Patents

Literature

2730 results about "Ferric Compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric oxide, commonly, though not precisely, called rust. Ferric refers to iron-containing materials or compounds. In chemistry the term is reserved for iron with an oxidation number of +3, also denoted iron(III) or Fe3+. On the other hand, ferrous refers to iron with oxidation number of +2, denoted iron(II) or Fe2+.

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

Multifunctional composite absorbing material for purifying water and preparation method thereof

ActiveCN102350298AReduce wasteEfficient removalOther chemical processesWater/sewage treatment bu osmosis/dialysisAcrylic resinCerium

The invention provides a multifunctional composite absorbing material for purifying water and a preparation method thereof, relating to an absorbing material. The invention provides the multifunctional composite absorbing material for purifying water, which can be used for effectively removing a plurality of harmful substances in the water and has higher removal efficiency and lower production cost, and the preparation method thereof. The absorbing material is selected from at least one of absorbing materials A, B and C; the absorbing material A takes a mesoporous adsorption ceramic material as a carrier to load nano metals including nano silver, nano zinc, nano iron and nano cerium; the absorbing material B takes the mesoporous adsorption ceramic material as the carrier to load nano metal oxides including nano titanium dioxide, nano zinc oxide, nano ferric oxide and nano cerium dioxide; and the absorbing material C is prepared from the following raw materials according to the mass ratio: 100-200 parts of active carbon powder, 20-30 parts of polyethylene powder, 10-30 parts of calcium sulfite powder, 10-30 parts of natural zeolite powder, 20-40 parts of macroporous acrylic resin and 10-20 parts of attapulgite powder.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

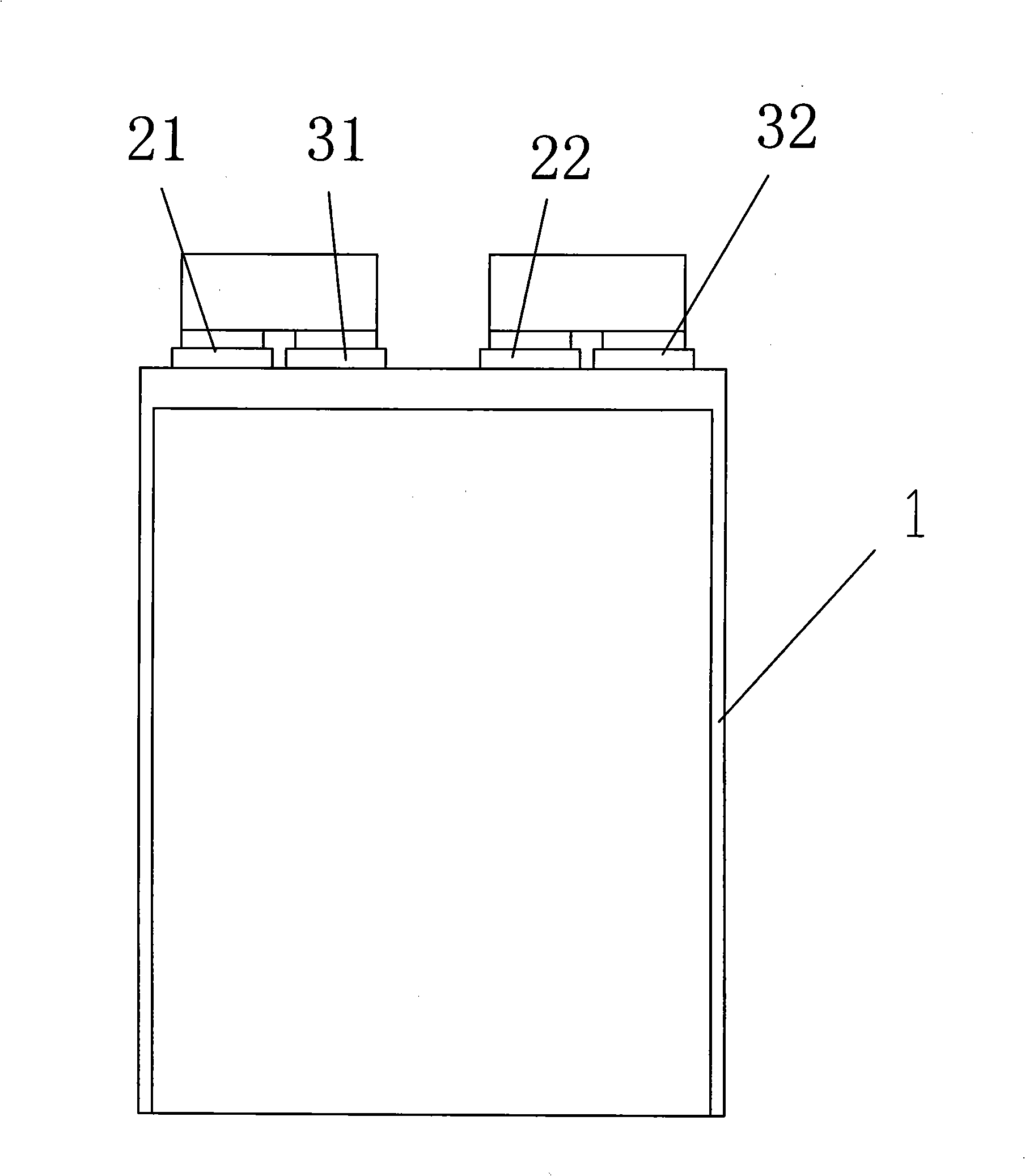

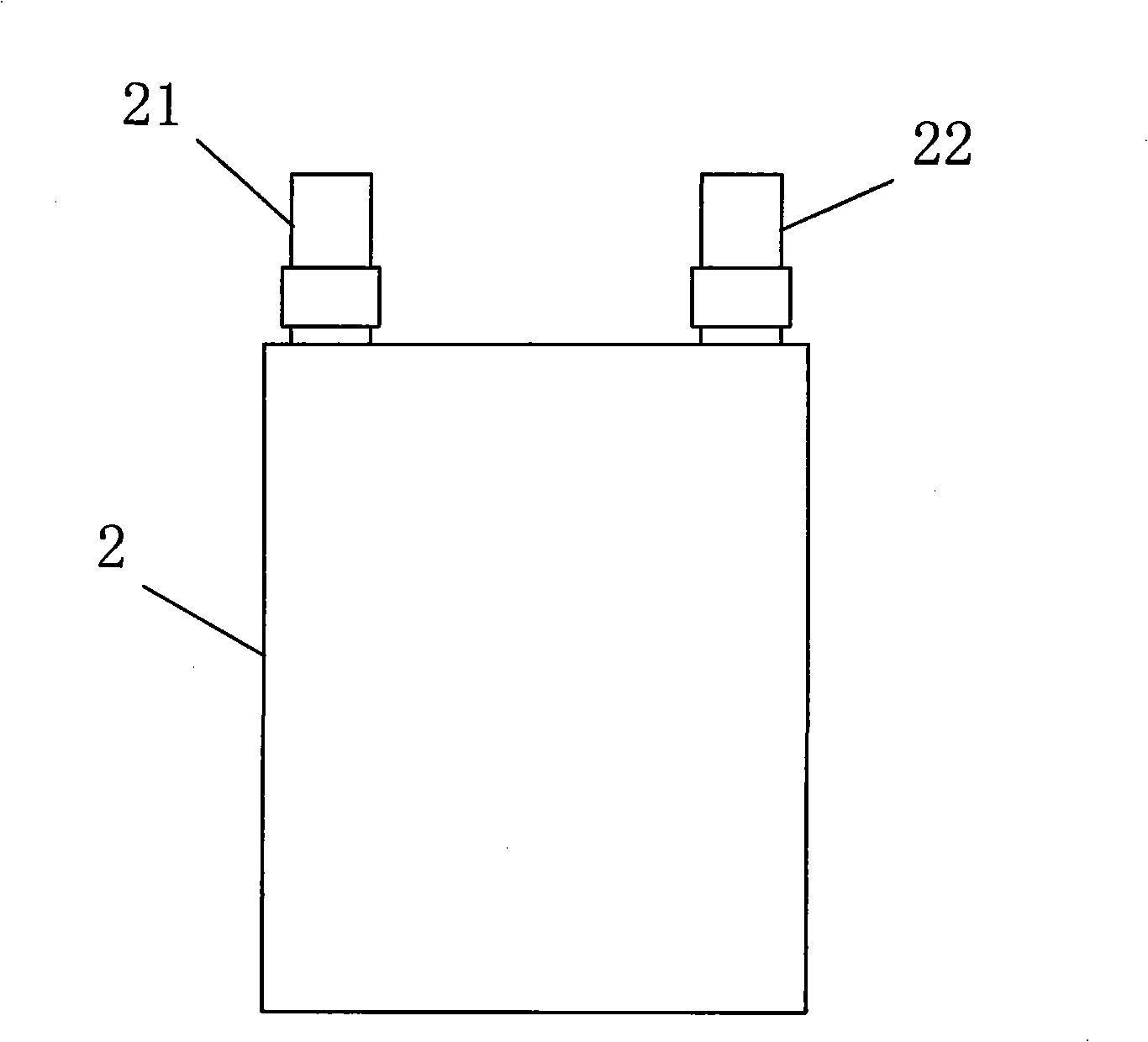

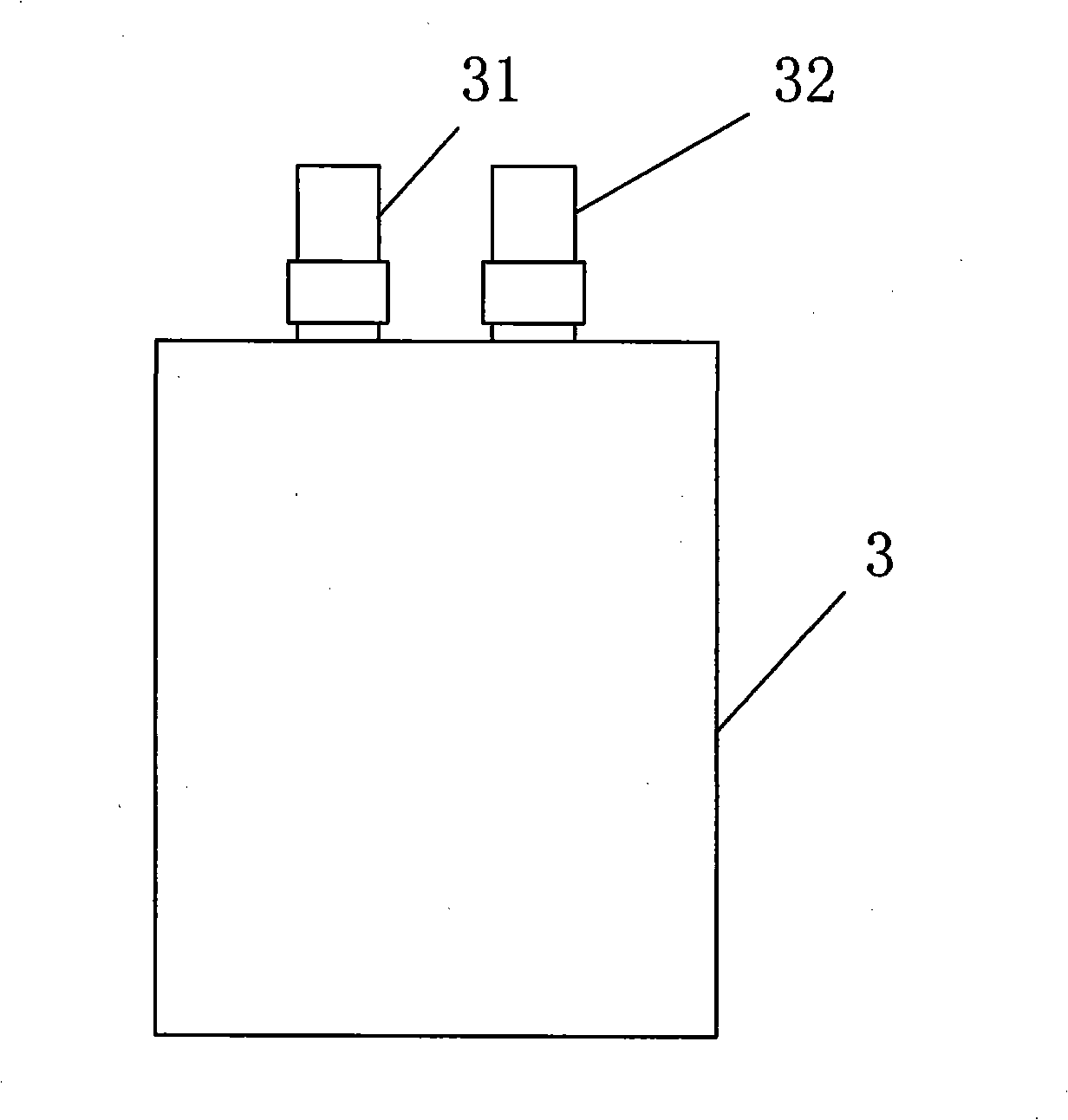

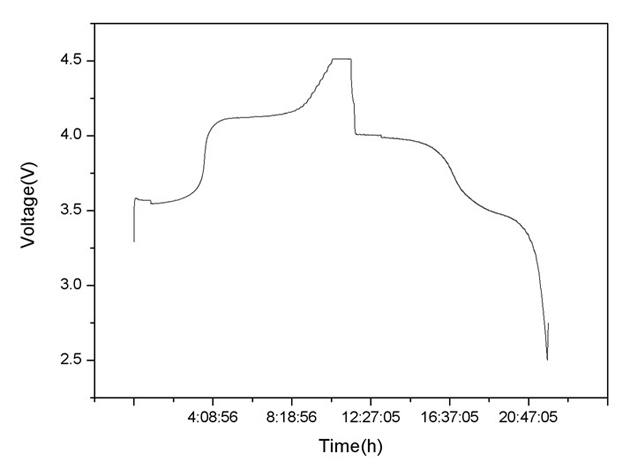

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Process for producing carbon coated iron lithium phosphate

InactiveCN101172599AElectrode manufacturing processesPhosphorus compoundsShortest distancePhosphate ion

The invention relates to a preparation method of lithium iron phosphate for the carbon cladding of a lithium ion battery. The prior lithium iron phosphate preparation technical art is complex, and has high cost. The invention has the synthetic process that: ferric oxide, phosphoric acid, simple organics and doped element compound are mixed and dried, the mol ratio of phosphate radical ion, ferric ion and doped element ion is 1:y:z, wherein, y is larger than or equal to 0.95 and smaller than or equal to 1, and y plus z is equal to 1; the mixture is added with lithium source compound, added with water to be mixed and dried, the mol ratio of lithium ion and phosphate radical ion is x:1, and x is larger than or equal to 0.95 and smaller than or equal to 1.05; the mixture which reacts for 2 to 20 hours under 500 to 800 DEG C is cooled in a furnace. The invention finally produces the precursor uniformly mixed with superfine crystal grain, and during the subsequent high temperature solid phase reaction, the end product lithium iron phosphate can be produced through shorter distance diffuseness of atoms. The end product has high purity, the crystallisation is good, the capacity is high, and the cycle stability is good.

Owner:HANGZHOU DIANZI UNIV

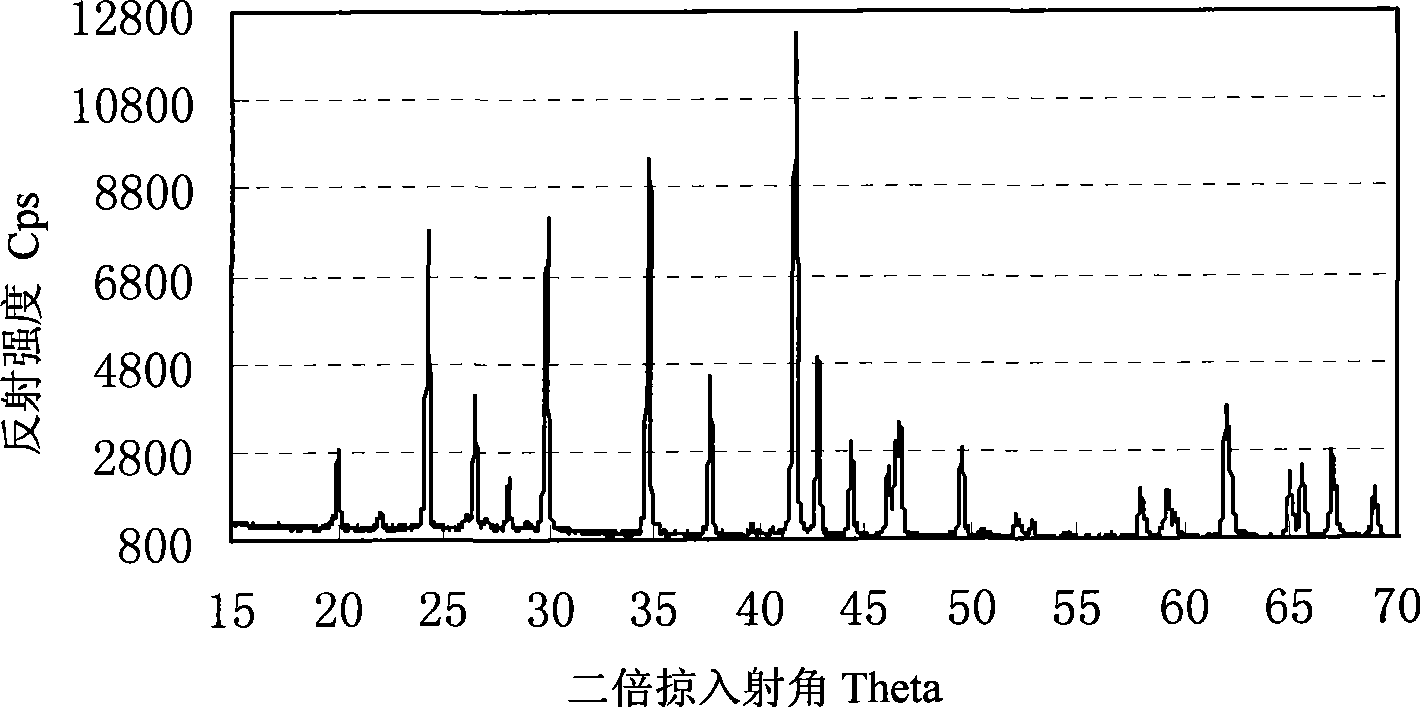

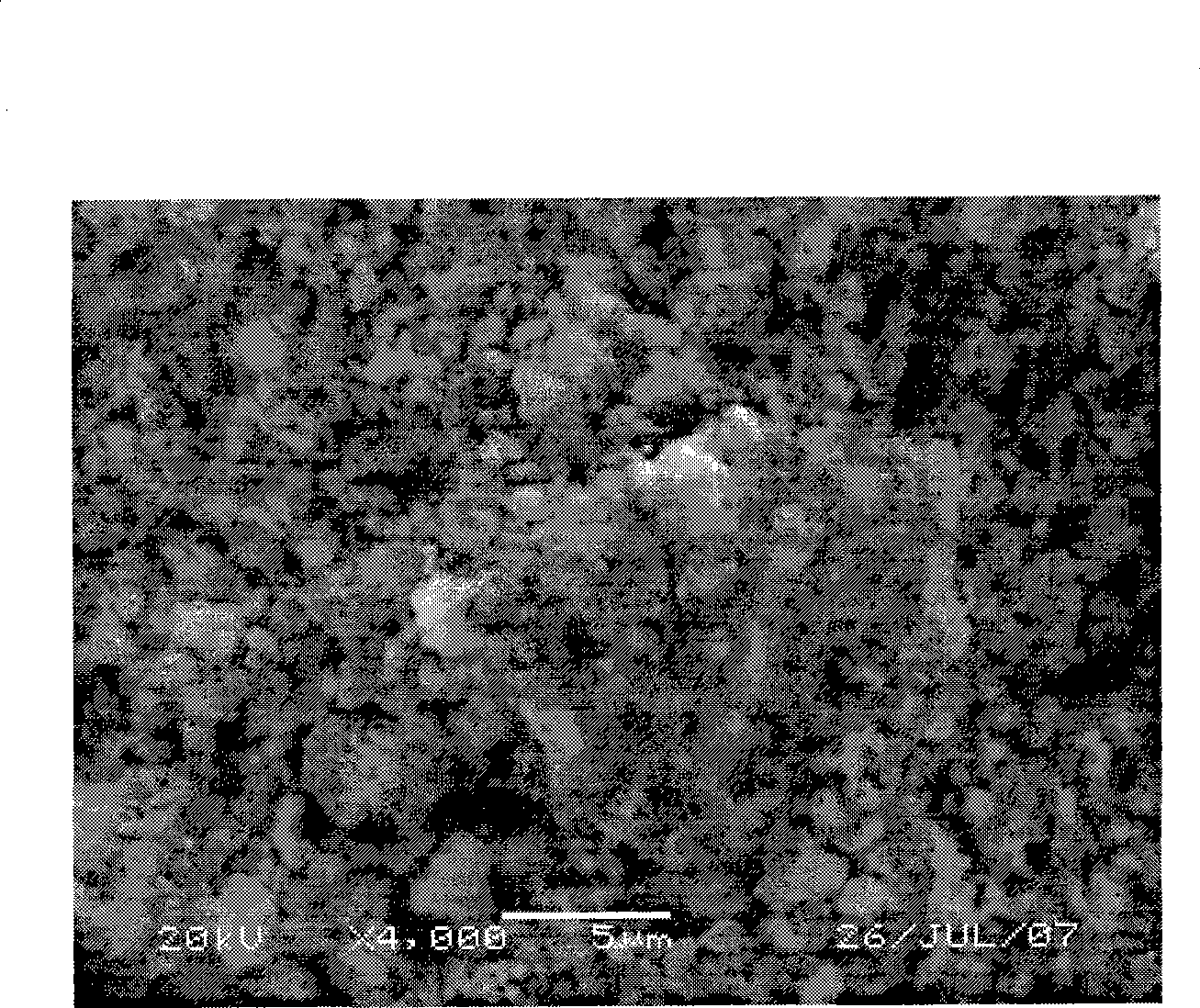

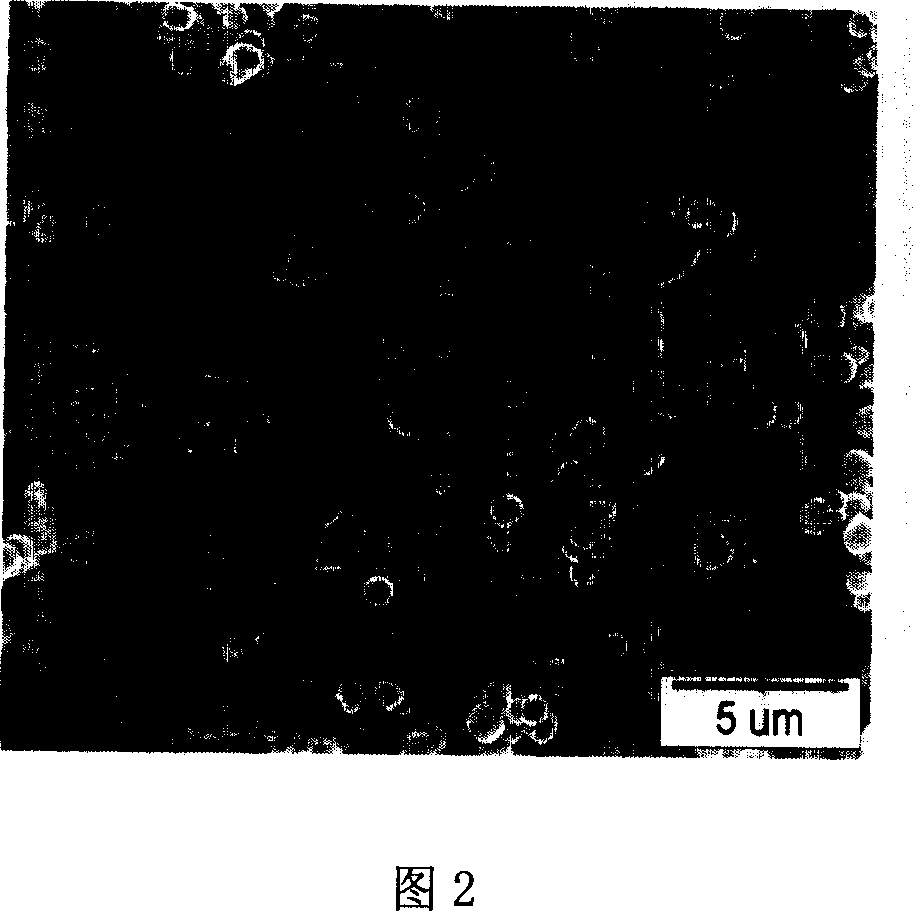

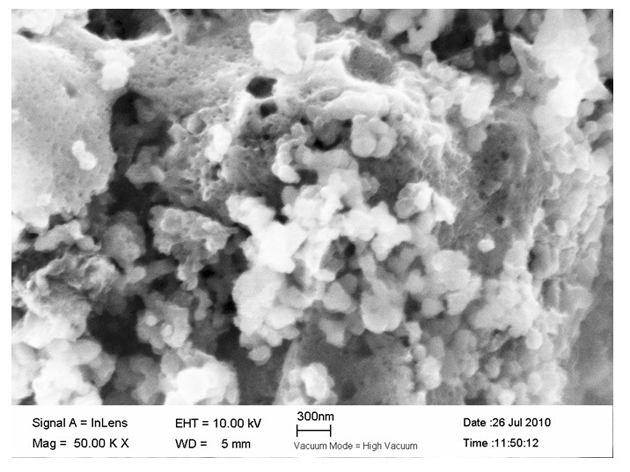

Method for preparing equal dispersion ferric phosphate lithium nano crystal by hydrothermal synthetis method

InactiveCN101047242AExcellent inert environmentElectrode manufacturing processesPhosphateFerrous salts

A method for preparing uniformly scattered nanocrystal of iron-lithium phosphate by hydrothermal synthesis includes using ferrous salt and phosphoric acid as well as lithium hydroxide as raw materials to obtain reaction pioneer matter under temperature of 40-100deg.c first, then reacting on obtained pioneer matter in high pressure reactor with temperature of 150-200deg.c under hydrothermal condition and processing obtained product by high temperature under protection of inert gas to finally obtain said uniformly scattered nanocrystal with average particle diameter of 0.2-0.5micron.

Owner:胜利油田华鑫石油材料有限公司

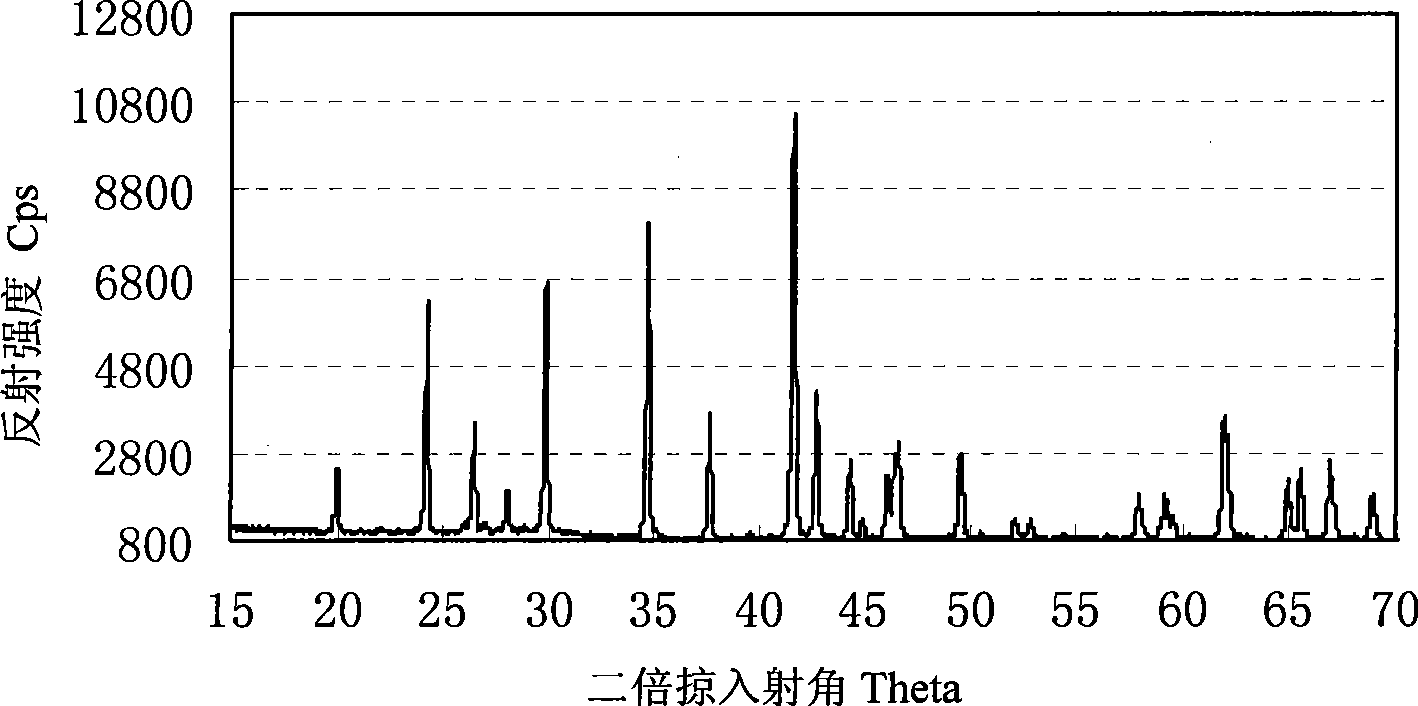

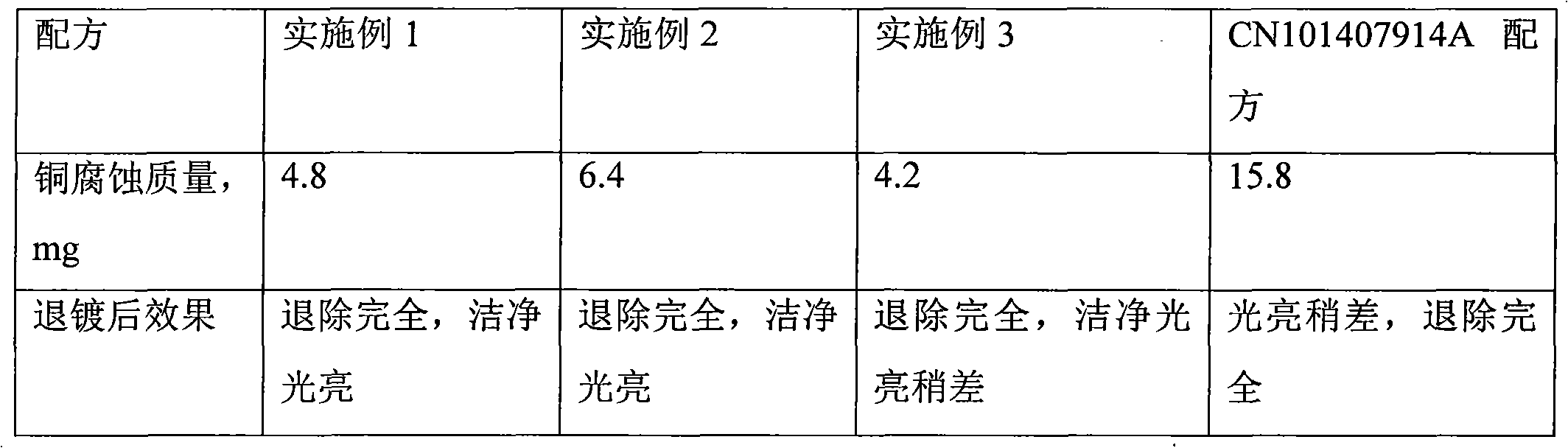

Solder stripping agent and preparation method thereof

InactiveCN101962776AReduce pollutionSolution to short lifeConductive material chemical/electrolytical removalNitric oxideTin

The invention discloses a solder stripping agent, which is prepared from the following components: 500 to 650g / L of 70 percent nitric acid, 50 to 70g / L of hydrochloric acid, 4.3 to 8.6g / L of ferric nitrate or 2.9 to 5.8g / L of ferric trichloride or 4.8 to 9.7g / L of ferric chloride hexahydrate, 0.5 to 25g / L of organic acid complexing agent, 1 to 50g / L of water-soluble organic amine, 1 to 10g / L of organic corrosion inhibitor for copper, 1 to 2g / L of stabilizing agent, 1 to 5g / L of surfactant, and 0.1 to 1g / L of small molecular alcohol. The solder stripping agent can quickly strip solder or solder alloy layers thoroughly, basically cannot generate or generates little salt mist containing nitric oxides in the stripping process, and has the advantages of small silt amount, long service life of stripping solution, no strong corrosion on copper at a bottom layer, bright substrate and the like.

Owner:济南德锡科技有限公司

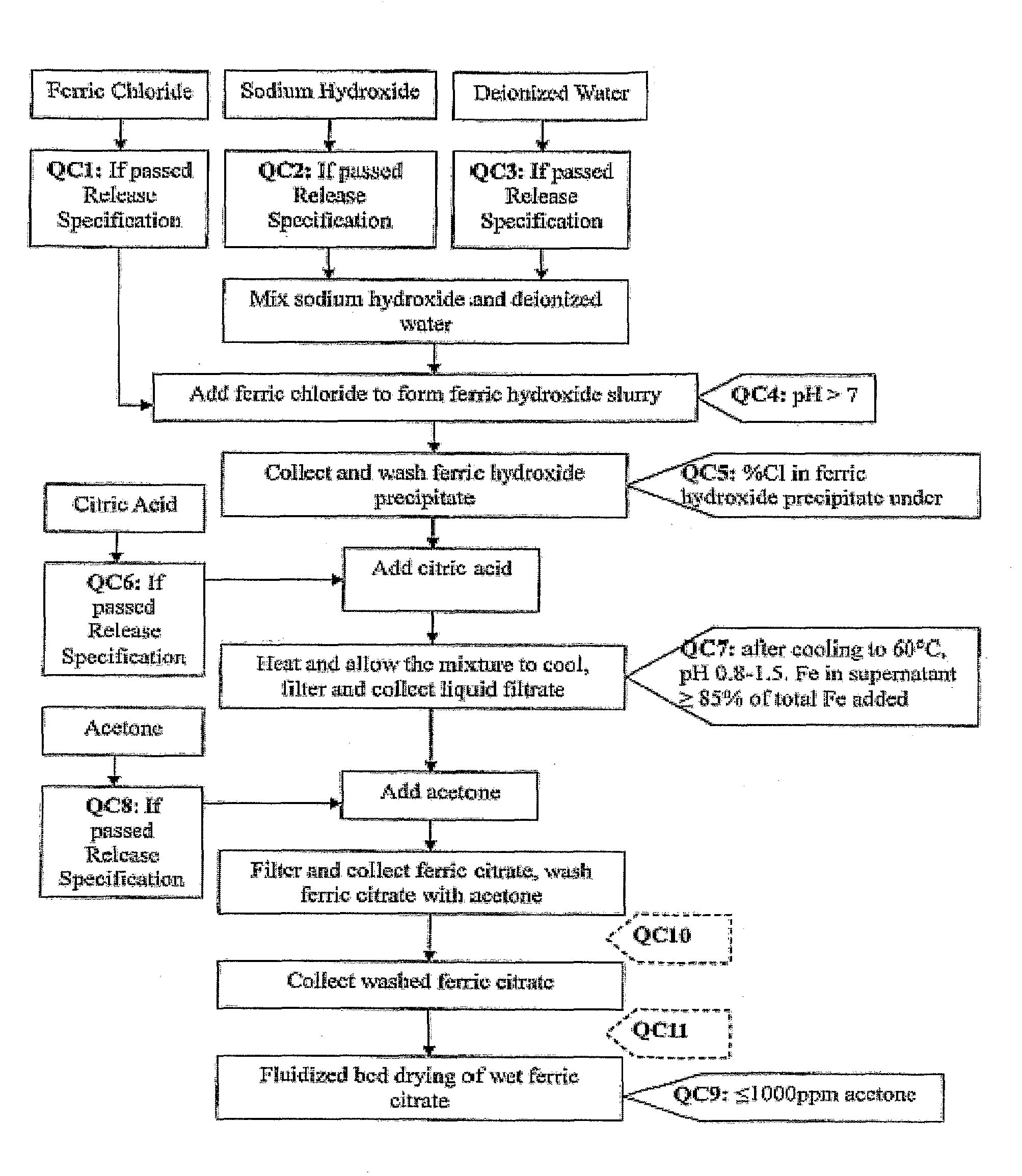

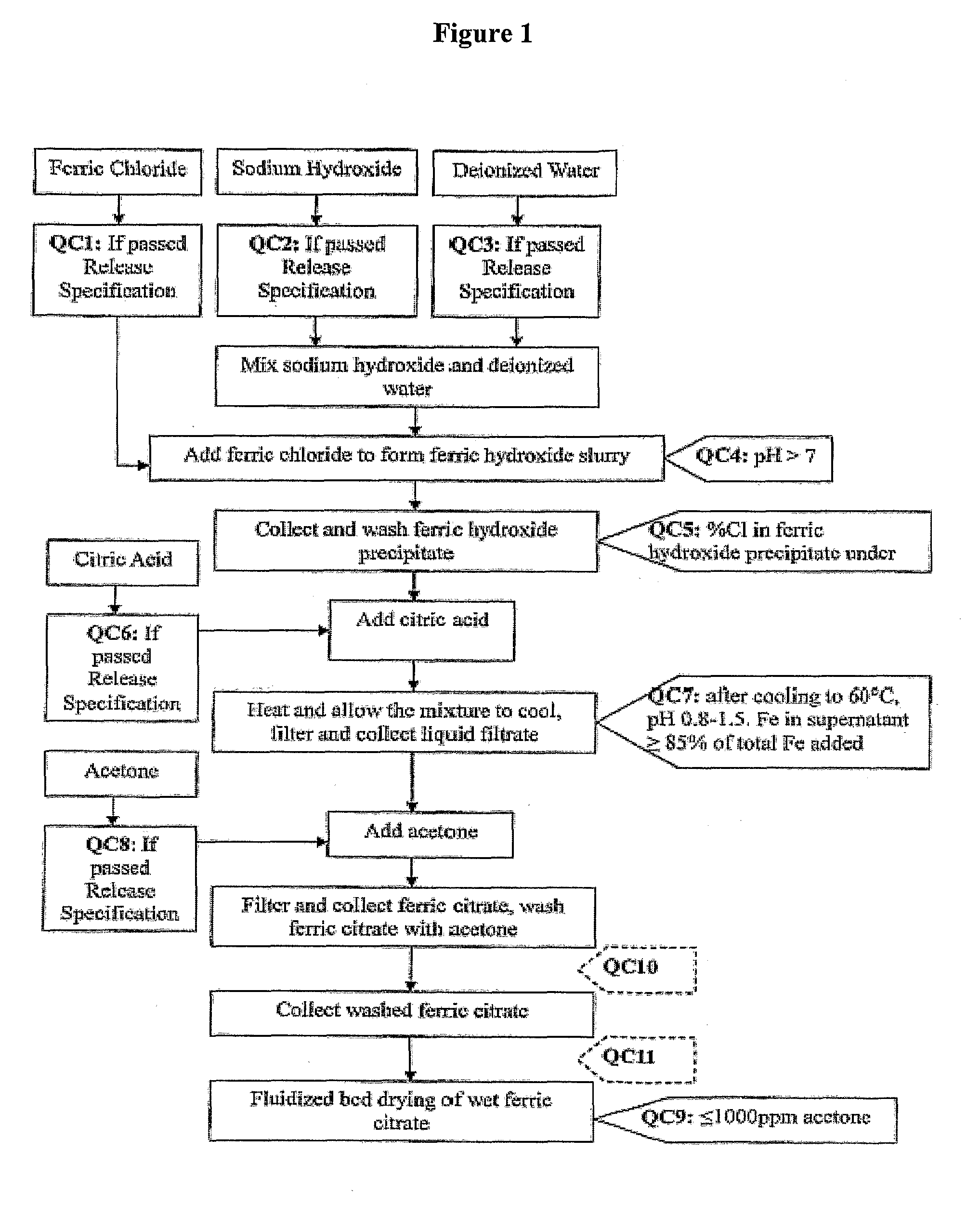

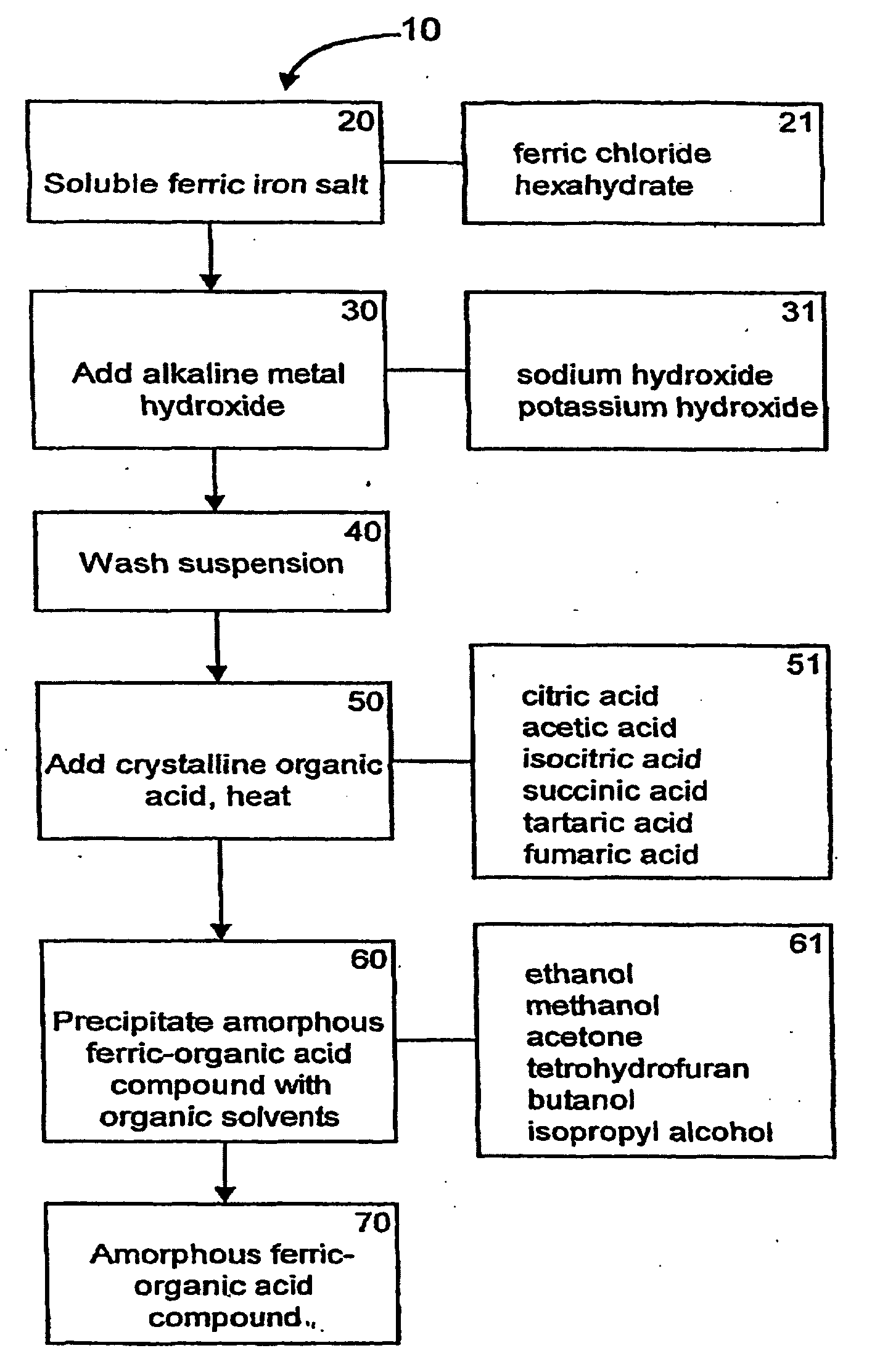

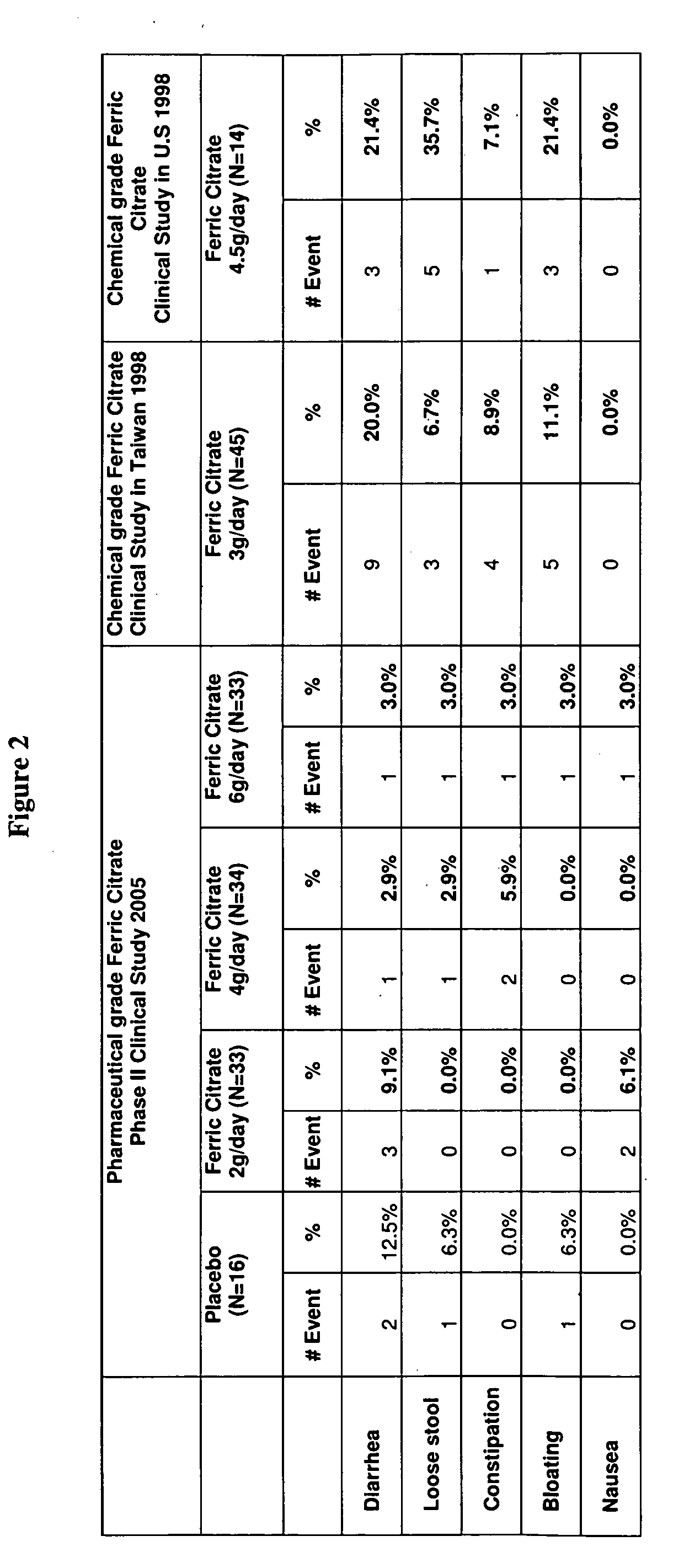

Pharmaceutical-Grade Ferric Organic Compounds, Uses Thereof and Method of Making Same

ActiveUS20080274210A1Long-term administrationHeavy metal active ingredientsOrganic active ingredientsDiseaseSerum phosphate

Owner:PANION & BF BIOTECH INC

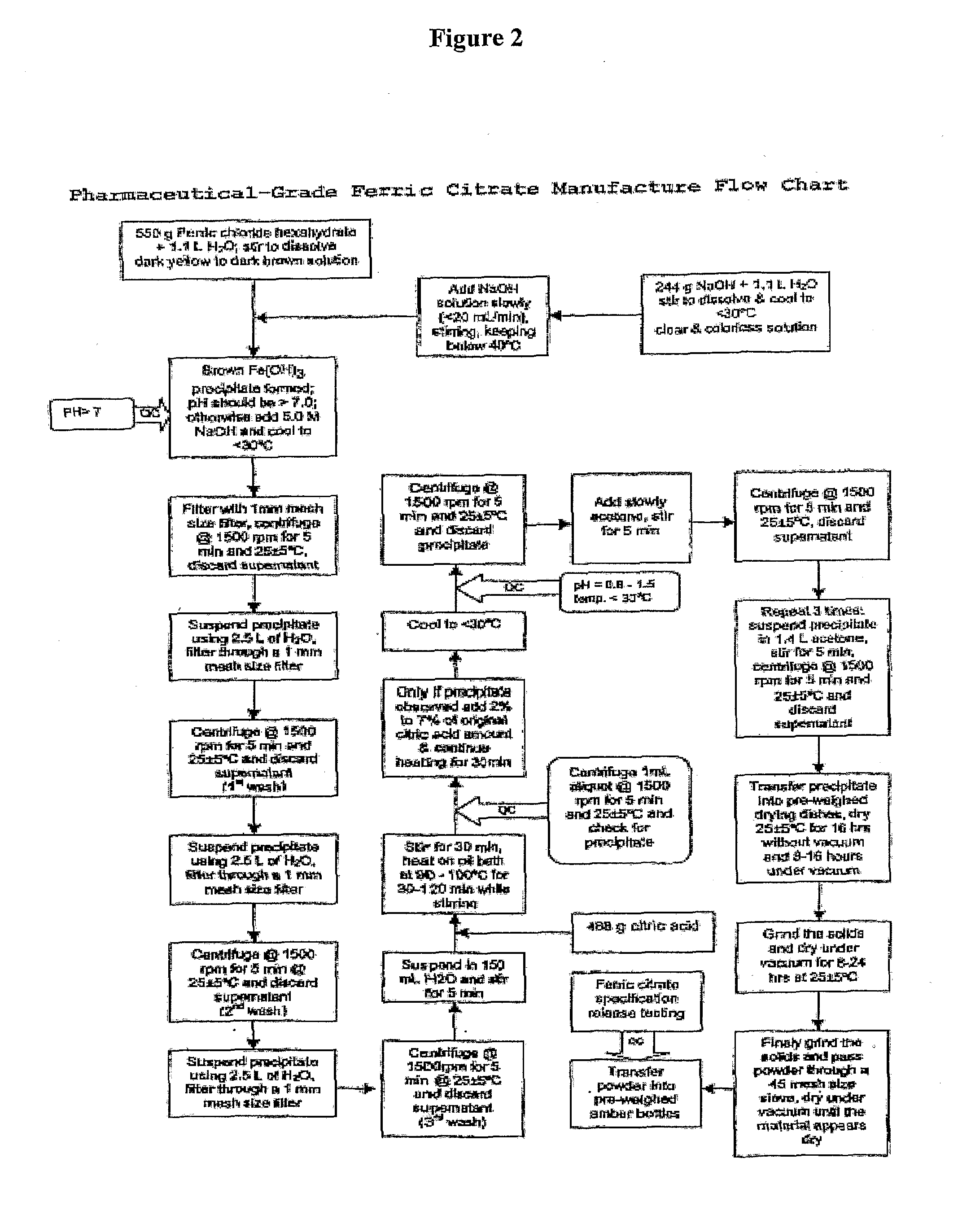

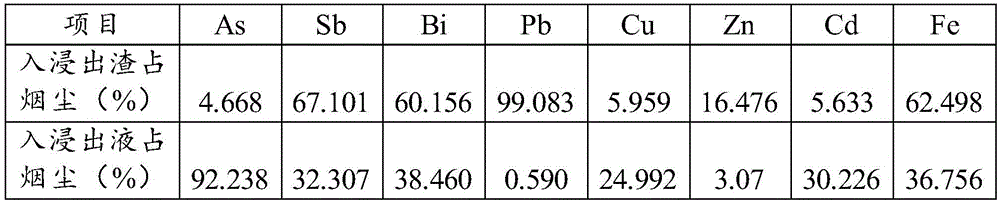

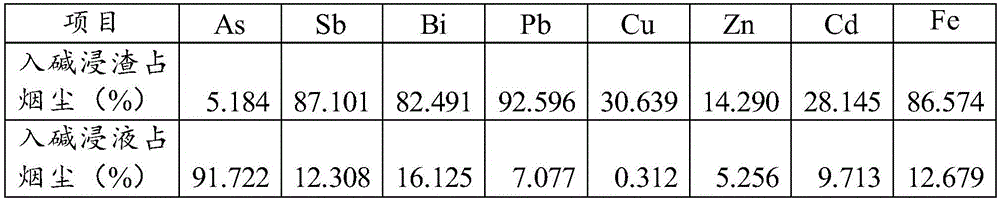

Soot treatment process in copper smelting process

ActiveCN105567983ARealize comprehensive utilizationLow arsenicProcess efficiency improvementArsenateSmelting process

The invention provides a soot treatment process in a copper smelting process. The soot treatment process comprises the following steps: firstly carrying out water leaching on copper smelting soot to obtain a water leaching fluid and water leaching residues; then, carrying out acid leaching on one part of the water leaching residues obtained in the last step to obtain an acid leaching fluid, and carrying out alkali leaching on the other part of the water leaching residues to obtain an alkali leaching fluid; carrying out metal replacement on the acid leaching fluid obtained in the last step to precipitate copper to obtain copper-precipitated filtrate; and finally, neutralizing and oxidizing the copper-precipitated filtrate obtained in the last step and the alkali leaching fluid obtained in the last step to obtain ferric arsenate precipitates and arsenic-precipitated filtrate. The soot treatment process provided by the invention, especially the treatment process for high-arsenic high-copper soot realizes the hazard-free treatment effect of arsenic in the high-arsenic high-copper soot, and comprehensively recycles valuable metal copper, zinc and the like in the high-arsenic high-copper soot, so that gradient recycling and comprehensive utilization of soot impurities are realized.

Owner:YANGGU XIANGGUANG COPPER

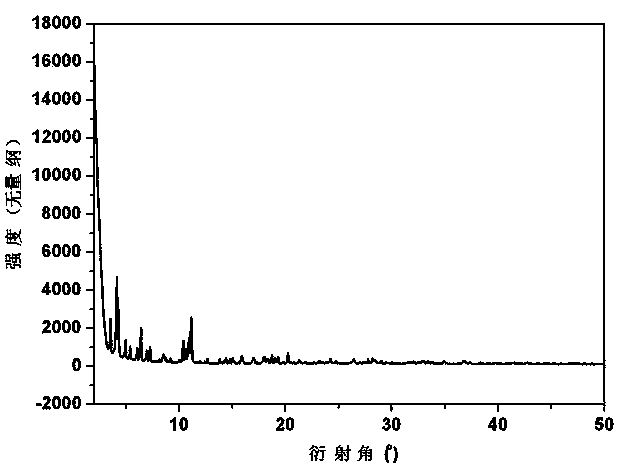

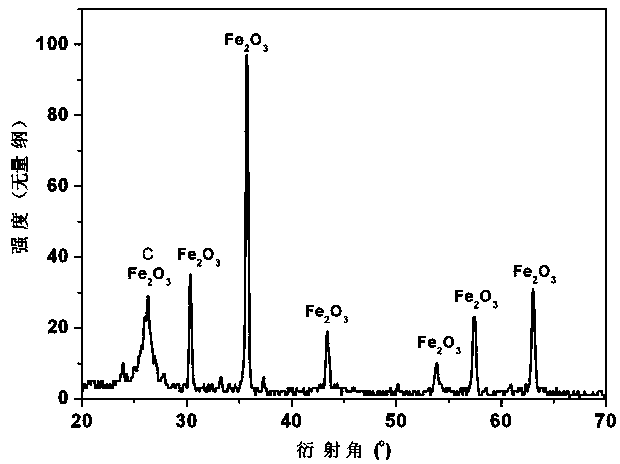

Preparation method of magnetic porous carbon/ ferric oxide nano composite material for oil-water separation

InactiveCN103908947ALarge specific surface areaMacroporous natureOther chemical processesAlkali metal oxides/hydroxidesPorous carbonMetal-organic framework

The invention discloses a preparation method of a magnetic porous carbon / ferric oxide nano composite material for oil-water separation, wherein the magnetic porous carbon / ferric oxide nano composite adsorption material for oil-water separation is porous carbon / Fe3O4 magnetic powder or porous carbon / gamma-Fe2O3 magnetic powder. The preparation method comprises the following steps: firstly, preparing a Fe-MIL-101 or Fe-MIL-100 metal-organic framework material of a porous structure by utilizing a hydrothermal method; then controlling the temperature to be 500-700 DEG C at the N2 / H2 atmosphere or the vacuum state, and forging for 2-8 hours, thereby obtaining the magnetic porous carbon / ferric oxide nano composite adsorption material for oil-water separation. The adsorption material can adsorb oil substances in water well; moreover, adsorption materials dispersed into a solution as well as the adsorbed oil materials can be recycled only by magnets; the preparation method is simple to operate, is low in production cost, is good safety performance, and is high in practicability.

Owner:SHANGHAI INST OF TECH

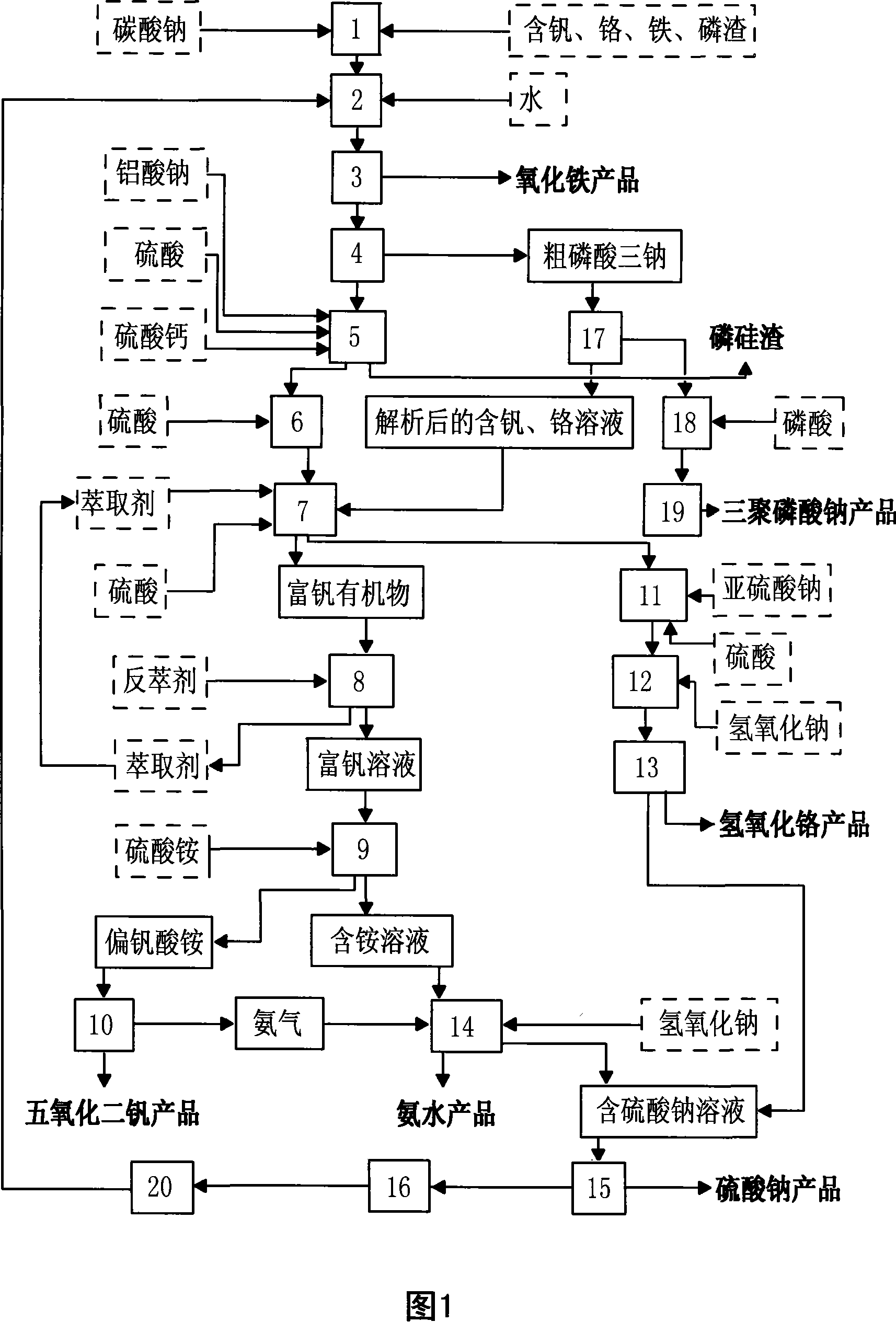

Method of reclaiming chemical industry products by using industrial slag containing vanadium, chromium, iron and phosphorous

ActiveCN101058853ATake advantage ofUsefulRaw phosphate material treatmentProcess efficiency improvementChemical industrySlag

The invention discloses a recovering chemical product method with a V, Cr, Fe and P industrial muck in the chemistry field, which comprises the following steps: roasting raw materials; heating and leaching the clinkers; separating ferric oxide from the solution containing V, Cr, Fe and P; crystallizing the solution in order to removing to P; removing P deeply; removing Si; adjusting the acidity of the solution containing V and Cr; extracting V; extracting V reversely; settling V; roasting metammonium vanadate; reducing Cr; settling chromic hydroxide; separating chromic hydroxide from sodium sulfate; removing NH3; getting sodium sulfate crystallization; purifying sodium sulfate mother liquor; adsorbing V, Cr, tertiary sodium phosphate solution with rough tertiary sodium phosphate refining resin and reacting with phosphoric acid; drying and roasting sodium tripolyphosphate; getting V, Cr, Fe and P from the industrial muck containing V, Cr, Fe and P and separating the secondary product of ammoniacal liquor and sodium sulfate in the heat exchange procedure. The invention saves the energy, which adapts to an industrial appliance.

Owner:辽宁虹京实业有限公司

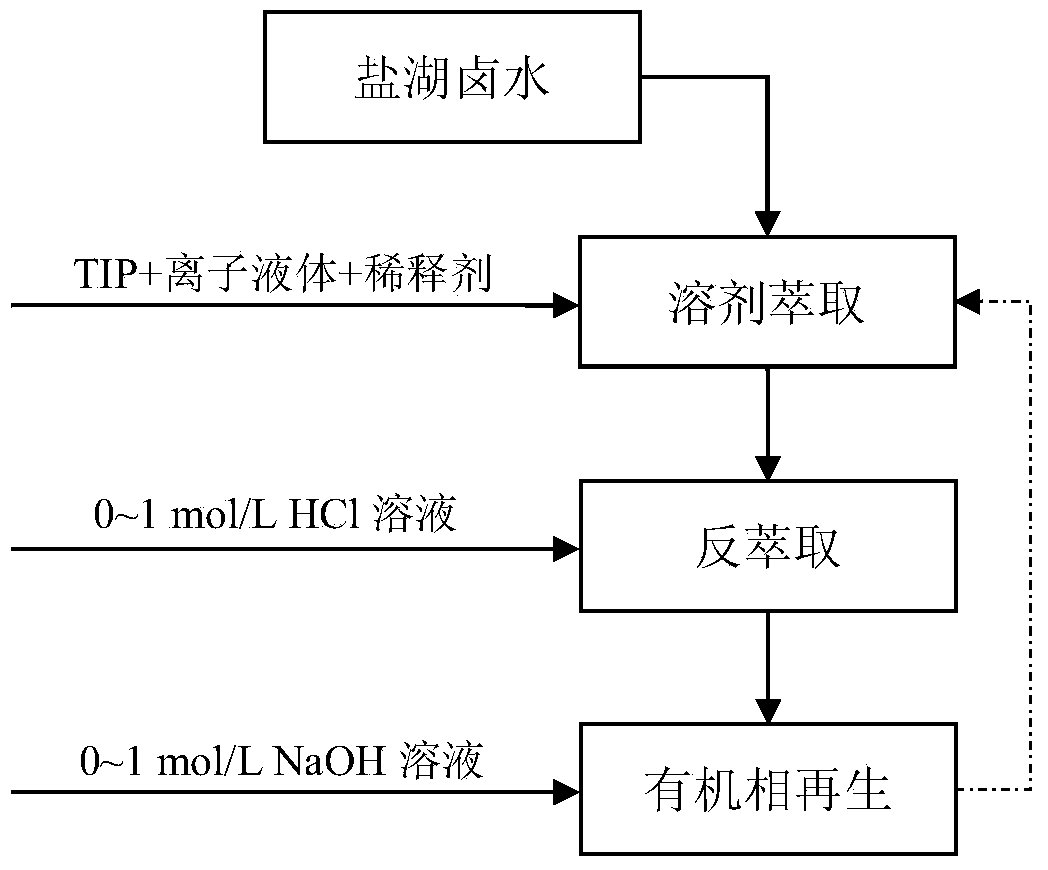

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

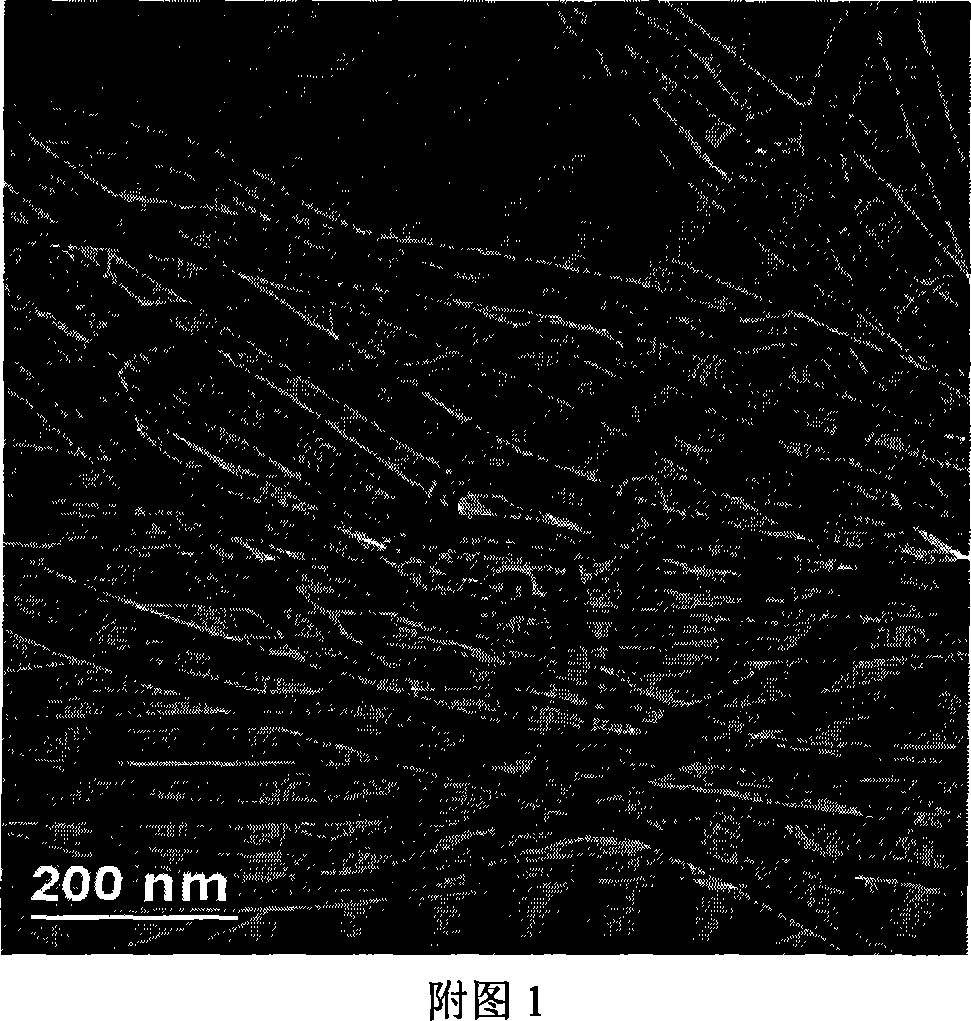

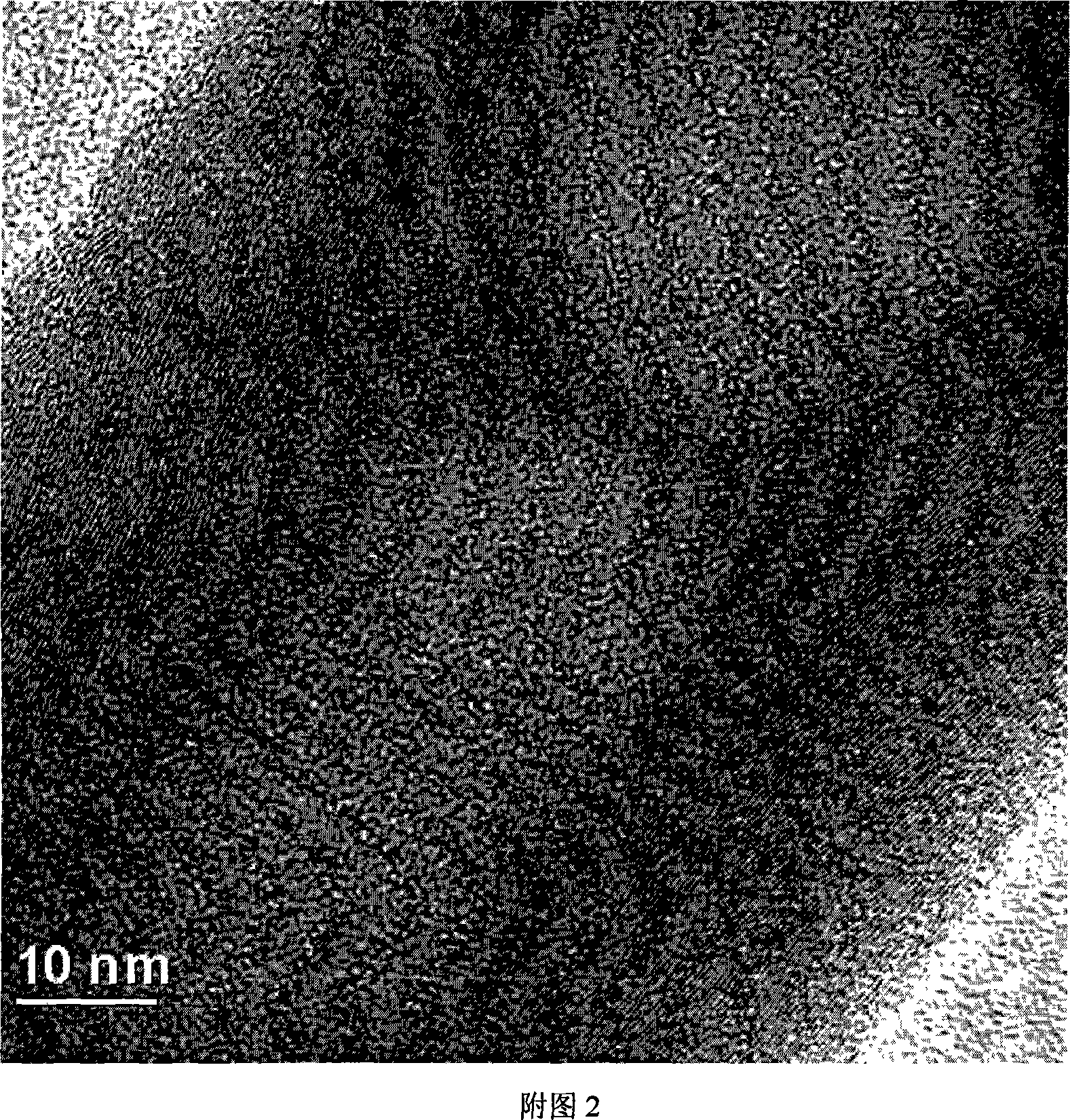

High nitrogen doped corrugated carbon nanotube material and its synthesis process

InactiveCN101066758AWide variety of sourcesSimple production processNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsIron(II) oxideCarbon nanotube

The present invention relates to high nitrogen doped corrugated carbon nanotube material and its synthesis process. The synthesis process includes the following steps: mixing Fe source and proper amount of distilled water, soaking porous molecular sieve to carry ferric oxide or ferrous oxide, stoving and roasting at 300-1000 deg.c for 0.5-24 hr to obtain catalyst; setting the catalyst inside a pipe furnace, leading organic amine into the furnace under the protection of Ar or N2 and reacting at 650-1000 deg.c for 0.2-4.0 hr to obtain high nitrogen doped corrugated carbon nanotube mixture containing the catalyst; soaking the mixture in proper amount of or excessive hydrofluoric acid, sulfuric acid, nitric acid or acid for 0.5-24 hr; and washing in distilled water, suction filtering and drying to obtain high nitrogen doped corrugated carbon nanotube material. The material has nitrogen content of 10-40 %, reinforced surface polarity, etc, and is suitable for industrial production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

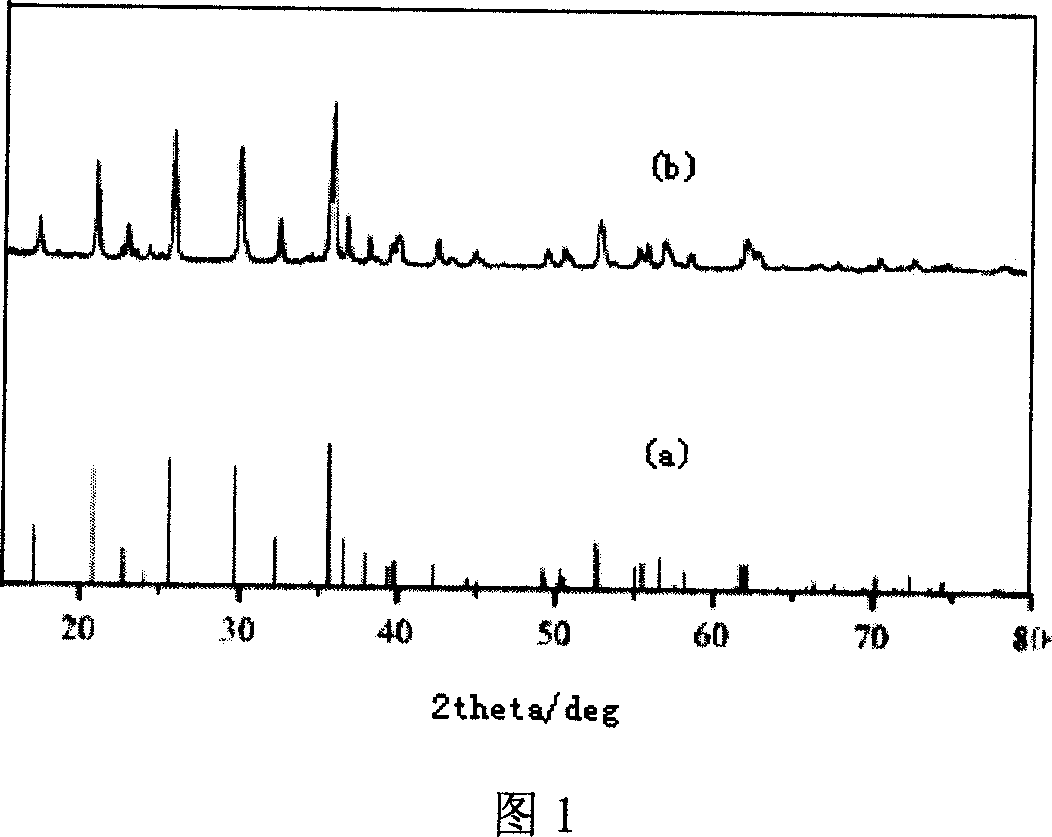

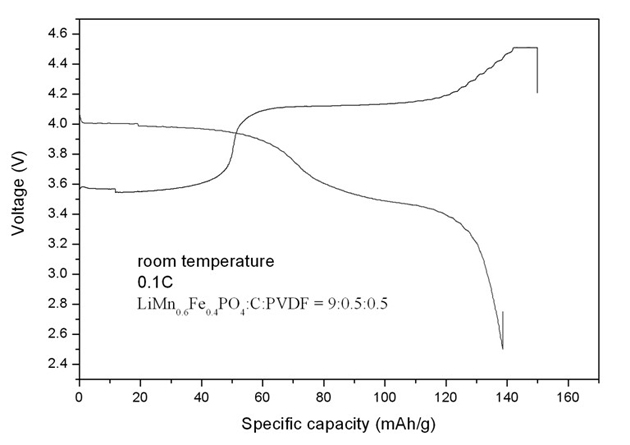

Lithium ferric manganese phosphate as cathode material of lithium ion battery and preparation method thereof

The invention relates to a lithium ferric manganese phosphate as a cathode material of a lithium ion battery and a preparation method thereof, belonging to the technical field of lithium ion batteries. The lithium ferric manganese phosphate as the cathode material has a chemical composition: Li1-yMyFel-xMnxPO4. The preparation method of the lithium ferric manganese phosphate as the cathode material comprises the following steps of: (1) synthesizing a precursor: placing raw materials into a container; adding a dispersant; grinding and dispersing 1-3 hours at rotation speed of 1000-2500r / min; and drying and grinding pasty paste; (2) preburning: heating to the temperature of 350-550 DEG C according to a heating rate of 1-10 DEG C / min; preburning 3-20 hours at constant temperature; cooling to room temperature along with a furnace; and preparing the lithium ferric manganese phosphate; and (3) coating carbon at high temperature: mixing and dispersing the lithium ferric manganese phosphate, a carbon source and the dispersant 1-3 hours; after drying, heating to the temperature of 600-850 DEG C by using a heating rate of 1-10 DEG C / min; insulating 3-20 hours; cooling to room temperature along with the furnace; and preparing the lithium ferric manganese phosphate. The invention has the advantages of simple technology, low cost of batteries, high safety of cathode materials, high thermal stability, electric conductivity increase, and the like.

Owner:天津斯特兰能源科技有限公司

Cyclone suspension flash magnetized roasting-magnetic separating method for refractory ferric oxide ore

The present invention relates to a cyclone suspension flash magnetizing roast-magnetic separation method for difficult-separable ironoxide ore. Its concrete steps are as follow: firstly, roasting the powdered difficult-separable ironoxide ore granules or fire-ground strong-magnetically-separated chats in the separation process under the condition of high-temperature reduction atmosphere and cyclone suspension fluidized state to make them be quickly dynamically reduced into magnetite within 5-100 sec. then adopting weak magnetic separation process to obtain high-quality acceptable iron headings.

Owner:湖南长拓高科冶金有限公司

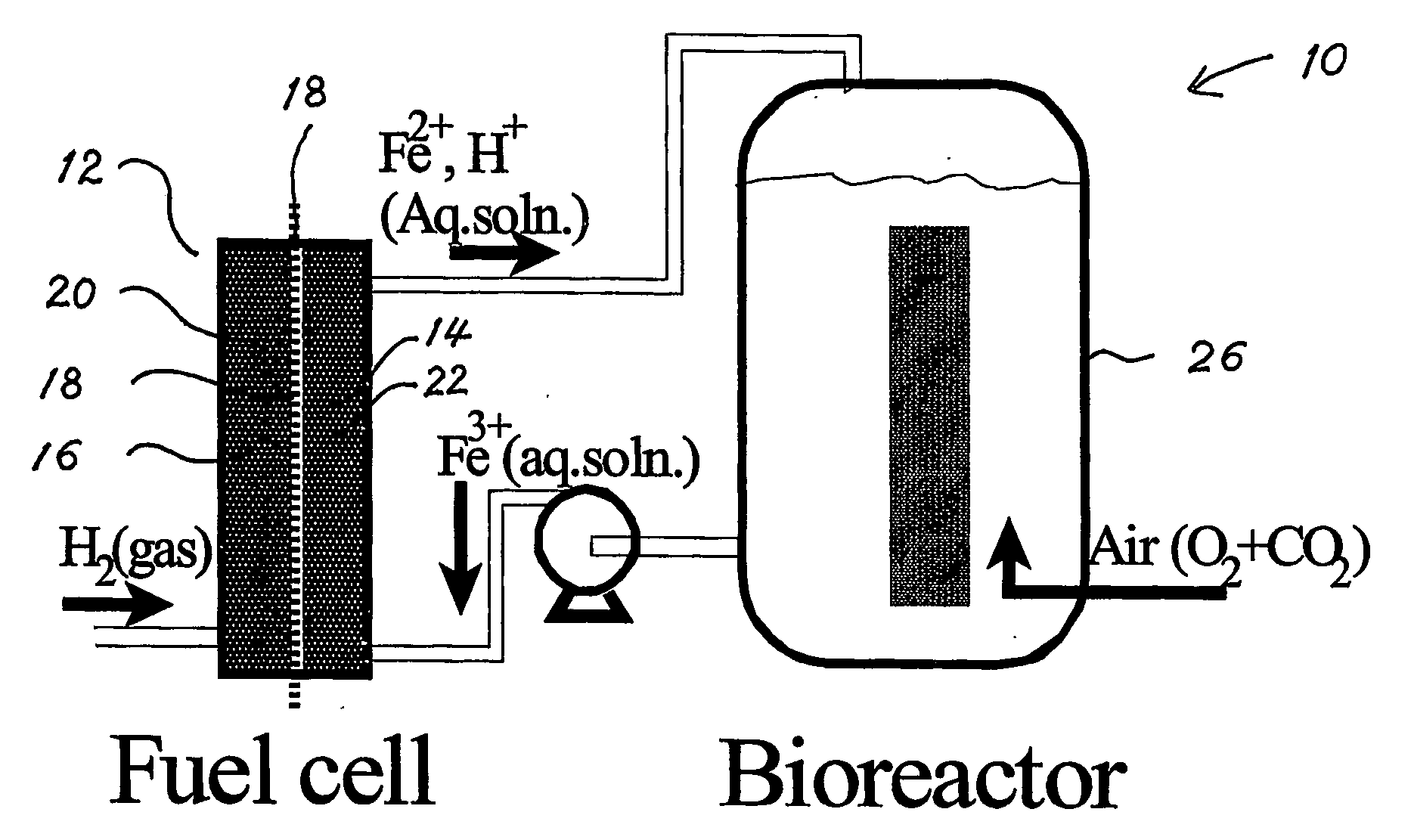

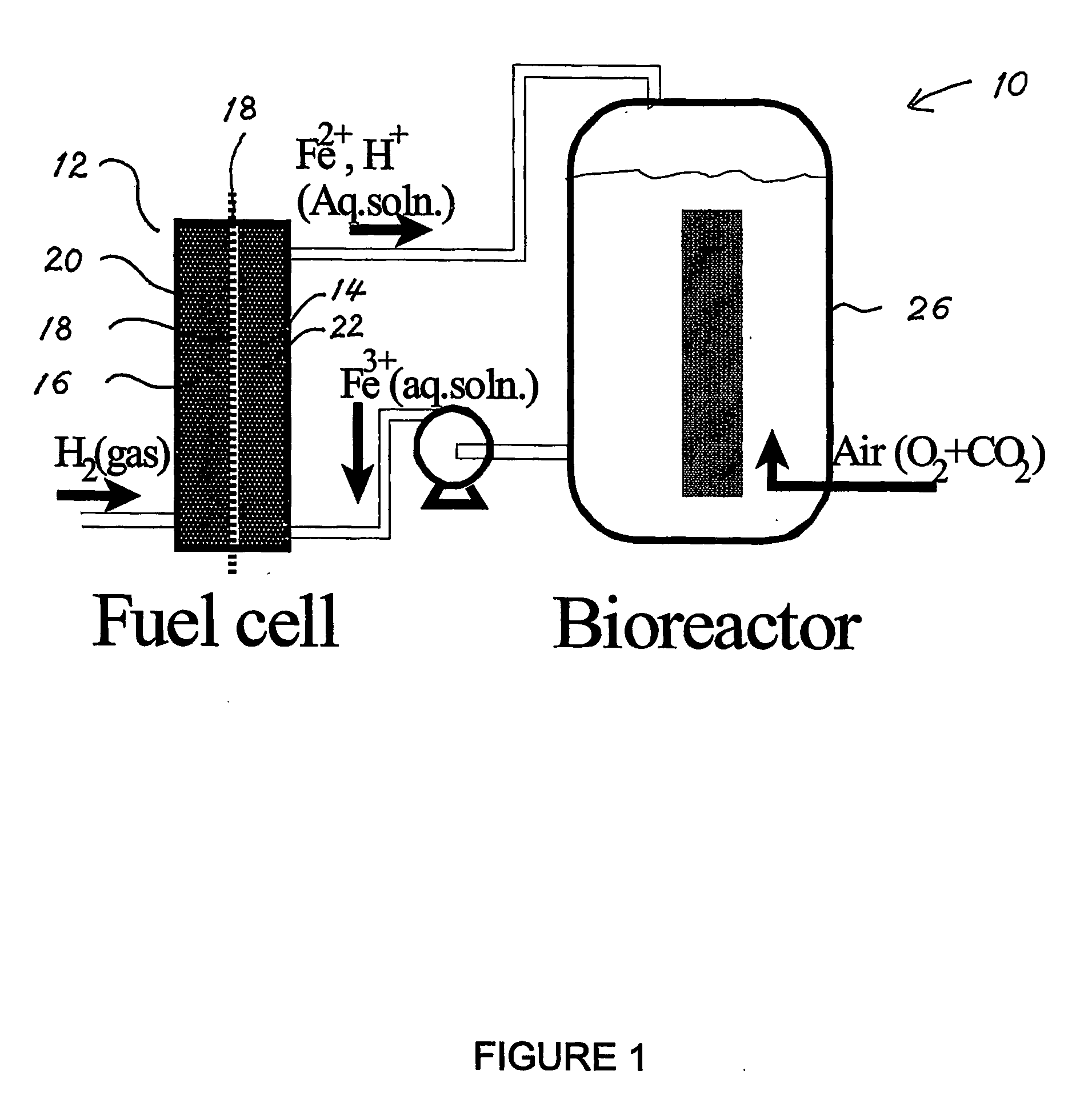

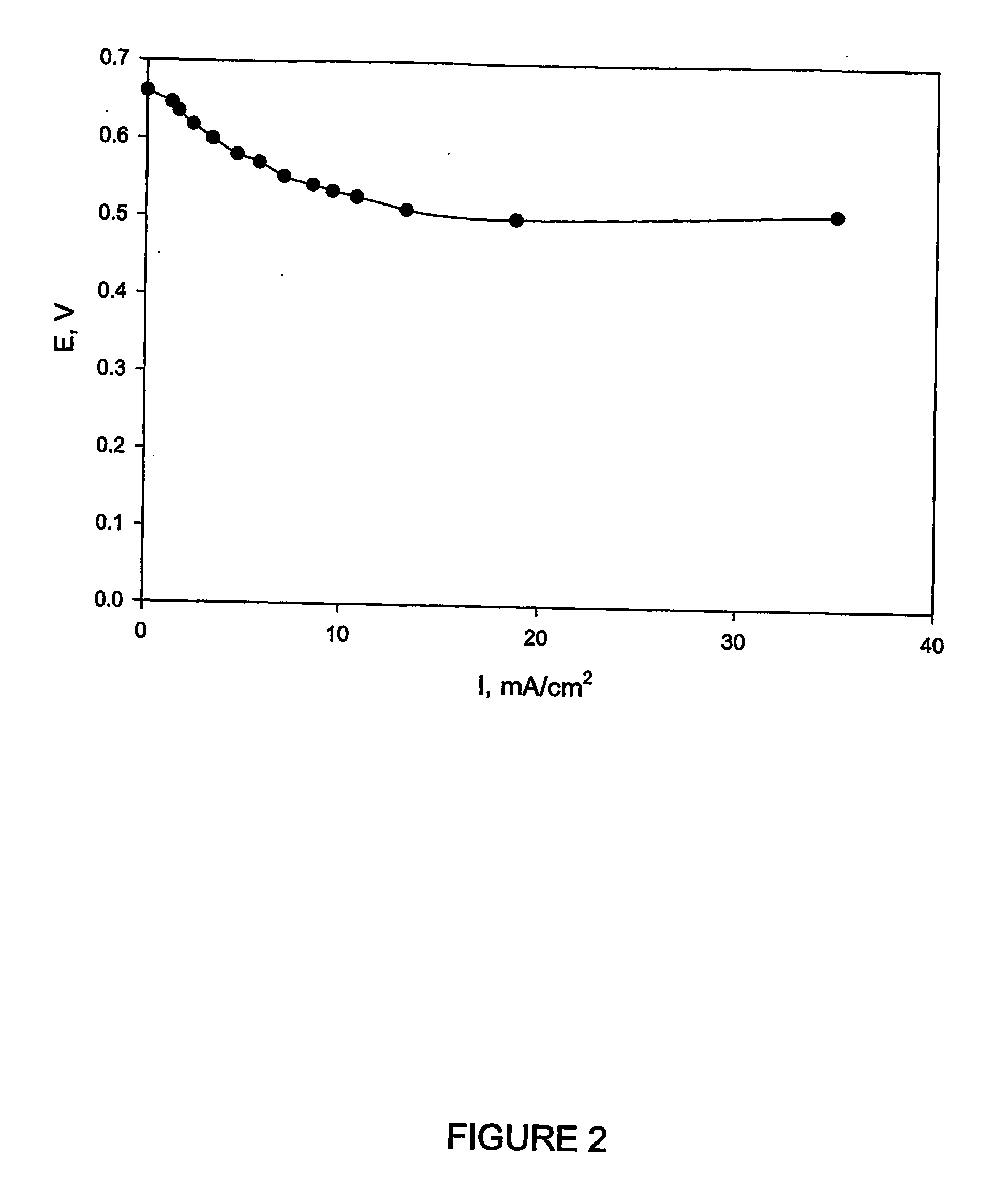

Biofuel cell

InactiveUS20060251959A1Promote growthElectrolyte holding meansRegenerative fuel cellsMicroorganismHydrogen

The present invention discloses a new type of biofuel cell, based on the microbial regeneration of the oxidant, ferric ions. The bio-fuel cell is based on the cathodic reduction of ferric to ferrous ions, coupled with the microbial regeneration of ferric ions by the oxidation of ferrous ions, with fuel (such as hydrogen) oxidation on the anode. The microbial regeneration of ferric ions is achieved by chemolithotrophic microorganisms such as Acidithiobacillus ferroxidans. Electrical generation is coupled with the consumption of carbon dioxide from atmosphere and its transformation into microbial cells, which can be used as a single-cell protein.

Owner:UNIV OF WESTERN ONTARIO

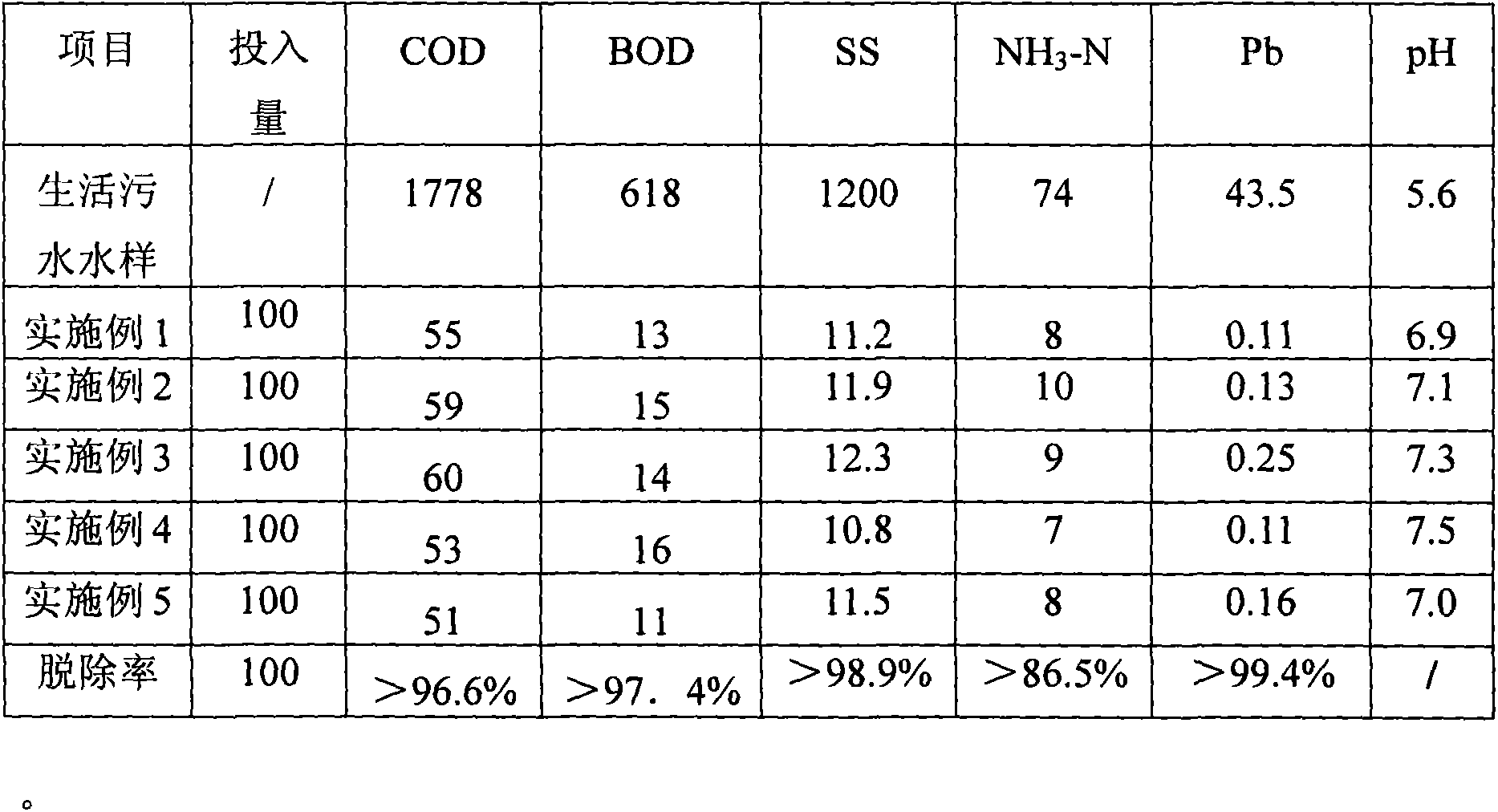

Domestic sewage treatment agent and preparation method thereof

ActiveCN103641247AImprove settlement performanceSolve the problem of small and difficult subsidenceScale removal and water softeningWater/sewage treatment by ion-exchangeHigh concentrationCross-link

The invention relates to the technical field of sewage treatment agents and specifically relates to a domestic sewage treatment agent and a preparation method thereof. The domestic sewage treatment agent comprises the following raw materials in parts by weight: 10-20 parts of ferric trichloride, 5-8 parts of ferrous sulfate, 5-8 parts of magnesium sulfate, 3-5 parts of polyacrylamide, 10-20 parts of caustic soda flakes, 20-35 parts of modified lignin sulfonate, 10-15 parts of starch xanthate, 20-30 parts of modified diatomite, 15-20 parts of cross-linked rectorite and 1-5 parts of chitosan-graphene composite material. The domestic sewage treatment agent provided by the invention is capable of continuously treating high-concentration domestic sewage under the coordination action of the compounded raw materials; in the meantime, the contents of COD (Chemical Oxygen Demand), BOD (Biological Oxygen Demand) and SS (Suspended solids) in the treated domestic sewage are obviously reduced; the treated water can be recycled repeatedly.

Owner:沧州市利达环保工程有限公司

Method for preparing coductive fiber and its product

The present invention relates to conductive fiber preparing process and product. The preparation process includes the following steps: 1. pre-treating base fiber of polyester, viscose or wool successively with acetone, ethanol and distilled water under room temperature condition; 2. compounding fiber treating liquid with oxidant ferric trichloride or ammonium persulfate 2-32 wt%, dopant ammonium cetyl trimethyl bromide or hydrochloric acid 0.1-7 wt% and distilled water; and soaking the base fiber inside the fiber treating liquid for 30 min; and 3. making conductive fiber via coating conducting liquid of aniline, pyrrole or thiophene onto the base fiber inside a continuous coating machine of 1-10 m / min speed, washing with hot water at 50-90 deg.c and drying with hot blast at 60 deg.c to obtain the conductive fiber.

Owner:TIANJIN POLYTECHNIC UNIV

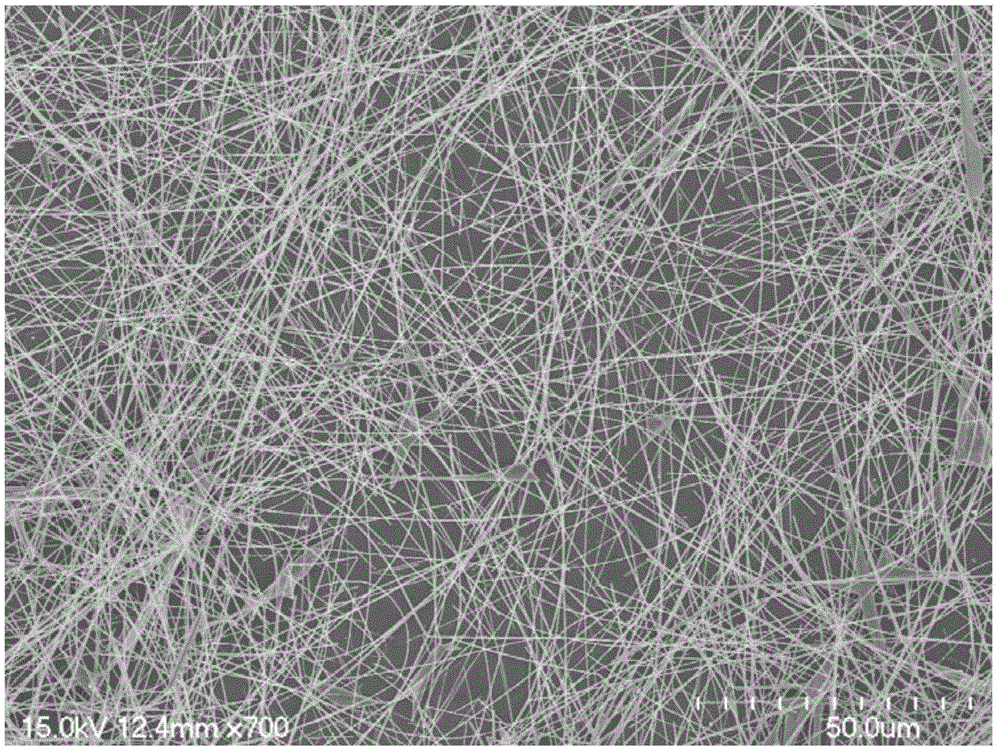

Silver nanowire preparation method

The invention relates to a silver nanowire preparation method which comprises the following steps: (a), taking polyvinylpyrrolidone, dissolving polyvinylpyrrolidone in ethylene glycol; (b), taking silver nitrate, and dissolving silver nitrate in ethylene glycol; (c), taking ferric chloride anhydrous and dissolving ferric chloride anhydrous in ethylene glycol; (d), mixing the silver nitrate-ethylene glycol solution with the polyvinylpyrrolidone-ethylene glycol solution to obtain a first mixed solution, wherein the mass ratio of polyvinylpyrrolidone to silver nitrate is 1-9 to 1; (e), respectively adding a ferric trichloride-ethylene glycol solution and an ionic liquid-ethylene glycol solution in the first mixed solution, and reacting for 2-24 hours at a temperature lower than the boiling temperature of ethylene glycol after stirring and mixing to obtain a shiny white mixed solution; (f), flushing silver nanowires obtained after solid-liquid separation with acetone, and dispersing the silver nanowires in water or absolute ethyl alcohol to obtain a nanowire dispersion liquid, wherein the step (a), the step (b) and the step (c) are not ordered. The average ratio of length and diameter of the silver nanowire is greater than 1,000.

Owner:SUZHOU UNIV

Chemical etching liquid for metals and etching method

The invention provides a chemical etching liquid for metals. The chemical etching liquid comprises ferric chloride, hydrochloric acid, phosphoric acid, hydrogen nitrate, a corrosion inhibitor and a surface active agent. The corrosion inhibitor is at least one of hexamethylene tetramine, ethidene diamine, triethanolamine and heptadecane amide; and the surface active agent is one or two of sodium lauryl benzenesulfate and dodecyl alcohol amine. The invention further discloses a chemical etching method for metals; with the method, the metals are etched through spraying the etching liquid; and the etching liquid is provided by the invention. The etching liquid provided by the invention can be applied to surface etching of various metals, particularly stainless steel, copper and aluminum alloy; and since the metals can be etched with the same etching liquid, the consumption of equipment is reduced.

Owner:南通麦特隆新材料科技有限公司

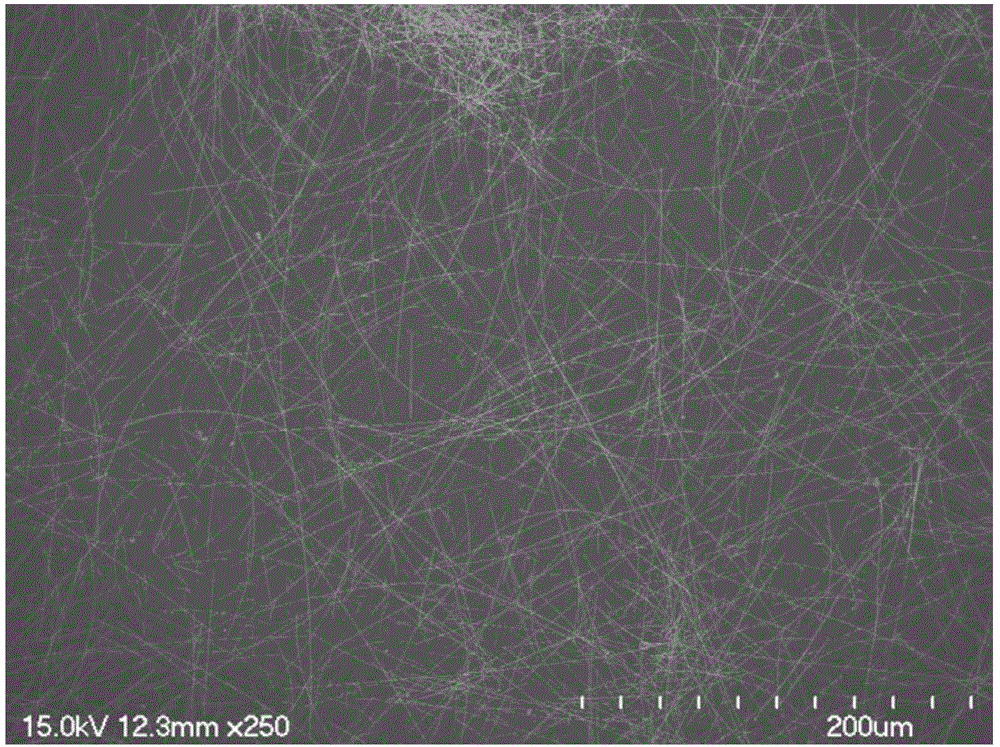

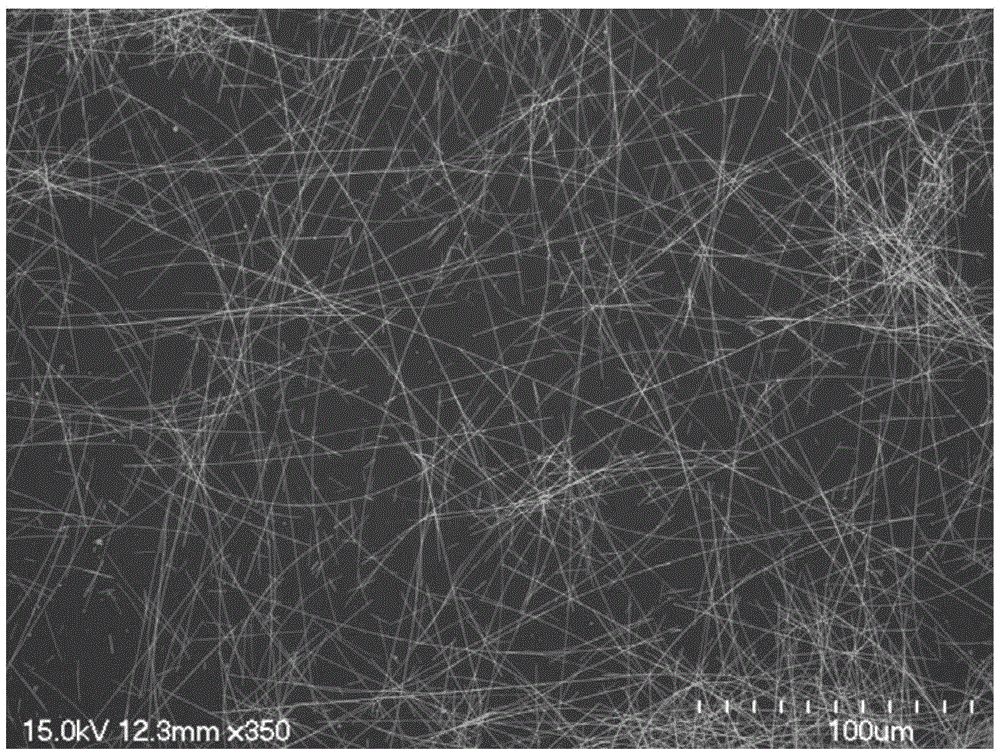

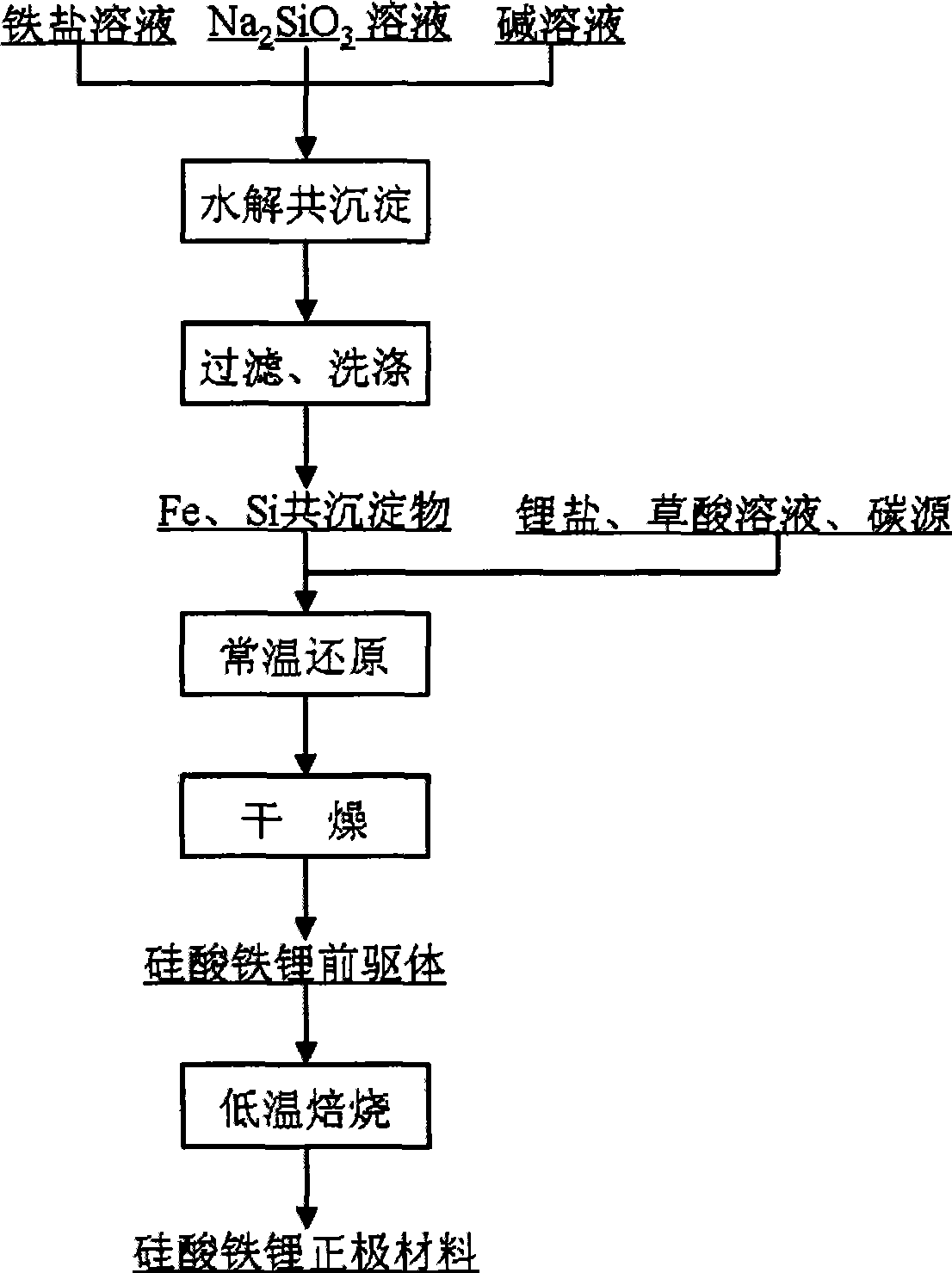

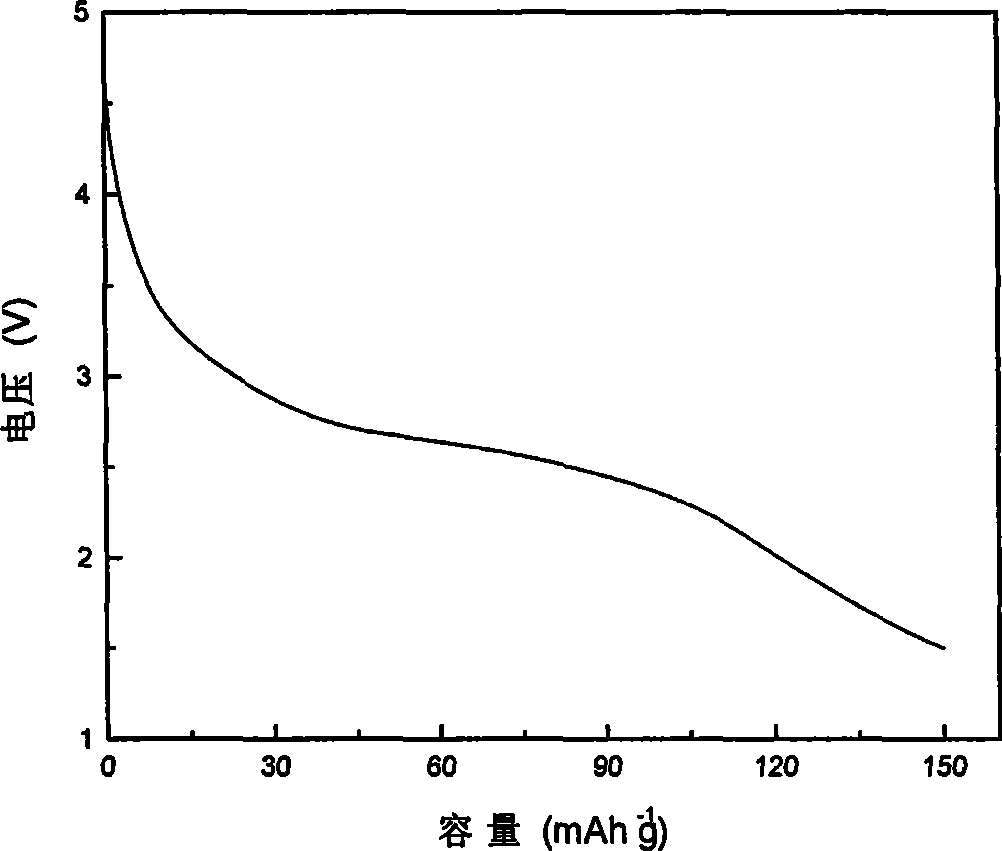

Production method of lithium ferric metasilicate anode material

InactiveCN101499527AWide variety of sourcesConvenient sourceElectrode manufacturing processesMetasilicateFERRIC IRON

The invention relates to a preparation method of lithium iron silicate cathode material. In the method, ferric saline, Na2SiO3 and lye are added into a reactor in a flowing way; the pH value of the reaction system is controlled, so that the hysrolysis reaction between the ferric iron and the SiO3 can occur; the common deposit of iron and silicon is prepared by filtering and washing; the common deposit of iron and silicon, the lithium source compound, the oxalic acid solution and the carbon source compound are mixedto become pulp state; the Fe is reduced to be Fe through ball milling; the precursor material of lithium iron silicate can be prepared by drying; the precursor material is calcinated under the conditions with the protective atmosphere and at the low temperature to form the agglomerated acidic lithium-iron anode material which is composed of nanoparticles. The method has the strong process adaptability; the industrial production can be easily realized; and the product has higher density and excellent electrochemical properties.

Owner:CENT SOUTH UNIV

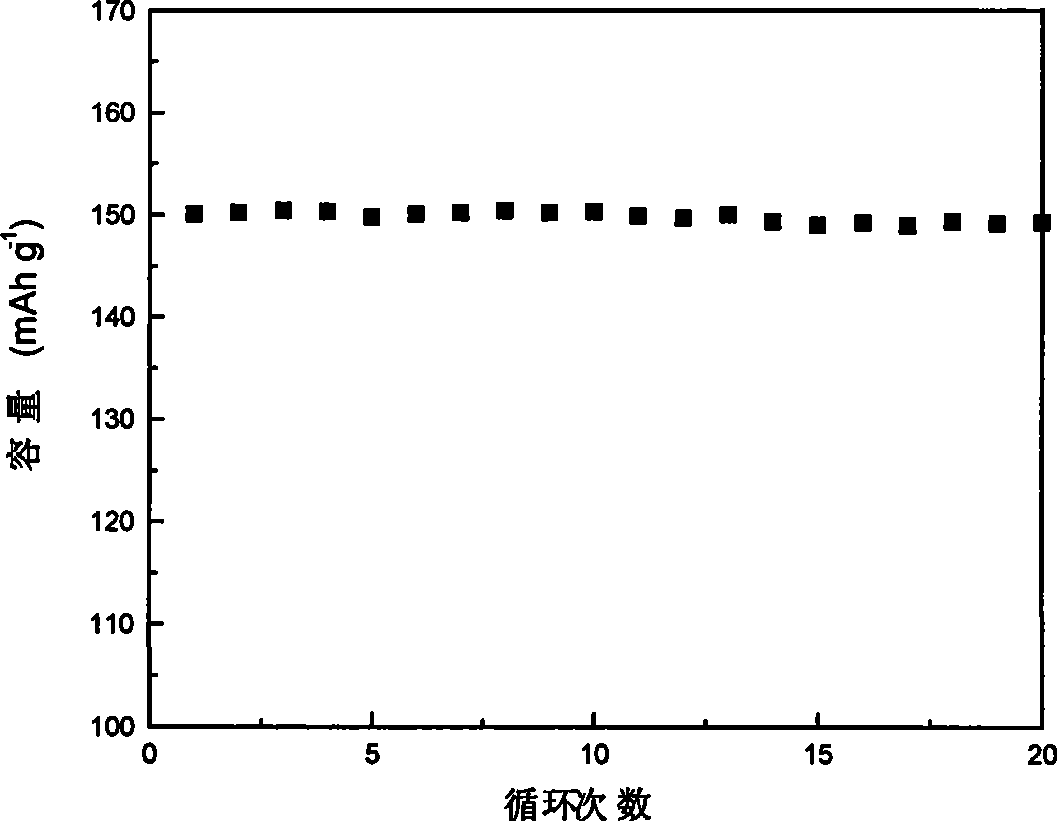

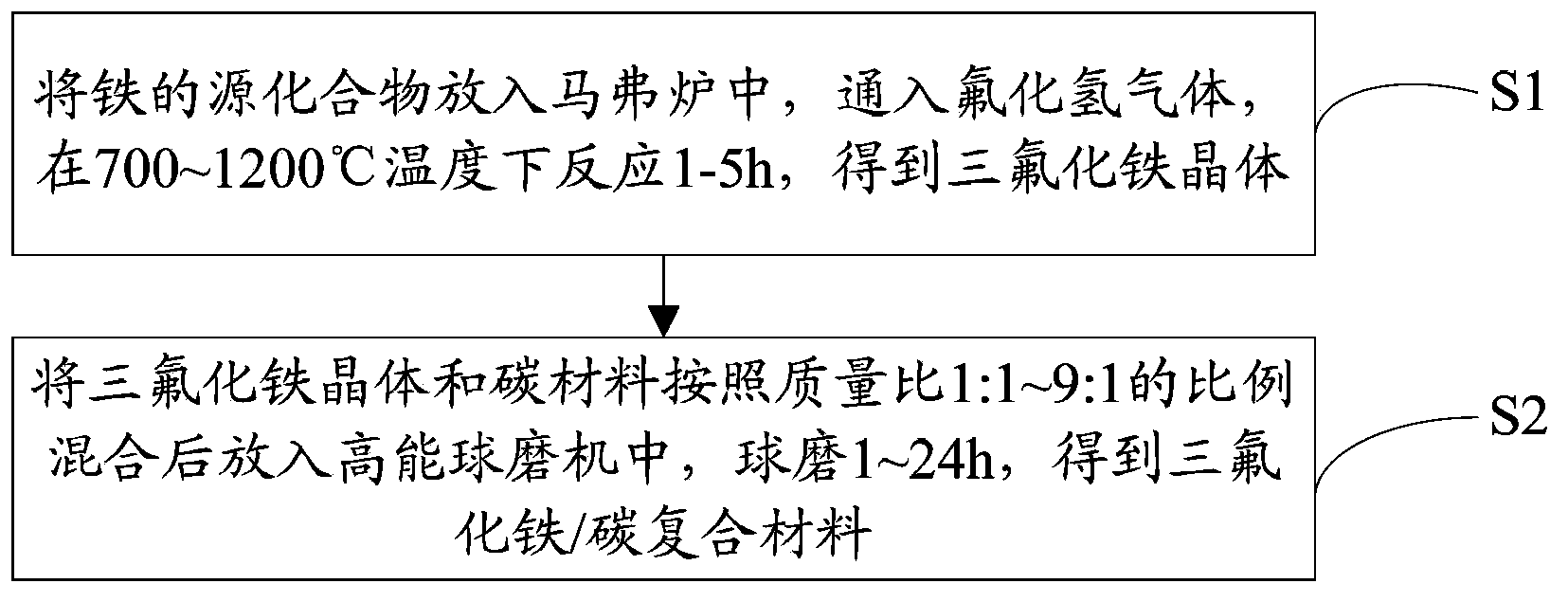

Ferric (III) fluoride / carbon composite material and its preparation method and application

InactiveCN103855389AImprove conductivityIncrease capacityCell electrodesSecondary cellsCarbon compositesElectrochemistry

The invention belongs to the field of electrochemical materials, and discloses a ferric (III) fluoride / carbon composite material and its preparation method and application; the composite material includes 50-90wt% of ferric (III) fluoride and 10-50wt% of a carbon material. By compounding of the high conductivity carbon material with a high conductivity, the problem of low conductivity of a ferric trichloride material can be well solved, and the capacity also is improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method of Treating Chronic Kidney Disease

InactiveUS20090186939A1Prevent and reverse and maintain and delay progressionAvoid developmentPowder deliveryBiocideSimple Organic CompoundsEnhanced dissolution

Owner:CSIR +1

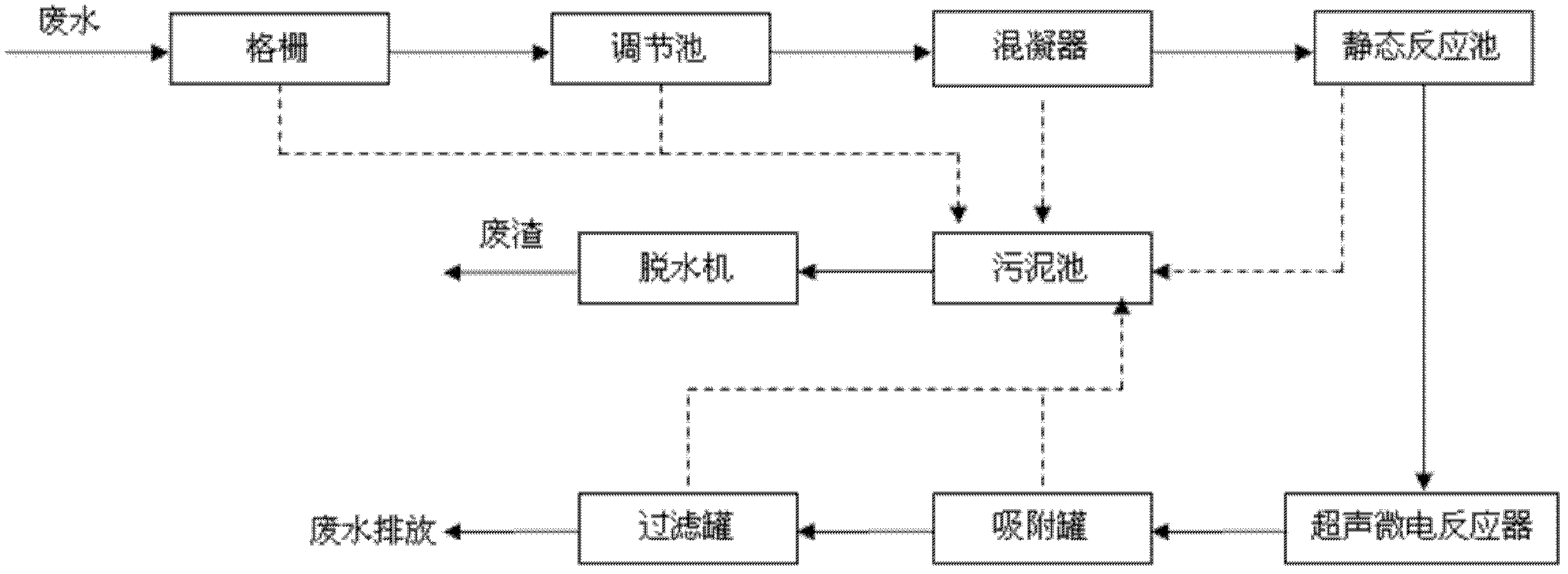

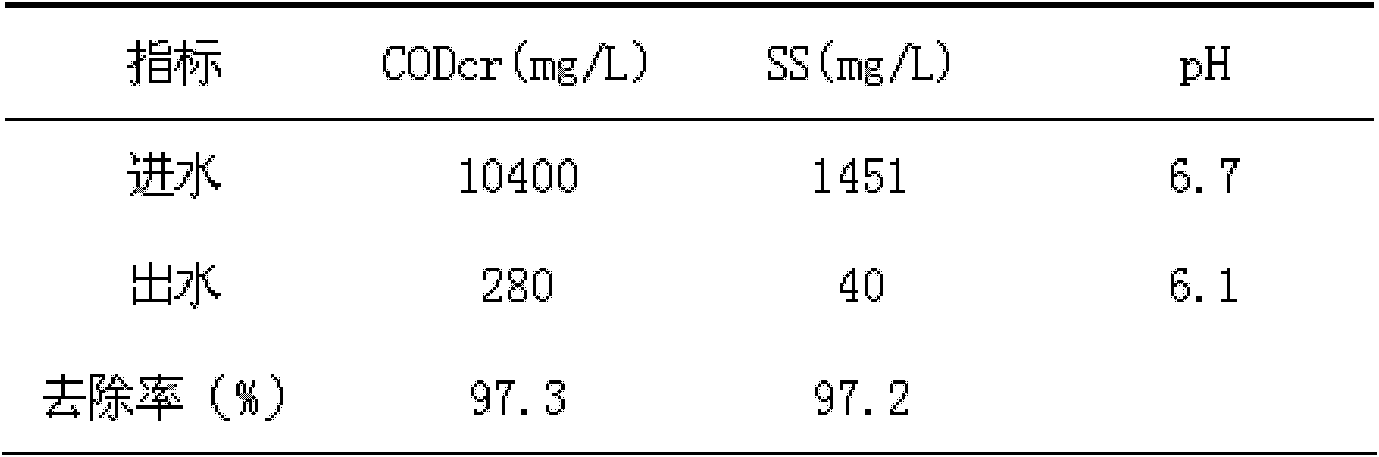

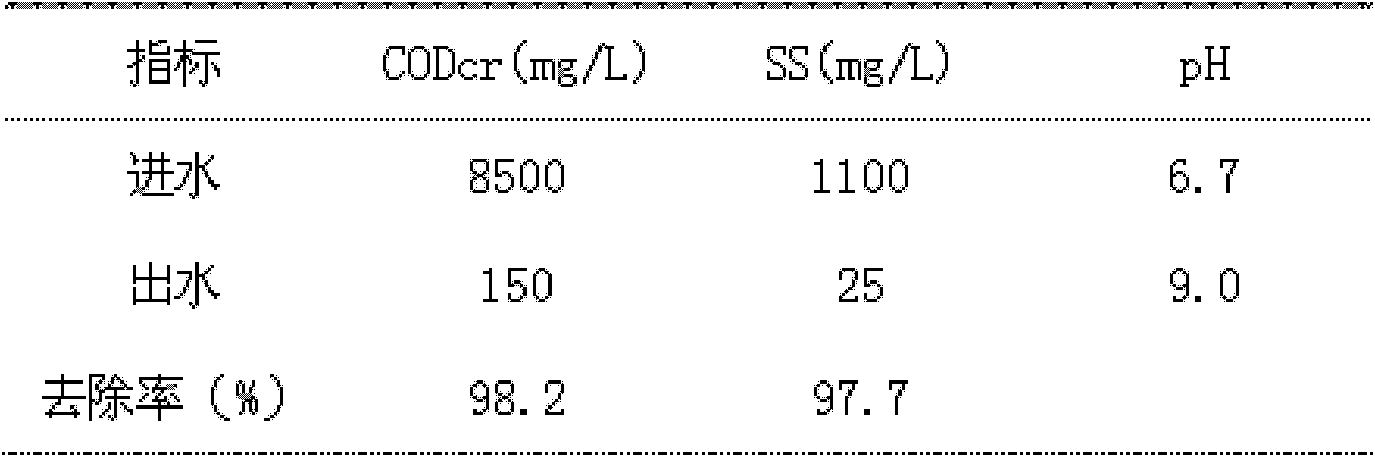

A method for treating waste water from papermaking tobacco sheet production

InactiveCN102276093AEasy to handleReduce processSludge treatment by de-watering/drying/thickeningBiofuelsChemical oxygen demandElectrolysis

The invention relates to a wastewater treatment method, in particular to a treatment method of papermaking method tobacco sheet production wastewater. The method comprises the following steps: (1) the production wastewater passes through a grid to perform coarse filtration and flows in a wastewater adjusting tank; (2) the wastewater in the wastewater adjusting tank is lifted to a coagulation device by a lift pump, a Ca-diatomite series composite coagulant is added in the coagulation device to react for 5-10 minutes, then polymeric ferric sulfate and polyacrylamide separating agents are added,the mixture enters a static reaction tank to react for 50-60 minutes; (3) the pH value of the low-concentration organic wastewater is adjusted to be less than 7, then the wastewater is pumped in a ultrasonic micro-electrolysis reactor, the chemical oxygen demand substances in the wastewater are fast digested under the combined action of ultrasonic wave and microelectrodes, the reaction time is 30-60 minutes; and (4) then the wastewater is adsorbed with activated carbon and filtered with quartz sand. The method has the advantages of short treatment time and good treatment effect and has wide applicability.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation method for coal combustion improver

The invention relates to a preparation method for a coal combustion improver. After common coal is added with coal additives for combustion, the effect of energy saving and emission reduction is obvious and effective. The preparation method comprises the following steps that: 1. high-stability sodium chlorate and potassium chloride react with each other to produce potassium chlorate when water is added and the sodium chlorate and the potassium chloride are dissolved; 2. leavening agent sodium acetate is introduced to conduct base exchange with humate in coal, low ignition point humate is produced and the ignition performance of the coal is reduced; and 3. ferric oxide required by the formula is compound insoluble in water. Thereby, ferric chloride and calcium oxide are used to react with each other to produce ferric oxide when water is added and the ferric chloride and the calcium oxide are dissolved. Other products in the market do not at all have the preparation and application characteristics of the three compounds.

Owner:GUANGHUA SCI & TECH SHANGHAI +1

Improved nanometer nulvalent iron particle and method for making same

The invention discloses a modified nanometer nulvalent ferric particle and preparing method with grain size at 20-50nm and even grain size at 30-40nm and specific surface at60-70m<2> / g, which comprises the following steps: allocating soluble ferric salt solution and NaBH4 or KBH4 alcohol-water composite solution with bulk rate at 1: 1-20, adding polyvinyl pyrrolidone in the soluble ferric salt solution according to rate, stirring evenly, adding NaBH4 or KBH4 alcohol-water composite solution in the soluble ferric salt solution, stirring continually until the solution becomes black, adopting magnetic method to select nanometer nulvalent ferric particle, washing through distilled water completely, washing through acetone or alcohol then, reserving in the acetone or alcohol.

Owner:NANJING UNIV

Honeycomb integral type low temperature denitrifying catalyst and preparation method thereof

ActiveCN105727985AImprove denitrification activityDenitrification suitableHeterogenous catalyst chemical elementsDispersed particle separationNickel saltCerium

The invention discloses a honeycomb integral type low temperature denitrifying catalyst and a preparation method thereof. The preparation method comprises the following specific steps: 1) dissolving ferric sat or cobalt salt or copper salt or nickel salt and manganous salt or cerium salt in water to form a metallic salt solution; 2) soaking titanium dioxide in the metallic salt solution to form suspension, using an impregnation method or coprecipitation method or hydrothermal method to prepare the suspension into catalyst active components; 3) mixing the catalyst active components with the inorganic binding agent, the organic polymer solution, the surfactant and water, stirring to form a slurry; 4) coating the slurry on a honeycomb cordierite carrier; and 5) drying the coated honeycomb cordierite carrier, and calcining, to obtain the honeycomb integral type low temperature denitrifying catalyst. The active components of the catalyst obtained through the preparation method of the invention are high in loading rate on the carrier, the coating and the carrier are firmly bound, and the low temperature denitrifying activity is high.

Owner:CHINA BUILDING MATERIALS ACAD

Low-cost domestic sewage treatment agent

InactiveCN103663577AGood effectLow production costWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionEcological environmentPollution

The invention discloses a low-cost domestic sewage treatment agent. The low-cost domestic sewage treatment agent contains polymerized ferric chloride, polyacrylamide, polyethyleneimine, bentonite, sodium chloride, lime, an adsorbate, sodium carbonate and a pH regulator. The treatment agent has the advantages that domestic sewage can be treated effectively, the cost is low, the effect is good, the pollution to ecological environment caused by the domestic sewage is alleviated, the removal ratio of suspended solids in the sewage reaches 98.3%, the BOD (Biochemical Oxygen Demand) removal ratio is 95.2%, the COD (Chemical Oxygen Demand) removal ratio is 96.8%, and the chroma is 5.

Owner:杭州浩蓝环境工程技术有限公司

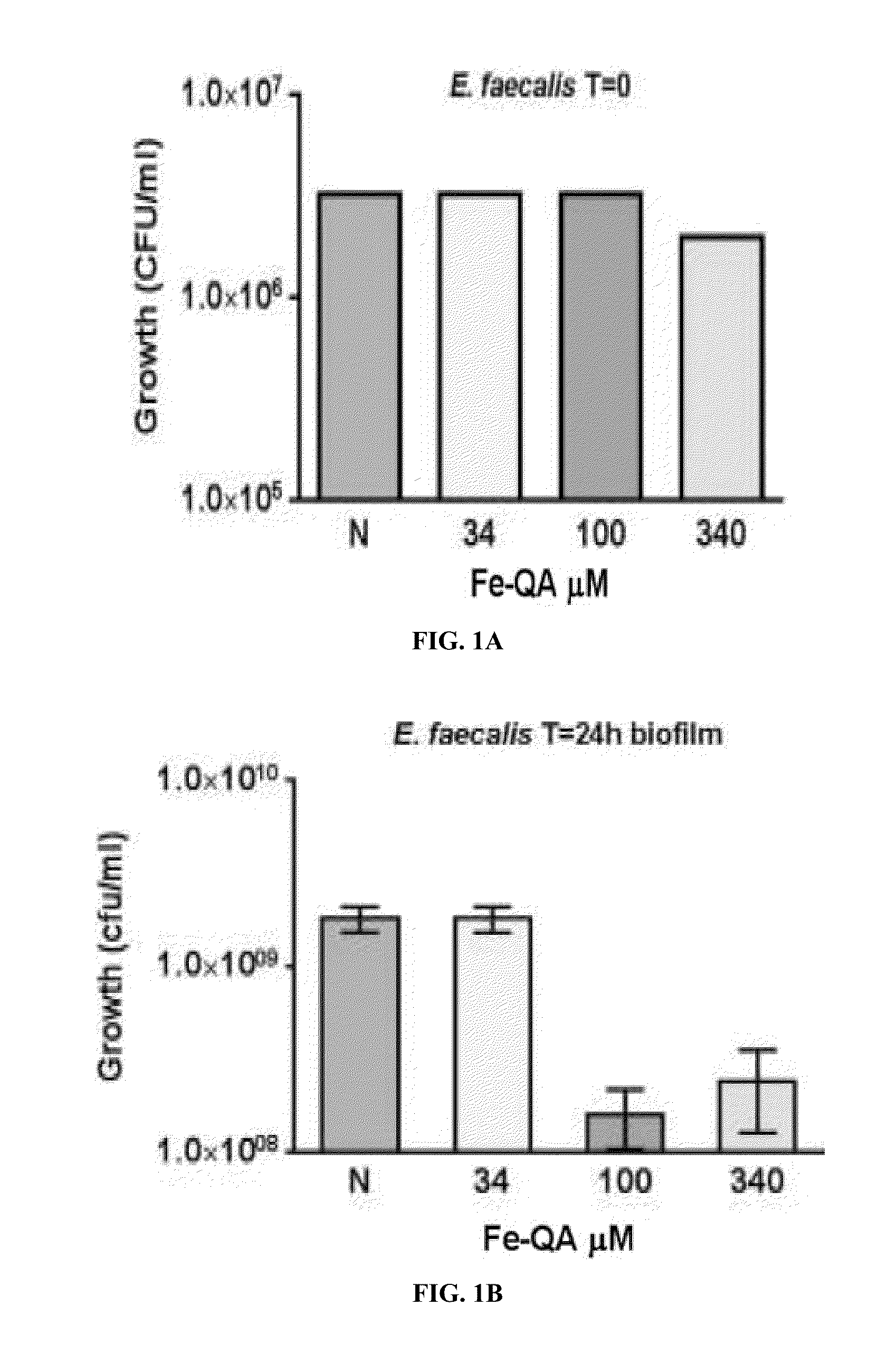

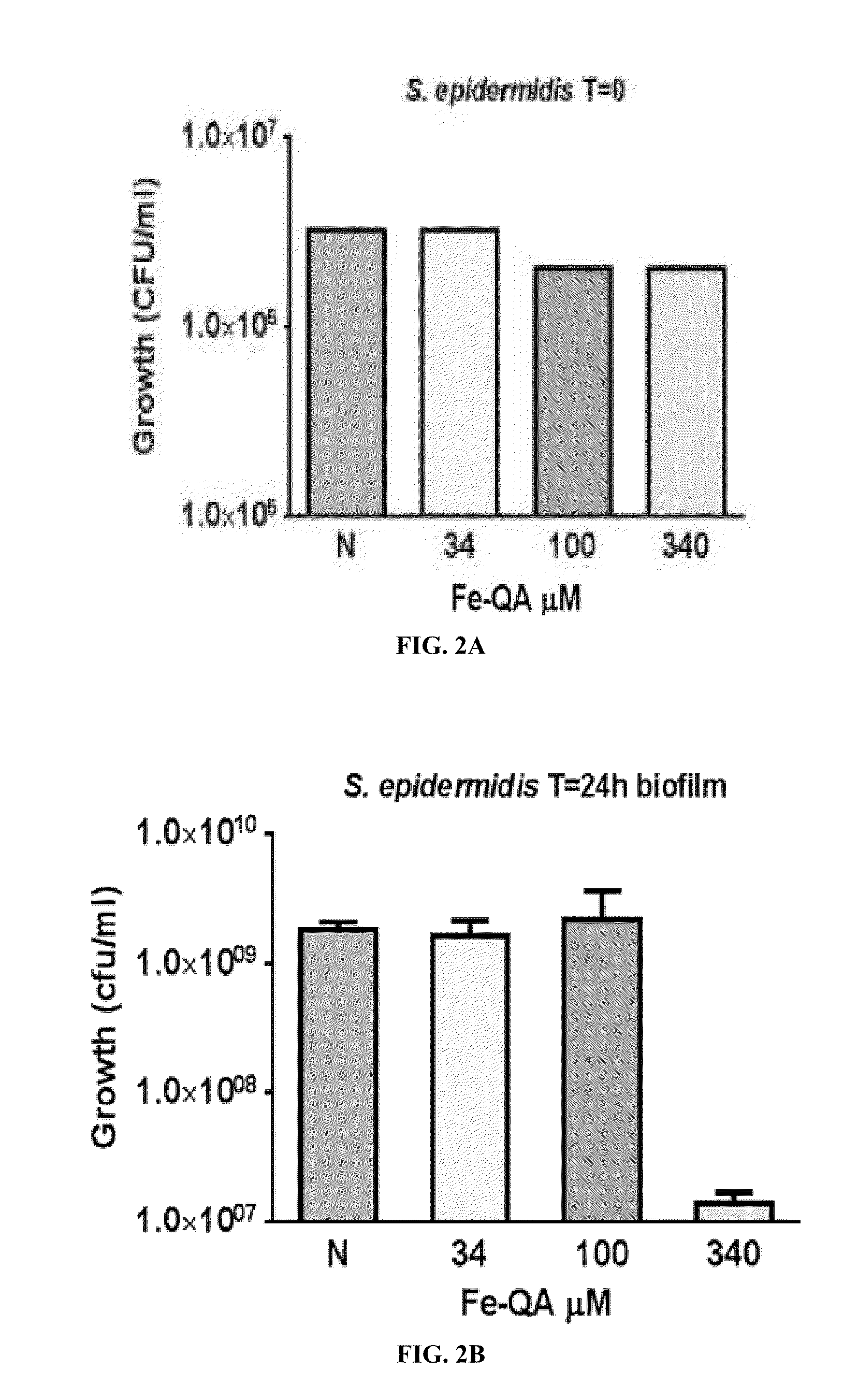

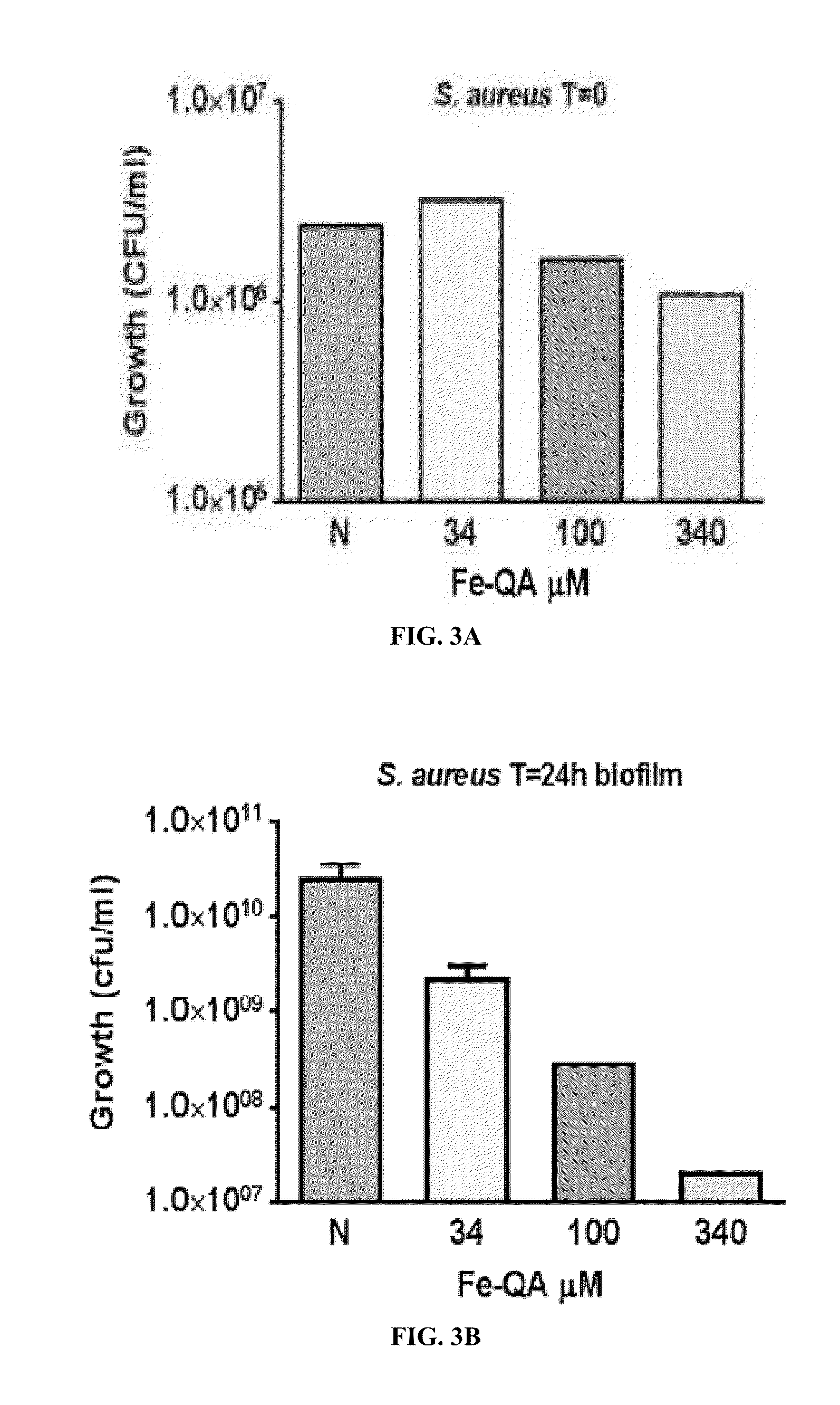

Antimicrobial compounds and compositions, and uses thereof

ActiveUS20160066578A1Improve growth performanceDecrease mortality adjusted feed conversion ratioCosmetic preparationsOrganic active ingredientsBenzoic acidMicrobial agent

A method of enhancing the growth of an animal is provided. The method includes causing the animal to ingest or absorb an effective amount of one or more Fe III complex compounds, including but not limited to Fe III complexes comprising ligands bound to the iron centre selected from amino acids or α-hydroxy acids, o-hydroxy benzoic acids or pyridine-2-carboxylic acids, such as ferric quinate, ferric tyrosine, ferric DOPA and ferric phenylalanine. Compounds which are structural and / or functional variants, derivatives and / or analogs of the foregoing compounds, as further described herein are also disclosed. Methods for inhibiting, reducing, or preventing biofilm formation or buildup on a surface; the treatment of, inhibition of growth of, and inhibition of colonization by, bacteria, both in biological and non-biological environments; disinfecting surfaces, potentiating the effects of antibiotics and other anti-microbial agents, and increasing the sensitivity of bacteria and other microorganisms, to anti-microbial agents are also provided.

Owner:AKESO BIOMEDICAL

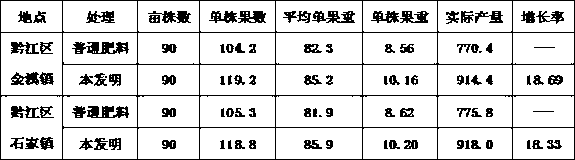

Controlled-release and slow-release compound fertilizer specialized for kiwi fruit

The invention provides a controlled-release and slow-release compound fertilizer specialized for kiwi fruit, and belongs to the technical field of fertilizers. The compound fertilizer comprises 8-9 parts of urea, 16-18 parts of calcium magnesium phosphate fertilizer, 1 part of potassium sulfate, 3.5-4.5 parts of potassium chloride, 60-70 parts of fermented chicken manure fertilizer, 7-9 parts of charcoal powder, 1.8-2.2 parts of calcium superphosphate, 0.8-1.2 parts of bentonite, 1 part of a solid inoculant, and 0.1 part of boric acid. The compound fertilizer provided by the invention has the beneficial effects that urea, the calcium magnesium phosphate fertilizer, potassium sulfate and potassium chloride are prepared according to the proportions, the demand of the kiwi fruit plants on nitrogen, phosphorous and potassium is satisfied, and needed secondary elements such as calcium, magnesium, chlorine, sulfur and boron are guaranteed at the same time; besides, large amounts of organic substances are supplied to the kiwi fruit by large amounts of the fermented chicken manure fertilizer; and moreover, needed trace elements such as ferric, copper, sodium, zinc, cobalt and the like are contained in the compound fertilizer, so the elements necessary for the kiwi fruit are basically completed.

Owner:重庆润绿生物有机肥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com