Patents

Literature

34results about How to "Improves stress cracking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

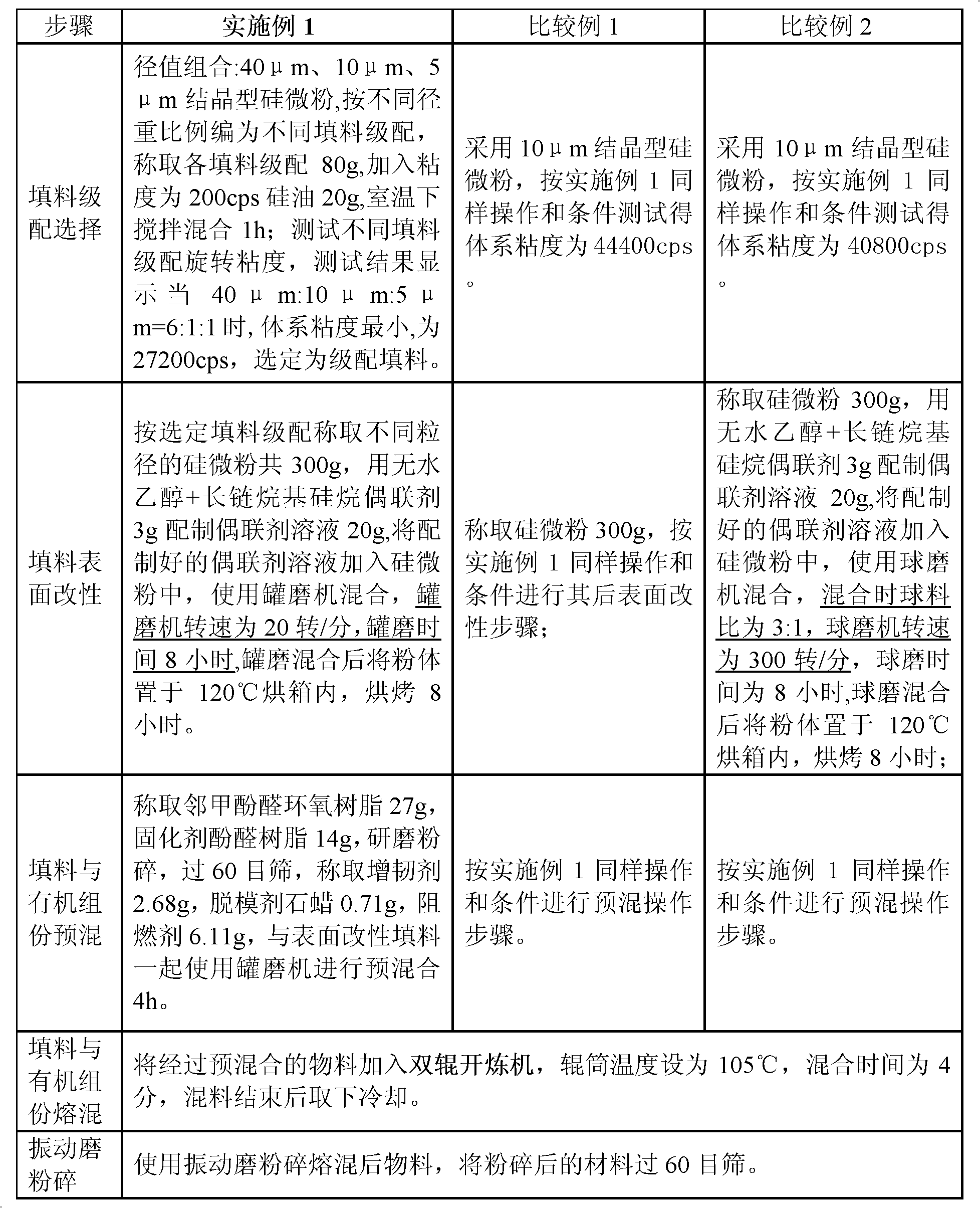

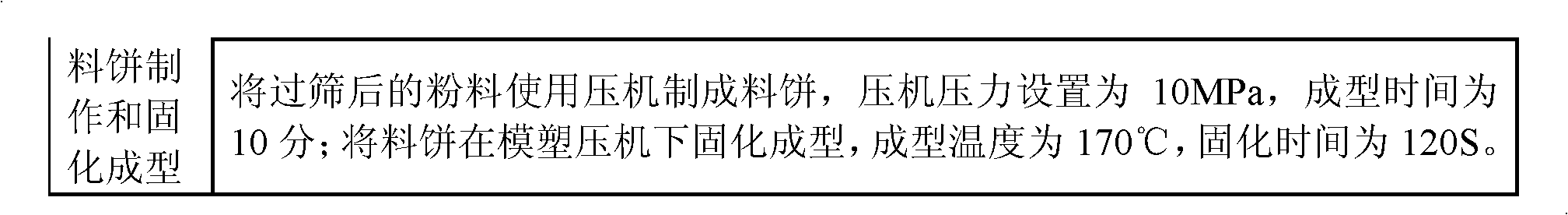

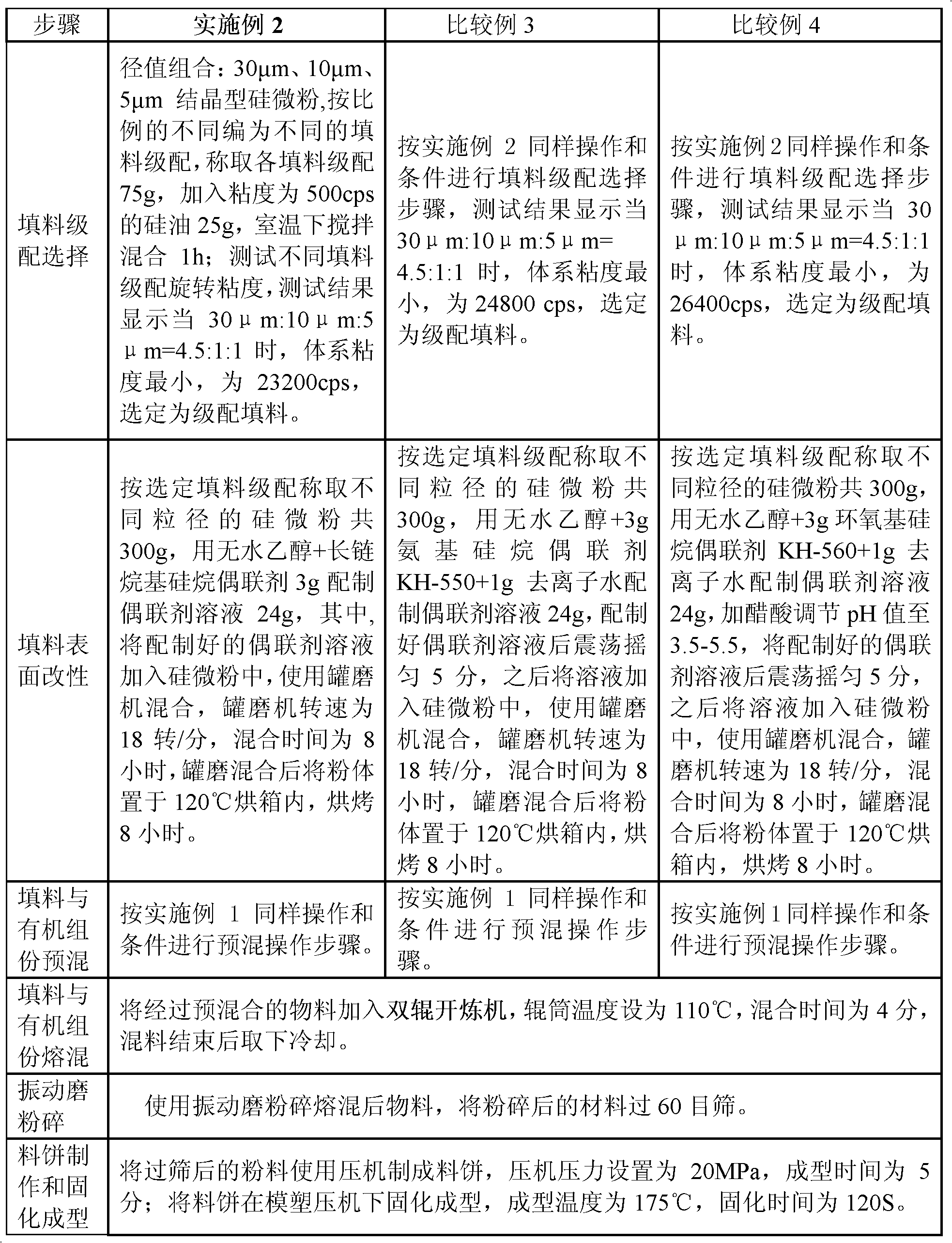

Composite material for packaging and preparation method thereof

The invention relates to a composite material for packaging and a preparation method thereof. The composite material comprises 60-90 wt% of inorganic powder filler, 10-40 wt% of organic component for bonding and consolidating, wherein the filler refers to inorganic powders with 2-5 grain size values which are mixed uniformly according to selected grain size-value combination and grain size-weight combination, a coupling layer formed in the presence of a long-chain alkyl silane coupling agent exists between the inorganic powder surface and the organic component. According to the invention, through the proper matching of inorganic fillers with different grain sizes, the dispersion viscosity of the inorganic fillers in an organic system can be reduced effectively so as to improve the flowability of the inorganic fillers, so that more inorganic fillers can be filled under the same viscosity or same forming conditions, thereby further reducing packaging cost, improving packaging efficiency, improving the thermal conductivity of a package and reducing the thermal expansion coefficient of the package; through the adoption of a novel coupling agent, the surface modification effect of powder can be improved, compatibility between the inorganic filler and the organic component and bonding force between interfaces can be enhanced remarkably, and the overall water absorption of the composite material and the package can be reduced.

Owner:GUANGDONG EAST SUNSHINE ALUMINUM

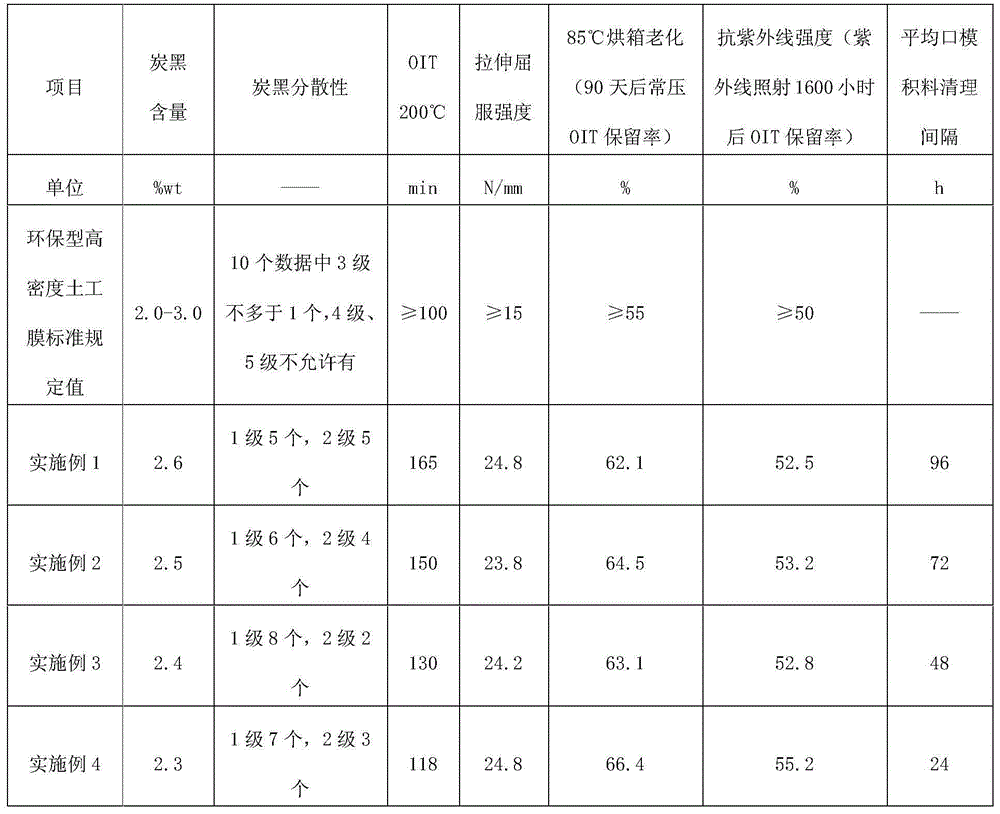

High-concentration carbon black master batch for polyethylene geomembrane

InactiveCN105017599AEasy to processLow impurity contentLinear low-density polyethyleneHigh concentration

The invention discloses a carbon black master batch for a polyethylene geomembrane. The carbon black master batch is composed of, by weight, 23%-40% of high-density polyethylene resin, 4%-12% of linear low-density polyethylene resin, 48%-55% of carbon black, 7%-10% of antioxygen and 0.05%-2% of fluorocarbon polymer. The master batch and a material special for the polyethylene geomembrane are used for conducting melt blending, and thus a geomembrane product capable of meeting GB-T 17643-2011, GM13, CJ 234 standard requirements can be obtained through squeezing or blowing. The geomembrane product prepared through the method has excellent performance on the aspects of tensile yield strength, anti-UV intensity and the like.

Owner:TIANJIN YISANYOU MASTERBATCH CO LTD

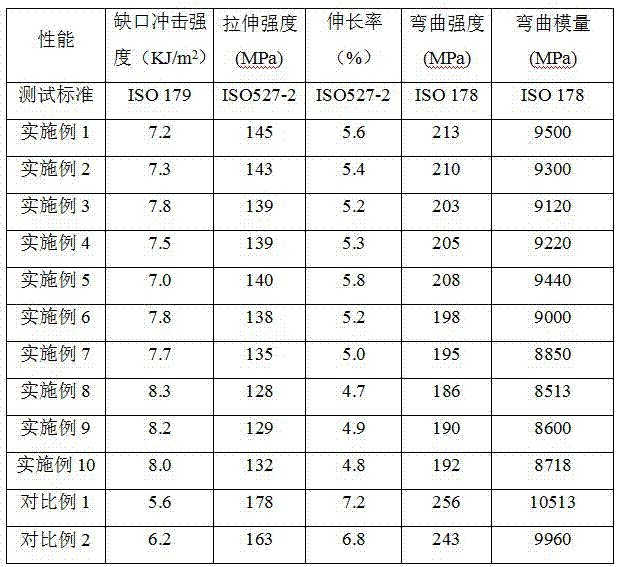

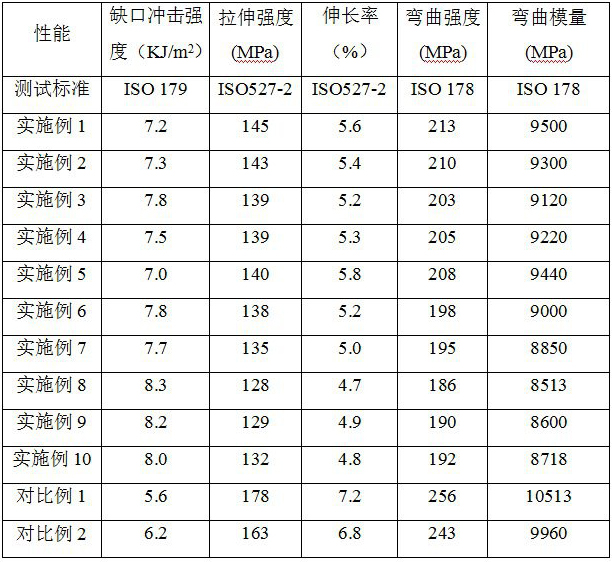

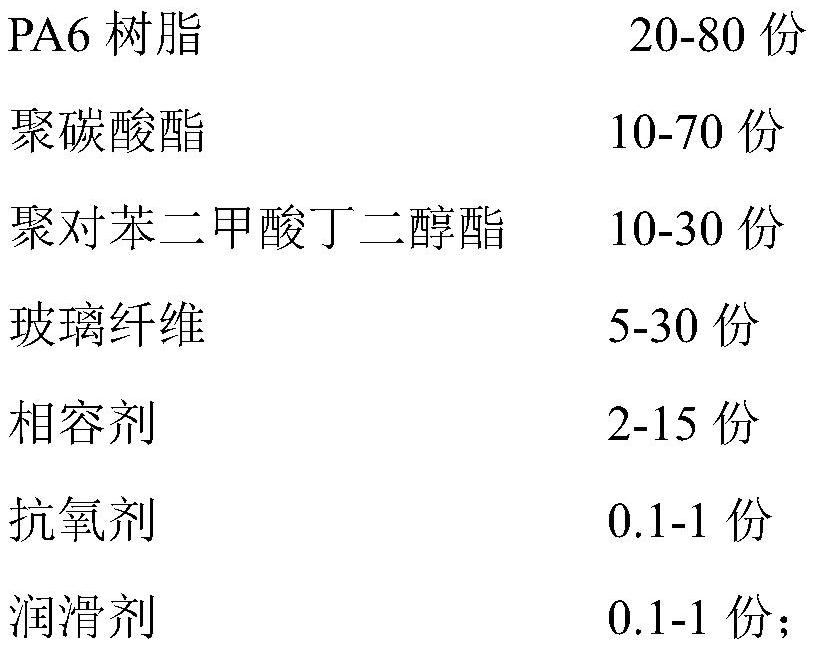

PA6/PC/ PBT ternary alloy material and preparation method thereof

ActiveCN107365494AImprove toughnessGood dimensional stabilityPolytetramethylene terephthalateCrack resistance

The invention relates to the technical field of polymer materials, in particular to a PA6 / PC / PBT ternary alloy material and a preparation method of the PA6 / PC / PBT ternary alloy material. The ternary alloy material comprises the following raw materials in parts by weight: 20 to 80 parts of PA6 resin, 10 to 70 parts of PC, 10 to 30 parts of polybutylene terephthalate, 5 to 30 parts of glass fibers, 2 to 15 parts of compatibilizers, 0.1 to 1 part of an antioxidant and 0.1 to 1 part of a lubricant. The PA6 / PC / PBT ternary alloy material disclosed by the invention has high performances of toughness, dimensional stability, corrosion resistance, stress cracking resistance, oil resistance, mechanical strength and the like, and is high in molding performance, excellent in processability, low in cost and high in use value, and the preparation method is simple, convenient to operate and control, stable in quality, high in production efficiency, low in production cost and suitable for large-scale industrial production.

Owner:广东壹豪新材料科技股份有限公司

Modified polyethylene-vinyl acetate hot melt adhesive applied to plastic bonding

InactiveCN107488427AReduce intensityHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyethylene vinyl acetateCrack resistance

The invention relates to the technical field of hot melt adhesive material processing and discloses a modified polyethylene-vinyl acetate hot melt adhesive applied to plastic bonding. The modified polyethylene-vinyl acetate hot melt adhesive is prepared from the following components in parts by weight: 50-60 parts of modified polyethylene-vinyl acetate resin, 40-50 parts of tackifier, 5-8 parts of filler, 3-5 parts of paraffin, 1-2 parts of antioxidant and 0.2-0.3 part of plasticizer. After resin modification, the toughness, impact resistance, softness, stress cracking resistance, viscosity, thermal airtightness and repeated bending property in a low-temperature state are enhanced; the peel strength of cementing is improved, and the rubber elasticity is boosted; moreover, the strength, hardness, melting point and thermal deformation temperature are raised along; the heat resistance and the coating uniformity are high; the modified hot melt adhesive has the characteristics of perfect flexibility and bonding strength and the like and also has the advantages of low melt viscosity and high heat resistance.

Owner:安徽嘉明新材料科技有限公司

Anti-tearing and anti-aging modified master batch

InactiveCN108264687ALarge specific surface areaHigh elongation at breakMonocomponent polyolefin artificial filamentArtifical filament manufactureAntioxidantFilling materials

The invention relates to an anti-tearing and anti-aging modified master batch. A formula of the anti-tearing and anti-aging modified master batch comprises the following ingredients in parts by weight: 15 to 25 parts of carrier resin, 70 to 80 parts of filling materials, 0.5 to 1 part of coupling agents, 2 to 4 parts of dispersing agents, 0.2 to 1 part of light stabilizers, 0.2 to 0.5 part of antioxidants and 0.2 to 1 part of graphene. The nanometer calcium carbonate or talc powder is used as filling materials; meanwhile, polyethylene, graphene, the light stabilizing agents and the antioxidants are added, so that the product has high anti-tearing performance, excellent UV-resistance effect and long service life; the heat degradation in the processing process can be effectively inhibited; the heat oxidization aging and light aging in the use process can be relieved; the anti-tearing and anti-aging modified master batch is applicable to plastic products such as polypropylene flexible freight bags, weaving bags and films with the anti-aging requirements.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

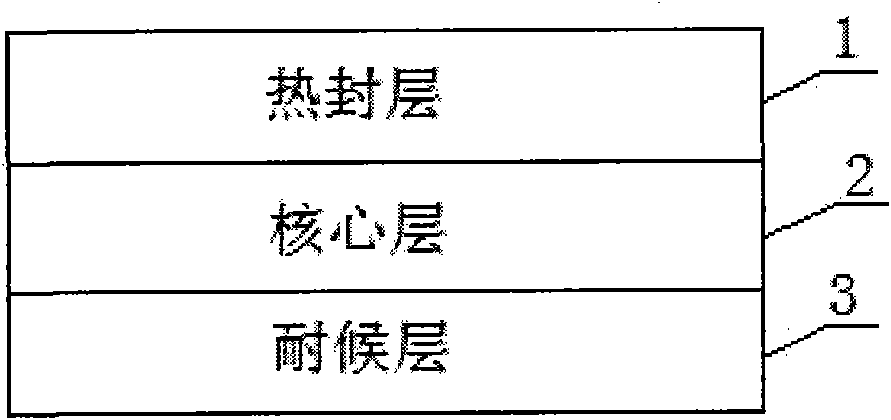

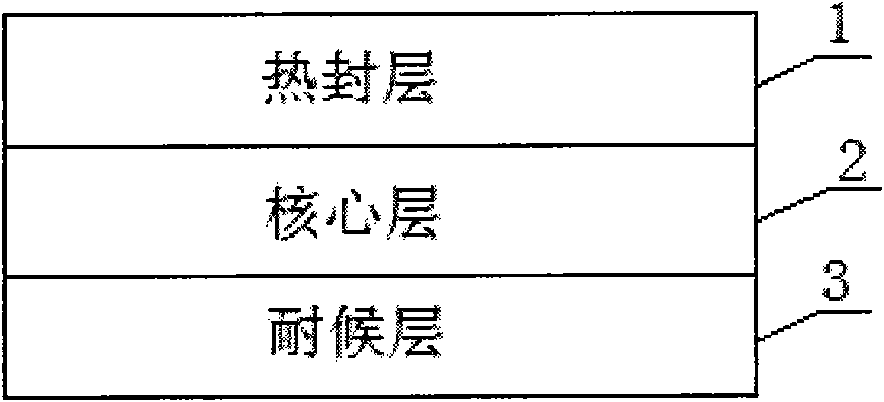

Multilayer co-extrusion cell culture container bag packaging film

InactiveCN102189732ANo low precipitationImprove cold resistanceFlexible coversWrappersSurface layerEngineering

The invention discloses a multilayer co-extrusion cell culture container bag packaging film, which comprises an upper surface layer, a middle layer and a lower surface layer which are sequentially arranged, wherein the upper surface layer, the middle layer and the lower surface layer are modified ethylene-vinyl acetate copolymer layers; the thickness of the upper surface layer is 25 to 35 percent of the total thickness of the film; the thickness of the middle layer is 35 to 45 percent of the total thickness of the film; and the thickness of the lower surface layer is 25 to 35 percent of the total thickness of the film. The multilayer co-extrusion cell culture container bag packaging film is a multilayer co-extrusion packaging film which has a high comprehensive property, particularly a high barrier property and a high sealing property which is suitable for multiple kinds of equipment and various interfaces, and has an extremely high protection property for culture of cellular fluid.

Owner:SUZHOU HAISHUN PACKAGING MATERIAL

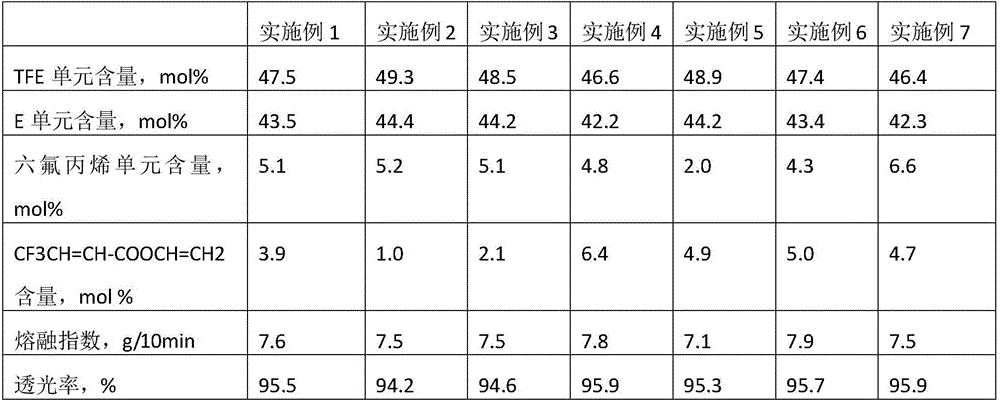

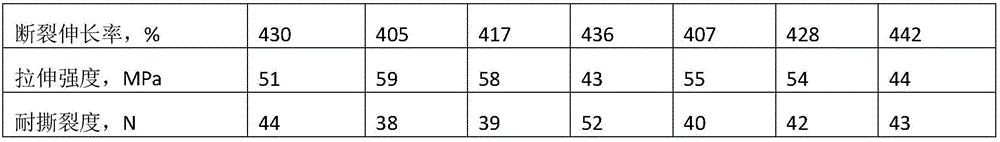

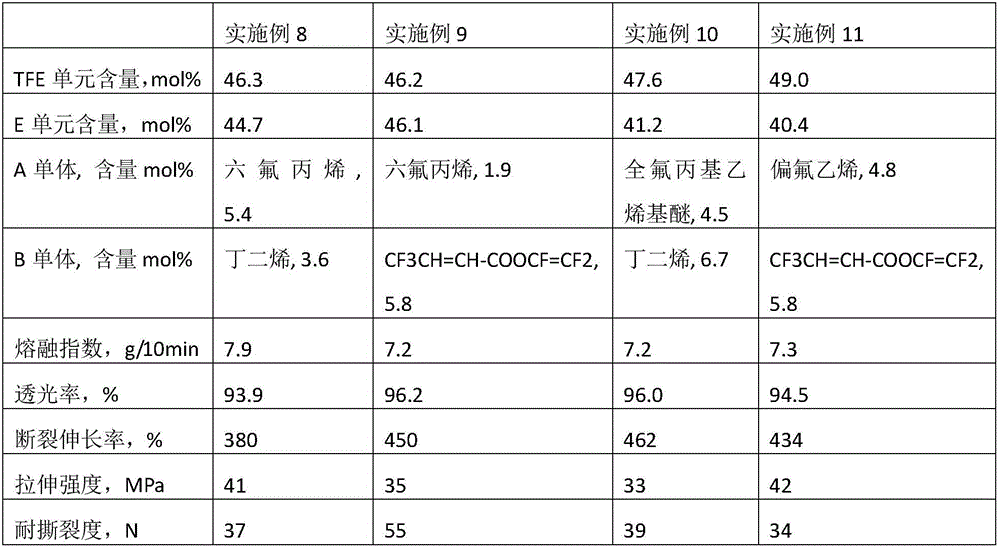

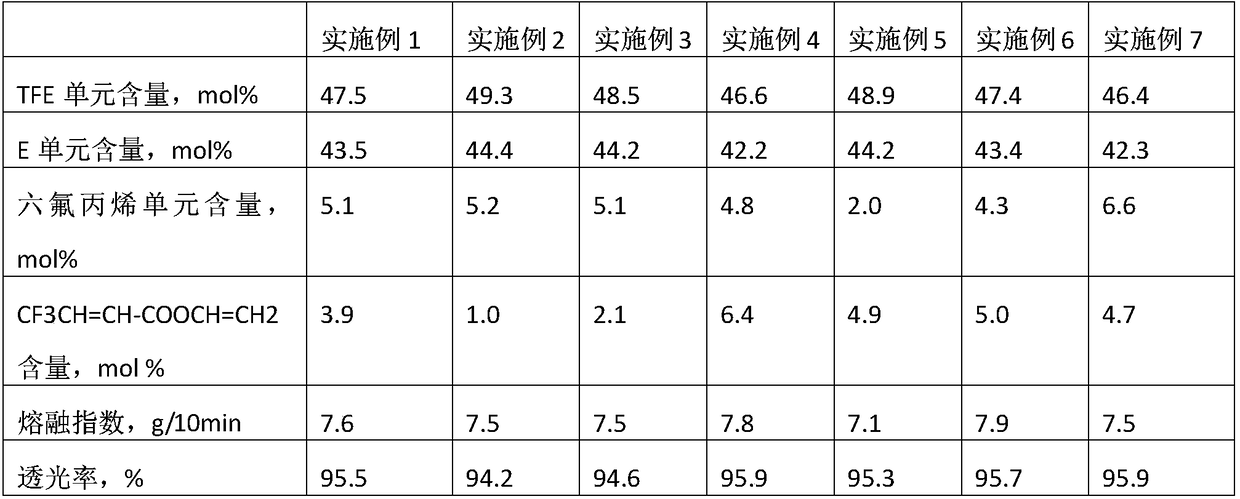

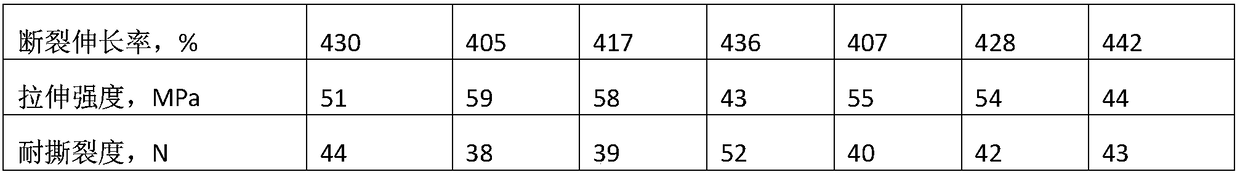

Cross-linkable ethylene-tetrafluoroethylene copolymer and synthetic method thereof

The invention relates to a cross-linkable ethylene-tetrafluoroethylene copolymer and a synthetic method thereof. A polymer is prepared from tetrafluoroethylene, ethylene, a monomer A and a monomer B through copolymerization, wherein the monomer A is a compound containing one double bond, and the monomer B is a compound containing two double bonds; and by virtue of proper crosslinking, the ethylene-tetrafluoroethylene copolymer can be endowed with relatively high radiation resistance, toughness, abradability, tensile strength and tear strength. The invention further provides a preparation method of the cross-linkable ethylene-tetrafluoroethylene copolymer and a cross-linkable copolymer composition. By controlling a polymerization process, too many low polymers can be reduced, and excellent performance of the polymer can be maintained.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

TRB (thermoplastic rubber) high-physical-property composite injection-molding rubber material

The invention discloses a TRB (thermoplastic rubber) high-physical-property composite injection-molding rubber material which is prepared from the following raw materials in parts by weight: 50-60 parts of SBS (styrene-butadiene-styrene), 10-20 parts of SEBS (styrene-ethylene-butadiene-styrene), 20-30 parts of nitrile-butadiene rubber, 15-20 parts of polystyrene, 15-20 parts of softening oil, 4-8 parts of silica white, 5-7 parts of nano calcium carbonate, 4-5 parts of low-temperature foaming agent, 1.5-2 parts of high-polymer wear-resistant oil and 5-10 parts of grafting substance.

Owner:广东志达行新材料有限公司

Stress cracking-resistant PC (Polycarbonate) material and preparation method thereof

InactiveCN109666278AGood shading effectImproves stress cracking resistanceVegetal fibresPolyethylene terephthalate glycolCrack resistance

The invention discloses a stress cracking-resistant PC (Polycarbonate) material and a preparation method thereof, and belongs to the technical field of high molecular chemical materials. The technicalpoint is that the stress cracking-resistant PC material is prepared from the following components in parts by mass: 50 to 80 parts of PC, 2 to 25 parts of titanium dioxide, 5 to 20 parts of PET (Polyethylene Terephthalate), 5 to 20 parts of PE (Polyethylene), 0.5 to 2 parts of MBS (Methyl Methacrylate Butadiene Styrene Terpolymer) resin, 0.2 to 0.5 part of diffusing oil, and 0.5 to 3 parts of other auxiliary agents. The preparation method of the stress cracking-resistant PC material comprises the following steps: 1, uniformly mixing the PC, the PE, the PET and 10 to 25 weight percent of the diffusing oil to obtain a premix; 2, adding 75 to 90 weight percent of a premix of the diffusing oil and an antioxidant, and uniformly mixing the premix with the premix which is obtained in the step 1according to the proportion; 3, adding the titanium dioxide, the MBS resin, nano-CaCO3, modified plant fibres / PE composite material, talcum powder and other toners into the mixed materials in proportion; after the materials are mixed, extruding and granulating at 260 to 300 DEG C, and drying the particles for 3 to 5 hours at the temperature of 100 to 120 DEG C to obtain the PC material. Accordingto the stress cracking-resistant PC material and the preparation method thereof, the shading property, the stress cracking resistance, the acid and alkaline resistance, the weather resistance and theimpact strength of the PC material can be improved, which is helpful to prolong the service life of the PC material.

Owner:东莞市旺品实业有限公司

Preparation method of TRB composite injection molded rubber material with high physical property

InactiveCN104262887AAbrasion resistance and low densityShorten processing timeCarbon blackWear resistant

The invention discloses a preparation method of a TRB composite injection molded rubber material with high physical property. The preparation method comprises the following steps: tabletting nitrile rubber into slices with the thickness of 0.5-0.8mm in a plastication mode firstly, cutting each slice until the weight of each slice is 0.5-1kg, then throwing in a stirring barrel, adding emulsified oil, soaking for 30min, then adding SBS and SEBS, stirring for 30-40min, taking out a mixture from the stirring barrel, standing for 5-7h, and naturally cooling; throwing the cooled material in an internal mixer, adding polystyrene, softening oil, white carbon black, nanometer calcium carbonate and polymer wear resistant oil, carrying out internal mixing for 3-4min, then adding a filler, a rubber additive and a lubricant, and carrying out internal mixing for 6-7min; after internal mixing, discharging the material by virtue of a double-shaft extruder, then cooling and pelleting the material to obtain particles, injecting the particles in a mold by virtue of an ejection pipe, and carrying out injection for 4-8min at temperature of 150-160 DEG C and pressure of 10-15mpa.

Owner:广东志达行新材料有限公司

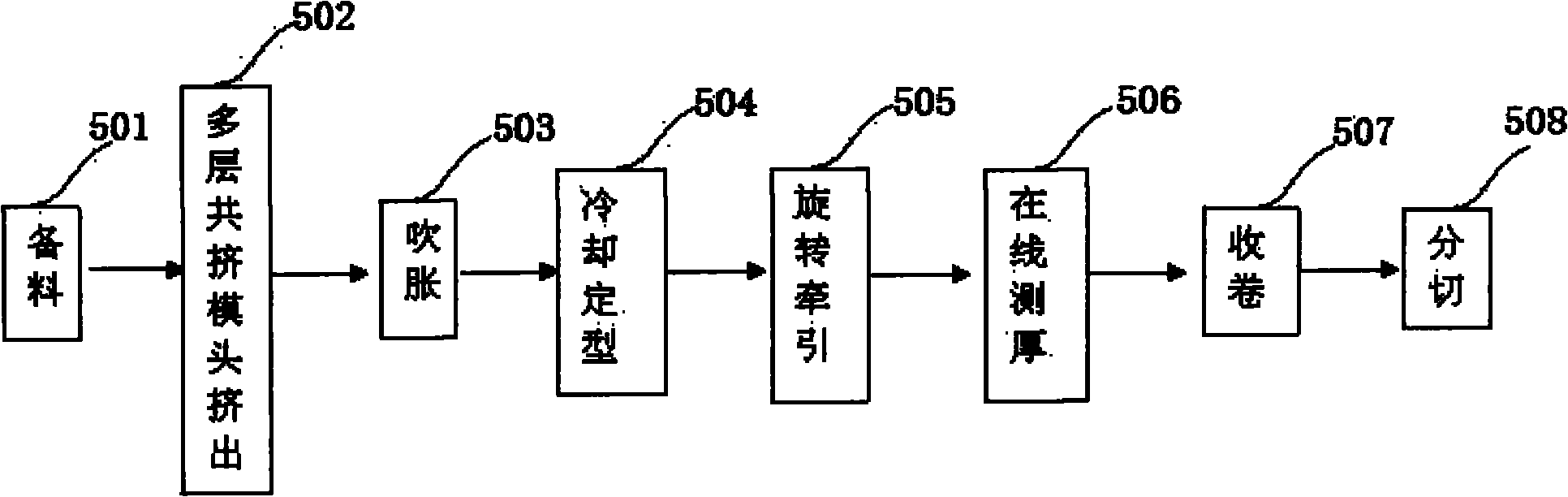

Packaging film for multilayer co-extruding urine bag and production method thereof

InactiveCN102371738AImprove toughnessPhysical properties unchangedSynthetic resin layered productsMedical treatmentEthylene

The invention discloses a packaging film for a multilayer co-extruding urine bag. The packaging film comprises a heat sealing layer, a core layer and a weather-resisting layer, which are arranged in turn, wherein the heat sealing layer, the core layer and the weather-resisting layer are modified ethylene-vinyl acetate copolymer layers. The invention also discloses a method for producing the packaging film for the multilayer co-extruding urine bag. The method comprises the following steps: preparing materials, extruding a multilayer co-extruding film head, blowing up, cooling and shaping, rotating and dragging, measuring thickness on line, coiling and cutting. The packaging film for the multilayer co-extruding urine bag provided by the invention is the packaging film which is excellent in comprehensive property, especially separating property, is suitable for various devices and interfaces, is excellent in properties for sealing and protecting urine, and is used as a urine packaging material applied to the medical field.

Owner:SUZHOU HAISHUN PACKAGING MATERIAL

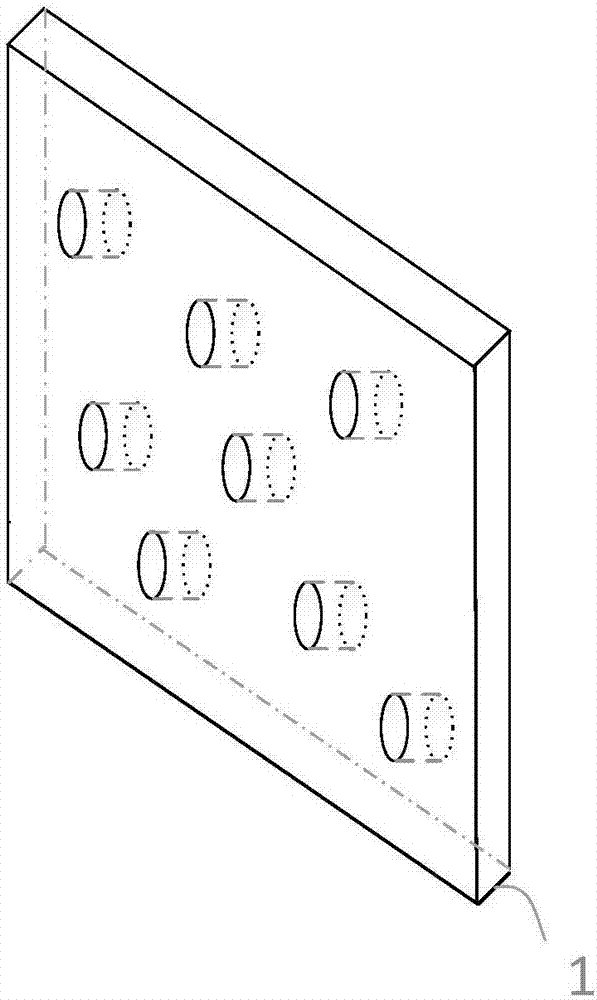

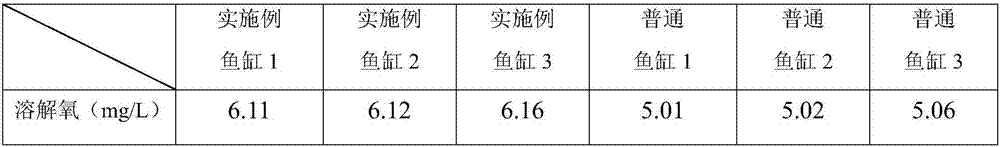

Transparent and breathable fish tank and preparing method thereof

The invention discloses a transparent and breathable fish tank. The fish tank is assembled by splicing transparent and breathable macromolecular panels. The top of the fish tank is opened, other parts, at least the ornamental side, of the tank body is made from the transparent and breathable macromolecular panels, the transparent and breathable macromolecular panels are provided with continuous cut-through pore ways in the thickness direction, and the continuous cut-through pore ways extend linearly and have the diameters of 0.6 micrometers or below. According to the comparison of the transparent and breathable fish tank and a common fish tank, an oxygenation pump is reduced, the production and operation cost of the fish tank is lowered, and the wholeness and the ornamental value of the fish tank are improved.

Owner:嘉兴市诚峰金属制品股份有限公司

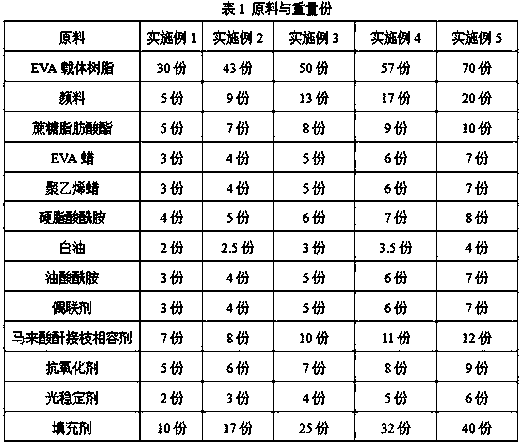

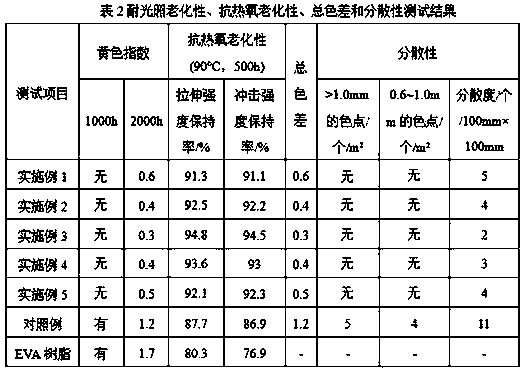

High dyeability EVA color master batch special for shoes and preparation method thereof

The invention provides a high dyeability EVA color master batch special for shoes. The high dyeability EVA color master batch comprises, by weight, 30-70 parts of an EVA carrier resin, 5-20 parts of apigment, 5-10 parts of sucrose fatty acid ester, 3-7 parts of EVA wax, 3-7 parts of polyethylene wax, 4-8 parts of octadecanamide, 2-4 parts of white oil, 3-7 parts of oleamide, 3-7 parts of a coupling agent, 7-12 parts of a maleic anhydride graft compatilizer, 5-9 parts of an antioxidant, 2-6 parts of a light stabilizer and 10-40 parts of a filler. The high dyeability EVA color master batch special for shoes is prepared from the above raw materials through processes, has the advantages of no flow pattern, no color point, small color difference, good light aging resistance, strong resistanceto thermo-oxidative aging and good dispersibility and solves the existing EVA master batch problems of uneven color and large color difference in coloring.

Owner:JINJIANG XINBANG NEW MATERIAL TECH

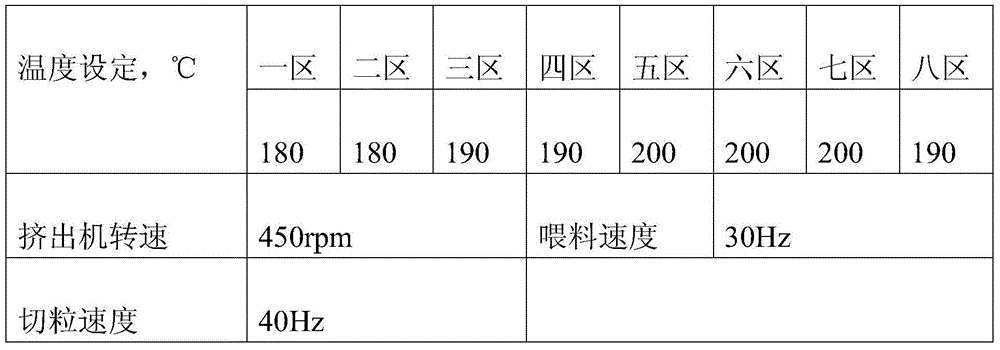

Electric-conducting flame-retarding thermoplastic powder, preparation method and applications thereof

InactiveCN103254487AGuarantee the appearance qualityHigh melt indexFireproof paintsPowdery paintsPolyolefinHigh intensity

The invention relates to electric-conducting flame-retarding thermoplastic powder, a preparation method and applications of the electric-conducting flame-retarding thermoplastic powder. The electric-conducting flame-retarding thermoplastic powder consists of the following components in percentage by weight: 20-25% of an electric-conducting master batch, 10-15% of a grafted adhesive master batch, 20-30% of a halogen-free flame-retarding master batch and 30-50% of a polyolefin mixture and accessory ingredients. According to the invention, the electric-conducting flame-retarding thermoplastic powder is formed through granulating and grinding the electric-conducting master batch, the flame-retarding master batch, the adhesive master batch and other compositions as well as accessory ingredients of the other compositions through a dual-screw extruder, has a favorable leveling property and a good adhesive force to steel tubes besides the anti-static and flame-retarding characteristics required by the use of an underground coal mine. The electric-conducting flame-retarding thermoplastic powder, the preparation method and applications of the electric-conducting flame-retarding thermoplastic powder, provided by the invention, can be used for coating inner surfaces and outer surfaces of steel tubes, combine the advantages of no rustiness of plastic and high intensity of metal tubular products, and prolong the service life of steel tubes on the basis of meeting the anti-static and flame-retarding characteristics and the like of pipelines used in the coal mine.

Owner:SHANXI ANDELU TECH

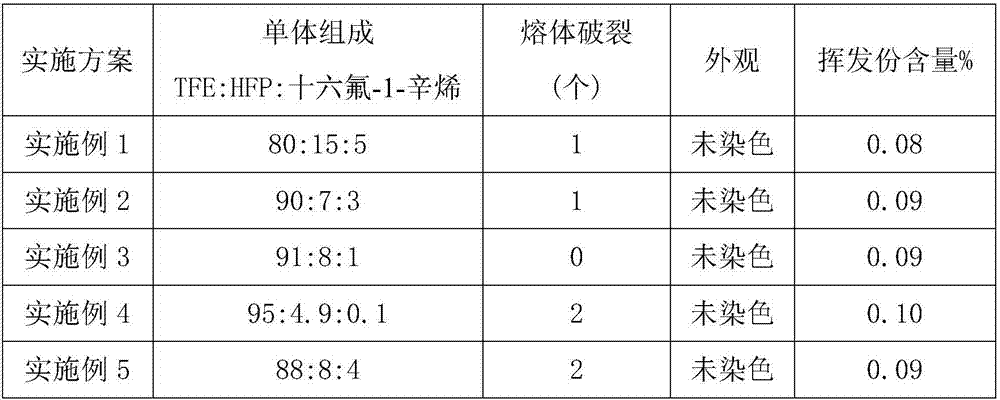

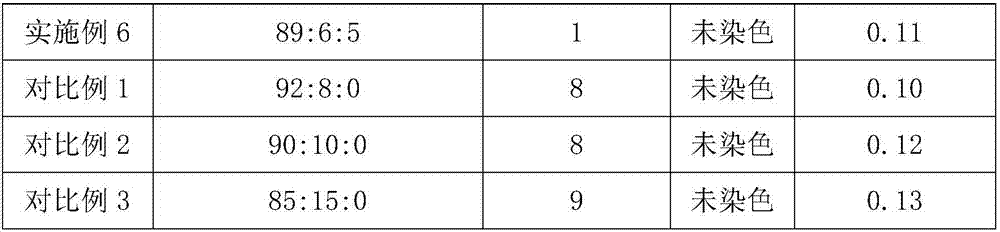

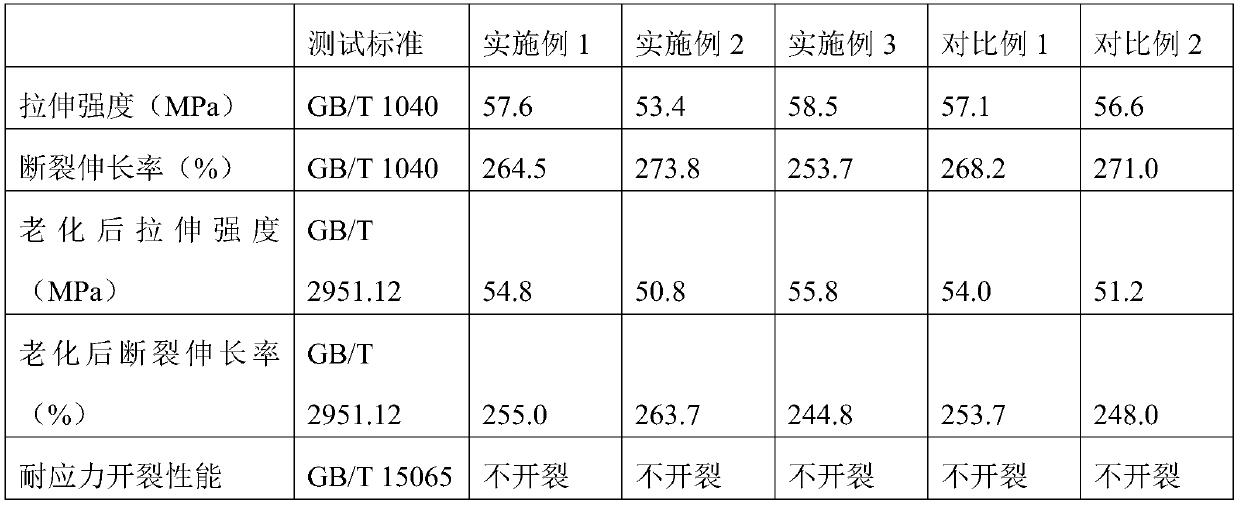

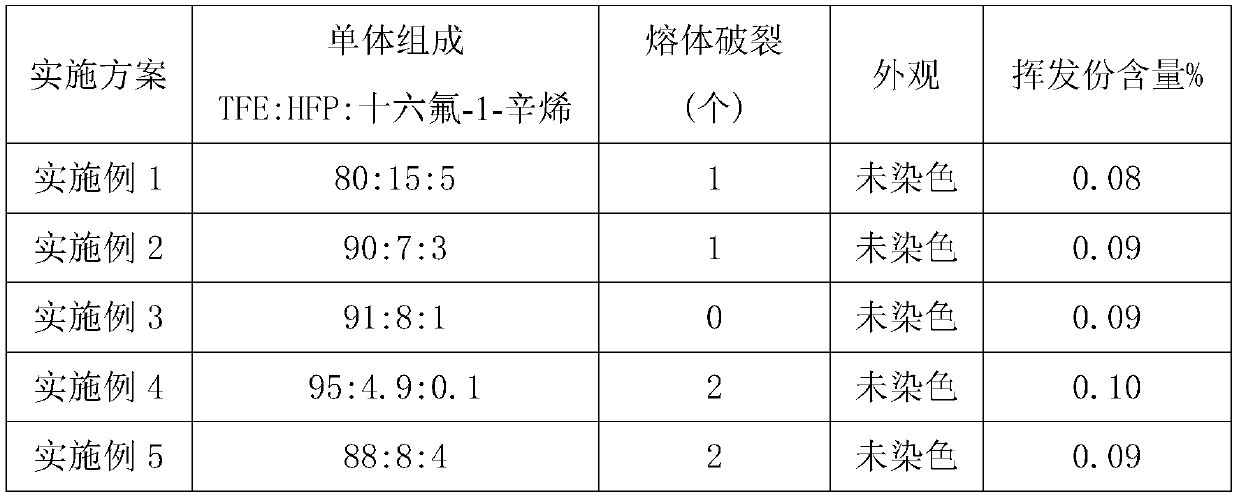

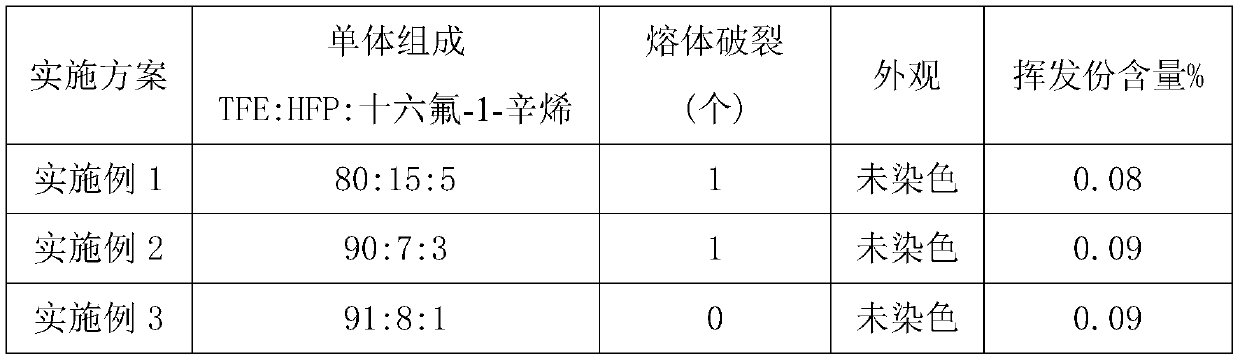

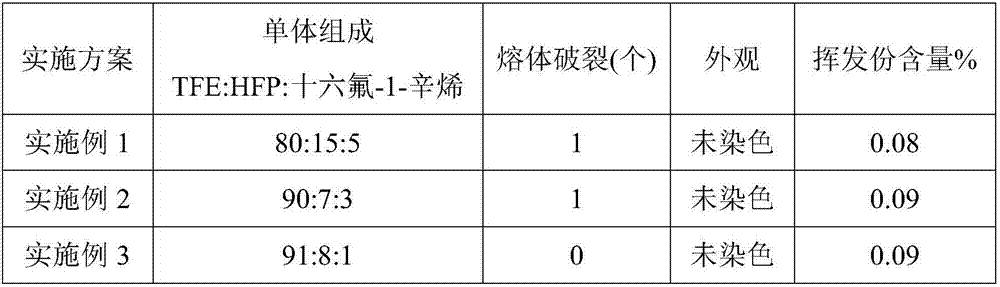

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and solution polymerization preparation method thereof

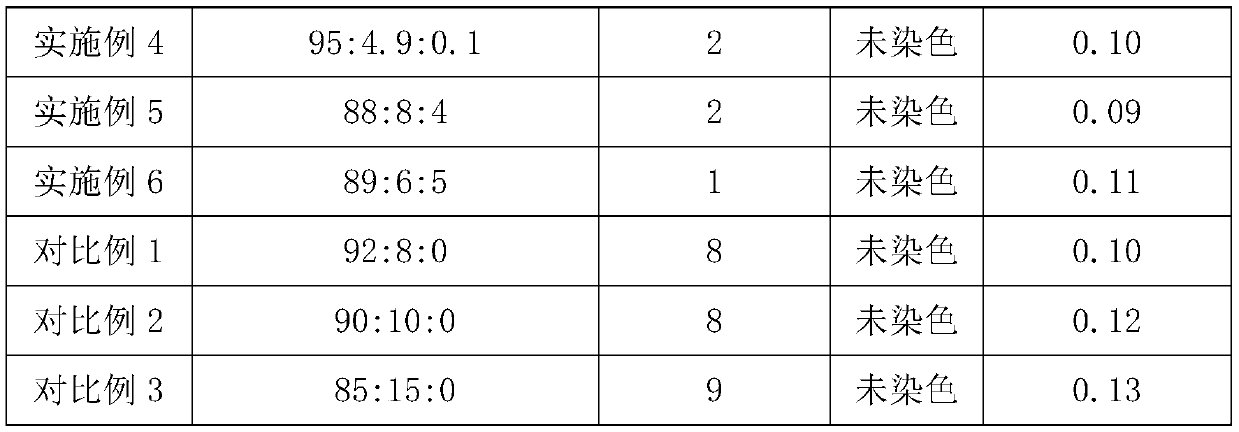

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and a solution polymerization preparation method thereof. According to the solution polymerization preparation method, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as copolymerizable monomers, wherein a molar fraction of the tetrafluoroethylene to hexafluoropropylene to hexadecafluoro-1-octene is (80-95):(4.9-15):(0.1-5). The preparation process comprises the following steps: adding a fluorine-containing solvent and copolymerizable monomers into a reactor at a certain temperature, raising the temperature to 20-60 DEG C, adding a perfluoro initiator to initiate a polymerization reaction under the pressure of 1.1-1.5MPa, supplementing the copolymerizable monomers in the reaction process, and finally preparing the modified polyperfluoro ethylene-propylene. The modified monomers are taken as polyperfluoro monomers, so that the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, causes no aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product and can be stably coated on a cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

Anti-aging abs-tpu plastic alloy

InactiveCN103360718BImproves stress cracking resistanceImprove impact resistanceCrack resistanceLow load

The invention discloses an anti-aging ABS-TPU plastic alloy composed of the components of, by weight: 100 parts of ABS, 15-25 parts of TPU, and 0.5-1.5 parts of an anti-aging agent. With the ABS-TPU plastic alloy, TPU stress resistance and cracking resistance are sufficiently improved; stabilities of TPU against oxygen, ozone, and ultraviolet rays can be improved; ABS impact resistance, wearing resistance, and forming and processing performances can be improved. The plastic alloy can be used for producing auto parts, pulleys, low-load gears, and gaskets. The plastic alloy has excellent thermal-aging resistance, and can be applied under extreme-high-temperature environments.

Owner:重庆市格林得斯塑胶有限公司

Fireproof polyvinyl chloride material

InactiveCN104262805AImprove liquidityImprove flame retardant performanceLow-density polyethyleneCellulose

The invention relates to a fireproof polyvinyl chloride material which comprises 110 parts of polystyrene, 1 part of silica white, 1 part of phthalate, 2 parts of nano activated calcium carbonate, 3 parts of polystyrene, 20 parts of ultra-low density polyethylene, 4 parts of zinc borate, 3 parts of polypropylene cellulose, 5 parts of triethyl phosphate, 4 parts of bromine flame retardant, 12 parts of antioxidant and 3 parts of dibutyl phthalate. The polyvinyl chloride composite material has the advantages of favorable flowability, favorable flame retardancy, higher viscosity, better processing flowing property, favorable heat resistance, favorable weather resistance, favorable ultraviolet resistance, high average application temperature, mature production and extrusion technique, extremely high stress cracking resistance, low production cost, tube cost saving and higher load-bearing capacity, and is an environment-friendly novel polyvinyl chloride composite material.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Special material for 5G optical fiber sheath and preparation method of special material

The invention belongs to the technical field of optical fiber sheath materials, and particularly relates to a special material for a 5G optical fiber sheath and a preparation method of the special material. The special material is prepared from PBT resin slices, an alpha-methylstyrene-acrylonitrile copolymer, aluminum silicate fibers, a titanate coupling agent, polyether, a light stabilizer, an ultraviolet light absorber and an antioxidant. According to the special material of the invention, the alpha-methylstyrene-acrylonitrile copolymer and the polyether are introduced into the PBT resin slices at the same time, so that the alpha-methyl styrene-acrylonitrile copolymer still can significantly increase the softening point of the PBT resin when being used at a low dosage, the heat resistance of the PBT resin is improved, and the problem of cost increase caused by a condition that that the heat resistance of the PBT resin is improved by adopting high-content alpha-methyl styrene-acrylonitrile copolymer in the prior art is solved; the polyether is doped into the PBT resin slices, so that the melt rheological property of the PBT resin slices in a melting processing process is improved,and the good processability of the PBT resin slices is ensured.

Owner:ANHUI GUANHONG PLASTIC IND

Hexadecafluoro-1-octene modified polyperfluoroethylene propylene resin and its solution polymerization preparation method

Owner:JUHUA GROUP TECH CENT

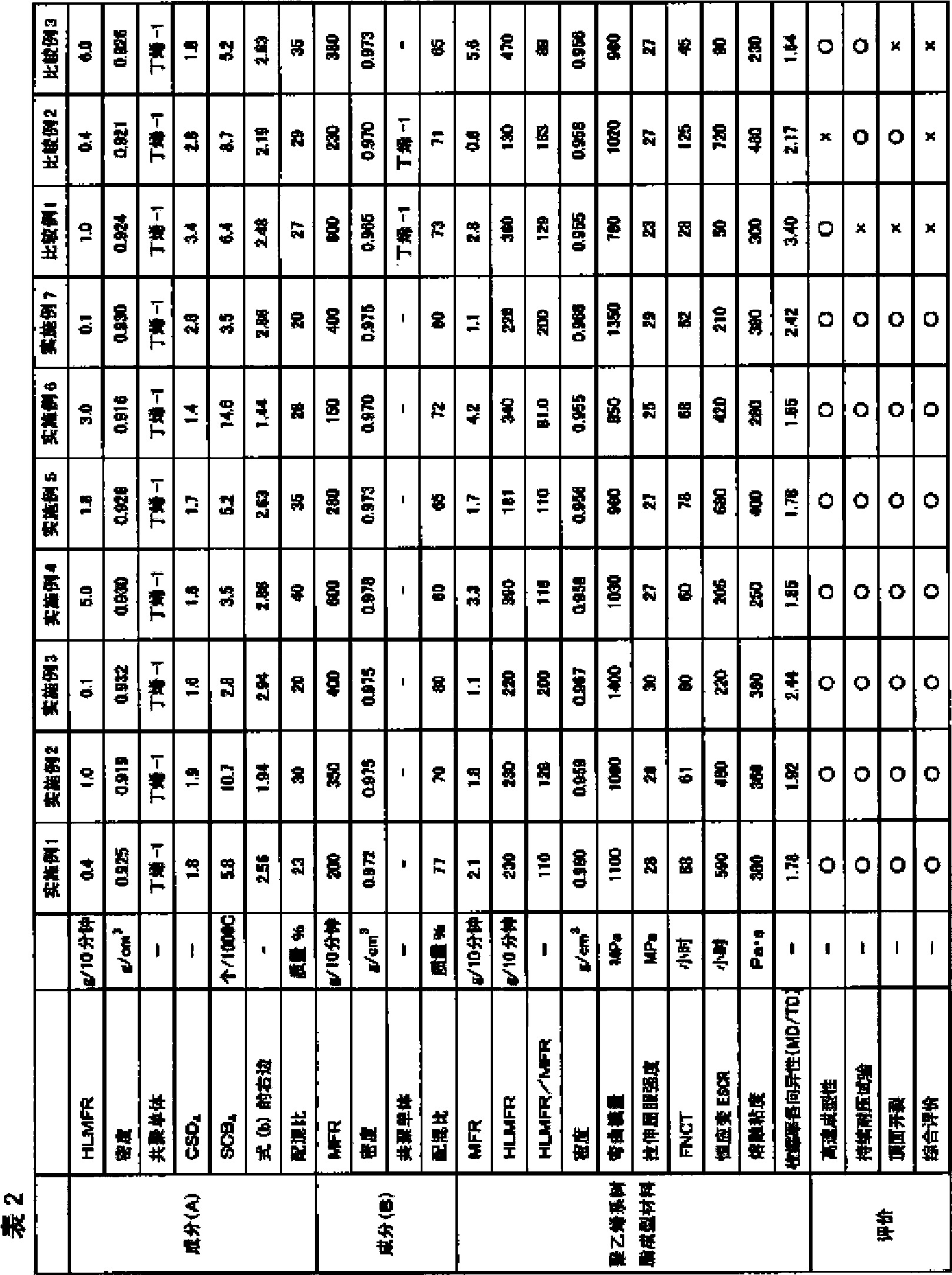

Polyethylene resin molding material for container lid

ActiveCN102822064BHigh speed formabilityImprove liquidityCapsClosure capsPolymer scienceCrack resistance

A polyethylene resin molding material for a lid of a container for carbonated beverages and the like, which has excellent high speed moldability, high fluidity, stiffness, impact resistance, durability, heat resistance, lubricity, low smelling properties and safety for foods, having good opening properties and sealing properties, and also having improved stress cracking resistance and FNCT fracture properties upon being handled at higher temperatures, and which contains, as the main component, a polyethylene polymer that fulfills the following characteristic properties: (1) the melt flow rate (MFR) at a temperature of 190°C·and a load of 2.16 Kg is not less than 0.8 g / 10 minutes and less than 5.0 g / 10 minutes, the high-load melt flow rate (HLMFR) at a temperature of 190°C and a load of 21.6 Kg is 180 to 400 g / 10 minutes inclusive, and the HLMFR / MFR ratio is 80 to 200; (2) the density is 0.955 to 0.970 g / cm3 inclusive; and (3) a CSD value of a component having a molecular weight of 105 or more is 0.0 to 3.0 as determined based on a measurement value obtained by 13C-NMR spectrometry.

Owner:JAPAN POLYETHYLENE CORP

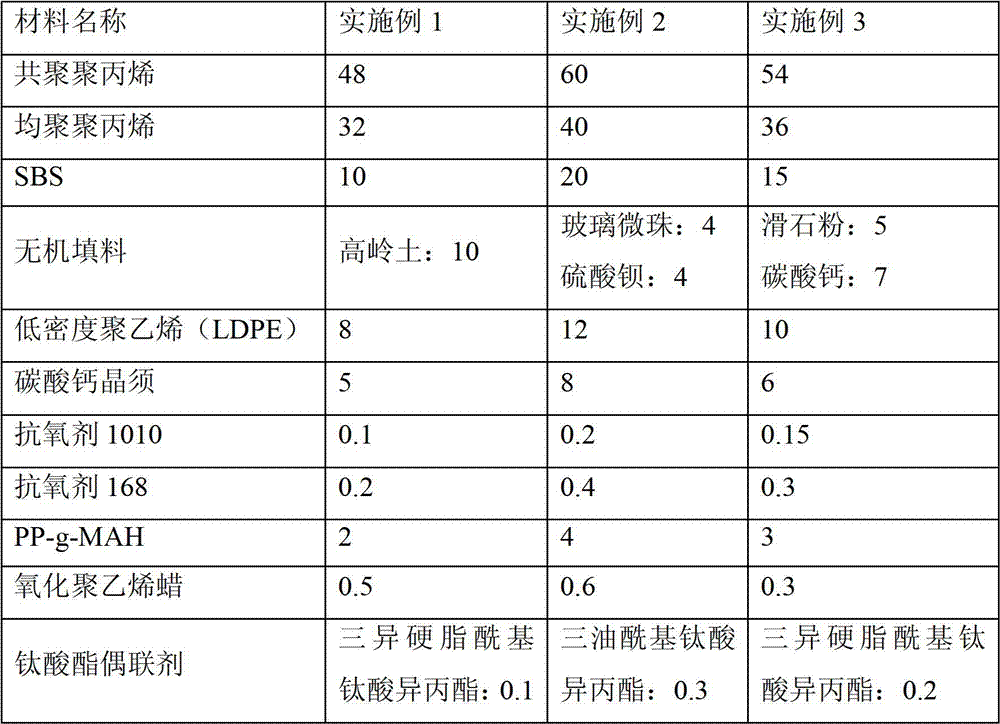

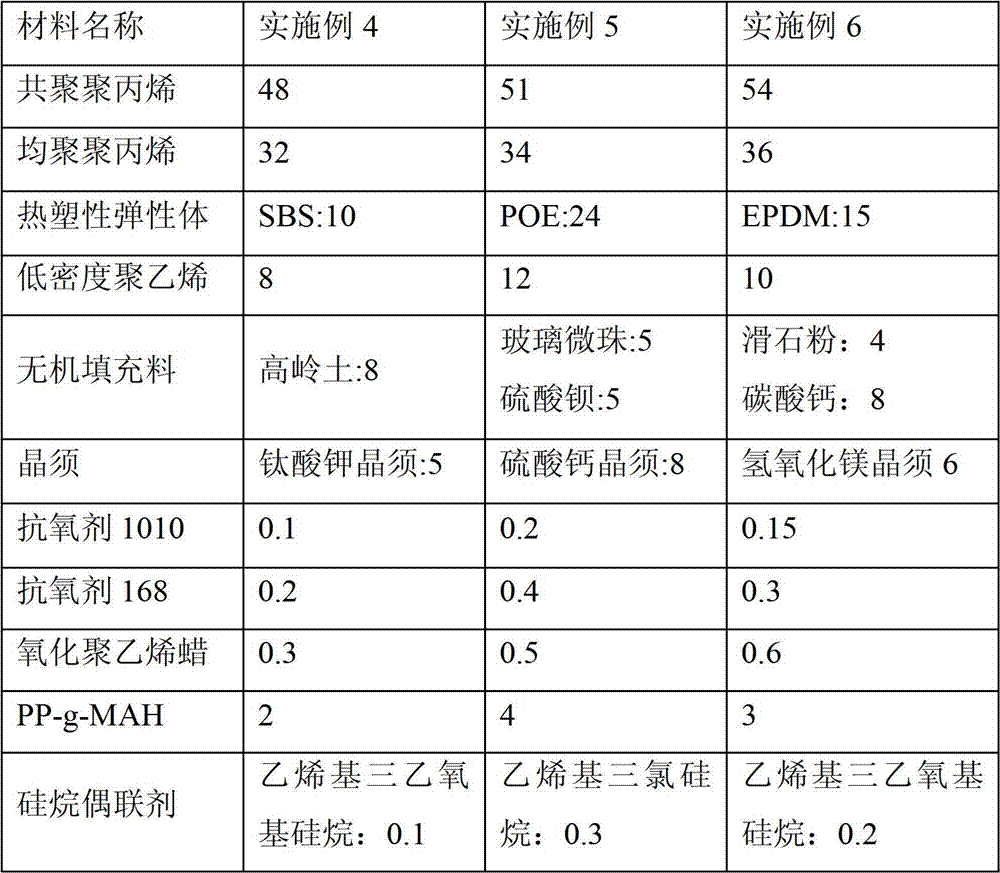

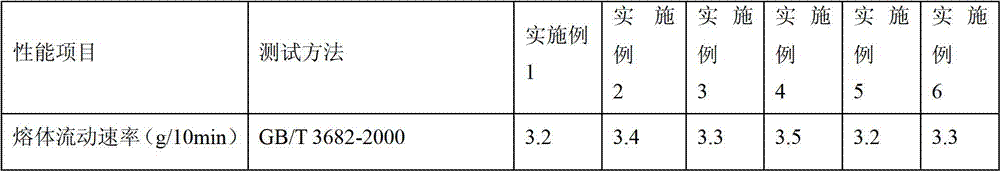

A kind of polypropylene composite material and its preparation method and application

ActiveCN103571059BSurface gloss is equal toUniform colorCoatingsLow-density polyethyleneCrack resistance

The invention belongs to the field of organic high molecular compounds, and relates to a polypropylene composite material as well as a preparation method and use thereof. The polypropylene composite material is prepared from the following components in parts by weight: 80-100 parts of polypropylene, 10-20 parts of thermoplastic elastomers, 8-12 parts of low density polyethylene, 8-12 parts of inorganic filler, 5-8 parts of crystal whiskers, 0.3-0.6 part of an antioxidant, 0.3-0.6 part of oxidized polyethylene wax, 2-4 parts of polypropylene-grafted maleic anhydride and 0.1-0.3 part of a coupling agent. The polypropylene composite material disclosed by the invention can be used for preparing steering wheels. The product produced by using the composite material has the advantages of uniform surface gloss, uniform color, comfortable feel, good stress cracking resistance, good comprehensive mechanical property and the like.

Owner:LIAONING LIAOJIE SCI & TECH

Hexadecafluoro-1-octene modified polyperfluoroethylene propylene resin and its bulk polymerization preparation method

The invention discloses hexadecafluoro-1-octene modified fluorinated ethylene-propylene resin and a bulk polymerization preparation method thereof. The method includes the steps that tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as comonomers, the comonomers are pre-added into a reactor under a certain temperature, the temperature is increased to 20-60 DEG C, the pressure is 1.1-1.5 MPa, a perfluoro initiator is added to initiate a polymerization reaction, a certain quantity of comonomers are replenished in the reaction process, and modified fluorinated ethylene-propylene is obtained finally. According to the method, the adopted modified monomers are perfluoro monomers, the obtained modified fluorinated ethylene-propylene resin is excellent in heat resistance, granules of the modified fluorinated ethylene-propylene resin are free of color staining, and the modified fluorinated ethylene-propylene resin can serve as a high-speed extrusion-grade product and can be stably smeared on the surface of a cable at the high speed of 300-500 m / min.

Owner:JUHUA GROUP TECH CENT

A kind of pa6/pc/pbt ternary alloy material and preparation method thereof

ActiveCN107365494BImprove toughnessGood dimensional stabilityPolytetramethylene terephthalateCrack resistance

The invention relates to the technical field of polymer materials, in particular to a PA6 / PC / PBT ternary alloy material and a preparation method of the PA6 / PC / PBT ternary alloy material. The ternary alloy material comprises the following raw materials in parts by weight: 20 to 80 parts of PA6 resin, 10 to 70 parts of PC, 10 to 30 parts of polybutylene terephthalate, 5 to 30 parts of glass fibers, 2 to 15 parts of compatibilizers, 0.1 to 1 part of an antioxidant and 0.1 to 1 part of a lubricant. The PA6 / PC / PBT ternary alloy material disclosed by the invention has high performances of toughness, dimensional stability, corrosion resistance, stress cracking resistance, oil resistance, mechanical strength and the like, and is high in molding performance, excellent in processability, low in cost and high in use value, and the preparation method is simple, convenient to operate and control, stable in quality, high in production efficiency, low in production cost and suitable for large-scale industrial production.

Owner:广东壹豪新材料科技股份有限公司

A kind of transparent breathable fish tank and preparation method thereof

InactiveCN107494385BSpeed up the flowQuick refillPisciculture and aquariaFisheryMechanical engineering

The invention discloses a transparent and breathable fish tank. The fish tank is assembled by splicing transparent and breathable macromolecular panels. The top of the fish tank is opened, other parts, at least the ornamental side, of the tank body is made from the transparent and breathable macromolecular panels, the transparent and breathable macromolecular panels are provided with continuous cut-through pore ways in the thickness direction, and the continuous cut-through pore ways extend linearly and have the diameters of 0.6 micrometers or below. According to the comparison of the transparent and breathable fish tank and a common fish tank, an oxygenation pump is reduced, the production and operation cost of the fish tank is lowered, and the wholeness and the ornamental value of the fish tank are improved.

Owner:嘉兴市诚峰金属制品股份有限公司

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and emulsion polymerization preparation method thereof

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and an emulsion polymerization preparation method thereof. The method comprises the following steps: adding deionized water accounting for 50-70% of total volume into a reactor with a stirrer; replacing until oxygen content is qualified, adding an emulsifier or other aids, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene and other pre-added copolymerizable monomers; starting to stir and raising the temperature to 60-120 DEG C, controlling the reaction pressure to be 2-5MPa, adding an initiator, supplementing a certain amount of copolymerizable monomers so as to obtain polymer emulsion; and condensing, washing and drying the emulsion, thereby obtaining the modified polyperfluoro ethylene-propylene resin. According to the method disclosed by the invention, the hexadecafluoro-1-octene modified monomer serves as a perfluoro monomer, the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, does not have an aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product, and can be stably coated onto the cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

Filler capable of improving heat-resistant strength of EVA hot melt adhesive

InactiveCN108977118AImprove liquidityWettability is not affectedNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberMolten state

The invention relates to the technical field of chemical materials, and discloses a filler capable of improving heat-resistant strength of an EVA hot melt adhesive. Inorganic materials such as ilicondioxide are adopted to be compounded with aluminum silicate fibers, so as to form a solid network structure; polyvinyl alcohol is adopted to improve the compatibility of a composite modified materialwith the EVA resin; the prepared filler can be tightly connected with EVA resin molecule, so that the crystallinity is changed, the melt index is improved, and the cure shrinkage is reduced; the meltadhesive in a molten state has better fluidity, the wetting property thereof is not influenced, the stress cracking property, tensile strength and tenacity of the melt adhesive are improved, and the breaking elongation, the yield strength and the rigidity are about 3-4 times of common levels; the filler dosage is 20-25% of a common filler, so that the cost is saved. By virtue of utilizing microstructure changes to determine macroscopical performances, the filler is capable of obviously improving the heat-resistant strength of the EVA hot melt adhesive, and realizing practical significance of high-quality low-cost production of hot melt adhesives, thereby being a technical scheme worthy of popularization and use.

Owner:ANHUI SOYA DECORATIVE MATERIALS

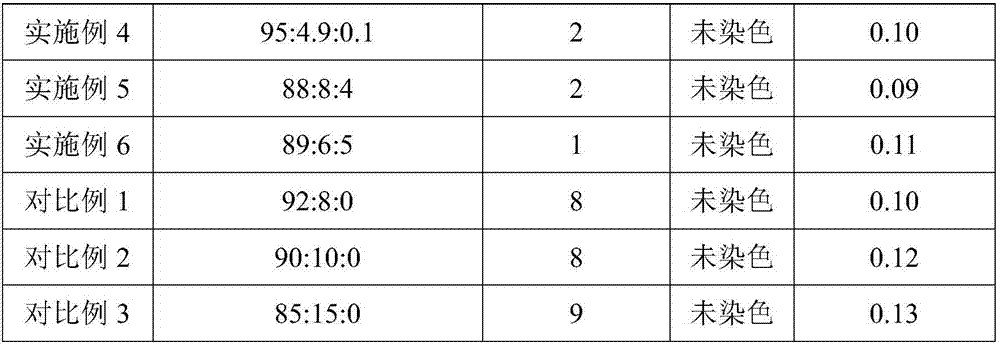

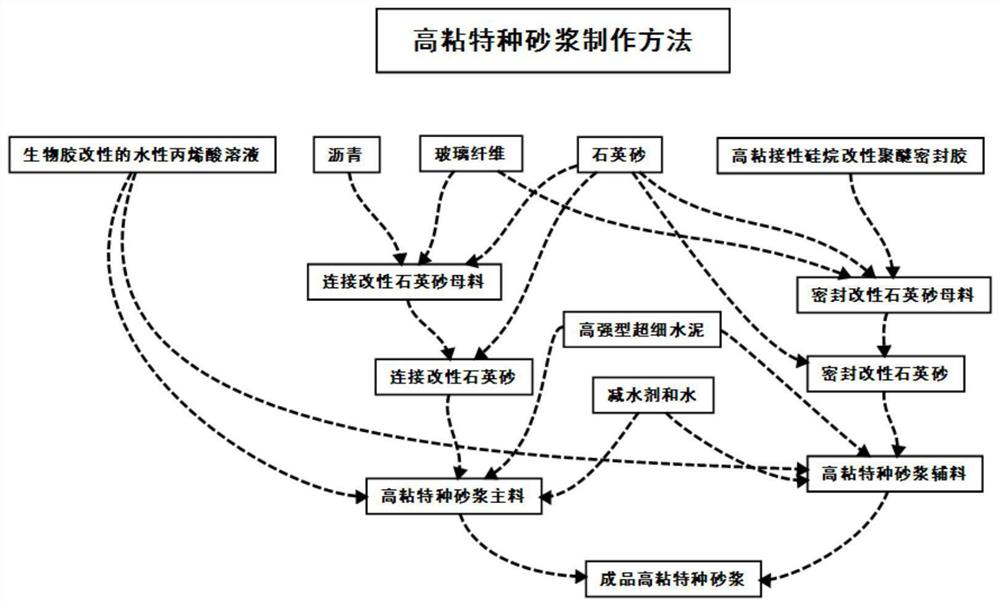

High-viscosity special mortar for prefabricated building and preparation method of high-viscosity special mortar

PendingCN113735497AEasy mass productionEvenly distributedBuilding repairsCeramic shaping apparatusAcrylic acidSealant

The invention discloses high-viscosity special mortar for prefabricated buildings and a preparation method of the high-viscosity special mortar, wherein the high-viscosity special mortar comprises a biogel modified aqueous acrylic acid solution, a high-adhesion silane modified polyether sealant, asphalt and glass fibers. The invention also provides the preparation method of the high-viscosity special mortar. The preparation method of the high-viscosity special mortar comprises a high-viscosity special mortar main material preparation method, a high-viscosity special mortar auxiliary material preparation method and a special mortar blending process. According to the method, large-batch rapid production of the fabricated building components can be met. The mortar has high viscosity and good shaping property after molding, is convenient for compression molding and rapid demolding, and greatly improves the molding efficiency; especially, when components are assembled and prevented from deforming, cracking and being repaired after being damaged, construction is convenient, connectivity is good, repairing efficiency is high, the service life is long, and defects are few.

Owner:江苏绿利新材料科技有限公司

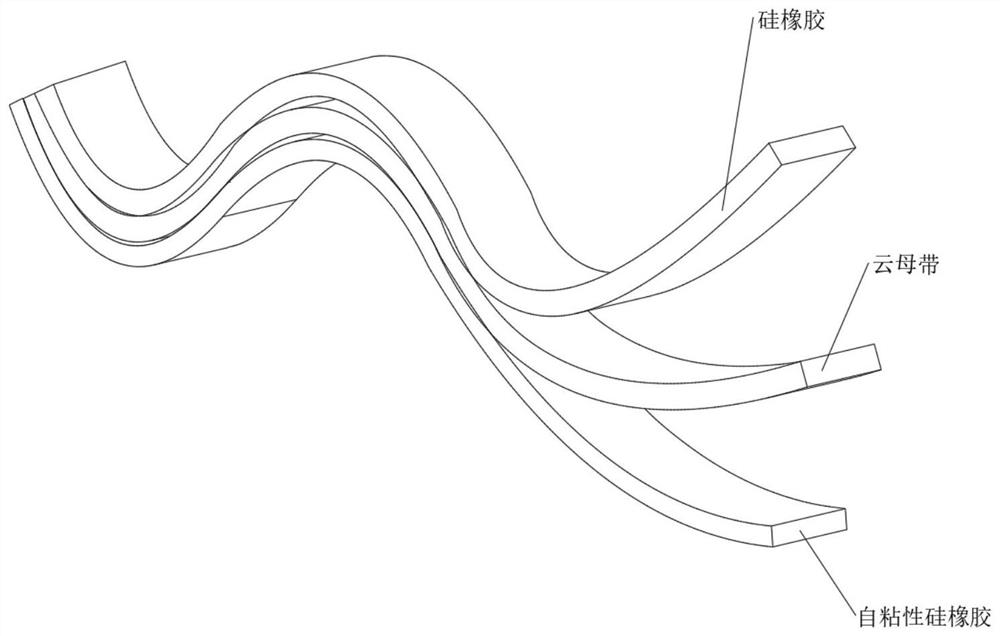

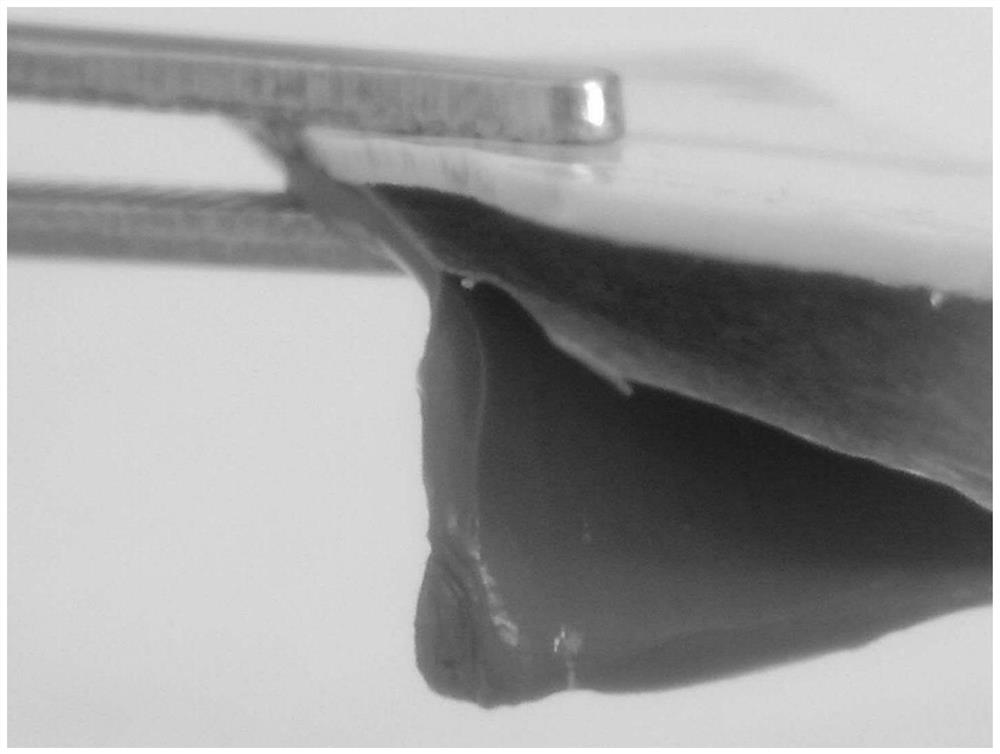

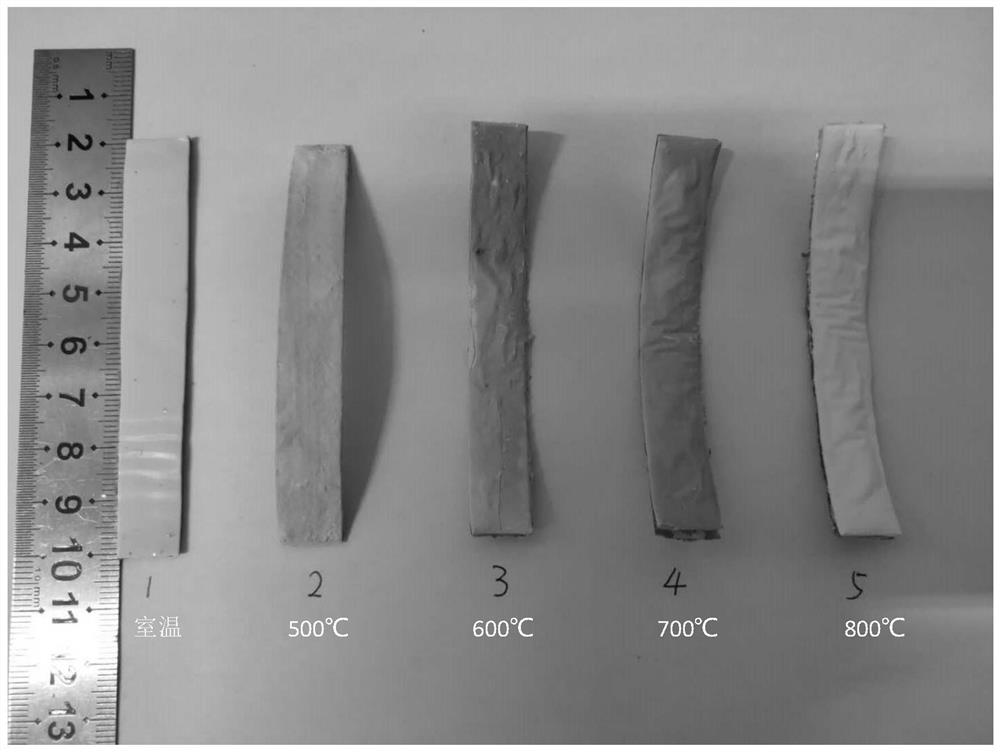

A kind of ceramic silicon rubber composite tape with mica layer and preparation method thereof

ActiveCN113402993BImprove flame retardant performanceHigh strengthRubber insulatorsNon-macromolecular adhesive additivesPolymer scienceElectric cables

The invention relates to a ceramic silicon rubber composite tape with a mica layer and a preparation method thereof. The composite tape has a three-layer structure and is prepared by the following steps: firstly preparing a ceramic silicon rubber sheet, and then preparing a self-adhesive silicone rubber Finally, the surface-treated mica tape is cold-pressed with three layers of ceramicized silicone rubber sheet and self-adhesive silicone rubber sheet, and cross-linked by irradiation to prepare a ceramicized silicone rubber composite tape with a mica layer in the middle. The invention obtains a composite tape with a three-layer structure, which has excellent high temperature resistance, flame retardant performance, mechanical strength and bonding performance, can be widely used in the wire and cable industry, and greatly improves the use safety of the cable.

Owner:中核同辐(长春)辐射技术有限公司 +3

A kind of crosslinkable ethylene-tetrafluoroethylene copolymer and its synthesis method

ActiveCN106046232BReduce crystallinityImproves stress cracking resistanceCross-linkTetrafluoroethylene

The invention relates to a cross-linkable ethylene-tetrafluoroethylene copolymer and a synthetic method thereof. A polymer is prepared from tetrafluoroethylene, ethylene, a monomer A and a monomer B through copolymerization, wherein the monomer A is a compound containing one double bond, and the monomer B is a compound containing two double bonds; and by virtue of proper crosslinking, the ethylene-tetrafluoroethylene copolymer can be endowed with relatively high radiation resistance, toughness, abradability, tensile strength and tear strength. The invention further provides a preparation method of the cross-linkable ethylene-tetrafluoroethylene copolymer and a cross-linkable copolymer composition. By controlling a polymerization process, too many low polymers can be reduced, and excellent performance of the polymer can be maintained.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

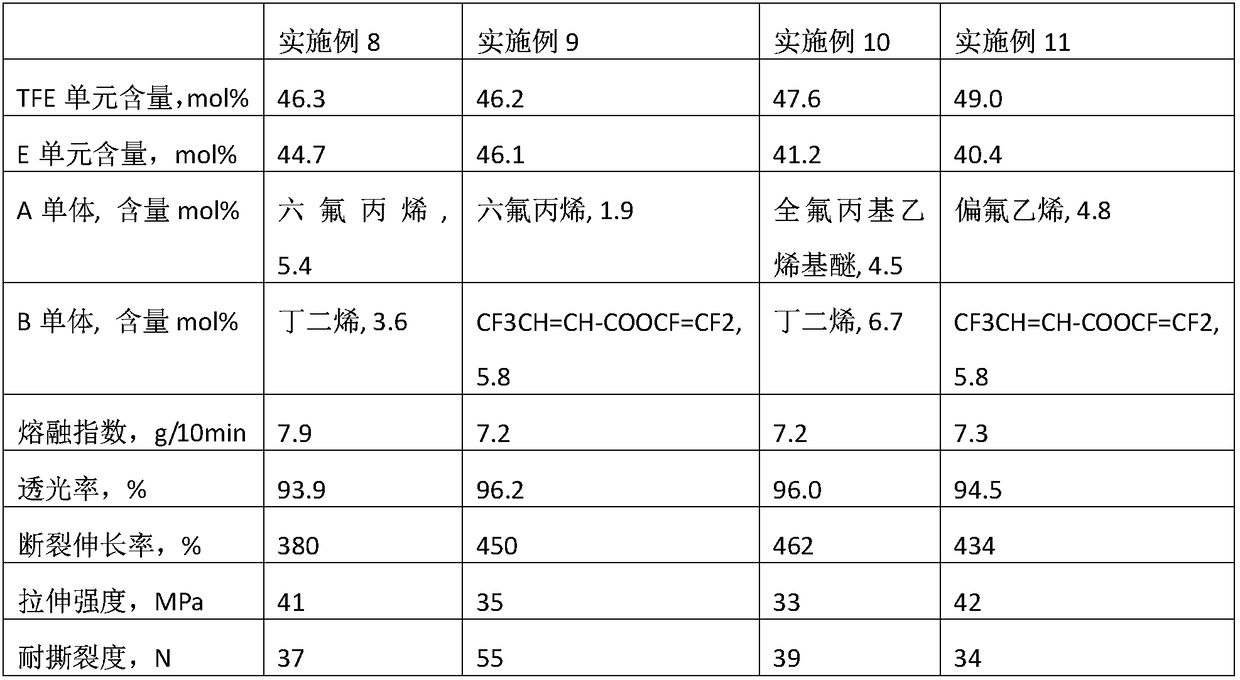

A radiation-crosslinked halogen-free flame-retardant polyurethane elastomer and its preparation method

ActiveCN106674999BGood compatibilityPrevent slippingPlastic/resin/waxes insulatorsPolyurethane elastomerPolymer science

The invention relates to a radiation crosslinking halogen-free flame retardant polyurethane elastomer and a preparation method thereof. The preparation method has the characteristic of being simple in process, and the provided elastomer has excellent technical performance. According to the technical scheme, the radiation crosslinking halogen-free flame retardant polyurethane elastomer comprises the components of thermoplastic polyurethane (TPU) and the like. The preparation method of the radiation crosslinking halogen-free flame retardant polyurethane elastomer is carried out in the following steps of (1) weighing various raw materials; (2) putting the TPU raw material into an oven; (3) putting the dried TPU into a stirrer, and then adding an auxiliary radiation crosslinking material and a sensitizer for stirring; (4) adding other materials to a mixture treated in the step (2), and then stirring and mixing evenly; (5) adding the mixed materials to a twin-screw extruder, extruding and carrying out water cooled pelletizing to obtain the crosslinking halogen-free flame retardant polyurethane elastomer; and (6) forming a finished product and carrying out radiation crosslinking.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com