Patents

Literature

231 results about "Iron(III) chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(III) chloride is the inorganic compound with the formula (FeCl3). Also called ferric chloride, it is a common compound of iron in the +3 oxidation state. The anhydrous compound is a crystalline solid with a melting point of 307.6 °C. The color depends on the viewing angle: by reflected light the crystals appear dark green, but by transmitted light they appear purple-red.

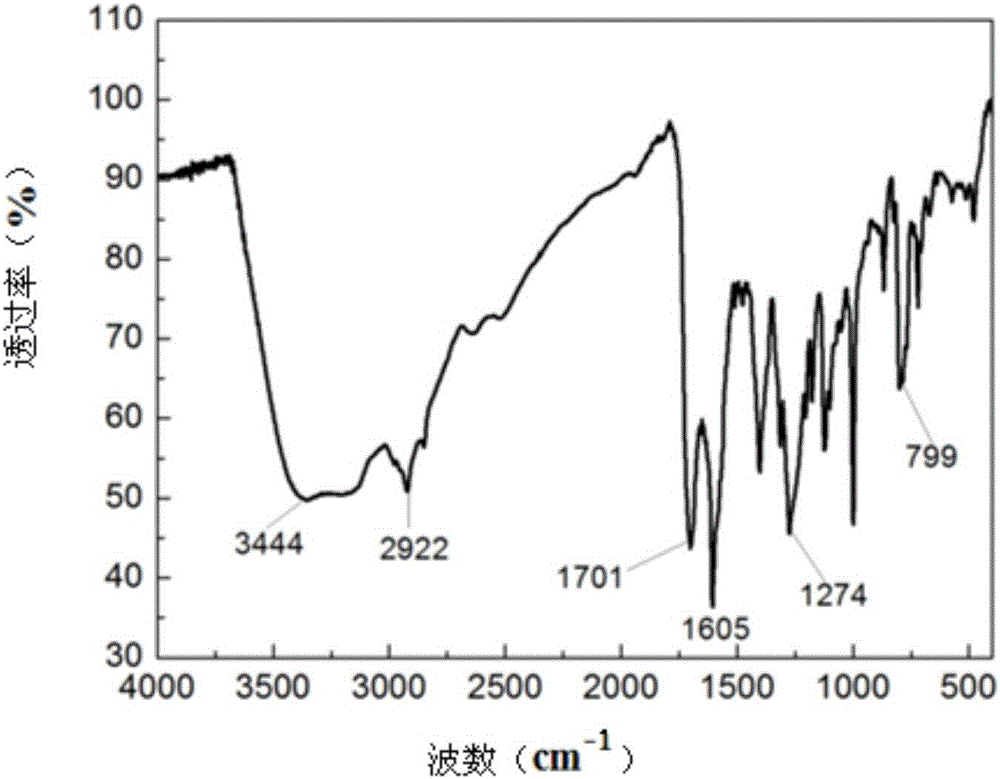

Method for preparing super-hydrophobic fabric through polyphenol modification

ActiveCN106087404AIncrease productivityGood soaping resistanceFibre treatmentTextile technologyIron(III) chloride

The invention discloses a method for preparing super-hydrophobic fabric through polyphenol modification, and belongs to the technical field of weaving. The method comprises dipping fabric successively in a ferric chloride solution and a polyphenol compound solution, so as to obtain fabric of which the surface is modified by a metal-polyphenol layer; then dipping the fabric of which the surface is modified by the metal-polyphenol layer into an ethanol-water mixed solution containing a low-surface-energy substance, reacting for 6-24 h, washing successively by deionized water and absolute ethyl alcohol, and drying the fabric at 40 DEG C in vacuum for 5-10 h, so as to obtain phenol-modified super-hydrophobic fabric. The super-hydrophobic fabric possesses extremely good soaping resistance and efficient endurable hydrophobicity, the static contact angle is still larger than 150 DEG after the fabric is washing for 20 times, the fabric variety is diversified, application is wide, and the preparation technology is simple, green, friendly to environment, low in cost and suitable for large-scale production.

Owner:DONGGUAN YIMAO FILTER MEDIA

Metallographic etched process for displaying G Cr15 original austenite grain border

InactiveCN101187606AShorten the timeGood reproducibilitySurface/boundary effectPreparing sample for investigationAlcoholMetallography

A metallographic corrosion method for displaying a GCr15 original austenitic grain boundary comprises adding picric acid 5g into distilled water100ml and mixing continuously, then adding sodium dodecyl benzene sulfonate 5ml 50% and mixing, finally adding ferric chloride 2g, and using after placing for 24 hours. A sample is grinded roughly, grinded finely, polished, cleared, dried, immersed into caustic erodent for 2-5 minutes according to normal method under a quenching tempering condition until etched surface is changed into silver grey, cleaned up through flowing water, cleaned with alcohol 95%, and dried. If the sample is over-corroded, polishing paste W0.5-1.0 or metallographic polishing egent0.5-1.0 is added on silk polishing cloth, the sample is polished slightly with hands, then cleaned with alcohol 95%, and dried. According to practical condition, grain granularity measurement can adopt methods of picture contrast, grid, intercept, quantitative metallography, and the like, to assess according to relevant standards.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

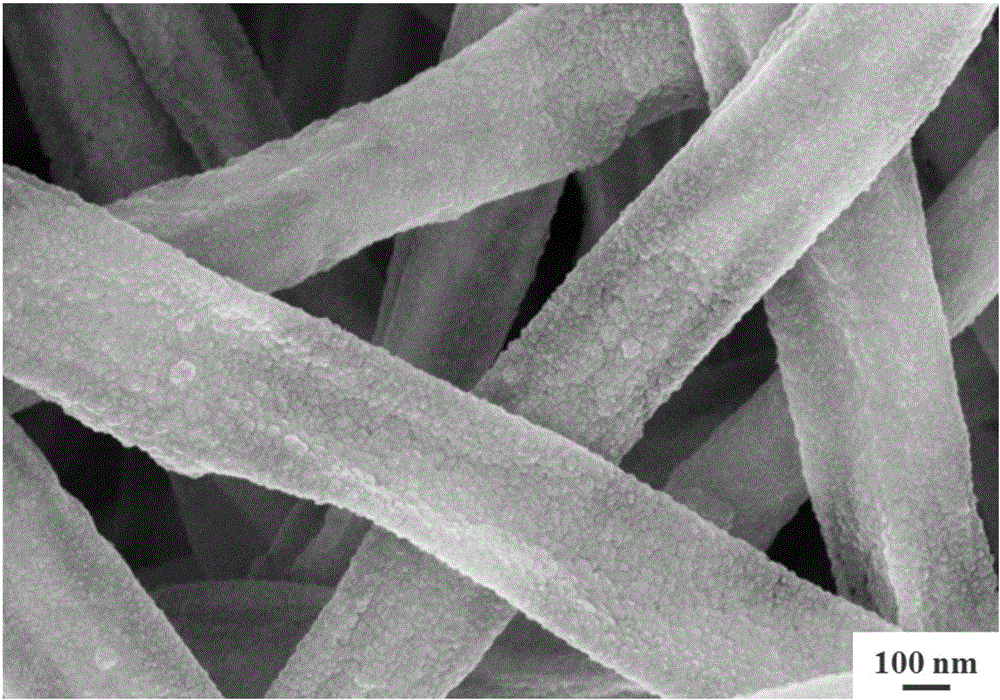

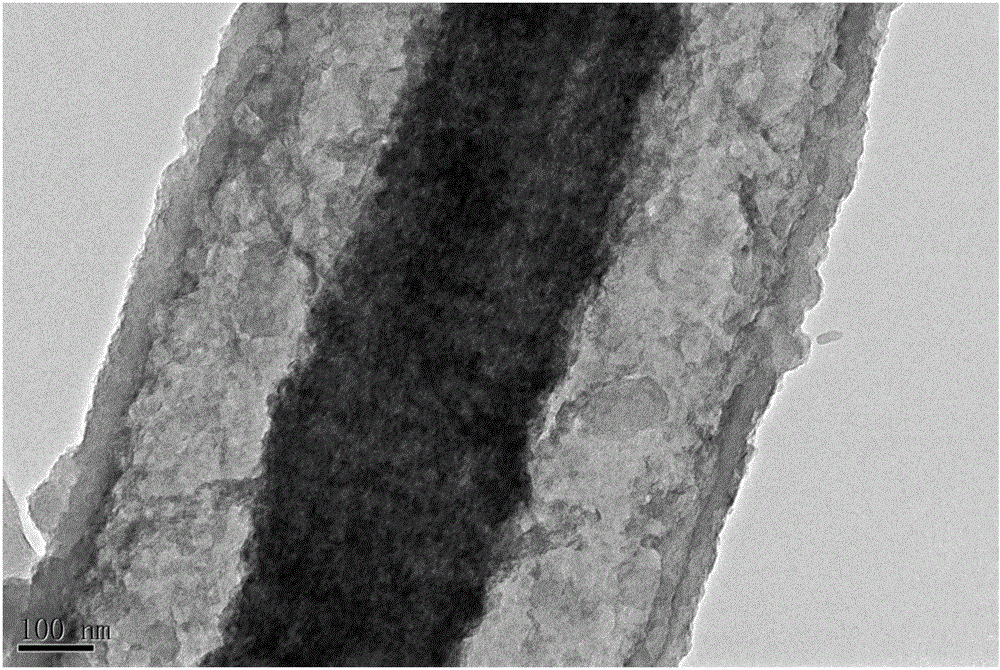

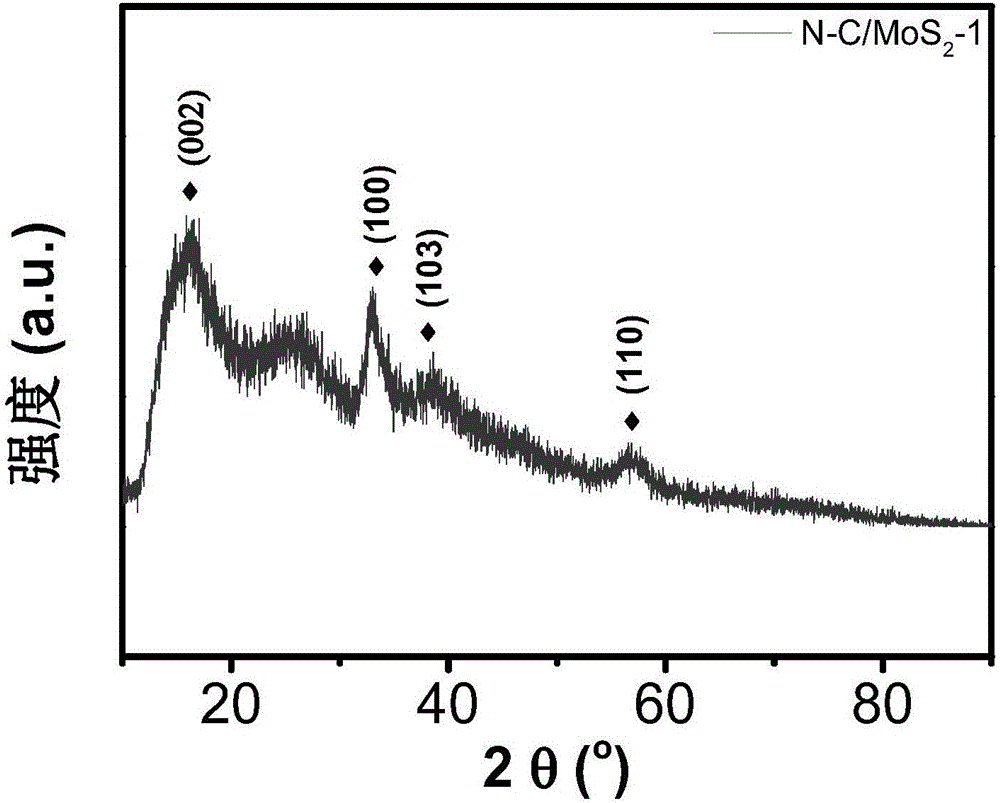

ActiveCN106450181AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsFiberIn situ polymerization

The invention relates to a molybdenum disulfide / nitrogen-doped carbon nanofiber composite material and a preparation method and an application thereof. The composite material is of a pipe sleeving structure, a molybdenum disulfide fiber core is arranged in the composite material and a nitrogen-doped carbon nanofiber shell is arranged outside the composite material; and a gap is arranged between the molybdenum disulfide fiber core and the nitrogen-doped carbon nanofiber shell. The preparation method comprises the steps of dissolving ammonium thiomolybdate and polymethyl methacrylate into a solvent and carrying out electrostatic spinning to obtain a polymethyl methacrylate / ammonium thiomolybdate nanofiber; carrying out drying and surface treatment, immersing the nanofiber into a pyrrole / hydrochloric acid solution, dropwise adding a ferric chloride / hydrochloric acid solution and carrying out in-situ polymerization to obtain the fiber coated with polypyrrole on the surface; and washing and drying the fiber, carrying out high-temperature reduction under the condition of taking an argon / hydrogen mixed gas as a protective atmosphere and then carrying out high-temperature carbonization under an argon condition. The composite material has high specific capacity and good cycle stability, and can be used as an efficient and safe novel negative electrode material of a lithium-ion battery.

Owner:DONGHUA UNIV

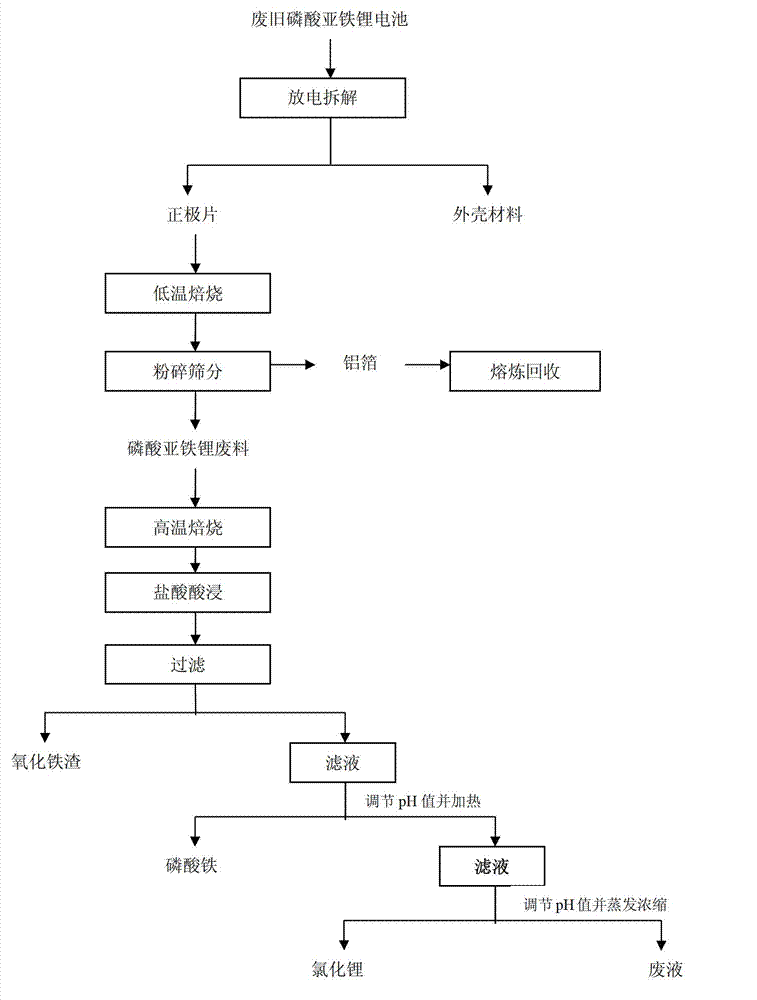

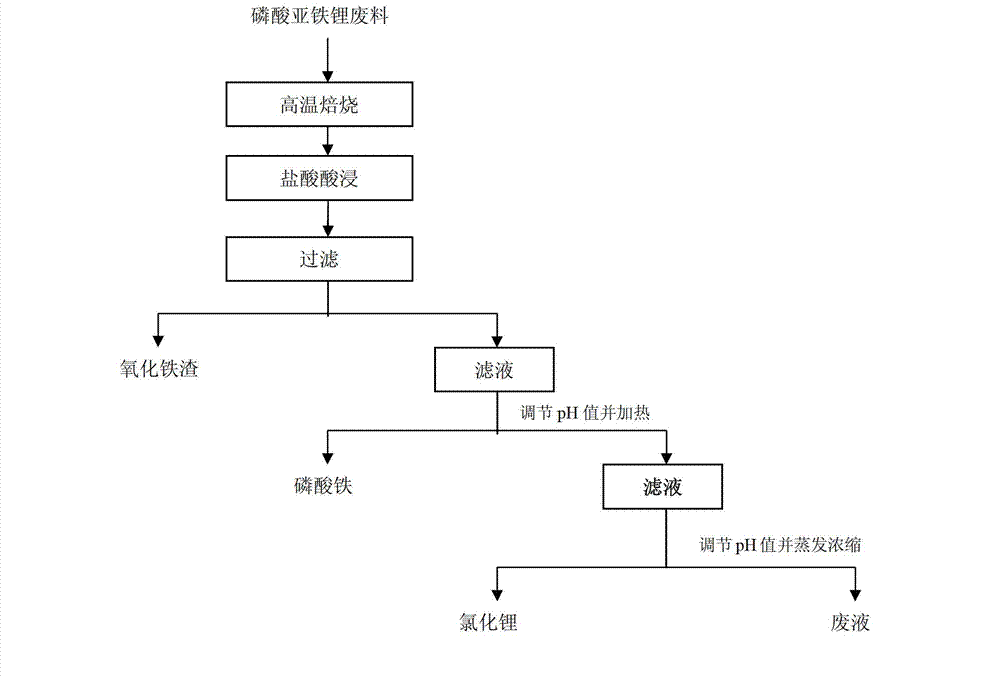

Method for recycling lithium chloride from waste lithium iron phosphate

ActiveCN102891345ASolve the problem of resource recyclingWaste accumulators reclaimingBattery recyclingLithium chlorideIron(III) chloride

The invention relates to a method for recycling lithium chloride from waste lithium iron phosphate, belongs to the technical field of waste and old lithium ion battery recycle, and solves the technical problem that the method for recycling lithium chloride from the waste lithium iron phosphate is provided. The method comprises the following steps of: roasting the waste lithium iron phosphate for 1-4hours under the temperature of 500-800 DEG C; leaching the materials after roasting by using hydrochloric acid, wherein the pH value is controlled to be within 0.5-1 during leaching; filtering so as to obtain a mixing liquid of lithium phosphate, iron phosphate and ferric chloride; heating the obtained mixing liquid to be at 80-100 DEG C; adjusting the pH value to be 2-2.5; reacting for 1-4hours; filtering; washing; drying so as to obtain the iron phosphate; adjusting the pH value of obtained filtrate to be 6-7; adding calcium chloride to perform phosphorous removal; and filtering; evaporating, concentrating, crystallizing, washing and drying the obtained filtrate to obtain lithium chloride.

Owner:天齐锂业(江苏)有限公司 +2

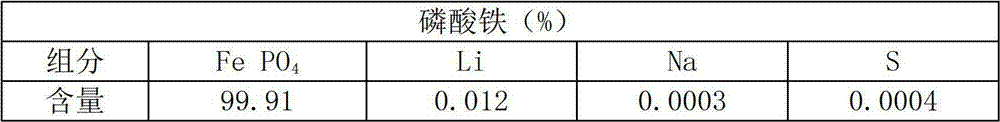

Method of eliminating sodium chloride in iron-dextran complex compound water solution and device thereof

ActiveCN101108194AEliminate burningEliminate explosion hazardsOrganic active ingredientsMetabolism disorderSolventAqueous solution

The invention relates to a method and device for eliminating sodium chloride in the aqueous solution for the complex of ferrodextran, which is characterized in that: the ferrodextran is prepared with dextran and ferric trichloride. The sodium chloride in the ferrodextran is eliminated with an electrodialysis film, that is, eliminating the sodium chloride of the solvent by electrodialysis process in the ferrodextran complex solvent with iron content is more than or equal to 40mg / ml, sodium chloride content is more than or equal to 5.0 per cent wt and viscosity of 3.0mpa is multiplied by s (20 DEG C.) under the temperature of 10 to 90 DEG C. Compared with the technique of eliminating sodium chloride with alcohol precipitation, the invention prevents the safety hazard from flammable and combustible alcohol and reduces the production cost.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Method for recycling iron and zinc containing waste hydrochloric acid solution

ActiveCN105696010ATake advantage ofSolve the problem of no separation and recyclingProcess efficiency improvementZinc hydroxideChloride

The invention discloses a method for recycling an iron and zinc containing waste hydrochloric acid solution. The method specifically comprises the following steps that 1, acid consuming and reducing are carried out, acidity is made to meet the requirement, and ferric iron in waste acid is reduced into ferrous iron; 2, zinc and iron are extracted and separated, and a ferrous chloride solution is obtained; 3, an organic phase transfers zinc into a strip liquor through reverse extraction, and the organic phase is extracted for reuse; and 4, the strip liquor is subjected to subsection kalizing treatment, zinc hydroxide is obtained, and the strip liquor is reused. According to the method, iron and zinc are separated through different extracting capacities of N235 to the ferrous iron and zinc, and therefore pure ferrous chloride liquid and zinc hydroxide solids are obtained. Ferrous chloride can be oxidized into ferric trichloride, and ferrous chloride and ferric trichloride both can be used as a water treatment agent; and zinc hydroxide can be used as a raw material for preparing zinc oxide or zinc chloride.

Owner:3R ENVIRONMENTAL TECH CO LTD

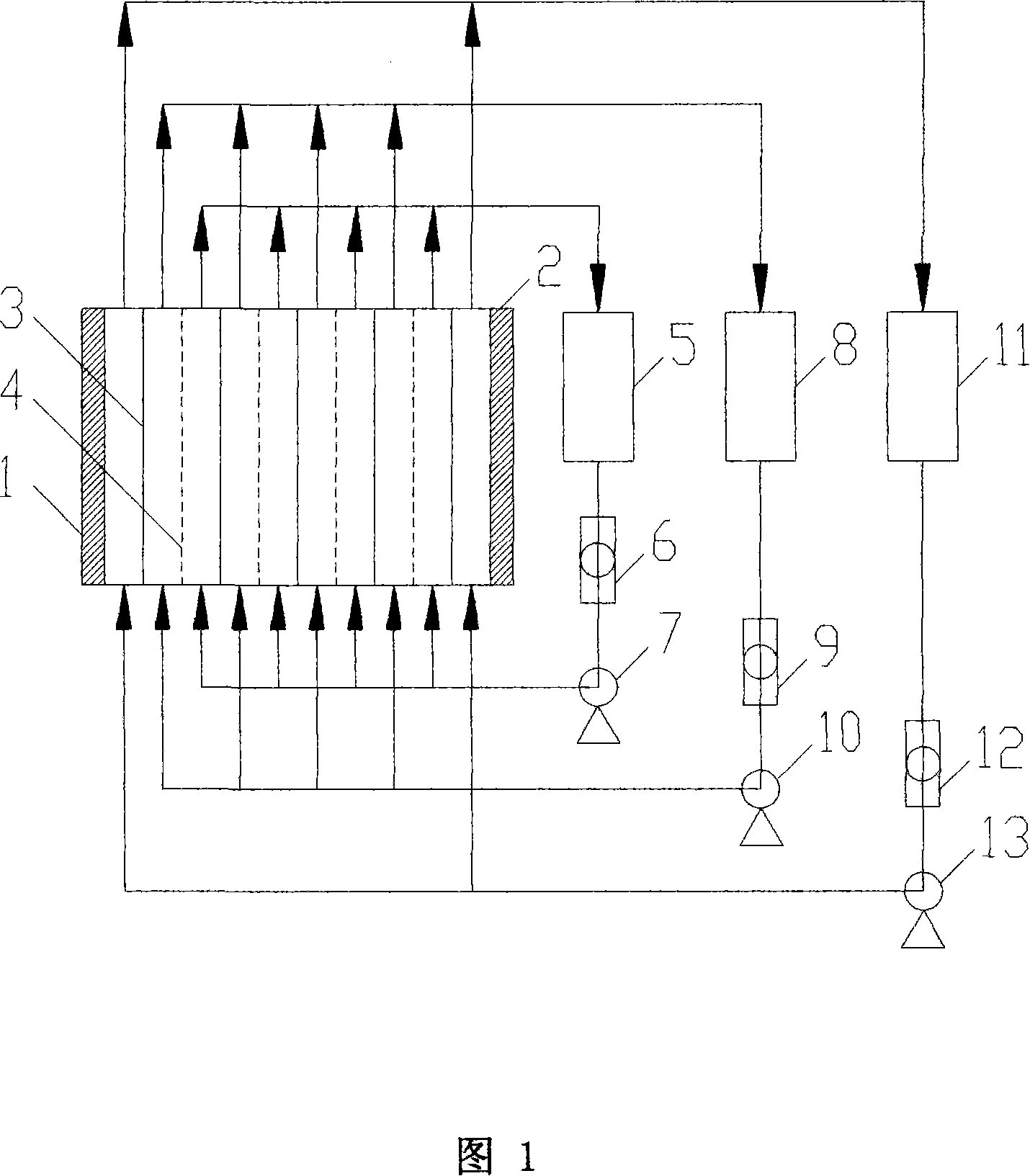

Preparation method of coal-based magnetic activated carbon and coal-based magnetic activated carbon

InactiveCN101972629AEasy to separate and recycleIncrease the areaOther chemical processesMagnetic materialsFerric hydroxideCarbonization

The invention relates to a preparation method of coal-based magnetic activated carbon and the coal-based magnetic activated carbon. The preparation method of the coal-based magnetic activated carbon comprises the following steps of: placing deashing coal dust and dodecyl sodium sulfate into a ferric chloride solution, sufficiently mixing, and then standing for adsorption; then adding ammonia water and a sodium hydroxide solution or a potassium hydroxide solution, sufficiently stirring, and then standing for transforming ferric chloride into ferric hydroxide; filtering and drying solid-phase materials to obtain a mixture of deashing coal and the ferric hydroxide, i.e. a precursor of the coal-based magnetic activated carbon; sufficiently mixing the precursor with activating agents, i.e. potassium hydroxide or sodium hydroxide, adding distilled water to stir into paste, and warming for carbonization under the protection of nitrogen; and heating and activating under the protection of the nitrogen. The obtained coal-based magnetic activated carbon has difficult blockage of pores because a magnet exists in a state of Fe3C, thereby having higher saturation and magnetization intensity and larger specific surface area. The invention has the advantages of extensive source of coal raw materials, low cost, simple preparation process and easy separation and recovery of the coal-based magnetic activated carbon.

Owner:CHONGQING UNIV

Preparation method of compound photocatalyst

InactiveCN105435826ALower bandgapImprove electronicsPhysical/chemical process catalystsHeterojunctionChemistry

The invention discloses a preparation method of a compound photocatalyst. The preparation method comprises steps as follows: mixing melamine and H2O, adding ferric chloride powder to the mixture, mixing the mixture, and dropwise adding ammonia water under the high-speed stirring condition until the pH of the solution ranges from 9 to 10 to obtain a mixed solution; adding high-purity montmorillonite to the mixed solution, performing high-speed stirring, standing and suction filtration, washing filter cakes until the pH ranges from 7 to 8, and drying the filter cakes at the temperature of 80-95 DEG C to obtain a melamine / Fe(OH)3 / montmorillonite mixture; calcining the obtained mixture at the N2 atmosphere to obtain the graphite phase carbon nitride g-C3N4 / Fe2O3 / montmorillonite photocatalyst. On the premise that Fe2O3 and g-C3N4 form a P-N heterojunction to enhance the visible light catalysis efficiency, inorganic montmorillonite nanosheets are added to compound graphite phase carbon nitride to enhance the adsorbability of the photocatalyst, and the catalytic efficiency of the photocatalyst is improved.

Owner:ZHEJIANG INST OF GEOLOGY & MINERAL RESOURCE +1

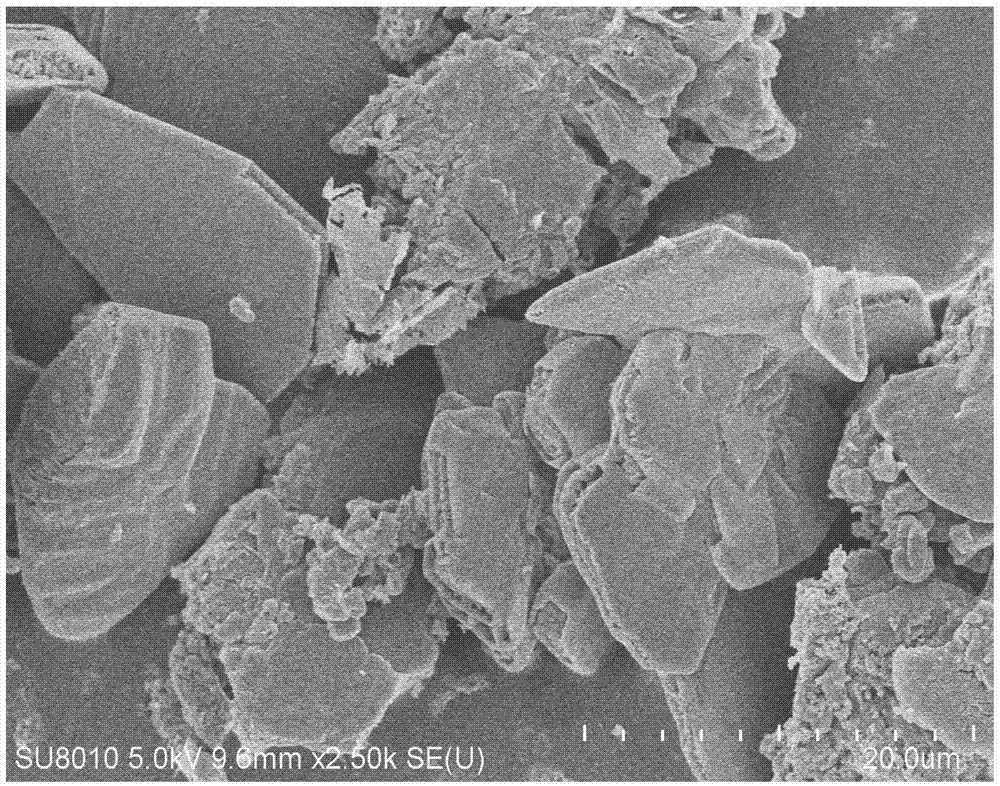

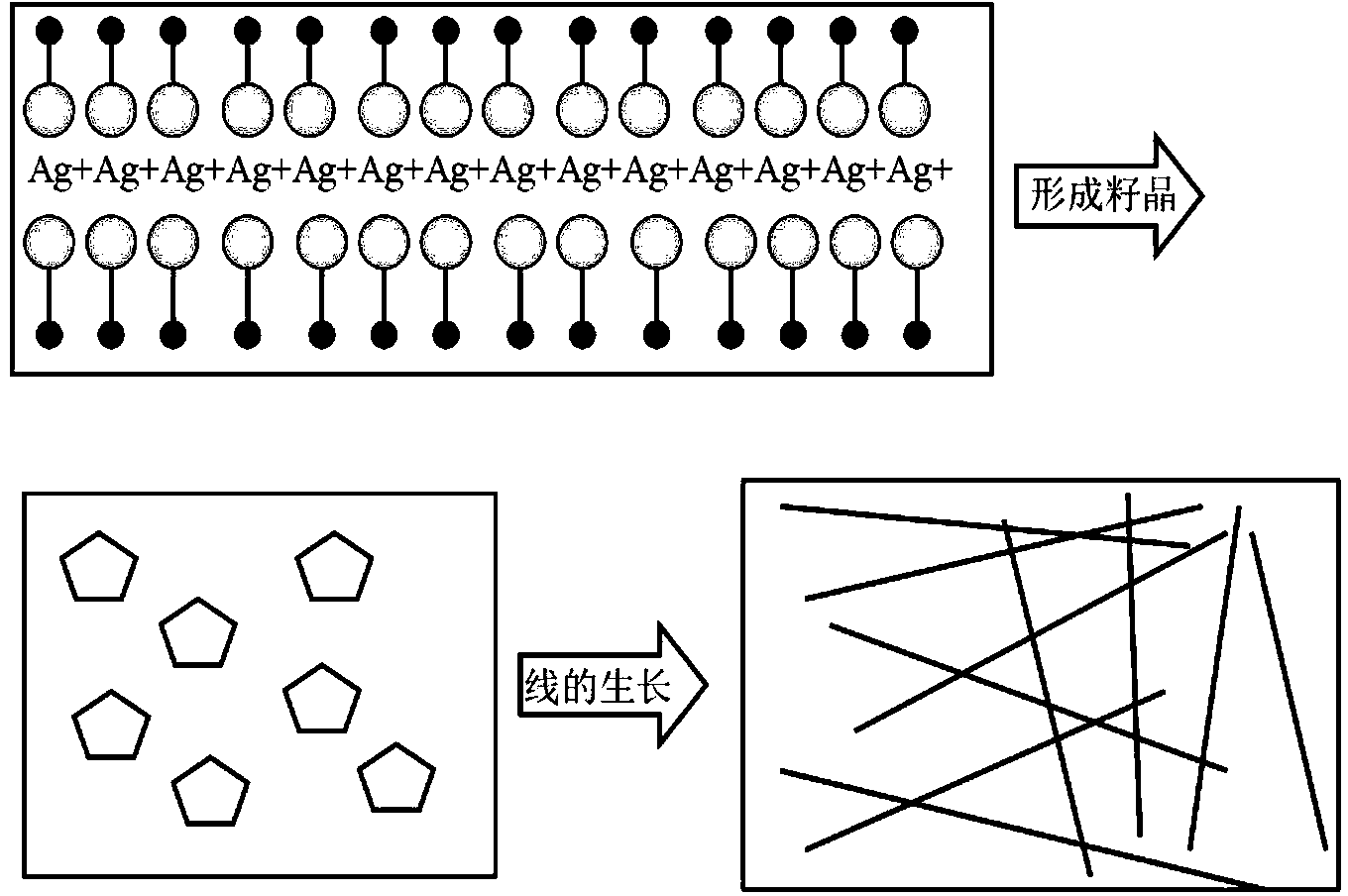

Method of adjusting and controlling length of silver nanowire by utilizing PVP (Polyvinyl Pyrrolidone) of different molecular weights and reaction temperature

The invention discloses a method of adjusting and controlling the length of a silver nanowire by utilizing PVP (Polyvinyl Pyrrolidone) of different molecular weights and reaction temperature. The method comprises the following steps of adding little ferric chloride and silver nitrate solution in ethylene glycol solution of the PVP (average molecular weight of 55000-1300000), which is heated at 120-240 DEG C, in 1 minute in sequence, and keeping warm for 0.5 hour to 8 hours to obtain the silver nanowire with the length of 10-100 microns. According to the method, by adopting a salt assisted polyhydric alcohol method, a silver source is added under the assistance of trace salt and the PVP, and the silver nanowires of different lengths are obtained through adjusting and controlling the molecular weight and the reaction temperature of the PVP. The silver nanowire is purified through simple filtration and centrifugation, and the purified silver nanowire can be used for preparing a transparent electrode with high performance. The method is simple and easy, and low in cost, and can be produced in a large scale.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

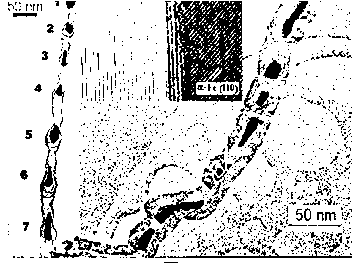

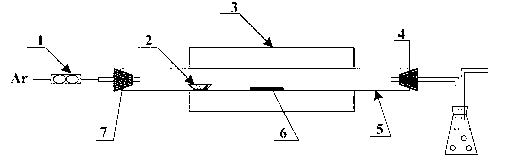

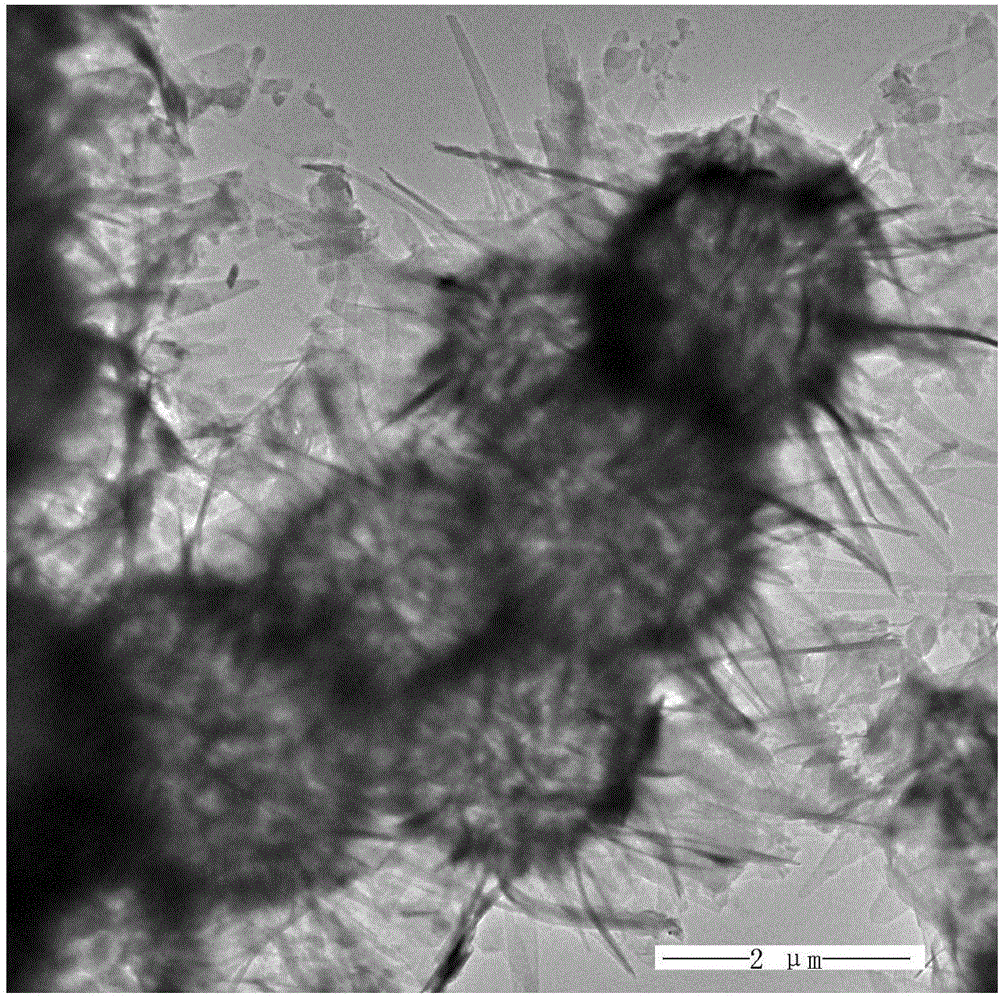

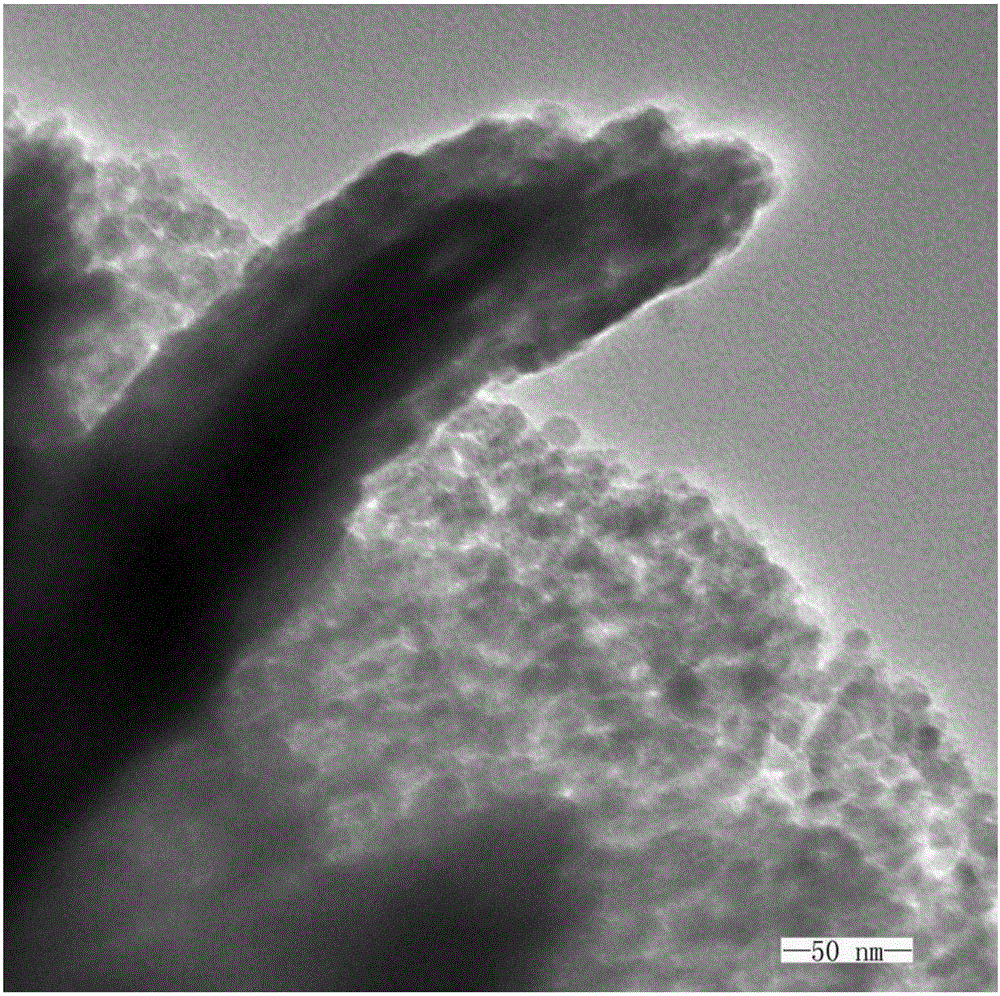

Preparation method of iron filled carbon nano tube and reaction device

InactiveCN103288072AImprove fill rateIncrease filling volumeMaterial nanotechnologyCarbon compoundsPtru catalystIron(III) chloride

The invention provides a preparation method of an iron filled carbon nano tube and a reaction device. The preparation method of the iron filled carbon nano tube comprises the following steps of: preparing the iron filled carbon nano tube by adopting an inorganic covalent compound of iron namely ferric chloride anhydrous as a catalyst precursor and selecting different carbon sources through floating catalysis chemical vapor deposition method, wherein the iron filled carbon nano tube comprises a non-nitrogen-doped iron filled carbon nano tube or a nitrogen-doped iron filled carbon nano tube. The preparation method of the iron filled carbon nano tube disclosed by the invention is simple and scientific in steps and can prepare a high-iron filled carbon nano tube. The invention further discloses a reaction device of the preparation method of the iron filled carbon nano tube. According to the preparation method of the iron filled carbon nano tube and the reaction device, a plurality of disadvantages in the prior art can be overcome; and the advantages that the preparation method is simple and the obtained iron filled carbon nano tube has high iron filling rate are realized.

Owner:DALIAN UNIV OF TECH

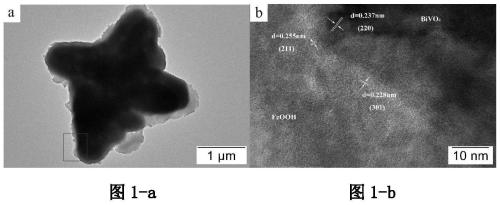

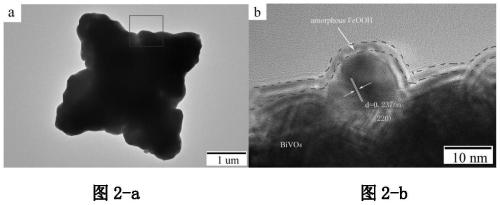

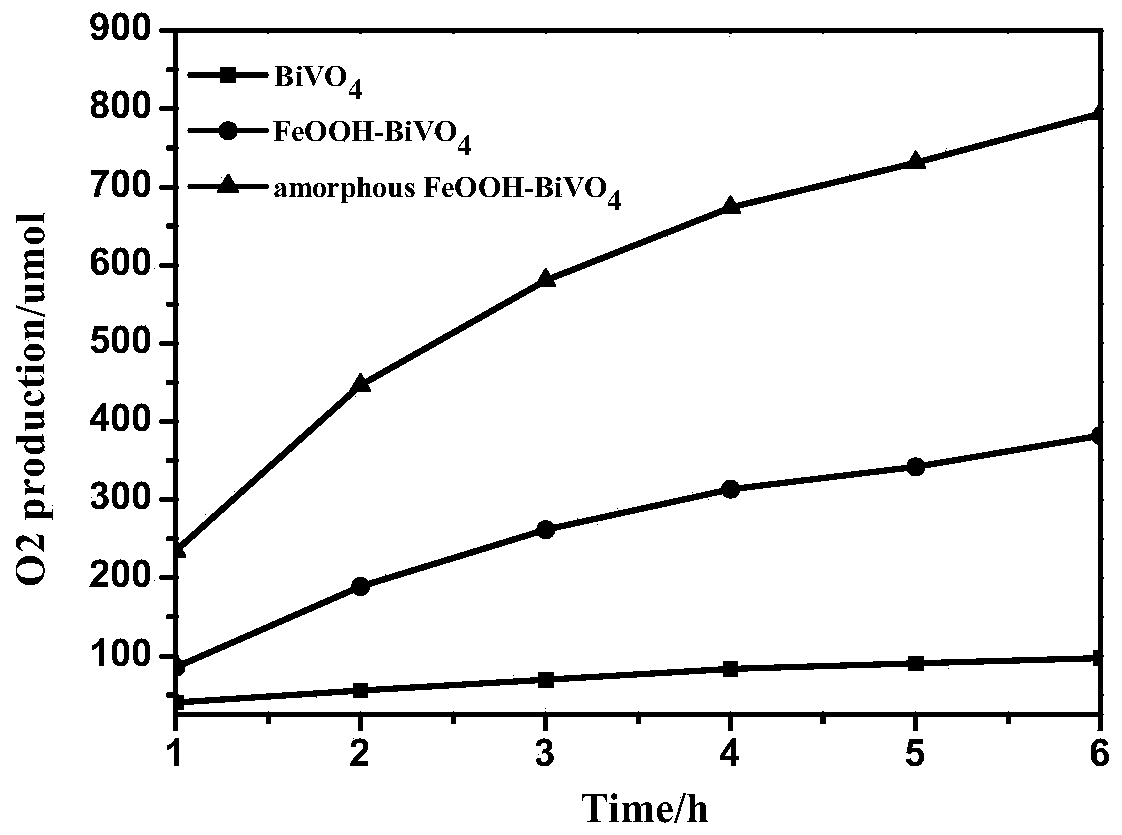

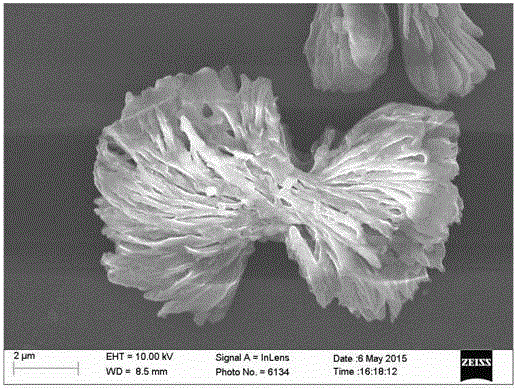

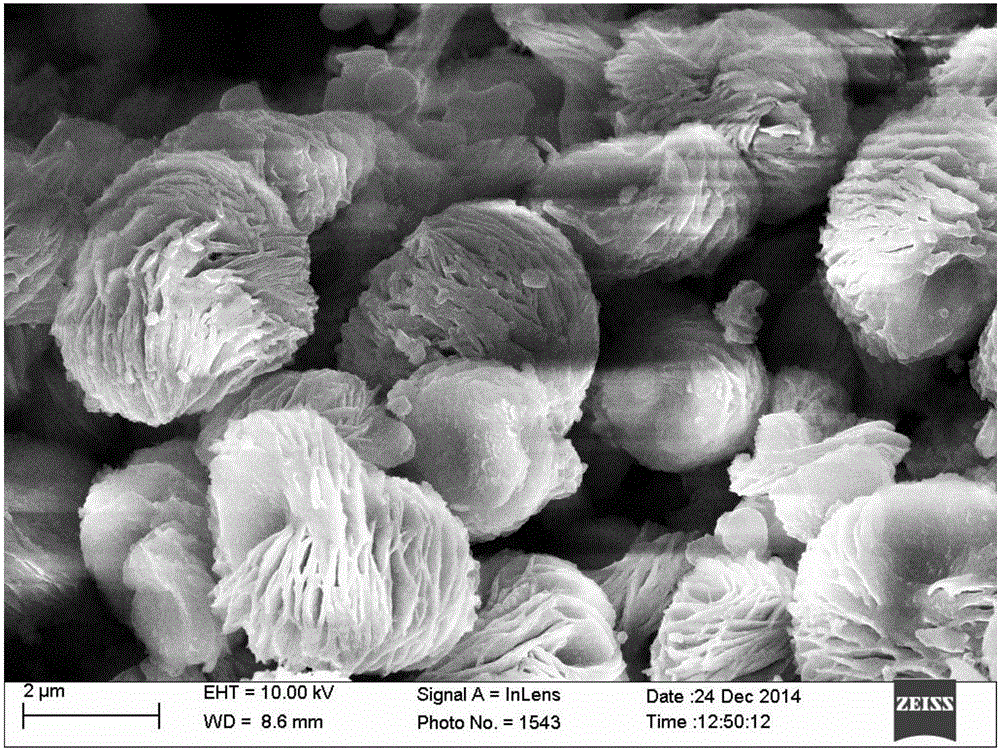

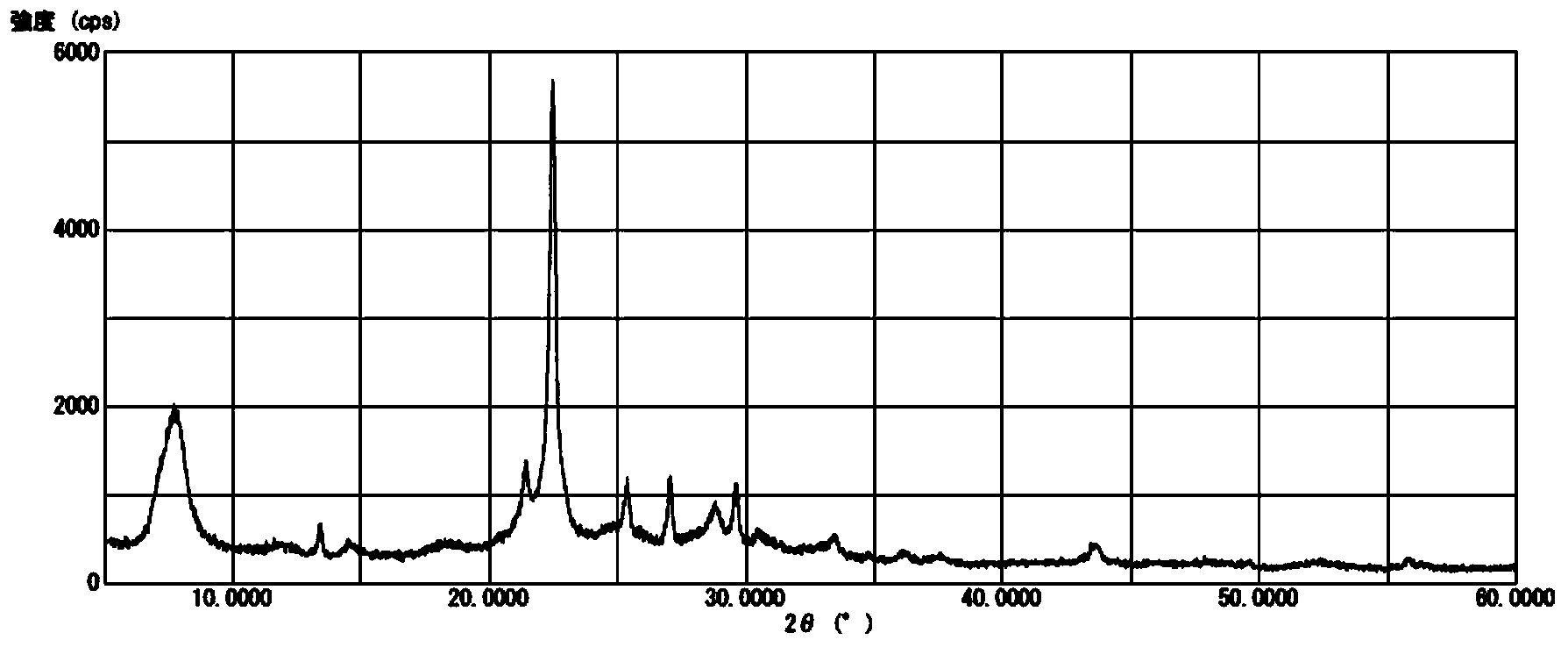

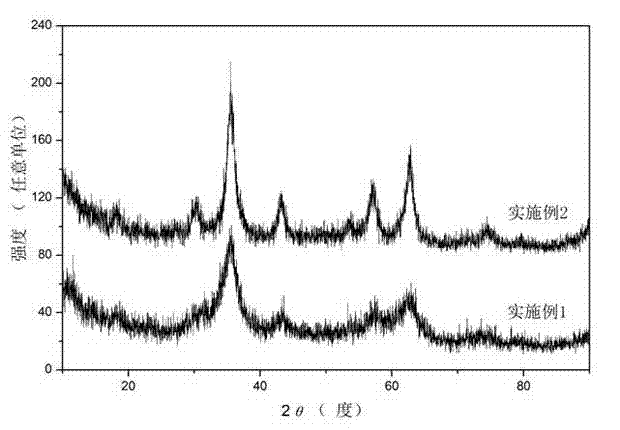

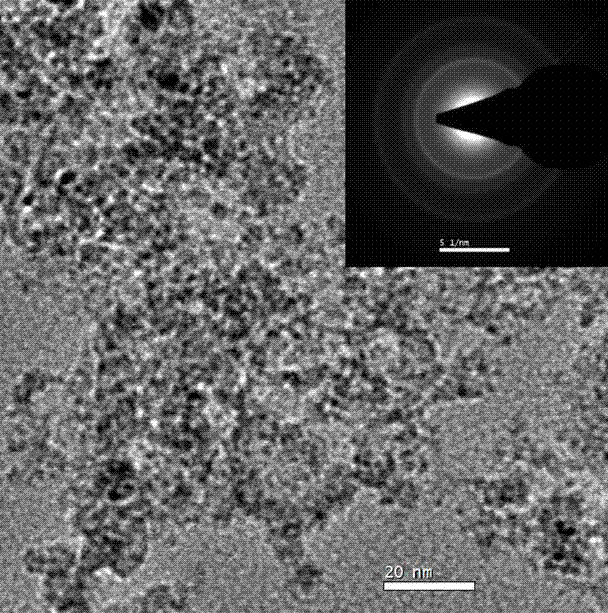

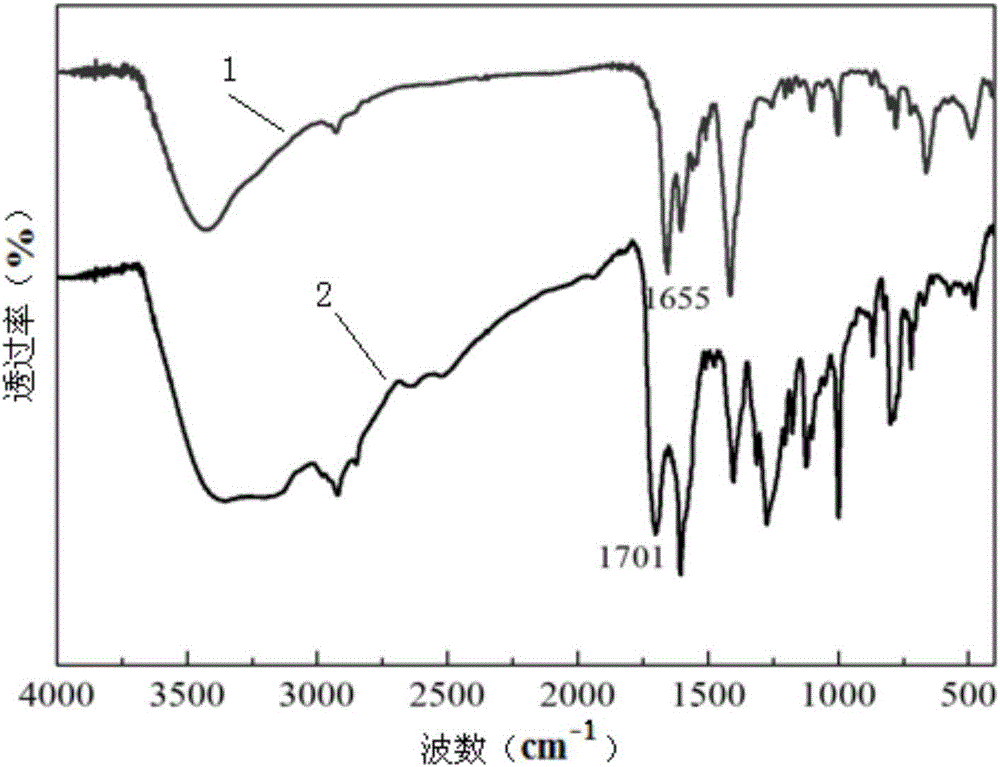

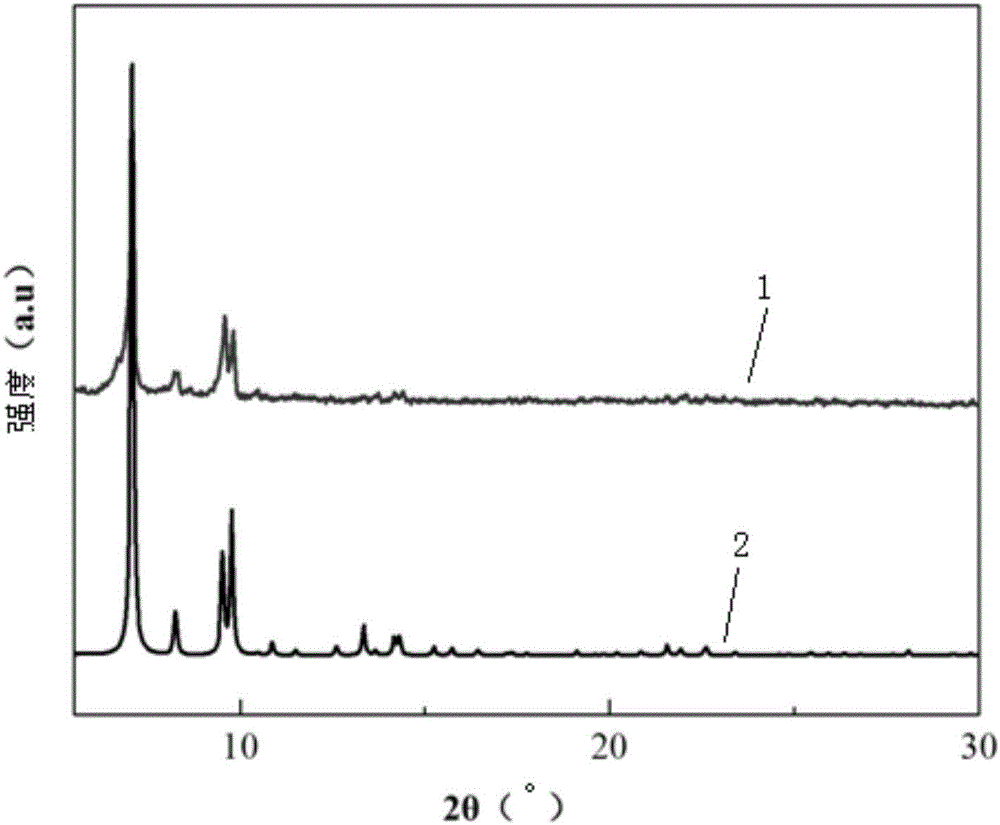

Preparation method of amorphous iron oxyhydroxide/bismuth vanadate composite photocatalytic material

ActiveCN109772355ANarrow band gapEasy transferCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIron(III) chlorideBismuth vanadate

The invention belongs to the field of photocatalyst preparation and particularly relates to a preparation method of an amorphous iron oxyhydroxide / bismuth vanadate composite photocatalytic material. The preparation method of the amorphous iron oxyhydroxide / bismuth vanadate composite photocatalytic material comprises the following process steps of synthesizing bismuth vanadate through a hydrothermal method, adopting synthesized bismuth vanadate as a substrate, putting the bismuth vanadate into a mixed solution of ferric chloride and ammonium bicarbonate for stirring, and drying the mixture after centrifuging to obtain a finished product, namely the amorphous iron oxyhydroxide / bismuth vanadate composite photocatalytic material. According to the preparation method, an amorphous material is used as a cocatalyst, and due to the special structure of the amorphous material, the amorphous material lacks ordered atomic arrangement and thus has narrower forbidden bands. These characteristics lead to more defects on the surface of a catalyst, more active sites are provided, the light absorption range is enlarged, and the photocatalytic performance is further improved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Magnetic composite metal organic framework material of multi-stage structure and manufacturing method thereof

ActiveCN104998688AEfficient Recycling PerformanceRich preparation methodWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsMetal frameworkMetal-organic framework

The invention discloses a magnetic composite metal organic framework material of a multi-stage structure and a manufacturing method thereof and belongs to the technical field of magnetic metal organic framework materials. The manufacturing method comprises the steps that one or more kinds of metal salt containing ferric chloride and aromatic carboxylic acid ligand are dissolved in high-boiling-point organic solvent according to a certain proportion, and the magnetic composite metal organic framework material, containing superparamagnetic Fe3O4, of the multi-stage structure is further grown in situ through a solvothermal method by controlling the molar ratio of the metal salt to aromatic carboxylic acid and the molar ratio of added ferric chloride and by using proper reducing agents and complexing agents in cooperation. Due to the fact that a Fe3O4 nano magnet and the metal framework material can be combined in situ at the same time, the manufacturing procedure of the magnetic metal framework material is greatly shortened, and the technique is greatly simplified. The novel magnetic composite metal organic framework material of the multi-stage structure can serve as a visible-light-induced photocatalyst for organic pollutants and has potential application value on the aspects of adsorption, separation, biological medicine and the like.

Owner:UNIV OF SCI & TECH BEIJING

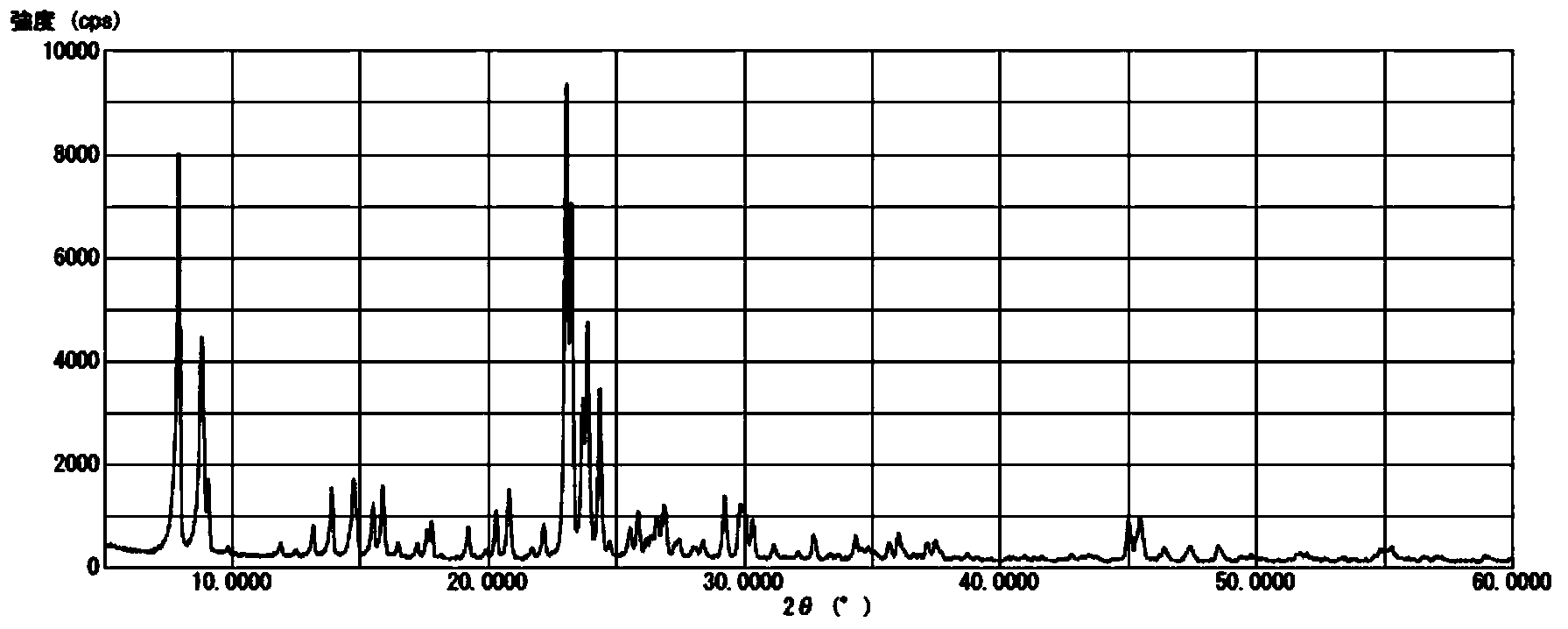

Iron-based SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

ActiveCN104226361AExcellent purificationLow costMolecular sieve catalystsDispersed particle separationOxygen cycleOxygen

The invention discloses an SCR (Selective Catalytic Reduction) catalyst containing synthetic zeolite and iron, and particularly relates to an SCR catalyst which always has an NOx purifying property in a low-temperature region after being subjected to relatively long-term action of hot water and relatively long-term action of sulfur oxides. A preparation method of the SCR catalyst, disclosed by the invention, comprises the following steps: crystallizing a hydrogenised synthetic zeolite with maximal oxygen cycle number of 8-12 and a three-dimensional structure by using a mixing procedure, and blending with a ferric nitrate (III) water solution or ferric chloride (III) water solution with a pH value of 0.1-0.7 to obtain the SCR catalyst without a filtering procedure and a cleaning procedure.

Owner:清华大学苏州汽车研究院(吴江) +1

Preparation method for water purifier capable of synchronously removing ammonia nitrogen and phosphorus in waste water

InactiveCN102942237AIncrease productionHigh post-processing costWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionEnvironmental resistanceChemical reaction

The invention discloses a preparation method for water purifier capable of synchronously removing ammonia nitrogen and phosphorus in waste water, which belongs to the water treatment chemicals production technology in the field of environmental protection. The preparation method for the water purifier comprises the following steps of (1) placing mineral powder containing magnesium and calcium with given percentage amount into steel acid-washing waste liquid to have chemical reaction with hydrochloric acid in the waste liquid; (2) oxidizing reacted products, oxidizing ferrous ions to be ferric ions, and generating ferric chloride solution containing magnesium and calcium ions; and (3) aging and filtering the ferric chloride solution containing the magnesium and the calcium ions, evaporating and concentrating the solution when necessary, and packing the product after the product meets the index requirements. Products prepared by the preparation method can conform to the category II standard of water purifier ferric chloride of GB4482-2006, have a remarkably effect for synchronously removing the ammonia nitrogen and phosphorus for industrial sewage, agricultural breeding waste water and domestic waste water while having all performance characteristics of the ferric chloride, the resource-oriented comprehensive utilization of the steel acid-washing waste liquid can be realized, and a purpose for controlling waste through waste can be realized.

Owner:天津市鑫昌科技有限公司

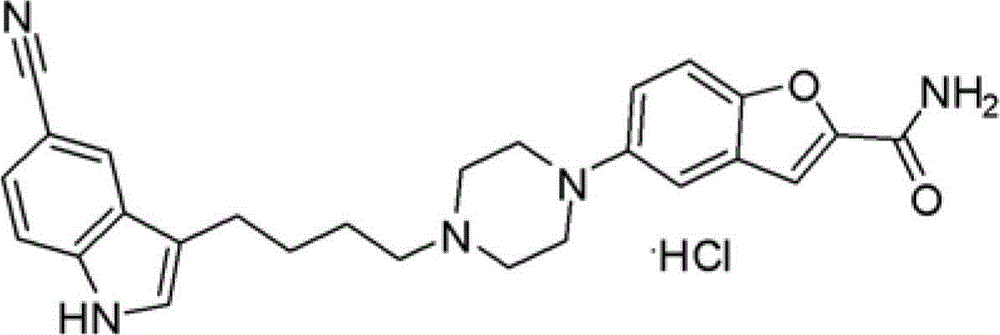

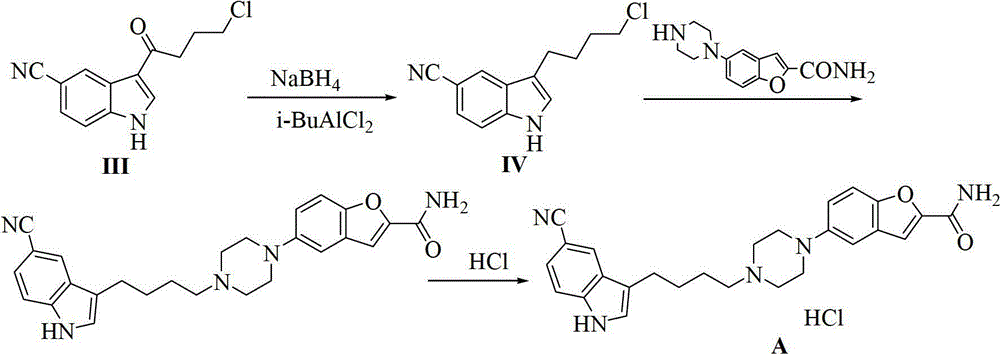

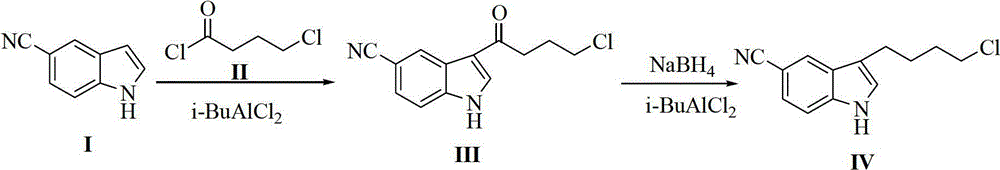

Preparation method of 3-(4-chlorobutyl)-5-cyanoindole

ActiveCN102875440AReduce usageOperational securityOrganic chemistryPotassium borohydrideLewis acid catalysis

The invention discloses a preparation method of 3-(4-chlorobutyl)-5-cyanoindole which is shown as the formula IV. The preparation method comprises the steps as follows: carrying out following carbonyl reduction reaction on a compound III and a hydroboron reducing agent in the solvent under the catalyzing of Lewis acid to obtain the product, wherein Lewis acid is one or more of aluminium trichloride, magnesium chloride, zinc chloride and ferric chloride; and the hydroboron reducing agent is one or more of sodium borohydride, potassium borohydride, lithium borohydride and borane. The preparation method disclosed by the invention is safe in operation, low in requirement on equipment, low in cost, simple in post-processing steps, high in yield of product, high in purity, and is suitable for industrialization.

Owner:CHIRAL QUEST (SUZHOU) CO LTD +1

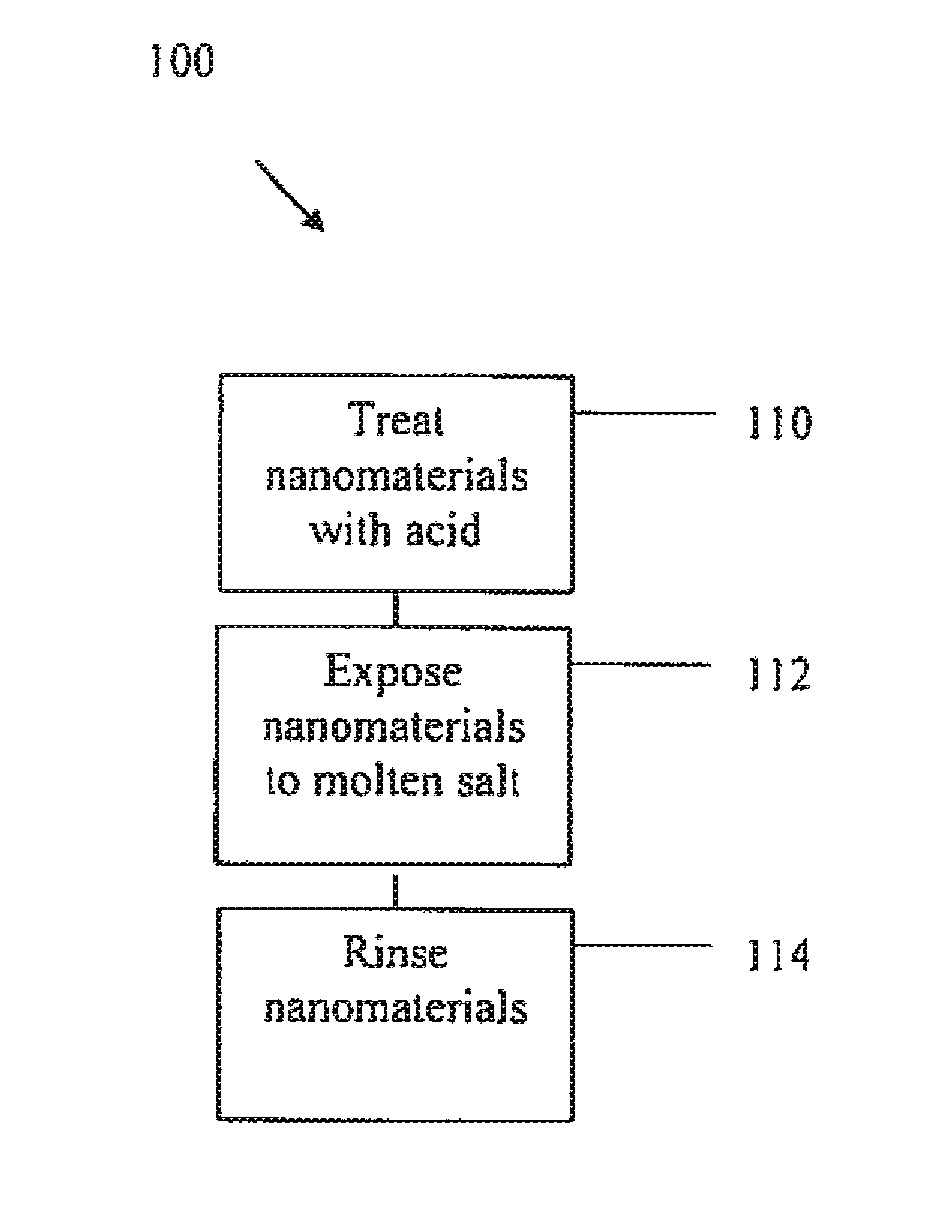

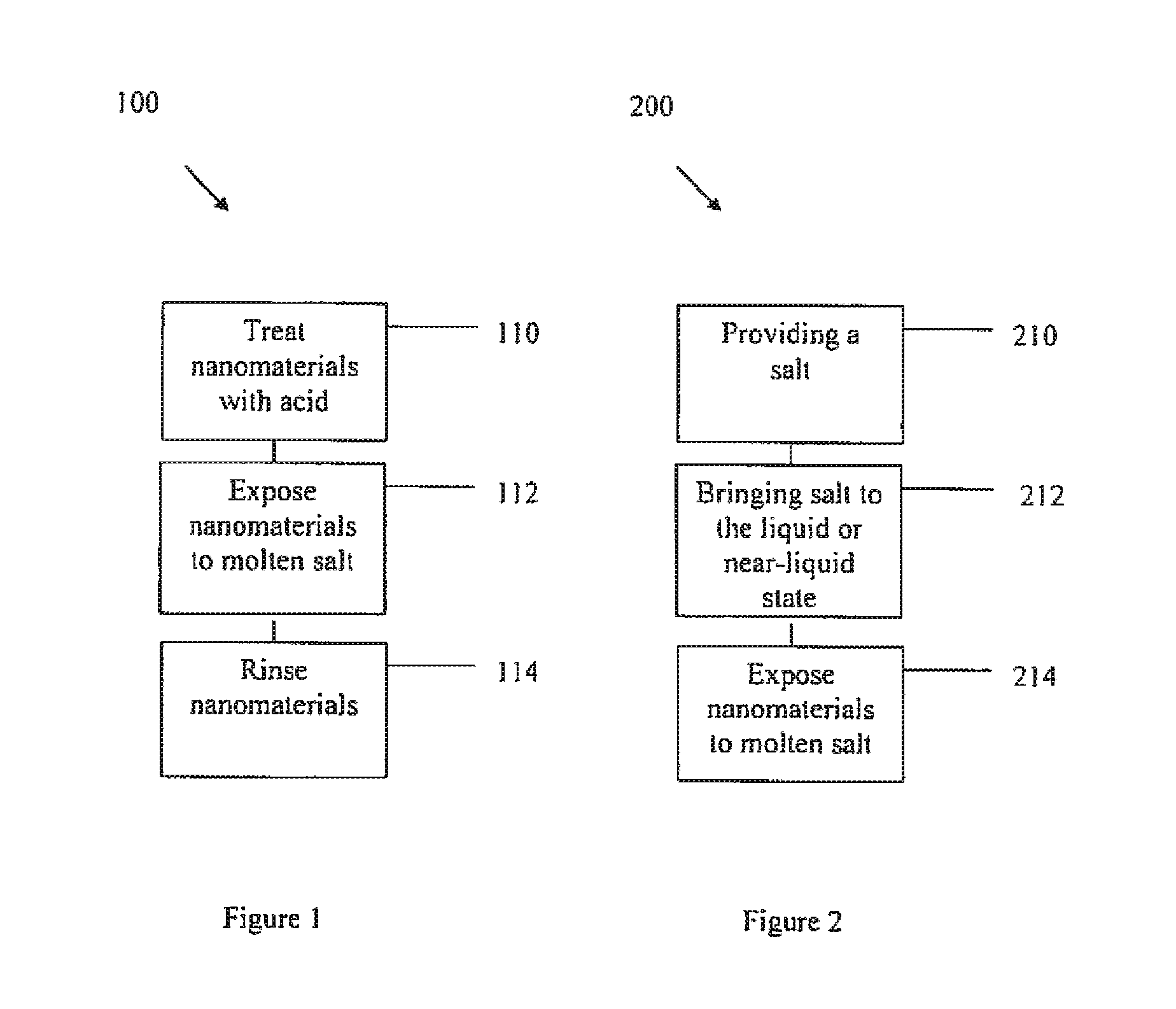

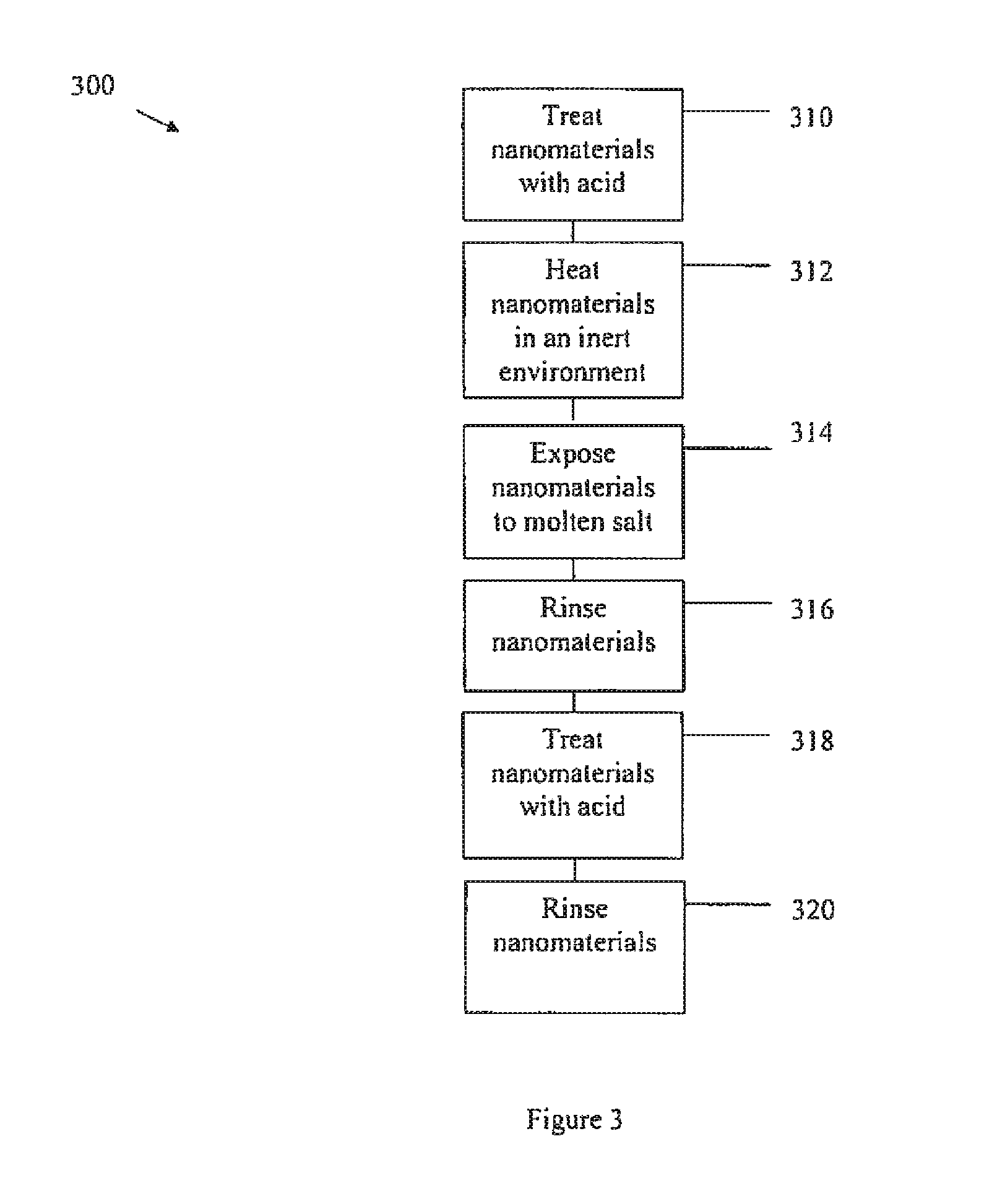

Purifying nanomaterials

A method of purifying a nanomaterial and the resultant purified nanomaterial in which a salt, such as ferric chloride, at or near its liquid phase temperature, is used to penetrate and wet the internal surfaces of a nanomaterial to dissolve impurities that may be present, for example, from processes used in the manufacture of the nanomaterial.

Owner:NASA

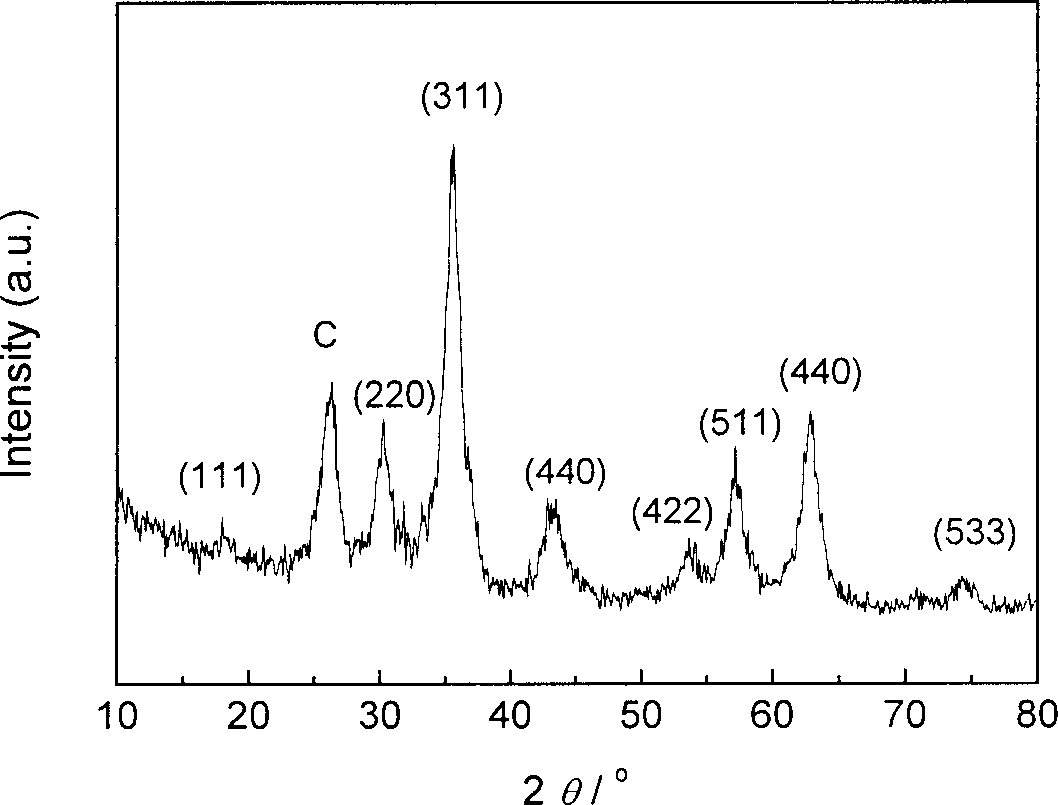

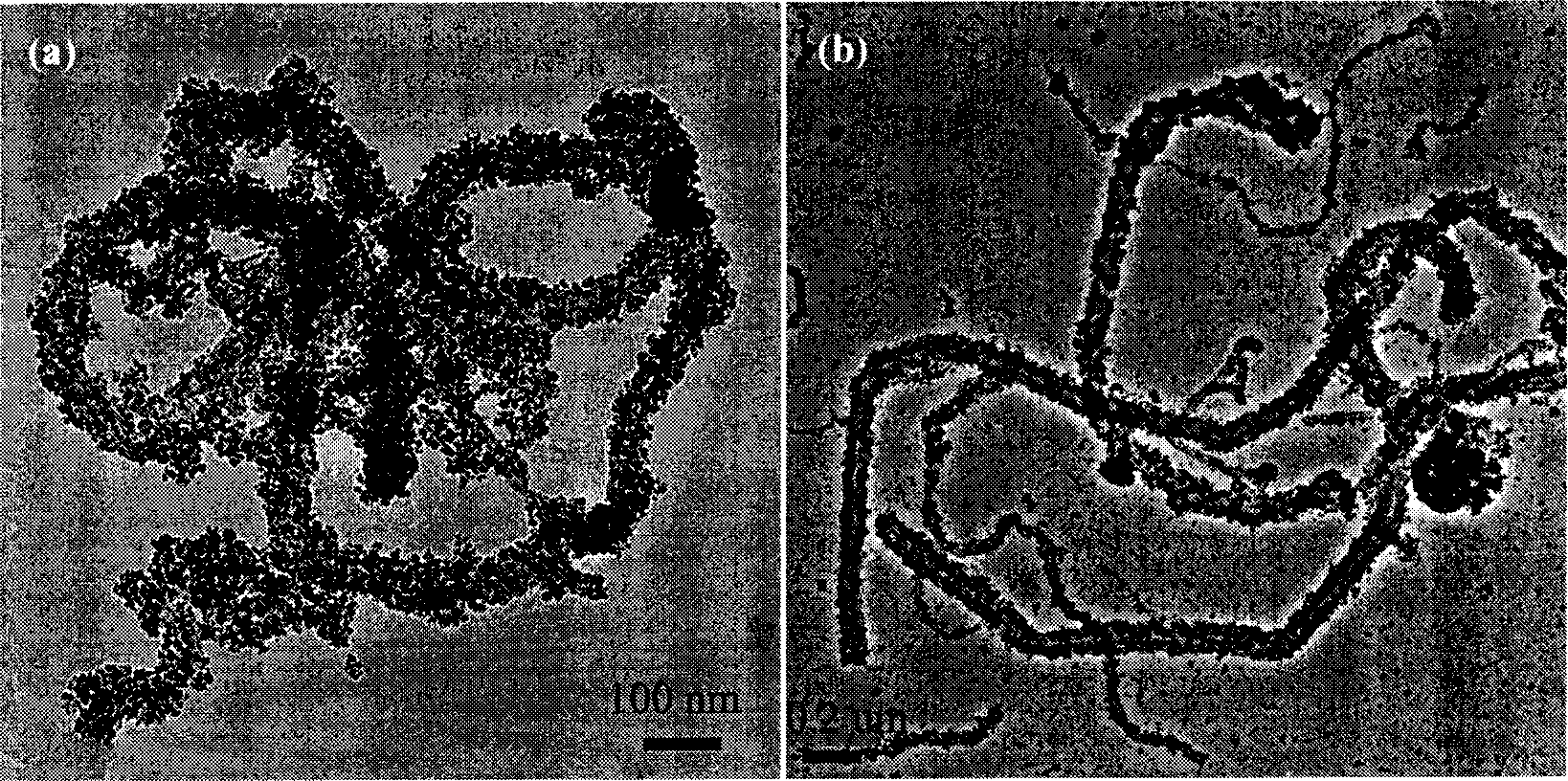

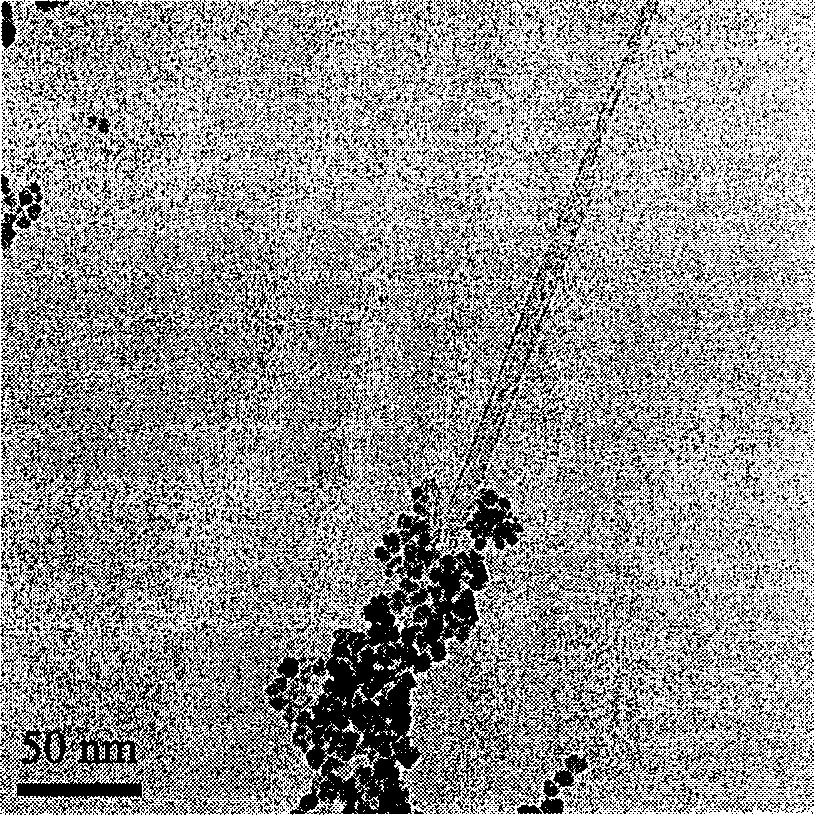

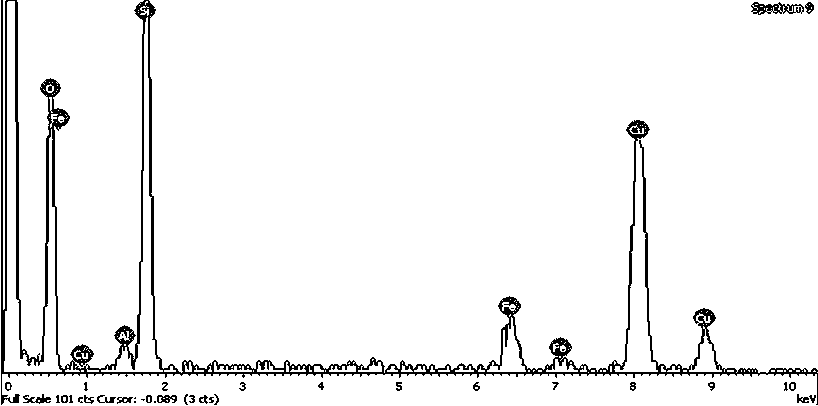

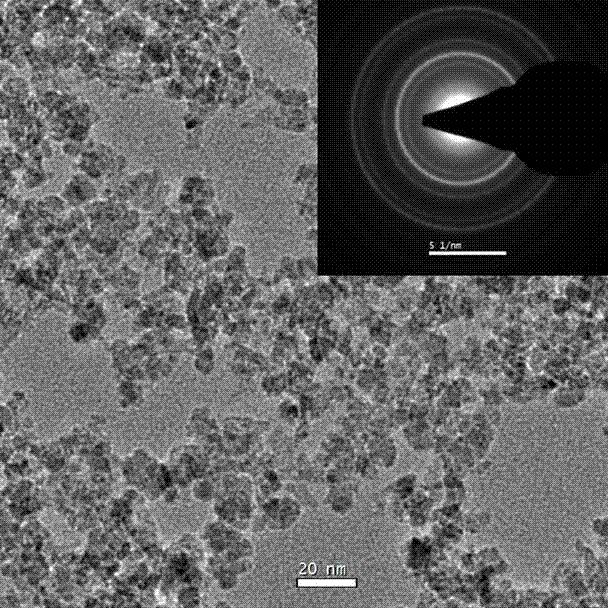

Magnetic composite powder for ferroferric oxide nanometer crystal modified carbon nanometer pipe and its preparation method

InactiveCN1794372AFerromagneticInductances/transformers/magnets manufactureMagnetic materialsModified carbonCarbon nanotube

This invention relates to a magnetic compound powder of Fe3O4 nm grains for the decoration of C nm tubes and its preparation method characterizing in taking multi-wall or single wall C nm tubes, triacetyl-acetonyl or FeCl3 as the raw materials, 2-ketopyrrolidine as the solution to flow back for 0.5-2 hours protected by 240-250deg.C N or Ar, the character of the powder is: Fe3O4 nm particles cover the surface of the multi-wall nm tubes uniformly and most of the Fe3O4 particles of 6-10nm are at the open-end of the single-wall tubes. The magnetic compound powder has ferromagnetism and a trend of directional aggregation and keeps its state after the field is removed.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method and application of nanoscale zero-valent iron-beta zeolite new composite nano material

InactiveCN104118920AFully dispersedEvenly combinedWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionIon exchangeChemistry

The invention relates to a preparation method and application of a nanoscale zero-valent iron-beta zeolite new composite nano material, an iron source is Fe<2+> or Fe<3+> iron containing compounds (such as anhydrous ferric chloride, ferrous sulfate, and the like), and a loading base is beta zeolite with total ion exchange capacity. The preparation is characterized in that a loading base material is fully dispersed and iron ions and the loading base are uniformly combined through the long time reaction under ultrasonic synergistic effect, free iron ions in the solution are removed by centrifugation, the iron-containing solution is recycled, the homogeneity of the properties of the synthetic material system is enhanced, iron ions absorbed on the loading base surface are reduced under the function of sodium borohydride, and anhydrous ethanol is used for cleaning and storage. The preparation method has the advantages of being low in cost, convenient, fast, low in technical threshold, and in favor of the popularization and promotion, and nano zero valent iron particles in the synthetic material are smaller, is not easy to agglomerate and have very good removal effect on heavy metal pollutant stibonium and the like difficult to remove in the environment.

Owner:TONGJI UNIV

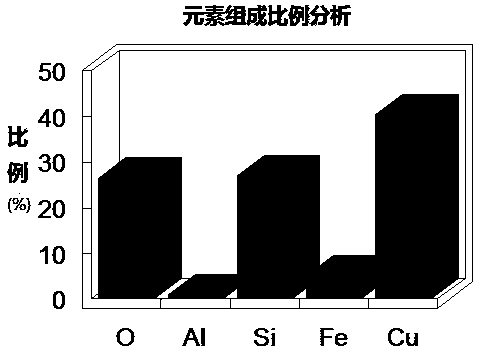

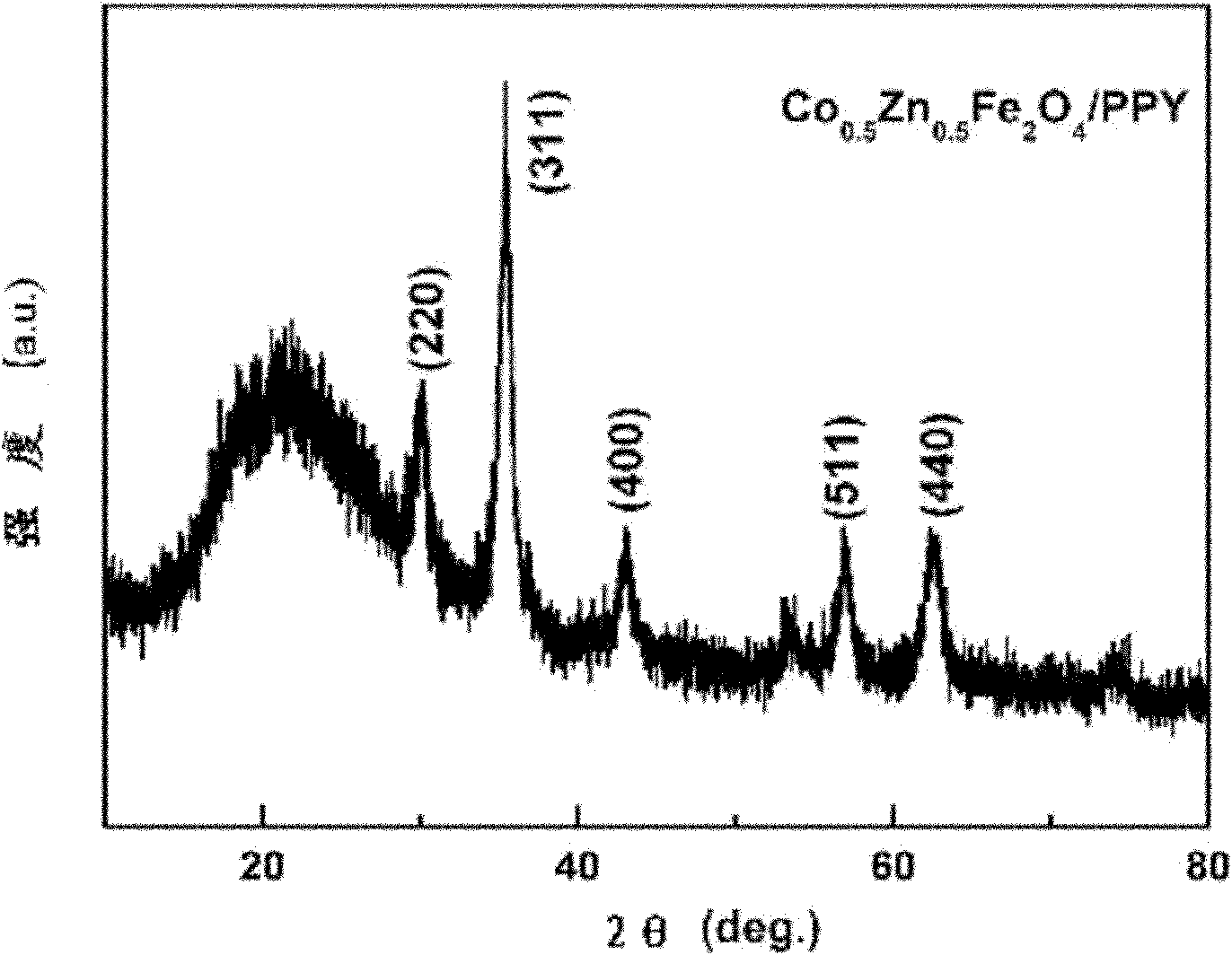

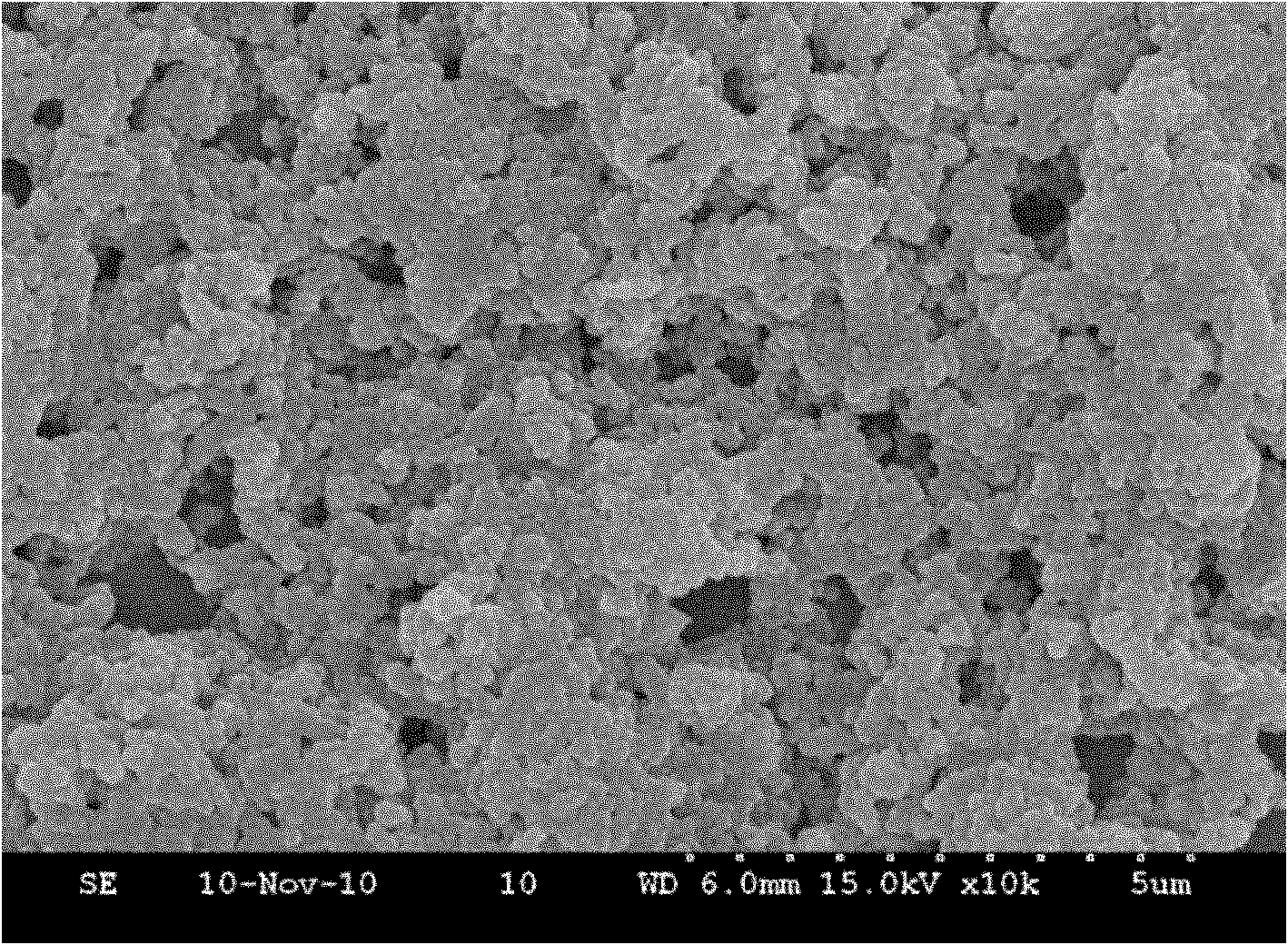

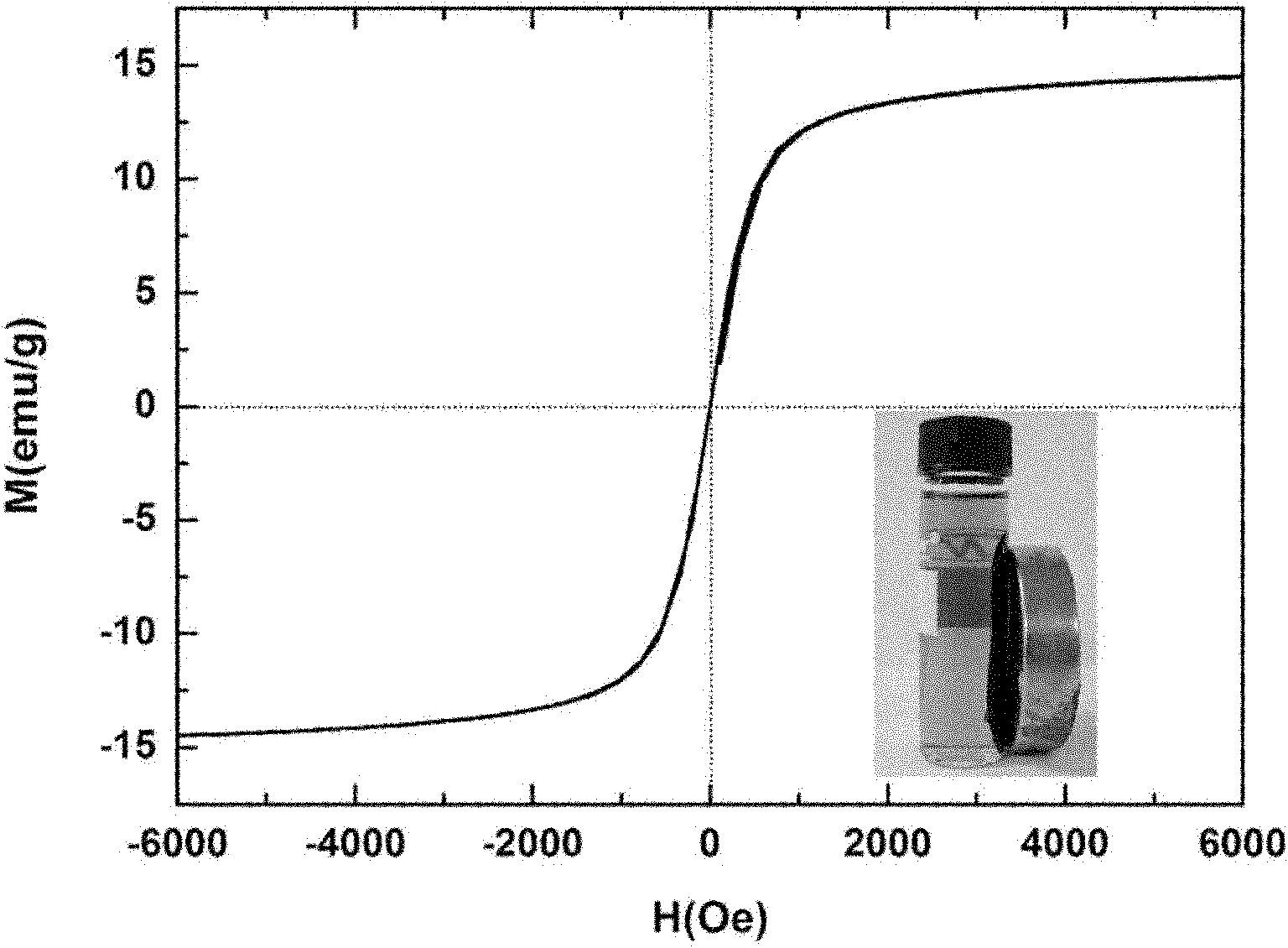

Method for preparing cobalt-zinc ferrite/polypyrrole nano composite material

InactiveCN102161764AImprove electrical performanceGood electromagnetic performanceIron oxides/hydroxidesCobalt oxides/hydroxidesNano compositesPolypyrrole

Owner:DONGHUA UNIV

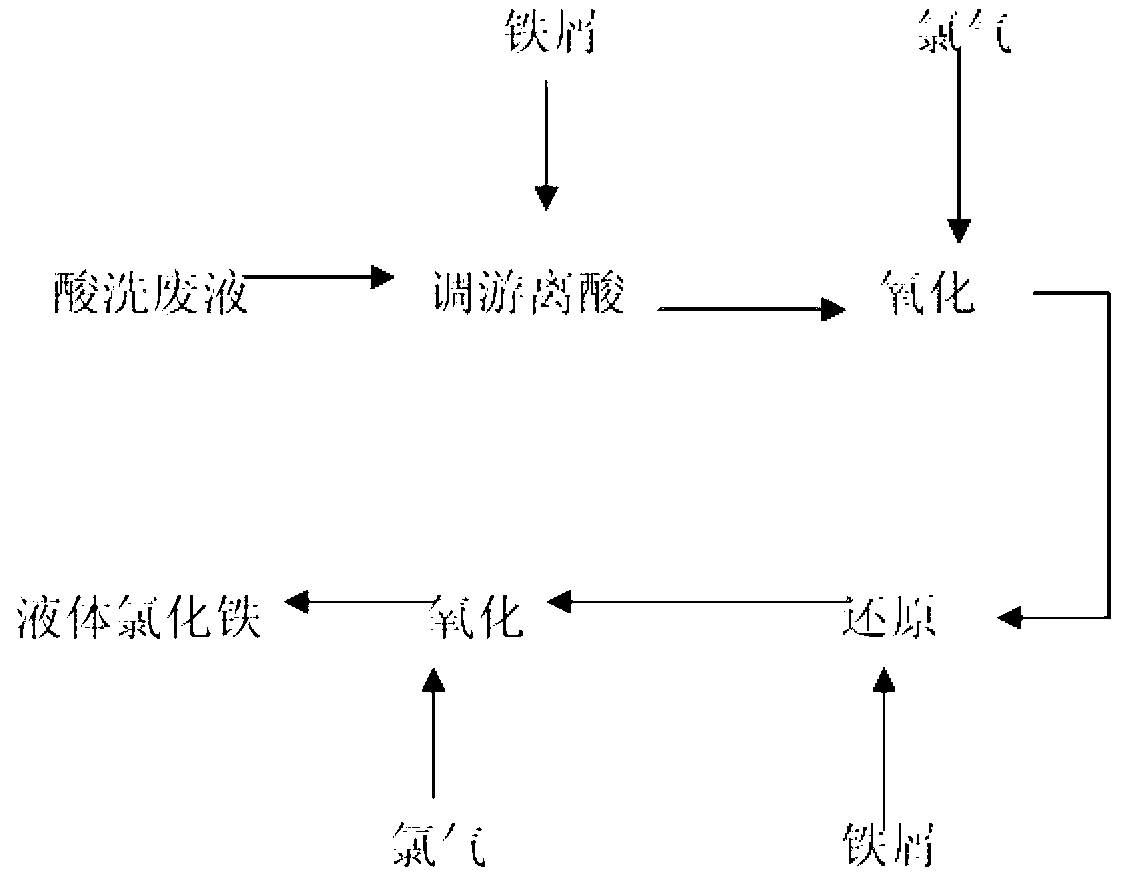

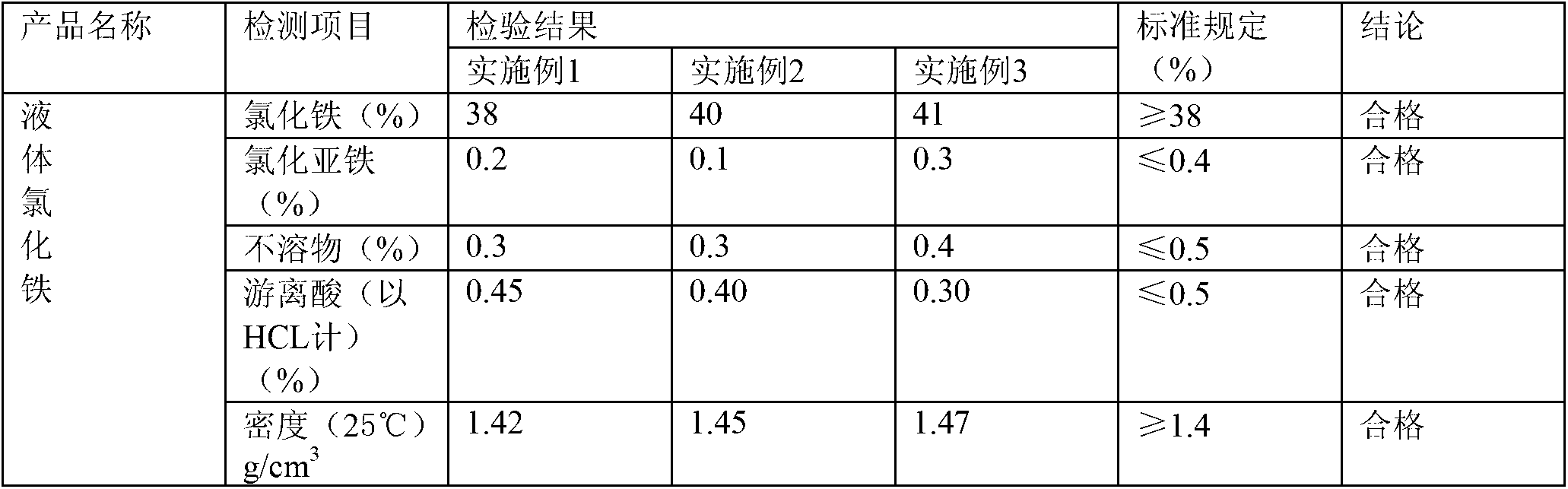

Method for producing ferric chloride by using pickle liquor

InactiveCN103073067AQuality improvementOperational securityIron halidesIron(III) chlorideSafe operation

The invention relates to a method for producing ferric chloride by using pickle liquor. The method comprises the following steps of: (1) replenishing scrap iron according to the iron content of the pickle liquor, and soaking; (2) after soaking, introducing chlorine gas for oxidizing ferrous ions in a solution into ferric ions; (3) after an oxidizing reaction is completed, replenishing scrap iron till the total iron content of every ton of pickle liquor is 130-140kg, and soaking; (4) after soaking, introducing chlorine gas for oxidizing ferrous ions in the solution into ferric ions; and (5) after an oxidizing reaction is completed, when the concentration of the solution is more than 43 Baume degree, inspecting qualification according to a GB / T1621-2008 standard to obtain liquid ferric chloride. Finished ferric chloride produced with the production method disclosed by the invention has the advantages of good quality, safe operation, no energy consumption, 100 percent application of waste acids, prevention of secondary pollution, realization of zero emission of three wastes, small investment and low production cost.

Owner:梁锡明

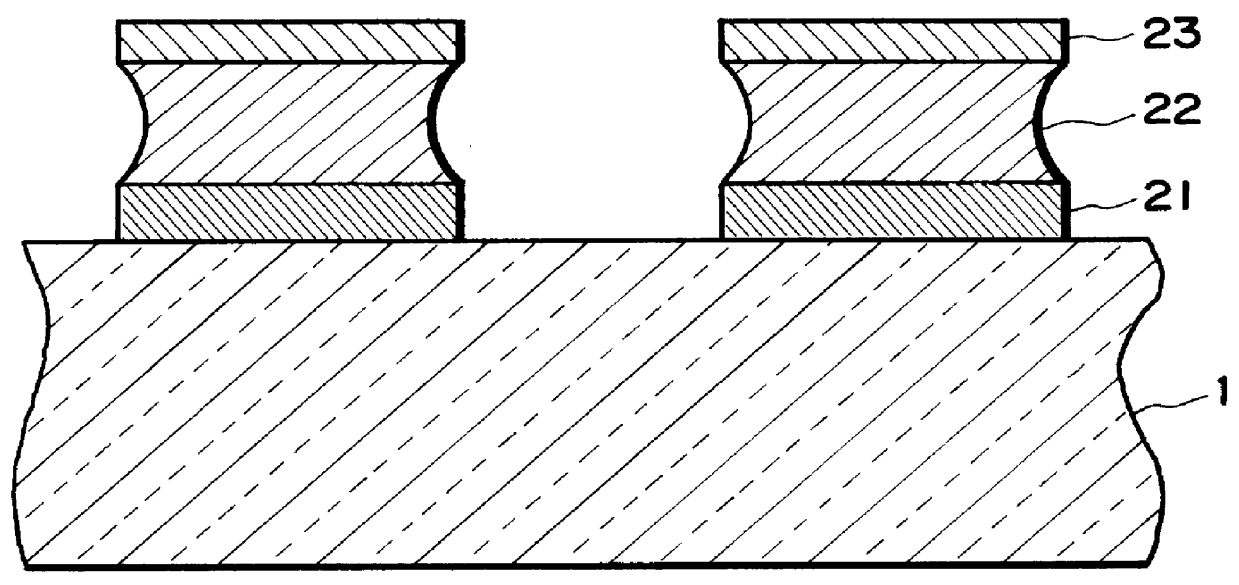

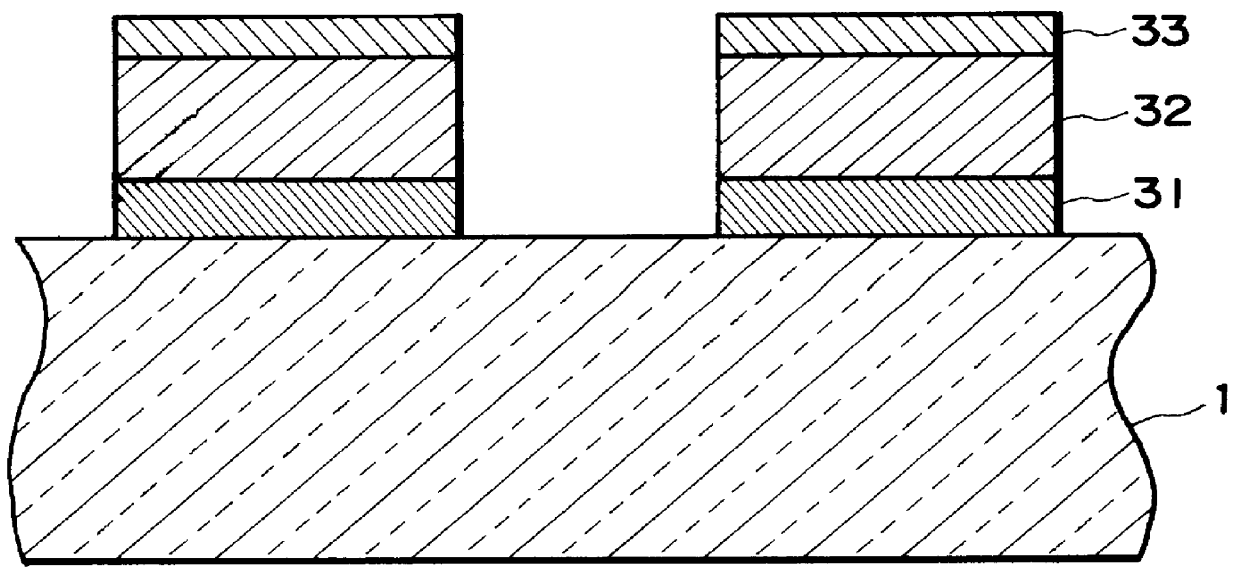

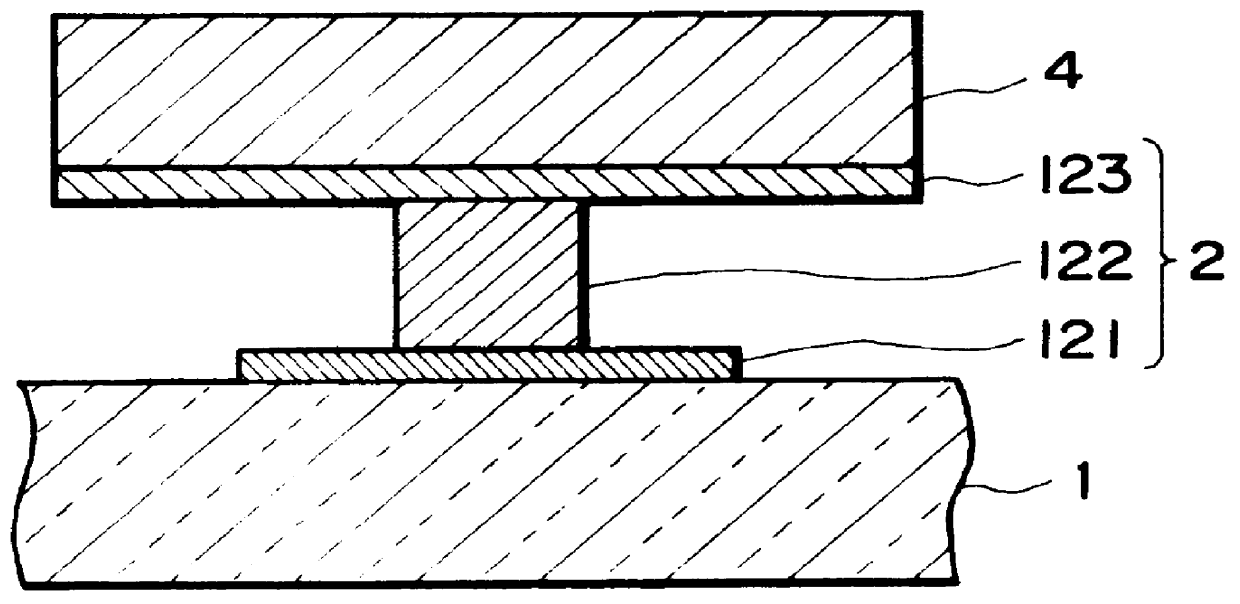

Etching process

An etching process includes the steps of: preparing an etchant containing ferric chloride and an anticorrosive agent for Cu, and etching with said etchant a multi-layer metal structure including a Cu layer and an Ni layer. The etchant may preferably further contain ferrous chloride. The etching process is effective in making etching rates of the respective substantially equal, thus suppressing occurrence of burr portions of the Ni layers.

Owner:CANON KK

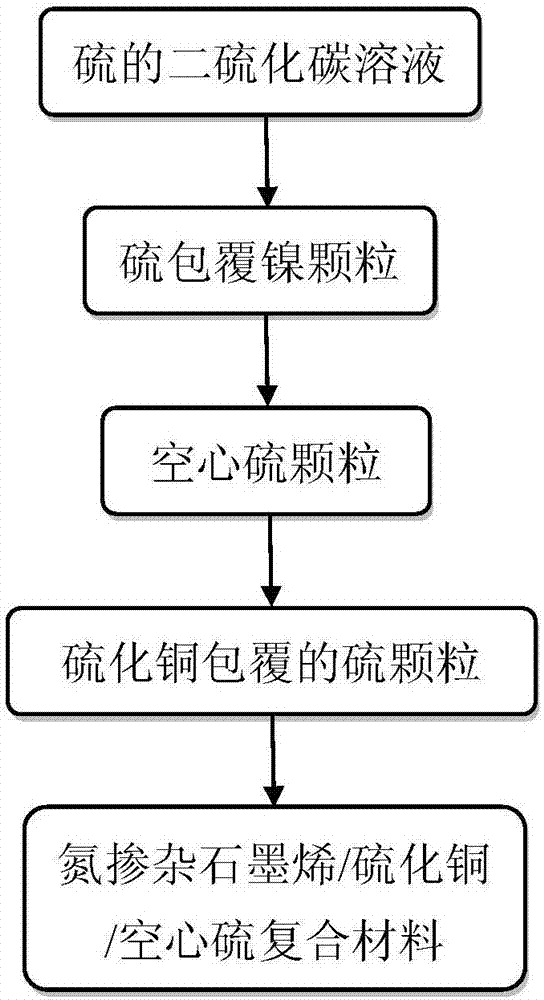

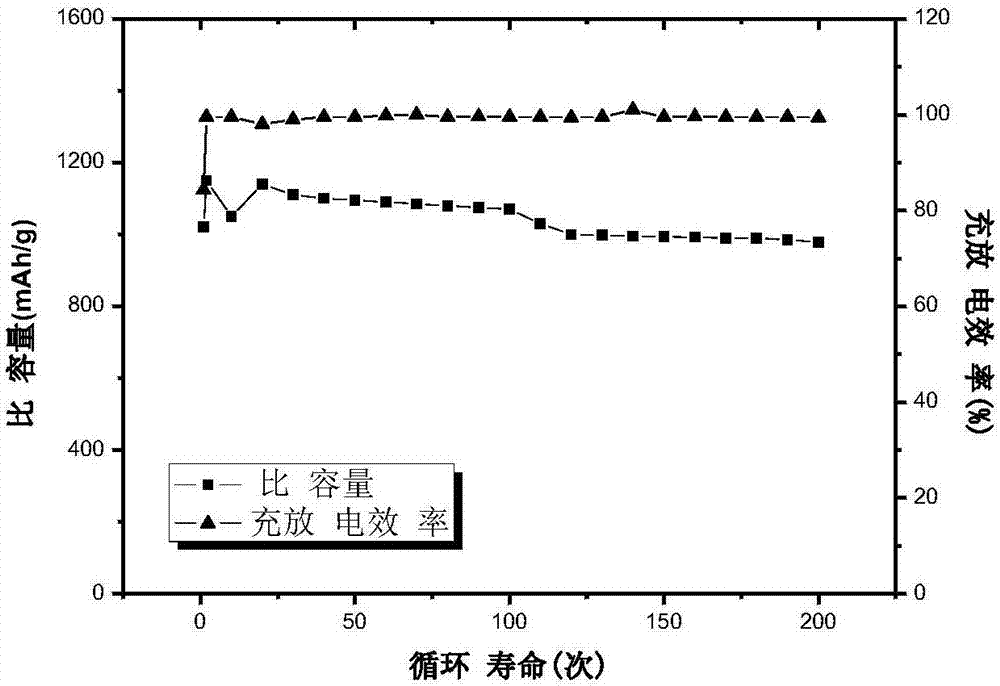

Preparation method of nitrogen-doped graphene/copper sulfide/hollow sulfur composite material

ActiveCN106972161AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesHigh energySpherical shaped

The invention discloses a preparation method of a nitrogen-doped graphene / copper sulfide / hollow sulfur composite material. The preparation method comprises the following steps: step (1), adding powdered sulfur into carbon dioxide, stirring and dissolving to form a uniform solution; step (2), ball-milling high-purity nickel powder through a high-energy ball grinding mill, adding the high-purity nickel powder after ball-milling into the solution, stirring to form uniform suspension liquid, mechanically stirring, and carrying out spray drying to form sulfur clad spherical particles; step (3), adding the spherical particles into a ferric chloride solution, stirring for reaction, washing and filtering; and step (4), adding a filtered precipitate into a solution containing copper chloride, thioacetamide and a surface active agent, stirring to form uniform suspension liquid, heating and stirring for reaction, centrifuging and washing to obtain copper sulfide clad sulfur particles. In the composite material, a space is reserved for the volume expansion, in the charging and discharging process, of sulfur material through the design of a hollow structure, so that the electrochemical performance can be effectively improved.

Owner:常熟东南高新技术创业服务有限公司

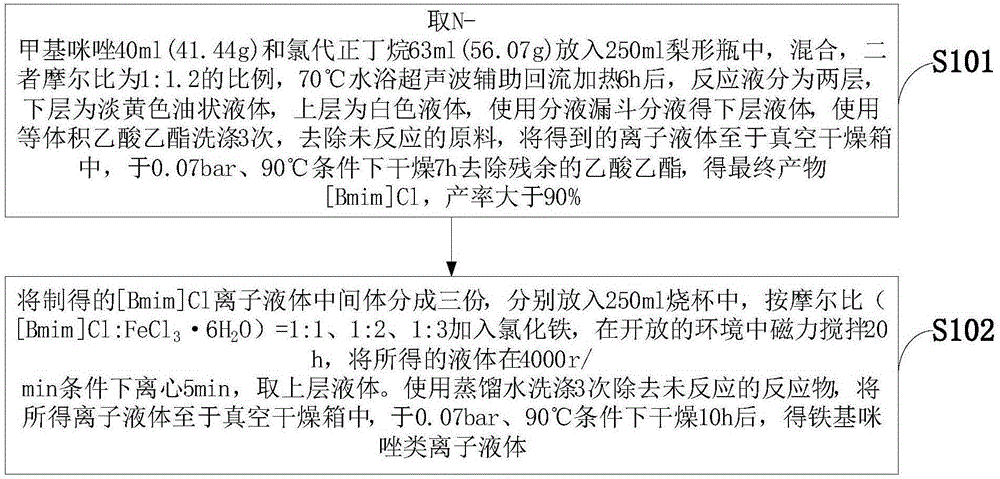

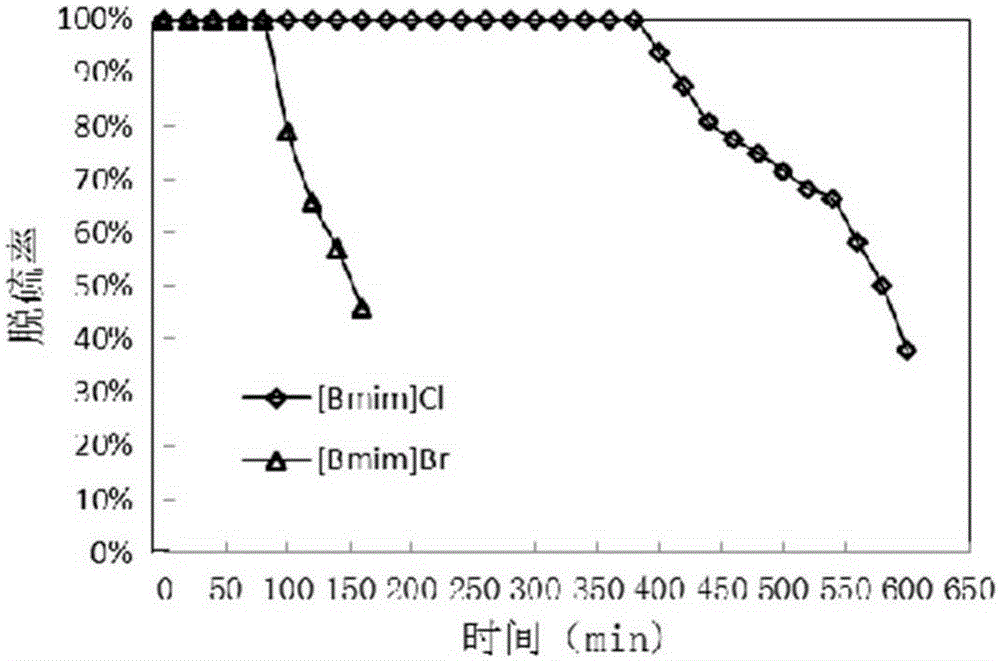

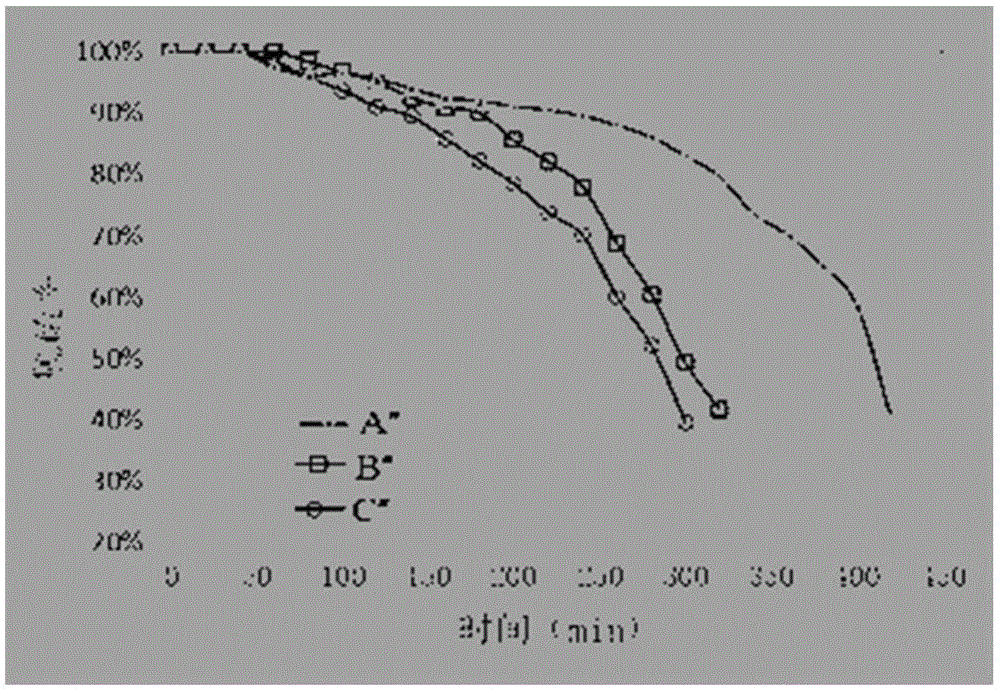

Iron-based imidazole ion liquid for removing SO2 from smoke and preparation method of iron-based imidazole ion liquid

InactiveCN105198815AImprove catalytic performanceGood removal effectOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsEthyl Chloride

The invention discloses iron-based imidazole ion liquid for removing SO2 from smoke and a preparation method of the iron-based imidazole ion liquid. Anions of the ion liquid are combined with hydrogen on imidazole rings in the form of FeCl4-. The method includes the steps of putting 40 ml or 41.44 g of N-methylimidazole and 63 ml or 56.07 g of n-chlorobutane in a 250-ml pear-shaped bottle to be mixed according to the molar ratio of 1 to 1.2, conducting water bath ultrasonic auxiliary backflow heating at the temperature of 70 DEG C for 6 h, conducting liquid separation through a liquid separation hopper to obtain lower layer liquid, conducting washing three times through ethyl acetate of equal volumes to remove unreacted raw materials, conducting drying for 7 h to remove residual ethyl acetate and obtain a product [Bmim]Cl, adding ferric chloride to be stirred for 20 h under the magnetic force, conducting centrifuging to obtain upper layer liquid, conducting washing three times through distilled water to remove unreacted reactant, and conducting drying for 10 h to obtain the iron-based imidazole ion liquid. The iron-based imidazole ion liquid is short in preparation cycle, high in yield and simple in reaction by-product removal.

Owner:SICHUAN UNIV

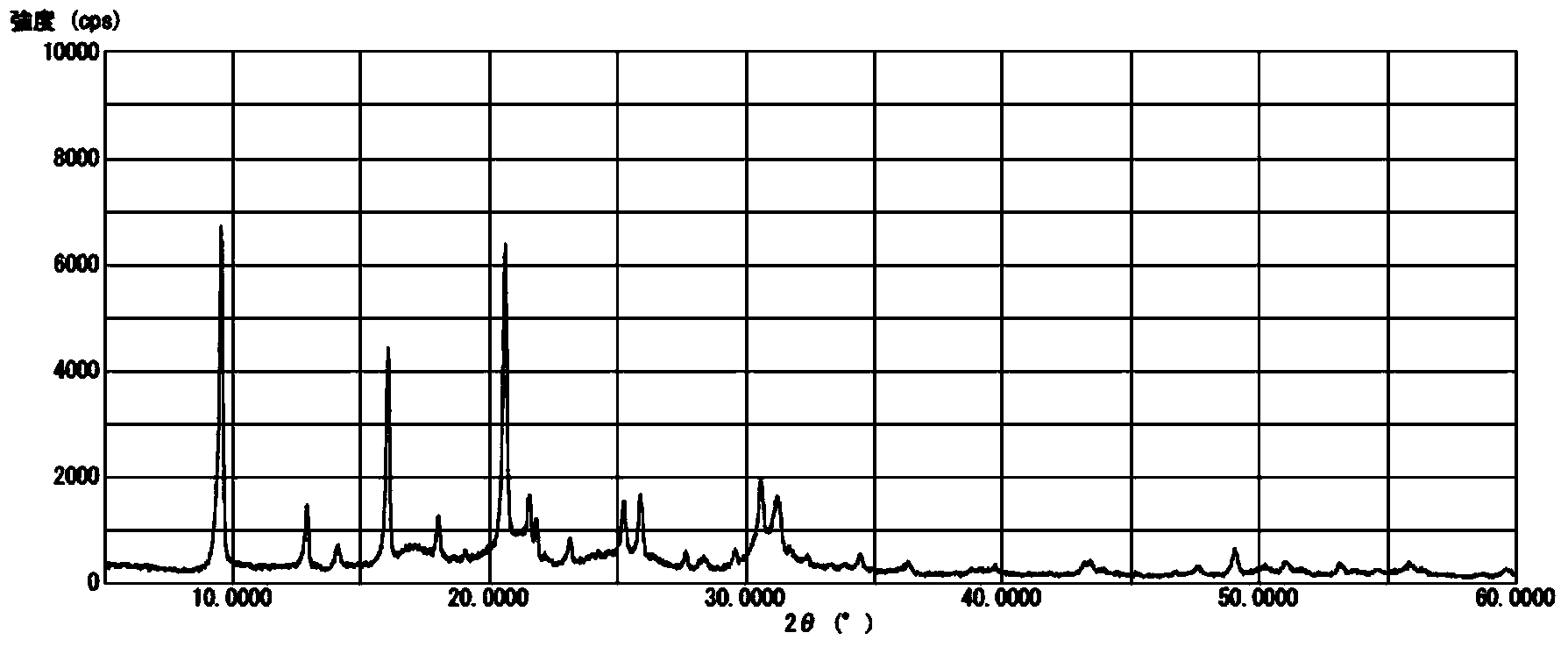

Method for preparing nano cobalt ferrite

The invention discloses a method for preparing nano-powder of nano cobalt ferrite (CoFe2O4) with a spinel structure at a low temperature. The preparation method comprises the steps of weighing ferric trichloride and cobaltous chloride in proportion, and mixing to prepare water solution A; evenly mixing the prepared NaOH or HOK aqueous alkali, and then dropwise adding N2H4.H2O to obtain solution B; rapidly stirring the water solution A obtained in the step 1 at 20-40 DEG C, and slowly dropwise adding the mixed solution B prepared in the step 2 into the water solution A to react, so as to obtain cobalt ferrite (CoFe2O4) powder sediment with a black spinel structure.

Owner:LANZHOU UNIVERSITY

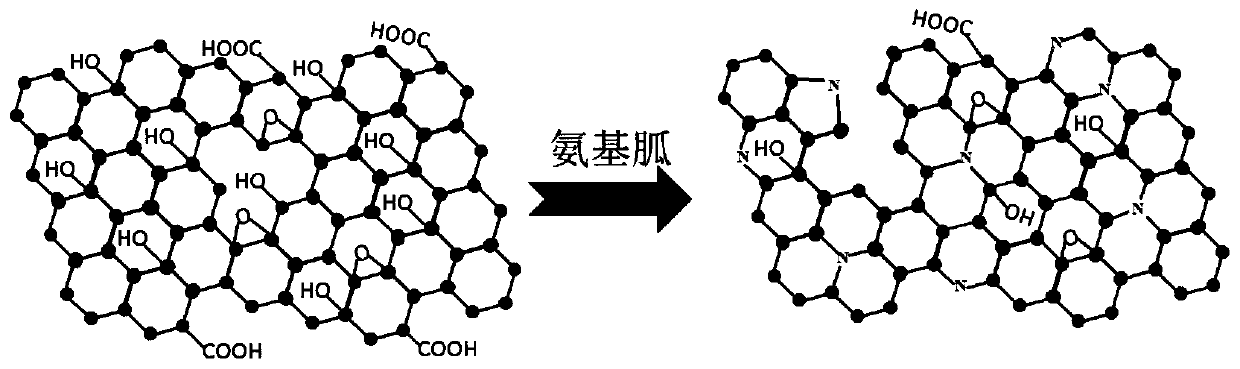

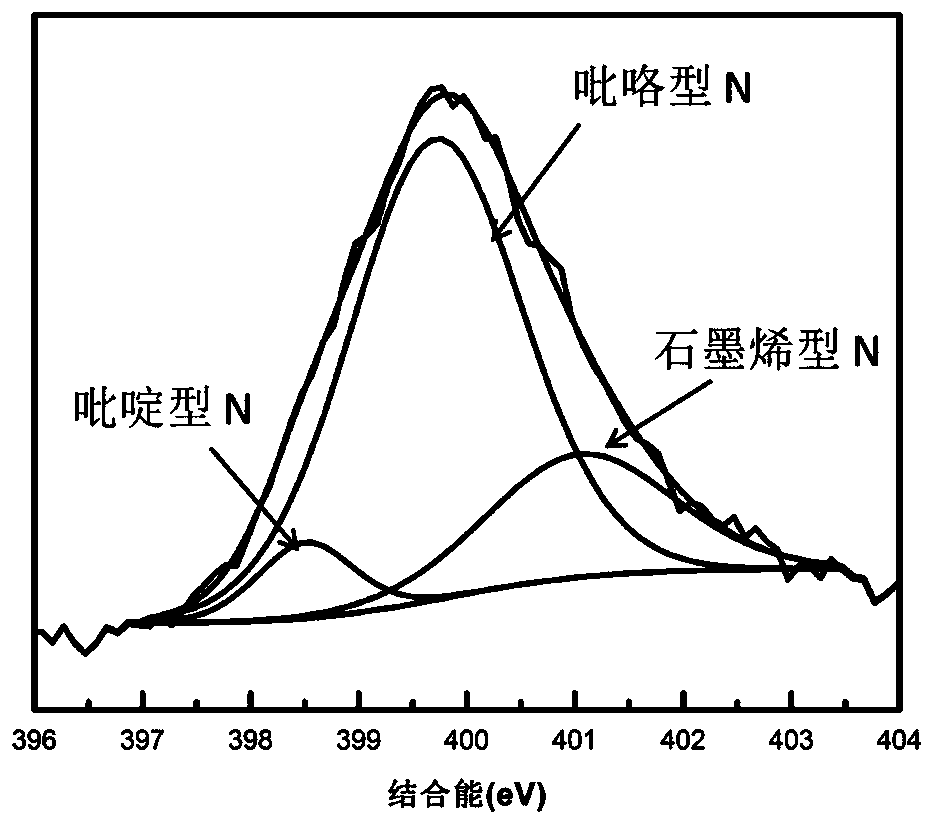

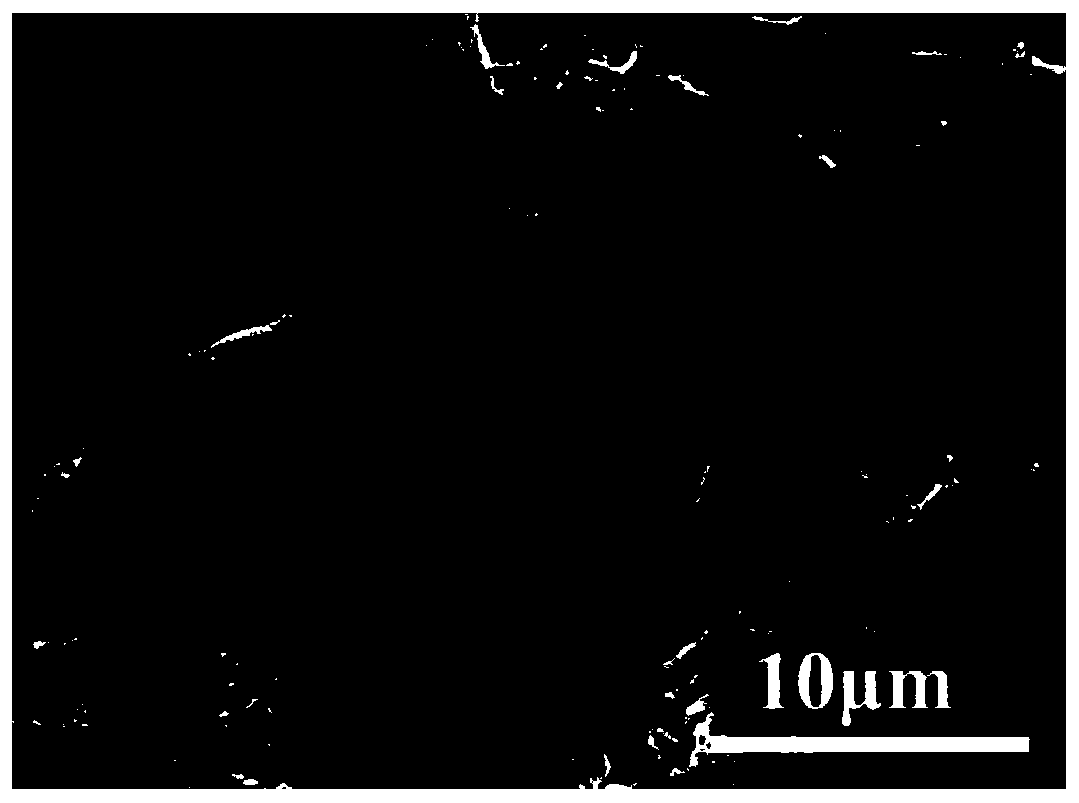

High-specific-capacitance bacterial cellulose-based flexible nitrogen-doped graphene supercapacitor electrode material and preparation method and application thereof

ActiveCN110289173AImprove conductivityLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceIce water

The invention relates to a high-specific-capacitance bacterial cellulose-based flexible nitrogen-doped graphene supercapacitor electrode material and a preparation method and application thereof. The preparation method comprises the following steps: adding a nitrogen source into graphene oxide dispersion liquid, and carrying out hydrothermal reaction to prepare nitrogen-doped reduced graphene oxide; adding a Py monomer and p-toluenesulfonic acid into the BC suspension, and performing uniform dispersing; adding a ferric chloride aqueous solution into the Py / BC suspension in an ice-water bath, and carrying out in-situ polymerization to form a PPy / BC suspension; adding the nitrogen-doped reduced graphene oxide dispersion liquid into the PPy / BC suspension liquid, and performing continuous reacting to obtain PPy / BC / N-rGO suspension liquid, and carrying out suction filtration and drying to obtain the high-specific-capacitance bacterial cellulose-based flexible nitrogen-doped graphene supercapacitor electrode material. The material provided by the invention has high specific capacity of 605F / g at most under the current density of 1A / g, shows good electrochemical performances, and also has the characteristics of high strength and flexibility.

Owner:SHAANXI UNIV OF SCI & TECH

Method and application for extracting iron and aluminum in red mud to prepare absorbent

InactiveCN106111051ADeepen resource utilizationReduce manufacturing costOther chemical processesWater contaminantsSorbentRed mud

The invention relates to a method and application for extracting iron and aluminum in red mud to prepare an absorbent with an aim to solve the problem that low cost and high adsorption capacity cannot be combined with an existing fluorine ion removal method. The method includes 1), acid leaching of the red mud, namely using diluted hydrochloric acid to leach the iron and aluminum from the red mud; 2), subjecting the iron and aluminum to separation and purification, adding sodium hydroxide into a leaching agent, generating sediment and subjecting to solid-liquid separation, adding the diluted hydrochloric acid into the sediment to obtain a ferric chloride solution, and subjecting the ferric chloride solution to evaporation concentration and cooling crystallization to obtain iron chloride hexahydrate; adding the diluted hydrochloric acid in supernate to obtain an aluminum chloride solution, and subjecting the aluminum chloride solution to evaporation concentration and cooling crystallization to obtain aluminum chloride hexahydrate; 3), preparation of the absorbent, namely taking ferric trichloride and aluminum trichloride obtained in the red mud as main materials and adjusting pH (potential of hydrogen) with a coprecipitation method under the room temperature to obtain sediment which is subjected to washing, drying and grinding to obtain the absorbent. The absorbent prepared with the method is applied to removal of fluorinion in water.

Owner:HEILONGJIANG UNIV

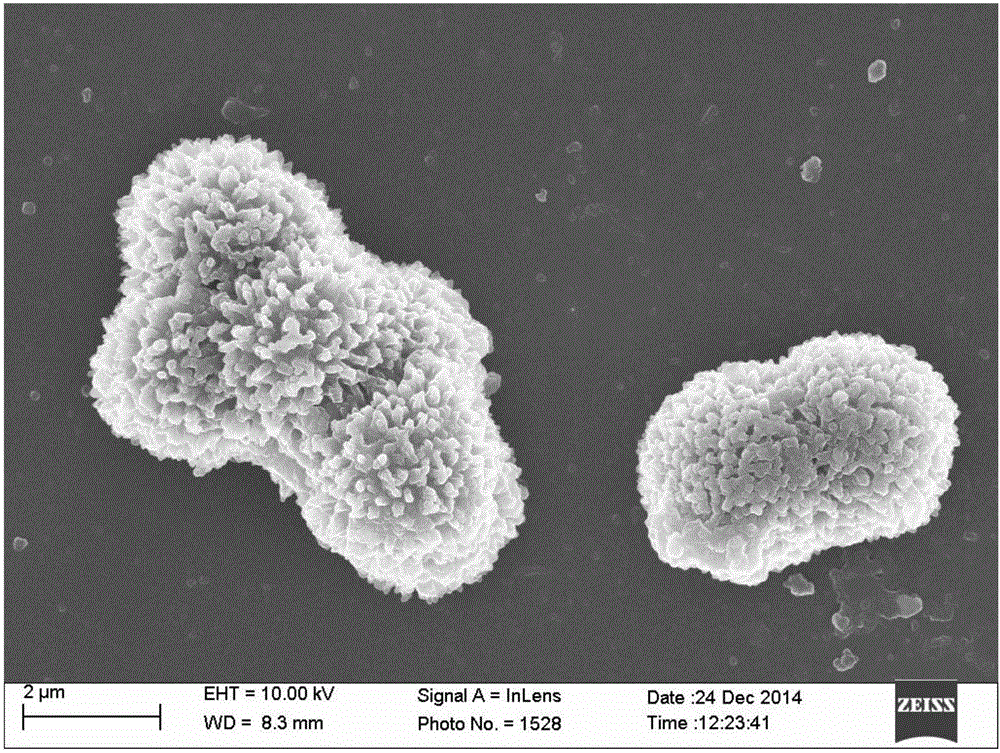

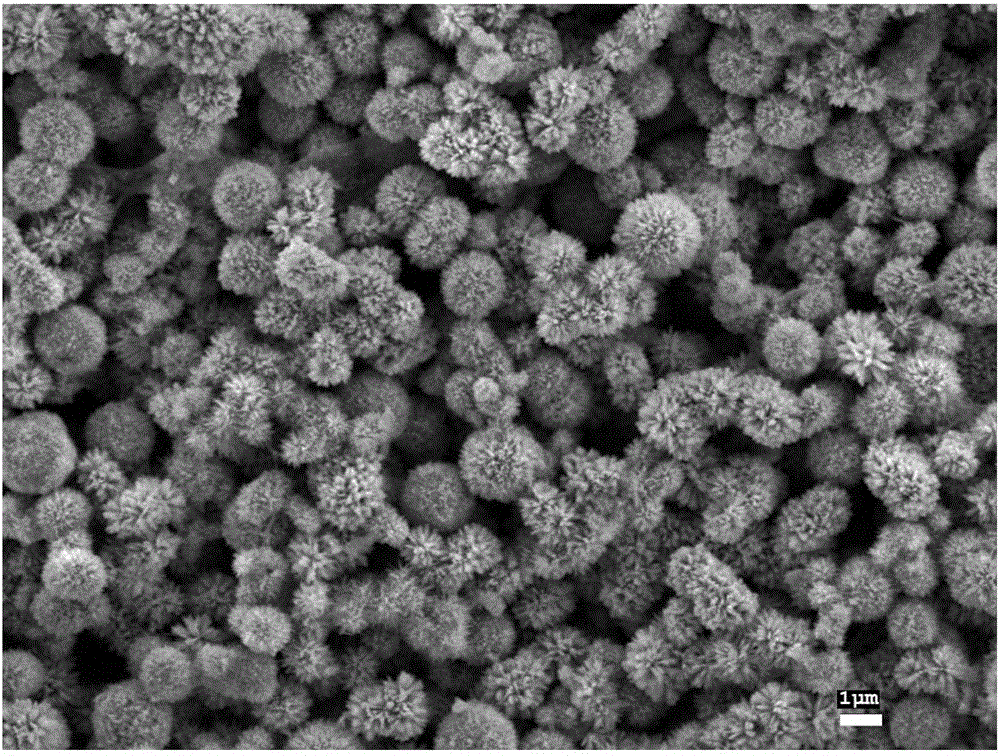

Porous sea-urchin-shaped Fe3O4@C composite material and preparation method thereof

InactiveCN106430327AGood dispersionNoveltyOther chemical processesFerroso-ferric oxidesDispersityPorosity

The invention belongs to the technical field of semiconductor composite nano material preparation and relates to a porous sea-urchin-shaped Fe3O4@C composite material and a preparation method thereof. The preparation method includes the steps of a, dissolving ferric chloride into ethylene glycol, and stirring to form a ferric chloride solution; b, adding diethylenetriamine into the ferric chloride solution, and stirring to obtain a mixed solution; c, adding the mixed solution obtained in the step b into a reaction kettle, heating to a certain temperature, and performing reaction for a certain period of time to form a precursor; d, calcining the precursor obtained in the step c under an inert gas or vacuum environment to obtain the porous sea-urchin-shaped Fe3O4@C composite material. The preparation method has the advantages that the method is simple in process, low in equipment requirement and high in controllable degree; the porous sea-urchin-shaped Fe3O4@C composite material is prepared by reasonable process control, the prepared sea-urchin-shaped Fe3O4@C is even in size, good in dispersity and novel in morphology, a spherical structure comprises through holes, and the porous sea-urchin-shaped Fe3O4@C composite material is good in porosity, large in specific surface area, good in absorption performance, high in heavy metal ion absorption ability and widely applicable to energy and environment protection industry.

Owner:南通特雷斯金属制品有限公司

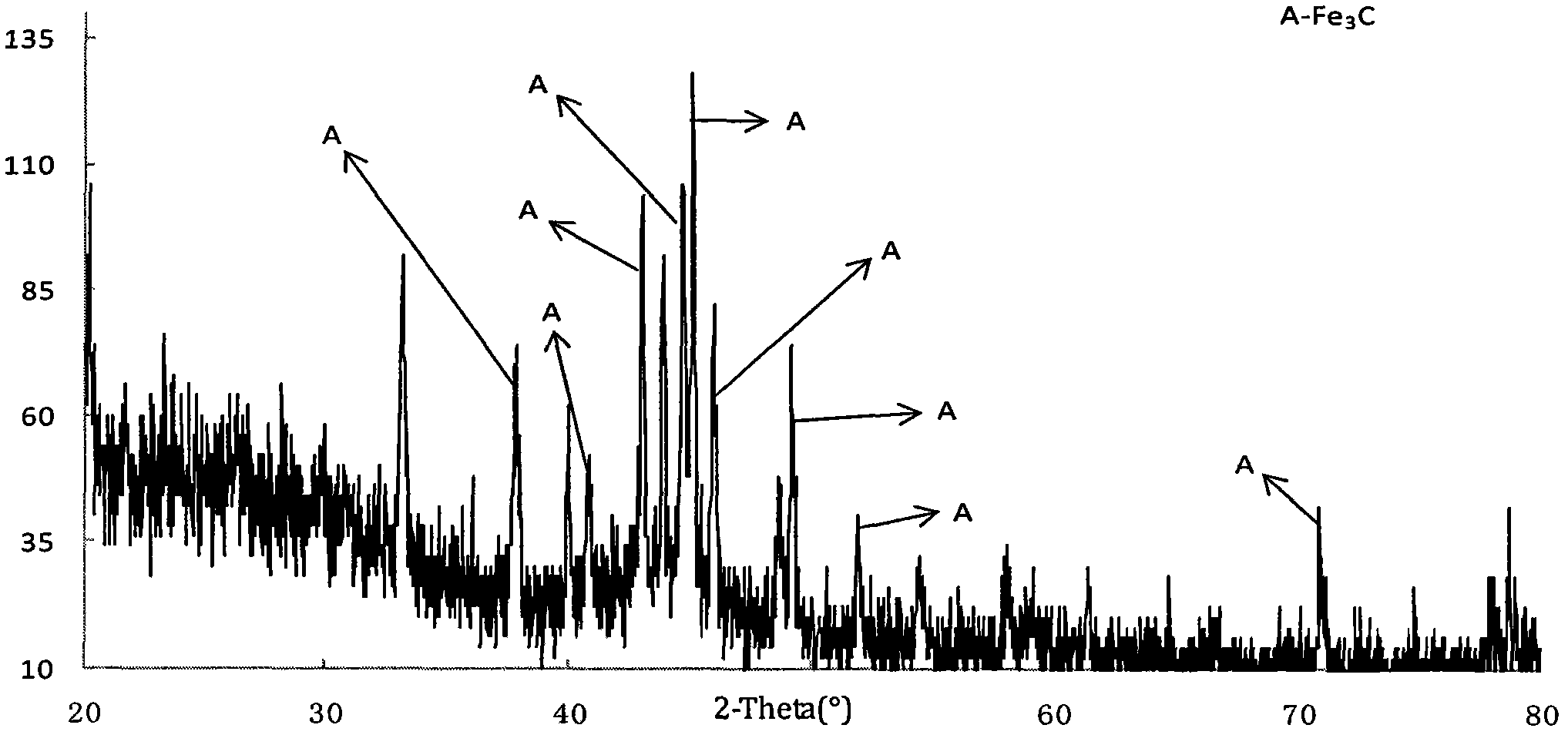

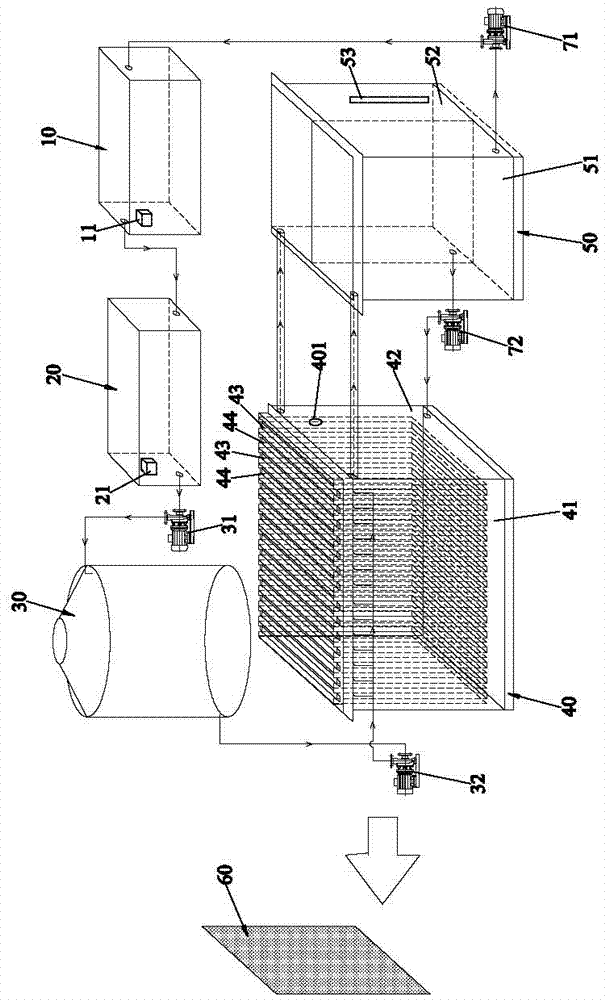

Copper, nickel and chromium-containing ferric chloride etching solution regeneration and reusing device and method

PendingCN107059011AImprove stabilityReduce concentrationPhotography auxillary processesElectrodesElectrolysisIron(III) chloride

The invention discloses a copper, nickel and chromium-containing ferric chloride etching solution regeneration and reusing device and method. The device comprises an etching machine, a waste liquor collection tank, a waste liquor storage tank, an ion film electrolyser and a circulating tank. The ion film electrolyser comprises an anode area and a cathode area. The circulating tank comprises an anode circulating tank and a cathode circulating tank. Anode liquor and cathode liquor which are electrolyzed in the ion film electrolyser flow into the anode circulating tank and the cathode circulating tank correspondingly. The anode liquor in the anode circulating tank is pumped into the etching machine by a first high-pressure pump. The cathode liquor in the cathode circulating tank is subjected to temperature regulation and then is pumped into the cathode area of the ion film electrolyser by a second high-pressure pump to form a cycle. The process is an online regeneration process. The concentrations of copper, nickel and chromium ions of the regenerated ferric chloride etching solution are reduced. The oxidation-reduction potential meets the requirement. The regenerated ferric chloride etching solution can be cyclically used. Recycled copper, nickel and chromium alloy can be sold directly. Economic benefits are remarkable.

Owner:广东三才环保科技有限公司

Three-dimensional nitrogen-doped foam composite electrode material and preparation method thereof

InactiveCN108400023ALarge specific surface areaPromote circulationHybrid capacitor electrodesHybrid/EDL manufacturePolymer scienceNew energy

The invention belongs to the technical field of the storage material preparation, specifically a three-dimensional nitrogen-doped foam composite electrode material and preparation method thereof. Thepreparation method comprises the following steps: firstly adding ferric chloride and hydrochloric acid into deionized water, and sufficiently mixing; immersing the melamine foam (MS) into the mixture,and then adding a certain amount of phenylamine monomer, stirring for 10-24h at 20-90 DEG C, washing and drying to obtain a product; and finally calcining the obtained product, namely obtaining the three-dimensional nitrogen-doped foam composite electrode material. Through the composite electrode material disclosed by the invention, the preparation method is simple and reliable, low in cost and environment-friendly. The obtained nitrogen-doped foam composite electrode material is large in specific surface area and excellent in cycle performance; the surface charge storage is fast in reactiondue to the nitrogen doping, and the material is the ideal new energy material, and can be used as the electrode material.

Owner:SHANGHAI INST OF TECH

Preparation and application of nano metal-organic framework material PCN-223 based on porphyrin ligand

InactiveCN106432366AGood release effectNano particle size is smallOrganic active ingredientsIron group organic compounds without C-metal linkagesIron(III) chloridePorphyrin

The invention provides preparation and application of nano metal-organic framework material PCN-223 based on porphyrin ligand. The invention relates to a preparation method and application of a metal-organic framework material. The invention aims at solving the problems that an existing carrier material used for loading a medicine 5-fluorouracil is poor in drug carrying performance and drug release performance. The preparation comprises the following steps of I, the synthesis of 5,10,15,20-tetra(4-methoxycarbonylphenyl)porphyrin; II, the synthesis of [5,10,15,20-tetra(4-methoxycarbonylphenyl)porphyrin] ferric chloride; III, the synthesis of organic ligand Fe(III)-TCPPCl; IV, the synthesis of the nano metal-organic framework material PCN-223. The maximum drug carrying amount of the nano metal-organic framework material PCN-223 prepared by the invention can reach 0.344g / g. The release performance of the medicine is also higher; the release rate can reach 90 percent. The convenience is provided for loading different medicines.

Owner:HARBIN UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com