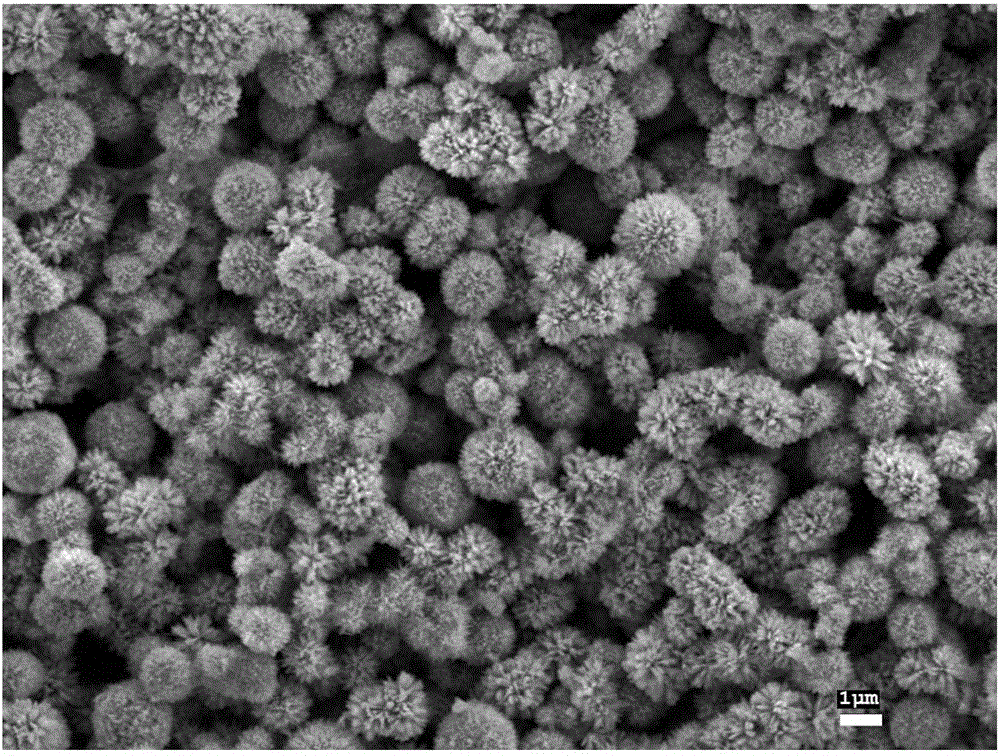

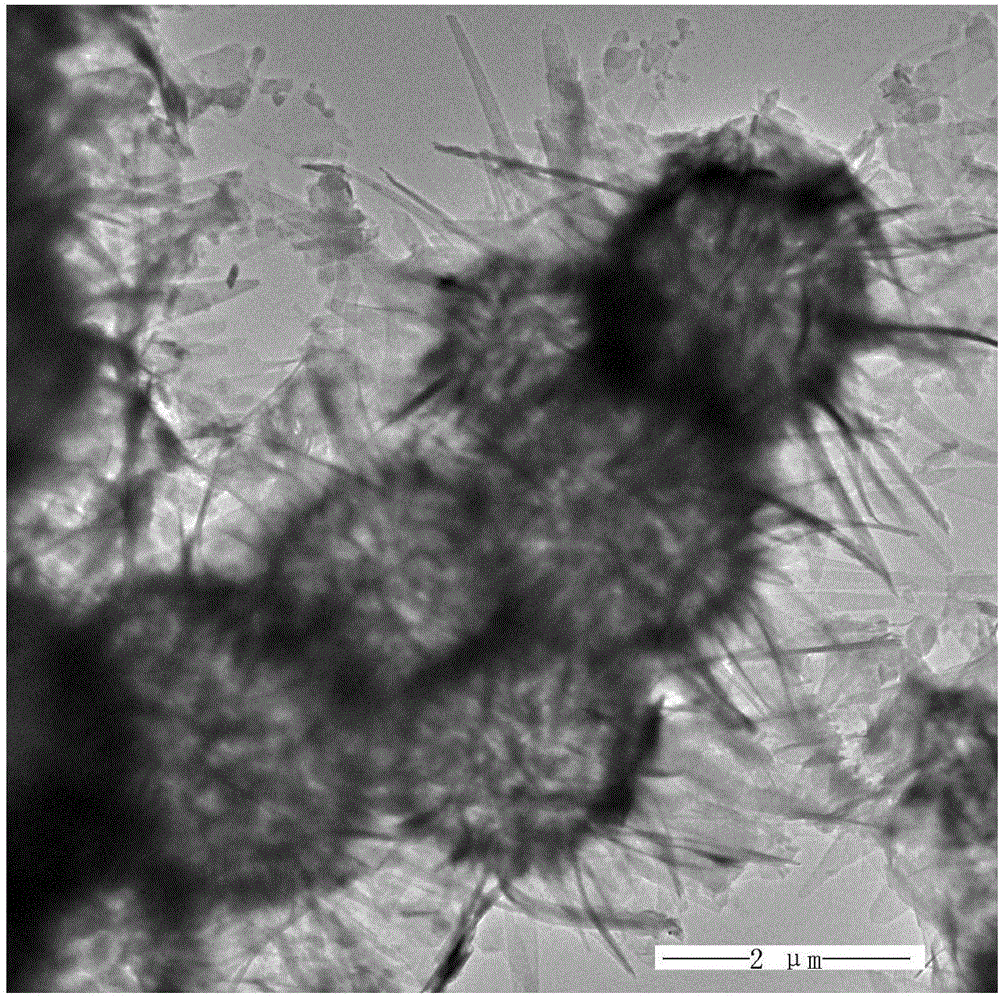

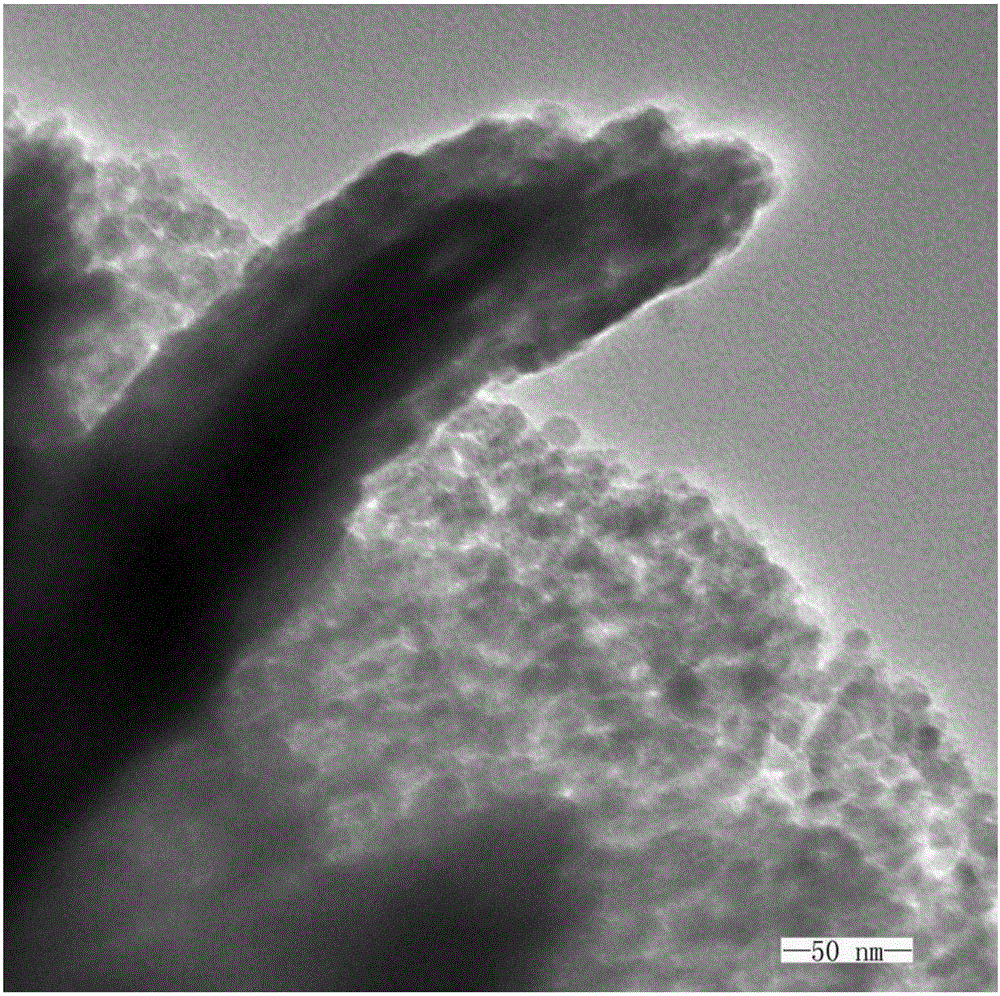

Porous sea-urchin-shaped Fe3O4@C composite material and preparation method thereof

A composite material and sea urchin-like technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of adsorption, low separation, unsuitability for mass production, and limitation of practical application, etc. Novelty, low equipment requirements, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A porous urchin-like Fe 3 o 4 The preparation method of @C composite material, concrete steps are as follows:

[0028] a. Dissolve 0.8g of ferric chloride hexahydrate in 50ml of ethylene glycol and stir for 40 minutes to form ferric chloride solution. The concentration of ferric chloride solution is 5.93×10 -5 mol / mL;

[0029] b. Add 1 g of diethylenetriamine (DETA) to the ferric chloride solution in step a, and stir for 40 minutes to form a mixed solution; the molar ratio of diethylenetriamine to ferric chloride hexahydrate is 3.02:1.

[0030] c. The mixed solution was added into a tetrafluoroethylene reactor, and the reactor was placed in an incubator. After reacting for 8 hours at 180° C., a black precipitate was obtained.

[0031] d. Process the black precipitate in step c, that is, take it out, centrifuge, wash, and dry to obtain porous sea urchin-like Fe 3 o 4 @C Precursor.

[0032]e. Put the precursor obtained in step d in a tube furnace, feed nitrogen as a...

Embodiment 2

[0034] a kind of Fe 3 o 4 The preparation method of @C porous sea urchin-like core-shell structure, the specific steps are as follows:

[0035] a. Dissolve 0.4g of ferric chloride hexahydrate in 40ml of ethylene glycol and stir for 30 minutes to form a ferric chloride solution with a concentration of 3.70×10 -5 mol / mL;

[0036] b. Add 0.5 g of diethylenetriamine (DETA) to the ferric chloride solution in step a, and stir for 30 minutes to form a mixed solution; the molar ratio of diethylenetriamine to ferric chloride hexahydrate is 3.02:1.

[0037] c. Add the mixed solution into the tetrafluoroethylene reactor, put the reactor into a constant temperature box, and react at 160° C. for 6 hours to obtain a black precipitate.

[0038] d. Process the black precipitate in step c, that is, take it out, centrifuge, wash, and dry to obtain porous sea urchin-like Fe 3 o 4 @C Precursor.

[0039] e. Put the precursor obtained in step d in a tube furnace, feed nitrogen as a protective...

Embodiment 3

[0042] The difference between this embodiment and embodiment 2 is that the amount of ferric chloride changes to 0.8g, and others are identical with embodiment 2, specifically as follows:

[0043] a. Dissolve 0.8g of ferric chloride hexahydrate in 40ml of ethylene glycol and stir for 30 minutes to form a ferric chloride solution with a concentration of 7.41×10 -5 mol / mL;

[0044] b. Add 0.5 g of diethylenetriamine (DETA) to the ferric chloride solution in step a, and stir for 30 minutes to form a mixed solution; the molar ratio of diethylenetriamine to ferric chloride hexahydrate is 1.51:1.

[0045] c. Add the mixed solution into the tetrafluoroethylene reactor, put the reactor into a constant temperature box, and react at 160° C. for 6 hours to obtain a black precipitate.

[0046] d. Process the black precipitate in step c, that is, take it out, centrifuge, wash, and dry to obtain porous sea urchin-like Fe 3 o 4 @C Precursor.

[0047] e. Put the precursor obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com