Flue gas dry-process desulfurization and denitrification method based on ozone and carbide slag

A desulfurization, denitrification and dry desulfurization technology is applied in the field of flue gas dry desulfurization and denitrification, which can solve the problems of unfavorable ozone oxidation and low denitration efficiency, and achieve the effects of good flue gas appearance and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

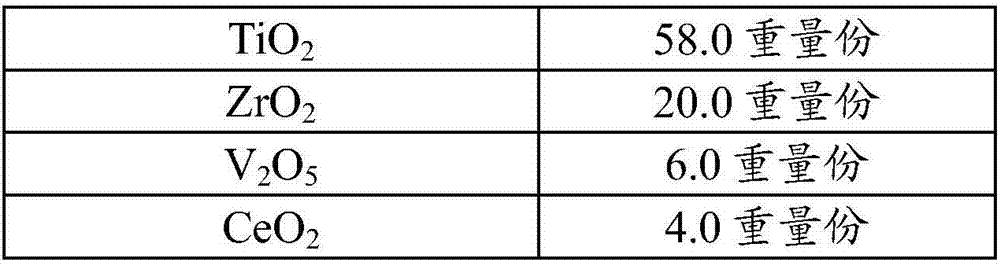

[0048] The desulfurization and denitrification agent in this embodiment contains 5 parts by weight of magnesium oxide (the content of active magnesium oxide is 70 wt%), 2 parts by weight of catalyst, and 93 parts by weight of carbide slag (with a particle size of 200 mesh and a sieving rate greater than 95%). The catalyst formulation is shown in Table 2 below. The following parts by weight represent the weight ratio between the components, and the specific usage can be calculated accordingly.

[0049] Table 2. Catalyst formulation

[0050] TiO 2

60.0 parts by weight

ZrO 2

20.0 parts by weight

V 2 o 5

4.0 parts by weight

CeO 2

4.0 parts by weight

co 2 o 3

4.0 parts by weight

MnO 2

8.0 parts by weight

[0051] The flue gas (see Table 1) passes through the pre-dust collector to remove large particles in advance, and the dust content of the flue gas after dust removal is 20mg / Nm 3 , and then...

Embodiment 2

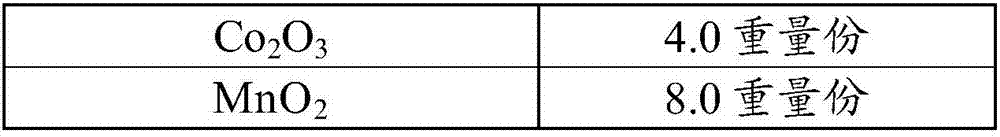

[0056] Desulfurization and denitrification were carried out in the same manner as in Example 1, except that the following conditions or material compositions were used. The desulfurization and denitrification agent in this embodiment includes: 10 parts by weight of magnesium oxide (active magnesium oxide content is 75 wt%), 2.4 parts by weight of catalyst, and 87.6 parts by weight of carbide slag. The catalyst formulation is shown in Table 4 below, increasing V 2 o 5 parts by weight. The following parts by weight represent the weight ratio between the components, and the specific usage can be calculated accordingly.

[0057] Table 4. Catalyst formulation

[0058]

[0059]

[0060] After desulfurization and denitrification with the above desulfurization and denitrification agents, the flue gas data at the detection outlet are shown in Table 5 below.

[0061] Table 5. Emissions from desulfurization and denitrification

[0062] serial number

Embodiment 3

[0064] Desulfurization and denitrification were carried out in the same manner as in Example 1, except that the following conditions or material compositions were used. The desulfurization and denitrification agent in this embodiment includes 15 parts by weight of magnesium oxide (the content of active magnesium oxide is 80 wt%), 3 parts by weight of catalyst, and 82 parts by weight of carbide slag. The catalyst formulation is shown in Table 6 below, MnO 2 Increased to 10 parts by weight. The following parts by weight represent the weight ratio between the components, and the specific usage can be calculated accordingly.

[0065] Table 6. Catalyst formulation

[0066] TiO 2

56.0 parts by weight

ZrO 2

20.0 parts by weight

V 2 o 5

6.0 parts by weight

CeO 2

4.0 parts by weight

co 2 o 3

4.0 parts by weight

MnO 2

10.0 parts by weight

[0067] Using this desulfurization and denitrification ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com