Patents

Literature

374results about How to "Improve denitrification activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature SCR denitration catalyst taking organic metal framework as carrier and preparation method thereof

ActiveCN101920213ARelieves poisoning and cloggingAvoid warm-up energy consumptionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEnvironmental chemistryOxide

The invention relates to a low temperature SCR denitration catalyst taking an organic metal framework as a carrier and a preparation method thereof, belonging to fields of an air pollution regulation technology and an environmental protection catalytic material. The preparation method comprises the following steps: loading oxides of one or more metal elements of Mn, Fe, Cu, V and Ce on an MOFs catalyst carrier to serve as effective components by an immersion method; and obtaining the catalyst by drying, calcinating and sieving, wherein in terms of the total mass of the catalyst, the content of the loaded active metal oxides is 1-20% by mass and the working temperature of the catalyst is 80-200 DEG C. The catalyst has larger specific area surface, higher low temperature catalytic activity, good denitration effect and wide industrial application prospect in the flue gas denitration process.

Owner:中建中环新能源有限公司 +1

Hydrogenation catalyst of containing fluorin with alumina being as carrier, and preparation

ActiveCN1872959AHigh activityImprove denitrification activityRefining to eliminate hetero atomsDenitrificationAluminium oxide

This invention provides a method for preparing hydrogenation catalyst containing fluorine supported by aluminum oxide. The catalyst is composed of nickel oxide 1-10 wt.%, molybdena oxide and tungsten oxide 10-50 wt.%, fluorine 1-10 wt.%, and aluminum oxide. The method comprises introducing nickel oxide, molybdena oxide, tungsten oxide and fluorine into aluminum oxide carrier. The catalyst has such advantage as high hydrogenation and denitrification activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

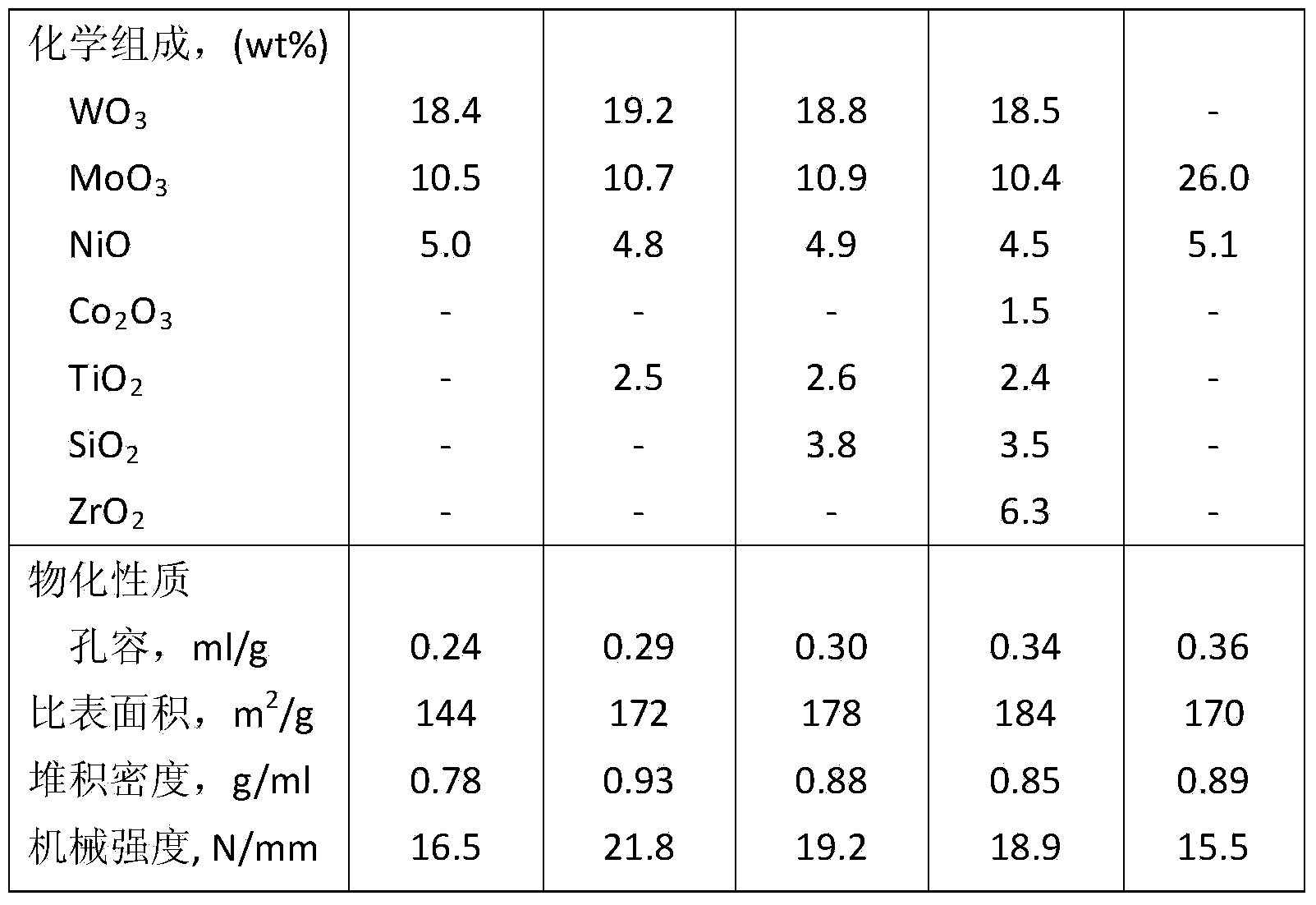

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Low-temperature selective catalytic reduction denitration catalyst and preparation method thereof

ActiveCN101658787ALow costWide variety of sourcesDispersed particle separationCatalyst activation/preparationManganese oxideHigh activity

The invention discloses a low-temperature selective catalytic reduction denitration catalyst and a preparation method thereof, wherein the catalyst takes an attapulgite as a carrier to load nano-composite materials of manganese oxide nano-particles; the structure thereof is as follows: manganese oxide particles with the particle diameter of less than 20nm are loaded on the rod-shaped crystal surface of the attapulgite with the diameter of 40-50nm; one or more types from iron, copper and nickel are added as an additive; and calculated according to the mass percentage of manganese, the content of the manganese oxide in the catalyst is 0.1-20. The preparation method comprises the steps of: firstly extruding, drying and crushing the attapulgite clay, and then preparing attapulgite clay powderinto suspension liquid; adding acid solution to wash and remove carbonate impurities, adding manganese salt, and then adding alkali solution for stirring so as to lead the manganese ion to be hydrolyzed and precipitated and loaded onto the crystal surface of the attapulgite, and finally obtaining the product after centrifugal washing, dewatering, drying and calcinations. The catalyst takes ammoniaas a reducing agent, and has higher activity of catalyzing NH3 and reducing NO reaction within the scope of 120 DEG C to 350 DEG C.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

ActiveCN1840618AHigh activityImprove hydrogenation activityRefining to eliminate hetero atomsSilicon oxideHydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

Scr flue gas denitrification catalyst based on tio2-zro2 composite carrier and preparation method

ActiveCN102266761AImprove adsorption capacityExtended service lifeCatalyst carriersDispersed particle separationActive componentFlue gas

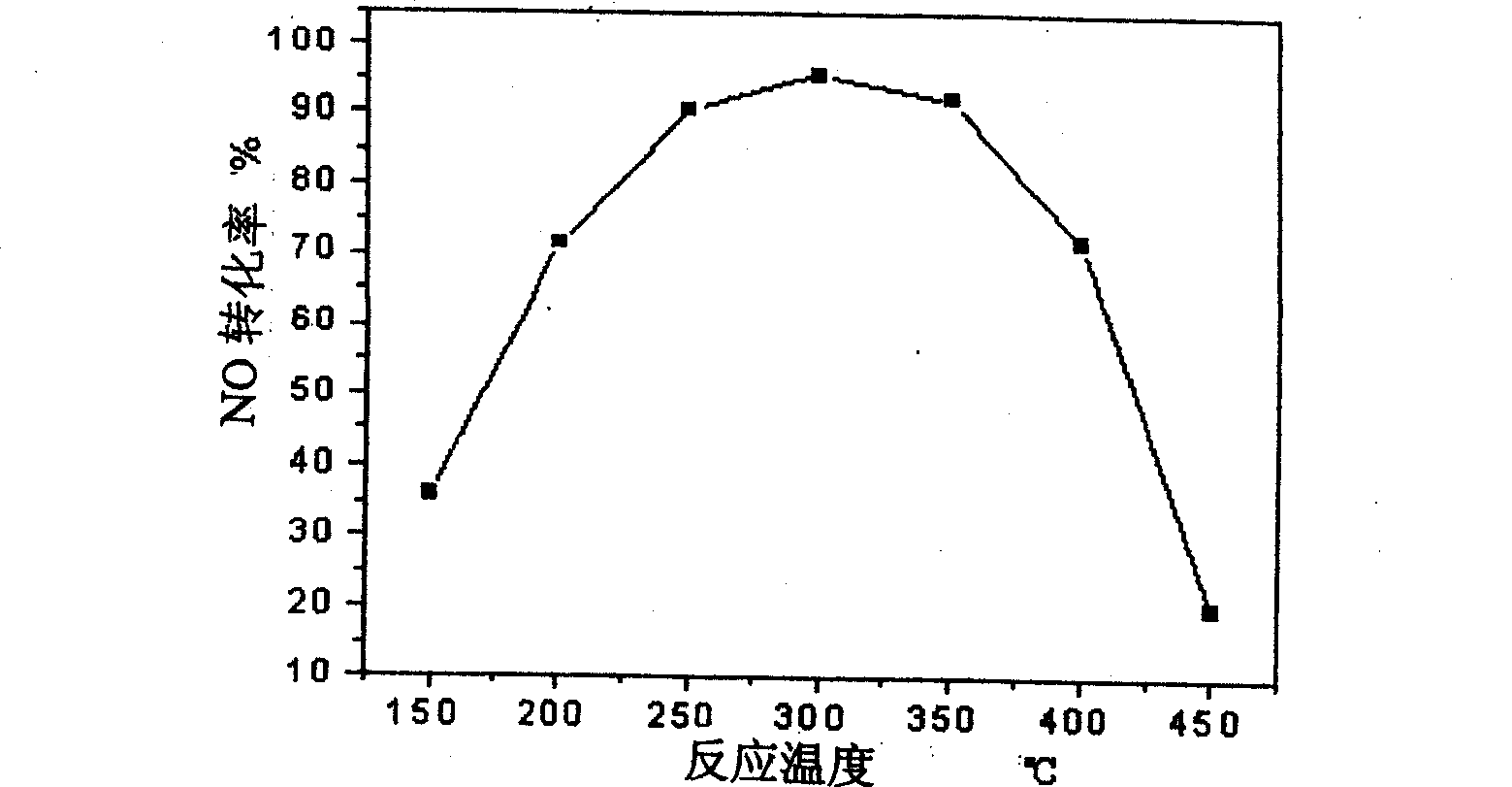

The invention mainly relates to a SCR (selective catalyctic reduction) flue gas denitration catalyst based on a TiO2-ZrO2 composite metal oxide carrier, belonging to the field of environment protection and environment catalysis. According to the invention, with the nanometer TiO2-ZrO2 as a carrier, WO3 and CeO2 as assistants and V2O5 as an active component, a low-and-medium temperature flue gas denitration catalyst based on the TiO2-ZrO2 composite carrier is obtained. The nanometer TiO2-ZrO2 substitutes the traditional nanometer TiO2 and is used as a carrier, thus the specific area, the heat stability and the acidity of the catalyst are improved; and denitration activity of the catalyst is improved through mutual action among V2O5, WO3 and CeO2; when the ammonia is used as a reducing agent, the catalyst can show very good catalyzing activity at150-450 DEG C.

Owner:北京华电光大环境股份有限公司

Fume denitration composite catalyst using titanium-base ceramics as carrier and preparation method thereof

ActiveCN101380543AGood chemical stabilityExtend your lifeCatalyst carriersDispersed particle separationCeriumChemical stability

The invention relates to a flue gas denitration composite catalyst and the preparation method thereof and pertains to the technical field of environment-friendly catalytic material and air pollution treatment. The invention is characterized in that aluminum-based or silicon-based ceramics is taken as a first carrier, aluminum-silicon composite oxide is taken as a second carrier, and cerium-zirconium composite metal oxide is taken as the catalyst active component. The aluminum-based or silicon-based ceramics is infused in the aluminum-silicon composite sol, after preparing a carrier coating by drying and baking, then the carrier coating is infused in cerium-zirconium composite solution for preparing the coating of active catalyst components. Compared with the prior art, the invention not only improves the activity and the chemical stability of the catalyst and enlarges the catalysis activity temperature window, but also improves the mechanical performance and thermal stability of the catalyst carrier, is environment-friendly and cheap, has no secondary pollution and lowers the loading quantity of the active components.

Owner:NANJING UNIV OF TECH

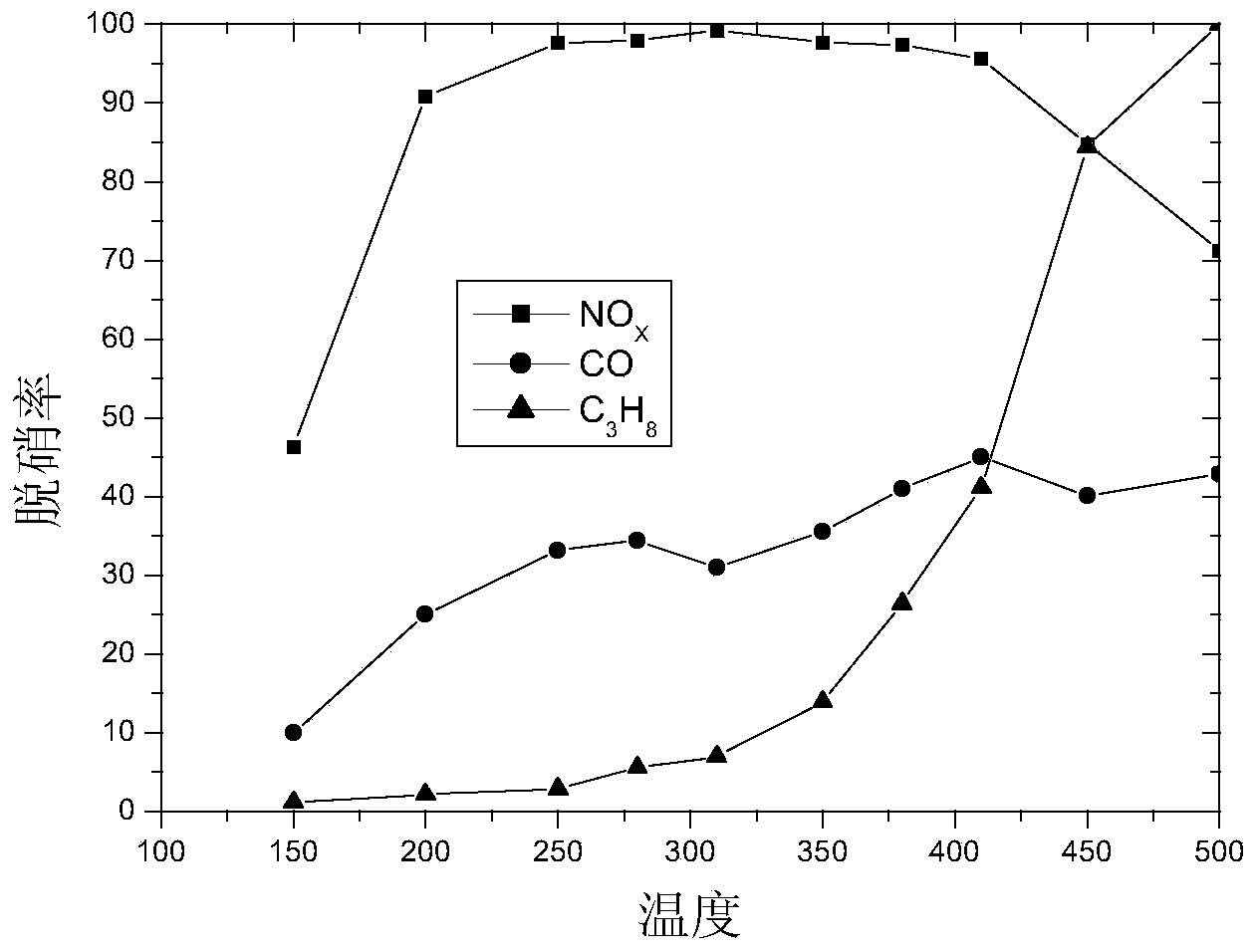

Three-way NOx, CO and HC removing catalyst used in marine engine, and preparation method thereof

ActiveCN103433028AImprove denitrification activityComponents are non-toxicDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCobalt

The invention relates to a three-way NOx, CO and HC removing catalyst used in a marine engine, and a preparation method thereof. The catalyst takes cerium-tin-tungsten composite oxide as an active component, takes one or more oxides of cobalt, ferrum, nickel, copper, lanthanum, molybdenum, manganese, zirconium, silver and yttrium as a promoter, and takes AlSiTi composite oxide as a carrier. A saturated active component solution, a saturated cobalt promoter ionic solution, strong acid alumina gel, diaspore, clayey, titanium dioxide and an organic forming agent are stirred uniformly, mixed, aged and extruded for formation, and the integral type catalyst is obtained through drying and roasting. According to the invention, the catalyst has high NOx removing efficiency, the active temperature window is wide, and the CO and HC removing efficiency is high in a low-temperature collaborated catalyzing manner. According to the catalyst, as the components of the catalyst are nontoxic and environmental-friendly, the catalyst has the advantages that the mechanical strength is high, the vibration resistance as well as the heat resistance is excellent, the preparation technology is simple, and the cost is low. The three-way NOx, CO and HC removing catalyst is applicable to treatment of NOx, CO and HC in tail gas of a marine diesel engine, and is also applicable to treatment to tail gas of other moving sources diesel engines such as automobiles.

Owner:南京环福新材料科技有限公司

Kocuria palustris strain and applications thereof

ActiveCN103103141AFast growthIncrease productionBacteriaMicroorganism based processesBiotechnologyHigh concentration

The invention relates to a Kocuria palustris strain and applications thereof. The strain is Kocuria palustris FSDN-A, and is preserved in the China General Microbiological Culture Collection Center on July 14, 2011, wherein a preservation number is CGMCCNO.5061. According to the present invention, the strain can adopt nitrite nitrogen or nitrate nitrogen as a substrate to complete a denitrification process; when the Kocuria palustris FSDN-A is adopted to treat ammonia-containing wastewater, characteristics of simple process, high denitrogenation activity, and high concentration organic carbon source tolerance are provided; after the strain is poured, the system is rapidly started; and the strain has broad application prospects in wastewater denitrogenation treatment processes, and is especially suitable for treatment of wastewater containing nitrogen oxides and organic pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cordierite-base copper oxide/ gamma-aluminium oxide catalyst used for flue gas denitration and preparation method and application

InactiveCN101053838AReduce coating cracksImprove smoothnessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasHigh intensity

Weight percent ratio of a flue gas Cuo / gamma-Al2O3 catalyst based on cordierite is in that: cordierite carrier is 78.7-93.8%, Al2O3 is 5-16% and CuO is 1.2-5.3%. Cordierite honeycomb ceramic with high intensity is adopted as a substrate, which is impregnated with CuO of a certain concentration after coated with the carrier gamma-Al2O3. The invention can reduce coating crack of the gamma-Al2O3 film and increase firmness of the gamma-Al2O3 coating and uploading capacity of the gamma-Al2O3 by using a simple and effective coating method, and has advantages of enhanced denitrification activity, life and stability of the catalyst.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

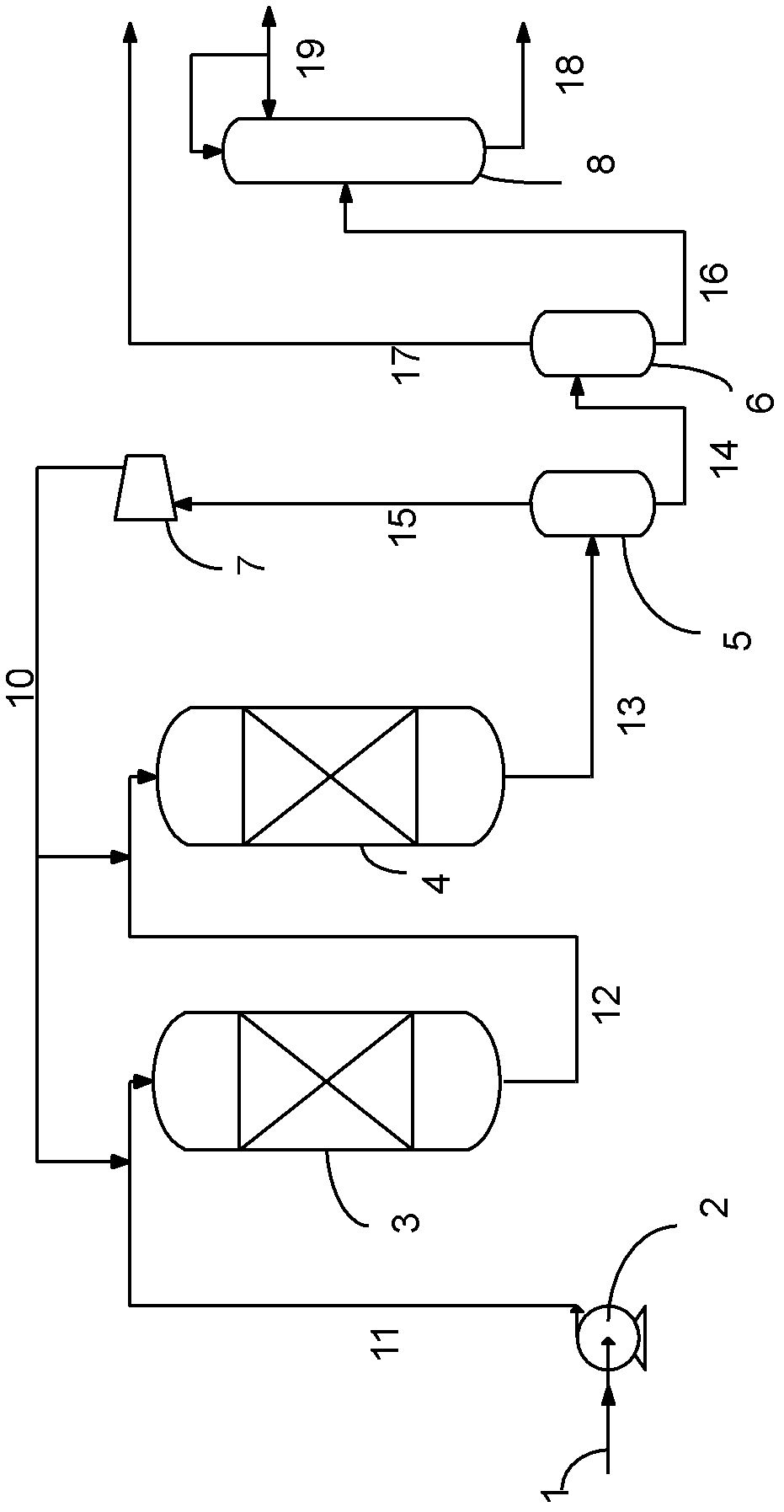

Hydrocracking method for producing gasoline blending component with high octane value

ActiveCN103184073ASimple processEasy to operateHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineReaction zone

The invention relates to a hyfrocracking method for producing a gasoline blending component with a high octane value. The hyfrocracking method controls aromatic saturation depth in a first reaction zone, that is, compared with a diesel oil raw oil, a saturation rate of aromatics with two or more aromatic rings in reaction effluent in the first reaction zone is over 60%, the content of monocyclic aromatics is increased to over 40 mass% on basis of liquid components of the reaction effluent in the first reaction zone; and at the same time, organic nitrogen content in feeding materials of a second reaction zone is no higher than 10 [mu]g.g<-1>. The method for controlling the aromatic saturation depth of a hydrofining section and reinforcing hydro-denitrification activity of a hydrofining catalyst, gasoline fractions with sulfur content less than 50 [mu]g / g and a research octane number higher than 90 can be produced from inferior diesel fractions with high content of the aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cellular activated carbon-based denitration catalyst as well as preparation and application thereof

InactiveCN102078753ALarge specific surface areaWell-developed pore structureCatalyst carriersDispersed particle separationMANGANESE ACETATEActivated carbon

The invention discloses a catalyst for smoke denitration. The catalyst comprises the following components in percentage by weight: 77-96% of cellular activated carbon carrier, 1.3-6.5% of MnO and 2.4-18.8% of CeO2, wherein the mixture of the MnO and the CeO2 serves as an active component. The preparation method is as follows: mixing activated carbon with an organic binder, a forming auxiliary and water, carrying out vacuum extrusion molding, drying, and carbonizing, thus obtaining the cellular activated carbon carrier; and preparing the catalyst by using an isopknic impregnation method based on a mixed liquid of magnganous nitrate or manganese acetate and cerous nitrate, wherein the mixed liquid serves as an impregnation liquid. The cellular activated carbon-based denitration catalyst has the advantages of high specific surface area of cellular activated carbon, developed pore structure and small bed pressure drop, and when being used in smoke denitration, the cellular activated carbon-based denitration catalyst has high denitration activity at the wide temperature range of 80-200 DEG C.

Owner:EAST CHINA UNIV OF SCI & TECH

Coal ash and attapulgite compound SCR denitration catalyst and preparation method thereof

InactiveCN102000564AHigh mechanical strengthImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceActive component

The invention discloses a coal ash and attapulgite compound SCR denitration catalyst and a preparation method thereof. Coal ash and attapulgite compound are used as catalyst carriers for carrying the compound material of manganese oxide. The preparation method comprises the following steps: mixing the coal ash with the attapulgite, making the mixture into coal ash and attapulgite compound catalyst carrier by scoring, molding, drying and burning, using the isopyknic immersion method to carry the compound carrier on the catalyst precursor, drying and burning so as to acquire the finished product. In the invention, the coal ash and the attapulgite cheaply obtained are used as the catalyst carriers, so the cost of the catalyst and the environmental loading of the catalyst are reduced, the mouldability and the heat stability are better, and the low-temperature activity of the catalyst is better because of the loading of manganese active component.

Owner:HEFEI UNIV OF TECH

Iolite honeycomb ceramic catalyst for denitrification of flue gas, preparing method and use thereof

InactiveCN1401416ALow costImprove denitrification activityCatalyst carriersDispersed particle separationHigh resistanceFlue gas

A cellular cordierite ceramic catalyst for denitrifying flue gas is composed of cellular cordierite ceramics as the first carrier, the active alumina film (3-5.3 wt.%) as the second carrier and CuO (1.25-15 wt.%) as active component. It is prepared through applying active alumina film on the first carrier, and carrying CuO. Its advantages are low cost, high strength and activity, and high resistance to water and SO2 poisoning.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

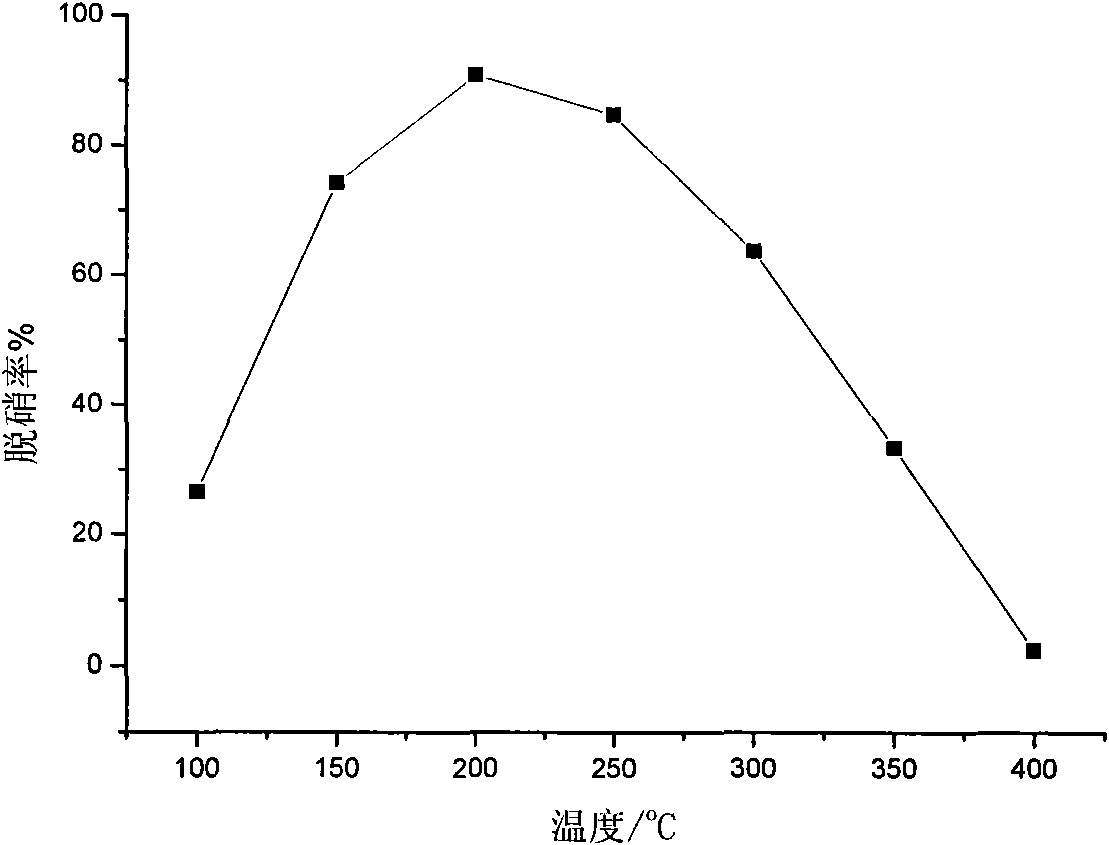

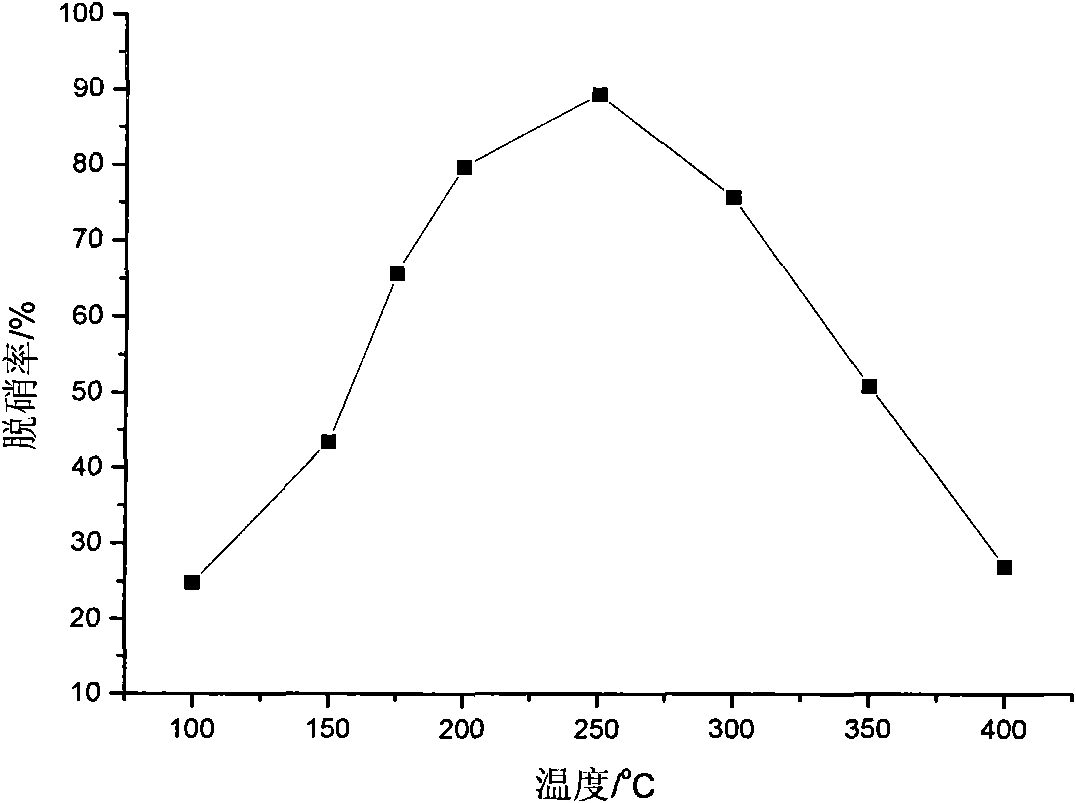

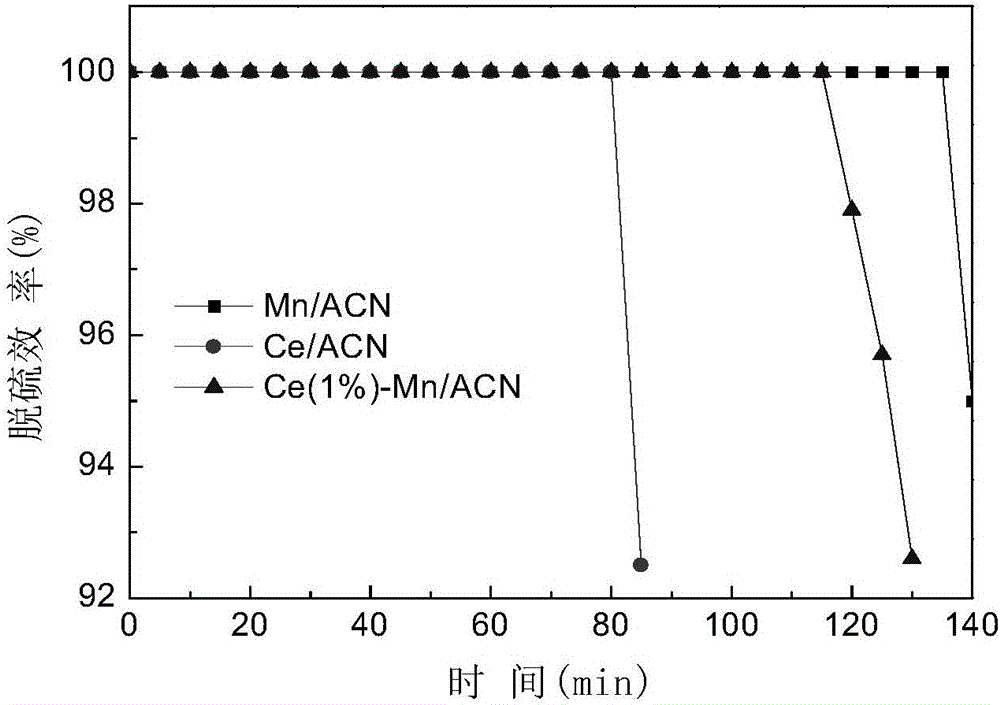

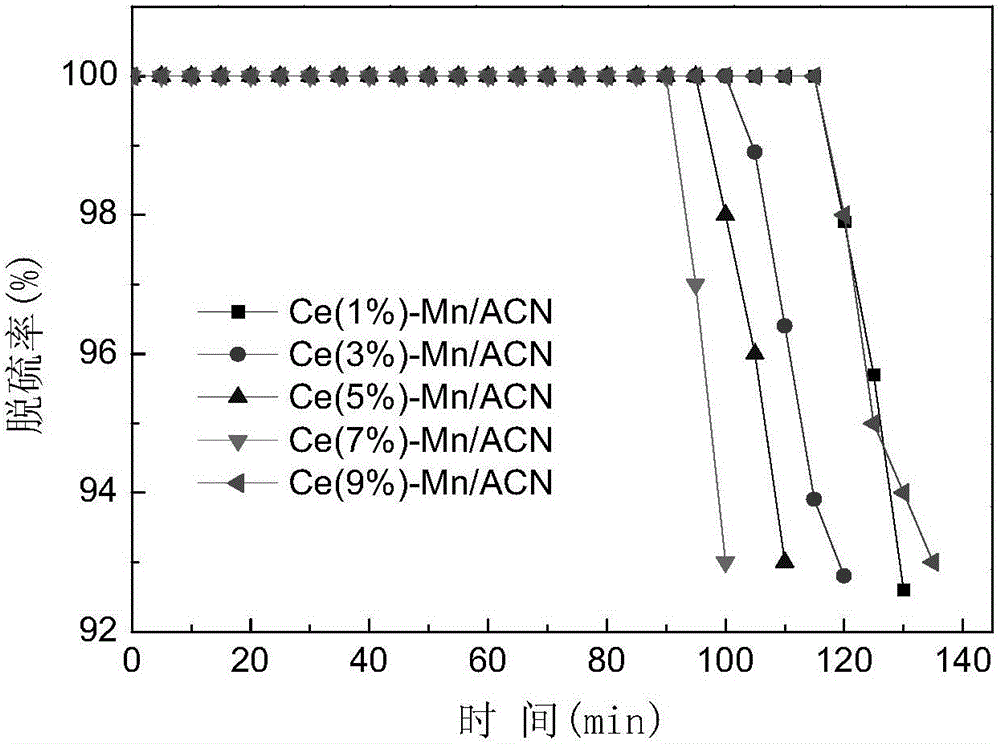

Catalyst used for low temperature desulphurization and denitration of flue gas and preparation method thereof

ActiveCN105032403AImprove denitrification activityDischarge directlyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementActivated carbon

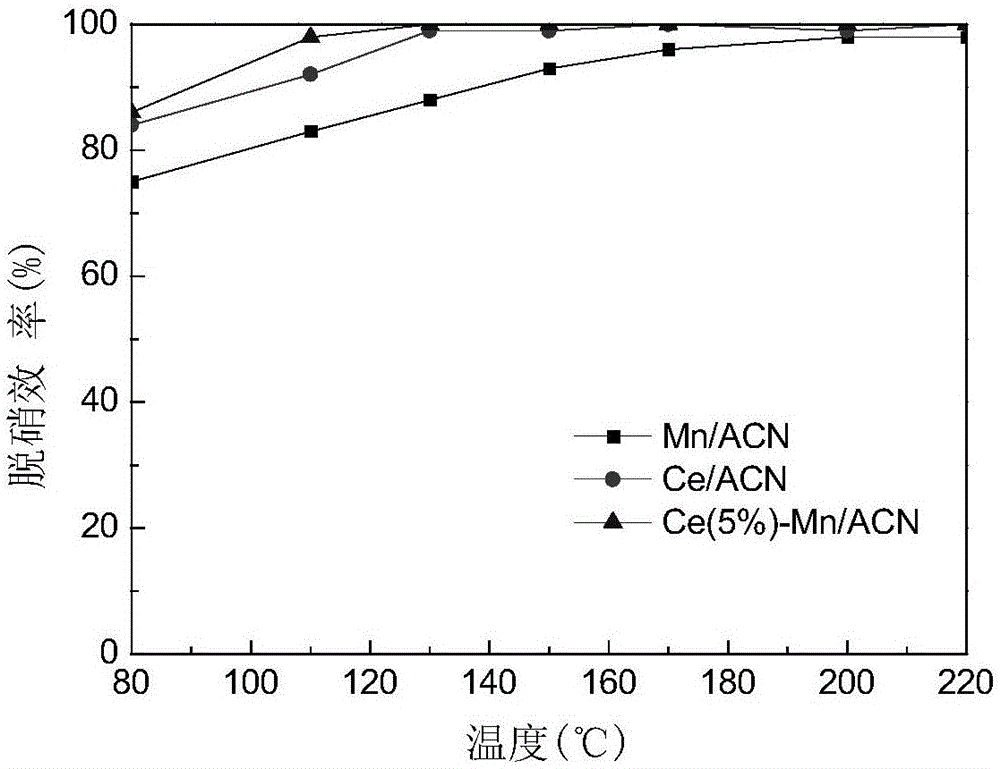

The invention discloses a catalyst used for low temperature desulphurization and denitration of flue gas and a preparation method thereof. The catalyst uses active carbon modified by nitric acid as a carrier and the transition metal Mn and / or the rare earth element as active components; the active components are loaded on the carrier through dipping and high temperature roasting; and the load amount of Mn is 0 to 7 wt% of the weight of the catalyst, the load amount of Ce is 0 to 9 wt% of the weight of the catalyst, and the total load amount of the active components is no less than 3 wt% of the weight of the catalyst. The preparation method for the catalyst comprises the following steps: soaking active carbon in nitric acid for modification, soaking the carbon modified by nitric acid in a manganese nitrate solution or / and cerium nitrate solution and evaporating a liquid phase to dryness so as to allow the modified active carbon to be infiltrated by Mn and / or Ce; and fully roasting the modified active carbon infiltrated by Mn and / or Ce in a roasting apparatus so as to obtain the active-component-loaded catalyst used for low temperature desulphurization and denitration of flue gas. The catalyst has high desulphurization and denitration efficiency in a temperature range of 80 to 220 DEG C.

Owner:成都达奇科技股份有限公司

SCR (Selective Catalytic Reduction) flue gas denitrification catalyst and preparation method thereof

InactiveCN106732759AFast hydrolysisTightly boundMolecular sieve catalystsDispersed particle separationCarboxylic saltPolyacrylamide

The invention discloses a preparation method of an SCR (Selective Catalytic Reduction) flue gas denitrification catalyst. The preparation method comprises the following steps: (1) firstly preparing a mixed solution of titanium sulfate and amino carboxylate, adding powdered molecular sieve into the mixed solution for dipping, and carrying out drying and roasting to prepare a TiO2-molecular sieve composite carrier; (2) dipping the TiO2-molecular sieve composite carrier prepared in the step (1) into dipping liquid containing an active component and an adjuvant precursor, and carrying out drying and roasting to obtain denitrification catalyst powder; (3) mixing the denitrification catalyst powder obtained in the step (2) with glass fiber, wood pulp, polyacrylamide, carboxymethyl cellulose, ammonia water and deionized water, and carrying out kneading, aging, extrusion, drying and roasting to obtain a cellular denitrification catalyst. The preparation method is simple in preparation process and low in cost; the obtained denitrification catalyst is wide in active temperature range, high in denitrification activity and high in SO2 and H2O poisoning resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

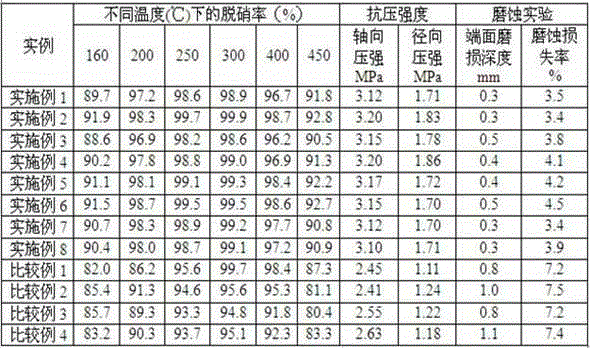

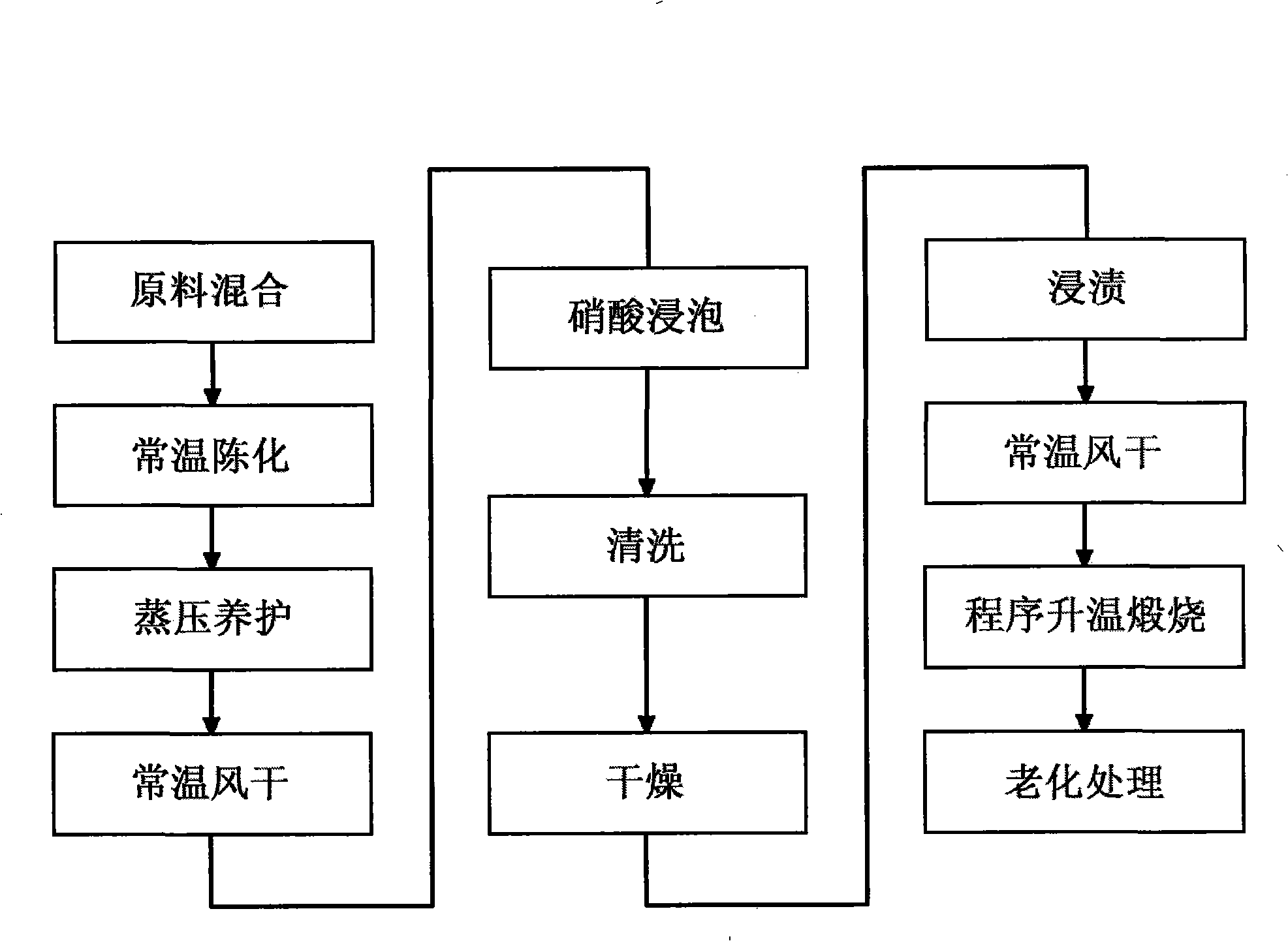

Preparation of iron-based selective catalytic reduction denitration catalyst

ActiveCN101279261AIncrease profitGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWorking temperatureCoal

The present invention relates to a preparation method for an iron-based selective reducing denitration catalyst which takes ferric oxide as an active component and coal powder ash as a carrier and achieves a certain denitration effect simultaneously when catalyzing a denitration action. 70 to 79 wt percent of the coal powder ash, 16 to 25 wt percent of calcium oxide, 5 to 14 wt percent of common silicate cement and a little additive are taken as the raw materials and mixed for autoclave curing so as to make the shaped coal powder ash; after cleanup acid treatment is carried out on the shaped coal powder ash, a dipping method and a program temperature-raising calcination are adopted to support 5 to 15wt percent of Fe2O3 as the active component, then the shaped coal powder ash is put into an atmosphere containing SO2 and O2 for heating and aging. The prepared catalyst has a low cost; the denitration activity can reach more than 90 percent; the desulfurized sulphur capacity can reach 5 to 30wt percent; the working temperature window of the catalyst is broad and more than 200 DEG C. The catalyst can be widely applied to the art of boiler smoke gas treatment in a power station.

Owner:TSINGHUA UNIV

Flue gas denitrification powder catalyst as well as preparation method and application thereof

InactiveCN105080566AExcellent resistance to SO <sub>2<</sub> Excellent sub>Dispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNiobiumWater vapor

The invention relates to a flue gas denitrification powder catalyst as well as a preparation method and application thereof. The catalyst comprises titanium dioxide and manganese oxide serving as main components, as well as auxiliaries which are any three or a combination of three or more in oxides of zirconium, copper, molybdenum, cerium, ferrum, nickel, cobalt, niobium and tungsten, wherein the molar ratio of Mn to Ti is equal to 0.01-1.0, and the molar ratio of each metal in the auxiliaries to a titanium element is equal to 0.01-1.0 independently. The catalyst is prepared through a co-precipitation method. The catalyst can be applied to purification with selective catalytic reduction of nitric oxide (NH3-SCR) in flue gas with a fixed source and a moving source. The catalyst prepared from the non-poisonous harmless raw materials has the advantages of convenient preparation method, high catalytic activity, high N2 selectivity, wide active window, resistance to low-concentration SO2 poisoning and water vapor poisoning, environmental friendliness, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

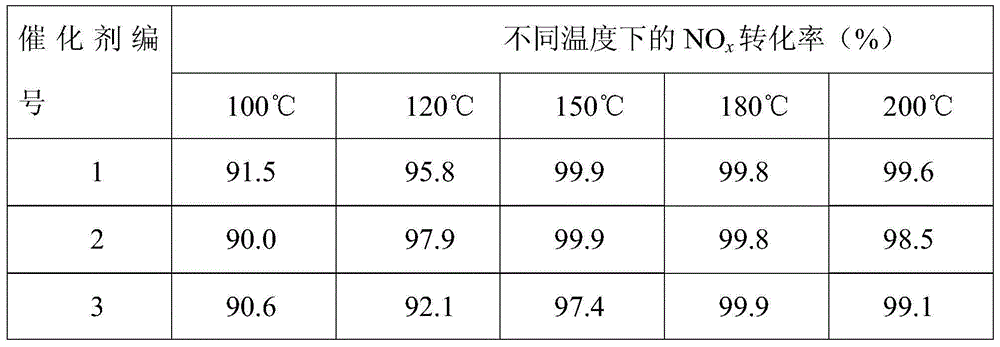

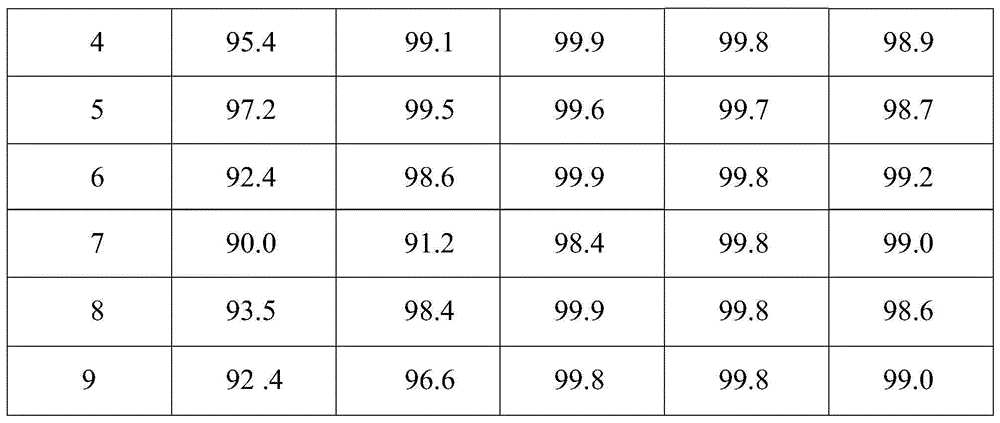

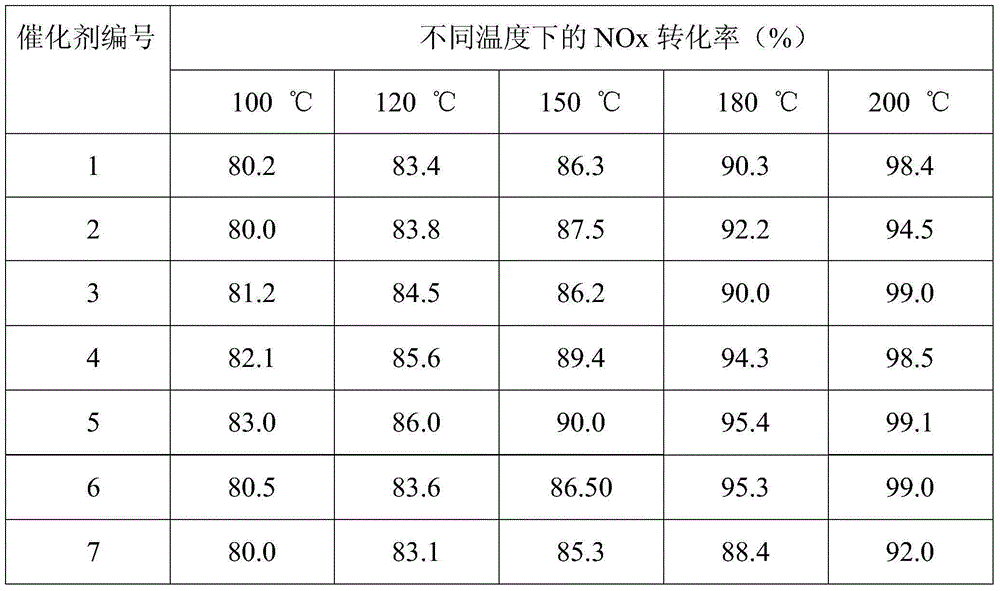

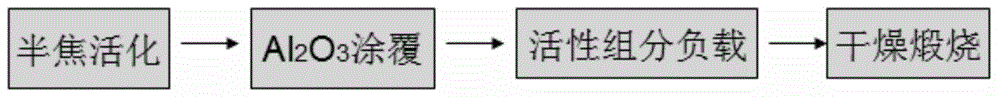

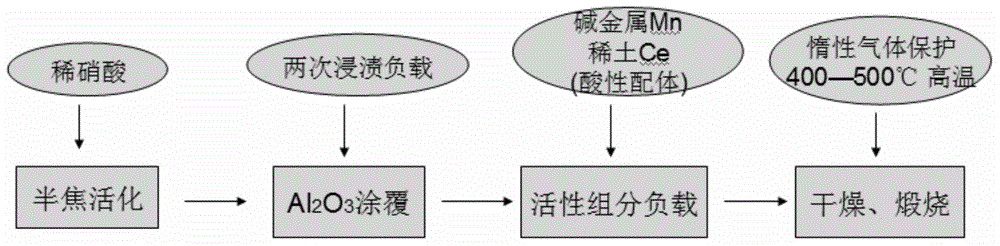

Low-temperature high-activity flue gas denitrification catalyst and preparation thereof

ActiveCN104941630ALow denitrification catalytic efficiencyHigh denitrification catalytic efficiency of flue gas at low temperature (90-120°C)Dispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementSinter Plant

The invention relates to a low-temperature high-activity flue gas denitrification catalyst and preparation thereof. According to the catalyst, a carbon-base material serves as a carrier and carries one or more metal active components of active Al2O3, Mn, Cu and Fe and one or two of rare earth active components of Ce and La. The content of the carbon-base carrier ranges from 35% to 65%, the carrying content of the Al2O3 ranges from 2% to 5% by the content of the aluminum element, the content of the metal active components ranges from 13% to 26% by the content of the metal elements, and the carrying content of the rare earth active components ranges from 20% to 39% by the content of the rare earth elements. According to the catalyst, the carbon-base material is activated through dilute nitric acid and then is coated with aluminum oxide sol, the metal active components and the rare earth active components are carried, then drying and sintering are carried out in the inert atmosphere, and the catalyst is obtained. The catalyst high in flue gas denitrification catalytic efficiently at the low temperature (90-120 DEG C) and not likely to cause poisoning and failures is obtained. The catalyst is low in production cost, simple in production technology and especially suitable for thermal power plants, steel plants, sintering plants and other enterprises with heavy fuel gas emission.

Owner:北京大学包头创新研究院

Vanadium-doped titanium-base flue gas denitration catalyst material and preparation method thereof

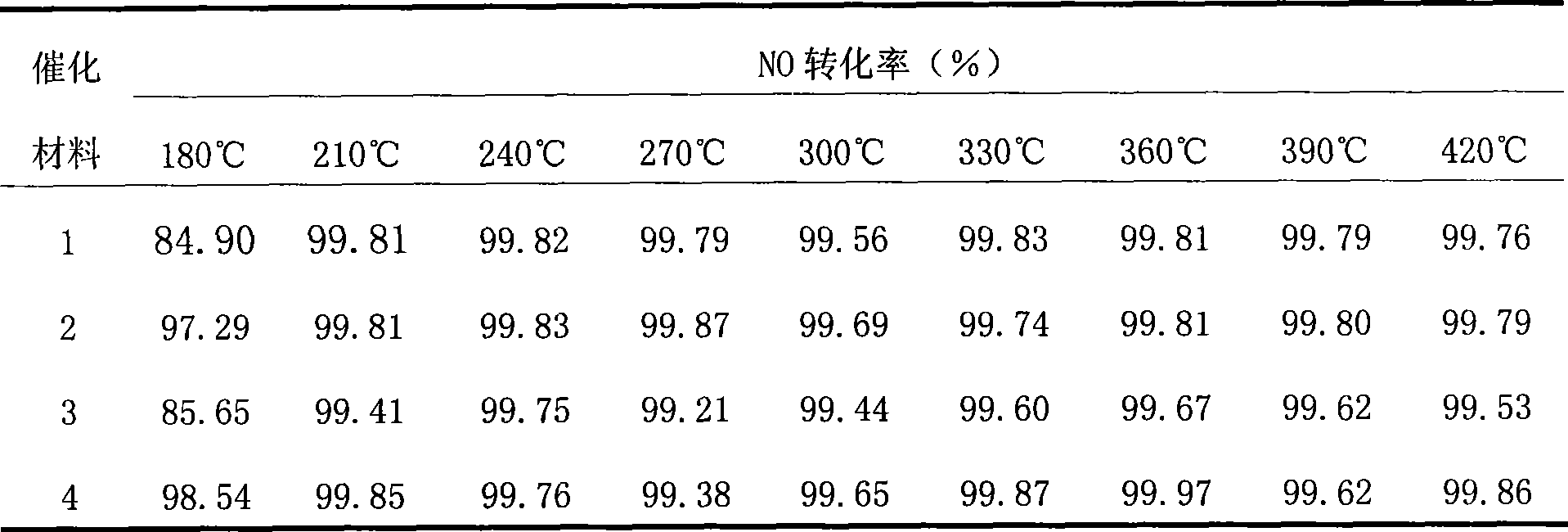

InactiveCN101480611ALarge specific surface areaImprove thermal stabilityDispersed particle separationCatalyst activation/preparationVanadium dopingActive agent

The invention relates to a vanadium doping type titanium base fume denitration catalytic material and a preparation method thereof. The material is characterized in that a surface active agent is used as a pore structure guiding agent, a water solution system sol-gel method is used for preparing the vanadium doping type titanium base catalytic material, and the doping content of active component vanadium is 0.5 to 20wt percent measured by V2O5. Because an in-situ doping loading mode is adopted in the sol-gel process, the preparation method is simple, and the production cost is low; in addition, the prepared denitration catalytic material has larger specific surface area, higher heat stability, higher denitration efficiency and wider active temperature window, and is suitable for the field of removal of coal-fired fume nitrogen oxide. The laboratory simulation fume evaluation shows that when the air speed is 10,000 / h, and under the condition that the content of NO is 1000ppm, the removal rate of NO achieves more than 95 percent at the temperature of 180 to 420 DEG C.

Owner:UNIV OF SCI & TECH BEIJING

Scr flue gas denitrification catalyst and preparation method based on tio2 carrier promoted by sulfate radical

ActiveCN102259009AStrong oxygen storage-release capacityStrong oxidation-reduction propertiesPhysical/chemical process catalystsDispersed particle separationSulfate radicalsFlue gas

The invention relates to a sulfate radical promoted nanometer TiO2 carrier based SCR (Selective Catalytic Reduction) flue gas denitration catalyst and a preparation method thereof, belonging to the fields of environmental protection and environmental catalysis. In the invention, a SO42- / TiO2 carrier based medium / low-temperature flue gas denitration catalyst is obtained through taking sulfate radical promoted nanometer TiO2 (SO42- / TiO2) as the carrier, taking WO3 and CeO2 as auxiliaries and taking V2O5 as an active component, wherein in the composite catalysis, the mass percentage of the V2O5 is 0.5-1.5%; the mass percentage of the WO3 is 4-10%; the mass percentage of the CeO2 is 1-5%; and the balance is SO42- / TiO2. The acidity of the catalyst is obviously increased after nanometer TiO2 issubject to sulfating treatment; the denitration activity of the catalyst is increased through interacting with the V2O5, the WO3 and the CeO2; and very good catalytic activity is showed through taking ammonia as a reducing agent at a temperature of 150-450 DEG C.

Owner:北京华电光大环境股份有限公司

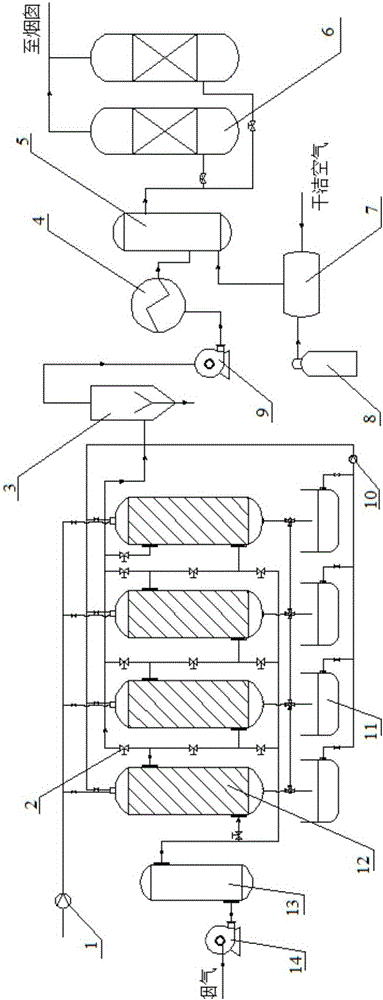

Flue gas low-temperature combined desulfurization and denitration technology method

InactiveCN105327612AAchieve recyclingNo entryDispersed particle separationFlue gasConcentration gradient

The invention discloses a flue gas low-temperature combined desulfurization and denitration technology method mainly including the steps: flue gas after dedusting having a purification temperature and humidity meeting desulfurization conditions is sent into a desulfurization tower to flow through a desulfurization catalyst bed, sulfur dioxide in the flue gas is oxidized into sulfur trioxide under the action of a catalyst, and sulfur trioxide acts with water in the flue gas to generate sulfuric acid; the desulfurization catalyst bed is regenerated through progressively-decreased sulfuric acid concentration gradient washing; the flue gas after desulfurization is sent into a denitration conditioning work section, is dehumidified and heated, and is adjusted to meet requirements of a denitration technology; the flue gas after dehumidification and heating is sent into a mixing tower and is mixed with injected ammonia gas, the mixed flue gas mixed with the ammonia gas is sent into a denitration tower to flow through a denitration catalyst bed, and NOx, NH3 and O2 in the mixed flue gas are converted into N2 and water under the action of a denitration catalyst. The problems that a conventional flue gas desulfurization and denitration technology is narrow in flue gas applicable scope, high in heating energy consumption, high in running cost and the like are overcome.

Owner:SICHUAN UNIV +1

Regeneration method for arsenic poisoning selective catalytic reduction denitration catalyst

InactiveCN103894240AClean up thoroughlyGain resistance to arsenic poisoningCatalyst regeneration/reactivationBULK ACTIVE INGREDIENTArsenic poisoning

The invention discloses a regeneration method for an arsenic poisoning selective catalytic reduction denitration catalyst. The regeneration method comprises the following four steps of blowing ash, dipping, dipping, and drying and roasting. According to the regeneration method, an arsenic component which can cause SCR (Selective Catalytic Reduction) denitration catalyst poisoning can be effectively removed by using regenerated liquid and active ingredients can be supplemented; an SCR denitration catalyst obtains a certain arsenic poisoning resisting capability; meanwhile, a regeneration process is greatly simplified and the regeneration cost of the SCR denitration catalyst is reduced; with the adoption of the method, the regenerated denitration catalyst can be used for carrying out denitration activity detection and the denitration rate can be up to 80-88%.

Owner:河北宏庚环保设备有限公司

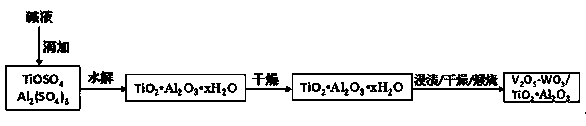

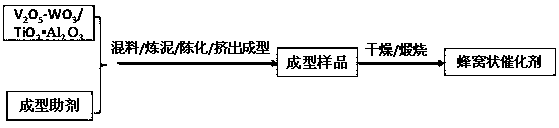

Honeycombed denitration catalyst taking titanium aluminum composite oxide as carrier and preparation method thereof

ActiveCN104190394AHigh mechanical strengthIncrease the areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPurification methodsAdhesive

The invention belongs to the field of chemistry and relates to an industrial gas purification method, in particular to a honeycombed denitration catalyst taking titanium aluminum composite oxide as a carrier and a preparation method thereof. The catalyst comprises the effective ingredients including the titanium aluminum composite oxide, vanadium pentoxide and tungsten trioxide and takes glass fiber as a reinforcing agent, polyacrylamide as an adhesive, glycerol as a lubricating agent and activated carbon as a pore-forming agent. The preparation method comprises the following steps: preparing the titanium aluminum composite oxide; preparing a powder catalyst; extruding and forming the honeycombed catalyst; post-treating the honeycombed catalyst. According to the invention, the flue gas denitration catalyst (SCR catalyst) prepared by the method has high mechanical strength, high denitration activity, good sulfur resistance and reliable production process and can meet the demands on the denitration of nitric oxide by industrial flue gas, thereby having better application prospect; the honeycombed denitration catalyst prepared by the method has great significance in breaking through the foreign technical barriers and promoting the development of the denitration industry in China.

Owner:HAO HUA CHENGDU TECH

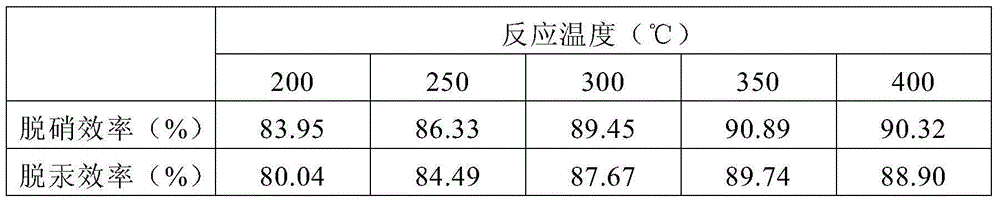

Regeneration method for inactivated TiV-based honeycomb denitration catalyst having combined denitration and demercuration modification function

ActiveCN104888806AImprove denitrification activityImprove mercury oxidation abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryStrong acids

The invention discloses a regeneration method for an inactivated TiV-based honeycomb denitration catalyst having the combined denitration and demercuration modification function. Firstly, the physical and chemical properties of an SCR denitration catalyst are detected, and the inactivated reasons of the catalyst are analyzed. Secondly, the regenerable catalyst is subjected to ultrasonic cleaning in deionized water, a strong alkaline solution or a strong acid solution, so that deposited ashes and pernicious elements in the catalyst can be removed. Thirdly, the cleaned catalyst is immersed in a combined denitration and demercuration regeneration solution, until the activity of the catalyst is stable. Finally, the activated catalyst is transferred to a microwave oven to be dried and calcined through the microwave heating process. The catalyst, obtained through the above method, successively has the combined oxidation and demercuration capacity, while the denitration activity of the catalyst is recovered at the same time. At a temperature smaller than 350 DEG C, the denitration efficiency of the catalyst is up to be equal to or over 90%, and the demercuration efficiency of the catalyst is up to be equal to or over 90%. Meanwhile, the condition that the cost is increased due to the demercuration process after the flue gas denitrification process can be avoided. Therefore, the method is economical and environmentally-friendly, thus being suitable for industrial promotion.

Owner:HUANENG CLEAN ENERGY RES INST

Hydroprocessing catalyst for heavy oil and preparing method thereof

InactiveCN1488718AReduce dosageAvoid damageRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The present invention relates to a preparation method of hydrogenation treatment catalyst. Said catalyst is prepared by loading molybdenum, nickel and phosphorus on a phosphorus and silicon contained alumina carrier prepared by adopting a special method, and said carrier prepared by special method is prepared by adding phosphorus adjuvant in the course of precipitation and ageing process and adding nano silicon-containing compound in the course of carrier forming process, for example, adding silicon dioxide. As compared with existent catalyst it has higher activity for hydro-desulfurization and hydro-denitrification of heavy oil, specially heavy fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

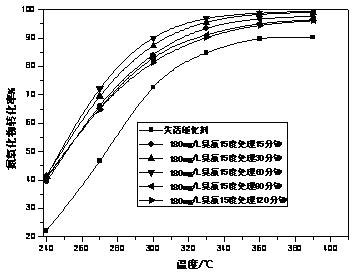

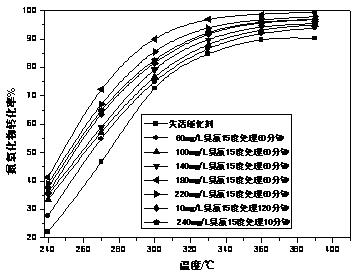

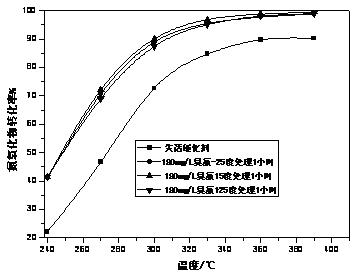

Ozone treatment regeneration method and device for vanadium titanium-based flue gas denitration catalyst

InactiveCN102133547AImprove denitrification activityAvoid the problem of decreased mechanical strengthDispersed particle separationCatalyst regeneration/reactivationExhaust gasEnvironmental chemistry

The invention discloses an ozone treatment regeneration method and an ozone treatment regeneration device for a vanadium titanium-based flue gas denitration catalyst. The method comprises the following steps of: filling an inactivated flue gas denitration catalyst into a catalyst regeneration reaction bed; introducing ozone-air mixed gas into the catalyst regeneration reaction bed; and finishing the catalyst regeneration process after oxidation. The ozone treatment regeneration device for the vanadium titanium-based flue gas denitration catalyst comprises an ozone generator, a four-way valve,the catalyst regeneration reaction bed and an ozone exhaust catalytic decomposition treatment device, wherein four connecting ports of the four-way valve are connected with two ends of the catalyst regeneration reaction bed, the ozone generator and the ozone exhaust catalytic decomposition treatment device through pipelines respectively; the flow direction of the ozone-air mixed gas is changed byadjusting the four-way valve; and MnO2-CO3O4 / TiO2 is filled into the ozone exhaust catalytic decomposition treatment device, and the exhaust is decomposed in the ozone exhaust catalytic decompositiontreatment device.

Owner:SOUTH CHINA UNIV OF TECH +1

Low-temperature denitration catalyst as well as preparation method and application thereof

InactiveCN103933971AImprove bindingNot easy to peel offDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioHoneycomb

The invention discloses a low-temperature denitration catalyst as well as a preparation method and application thereof. Cordierite honeycomb ceramics are taken as a first carrier of the low-temperature denitration catalyst, and activated titanium dioxide is taken as a second carrier, and the activated components of manganite and auxiliary cerium oxide are loaded. The catalyst comprises the following composition in percentage by weight: TiO2 accounts for 1.7-15.0% of the cordierite honeycomb ceramic carrier, and manganese cerium oxide accounts for 0.64-2.00% of the cordierite honeycomb ceramic carrier, wherein the mass ratio of cerium oxide to manganese oxide is (0-2.1):1. The low-temperature denitration catalyst has the advantages of simple preparation technology, low cost, high low-temperature activity and large-scale industrialization.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Denitration catalyst regeneration solution and preparation method thereof as well as catalyst regeneration method

ActiveCN103949291AGood water solubilityImprove catalytic performanceCatalyst regeneration/reactivationIonCopper nitrate

The invention discloses a denitration catalyst regeneration solution and a preparation method thereof as well as a catalyst regeneration method. The denitration catalyst regeneration solution comprises the following raw material ingredients in parts by weight: 4-6 parts of vanadyl oxalate, 0.08-0.10 part of cerium nitrate, 0.11-0.13 part of lanthanum nitrate, 0.05-0.07 part of copper nitrate, 0.4-0.6 part of silica sol ST-O and 95 parts of deionized water. The catalyst regeneration method comprises the following steps of firstly, evenly mixing vanadyl oxalate and the deionized water; then, feeding cerium nitrate, lanthanum nitrate and copper nitrate into mixed solution, and fully stirring until the mixture is completely dissolved; finally, feeding silica sol ST-O, and continuing to stir until homogeneous phase is obtained; and sequentially carrying out strong scavenging and ultrasonic cleaning on an inactivated denitration catalyst module, soaking the module in cleaning solution for 18-25 minutes, continuing soaking the module in the regeneration solution for 25-40 minutes, taking out the denitration catalyst module and drying. After the denitration catalyst regeneration solution and the catalyst regeneration method are adopted, the activity of the inactivated denitration catalyst can be efficiently recovered, and the temperature range of the catalyst activity is widened.

Owner:江苏万德环保科技有限公司

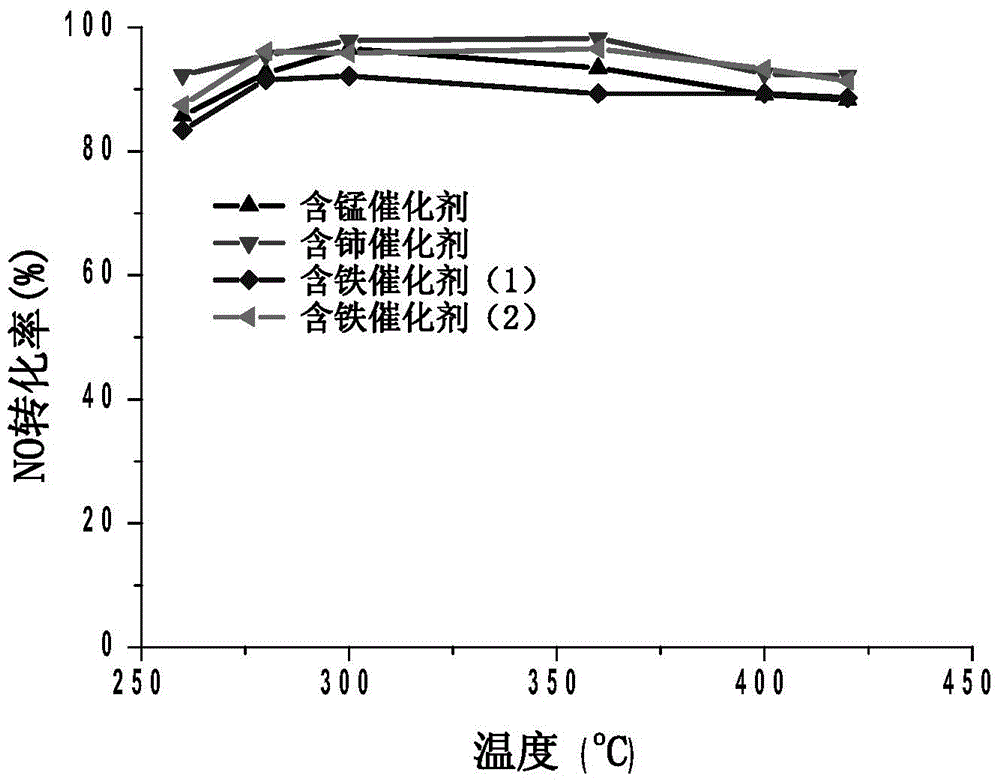

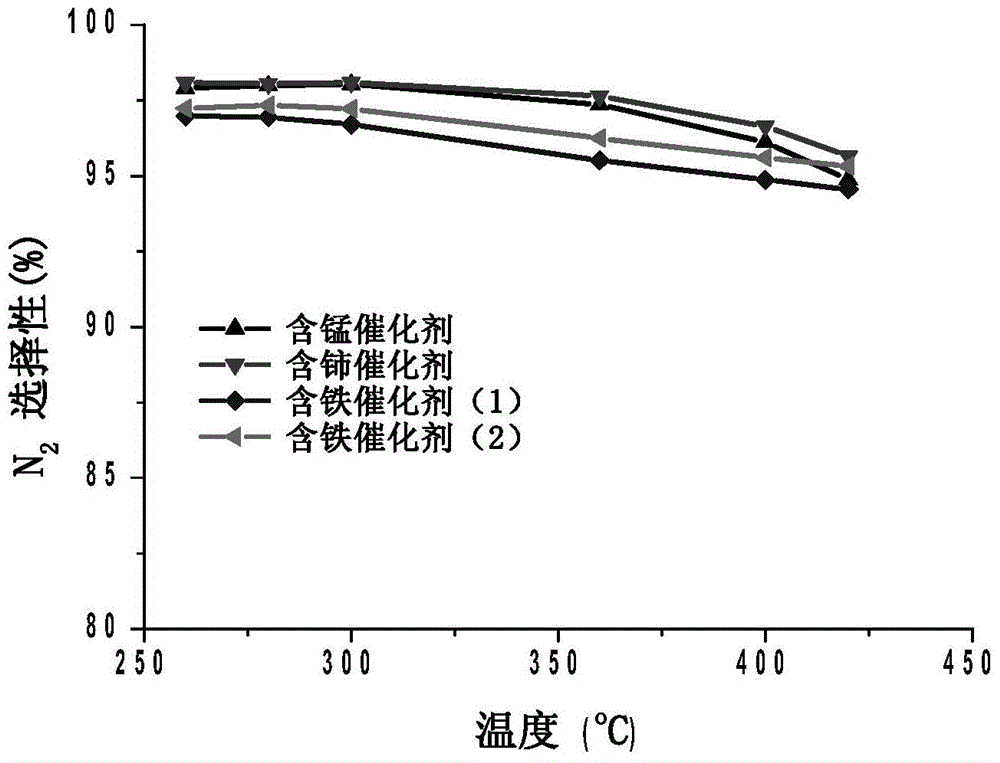

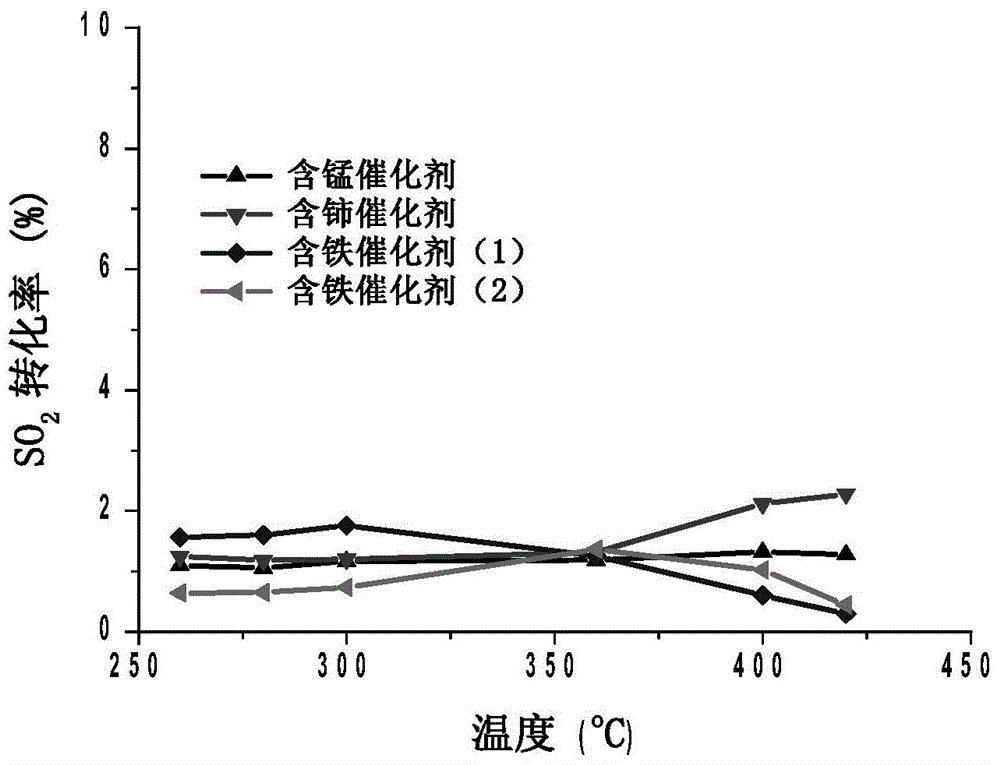

Denitration catalyst for wide temperature window under high sulfur condition and preparation method thereof

ActiveCN104525216ASimple processImprove denitrification activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATERare earth

The invention discloses a denitration catalyst for a wide temperature window under a high sulfur condition and a preparation method thereof. The catalyst is prepared from the following components in percentage by weight of the denitration catalyst: 1wt% of vanadium pentoxide, 6wt% of tungsten trioxide, 5wt% of one of manganese oxide, cerium oxide, ferric oxide without sulfur or ferric oxide with sulfur, and the balance of titanium dioxide. The preparation method comprises the following step: adjusting a commercial V2O5-WO3 / TiO2 catalyst by adding traditional metals iron and manganese and rare earth cerium, specifically, in the preparation process of the catalyst, adding ferric nitrate, ferric sulfate, manganese acetate or cerous nitrate to obtain the highly active catalyst which has good SO2 poisoning resistance and has the denitration activity over 80% under the condition that the temperature is 260-420 DEG C in a relatively wide high-temperature region and the SO2 concentration is high (1000ppm).

Owner:江苏中创清源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com