Catalyst used for low temperature desulphurization and denitration of flue gas and preparation method thereof

A desulfurization and denitrification, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poor toxicity, short service life, and low sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

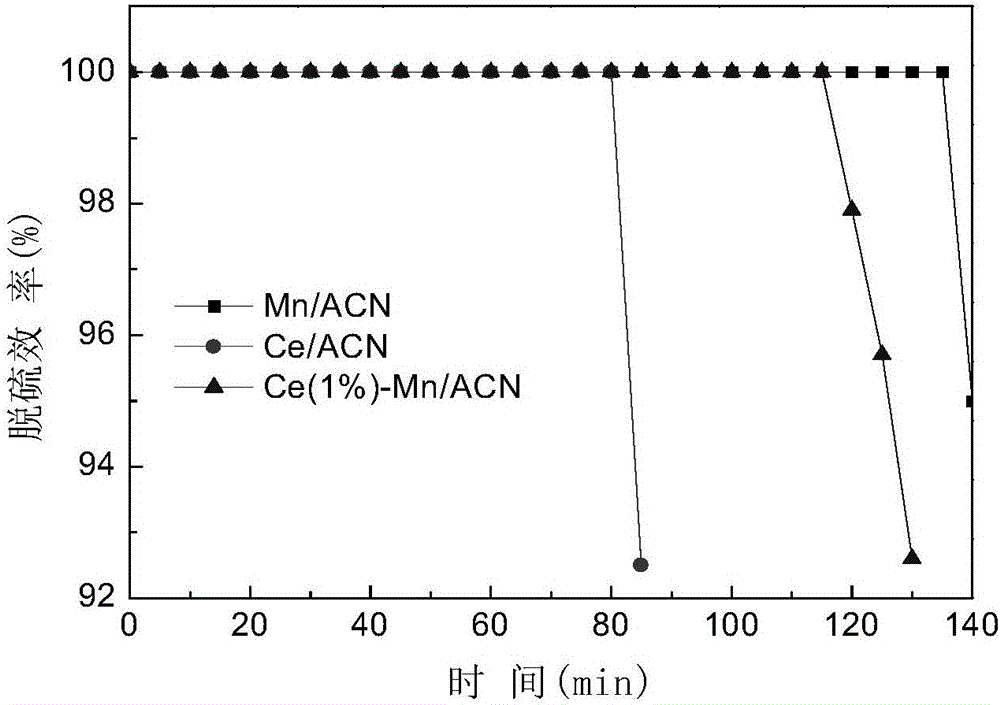

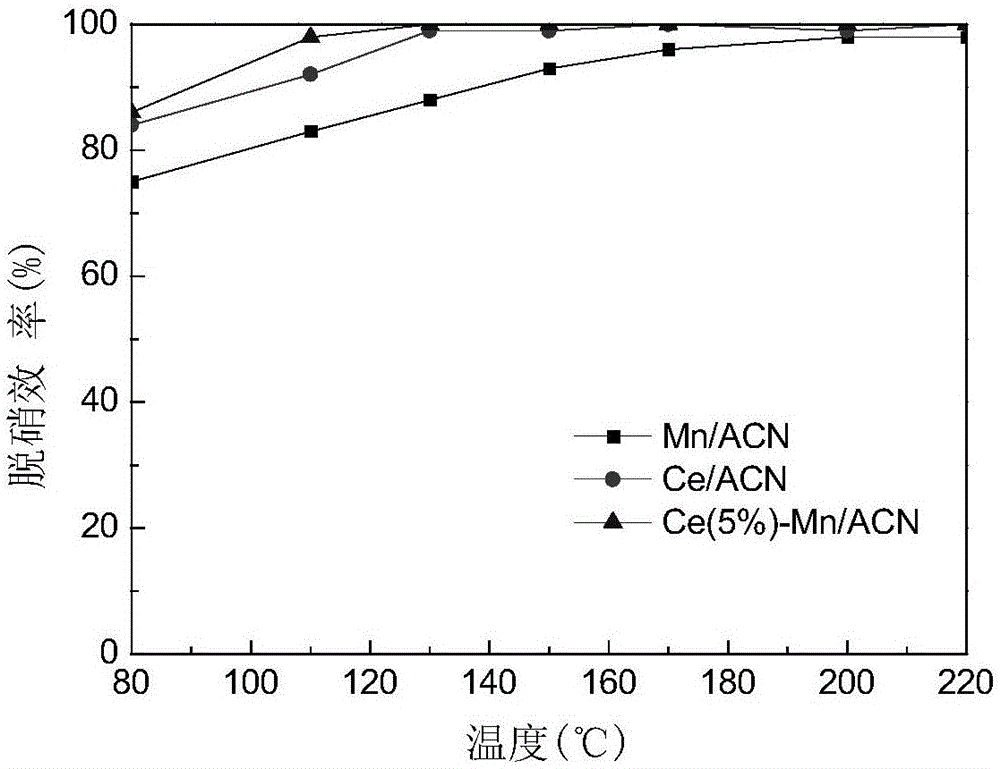

Embodiment 1

[0027] Activated carbon (AC) was placed in a beaker, and nitric acid with a weight concentration of 39% was added to immerse the AC in the nitric acid, sealed and left to stand for about 12 hours. After full immersion, wash with water until the eluate is neutral, filter with suction, and dry. The obtained sample is recorded as ACN. Weigh 25g of ACN, calculate the required amount of manganese nitrate solution according to the loading of Mn being 5wt% of the catalyst weight and the law of conservation of Mn element. Mix CAN with manganese nitrate solution, add an appropriate amount of distilled water, make the liquid submerged in CAN, let it stand for about 10 hours, put it in a water bath and evaporate to dryness, so that Mn is impregnated on CAN. The Mn-impregnated CAN was calcined at about 650 °C in a pure nitrogen atmosphere for about 3 hours to obtain a desulfurization and denitration catalyst with a Mn loading of 5%, which was denoted as Mn / ACN. According to the evaluatio...

Embodiment 2

[0029] Activated carbon (AC) was placed in a beaker, and nitric acid with a weight concentration of 20% was added to immerse the AC in the nitric acid, sealed and left to stand for about 10 hours. Then wash with water until the eluate is neutral, filter with suction and dry, and the obtained sample is recorded as ACN. Weigh 25g of ACN, calculate the required amount of cerium nitrate solution according to the Ce loading amount is 5wt% of the catalyst weight and the Ce element conservation law. Mix CAN with cerium nitrate solution, add an appropriate amount of distilled water, make the liquid submerged in CAN, let it stand for about 12 hours, put it in a water bath and evaporate to dryness, so that Ce is impregnated on CAN. A desulfurization and denitration catalyst with a Ce loading of 5% can be obtained by calcining the CAN impregnated with Ce in a pure nitrogen atmosphere at about 450 °C for about 3 hours, which is denoted as Ce / ACN. According to the evaluation conditions in...

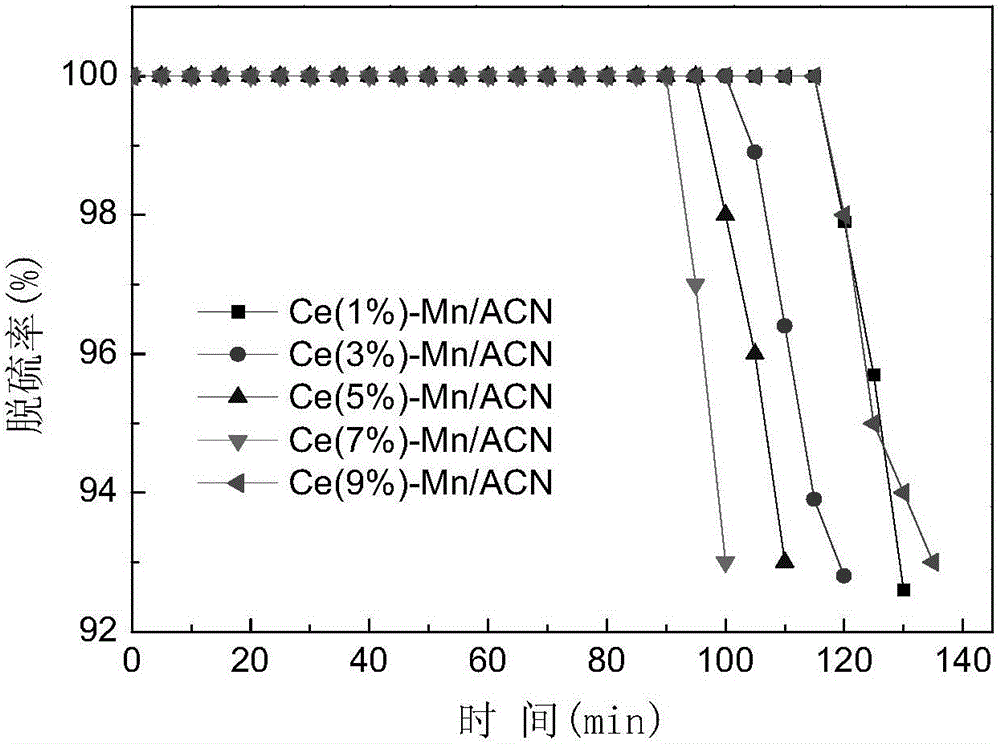

Embodiment 3

[0031] Activated carbon (AC) was placed in a beaker, and nitric acid with a weight concentration of 30% was added to immerse the AC in the nitric acid, sealed and left to stand for about 10 hours. Then wash with water until the eluate is neutral, filter with suction and dry, and the obtained sample is recorded as ACN. Weigh 25g of ACN, calculate the required amount of manganese nitrate solution according to the loading of Mn being 5wt% of the catalyst weight and the law of conservation of Mn element. Mix CAN with manganese nitrate solution, add an appropriate amount of distilled water, make the liquid submerged in CAN, let it stand for about 10 hours, put it in a water bath and evaporate to dryness, so that Mn is impregnated on CAN. The Mn-impregnated CAN was calcined at about 650 °C in a pure nitrogen atmosphere for about 3 hours to obtain a desulfurization and denitration catalyst with a Mn loading of 5%, which was denoted as Mn / ACN. On the as-prepared Mn / ACN catalyst, 1% C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com