Composite material for packaging and preparation method thereof

A composite material and a manufacturing method technology, applied in the field of composite materials, can solve the problems of reducing the molding fluidity of plastic sealing materials, increasing the pressure required for packaging, and difficulty in heat dissipation of electronic devices, and achieving improved heat resistance, improved bonding force, and low thermal expansion. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The method of the present invention pre-constant filler diameter combination / weight ratio of filler relative to silicone oil; then prepare multiple diameter weight combinations; then test the kinematic viscosity of multiple diameter weight combinations one by one, and test the bulk density of each diameter weight combination one by one to obtain The combination of diameter value and diameter weight of the one with the lowest kinematic viscosity is confirmed and selected as the best filler gradation with the largest bulk density. The specific process is shown in Examples 1 and 2 below.

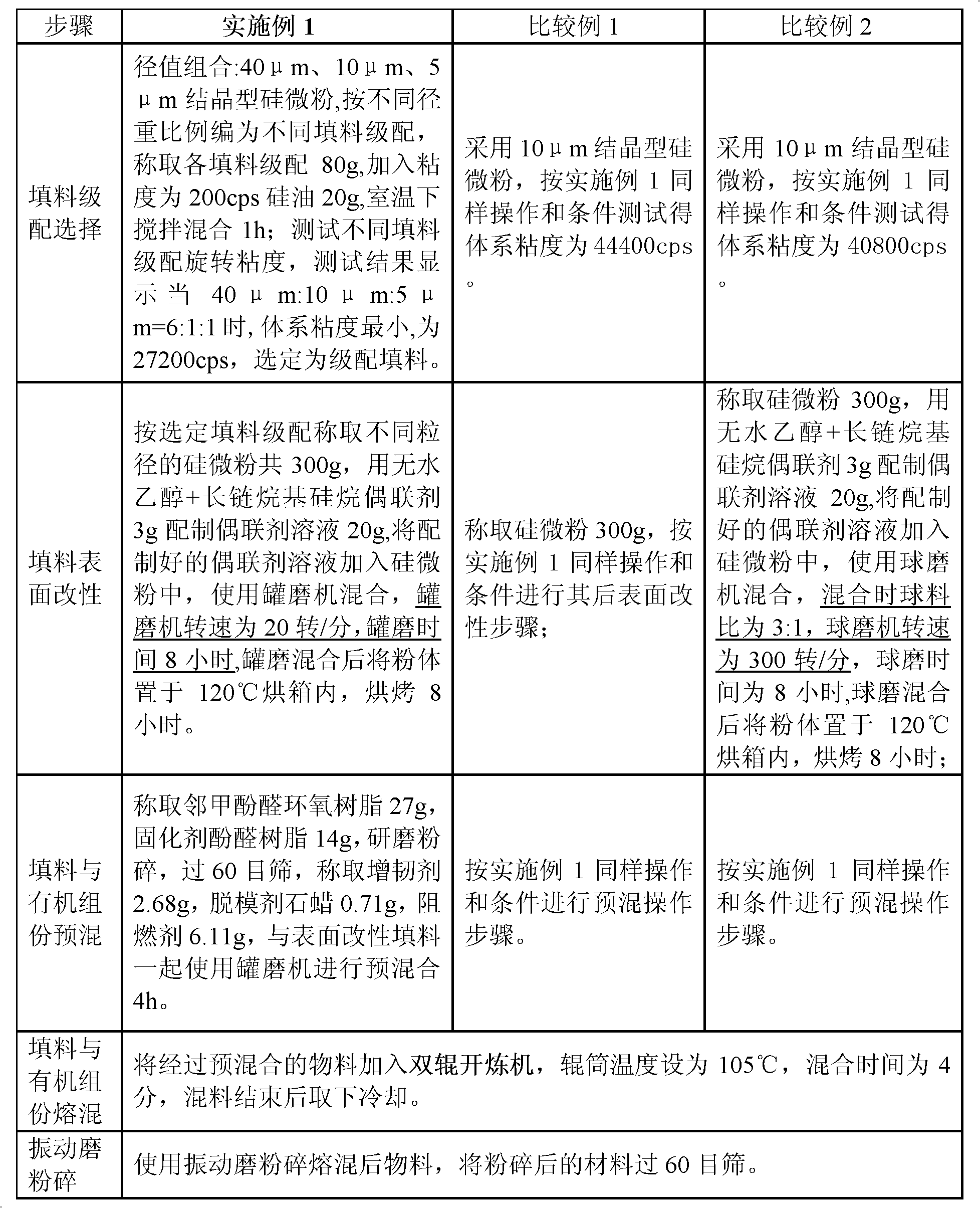

[0035] Table 1 Embodiment 1 and corresponding comparative example

[0036]

[0037]

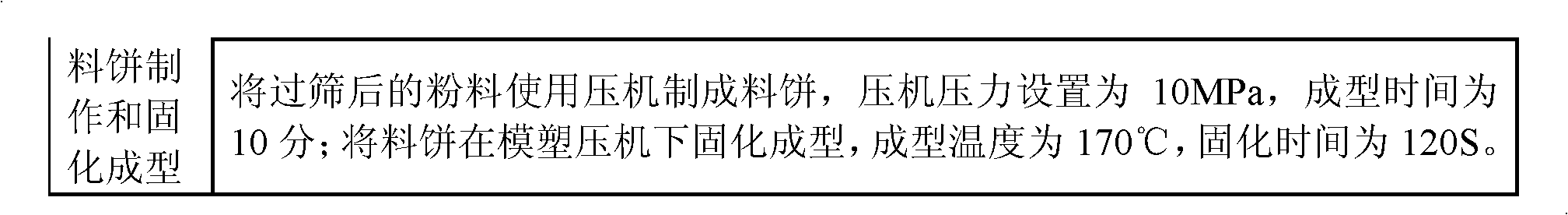

[0038] Table 2 Embodiment 2 and corresponding comparative example

[0039]

[0040] Table 3 Comparison of performance of the packaging composite material between Example 1 and Comparative Examples 1 and 2:

[0041]

[0042] Table 4 Example 2 and Comparative Examples 3 and 4 Encapsulation C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com