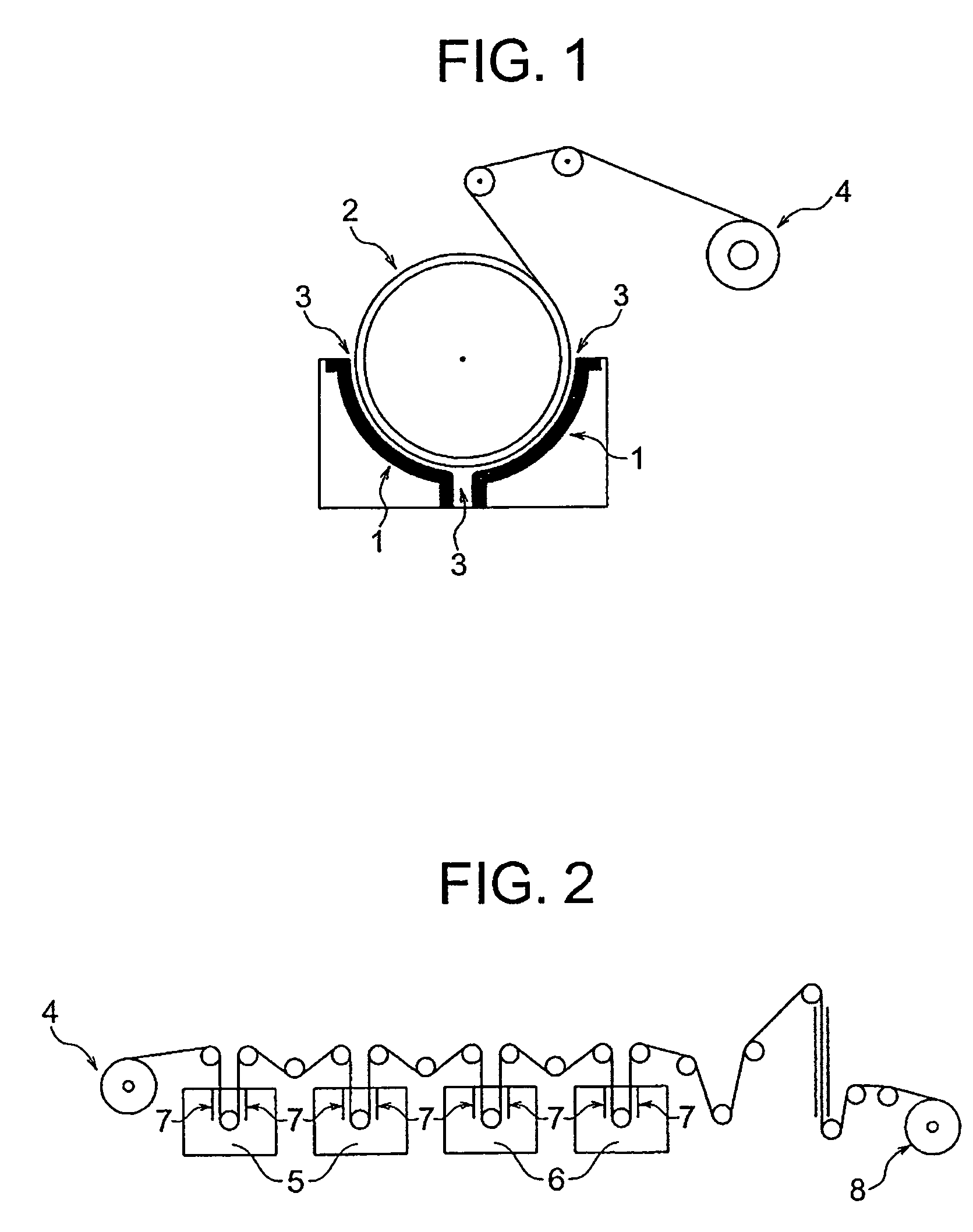

Surface treated copper foil and circuit board

InactiveUS20060088723A1High frequency characteristicHigh peel strengthInsulating substrate metal adhesion improvementPrinted circuit aspectsCopper foilMetallurgy

A surface treated copper foil having high frequency characteristics, capable of forming fine pattern and having sufficient peel strength, wherein surface roughness Rz of roughening treated surface made by adhering roughening particles on at least one surface side of untreated copper foil is 0.6 to 1.5 μm and a brightness value is 35 or smaller; and a circuit board, on which wiring pattern is formed by the same surface treated copper foil, are provided.

Owner:FURUKAWA ELECTRIC CO LTD

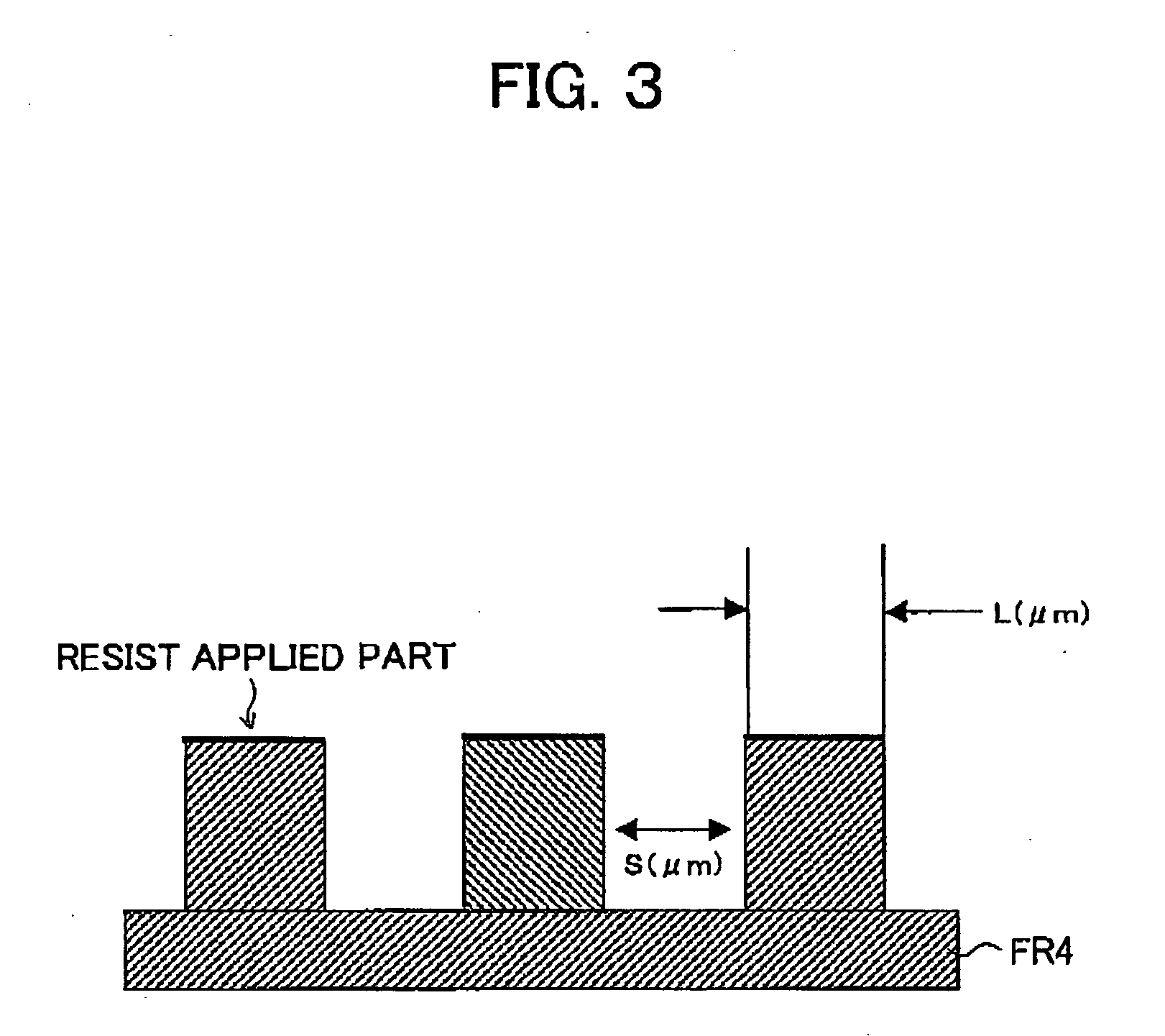

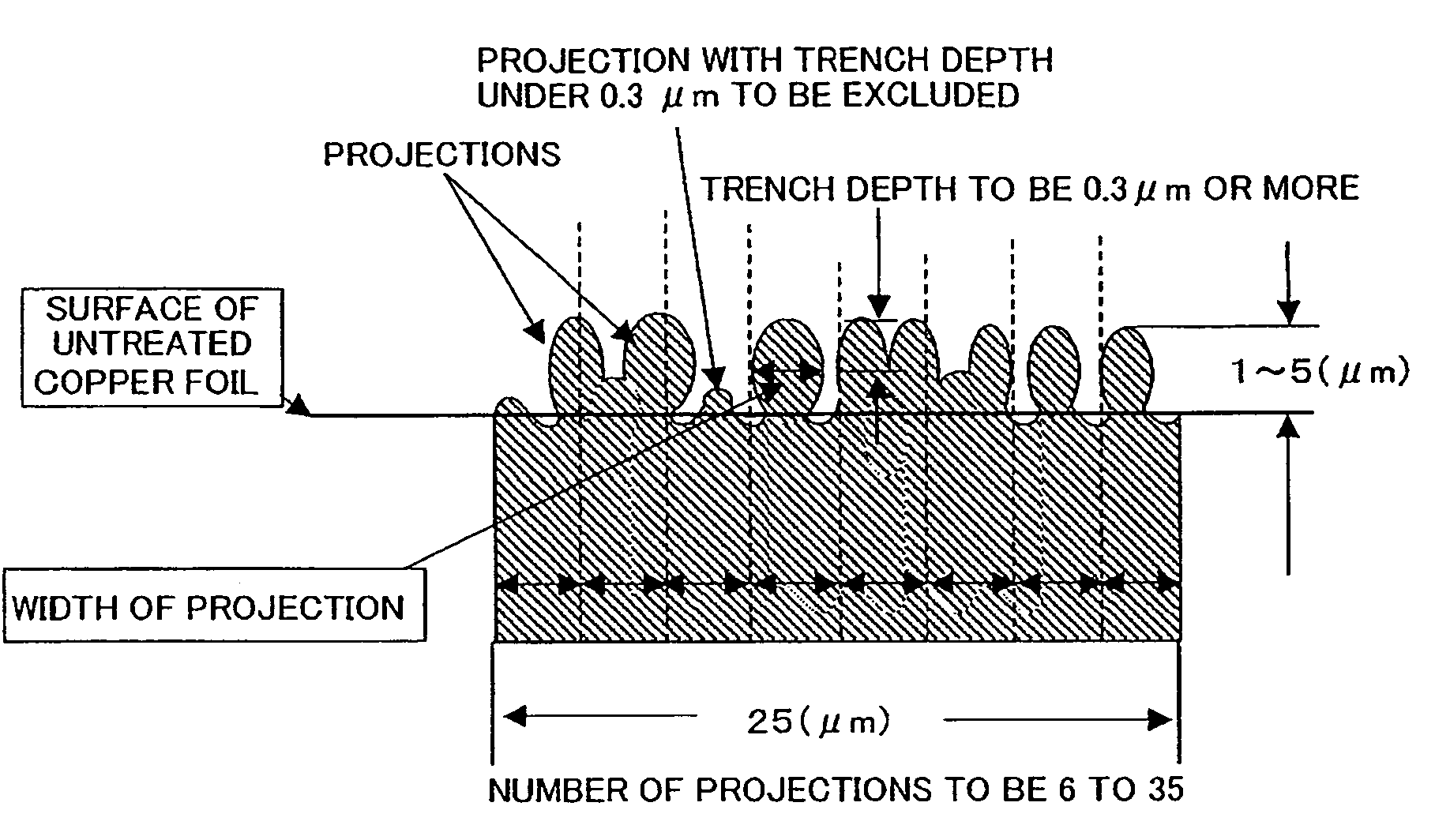

Treated copper foil and circuit board

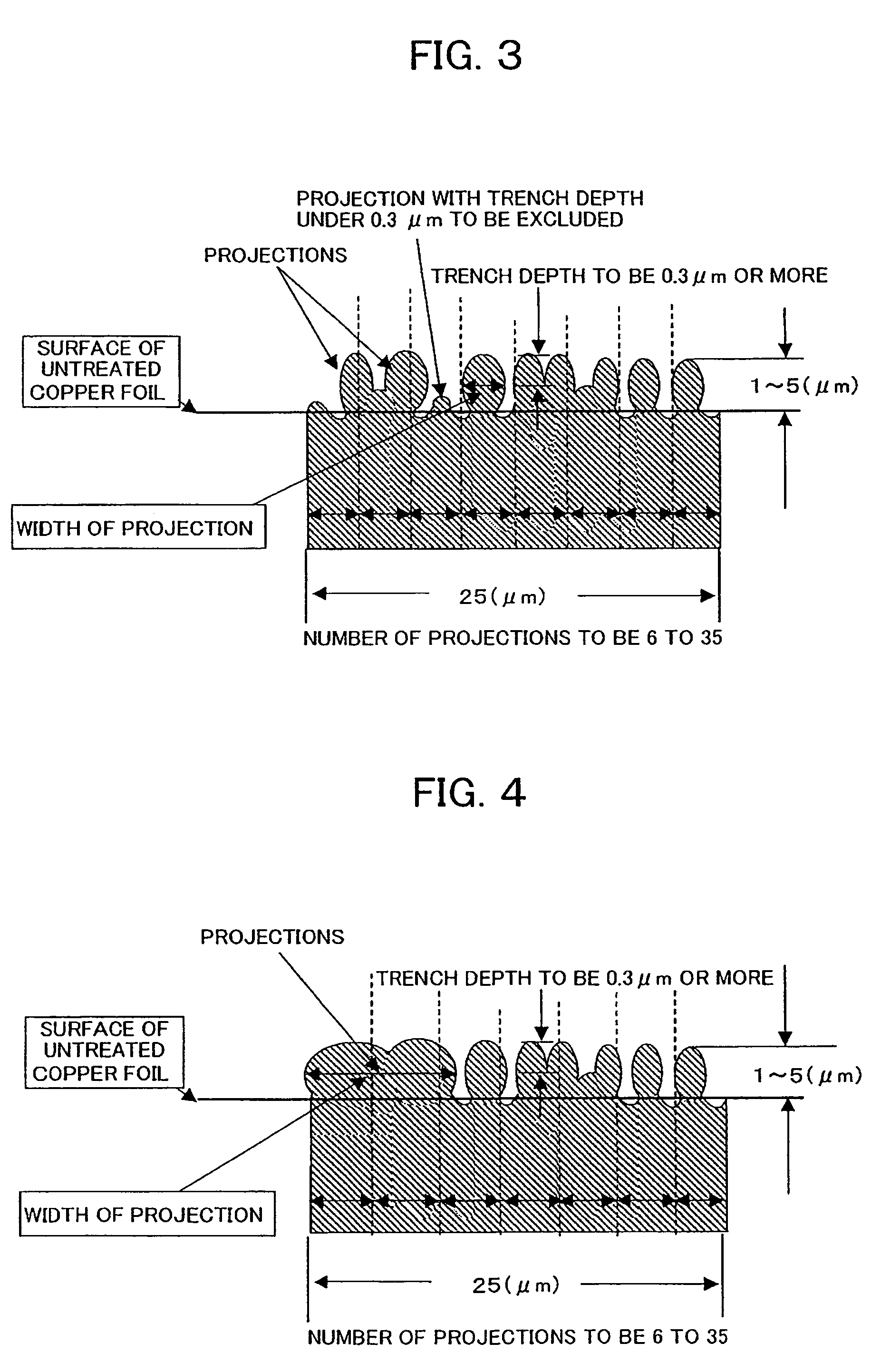

InactiveUS7381475B2High peel strengthLittle changeInsulating substrate metal adhesion improvementPrinted circuit aspectsMetallurgyHeat resistance

An object of the present invention is to provide a treated copper foil laminated with a mesomorphic polymer film having low hygroscopicity and superior high thermal resistance to make a circuit board composite materials having large peel strength and compatibility with fine pattern processes, which a copper foil being deposited with roughening particles to make the treated copper foil having a roughening treated side with surface roughness of 1.5 to 4.0 μm and luminosity of not more than 30, having projections formed from the roughening particles with a height of 1 to 5 μm, preferably 6 to 35 thereof are uniformly distributed in a 25 μm of surface length of copper foil cross-section observed, and its maximum width being at least 0.01 μm and not more than twice of 25 μm divided by the number of projections in the 25 μm surface length.

Owner:FURUKAWA ELECTRIC CO LTD

Easily openable closure for a retortable container having a metal end to which a membrane is sealed

A retortable, easily openable closure of the type having a metal end and a membrane closure heat-sealed thereto, wherein the metal end has a coating of a heat-seal composition comprising a food-compatible metal-coating composition blended with polypropylene. The polypropylene disperses within the food-compatible metal-coating composition during curing of the coating on the metal end such that an outer surface of the coating defines a multitude of separate, spaced islands of polypropylene dispersed within the food-compatible metal-coating composition so as to form bonding sites. The membrane closure's lower surface has a heat-seal layer of polypropylene for sealing to the coating on the metal end.

Owner:SONOCO DEV INC

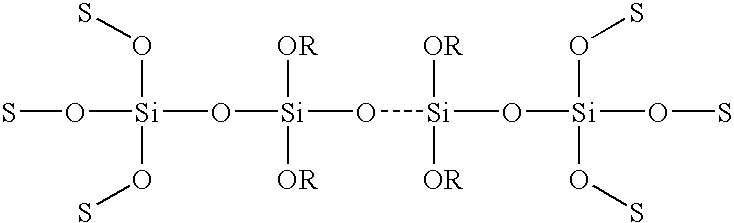

Easy-stripping type room temperature vulcanizing silicone rubber and preparation method thereof

ActiveCN101724269AGood sealing performanceConvenient secondary maintenanceOther chemical processesSiloxanePlasticizer

The invention provides an easy-stripping type room temperature vulcanizing silicone rubber, which contains hydroxy-terminated dimerization organic group siloxane, a functional filling material, a crosslinking agent, gas phase silicon dioxide, a catalyst, an additive and a plasticizer. The invention also provides a method for preparing the easy-stripping type room temperature vulcanizing silicone rubber, which comprises the following steps: firstly, vacuum-stirring the hydroxy-terminated dimerization organic group siloxane, the plasticizer and the functional filling material in formula proportions in a closed reaction kettle evenly; secondly, adding the crosslinking agent, the gas phase silicon dioxide, the catalyst and the additive in formula proportions in to the closed reaction kettle, and vacuum-stirring the mixture for 30 to 60 minutes; and thirdly, releasing the vacuum by using nitrogen gas, and putting the mixture into a closed packaging container. The easy-stripping type room temperature vulcanizing silicone rubber is particularly suitable for sealing a joint on the surface of a component of a motor vehicle, has excellent sealing performance and stripping performance, and simultaneously is of room temperature vulcanizing type, is cured by moisture, is molded in place and can replace various solid gaskets, so the easy-stripping type room temperature vulcanizing silicone rubber is suitable for manufacturing and maintaining various types of motor vehicles, and can shorten the labour hour and save the cost.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Copper foil for printed circuit board and copper clad laminate for printed circuit board

InactiveUS8142905B2High peel strengthEffectively preventing the circuit corrosion phenomenonAnodisationBaby linensCopper foilNickel zinc

Provided is a copper foil for a printed circuit board comprising a layer including nickel, zinc, a compound of nickel and that of zinc (hereinafter referred to a “nickel zinc layer”) on a roughened surface of a copper foil, and a chromate film layer on the nickel zinc layer, wherein the zinc add-on weight per unit area of the nickel zinc layer is 180 μg / dm2 or more and 3500 μg / dm2 or less, and the nickel weight ratio in the nickel zinc layer {nickel add-on weight / (nickel add-on weight+zinc add-on weight)} is 0.38 or more and 0.7 or less. This surface treatment technology of a copper foil is able to effectively prevent the circuit corrosion phenomenon in cases of laminating a copper foil on a resin base material and using a sulfuric acid hydrogen peroxide etching solution to perform soft etching to the circuit.

Owner:JX NIPPON MINING & METALS CORP

Method for cleaning surface of resin layer

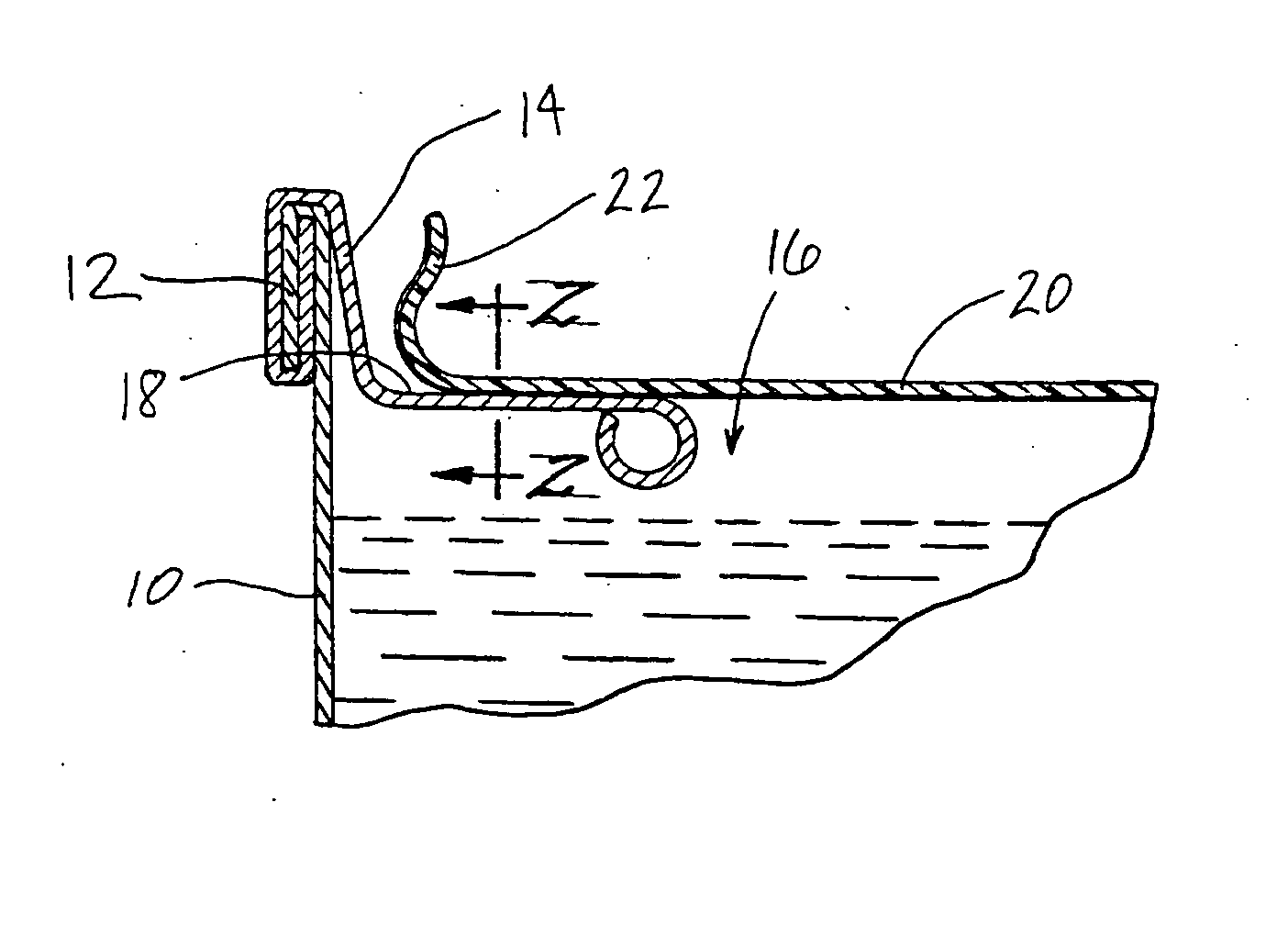

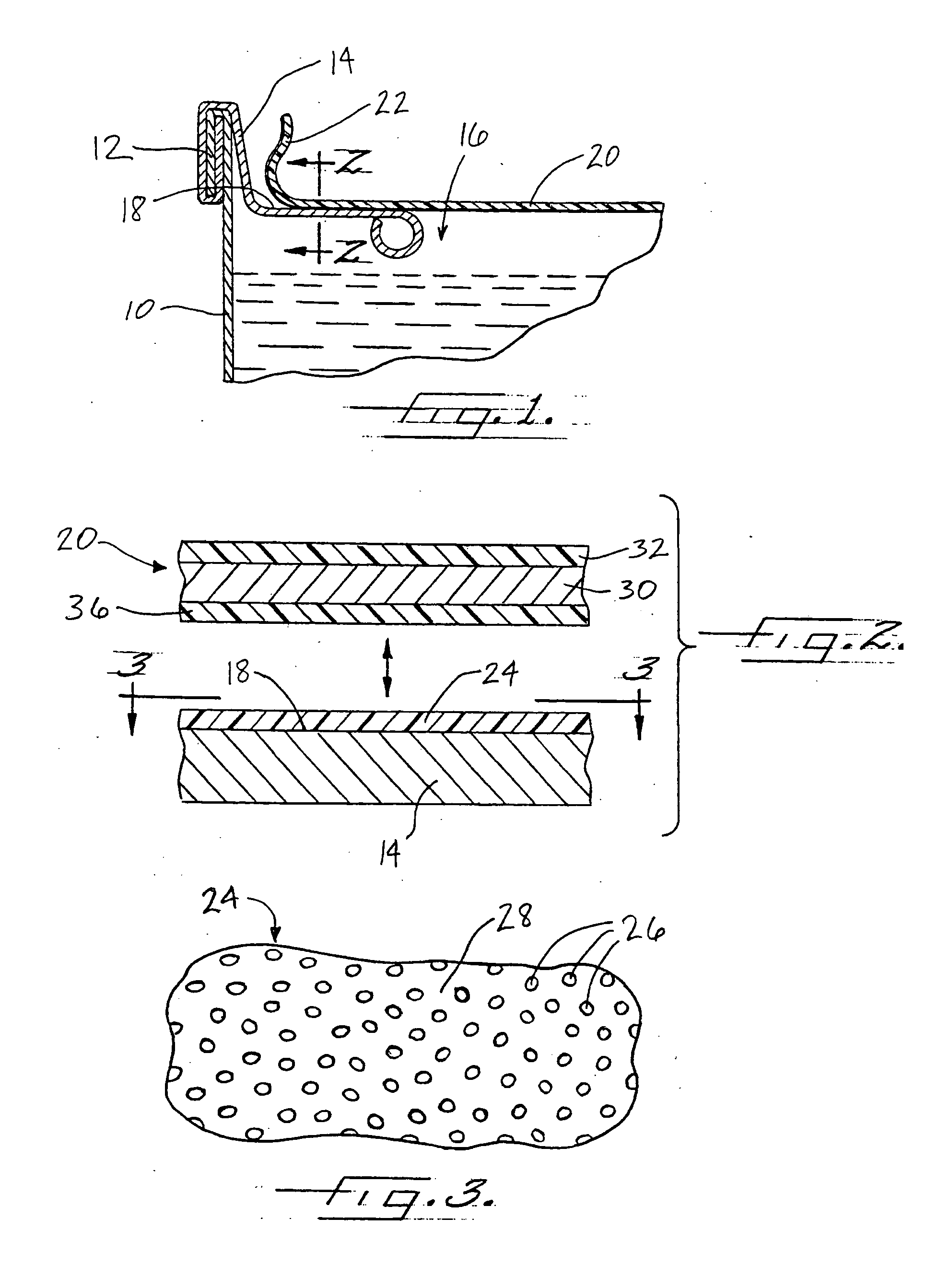

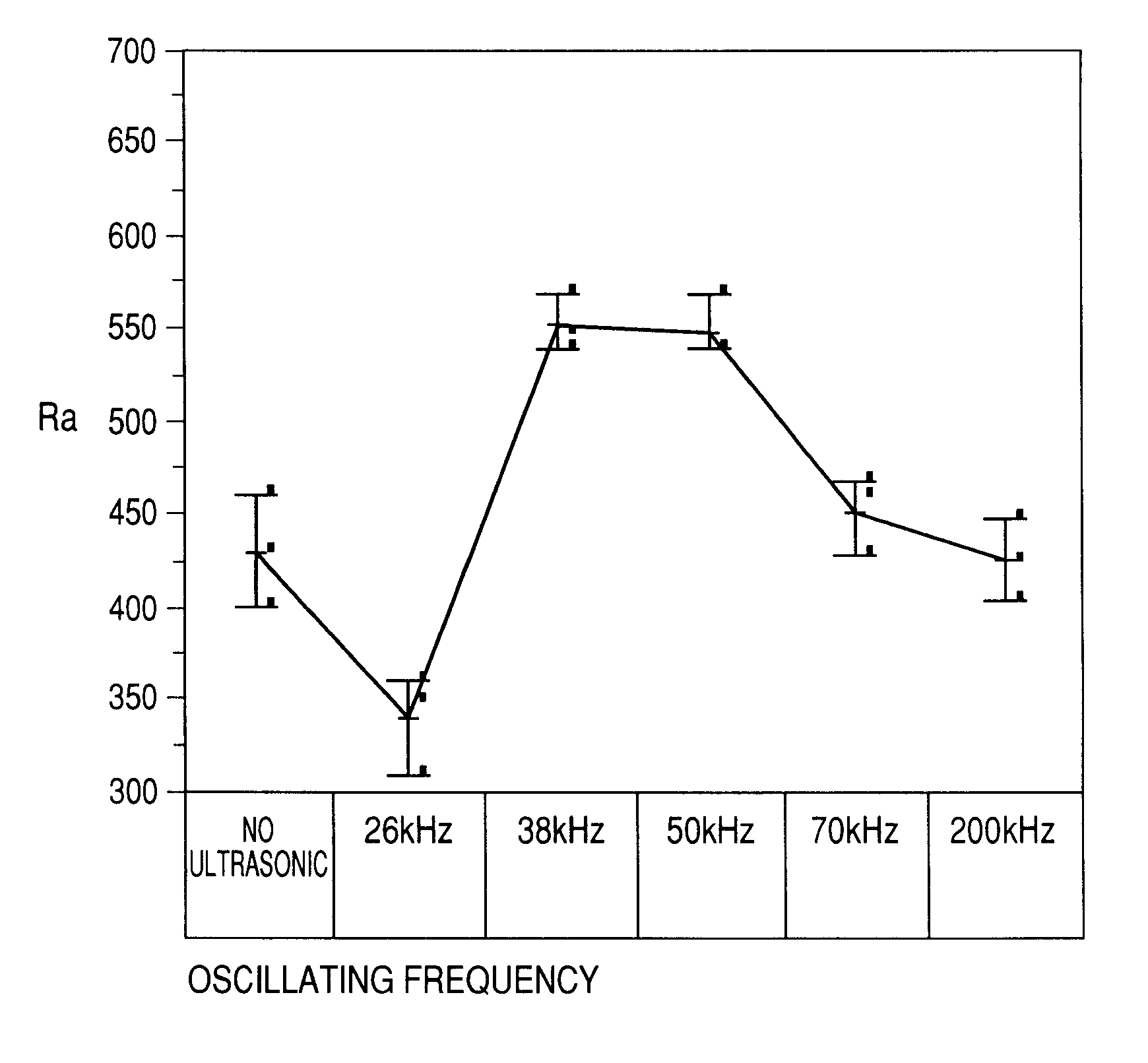

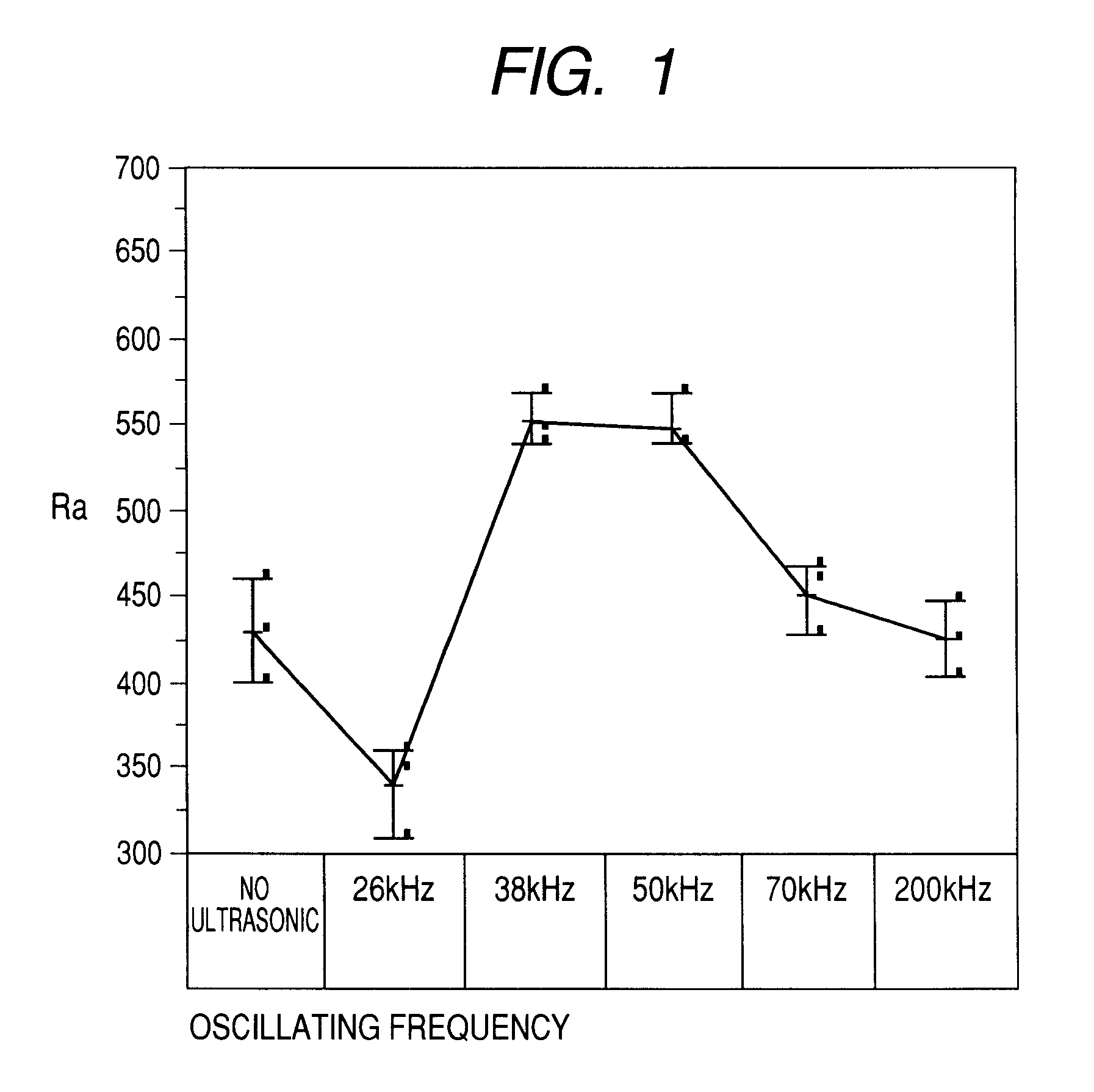

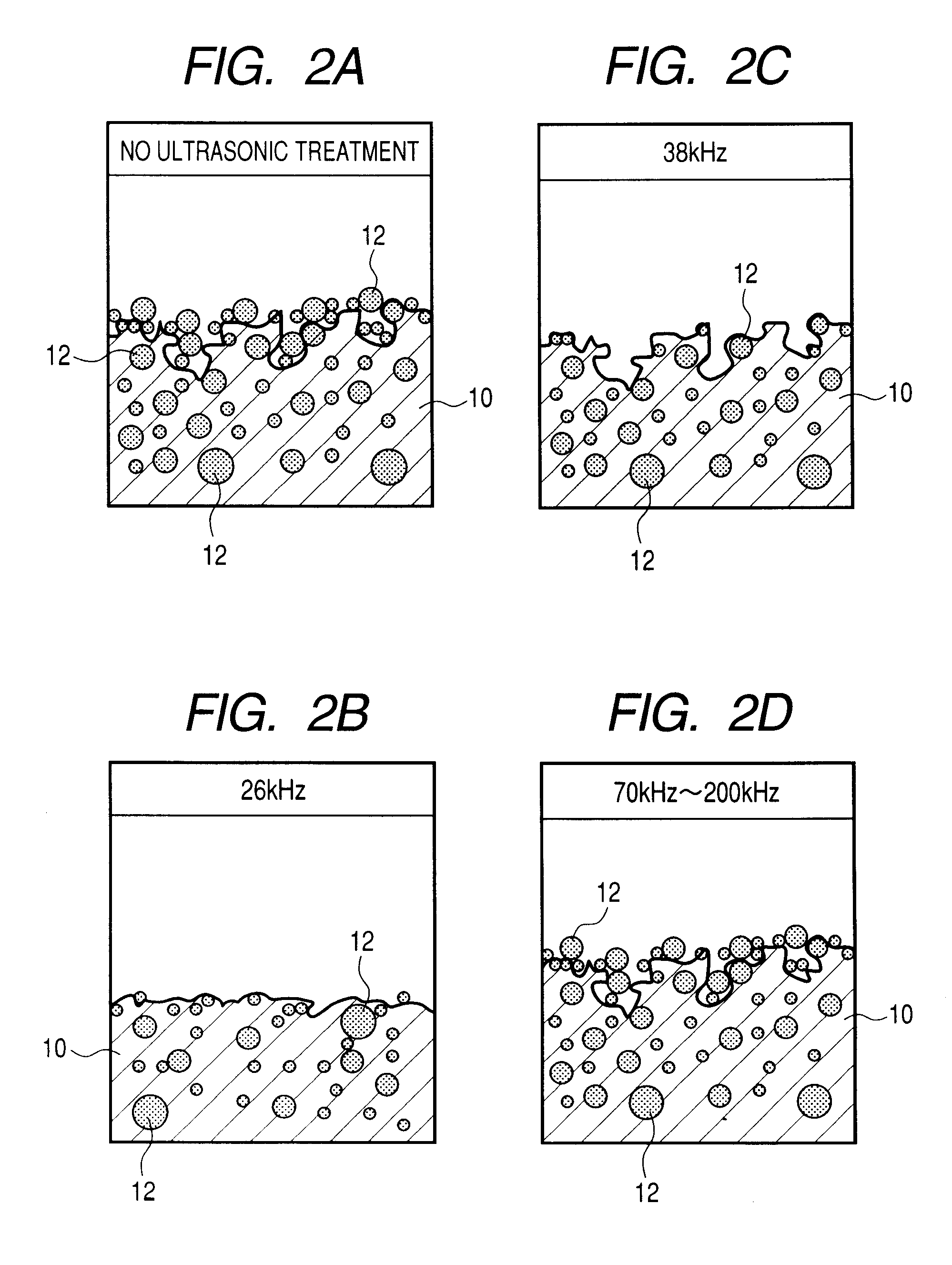

ActiveUS20070131243A1Easy to peelHigh peel strengthPrinted circuit aspectsElectrostatic cleaningMegasonic cleaningThermal expansion

A method for cleaning a surface of a resin layer capable of sufficiently improving peel strength of a metal film formed by plating on a surface which is roughened by performing a desmear treatment on a resin layer containing a resin added with a large amount of filler is provided. The method is characterized in that, when a surface of a resin layer on which a metal film is formed by plating is roughened by a desmear treatment and, then, the thus-roughened surface of the resin layer is cleaned, the surface of the resin layer formed with a resin compounded with a filler in an amount of 20 wt % or more such that a difference of a coefficient of thermal expansion between the resin layer and the metal film is allowed to be reduced is roughened by subjecting it to the desmear treatment and, secondly, the filler which is deposited on the thus-roughened surface of the resin layer is removed by ultrasonic cleaning in which ultrasonic vibration of a frequency of from 35 to 50 kHz is applied.

Owner:SHINKO ELECTRIC IND CO LTD

Copper Foil for Printed Circuit Board and Copper Clad Laminate for Printed Circuit Board

InactiveUS20100261033A1Prevent deterioration in peel strengthImprove heat-resistant peel strengthAnodisationPrinted circuit secondary treatmentCopper foilNickel zinc

Provided is a copper foil for a printed circuit board comprising a layer including nickel, zinc, a compound of nickel and that of zinc (hereinafter referred to a “nickel zinc layer”) on a roughened surface of a copper foil, and a chromate film layer on the nickel zinc layer, wherein the zinc add-on weight per unit area of the nickel zinc layer is 180 μg / dm2 or more and 3500 μg / dm2 or less, and the nickel weight ratio in the nickel zinc layer {nickel add-on weight / (nickel add-on weight+zinc add-on weight)} is 0.38 or more and 0.7 or less. This surface treatment technology of a copper foil is able to effectively prevent the circuit corrosion phenomenon in cases of laminating a copper foil on a resin base material and using a sulfuric acid hydrogen peroxide etching solution to perform soft etching to the circuit.

Owner:JX NIPPON MINING& METALS CORP

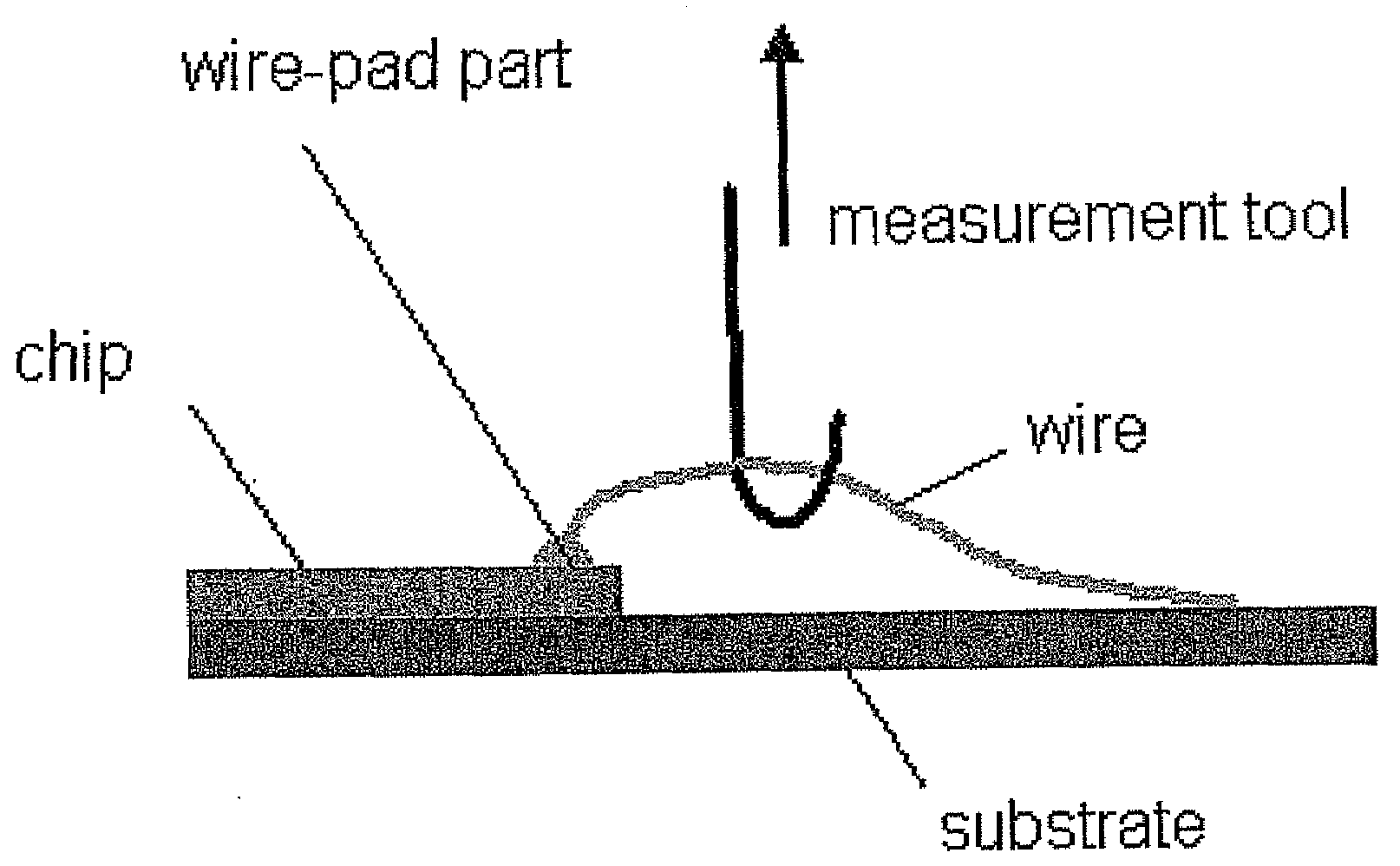

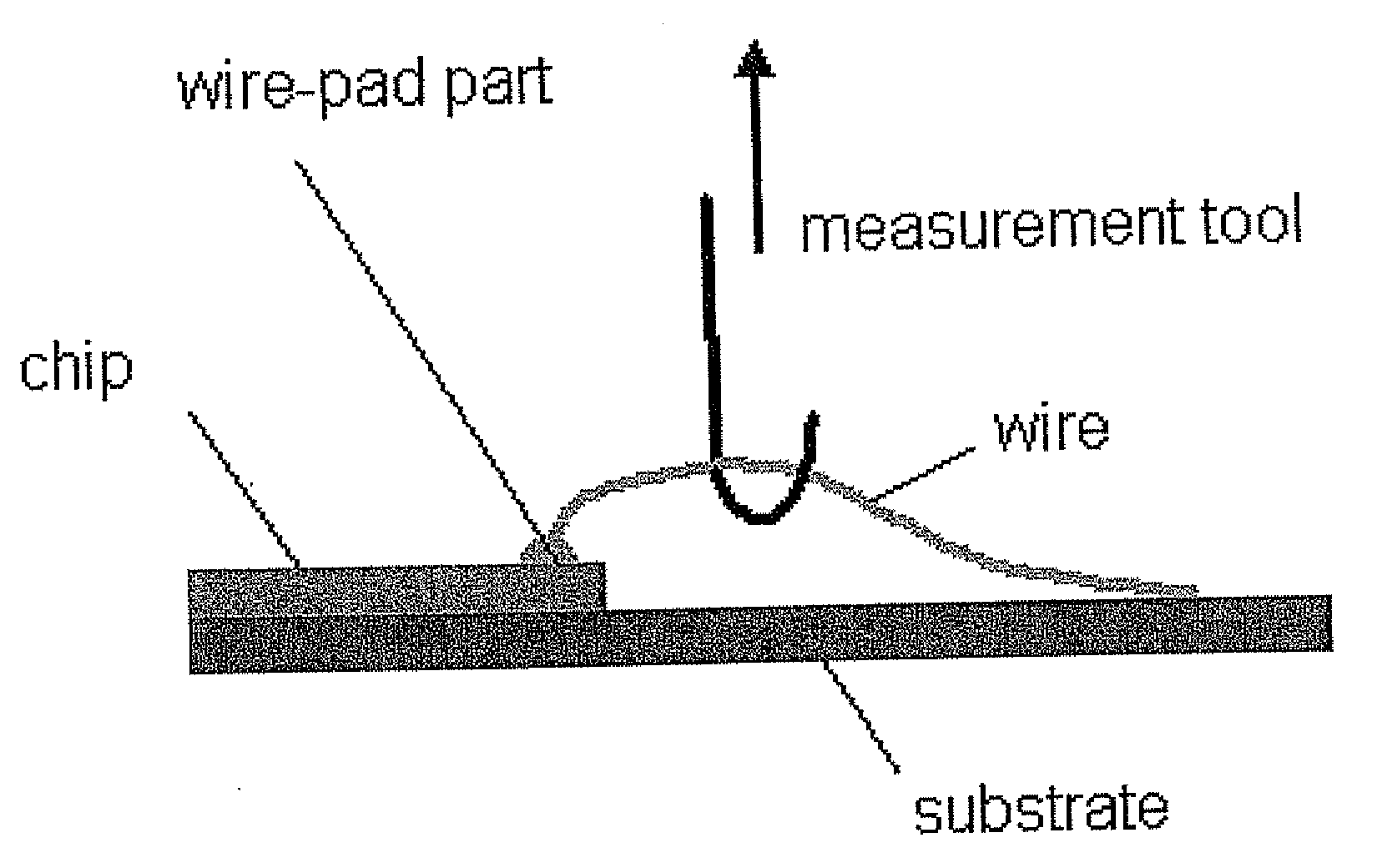

Adhesive Composition, Adhesive Sheet and Production Method of Semiconductor Device

InactiveUS20090246915A1Improve production yieldReduced strengthFilm/foil adhesivesSemiconductor/solid-state device detailsEpoxyLead bonding

The object of the present invention is to provide an adhesive composition that enables to produce conforming products with a high manufacturing yield and without breaking or chipping of the chips in the picking-up step and that enables to stably connect a wire without contaminating a wire pad part disposed at the circumference of a bonding surface during a wire bonding step that is performed after die bonding, even in the case of chips being reduced in a thickness.The adhesive composition of the present invention comprises:(A) an acrylic polymer;(B) an epoxy resin;(C) a thermosetting agent; and(D) a silicone compound,wherein the silicone compound (D) has one kind of reactive organic functional group and a kinematic viscosity within a specific range.

Owner:LINTEC CORP

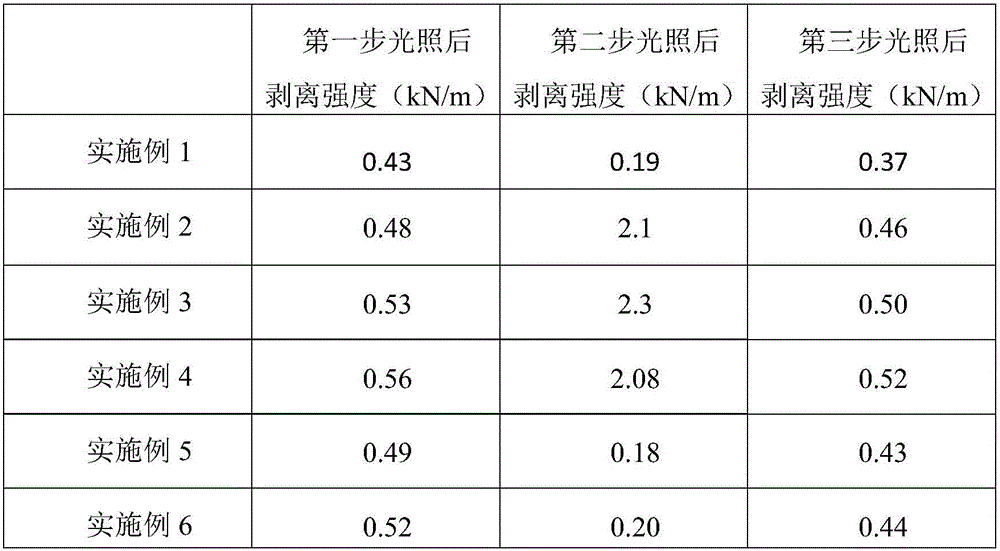

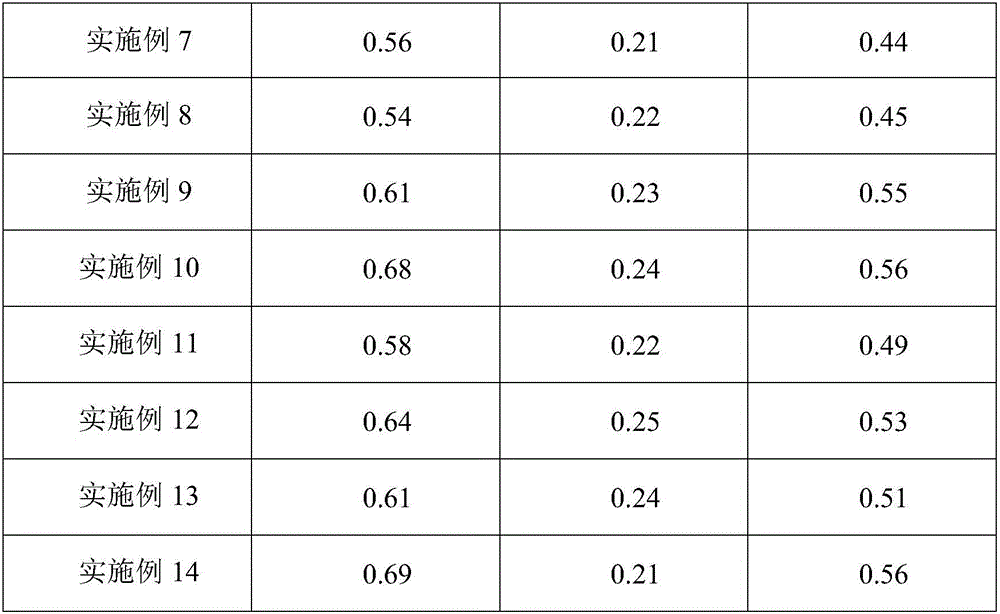

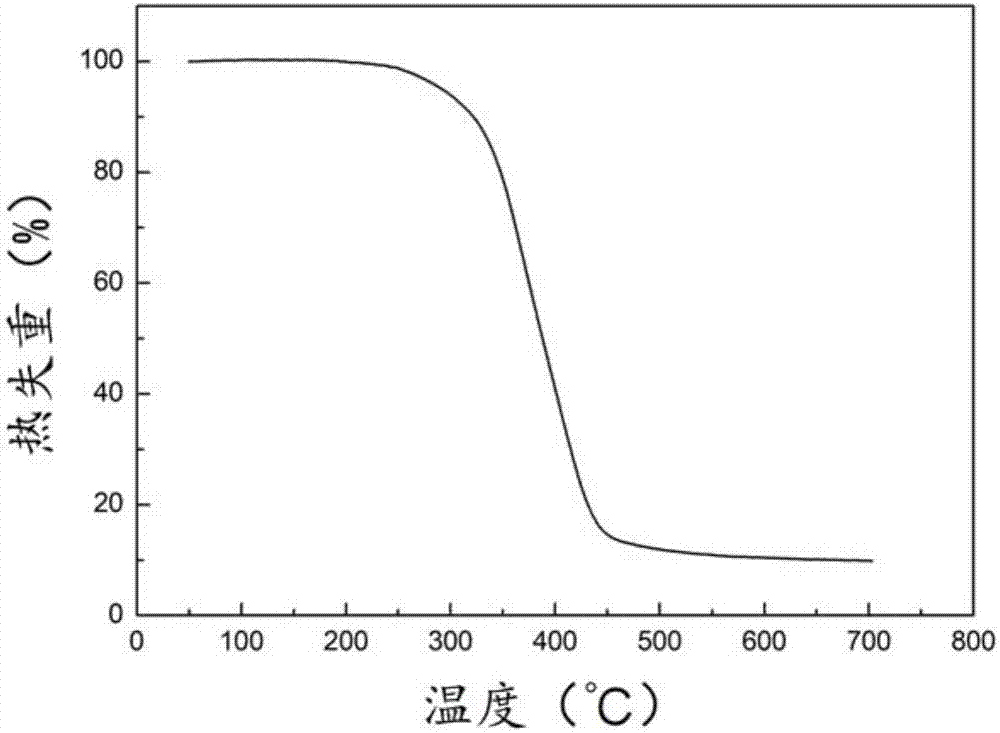

Photo-responsive UV pressure-sensitive adhesive and preparation method of same

InactiveCN106566424AHigh peel strengthLow peel strengthFilm/foil adhesivesOrganic non-macromolecular adhesiveEnvironmental resistancePolymer dissolution

A photo-responsive UV pressure-sensitive adhesive and a preparation method of same. The pressure-sensitive adhesive is composed of four parts including 30-70% of an acrylate-type copolymer, 3-21% of a photo-responsive monomer, 21-63% of a photo-polymerization monomer, and 0.6-1.4% of a photoinitiator. The pressure-sensitive adhesive is prepared through the steps of: dissolving the polymer in the photo-polymerization monomer, adding the photo-responsive monomer and the photoinitiator and uniformly mixing the components; and irradiating the mixture by means of ultraviolet light of which the wavelength [lambda] is more than 390 nm and is less than 450 nm to cure the mixture to prepare the pressure-sensitive adhesive, and meanwhile, performing mask exposure to form patterns. The pressure-sensitive adhesive is reduced in stripping strength after being irradiated by means of ultraviolet light of which the wavelength [lambda] is more than 300 nm and is less than 360 nm, so that the pressure-sensitive adhesive is easy to strip. The stripping strength is recovered after the pressure-sensitive adhesive is irradiated by means of ultraviolet light of which the wavelength [lambda] is more than 200 nm and is less than 270 nm. The pressure-sensitive adhesive, when being used, has high stripping strength and good adhesion performance. When the pressure-sensitive adhesive is used or is mis-adhered, stripping strength of the pressure-sensitive adhesive can be reduced just by irradiating the pressure-sensitive adhesive by light, so that the pressure-sensitive adhesive is easy to strip. The stripping strength is recovered when the stripped pressure-sensitive adhesive is irradiated by light, and the pressure-sensitive adhesive can be used continuously. The pressure-sensitive adhesive is energy-saving, environment-protective and can be used repeatedly.

Owner:BEIJING UNIV OF CHEM TECH

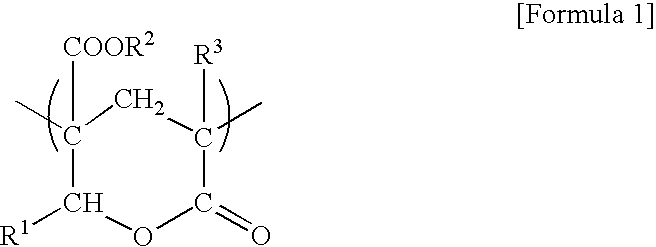

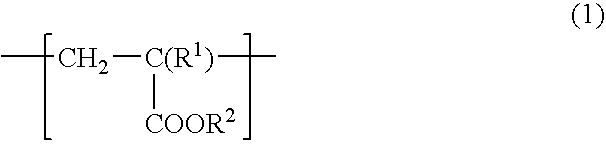

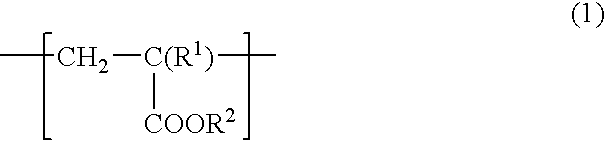

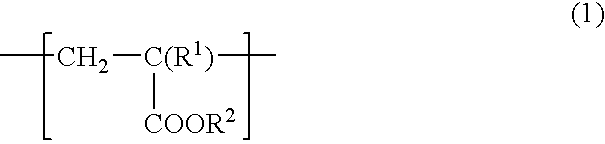

Release agent composition and release liner

ActiveUS20070112142A1Good solvent resistanceImprove heat resistanceSynthetic resin layered productsCellulosic plastic layered productsHydrogenMethyl group

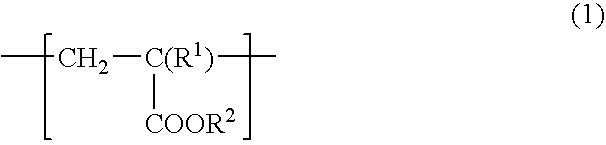

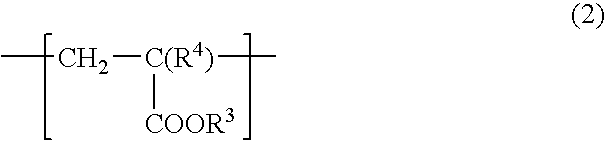

A release agent composition includes a poly(meth)acrylate (A) containing a structural unit (1) represented by the following formula (1); in which R1 represents hydrogen or a methyl group and R2 represents a long-chain alkyl group having 12 to 28 carbon atoms, a liquid polymer (B) and a crosslinking agent (C), wherein at least one of the poly(meth)acrylate (A) and the liquid polymer (B) has a reactive functional group, and the crosslinking agent (C) is a compound having a functional group capable of reacting with the reactive functional group.

Owner:LINTEC CORP

Curable Resin Composition

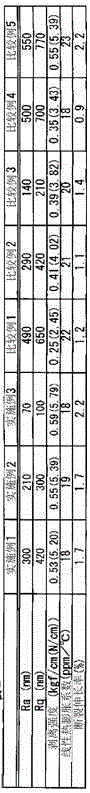

ActiveCN104098871AHigh strengthArithmetic mean roughness is lowPrinted circuit detailsNon-metallic protective coating applicationEpoxyAnthracene

The object of the present invention is to provide a curable resin composition which is excellent in cracking elongation rate, is low in arithmetic average roughness of an insulating layer surface in a wet roughing process, is also low in root mean square roughness, can form a plated and inlaid conductor layer having enough peel strength, and is also low in coefficient of linear thermal expansion. The curable resin composition provided by the present invention comprises a phenoxy resin (A) having an anthracene structure, an epoxy resin (B) and a curing agent (C),and is characterized in that the total quantity of the phenoxy resin (A), the epoxy resin (B) and the curing agent (C) is set as 100% by mass, the above phenoxy resin (A) is 1-15% by mass, and the epoxide equivalent of the above phenoxy resin (A) is more than 5000.

Owner:AJINOMOTO CO INC

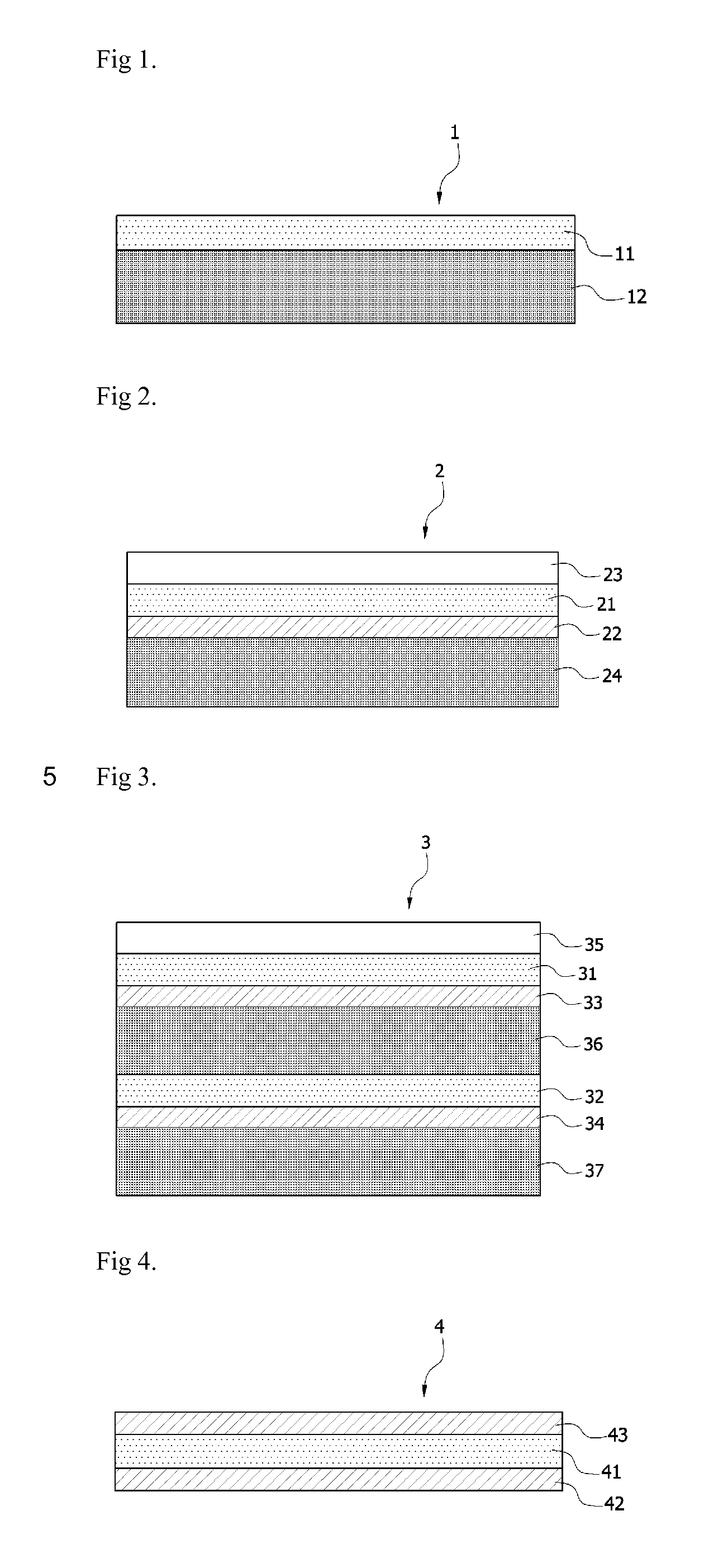

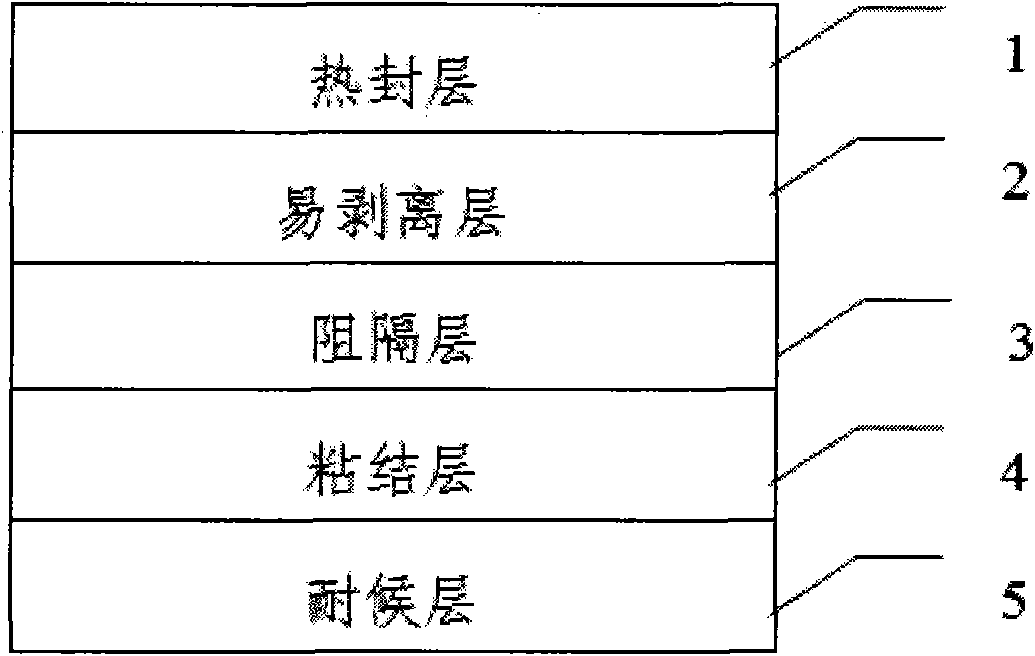

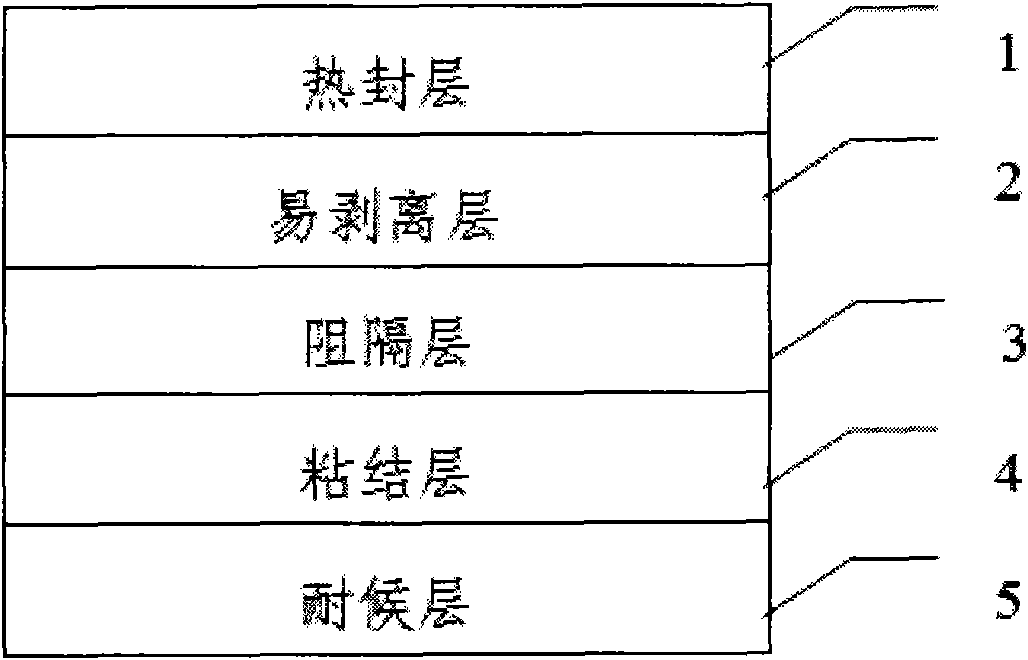

Easy-to-peel cover film

InactiveCN102380983AImproves stress cracking resistanceLow melting pointSynthetic resin layered productsSealingLow-density polyethylenePolyester

The invention discloses an easy-to-peel cover film, which comprises a hot sealing layer, an easy-to-peel layer, a blocking layer, a bonding layer and a weatherproof layer in sequence arrangement, wherein the hot sealing layer is an ethylene-vinyl acetate copolymer film layer modified by low-density polyethylene and metallocene low-density polyethylene, the easy-to-peel layer is a low-density polyethylene layer, the blocking layer is a soft-state aluminum foil layer, the bonding layer is a polyester type polyurethane layer, and the weatherproof layer is a polyester layer. The easy-to-peel cover film is an easy-to-peel cover film with the advantages that the integral performance is excellent, the easy-to-peel cover film is particularly suitable for various containers, and the easy-to-peel performance, the sealing performance and the ventilation performance are better.

Owner:SUZHOU HAISHUN PACKAGING MATERIAL

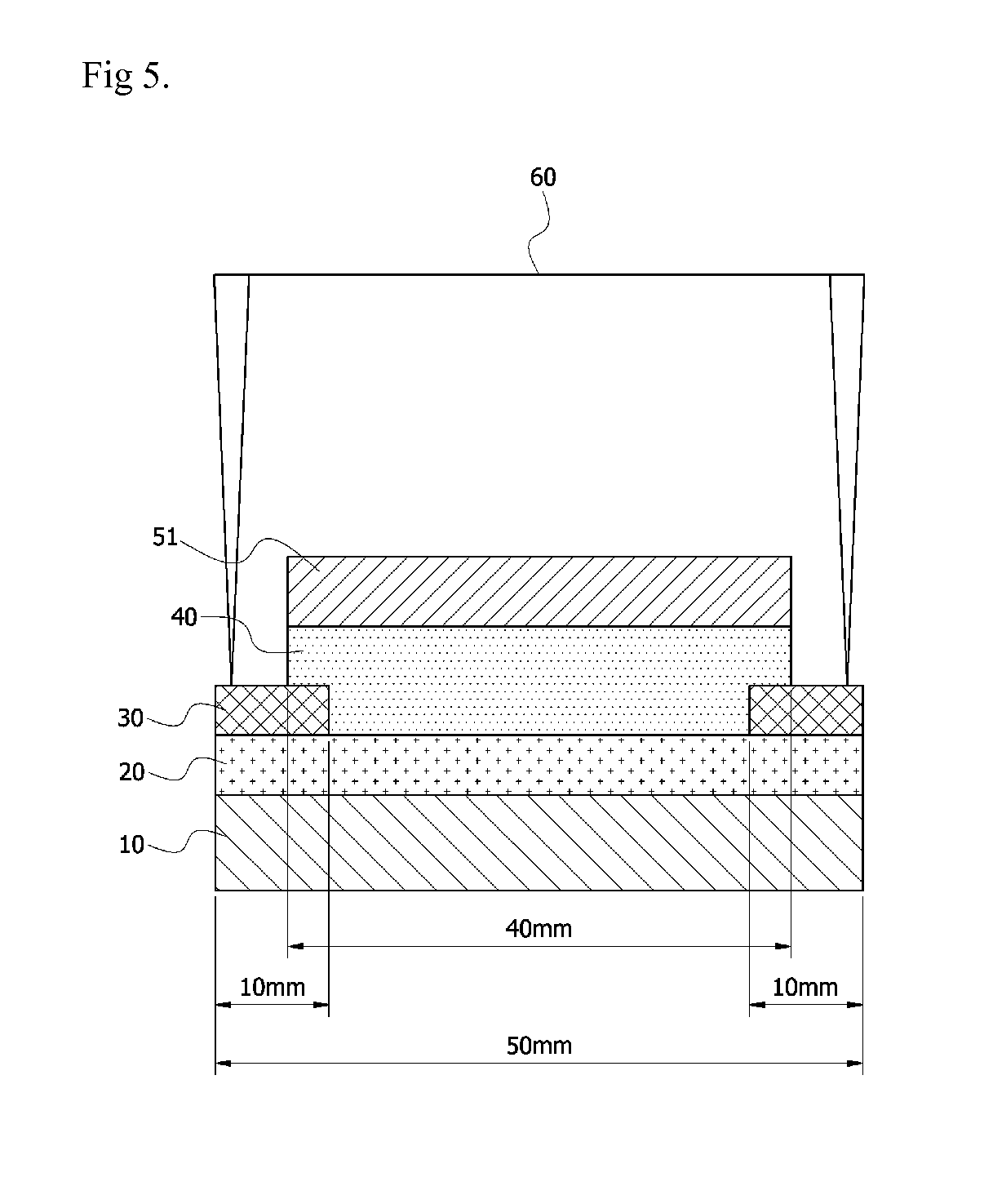

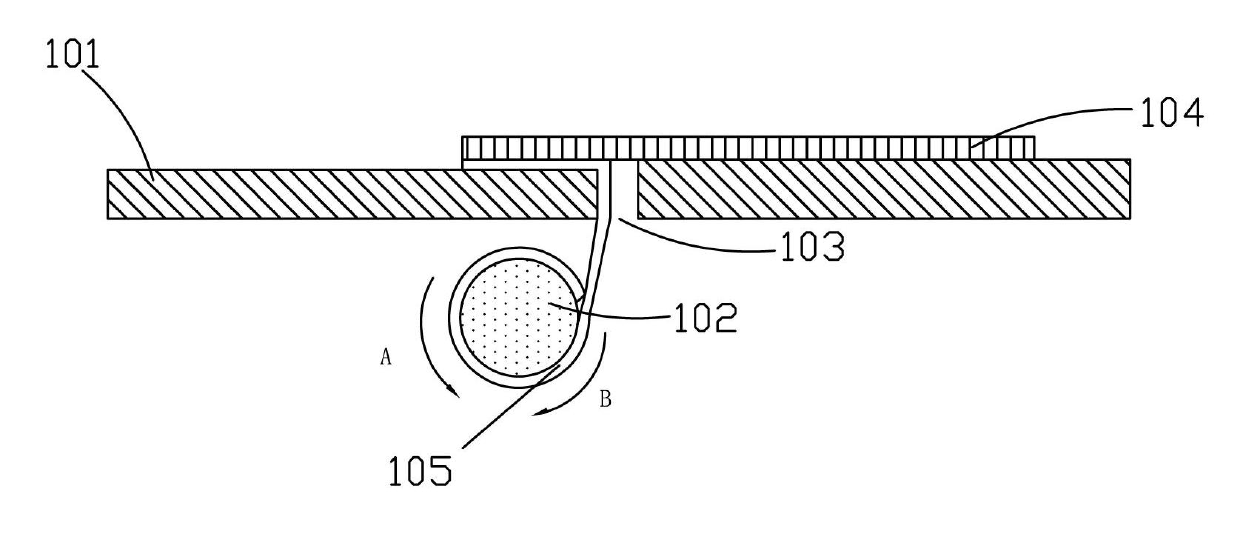

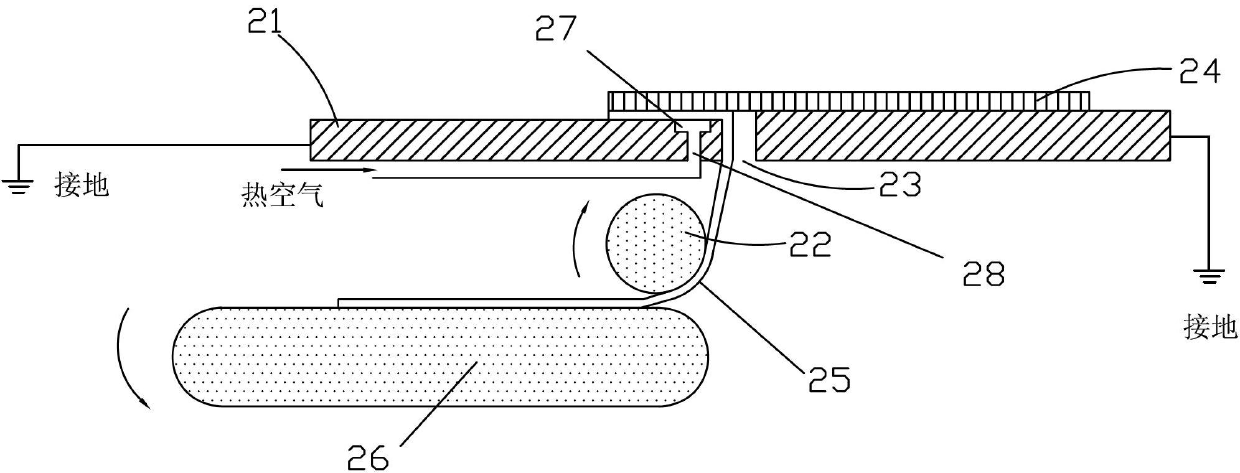

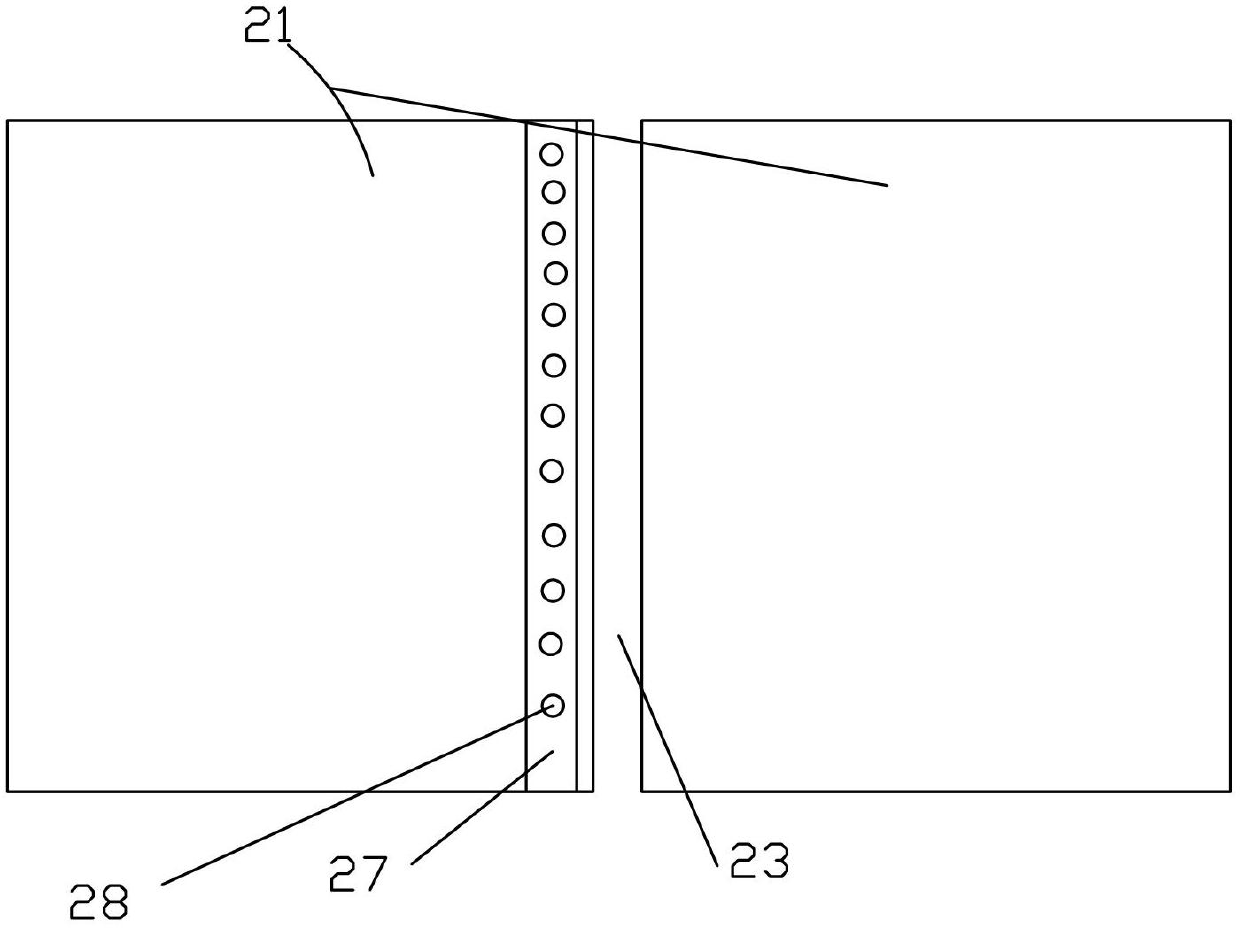

Polaroid stripping machine and method for stripping polaroid

ActiveCN102632685AEliminate hazardsLow peel strengthLamination ancillary operationsLaminationEngineeringUltimate tensile strength

The invention relates to a polaroid stripping machine and a method for stripping a polaroid. The polaroid stripping machine comprises an operation platform and a conveying device with a translatable surface, wherein the operation platform is provided with a gap which is used as a polaroid stripping position; the translatable surface of the conveying device is located below the gap; when the polaroid is stripped, a glass substrate with the polaroid to be stripped slides through the gap along the upper surface of the operation platform; and the stripped polaroid downwards extends and is paved on the translatable surface of the conveying device by the gap, and horizontally moves along with the translatable surface of the conveying device. The polaroid stripping machine and the method for stripping the polaroid, disclosed by invention, change the polaroid stripping operation into a continuous process, can eliminate the damages of static electricity accumulation in the polaroid stripping process to a panel and an operator, can heat the polaroid, and reduce the stripping strength and the fragmenting possibility.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Release agent composition and release liner

InactiveUS7312293B2Improved solvent resistance and heat resistance and adhesion to substrateLow peel strengthMethacrylatePolymer science

An acrylic resin type release agent composition comprising (A) a polymer which comprises a (meth)acrylate containing a constituent unit represented by the following formula (1) and (B) a crosslinking agent which comprises an amino resin, wherein a weight ratio (A) / (B) is in the range of 99.99 / 0.1 to 30 / 70:wherein R1 is a hydrogen atom or a methyl group, and R2 is a long-chain alkyl group of 12 to 28 carbon atoms. Also described herein is a release liner having a release layer made of the release agent composition. The acrylic resin type release agent composition exhibits excellent solvent resistance, heat resistance and adhesion to substrate without exerting evil influence on electronic parts and the like, and is capable of controlling peel strength.

Owner:LINTEC CORP

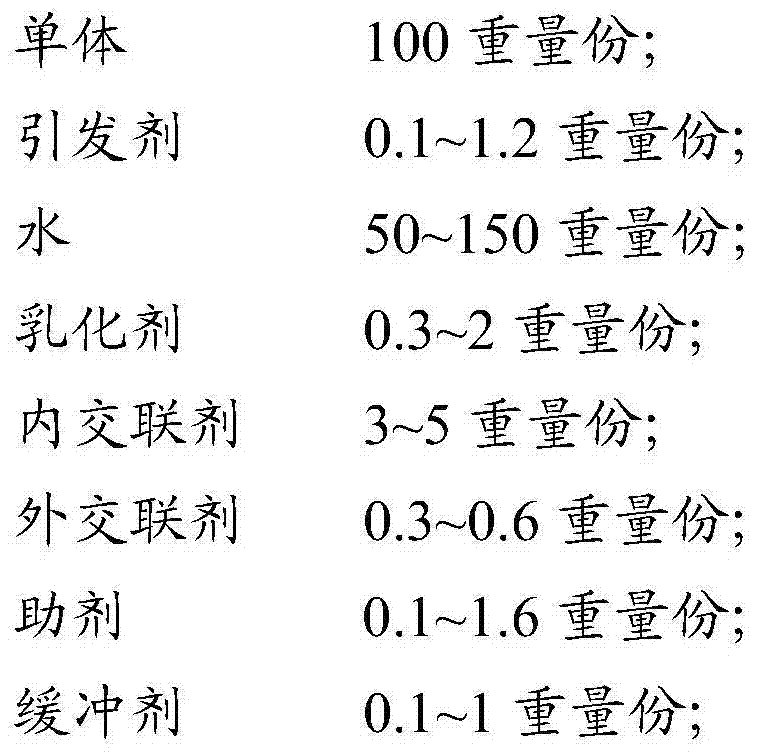

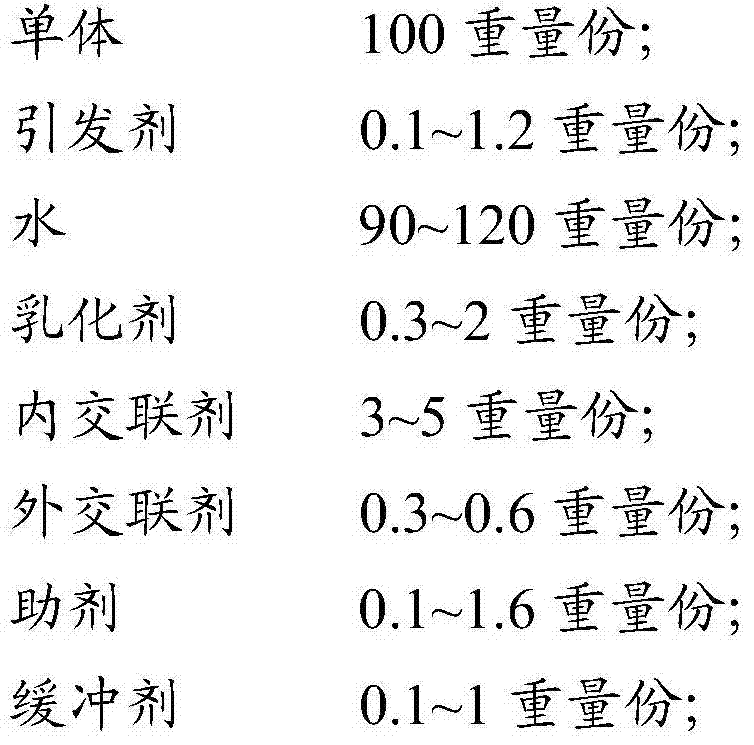

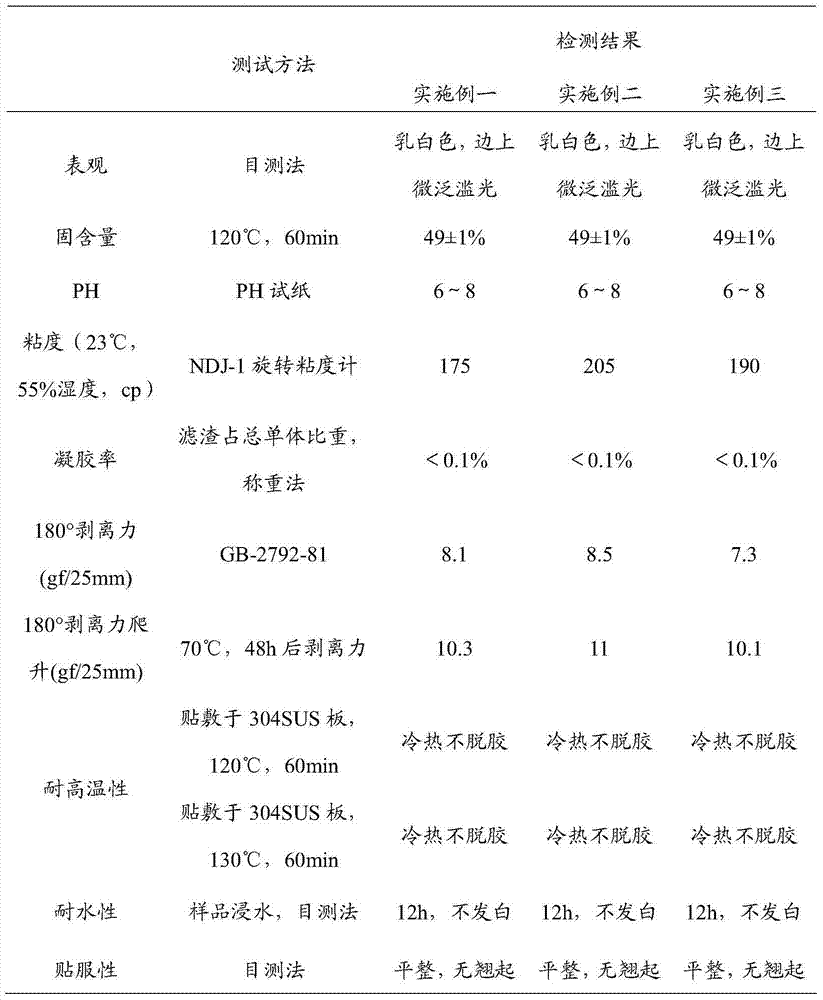

Ultralow-viscosity pressure-sensitive adhesive and ultralow-viscosity protective film

InactiveCN103965815AHigh molecular weightLow peel strengthFilm/foil adhesivesEster polymer adhesivesTectorial membraneTemperature resistance

The invention provides an ultralow-viscosity pressure-sensitive adhesive and an ultralow-viscosity protective film. The ultralow-viscosity pressure-sensitive adhesive is composed of the following components in parts by weight: 100 parts of monomer, 0.1-1.2 parts of initiator, 50-150 parts of water, 0.3-2 parts of emulsifier, 3-5 parts of inner crosslinking agent, 0.3-0.6 part of outer crosslinking agent, 0.1-1.6 parts of assistant and 0.1-1 part of buffering agent. Compared with the prior art, the glass transition temperature of the monomer is lower, thereby ensuring the softness required by the adhesive layer; the inner crosslinking agent is added to increase the molecular weight of the ultralow-viscosity pressure-sensitive adhesive part, so that macromolecules and micromolecules are distributed in a certain state, thereby compromising the balance between the initial viscosity and cohesive force; and the outer crosslinking agent is added into the ultralow-viscosity pressure-sensitive adhesive, so that molecular chains are further crosslinked in the film formation process of the pressure-sensitive adhesive, thereby effectively lowering the peel strength of the pressure-sensitive adhesive and enhancing the high temperature resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

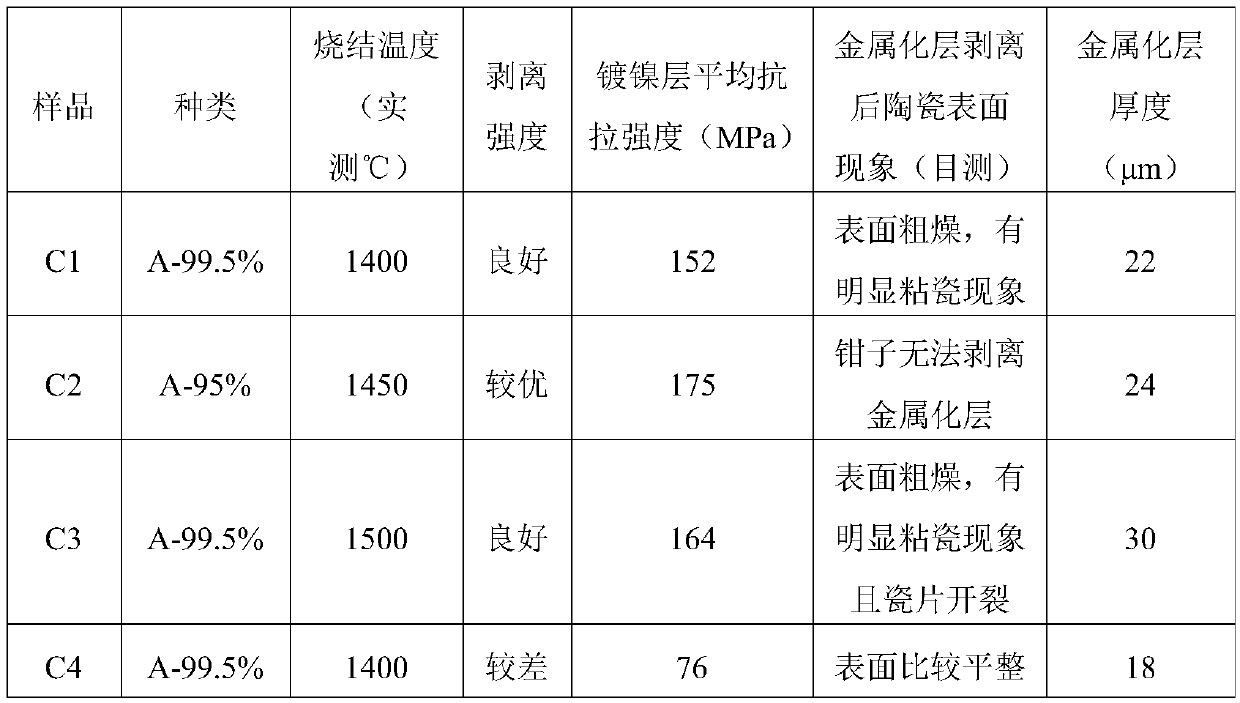

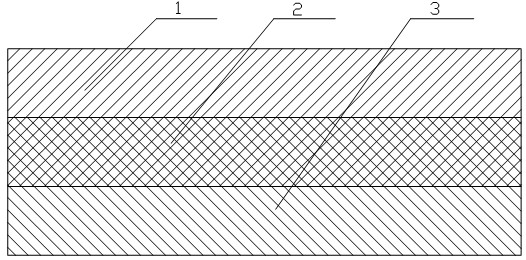

Ultrahigh-purity aluminum oxide ceramic metallization method

The invention belongs to the technical field of electronic functional ceramic materials, and particularly relates to an ultrahigh-purity aluminum oxide ceramic metallization method. Aiming at the problems of low strength, poor heat conductivity, and poor air tightness of a ceramic matrix caused by an aluminum oxide ceramic metallization sintering process, the invention provides an ultrahigh-purityaluminum oxide ceramic metallization method. The method comprises the following steps: a, weighing raw material powder, dispersing the raw material powder into alcohol, ball-milling, and drying to prepare a metallized slurry additive; b, mixing molybdenum powder, molybdenum trioxide powder, manganese powder and the metallized slurry additive to obtain powder, and ball-milling the powder to obtainmetallized powder; c, subjecting the metallized powder to vibration grinding to obtain metallized slurry; and d, printing or coating the metallized slurry, and sintering to obtain a metallized product. The sintering temperature of the metallized slurry is lower than an existing sintering temperature, multiple times of metallized sintering can be achieved, the thickness of a metallized layer is increased, and after nickel plating, the metallized layer is good in stripping effect, high in stripping strength and good in metallized tensile strength performance.

Owner:宜宾红星电子有限公司

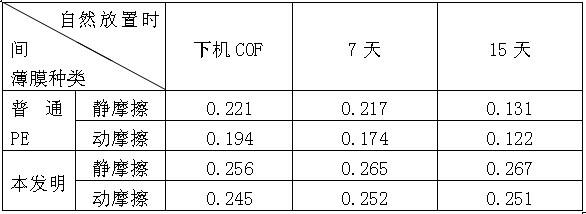

Highly-smooth polyethylene film and manufacturing method thereof

InactiveCN102673060AEvenly distributed and stableHigh Slippery Coefficient of FrictionFlexible coversWrappersHigh-density polyethyleneLow-density polyethylene

The invention discloses a highly-smooth polyethylene film and a manufacturing method thereof. The highly-smooth polyethylene film comprises an outer layer, a middle layer and an inner layer. The outer layer is made of, by weight ratio, 10:90-90:10 of low-density polyethylene and linear low-density polyethylene. The middle layer is made of, by weight ratio, 10:90-90:10 of low-density polyethylene and linear low-density polyethylene. The inner layer is made of, by weight ratio, 50:50:0.5-50:50:10 of low-density polyethylene, linear low-density polyethylene and anti-plastering agents. The manufacturing method includes mixing the outer layer, the middle layer and the inner layer by a quantitative batcher, adding the layers to an extruder to be subjected to plastifying extrusion, extruding the layers into film tubes by triple coextrusion die heads, and wrapping up the layers after the layers are blown up. Compared with the prior art, the highly-smooth polyethylene film is more precise and stable in friction coefficient and well solves the problems of slipping of composite films on a package machine and slipping agent precipitation.

Owner:浙江粤海包装新材料有限公司

Acrylic pressure-sensitive adhesive composition

ActiveUS8664326B2Improve protectionHigh strengthLiquid surface applicatorsOther chemical processesAcetic acidPolymer science

Owner:LG CHEM LTD

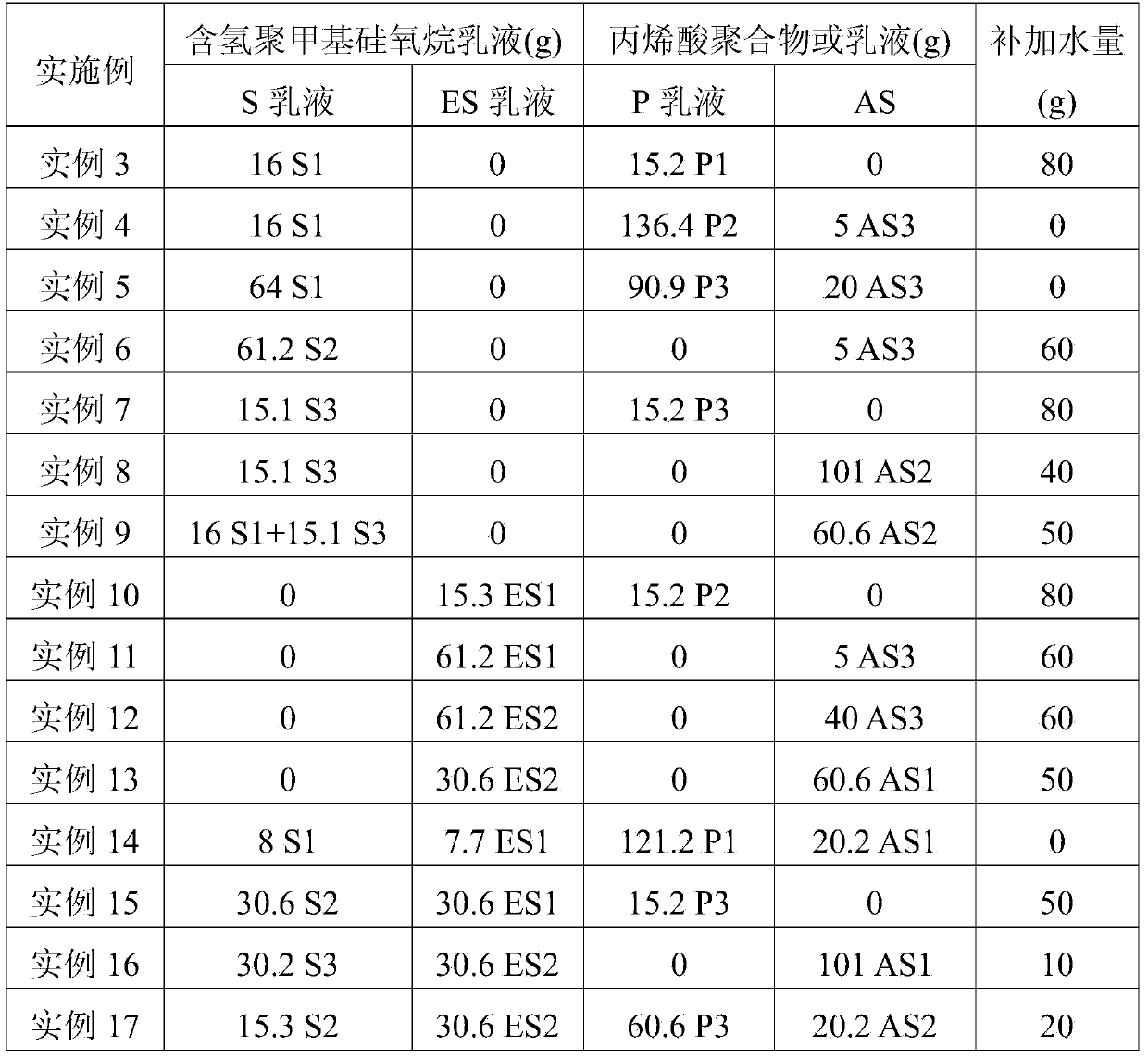

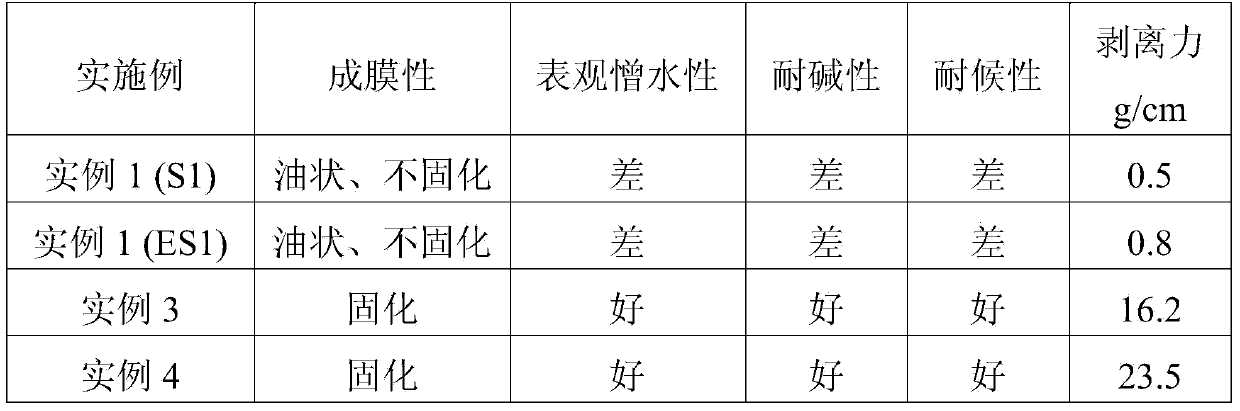

Acrylic organosilicone water-emulsion coating as well as preparation method and application for same

The invention belongs to the technical field of acrylic coatings, and discloses an acrylic organosilicone water-emulsion coating as well as a preparation method and an application for the same. The acrylic organosilicone water-emulsion coating comprises the following components in the following parts by weight: 100 parts of water, 0.1-4 parts of an emulsifier, 5-20 parts of liquid hydrogen-containing polymethyl siloxane, and 5-50 parts of acrylic polymers. The organosilicone content of the acrylic organosilicone water-emulsion coating disclosed by the invention is up to more than 10% in the polymers, organosilicone and the acrylic polymers are compounded in a wide range, and curing film-forming is performed at a room temperature. The preparation process disclosed by the invention is simple, and the obtained emulsion is good in stability; and after curing film-forming, the acrylic organosilicone water-emulsion coating is good in mechanical performance (wherein the hardness can be up to 3 H), excellent in waterproof and hydrophobic performances, acid-base resistance, weather resistance, and adhesive force (which can be up to 2.5 MPa), and proper in peel strength (which can be up to 23 g / cm).

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Aqueous Self-Adhesive Coating for Electrical Steel and its Uses

ActiveUS20070231463A1Friendly and safe to environmentLong shelf lifeNon-fibrous pulp additionCoatings with pigmentsEpoxyElectrical steel

The present invention relates to a self-adhesive coating for electrical steel and its uses. The coating comprises 81-99.9 weight parts of aqueous epoxy resin emulsion, 0.07-17 weight parts of curing agent, and optionally 0.3 weight parts of accelerant. If required, said coating can optionally contain additives selected from diluent, filler, toughener, colorant, fire retardant, antirusting agent, antisettling agent, thixotropic agent or antifoamer, thickener, pigment dispersant, preservative, and the like. The coating can be used as electrical steel coating. The present coating is capable of making electrical steel with a self-adhesive coating in a way of heat by naked-flame, and also there are no poisonous organic solvents to volatilize during the entire process. Furthermore, the coating permits to omit apparatus for burning organic solvents, and the cost is thereby reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

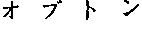

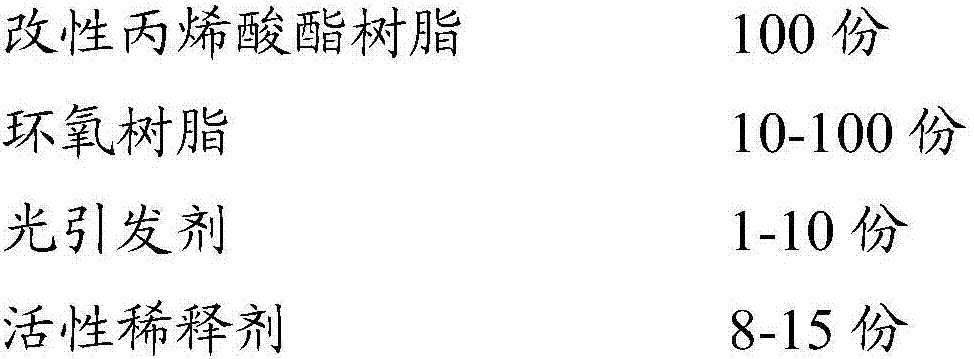

Adhesive for flexible electronic substrate as well as preparation method and application thereof

ActiveCN107384282AHigh bonding strengthLess residual gluePolyureas/polyurethane adhesivesSemiconductor/solid-state device manufacturingAdhesiveReactive diluent

The invention discloses an adhesive for a flexible electronic substrate and a preparation method thereof. The adhesive is prepared by mixing the following components in parts by weight: 100 parts of modified acrylate resin, 10-100 parts of epoxy resin, 1-10 parts of a photoinitiator, 8-15 parts of a reactive diluent and 1-15 parts of a thermal initiator. The invention also discloses application of the adhesive in manufacturing procedure of the flexible electronic substrate. The BDB (Bonding and Debonding) adhesive prepared by the invention combines the advantages of the epoxy resin and the acrylate resin, solves the problem that an ordinary adhesive cannot be stripped or greatly remains after being stripped, has the characteristics of being firm in combination with glass and flexible plastic electronic substrates, liable to strip, small in adhesive residual amount and convenient in construction, being safe and environment friendly and the like, can replace the traditional unpeelable type adhesive and is used for preparation of flexible display screens of electronic equipment such as tablet personal computers, mobile phones, kindle.

Owner:ZHEJIANG UNIV

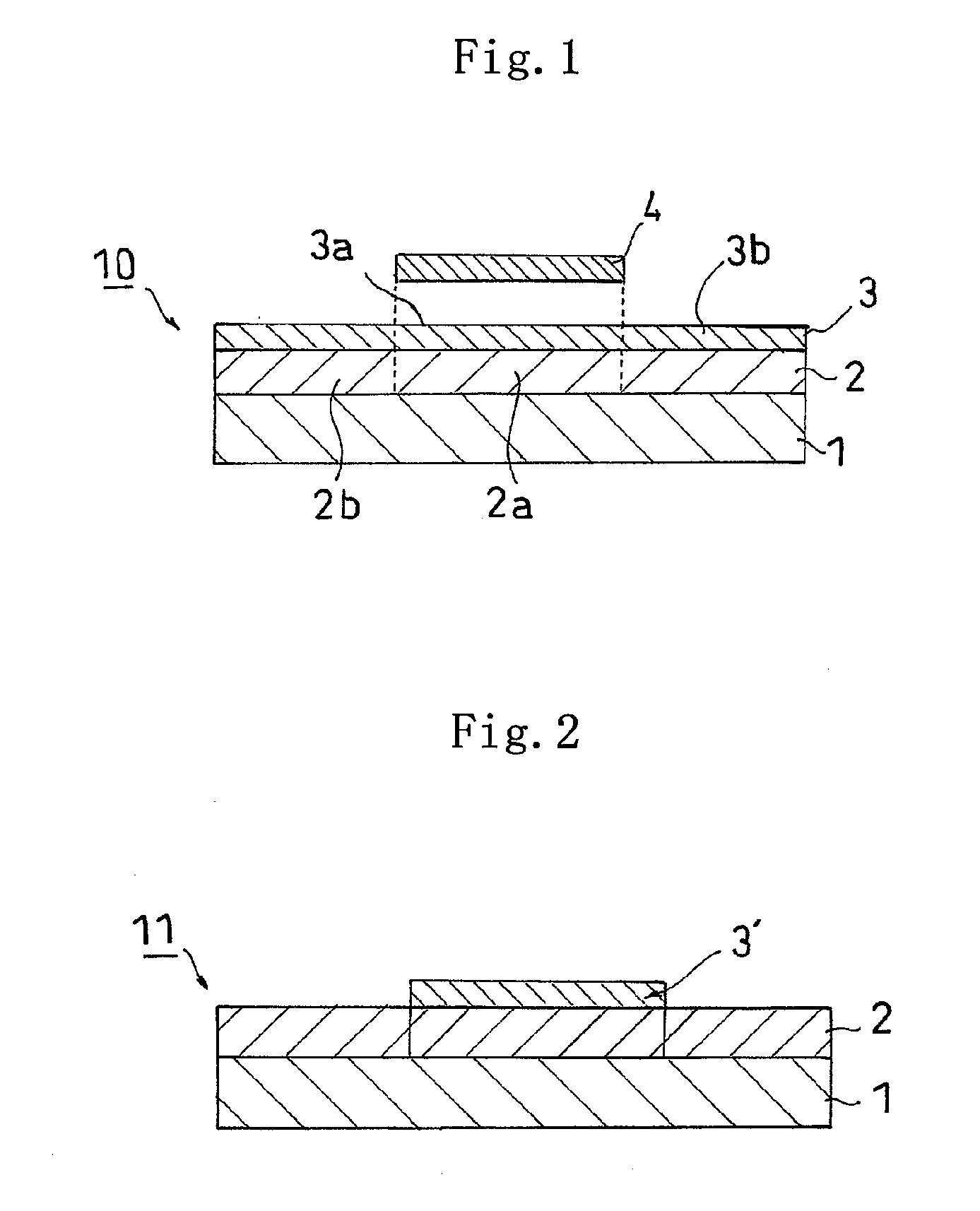

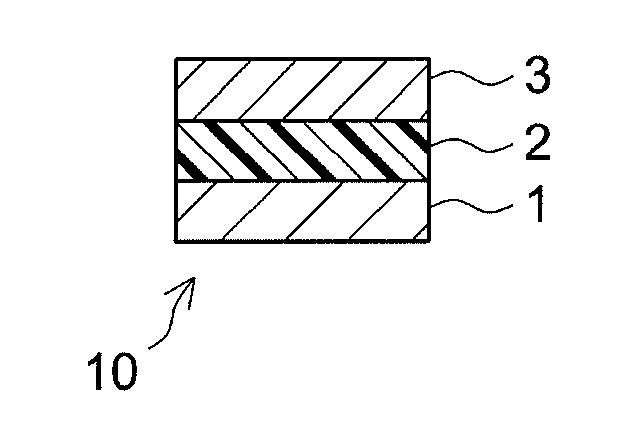

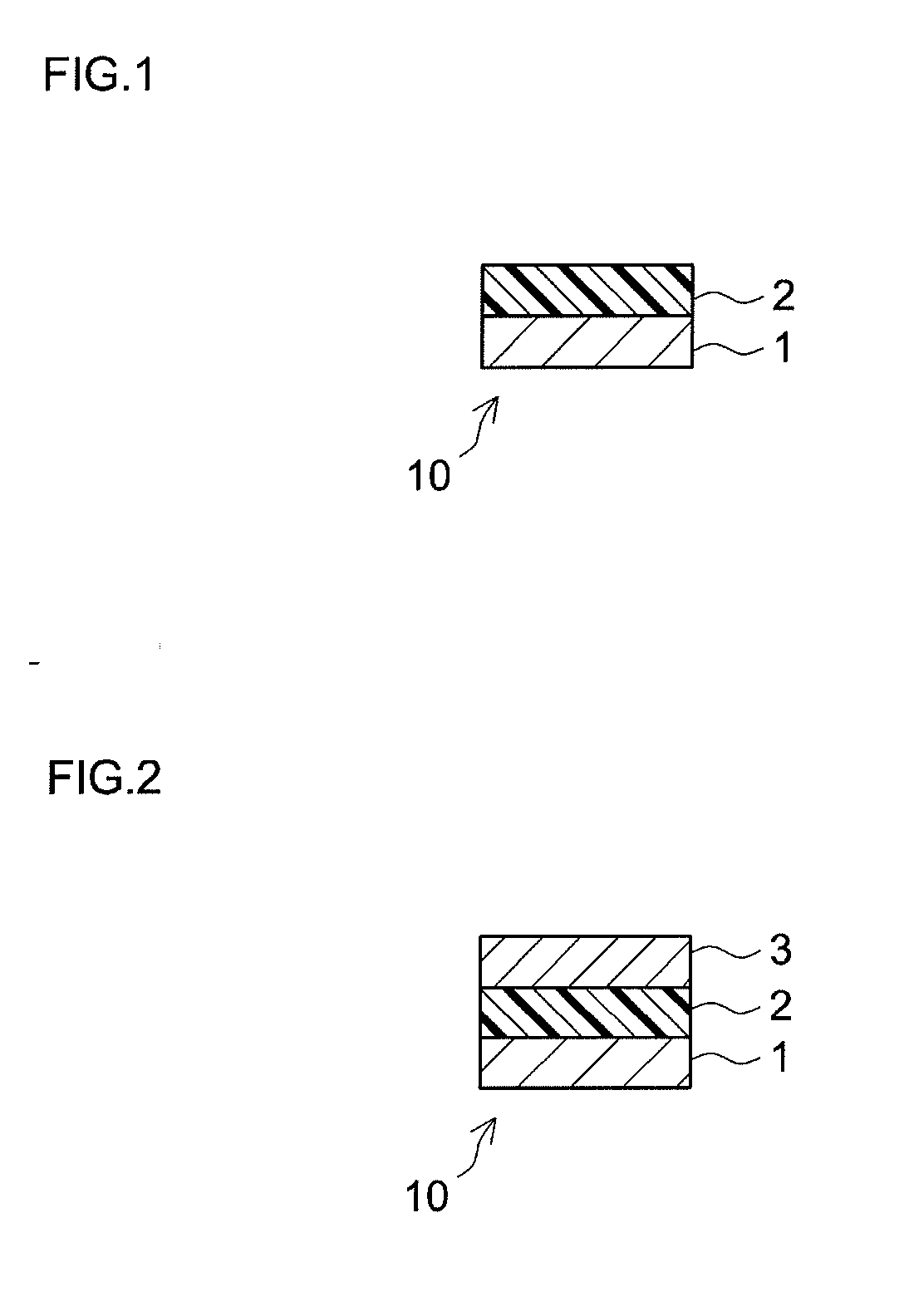

Pressure-sensitive adhesive composition for surface protective films and use thereof

InactiveUS20120064339A1Easy to controlImprove performanceFilm/foil adhesivesEster polymer adhesivesUltimate tensile strengthAcrylic polymer

The present invention provides a surface protective film that exhibits small differences in peel strength on account of the surface state of an adherend and that is excellent in anti-contamination to adherends, and a pressure-sensitive adhesive (PSA) composition for the protective film. The PSA composition provided by the present invention comprises 0.01 to 5 parts by weight of a compound containing an oxypropylene group with respect to 100 parts by weight of an acrylic polymer as a base polymer. A surface protective film 10 provided by the present invention has a PSA layer 2, formed using the above PSA composition, on one or both sides of a support 1.

Owner:NITTO DENKO CORP

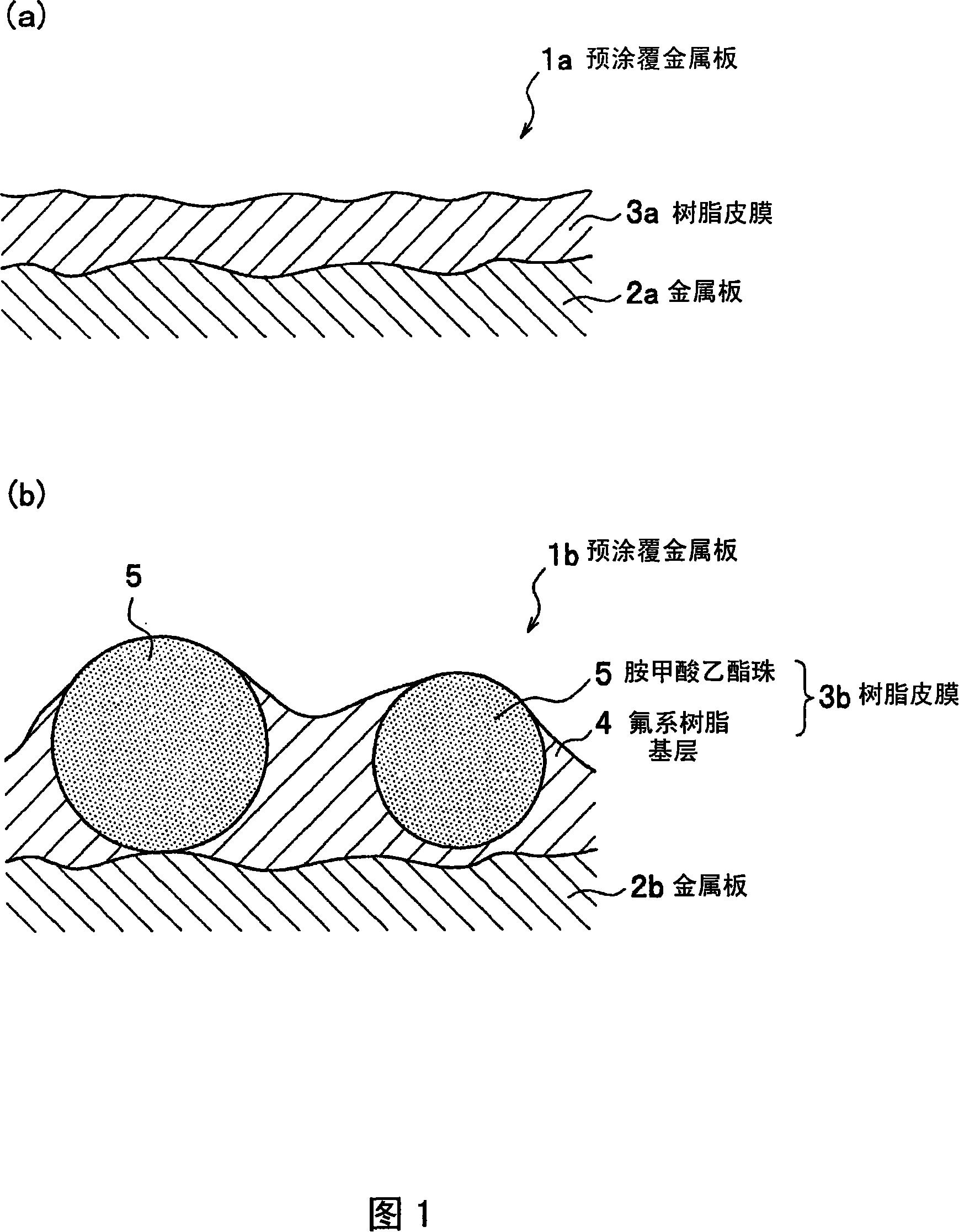

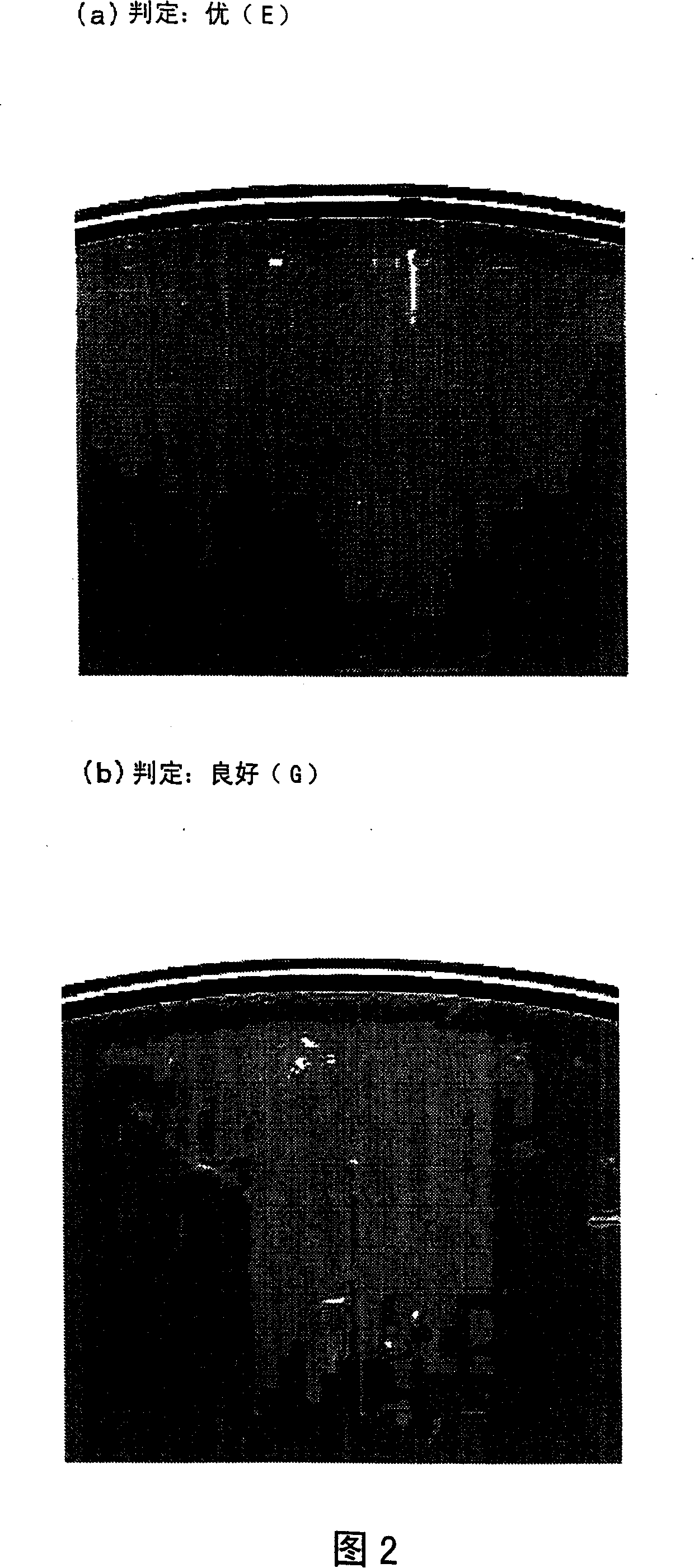

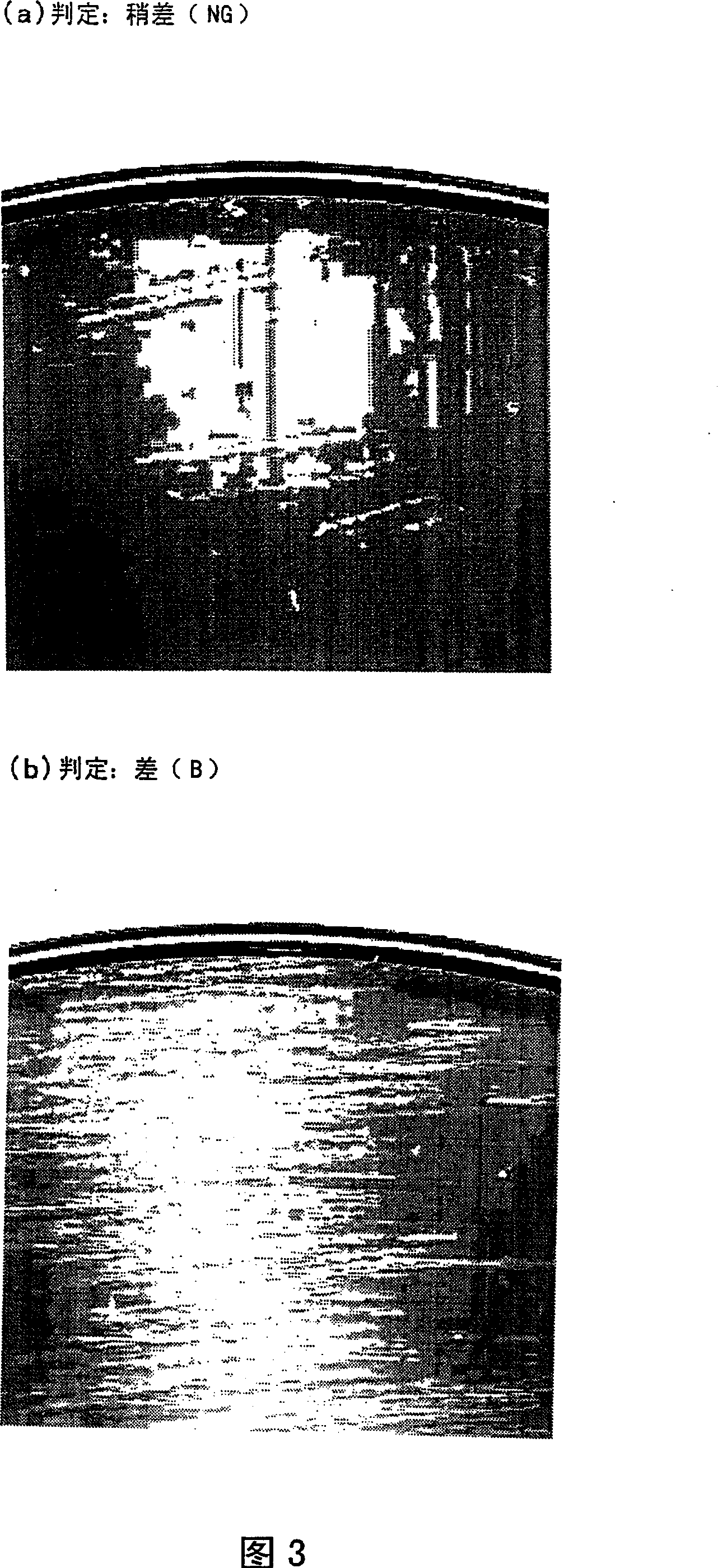

Precoat metal plate and its manufacturing method

InactiveCN101124084ALow peel strengthGood adhesionPretreated surfacesSpecial surfacesNitrogenResin coating

A precoated metal sheet which comprises a metal sheet and, formed on a surface thereof, a resin coating film comprising a fluororesin, wherein the concentration proportion of fluorine in an uppermost layer of the resin coating film, as calculated using the equation (1), is 20% or higher and the concentration proportion of fluorine in an inner layer located in a position about 1 / 2 the thickness of the coating film, as calculated using the following equation (1), is 15% or lower. A(%) = {F / (F+C+O+N100 (1) (In the equation (1), A is the concentration proportion of fluorine; F is the amount of fluorine in mass%; C is the amount of carbon in mass%; O is the amount of oxygen in mass%; and N is the amount of nitrogen in mass%.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com