Patents

Literature

234results about How to "Improve desulfurization and denitrification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

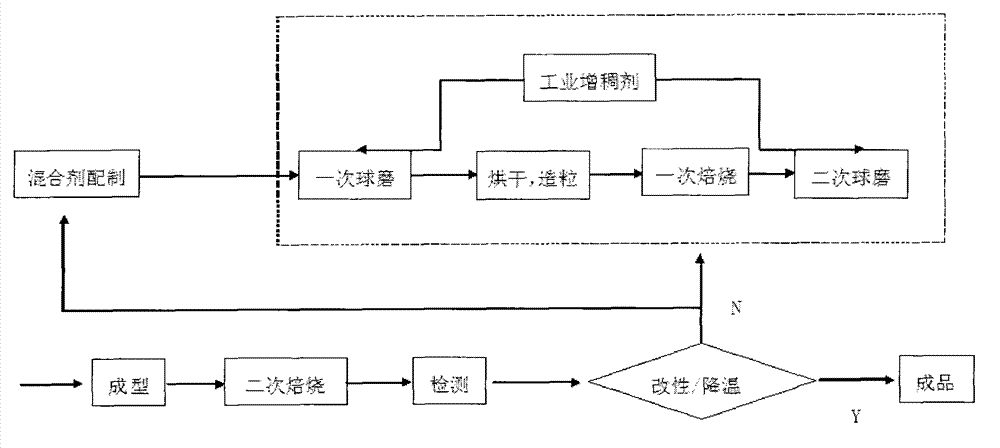

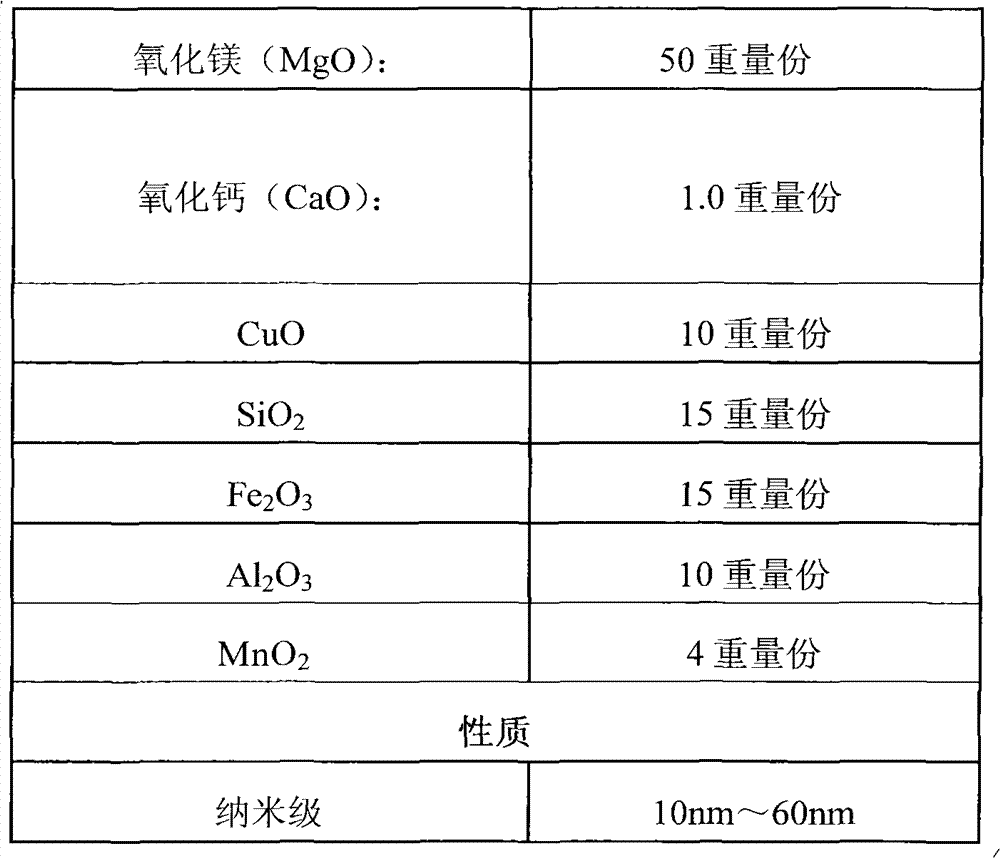

Desulfurization and denitrification agent, preparation method and application thereof

ActiveCN102824844ALarge specific surface areaEnhanced adsorption functionOther chemical processesDispersed particle separationChemistryFlue-gas desulfurization

The invention discloses a desulfurization and denitrification agent, a preparation method and application thereof. The desulfurization and denitrification agent is a nanometer material and comprises the following components: MgO, SiO2, CaO, Fe2O3, Al2O3, CuO and MnO2. Preferentially, the desulfurization and denitrification agent also comprises a strong oxidant KMnO4. By using the nanometer desulfurization and denitrification agent disclosed by the invention, NOX can be synchronously removed during a flue gas desulfurization process, and the desulfurization and denitrification efficiency is high.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

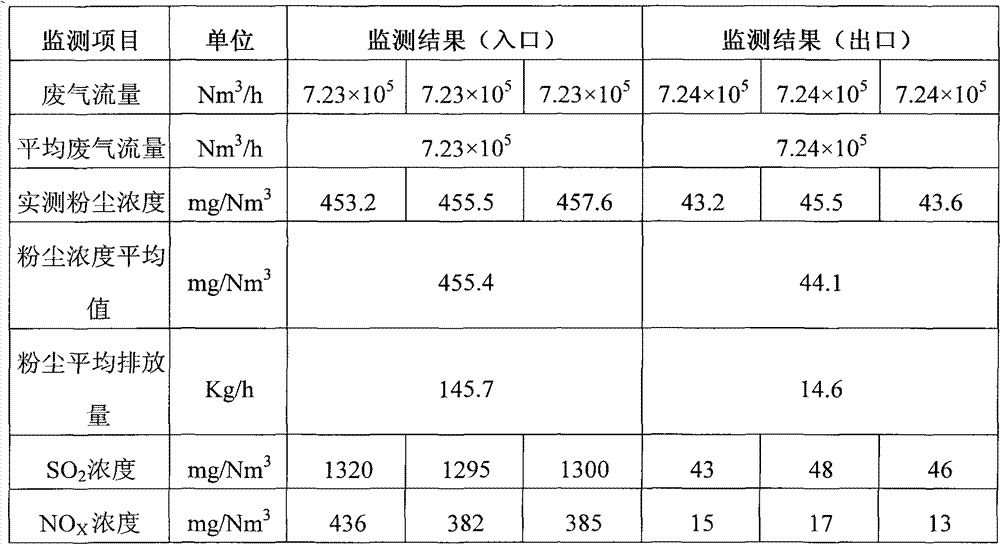

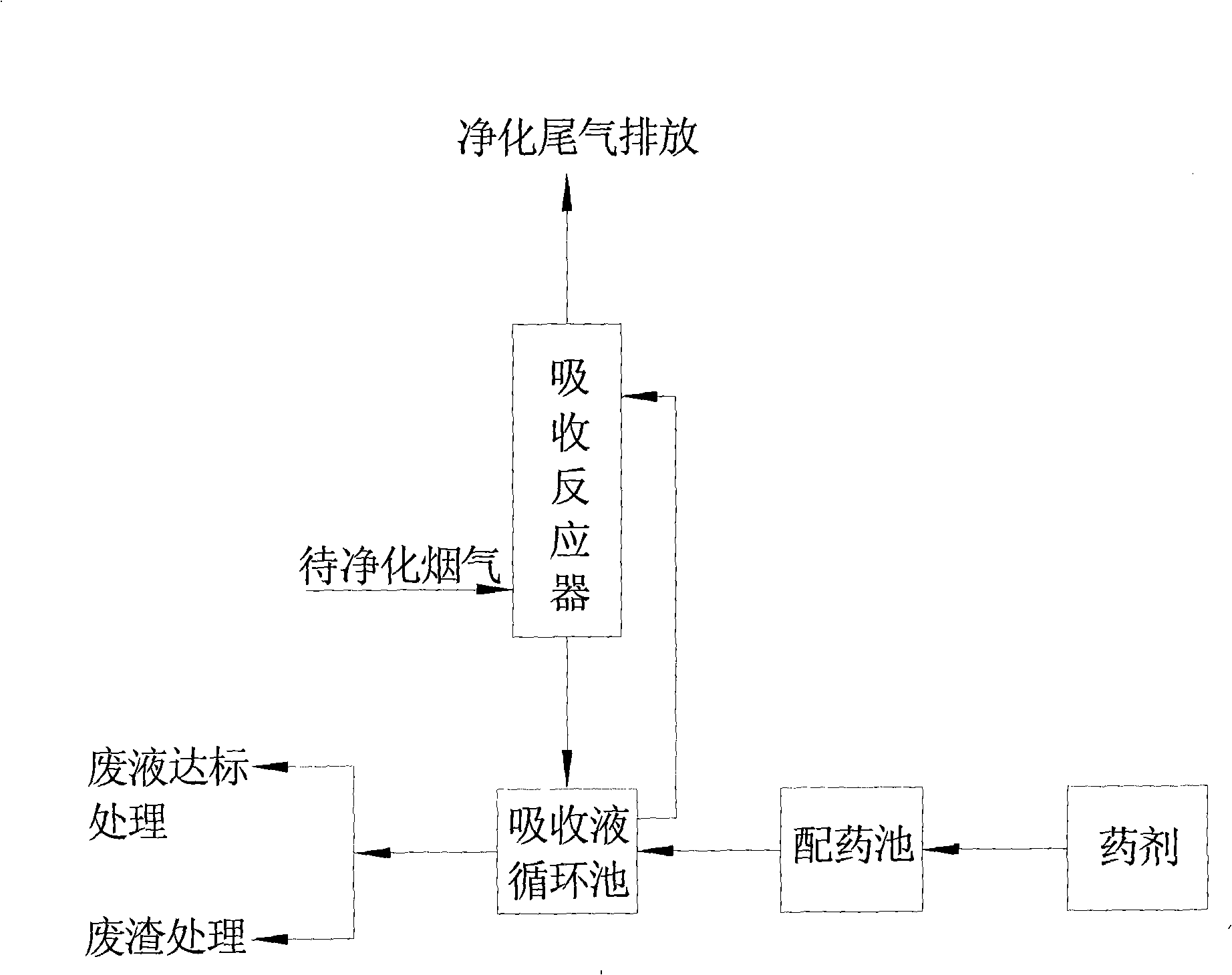

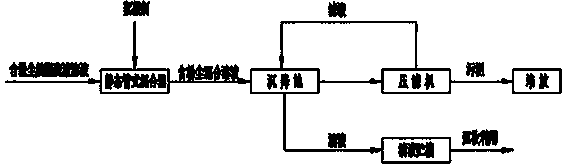

Simultaneous desulfuration and denitration technique by wet flue gas method

ActiveCN101352647AReduce usageWide variety of sourcesDispersed particle separationAir quality improvementFlue gasWastewater

The invention provides a process which carries out desulfurization and denitration at the same time by a smoke wet-method; the smoke to be purified enters an absorbing reactor and is sufficiently contacted with absorbent containing alkali desulfurizer (such as one out of lime, limestone, Na alkali or alkali wastewater), urea and strong oxidant, and the SO2 and NOx in the smoke can be purified at the same time. When the process of the invention is adopted to purify the smoke, more than 90% of desulfurization and 50-95% of denitration efficiency can be achieved. The process of the invention realizes the desulfurization and denitration at the same time on the basis of alkali desulfurizer wet-method desulfurization process widely adopted at present; furthermore, the absorbent has wide source and low cost; the dosage of the strong oxidant is small, and the desulfurization and denitration efficiency is high so as to generate larger environmental benefits with less investment.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

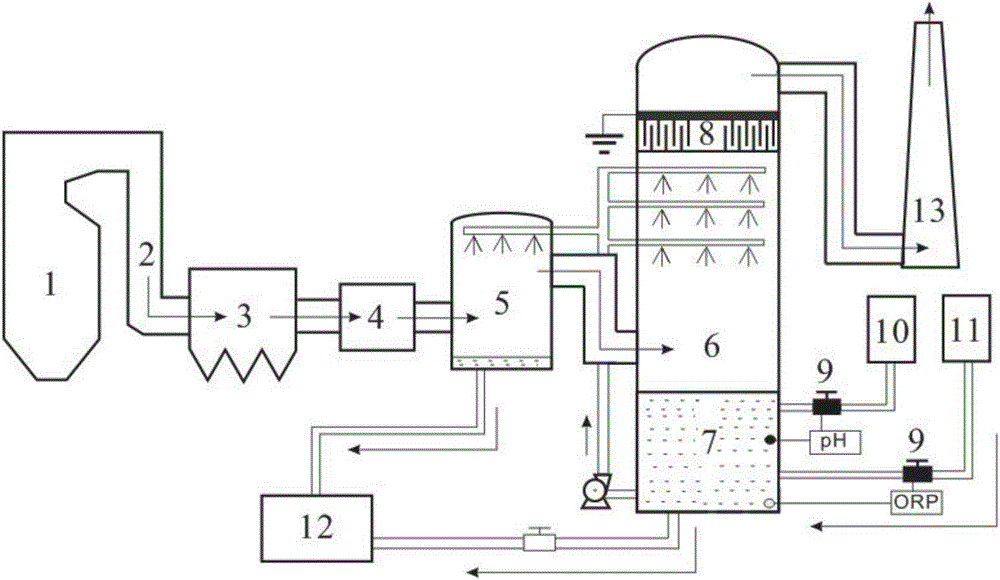

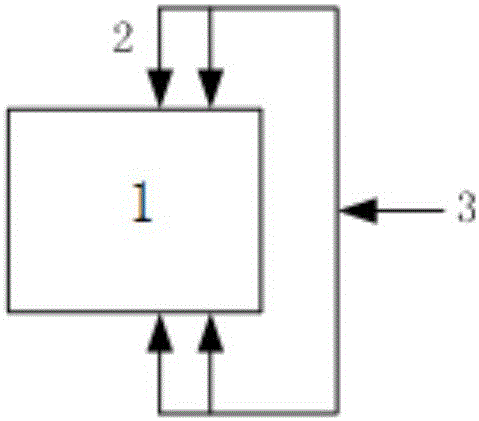

Method for automatically controlling desulphurization and denitration by flue gas based on pH value and ORP value and apparatus thereof

InactiveCN102716648AImprove desulfurization and denitrification efficiencySimple processLighting and heating apparatusDispersed particle separationElectricityAutomatic control

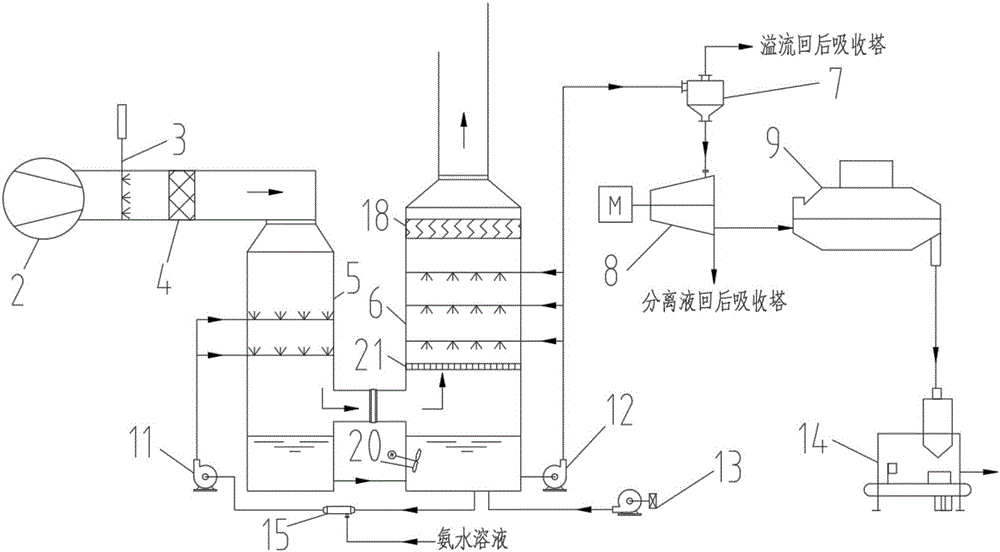

The invention discloses a method for automatically controlling desulphurization and denitration by flue gas based on pH value and ORP value and an apparatus thereof. The method comprises the following steps: dedusting and preoxidazing flue gas, oxidizing NO to NO2, precleaning and processing flue gas by a prewashing system, then taking ammonium sulfite as a absorption liquid, absorbing SO2 and NOx(x is 1 or 2) in flue gas, keeping the pH value and ORP value of the absorption liquid in a set scope during the absorption process for ensuring the absorption efficiency of desulphurization and denitration as well as operation stability, passing the flue gas through an electric demister, and removing the ammonia mist in the flue gas for preventing the ammonia leakage. When the concentration ratio of the absorption liquid (NH4)2SO3 / NH4HSO3 decreases to 0.9, a part of the absorption liquid in a washing tower reservoir is introduced into an ammonium sulfate byproduct treatment system, and the resource and recovery utilization can be realized. The provided desulphurization and denitration method has desulphurization efficiency with more than 95% and denitration efficiency with more than 85%, the ammonia escape amount is lower than 5mg / m<3>, and the sulfur resource can be simultaneously recovered.

Owner:山东航源环境科技有限公司

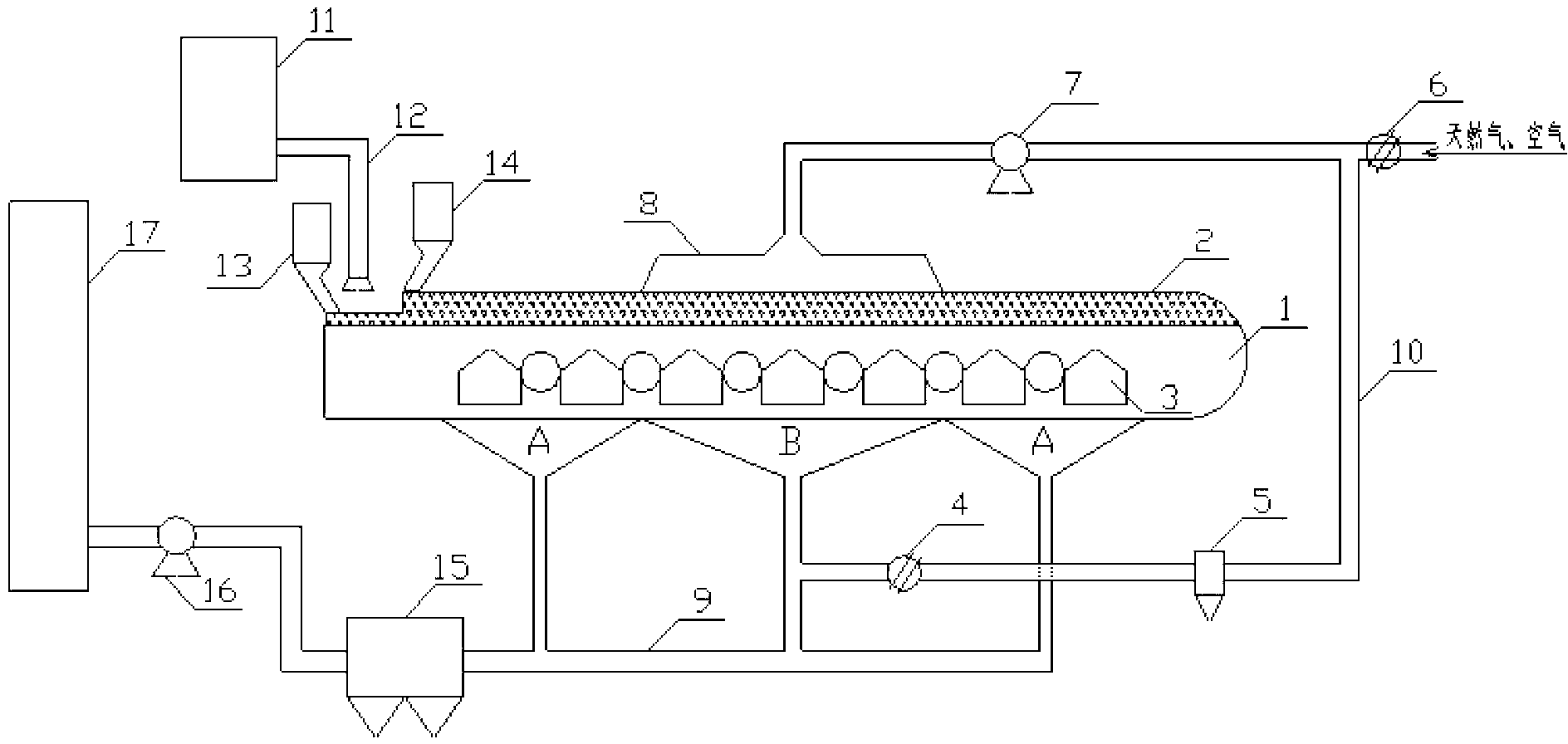

Simultaneous sintering and desulphurization and denitration system, and desulphurization and denitration method

ActiveCN102936651AEmission reductionLess investmentDispersed particle separationAir quality improvementElectrostatic precipitatorFlue gas

The invention discloses a simultaneous sintering and desulphurization and denitration system. The system comprises a sintering machine, a bellows, an electrostatic precipitator, a main exhaust fan and a chimney which are connected through a flue gas main pipeline. A branched pipeline is led out from an SO2 and NOx high-concentration-region bellows outlet pipeline, and is adopted as a sintering flue gas circulation pipeline. With the sintering flue gas circulation pipeline, a circulation flue gas flapper valve, a precipitator, a natural gas inlet valve connected to an outer gas inlet pipe, a circulation fan, and circulation flue gas mask are sequentially connected. The flue gas mask is covered on a sintering material layer right above the SO2 and NOx high-concentration-region bellows. A sprayer is arranged between a sintering grate-layer material system and a sintering material feeding system of the sintering machine. A residual ammonia water solution tank is connected with the sprayer. The cost of the system and the method are low. With the method and the system, discharge concentration of SO2 and NOx in sintering flue gas can be effectively reduced, and desulphurization and denitration can be simultaneously carried out during the sintering process. Therefore, environment pollution caused by sintering flue gas can be reduced.

Owner:ANGANG STEEL CO LTD

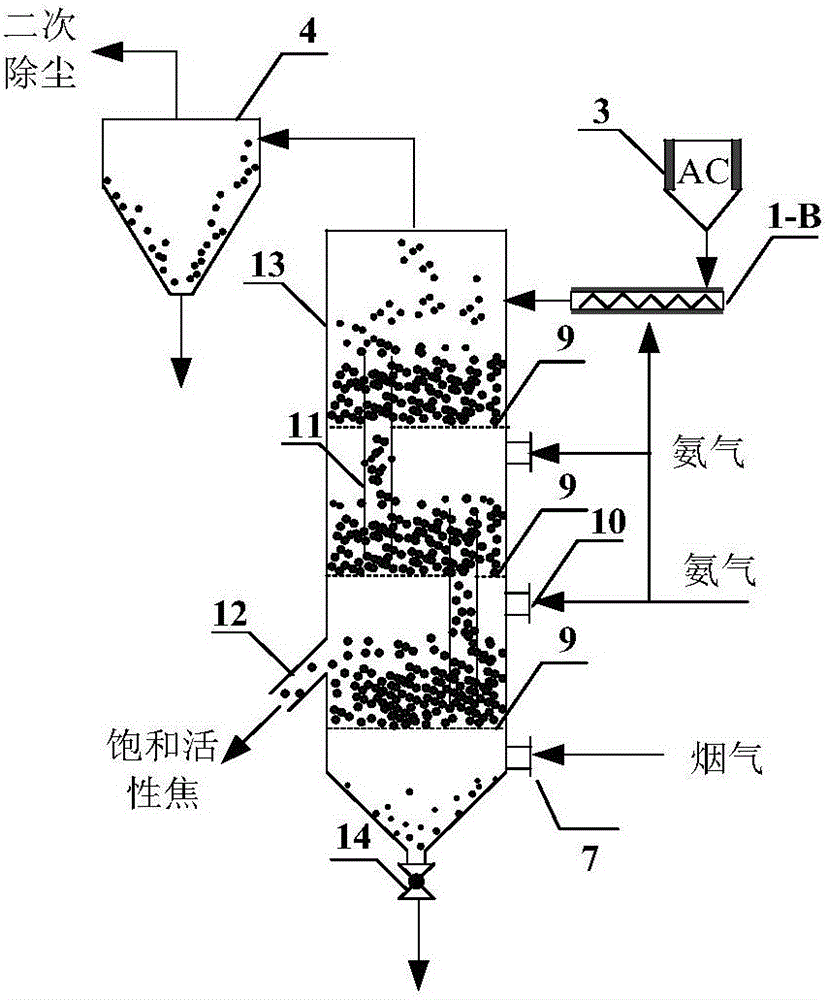

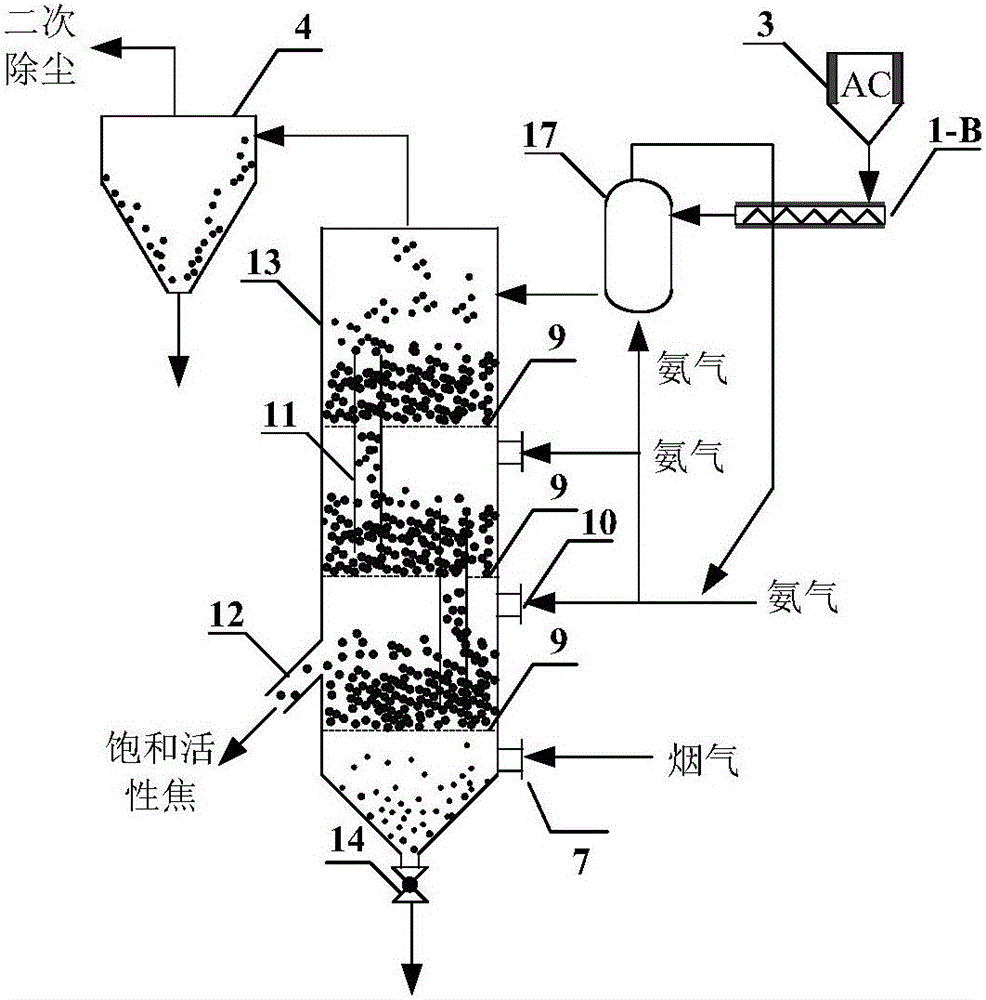

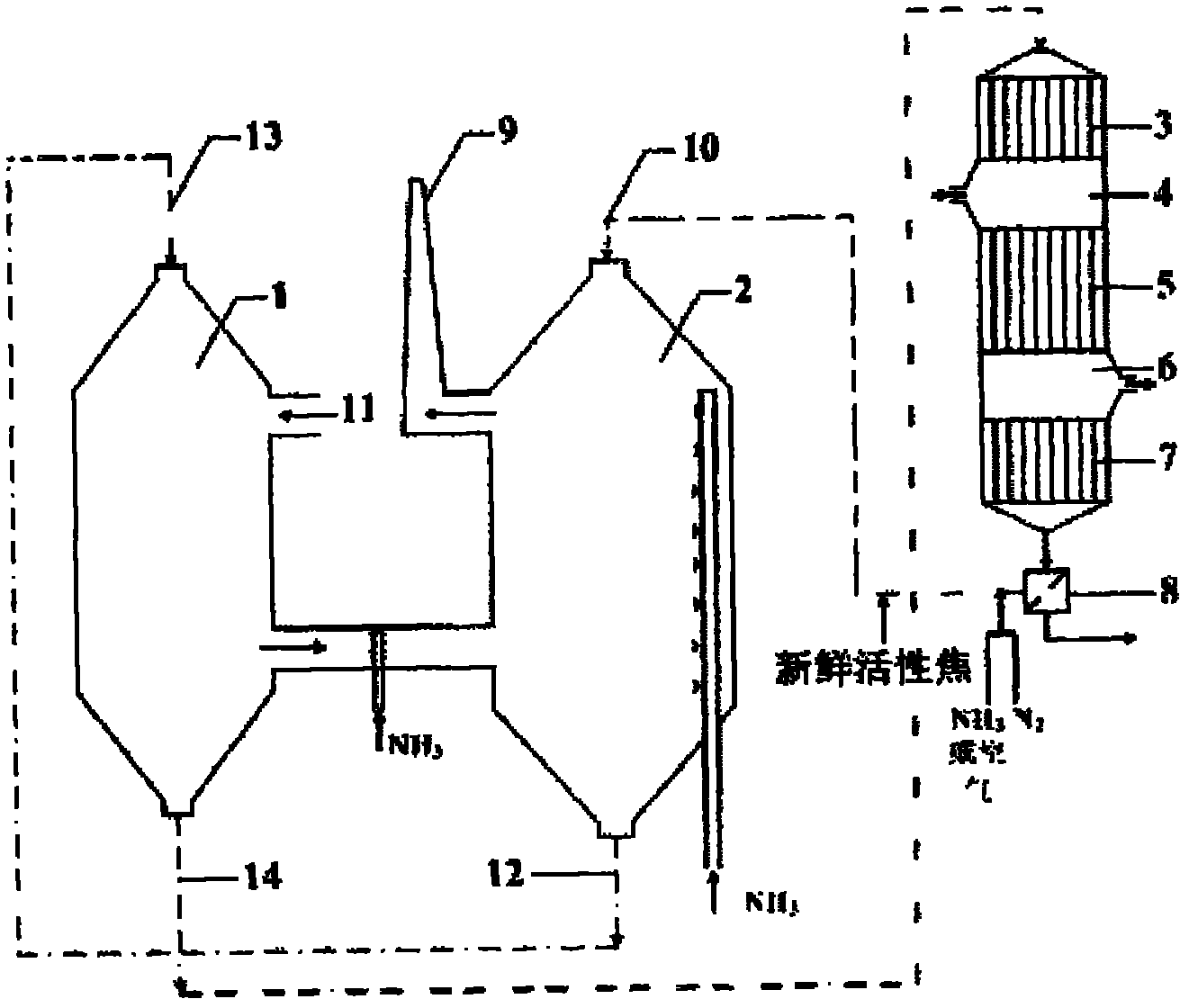

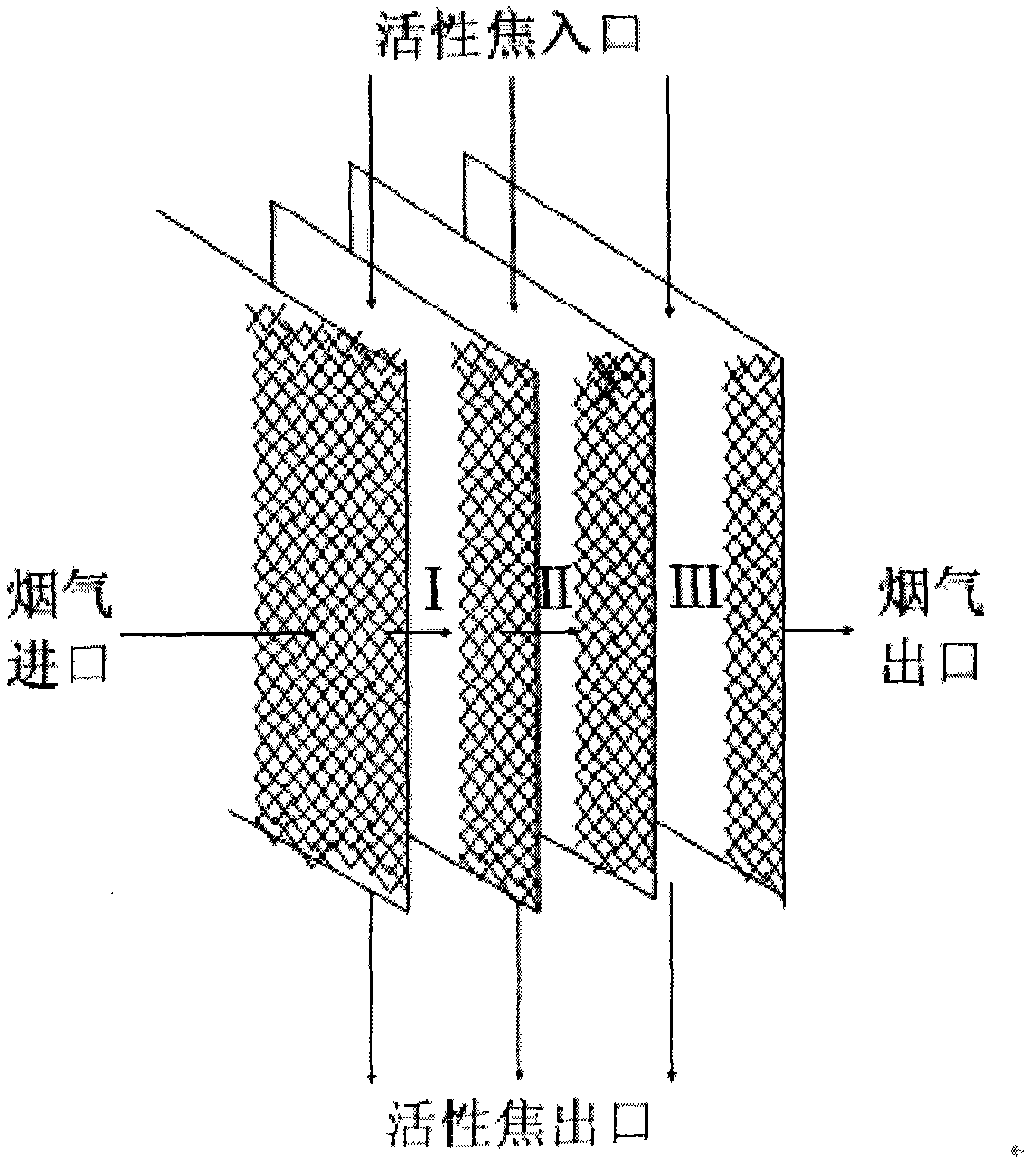

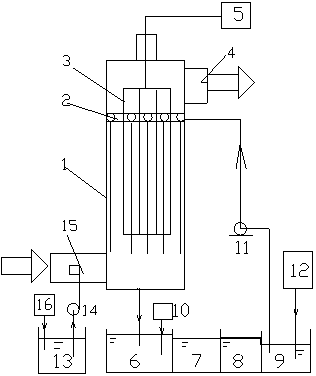

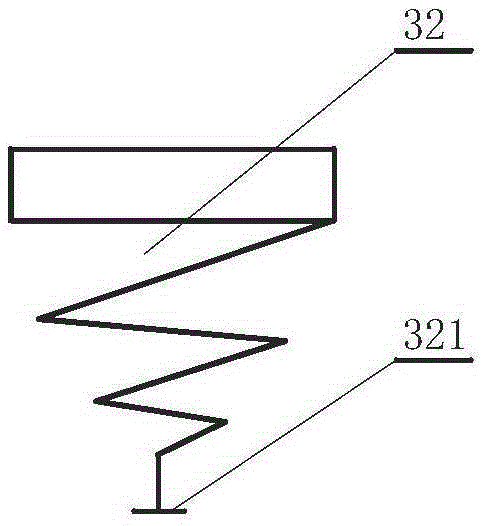

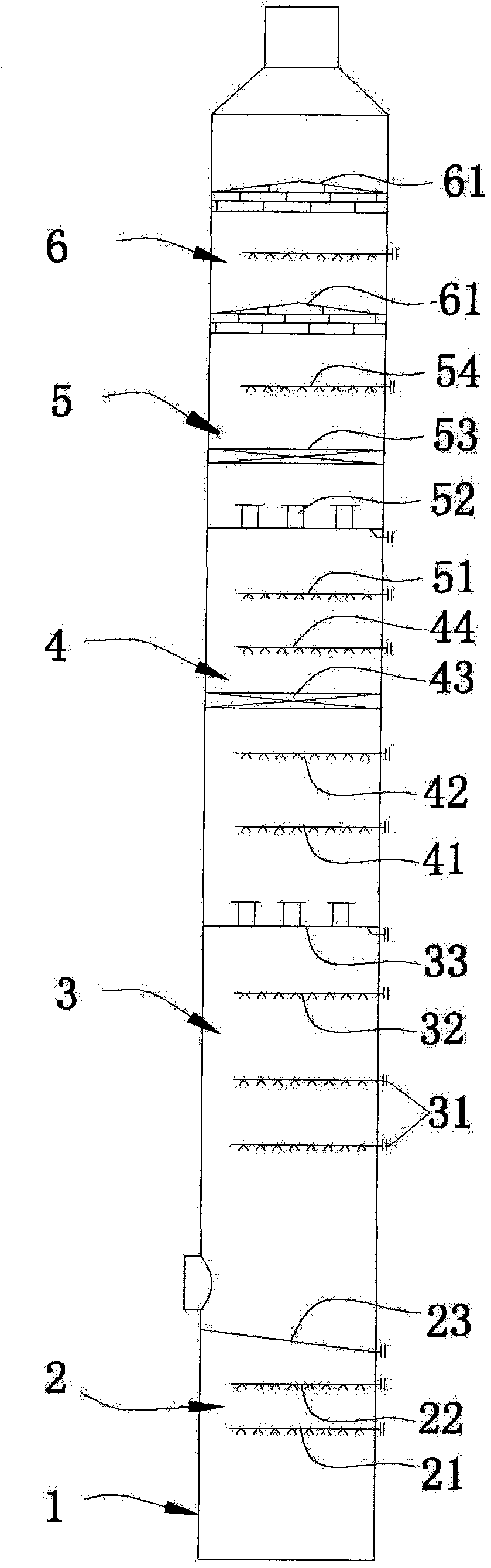

Multi-layer fluidized bed two-stage activated carbon/coke flue gas simultaneous-desulfurization and denitrification system and method

ActiveCN105727708ASave spaceEfficient use ofGas treatmentDispersed particle separationInjection portFluidized bed

The invention relates to the field of industrial flue gas pollution control. A multi-layer fluidized bed two-stage activated carbon / coke flue gas simultaneous-desulfurization and denitrification system of the invention comprises a dust removal device (4) and further comprises a desulfurization and denitrification multi-layer fluidized bed reactor (13), wherein a feed port of the dust removal device (4) is communicated with the top of the desulfurization and denitrification multi-layer fluidized bed reactor (13); the desulfurization and denitrification multi-layer fluidized bed reactor (13) is divided into an upper denitrification section and a lower desulfurization section; the denitrification section comprises several layers of fluidized beds; an ammonia gas injection port (10) is formed in a side wall corresponding to a position below the bottom of each layer of fluidized bed; the desulfurization section comprises several layers of fluidized beds; a flue gas inlet (7) is formed in the side wall corresponding to the position below the bottom of a lowest layer of fluidized bed. The system provided by the invention can enhance the mass transfer and heat transfer, improve the efficiency of desulfurization and denitrification, replace high-cost formed activated carbon / coke with fine granular activated carbon / coke to reduce the costs for desulfurization and denitrification, and is suitable for the flue gas purification of power plant boilers, industrial boilers, heating boilers and coking industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

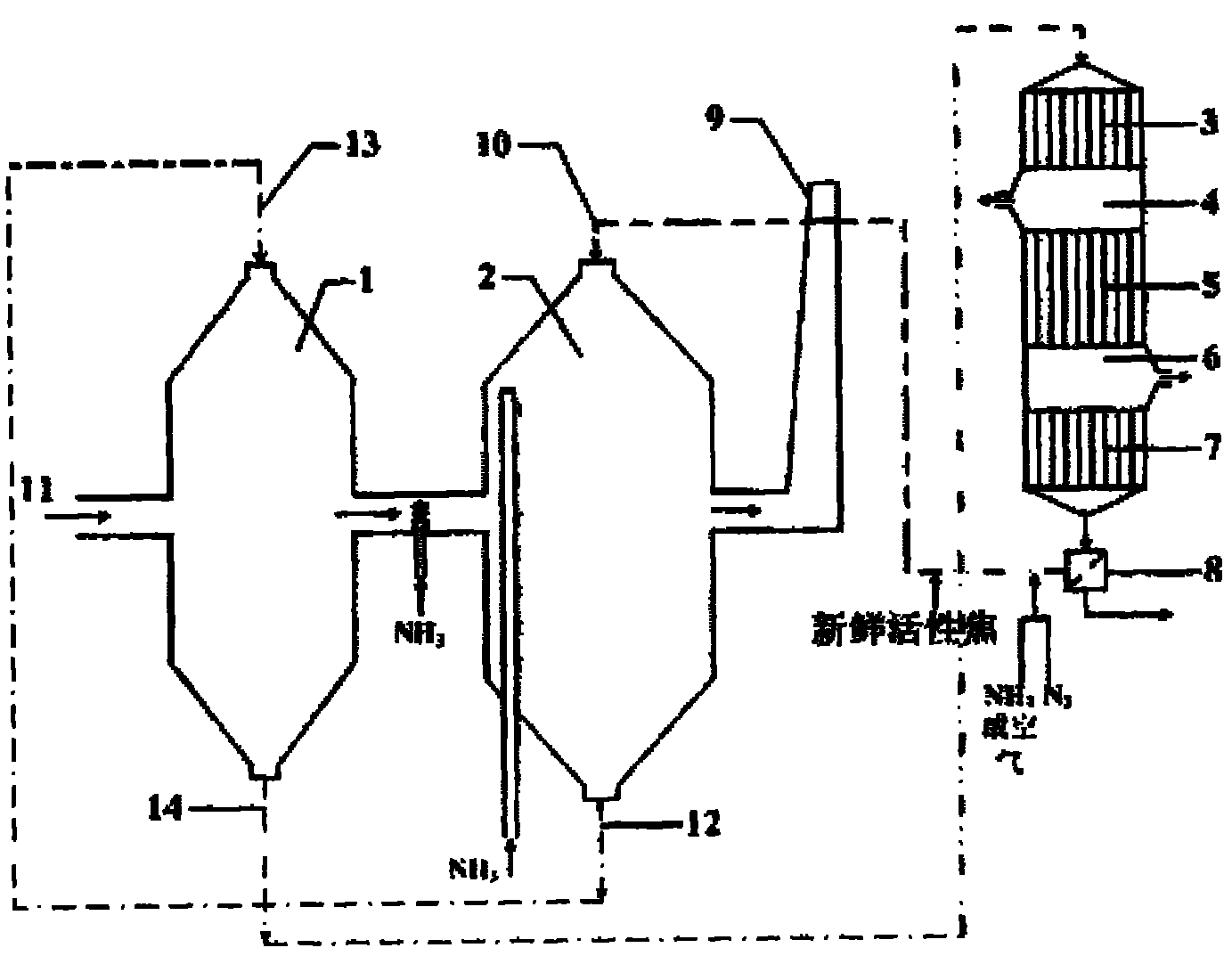

Flue gas-based combined desulfuration and denitration method and special device for method

ActiveCN102019135AImprove distributionImprove denitrification efficiencyDispersed particle separationFlue gasProcess engineering

The invention discloses a flue gas-based desulduratoin and denitration method and a special device for the flue gas-based desulduratoin and denitration method. The special device comprises a denitration reactor body and a desulphurization reactor body, wherein the side wall of the desulphurization reactor body is provided with a flue inlet; the desulphurization reactor body and the denitration reactor body are communicated in parallel; the volume of the denitration reactor body is 1-2 times that of the desulphurization reactor body; the communicating position of the desulphurization reactor body and the denitration reactor body is provided with a device for spraying NH3; the top of the denitration reactor body is provided with a denitration reactor inlet for active coke; the bottom of thedenitration reactor is provided with a denitration reactor outlet for the active coke; the top of the desulphurization reactor is provided with a desulphurization reactor inlet for the active coke; the bottom of the desulphurization reactor is provided with a desulphurization reactor outlet for the active coke; and the denitration reactor outlet for the active coke is communicated with a desulphurization reactor inlet for the active coke through a pipeline, and the desulphurization reactor outlet for the active coke is communicated with a regeneration reactor. The invention also provides a method for flue gas desulfurization and denitration by using the device.

Owner:CCTEG CHINA COAL RES INST

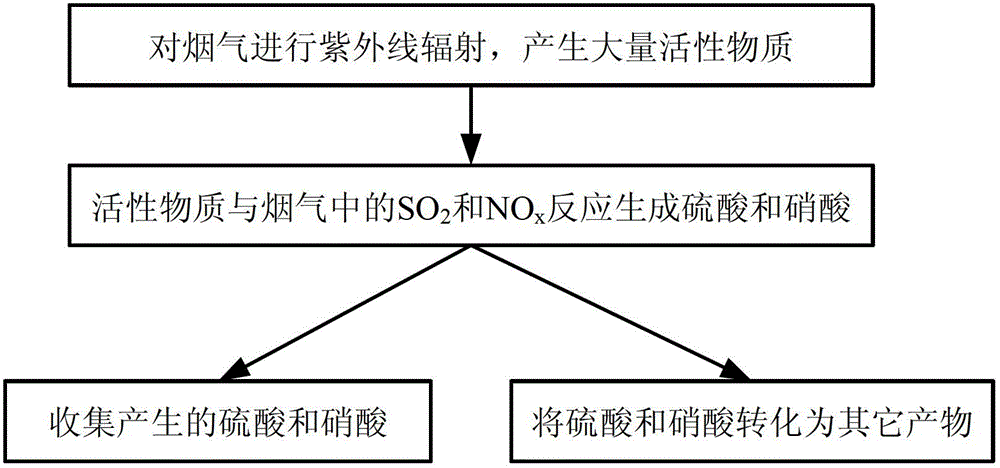

Method for simultaneously desulfurizing and denitrating flue gas

ActiveCN102908883APromote oxidationTo achieve the purpose of simultaneous desulfurization and denitrificationDispersed particle separationAir quality improvementAmmonium nitrateAmmonium sulfate

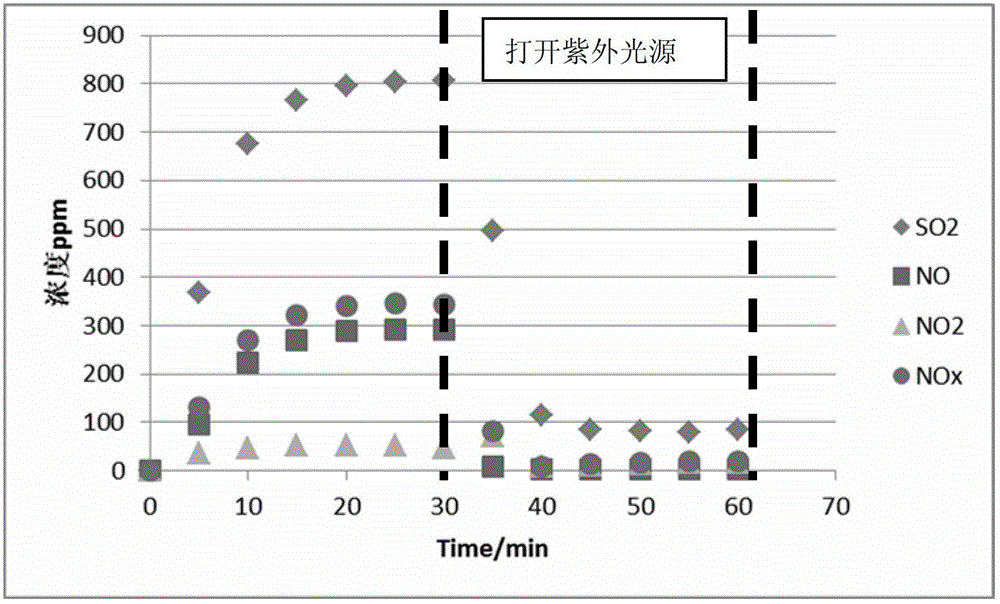

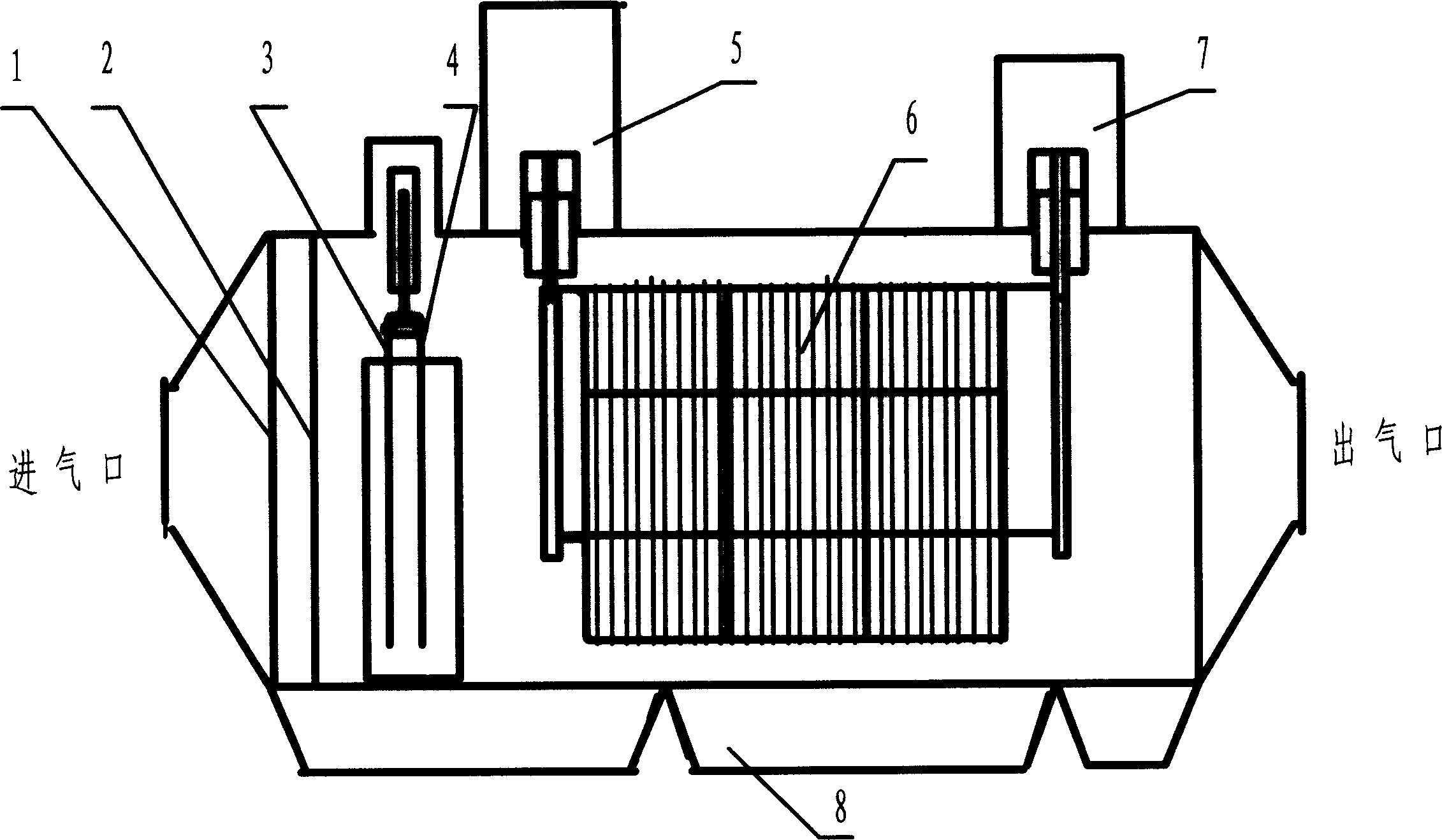

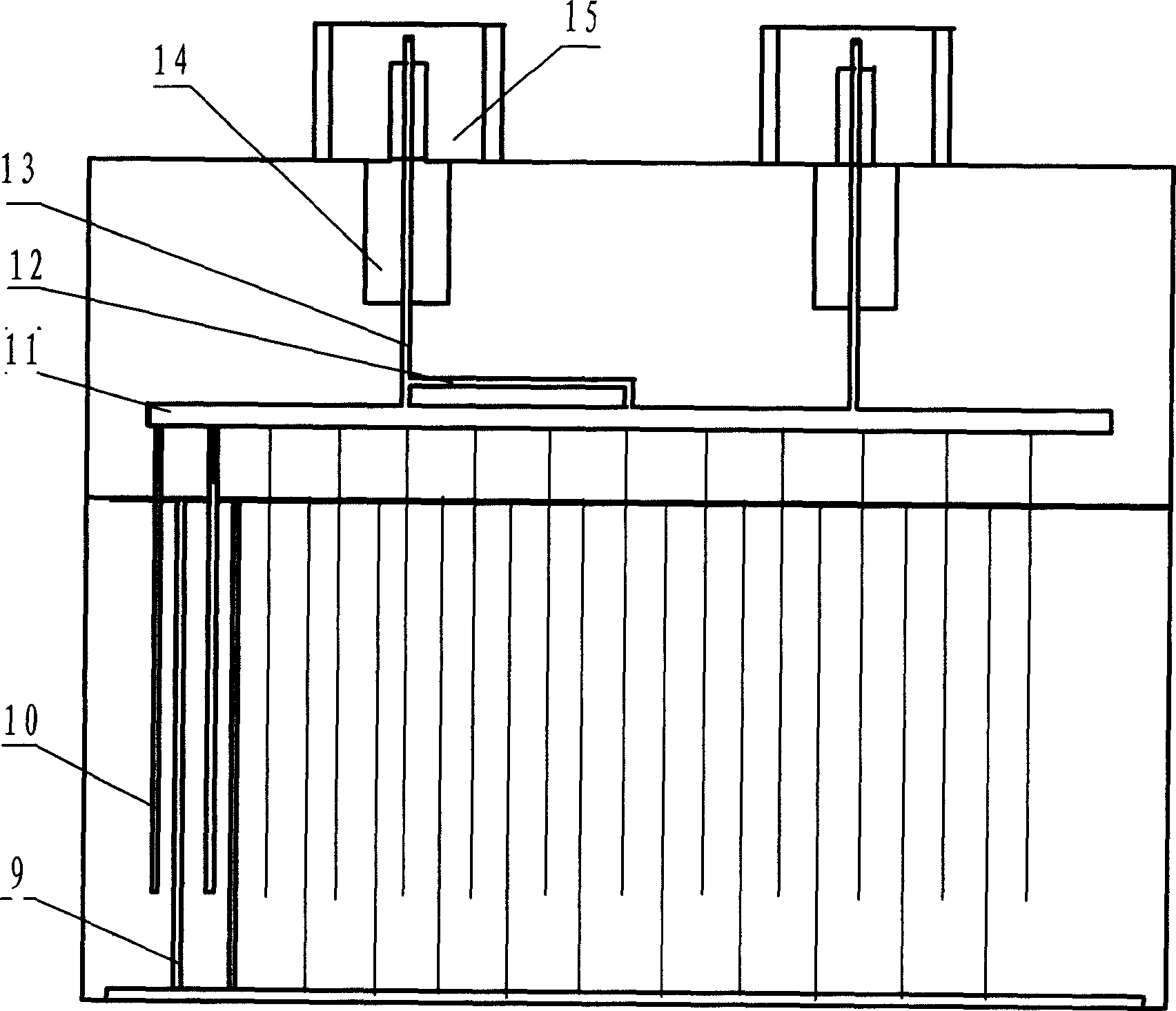

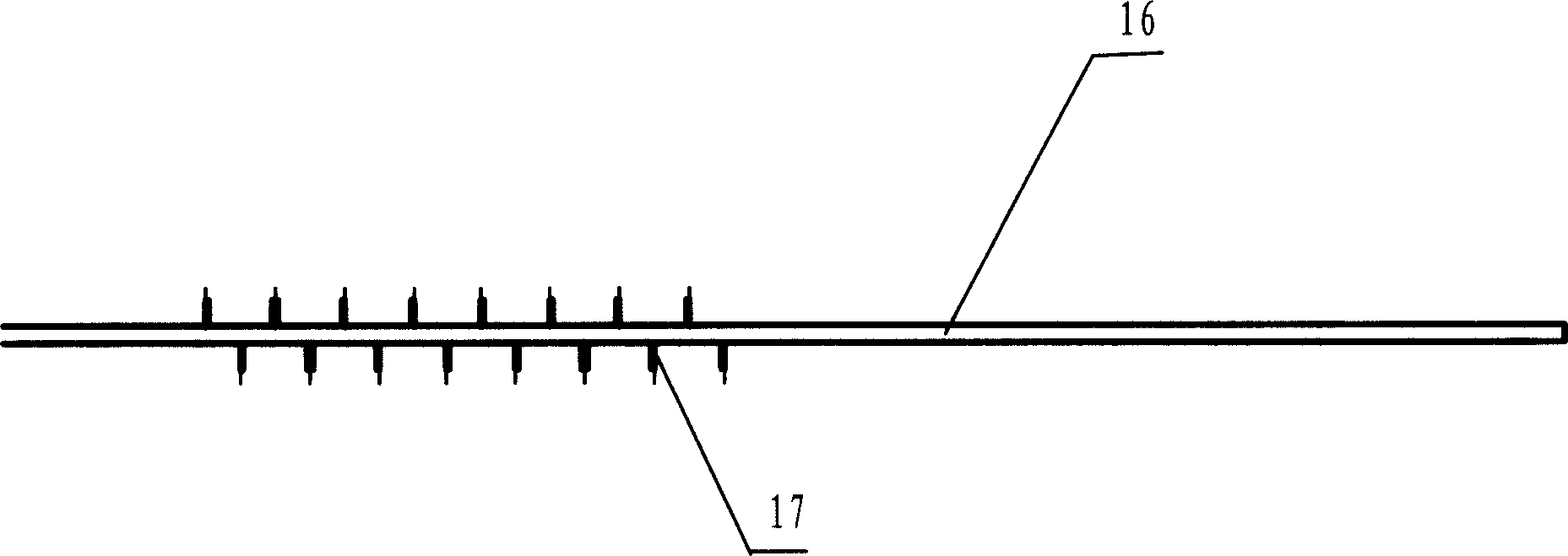

The invention provides a method for simultaneously desulfurizing and denitrating flue gas. The method comprises the step that: a large number of active materials produced by the flue gas under ultraviolet radiation are reacted with SO2 and NOx in the flue gas so as to produce stable sulfuric acid and nitric acid which are important industrial products. The two products can be collected by an acid mist removing device, or ammonia can be introduced into the two products to produce ammonium sulfate and ammonium nitrate which are important chemical fertilizers, or calcium carbonate is sprayed into the two products to produce calcium sulfate and calcium nitrate; and then, SO2 and NOx in the flue gas are removed from the flue gas to be converted into the products with the industrial or agricultural value. The method for simultaneously desulfurizing and denitrating the flue gas is suitable for desulfurizing and denitrating the flue gas of large newly-built boilers, or reforming and applying built burning equipment, and can realize the effect of simultaneously removing SO2 and NOx.

Owner:PEKING UNIV

Exbaust gas purification method and device by pulse corona dicharging method

InactiveCN1559651AImprove dust removal efficiencyImprove qualityDispersed particle separationCooling towerPurification methods

A dry pulse corona discharge method for cleaning fume features that the high-temp fume is moistened and cooled, and then reacted on ammonia gas under high pressure to generate by-product which is collected. Its apparatus is composed of a moistening-cooling tower, an ammonia gas feeder, a ns-class high-voltage pulse power supply, plasma reactor and by-product collector.

Owner:ENVIROMENT PROTECTION ENG RES CENT CHINA ENG PHYSICS INST +1

Flue gas desulfurization and denitration integrated process

InactiveCN102772986ANon-irritatingReduce riskDispersed particle separationAir quality improvementFlue gasSlurry

The invention relates to a flue gas desulfurization and denitration integrated process. An absorbent serous fluid containing limestone, activated coke, catalytic agents and water is used for absorbing and removing nitric oxide and sulfur dioxide in flue gases. The flue gas desulfurization and denitration integrated process has the advantages of being small in investment, simple in operation and high in denitration efficiency; used absorbents are non-toxic, non-irritant, small in dangerousness, convenient to store and transport and low in using costs; and the process is particularly suitable for desulfurization and denitration of flue gases of small and medium-sized industrial boilers, live heating boilers and hot water supply boilers.

Owner:北京至清时光环保工程技术有限公司

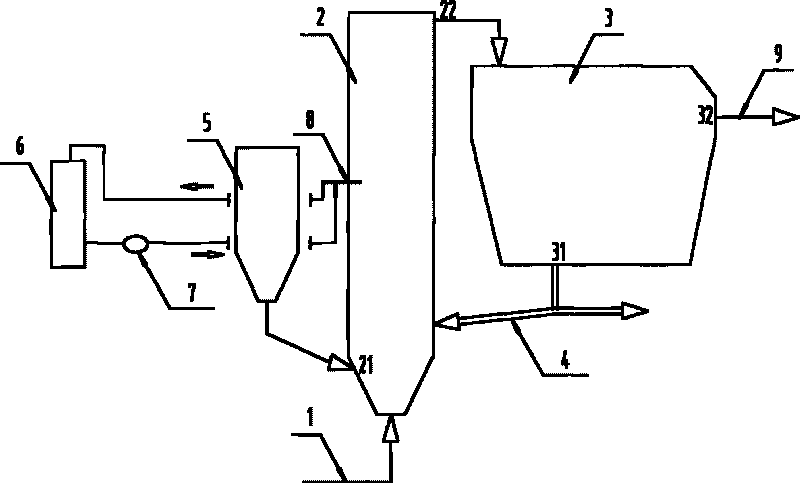

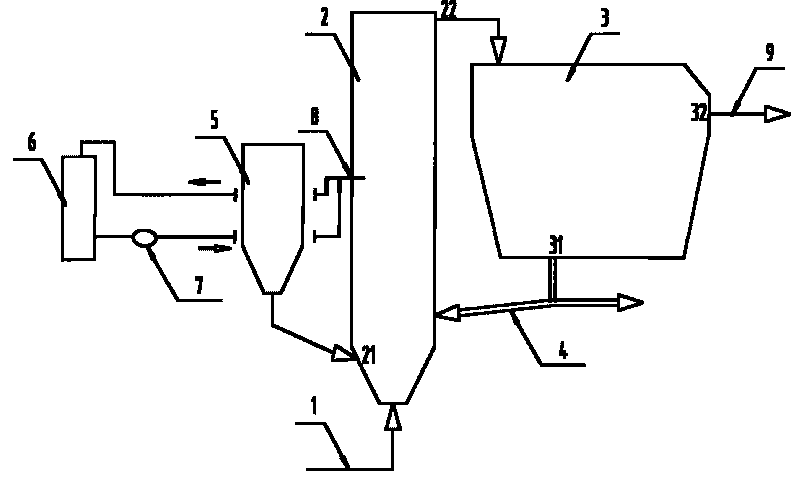

Dry-method fume gas purification method and device for synchronous desulfurization and denitrification

ActiveCN101695627AGuaranteed evaporationEnhanced mass transferDispersed particle separationPurification methodsEngineering

The invention relates to fume purification and provides dry-method fume purification method and device for synchronous desulfurization and denitrification. The purification device is provided with an inlet flue, an absorption tower, a dust collector, a material circulating air chute, an absorbent cabin, a water box, a water pump, an atomization spray gun and an outlet flue. In the invention, an additive water solution is stored in a process water box; a primary fume enters the absorption tower through the inlet flue, mixes with an absorbent added form the absorbent cabin and cycled materials returned from the material circulating air chute, and then performs cooling and moistening reaction with the additive water solution pumped by the high-pressure pump from the water box to the atomization spray gun and sprayed by the atomization spray gun to the absorption tower; the outlet fume of the absorption tower enters the dust collector, incompletely reacted materials in the fume are collected, and the major part of the fume enters a circulating fluidize bed absorption tower with the absorbent added in the absorbent cabin through the material circulating air chute to continue the reaction; circulation continues in the same way; and the fume purification is then achieved when the cleaned fume is exhausted from a chimney from the dust collector through the outlet flue.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

Agent for desulphurization and denitration

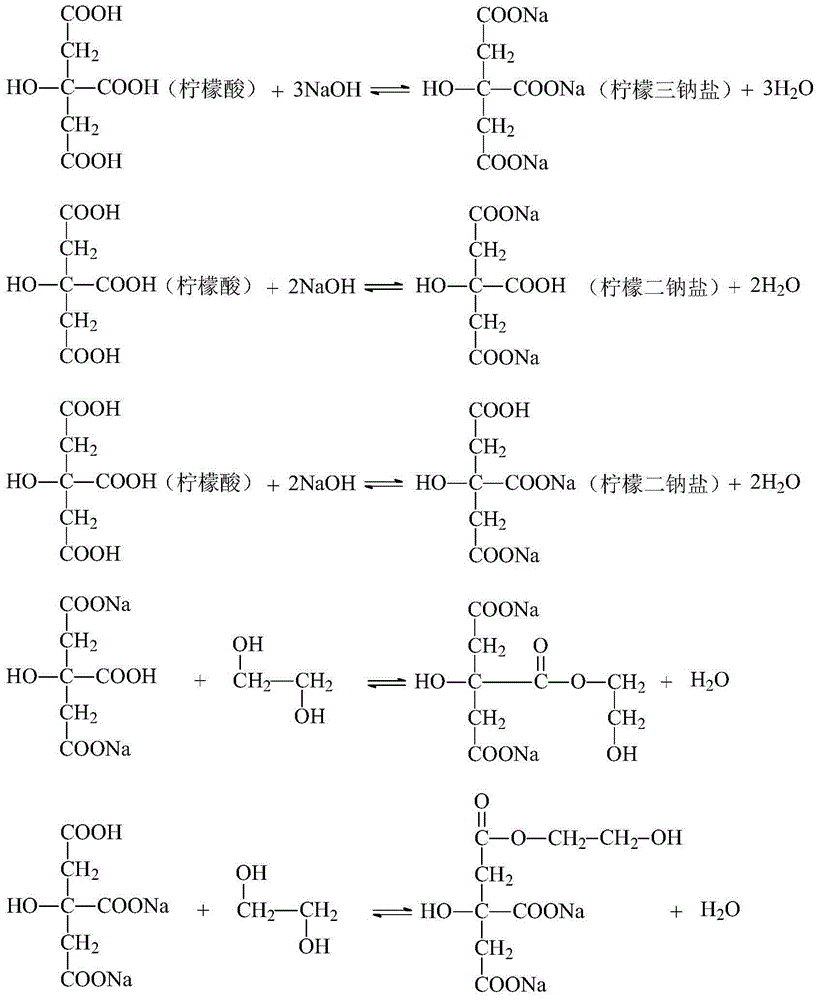

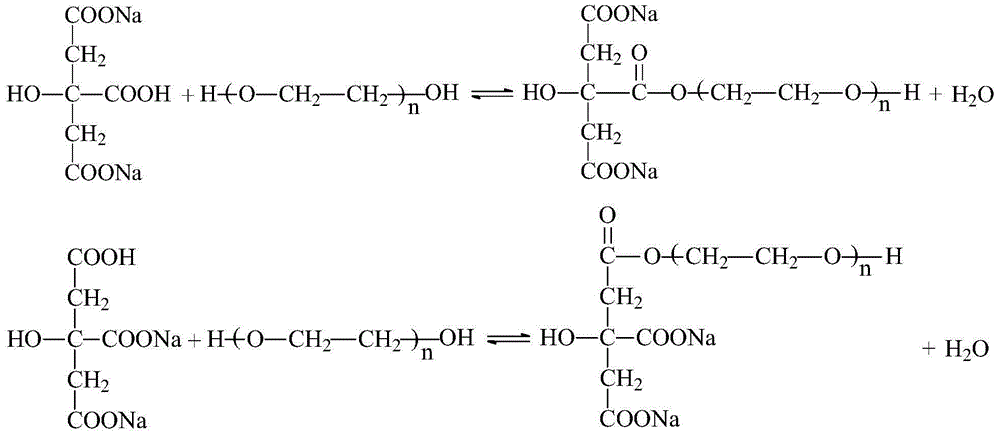

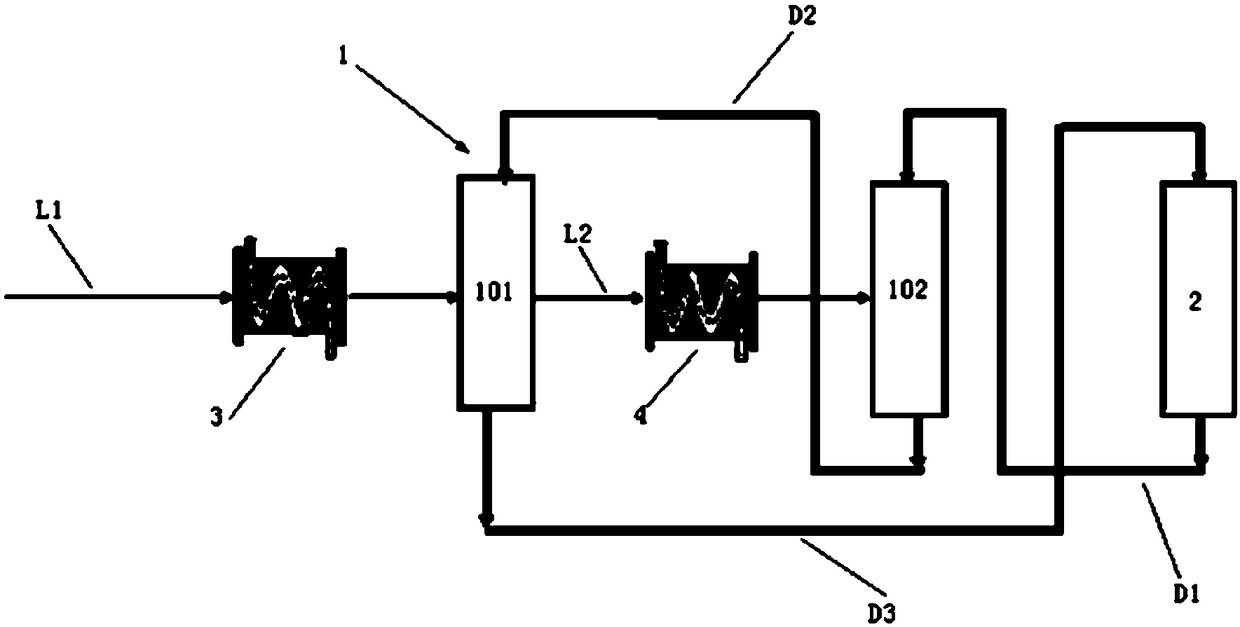

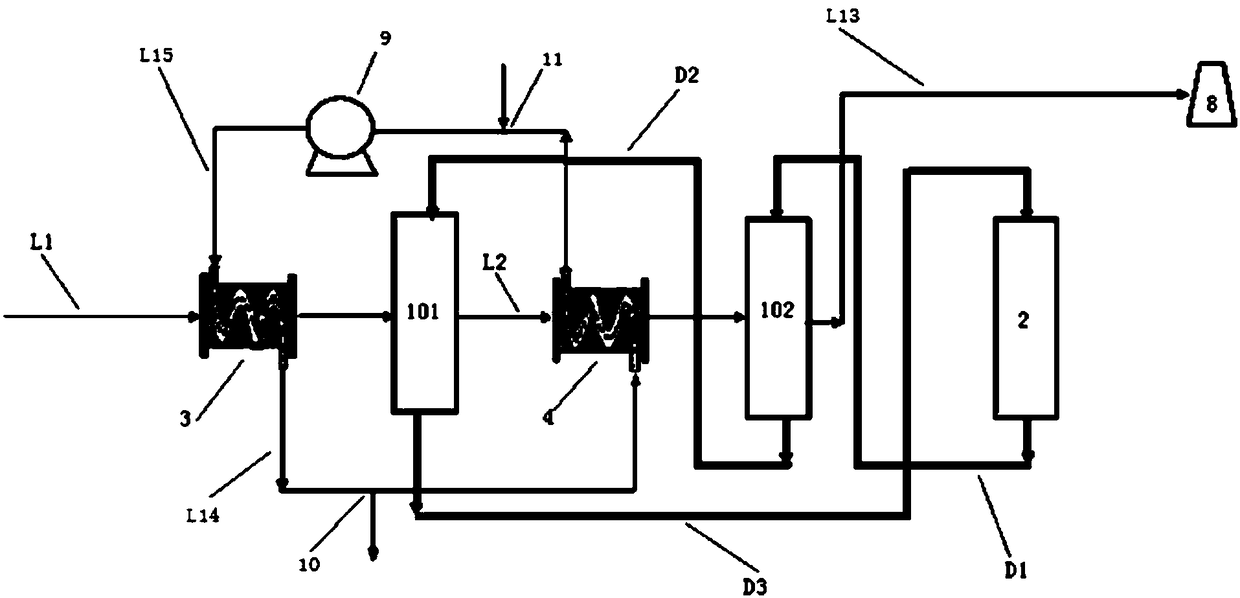

ActiveCN106031844ABroad marketHigh operating costsGas treatmentDispersed particle separationPolyolNitrogen oxides

The invention discloses an agent for desulphurization and denitration. The agent is prepared by mixing polyol and / or polymerized polyol substances, polycarboxylic acid substances and alkaline substances; the raw materials are heated to 90 DEG C or above, condensation and / or polymerization are carried out in order to obtain ether and / or ester substances of macromolecule or high polymer. The agent for desulphurization and denitration has wide industrial applications, and is used for simultaneously or separately removing sulfur dioxide and nitrogen oxide in gas; compared with traditional agents for desulphurization and / or denitration, the agent has the advantages of renewable properties without secondary pollution, low energy consumption, low operation cost, high desulphurization and denitration efficiency, and simple operation.

Owner:YONGFENG BOYUAN IND CO LTD JIANGXI PROVINCE

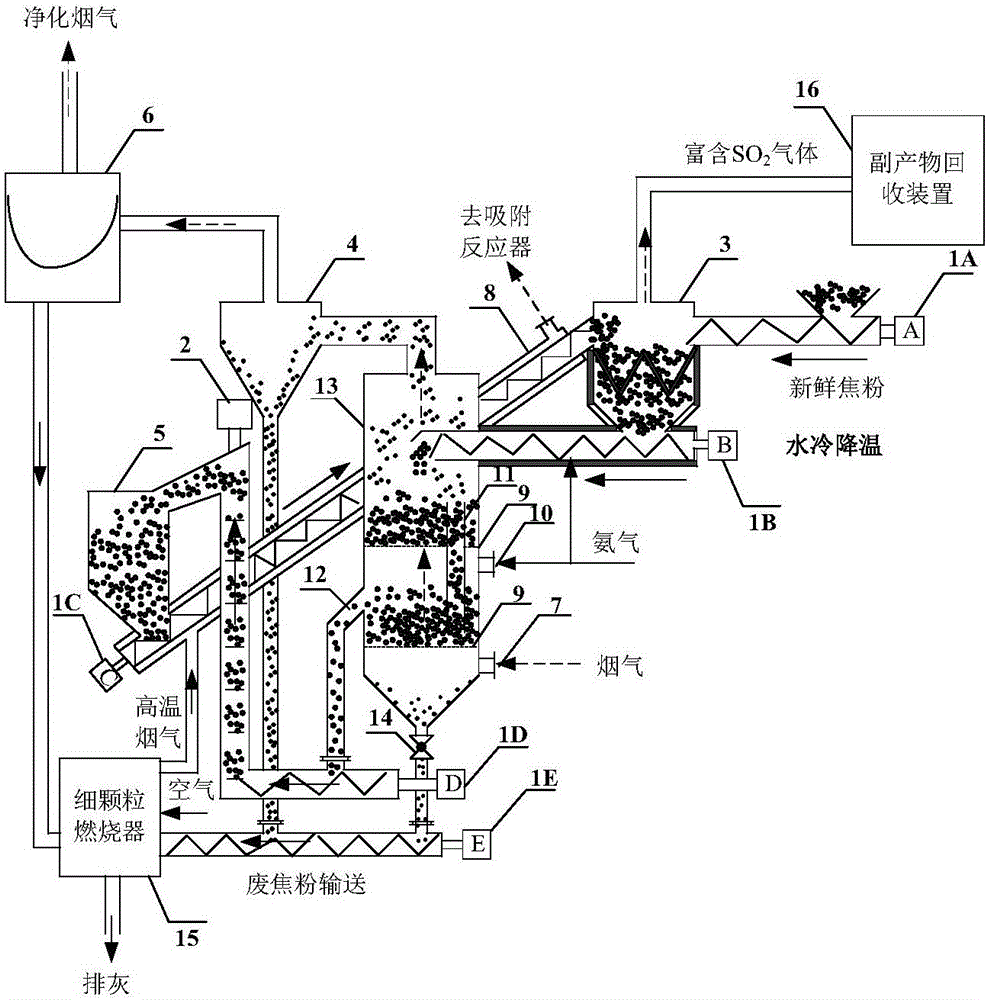

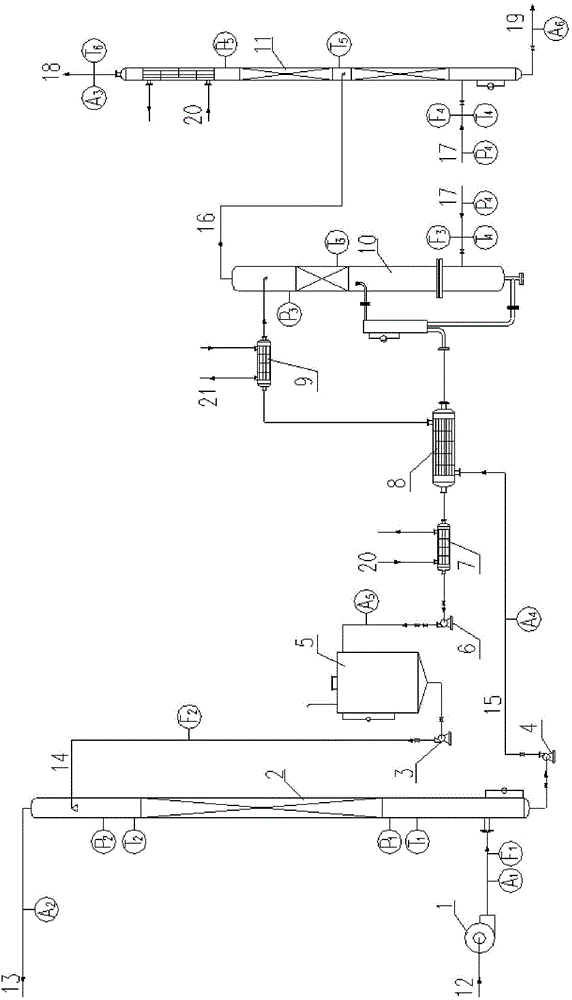

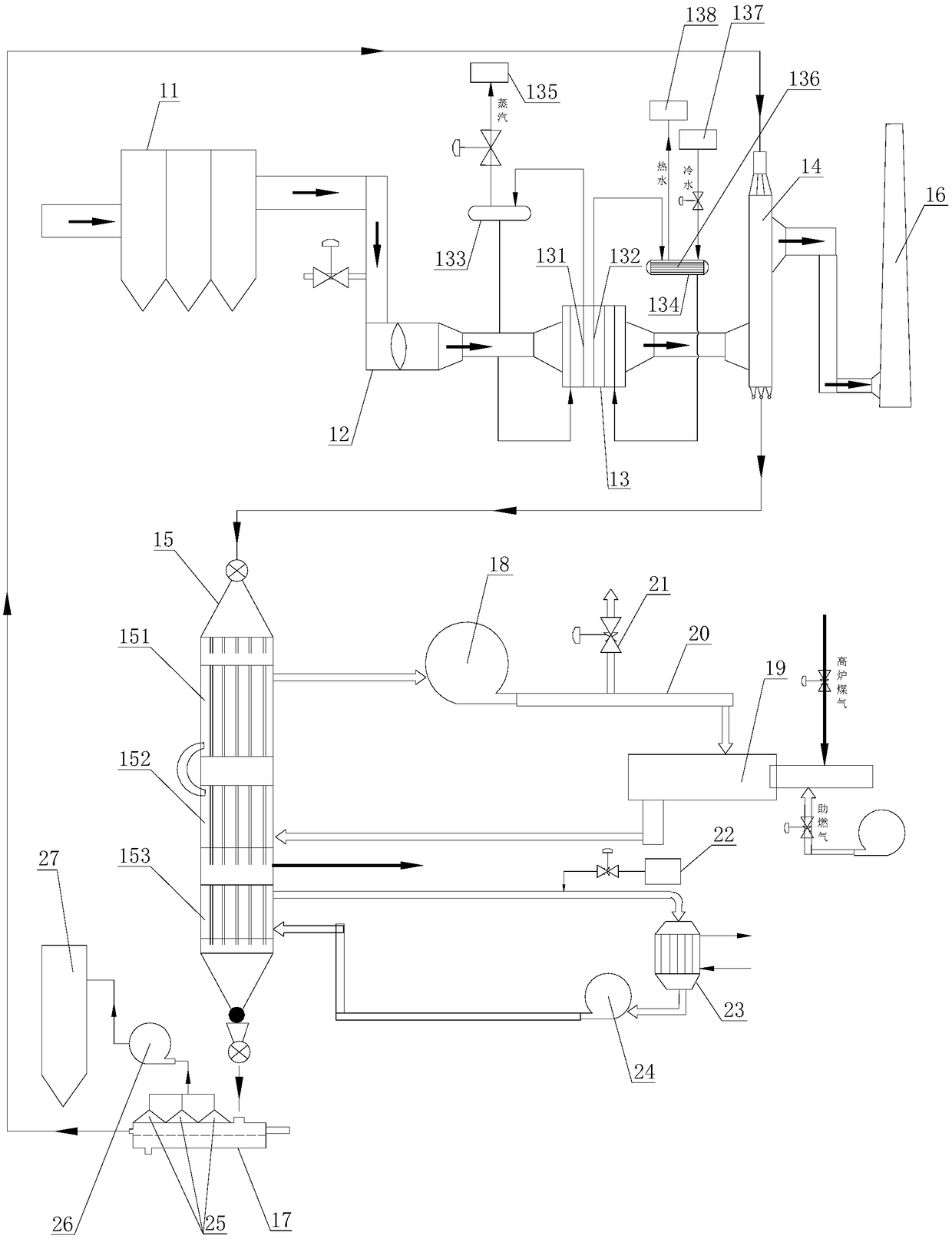

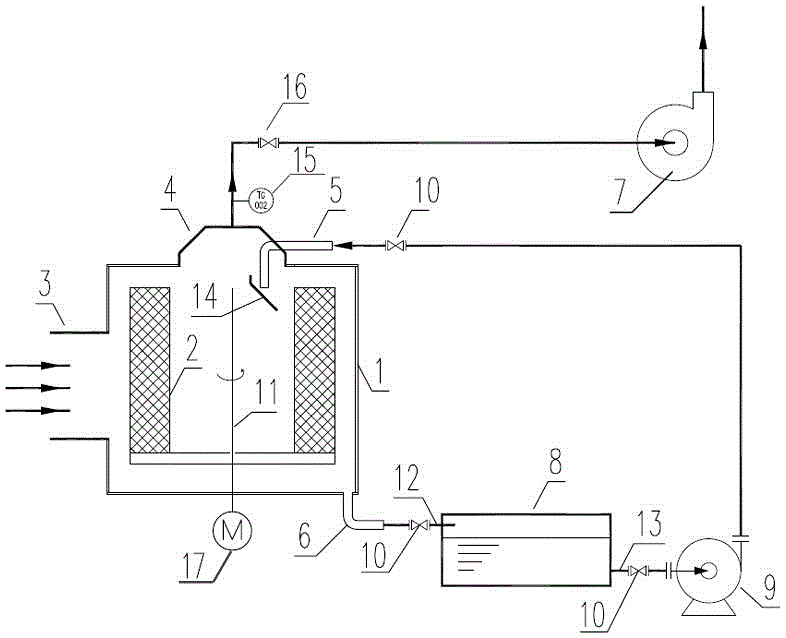

Activated carbon treatment system for improving waste heat utilization rate and denitration rate and using method thereof

ActiveCN108939808AGuaranteed temperatureImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationActivated carbonFlue gas

The invention provides an activated carbon treatment system for improving waste heat utilization rate and denitration rate and a using method thereof. Heat exchangers are separately disposed before flue gas is input into a first-stage adsorption column and a second-stage adsorption column, the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column is controlled, thereby ensuring the temperature of desulfurization and denitration. The activated carbon treatment system utilizes high-temperature flue gas (about 150-170 DEG C) after a main exhaust blower, adopts a mode of heat exchange, artificially controls the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column, and enables the efficiency of removal of SO<2> and NO<x>; and the utilization rate of the high-temperature flue gas after the main exhaust blower is increased, and the temperature of the flue gas entering a desulfurization tower and a denitration tower is controlled to improve the efficiency of desulfurization and denitration.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

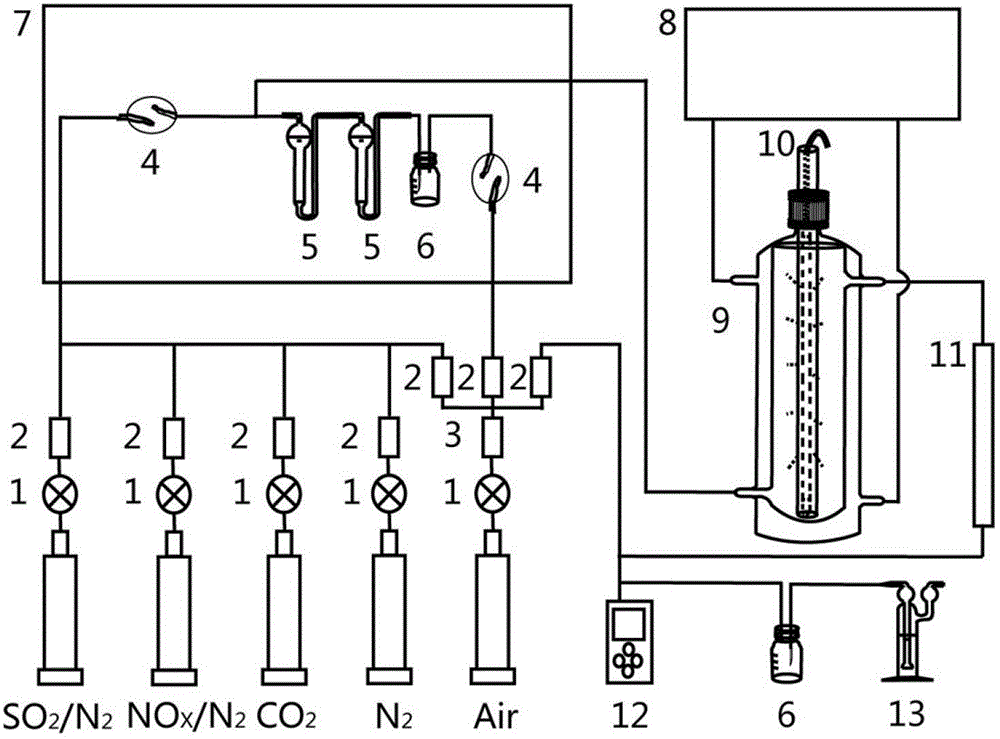

Method for removing SO2 and NOX in combustion coal flue gas through corona discharge and liquid phase oxidation

ActiveCN103611419ASimple structurePromote absorptionDispersed particle separationAir quality improvementFluid phaseFlue gas

The present invention discloses a method for concurrently removing SO2 and NOX in combustion coal flue gas through combination of corona discharge and liquid phase oxidation. The method comprises that: combustion coal flue gas requiring treatment is introduced into a corona discharge reactor inlet, is treated through a pre-oxidation spraying system, and then enters a corona discharge reactor electric field, and part of SO2 and part of NO in the flue gas are respectively oxidized into SO3 and NO2 with free radicals and active substances produced through high voltage corona electric field discharge; and with the combination effect of the electric field and the diffusion, SO3, NO2, the unoxidized SO2 and the unoxidized NO enter a spraying water type electrode liquid in the reactor in a migration manner, SO2 is further oxidized into S(VI) through liquid phase catalysis to finally form a high valence state acid, and NO and NO2 are subjected to absorption reduction through a urea solution so as to achieve a purpose of combustion coal flue gas purification. With the method, concurrent desulfurization and denitrification on coal flue can be achieved, the investment is low, running is economical, and characteristics of high desulfurization and denitrification efficiency, high corona discharge energy utilization rate, solution recycling, sulfur resource recycling and broad application prospect are provided.

Owner:浙江欧托电气有限公司

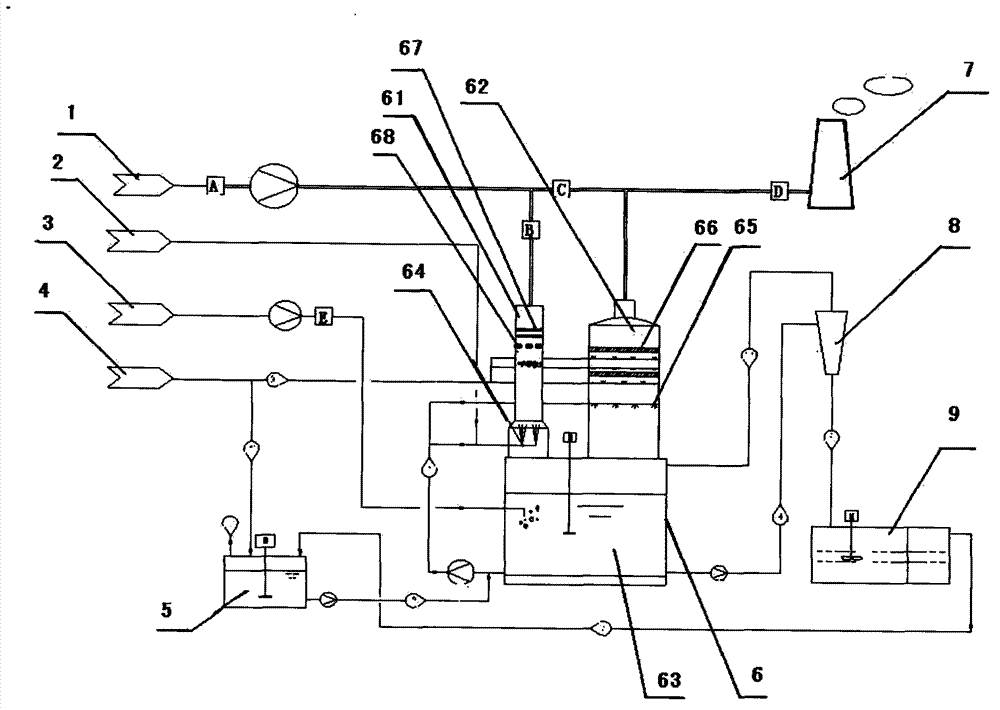

NOx and SO2 simultaneous absorption apparatus of coal-fired industrial boiler, and method thereof

ActiveCN105344235AEmission reductionImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationOxidation zoneAmmonium nitrate

The invention relates to a NOx and SO2 simultaneous absorption apparatus of a coal-fired industrial boiler, and a method thereof. The apparatus comprises a deduster, an air heater, an absorption tower, a GGH heat exchanger, an induced draught fan and a chimney which are arranged behind the boiler. The internal of the absorption tower is divided into a spray zone, a refluxing and collecting zone, an oxidation zone and a concentration and crystallization zone. The method comprises the processes of absorbent preparation, absorbent absorption, absorbent regeneration and byproduct recovery. The method concretely comprises the following steps: Co(NH3)<6><2+> formed by complexing NH3 generated by decomposing ammonium bicarbonate and Co<2+> is adopted as an absorbent to absorb SO2 and NOx in flue gas, NH4NO2, NH4NO3, NH4HSO3, (NH4)2SO3 and (NH4)2SO4 generated after absorption are crystallized through a drying technology and then are recovered, Co(NH3)<6><3+> generated after oxidation in the absorption process undergoes membrane separation, and then is electrolyzed and reduced to form Co<2+> for reuse. The SO2 and NOx in the flue gas can be simultaneously absorbed by using only one apparatus, and the desulphurization and denitration efficiency is high; and ammonium nitrate and ammonium sulfate generated after the desulphurization and denitration can be used as raw materials for producing fertilizers, so discharge of pollutants is reduced, and resources are recovered.

Owner:TSINGHUA UNIV +1

Efficient desulfurization and dust removal integrated device and dust removing method thereof

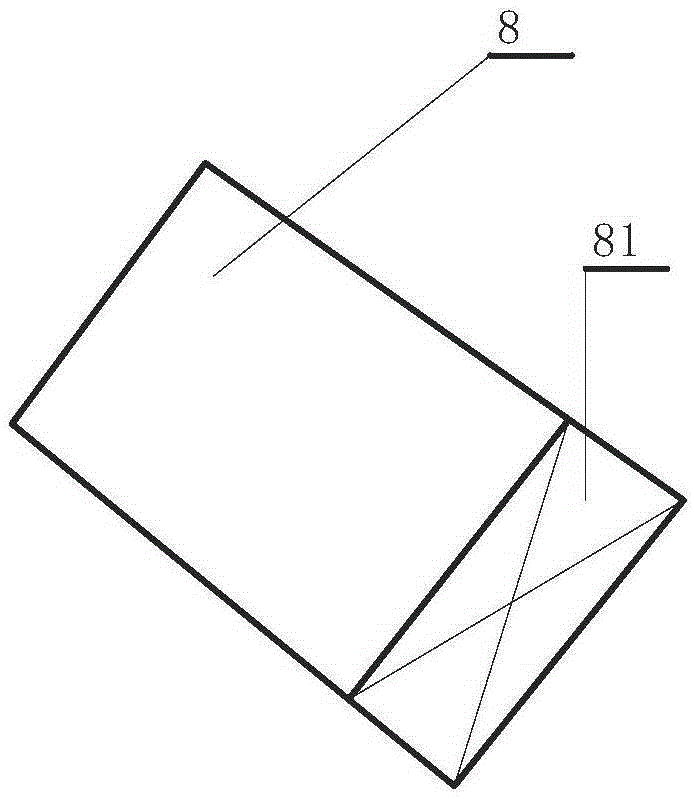

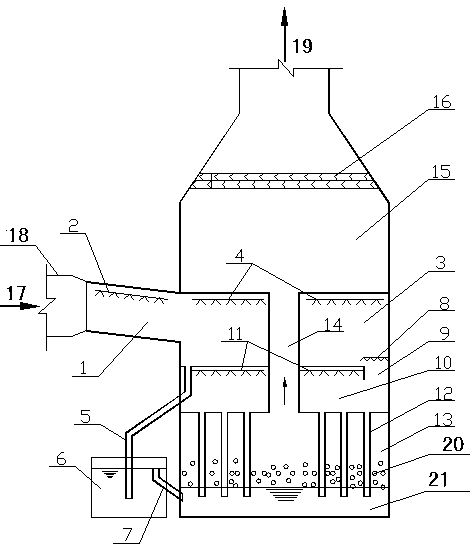

InactiveCN104069702ASimple structureEasy to useCombination devicesUsing liquid separation agentWater bathsInsertion depth

The invention relates to an efficient desulfurization and dust removal integrated device and a dust removing method of the efficient desulfurization and dust removal integrated device. The efficient desulfurization and dust removal integrated device comprises an atomizing chamber, wherein the atomizing chamber is connected with a spray dust settling chamber, a distribution chamber and a reaction chamber which are connected in sequence are arranged below the spray dust settling chamber, a gas collection chamber and a demister are arranged above the spray dust settling chamber in sequence, a nozzle for an oxidizing agent is arranged at a connecting opening of the spray dust settling chamber and the distribution chamber, and a nozzle for slurry for spray desulfuration, denitration and dust removal for the first time is installed in the spray dust settling chamber. The integrated device disclosed by the invention has the advantages of simple structure and convenience in use. According to the dust removing method implemented by the device, water spray dust removal, water bath dust removal, spray desulfuration and denitration, bubbling desulfuration and denitration, oxidizing agent oxidation and foam dust removal are organically combined, two-time desulfuration, denitration and dust removal are performed, the blocking problem of an aerator pipe is solved, the insertion depth of an aerator pipe is reduced, the resistance and the running cost are reduced, and the desulfuration, denitration and dust removal efficiencies are improved.

Owner:LANZHOU HUIYU ENVIRONMENTAL PROTECTION EQUIP CO LTD

Method for performing smoke desulfurization and denitrification by using urea co-production preparation technology

InactiveCN104014232AImprove efficiencyReduce investment and operating costsOrganic chemistryChemical industryUreaChemistry

The invention relates to a method for performing smoke desulfurization and denitrification by using a urea co-production preparation technology. Ammonia gas generated by the method can be independently used for smoke desulfurization and denitrification, obtained cyanuric acid can also be independently used for smoke desulfurization and denitrification, and the ammonia gas and the cyanuric acid can be combined for simultaneously performing desulfurization and denitrification. The method has the advantages of being simple in operation, increasing the desulfurization and denitrification efficiency, and greatly lowering the desulfurization and denitrification operation cost; the operation cost of the method is lower than that of an existing desulfurization and denitrification method; the economic benefit of the method is remarkable, and the problems of high infrastructure investment, high operation and maintenance cost and complicated operation of an existing desulfurization and denitrification technology are overcome; and the method can be suitable for smoke or tail gas treatment of multiple industrial boilers and industrial kilns.

Owner:SHANDONG UNIV

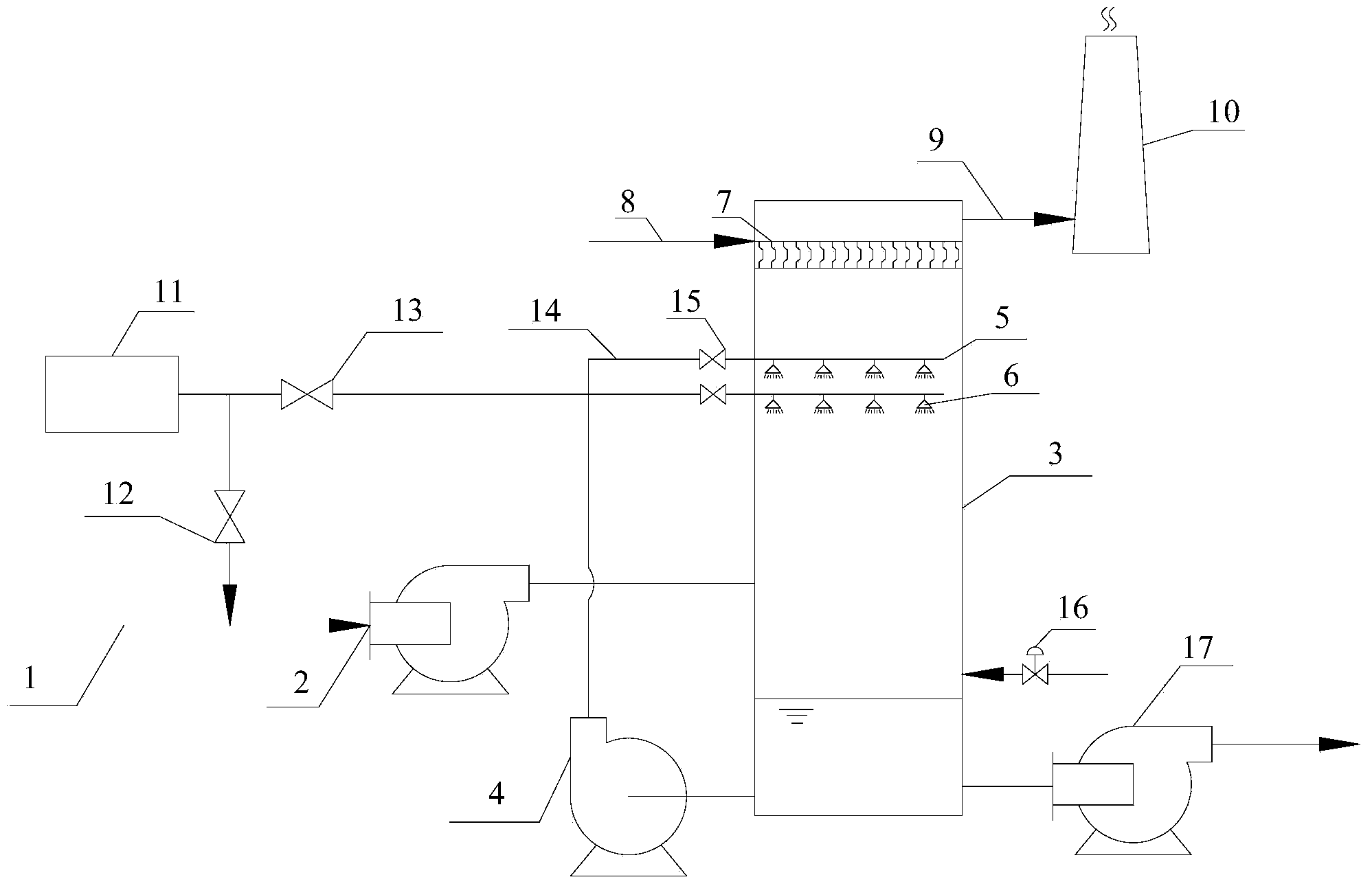

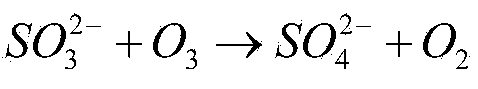

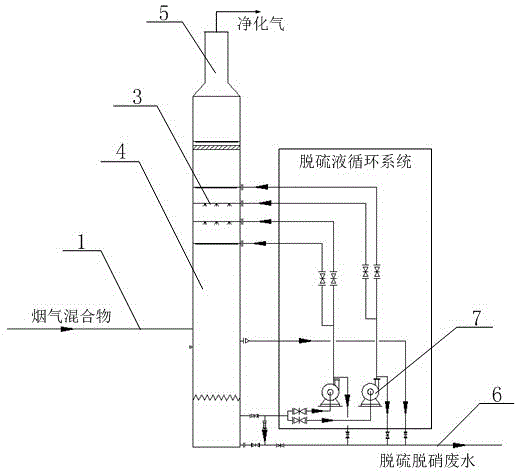

Flue gas purifying system and method with integration of desulfurization and denitrification

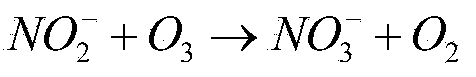

ActiveCN104056538APromote absorptionFully absorbedDispersed particle separationOzone generatorGas phase

The invention provides a flue gas purifying system with integration of desulfurization and denitrification. The flue gas purifying system comprises an ozone generator, a washing absorption tower and a chimney, wherein the washing absorption tower comprises a demisting layer, spraying layers and a tower kettle which are sequentially arranged from top to bottom; the tower kettle is externally provided with a circulation pump; the ozone generator is communicated with a flue gas inlet of the washing absorption tower by a first pipeline, so that flue gas is mixed with ozone before entering the washing absorption tower; the ozone generator is communicated with the spraying layers by a second pipeline, and guides ozone into spraying pipelines, so that ozone is mixed with an absorption liquid, and then is sprayed out from the spraying layers; the tower kettle is communicated with the spraying layers by the circulation pumps; a purified flue gas outlet of the washing absorption tower is communicated with the chimney. According to the invention, the process is simple; the occupied area is small; the cost of investment is low; the absorption effect is improved by combining ozone gas phase and liquid phase oxidation; the desulfurization and denitrification rate of the system is improved.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

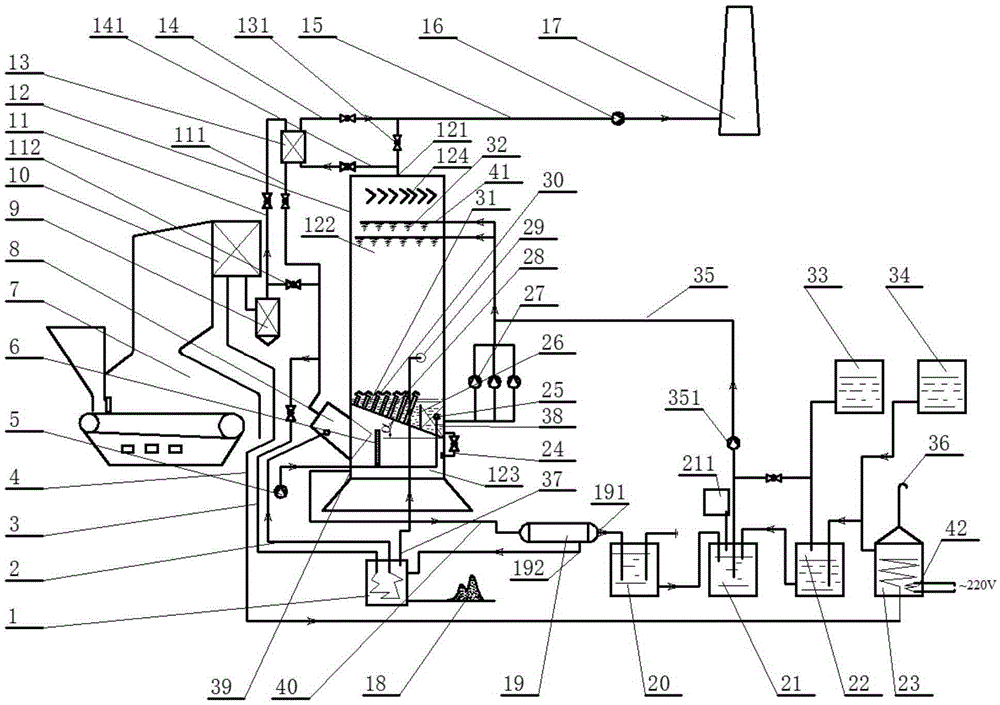

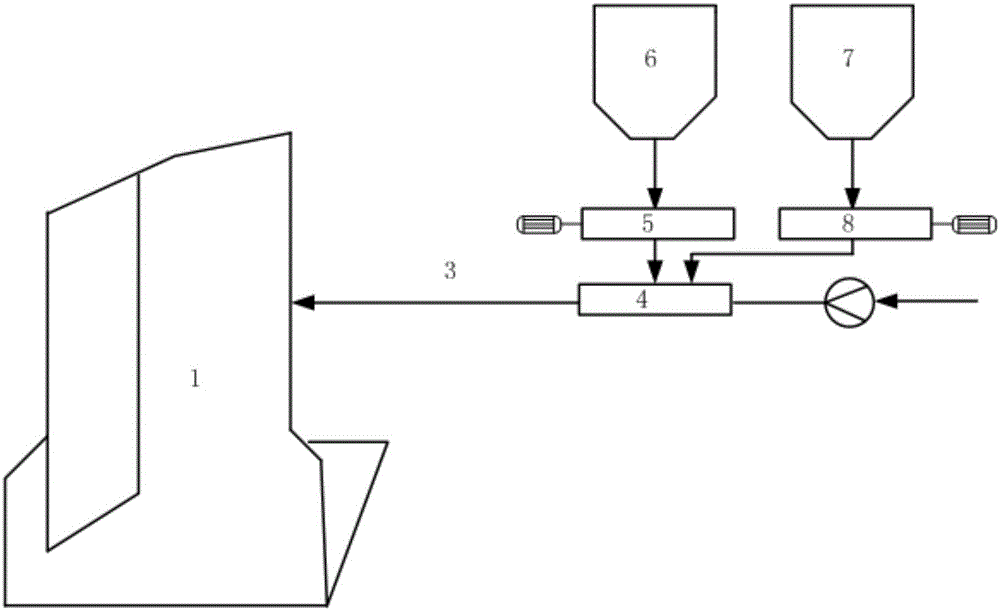

In-boiler desulfurization and denitration system and method for chain grate boiler

The invention discloses an in-boiler desulfurization and denitration system and method for a chain grate boiler. The system comprises the chain grate boiler, a feed bin and a smoke and powder mixer, wherein the feed bin is used for providing a space for containing a desulfurization agent and / or a denitration agent; the smoke and powder mixer is connected with the feed bin, a flue gas pipeline and the chain grate boiler respectively; flue gas is mixed with the desulfurization agent and the denitration agent in the smoke and powder mixer to provide power to deliver the desulfurization agent and the denitration agent to an injection pipeline component mounted in the chain grate boiler for injection; the desulfurization agent and the denitration agent are a calcium-based desulfurization agent and urea powder respectively. The desulfurization agent and the denitration agent are delivered into the chain grate boiler through the tail flue gas of the boiler, so that the urea powder can be effectively prevented from absorbing moisture for agglomeration; in addition, compared with that of hearth flue gas, the temperature and oxygen content of the tail flue gas are lower, so that an area of which the temperature is relatively proper and the oxygen concentration is relatively lower can be provided for denitration reaction in a higher-temperature area of a hearth, and the problems of instable hearth temperature, small reaction space and the like of the chain grate boiler can be solved.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL +1

Desulfurization and denitration technology and system by ozone oxidation double-tower ammonia method

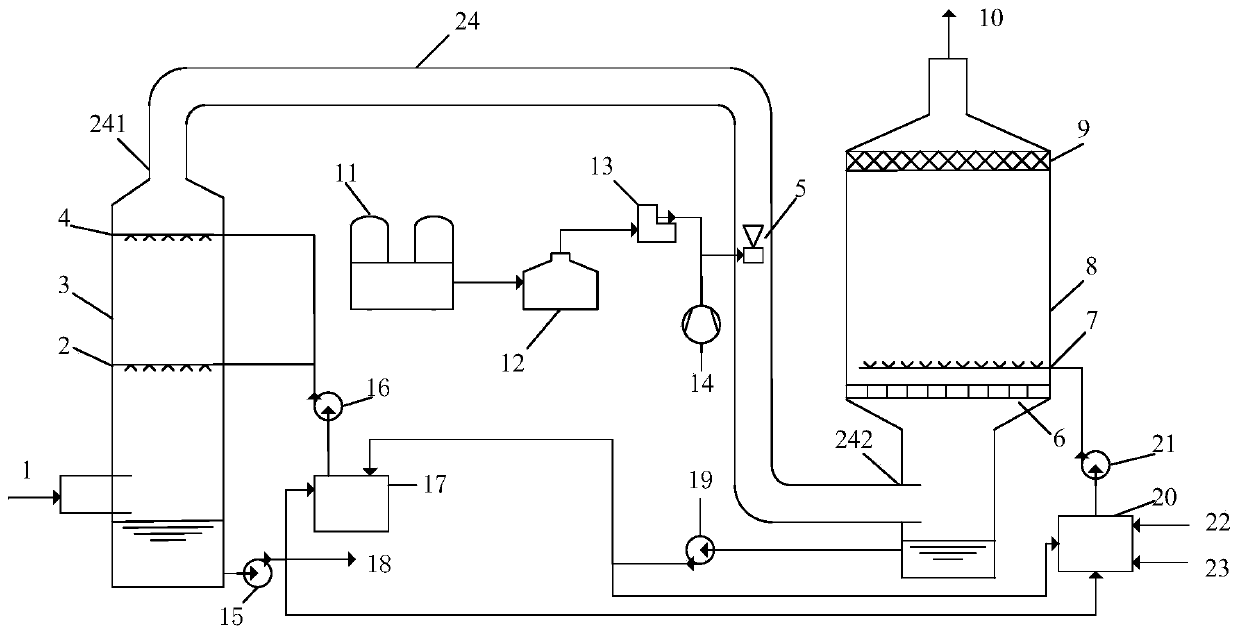

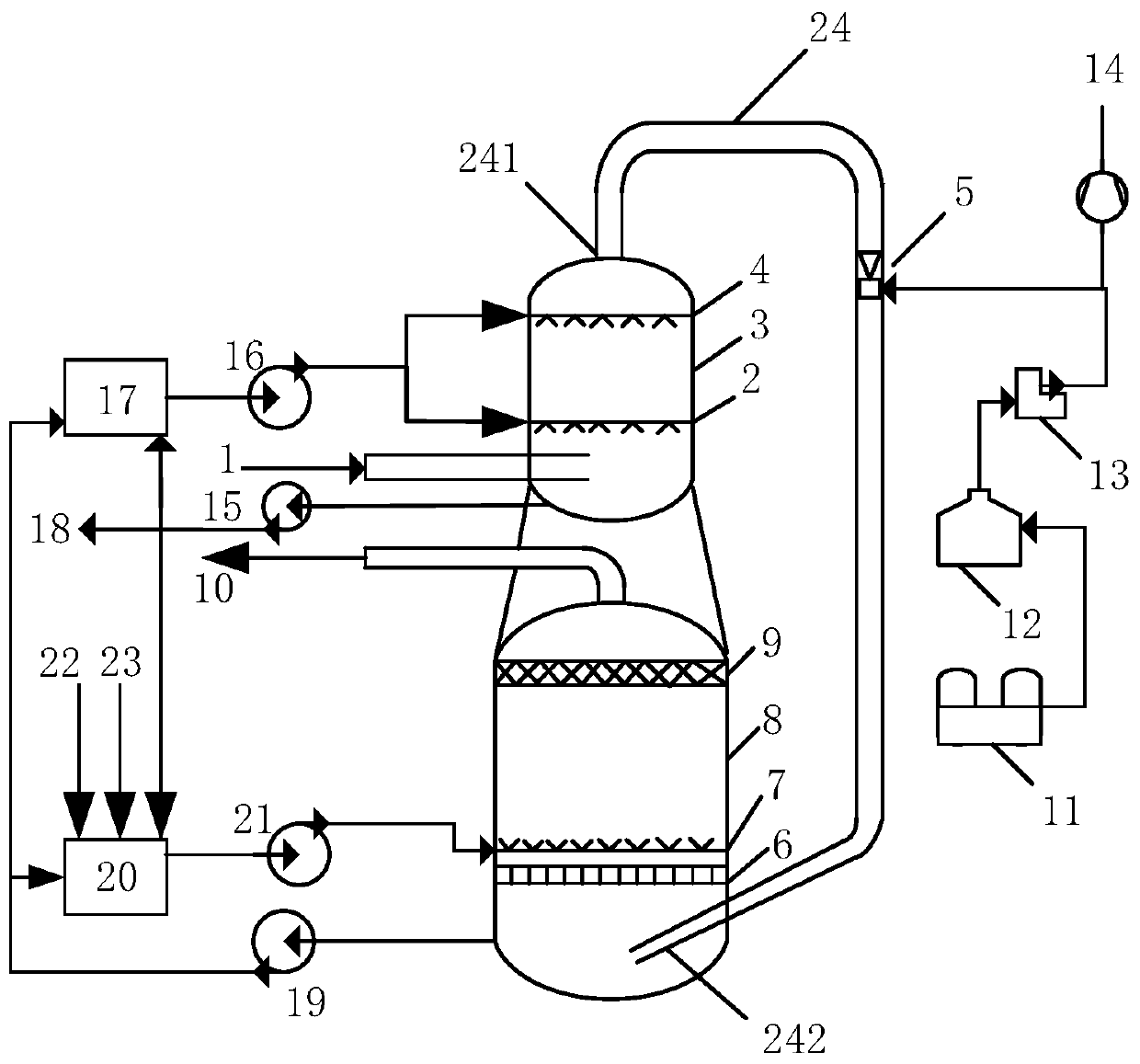

ActiveCN106166434AHigh process integrationReduce resistanceDispersed particle separationAir preheaterFlue gas

The invention relates to a desulfurization and denitration system by an ozone oxidation double-tower ammonia method. The desulfurization and denitration system sequentially comprises a hydrogen peroxide spraying device, a draught fan, an ozone spraying device, a flue gas mixing device, a front adsorption tower, a rear adsorption tower, a cyclone separator, a centrifugal separator and a drier, wherein the hydrogen peroxide spraying device is arranged at an outlet of a boiler coal economizer, the outlet of the boiler coal economizer is connected to the draught fan through an air preheater and a dust remover and is connected to the front adsorption tower; the ozone spraying device is mounted in front of an inlet flue of the front adsorption tower; and the flue gas mixing device is arranged between the ozone spraying device and the inlet flue of the front adsorption tower. The desulfurization and denitration system disclosed by the invention has the beneficial effects that the integration degree of a technology is high, the desulfurization and the denitration are integrated, the double-tower structure are stable in properties, the desulfurization efficiency and the denitration efficiency are high, the source of an adsorption tower machine is reliable, the added value of by-products is high, little secondary pollution exists, and the operation cost is low.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

Flue gas desulfurization and denitration device and method

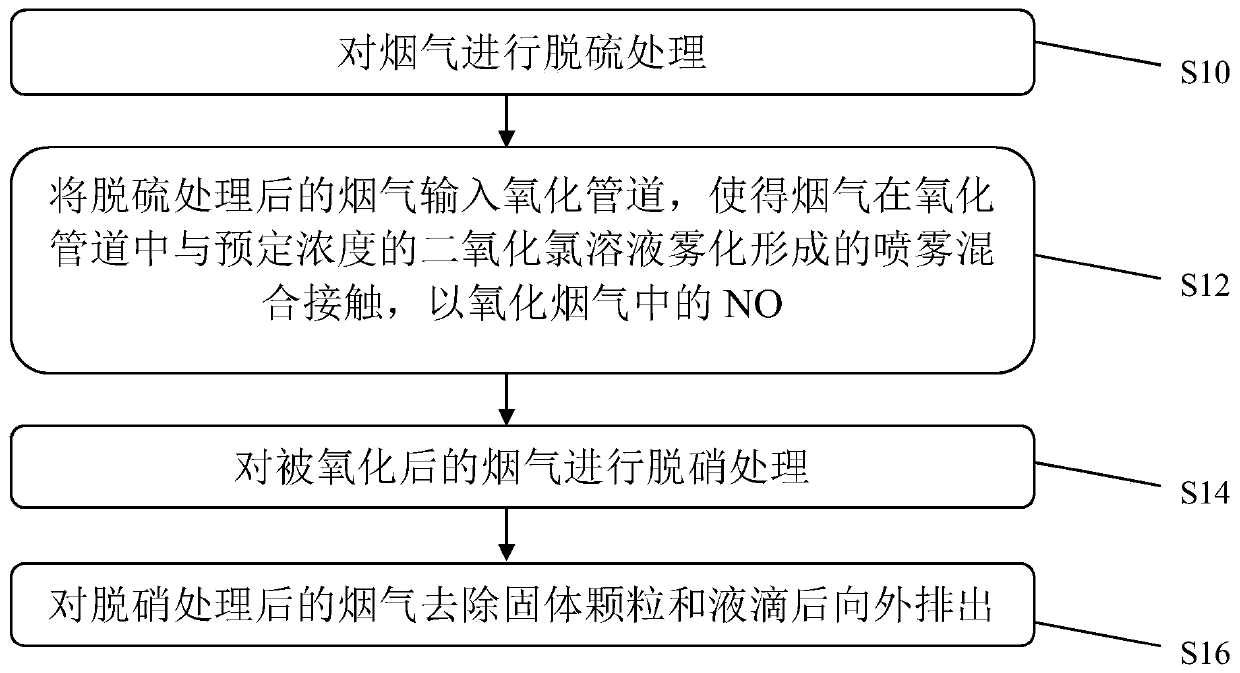

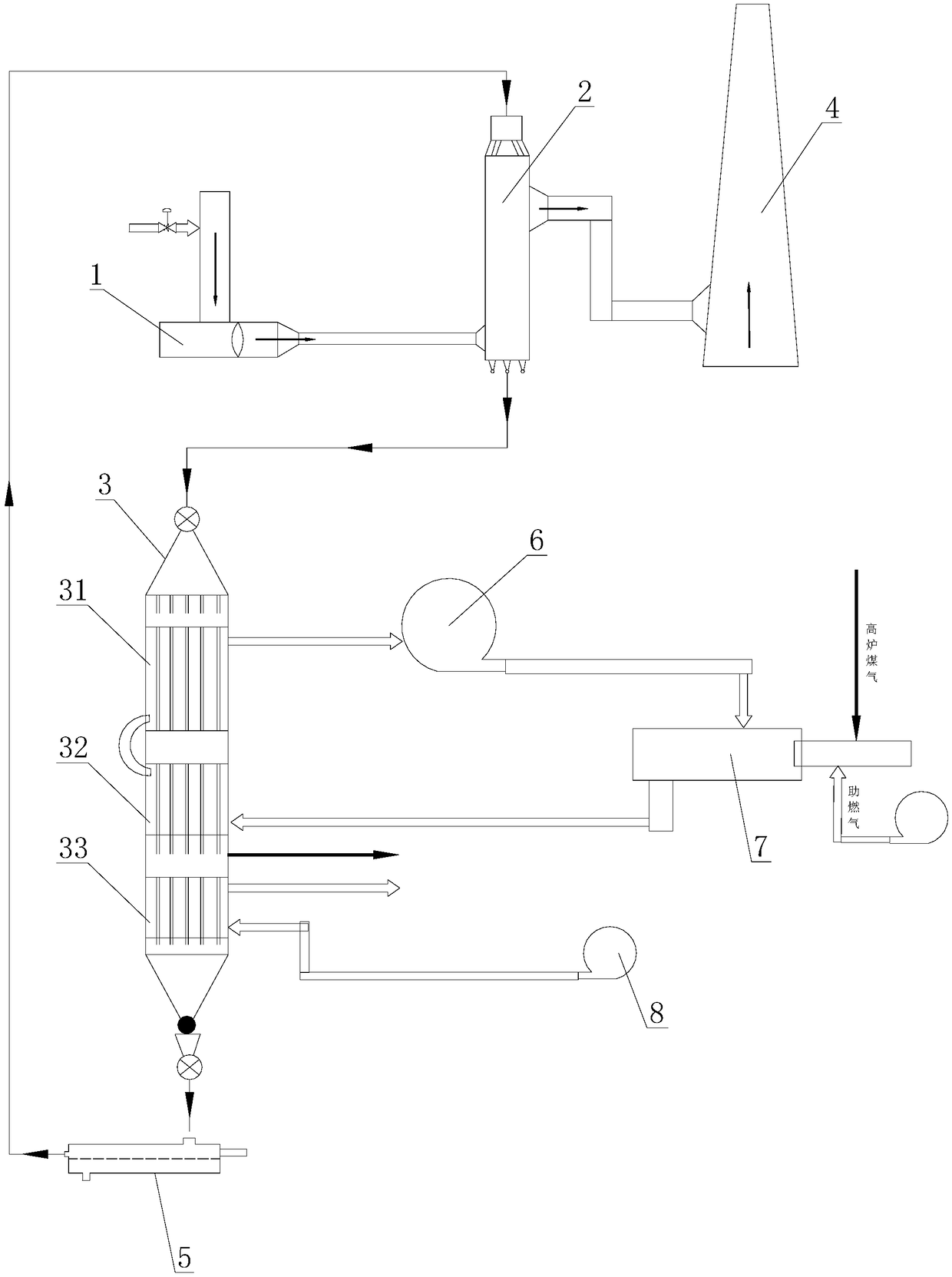

ActiveCN109718653AHigh gas velocityOxidation achievedDispersed particle separationChlorine dioxideFlue gas

The invention discloses a flue gas desulfurization and denitration device and method. The device comprises: a desulfurization container, the bottom of which is equipped with a desulfurization liquid material storage area, above which a flue gas inlet is disposed, with a flue gas washing and desulfurization structure being arranged above the flue gas inlet; a denitration container, the bottom of which is equipped with a denitration liquid material storage area, above which a flue gas washing and denitration structure is arranged, with a separation structure for removing solid particles and liquid drops being disposed above the flue gas washing and denitration structure, and a gas outlet being disposed at the top of the denitration container; an oxidization pipeline for communicating the desulfurization container and the denitration container; an atomization spray structure that is disposed in the oxidization pipeline and capable of providing structure connection together with chlorine dioxide, with the chlorine dioxide mist sprayed by the atomization spray structure being mixed with the flue gas in the oxidization pipeline. The flue gas desulfurization and denitration device and method provided by the invention can realize high efficiency and high utilization oxidation of ClO2 to NO, are safe and convenient to operate, and are convenient for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Flue gas desulfurization and denitration system

PendingCN109173570ATower resistance does not riseWill not cause forced production cutsGas treatmentDispersed particle filtrationBaghouseProcess engineering

The invention discloses a flue gas desulfurization and denitration system. The system comprises a bag deduster, a booster fan, a waste heat boiler, an adsorption tower and a regeneration tower, the outlet of the bag deduster is communicated with the flue gas inlet of the waste heat boiler through the booster fan, the flue gas outlet of the waste heat boiler is communicated with the flue gas inletof the adsorption tower, the flue gas outlet of the adsorption tower is communicated with the chimney, a material outlet at the bottom of the adsorption tower is communicated with a material inlet atthe top of the regeneration tower, a material outlet at the bottom of the regeneration tower is communicated with a material inlet of a vibrating screen, and the oversize product outlet of the vibrating screen is communicated with a material inlet at the top of the adsorption tower. The system has the advantages of high long-term running stability, high safety, high desulfurization and denitrationefficiency, and realization of safe and ultralow emission of the flue gas.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

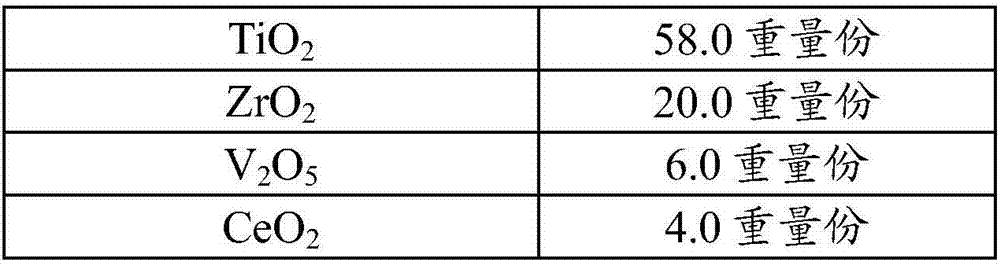

Flue gas desulfurization and denitration agent, preparation method and application thereof

InactiveCN107648990ARealize secondary useReduce dosageGas treatmentDispersed particle separationSlagFerrocobalt

The invention discloses a flue gas desulfurization and denitration agent, a preparation method and application thereof. The flue gas desulfurization and denitration agent comprises the following components: 70-93 parts by weight of carbide slag, 5-25 parts by weight of magnesium oxide, and 1-5 parts by weight of a catalyst, wherein the catalyst is selected from one or more of TiO2, Al(OH)3, V2O5,WO3, K2O, binuclear ferrocobalt phthalocyanine (II) or CaSiO3, and the flue gas desulfurization and denitration agent does not contain calcium oxide. The flue gas desulfurization and denitration agentprovided by the invention can remove SO2 and NOX from flue gas simultaneously. In addition, during use of the flue gas desulfurization and denitration agent provided by the invention, under the premise of satisfying high desulfurization and denitration efficiency, the carbide slag dosage needed by unit removal can be significantly reduced.

Owner:ZHONGJING ECO IND CO LTD

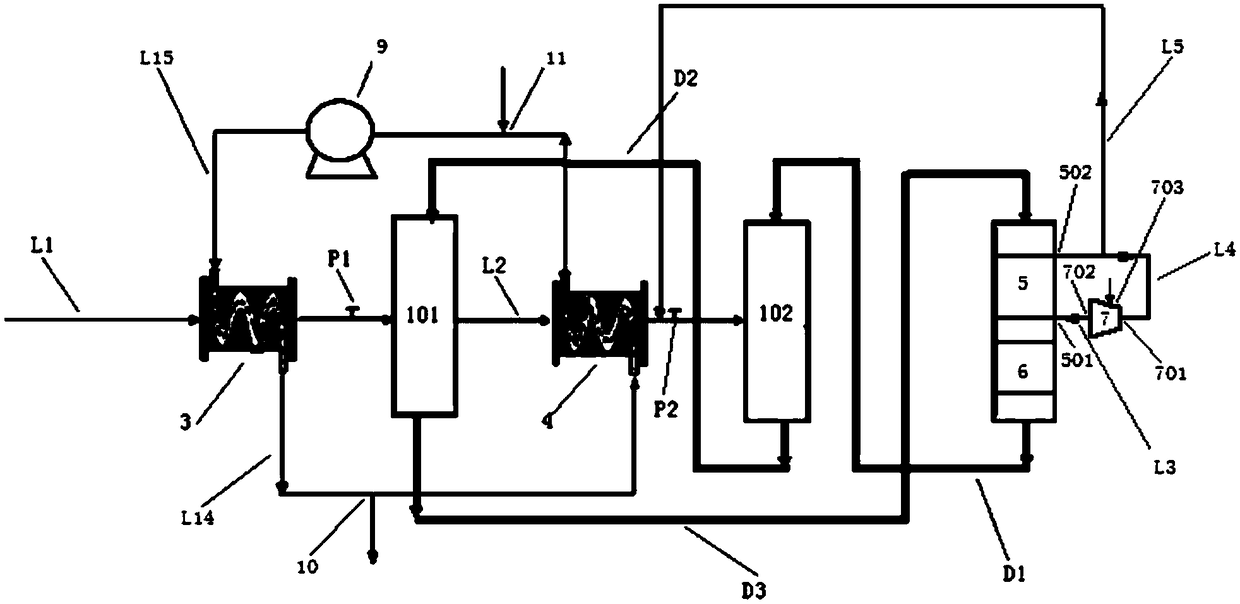

System and method for desulphurization and denitration

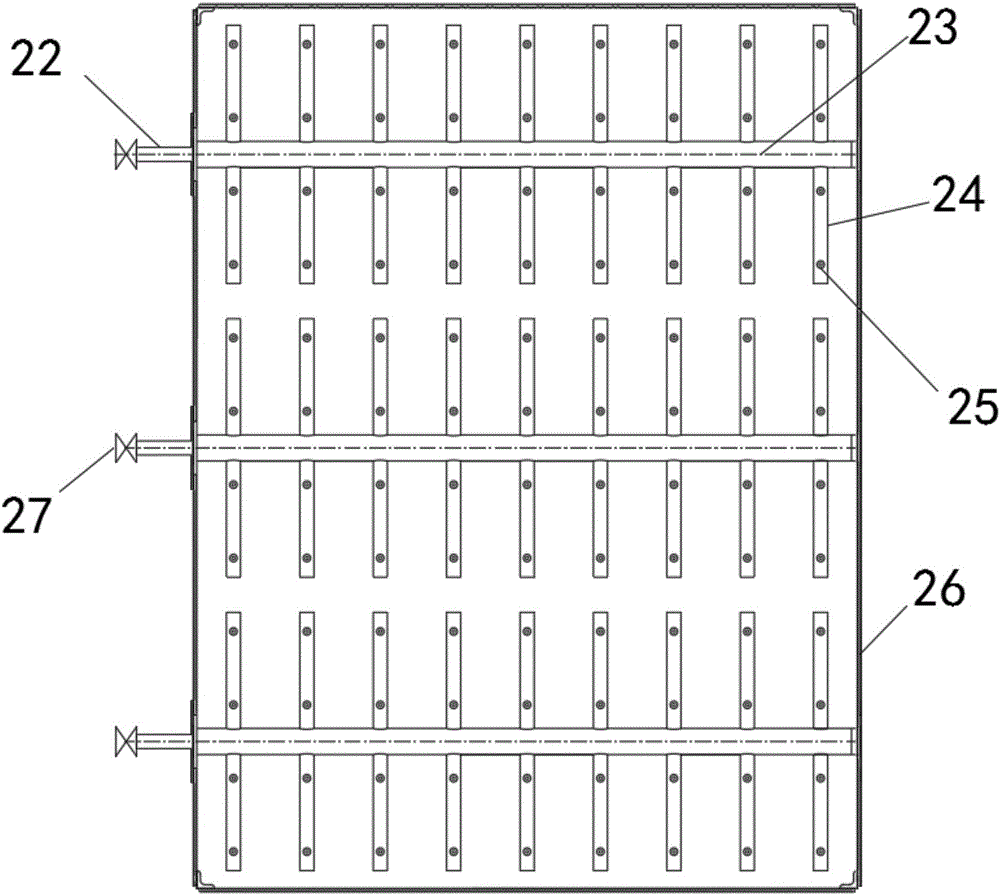

ActiveCN103585874AIngenious structural designReasonable structural designDispersed particle separationFlue gasEngineering

The invention discloses a system for desulphurization and denitration. The system comprises a tower body. A lower part of the tower body is provided with a flue gas inlet. The interior of the tower body corresponding to a position below the flue gas inlet is provided with an oxidization section. The interior of the tower body corresponding to a position above the flue gas inlet is orderly provided with a concentration section, an absorption section, a purification washing section and a demisting section from bottom to top. The invention also discloses a method for desulphurization and denitration by the system. The system for desulphurization and denitration has an ingenious and reasonable design, effectively solves the problem of a high operation cost, has stable processes, realizes absorption and concentration crystallization combination, does not produce waste liquid, limits ammonia escape and discharge and thoroughly solves the problems of ammonia escape and aerosol. The method for desulphurization and denitration has simple processes, realizes desulphurization and denitration, has high desulphurization and denitration efficiency, saves energy, is environmentally friendly, has a low cost, can be operated safely and stably, changes wastes into valuables, and indicates a key direction for environmentally-friendly desulphurization development.

Owner:SHANDONG MINGSHENG CHEM ENG CO LTD

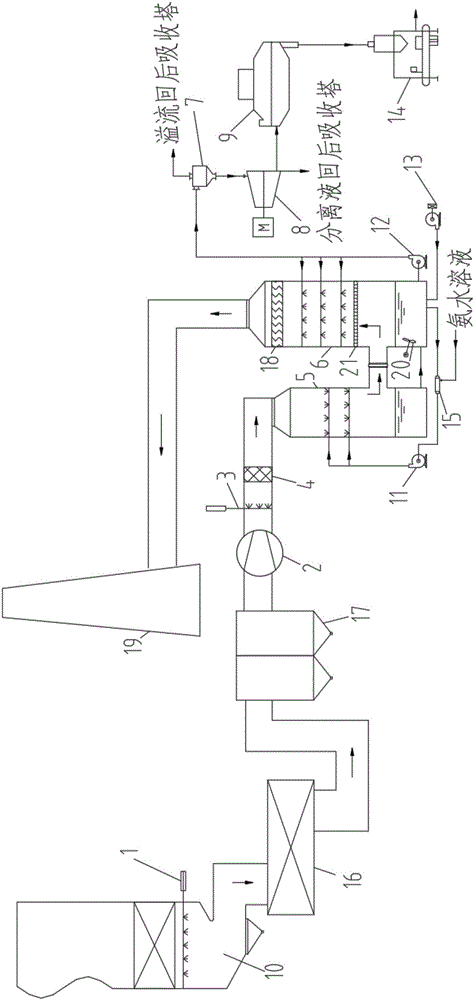

Desulphurization denitration method for ammonium sulfide solution

ActiveCN105233647AEmission complianceImprove removal efficiencyAmmonium nitratesUsing liquid separation agentEvaporationNitric oxide

The invention discloses a desulphurization denitration method for ammonium sulfide solution, and belongs to the technical field of flue gas purification. The method comprises employing an ammonium sulfide solution as an absorbent to absorb sulfur dioxide (SO2) and nitrogen oxides (NOx); performing dust removal and water-washing pretreatment on industrial kiln and furnace flue gas, and blowing proper amount of air into a flue gas pipe, so as to oxidize nitrogen monoxide in the nitrogen oxides into nitrogen dioxide under a slight hot condition, performing two-stage absorption on the flue gas by ammonium sulfide, so as to enable sulfur dioxide and nitrogen oxides in the gas to be absorbed and converted into salts and left in the solution; after the absorption reaction is finished, filtering and recovering sulfur, and performing neutralization, oxidation, evaporation crystallization and drying processing on the filtrate, so as to obtain a solid mixture of ammonium sulfate and ammonium nitrate, wherein the solid mixture can be sold directly as a fertilizer. The method is simple in technology, easy to operate, high in desulphurization denitration efficiency, low in cost and suitable for industrialized application.

Owner:KUNMING UNIV OF SCI & TECH

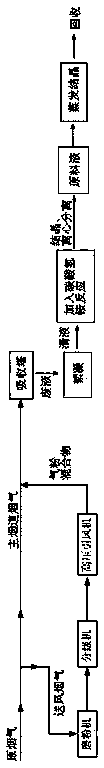

Waste recycling and regenerating device used in flue gas purification method

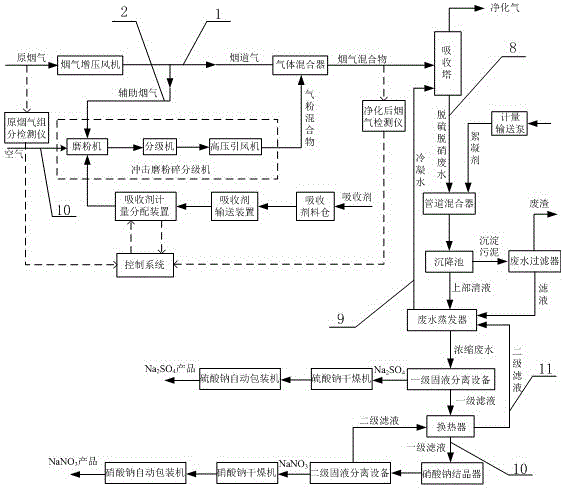

ActiveCN104399363APrevent dust leakageReduce dosageDispersed particle separationAlkali metal nitrate preparationAtmospheric pollutantsFlue gas

The invention discloses a waste recycling and regenerating device used in a flue gas purification method. The waste recycling and regenerating device comprises a wastewater regeneration system which is connected with flue gas purification equipment, wherein the flue gas purification equipment is a treatment unit for achieving desulfurization and denitrification of original flue gas; the wastewater regeneration system is a reuse unit which is used for separating the wastewater generated from desulfurization and denitrification by the flue gas purification unit and used for respectively preparing products of Na2SO4 and NaNO3. The waste recycling and regenerating device is simple to operate, pollutants in original flue gas are removed, and environment pollution is reduced, products of Na2SO4 and NaNO3 can be produced, the cost of atmospheric pollutant treatment is greatly lowered, the secondary pollution is avoided, and good social benefits and economic values are achieved.

Owner:CHENGDU HUAXITANG INVESTMENT

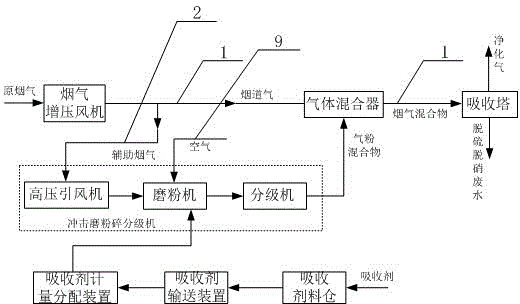

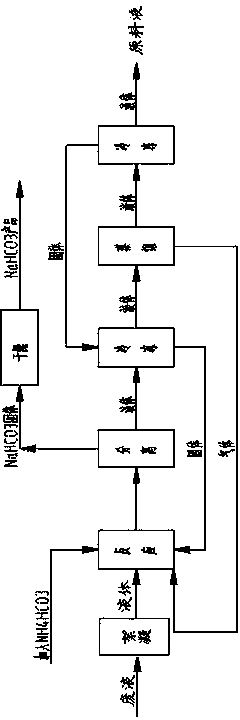

Dry-wet purifying recovery treatment process of smoke gas

ActiveCN104383797AIncrease the areaHigh porosityAmmonium nitratesChemical industryProcess engineeringAmmonium Hydrogen Carbonate

The invention provides a dry-wet purifying recovery treatment process of smoke gas. The dry-wet purifying recovery treatment process is characterized in that blowing smoke gas and a dry powder absorbant enter a grinding machine with a high-pressure induced draft fan for crushing treatment, and the crushed absorbant is delivered into a grader with an air flow; a screened gas-powder mixture enters a main flue to be reacted with the smoke gas inside the main flue so that the primary purification of the smoke gas is realized; the smoke gas subjected to the primary purification enters an absorption tower from the main flue and is subjected to wet purification and then directly discharged; and waste liquor inside the absorption tower is flocculated, then clear liquor enters a reactor to be reacted with ammonium hydrogen carbonate, after the reaction is finished, an obtained solid as an absorbant is recycled to a smoke gas purifying section, the clear liquor, which is obtained after liquor is cooled and crystallized, as a raw material solution enters an evaporation system, and an ammonium salt crystal obtained through evaporation and crystallization is recycled.

Owner:CHENGDU HUAXITANG INVESTMENT

Oxidation-absorption supergravity desulfurization and denitrification system and method

InactiveCN106110860AEfficient oxidationEfficient responseGas treatmentDispersed particle separationMedicinePotassium

The invention provides an oxidation-absorption supergravity desulfurization and denitrification system and method. The system is composed of a medicament feeding device and a supergravity reactor, the medicament feeding device comprises a medicament pool, a medicament liquid outlet of the medicament pool is connected with an outlet of a medicament adding pump, and an outlet of the medicament adding pump is connected with a medicament inlet of the supergravity reactor; the supergravity reactor comprises a shell, an annular filler rotor is arranged inside the shell, a gas inlet, a gas outlet, a medicament inlet and a medicament outlet are arranged on the shell, the gas outlet is connected with an induced draft fan, and the medicament outlet is connected with a backflow port of the medicament pool. The method includes: preparing a potassium monopersulfate solution of 0.1-1% in mass concentration; constantly guiding the potassium monoperfulfate solution into the inside of a filler of the annular filler rotor of the supergravity reactor, guiding dedusted mixed smoke into the supergravity reactor, and controlling the annular filler rotor to rotate at a constant speed to desulfurize and denitrify the mixed smoke; controlling flow velocity of a gas adjusting valve, and discharging desulfurized and denitrified smoke.

Owner:沈阳汇川环境工程有限公司 +1

Flue gas dry-process desulfurization and denitrification method based on ozone and carbide slag

InactiveCN107970769AGood lookingImprove desulfurization and denitrification efficiencyCombination devicesGas treatmentFlue gasSlag

The invention discloses a flue gas dry-process desulfurization and denitrification method based on ozone and carbide slag. The flue gas dry-process desulfurization and denitrification method comprisesthe following steps: (1) a pre-oxidization step: enabling the ozone to be in contact with flue gas with the temperature of 100 to 130 DEG C and the flow speed of less than 5m / s, oxidizing at least part of nitrogen oxide in the flue gas, so as to form pre-oxidized flue gas; (2) a desulfurization and denitrification step: enabling the pre-oxidized flue gas to be in contact with dry powder of a desulfurization and denitrification agent, so as to remove at least part of sulfur dioxide and the nitrogen oxide in the flue gas, wherein the dry powder of the desulfurization and denitrification agent is prepared from the following components in parts by weight: 60 to 95 parts of the carbide slag, 5 to 30 parts of magnesium oxide and 1 to 5 parts of a catalyst. The method disclosed by the inventionhas high desulfurization and denitrification efficiency and the flue gas subjected to desulfurization and denitrification treatment has a good appearance.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

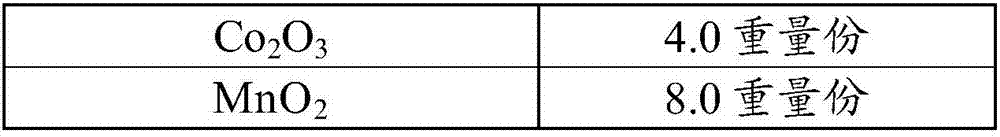

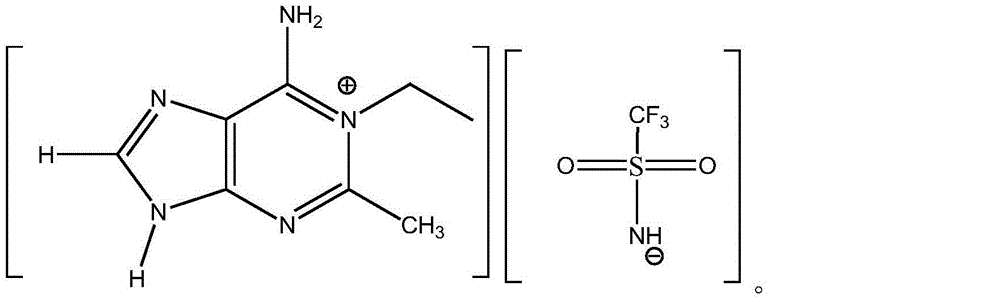

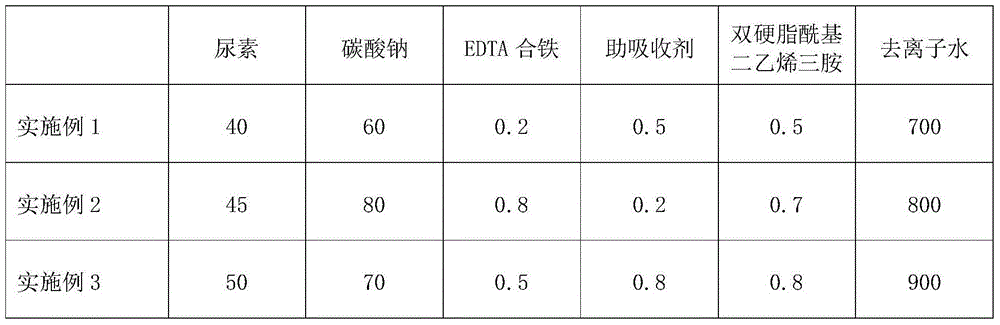

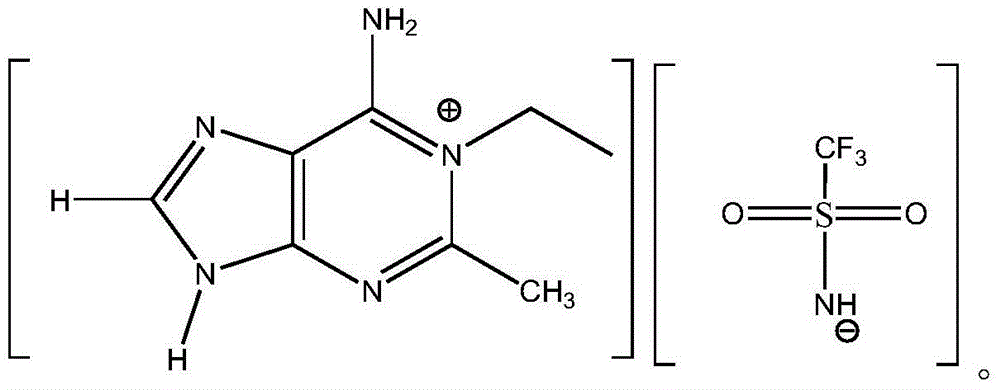

Composite desulfurization and denitration agent

InactiveCN103816766AImprove efficiencyFast absorptionDispersed particle separationAir quality improvementDiethylenetriamineAbsorption rate

The invention provides a composite desulfurization and denitration agent, and belongs to the technical field of industrial gas purification. The composite desulfurization and denitration agent is characterized by being prepared through the following steps: mixing the following raw materials in parts by weight: 40 to 50 parts of urea, 60 to 80 parts of sodium carbonate, 0.2 to 0.8 part of EDTA-Fe, 0.2 to 0.8 part of absorption enhancer, and 0.5 to 0.8 part of distearoyl diethylenetriamine, wherein the total parts by weight of the EDTA-Fe, absorption enhancer, and surfactant are more than 1.2 parts by weight; adding 700 to 900 parts by weight of water into the mixture, evenly mixing, and adding a proper amount of sodium hydroxide to adjust the pH value to a range of 10 to 12. The composite desulfurization and denitration agent is used to remove high-valence oxynitride and sulfur dioxide at a normal temperature and under a normal pressure; the nitrogen dioxide absorption rate of the agent is 95% or more, the sulfur dioxide absorption rate of the agent is 90% or more, and the agent has the advantages of rapid absorption speed and high efficiency.

Owner:SHANDONG AMETHYST PHOTOELECTRIC NEW MATERIAL

Dry method combined desulfurization and denitration technology and device for activated coke

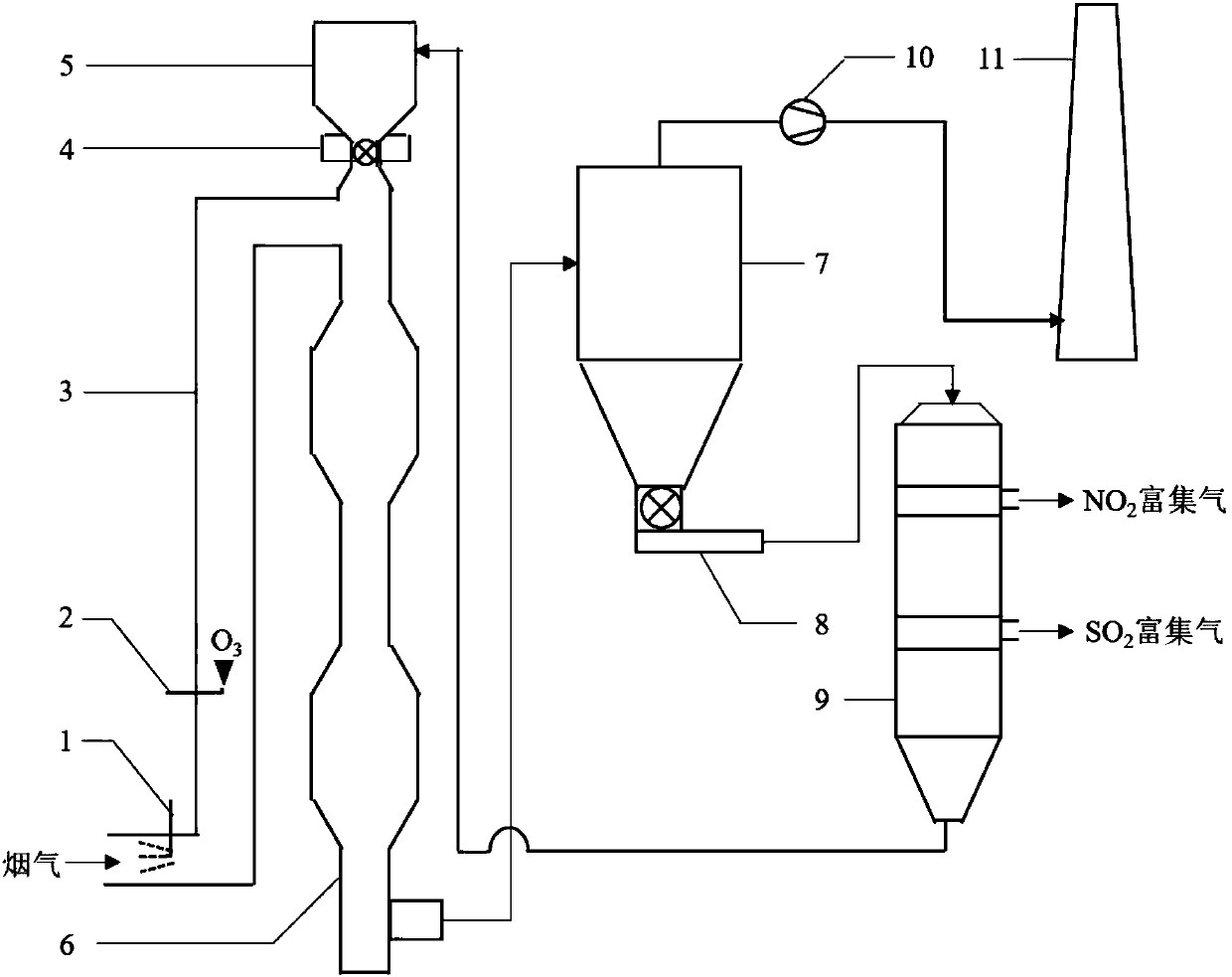

InactiveCN108043212AIncrease contactUniform gas-solid flowGas treatmentDispersed particle separationFluidized bedDesorption

The invention relates to a dry method combined desulfurization and denitration technology and device for activated coke. The desulfurization and denitration device is a multi-section diameter-expanding fluidized bed concurrent with a gravity field. Exhaust gas containing NOx and SO2 firstly enters an ascending flue at the front end of a desulfurizing tower, cooling and humidifying are performed bya water atomizing nozzle, and ozone sprayed in the ascending flue oxidizes NOx and SO2 into high-valent-state NOx and SOx respectively; the exhaust gas enters the top of the fluidized bed and is mixed with the activated coke discharged from a stock bin, and the activated coke is fluidized; the activated coke moves downwards and enters diameter-expanding sections to finish the desulfurization anddenitration adsorption reaction; the exhaust gas enters a gas-solid separation device, the separated activated coke is fed into an desorption tower for regeneration, and enriched NO2 and SO2 gas are obtained respectively; finally, the regenerated activated coke is sent to the stock bin to participate in desulfurization and denitration again. The integrated desulfurization and denitration technology has the advantages of high efficiency, simple process, considerable comprehensive benefits and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com