Patents

Literature

1768 results about "Contact reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact urticaria reactions appear within minutes to about one hour after exposure of the offending substance to the skin. Signs and symptoms of affected skin areas include: Local burning sensation, tingling or itching. Localised or generalised red swellings or weals may occur, especially on the hands.

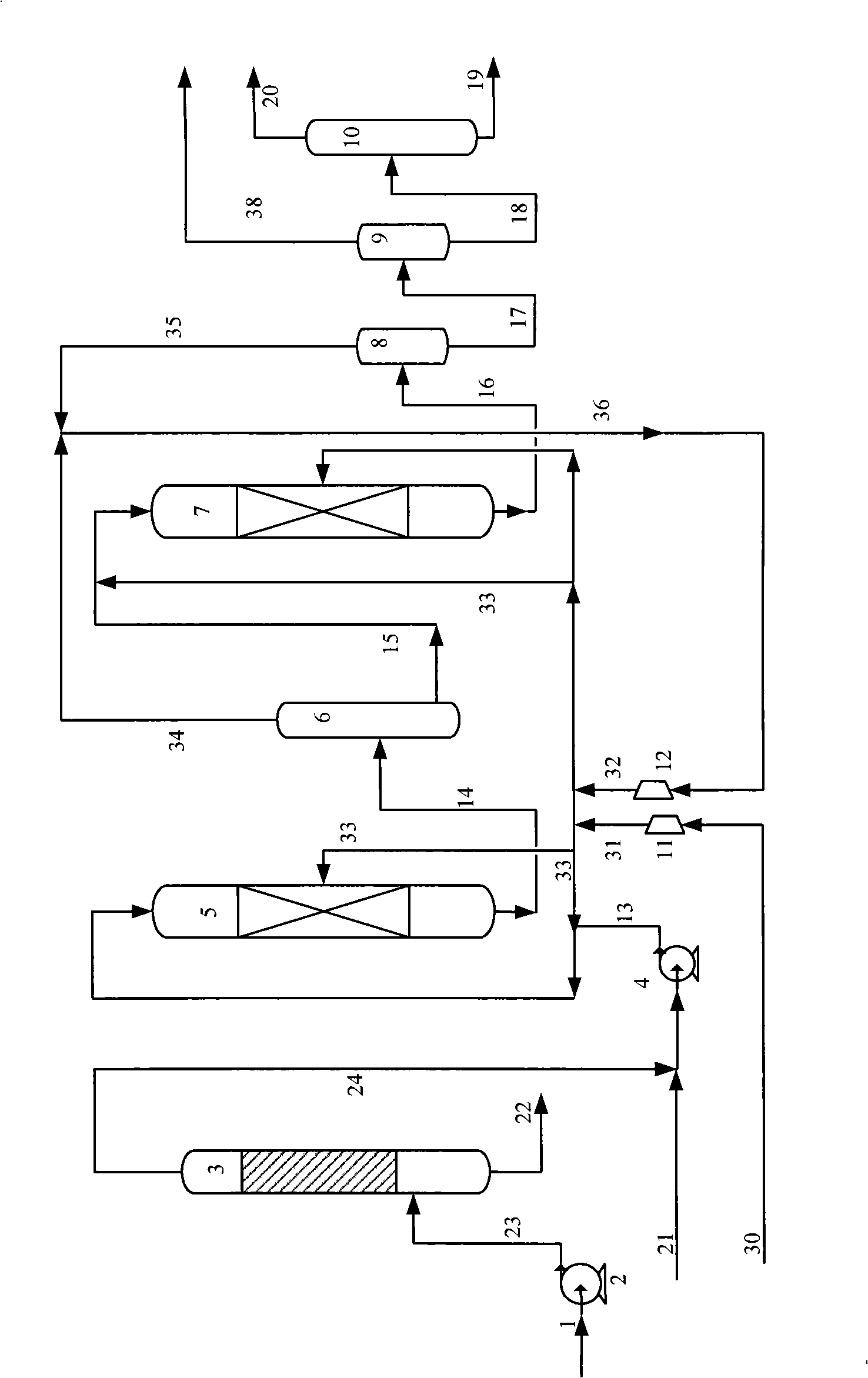

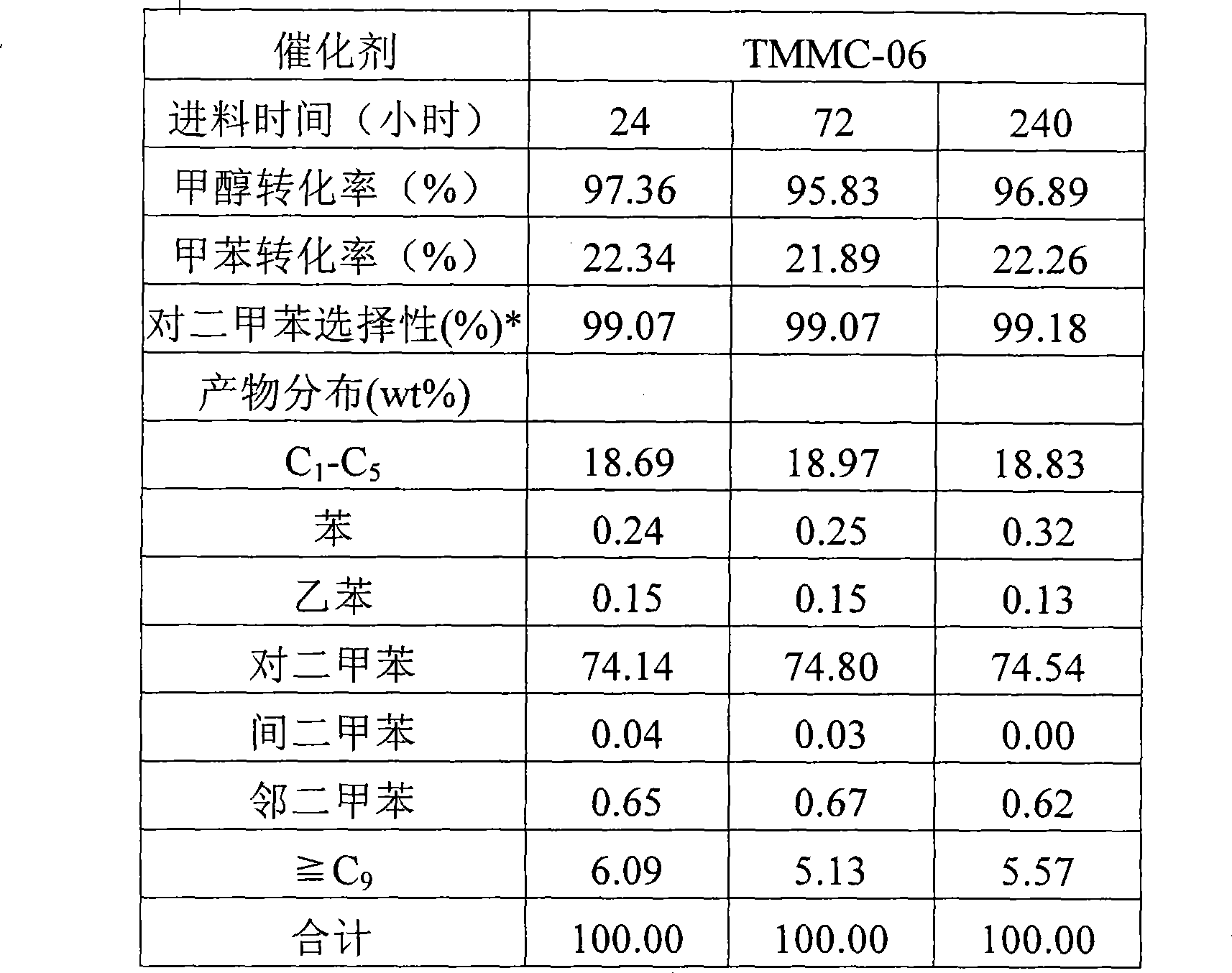

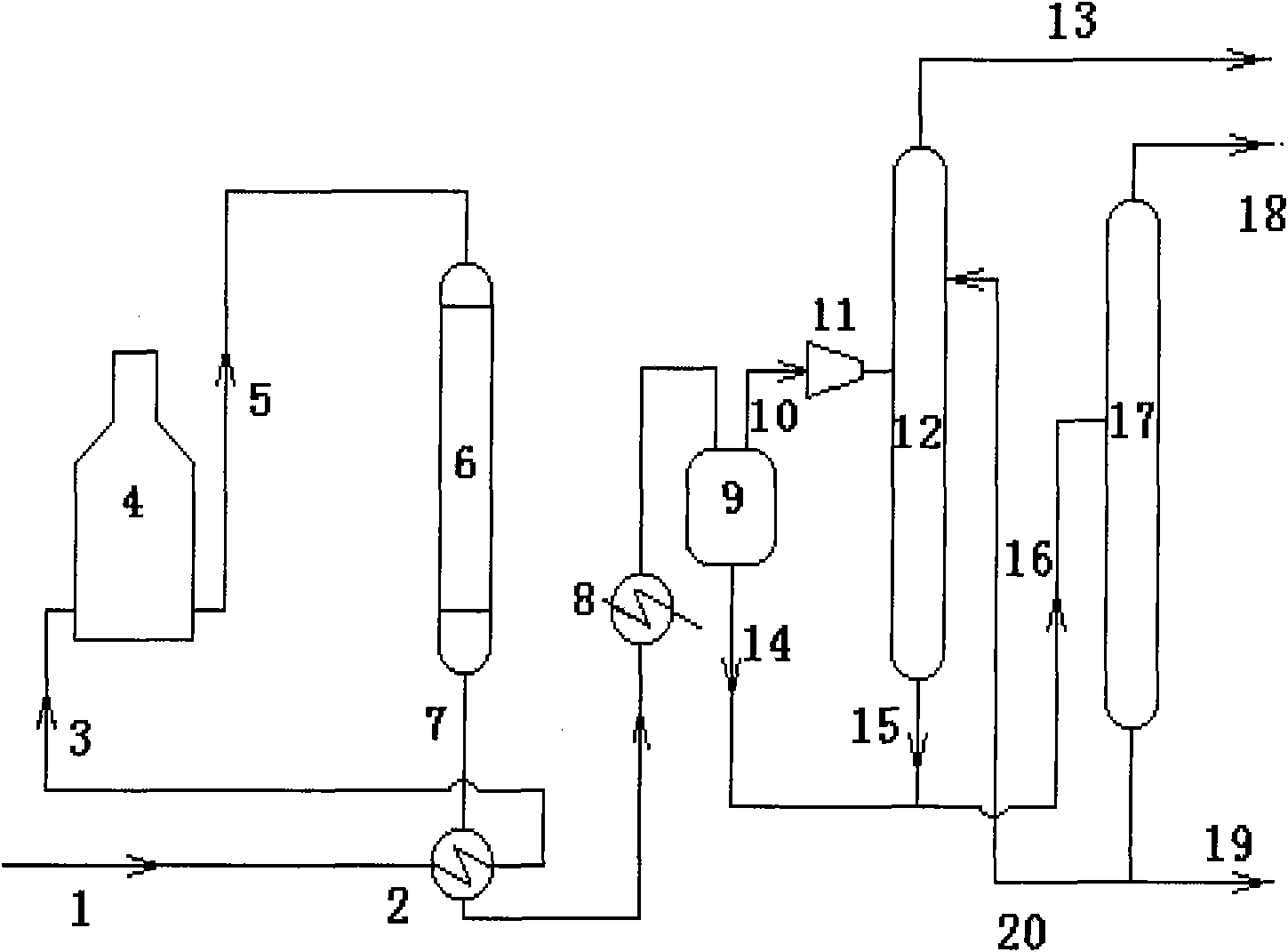

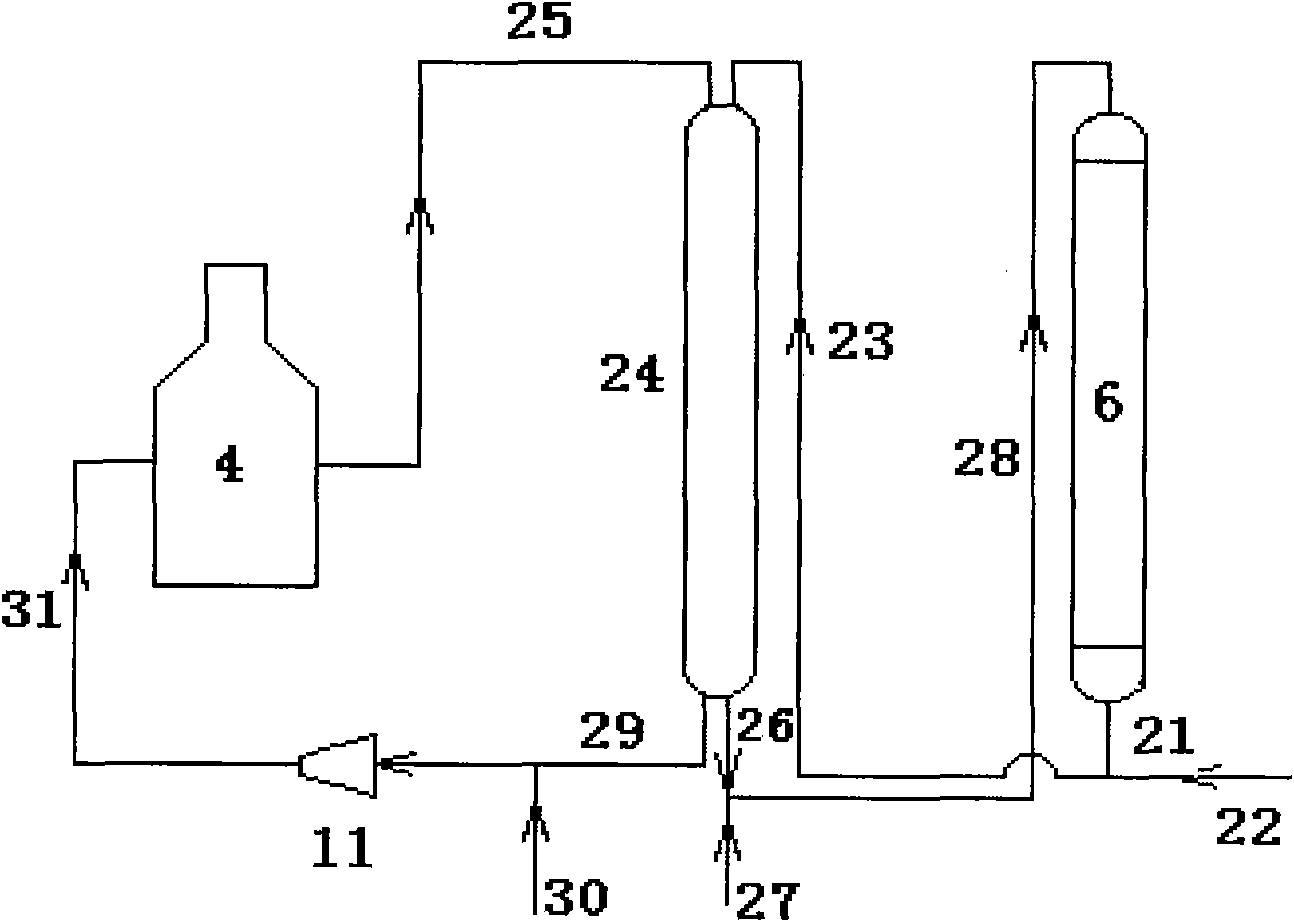

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

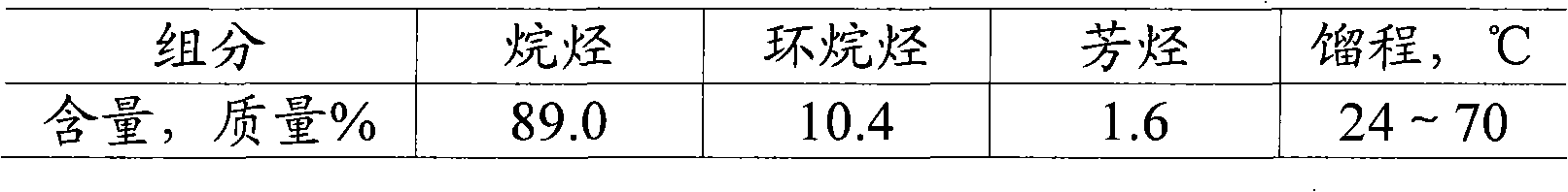

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of hexapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the hexapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of octapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the octapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

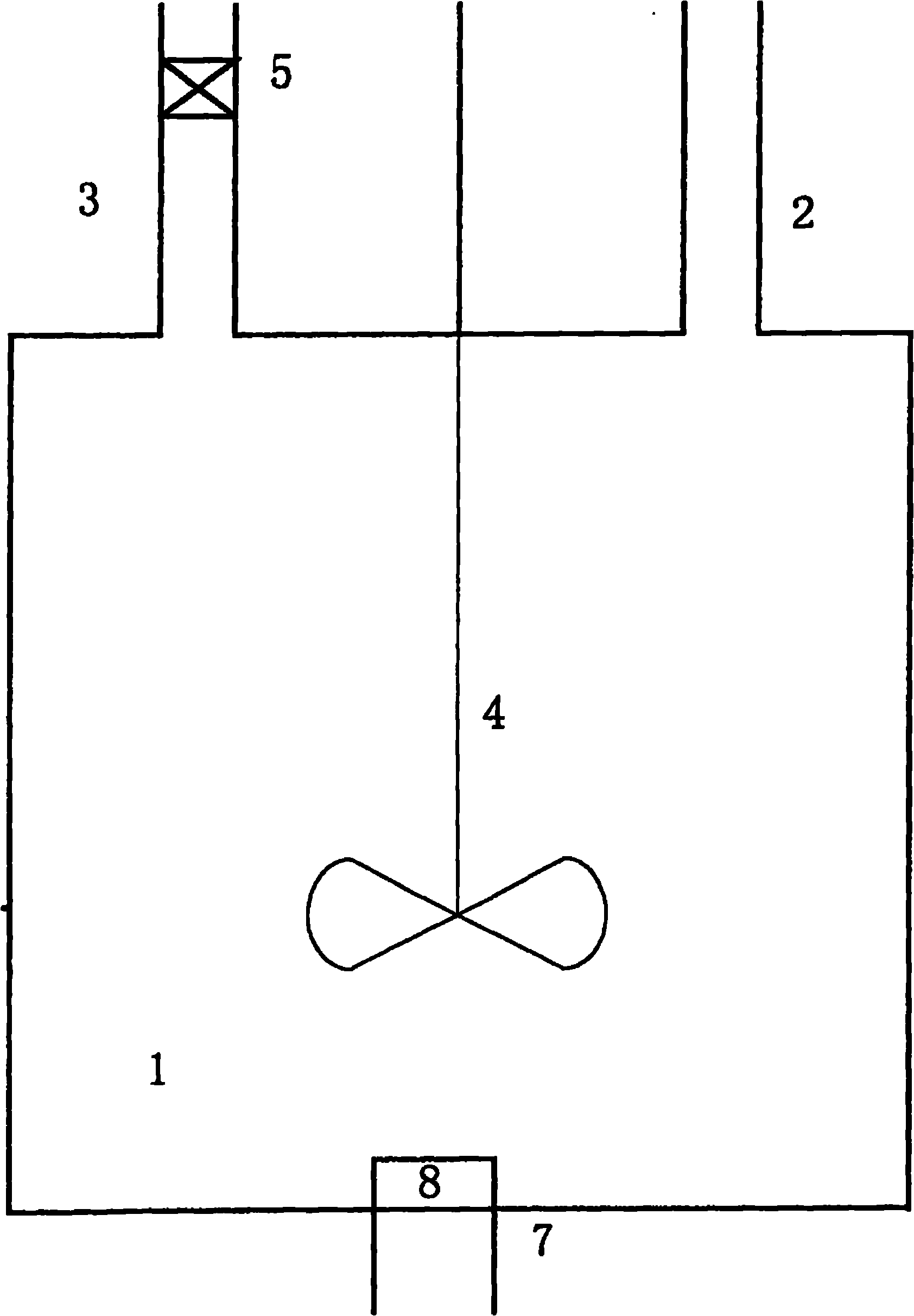

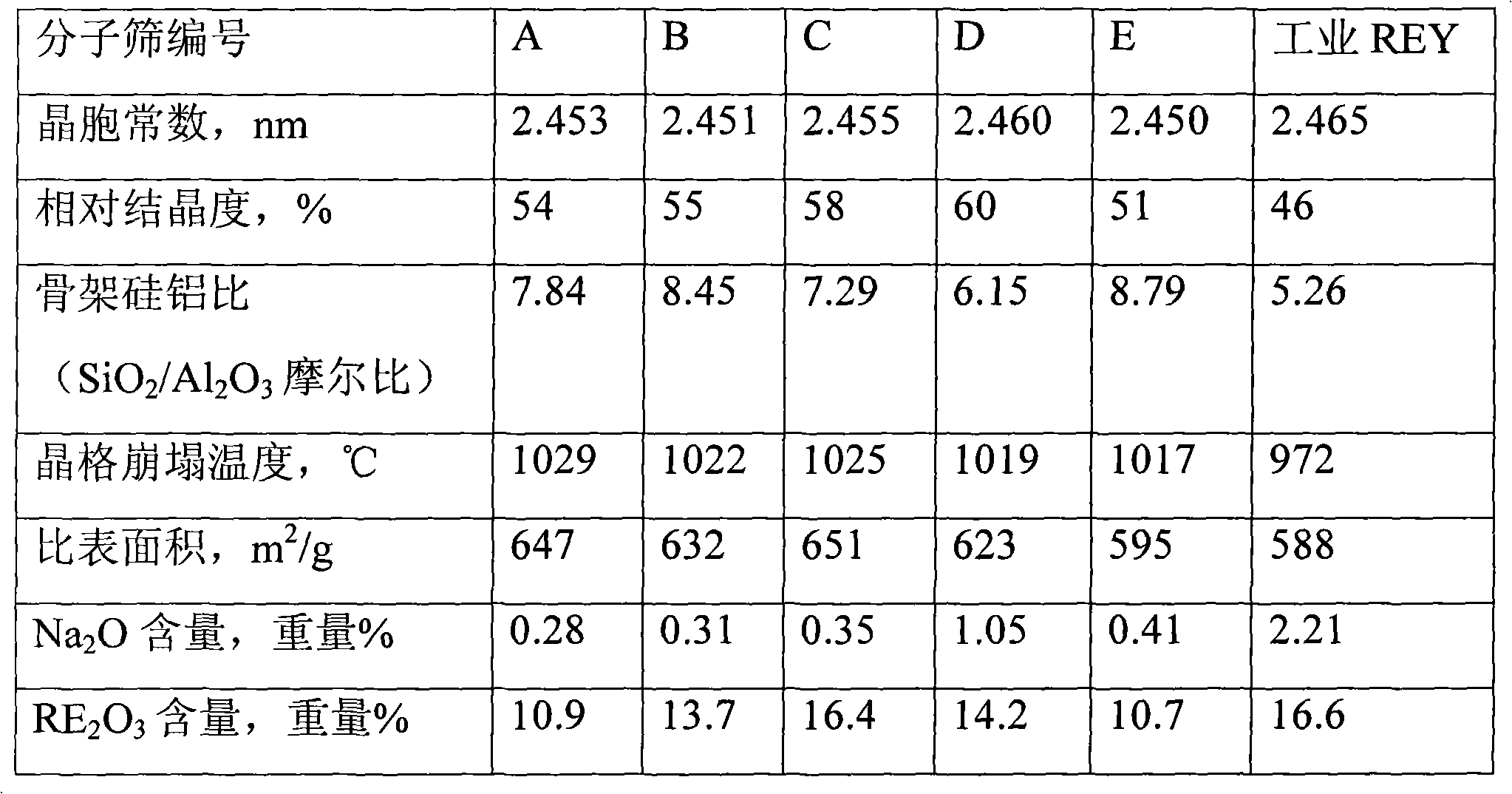

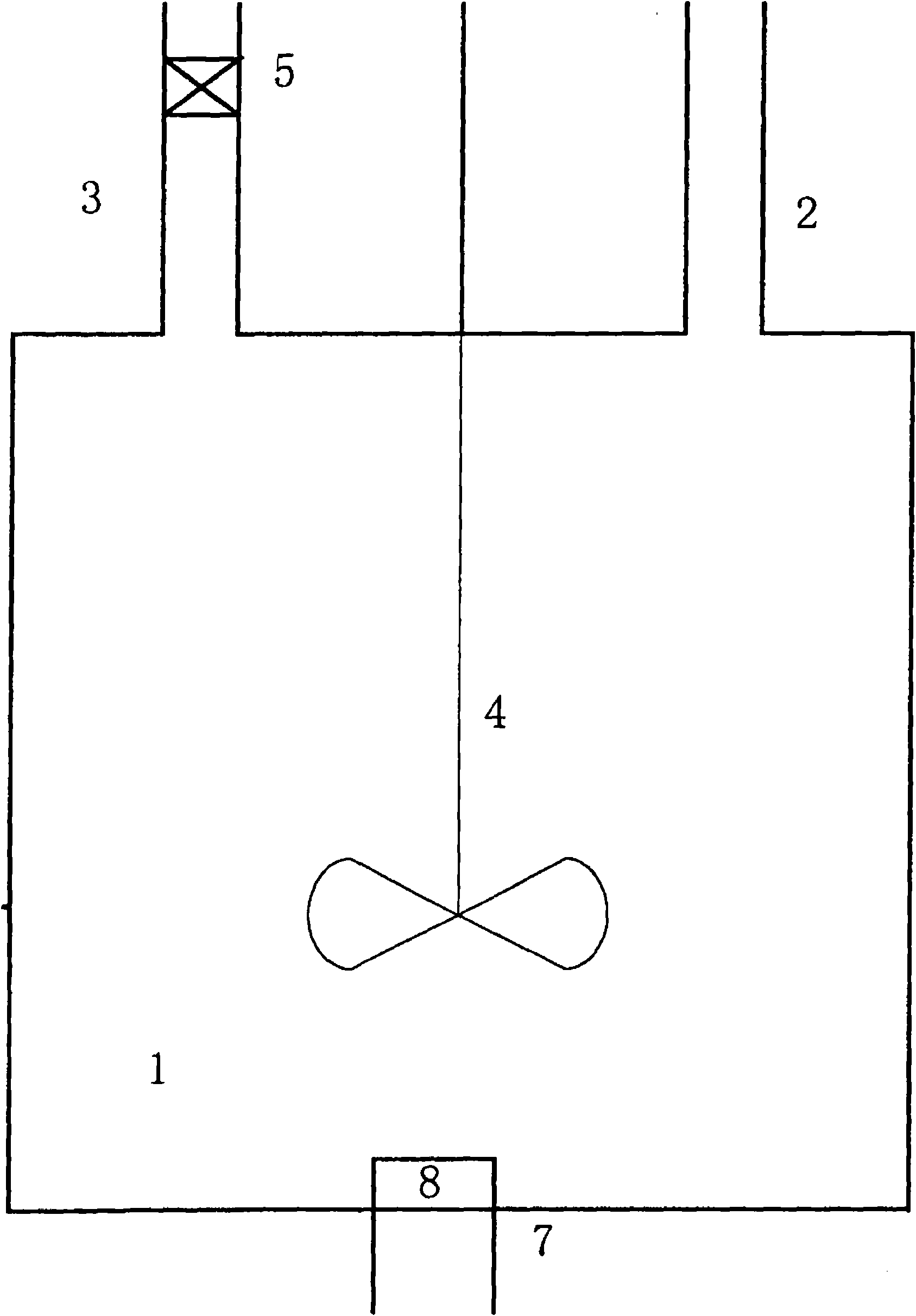

Method for preparing high silicon molecular sieve

ActiveCN102050459AAdequate contact responseContinuous contact reactionFaujasite aluminosilicate zeoliteMolecular-sieve compoundsMolecular sieveGas phase

The invention relates to a method for preparing a high silicon molecular sieve. The method comprises the following steps: circulating a molecular sieve along with inert carrier air under the carrying of inert carrier air flow and contacting the molecular sieve with gas-phase SiCl4 in a flowing sate, wherein the contact time of the molecular sieve and the gas-phase SiCl4 is from 10 seconds to 100 minutes. By using the method for preparing the high silicon molecular sieve in the invention, the continuous contact reaction of the molecular sieve and the SiCl4 can be achieved, and the contact time of the molecular sieve and the SiCl4 can be controlled through controlling the flow speed of the carrier air and the length of a tubular reactor, thus the contact reaction of the molecular sieve and the SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP

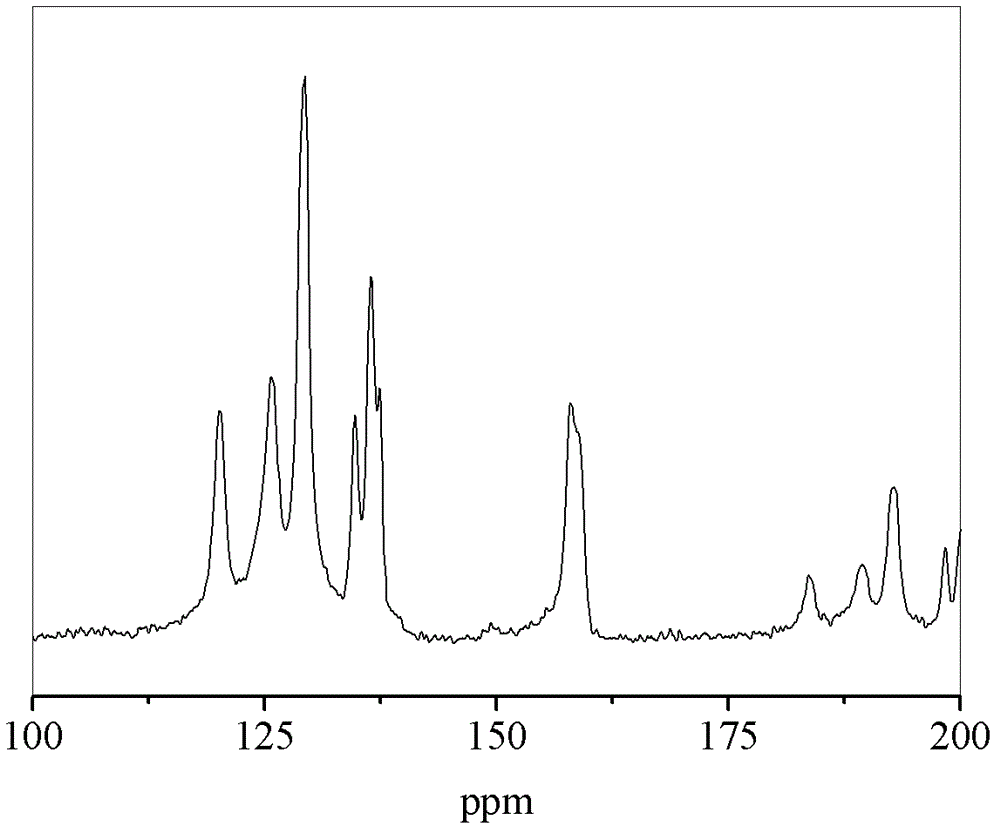

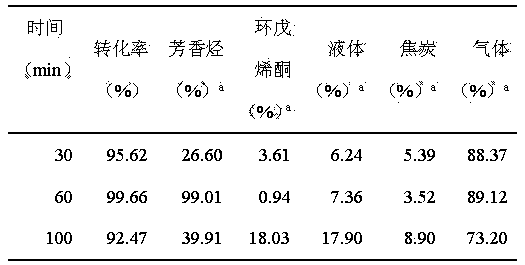

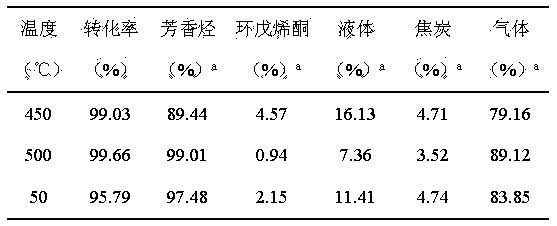

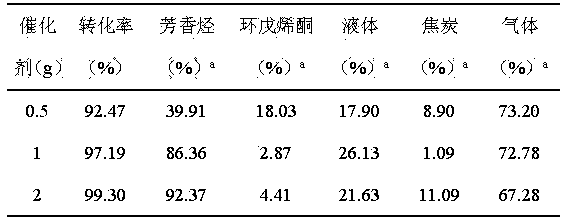

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

Spherical magnesium halide adduct and preparation method and application thereof

ActiveCN102796132AParticles in good shapeFlat surfaceMagnesium organic compoundsLiquid mediumSolid particle

The invention provides a spherical magnesium halide adduct and a preparation method thereof. The method comprises the following steps of: (1) mixing magnesium halide and alcohols except methanol with optional inert liquid media and heating the obtained mixture under stirring until a melt of the magnesium halide adduct is formed; (2) adding the melt of the magnesium halide adduct to cooling media after shearing and dispersing the melt to form spherical solid particles; and (3) carrying out contact reaction on the spherical solid particles and dimethoxy propane in the inert dispersion media. The invention also provides application of the magnesium halide adduct as a catalyst carrier. The magnesium halide adduct has the following beneficial effects: the morphology of particles of the magnesium halide adduct is more regular and is basically spherical; the particle size distribution is more concentrated; basically special-shaped particles do not exist; and the catalyst prepared by adopting the spherical magnesium halide adduct as the catalyst carrier has better hydrogen regulation sensitivity in propylene polymerization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

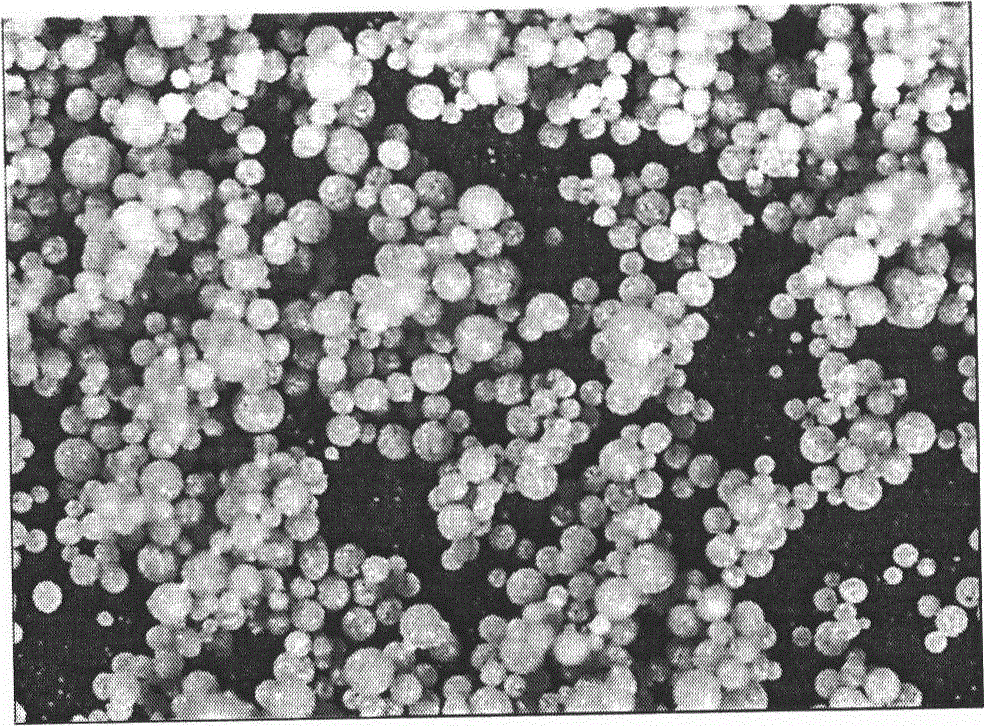

Spherical magnesium halide adduct and preparation method and application thereof

ActiveCN102796129AParticles in good shapeFlat surfaceMagnesium organic compoundsLiquid mediumSolid particle

The invention provides a spherical magnesium halide adduct and a preparation method and application thereof. The method comprises the following steps of: (1) mixing magnesium halide, alcohol except methanol, and an optional inert liquid medium, and heating the obtained mixture with stirring to form a magnesium halide adduct melt; (2) performing shear dispersion on the magnesium halide adduct melt, and adding into a cooling medium to form spherical solid particles; (3) performing contact reaction on the spherical solid particles and dimethoxy propane in an inert dispersion medium; and (4) performing contact reaction on a product obtained in the step (3) and a polyol ester compound in the inert dispersion medium. The magnesium halide adduct has a good particle shape, a smooth surface and high liquidity, and special-shaped particles do not exist; and a catalyst prepared by taking the magnesium halide adduct as a catalyst carrier has high hydrogen regulation sensitivity when used for olefin polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

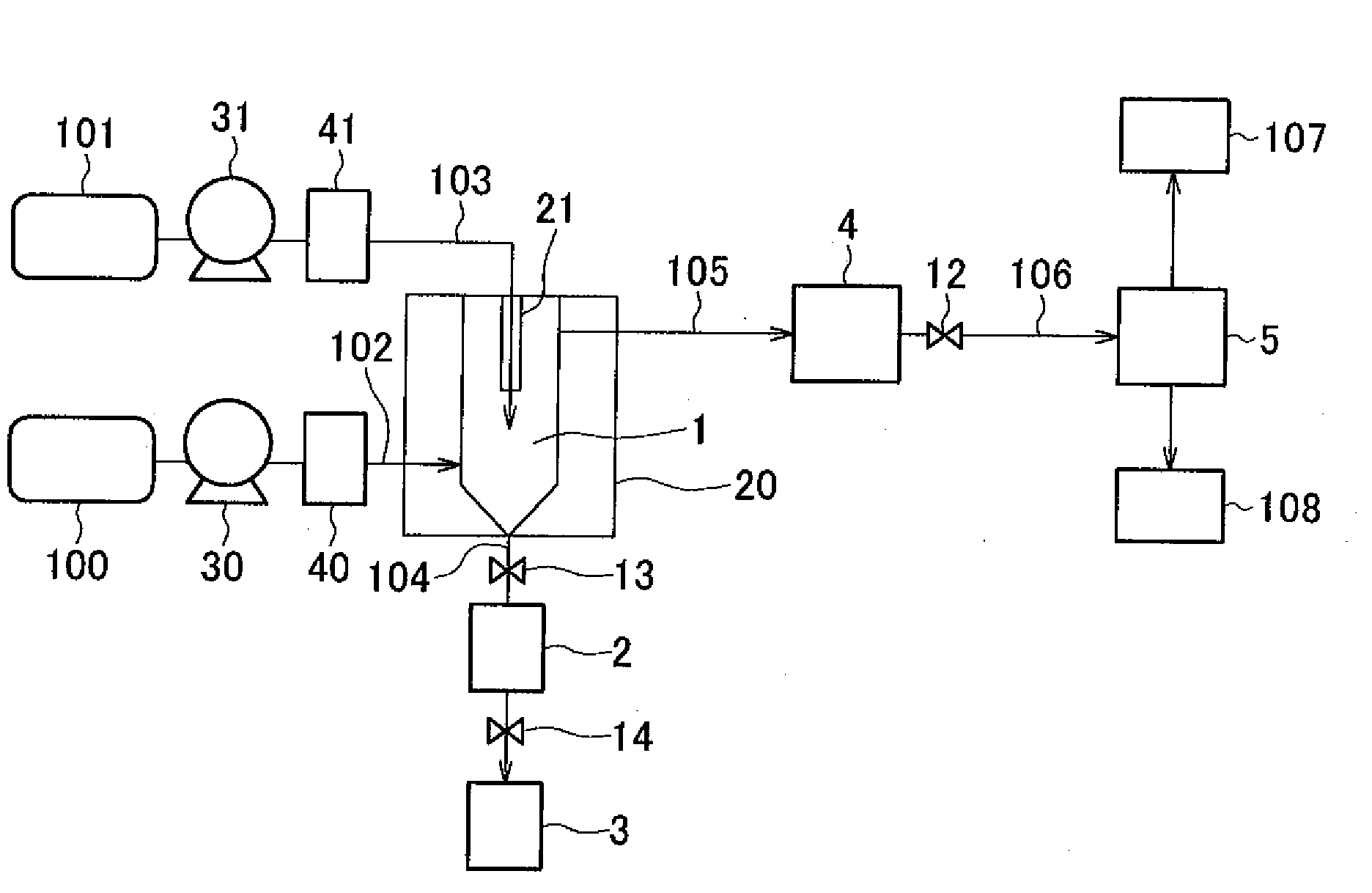

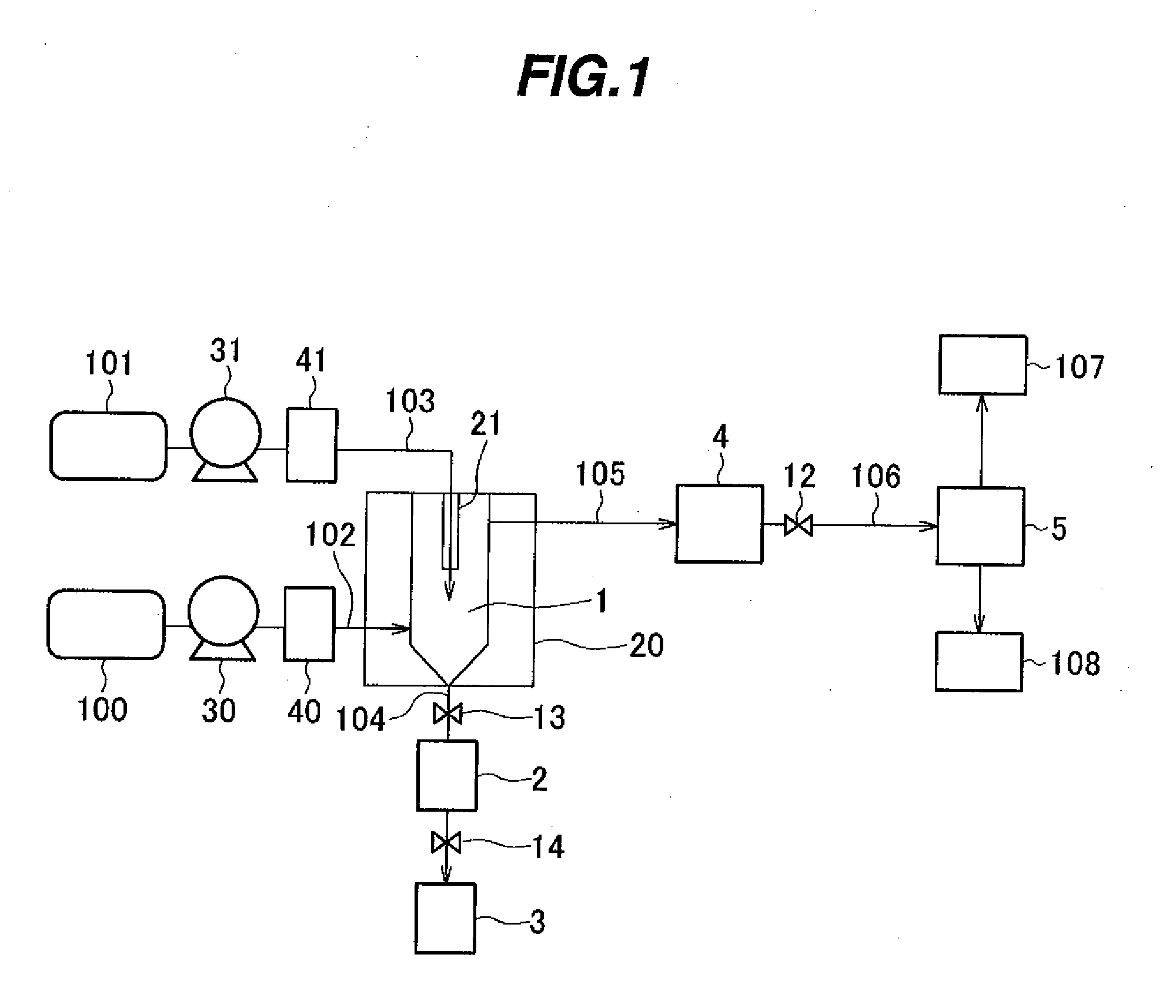

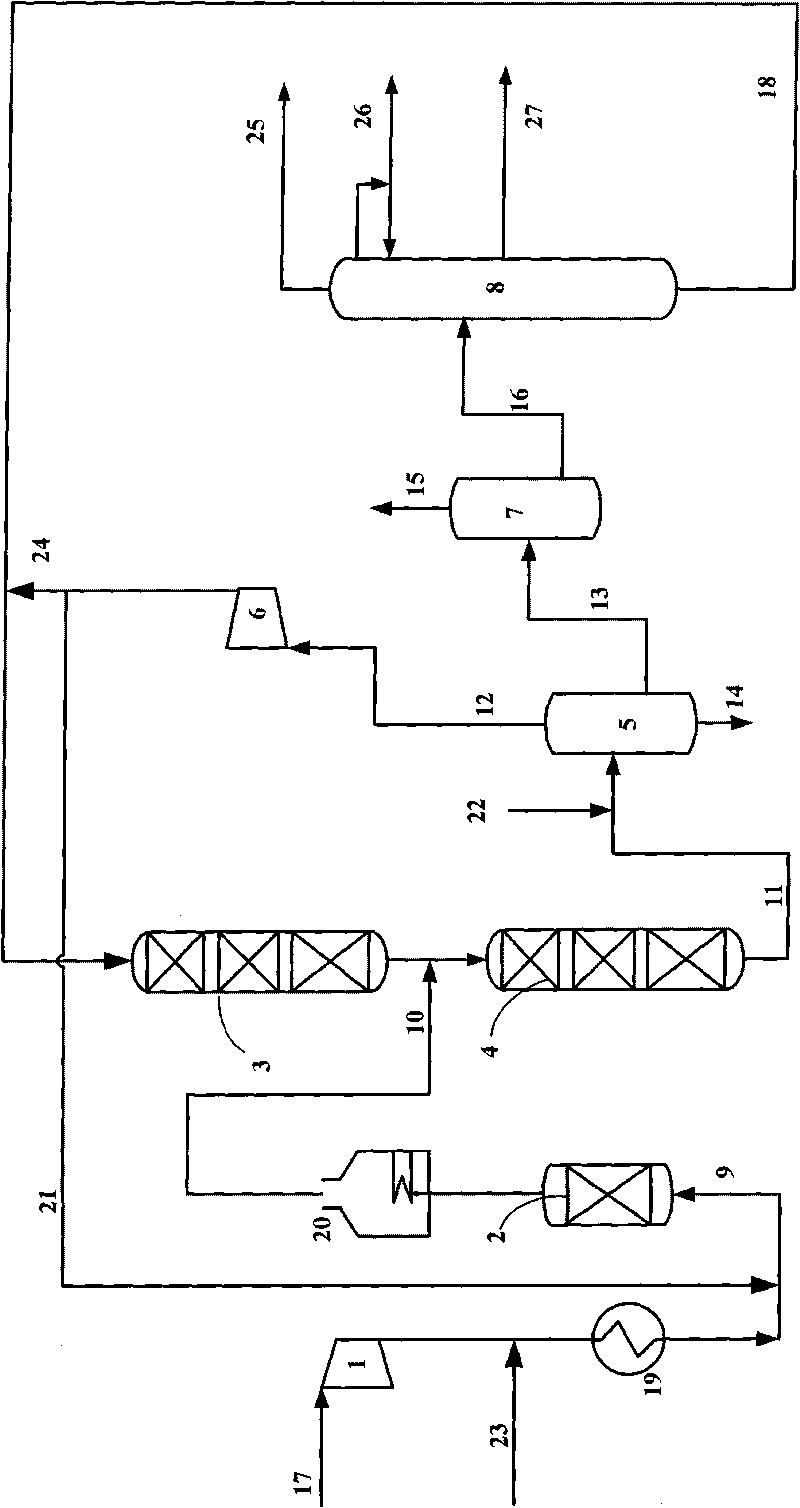

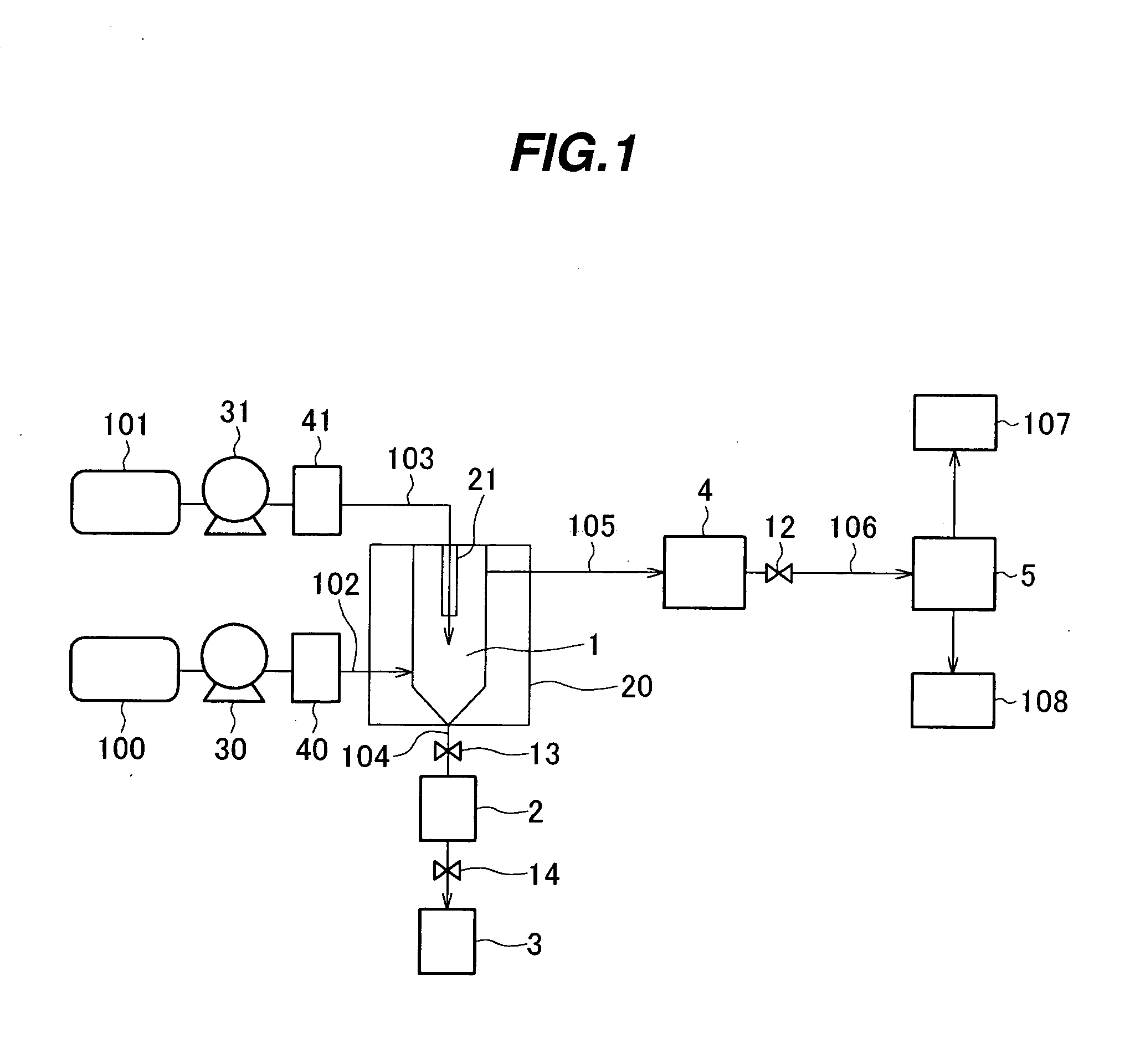

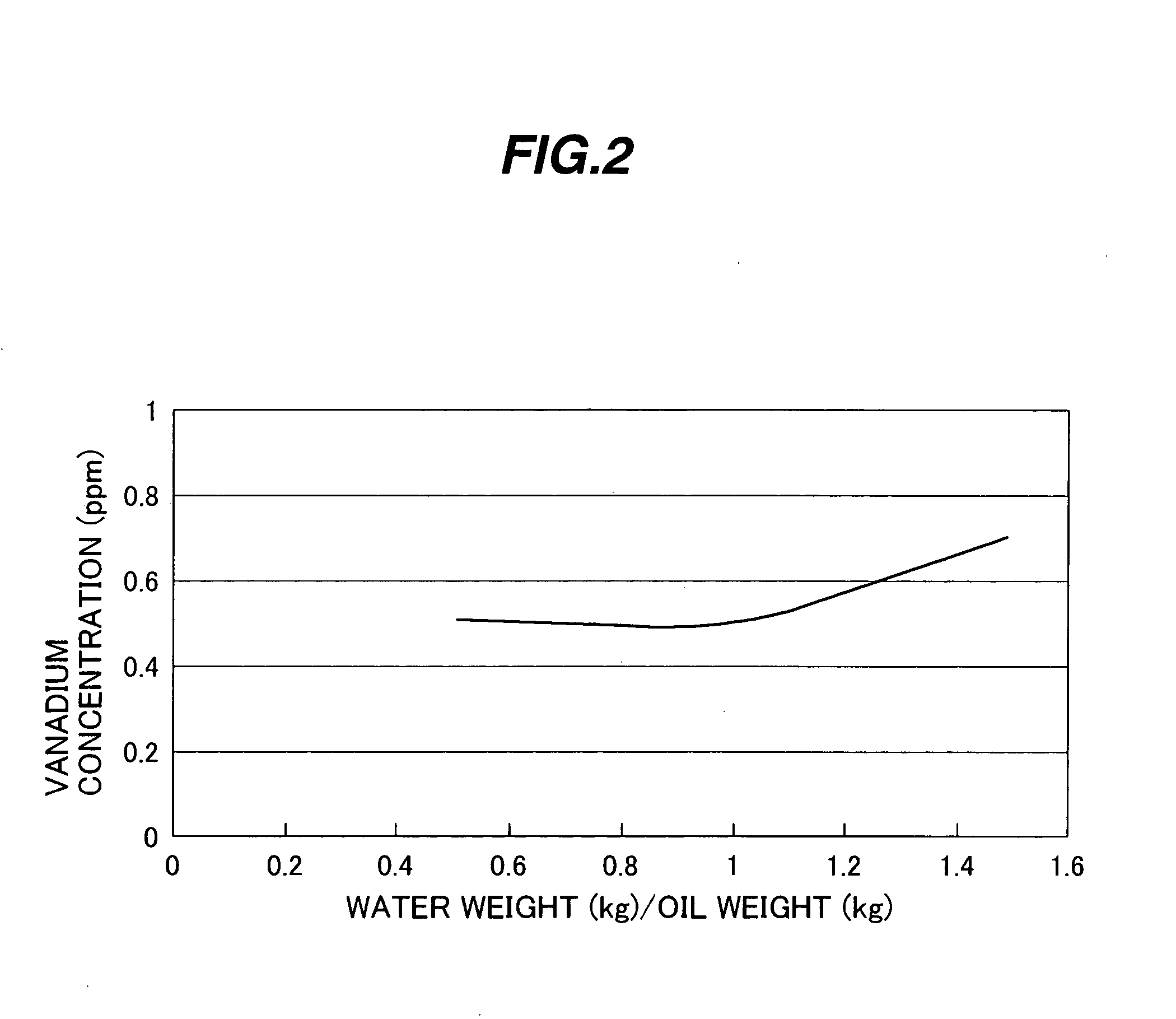

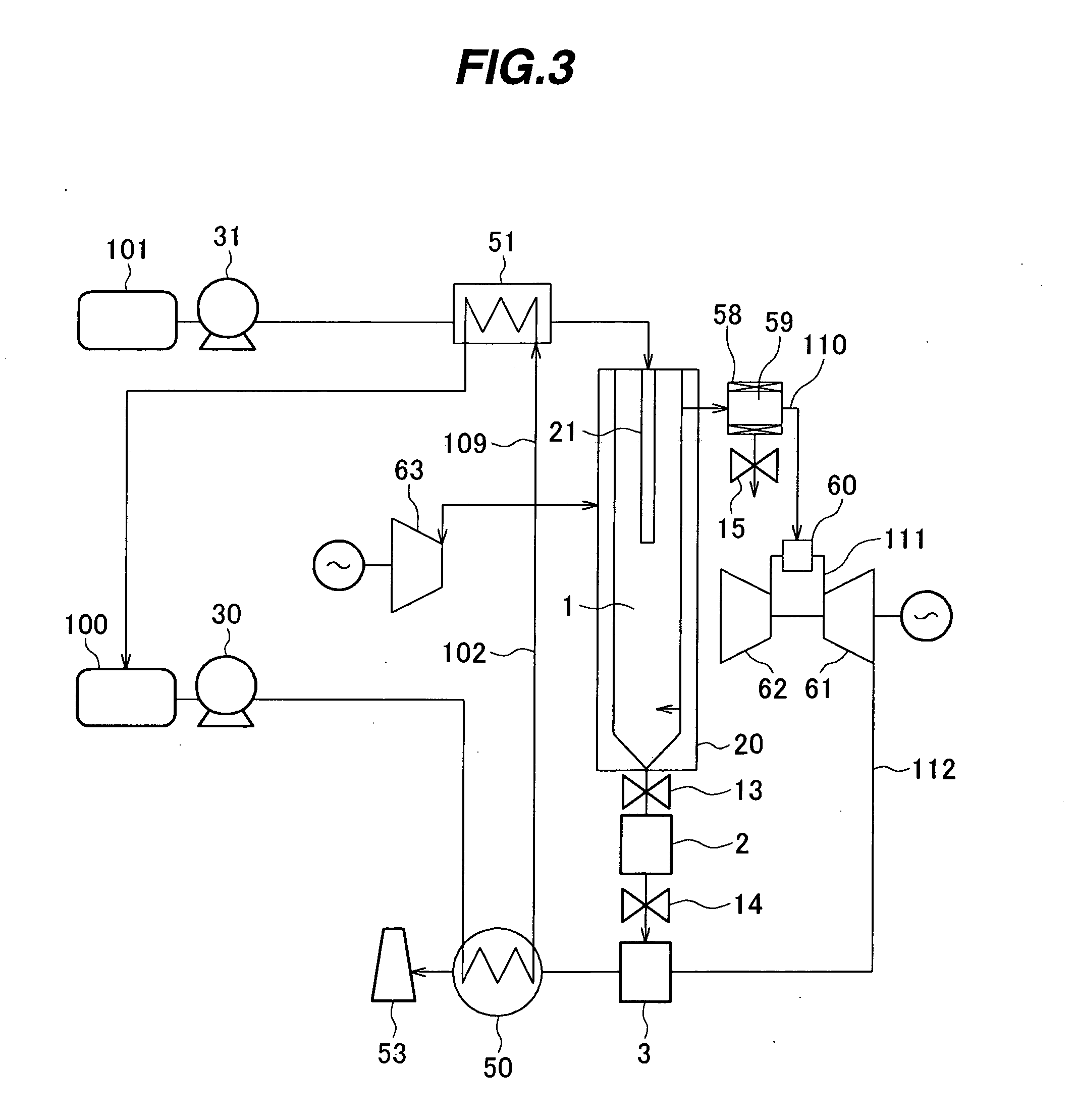

Heavy oil treating method and heavy oil treating system

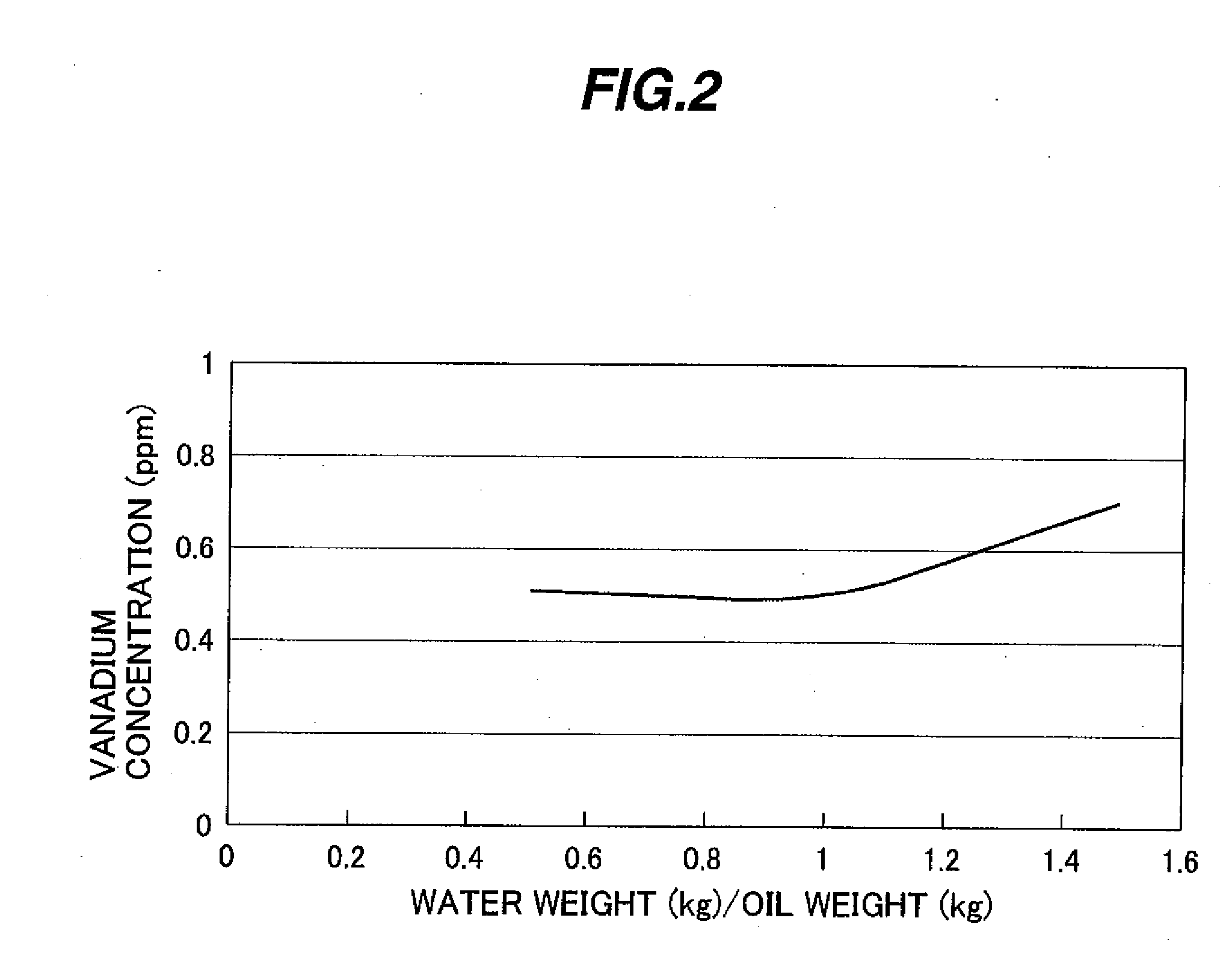

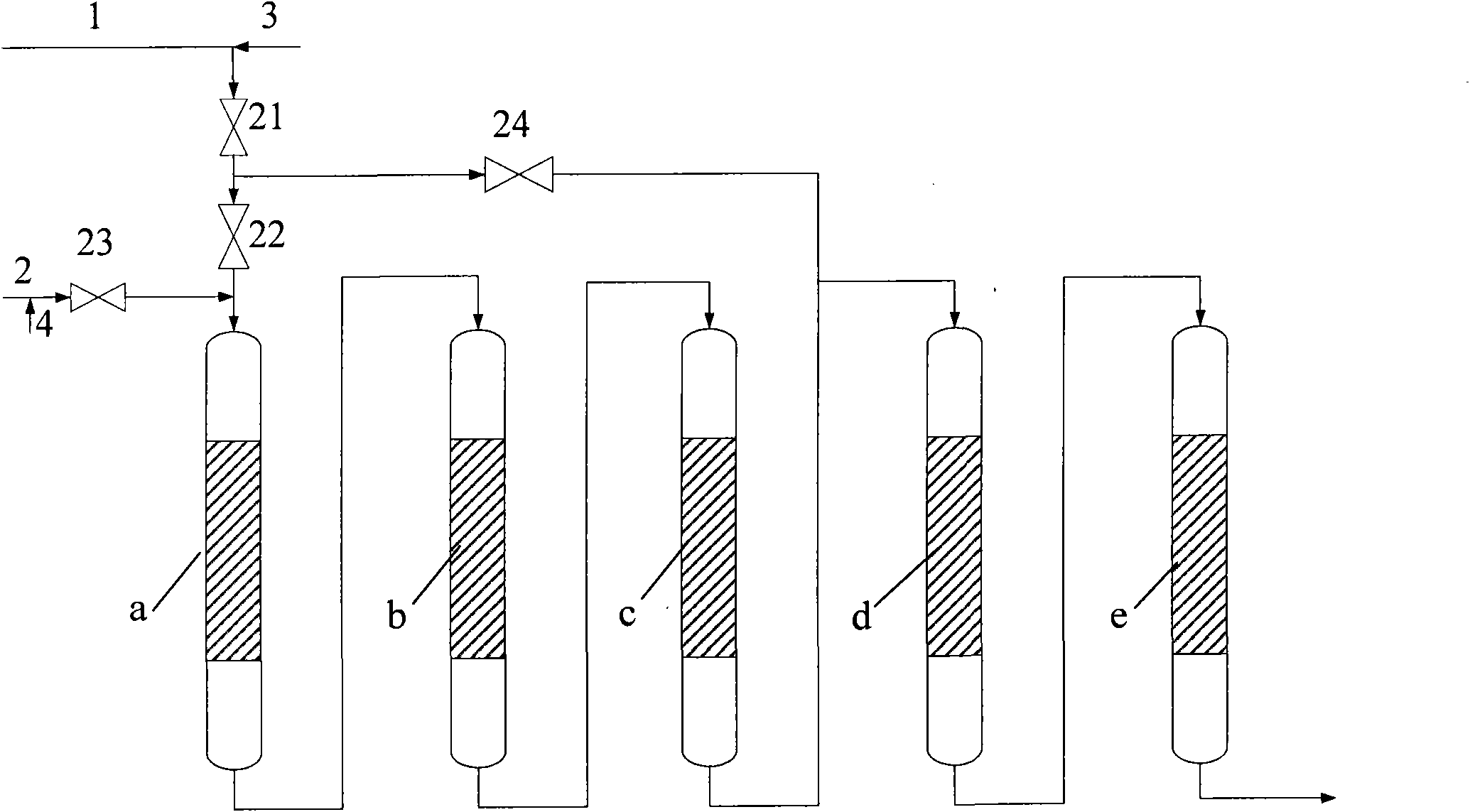

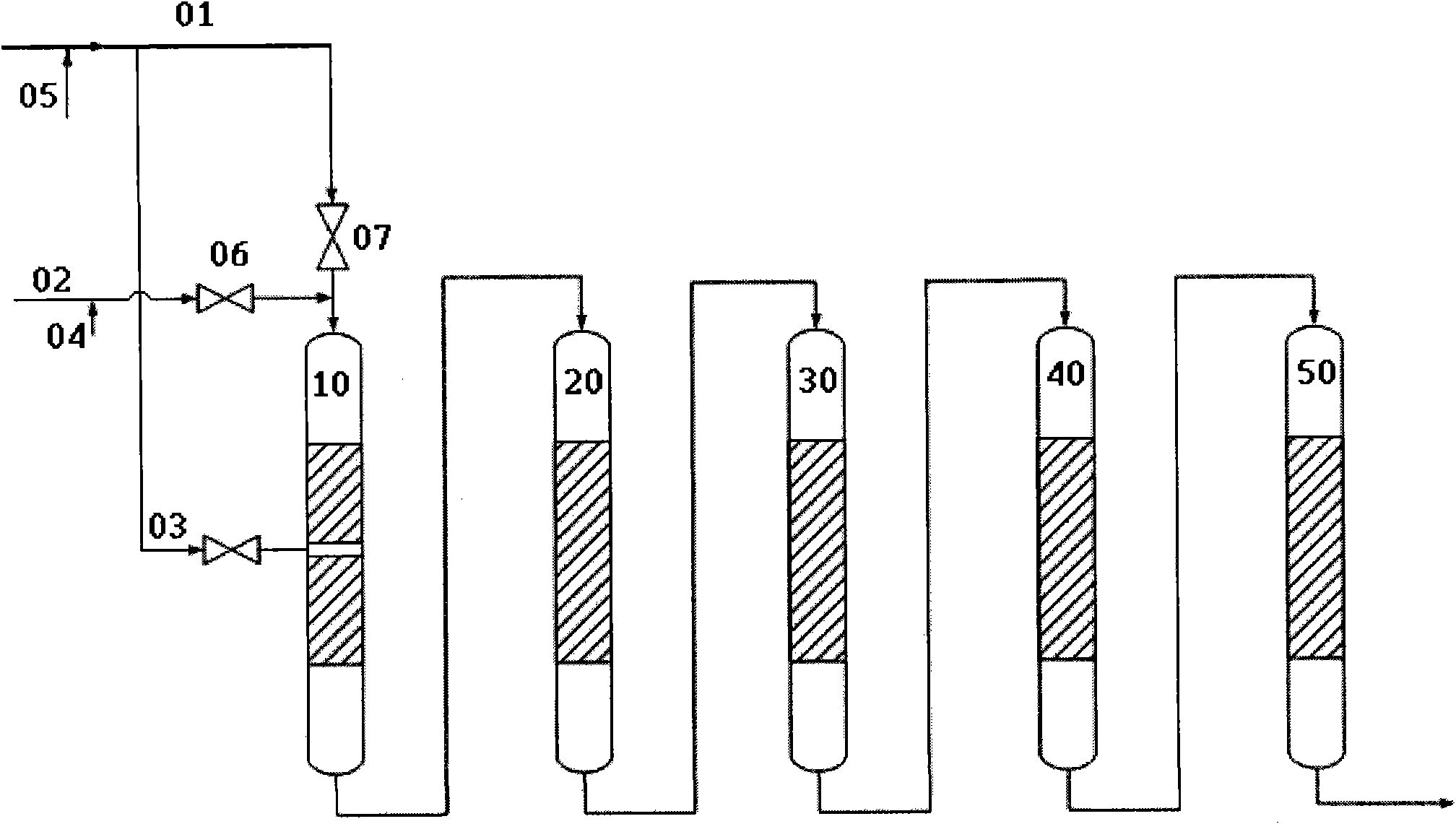

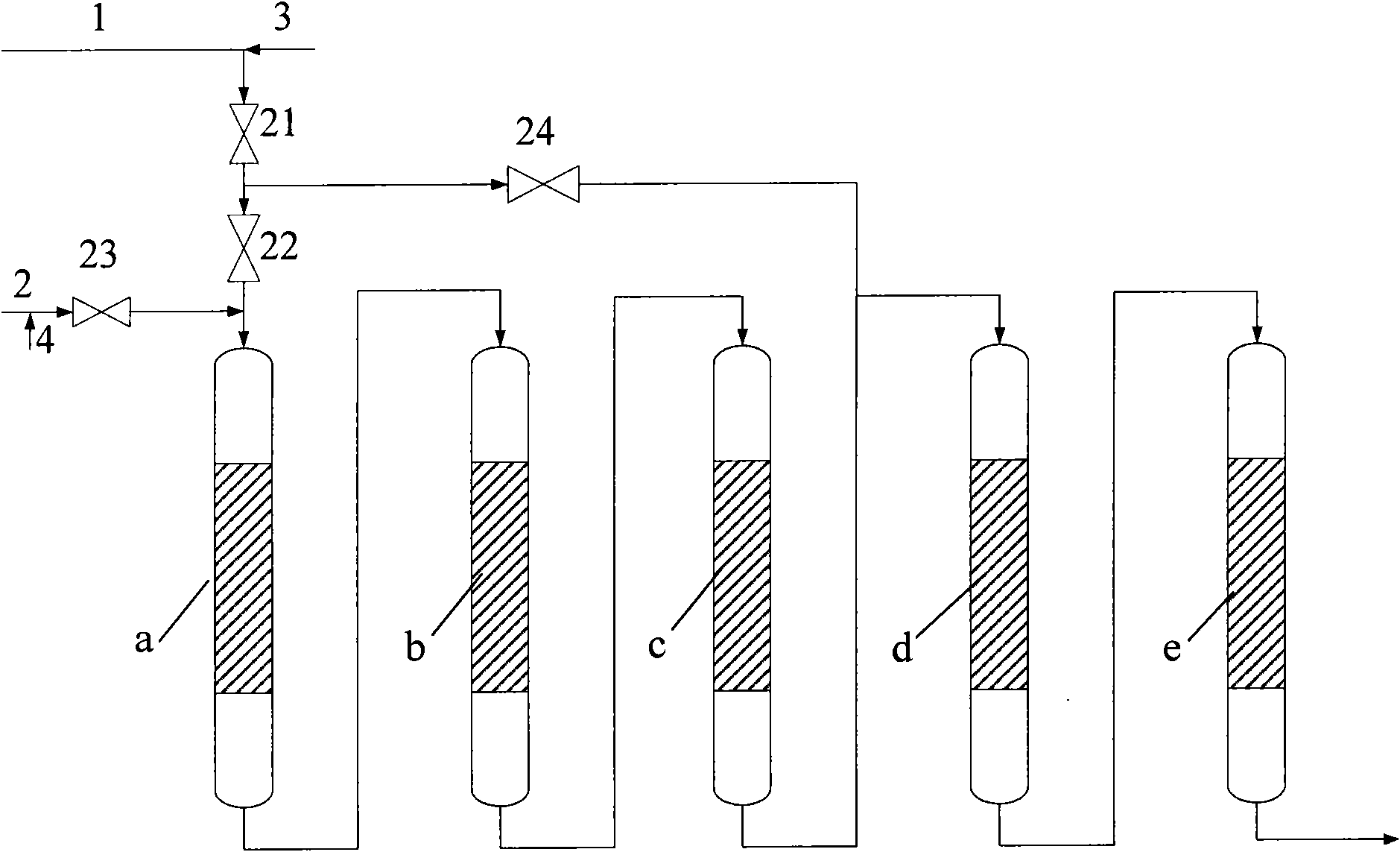

InactiveUS20090032436A1Eliminate needMolecular sieve catalystsRefining with oxygen compoundsLighter fuelHigh pressure water

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:TAKAHASHI HIROKAZU +6

Hydrogenation method for residual oil

ActiveCN101768468ATake advantage ofExtended operating cycleTreatment with hydrotreatment processesHydrodesulfurizationHydrogenation reaction

The invention provides a hydrogenation method for residual oil. The method includes the following steps: under the condition of hydrogenation reaction, residual oil raw materials and hydrogen gas are sequentially guided into two hydrogenation reaction zones connected in series to carry out contact reaction with a plurality of catalyst beds in the hydrogenation reaction zones; according to the flowing directions of a reactant and the hydrogen gas, the first and second hydrogenation reaction zones respectively comprise a hydrogenation protecting catalyst, a hydrogenation de-metallization catalyst and a hydrogenation desulfurization catalyst which are sequentially filled in the catalyst beds; when the pressure drop of at least one catalyst bed in the first hydrogenation reaction zone reaches the upper limit or hot spots appear in the reaction zone, at least one part of the residual oil raw materials and the hydrogen gas is directly guided into the second hydrogenation reaction zone. Compared with the prior art, the method in the invention can prolong the running period of a residual oil hydrogenation device, thereby increasing the running efficiency of the device and improving the economical property of the device as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

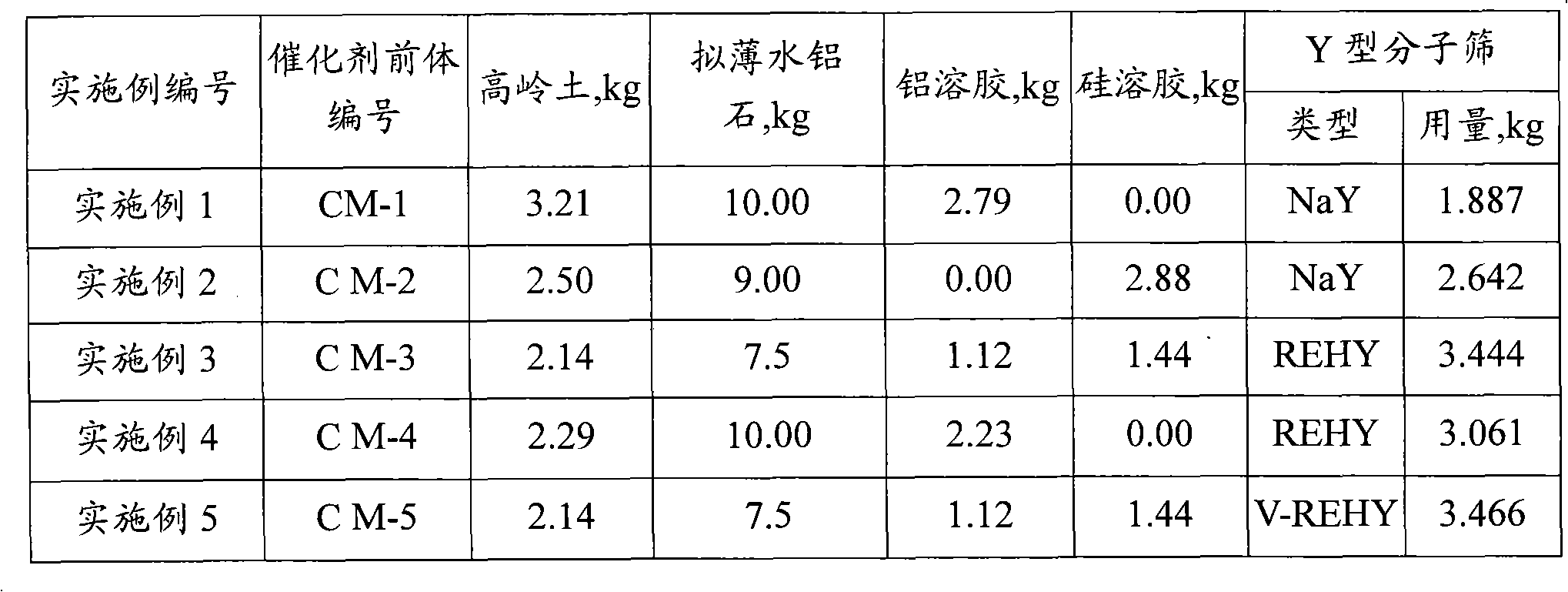

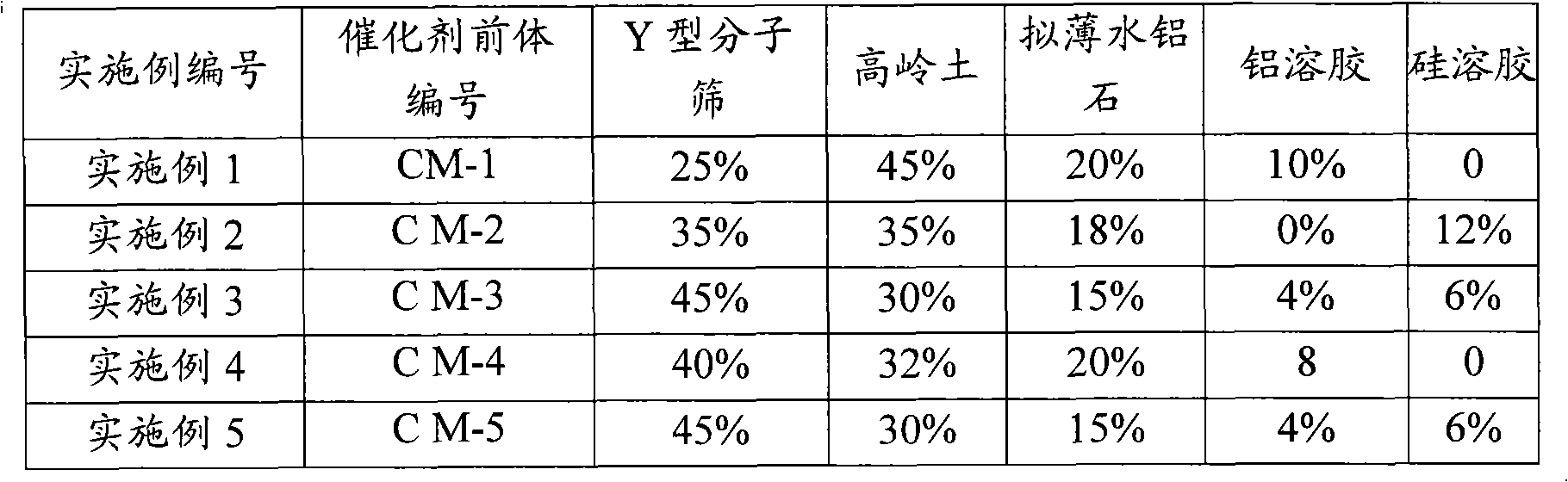

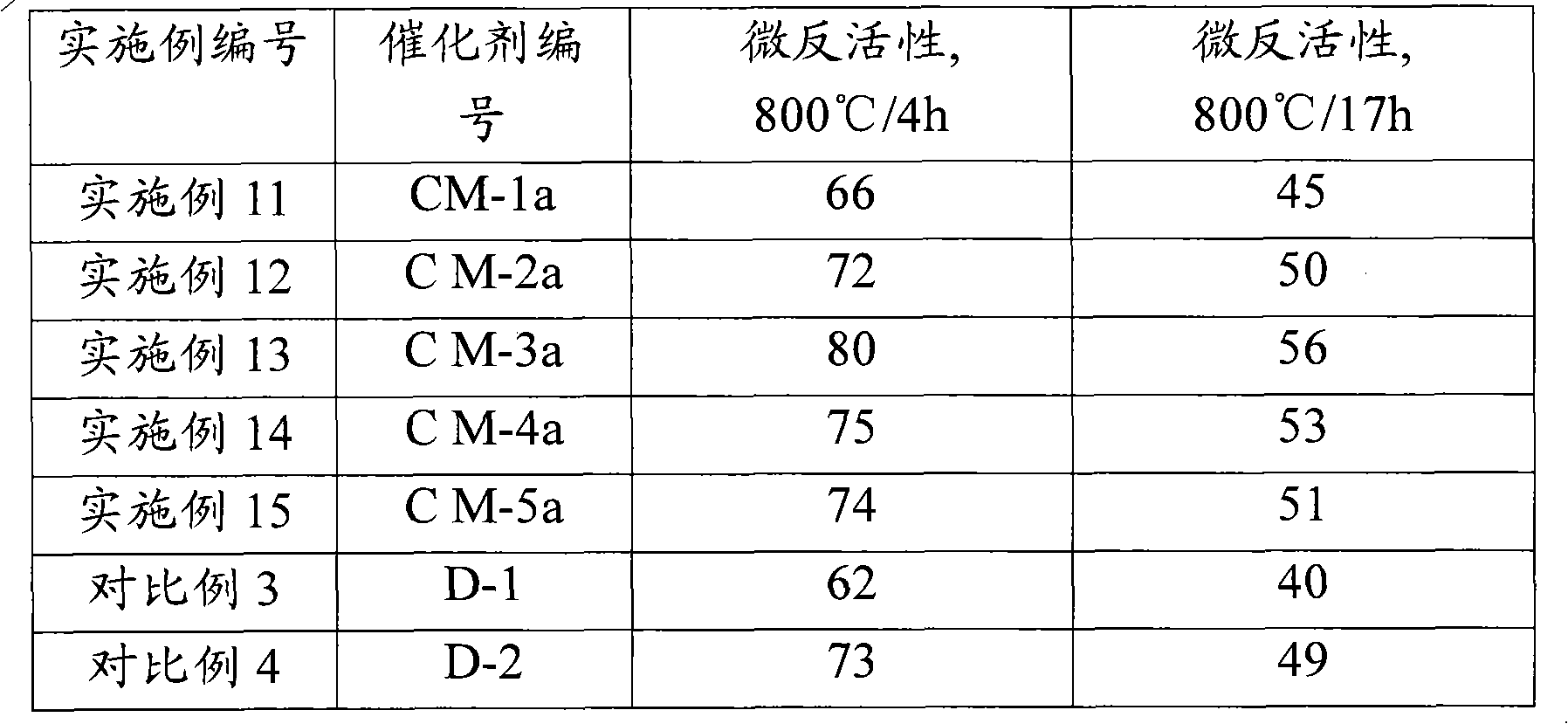

Method for preparing catalytic cracking catalyst

ActiveCN102049315AAdequate contact responseContinuous contact reactionCatalytic crackingMolecular sieve catalystsMolecular sieveContact time

The invention relates to a method for preparing a catalytic cracking catalyst. The method comprises the following steps: a molecular sieve flows along with inert carrier gas under the condition of being carried by the inert carrier gas flow, and is in contact with gas phase SiCl4 under the flow state; the contact time between the molecular sieve and the gas phase SiCl4 is 10 seconds to 100 minutes; and then the molecular sieve in contact with the gas phase SiCl4 is mixed with a binding agent, clay and water for pulping and pelleting to obtain the catalytic cracking catalyst. The provided preparation method for the catalytic cracking catalyst can realize the continuous contact reaction between the molecular sieve and the gas phase SiCl4 and can control the contact time between the molecular sieve and the gas phase SiCl4 by controlling the flow velocity of the carrier gas and the length of the tubular reactor, so that the contact reaction between the molecular sieve and the gas phase SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing modified urea-formaldehyde resin

InactiveCN101134835ALow free formaldehyde contentReduce formaldehyde emissionPolymer chemistryContact reaction

The process of preparing modified urea-formaldehyde resin includes the contact reaction of formaldehyde and urea, and the mixing of the resultant and the modifier added into urea-formaldehyde resin in at least two times. The modified urea-formaldehyde resin has very low content of free formaldehyde, say, below 0.20 %. When it is used in making artificial board, the artificial board will have very low formaldehyde releasing amount. In addition, the modified urea-formaldehyde resin may be in liquid and powder form, and may be applied in different conditions, including moist condition and outdoor condition.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of bipolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the bipolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

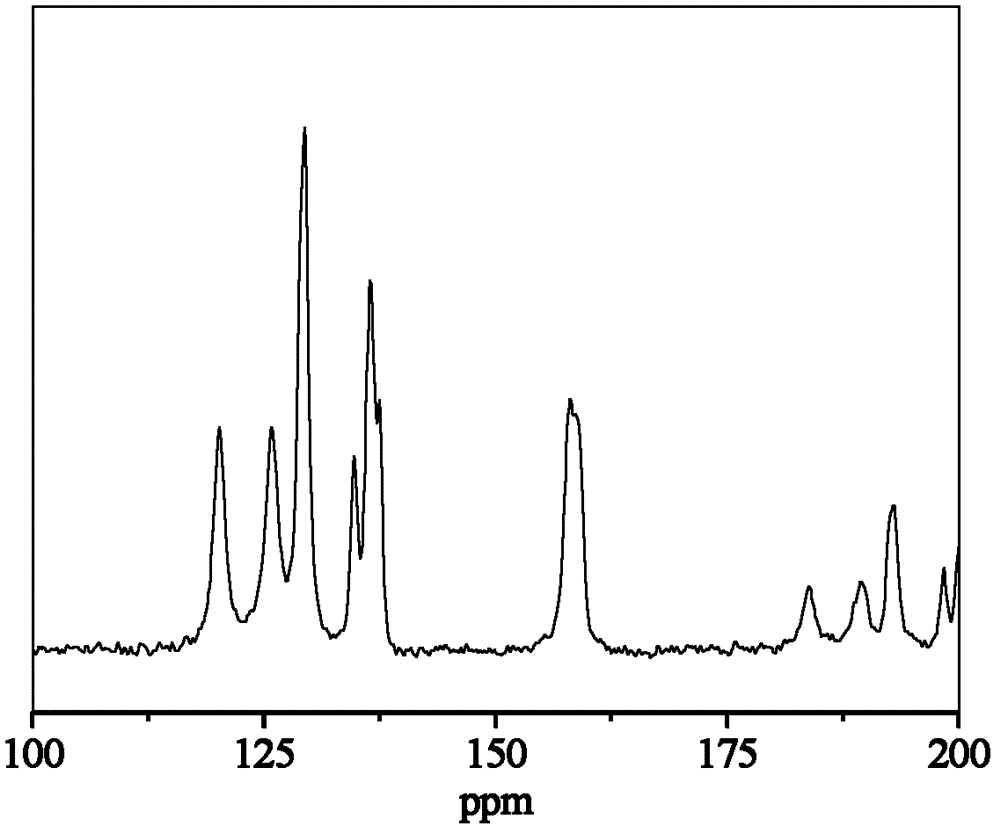

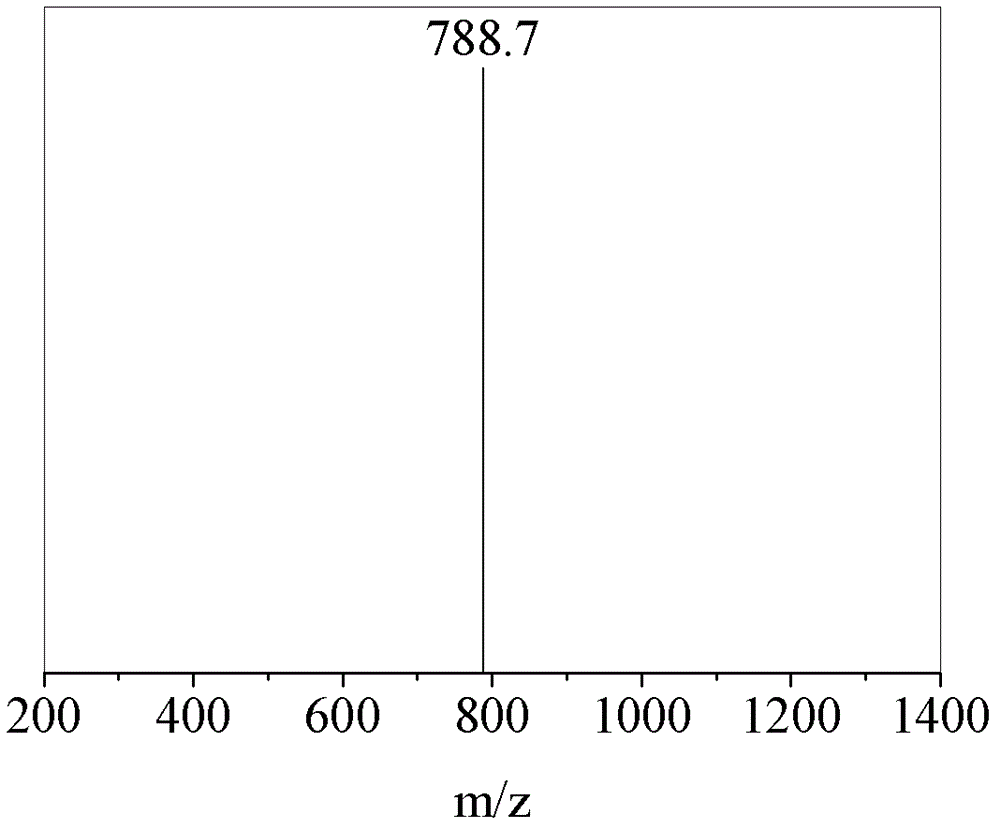

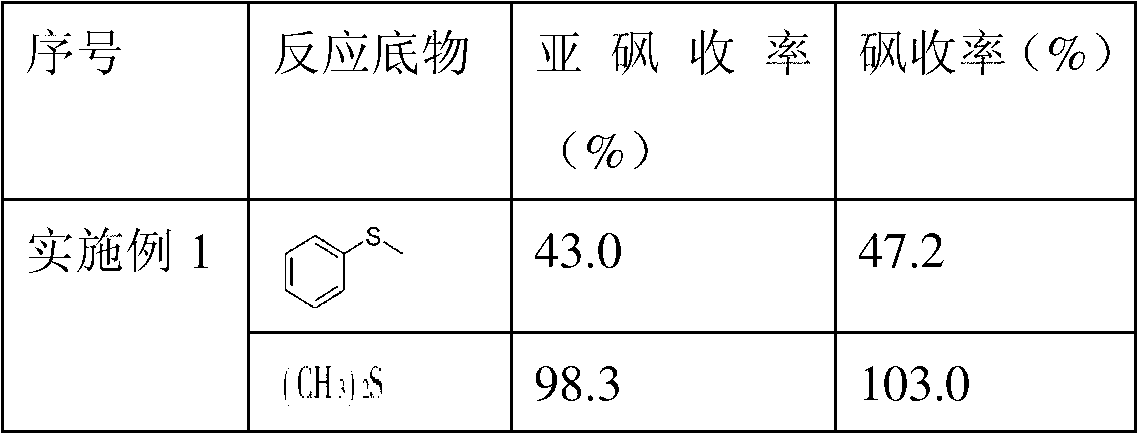

Preparation method for sulfoxide and sulphone

InactiveCN102838516AImprove conversion rateGood choiceOrganic chemistryMolecular sieve catalystsFixed bedReaction temperature

The invention discloses a preparation method for sulfoxide and sulphone. The preparation method comprises the following steps: conducting contact reaction on thioether and hydrogen peroxide, and catalyst in a fixed bed reactor, wherein the mole ratio of thioether and hydrogen peroxide is 1:0-1.5, the space velocity of the reaction system is 5-100, the reaction temperature ranges from normal temperature to 100 DEG C, the reaction pressure is 0.1-1.0 MPa, and the catalyst is obtained from one or more titaniferous molecular sieve raw powder or formed titaniferous molecular sieve. The method has the advantages of convenient operation, mild reaction conditions, easy separation, high product yield and the like, and the utilization rate of oxidant hydrogen peroxide can be greatly improved.

Owner:宁夏富诚生物科技有限公司

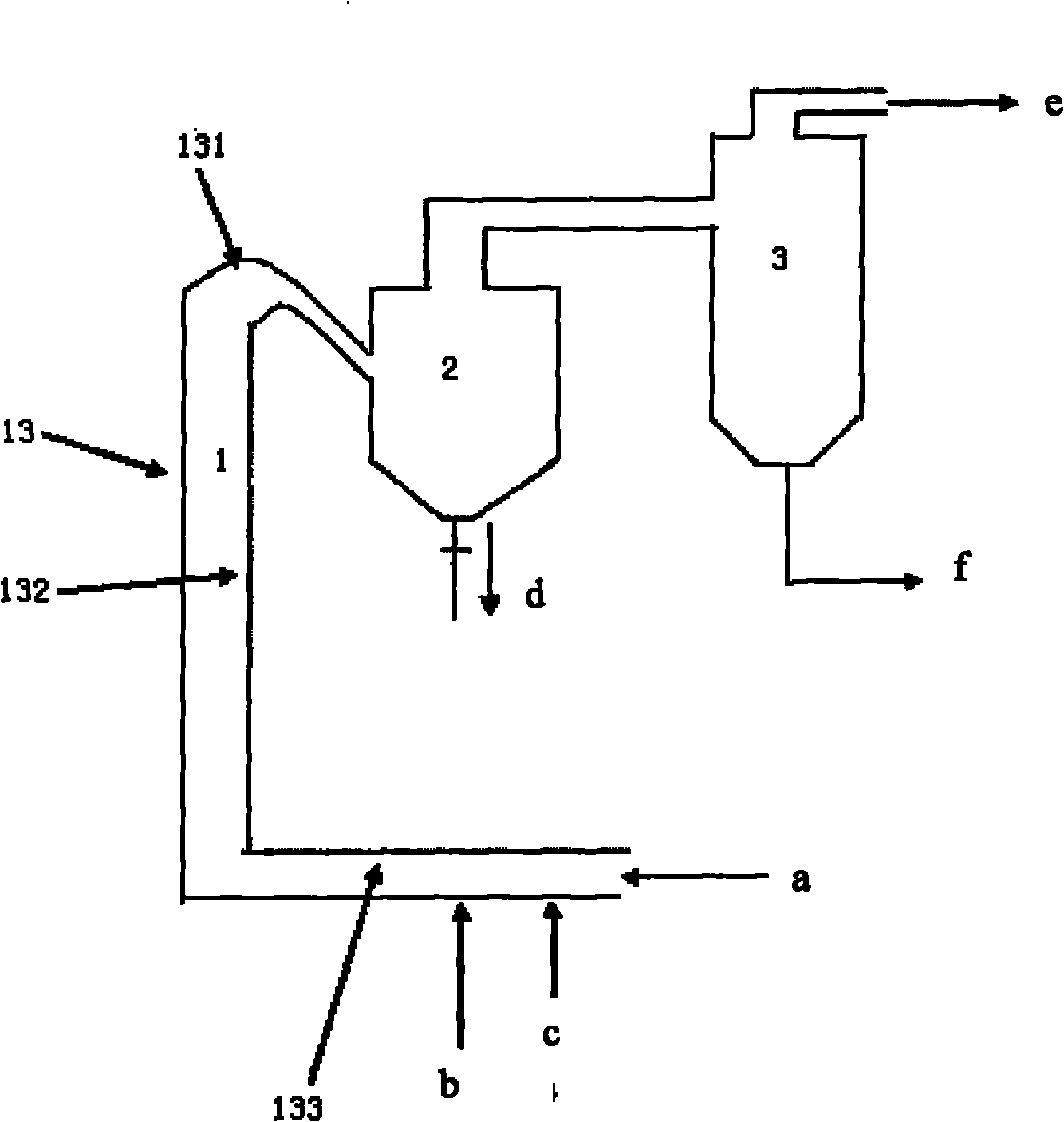

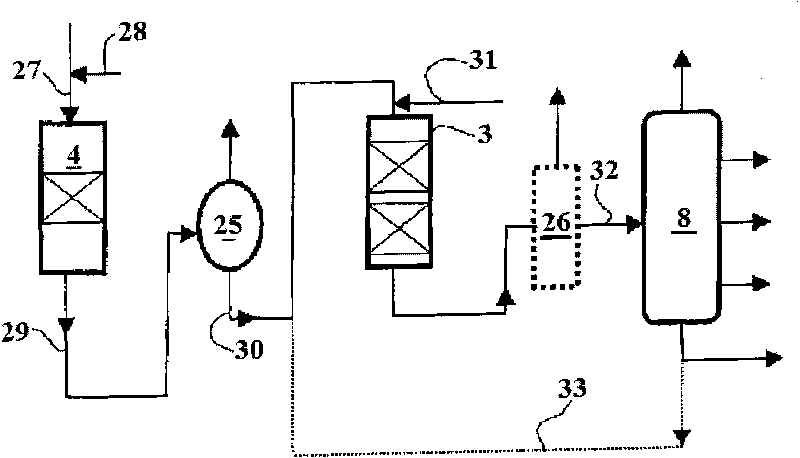

Coal tar hydrogenating modified method by two-stage method

ActiveCN101307257AGood Ring Opening Cracking PerformanceGood nitrogen resistanceTreatment with hydrotreatment processesGas phaseDistillation

The invention discloses a two-stage method coal tar hydro-upgrading method. Coal tar is subject to the atmospheric distillation and / or the reduced pressure distillation and is cut into coal tar light cut and coal tar heavy cut; after the coal tar light cut and optional distillate oil are mixed with hydrogen, the mixture enters a first hydrogeneration reaction zone and performs the contact reaction with hydrorefining catalyst; gas phase impurities of a reaction effluent is removed through an intermediate flash distillation column or a high-pressure stripping tower, and then the reaction effluent enters a second hydrogeneration reaction zone to perform the contact reaction with the hydro-upgrading catalyst or the hydrocracking catalyst; and the obtained reaction effluent is cooled, separated and fractionated to produce diesel fraction and naphtha cut. The invention provides a clean and effective coal tar processing and utilizing method, the coal tar light cut is hydro-upgraded to produce diesel oil for vehicles, the sulfur content of the obtained diesel product is less than 50 mu g / g, the content of polycyclic aromatic hydrocarbon is less than 11 weight percent, and the diesel oil cetane number of the product is improved by not less than 20.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrocracking of coked wax oil

The invention provides a method for hydrocracking of coked wax oil, which comprises: contact reaction of raw materials, hydrogen and a hydrogenation protection catalyst under the condition for hydrogenation protection reaction, wherein oil in the raw materials is coked wax oil or mixed oil containing coked wax oil; contact reaction of products in the hydrogenation protection reaction, products ofhydrocracking reaction and a hydrogenation refining catalyst under the condition for hydrogenation refining reaction; separation of light distillates, intermediate distillates and heavy distillates with initial boiling points being 350-360 DEG C from products of the hydrogenation refining reaction; and contact reaction of the heavy distillates with the initial boiling points being 350-360 DEG C and a hydrocracking catalyst under the condition for hydrocracking reaction, thereby obtaining products of the hydrocracking reaction. The method of the invention prolongs the operating cycle of the device, the consumption of the hydrocracking catalyst is low, and the yield of the intermediate distillates in the products is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

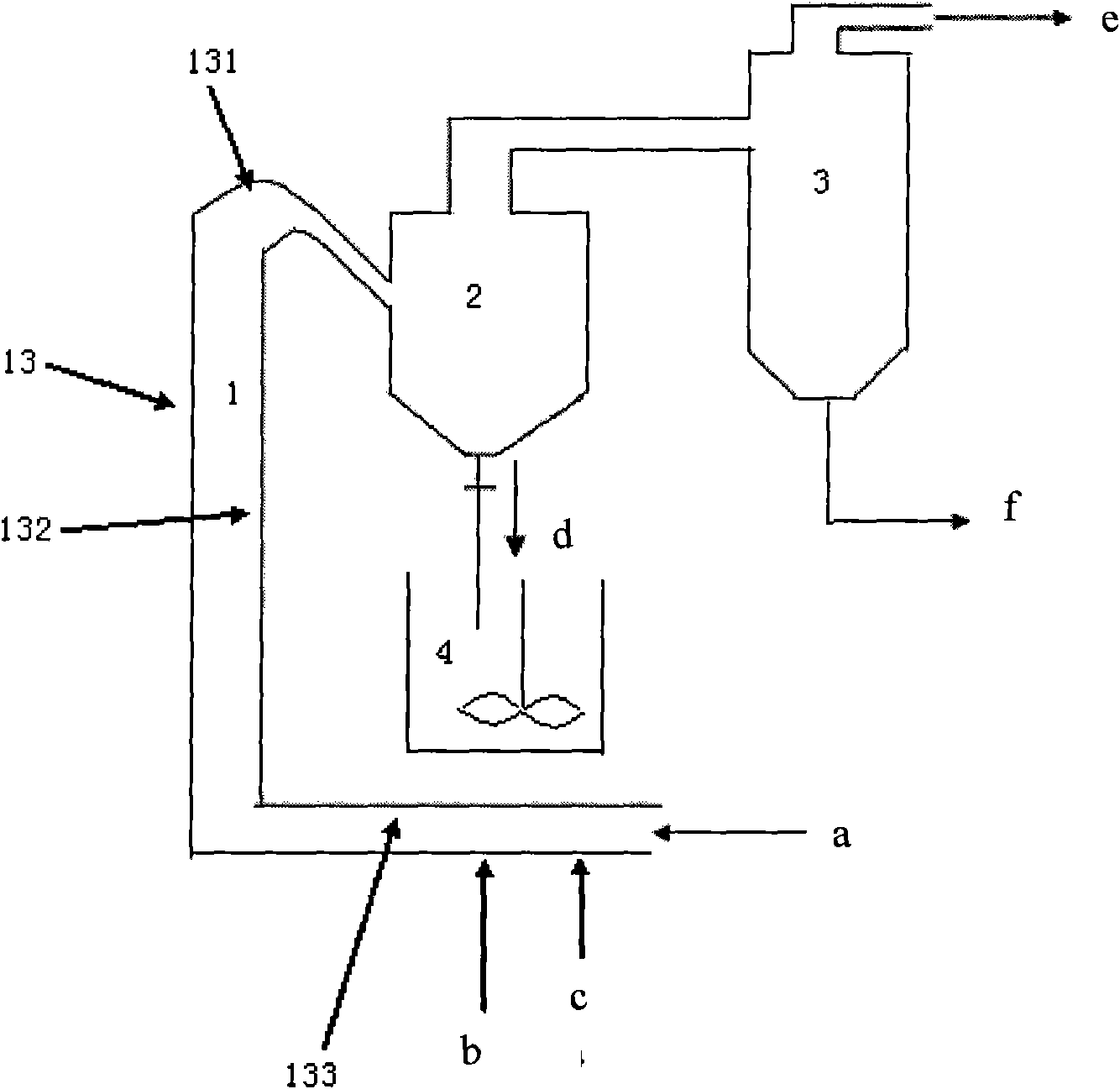

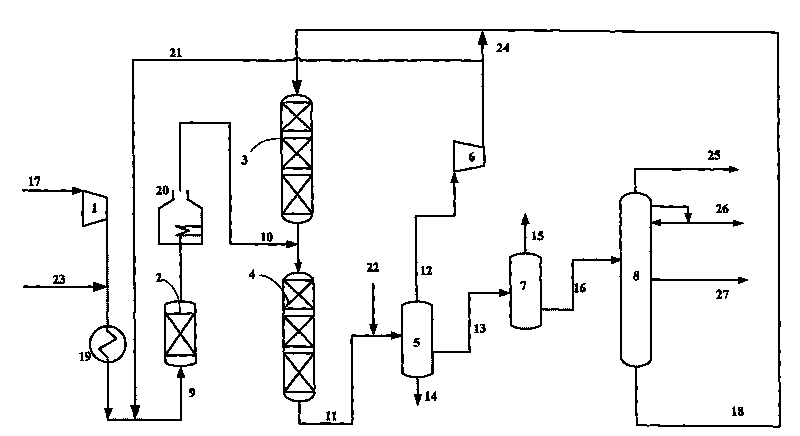

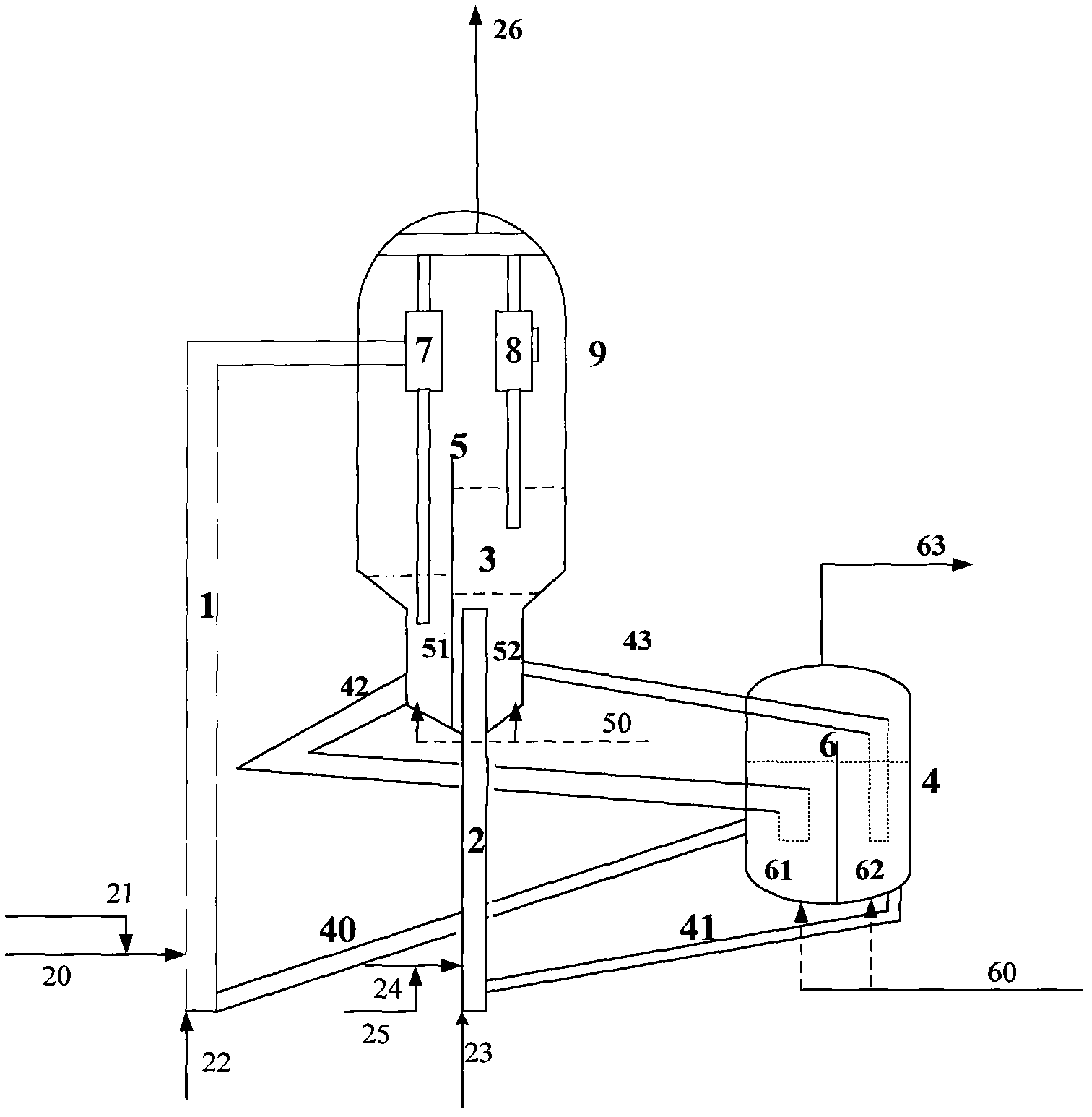

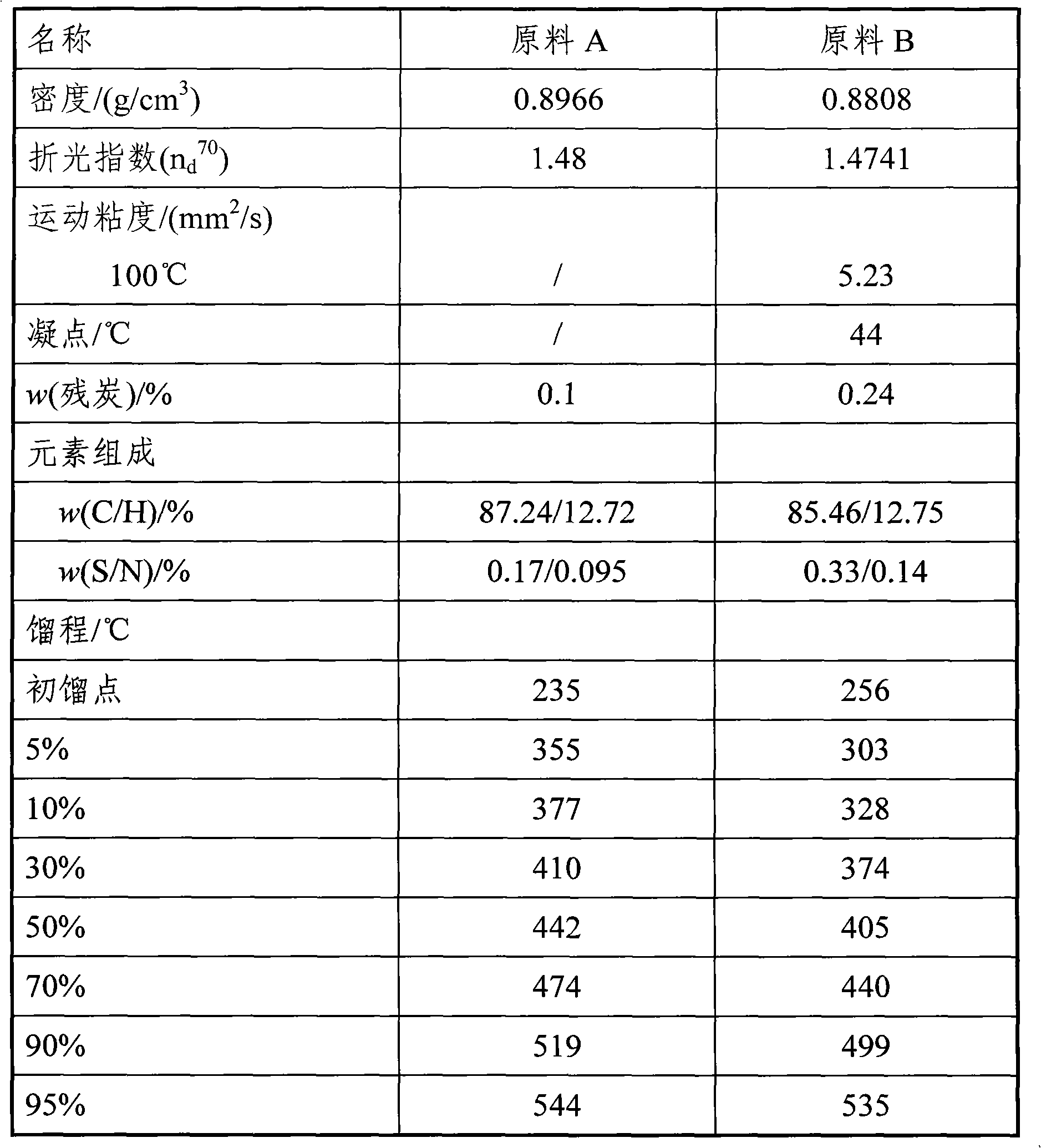

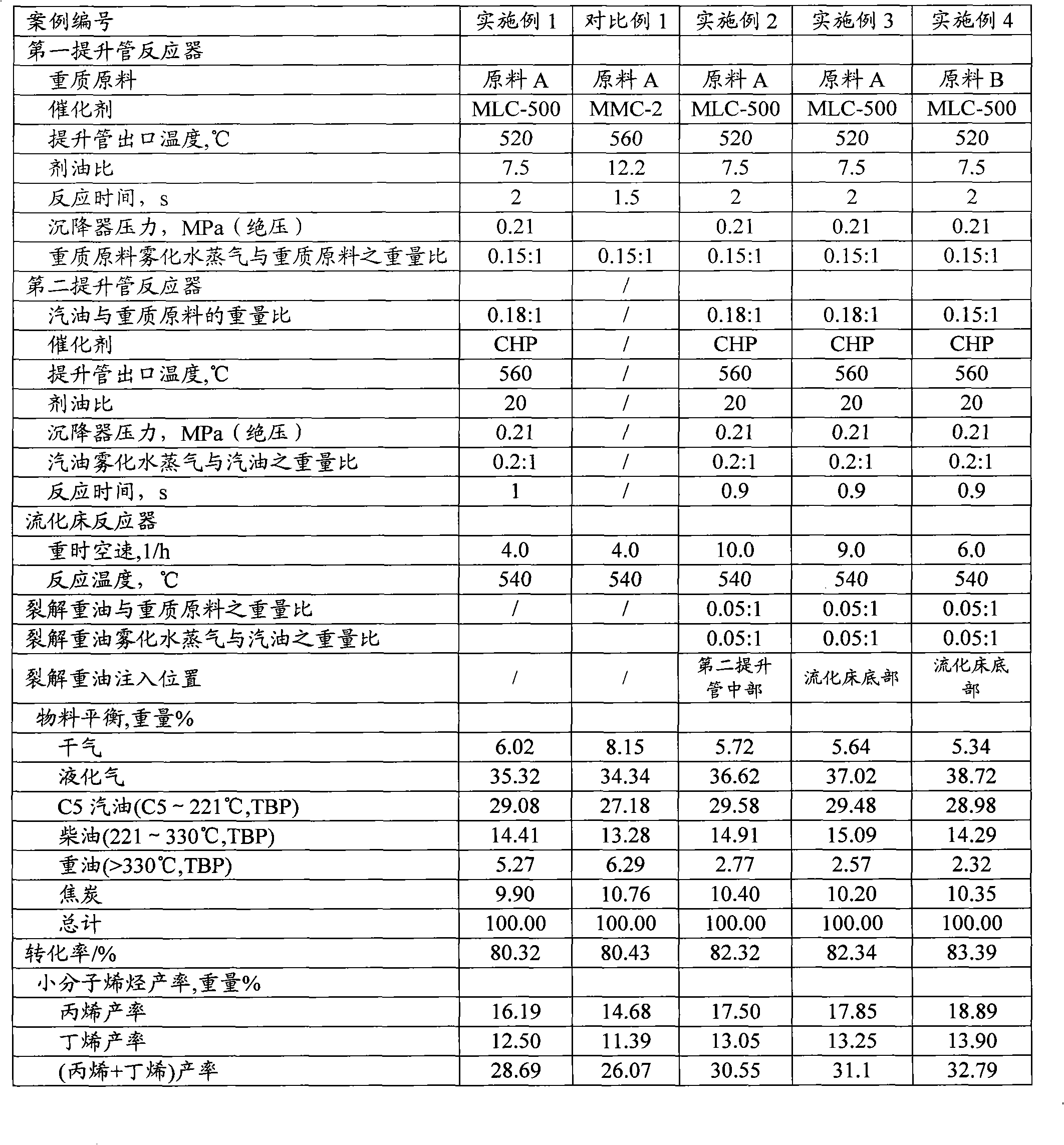

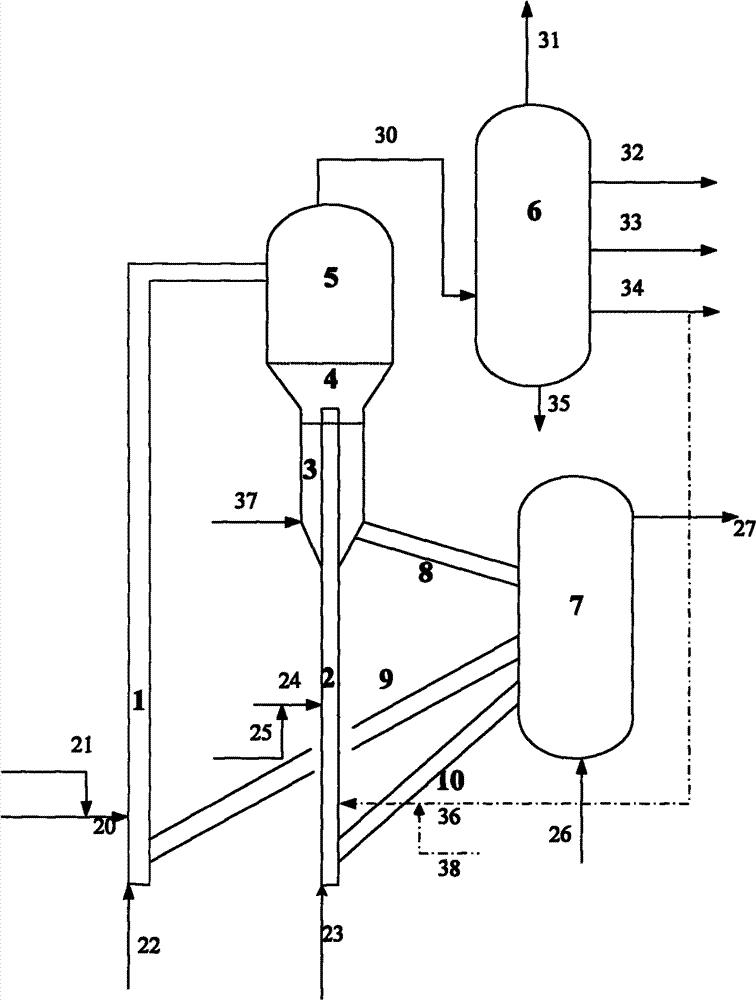

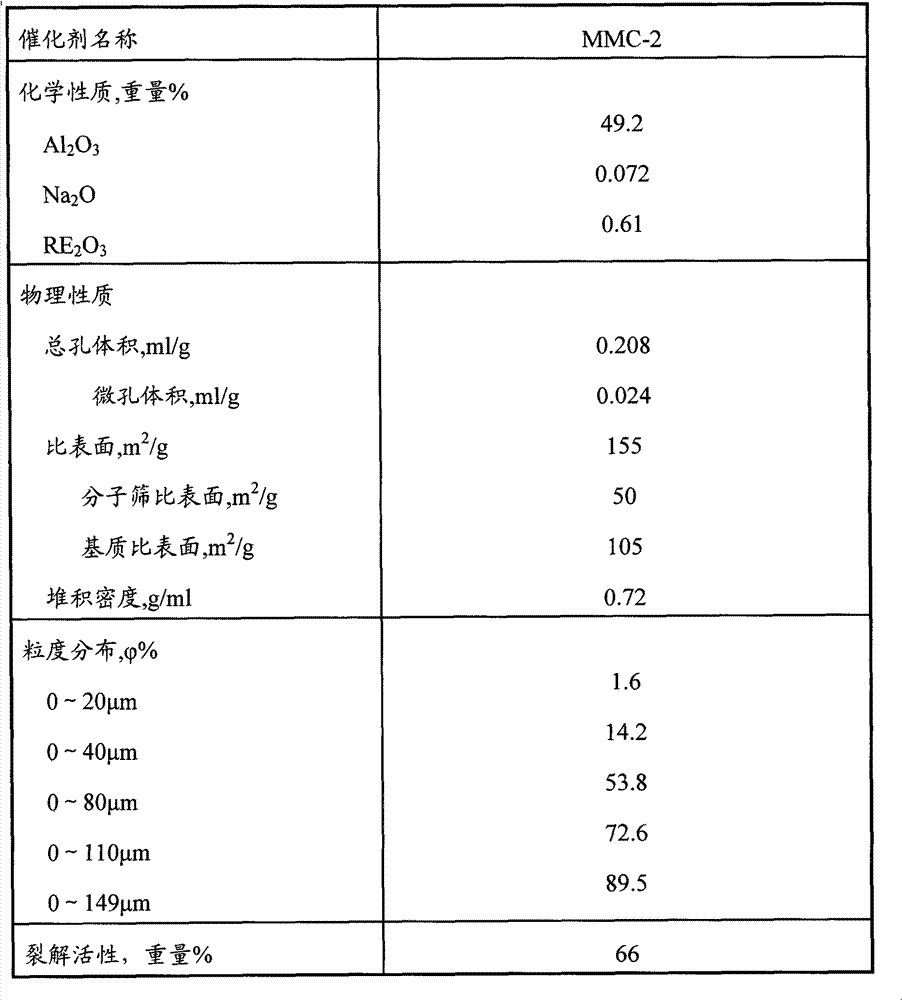

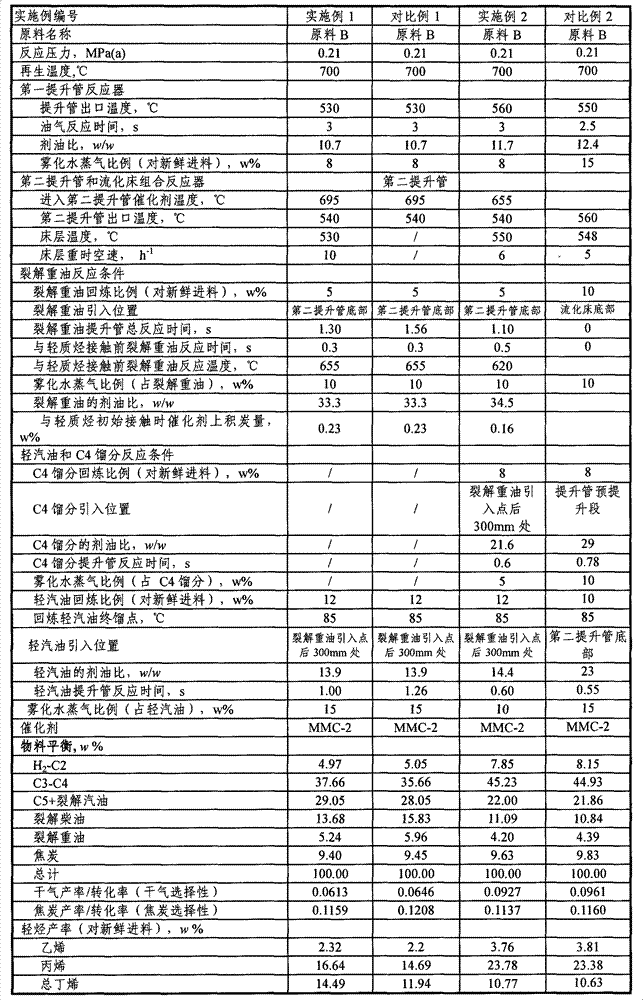

Catalytic cracking method and catalytic cracking device for producing propylene

ActiveCN102690682AHigh yieldImprove conversion rateTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionButeneFluidized bed

The invention discloses a catalytic cracking method and a catalytic cracking device for producing propylene. The catalytic cracking method comprises the following steps that one or more heavy raw materials and a first catalytic cracking catalyst comprising a main active component of Y-type zeolite undergo a contact reaction in a first riser reactor; one or more light hydrocarbons and a second catalytic cracking catalyst comprising a main active component of shape-selective zeolite having aperture sizes less than 0.7nm undergo a contact reaction in a second riser reactor; and reacted oil gas and the catalysts are introduced into a fluidized bed reactor connected to the second riser reactor in series and then undergo a reaction. A stripper of the catalytic cracking device is divided into two independent stripping zones by a separator plate, wherein one of the two independent stripping zones and a combined reactor composed of one riser and a fluidized bed form one reaction and stripping route; and the other one of the two independent stripping zones and the other riser form the other one reaction and stripping route. The catalytic cracking method has high propylene and butene yields. The catalytic cracking device has a simple structure and can respectively realize a reaction and regeneration in a device by two catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

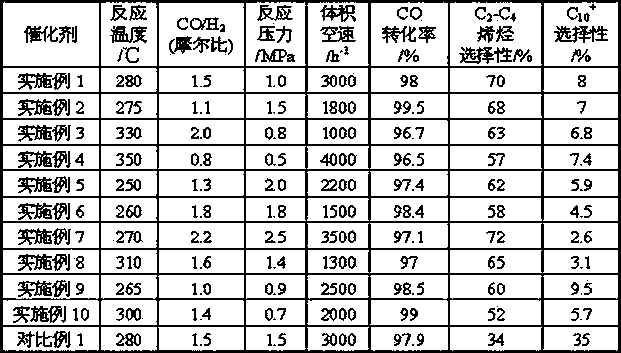

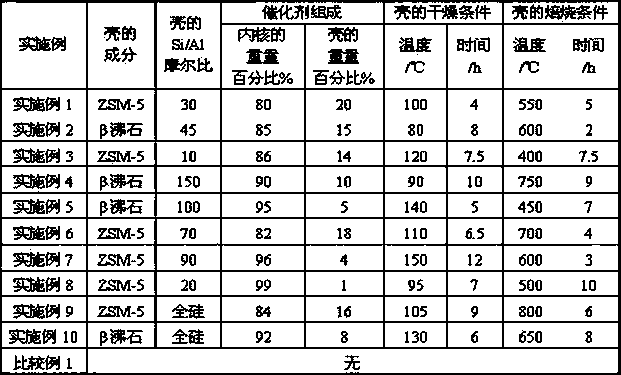

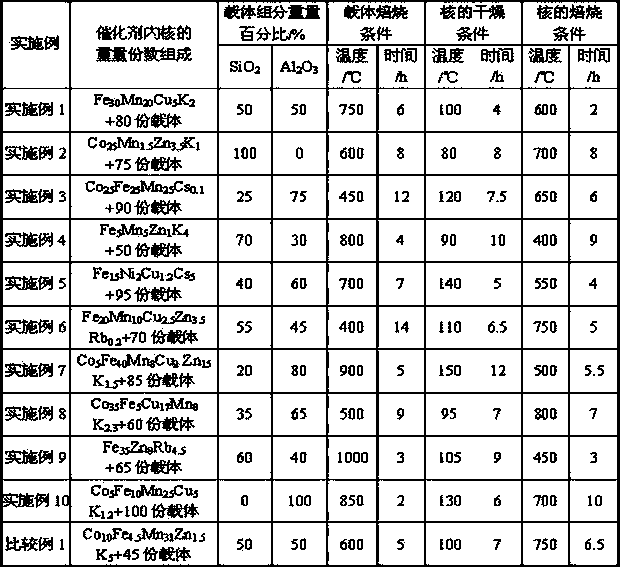

Method for preparing olefine from synthesis gas

ActiveCN103664447ALimit generationPromote generationHydrocarbon from carbon oxidesMolecular sieve catalystsMixed gasContact reaction

The invention relates to a method for preparing olefine from synthesis gas, which mainly solves the problem of poor low-carbon olefine selectivity in the existing technology. According to the technical scheme of the invention, the method for preparing olefine from synthesis gas comprises the following step: by taking CO and H2 mixed gas as a raw material, performing contact reaction on the raw material and a catalyst to generate olefine, wherein the used catalyst comprises the following components in parts by weight: 1-20 parts of one shell selected from ZSM-5 or beta zeolite and 80-99 parts of core; and the core comprises the following components in parts by weight: 50-100 parts of at least one oxide carrier selected from Al2O3 and SiO2 and the following components carried thereon: 5-50 parts of at least one metal of Fe and Co or oxide thereof, 1-30 parts of at least one metal selected from Mn, Zn and Cu and oxide thereof, and 0.1-5 parts of oxide or hydroxide of at least one selected from K, Rb and Cs. Thus, favorable technical effect is achieved; and the method can be used for preparing olefine from synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil treating method and heavy oil treating system

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

A kind of separation method of oil sludge sand

ActiveCN102276127AEasy to desorbEfficient separationWaste water treatment from quariesSludge treatment by oxidationSludgeViscosity

The invention discloses a method for separating oily sludge and sands, which comprises the steps of: in the presence of water, carrying out a contact reaction on the oily sludge and sands and a catalyst and an oxidizing agent, and separating to obtain a water phase, a grease phase and sand, wherein the oxidizing agent is a matter capable of oxidizing grease in the oily sludge and sands and reducing the viscosity of the oily sludge and sands, and the catalyst is a matter capable of promoting the oxidizing agent to generate radicals with strong oxidability. According to the method for separating the oily sludge and sands, provided by the invention, the content of oil in oily sludge and sands can be remarkably reduced, therefore, grease, sand and water in oily sludge and sands can be effectively and efficiently separated.

Owner:CHINA PETROLEUM & CHEM CORP +1

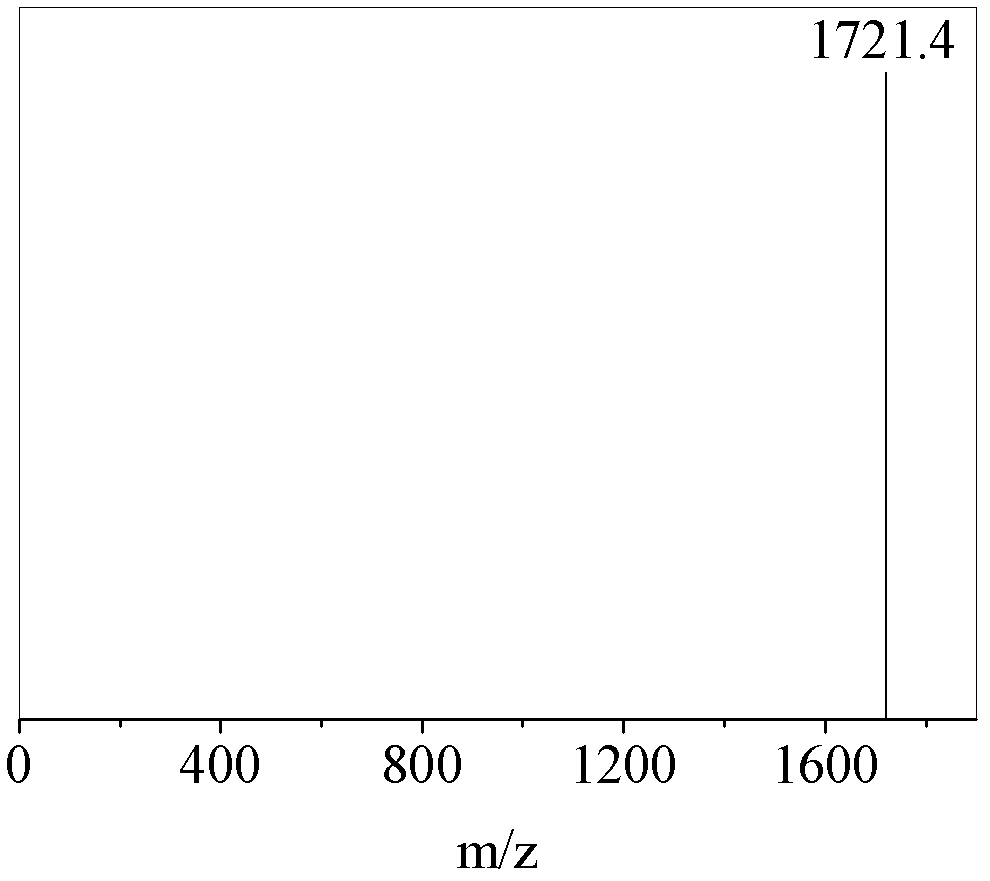

Methods for preparing phosphorus pentafluoride gas and preparing lithium hexafluorophosphate using the gas

ActiveCN101353161AEasily hydrolyzedStrong moisture absorptionPhosphorus halides/oxyhalidesLithiumPhysical chemistry

A preparation method of phosphorus pentafluoride gas comprises a step of causing phosphorus pentachloride to react with anhydrous hydrogen fluoride, wherein, the reaction occurs in the presence of a solvent. A preparation method of lithium hexaflourophosphate comprises a contact reaction between solid lithium fluoride and phosphorus pentafluoride gas, wherein the phosphorus pentafluoride gas is prepared by the method of the invention. Compared with the preparation method of the lithium hexaflourophosphate with the phosphorus pentafluoride gas as the raw material in the prior art, the phosphorus pentafluoride gas prepared by the preparation method of the invention has higher purity and lower cost. The yield of the lithium hexaflourophosphate prepared by the method of the invention is higher than 93%, and the purity thereof is up to 99.95%.

Owner:BYD CO LTD

Catalytic cracking method for producing propylene

ActiveCN102899078AImprove conversion depthHigh yieldCatalytic crackingTreatment with plural serial stages onlyButeneFluidized bed

The invention discloses a catalytic cracking method for producing propylene, comprising the following steps: contacting heavy feed stock with a first stream of a catalyst containing shape-selective zeolite with an average pore size being less than 0.7nm in a first riser reactor to conduct cracking reaction, then separating the oiling agent, introducing oil gas into a product separation system, and introducing the catalyst into a stripper or a fluidized bed reactor; contacting the recycled cracking heavy oil with a second stream of the catalyst containing shape-selective zeolite with an average pore size being less than 0.7nm in a second riser reactor to conduct cracking reaction, then letting the obtained oiling agent mixture and the light hydrocarbon introduced into the second riser reactor be subject to contact reaction, then introducing the reaction mixture into a fluidized bed combined reactor for reacting, introducing the reacted oil gas into the product separation system, and introducing the reacted catalyst into the stripper. According to the invention, the method is used for heavy oil catalytic cracking, the heavy oil conversion rate is high, the yields of propylene and butene are high, and the selectivity of dry gas and coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

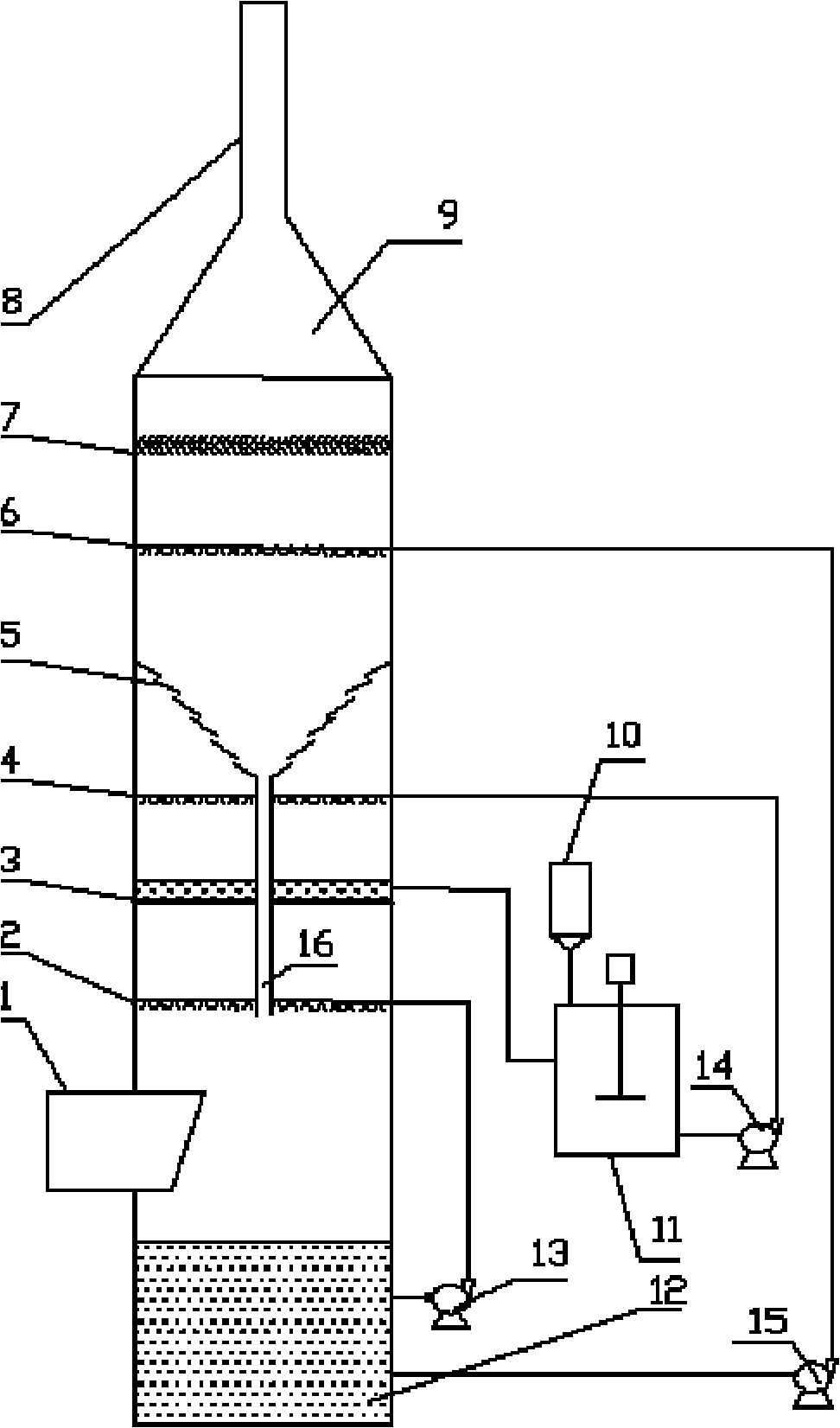

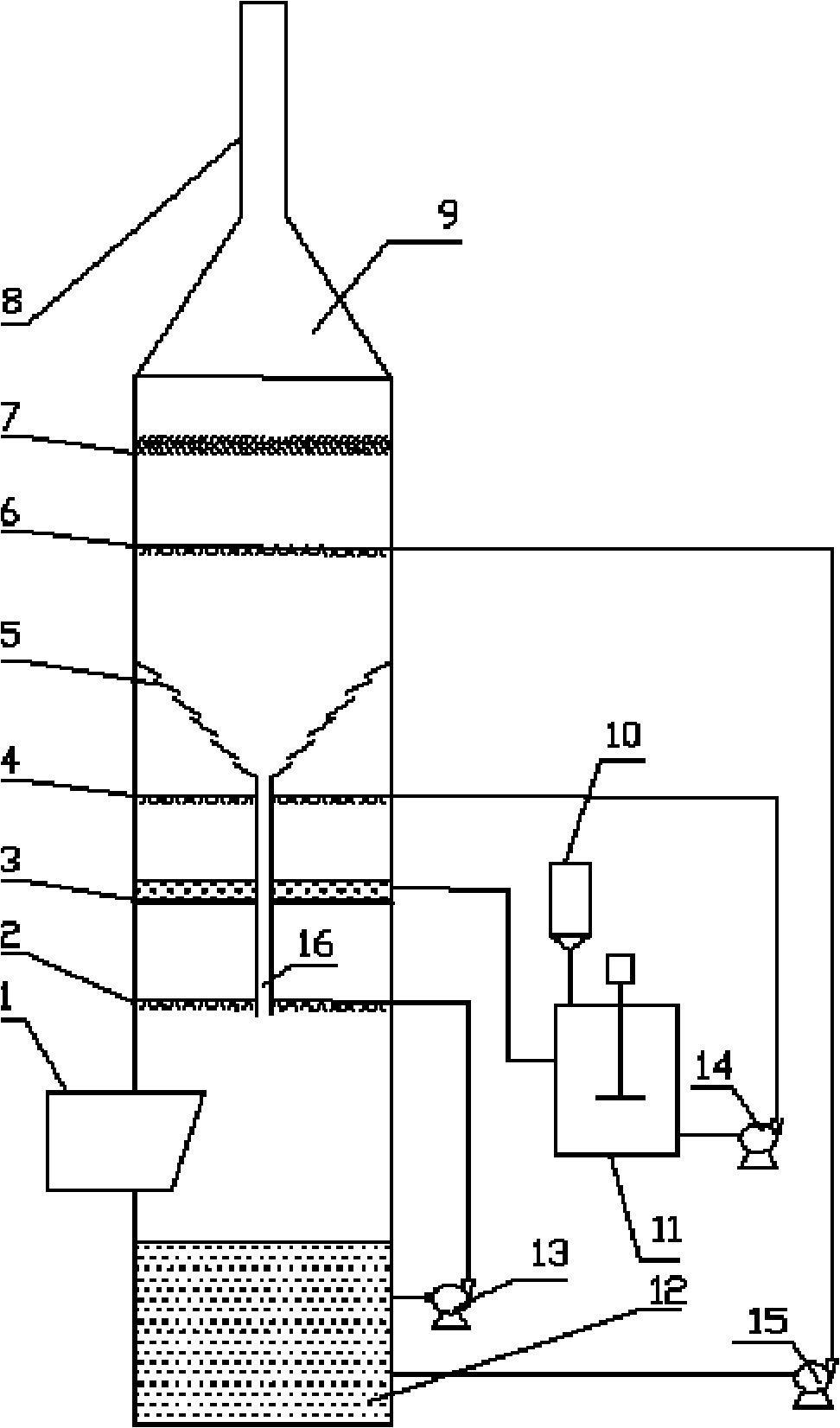

Liquid-phase oxidation multistage absorbed flue gas desulfurization and denitrification technology and device

ActiveCN102580496ASimple processSmall footprintDispersed particle separationAir quality improvementFlue gasNitrogen dioxide

The invention discloses a liquid-phase oxidation multistage absorbed flue gas desulfurization and denitrification technology and a liquid-phase oxidation multistage absorbed flue gas desulfurization and denitrification device, and belongs to the technical field of flue gas treatment. The technology comprises the following steps of: performing pre-desulfurization by contact reaction of flue gas and a desulfurizing agent which absorbs a part of sulfur dioxide in the flue gas to obtain desulfurized slurry; performing liquid-phase oxidation and partial absorption on the pre-desulfurized flue gas, and oxidizing nitric oxide in the flue gas into nitrogen dioxide; and performing contact reaction on the oxidized flue gas and the desulfurized slurry to absorb the nitrogen dioxide and the rest sulfur dioxide in the flue gas. The device comprises a desulfurization and denitrification tower and a tower kettle arranged at the bottom of the desulfurization and denitrification tower, wherein a first spraying layer, a sieve plate layer, a second spraying layer and a third spraying layer are sequentially arranged above the tower kettle from bottom to top; and the sieve plate layer is communicated with the second spraying layer through an oxidant slurry tank positioned outside the desulfurization and denitrification tower, and the first spraying layer and the third spraying layer are communicated with the tower kettle through external circulating pumps respectively. The technology is simple and high in desulfurization and denitrification efficiency during desulfurization and denitrification of the flue gas.

Owner:HANGZHOU TIANLAN ENVIRONMENTAL PROTECTION EQUIP

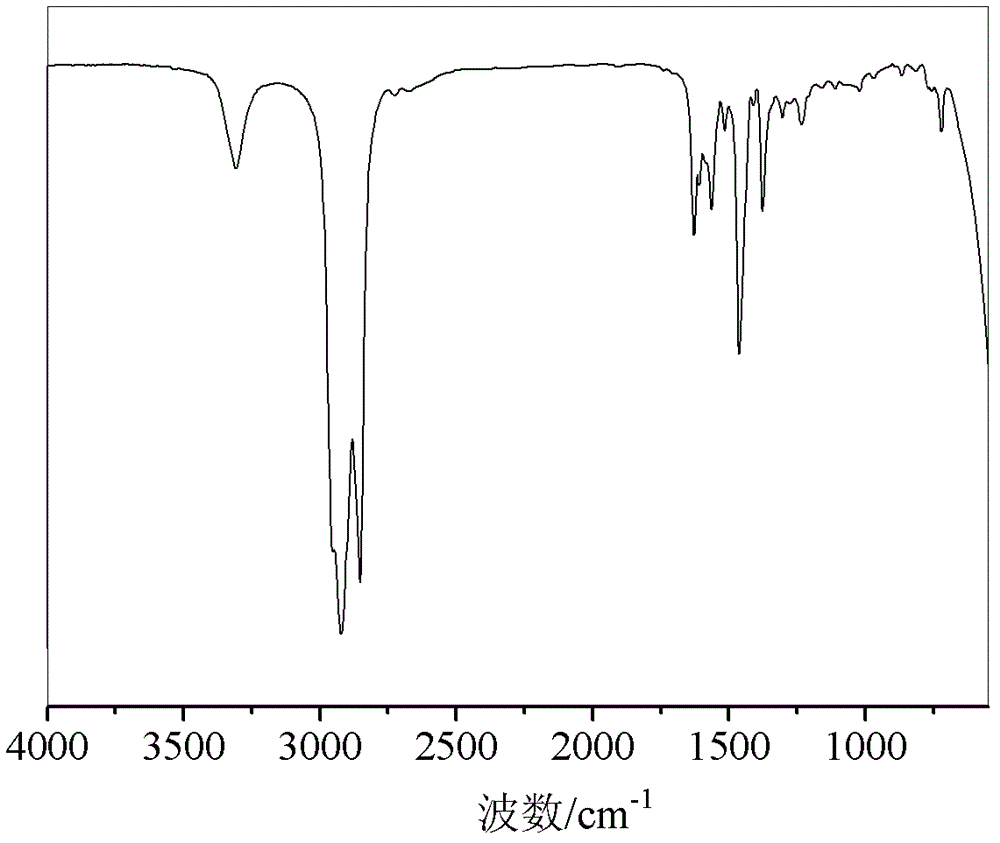

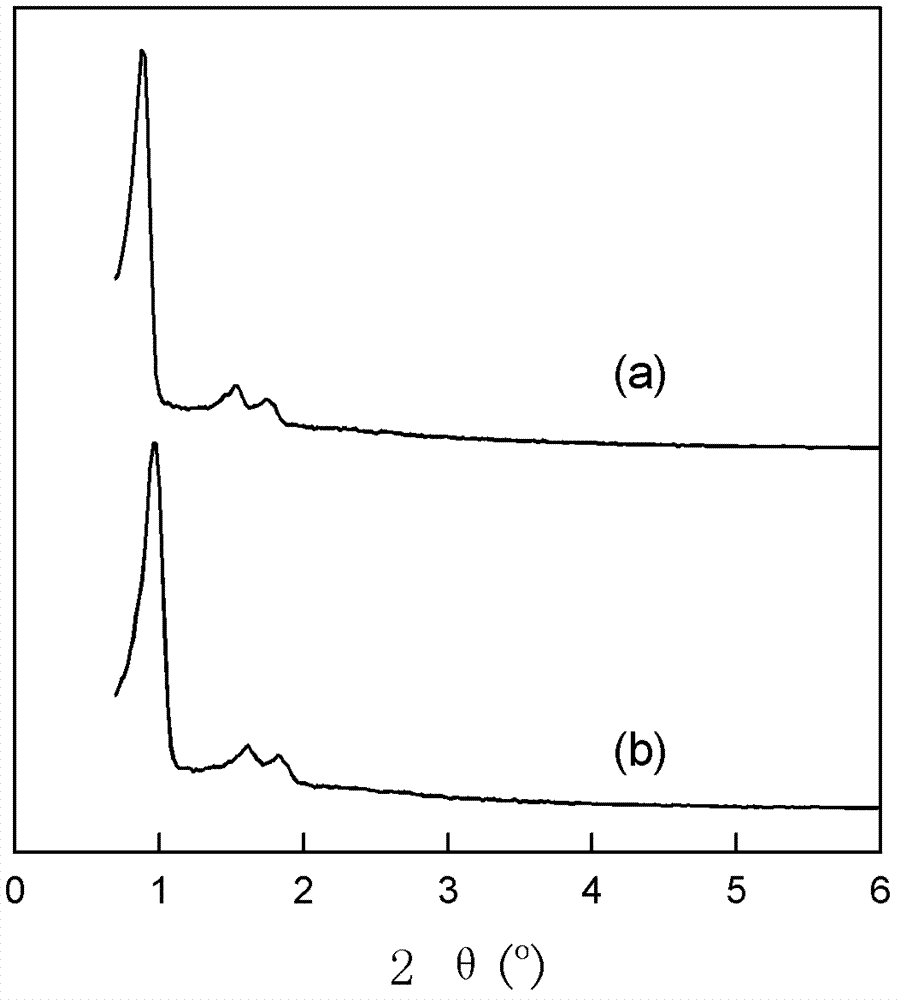

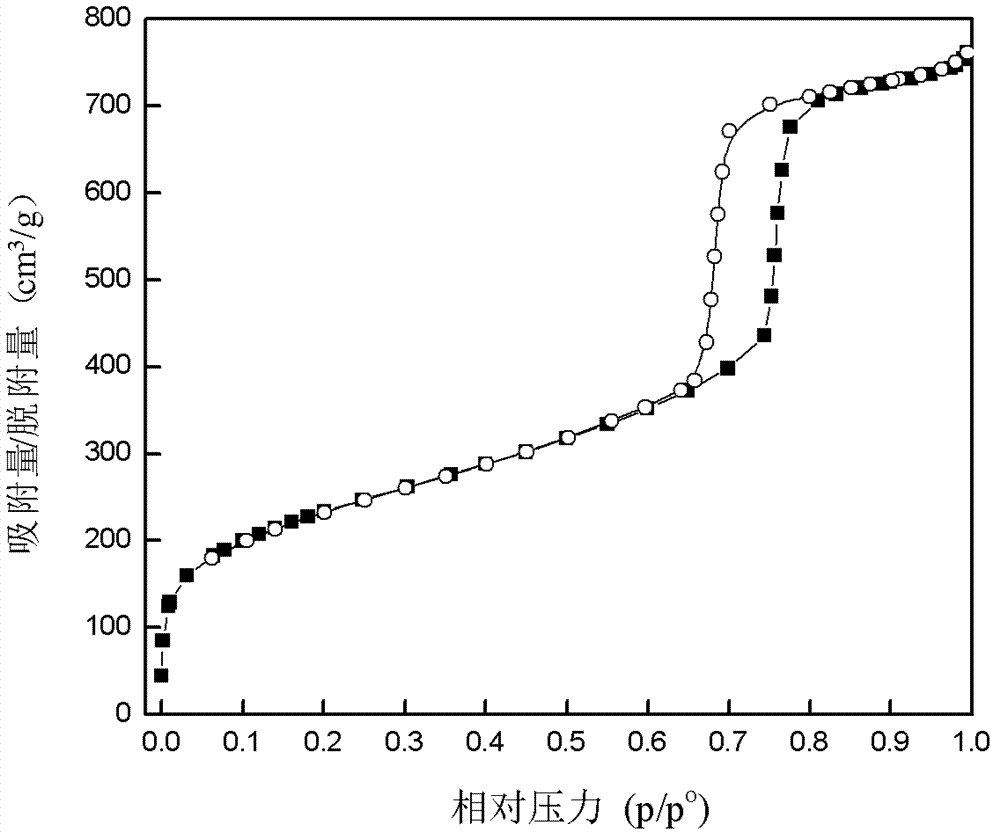

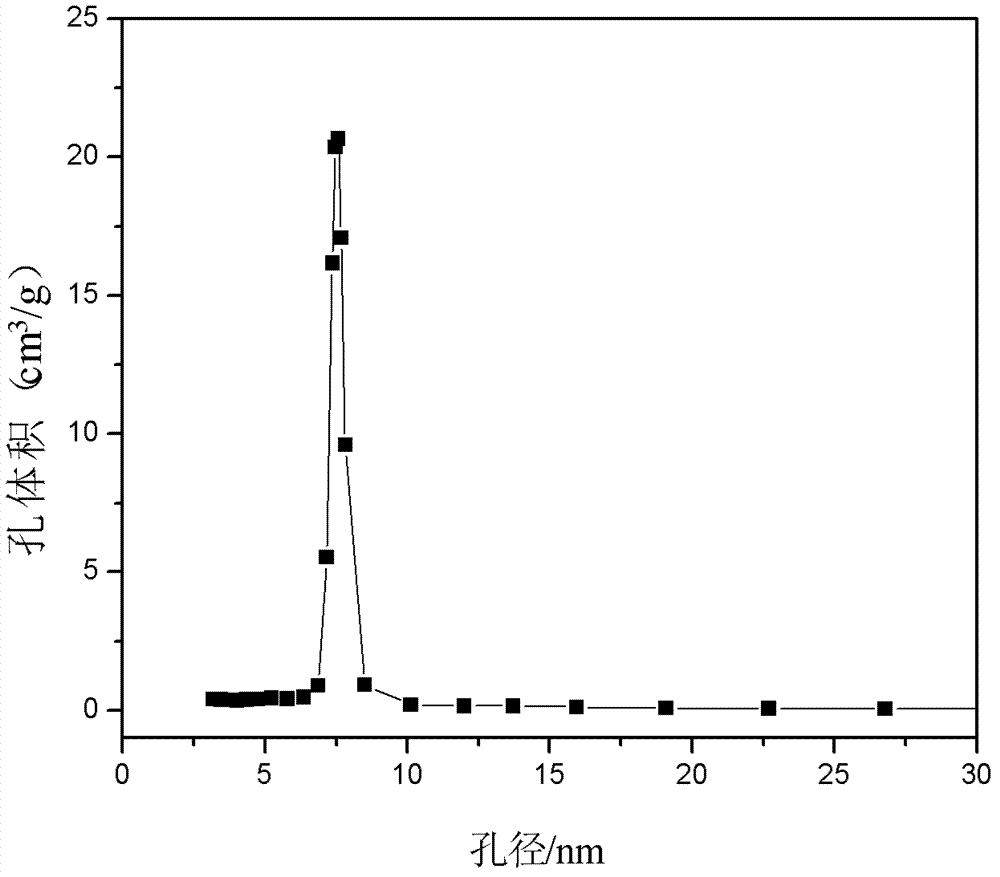

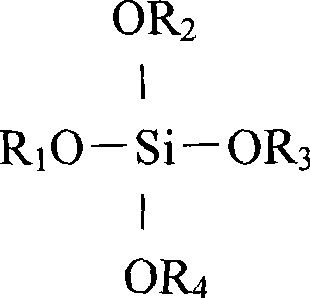

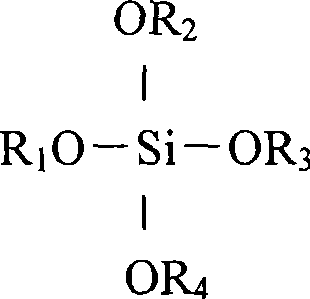

Ti-SBA-15 molecular sieve, modified Ti-SBA-15 molecular sieve, their preparation methods and preparation method of epoxy propane

ActiveCN102895994AHigh selectivityPromote formationOrganic chemistryMolecular sieve catalystsEpoxyContact reaction

The invention discloses a Ti-SBA-15 molecular sieve and its preparation method. The method includes: (1) under the reaction conditions of titanium introduction through liquid phase grafting and in the presence of a first organic solvent, subjecting a titanium source and an SBA-15 molecular sieve to a contact reaction in the presence of 100-300W ultrasonic waves, and conducting solid-liquid separation on a product of the contact reaction; and (2) carrying out washing, drying and roasting on a solid product obtained in step (1). Specifically, the titanium source is titanate with a general formula as Ti(OR)4 and / or an inorganic titanium source, and the first organic solvent is an alcohol compound with a general formula as R' OH, wherein R' is an alkyl group with a carbon atom number of 1-5. The invention also provides a modified Ti-SBA-15, its preparation method, and a preparation method of epoxy propane. The Ti-SBA-15 molecular sieve and the modified Ti-SBA-15 molecular sieve prepared in the invention can present good catalytic performance when applied to preparation of epoxy propane.

Owner:CHINA PETROLEUM & CHEM CORP +1

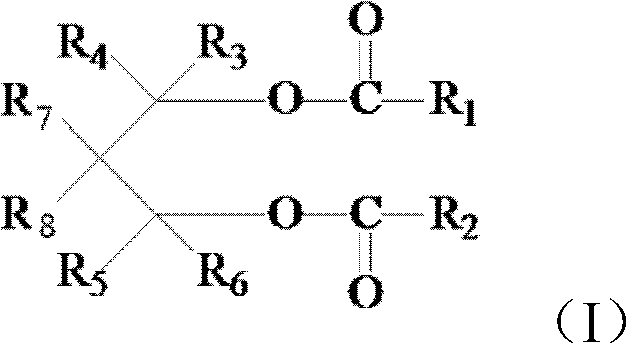

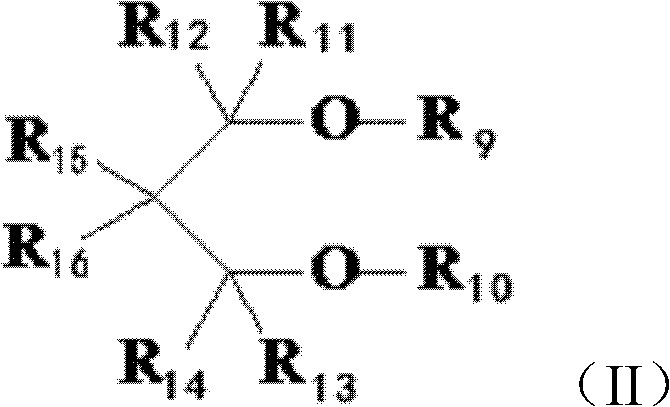

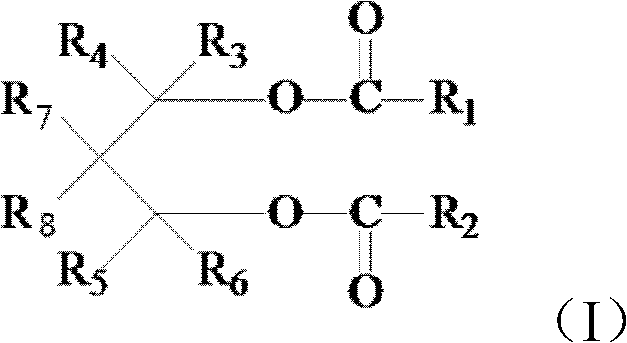

Olefin polymerization catalyst ingredient, preparation method and use of the olefin polymerization catalyst ingredient, catalyst system, use of the catalyst system, and olefin polymerization method

The invention relates to a preparation method of an olefin polymerization catalyst ingredient. The preparation method comprises the following steps that 1, a uniform solution is prepared; 2, the uniform solution obtained by the step 1 and a titanium compound undergo a contact reaction in the presence of separation assistants to produce a mixture; and 3, the mixture obtained by the step 2 and an internal donor undergo a contact reaction, wherein the separation assistants comprise a separation assistant A, a separation assistant B, a separation assistant C and a separation assistant D; the separation assistant A is a glycol ester compound shown in the formula (I); the separation assistant B is an alkyl ester of a carboxylic acid; the separation assistant C is a titanate compound; the separation assistant D is a 1,3-diether compound shown in the formula (II); and the separation assistant A is different from the separation assistant B. The invention also relates to the olefin polymerization catalyst ingredient, a use of the olefin polymerization catalyst ingredient, a catalyst system, a use of the catalyst system, and an olefin polymerization method. Catalyst particles prepared from the olefin polymerization catalyst ingredient have good particle morphology and have a high polymerization activity and good dynamic performances in propylene polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

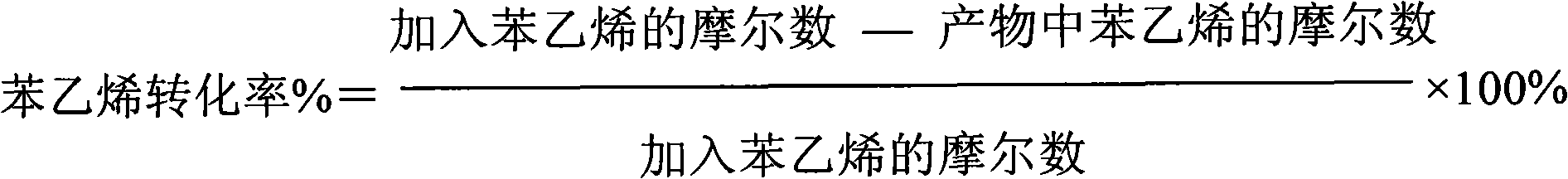

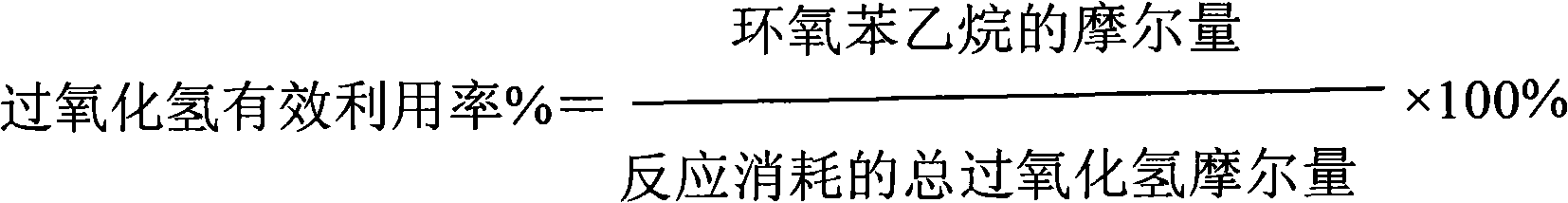

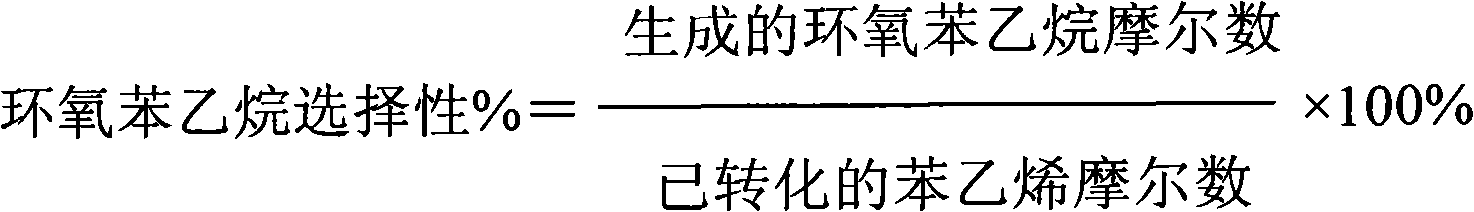

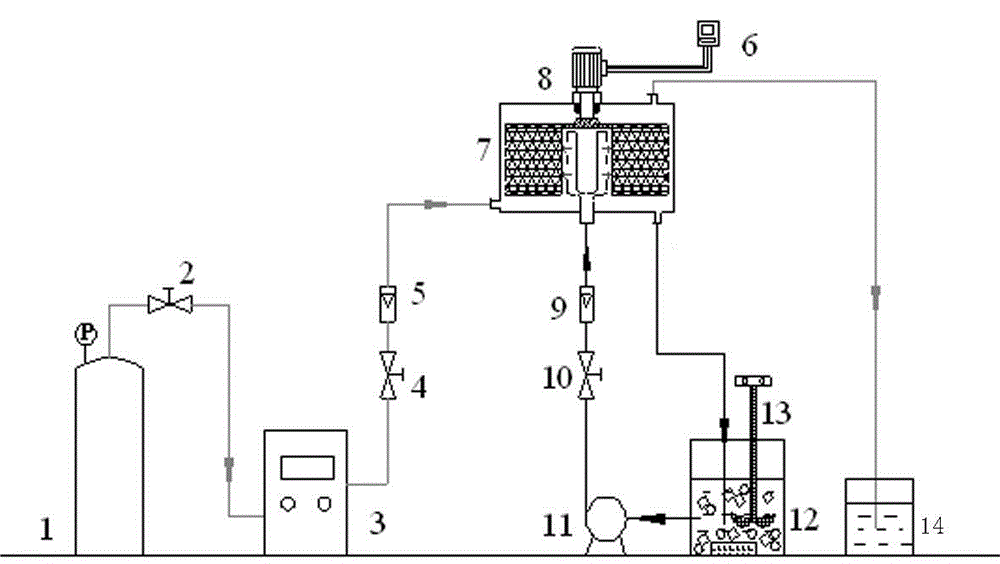

Catalytic oxidation method of styrene

ActiveCN103204830AHigh selectivityImprove effective utilizationOrganic chemistryMolecular sieve catalystsMolecular sieveCatalytic oxidation

The invention discloses a catalytic oxidation method of styrene. According to the method, under oxidation reaction conditions, styrene, an oxidant, a solvent and a catalyst are mixed and subjected to a contact reaction. The method is characterized in that the catalyst is a soluble zinc salt modified heteroatom molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

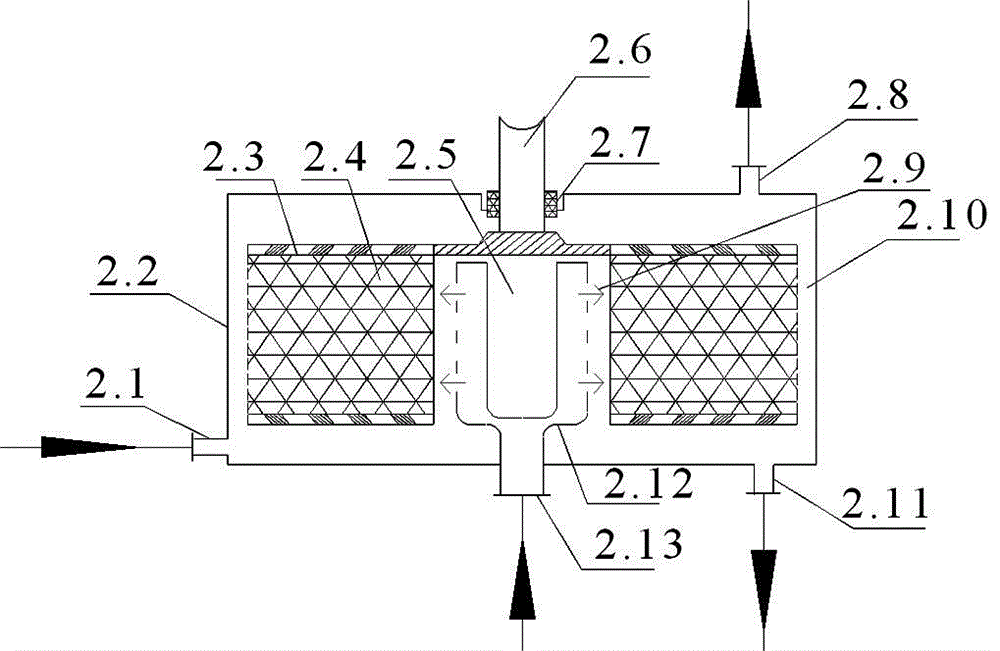

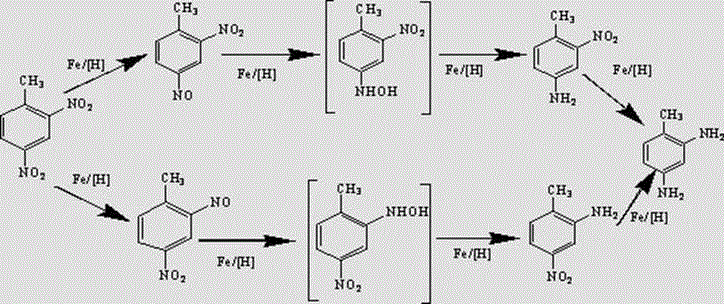

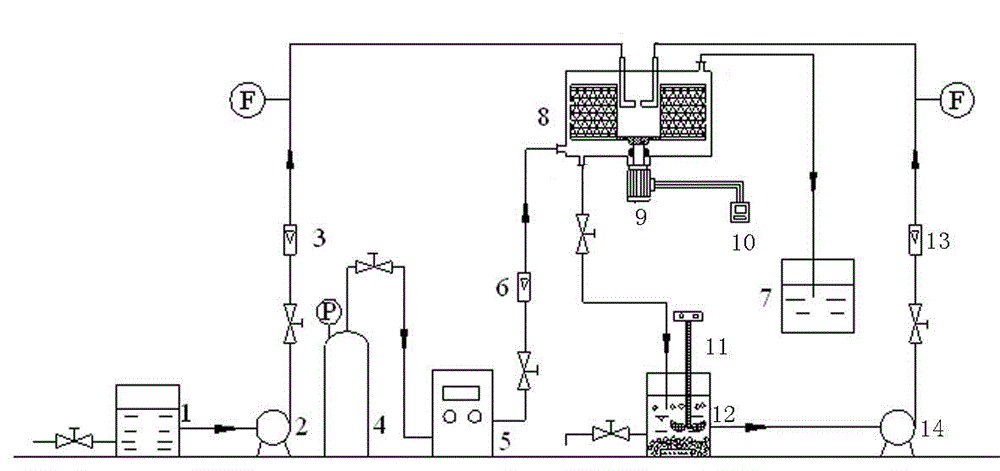

Method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater

ActiveCN103145273ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater contaminantsMultistage water/sewage treatmentOzone generatorGas liquid reaction

The invention belongs to the technical field of nitrobenzene wastewater, in particular relates to a method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater, and solves the problem of the existing method for degrading nitrobenzene wastewater. The method comprises the following steps of performing a reduction reaction on nitrobenzene wastewater in a micro-electrolysis bath; performing a sufficient contact reaction with ozone in gas-liquid reaction equipment; further degrading pollutants in the wastewater in the gas-liquid reaction equipment; and circularly treating the wastewater in the micro-electrolysis bath and the gas-liquid reaction equipment. The device comprises a rotary packed bed device, wherein a gas inlet is connected with an ozone generator; and a liquid inlet and a liquid outlet are connected with the micro-electrolysis bath. The method and the device have the beneficial effects that the process flow is simple and convenient to operate; the advantages of various technologies are given a full play by coupling the three technologies to reach the aim of treating waste by using waste, so that the treatment cost can be furthest reduced.

Owner:ZHONGBEI UNIV

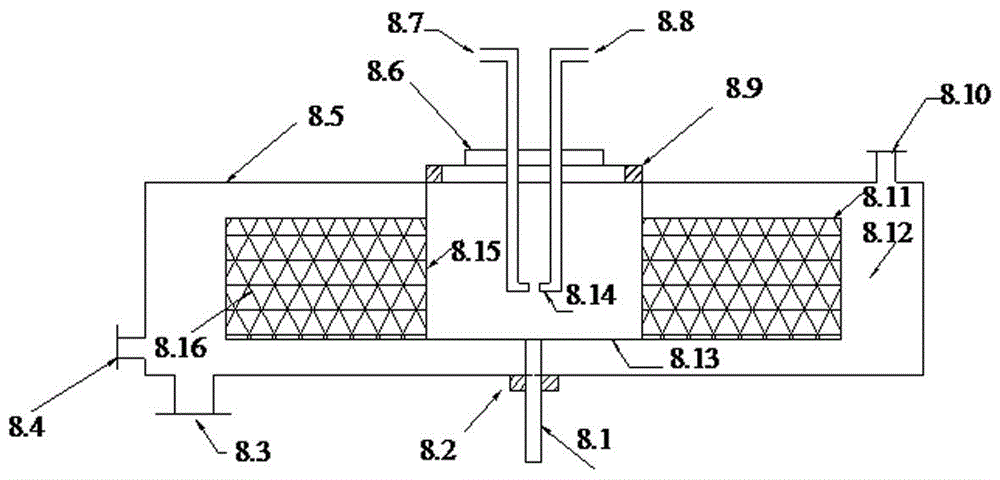

Method and device for treating wastewater by advanced oxidation process

ActiveCN103145274ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentElectrolysisFenton reagent

The invention belongs to the technical field of treatment for industrial production wastewater, and particularly relates to a method and a device for treating wastewater by an advanced oxidation process, which solve the shortages in the existing methods for treating industrial wastewater. The method comprises the following steps of: performing micro-electrolysis reduction reaction on wastewater; impinging the wastewater with hydrogen peroxide in liquid-liquid reaction equipment; forming Fenton reagent by Fe<2+> and hydrogen peroxide in the wastewater; and performing contact reaction on the wastewater and ozone in the liquid-liquid reaction equipment. The device comprises an impinging stream-rotating packed bed device, wherein nozzles are formed at the outlets of two liquid inlet tubes respectively, the two nozzles are coaxial and the outlets are oppositely arranged, the two liquid inlet tubes are connected with a hydrogen peroxide storage tank and a micro-electrolysis tank respectively, and liquid outlets are connected with the micro-electrolysis tank; and an intake port is connected with an ozone generator, and an exhaust port is connected with a KI adsorption liquid storage tank. The method and the device disclosed by the invention have the beneficial effects that the technical process is simple, the operation is convenient, and wastes are used for treating wastes, thus furthest reducing the treatment cost.

Owner:ZHONGBEI UNIV

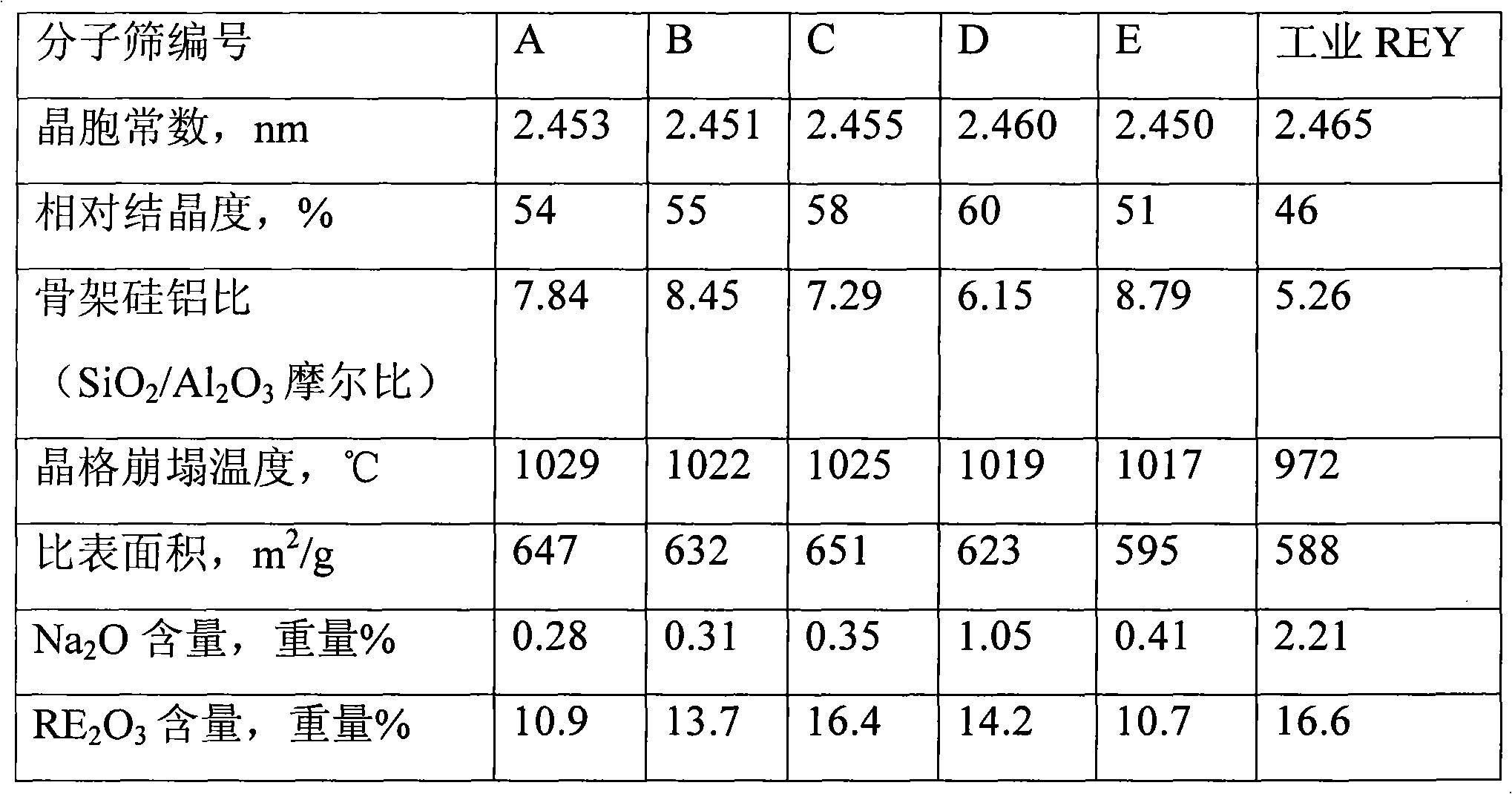

Cracking catalyst and preparation method thereof

ActiveCN102029177AHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing p-xylene and co-producing light olefins by toluene and methylating reagent

InactiveCN101456784AReduce wearHigh activityHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical recyclingMoving bedResidence time

The invention relates to a method for preparing para-xylene and coproducing low-carbon olefin from toluene and a methylated reagent. The method comprises: a granular catalyst is continuously added from the top of a reactor by moving bed reaction technology, and gradually moved down along with the reaction, continuously flows out from the bottom to a regenerator, and is regenerated; the raw materials, namely the toluene and the methylated reagent, enter a vaporizer for mixing and gasification, enter the reactor, pass through a catalyst bed from the bottom up (or top down), and are subjected to contact reaction with the catalyst; and gaseous mixture products after reaction flow out from the top (or bottom) of the reactor and are separated. The selectivity of the para-xylene in the products in a xylene isomer is more than 99 weight percent, and the selectivity of ethylene and propylene in low-carbon hydrocarbon between C1 and C5 is more than 90 weight percent. The moving bed catalyst has stable activity and can be continuously regenerated; the residence time of solid and fluid in the moving bed reactor can be adjusted; back mixing of materials is small; the conversion rate of the raw materials is improved; and abrasion of the catalyst is small.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for aromatizing light hydrocarbons

ActiveCN101538184AHigh mechanical strengthHigh aromatic contentMolecular sieve catalystsHydrocarbonsAdhesiveRare earth

The invention discloses a method for aromatizing light hydrocarbons, which comprises the following step that: the contact reaction of C3-C12 hydrocarbons and an aromatization catalyst is performed to produce aromatic hydrocarbons and liquefied gas at a temperature of between 250 and 650 DEG C under the pressure of between 0.1 and 4.0MPa, wherein the aromatization catalyst comprises a complex carrier and compositions with the following content: 0.5 to 5.0 mass percent of ZnO, 0.1 to 5.0 mass percent of rare earth oxide, and 1.0 to 7.0 mass percent of VA group element. The complex carrier comprises 20 to 50 mass percent of ZSM series zeolite and 50 to 80 mass percent of adhesive. The method is suitable for a reaction-regeneration method of a moving bed, and has higher liquid yield and steady catalytic reaction activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com